Preparation method and application of quinonoid compound modified nylon membrane biological carrier

A biological carrier and nylon membrane technology, which is applied in chemical engineering, material engineering, and environmental engineering, can solve the problems of microbial system toxicity, secondary pollution, poor mechanical strength, etc., achieve good biocompatibility, and reduce secondary pollution , the effect of increasing the content of quinone groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Put 20 nylon membranes with a radius of 1 cm into a 3 mol / L hydrochloric acid solution for hydrolysis. After hydrolyzing at 35°C for 12 hours, they were washed with distilled water and dried for later use. Place a 250ml four-necked flask on a magnetic stirrer, add 5 pieces of hydrolyzed nylon membrane, 50ml of 2mol / L NaOH solution to the flask in turn; dissolve 0.1g of anthraquinone-2-sulfonyl chloride into 30ml of dimethyl The sulfoxide was added dropwise to the flask with a constant pressure dropping funnel at 30°C, and the reaction was continued for 6 hours under stirring to obtain a nylon membrane grafted with quinone groups, in which the content of quinone groups was 0.4 mmol / g. Take out the nylon membrane grafted with quinone groups, wash with dimethyl sulfoxide, wash off the attached surface of anthraquinone-2-sulfonyl chloride, then wash with distilled water, and dry to obtain a fixed nylon membrane modified by quinone compounds Nylon membrane with quinone compou...

Embodiment 2

[0029] Put 20 nylon membranes with a radius of 1 cm into a 2mol / L hydrochloric acid solution for hydrolysis. After hydrolyzing at 40°C for 10 hours, they were washed with distilled water and dried for later use. Place a 250ml four-necked flask on a magnetic stirrer, add 5 pieces of hydrolyzed nylon membrane, 50ml of 1mol / L NaOH solution to the flask in turn; dissolve 0.1g of anthraquinone-2-sulfonyl chloride into 30ml of dimethyl The base sulfoxide was added dropwise to the flask with a constant pressure dropping funnel at 35°C, and the reaction was continued for 5 hours under stirring to obtain a nylon membrane grafted with quinone groups, in which the content of quinones was 0.3 mmol / g. The nylon membrane grafted with the quinone group is taken out, washed with dimethyl sulfoxide to remove the anthraquinone-2-sulfonyl chloride on the attached surface, washed with distilled water, and dried to obtain a nylon membrane modified with quinone compounds.

Embodiment 3

[0031] Put 20 nylon membranes with a radius of 1 cm into a 4mol / L hydrochloric acid solution for hydrolysis. After hydrolyzing at 30°C for 15 hours, they were washed with distilled water and dried for later use. Place a 250ml four-necked flask on a magnetic stirrer, add 5 pieces of hydrolyzed nylon membrane and 50ml of 3mol / L NaOH solution to the flask in turn; dissolve 0.1g of anthraquinone-2-sulfonyl chloride into 30ml of dimethyl The sulfoxide was added dropwise to the flask with a constant pressure dropping funnel at 30°C, and the reaction was continued for 4 hours under stirring to obtain a nylon membrane grafted with quinone groups, in which the quinone content was 0.2 mmol / g. The nylon membrane grafted with quinone groups is taken out, washed with dimethyl sulfoxide to remove the attached anthraquinone-2-sulfonyl chloride on the surface, washed with distilled water, and dried to obtain a nylon membrane modified with quinone compounds.

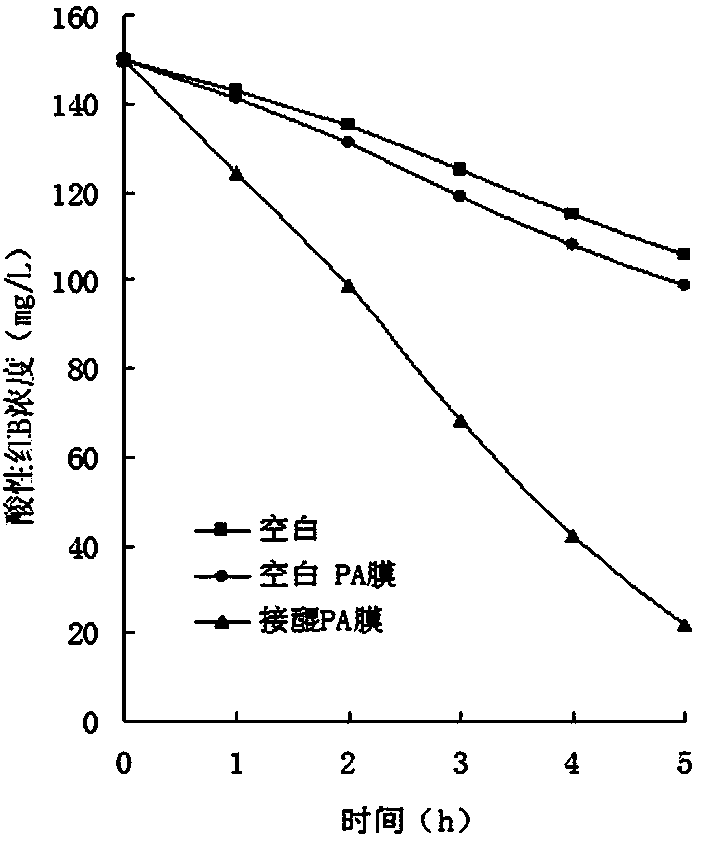

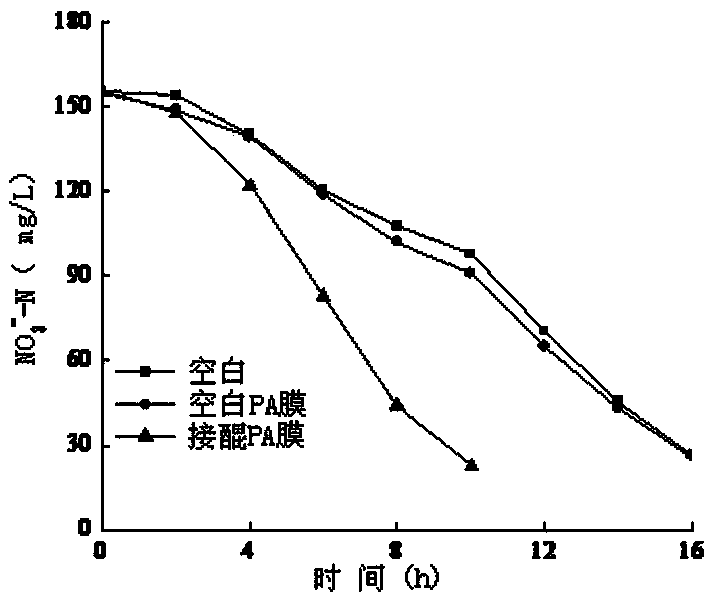

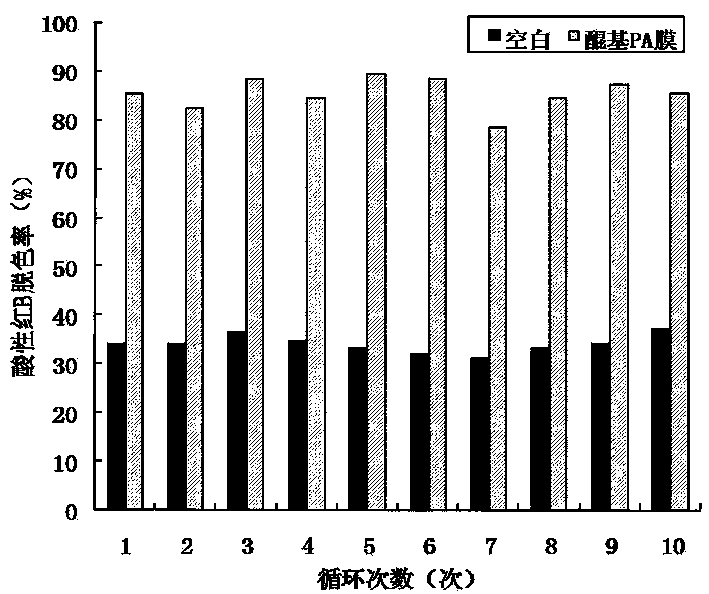

[0032] The nylon membrane biological...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com