Patents

Literature

1223 results about "Moisture barrier" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

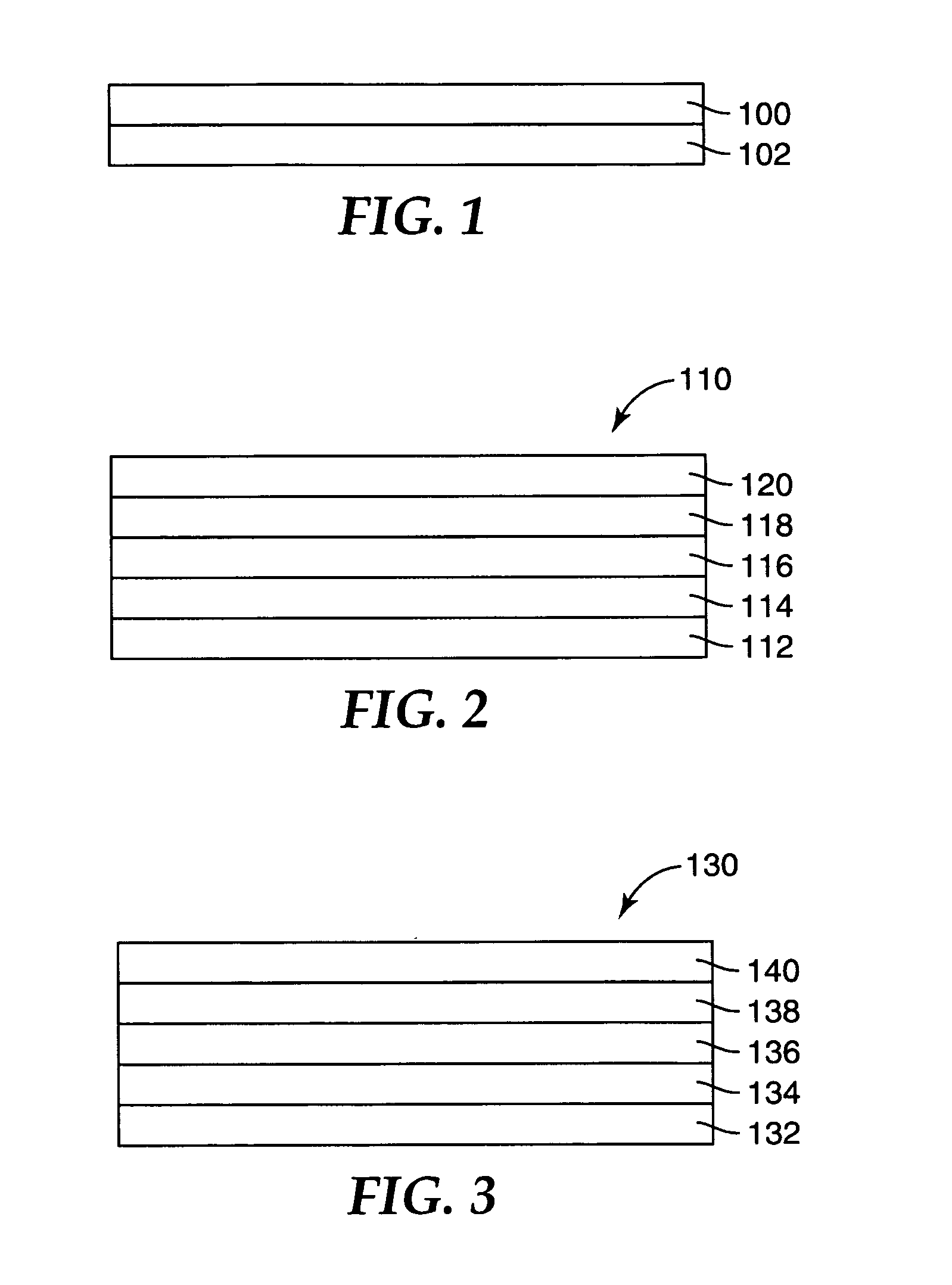

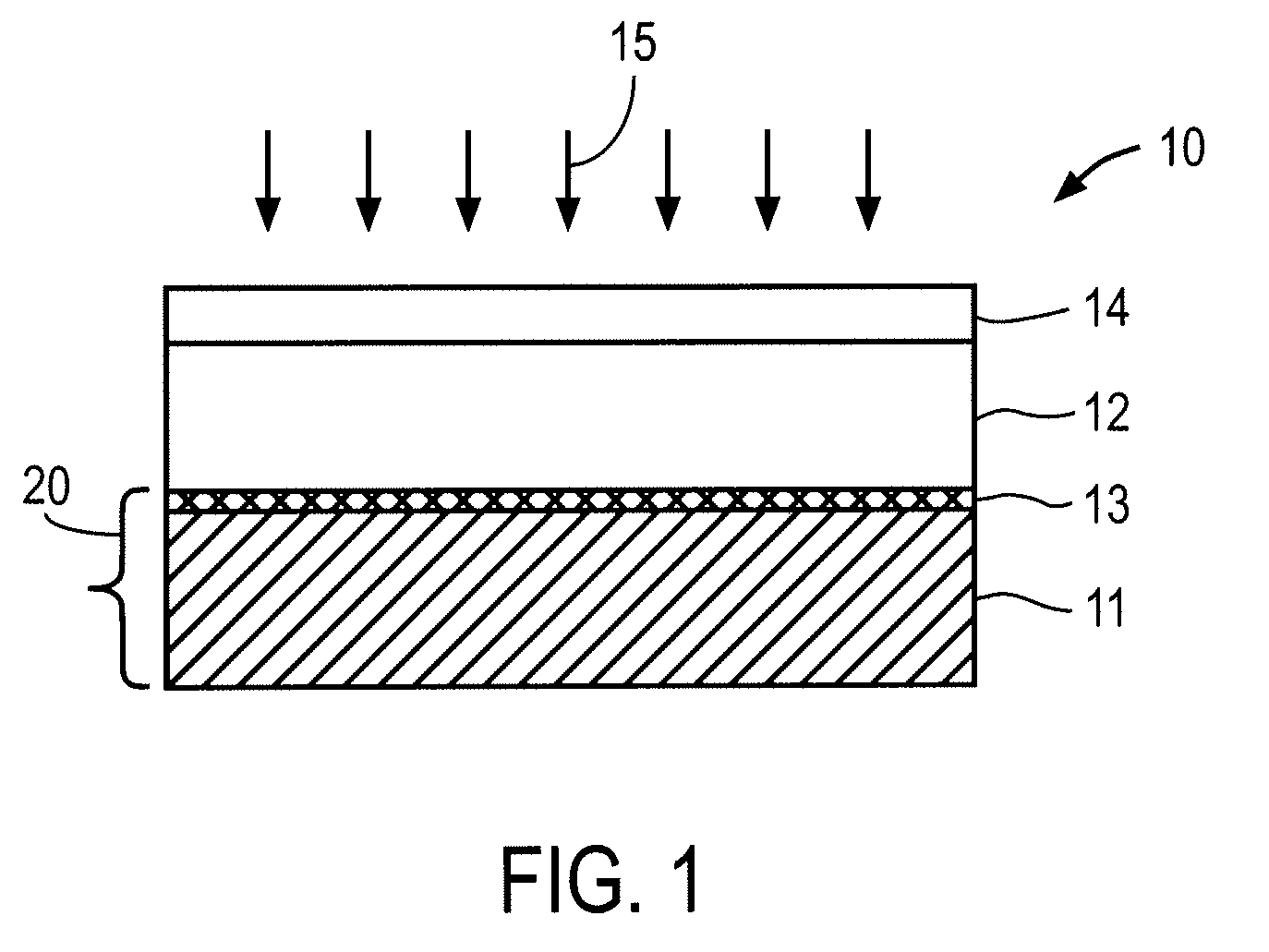

Method of forming a hybrid polymer film

InactiveUS6214422B1Fine surfaceLow costFixed capacitor dielectricSynthetic resin layered productsThermoplasticCross-link

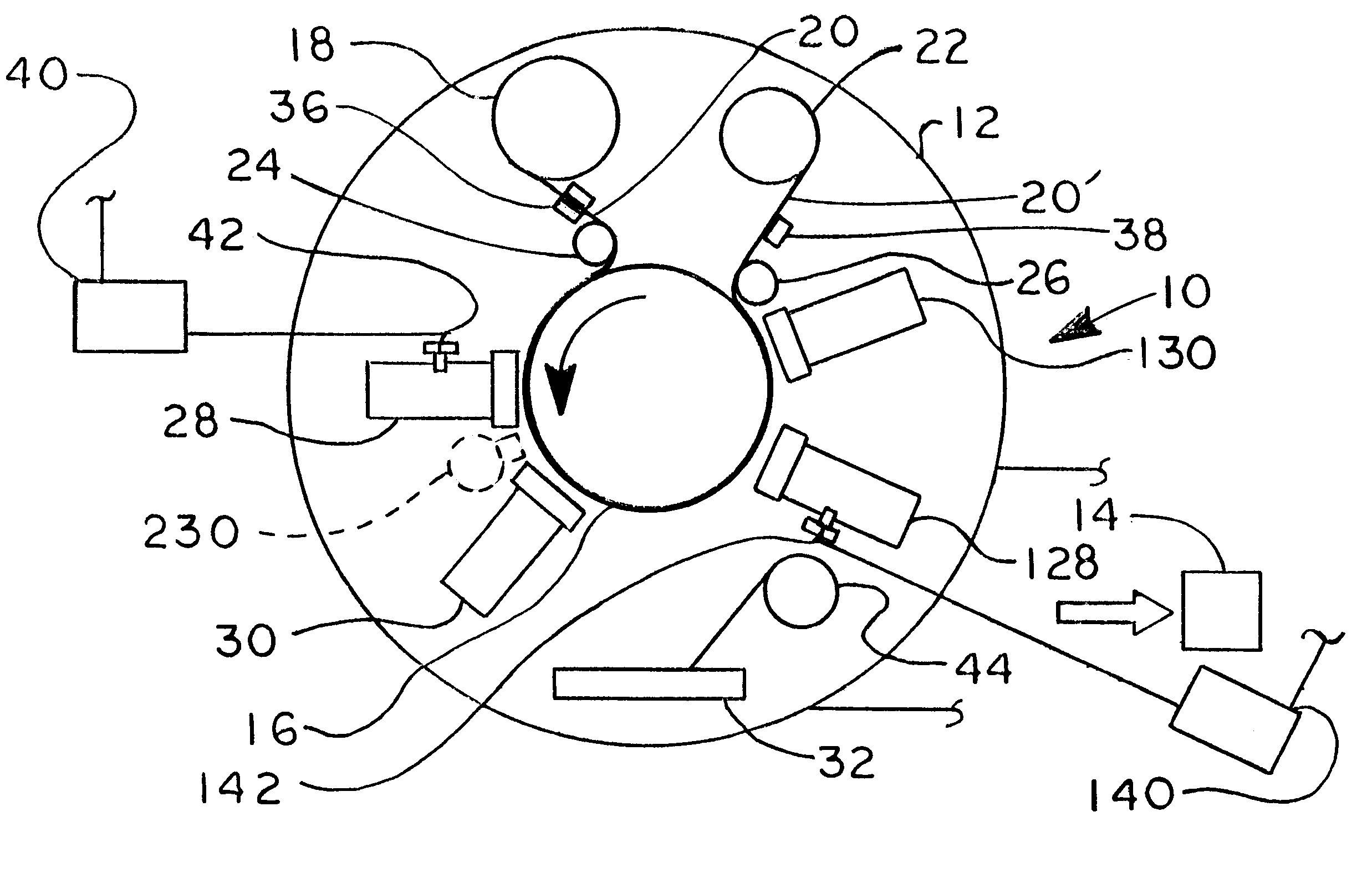

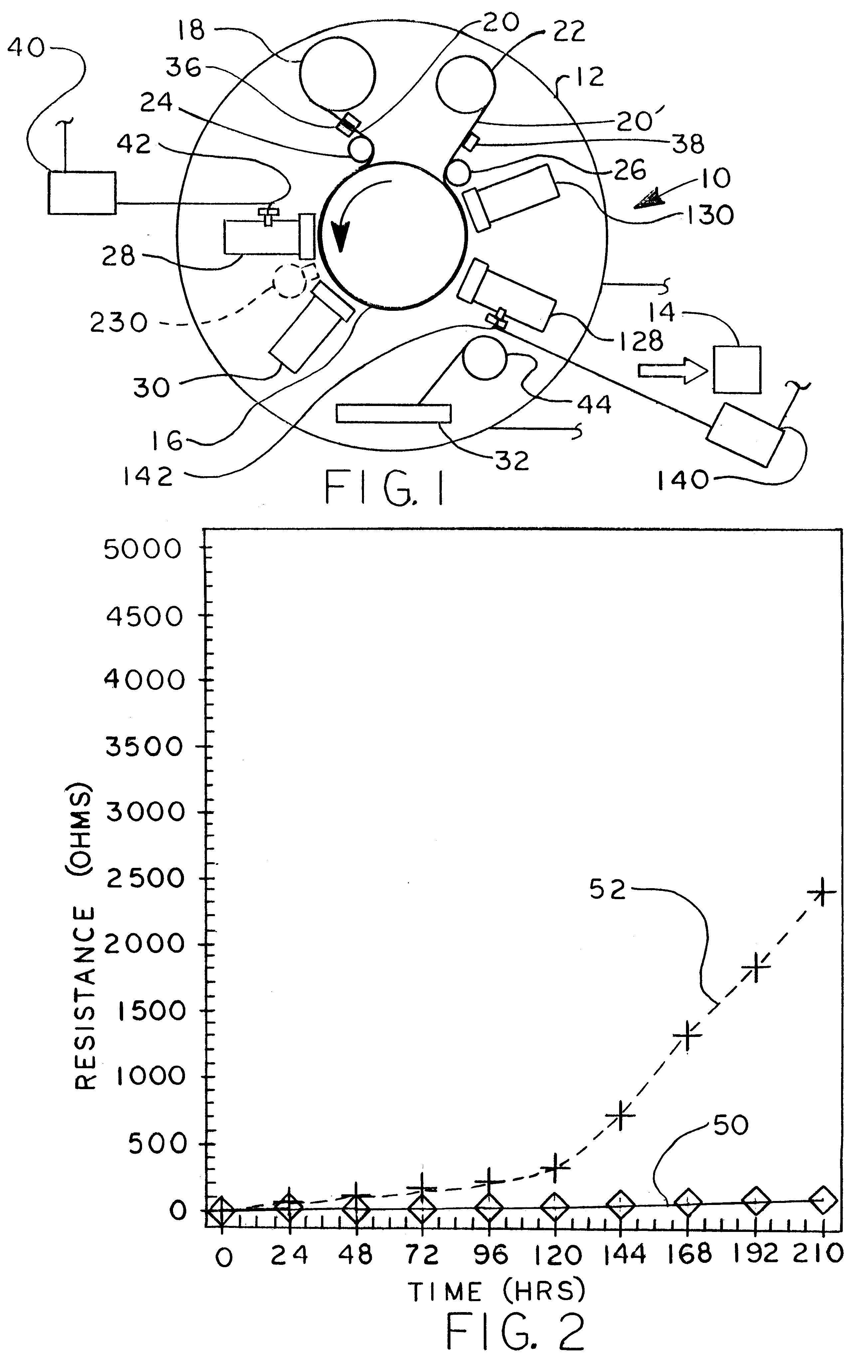

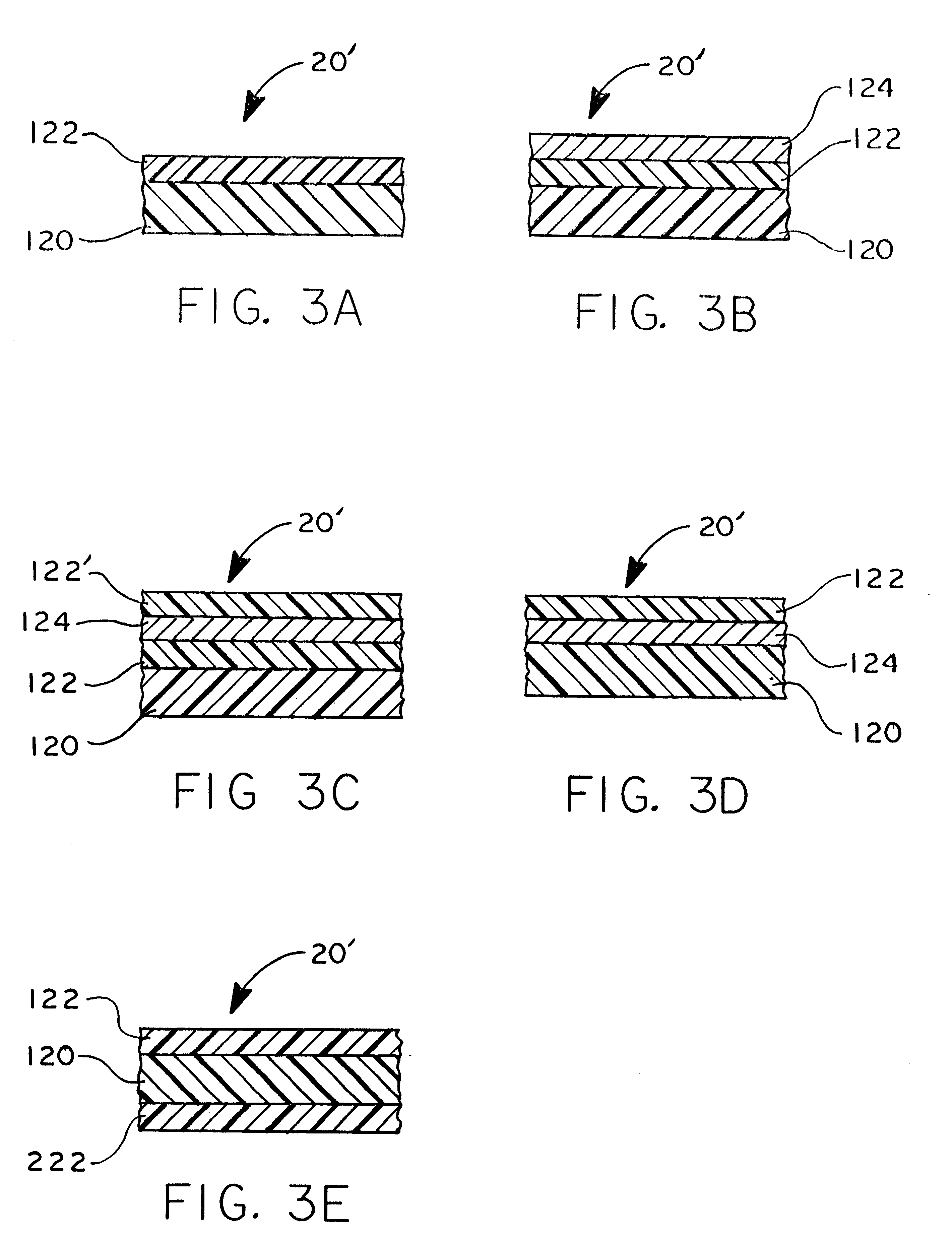

A hybrid film, comprising a first polymer film having a plasma-treated surface and a second polymer film having first and second surfaces, with the first surface of the second polymer film being disposed along the first plasma-treated surface of the first polymer film, has superior thermal and mechanical properties that improve performance in a number of applications, including food packaging, thin film metallized and foil capacitors, metal evaporated magnetic tapes, flexible electrical cables, and decorative and optically variable films. One or more metal layers may be deposited on either the plasma-treated surface of the substrate and / or the radiation-cured acrylate polymer A ceramic layer may be deposited on the radiation-cured acrylate polymer to provide an oxygen and moisture barrier film. The hybrid film is produced using a high speed, vacuum polymer deposition process that is capable of forming thin, uniform, high temperature, cross-liked acrylate polymers on specific thermoplastic or thermoset films. Radiation curing is employed to cross-link the acrylate monomer. The hybrid film can be produced in-line with the metallization or ceramic coating process, in the same vacuum chamber and with minimal additional cost.

Owner:SIGMA LAB OF ARIZONA

Novel film for copper diffusion barrier

InactiveUS20060019486A1Semiconductor/solid-state device detailsSolid-state devicesAtmospheric airBoron nitride

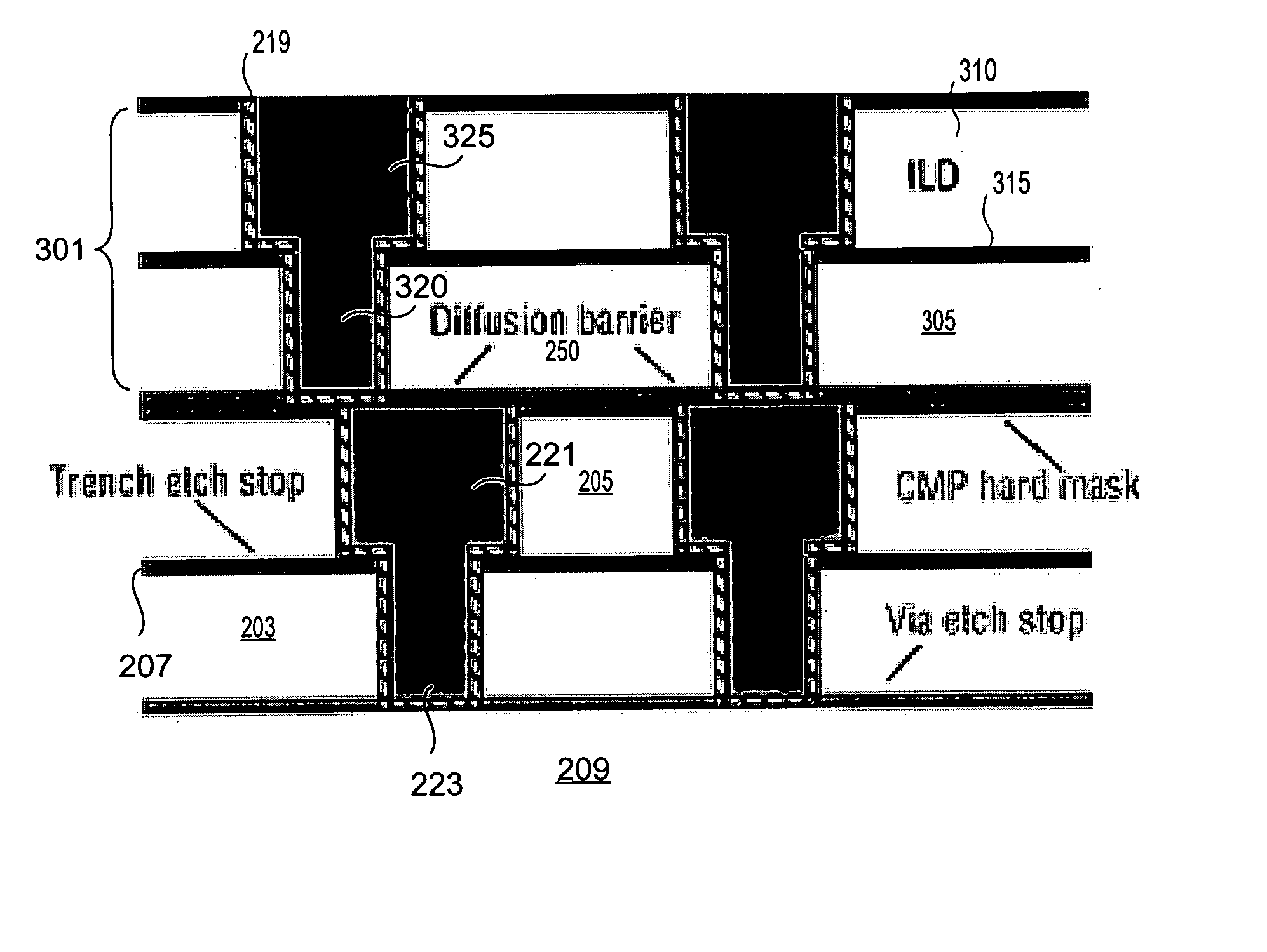

The present invention provides a low dielectric constant copper diffusion barrier film suitable for use in a semiconductor device and methods for fabricating such a film. Some embodiments of the film are formed of a silicon-based material doped with boron. Other embodiments are formed, at least in part, of boron nitride. Some such embodiments include a moisture barrier film that includes oxygen and / or carbon. Preferred embodiments of the copper diffusion barrier maintain a stable dielectric constant of less than 4.5 in the presence of atmospheric moisture.

Owner:NOVELLUS SYSTEMS

Hybrid polymer film

InactiveUS6083628AFine surfaceLow costFixed capacitor dielectricSynthetic resin layered productsThermoplasticCross-link

A hybrid film, comprising a first polymer film having a plasma-treated surface and a second polymer film having first and second surfaces, with the first surface of the second polymer film being disposed along the first plasma-treated surface of the first polymer film, has superior thermal and mechanical properties that improve performance in a number of applications, including food packaging, thin film metallized and foil capacitors, metal evaporated magnetic tapes, flexible electrical cables, and decorative and optically variable films. One or more metal layers may be deposited on either the plasma-treated surface of the substrate and / or the radiation-cured acrylate polymer. A ceramic layer may be deposited on the radiation-cured acrylate polymer to provide an oxygen and moisture barrier film. The hybrid film is produced using a high speed, vacuum polymer deposition process that is capable of forming thin, uniform, high temperature, cross-linked acrylate polymers on specific thermoplastic or thermoset films. Radiation curing is employed to cross-link the acrylate monomer. The hybrid film can be produced in-line with the metallization or ceramic coating process, in the same vacuum chamber and with minimal additional cost.

Owner:SIGMA LAB OF ARIZONA

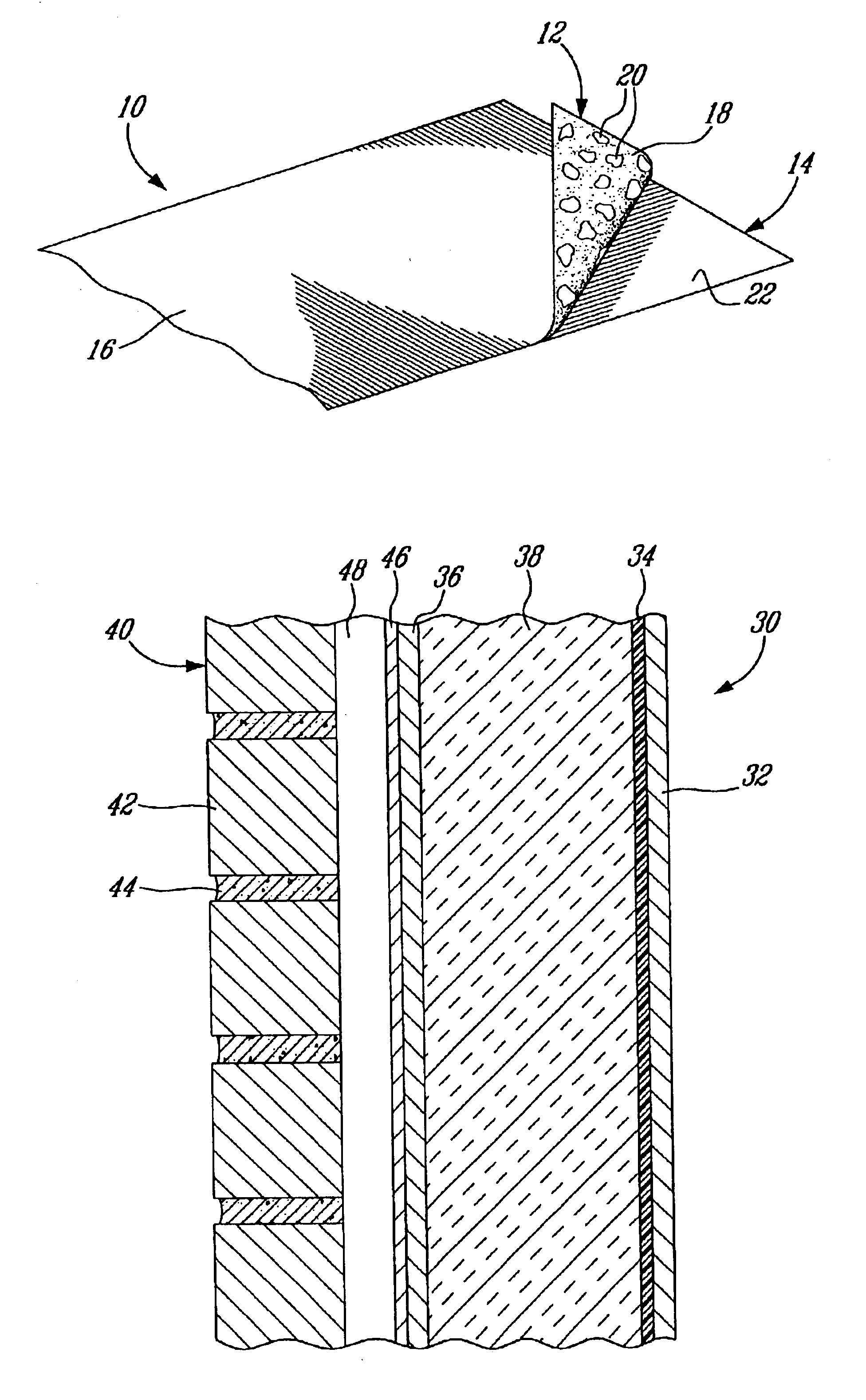

Moisture barrier coatings

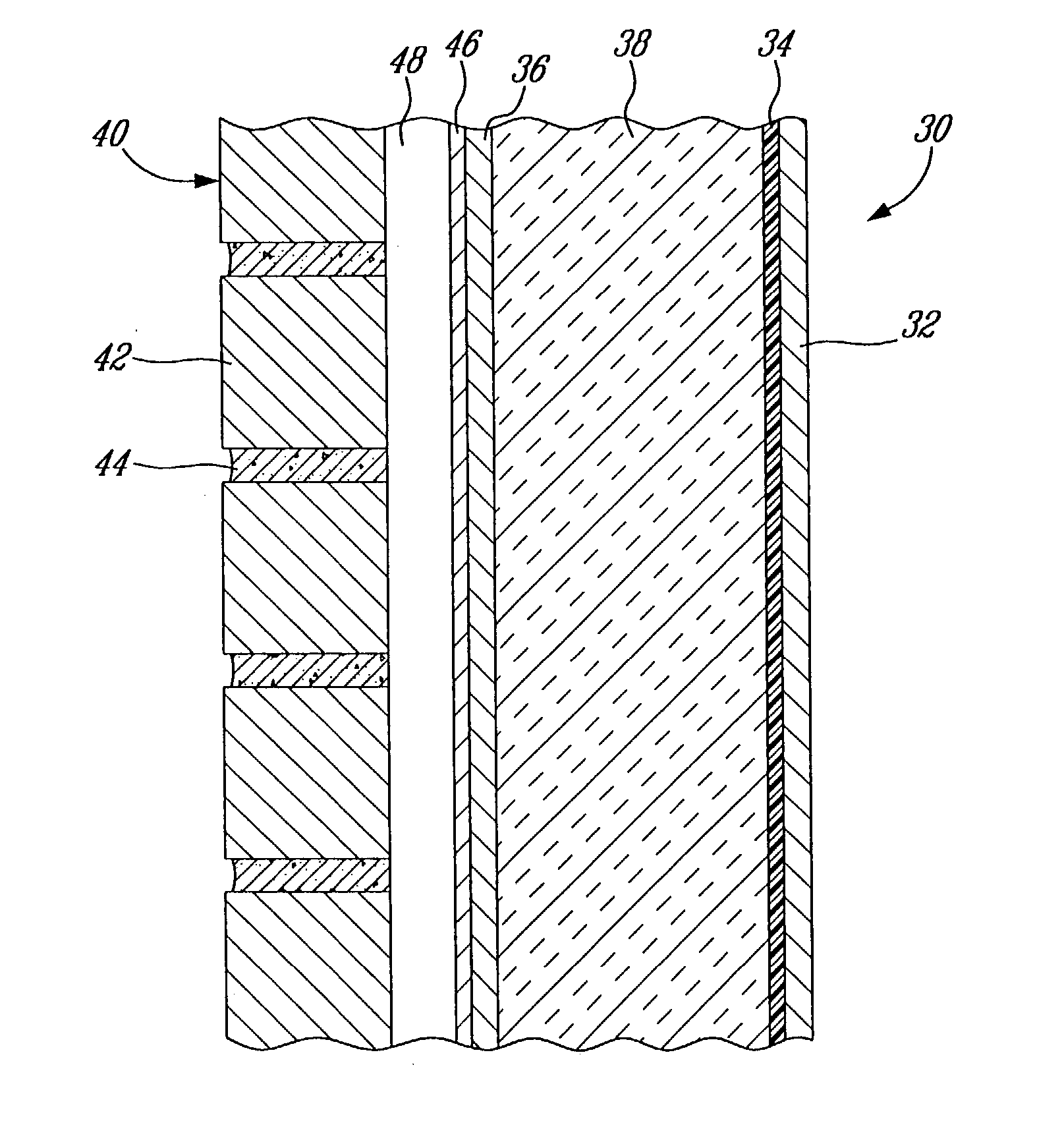

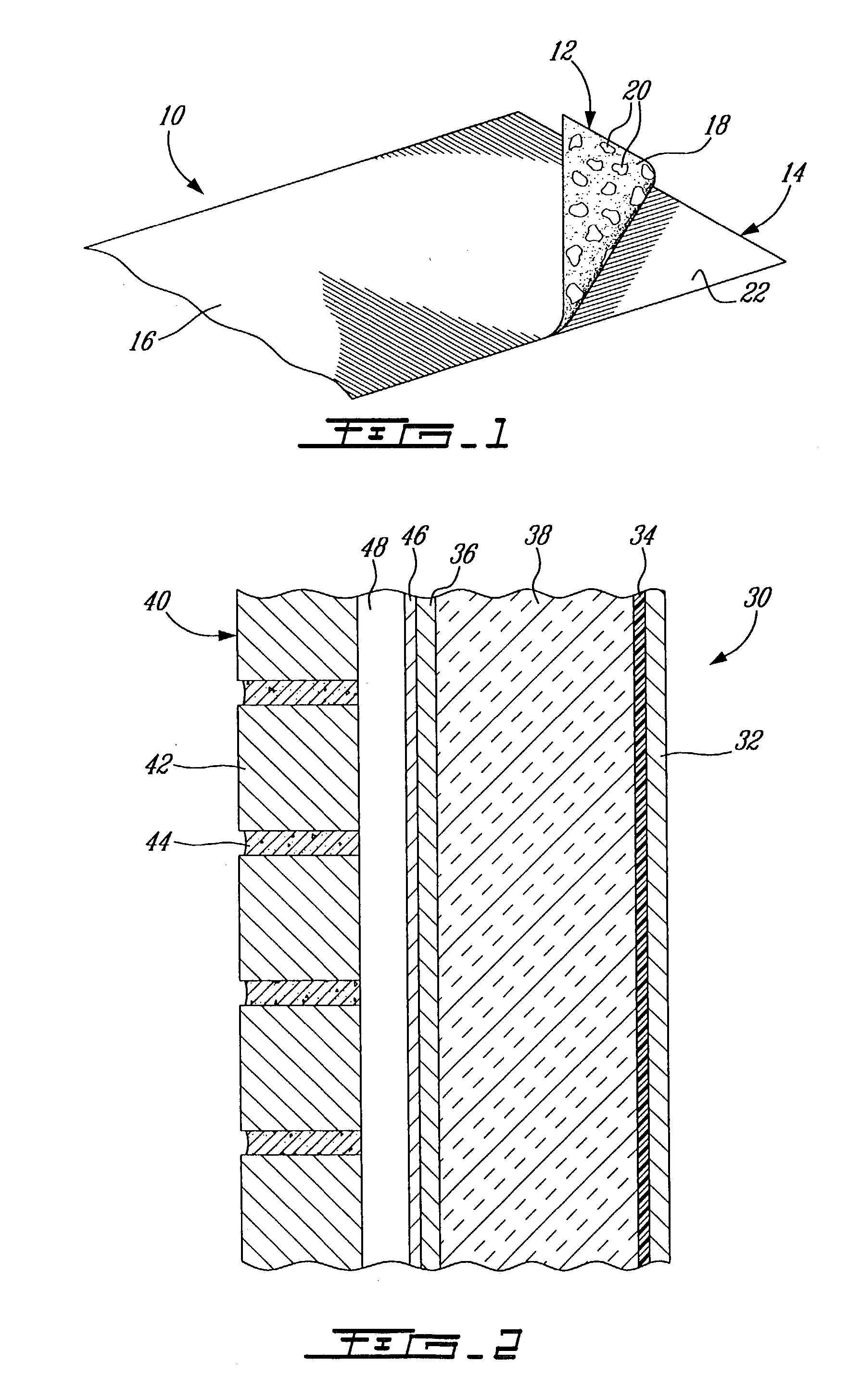

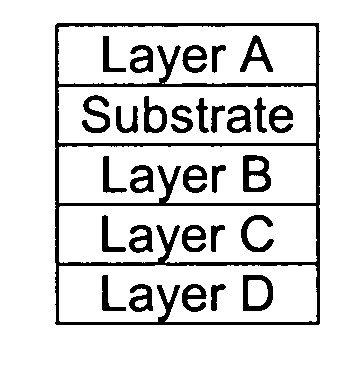

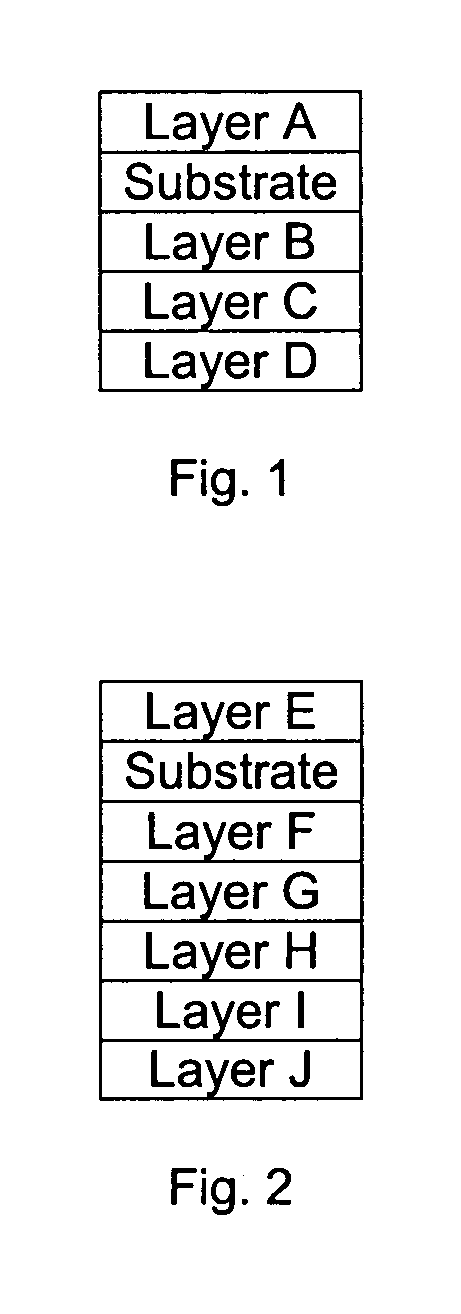

InactiveUS20070020451A1Liquid surface applicatorsSynthetic resin layered productsCarbon layerMoisture barrier

A barrier assembly having a flexible or rigid substrate overcoated with an all polymer multilayer stack. A multilayer on the substrate includes alternating diamond-like glass or carbon layers with polymer layers. Another multilayer includes alternating polymer layers using different types of polymers. The barrier layers can be used to mount, cover, encapsulate or form composite assemblies for protection of moisture or oxygen sensitive articles

Owner:3M INNOVATIVE PROPERTIES CO

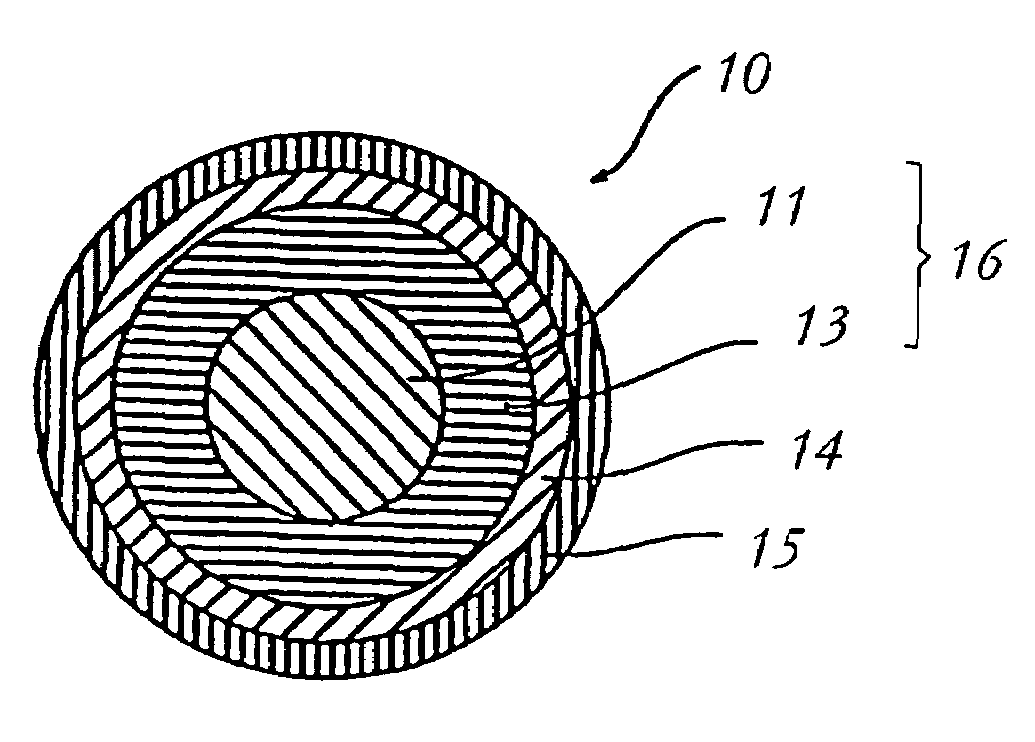

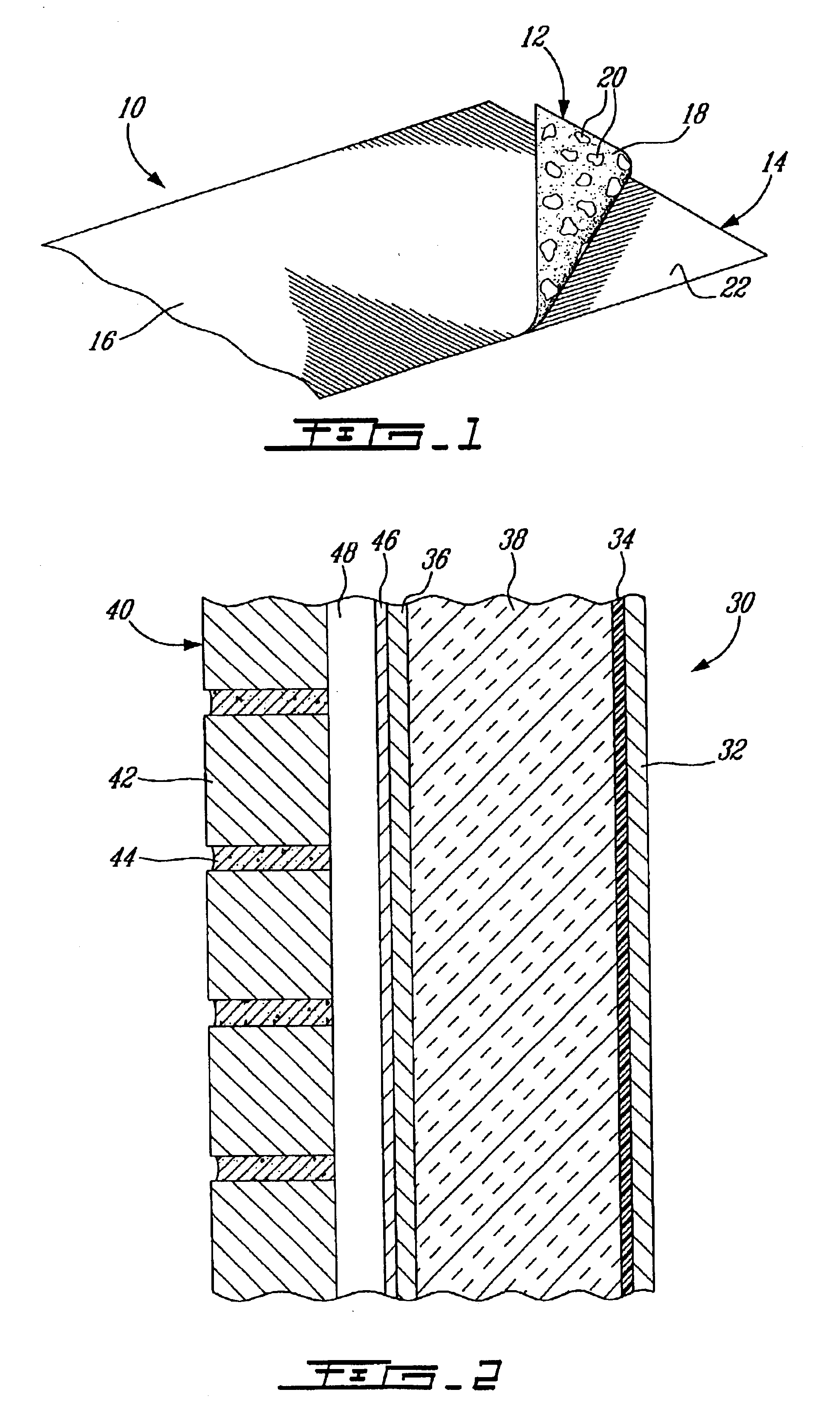

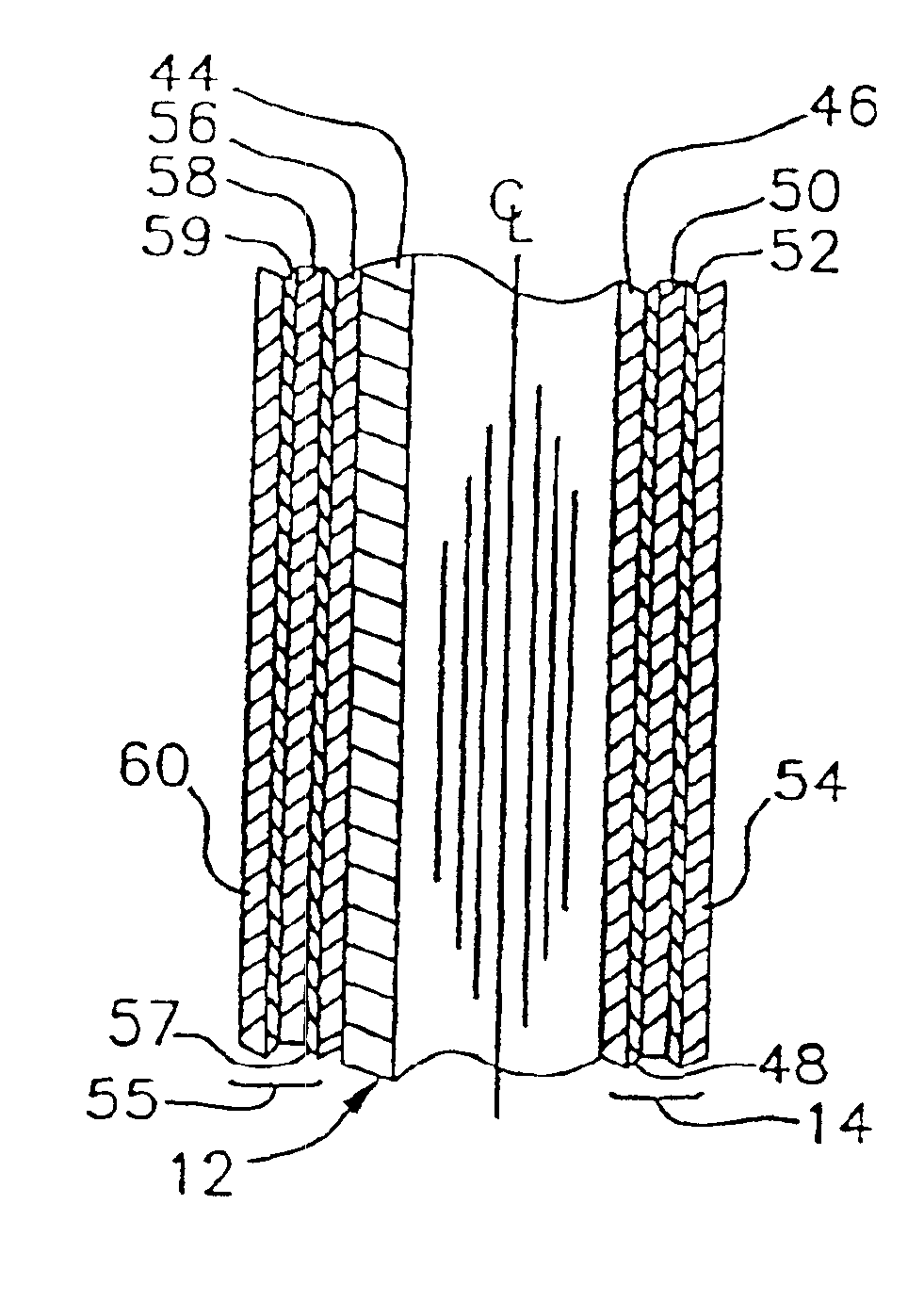

Multi-layer core golf ball

InactiveUS7255656B2Extended service lifeGolf ballsDomestic articlesMoisture vapor transmission rateEngineering

The present invention is directed to an improved golf ball displaying the desired spin profile and having a generally rigid, thermoset polybutadiene outer core surrounding a relatively soft, low compression inner core. In general, this golf ball has an inner core and at least one outer core layer surrounding the inner core. The inner core has a hardness less than a hardness of the outer core and a specific gravity less than or equal to the outer core specific gravity. Overall the inner core compression and outer core are formulated to provide a combined overall core compression of greater than about 50, preferably greater than about 70. A cover layer is provided to surround and to cover the outer core layer. A moisture barrier layer is provided between the outer core layer and the cover layer to protect the inner and outer cores from degradation due to exposure to water. The moisture vapor transmission rate of the moisture barrier layer is selected to be less than the moisture vapor transmission rate of the cover layer.

Owner:ACUSHNET CO

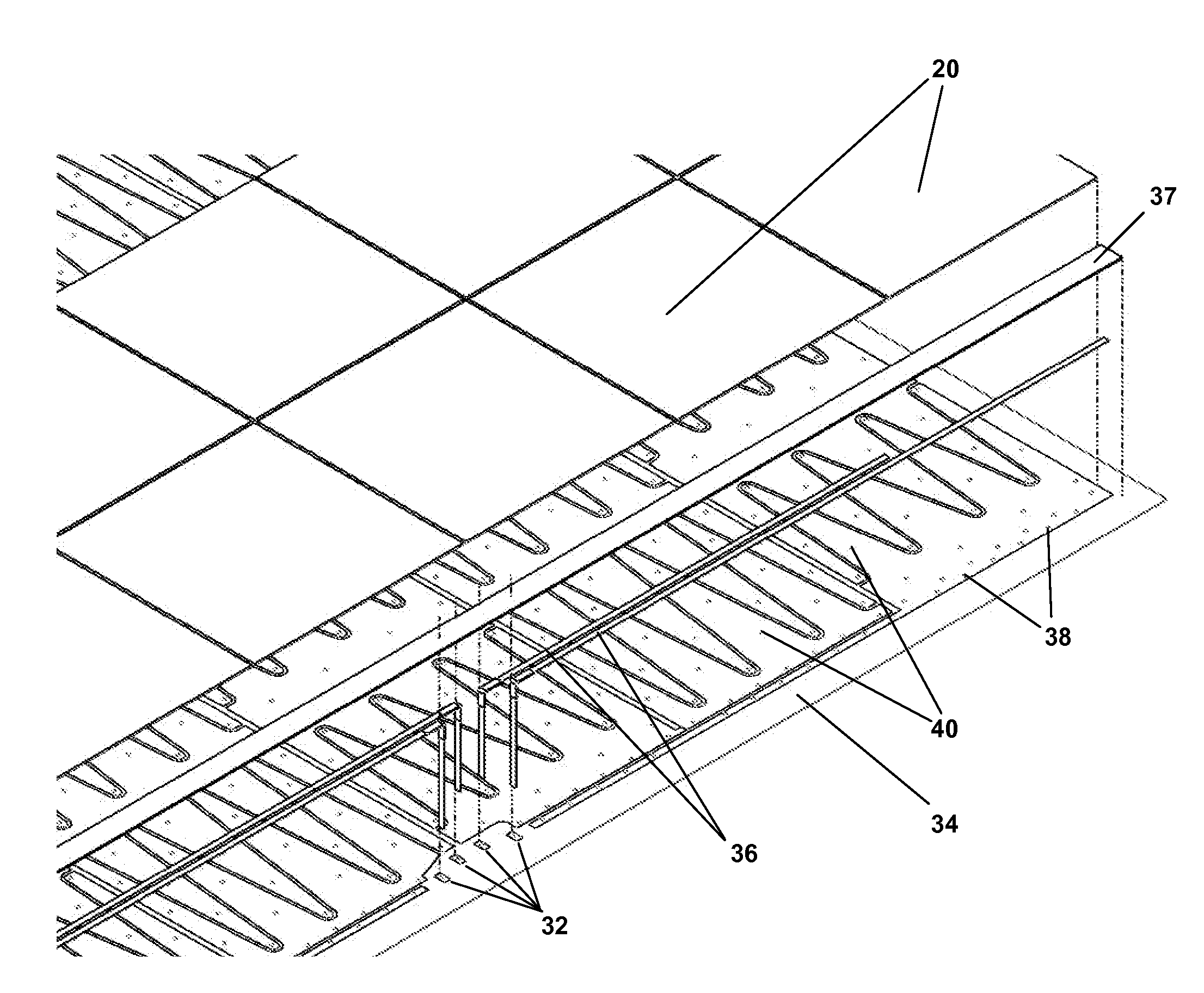

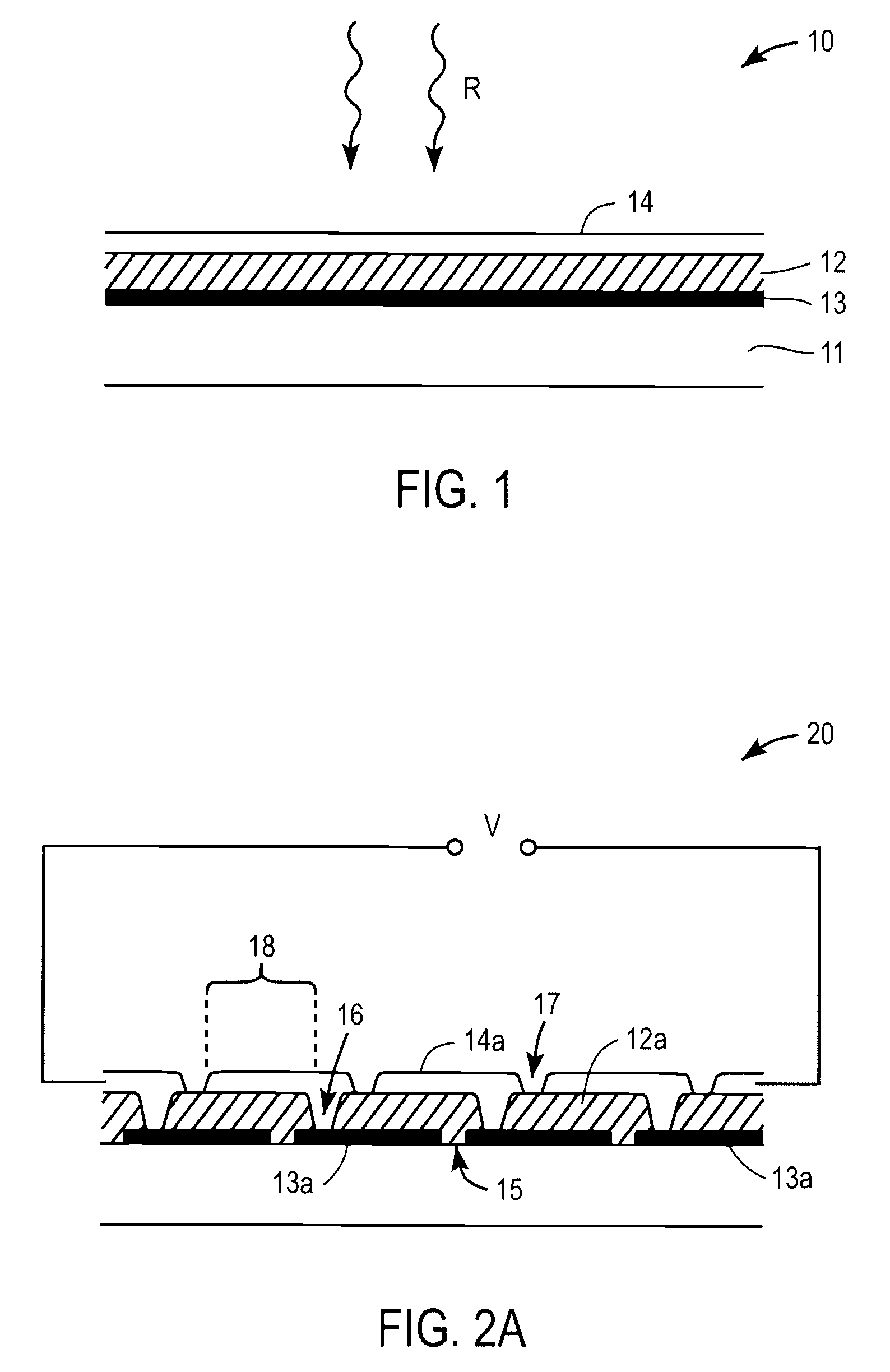

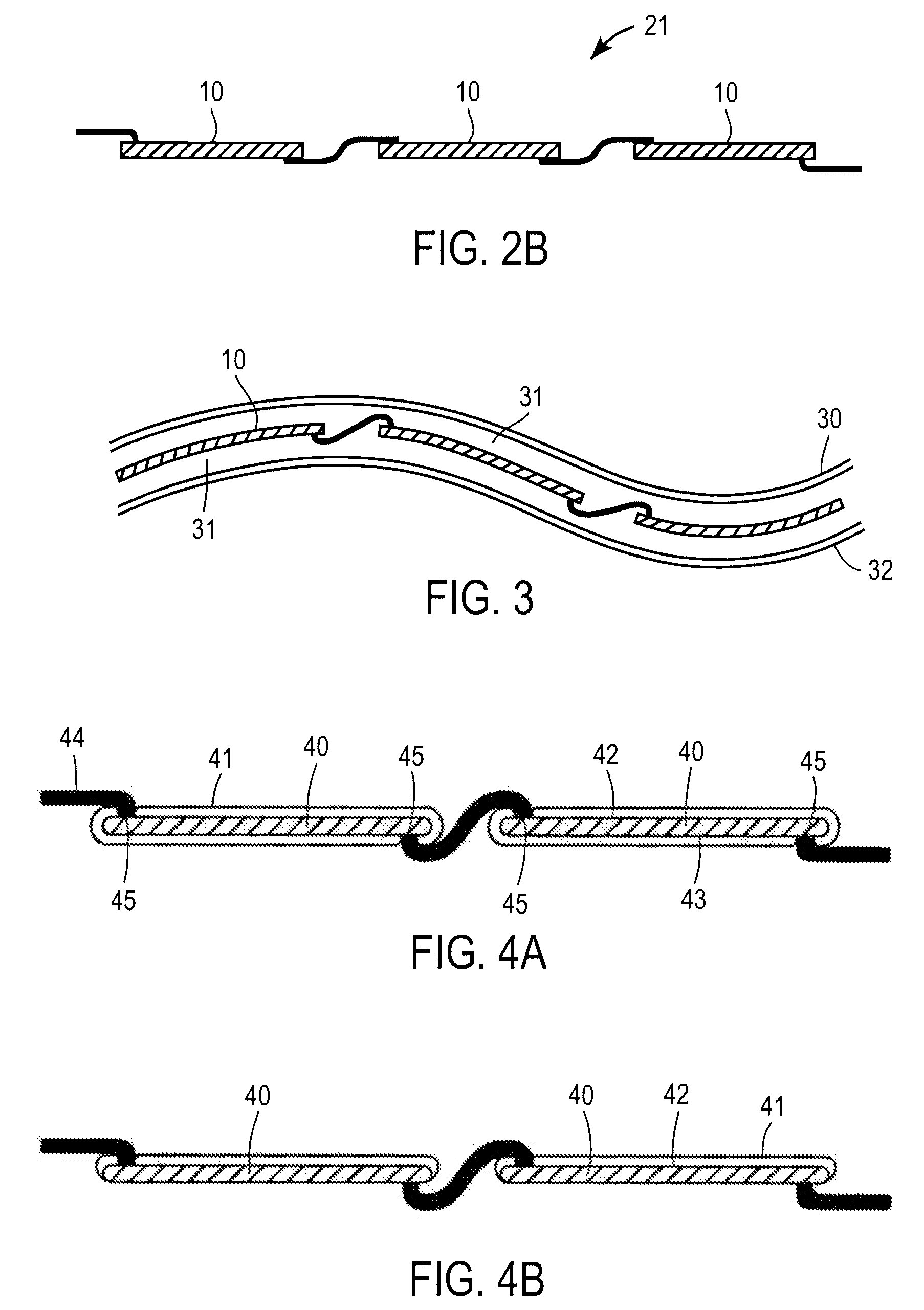

Photovoltaic Modules Manufactured Using Monolithic Module Assembly Techniques

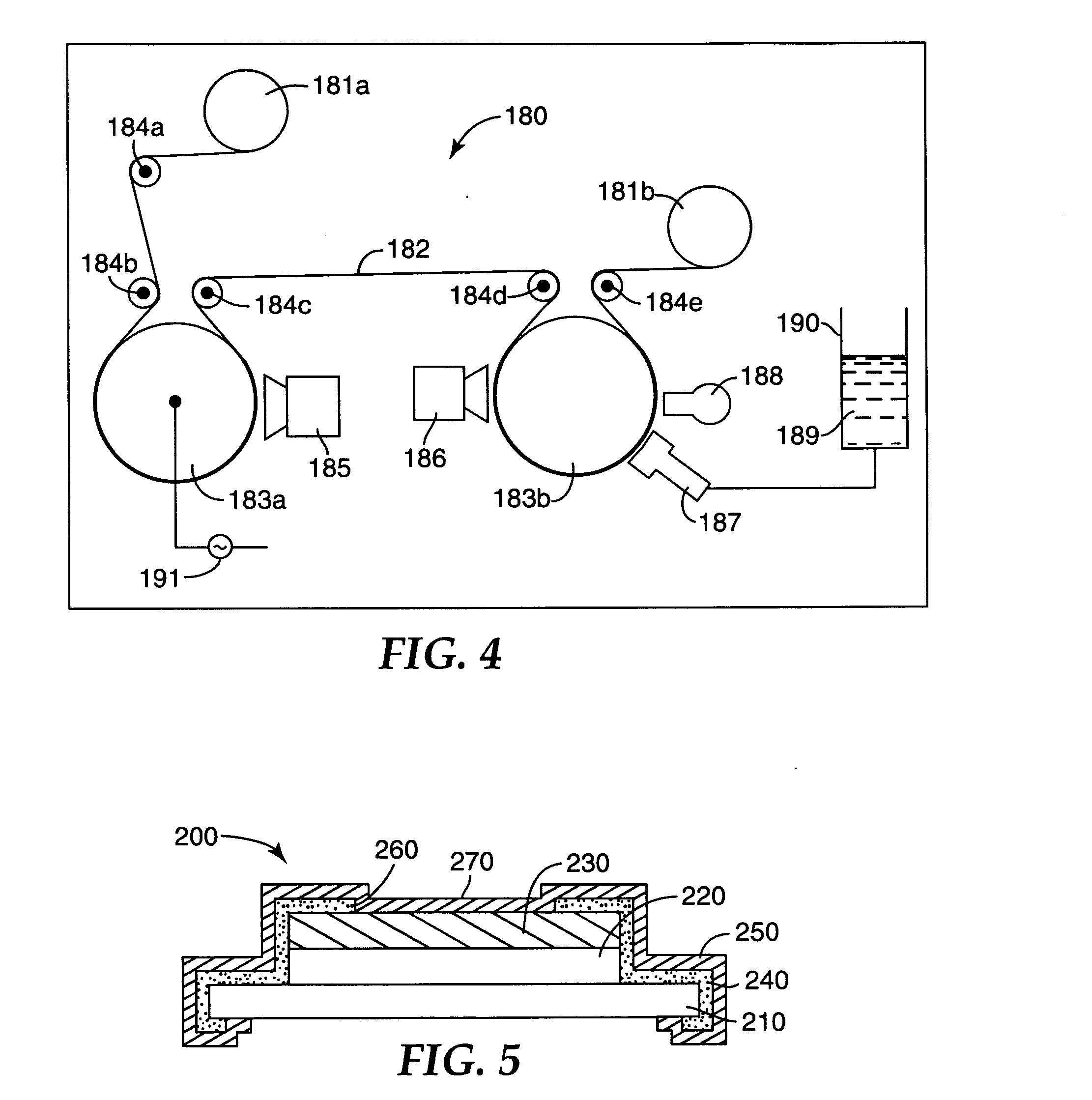

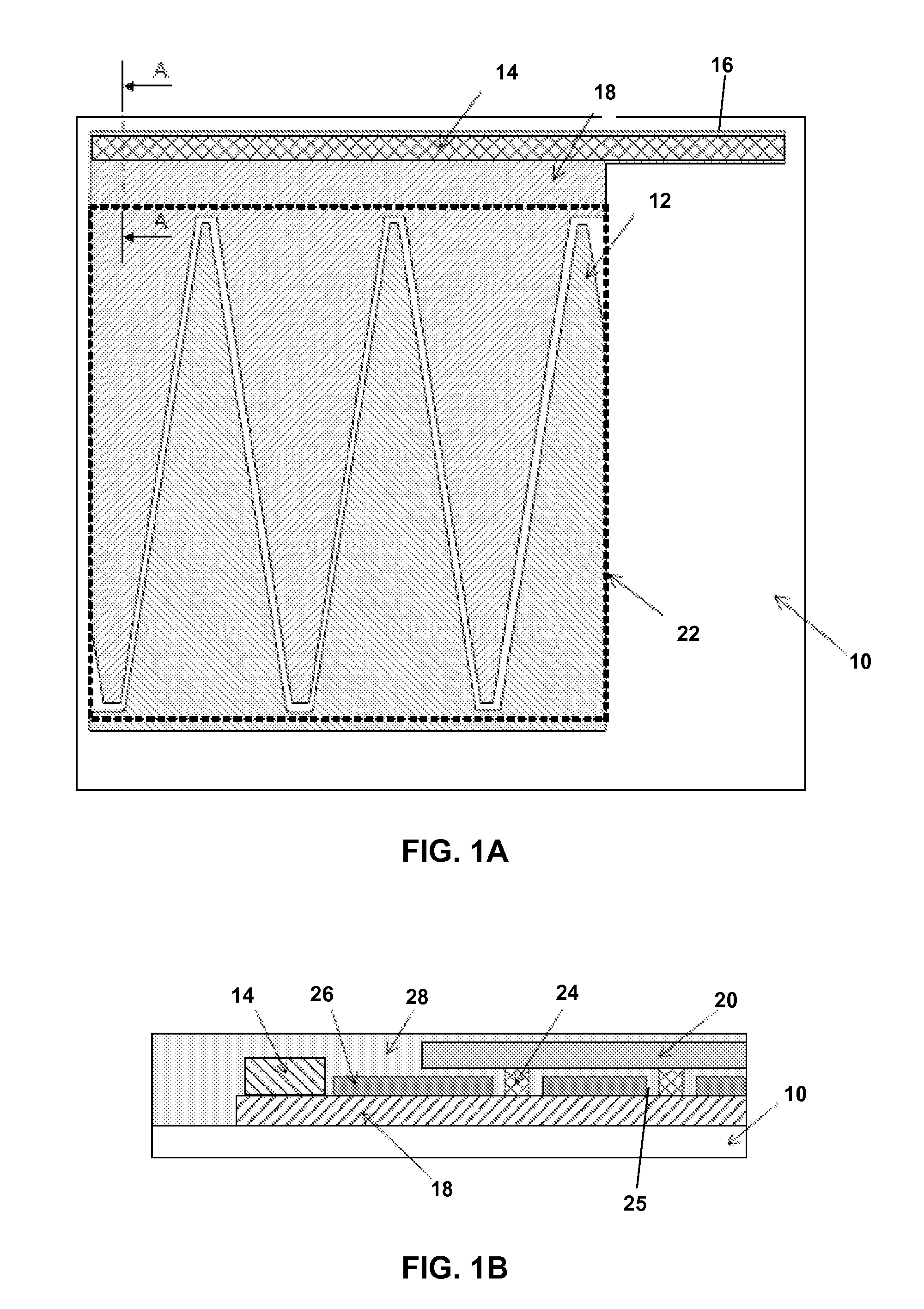

InactiveUS20100012172A1Substantial electrical conductivityLower resistancePV power plantsPhotovoltaic energy generationRoll-to-roll processingFlexible circuits

Photovoltaic modules comprising back-contact solar cells manufactured using monolithic module assembly techniques comprising a flexible circuit comprising a back sheet and a patterned metallization. The module may comprise busses in electrical contact with the patterned metallization to extract the current. The module may alternatively comprise multilevel metallizations. Interlayer dielectric comprising islands or dots relieves stresses due to thermal mismatch. The use of multiple cord plates enables flexible circuit layouts, thus optimizing the module. The modules preferably comprise a thermoplastic encapsulant and / or hybrid adhesive / solder materials. An ultrathin moisture barrier enables roll-to-roll processing.

Owner:APPLIED MATERIALS INC

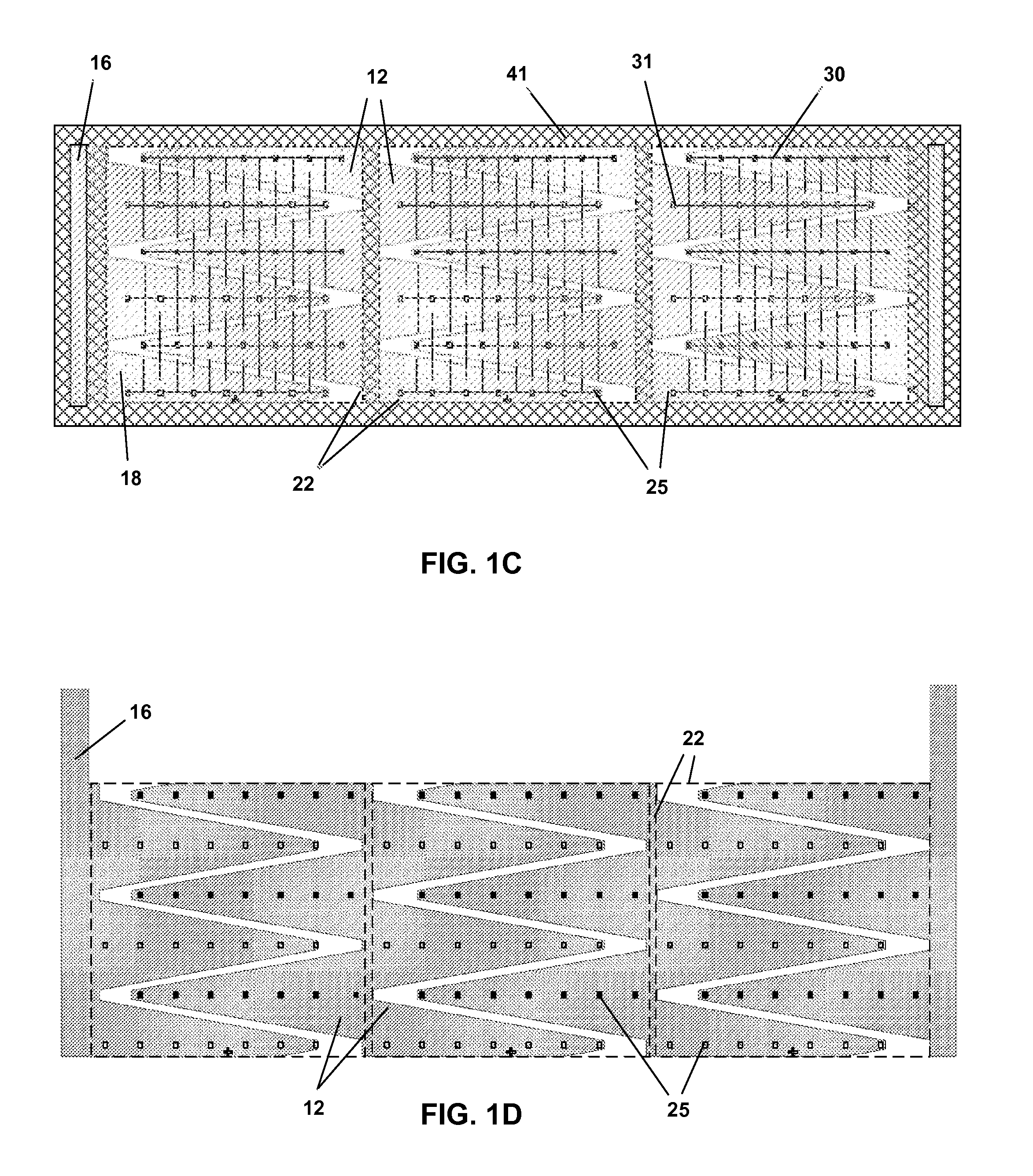

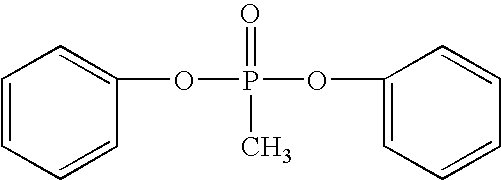

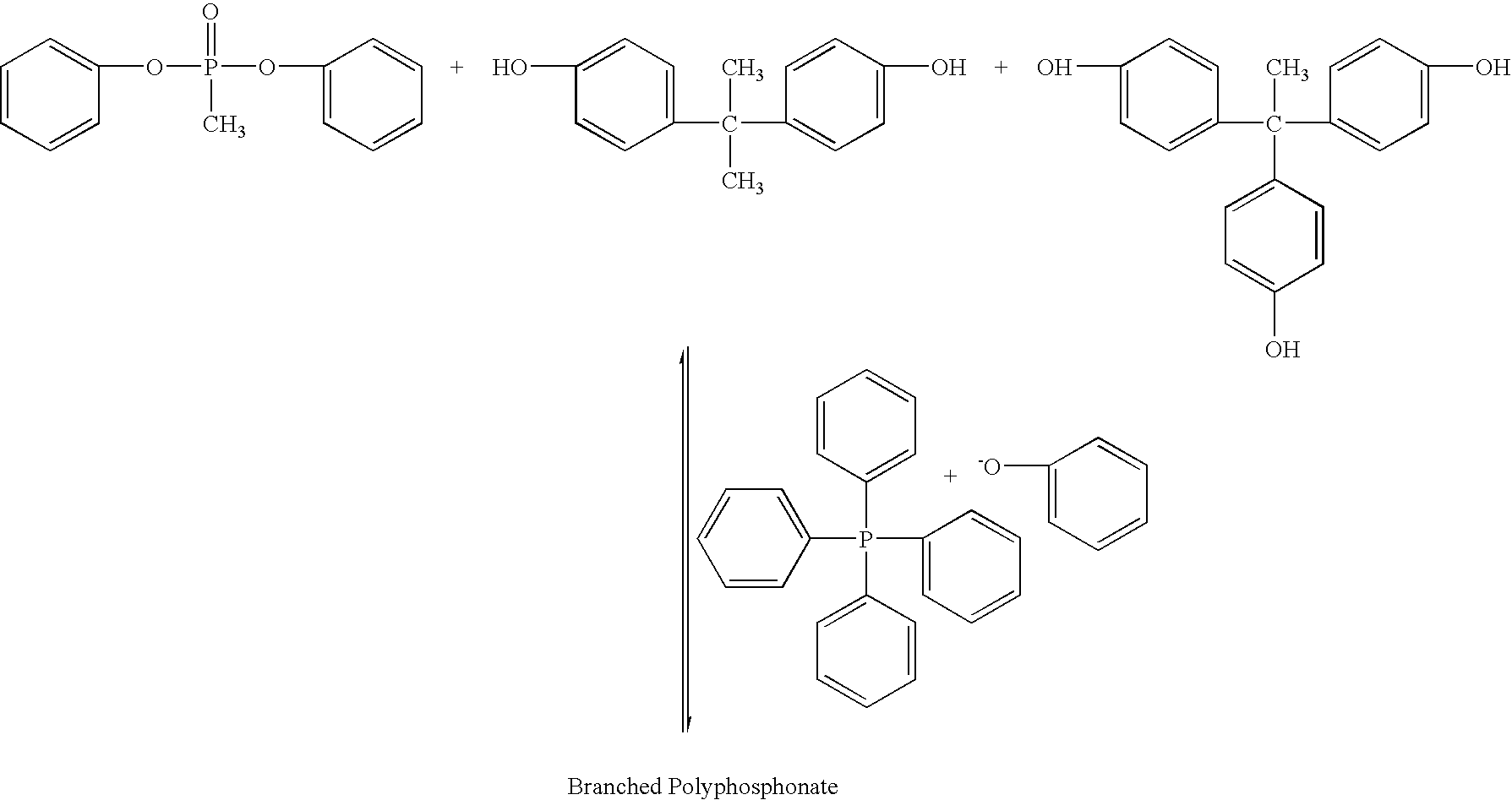

Branched polyphosphonates that exhibit an advantageous combination of properties, and methods related thereto

Disclosed are branched polyphosphonates produced via a superior transesterification process, and methods related thereto. These branched polyphosphonates exhibit a unique and advantageous combination of properties, such as outstanding fire resistance, improved heat stability, improved toughness, and superior processing characteristics. Also disclosed are polymer compositions that comprise these branched polyphosphonates and at least one other polymer, wherein the resulting polymer compositions exhibit flame retardant properties. Further disclosed are articles of manufacture produced from these polymers, such as fibers, films, coated substrates, moldings, foams, fiber-reinforced articles, or any combination thereof; these articles may be coated with a moisture barrier to enhance their moisture resistance properties.

Owner:FRX POLYMERS LLC

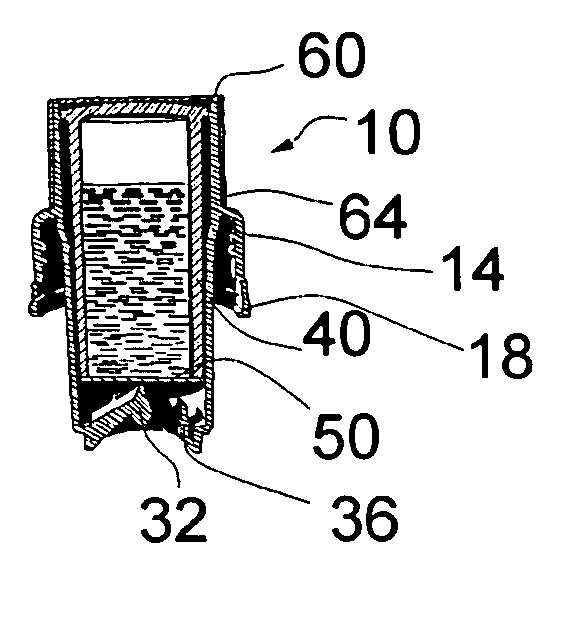

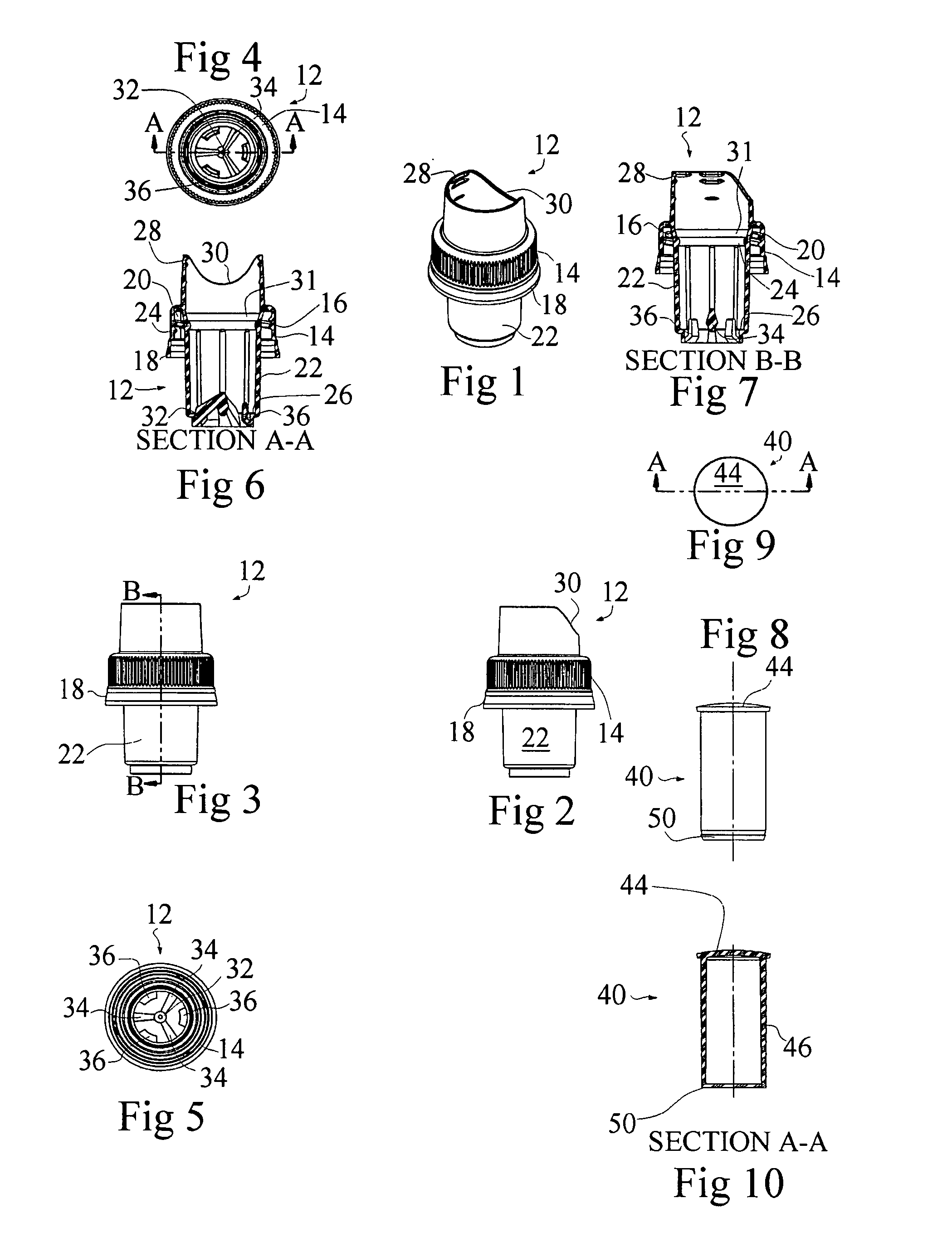

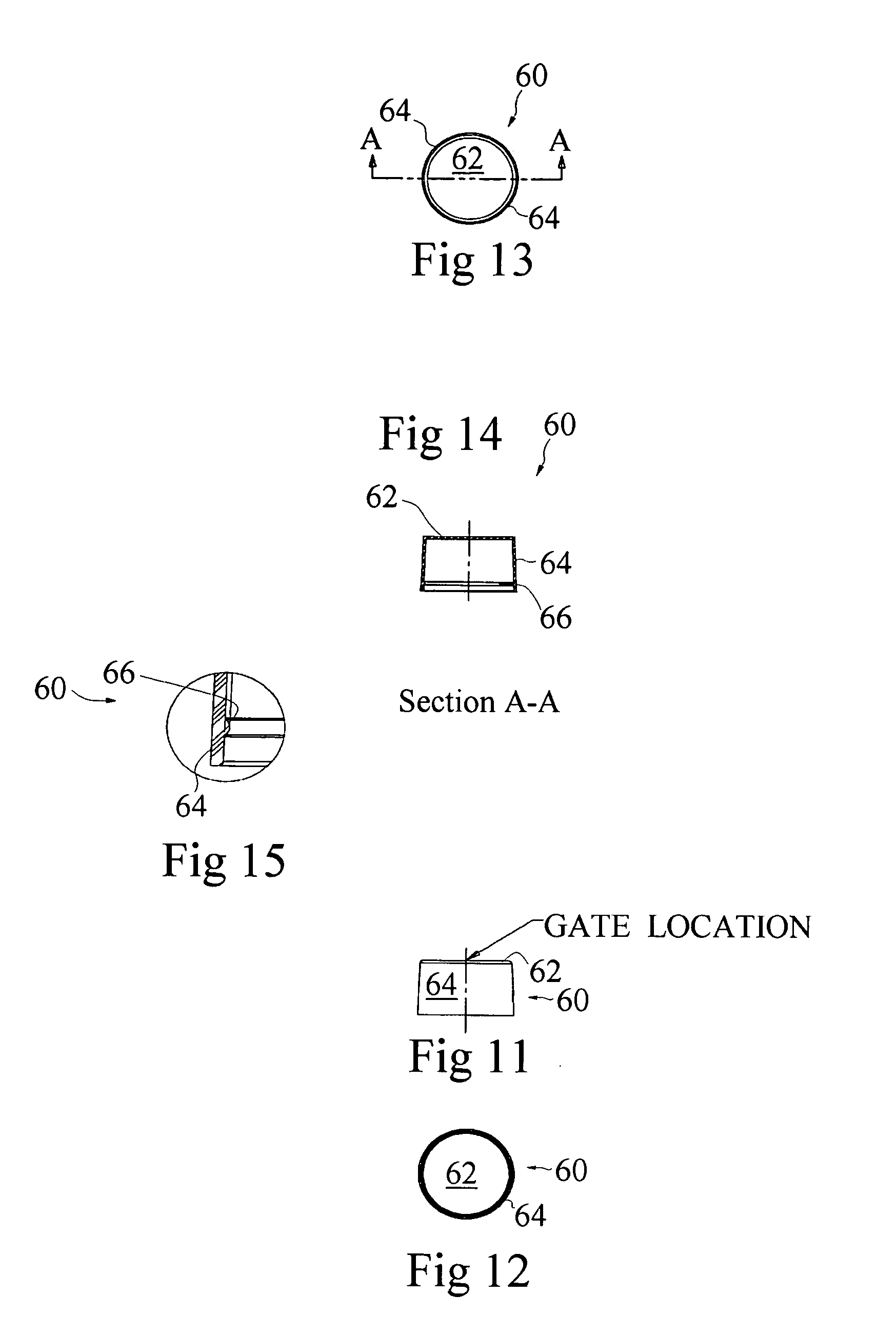

Dispensing closure with integral piercing unit

A single use unit dosage dispensing closure includes a shell attached to a container with an integral piecing member, an axial movable cap attached to the shell and a sealing member coupled to the cap. The shell has an inner guide in communication with the container and the cap is moveable along the guide. The cap has a chamber adapted to dispense material into the container. The chamber is sealed with the sealing member extending across a lower open end thereof, wherein axial movement of the cap along the inner guide member will cause the sealing member to be pieced by the piercing member to open the chamber and dispense the contents of the chamber into the container. The axial movable cap is formed from a material with a higher oxygen and moisture barrier property than the material forming the shell.

Owner:BERRY PLASTICS CORP

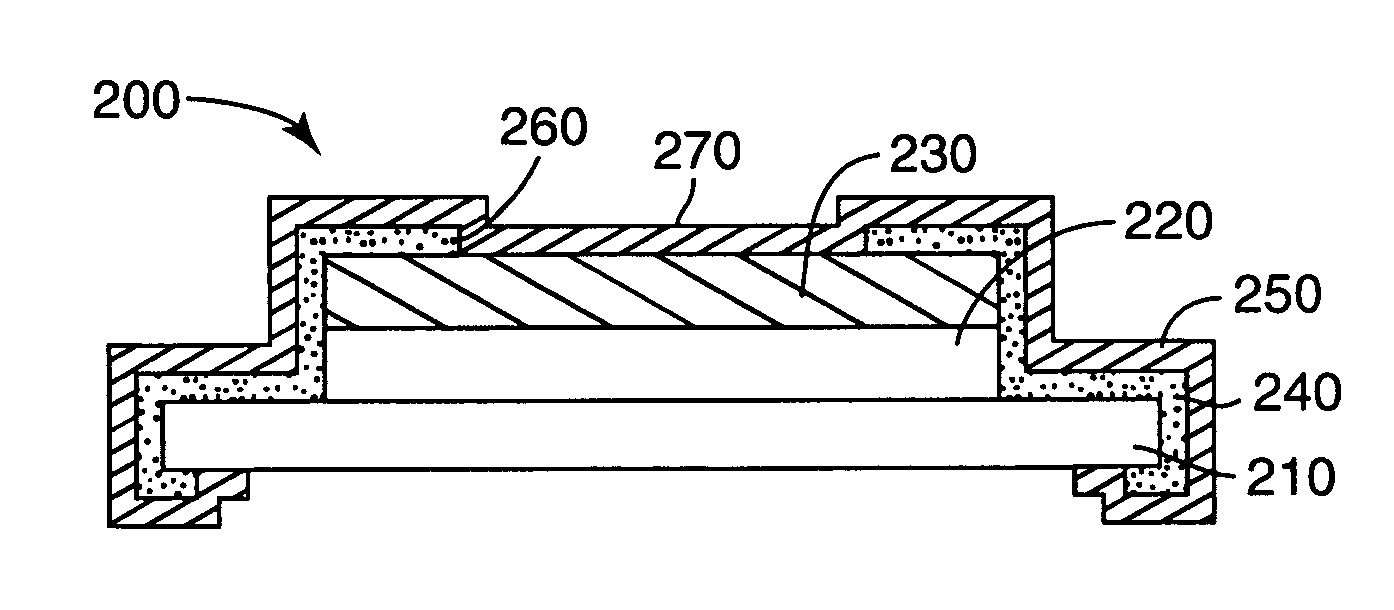

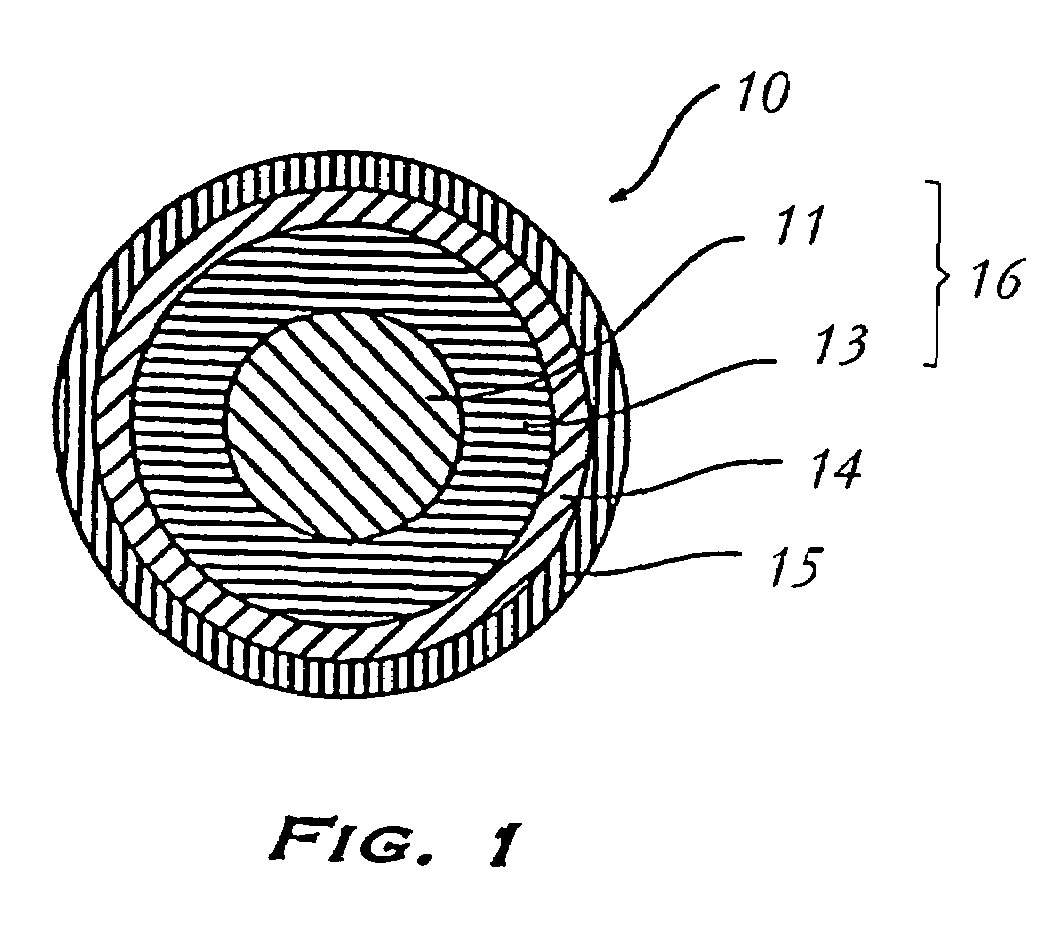

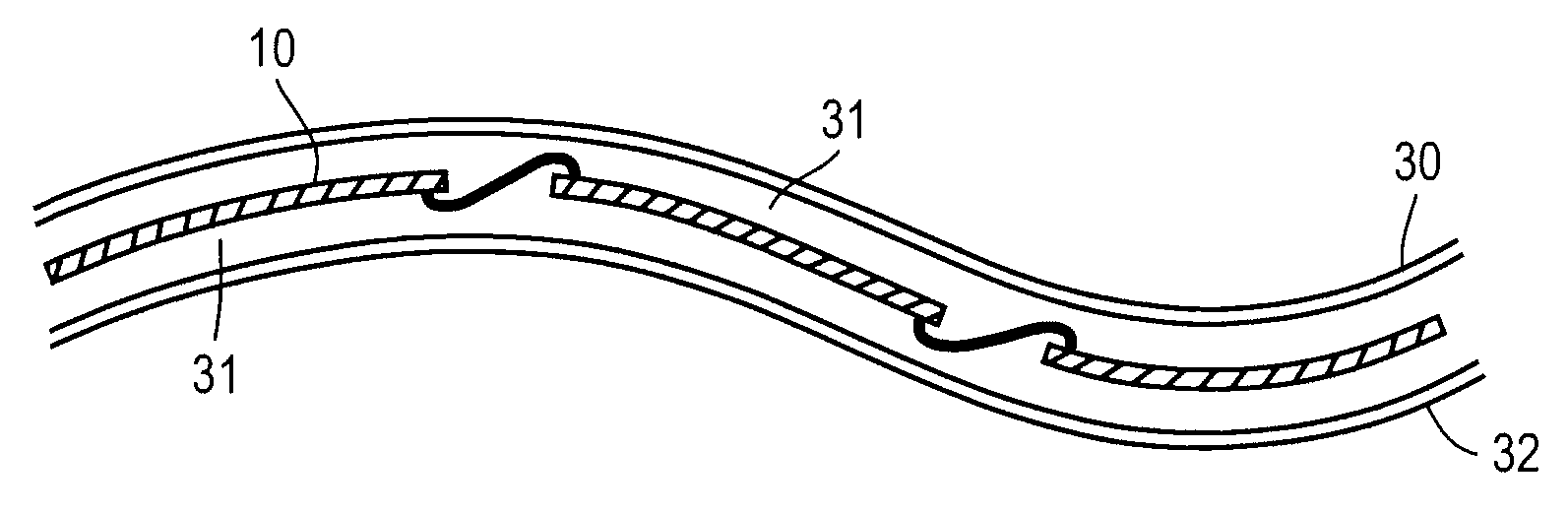

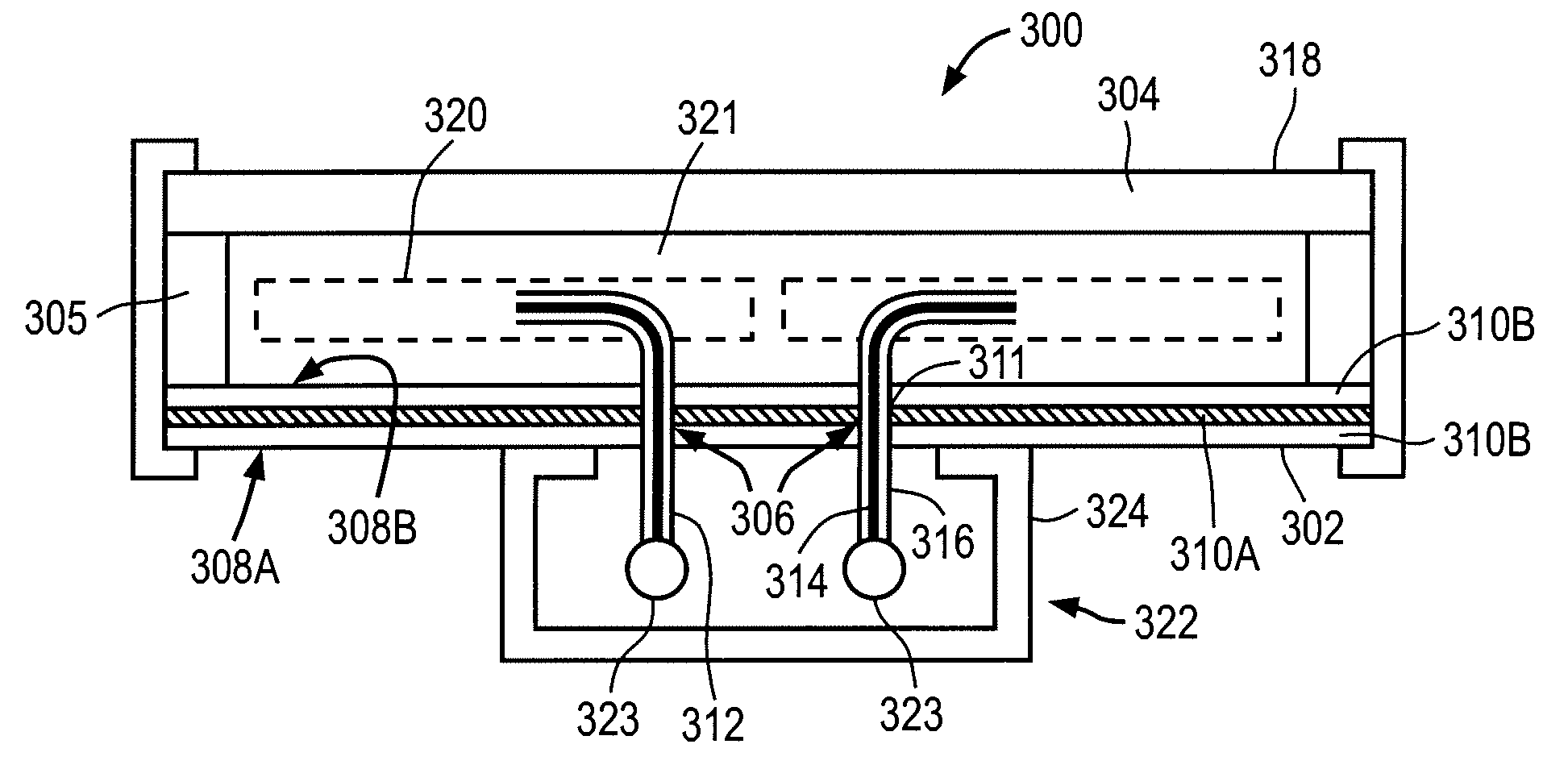

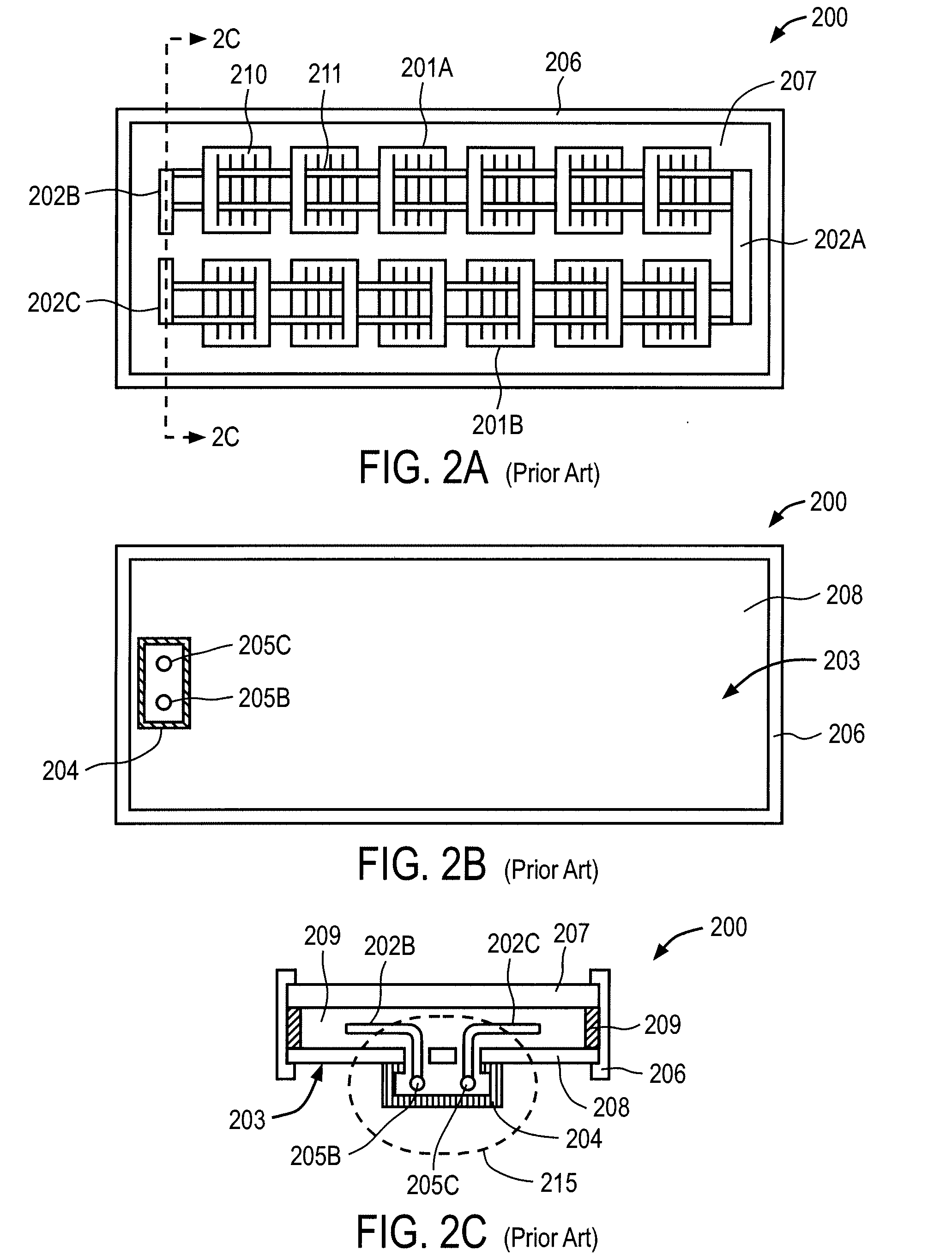

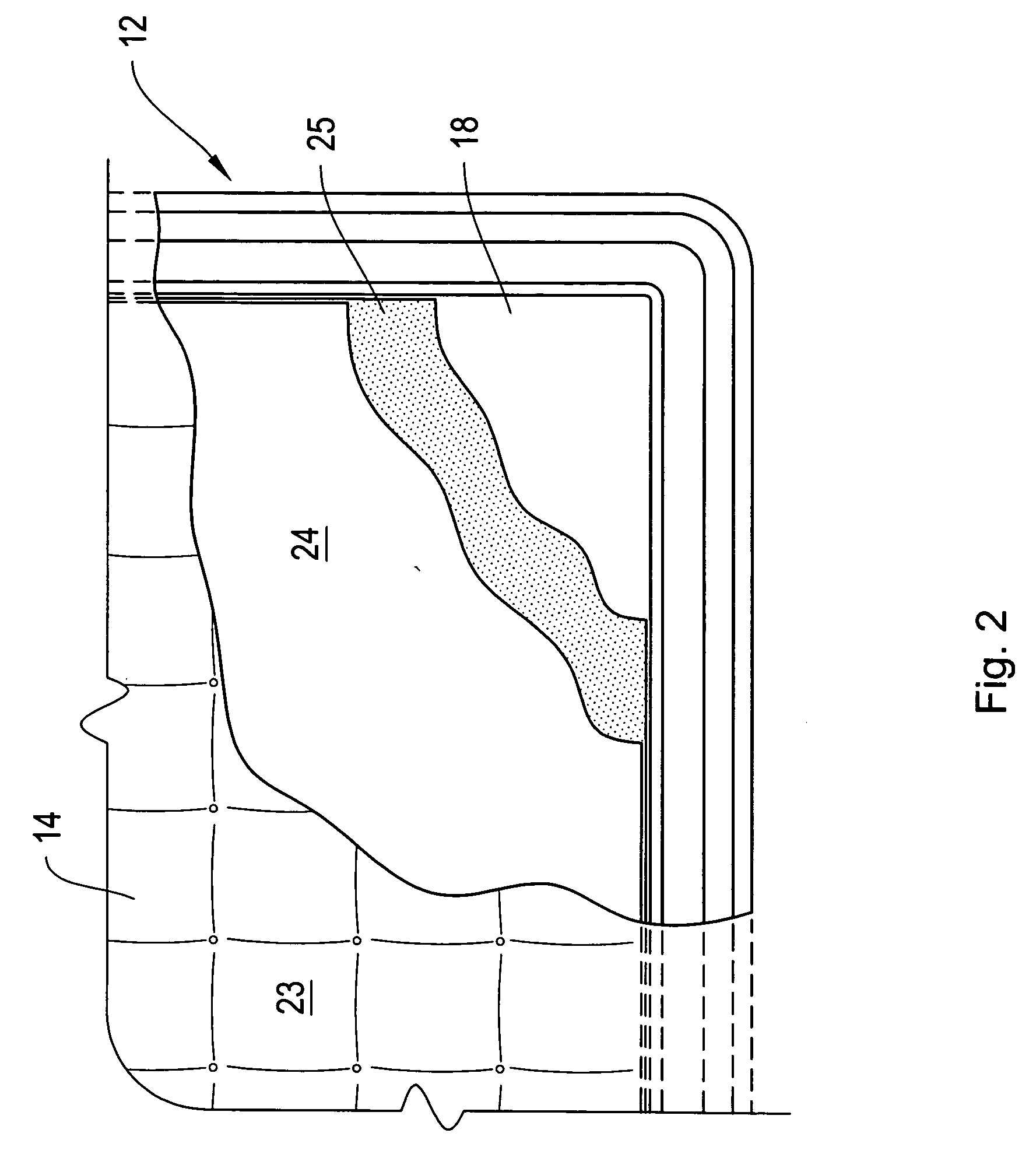

Multi-layer sheet for use in electro-optic displays

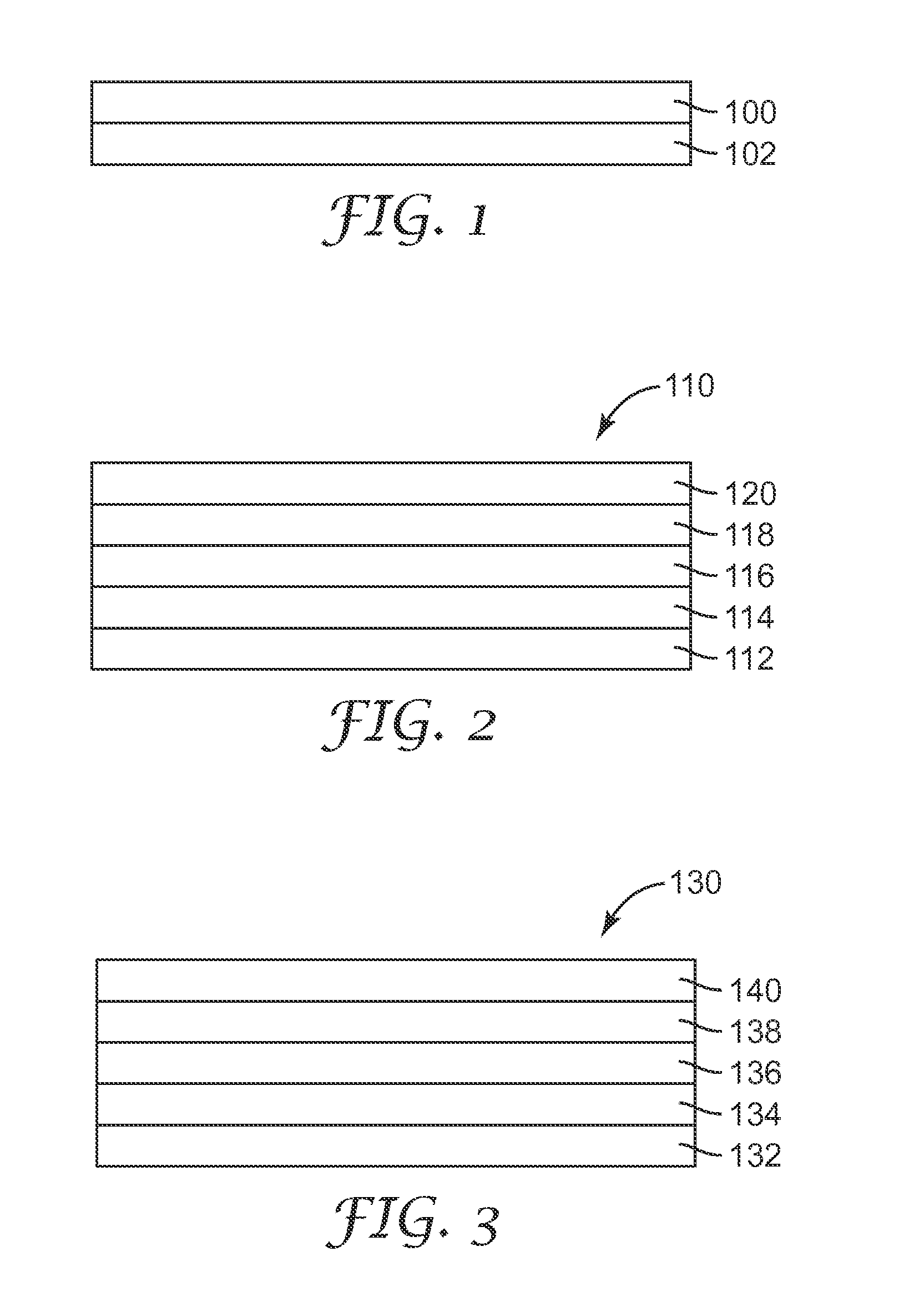

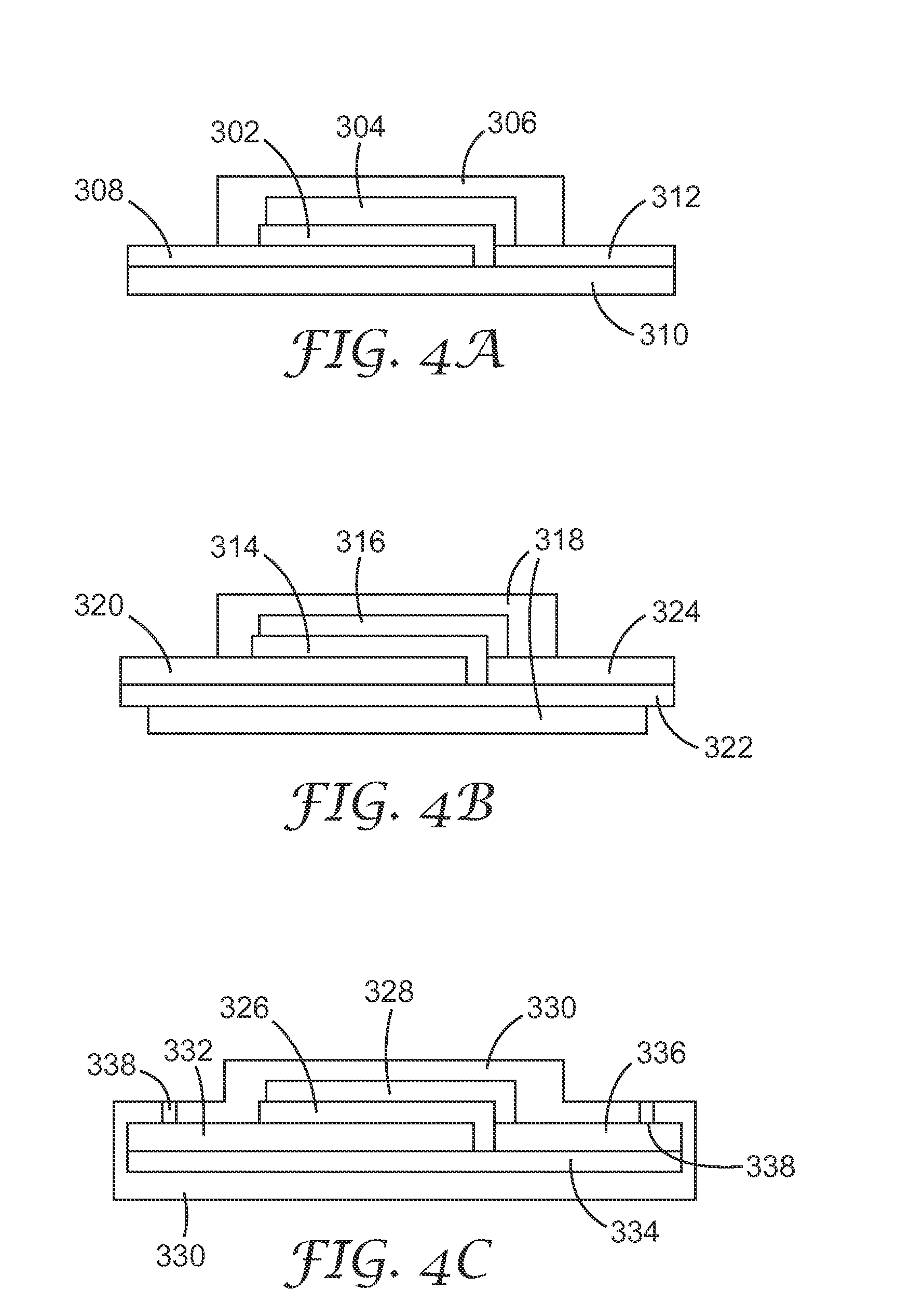

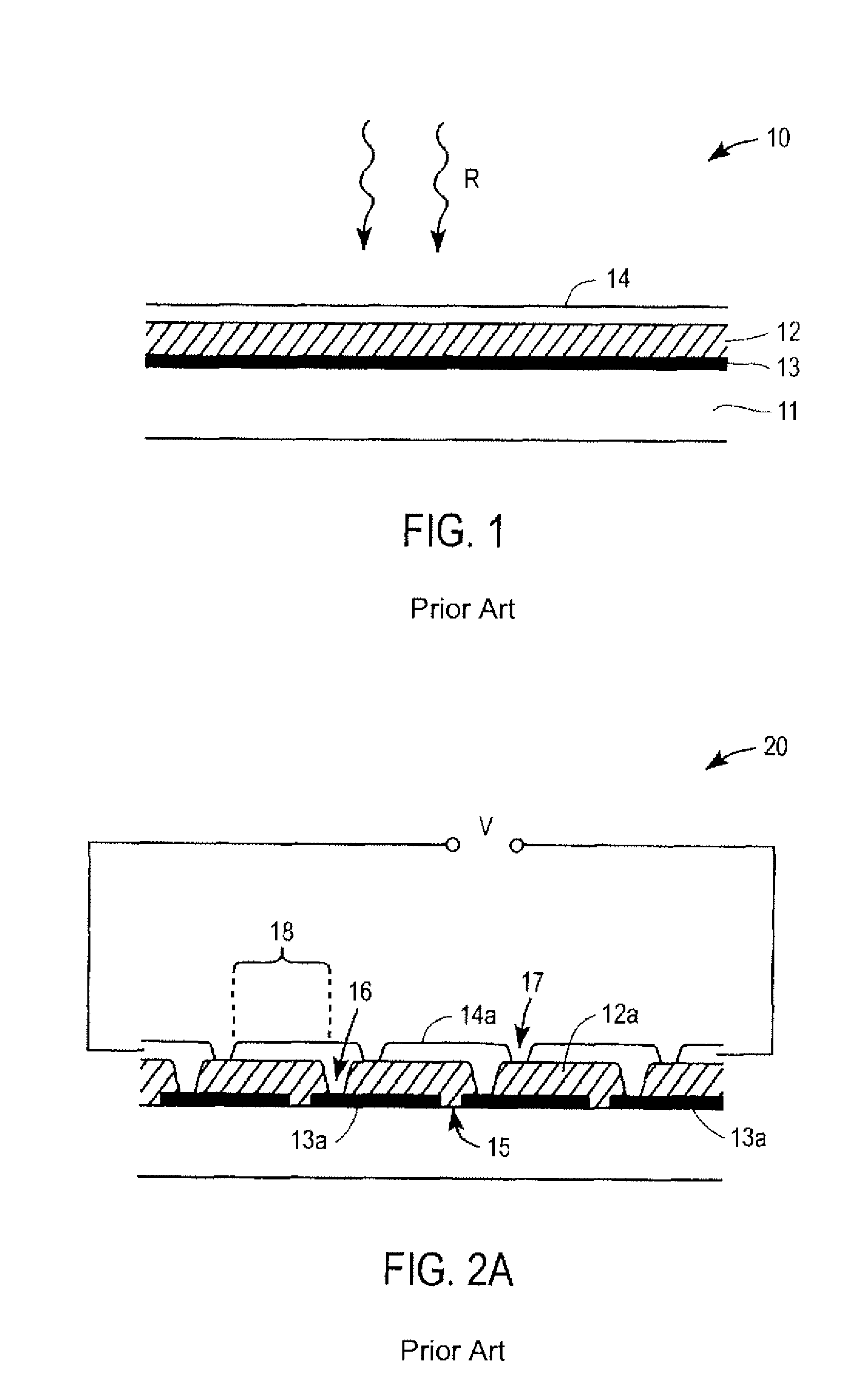

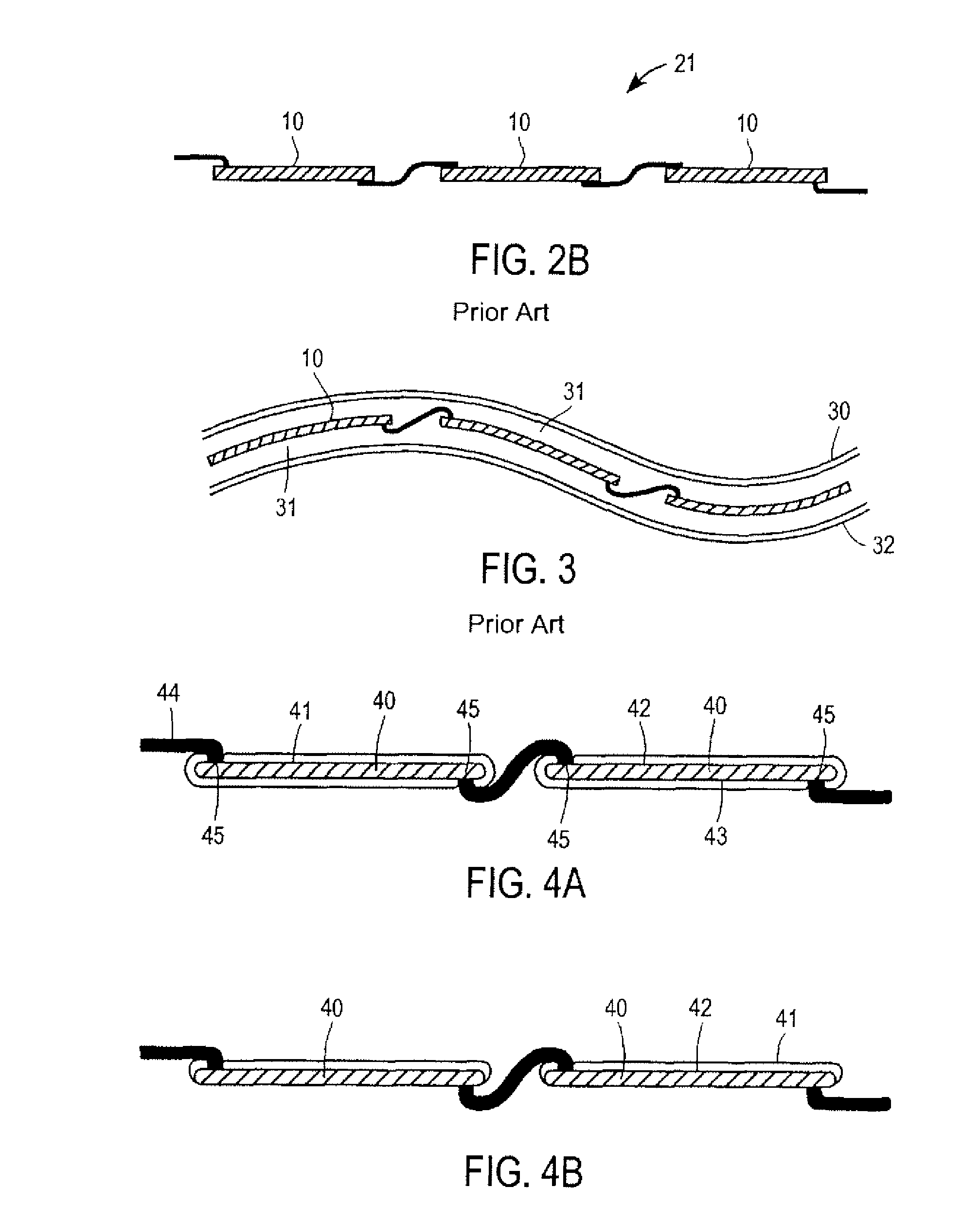

ActiveUS7667886B2Produced economicallyStatic indicating devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

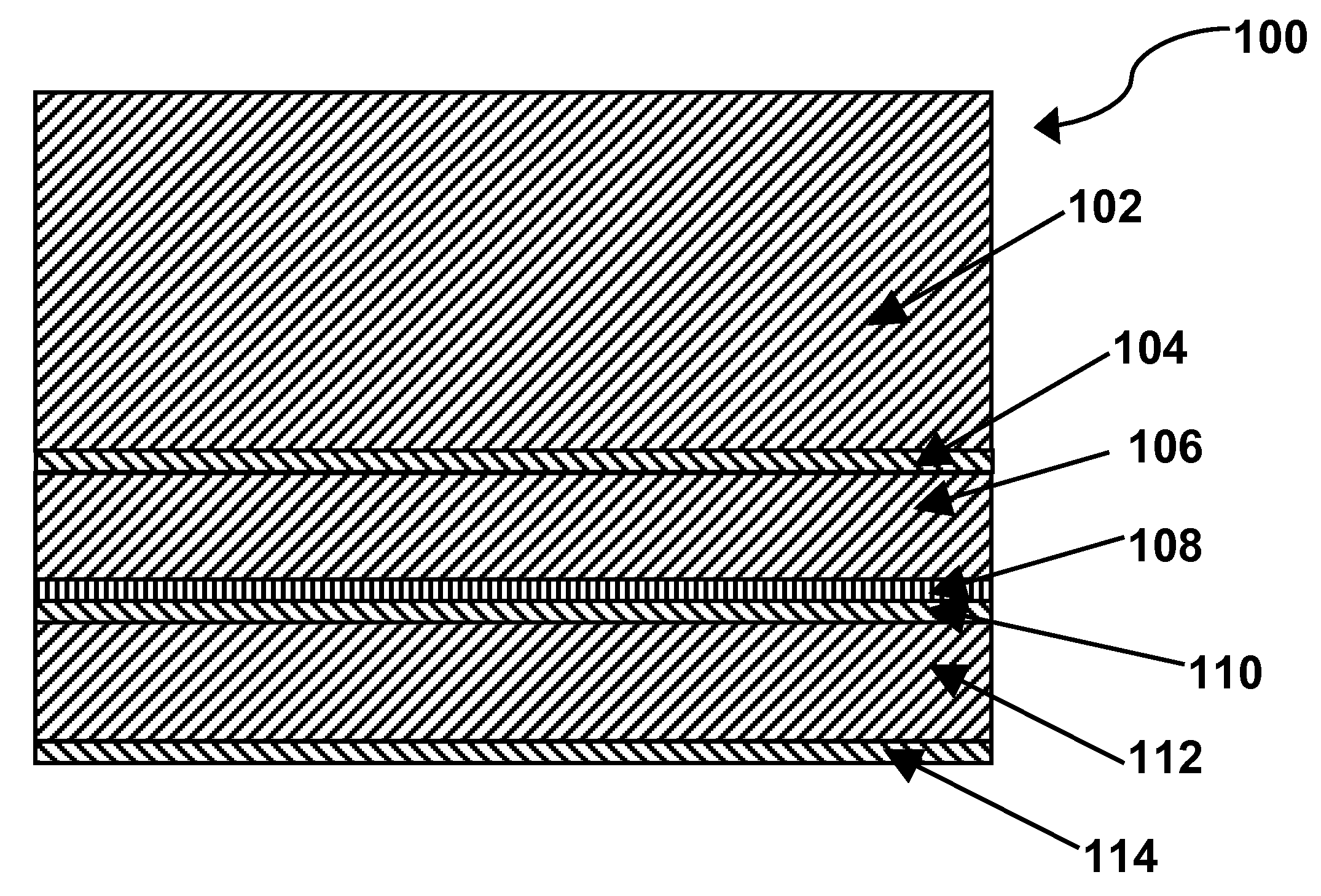

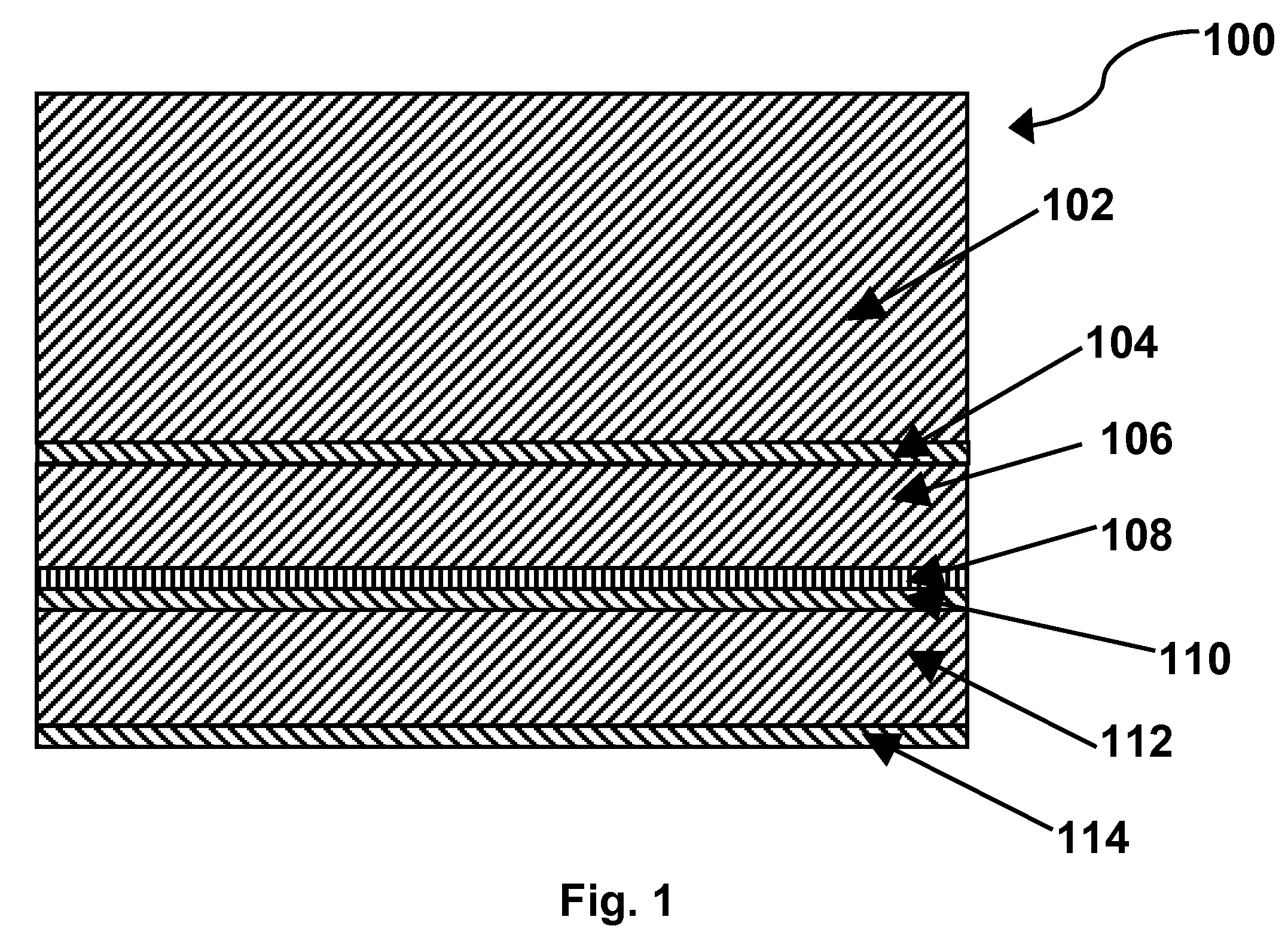

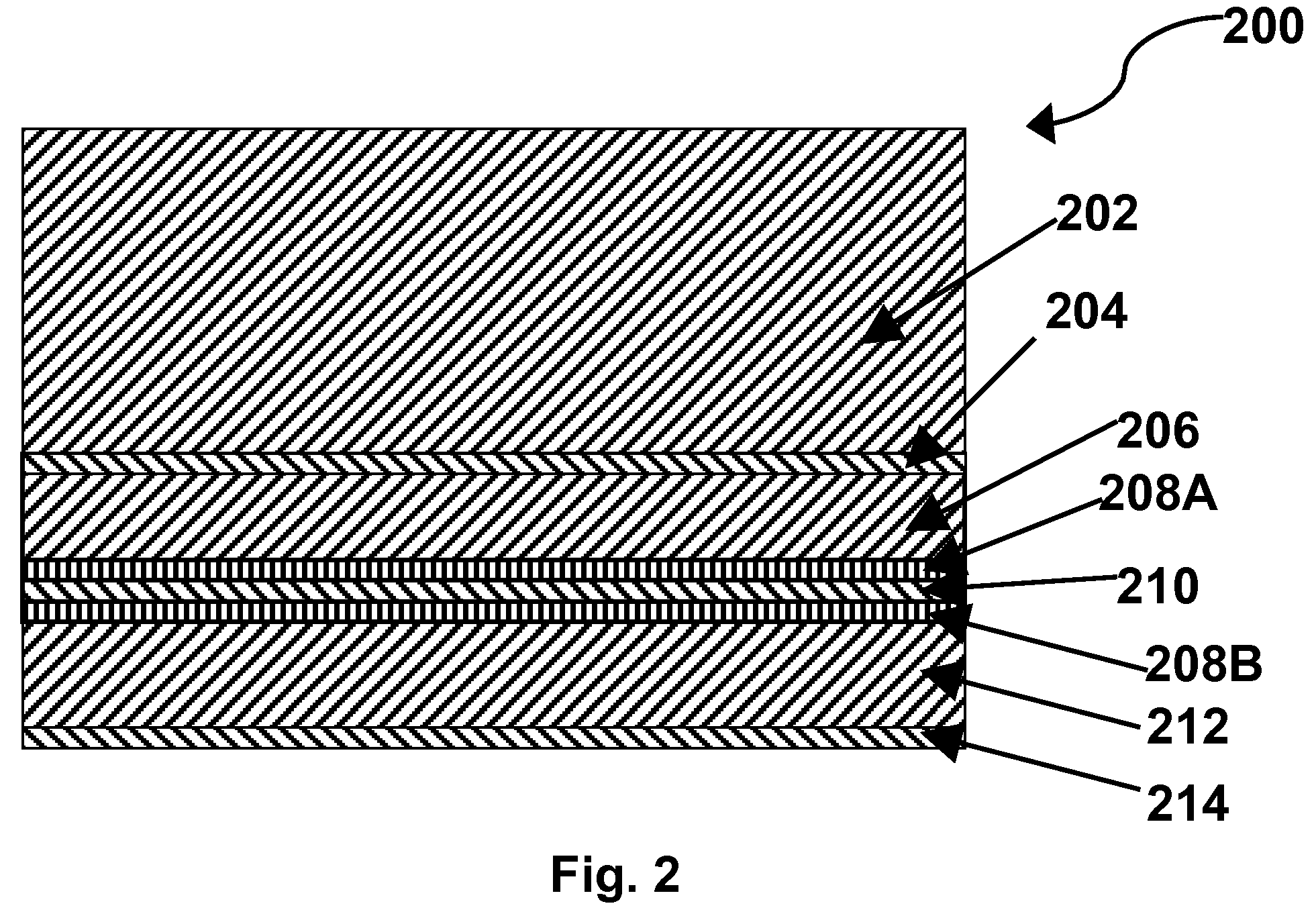

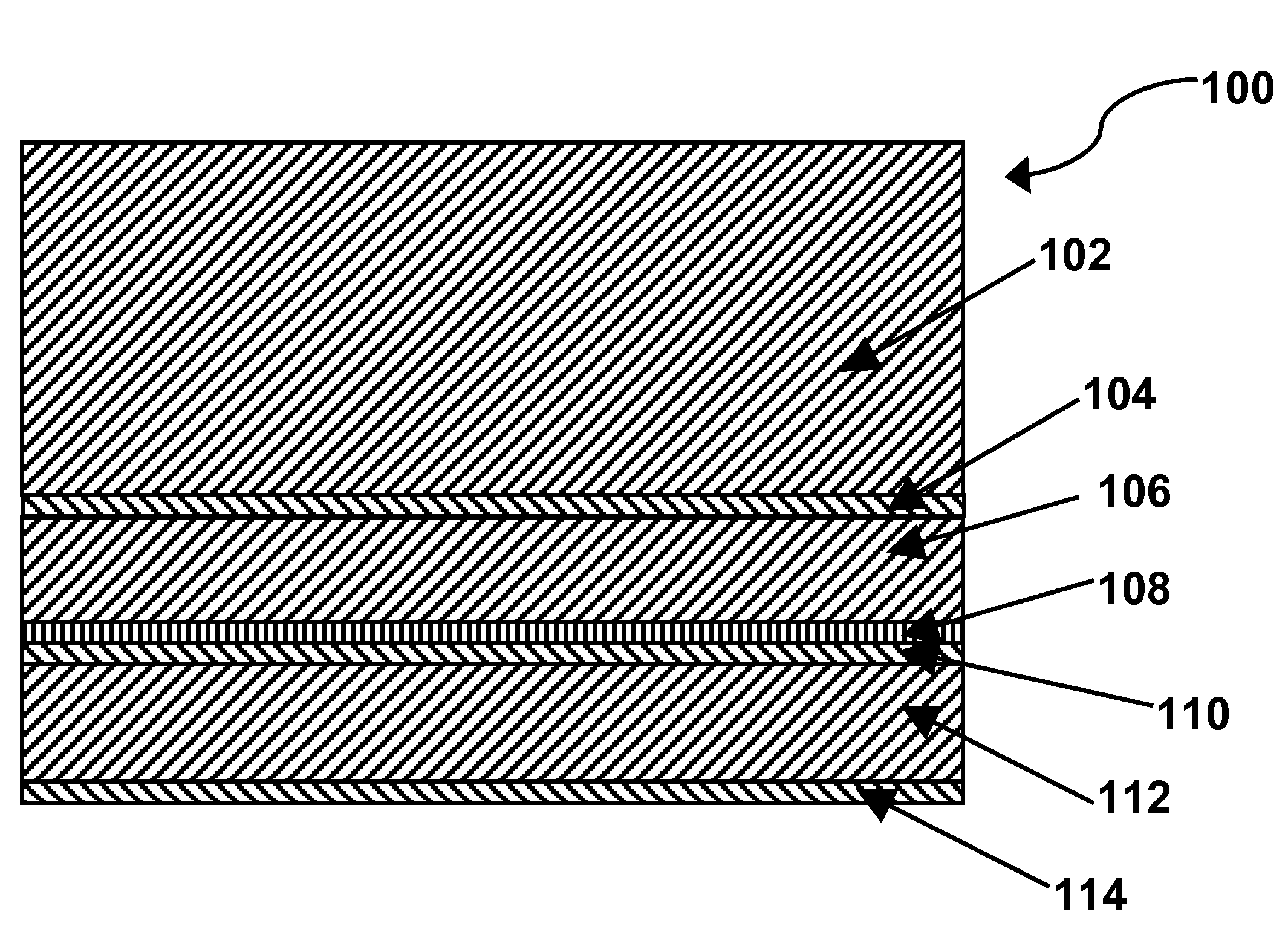

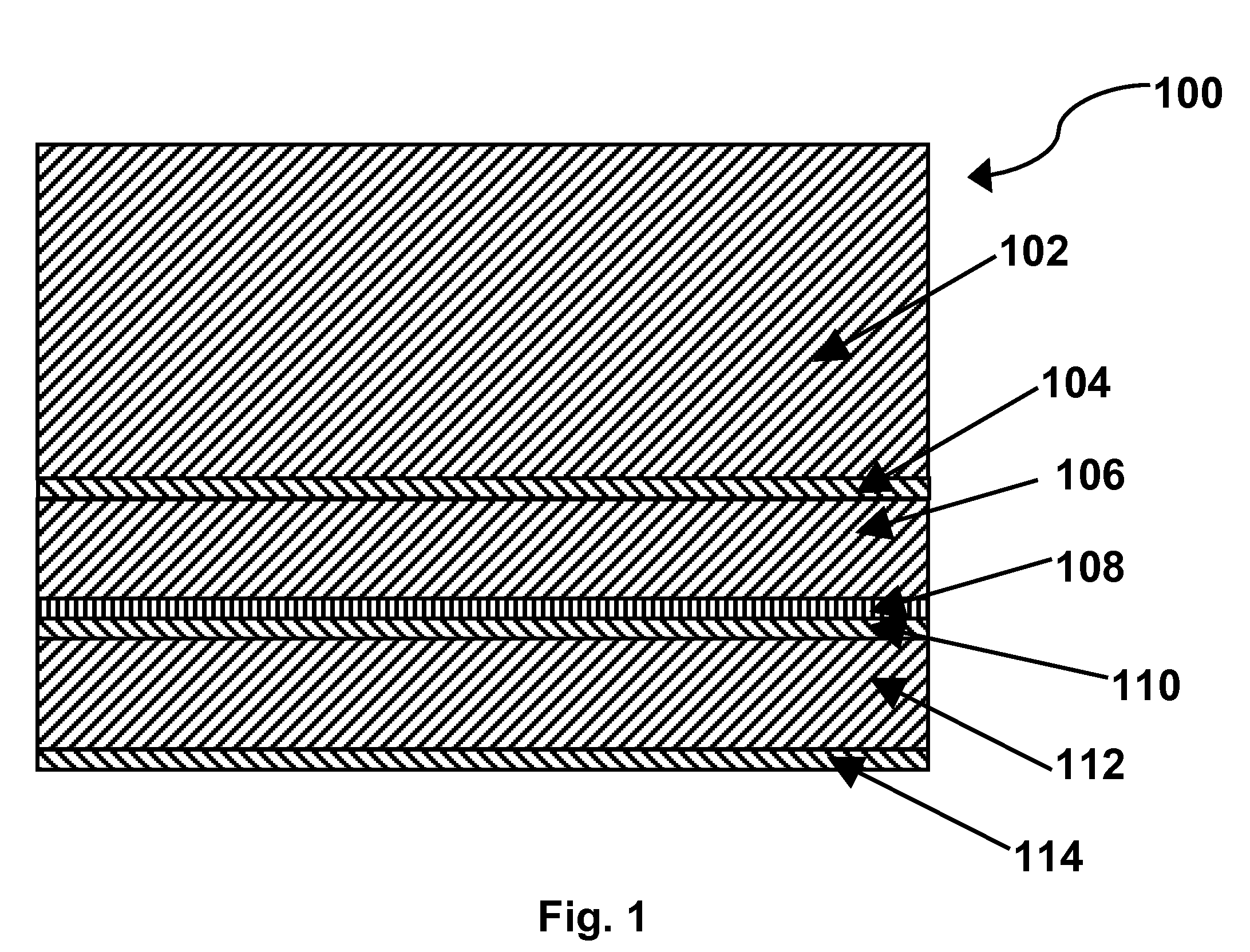

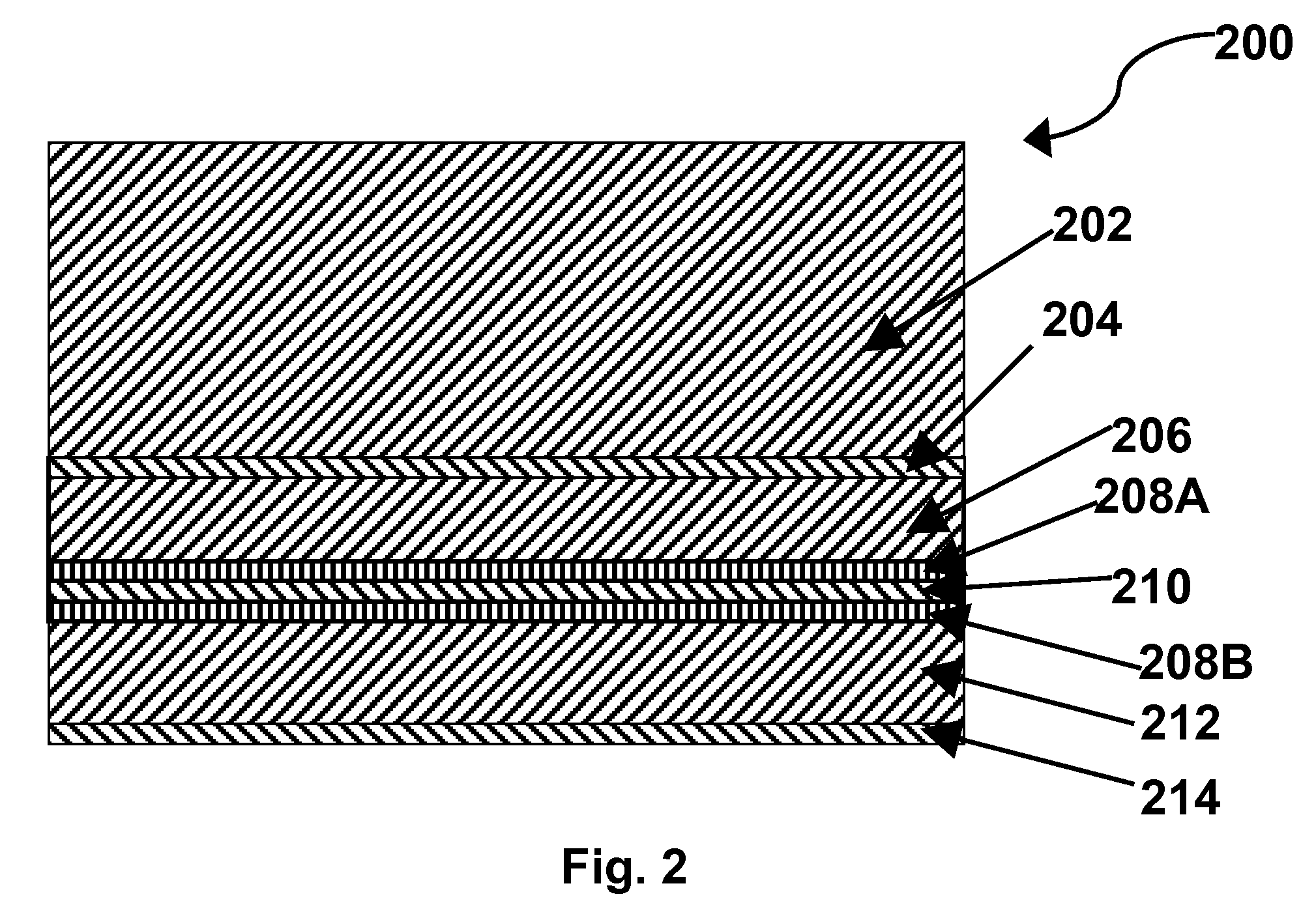

A multi-layer film, useful as a front sub-assembly in electro-optic displays, comprises, in this order: a light-transmissive electrically-conductive layer (114); a light-transmissive first protective layer (112); a light-transmissive moisture barrier layer (108); and a light-transmissive second protective layer (106). This multi-layer film can be used in forming an electro-optic display by the processes described in U.S. Pat. No. 6,982,179 or Patent Publication No. 2007 / 0109219.

Owner:E INK CORPORATION

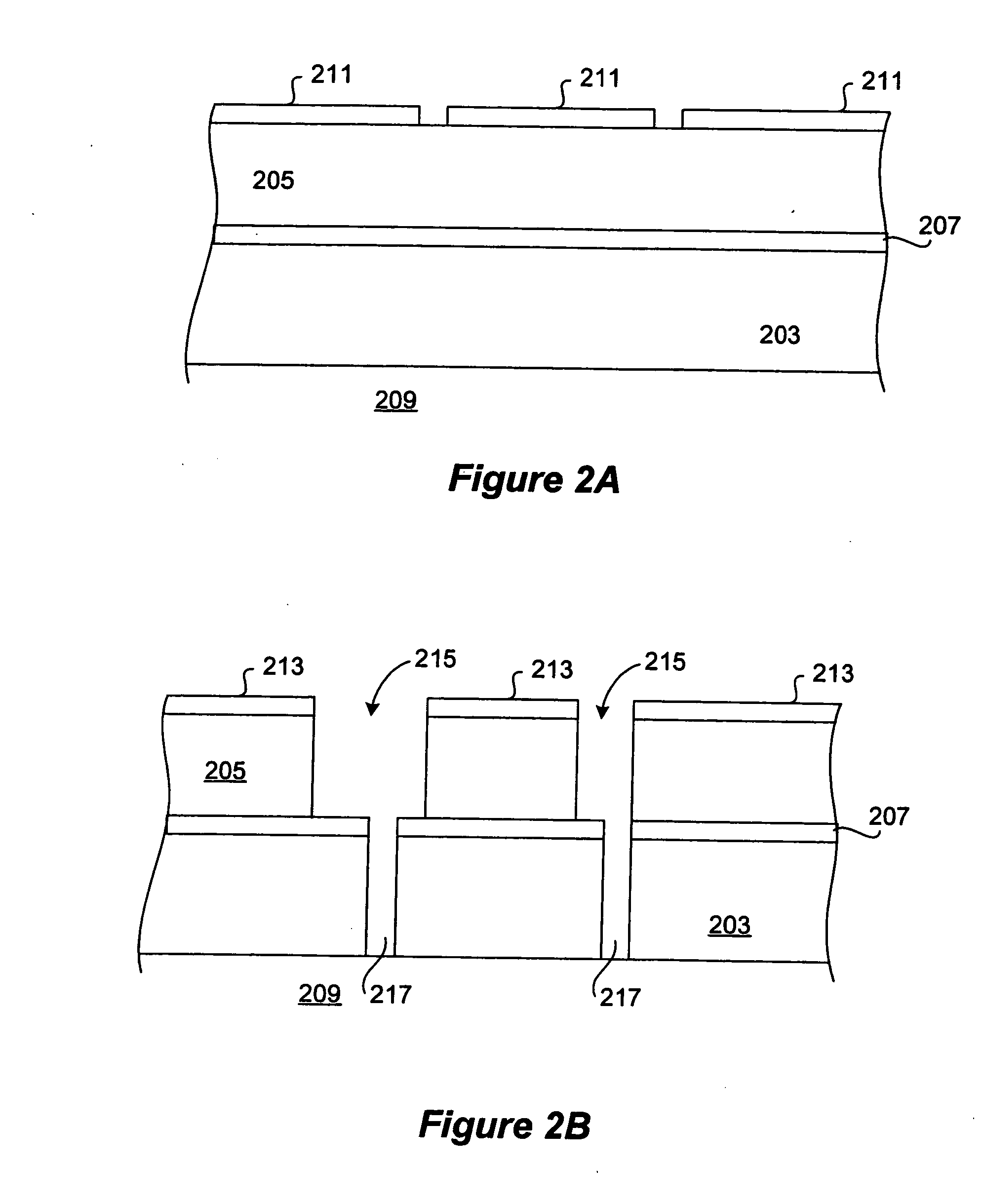

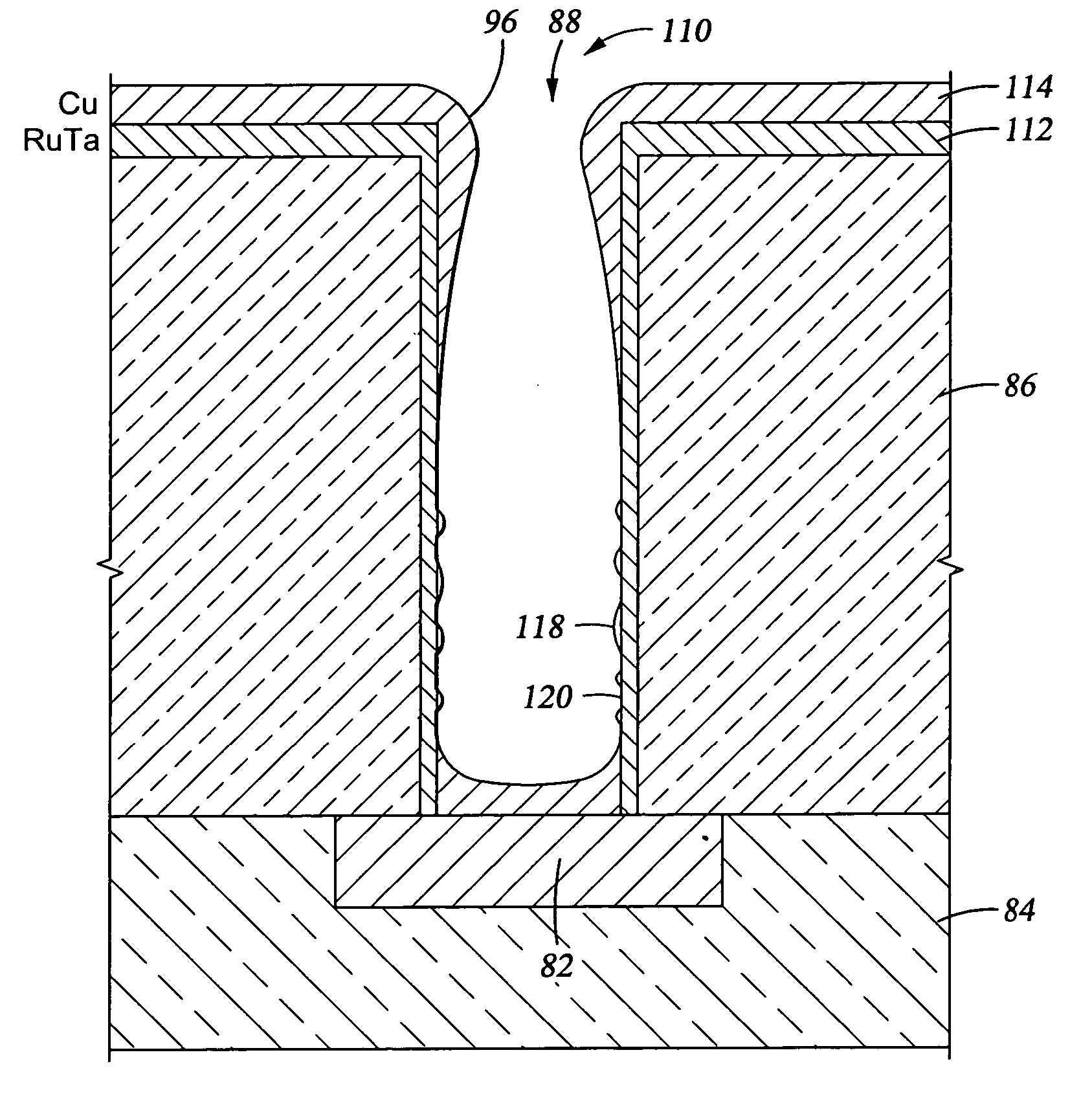

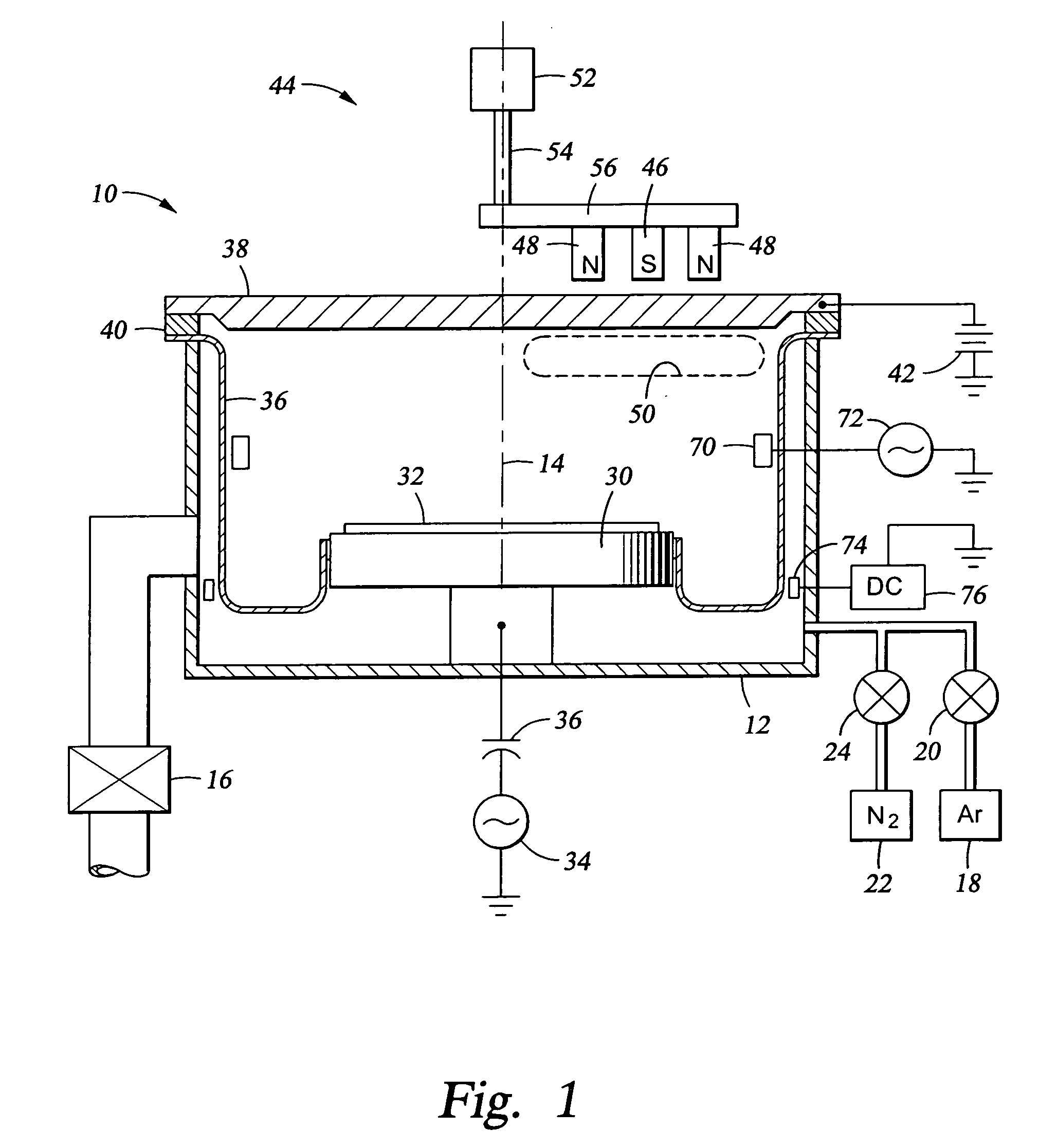

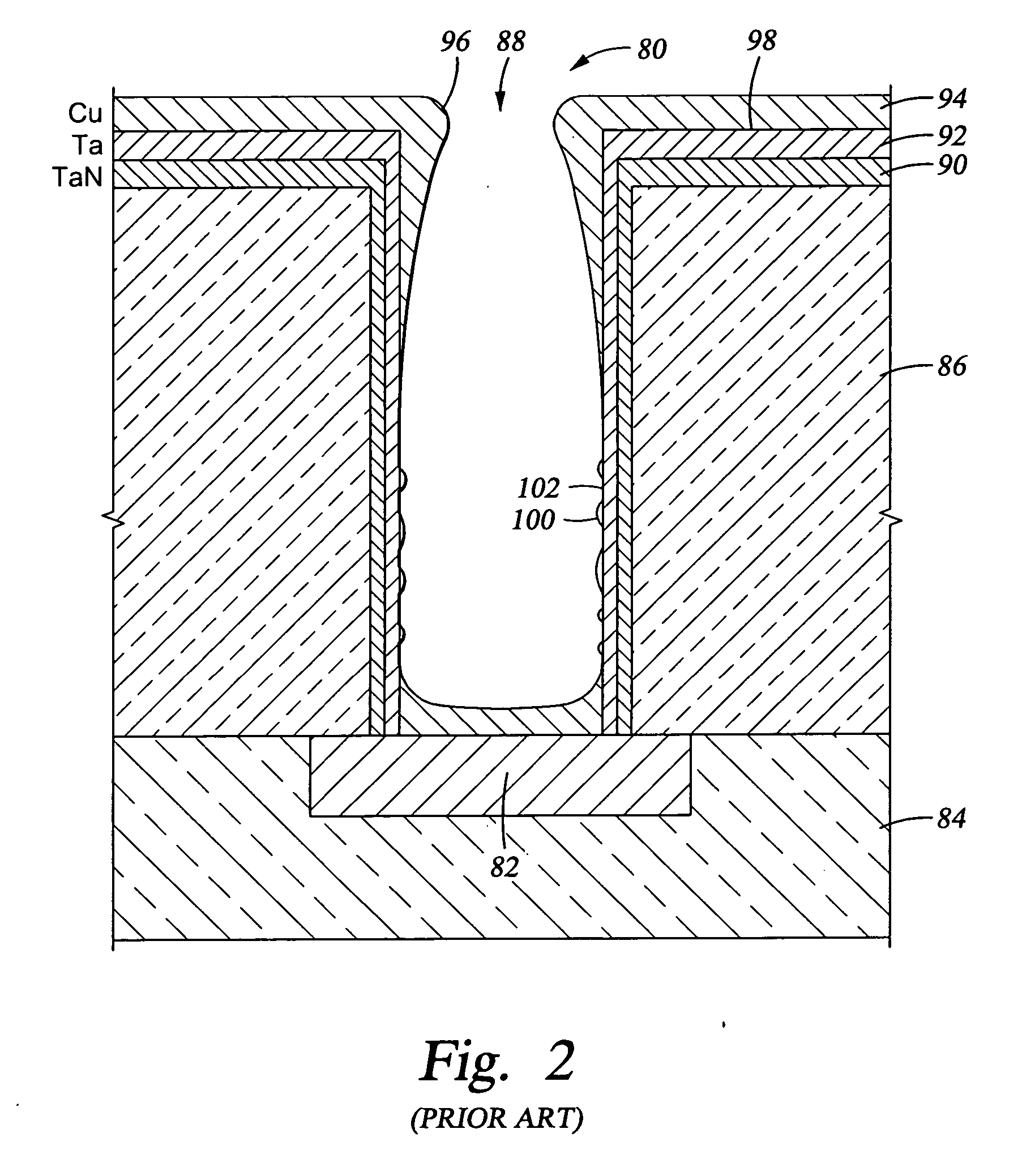

Integrated process for sputter deposition of a conductive barrier layer, especially an alloy of ruthenium and tantalum, underlying copper or copper alloy seed layer

InactiveUS20070059502A1Effective interfacial barrierGood suitSemiconductor/solid-state device detailsVacuum evaporation coatingMoisture barrierRefractory metals

A fabrication method and a product for the deposition of a conductive barrier or other liner layer in a vertical electrical interconnect structure. One embodiment includes within a a hole through a dielectric layer a barrier layer of RuTaN, an adhesion layer of RuTa, and a copper seed layer forming a liner for electroplating of copper. The ruthenium content is preferably greater than 50 at % and more preferably at least 80 at % but less than 95 at %. The barrier and adhesion layers may both be sputter deposited. Other platinum-group elements substitute for the ruthenium and other refractory metals substitute for the tantalum. Aluminum alloying into RuTa when annealed presents a moisture barrier. Copper contacts include different alloying fractions of RuTa to shift the work function to the doping type.

Owner:APPLIED MATERIALS INC

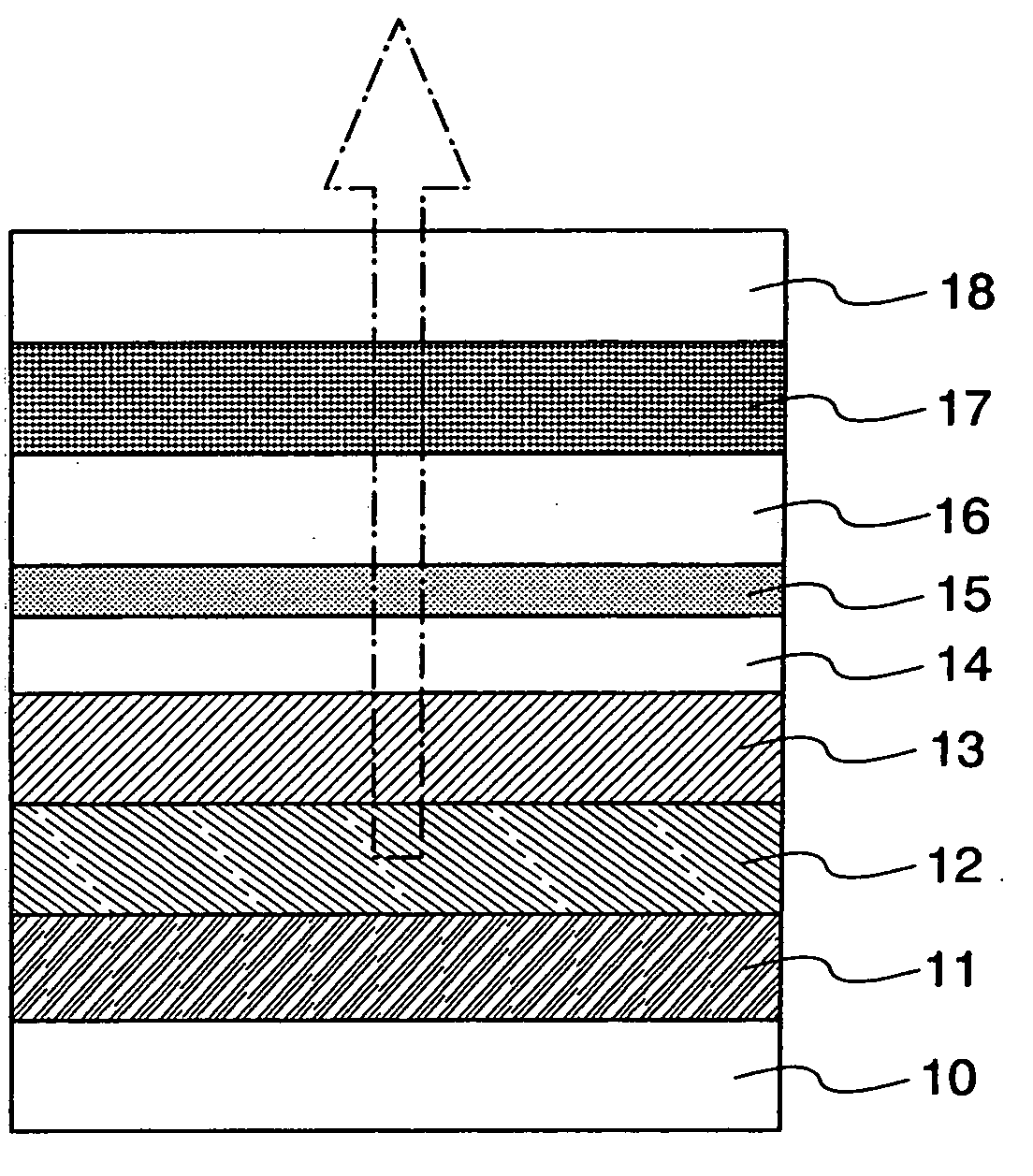

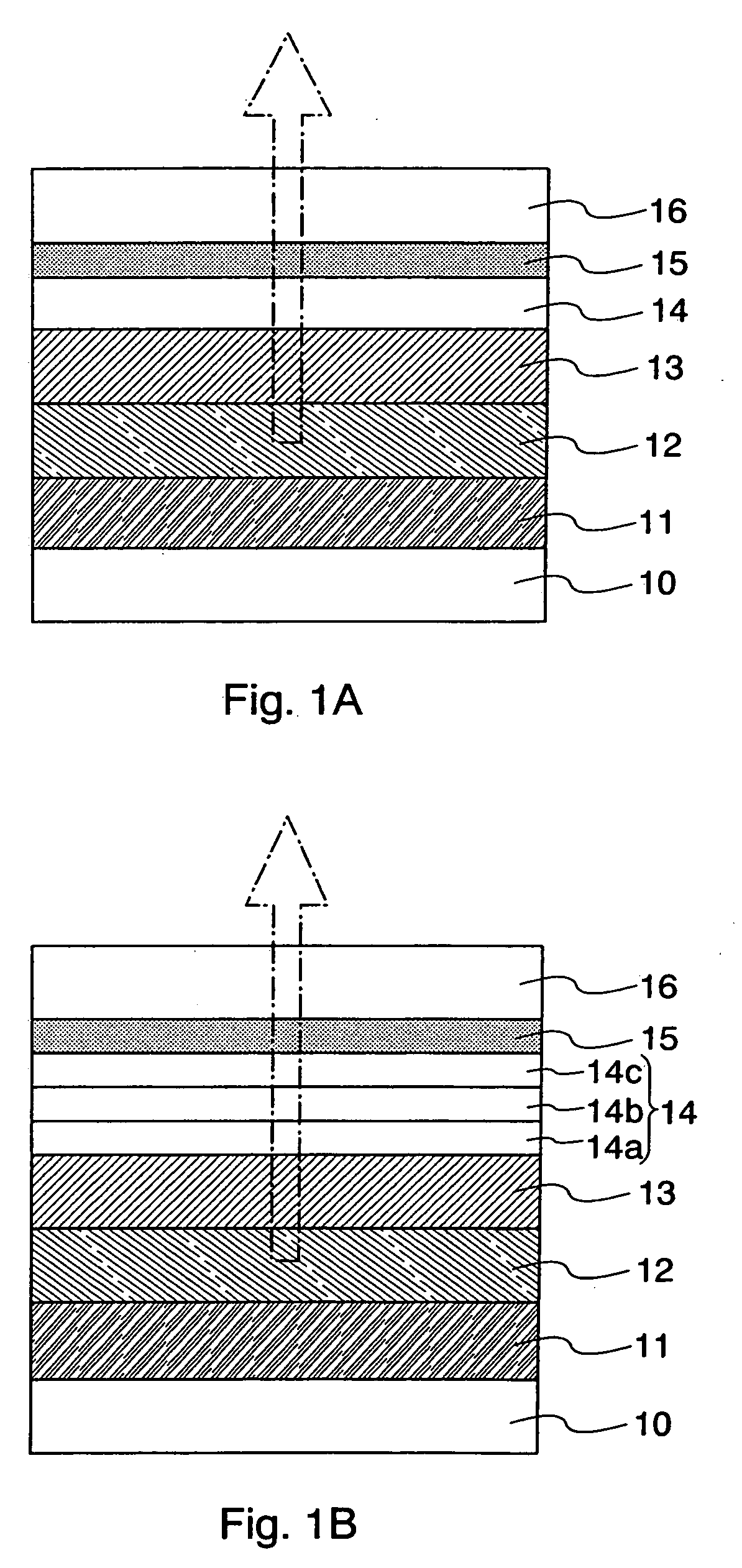

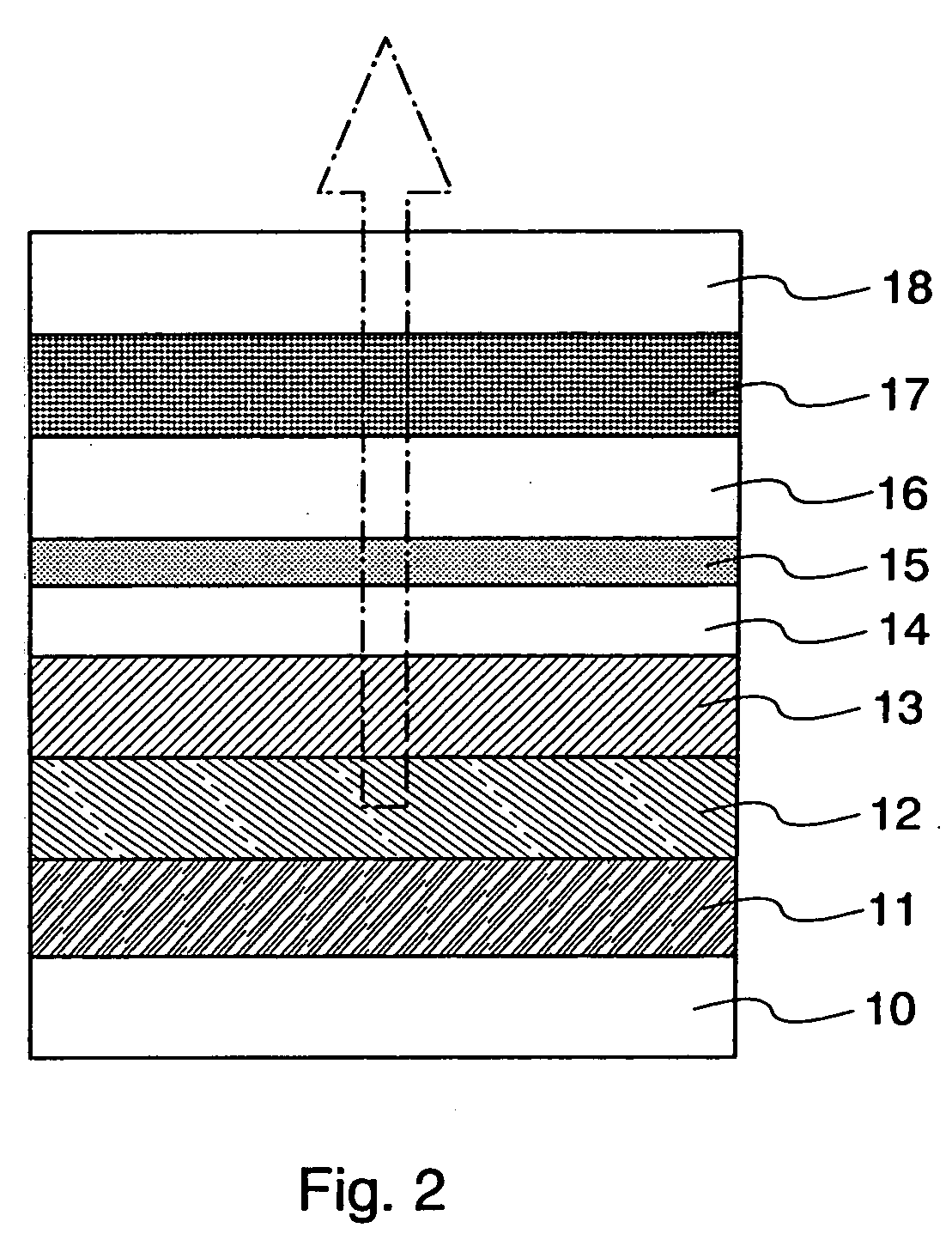

Light-emitting element and display device

InactiveUS20050263775A1Improve reliabilityImprove light extraction efficiencyStatic indicating devicesElectroluminescent light sourcesStress relievingRefractive index

There has been a problem that difference in refractive index between an opposite substrate or a moisture barrier layer (passivation film) such as SiN provided thereover, and air is maintained large, and light extraction efficiency is low. Further, there has been a problem that peeling or cracking due to the moisture barrier layer is easily generated, which leads to deteriorate the reliability and lifetime of a light-emitting element. According to the present invention, a light-emitting element comprises a pixel electrode, an electroluminescent layer, a transparent electrode, a passivation film, a stress relieving layer, and a low refractive index layer, all of which are stacked sequentially. The stress relieving layer serves to prevent peeling of the passivation film. The low refractive index layer serves to reduce reflectivity of light generated in the electroluminescent layer in emitting to air. Therefore, a light-emitting element with high reliability and long lifetime and a display device using the light-emitting element can be provided.

Owner:SEMICON ENERGY LAB CO LTD

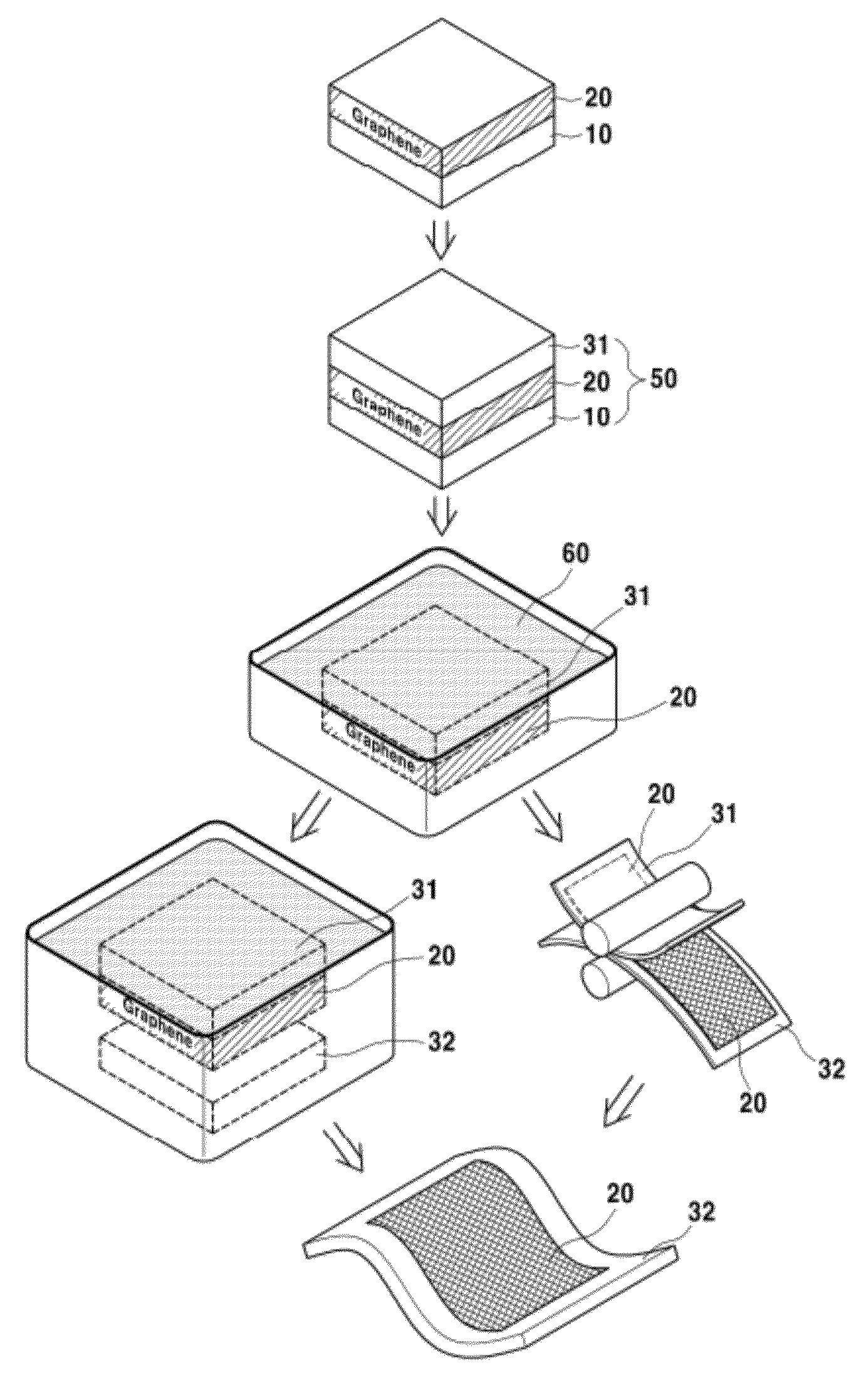

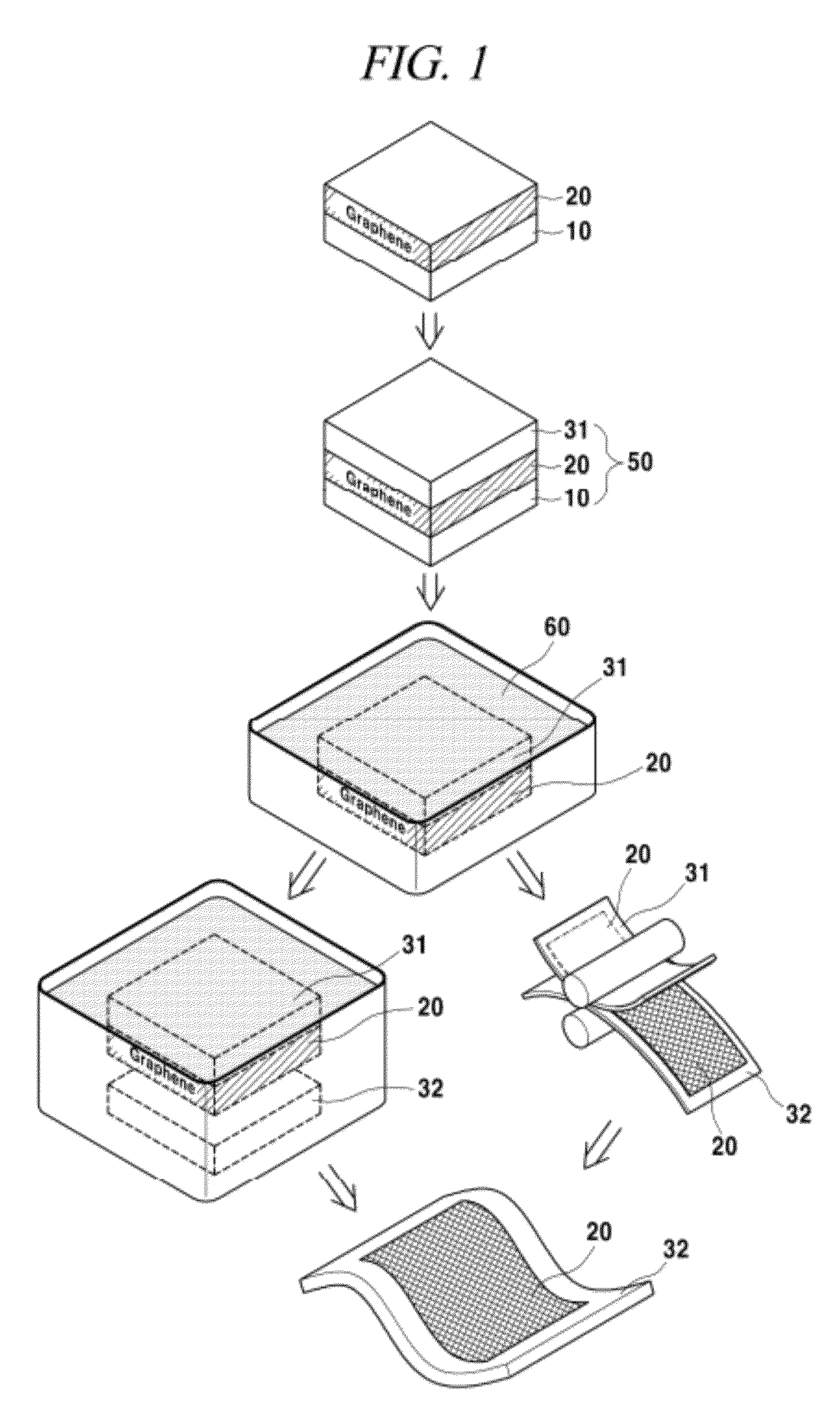

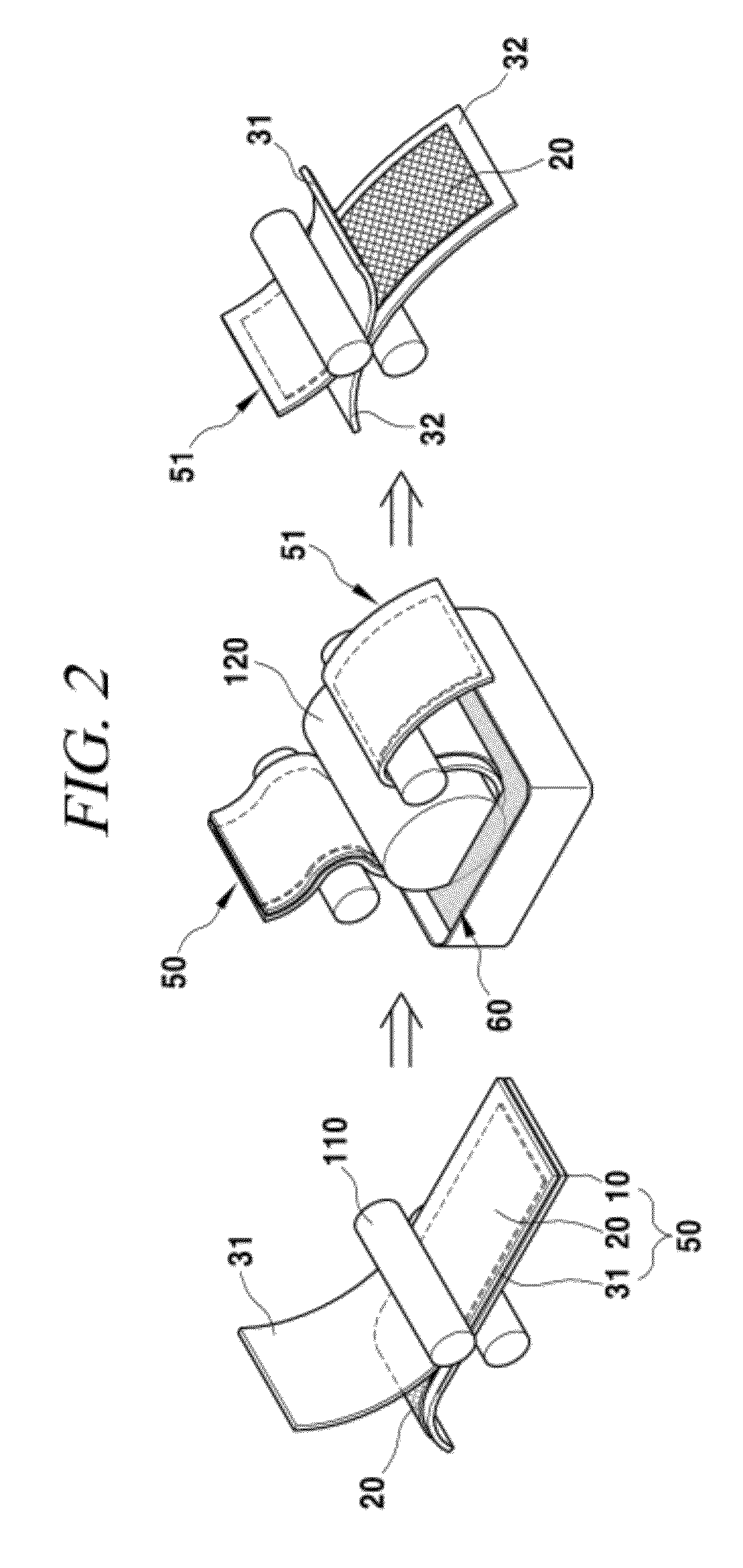

Graphene protective film serving as a gas and moisture barrier, method for forming same, and use thereof

ActiveUS20120282419A1Improve featuresImprove electrical characteristicsMaterial nanotechnologyDecorative surface effectsTectorial membraneGraphene

The present invention relates to a method for forming a graphene protective film having gas and moisture barrier properties, to a graphene protective film formed by the method, and to the use thereof. A single-layer or multi-layer graphene protective film can be used as a material for a barrier coating or bags, and improves the gas and moisture barrier properties of a variety of devices in a wide array of industrial fields to thereby maintain the electrical characteristics of devices over a long period of time.

Owner:GRAPHENE SQUARE

Self-adhering vapor permeable air and moisture barrier membrane

InactiveUS6901712B2Prevent lateral movementEliminate channelingCovering/liningsWallsAdhesiveWater vapor

Owner:HENRY COMPANY CANADA

Technique for Manufacturing Photovoltaic Modules

The present invention, in one aspect, is directed to methods for manufacturing solar or photovoltaic modules for better environmental stability. In another aspect, the present invention is directed to environmentally stable solar or photovoltaic modules. These method and apparatus use a moisture barrier film to form a moisture-resistant surface on the circuit, preferably on an illuminating surface of solar cells, or an entire side of a circuit formed of a plurality of solar cells that includes the illuminating surface of solar cells. In certain embodiments, the moisture-resistant film is applied conformally, and in other embodiments the moisture-resistant film is substantially transparent.

Owner:SOLOPOWER

Reliable thin film photovoltaic module structures

The inventions described herein generally relate to photovoltaic or solar module design and fabrication and, more particularly, to modules utilizing thin film solar cells. In one aspect is described a solar module and method of making the same that has a shield material that is both an electrical insulator and a moisture barrier provided at a location corresponding to at least one hole that is used to route a wiring member, such that the shield material seals the at least one hole against moisture entering into the internal space and electrically insulates the wires of the wiring member from the at least one metallic layer of the back protective sheet.

Owner:SOLOPOWER

Multi-layer sheet for use in electro-optic displays

ActiveUS7688497B2Produced economicallyStatic indicating devicesSolid-state devicesInter layerDisplay device

Owner:E INK CORPORATION

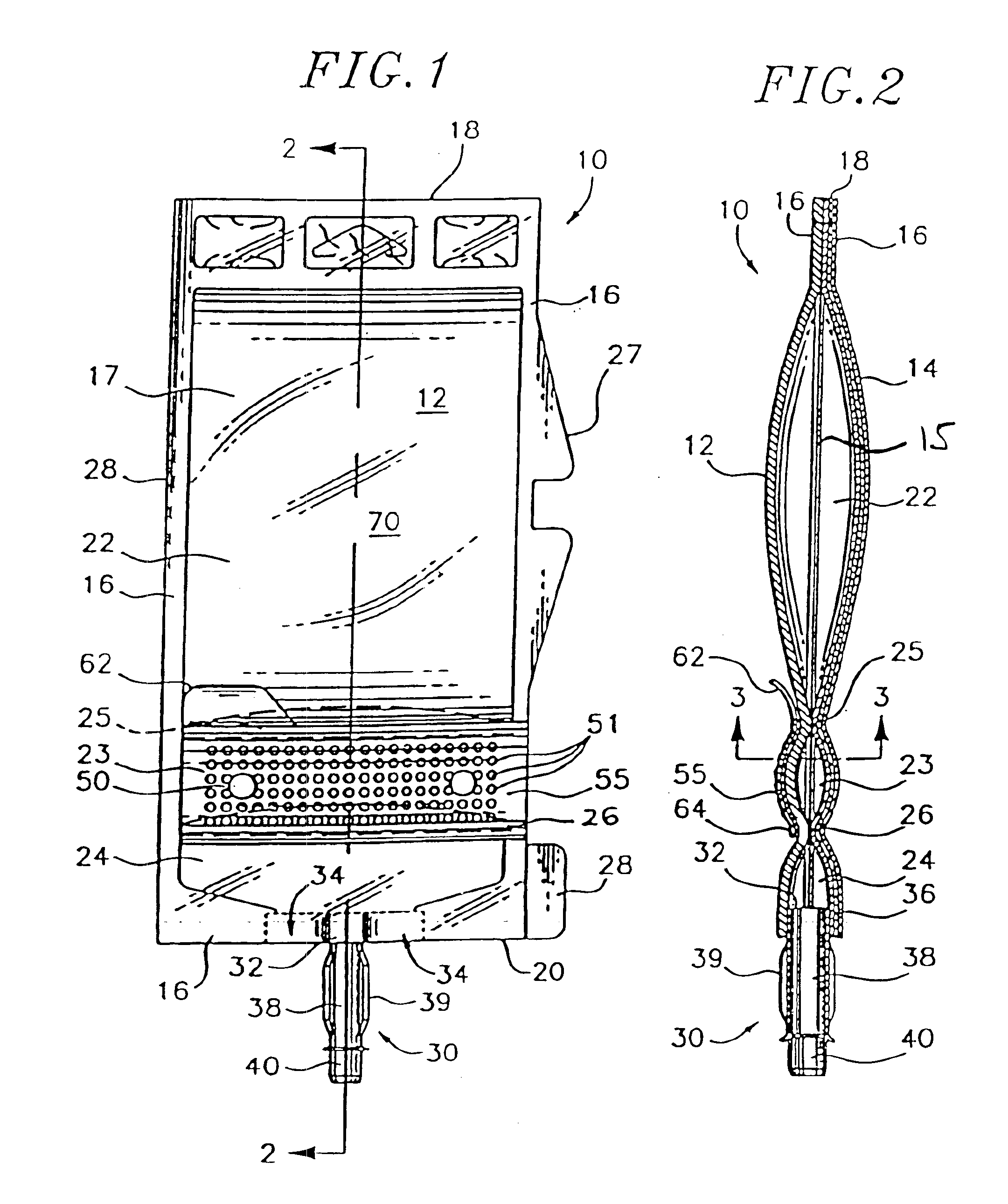

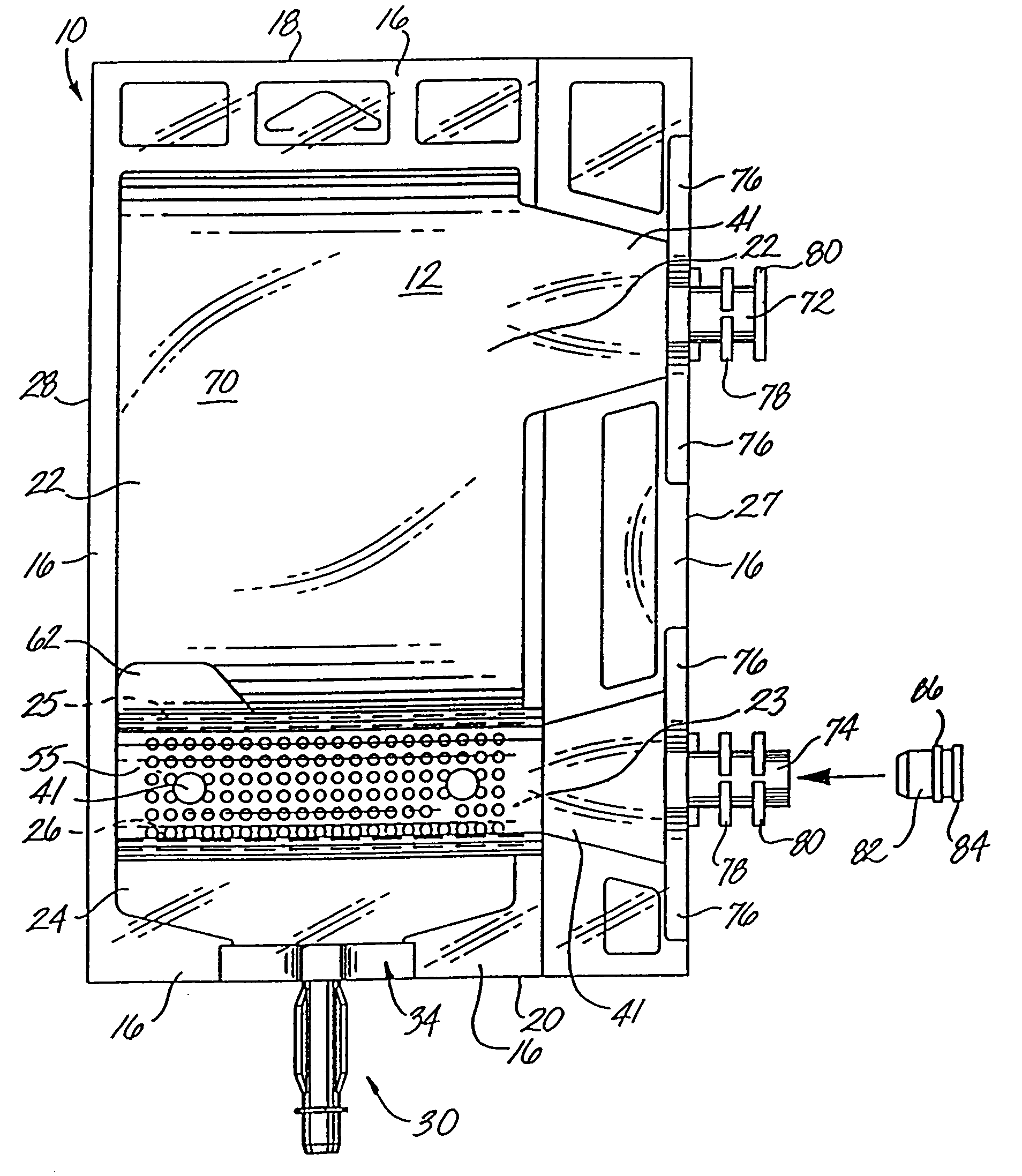

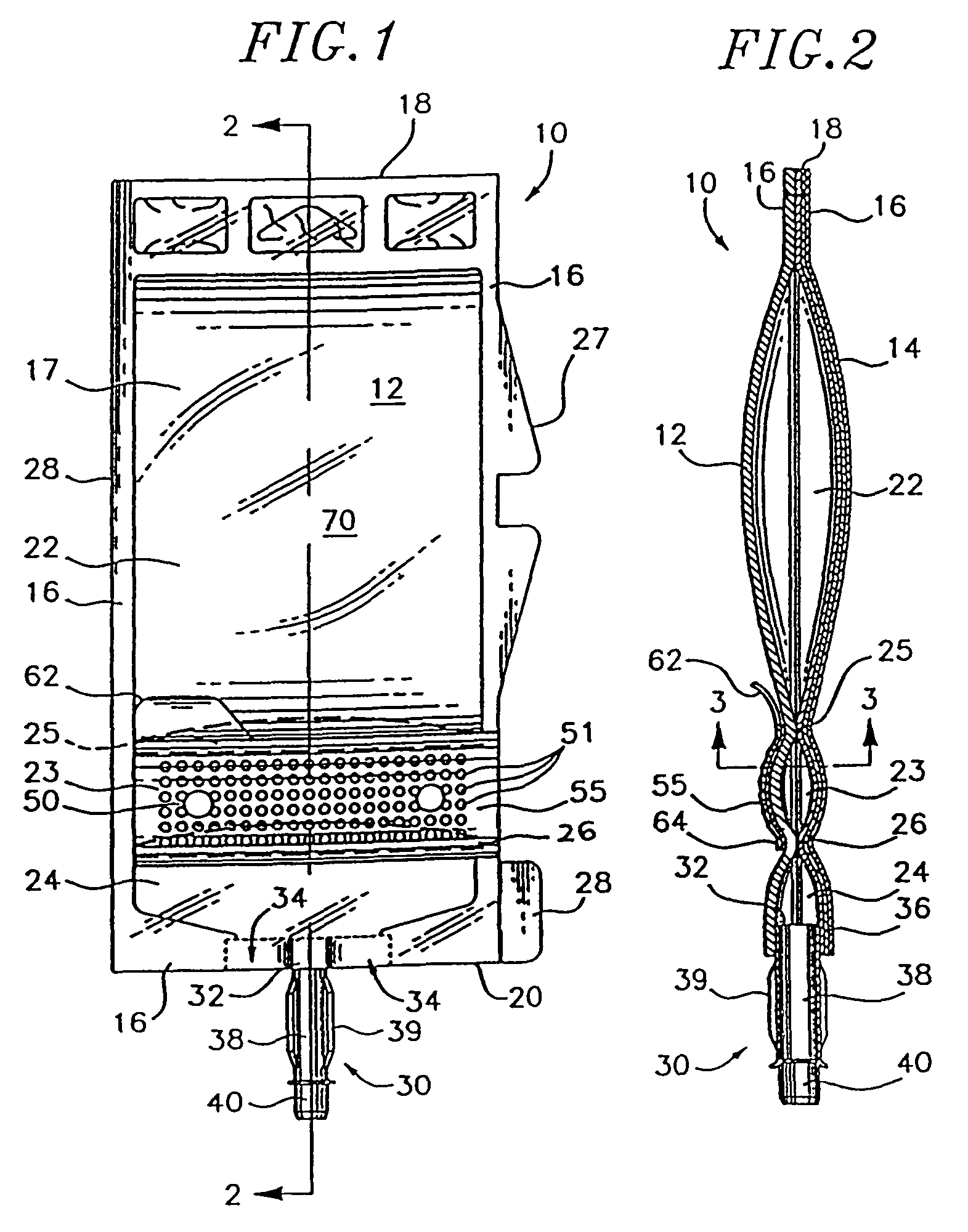

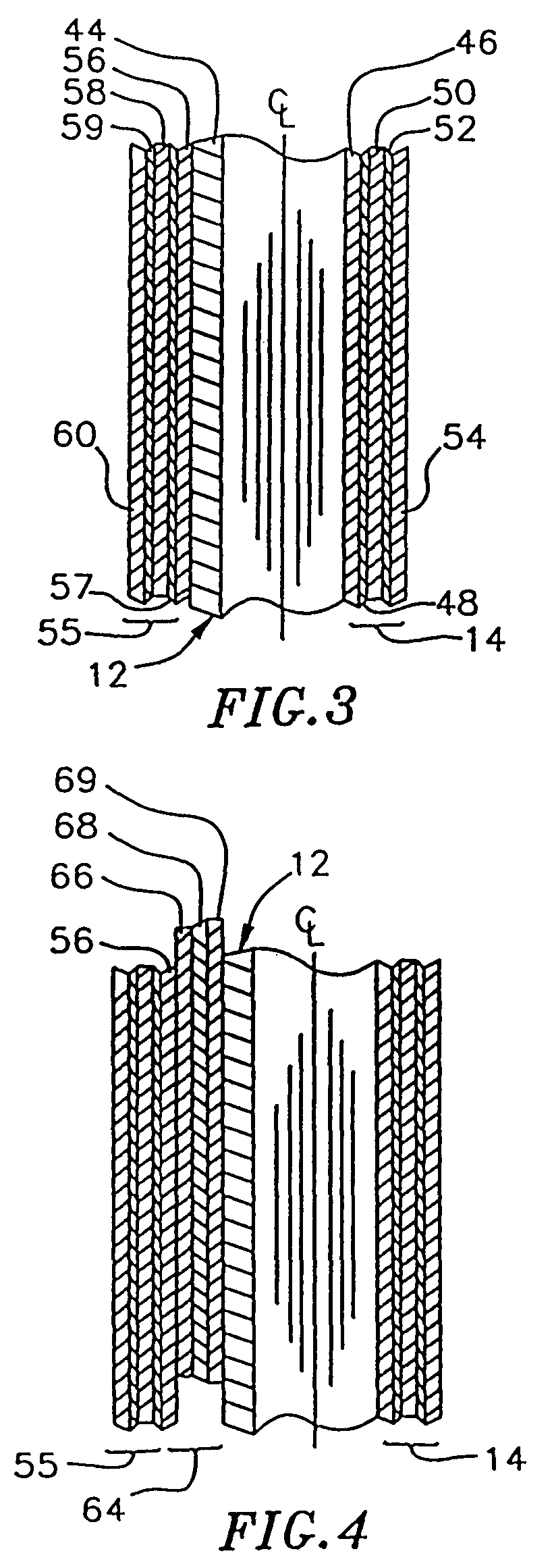

Flexible multi-compartment container with peelable seals and method for making same

InactiveUS6846305B2Increase capacityIncrease storage capacityWrappersMedical devicesThermoplasticDiluent

A flexible container is provided for the storage and administration of medical solutions. The container incorporates a transparent front sheet made from a planar layer of a polymer and an opposing rear sheet. The rear sheet is made from a planar laminate layer. The front and rear sheets are sealed together along a common peripheral edge to form a volume enclosure. The volume enclosure is constructed of materials having high oxygen and moisture barrier properties which allows the container thermoplastic to be stored for extended periods of time without degrading the contents. The volume enclosure is then inflated with a pressurized gas to permanently stretch the front and rear sheets outwardly and to thereby increase the volume capacity of the container. An alternative embodiment of the container incorporates multiple compartments, separated by peelable seals, for containing a diluent and a medicament. The seals are ruptured by manipulation of the container to thereby mix the contents together for delivery through standard IV arrangement to a patient.

Owner:B BRAUN MEDICAL

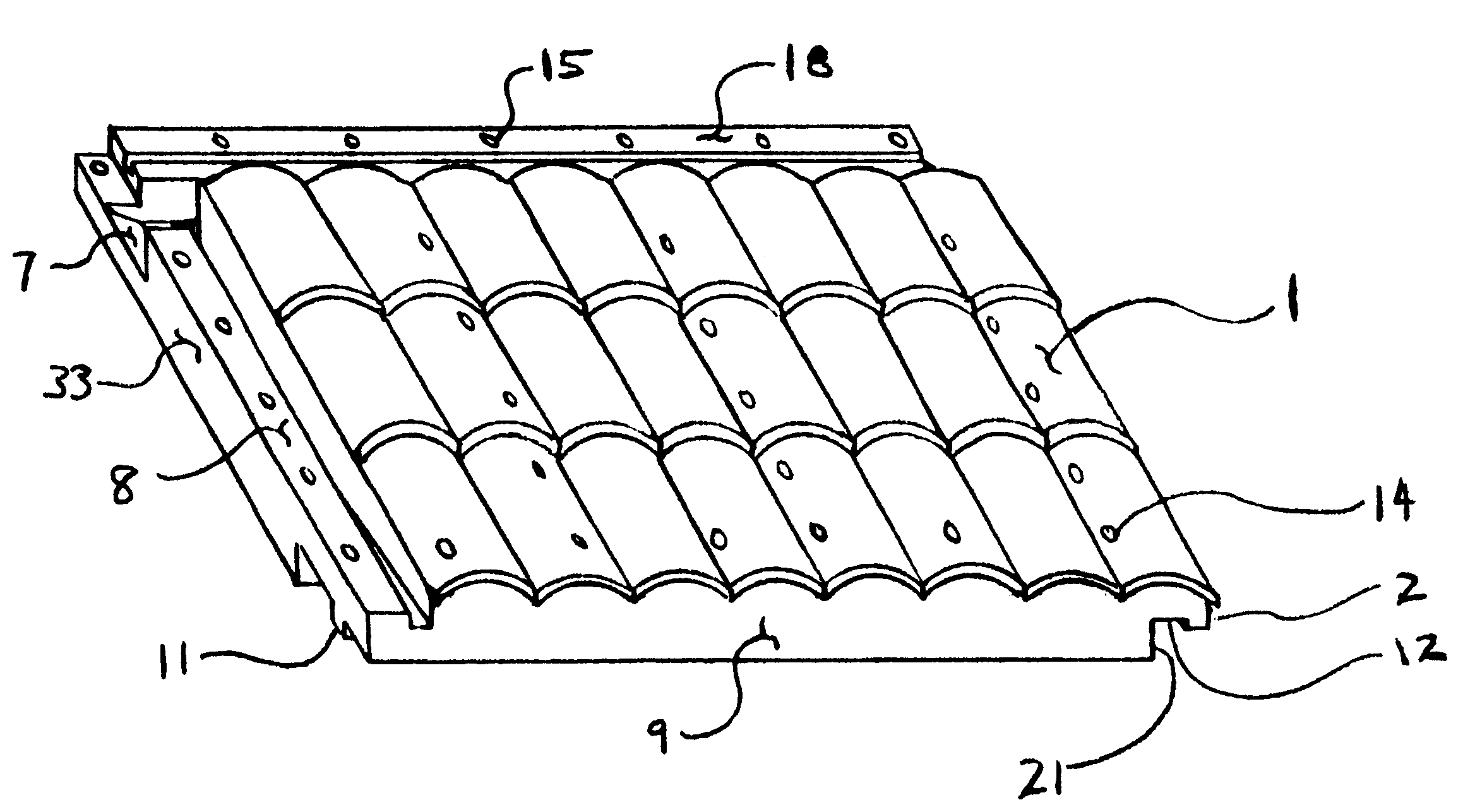

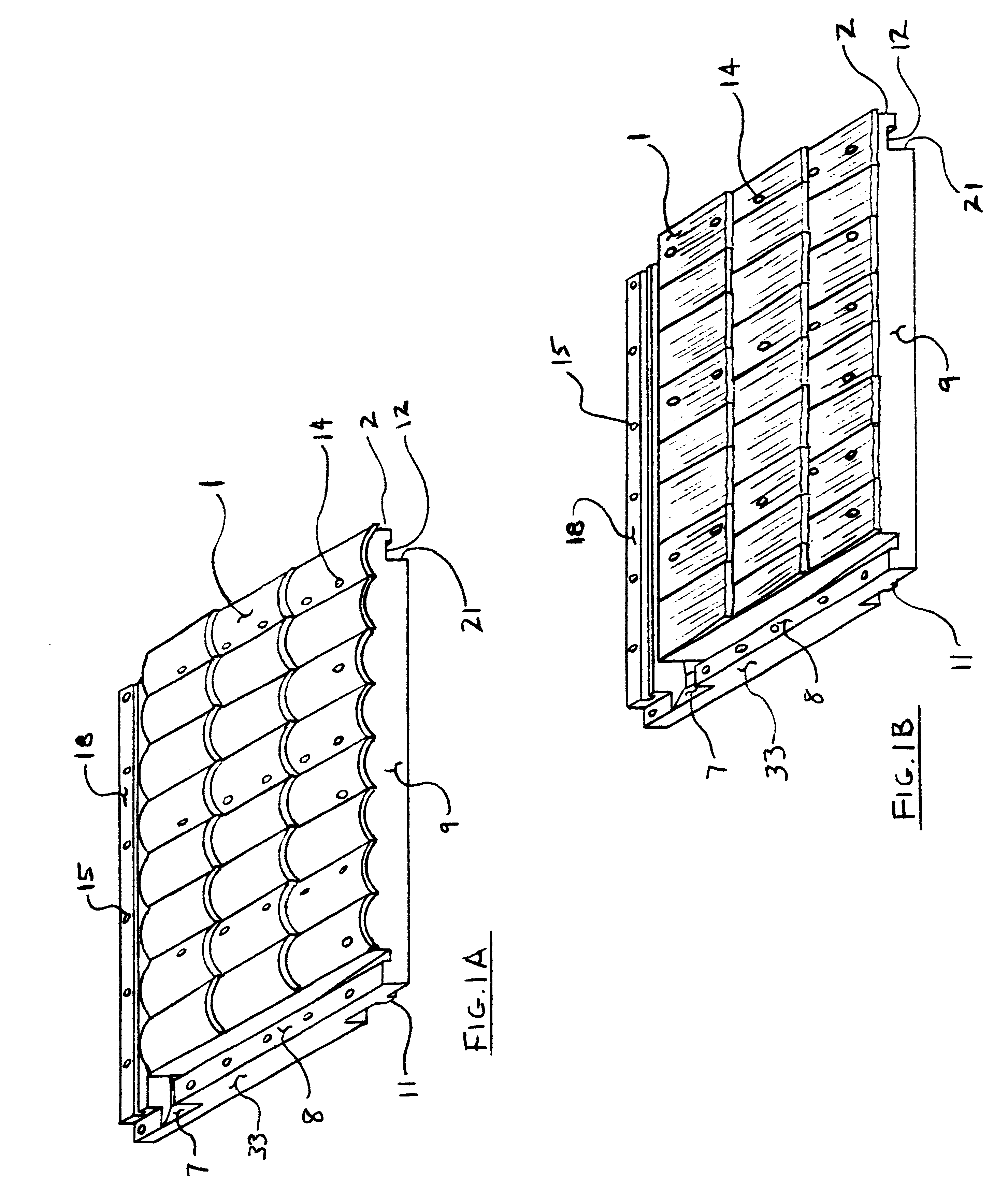

Roofing panel system and method for making same

InactiveUS6282858B1Eliminate needSimple and accurate methodRoof covering using tiles/slatesWallsFiberglass meshWater channel

An injection molded rigid roof panel system for constructing pitched roof structures of the type affixed directly to roof trusses or rafters and needing no structural or supporting sheathing surface or moisture barrier. Comprised of no less than (23) standard roof panel components of varying shapes, sizes, colors and exposed surfaces replicating conventional roofing surfaces. Panels overlap, underlap and interlock by means of an array of shoulders, locating ribs and clearance channels creating a unitized roof system utilizing integral seals at the seams, subsurface water channels and self sealing, threaded fasteners whose molded-in, counter-bored holes are further sealed by composite plugs. Panels are produced by mixing, extruding and pelletizing a compound of over 60% recycled materials and encapsulating a semi-rigid fiberglass mesh sheet in the panels during the injection molding process producing a roofing product that is fire retardant, impervious to moisture, insects, ultraviolet rays and winds in excess of 130 mph.

Owner:SWICK ANDREW C

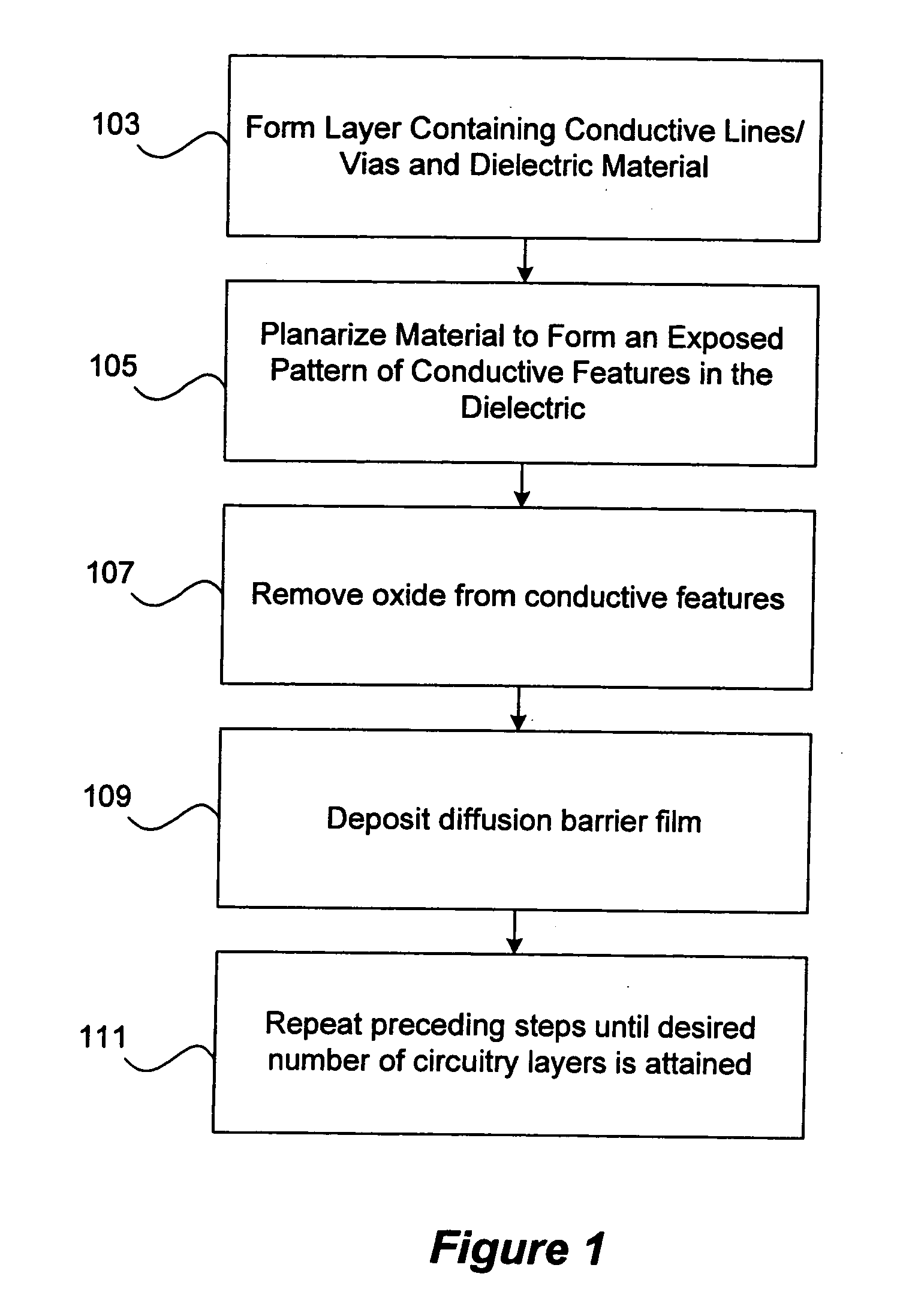

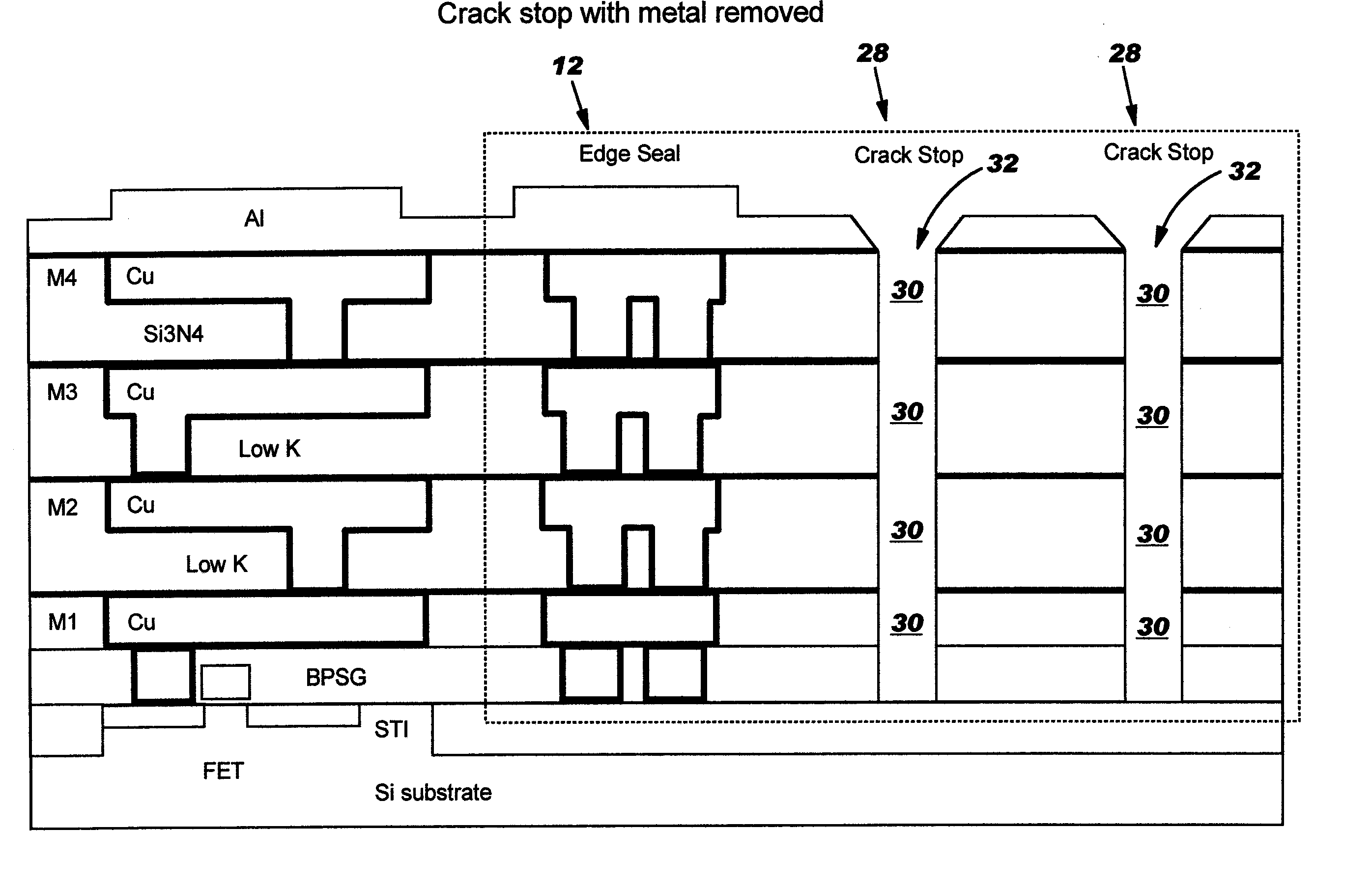

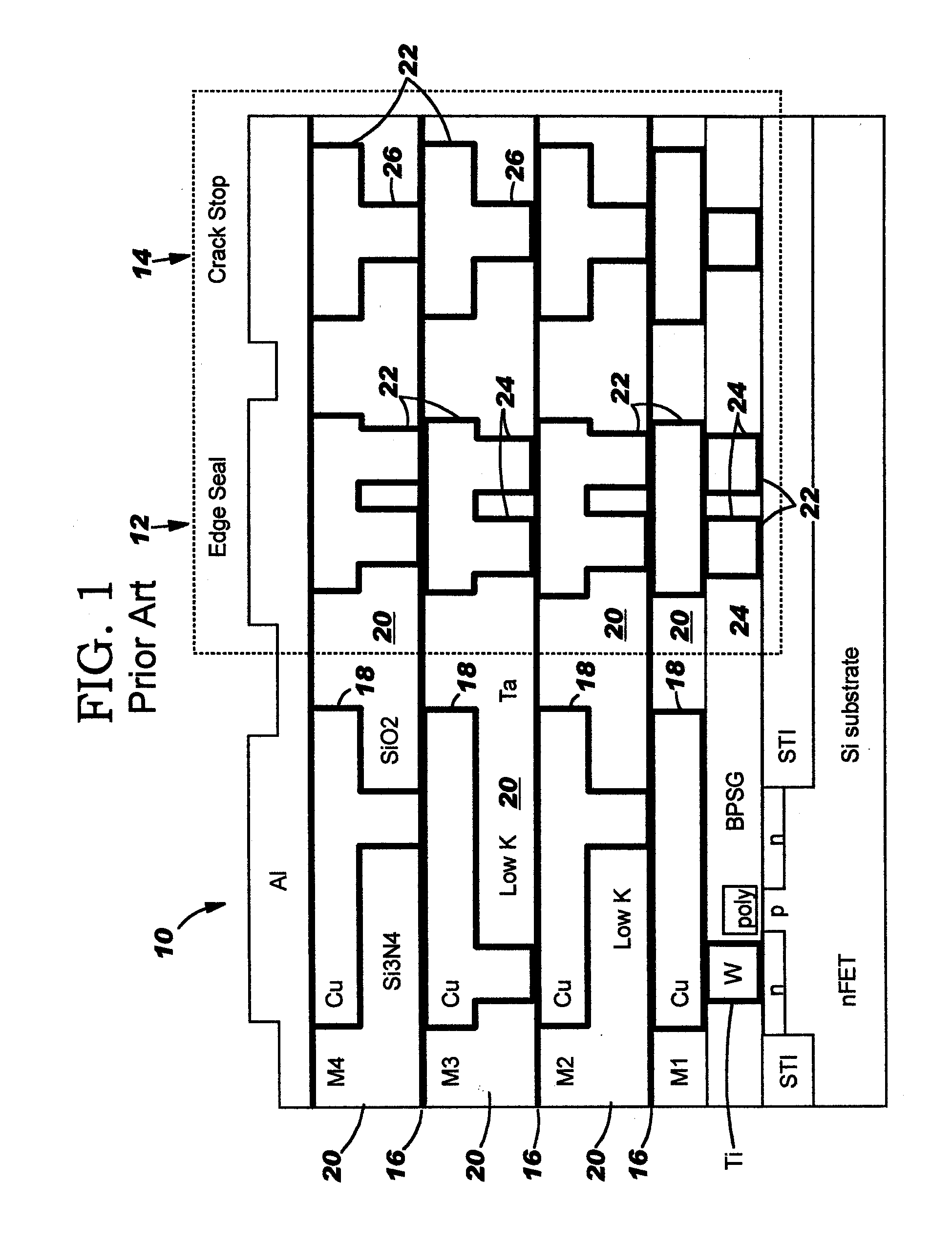

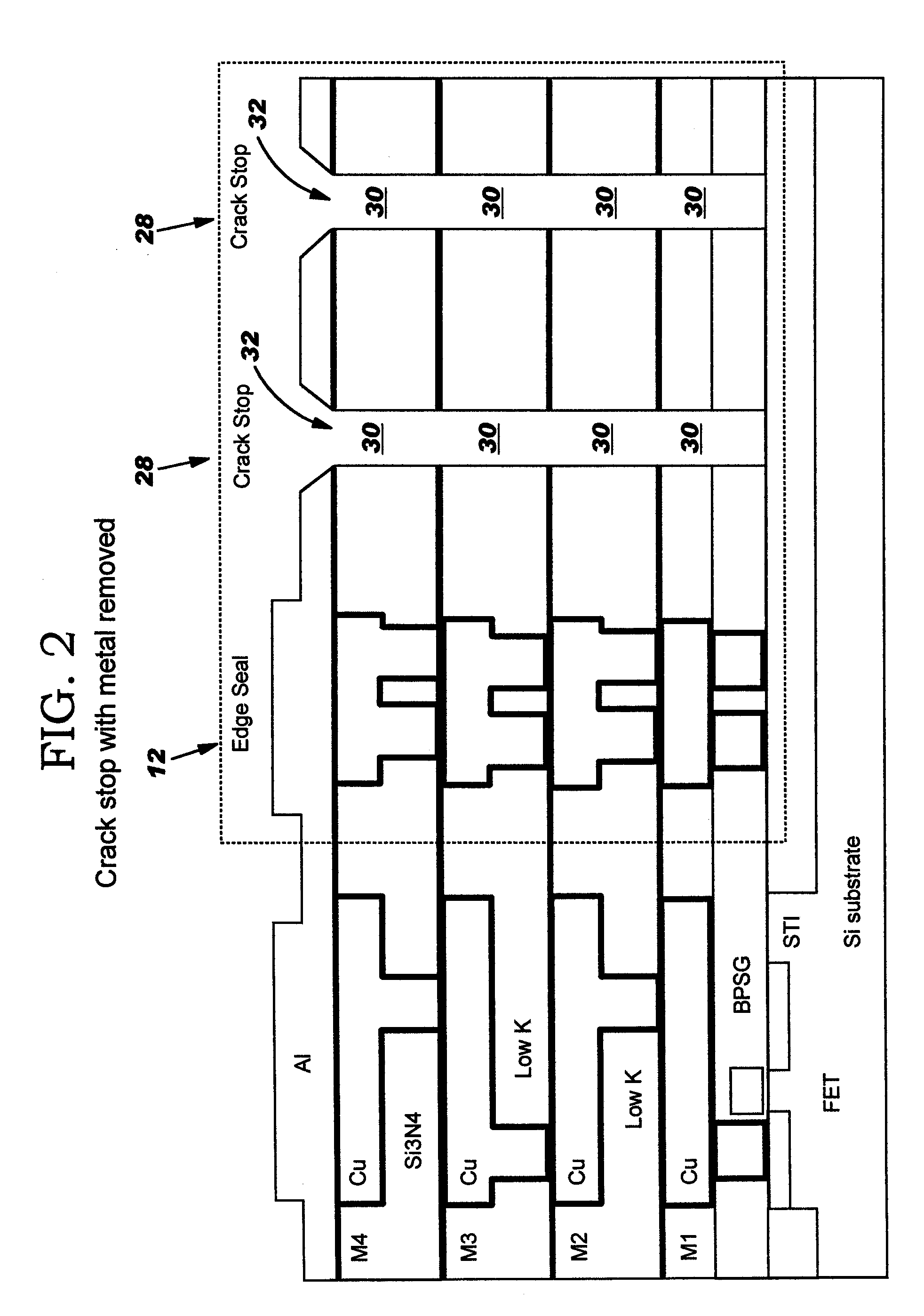

Crack stop for low k dielectrics

InactiveUS20050026397A1Hinders its propagationSemiconductor/solid-state device detailsSolid-state devicesMetal interconnectCrazing

A crack stop for low K dielectric materials of an integrated circuit (IC) formed on an IC chip using metal interconnects which do not form a self-passivating oxide layer, such as copper or silver interconnects, in a low-K dielectric material to prevent damage to the active area of the IC chip caused by chipping and cracking formed along peripheral edges of the IC chip during a dicing operation. A moisture barrier or edge seal is formed as a metal stack positioned along the outer peripheral edges of the active area of the IC chip. The crack stop is formed by at least one trench or groove positioned outside of the moisture barrier / edge seal on the outer periphery of the IC chip.

Owner:GLOBALFOUNDRIES INC

Self-adhering vapor permeable air and moisture barrier membrane

A self-adhering air and moisture barrier sheet membrane for structural surfaces of buildings, which is permeable to the passage of water vapor, is comprised of a water vapor permeable sheet onto one surface of which is applied an adhesive in a non-continuous film.

Owner:HENRY COMPANY CANADA

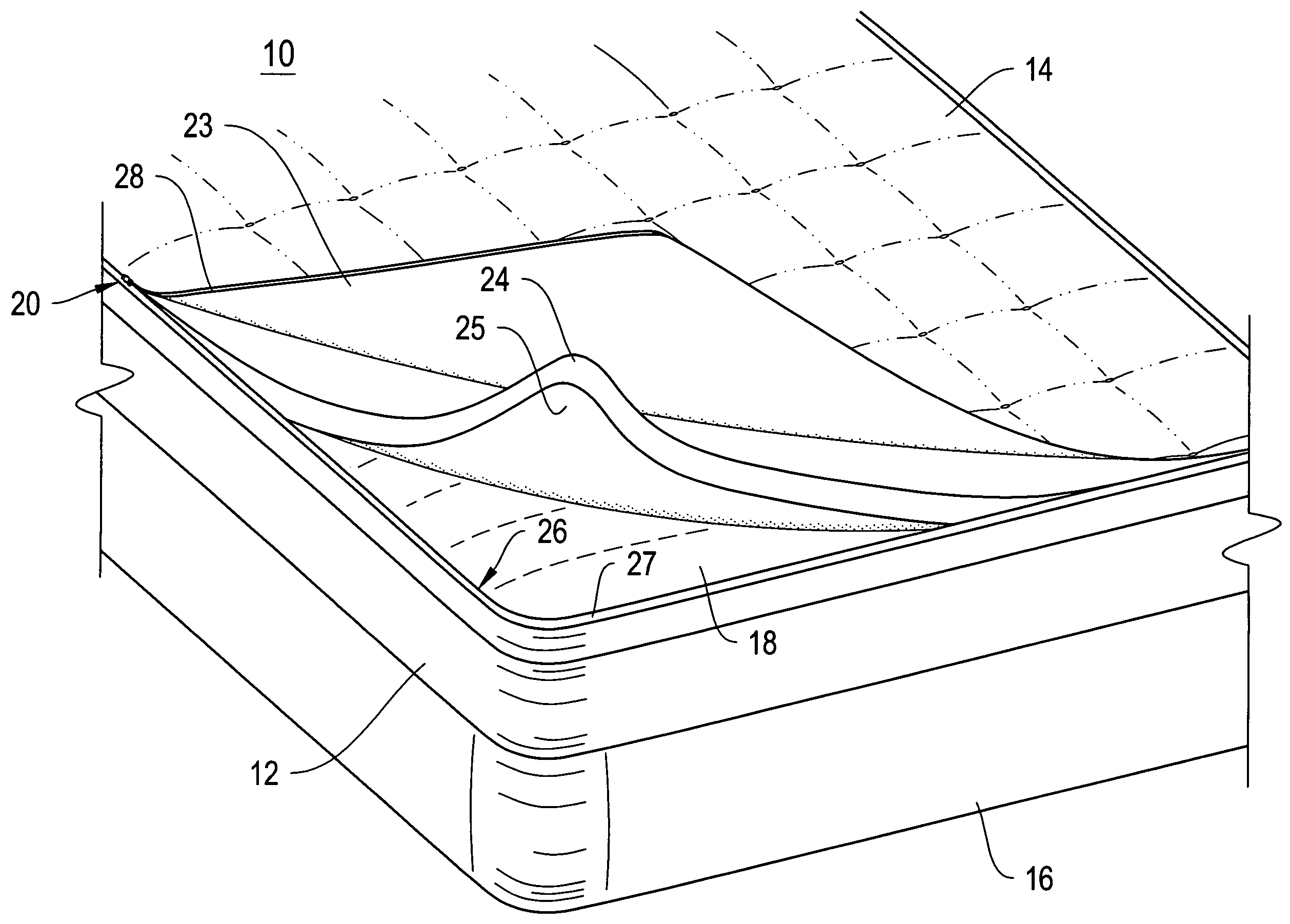

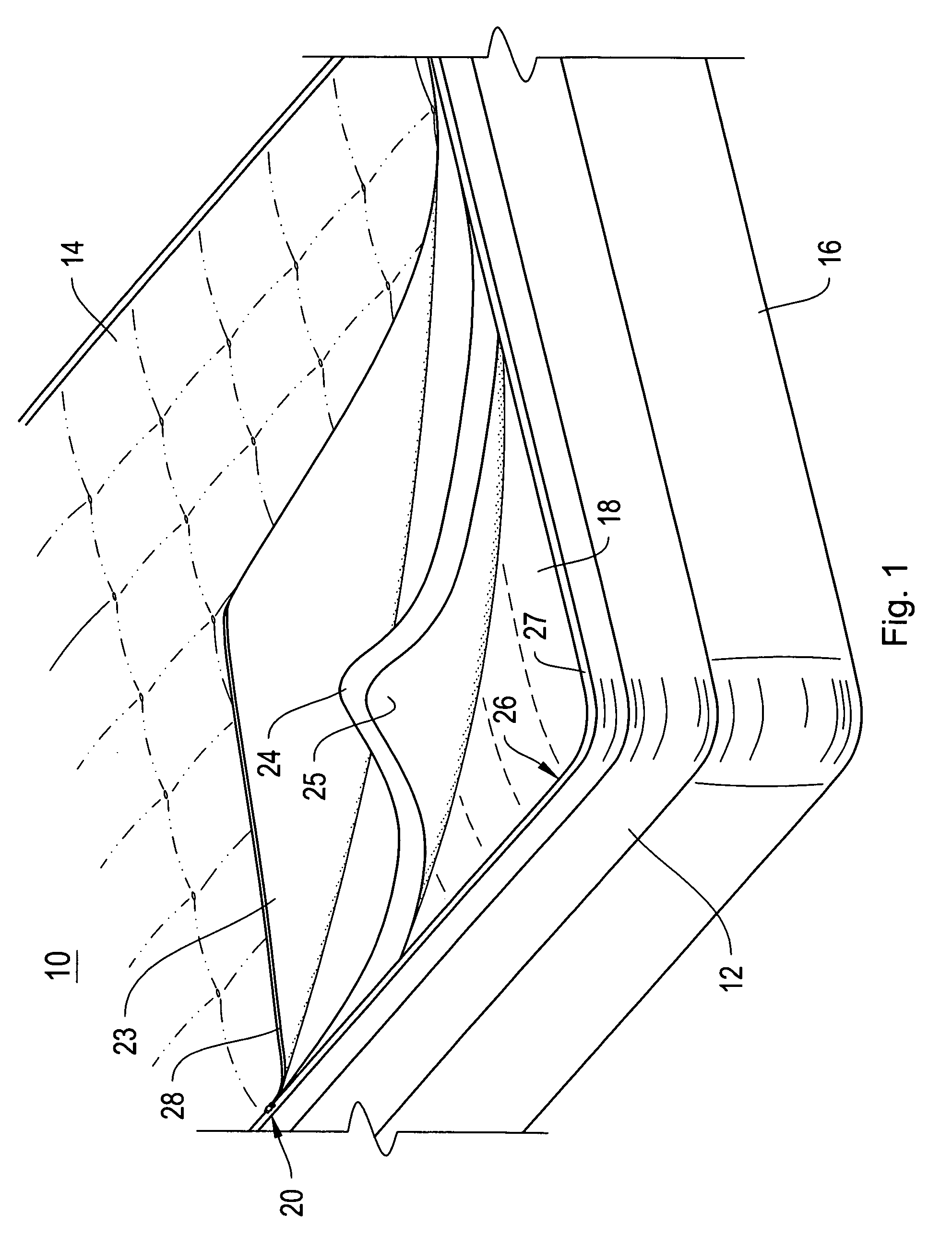

Mattress with removable top

ActiveUS20060010608A1Improve breathabilityGood moisture permeabilityStuffed mattressesSpring mattressesMoisture barrierFastener

A mattress is constructed from a mattress body having an upper and a lower deck, which is preferably pervious to moisture and air. A removable panel, which includes a top layer of breathable fabric, a bottom layer of a fabric that forms a moisture barrier, and a batting layer, is placed on at least the upper deck of the mattress body. The removable panel is removably attached along the perimeter of the deck or decks by a fastener, such as a zipper. The panel can be removed from the deck for cleaning and folded and secured by the fastener in an inverted configuration, with the top layer facing outward.

Owner:DREAMWELL

Flexible multi-compartment container with peelable seals and method for making same

InactiveUS6996951B2Increase storage capacityIncrease capacityEnvelopes/bags making machineryBoxes/cartons making machineryThermoplasticDiluent

A flexible container is provided for the storage and administration of medical solutions. The container incorporates a transparent front sheet made from a planar layer of a polymer and an opposing rear sheet. The rear sheet is made from a planar laminate layer. The front and rear sheets are sealed together along a common peripheral edge to form a volume enclosure. The volume enclosure is constructed of materials having high oxygen and moisture barrier properties which allows the container thermoplastic to be stored for extended periods of time without degrading the contents. The volume enclosure is then inflated with a pressurized gas to permanently stretch the front and rear sheets outwardly and to thereby increase the volume capacity of the container. An alternative embodiment of the container incorporates multiple compartments, separated by peelable seals, for containing a diluent and a medicament. The seals are ruptured by manipulation of the container to thereby mix the contents together for delivery through standard IV arrangement to a patient.

Owner:B BRAUN MEDICAL

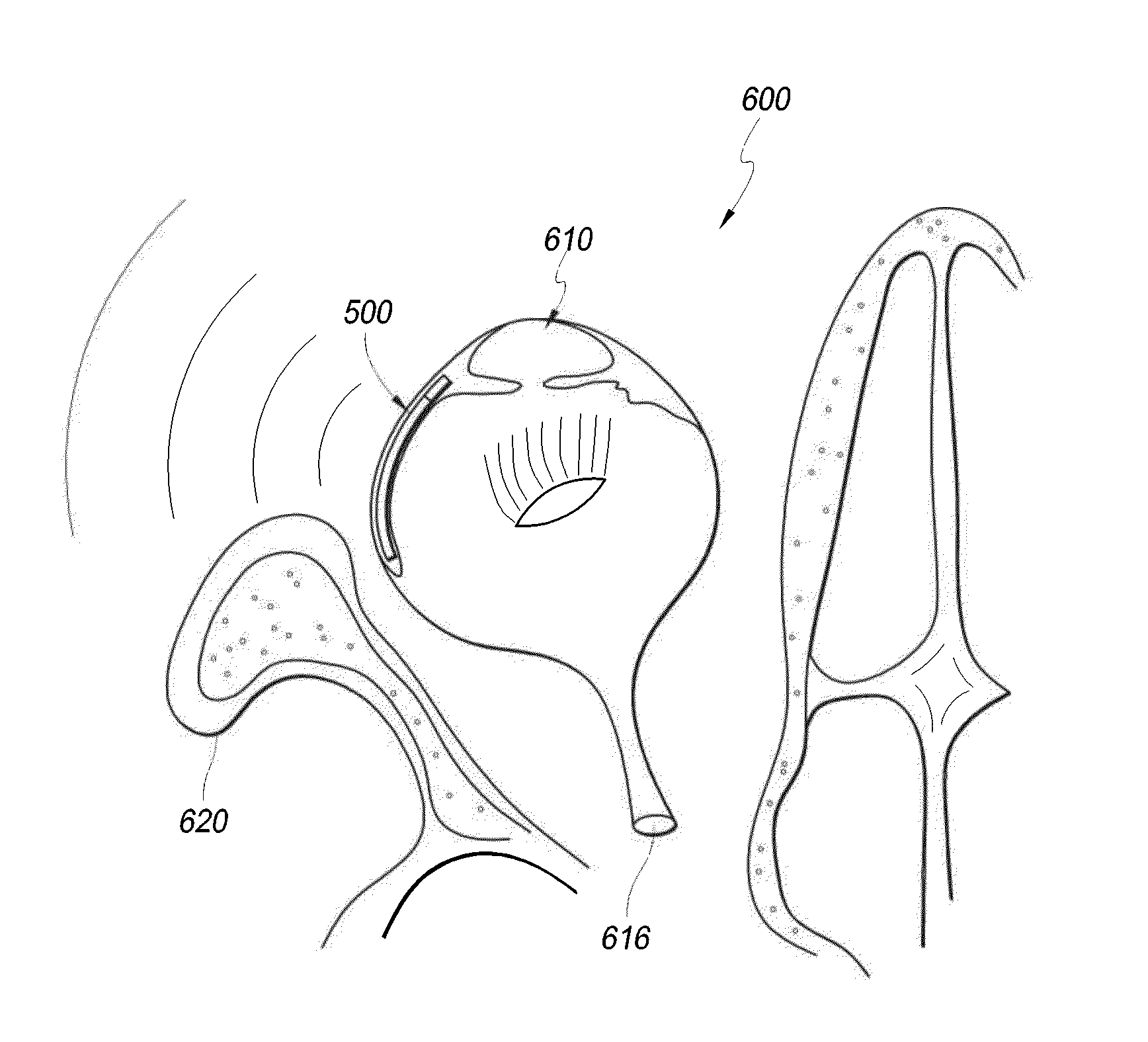

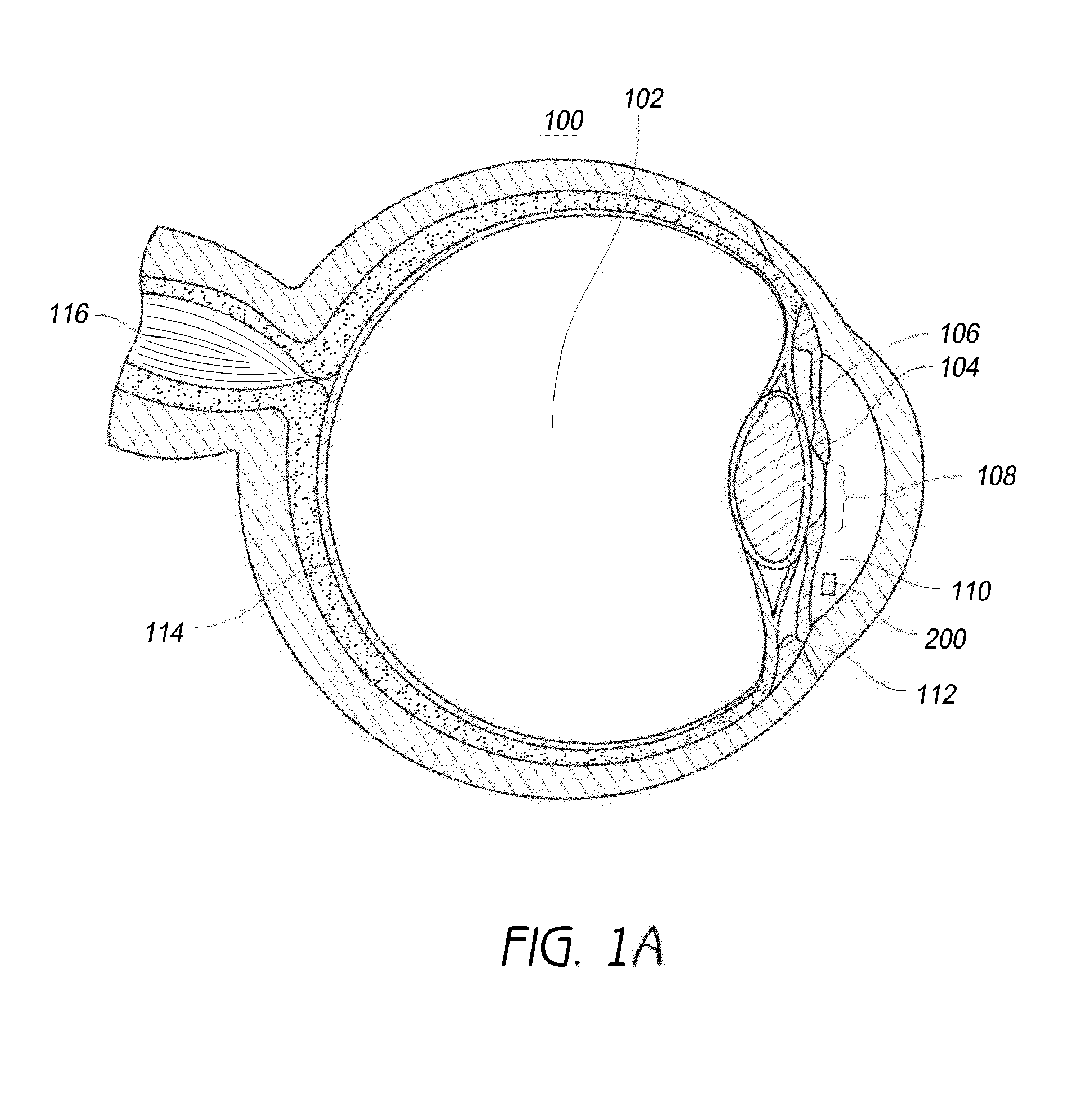

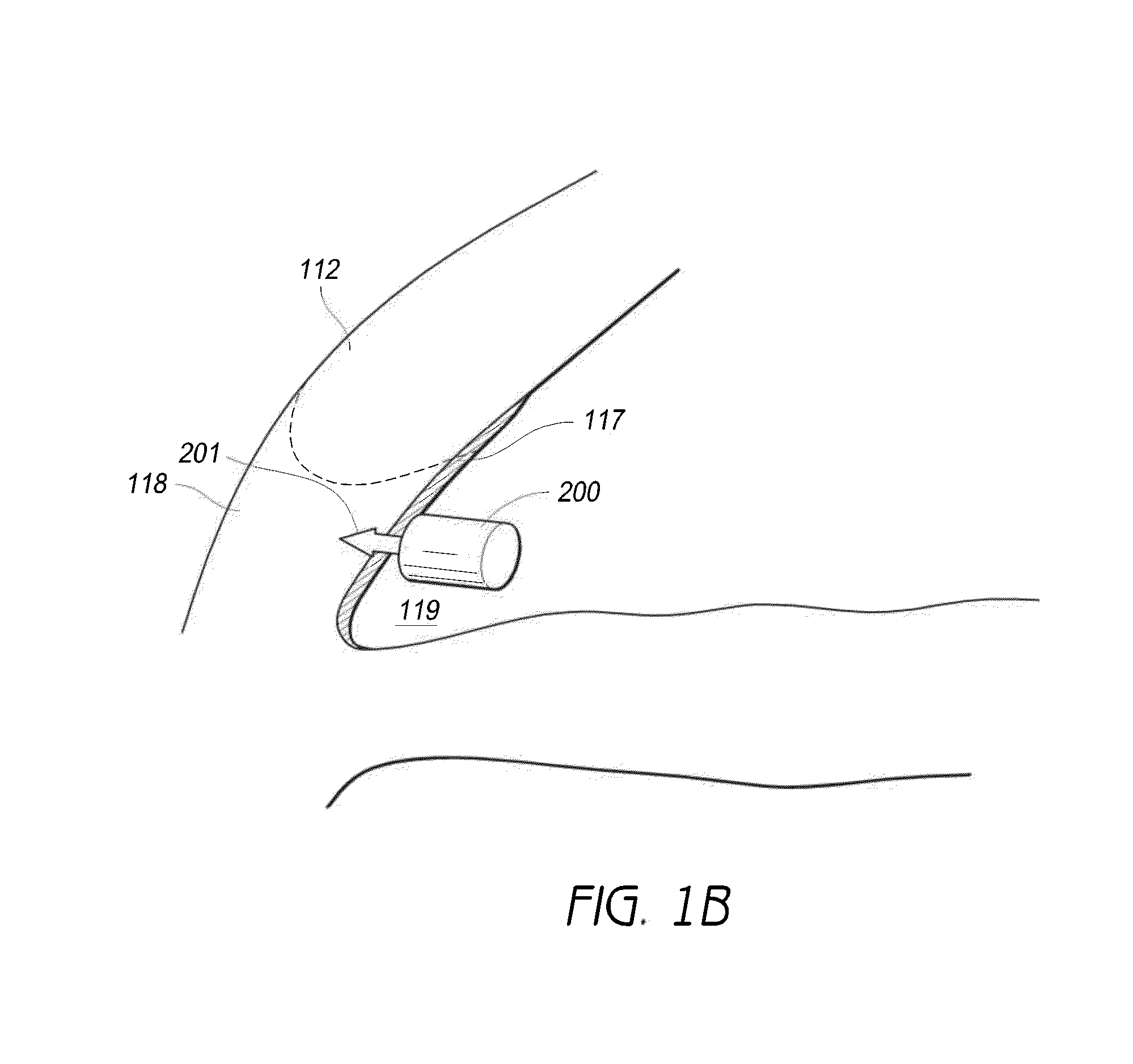

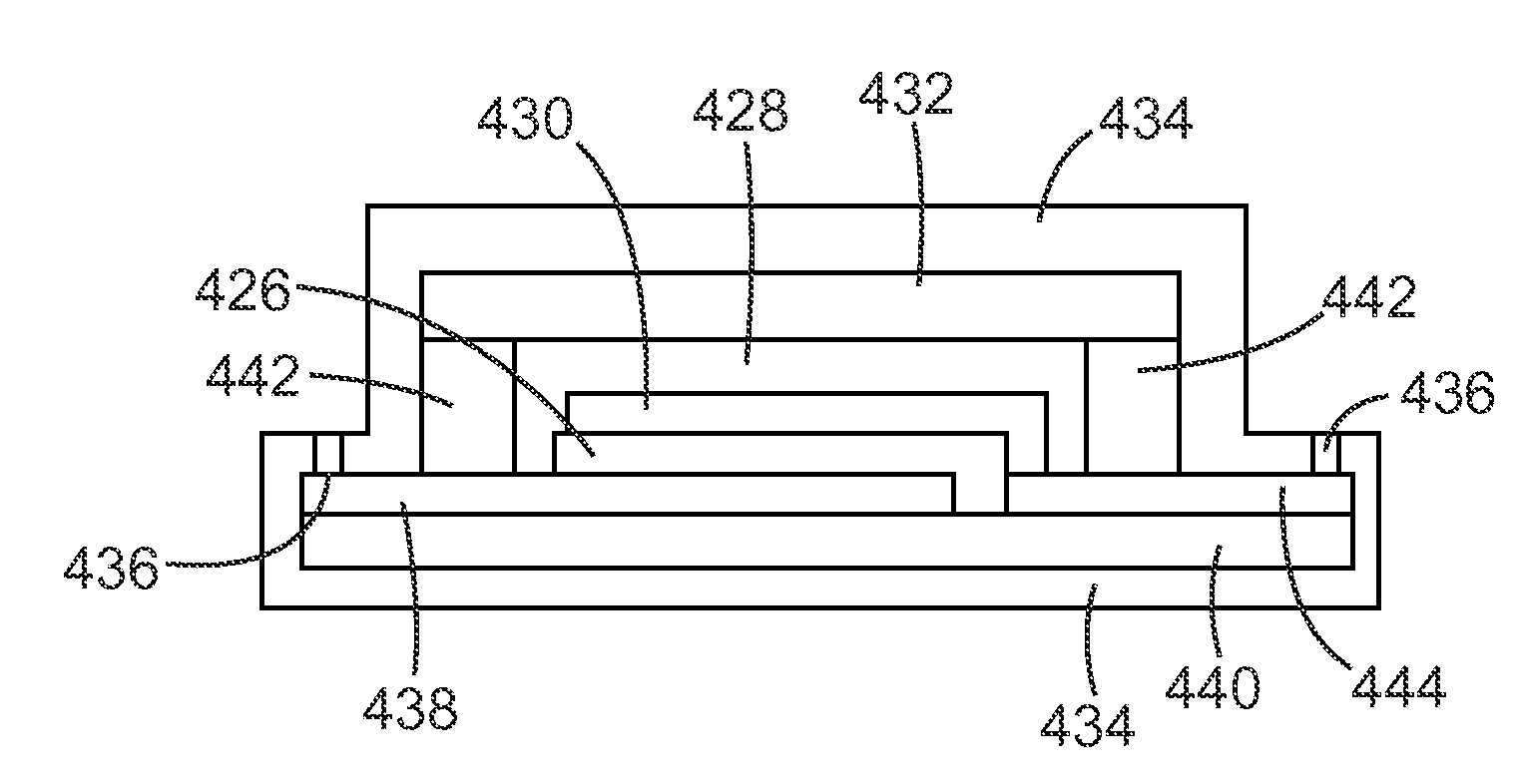

Intraocular physiological sensor

An implantable intraocular physiological sensor for measuring a physiological characteristic, such as intraocular pressure. The implantable intraocular physiological sensor may include a tubular main body configured to house one or more electrical components. The implantable intraocular physiological sensor may also include a sensor cap configured to be inserted into a first end of the tubular main body with a moisture barrier seal. The implantable intraocular physiological sensor may wirelessly transmit measurements to an external device.

Owner:GLAUKOS CORP

Moisture barrier coatings for organic light emitting diode devices

A barrier assembly having a flexible or rigid substrate, an organic electronic device, and one or more layers of diamond-like film. The diamond-like film layers can be used to mount, cover, encapsulate or form composite assemblies for protection of moisture or oxygen sensitive articles such as organic light emitting diode devices, photovoltaic devices, organic transistors, and inorganic thin film transistors. The diamond-like film layers can also provide for edge sealing of adhesive bond lines in the assemblies.

Owner:3M INNOVATIVE PROPERTIES CO

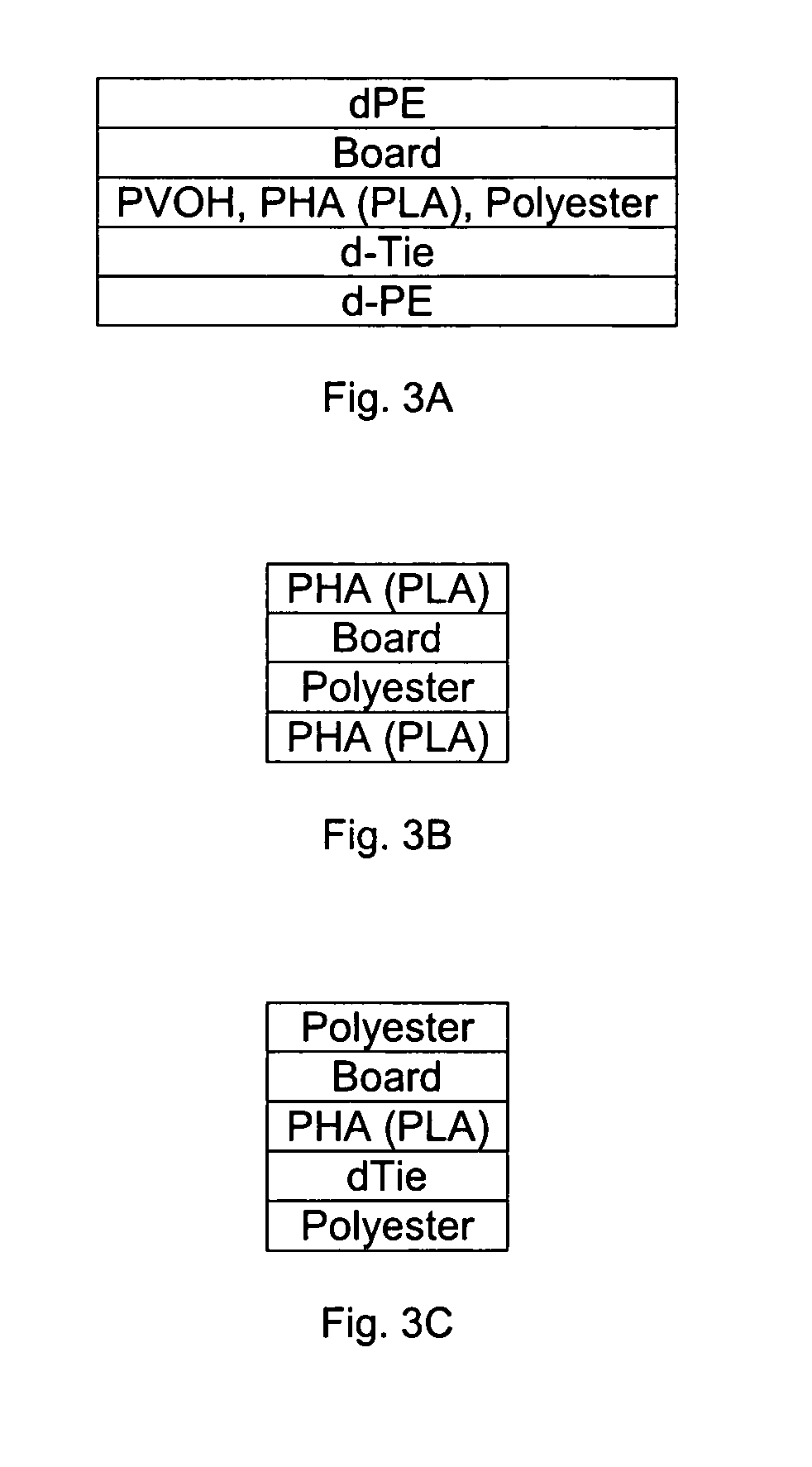

Biodegradable paper-based laminate with oxygen and moisture barrier properties and method for making biodegradable paper-based laminate

Biodegradable laminates including biodegradable polymers have oxygen and moisture barrier properties. The oxygen and moisture barrier layers are biodegradable. If the barrier layers have poor adhesion, degradable tie layers can be included to improve adhesion. Combination of laminate structures can be formed to increase the overall oxygen and moisture barrier characteristics. The biodegradable laminates can be formed by extrusion.

Owner:GRAPHIC PACKAGING INT

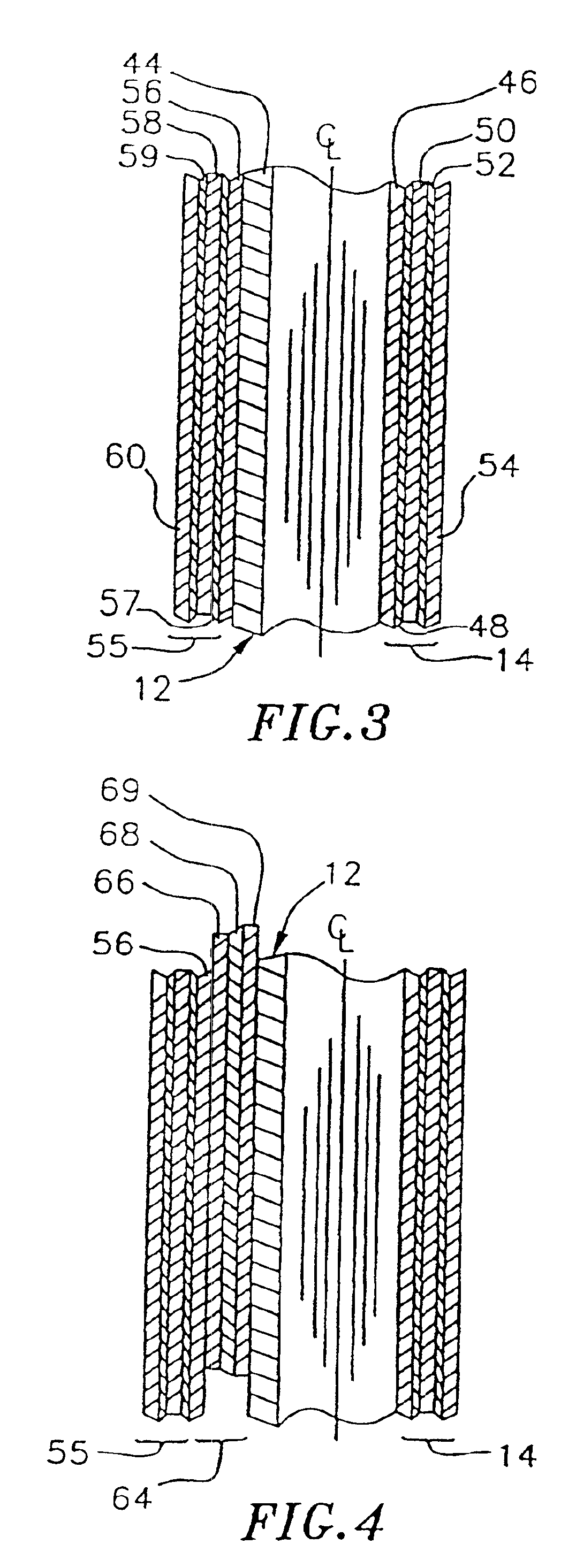

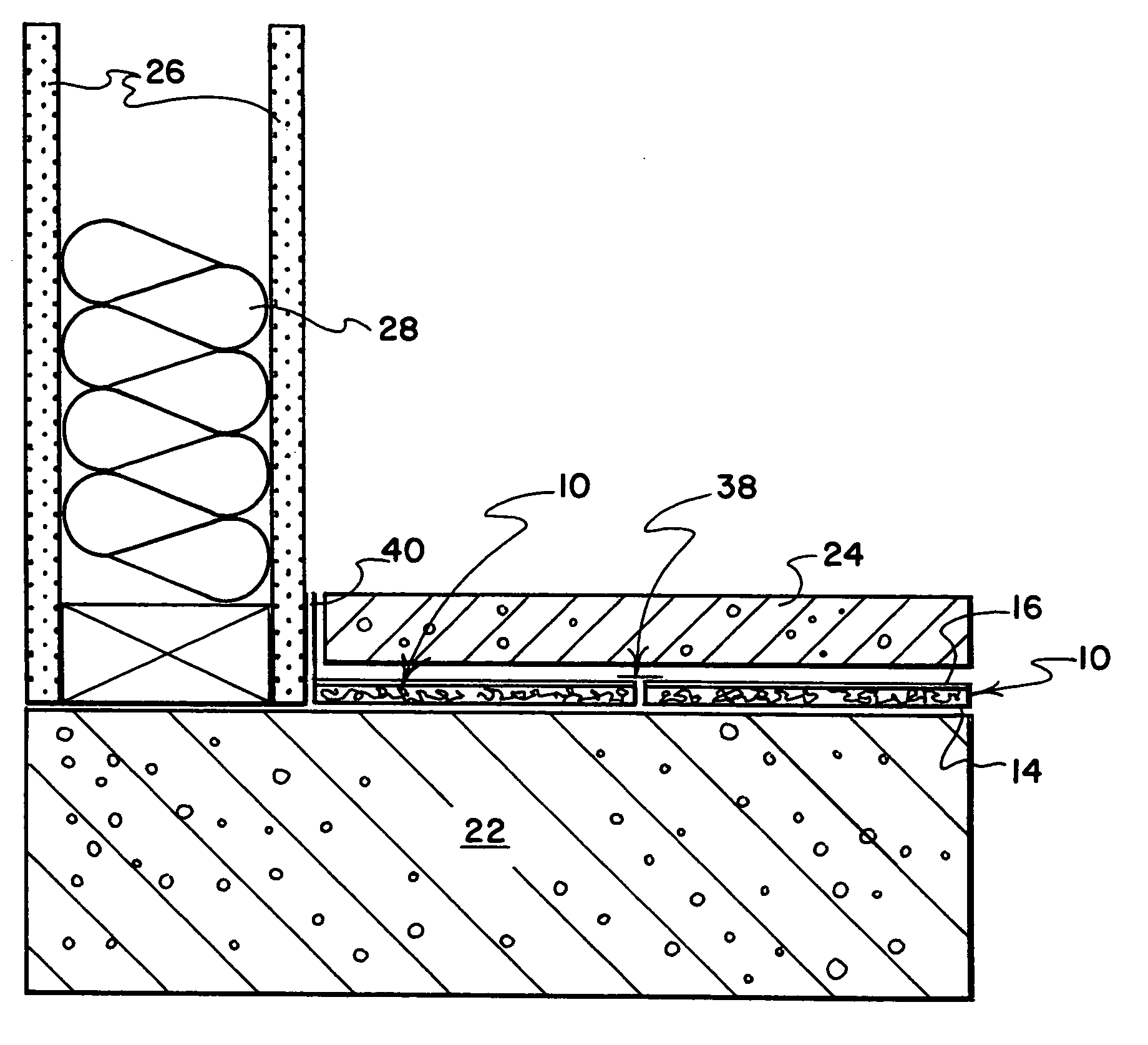

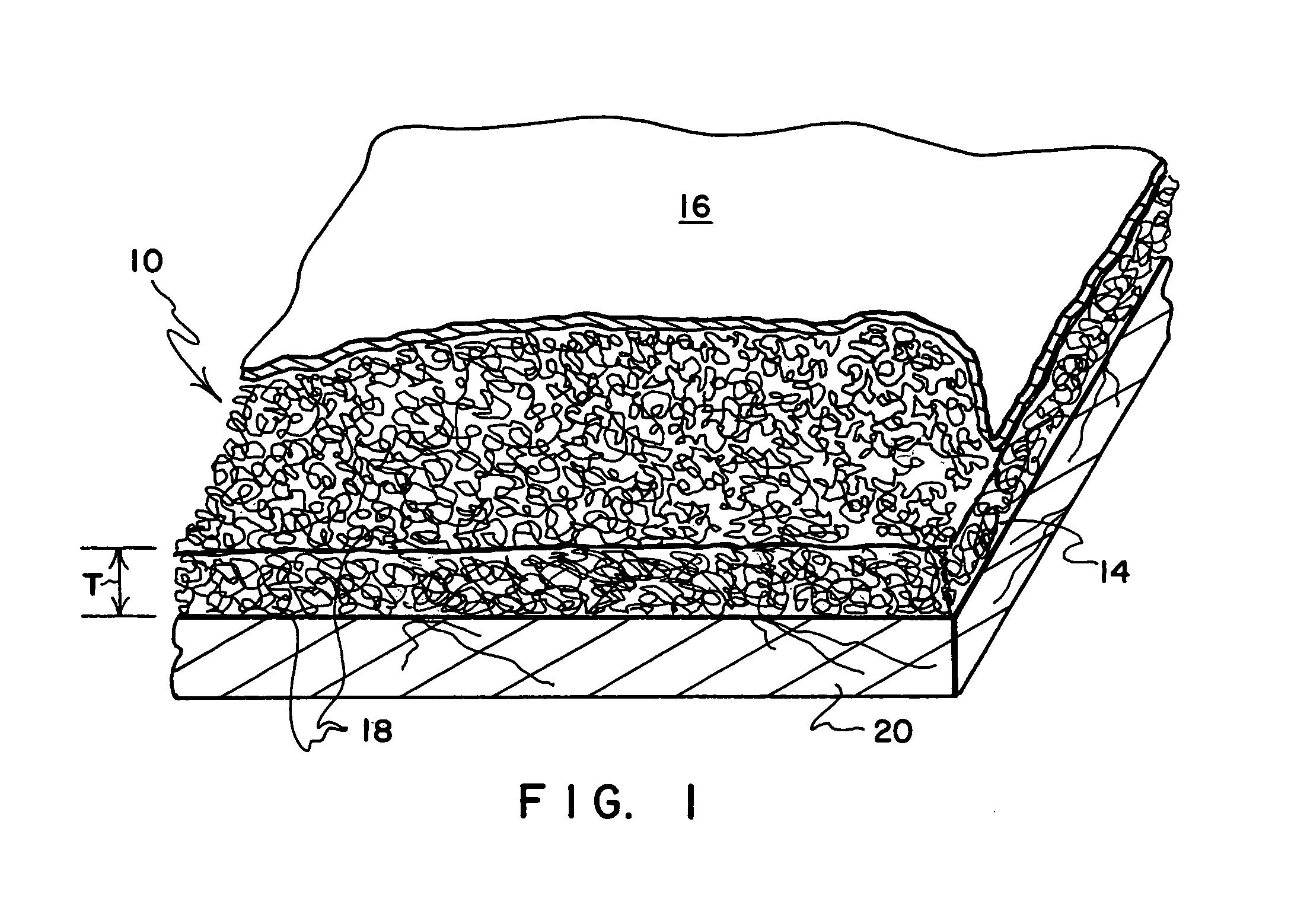

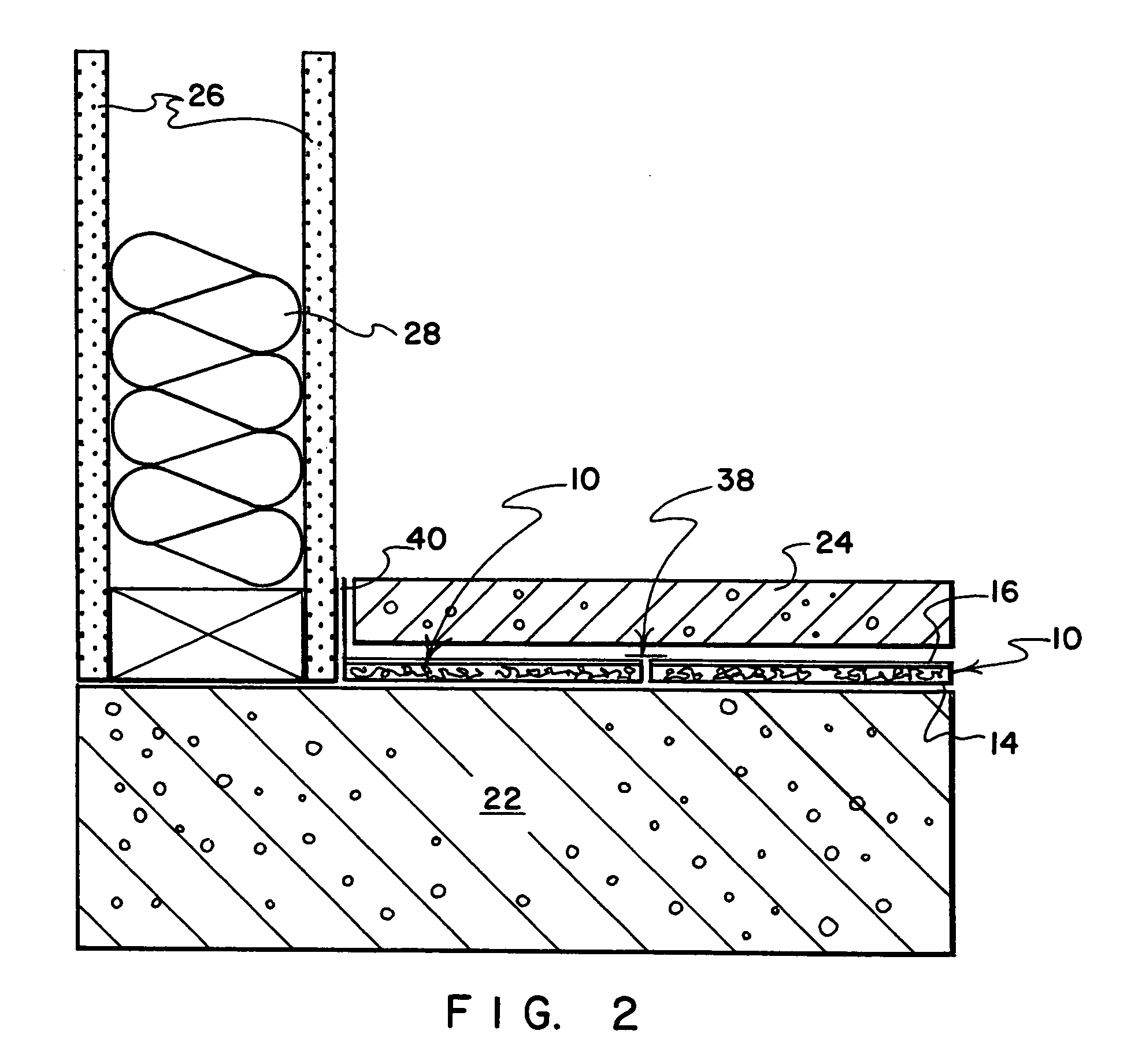

Composite tangled filament mat with overlying liquid moisture barrier for cushioning and venting of vapor, and for protection of underlying subfloor

ActiveUS7096630B1Dampen and minimize noise transmissionCushion and dampen and absorbFloorsFoundation engineeringCushioningWater vapor

A composite mat and sheet structure for installation atop a subfloor to underlie a layer of hardenable, cementicious material such as gypsum concrete or Portland concrete that is poured atop the composite structure to harden in situ. The composite structure includes 1) a mat of substantially uniform thickness defined by an array of entangled, intertwined polymeric filaments that twist and turn at random, that are spaced from each other along a majority of their lengths, that preferably are bonded at their randomly located intersections, and that cooperate to give the mat an open-space character well suited for venting vapor from an area beneath the layer of hardenable cementicious material during hardening or curing thereof; and 2) a sheet of barrier material that overlies the mat, is bonded to the mat, and is pervious to water vapor but impervious to water in liquid form, thereby to permit water in vapor form to escape from the hardenable material through the barrier sheet into the mat and to be vented through the open-space area of the mat while the barrier sheet protects the subfloor from damage by water in liquid form that should be confined atop the barrier.

Owner:MFG IDEAS LLC

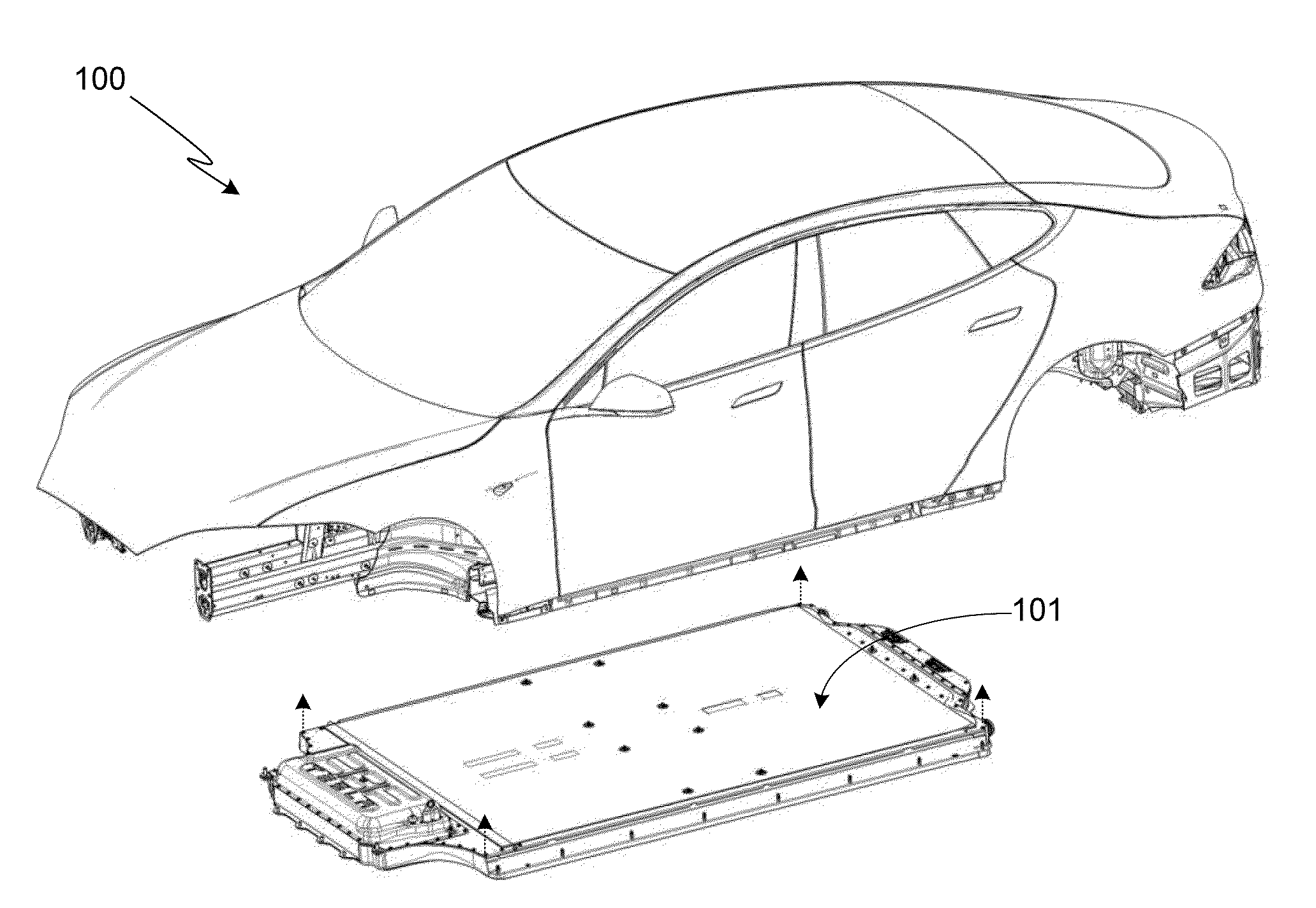

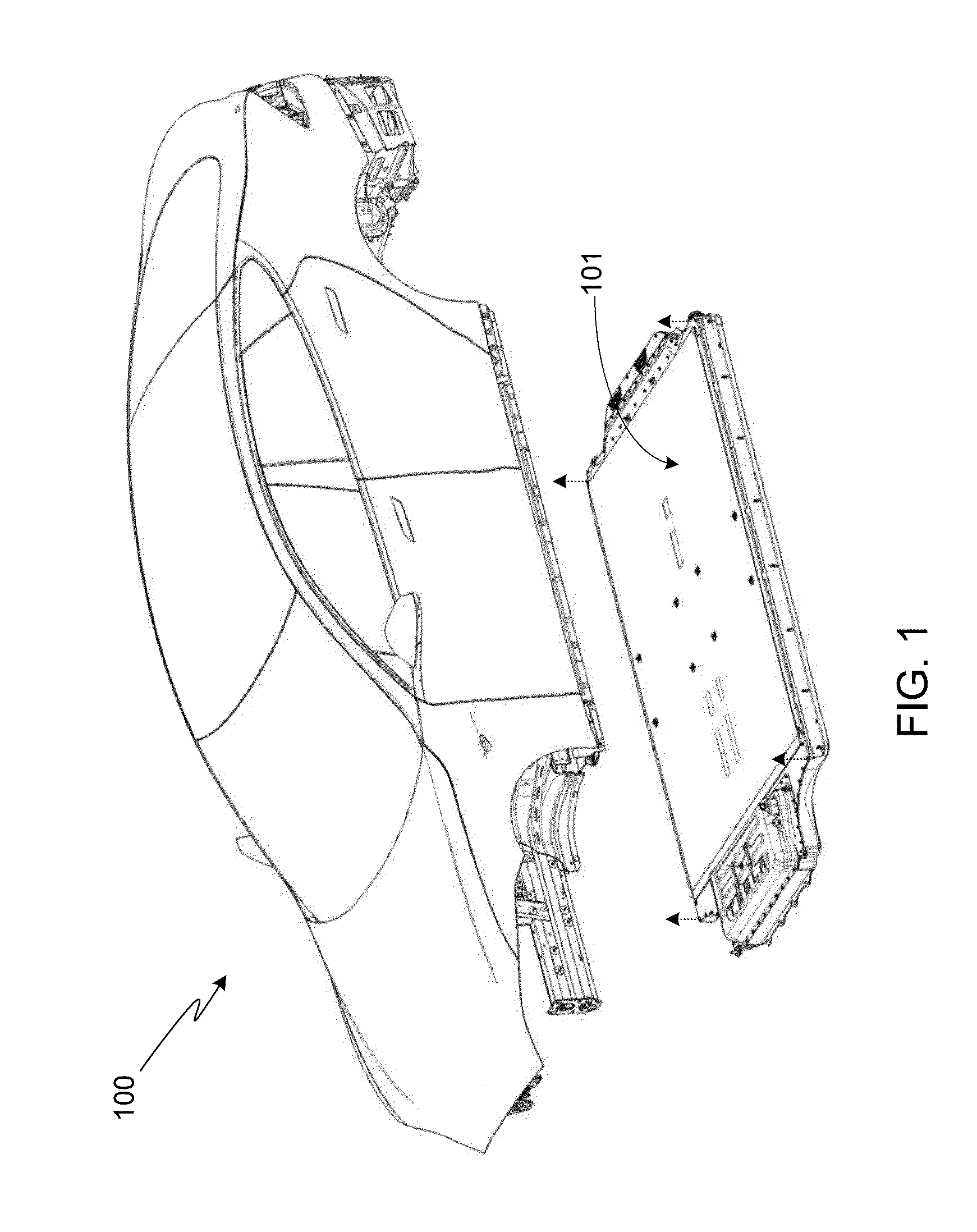

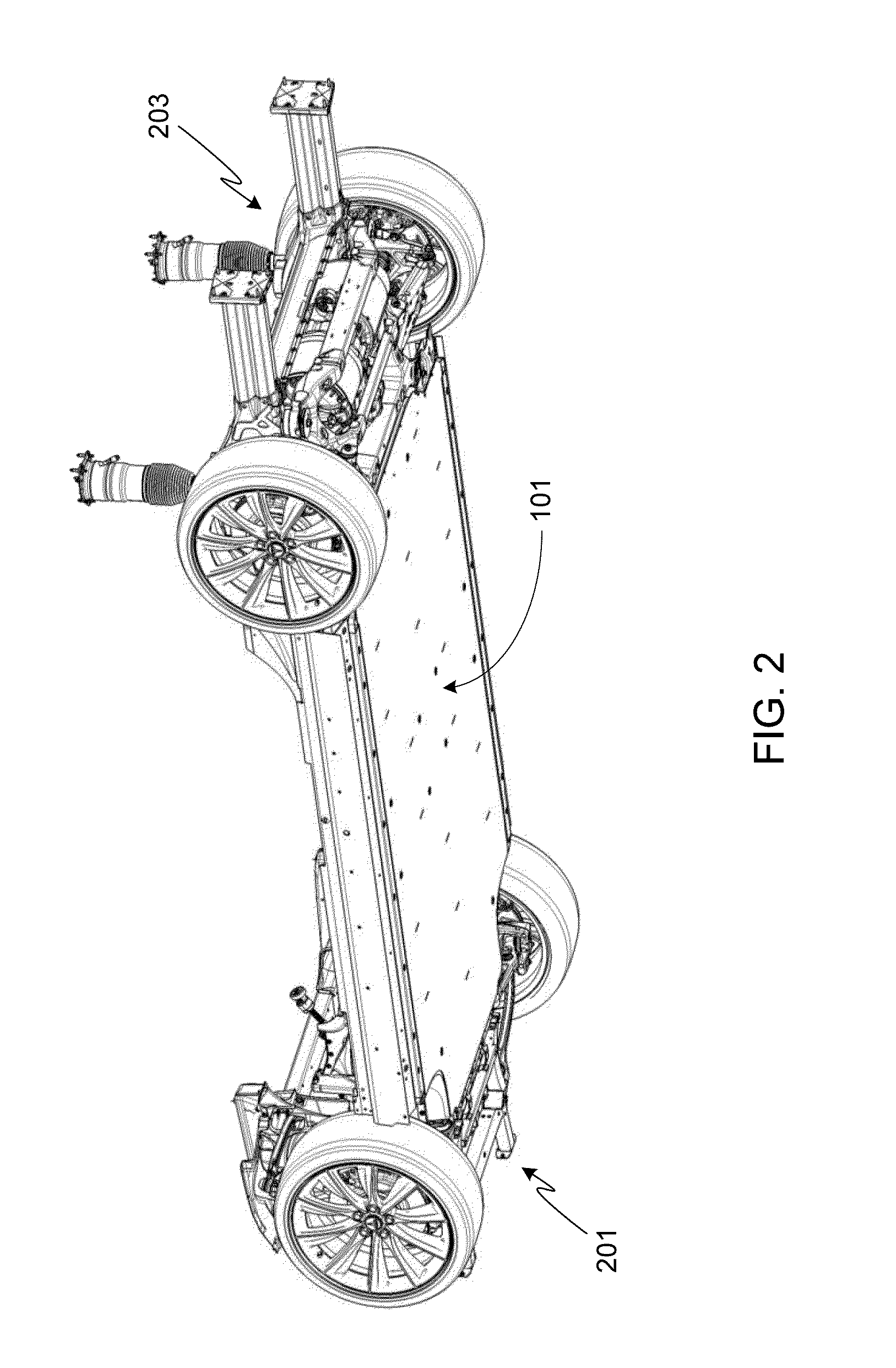

Vehicle Battery Pack Thermal Barrier

An integration assembly for a battery pack mounted between the passenger cabin floor panel of an electric vehicle and the driving surface is provided, the assembly utilizing a multi-layer thermal barrier interposed between the battery pack enclosure and the passenger cabin floor panel, where the multi-layer thermal barrier provides noise isolation, thermal isolation and vibration damping, and where the multi-layer thermal barrier is compressed when the battery pack enclosure is mounted to the vehicle. The multi-layer thermal barrier is comprised of a first layer formed from a compressible and conformable elastic material and a second layer formed from a conformable thermally insulating material. The multi-layer thermal barrier may also include a moisture barrier layer that encases the first and second layers, for example a moisture barrier layer fabricated from a plastic. A sealant may be used to seal and bond the moisture barrier layer to the battery pack enclosure.

Owner:TESLA INC

Moisture barrier film coating composition, method and coated form

A dry moisture barrier film coating composition for forming a moisture barrier film coating for pharmaceutical tablets and the like comprises polyvinyl alcohol, soya lecithin, and optionally a flow aid, a colorant, and / or a suspending agent. A liquid coating solution or dispersion for forming a moisture barrier film coating for pharmaceutical tablets and the like comprises polyvinyl alcohol, soya lecithin, water, and optionally a flow aid, a colorant, and / or a suspending agent. A method of coating pharmaceutical tablets and the like with a moisture barrier film coating comprises forming a liquid coating solution or dispersion for forming a moisture barrier film coating for pharmaceutical tablets and the like comprising polyvinyl alcohol, soya lecithin, water, and optionally a flow aid, a colorant, and / or a suspending agent, applying the coating solution or dispersion onto the tablets to form a film coating on the tablets, and drying the film coating on the tablets.

Owner:BPSI HLDG LLC

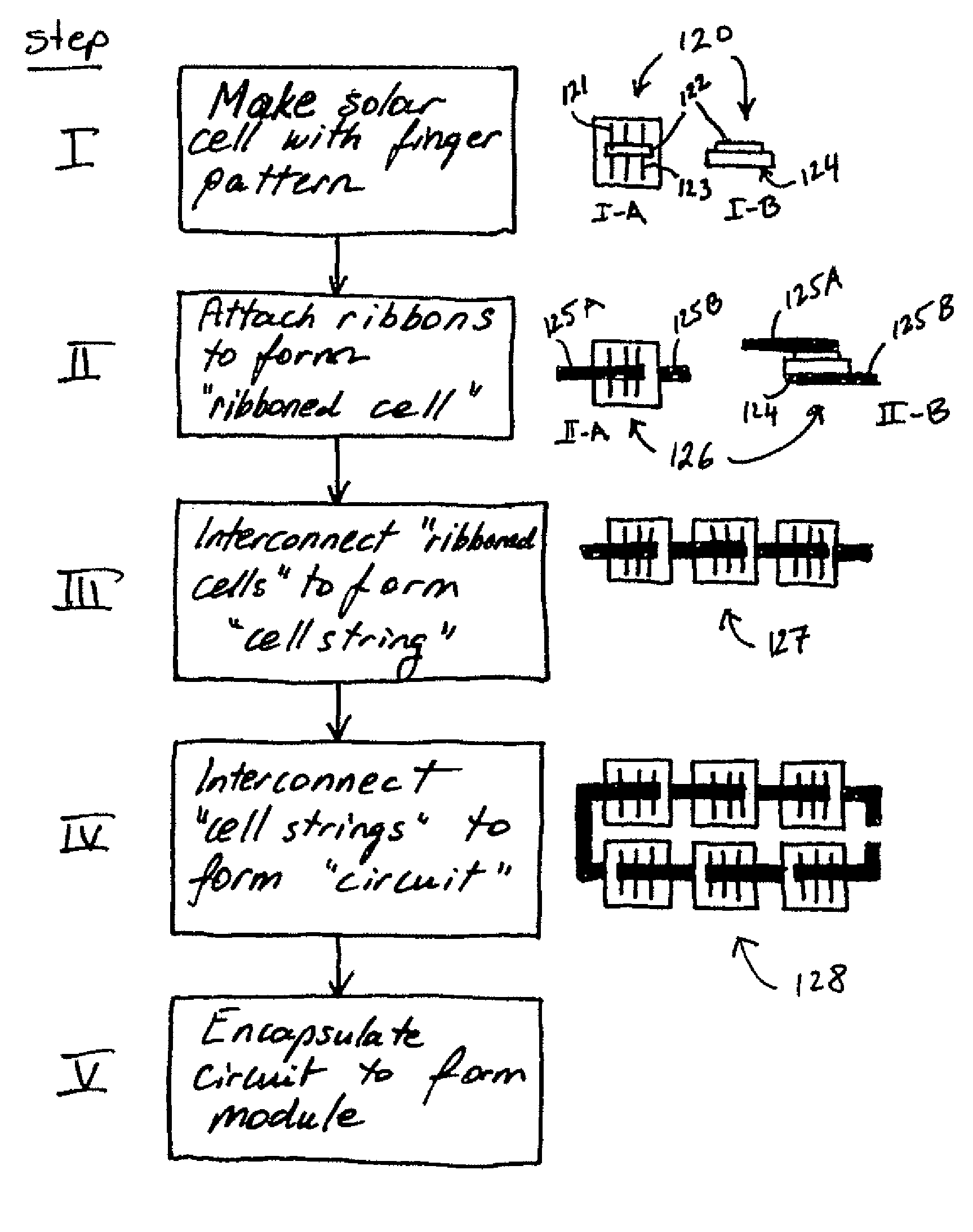

Technique and apparatus for manufacturing flexible and moisture resistive photovoltaic modules

InactiveUS20090159119A1Reduce roughnessFinal product manufacturePV power plantsElectricityElectrical battery

An apparatus and method of making moisture resistant solar cells, strings and modules is provided. The method includes reducing the roughness of the finger patterns by coating them fully or partially with a surface preparation film. The surface preparation film firmly attaches itself to underlying finger patterns and electrical leads while forming a smooth surface on which a moisture barrier film is subsequently deposited. Process flows to obtain moisture resistive solar cells, solar cell strings are described.

Owner:SOLOPOWER

Lactic acid-based resin composition

InactiveUS20050151296A1Increase in melt tensionEfficiently formedSynthetic resin layered productsLaminationMoisture barrierSealant

Provided is a lactic acid-based resin composition that comprises a lactic acid-based resin (component (A)), and an ethylene-unsaturated carboxylic acid copolymer (component (B)) and / or an ethylene-unsaturated carboxylic acid copolymer ionomer (component (C)). The lactic acid-based resin composition has good physical properties in melt and can be efficiently formed into films and laminates through casting or extrusion lamination. The paper laminates obtained through extrusion lamination with the resin composition have good moisture barrier property, and have the advantages of good antibacterial ability, good biodegradability and low combustion heat. And the moldings obtained from the resin composition of the invention have a characteristic which is excellent in impact strength. Further, the films and sheets formed of the resin composition have good low-temperature heat-sealability and hot-tack sealability, and the resin composition well serves as a sealant. The resin composition is favorable to various materials in a broad range, for example, for wrapping and packaging materials for foods, drinks, electronic appliances, medicines and cosmetics, for materials for use in agriculture, civil engineering and construction and for materials for compost, etc.

Owner:MITSUI CHEM INC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com