Patents

Literature

31 results about "Fourth Dimension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Denoting a process that involves all 3 spatial dimensions in addition to some type of time information.

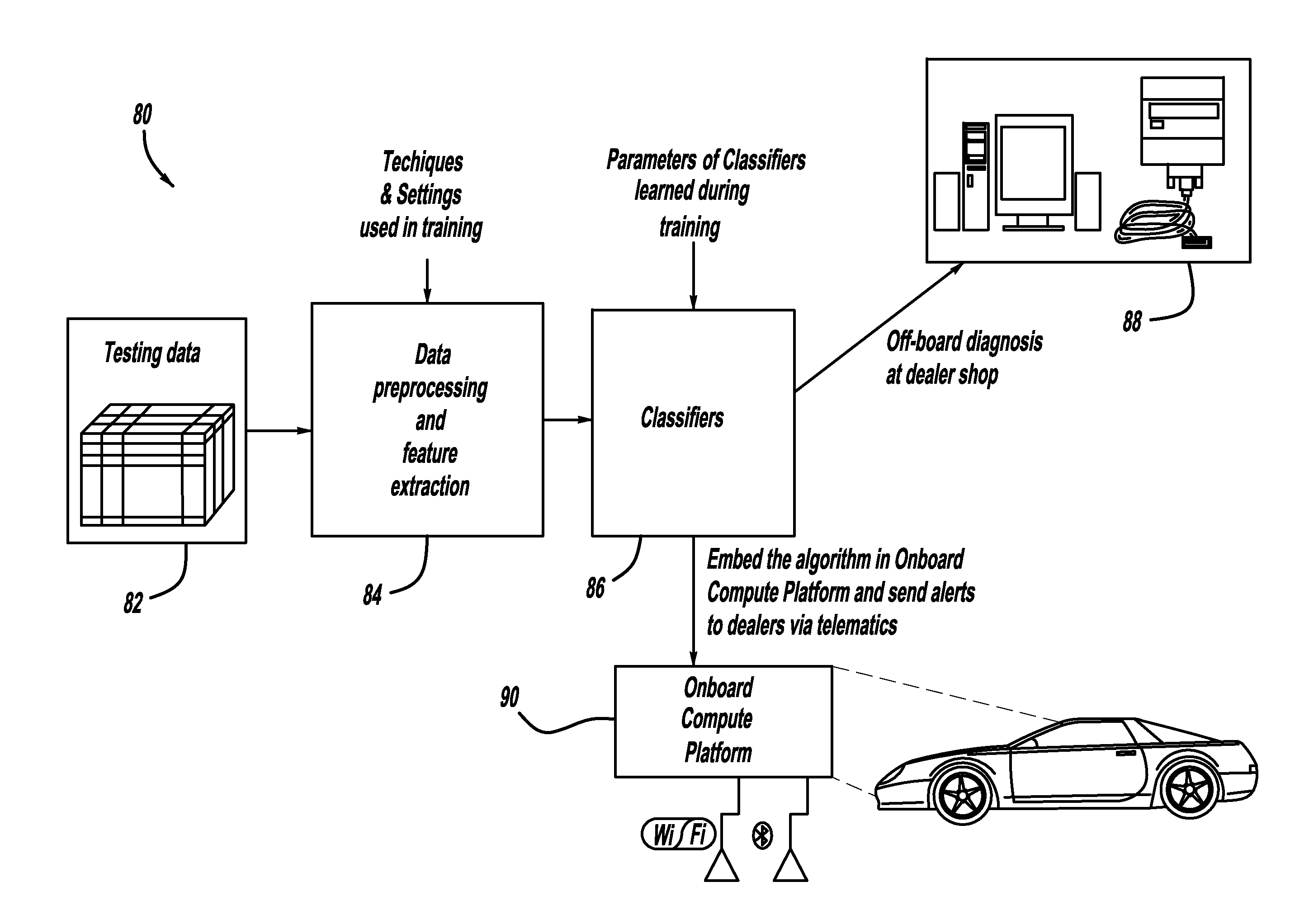

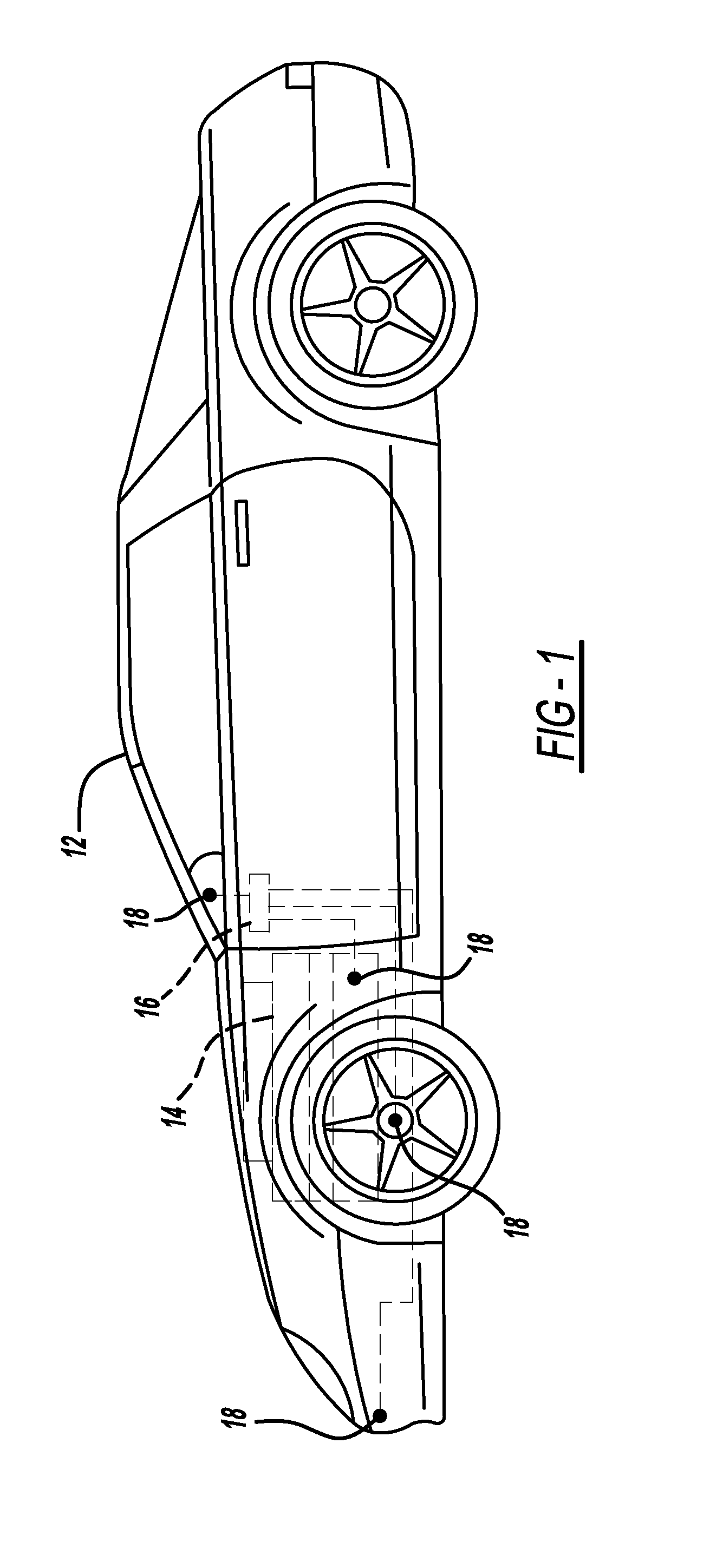

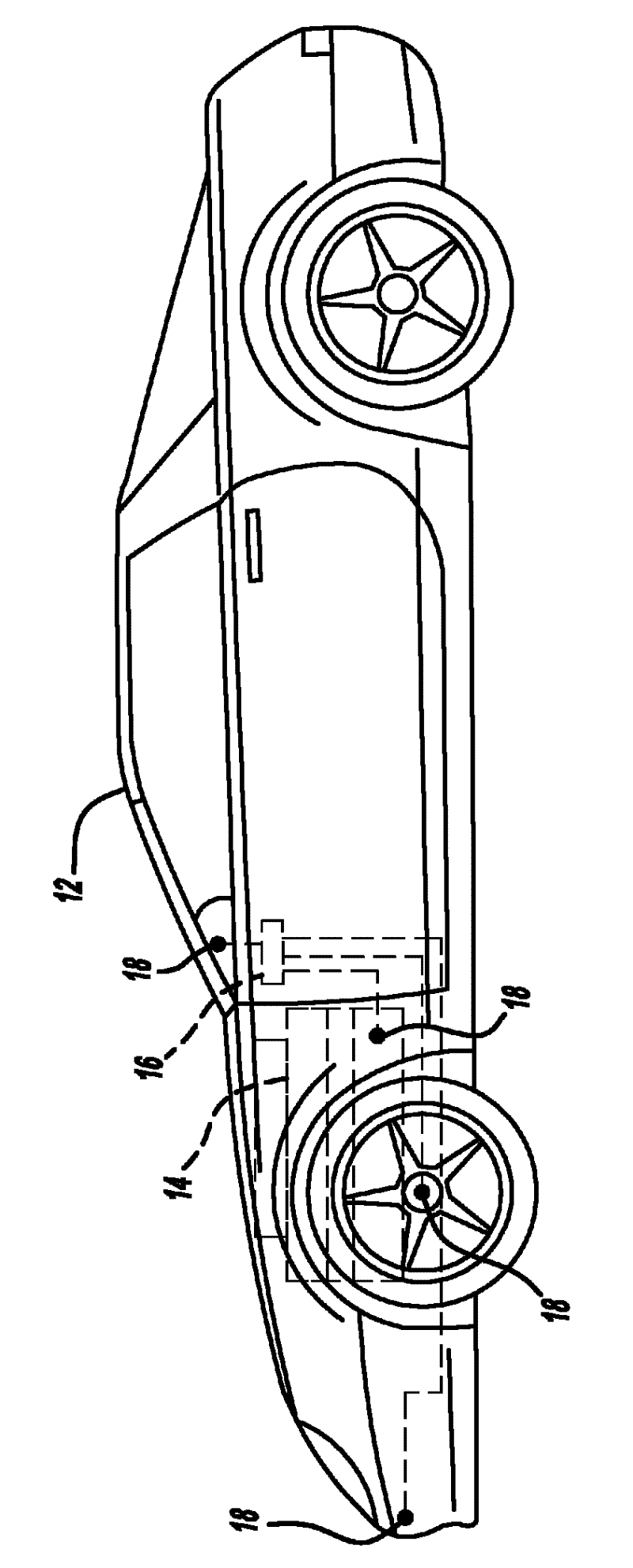

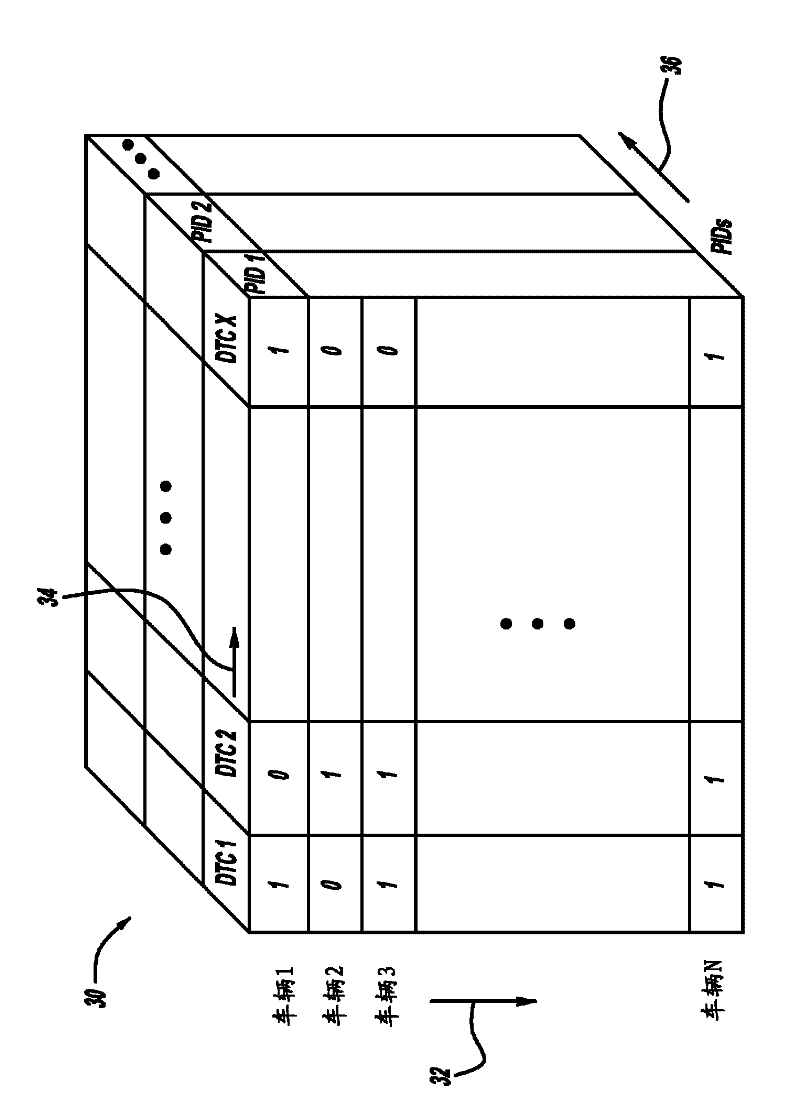

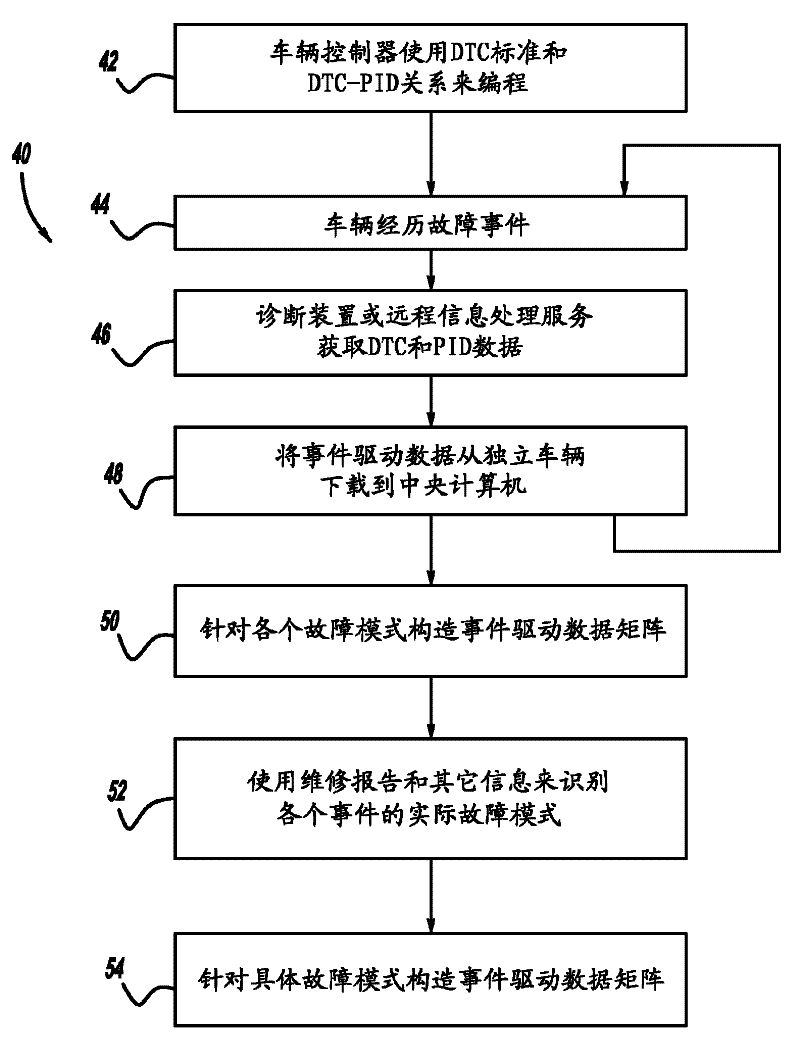

Event-driven fault diagnosis framework for automotive systems

ActiveUS20110238258A1Remaining useful lifeVehicle testingRegistering/indicating working of vehiclesAutomotive systemsWireless data

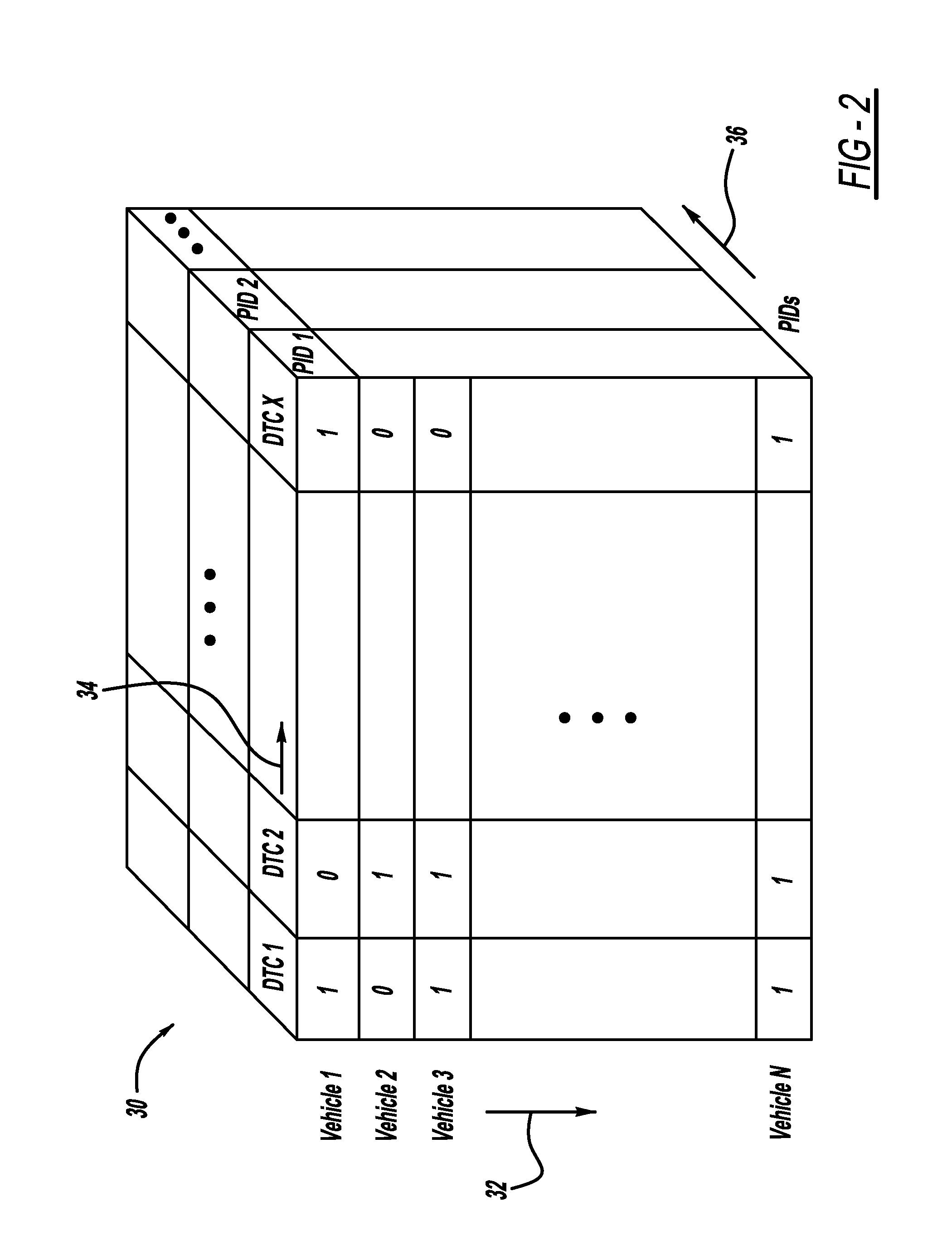

Systems and methods for capturing and analyzing significant parameter data from vehicle systems whenever a diagnostic trouble code (DTC) is triggered. A multi-dimensional matrix is constructed, with vehicles, DTCs, and parameter data comprising three dimensions of the matrix. The data matrix is populated with DTC and parameter data from many different vehicles, either when vehicles are taken to a dealer for service, or via wireless data download. Time can be added as a fourth dimension of the matrix, providing an indication of whether a particular system or component is temporally degrading. When sufficient data is accumulated, the data matrix is pre-processed, features are extracted from the data, and the features are classified, using a variety of mathematical techniques. Trained classifiers are then used to diagnose the root cause of any particular fault signal, and also to provide a prognosis of system health and remaining useful life.

Owner:GM GLOBAL TECH OPERATIONS LLC

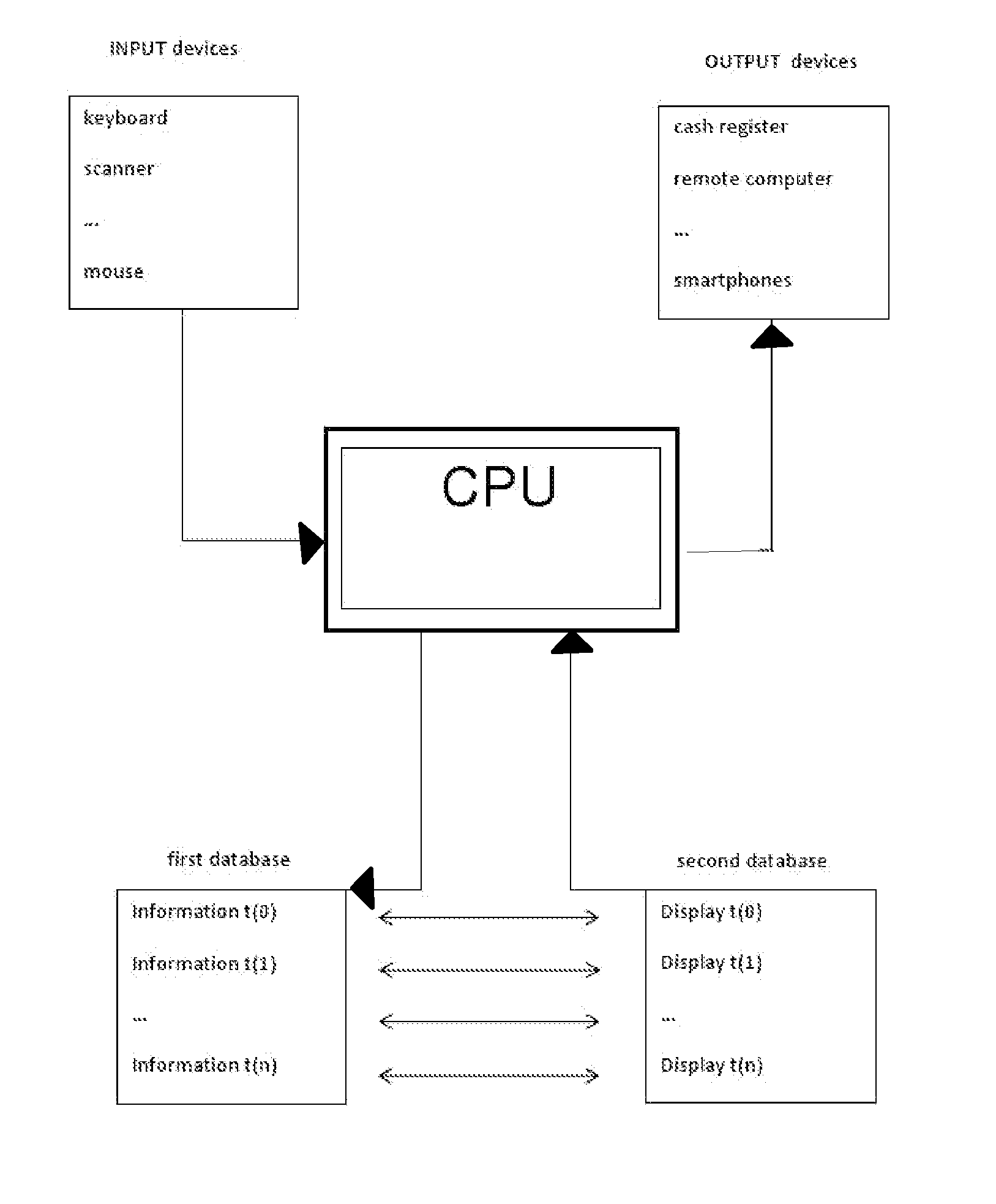

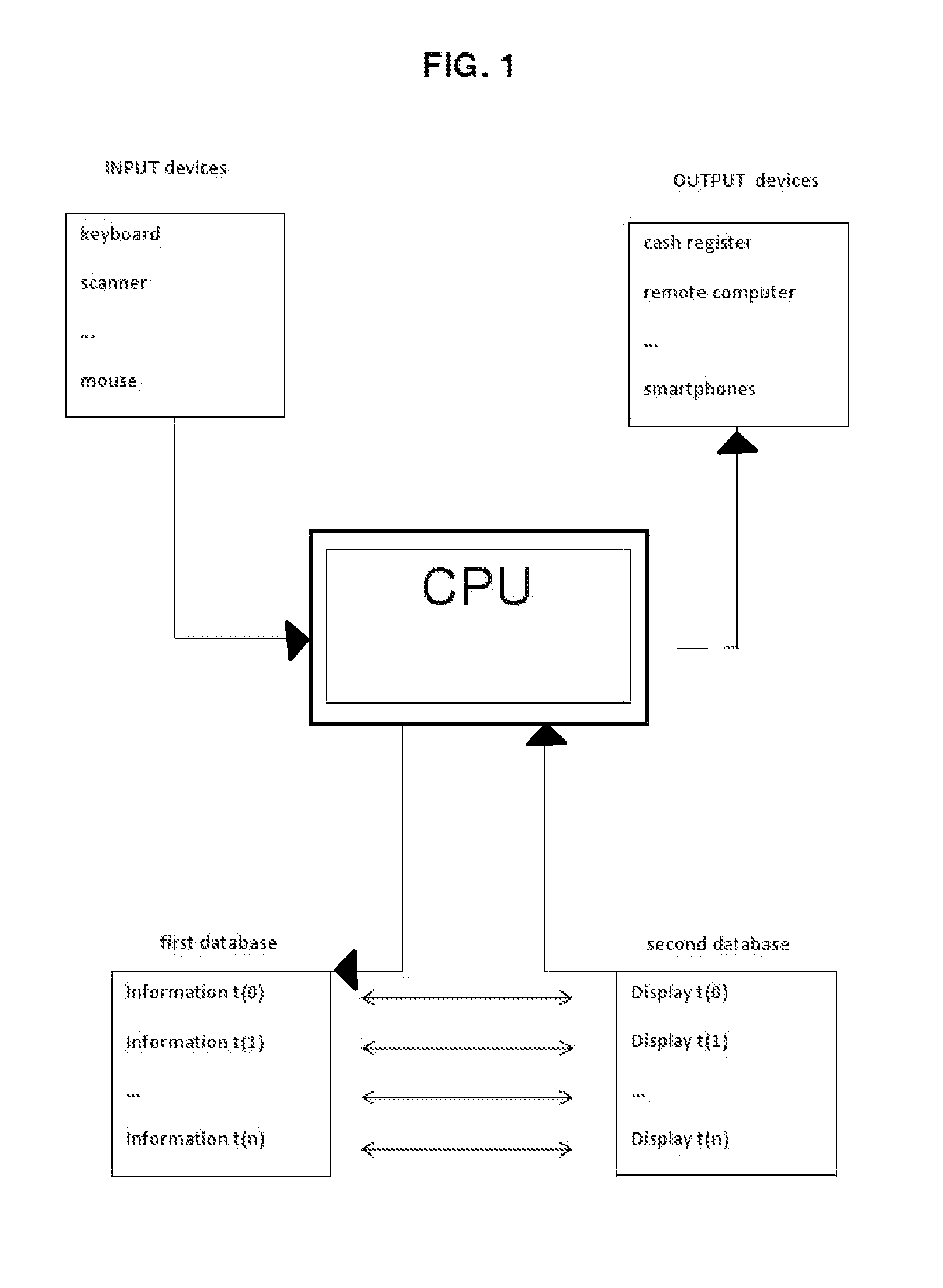

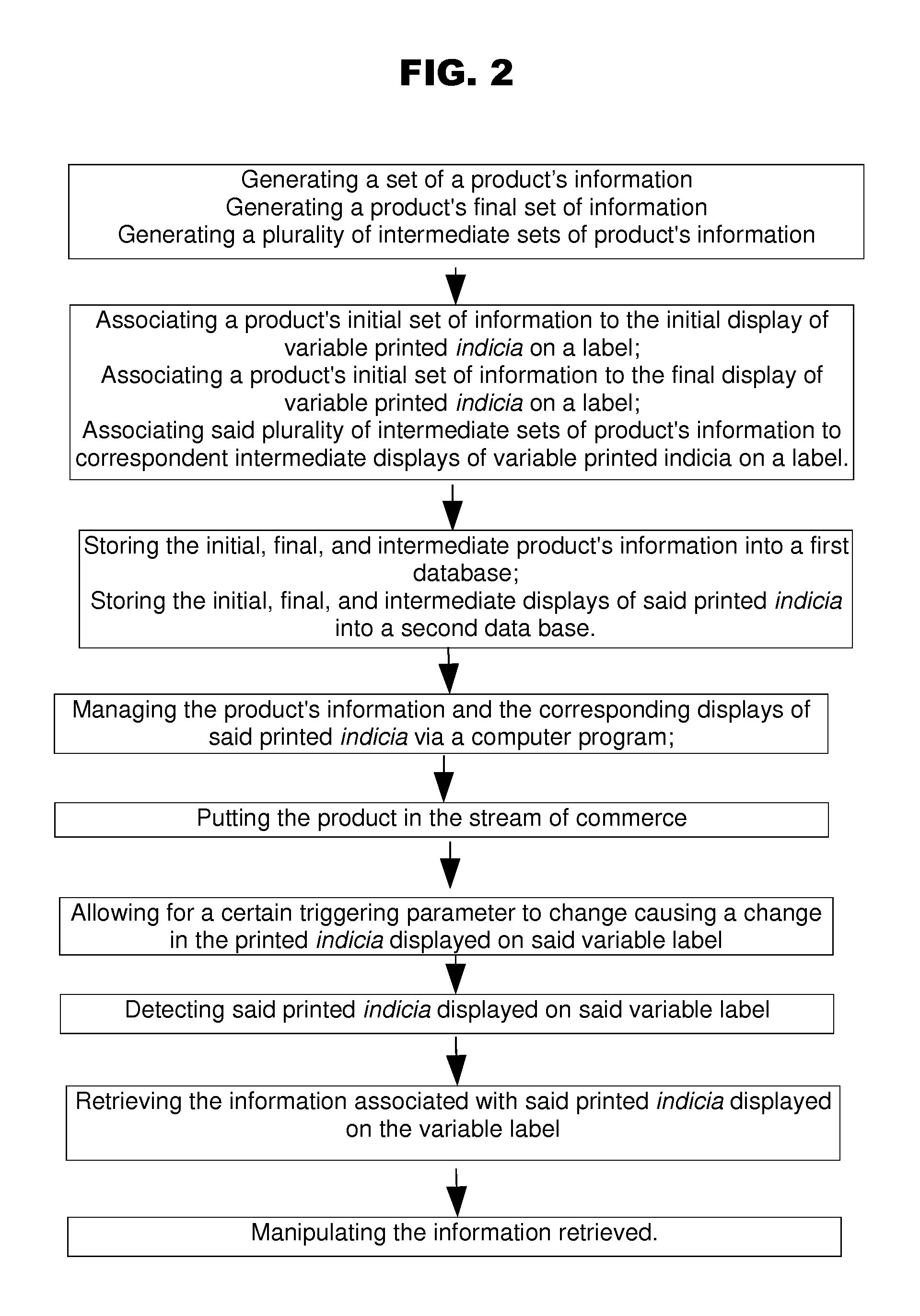

Time management system and value bar code

InactiveUS20130048736A1Easy to understandEasy to readCharacter and pattern recognitionVisual presentationUniversal Product CodeTemporal change

They object of the present invention is an TIME MANAGEMENT SYSTEM that integrates a static barcode together with a TIME VARIABLE label referred as TIME VALUE BAR or TVB. The TVB is then linked via a database to product information that vary with time such as useful shelf life, remaining shelf life, price, identity, and expiration of the article. The information is input, stored, linked, output, and managed by a Central Processing Unit (CPU), but it is also partially available to the public via the TVB. In one of the preferred embodiments of the invention the variable bar code system is compatible with the Universal Product Code (UPC) currently in use in most retail shops. In another embodiment the TIME VALUE BAR of the present invention relates a 3D barcode with a VARIABLE TIME label effectively adding a fourth dimension to the barcode thus becoming a 4D barcode system.

Owner:TIME LABEL TECH CORP

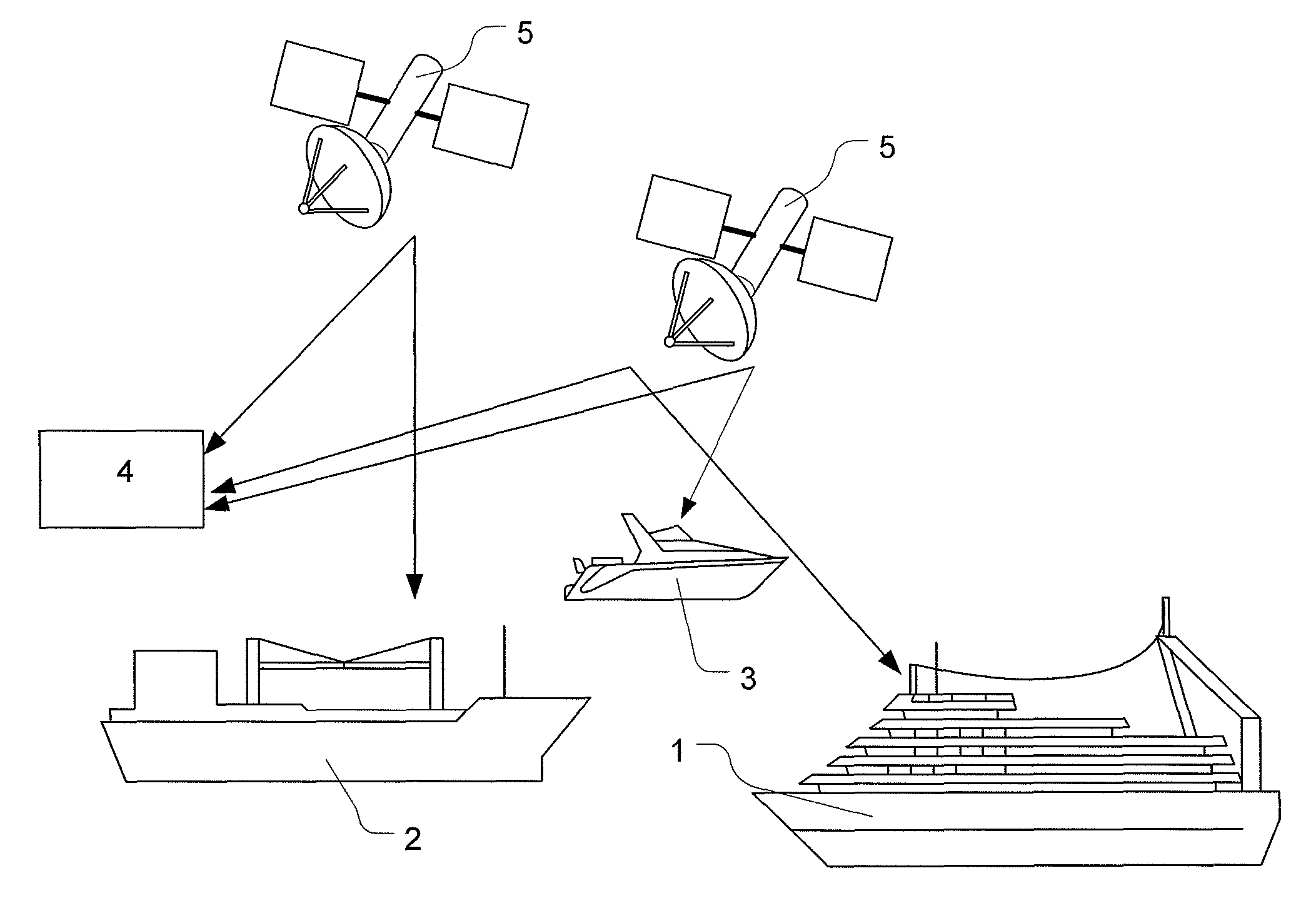

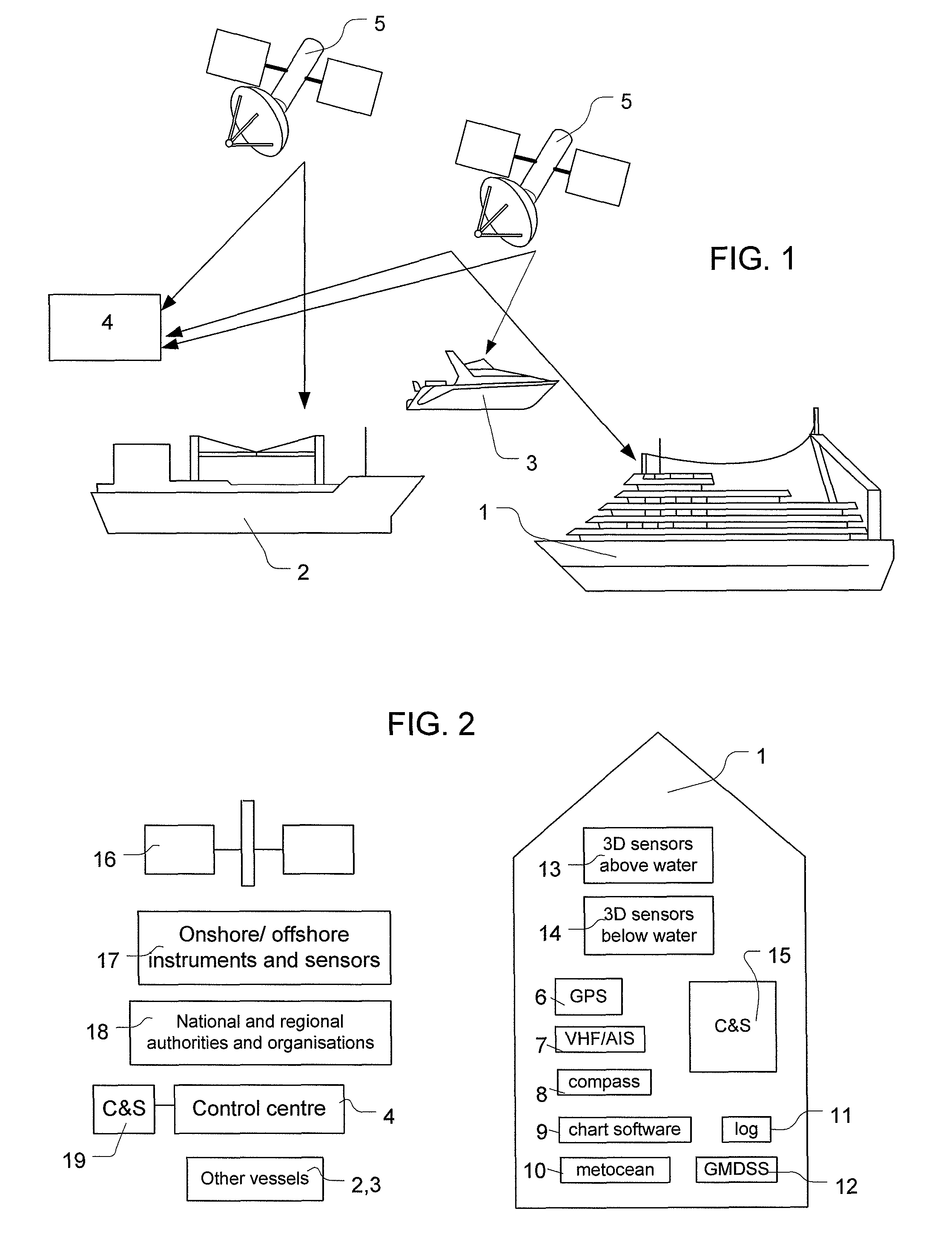

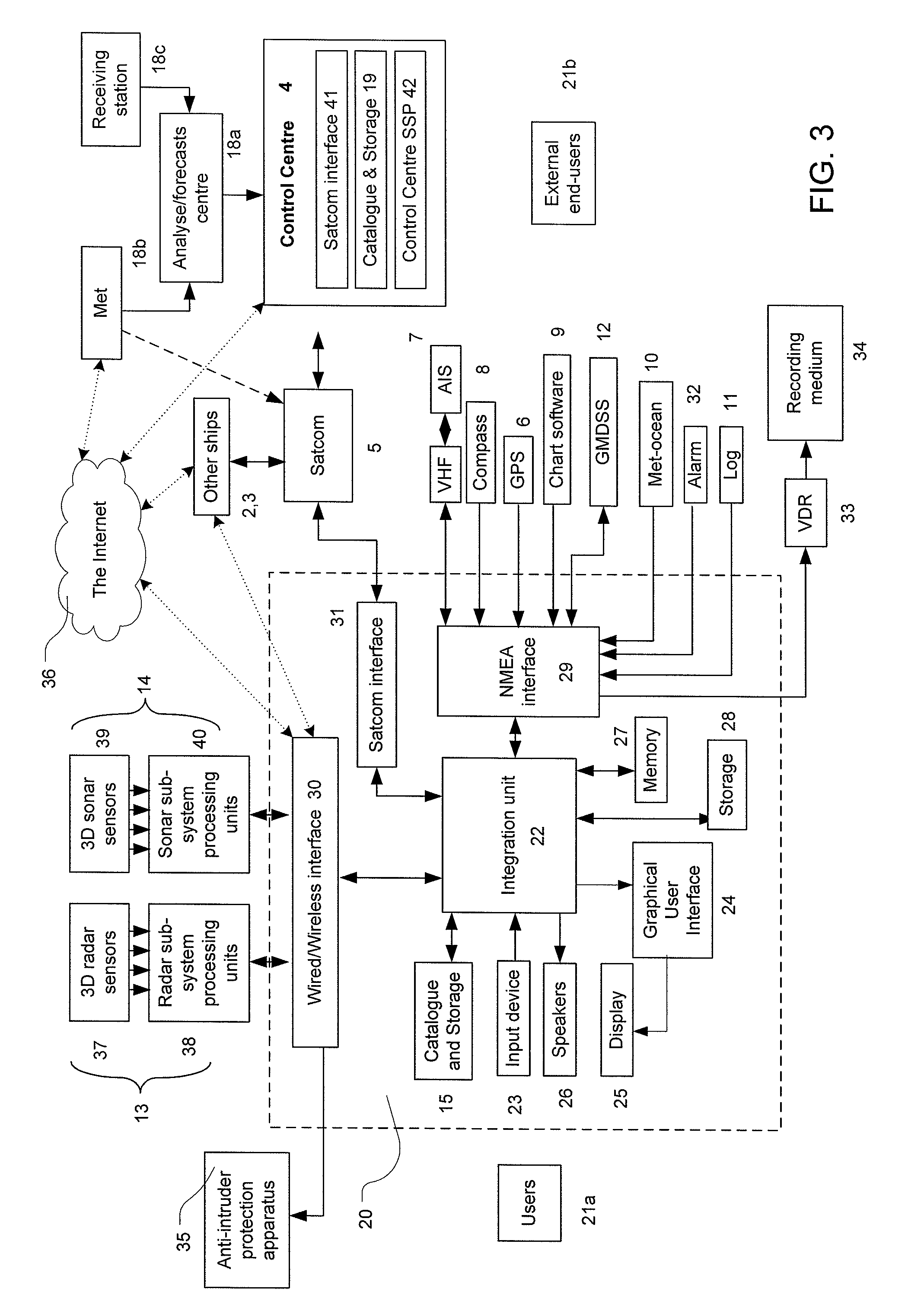

Manoeuvre and safety system for a vehicle or an installation

A system for a vehicle is provided for allowing a user of the vehicle or installation to obtain advanced and up-to-date information about the surroundings of the vehicle or installation and the vehicle or installation itself. The system may be located on a marine vessel and it integrates information from a number of different information sources, located both on and off the vessel, en including information from advanced radar and sonar subsystems on the ship, information from conventional instruments and sensors and information from onshore and offshore installations and EO satellites accessed via a control center onshore. The system may communicate with the control center via a communication satellite and / or wireless Internet, if available. A data processing apparatus for processing and presenting the data is also provided. The data is received, processed and presented in three dimensions in space and updated in real time or near real time such that time provides a fourth dimension to the data. A graphical user interface for presenting the data is also provided. The graphical user interface provides functionality for reporting an error in the system if the end user's own observations do not match the presented data. Additionally, a system for collecting data comprising more than one ship, the control center and means for the ships and the control center to communicate is provided. The system comprises a catalogue and storage network for storing collected data. All data is stored with an associated quality measure of the data.

Owner:FLIR SYST LTD

Event-driven fault diagnosis framework for automotive systems

ActiveCN102200487AVehicle testingRegistering/indicating working of vehiclesData ingestionAutomotive systems

The invention relates to an event-driven fault diagnosis framework for automotive systems. Systems and methods are used for capturing and analyzing significant parameter data from vehicle systems whenever a diagnostic trouble code (DTC) is triggered. A multi-dimensional matrix is constructed, with vehicles, DTCs, and parameter data comprising three dimensions of the matrix. The data matrix is populated with DTC and parameter data from many different vehicles, either when vehicles are taken to a dealer for service, or via wireless data download. Time can be added as a fourth dimension of the matrix, providing an indication of whether a particular system or component is temporally degrading. When sufficient data is accumulated, the data matrix is pre-processed, features are extracted from the data, and the features are classified, using a variety of mathematical techniques. Trained classifiers are then used to diagnose the root cause of any particular fault signal, and also to provide a prognosis of system health and remaining useful life.

Owner:GM GLOBAL TECH OPERATIONS LLC

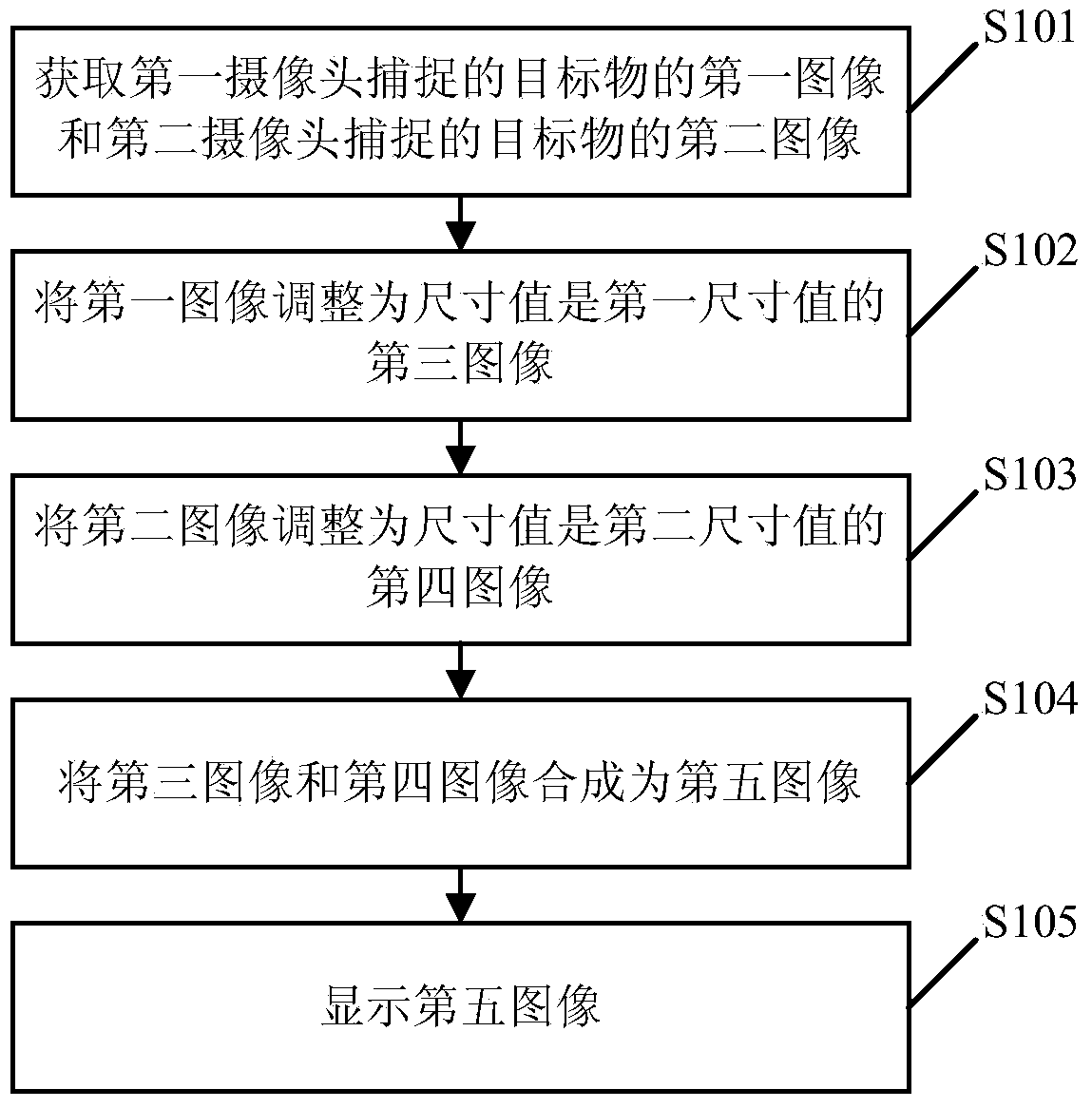

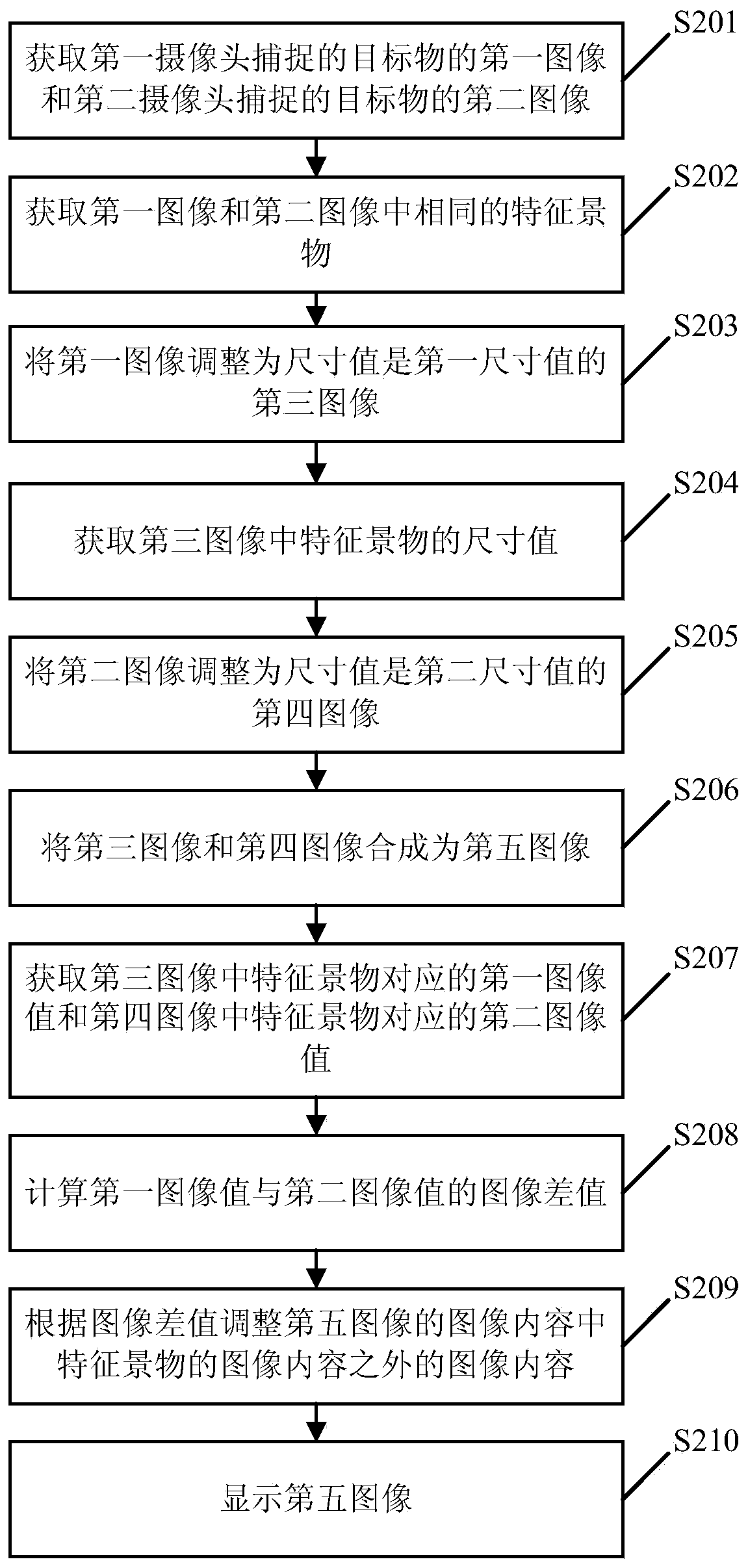

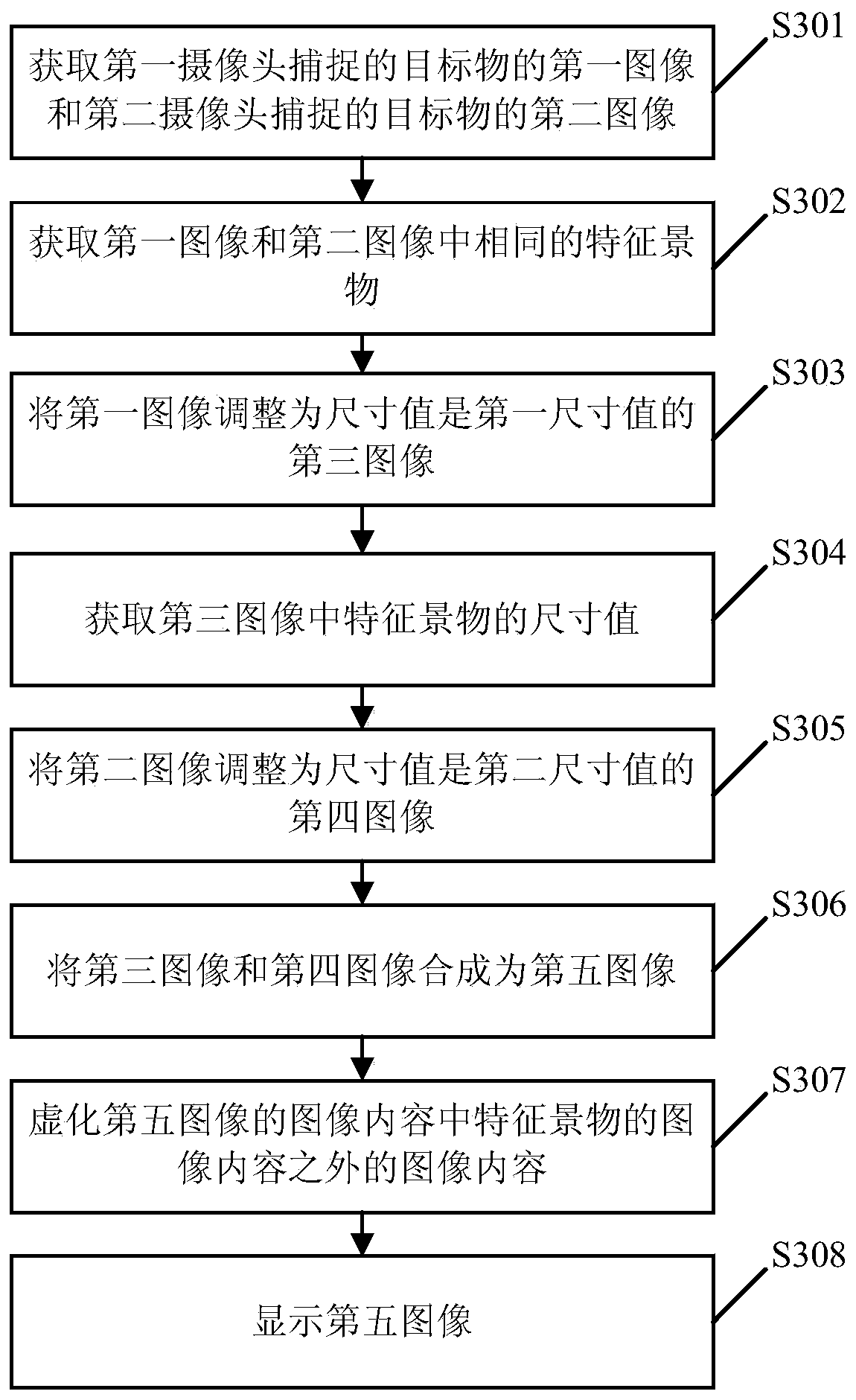

Photographing method and terminal

InactiveCN103856719AAchieve optical zoomSimple structureTelevision system detailsColor television detailsTarget captureFourth Dimension

The embodiment of the invention discloses a photographing method and a terminal. The photographing method comprises the following steps: acquiring a first image of a target captured by a first camera and a second image of the target captured by a second camera, wherein the focal length of the first image captured by the first camera is smaller than that of the second image captured by the second camera; adjusting the first image to be a third image of a first dimension value; adjusting the second image to a fourth image of a fourth dimension value; synthesizing the third image and the fourth image to form a fifth image; displaying the fifth image. By adopting the embodiment, the optical zoom can be realized by utilizing two cameras, and the structure is simple.

Owner:SHENZHEN GIONEE COMM EQUIP

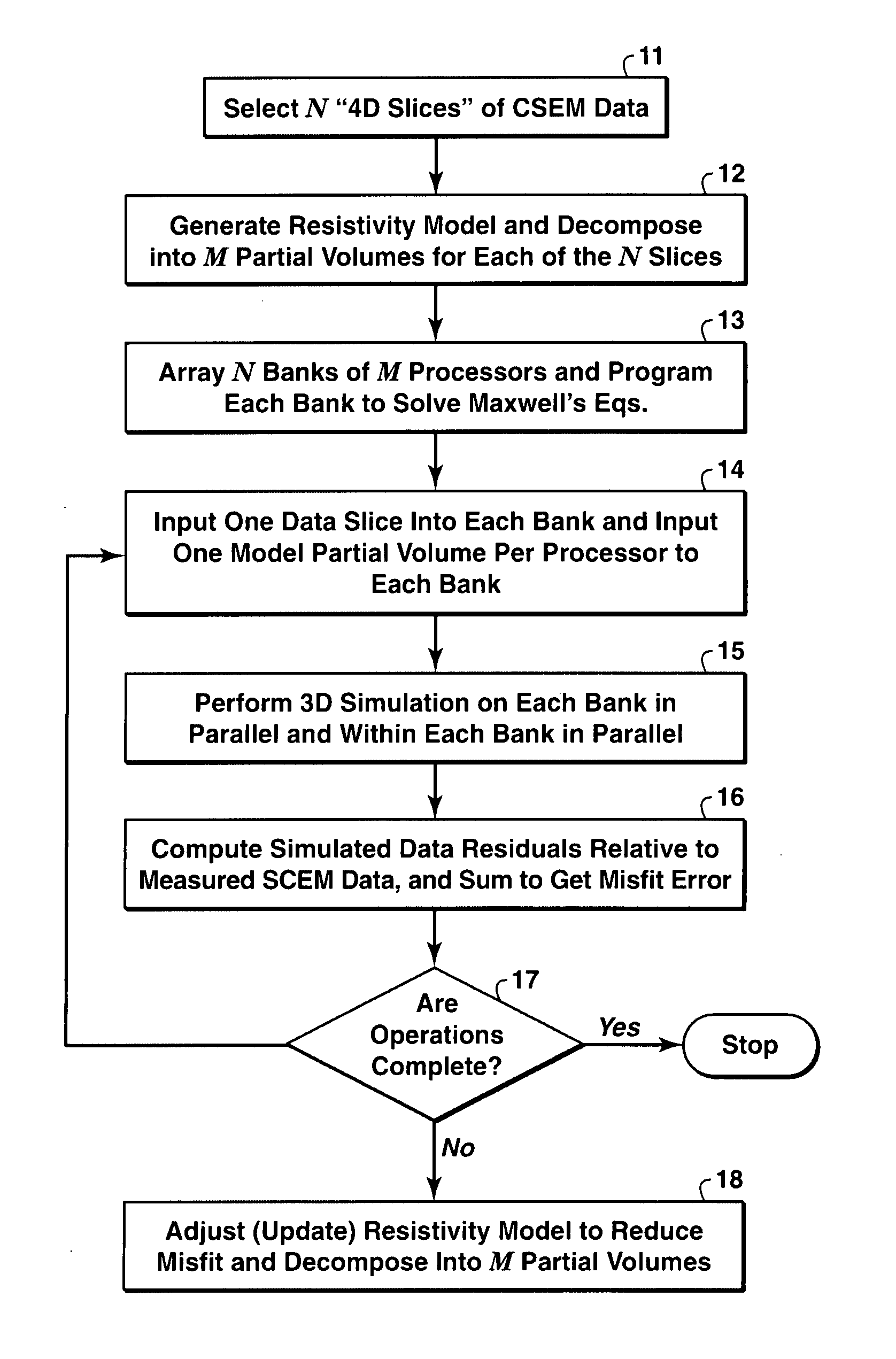

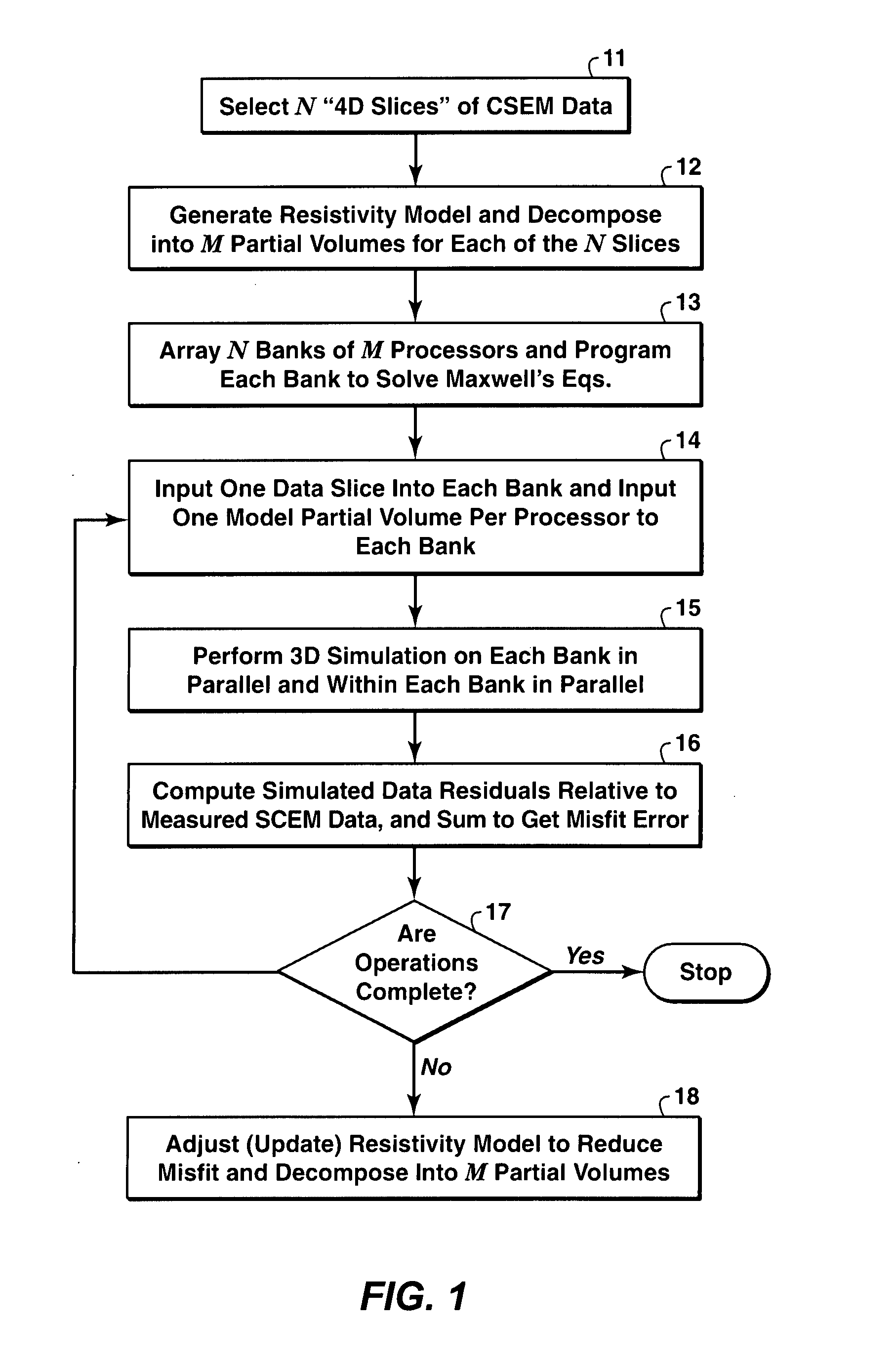

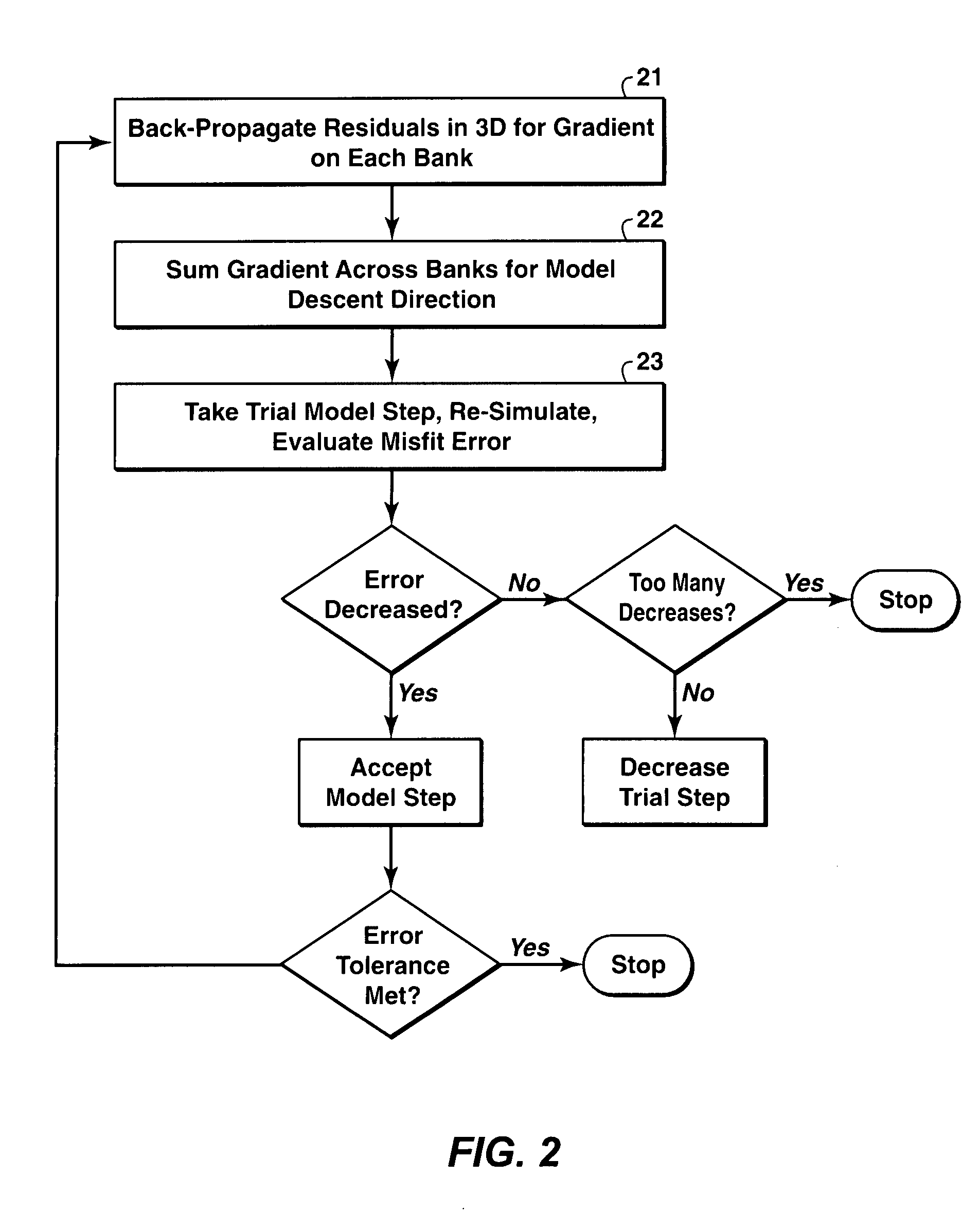

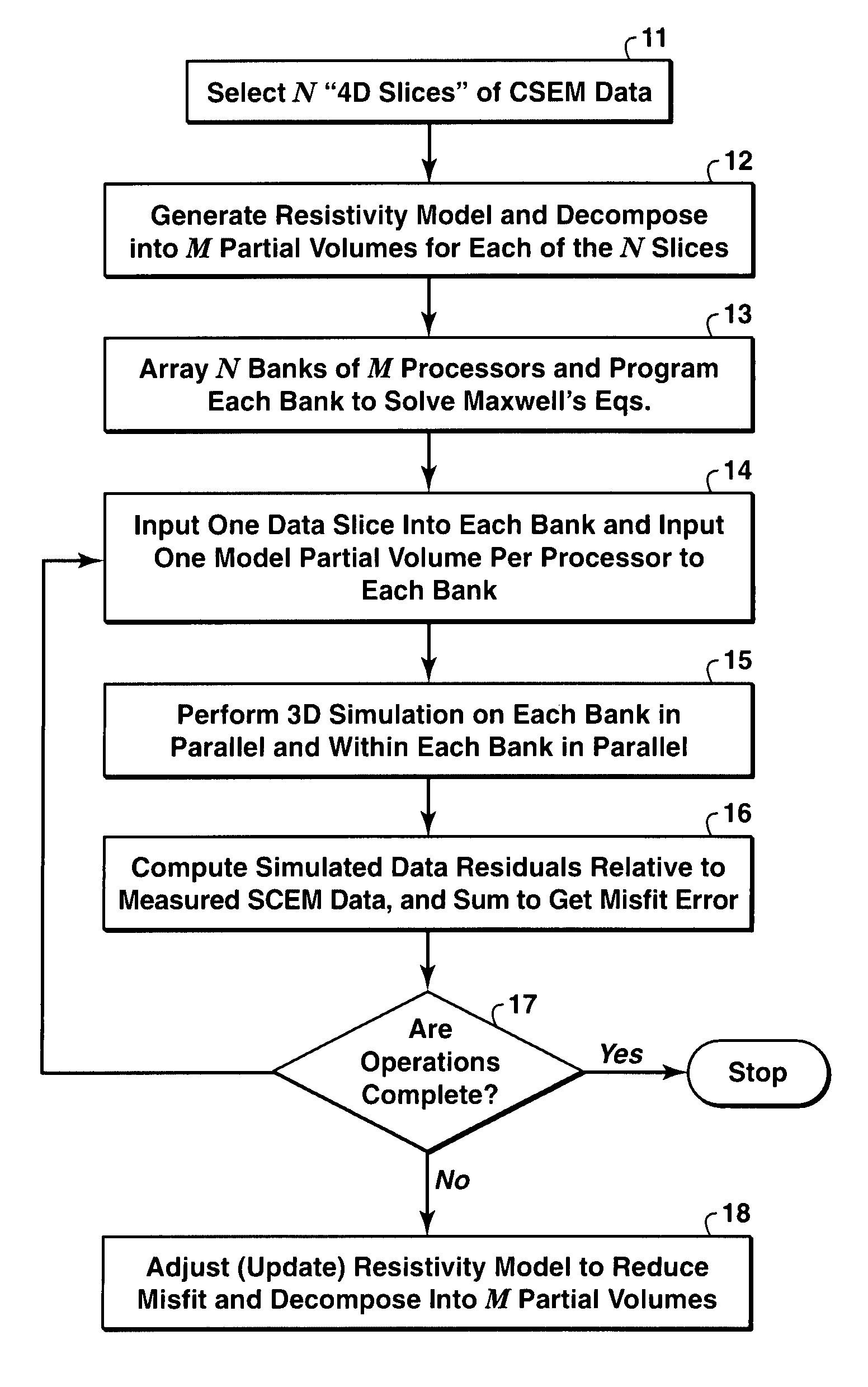

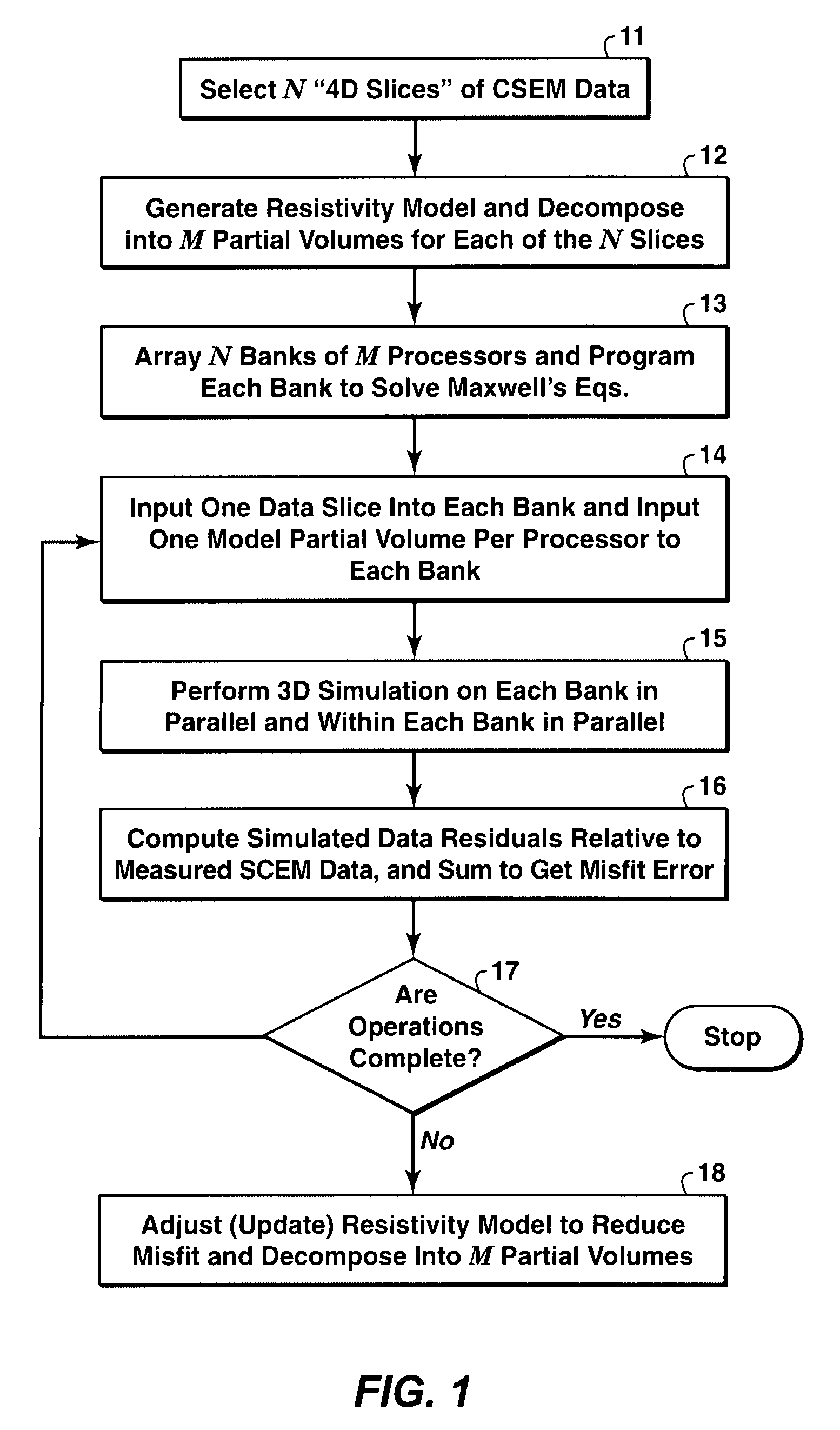

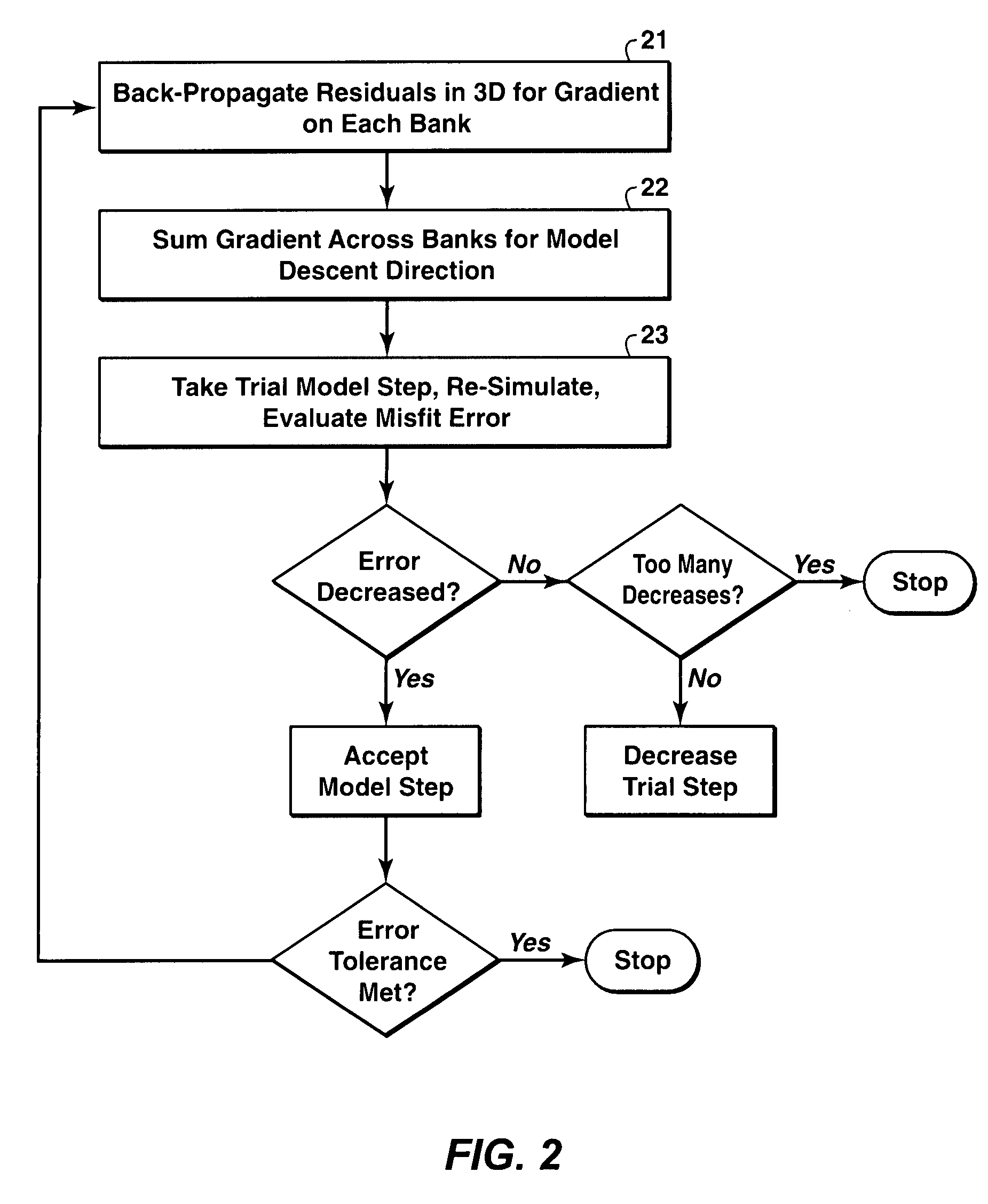

Electromagnetic Imaging By Four Dimensional Parallel Computing

ActiveUS20100224362A1Reduce the differenceSurveyFluid removalControlled source electro-magneticFourth Dimension

Method for organizing computer operations on a system of parallel processors to invert electromagnetic field data (11) from a controlled-source electromagnetic survey of a subsurface region to estimate resistivity structure (12) within the subsurface region. Each data processor in a bank of processors simultaneously solves Maxwell's equations (13) for its assigned geometrical subset of the data volume (14). Other computer banks are simultaneously doing the same thing for data associated with a different source frequency, position or orientation, providing a “fourth dimension” parallelism, where the fourth dimension requires minimal data passing (15). In preferred embodiments, a time limit is set after which all processor calculations are terminated, whether or not convergence has been reached.

Owner:EXXONMOBIL UPSTREAM RES CO

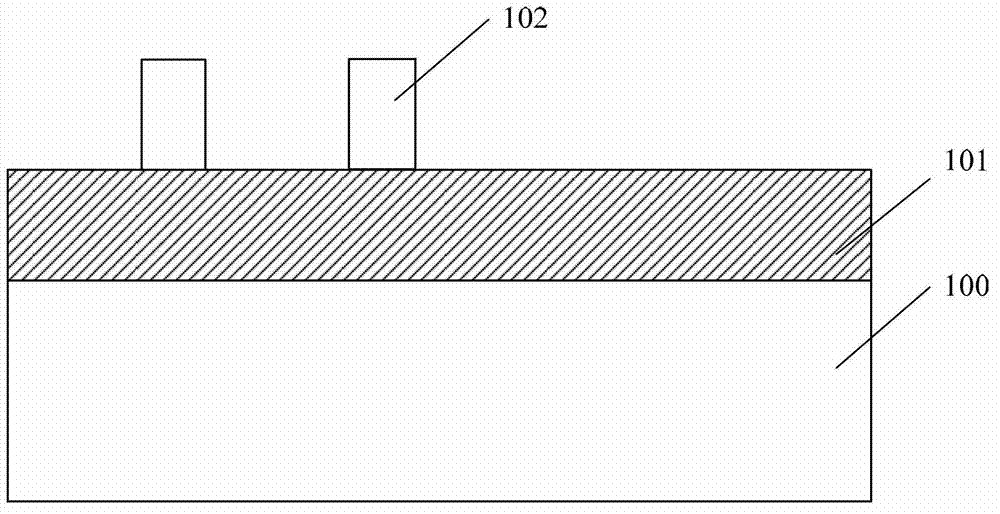

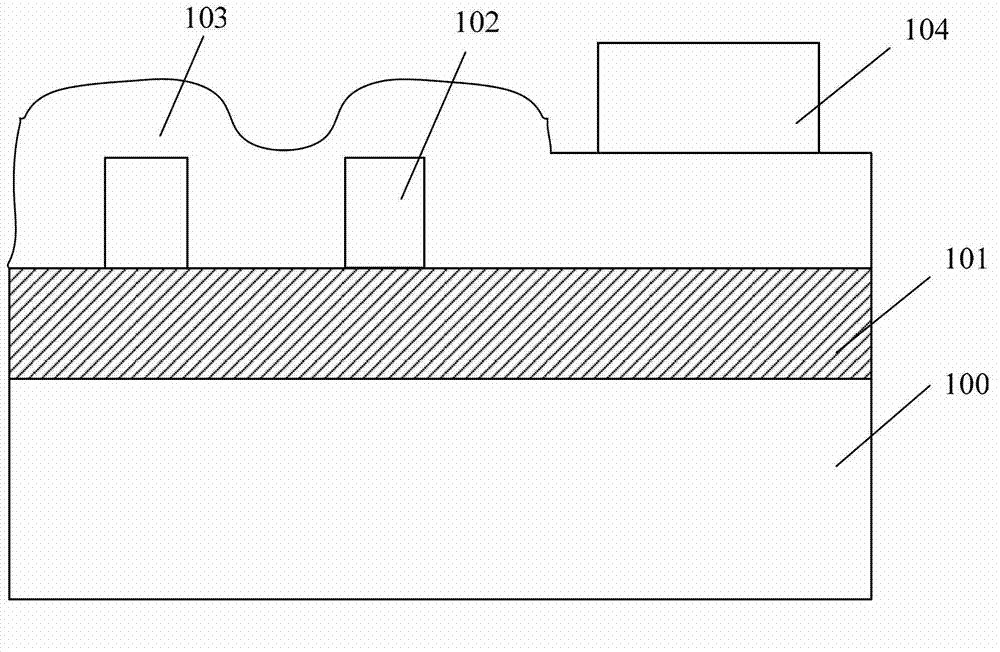

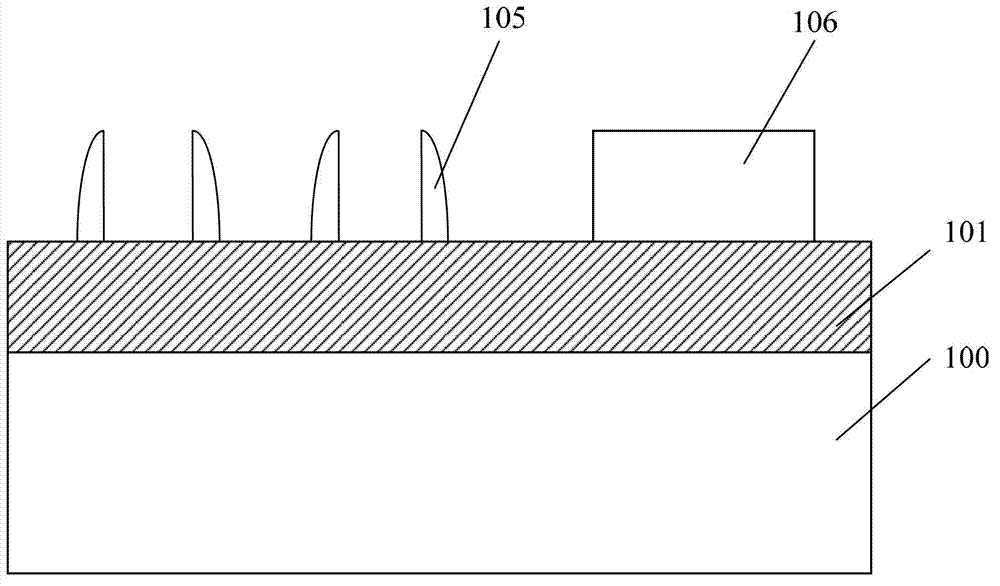

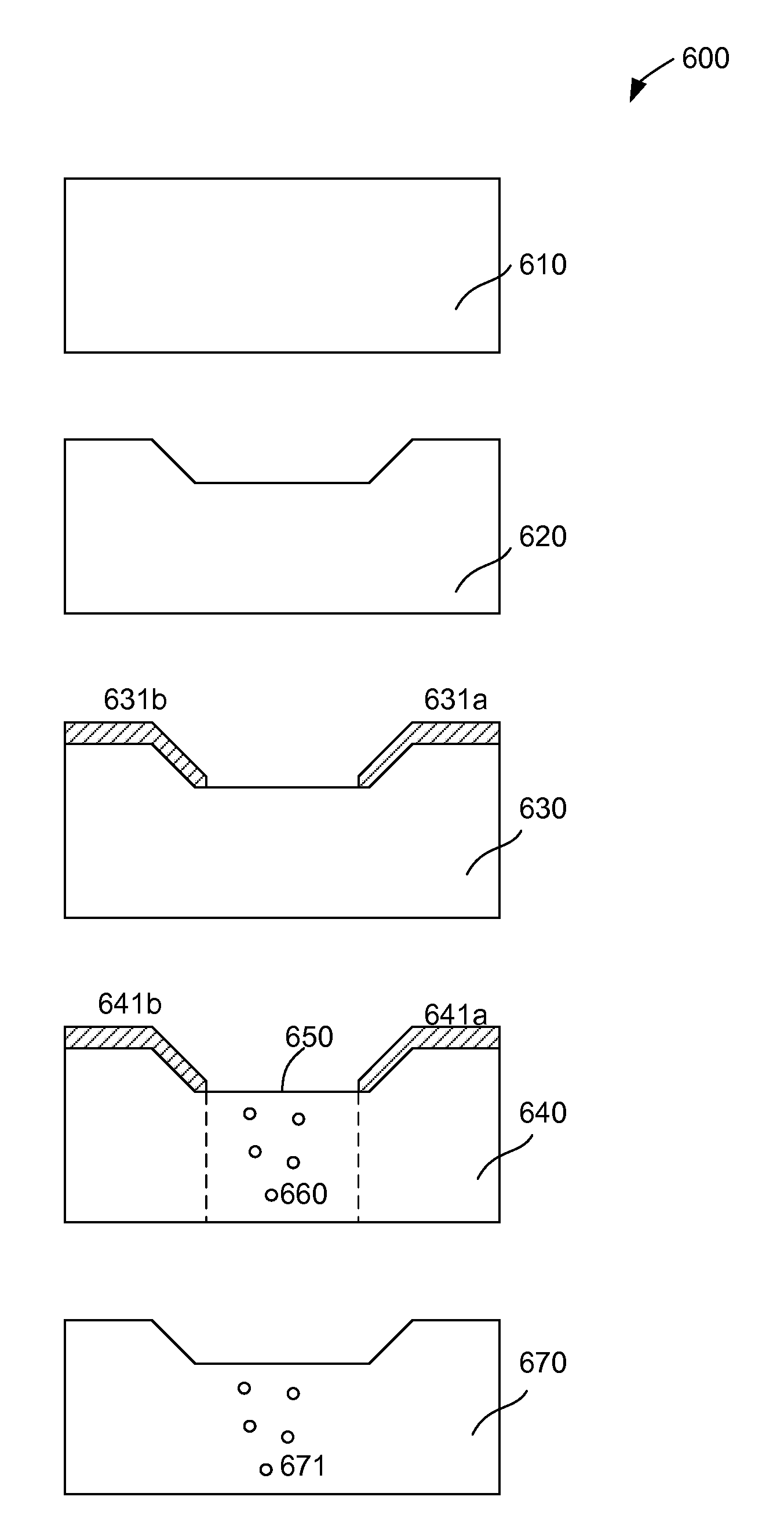

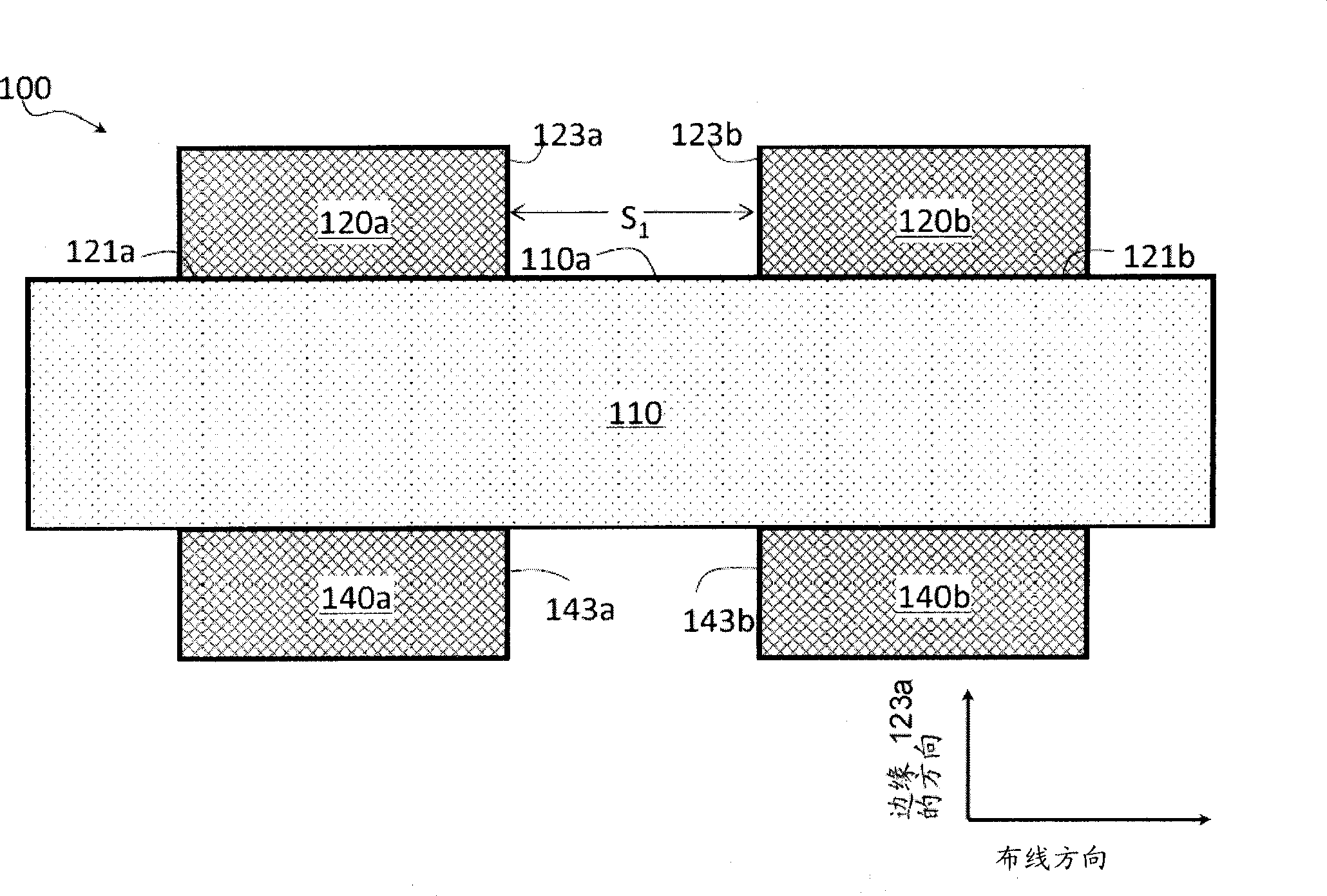

Forming method of multiple patterns

InactiveCN103928303ASimple processLow costSemiconductor/solid-state device manufacturingFourth DimensionSemiconductor

Disclosed is a forming method of multiple patterns. The method comprises: providing a semiconductor substrate, and forming an etching target layer on the semiconductor substrate; forming a first mask layer on the etching target layer, the first mask layer being provided with a first dimension pattern and a second dimension pattern; forming a first side wall material layer and a second side wall material layer on the etching target layer; performing back-etching on the second side wall material layer to form a side wall, and by taking the side wall as a mask, etching the first side wall material layer, the side wall disposed around the first dimension pattern and the residual first side wall material layer forming a third dimension pattern, the side wall disposed around the second side wall material layer and the residual first side wall material layer forming a fourth dimension pattern; and by taking the first dimension pattern, the second dimension pattern, the third dimension pattern and the fourth dimension pattern as masks, etching the etching target layer, and forming a target pattern. The forming method of the multiple patterns has the advantages of simple process and low cost.

Owner:SEMICON MFG INT (SHANGHAI) CORP

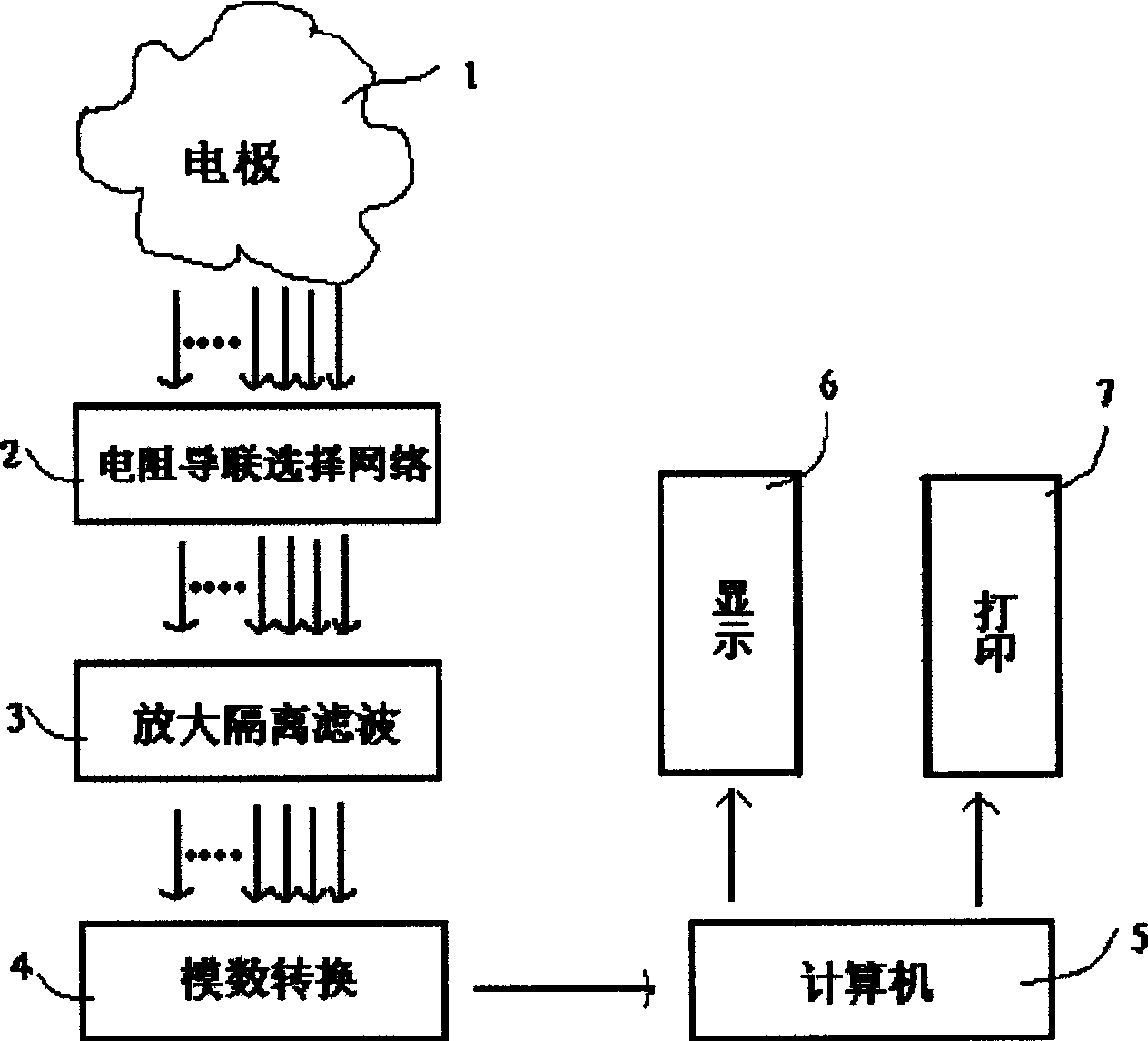

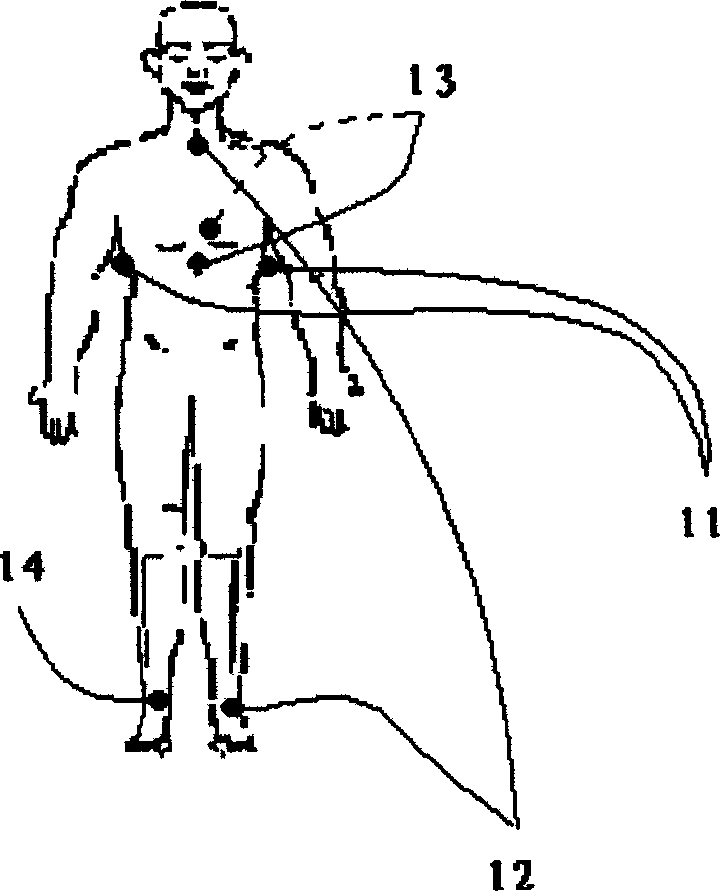

Realtime four-dimensional electro cardiogram imaging method and device

A real-time 4D electrocardiogram imaging method and its apparatus are disclosed. The mutually perpendicular three pairs of electrodes are arranged around heart to form a 3D space. Their intersection point is the origin point of said 3D space. Said three pairs of electrodes express X, Y and Z axises and time expressed the fourth dimension. The instantaneous cardioelectric voltages recorded by three pairs of electrodes form the instantaneous position of 3D cardioelectric vector. The continuous instantaneous positions are linked by lines to form the 4D electrocardiogram, which is dynamically displayed by computer.

Owner:张士东

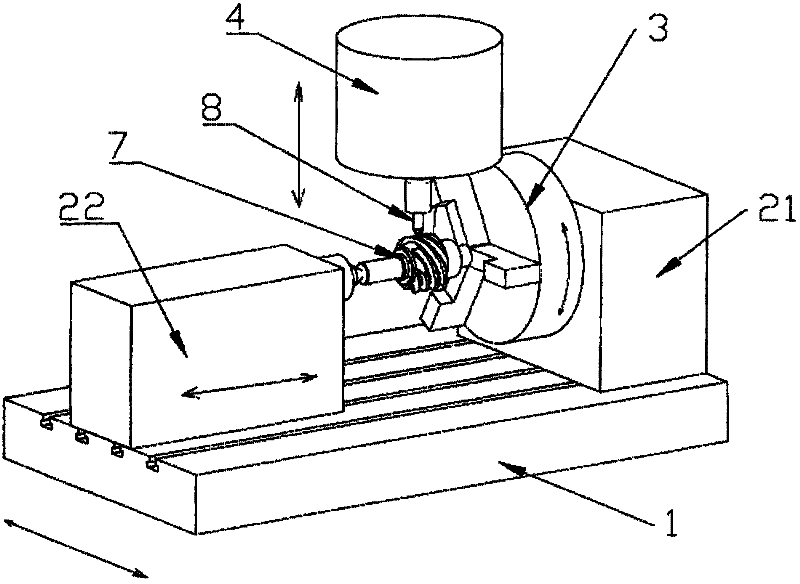

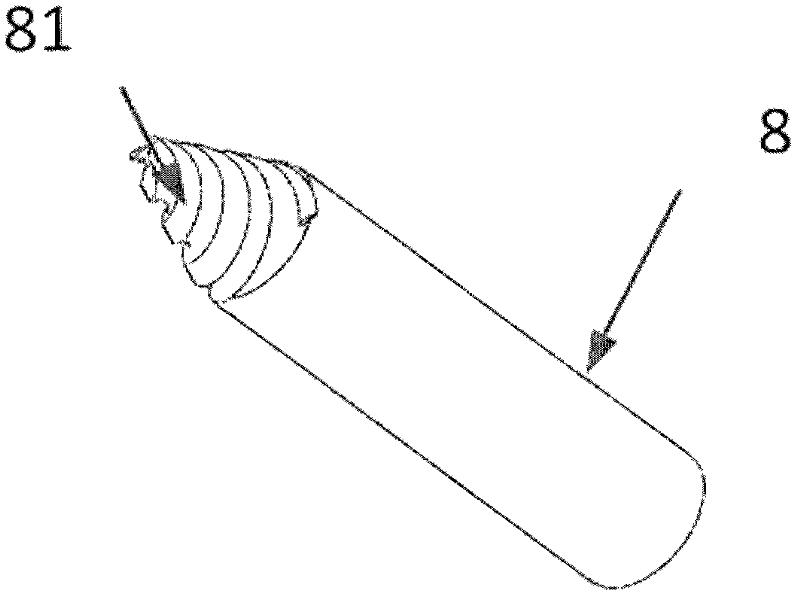

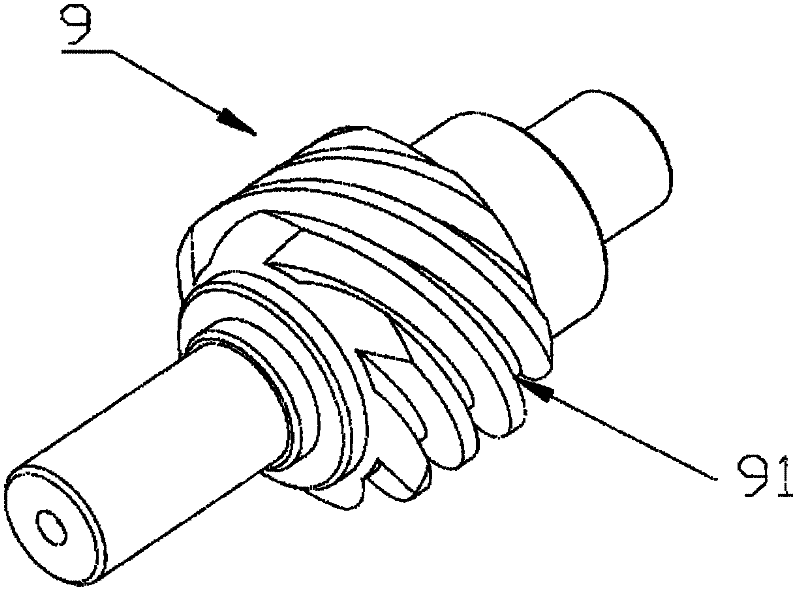

Machining method of worm by milling instead of turning and implementation device thereof

The invention discloses a machining method of a worm by milling instead of turning and an implementation device thereof, wherein a numerically-controlled machine is adopted to assemble and fix a worm blank to be machined, and the worm blank is driven to respectively do program-controlled displacements in a two-dimensional plane where a central shaft is located along the extending axial direction of the central shaft and the axial direction vertical to the central shaft through program control, and further, do program-controlled autorotation along the one-dimensional axial direction of the central shaft; meanwhile, the program-controlled telescopic adjustment relative to the surface of the worm blank of a milling cutter is adopted to carry out milling machining in a fourth-dimension axial direction vertical to the two-dimensional plane; and the driving on the fourth-dimension axial direction is controlled through a numerically-controlled machine controller, so as to realize the full-automatic machining of the worm. Compared with the traditional machining manner, the processing hour for machining the worm is obviously shortened, the efficiency and the quality for machining are improved, meanwhile, the dependence on technicians and the labor operating intensity of workers are lowered, so that the machining method of the worm by milling instead of turning and the implementation device thereof are more focused on holding the pass of the quality of a finished product. In addition, the implementation conditions of the machining method which uses milling instead of turning are mature, thus, the method is easy to be popularized.

Owner:SUZHOU LIDE PRECISION IND

Electromagnetic imaging by four dimensional parallel computing

ActiveUS7808420B2Reduce the differenceSurveyFluid removalControlled source electro-magneticTime limit

Owner:EXXONMOBIL UPSTREAM RES CO

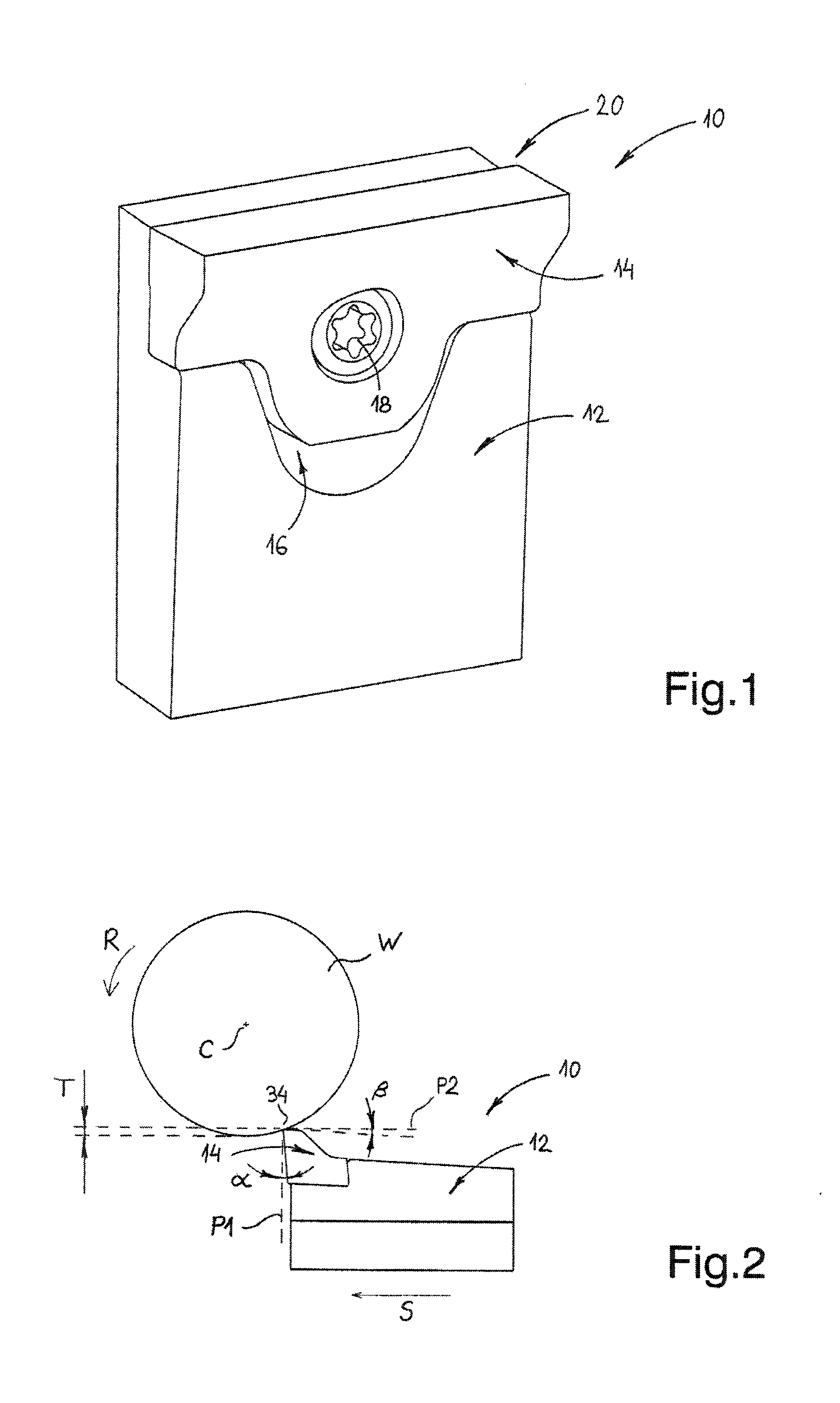

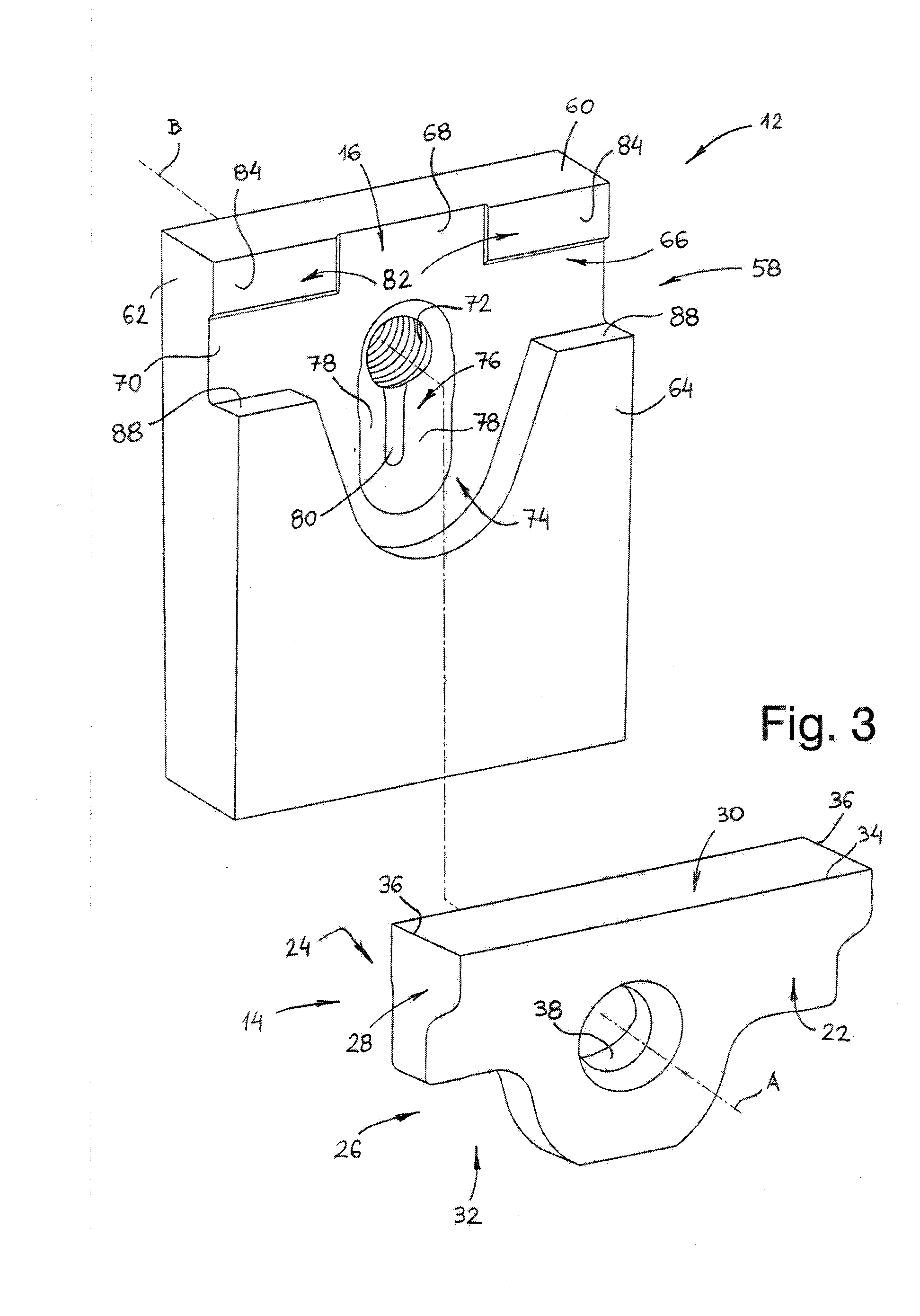

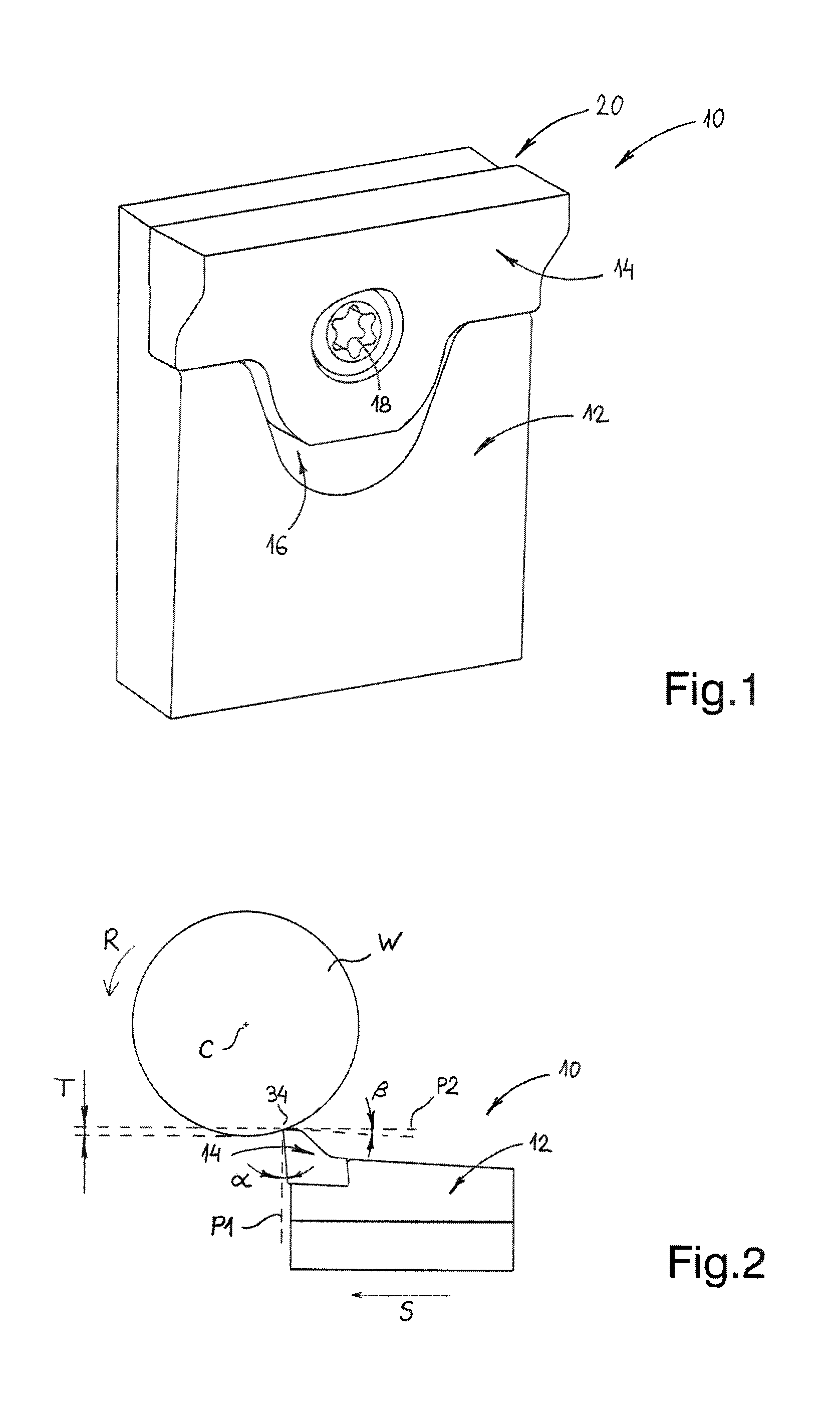

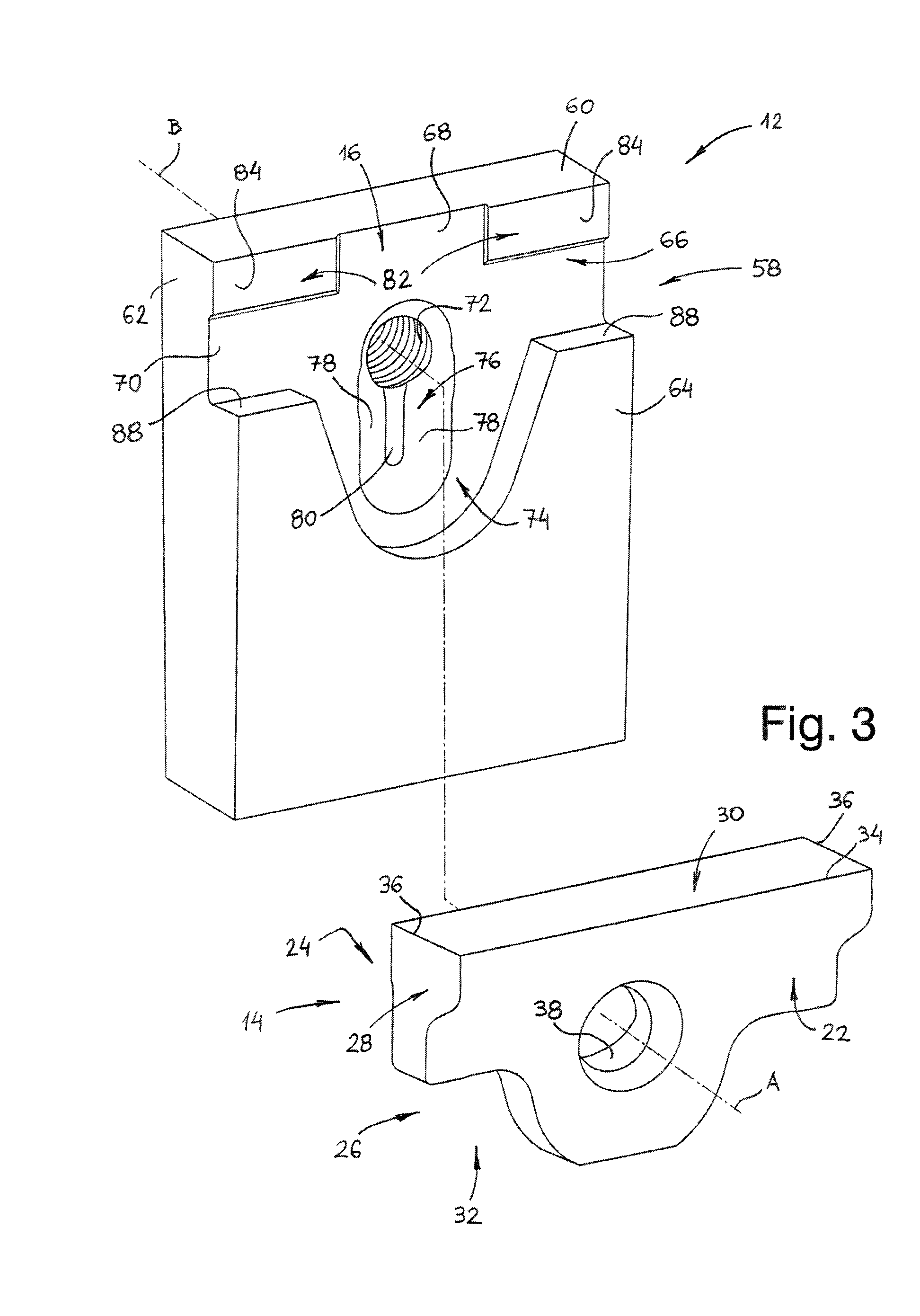

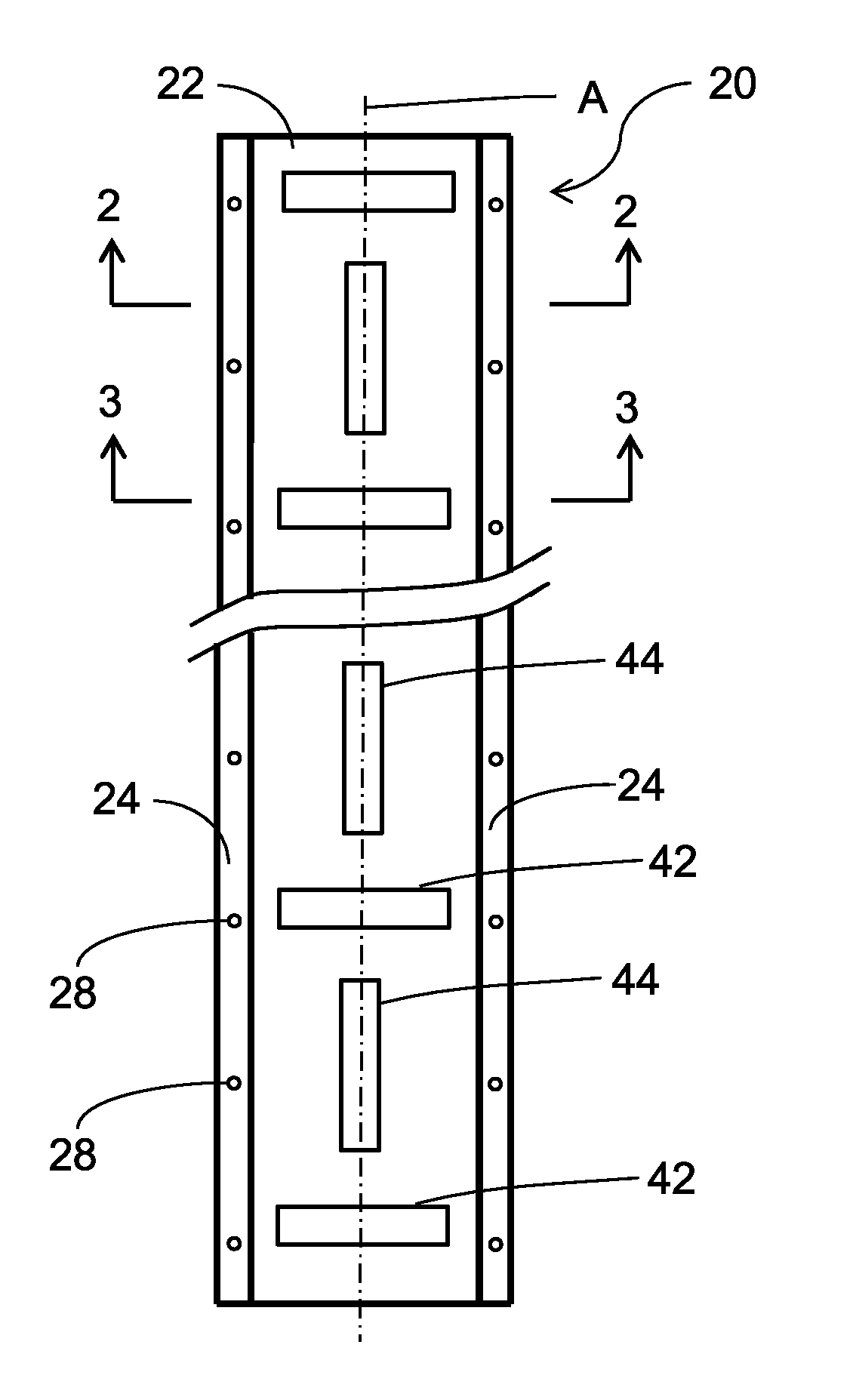

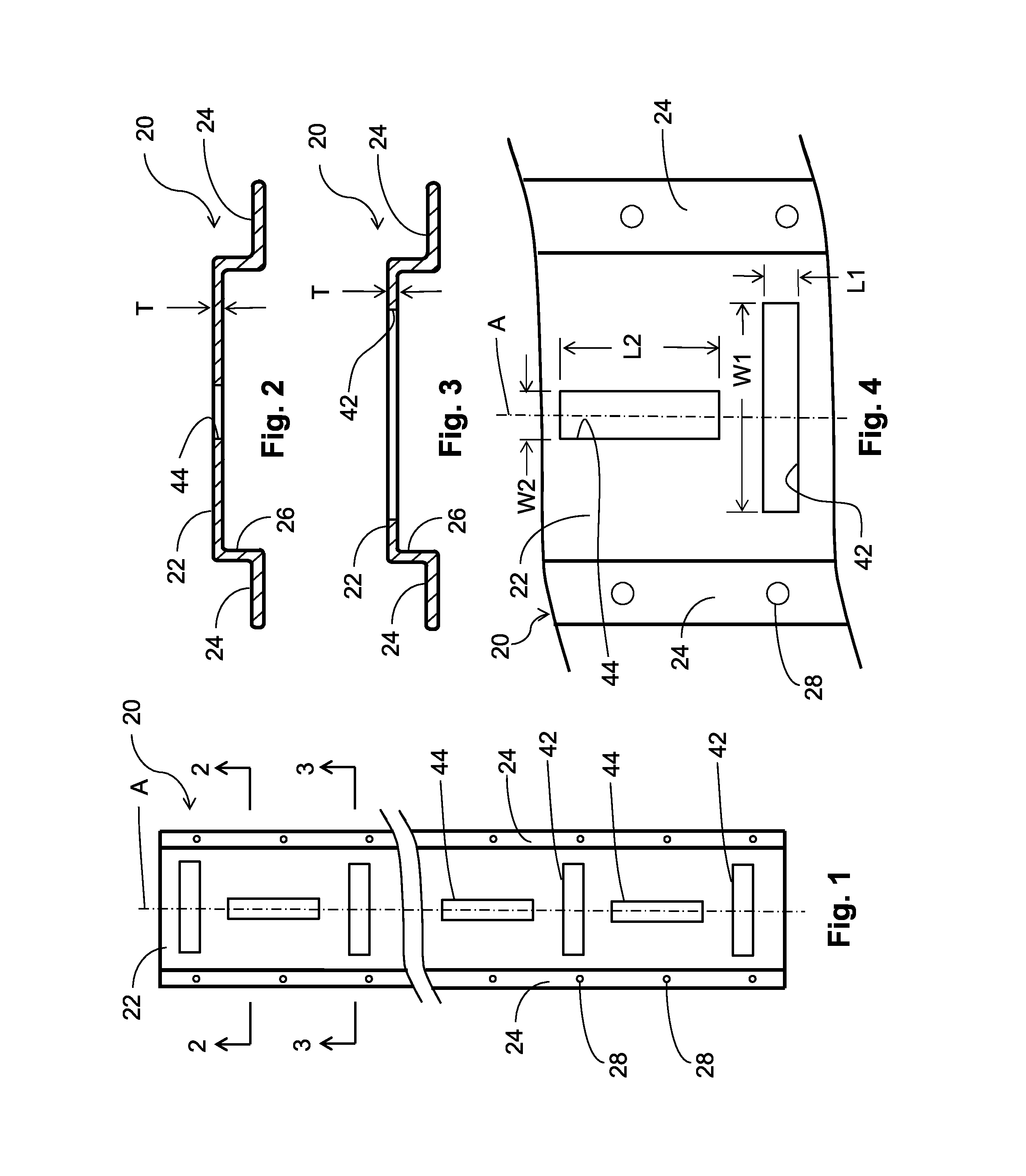

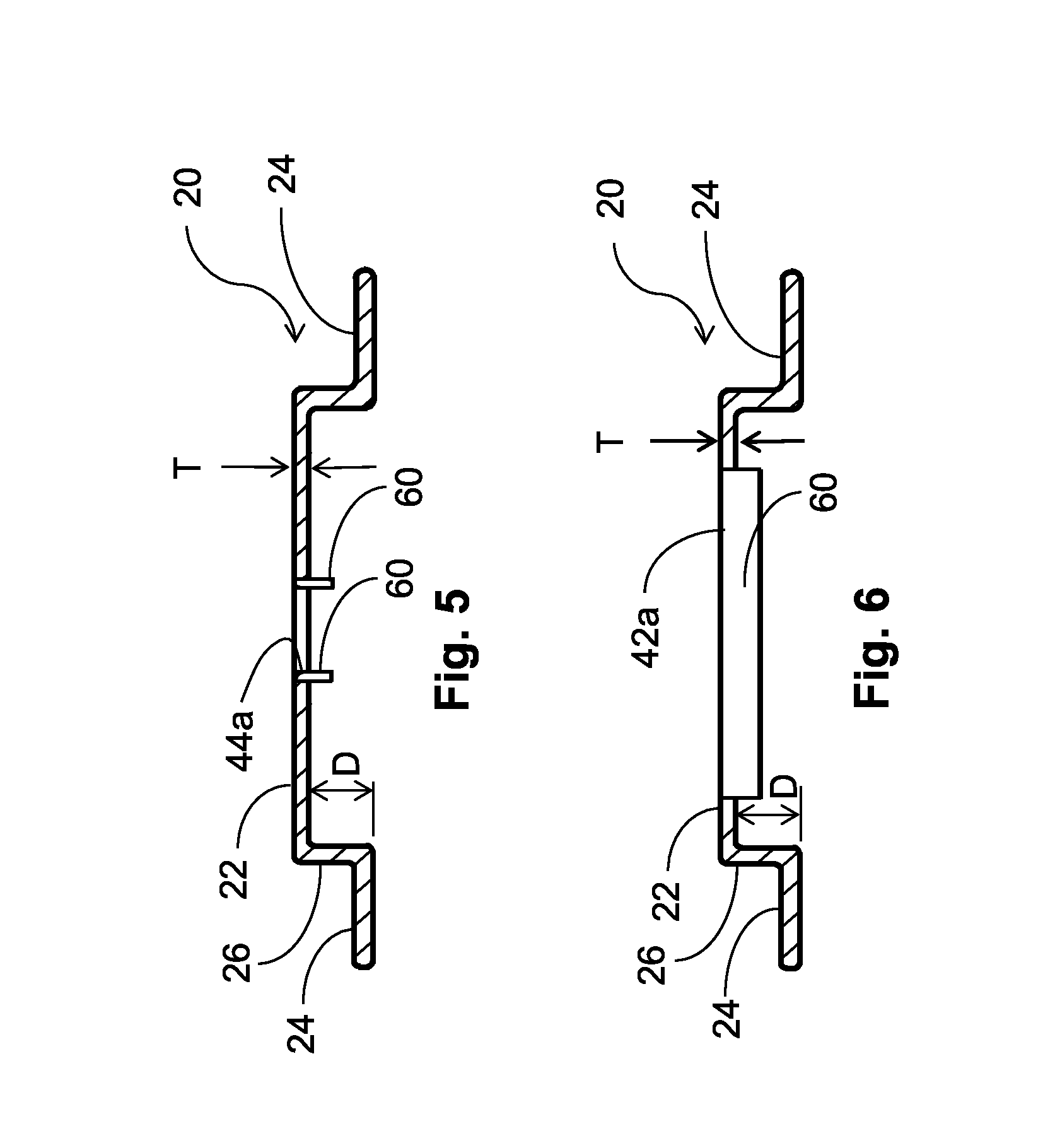

Cutting Tool and Cutting Insert Therefor

A cutting tool has a cutting insert retained within an insert pocket of an insert holder by a retaining screw. Spaced apart first insert rear abutment surfaces abut spaced apart first pocket rear abutment surfaces, a second insert rear abutment surface abuts a second pocket rear abutment surface, and spaced apart insert lower abutment surfaces abut spaced apart pocket lower abutment surfaces. The cutting insert has a first dimension taken between extremities of the insert side surfaces, a second dimension taken between extremities of the insert upper and lower surfaces, and, a fourth dimension taken between the insert lower abutment surfaces and the insert upper surface. The size ratio between the fourth dimension and the second dimension is in the range of 0.2 to 1, and, preferably, in the range of 0.55 to 0.6. The size ratio between the first dimension and the second dimension is in the range of 1 to 2.

Owner:ISCAR LTD

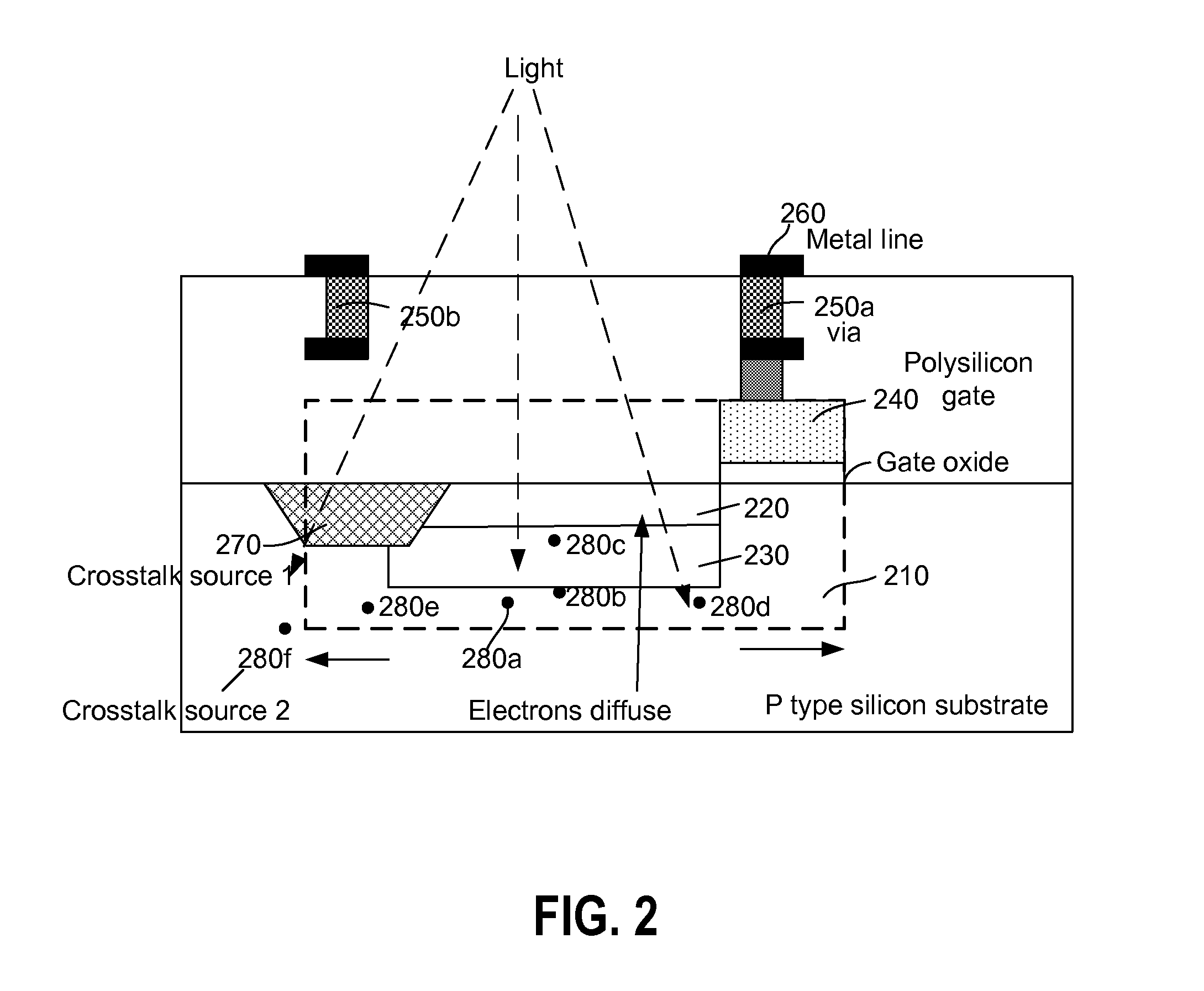

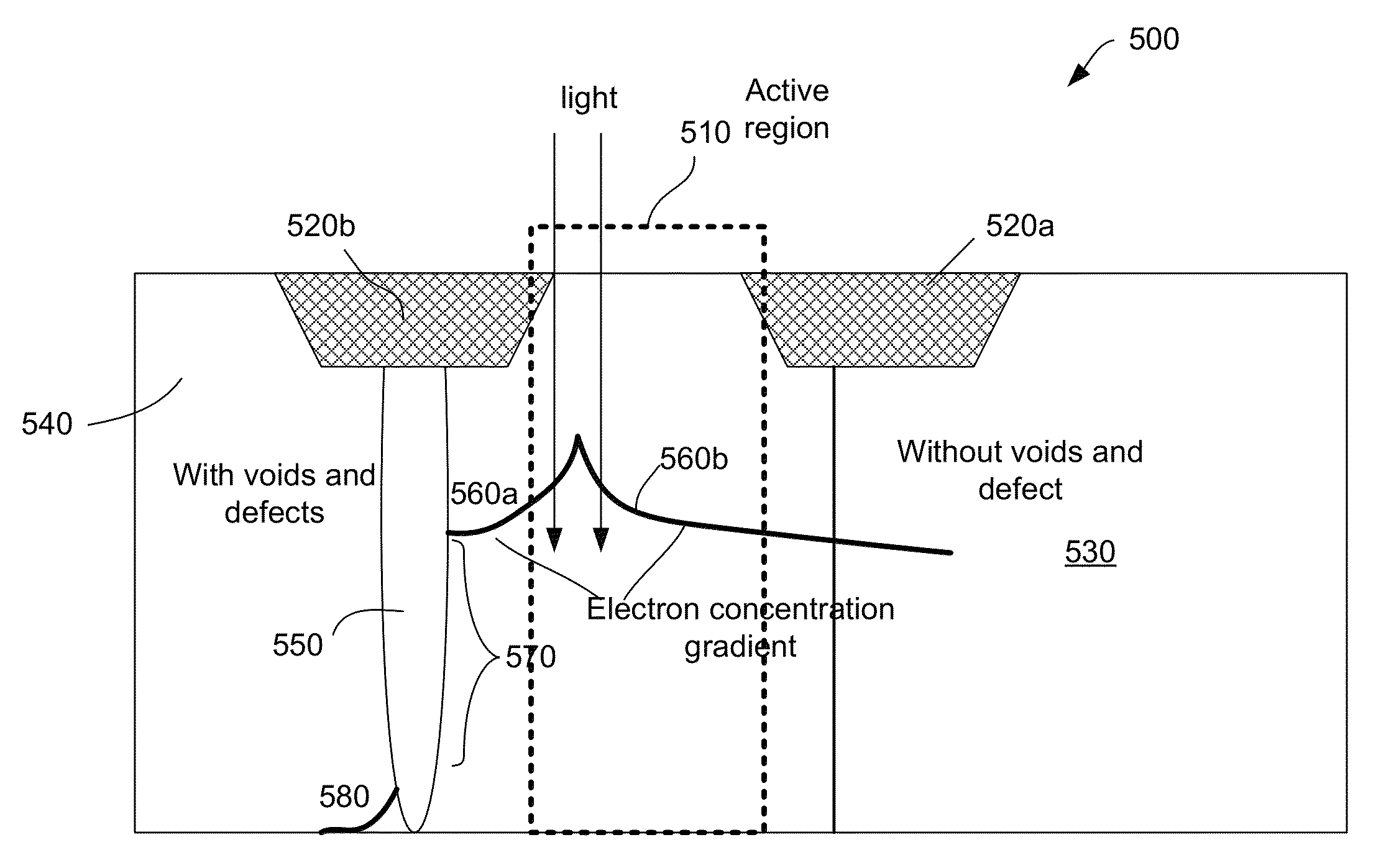

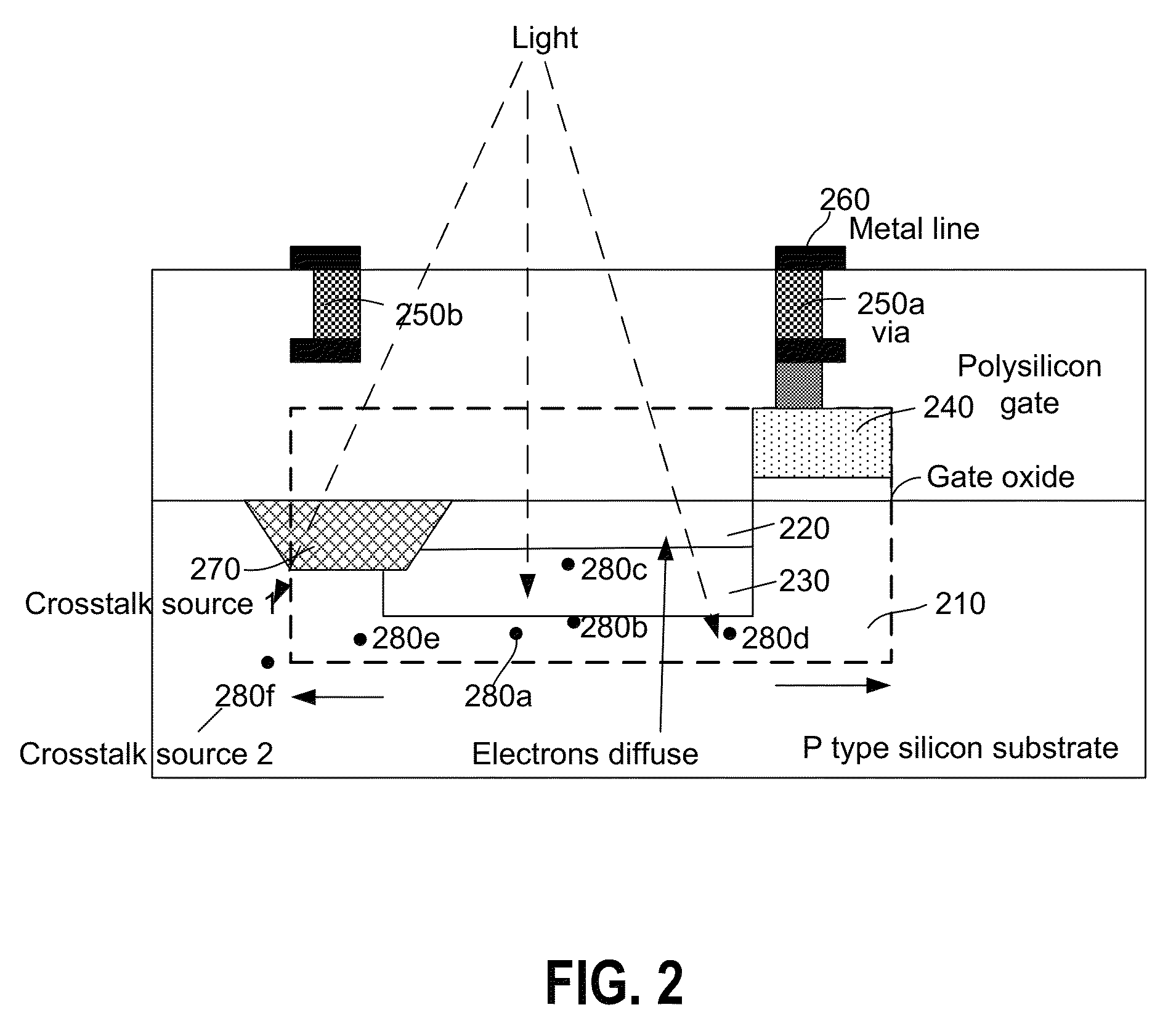

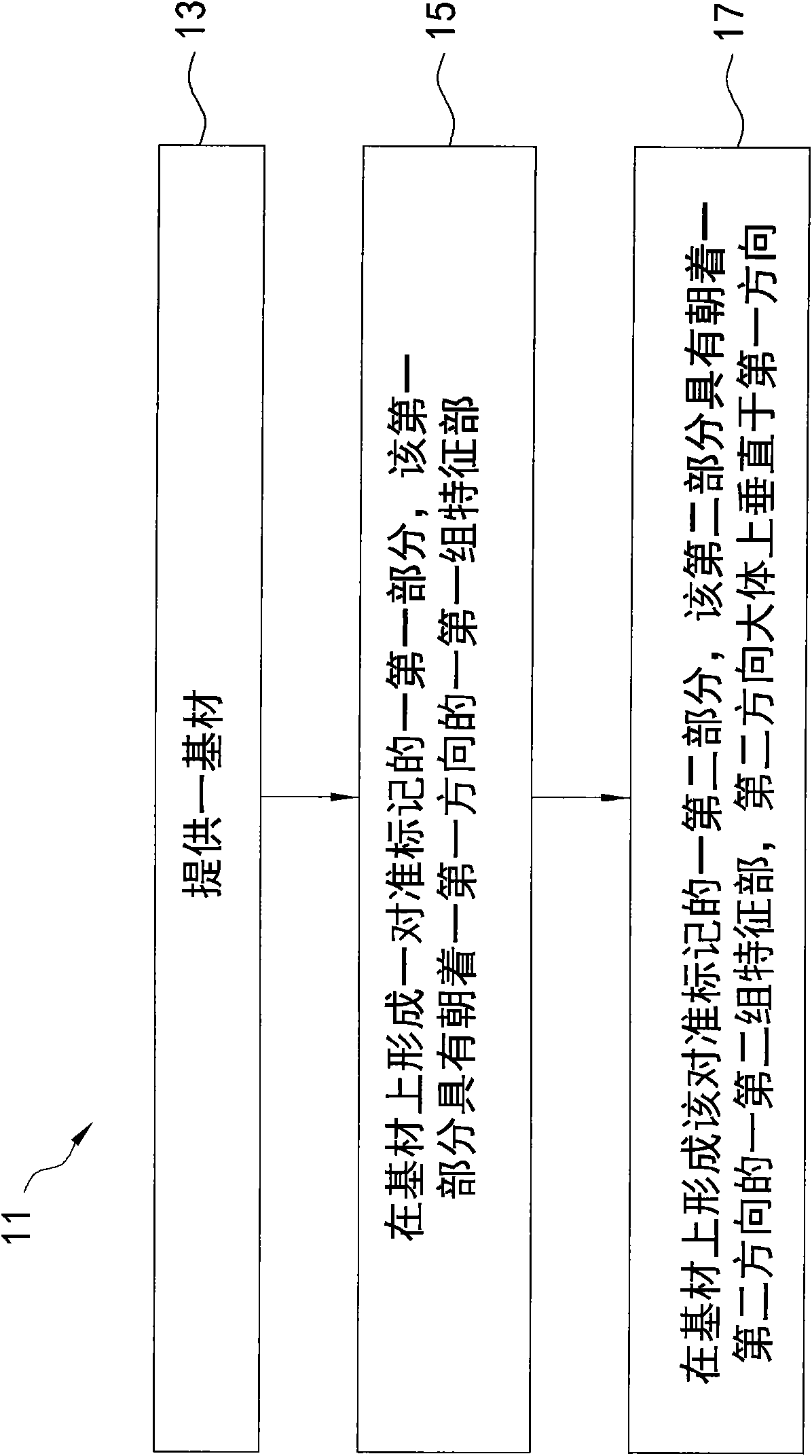

Method and system for CMOS image sensing device

ActiveUS20110187909A1Wide rangeReduce and eliminate blooming effects in image capturingTelevision system detailsTelevision system scanning detailsCMOSFourth Dimension

Method and system for manufacturing CMOS image sensing device with reduced blooming. The method includes a step for providing a substrate material. The substrate material can be characterized by a first dimension and a second dimension. In addition, the method includes a step for defining an active region on the substrate material. The active region is characterized by a third dimension and a fourth dimension. The method further includes a step for defining a non-active region on the substrate material. The non-active region is different from the active region. The non-active region is characterized by a fifth dimension and a sixth dimension, the non-active region including a silicon material. The method includes a step for defining a depletion region within the active region. In addition, the method includes a step for forming an n-type region positioned above the depletion region.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

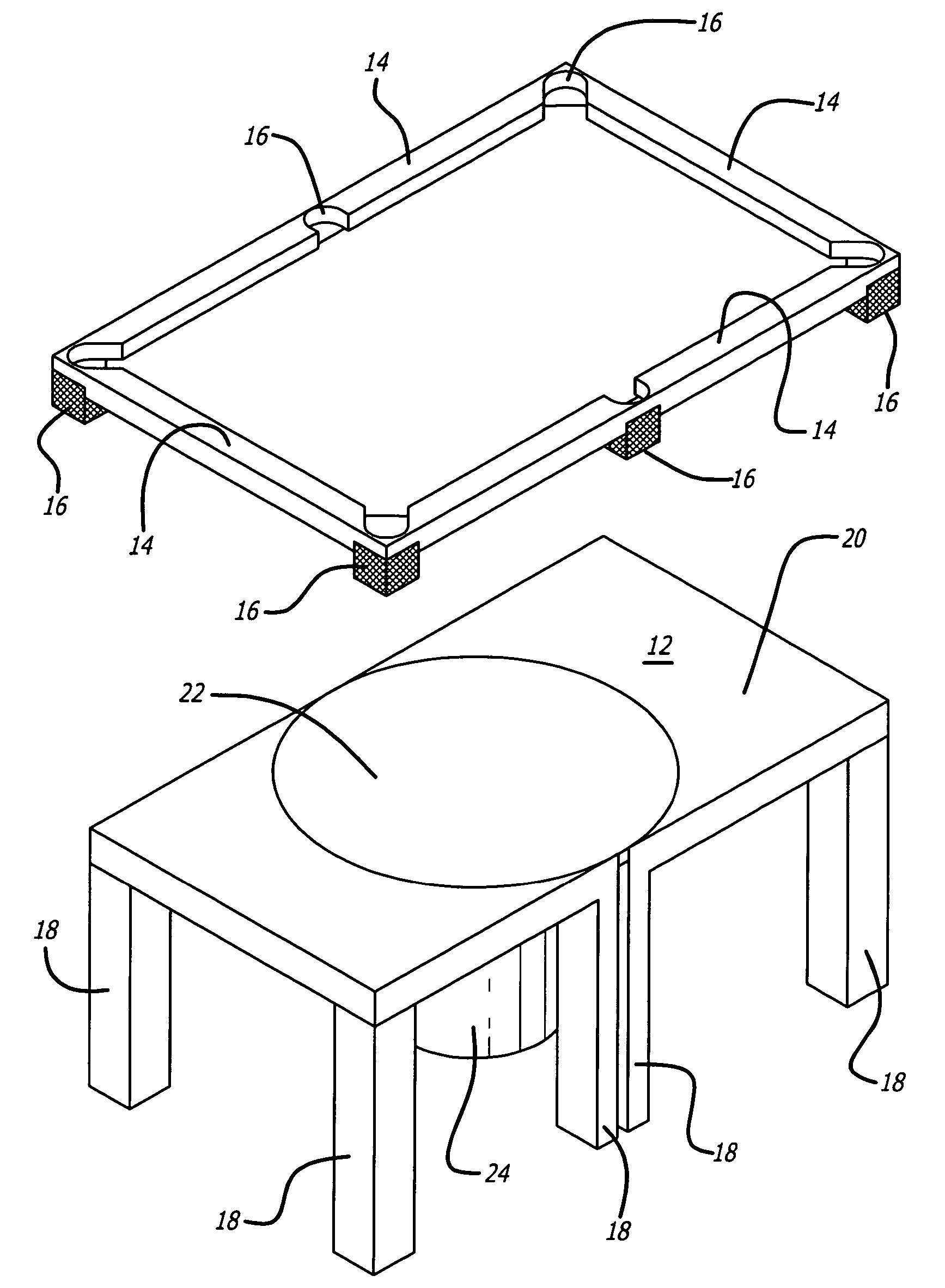

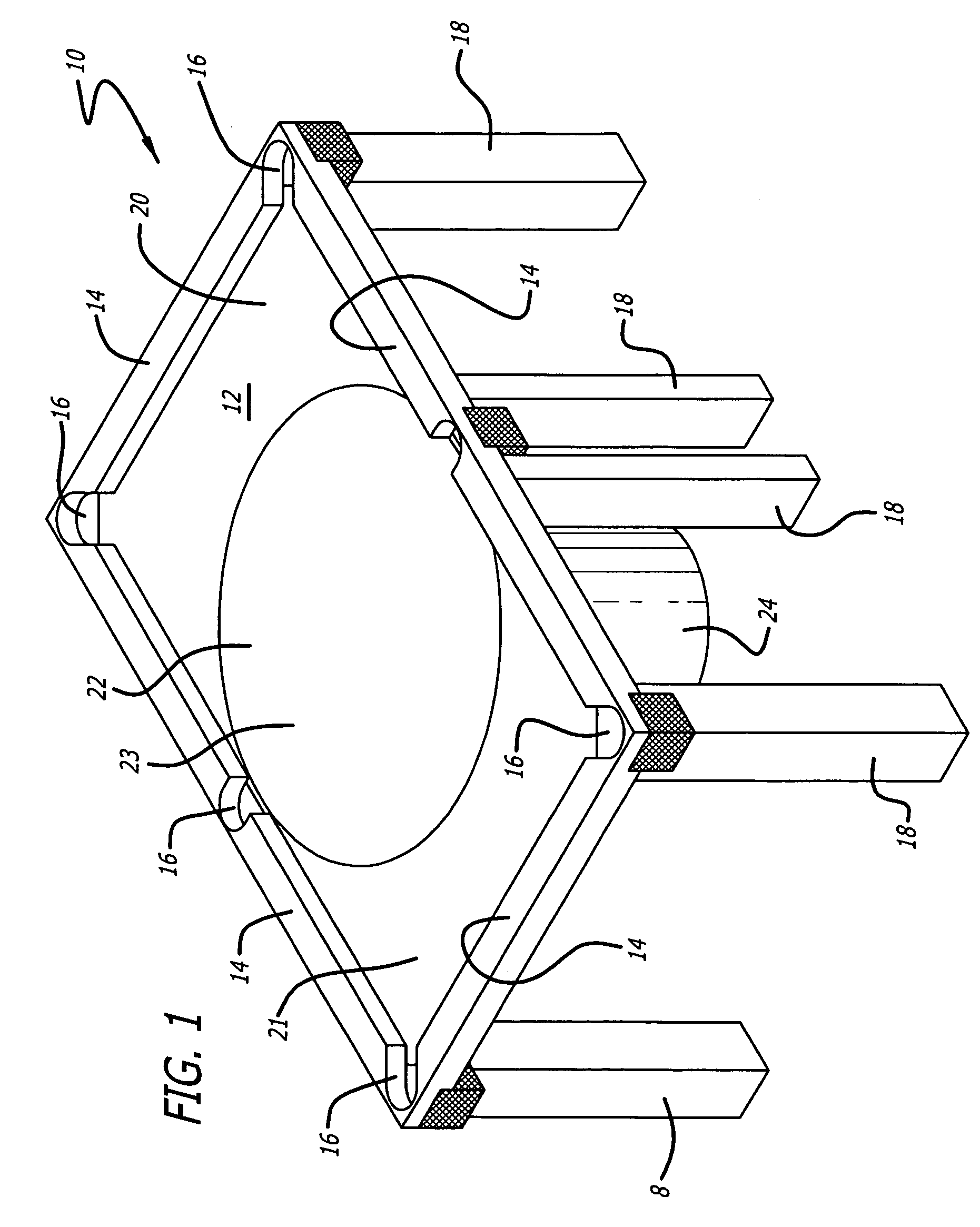

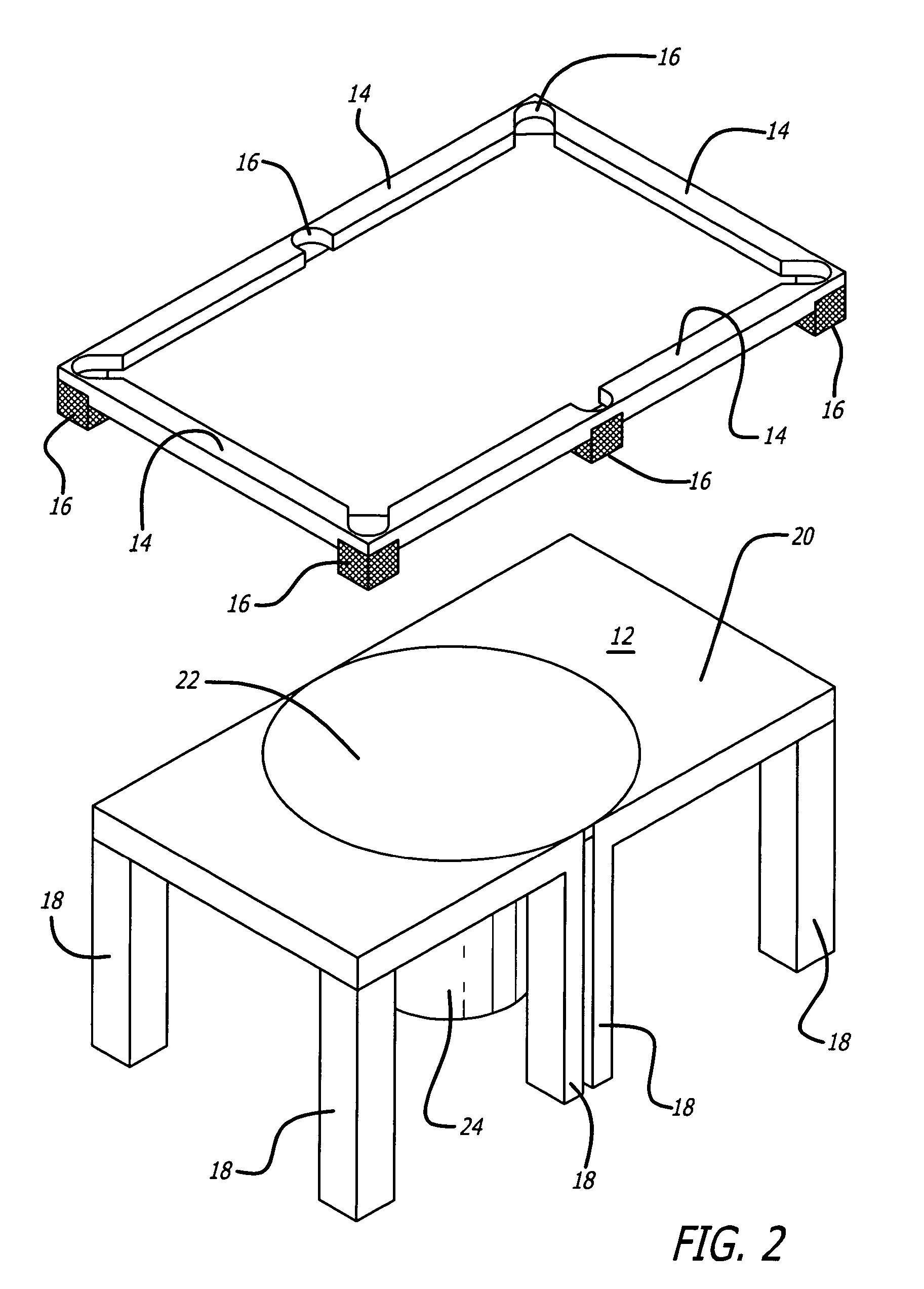

Four dimensional billiards

Owner:GHAHRAMAN CARLIN

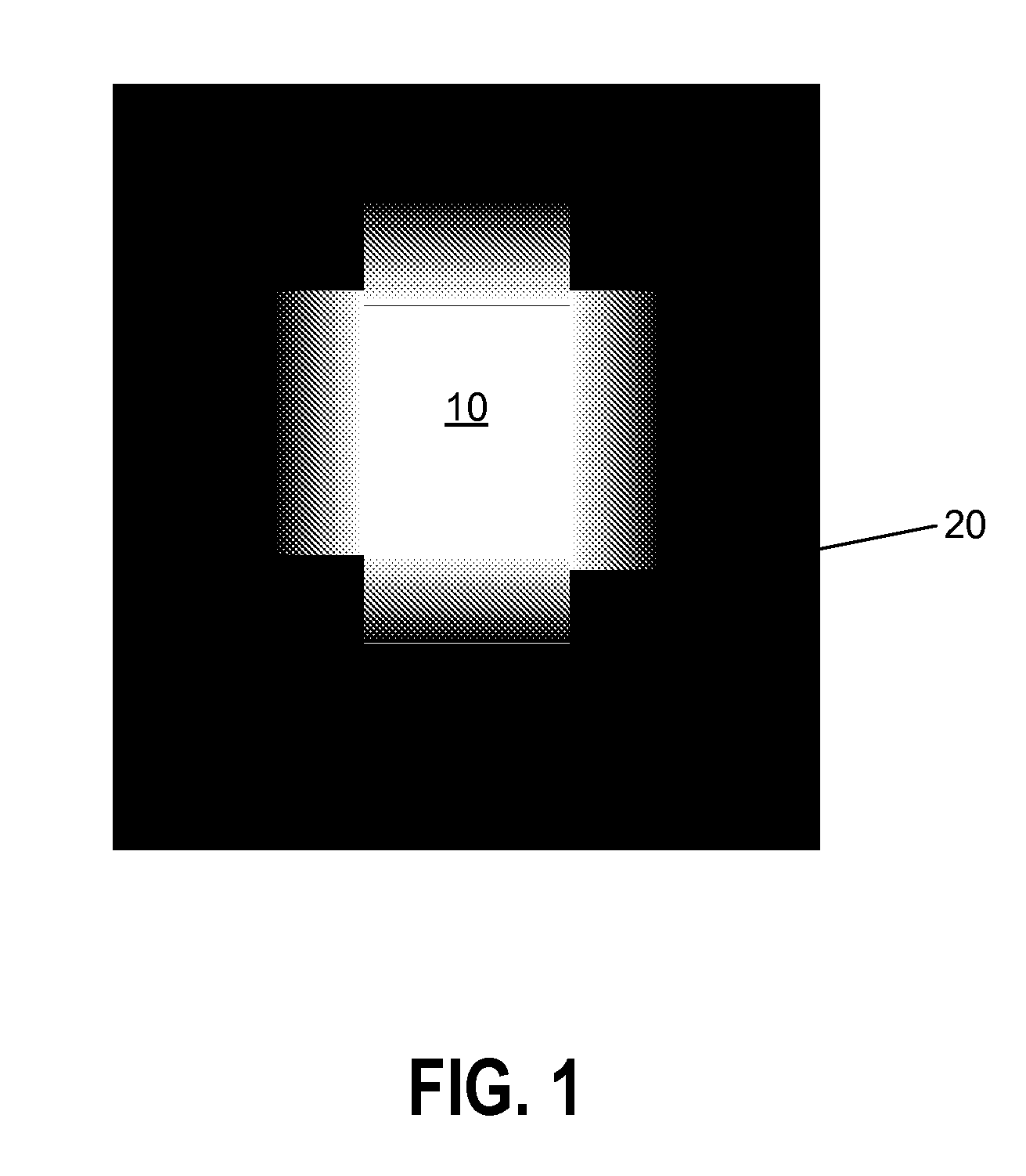

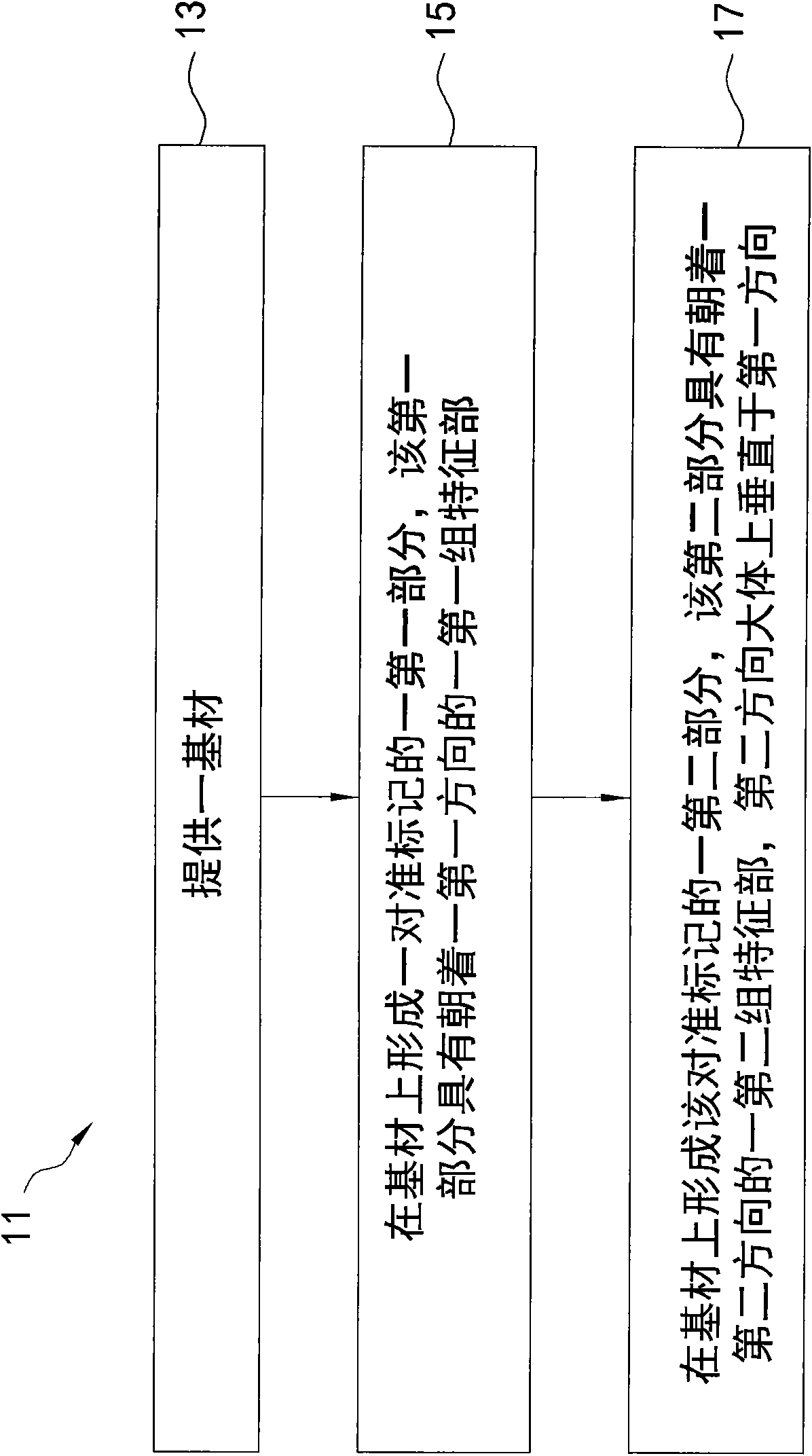

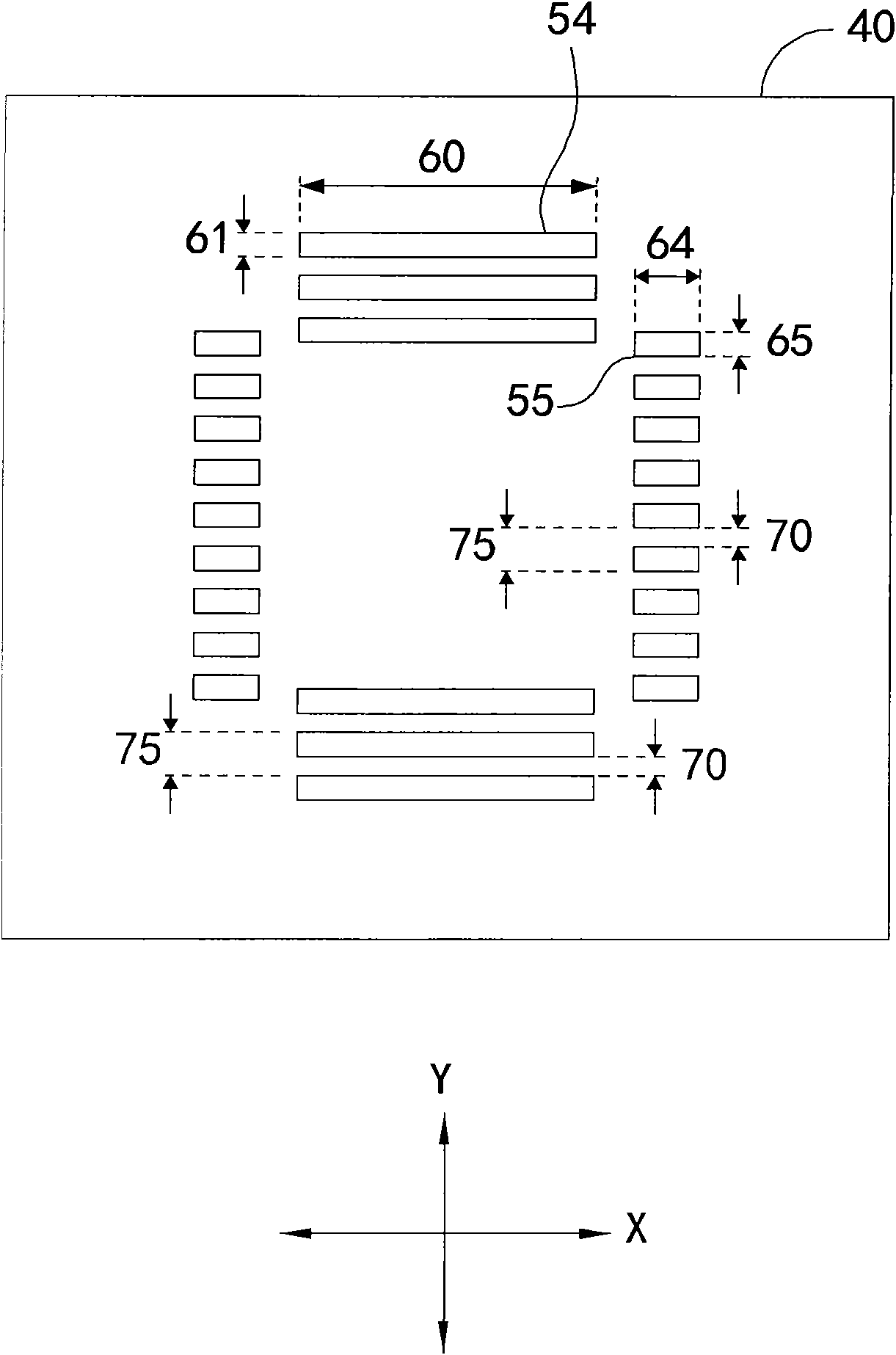

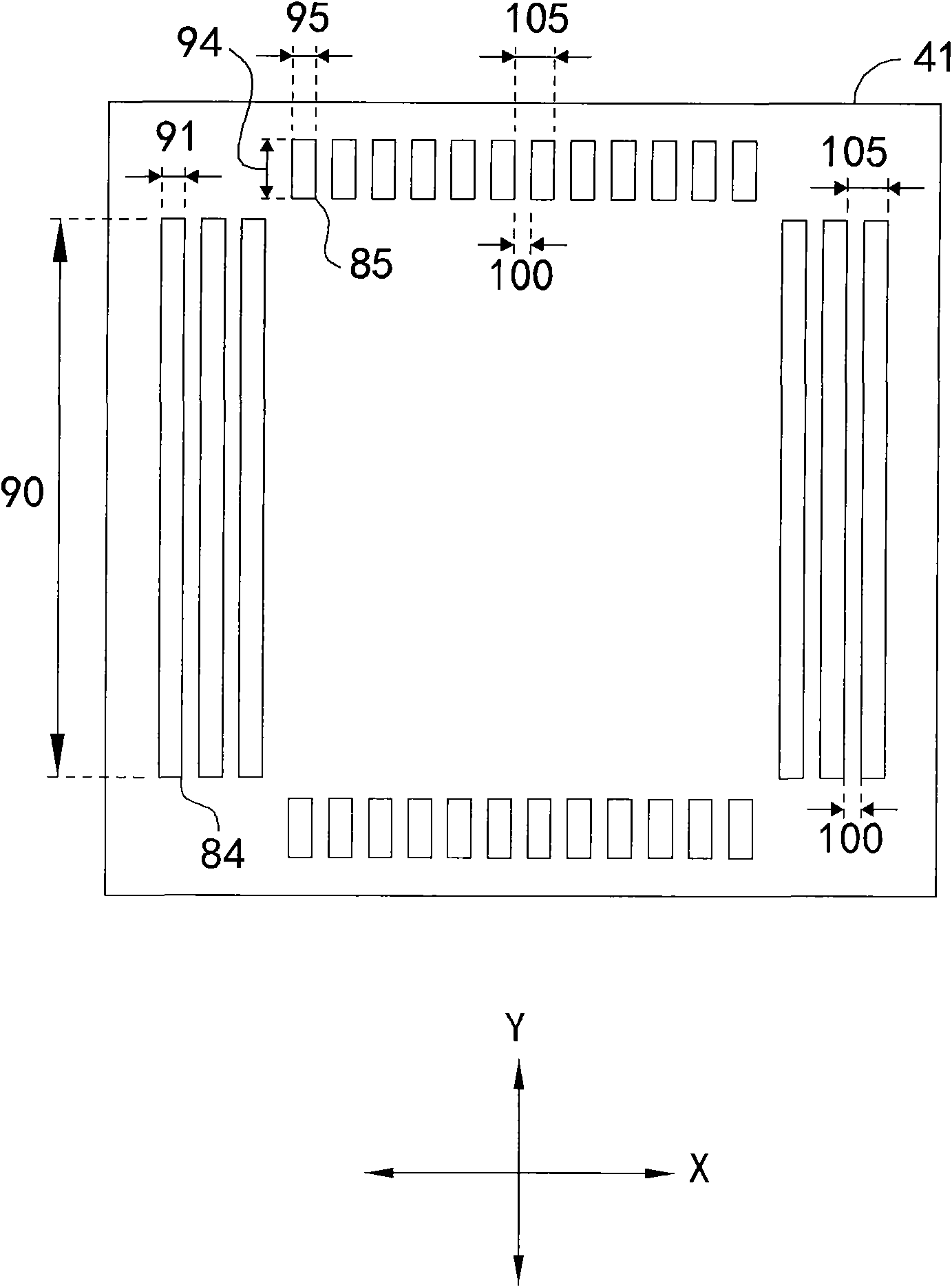

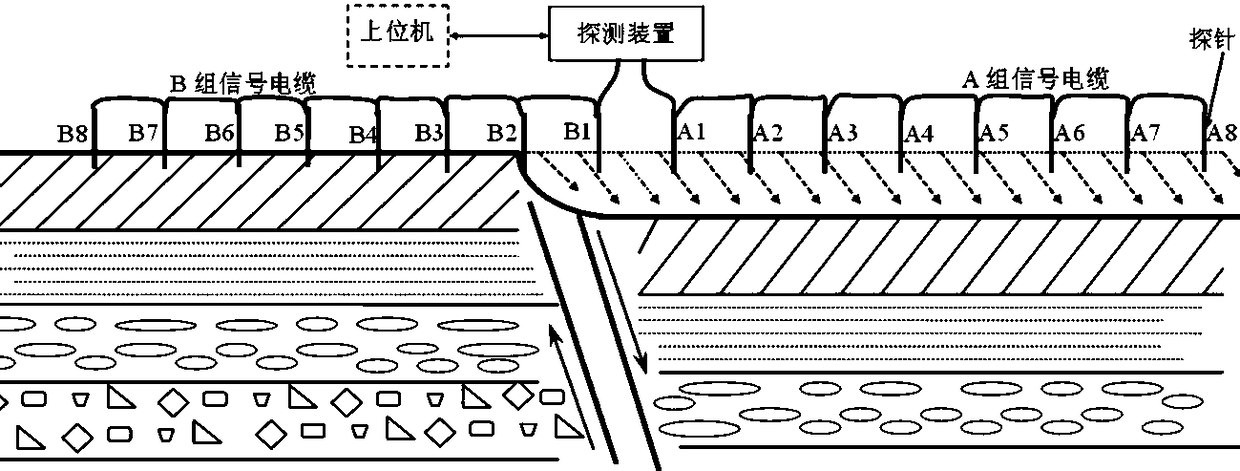

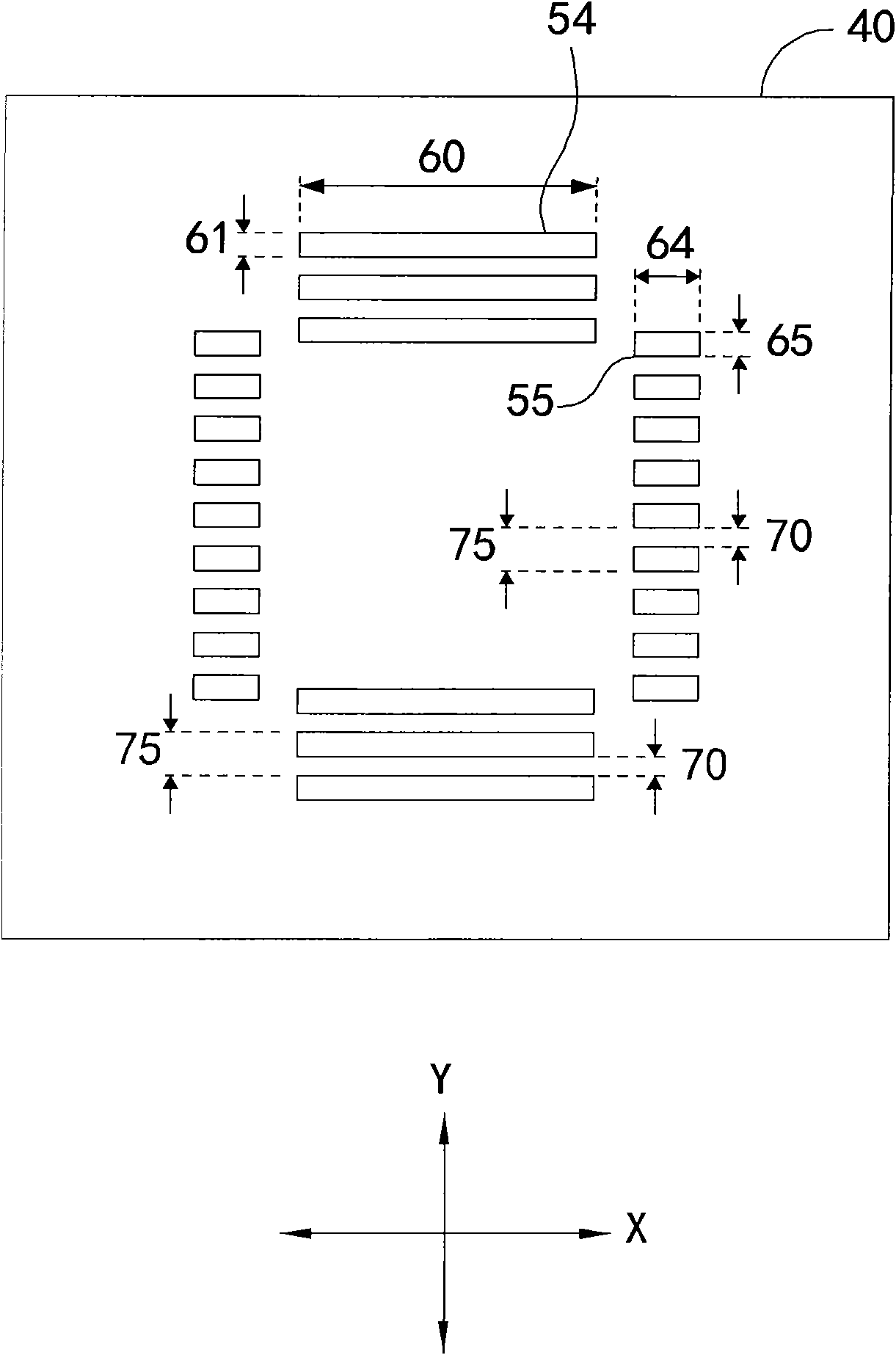

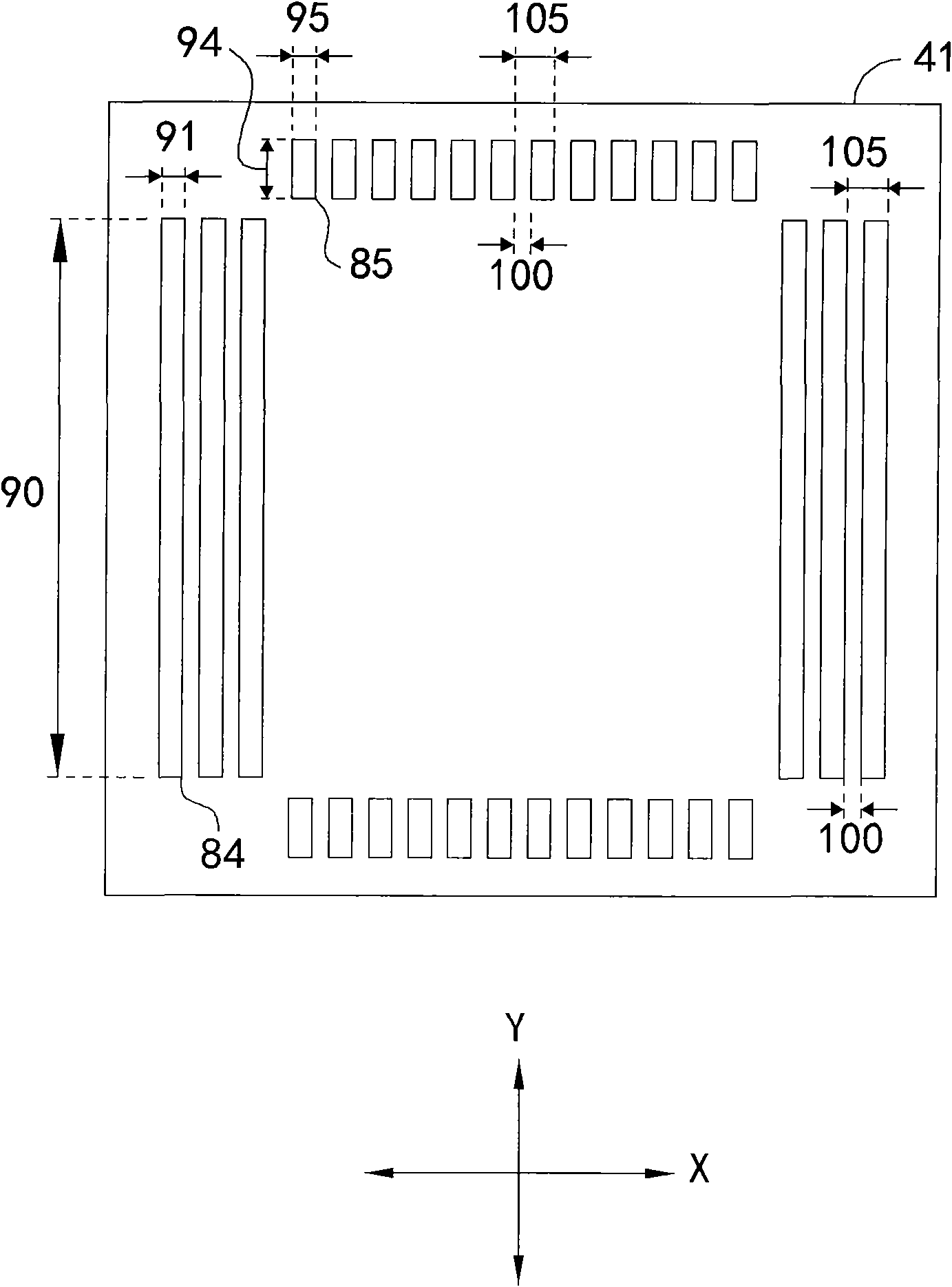

Apparatus including an overlay mark and method of producing semiconductor assembly

ActiveCN102087488AAlignment is precise and accurateAccurate alignment error measurementSolid-state devicesPhotomechanical apparatusFourth DimensionSoftware engineering

The present invention provides an apparatus that includes an overlay mark and a method of producing a semiconductor assembly. The overlay mark includes a first portion that includes a plurality of first features. Each of the first features have a first dimension measured in a first direction and a second dimension measured in a second direction that is approximately perpendicular to the first direction. The second dimension is greater than the first dimension. The overlay mark also includes a second portion that includes a plurality of second features. Each of the second features have a thirddimension measured in the first direction and a fourth dimension measured in the second direction. The fourth dimension is less than the third dimension. At least one of the second features is partially surrounded by the plurality of first features in both the first and second directions.

Owner:TAIWAN SEMICON MFG CO LTD

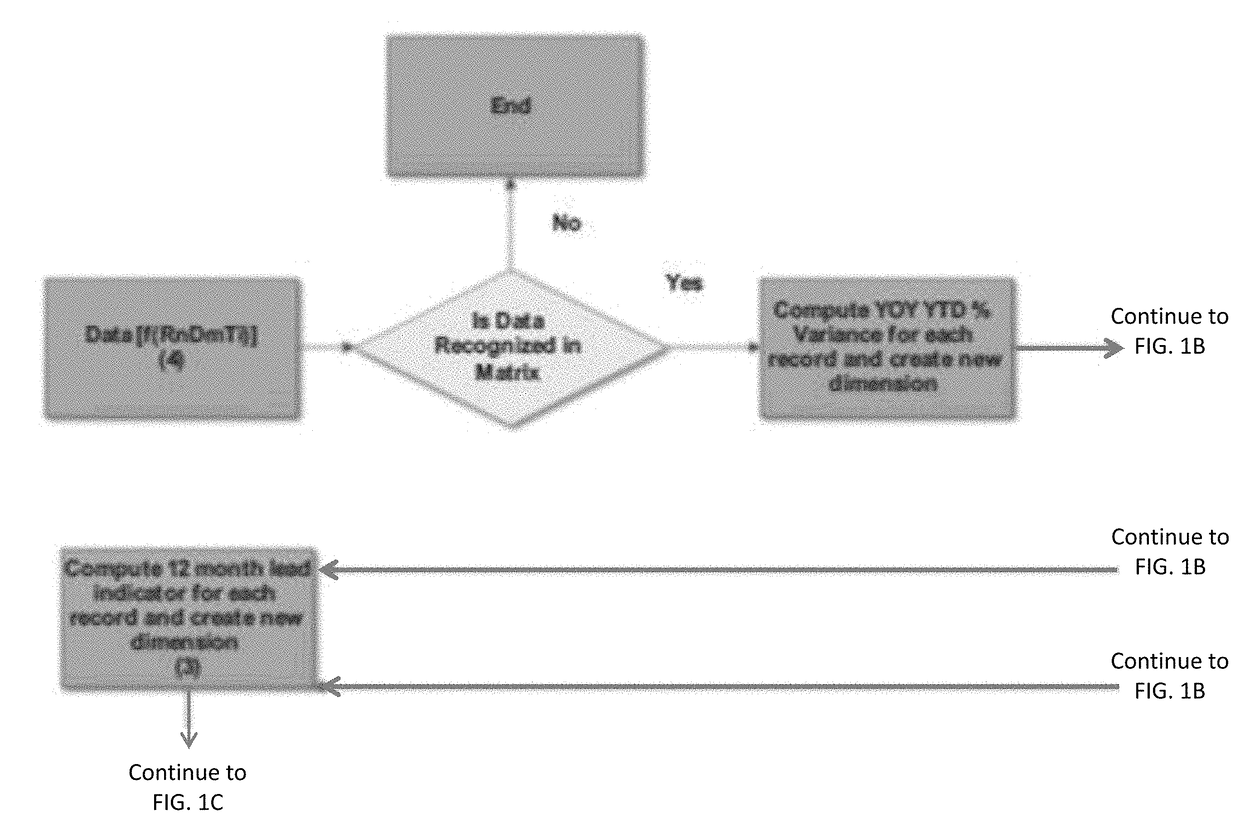

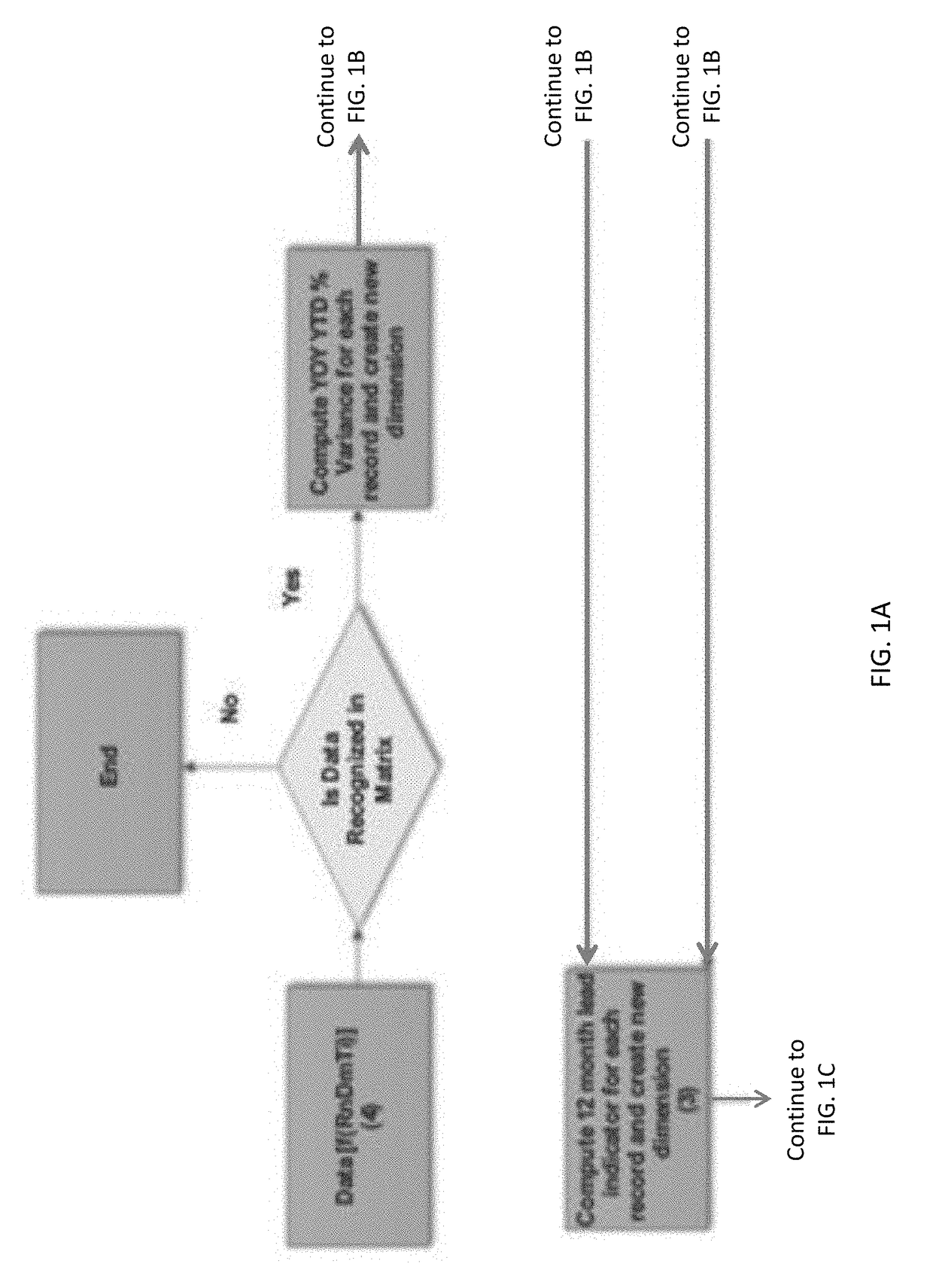

Performance & predictive dimensions for business intelligence data

Disclosed is a non-RDB geo-spatial database with a display interface enabling the computation of performance and predictive mathematical dimensions without requiring a dramatic increase in computational resources for every fourth dimension. Accordingly, dimensions can be added at any time and combined in an intelligent hierarchy to filter, segment, and predict data. The creation of performance dimensions and a hierarchical drill path can be developed without the aid of IT programming.

Owner:AURORA PREDICTIONS LLC

Cutting tool and cutting insert therefor

A cutting tool has a cutting insert retained within an insert pocket of an insert holder by a retaining screw. Spaced apart first insert rear abutment surfaces abut spaced apart first pocket rear abutment surfaces, a second insert rear abutment surface abuts a second pocket rear abutment surface, and spaced apart insert lower abutment surfaces abut spaced apart pocket lower abutment surfaces. The cutting insert has a first dimension taken between extremities of the insert side surfaces, a second dimension taken between extremities of the insert upper and lower surfaces, and, a fourth dimension taken between the insert lower abutment surfaces and the insert upper surface. The size ratio between the fourth dimension and the second dimension is in the range of 0.2 to 1, and, preferably, in the range of 0.55 to 0.6. The size ratio between the first dimension and the second dimension is in the range of 1 to 2.

Owner:ISCAR LTD

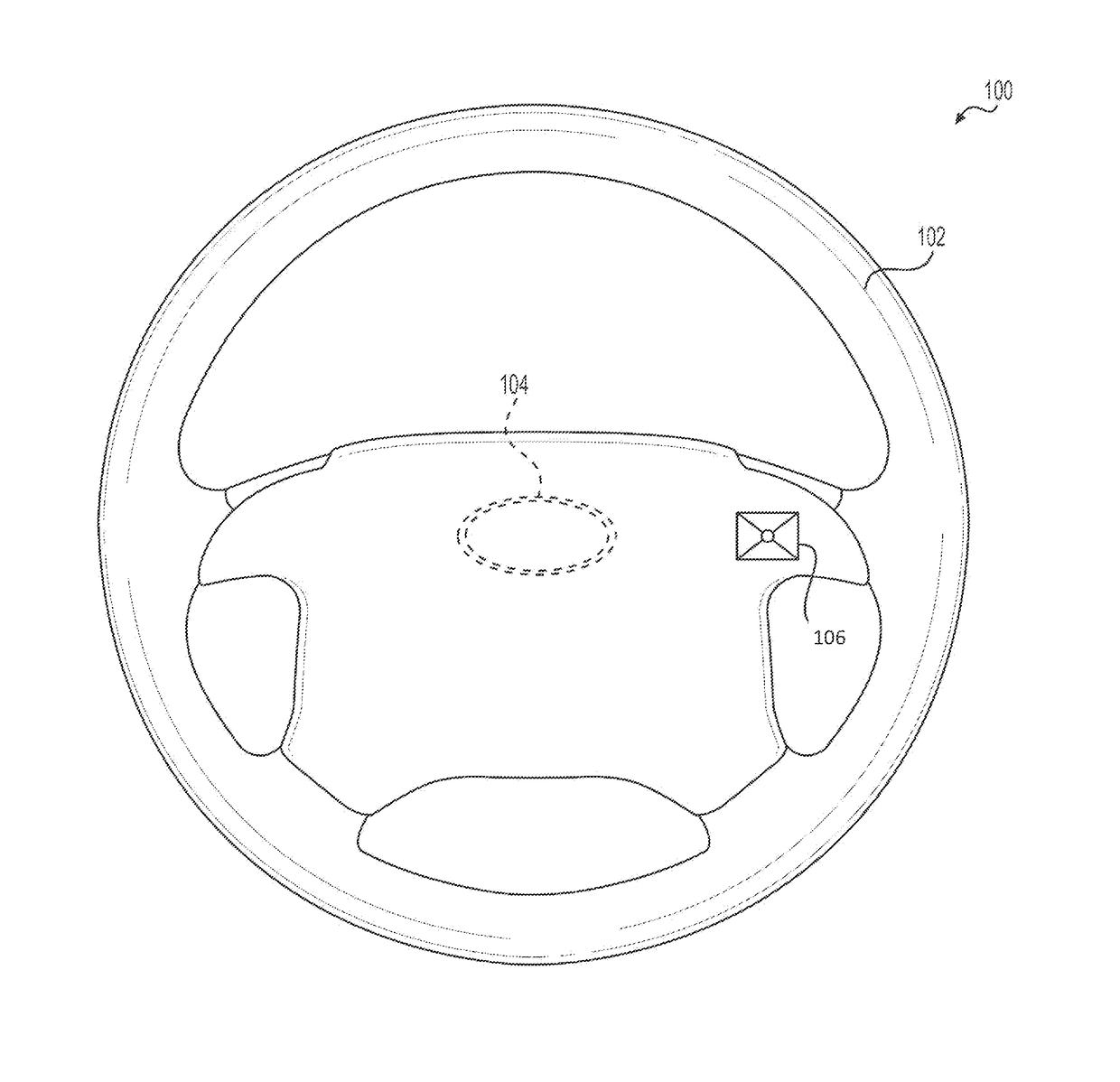

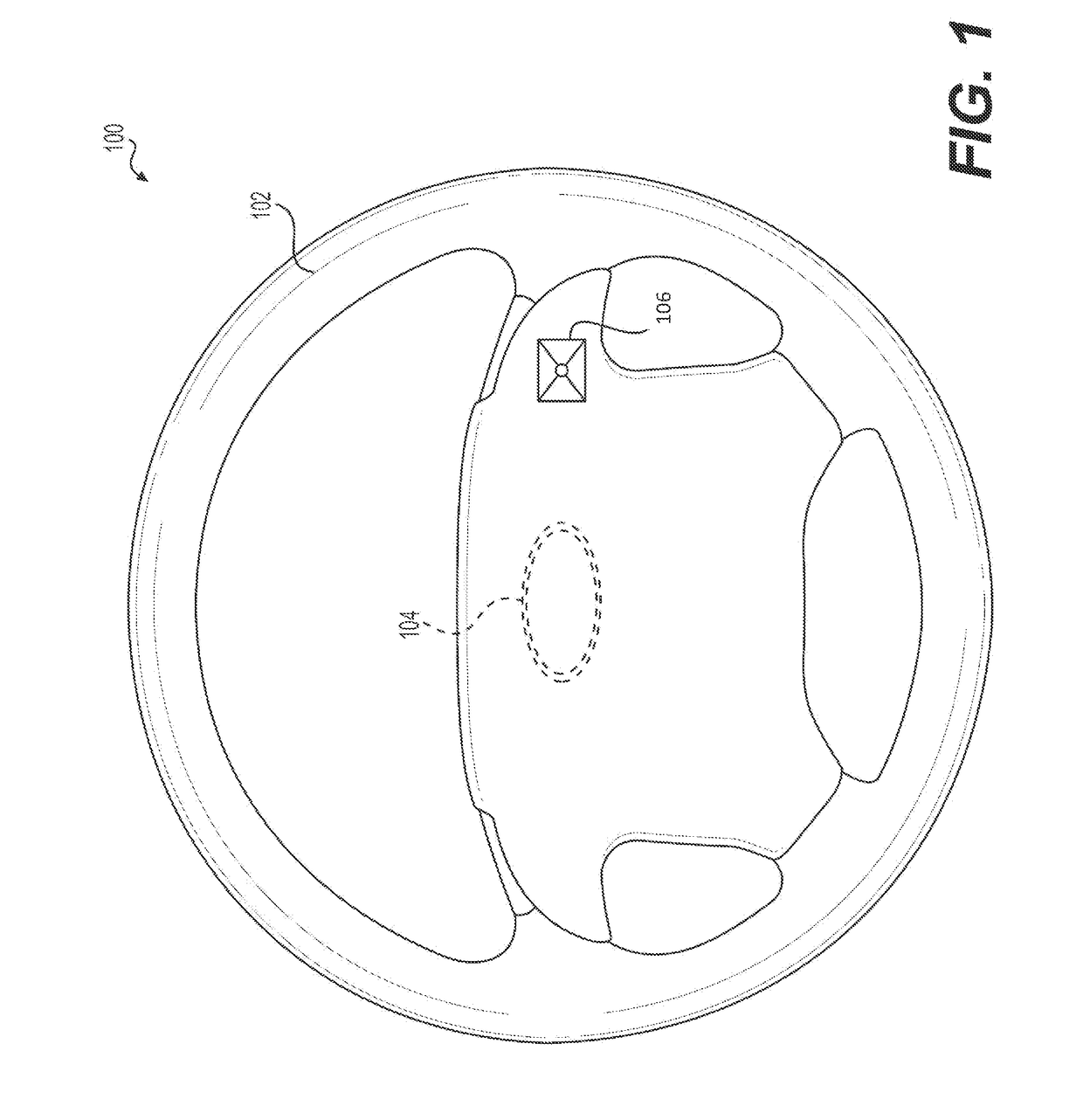

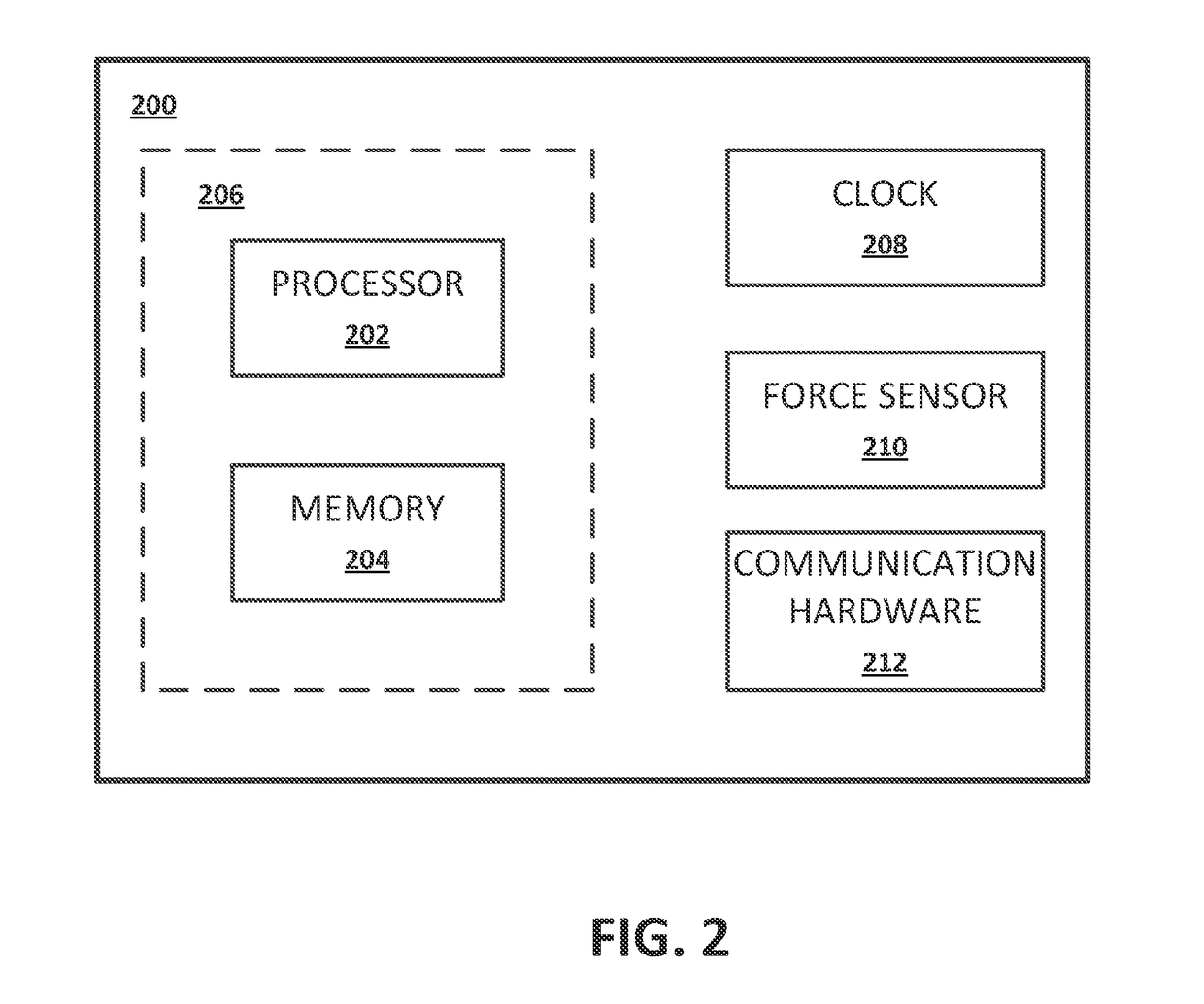

Multi-dimensional trackpad

ActiveUS10067567B2Input/output for user-computer interactionDashboard fitting arrangementsHuman–machine interfaceTouch Perception

A multi-dimensional track pad is described that acts as human-machine interface (HMI). Inputs to the HMI can be made not only using the tradition two-dimensional (X-Y) inputs of a track pad, but also a third dimension, force, and even a fourth dimension, time. Tactile or audible feedback to the inputs can be provided. Methods of using the HMI to control a system are described as well as a track pad system that utilizes the HMI in communication with a processor.

Owner:JOYSON SAFETY SYST ACQUISITION LLC +1

Method and system for CMOS image sensing device

ActiveUS9269625B2Reduce and eliminate blooming effects in image capturingEliminate the effects ofTelevision system detailsTelevision system scanning detailsCMOSFourth Dimension

Method and system for manufacturing CMOS image sensing device with reduced blooming. The method includes a step for providing a substrate material. The substrate material can be characterized by a first dimension and a second dimension. In addition, the method includes a step for defining an active region on the substrate material. The active region is characterized by a third dimension and a fourth dimension. The method further includes a step for defining a non-active region on the substrate material. The non-active region is different from the active region. The non-active region is characterized by a fifth dimension and a sixth dimension, the non-active region including a silicon material. The method includes a step for defining a depletion region within the active region. In addition, the method includes a step for forming an n-type region positioned above the depletion region.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

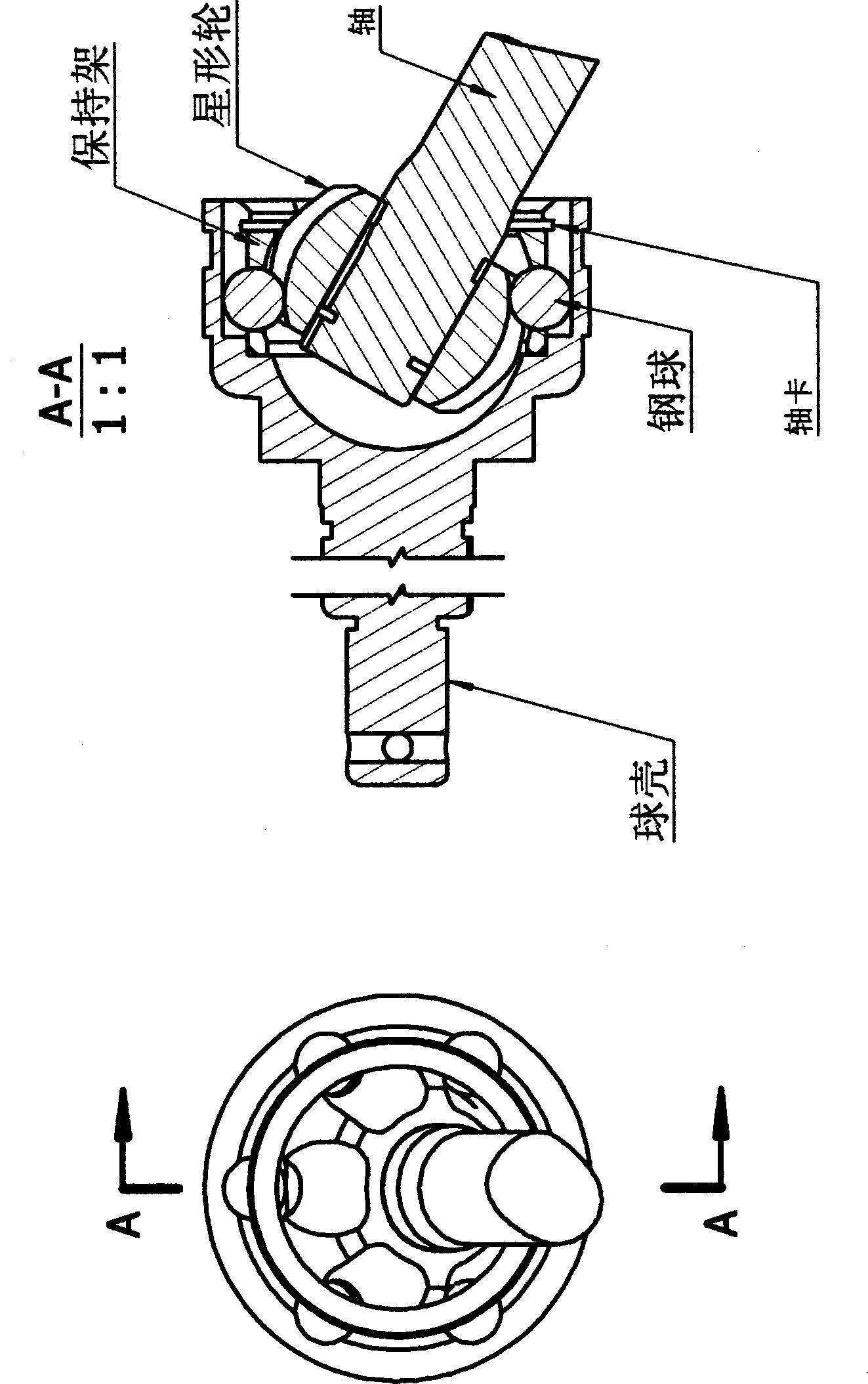

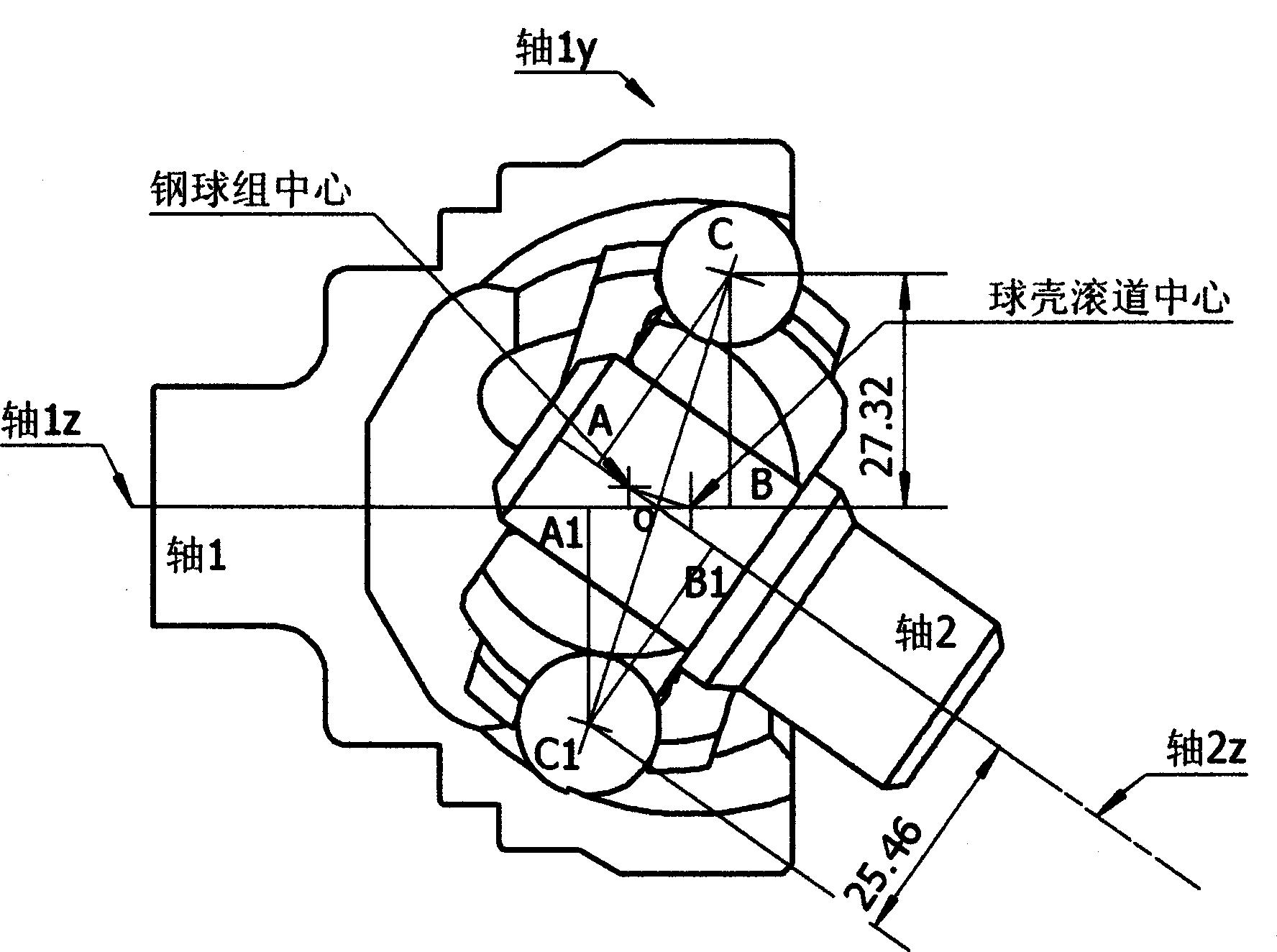

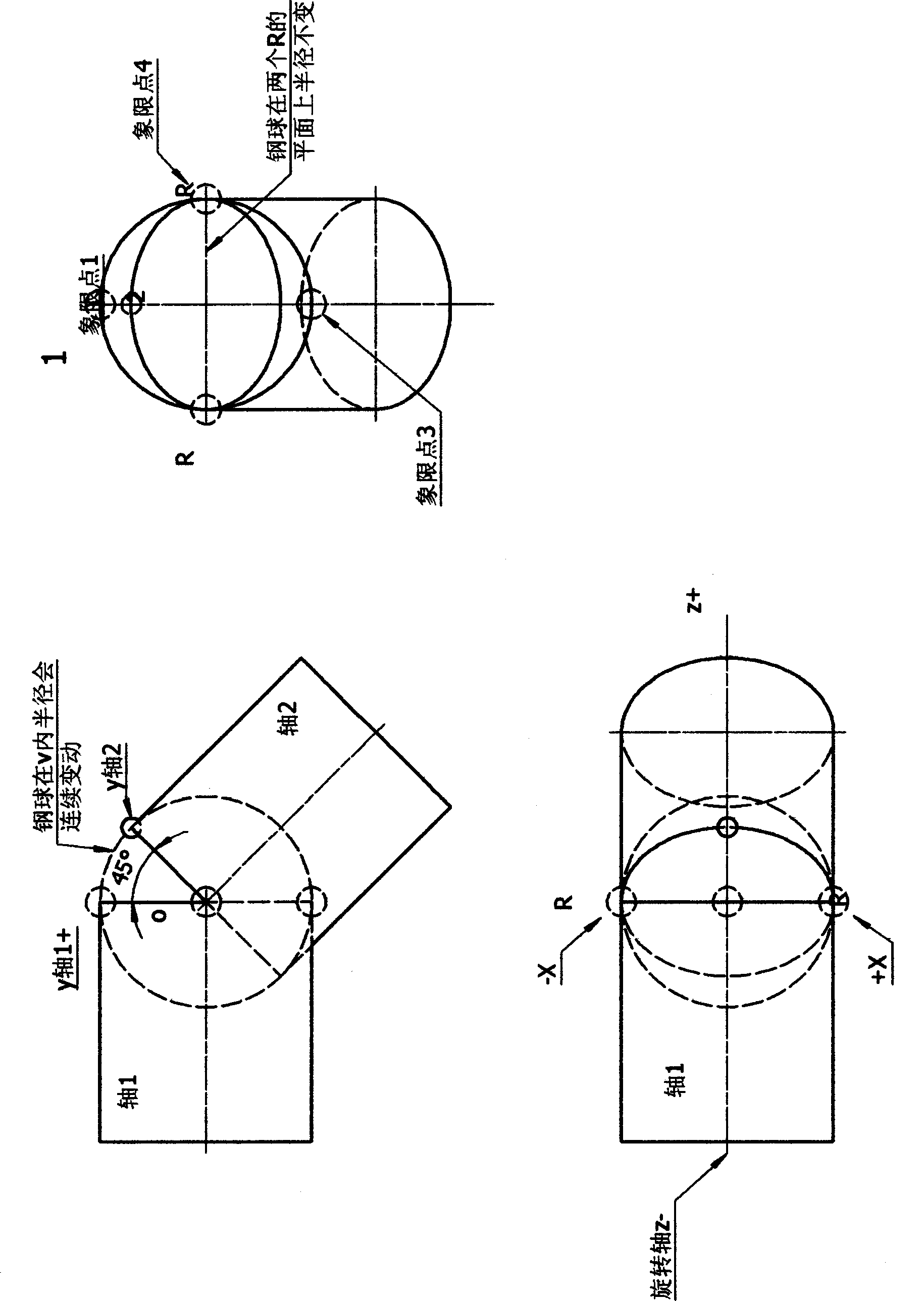

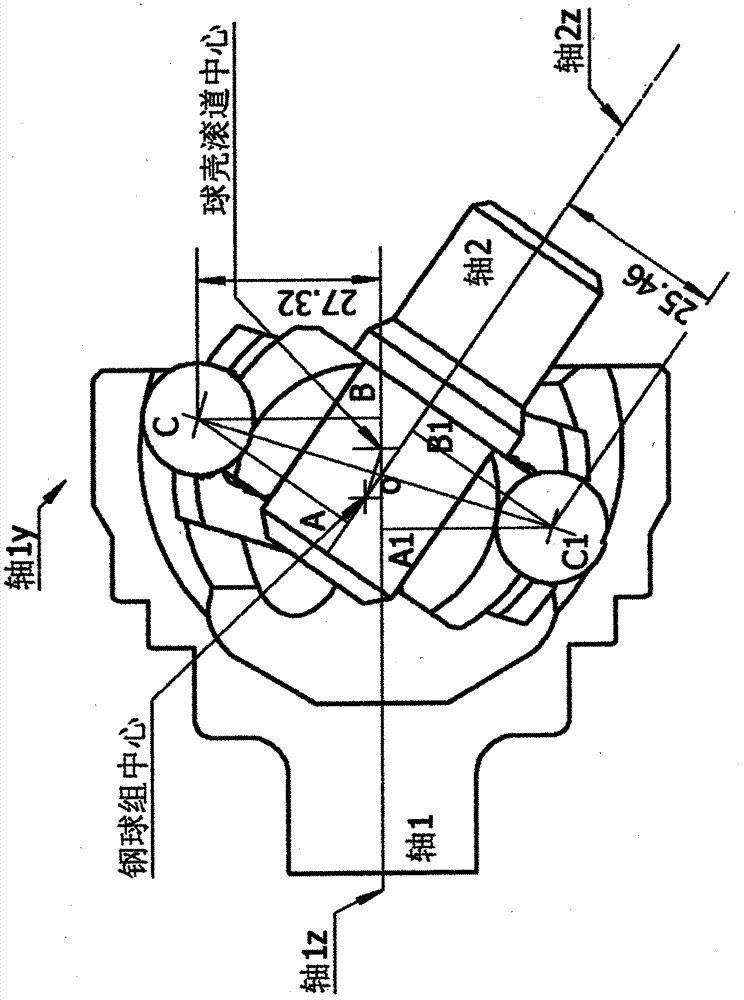

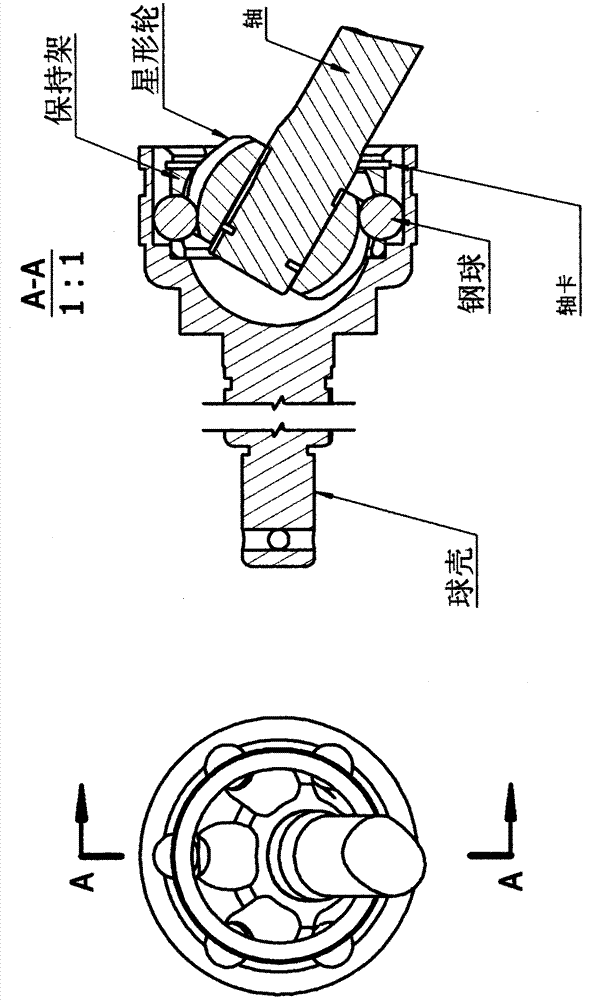

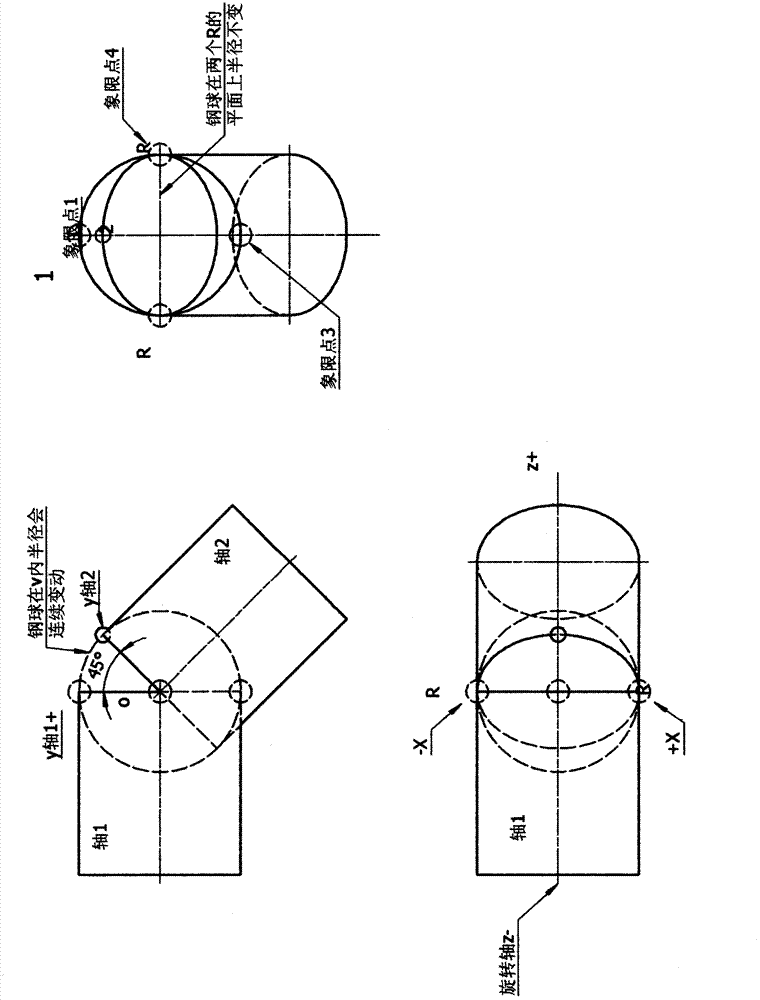

Directional constant velocity ball cage universal joint

The invention provides a novel directional constant velocity ball cage universal joint. A steel ball is fixed on the central line of the input end, and a space track is customized according to a periodic time to be used as the output end. The time and space switching principle is applied, a directional track is overlapped on the steel ball, and therefore a speed equal to the input speed is obtained. The geometric principle of the novel directional constant velocity ball cage universal joint is that a three-dimensional ball is stable and can not move in a three-dimensional mode, three-dimensional movement is generated in a four-dimensional space, the fourth dimension is time, and walking space of the steel ball is made according to the periodic time. The overall path of the novel directional ball cage constant velocity universal joint is a Mobius ring, and the novel directional constant velocity ball cage universal joint turns four times and goes in the reverse direction two times in the process to transfer the turning included angle to a spherical surface. A directional ball cage operates in a three-dimensional mode, and the feature, changing obviously, of the ball cage is that the size and the weight of the ball cage can be lowered by 40%. The output mode of the directional constant velocity ball cage universal joint is that the front face and the back face act in a coupling mode, the contact effect and the bearing capacity both are increased in a multiplied mode, the directional constant velocity ball cage universal joint has three complete degrees of freedom, and no matter how the turning included angle changes, the directional constant velocity ball cage universal joint can keep constant. A star gear works in a suspended mode, and self consumption can be basically eliminated.

Owner:丛滨江 +1

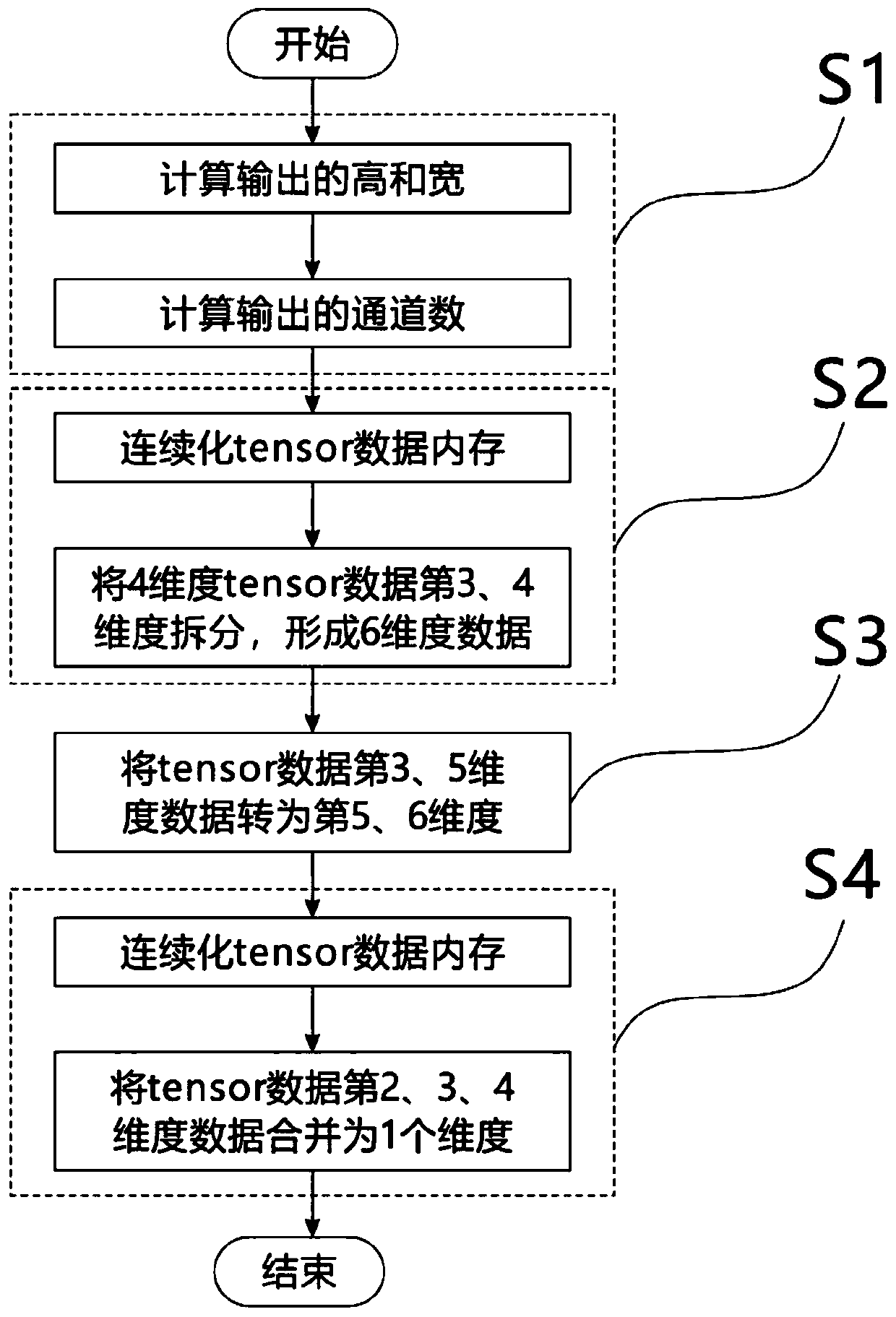

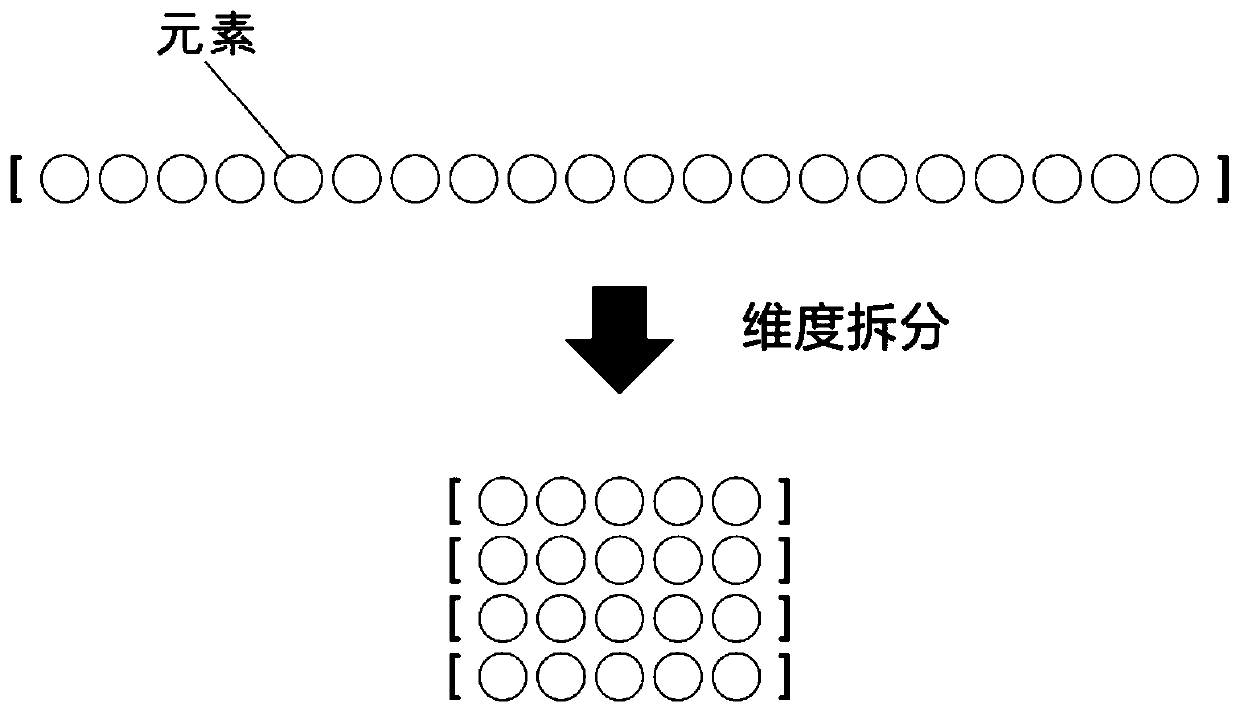

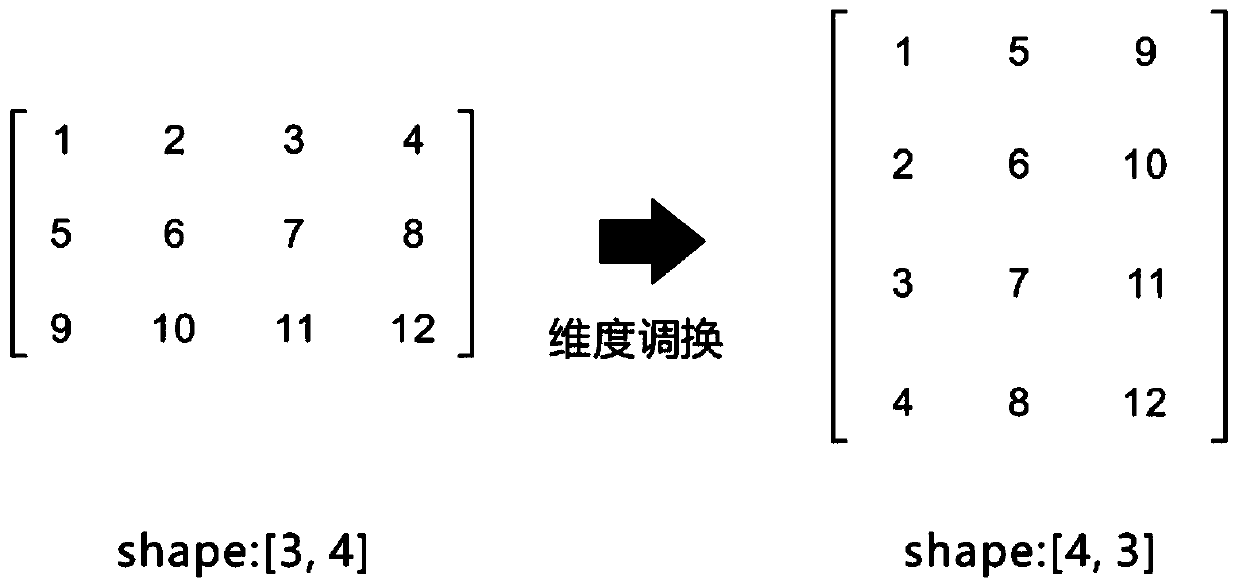

Channel extension method based on convolutional neural network

ActiveCN110619387AReduce stepsReduce consumptionCharacter and pattern recognitionNeural architecturesImage resolutionFourth Dimension

The invention provides a channel extension method based on a convolutional neural network. The method is used for replacing a general convolution extension channel and pooling operation in the convolutional neural network, so the redundant data of intermediate operations of the convolutional neural network can be reduced without losing valid data. The method is characterized by comprising the following steps: step S1, calculating the resolution and the channel number of feature map data according to the resolution change rate of feature maps before and after convolution pooling, and calculating the channel number of the feature map data according to the channel number of the feature map data after convolution pooling; s2, performing dimension splitting on channels with corresponding heights and widths in the feature map data of the four dimensions to form six dimensions; s3, carrying out dimension turning on the split feature map data, wherein the third dimension and the fifth dimension are changed into the fifth dimension and the sixth dimension; and S4, carrying out dimension combination on the second dimension, the third dimension and the fourth dimension in the changed featuremap data, and re-integrating into four dimensions.

Owner:FUDAN UNIV

Five-dimensional stereo repair system

InactiveCN103655222AImprove sensitivity and vulnerabilityImprove dry agingCosmetic preparationsElectrotherapyNasolabial foldStratum basale

The invention discloses a five-dimensional stereo repair system, relating to the technical field of skincare and beauty. A repair method of the system comprises the following steps: (I) the first dimension: stratum corneum repair; (II) the second dimension: stratum basale repair; (III) the third dimension: superficial-layer repair of dermis; (IV) the fourth dimension: deep-layer repair of dermis; and (V) the fifth dimension: soft tissue repair. The five-dimensional stereo repair system improves the sensitivity and fragility, redness, red blood, drying and aging, lines and under-eye puffiness, dull skin, sunburn, acnes and laxity and aging, realizes after-sun repair, repair after various high-technology beauty and early and later repair of various pigments, dredges and shrinkages the pores, brightens the skin and effectively repairs the lax outline so that the apple muscle is sweet and the silkworm comes back again, the tear lines, bitter lines and nasolabial folds shallow or disappear, the muscle layer is stimulated to become tight, the fat fades away and the bottommost layer of the skin is improved.

Owner:徐红意

Directional Constant Velocity Cage Universal Joint

The invention provides a novel directional constant velocity ball cage universal joint. A steel ball is fixed on the central line of the input end, and a space track is customized according to a periodic time to be used as the output end. The time and space switching principle is applied, a directional track is overlapped on the steel ball, and therefore a speed equal to the input speed is obtained. The geometric principle of the novel directional constant velocity ball cage universal joint is that a three-dimensional ball is stable and can not move in a three-dimensional mode, three-dimensional movement is generated in a four-dimensional space, the fourth dimension is time, and walking space of the steel ball is made according to the periodic time. The overall path of the novel directional ball cage constant velocity universal joint is a Mobius ring, and the novel directional constant velocity ball cage universal joint turns four times and goes in the reverse direction two times in the process to transfer the turning included angle to a spherical surface. A directional ball cage operates in a three-dimensional mode, and the feature, changing obviously, of the ball cage is that the size and the weight of the ball cage can be lowered by 40%. The output mode of the directional constant velocity ball cage universal joint is that the front face and the back face act in a coupling mode, the contact effect and the bearing capacity both are increased in a multiplied mode, the directional constant velocity ball cage universal joint has three complete degrees of freedom, and no matter how the turning included angle changes, the directional constant velocity ball cage universal joint can keep constant. A star gear works in a suspended mode, and self consumption can be basically eliminated.

Owner:丛滨江 +1

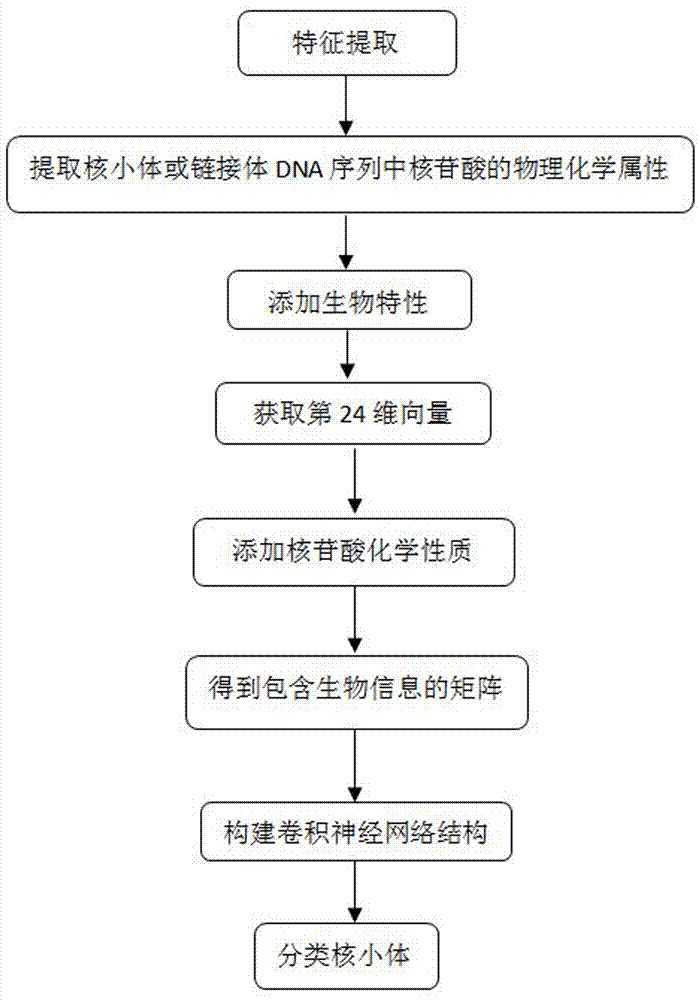

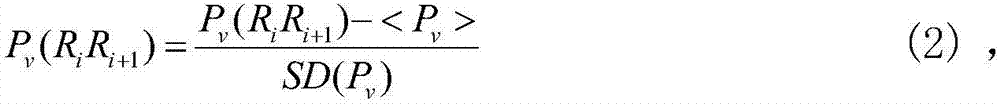

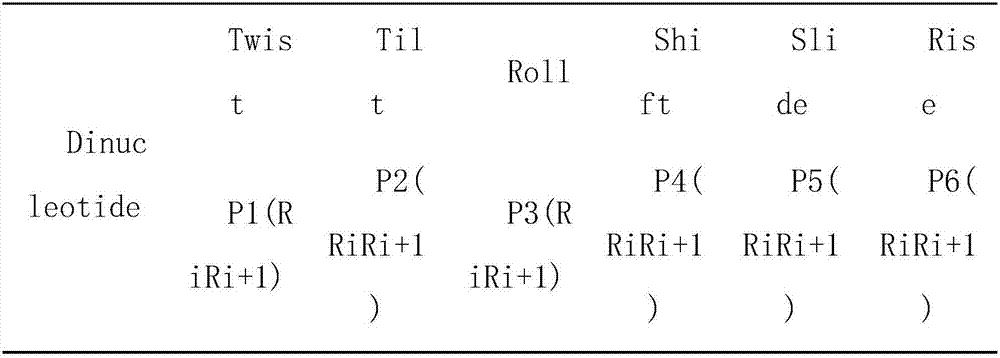

Nucleosome classification forecasting method based on convolutional neural network

ActiveCN107545153ANeural architecturesSpecial data processing applicationsFeature extractionNucleotide

The invention discloses a nucleosome classification forecasting method based on a convolutional neural network. The nucleosome classification forecasting method is characterized by comprising the following steps that firstly, feature extraction is conducted; secondly, the physical and chemical properties of nucleotides in nucleosomes or in the DNA sequence of a linking body are extracted; thirdly,biological characteristics are added; fourthly, the twenty-fourth dimension vector is obtained; fifthly, the chemical properties of the nucleotides are added; sixthly, a matrix containing biologicalinformation is obtained; seventhly, the structure of the convolutional neural network is built; eighthly, the nucleosomes are classified. By means of the method, the classification of the nucleosomescan be precisely forecasted.

Owner:GUILIN UNIV OF ELECTRONIC TECH

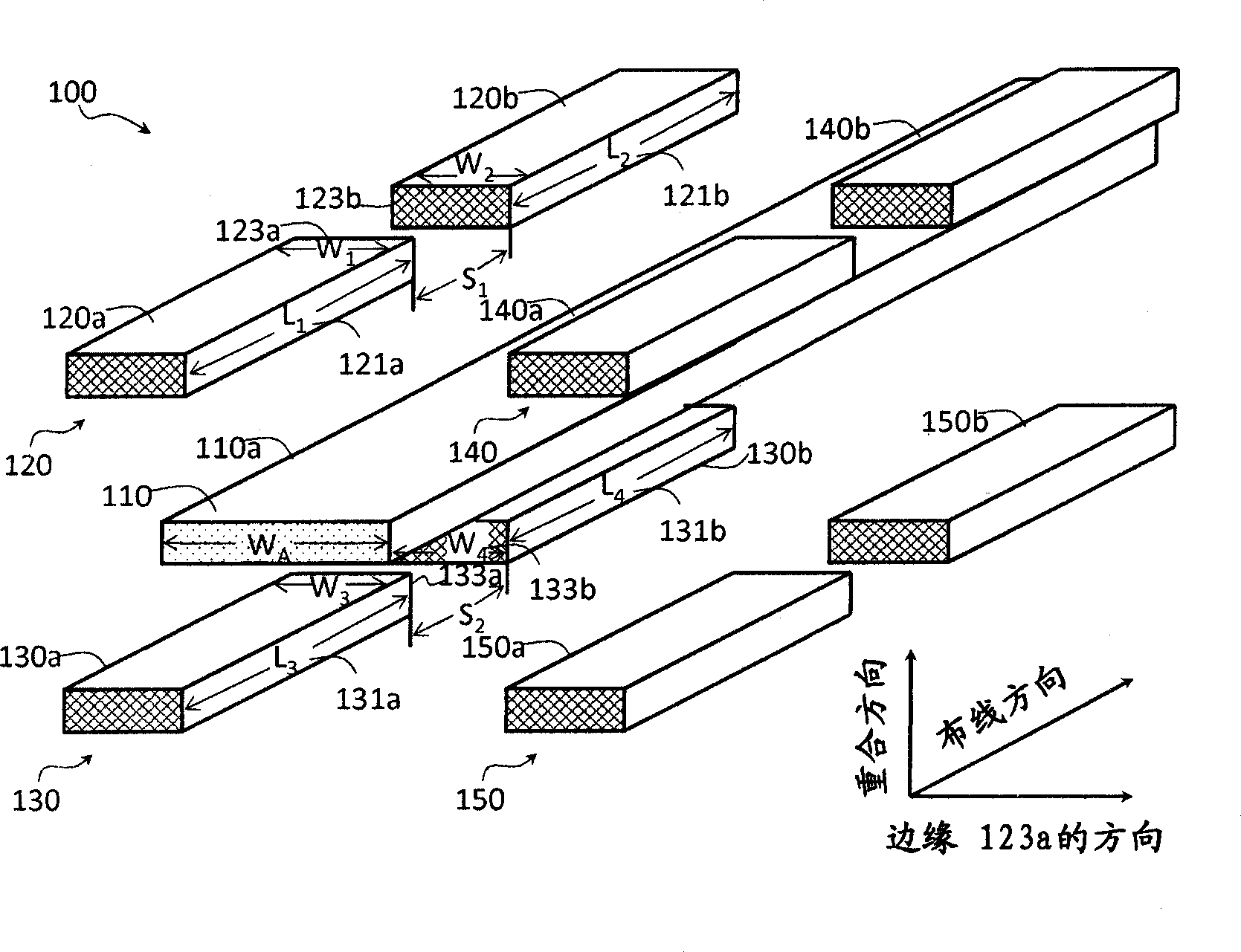

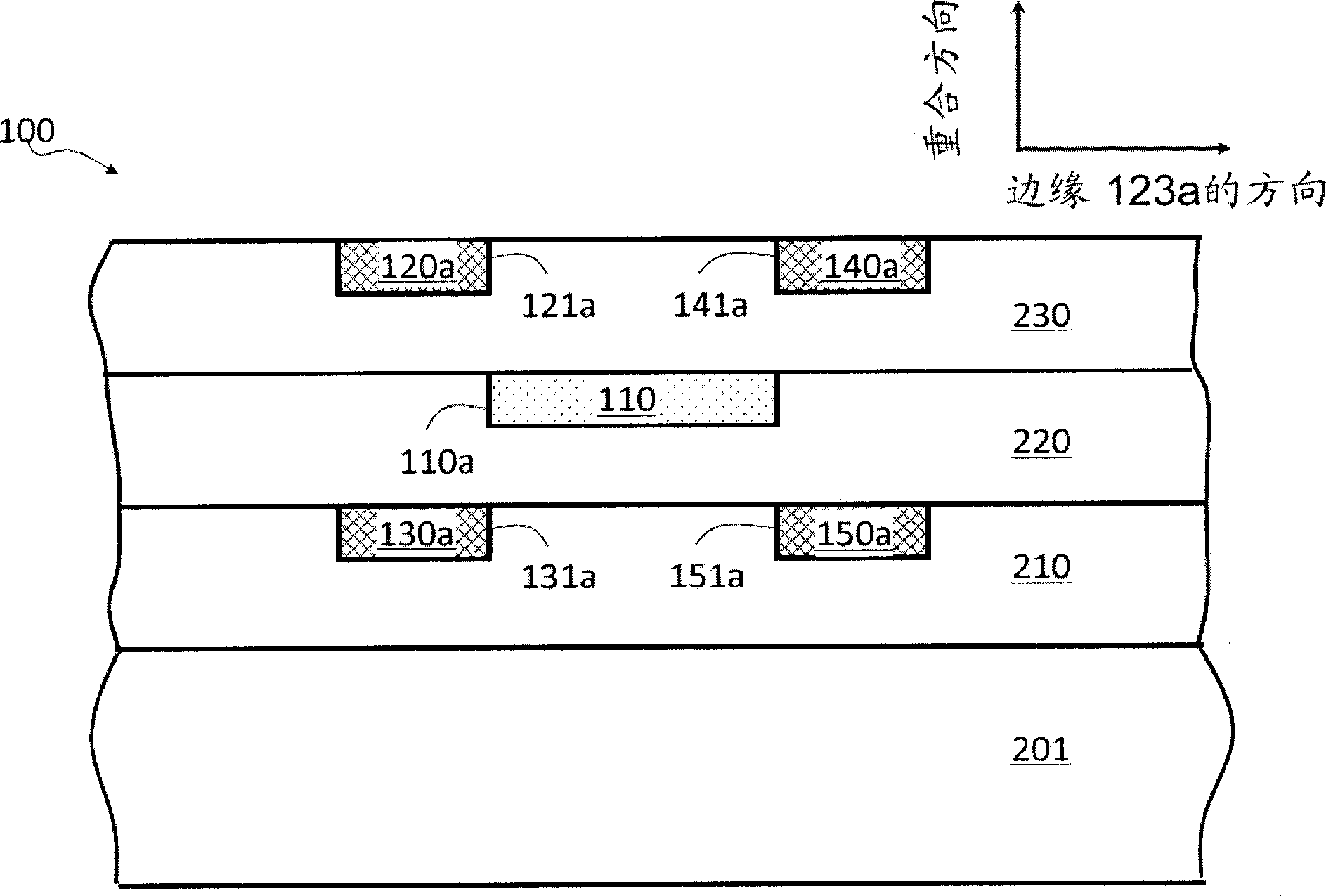

Integrated circuits and fabrication methods thereof

ActiveCN102569264ASemiconductor/solid-state device detailsSolid-state devicesFourth DimensionEngineering

An integrated circuit includes a signal line routed in a first direction. A first shielding pattern is disposed substantially parallel with the signal line. The first shielding pattern has a first edge having a first dimension and a second edge having a second dimension. The first edge is substantially parallel with the signal line. The first dimension is larger than the second dimension. A second shielding pattern is disposed substantially parallel with the signal line. The second shielding pattern has a third edge having a third dimension and a fourth edge having a fourth dimension. The third edge is substantially parallel with the signal line. The third dimension is larger than the fourth dimension. The fourth edge faces the second edge. A first space is between the second and fourth edges.

Owner:TAIWAN SEMICON MFG CO LTD

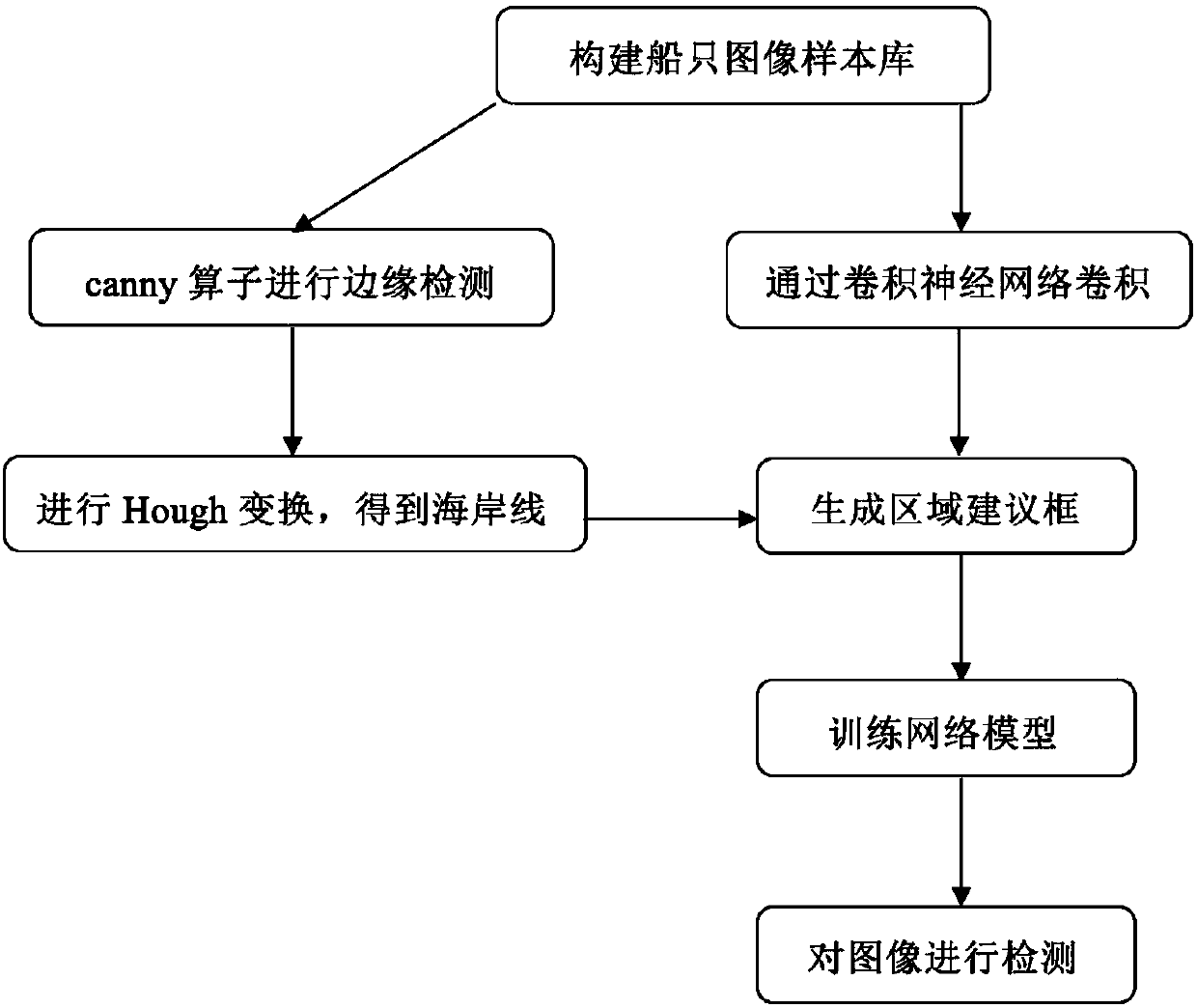

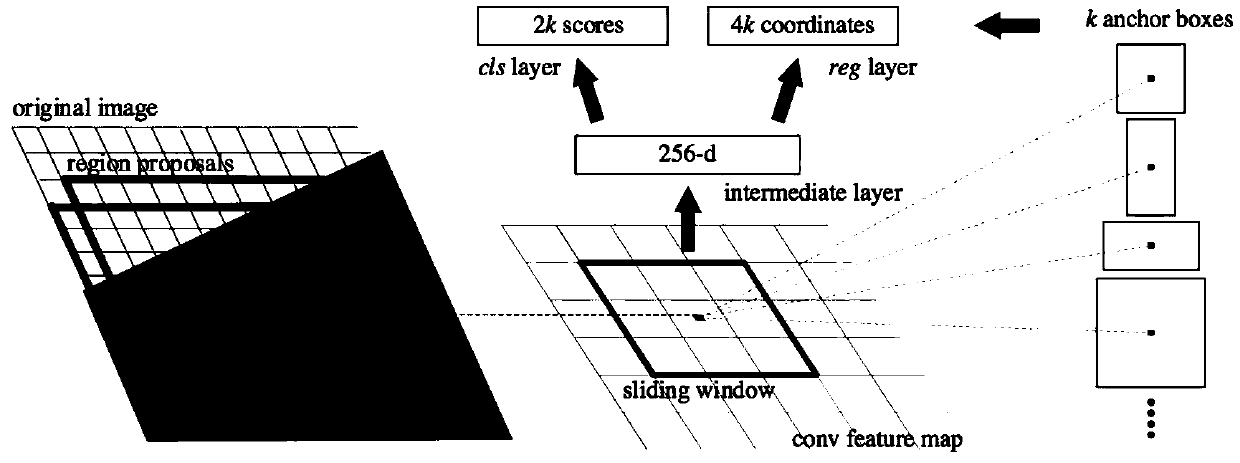

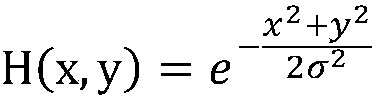

A ship detection method and system based on scene multi-dimensional features

ActiveCN107818326BAvoid interferenceImprove accuracyImage enhancementImage analysisPattern recognitionSlide window

The present invention provides a ship detection method and system based on multi-dimensional features of the scene, including building a ship image sample library, extracting all edges of each frame of image as the fourth dimension of the image; extracting the coastline, making the sea surface area the area where the ship appears; constructing The Faster RCNN-like convolutional network is used as a deep learning network, and the sample data is input into the deep learning network; the RPN network is constructed, and the sliding window is used to generate area suggestion boxes of different sizes in the area where ships appear. Position training model; based on the trained model on the detection image, ship detection is performed on the part between the coastlines. The present invention avoids the interference of land houses by extracting the coastline, and only proposes areas for the ship area, which improves the accuracy and speed of the area suggestion frame; and adds edge features as the fourth dimension of the image in the target detection, which improves the detection precision and speed.

Owner:ZHUHAI DAHENGQIN TECH DEV CO LTD

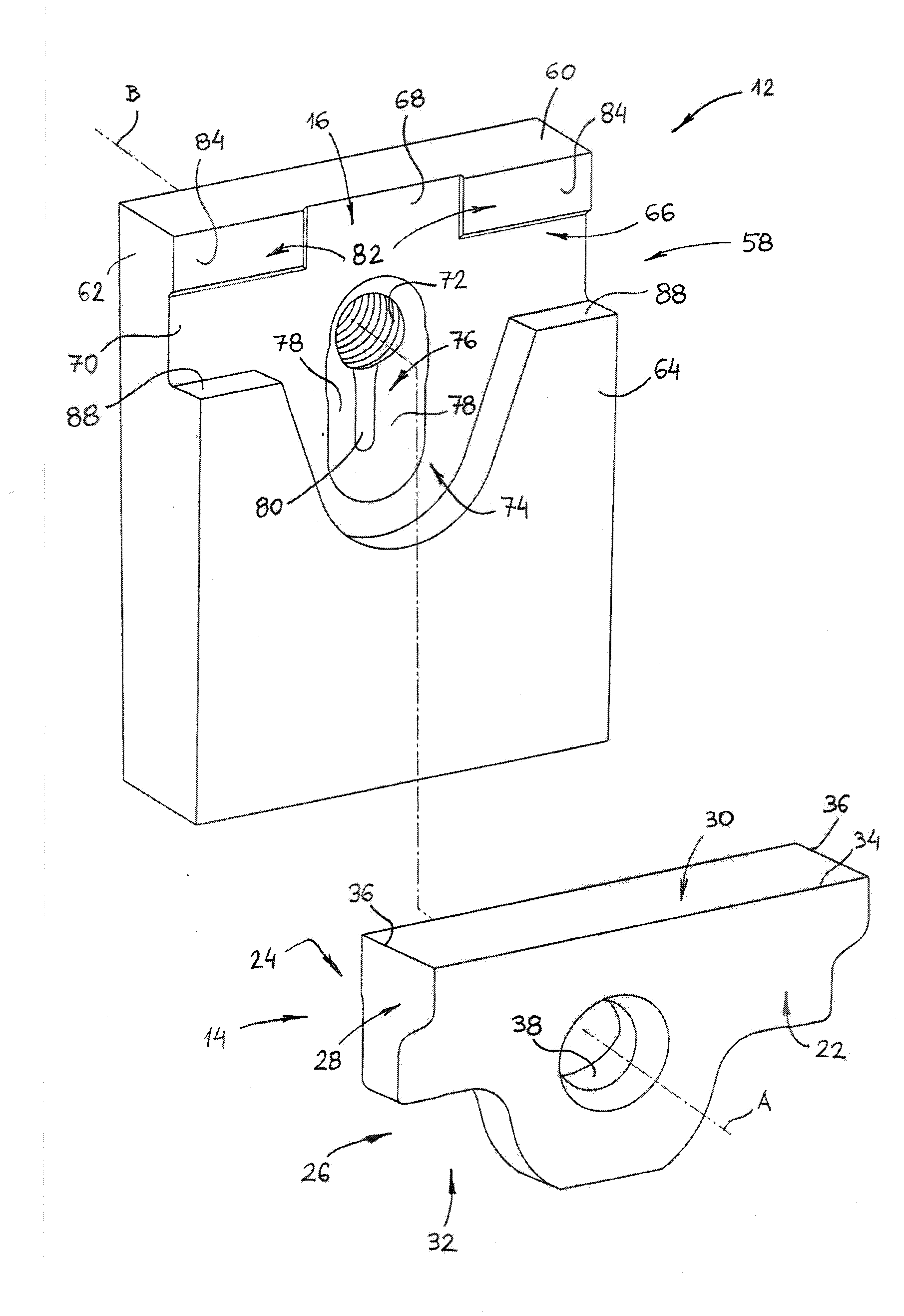

Connector anchor having multiple direction connectivity

InactiveUS20150360600A1Well formedFlexible elementsLoad securingFourth DimensionMechanical engineering

A connector anchor has a longitudinal axis and at least two spaced apart apertures each of which may receive a buckle clip. The first aperture has a first dimension and a second dimension less than the first dimension. The second dimension of the first aperture extends in a direction along the longitudinal axis of the connector anchor. The second aperture has a third dimension and a fourth dimension less than the third dimension. The second aperture is spaced from the first aperture. The third dimension of the second aperture extends in a direction along the longitudinal axis of the connector anchor.

Owner:WINSTON PRODS

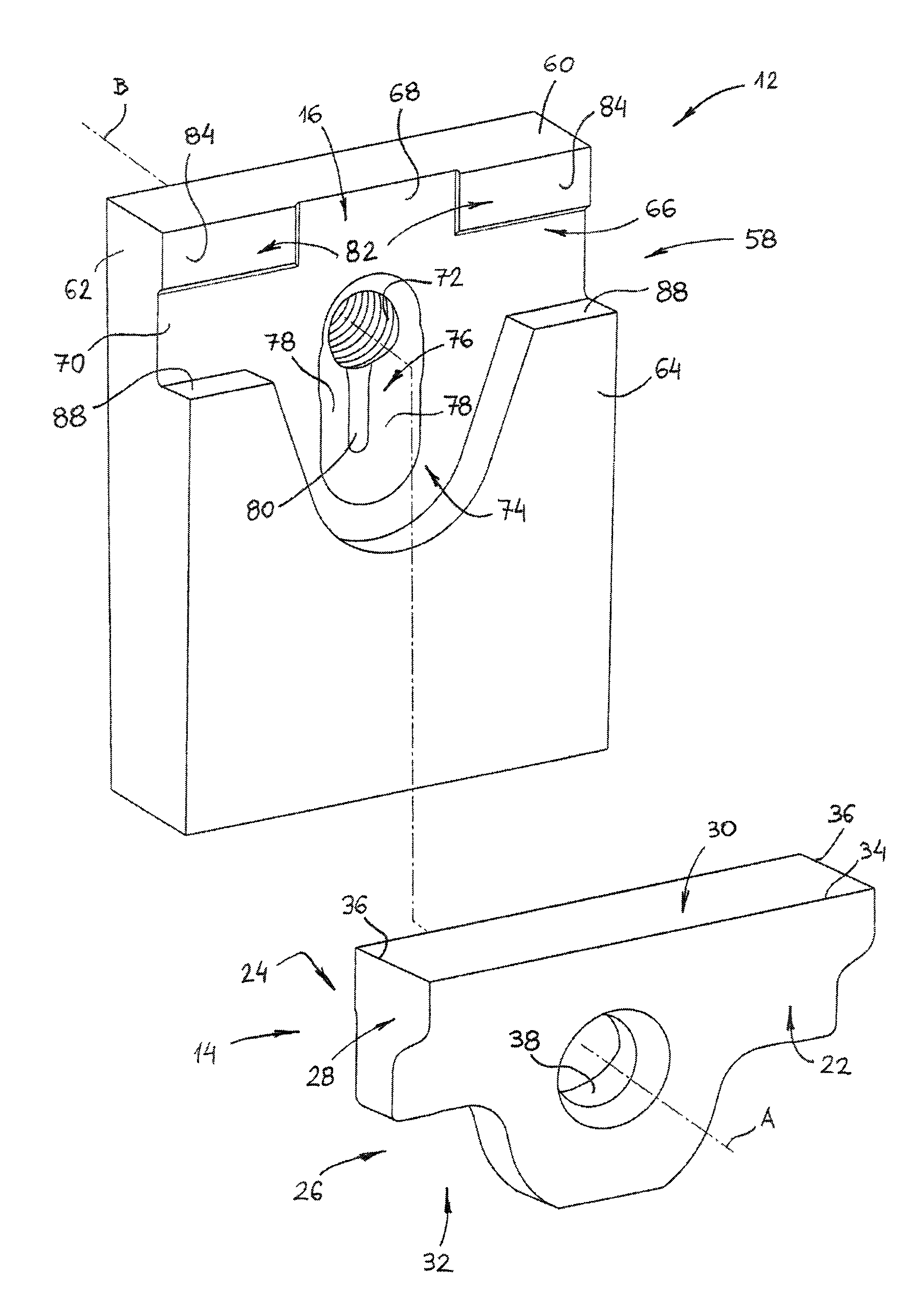

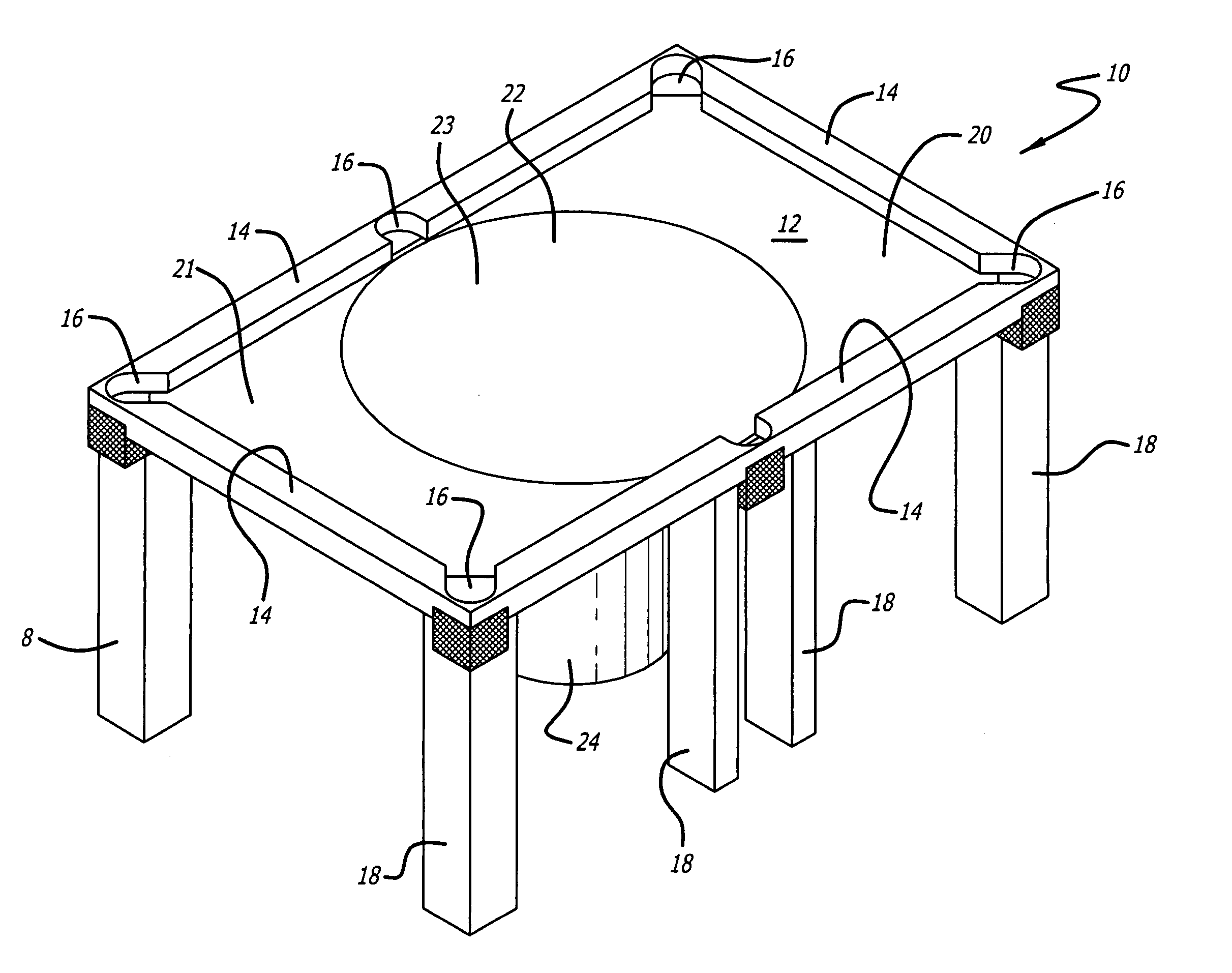

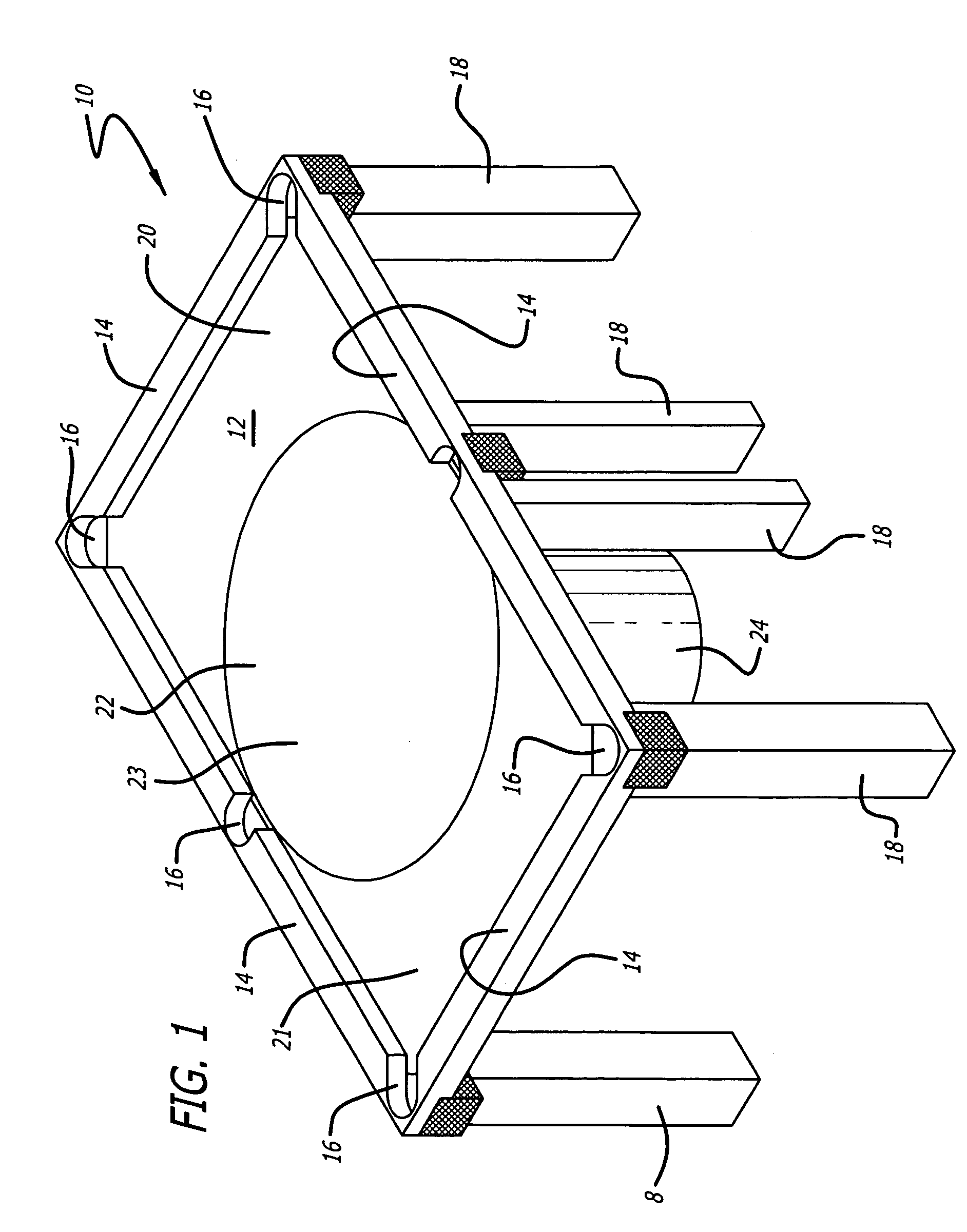

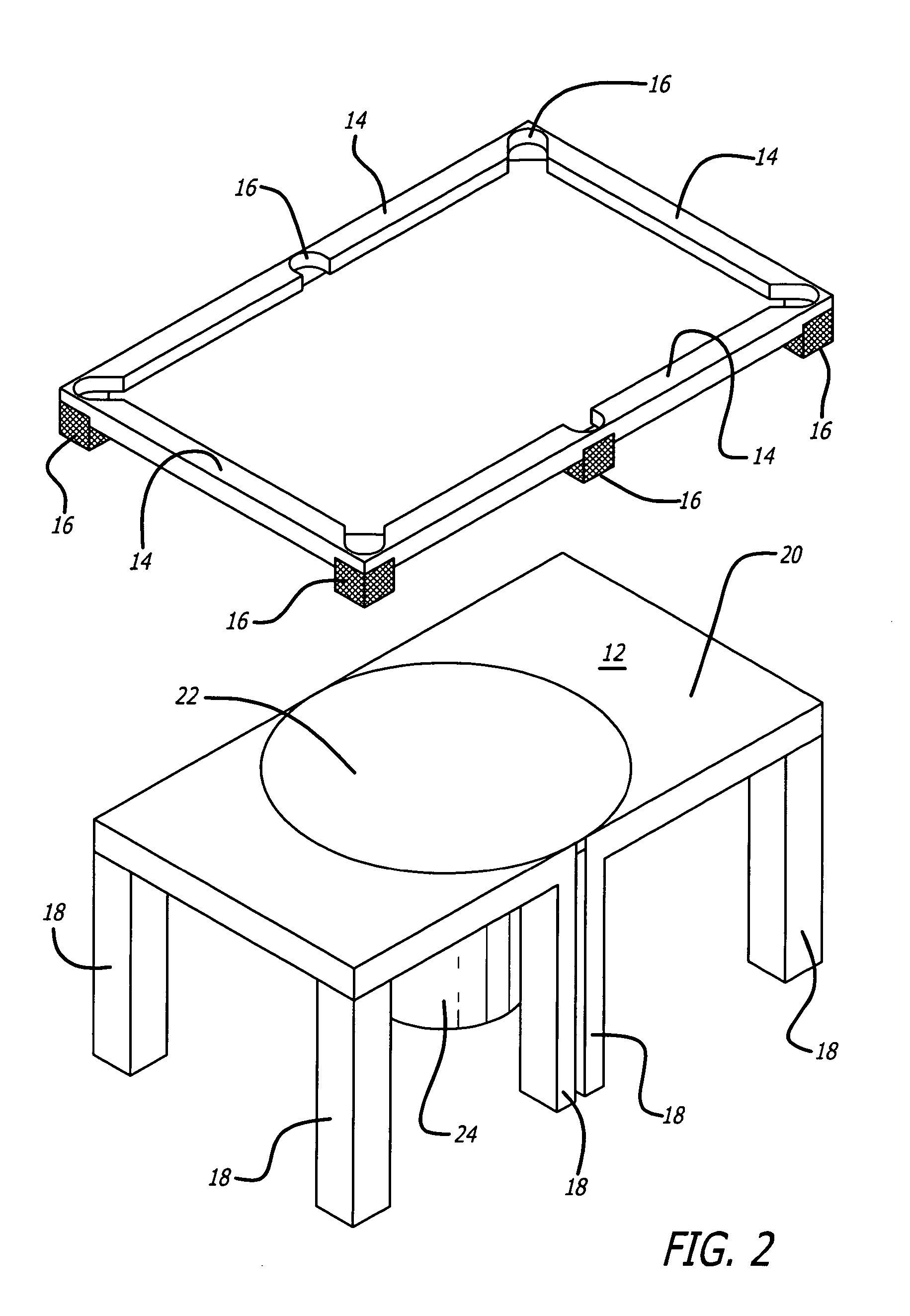

Four dimensional billiards

A Playing surface (12) that introduces “movement” or “motion” as a fourth dimension to the traditional game of billiards by altering the natural inertia of the billiard balls is disclosed. In one embodiment of the playing surface (12), “motion” is introduced through turning or rotating of a portion (22) of the playing surface (12) of the billiards table (10) in the same plane as the playing surface. By affecting introducing a new element that would affect the inertia of the balls, players would then be required to not only make judgments about the distance, angle and force that the cue ball should strike the target ball, but must also consider how those factors may be effective by the introduction of an element that may alter the typical movement of the balls. Accordingly, players will be faced with moving targets, moving obstacles and the possible redirection and / or change in speed of the target balls as they attempt to hit the balls into the pockets of the table.

Owner:GHAHRAMAN CARLIN

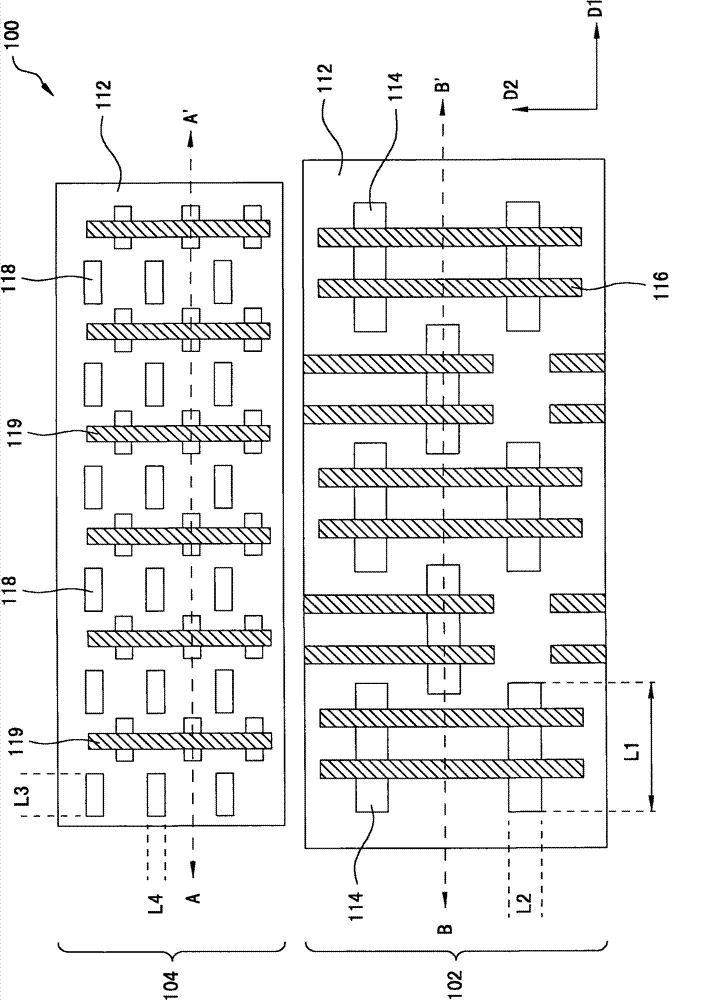

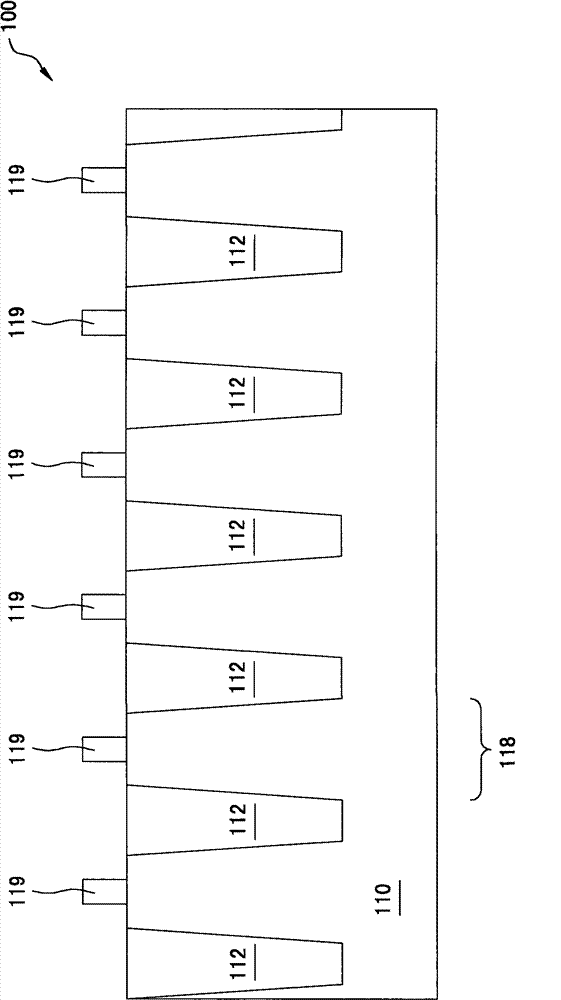

Semiconductor structure and manufacturing method thereof

ActiveCN102117805BOvercoming uneven performanceQuality improvementSolid-state devicesSemiconductor/solid-state device manufacturingElectrical conductorSemiconductor structure

The present disclosure provides a semiconductor structure and a manufacturing method thereof. The semiconductor structure includes a semiconductor substrate having a device region and a dummy region adjacent the device region; a plurality of active regions in the device region; and a plurality of dummy active regions in the dummy region, where each of the active regions has a first dimension in afirst direction and a second dimension in a second direction perpendicular to the first direction, and the first dimension is substantially greater than the second dimension; and each of the dummy active regions has a third dimension in the first direction and a fourth dimension in the second direction, and the third dimension is substantially greater than the fourth dimension. The plurality of dummy active regions are configured such that thermal annealing effect in the dummy region is substantially equal to that of the device region.

Owner:TAIWAN SEMICON MFG CO LTD

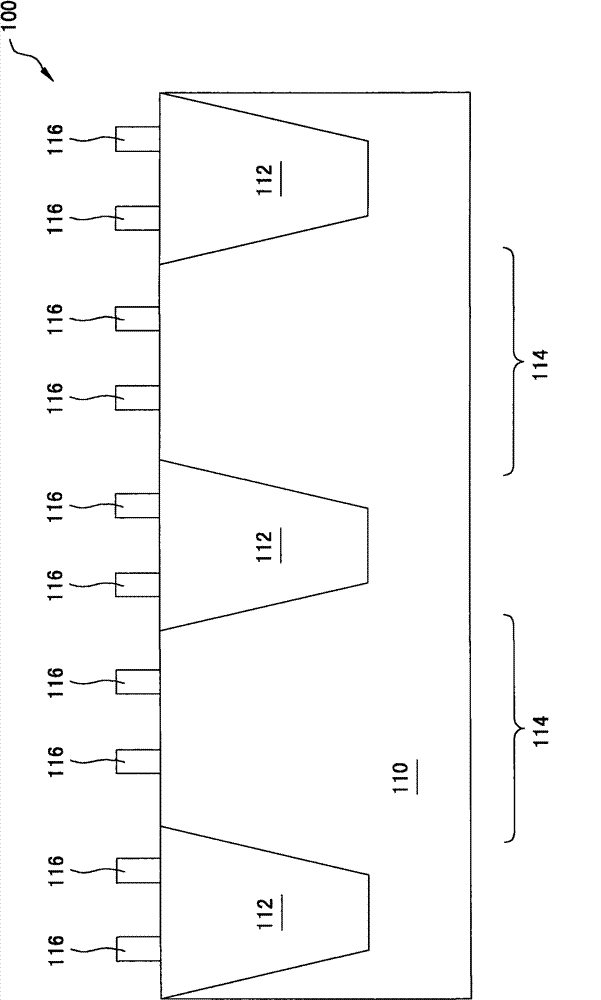

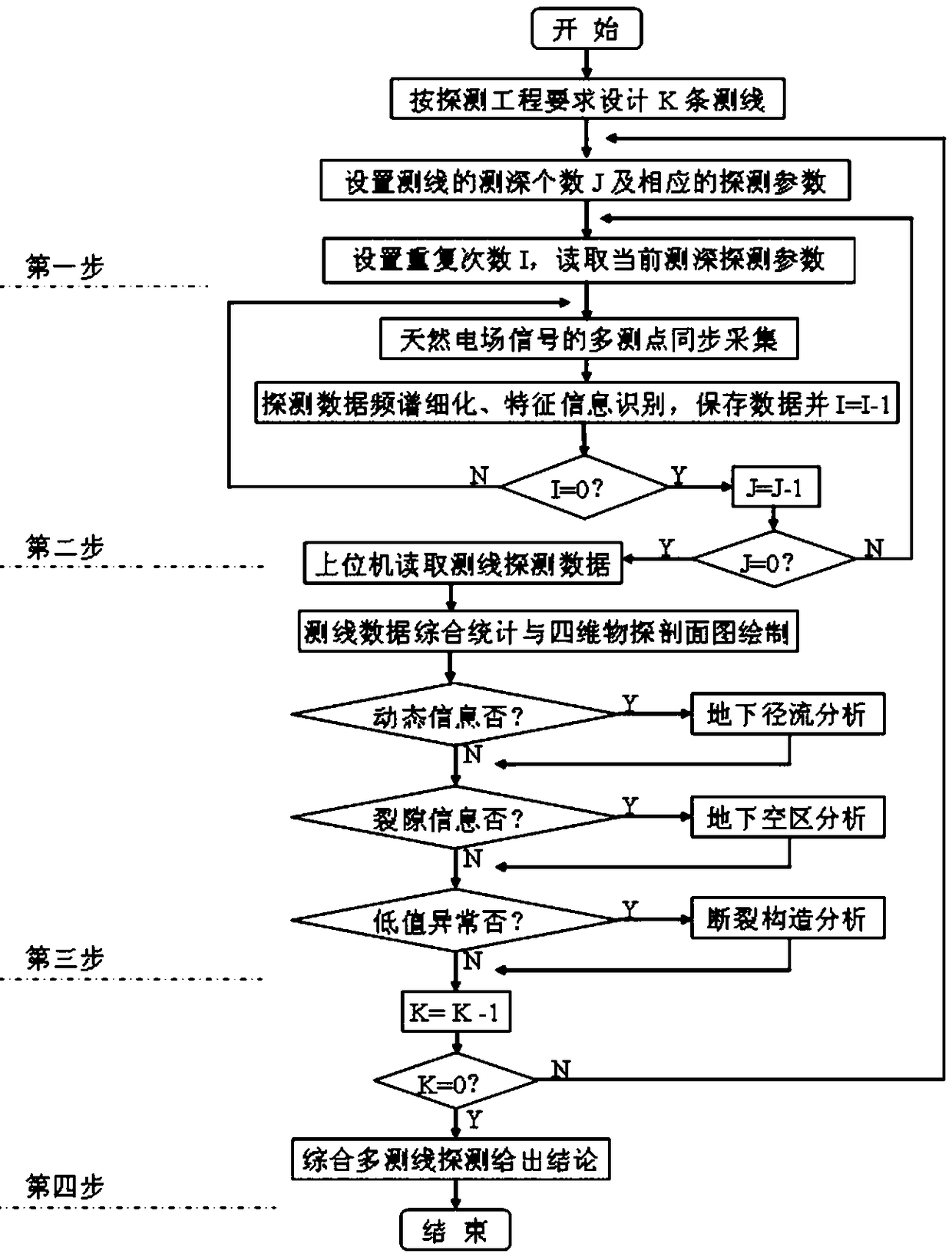

Four-dimensional geophysical prospecting method based on natural electric field

ActiveCN105911603BSave storage spaceGood correlationElectric/magnetic detectionAcoustic wave reradiationFrequency spectrumTime spectrum

The invention discloses a natural electric field based four-dimensional geophysical prospecting method, which is performed as follows. Prior to acquiring onsite data, a prospecting project has to undergo thorough designs. Detection apparatuses work at the same time on the ground to acquire electric field distribution signals formed on the ground after the penetration into stratigraphic texture of electromagnetic waves received by a plurality of probe pins on each survey line. The electric field distribution signals are stored after real time spectrum refinement and characteristics information identification. A master computer accesses the data from the detection apparatuses and after comprehensive analysis, draws a survey line provided four-dimensional geophysical prospecting sectional view, conducts qualitative and quantitative analysis on survey lines with characteristics information and arrives at conclusions of the prospecting project by the combination of prospecting analyzing results of a plurality of survey lines. In addition to effectively using a frequency domain three-dimensional geophysical prospecting method, the method of the invention introduces a fourth dimension featuring characteristics parameters varying from time. Compared to the prior art, detection apparatuses require smaller storage space, data from synchronizing detection spots are well correlated and strong enough to resist interference; these advantages allow comprehensive qualitative and quantitative analysis on a detected geological body.

Owner:HUNAN UNIV OF SCI & TECH

Apparatus including an overlay mark and method of producing semiconductor assembly

ActiveCN102087488BAlignment is precise and accurateAccurate alignment error measurementSolid-state devicesPhotomechanical apparatusFourth DimensionEngineering

Provided is an apparatus that includes an overlay mark. The overlay mark includes a first portion that includes a plurality of first features. Each of the first features have a first dimension measured in a first direction and a second dimension measured in a second direction that is approximately perpendicular to the first direction. The second dimension is greater than the first dimension. The overlay mark also includes a second portion that includes a plurality of second features. Each of the second features have a third dimension measured in the first direction and a fourth dimension measured in the second direction. The fourth dimension is less than the third dimension. At least one of the second features is partially surrounded by the plurality of first features in both the first and second directions.

Owner:TAIWAN SEMICON MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com