A method suitable for multi-material multi-process 3D printing and printing device used

A 3D printing and multi-material technology, applied in the field of 3D printing, can solve the problems of slow molding speed, complicated printing methods, and the inability to print multi-material parts and multi-material assemblies, and achieve the effect of improving efficiency and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

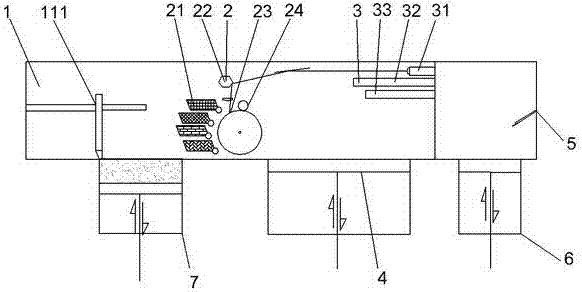

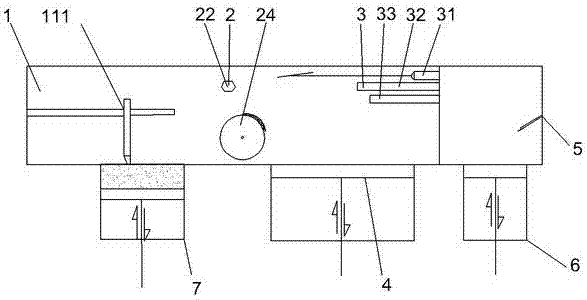

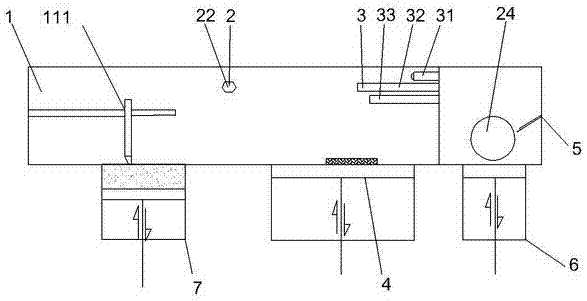

[0038] see figure 1 As shown, one of the printing devices of the present invention suitable for multi-material and multi-process 3D printing methods is composed of a moving bed device 1, an induction drum processing device 2, a heating and curing device 3, a forming table 4, a cleaning device 5, and waste materials The bin 6 and the feeding bin 7 are composed of the forming table 4, the cleaning device 5 and the feeding bin 7 respectively arranged on the moving bed device 1, the waste bin 6 is arranged at the lower end of the cleaning device 5, the induction drum processing device 2 and the heating and curing device respectively Set in the kinematic bed device 1;

[0039] There is a scraper 111 on the moving bed device 1;

[0040] The induction drum processing device 2 includes several powder boxes 21, several magnetic rollers 22, a photosensitive drum 23 and a charging roller 24, the magnetic roller 22 is fixedly arranged on the powder box 21, and the charging roller 24 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com