Patents

Literature

371results about How to "Reduce high cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

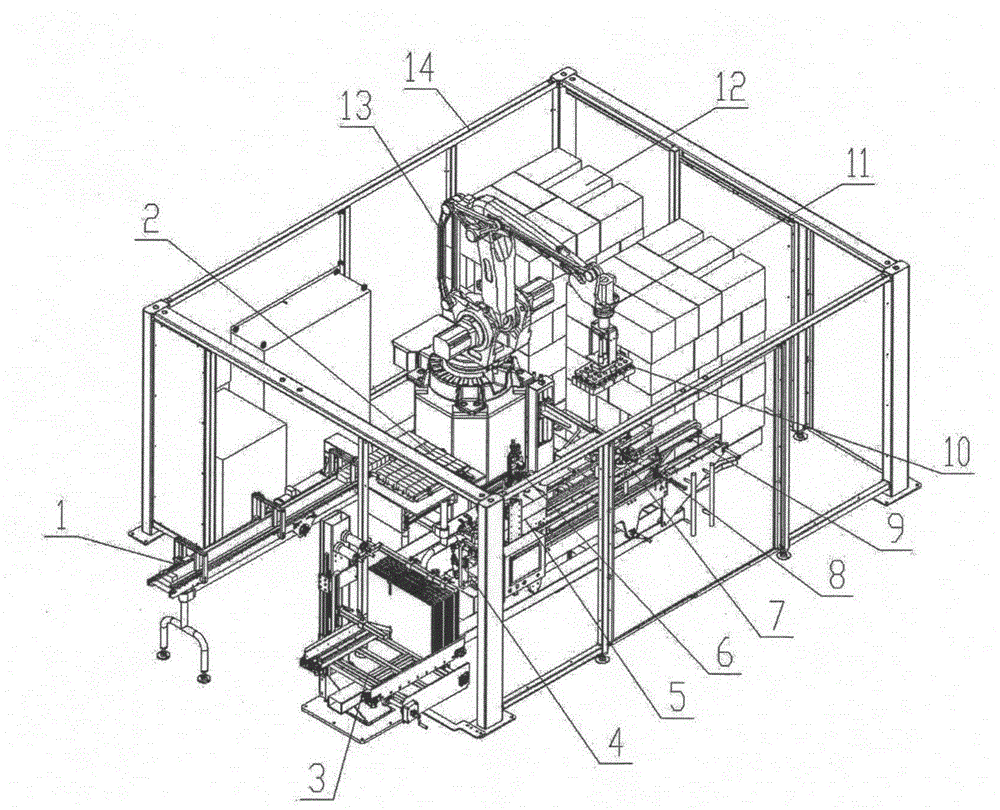

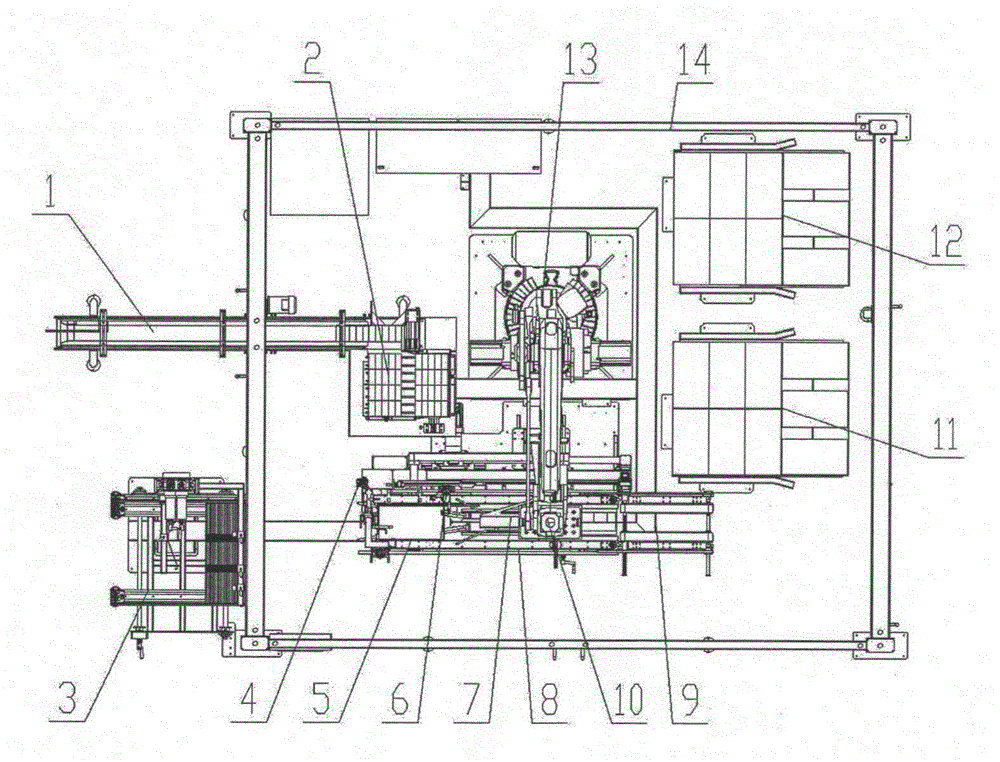

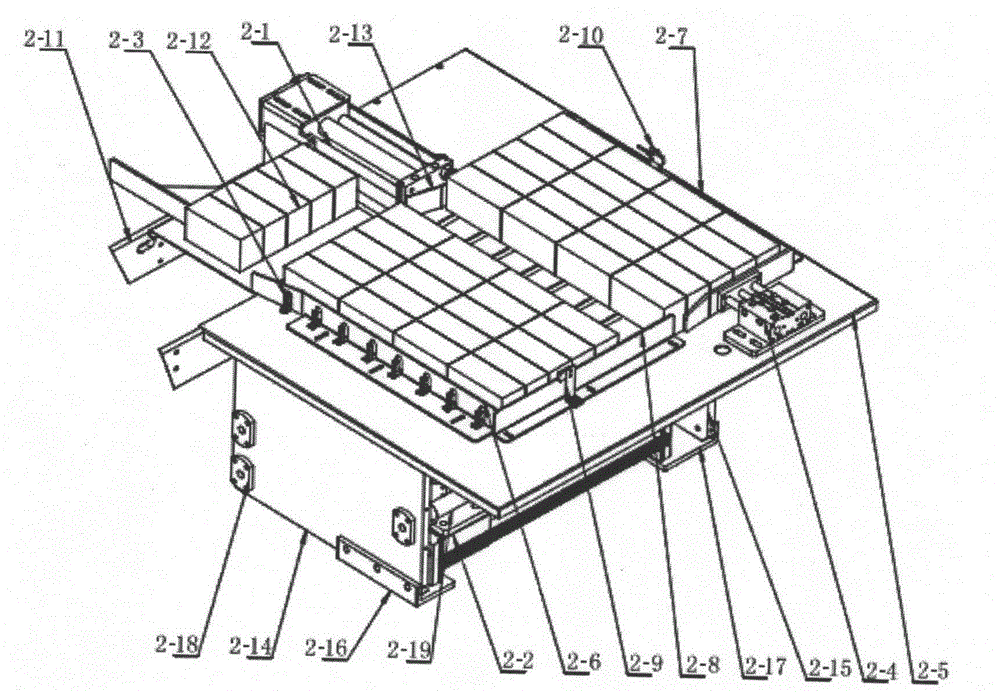

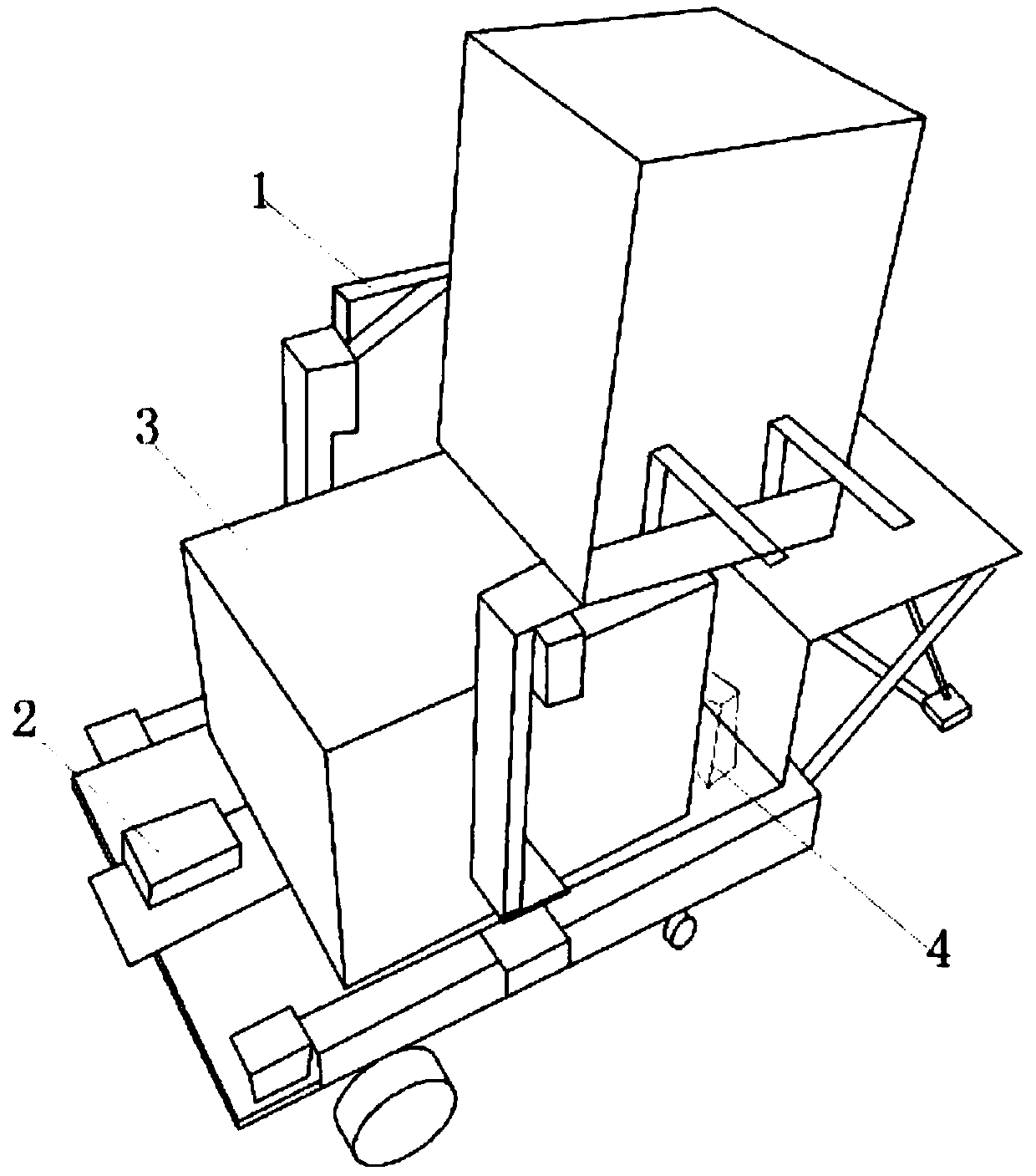

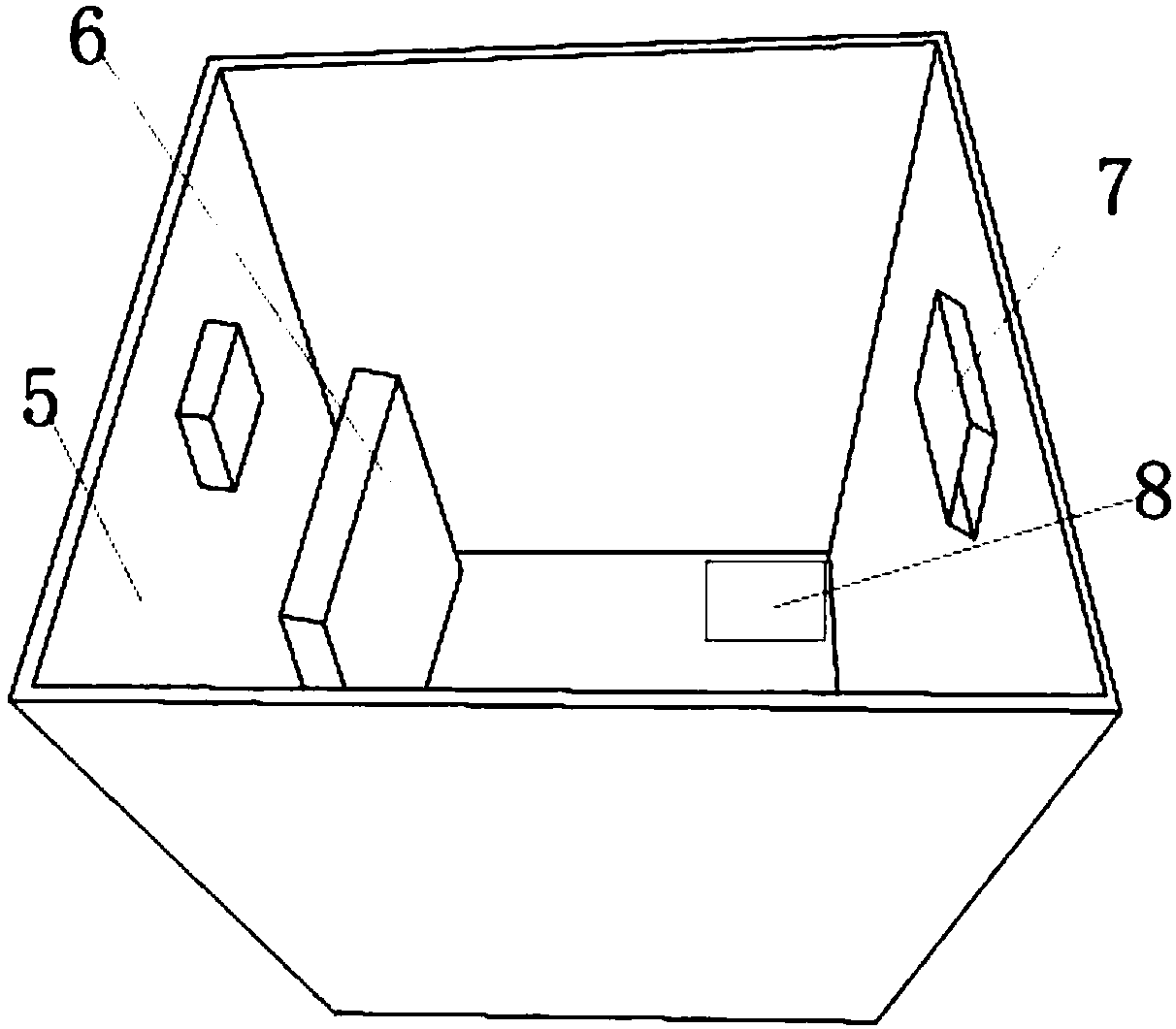

Carton filling and stacking all-in-one machine

ActiveCN104859894AReduce the difficulty of operationSmall footprintPackaging machinesCartonEngineering

The invention discloses a carton filling and stacking all-in-one machine. The carton filling and stacking all-in-one machine is characterized by comprising a carton conveying line and a storage device, wherein the head portion of the carton conveying line is connected with one side of a carton alignment device; the storage device is connected with one side of a carton filling station through an unpacking forming mechanism; the other side of the carton filling station is connected with one side of a carton strutting device; the other side of the carton alignment device is provided with a robot body; the robot body is provided with a carton filling and stacking grasp structure; a carton clamping and conveying device is arranged on the other side of the carton strutting device and connected with a carton sealing device; a carton labeling station is arranged on one side of the carton sealing device; a first tray and a second tray are arranged on one side of the carton labeling station. The functions of existing single machines are completely integrated on one machine, stations are linked tightly, the structure is compact, and operation is easy. The carton filling and stacking all-in-one machine is suitable for various specifications, stable in performance, high in efficiency and capable of greatly reducing labor cost.

Owner:SHANGHAI TOFFLON SCI & TECH CO LTD

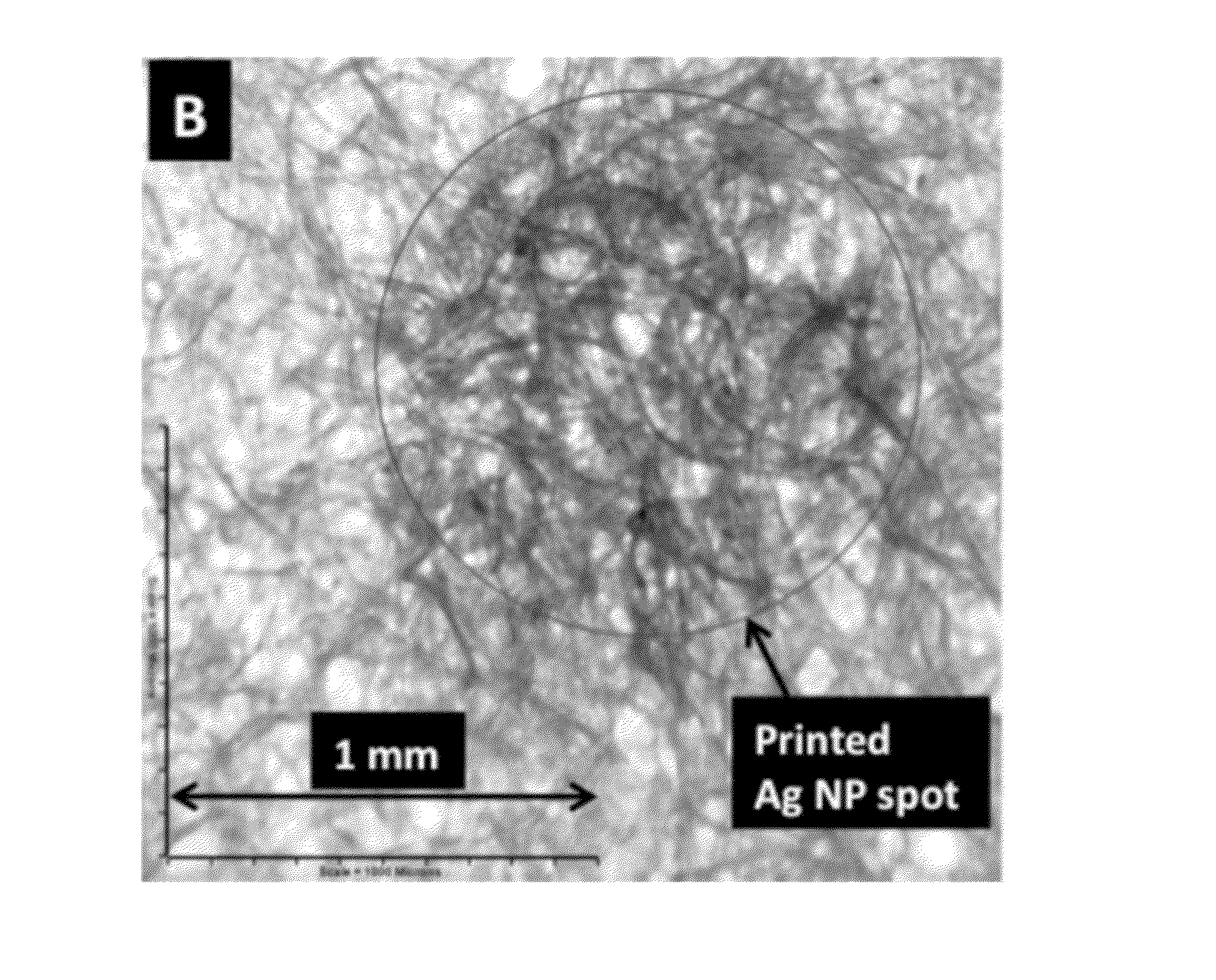

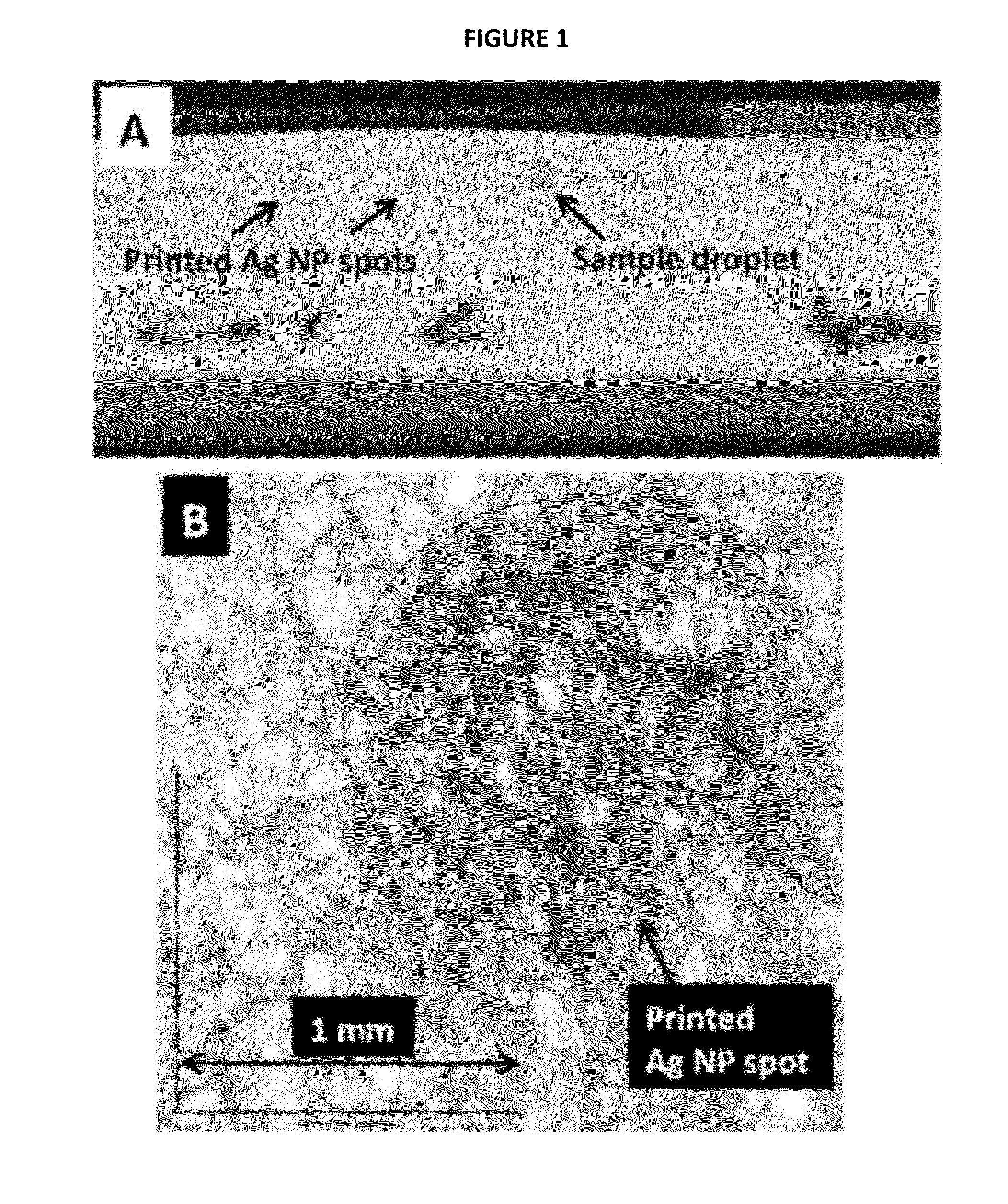

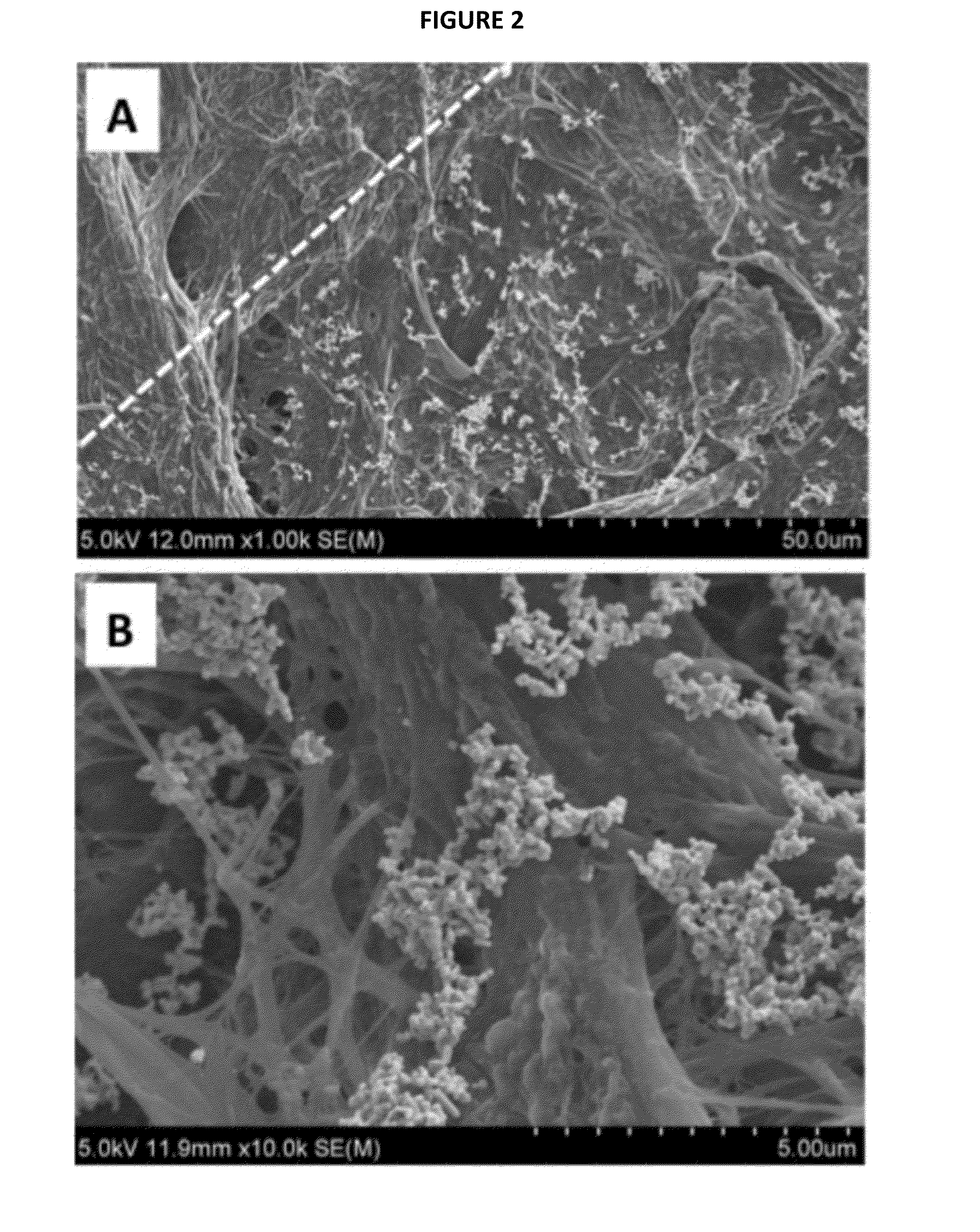

Porous SERS Analytical Devices and Methods of Detecting a Target Analyte

ActiveUS20130107254A1Avoid spreadingHigh complexityMaterial nanotechnologyRadiation pyrometryTarget analysisAnalyte

A surface enhanced Raman spectroscopy (SERS) analytical device includes a substrate having a porous structure, and a plurality of plasmonic nanoparticles embedding in the porous structure and forming a sensing region. A method of detecting a target analyte in a sample includes contacting the sample with the substrate, whereby the target analyte, if present in the sample, is concentrated in the sensing matrix. The substrate may then be analyzed using SERS detection equipment.

Owner:UNIV OF MARYLAND

Preparation method of organic-inorganic composite capsule wall energy-storage microcapsule

ActiveCN103769021AImprove thermal stabilityHigh mechanical strengthHeat-exchange elementsMicroballoon preparationFiltrationOil phase

The invention discloses a preparation method of an organic-inorganic composite capsule wall energy-storage microcapsule. The method is as below: mixing an organic phase change material and a surface active agent, heating with stirring to obtain an even oil phase material; adding silica-containing silica sol and ethyl orthosilicate in a mass ratio of 1:1-10:1 into deionized water to prepare a water phase material; then adding an oil phase material into the water phase material, and uniformly dispersing into an emulsion; then adding polyisocyanate and a crosslinking agent, maintaining the original temperature and stirring speed, so as to obtain the microcapsule with the organic-inorganic composite capsule wall; and finally, conducting vacuum filtration, washing and drying on the obtained liquid substance to obtain the product. The phase change energy-storage microcapsule obtained by the method can be used in several fields such as building energy saving and insulation of pipeline storage tank, and the capsule wall of the microcapsule has the advantages of organic material and inorganic material and longer cycle of usage.

Owner:CHINA PETROLEUM & CHEM CORP +1

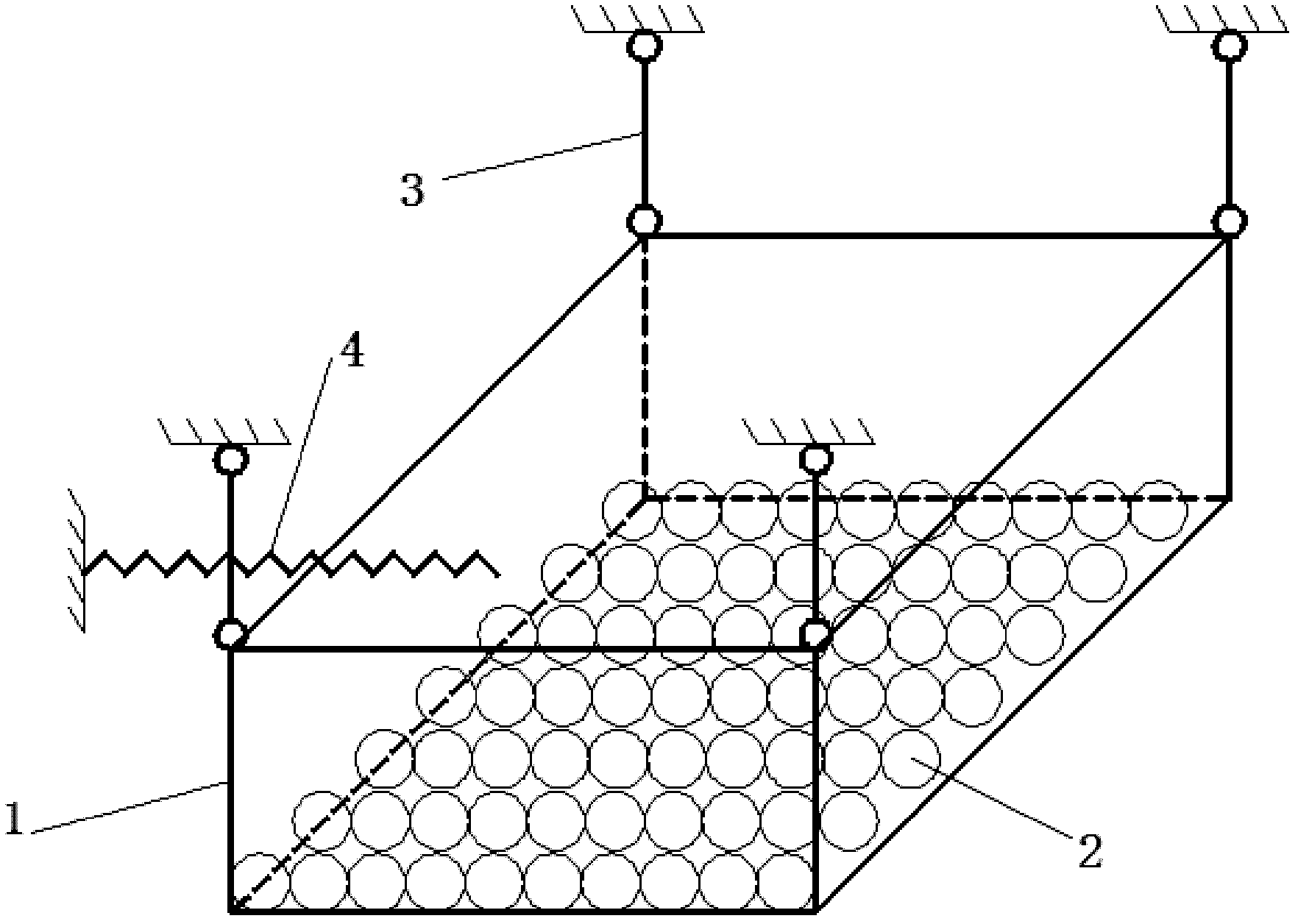

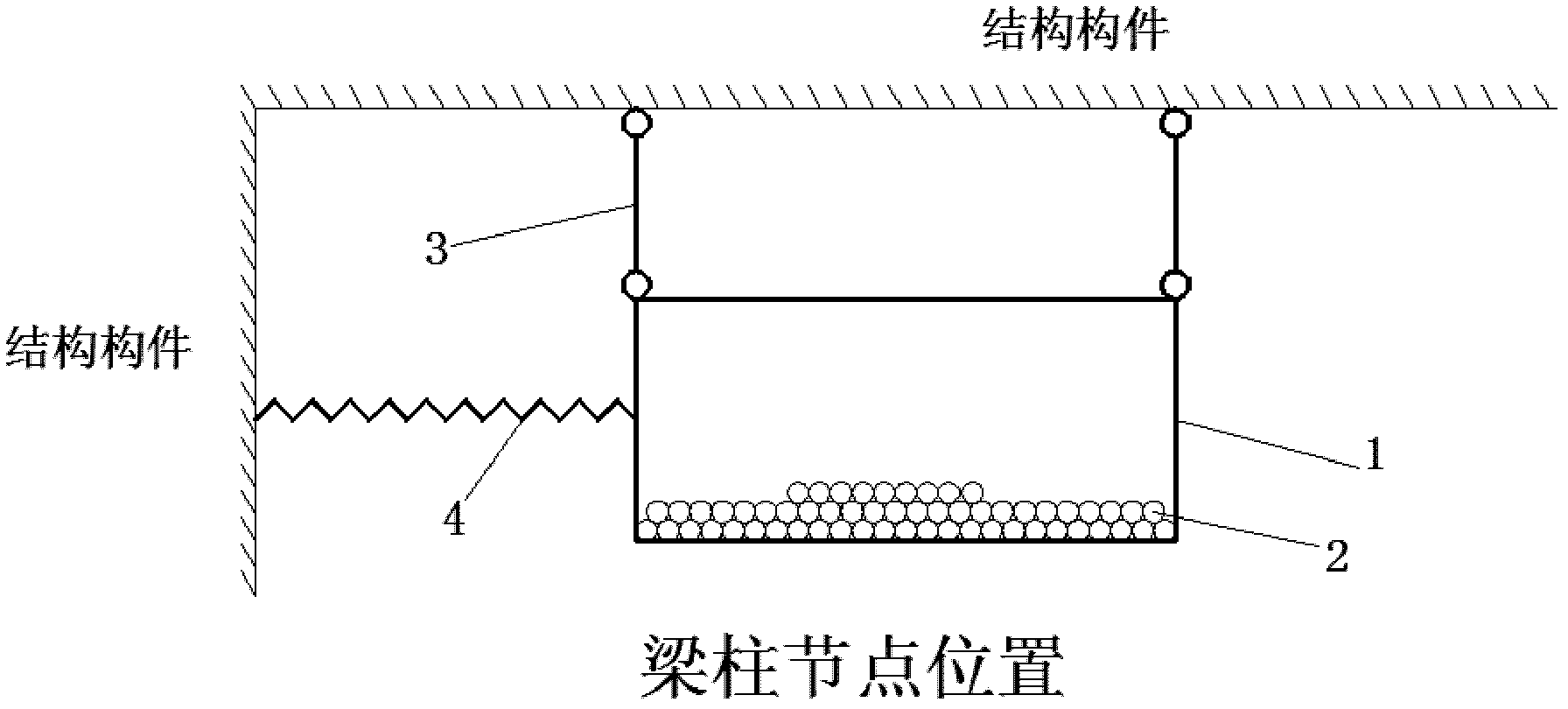

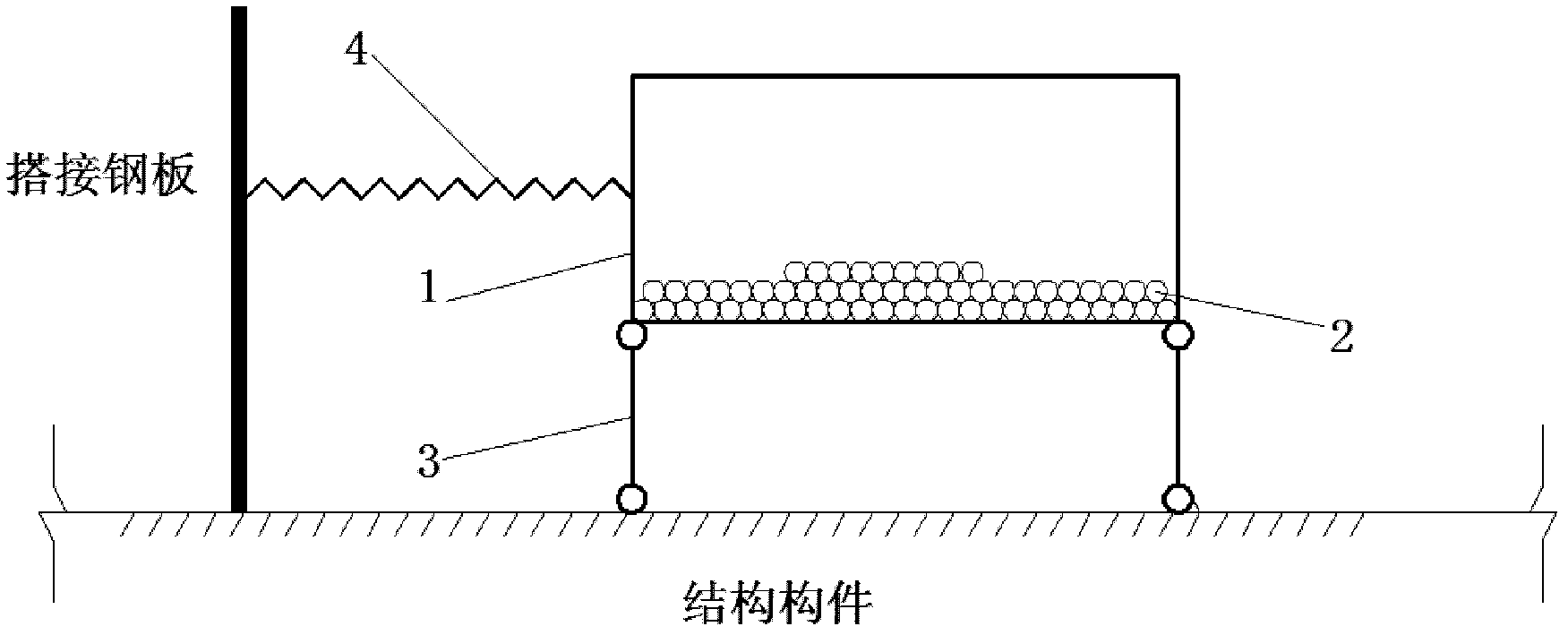

Mass tuned grain damper

InactiveCN102425243ATuning the frequency of structural vibrationsSimple structureShock proofingSnubberControl theory

The invention relates to a mass tuned grain damper and belongs to the field of building shock absorption. The mass tuned grain damper comprises a damper cavity, damping grain groups, a one-way hinge system and a resetting spring, wherein the damping grain groups are uniformly placed in the damper cavity; an embedded part in a building structure or bridge structure is fixedly connected to the damper cavity by the one-way hinge system; and the resetting spring is arranged outside the damper cavity, thereby forming a substructure with a certain mass and a certain natural frequency of vibration. Under the effect of wind and / or an earthquake, the mass tuned grain damper can oscillate back and forth along the arrangement direction of the resetting spring so as to tune the natural frequency of vibration of the structure. Under the actions of the rolling or sliding, friction and colliding of the damping grain groups in the damper cavity, the kinetic energy of the structure can be transferred and consumed, the distribution additional damping is supplied to the structure in a flexible and scattered arranging mode, thereby restraining the structure vibration and ensuring the structure safety.

Owner:BEIJING UNIV OF TECH

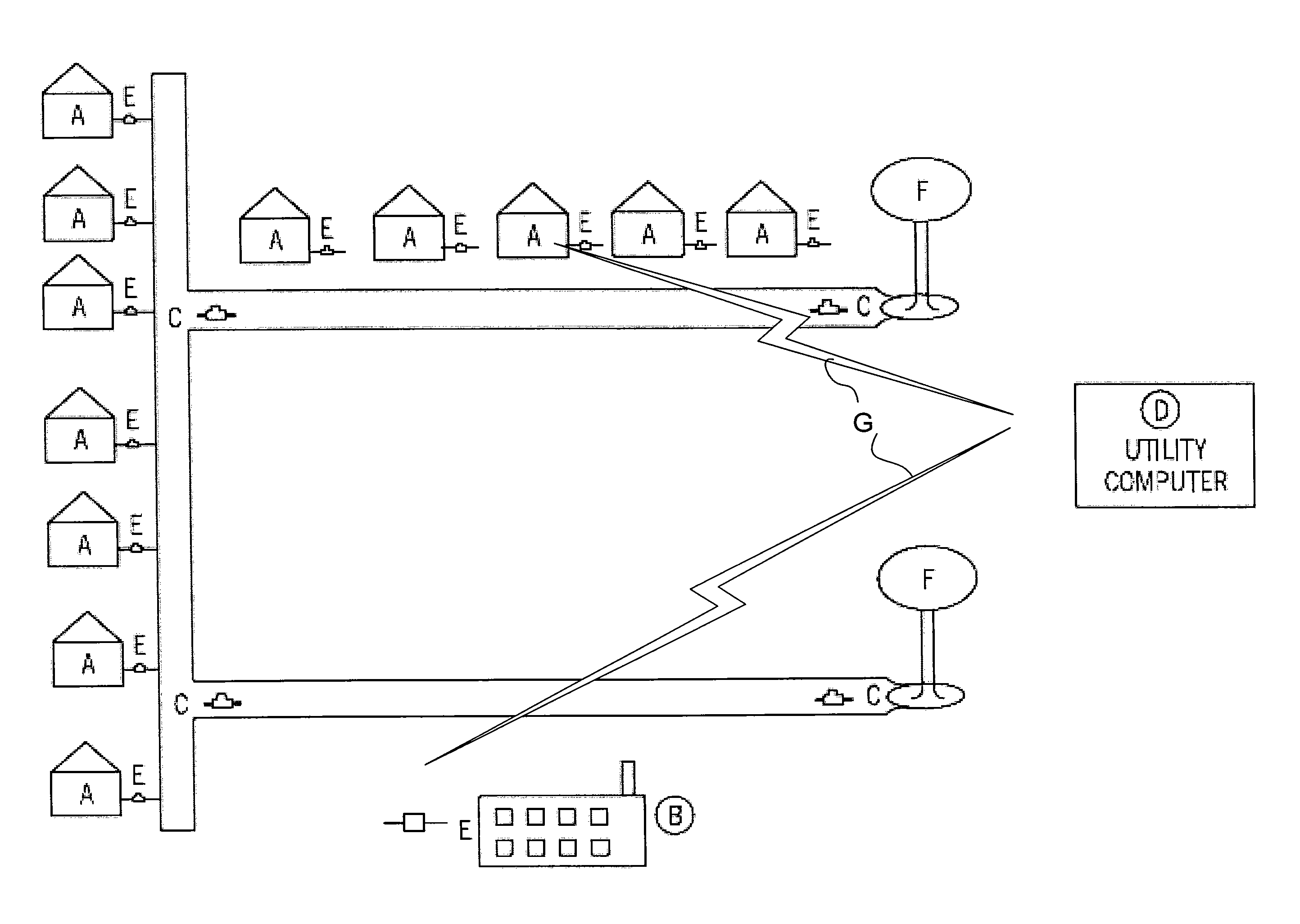

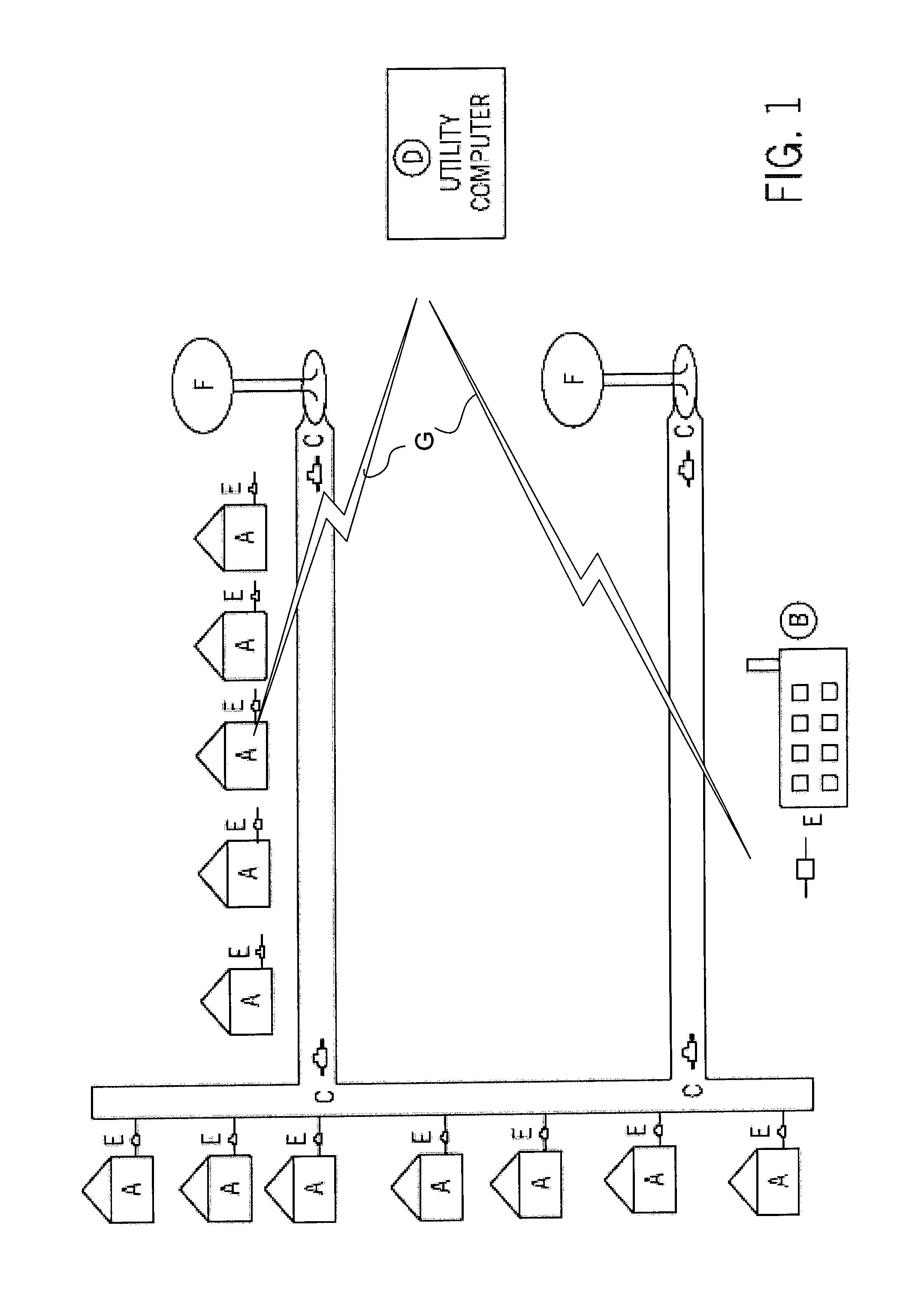

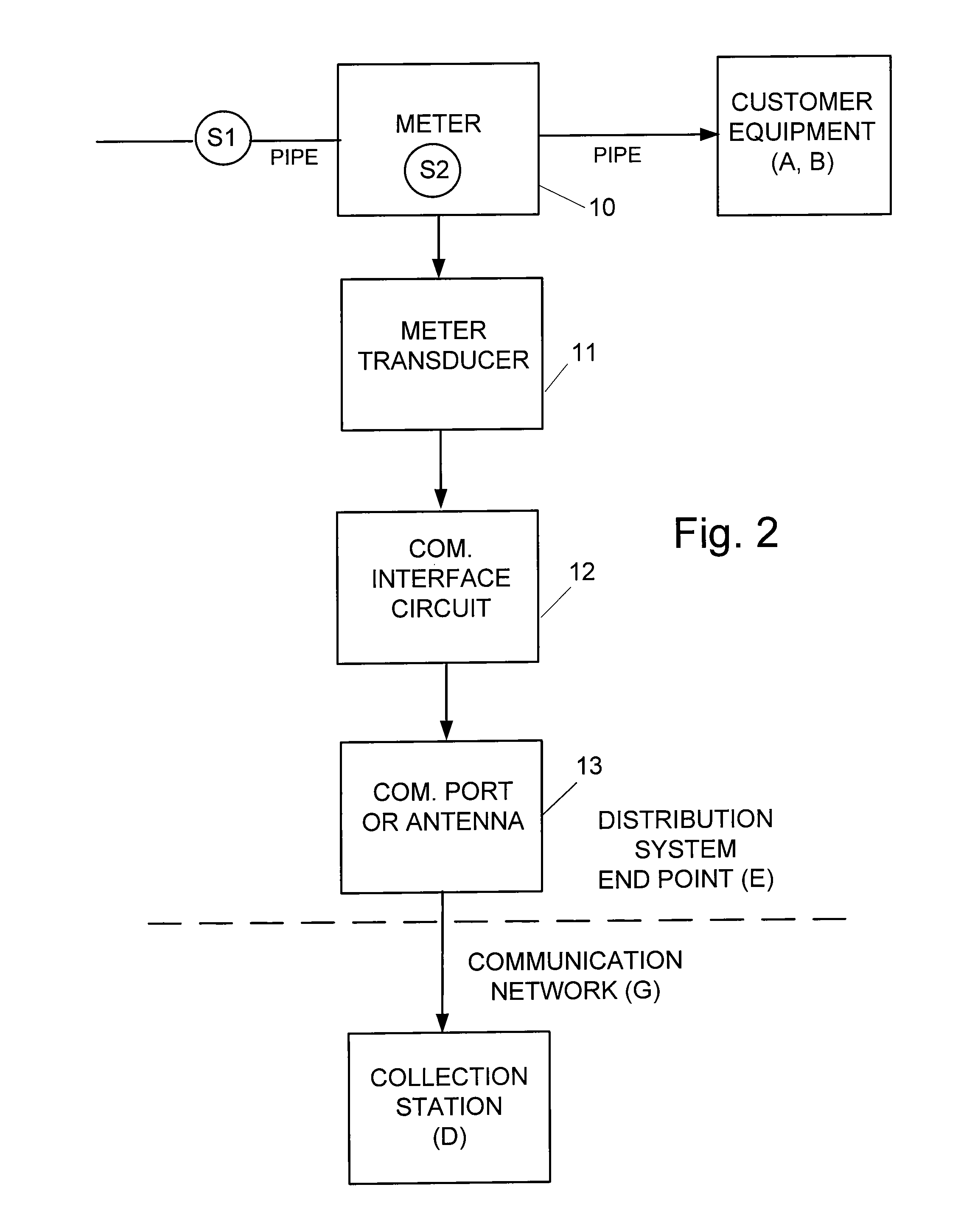

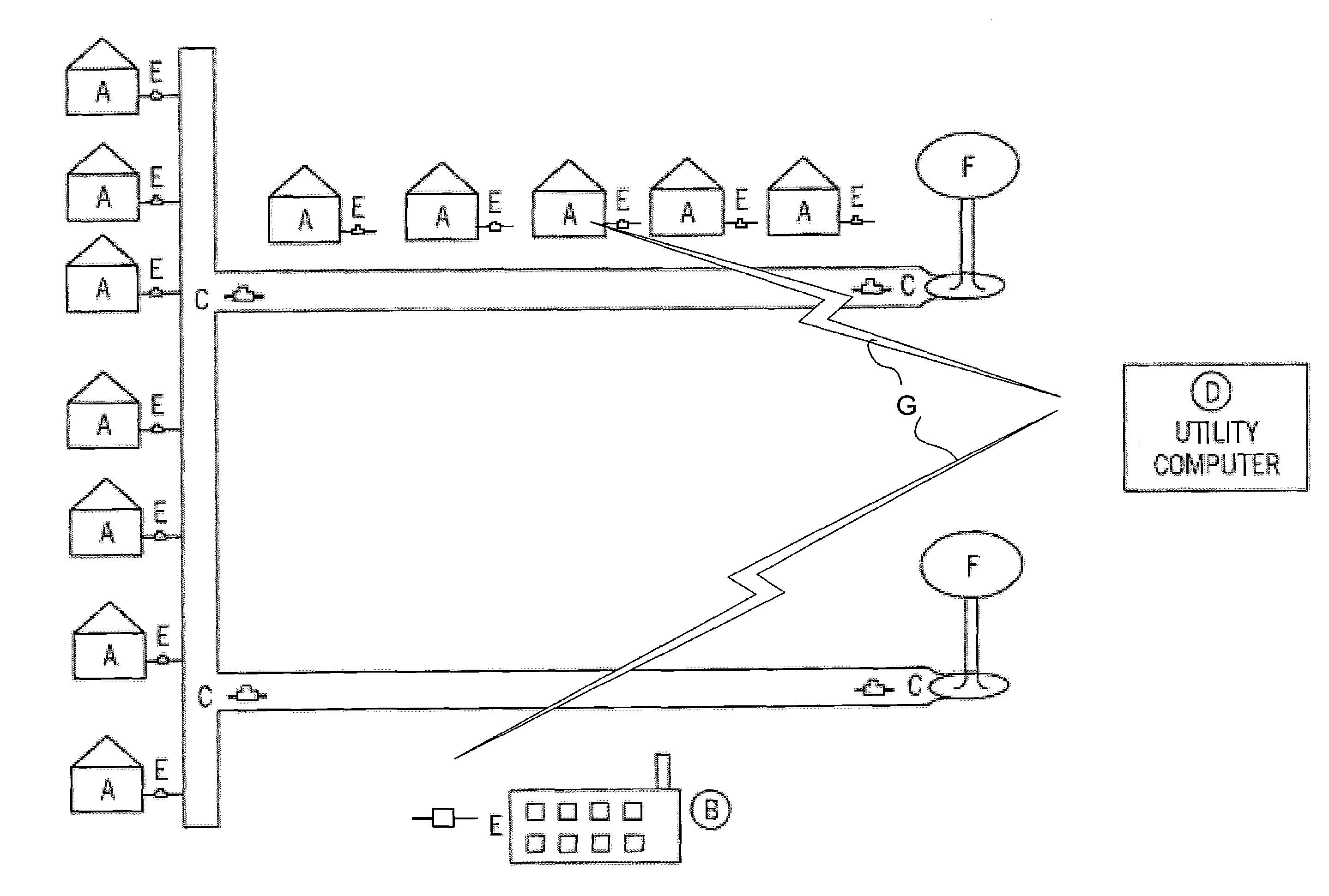

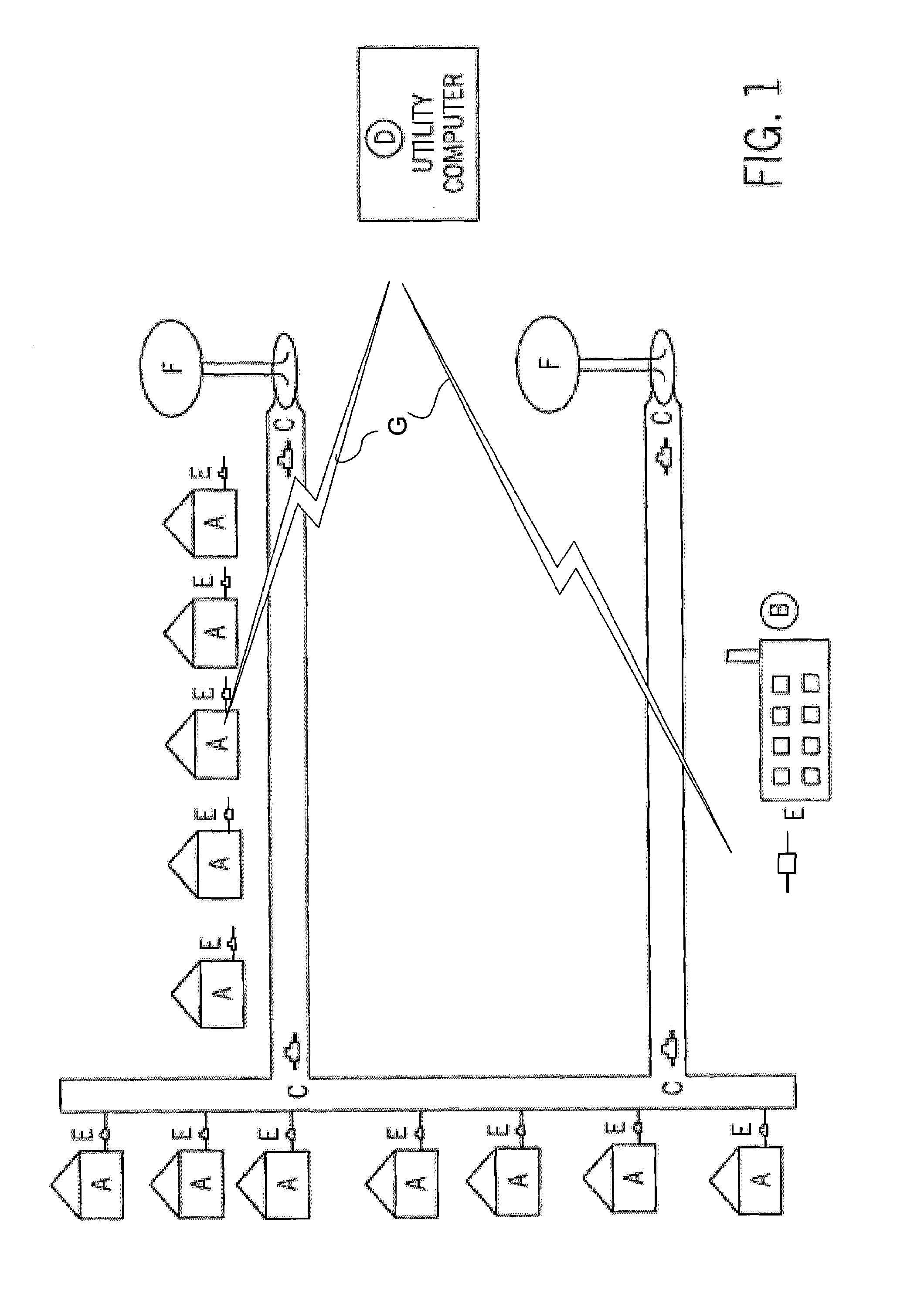

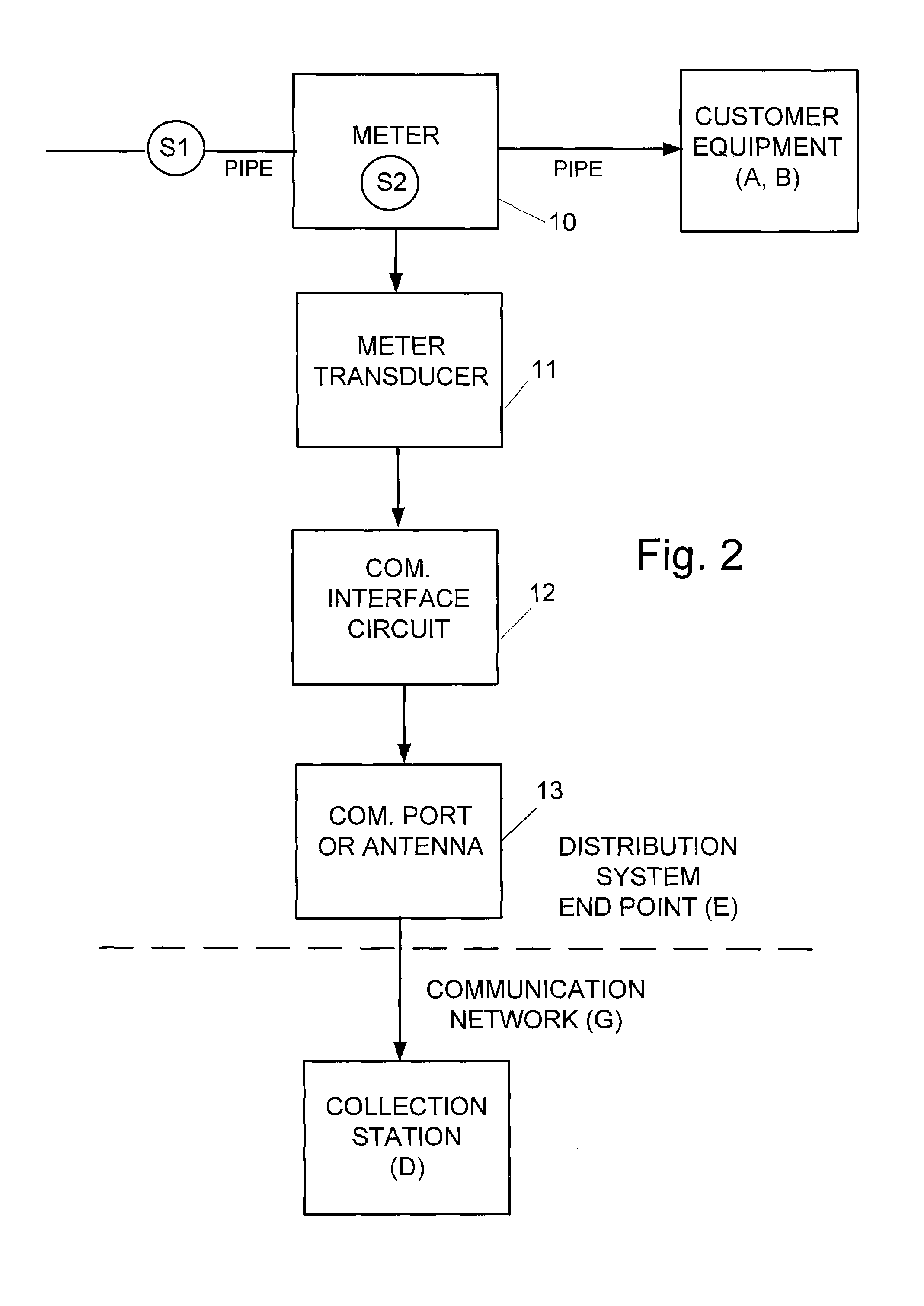

Apparatus and Method for Measuring Water Quality in a Water Meter Data Collection System

InactiveUS20110030482A1Reduce high costVolume/mass flow by electric/magnetic effectsTesting waterDistribution systemWater quality

A system for monitoring water quality in a water meter data collection system having a plurality of metering end points (E) for measuring consumption includes a plurality of chemical biological and environmental sensors (S1, S2) disposed in a distribution system near or within the distribution end points (A, B), with the sensors (S1, S2) generating electrical signals through a network (G) that can be processed and communicated with the water meter data to a collection station (D) from the metering end points (E).

Owner:MEEUSEN RICHARD A +5

Automatic vehicle carrying and transferring method and system, and application

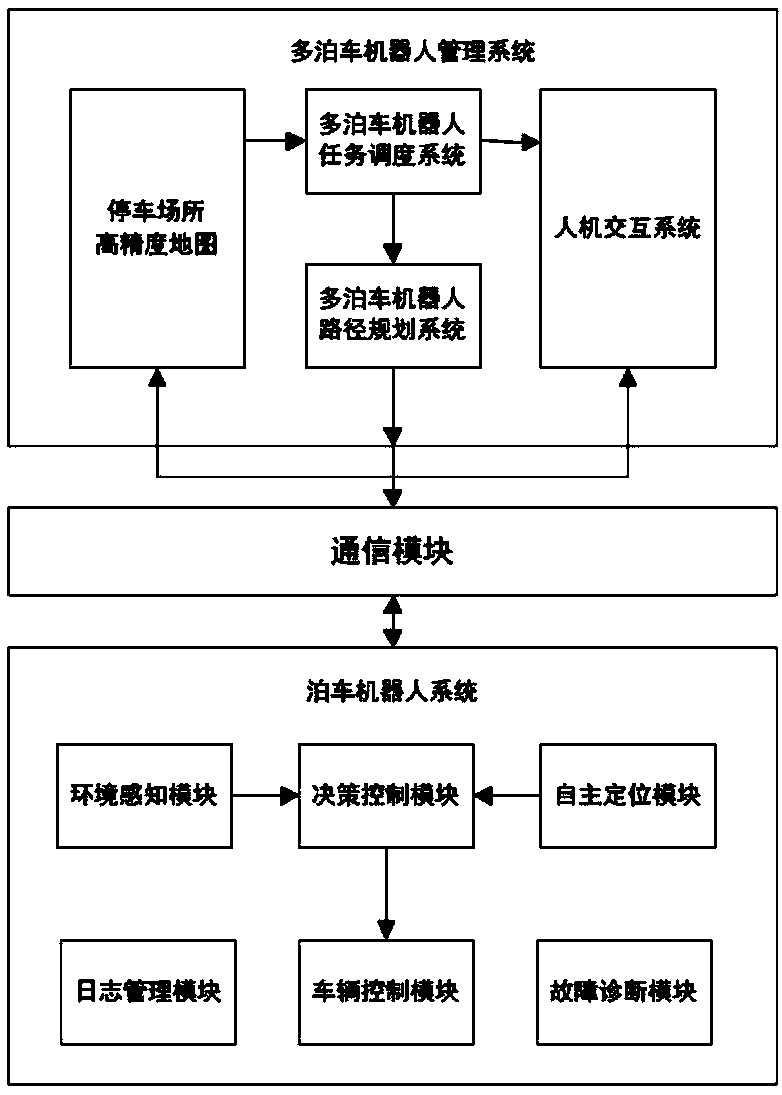

InactiveCN109403690AExcellent input costEnsure the cost of waitingParkingsTransfer systemSoftware system

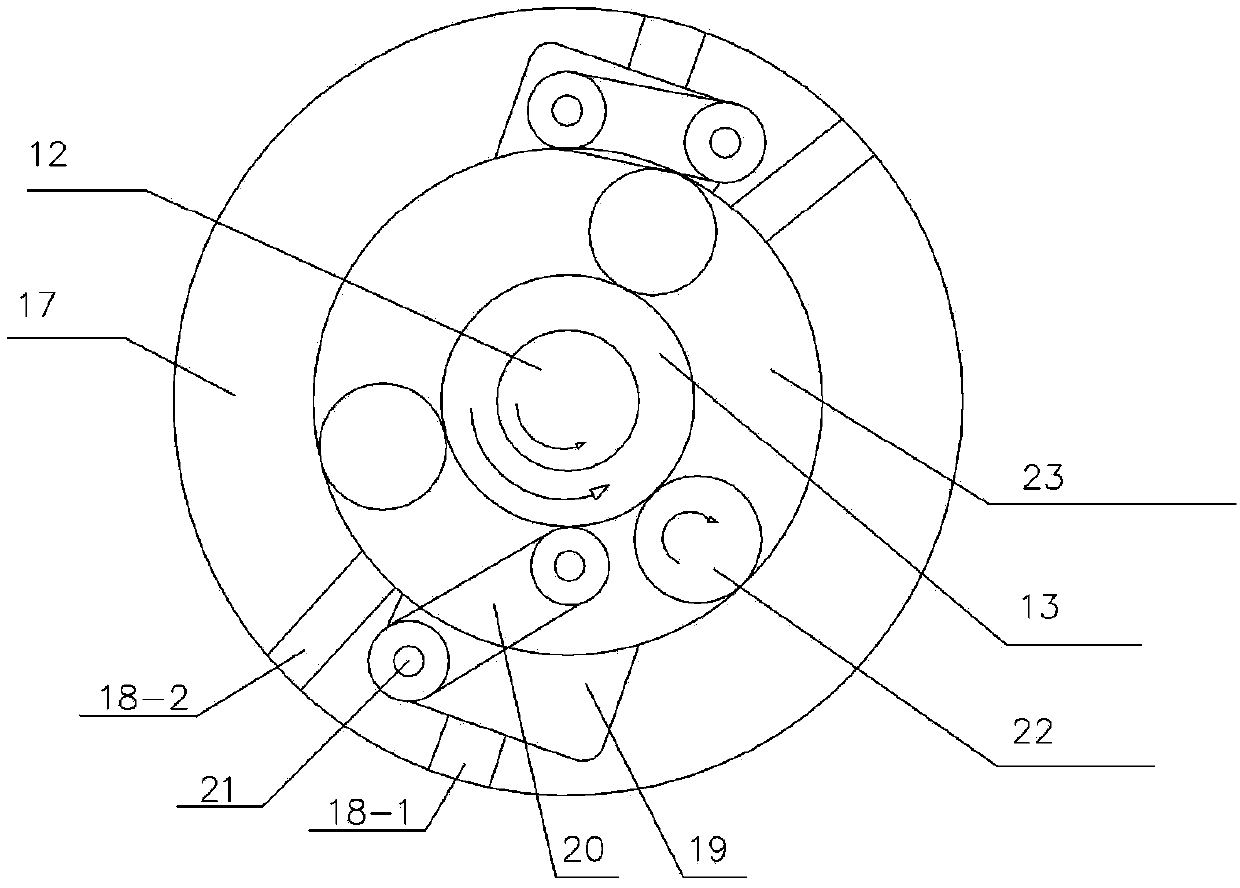

The invention discloses an automatic vehicle carrying and transferring method and system. The automatic vehicle carrying and transferring method comprises the following steps that the interactive relation is established with a user; the parking request of the user is obtained, and a loading and transporting device for loading and transporting a vehicle of the user is dispatched to the parking position of the user; the loading and transporting device automatically loads and transports the vehicle of the user to be parked on a designated parking position; the pick-up request of the user is obtained, and the loading and transporting device for loading and transporting the vehicle of the user is dispatched to the designated parking position; and the loading and transporting device automatically loads and transports the vehicle of the user to be parked on a designated pick-up position. The automatic vehicle carrying and transferring system comprises the loading and transporting device, a multiple loading and transporting device task scheduling system, a loading and transporting device vehicle-mounted automatic navigation hardware platform and software system, a vehicle transferring station system and a man-machine interaction subsystem, wherein the loading and transporting device is a parking robot. The comfort of vehicle parking and picking-up of the user is improved, the operationefficiency is improved, the space utilization rate is increased, the construction cost is lowered, and complicated and tedious operation and maintenance are relatively avoided.

Owner:TONGJI UNIV

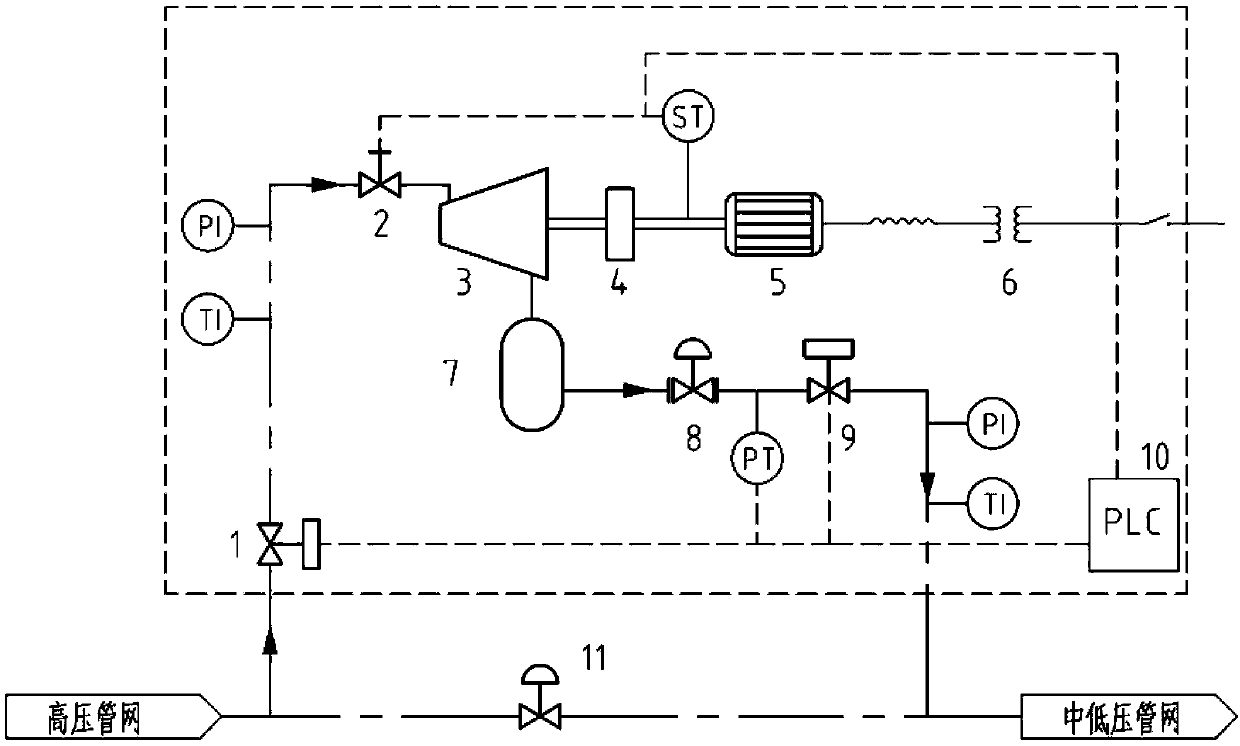

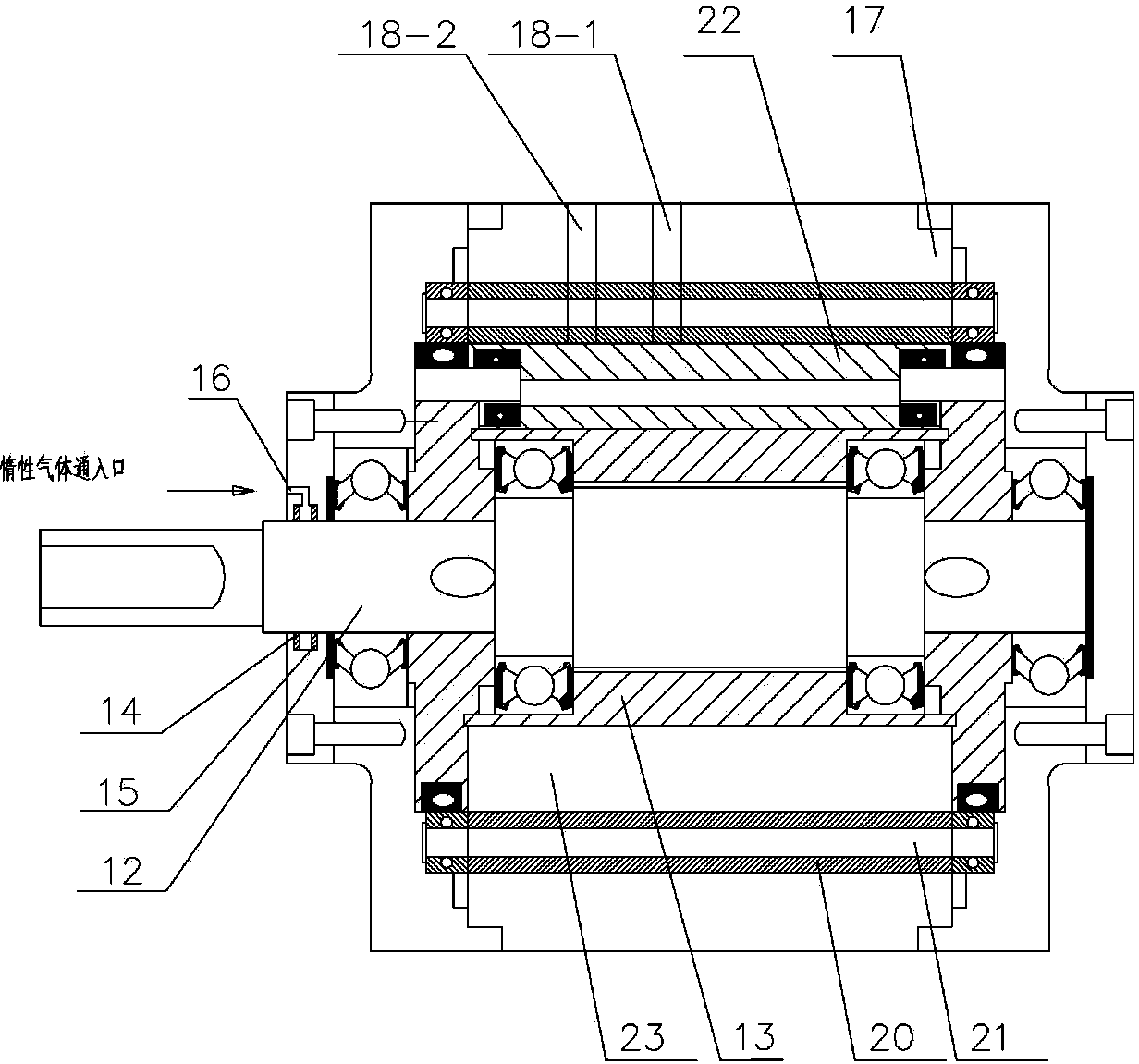

Process and device for generating power by pressure energy of small natural gas pipeline network

InactiveCN103422899ALeak will notSolve the problem that cannot be explosion-proofSealing arrangements for enginesMachines/enginesGas cylinderPower user

The invention discloses a process and a device for generating power by pressure energy of a small natural gas pipeline network. A high-pressure pipeline network of the device is connected with a gas inlet of an expansion machine through a pipeline; a gas outlet of the expansion machine is connected with a gas inlet of a temperature balancer through a pipeline; an outlet of the temperature balancer is connected with a low and medium-pressure gas pipeline network through a pipeline; a main shaft of the expansion machine is connected with a gearbox; the gearbox is connected with a power generator; the power generator is connected with a transformer synchronizer; the expansion machine adopts an improved AT15-65 type gas expansion machine; one end of the main shaft is connected with an air cylinder in a totally-closed way; a first seal ring and a second seal ring, which have sealing effects, are arranged between the other end of the main shaft and a wheel drum; a flow guide pipe is arranged in a closed cavity between the two seal rings; the flow guide pipe is connected with an inert gas bottle. The device can be used for continuously and stably providing a 220 V / 380 V stable power supply for an interruptible and closed 1-5 kW low-power user.

Owner:SOUTH CHINA UNIV OF TECH +1

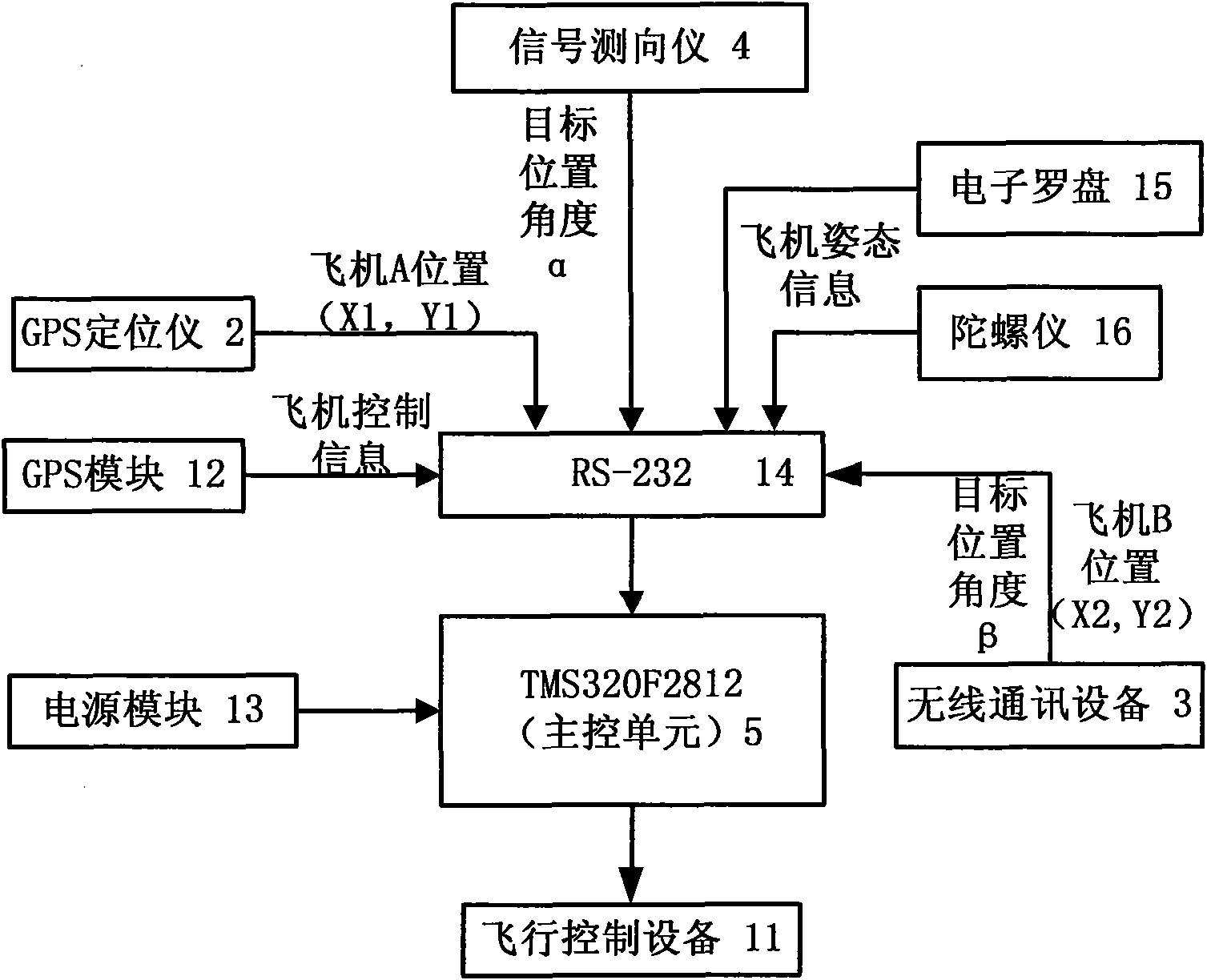

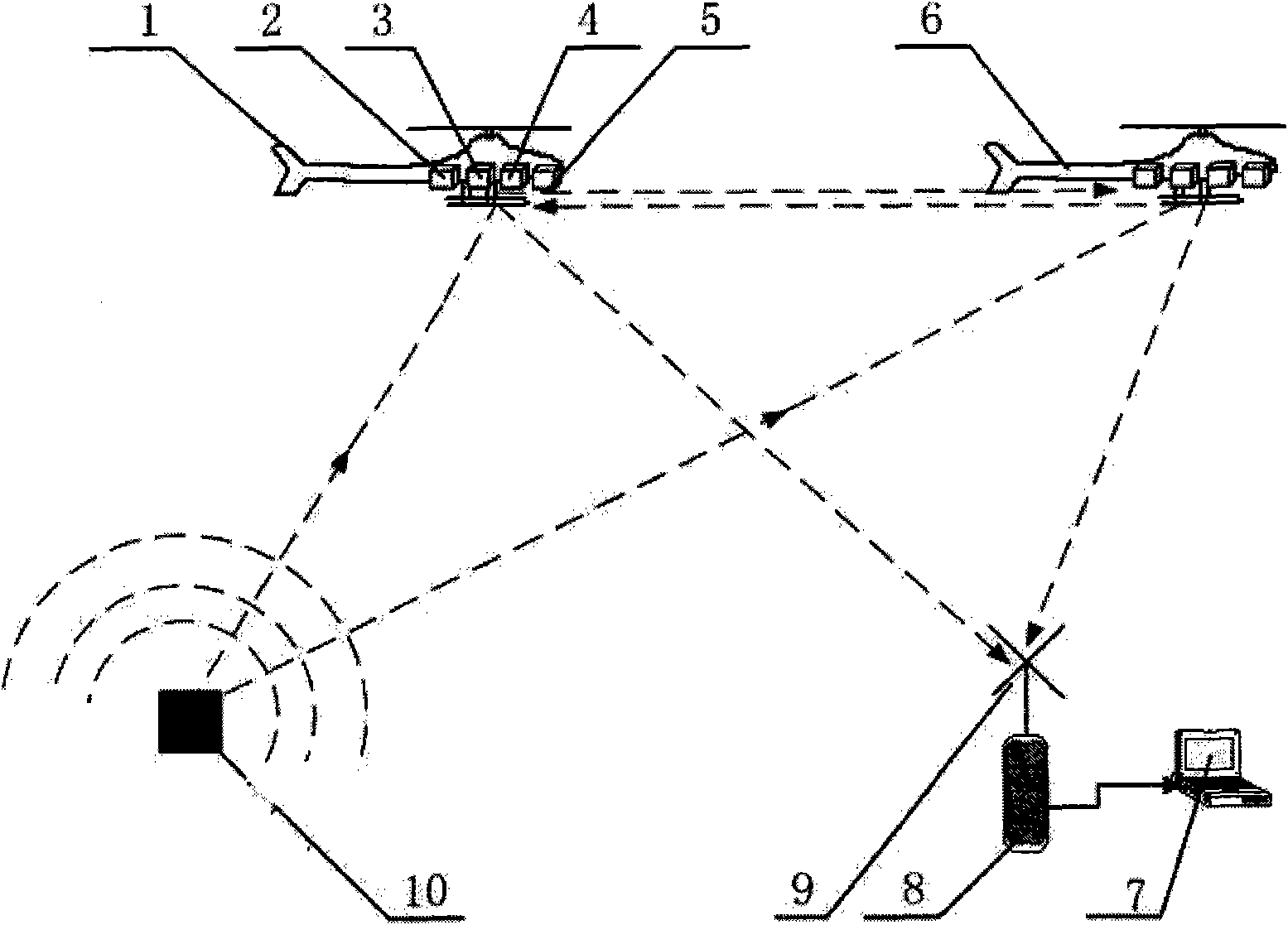

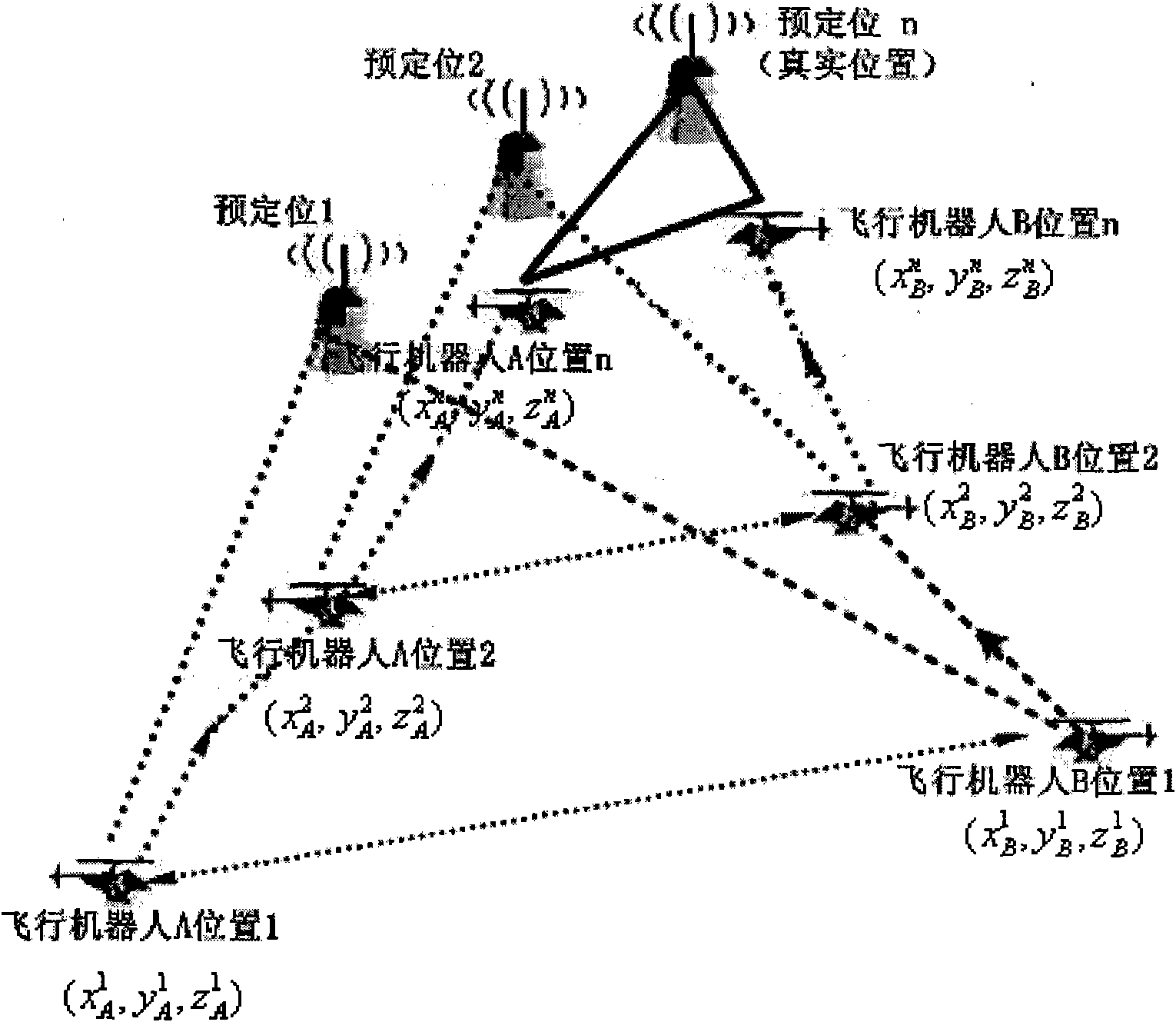

Double flying robot-based method and double flying robot-based system for positioning active target

InactiveCN101561493ALow costReduce volumeInstruments for comonautical navigationPosition fixationFly controlControl system

The invention relates to a double flying robot-based method and a double flying robot-based system for positioning a radiant source target. The method comprises: adopting vehicle-mounted master control systems of two unmanned flying robots, measuring signal direction by acquiring a target signal, using the measurement result for the communication between the two unmanned flying vehicles through radio communication, positioning the target by using a triangulation positioning method, correcting the positioning, correcting course, repeatedly and constantly positioning the target, and, at the same time, performing flyby to realize accurate positioning of the target. In the system, GPS positioners, radio-communication equipment, flying control equipment, master control units and signal direction detectors are arranged on the two unmanned flying robots and a central control unit and radio-communication equipment and antennae are arranged on a base station so as to realize the radio communication between the two unmanned flying robots and the base station. The method and the system can search and position the radiant source target quickly and accurately.

Owner:SHANGHAI UNIV

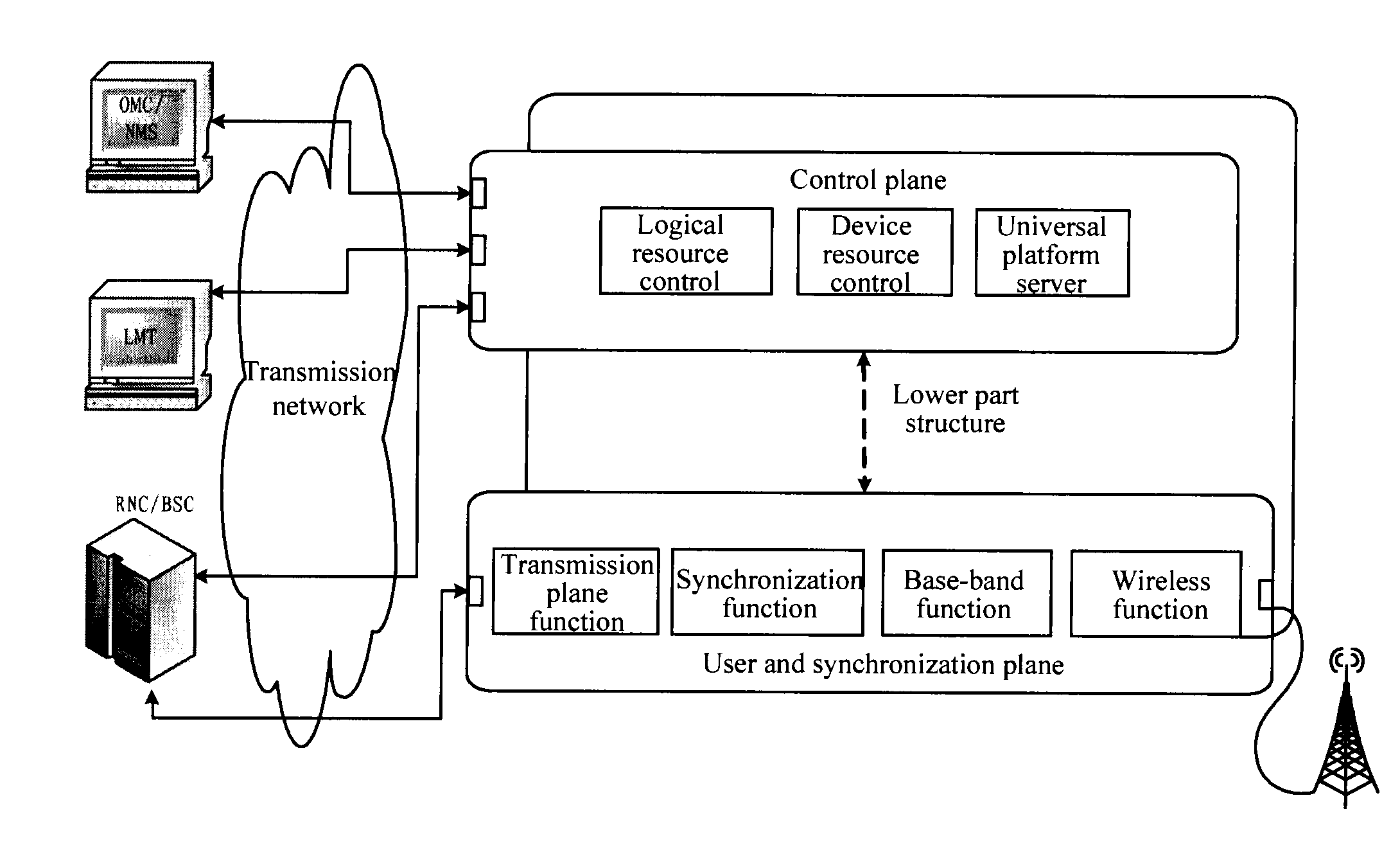

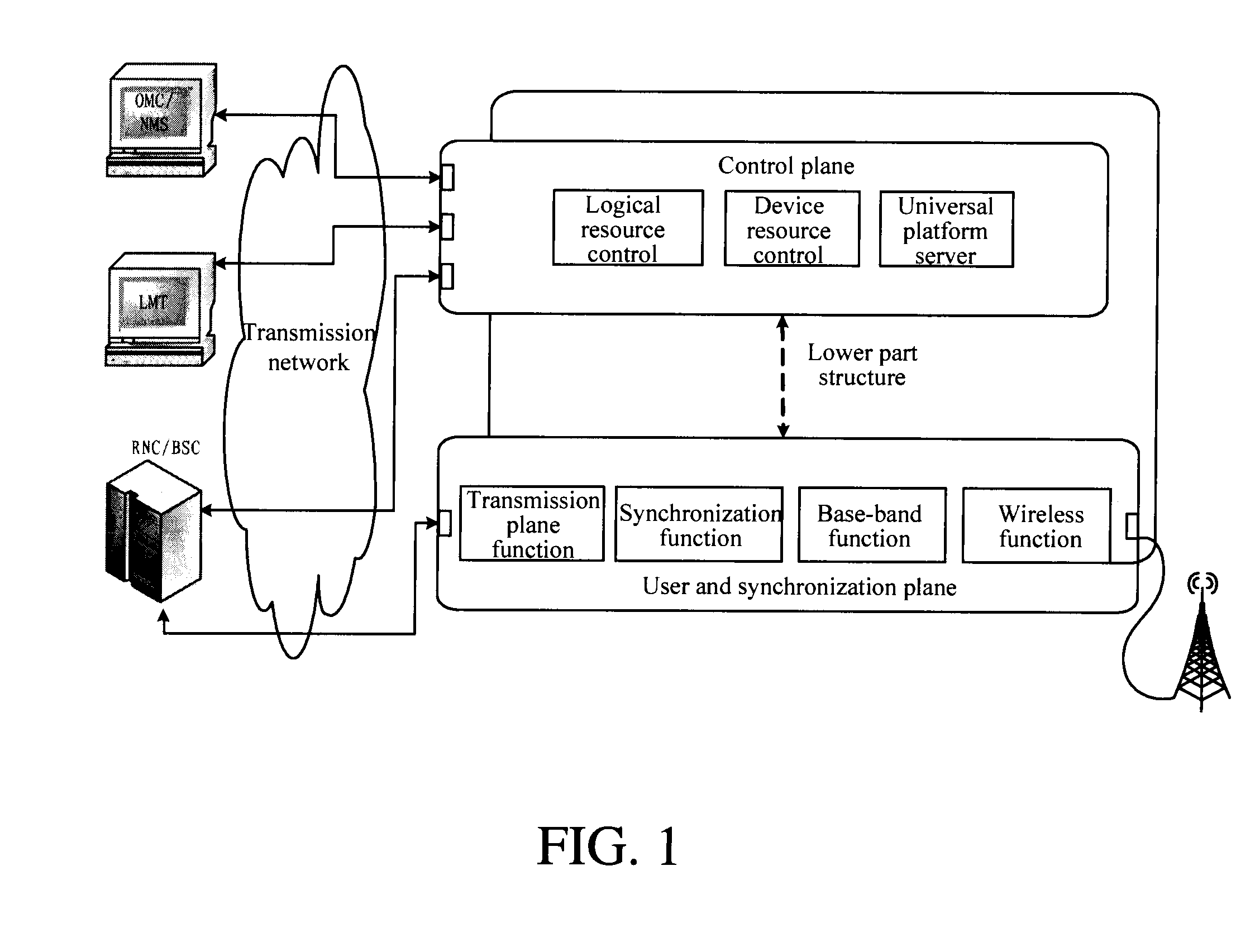

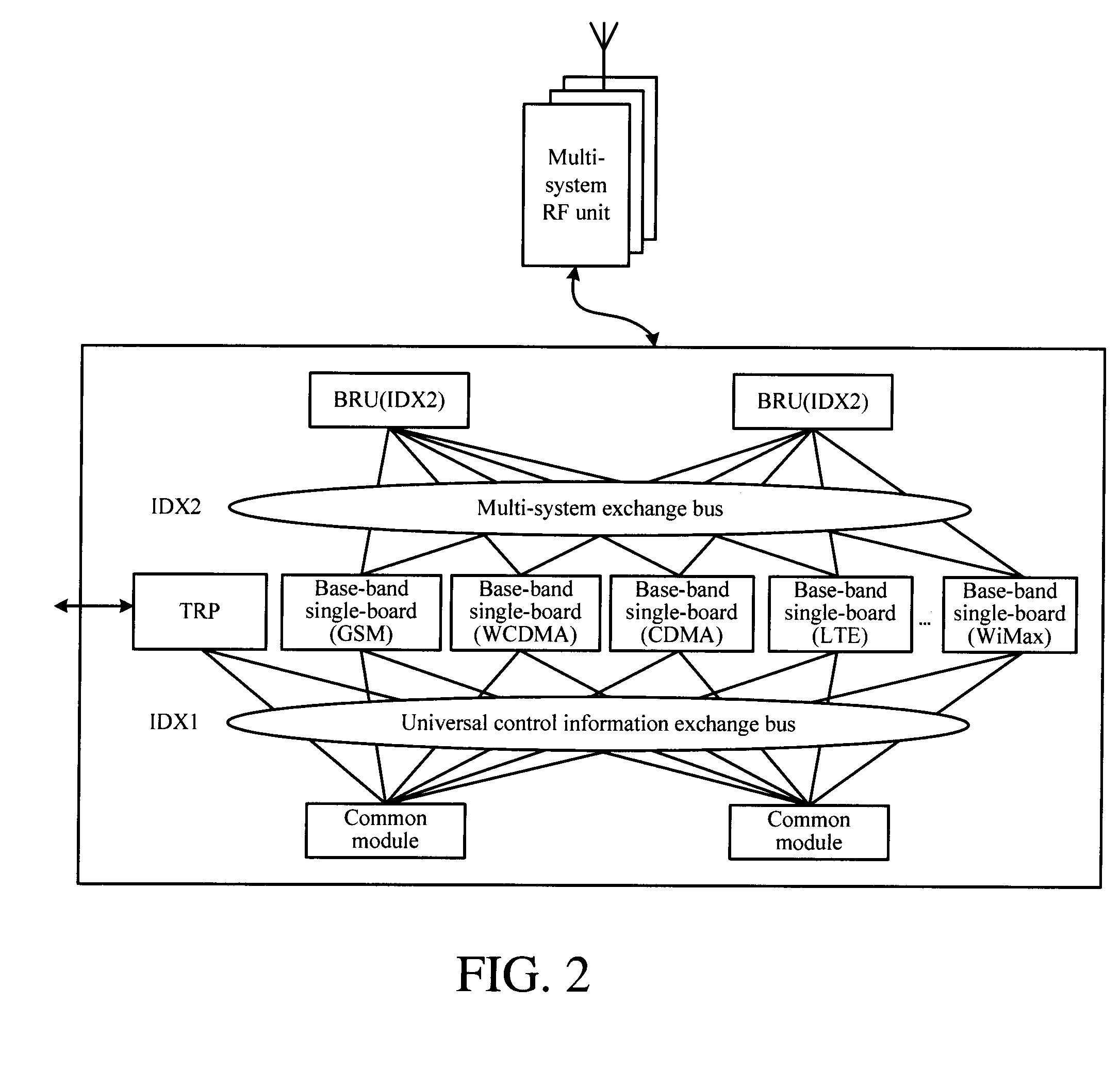

Multi-mode base station and method for sending/receiving signal thereof

ActiveUS20090221319A1Low costReduce high costResonant long antennasSubstation equipmentMultiplexingEngineering

A multi-mode base station and a method for sending / receiving signals thereof are provided. In the base station, each base-band single-board is connected to a corresponding radio frequency (RF) unit through a multi-mode exchange bus, and the base-band single-boards of different modes are intermixed by using the compatibility of the exchange bus with in-phase / quadrature (IQ) data of various modes. Synchronization information, such as frame numbers required by various modes, forms a synchronization burst through multiplexed framing. Meanwhile, by using the same system clock, the synchronization burst and system clock are transmitted to the base-band single-boards of various modes through a set of synchronization clock buses. The main control and transmission functions are uniformly provided for each base-band single-board in the base station by a shared common module. The filling and synchronization of wireless IQ data of various modes are realized according to common-multiple relation mapping.

Owner:HUAWEI TECH CO LTD

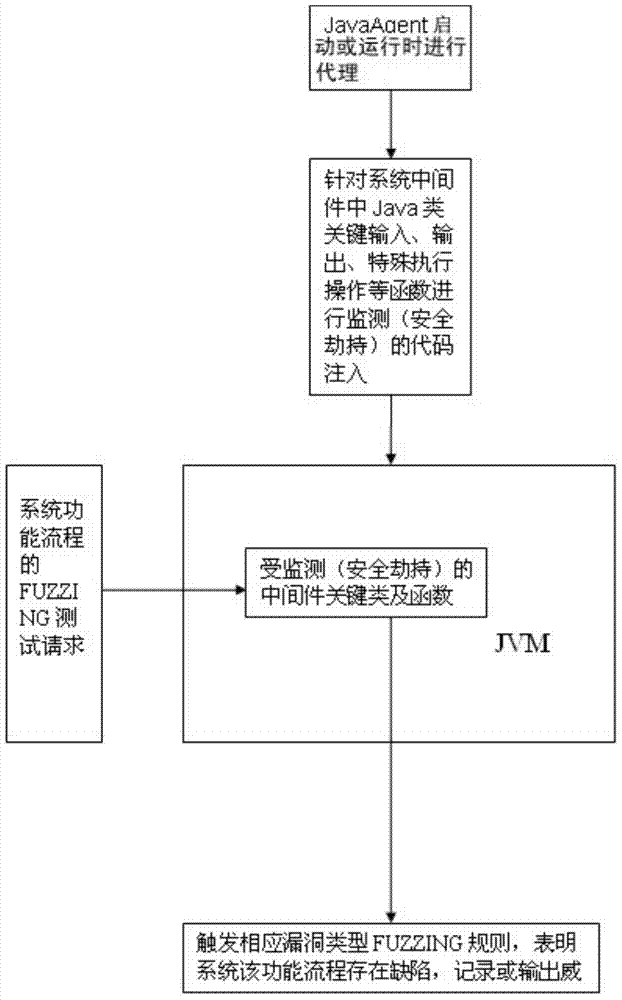

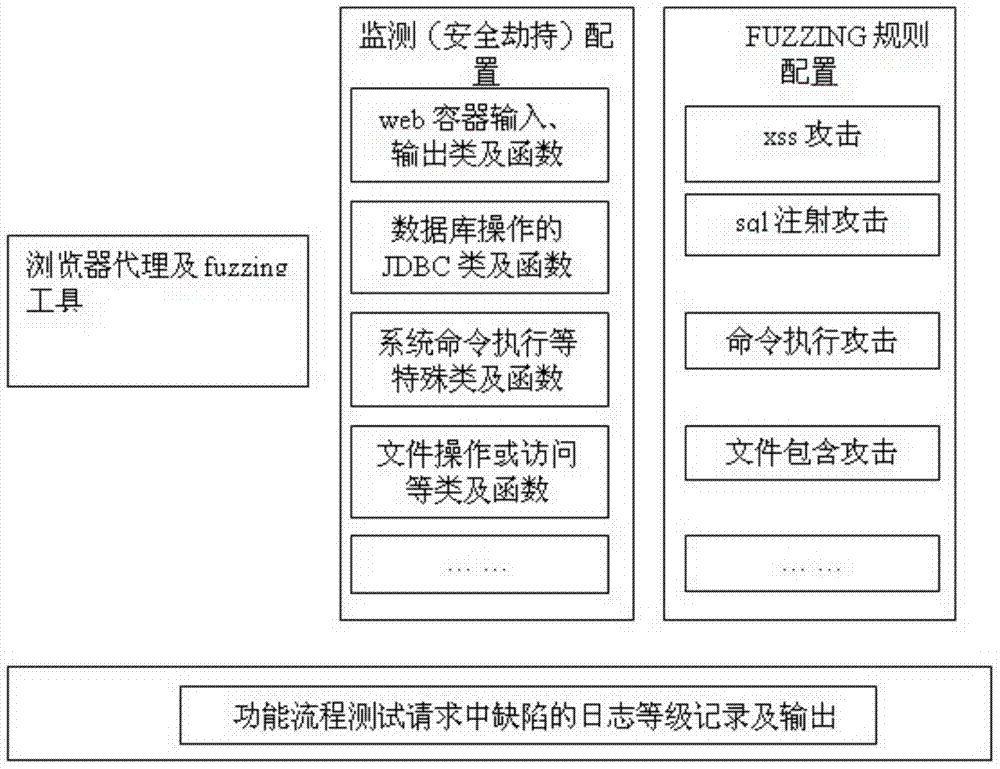

WEB dynamic security flaw detection method based on JAVA

The invention relates to a security test of WEB application, and aims to provide a WEB dynamic security flaw detection method based on JAVA. The WEB dynamic security flaw detection method based on JAVA is used for detecting the security flaws of a WEB application system, and comprises the following steps: modifying JAVA middleware; performing fuzzing test and dynamic flaw tracking. Due to the adoption of the WEB dynamic security flaw detection method, more WEB security flaw problems can be found rapidly, the security flaw range of black box test can be better covered, more deep WEB security problems can be found, the problem of high cost in white box test can be solved, the specific position of a flaw code can be determined more accurately, and lower missing report rate and error report rate in a detection process are ensured.

Owner:HANGZHOU ANHENG INFORMATION TECH CO LTD

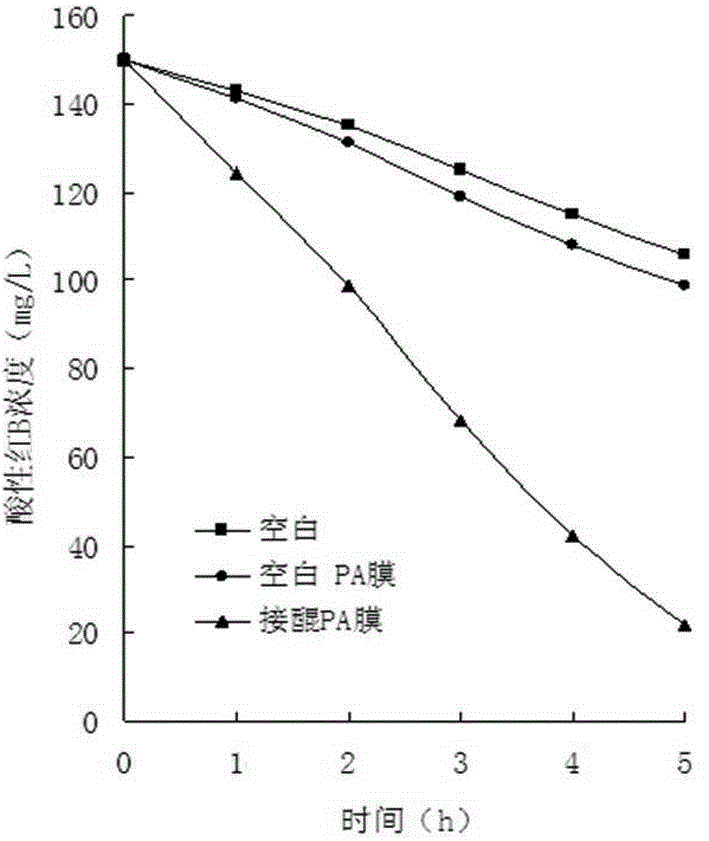

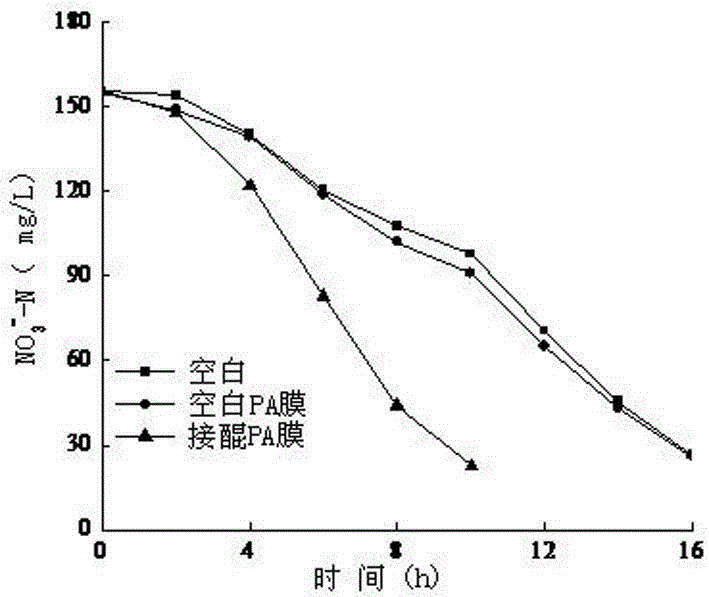

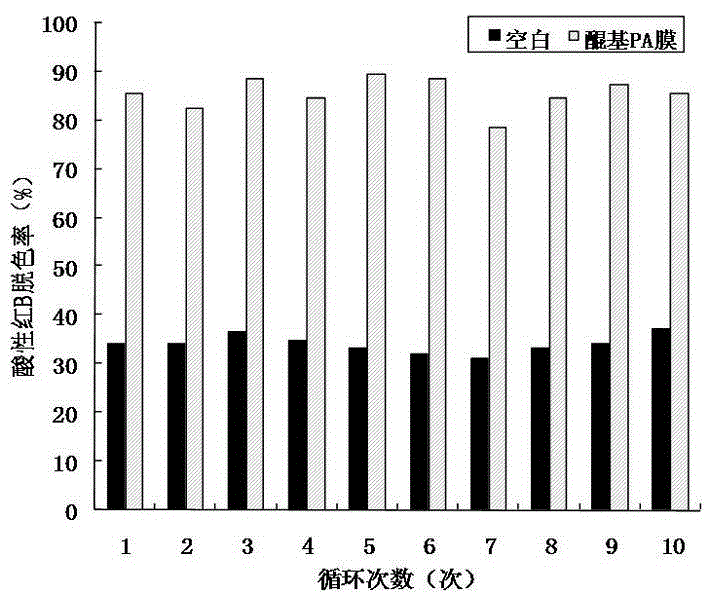

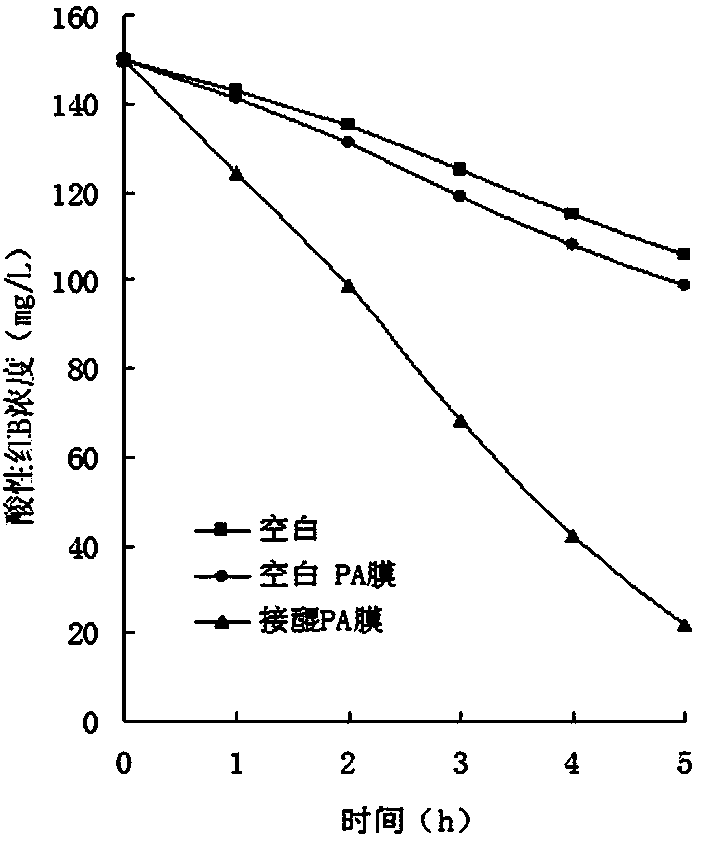

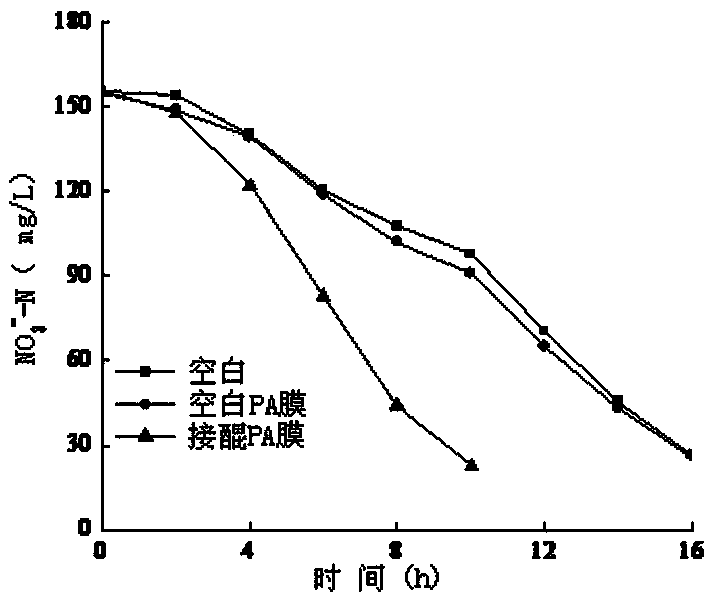

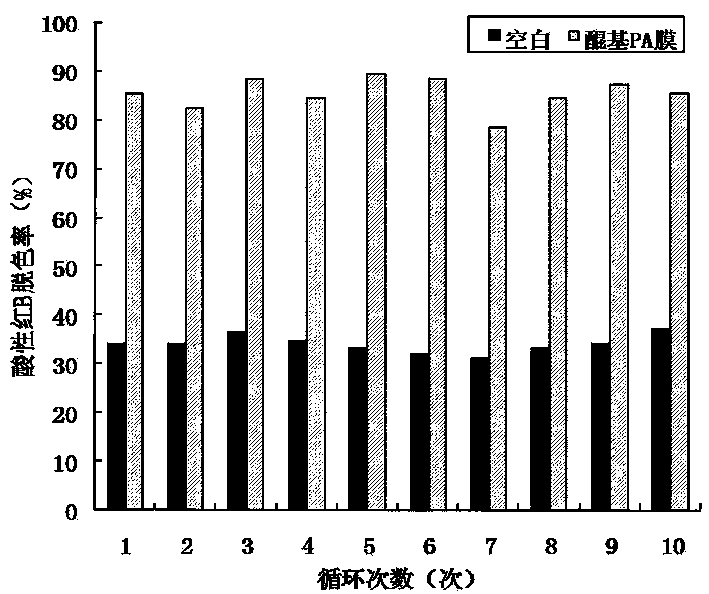

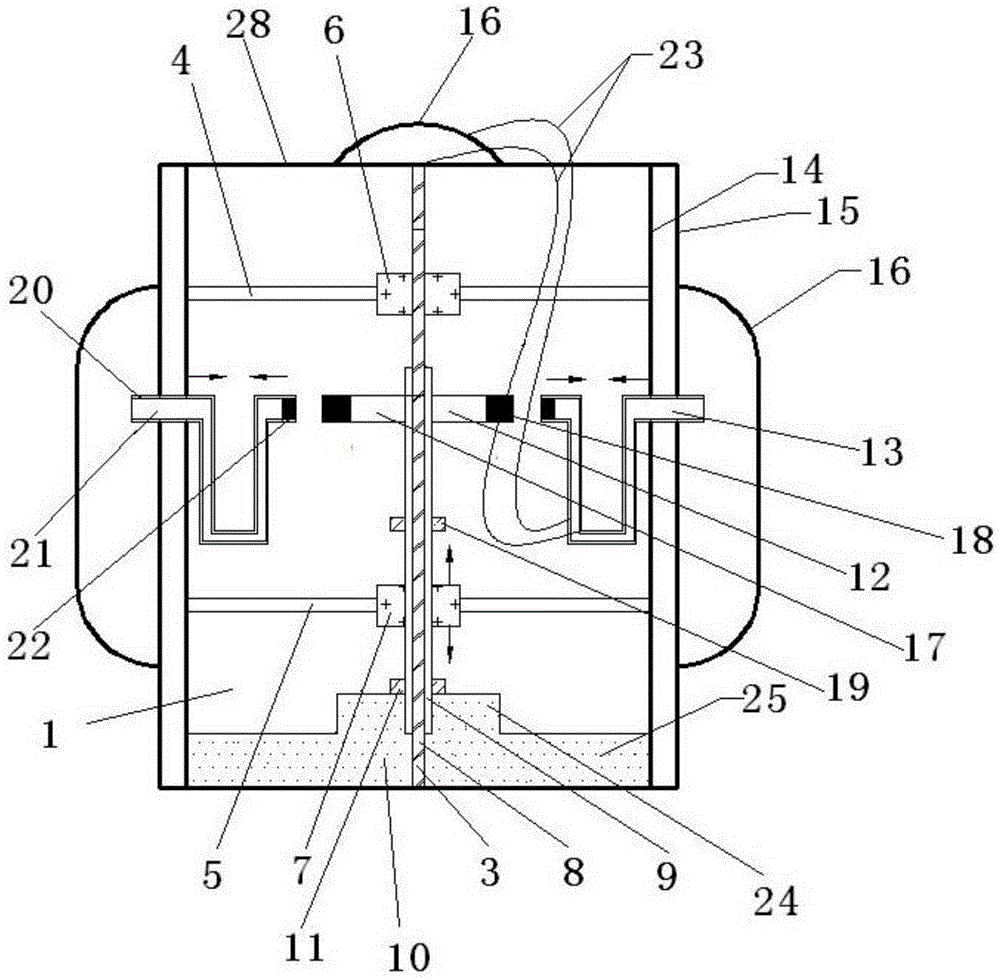

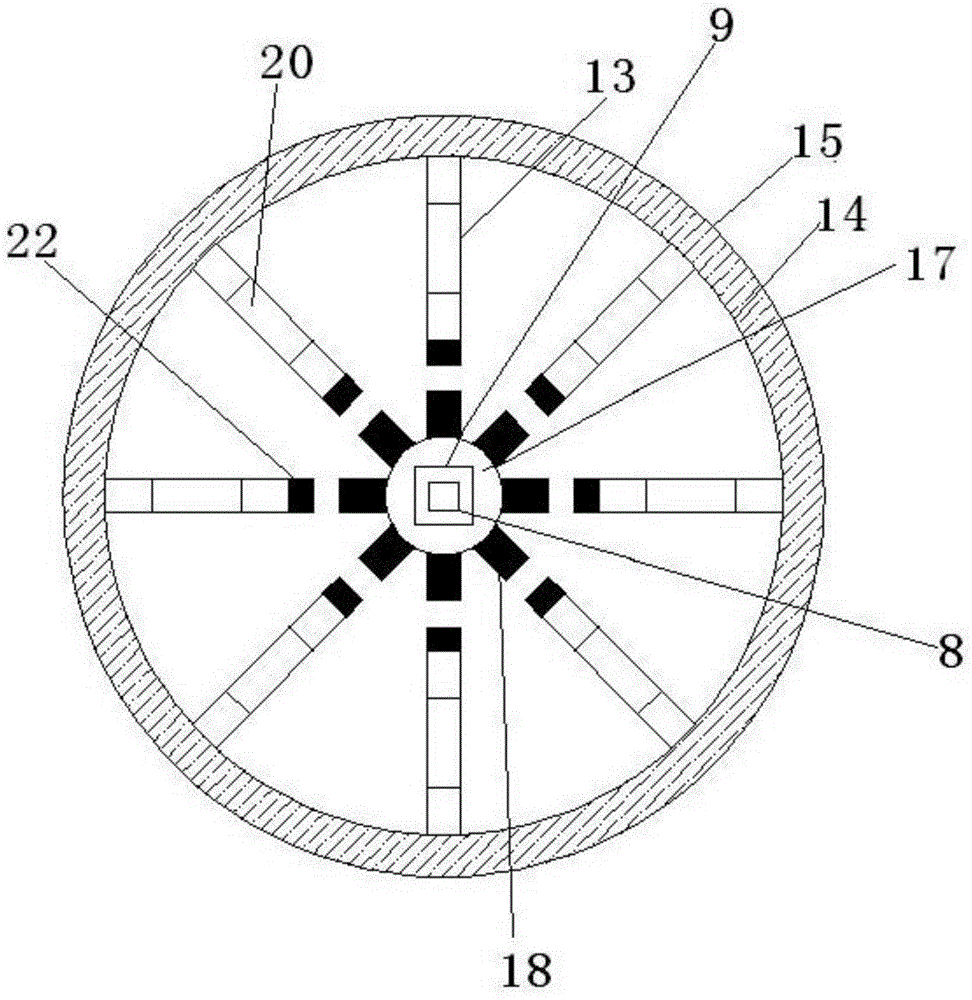

Preparation method and application of quinonoid compound modified nylon membrane biological carrier

InactiveCN103936146BIncrease surface areaIncrease contact areaTreatment with anaerobic digestion processesMicrobiologyCompatibilization

The invention discloses a quinonoid compound modified nylon membrane biological carrier and a preparation method and application thereof and belongs to the field of environmental engineering, chemical engineering and materials engineering. By adoption of the technical scheme, a quinonoid compound is fixed to a nylon membrane with excellent pore structure properties and amino active groups through a chemical grafting method, and a quinonoid compound modified nylon membrane biological carrier which is large in quinonoid grafting amount, high in water scouring resistance, stable in mechanical performance, free in biological toxic properties and high in catalytic efficiency is prepared and is applied to biodegradation and bio-denitrification of azo dyes. The quinonoid compound modified nylon membrane biological carrier has the beneficial effects that the preparation method is simple, and the reaction time and cost are saved; the carrier bonding is stable, and the catalytic efficiency is high. In addition, for a microbial denitrification process, the nylon membrane has high toughness and high biocompatibility, is easy to hang, has the characteristic of forming a stable microbial community and is suitable for industrial production and popularization and application.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

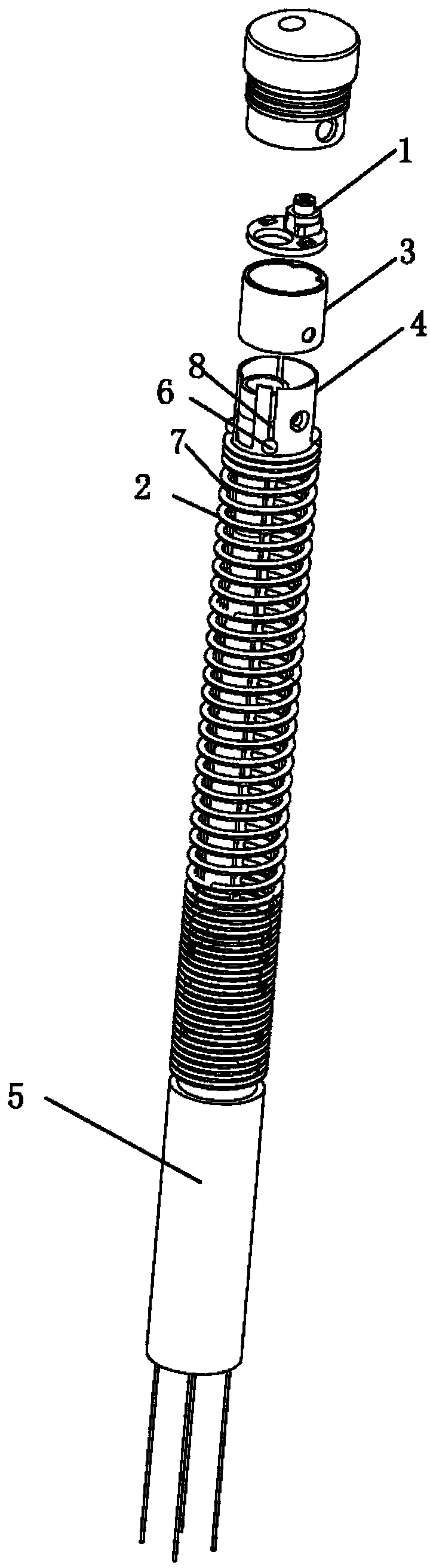

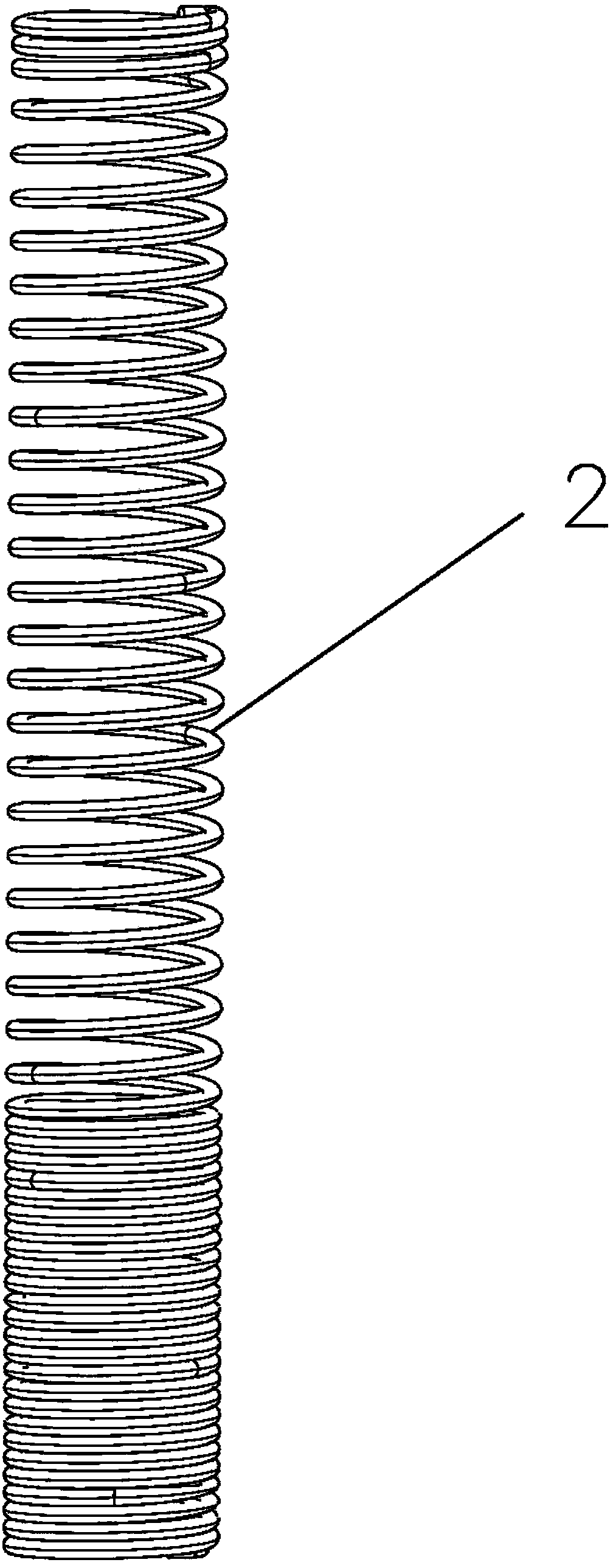

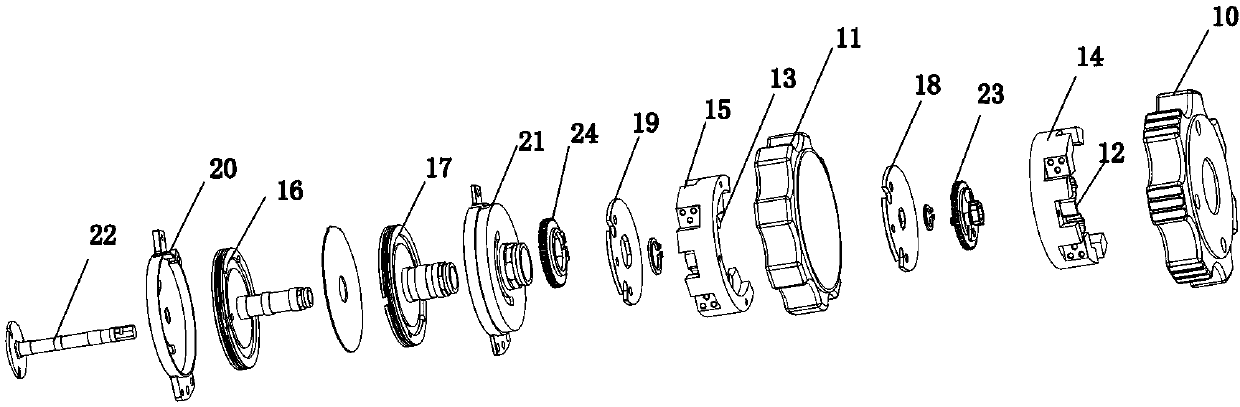

Bending controlling mechanism of medical endoscope

The invention provides a bending controlling mechanism of a medical endoscope. The bending controlling mechanism comprises a bending portion, a bending driving unit and a hand wheel adjusting device. The bending portion is provided with an outer cover, a bending assembly and a fixed barrel, the bending assembly is sleeved with the outer cover, and the fixed barrel is fixedly connected to the front end of the bending assembly. The bending driving unit comprises at least four control cables and control balls, the positions, corresponding to the control cables, of the fixed barrel is provided with connecting grooves in the circumferential direction, and the control balls at the end portions of the control cables are arranged in the connecting grooves respectively. The hand wheel adjusting device is connected with the control cables in a driving mode, and the hand wheel adjusting device is further provided with two sets of limiting and self-locking mechanisms. The bending assembly variable in range is adopted in the bending controlling mechanism, free bending is achieved through a controlling mechanism arranged in the bending controlling mechanism, resetting is achieved through the bending assembly variable in range, and the bending controlling mechanism has bending and resetting effects, reduces high cost in the whole operation process, achieves disposable use really, and is high in control accuracy and good in control effect.

Owner:姜泊

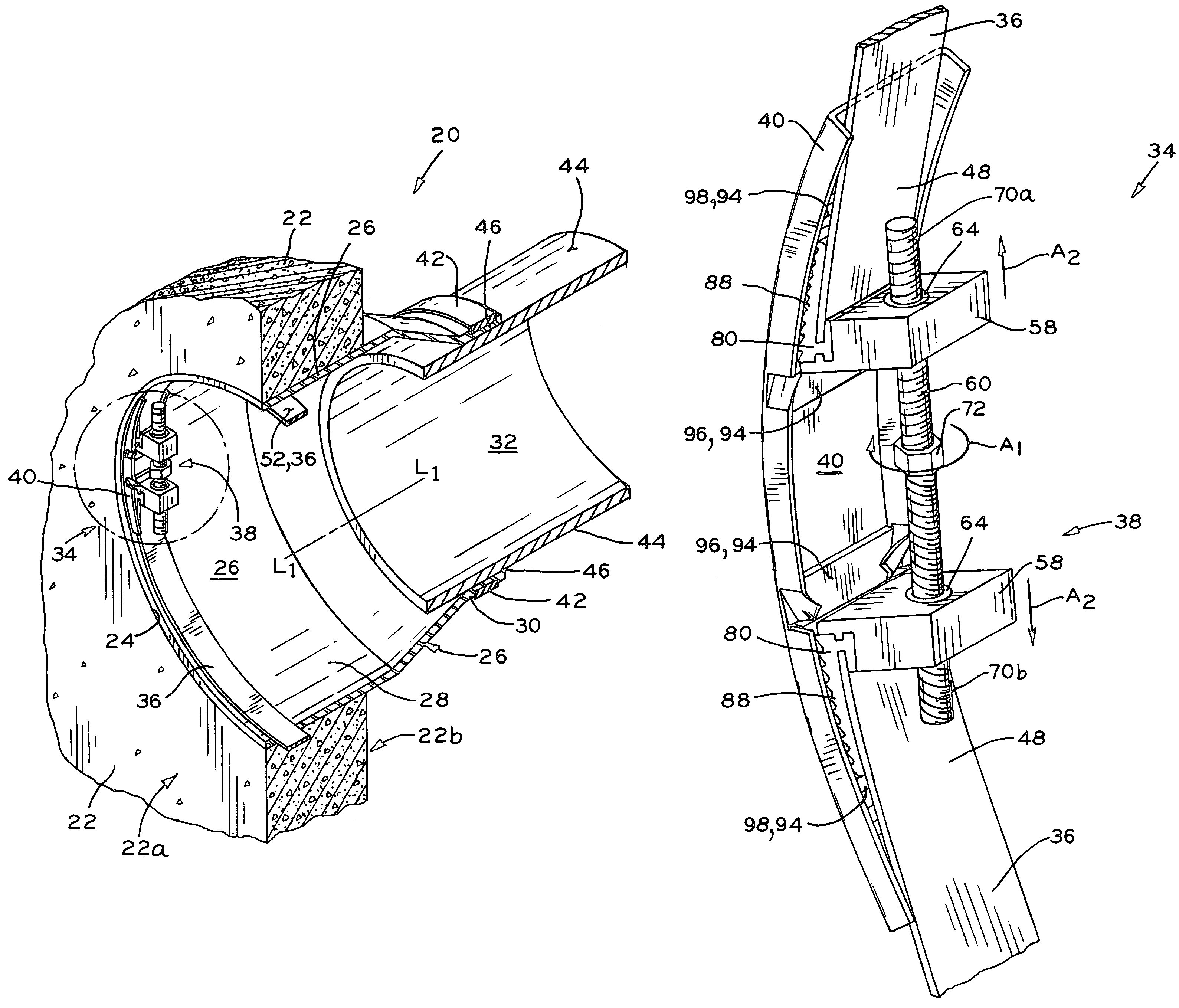

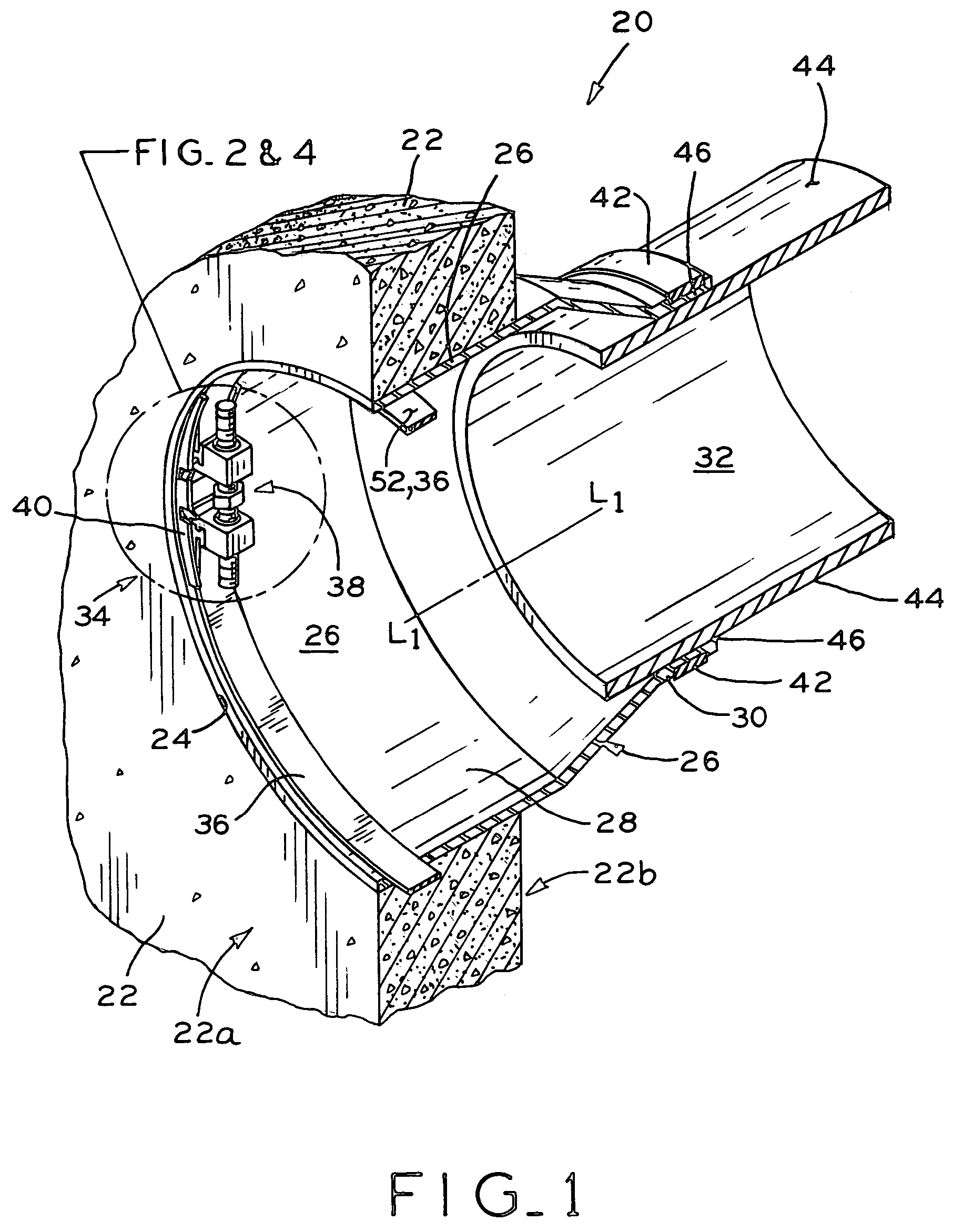

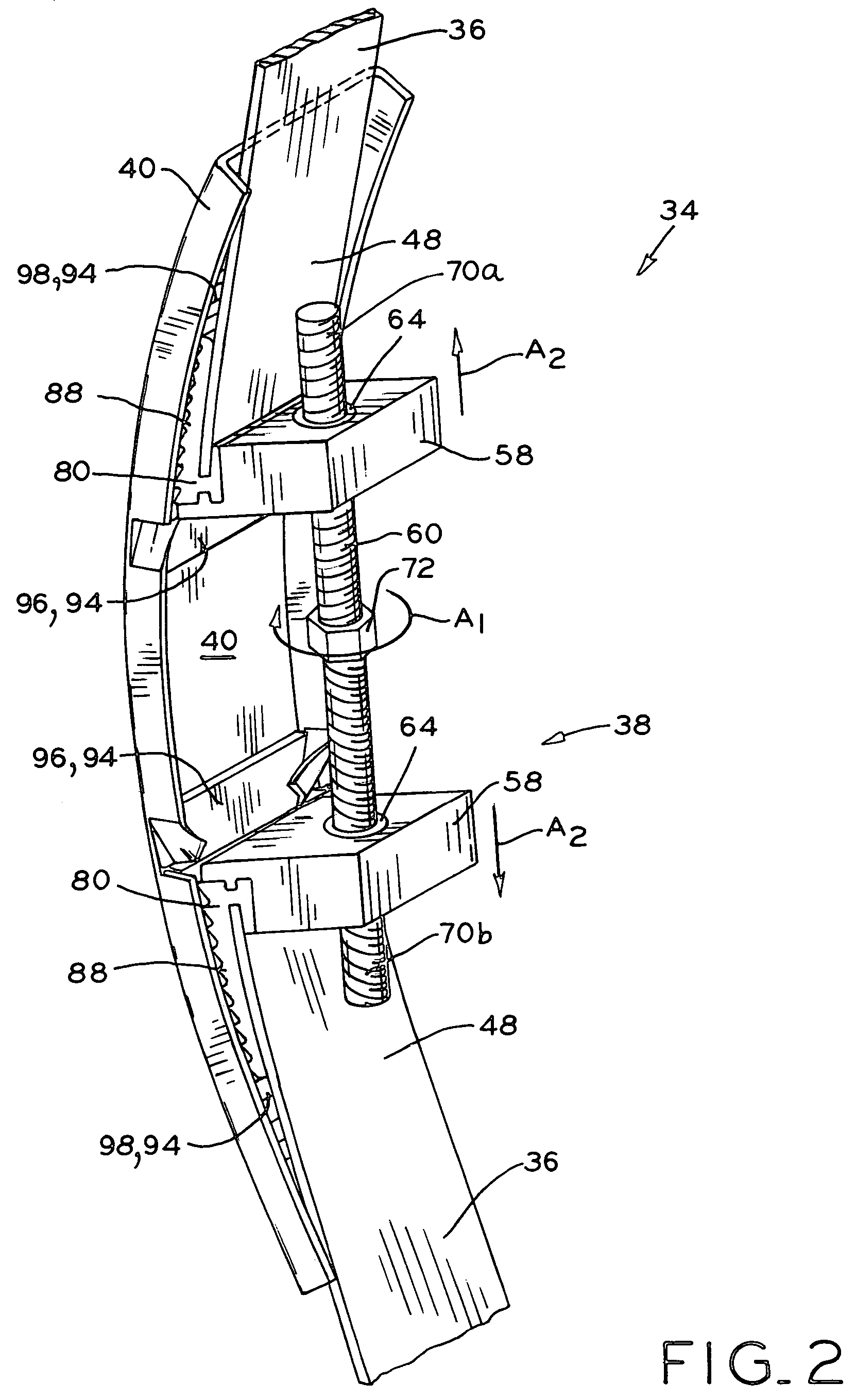

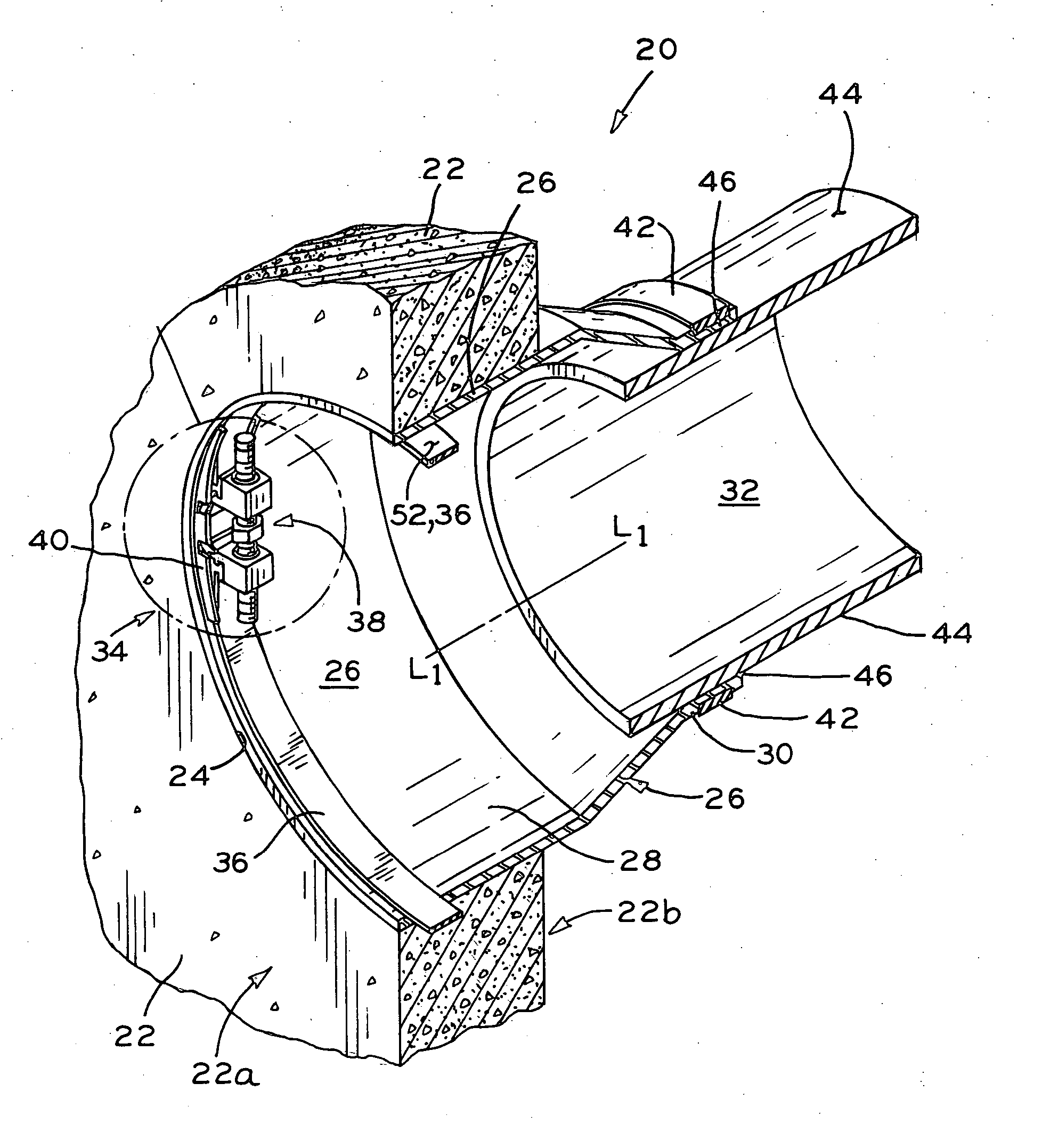

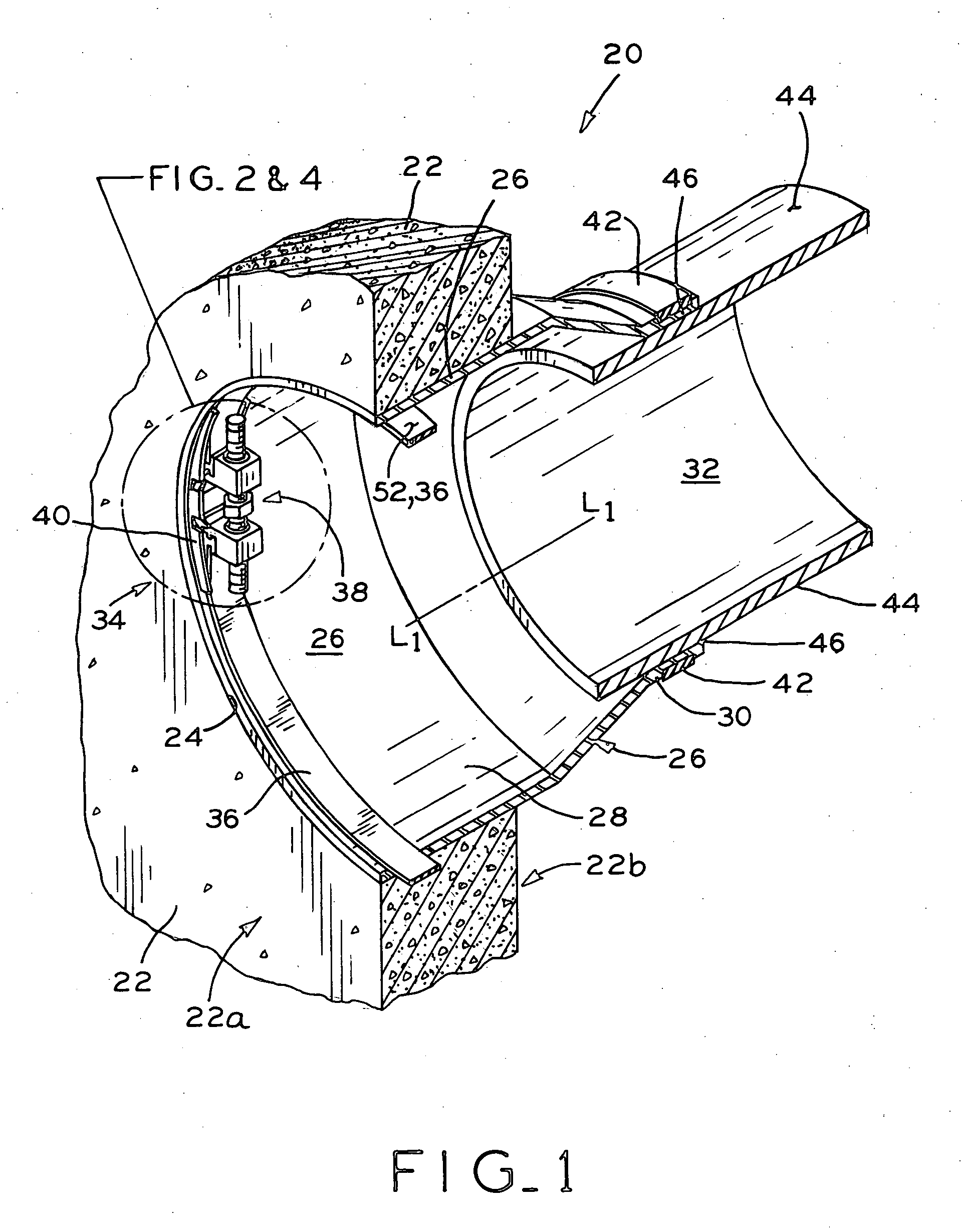

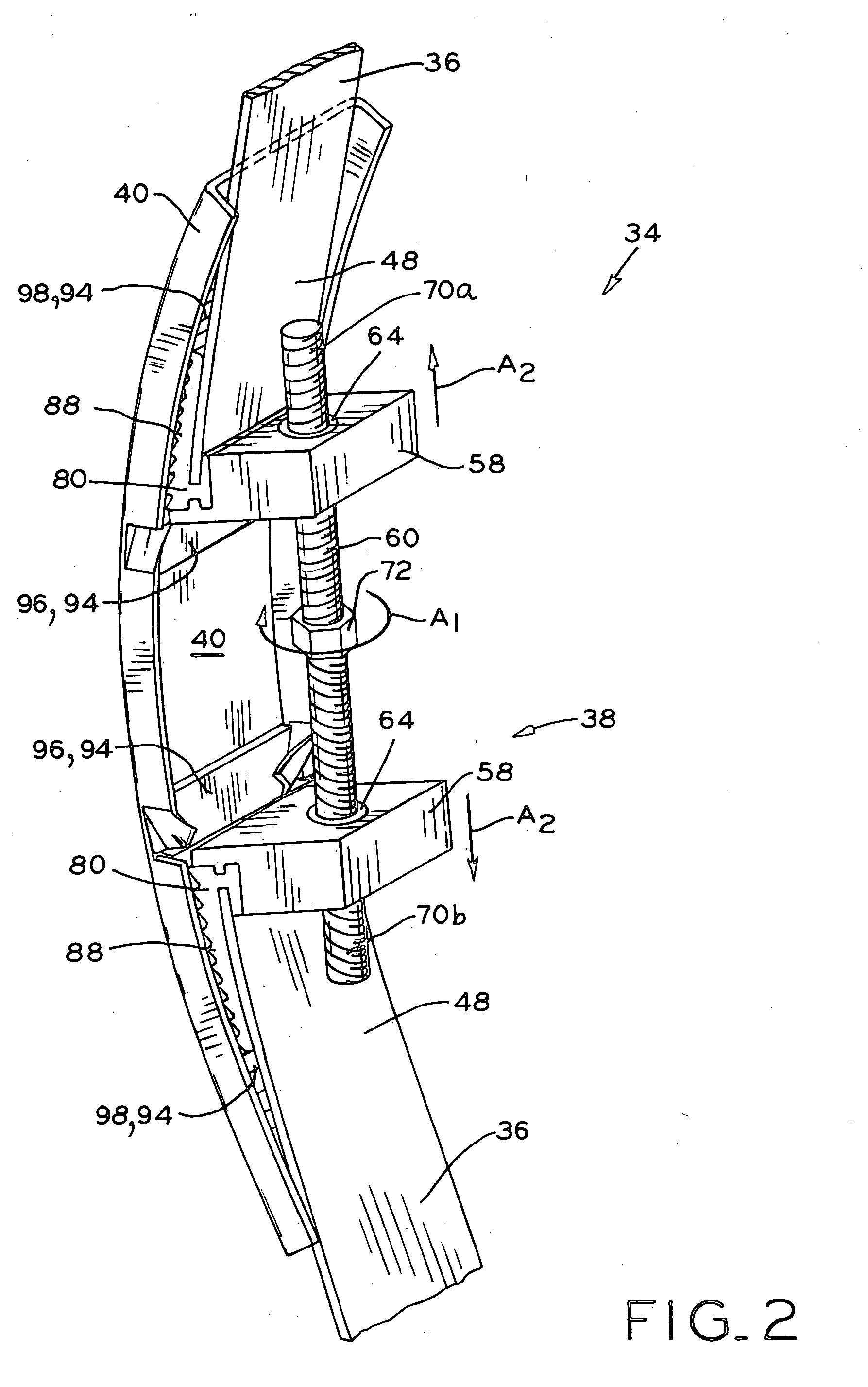

Expansion ring assembly with removable drive mechanism

Owner:PRESS SEAL GASKET

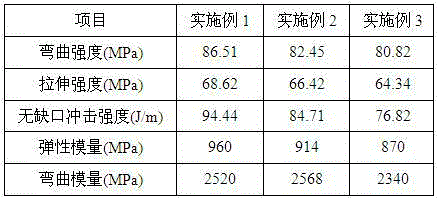

High-toughness high-modulus polypropylene composite material and preparation method thereof

The invention discloses a high-toughness high-modulus polypropylene composite material and a preparation method thereof. The high-toughness high-modulus polypropylene composite material consists of 50-62.5 parts of a polypropylene base body, 10-12 parts of high-density polyethylene, 12-15 parts of a polyolefin elastomer, 6-9 parts of modified wollastonite, 0.5-2 parts of nano modified particles, 1-2 parts of modified boron nitride, 5-6 parts of a compatibilizer, 1-1.5 parts of an antioxidant and 2-2.5 parts of a lubricating agent, wherein the nano modified particles are obtained by mixing a silane coupling agent and nano titanium dioxide in a weight ratio of 1 to 100. The preparation process is simple and convenient, the adopted materials are cheap, the comprehensive cost is lower than that of conventional toughness-modified polypropylene, and the produced high-toughness high-strength high-modulus polypropylene is excellent in performance. A composite system disclosed by the invention forms a polymer / flexible interface layer / inorganic particle three-phase composite system.

Owner:HENAN UNIV OF SCI & TECH

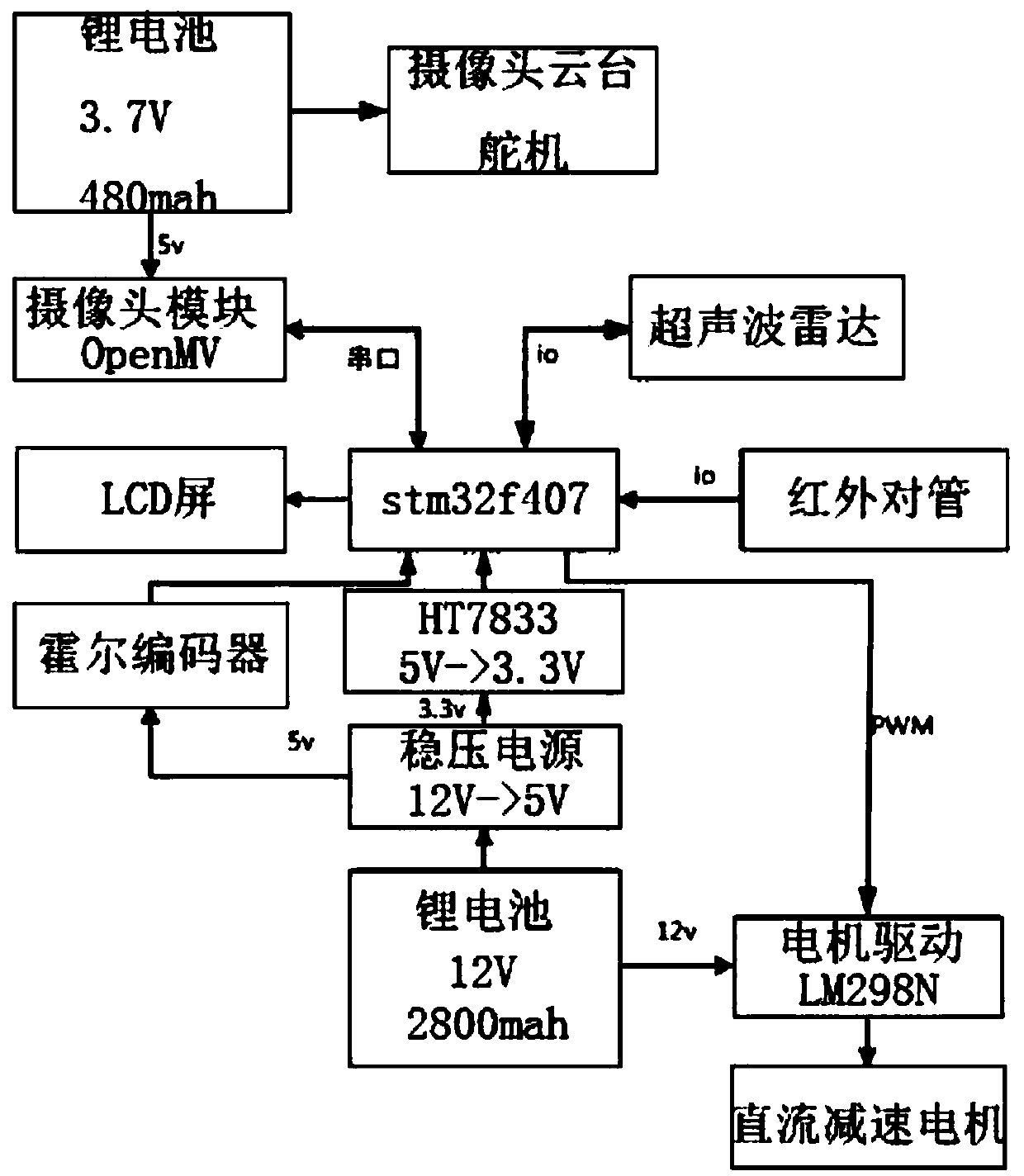

Intelligent garbage recovery system and dustbin overflow processing method

PendingCN107918316AImprove accuracyReduce high costProgramme controlComputer controlComputer monitoringNetwork communication

The invention discloses an intelligent garbage recovery system and a dustbin overflow processing method; the intelligent garbage recovery system comprises an intelligent dustbin, an intelligent garbage truck, a wechat mini app client end and a host computer monitoring center; the intelligent dustbin comprises a dustbin body, a dustbin controller, a garbage detector, a dustbin cover turning device,a dustbin positioning device and a dustbin communication device; the dustbin positioning device can position through GPS. The dustbin can detect garbage through an infrared paired transistor; when the garbage in the dustbin reaches certain height and blocks the infrared rays, a garbage overflow alarm signal can be triggered; compared with the prior art, the garbage quantity detection mode is higher in accuracy; the Zigbee network technology and the GPRS communication mode technology are combined, thus reducing the expensive cost of an existing intelligent dustbin employing the GPRS network communication.

Owner:WUYI UNIV

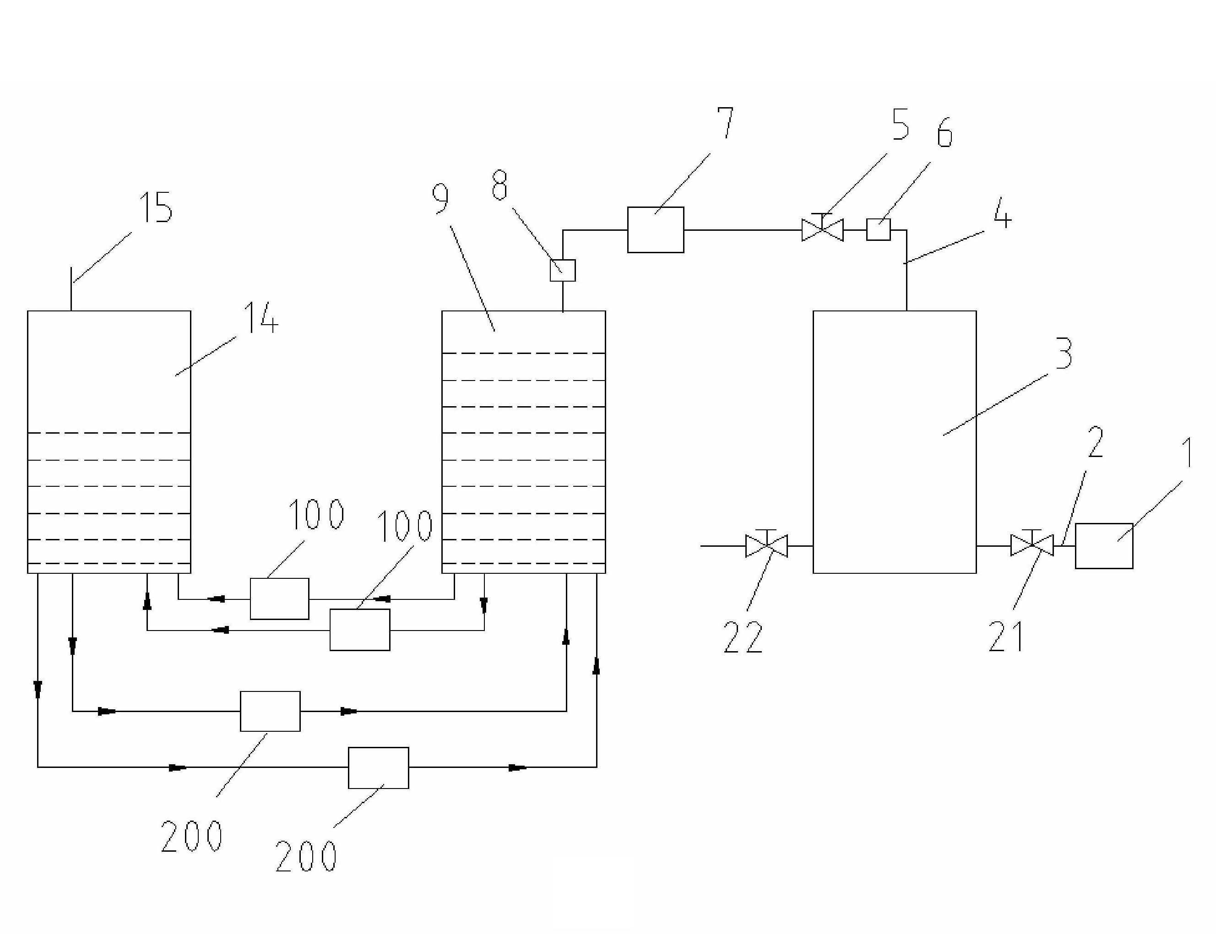

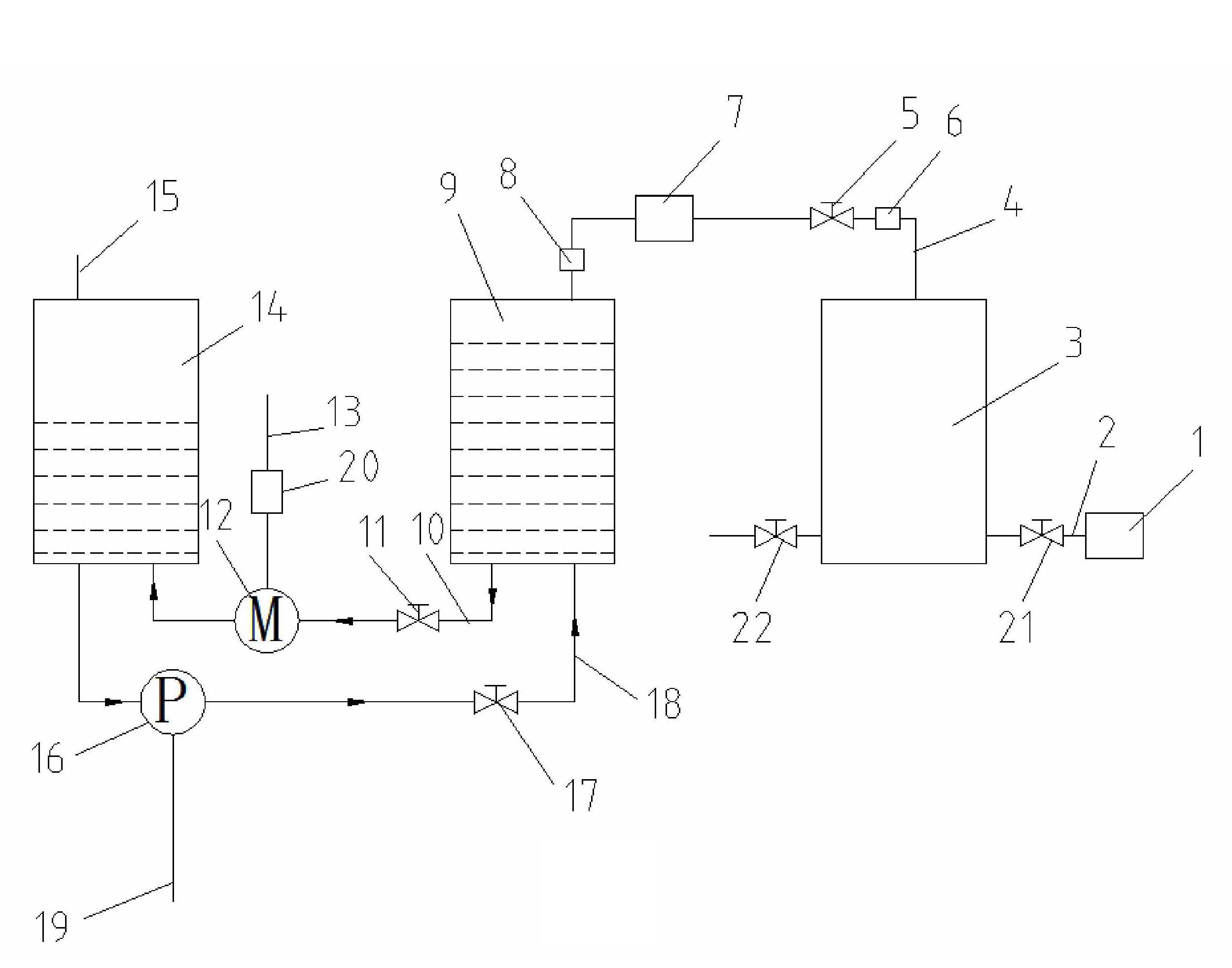

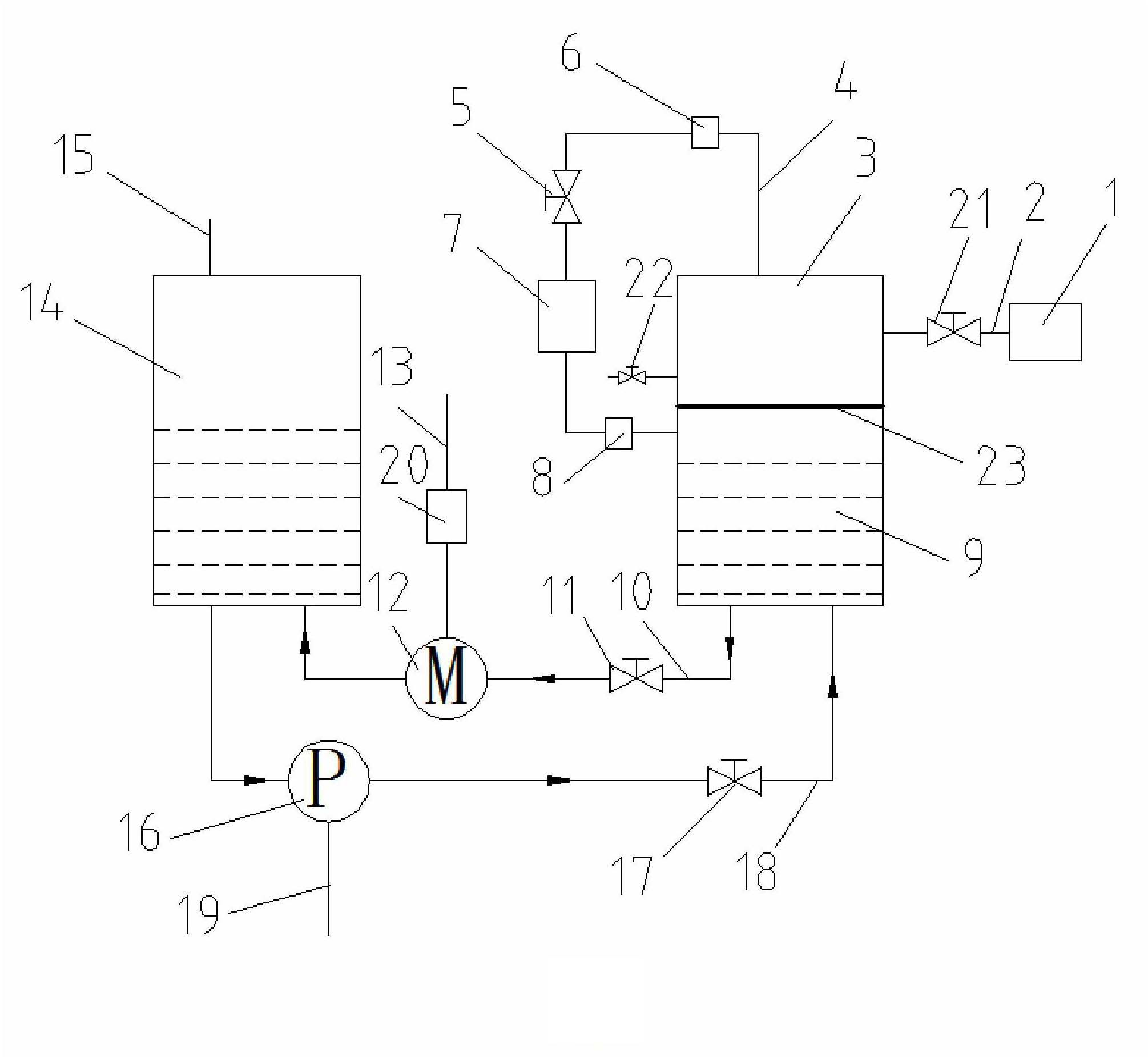

Water/gas chamber energy storage system

ActiveCN102661228ASolve the cost problemSolve complexityEngine componentsPump installationsAtmospheric airHigh pressure water

The invention discloses a water / gas chamber energy storage system and relates to a physical electric energy storage system. The system comprises an air compressor pump group, a high-pressure gas chamber, a high-pressure water chamber, power generation / energy storage devices and a water storage chamber, wherein the high-pressure gas chamber and the high-pressure water chamber are independently arranged; the water storage chamber is communicated with atmosphere; the air compressor pump group is communicated with the high-pressure gas chamber through a first pipeline; a first valve is arranged on the first pipeline; the high-pressure gas chamber is communicated with the high-pressure water chamber through a second pipeline; a second valve is arranged on the second pipeline; and at least one power generation / energy storage device is arranged between the high-pressure water chamber and the water storage chamber. By the simple structure, the energy is converted, the construction cost of the system is reduced, and the problems that the traditional compressed air energy storage system is high in construction cost of equipment and complex in heat exchange systems are solved. In addition, due to the high-pressure gas chamber and the high-pressure water chamber which are independently arranged and communicated with each other, the output of gas pressure is controllable, the output of water pressure is controllable, and the output power of generators / motors is controllable.

Owner:王静然

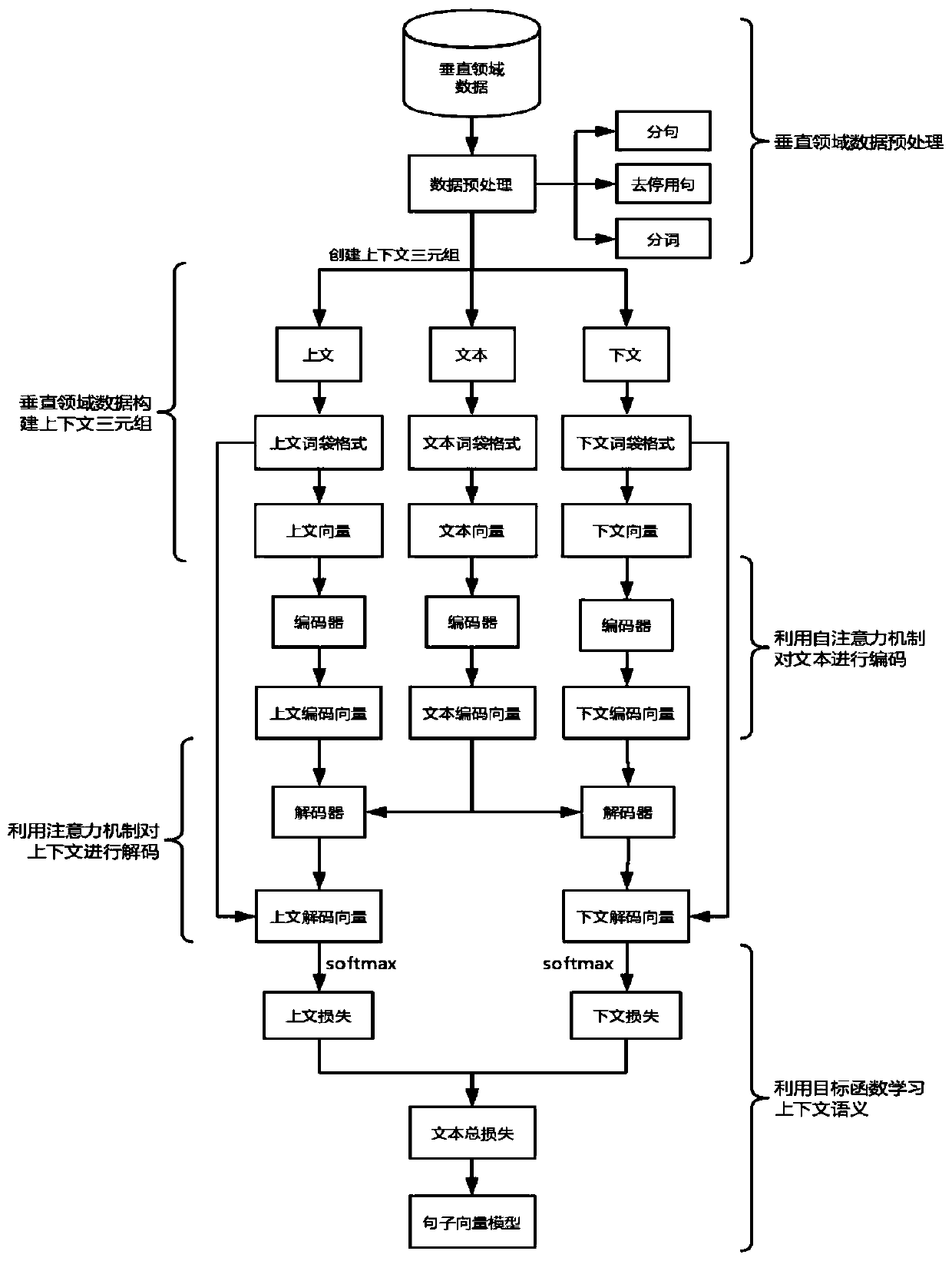

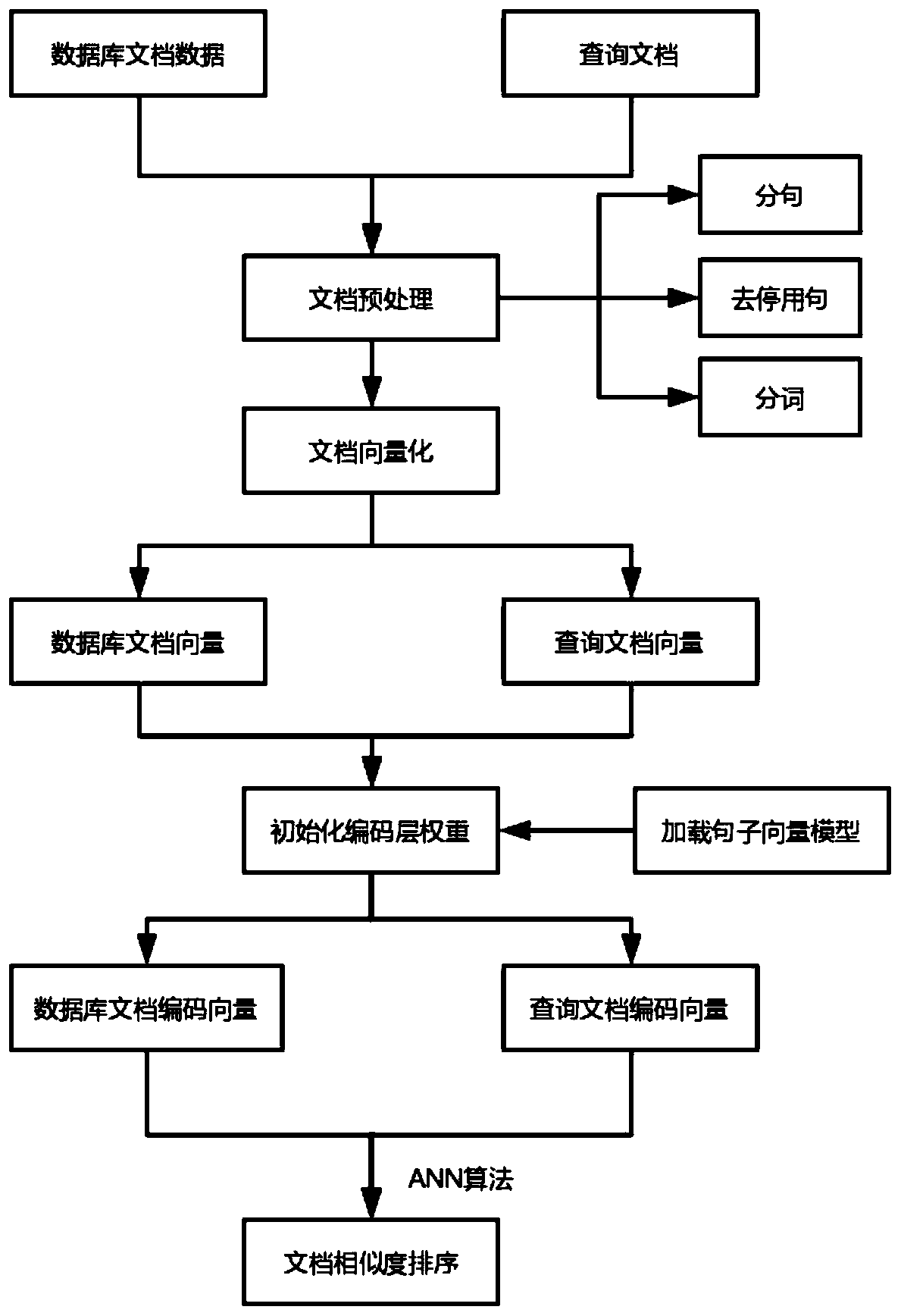

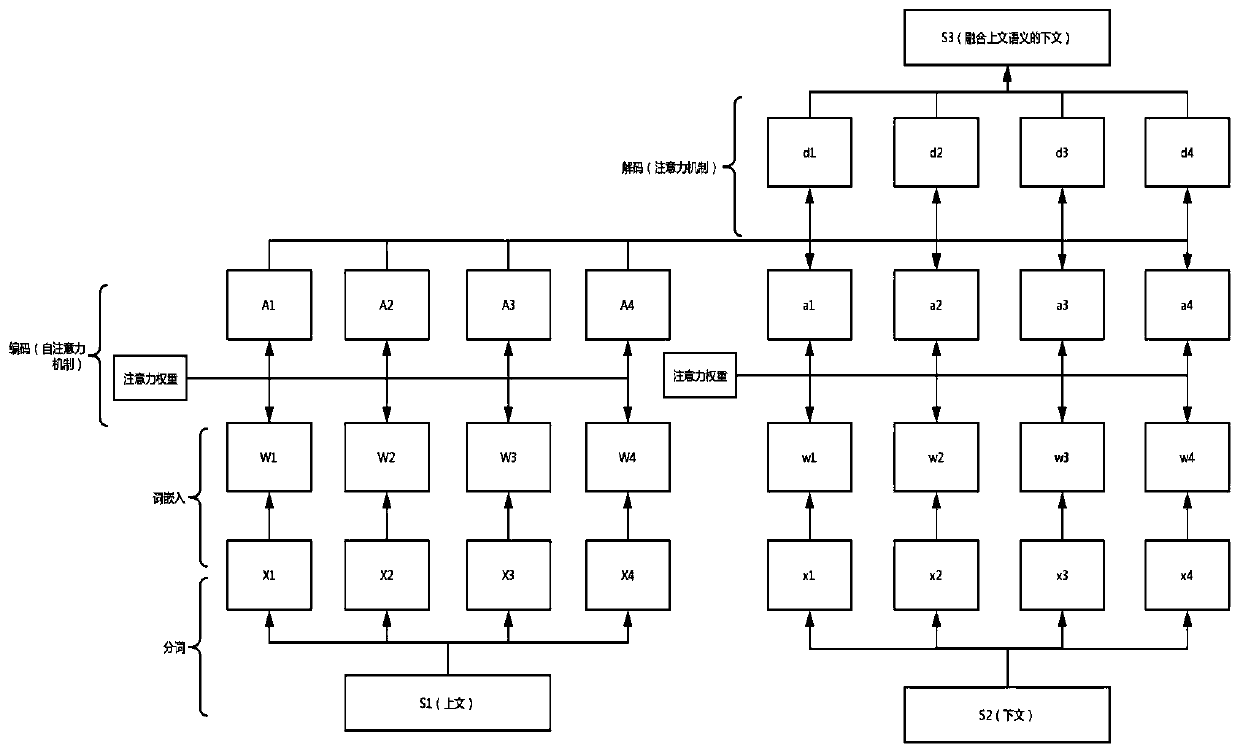

Similar legal case retrieval method based on self-coding neural network

ActiveCN110275936AImprove generalization abilityRich in featuresData processing applicationsText database queryingData setNear neighbor

The invention discloses a similar legal case retrieval method based on a self-coding neural network. The similar legal case retrieval method constructs a legal case feature vector model, calculates the similarity between a legal case to be retrieved and legal cases in a database by adopting an approximate nearest neighbor ANN algorithm, and outputs similar legal cases, wherein a legal case feature vector model is generated by creating a context triple and adopting a self-attention mechanism and a codec to train and learn a legal case data set. According to the invention, the unsupervised learning method is utilized to save the high cost of the data labeling process, and the adopted coding and decoding network structure shares context semantics, and the characteristics of the text are enriched, and the retrieval efficiency of similar legal cases is improved.

Owner:ZHEJIANG UNIV OF TECH +1

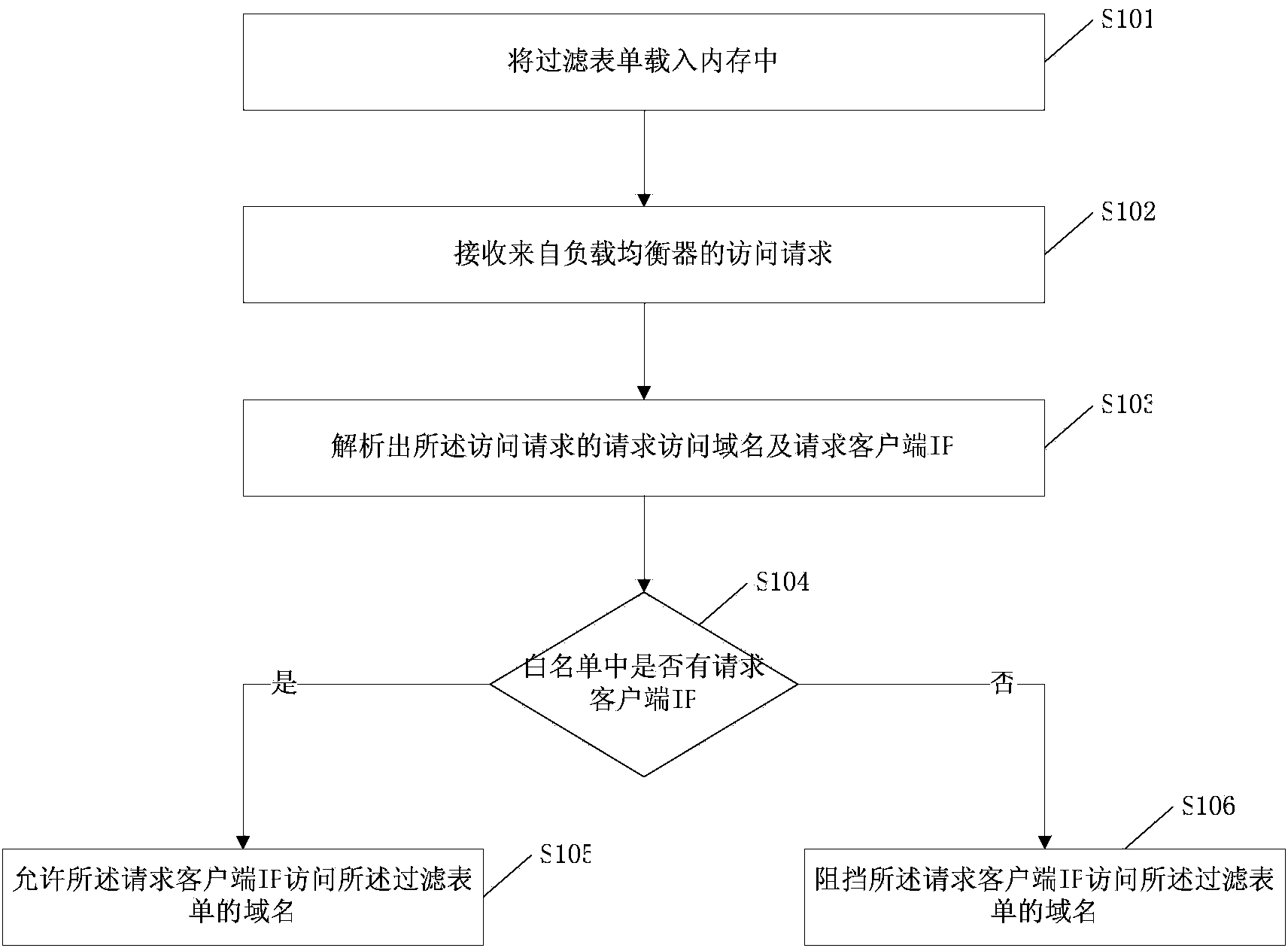

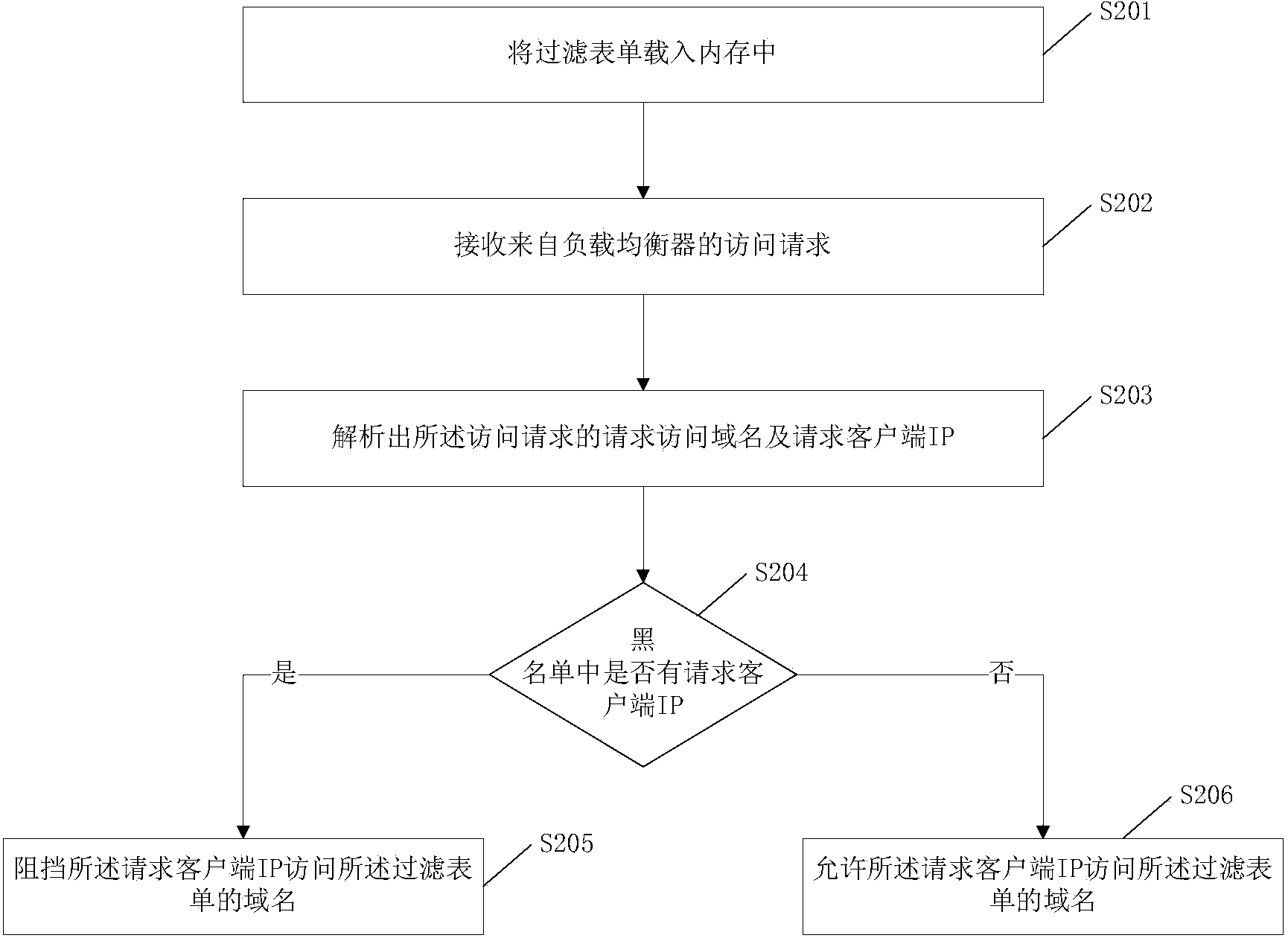

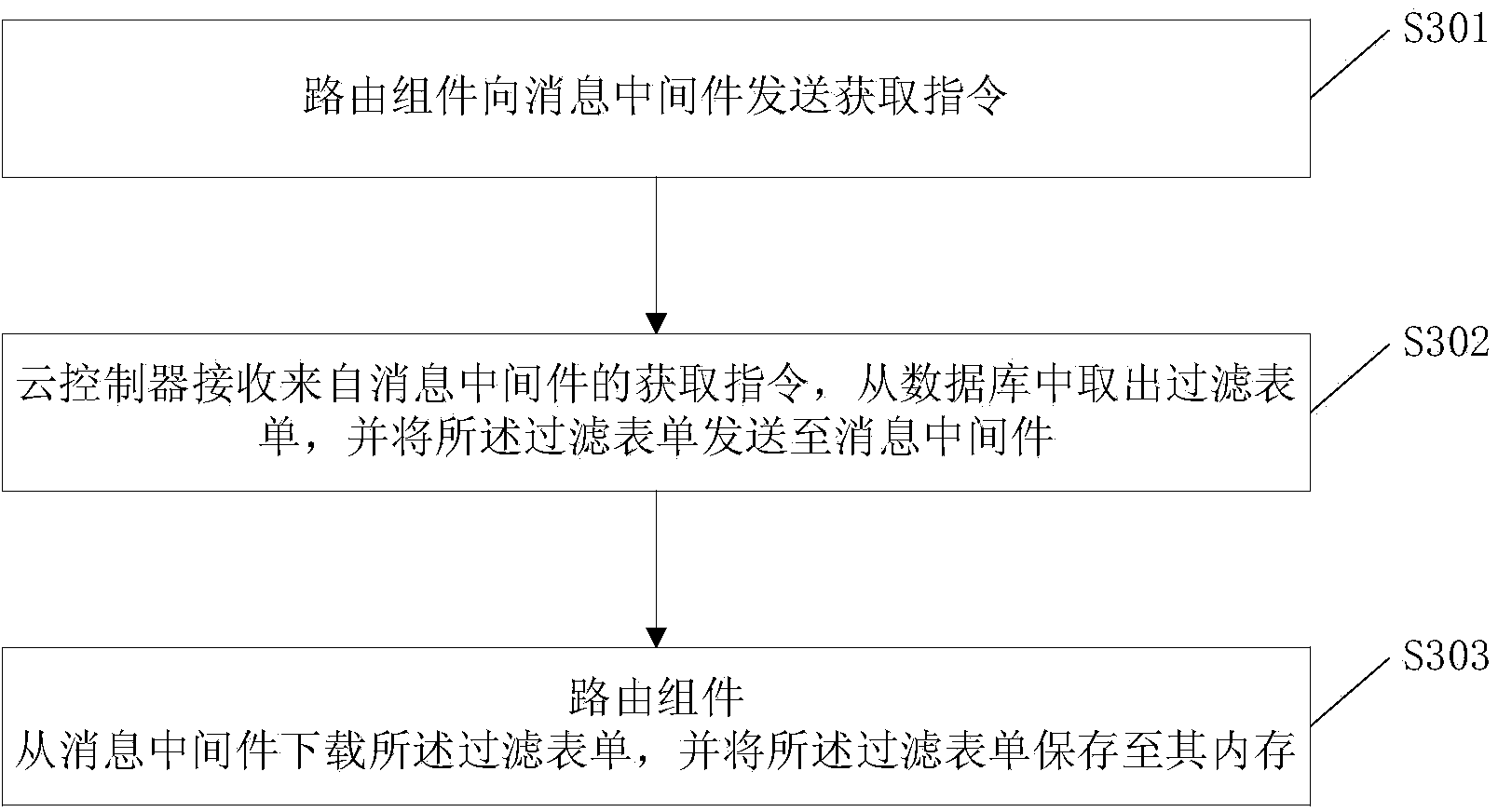

Website access method and device and filter form downloading and updating method and system

The invention relates to a website access method and device and a filter form downloading and updating method and system. The website access method is used for a route assembly, and comprises the steps that a filter form is loaded in internal storage, the corresponding relation of a domain name and a white list is recorded in the filter form, and the white list comprises at least one IP address; an access request from a load balancer is received; a request access domain name and a request client side IP of the access request are analyzed; whether the request client side IP exits in the white list corresponding to the domain name of the filter form matched with the request access domain name of the access request or not is judged according to the filter form, if the request client side IP exits, the request client side IP is allowed to have the access to the domain name of the filter form, and if the request client side IP does not exist, the request client side IP is stopped from having the access to the domain name of the filter form. A black list and the white list are moved to a route layer from a firewall or the load balancer, and the restrict access to seven layers of network protocols (http) is achieved.

Owner:云宏信息科技股份有限公司

Preparation method and application of quinonoid compound modified nylon membrane biological carrier

InactiveCN103936146AGood biocompatibilityGood adhesionTreatment with anaerobic digestion processesMicrobiologyCompatibilization

The invention discloses a quinonoid compound modified nylon membrane biological carrier and a preparation method and application thereof and belongs to the field of environmental engineering, chemical engineering and materials engineering. By adoption of the technical scheme, a quinonoid compound is fixed to a nylon membrane with excellent pore structure properties and amino active groups through a chemical grafting method, and a quinonoid compound modified nylon membrane biological carrier which is large in quinonoid grafting amount, high in water scouring resistance, stable in mechanical performance, free in biological toxic properties and high in catalytic efficiency is prepared and is applied to biodegradation and bio-denitrification of azo dyes. The quinonoid compound modified nylon membrane biological carrier has the beneficial effects that the preparation method is simple, and the reaction time and cost are saved; the carrier bonding is stable, and the catalytic efficiency is high. In addition, for a microbial denitrification process, the nylon membrane has high toughness and high biocompatibility, is easy to hang, has the characteristic of forming a stable microbial community and is suitable for industrial production and popularization and application.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Nonferrous mine graphite scrap concrete for backfill and method of manufacturing the same

The invention discloses nonferrous mine mullock concrete used as filling and the preparation method thereof, and relates to the concrete which is used for mining backfilling and the preparation method thereof. The preparation method includes the following steps: at first, the mullock is crushed into grains with the diameter being 5 to 30 mm, then the mullock, ore dressing milltailings and fly ashes are adopted to be used as aggregate according to the weight rate of (5 to 7):(4 to 6):(0 to 3), and cement is adopted according to the weight rate (7 to 11): 1 part of the cement, then admixture is adopted with the weight of 0.3 to 1.5 percent of the cement. Then the aggregate, the cement, the admixture and mining wastewater are put into an agitator to agitate and make mortar with 65 to 88 percent of weight percentage concentration, then the mortar is cast and molded to be mullock concrete on the spot, or a mortar pump is sent to the site of the backfill mine, then cast and moulded to be the mullock concrete. Through detecting, the mullock concrete satisfies the strength requirement that R3 is equal to or larger than 1.5 MPa, R7 is equal to or larger than 2.5 MPa, R28 is equal to or larger than 5.0 MPa, the slump is equal to or larger than 22 cm, and the horizontal distance is equal to or larger than 500 m, and the height is equal to or larger than 30 m. The invention has the advantages of saving material by 10 to 20 percent, recycling the mullock and reducing the mine construction cost, thereby having obvious economic and environmental benefits.

Owner:TONGJI UNIV

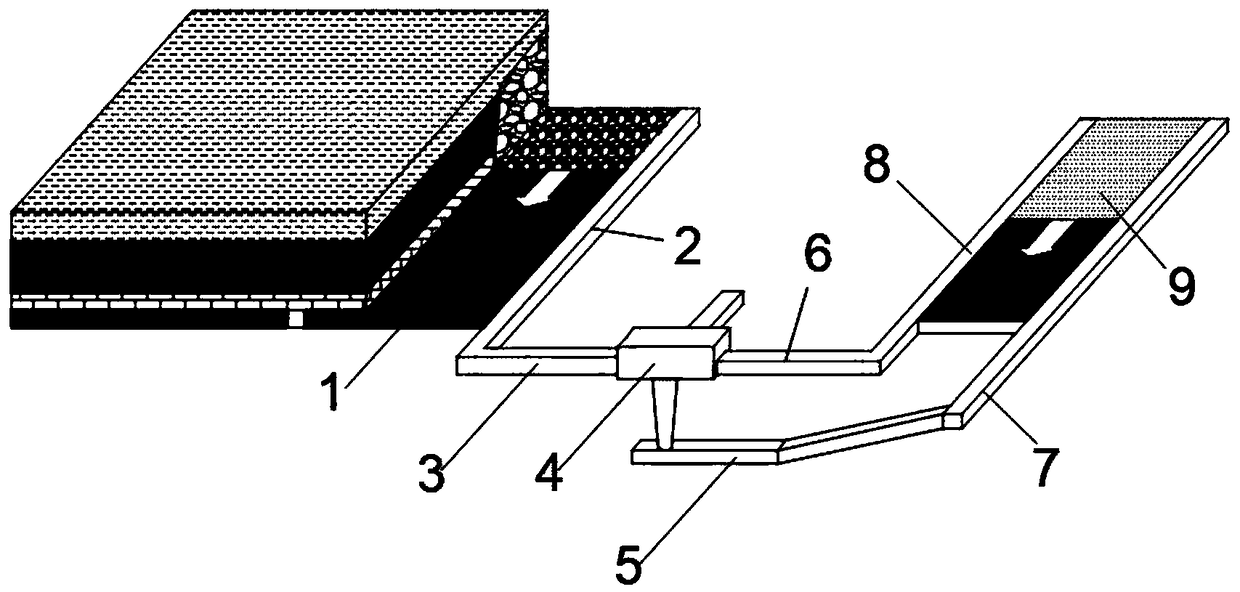

Wave-energy piezoelectric power generation device based on fixed frequency and natural vibration

InactiveCN104362899ALow costImprove use valuePiezoelectric/electrostriction/magnetostriction machinesMachines/enginesElectricityFixed frequency

The invention discloses a wave-energy piezoelectric power generation device based on fixed frequency and natural vibration. The wave-energy piezoelectric power generation device is characterized in that the wave-energy piezoelectric power generation device comprises a power generation device body (1) and a fixing device (2) used for fixing the power generation device body to the sea surface; the power generation device body comprises a spindle (3), the spindle (3) is provided with an upper water stop plate (4) and a lower water stop plate (5), and the upper water stop plate (4) and the lower water stop plate (5) penetrate the spindle (3) and are fixed to the spindle (3) through an upper fixing bearing (6) and a lower fixing bearing (7) respectively. The wave-energy piezoelectric power generation device has the advantages of capability of achieving fixed-frequency conversion of wave energy simply and effectively, remarkable environmental and economic benefits, simple structure, low cost, capability of being produced massively and capability of being widely applied to the wave energy power generation industry and the production field of products such as beacon lights to realize commercial development.

Owner:HOHAI UNIV

Expansion ring assembly with removable drive mechanism

An expansion ring assembly for sealing a gasket within an opening in the wall of a structure, the assembly including a drive mechanism having a pair of block members each having a threaded bore, and a bolt having oppositely threaded ends respectively threaded within the bores. The block members are removably engaged with respective ends of the expansion ring. An oversleeve is disposed in overlapping relationship with the expansion ring ends, and the expansion ring ends and the oversleeve include cooperating ratcheting structures. Rotation of the bolt of the drive mechanism in a first direction causes the block members to move outwardly along the bolt to expand the expansion ring and concurrently sequentially engage the ratcheting structures of the expansion ring ends and the oversleeve. Once the expansion ring is expanded to a desired extent, the bolt of the drive mechanism may be rotated in a second direction opposite the first direction to move the block members inwardly along the bolt and allow disengagement of the block members from the expansion ring ends and removal of the drive mechanism. The expansion ring ends are maintained in their expanded condition by the engagement of the ratcheting structures of the expansion ring ends and the oversleeve. In another embodiment, overlapping ends of the expansion ring have ratcheting structure therebetween, and are driven apart by the removable the drive mechanism, wherein the oversleeve member is eliminated.

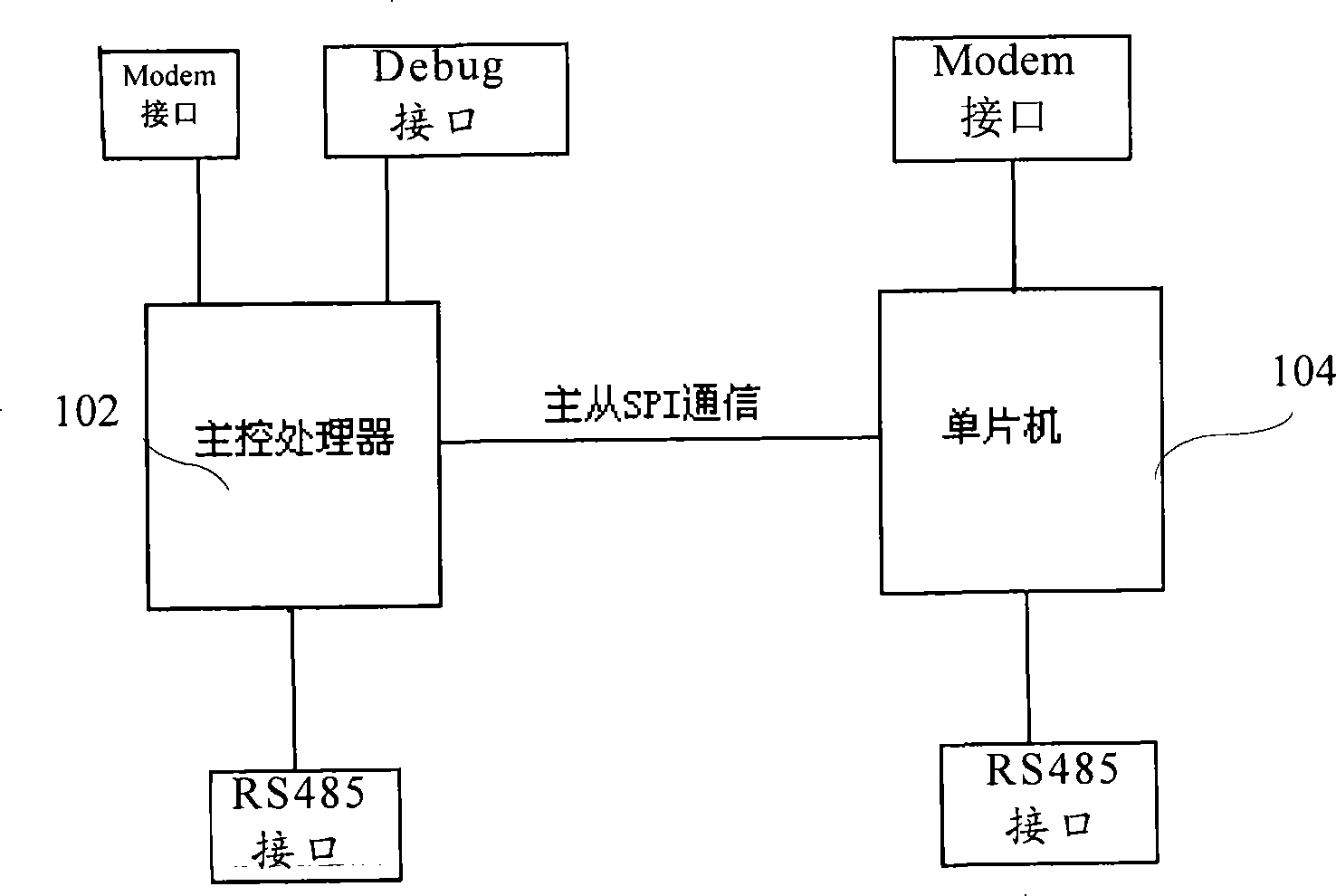

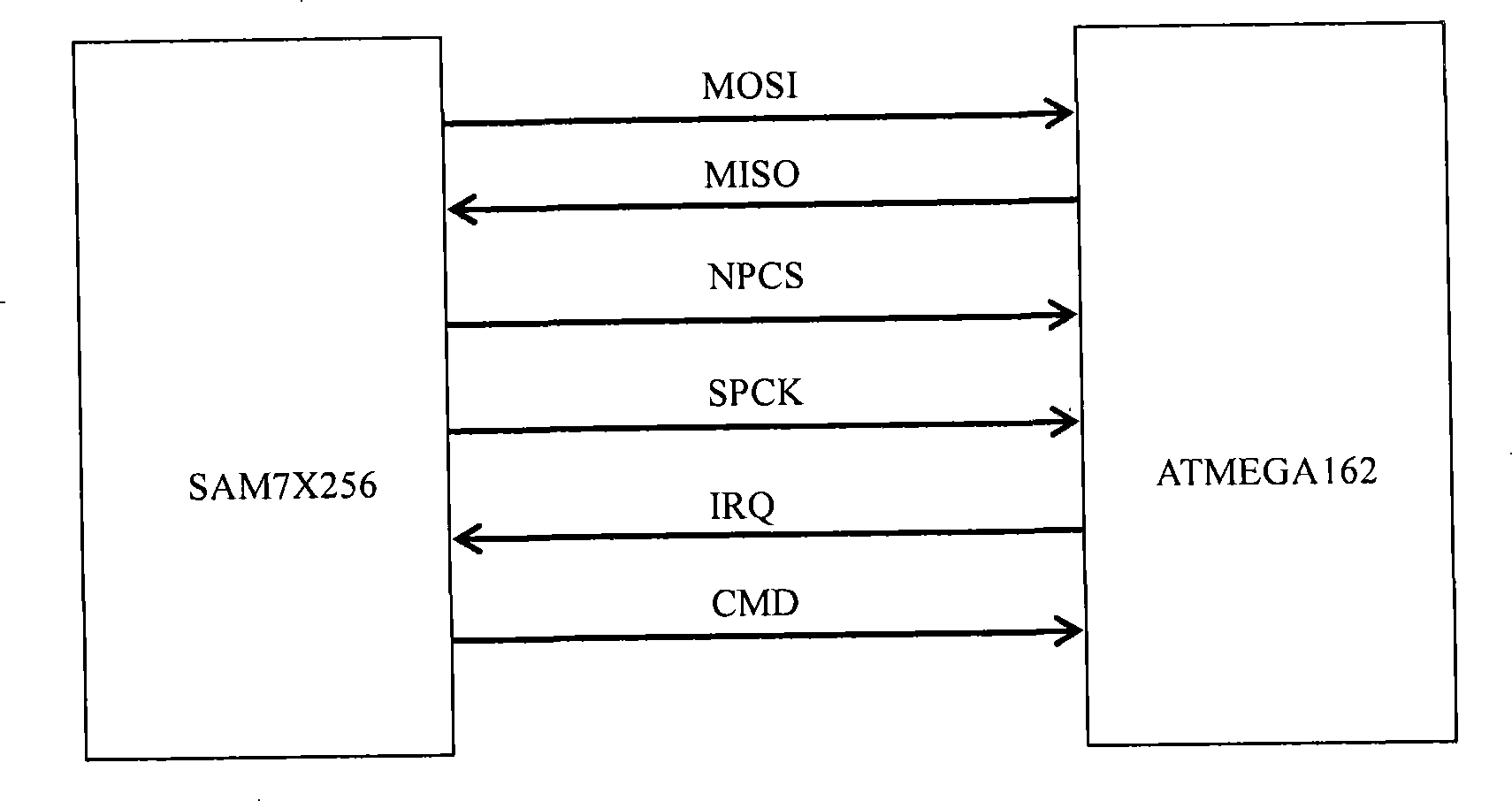

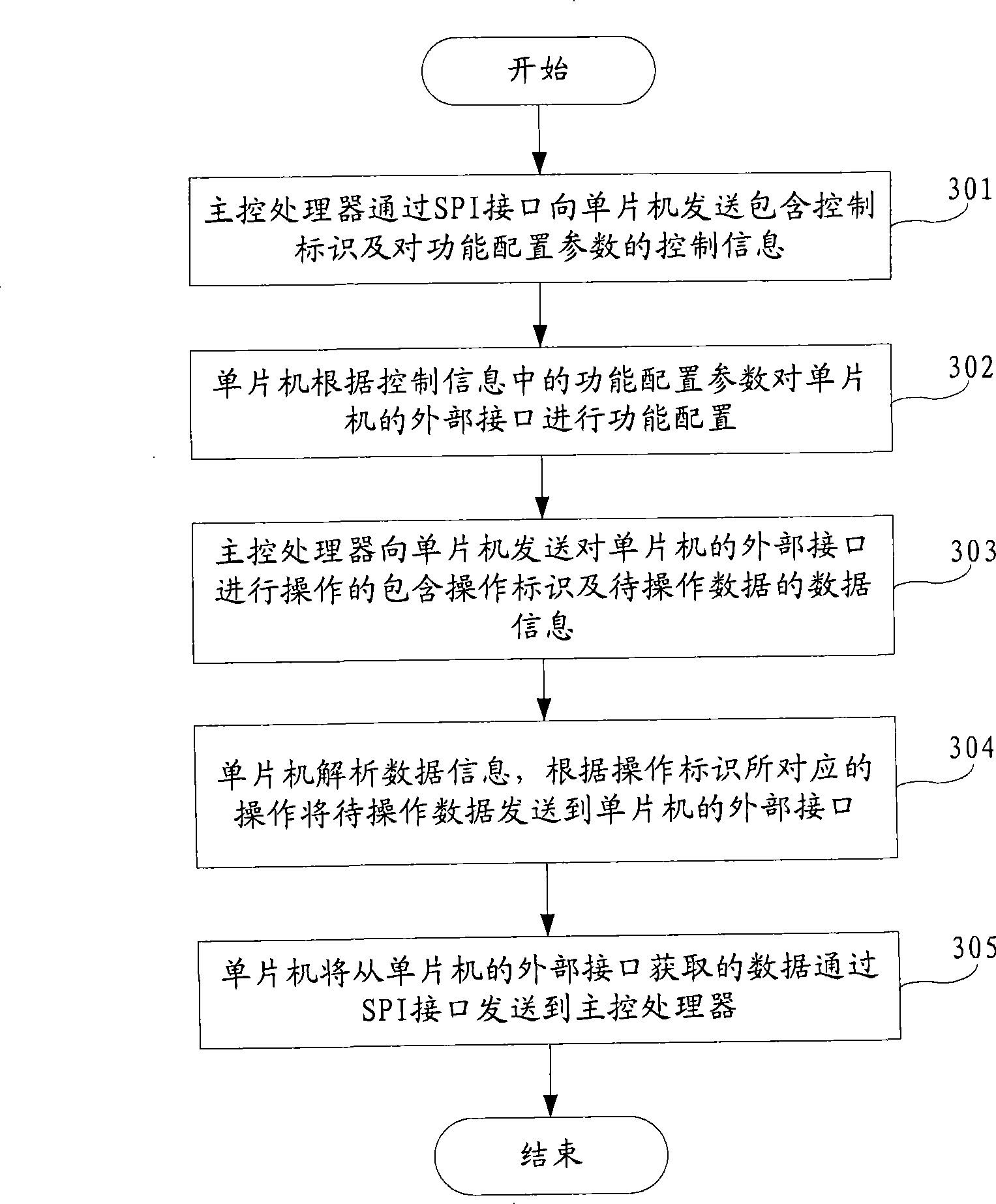

Periphery communication interface extension device and method

InactiveCN101246462AReduce expansion costsReduce the number of components usedElectric digital data processingCommunication interfaceCost savings

Provided is an expansion apparatus and method of external communication interface. The apparatus includes a master control processor and a single chip microcomputer connected to SPI external interface of the master control processor with which the single chip microcomputer communicates via the SPI external interface by SPI communication mode. The invention proves an effective cost-saving expansion, a decrease in the number of used devices and an improvement in system design flexibility.

Owner:ZTE CORP

Apparatus and Method for Measuring Water Quality in a Water Distribution System

InactiveUS20100105146A1Reduce high costVolume/mass flow by electric/magnetic effectsTesting waterDistribution systemWater quality

A system for monitoring water quality in a water distribution system having a plurality of metering end points (E) for measuring consumption includes a plurality of chemical biological and environmental sensors (S1, S2) disposed in a distribution system near or within the distribution end points (A, B), with the sensors (S1, S2) generating electrical signals through a network (G) that can be processed and communicated to a collection station (D) from the metering end points (E).

Owner:BADGER METER

Underground mining, selecting and filling synergic mining method for close distance coal seam group

InactiveCN109162714ARelieve lifting pressureReduce high costUnderground miningTunnel/mines ventillationDynamic pressureCoal

The invention relates to an underground mining, selecting and filling synergic mining method for a close distance coal seam group and belongs to the field of mineral engineering. The method comprisesthe following steps: carrying out full-mechanized caving mining on the close distance coal seam group and designing an underground gangue sorting system and a filling working face according to a gangue output quantity in the production process; conveying the gangues produced in the mining process to an underground gangue sorting chamber, and conveying the sorted chambers to the filling working face for filling mining; and after underground washing of the gangues generated by the filling working face, conveying the gangues to the filling working face for backfilling. The method achieves zero emission of the gangues under an integrated mining condition of the gangues of the close distance coal seam group, eliminates adverse influence of ground gangues to the environment, increases the fine coal promoting rate, and liberates the primary lifting pressure. Meanwhile, the gangues are sorted nearby and fill in selected positions, so that damage and disturbance to underground rock bodies by aconventional mining method are alleviated greatly, and the strong dynamic pressure governing problem is pre-solved.

Owner:CHINA UNIV OF MINING & TECH

Method for utilizing 3D printing technology to manufacture intravascular inner wall stent and product thereof

InactiveCN106214296AShorten production timeIncrease flexibilityStentsAdditive manufacturing apparatusHuman bodyMedicine

The invention discloses a method for utilizing a 3D printing technology to manufacture an intravascular inner wall stent and a product thereof. The method comprises the steps that a human body scanning device is utilized to scan the human body blood vessel part of the intravascular inner wall stent to be manufactured so as to preliminarily obtain a 3D model figure of the part needing the stent; computer drawing software is utilized to draw the rudiment of the intravascular inner wall stent needed to be erected in the obtained 3D model figure, then the stent rudiment is isolated and taken from the model figure, then finishing processing is performed, and finally the stent rudiment is converted into a file format which can identified by a 3D printer to be output; 3D printer software is utilized to read and identify a file as a main body of a model; then, the software is utilized to perform model stenting body establishment so as to obtain a model section file to be printed; a main body material and a supporting body material are loaded into two consumable chambers of the 3D printer, printing parameters are arranged for printing, then the established supporting body is removed to obtain the intravascular inner wall stent. The stent is low in cost and is more suitable for an individual.

Owner:SOUTH CHINA AGRI UNIV

Spectral catalysts

InactiveUS6033531AEfficient processingIncrease ratingsCatalyst activation/preparationHydrocarbonsSpectral patternMolecular physics

A wide variety of reactions can be advantageously affected and directed by a spectral catalyst which duplicates the electromagnetic energy spectral pattern of a physical catalyst and when applied to a reaction system transfers a quanta of energy in the form of electromagnetic energy to control and / or promote the reaction system. The spectral catalysts utilized in this invention can replace and / or augment the energy normally provided to the reaction system by a physical catalyst. A spectral catalyst may also act as both a positive catalyst to increase the rate of a reaction or as a negative catalyst to decrease the rate of reaction.

Owner:GR INTELLECTUAL RESERVE LLC

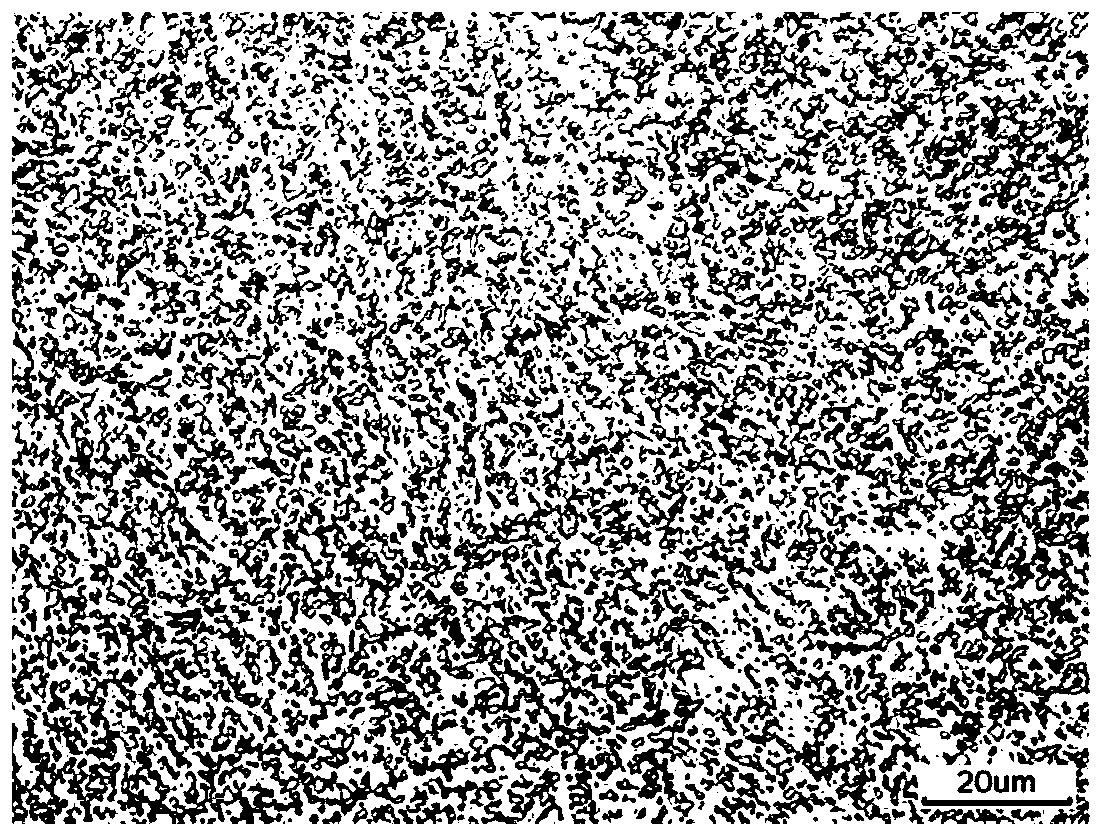

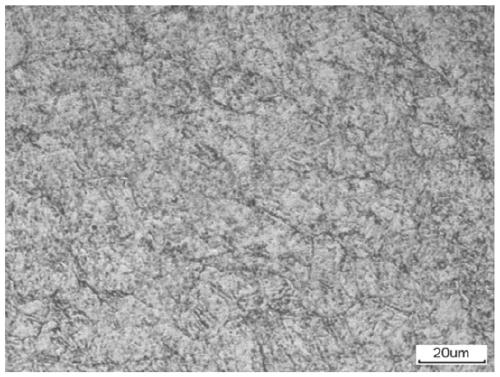

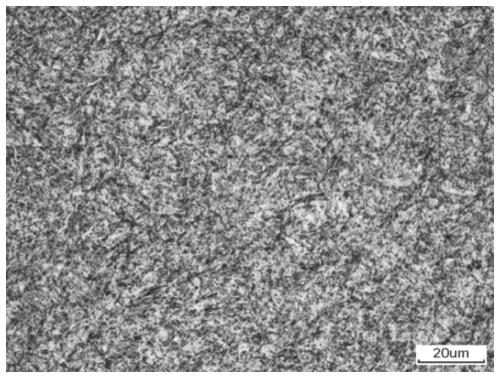

High-heat-strength hot-work die steel and manufacturing method thereof

InactiveCN109852880AImprove and stabilize processing performanceEasy to processElectro-slag remeltingImpurity

The invention relates to a high-heat-strength hot-work die steel. The high-heat-strength hot-work die steel comprises the following alloy elements of, in percentage by mass, 0.40-0.45% of C, 0.10-0.30% of Si, 0.30-0.50% of Mn, 4.50-5.00% of Cr, 2.10-2.50% of Mo, 0.60-0.90% of V, 0.80-1.50% of Co, less than or equal to 0.015% of P, less than or equal to 0.002% of S, and the balance Fe and inevitable impurities. The invention also provides a preparation and heat treatment method of a cobalt alloying hot-work die steel, the method comprises the following steps of burdening, smelting, casting andelectroslag remelting; high-temperature diffusion annealing and multi-direction forging hot working are carried out; preparation heat treatment is carried out; and final heat treatment is carried out.According to the steel prepared by the preparation method, the defect that 4Cr5MoSiV1 steel carbide is prone to coarsening and growing under the high-temperature condition is overcome, the solid solution strengthening effect of the cobalt element is utilized and the proportion of the components is reasonably adjusted, a proper preparation method is combined, so that the high-temperature strength,the tempering-resistant softening performance, the heat-resistant fatigue resistance and the heat-melt-loss resistance of the material are greatly improved, and the requirement for the high-temperature comprehensive performance of the material for the manufacturing of the current hot-work die is met.

Owner:SHANGHAI UNIV

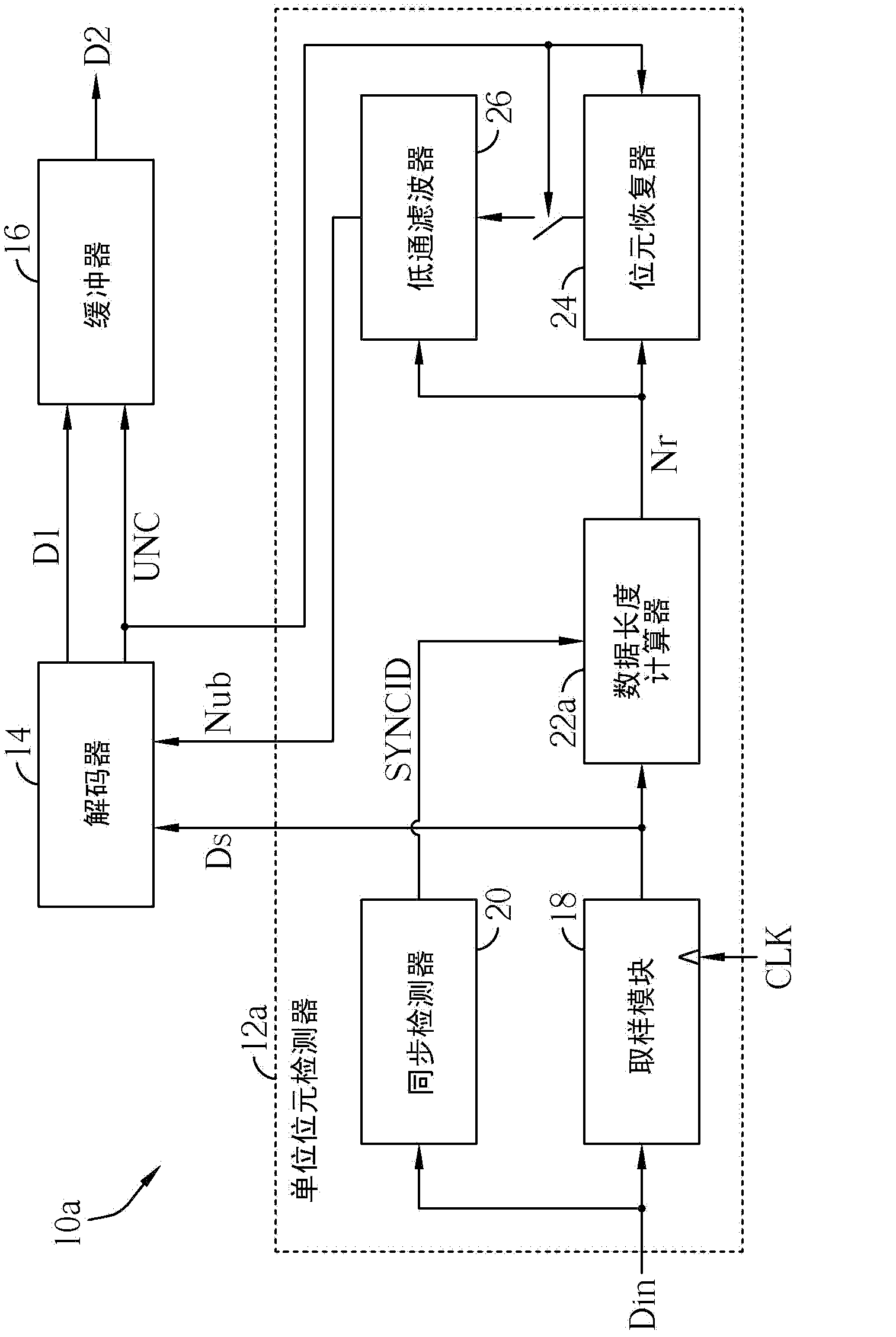

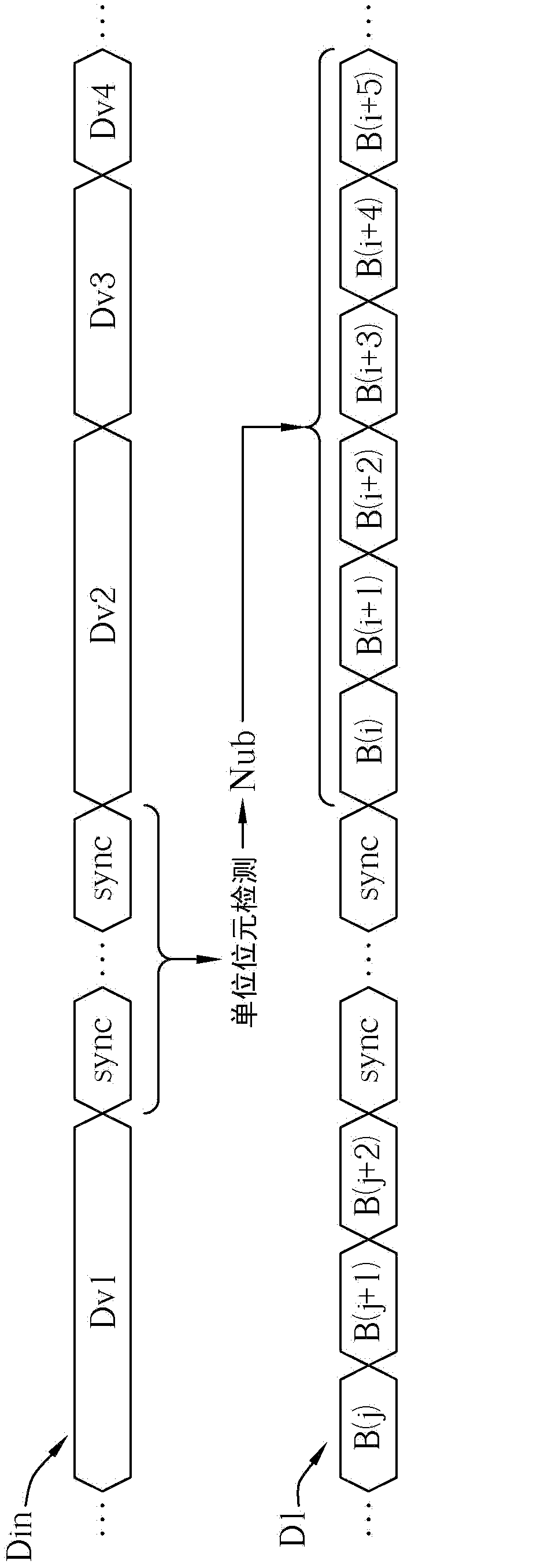

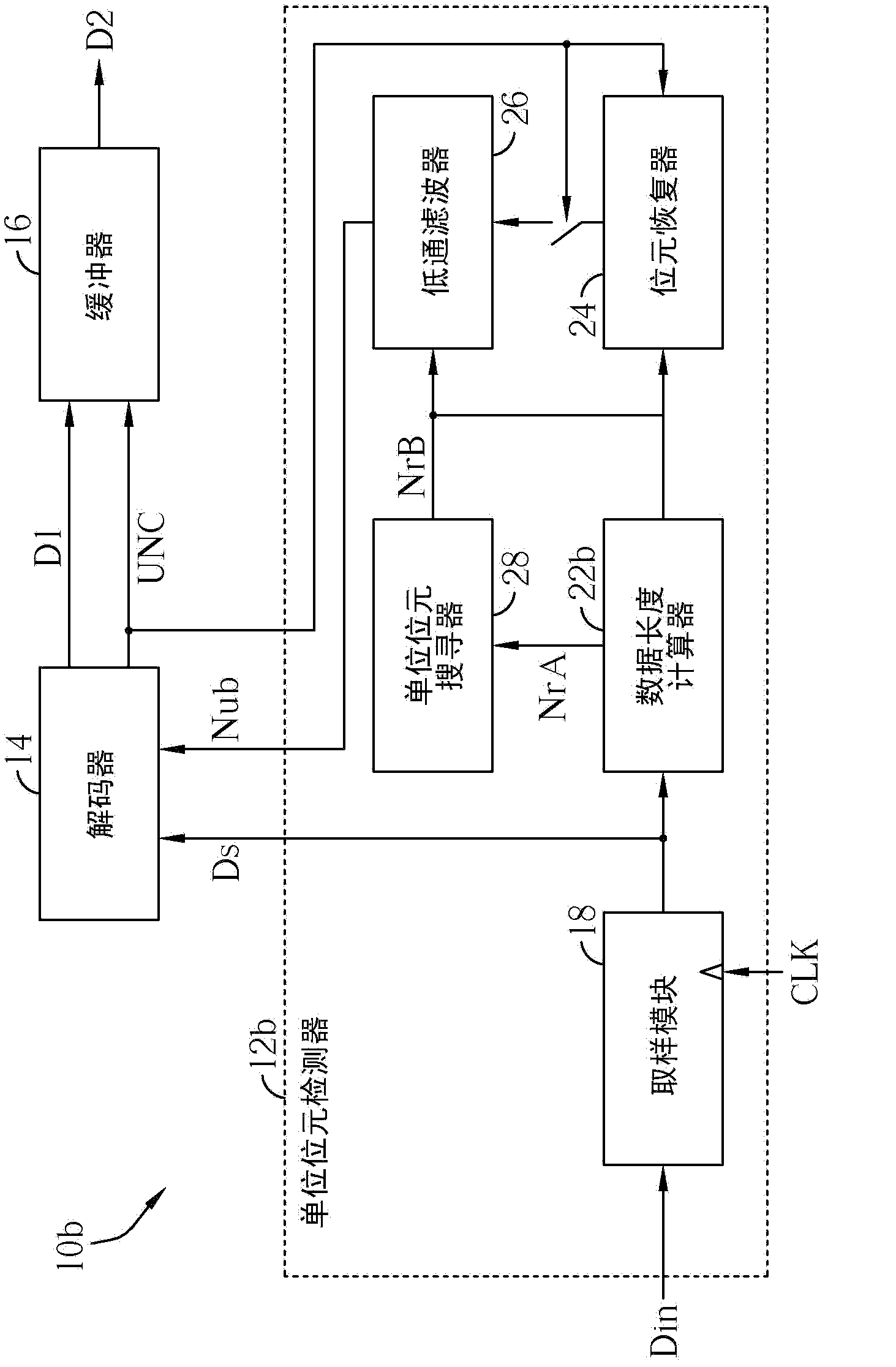

Data extracting method and data extracting device

ActiveCN102931969AImprove fault toleranceReduce high costLogic circuit coupling/interface arrangementsComputer scienceSample number

The invention discloses a data extracting method and a data extracting device. The data extracting method comprises the steps of: sampling a signal so as to obtain a plurality of sampling values; providing a reference sampling number value when states of the sampling values are changed, and providing a unit bit sampling number value according to the reference sampling number value; and corresponding each sampling value to each bit datum in the signal according to the unit bit sampling number value. According to the data extracting method and the data extracting device, the high cost of external oscillators, such as crystal oscillators, and external connecting pins can be saved.

Owner:FARADAY TECH CORP

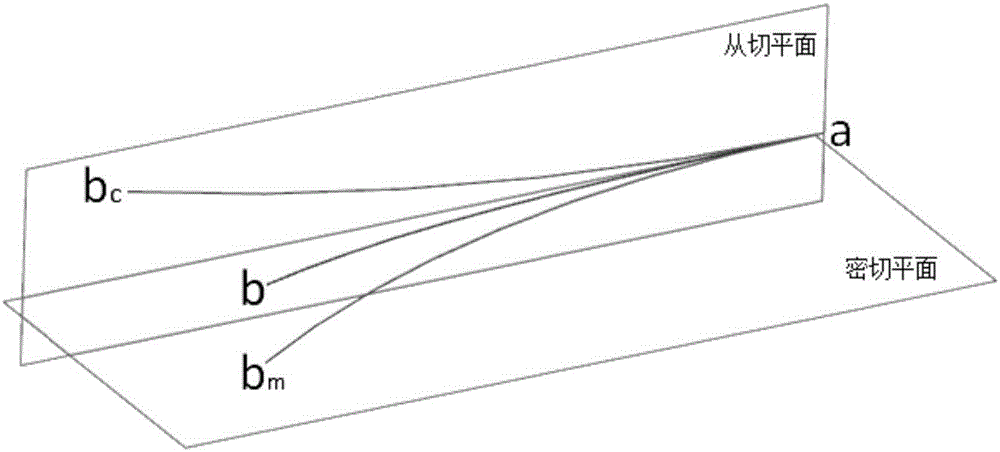

Shape acquisition method of high-strength steel pipe after three-dimensional bending forming resilience

InactiveCN106599452AReduce high costsIncrease productivityGeometric CADSpecial data processing applicationsCurved TubePlanar curve

The invention discloses a shape acquisition method of a high-strength steel pipe after three-dimensional bending forming resilience. The shape acquisition method comprises the following steps of 1, acquiring radius values of all two-dimensional planar curves after performing arc fitting and approximation and performing division and projection on a central axis of a die to form the two-dimensional planar curves; 2, acquiring a central axis of a shape after three-dimensional bending resilience when the pipe is independently under each segment of die; 3, splicing the central axis of the shape after three-dimensional bending resilience when the pipe is independently under each segment of die to obtain a spliced curve Q; and 4, correcting the spliced curve Q to acquire the shape of the pipe after three-dimensional bending forming. By the method, the shape of the pipe after three-dimensional bending forming can be acquired on the condition of no test, the method is used for guiding die design, high cost brought by experiments is reduced, and the production efficiency is improved.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com