Patents

Literature

211 results about "Self consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Definition of Self Consumption. Self Consumption means that portion of the total energy generated by the Project but used for the Project's operations.

Multi-series connection type battery cell pack for reducing self-consumption over a long period of time

ActiveUS6930467B2Easy to implementReduce self consumptionPrimary cell to battery groupingBatteries circuit arrangementsFailure rateMicrocomputer

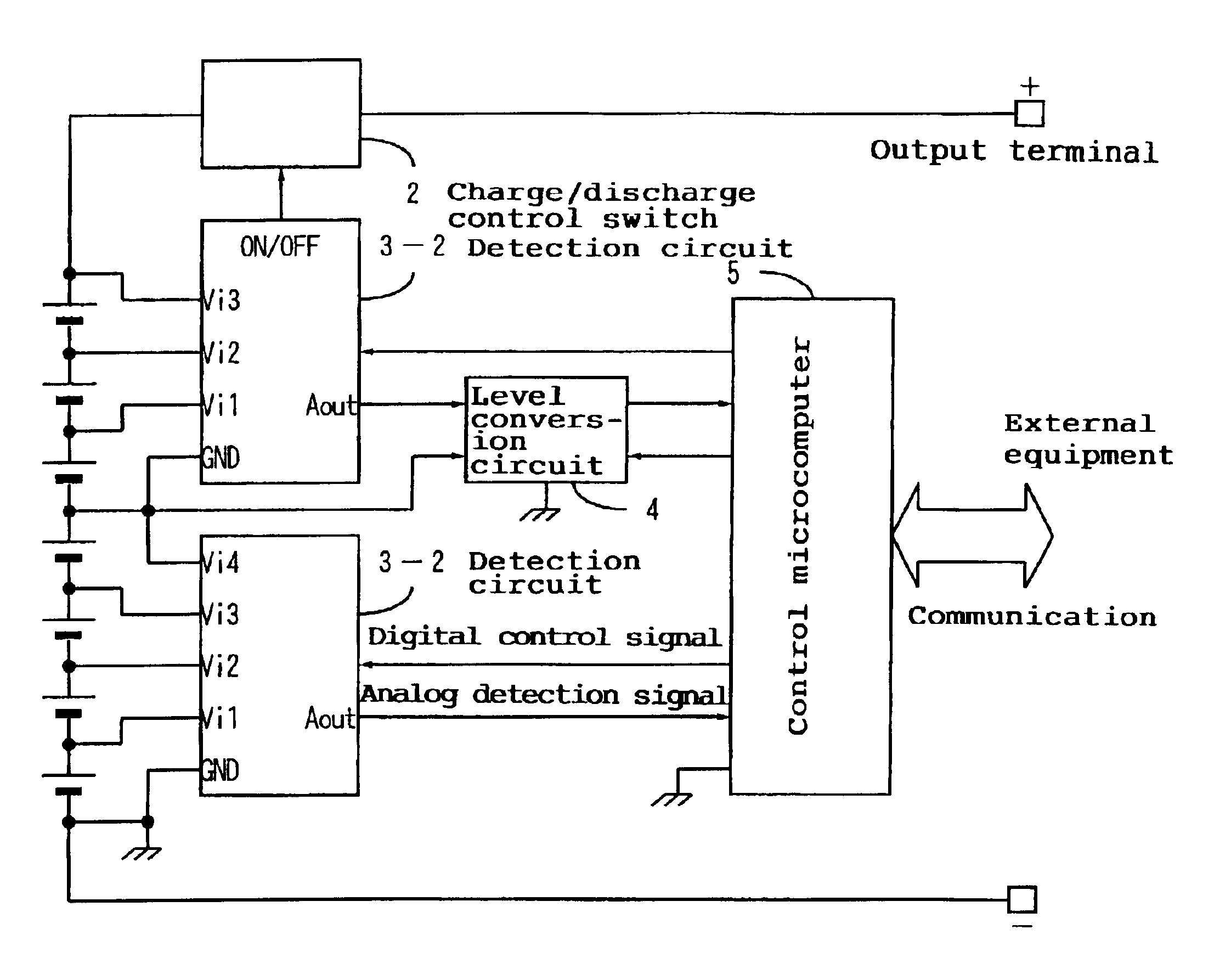

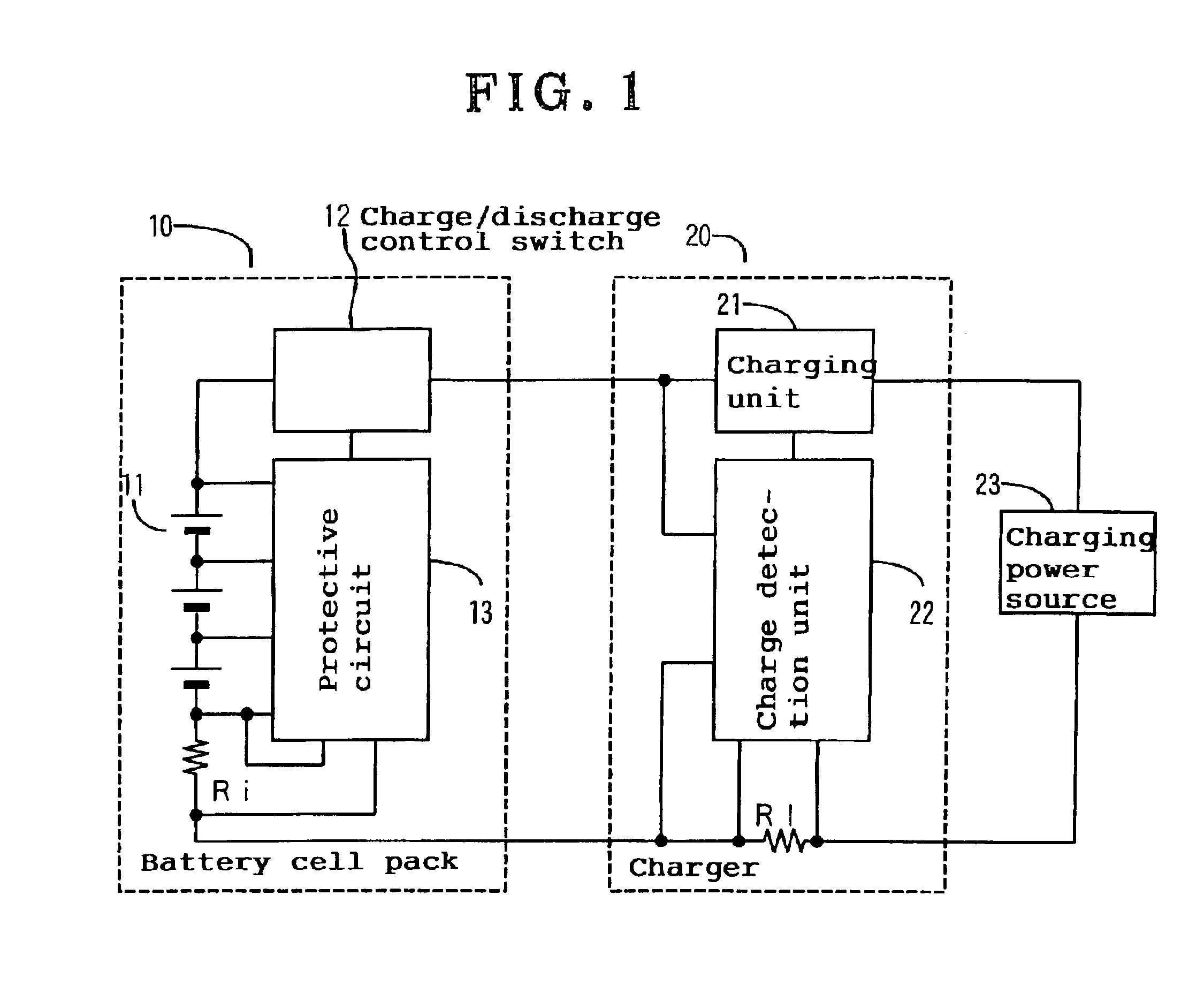

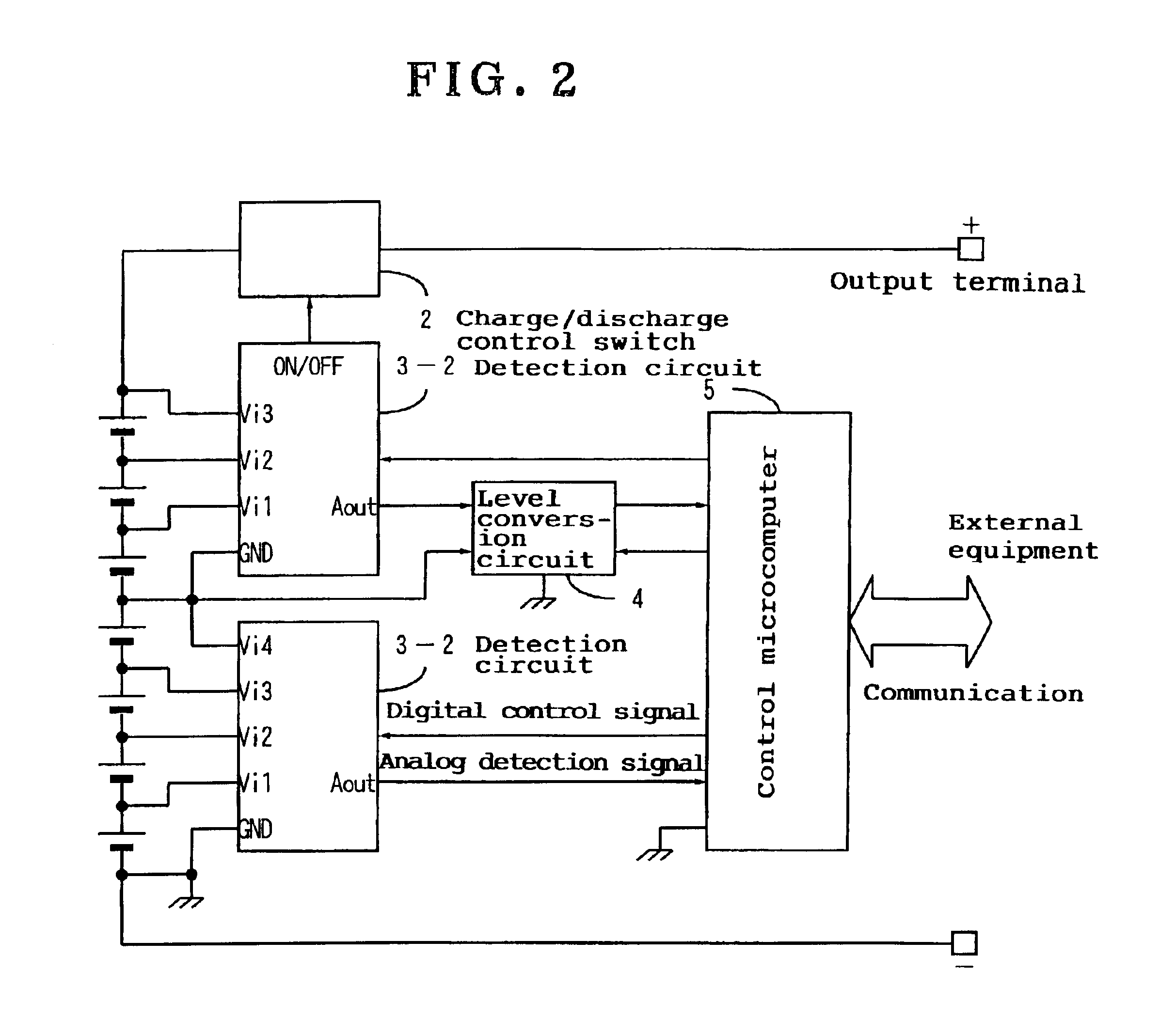

The invention provides a multi-series connection type battery cell pack, characterized by comprising a plurality of series-connected battery cells 1, a charge / discharge control switch 2 for performing charge / discharge control, a plurality of protective circuits 3-1 and 3-2 for dividing the plurality of battery cells 1 into a plurality of blocks to detect at least the voltage of each battery cell, a computing circuit 5 for performing computation of pack detection signals and a level conversion circuit 4 for unifying voltages references of the detection signals between the plurality of protective circuits 3-1 and 3-2 and the computing circuit 5, wherein the plurality of protective circuits 3-1 and 3-2 are joined in parallel with the battery cells 1 in a multistage fashion. It is thus possible to unify the voltage references while computation and communication are executed irrespective of control. It is then possible to manage the battery cell pack in a unified manner using a microcomputer or the like and, hence, to determine management specific to batteries and operational criteria specific to battery products at users' disposal. It is also possible to make a switching between a mode wherein current consumption in the pack minimizes and a normal operation mode and, hence, switch the pack over to the minimum current consumption mode when it is not in use, thereby reducing the failure rate during long-term storage.

Owner:NEC TOKIN TOCHIGI

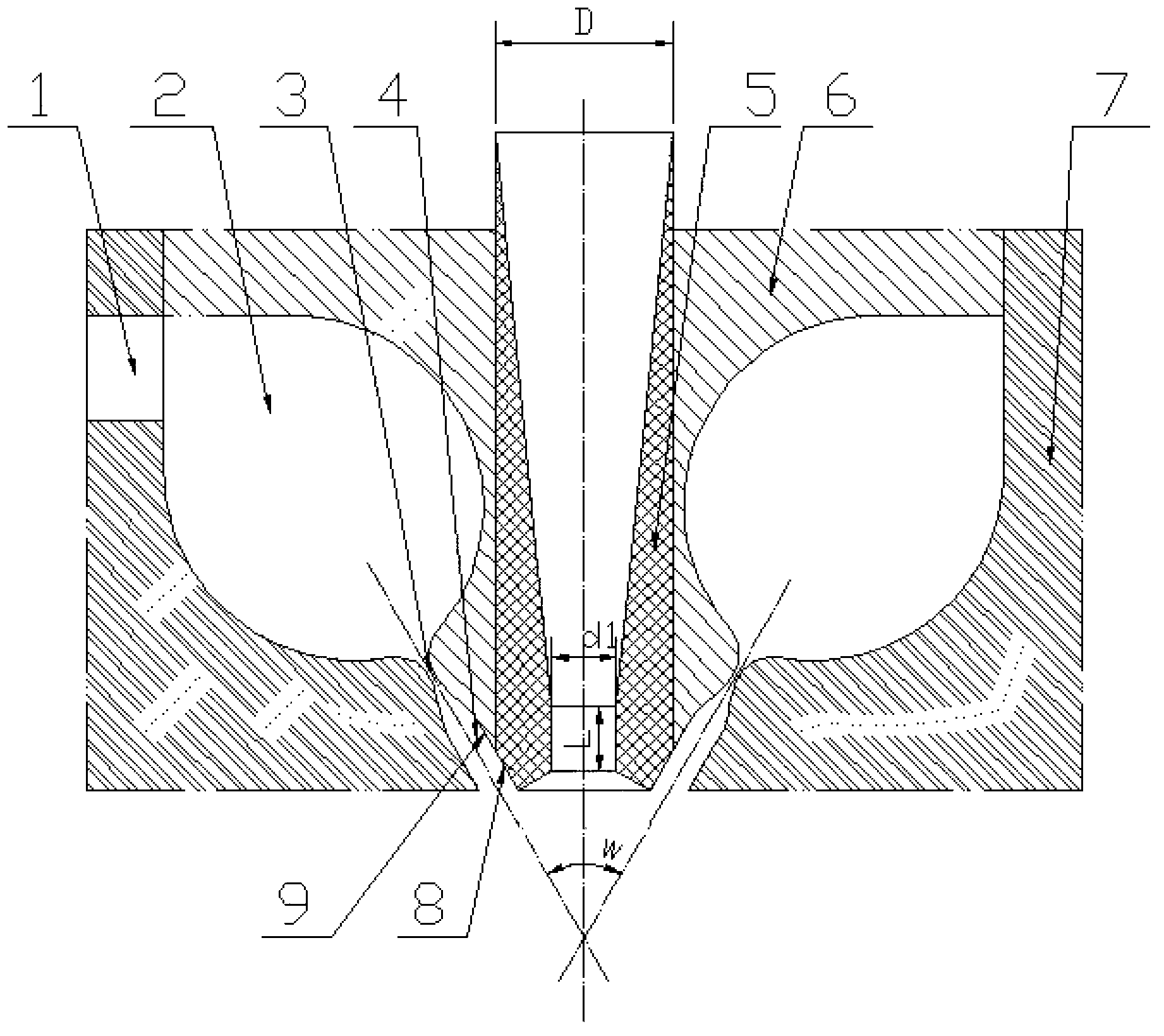

Continuous casting crystallizer capable of controlling liquid level flow field and wave motion

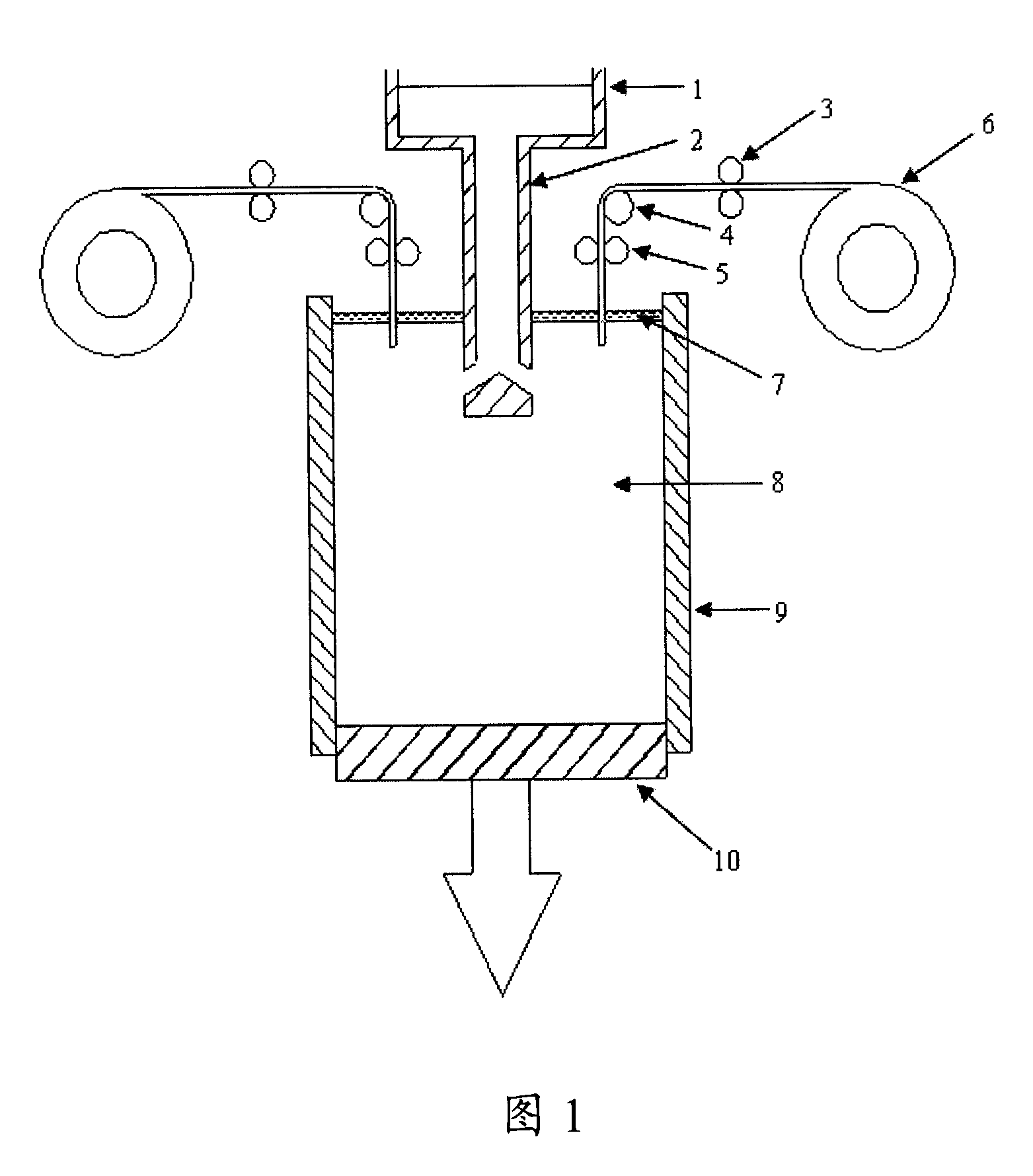

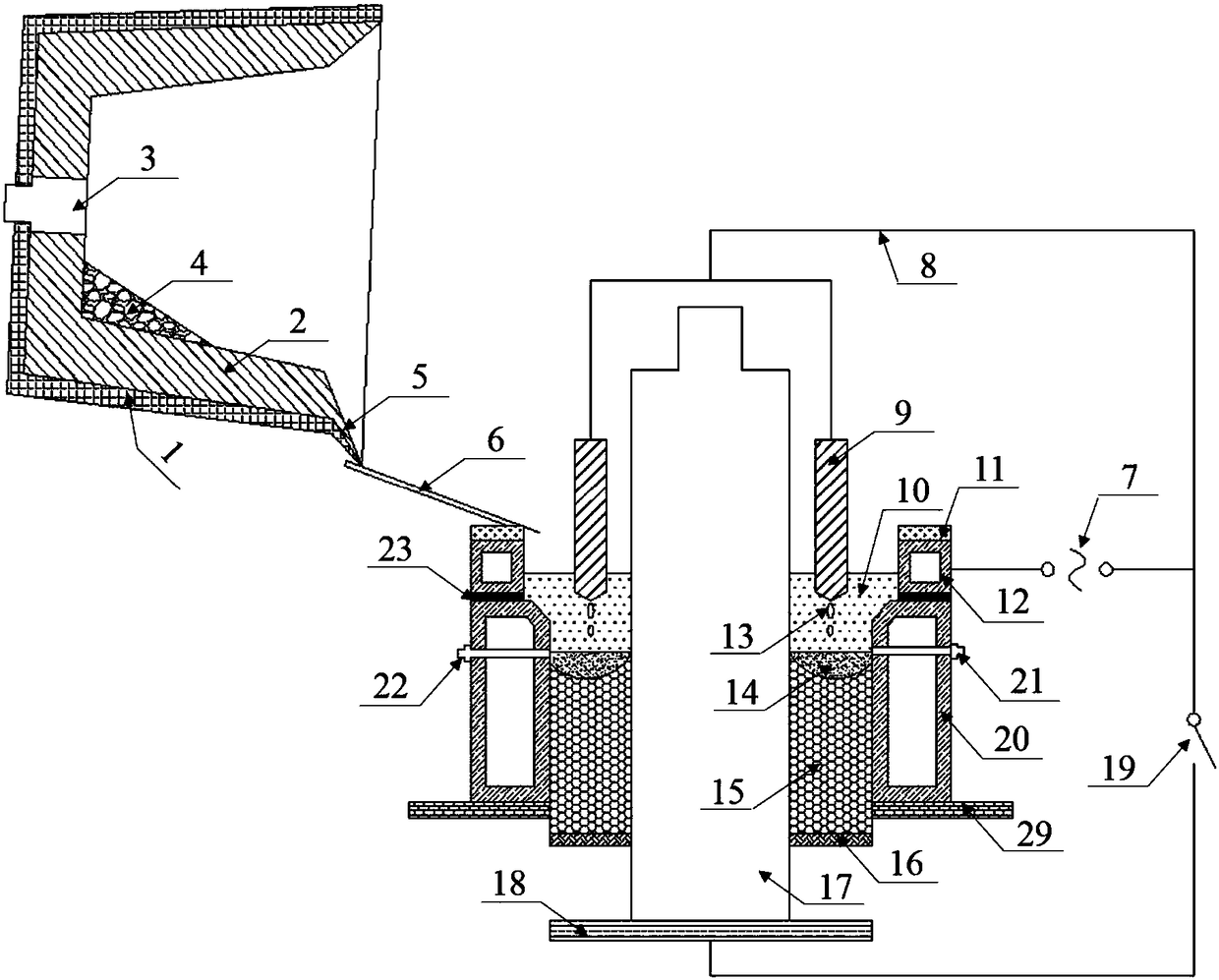

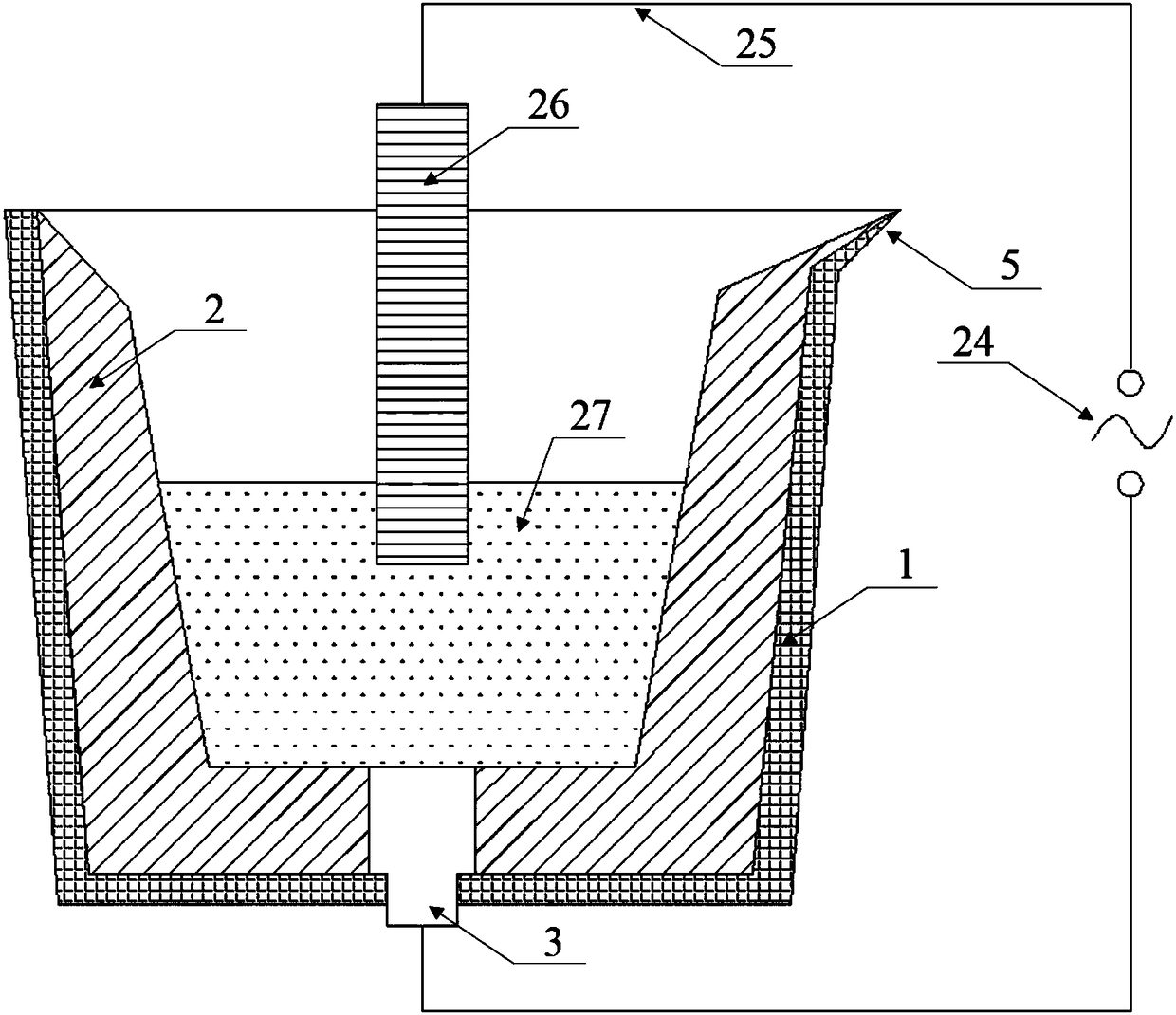

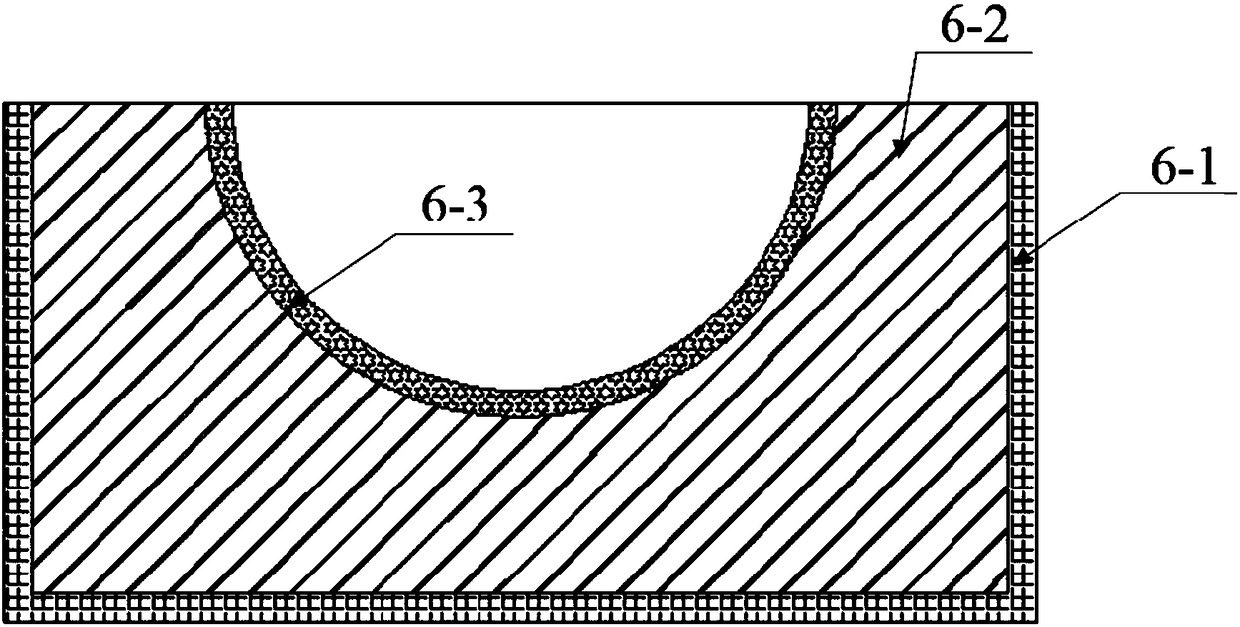

The invention relates to a device of continuous casting crystallization mould with a controllable liquid level and fluctuation, pertaining to the metal continuous casting process technology field. The invention can reduce slag entrapment on liquid surface of crystallization mould according to the mechanism of slag entrapment production in crystallization mould to inhibit metallic liquid flow horizontally. The main part of the invention is basically the same as the traditional crystallization mould, while the difference lies in that the two sides of the crystallization mould upper part are provided with self consumption metal plates and feeding mechanisms; the self consumption metal plate is inserted into the metallic liquid of the crystallization mould through a straightening roller, a guide roller and a transport roller; continuously casting billets are finally drawn off by a dummy bar. The structure of the invention comprises: a metallic pouring basket (1), a submerged nozzle (2), a straightening roller(3), a guide roller(4), a conveying roller (5), a self-consumption metal plate (6), mould power (7), casting billets (8), a water cooled crystallization mould (9) and a dummy bar (10). The invention can reduce and inhibit the slag entrapment production in the crystallization mould, thereby improving quality of continuous casting billet.

Owner:SHANGHAI UNIV

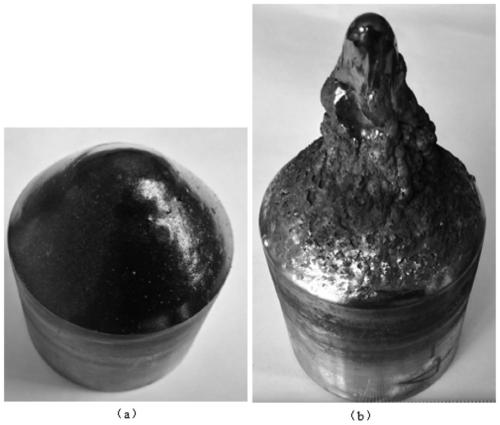

Precision casting method for graphite mould-ceramic core titanium alloy

ActiveCN101733383AHigh dimensional accuracyImprove internal qualityFoundry mouldsFoundry coresSelf consumptionGraphite

This invention claims a precision casting method for a graphite mould-ceramic core titanium alloy, which comprises the following process steps: 1) preparing a ceramic core; 2) preparing a graphite shell; 3) degassing the graphite shell and the ceramic core; 4) assembling the ceramic core and the graphite shell into a casting mould according to a casting shell drawing; and 5) smelting and casting. The method is characterized in that: the step of degassing the ceramic core comprises the following steps: putting the formed ceramic core into a vacuum degassing furnace, heating the furnace to 200 DEG C, preserving heat for 1 hour, cooling the ceramic core to an indoor temperature with the furnace; the step of degassing the graphite shell comprises the following steps: putting the graphite shell into the vacuum degassing furnace, heating the furnace to 800 DEG C, preserving heat for 3 hours and cooling the graphite shell to the indoor temperature with the furnace; and the ceramic core and the graphite type shell subjected to the degassing process are put into a vacuum self-consumption electrode skull furnace for smelting and casting according to a titanium alloy smelting and casting process. The method has the following advantages that: aiming at a complicated three-dimensional variable camber titanium alloy precision casting, for the titanium alloy casting cast by the method, the size precision, internal quality and surface quality are improved, the rejection rate of the casting is greatly decreased, the casting cost of the casting is reduced and the production period of the casting is shortened.

Owner:SHENYANG RES INST OF FOUNDRY

Non-phosphate degreasant

ActiveCN101314855AImprove convenienceFulfil requirementsInorganic/elemental detergent compounding agentsSurface-active detergent compositionsSelf consumptionPhosphate

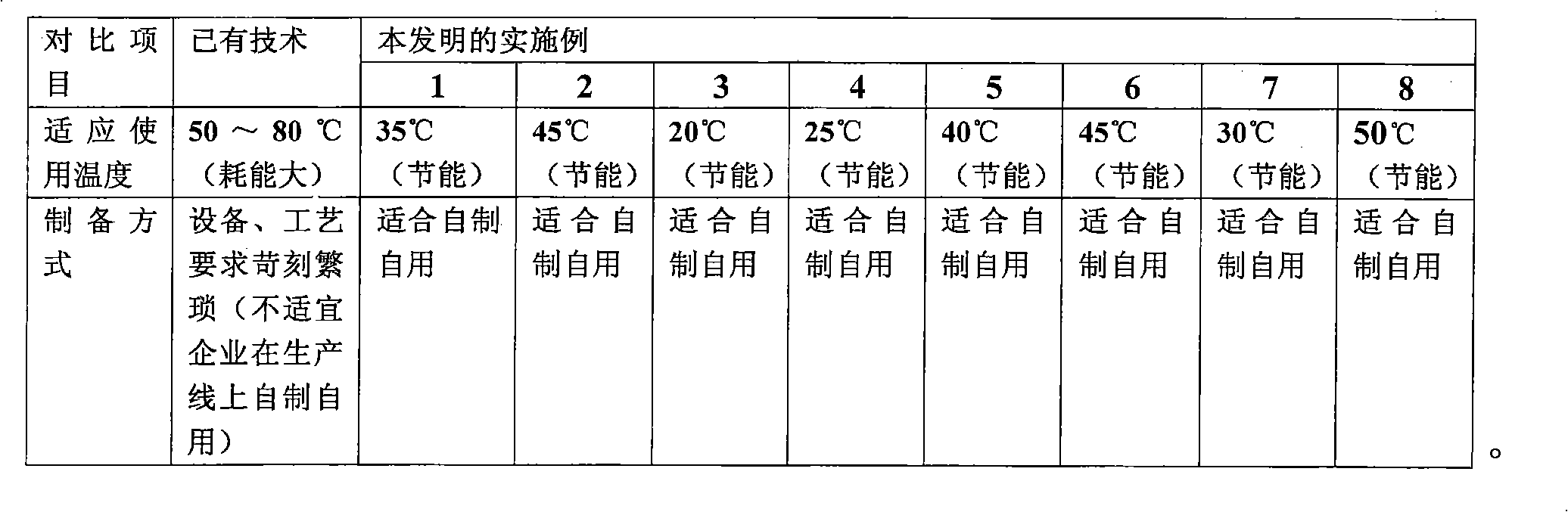

The invention relates to a non-phosphate degreasant belonging to the surface cleaning agent technology field of metallic material, which comprises the raw materials by weight parts as follows: a surface active agent is 1 to 15 parts, a self-defoaming emulsifier is 1 to 5 parts, sodium hydroxide is 15 to 25 parts, sodium citrate is 0.1 to 3 parts, sodium carbonate is 0.1 to 5 parts, 9H2O-sodium silicate is 1 to 10 parts, and water is 40 to 99 parts. The non-phosphate degreasant has the advantages that all raw materials of the degreasant are easy to get in the market; various raw materials can be used only through evenly stirring by hand or mechanically without fussy manufacturing process just like the prior art, thereby satisfying the convenient and time-saving requirements for self-making and self-consumption on a product line of a zincification enterprise; the adaptive temperature ranges from 20 to 48 DEG C (the adaptive temperature of the degreasant in the prior art ranges from 50 to 80 DEG C), and the advantage of saving energy sources is realized.

Owner:CHANGSHU HUAYE STEEL STRIP

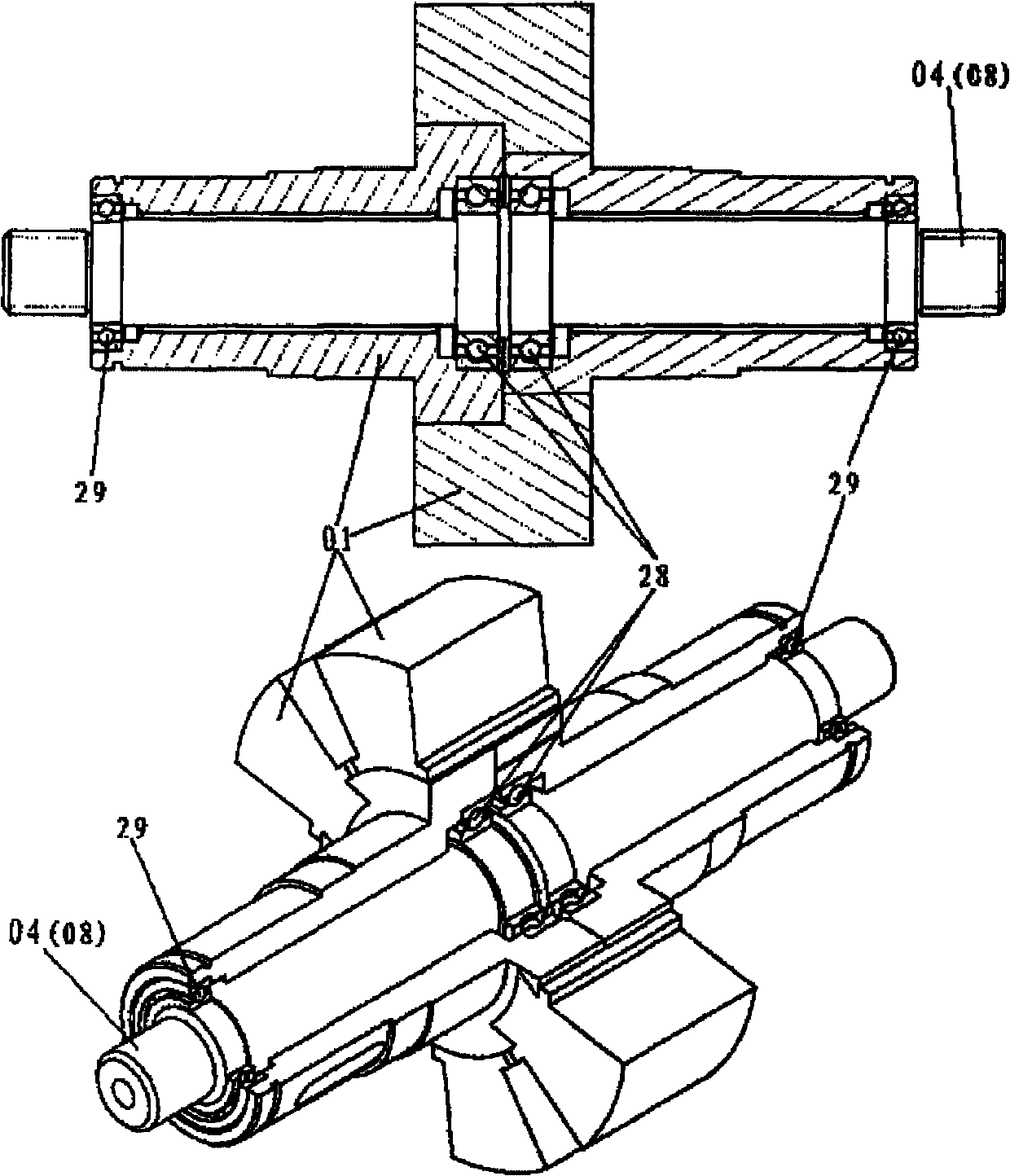

Device and method for preparing bimetallic compounding roll by electric slag remelting method

The invention relates to a device and a method for preparing a bimetallic compounding roll by an electric slag remelting method. The device comprises an upper crystallizer and a lower water-cooling crystallizer, wherein the upper crystallizer and the lower water-cooling crystallizer form a T-shaped crystallizer; the upper crystallizer is a conductive crystallizer, and is insulated and isolated from the lower water-cooling crystallizer, and the lower water-cooling crystallizer is provided with a liquid level detector; a remelting compounding transformer is connected with the upper crystallizerthrough a short electrified wire. The method comprises the following steps of after slagging is finished, disengaging a slagging power supply loop; during slag firing, when the liquid level of a slagtank in the crystallizer submerges the lower edge of a conductive graphite block, conducting a roll core preheating power supply loop, and preheating a roll core; after preheating is finished, closingthe loop, lowering a self-consumption electrode to the end part, inserting into the slag tank, conducting an electrode melting and bimetallic compounding power supply loop, and finally performing thebimetallic melting compounding. The device and the method have the advantages that by adopting a method for improving the electric slag testing device and the power supply loop, the temperature fieldat the surface of the roll core is reasonably optimized, so as to prepare the bimetallic compounding roll with better interface bonding quality.

Owner:NORTHEASTERN UNIV

Switching room user identification method and switching room user identification device

InactiveCN103063967AImprove reliabilityElectrical testingMeasurement using digital techniquesSelf consumptionIdentification device

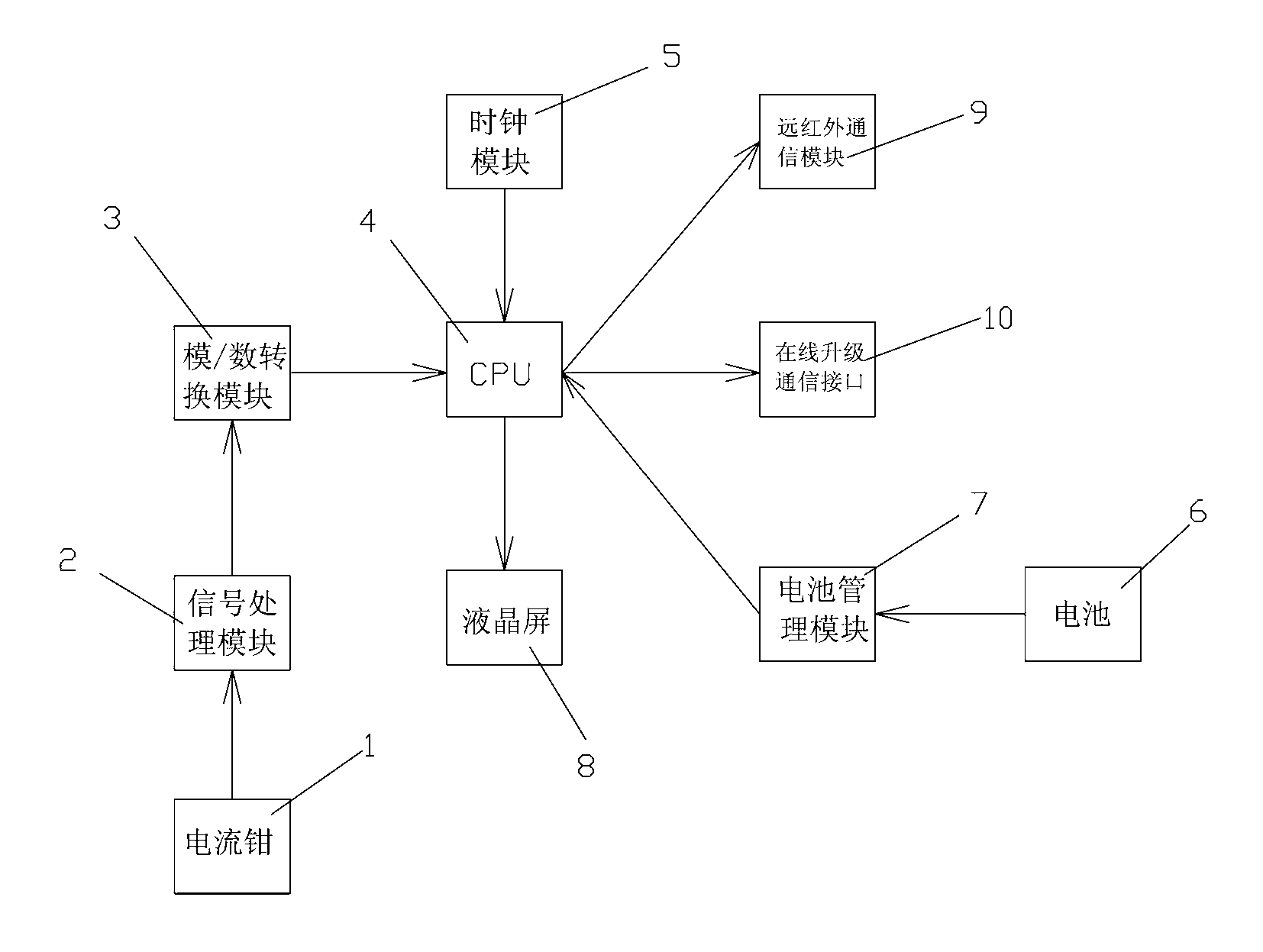

Disclosed are a switching room user identification method and a switching room user identification device. The identification method comprises that the user identification device is clamped on a circuit of an identified user, and when a power-supplying state of the identified user changes from one state to another state, the user identification device adjusts and notes data of the moment the power-supplying state changes; outage or delivery of currents is conducted on the circuit of the identified user so as to note moment of the outage and moment of the delivery of the currents; data noted by the user identification device at the moment the power-supplying state changes is compared with the manually noted moment of the outage or manually noted moment of the delivery of the currents, and if the data noted by the user identification device at the moment the power-supplying state changes fits the manually noted moment of the outage or manually noted moment of the delivery of the currents, the identified user belongs to a preset switching room, or the identified user does not belong to the preset switching room. The identification device only needs clamping on a coat of the circuit of the user, and a current with a capacity of only 0.005A is needed on the circuit, namely, self-consumption of a watt hour meter can generate a current with a capacity of more than 0.005A as long as the user is provided with the watt hour meter and the watt hour meter normally works. Therefore, self-consumption of the watt hour meter can be detected by the identification device, and high detection reliability is guaranteed.

Owner:余力鑫

Performance-adjustable low-cost titanium alloy

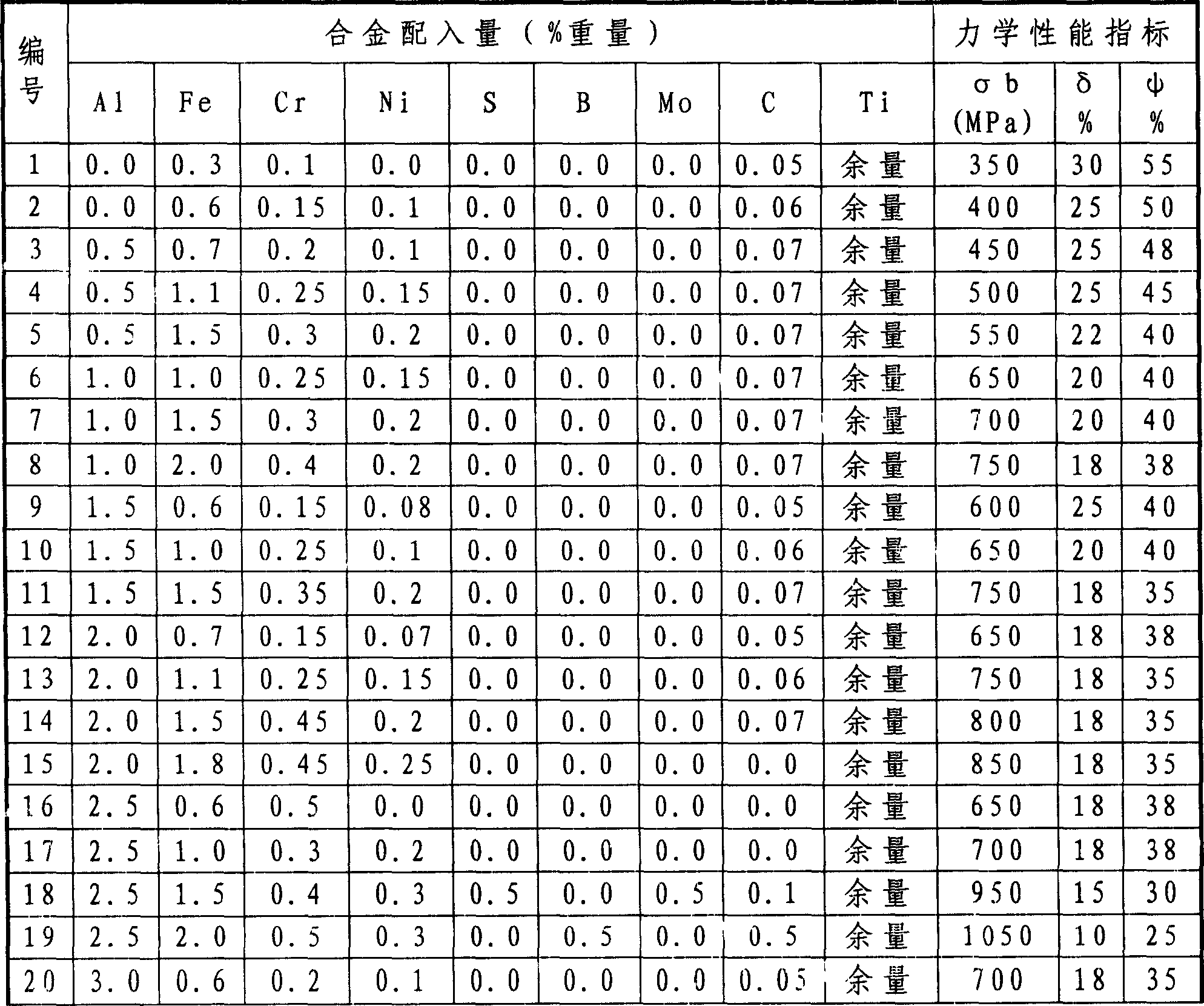

The invention discloses a low-cost adjustable titanium alloy, which is characterized by the following: adding Al, Fe, Cr, Ni, S, B, C and Mo in the titanium with weight percentage of X+Y+Z+Ti at 100%(X=Al<=6%,Y=[(0.3<=Fe <=5%)+(0.1<=Cr<=2%)]<=7%,Z=[(Ni<=0.5%)+(S<=1%)+(B<= 0.5%)+(Mo<=0.8%)+(C<=0.5%)]<=3%); blending allocated alloy materials to form self-consumption electrode; fusing in the vacuum arc furnace twice; fixing one parameter of X, Y and Z and changing other two values to allocate the needed dynamic property of titanium alloy; adjusting delta b within 350Mpa-1250Mpa with delta at 5-30% and phi at 10-55%.

Owner:江苏金火炬金属制品有限公司

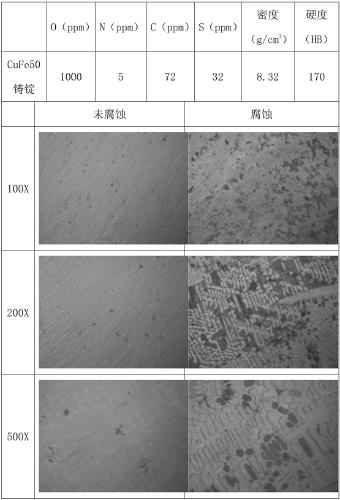

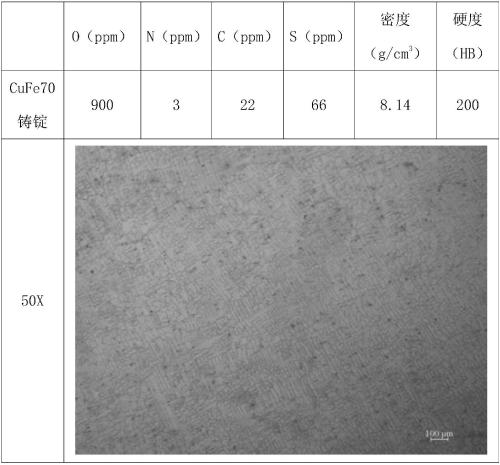

Preparing method for adopting vacuum self-consumption arcs to smelt CuFe alloy materials

The invention discloses a preparing method for adopting vacuum self-consumption arcs to smelt CuFe alloy materials. The preparing method comprises the following steps that firstly, raw material mixingis conducted, raw materials include, by weight percent, 70%-30% of Cu and 30%-70% of Fe, the needed raw materials are weighed according to the proportion and mixed in a mixing machine, and the mixingtime is 2-4 h; secondly, pressing is conducted, the mixed powder obtained after mixing is arranged in a rubber sleeve to be mechanically vibrated for 30s-60s, then, material rolling is conducted for3-6 min, reverse material mounding is conducted 3-5 times, the treated mixed powder is pressed through an isostatic cool pressing method, the pressure ranges from 150 MPa to 300 MPa, and the pressuremaintaining time is 3-10 min; thirdly, sintering is conducted, a pressed consumable electrode is arranged in a vacuum sintering furnace to be sintered, the highest sintering temperature is controlledto range from 800 DEG C to 1,080 DEG C, the heat preservation time is 30-240 min, and the vacuum degree is larger than 5 pa; and fourthly, smelting is conducted, the sintered consumable electrode is arranged in a vacuum self-consumption arc smelting furnace to be smelted, and the smelting current is 1,000-4,000 A. According to the preparing method, the gas content is low, few inclusions exist, structure components are uniform, and Cr and Fe enrichment and other macroscopic and microscopic defects are avoided.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

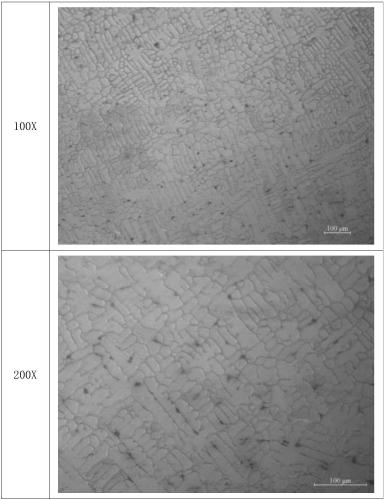

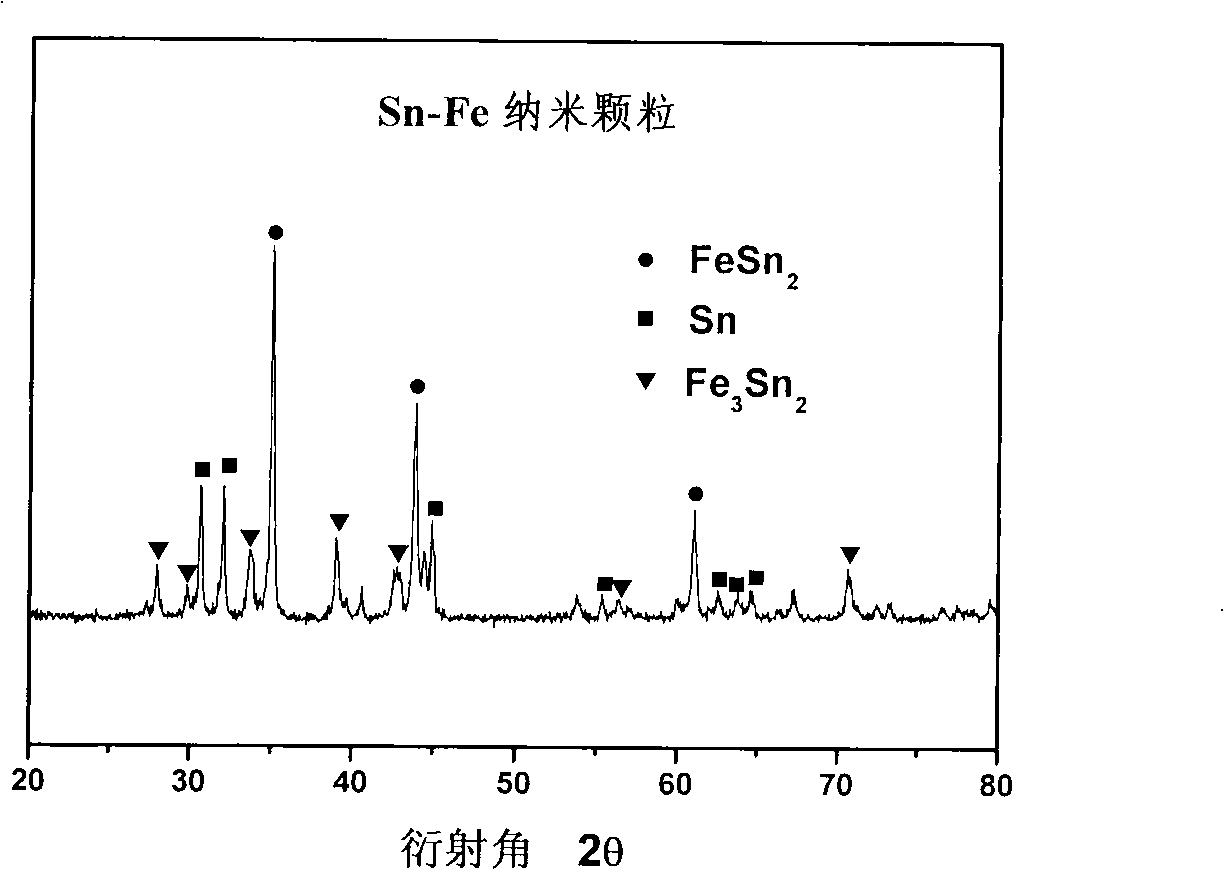

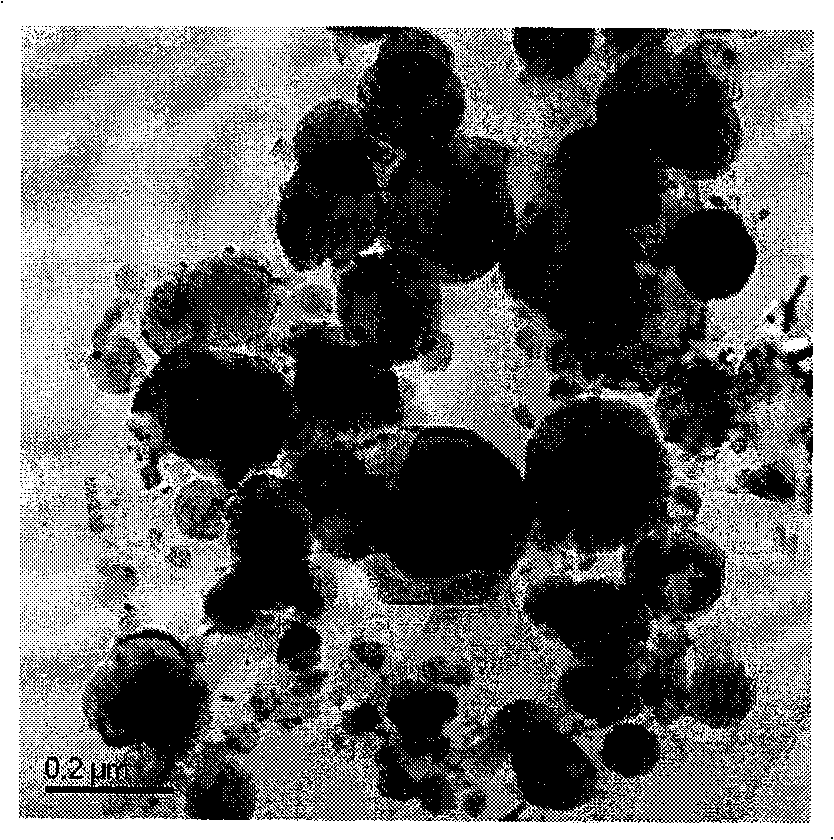

Synthesis in situ of intermetallic compound nano-particle

The invention provides an in situ synthesis method for an intermetallic compound nano particle, which belongs to the technical field of synthesizing a nano particle material. The method is characterized in that tin or magnesium and alloy micron powder which are low in melting point as well as a metal and alloy micron powder which are high in melting point are taken as materials; the materials are evenly mixed and pressed into a block target material which is used as a self-consumption anode; in the mixing atmosphere of active and inert gases, by utilizing a plasma heat source, the block target material is evaporated and subjected to gas-liquid-solid phase change; and the tin based and magnesium based binary or multiple intermetallic compound nano particle is prepared on the normal position. The method has the advantages of adopting the composite block target material, and synthesizing the intermetallic compound nano particle on the normal position, and has the characteristics of simple method, low cost, less impurities, clear and neat particle shape and suitability for mass production. The tin based or magnesium based intermetallic compound nano particle prepared by the method has wide application prospect in fields such as lithium ion cathode materials, hydrogen storage materials and the like.

Owner:DALIAN UNIV OF TECH

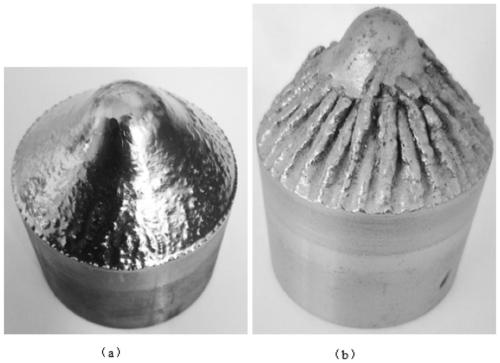

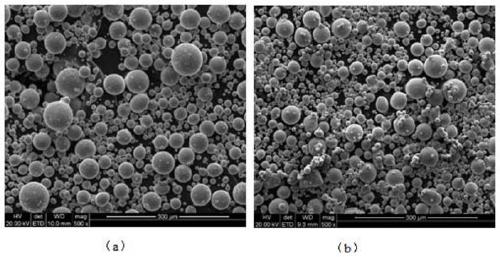

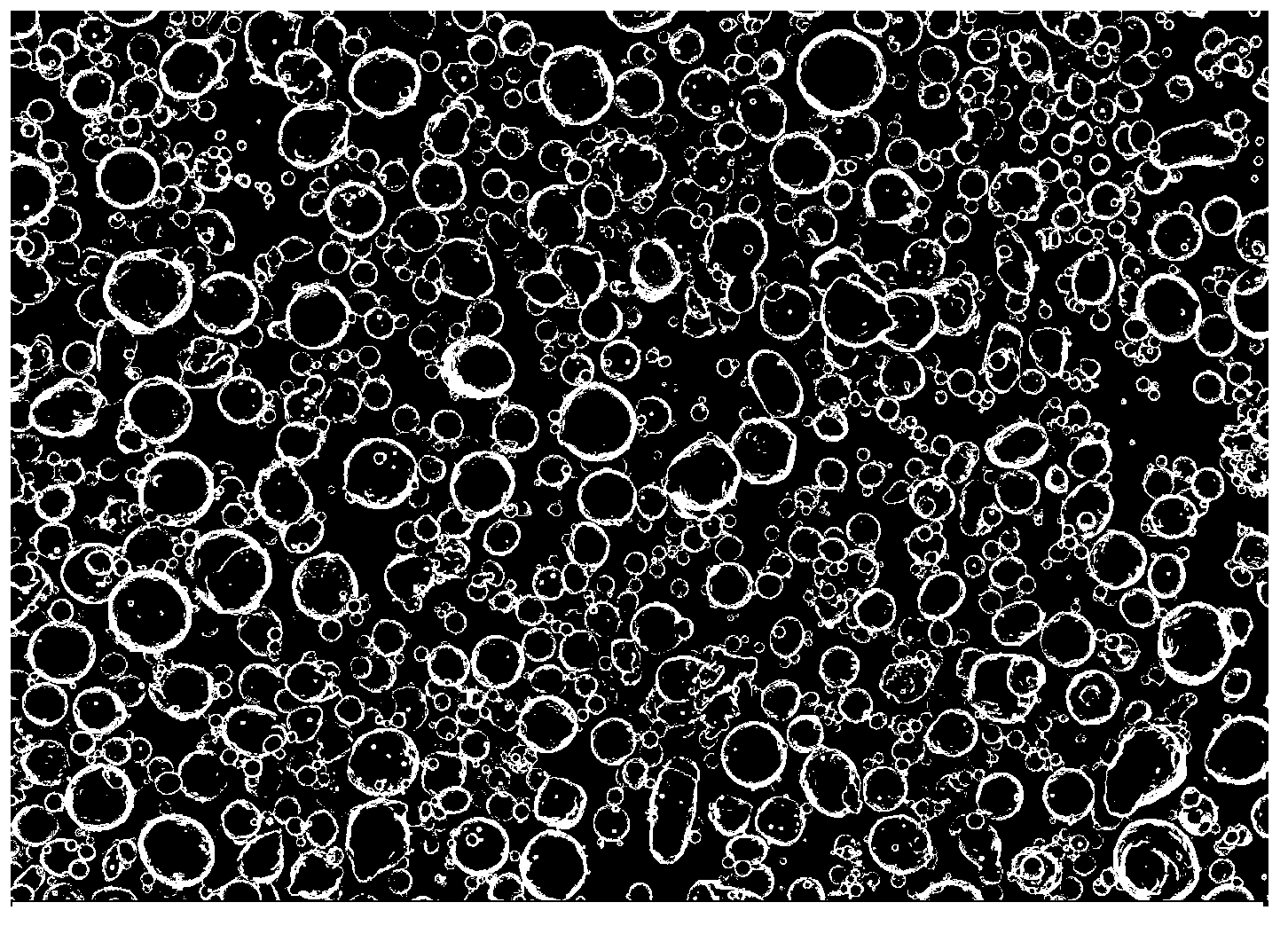

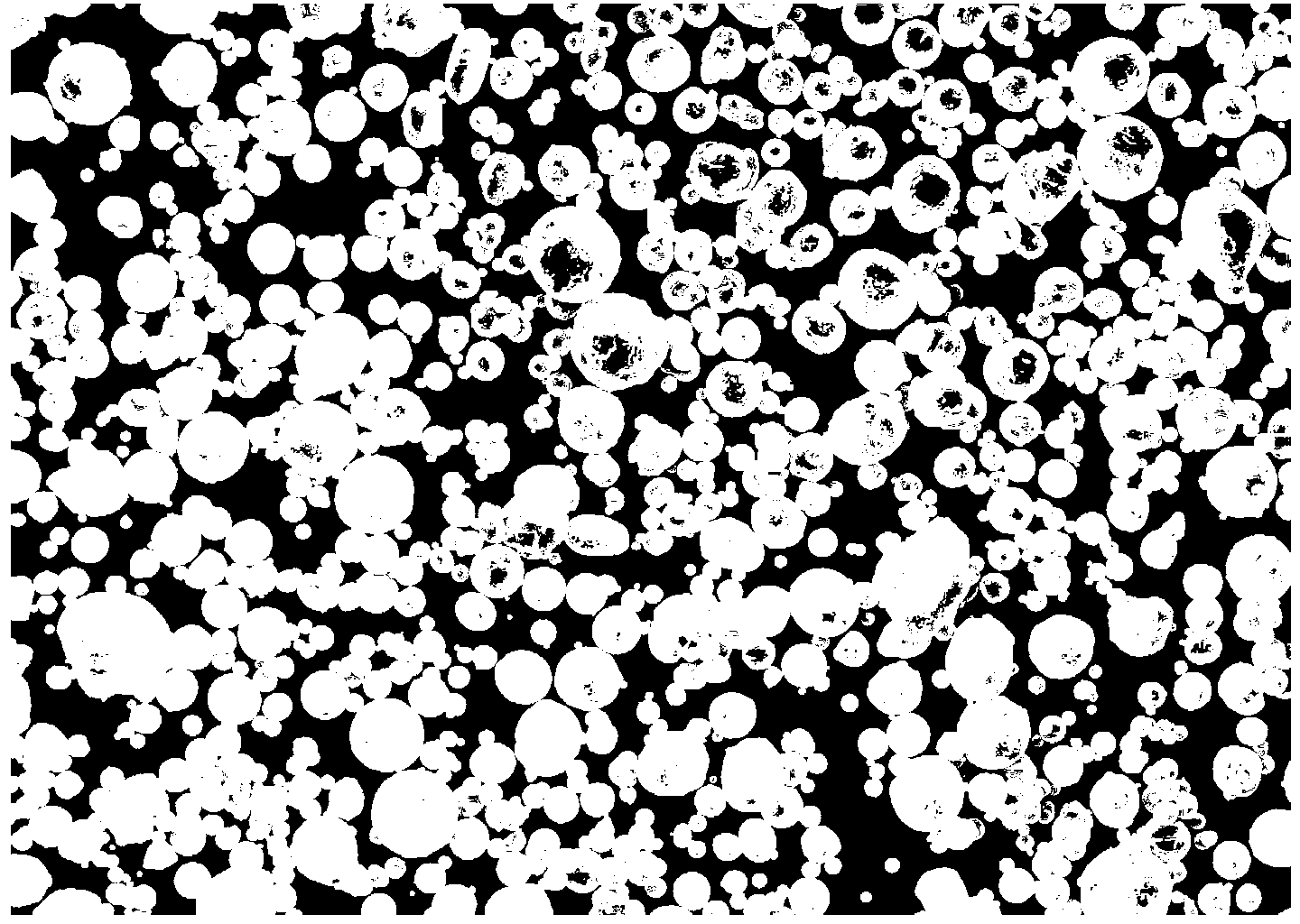

Method for increasing fine powder rate of gas atomization powder of titanium or titanium alloys

InactiveCN109877332AImprove fine powder rateLow costAdditive manufacturing apparatusRare-earth elementSelective laser melting

The invention relates to a method for increasing fine powder rate of gas atomization powder of titanium or titanium alloys. The method comprises the following steps of adding a small quantity of rare-earth elements to the titanium or the titanium alloys, so as to obtain an electrode bar, and then performing gas atomization to prepare powder. Compared with the prior art, the method disclosed by theinvention adds the rare-earth elements to the titanium or the titanium alloys to reduce the viscosity of a molten mass, so that the fine powder rate of the gas atomization powder is increased; the rare-earth elements can be added by methods including powder metallurgy or vacuum self-consumption melting and the like; the method disclosed by the invention can be widely applied to all kinds of titanium alloys including an alpha titanium alloy, an alpha and beta titanium alloy and a beta titanium alloy; through the adoption of the method disclosed by the invention, based on the situation that a conventional production line is not changed, the fine powder rate of the gas atomization powder of the titanium or the titanium alloys is notably increased, the produced fine powder can meet the requirements of additional material manufacturing process including selective laser melting and the like; and the method has good popularization application prospect.

Owner:SHANGHAI RES INST OF MATERIALS CO LTD

Preparation method of titanium alloy seamless pipe in petroleum and natural gas industry

InactiveCN109280787AImprove plasticityImprove impact performanceFurnace typesMetal rolling arrangementsSelf consumptionBeta phase

The invention discloses a preparation method of a titanium alloy seamless pipe in the petroleum and natural gas industry. The preparation method comprises the following steps that S1, electrodes are prepared according to nominal compositions of the titanium alloy in the petroleum and natural gas industry, vacuum self-consumption smelting and vacuum casting are conducted, and titanium alloy skew rolling punching rod blanks are obtained after high temperature homogenization heat treatment; S2, the titanium alloy skew rolling punching rod blanks are subjected to skew rolling punching to obtain titanium alloy punching pipe blanks; S3, the titanium alloy punching pipe blanks are subjected to diameter determining and rolling to obtain titanium alloy seamless pipes; and S4, the titanium alloy seamless pipes are subjected to isothermal annealing heat treatment to obtain titanium alloy seamless pipes for the petroleum and natural gas industry. The titanium alloy cast rod blanks prepared by vacuum self-consumption smelting and vacuum casting are subjected to high temperature homogenization heat treatment, and are subjected to skew rolling punching at the beta phase transformation point to obtain the punching pipe blanks, the casting process is omitted, procedures are shortened, and the yield rate is improved. With combination of isothermal annealing heat treatment above the beta phase transformation point, microstructure uniformity is improved. The mechanical property of products is improved, and application in the petroleum and natural gas industry is achieved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

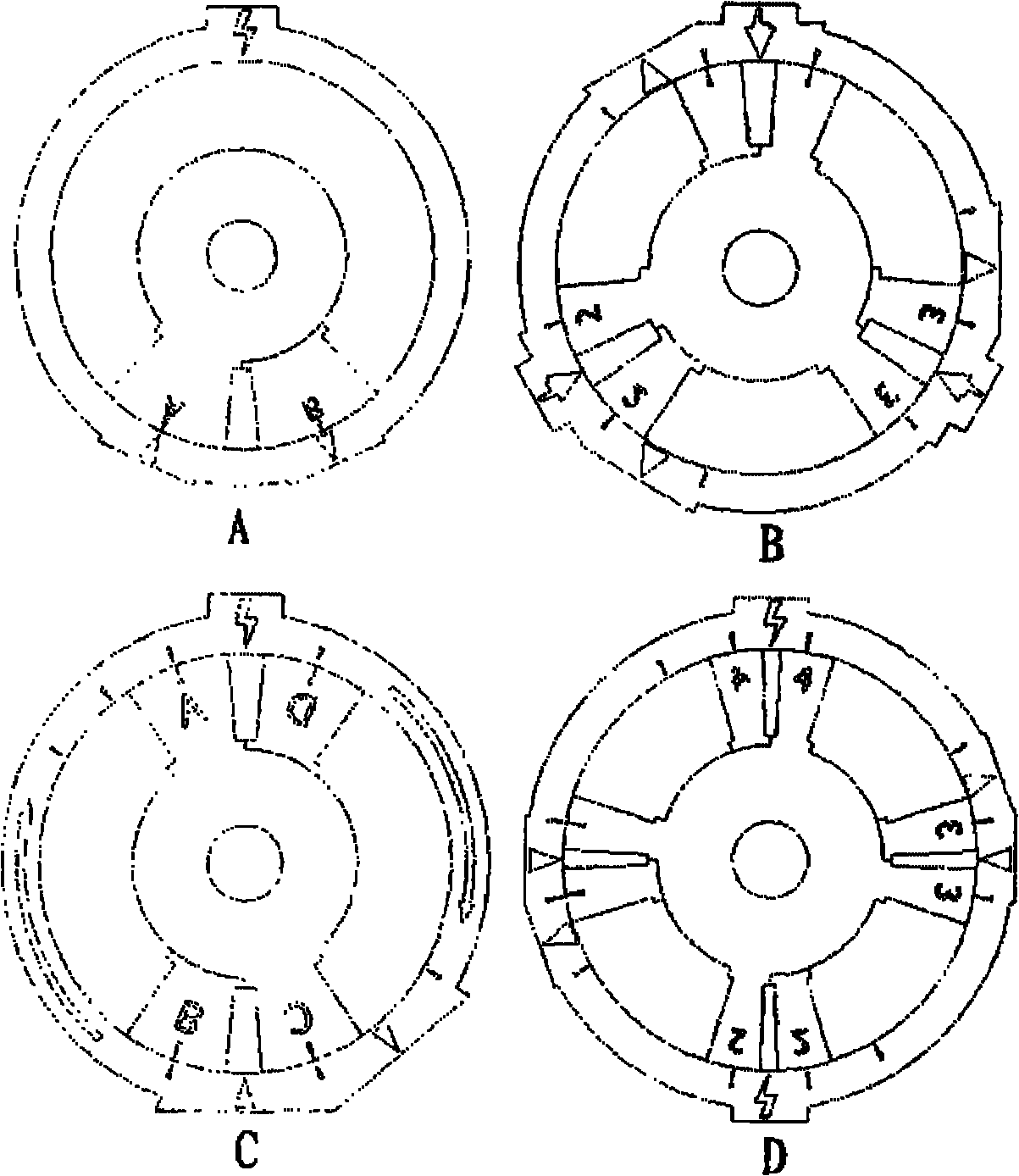

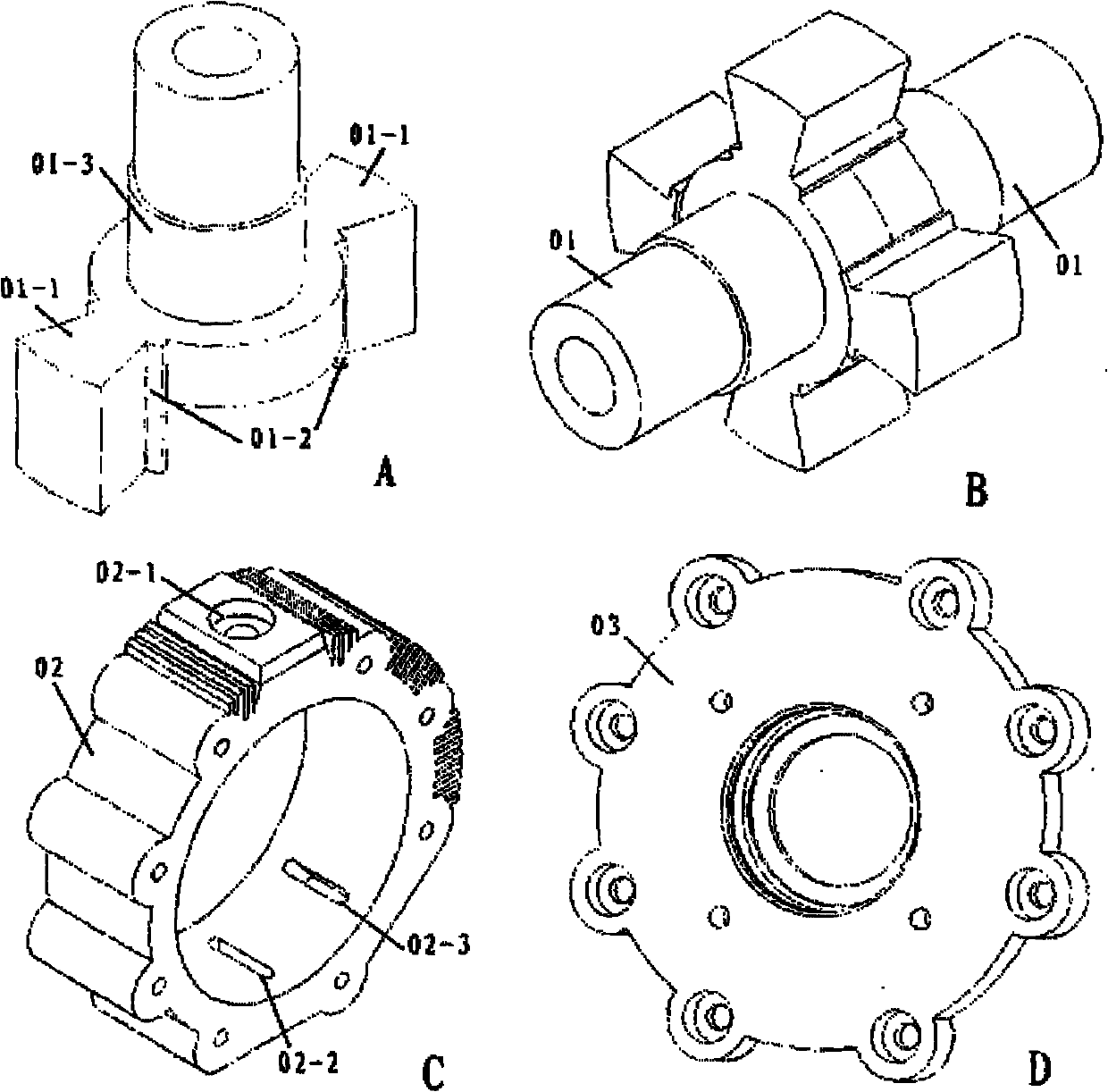

Internal combustion engine with double rotor pistons

ActiveCN102562283ABurn fullyImprove protectionInternal combustion piston enginesSelf consumptionReciprocating motion

The invention relates to the field of power machinery, in particular to an internal combustion engine with rotor pistons. The internal combustion engine is characterized in that 1, the two pistons which are mounted oppositely intermittently rotate around a center shaft in a cylindrical cylinder, air suction, compression, explosion and exhaust stoke are completed, energy of exploded gas acts on side surfaces of the pistons, output shafts are directly pushed to rotate, and the problem of energy dissipation of an engine with a reciprocating piston due to change of an included angle between a crank and a connecting rod is avoided; 2, compared with an engine with a reciprocating piston and a triangular rotor, the internal combustion engine does not have a reciprocating part or a movable valve or components thereof, does not realize eccentric movement, accordingly does not cause structural vibration, and is low in self consumption; 3, compared with a triangular rotor engine adopting a linear sealing component, the engine realizes surface sealing, does not need parts such as sealing strips and the like which are difficult in processing and easy to be worn, and is fine in sealing performance and high in reliability; 4, abrasion rate is low, abrasion of a main portion only depends on the abrasion degree of a bearing; and 5, the total engine is simple and compact in structure and high in thermal efficiency.

Owner:苏承寰

Method for producing aluminium-lithium alloy with high lithium content by low-temperature molten salt electrolysis

The invention provides a method for producing an aluminium-lithium alloy with high lithium content by low-temperature molten salt electrolysis. In an electrolytic furnace, aluminium is taken as a cathode, a cathode sleeve is sheathed thereon, graphite is taken as an anode, an electrolyte system is formed from LiCl and KCl, wherein, the weight ratio of LiCl: KCl is equal to 45: 55, the electrolysistemperature is 380-450 DEG C, the self-consumption cathode method is adopted for carrying out electrolysis, the current density of the cathode is 1-3.0A / cm<2>, the current density of the anode is 0.5A / cm<2>, the cell voltage is 4.1-5.6V, LiCl is supplemented during the electrolysis process for leading the mixing ratio of LiCl: KCl of the electrolyte to be in the vicinity of an eutectic point, theliquid aluminium-lithium alloy with high lithium content is deposited in the vicinity of the cathode in a molten salt electrolytic cell by 1-4 hours of electrolysis, and the solid aluminium-lithium alloy is prepared by solidification. The method can obtain the liquid aluminium-lithium alloy with evenly distributed alloy components at low temperature. The method can avoid the defects of burning loss of lithium during the doping process and the like, simultaneously save energy consumption of doping, mixing and melting process, avoid cracking of the cathode and uneven components, and avoid the defects of burning loss of the lithium caused by higher temperature and volatilization loss of LiCl.

Owner:HARBIN ENG UNIV

Preparation method of Ti2AlNb alloy material

ActiveCN106319236AImproves ingredient uniformityGood chemical uniformitySelf consumptionHeating time

The invention discloses a preparation method of a Ti2AlNb alloy material. The method comprises the steps of 1, preparing a Ti2AlNb alloy ingot through vacuum self-consumption electric arc melting, kish furnace smelting and vacuum self-consumption electric arc melting; 2, conducting primary homogenization treatment on the Ti2AlNb alloy ingot; and 3, wrapping the Ti2AlNb alloy ingot with asbestos cloth, then conducting heat-preservation heat treatment, and then sequentially conducting cogging forging, improved forging and finished product forging, so that the Ti2AlNb alloy material is finally obtained. The preparation method of the Ti2AlNb alloy material is simple in preparation process and reasonable in process design; an alloy is uniform in structure and stable in performance; the alloy ingot can be effectively refined, purified and homogenized through a smelting method; through the high-quality ingot, smooth implementation of subsequent hot working is guaranteed; by means of homogenization treatment, uniformity of alloy elements can be further improved through element diffusion; and wrapping treatment is conducted with the asbestos cloth, the temperature of the material can be effectively prevented from being lowered in the whole forging process, and large-deformation-amount forging for one heating time is achieved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

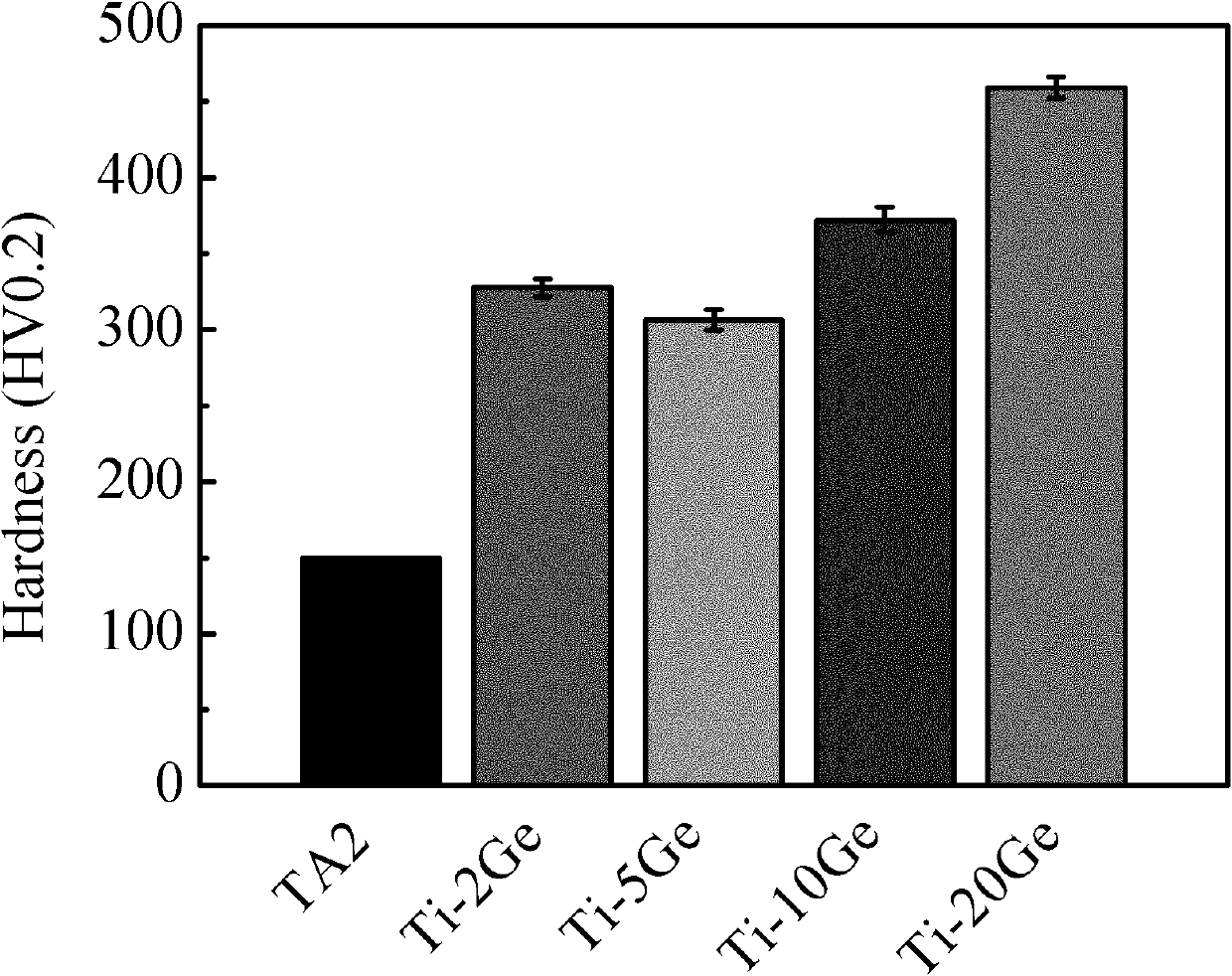

Multipurpose Ti-Ge series alloy with adjustable property for oral cavity and preparation method thereof

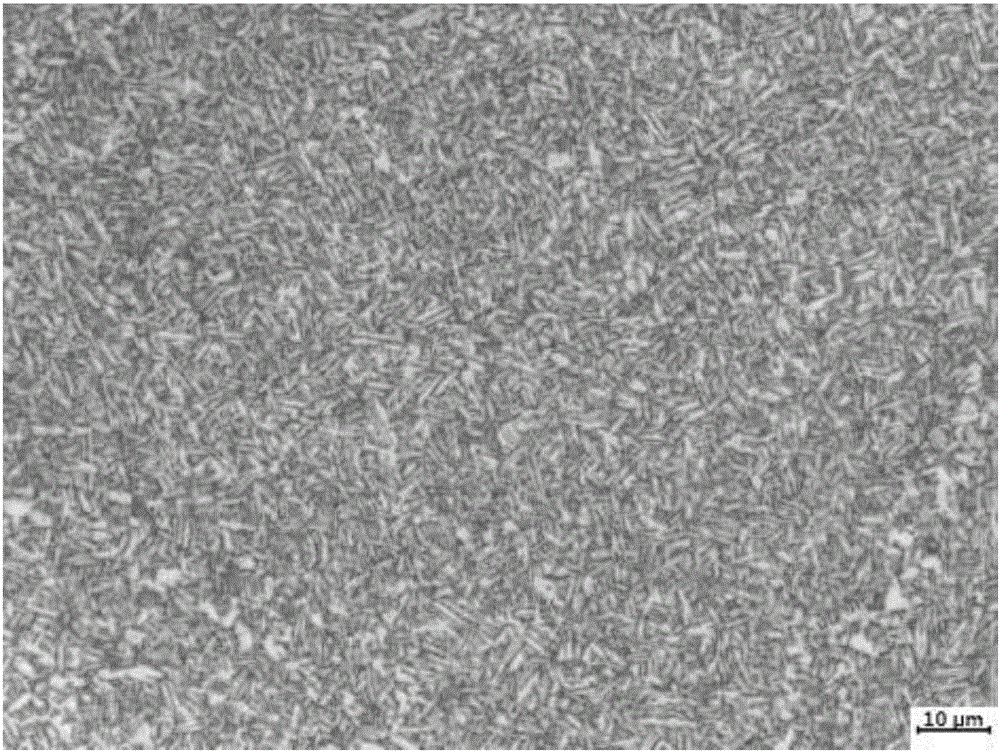

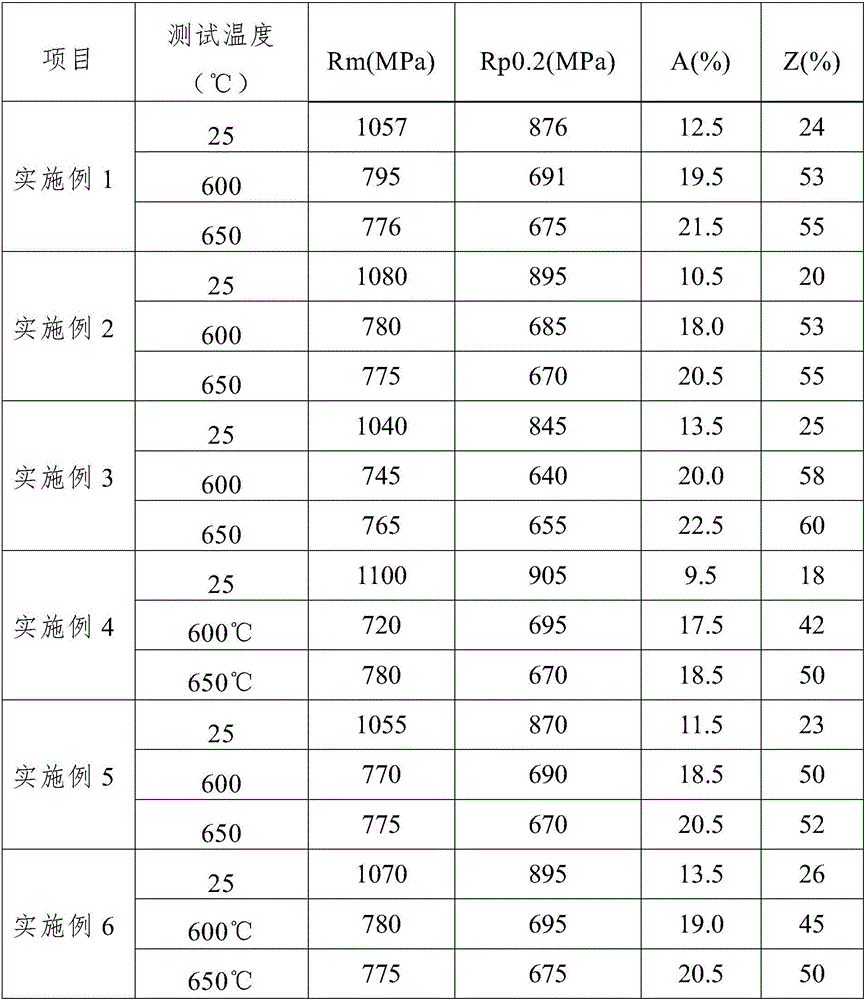

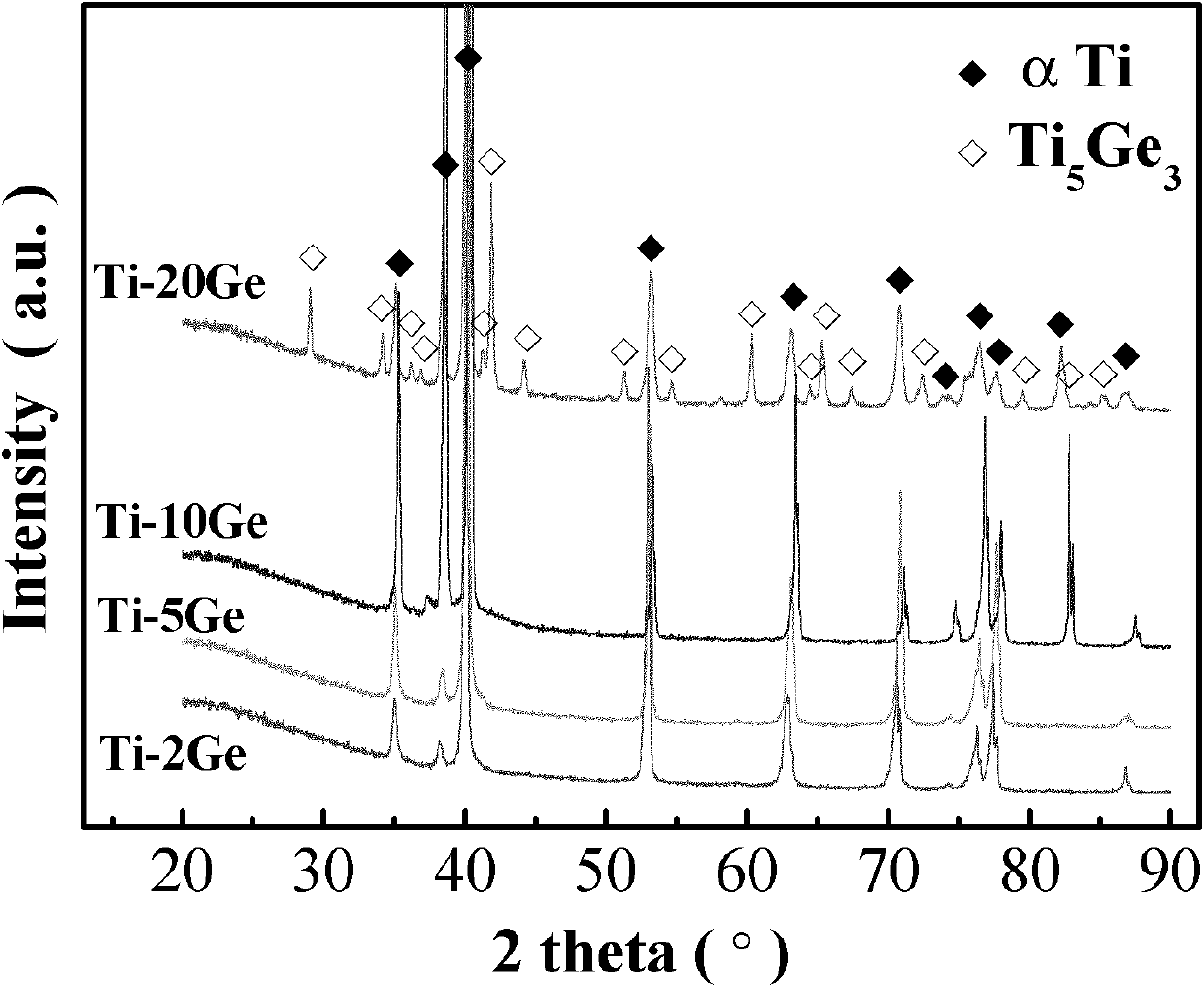

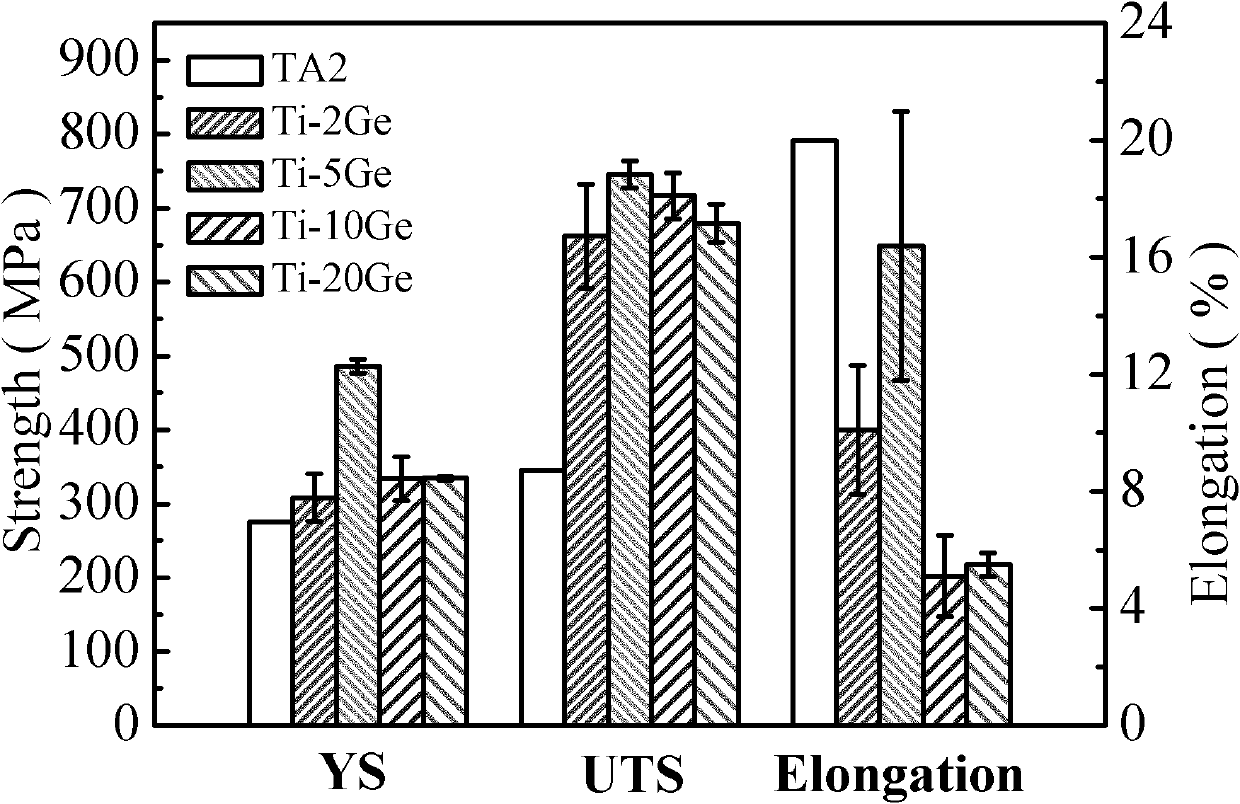

InactiveCN102021362AHigh biosecurityLow melting pointProsthesisSelf consumptionDifferential pressure

The invention provides a multipurpose Ti-Ge series alloy with adjustable property for oral cavity and a preparation method thereof. The alloy with designed components is prepared from titanium sponge and germanium particles according to the mass ratio of 99-75:1-25; a Ti-Ge series alloy with uniform components is prepared by adopting a vacuum non-self-consumption melting method, wherein the melting vacuum degree is 0.1-5*10<-4>Pa under argon shielding, the melting current is 500-1,000A, and the melting voltage is 10-20V; an alloy ingot is turned for 180 DEG and repeatedly re-molten for 3-6 times; and the alloy ingot is cast by adopting vacuum differential pressure, and a bar with diameter of 3-10mm is obtained through vacuum suction casting. The titanium alloy has the characteristics of no toxicity, adjustable mechanical property, corrosion resistance, good casing property and good biocompatibility; and the preparation method is simple, and can meet the requirement for the properties of a plurality of dental prosthetic alloys of the crown, the bridge, the false tooth stent, the planting body and the like.

Owner:HARBIN ENG UNIV

High-energy gas atomizing nozzle for preparing metal and alloy powder

The invention relates to a high-energy gas atomizing nozzle for preparing metal and alloy powder. The conventional atomizing nozzle generates unsteady supersonic gas flow, and is easy to have turbulence phenomenon to cause self-consumption loss of the energy of the supersonic gas flow. The high-energy gas atomizing nozzle comprises an intake pipe, a guide pipe, an upper end cover and a lower end cover, wherein a gas cavity encircled around the guide pipe is formed between the upper end cover and the lower end cover, inner sidewalls of the upper end cover and the lower end cover form an Laval spray pipe structure near the bottom end of the guide pipe, the Laval spray pipe structure comprises a contraction section, a throat and an expansion section, the high-energy gas atomizing nozzle is characterized in that the gas cavity is a symmetrical streamline structure, and the lower sidewall of the guide pipe is tangential to the outer wall of an outlet of the expansion section. According to the invention, through the Laval contraction-expansion type spray pipe in the symmetrical structure, the turbulence between the accelerated airflow can be reduced, the steady high-energy supersonic gas stream is generated, the efficient atomizing rate of the metal and the alloy thereof can be realized, and superfine powder of lower than 500 meshes reaches more than 65% in the prepared metal powder.

Owner:ZHEJIANG ASIA GENERAL SOLDERING & BRAZING MATERIAL

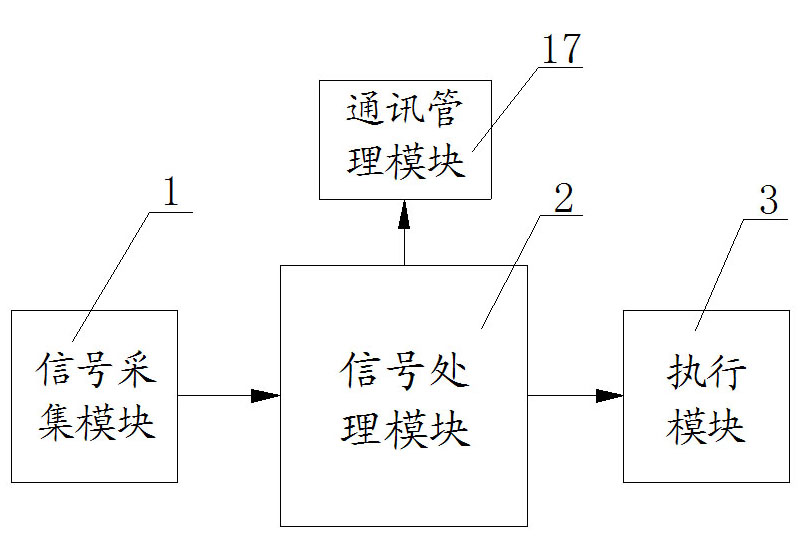

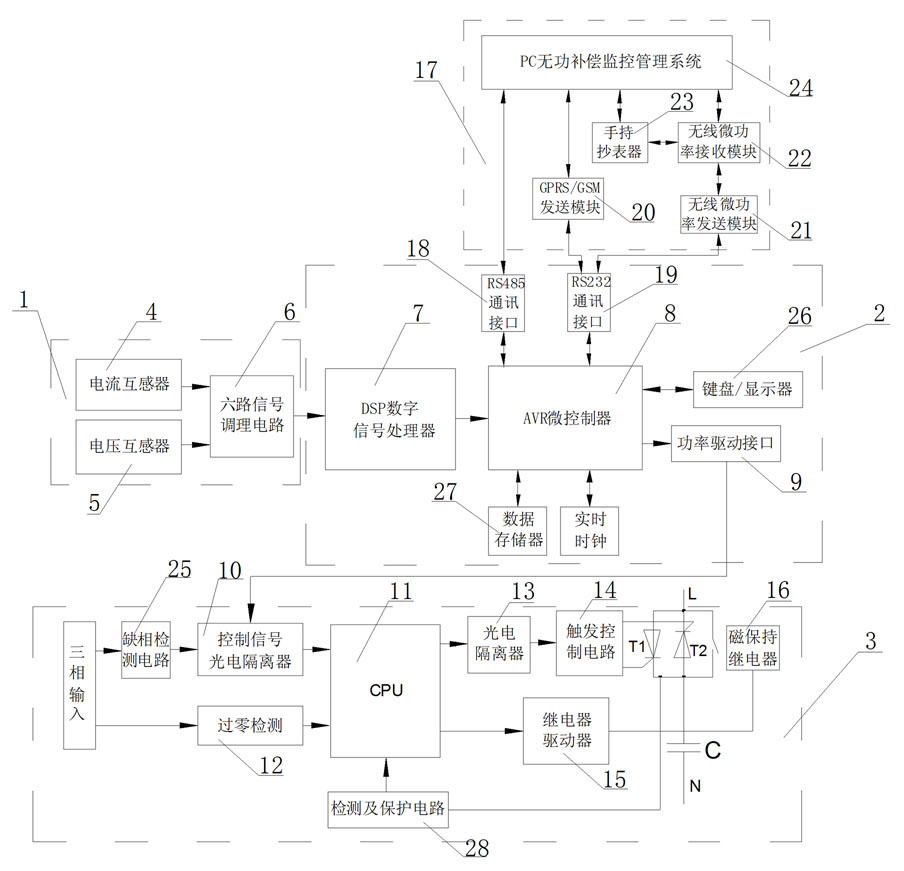

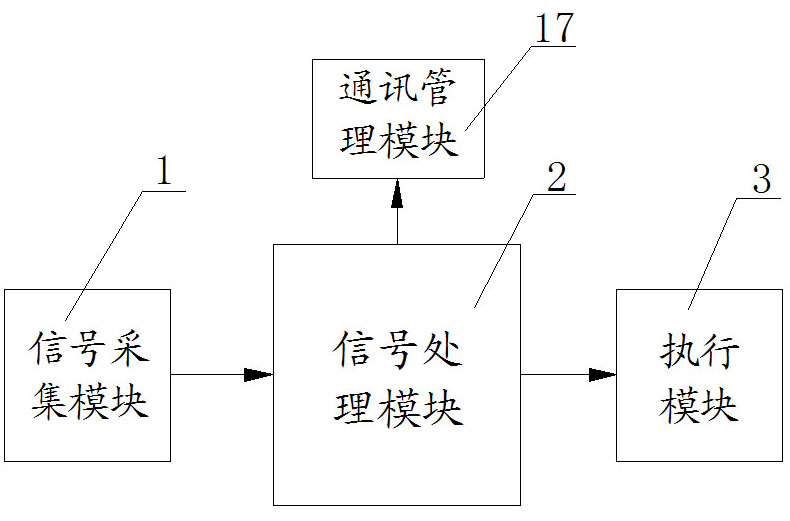

Reactive compensation intelligent monitoring management system

ActiveCN102055198ARealize reasonable switchingRealize no inrush inputReactive power adjustment/elimination/compensationSystems intergating technologiesCapacitanceSelf consumption

The invention discloses a reactive compensation intelligent monitoring management system comprising a signal acquisition module (1), wherein the signal output end of the signal acquisition module (1) is connected with the signal input end of a signal processing module (2); and the signal output end of the signal processing module (2) is connected with the signal input end of an execution module (3). The invention has the remarkable benefits that a power grid achieves the ideal balanced compensation effect by reasonable switching of a capacitor; the power self consumption of a compensation device is reduced to be minimized by inrush current-free input of the capacitor; and the health condition of the system equipment can be monitored and judged in real time and the effect of reactive compensation can be known.

Owner:重庆樱花能源科技有限公司 +2

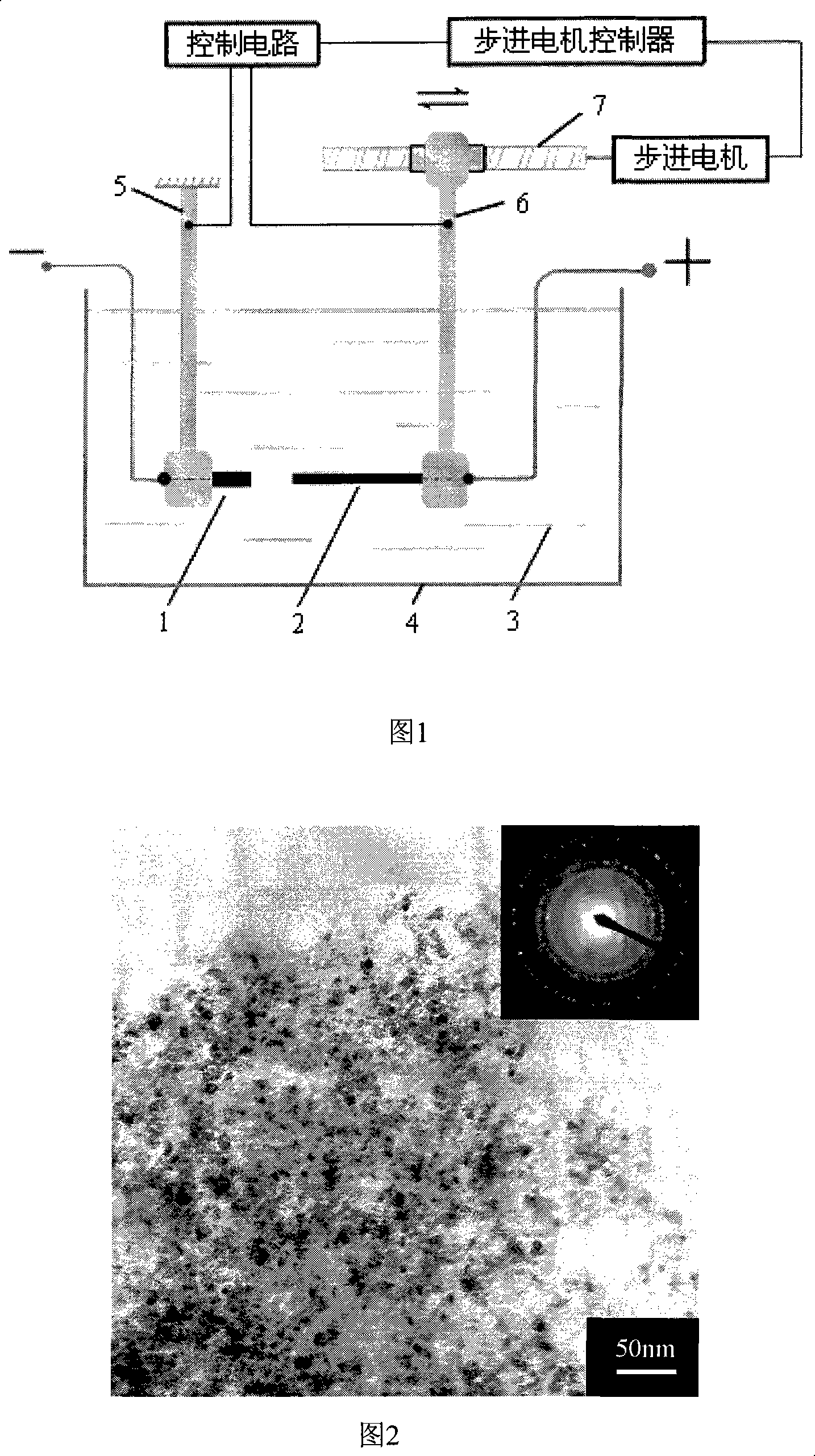

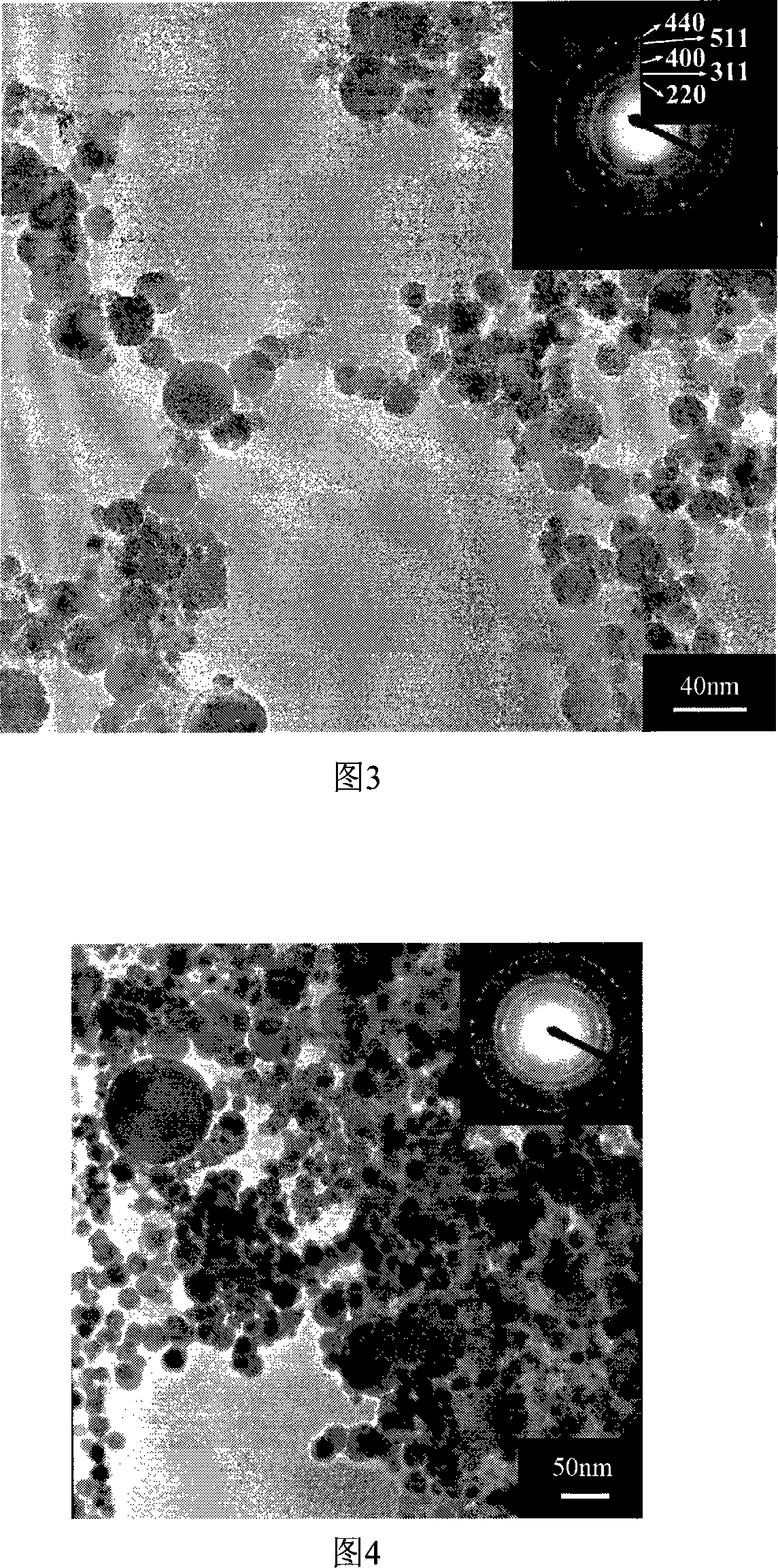

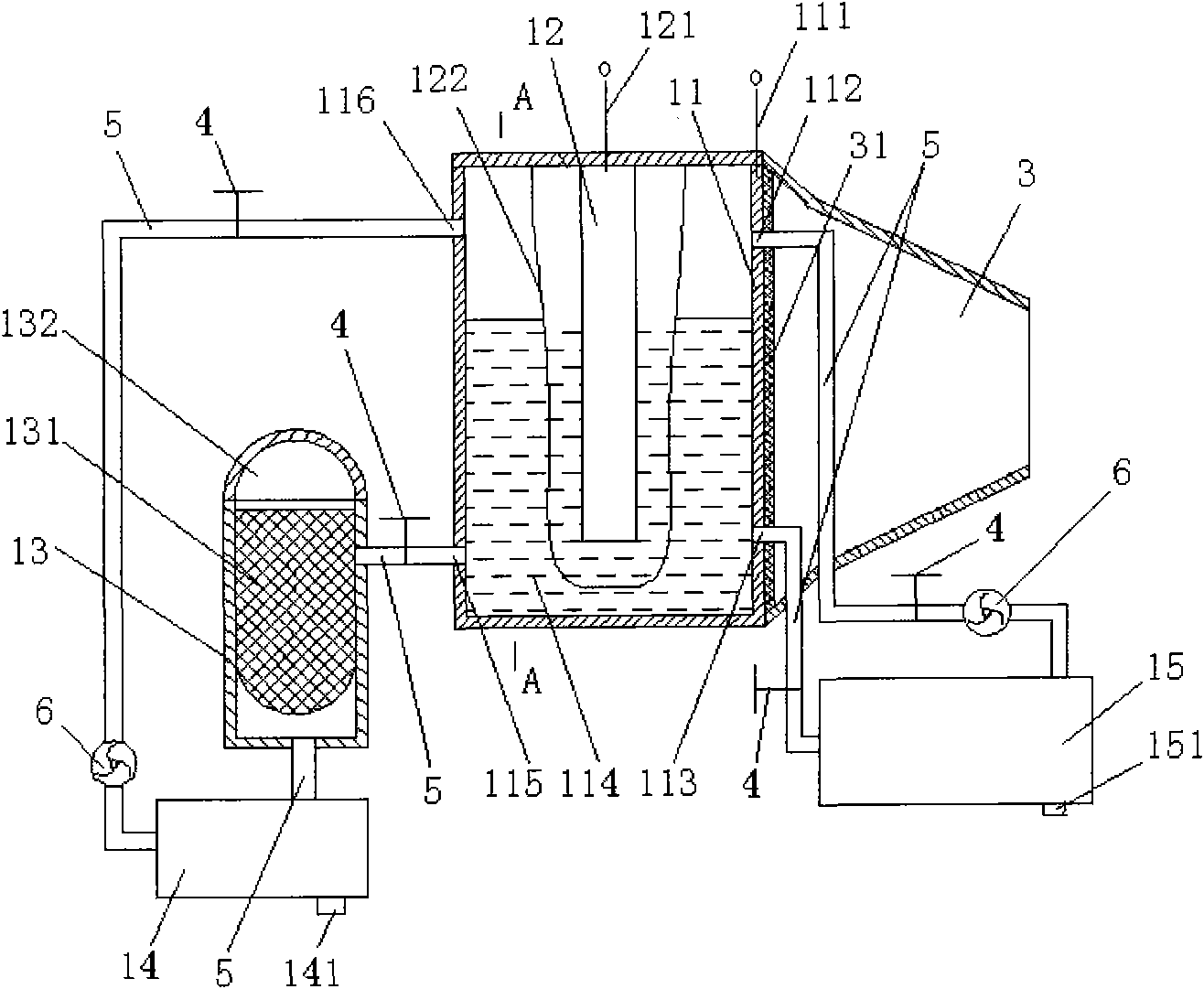

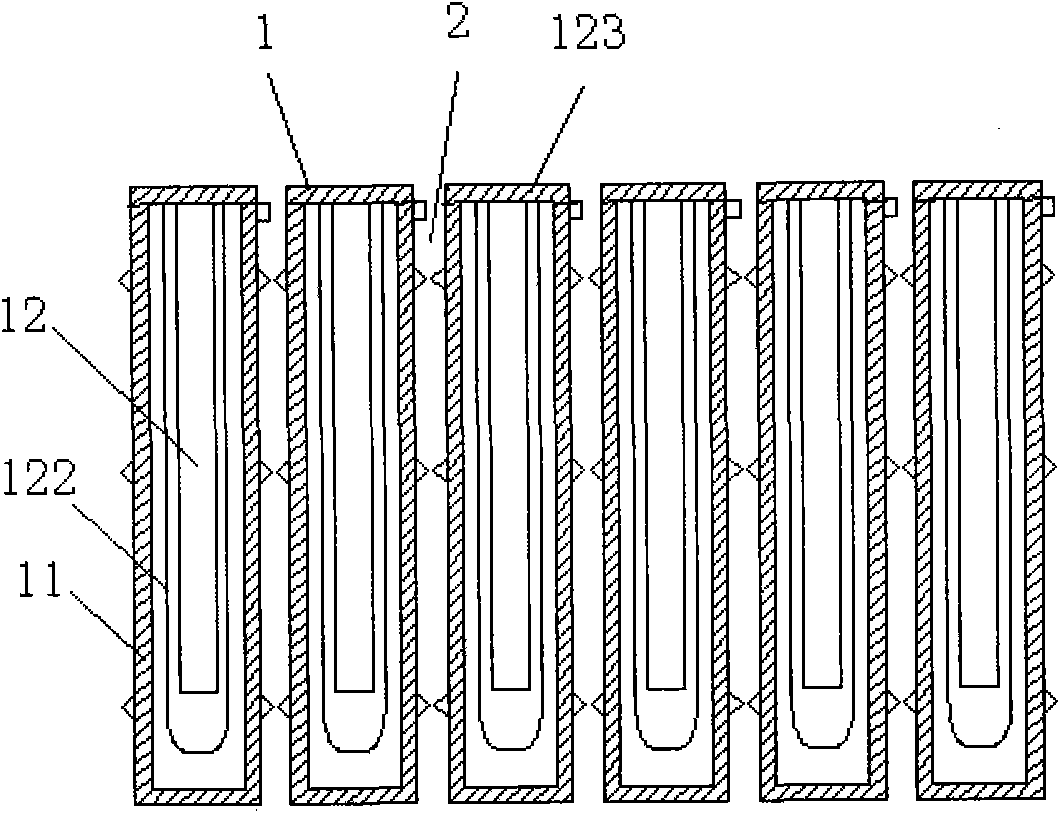

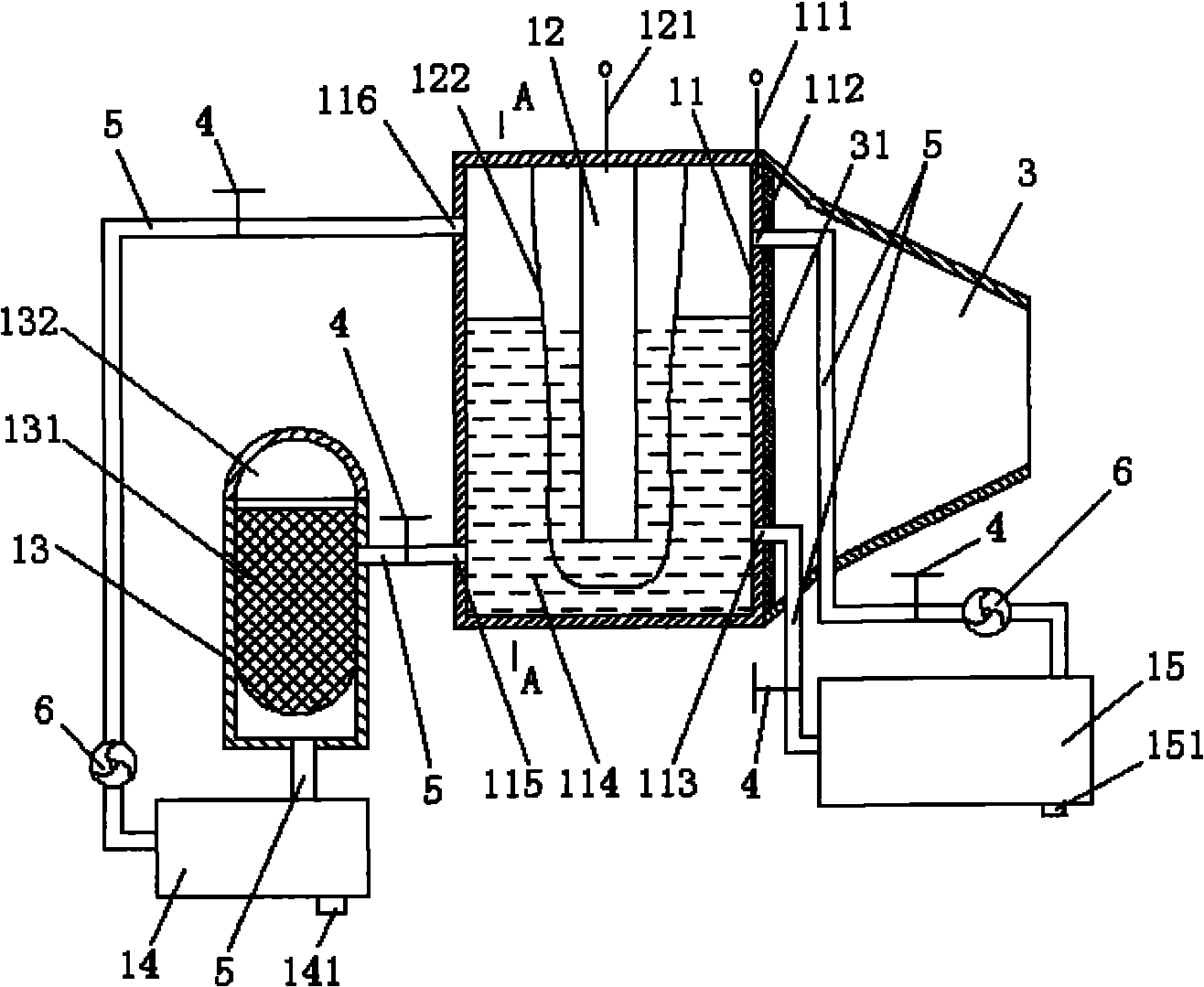

Preparation method for Fe3O4 nano particles

InactiveCN101100315AUniform sizeImprove performanceFerroso-ferric oxidesParticulatesSelf consumption

This invention discloses a method for preparing nanometer particulates of Fe304. It is characterized by: arc discharging is used, with self-consumption of pure iron anode proceeded in water medium to produce nanometer particulates of Fe304. This inventive Fe304 magnetic nanometer particulates are of spherical with even size, having various kinds of excellent properties. The raw material of this invention is industrial pure iron rod, being of easily available, low cost, the advantages of this inventive method are: simple equipment, controllable process parameters, continuous and in large scale production.

Owner:TSINGHUA UNIV

Carbon-free metal generator

The invention provides a carbon-free metal generator. In the generator, a plurality of reaction units are arrayed at intervals to form a generator set; an air channel is formed between two reaction units; and each reaction unit comprises an air electrode, electrolyte in the air electrode and a metal electrode inserted in the electrolyte and positioned between the air electrodes. The generator is characterized in that the liquid outlet through hole of each of the reaction units, a filter, a reservoir tank and the liquid inlet through hole of each of the reaction units are communicated sequentially; and both the liquid inlet through hole and the liquid outlet through hole of each of the reaction units are communicated with the reservoir tank. The generator has the advantages of avoiding the entire replacement thereof, saving time and labor, greatly facilitating the recovery processing and recycling use of renewable resources, eliminating the self-discharging phenomenon and preventing the self-consumption of the metal electrode so as to be an effective way for strengthening and developing the application of a novel metal generator in the fields of cars and ships without using fuel oil and discharging pollutants and with capability of circularly using the renewable resources.

Owner:余建岳

Cultivation method of stone fruit trees for protected areas

ActiveCN104620833AGood colorEasy to trainFertilising methodsCultivating equipmentsFruit treeSelf consumption

The invention discloses a cultivation method of stone fruit trees for protected areas. The method includes selecting branched big seedlings secondarily raised, planting two trees side by side in the east-west direction in each hole, with spacing of the two seedlings being 5cm to 15cm, and obliquely planting the seedlings, with the included angle of every two seedlings being 50 degrees to 100 degrees. The method has the advantages that the trees grow neatly and evenly, the shape of each tree is clearly layered, ventilation and light permeability are good, skeletons are few, ineffective branches are few, self-consumption is low, respiration-based consumption is low, nutrition accumulation is high, fruits are well colored and good in quality, early high yield is benefited, and the yield is high and stable.

Owner:SHANDONG WEIFANG ACADEMY OF AGRICULTURAL SCIENCES

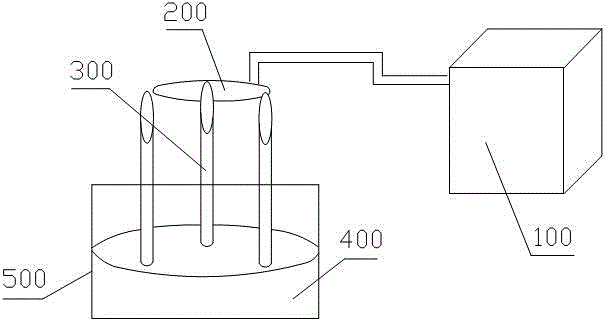

Ultrasonic treatment device for metal melt

InactiveCN102978412AImprove refinementImprove consistencyProcess efficiency improvementSelf consumptionEnergy control

The invention discloses an ultrasonic treatment device for metal melt, which comprises an ultrasonic energy control and generating device, an ultrasonic conduction frame, a self-consumption amplitude transformer and a crucible containing metal melt, wherein the ultrasonic conduction frame is connected with the ultrasonic energy control and generating device; one end of the self-consumption amplitude transformer is connected with the ultrasonic conduction frame, and the other end is inserted into the metal melt; and the self-consumption amplitude transformer and the metal melt are made from the same material. The amplitude transformer is a self-consumption amplitude transformer, so that the amplitude transformer can be molten in the metal melt in the ultrasonic treatment process, thereby enhancing the consistency of the metallurgical structure, overcoming the long-lasting defects in the metallurgical structure and enhancing the refinement effect of the metal melt.

Owner:XIANOUTONG SCI & TECH SHENZHEN CO LTD

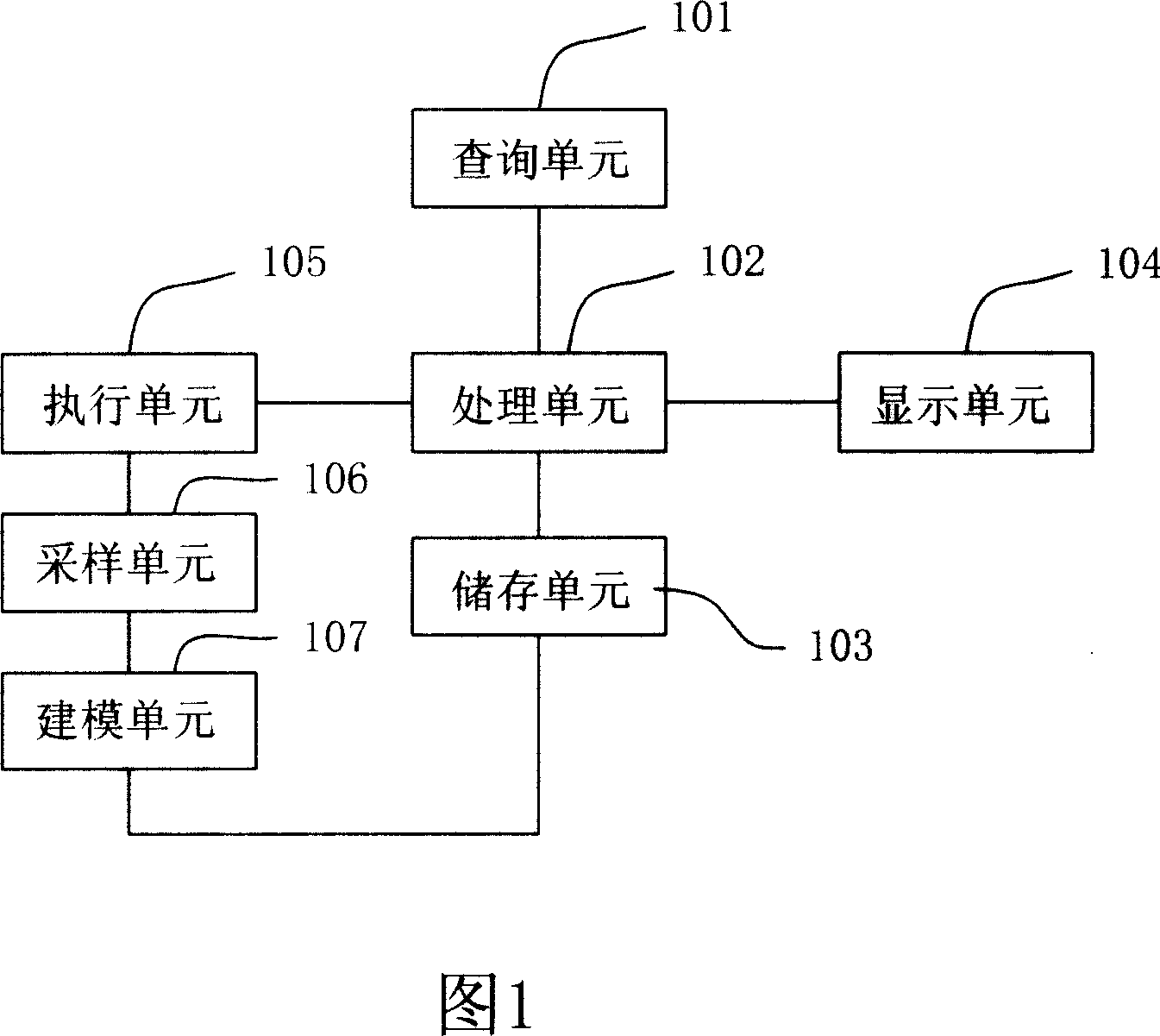

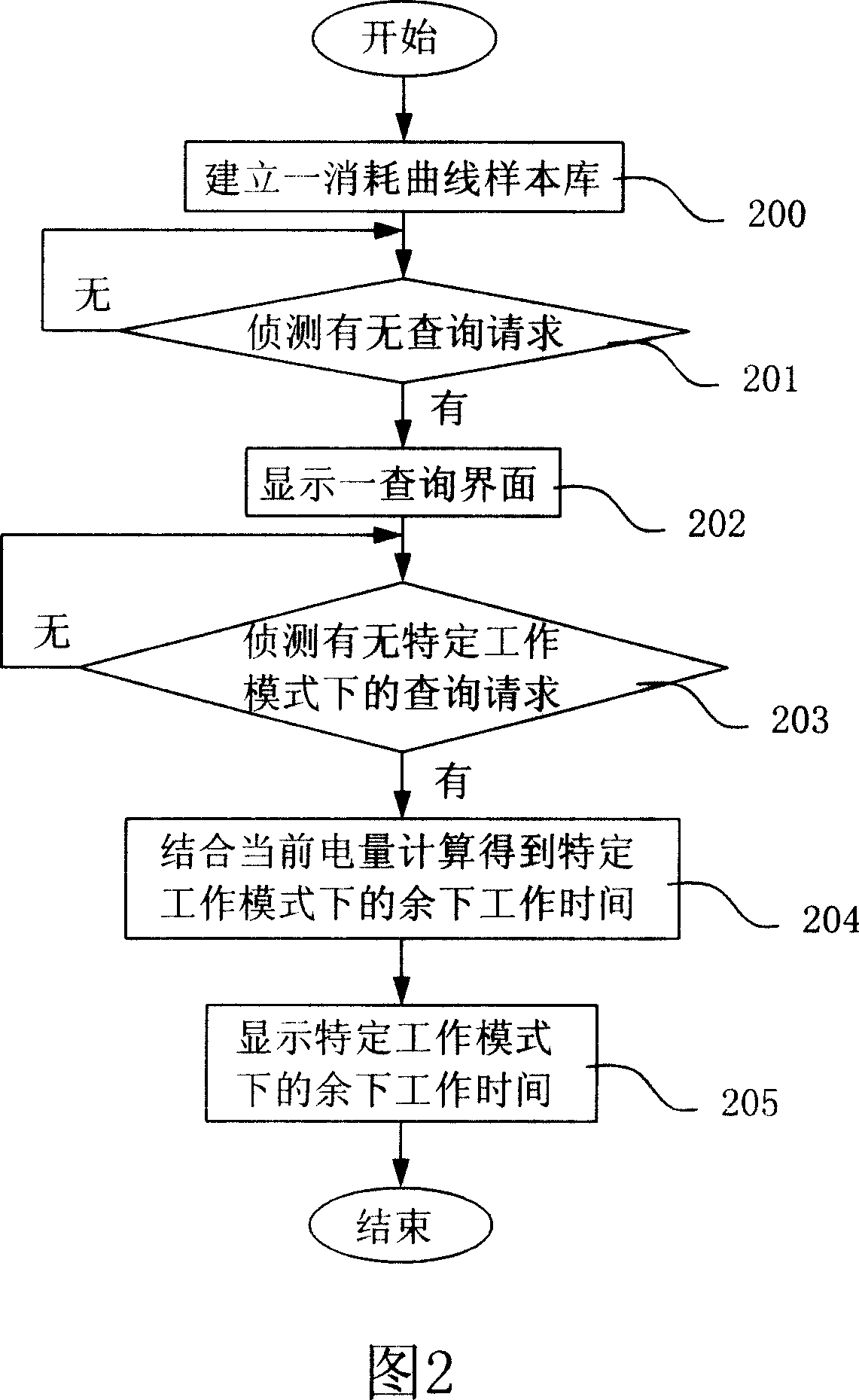

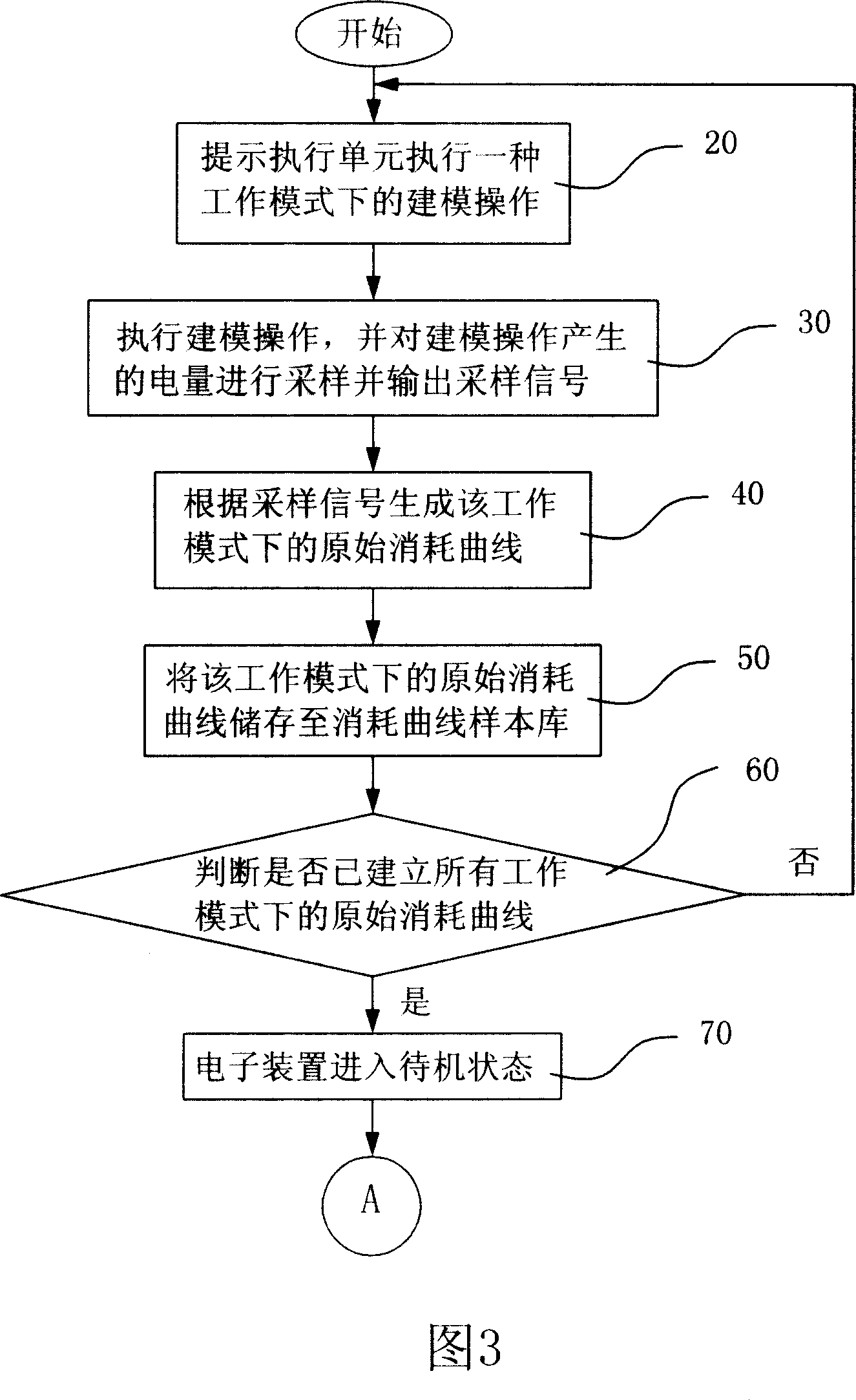

Method for enquiring electric quantity of power supply

InactiveCN101063705AEasy to useCalmly respond to unforeseen needsPower supply testingWork patternSelf consumption

This invention relates to one power electricity inquire method applied in one electron device, wherein the electron device comprises one inquire unit coupled with one process unit; the process unit is coupled with display unit and the process unit is coupled with one memory unit. The method comprises the following steps: establishing one consumption curve sample database set inside memory unit; the inquire unit detecting whether there is require; if yes, then display unit for one inquire interface; the inquire unit detecting whether there is special work mode inquire require; if yes, process unit takes and combines current electricity to get special work mode remaining time from self-consumption sample database; display unit receives and displays the special work mode remaining work time.

Owner:HUANDA COMPUTER (SHANGHAI) CO LTD

Method for preparing Dy-Fe alloy through oxide molten salt electrolysis

The invention discloses a method for preparing a Dy-Fe alloy by electrolyzing an oxide molten salt. The method comprises the following steps of: adding a mixture of Dy2O3 and Fe2O3 into a fluoride molten salt electrolyte system; and electrolyzing to prepare the Dy-Fe alloy. In the invention, a tungsten rod is utilized as a cathode, and element Fe is obtained from electrolyzing ferric oxide, thus the distribution of Dy and Fe in the produced Dy-Fe alloy is strong in controllability, and the error is less than 1%. As a high-density cathode current is utilized, during the electrolysis production process, the slagging amount is greatly reduced, the yield is improved, and the production cost is reduced; no self-consumption ferric cathode is utilized, thereby reducing the labor intensity of frequently replacing the ferric cathode; and a 10000A-30000A large-scale electrolysis stove can be used for production, thereby greatly improving alloy consistency.

Owner:カン州晨光希土新材料有限公司

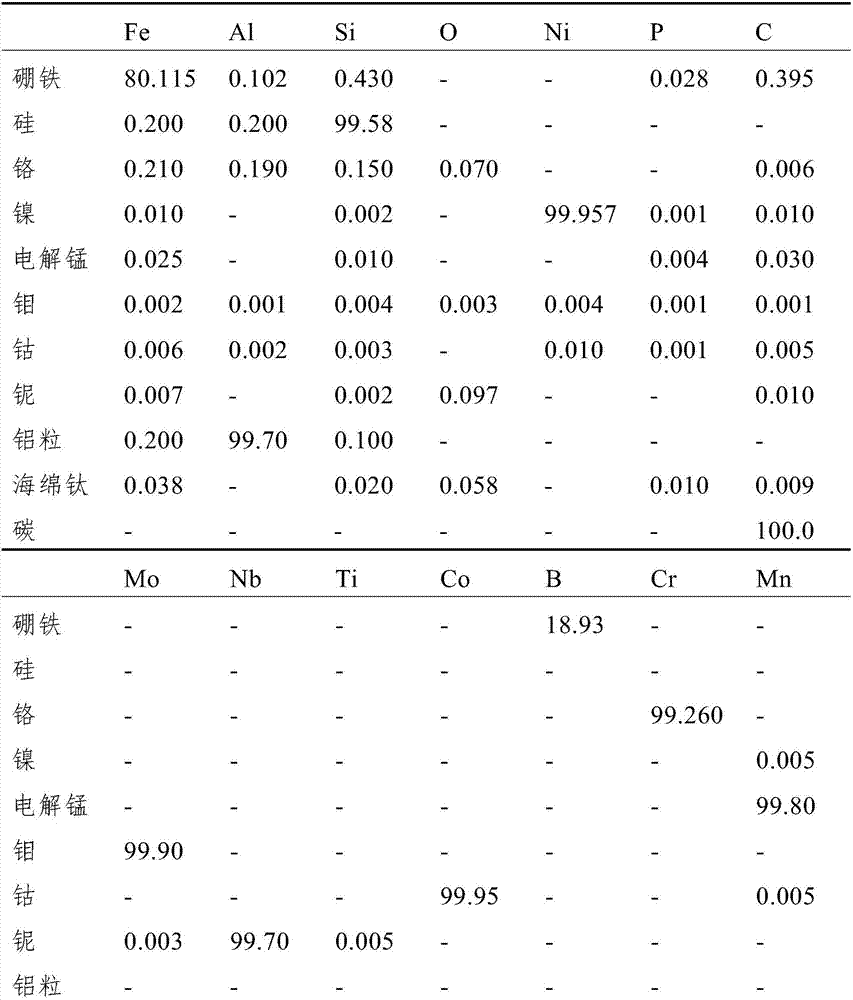

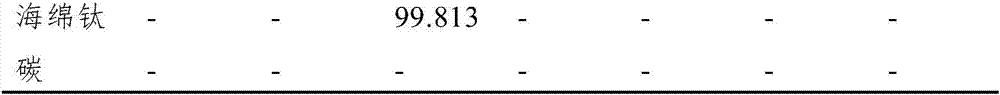

Technique for preparing advanced ultra-super critical heat-resisting alloy

The invention relates to a technique for preparing an advanced ultra-super critical heat-resisting alloy. According to the technique, smelting raw materials are prepared according to target components of the advanced ultra-super critical heat-resisting alloy, wherein by weight, 0.01-0.04% of carbon is added on the basis of the target carbon content, and 0.3-0.5% of aluminum is added on the basis of the target aluminum content; and the alloy raw materials are smelted into an alloy ingot under the protective atmosphere through a vacuum induction furnace, the alloy ingot serves as a self-consumption electrode base material, and the advanced ultra-super critical heat-resisting alloy is obtained through electro-slag remelting under the protective atmosphere. According to the technique for preparing the advanced ultra-super critical heat-resisting alloy, accurate control over alloy elements is achieved, the oxygen content in a low-heat-resisting alloy is decreased, the harmful elements such as P and S are effectively reduced through subsequent electro-slag remelting under the protective atmosphere, and segregation is overcome, so that the alloy is uniform, and compactness is improved; and the advanced ultra-super critical heat-resisting alloy which is few in non-metallic inclusions, low in sulphur content, compact in organization structure and high in surface quality is obtained.

Owner:NORTHEASTERN UNIV

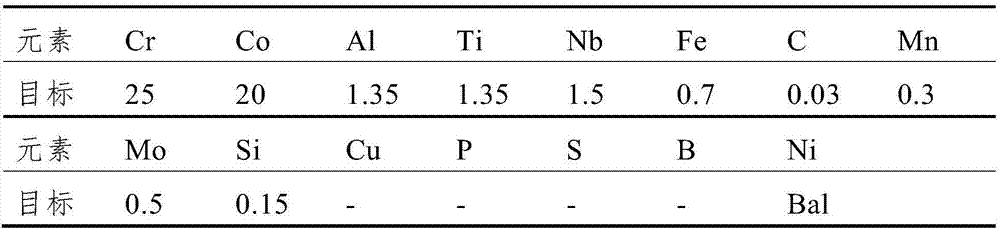

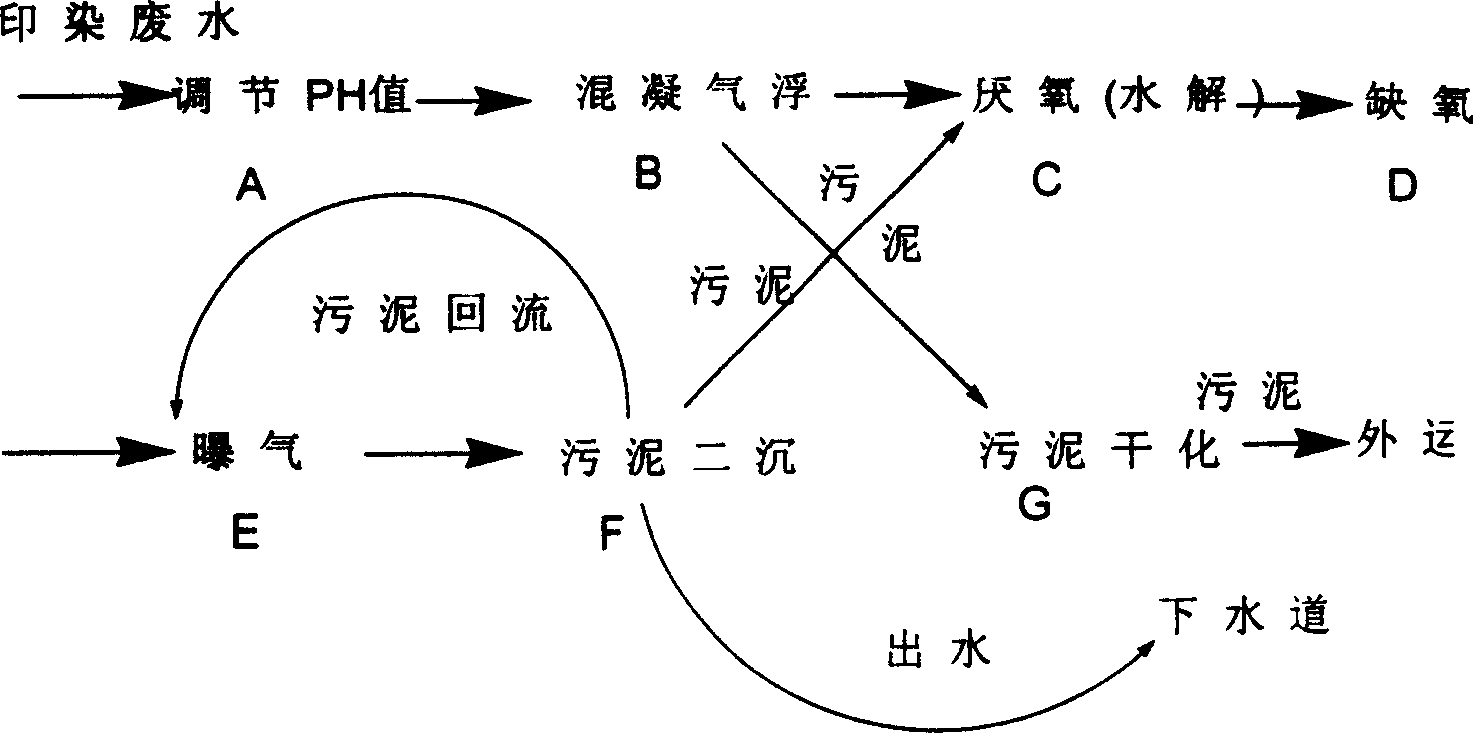

Printing and dyeing waste water disposal process

InactiveCN1762861AHydrolysis process does not require aerationBreeding is easySludge treatment by de-watering/drying/thickeningTreatment with aerobic and anaerobic processesSelf consumptionAnaerobic bacteria

The present invention relates to printing and dyeing waste water treating process and features that the printing and dyeing waste water treating process includes the following successive steps: regulating pH value, coagulating air floatation, anaerobic hydrolysis, anoxic treatment, aeration, secondary sludge setting and drying sludge. During the process, the exhaust water after secondary sludge setting is drained to sewer, the sludge after coagulating air floatation is dried and externally transported, the sludge after secondary sludge setting is returned to the aeration step continuously, the excessive sludge is exhausted from the aeration tank to the anaerobic hydrolysis unit for self consumption, and the anaerobic hydrolysis at pH 6.5-8 generates anaerobic bacteria for hydrolysis at temperature from room temperature to 37 deg.c. The present invention has the features of fast propagation of hydrolysis bacteria, high adaptability, etc. and is suitable for treatment of various kinds of printing and dyeing waste water.

Owner:上海望春花(集团)股份有限公司

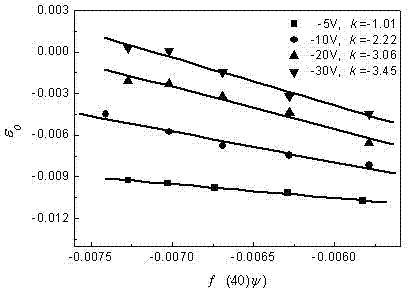

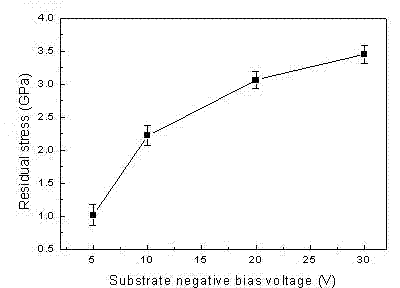

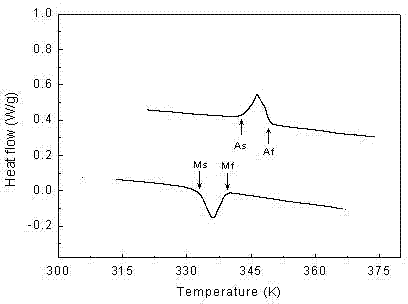

Preparation method of high-residual internal stress Ni-Mn-Ga magnetically-driven memory alloy film

InactiveCN102345105AIncrease the residual compressive stressLower Magnetic Field ThresholdVacuum evaporation coatingSputtering coatingSputteringSelf consumption

The invention relates to a preparation method of a high-residual internal stress Ni-Mn-Ga magnetically-driven memory alloy film. The preparation method comprises the steps of: 1, preparing an Ni-Mn-Ga alloy target material: respectively taking 47 parts of Ni, 32 parts of Mn and 21 parts of Ga according to the mol part ratio for preparing materials, and preparing the target material by using a non-self-consumption vacuum arc furnace under the argon protection atmosphere; 2, cleaning a substrate; and 3, preparing an Ni-Mn-Ga film by using a high-vacuum magnetic control sputtering instrument: placing the target material prepared in the step 1 on the monocrystalline silicon substrate cleaned in the step 2, applying bias voltage on the substrate by using the high-vacuum magnetic control sputtering instrument to generate magnetic control sputtering, and preparing the Ni-Mn-Ga film. The Ni-Mn-Ga alloy film prepared by optimizing bias process parameters of the magnetic control sputtering substrate has high residual stress which can assist an external magnetic field to drive a martensite twin-plane boundary to move, thus the threshold value of the magnetic filed can be effectively reduced.

Owner:NORTHEAST GASOLINEEUM UNIV

Soil improvement method by intercropping leguminous grass and stocking poultry in orchard

PendingCN107484451AReduce the temperatureReduce healthSoil lifting machinesBio-organic fraction processingGrazingSelf consumption

The invention discloses a soil improvement method by intercropping leguminous grass and stocking poultry in an orchard. From three aspects of planting of fruit trees, intercropping of leguminous grass, continuous stocking of various different poultries, the invention provides a method for locally improving soil through intercropping and poultry stocking in a systematic manner. The method effectively reduces destruction phenomenon of land vegetation caused by gaggle blind grazing. Leguminous plants can absorb nitrogen in air, and leguminous grass root systems improve ventilation of soil, promoting growth of a fruit tree root system. Grass growth covers the earth's surface and reduces soil temperature. Leguminous plants provide fodder sources for bred poultry and restore natural grassland degeneration caused by fruit tree plantation, preventing water and soil loss and ecological damages and other problems caused by vegetation reduction. The method realizes a self consumption system of fouled manure of an animal husbandry, changes phenomenon that conventional animal husbandry is severe in pollution, and effectively promotes healthy and sustainable development of the animal husbandry.

Owner:JURONG YANGXIULIN ORCHARD

Antifreezing and anti-blocking method of natural gas runner

ActiveCN101776209ASolve the problem of clogged natural gas flow channelLower dew pointOther chemical processesPipeline systemsSelf consumptionPollution

The invention discloses an antifeezing and anti-blocking method of a natural gas runner, which comprises the following steps: periodically adding antifreeze into the natural gas runner so as to reduce the dew point of the natural gas and the freezing point of the water in the natural gas runner, and prevent the water from freezing and blocking the natural gas runner. The invention can effectively solve the problems that the natural gas runner is frozen and blocked, mixed solid content formed by natural gas hydrate and ice block the natural gas runner, also can greatly reduce the dew point of the natural gas, cosmically simplify the productive process of the natural gas, particularly, cosmically simplify the natural gas ground surface gathering process, greatly reduce the cost of the natural gas production, energy consumption, gas self consumption, management working load, and the like, fundamentally eliminate methanol harm and pollution in the natural gas production, realize non alcoholization of the natural gas productive process, and has the advantages of easy implementation, safety and reliability, wide application, easy popularization and the like. The economic benefit, environmental protection benefit and safety benefit are remarkable.

Owner:BEIJING UNITY BENEFICIAL TECH CO LTD

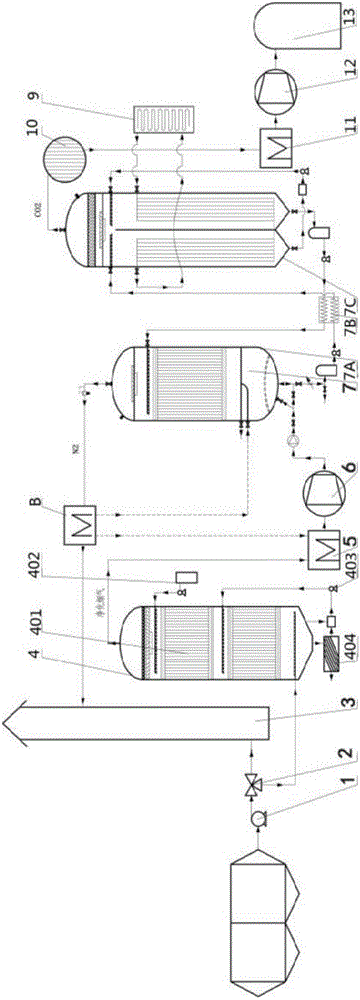

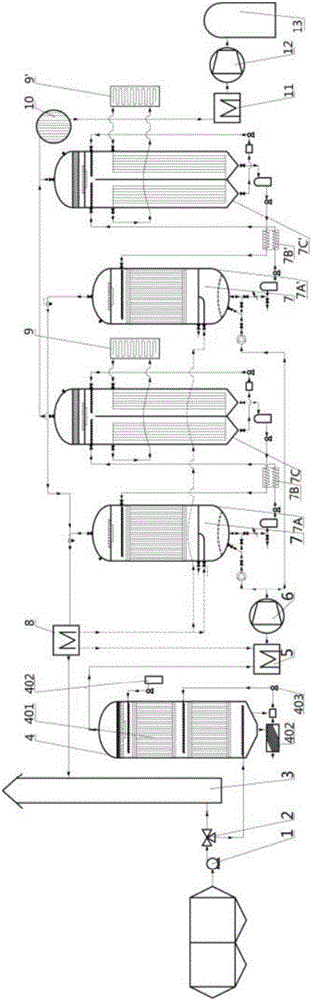

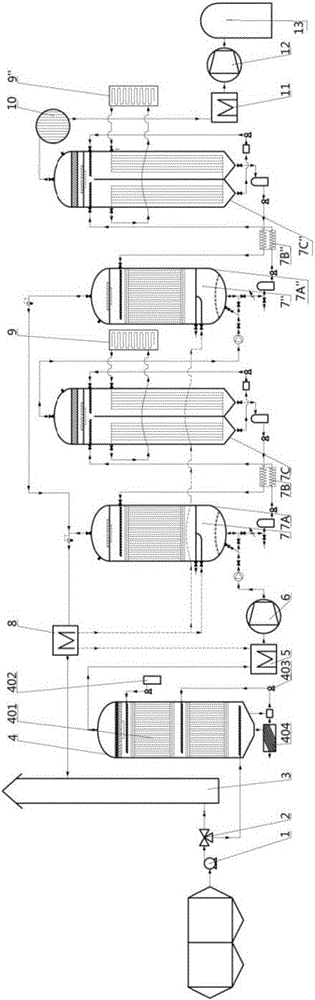

Device system for continuously trapping CO2 in flue gas of cement kiln through hydrate method

ActiveCN106823754ACapture completelyCapture thoroughlyProductsGas treatmentSelf consumptionProcess equipment

The invention provides a device system for continuously trapping CO2 in flue gas of a cement kiln through a hydrate method. The device system comprises a tail exhaust fan, an electric three-way air valve, a chimney, a flue gas purifying device, a cooler, a flue gas compressor, a CO2 absorbing tower-regeneration tower unit, a cold energy recovery device, a waste heat energy storage device, a dehydration dryer, a CO2 cooler, a CO2 compressor and a liquefied CO2 storage tank. The CO2 absorbing tower-regeneration tower unit comprises a CO2 absorption tower, a poor / rich fluid heat exchanger device and a CO2 regeneration tower, and the above parts are orderly connected. The device system is based on a cement production line process and process equipment, utilizes cement production waste heat as heat exchange energy, utilizes a hydrate accelerator to continuously capture the CO2 in flue gas of the cement kiln, can purify the flue gas, and realizes high efficiency, low self-consumption, low investment and low operating cost.

Owner:长沙紫宸科技开发有限公司

Welding process of VAR titanium alloy ingot castings

ActiveCN109702292AFix stability issuesSolution areaWelding accessoriesSelf consumptionElectric arc furnace

The invention relates to a welding process of VAR titanium alloy ingot castings. The welding process comprises the following steps that 1, a plurality of large-specification ingot castings are sequentially assembled in a crucible in the mode that the head portions are downward and the bottoms are upward; 2, an auxiliary electrode is installed on an electrode rod pneumatic clamp head, the crucibleis arranged inside a vacuum self-consumption electric arc furnace, and the furnace is sealed and vacuumized; 3, the auxiliary electrode and the ingot castings in the step 1 are subjected to head welding in the vacuum self-consumption electric arc furnace; and 4, the ingot castings are subjected to middle welding. The current, voltage, stable arc and other parameters in the welding process are controlled in the step 3 and the step 4. The problems that existing ingot castings with the diameter of 820 mm are poor in welding weld joint quality, insufficient in welding area, poor in smelting safety, poor in quality stability and the like are solved.

Owner:西部超导材料科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com