Performance-adjustable low-cost titanium alloy

A titanium alloy, low-cost technology, applied in the field of titanium alloys, to achieve the effect of reduced production costs and wide application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

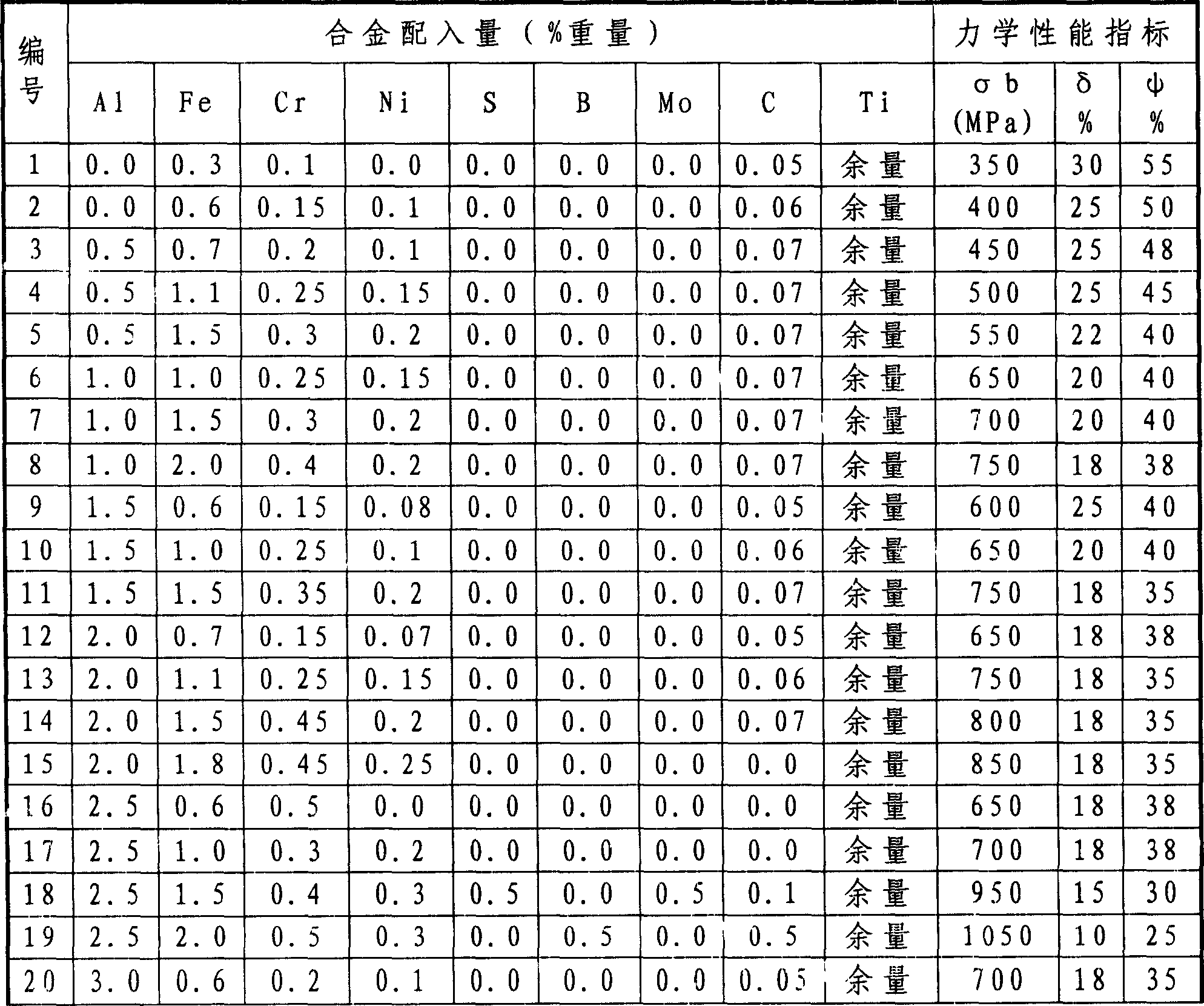

[0010] A low-cost titanium alloy with adjustable performance is briefly described below in conjunction with specific embodiments. Eight elements such as Al, Fe, Cr, Ni, S, B, C, and Mo are added to titanium, and the weight percentage composition of the alloy is Described by the following formula: X+Y+Z+Ti=100%, where X=Al≤6%, Y=[(0.3≤Fe≤5%)+(0.1≤Cr≤2%)]≤7%, Z =[(Ni≤0.5%)+(S≤1%)+(B≤0.5%)+(Mo≤0.8%)+(C≤0.5%)]≤3%, and unavoidable impurity elements. The alloy material prepared according to the above formula is fully mixed, pressed into a consumable electrode, and melted into an ingot in a vacuum electric arc furnace for the second time, and can be processed into various specifications such as rods, plates, pipes, strips, and wires. Variety of titanium alloy products.

[0011] The present invention fixes the content of X and Y in the above formula, changes the content of Z within a given value, and can adjust the mechanical properties of the finished alloy: or change the content of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com