Patents

Literature

4379results about "Applying layer means" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

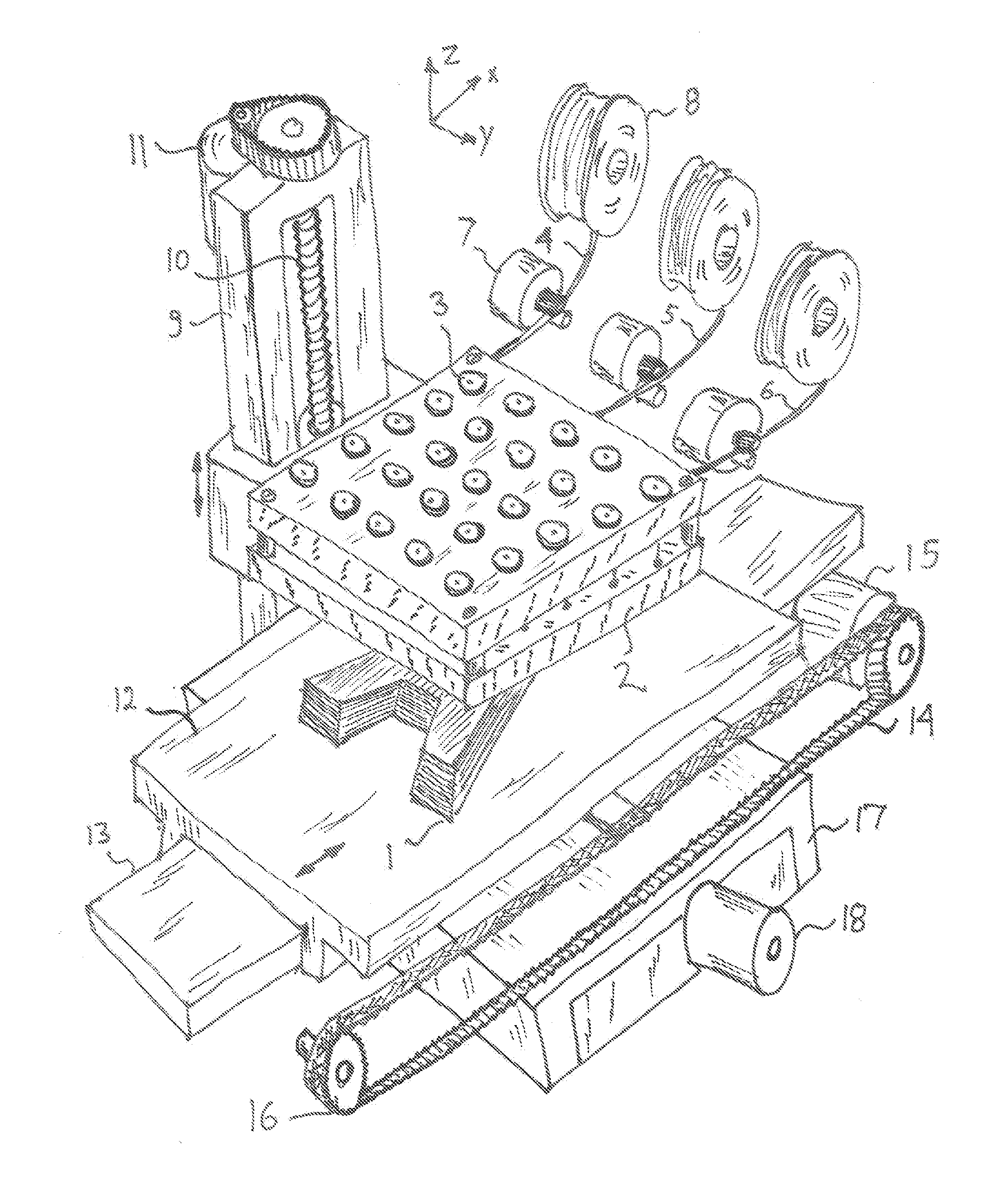

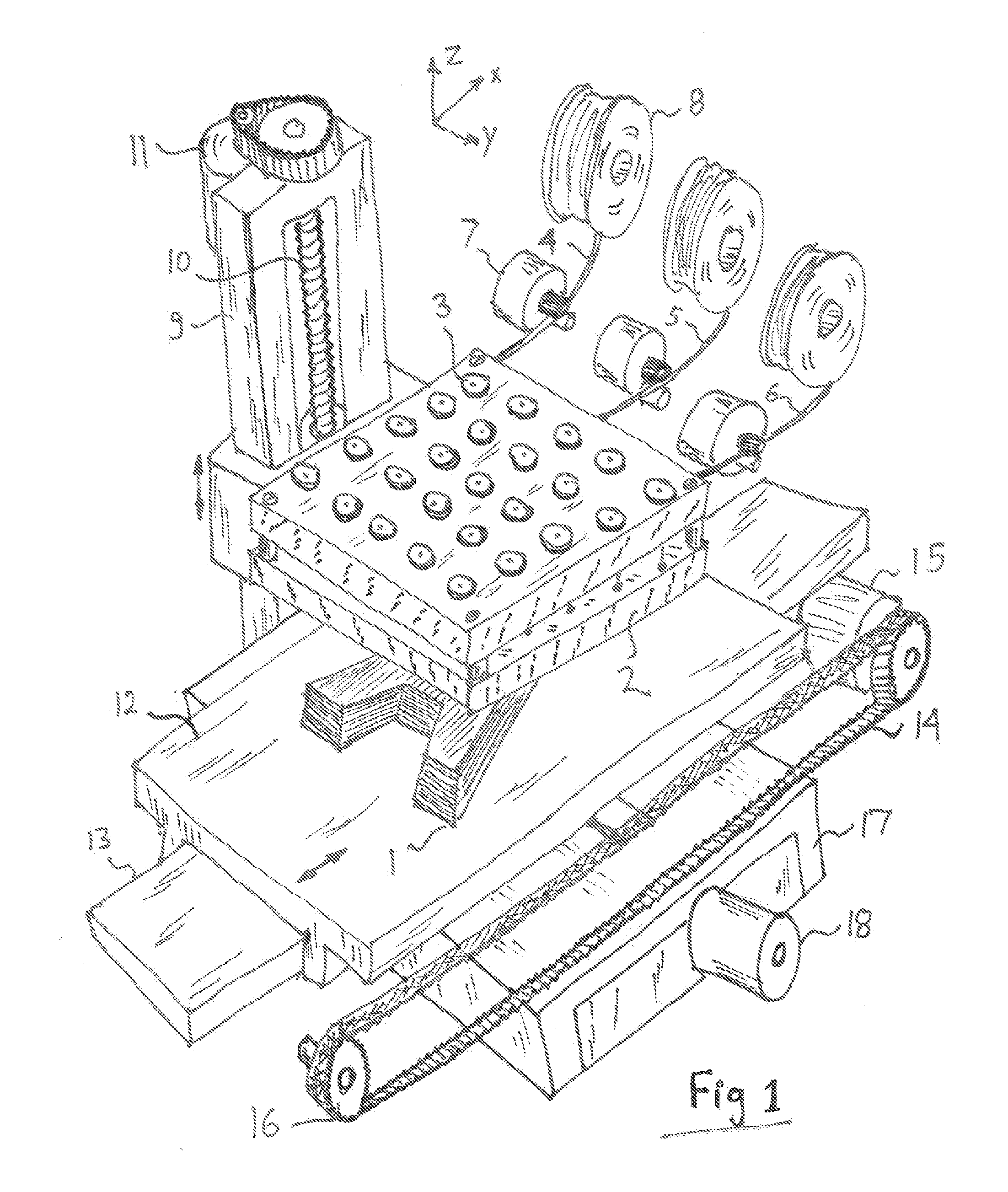

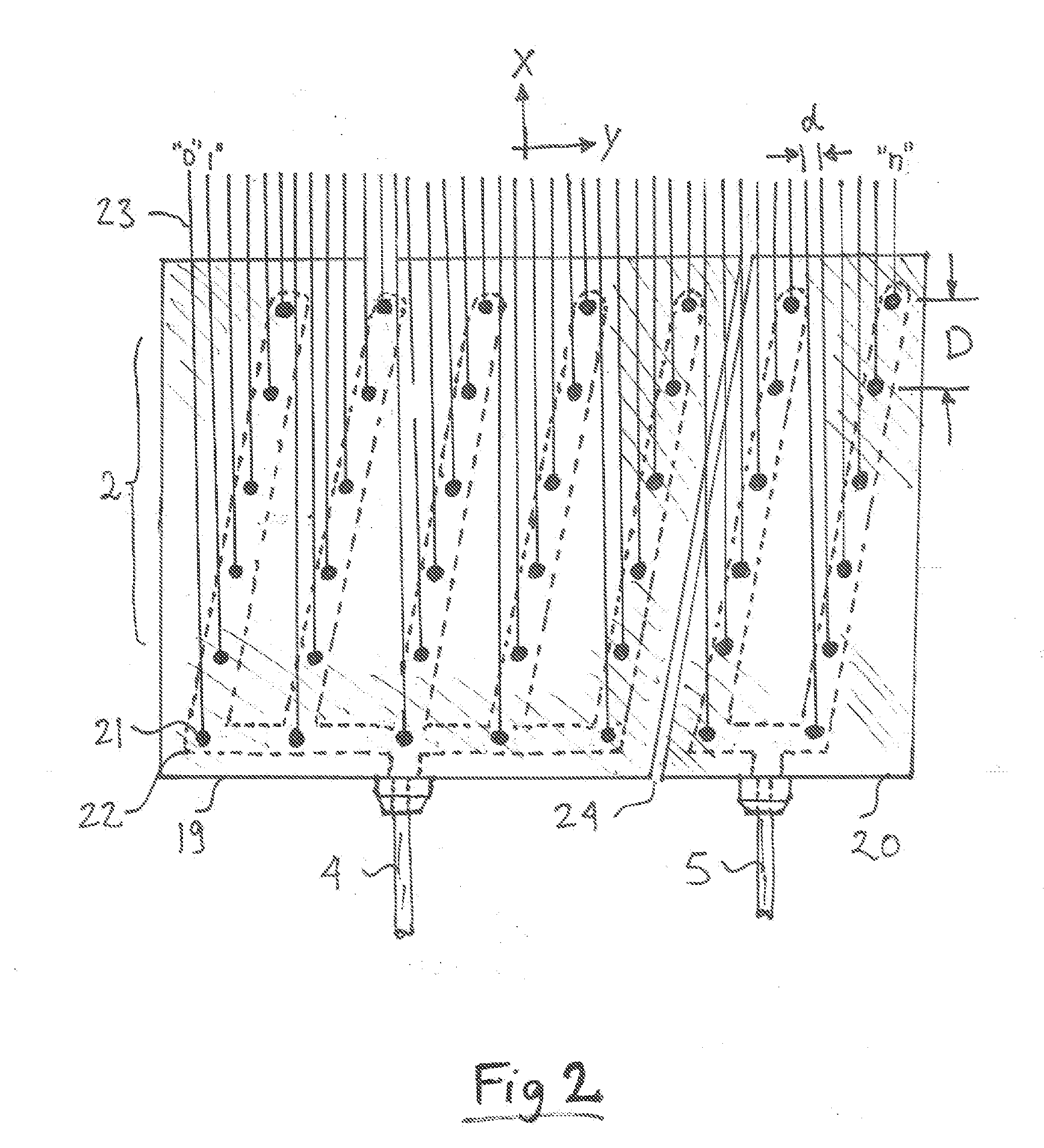

Rapid prototyping apparatus

ActiveUS7500846B2Improve operating characteristicsRapid productionConfectionerySweetmeatsThin layerEngineering

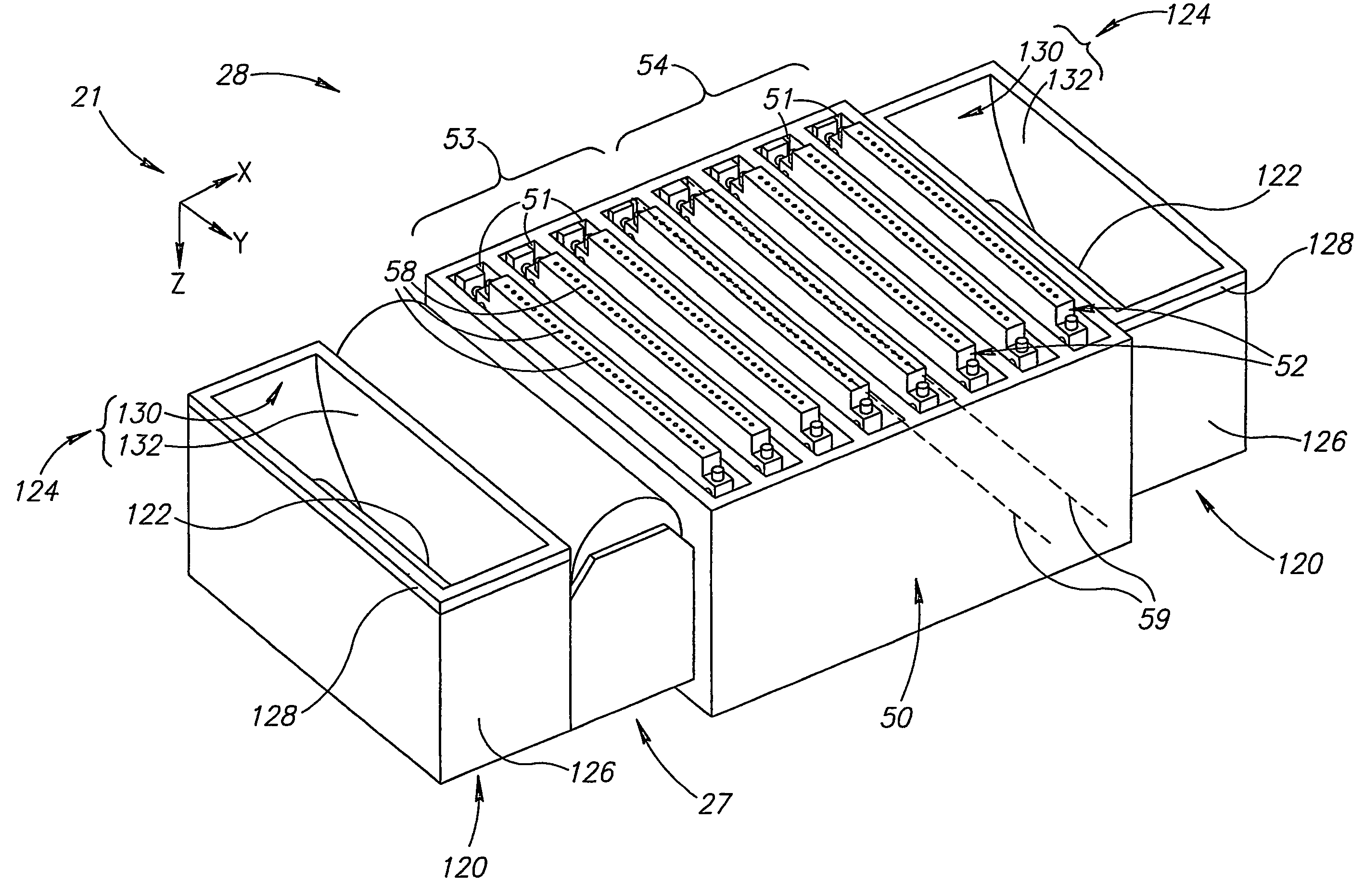

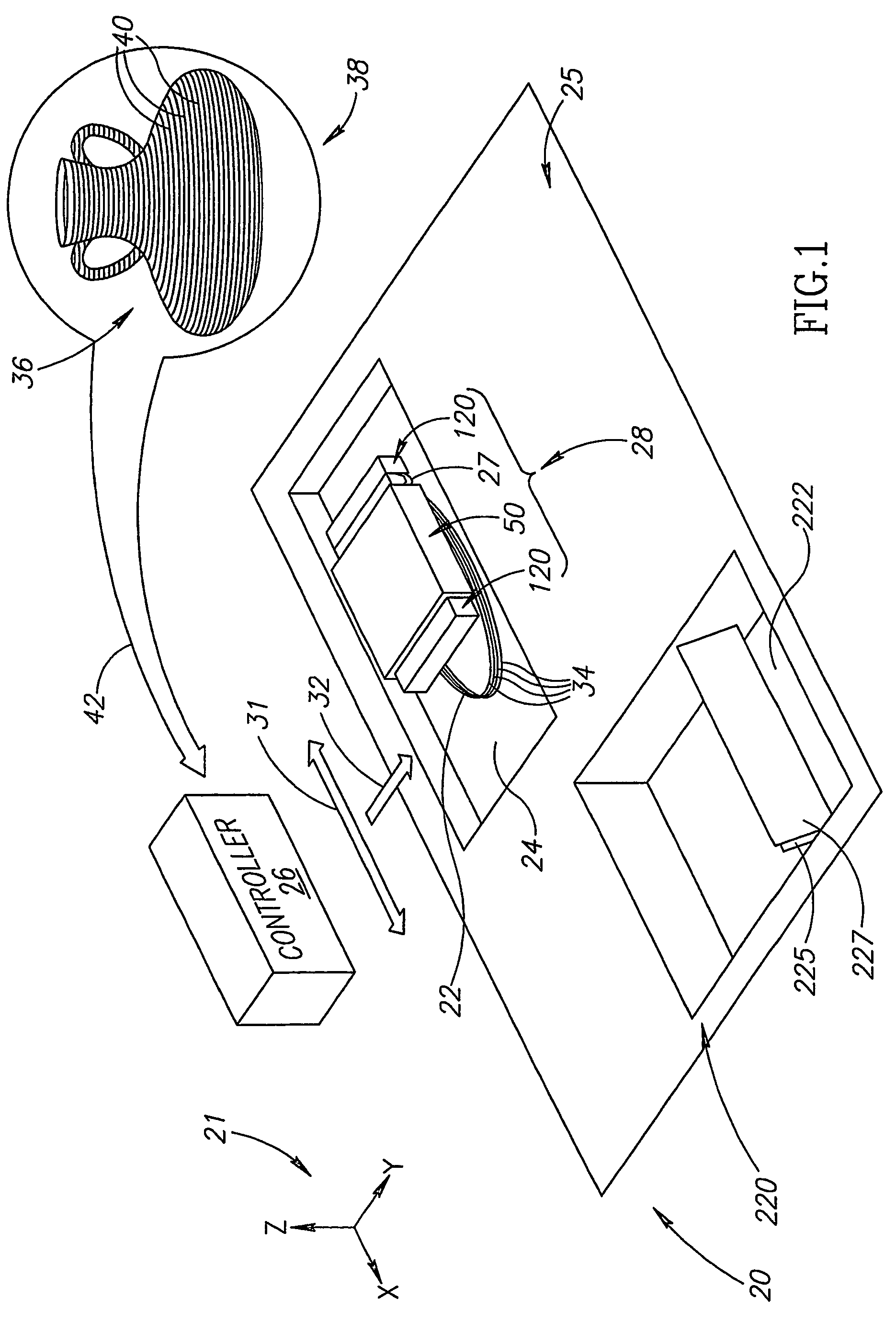

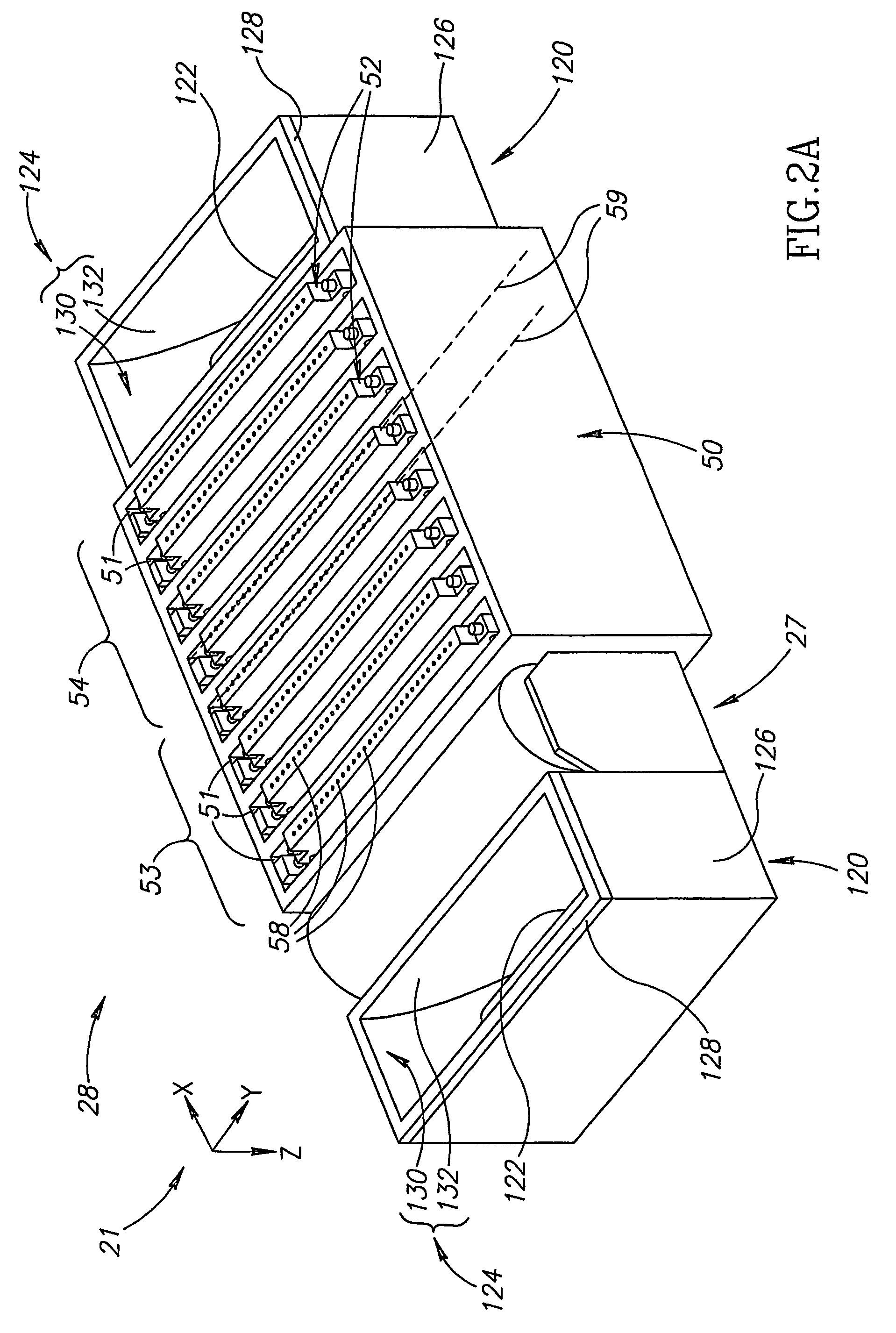

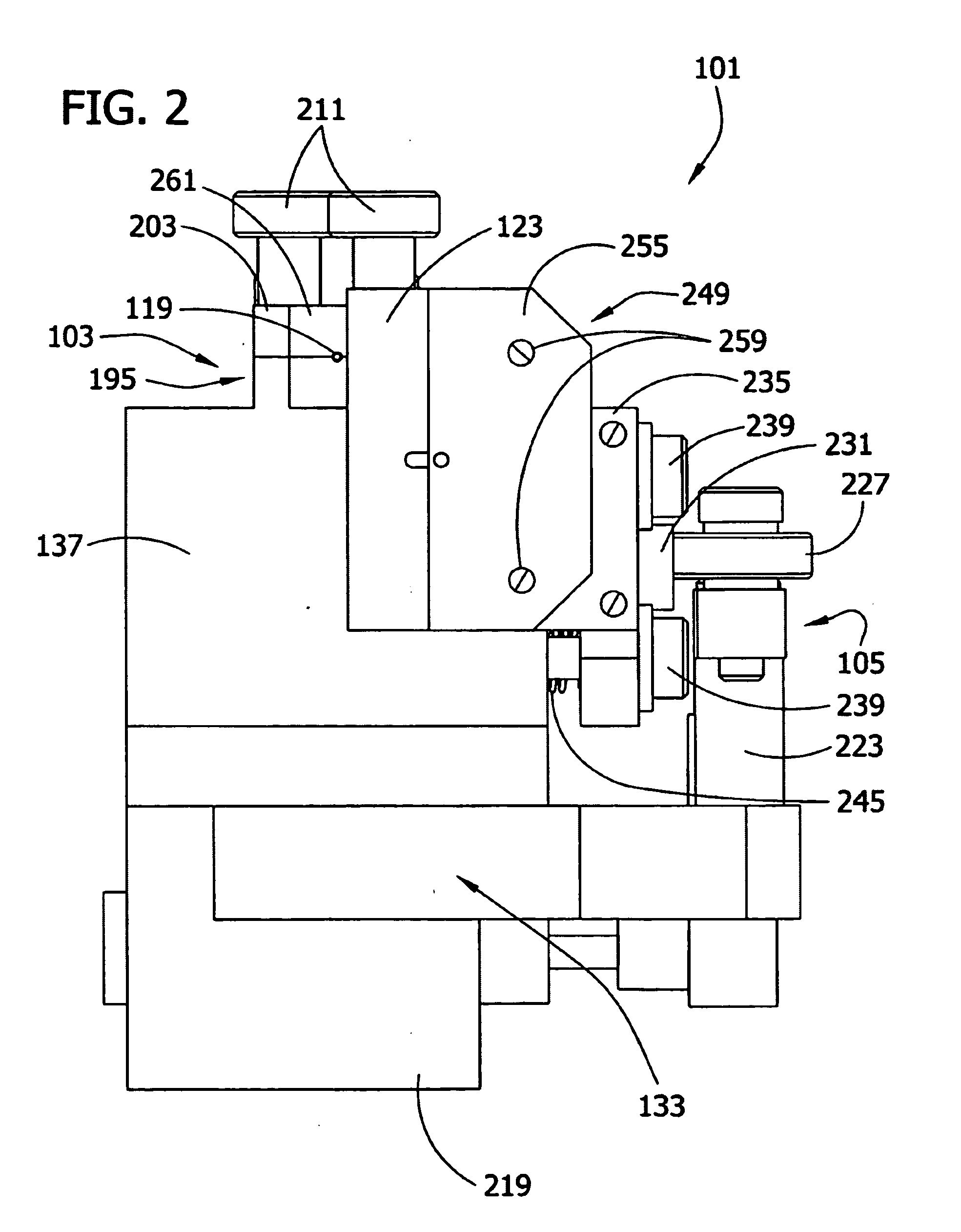

Apparatus for producing an object by sequentially forming thin layers of a construction material one on top of the other responsive to data defining the object, the apparatus comprising: a plurality of printing heads each having a surface formed with a plurality of output orifices and controllable to dispense the construction material through each orifice independently of the other orifices; a shuttle to which the printing heads are mounted; a support surface; and a controller adapted to control the shuttle to move back and forth over the support surface and as the shuttle moves to control the printing heads to dispense the construction material through each of their respective orifices responsive to the data to form a first layer on the support surface and thereafter, sequentially the other layers; wherein each printing head is dismountable from the shuttle and replaceable independently of the other printing heads.

Owner:OBJET GEOMETRIES

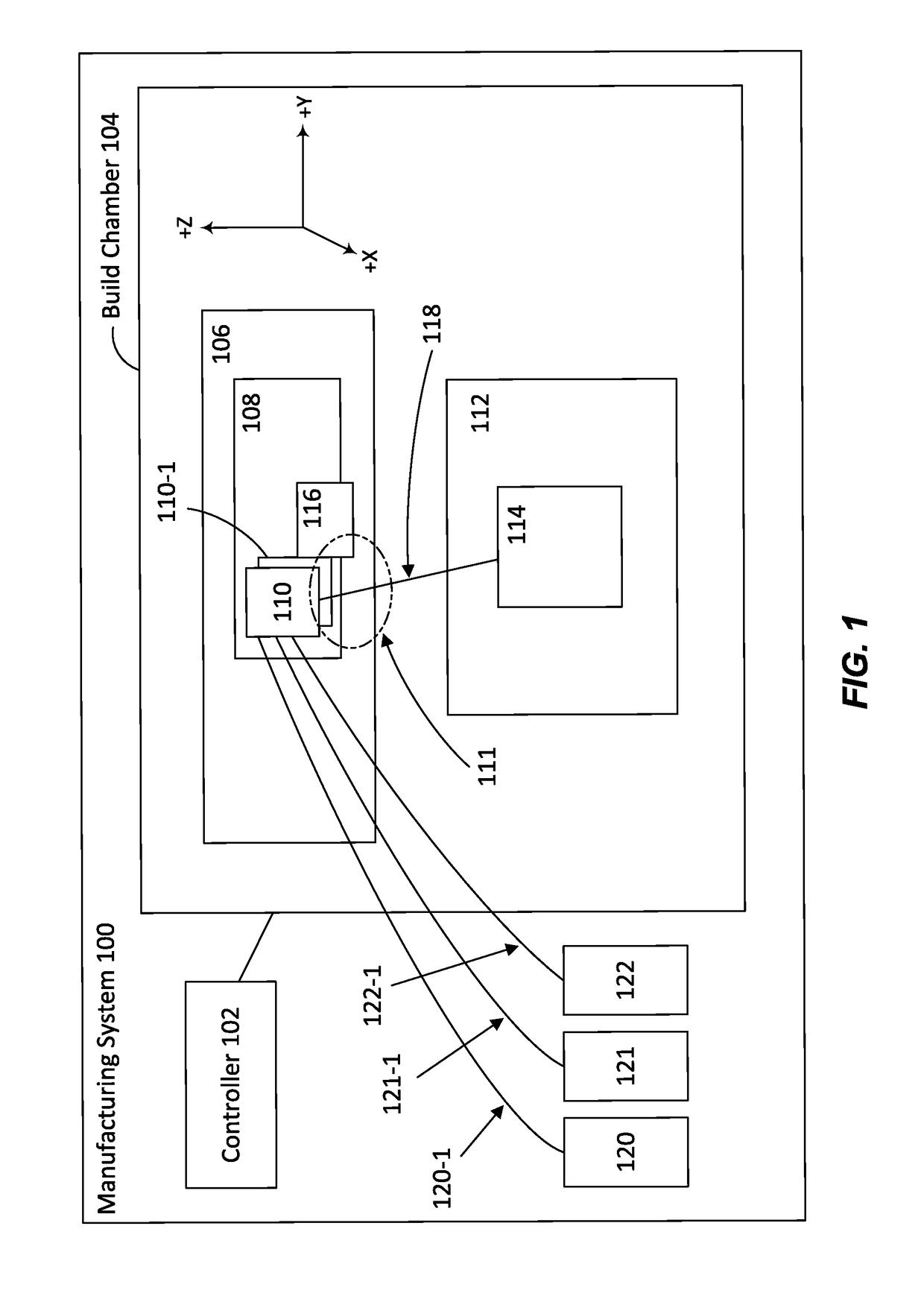

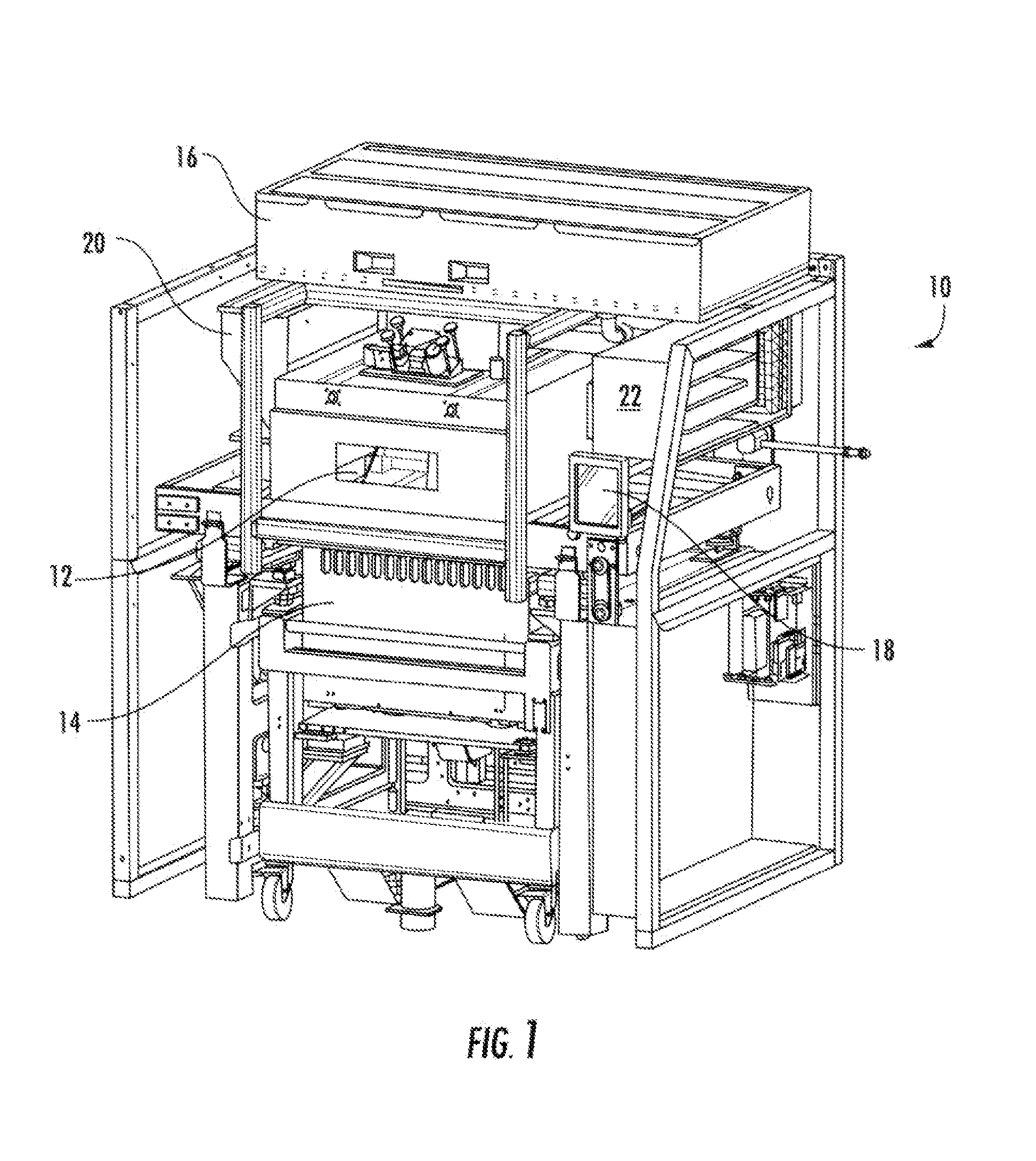

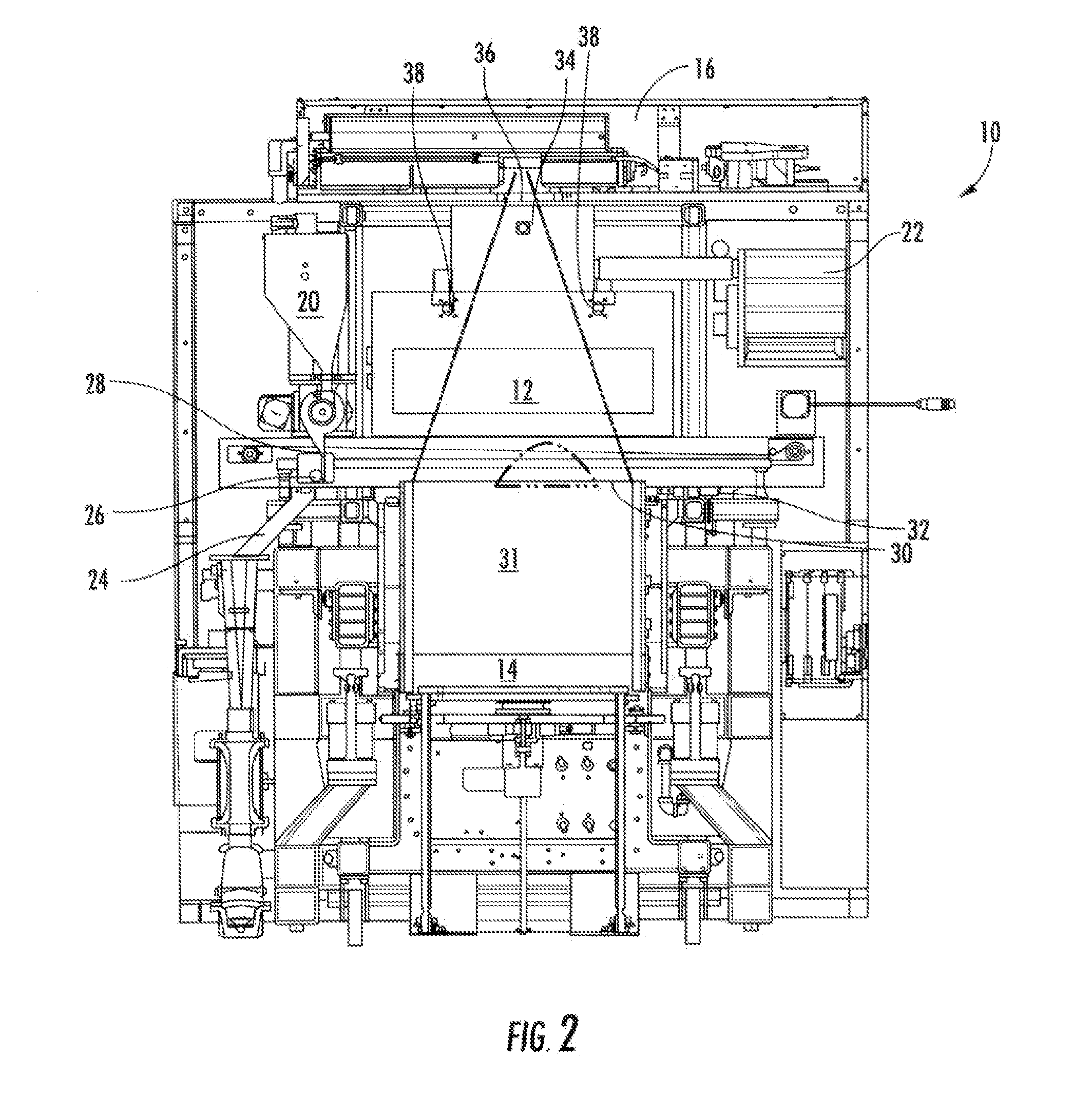

Modular fabrication systems and methods

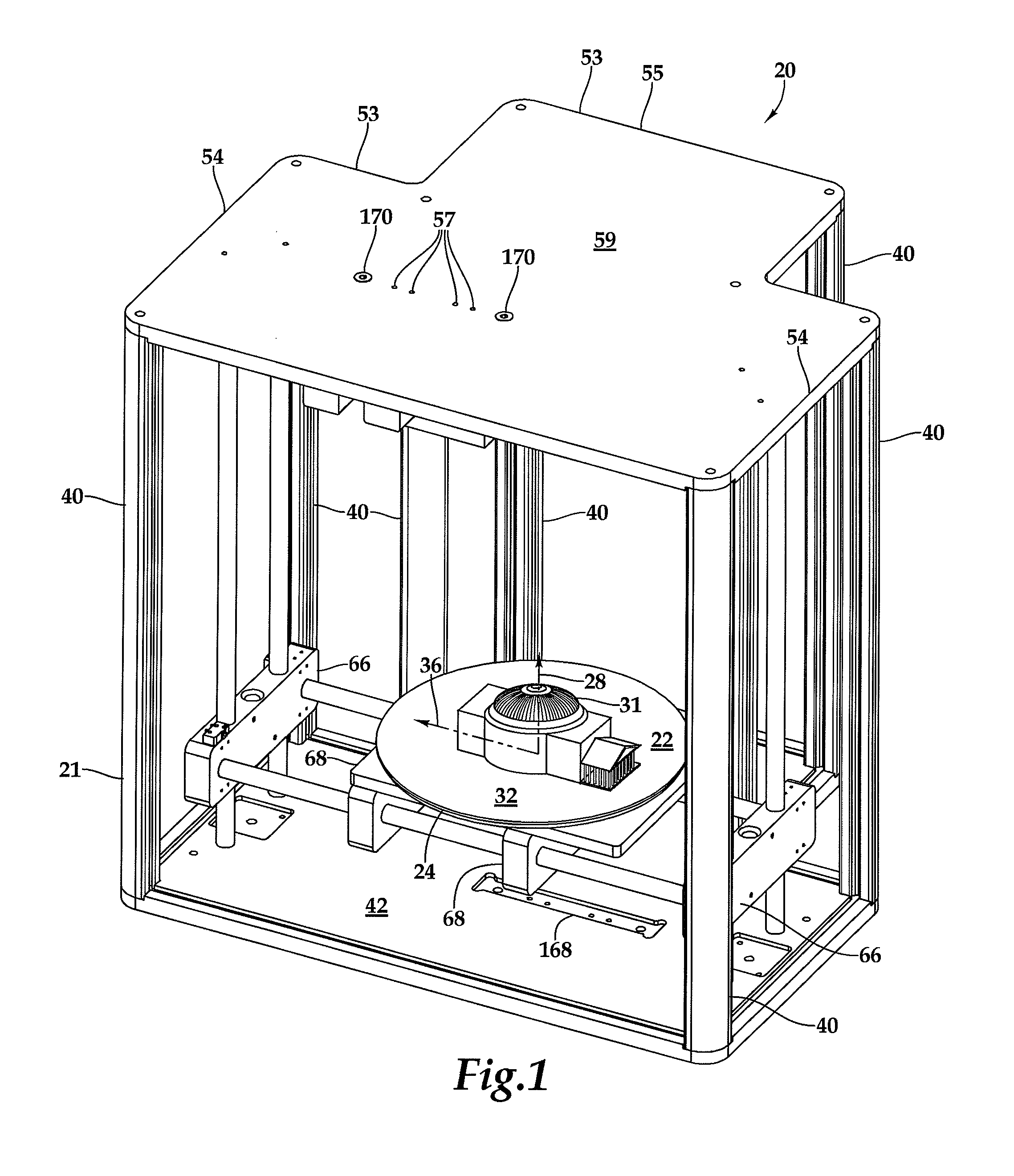

ActiveUS20130089642A1Improve throughputHigh-throughput applicationsReady-for-oven doughsAuxillary shaping apparatusEngineeringSystem controller

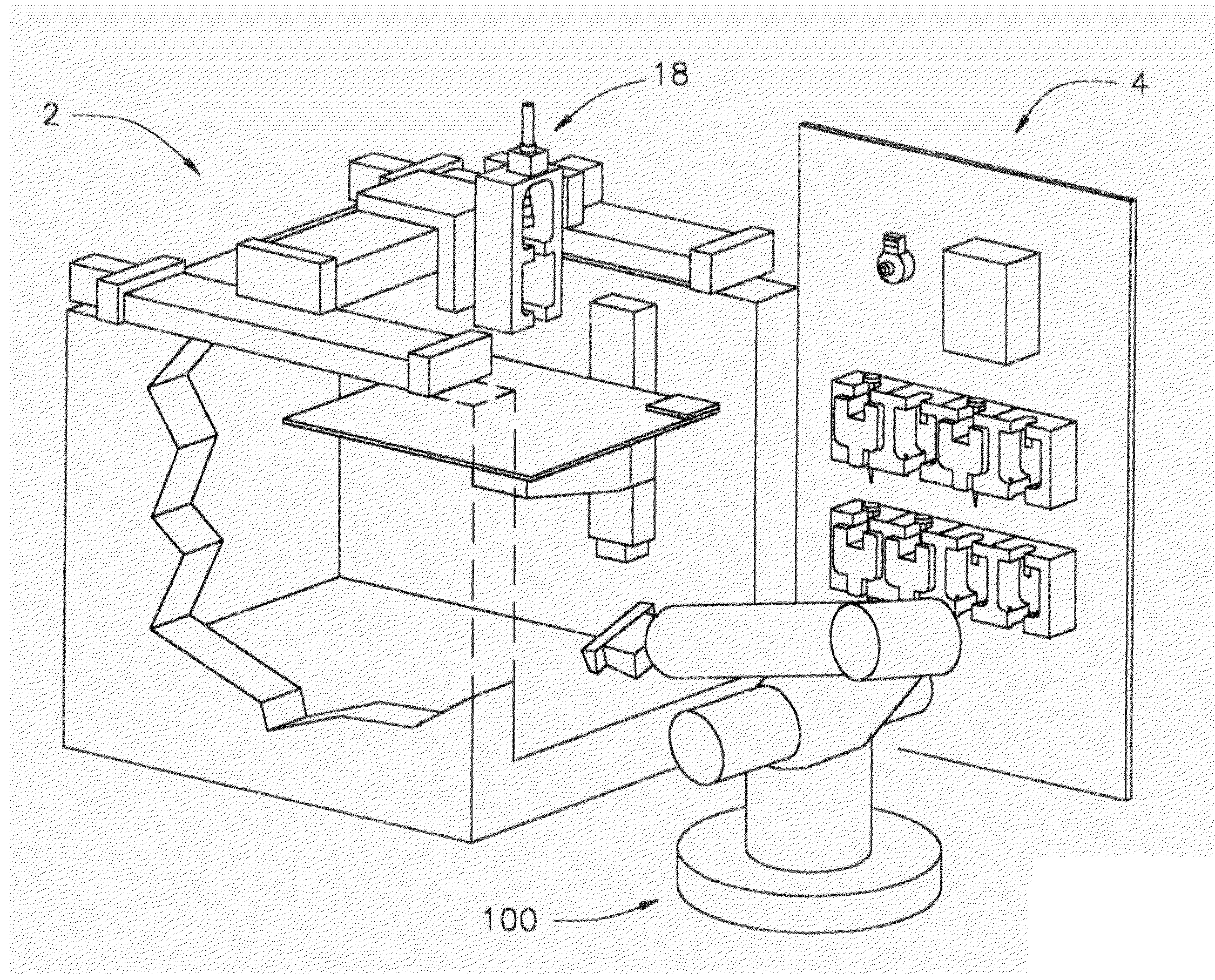

The present invention relates to an article fabrication system having a plurality of material deposition tools containing one or more materials useful in fabricating the article, and a material deposition device having a tool interface for receiving one of the material deposition tools. A system controller is operably connected to the material deposition device to control operation of the material deposition device. Also disclosed is a method of fabricating an article using the system of the invention and a method of fabricating edible foodstuffs.

Owner:CORNELL UNIVERSITY

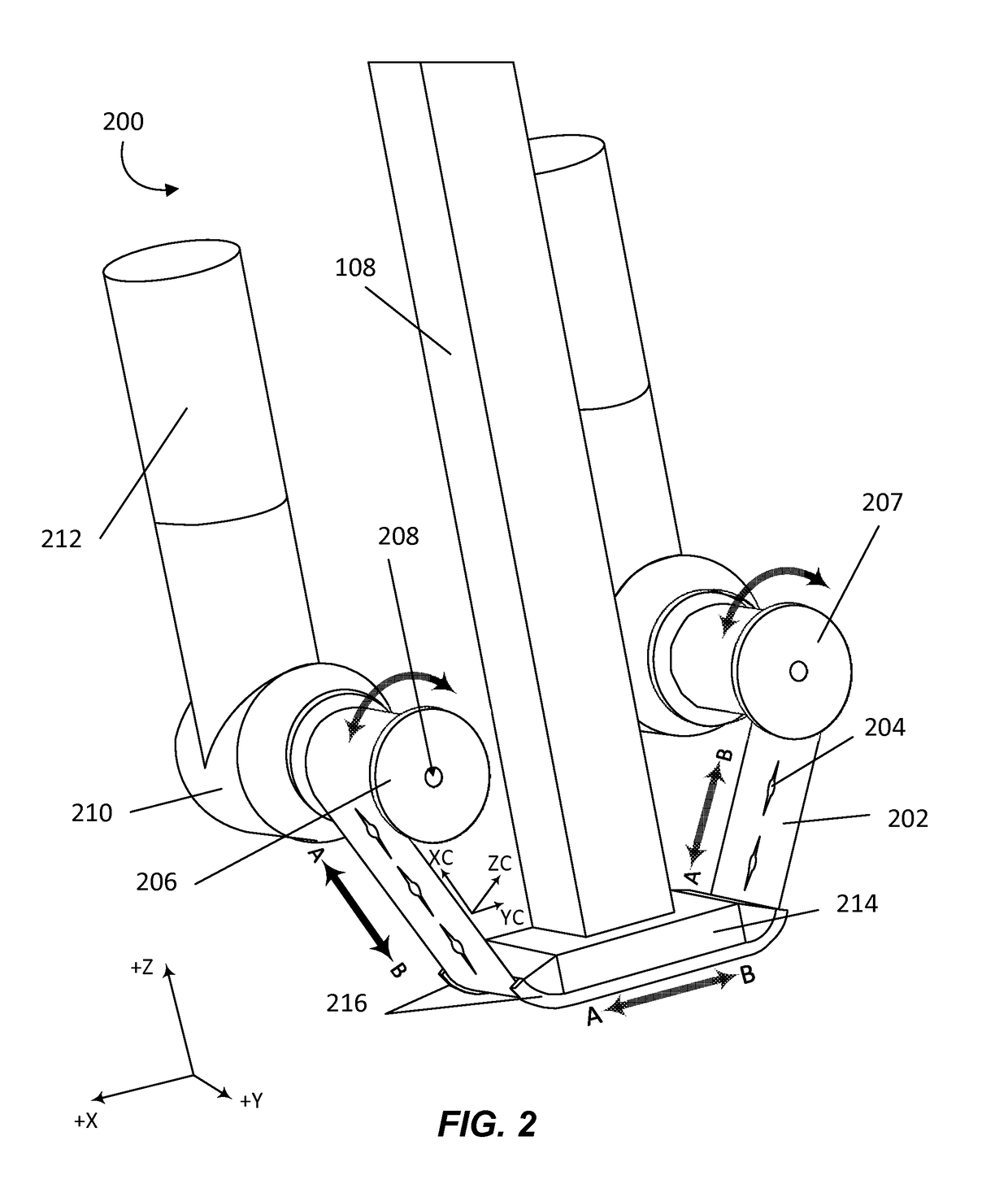

Additive manufacturing of composite materials

ActiveUS20170259502A1Manufacturing driving means3D object support structuresEngineeringMovement system

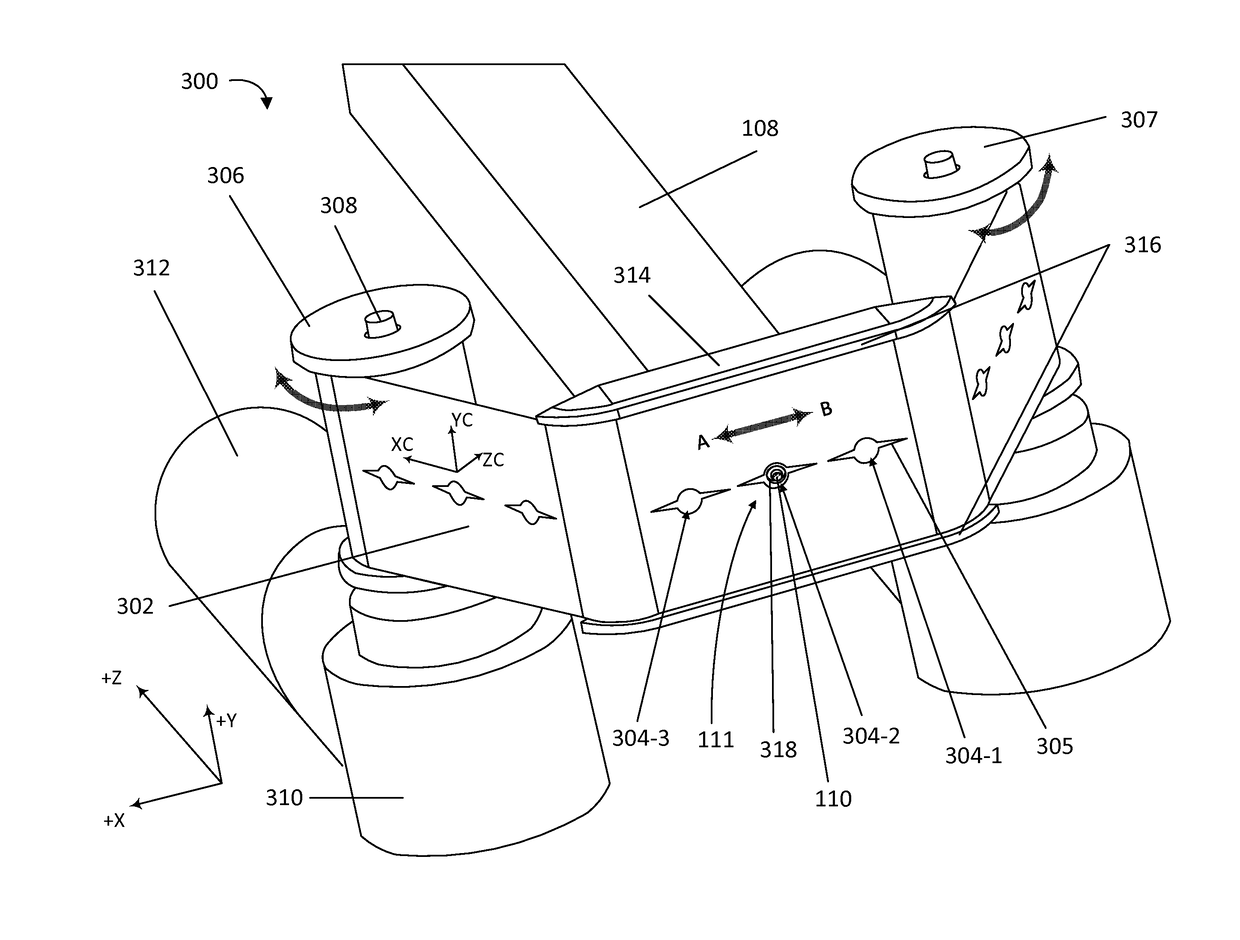

An additive manufacturing apparatus having a three-dimensional movement system comprising a first part; a second part coupled to the first part and movable relative to the first part; a third part coupled to the first part and the second part and movable relative to the first part and movable relative to the second part wherein the three-dimensional movement system moves an assembly in three dimensions relative to a base; a rotatable build table coupled to the base, and rotatable in a first plane parallel to the base; and a nozzle, wherein the assembly comprises the nozzle, wherein the nozzle is rotatable in a second plane not parallel to the base, wherein the nozzle comprises an opening for passing a printer filament through the nozzle, and for depositing the printer filament onto the build plate.

Owner:MANTIS COMPOSITES INC

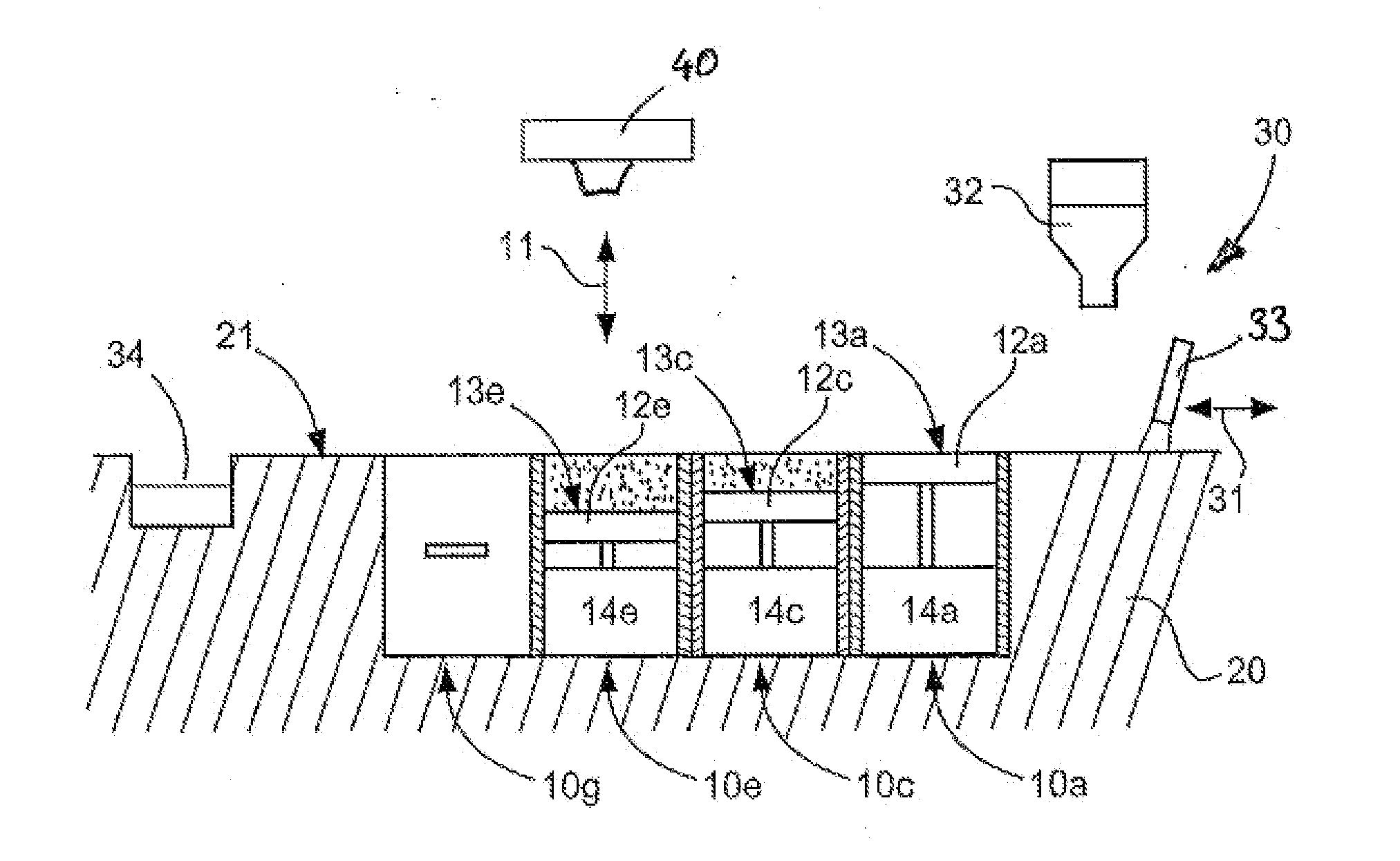

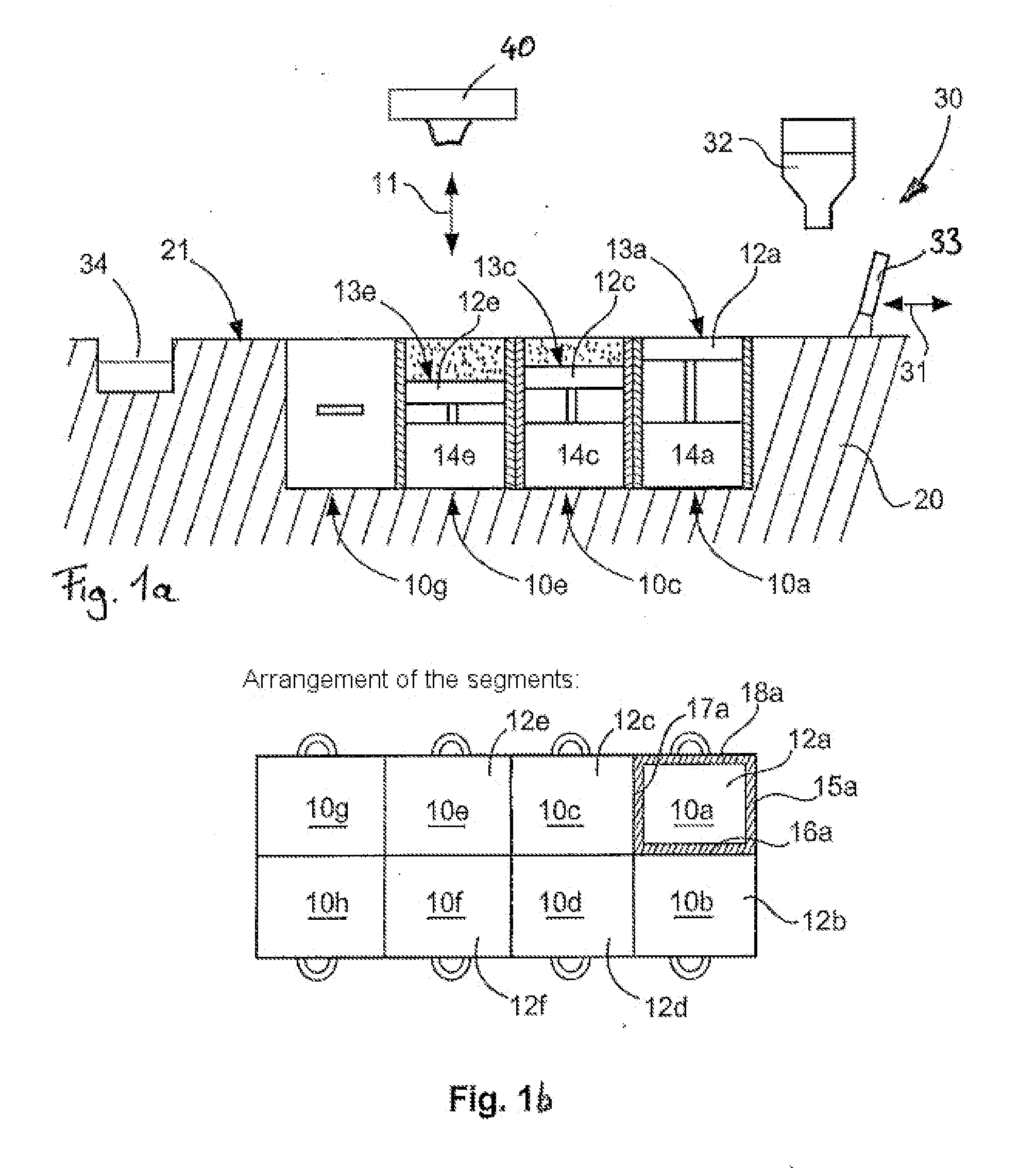

Device for the generative manufacturing of three-dimensional components

ActiveUS20130108726A1Efficient and cost-effective operationEfficiently formedManufacturing platforms/substratesConfectioneryEngineeringMonochrome

The invention relates to a device for producing products having individual geometries, comprising a substrate carrier device, a material application device for applying material, preferably above the substrate carrier device, which material application device can be moved relative to the substrate carrier device, and a control device which is coupled to the material application device for signaling. According to the invention, the material application device is coupled to an input interface for signaling and for selection of a first or a second application mode, the control device and the application device being designed such as to produce, in the first application mode, a three-dimensional product on the surface of a substrate plate by way of an additive production method, said substrate plate being connected to the substrate carrier device. According to the additive production method, a curable material is applied in consecutive layers, one or more predetermined regions are selectively cured after or during each application of a layer, the predetermined regions being bonded to one or more regions of the underlying layer. The predetermined region(s) is / are predetermined by a cross-section geometry of the product in the respective layer and is / are stored in the control device, and the curable material is applied in a plurality of consecutive layers to produce the three-dimensional product. The control device and the application device are further designed such that in the second mode of application one or more colors are applied to predetermined regions of a print substrate material connected to the substrate carrier device to produce a monochrome or polychrome print.

Owner:BEGO MEDICAL

3D printer and printhead unit with multiple filaments

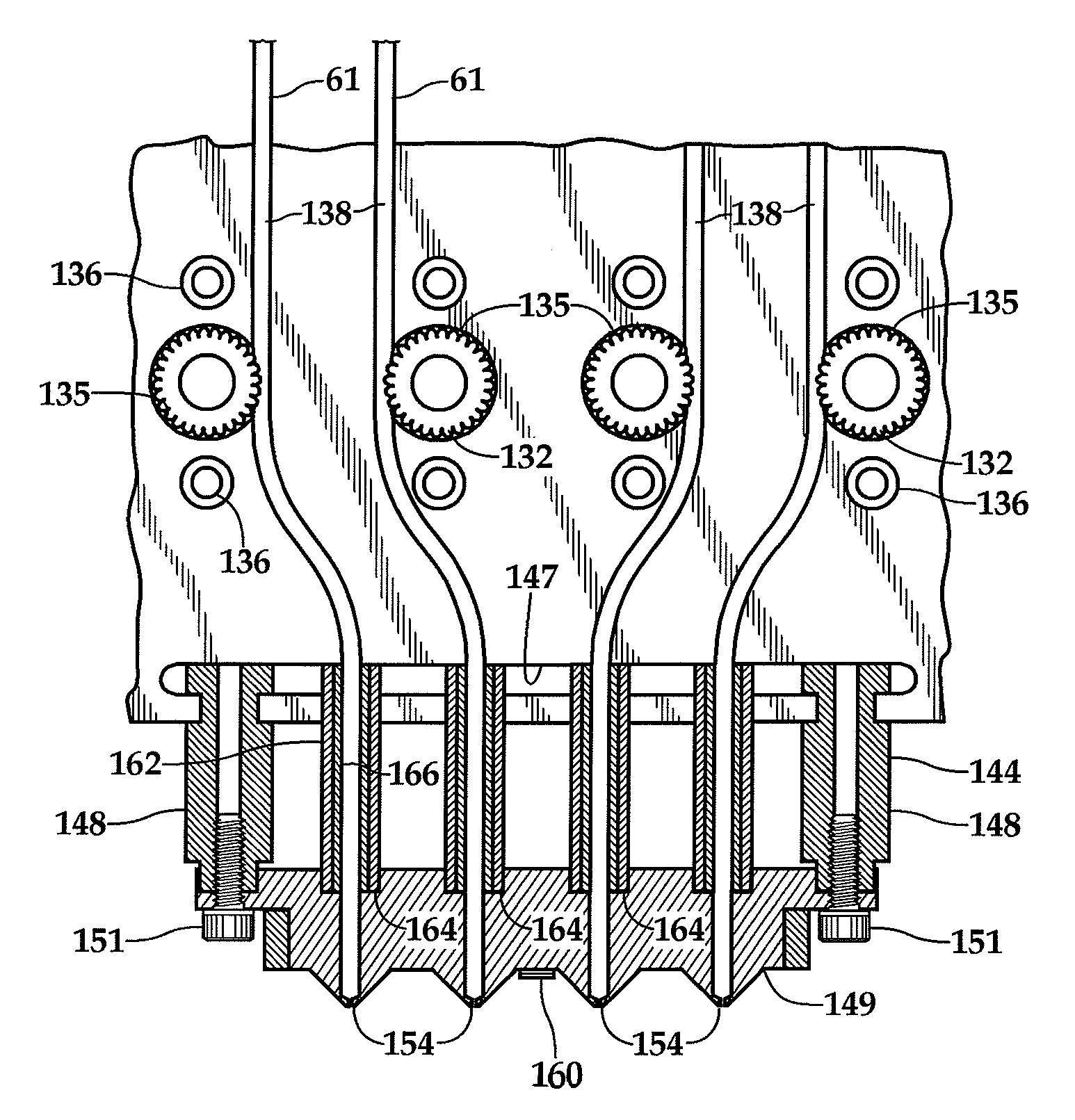

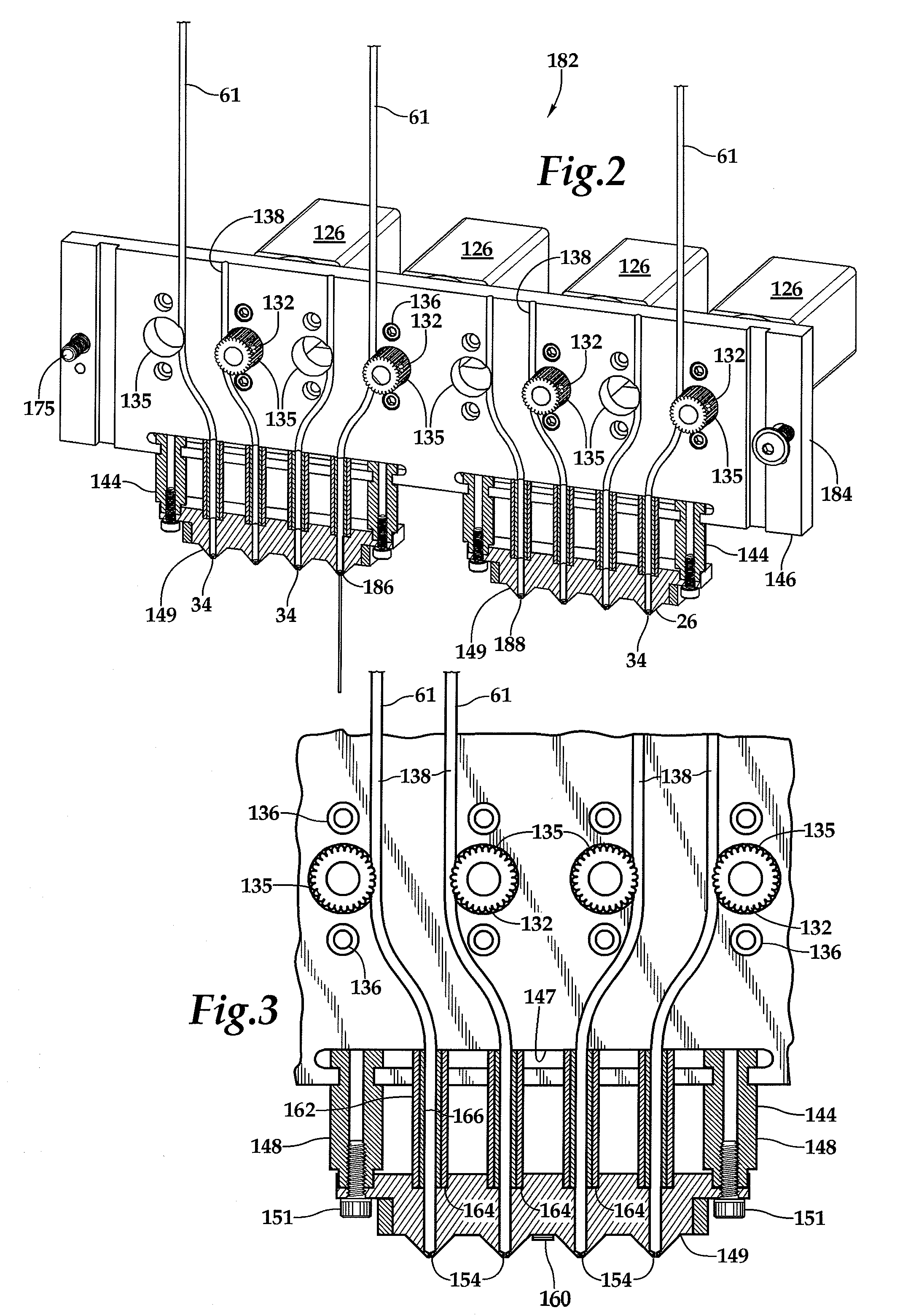

InactiveUS8827684B1Reduce complexityIncrease speedConfectionerySweetmeatsFused filament fabricationMetal filament

A fused filament fabrication printer has a fixed extrusion module having multiple printheads having print tips. The fixed arrangement of the printing heads allows the close spacing of multiple print tips in a printhead unit, and the simple routing of multiple plastic or metal filaments to the individual printing heads. The closely spaced print tips in the printhead unit share common components. An exemplary printhead unit has four printing heads which share a common heating block and heating block temperature sensor. The heating block incorporates a group of four print tips evenly spaced along a line. Each printing head has a separate filament which is controlled and driven by its own stepper motor through the heating block to one of the print tips. Printing of a part is by control of individual stepper motors which drive filaments through the heating block and through one of the printing tips.

Owner:RADIANT FABTION

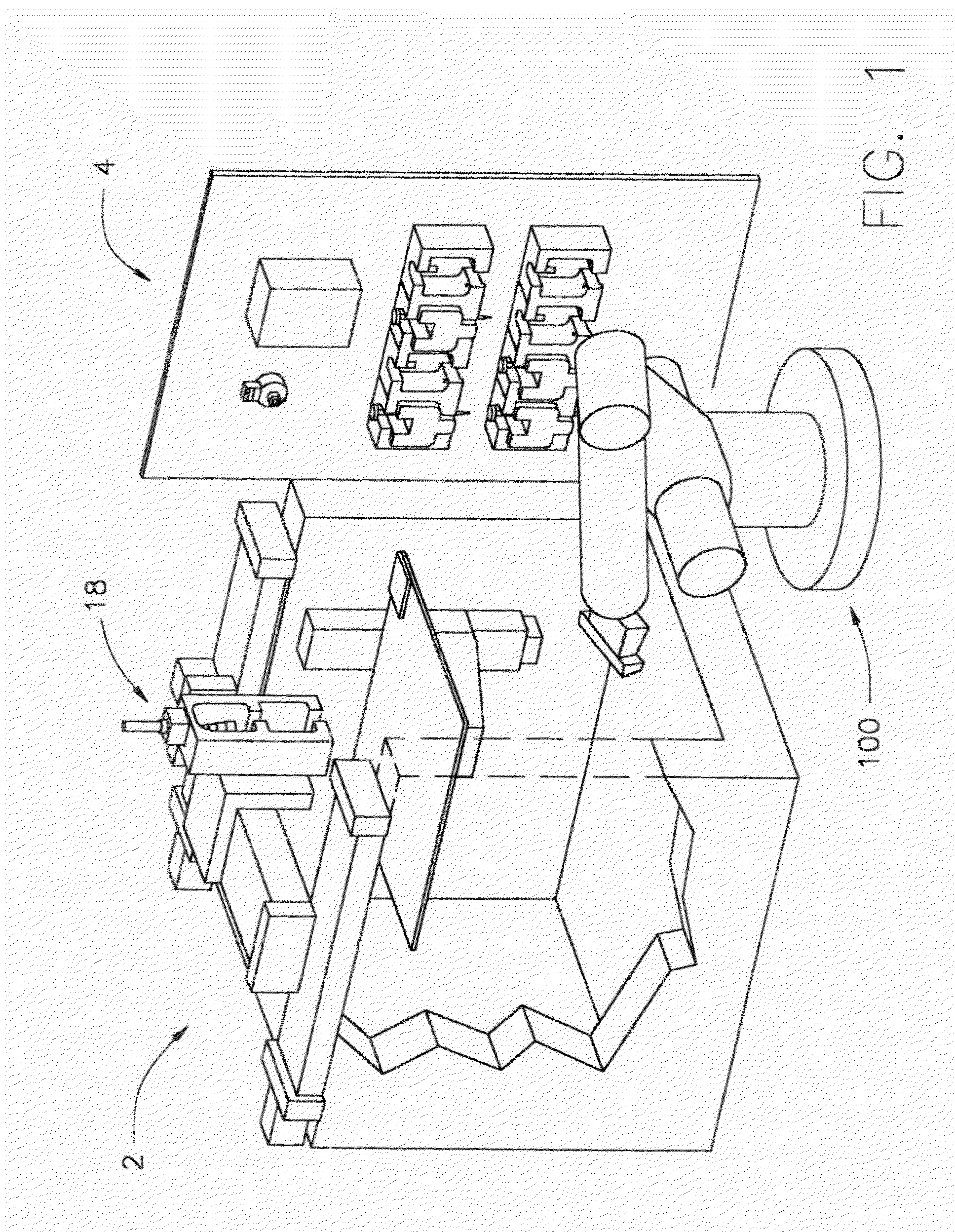

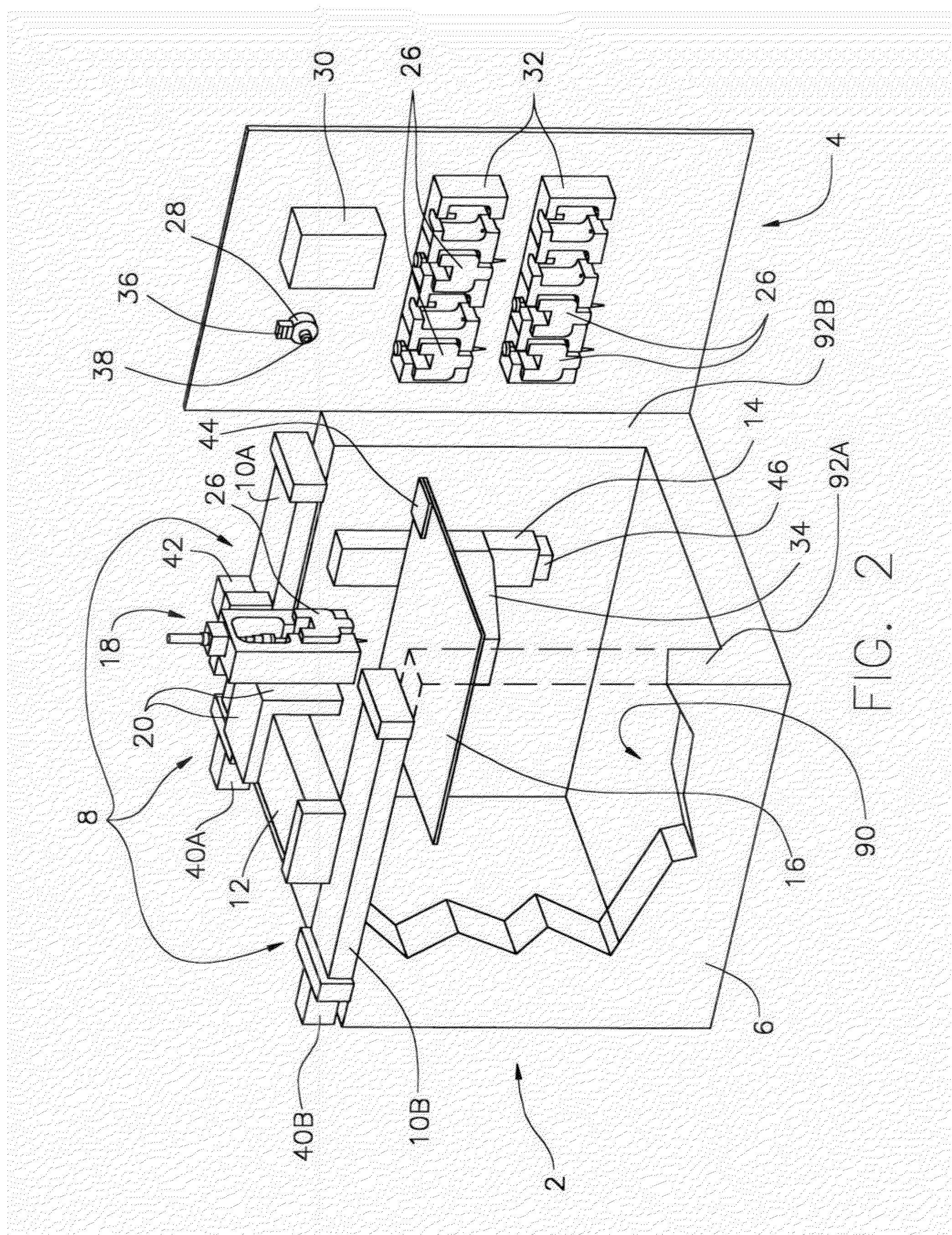

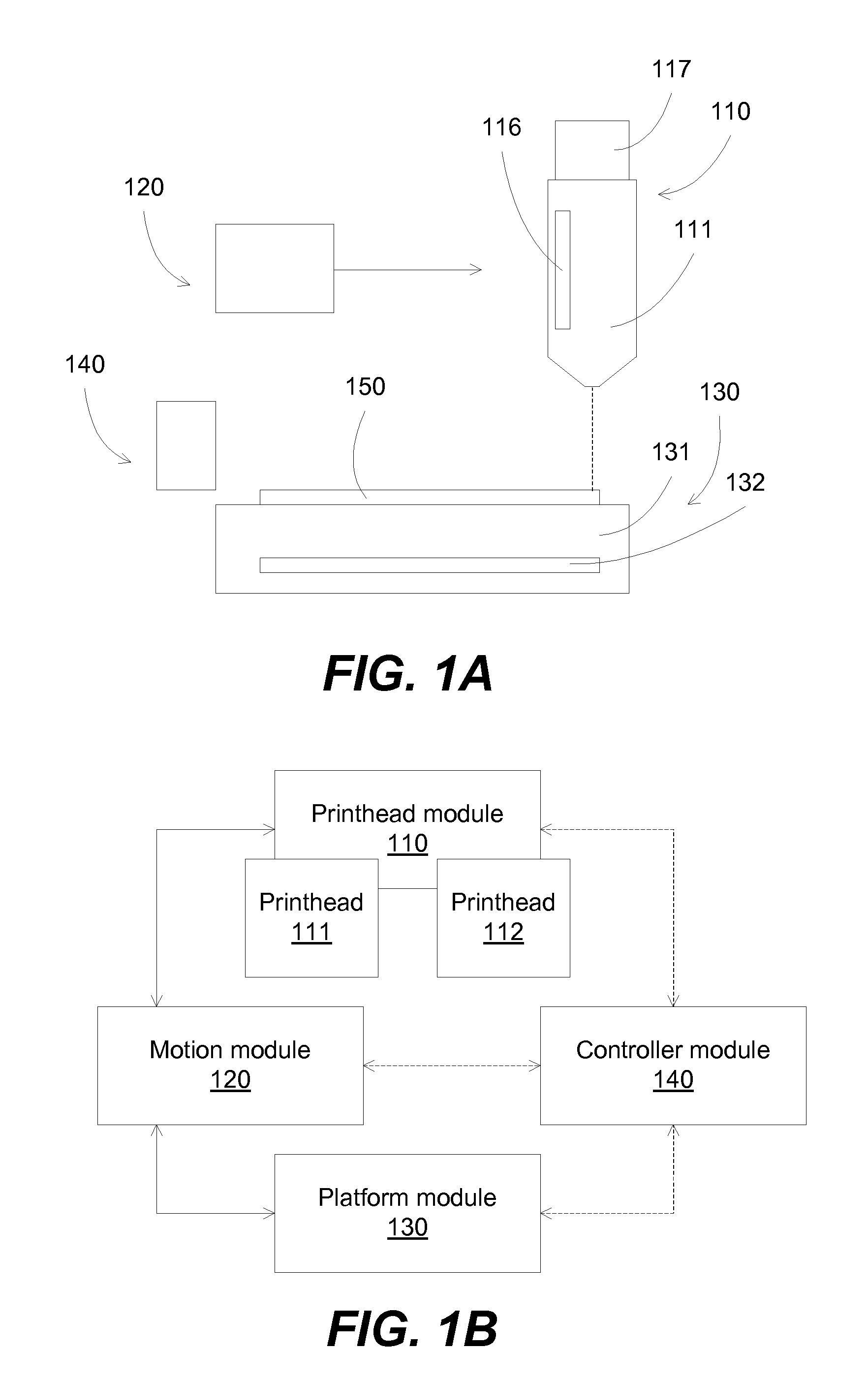

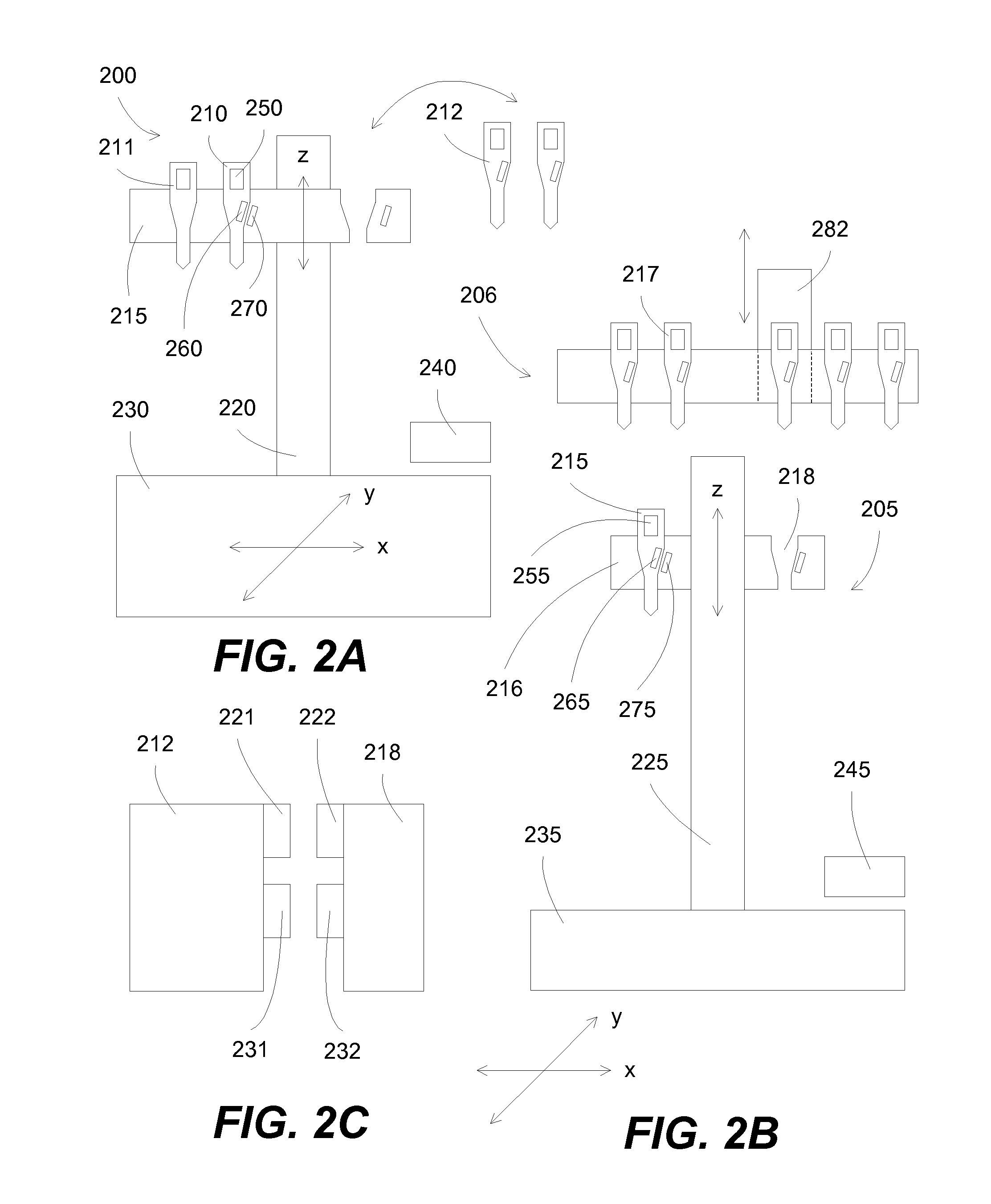

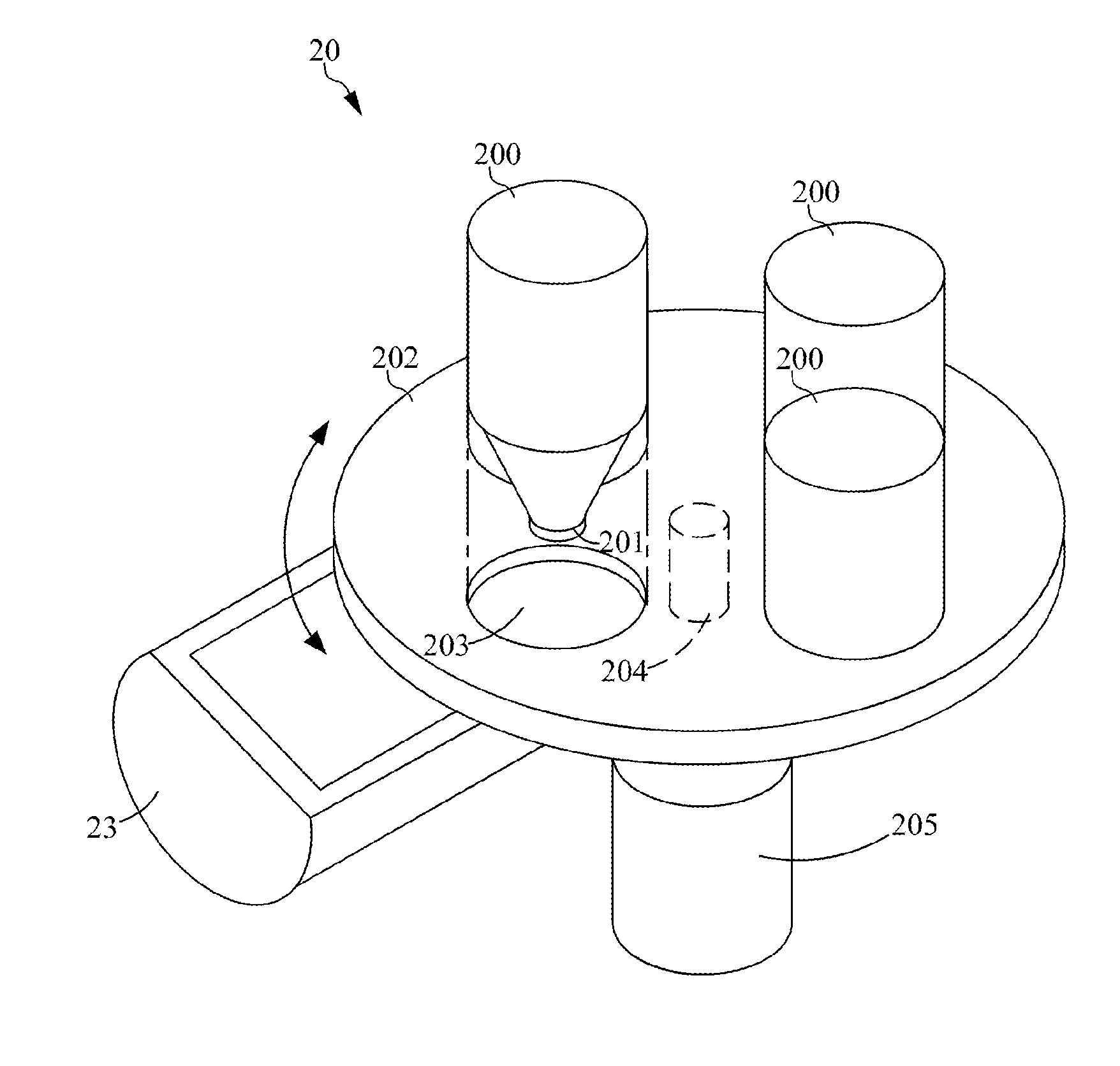

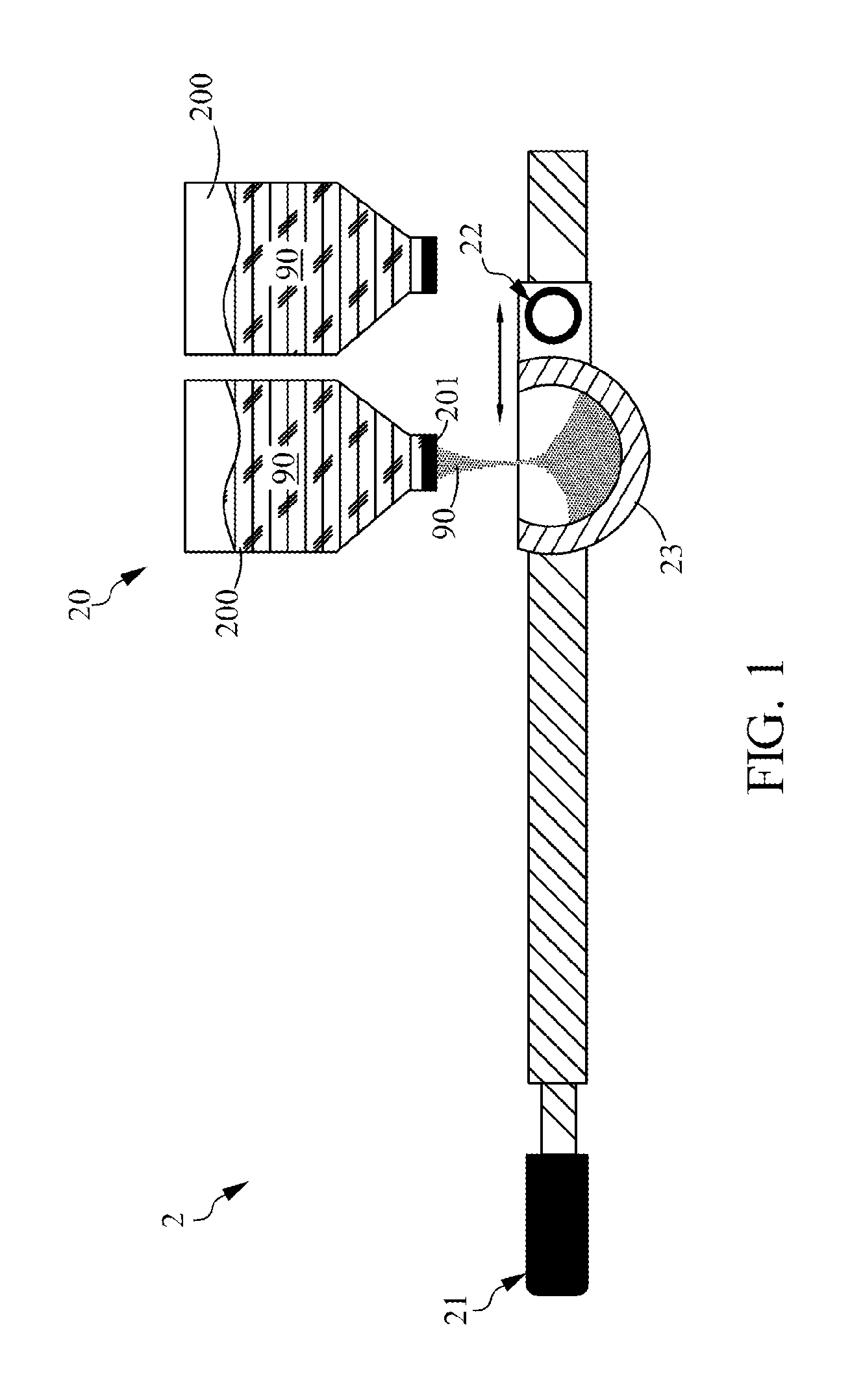

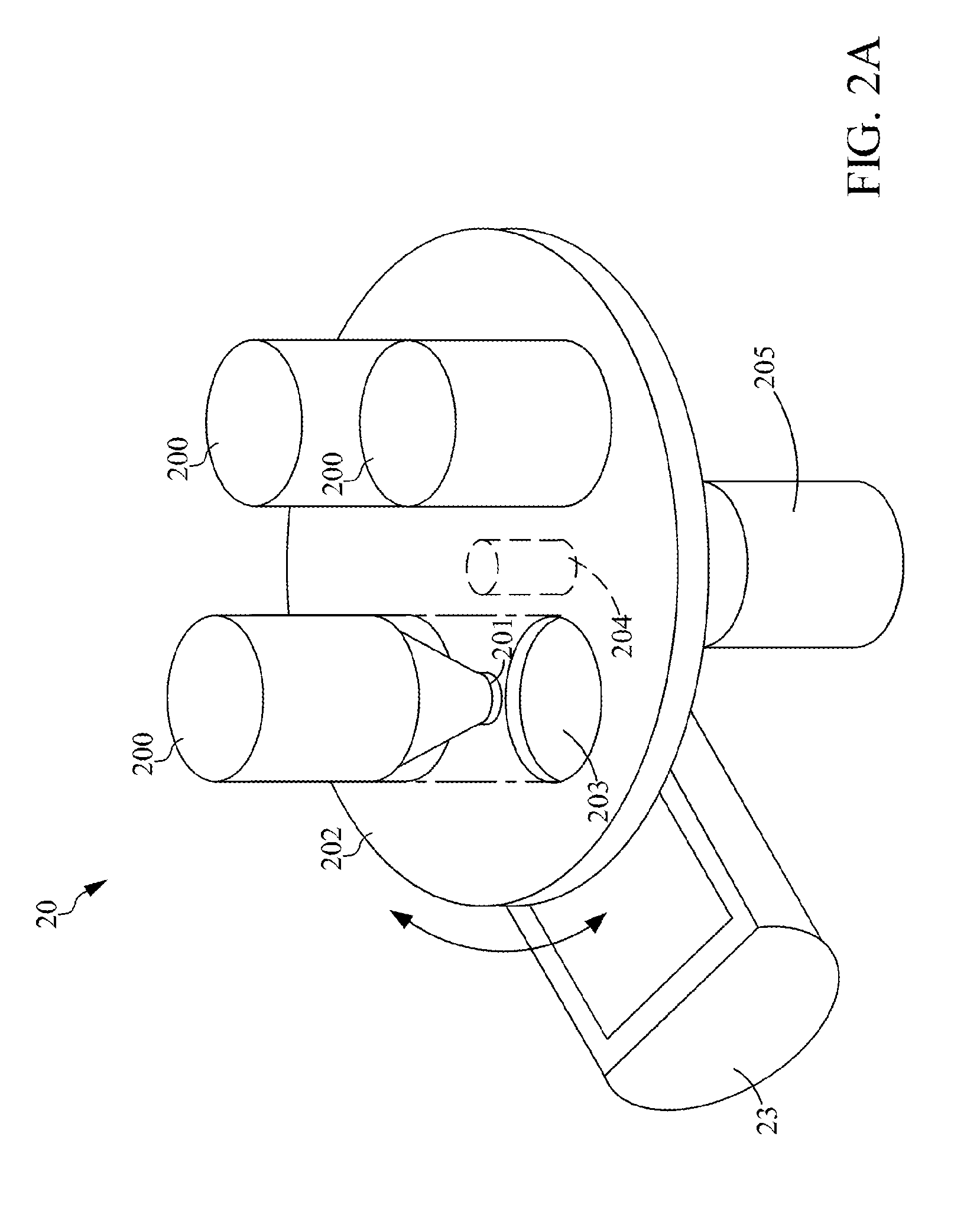

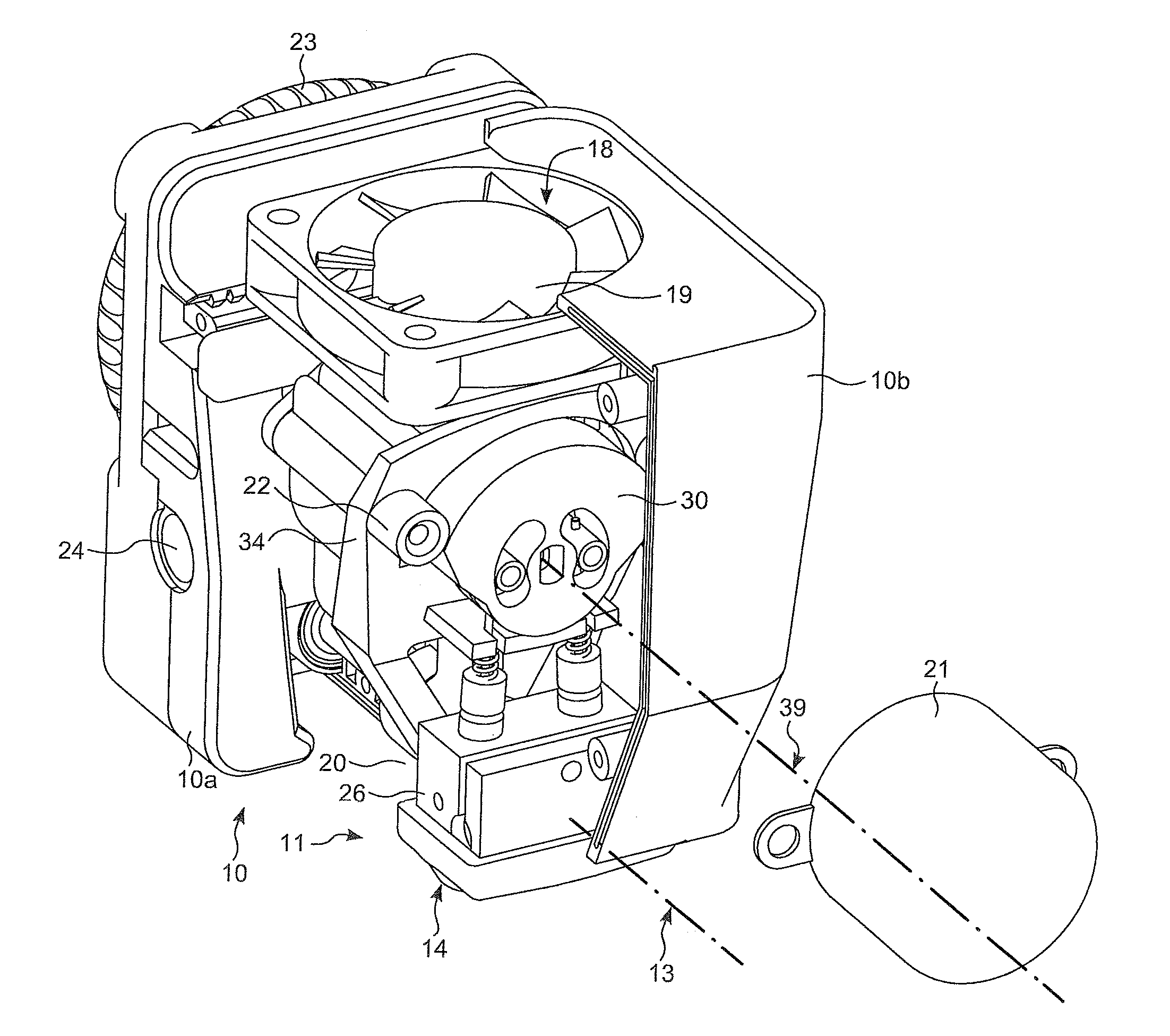

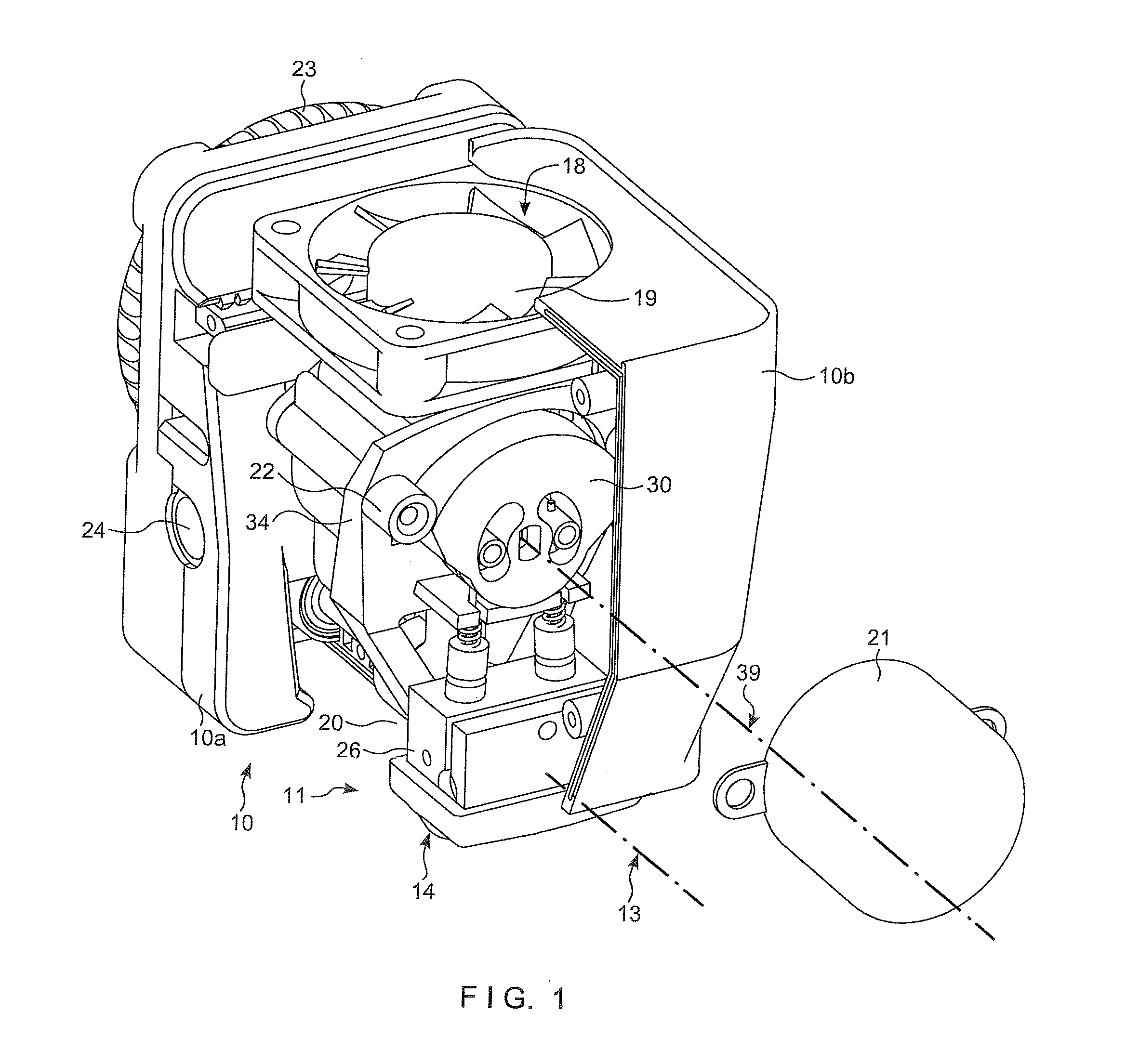

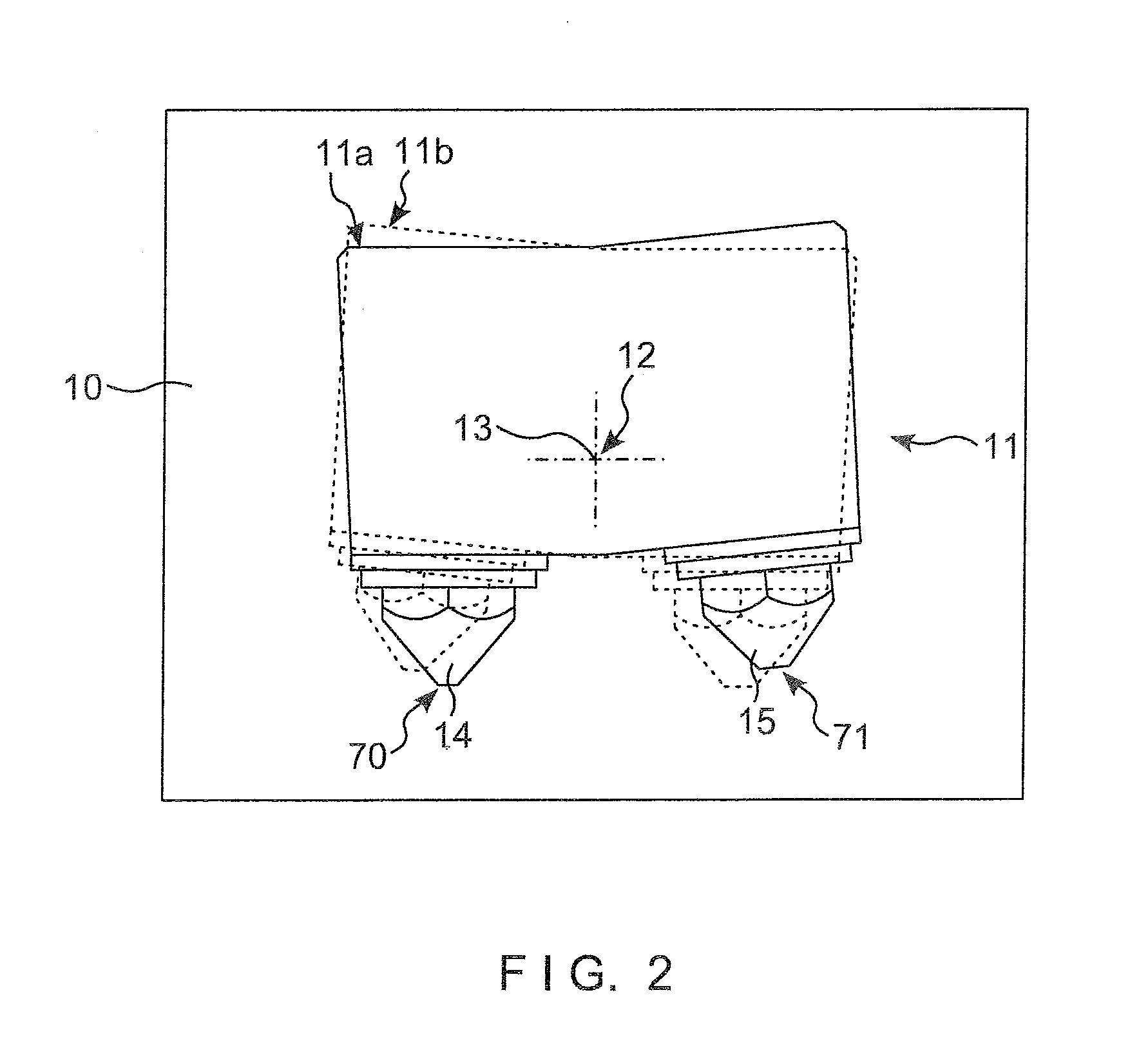

Systems and methods for 3D printing with multiple exchangeable printheads

A modular 3D printer system can include a base subsystem and multiple exchangeable components. The base subsystem can have a 3D motion module, a printhead module and a platform module. The multiple exchangeable components can include printheads having different configurations and functionalities, which can be exchangeably installed in the printhead module. The multiple exchangeable components can include platform supports having different configurations and functionalities, which can be exchangeably installed in the platform module.

Owner:GIFFORD KARL JOSEPH +3

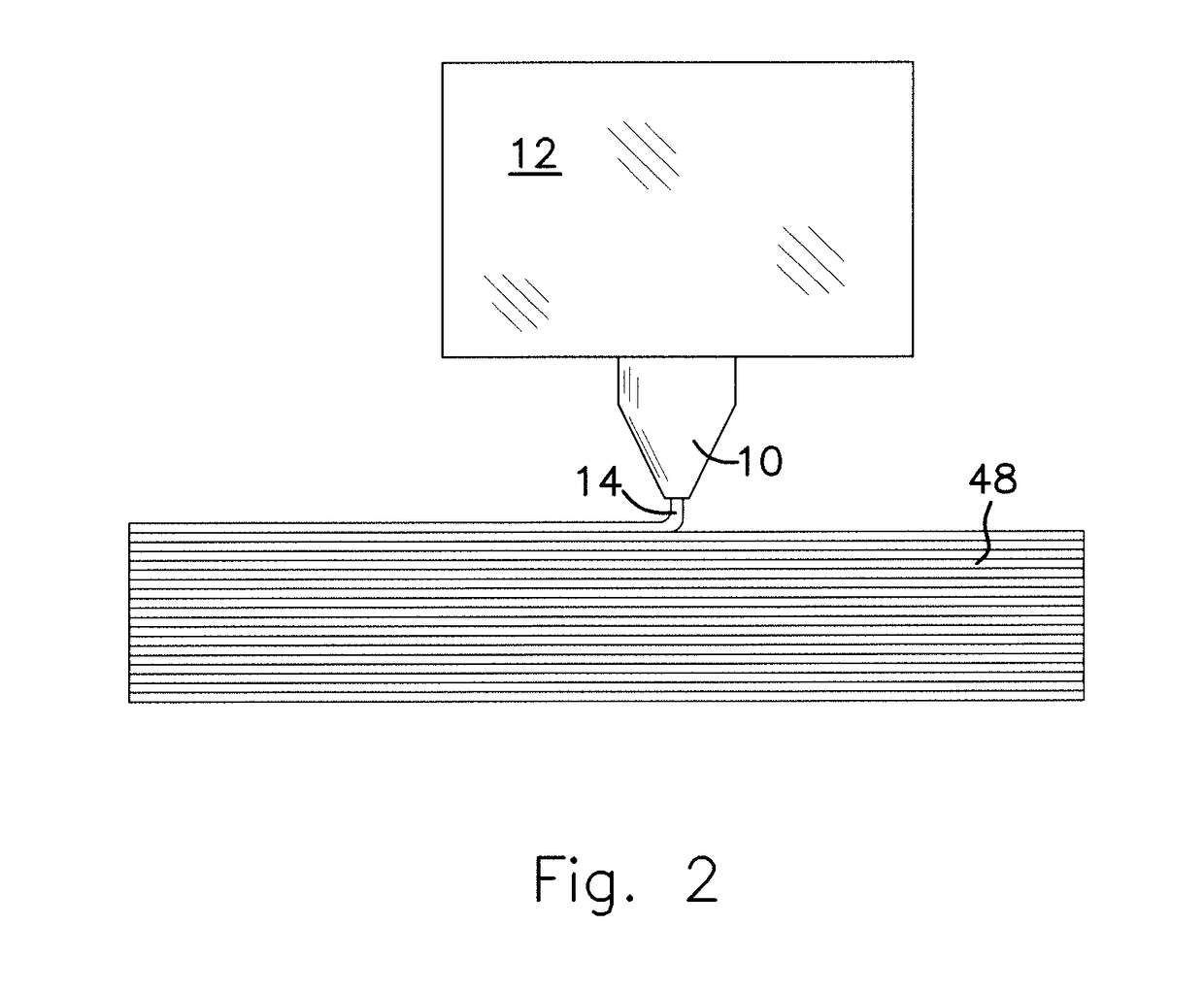

Method and Apparatus for Additive Mechanical Growth of Tubular Structures

InactiveUS20160031155A1High strengthEliminate needLiquid surface applicatorsManufacturing driving meansAdditive layer manufacturing3D printing

Owner:CONTINUOUS COMPOSITES INC

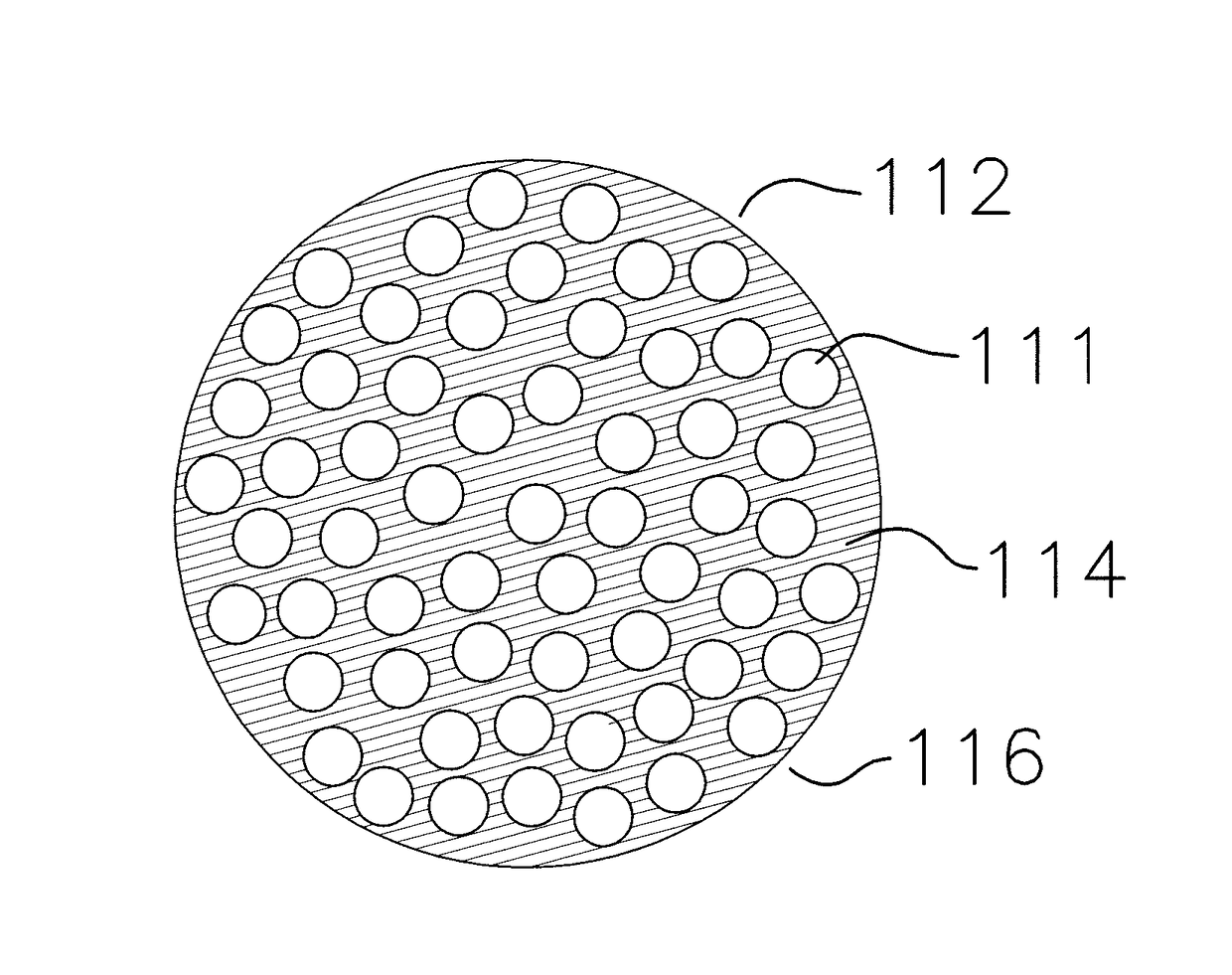

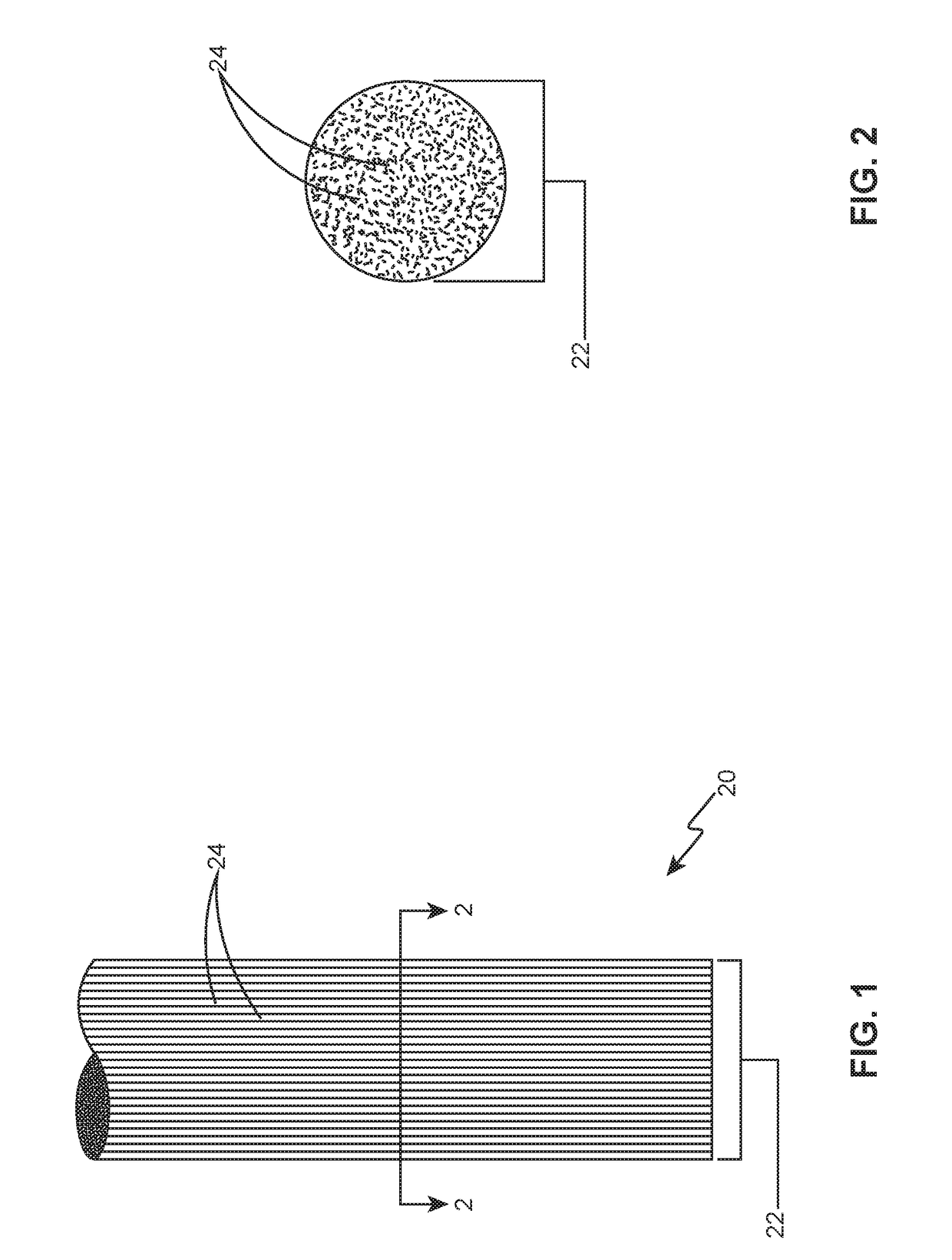

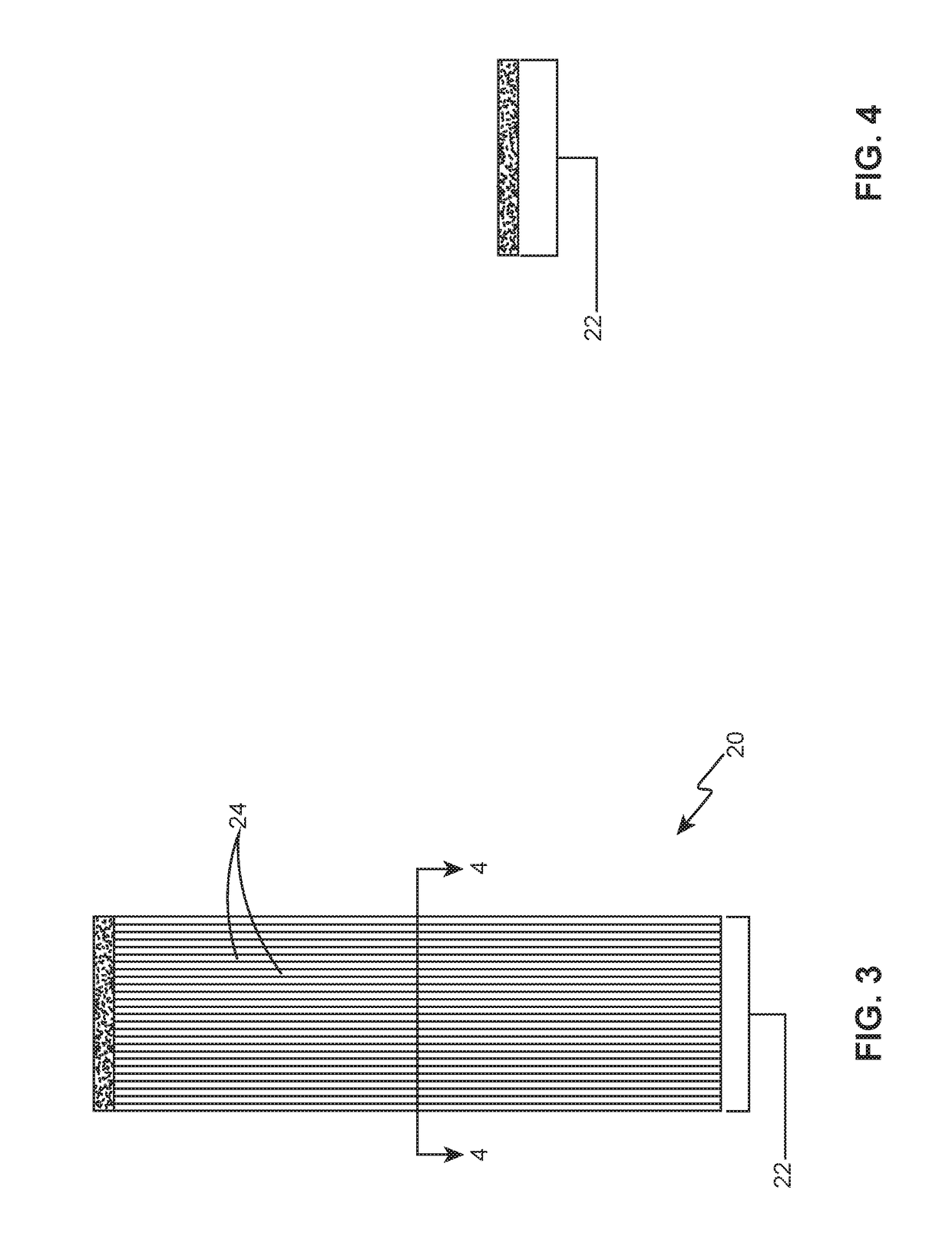

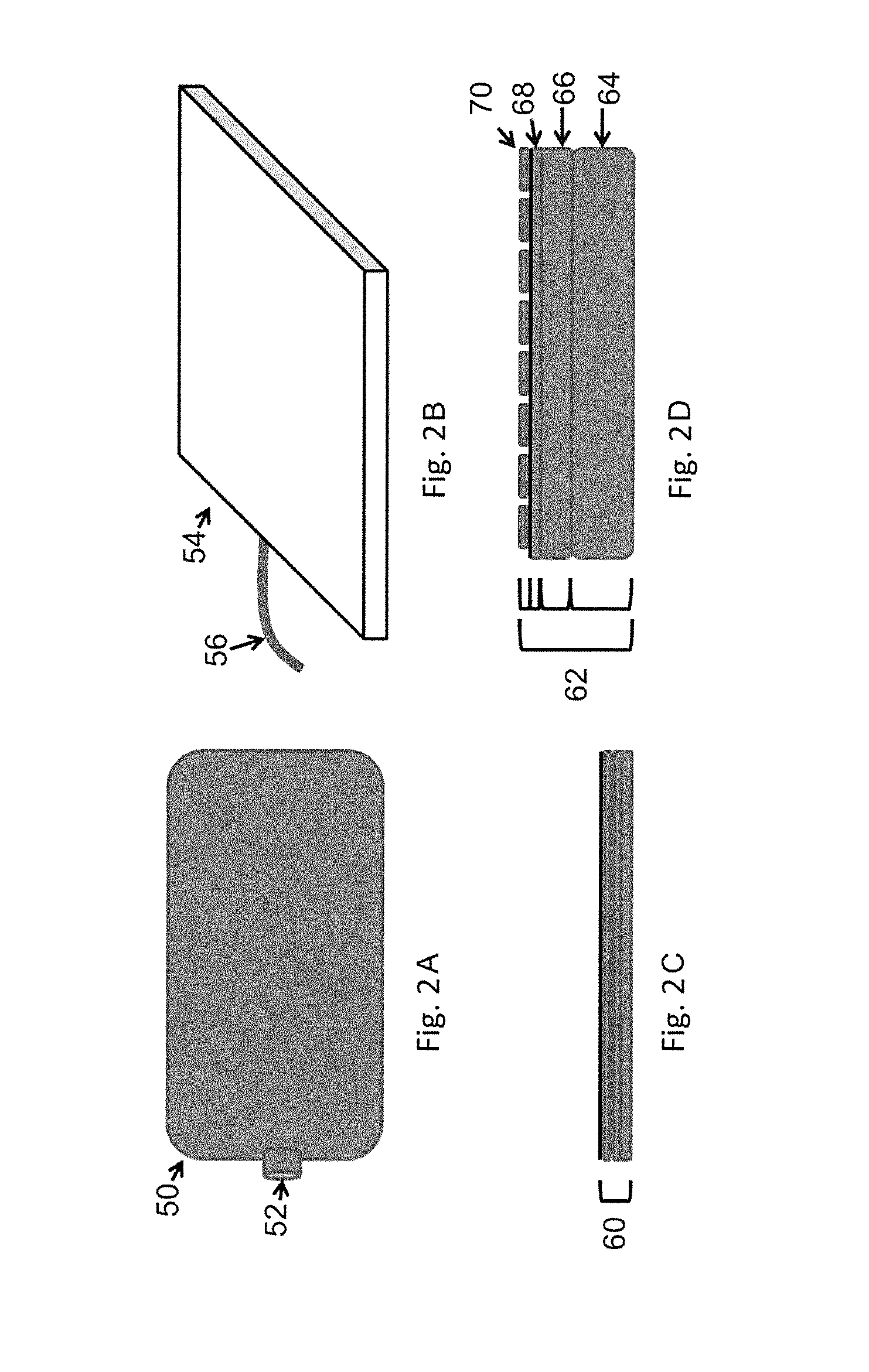

3D Print Bed Having Permanent Coating

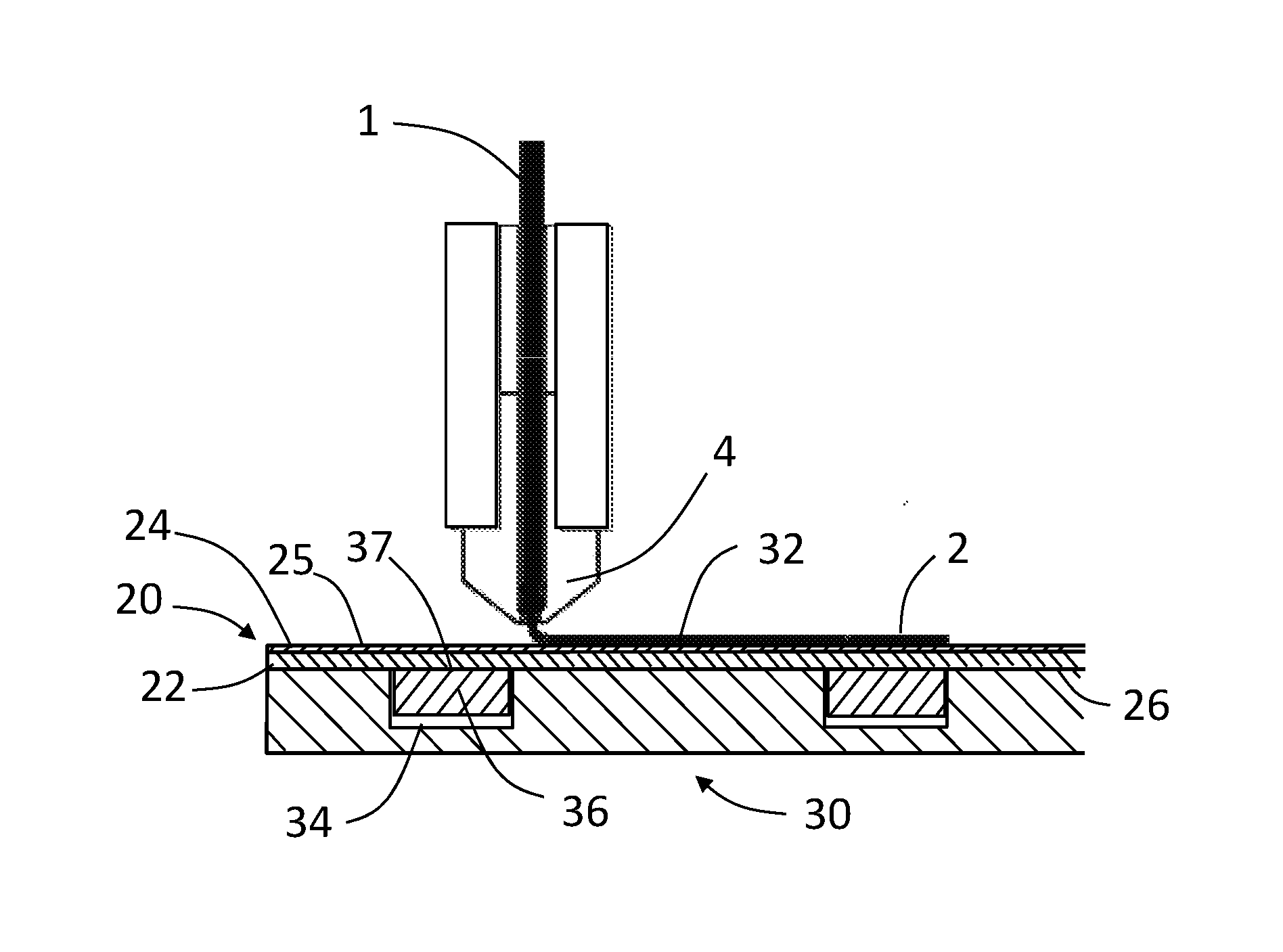

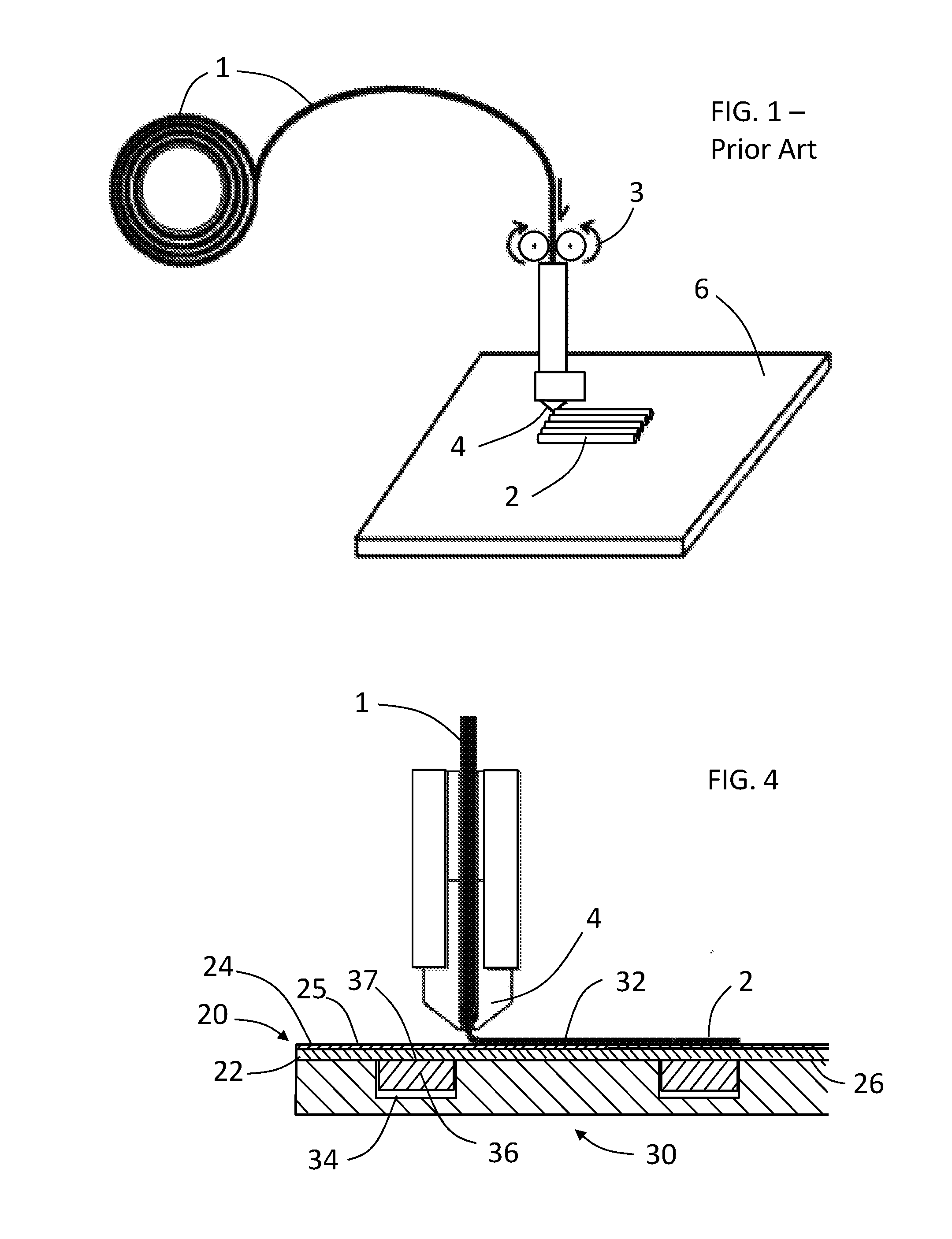

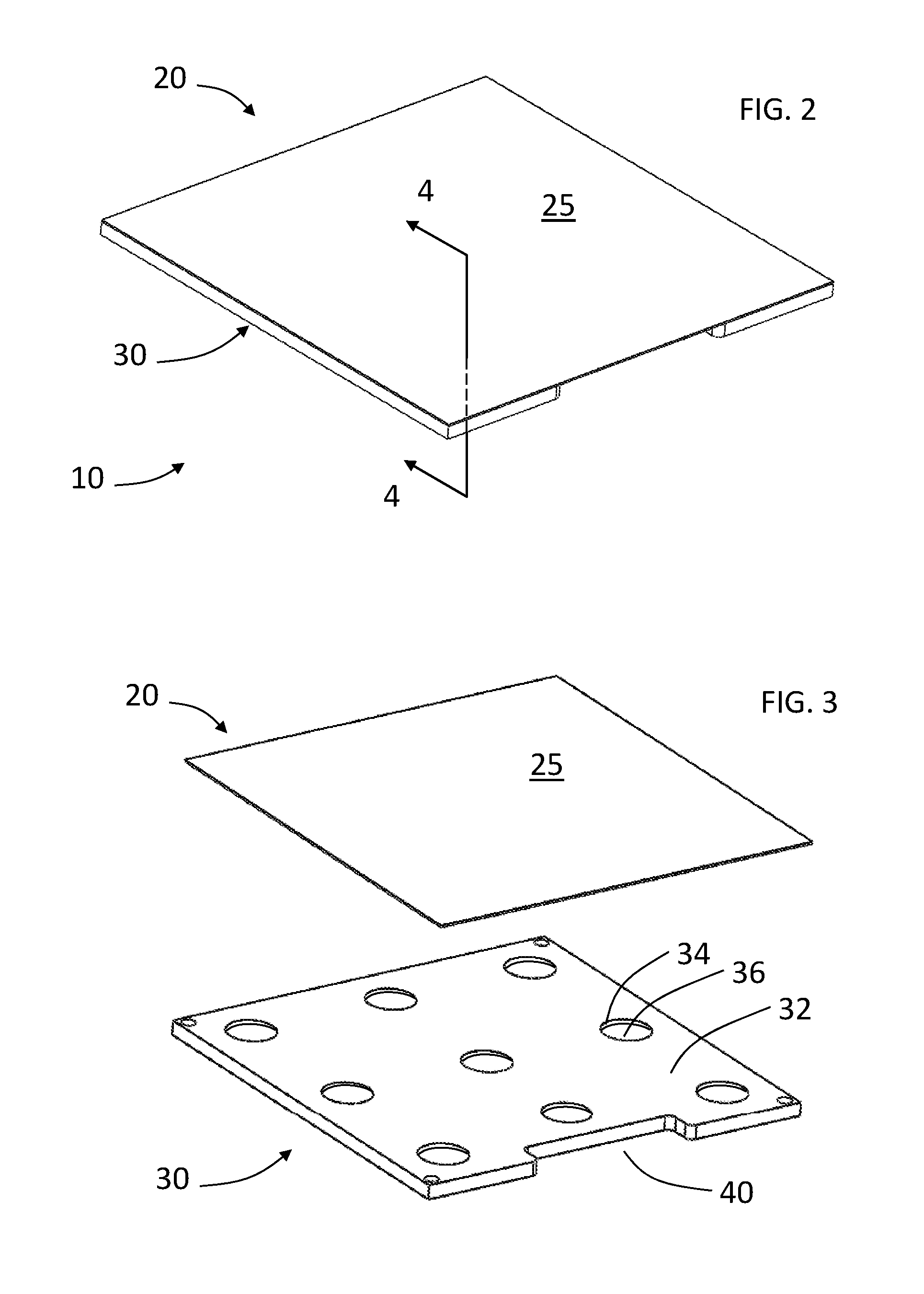

PendingUS20170036403A1Improve adhesionSufficient level of adhesionManufacturing platforms/substratesPretreated surfacesEpoxyWater based

A coated print bed for a 3D printer having a permanent print-surface coating permanently secured to a print bed substrate plate, having a smooth, planar surface that provides an adhesive interface layer between a first layer of an applied plastic print material and the coated print bed. The coating contains a matrix-forming compound, such as a solvent- or water-based epoxy resin, an adhesive material, and optionally a filler. The user can print a series of print object directly onto the permanent print surface coating of the coated print bed, without having to refresh or refurbish the print surface, such as by applying to the print bed surface a temporary coating such as painter's tape, or a liquid adhesive.

Owner:EZ PRINT

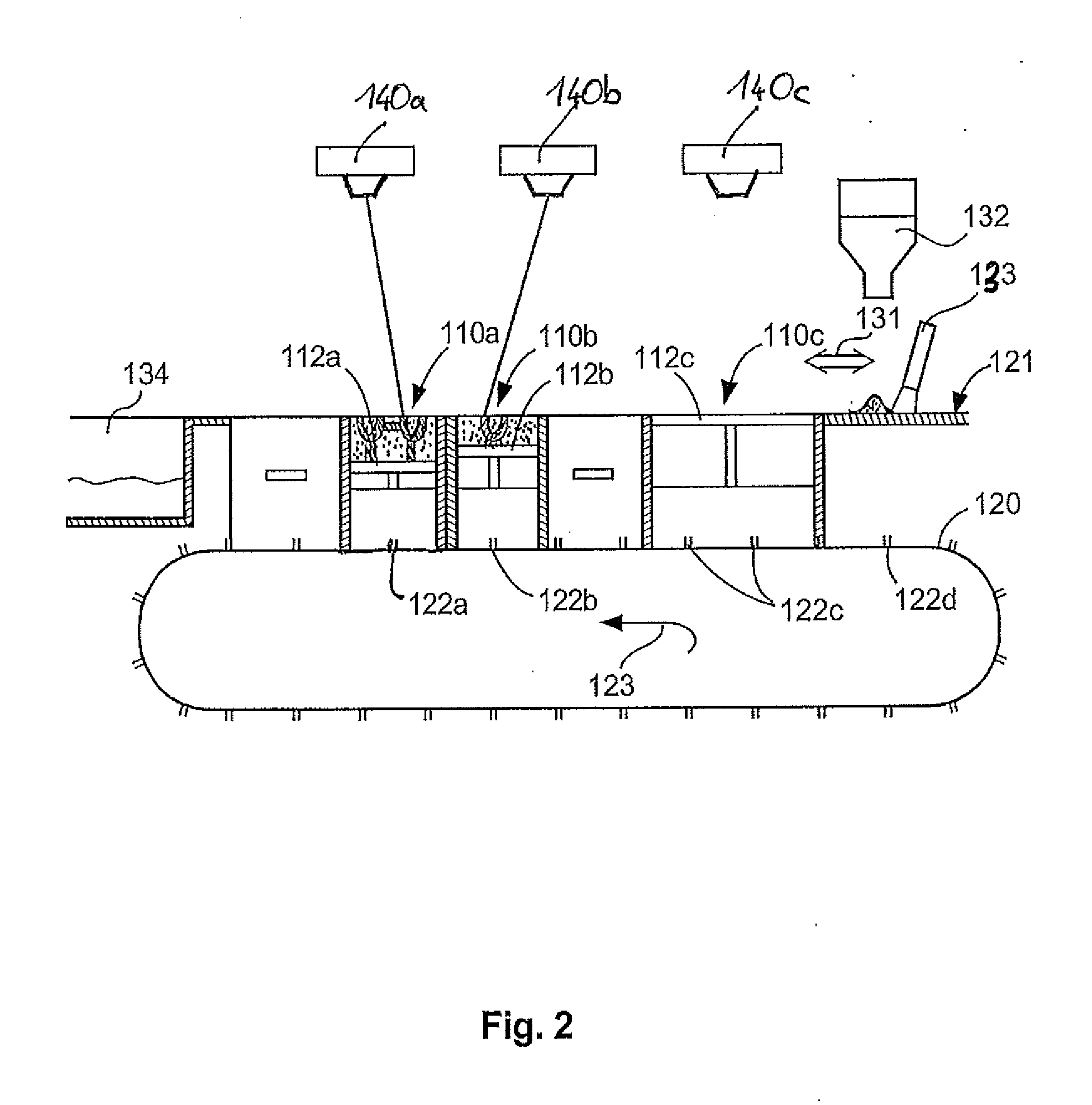

Device and method for powder distribution and additive manufacturing method using the same

ActiveUS20130186514A1Improve compactnessWell mixedLiquid surface applicatorsManufacturing driving meansMetallurgyThermal deformation

The present disclosure provides a device and method for powder distribution and an additive manufacturing method, wherein different size or kind of powders could be chosen to be accommodated within a receptacle. The receptacle can uniformly mix the powder by a rotation movement, pour out the powders by the rotation movement and distribute the powders for forming a layer by a translation movement. In another embodiment, the receptacle further comprises a heating element for preheating the powders. Not only can the present disclosure uniformly mix the powders so as to reduce the thermal deformation and distribute the powder layer compactly, but also can the present disclosure distribute different kinds of powder in different layer so as to increase the diversity in additive manufacturing.

Owner:IND TECH RES INST

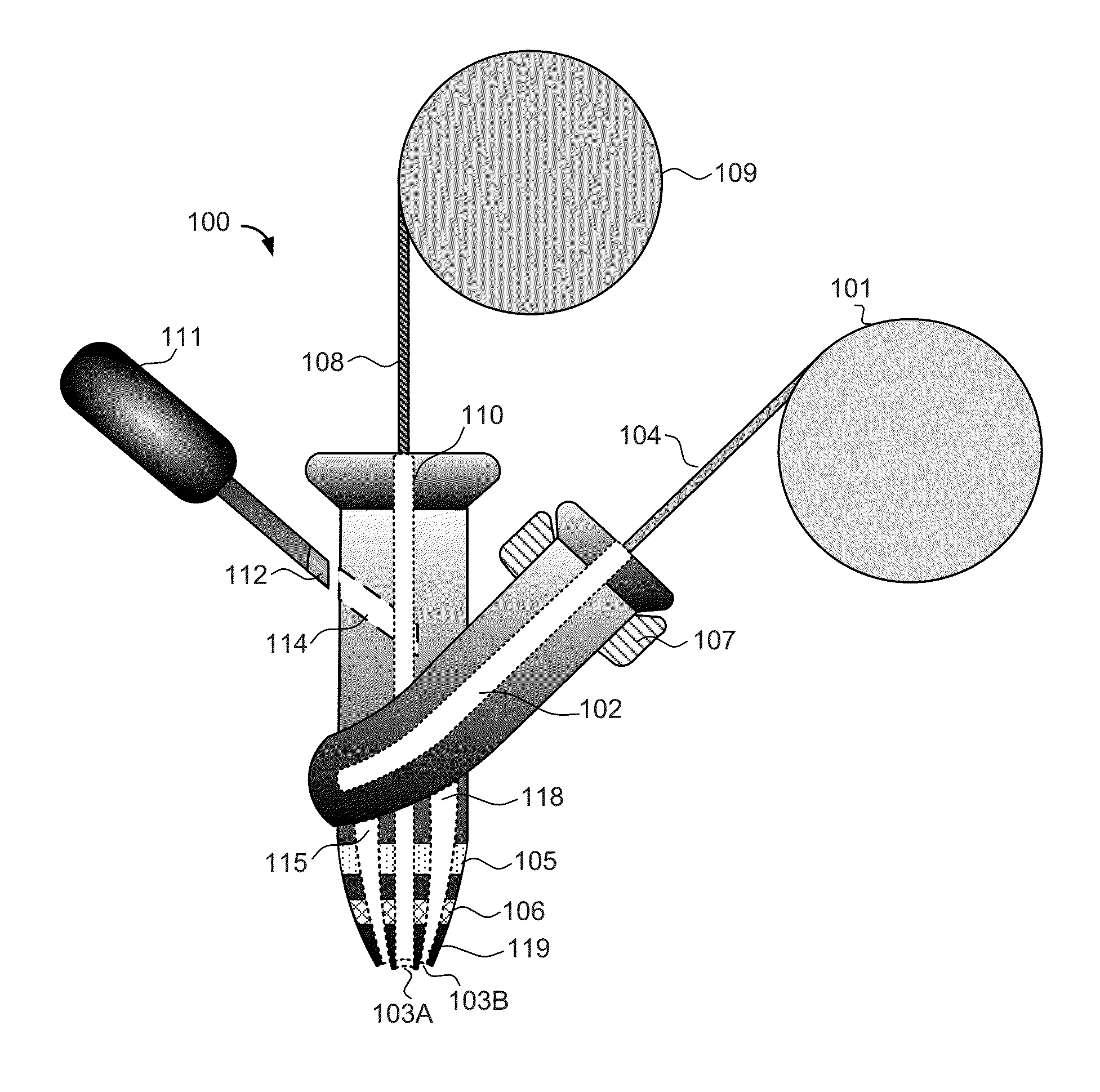

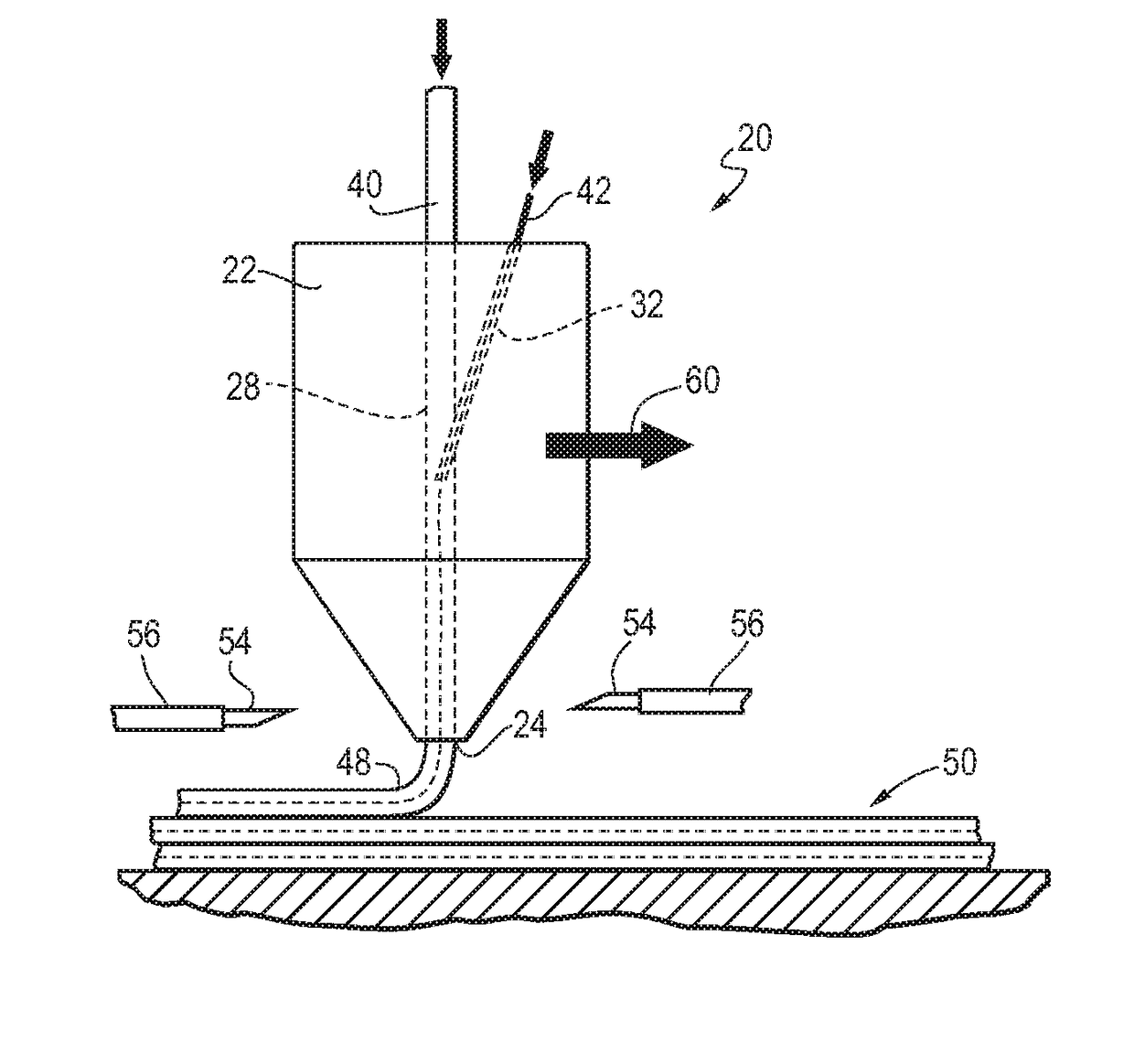

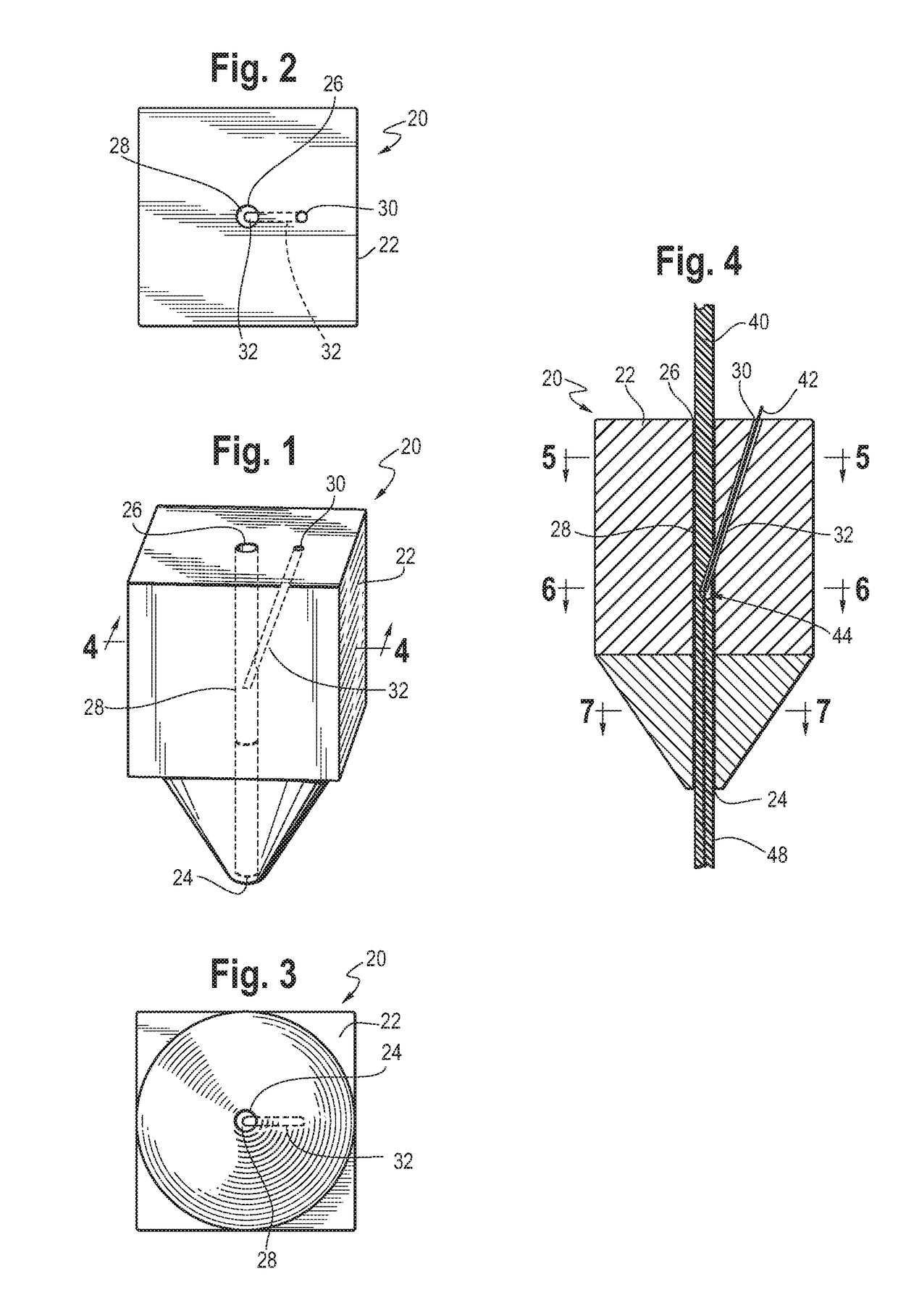

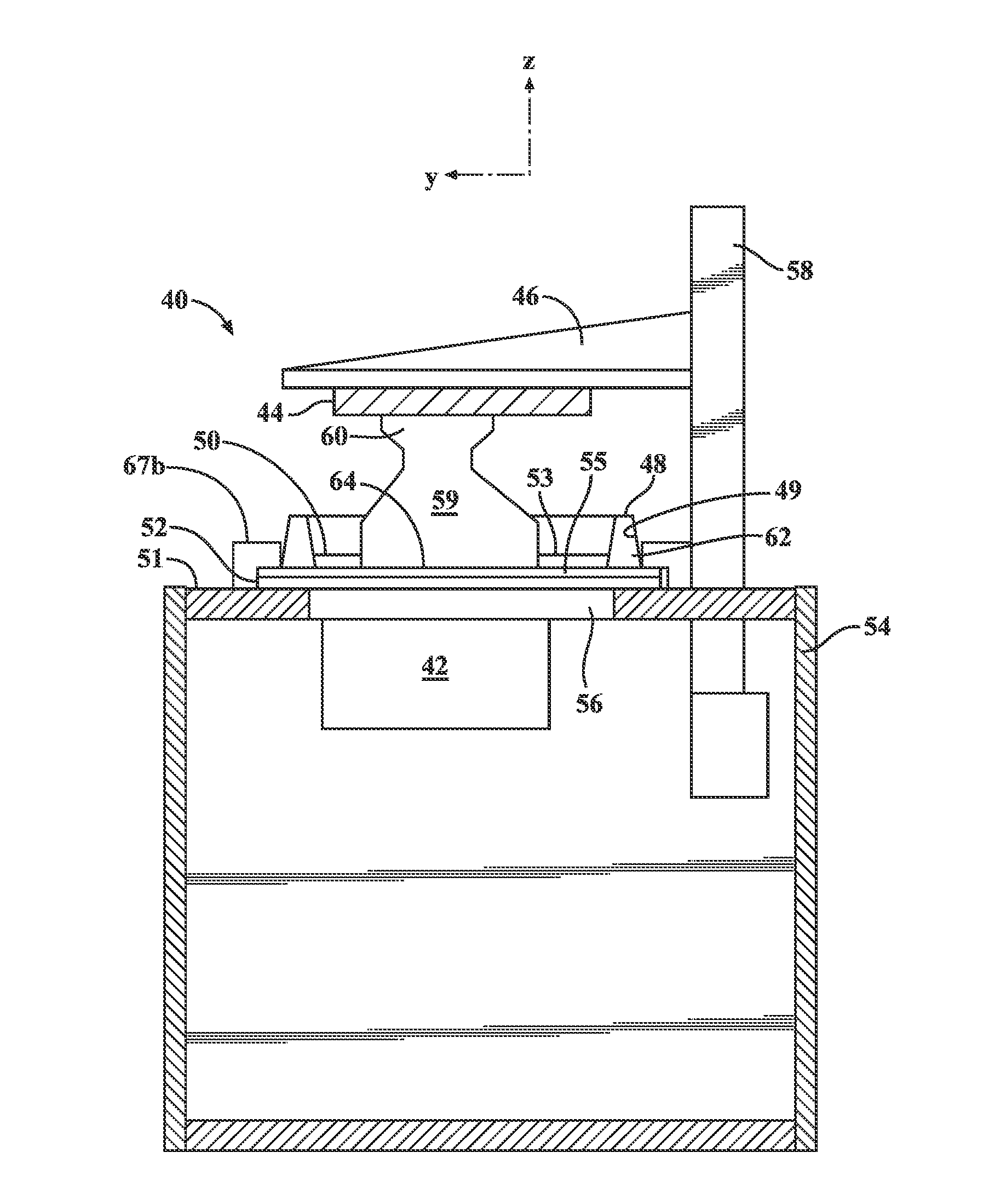

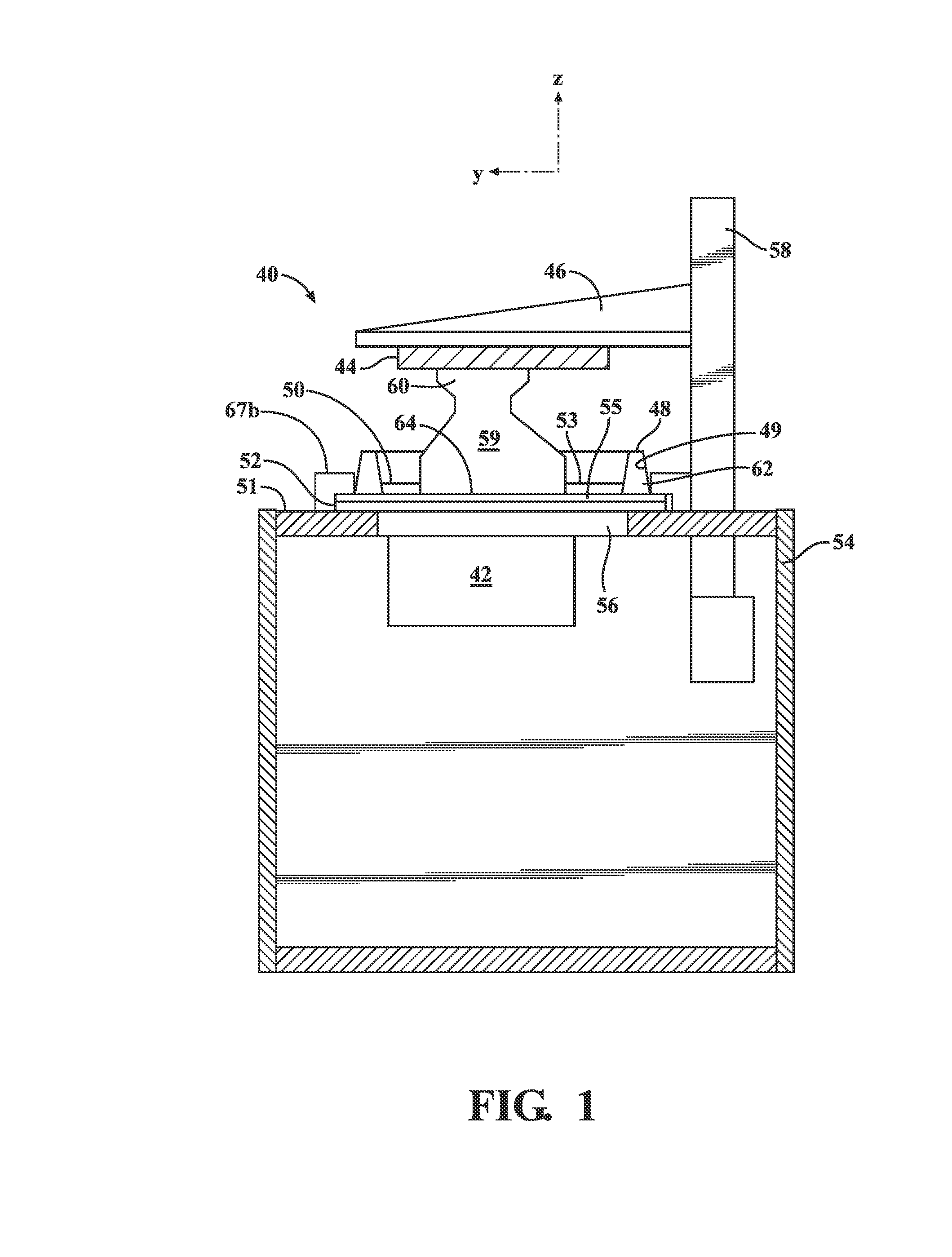

Additive manufacturing techniques and systems to form composite materials

InactiveUS20160136885A1Well formedConfectioneryCeramic shaping apparatusAdditive layer manufacturingHeating element

A printer system may include a coaxial extruder head that extrudes a core, a bulk, and / or a core and bulk cladding to form complex structures without retooling. The coaxial extruder head may include a distribution channel with an entrance and an exit, a priming chamber that surrounds the distribution channel. The priming chamber may include an outlet and a first inlet, a heating element thermally connected to the priming chamber, and a nozzle connected to the outlet of the priming chamber. Further, the nozzle may converge from the outlet of the priming chamber to an orifice of the nozzle. In addition, the exit of the distribution channel may be disposed at the orifice of the nozzle. This structure facilitates extruding a core and cladding type composite from the extruder head.

Owner:ORBITAL COMPOSITES INC

Self-Assembling Cell Aggregates and Methods of Making Engineered Tissue Using the Same

Owner:MUSC FOUND FOR RES DEV +1

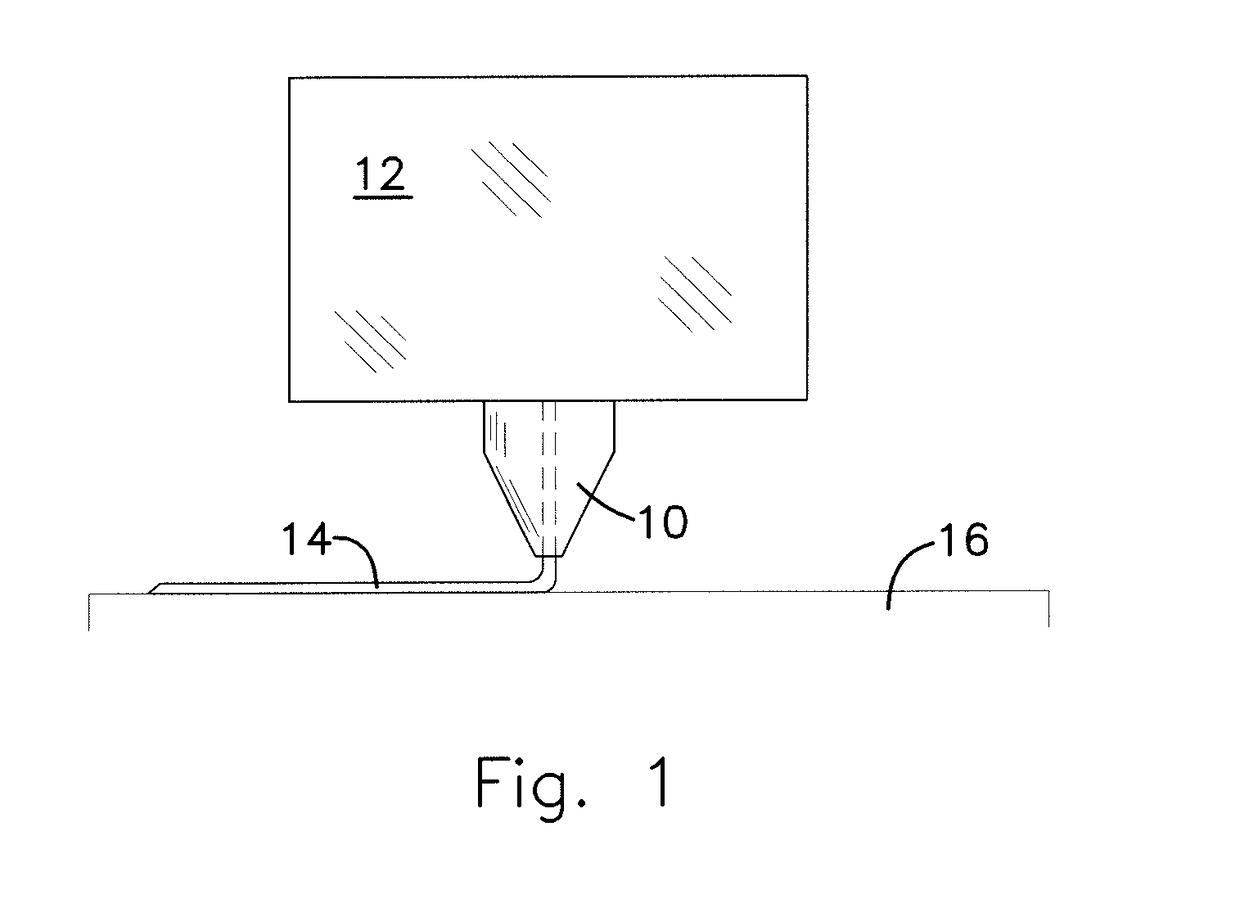

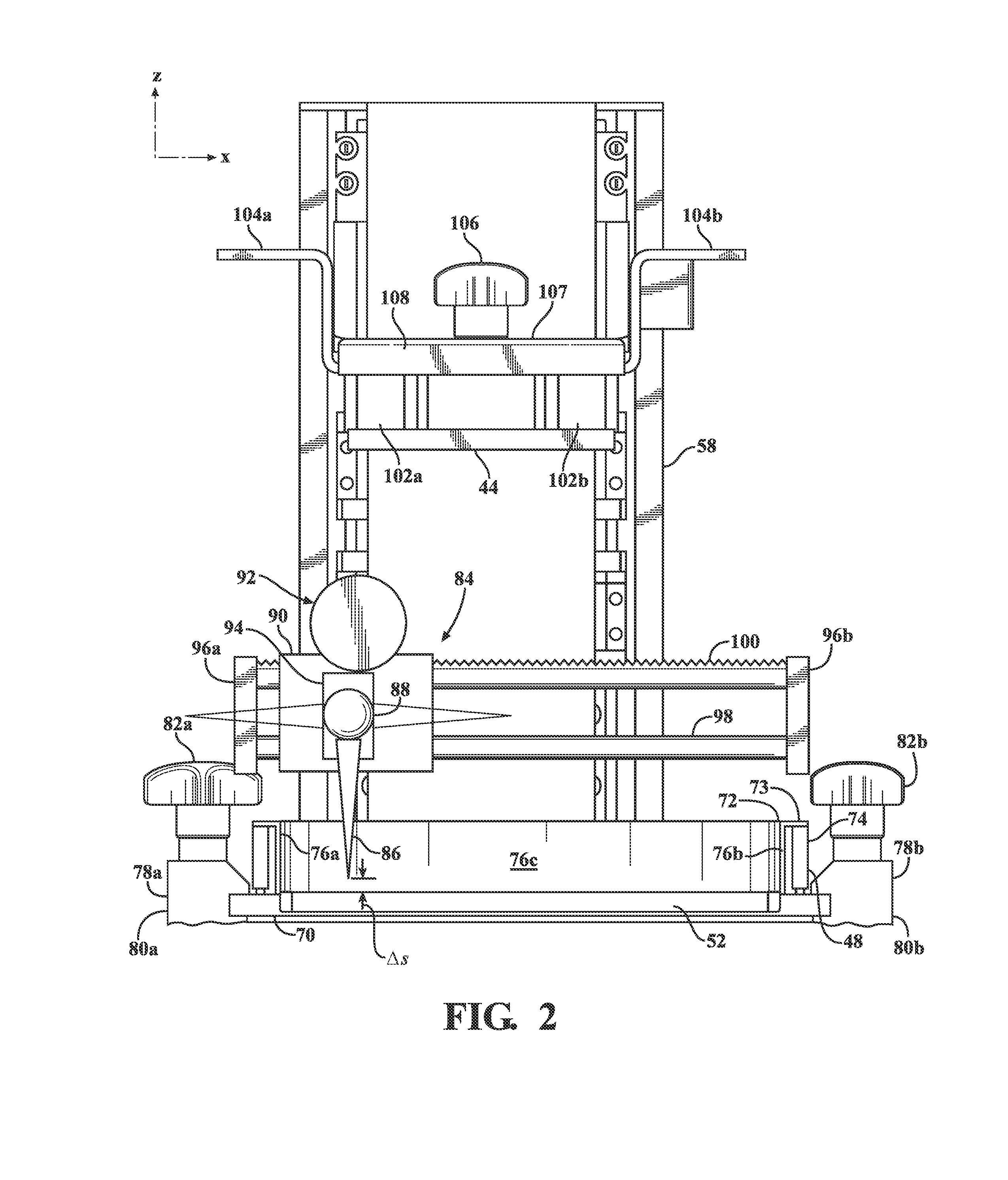

Machine and a Method for Additive Manufacturing with Continuous Fiber Reinforcements

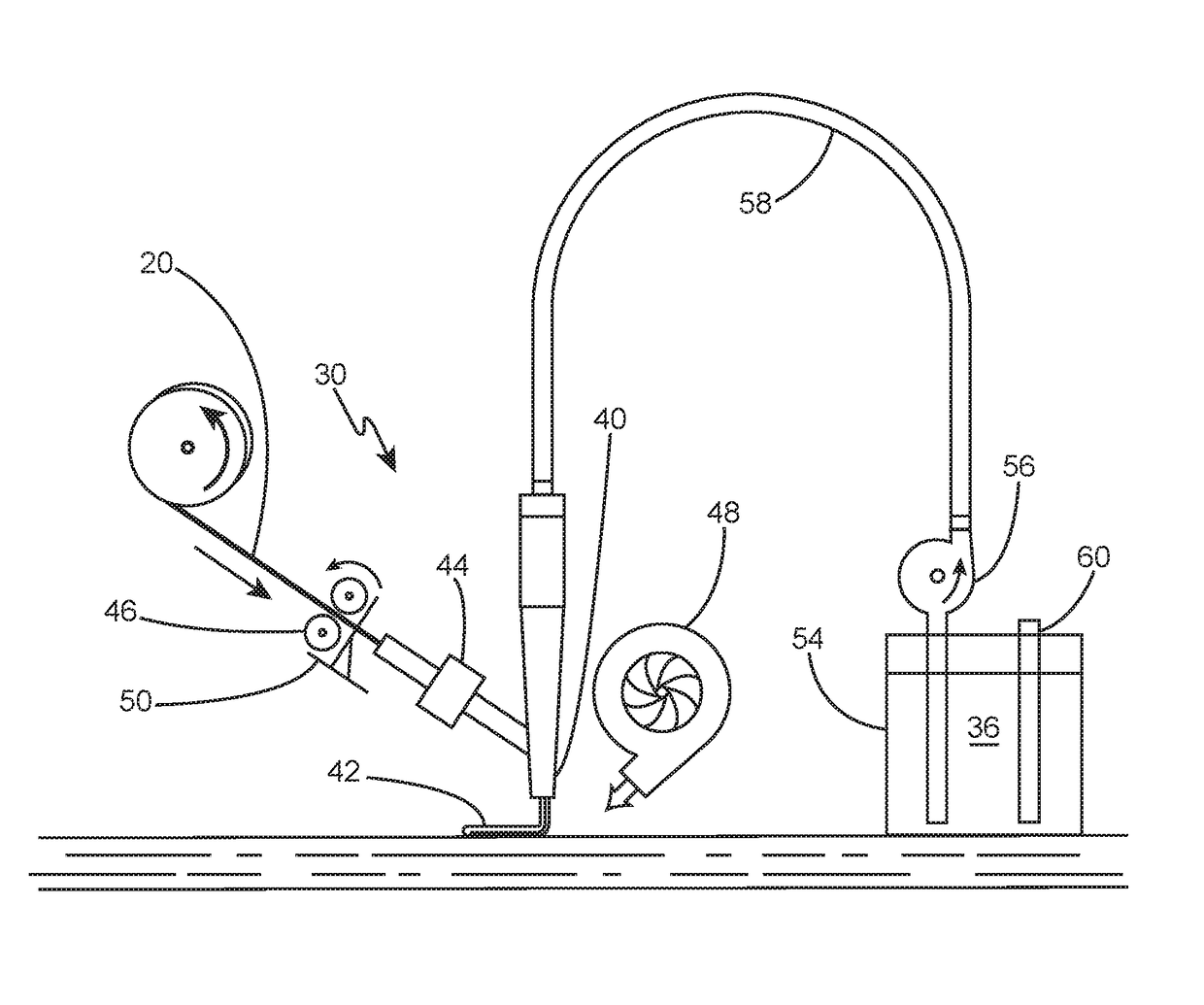

InactiveUS20170151728A1Manufacturing heating elementsAdditive manufacturing with liquidsUltimate tensile strengthPolymer

Several examples of additive manufacturing machines and methods for depositing a bead of composite polymer material having continuous fiber reinforcement are disclosed. A length of fiber reinforcement is provided to a nozzle. The fiber reinforcement is embedded into a stream of a base polymer material at the nozzle and deposited as a bead of composite polymer material having fiber reinforcement. The fiber reinforcement may be dry or pre-impregnated with a reinforcing polymer. The additional strength of the composite polymer material having fiber reinforcement allows for true, three-dimensional printing of articles having unsupported regions.

Owner:UT BATTELLE LLC

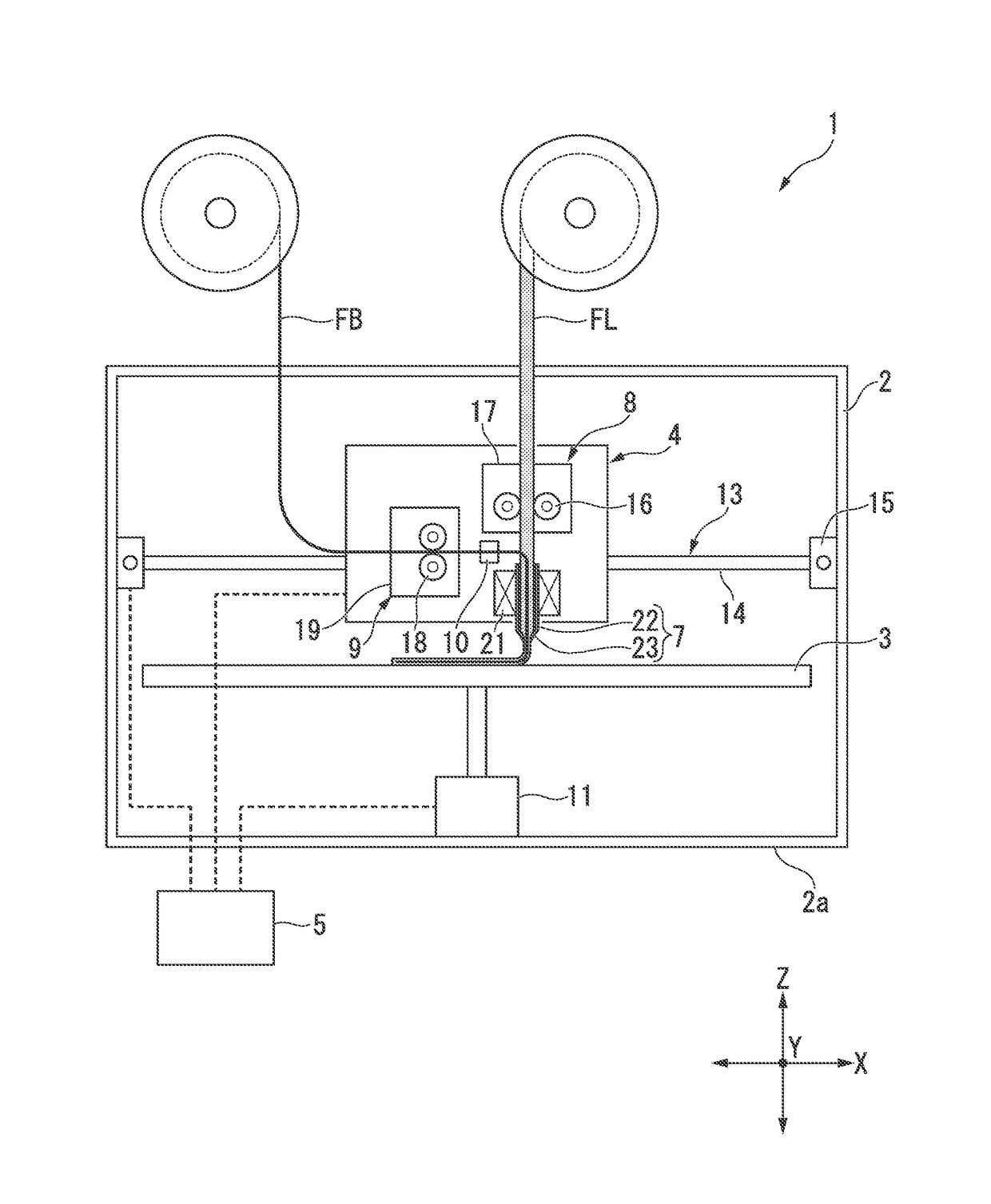

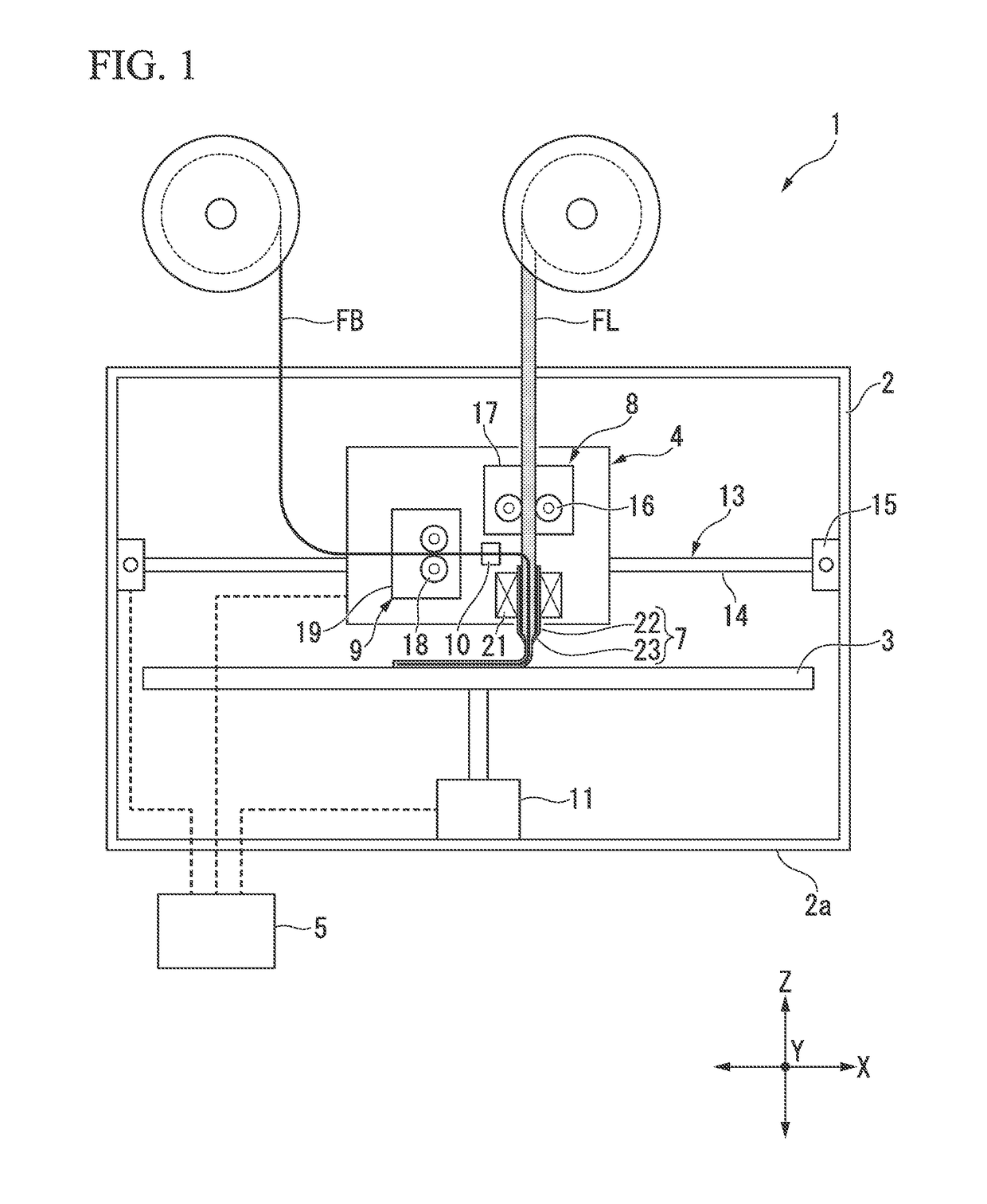

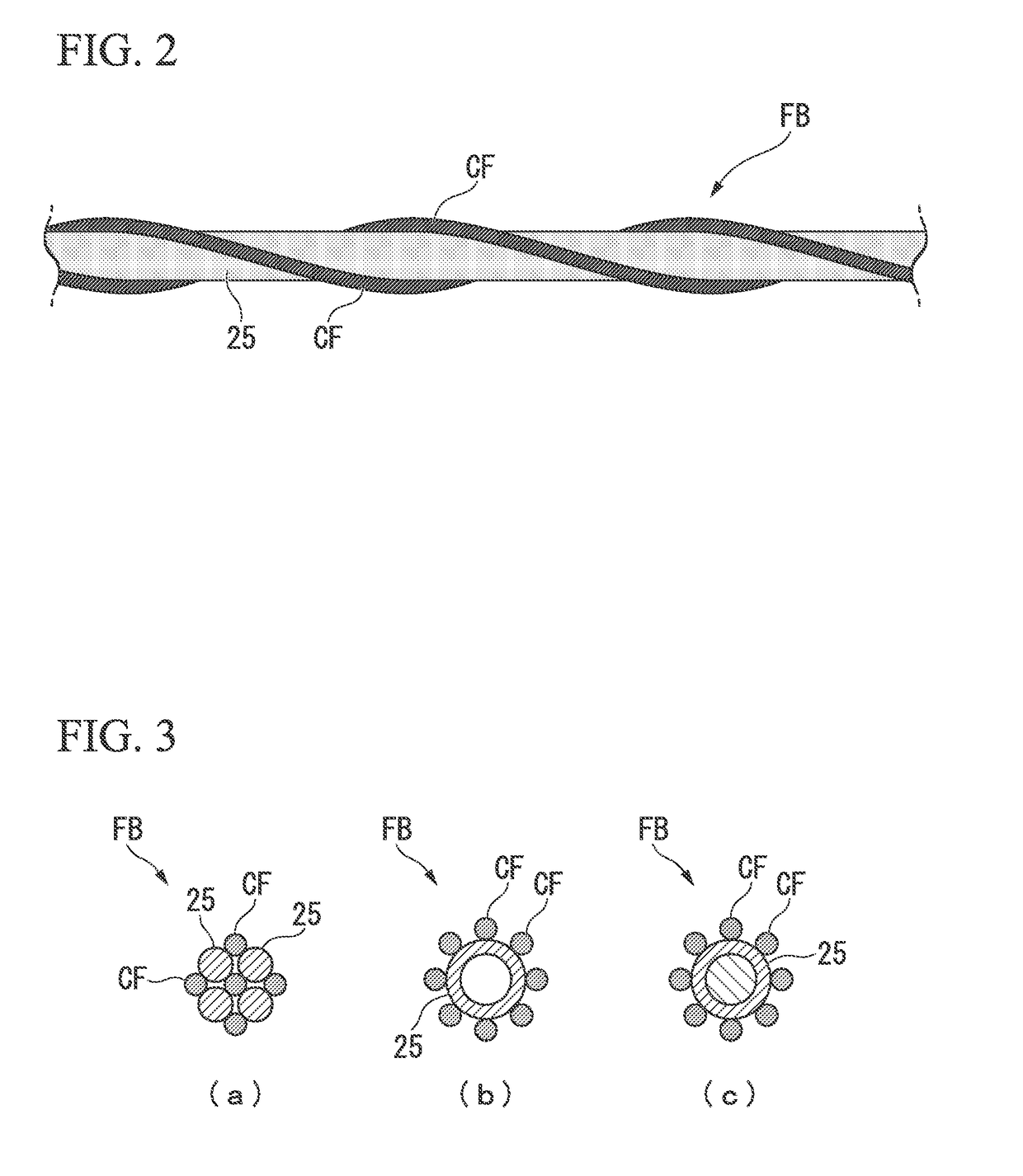

Three-dimensional printing system, three-dimensional printing method, molding device, fiber-containing object, and production method thereof

ActiveUS20170210074A1Improve structural strengthHigh strengthManufacturing heating elements3D object support structuresFiber3 dimensional printing

A three-dimensional printing system (1) includes: a head (2) to which a first continuous material (FL) including a resin and a second continuous material (FB) including fibers are fed; a platform (3) on which a printing material based on the first and second continuous materials from the head is stacked; a cutting device (10) which is capable of cutting at least fibers; and a controller (5) which controls an operation device including at least one of the head, the platform, and the cutting device.

Owner:NIHON UNIVERSITY +1

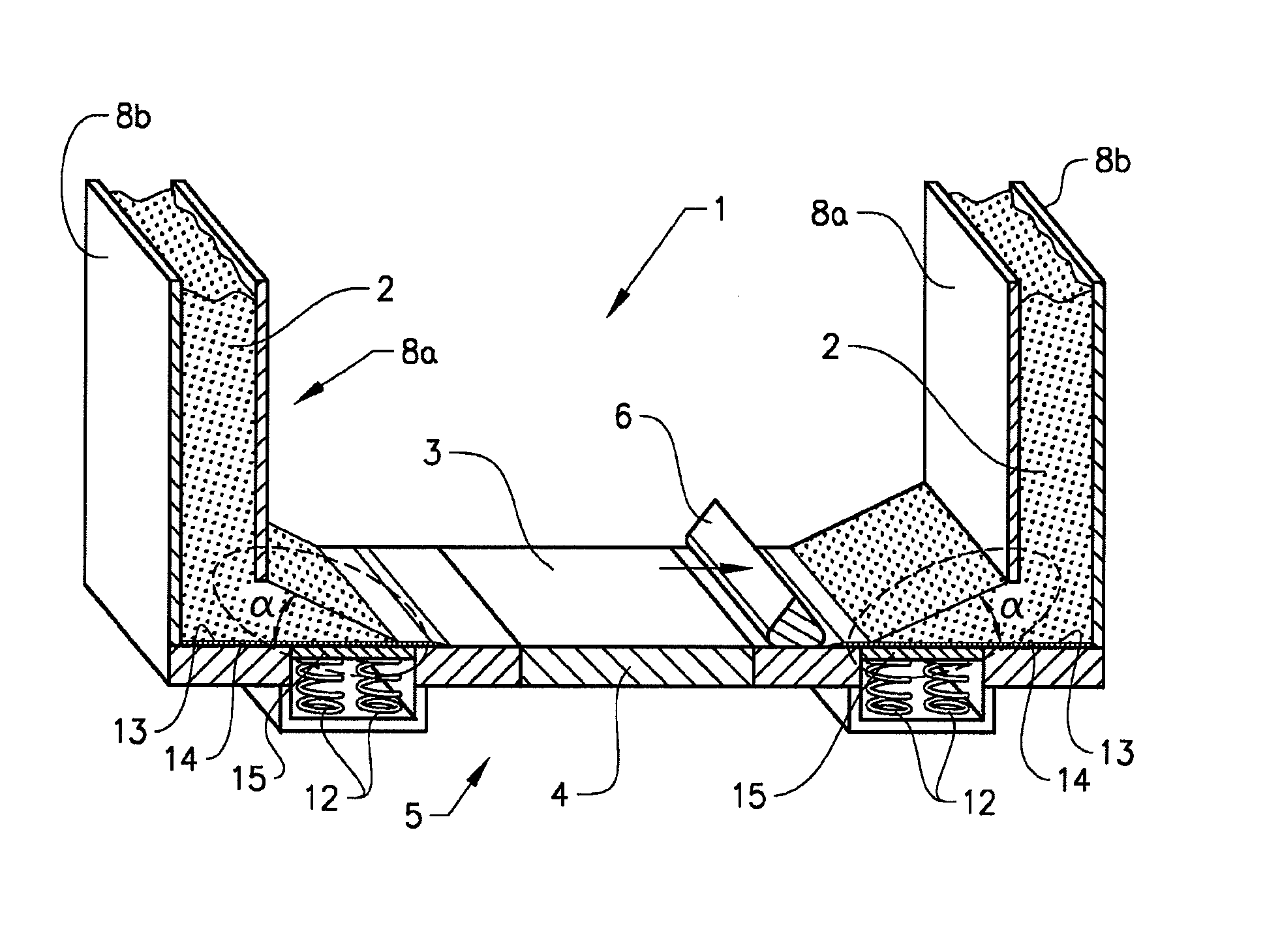

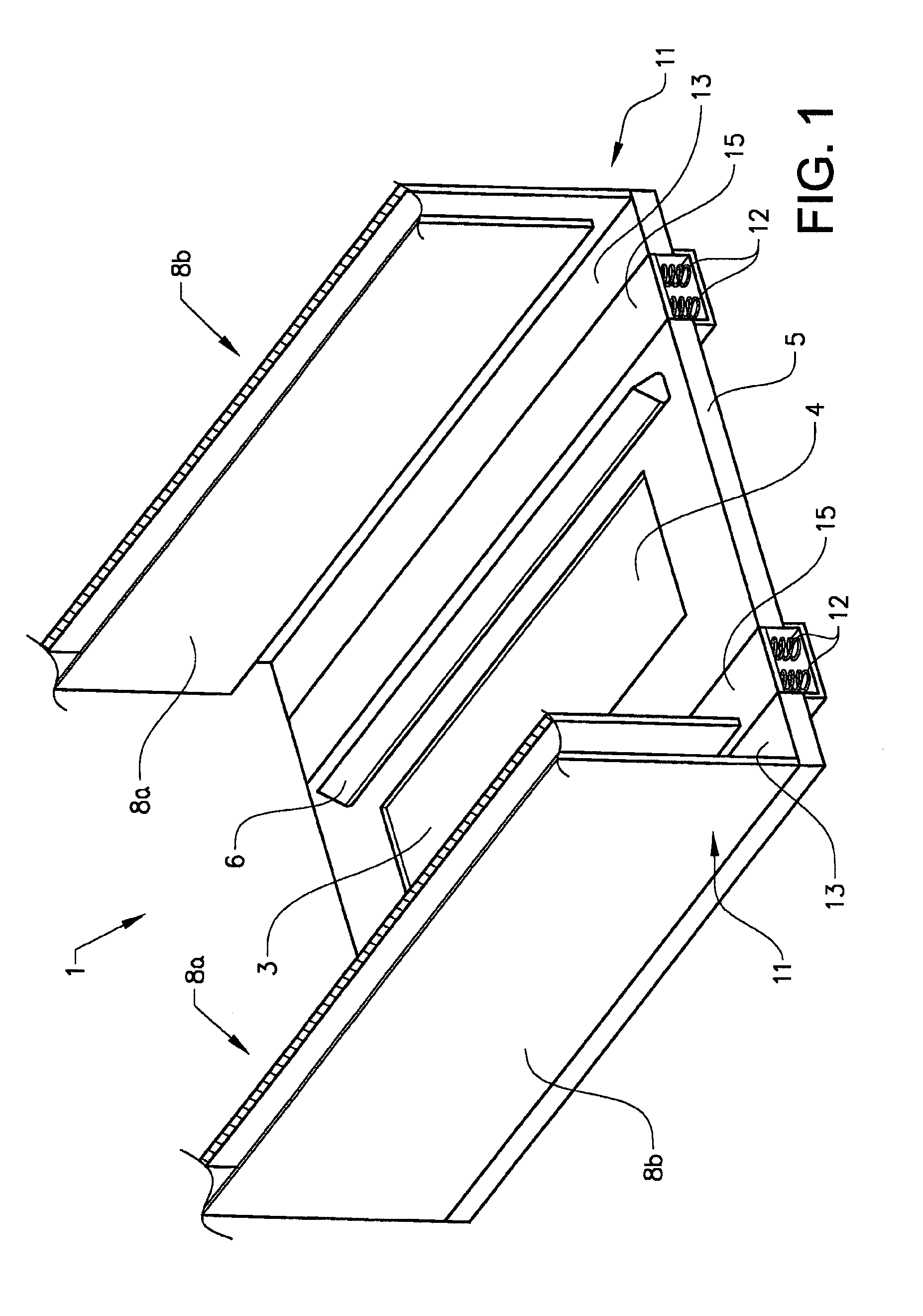

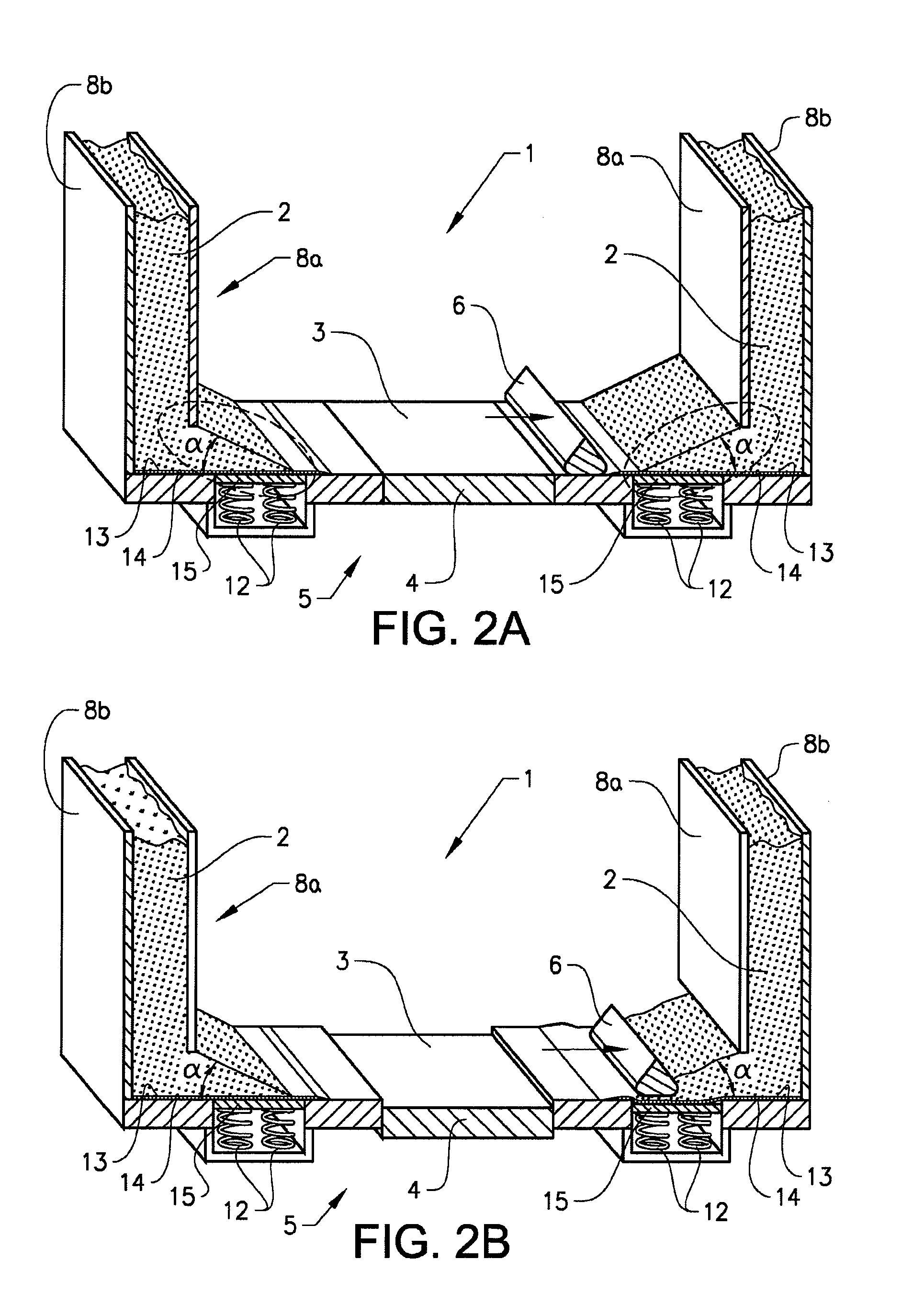

Apparatus for producing a three-dimensional object

ActiveUS8308466B2Control of sizeEasy to controlConfectionerySweetmeatsElectromagnetic radiationElectron

The invention concerns an apparatus (1) for producing a three-dimensional object layer by layer using a powdery material which can be solidified by irradiating it with an energy beam, such as electromagnetic radiation or an electron beam, said apparatus (1) comprising: a working area (3) onto which layers of powdery material are to be placed; a powder storage unit (11) comprising a base surface (13) for supporting a supply of powder (2); and a powder distribution member (6); wherein the base surface (13) extends along a side of the working area (3), wherein the distribution member (6) extends in a direction along the base surface (13) and said side of the working area (3) and is arranged to be moveable in a plane above, and substantially parallel to, the base surface (13) and the working area (3), and wherein the distribution member (6) is arranged to be moveable into a supply of powder (2) placed onto the base surface (13) such as to bring about a transfer of a portion of powder from a side of the distribution member (6) facing away from the working area (3) to an opposite side of the distribution member (6) facing the working area (3), said distribution member (6) further being arranged to be moveable towards and across the working area (3) so as to distribute the portion of powder onto the working area (3). The invention is characterized in that at least a part (15) of the base surface (13) is arranged to be resilient in a vertical direction.

Owner:ARCAM AB

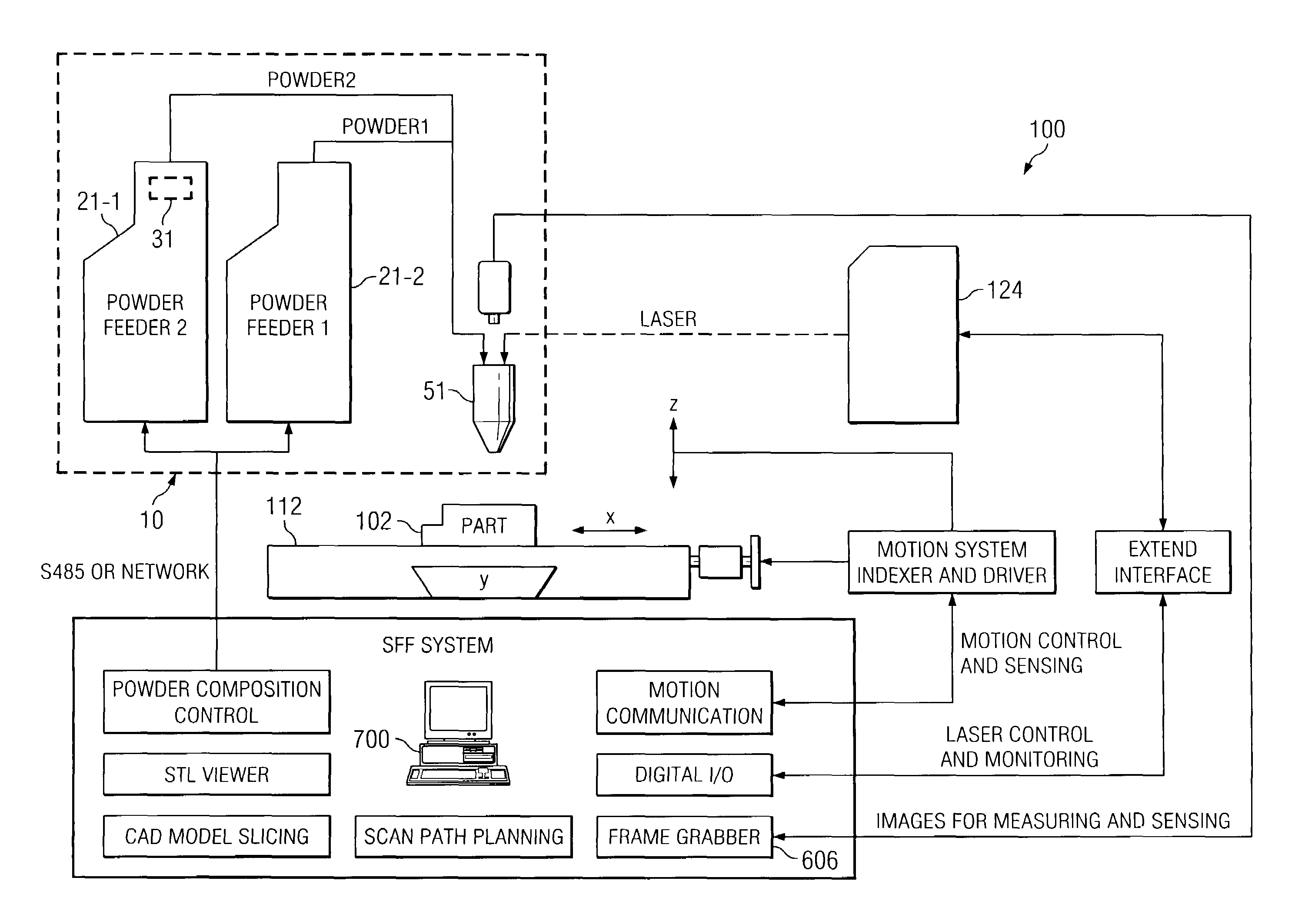

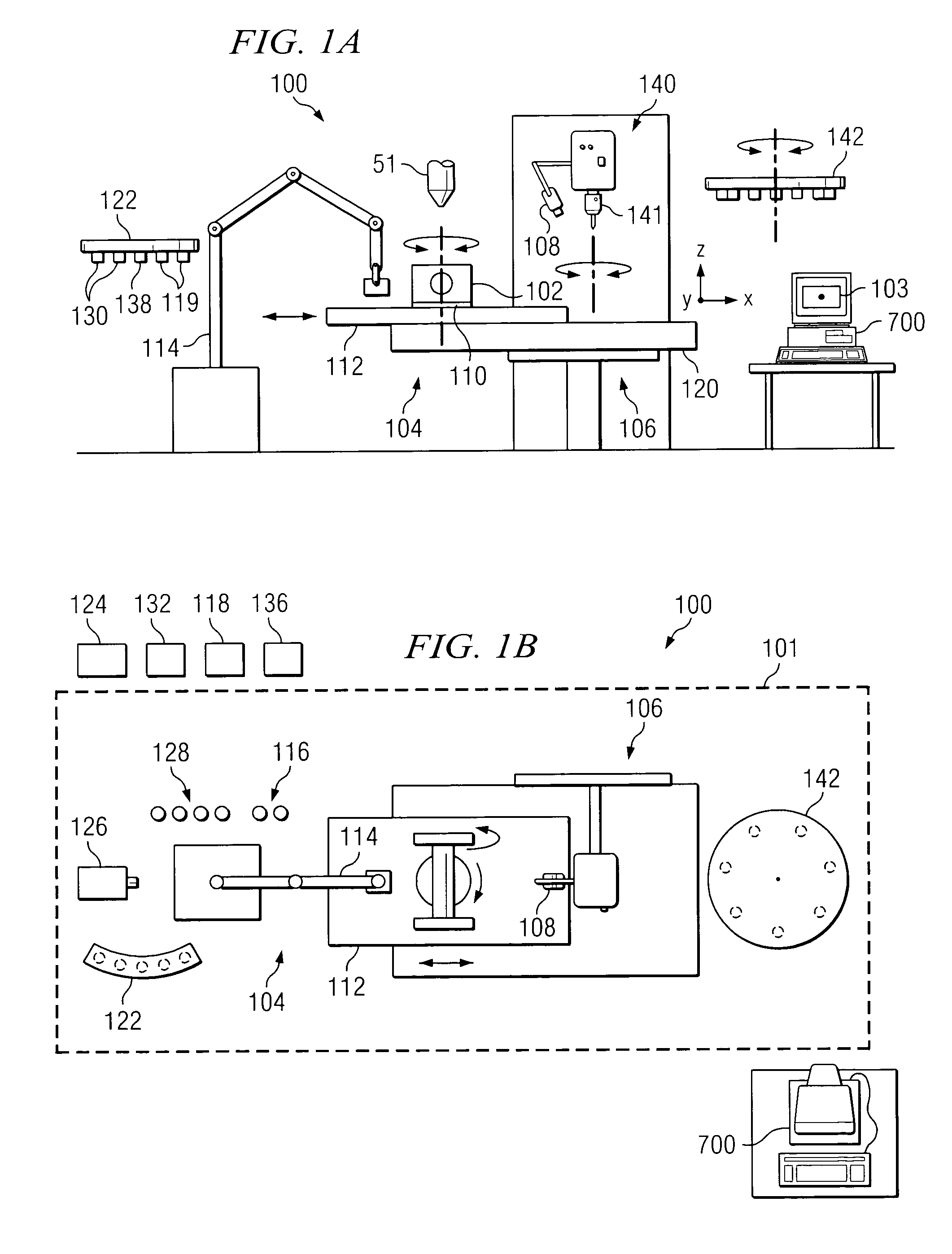

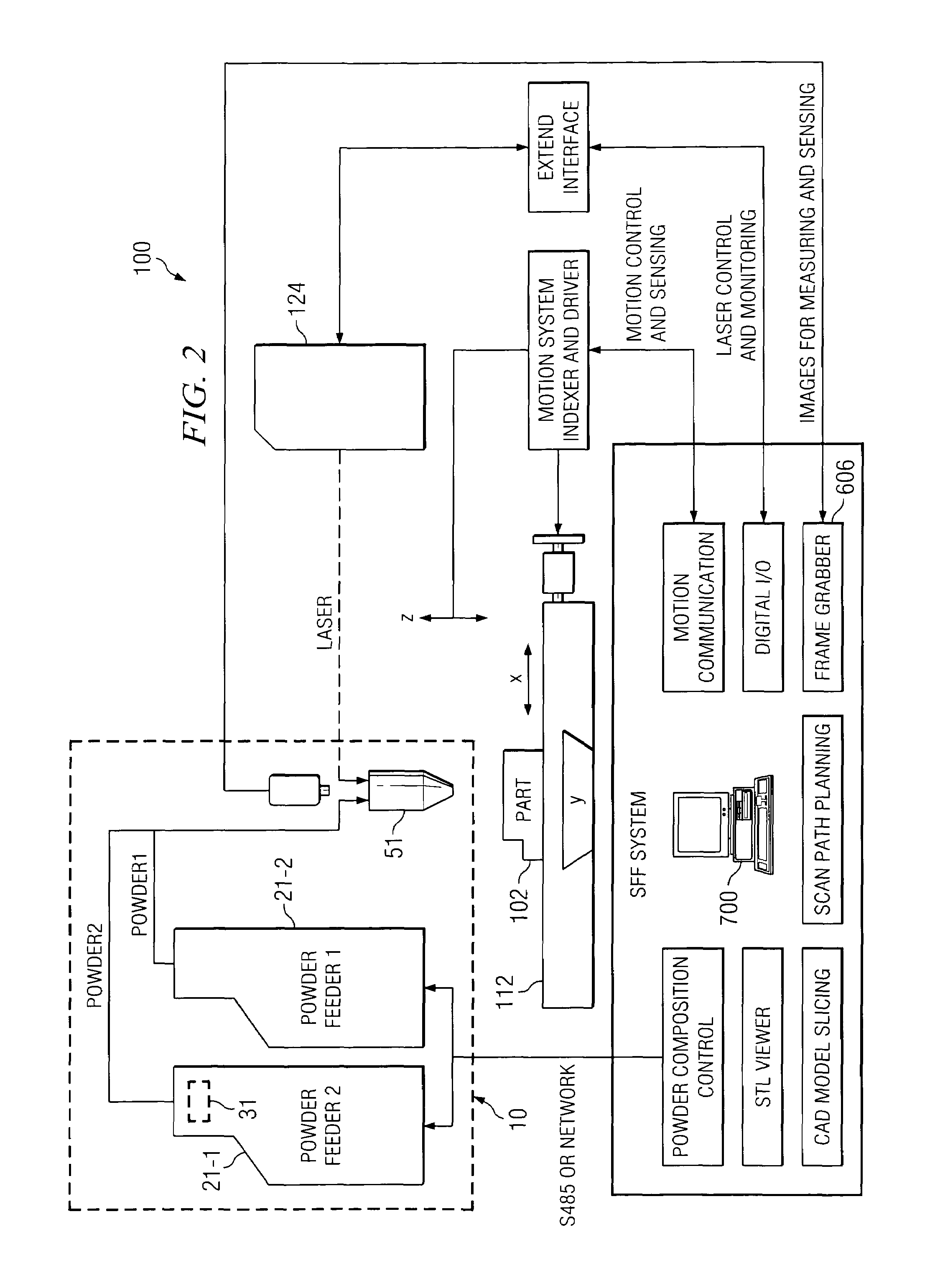

Powder delivery system and method

ActiveUS7045738B1High geometric accuracyEasy to controlWelding/cutting auxillary devicesArc welding apparatusMechanical engineeringDelivery system

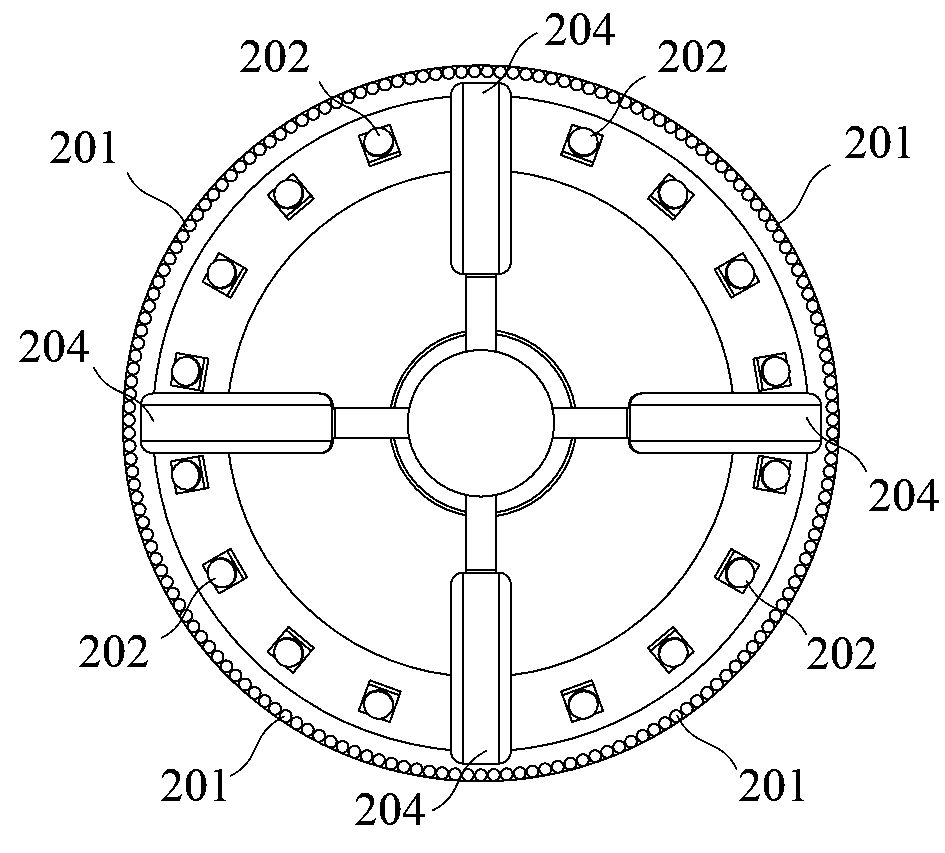

A powder delivery system for a laser-based additive manufacturing process includes a hopper adapted to contain a powder and continuously feed the powder through an output of the hopper, a rotatable disk having a top surface that is substantially flat, the top surface adapted to receive the powder continuously fed through the output of the hopper, the top surface being disposed below the output of the hopper by a prescribed gap, and a vacuum powder removal device operable to remove the powder from the top surface via a vacuum.

Owner:SOUTHERN METHODIST UNIVERSITY

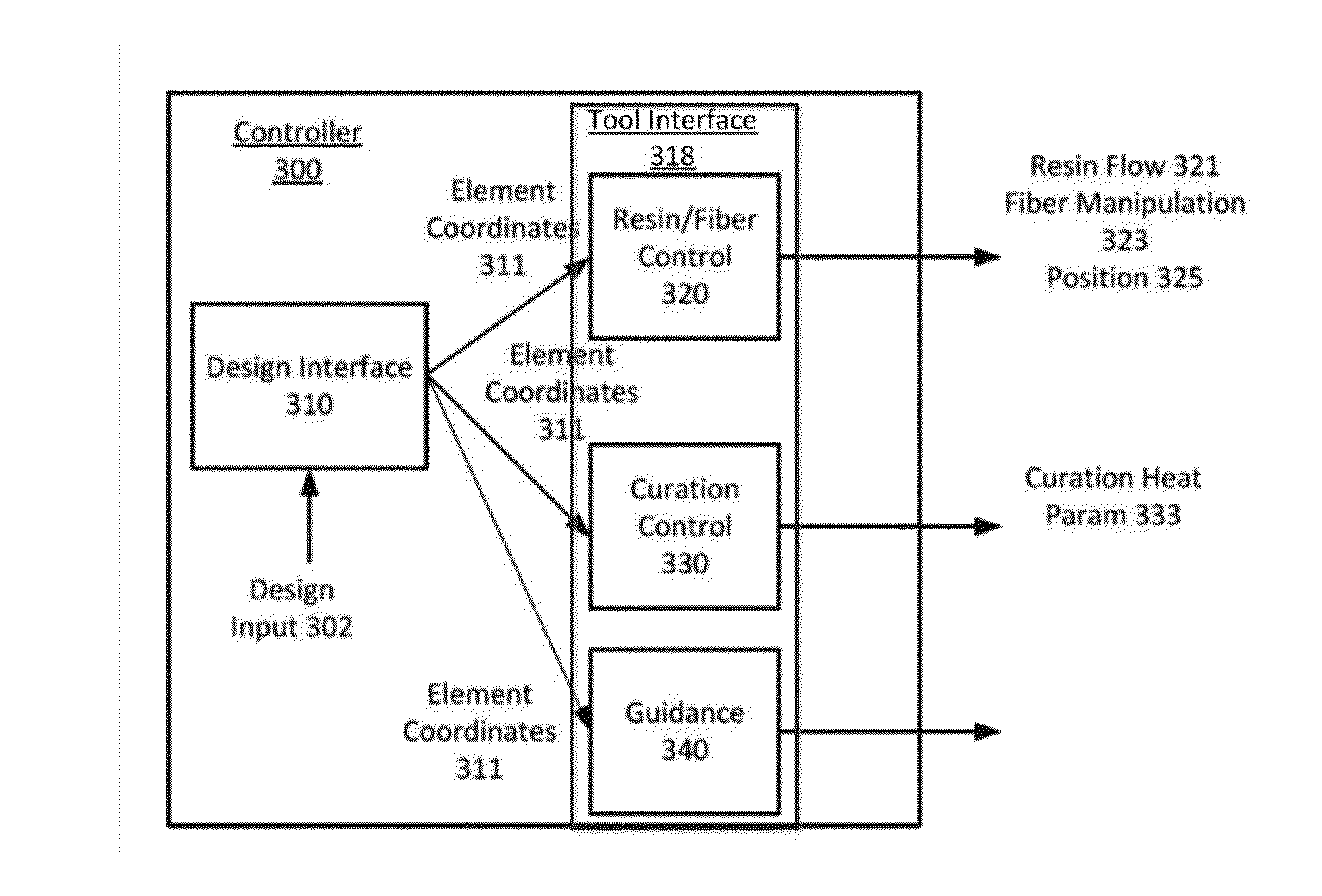

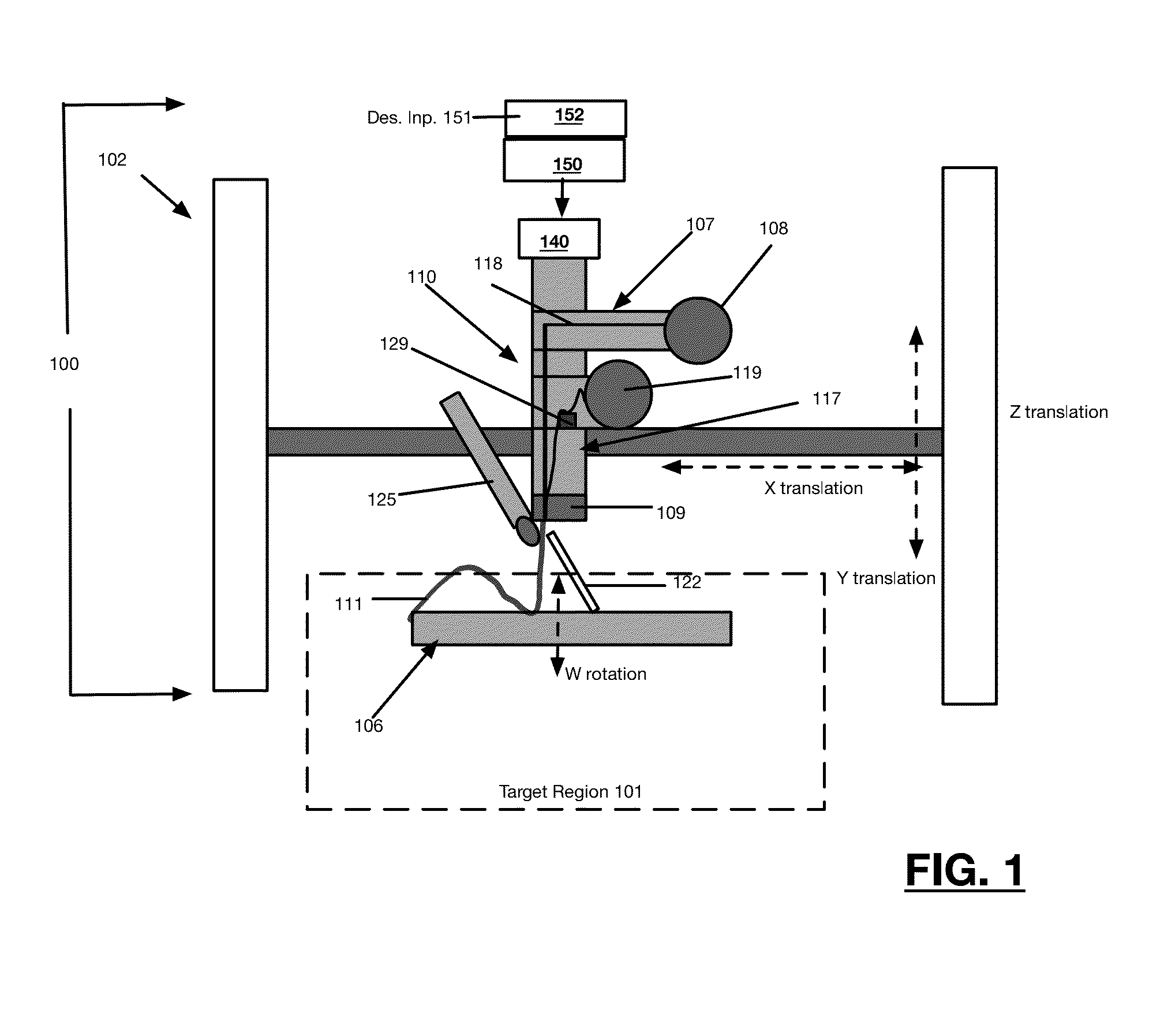

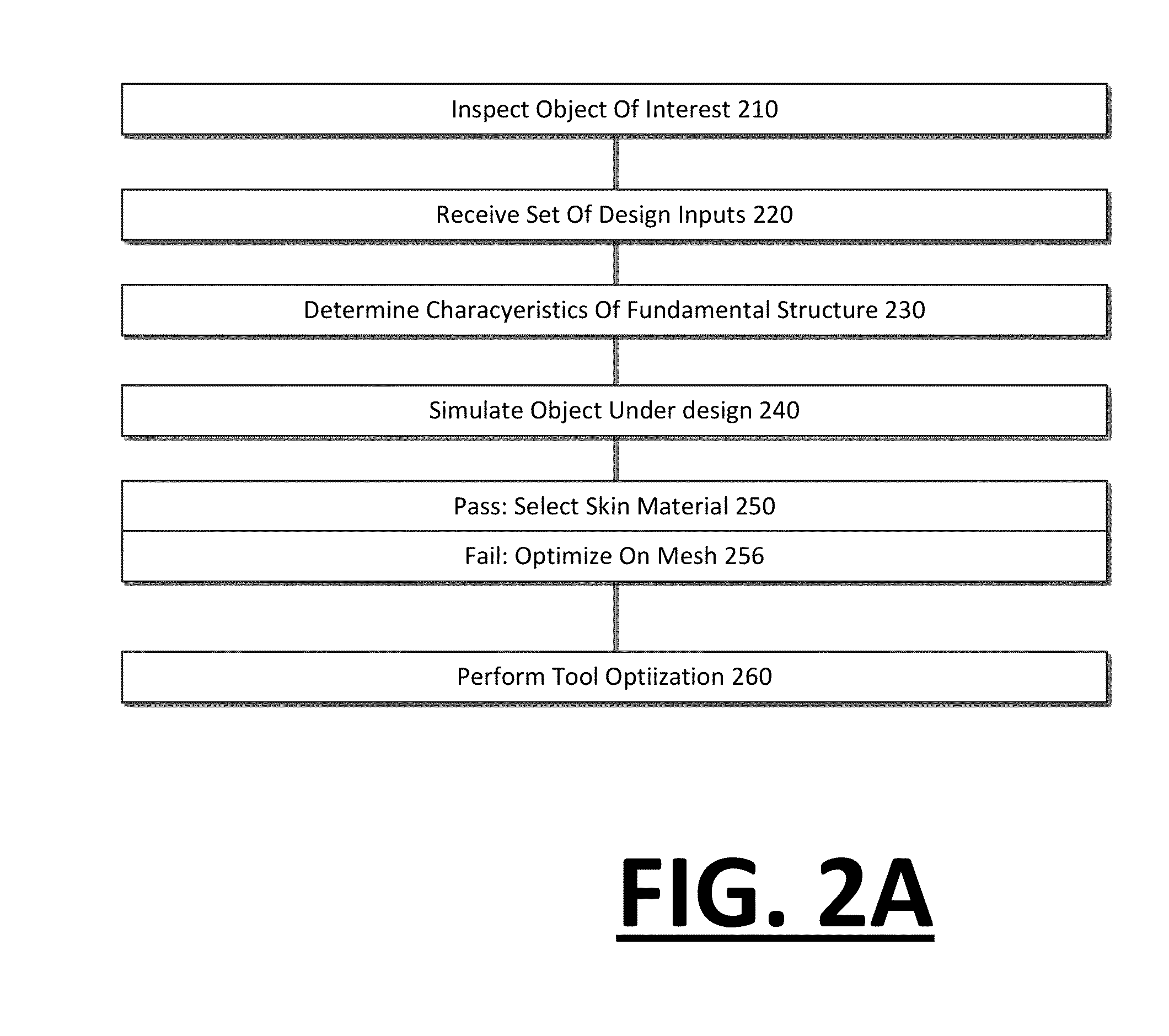

Automated design, simulation, and shape forming process for creating structural elements and designed objects

InactiveUS20160243762A1Additive manufacturing with liquidsPrinted circuit manufactureEngineeringStructuring element

A three-dimensional printer, system and method is provided for individually creating three-dimensional structural elements (individually termed fundamental structures) which are sequentially positioned into formation of a shaped object.

Owner:FLEMING ROBERT J

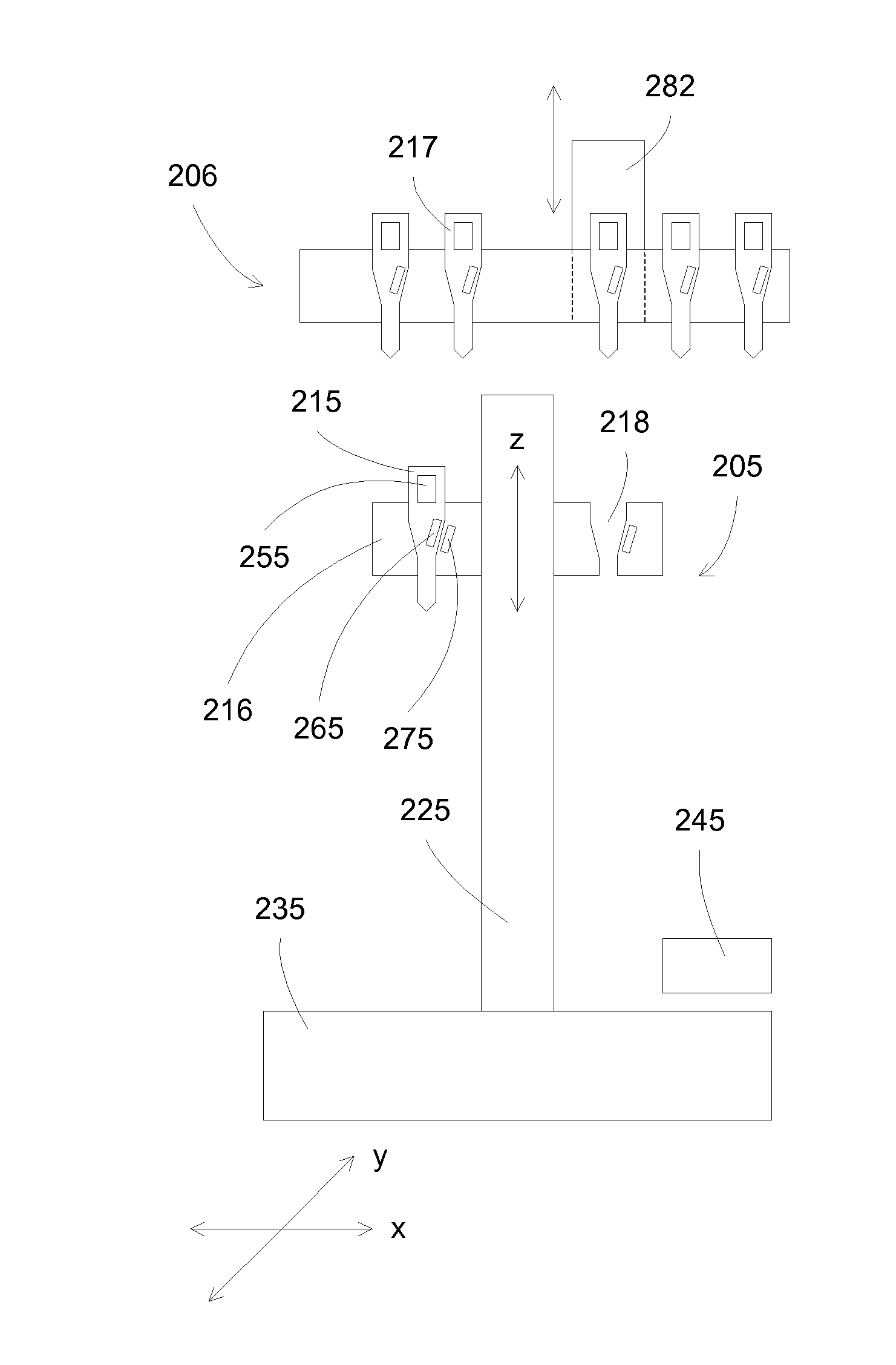

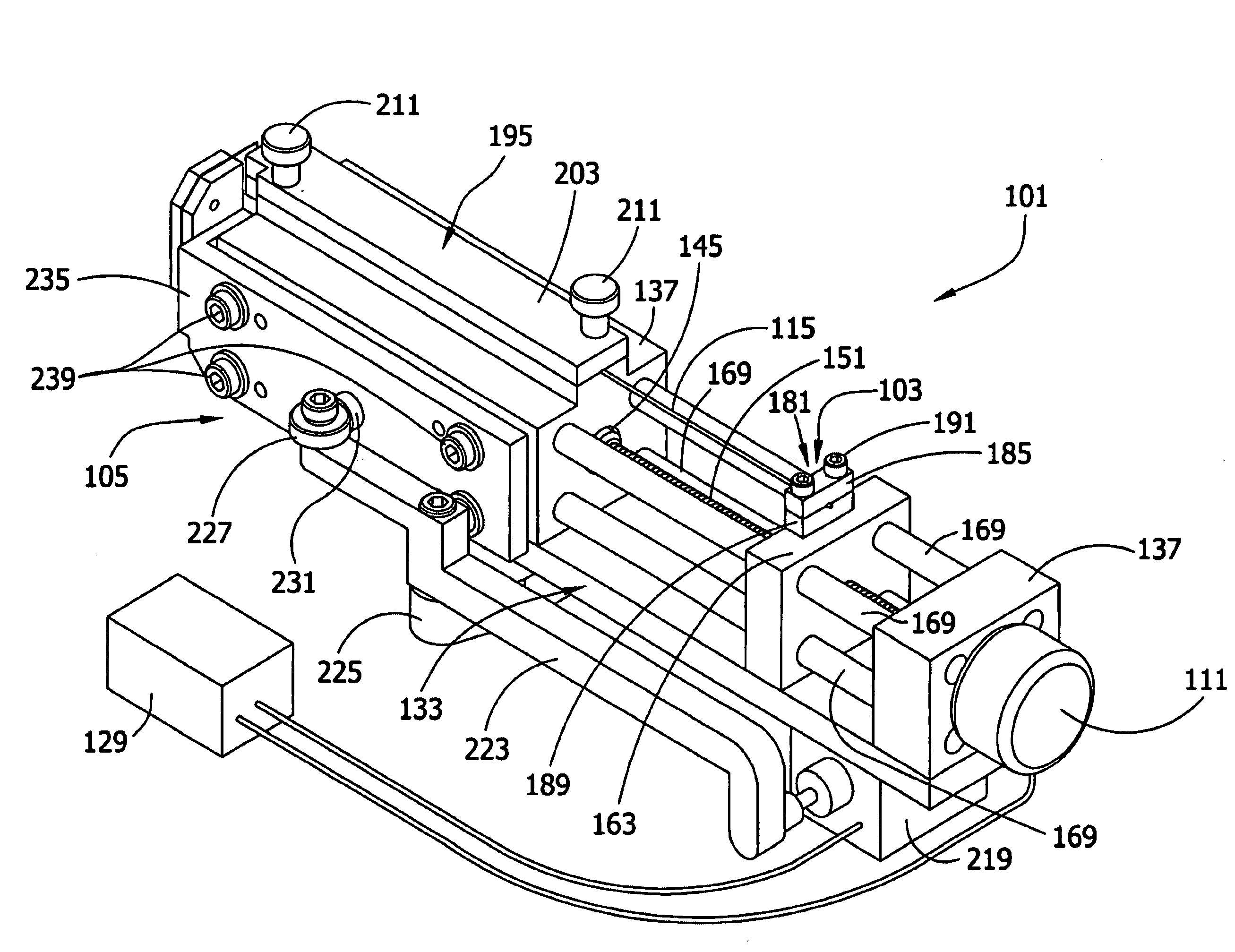

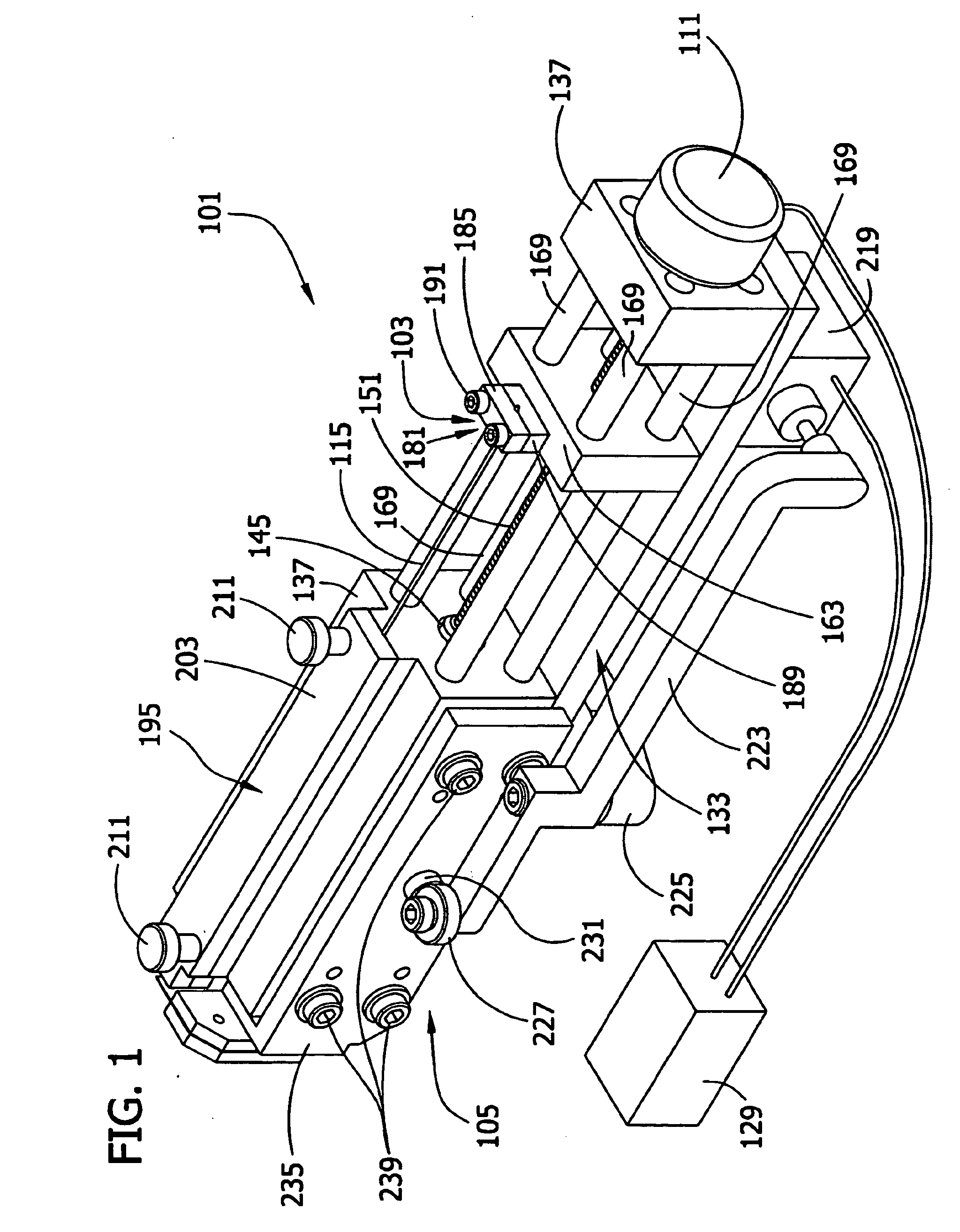

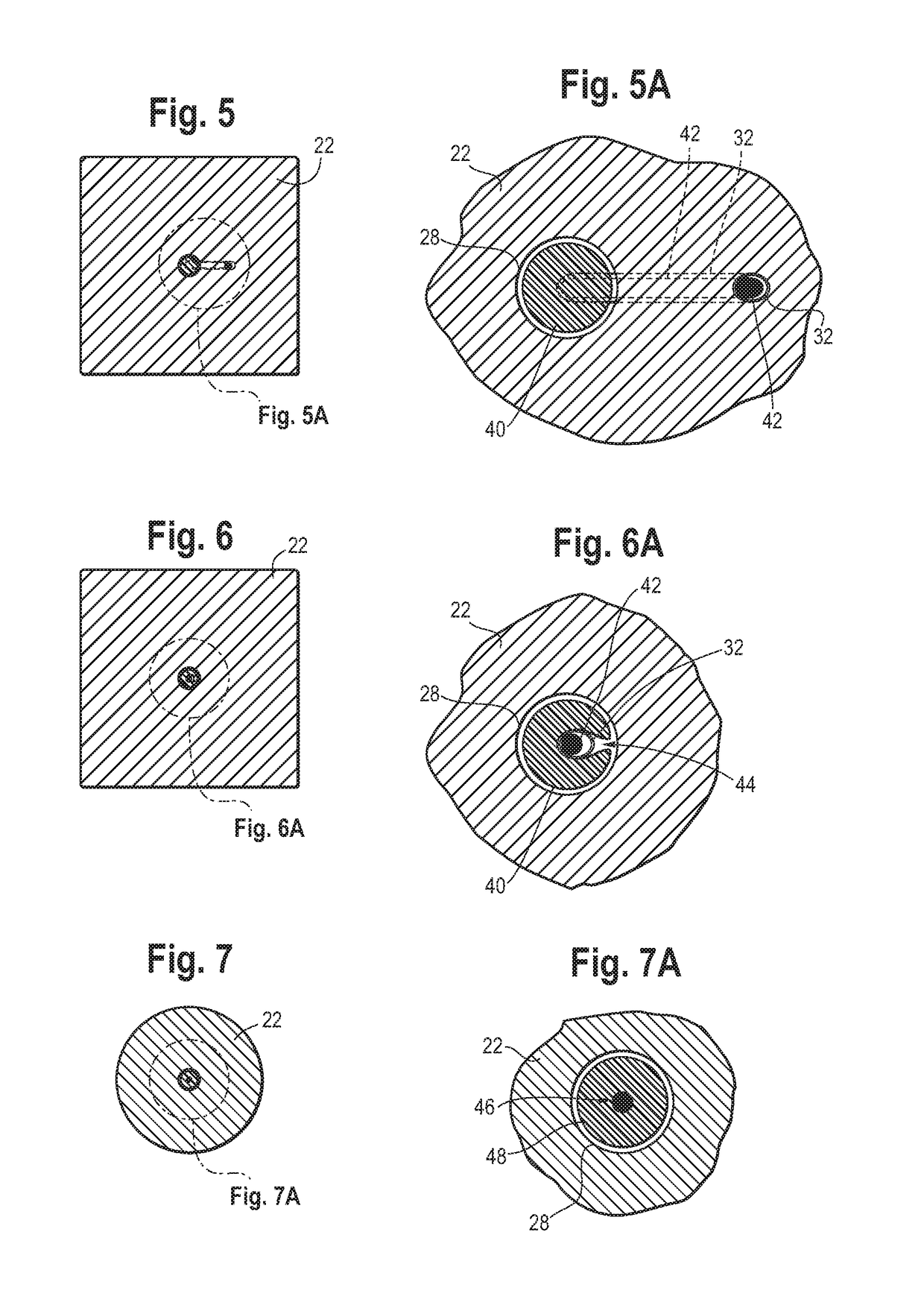

Devices, systems, and methods for the fabrication of tissue

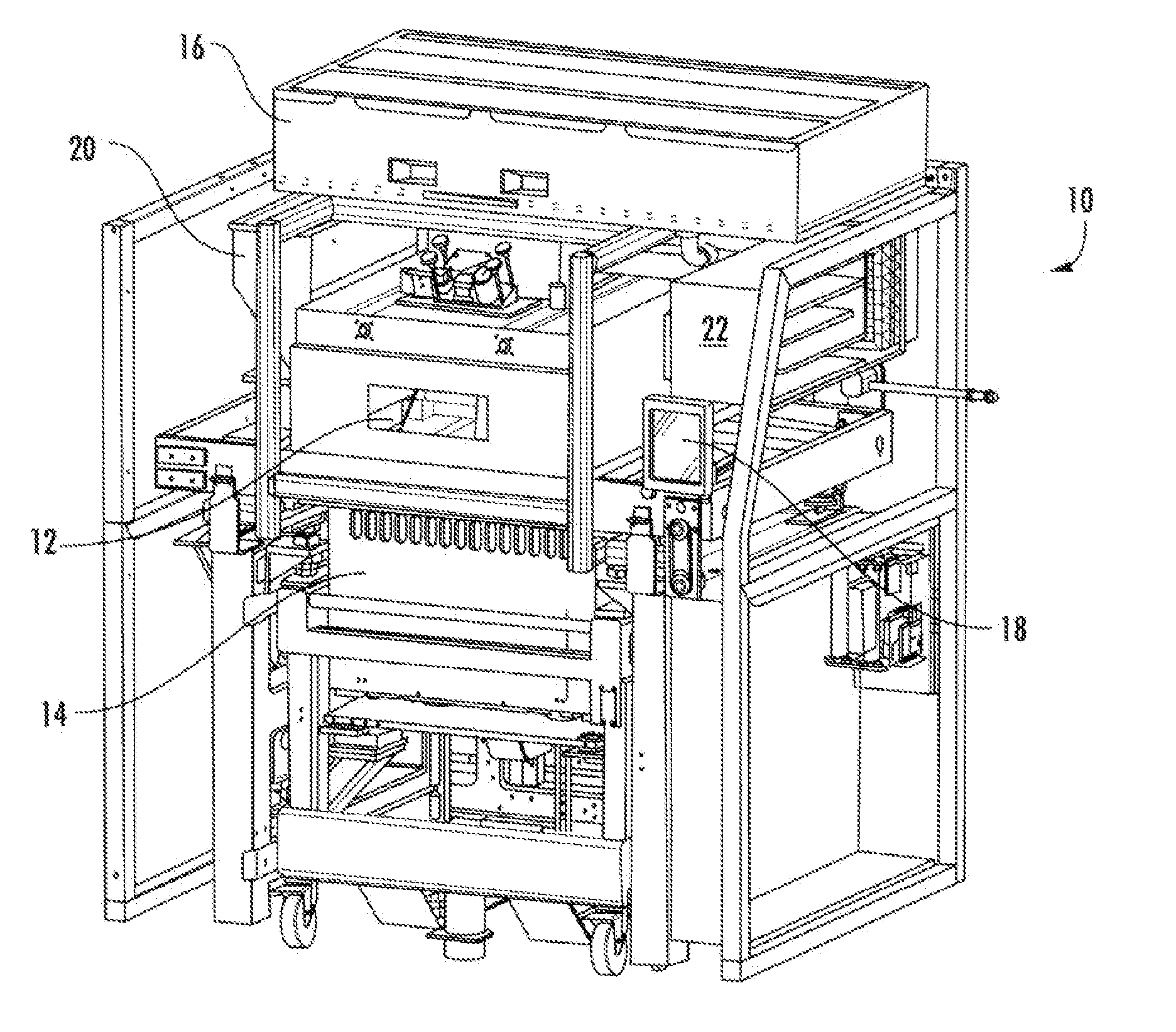

ActiveUS20120116568A1Increase the number ofQuality improvementManufacturing platforms/substratesLiquid surface applicatorsComputer moduleEngineering

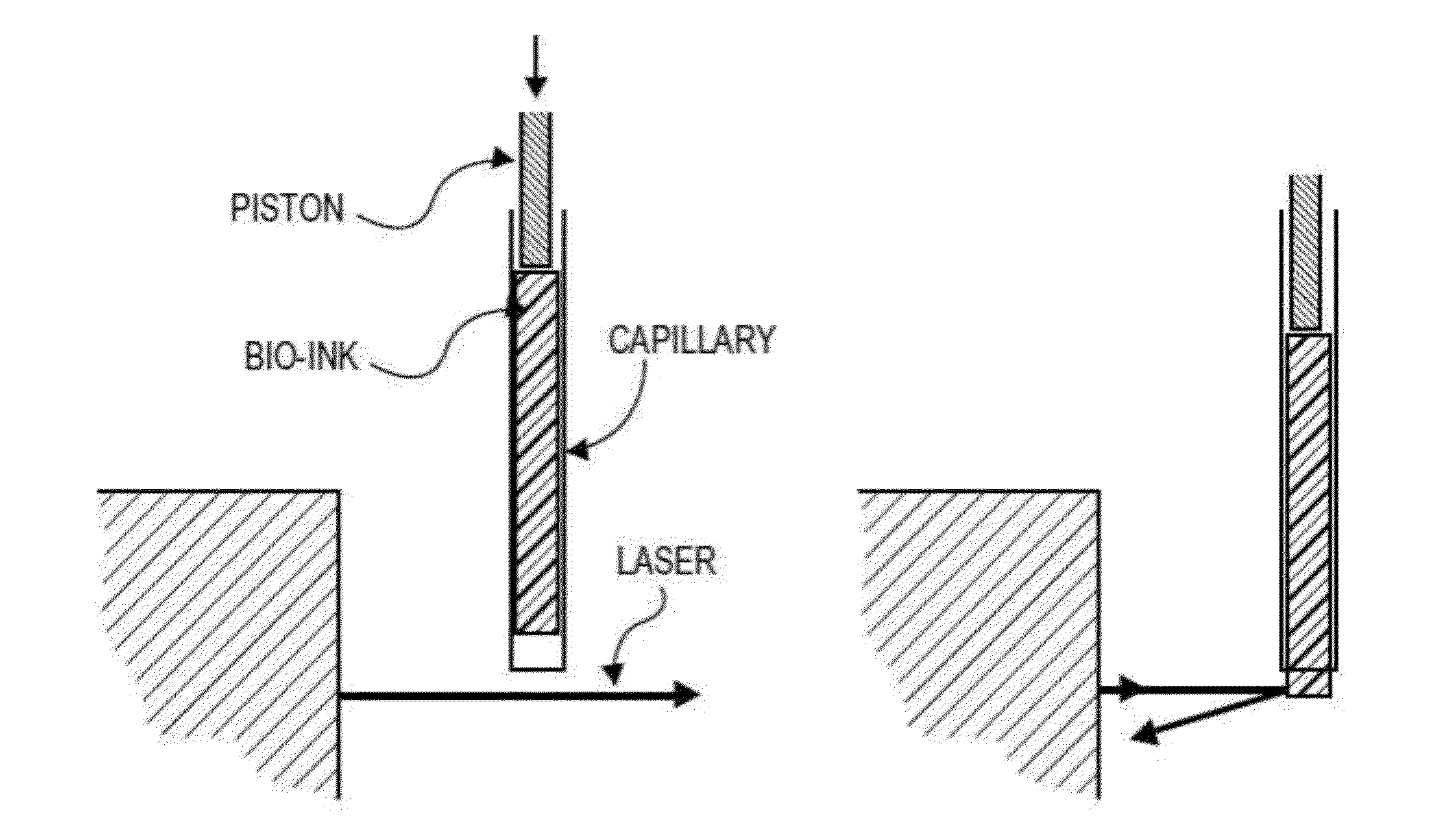

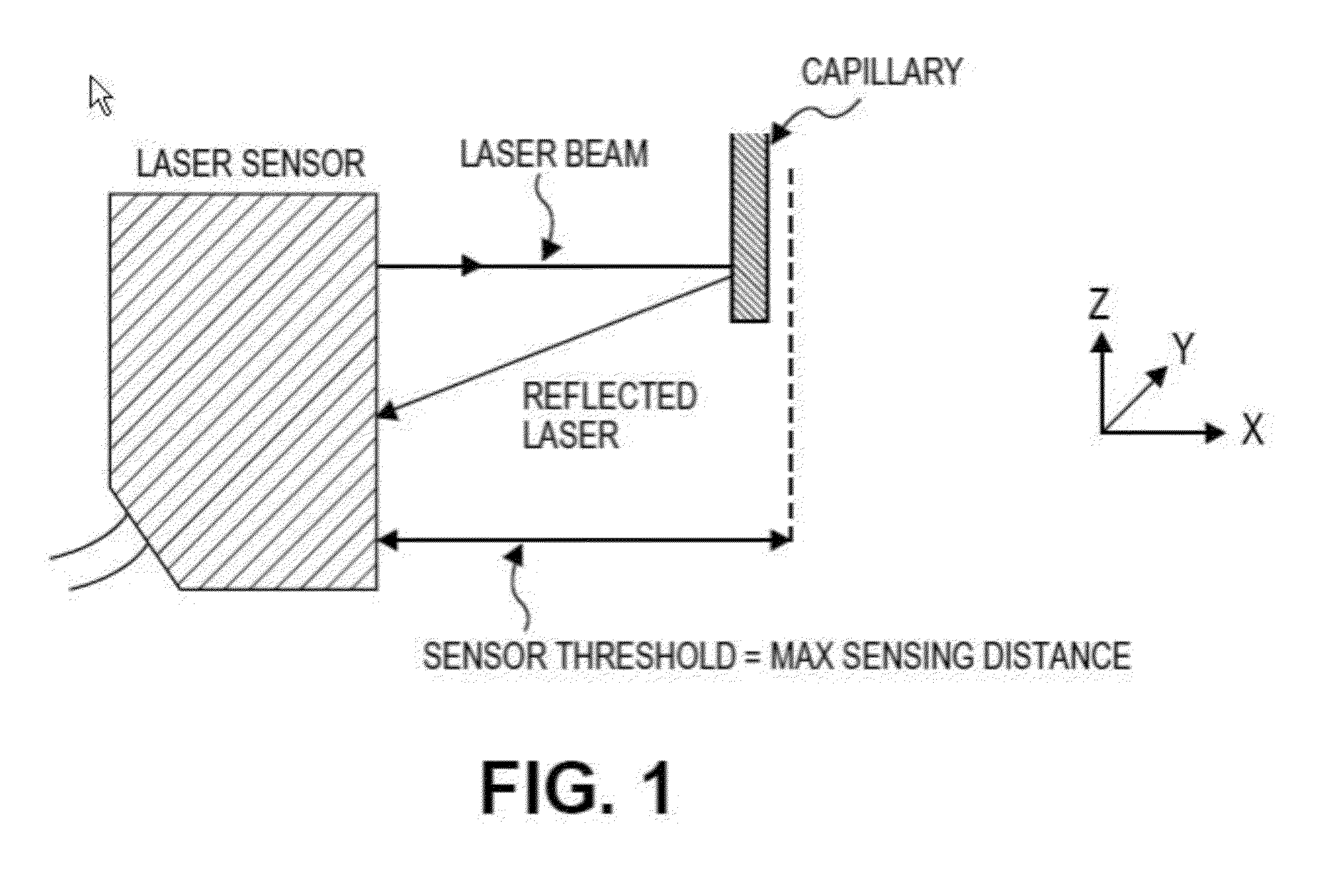

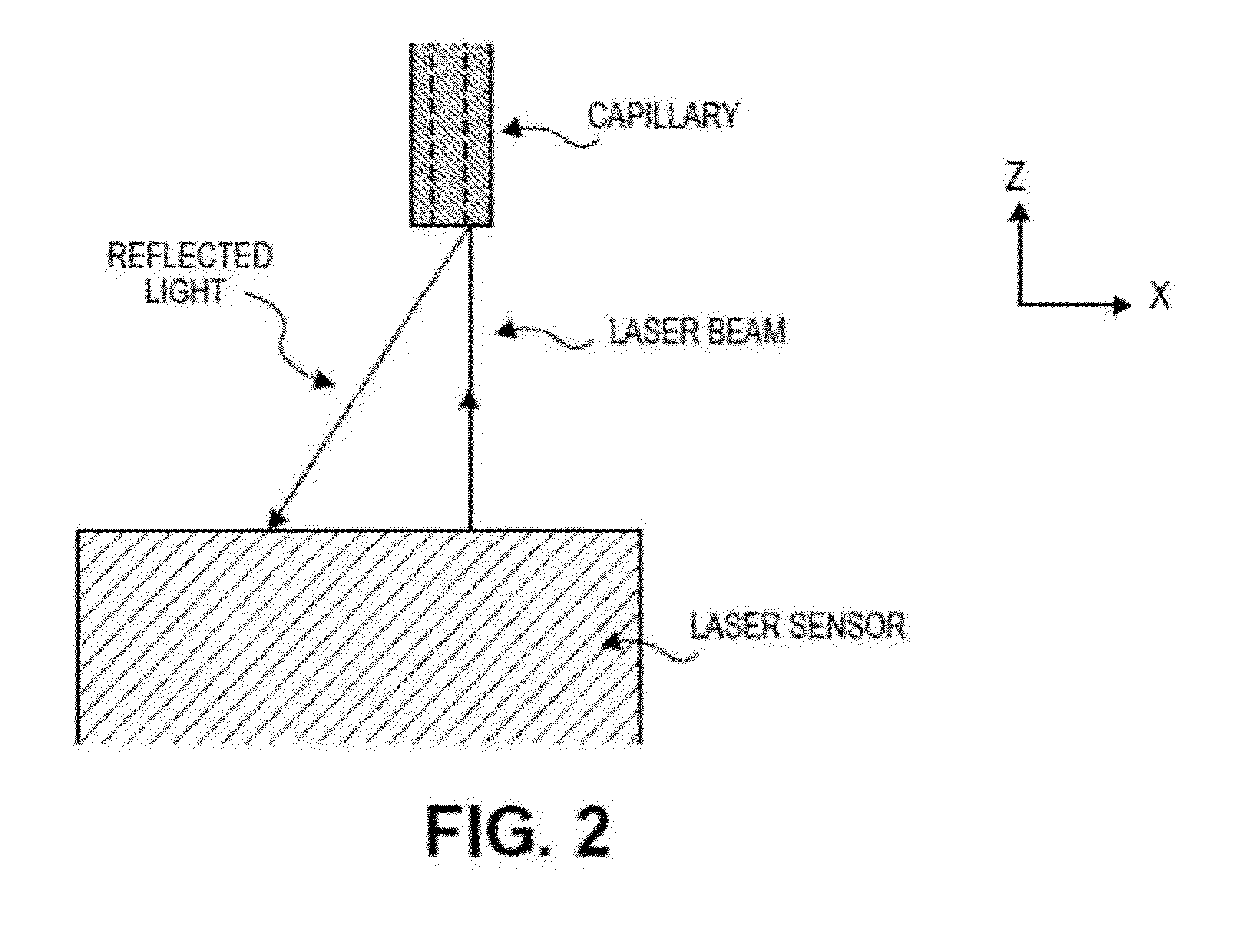

Described herein are bioprinters comprising: one or more printer heads, wherein a printer head comprises a means for receiving and holding at least one cartridge, and wherein said cartridge comprises contents selected from one or more of: bio-ink and support material; a means for calibrating the position of at least one cartridge; and a means for dispensing the contents of at least one cartridge. Further described herein are methods for fabricating a tissue construct, comprising: a computer module receiving input of a visual representation of a desired tissue construct; a computer module generating a series of commands, wherein the commands are based on the visual representation and are readable by a bioprinter; a computer module providing the series of commands to a bioprinter; and the bioprinter depositing bio-ink and support material according to the commands to form a construct with a defined geometry.

Owner:ORGANOVO

System and method for cutting material in continuous fiber reinforced additive manufacturing

ActiveUS20170144375A1Additive manufacturing with liquids3D object support structuresEngineeringKnife blades

Methods, apparatus, and systems for cutting material used in fused deposition modeling systems are provided, which comprise a ribbon including one or more perforations. Material is passed through at least one perforation and movement of the ribbon cuts the material. A further embodiment comprises a disk including one or more blade structures, each forming at least one cavity. Material is passed through at least one cavity and a rotational movement of the disk cuts the material. A further embodiment comprises a slider-crank mechanism including a slider coupled to a set of parallel rails of a guide shaft. The slider moves along a length of the rails to cut the material. Yet another embodiment comprises one or more rotatable blade structures coupled to at least one rod. The rotation of the blade structures causes the blade structures to intersect and cut extruded material during each rotation.

Owner:THE BOEING CO

Device and method for 3D printing with long-fiber reinforcement

ActiveUS20170157851A1Eliminate point3D object support structuresAdditive mnaufacturing with solid and fluidAdvanced composite materialsPolymer

A process and device for 3D printing parts incorporating long-fiber reinforcements in an advanced composite material is disclosed. A nozzle for a 3D printing device receives a polymer material and a reinforcing fiber through separate inlets. A passage from the reinforcing fiber inlet cleaves the passage containing the polymer material, creating an interstitial cavity into which the reinforcing fiber is introduced. The polymer material closes back on itself and encapsulates the reinforcing fiber, then drags the fiber along with the flow and exits nozzle to be deposited on a work surface or part being manufactured.

Owner:NORTHROP GRUMMAN SYST CORP

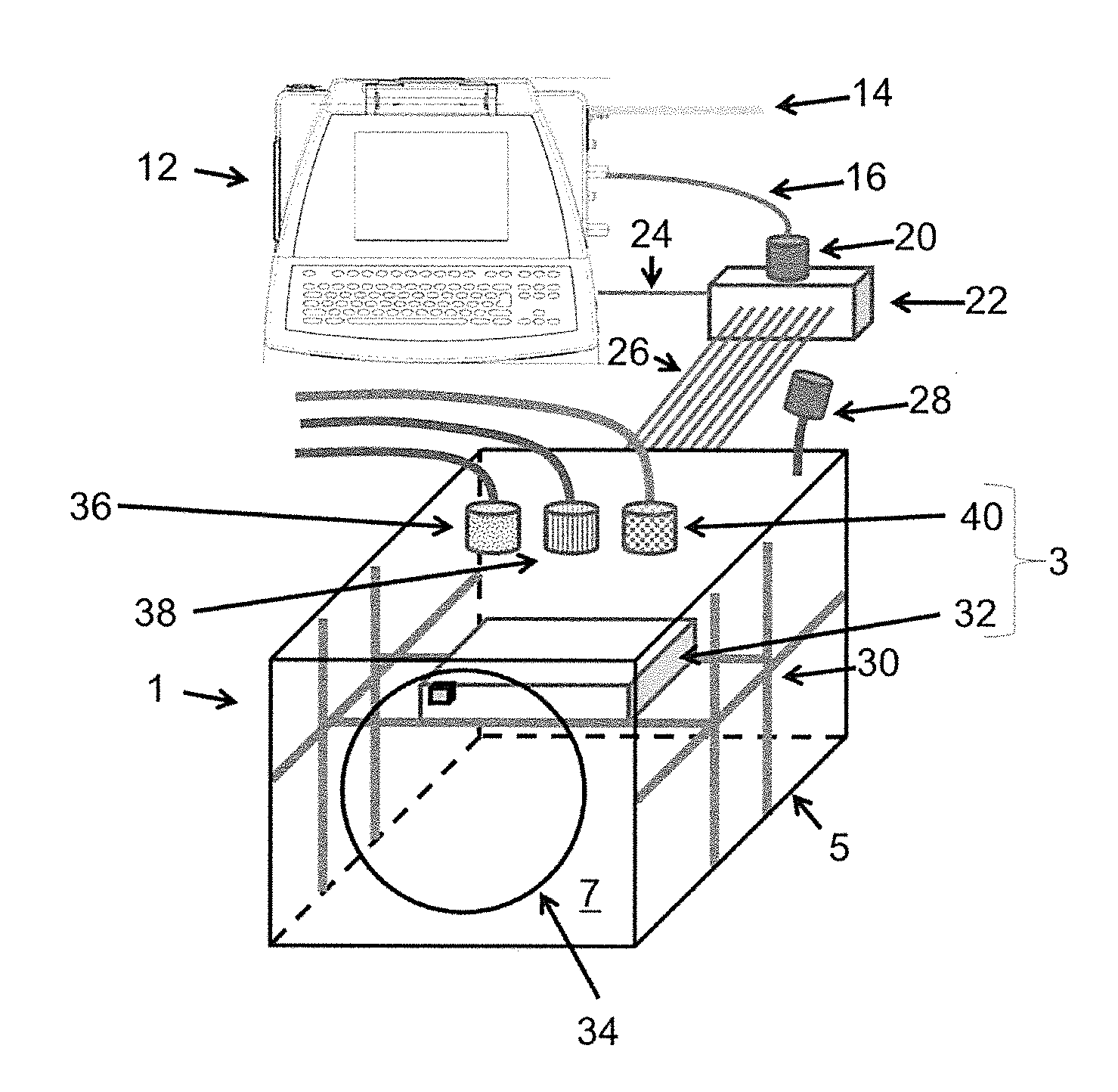

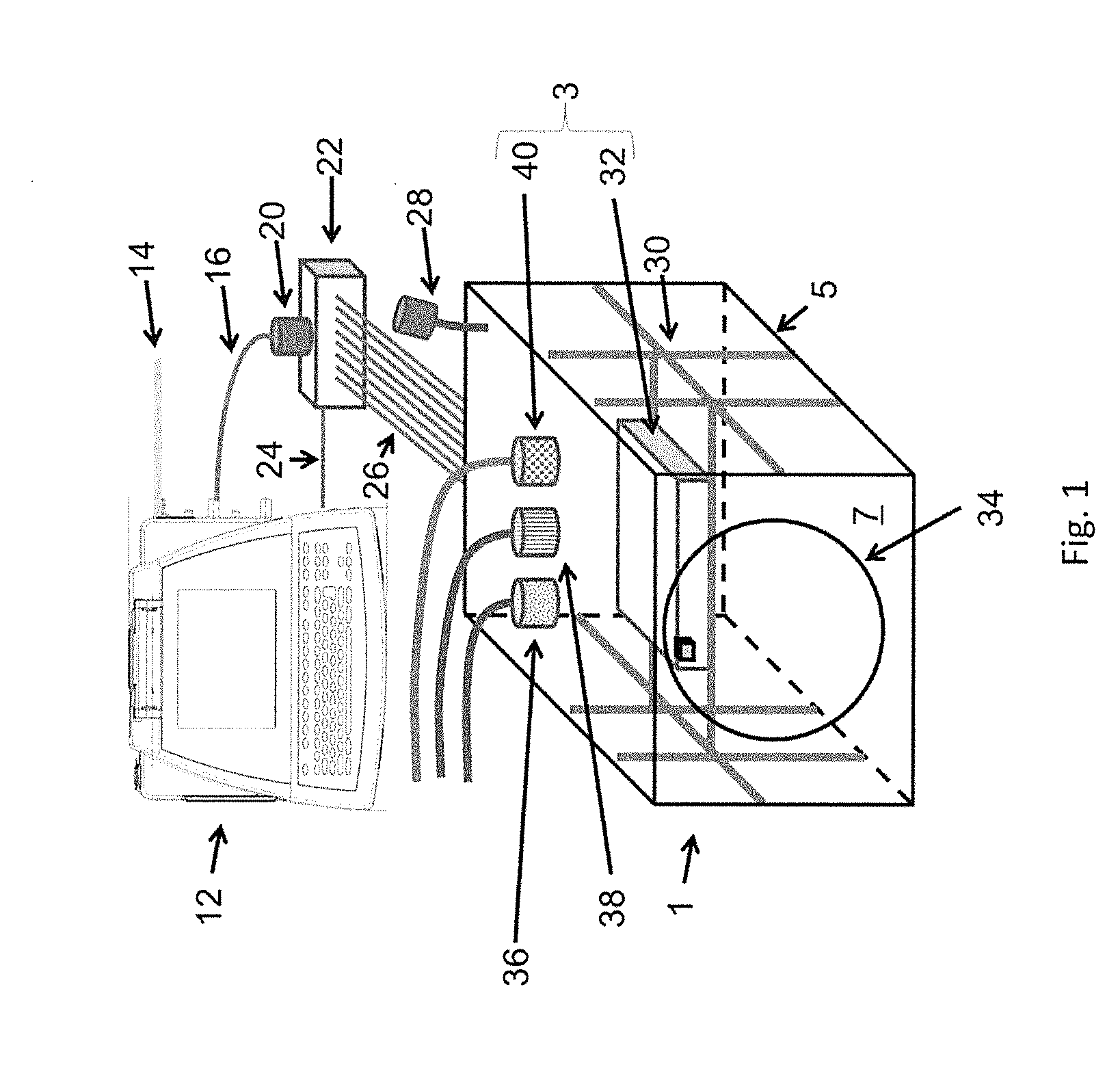

Manufacturing within a single-use container

ActiveUS20160068793A1Function increaseProgramme-controlled manipulatorBioreactor/fermenter combinationsNumerical controlThree degrees of freedom

A manufacturing assembly has at least a sterilizable chamber containing at least one of a three-dimensional printing device (additive manufacturing), a Computer Numerical Controlled (CNC) finishing head (subtractive manufacturing), a vacuum-forming unit, an injection-molding unit, a laser-cutting unit, a ultrasonic-welding unit, a robotic arman analysis device, a sampling device or a combination thereof. A plurality of individual sterilizable chambers may be aseptically connected into a network of sterilizable chambers that provides additional functionality for the manufacturing assembly. A sterilizable printer assembly may include at least one printing head, a printing platform, and a driving mechanism adapted to perform a movement of the at least one printing head relative to the printing platform along three degrees of freedom; a printer housing enclosing the printer assembly in a sterile manner, at least one aseptic connector fluidly connected to a corresponding one of the at least one printing head.

Owner:SARTORIUS STEDIM BIOTECH GMBH

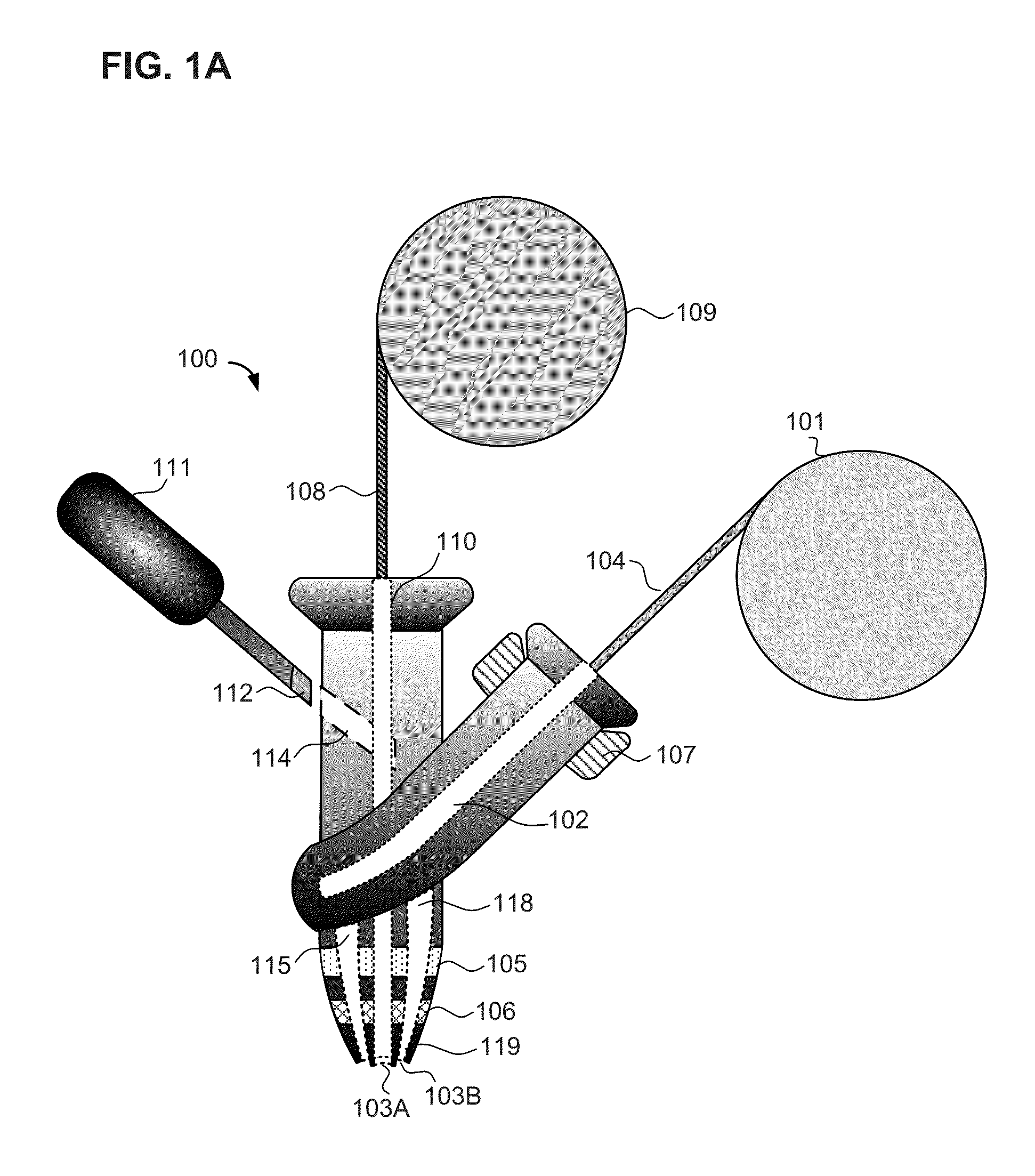

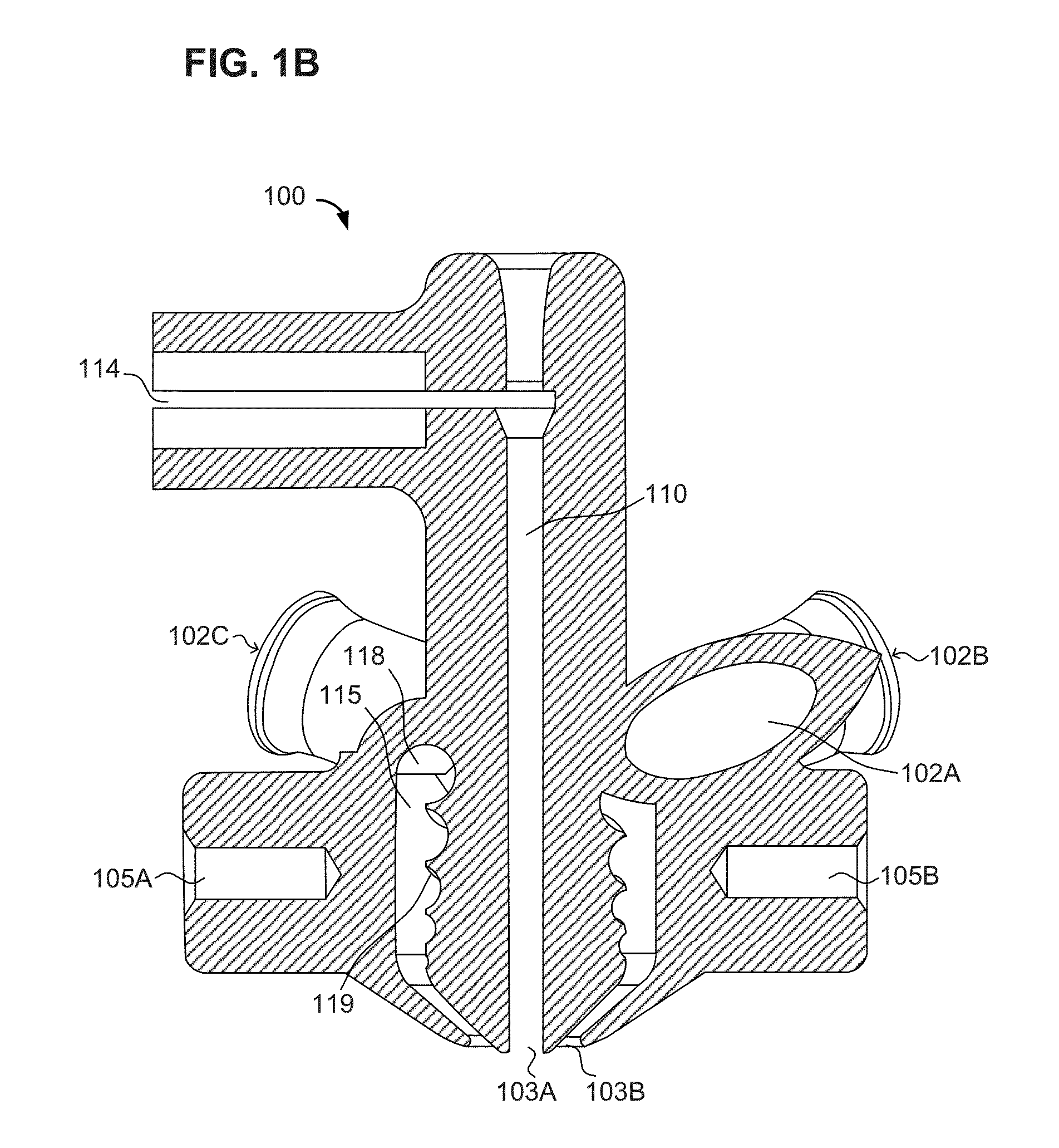

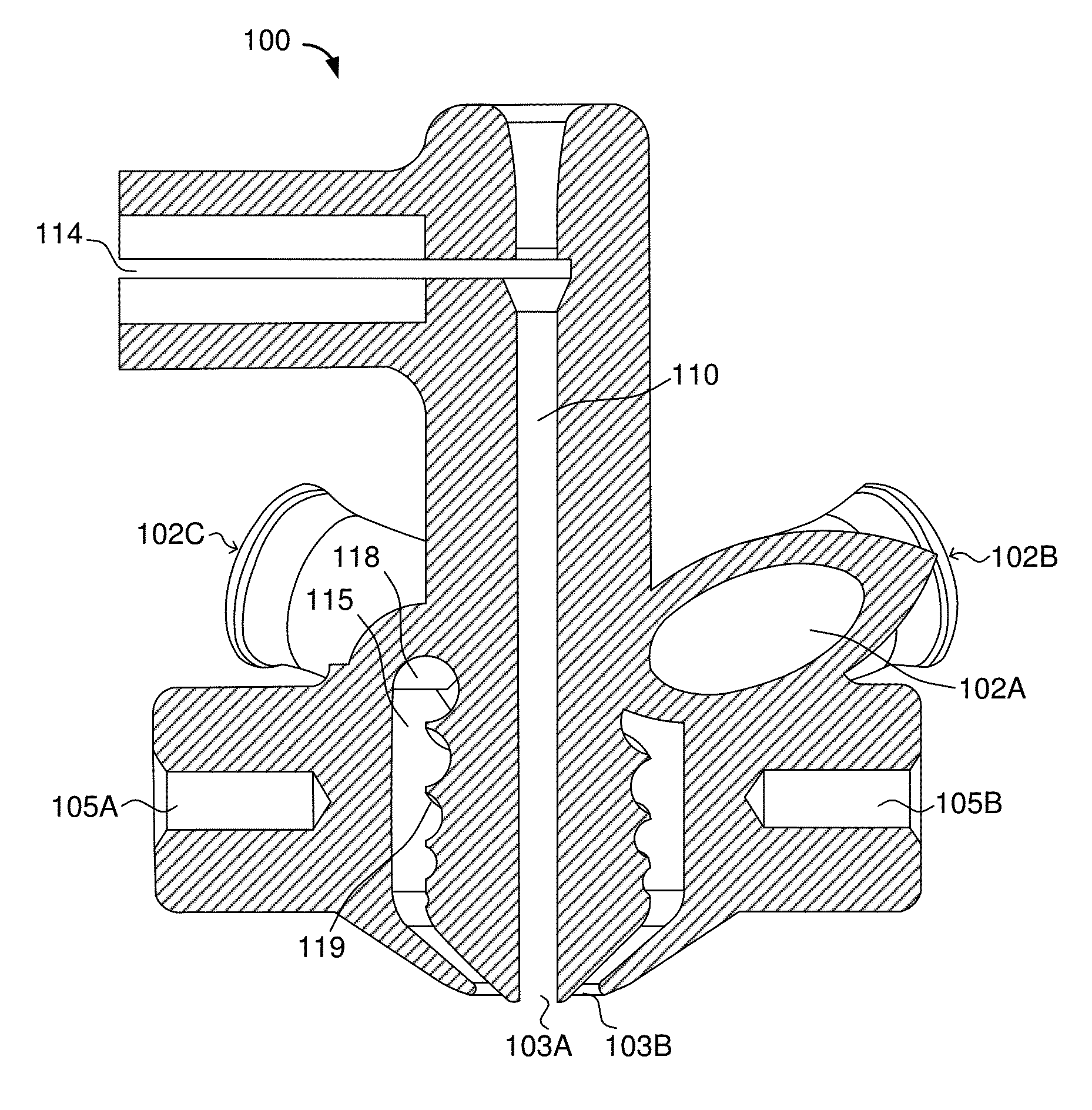

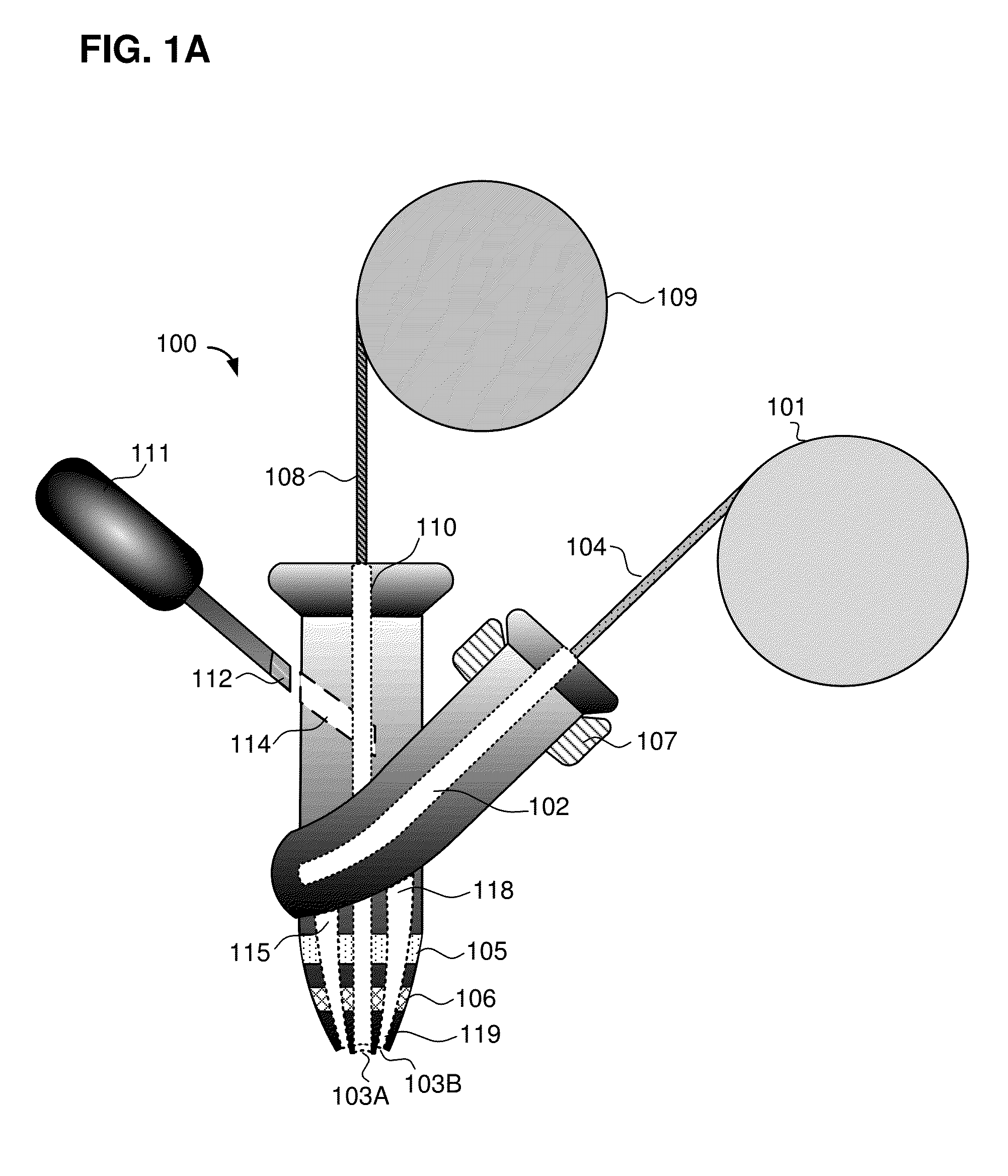

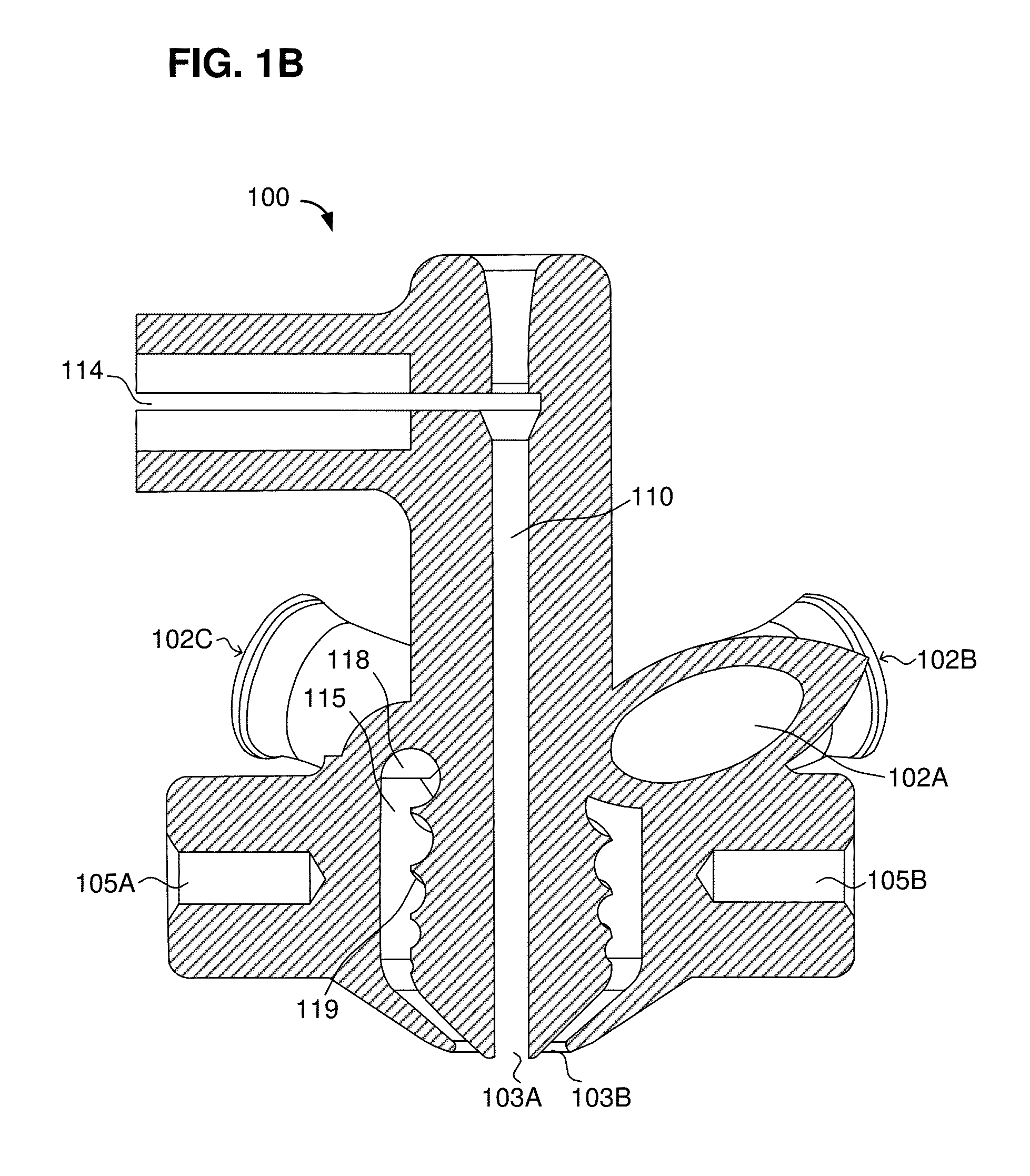

Fluid-dispensing head for a 3D printer

ActiveUS20140242208A1Readily switched into operationIncrease flexibilityConfectionerySweetmeatsInfill3d printer

A head assembly for an extrusion-based 3D printer includes: a fluid-dispensing head having a manifold and at least two fluid-dispensing nozzles, of different sizes, which are mounted in communication with a melt chamber in a manifold. Outlets of each nozzle are closed by respective valve members. A rocker serves both to pivot the nozzles to their lowermost nozzle-operating position and to actuate the valve members, for ready switching between the valves, such that the smaller nozzle can be used for high resolution work, and the larger nozzle can be used for bulk infill.

Owner:CEL TECH

Additive manufacturing techniques and systems to form composite materials

A printer system may include a coaxial extruder head that extrudes a core, a bulk, and / or a core and bulk cladding to form complex structures without retooling. The coaxial extruder head may include a distribution channel with an entrance and an exit, a priming chamber that surrounds the distribution channel. The priming chamber may include an outlet and a first inlet, a heating element thermally connected to the priming chamber, and a nozzle connected to the outlet of the priming chamber. Further, the nozzle may converge from the outlet of the priming chamber to an orifice of the nozzle. In addition, the exit of the distribution channel may be disposed at the orifice of the nozzle. This structure facilitates extruding a core and cladding type composite from the extruder head.

Owner:ORBITAL COMPOSITES INC

Multicolour extrusion-based 3D print process

A 3D extrusion print process for producing multicolored three-dimensional objects is provided. The process produces mechanically stable, multicolored 3D objects with good color definition. The process according to the invention is based on coating, upstream of the printing head, of the polymer strand used for producing the actual object, and on fixing of the coating upstream of entry of the polymer strand into the printing head. Downstream of the extrusion process in the printing head, the coating remains predominantly at the surface of the extruded strand.

Owner:EVONIK OPERATIONS GMBH

Cutting mechanism for carbon nanotube yarns, tapes, sheets and polymer composites thereof

ActiveUS20170129182A1Easy to cutRobust cutting method3D object support structuresManufacturing data aquisition/processingPower flowCarbon nanotube yarn

A cutting mechanism includes electrodes that are utilized to cut or score a non-conductive outer material of a filament or sheet. The electrodes contact a conductive reinforcing material of the filament or sheet to complete an electric circuit. Electric current flows through and heats the conductive material to oxidize or otherwise separate / cut the conductive material and any remaining non-conductive material.

Owner:NAT INST AEROSPACE ASSOC +1

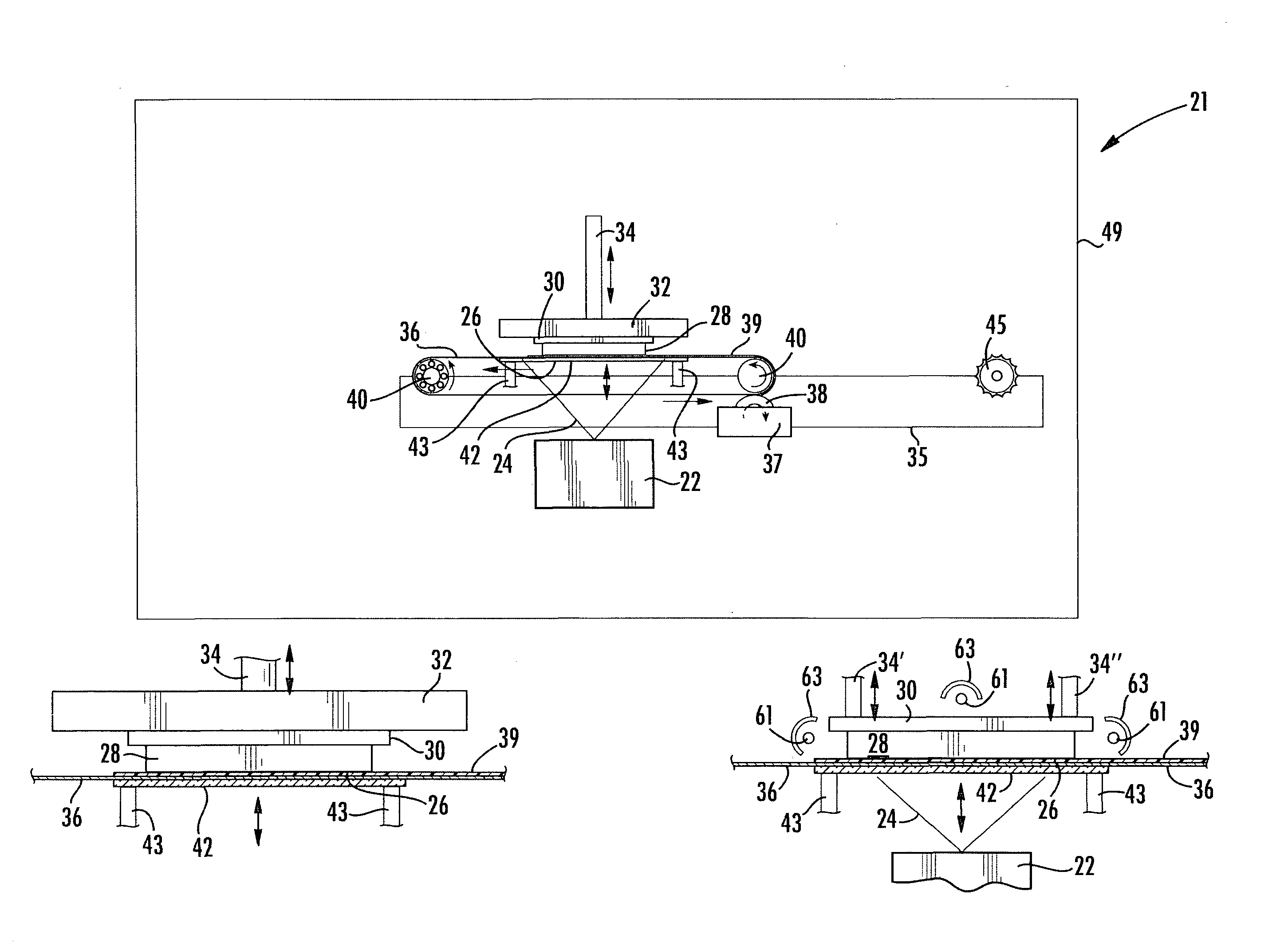

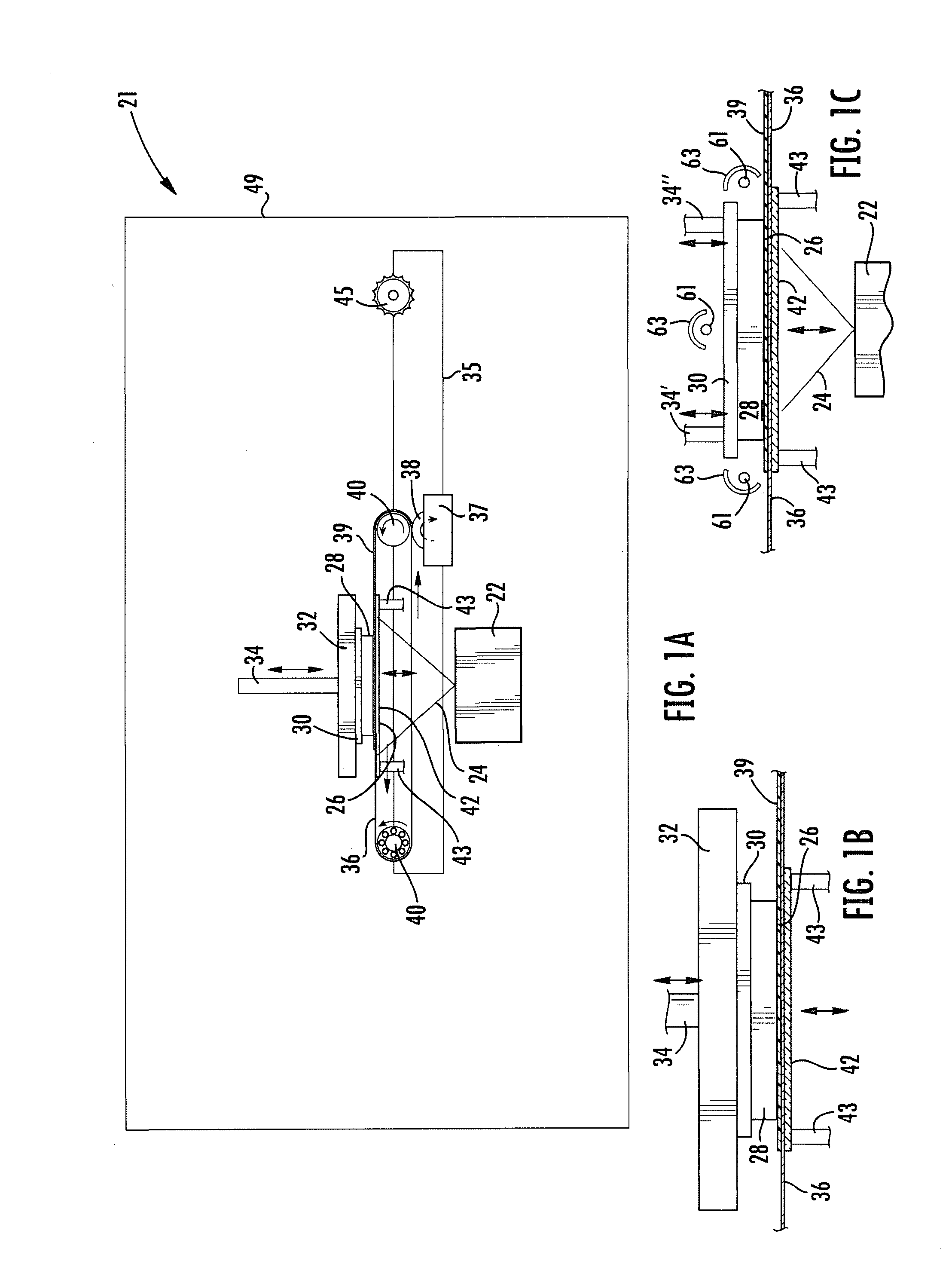

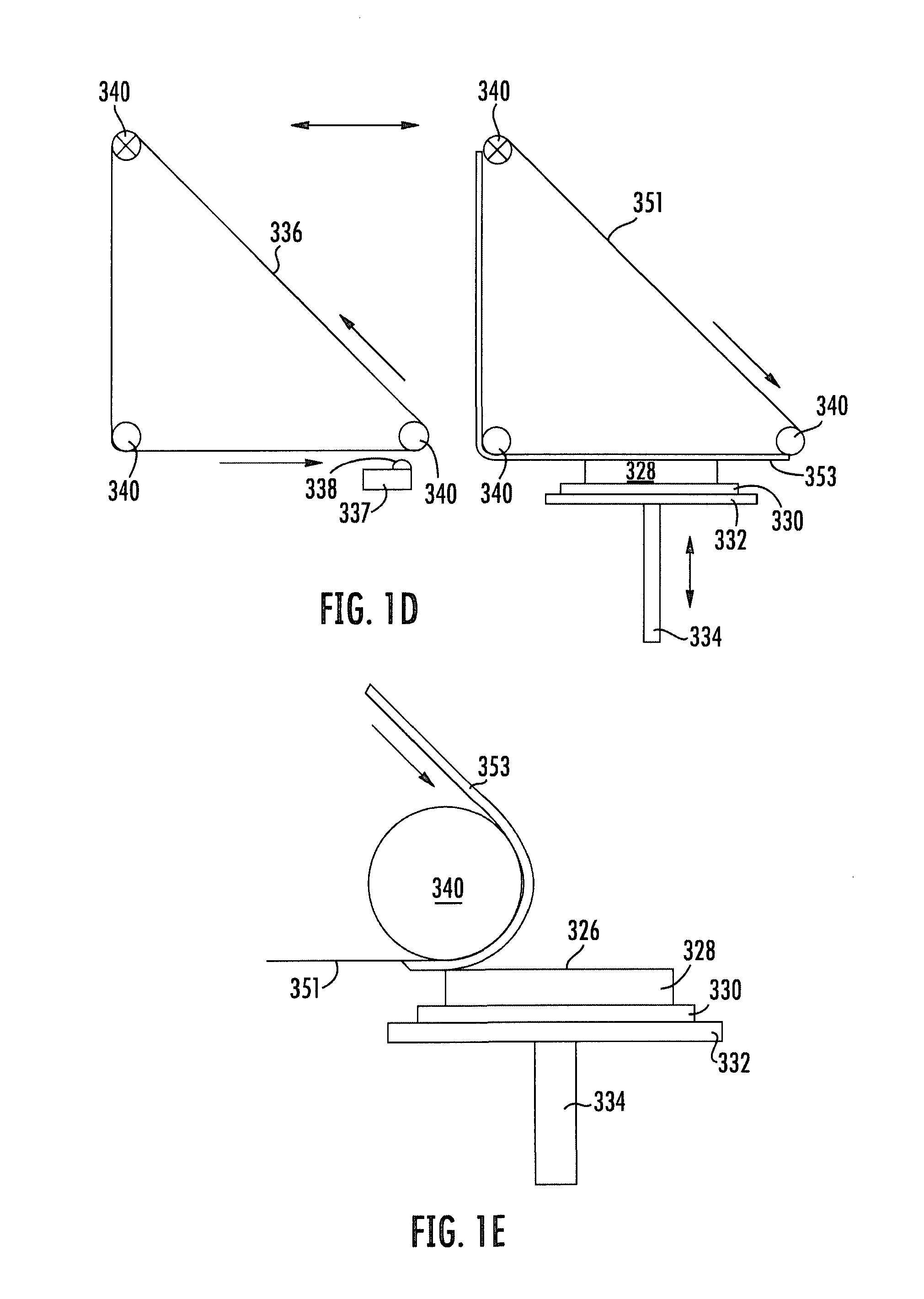

Inkjet Solid Imaging System and Method for Solid Imaging

InactiveUS20080226346A1Reduced post-build processing requirementPrecise alignmentAdditive manufacturing with liquidsElectrographic process apparatusEngineeringUltimate tensile strength

Solid imaging apparatus and methods for use are disclosed that reduce the amount of uncured solid imaging build material remaining on a completed build object following the completion of the solid imaging build process. The amount of uncured build material is reduced through the use of either an uncoating web that removes excess build material from the build object during the course of the building process or an ink jet source of build material that uses only as much build material as is necessary for the fabrication of the build part. Also disclosed is an imager assembly for use with such a solid imaging apparatus that incorporates two or more individual imagers in an array and accounts for variations in the intensity and alignment of adjacent imagers. The apparatus can be modified for semi-continuous operation and for integrating into a manufacturing operation, if desired.

Owner:3D SYST INC

3D Printer Based on a Staggered Nozzle Array

InactiveUS20160325498A1Increase deposition rateIncrease pressureAdditive manufacturing with liquids3D object support structuresGratingEngineering

A 3D printer is based on a two dimensional staggered nozzle array, depositing each layer in a raster scan mode. Each nozzle contains an individually controlled mechanical high speed valve, and multiple nozzles are fed from a constant pressure reservoir, typically containing molten polymer.

Owner:GELBART DANIEL

Apparatus and method for forming three-dimensional objects from solidifiable paste

ActiveUS20150224710A1Manufacturing driving meansAuxillary shaping apparatusEngineeringMechanical engineering

An apparatus and method for making a three-dimensional object from a solidifiable paste is shown and described. The apparatus includes a pastes spreader, at least a portion of which extends into the solidifiable paste. The container holding the solidifiable paste and the spreader are movable relative to one another. In one system, the spreader vibrates as the container and the spreader move relative to one another. In another system, the spreader is part of a spreader assembly in which a first spreader and second spreader are angled with respect to one another, and the assembly is rotatable and lockable into multiple rotational positions. The apparatus and method allow three-dimensional objects to be progressively built upside down by ensuring that the previously solidified object section has a substantially homogeneous layer of solidifiable material available for forming a new layer of the solidified object prior to exposure to solidification energy.

Owner:GLOBAL FILTRATION SYST

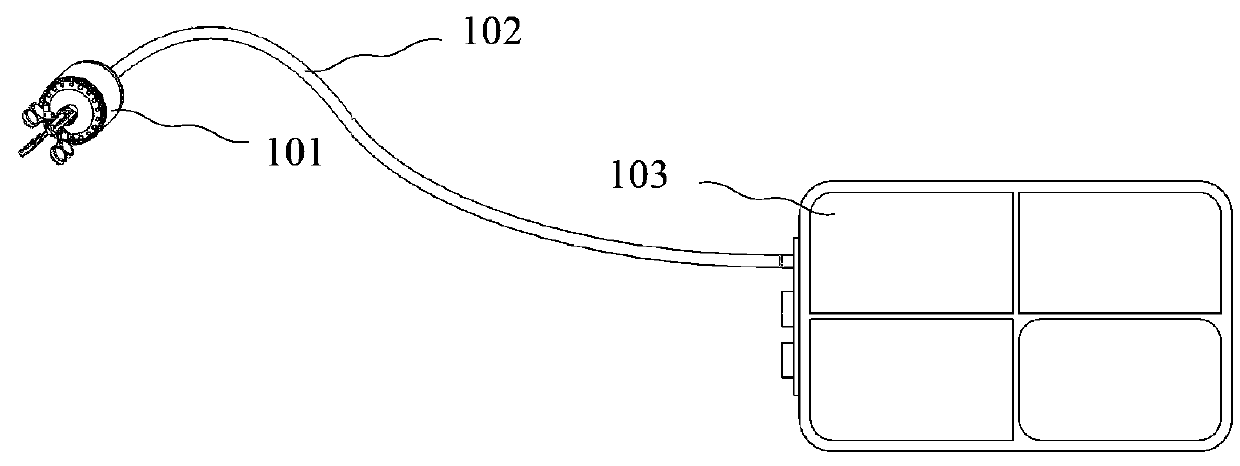

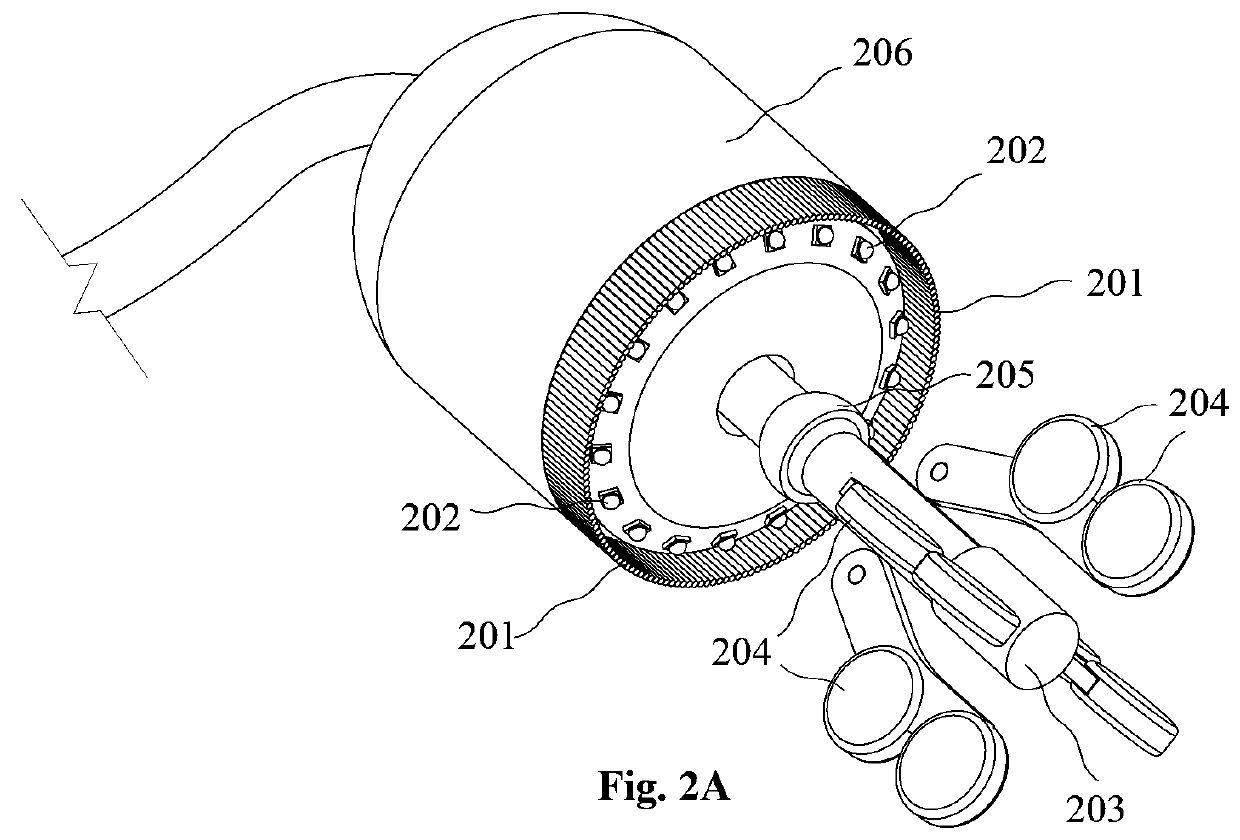

Three-dimensional printer with replaceable nozzle

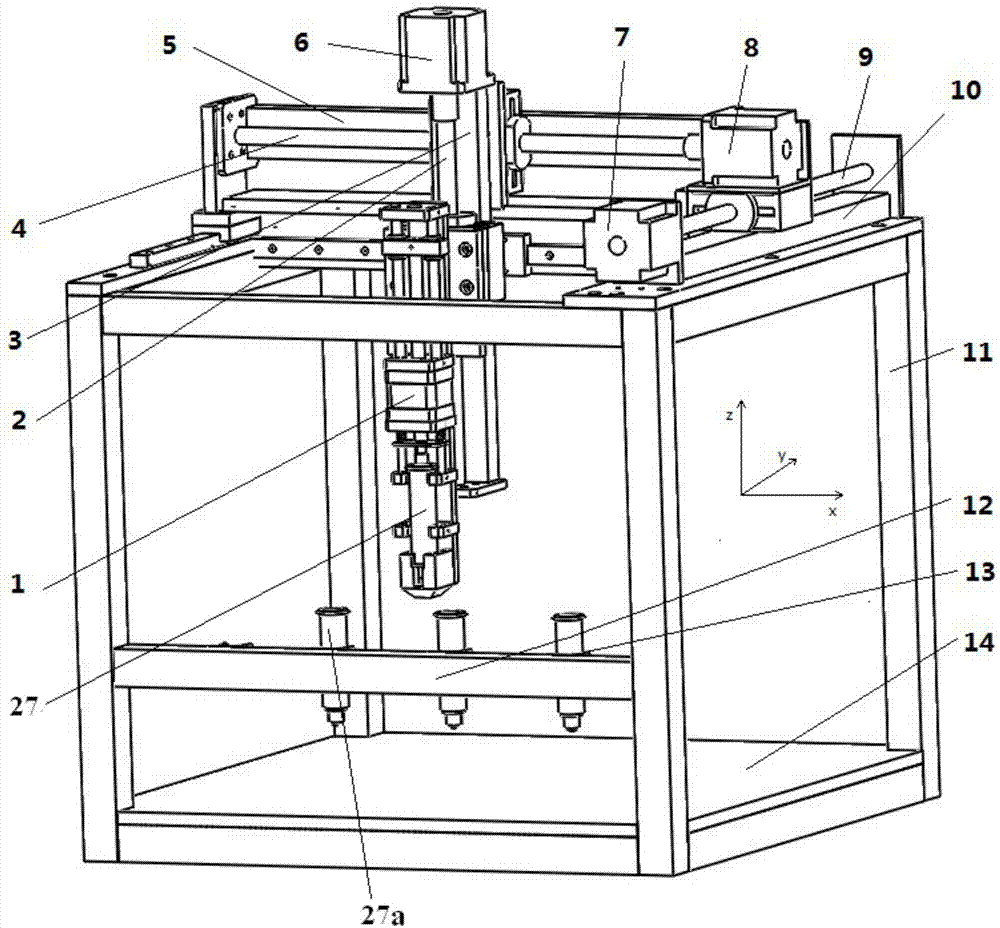

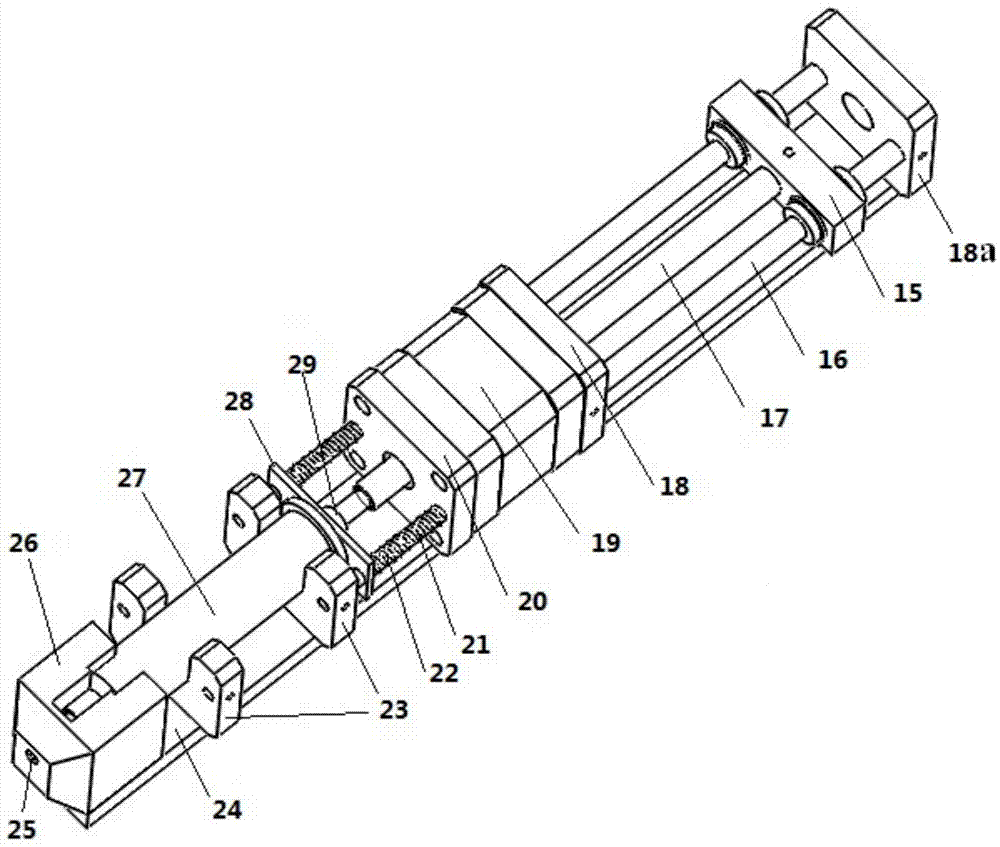

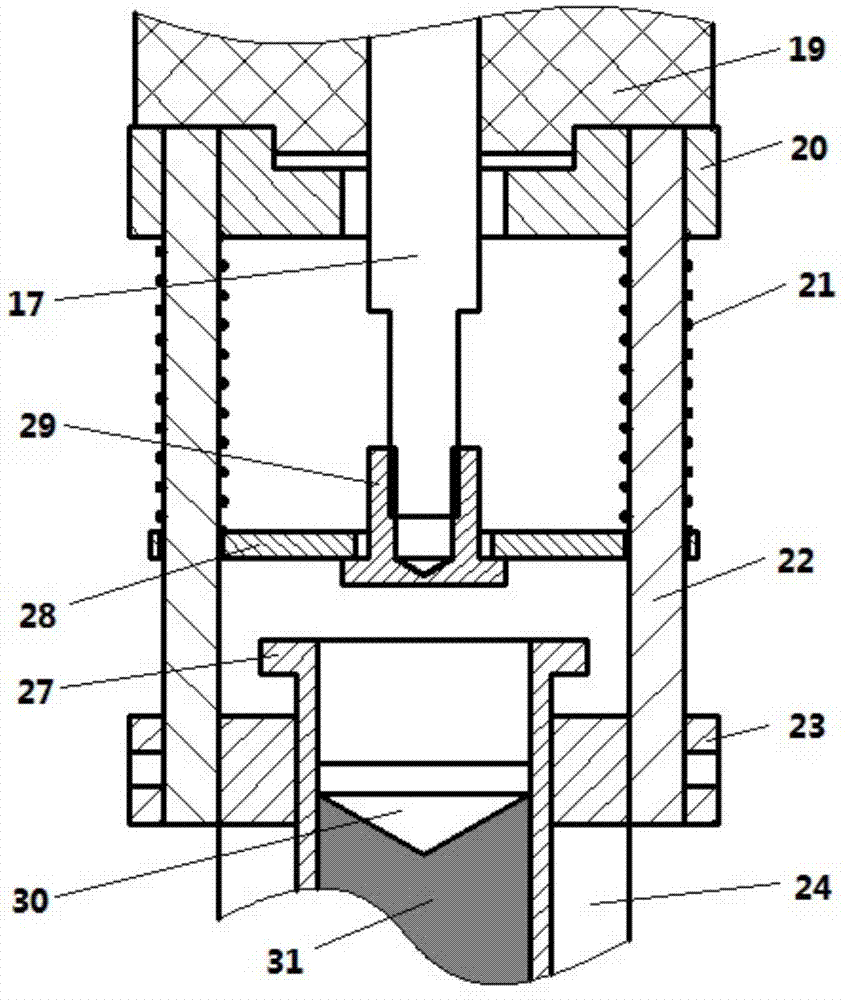

ActiveCN103878980AAchieve relatively fixedPracticalTool changing apparatusApplying layer meansLiquid foodPiston

The invention discloses a three-dimensional printer with a replaceable nozzle. The three-dimensional printer comprises a three-dimensional adjusting mechanism, and the printing nozzle which performs three-dimensional printing under the adjustment of the three-dimensional adjusting mechanism, wherein the printing nozzle comprises a nozzle bottom plate, a nozzle thermal preservation sleeve which is fixed on the nozzle bottom plate and is provided with a printing through hole and a positioning notch, a material tube which is radially clamped on the nozzle bottom plate, and a linear stepping motor; the material tube is axially clamped in the positioning notch through a material tube pressing plate which is in sliding fit with the nozzle bottom plate; a piston presser used for pushing a piston in a first material tube is fixed at the output end of a lead screw of the motor. When materials in the material tube are used up or the materials are needed to be replaced, the printing nozzle is controlled to automatically replace the material tube, and a three-dimensional object consisting of multiple materials can be printed. The piston is driven to be extruded by adopting the linear stepping motor, thrust is high and can be accurately controlled, and the blockage of the nozzle is avoided. According to the printer, liquid foods and multiple liquid materials such as gel and ceramic powder can be printed.

Owner:ZHEJIANG UNIV

Chute for Laser Sintering Systems

ActiveUS20140265045A1Reduce the possibilityHigh densityManufacturing heating elementsAuxillary shaping apparatusRadiant heaterUltimate tensile strength

There is provided improved laser sintering systems that increase the powder density and reduce anomalies of the powder layers that are sintered, that measure the laser power within the build chamber for automatic calibration during a build process, that deposit powder into the build chamber through a chute to minimize dusting, and that scrubs the air and cools the radiant heaters with recirculated scrubbed air. The improvements enable the laser sintering systems to make parts that are of higher and more consistent quality, precision, and strength, while enabling the user of the laser sintering systems to reuse greater proportions of previously used but unsintered powder.

Owner:3D SYST INC

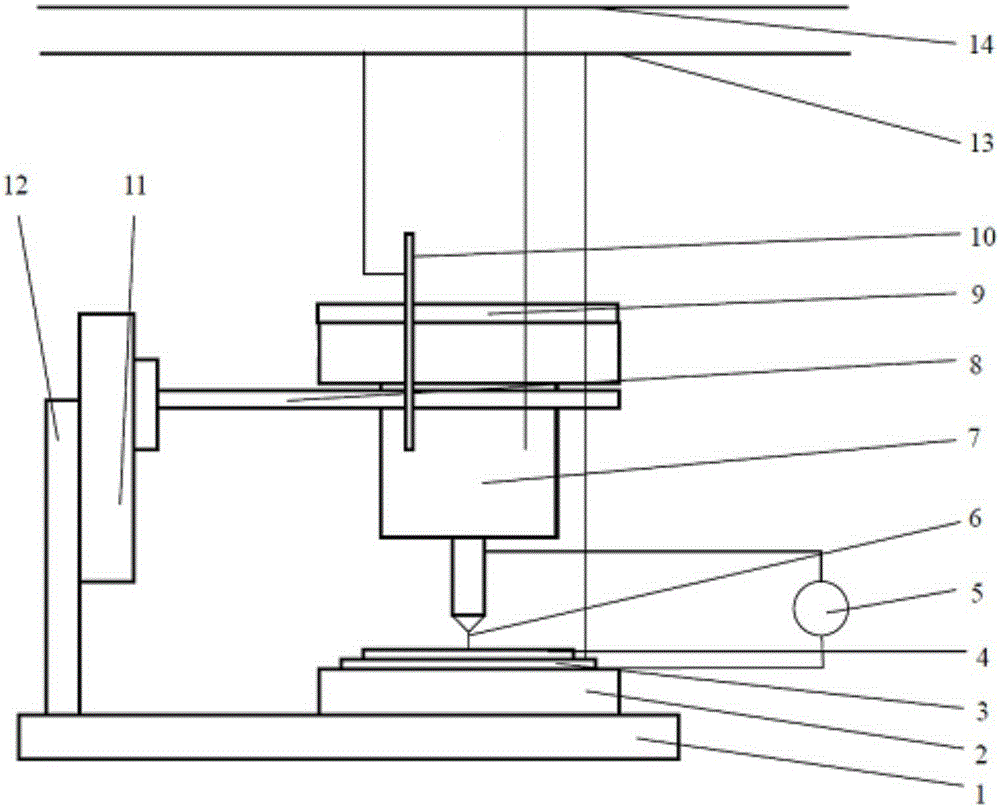

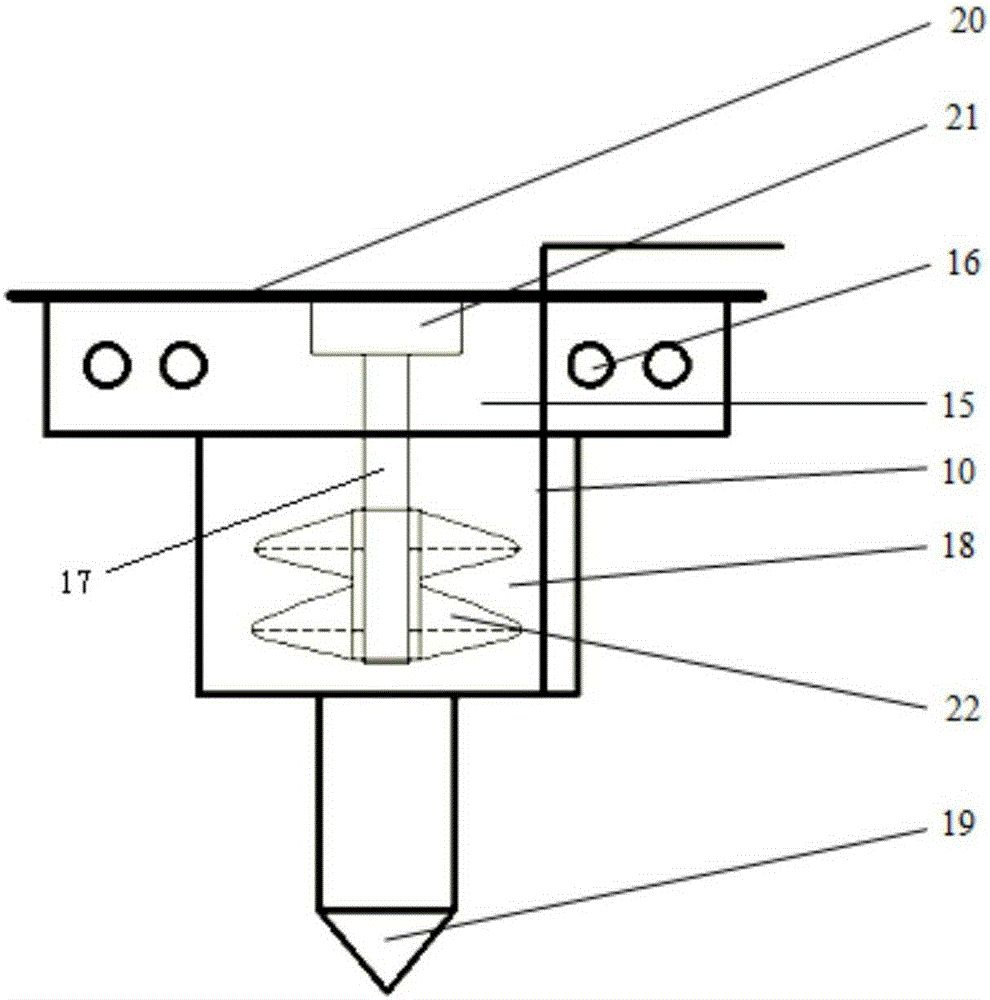

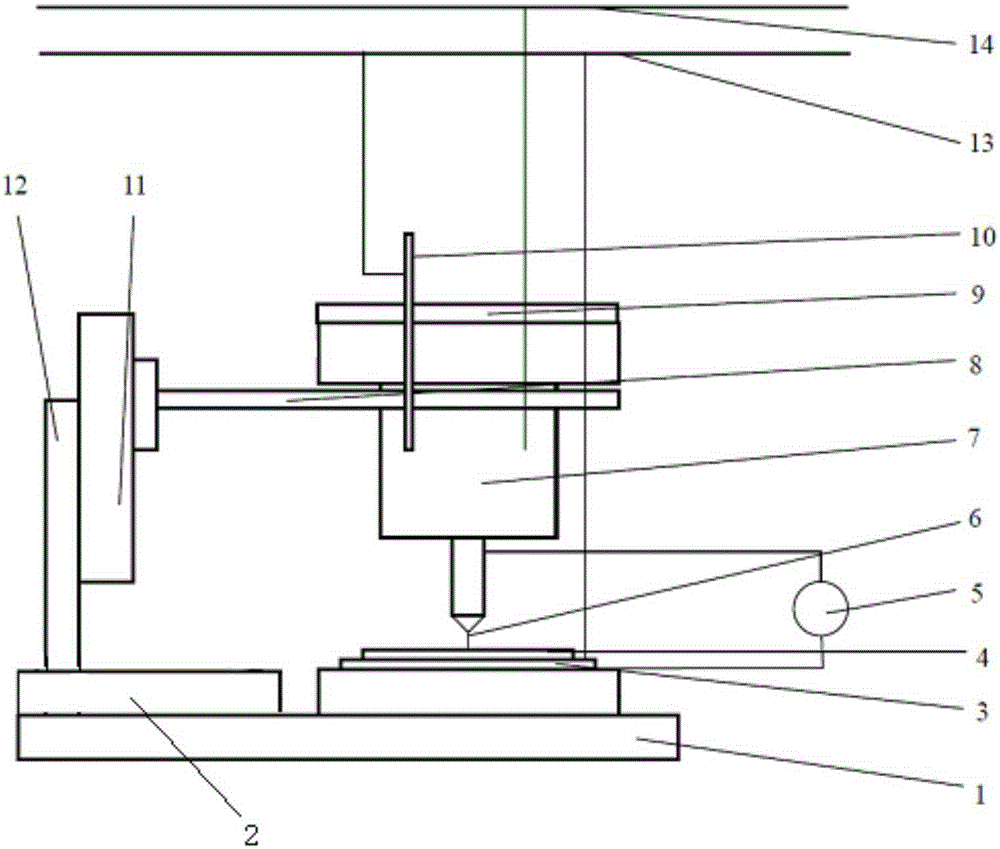

Multi-material multi-scale 3D (3-dimensional) printing device provided with single spray nozzle as well as working method of 3D printing device

ActiveCN105196550ARealize printingReasonable control of macro geometryManufacturing platforms/substratesTransportation and packagingMulti materialSpray nozzle

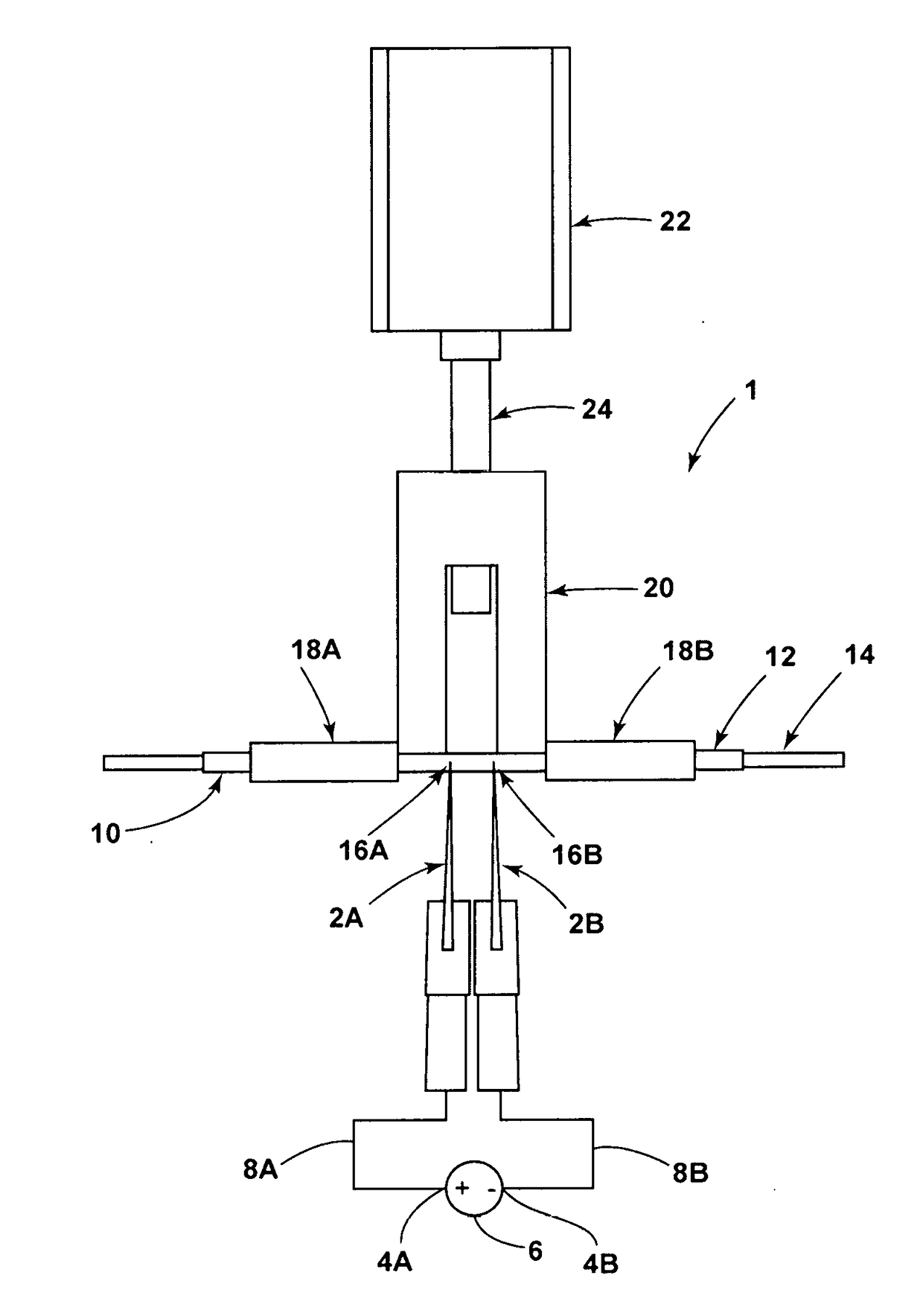

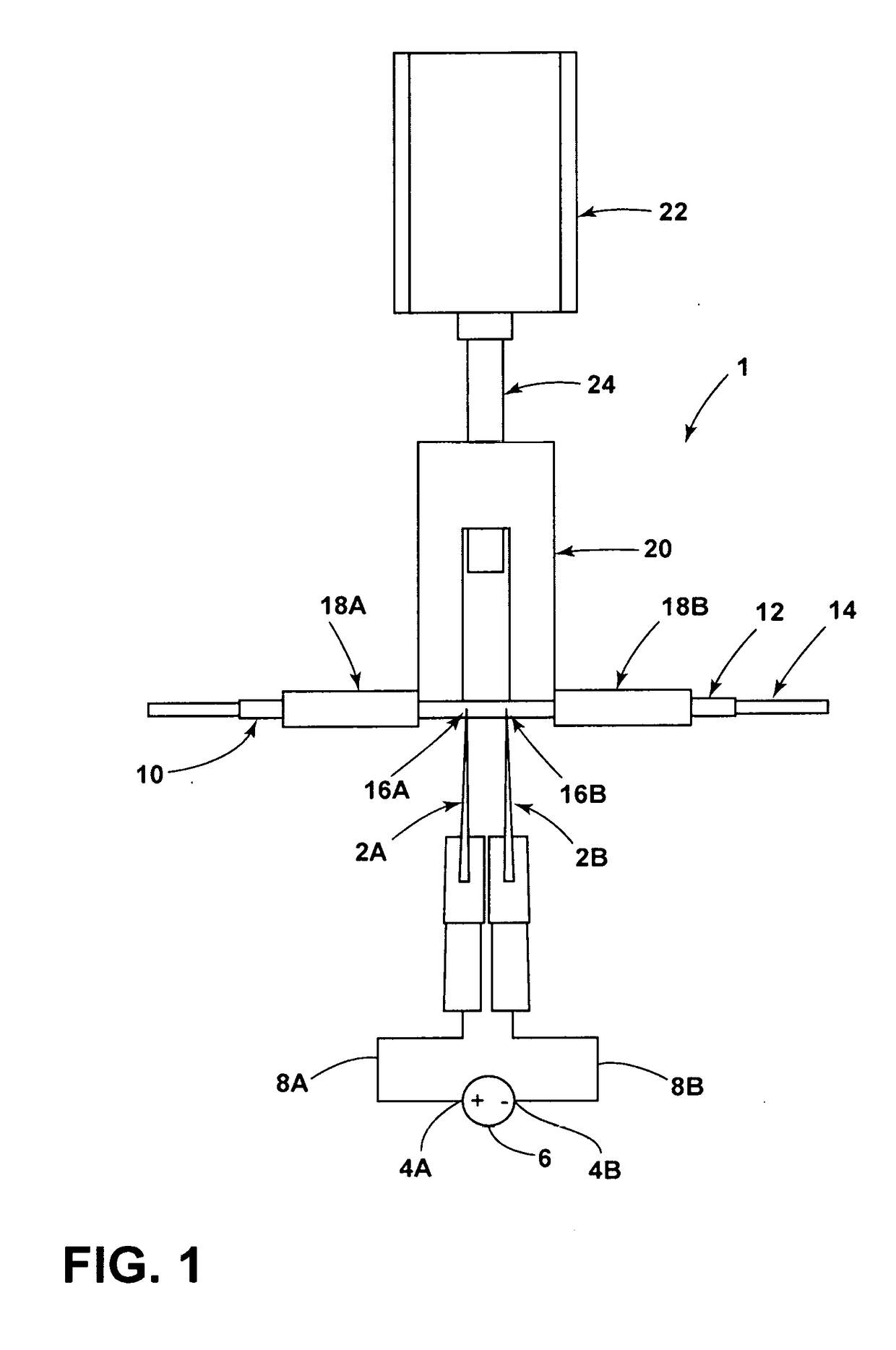

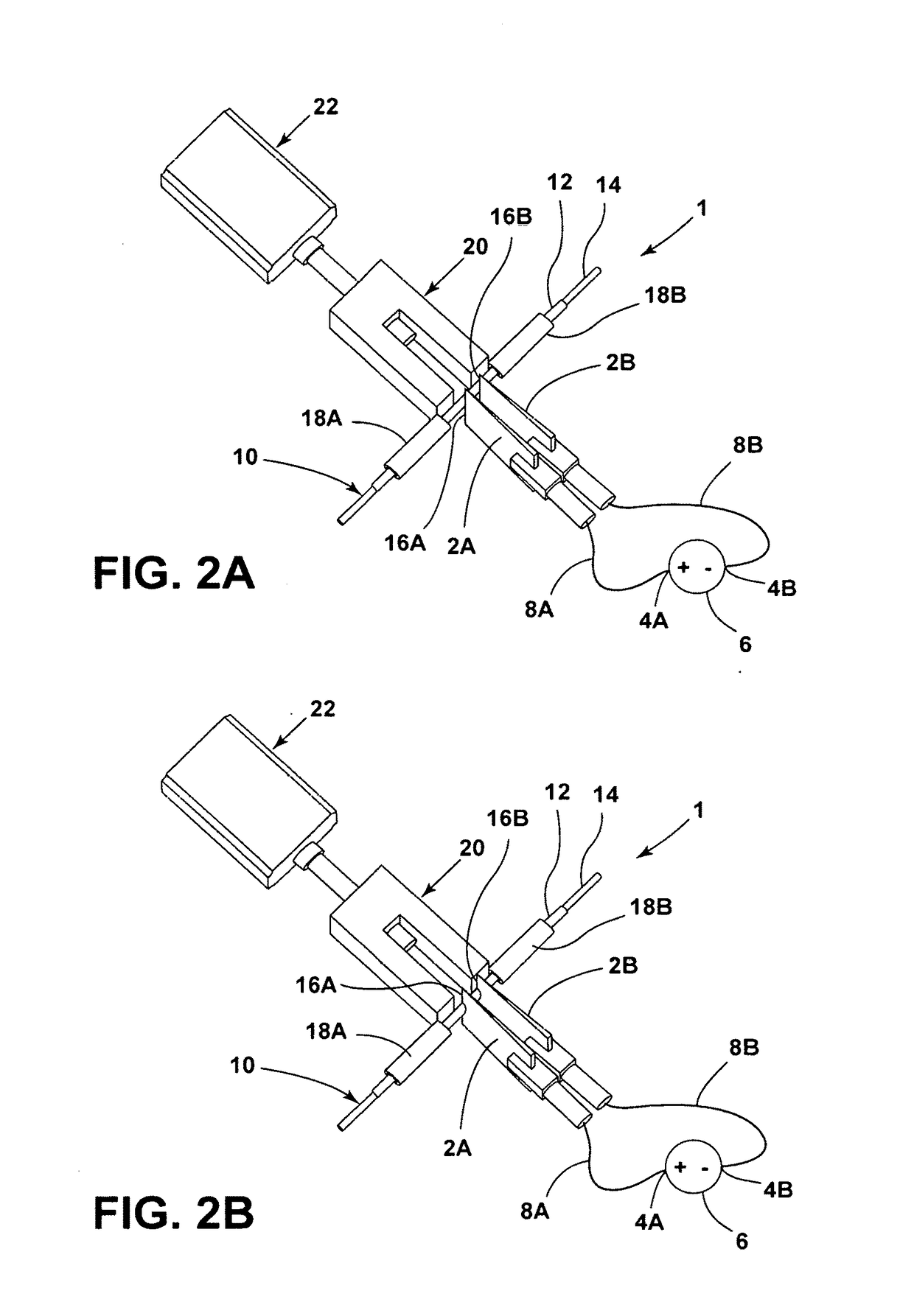

The invention discloses a multi-material multi-scale 3D (3-dimensional) printing device provided with a single spray nozzle as well as a working method of the 3D printing device. The 3D printing device comprises a base, a work table, a bearing table, a substrate, a power supply, the spray nozzle and a bracket, wherein the base is mounted at the bottommost part, the bracket and the work table are mounted above the base, the spray nozzle is mounted on the bracket, the bearing table is fixed on the work table, and the substrate is fixed above the bearing table; an anode and a cathode of the power supply are connected with a nozzle body of the spray nozzle and the bearing table respectively; relative motion between the spray nozzle and the substrate in x, y and z directions is realized by the aid of relative motion between the work table and the bracket. The spray nozzle is provided with a plurality of feed openings connected with different trace feeding pumps, multiple materials are thoroughly mixed under the action of a stirrer after entering the spray nozzle, and multi-material printing is realized. The macroscopic geometrical shape as well as microstructures in an object and on the surface of the object is controlled reasonably, and multi-scale structural integrated manufacture is realized.

Owner:兰红波

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com