Patents

Literature

4743 results about "Tantalum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tantalum is a chemical element with the symbol Ta and atomic number 73. Previously known as tantalium, its name comes from Tantalus, a villain from Greek mythology. Tantalum is a rare, hard, blue-gray, lustrous transition metal that is highly corrosion-resistant. It is part of the refractory metals group, which are widely used as minor components in alloys. The chemical inertness of tantalum makes it a valuable substance for laboratory equipment and a substitute for platinum. Its main use today is in tantalum capacitors in electronic equipment such as mobile phones, DVD players, video game systems and computers. Tantalum, always together with the chemically similar niobium, occurs in the mineral groups tantalite, columbite and coltan (a mix of columbite and tantalite, though not recognised as a separate mineral species). Tantalum is considered a technology-critical element.

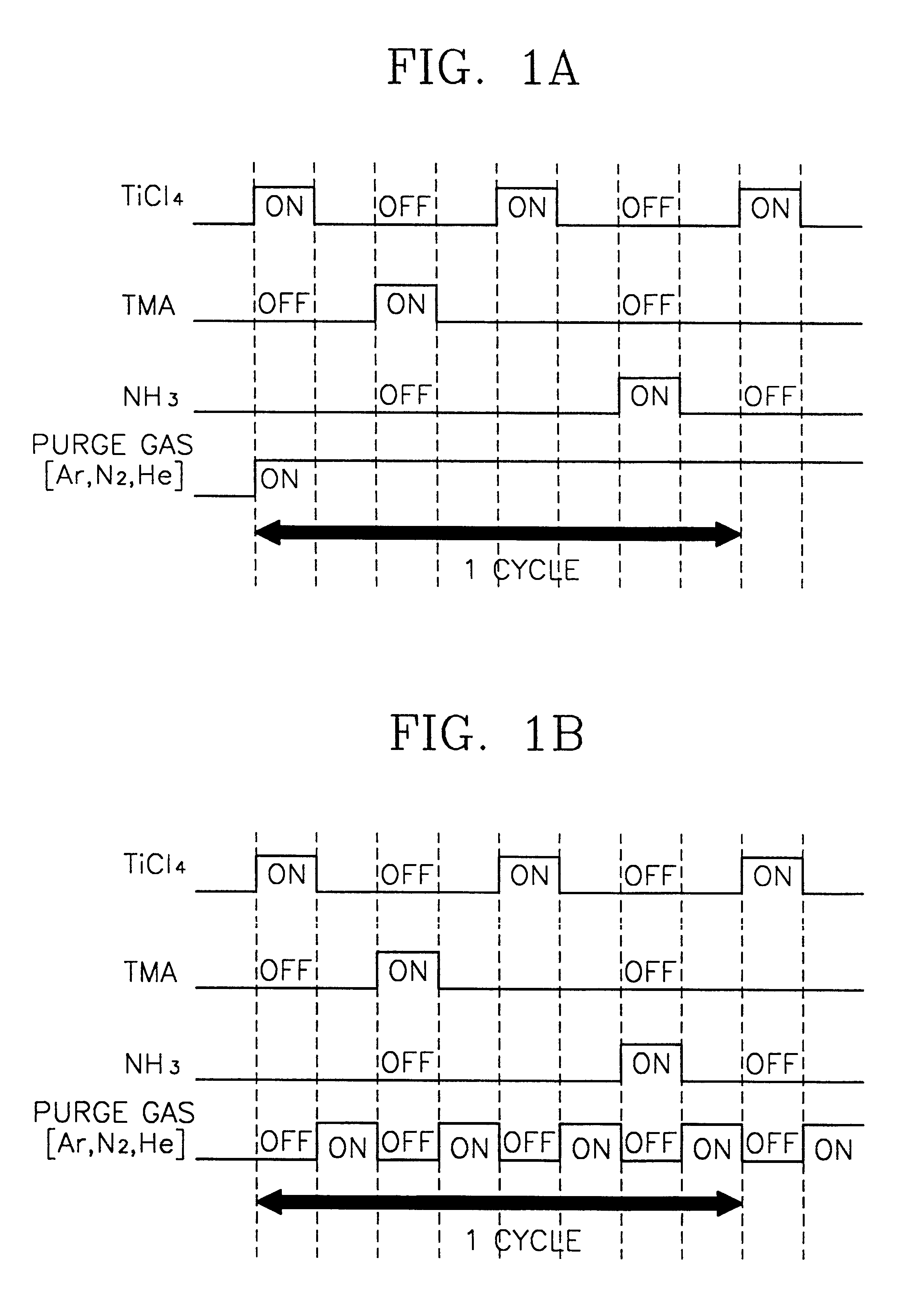

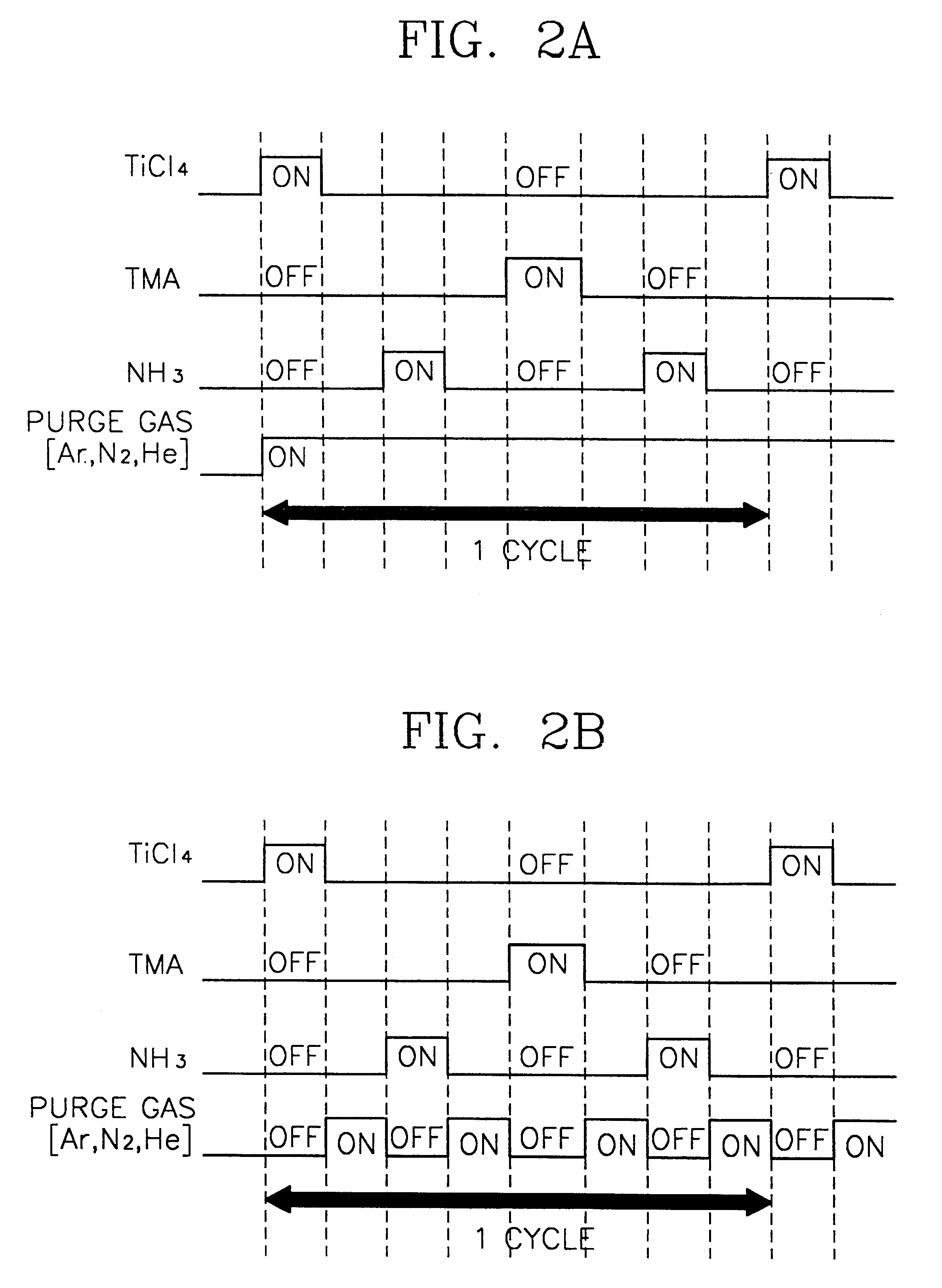

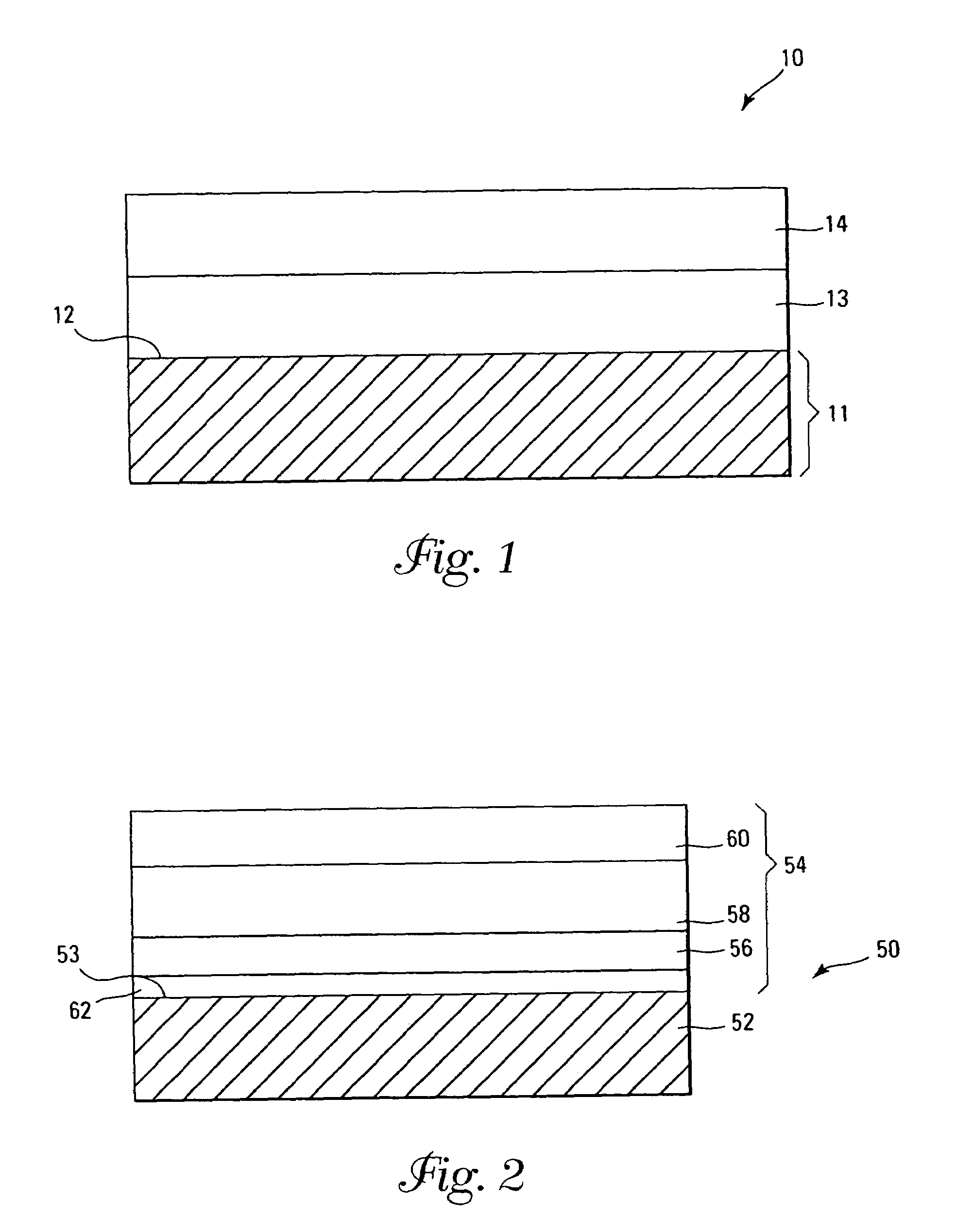

Method of forming metal layer using atomic layer deposition and semiconductor device having the metal layer as barrier metal layer or upper or lower electrode of capacitor

InactiveUS6287965B1High thermal resistantEasy to adjustSemiconductor/solid-state device manufacturingCapacitorsNiobiumDevice material

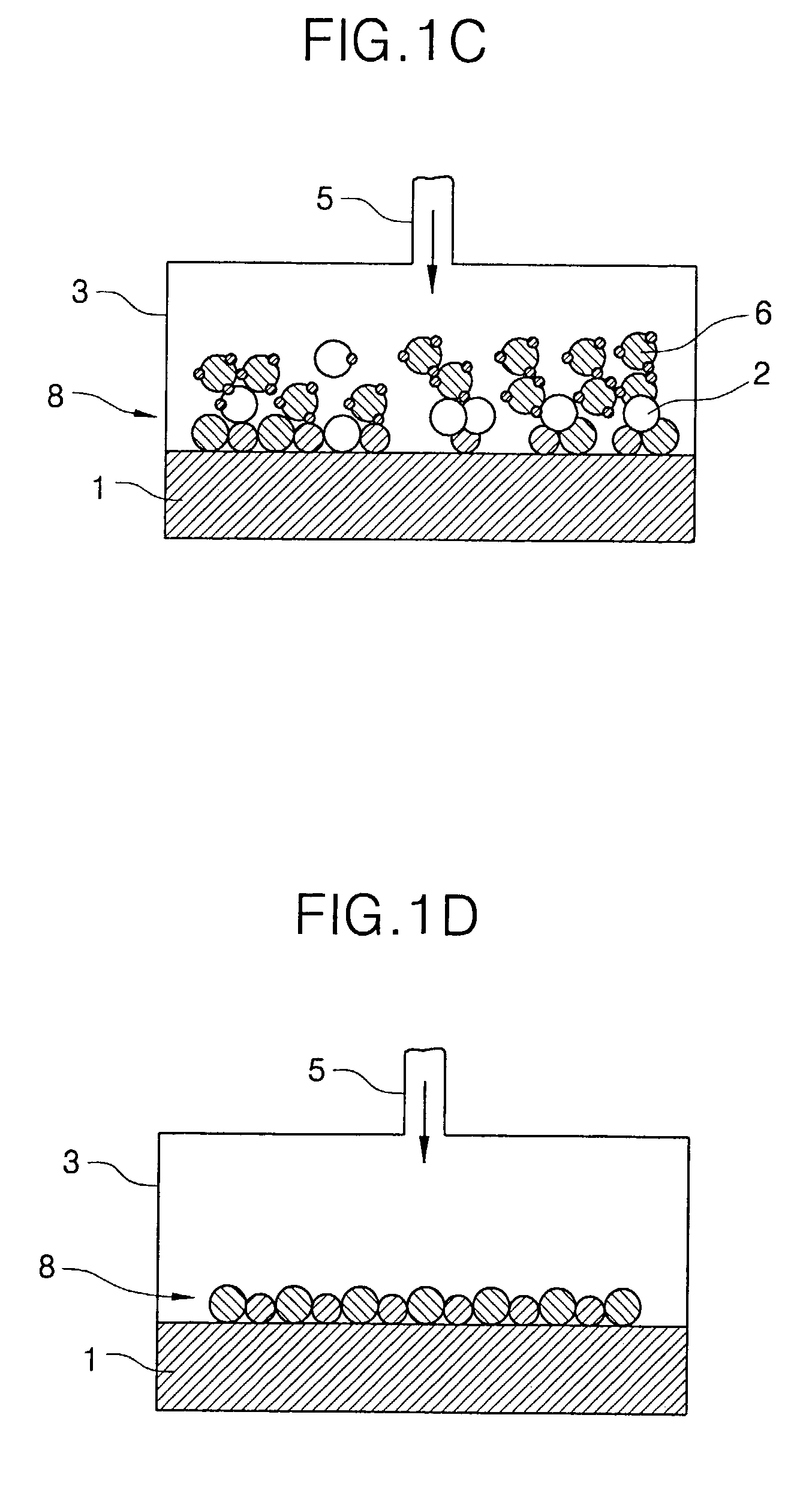

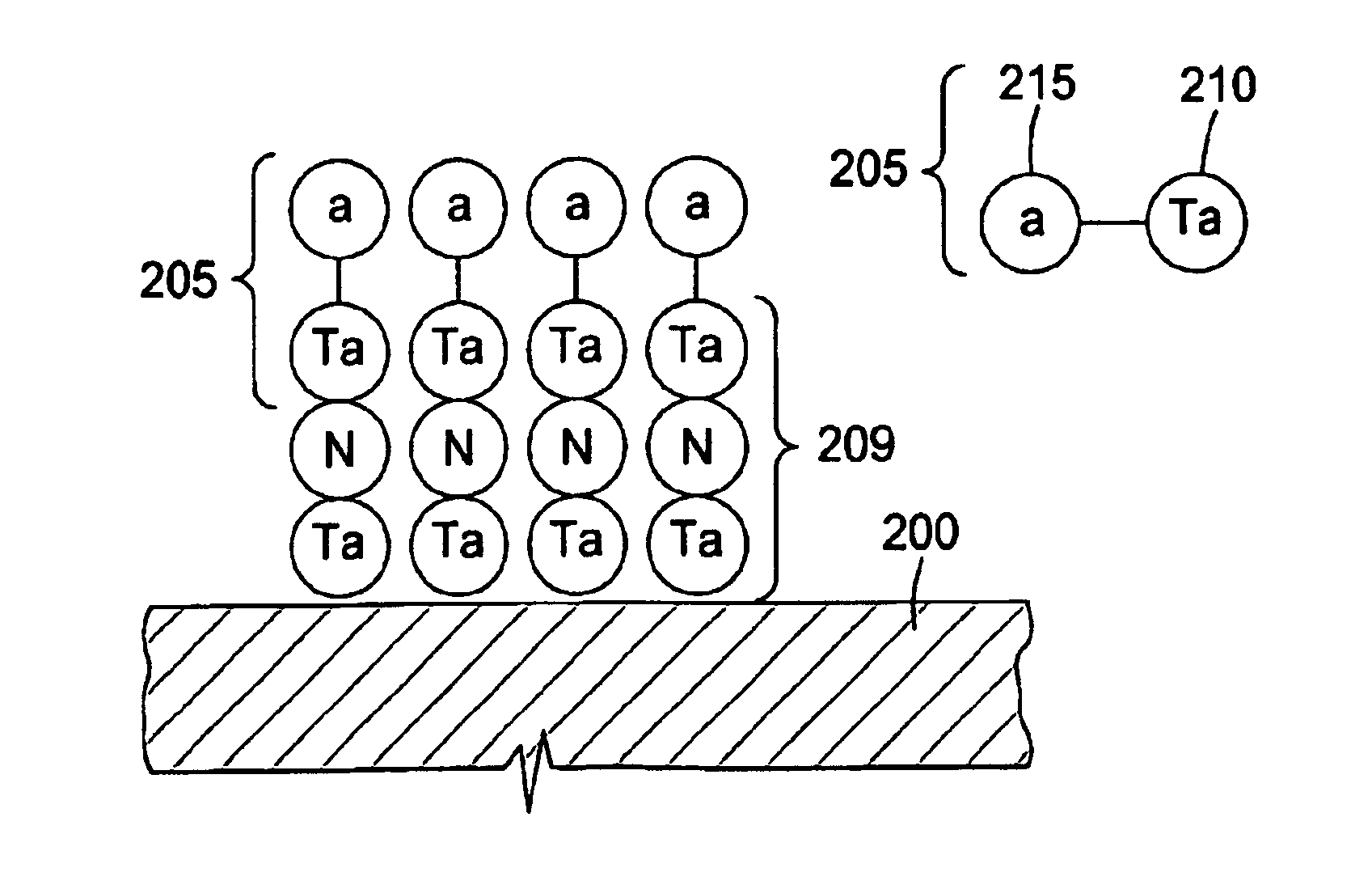

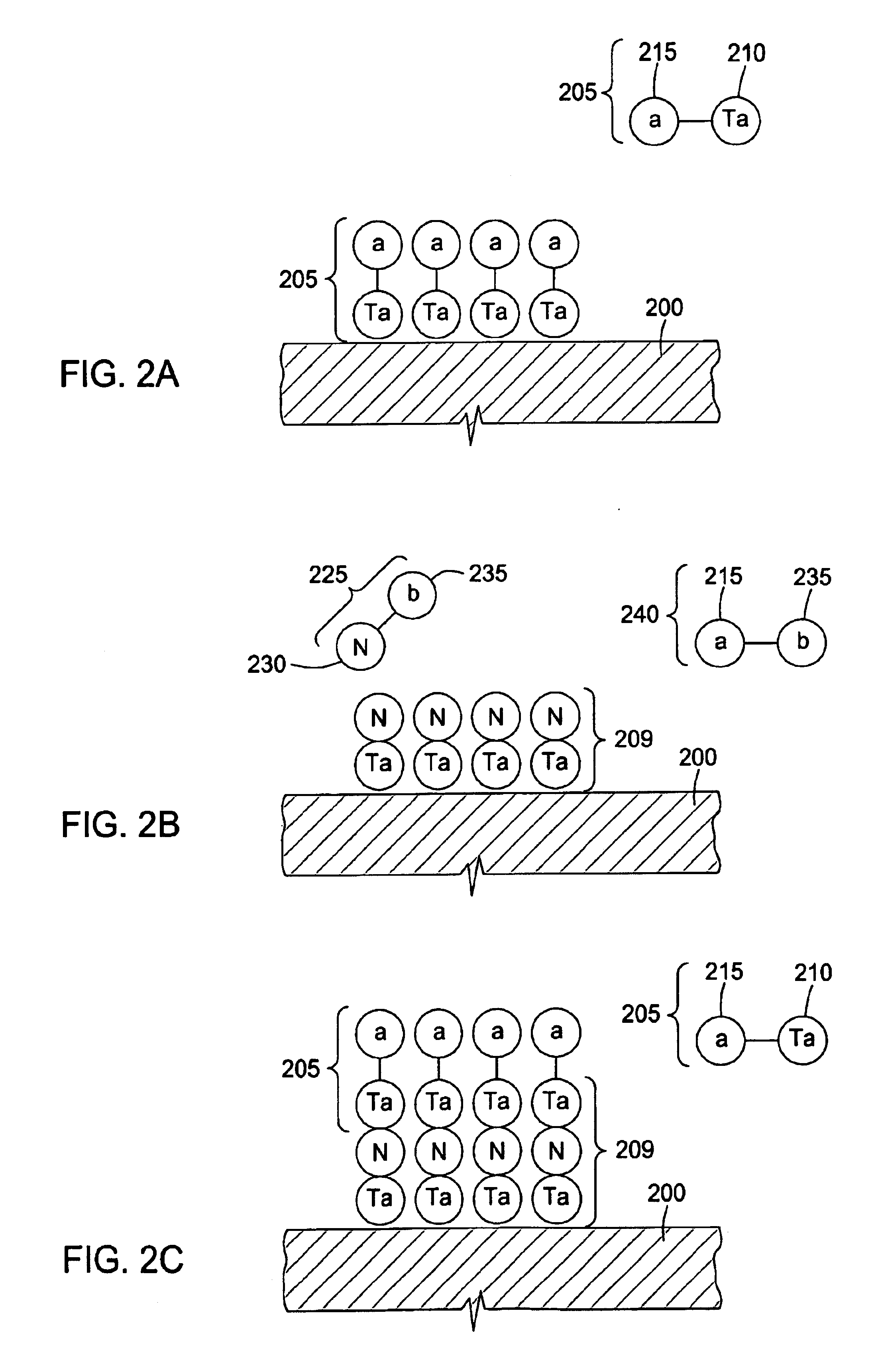

A method of forming a metal layer having excellent thermal and oxidation resistant characteristics using atomic layer deposition is provided. The metal layer includes a reactive metal (A), an element (B) for the amorphous combination between the reactive metal (A) and nitrogen (N), and nitrogen (N). The reactive metal (A) may be titanium (Ti), tantalum (Ta), tungsten (W), zirconium (Zr), hafnium (Hf), molybdenum (Mo) or niobium (Nb). The amorphous combination element (B) may be aluminum (Al), silicon (Si) or boron (B). The metal layer is formed by alternately injecting pulsed source gases for the elements (A, B and N) into a chamber according to atomic layer deposition to thereby alternately stack atomic layers. Accordingly, the composition ratio of a nitrogen compound (A-B-N) of the metal layer can be desirably adjusted just by appropriately determining the number of injection pulses of each source gas. According to the composition ratio, a desirable electrical conductivity and resistance of the metal layer can be accurately obtained. The atomic layers are individually deposited, thereby realizing excellent step coverage even in a complex and compact region. A metal layer formed by atomic layer deposition can be employed as a barrier metal layer, a lower electrode or an upper electrode in a semiconductor device.

Owner:SAMSUNG ELECTRONICS CO LTD

Ampoule with a thermally conductive coating

ActiveUS20080149031A1Improve temperature uniformityChemical vapor deposition coatingConductive coatingCompound (substance)

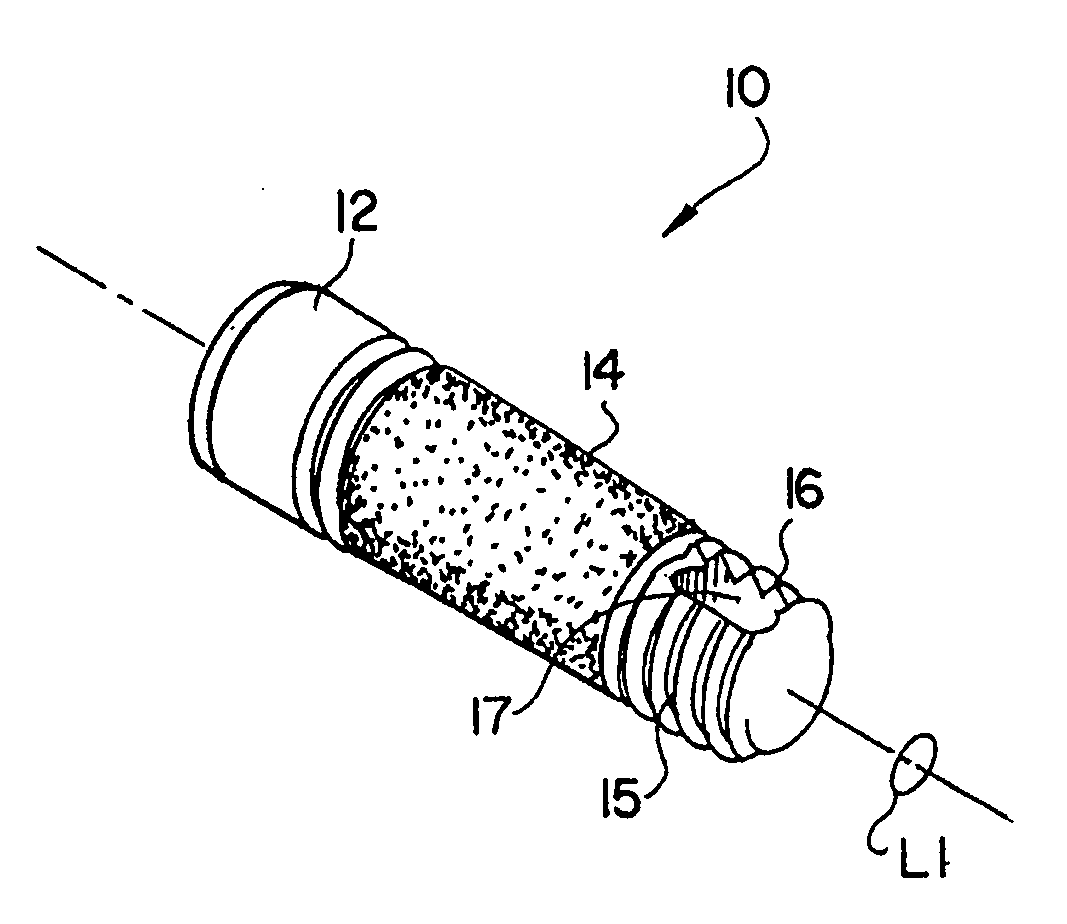

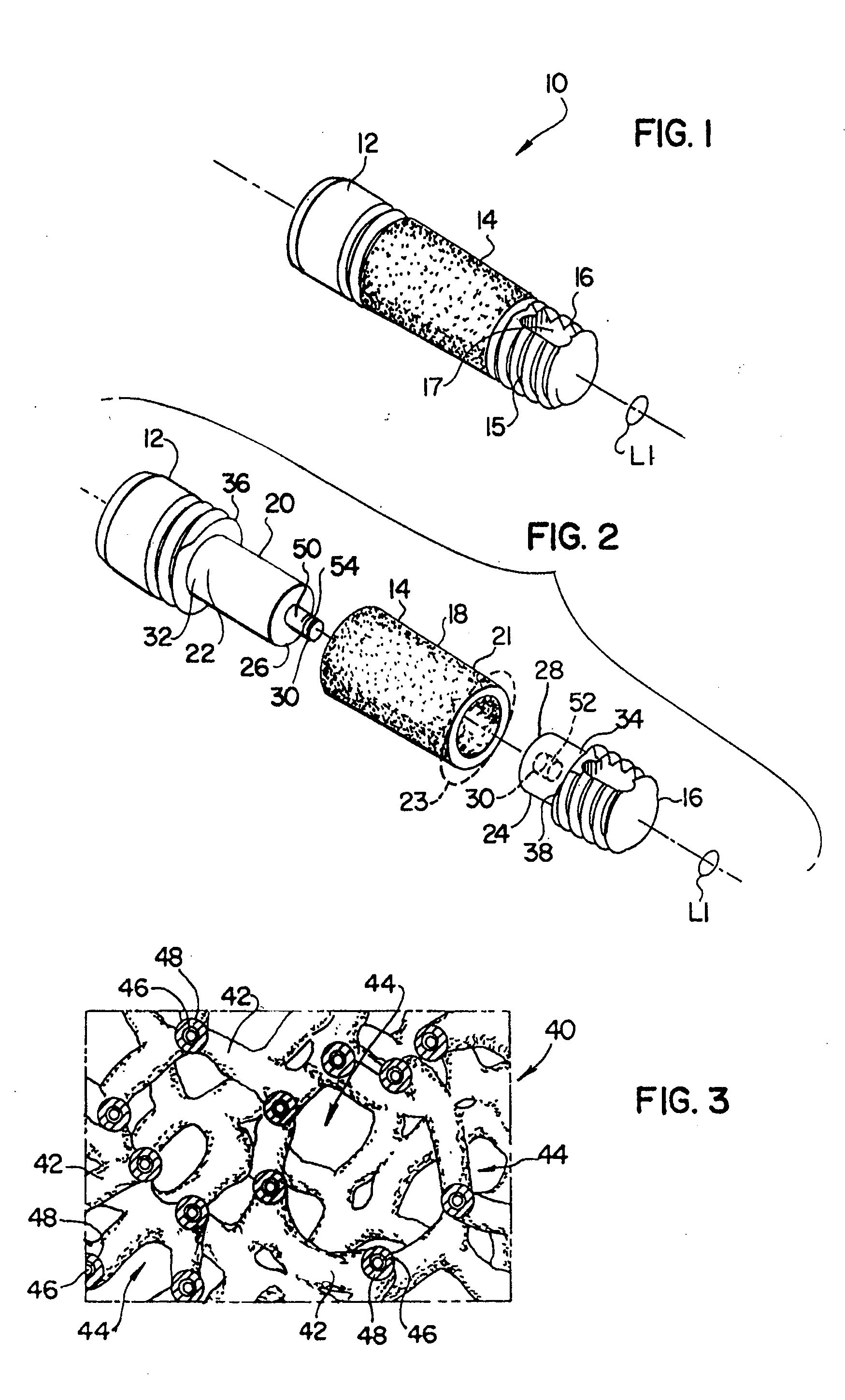

Embodiments of the invention provide an apparatus and a process for generating a chemical precursor used in a vapor deposition processing system. The apparatus includes a canister (e.g., ampoule) having a sidewall, a top, and a bottom encompassing an interior volume therein, inlet and outlet ports in fluid communication with the interior volume, and a thermally conductive coating disposed on or over the outside surface of the canister. The thermally conductive coating is more thermally conductive than the outside surface of the canister. The thermally conductive coating may contain aluminum, aluminum nitride, copper, brass, silver, titanium, silicon nitride, or alloys thereof. In some embodiments, an adhesion layer (e.g., titanium or tantalum) may be disposed between the outside surface of the canister and the thermally conductive coating. In other embodiments, the canister may contain a plurality of baffles or solid heat-transfer particles to help evenly heat a solid precursor therein.

Owner:APPLIED MATERIALS INC

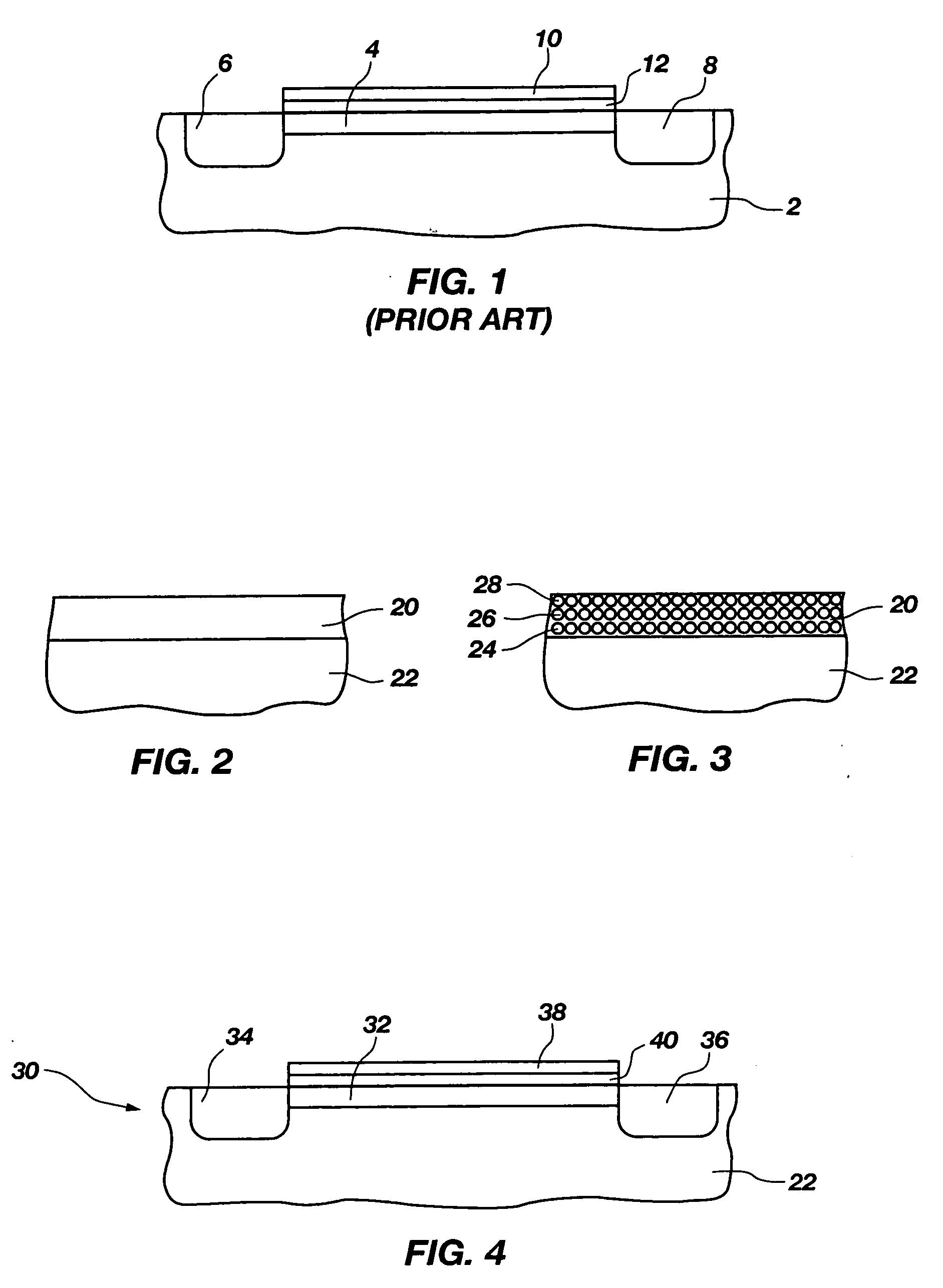

Atomic layer deposition of metal oxynitride layers as gate dielectrics

InactiveUS20060051925A1Semiconductor/solid-state device manufacturingSemiconductor devicesGate dielectricHafnium

A metal oxynitride layer formed by atomic layer deposition of a plurality of reacted monolayers, the monolayers comprising at least one each of a metal, an oxide and a nitride. The metal oxynitride layer is formed from zirconium oxynitride, hafnium oxynitride, tantalum oxynitride, or mixtures thereof. The metal oxynitride layer is used in gate dielectrics as a replacement material for silicon dioxide. A semiconductor device structure having a gate dielectric formed from a metal oxynitride layer is also disclosed.

Owner:AHN KIE Y +1

Methods of forming atomic layers of a material on a substrate by sequentially introducing precursors of the material

InactiveUS7201943B2Easy to integrateHigh dielectric constantVacuum evaporation coatingSemiconductor/solid-state device manufacturingGate dielectricTitanium

A thin film is formed using an atomic layer deposition process, by introducing a first reacting material including tantalum precursors and titanium precursors onto a substrate. A portion of the first reacting material is chemisorbed onto the substrate. Then, a second reacting material including oxygen is introduced onto the substrate. A portion of the second reacting material is also chemisorbed onto the substrate, to form an atomic layer of a solid material on the substrate. The solid material may be used as a dielectric layer of the capacitor and / or a gate dielectric layer of the transistor.

Owner:SAMSUNG ELECTRONICS CO LTD

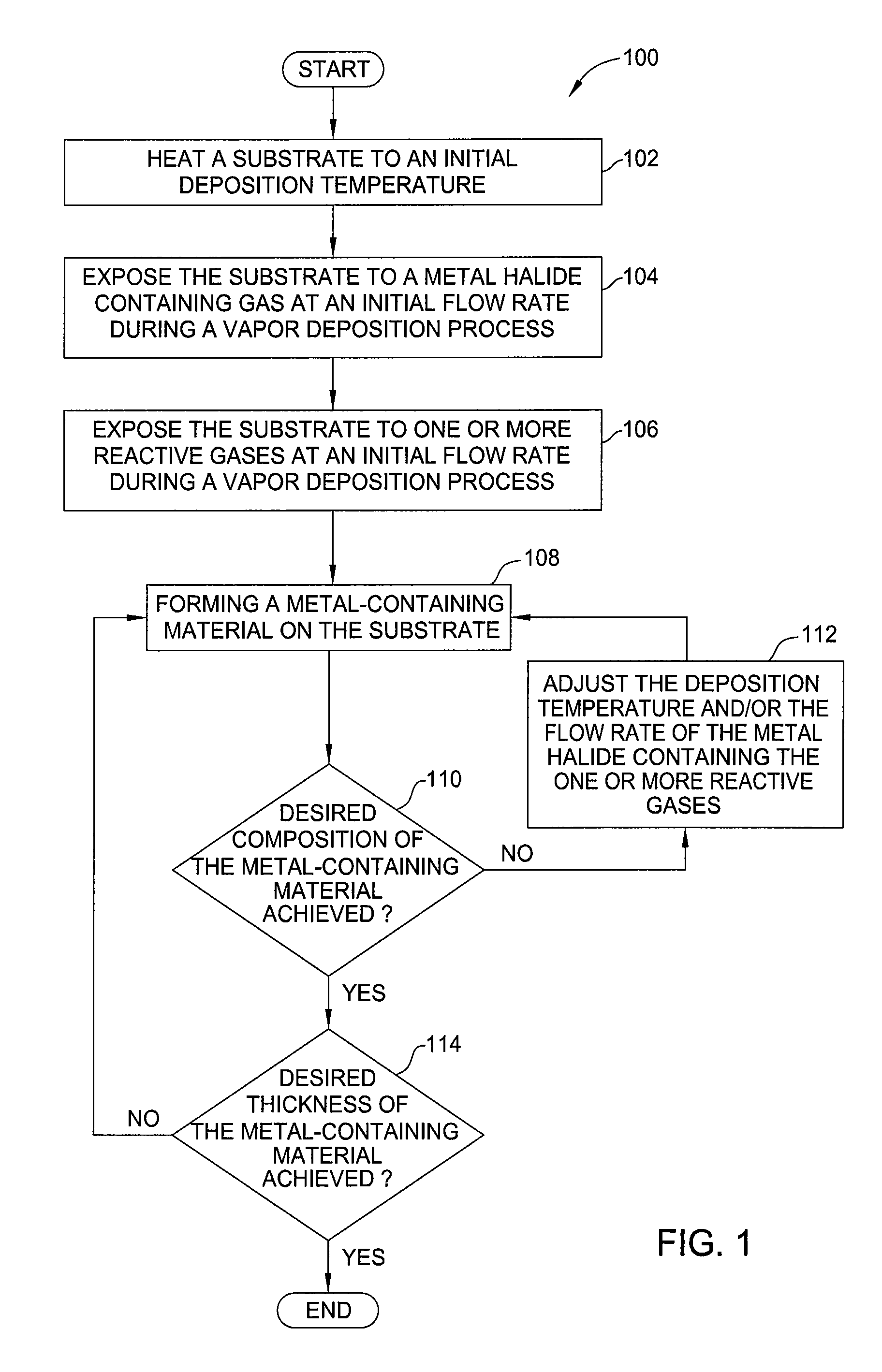

Nmos metal gate materials, manufacturing methods, and equipment using CVD and ald processes with metal based precursors

ActiveUS20110263115A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseMetallic materials

Embodiments of the invention generally provide methods for depositing metal-containing materials and compositions thereof. The methods include deposition processes that form metal, metal carbide, metal silicide, metal nitride, and metal carbide derivatives by a vapor deposition process, including thermal decomposition, CVD, pulsed-CVD, or ALD. In one embodiment, a method for processing a substrate is provided which includes depositing a dielectric material having a dielectric constant greater than 10, forming a feature definition in the dielectric material, depositing a work function material conformally on the sidewalls and bottom of the feature definition, and depositing a metal gate fill material on the work function material to fill the feature definition, wherein the work function material is deposited by reacting at least one metal-halide precursor having the formula MXY, wherein M is tantalum, hafnium, titanium, and lanthanum, X is a halide selected from the group of fluorine, chlorine, bromine, or iodine, and y is from 3 to 5.

Owner:APPLIED MATERIALS INC

Organometallic precursors for seed/barrier processes and methods thereof

InactiveUS20080194105A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseRuthenium

Organometallic precursors and methods for deposition on a substrate in seed / barrier applications are herein disclosed. In some embodiments, the organometallic precursor is a ruthenium-containing, tantalum-containing precursor or combination thereof and may be deposited by atomic layer deposition, chemical vapor deposition and / or physical vapor deposition.

Owner:INTEL CORP

Slurry compositions for chemical mechanical polishing of copper and barrier films

InactiveUS20050090104A1High selectivityShorten the counting processSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesSlurryPolymer

Owner:INNOVATIUM TECH

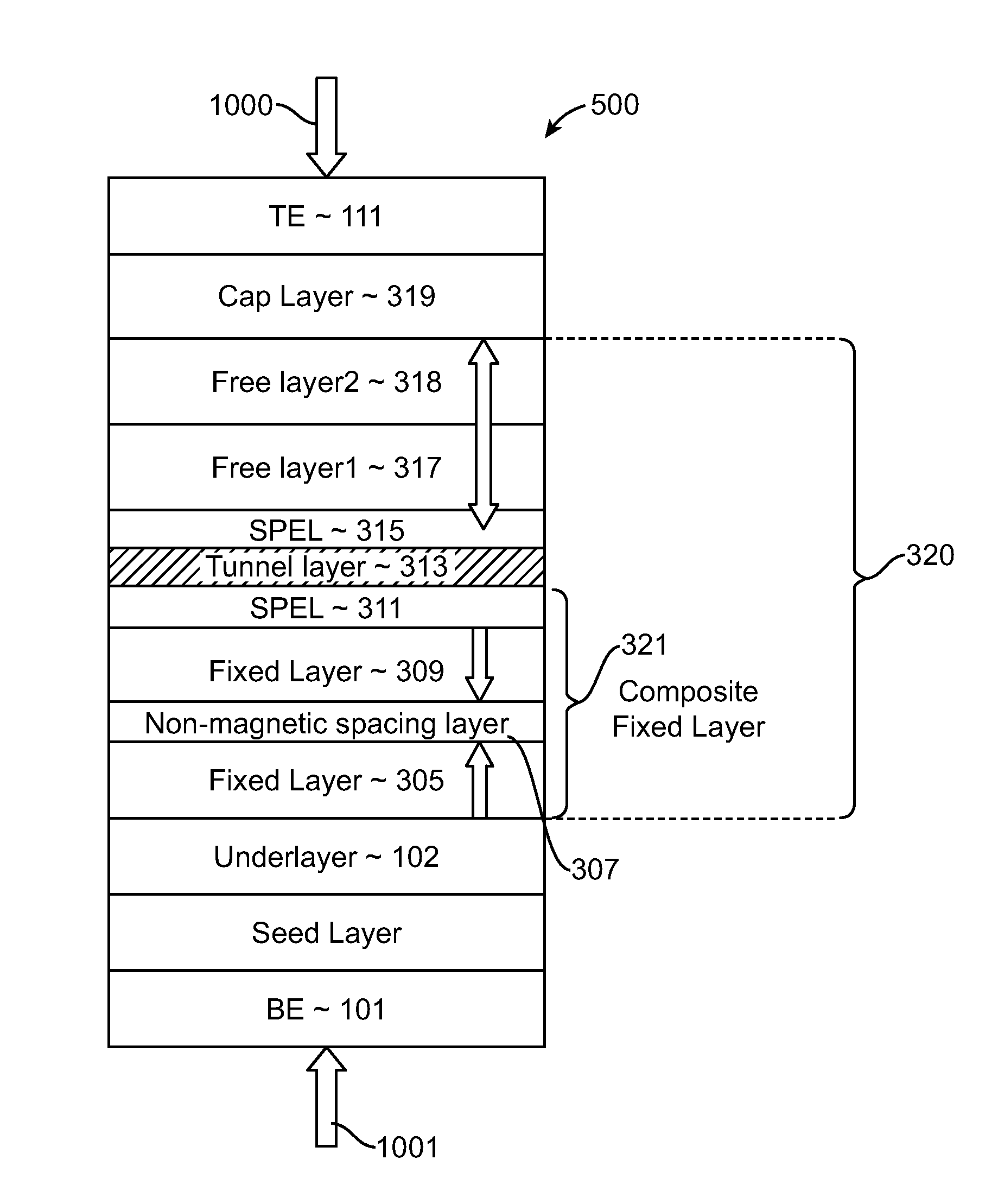

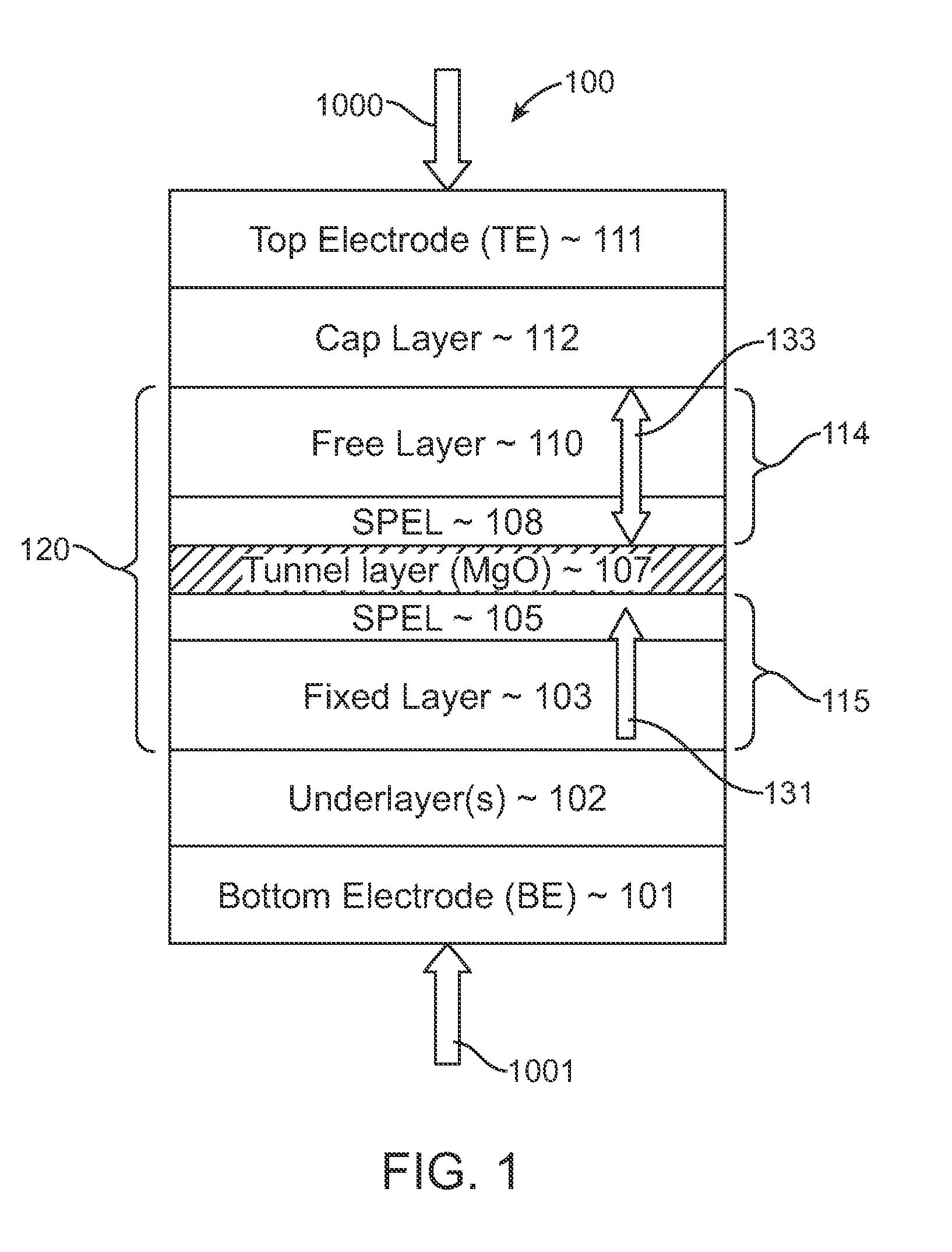

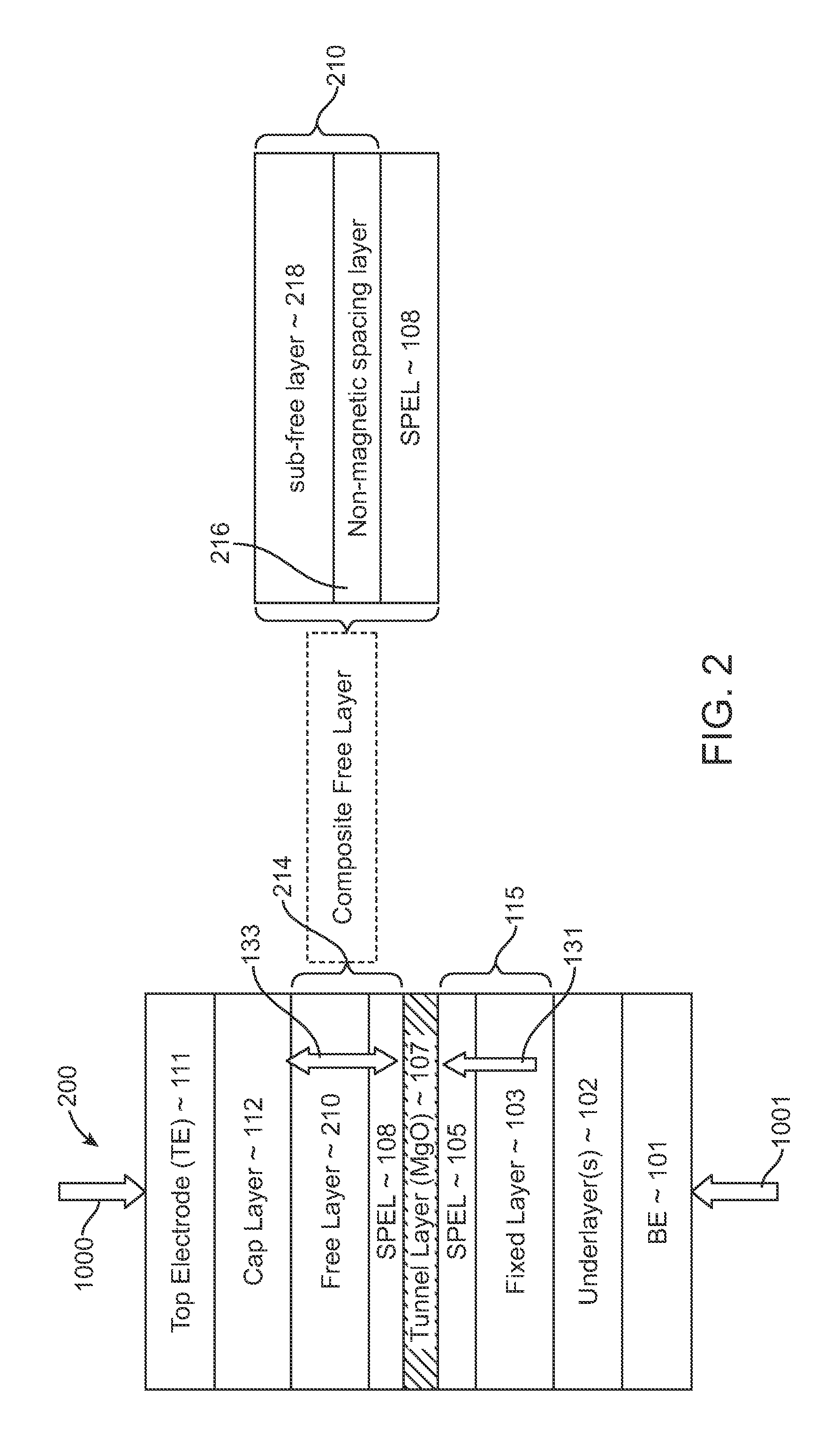

Spin-transfer torque magnetic random access memory having magnetic tunnel junction with perpendicular magnetic anisotropy

A spin-torque transfer memory random access memory (STTMRAM) element includes a fixed layer formed on top of a substrate and a a tunnel layer formed upon the fixed layer and a composite free layer formed upon the tunnel barrier layer and made of an iron platinum alloy with at least one of X or Y material, X being from a group consisting of: boron (B), phosphorous (P), carbon (C), and nitride (N) and Y being from a group consisting of: tantalum (Ta), titanium (Ti), niobium (Nb), zirconium (Zr), tungsten (W), silicon (Si), copper (Cu), silver (Ag), aluminum (Al), chromium (Cr), tin (Sn), lead (Pb), antimony (Sb), hafnium (Hf) and bismuth (Bi), molybdenum (Mo) or rhodium (Ru), the magnetization direction of each of the composite free layer and fixed layer being substantially perpendicular to the plane of the substrate.

Owner:AVALANCHE TECH

Lead free reduced ricochet limited penetration projectile

A frangible projectile with a specific gravity similar to a lead projectile. The projectile comprises 34-94%, by weight, binder. The binder comprises poly ether block amide resin. The projectile further comprises 6-66%, by weight, ballast. The ballast comprises at least one member selected from a group consisting of tungsten, tungsten carbide, molybdenum, tantalum, ferro-tungsten, copper, bismuth, iron, steel, brass, aluminum bronze, beryllium copper, tin, aluminum, titanium, zinc, nickel silver alloy, cupronickel and nickel. The projectile can be prepared with a particularly preferred specific gravity of 5-14 and more preferably 11-11.5.

Owner:ACCUTEC USA

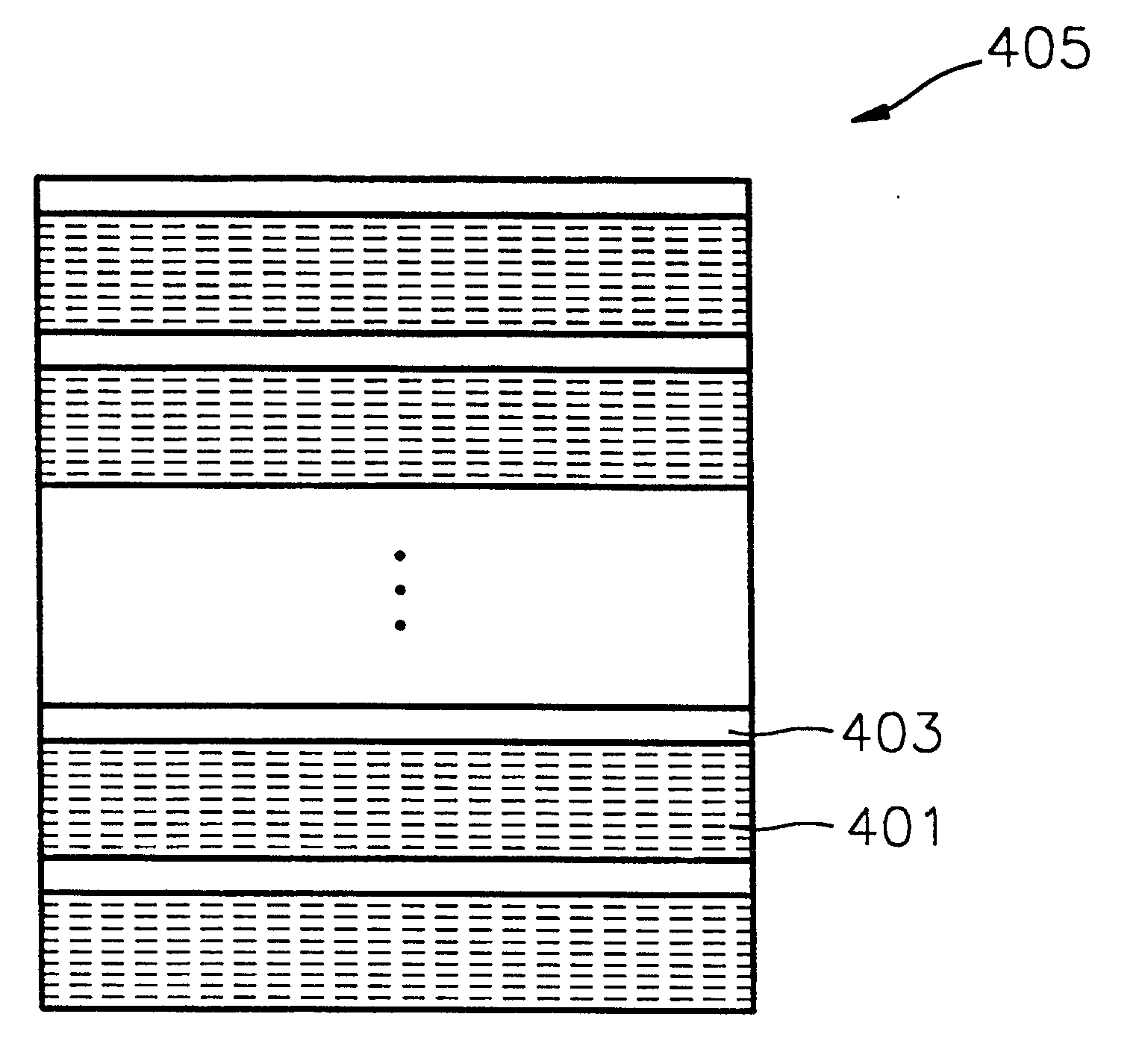

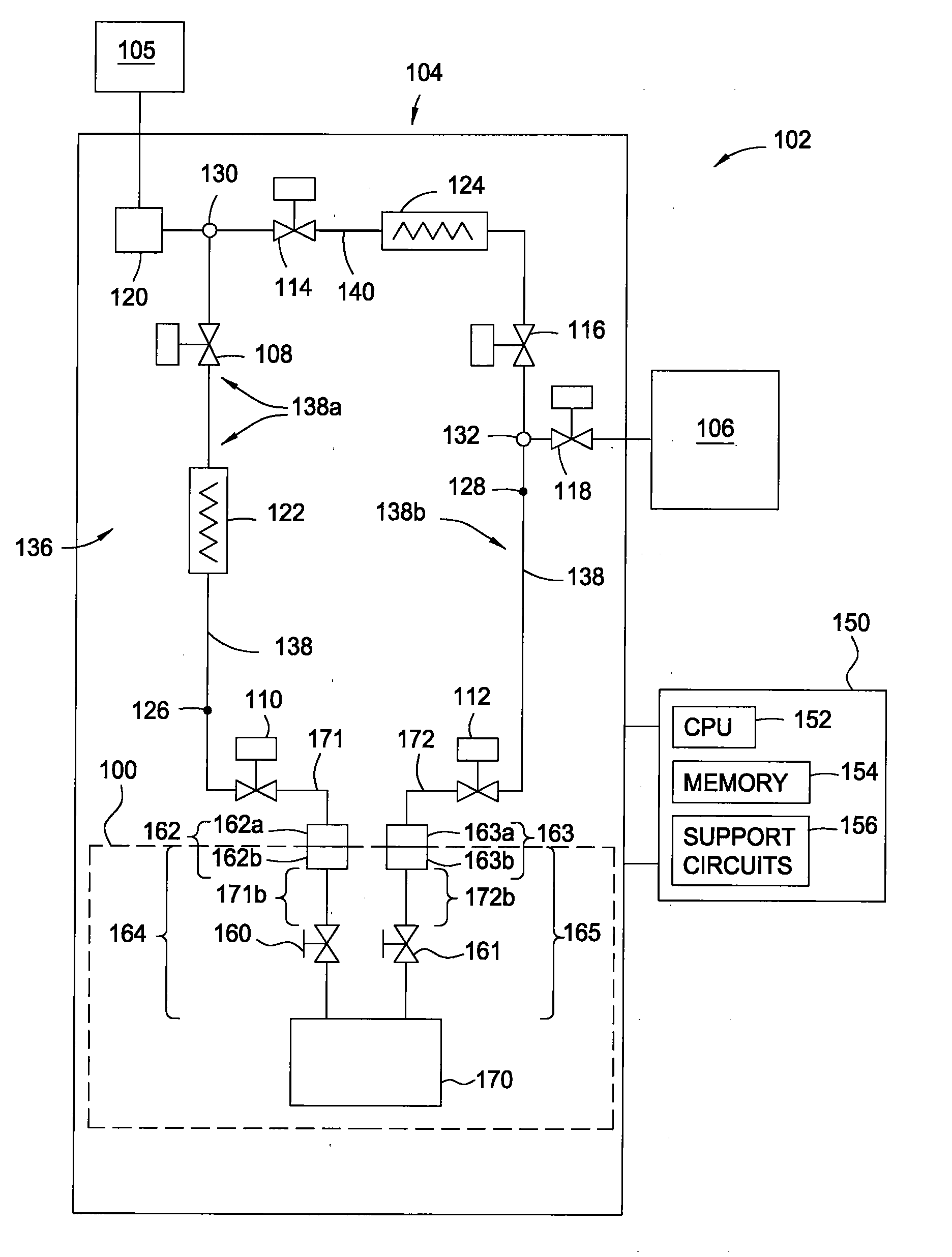

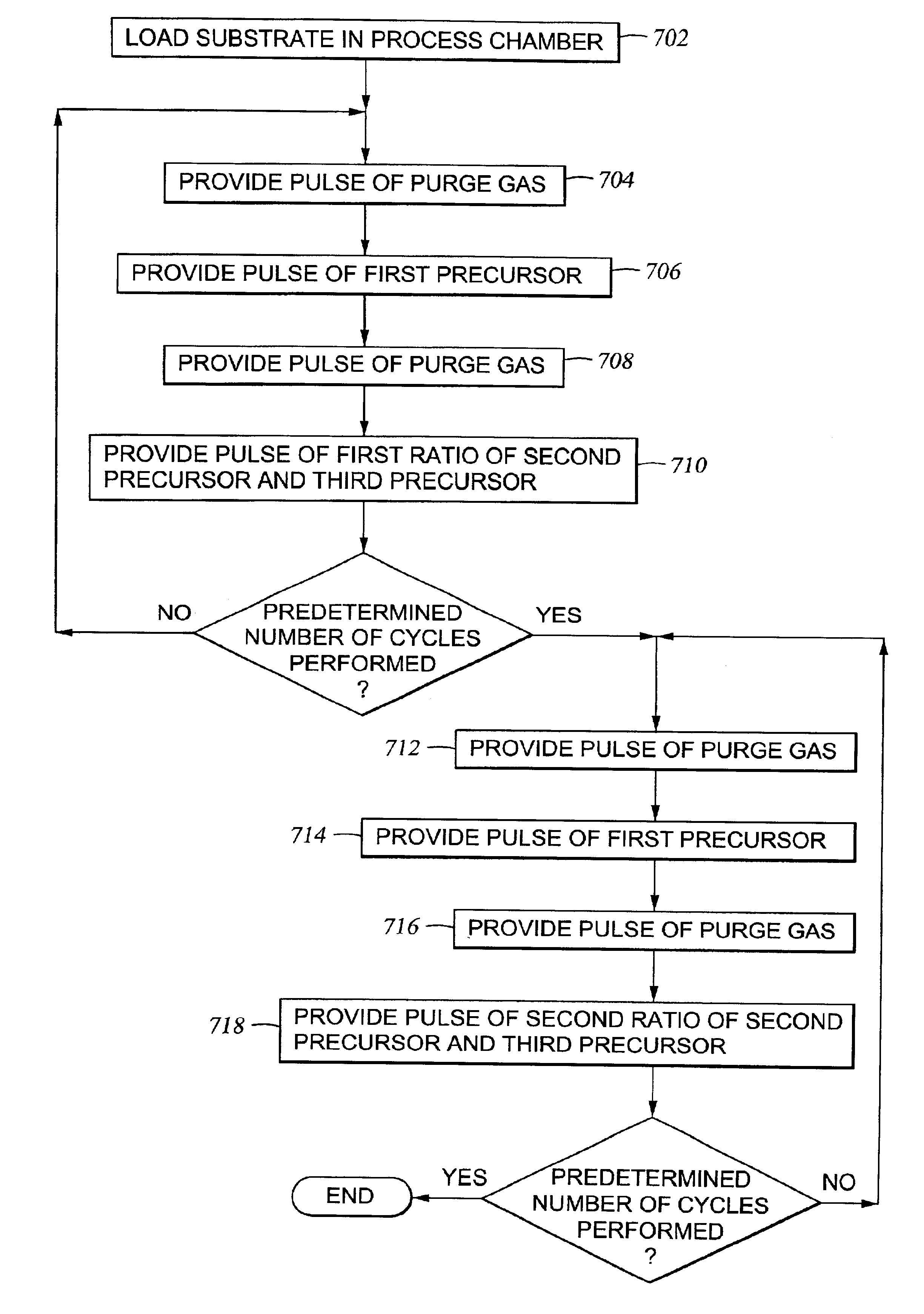

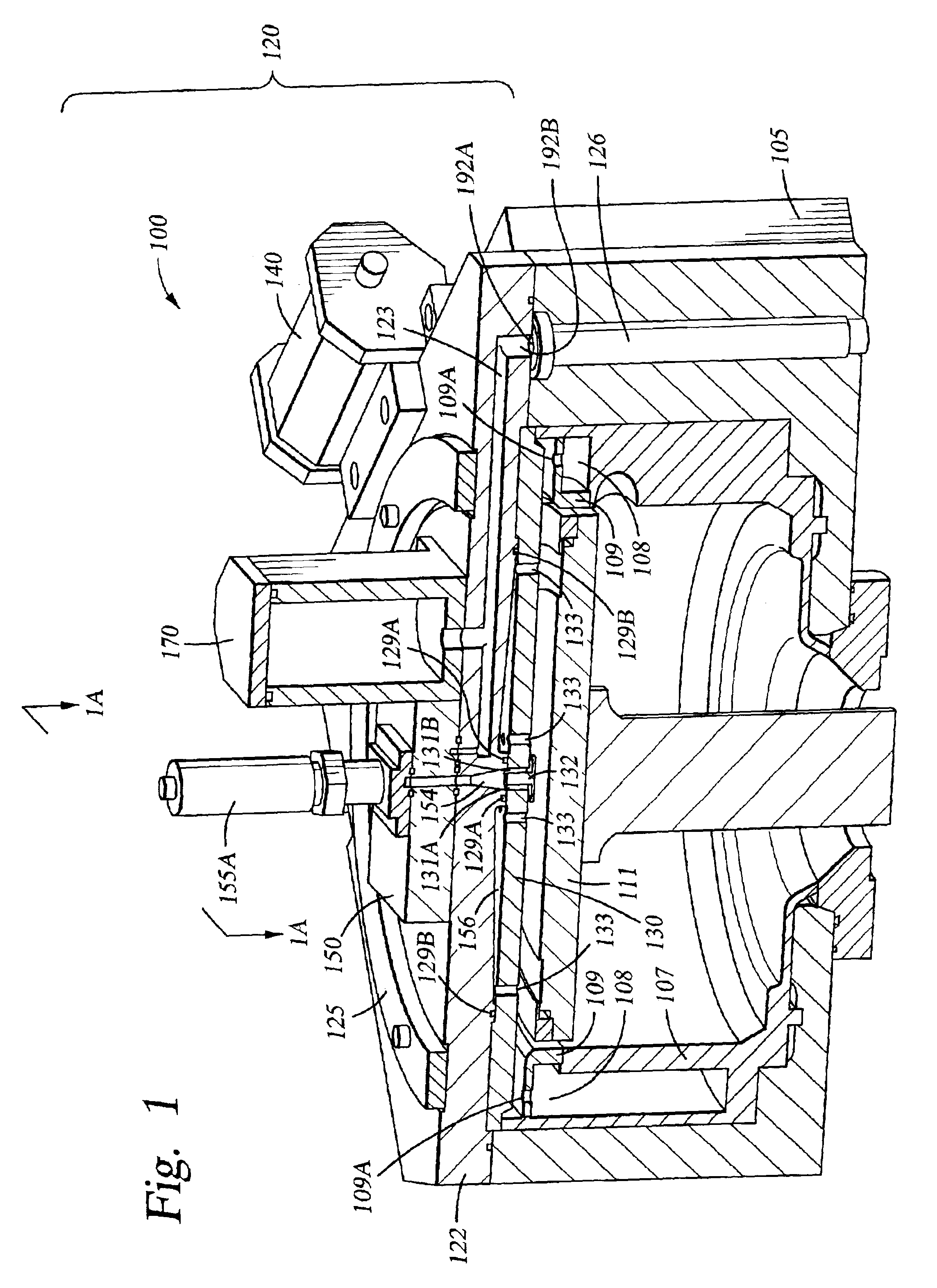

Multiple precursor cyclical deposition system

Embodiments of the present invention relate to an apparatus and method of cyclical deposition utilizing three or more precursors in which delivery of at least two of the precursors to a substrate structure at least partially overlap. One embodiment of depositing a ternary material layer over a substrate structure comprises providing at least one cycle of gases to deposit a ternary material layer. One cycle comprises introducing a pulse of a first precursor, introducing a pulse of a second precursor, and introducing a pulse of a third precursor in which the pulse of the second precursor and the pulse of the third precursor at least partially overlap. In one aspect, the ternary material layer includes, but is not limited to, tungsten boron silicon (WBxSiy), titanium silicon nitride (TiSixNy), tantalum silicon nitride (TaSixNy), silicon oxynitride (SiOxNy), and hafnium silicon oxide (HfSixOy). In one aspect, the composition of the ternary material layer may be tuned by changing the flow ratio of the second precursor to the third precursor between cycles.

Owner:APPLIED MATERIALS INC

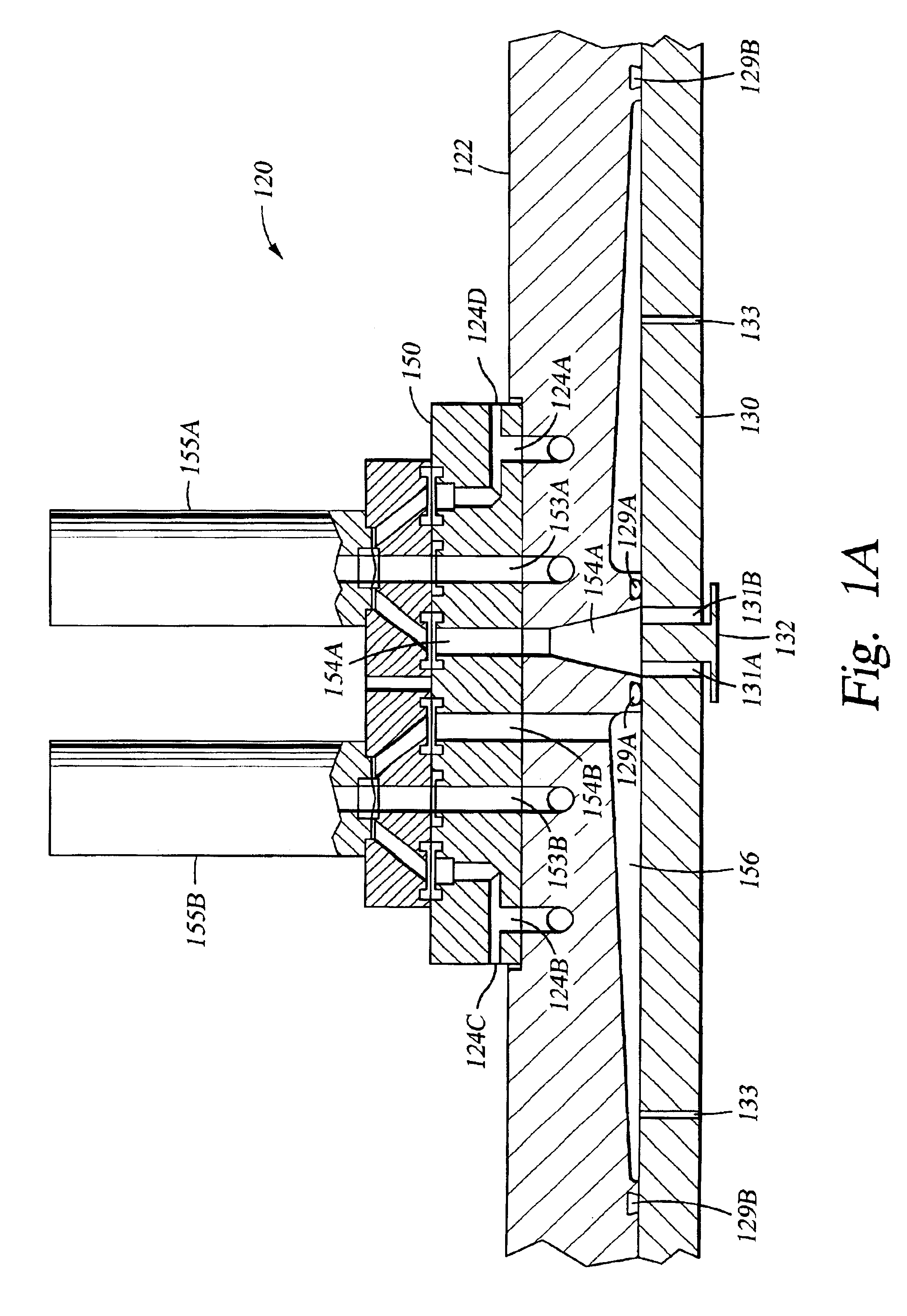

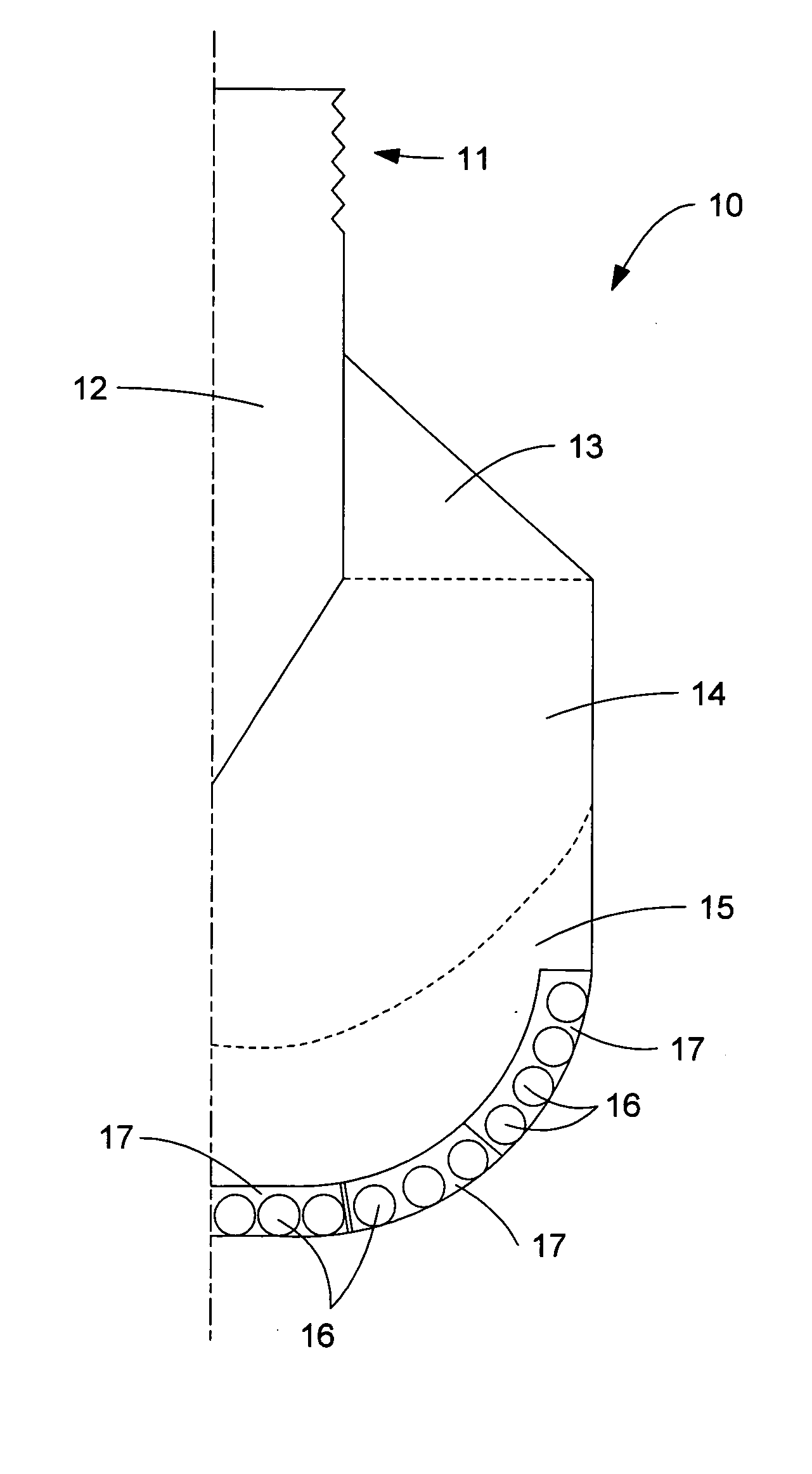

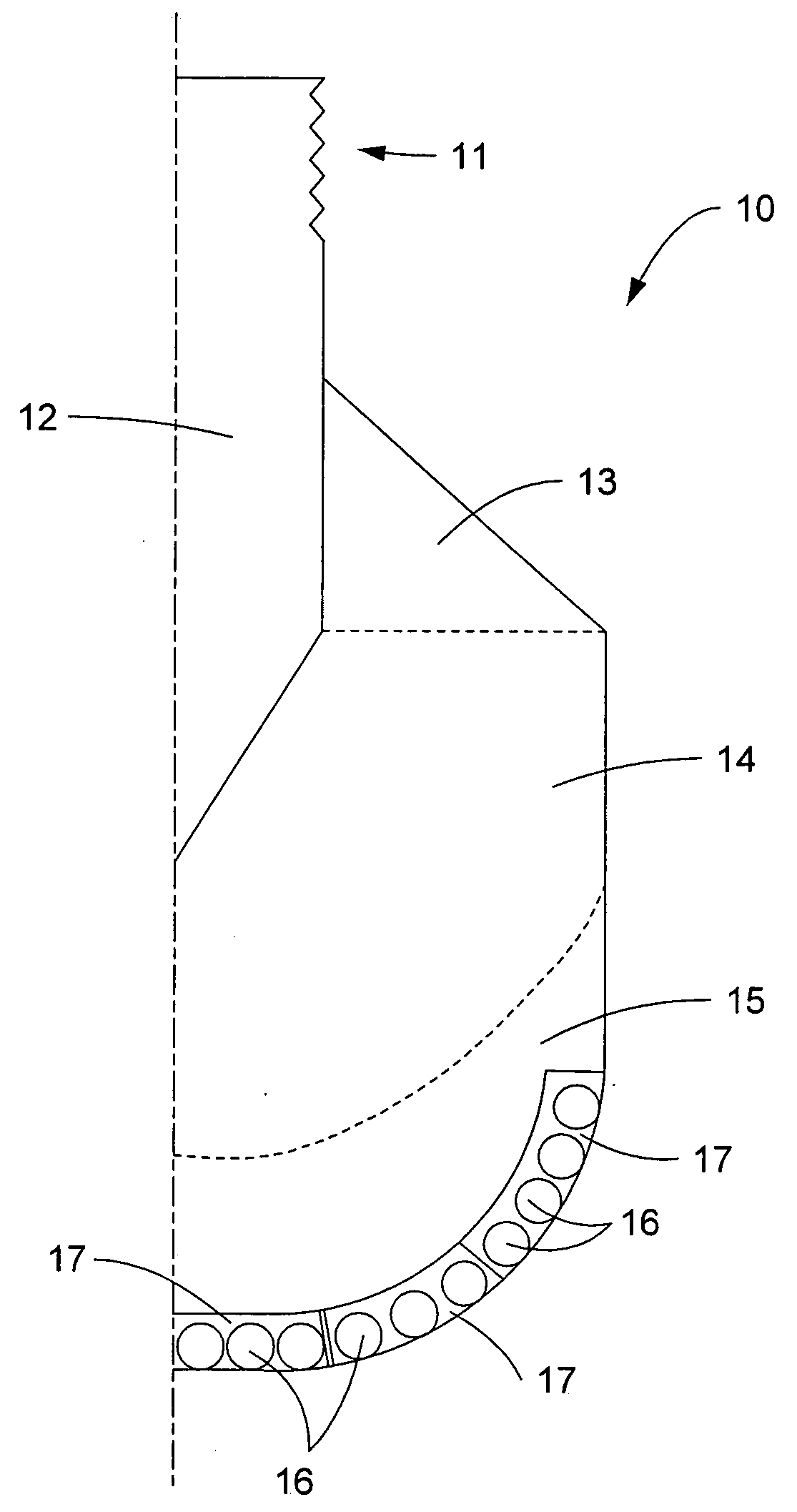

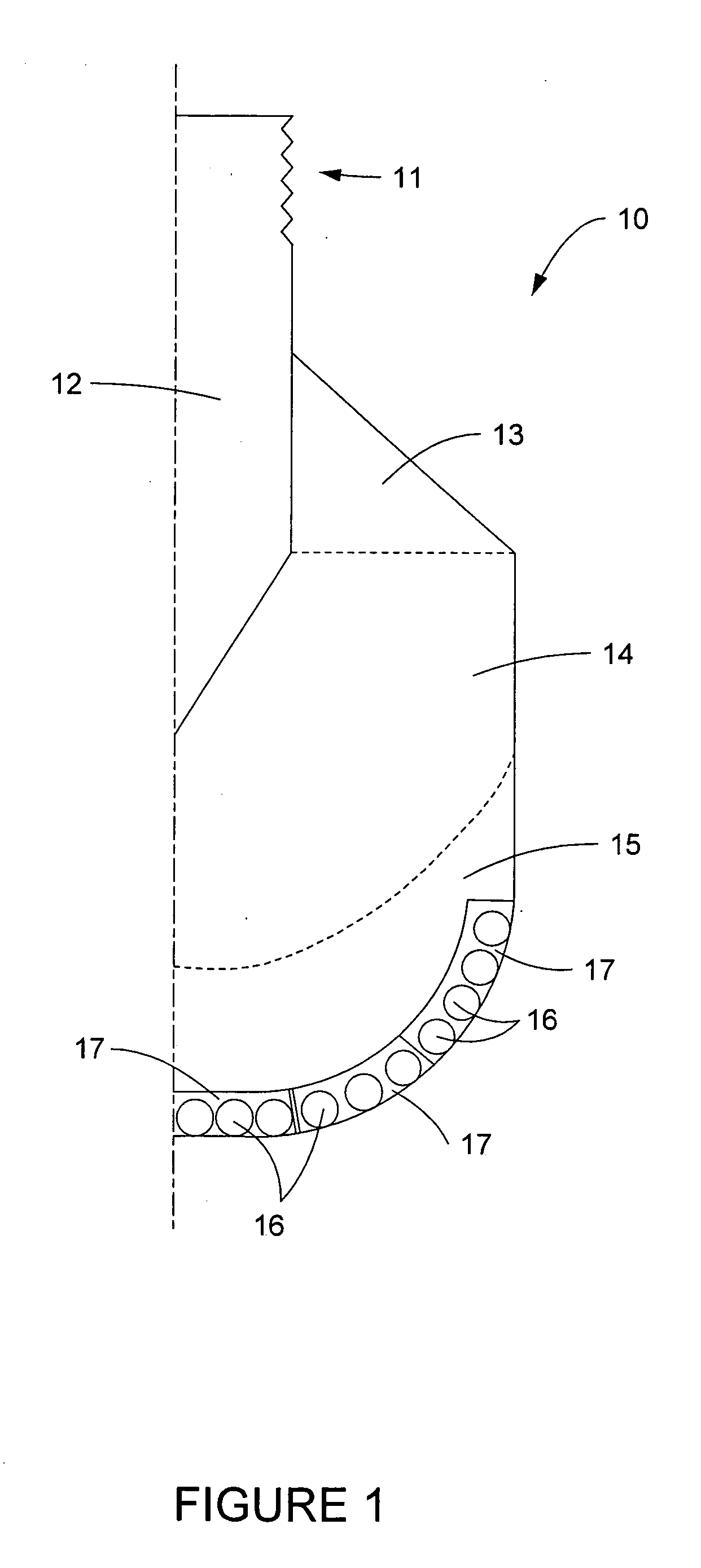

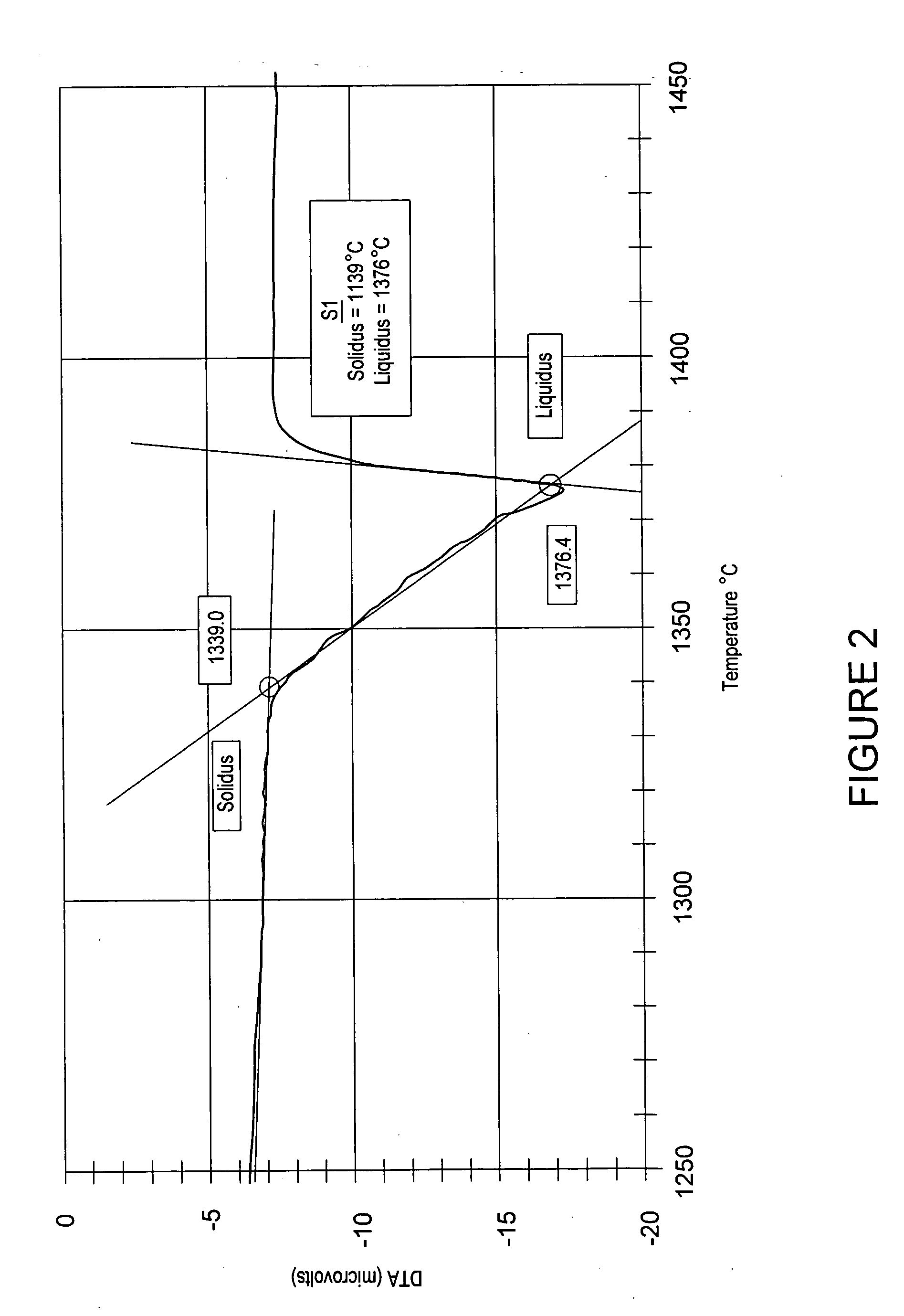

Earth-boring bits

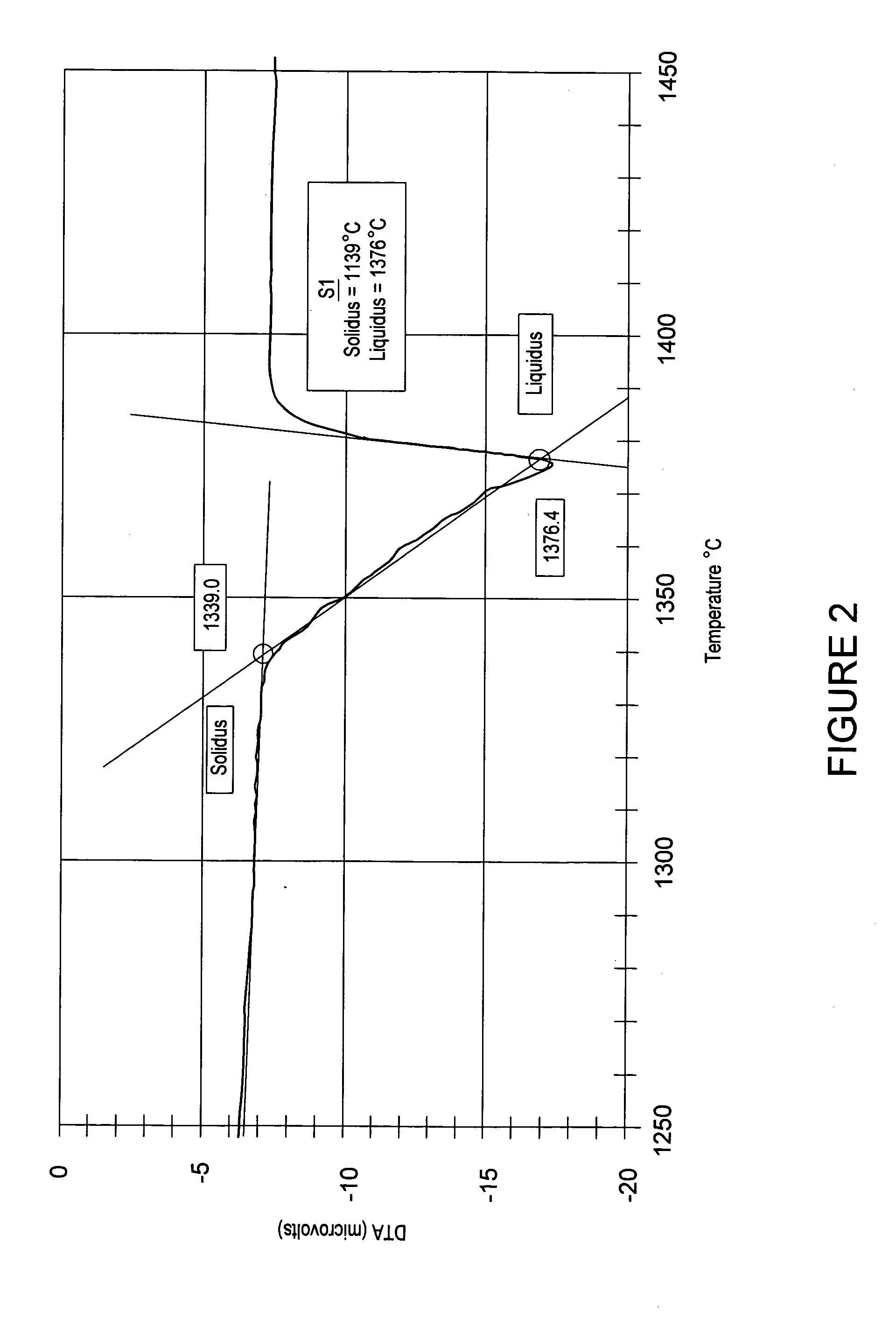

ActiveUS20050247491A1Low melting pointLowered melting point of the binder facilitates proper infiltration of the massDrill bitsCutting machinesBorideNiobium

The present invention relates to compositions and methods for forming a bit body for an earth-boring bit. The bit body may comprise hard particles, wherein the hard particles comprise at least one carbide, nitride, boride, and oxide and solid solutions thereof, and a binder binding together the hard particles. The binder may comprise at least one metal selected from cobalt, nickel, and iron, and, optionally, at least one melting point reducing constituent selected from a transition metal carbide in the range of 30 to 60 weight percent, boron up to 10 weight percent, silicon up to 20 weight percent, chromium up to 20 weight percent, and manganese up to 25 weight percent, wherein the weight percentages are based on the total weight of the binder. In addition, the hard particles may comprise at least one of (i) cast carbide (WC+W2C) particles, (ii) transition metal carbide particles selected from the carbides of titanium, chromium, vanadium, zirconium, hafnium, tantalum, molybdenum, niobium, and tungsten, and (iii) sintered cemented carbide particles.

Owner:BAKER HUGHES INC +1

Radiopaque nitinol alloys for medical devices

Owner:ABBOTT CARDIOVASCULAR

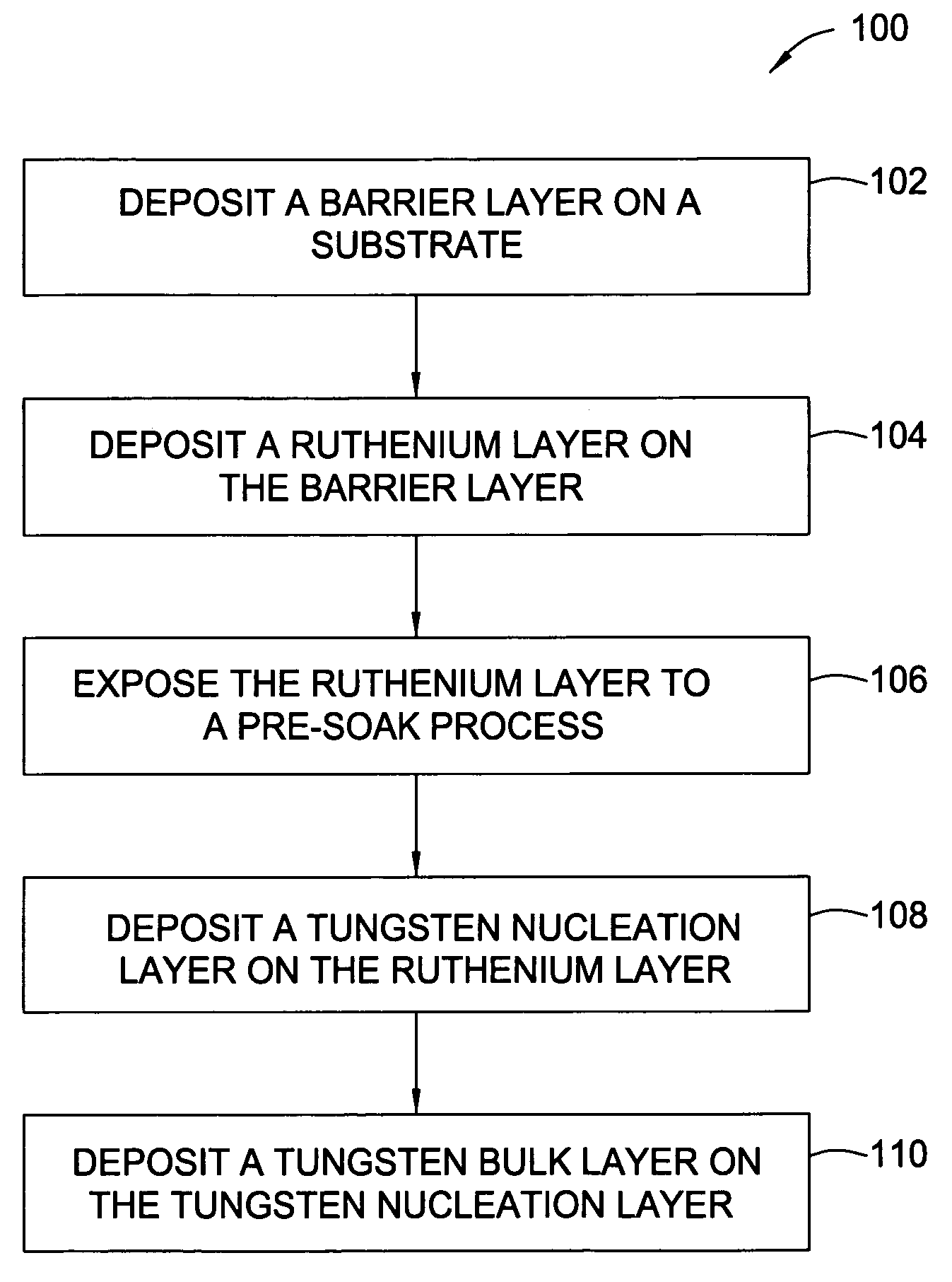

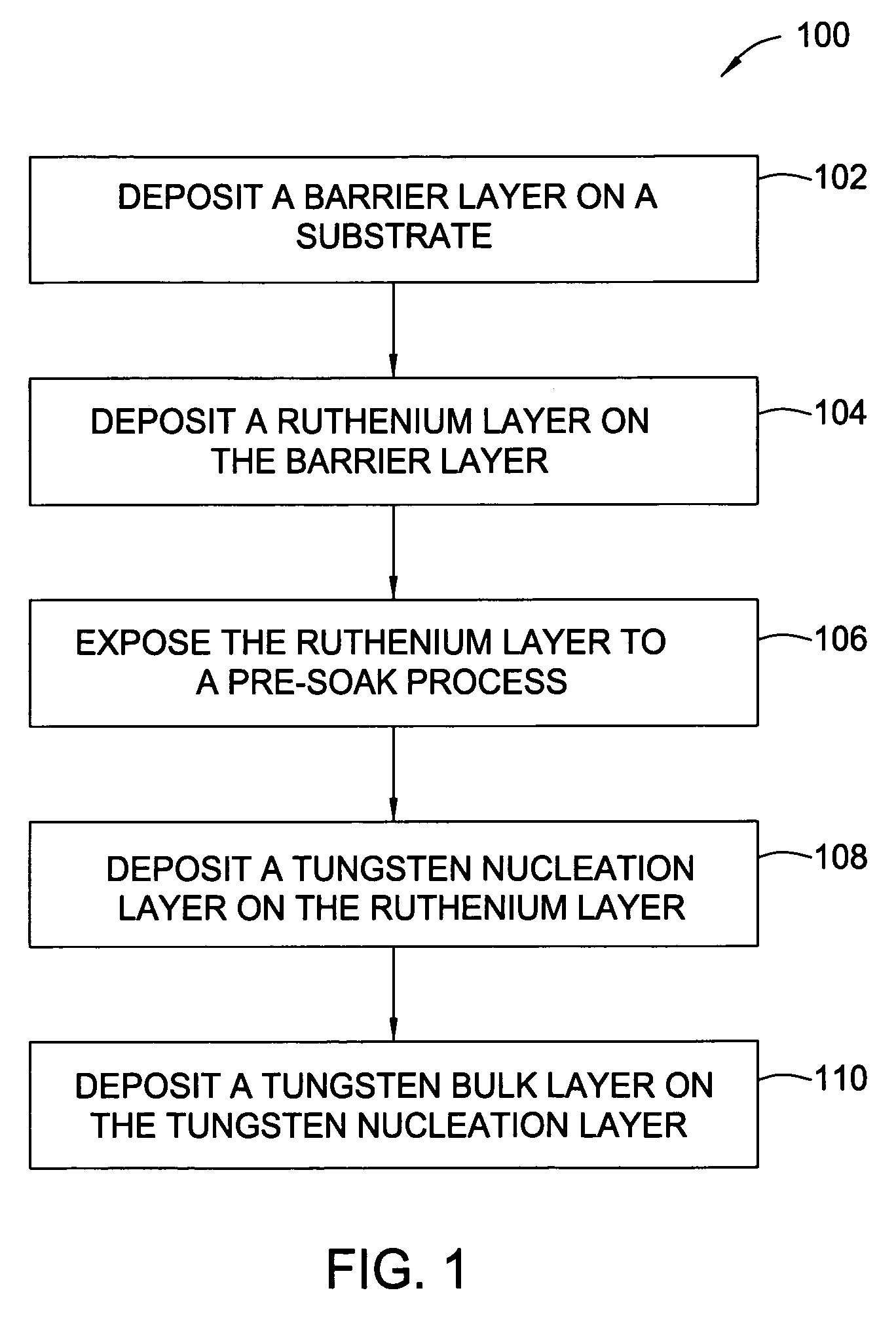

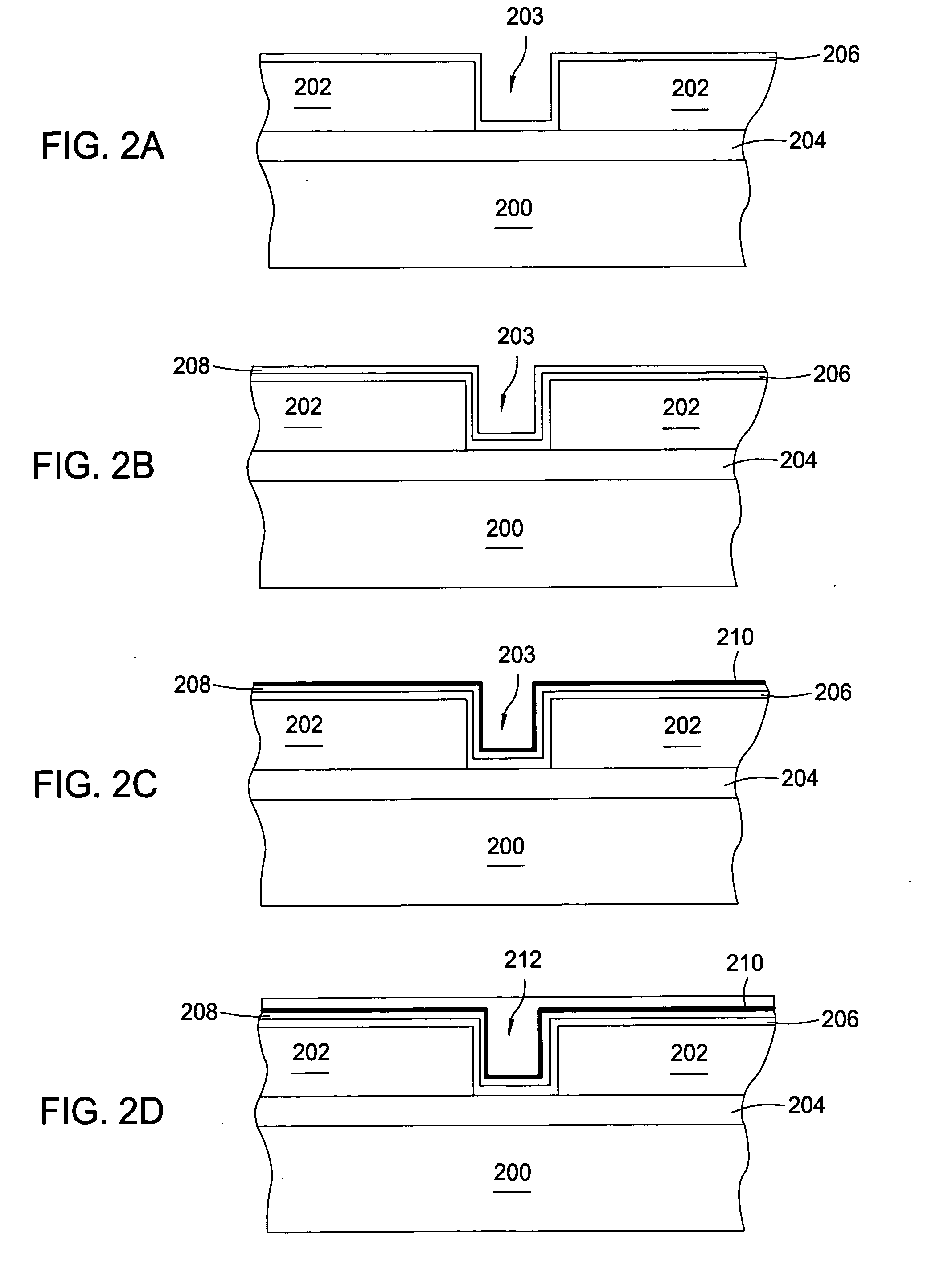

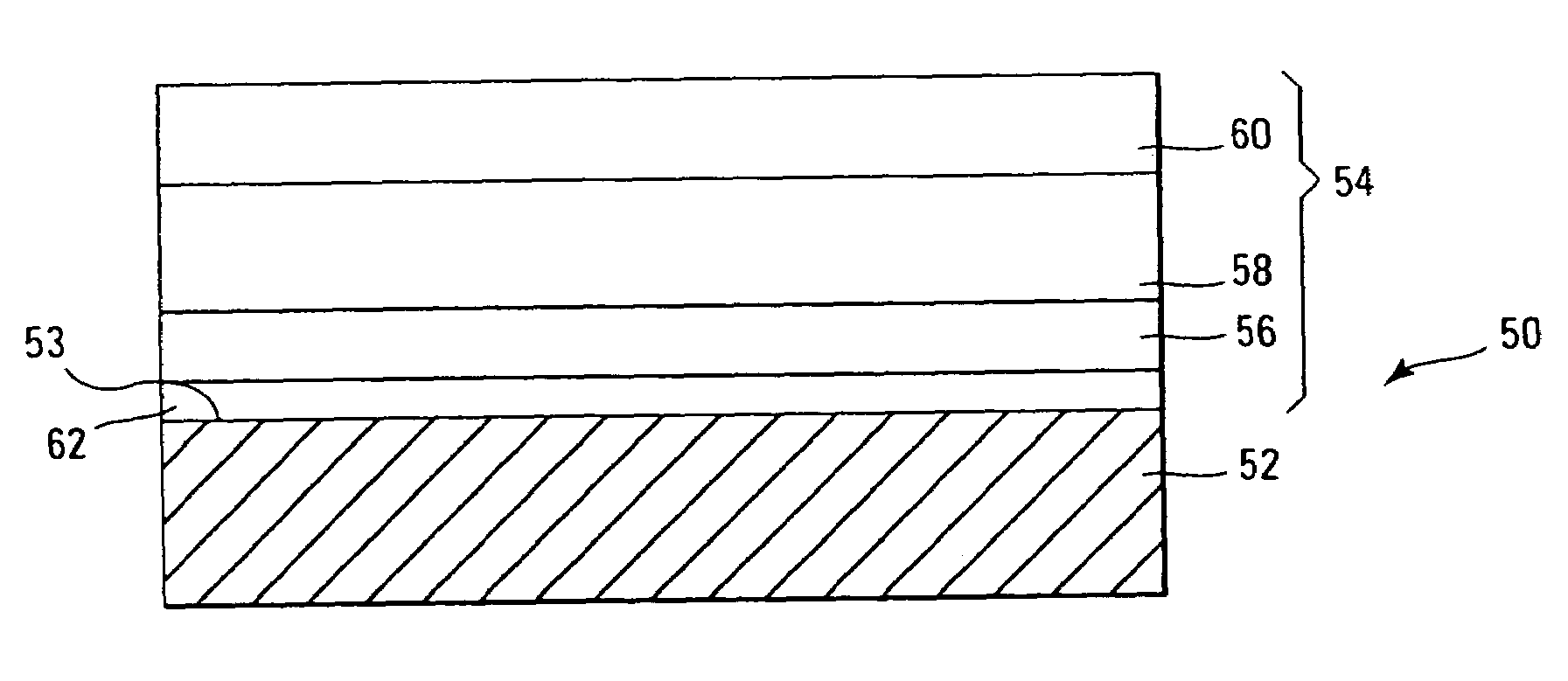

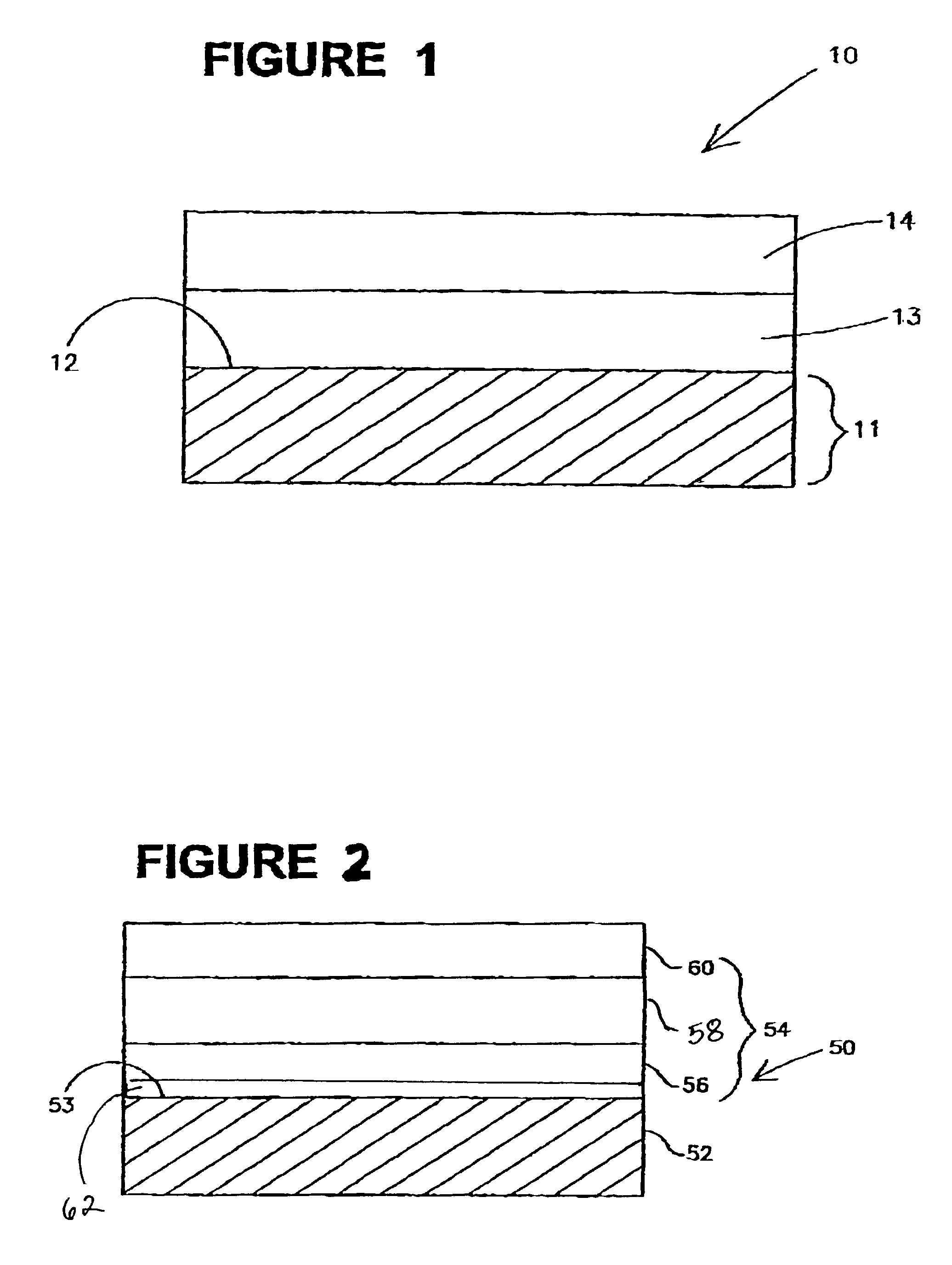

Ruthenium as an underlayer for tungsten film deposition

InactiveUS20060128150A1Semiconductor/solid-state device manufacturingSpecial surfacesRutheniumTitanium

In one embodiment, a method for depositing a tungsten-containing film on a substrate is provided which includes depositing a barrier layer on the substrate, such as a titanium or tantalum containing barrier layer and depositing a ruthenium layer on the barrier layer. The method further includes depositing a tungsten nucleation layer on the ruthenium layer and depositing a tungsten bulk layer on the tungsten nucleation layer. The barrier layer, the ruthenium layer, the tungsten nucleation layer and the tungsten bulk layer are independently deposited by an ALD process, a CVD process or a PVD process, preferably by an ALD process. In some examples, the substrate is exposed to a soak process prior to depositing a subsequent layer, such as between the deposition of the barrier layer and the ruthenium layer, the ruthenium layer and the tungsten nucleation layer or the tungsten nucleation layer and the tungsten bulk layer.

Owner:APPLIED MATERIALS INC

Earth-boring bits

InactiveUS20050211475A1Low melting pointLowered melting point of the binder facilitates proper infiltration of the massDrill bitsMetal-working drilling toolsBorideNiobium

The present invention relates to compositions and methods for forming a bit body for an earth-boring bit. The bit body may comprise hard particles, wherein the hard particles comprise at least one carbide, nitride, boride, and oxide and solid solutions thereof, and a binder binding together the hard particles. The binder may comprise at least one metal selected from cobalt, nickel, and iron, and at least one melting point reducing constituent selected from a transition metal carbide in the range of 30 to 60 weight percent, boron up to 10 weight percent, silicon up to 20 weight percent, chromium up to 20 weight percent, and manganese up to 25 weight percent, wherein the weight percentages are based on the total weight of the binder. In addition, the hard particles may comprise at least one of (i) cast carbide (WC+W2C) particles, (ii) transition metal carbide particles selected from the carbides of titanium, chromium, vanadium, zirconium, hafnium, tantalum, molybdenum, niobium, and tungsten, and (iii) sintered cemented carbide particles.

Owner:ATI PROPERTIES +1

Systems and methods of forming refractory metal nitride layers using disilazanes

InactiveUS7122464B2Reduce diffuseReduce layeringSemiconductor/solid-state device manufacturingCapacitorsGas phaseDeposition process

A method of forming (and apparatus for forming) refractory metal nitride layers (including silicon nitride layers), such as a tantalum (silicon) nitride barrier layer, on a substrate by using a vapor deposition process with a refractory metal precursor compound, a disilazane, and an optional silicon precursor compound.

Owner:MICRON TECH INC

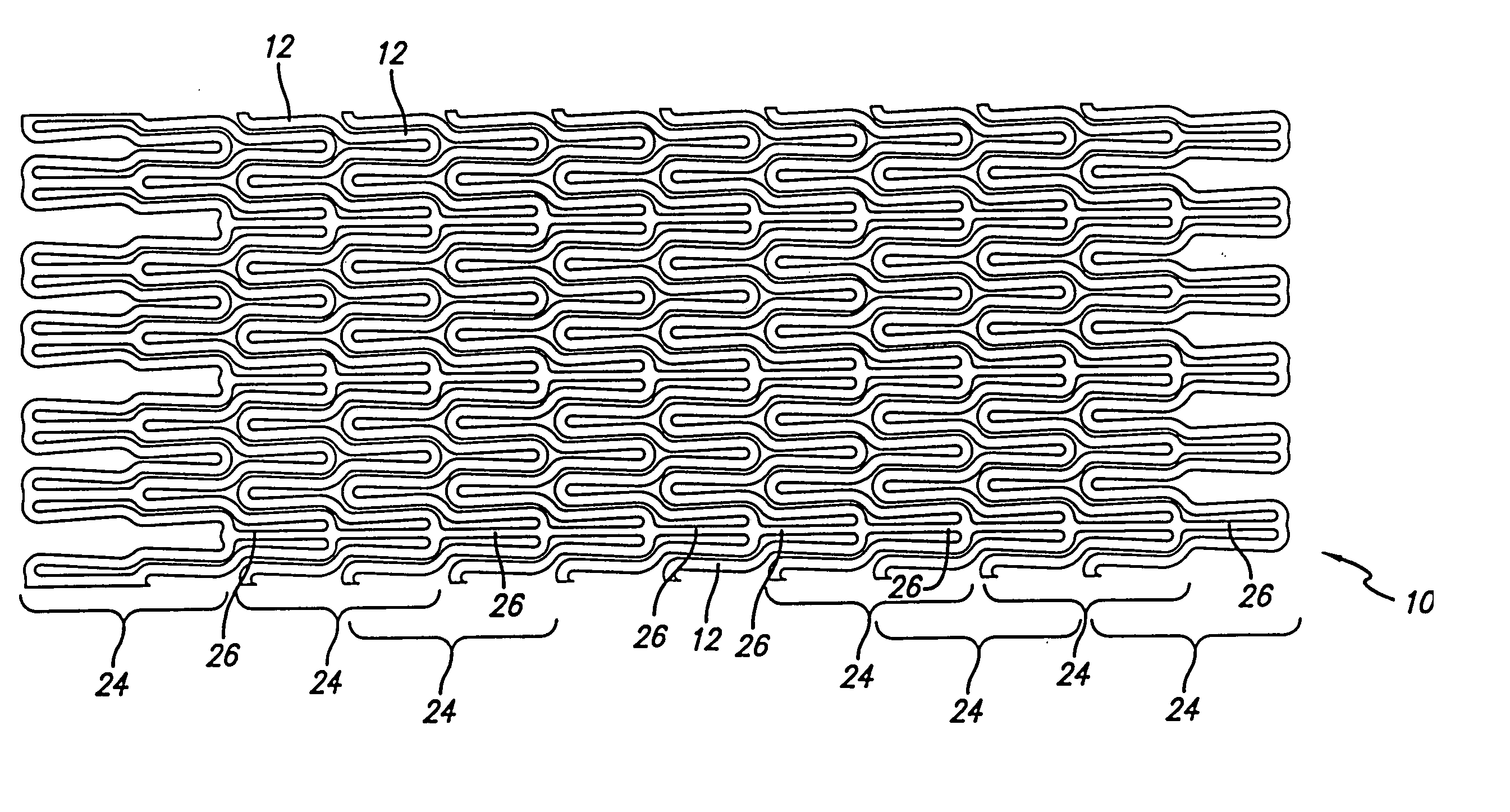

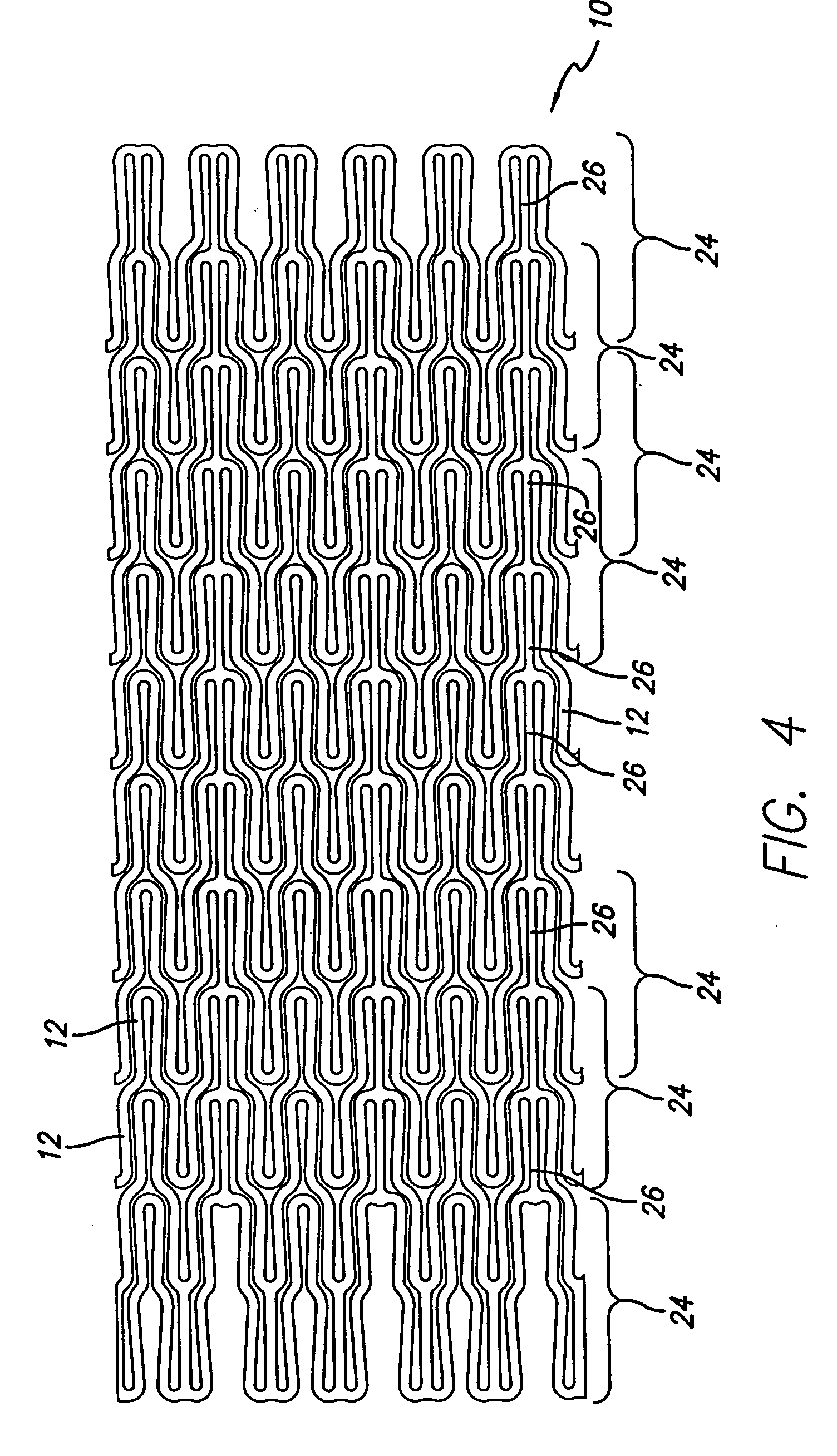

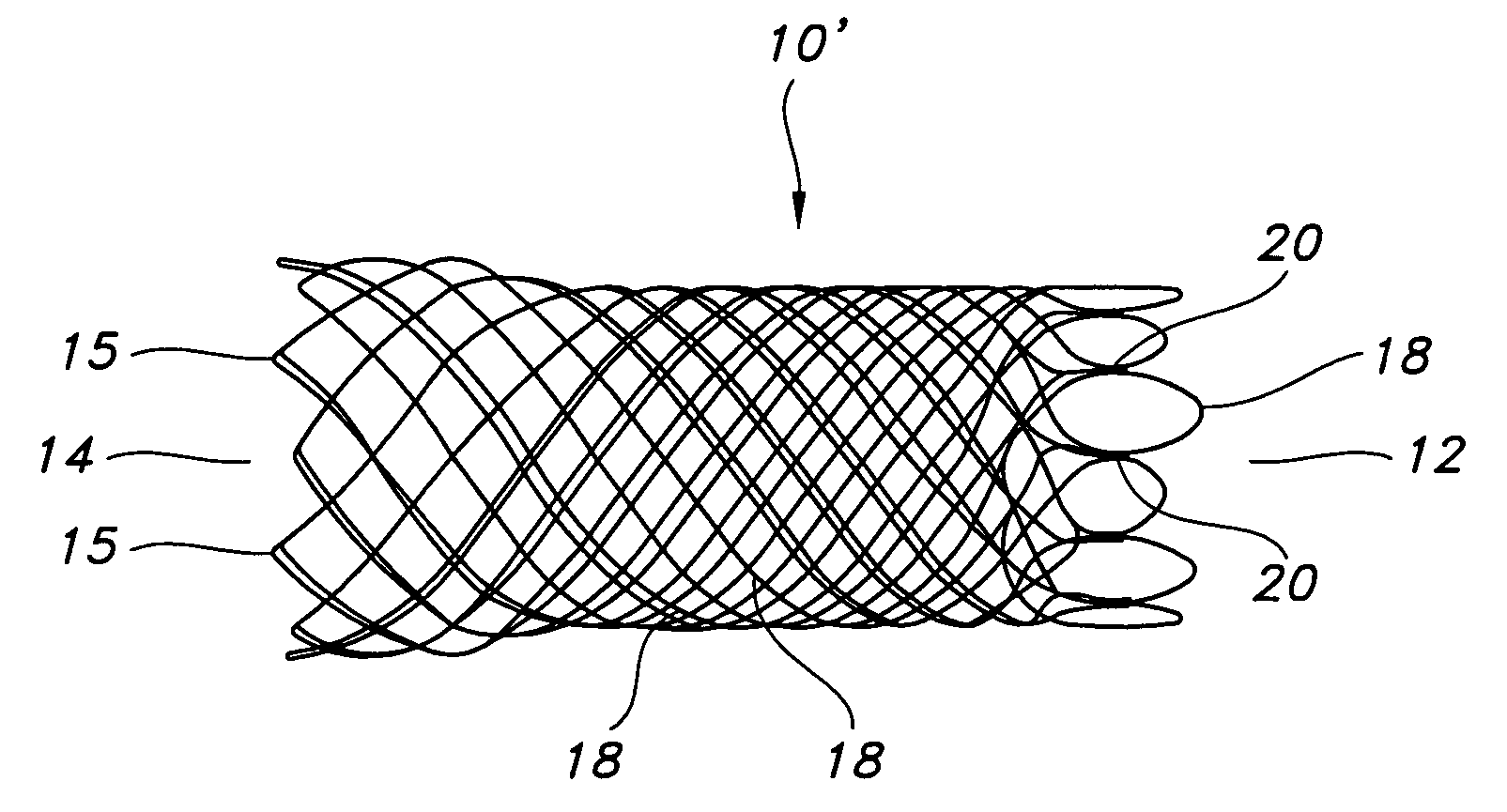

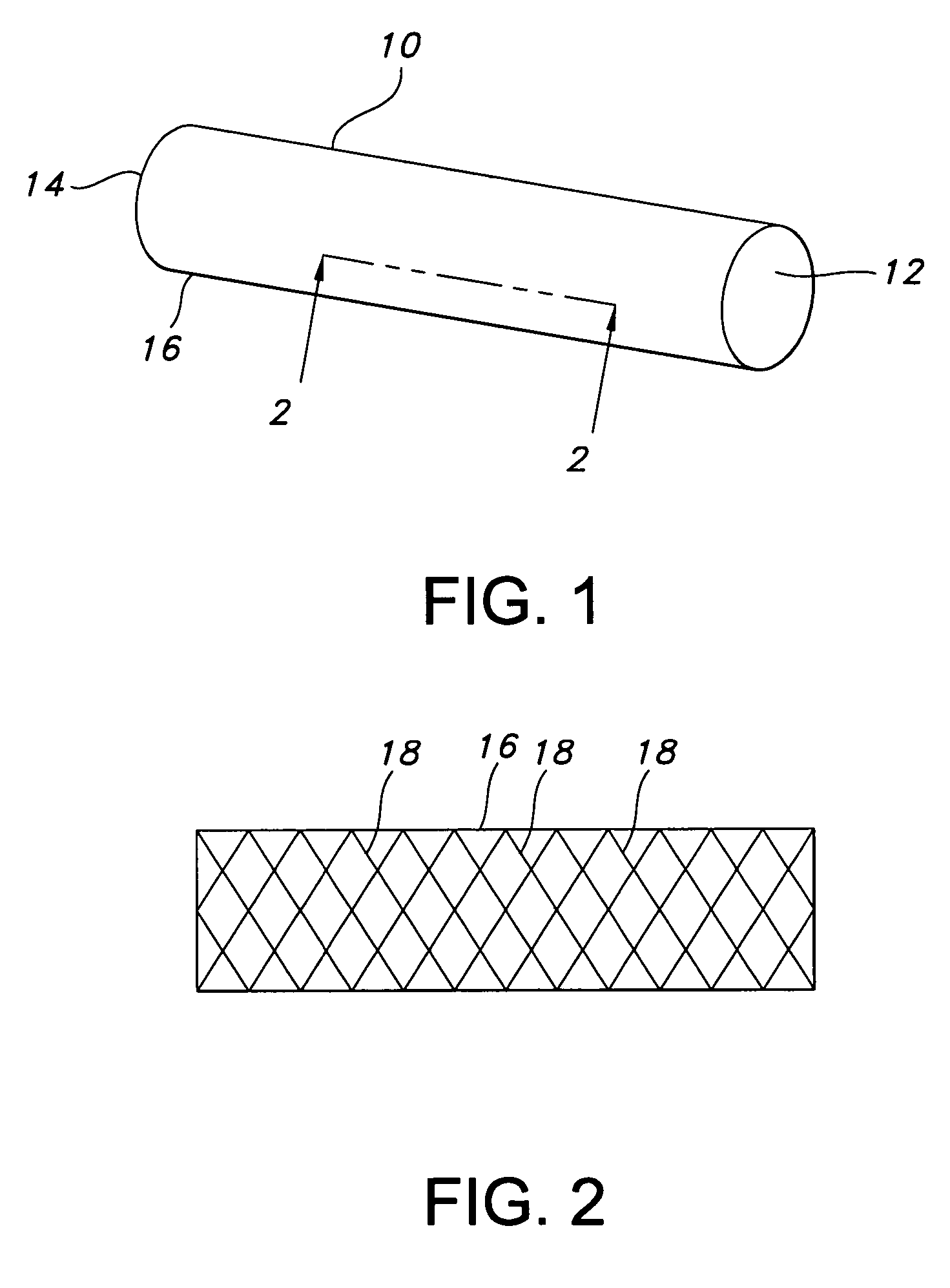

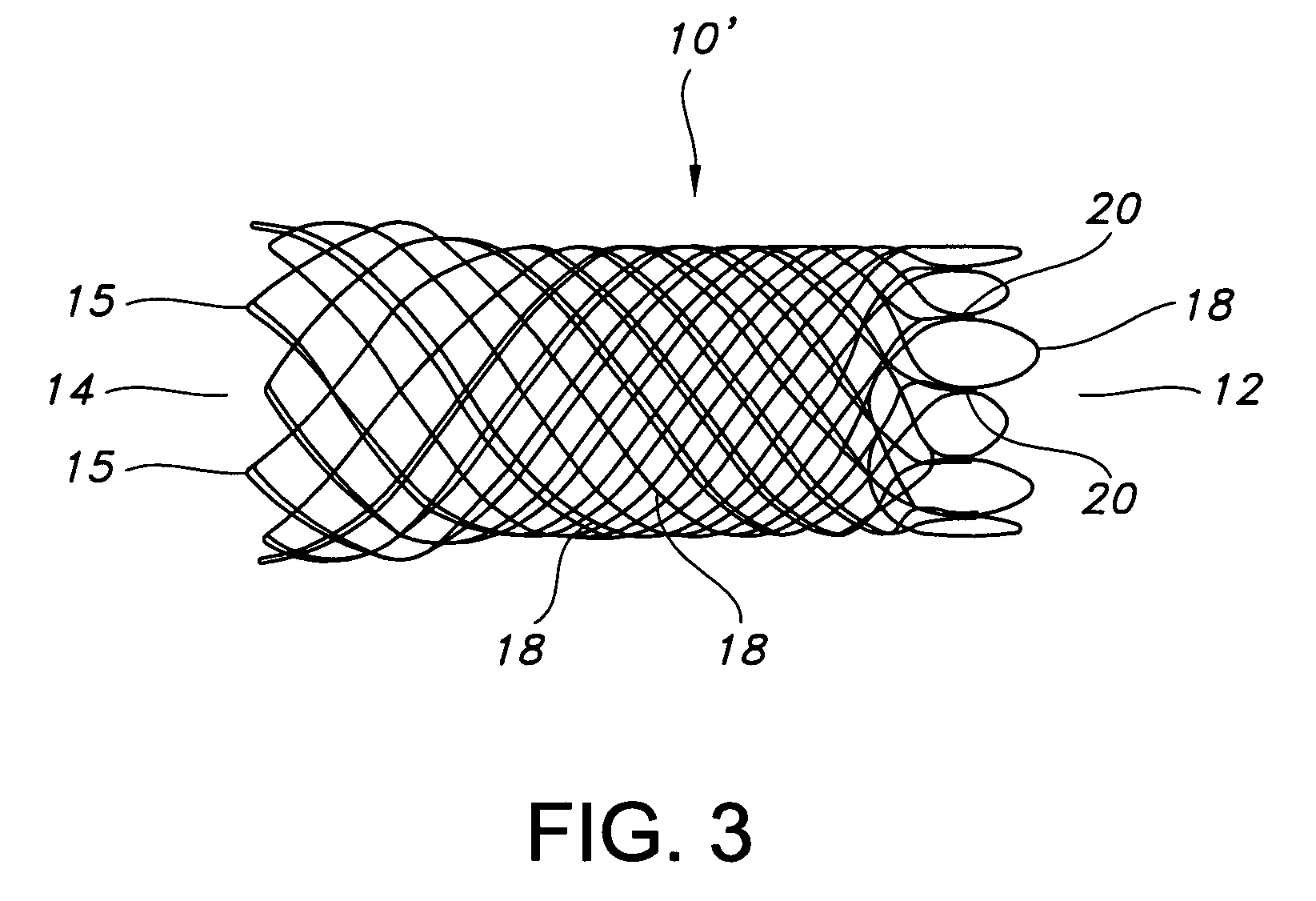

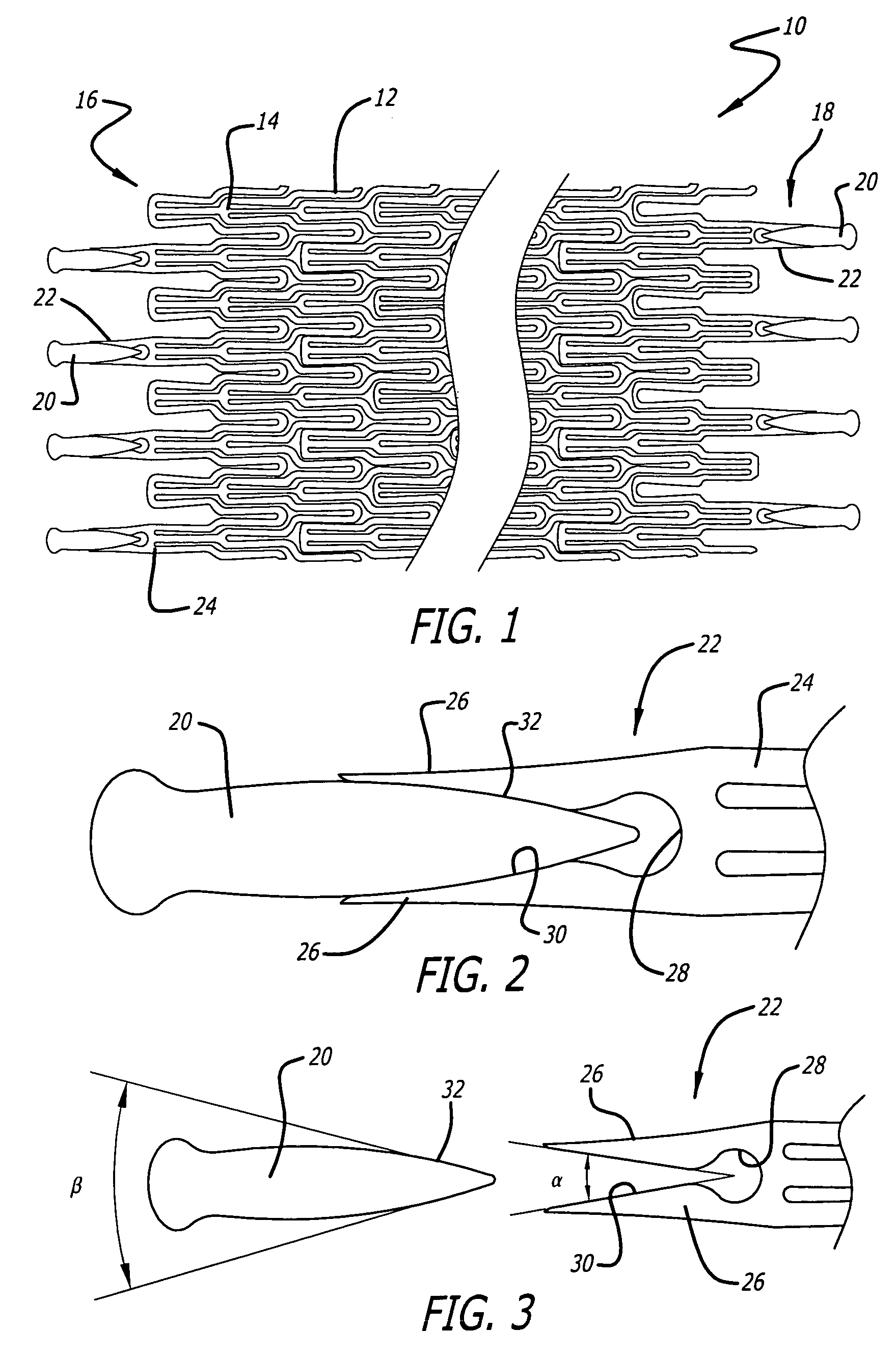

Atraumatic stent with reduced deployment force, method for making the same and method and apparatus for deploying and positioning the stent

An implantable stent includes a plurality of elongate wires braided to form a hollow tubular structure having a tubular wall to define an interior surface and an exterior surface and having opposed open first and second ends, wherein the opposed open first and second ends are atraumatic ends The atraumatic ends of the stent are desirably free of any loose wire ends. The wires include composite wires to enhance visibility of the wires to provide improved external imaging of the wires in the body. The elongate composite wires of the stent may be metallic wires having an outer metallic portion including a first metal, such as nitinol, and an inner metallic core portion including a second metal, which is a radiopaque material, such as gold, barium sulfate, ferritic particles, platinum, platinum-tungsten, palladium, platinum-iridium, rhodium, tantalum or combinations thereof.

Owner:BOSTON SCI SCIMED INC

High purity tantalum, products containing the same, and methods of making the same

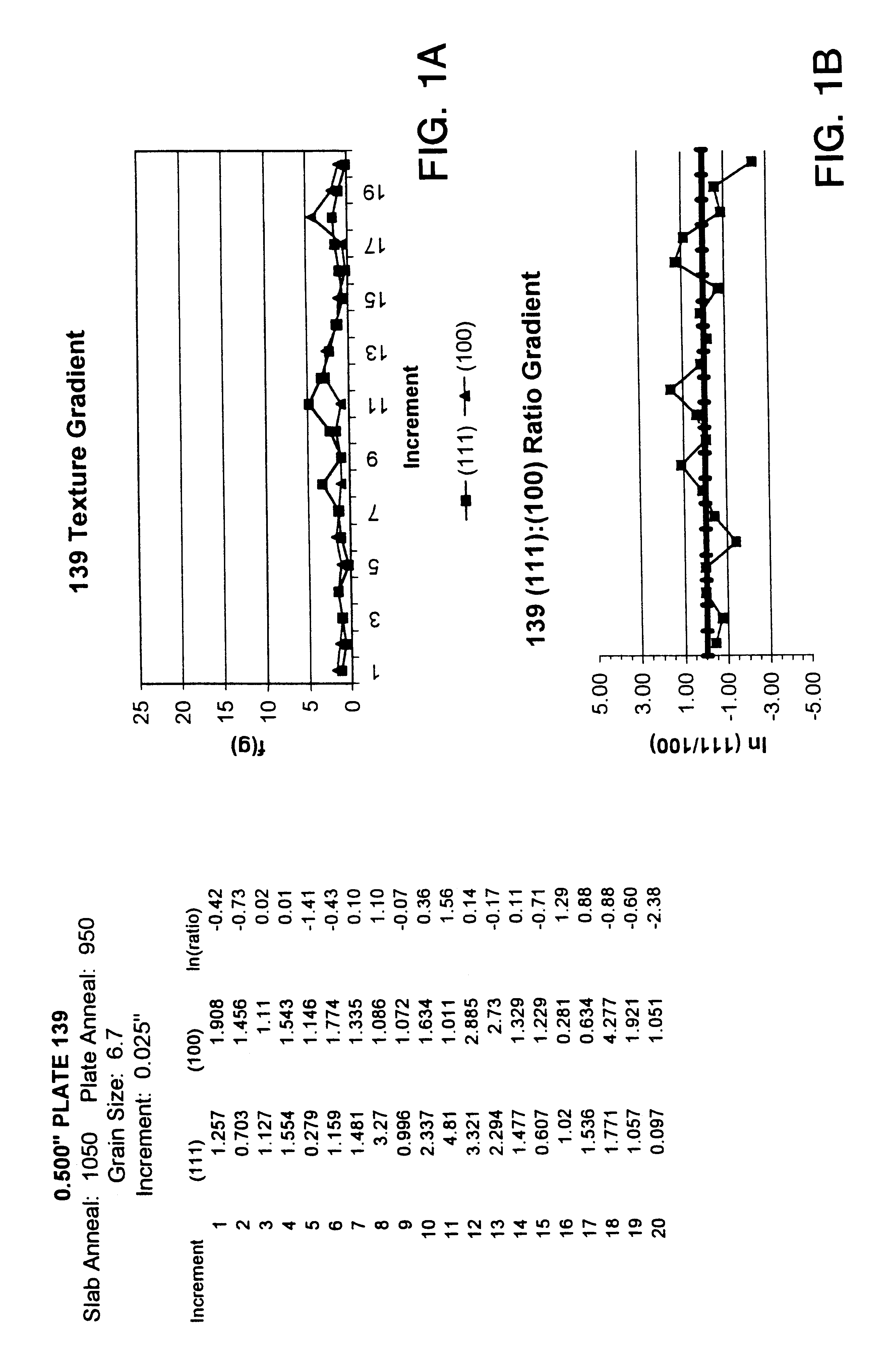

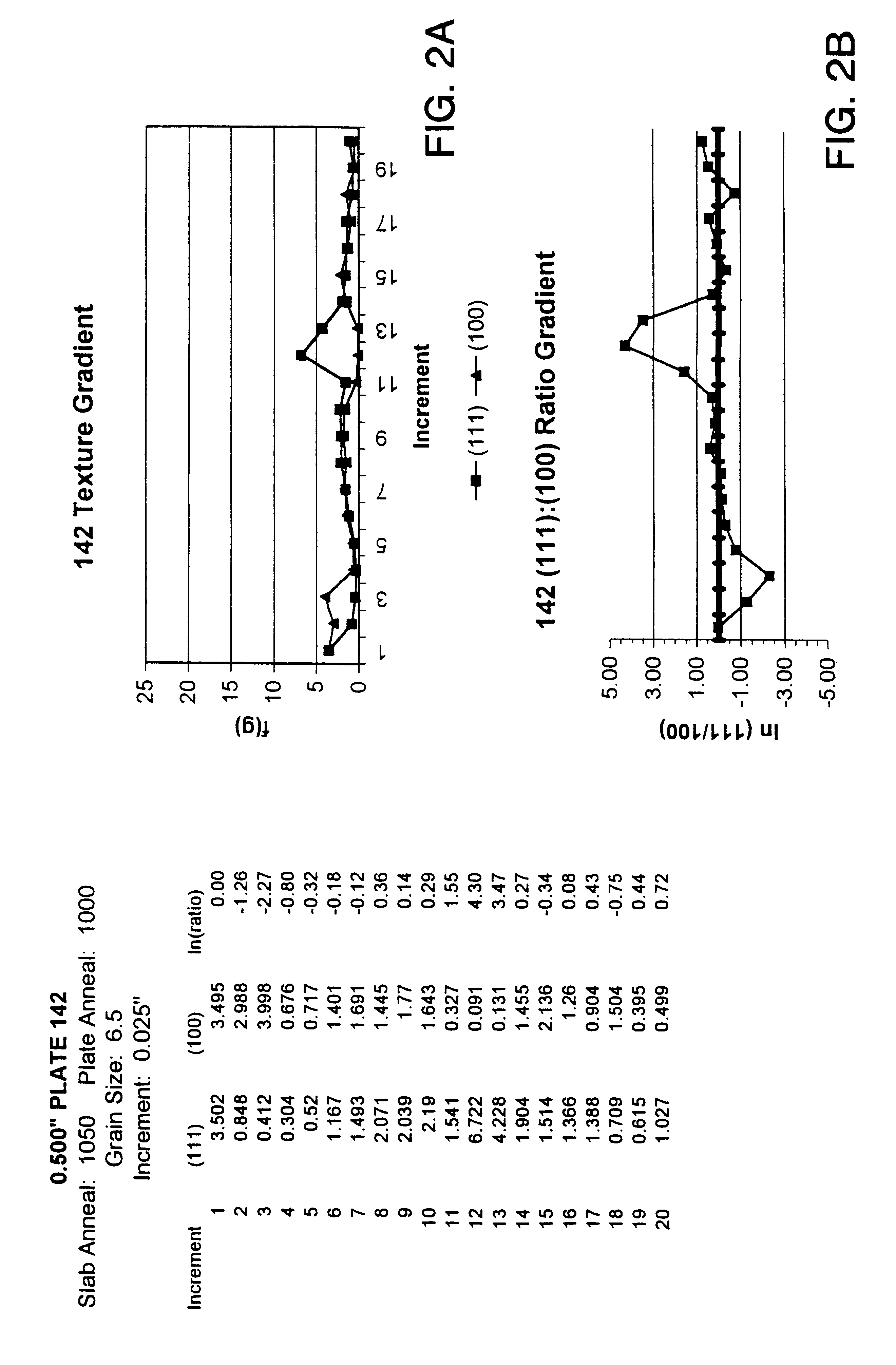

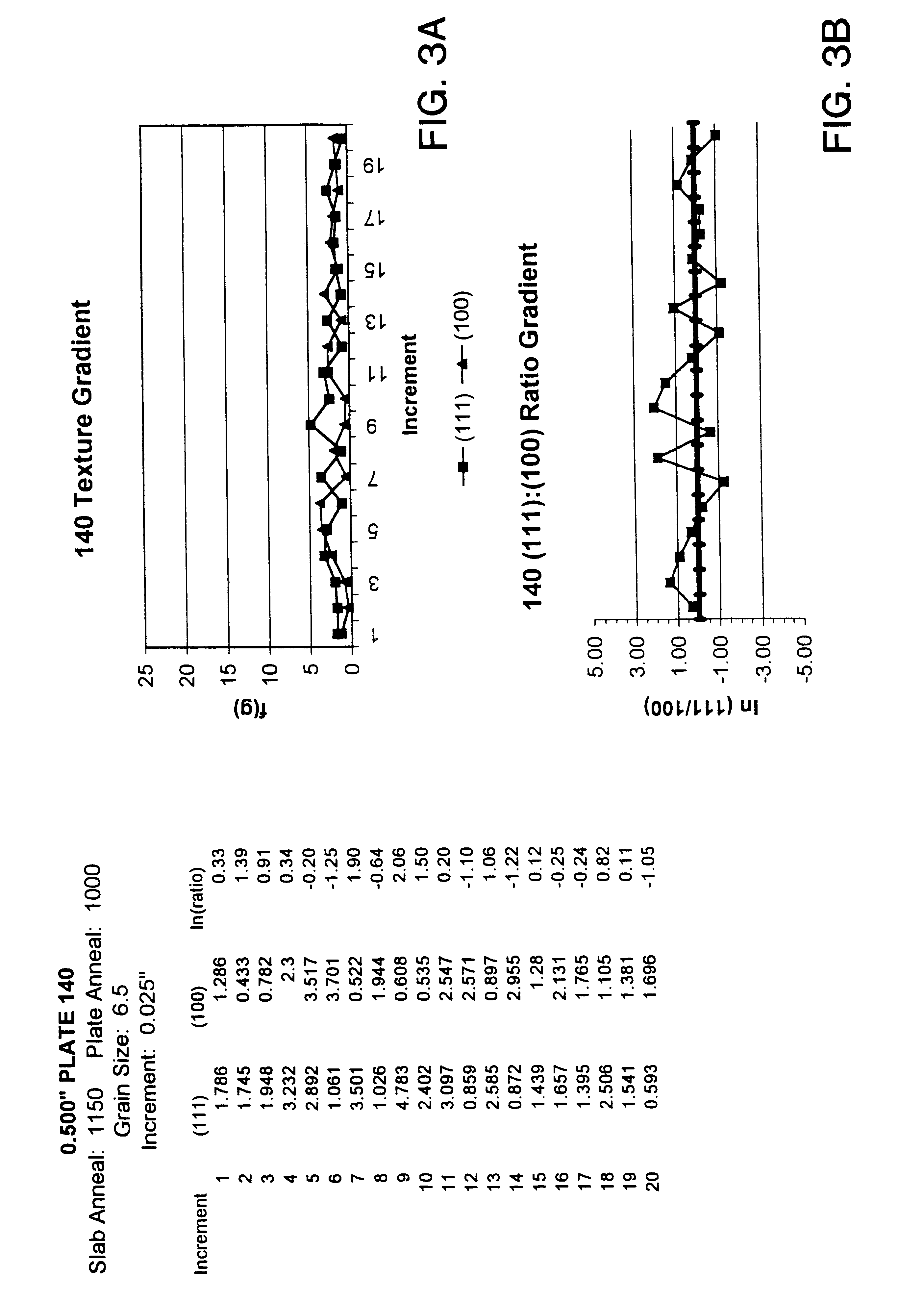

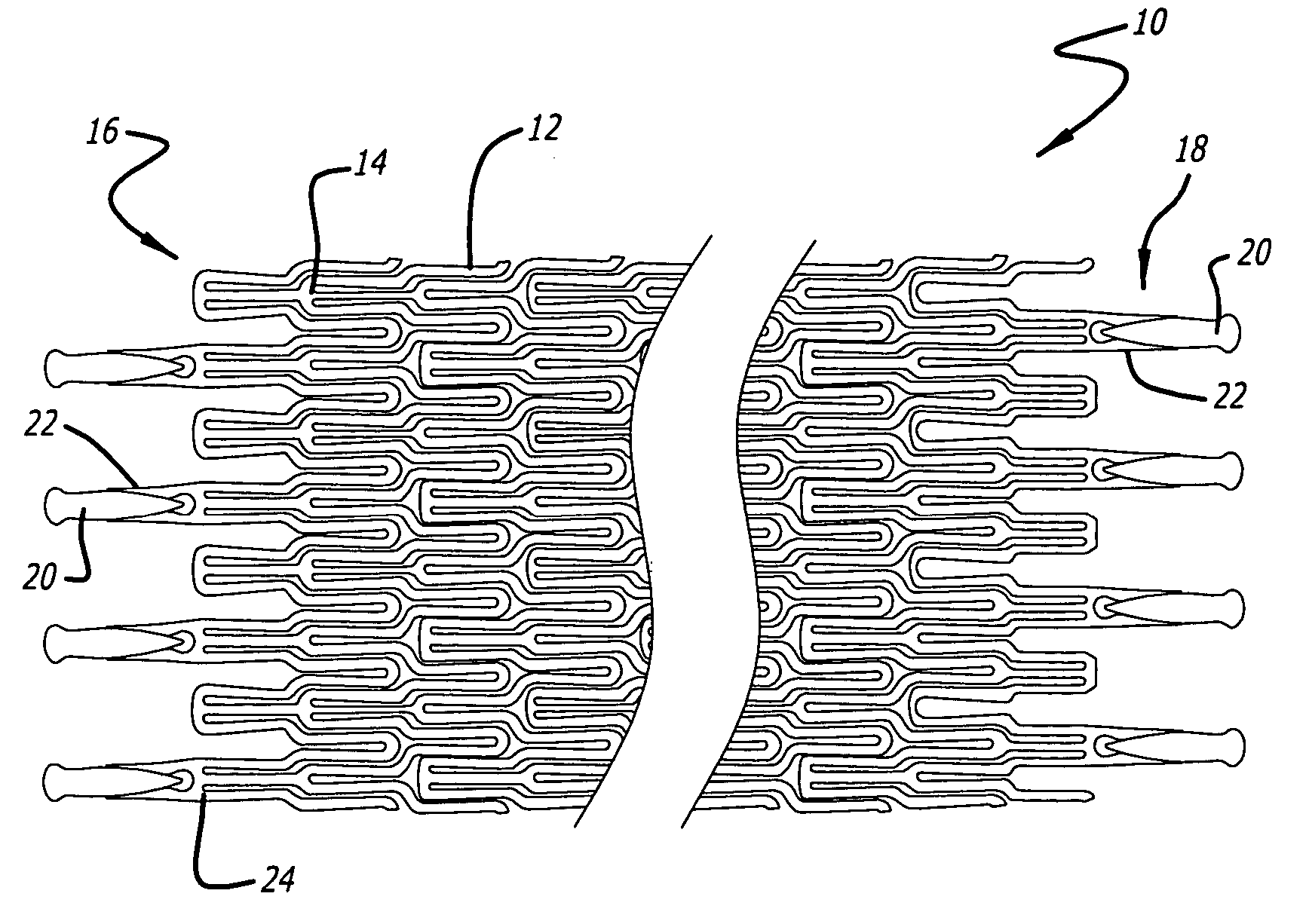

InactiveUS6348113B1Fine grain structureUniform textureVacuum evaporation coatingSputtering coatingMetallic materialsUltimate tensile strength

High purity tantalum metals and alloys containing the same are described. The tantalum metal preferably has a purity of at least 99.995% and more preferably at least 99.999%. In addition, tantalum metal and alloys thereof are described, which either have a grain size of about 50 microns or less, or a texture in which a (100) intensity within any 5% increment of thickness is less than about 15 random, or an incremental log ratio of (111):(100) intensity of greater than about -4.0, or any combination of these properties. Also described are articles and components made from the tantalum metal which include, but are not limited to, sputtering targets, capacitor cans, resistive film layers, wire, and the like. Also disclosed is a process for making the high purity metal which includes the step of reacting a salt-containing tantalum with at least one compound capable of reducing this salt to tantalum powder and a second salt in a reaction container. The reaction container or liner in the reaction container and the agitator or liner on the agitator are made from a metal material having the same or higher vapor pressure of melted tantalum. The high purity tantalum preferably has a fine and uniform microstructure.

Owner:GLOBAL ADVANCED METALS USA

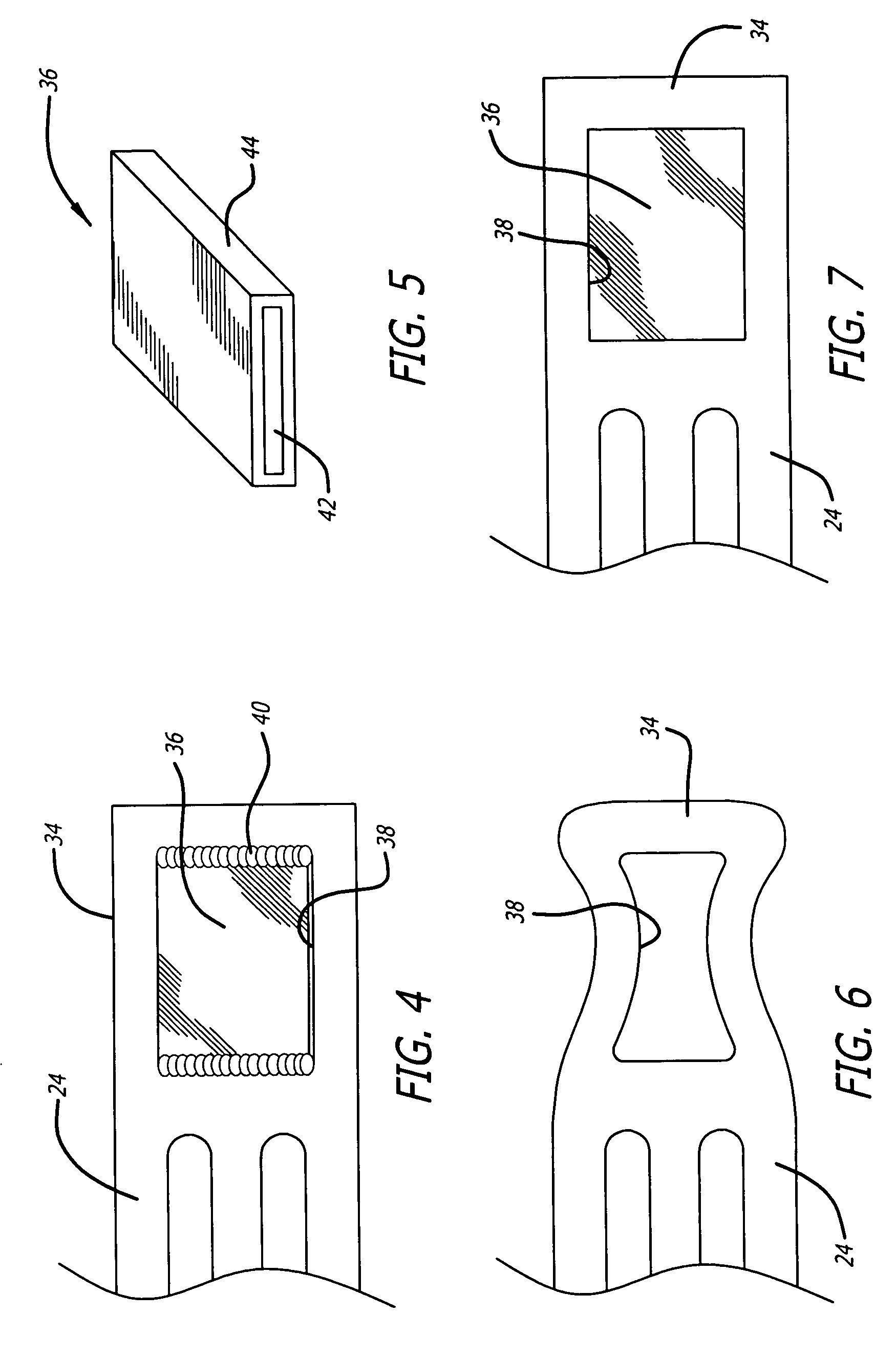

Radiopaque markers for medical devices

InactiveUS20050060025A1High level of radiopacitySufficient radiopacityStentsBlood vesselsIridiumRhenium

An implantable medical device includes a structural body made from a superelastic material and includes one or more marker holders integrally formed on the structural body. Each marker holder is designed to hold a radiopaque marker which has a level of radiopacity greater than the superelastic material. The radiopaque marker can be made from a nickel-titanium alloy which includes a ternary element. The ternary element can be selected from the group of elements consisting of iridium, platinum, gold, rhenium, tungsten, palladium, rhodium, tantalum, silver, ruthenium, and hafnium. In one form, the marker holder includes a pair of projecting fingers connected together at a notched region to cooperatively create a particular-shaped opening. This opening, in turn, is adapted to receive a similarly shaped portion formed on the radiopaque marker. In one form, the radiopaque marker includes an inner core which is partially, or completely, encased by an outer layer. This inner core can be made from a highly radiopaque material while the outer layer is formed from a material that is easier to weld to the marker.

Owner:ABBOTT VASCULAR SOLUTIONS

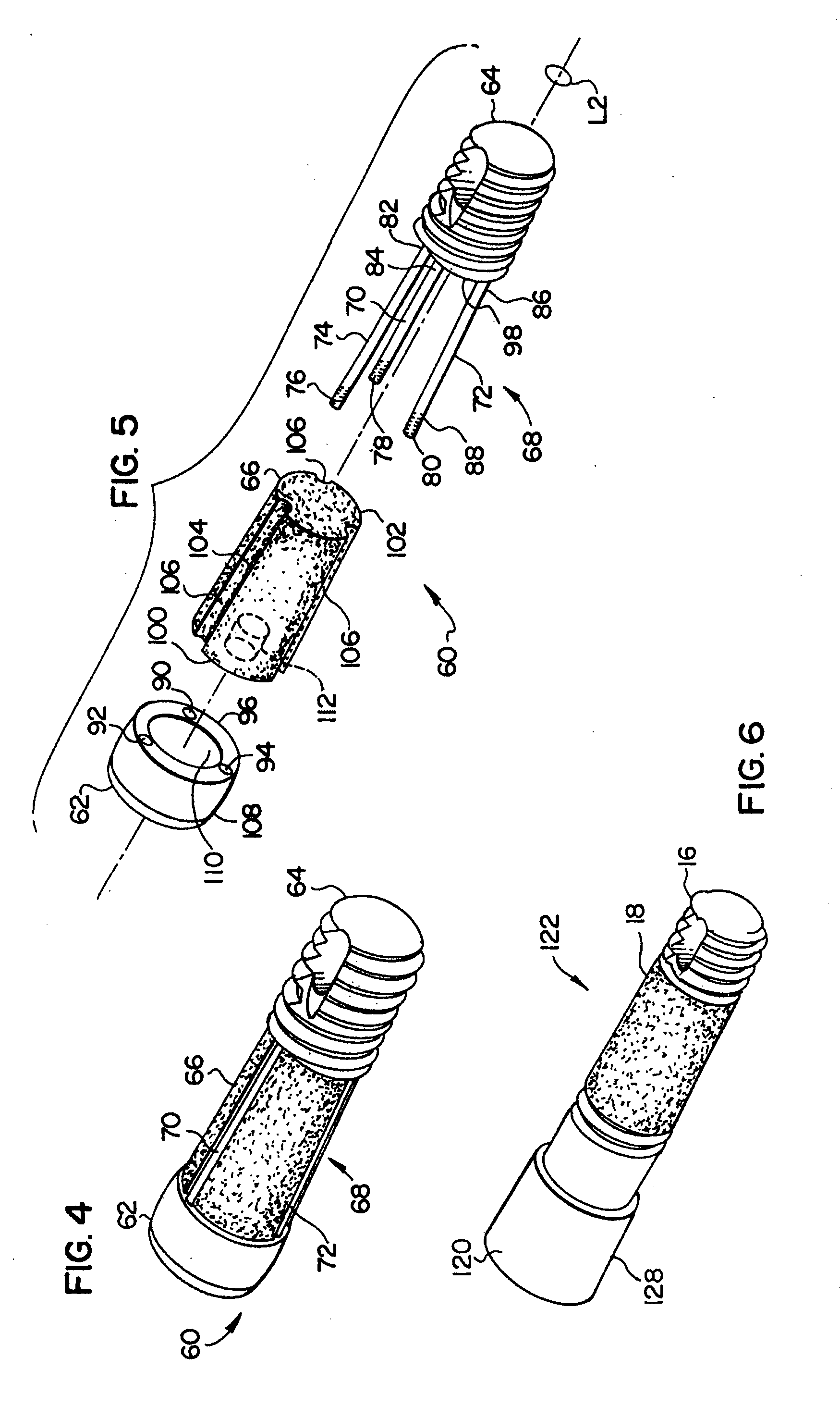

Modular implant with secured porous portion

A modular implant includes a head, an intermediate part configured to engage bone, and an initially separate anchor configured to engage the head so that at least the head and the anchor cooperatively secure the intermediate part on the implant to form the modular implant. At least one of the head, the intermediate part, and the anchor has a plurality of forms, and each form is configured to be assembled on at least one form of the other two of the head, intermediate part, and anchor. The intermediate part may include a porous metal such as tantalum.

Owner:ZIMMER DENTAL INC

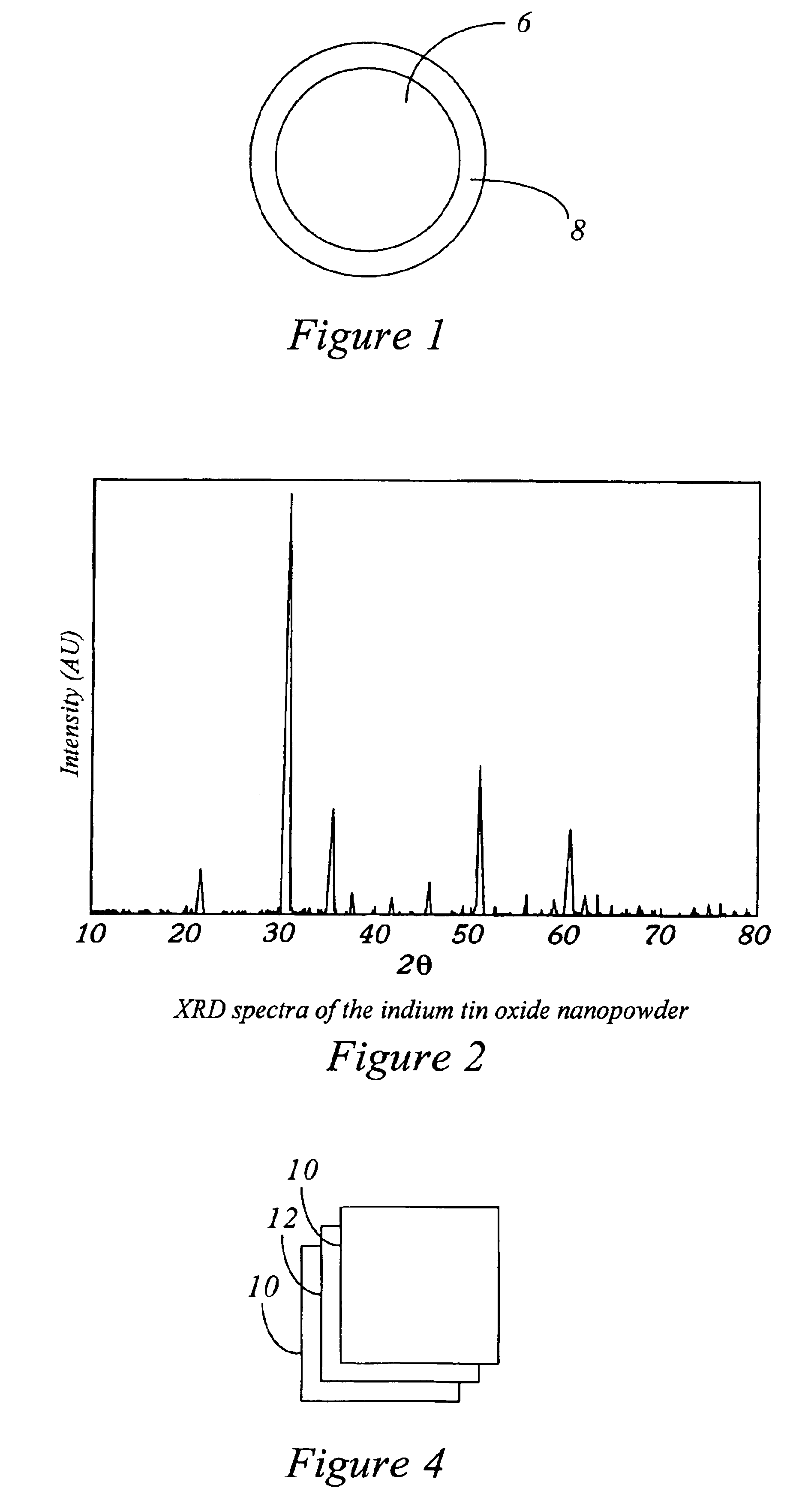

Polymer nanocomposite implants with enhanced transparency and mechanical properties for administration within humans or animals

Polymer nanocomposite implants with nanofillers and additives are described. The nanofillers described can be any composition with the preferred composition being those composing barium, bismuth, cerium, dysprosium, europium, gadolinium, hafnium, indium, lanthanum, neodymium, niobium, praseodymium, strontium, tantalum, tin, tungsten, ytterbium, yttrium, zinc, and zirconium. The additives can be of any composition with the preferred form being inorganic nanopowders comprising aluminum, calcium, gallium, iron, lithium, magnesium, silicon, sodium, strontium, titanium. Such nanocomposites are particularly useful as materials for biological use in applications such as drug delivery, biomed devices, bone or dental implants.

Owner:PPG IND OHIO INC

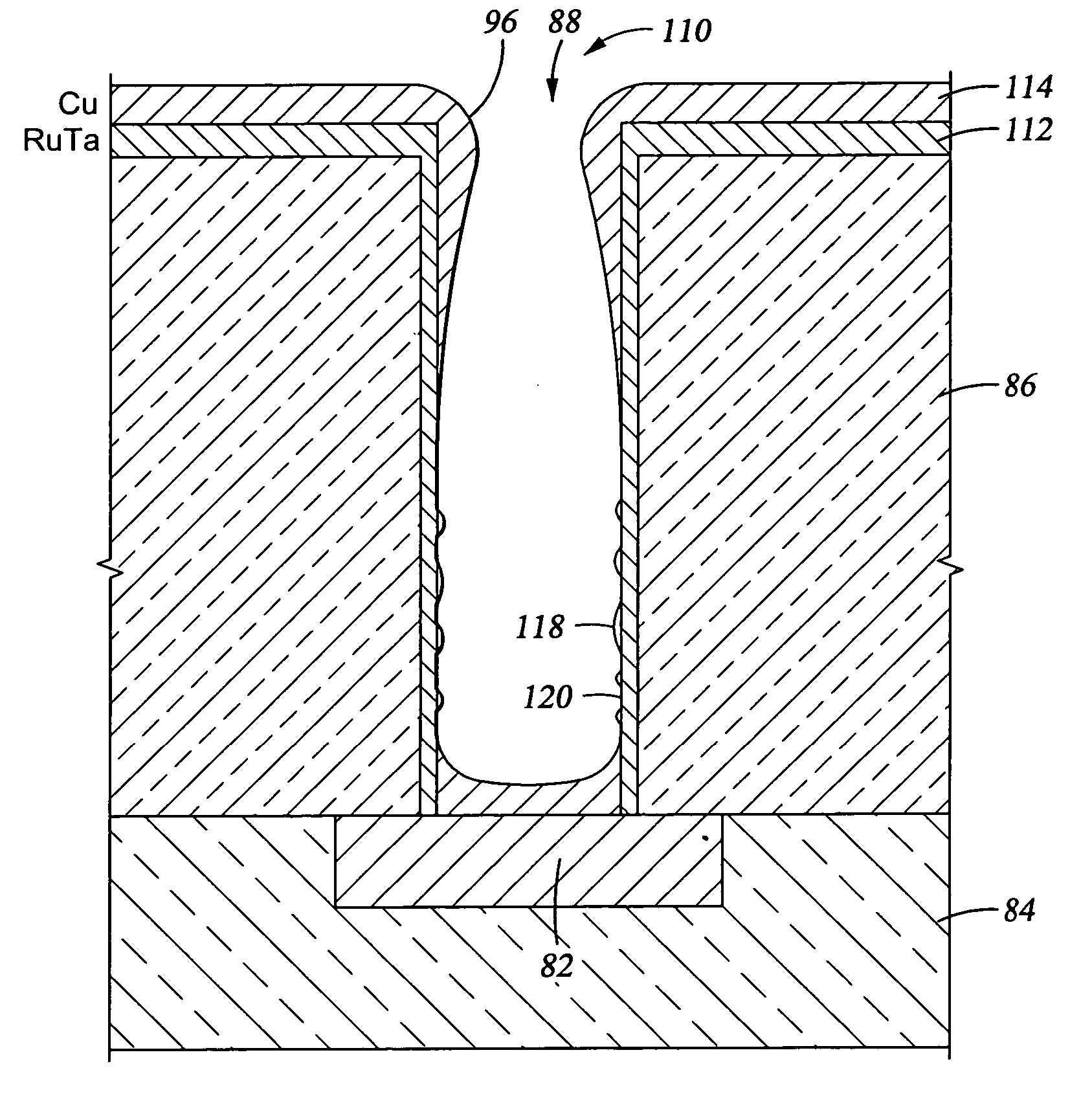

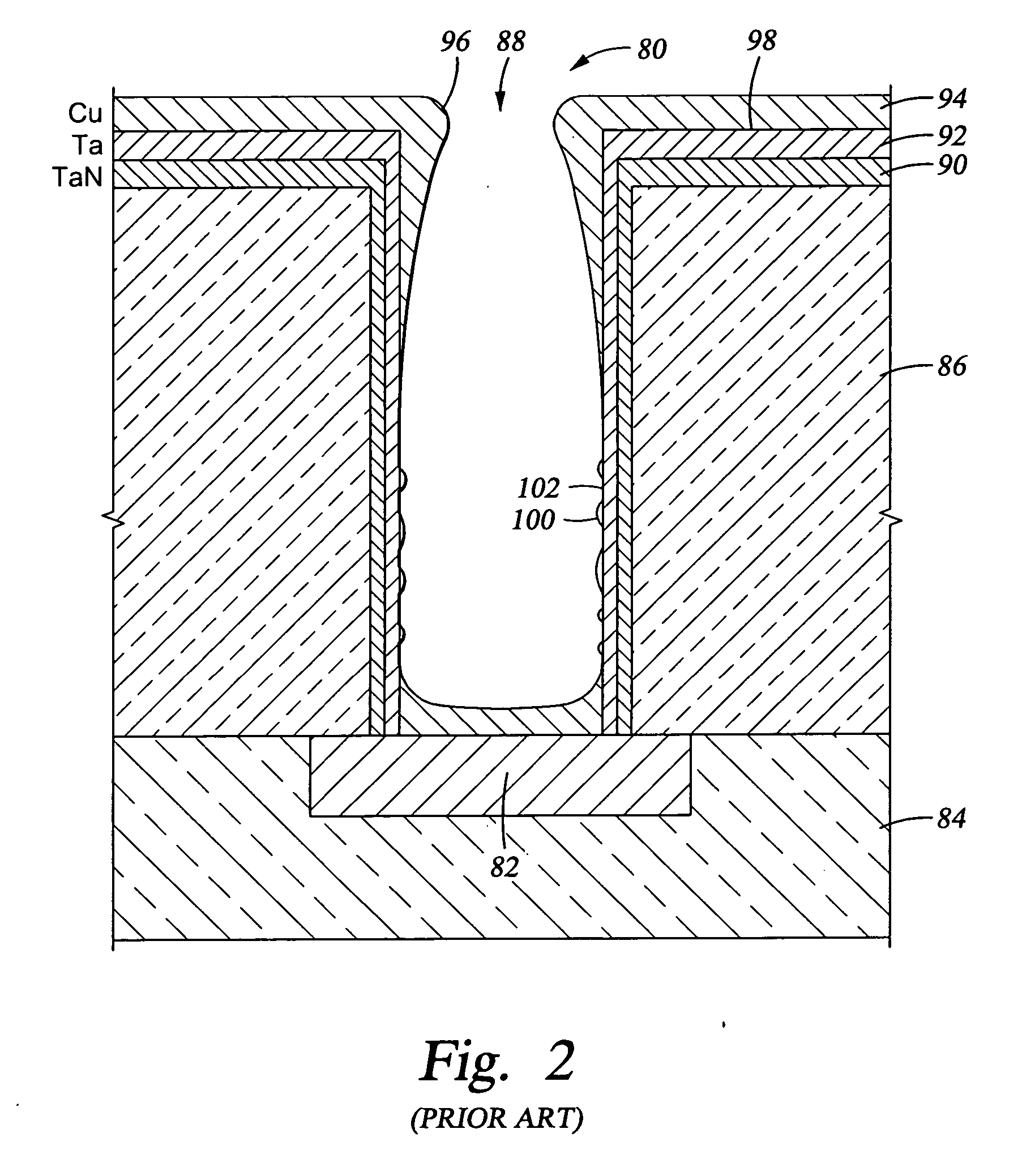

Integrated process for sputter deposition of a conductive barrier layer, especially an alloy of ruthenium and tantalum, underlying copper or copper alloy seed layer

InactiveUS20070059502A1Effective interfacial barrierGood suitSemiconductor/solid-state device detailsVacuum evaporation coatingMoisture barrierRefractory metals

A fabrication method and a product for the deposition of a conductive barrier or other liner layer in a vertical electrical interconnect structure. One embodiment includes within a a hole through a dielectric layer a barrier layer of RuTaN, an adhesion layer of RuTa, and a copper seed layer forming a liner for electroplating of copper. The ruthenium content is preferably greater than 50 at % and more preferably at least 80 at % but less than 95 at %. The barrier and adhesion layers may both be sputter deposited. Other platinum-group elements substitute for the ruthenium and other refractory metals substitute for the tantalum. Aluminum alloying into RuTa when annealed presents a moisture barrier. Copper contacts include different alloying fractions of RuTa to shift the work function to the doping type.

Owner:APPLIED MATERIALS INC

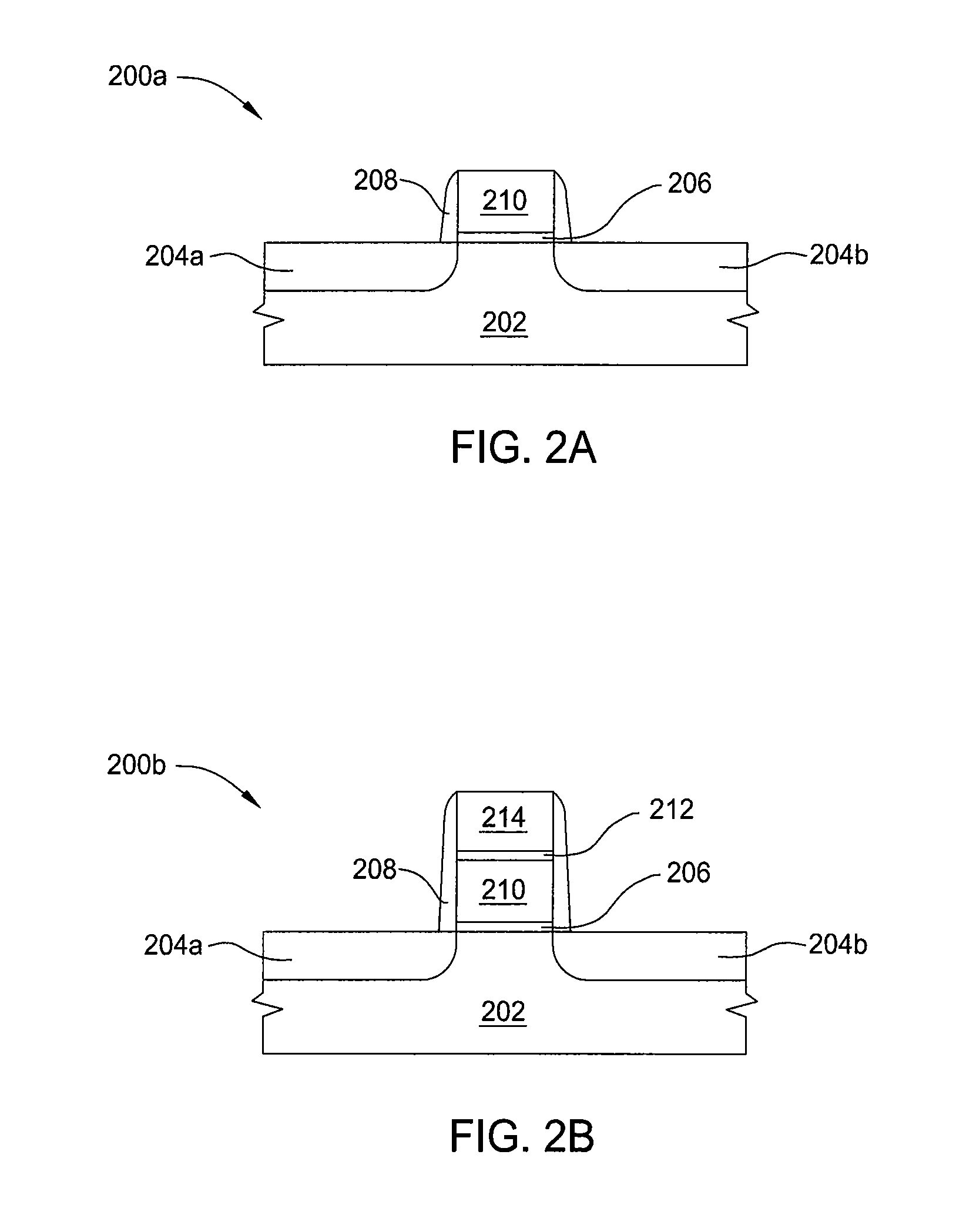

Systems and methods for forming tantalum silicide layers

InactiveUS6995081B2Easy to controlMinimizing detrimental gas phase reactionSemiconductor/solid-state device manufacturingCapacitorsGas phaseNitrogen

A method of forming (and apparatus for forming) tantalum suicide layers (including tantalum silicon nitride layers), which are typically useful as diffusion barrier layers, on a substrate by using a vapor deposition process with a tantalum halide precursor compound, a silicon precursor compound, and an optional nitrogen precursor compound.

Owner:MICRON TECH INC

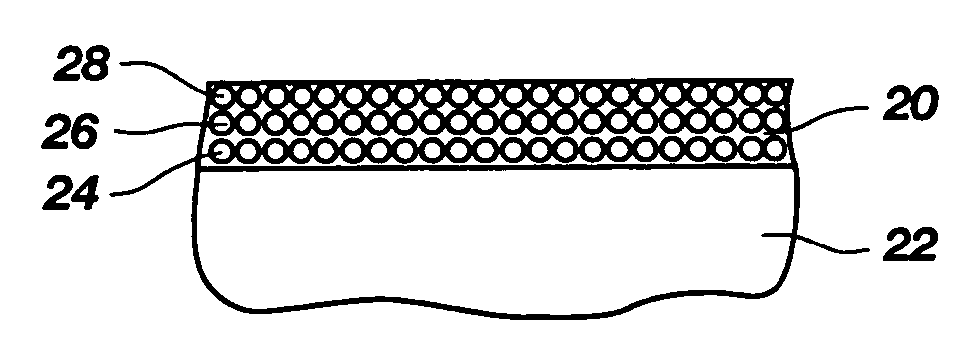

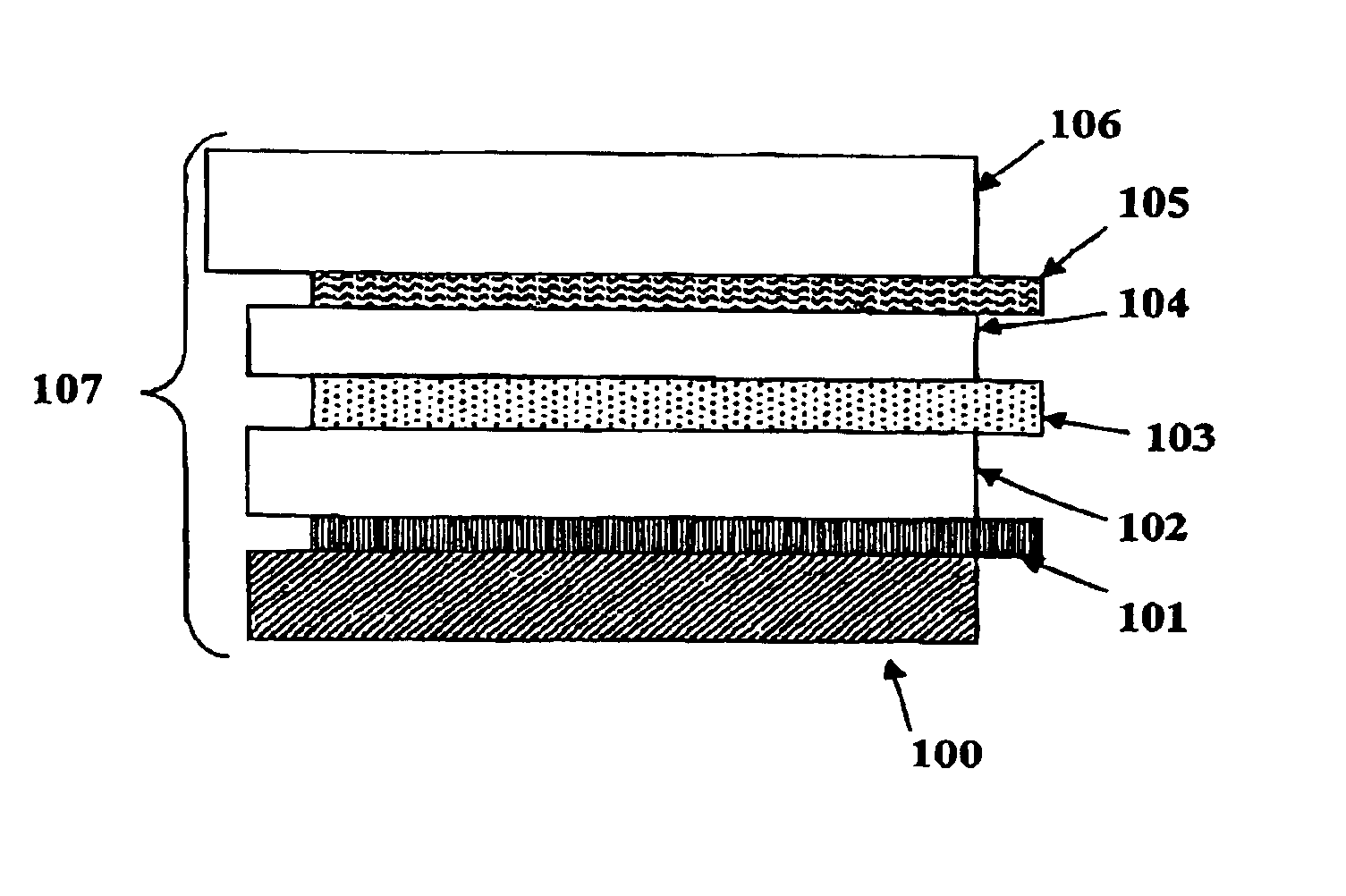

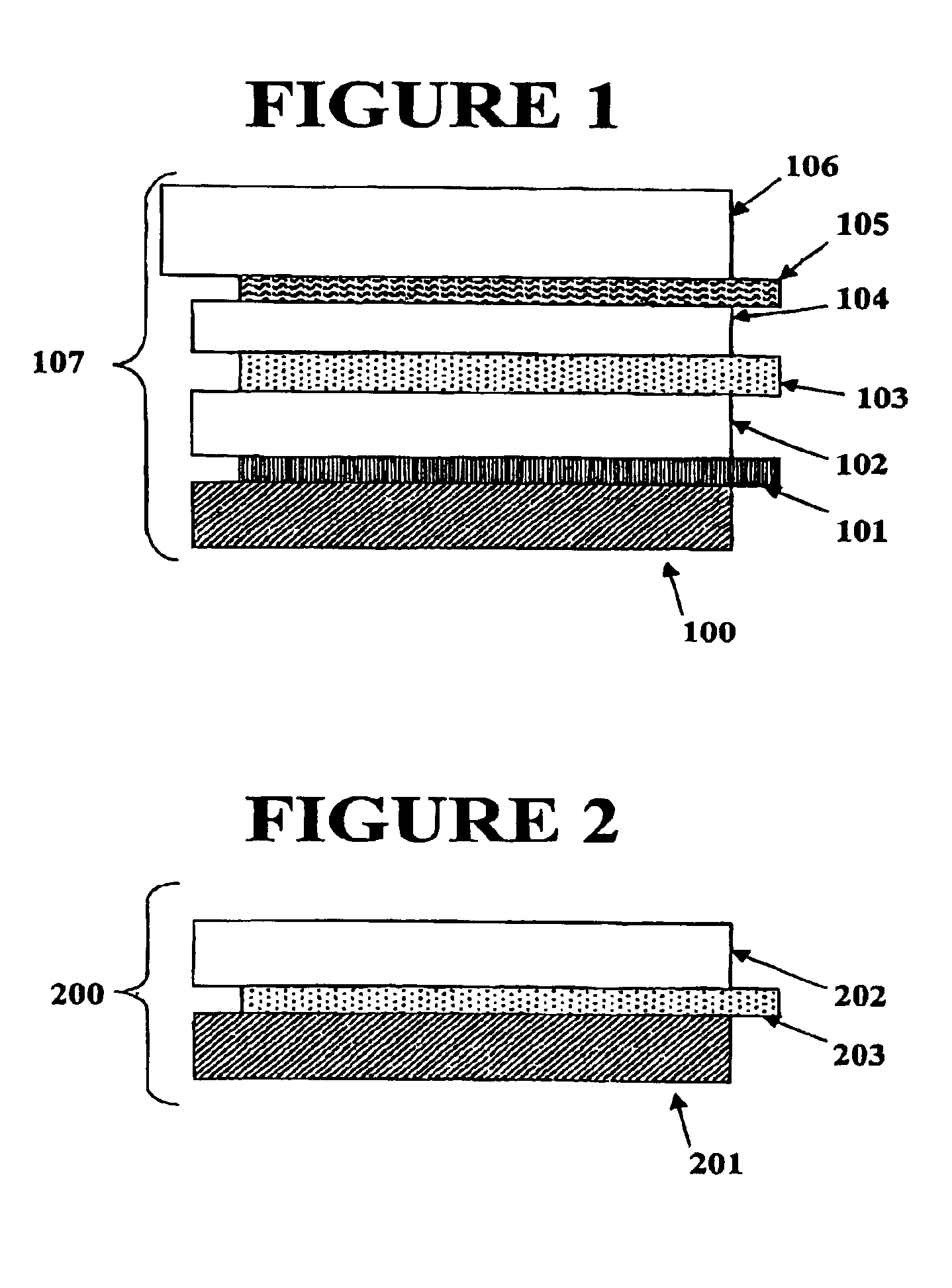

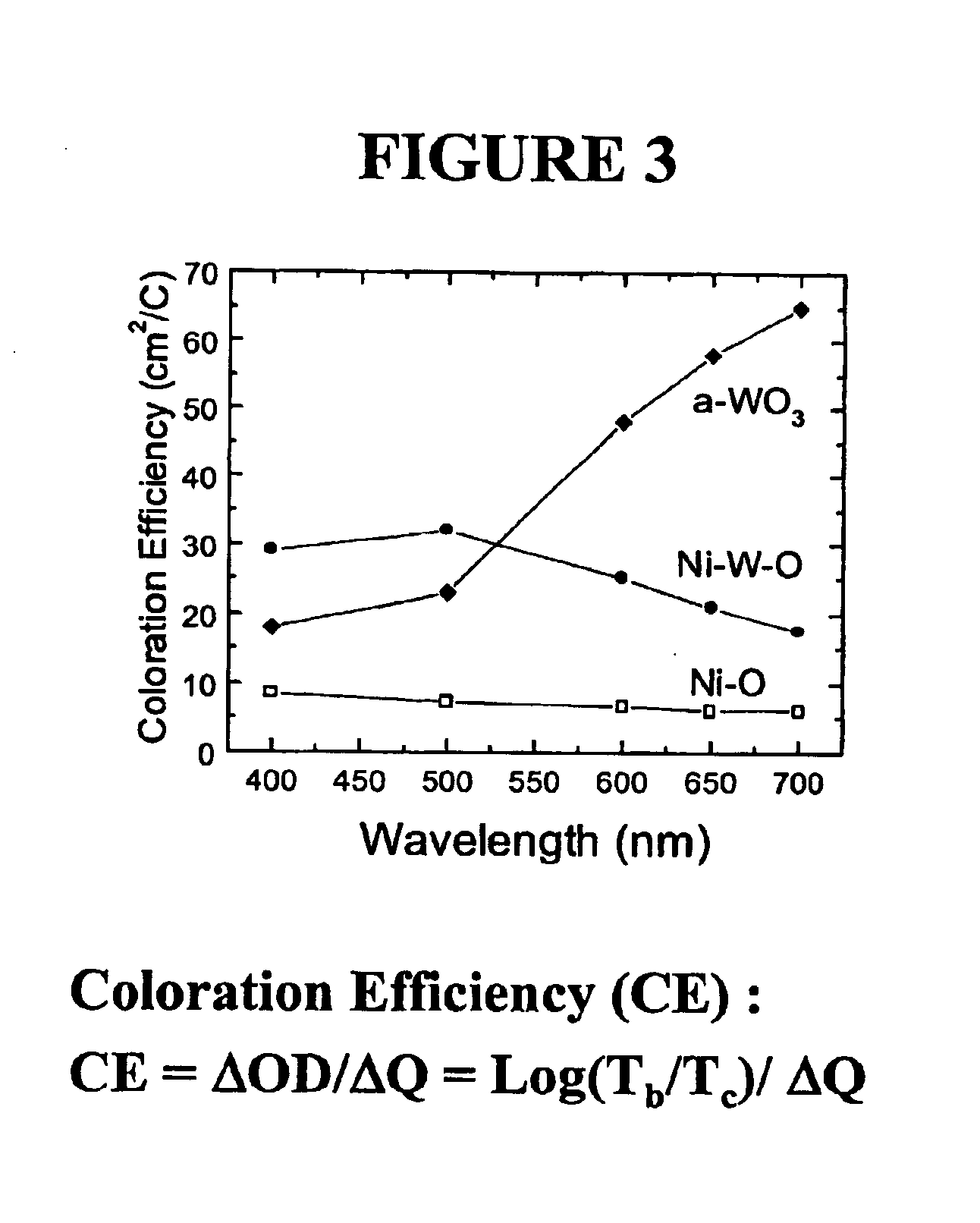

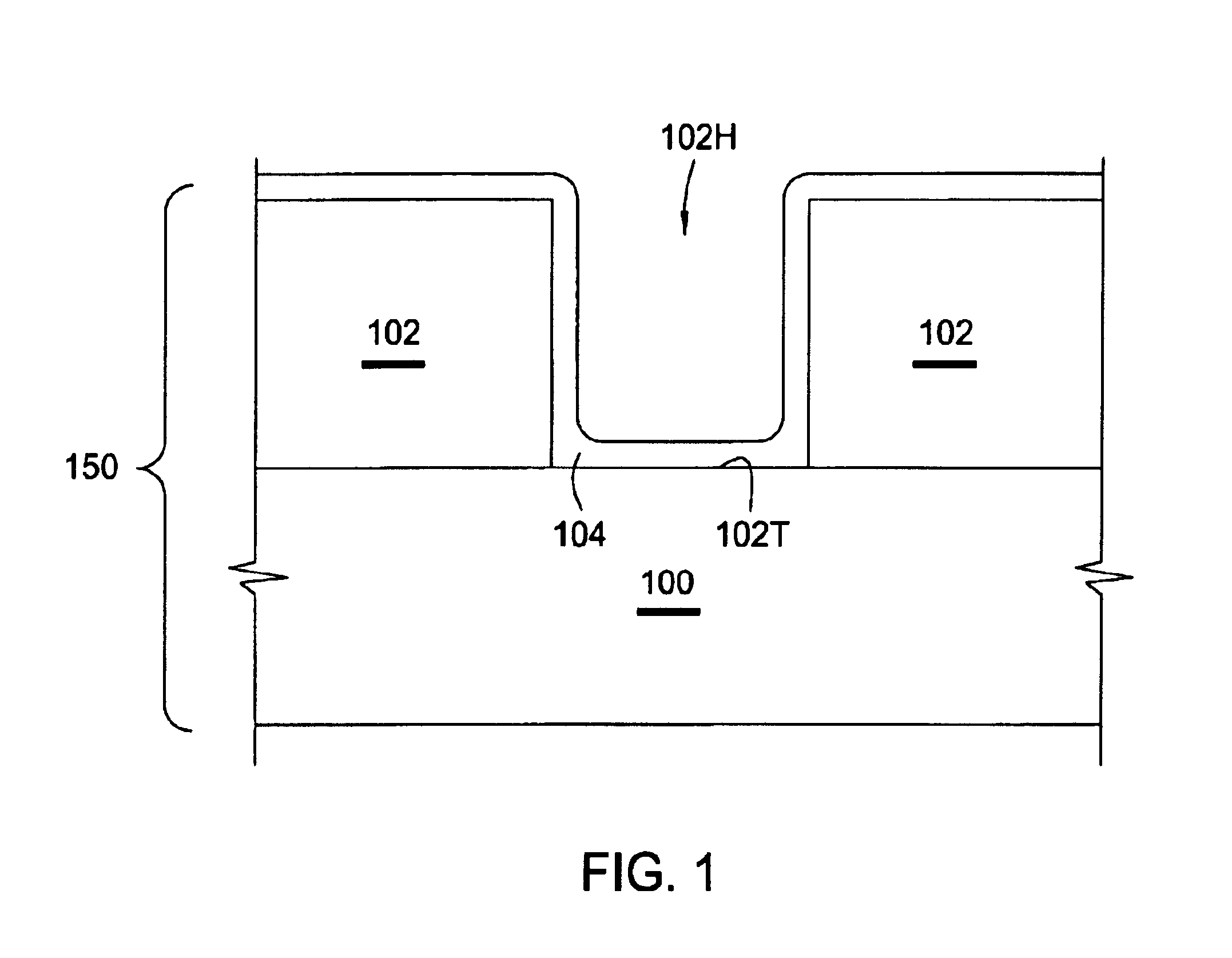

Electrochromic counter electrode

The present invention discloses an amorphous material comprising nickel oxide doped with tantalum that is an anodically coloring electrochromic material. The material of the present invention is prepared in the form of an electrode (200) having a thin film (202) of an electrochromic material of the present invention residing on a transparent conductive film (203). The material of the present invention is also incorporated into an electrochromic device (100) as a thin film (102) in conjunction with a cathodically coloring prior art electrochromic material layer (104) such that the devices contain both anodically coloring (102) and cathodically coloring (104) layers. The materials of the electrochromic layers in these devices exhibit broadband optical complimentary behavior, ionic species complimentary behavior, and coloration efficiency complimentary behavior in their operation.

Owner:ALLIANCE FOR SUSTAINABLE ENERGY

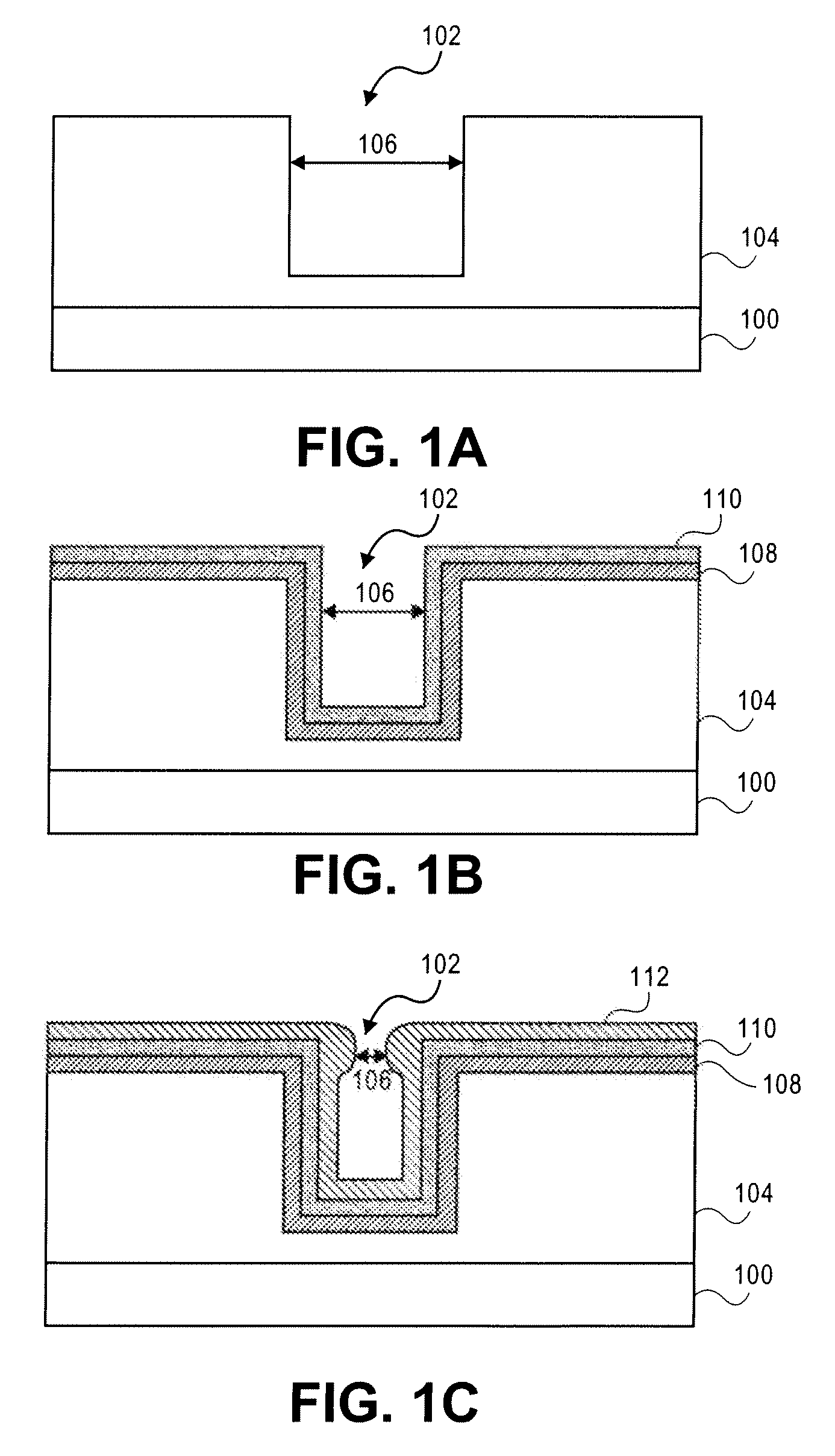

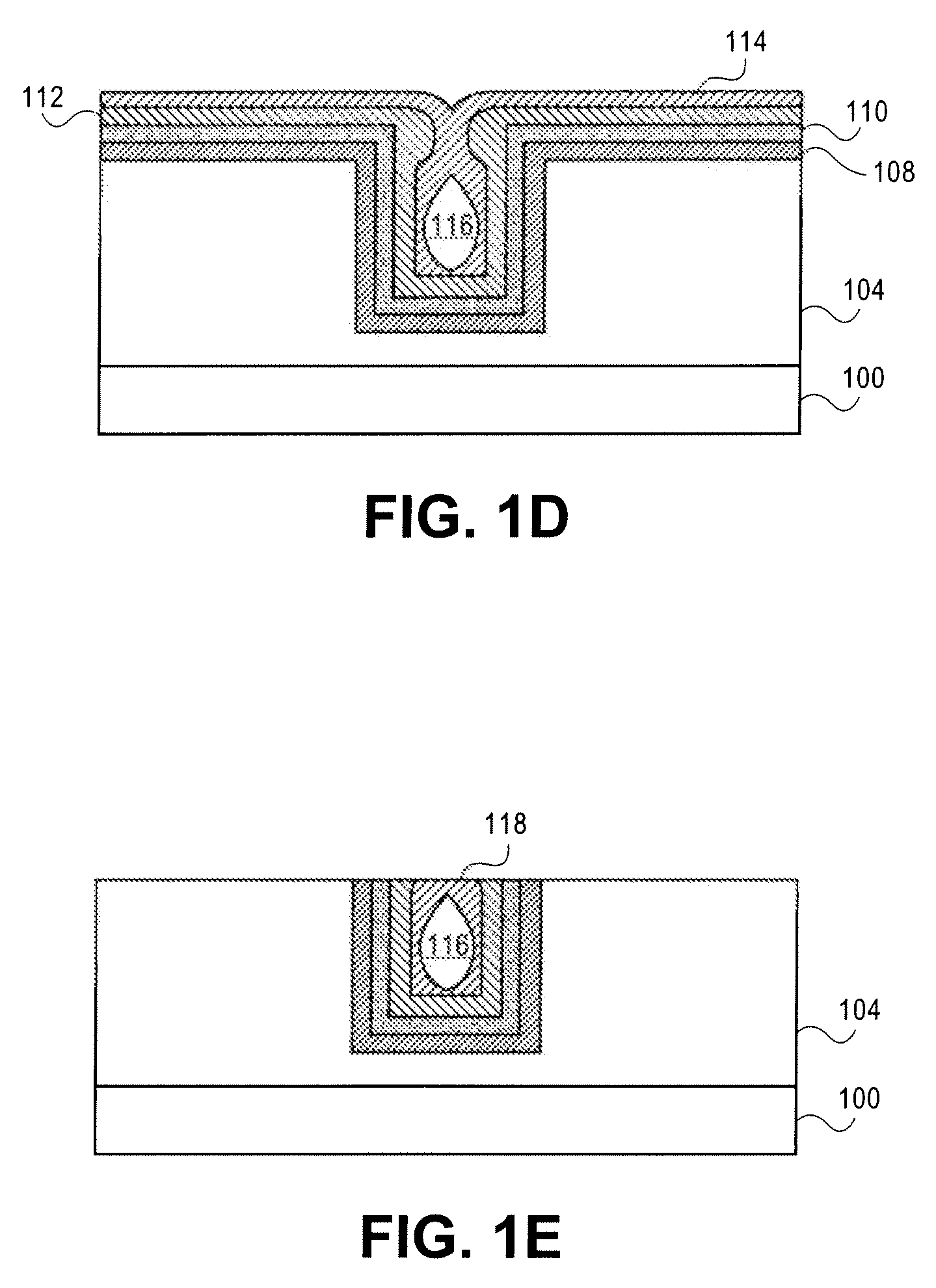

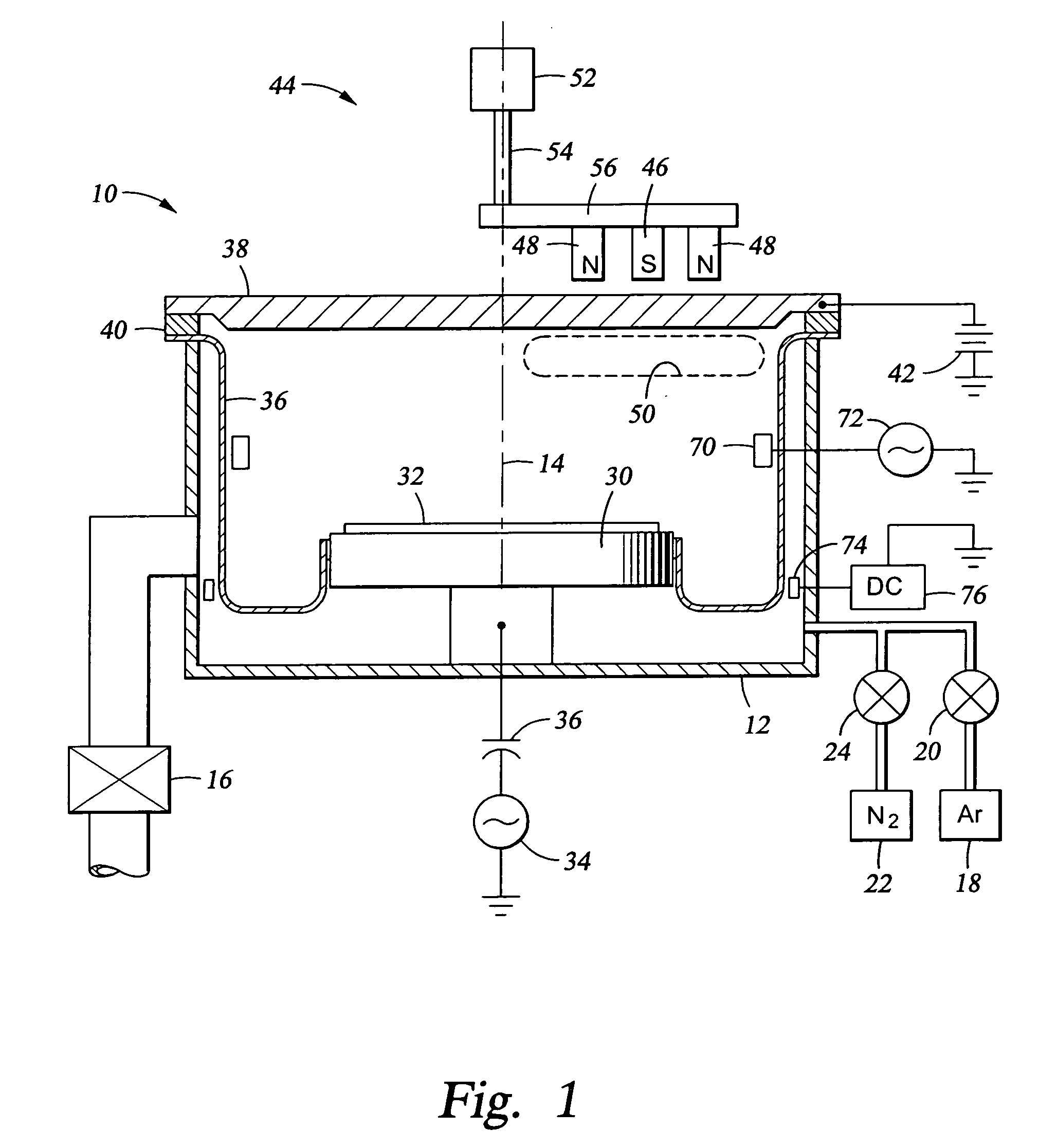

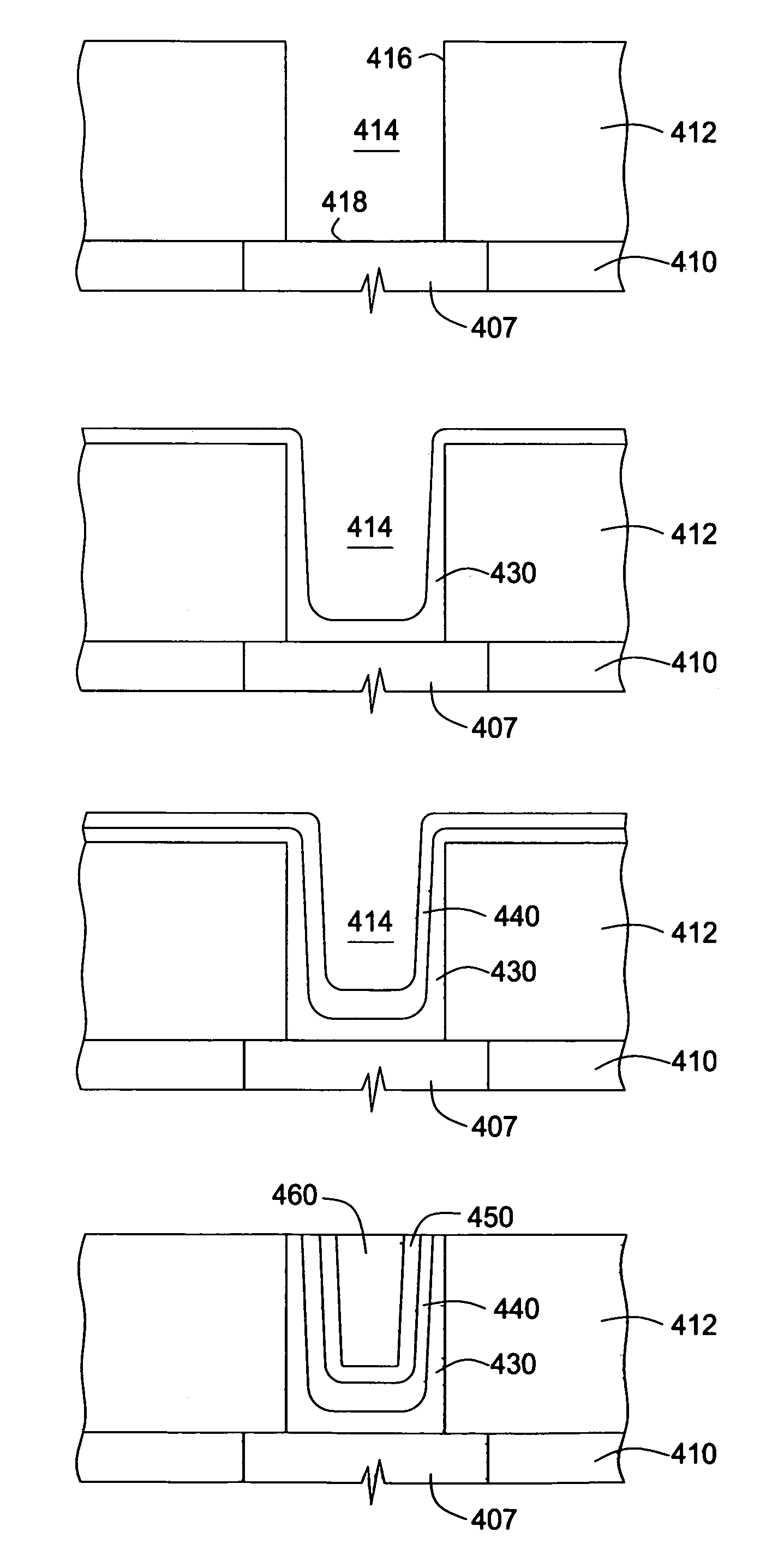

Atomic layer deposition of tantalum based barrier materials

InactiveUS7211508B2Material nanotechnologySemiconductor/solid-state device manufacturingNitrogenNitride

Methods for processing substrate to deposit barrier layers of one or more material layers by atomic layer deposition are provided. In one aspect, a method is provided for processing a substrate including depositing a metal nitride barrier layer on at least a portion of a substrate surface by alternately introducing one or more pulses of a metal containing compound and one or more pulses of a nitrogen containing compound and depositing a metal barrier layer on at least a portion of the metal nitride barrier layer by alternately introducing one or more pulses of a metal containing compound and one or more pulses of a reductant. A soak process may be performed on the substrate surface before deposition of the metal nitride barrier layer and / or metal barrier layer.

Owner:APPLIED MATERIALS INC

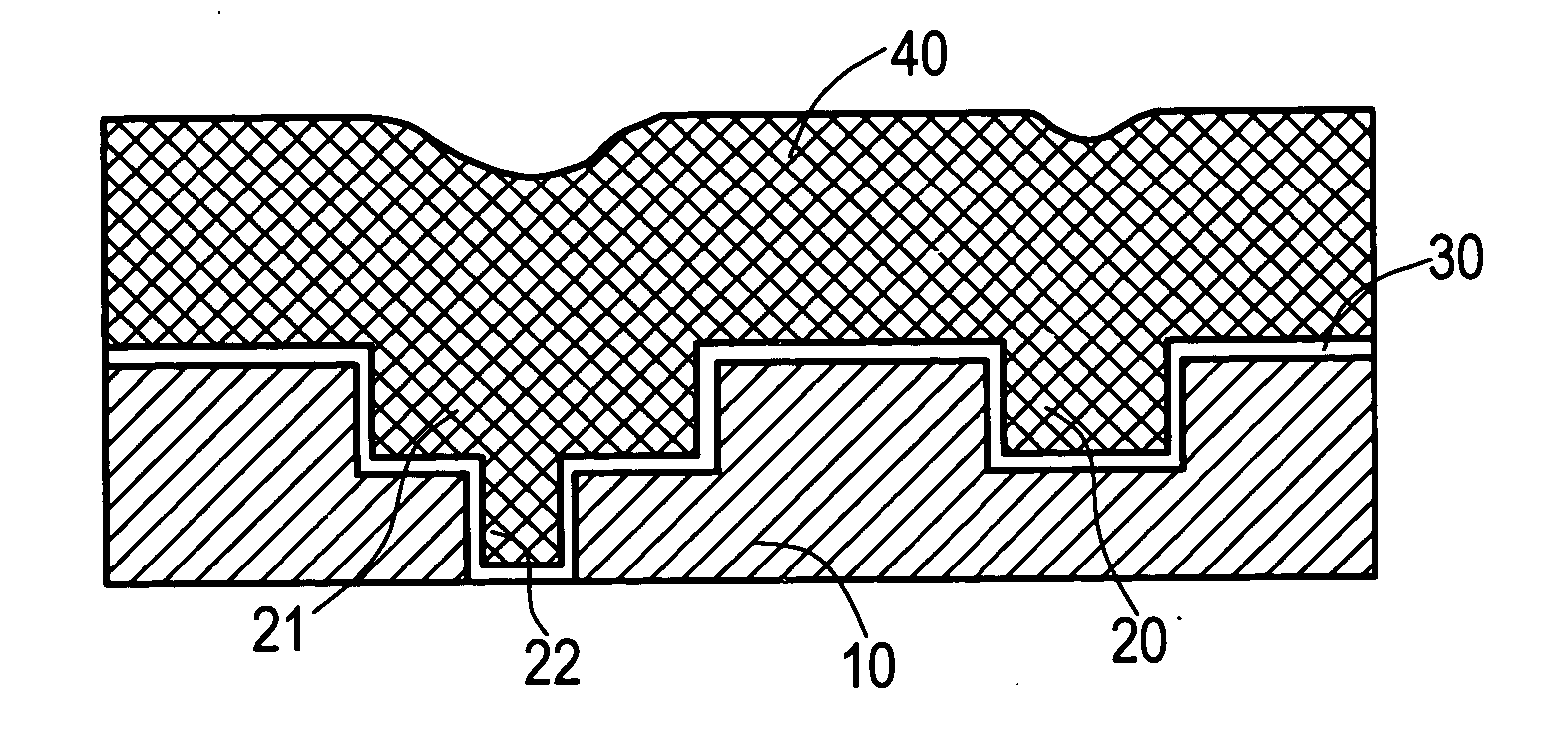

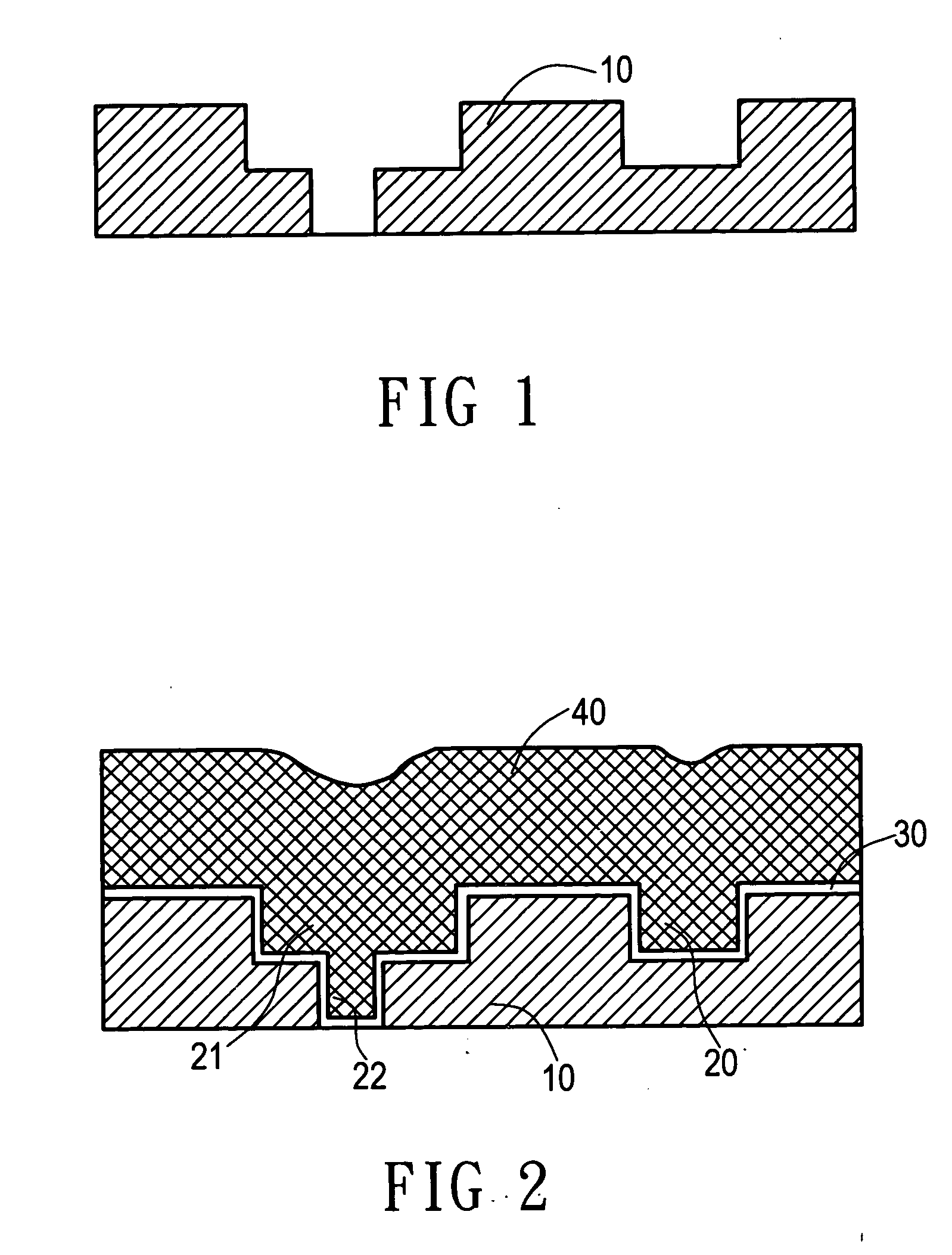

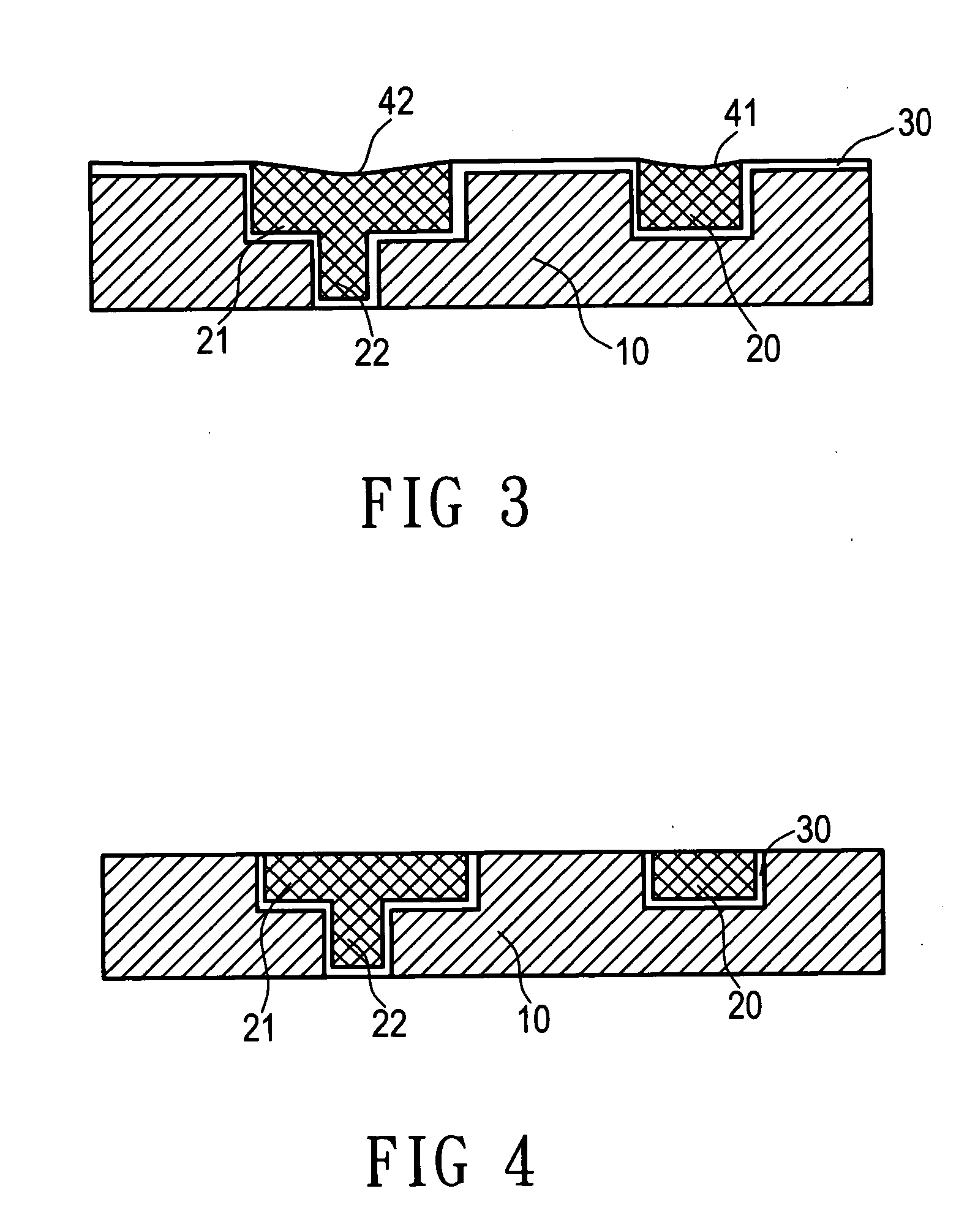

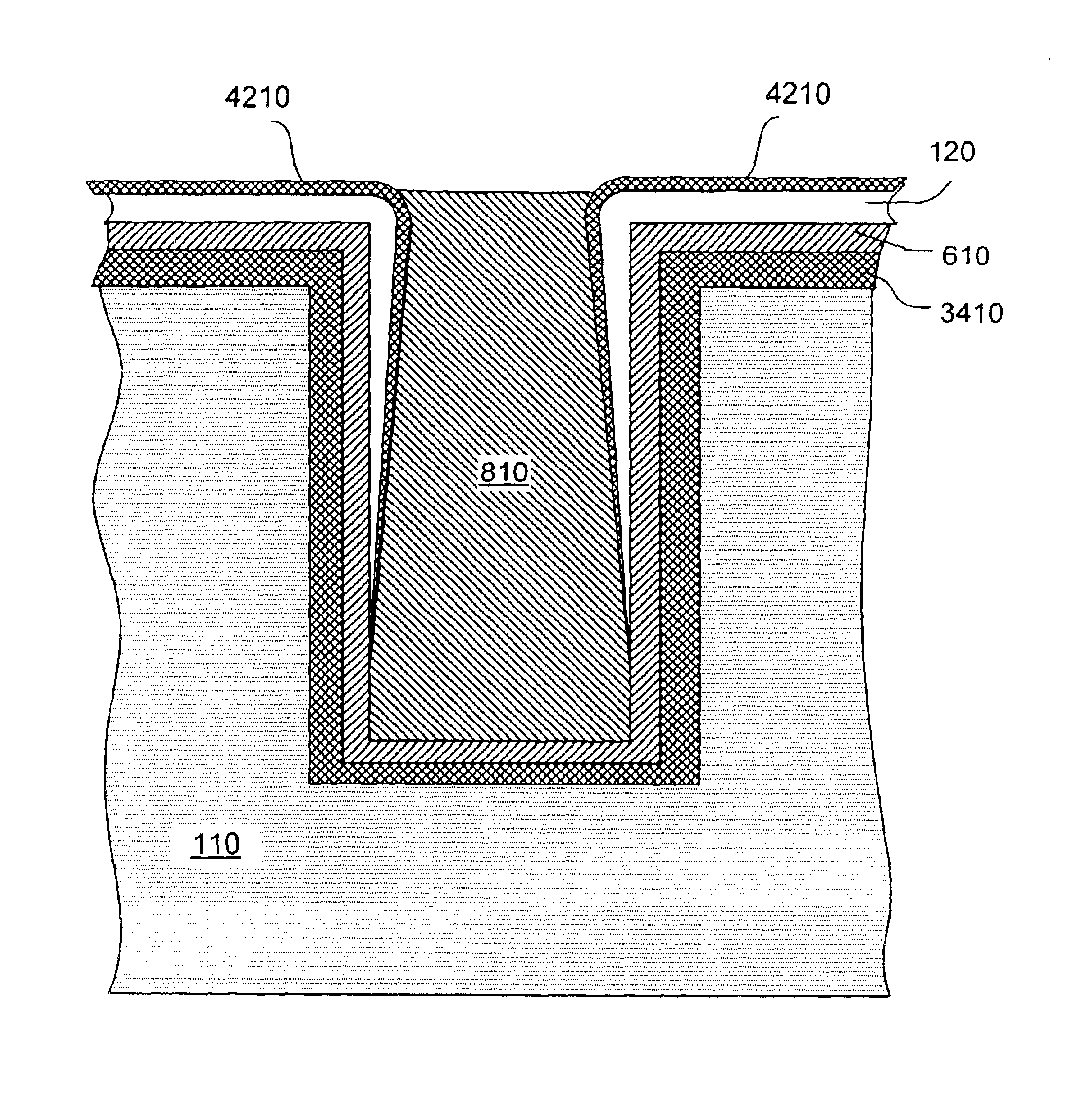

Electroplating and electroless plating of conductive materials into openings, and structures obtained thereby

InactiveUS6897148B2Improve throughputReduce tooling costsSemiconductor/solid-state device detailsSolid-state devicesResistDielectric

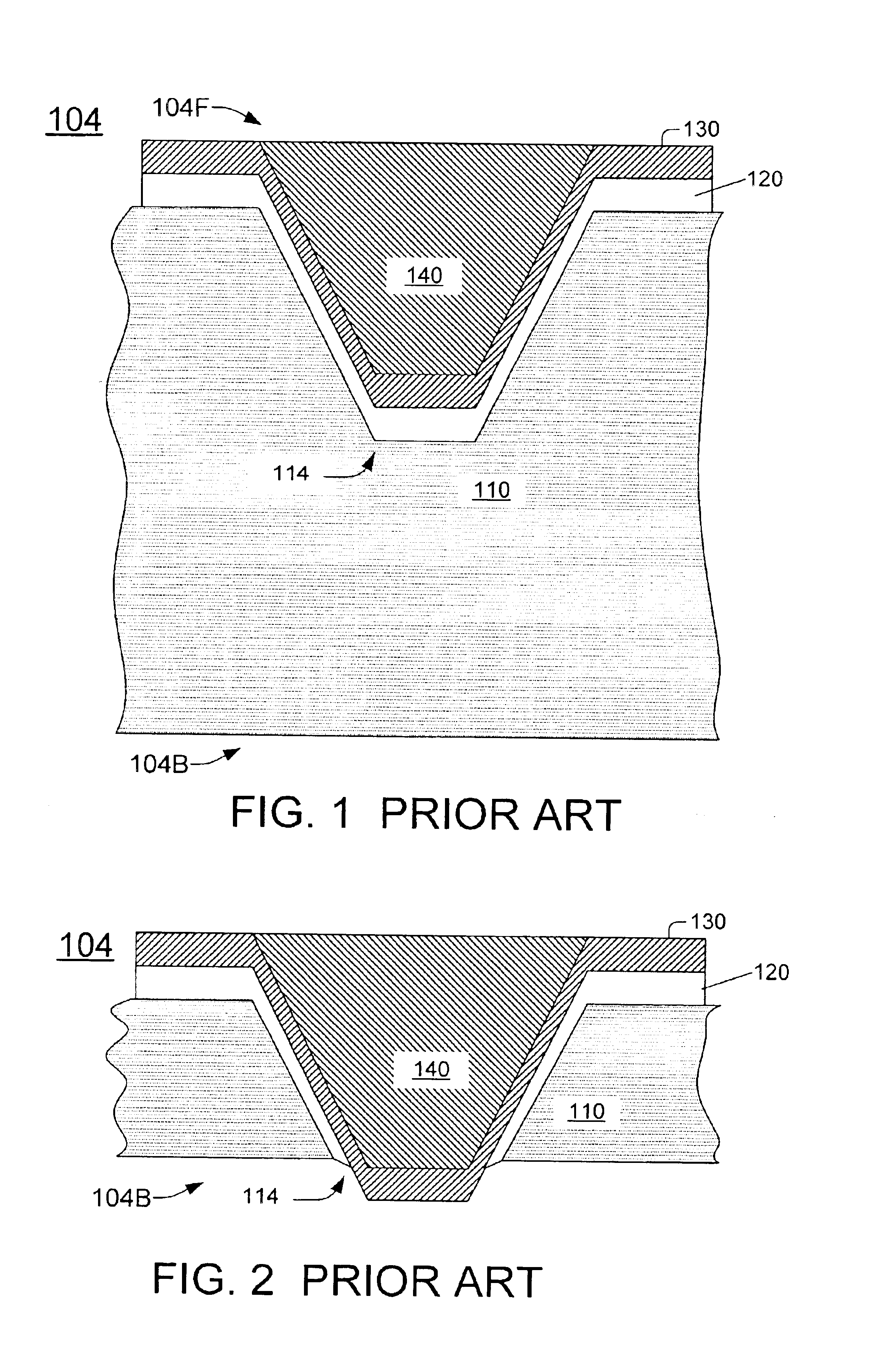

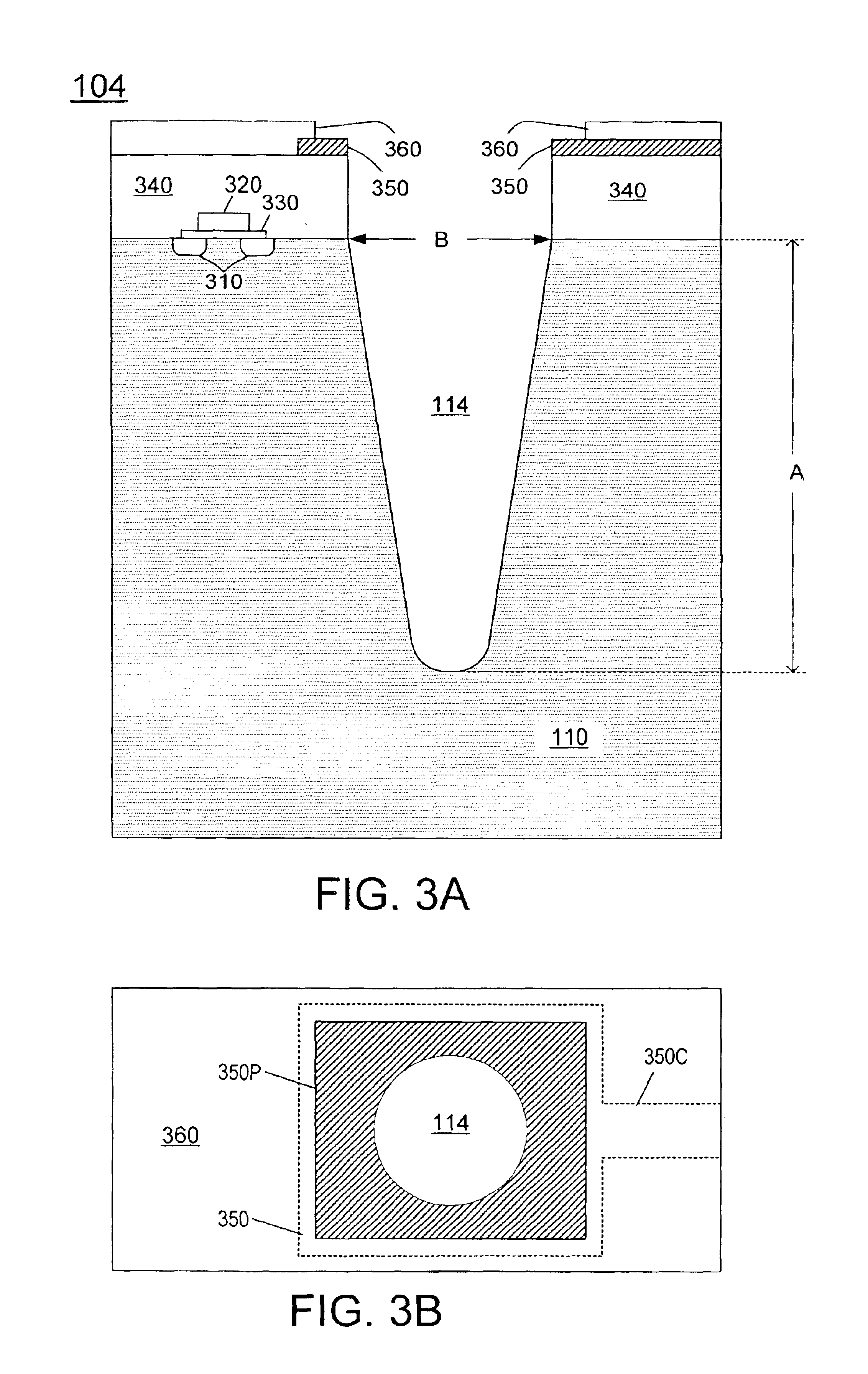

A through hole (114) is formed in a wafer (104) comprising a semiconductor substrate (110). A seed layer (610) is sputtered on the bottom surface of the wafer. The seed is not deposited over the through hole's sidewalls adjacent the top surface of the wafer. A conductor (810) is electroplated into the through hole. In another embodiment, a seed is deposited into an opening in a wafer through a dry film resist mask (1110). The dry film resist overhangs the edges of the opening, so the seed is not deposited over the opening's sidewalls adjacent the top surface of the wafer. In another embodiment, a dielectric (120) is formed in an opening in a semiconductor substrate (110) by a non-conformal physical vapor deposition (PVD) process that deposits the dielectric on the sidewalls but not the bottom of the opening. A seed (610) is formed on the bottom by electroless plating. A conductor (810) is electroplated on the seed. In another embodiment, a dielectric (2910) is formed in the opening to cover the entire surface of the opening. A non-conformal layer (120) is deposited by PVD over the sidewalls but not the bottom of the opening. The dielectric (2910) is etched off the bottom with the non-conformal layer (120) as a mask. A seed (610) is formed on the bottom by electroless plating. The non-conformal layer can be formed by electroplating. It can be tantalum deposited by electroplating, then anodized. Other embodiments are also provided.

Owner:INVENSAS CORP

Inorganic dopants, inks and related nanotechnology

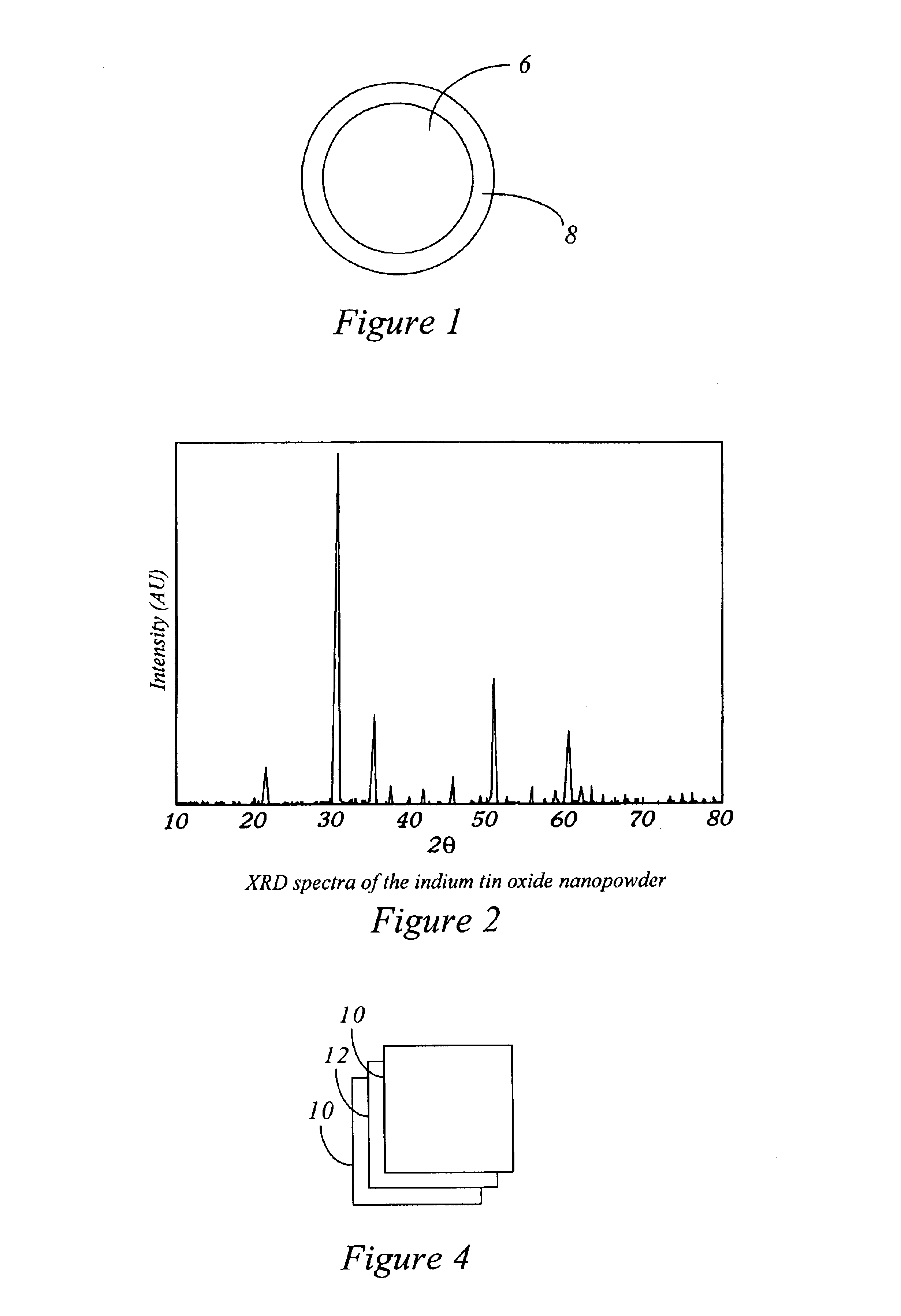

InactiveUS6849109B2Facilitated DiffusionLower transition temperatureSelenium/tellurium compundsCell electrodesIndiumCerium

Ink compositions with modified properties result from using a powder size below 100 nanometers. Colored inks are illustrated. Nanoscale coated, uncoated, whisker inorganic fillers are included. The pigment nanopowders taught comprise one or more elements from the group actinium, aluminum, antimony, arsenic, barium, beryllium, bismuth, cadmuim, calcium, cerium, cesium, chalcogenide, cobalt, copper, dysprosium, erbium, europium, gadolinium, gallium, gold, hafnium, hydrogen, indium, iridium, iron, lanthanum, lithium, magnesium, manganese, mendelevium, mercury, molybdenum, neodymium, neptunium, nickel, niobium, nitrogen, oxygen, osmium, palladium, platinum, potassium, praseodymium, promethium, protactinium, rhenium, rubidium, scandium, silver, sodium, strontium, tantalum, terbium, thallium, thorium, tin, titanium, tungsten, vanadium, ytterbium, yttrium, zinc, and zirconium.

Owner:PPG IND OHIO INC

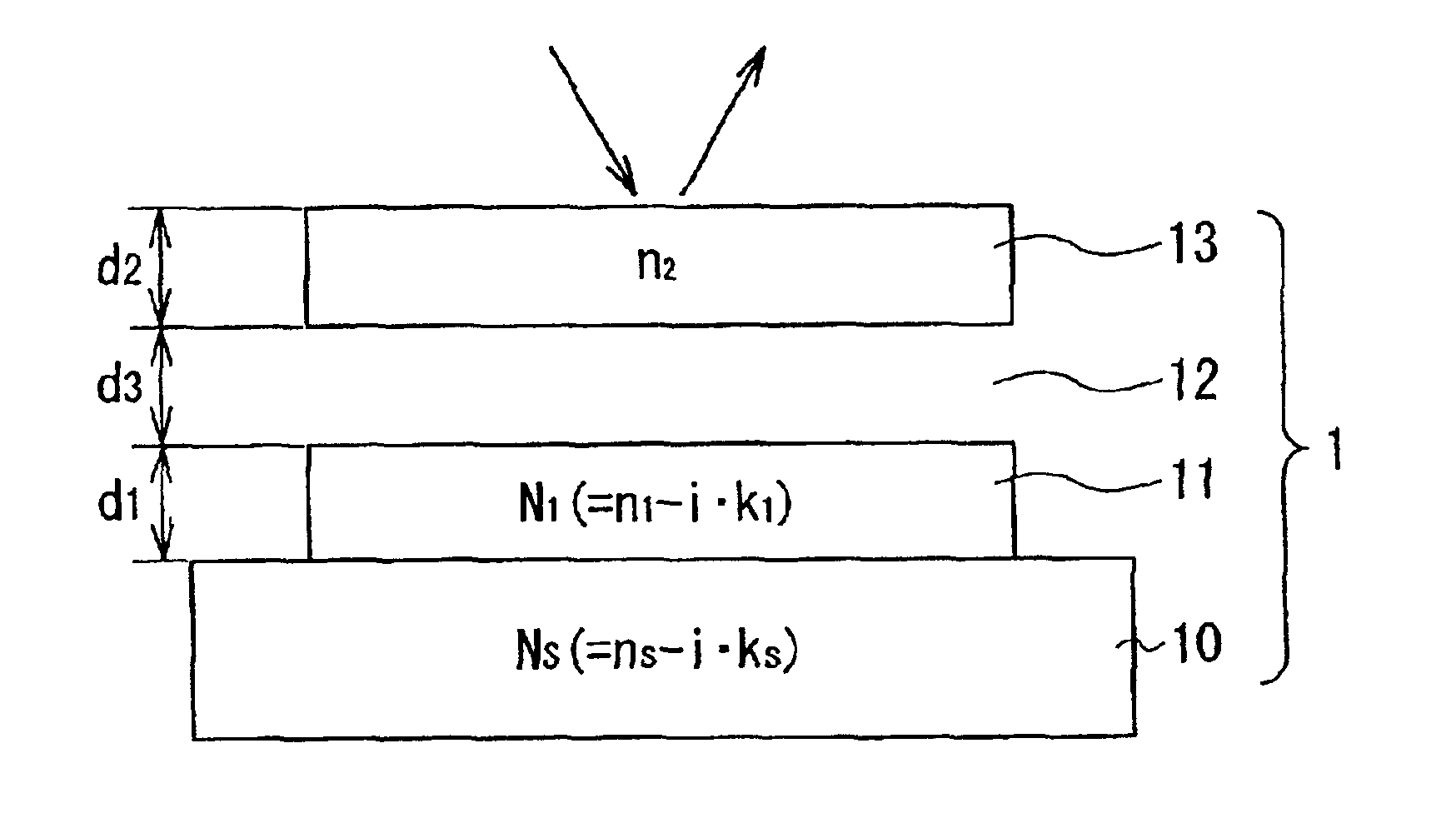

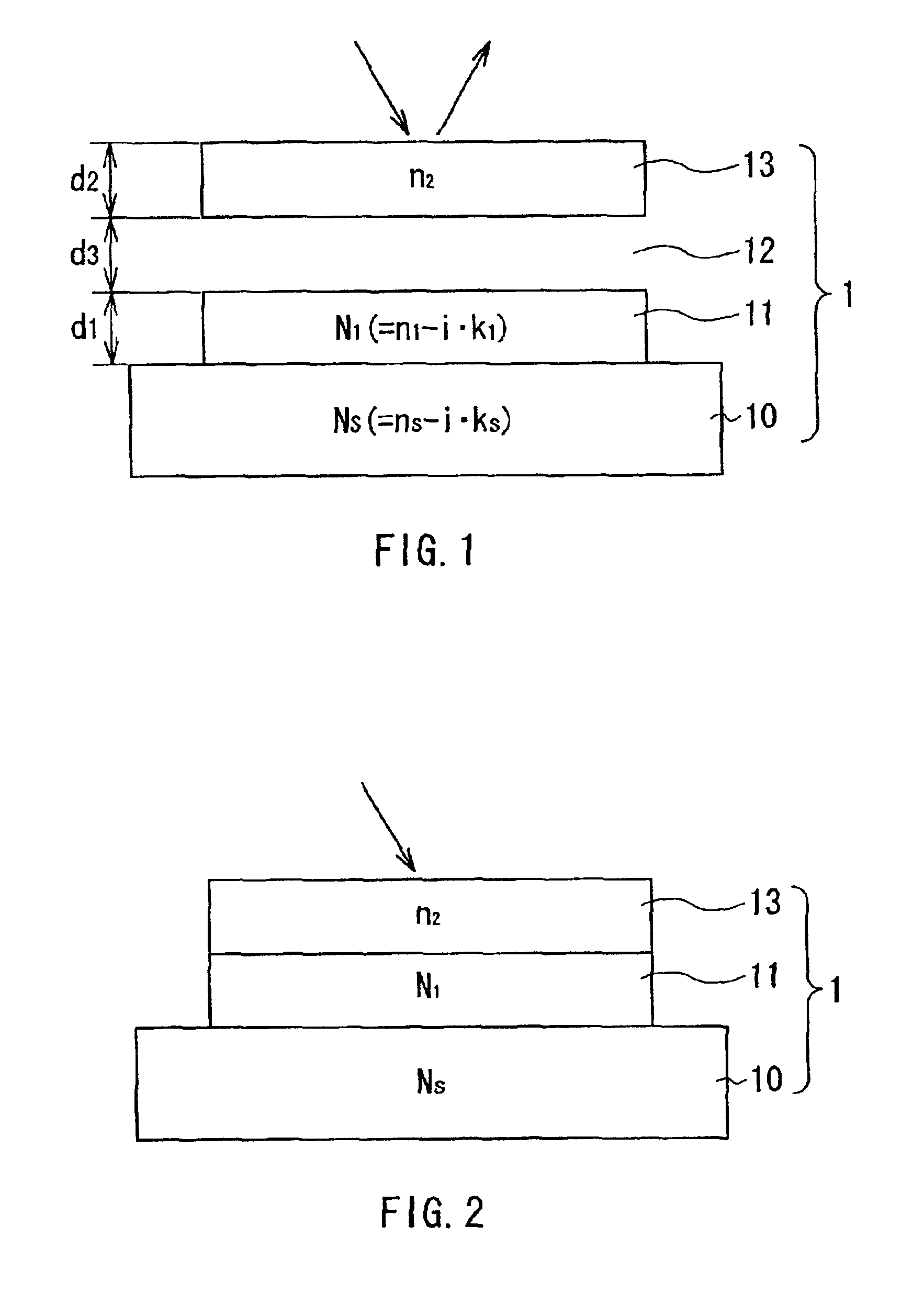

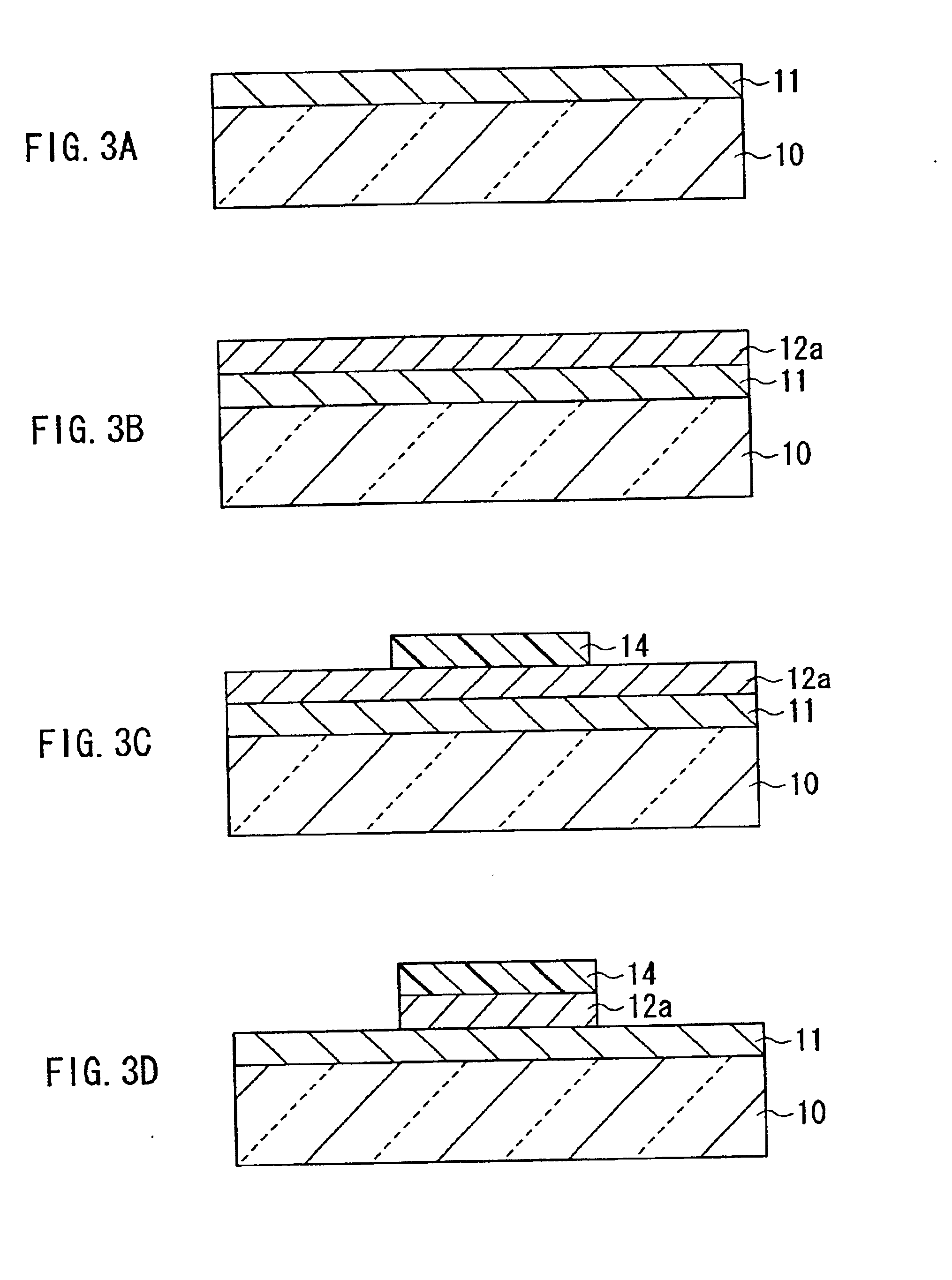

Optical multilayer structure, optical switching device, and image display

InactiveUS6940631B2Simple configurationSmall structureCathode-ray tube indicatorsCoupling light guidesInterference phenomenonRefractive index

An optical multilayer structure has a substrate, a light-absorbing first layer in contact with the substrate, a gap portion having a changeable size capable of causing an optical interference phenomenon, and a second layer. By changing the size of the gap portion, an amount of reflection, transmission, or absorption of incident light can be changed. For example, the substrate is made of carbon (C), the first layer is made of tantalum (Ta), and the second layer is made of silicon nitride (Si3N4). Also in a visible light area, high response is realized. Consequently, the optical multilayer structure can be suitably used for an image display. The optical multilayer structure may be obtained by stacking, on a substrate made of a metal such as chromium (Cr), a first transparent layer made of a material having a high refractive index such as TiO2 (n=2.40), a second transparent layer made of a material having a low refractive index such as MgF2 (n=1.38), a gap portion having a changeable size capable of causing an optical interference phenomenon, and a third transparent layer made of a material having a high refractive index such as TiO2.

Owner:SONY CORP

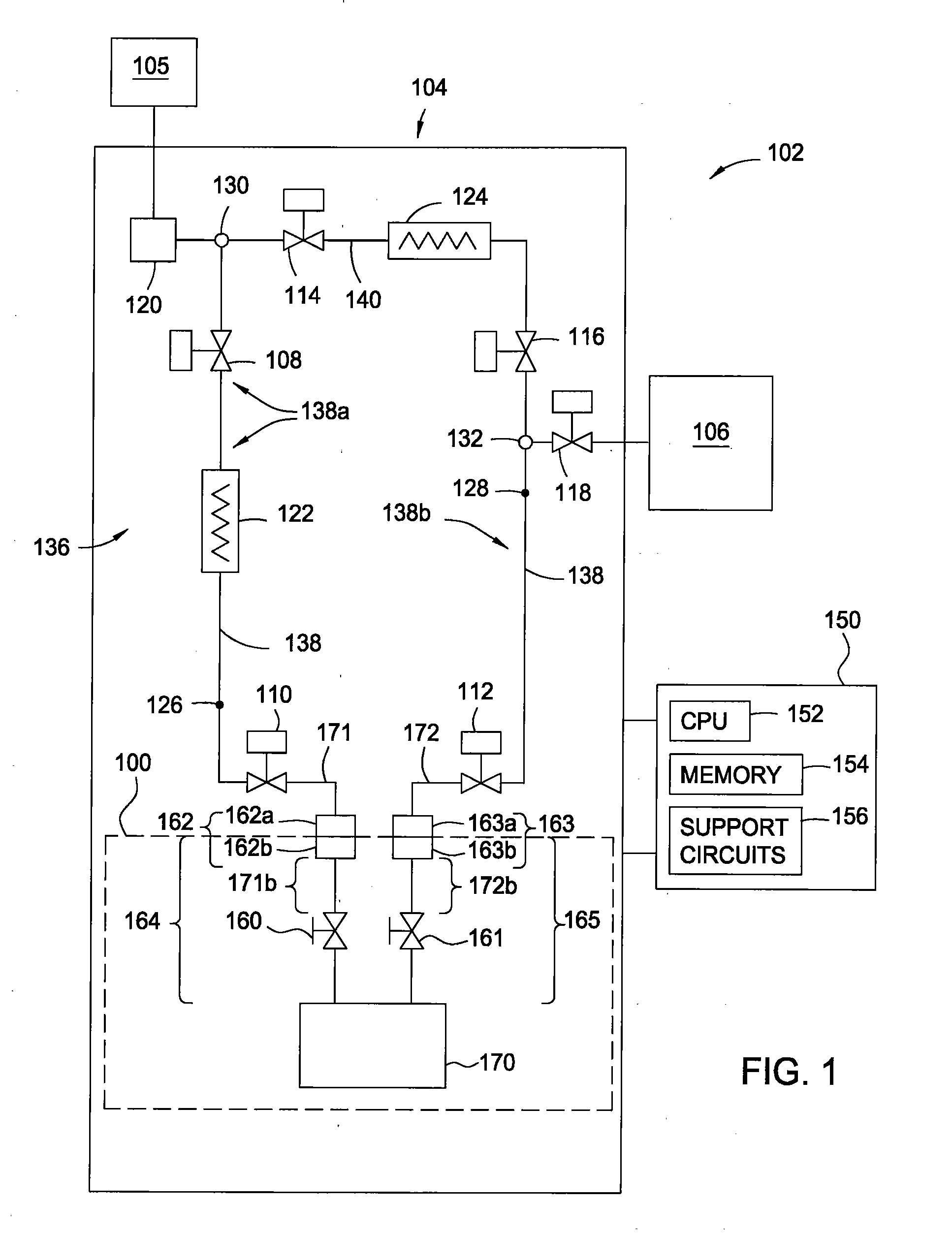

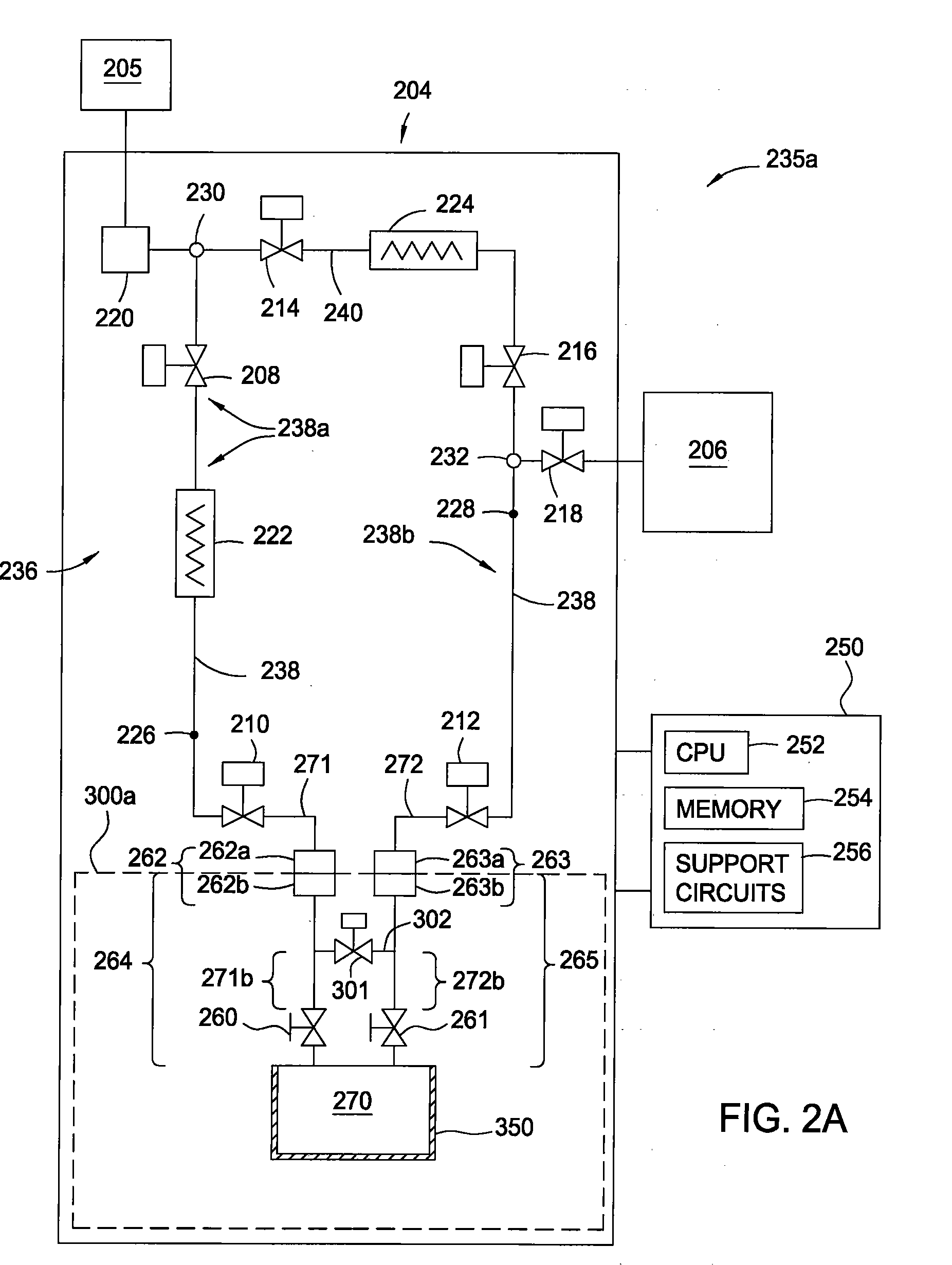

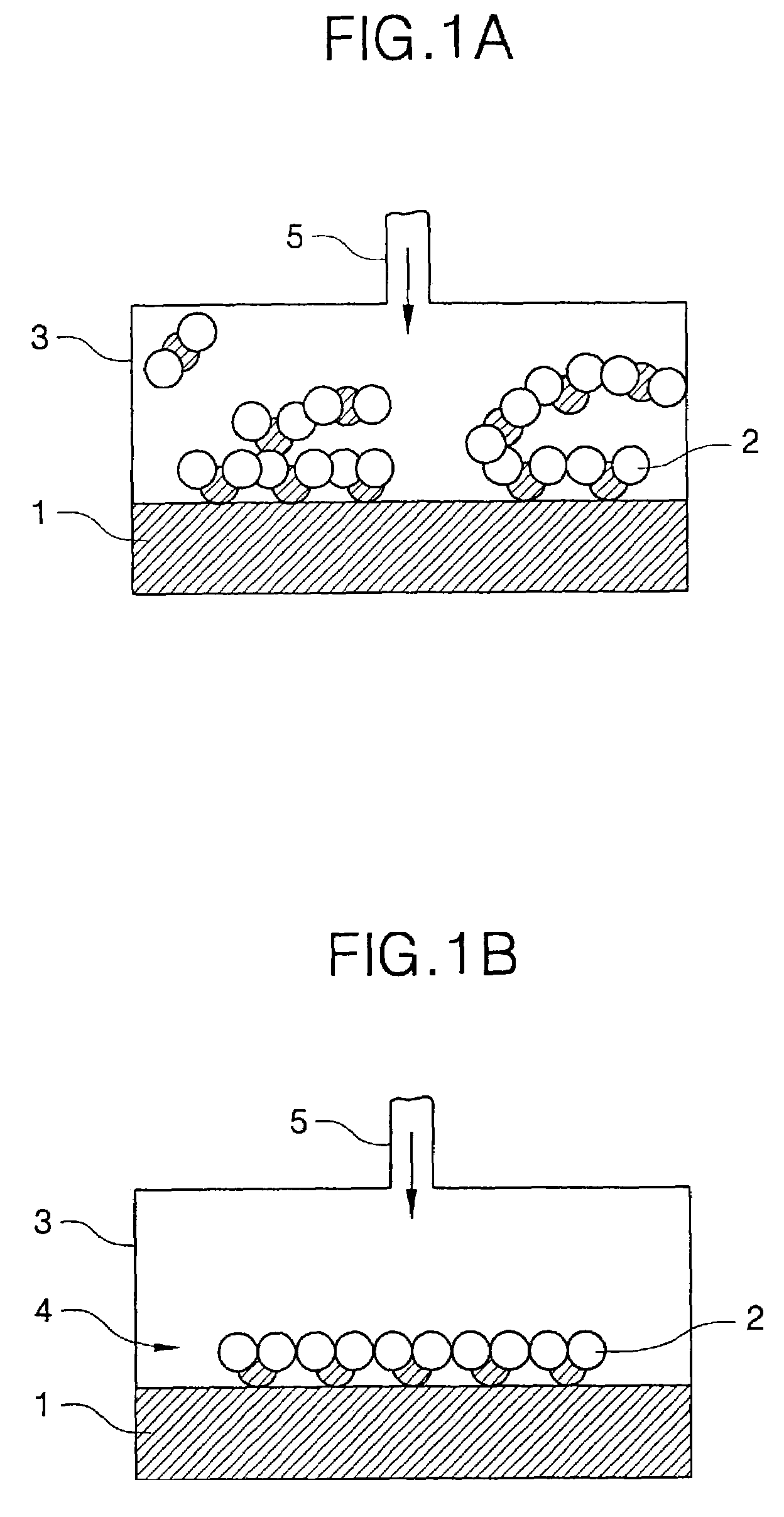

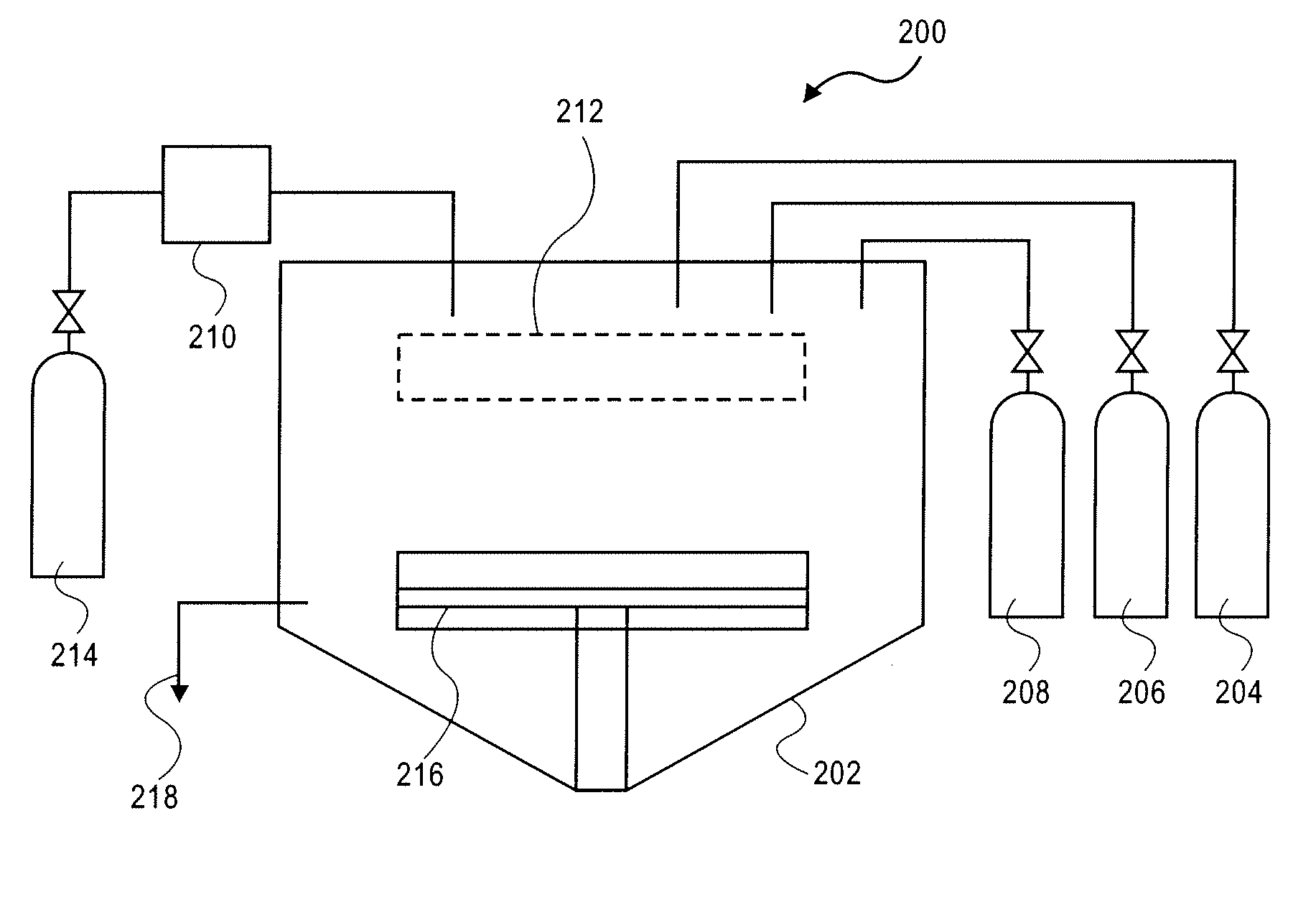

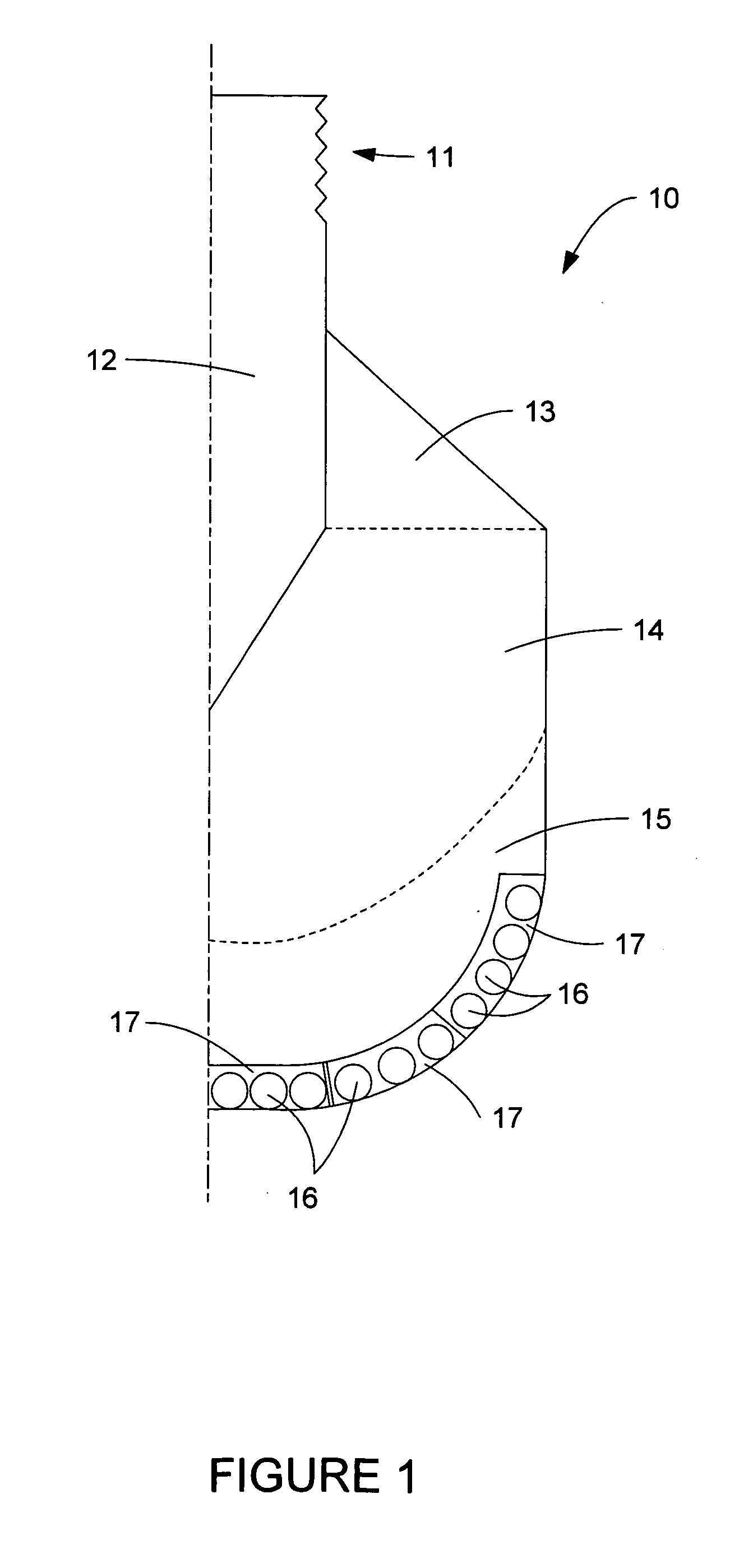

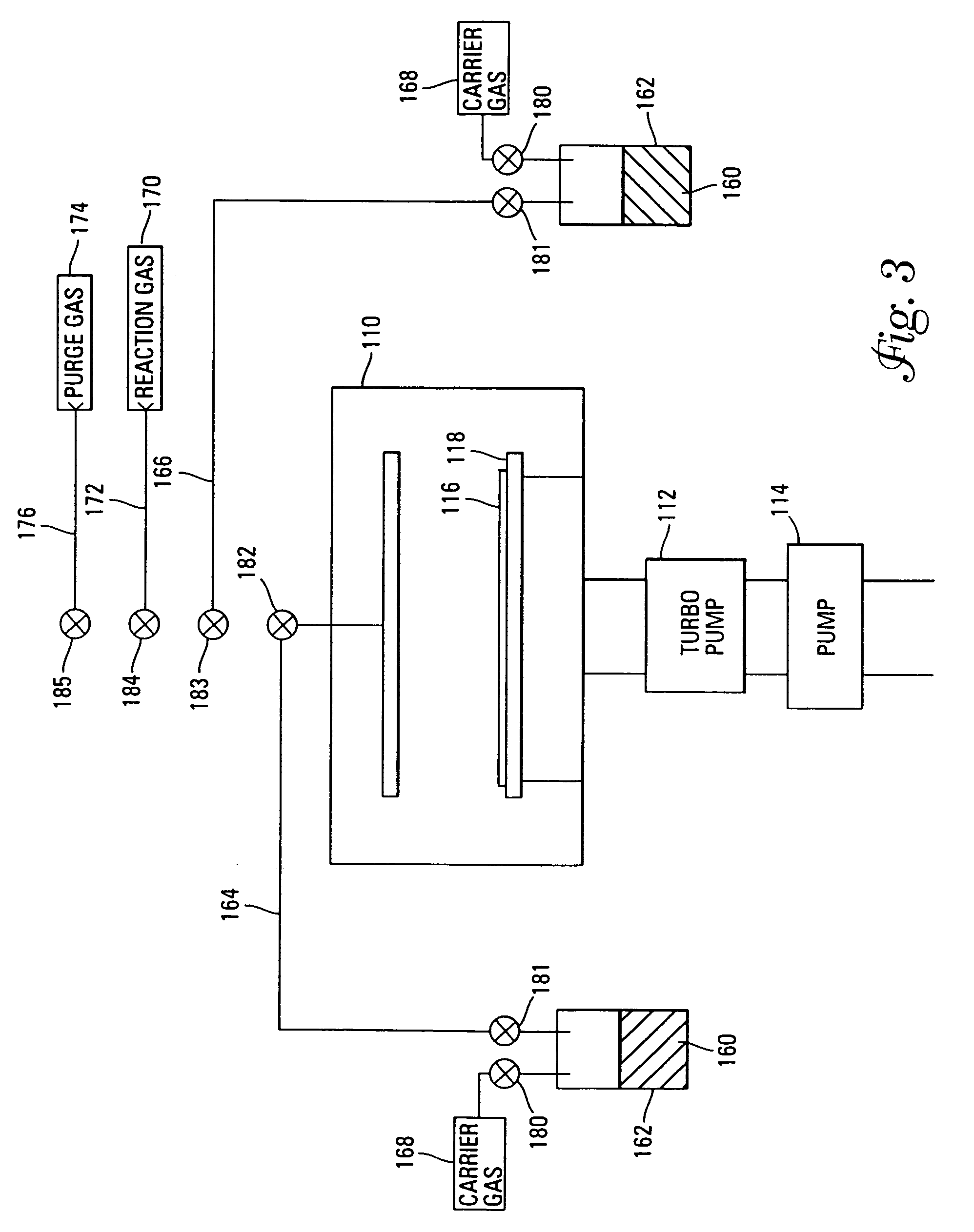

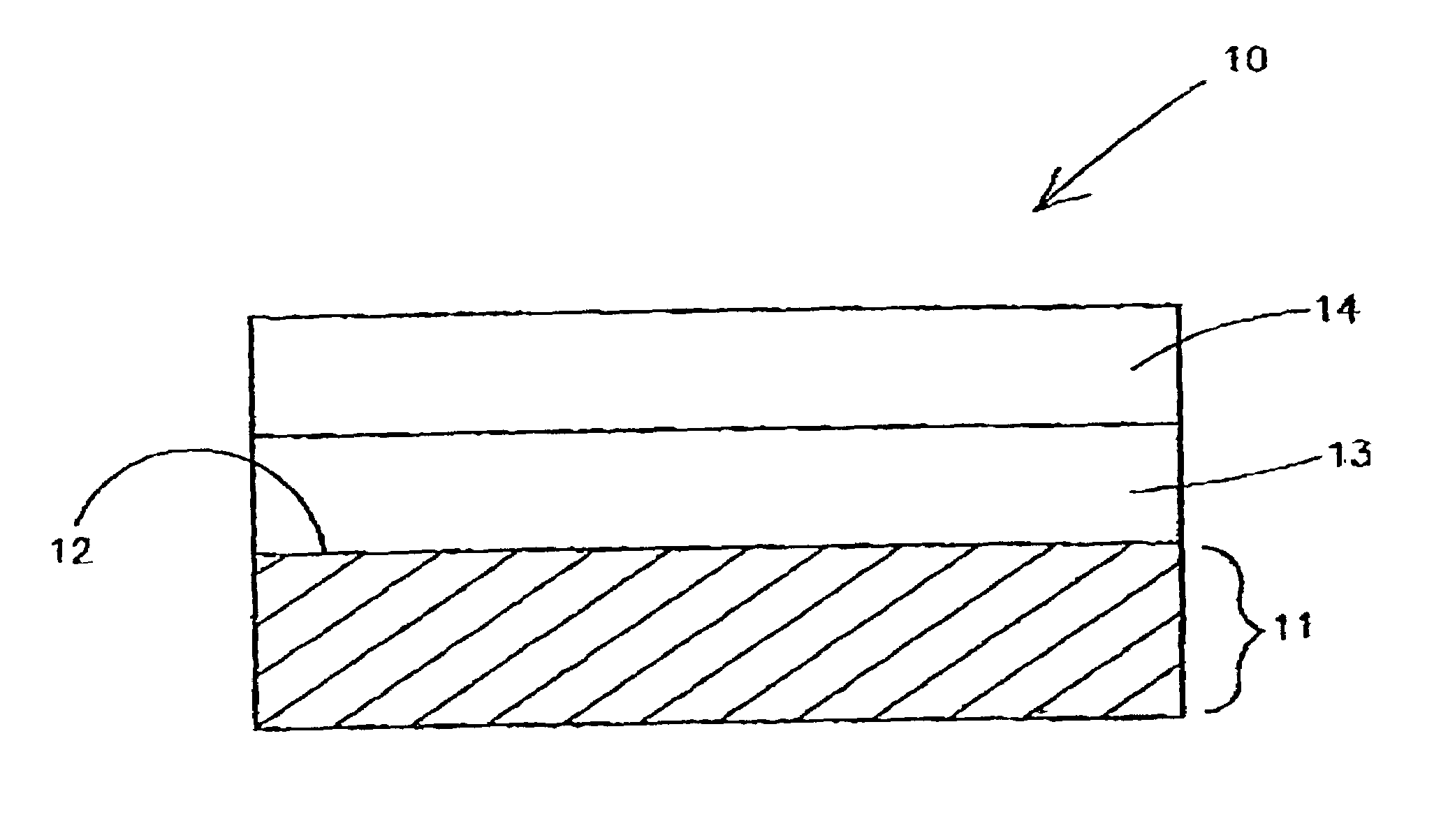

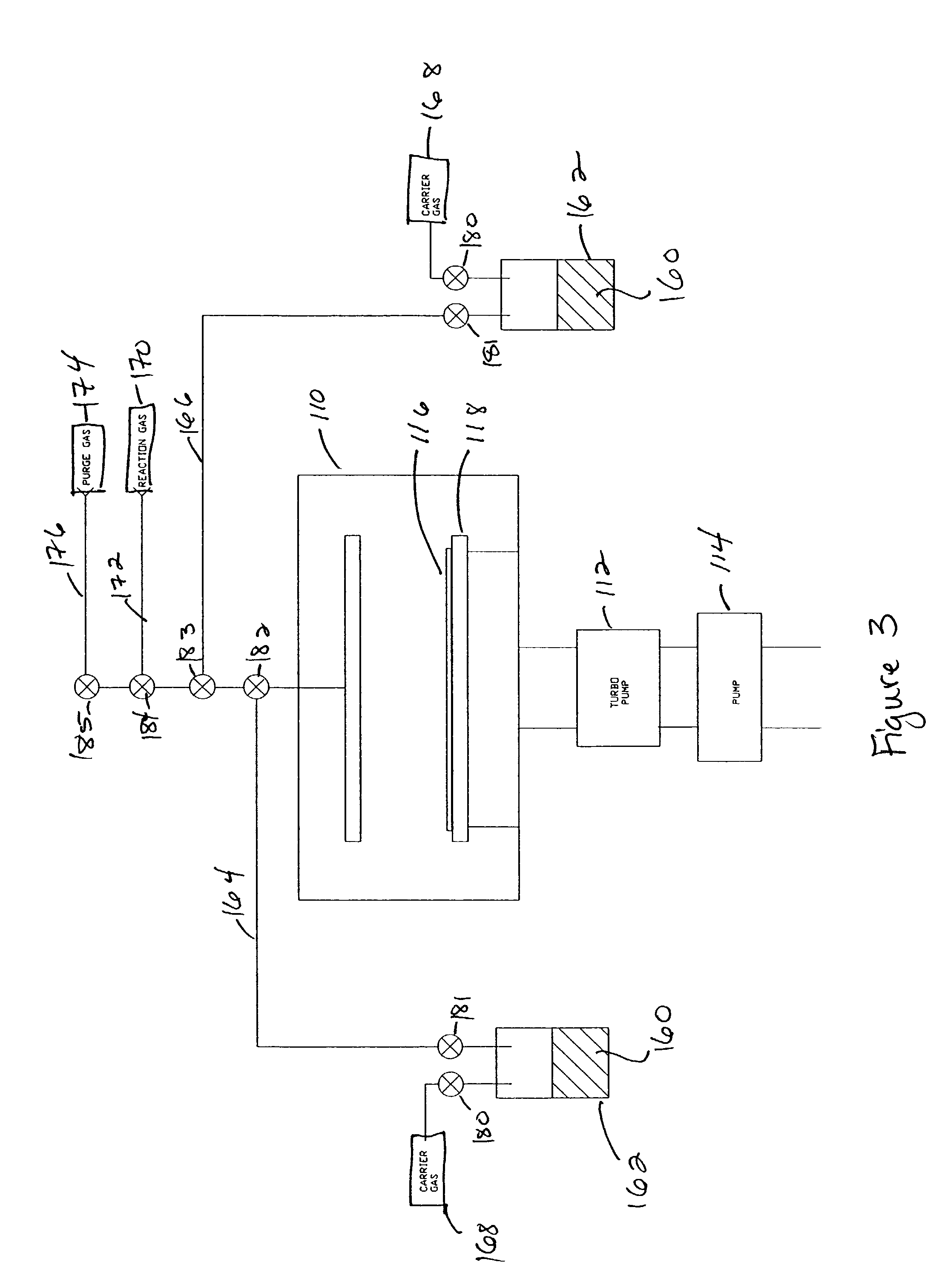

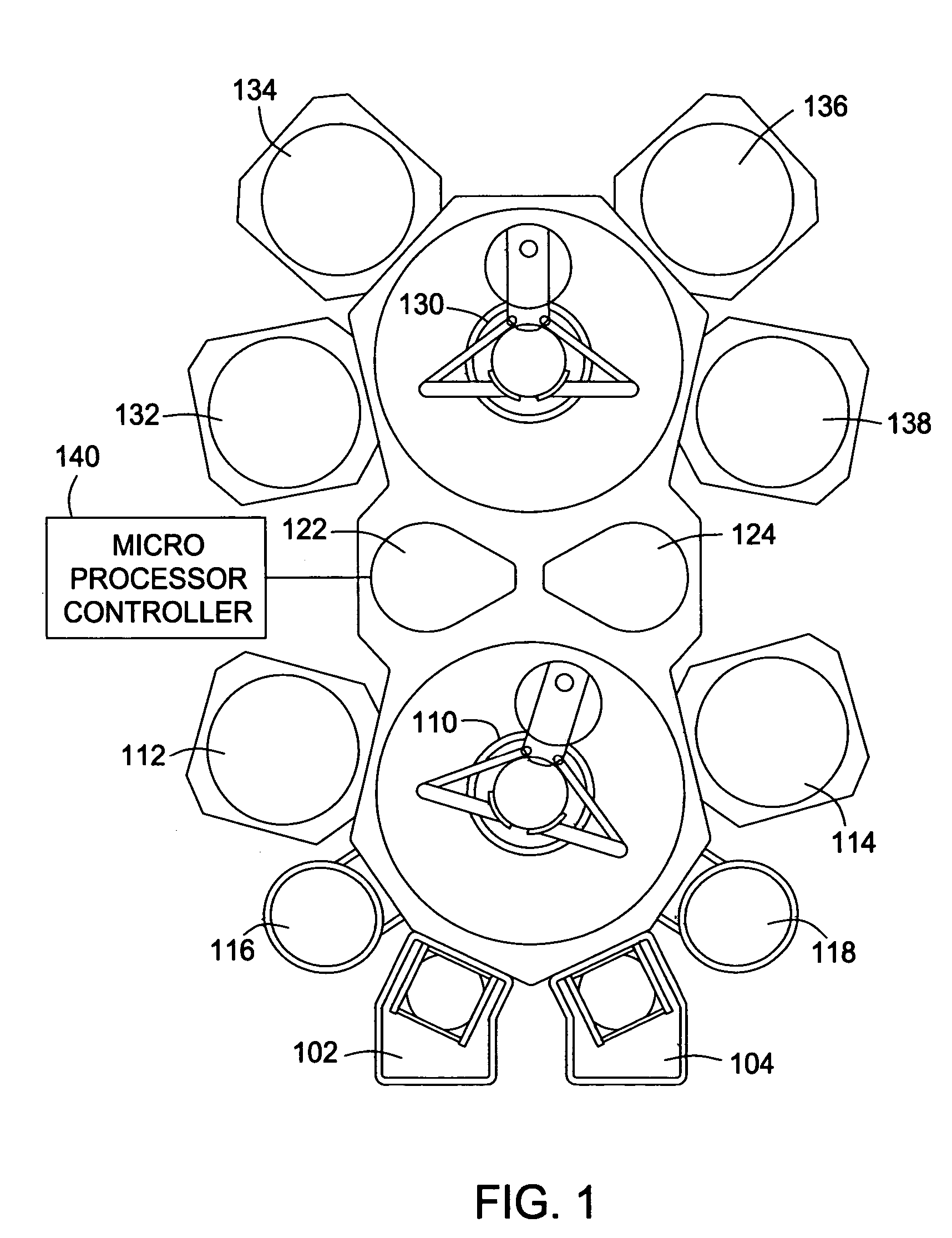

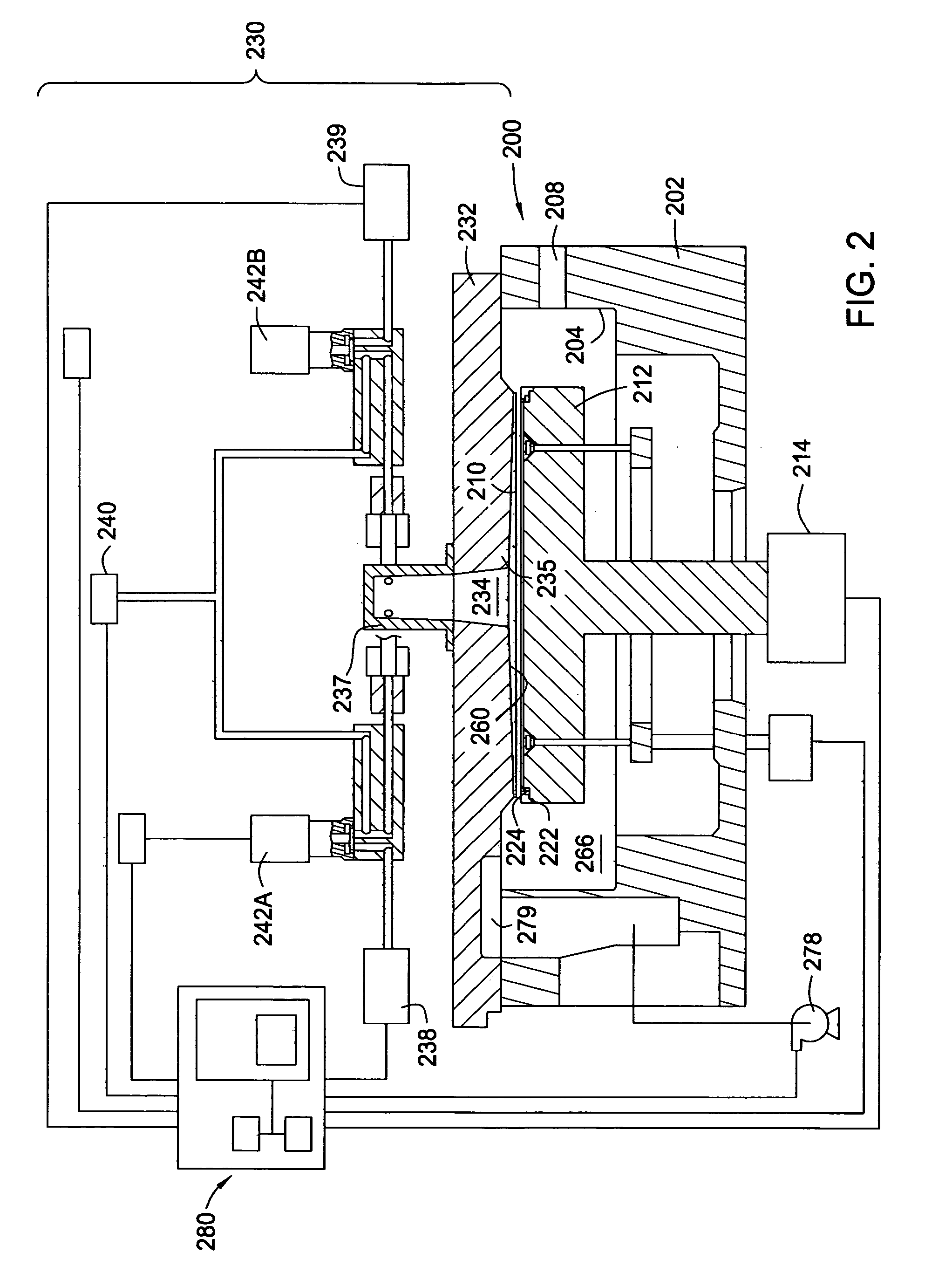

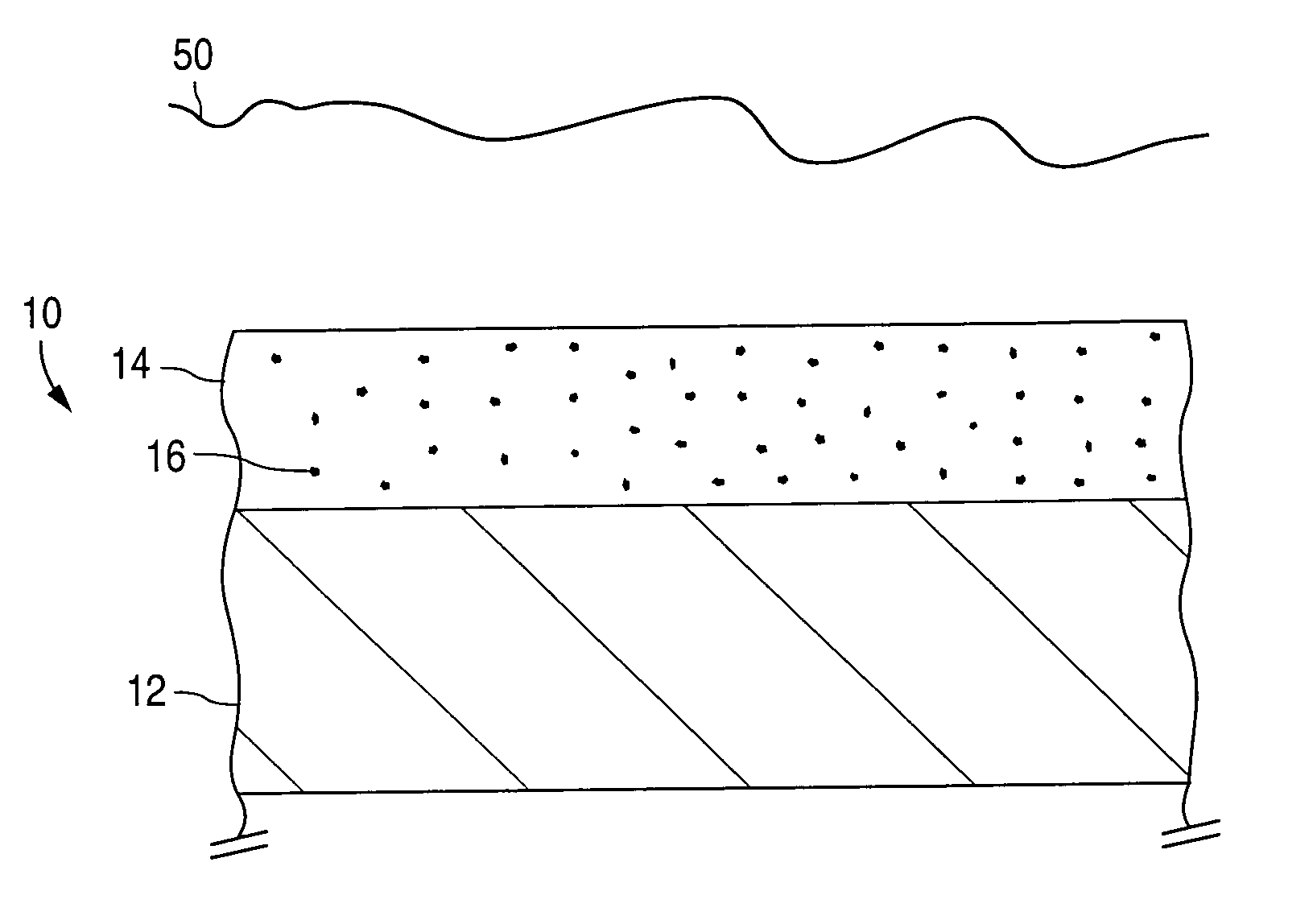

Method and apparatus of generating PDMAT precursor

InactiveUS6905541B2Polycrystalline material growthSemiconductor/solid-state device manufacturingEngineeringImpurity

A precursor and method for filling a feature in a substrate. The method generally includes depositing a barrier layer, the barrier layer being formed from pentakis(dimethylamido)tantalum having less than about 5 ppm of chlorine. The method additionally may include depositing a seed layer over the barrier layer and depositing a conductive layer over the seed layer. The precursor generally includes pentakis(dimethylamido)tantalum having less than about 5 ppm of chlorine. The precursor is generated in a canister having a surrounding heating element configured to reduce formation of impurities.

Owner:APPLIED MATERIALS INC

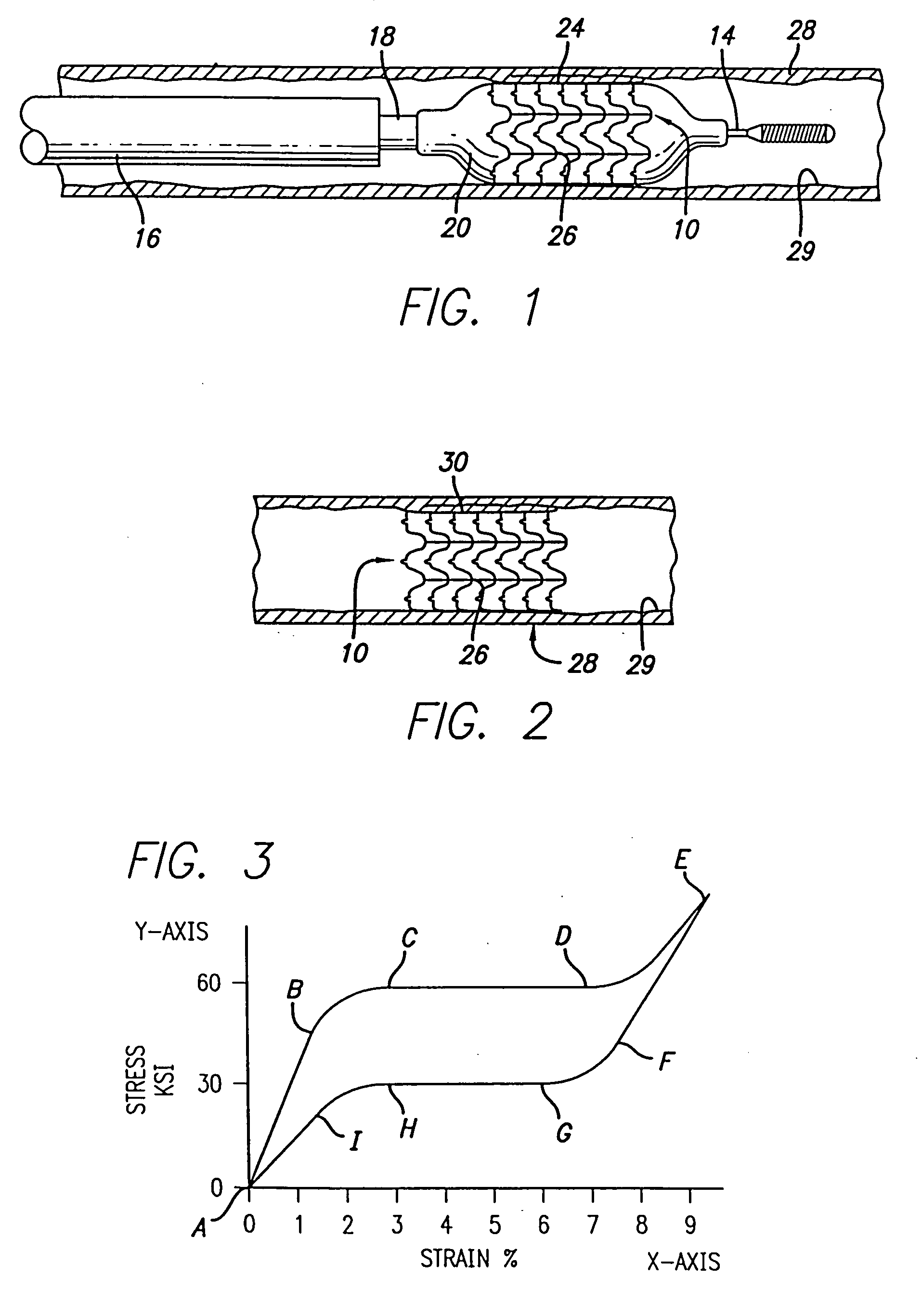

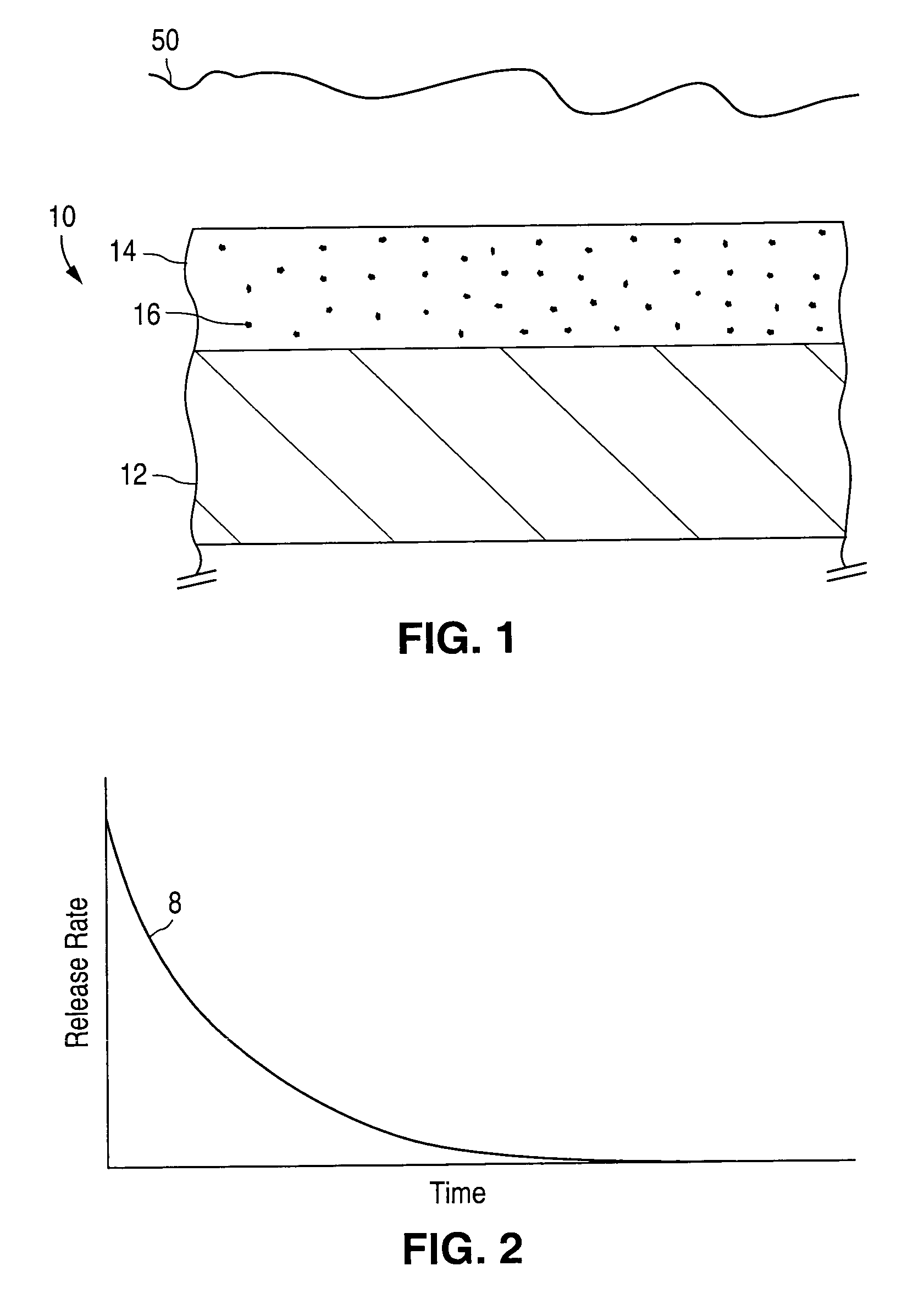

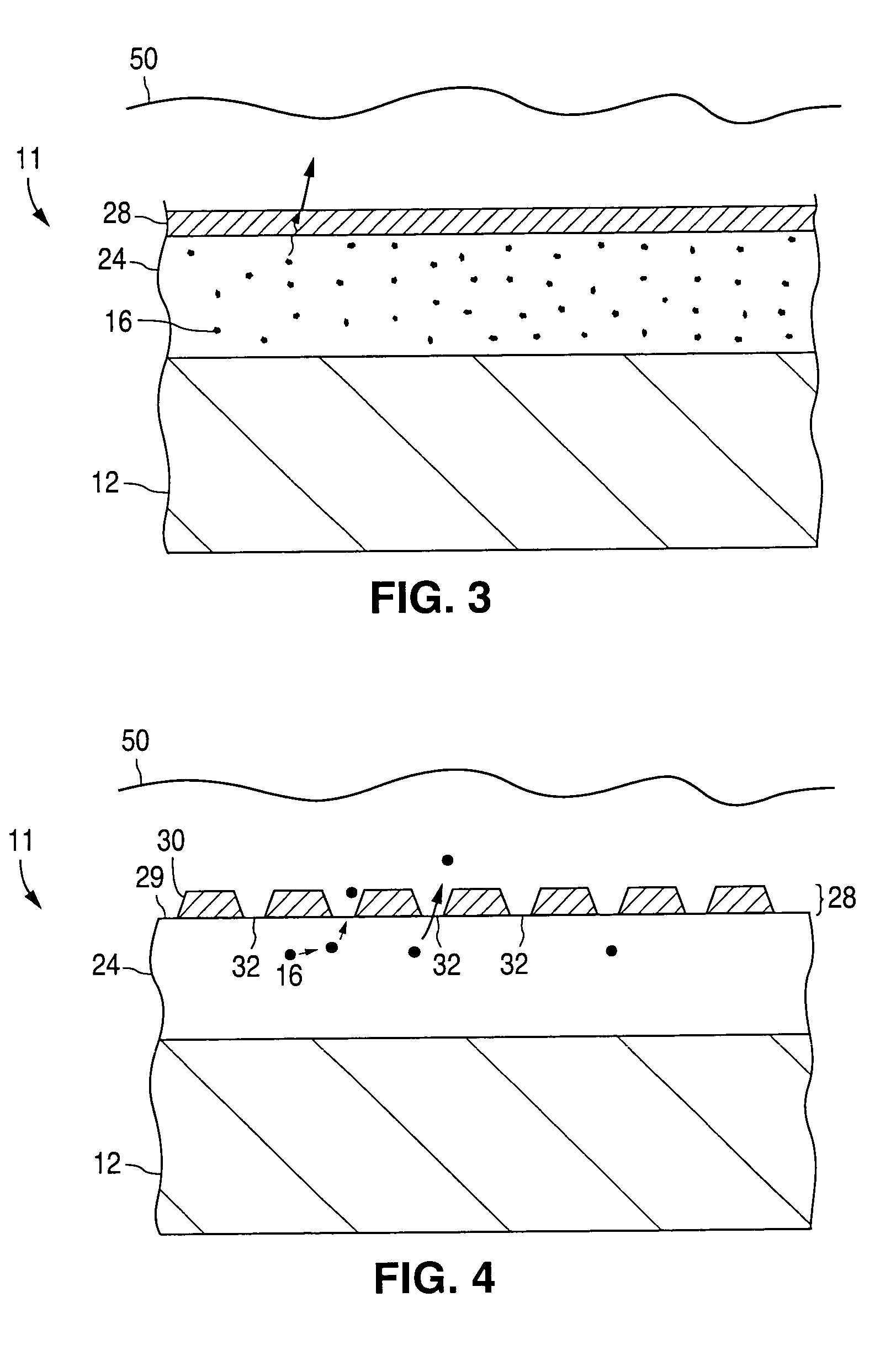

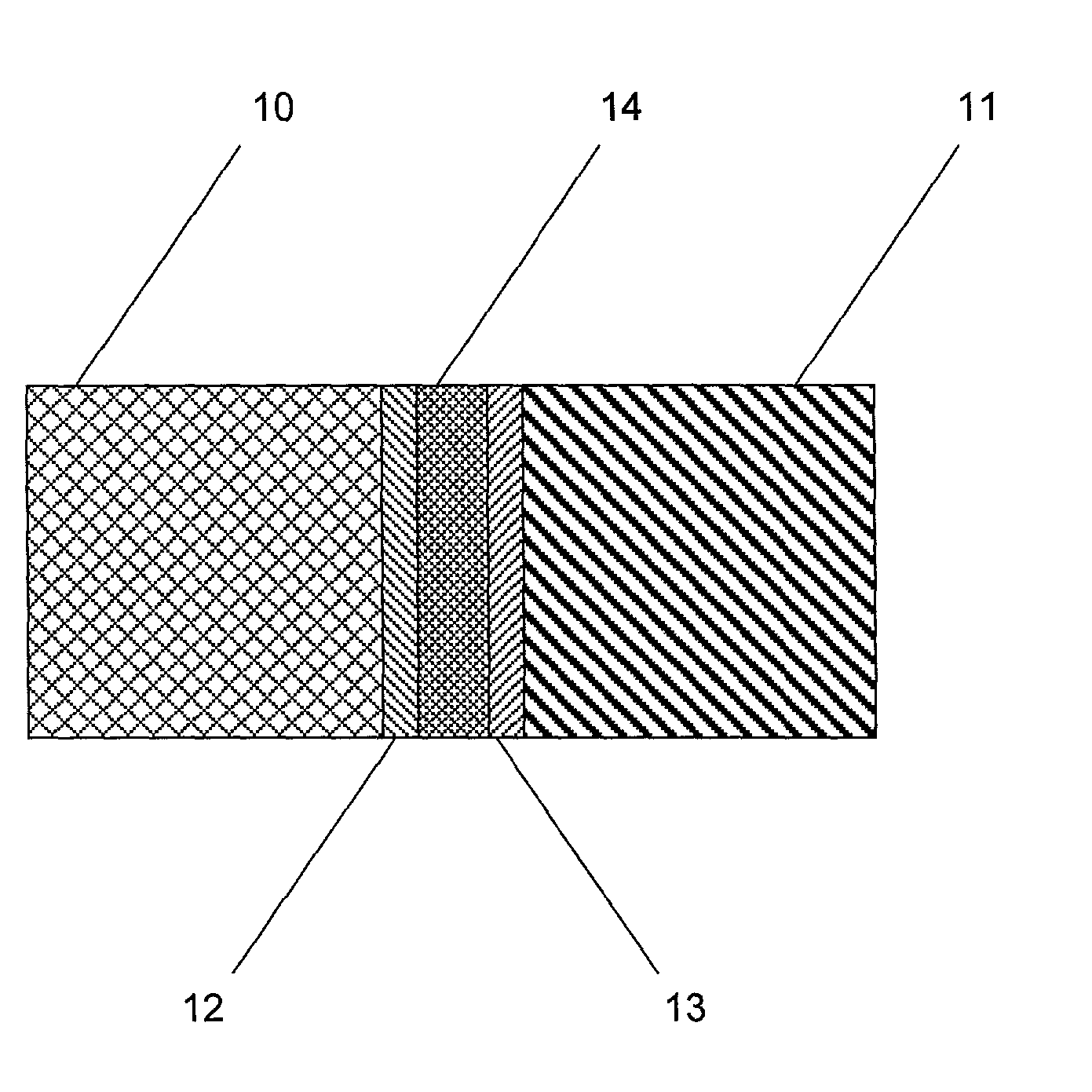

Barriers for polymer-coated implantable medical devices and methods for making the same

InactiveUS6953560B1Reduce and prevent and inflammationReduce and prevent proliferationStentsSurgeryHafniumPt element

An implantable medical device and methods for making the implantable medical device are disclosed. The implantable medical device includes a substrate. At least a portion of the substrate is coated with a first layer including a polymer containing a drug. A barrier overlies the first layer. The barrier significantly reduces the rate of release of the drug from the polymer, thereby sustaining release of the drug from the medical device for a longer time.The barrier may be a homogeneous layer overlying the first layer, or a number of discrete deposits over the first layer. Alternatively, the barrier may be intermixed with an outer portion of the first layer. The barrier material is biocompatible, and typically has a thickness ranging from about 50 angstroms to about 20,000 microns. Suitable materials for the barrier include, but are not limited to, inorganic compounds, such as inorganic silicides, oxides, nitrides, carbides, as well as pure metals such as aluminum, chromium, gold, hafnium, iridium, niobium, palladium, platinum, tantalum, titanium, tungsten, zirconium, and alloys of these metals. The barriers disclosed may be applied to the first layer by several techniques, depending on the material being applied. Exemplary deposition techniques include physical vapor deposition, alkoxide hydrolysis, and electroless plating.The implantable device may be a stent or a graft, among other possibilities.

Owner:ABBOTT CARDIOVASCULAR

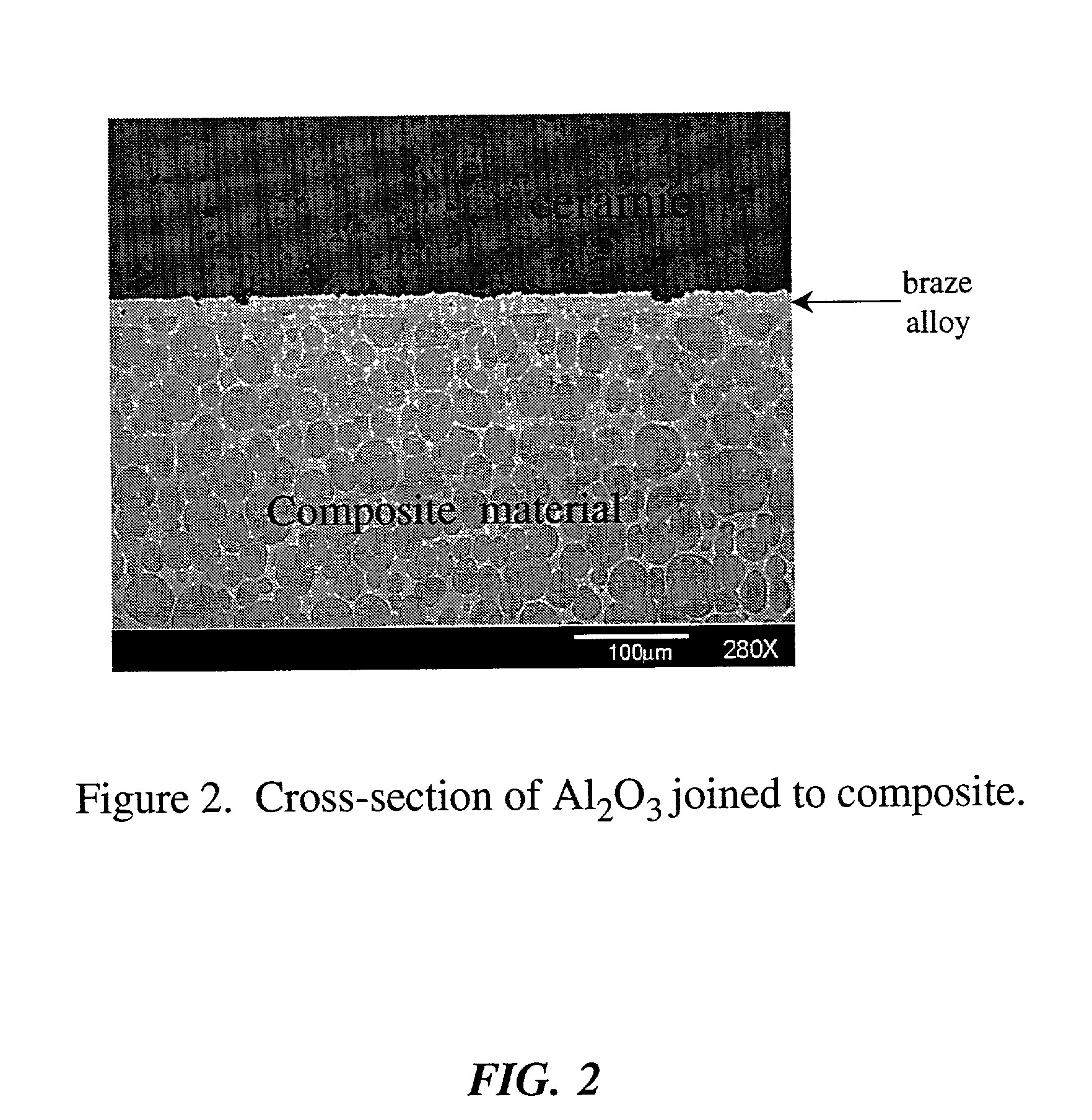

Braze system and method for reducing strain in a braze joint

A system for joining a pair of structural members having widely differing coefficients of thermal expansion is disclosed. A mechanically "thick" foil is made by dispersing a refractory metal powder, such as molybdenum, niobium, tantalum, or tungsten into a quantity of a liquid, high expansion metal such as copper, silver, or gold, casting an ingot of the mixture, and then cutting sections of the ingot about 1 mm thick to provide the foil member. These foil members are shaped, and assembled between surfaces of structural members for joining, together with a layer of a braze alloy on either side of the foil member capable of wetting both the surfaces of the structural members and the foil. The assembled body is then heated to melt the braze alloy and join the assembled structure. The foil member subsequently absorbs the mechanical strain generated by the differential contraction of the cooling members that results from the difference in the coefficients of thermal expansion of the members.

Owner:SANDIA NAT LAB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com