Multi-material multi-scale 3D (3-dimensional) printing device provided with single spray nozzle as well as working method of 3D printing device

一种3D打印、多材料的技术,应用在增材制造领域,能够解决设备成本高、难一体化制造、打印效率低等问题,达到打印材料广泛、减小定位误差、可控性好的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

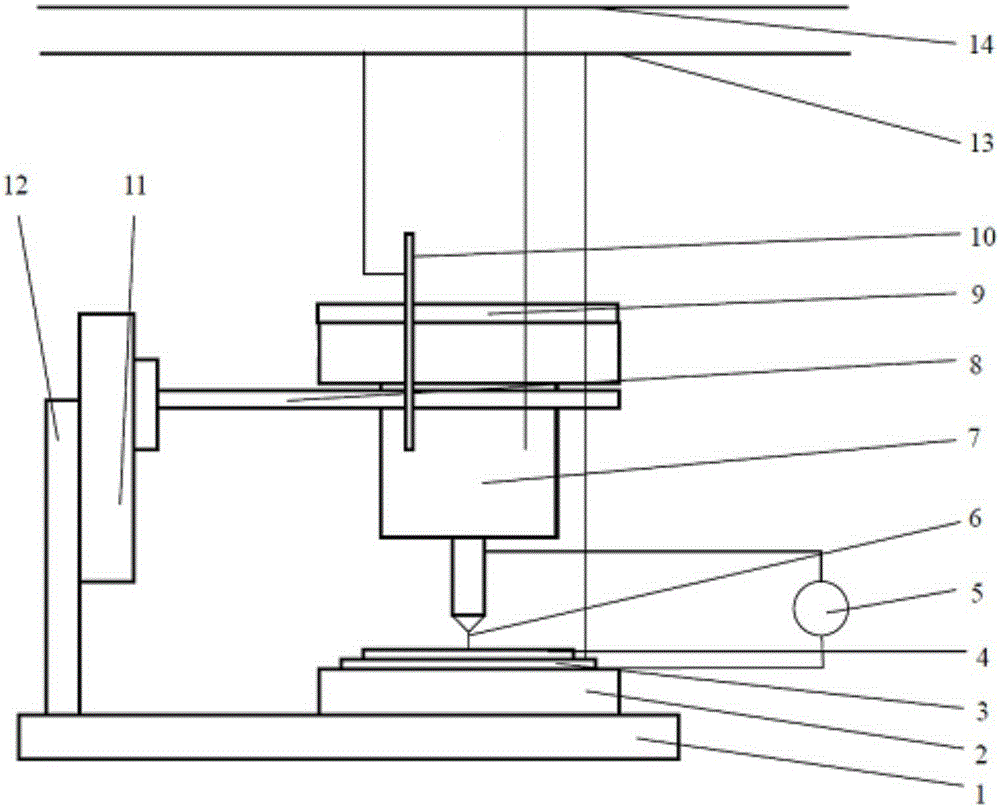

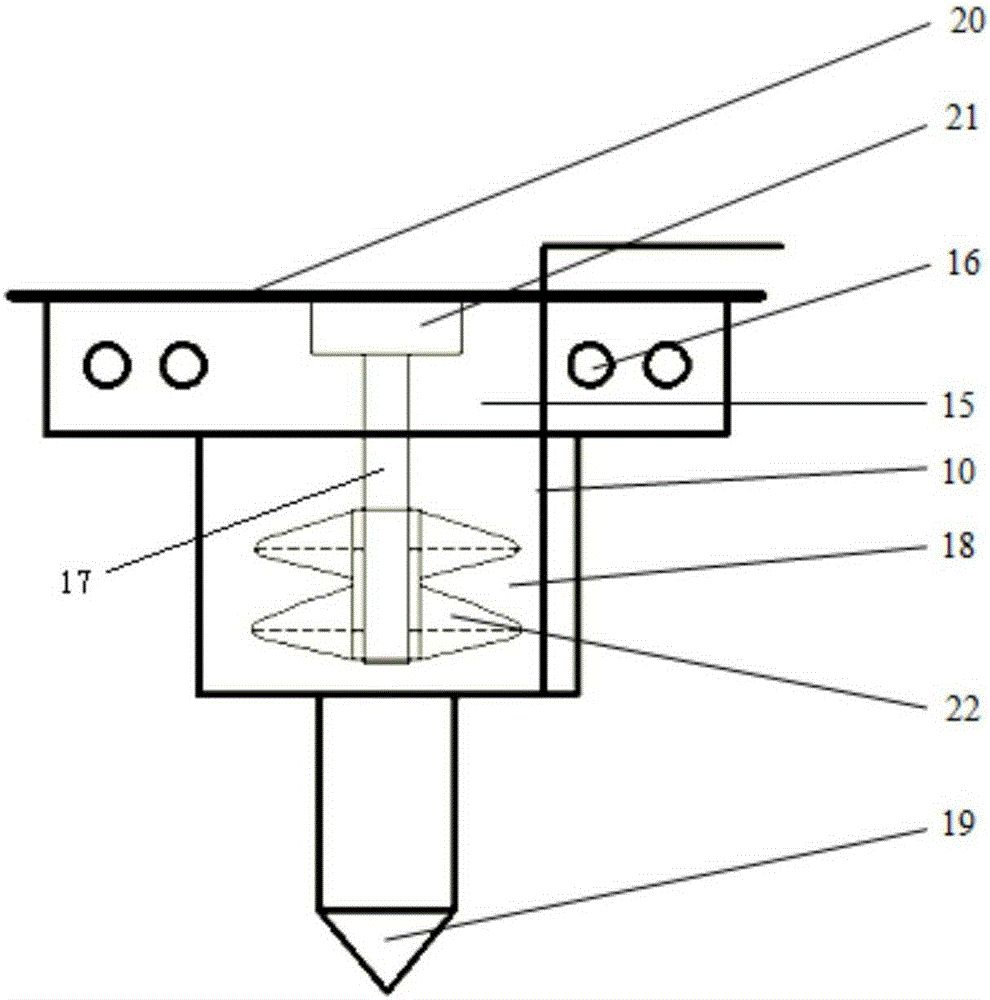

[0045] figure 1 It is a structural schematic diagram of the multi-material and multi-scale 3D printing device of the present invention, which includes: base 1, x-y workbench 2, film holder 3, base material 4, high-voltage power supply 5, printing material 6, nozzle 7, connecting frame 8, mixing Stirrer 9, waste liquid collector 10, z-direction workbench 11, support 12, vacuum pipeline 13, pressure pipeline 14; wherein the base 1 is placed at the bottom, and the x-y workbench 2 is placed on the base 1; Fixed on the x-y workbench 2; the base material 4 is fixed on the carrier table 3; the nozzle 7 is placed directly above the base material 4 and fixed on the connecting frame 8; the connecting frame 8 is fixed on the z-direction workbench 11; the z-direction The workbench 11 is fixed on the bracket 12; the bracket 12 is fixed on the base 1; a mixing agitator 9 is arranged inside the nozzle 7, the upper part of the mixing agitator 9 is fixed on the upper surface of the nozzle, and...

Embodiment 2

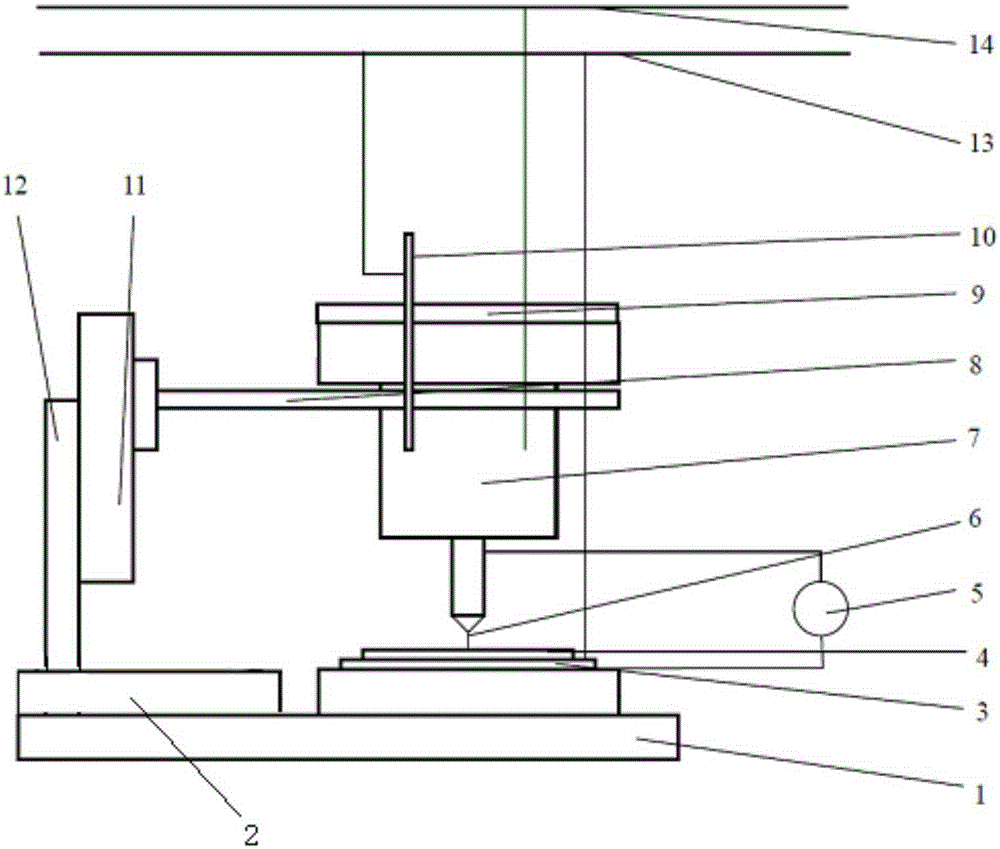

[0058] Such as image 3 As shown, the structure diagram of the multi-material and multi-scale 3D printing device of the present invention includes: a base 1, an x-y workbench 2, a film holder 3, a base material 4, a high-voltage power supply 5, printing materials 6, a nozzle 7, and a connecting frame 8 , mixing agitator 9, waste liquid collector 10, z-direction workbench 11, support 12, vacuum pipeline 13, pressure pipeline 14; wherein the base 1 is placed at the bottom, and the x-y workbench 2 is placed on the base 1; Table 3 is fixed on the base 1; base material 4 is fixed on the support table 3; the nozzle 7 is placed directly above the base material 4 and fixed on the connecting frame 8; the connecting frame 8 is fixed on the z-direction workbench 11; the z-direction The workbench 11 is fixed on the support 12; the support 12 is fixed on the x-y workbench 2, and the x-y workbench 2 is fixed on the base 1.

[0059] The x-y workbench 2 is a two-dimensional precision displac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com