3D printing method suitable for multiple materials and multiple processes and used printing device

A 3D printing and multi-material technology, applied in the field of 3D printing, can solve the problems of slow molding speed, complicated printing methods, inability to print multi-material parts and multi-material assemblies, and achieve the effect of improving efficiency and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

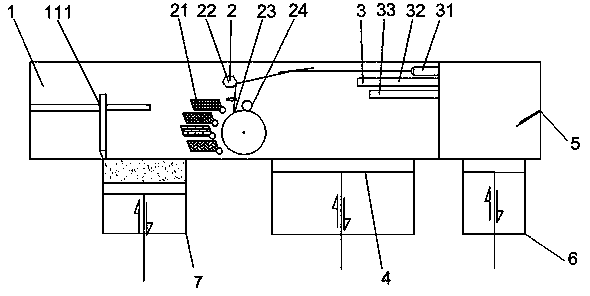

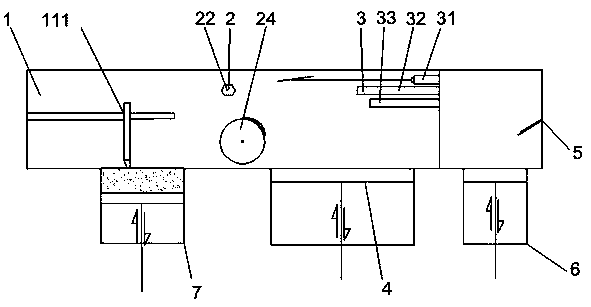

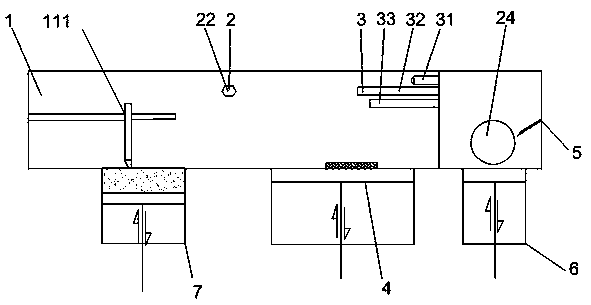

[0039] see figure 1 As shown, one of the printing devices of the present invention suitable for multi-material and multi-process 3D printing methods is composed of a moving bed device 1, an induction drum processing device 2, a curing device 3, a forming table 4, a cleaner 5, and a waste bin 6 and feeding bin 7, the forming table 4, cleaning device 5 and feeding bin 7 are respectively set on the moving bed device 1, the waste bin 6 is set at the lower end of the cleaning device 5, and the induction drum processing device 2 and the curing device are respectively set for moving Inside the bed device 1;

[0040] There is a scraper 111 on the moving bed device 1;

[0041] The induction drum processing device 2 includes several powder boxes 21, several magnetic rollers 22, a photosensitive drum 23 and a charging roller 24, the magnetic roller 22 is fixedly arranged on the powder box 21, and the charging roller 24 is arranged on the photosensitive drum 23;

[0042] The curing devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com