Formula and preparation technology of light fiber-reinforced thermoplastic resin composite sheet material with high flame resistance

A technology for reinforcing thermoplastics and thermoplastic resins, which is applied in the field of manufacturing and molding fiber-reinforced thermoplastic resin composite materials, which can solve the problems of high processing costs of flame-retardant fibers, and achieve the effects of shortened production time, low cost, and simple and easy-to-operate production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

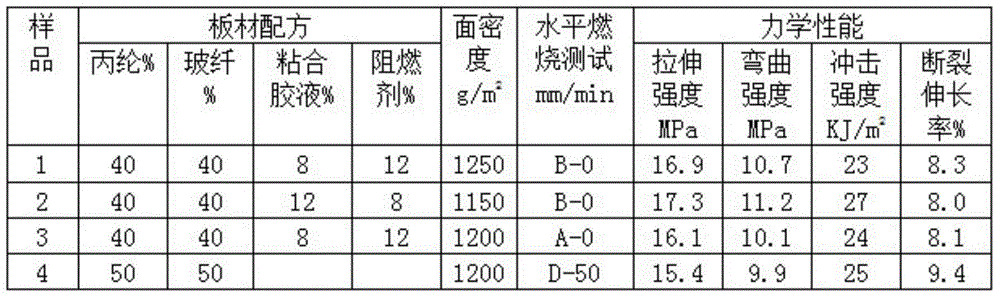

Examples

Embodiment 1

[0043] 40kg of basalt fiber and 40kg of polypropylene fiber are fed in the opener, after initial mixing, transported to the cotton storage bin, carded into a thin net, then 8kg of adhesive glue is sprayed on the thin net, and then 12kg of aluminum hydroxide is blocked. The burning agent is sprayed on the mixed fiber net, and the adhesive glue is mixed with 6.8kg of acrylate adhesive, 0.2kg of titanate coupling agent, 0.8kg of sodium montmorillonite, and 0.2kg of antioxidant 1010. The mixed fiber web of flame retardant is laid by a web laying machine, and then passed through a needle punching machine to form an intermediate product. The intermediate product is aged in a tenter oven at 190°C at a speed of 5m / min, and then enters into a 210°C hot press for 2s together with the adhesive film and non-woven fabric for molding, with a pressure of 10MPa, and is then cooled and shaped by a 25°C cold pressing roller. , made of flame retardant lightweight fiber reinforced thermoplastic r...

Embodiment 2

[0045] 40kg of bamboo fiber and 40kg of polyamide fiber were fed into the bale opener, after initial mixing, transported to the cotton storage bin, carded into a thin net, then 12kg of adhesive glue was sprayed on the thin net, and then 8kg of magnesium hydroxide was blocked. The burning agent is sprayed on the mixed fiber net, and the adhesive glue is mixed with 10.5kg of acrylate adhesive, 0.3kg of titanate coupling agent, 1kg of sodium montmorillonite, and 0.2kg of antioxidant 1010. The mixed fiber web of the fuel is laid by a web laying machine, and then an intermediate product is formed by a needle punching machine. The intermediate product is aged in a tenter oven at 210°C at a speed of 4m / min, and then enters into a 230°C hot press for 10s together with the adhesive film and non-woven fabric for molding at a pressure of 10MPa, and is then cooled and shaped by a 25°C cold pressing roller. , made of flame retardant lightweight fiber reinforced thermoplastic resin composit...

Embodiment 3

[0047] 40kg of carbon fiber fibers and 40kg of polyester fibers are fed into the opener, after initial mixing, transported to the cotton storage bin, carded into a thin net, and then sprayed with 8kg of adhesive glue on the thin net, and then 9kg of ammonium polyphosphate and 3kg of pentaerythritol flame retardant was sprayed on the mixed fiber net, and the adhesive glue was mixed with 6.8kg of acrylate adhesive, 0.2kg of titanate coupling agent, 0.8kg of sodium-based montmorillonite, and 0.2kg of antioxidant 1010. The mixed fiber web sprayed with flame retardant is laid by a web laying machine, and then passed through a needle punching machine to form an intermediate product. The intermediate product is aged in a tenter oven at 210°C at a speed of 4m / min, and then enters into a 250°C hot press for 5s together with the adhesive film and non-woven fabric for molding, and then goes through a 25°C cold-pressing roller to cool and shape. Flame retardant lightweight fiber reinforce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com