Patents

Literature

9388 results about "Adhesive glue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

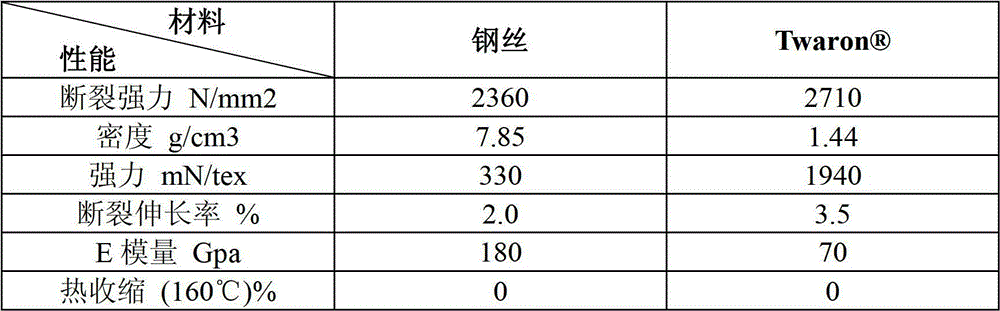

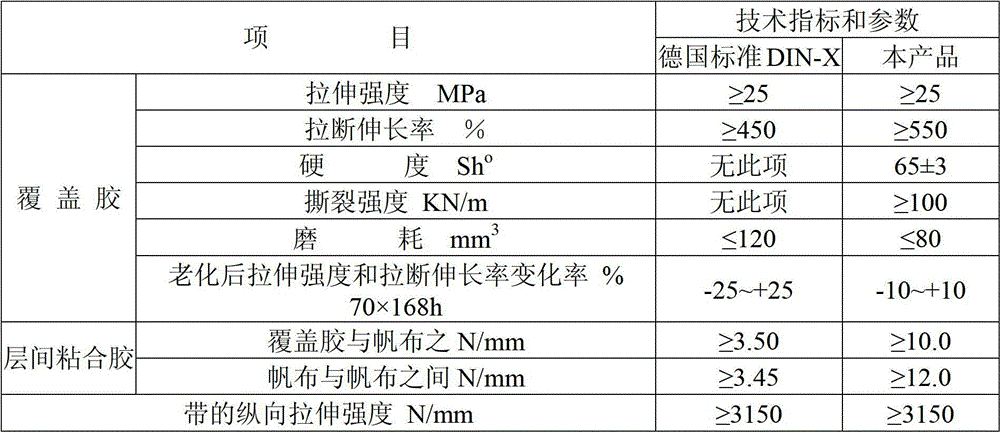

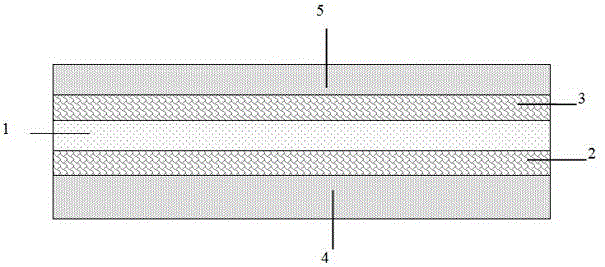

Energy-saving high strength aramid fiber conveyer belt and preparation method thereof

The invention relates to an energy-saving high strength aramid fiber conveyer belt and a preparation method thereof. The conveyer belt is composed of a skeleton layer, adhesive glue and an upper-lower cover adhesive laminated structure. Firstly, the skeleton layer employs aramid fiber canvas after dipping treatment to replace a conventional steel wire rope, so that the problems of large weight of the steel wire rope which brings much inconvenience for processes of shaping, installing, maintaining and the like is solved. Secondly, the aramid fiber canvas has structure in broadwise direction, has excellent anti-tear and anti-impact performances, so that phenomena of longitudinal tear and the like of the steel wire rope conveyer belt cab be prevented. Compared with a conventional steel wire rope high strength conveyer belt, the energy-saving high strength aramid fiber conveyer belt has high strength, good corrosion resistance, wear resistance and impact and fatigue resistance, and greatly reduce the weight and thickness of the conveyor belt, so that conveying power energy consumption is saved. The energy-saving high strength aramid fiber conveyer belt is expected to have longer service life and better energy-saving and environment-friendly properties, and is particularly suitable for long-distance material conveyance in industries such as coal mine, metallurgy, mine, etc.

Owner:WUXI BOTON TECH CO LTD +1

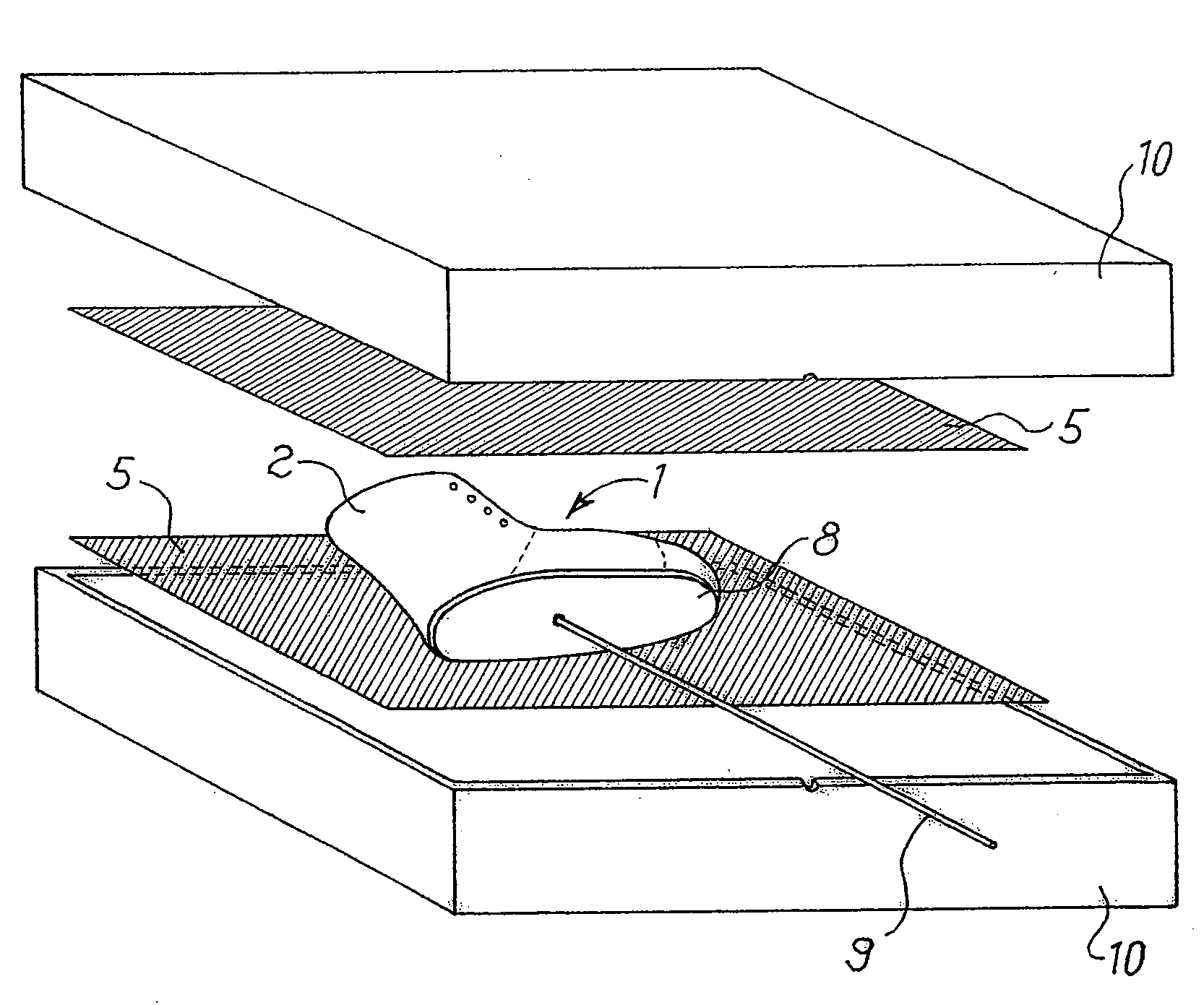

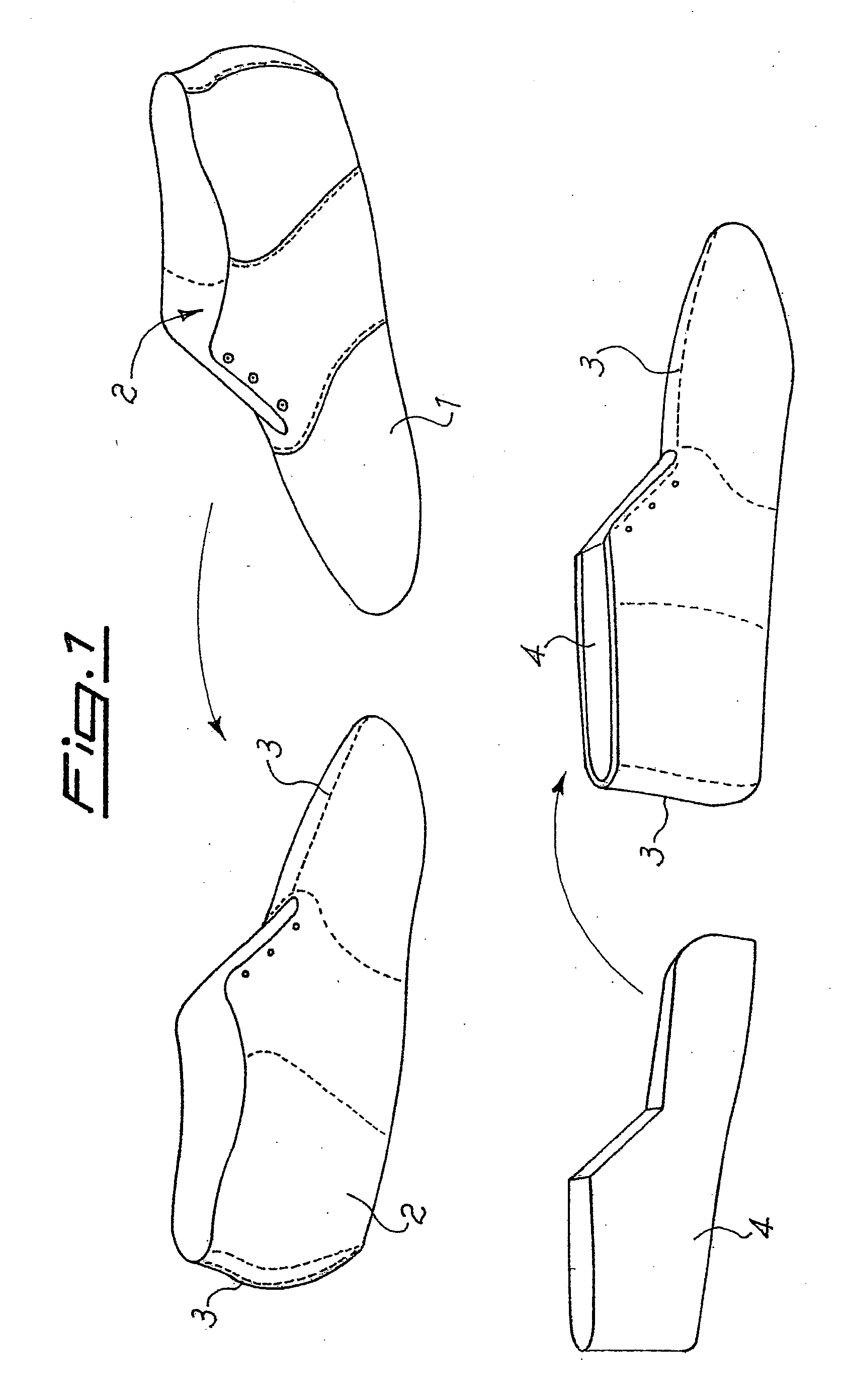

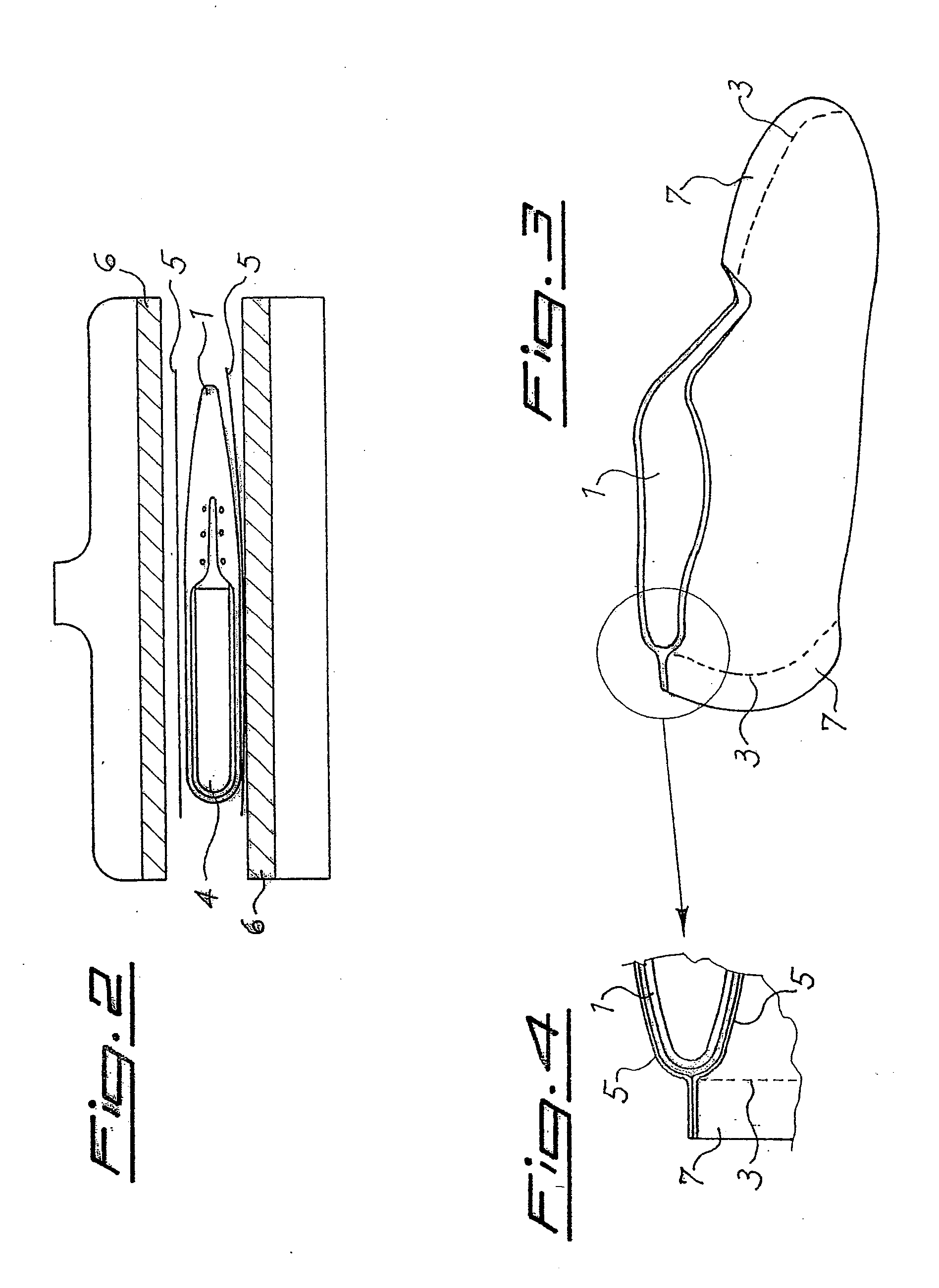

Semimanufactured Waterproofed Products, Particularly Shoes, Clothing Items and Accessories

InactiveUS20080127426A1Improve adhesionPhysical treatmentInsolesWork in processBiomedical engineering

Owner:OUTDRY TECH

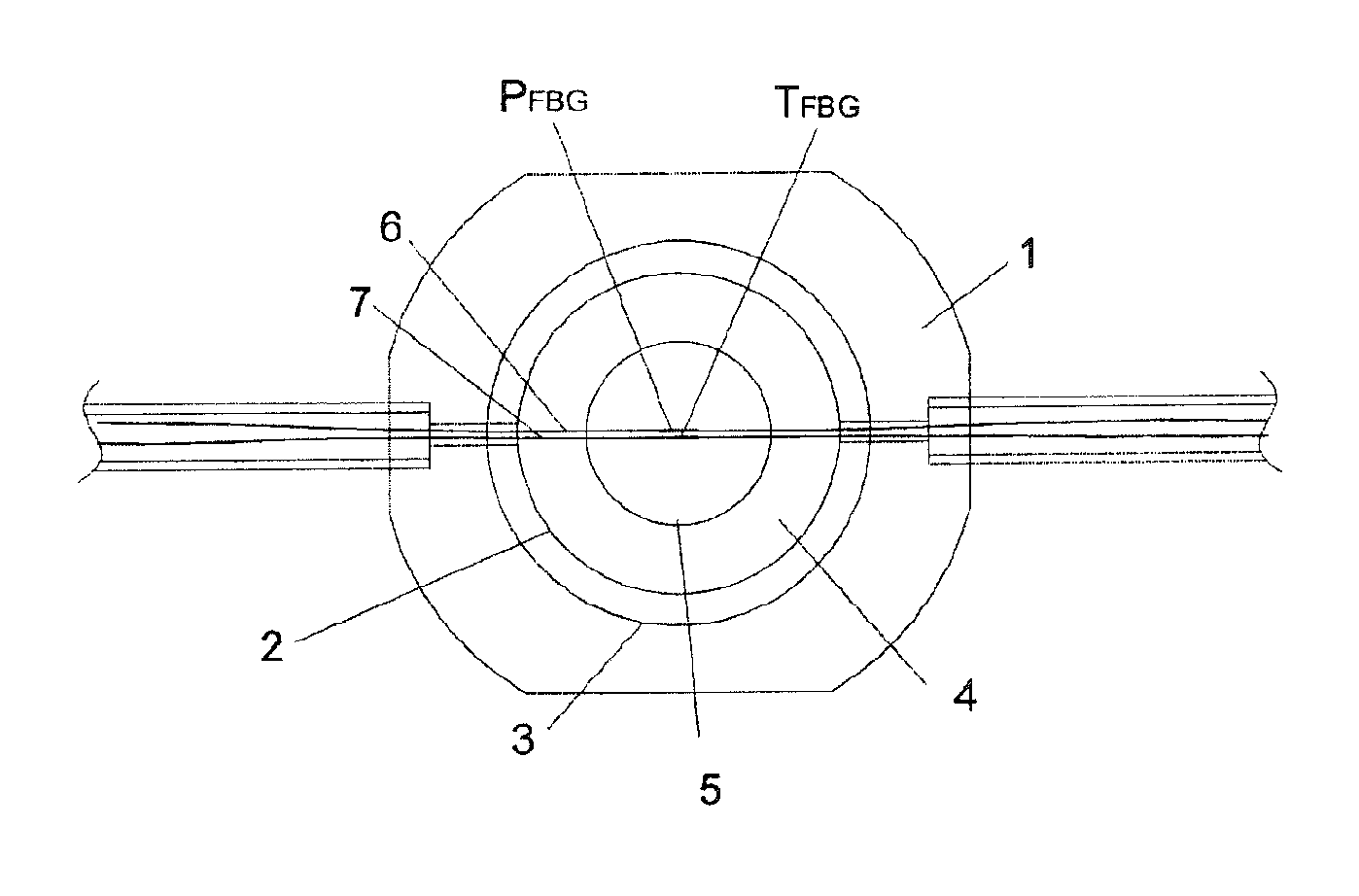

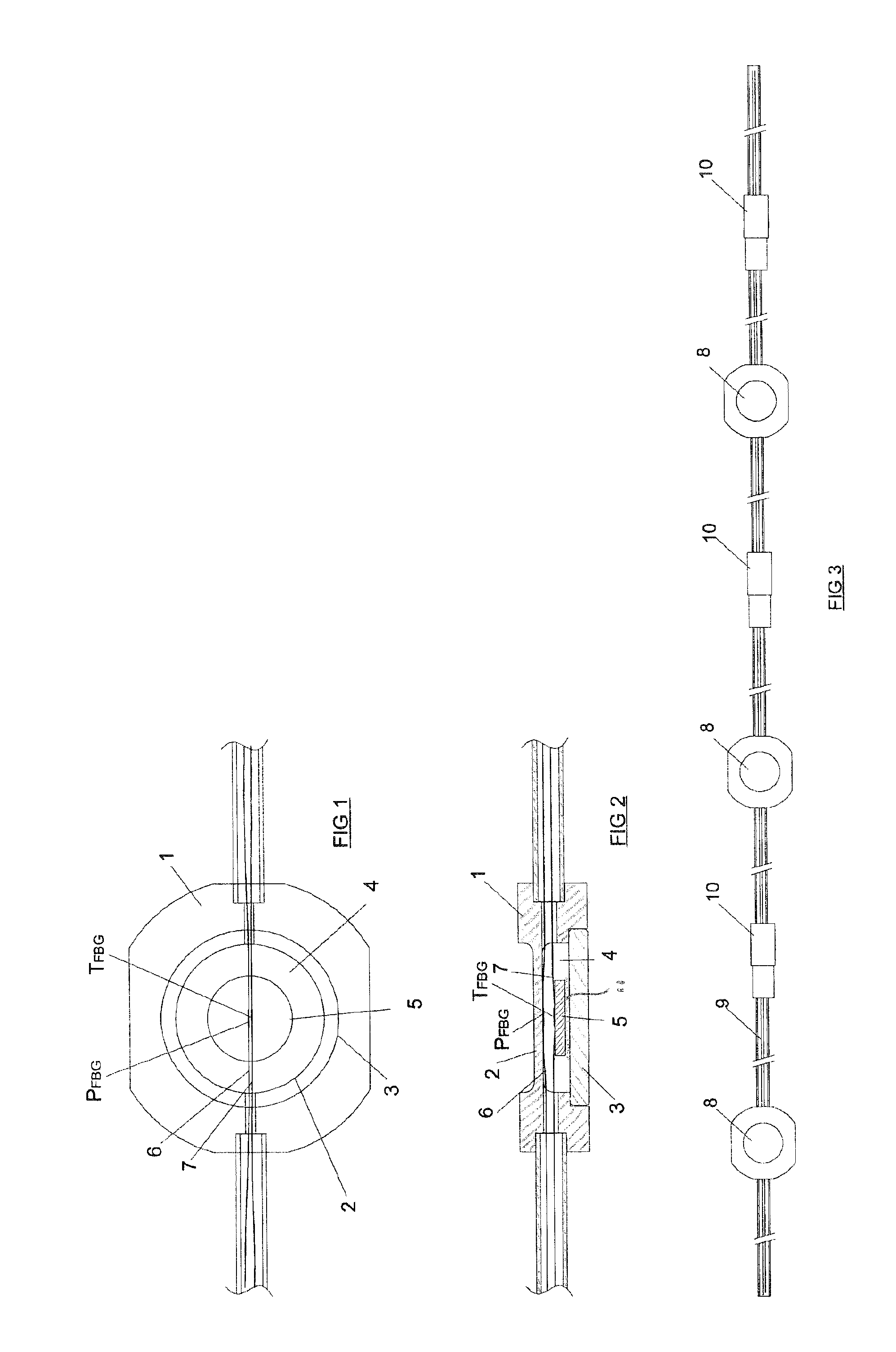

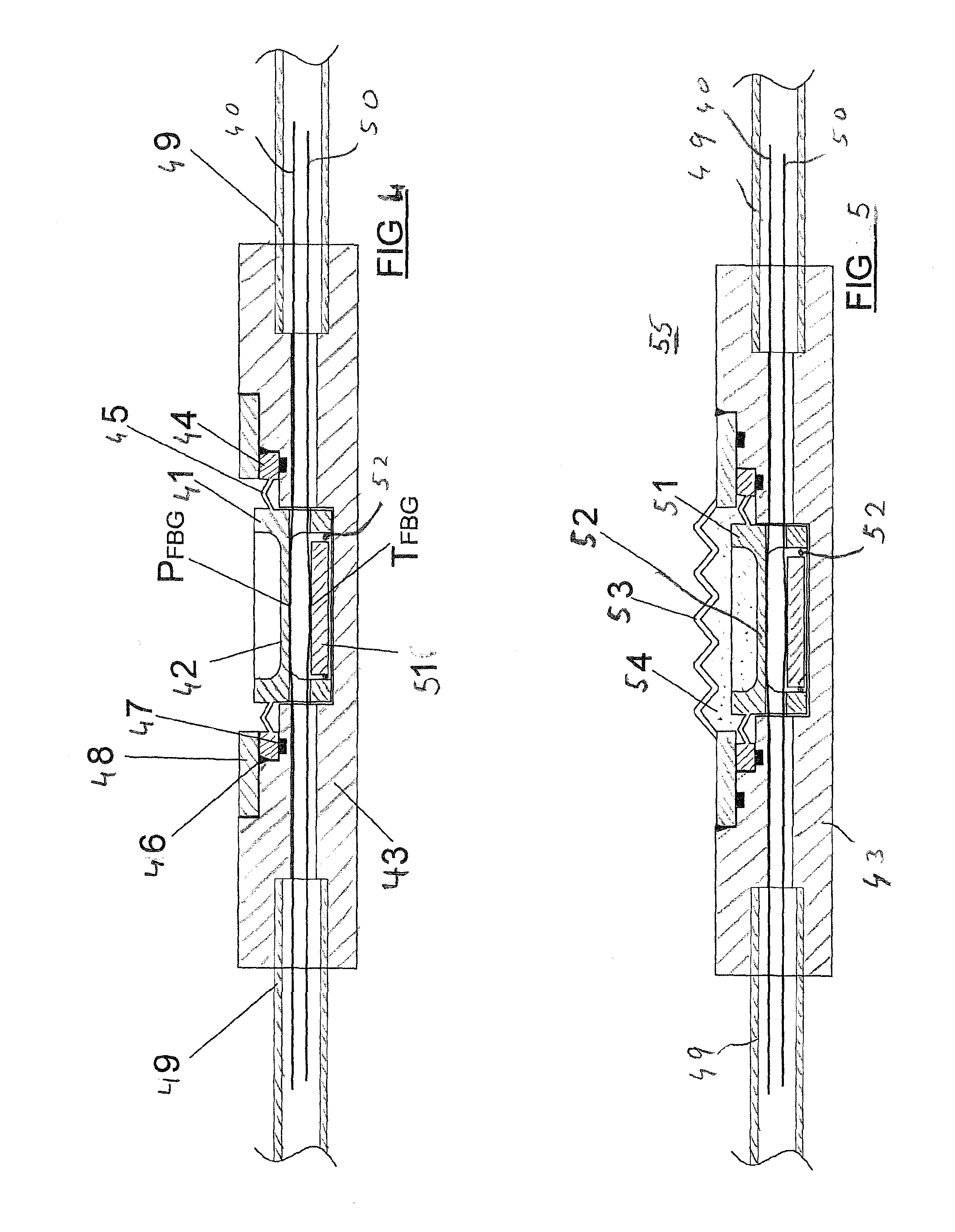

Pressure sensor assembly and method of using the assembly

A pressure sensor assembly comprises a sensor housing having a flexible wall that is configured to deform in response to a pressure difference between the interior and exterior of the sensor housing; —a first fiber optical cable section that is bonded to the flexible wall of the sensor housing such that the length of the first fiber optical cable section changes in response to deformation of the wall in response to the said pressure difference; a second fiber optical cable section which is bonded to a thermal reference body, which body is connected to the sensor housing by a strain decoupled connection mechanism, such as a tack weld or flexible glue, and is configured to deform substantially solely in response to thermal deformation, such that the length of the second fiber optical cable section solely changes in response to thermal deformation of the thermal reference body.

Owner:SHELL USA INC

Method and Composition for Treatment of a Well

InactiveUS20080261834A1Without increasing cost of placementLow costLayered productsFlushingEngineeringSolid material

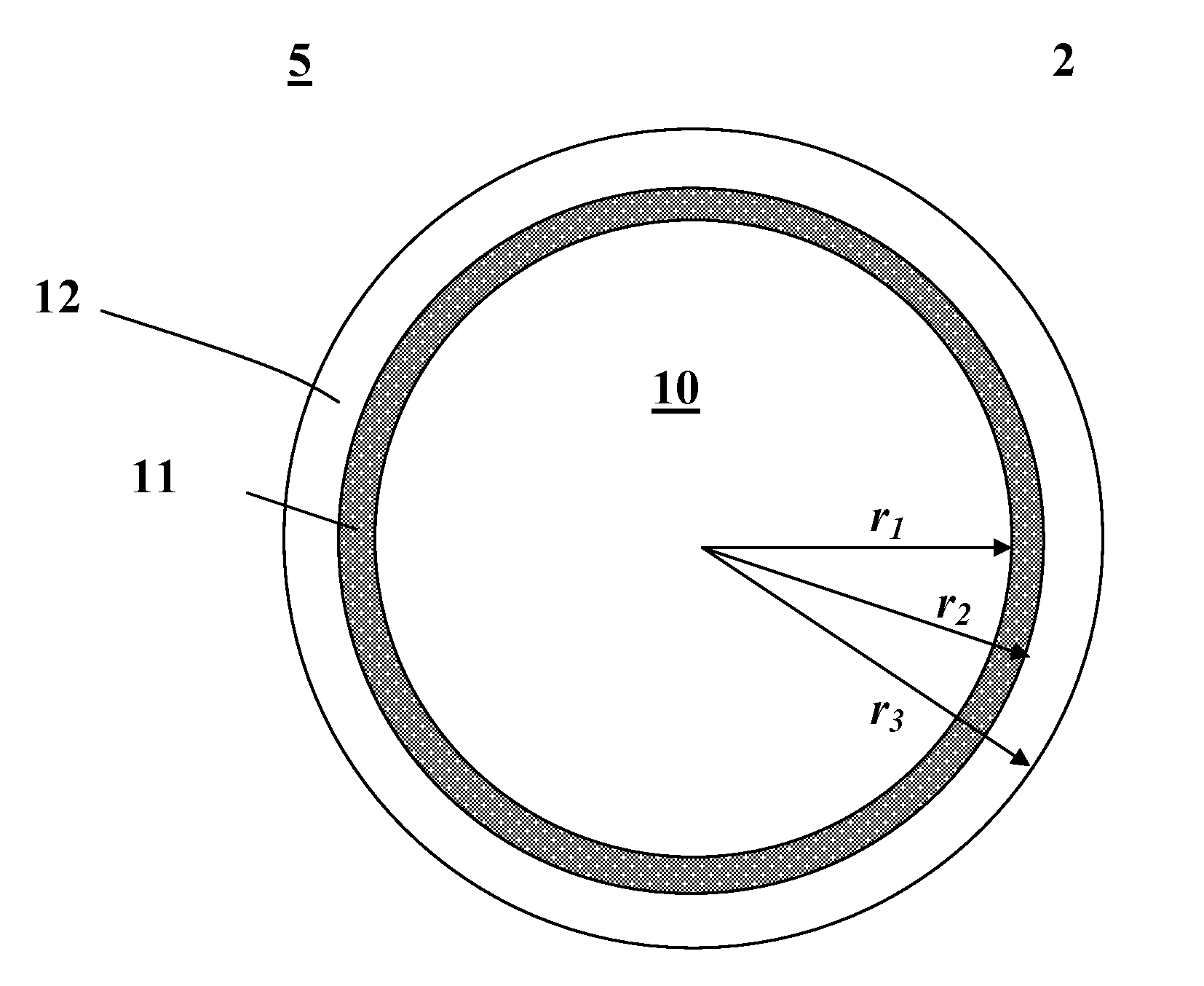

The invention provides a material comprising: a core made of a solid material; a first layer surrounding the core made of a swellable material able to swell in contact with a fluid ; a second layer surrounding the first layer made of a glue material able to glue to a third element.

Owner:SCHLUMBERGER TECH CORP

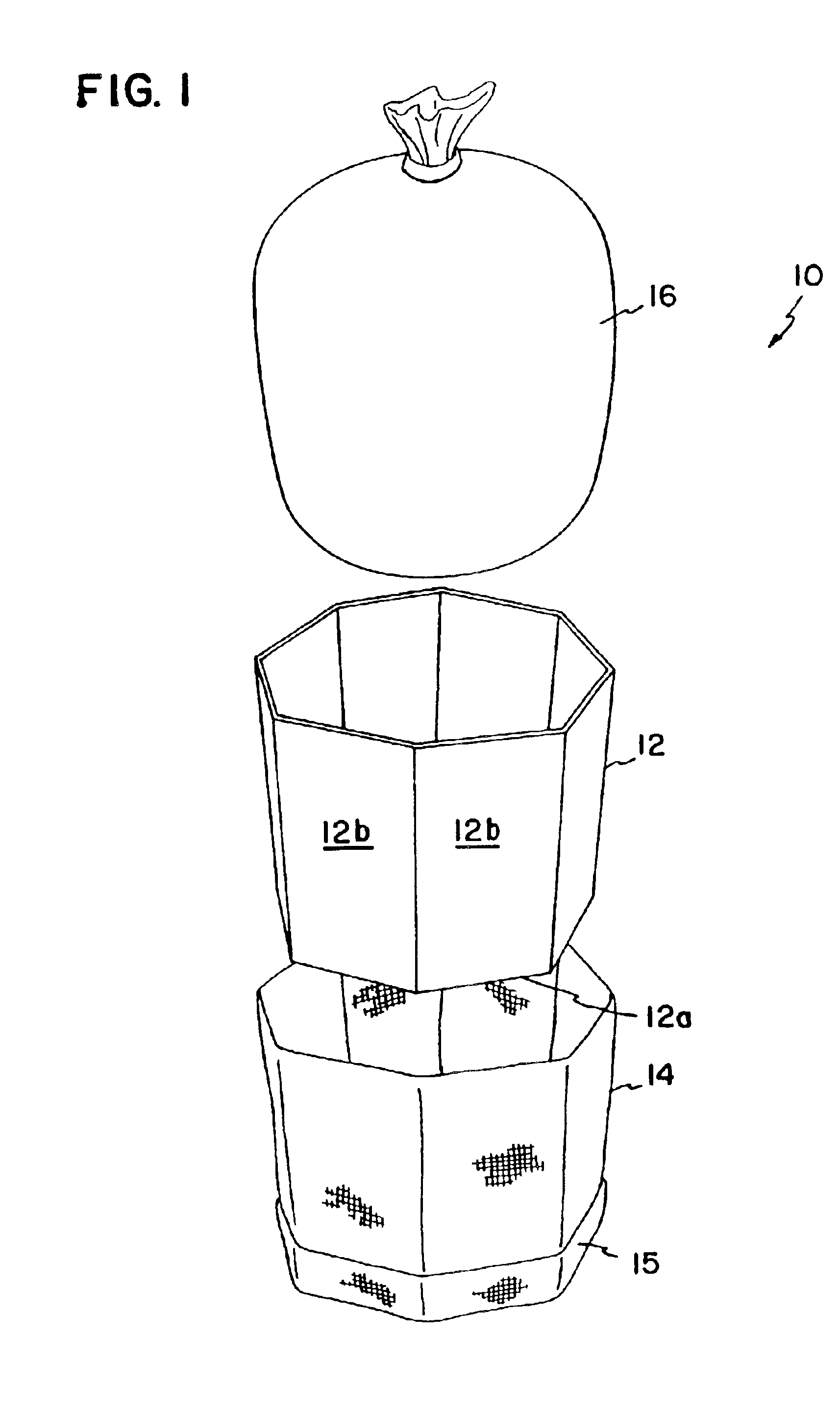

Collapsible bulk material container

InactiveUS6932266B2Easy erectionHigh strengthMetal working apparatusRigid containersPolypropyleneStructural shapes

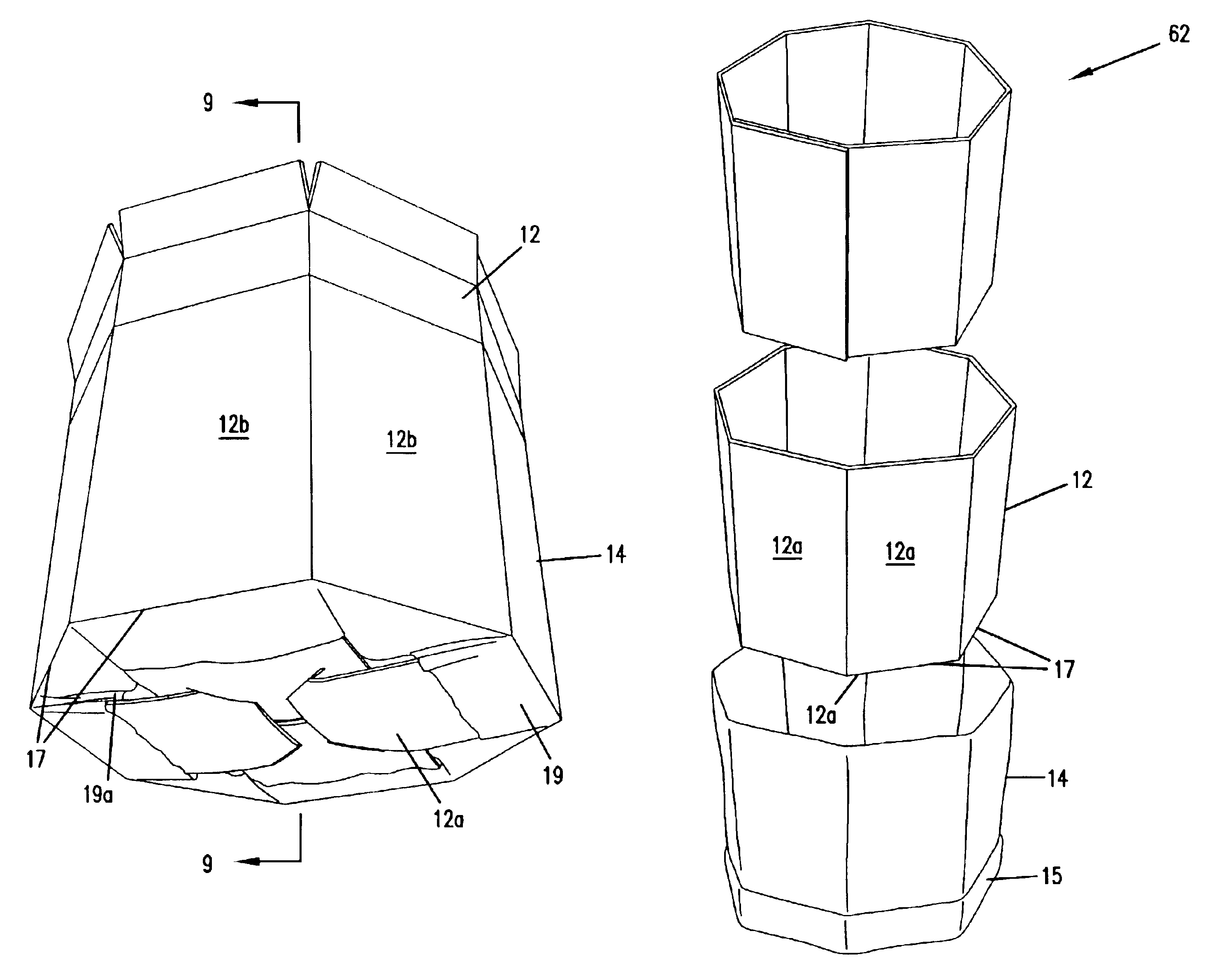

A container assembly for bulk materials and a kit for assembling same are disclosed. A forming member having a plurality of sidewalls defines an internal cavity for receiving bulk materials. The sidewalls are arranged relative to one another and are locked into position so as to define a geometric volume of predetermined shape, by means of a locking assembly. The locking assembly can be integrally attached to or can be separable from the sidewalls, and can form a bottom of the container assembly. A tubular sleeve of continuous material is sized to snugly engage and overlie substantially the entire outer surface area of the sidewalls. The sleeve provides the containment strength, while the forming member provides structural shape and stability to the container assembly. Additional layers of corrugated material or woven polypropylene material or their combination may be used as inserts engaging the inner peripheral sidewall areas of the forming member to provide additional strength to the container assembly. The forming member sidewalls may be freely slidable relative to one another or may be slidably affixed to one another by releasable glue.

Owner:RMC JONES

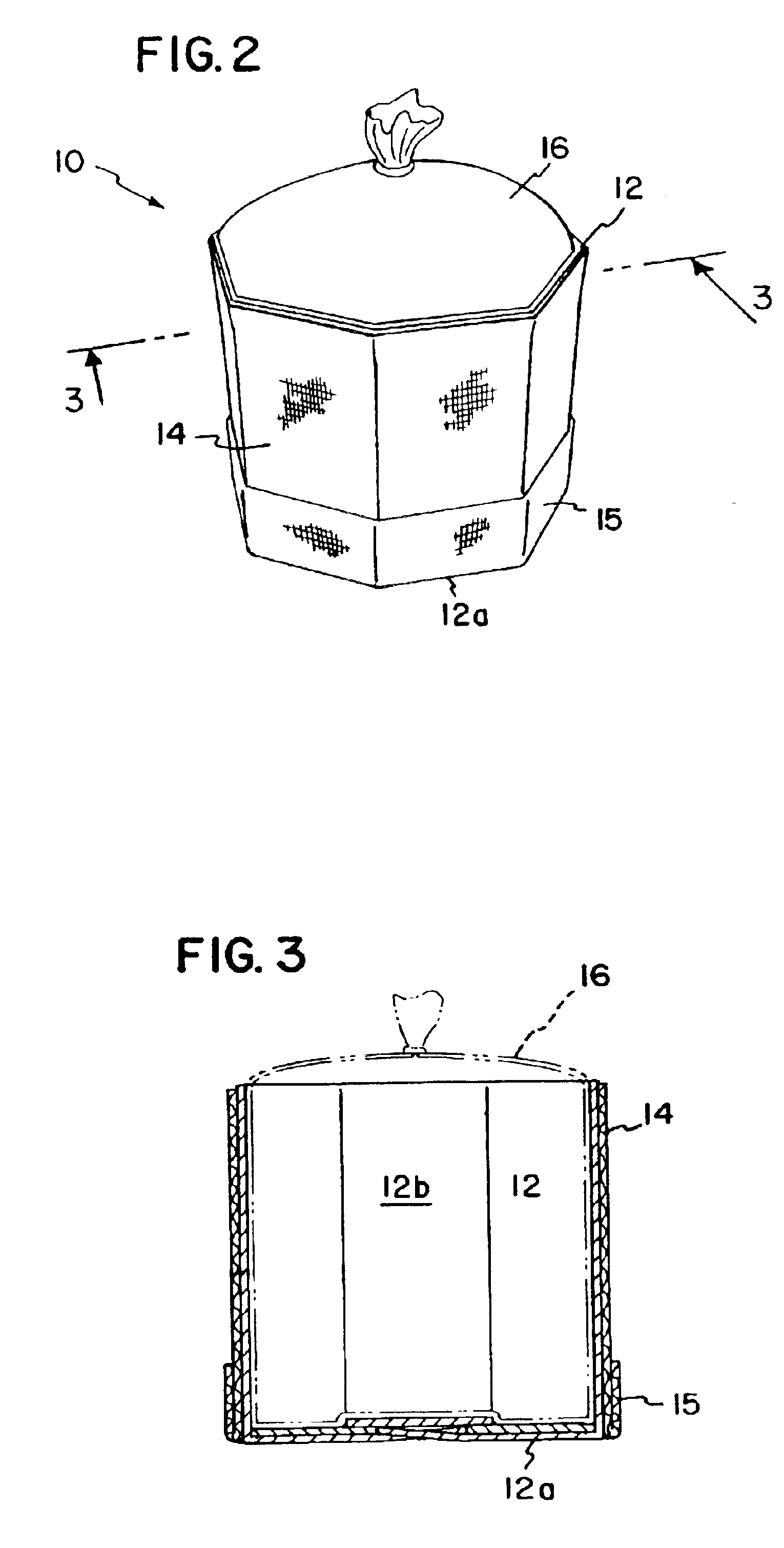

Heating cable guide strip for electric radiant floor heating and method of use

ActiveUS7250570B1Quick and efficientEasy to installLighting and heating apparatusHeater elementsEngineeringFlexible cable

A heating cable guide strip for retaining and guiding a resistance heating cable in a serpentine path on a sub-floor adapted to receive a cementitious material to form a radiant heated floor is described. The method of use is also described. The heating cable guide strip is molded of plastics material and defines an elongated flat base having a plurality of spaced-apart wire retaining guide members. The retaining guide members have at least a curved section for guiding the heating cable along a curved path about one or more of the guide members. The guide members further have a flexible cable retention flange to permit the positioning and retention of the cable captive between opposed ones of the retaining guide members. The heating cable guide strip is attached to the sub-floor by glue, nails or screws.

Owner:FLEXTHERM

Unbonded non-masonry building block components

Non-masonry building block components, including a standard hollow-bodied block component with horizontal and vertical locking capabilities which removes the need for bonding material such as glue, mortar or other adhesives. Modified dovetails on the upper and lower surface of the building components prevent vertical movement while resistance locks on each end of the block prevent horizontal movement. Typically, use of the non-masonry building components would allow for constructing permanent or temporary structures having vertical and horizontal channels in which to allow plumbing or electrical conduit. The incorporation of materials, such as sand or similar substance, would form a bullet-resistant barrier for use in military operations. Additionally, structures formed from the block components could easily be assembled or disassembled on site without the need for skilled labor, specialized tools, demolition and clean up.

Owner:HUMPHRESS DAVID L +1

Peelable sealing sheet for individual pill containers and method for manufacturing the same

A sealing sheet for use to close in a reversible manner a plurality of individual pill containers formed in a plastic sheet. The sealing sheet has a top layer, an adhesive layer and a peelable backing. The top layer and the adhesive layer are made of paper. The adhesive layer has a plurality of spaced apart holes punched therein, which are surrounded by adhesive layer bands having an upper surface that is covered with an upper layer of pressure sensitive adhesive glue and is attached by this glue to the top layer, and a lower surface covered with a lower layer of removable re-positionable pressure sensitive adhesive glue. The peelable backing also has a plurality of spaced apart holes that are positioned, shaped and sized to be in exact superimposition below the holes of the pressure sensitive adhesive glue layer. The holes of the backing are surrounded by backing bands having an upper surface detachably fixed to the lower surface of the adhesive layer bands by means of the lower layer of removable re-positionable pressure sensitive adhesive glue. In use, the backing bands can be peeled off from the pressure sensitive adhesive glue layer bands to allow fixation of the sealing sheet onto the container-defining sheet. Tearing lines are punched into both the top layer and the pressure sensitive adhesive glue layer bands in such a manner and position as to allow the top layer and pressure sensitive adhesive glue layer to be split into a number of cover pieces equal to the number of holes made in the pressure sensitive adhesive glue layer.

Owner:9155 0020 QUEBEC

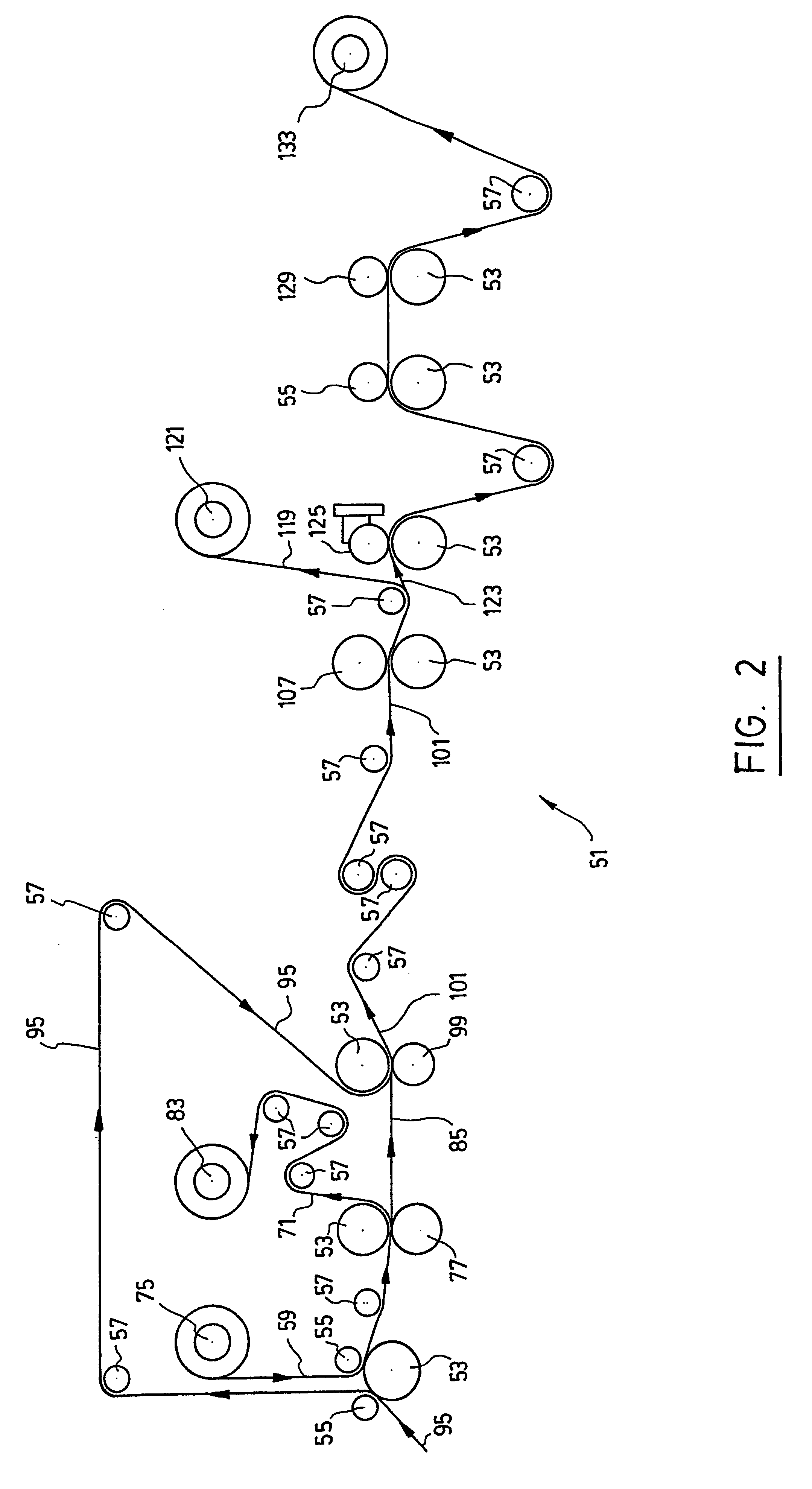

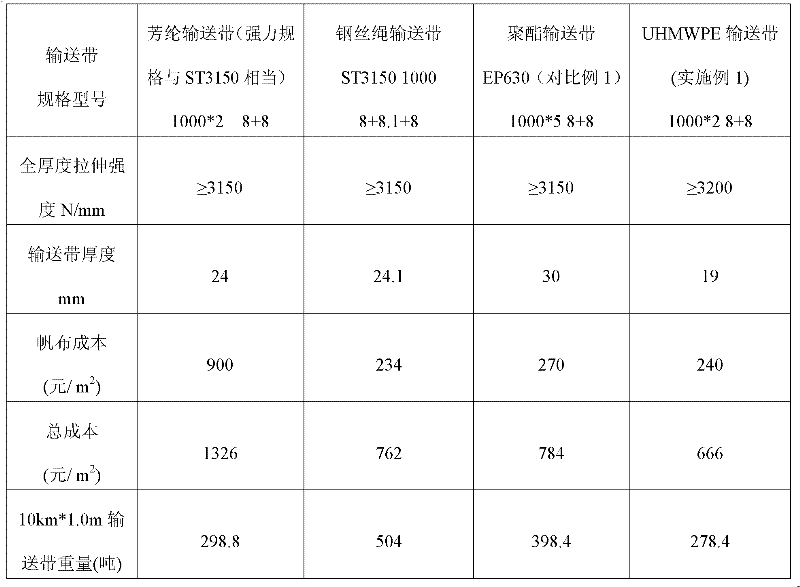

Light and high-strength rubber conveyor belt and preparation method thereof

The invention relates to a light and high-strength rubber conveyor belt and a preparation method tof the conveyor belt. The conveyor belt comprises a framework layer, an adhesive glue, and upper and lower cover rubber laminated structures; the framework layer adopts mixed woven canvas of ultra-high molecular weight polyethylene fibers and polyester fibers which are treated by plasma, simultaneously adopts low-temperature vulcanization technology to be subjected to covulcanization with the adhesive glue and a cover rubber at a low temperature, and solves the problem of the bonding of ultra-high molecular weight polyethylene fiber cloth and rubber. Compared with the conventional high-strength conveyor belt of wire rope core, the light and high-strength rubber conveyor belt in the invention not only has high strength, and good corrosion resistance, wear resistance, shock resistance and fatigue resistance, but also greatly reduces the weight and thickness, thereby reducing the conveying power energy consumption, which is expected to have long service life and good energy saving and environment friendly performances. Therefore the light and high-strength rubber conveyor belt disclosed in the invention is particularly suitable for the long-distance material conveying in the industries of coal mine, metallurgy, mine and the like.

Owner:BEIJING UNIV OF CHEM TECH +1

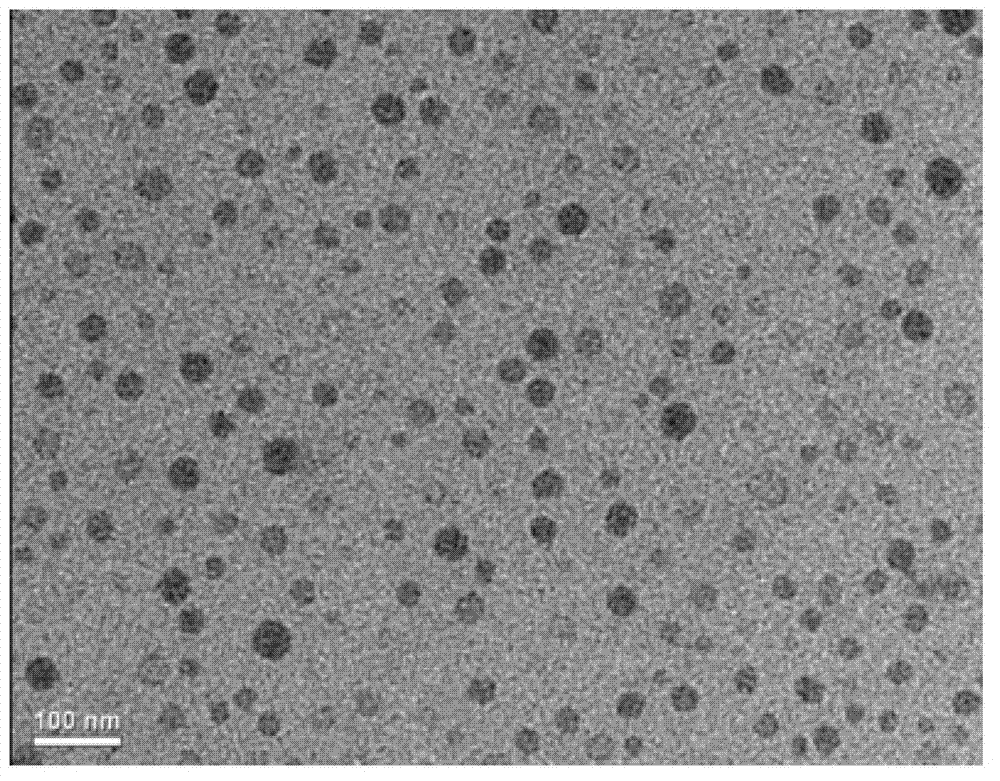

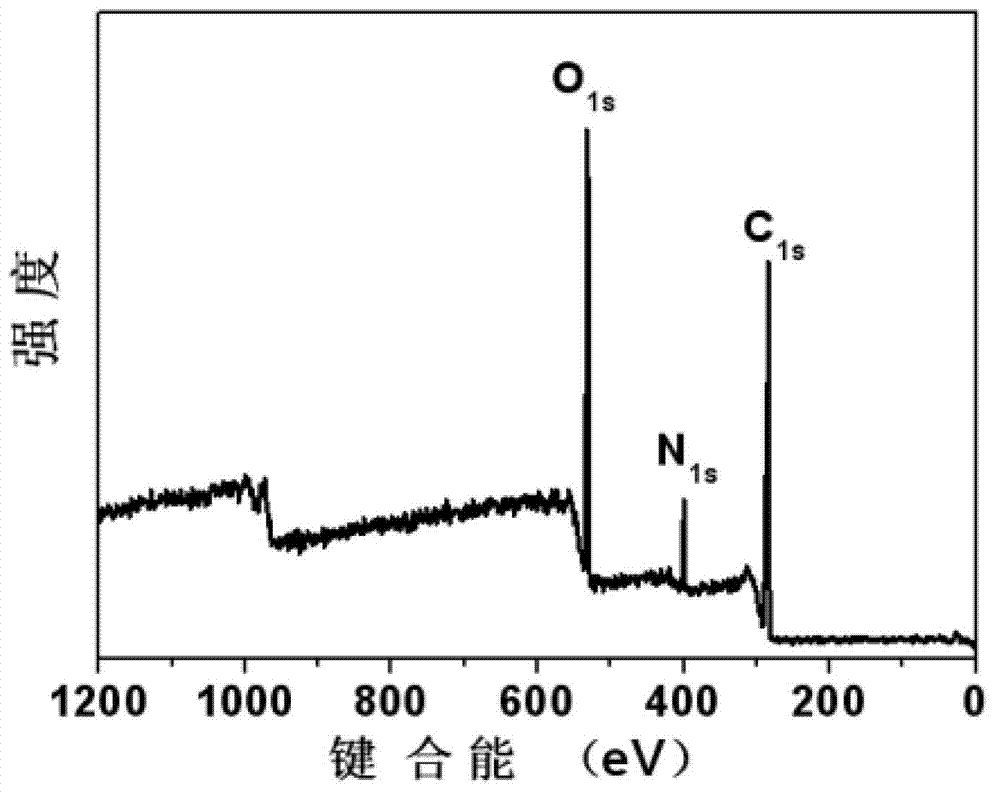

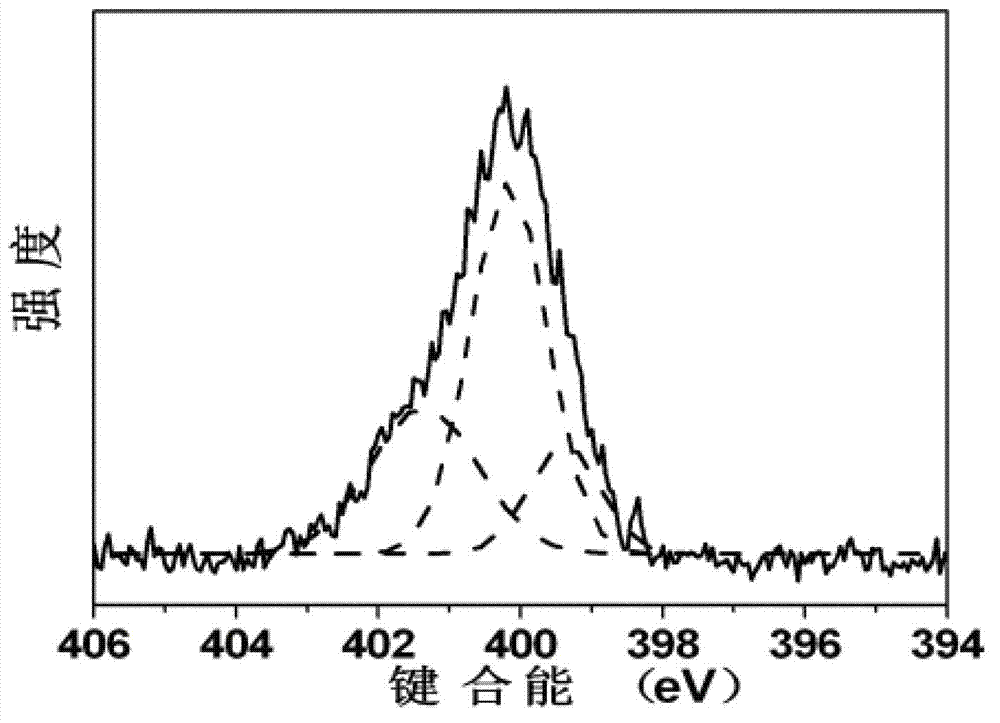

Nitrogen-doped carbon nanometer particle as well as preparation method and application thereof

InactiveCN103113886AOvercoming the technical problem of easy fluorescence quenchingEasy to prepareNon-macromolecular adhesive additivesInksMicrowave methodSolvent

The invention discloses a nitrogen-doped carbon nanometer particle as well as a preparation method and application thereof, belongs to the field of nanometer material science and is used for solving the technical problems that fluorescence quenching is easily caused to the aggregative state of the carbon nanometer particle due to surface passivation modifier which is added for the preparation of existing carbon nanometer particles. The nitrogen-doped carbon nanometer particle is prepared through a microwave method by using organic compounds containing polycarboxyl or polyhydroxy as materials and using ammonia water as a solvent and a nitrogen doping source. The invention further provides the application of the nitrogen-doped carbon nanometer particle as fluorescent ink and fluorescent glue. The preparation method disclosed by the invention is simple, low in cost, and convenient to realize large-scale production; the maximal fluorescent quantum efficiency of the solid film formed by the prepared fluorescent glue is as high as 84%; the prepared fluorescent ink is non-toxic, generates no precipitates after being placed for a long time, is strong in fluorescence characteristic and can be applied to various fields such as bio-imaging, biological product identification, information storage, information encryption, counterfeiting prevention, illumination and display, sensing and photovoltaic devices.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

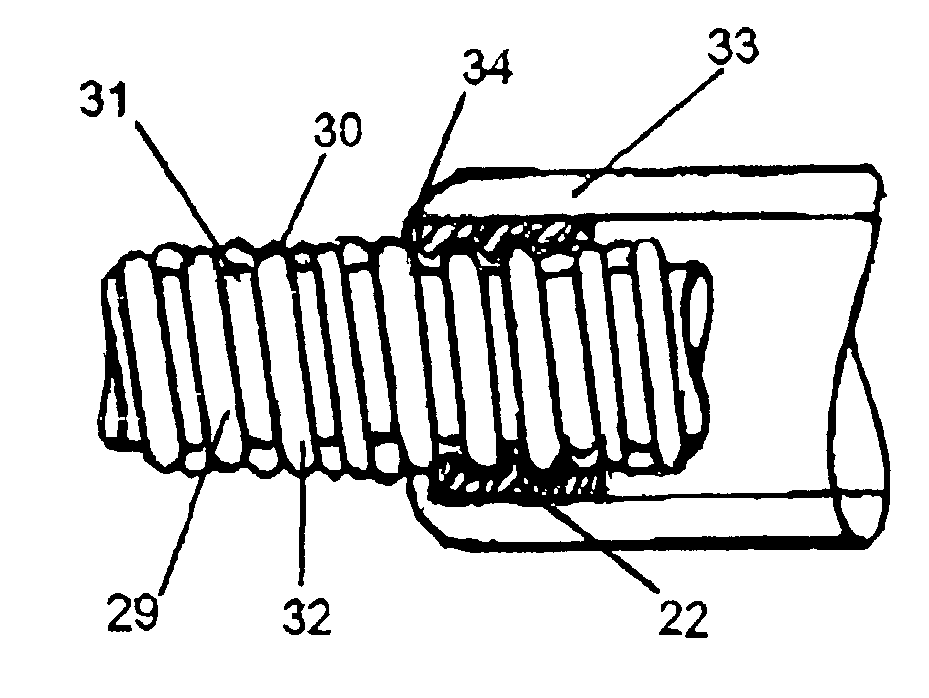

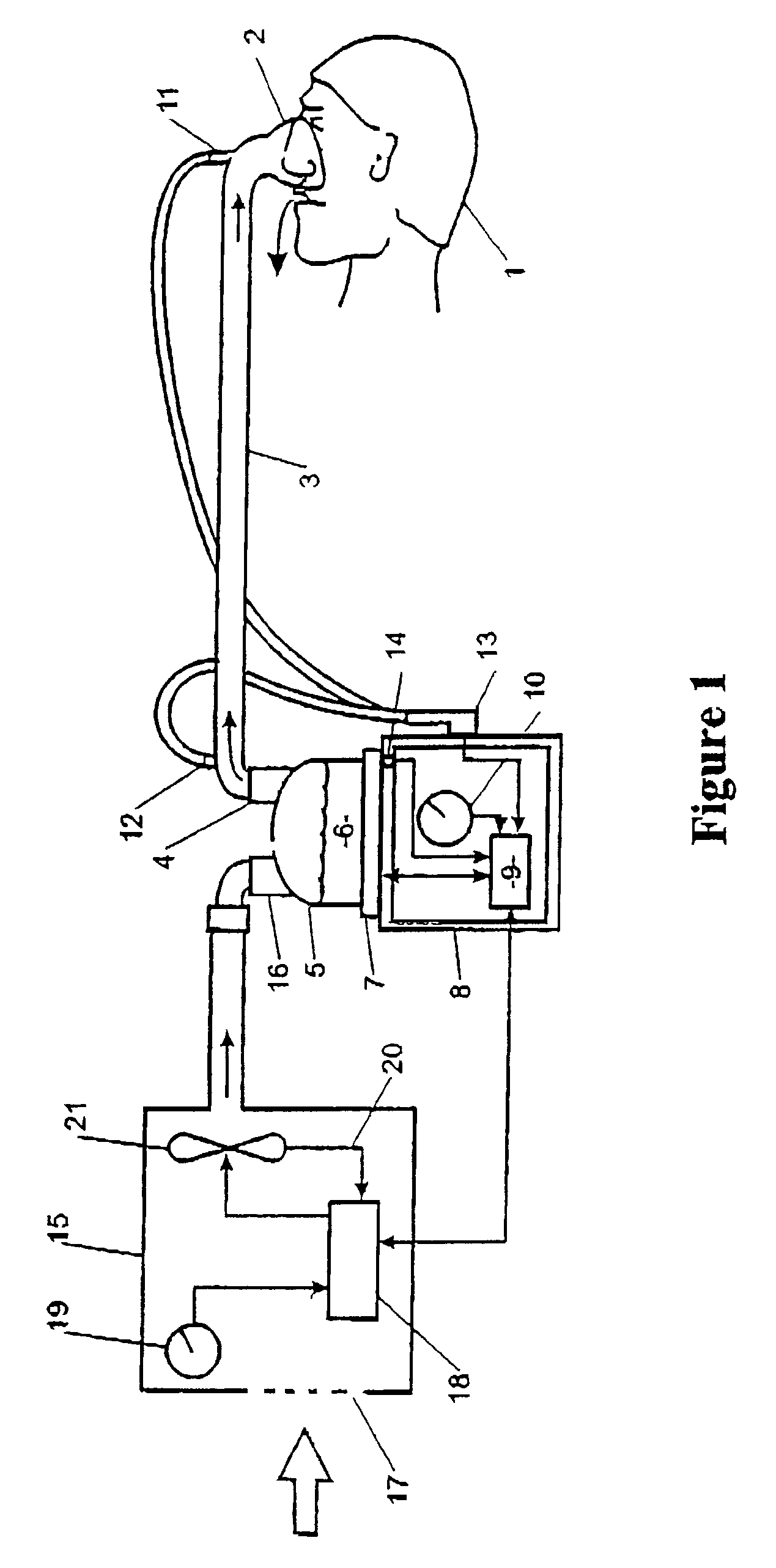

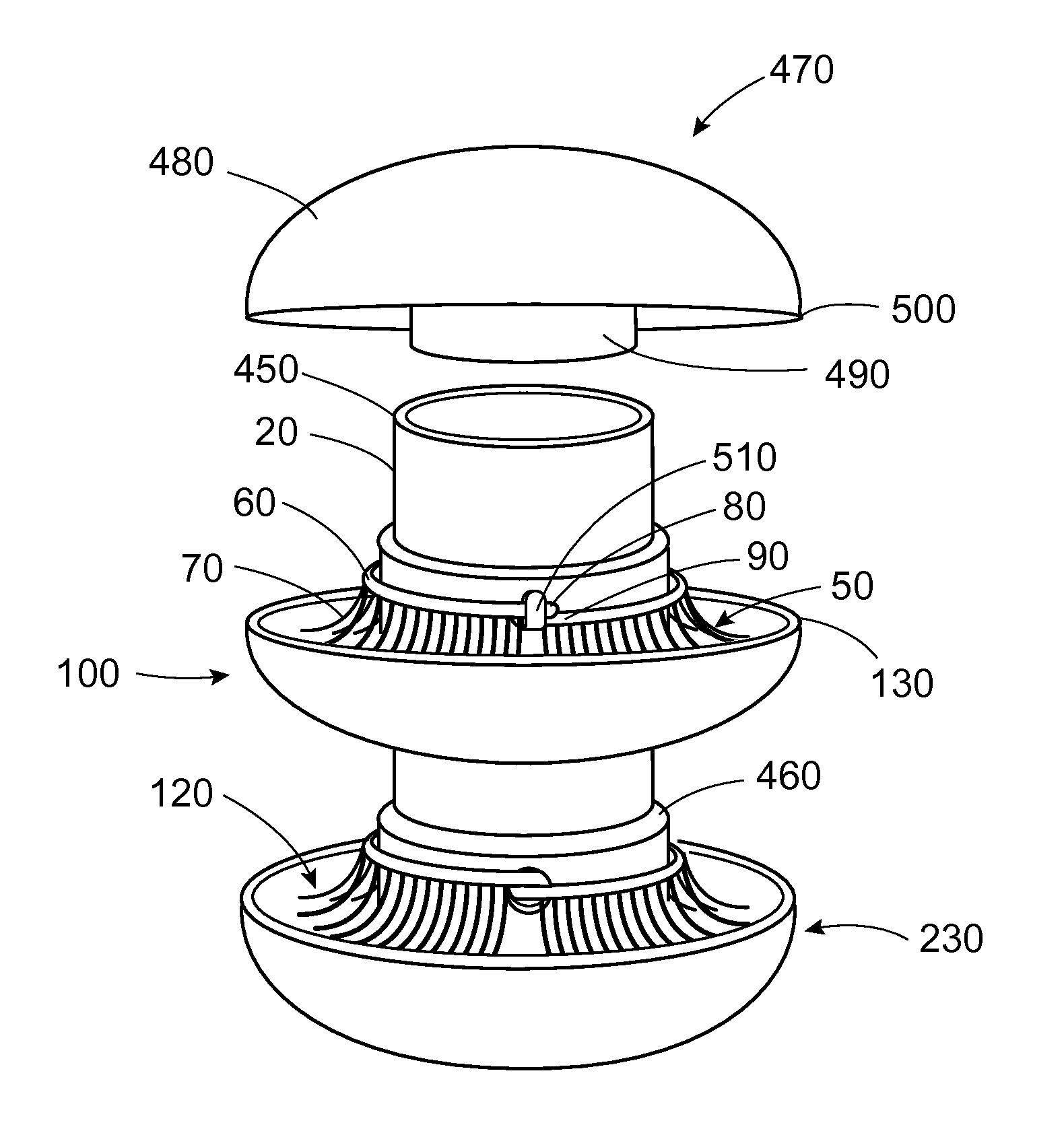

Method of forming a respiratory conduit

The present invention relates to delivery conduits used in systems that provide positive pressure ventilation therapy. In particular, the present invention relates to a sleeve that allows flexible conduits to be joined and sealed to a thermoplastic connector, allowing for gases to be supplied to the conduit. The sleeve is used in the over moulding of an end connector onto the conduit. The sleeve and method of attaching a connector to a conduit of the present invention has the advantage that it prevents the connector from loosening or breaking when the conduit is bent, pulled or stressed, which can occur in some cases where the connector is attached to the conduit using a bond, such as glue. Furthermore, the occurrences of flashing of plastic across the conduit walls will be prevented during moulding, ensuring that no air or water leakages occur within the conduit walls.

Owner:FISHER & PAYKEL HEALTHCARE LTD

Internal wall putty and production process thereof

The invention belongs to the technical field of building materials, and particularly relates to an internal wall putty which comprises the following components in parts by weight: 150-300 parts of white cement, 500-900 parts of calcium carbonate powder, 10-50 parts of grey desert soil, 1-8 parts of cellulose ether, 7-30 parts of polymer latex powder, 1-10 parts of water repellent, 0.05-3 parts of starch ether and 0.5-7 parts of wood fiber. Compared with the prior art, the internal wall putty has the advantages that 107 glue water or 801 glue water is not used, thus formaldehyde is not contained, the environment is protected; and pregelatinized starch is not used, and the water repellent is added, thus the internal wall putty has the function of preventing water and moisture. In addition, with the white cement and the calcium carbonate powder as the strength basis and the grey desert soil as an auxiliary strength material, the strength of the internal wall putty is ensured; due to the synergistic effect of the cellulose ether and the starch ether, the water-retaining property and the application property of the internal wall putty are ensured; and because the polymer latex powder is added, the flexibility of the internal wall putty and the adhesion of the polymer latex powder and the wall are improved.

Owner:黄明杰

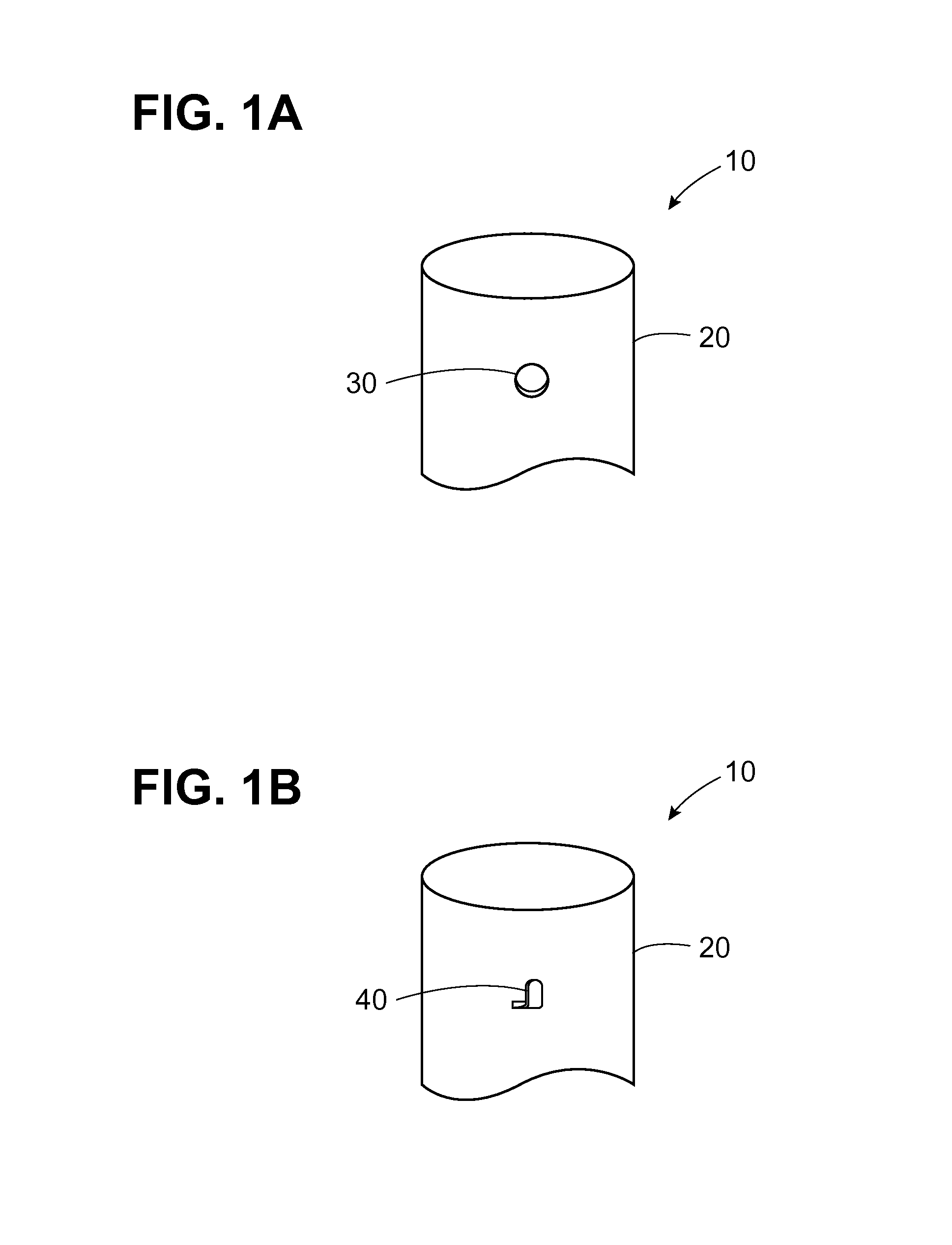

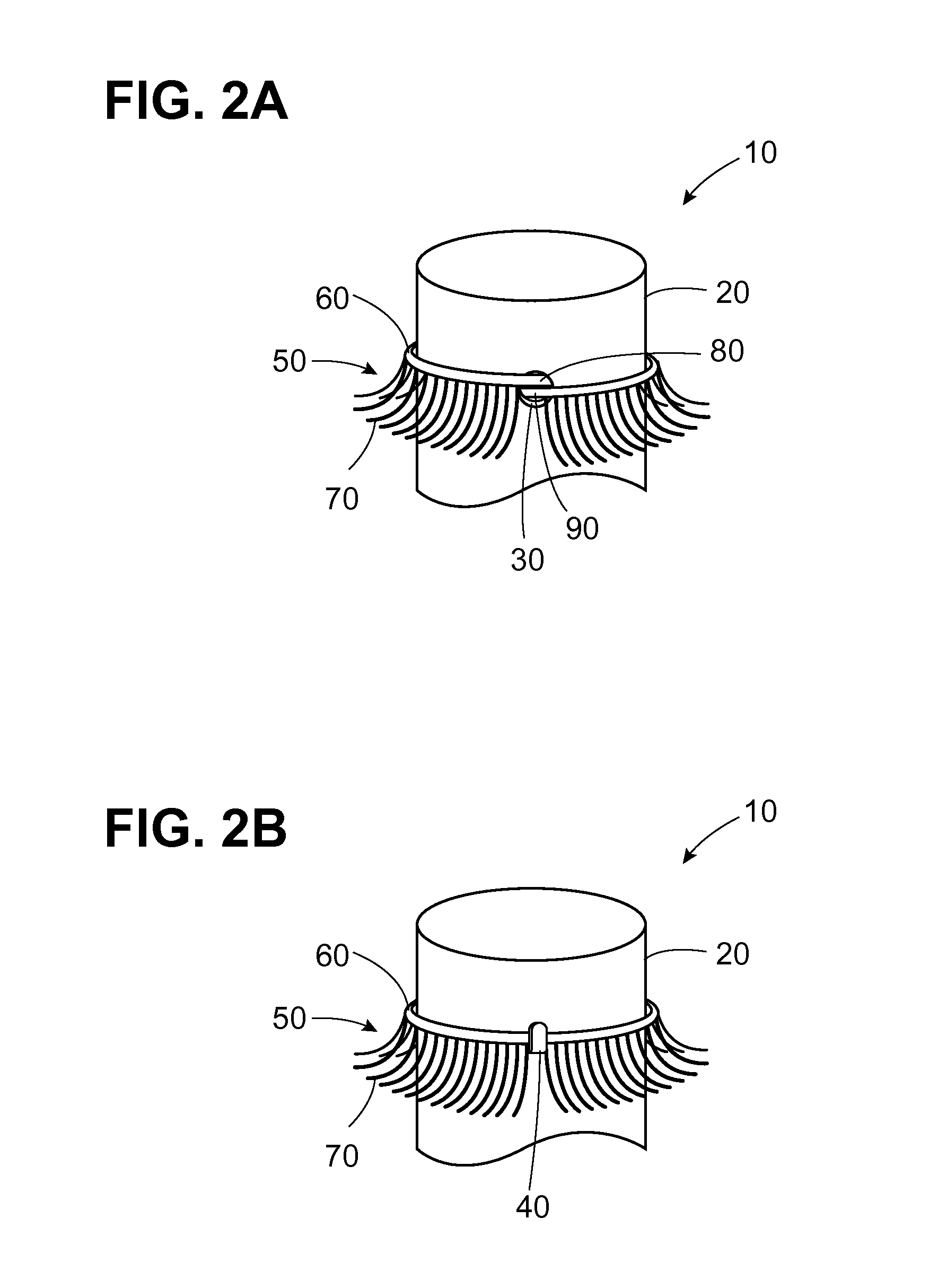

False eyelash holder

The invention is directed to a housing to hold false eyelashes without the need of glue to hold the eyelashes in place. The inventive housing has a cylindrical base that maintains the desired curvature of the eyelashes during storage and / or transportation and non-adhesive attachments secure the eyelashes to the cylindrical base.

Owner:AVON PROD INC

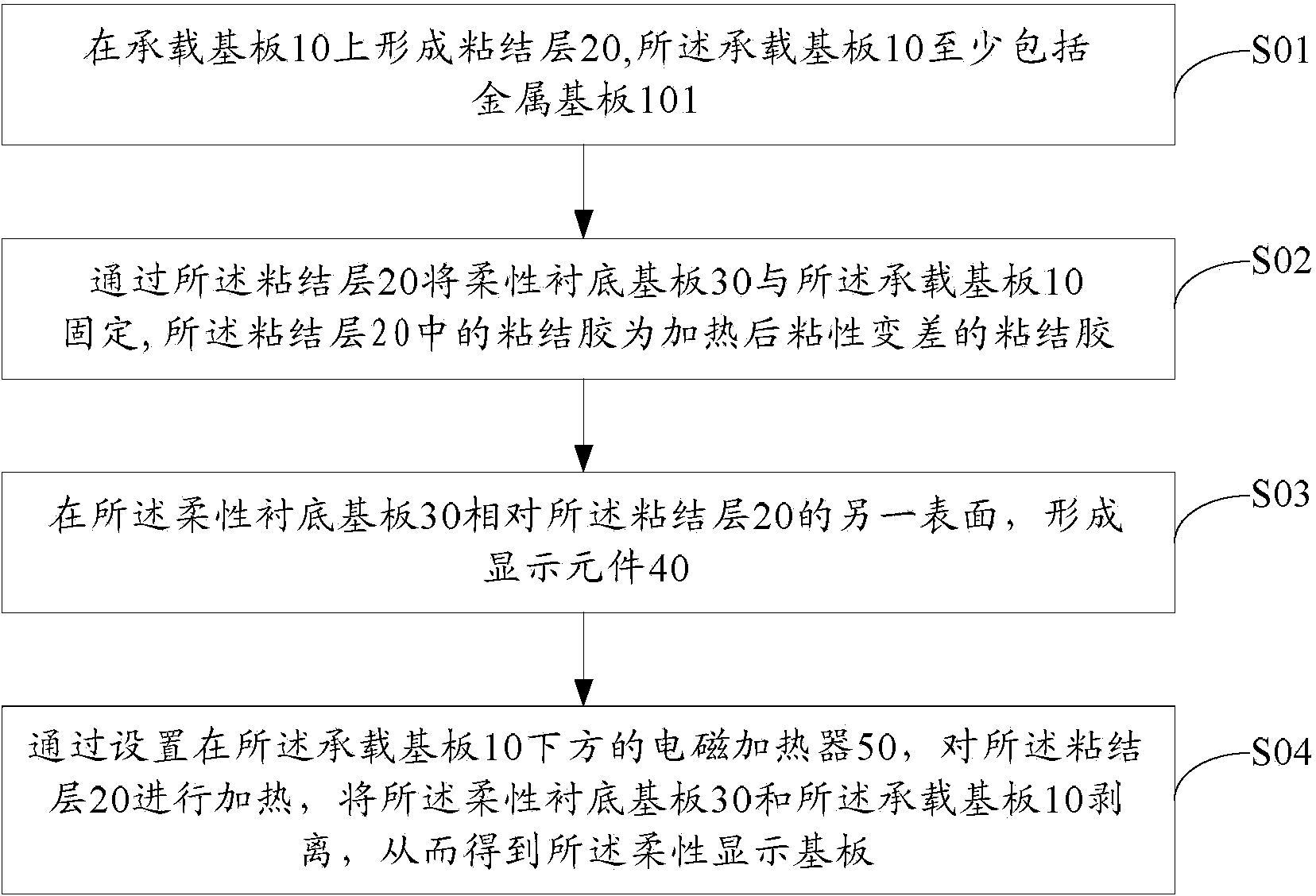

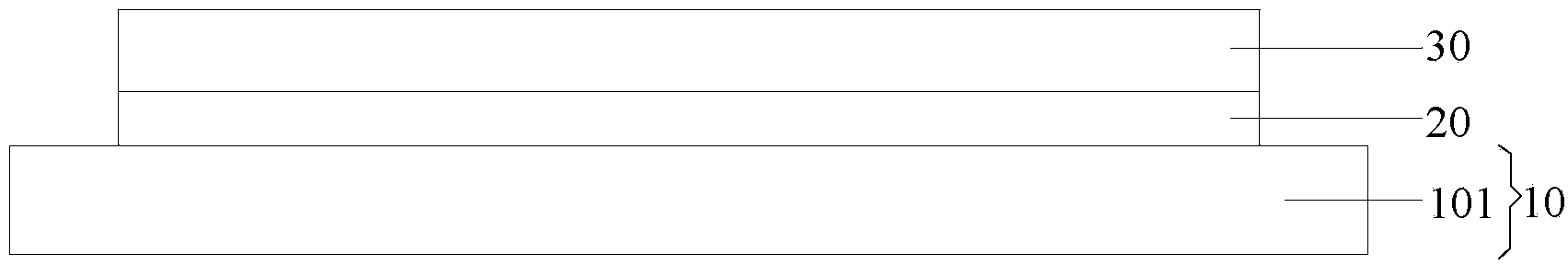

Method for manufacturing flexible display substrate

The embodiment of the invention provides a method for manufacturing a flexible display substrate and relates to the technical field of display. By the adoption of the method for manufacturing the flexible display substrate, even stripping of a flexible lining substrate of the flexible display substrate and a bearing substrate of the flexible display substrate can be achieved. The method for manufacturing the flexible display substrate comprises the steps that a bonding layer is formed on the bearing substrate; the flexible lining substrate is fixed to the bearing substrate through the bonding layer; a display element is formed on the other surface, opposite to the bonding layer, of the flexible lining substrate; the bonding layer is heated through an electromagnetic heater which is arranged below the bearing substrate, and then the flexible display substrate is obtained by stripping the flexible lining substrate and the bearing substrate. The viscidity of the adhesive glue in the bonding layer becomes poor after the adhesive glue is heated, and the bearing substrate at least comprises a metal substrate. The method is used for manufacturing the flexible display substrate.

Owner:BOE TECH GRP CO LTD

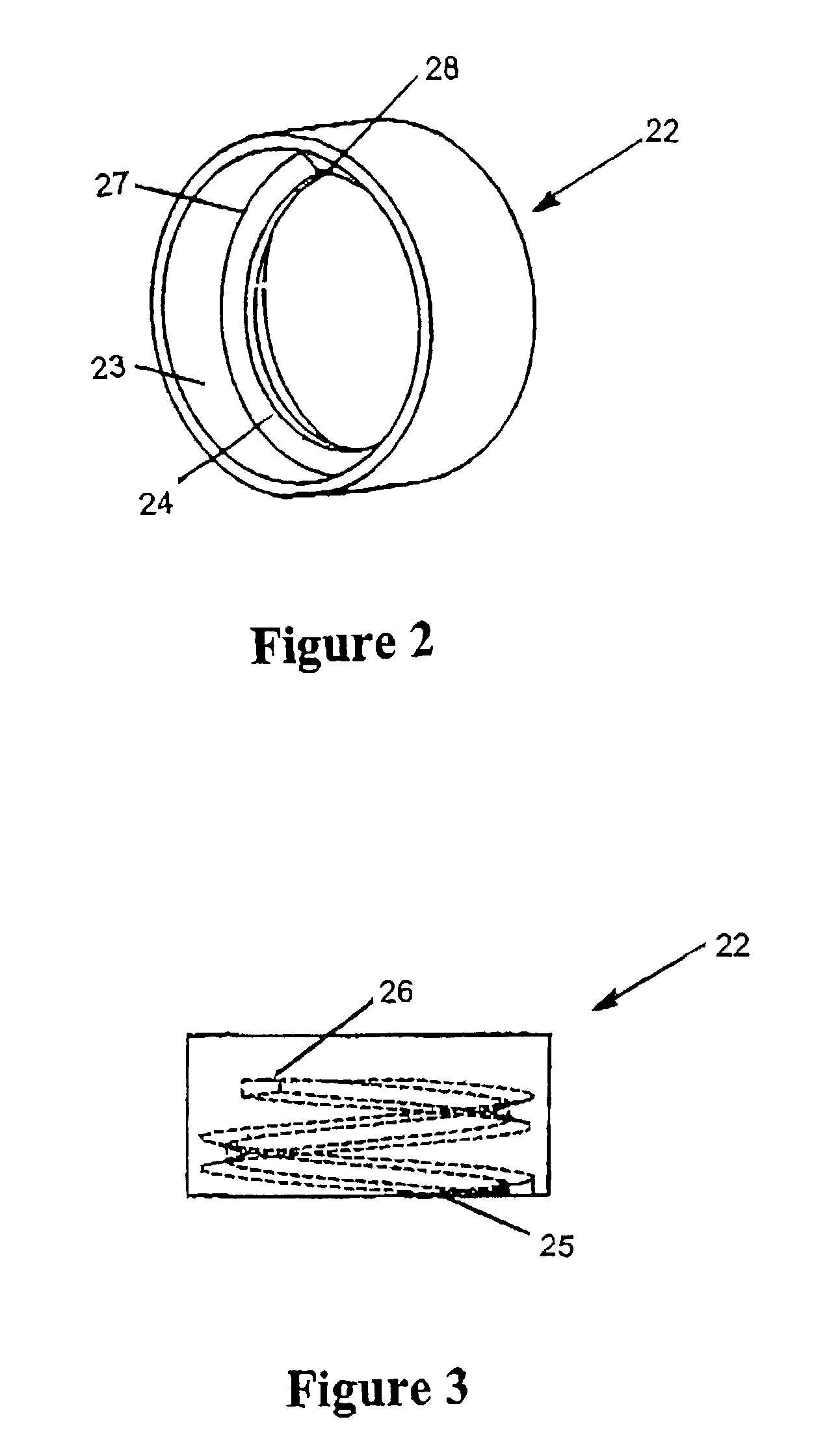

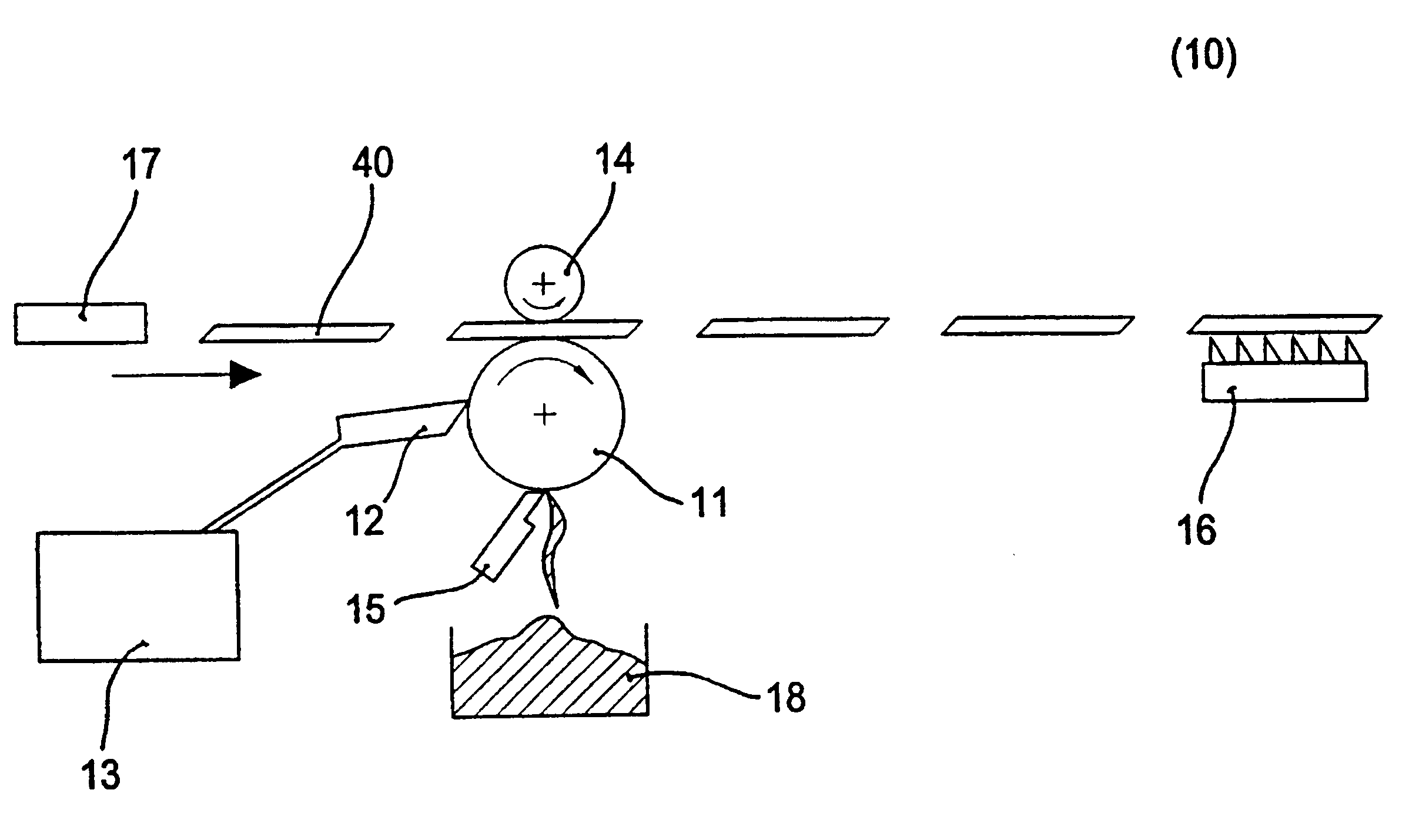

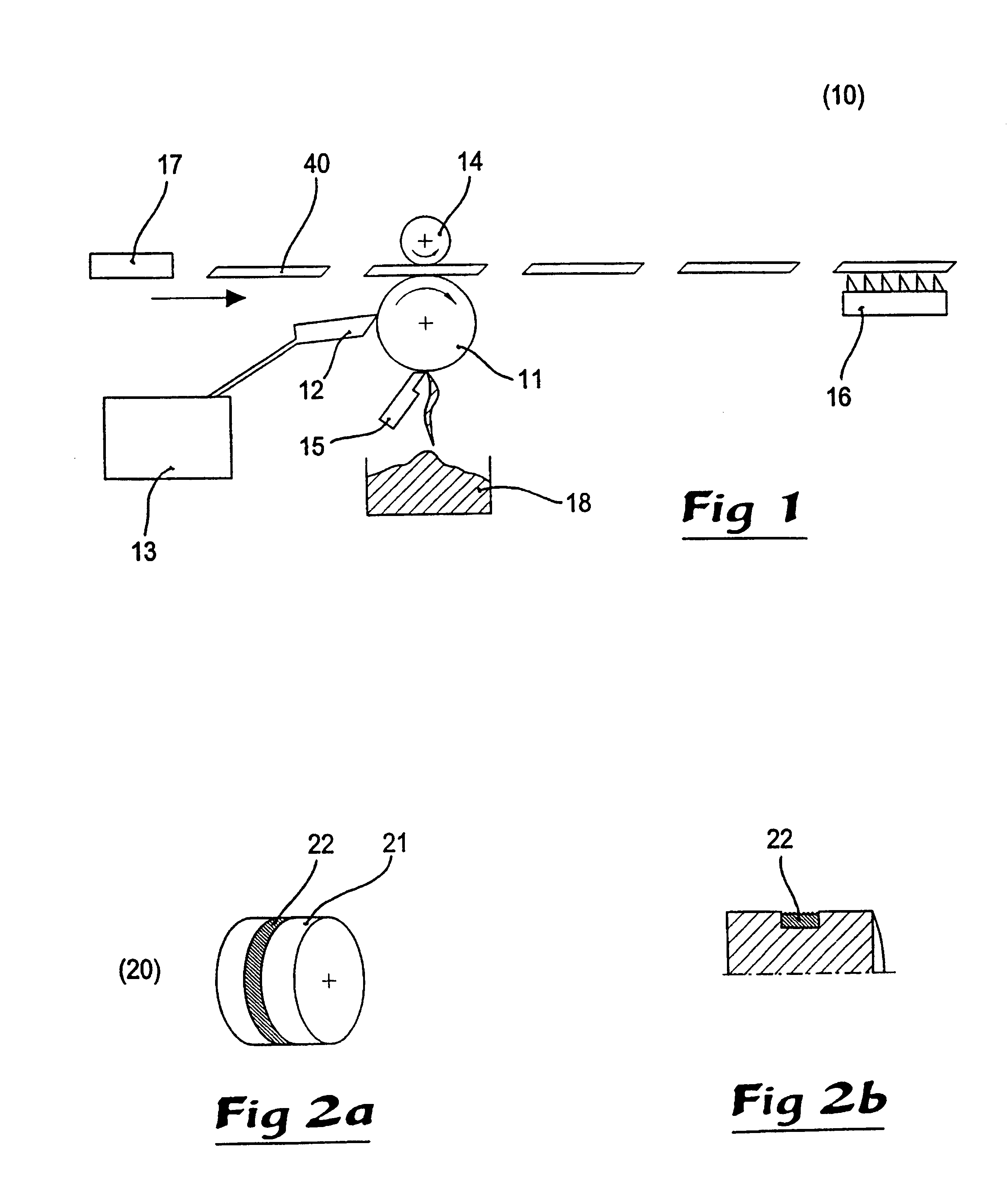

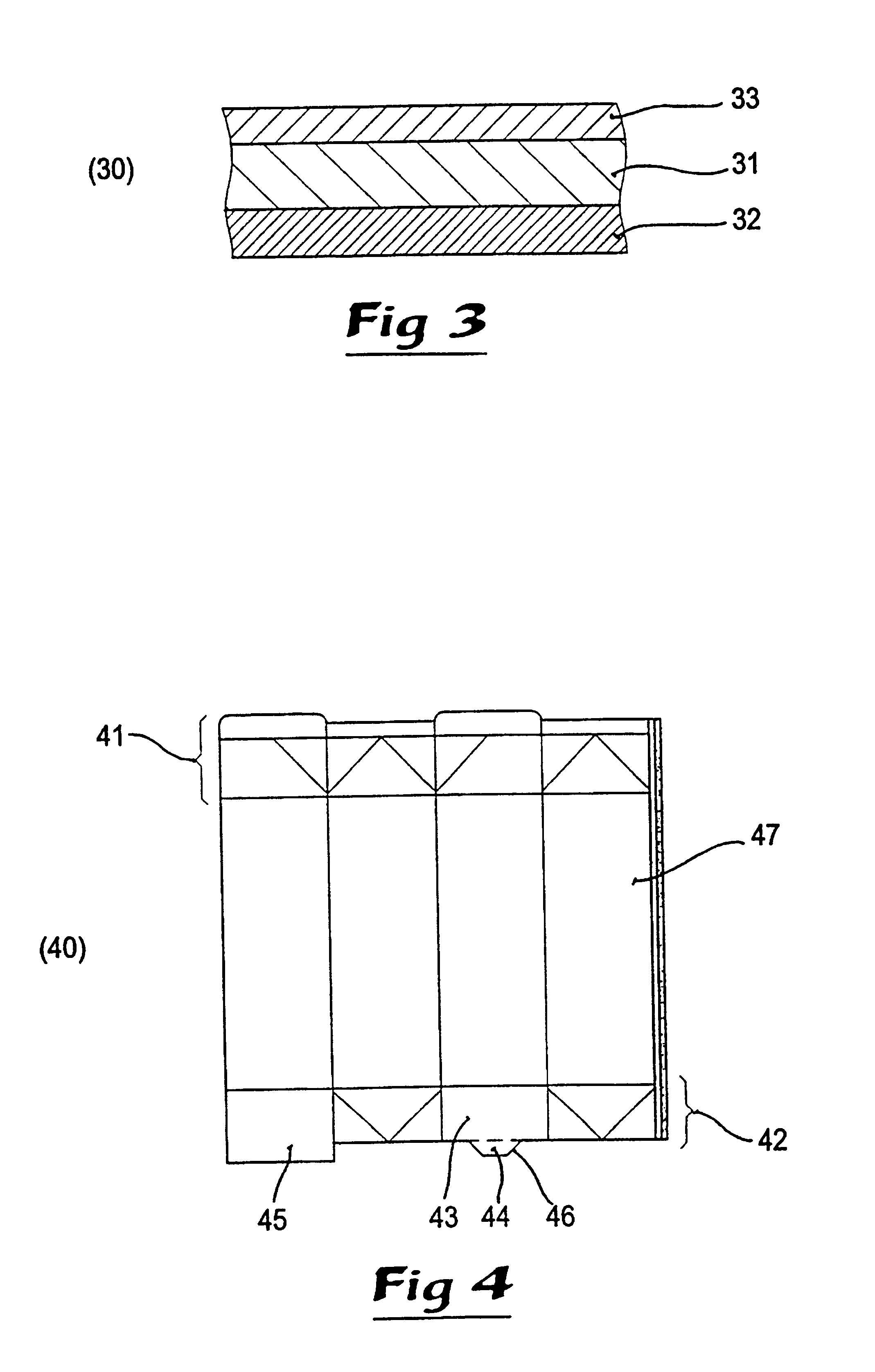

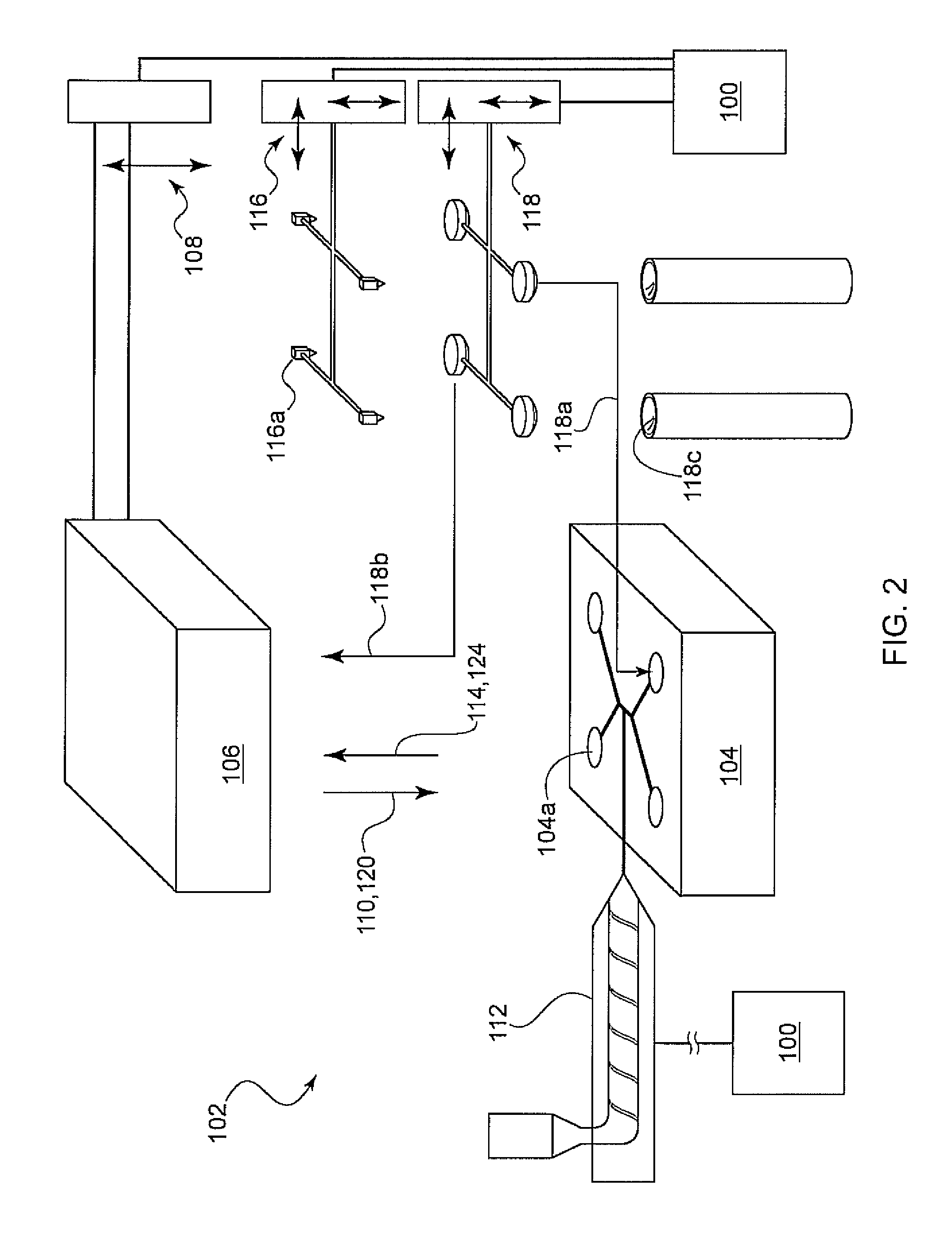

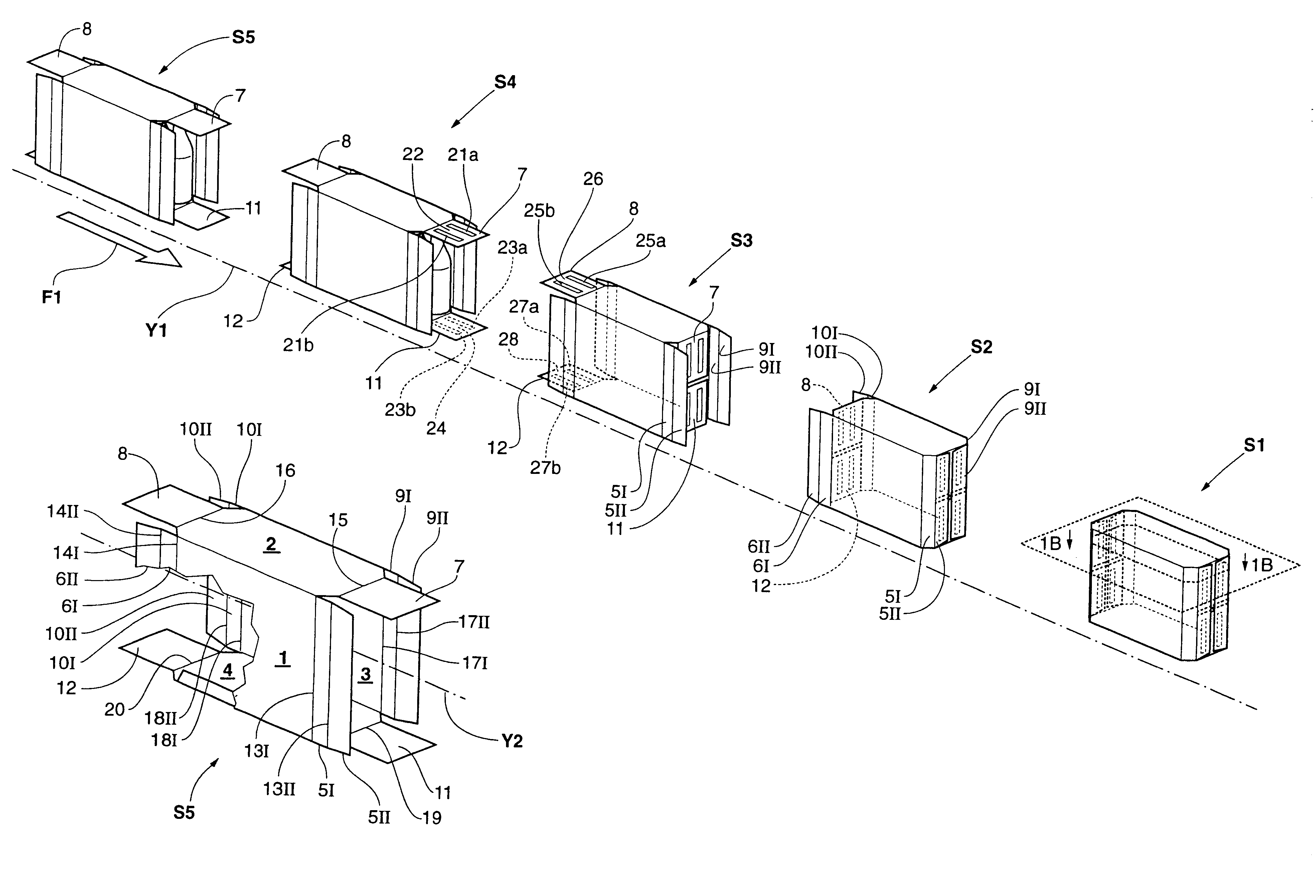

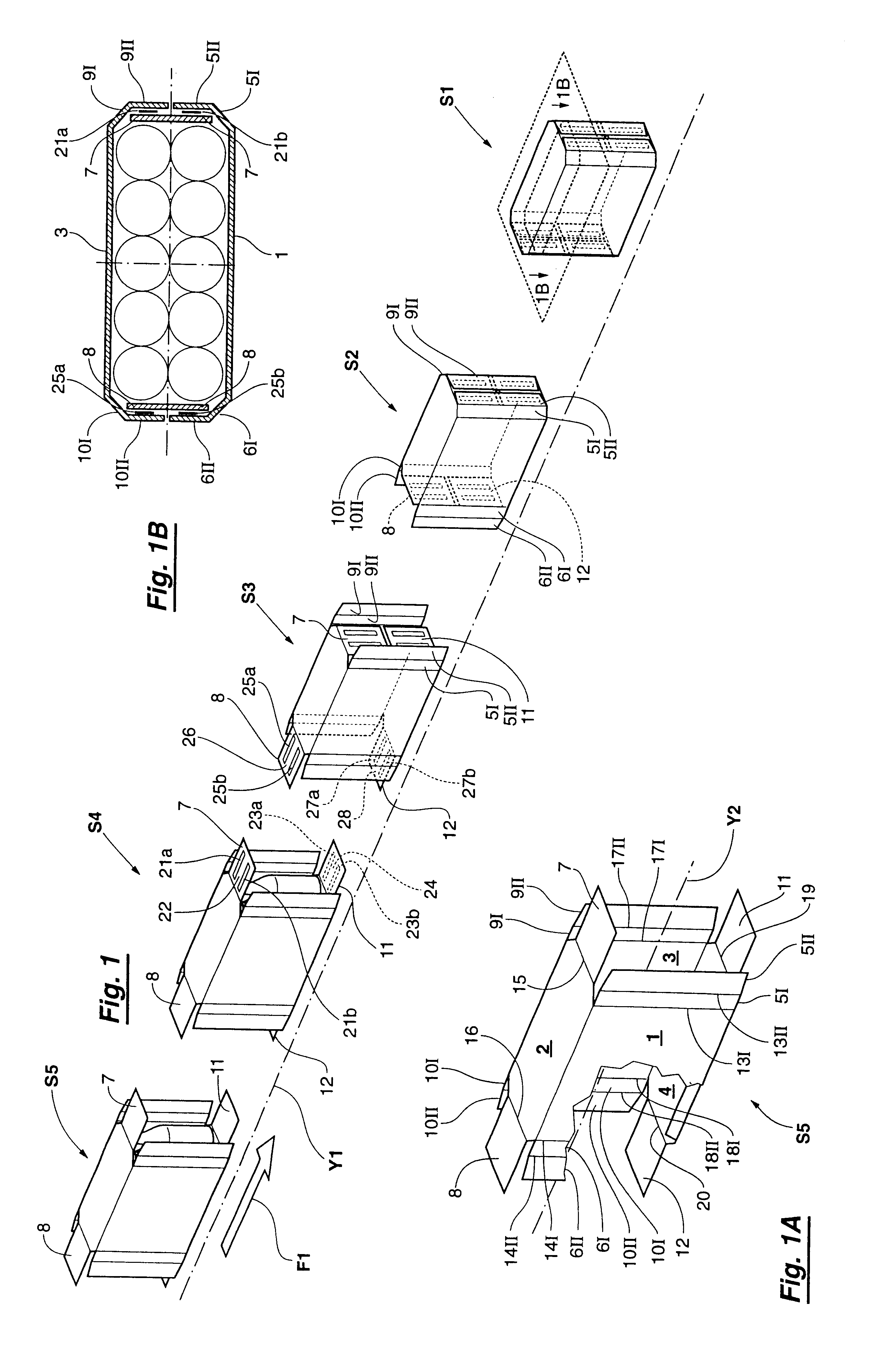

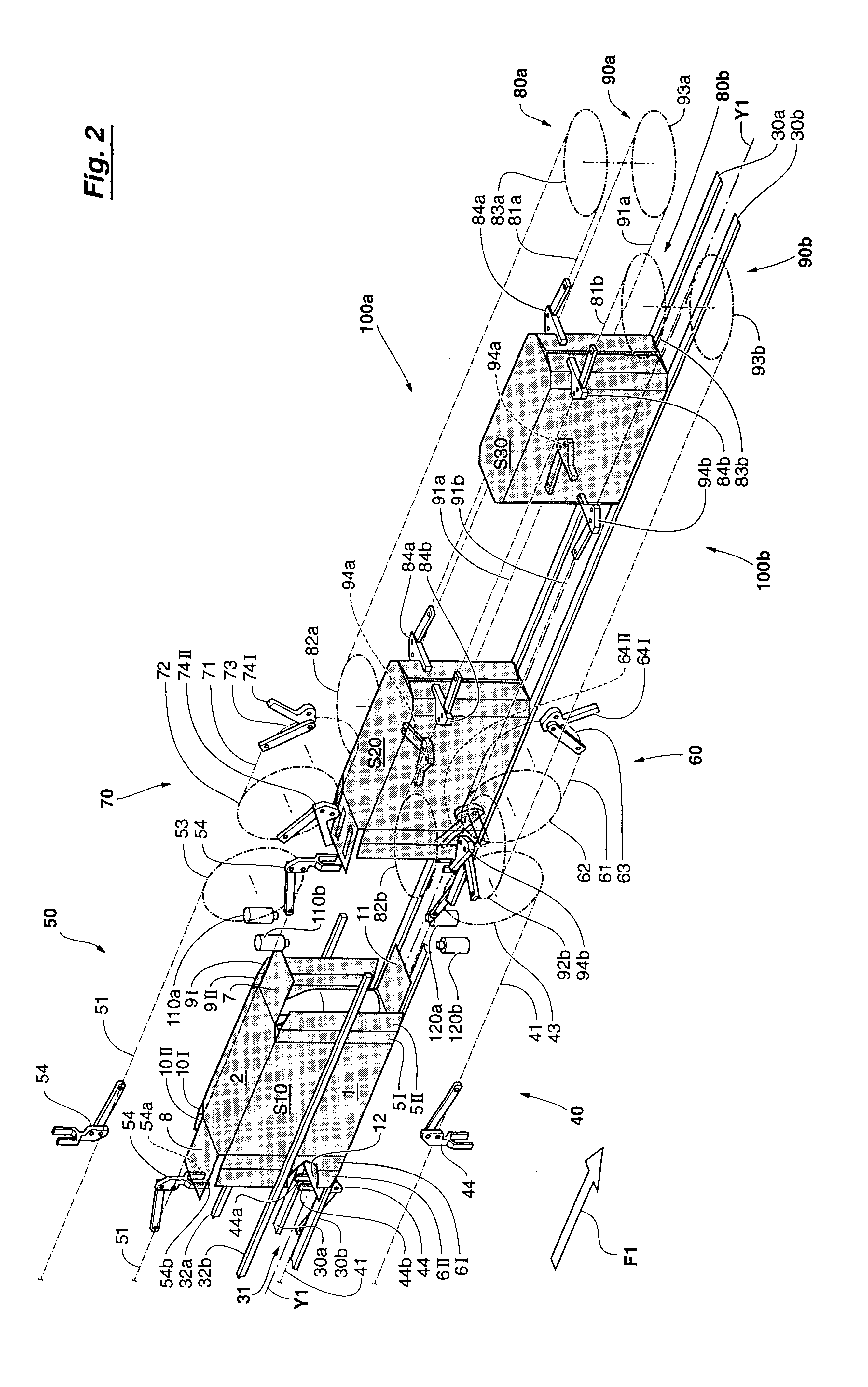

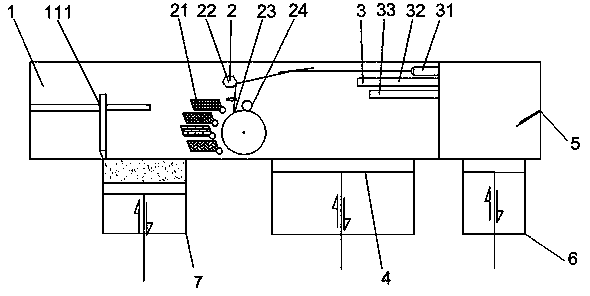

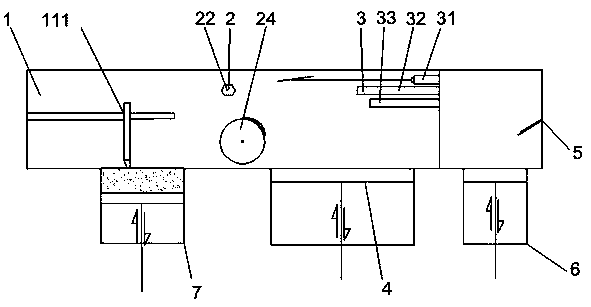

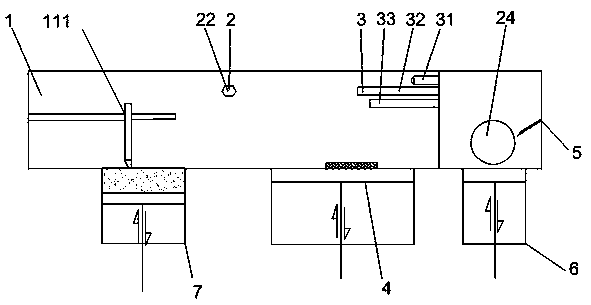

Method and an apparatus for producing packaging containers for liquid foods, as well as packaging containers

The disclosure relates to a method and an apparatus (10) for producing a packaging container for liquid foods from a packaging container blank (40) by permanently uniting and sealing at least two of its edges (61, 65) with the aid of a hot melt glue, the hot melt glue being applied along one of the two edges with the aid of a heated applicator roller (11). The circumferential surface (21) of the hot roller is preferably made of hardened steel with a coating (22) countersunk in a groove int he surface along the circumference of the circumferential surface, the coating possessing good slippage properties in relation to the hot melt glue and the coating being of a width which corresponds to the region intended for application. A counter roller (14) acts on the opposite side of the packaging laminate blank against the applicator roller for controlling the outflow of the applied hot melt glue strand. How melt glue is applied to the applicator roller by means of a heated nozzle (12) and the surplus which is not transferred to the packaging laminate blank is scrapped off from the applicator roller by means of a doctor blade (15). The hot melt glue is preferably an ethylene vinyl acetate based composition with a high melting point and high viscosity which is applied at least approx. 180° C.

Owner:TETRA LAVAL HLDG & FINANCE SA

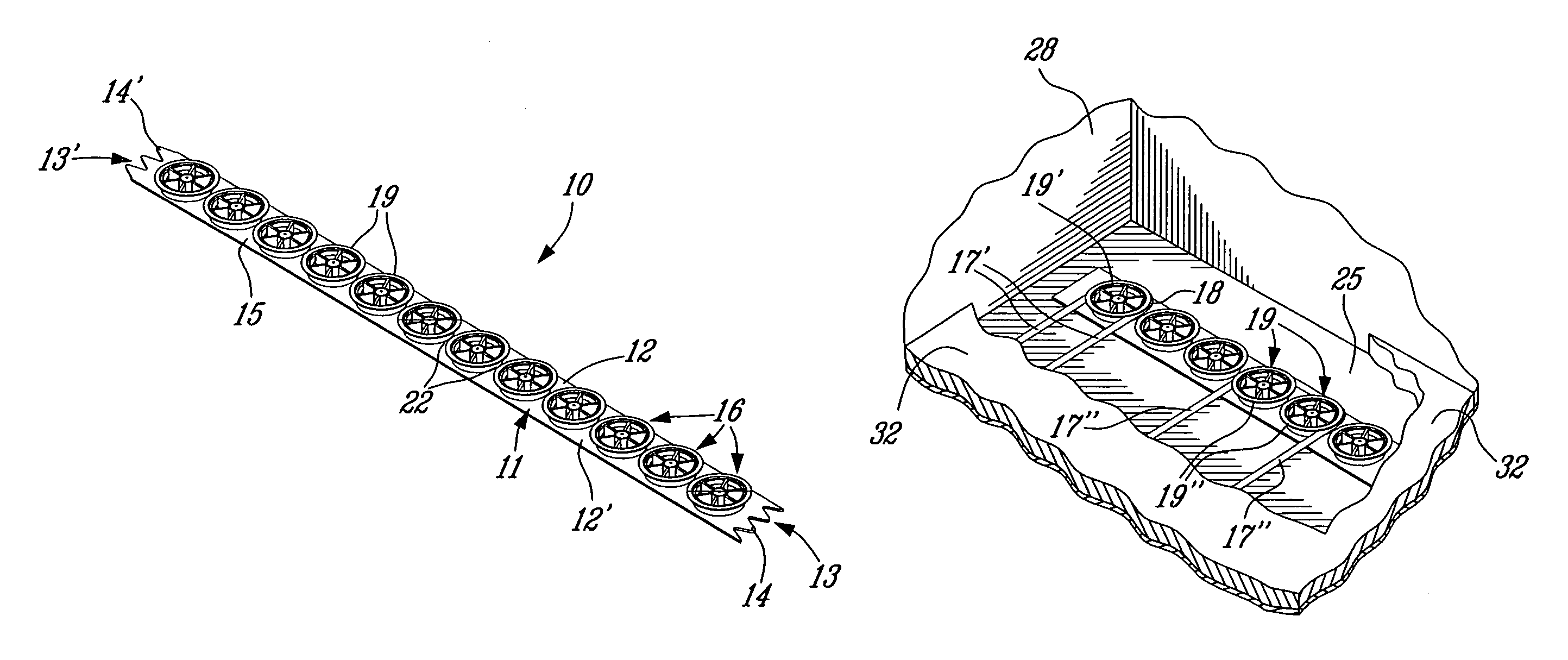

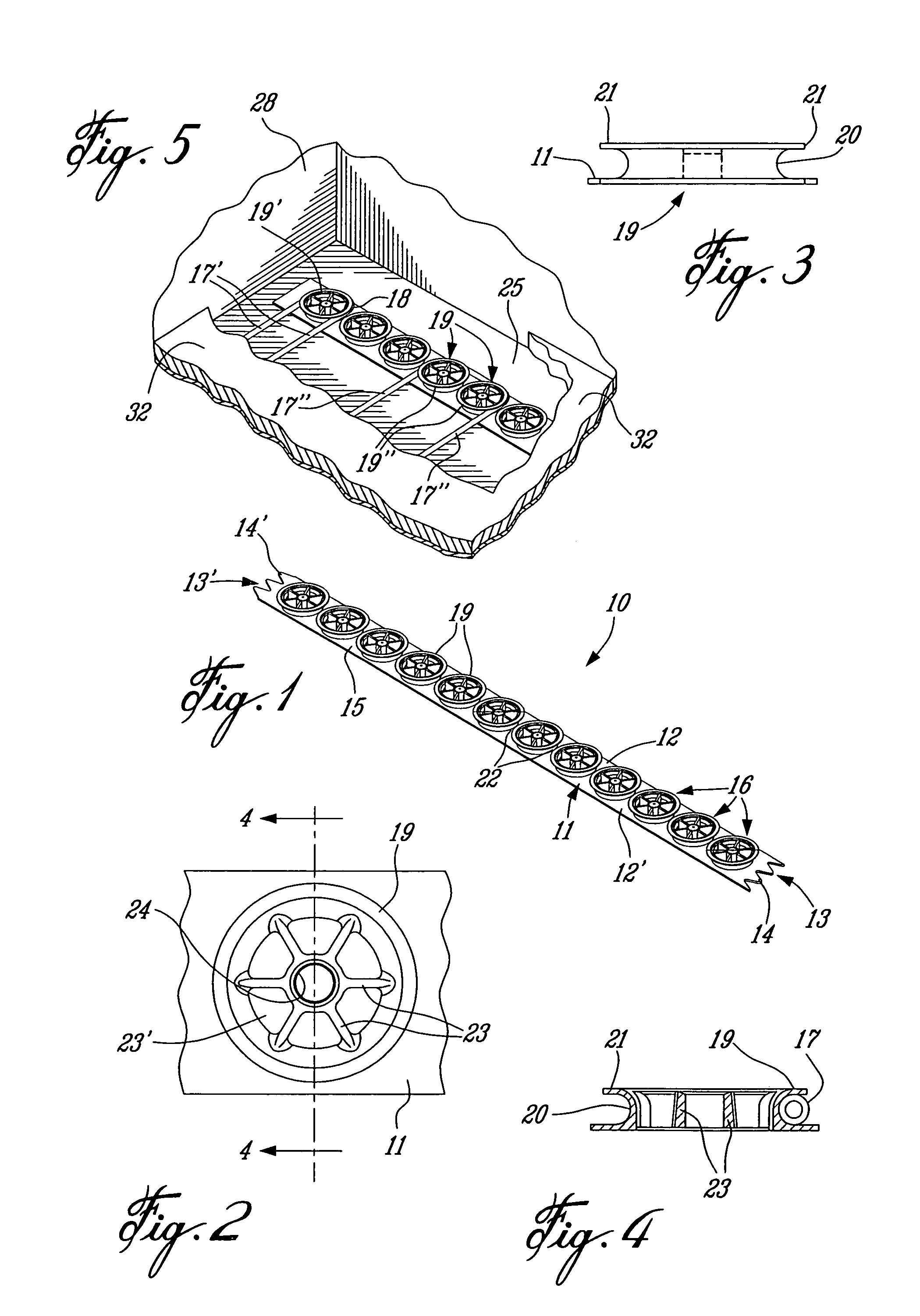

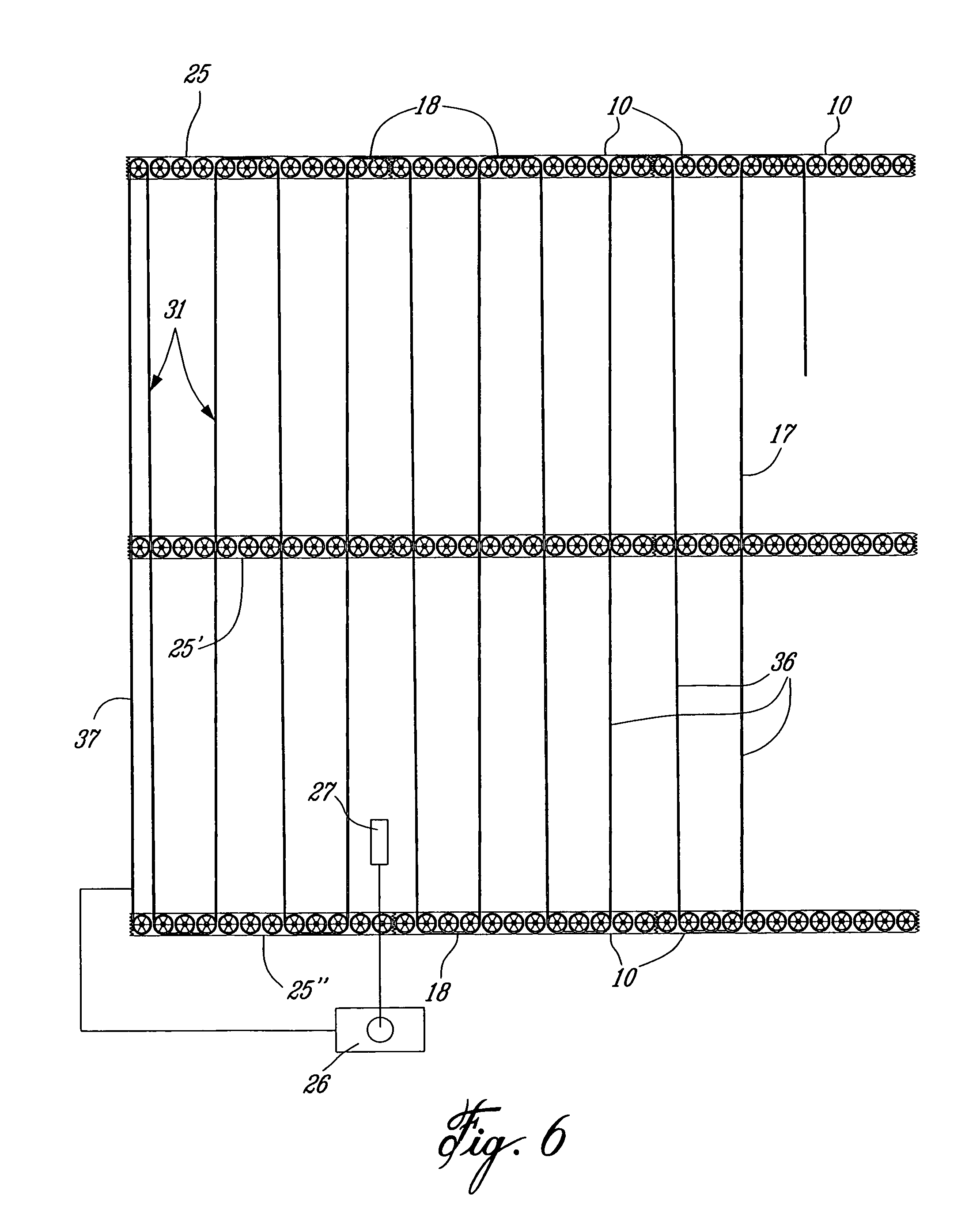

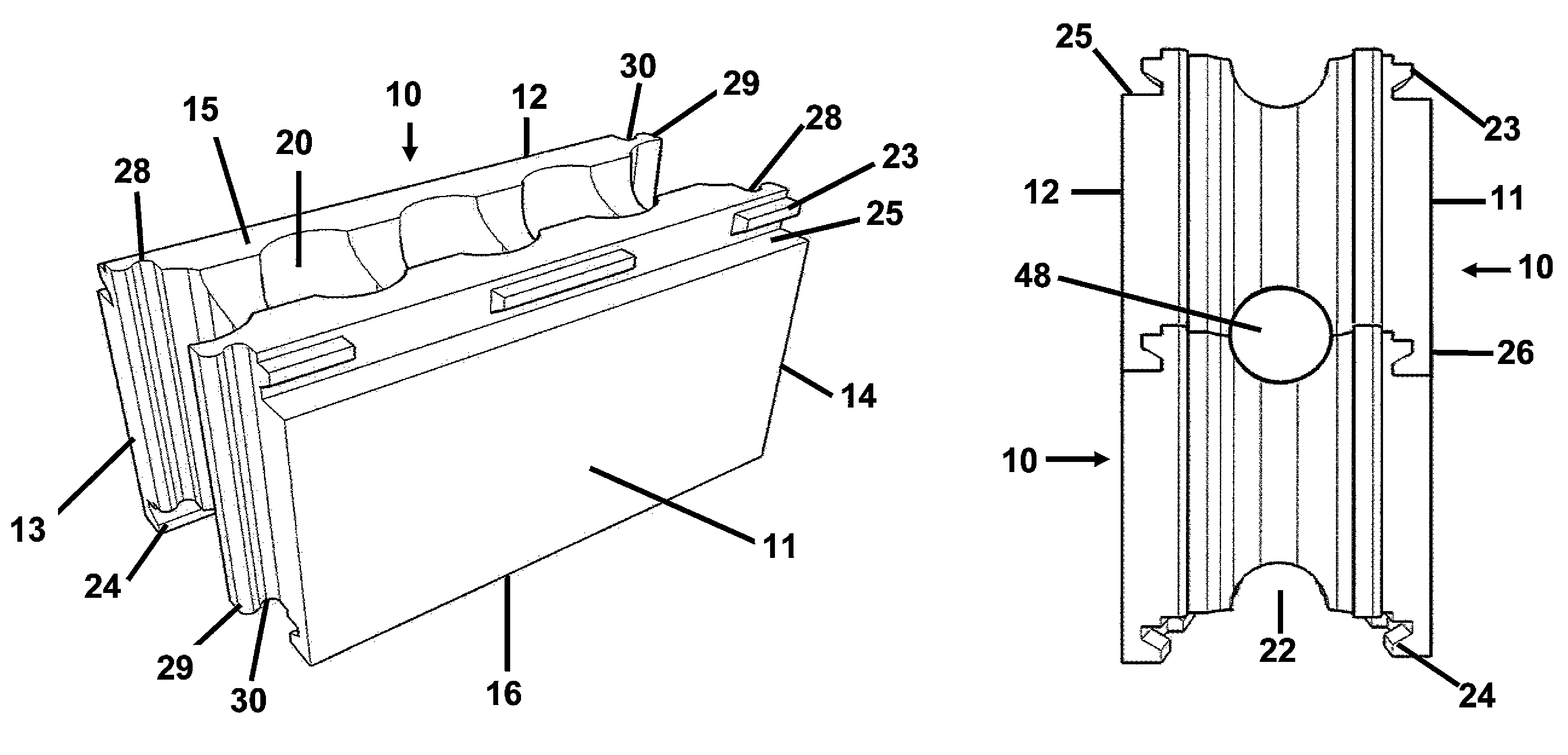

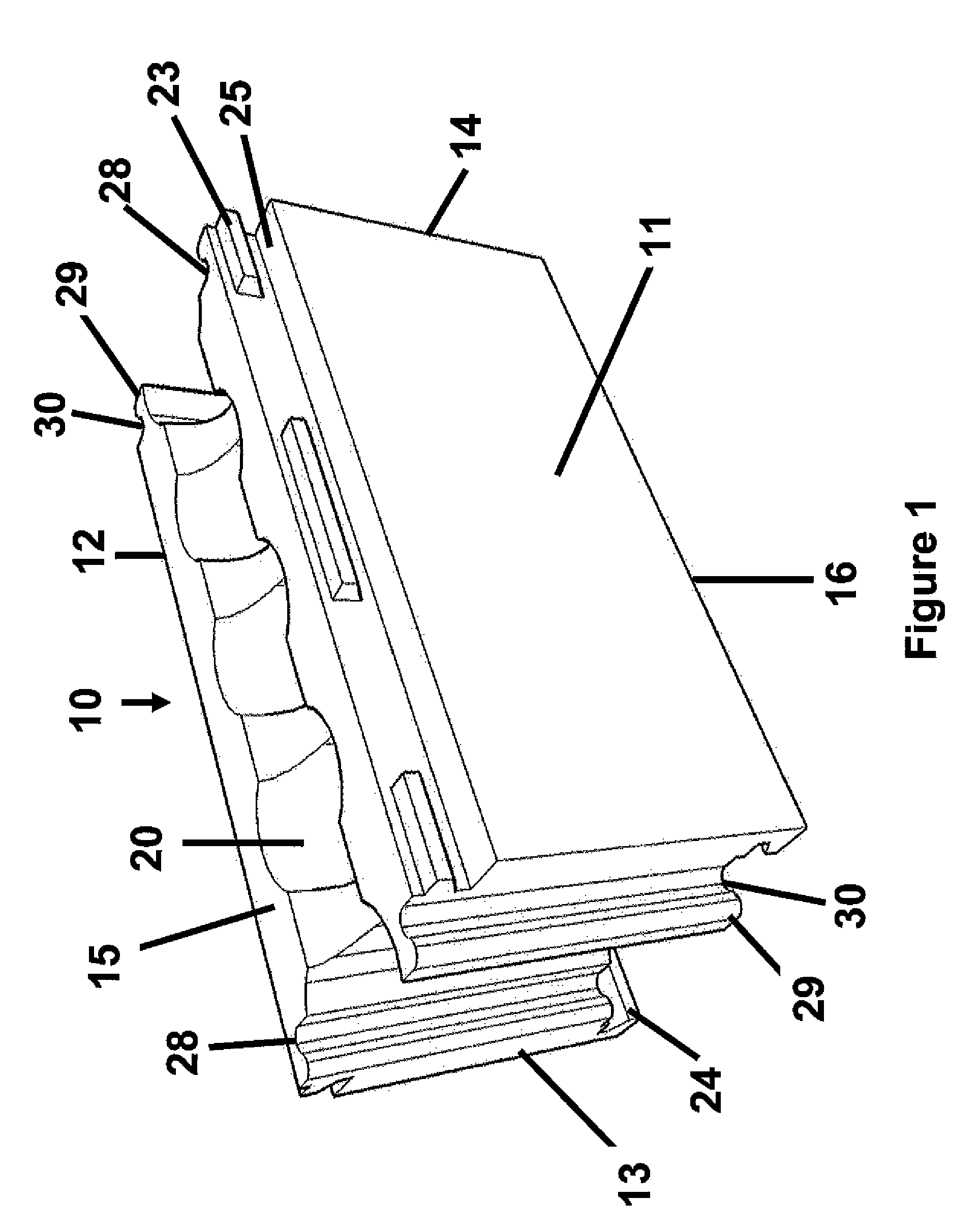

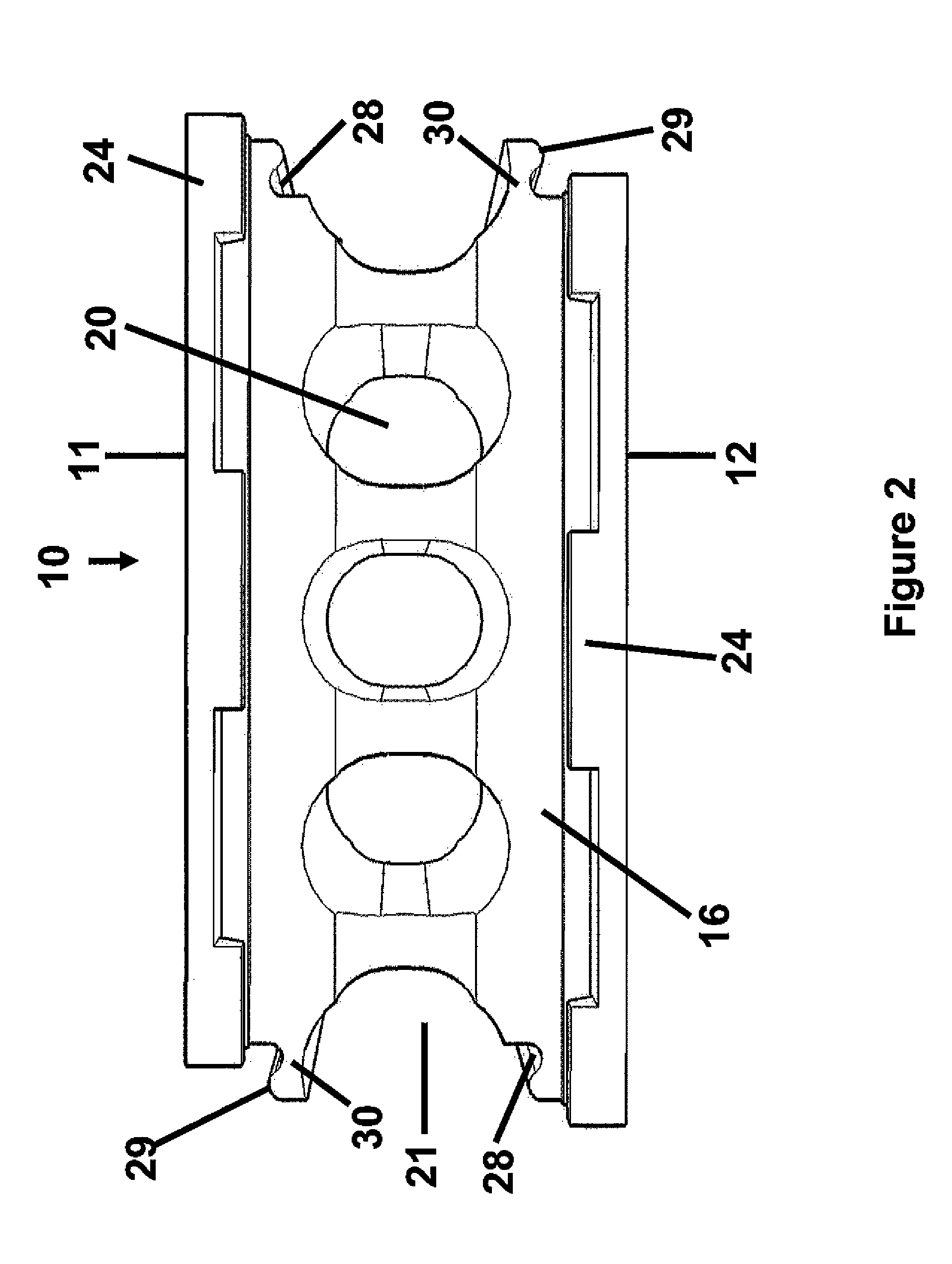

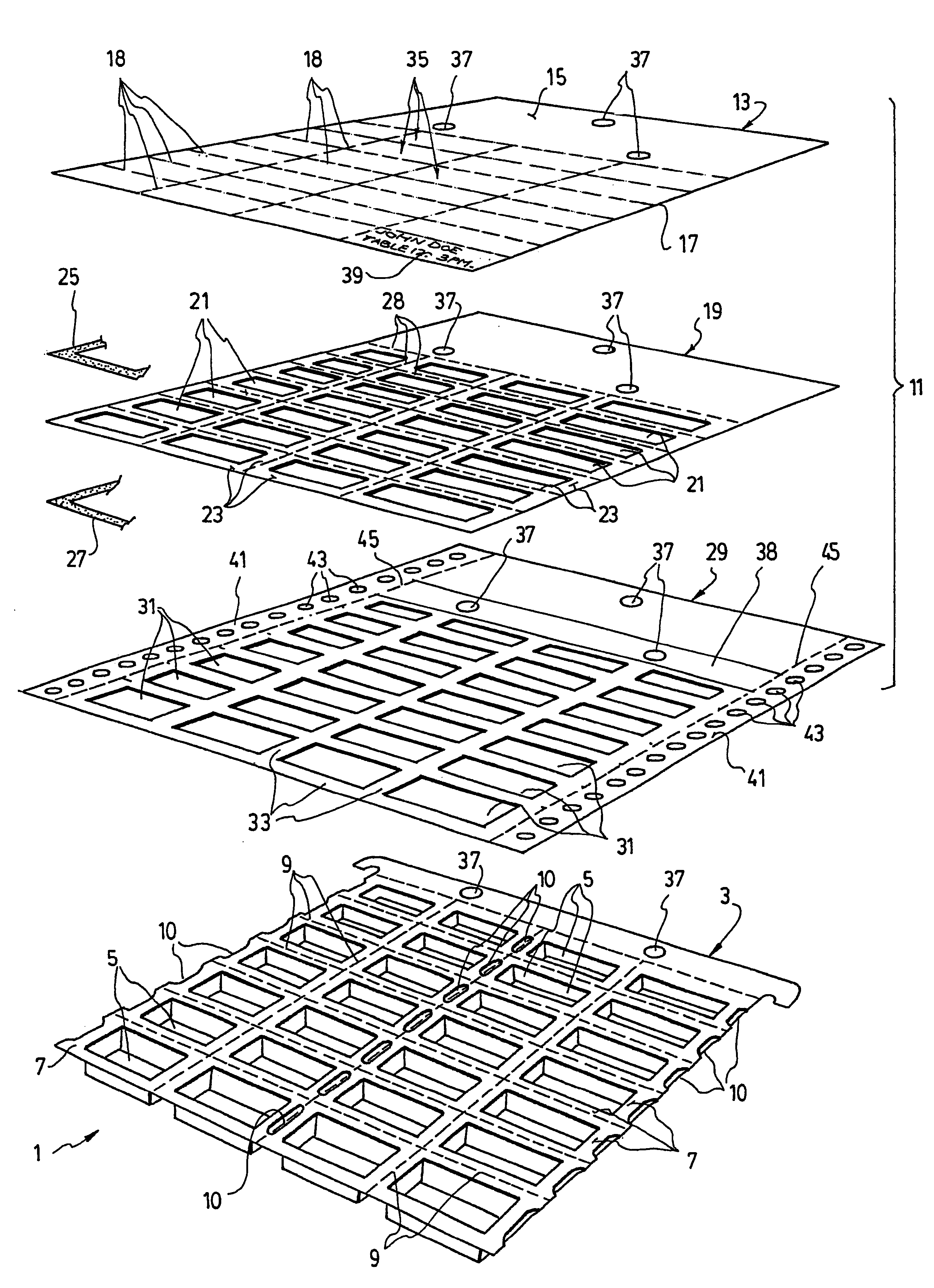

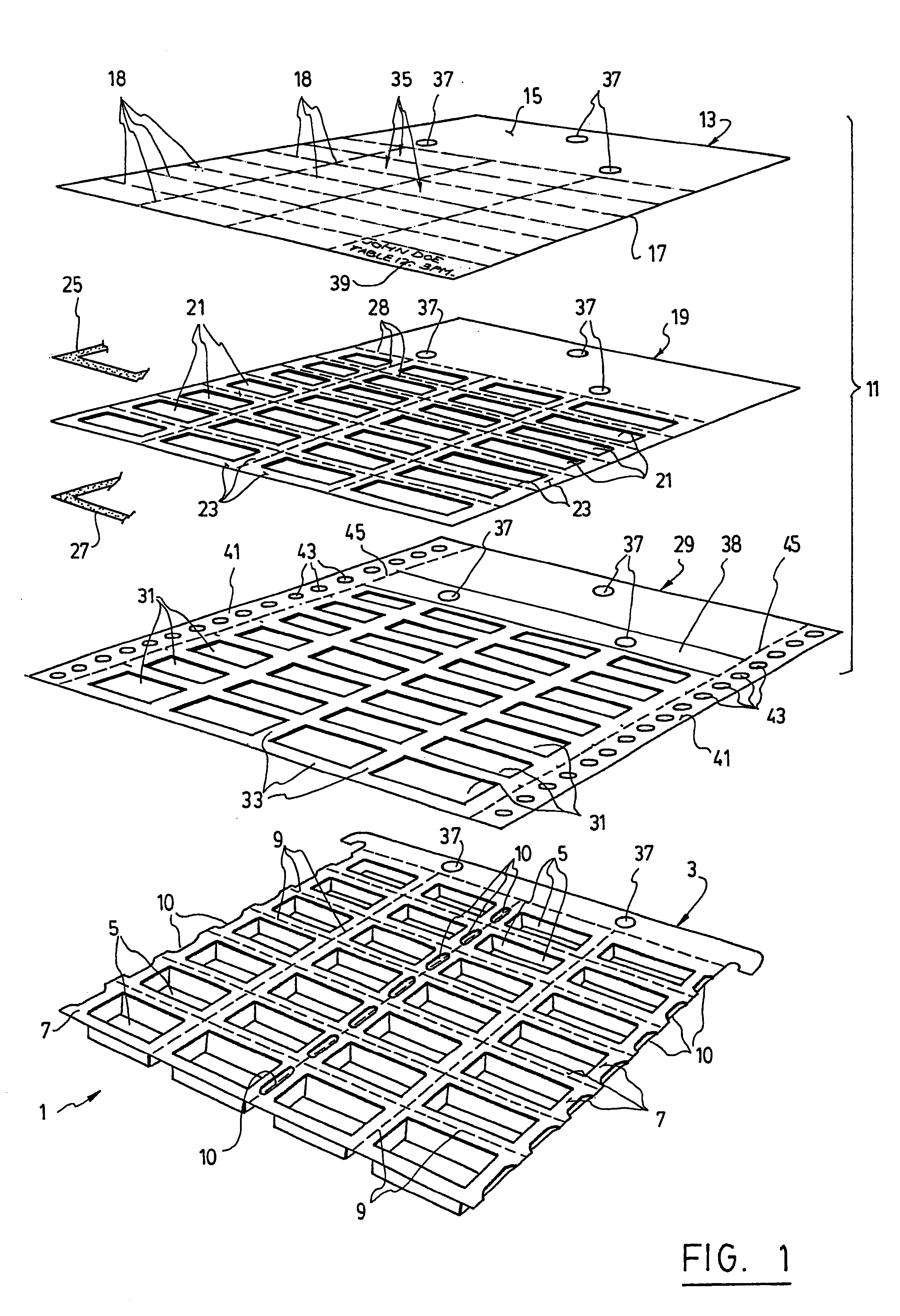

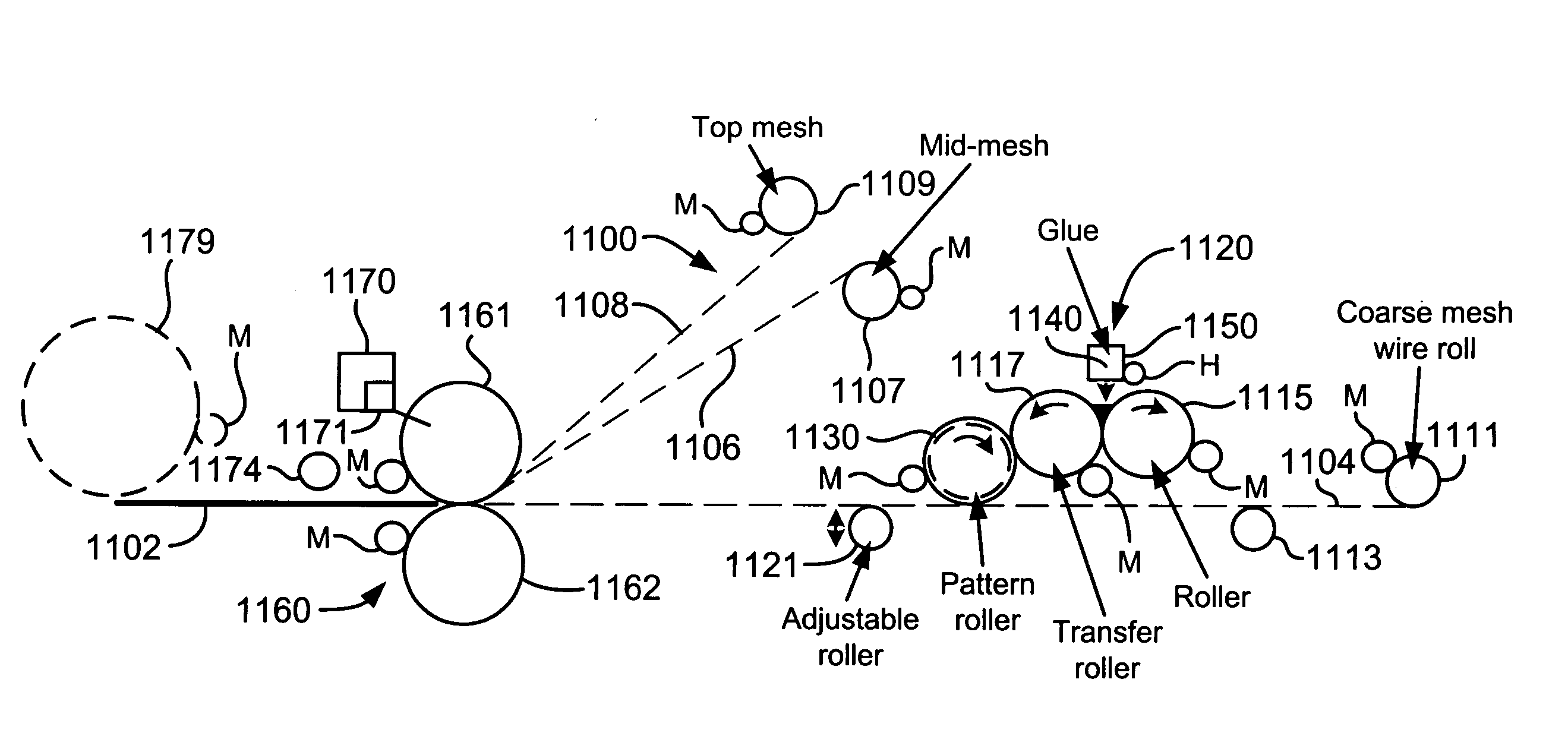

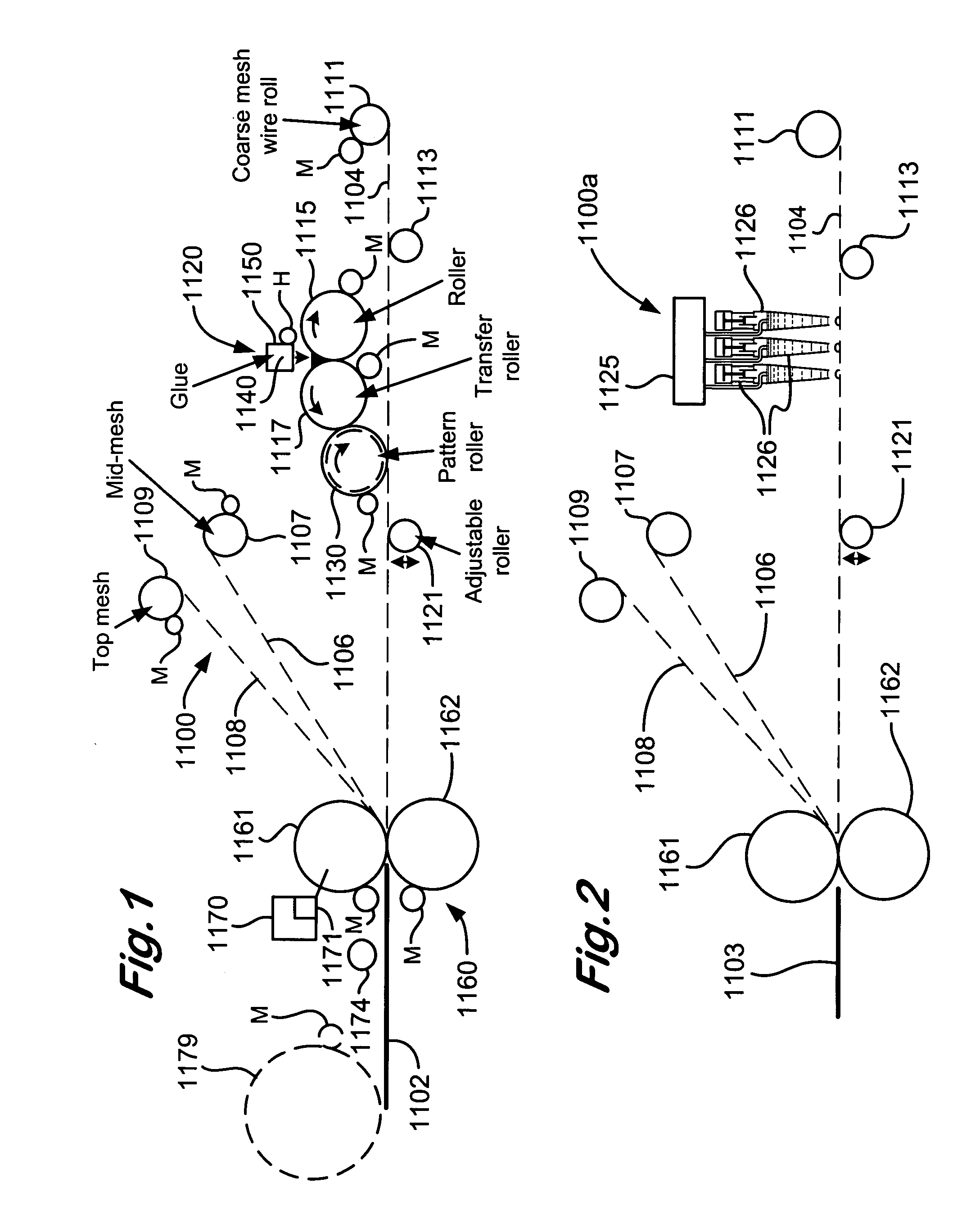

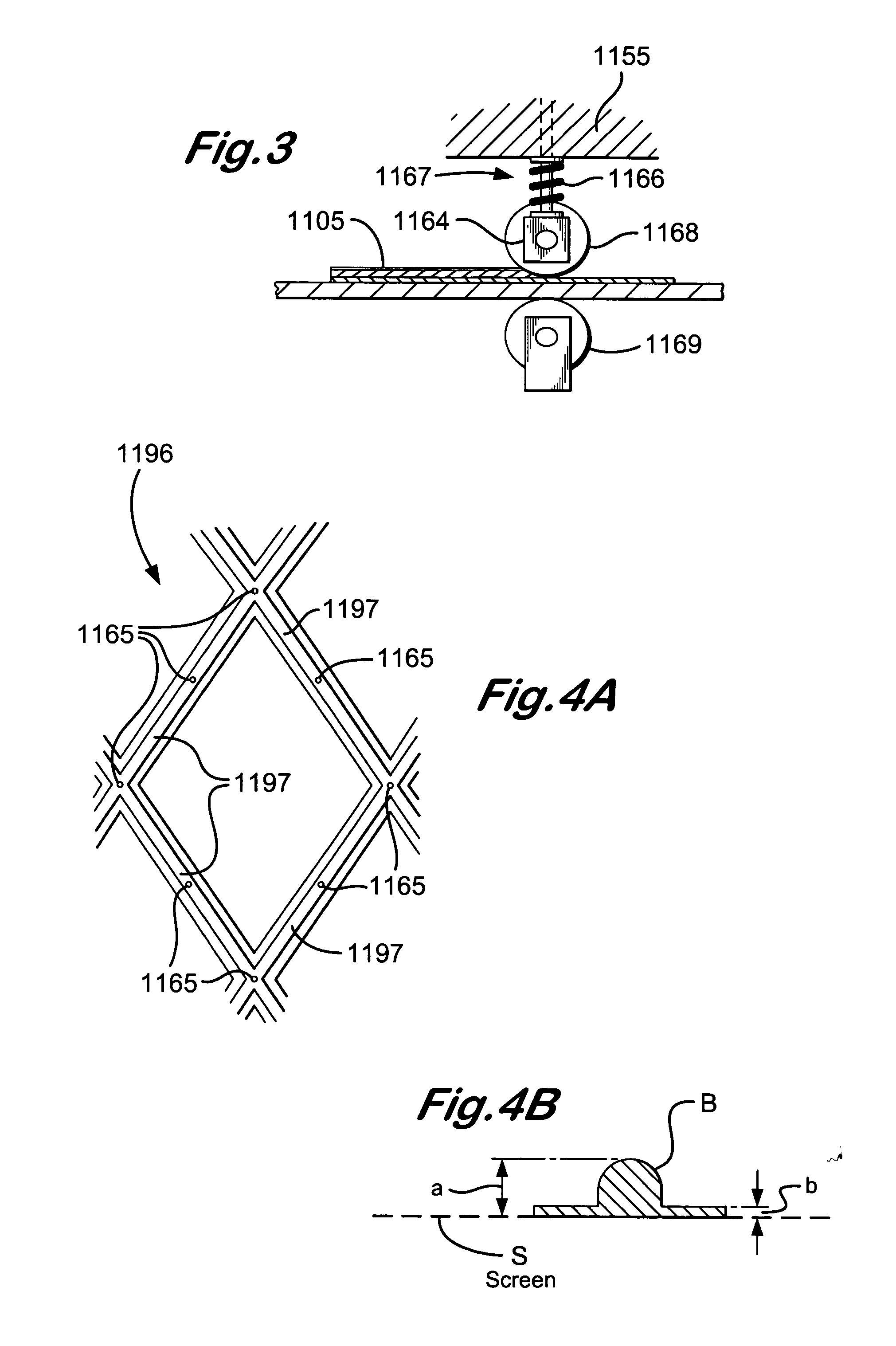

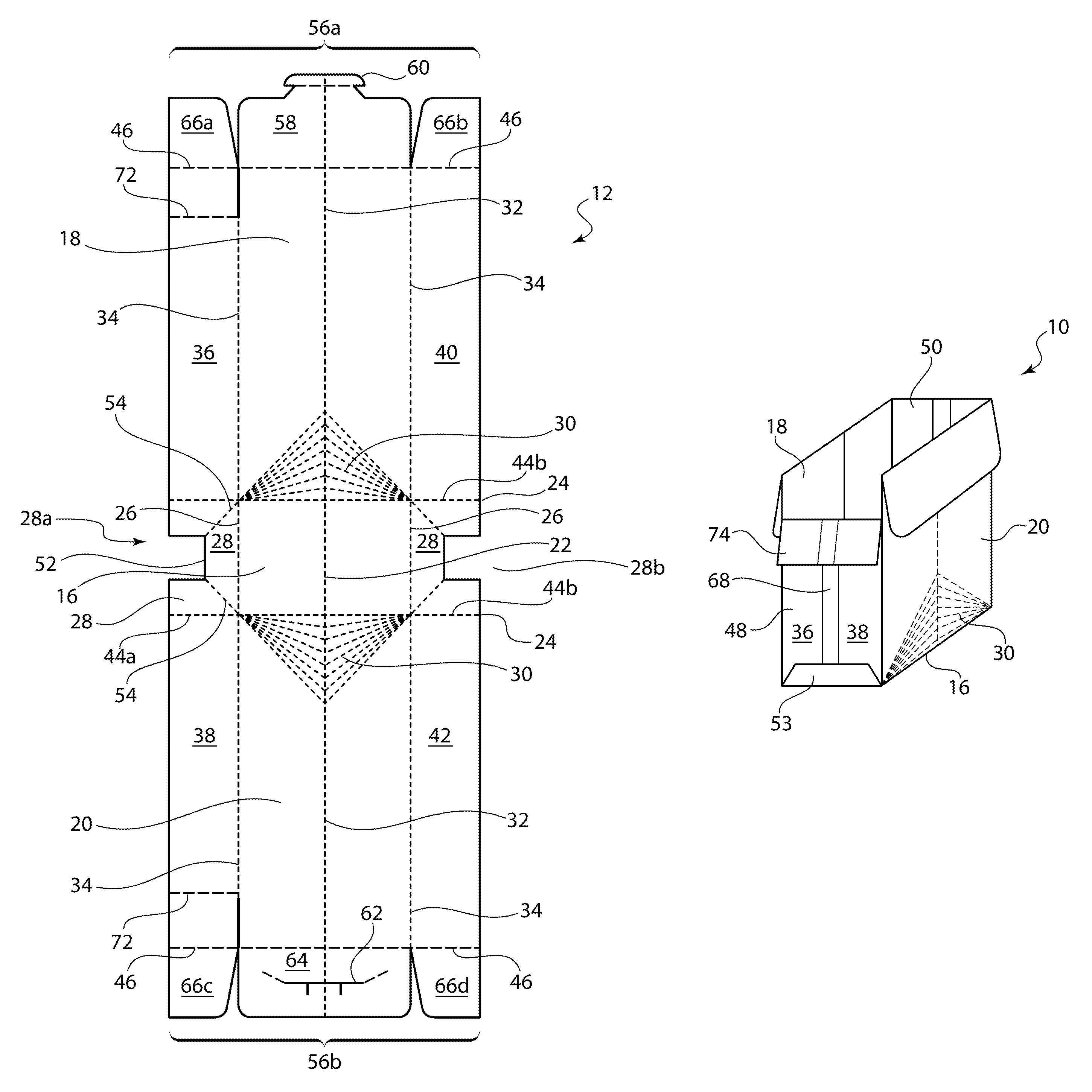

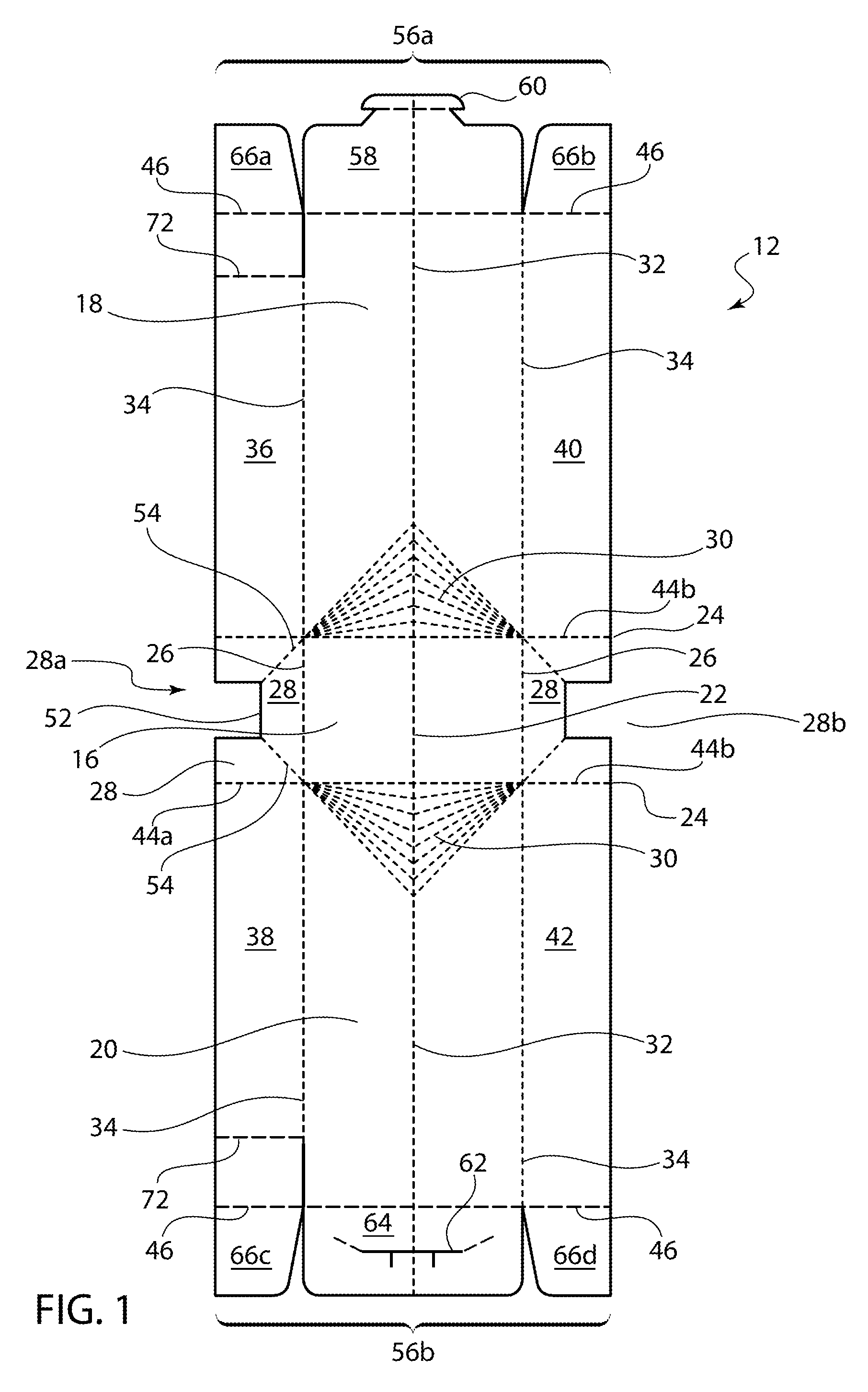

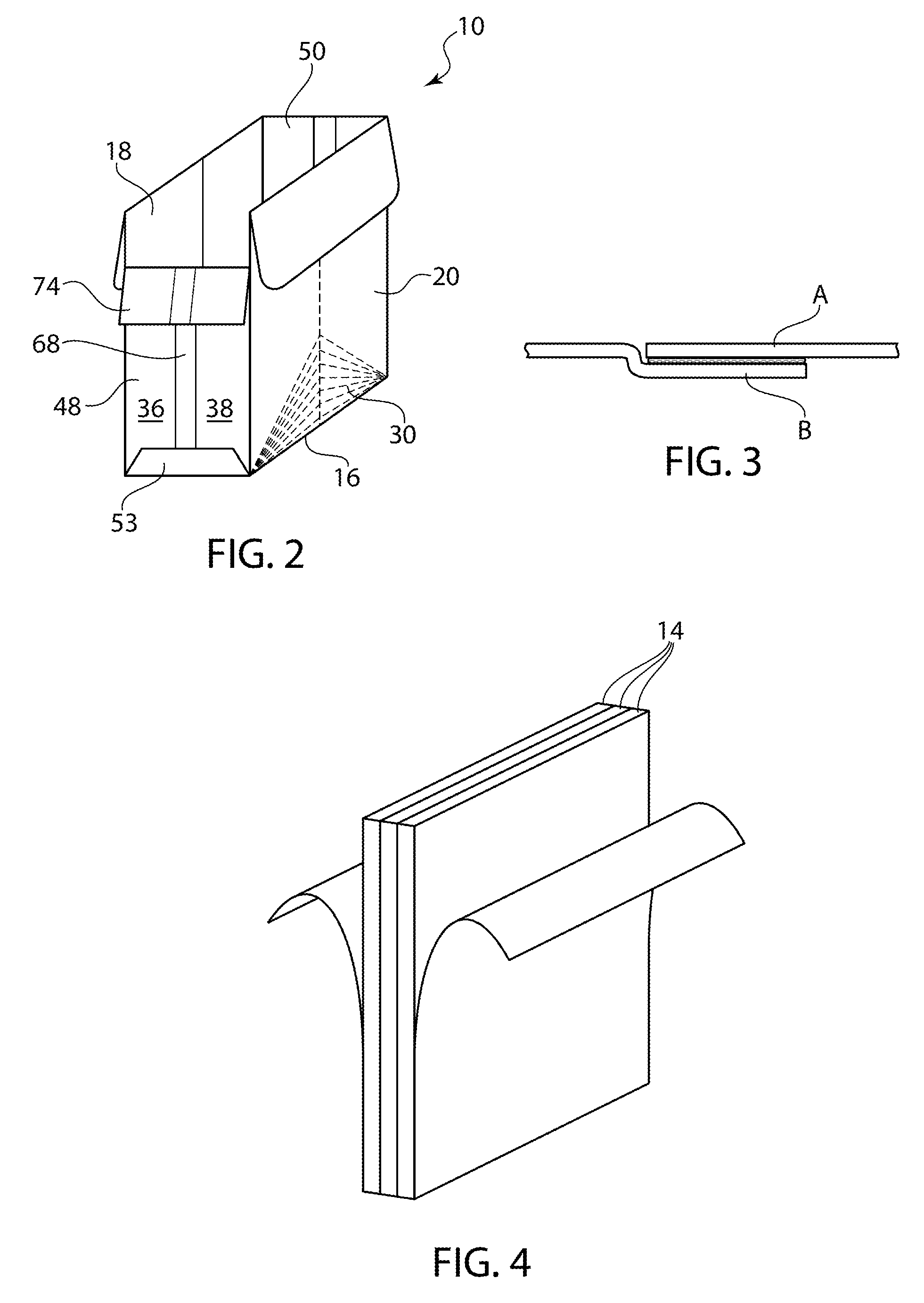

Apparatuses and methods for making glued screen assemblies

Screen assemblies for a vibratory separator, and methods for making them, the method in one aspect including: applying glue in a glue pattern to at least one layer of screening material useful for screening fluid, said applying done by powered moving mechanical glue application apparatus; moving at least one glue dispensing manifold with a plurality of spaced-apart glue dispensing nozzles above the at least one layer of screening material to apply the glue pattern; combining the at least one layer of screening material to a second layer forming a screen combination; moving the screen combination apart from the powered moving mechanical glue application apparatus; and cutting part of the screen combination from the screen combination.

Owner:VARCO I P INC

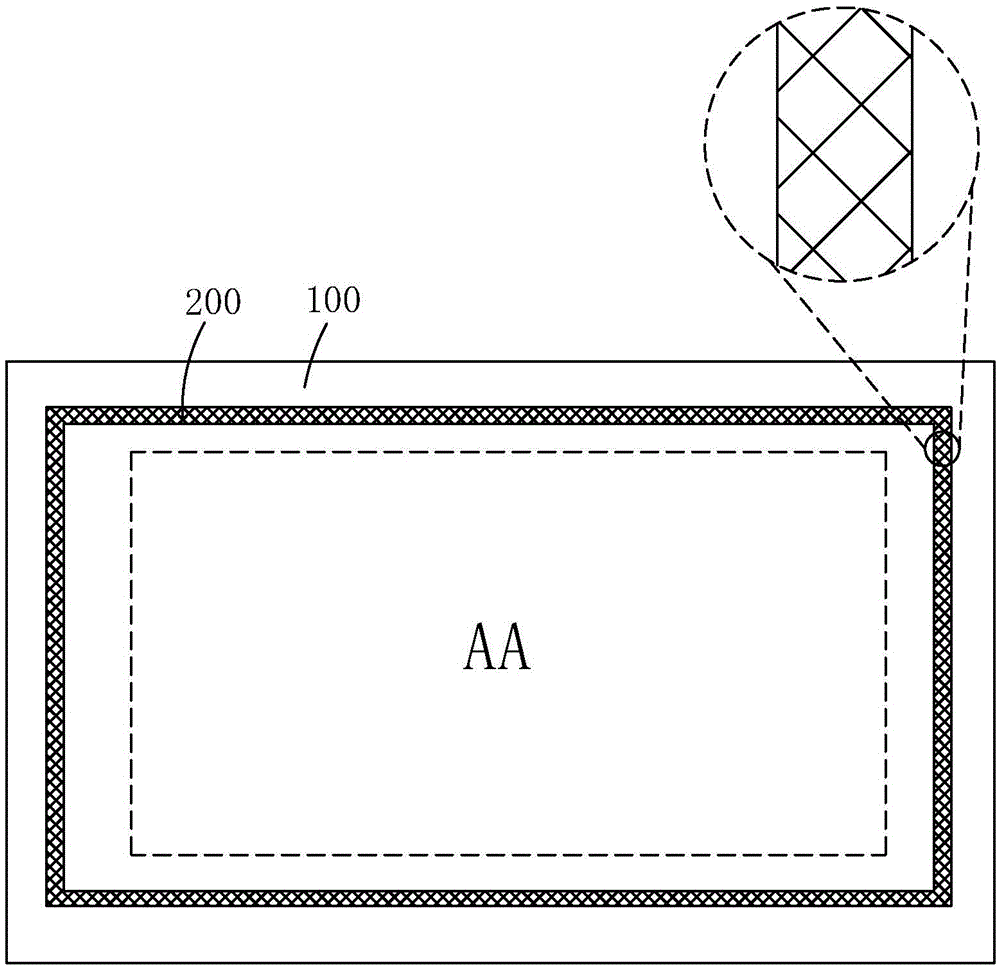

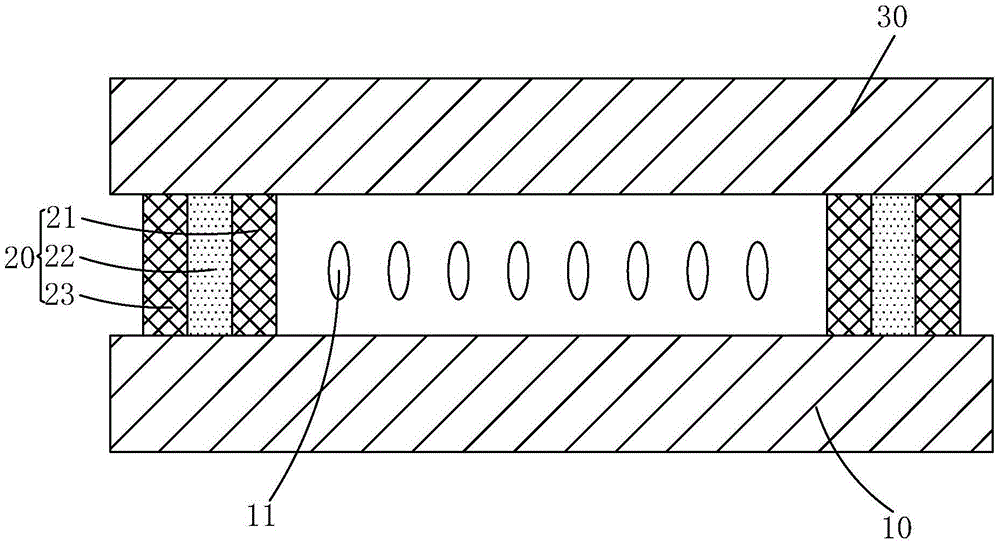

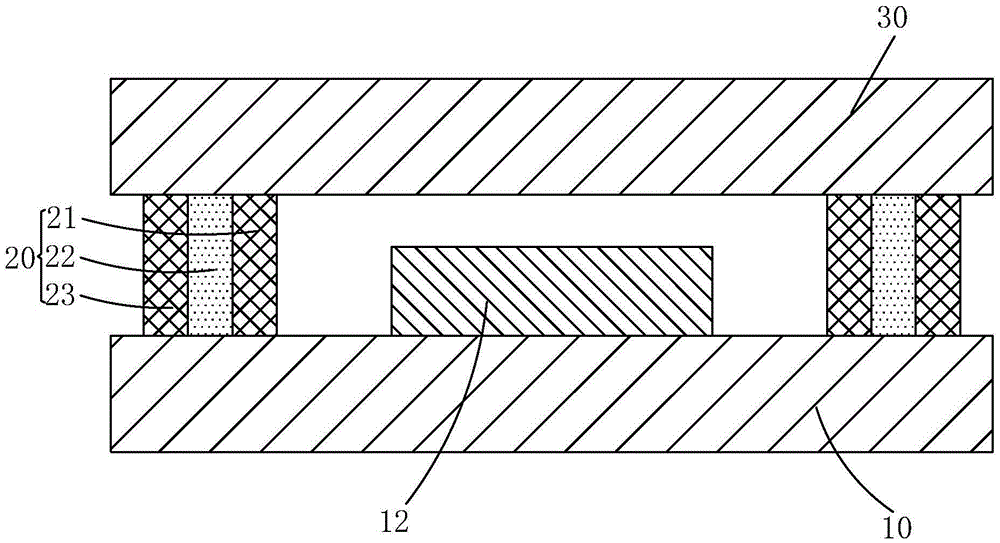

Packaging structure and method of display panel

InactiveCN105549272AImprove sealingImprove yieldNon-linear opticsIdentification meansAdhesive glueMoisture absorption

The invention provides a packaging structure and method of a display panel. The packaging structure comprises a first substrate (10), a second substrate (30) and frame sealing glue (20) bonding the first substrate (10) and the second substrate (30). The frame sealing glue (20) comprises a first frame sealing glue layer (21), a second frame sealing glue layer (22) and a third frame sealing glue layer (23) which are sequentially distributed from inside to outside. The first frame sealing glue layer (21) and the third frame sealing glue layer (23) are made from adhesive glue materials. The second frame sealing glue layer (22) is made from a moisture prevention material or a moisture absorption material. Therefore, the moisture prevention effect of the frame sealing glue is effectively improved under the condition that the bonding force of the frame sealing glue is ensured, and the sealing effect of the display panel is improved. According to the packaging method, packaging is conducted through the frame sealing glue of the packaging structure, and the sealing effect of the display panel is improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

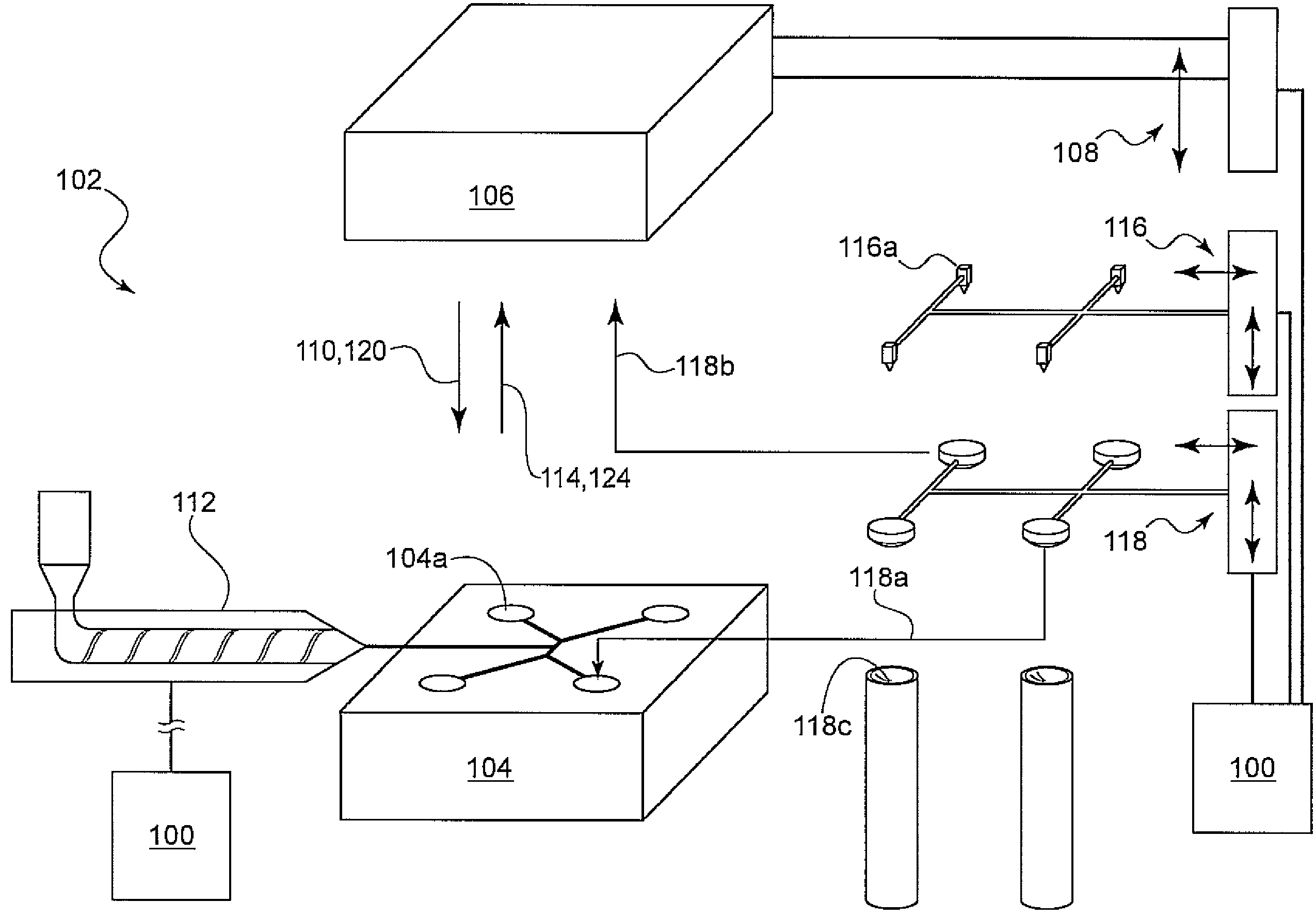

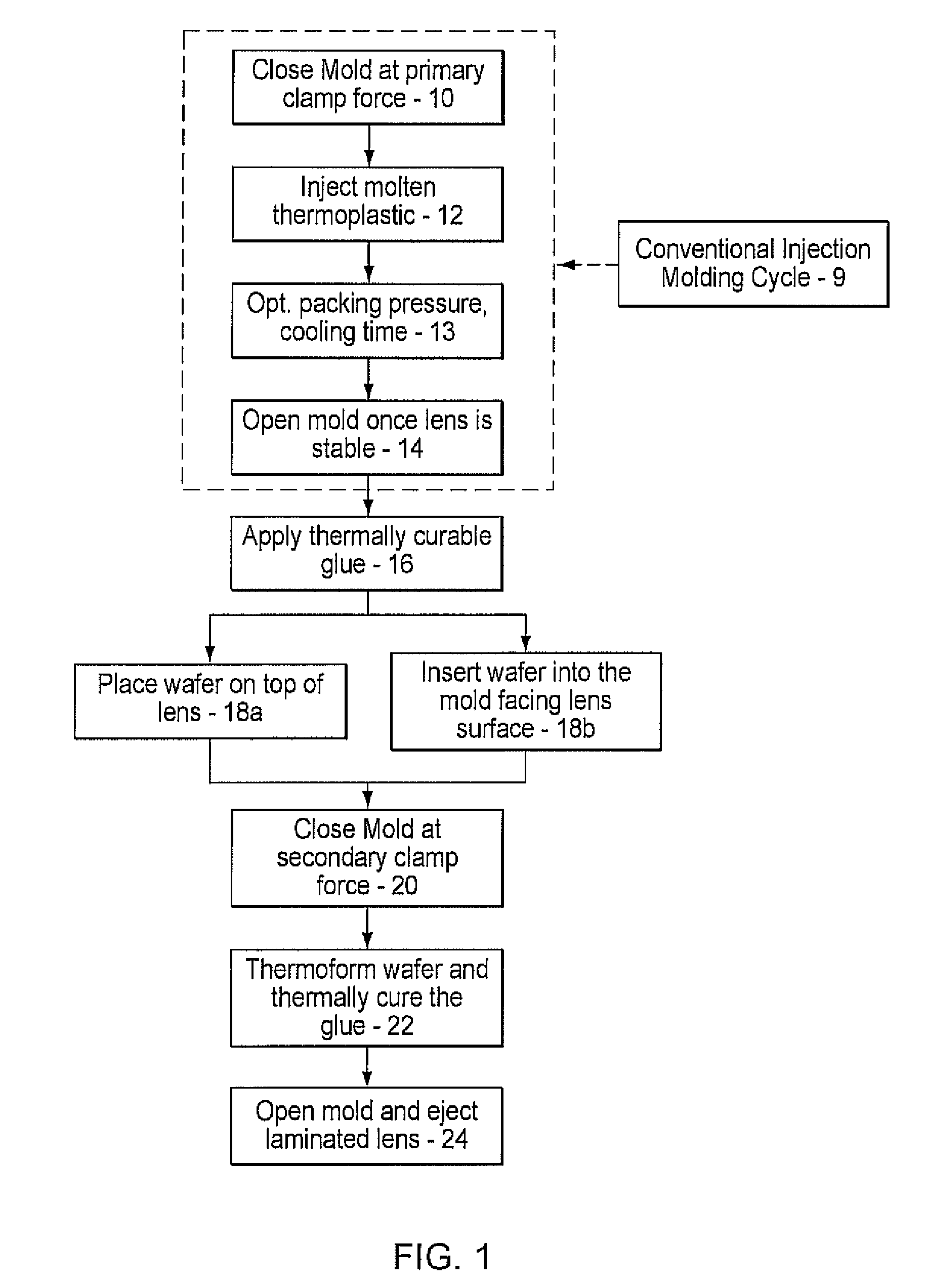

Method for post-injection lamination to add a functional film to an optical lens

ActiveUS7820081B2Easy to combineIncrease rangePolarising elementsOptical articlesAdhesive glueThin membrane

A method for laminating a functional film on to a thermoplastic injection molded lens. A thermally curable glue is deposited on the lens while it is still in the mold. A functional film is introduced and the mold is closed again. The heat from the mold and the clamping pressure thermoform the film and cure the glue, in a lamination process. A functionally enhanced lens having a film intimately laminated on to one side.

Owner:ESSILOR INT CIE GEN DOPTIQUE

Self-sealing box for trash compactors

ActiveUS8875983B2Use minimizedMinimize the numberPaper/cardboardRigid containersAdhesiveWaste collection

Embodiments of the present invention provide boxes that are particularly useful in connection with trash collection and trash compaction. The boxes are designed as having a single-piece board construction with a strength that can contain mixed types of trash, including solids and liquids, and to effectively contain the trash during the pressure of a compaction process without tearing, splitting and / or leaking. They are also designed to use a waterproof coating for adhering seams, reducing the extra step and expense of using a glue or an adhesive to secure the box seams. The trash compaction boxes provided herein are particularly useful on aircraft and other passenger transport vehicles, where weight and performance are of primary concern.

Owner:DURA FIBER +1

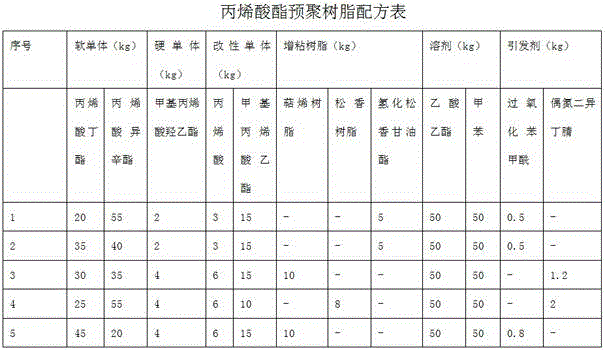

Ultra-thin polyester double-sided adhesive tape, glue thereof, and preparation method thereof

ActiveCN104152077AHigh bonding strengthImprove cohesionFilm/foil adhesivesEster polymer adhesivesPolyesterAdhesive

The invention discloses an ultra-thin polyester double-sided adhesive tape comprising a polyester thin film layer and two glue layers formed by glue coated on front and back sides of the polyester thin film. The thickness of the polyester thin film is 0.001-0.0012mm. The thickness of the glue layer is 0.002mm. Therefore, the thickness of the double-sided adhesive tape is only 0.005mm, such that electronic product development trends of thin and light can be satisfied. The total thickness of adhesive is 0.004mm, such that the tape has ultra-low thermal resistance, and heat generated by electrical components can be conducted in time. Therefore, electrical component damage caused by long-term working under high temperature is avoided. Also, the invention discloses a formula for the glue used in the ultra-thin polyester double-sided adhesive tape. The glue comprises the raw materials of, by weight, 100 parts of acrylate prepolymer resin, 0.5-3 parts of a curing agent, and 100-200 parts of ethyl acetate. With the glue, a single side thickness is 0.002mm, and high adhesive performance can be provided.

Owner:四川羽玺新材料股份有限公司

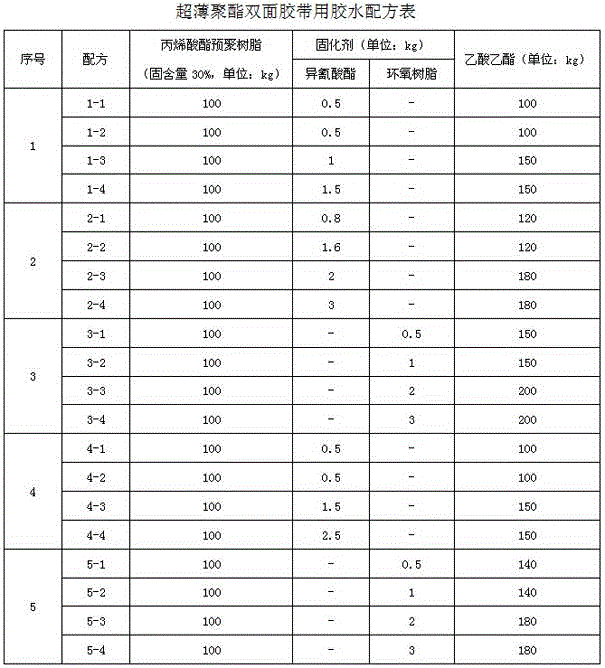

Super-hydrophobic adhesive film

ActiveCN101481590AHigh strengthEasy to useFilm/foil adhesivesSynthetic resin layered productsAdhesive glueEngineering

The invention discloses a super-hydrophobic glue film comprising a super-hydrophobic film with a super-hydrophobic surface. The super-hydrophobic glue film is characterized in that the non-super-hydrophobic surface of the super-hydrophobic film is provided with an adhesive glue layer. When in use, the super-hydrophobic film can be stuck on any surface. The invention has the advantages of convenient use, simple structure, easy production, high strength, low cost and capability of scale production and application.

Owner:CHONGQING UNIV +1

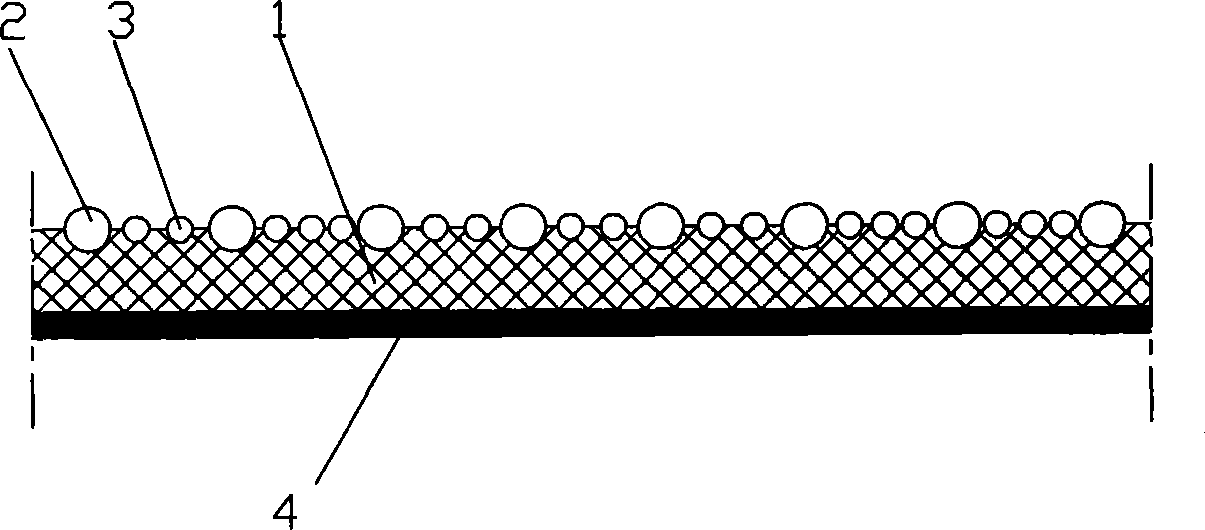

Composite electromagnetic shield materials and method for preparing same

InactiveCN101704312ALow costImprove shielding effectMagnetic/electric field screeningMetal layered productsMetal coatingAdhesive glue

The invention relates to a composite electromagnetic shield material with a laminated structure. The laminated structure comprises a magnetic material coating, a metal coating, an adhesive glue coating and a plastic protective coating, wherein one side of the metal coating is jointed with the magnetic material coating, the other side of the metal coating is jointed with one side of the adhesive glue coating, and the other side of the adhesive glue coating is jointed with the plastic protective coating. The invention has the advantages that: firstly, the theory of electromagnetic shield shows that the composition of the metal coating and the magnetic material coating can well shield high-frequency and low-frequency interference; secondly, the technology is simple, the cost is low, and the technical requirements of most electromagnetism compatibility engineering can be satisfied through adjusting the thickness of the metal coating, the thickness and magnetic permeability of soft magnetic material and other parameters; and thirdly, the shield material is easy to adhere outside or inside plastic casings of electrical appliances according to requirements of use after tearing off the plastic protective coating on the adhesive glue coating.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Method and system for closure of the flaps of the end sides of a package in the form of a sleeve

InactiveUS6622461B2Increase capacityBoxes/cartons making machineryPaper-makingAdhesive glueStructural engineering

A sleeve-type half package is closed by applying two beads of glue on each of two flaps on each end of the sleeve, folding those flaps inwardly by engagement with a nonglued strip between the beads and then folding the other two flaps at each end inwardly to engage a bead of glue on each of the two first-folded flaps at each end. The folding is done by thrust members as the half package is displaced linearly along a transport path.

Owner:BAUMER

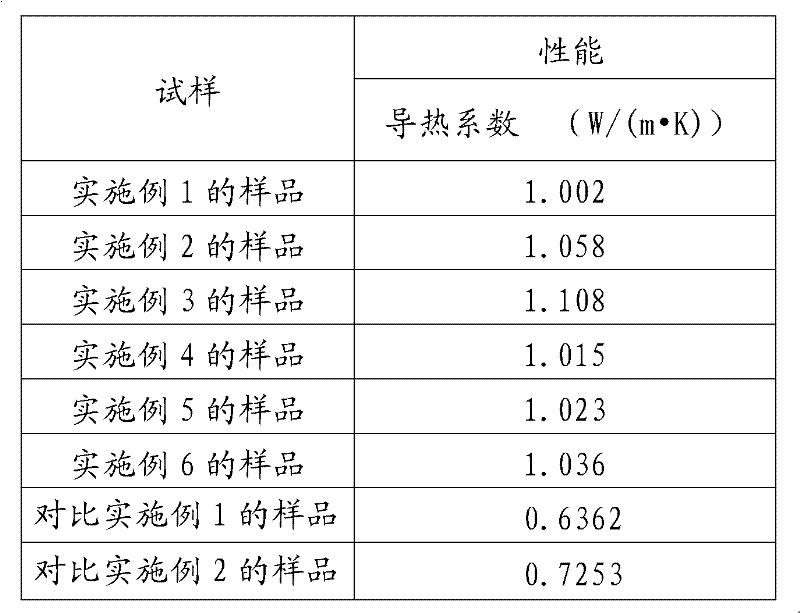

Flame retardant high-heat-conductivity epoxy resin electronic adhesive glue

InactiveCN102533192AImprove thermal conductivityDisperse quicklyNon-macromolecular adhesive additivesEpoxynovolac adhesivesHalogenAdhesive glue

The invention relates to flame retardant high-heat-conductivity epoxy resin electronic adhesive glue, which is formed by mixing ingredients A with amine curing agents according to the weight ratio of 100:(5-12), wherein the ingredients A comprises the following ingredients in parts by weight: 50 to 60 parts of spherical alumina powder, 20 to 30 parts of flame retardant fillings, 10 to 20 parts of epoxy resin, 1.5 to 2.5 parts of reactive diluents, 2 to 3 parts of halogen-free liquid flame retardants, 2 to 3 parts of toughening agents, 0.2 to 0.8 parts of thixotropic agents and 0.1 to 0.5 parts of coupling agents. According to the adhesive glue provided by the invention, the adhesive glue filled by the spherical alumina has higher condensate heat conductivity when being compared with the adhesive glue filled by the non-spherical alumina, and the heat accumulation of heating devices can be fast dispersed.

Owner:YANTAI DARBOND TECH

PE (polyurethane) protective film glue and preparation method thereof

InactiveCN102206476AStrong adhesionHigh bonding strengthFilm/foil adhesivesEster polymer adhesivesIsooctyl acrylateWater based

The invention discloses PE (polyurethane) protective film glue and a preparation method thereof. The PE protective film glue consists of the following components in parts by weight: monomers: 20-60 parts of butyl acrylate, 25-45 parts of methyl methacrylate, 12-32 parts of methyl acrylate, 5-15 parts of acrylic acid, 10-24 parts of hydroxyethyl acrylate, 120-140 parts of enthyl hexyl acrylate; emulsifying agents: 0.5-1.5 parts of polyoxyethylene octyl phenyl ether, 0.5-1.5 parts of sodium dodecyl sulphate, 0.5-1.5 parts of sodium dodecyl benzene sulfonate; a solvent: 280-350 parts of deionized water; and an initiating agent: 0.6-1.5 parts of ammonium persulfate. The PE protective film glue provided by the invention is the water-based adhesive and has the advantages of environment friendliness, no pollution, strong adhesive force and adhesive strength, and short drying time. A PE protective film coated with the PE protective film glue provided by the invention can be used for a vehicleprotective film, the protective films of all home appliances and so on. The effects of non-degumming and no residue glue can be realized.

Owner:BOLEX SHENZHEN ADHESIVE PROD

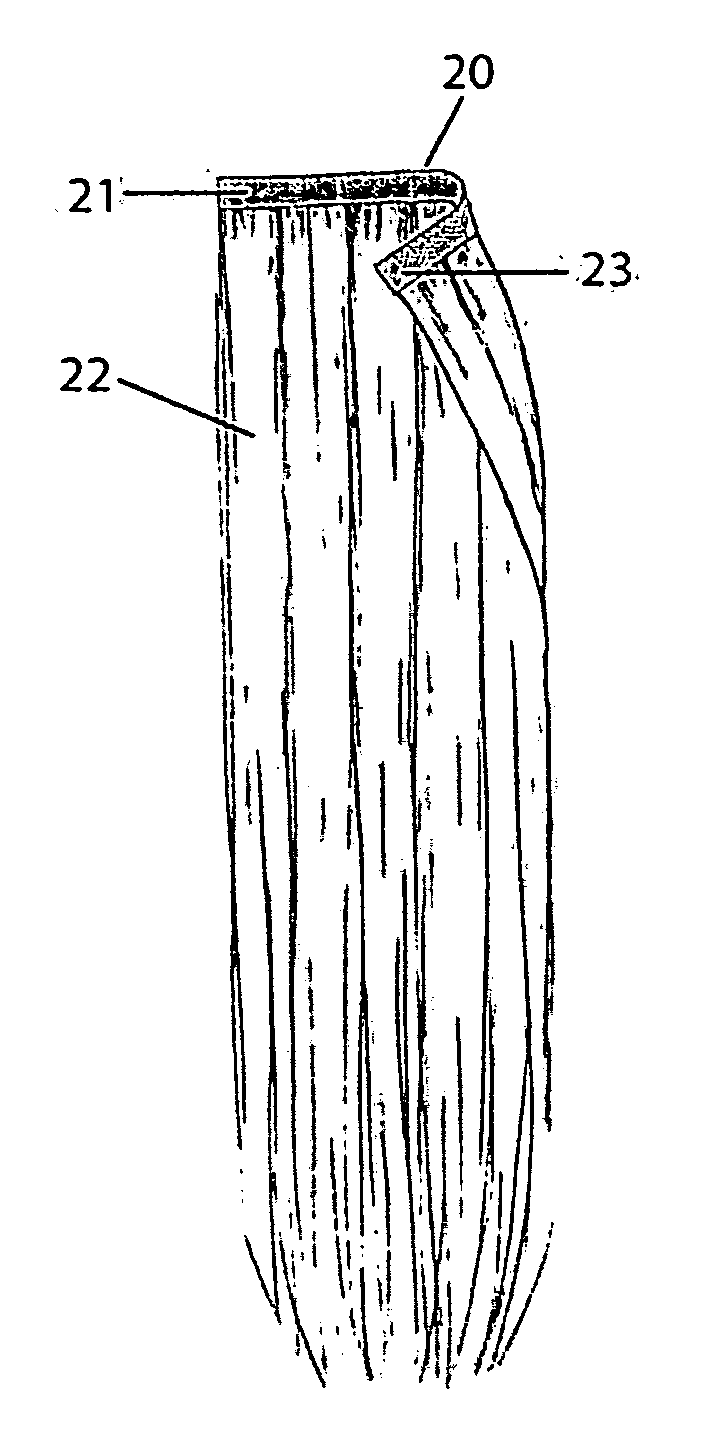

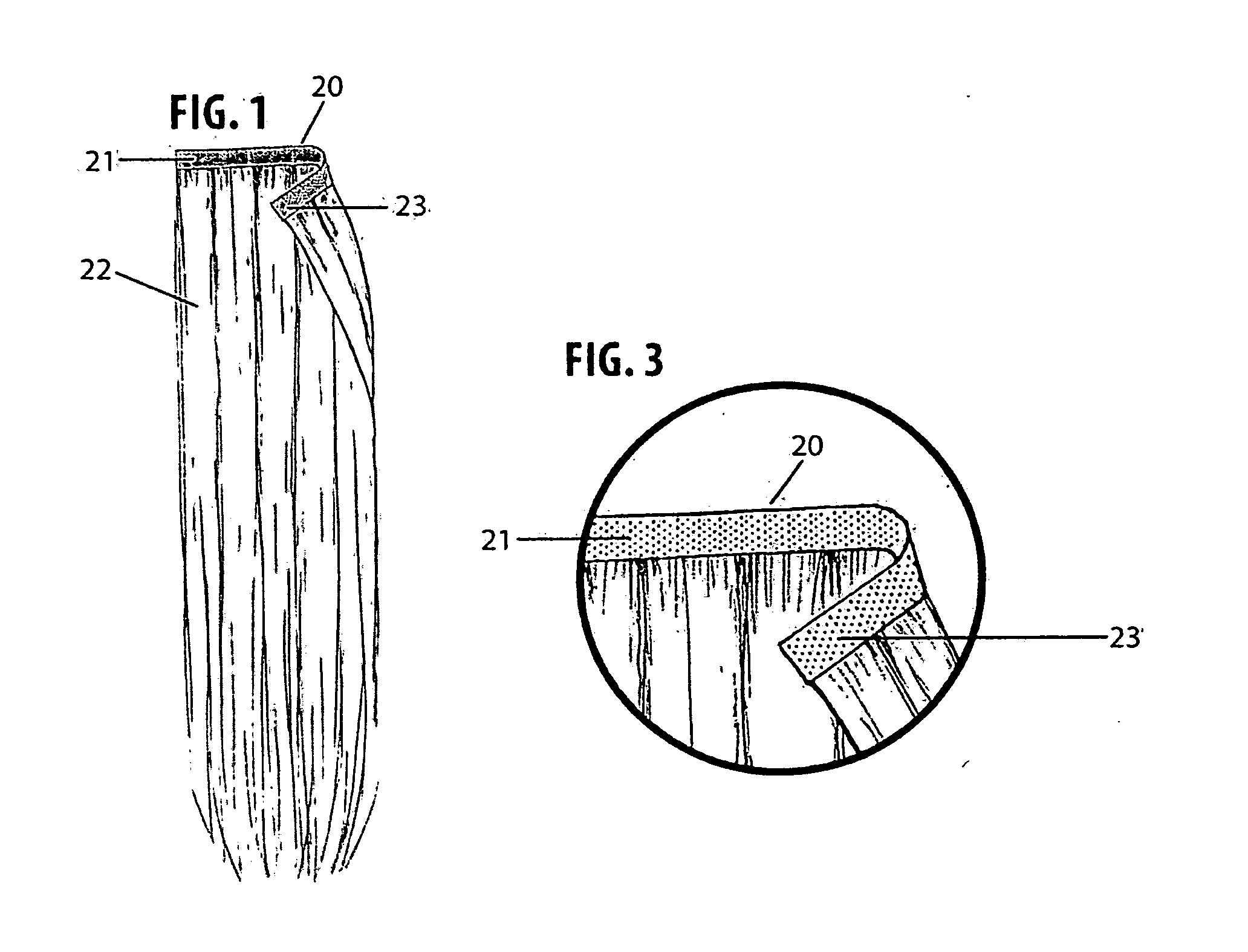

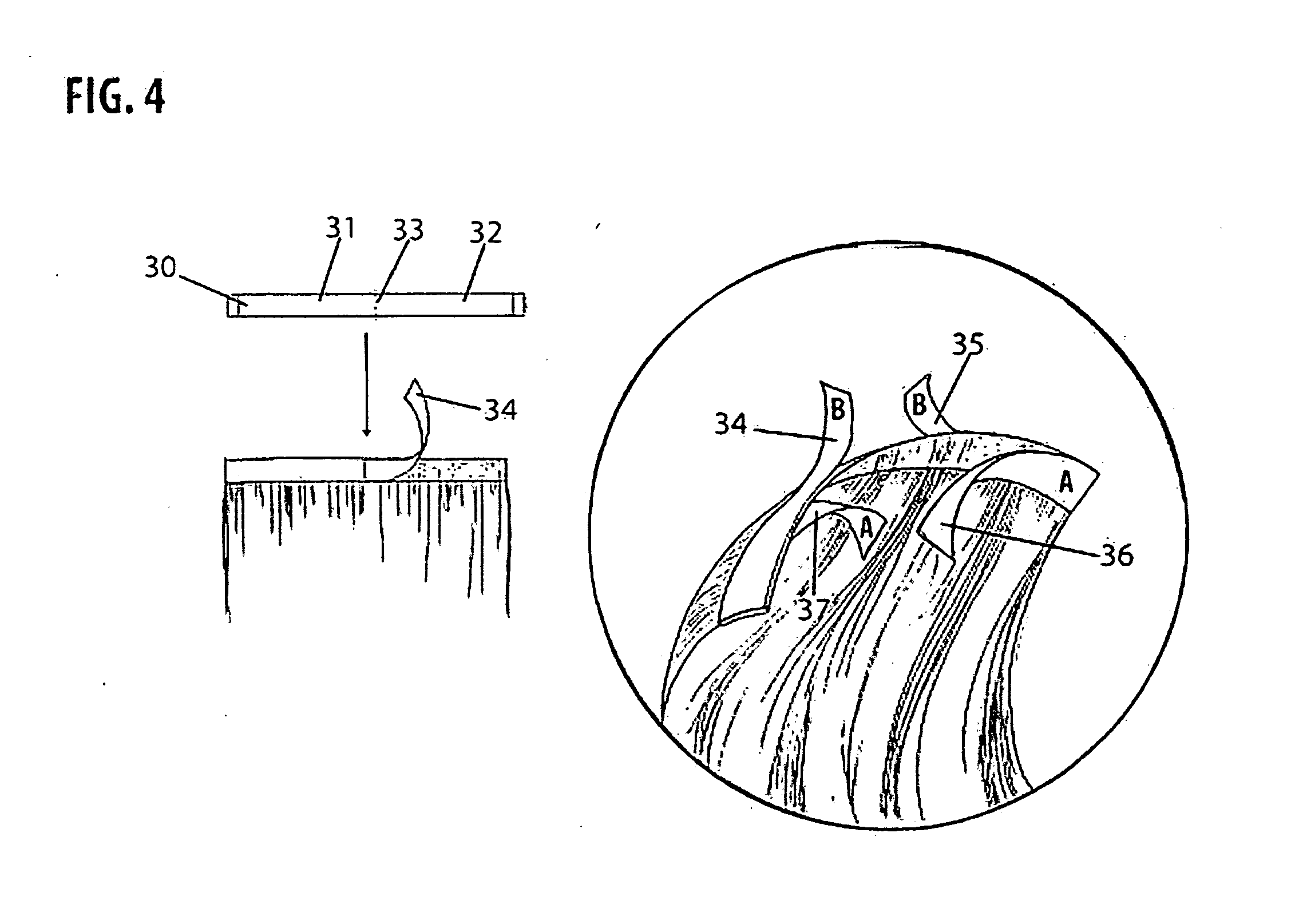

Hair extension system and method

A hair extension includes a hair weft. The hair weft is made of individual strands of human or synthetic hair. Far infrared powder is deposited onto Polyurethane (PU) and / or Keratin adhesive glue and webbing of silk or synthetic lace is incorporated with hair weft to create the human or synthetic hair PU and / or Keratin skin as connection strip(s). A connection strip receives connected ends of the individual strands of human or synthetic hair. A top adhesive strip is disposed on a top side of the connection strip and a bottom adhesive strip is disposed on a bottom side of the connection strip. The top and bottom adhesive strips both have a left side and a right side. The left side of the top adhesive strip and right side of the top adhesive strip are divided by an adhesive parting line.

Owner:WANG RYAN

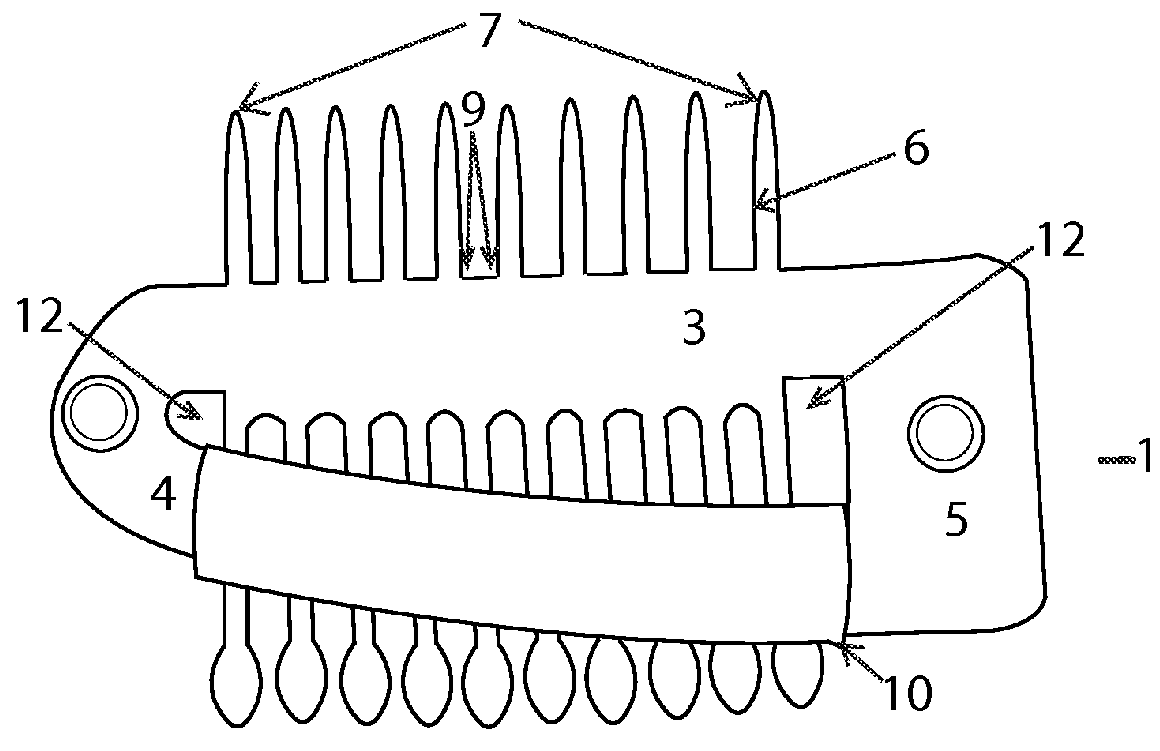

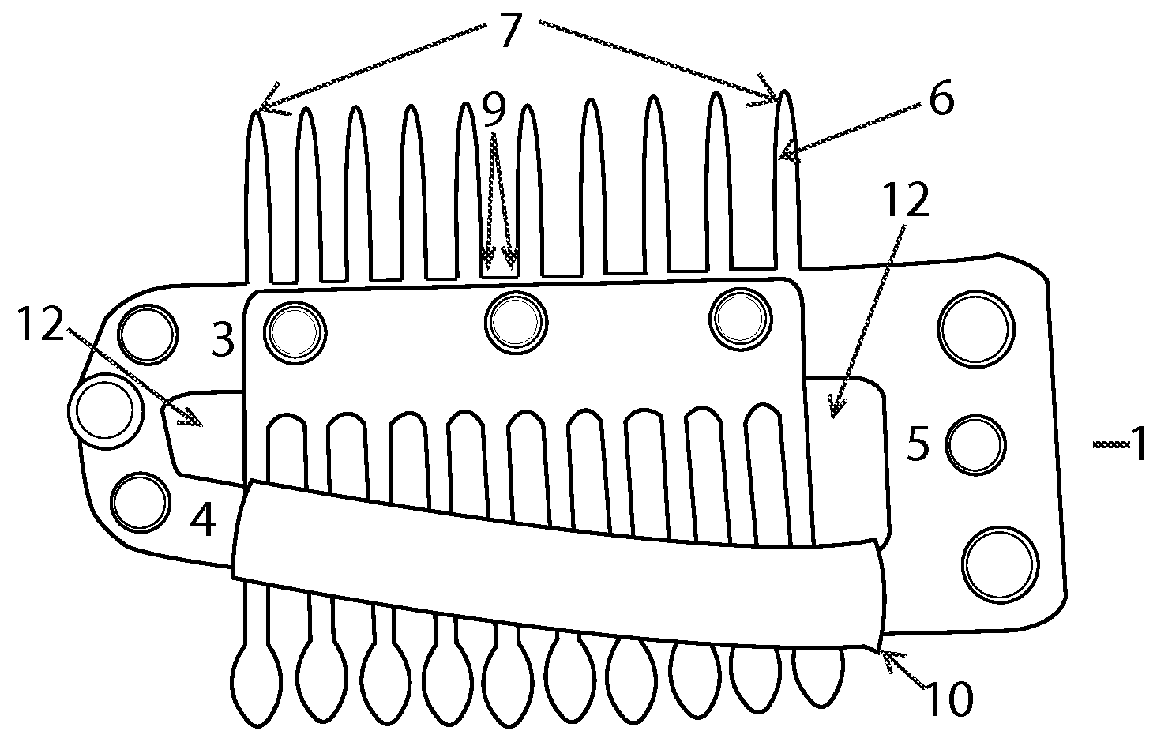

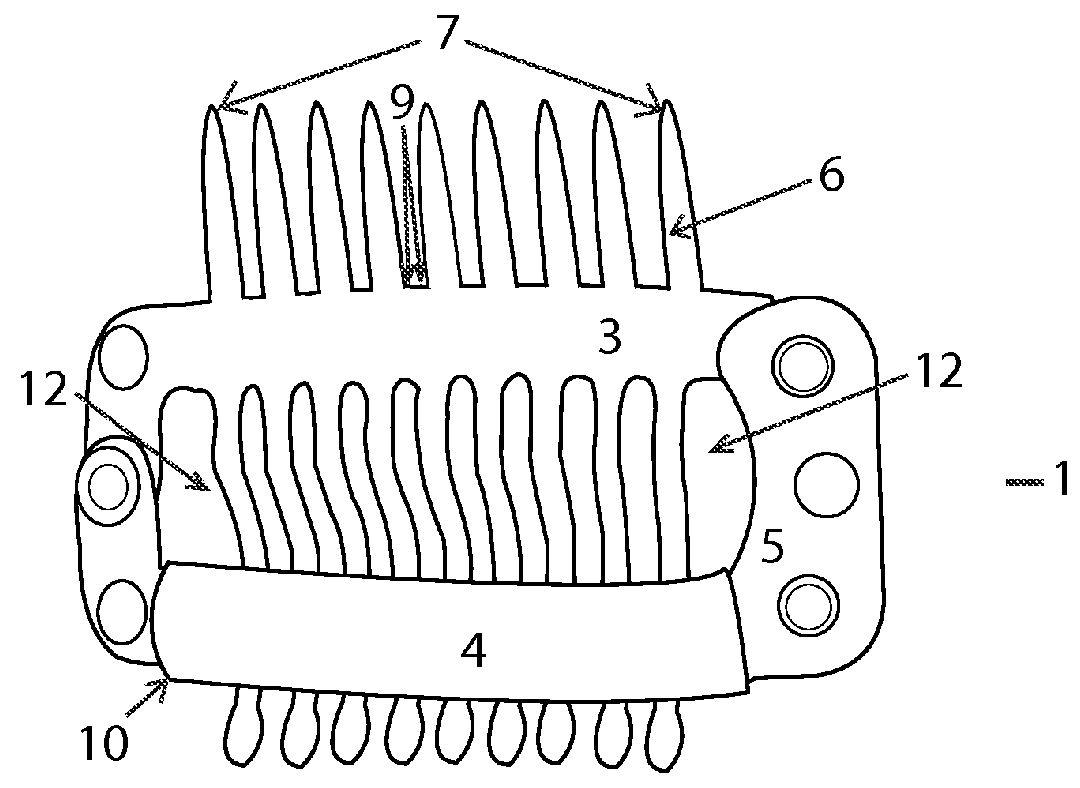

Hair Clip for Hair Extensions or Wigs and a Method Therefor

InactiveUS20160050996A1Efficiently attachEfficient removalHair accessoriesToupeesHairpiece/toupeeEngineering

Owner:KWON YOUNG JOON

3D printing method suitable for multiple materials and multiple processes and used printing device

ActiveCN105500720AAchieve laser sinteringAchieving cohesionAdditive manufacturing apparatusCeramic shaping apparatusMulti materialEngineering

The invention discloses a 3D printing method suitable for multiple materials and multiple processes and a used printing device. The used printing device comprises a moving lathe bed device, a sensing drum processing device, a curing device, a forming table, a cleaner, a waste material bin and a material supply bin; the forming table, the cleaner and the material supply bin are arranged on the moving lathe bed body; the waste material bin is arranged at the lower end of the cleaner; the sensing drum processing device and the curing device are arranged in the moving lathe body device. The 3D printing method comprises the following steps: using a photosensitive drum to selectively adsorb solid powder materials, then carrying out directional rolling on the processed forming table to realize selective powder laying, curing the different types of powder materials according to technique information, then using an auxiliary powder paving system to lay a supporting material on the forming table, descending the thickness of a powder layer, and repeating the steps to obtain a multi-material and multi-functional three-dimensional object through overlapping layer by layer. Selective powder laying is realized, the efficiency is improved, the materials are saved, and multi-process forming of laser sintering, glue bonding and thermocuring is realized.

Owner:JILIN UNIV

Construction method of reinforcing large-span concrete structure with prestressed carbon fiber sheet

InactiveCN103321430AWidely applicable reinforcementImprove mechanical performanceBridge erection/assemblyBuilding material handlingFiberCarbon fibers

A construction method of reinforcing a large-span concrete structure with prestressed carbon fiber sheet comprises the following steps of forming bolt embedding holes on the side surface to be reinforced of the large-span concrete structure, and embedding high-strength bolts of different specifications into the bolt embedding holes through adhesive glue; fabricating stretch sheet fixing portions, stretch sheet moving portions and stretch power fixing portions; mounting the stretch sheet fixing portions, stretch sheet moving portions, stretch sheet assembling units, stretch power fixing portions and stretch power portions, wherein the stretch sheet assembling units, the stretch power fixing portions and the stretch power portions are made of carbon fiber materials; stretching stretch sheet; and removing stretching power and tightly pressing and adhering the stretch sheet onto the surface of the large-span concrete structure. The construction method of reinforcing the large-span concrete structure with the prestressed carbon fiber sheet can achieve the gapless adhesion between the prestressed stretch sheet and the concrete structure to be reinforced, facilitate the coordination of the uniform stress force of the same sections of the carbon fiber filaments of the stretch sheet, improve the integral stress performance of the prestressed carbon fiber sheet and the coordination deformation capability of the prestressed carbon fiber sheet and the concrete structure and give full play to the high-strength characters of the carbon fiber sheet.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER +1

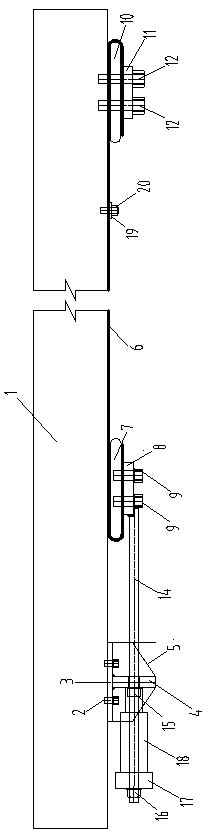

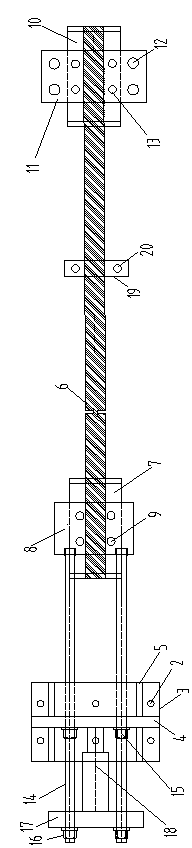

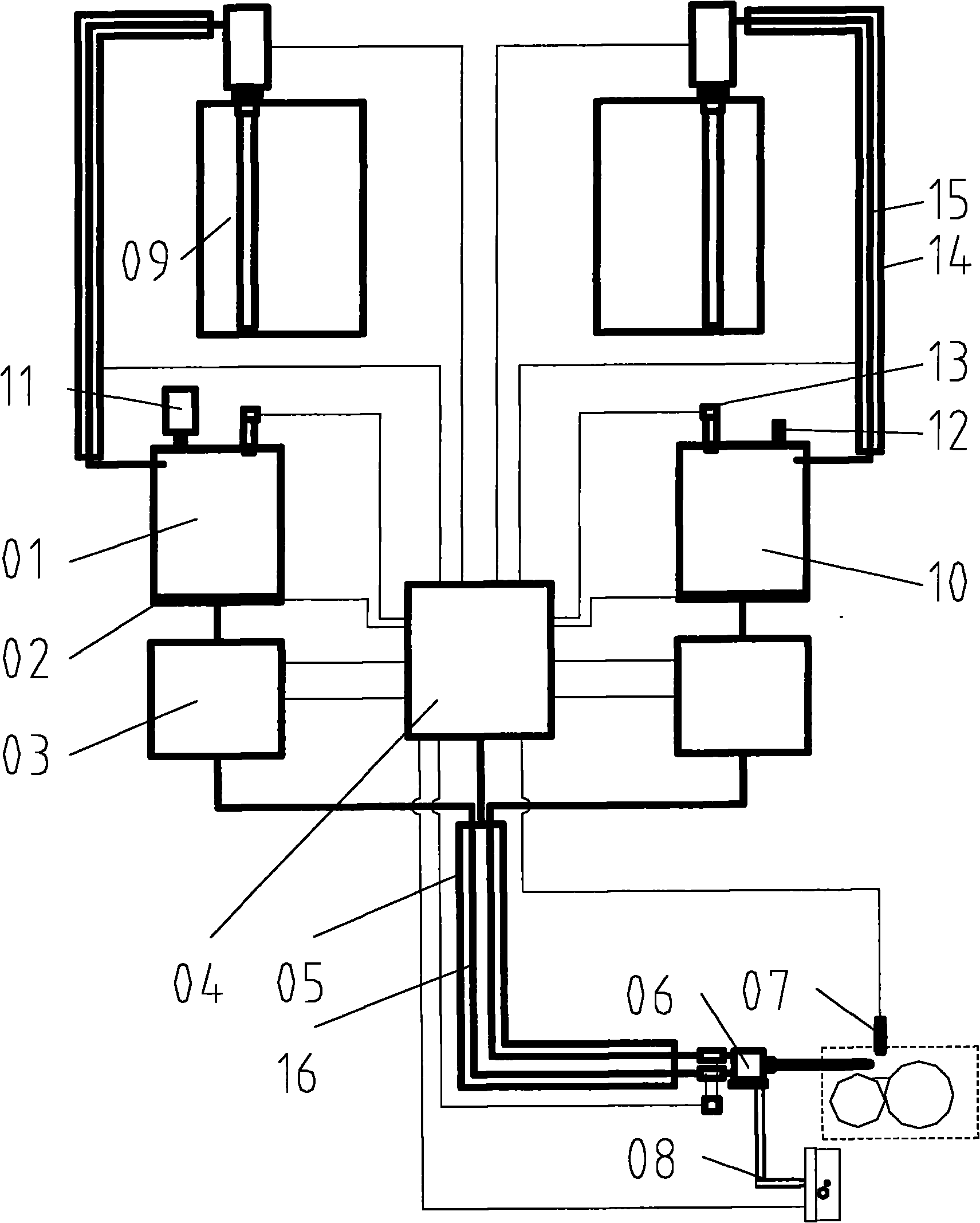

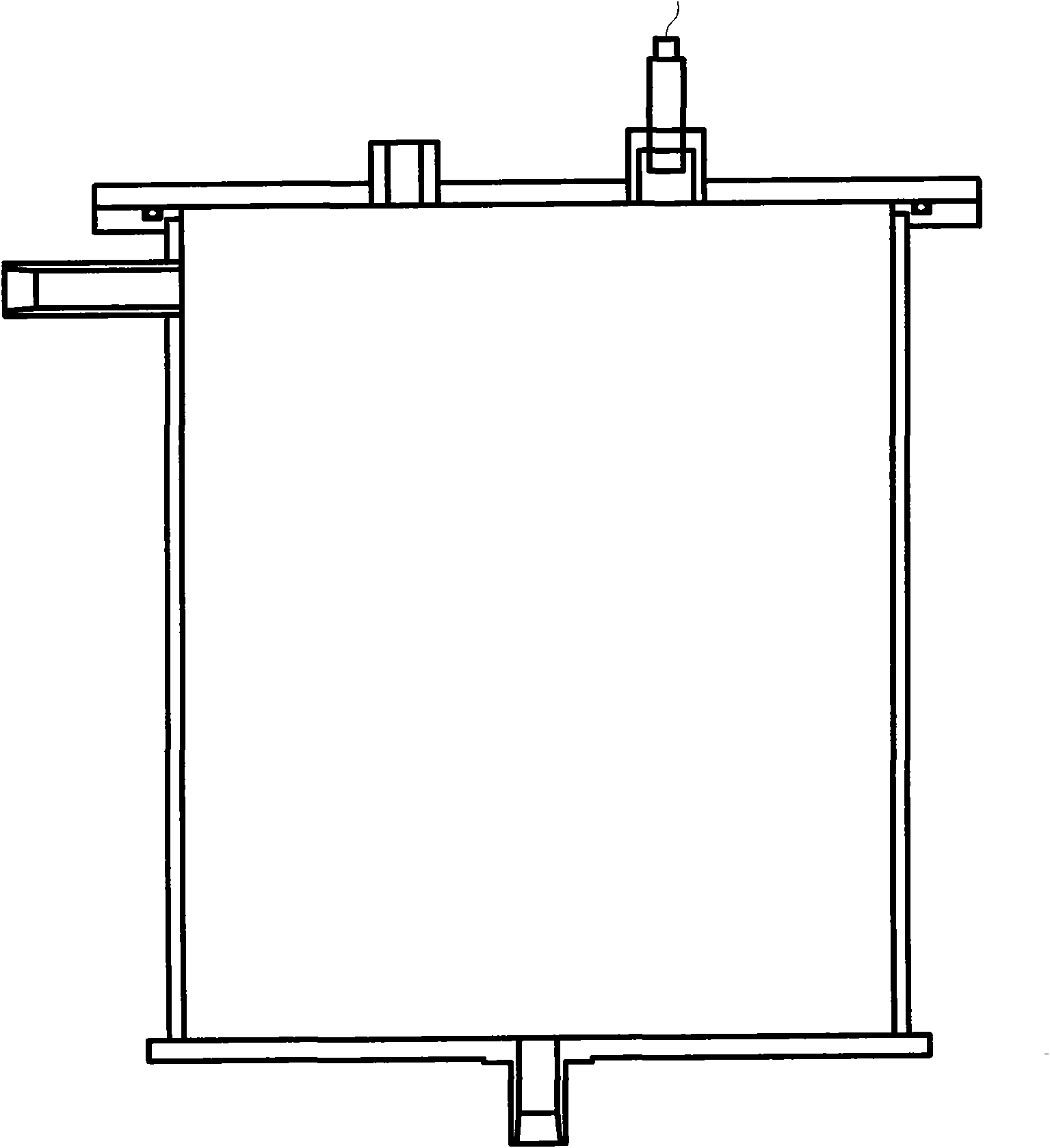

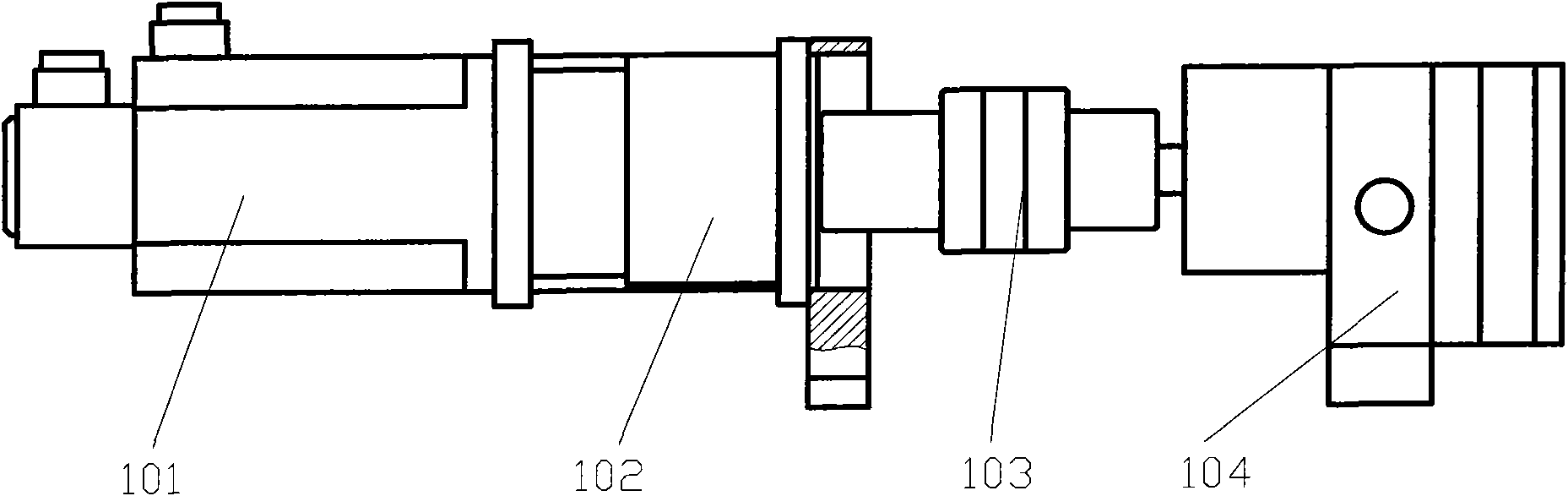

Double-component glue automatic glue mixer

InactiveCN102240514AImprove securityIncrease productivityRotary stirring mixersMixing methodsAutomatic controlReciprocating motion

The invention aims to provide a double-component glue automatic glue mixer with high safety performance, high production efficiency and good finished product quality. The automatic glue mixer comprises a glue storage mechanism, a glue transporting mechanism, a glue mixing mechanism, a reciprocating sizing mechanism, a heating insulation mechanism, a vat glue providing mechanism and a liquid level detection and electric control system. The glue storage mechanism employs a double glue storage barrel sealed structure. The glue transporting mechanism employs a structure of two motors connecting with the electric control system to ensure that an output glue proportion equals to a required glue proportion. The glue mixing mechanism employs a pneumatic performer to control two glues to enter into a mixing tube simultaneously and to mix fully through a double-spiral structured mixing core rod. The reciprocating sizing mechanism employs an automatic back-and-forth reciprocating motion apparatus. The heating insulation mechanism employs a multi-position heating to realize constant temperature of glue during an output process, so that an output proportion is more accurate. The vat glue providing mechanism realizes glue injection into the two glue storage barrels through the electric control system. The liquid level detection and electric control system realizes automatic control on an integral machine operation and controls glue proportion in a digitization approach with accurate proportion; besides the system can provide glue continuously to adapt high-speed automation production. The automatic glue mixer can ensure production efficiency, quality and safety; and compared with prior equipment, the automatic glue mixer is more convenient for operation, has a more reasonable structure and a more beautiful appearance.

Owner:SINOMECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com