Patents

Literature

448results about How to "Does not affect productivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dedusting system of whole factory building

ActiveCN101619881ACause secondary pollutionDoes not affect productivityLighting and heating apparatusAir conditioning systemsAir treatmentWelding fume

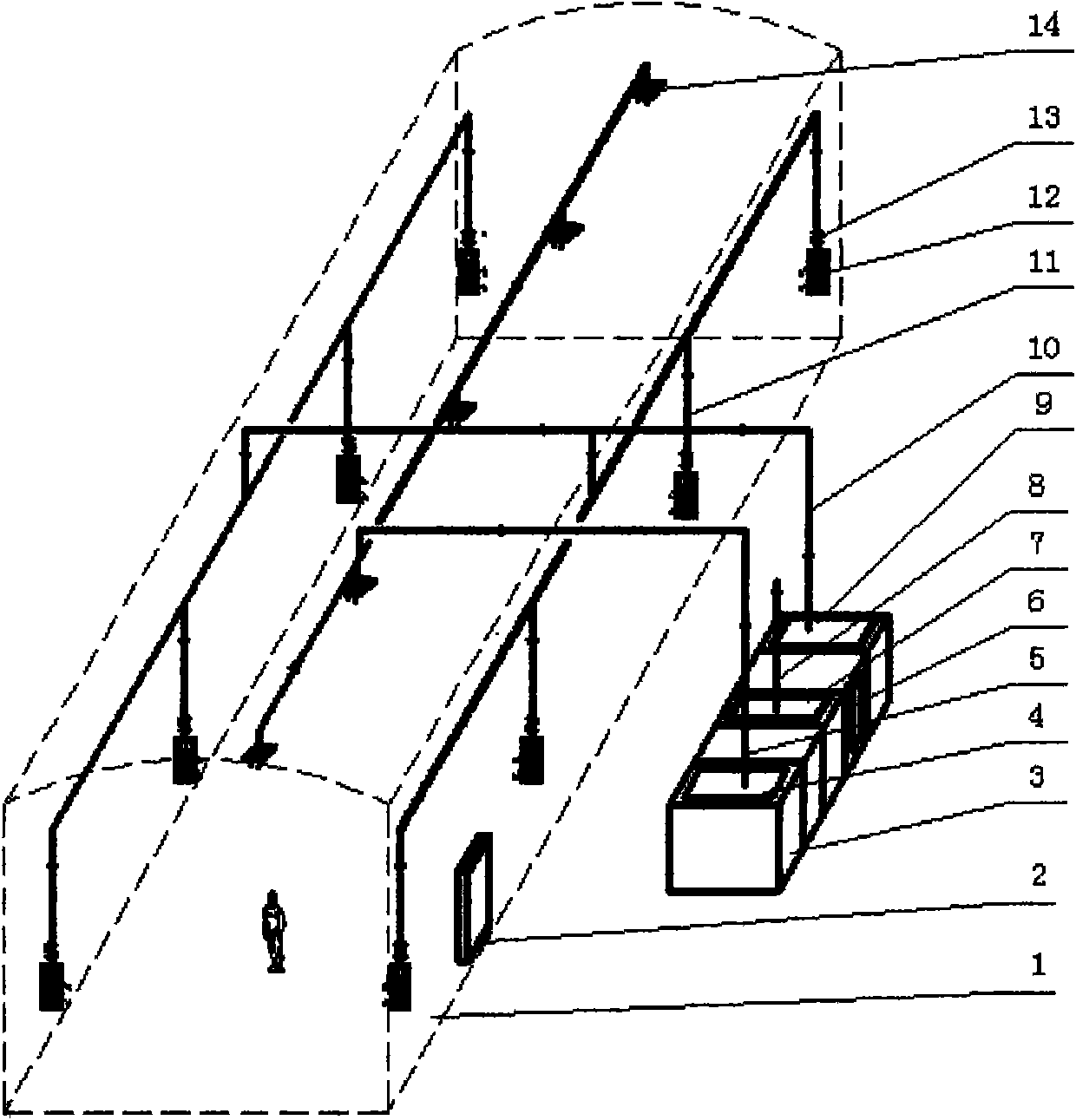

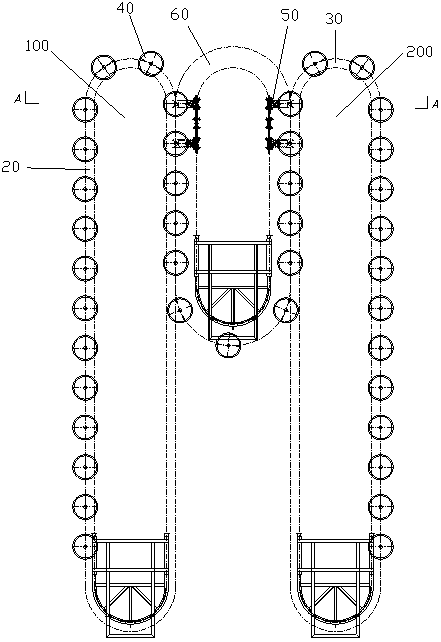

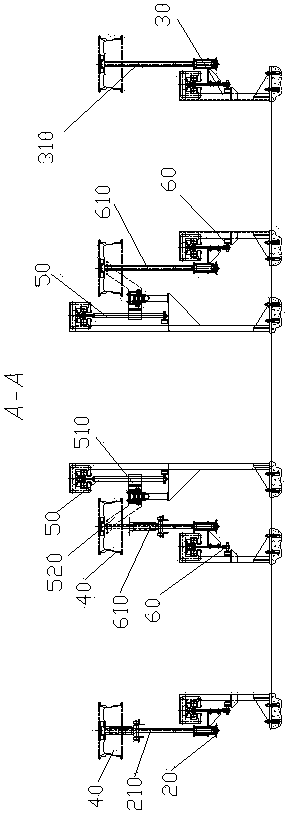

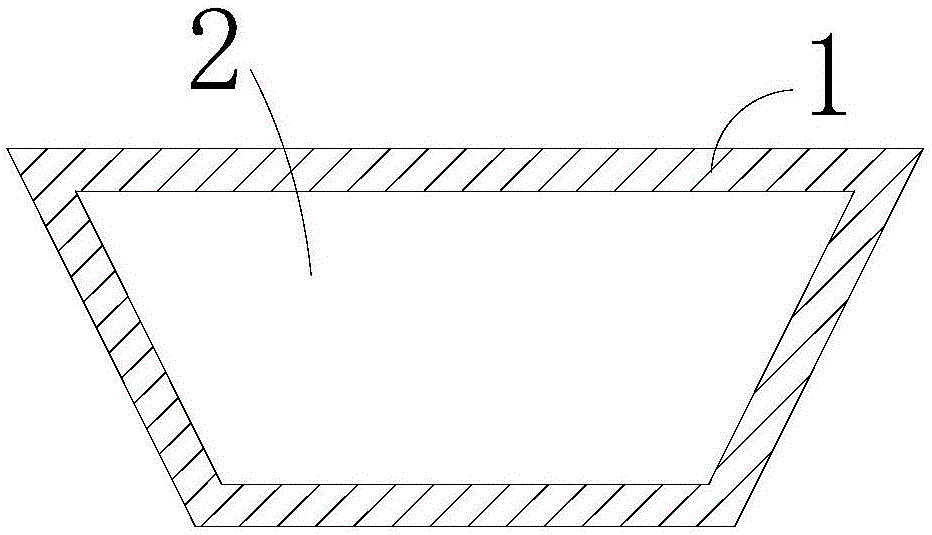

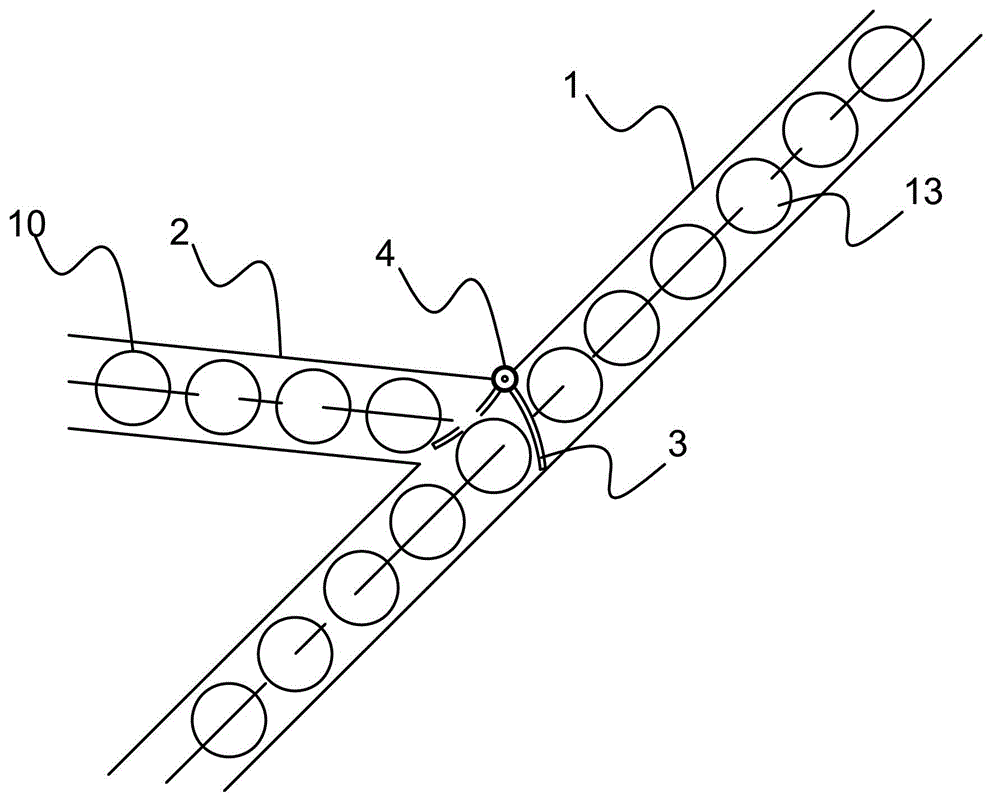

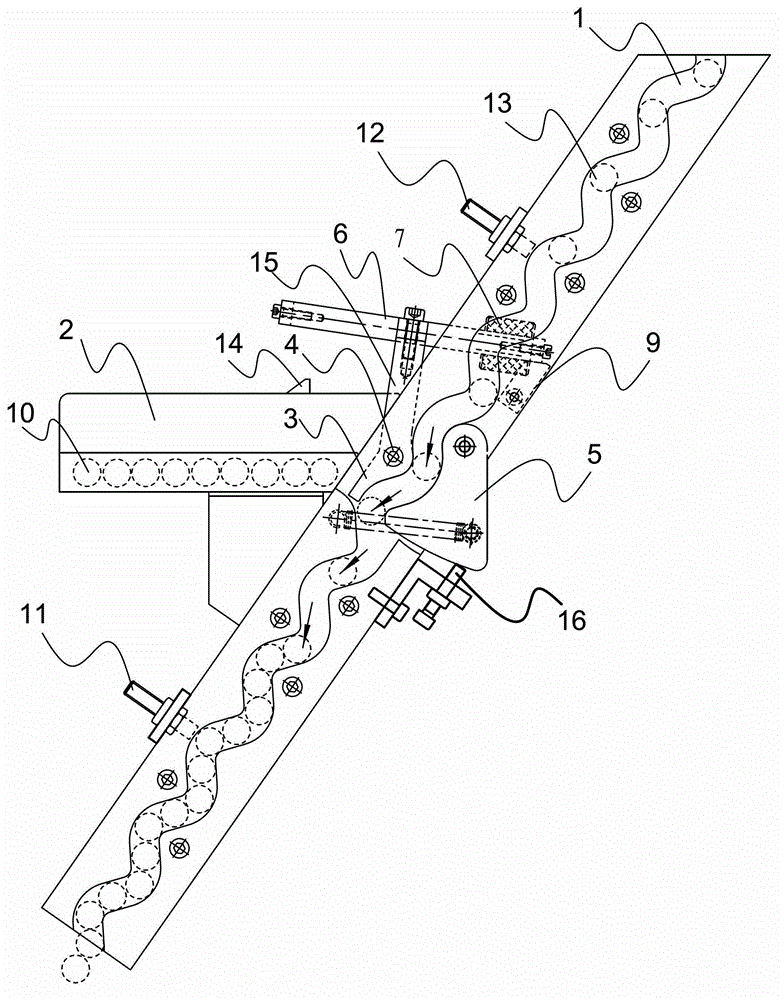

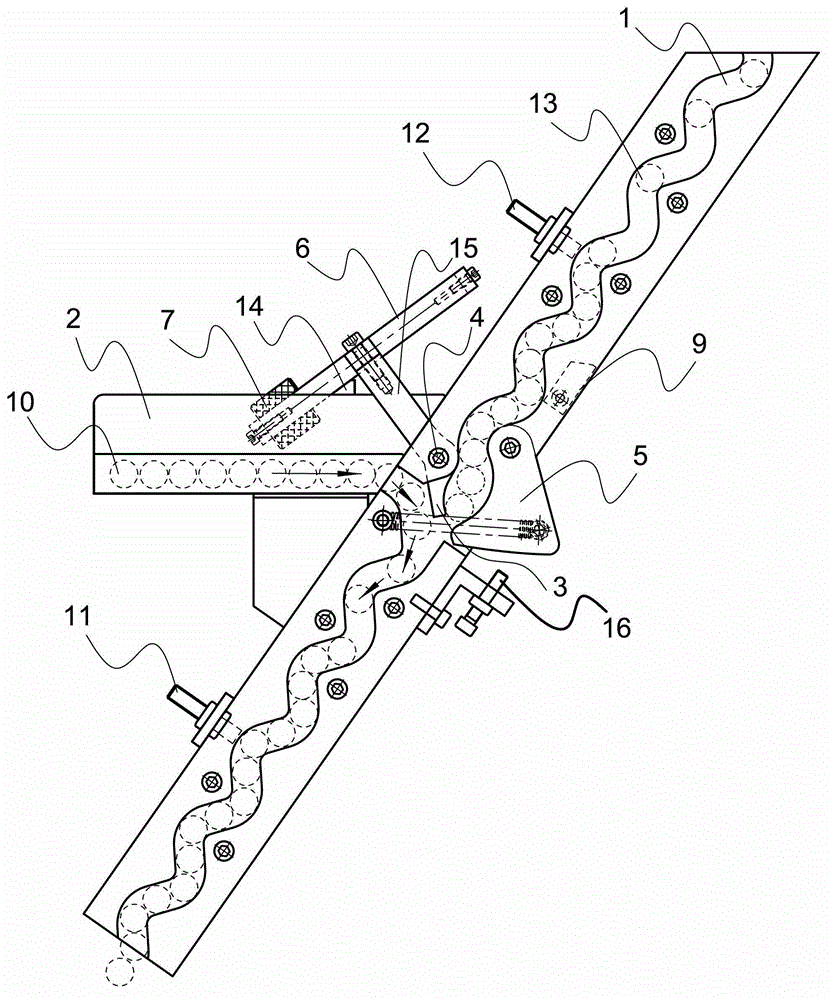

The invention discloses a dedusting system of a whole factory building, which comprises an air funnel, an air handling unit, a top air-return opening, an air supply pipeline and an air-return pipeline, wherein the air handling unit is arranged outside a workshop, the air funnel is arranged at the lower part of the inner side of the workshop, one end of the air supply pipeline is connected with the air funnel, and the other end of the air supply pipeline is connected with the air handling unit through the air supply pipeline; the top air-return opening is arranged at the top inside the workshop, one end of the air-return pipeline is connected with the top air-return opening and the other end of the air-return pipeline is connected with the air handling unit. The air supply direction of the air funnel is adjusted to change the air distribution of returned air, welding fume with higher temperature drifts upwards under the action of hot buoyancy, the fume further drifts upwards by the push of air sent out from the air funnel and does not move transversely, thereby the welding fume can be avoided from passing through the respiratory zone of the human body; and the fume and harmful gases are sucked into the air handling unit through the air-return pipeline under the suction action of the air-return opening at the top of the workshop and can not be directly removed outdoors, thereby the secondary pollution can not be caused.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD

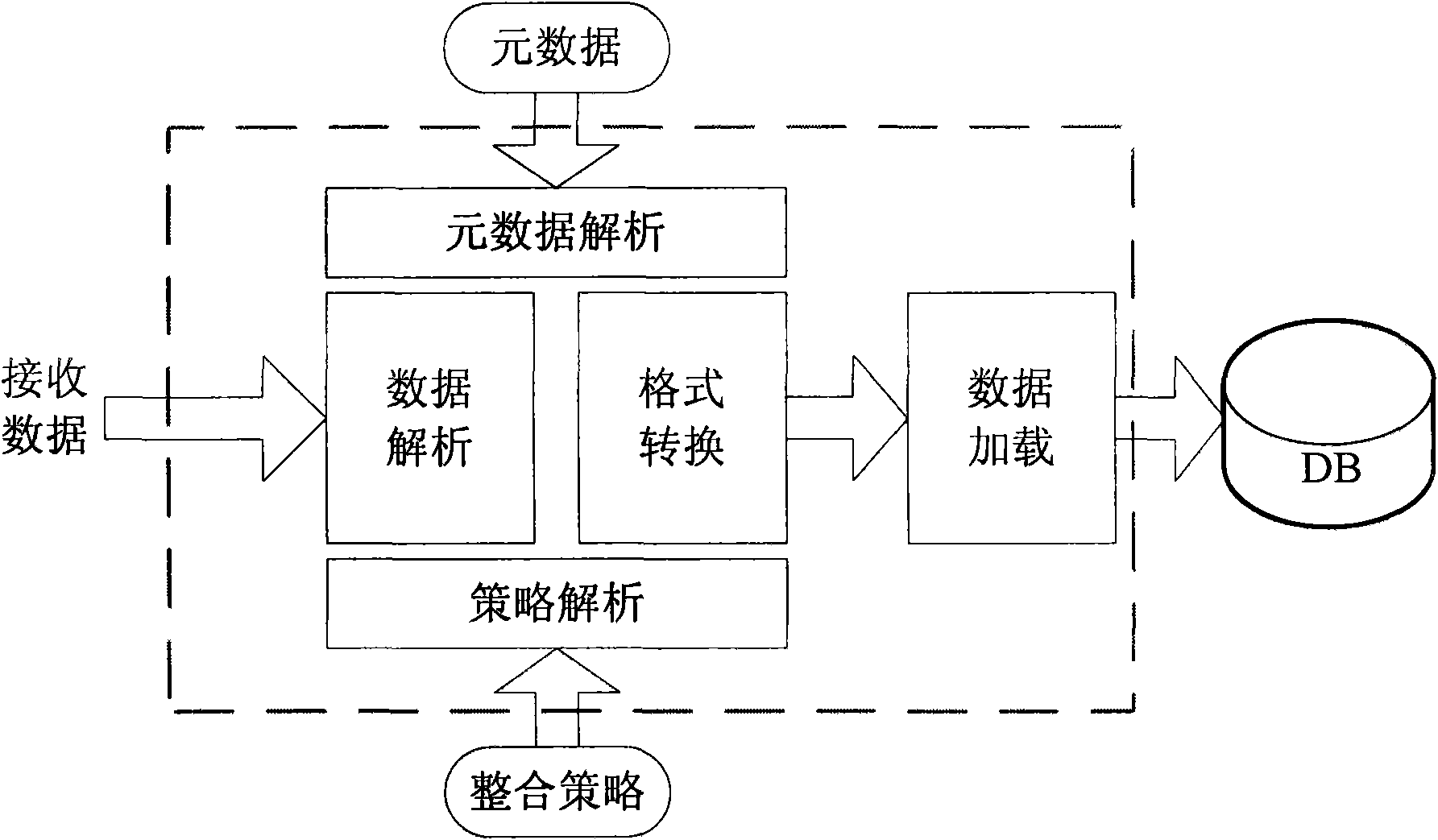

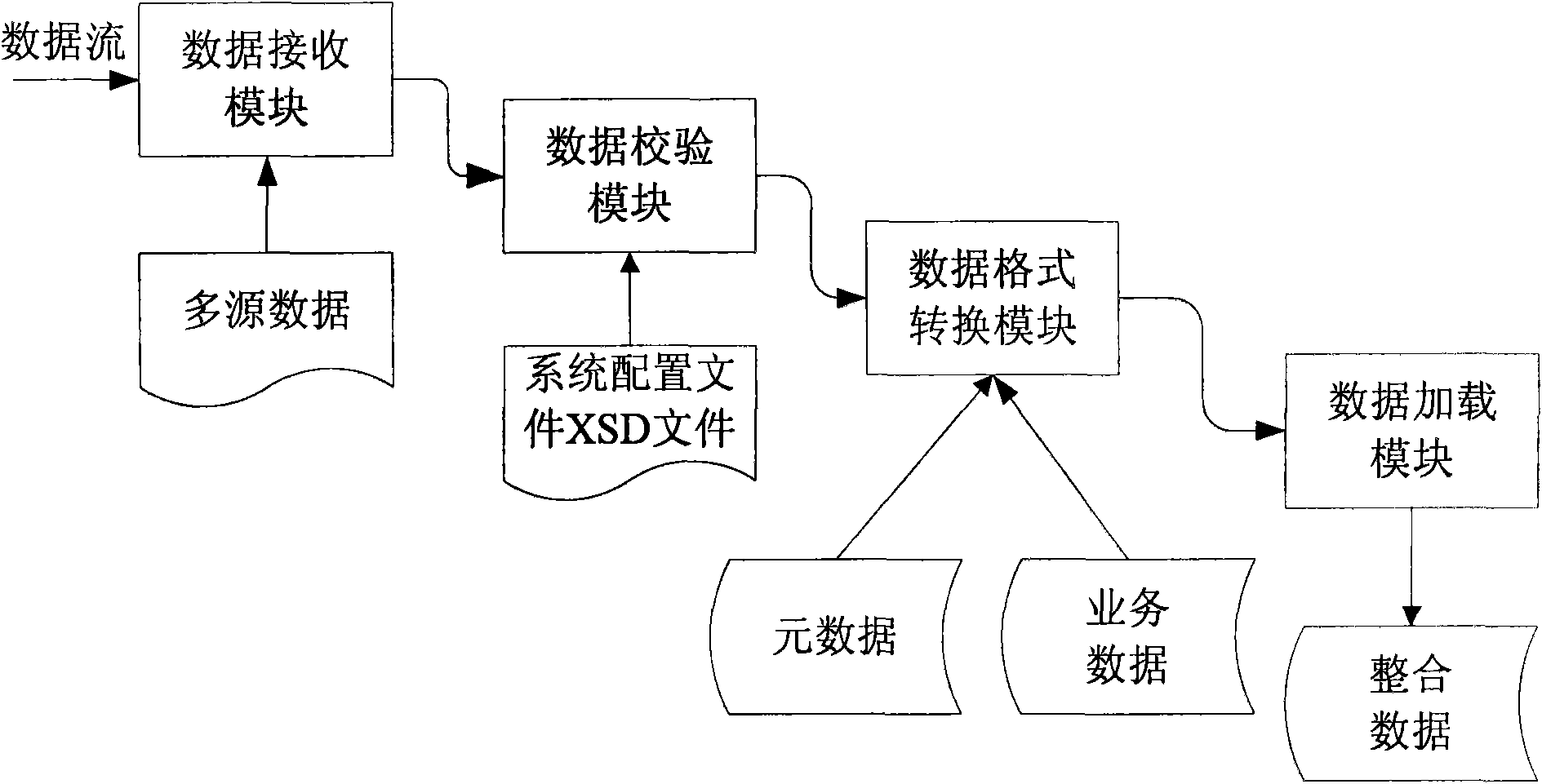

Flight dynamic information data integrator and processing method

InactiveCN101539931AFlexible settingsMeet the businessSpecial data processing applicationsAircraft traffic controlIntegratorData center

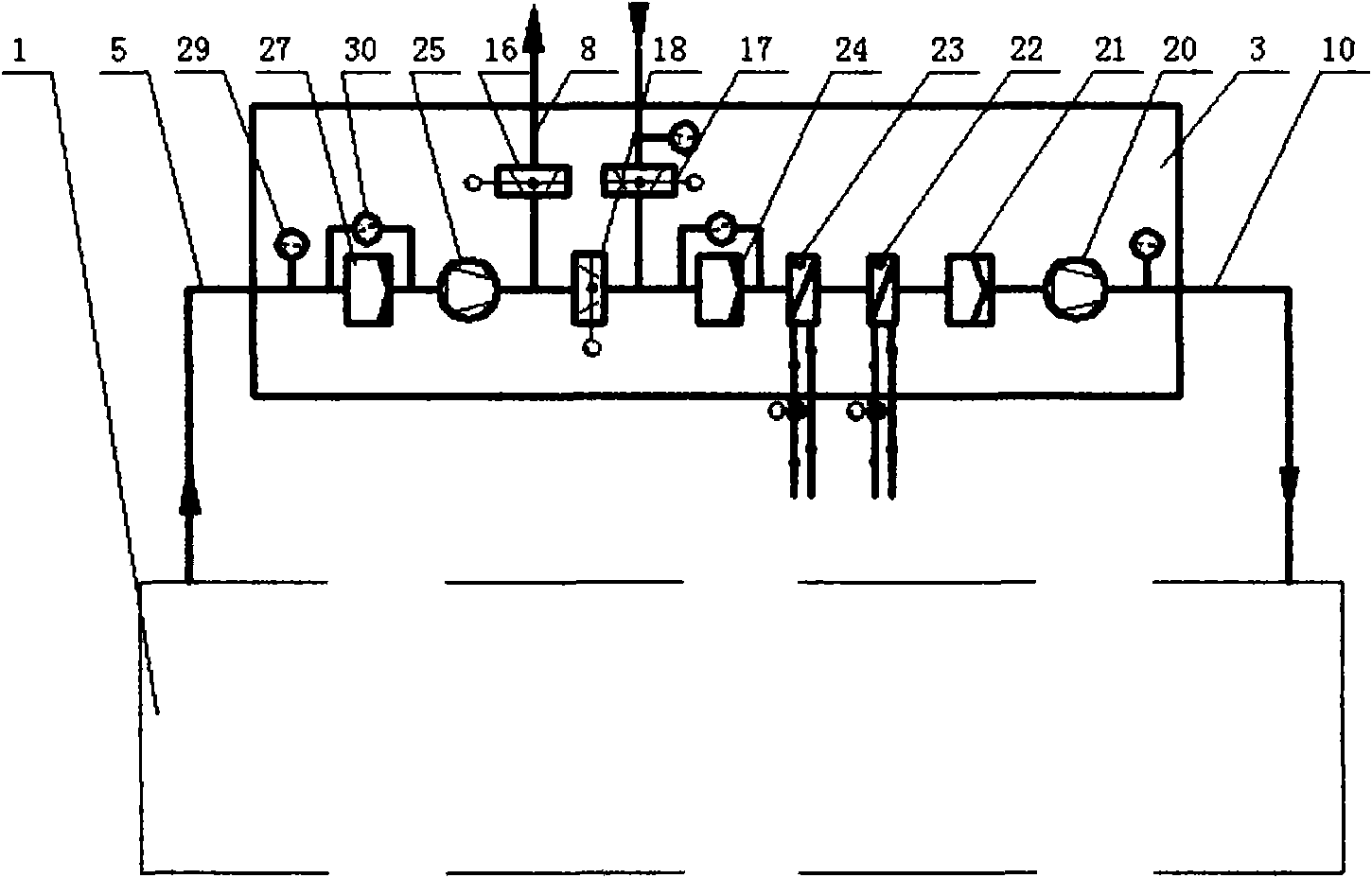

The invention relates to a flight dynamic information data integrator and a processing method, belonging to the field of civil aviation technology. The flight dynamic information data integrator comprises a power-supply system, a microprocessor, an input control display unit, a communication unit, a data receiving unit, a data processing unit and a data storage unit; wherein, the data receiving unit is internally provided with a receiving process program module which can realize real-time physical reception of the transmitted data and executes data decompression, data source feature recognition and classification treatment to realize data interchange and share. The processing method of the integrator comprises dynamic information of production departments such as air traffic control (ATC), airports and airline companies are integrated into a platform database for supplying data service; standard flight information is formed by integrating the received related data of the flights and then stored in a data center; meanwhile, the integrative process is monitored, and the integration results are analyzed. The invention can realize data interchange and share, and provides complete, accurate and timely data service.

Owner:CIVIL AVIATION UNIV OF CHINA

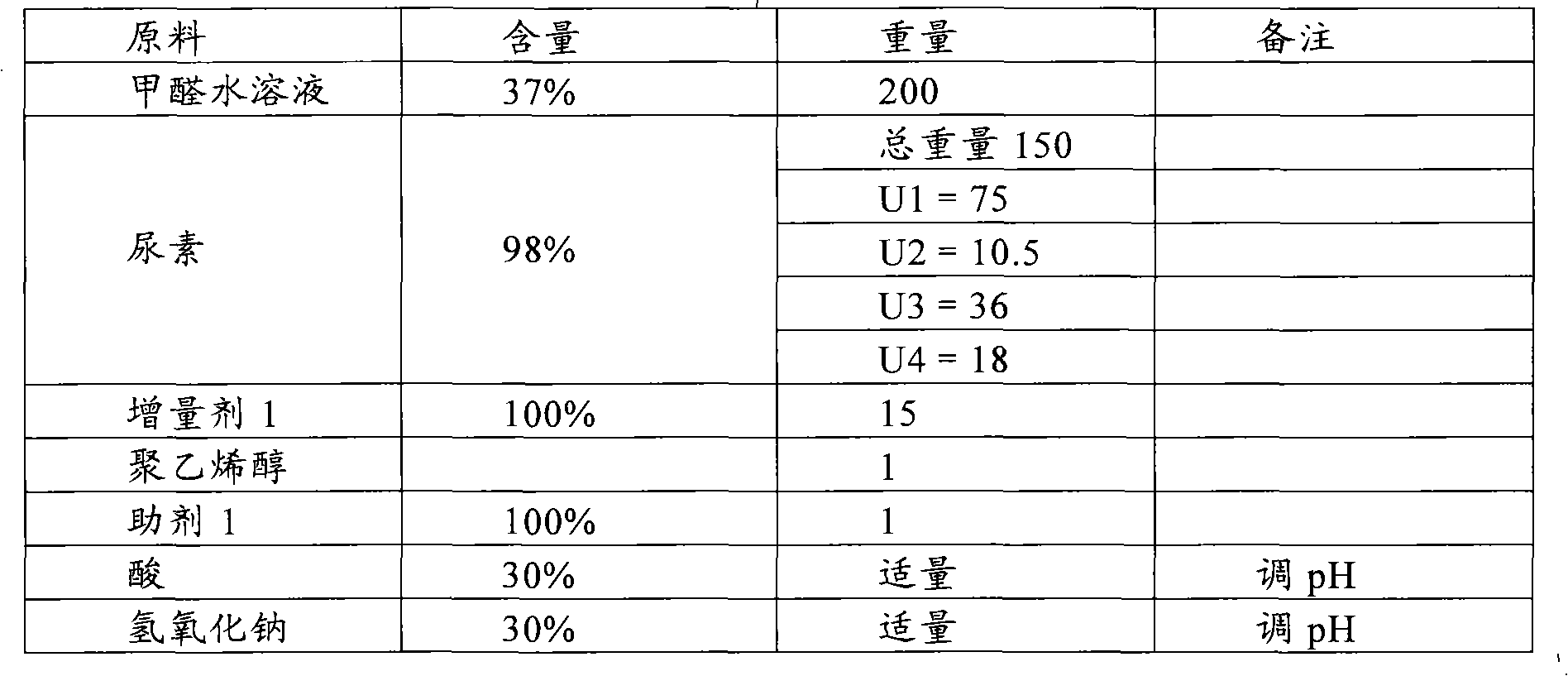

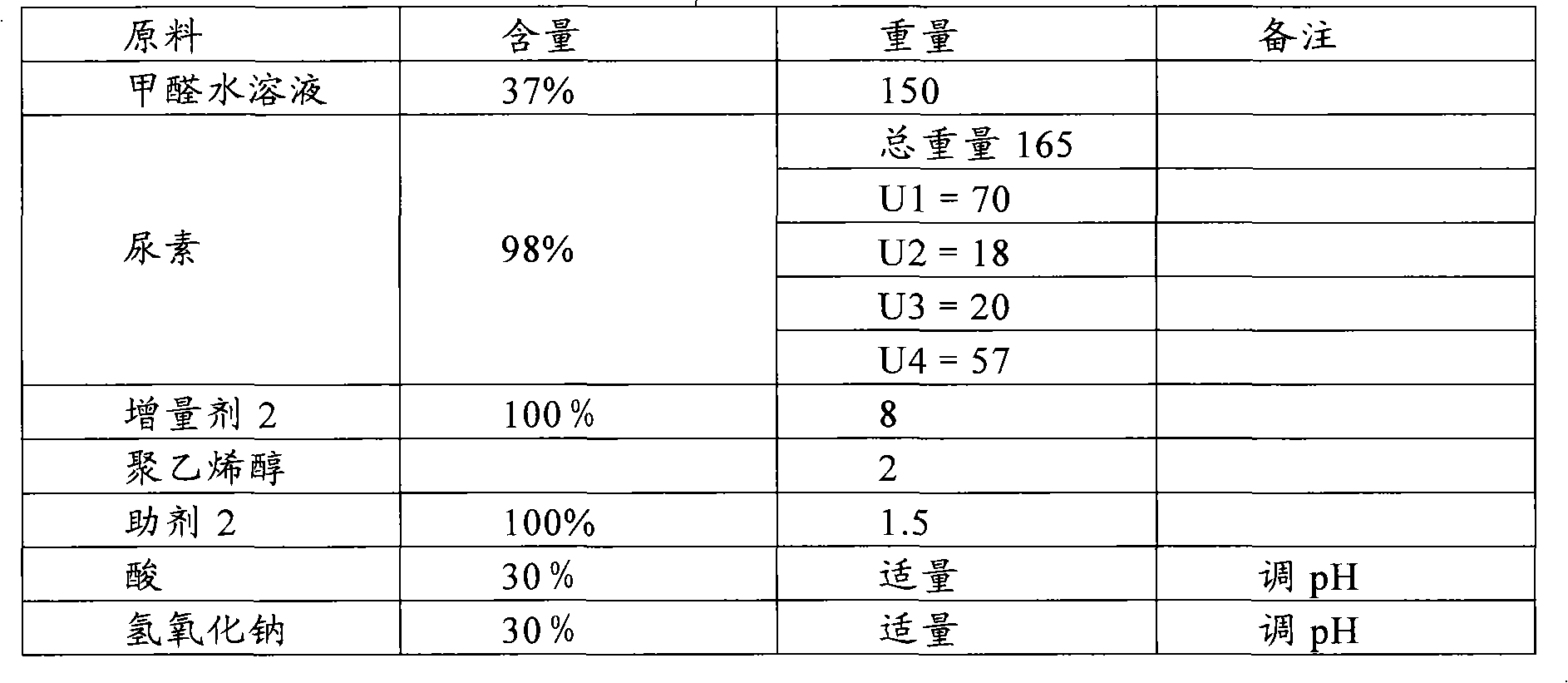

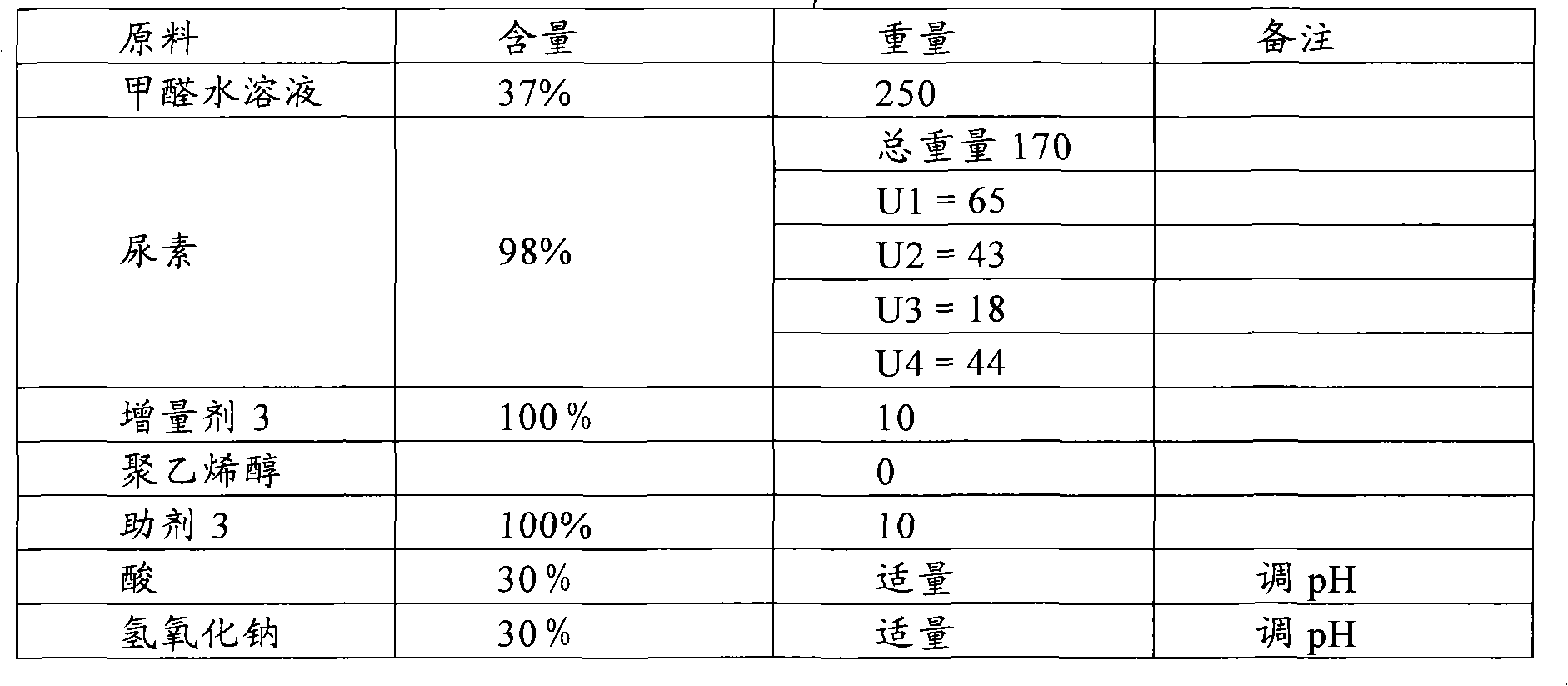

Urea-formaldehyde resin for non-dewatering particleboard and preparation method thereof

ActiveCN102086295AShorten the production cycleLower unit production costAldehyde/ketone condensation polymer adhesivesPolyvinyl alcoholWastewater

The invention relates to urea-formaldehyde resin and a preparation method thereof. The urea-formaldehyde resin comprises the following components in parts by weight: 200 parts of formaldehyde solution, 120-170 parts of urea, 0-2 parts of polyvinyl alcohol, 1-10 parts of additive and 3-20 parts of extender, wherein the concentration of formaldehyde solution is 37%; in the preparation process, ureais added three or four times and the reaction is performed in weakly alkaline medium, weakly acidic medium and neutral medium in turn; and additive and extender are added in the synthesis of urea-formaldehyde resin. The urea-formaldehyde resin can be used in the production of the particleboard without being dewatered, thus the problems of wastewater discharge and environmental pollution can be solved and the production cost of the particleboard can be greatly reduced; and the urea-formaldehyde resin is suitable for various large, medium and small particieboard enterprises.

Owner:江苏露水河人造板有限公司

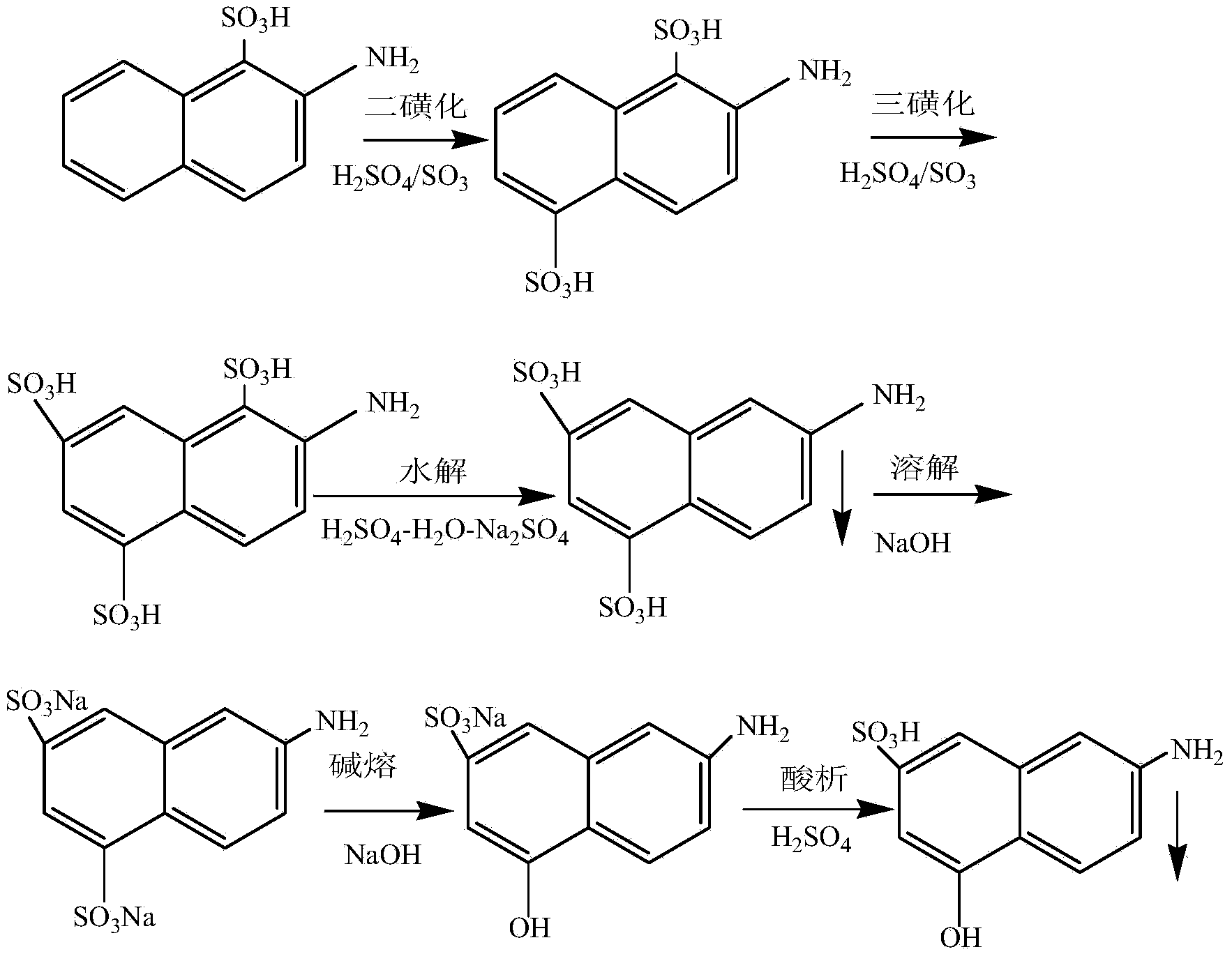

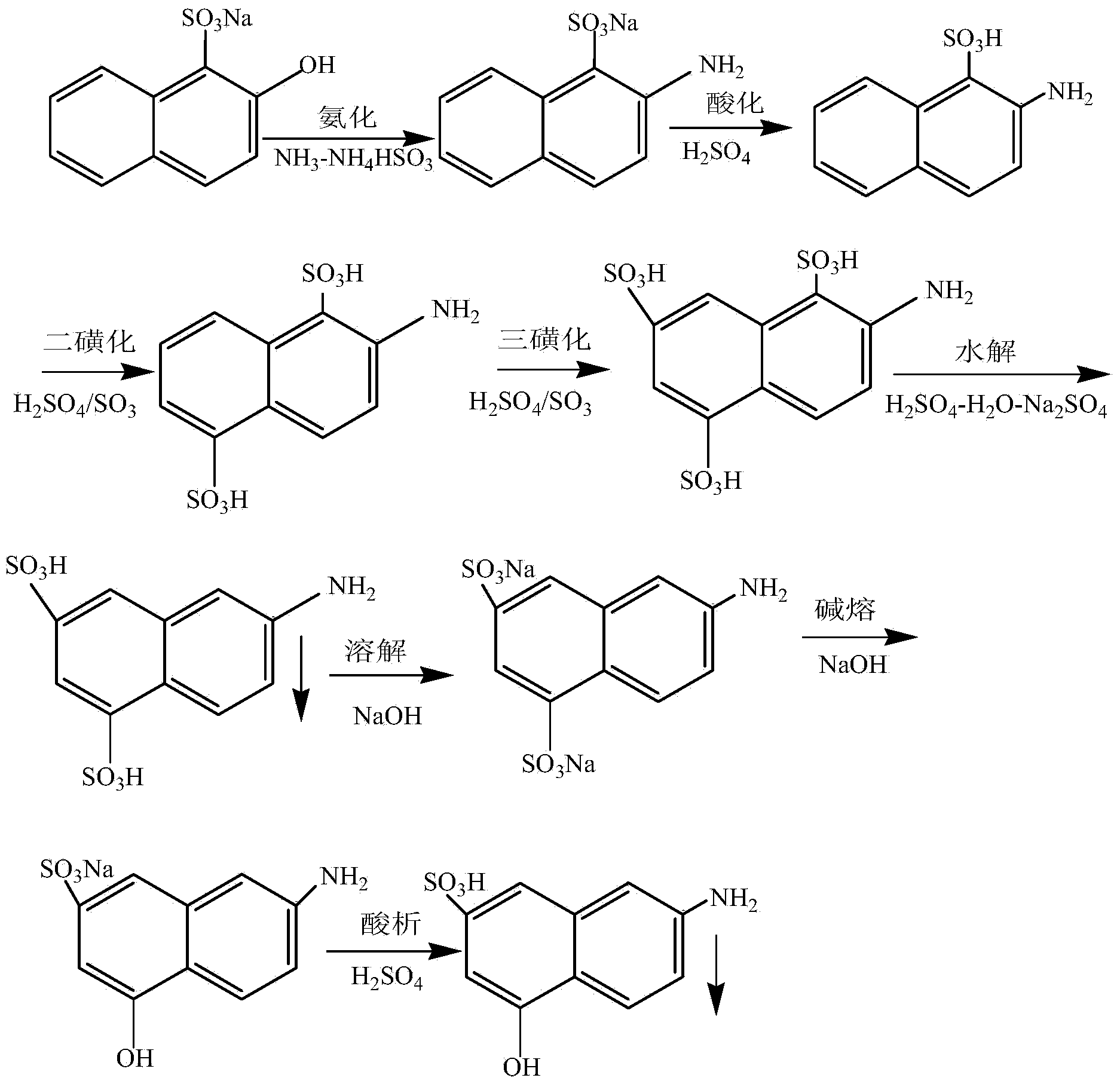

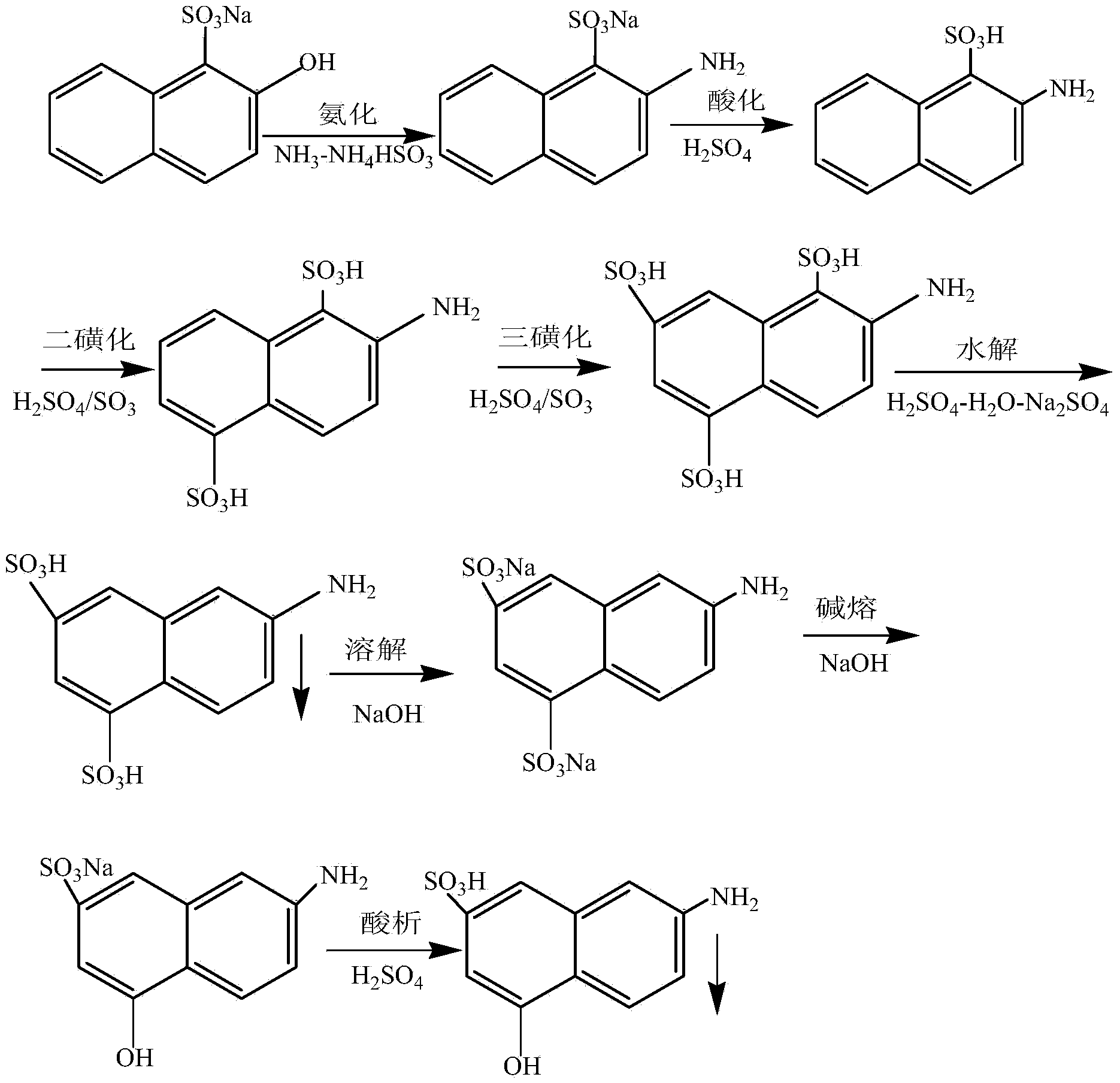

Preparation method of J acid and J acid waste water comprehensive treatment and recycling method

ActiveCN103896438ALow costDoes not affect productivityMultistage water/sewage treatmentSulfonic acid preparationWastewaterHydrolysis

The invention relates to a preparation method of J acid and a J acid waste water comprehensive treatment and recycling method. The J acid waste water comprehensive treatment and recycling method is as follows: the following treatment is carried out on hydrolysis waste water: (1) 30-40% of the total quantity of the hydrolysis waste water is used in an acidification reaction for preparing 2-naphthylamine-1-sulphonic acid by utilizing sodium 2-naphthylamine-1-sulphonate; (2) extraction and reextraction are carried out on the residual hydrolysis waste water, so that Na2SO4 and extraction waste liquor are obtained, the extraction waste liquor is used in a hydrolysis working procedure in a J acid production process, an extraction agent adopted during extraction is composed of 10-30wt% of complex agent, 30-70wt% of diluent and 5-20wt% of tributyl phosphate, and the complex agent is trioctylamine, or trialkyl tertiary amine or combination of trioctylamine and trialkyl tertiary amine. By adopting the preparation method of the J acid, the cost of water for the J acid and waste water treatment cost can be greatly reduced, and environmental pollution can be reduced.

Owner:XIANGSHUI HENRYDA TECH CHEM

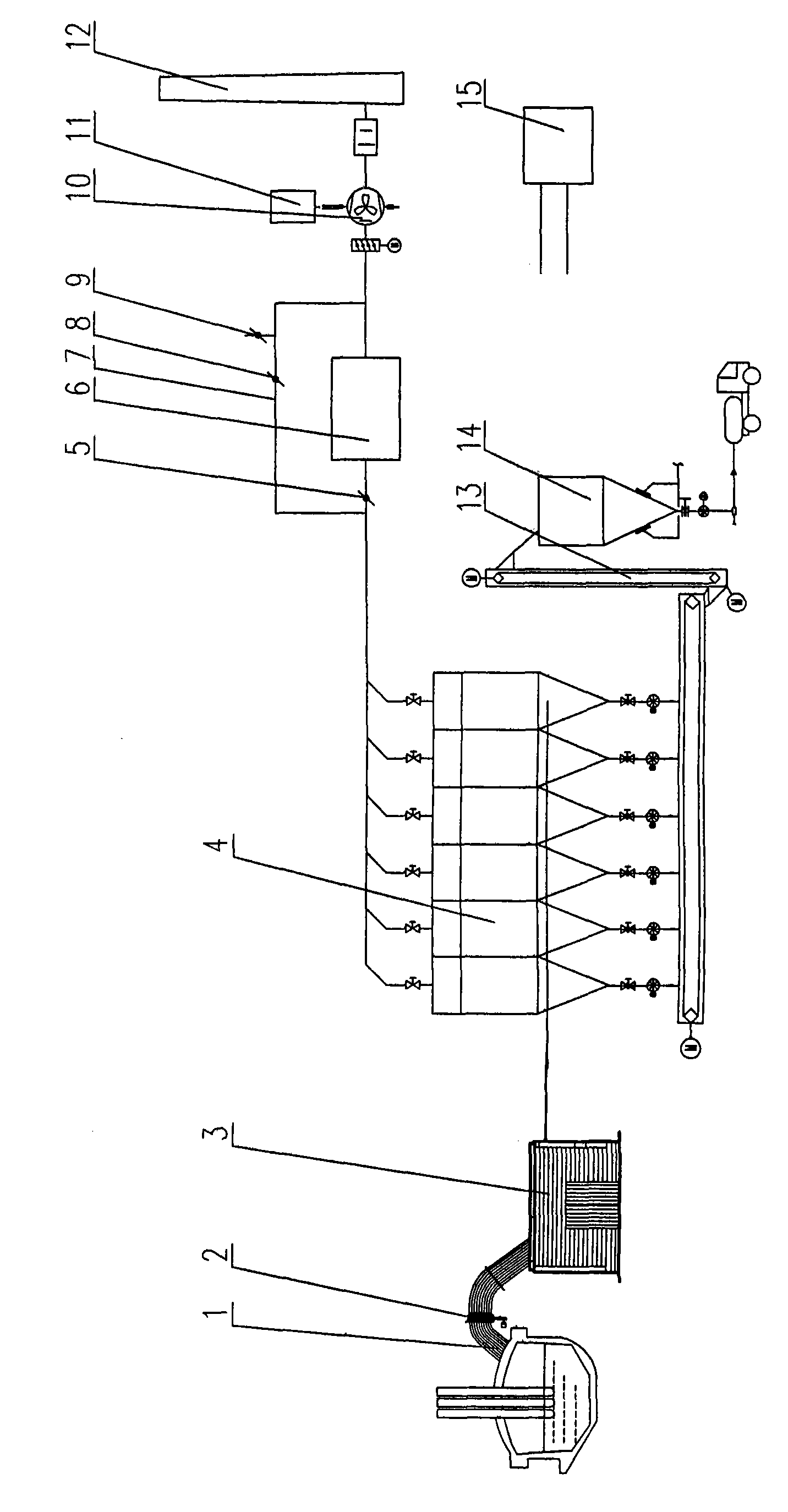

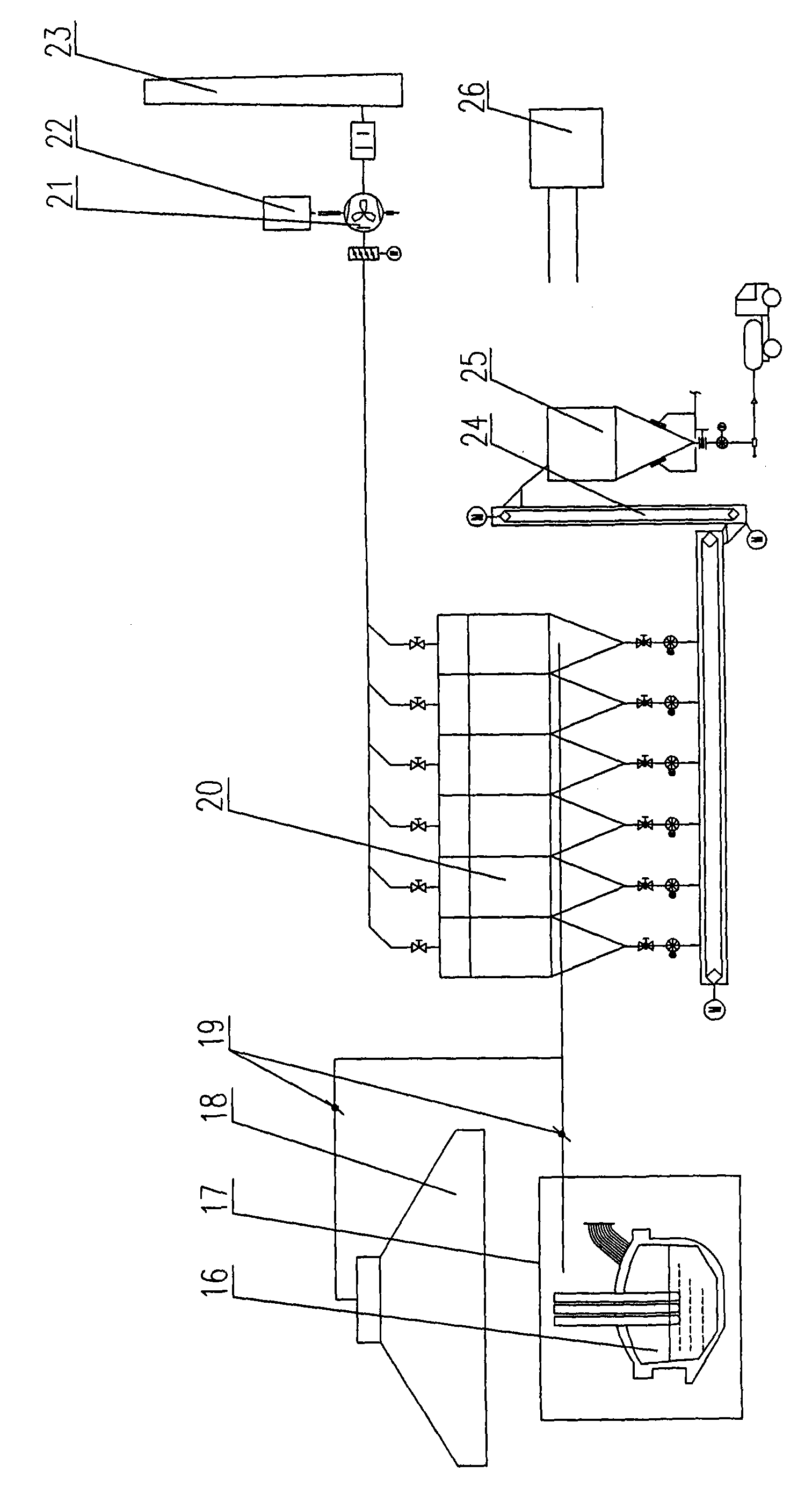

Flue gas waste heat recovery and negative energy consumption dust-removal system for electric stove

InactiveCN101539369AEasy to recycleSave on wear and maintenance costsDispersed particle filtrationIncreasing energy efficiencyCombustion chamberEvaporation

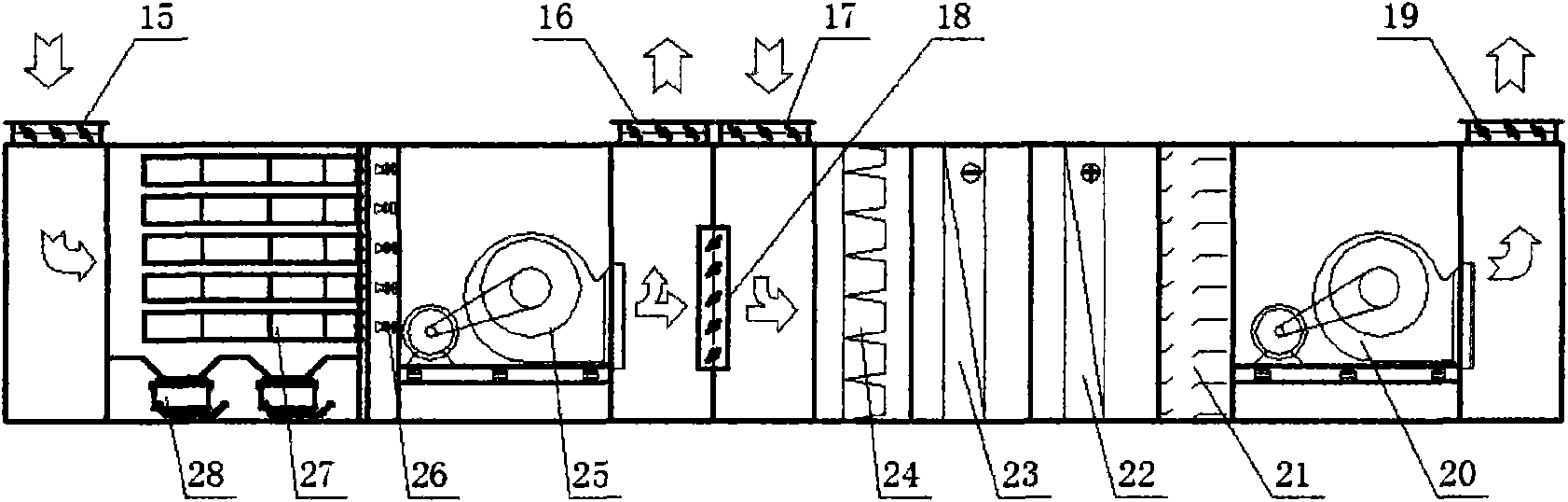

The invention relates to a flue gas waste heat recovery and negative energy consumption dust-removal system for an electric stove, comprising a first flue gas dust-removal and waste heat recovery system for the electric stove which is connected with the smoke hole of the electric stove to absorb high temperature flue gas generated by the electric stove during smelting phase and a secondary flue gas dust-removal system for the electric stove which is in charge of absorbing the flue gas generated by the electric stove during charging and tapping phase. The first flue gas dust-removal and waste heat recovery system for the electric stove comprises a water cooling travelling tube, an evaporation cooling device, a high temperature resistant dust remover, a waste heat boiler, a dust removal fan and a chimney; wherein the evaporation cooling device replaces the original water cooling flue gas path and combustor. The secondary flue gas dust-removal system for the electric stove comprises a collecting cover, a dust remover worked at normal temperature, a dust removal fan and a chimney. The invention is high in dust removal efficiency and high in vapor recovery rate, saves a first cooling device and a secondary cooling device, reduces device investment and maintenance charge and prolongs the service life of the filter pocket of the dust remover.

Owner:BAOSTEEL ENG & TECH GRP

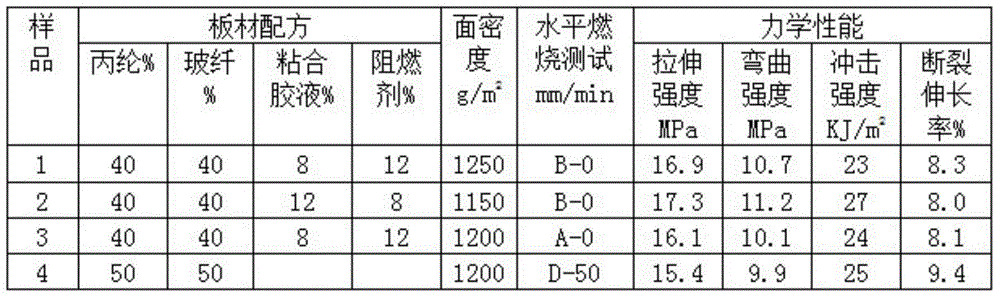

Formula and preparation technology of light fiber-reinforced thermoplastic resin composite sheet material with high flame resistance

ActiveCN103950251AImprove mechanical propertiesImprove flame retardant performanceSynthetic resin layered productsLaminationHigh resistanceFree falling

The invention discloses a formula and a preparation technology of a light fiber-reinforced thermoplastic resin composite sheet material with high flame resistance. The sheet material is composed of, 30-50% of reinforced fiber, 30-50% of thermoplastic resin fiber, 5-15% of halogen-free fire retardant powder and 5-15% of a bonding glue solution. The preparation technology comprises: weighing reinforced fiber and thermoplastic resin fiber according to the ratio, and performing preliminary mixing; utilizing a blower fan to convey reinforced fiber and thermoplastic fiber to a cotton storage bin; and utilizing the effect of free fall to enable fiber to be mixed fully, dispersed uniformly and the like. The light fiber-reinforced thermoplastic resin composite sheet material with high flame resistance has the advantages of simple production technology, low cost, excellent flame resistance and no obvious reduction on mechanical properties, is extremely applicable to fields of automotive trims, building decoration and the like, and has great practical value.

Owner:浙江华江科技股份有限公司

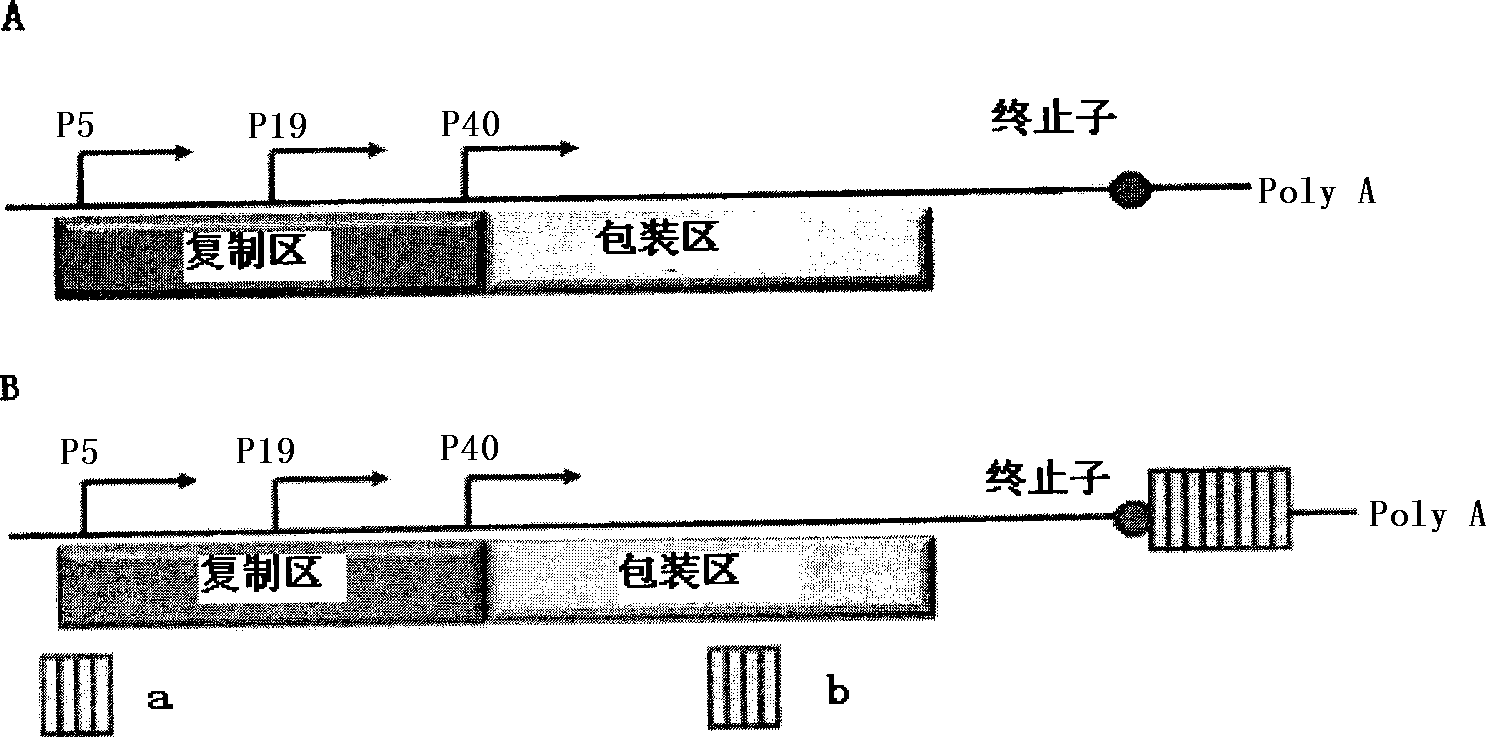

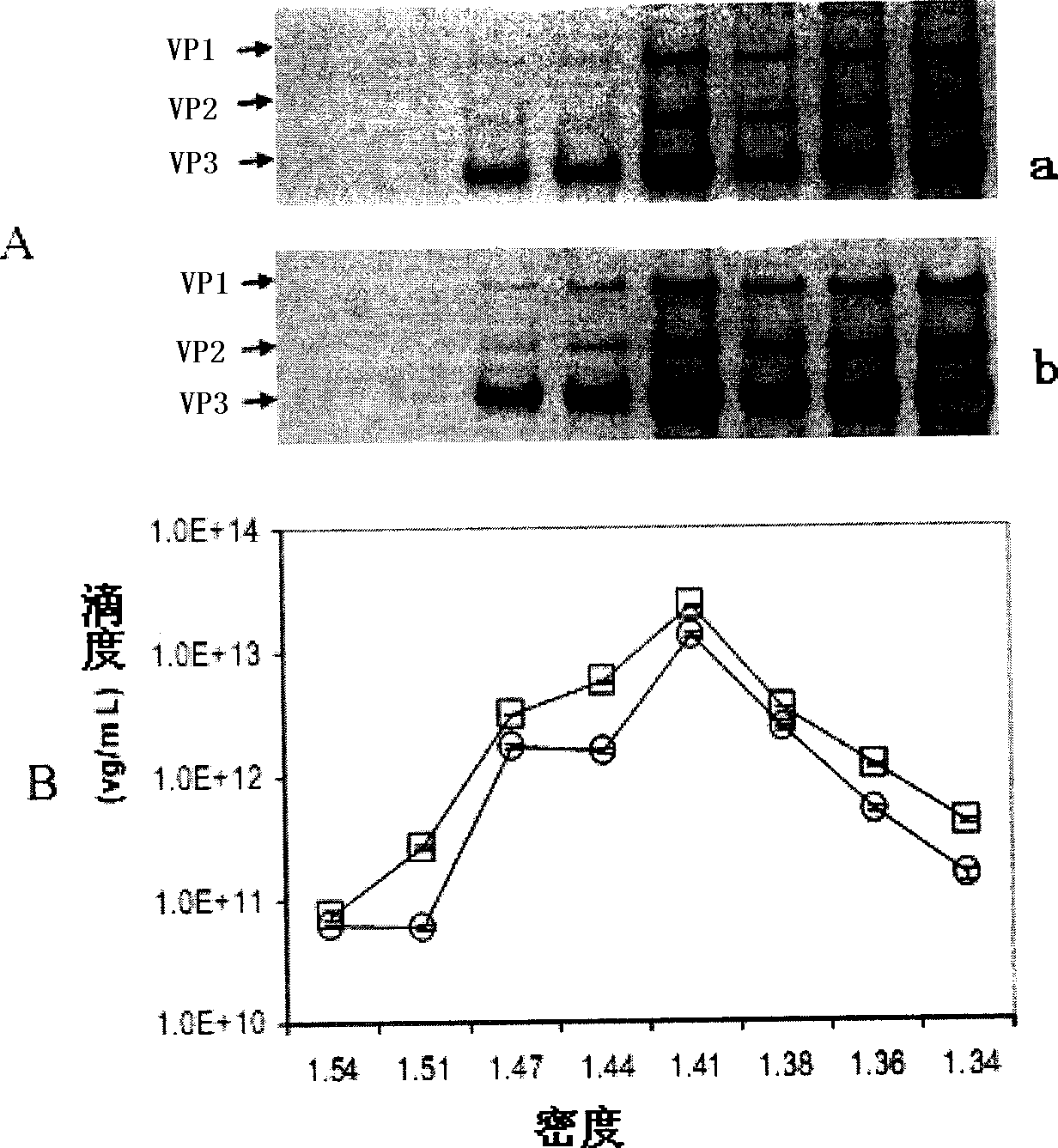

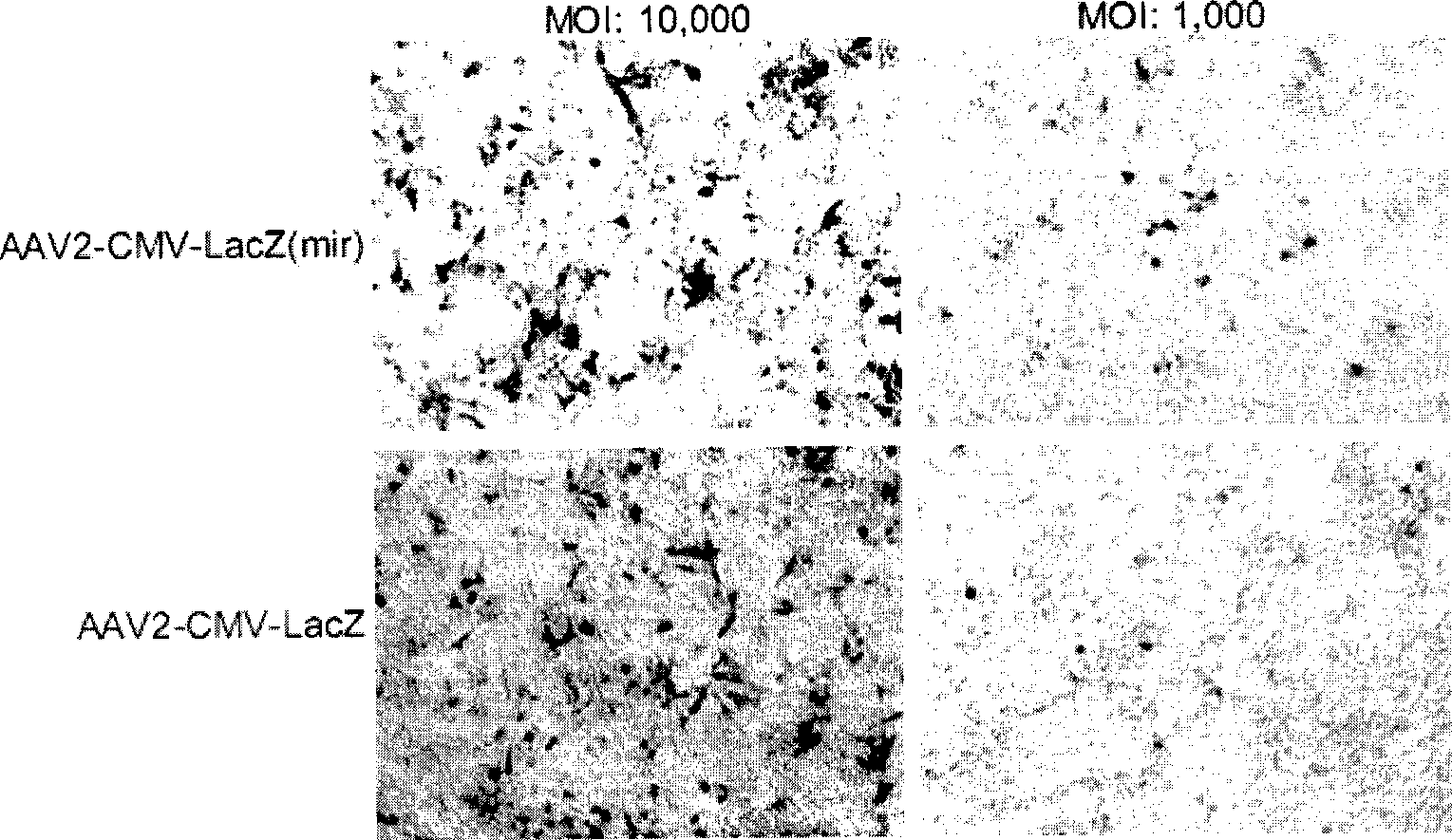

New type cell special gene HAAVmir containing microRNA combined sequence for gene treating

InactiveCN101532024ADoes not affect appearanceDoes not affect productivityGenetic material ingredientsMicroorganism based processesMicroRNACell strain

Owner:许瑞安 +2

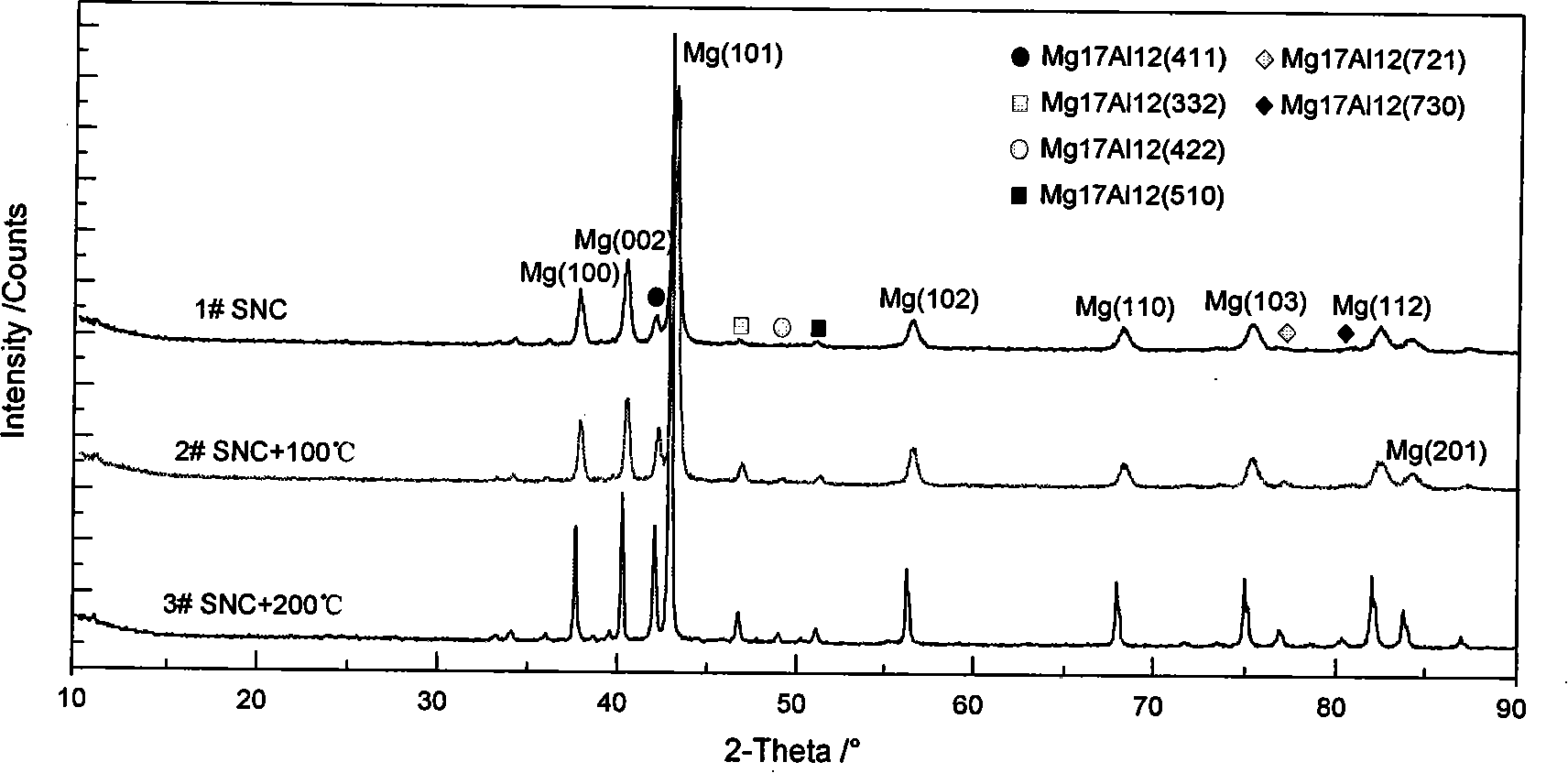

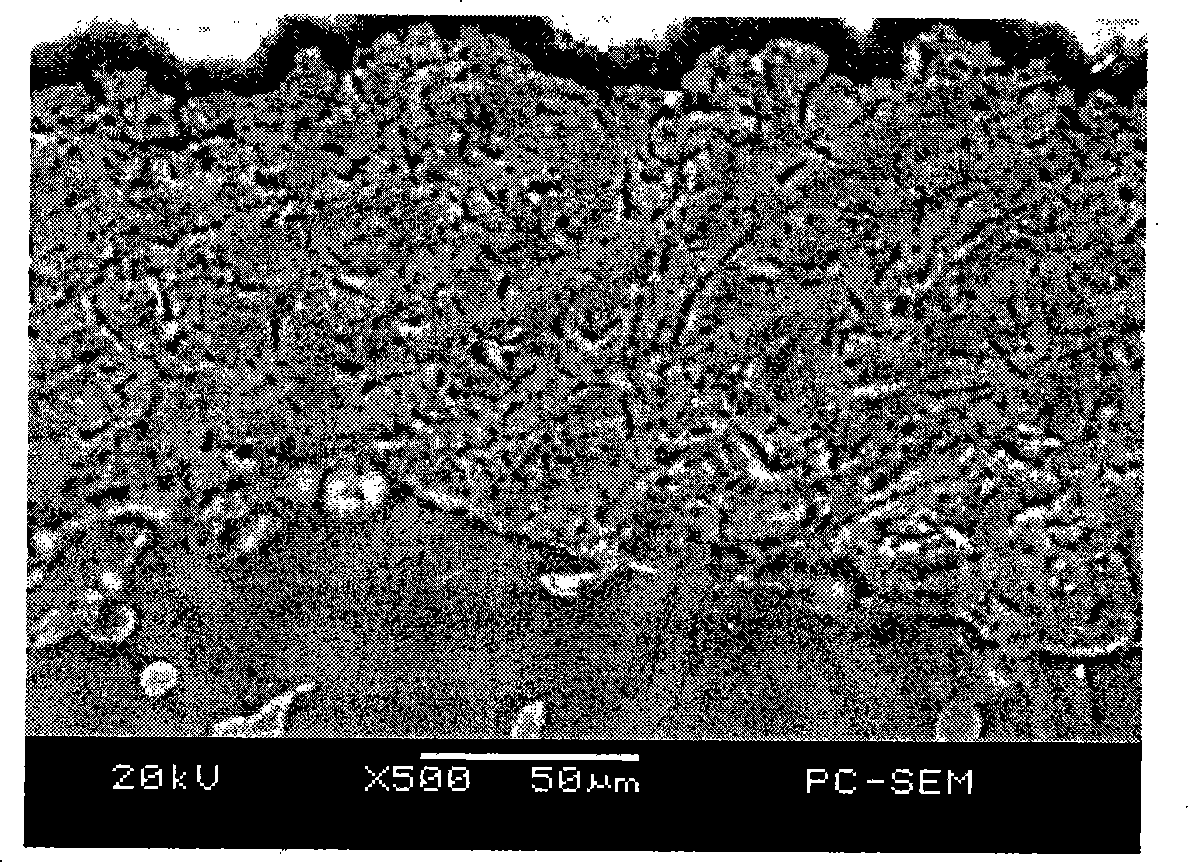

Method for reducing diffusion temperature of magnesium alloy surface spraying coating

InactiveCN101161853AIncreased diffusion rateImprove diffusion abilityMolten spray coatingNano sizeThermal spraying

The invention provides a method for reducing the diffusion temperature of spraying coating of magnesium alloy surface. First, nanocrystallization treatment is done on the magnesium alloy surface before the hot spray coating is done on the magnesium alloy matrix surface, which ensures the thinning of the crystal grain on the magnesium surface to the size of nanometer and eliminates the roll scale of the magnesium surface and coarsening to increase the mechanical riveted bonding force of matrix and coating; and then the magnesium alloy surface is hot sprayed by aluminum or zinc or a zinc / aluminium complex coating; finally, the magnesium alloy is treated to preserve heat in an ordinary heat treatment furnace at a temperature of 200 to 400 degrees, which facilitates the coating and the matrix to form metallurgical bonding. The invention adopts the surface nanocrystallization technique, which can not only reduce the diffusion temperature of spraying coating of magnesium alloy surface, but also avoid the necessary sand blasting pretreatment technology before spray finishing. In addition, special processing step is not needed, which eliminates the roll scale of the matrix surface and coarsening surface and ensures that a layer of nanocrystal is formed on the magnesium alloy matrix surface, thereby saving the processing time before spray finishing and raising the productivity effect.

Owner:重庆工学院

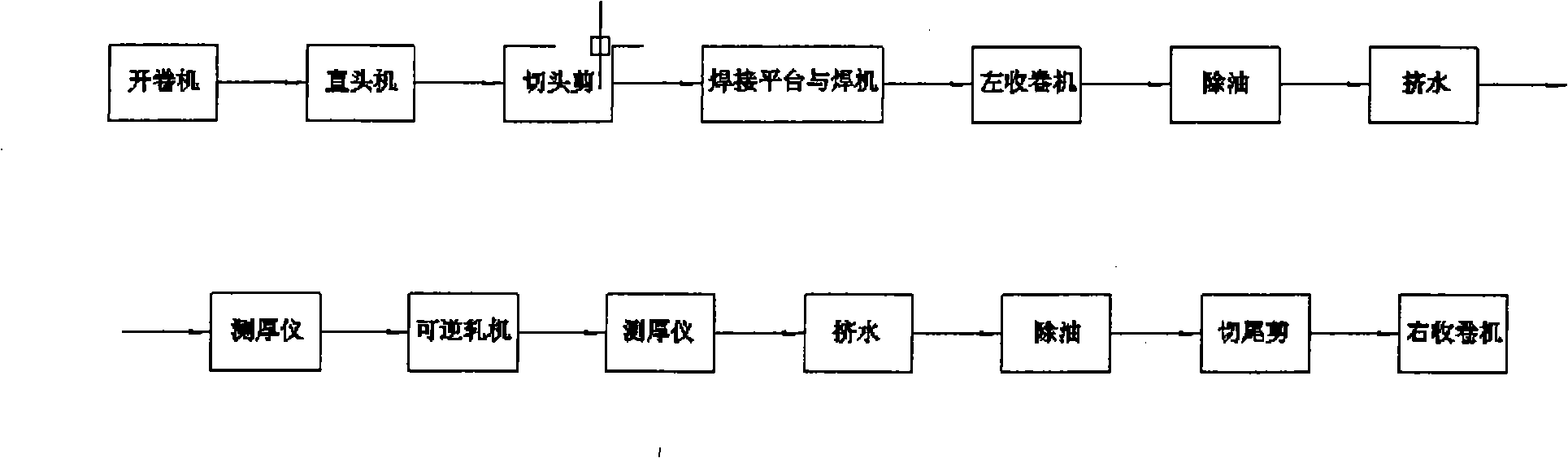

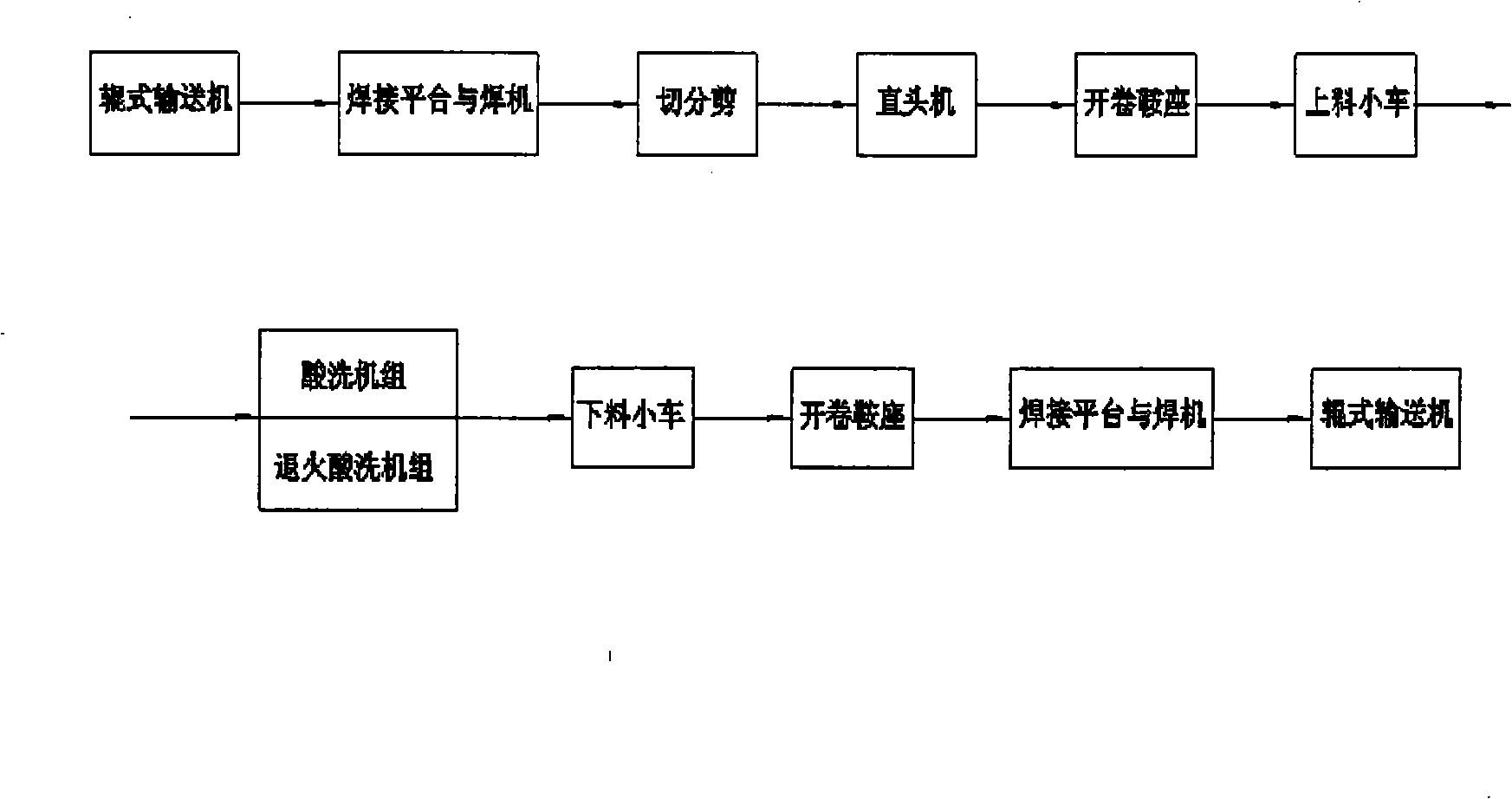

Technique method for improving product rate of reversible cold-rolled steel strip

InactiveCN101264487AIncrease profitDoes not affect productivityWork treatment devicesMetal rolling arrangementsAcid washingSteel belt

The invention provides a technological method for improving the rolling yield of reversible cold rolled steel strips, applicable for the production field of preliminary treatment acid washing and annealing acid washing of the cold rolled steel strip production. The technological method is characterized in that a guiding tape, the length of which is required by tape tail welding of the coil of strip, is added at the uncoiling point in front of the preliminary treatment acid washing and annealing acid washing machine group in the technological procedure of the reversible cold rolling. The technological method has the advantages that the technological method does not consume the production time of the machine group and at the same time solves the problems of low rolling yield of the reversible cold rolled steel strips in subsequent process steps; thus, the technological method improves the rolling yield of the strip material and saves production cost.

Owner:BEIJING STAR RIVER INTEGRATED EQUIP TECH

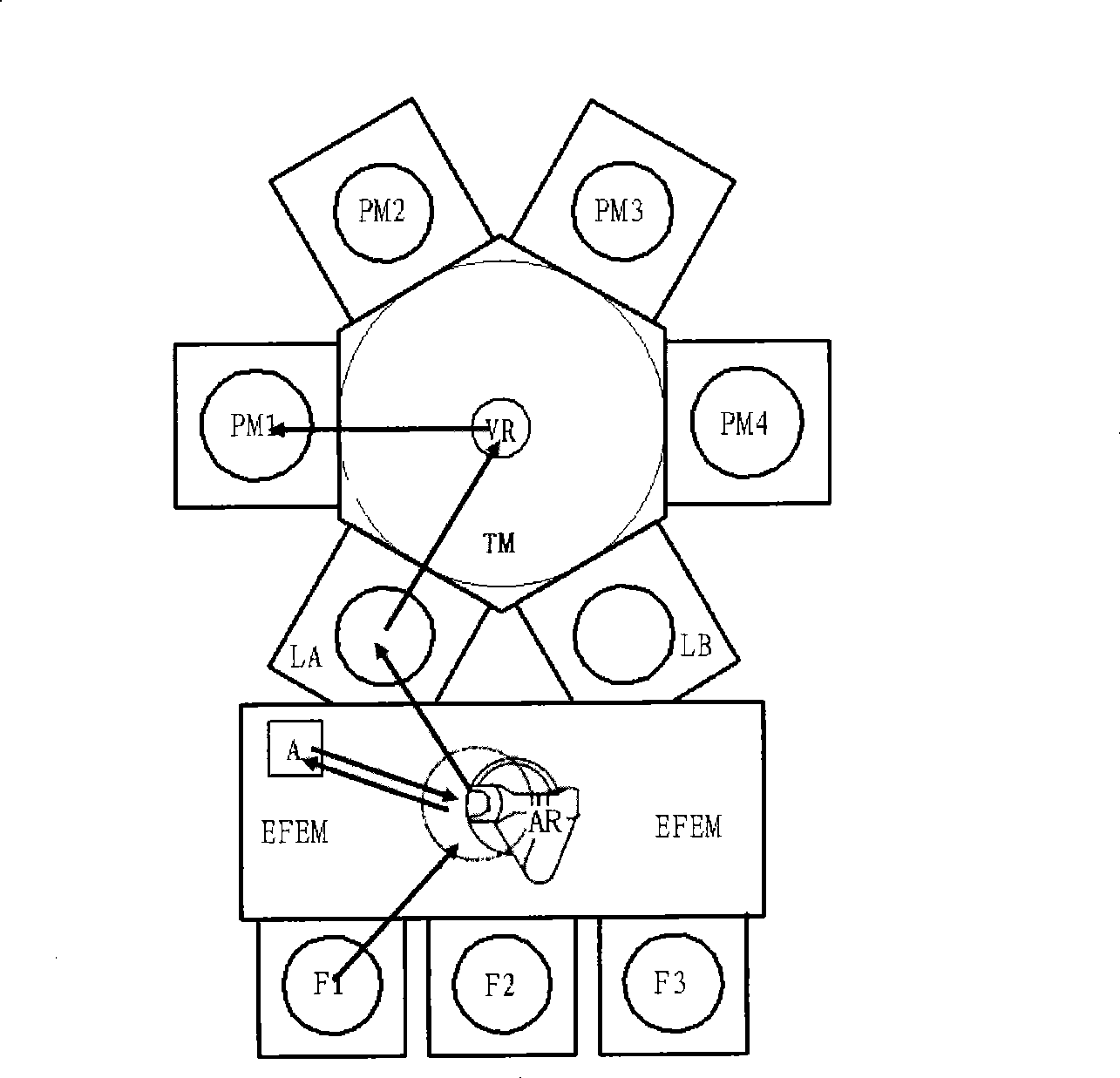

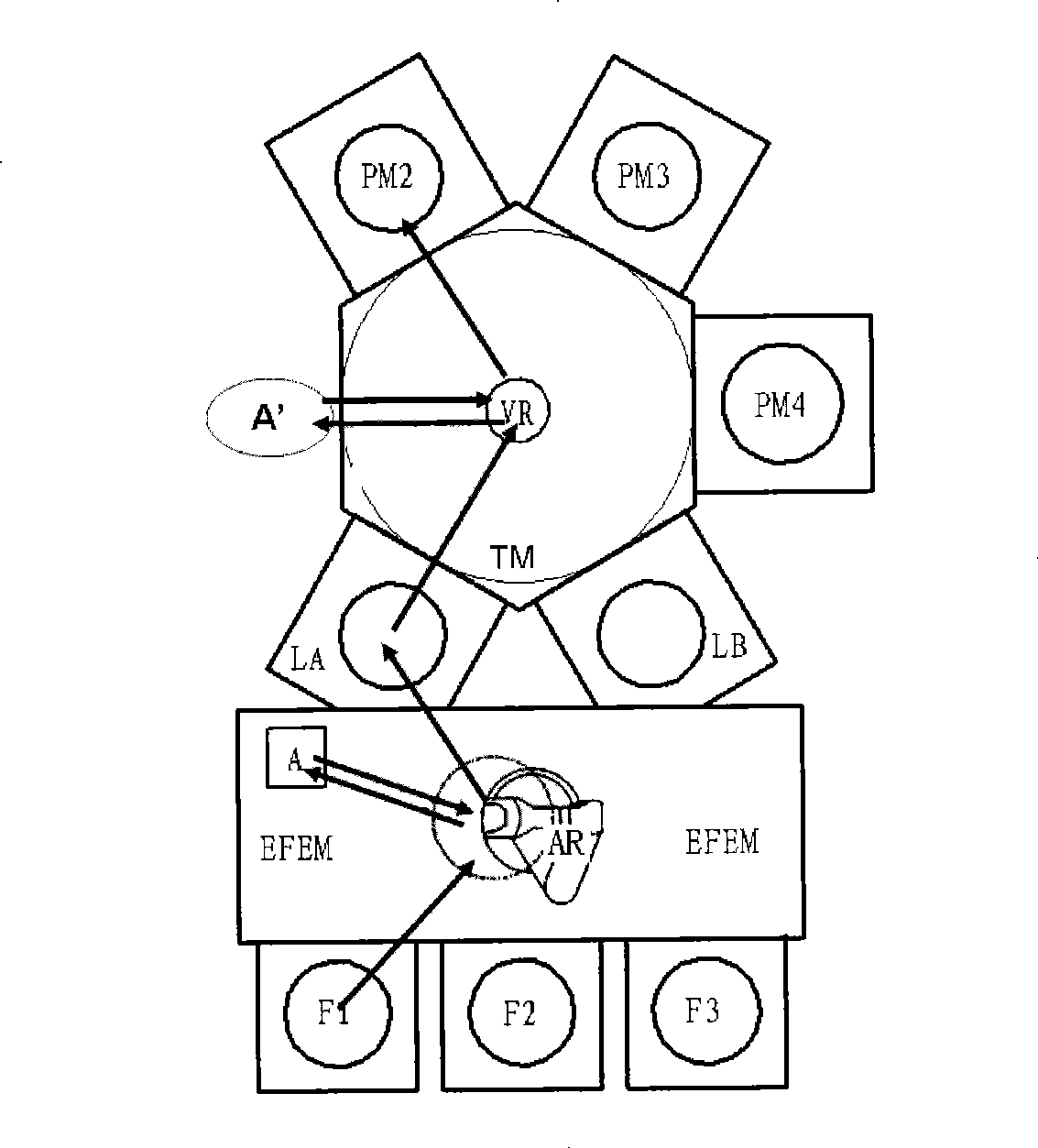

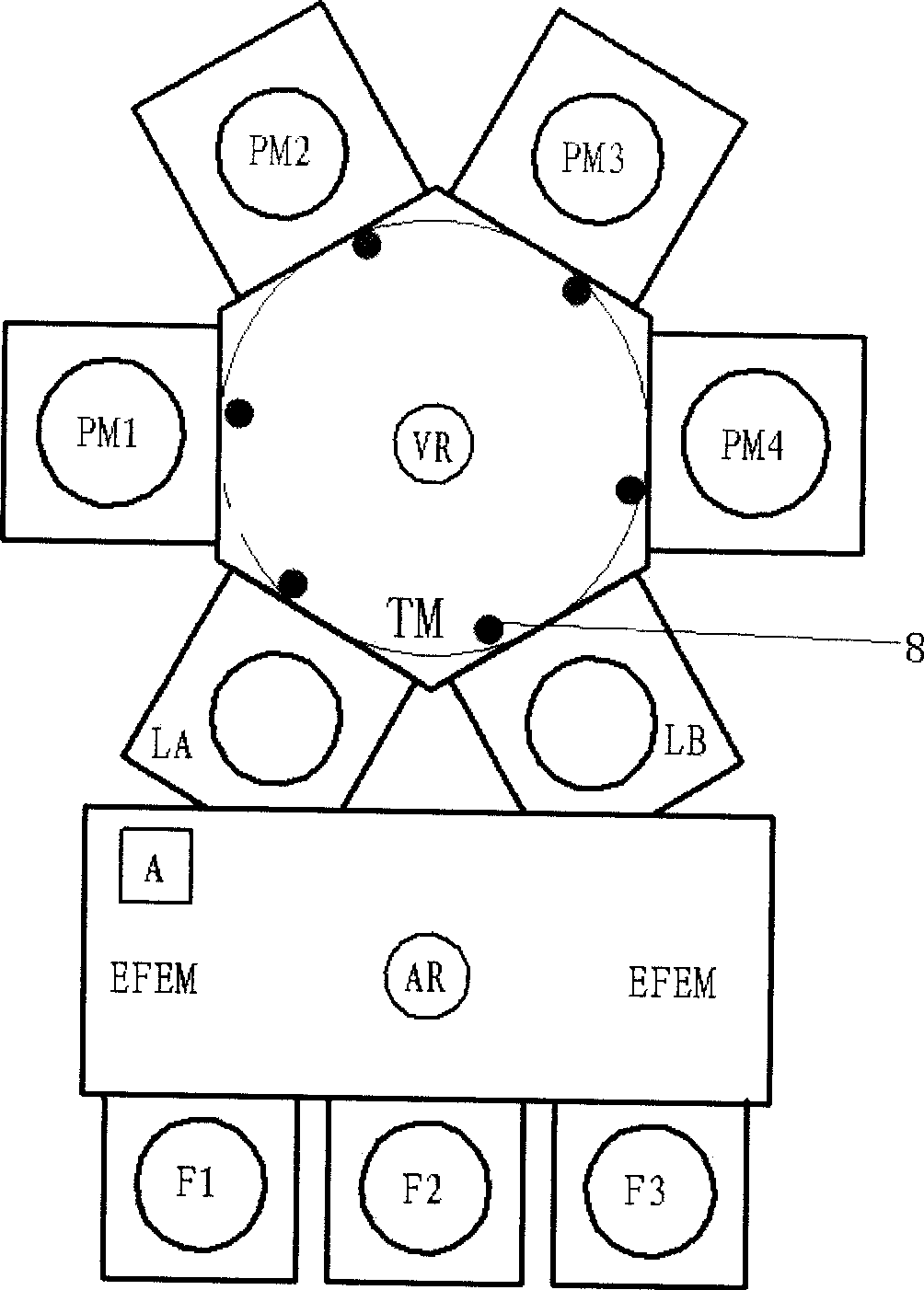

Wafer transmission system

ActiveCN101383311ADoes not affect processabilityDoes not affect productivityConveyor partsEngineeringManipulator

The invention discloses a wafer transmission system which comprises a vacuum transmission cavity connected with a plurality of cavities, and each wafer channel which is arranged between the vacuum transmission cavity and each cavity is provided with an optical fibre sensor which is used for sensing the position information of a wafer; the optical fibre sensor comprises a transmitting terminal and a receiving terminal, a light which is transmitted by the transmitting terminal is perpendicular to the surface of the wafer, and the position of the optical fibre sensor slightly deflects to a center line of the wafer channel. When a vacuum mechanical arm is used for transmitting the wafer among the cavities, the position information of the wafer can be sensed by the sensor, the transmission system can calibrate the position bias of the wafer according to the position information, and the processing capability and the output rate of a mechanical table can not be influenced.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

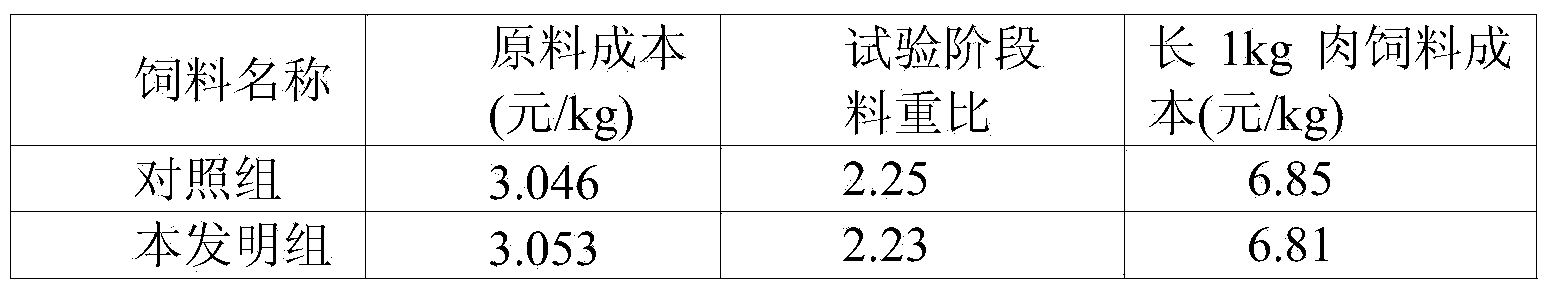

Yellow broiler feed containing chrysanthemum meal and preparation method thereof

The invention discloses a yellow broiler feed containing chrysanthemum meal and a preparation method thereof. The preparation method comprises the following steps: smashing and evenly mixing raw materials including chrysanthemum meal, wheat bran, corn distilled grain, corn, bean pulp, cottonseed meal, rapeseed meal and the like; adding nutrition preparations, such as soya-bean oil, vitamin, aminoacid and the like, evenly mixing, and carrying out steam blending so that the raw powder is cured to a certain degree; and then, pelletizing to obtain a finished product. The yellow broiler feed containing chrysanthemum meal has the functions of improving carcass coloring effect of the yellow broiler and improving the sensuous performance of the yellow broiler product, the preparation method is simple, safe and reliable, and the growing vigour and the culture effect of the broiler are not affected.

Owner:TONGWEI

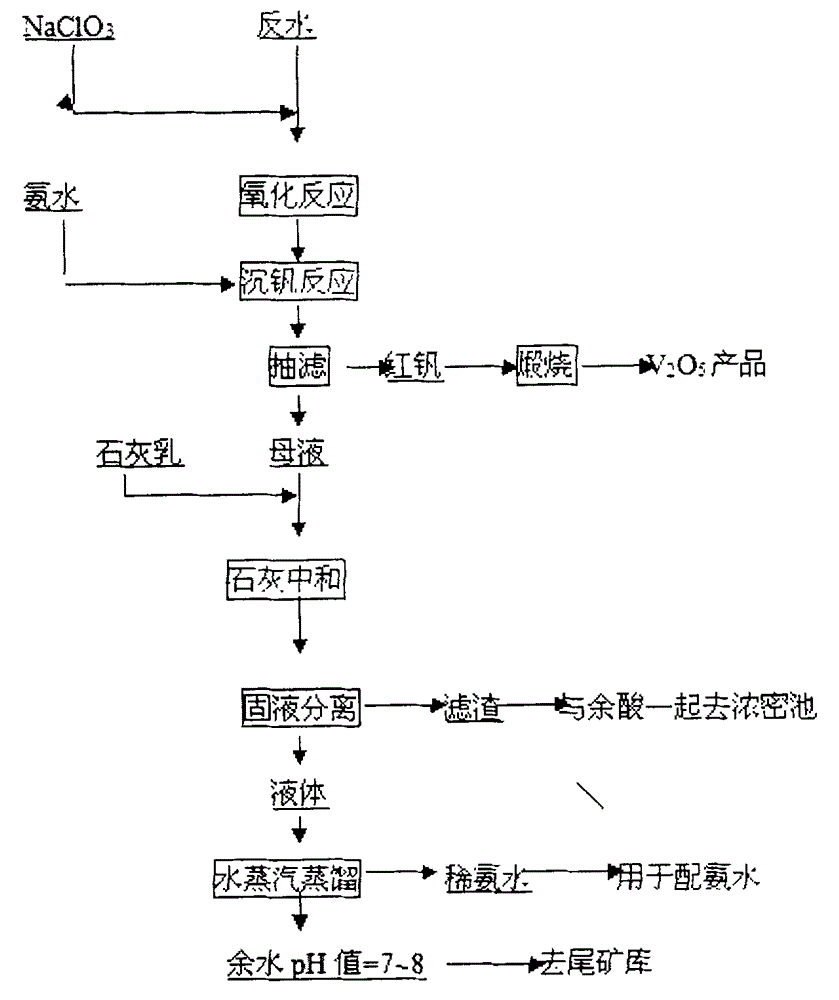

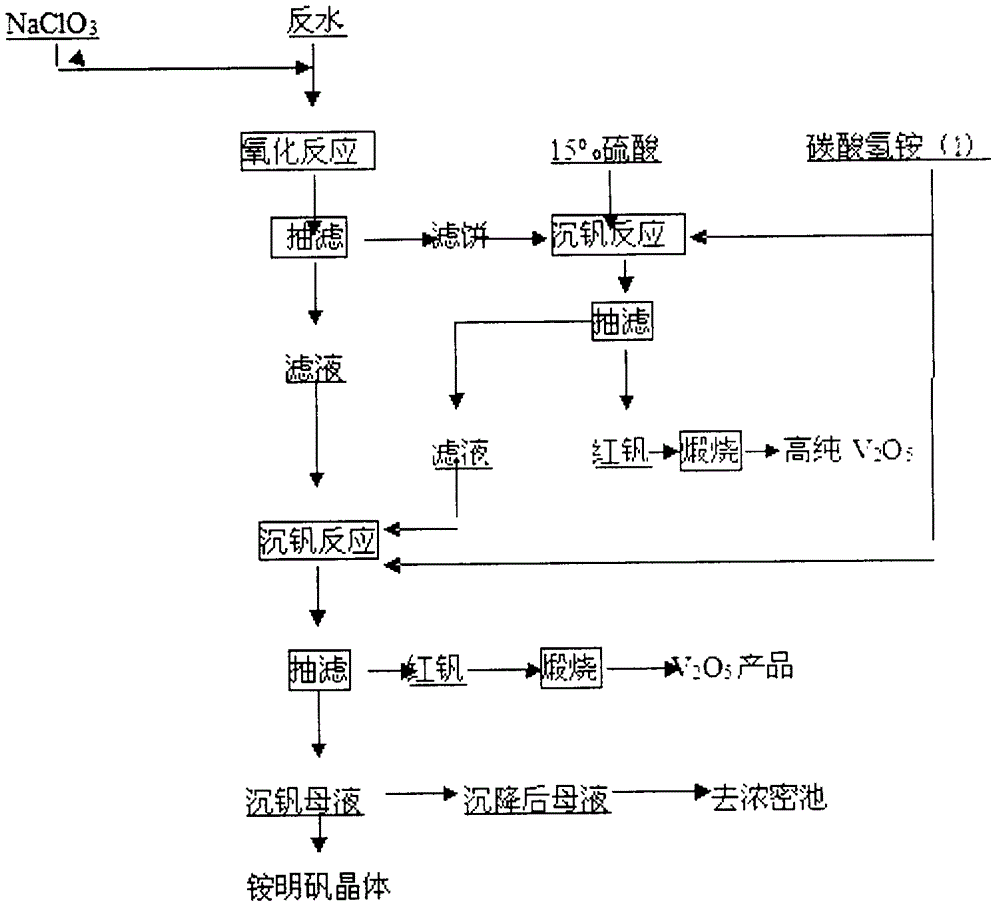

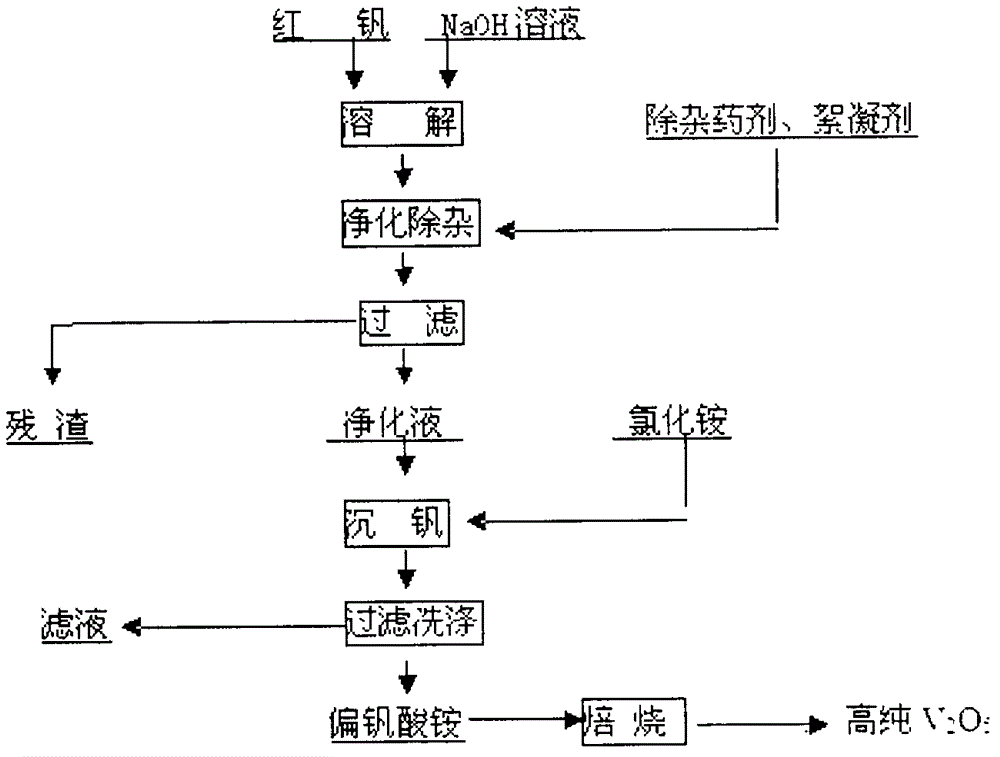

Preparation method of highly pure vanadium pentoxide

InactiveCN104099483ANo pollution in the processDoes not affect the processProcess efficiency improvementSolubilityChemical industry

The invention relates to the field of the chemical industry, and especially relates to a preparation method of highly pure vanadium pentoxide. The method comprises the following steps: oxidizing tetravalent vanadium in back extraction water obtained in a total hydrometallurgical vanadium extraction process to form pentavalent vanadium; forming an oversaturated system of pentavalent vanadium, precipitating to obtain a polyvanadic acid precipitate, carrying out solid-liquid separation to separate a solution containing a high content of impurities, washing the polyvanadic acid precipitate, adding the washed precipitate to a sulfuric acid solution, carrying out heat insulation uniform stirring, and adding an ammonium bicarbonate solution to prepare a highly pure product, wherein polyvanadic acid gradually forms a polyammonium vanadate precipitate having a lower solubility due to the solubility of polyammonium vanadate is less than the solubility of polyvanadic acid; and calcining the polyammonium vanadate precipitate to generate vanadium pentoxide. The method has the advantages of no influences on present technologic main flow or production equipment, short production flow, low production cost, and no leakage or environmental protection due to closed circular running of the highly pure vanadium pentoxide production flow and original flow. 3000t of the highly pure vanadium pentoxide can be produced yearly.

Owner:SHAANXI WUZHOU MINING +1

Dorking feed and preparation method thereof

InactiveCN101999559AIncrease contentDoes not affect productivityFood processingAnimal feeding stuffBiotechnologyInosinic acid

The invention discloses dorking feed and a preparation method thereof. The dorking feed can be prepared by crushing and uniformly mixing wheat bran, distillers dried grains with soluble, maize, soybean meal, cotton dregs, rapeseed meal and other raw materials; adding disodium 5'-inosinate, disodium 5'-guanylate, methionine, threonine and other nutrition agents for uniformly mixing and then modulating by steam to cure cornstarch to a certain extent; and granulating to obtain the finished product. By using the invention, the content of the disodium 5'-inosinate in chicken can be improved and the edible flavor of the dorking can be improved. In addition, the method is simple, safe and reliable and cannot influence the growing vigor and the raising effect of the dorking.

Owner:TONGWEI

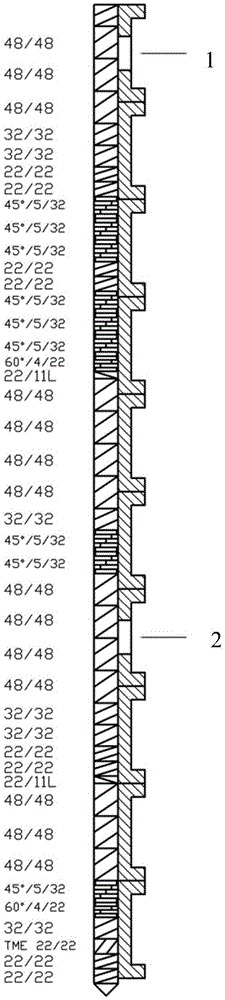

High performance short glass fiber enhanced polypropylene composite material and preparation method thereof

The invention discloses a high performance short glass fiber enhanced polypropylene composite material, which is composed of the following components in percentage by weight: 50 to 85% of polypropylene, 2 to 8% of modified polypropylene, 10 to 40% of modified short-cut glass fiber, 0.1 to 5% of antioxidant, and 0.5 to 5% of lubricant, wherein the modified polypropylene is prepared by modifying polypropylene with dicumyl peroxide and a silane coupling agent, and the modified short-cut glass fiber is prepared by modifying short-cut glass fiber with dicumyl peroxide and a silane coupling agent. Through the formula mentioned above, the provided composite material has the advantages of high modulus, high strength, and high impact strength. The invention also discloses a preparation method of the high performance short glass fiber enhanced polypropylene composite material. According to the preparation method, a same direction double-screw extruder is adopted, a specific screw combination is used to ensure that the length of glass fiber is short and the length distribution is in a narrow range, and thus a high performance polypropylene material is obtained.

Owner:CGN JUNER NEW MATERIALS +1

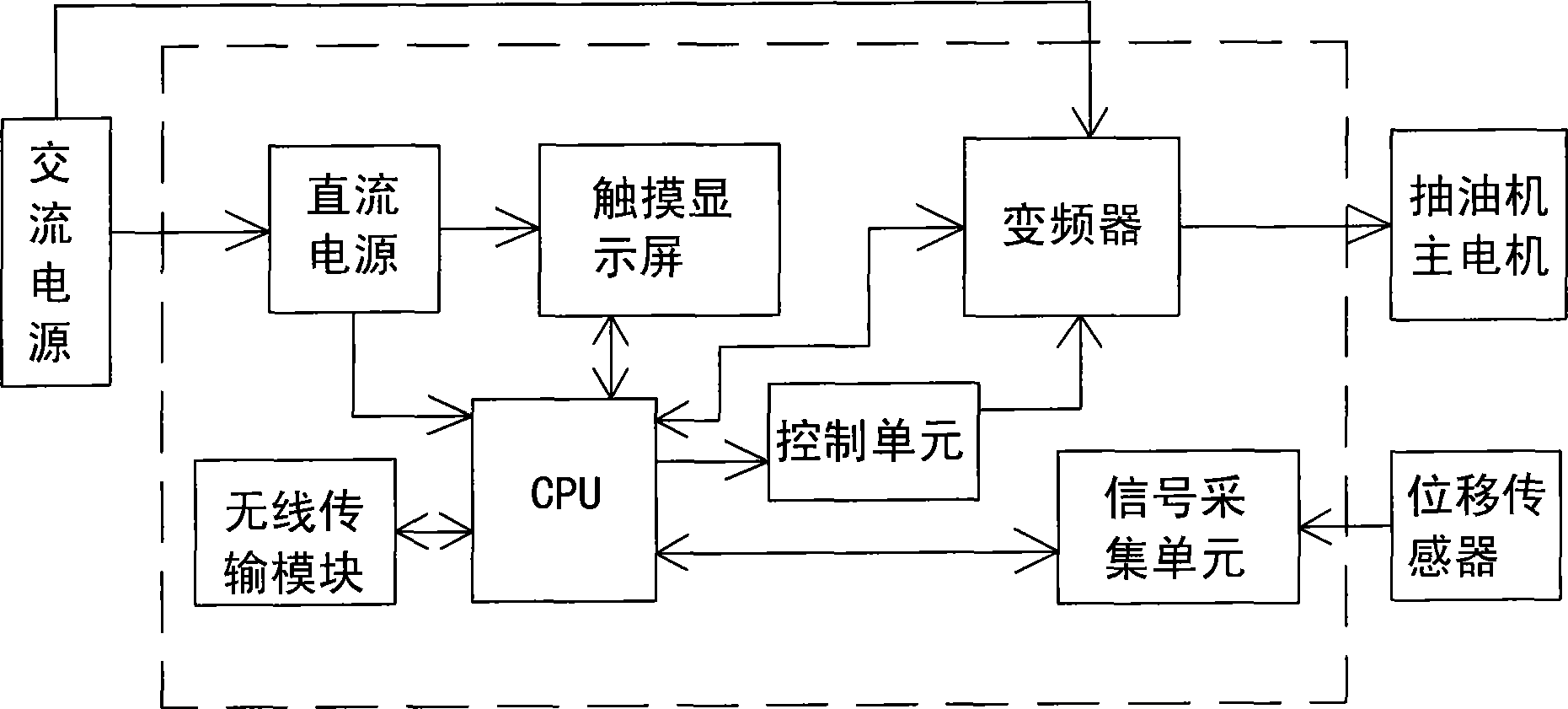

Measuring means for oilfield oil pump indicating diagram without load transducer

InactiveCN101498296AKeep abreast of the work situationKeep abreast of runningPump testingConstructionsFrequency changerElectric machine

The invention relates to a method for measuring a indicating diagram of an oil filed oil extractor without a load sensor, which comprises the following steps: the indicating diagram of an oil filed oil extractor is used for measuring and calculating a self machine of an oil extractor, a CPU controls the operating state of a transducer through a control unit, the transducer controls a main motor of the oil extractor according to signals transmitted by the CPU, one side of a balancing weight block of a crank device of the oil extractor is provided with a displacement sensor which can transmit a displacement signal to the CPU through a signal collecting unit, the operating data of the collection transducer are transmitted to the CPU, the CPU carries out coordinate treatment for the displacement signal and the operating data of the collection transducer to obtain a main motor indicating diagram, the CPU carries out vectorial resultant treatment for the main motor indicating diagram and the oil extractor indicating diagram to obtain a feed rod indicating diagram of an oil extractor feed rod, and the feed rod indicating diagram comprises displacement data and load data. In the invention, load sensors, pressure sensors, and the like do not need to be arranged on the oil extractor feed rod or a walking beam, and the like, and the invention can accurately and reliably measure the indicating diagram of the oil extractor without stopping unloading, and the like.

Owner:山东亚华电子股份有限公司

Method for preparing PET-organic intercalated montmorillonite composite material

InactiveCN102432985AImprove barrier propertiesNo change in injection molding processCoatingsPhosphonium saltPolyethylene terephthalate glycol

The invention discloses a method for preparing a PET (Polyethylene Terephthalate)-organic intercalated montmorillonite composite material, comprising the following steps of: 1) mixing organic intercalated montmorillonite and fully dried PET according to the weight ratio of 20: 80 to 80: 20 to obtain mixed materials, and preparing the mixed materials into a PET master batch containing the organic intercalated montmorillonite, in which the organic intercalated montmorillonite is obtained by reacting a quaternary phosphonium salt or a silane coupling agent and a sodium montmorillonite intercalation; and 2) uniformly mixing the PET master batch containing the organic intercalated montmorillonite prepared in the step 1) and the PET, so that the mass percentage of the montmorillonite in the mixture is 1-10%; and moulding in an injection way by an injection moulding machine to obtain the product. By mixing the quaternary phosphonium salt or the silane coupling agent organic intercalation modified sodium montmorillonite and the PET to obtain the PET master batch containing the organic intercalated montmorillonite, and then mixing with the pure PET proportionally and moulding in the injection way to obtain the product, the method disclosed by the invention provides a new technology applied to the large-scale production, and can obtain the PET product with good water and gas barrier properties.

Owner:GUANGZHOU IMPROVE MEDICAL TECH CO LTD +1

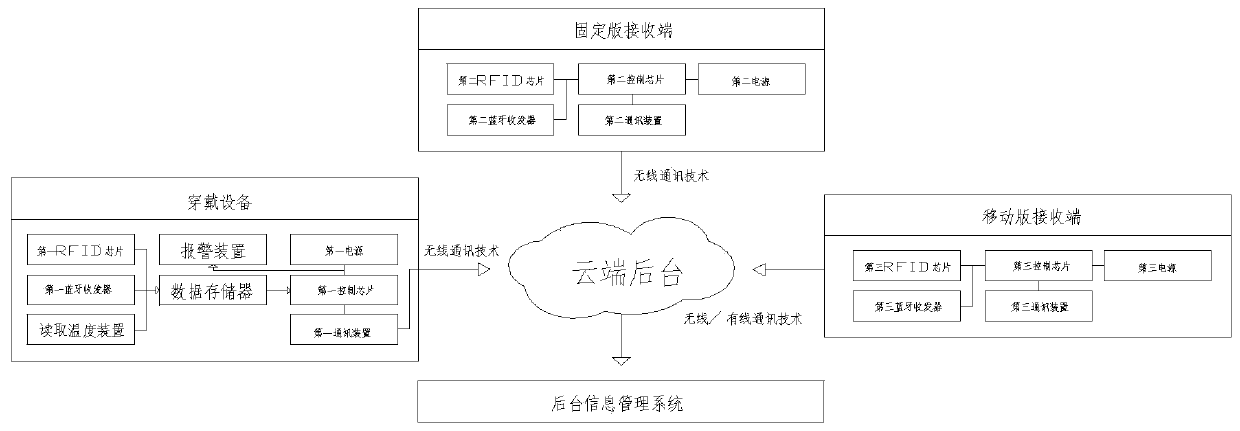

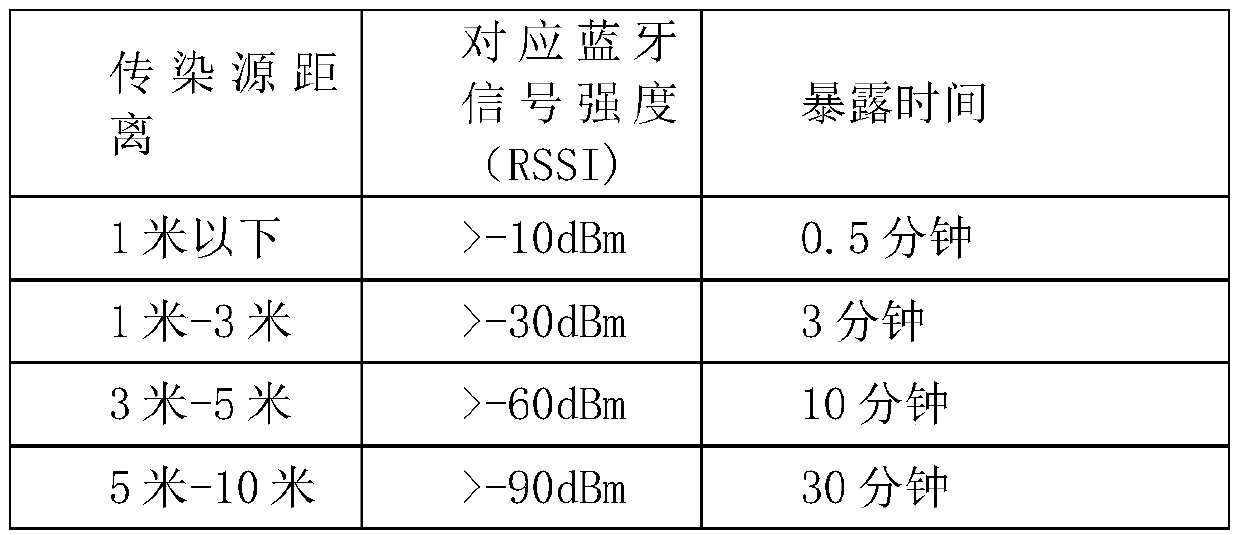

Epidemic prevention system for implementing efficient tracing of close contact person by using Bluetooth technology

InactiveCN111601242AReduce risk exposureReal-time monitoring of body temperatureThermometer detailsTransmission systemsGuard - securitySimulation

The invention discloses an efficient epidemic prevention system and method implemented by using wearable equipment. Identity identification and binding are realized through the FRID. A receiving end is arranged at the entrance and exit of the field; manual temperature measurement and code scanning are not needed at an entrance and an exit, receiving ends are arranged in different sub-places respectively, positioning management and temperature measurement second-level implementation of the user are achieved, manual intervention is not needed, and when the user with abnormal body temperature passes through the entrance receiving end, the background automatically displays the name and body temperature of the abnormal user, prompts security intervention and pays attention to personal protection; once a definite case occurs, if the patient is in direct close contact with the patient, the system background calls related data, the contact time and the contact place of the direct close contactperson and the indirect contact person of the patient can be quickly and accurately positioned, epidemiological investigation is completed, accurate isolation and medical observation are implementedby adopting broken and appropriate measures, and normal production and teaching are not affected.

Owner:深圳市本示科技有限公司

Silicon carbide ceramic material and preparation method thereof

The present invention discloses a silicon carbide ceramic material and a preparation method thereof. The method comprises: (1) irradiating polycarbosilane having a number average molecular weight of 300-4000 with high energy rays, wherein the absorbed dose of the polycarbosilane is 50-2000 kGy; and (2) carrying out pyrolysis on the irradiated polycarbosilane to obtain the silicon carbide ceramic material. According to the present invention, the silicon carbide ceramic material is prepared by using the in-situ irradiation method, such that only the chemical structure of the polymer is changed, and the impurity is not introduced; the irradiation process is completely controllable and the irradiation dose can be controlled according to the raw material characteristics to achieve the best effect, such that the yield of the silicon carbide ceramic material can be significantly improved, the production cost can be reduced, the production period can be shortened, and various molding processes and the production processes of the irradiated polycarbosilane cannot be affected; and the silicon carbide ceramic material prepared by using the preparation method has advantages of uniformity, further improved temperature resistance, further improved compactness, further improved tensile strength, and other properties.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

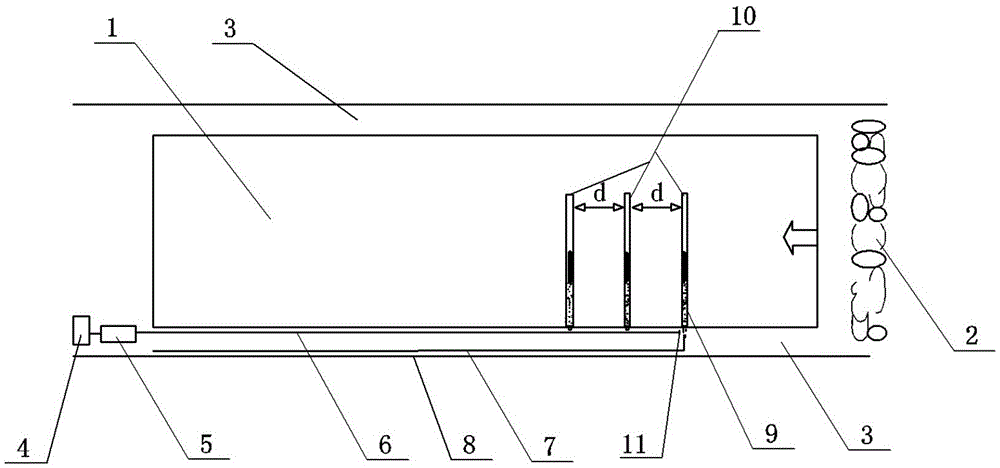

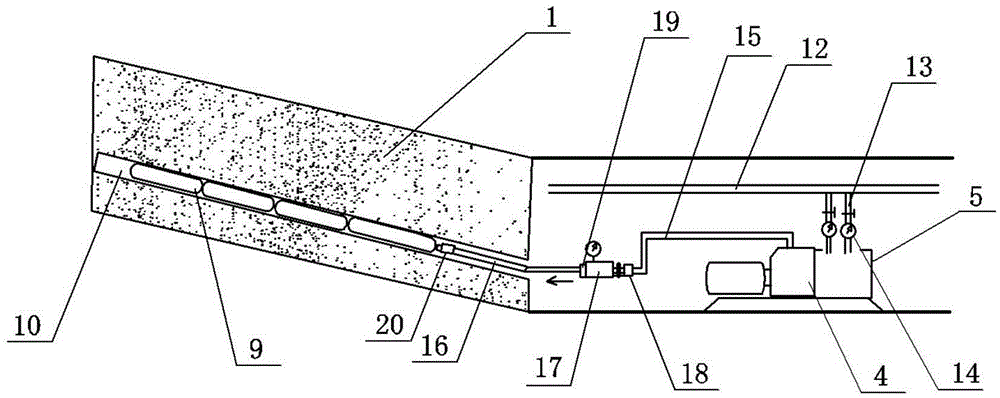

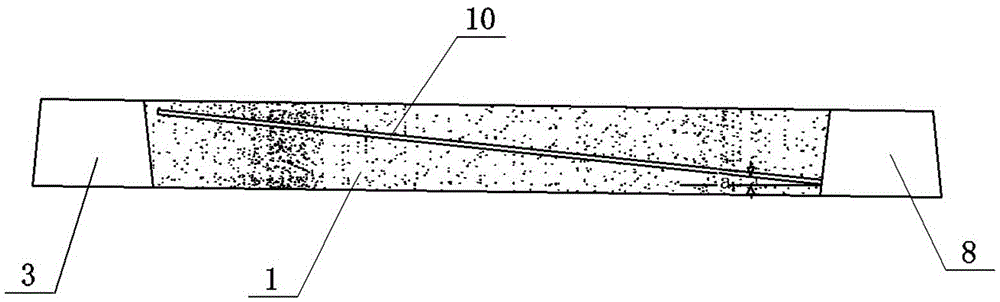

Efficient water injection method and device of hydraulic fracture permeability increase auxiliary coal seam

InactiveCN105422164AGood water permeabilityHigh densityDust removalFire preventionHydraulic fracturingHigh pressure water

The invention discloses an efficient water injection method and device of a hydraulic fracture permeability increase auxiliary coal seam. Before coal seam static pressure water injection, high pressure water generated by an emulsion pump is injected into a drilled static pressure water injection drilled hole through a high pressure pipeline, high pressure water is injected into a coal body fracture by means of the cutting and fracturing effect of a water wedge generated by the high pressure water on the coal seam on the periphery of the drilled hole to overcome the minimum principal stress and the anti-fracture pressure of the coal body, so that fractures are broadened, extended and communicated; in the fracturing process, quartz sand is added into the high pressure water, the quartz sand enters the fractures along with the high pressure water, the effect of a supporting agent is achieved, and the water injection drilled hole is connected to a static pressure pipeline to perform static pressure water injection on the coal seam after hydraulic fracturing is finished. Before static pressure water injection is performed, the breathability of a water pre-injection coal seam is increased, so that the coal seam water injection speed is increased, and the water injection efficiency and effect are improved. According to the method, no special emulsion pump is needed, the running time of the emulsion pump is short, the drilling construction work amount can be decreased, and the water injection working efficiency is improved.

Owner:HENAN POLYTECHNIC UNIV

Workpiece spraying and processing device as well as processing method thereof

InactiveCN103962282AAvoid pollutionReduce labor costsLiquid surface applicatorsSpraying apparatusMechanical engineeringEngineering

The invention discloses a workpiece spraying and processing device as well as a processing method thereof. The device comprises a spraying device arranged at a spraying area, a drying chamber for drying workpieces and conveying devices arranged at the spraying area and the drying chamber, wherein the conveying devices comprise a first conveying device and a second conveying device which are respectively arranged at the spraying area and the drying chamber; a piece transferring device which is used for transferring workpieces is arranged between the spraying area and the drying chamber. According to the workpiece spraying and processing device provided by the invention, because the conveying devices at the spraying area and the drying chamber are arranged independently and separately, and the workpiece transferring device for transferring pieces is arranged between the spraying area and the drying chamber, each part of the conveying devices can be prevented from being polluted, and the transferring not only cannot increase labor cost, but also cannot lower the production efficiency, and additionally, the product quality is not affected, thereby saving energy, reducing consumption, improving the product quality, and improving the production efficiency and economical benefit of enterprises.

Owner:SHENZHEN LIUSH MACHINERY EQUIP

Piglet's mixed feed composition using dephenolized cottonseed protein

The invention discloses a piglet's mixed feed composition using dephenolized cottonseed protein. The piglet's mixed feed composition comprises the following raw materials by weight percent: 50-60 percent of corn, 6-15 percent of extruded corn, 3-8 percent of wheat bran, 8-15 percent of soybean meal, 6-10 percent of dephenolized cottonseed protein, 3-5 percent of fermented soybean meal, 0.6-1.2 percent of calcium hydrophosphate, 0.6-1.2 percent of stone powder, 0.10-0.50 percent of 98% lysine, 0.01-0.05 percent of methionine, 0.05-0.1 percent of choline chloride, 0.2-0.5 percent of salt and 1-1.5 percent of premix. The mixed feed is based on the normal corn and soybean meal type piglet's feed formula, and adopts 6-10 percent of dephenolized cottonseed protein to replace part of soybean meal to supplement part of synthetic amino acid without influencing the performance trait of piglets, and meanwhile, the weight gain cost of pork pigs is also lowered.

Owner:GUANGDONG EVERGREEN FEED INDAL +5

Production method of ferrotitanium

InactiveCN102392133AGranularity requirements are relaxedDoes not affect reactivitySmelting processFerrosilicon

The invention relates to a production method of ferrotitanium. The production method is characterized by comprising the following steps: carrying out arc strike by using ferrum-contained raw material to form a molten pool; putting titanium-containing raw material and lime into a refined electric furnace; carrying out electric-arc heating; in the melting process, adding ferrosilicon into the refined electric furnace to prepare slag and iron; adding the ferrum-containing raw material, lime and aluminum into the refined electric furnace to react with the slag, wherein the alloy generated in the reaction process sink and the slag floats up in the reaction process, and slag and iron are separated until reaction is finished; deslagging, and continuously smelting to finish the whole smelting process; and cutting off power supply, cooling and finishing to obtain the ferrotitanium. The production method has the advantages that requirement on the granularity of each raw material is not strict, processing procedures are reduced, the labor intensity of workers is lowered, the safety coefficient in the ferrotitanium production can be improved, the product recovery rate is improved, aluminum consumption is lowered, and production cost is lowered; and different models of ferrotitanium are produced, thereby breaking through a pattern that a single method can be used for smelting limited models of ferrotitanium.

Owner:CITIC JINZHOU METAL

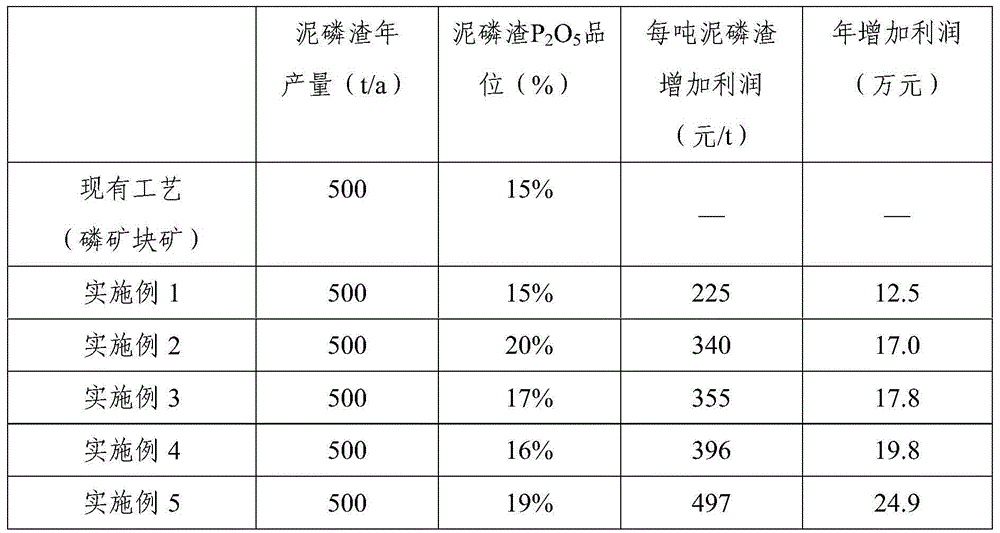

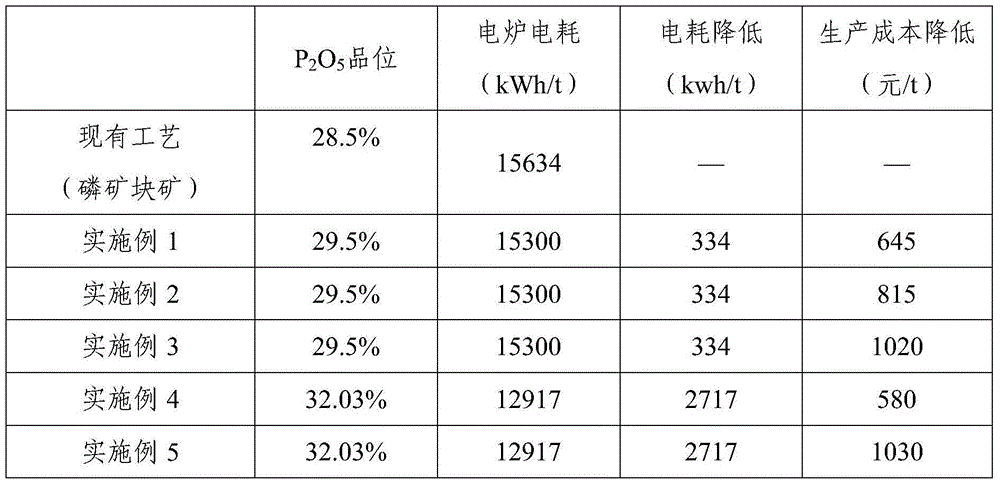

Method for producing yellow phosphorus with phosphor residue slag and ground phosphate rock

InactiveCN104925773ASolve the use problemDoes not affect productivityPhosphorus compoundsSlagPhosphor

The invention provides a method for producing yellow phosphorus with phosphor residue slag and ground phosphate rock. The phosphor residue slag and the ground phosphate rock are mixed according to the proportion being 1:1.0-3.0, a binder is added, a mixed material is obtained, the mixed material is equalized to be pressed into pallets, drying and solidification on the pallets are carried out, and the pallets are fed into a yellow phosphorus electric furnace for preparing the yellow phosphorus. By means of the method, comprehensive utilization of resources is achieved, environment pollution is reduced, and the aim of comprehensively using the phosphor residue slag and the ground phosphate rock is effectively achieved.

Owner:CHENGDU LESHI CHEM ENG

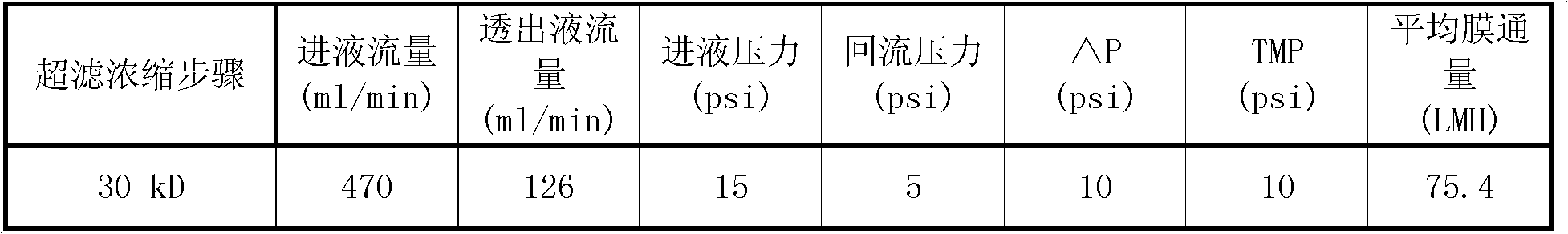

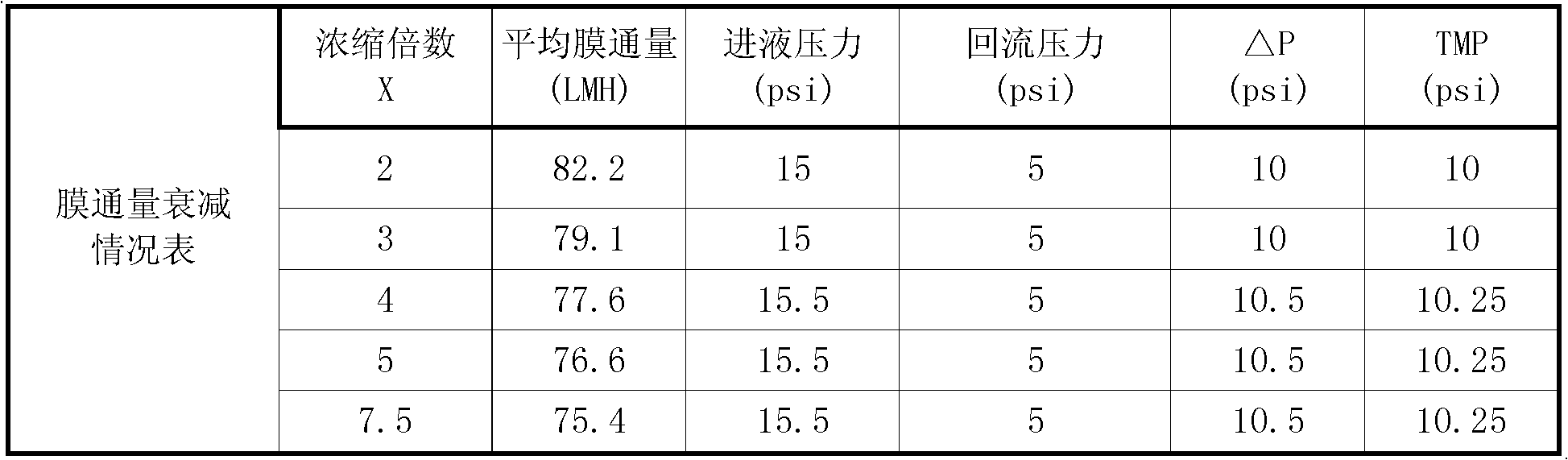

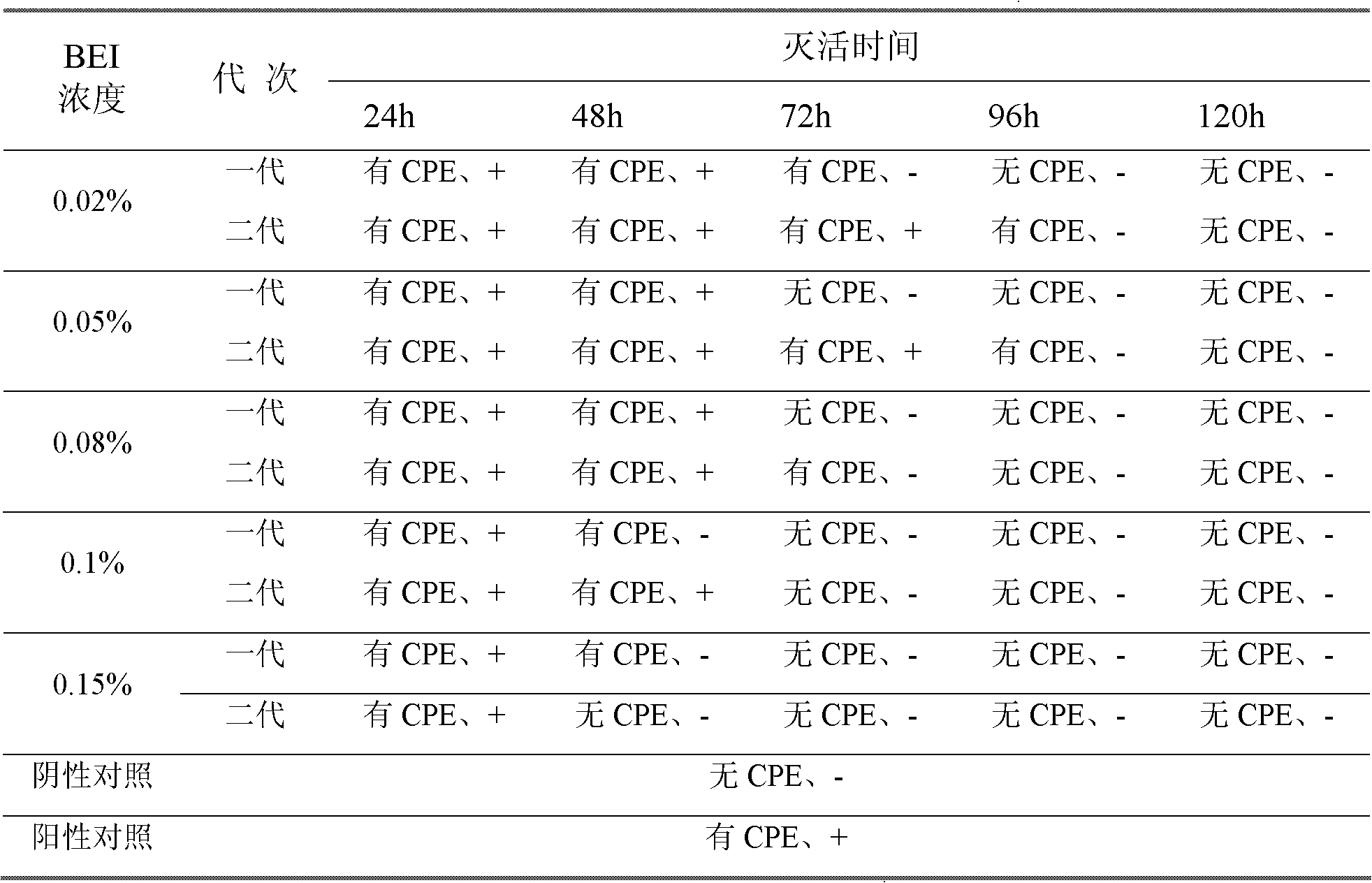

Preparation method of porcine parvovirus inactivated vaccine

InactiveCN102688485AHigh antigen contentRemove impuritiesAntiviralsAntibody medical ingredientsAntigenChemistry

The invention relates to a preparation method of a porcine parvovirus inactivated vaccine. The preparation method comprises the following preparation steps of: (1) taking a porcine parvovirus fluid out of a raw material tank, placing the porcine parvovirus fluid into a microfiltration system, filtering to obtain a penetrating fluid and a concentrated solution, returning the concentrated solution to the raw material tank, and discharging the porcine parvovirus fluid after the solid content of the porcine parvovirus fluid is larger than or equal to 1g / L; (2) carrying out ultrafiltration treatment on the penetrating fluid, and further concentrating the porcine parvovirus fluid until the virus hemocoagulate value is up to 28-213 to obtain a concentrated solution; (3) filtering the concentrated solution again by using the microfiltration system to obtain a parvovirus fluid with the hemocoagulate value of 28-213 after the treatment; and (4) inactivating the parvovirus fluid and preparing the concentrated and inactivated parvovirus fluid into a vaccine product. The invention provides a safe and feasible vaccine production method so that vaccine production is not dependent on the traditional process again, high-titer parvovirus fluid is produced, the antigen content is increased, and the requirement for immune production is met.

Owner:扬州优邦生物药品有限公司

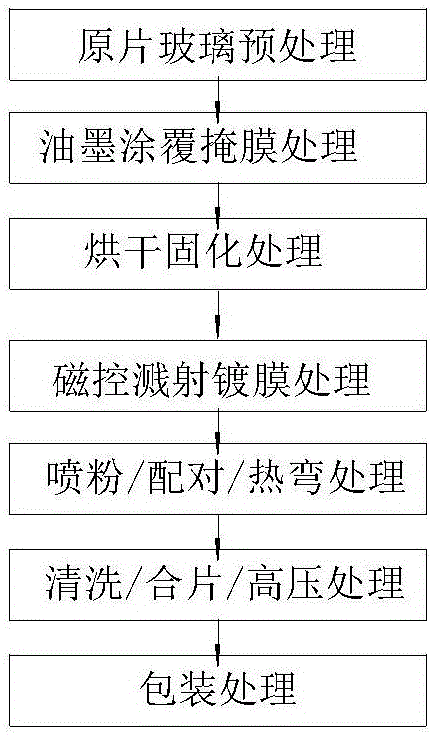

Method of removing film from edge of coated glass

The invention discloses a method of removing a film from edge of coated glass. The method at least comprises the following steps: 1) carrying out mask coating treatment on a region, without needing to coat the film, of glass to be coated by adopting low-temperature thermal decomposition ink; 2) carrying out drying and solidification treatment on the glass to be coated, which is treated in the first step; 3) carrying out magnetron sputtering coating treatment on the glass to be coated, which is obtained in the second step; and 4) carrying out powder spraying, matching, hot bending, cleaning, laminating, high pressure and packaging treatments on the glass obtained in the third step. A coated glass product prepared by the film removing method is beautiful in side boundary and reliable in quality and is suitable for edge film removing process of automobile glass.

Owner:信义超薄玻璃(东莞)有限公司

Method for synthesizing tetrabasic lead sulfate by utilizing positive electrode waste lead plaster and application thereof

InactiveCN103482690ALead sulfate accurateLead oxide accurateWaste accumulators reclaimingLead sulfatesCapacity lossElectrical battery

The invention discloses a method for synthesizing tetrabasic lead sulfate by utilizing positive electrode waste lead plaster and application thereof. The method comprises the following steps of washing, filtering, separating, dehydrating, drying, sieving and purifying the positive electrode waste lead plaster, and then, carrying out chemical analysis on a treated mixture, thereby obtaining contents of various components of lead sulfate, lead oxide and free lead in the treated mixture according to chemical analysis, adding lead powder to carry out mixing, grinding and sieving, so that the molar ratio of the lead oxide to lead sulfate after hybrid reaction is (4-5):1; and preserving the heat and presintering the sieved mixture in a resistance furnace, and then heating up to sinter, cooling and drying to obtain the tetrabasic lead sulfate. The method can be used for a storage battery manufacturer to prepare according to convenient conditions of the manufacturer, is simple and easy to implement; the prepared tetrabasic lead sulfate can completely satisfy performance requirements while being applied to battery production, so that early capacity loss of a lead storage battery is restrained, various electrical performances of the battery and a cycle life of the storage battery are greatly improved and prolonged, respectively, thereby not only solving a treatment problem of lead-containing waste materials of the storage battery enterprises, but also lowering production cost of enterprises and changing waste into things of value.

Owner:TIANNENG GRP JIANGSU SPECIAL POWER SUPPLY

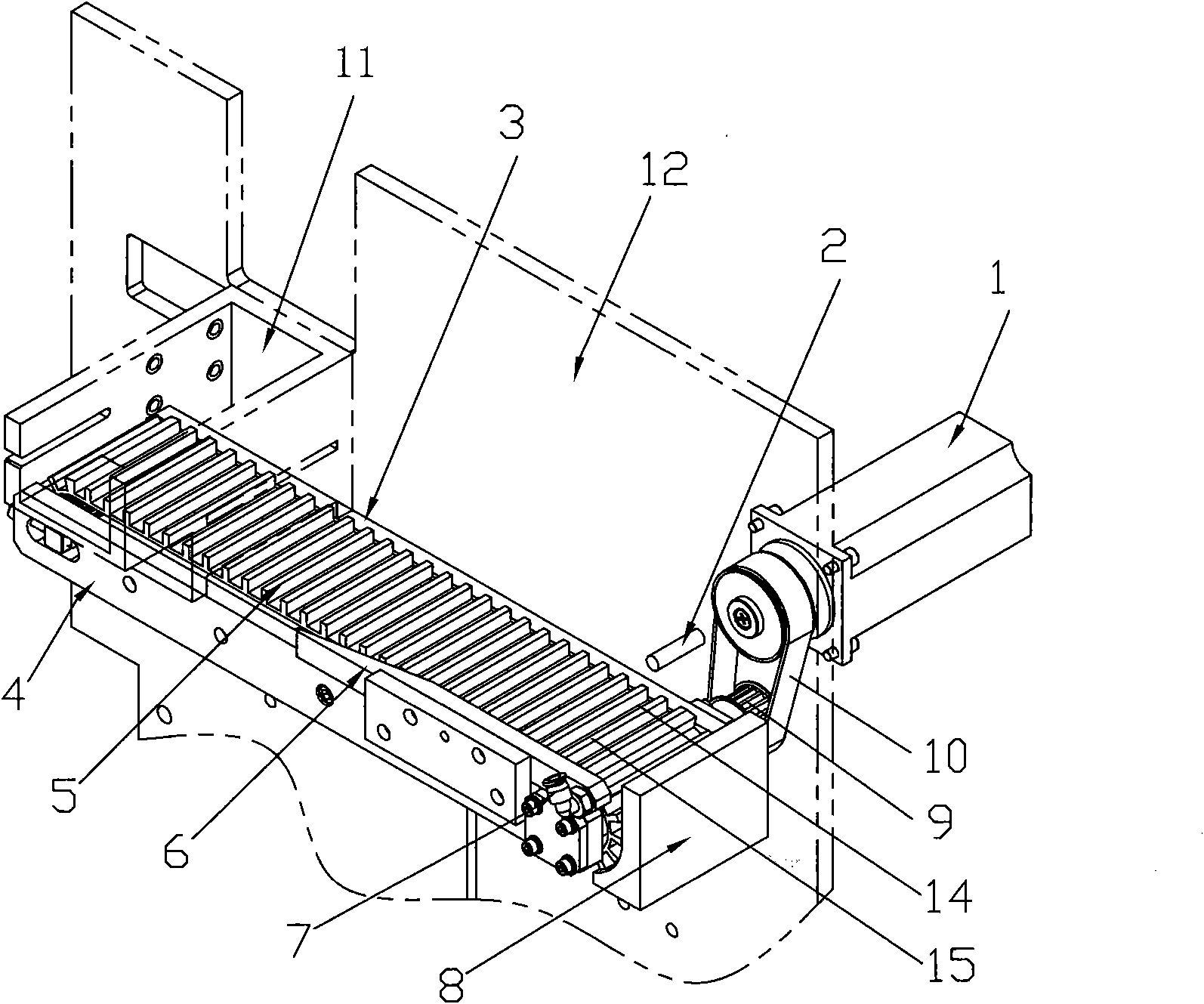

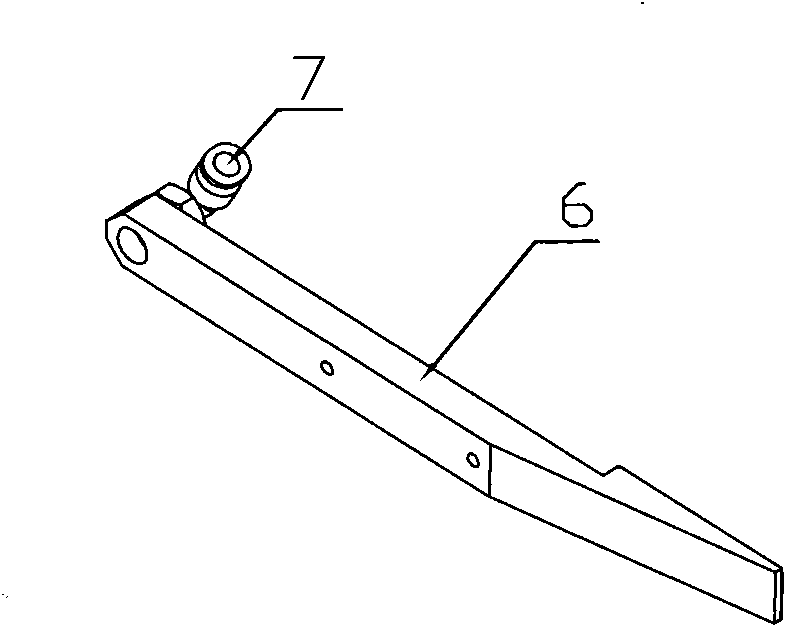

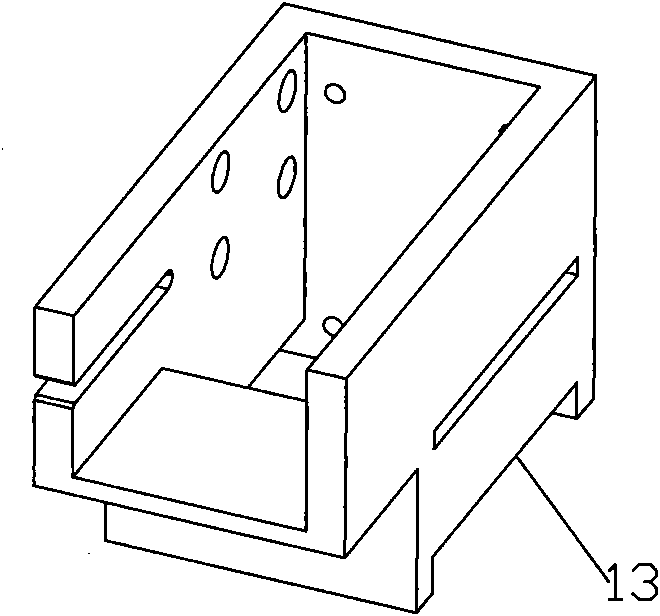

Battery replenishment device

InactiveCN103332427AWill not cause horizontalWill not cause overflow, etc.ChutesElectrical batteryElectrical and Electronics engineering

The invention provides a battery replenishment device, and belongs to the field of battery production. The replenishment device solves the problem that the existing battery replenishment device can complete battery replenishment only when production equipment is stopped. The battery replenishment device comprises a conveying trough conveying a battery from a previous procedure to a next procedure, a replenishment trough conveying the replenishment battery to an external wall of the conveying trough, and a switching mechanism, wherein a notch is formed in the external wall, where the replenishment battery reaches, of the conveying trough; the switching mechanism comprises a shifting block mounted at and articulated with the notch; and the shifting block is provided with a first limiting position rotating to the notch to close the notch, and a second limiting position rotating to the conveying trough to cut off a feeding channel of the conveying trough. The battery replenishment device has the advantage that the battery replenishment can be completed online without stopping the production equipment.

Owner:ZHONGYIN NINGBO BATTERY CO LTD

On-line detection and rejection device for cigarette packaging machine to reject cigarette

InactiveCN102431668AOrderly rowsReduce wastePackaging cigarettePackaging cigarsDrive shaftEngineering

The invention discloses an on-line detection and rejection device for a cigarette packaging machine to reject cigarettes and belongs to the technical field of cigarette making machines. The on-line detection and rejection device comprises a detection belt, a drive motor, a baffle, a wedge-shaped stop dog, side plates arranged on two sides of the detection belt and a hollow-head detection sensor, wherein a motor output shaft and the drive shaft of the detection belt are connected by virtue of a driving belt; one end of the detection belt is positioned below the smoke outlet of a baiting hopper; the other end of the detection belt is provided with the baffle; the side plate on one side of the detection belt is provided with the wedge-shaped stop dog; the end part, adjacent to the baffle, of the wedge-shaped stop dog is provided with a rejection air tap; and the part, which corresponds to the wedge-shaped stop dog, of the side plate on the other side is provided with the hollow-head detection sensor. According to the on-line detection and rejection device, hollow-head cigarettes in the baiting hopper of a recovery plant can be detected and rejected to reduce waste in the cigarette package and improve the effective operation rate. In addition, a plurality of cigarettes can be simultaneously discharged so as to improve the detection and rejection efficiencies.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

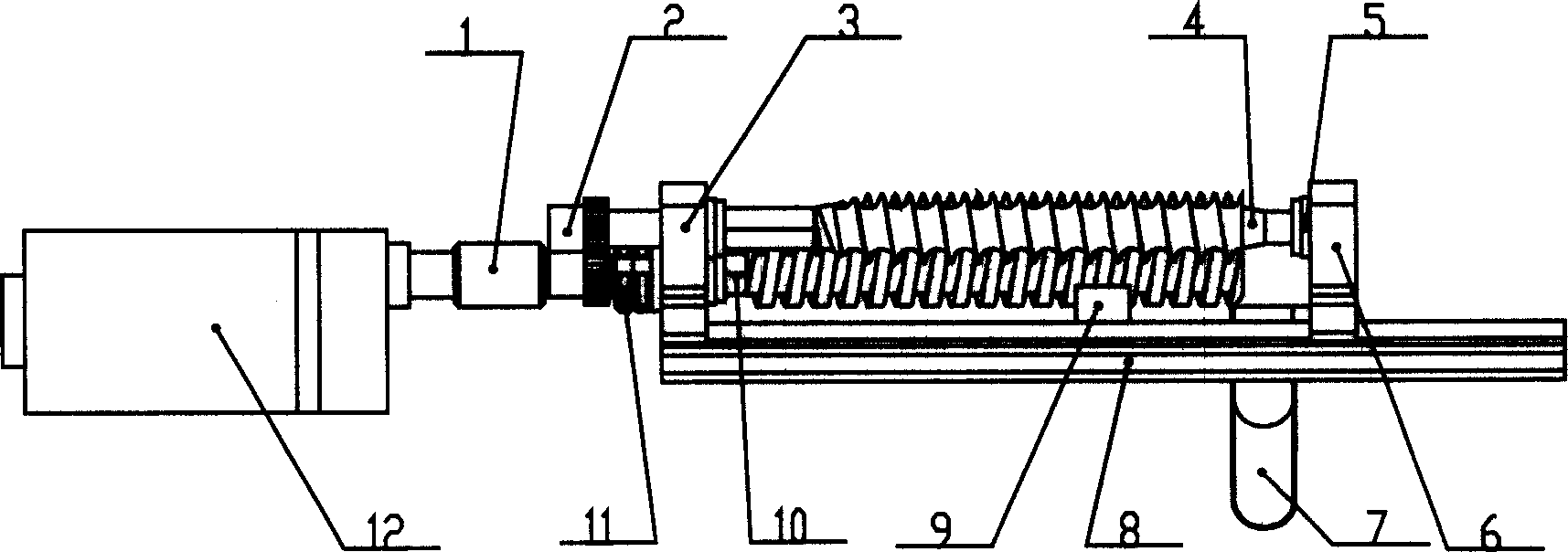

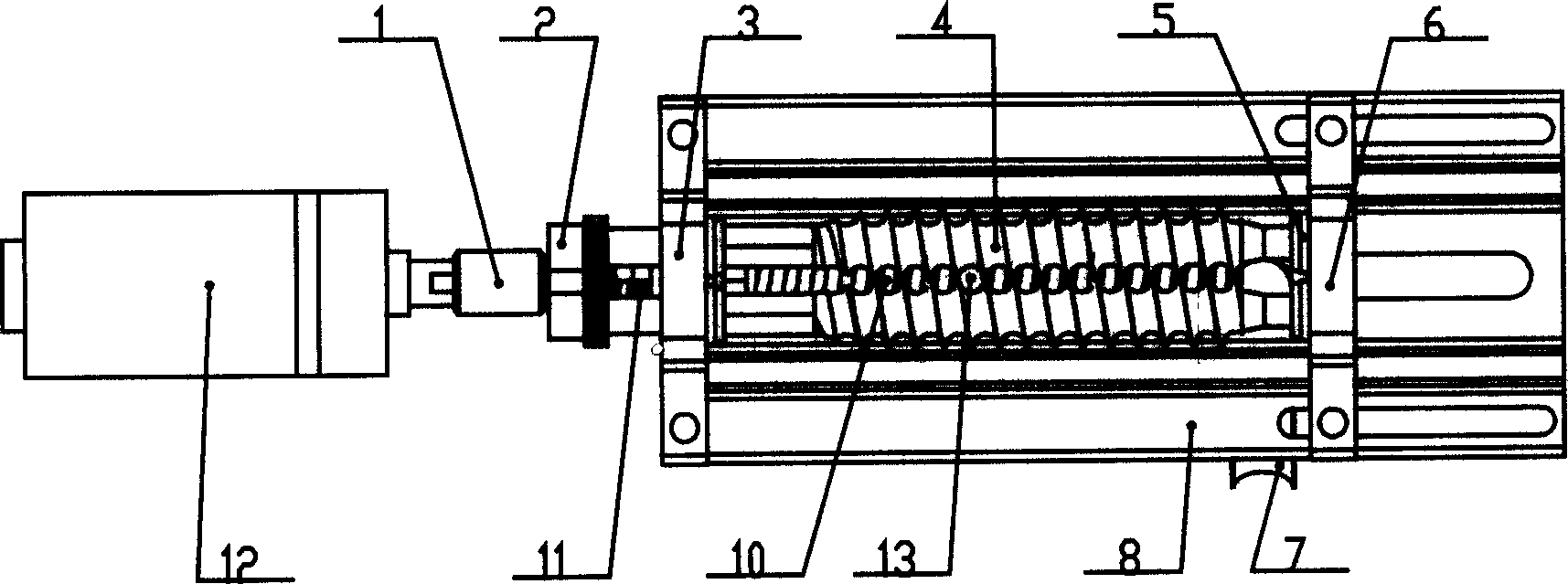

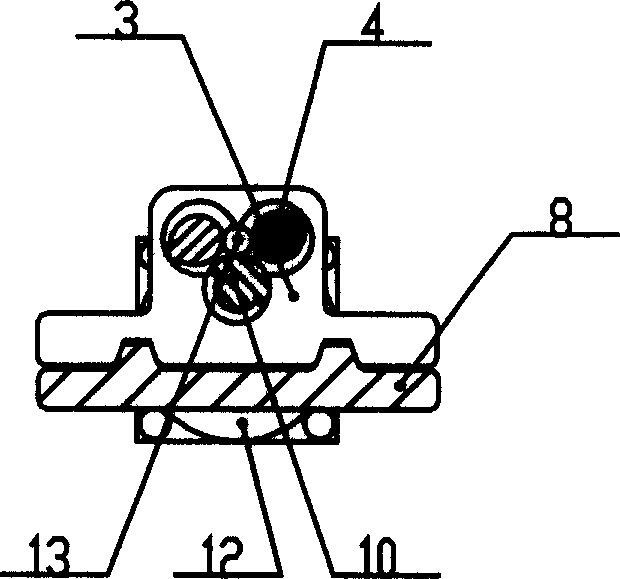

Machine for pelletizing Chinese gerbal medicine

InactiveCN1480122AThe process is simple and efficientAbandon productivityPharmaceutical product form changeCouplingGear wheel

A machine for preparing Chinese-medicinal pills is composed of AC motor with frequency varying speed regulation, supporting roller coupled to said motor via shaft coupling, two kneading rollers fixed via slide supporter, fixed supporter and bearing, guide track, and pill collecting slide way. Its advantage is high roundness and smooth surface of pills.

Owner:HEBEI UNIV OF TECH

Method for producing yellow phosphorus from phosphate rock powder and carbon powder

InactiveCN104891461ASolve the use problemDoes not affect productivityPhosphorus compoundsPhosphateYellow phosphorus

The invention provides a method for producing yellow phosphorus from phosphate rock powder and carbon powder. The method comprises steps as follows: the phosphate rock powder and the carbon powder are mixed in a production ratio and are pressed to form pellets after a binding agent is added, the pellets are dried and solidified, silica is added, and the mixture is sent into a yellow phosphorus electric furnace to prepare the yellow phosphorus. With the adoption of the method, the production cost of the yellow phosphorus can be averagely reduced by more than 800 yuan / ton; the problem about comprehensive utilization of the phosphate rock powder and the carbon powder is solved, and the problems of arching, material collapse and electrode breakage of the yellow phosphorus electric furnace are completely solved; the method has remarkable effects in the aspects of improvement of the yellow phosphorus production environment and realization of cleaner production.

Owner:CHENGDU LESHI CHEM ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com