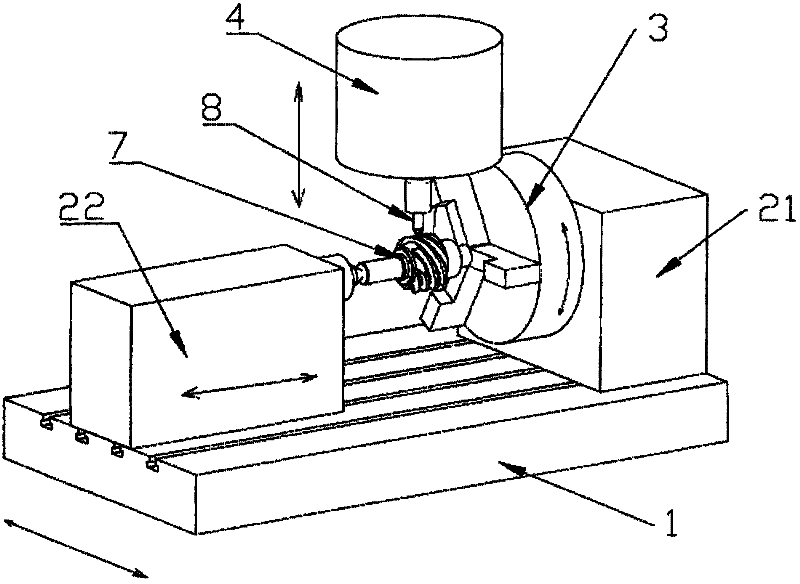

Machining method of worm by milling instead of turning and implementation device thereof

A processing method and worm technology, which can be applied to worms, components with teeth, belts/chains/gears, etc., can solve problems such as high requirements of processing technicians, reduce dependencies, shorten processing hours, and improve processing efficiency and quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

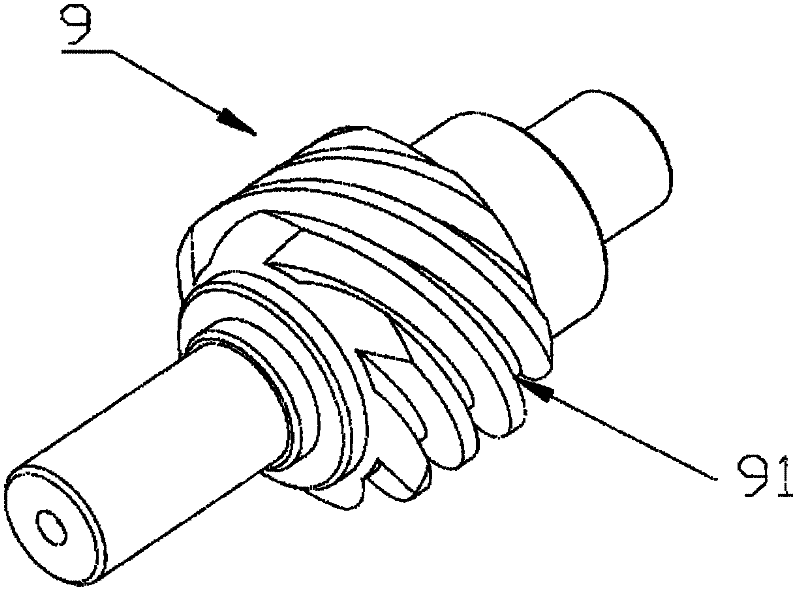

[0033] The following will take the ZN type normal straight profile worm as an example to introduce in detail the whole process of machining the worm by using the four-way linkage CNC boring and milling center and the coating forming milling cutter. The auxiliary software is UGNX as an example.

[0034] First, prepare drawings and shapes according to the processing requirements. After knowing the key parameters such as the number of worm heads, modulus, and diameter coefficient, convert the parameter equations recognized by the computer according to the worm formula. The following examples are only the key parameters of specific worm models and their converted parameter equations. In actual processing, these key parameters and their specific assignments in the parameter equations will vary depending on the type and model of the worm.

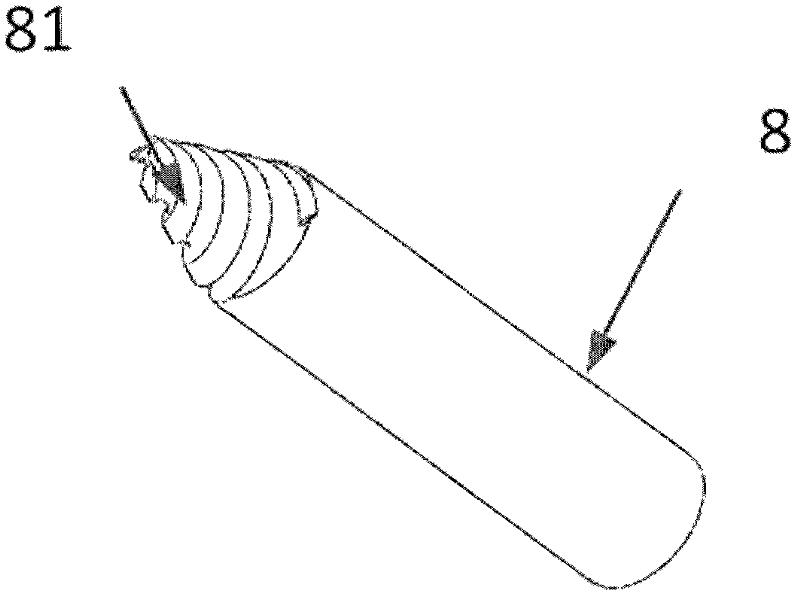

[0035] Then, choose the appropriate milling cutter according to the worm parameters. In this example, the worm is a normal straight-profile worm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com