Patents

Literature

95results about "Manufacturing irradiation arrangements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

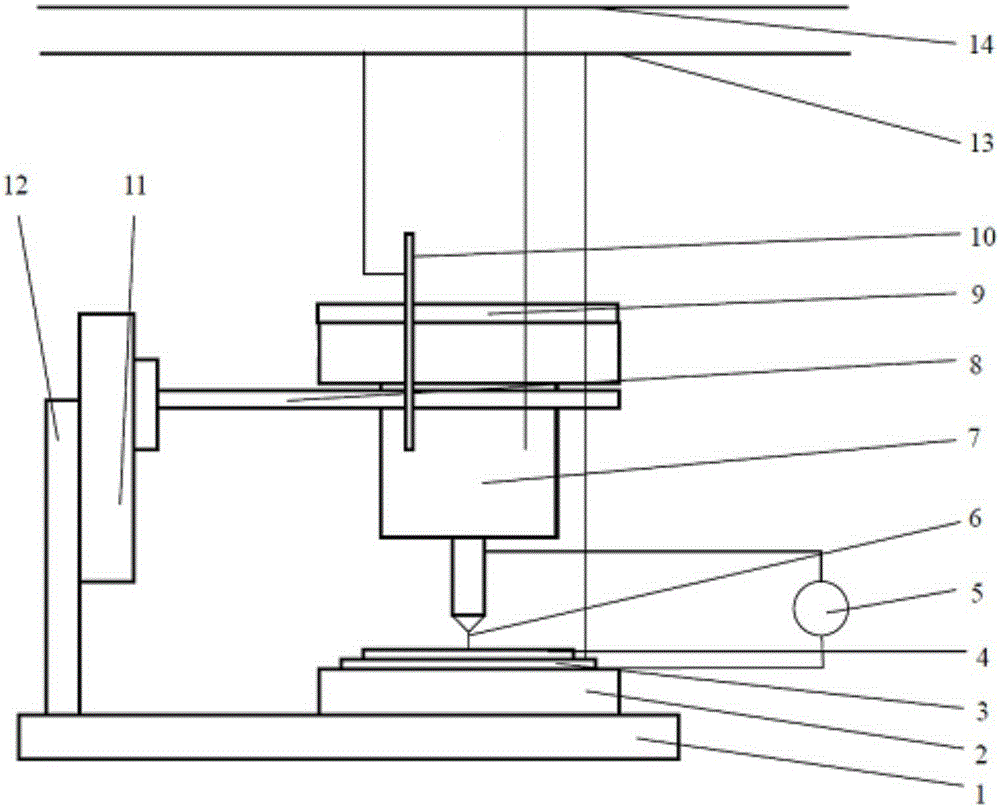

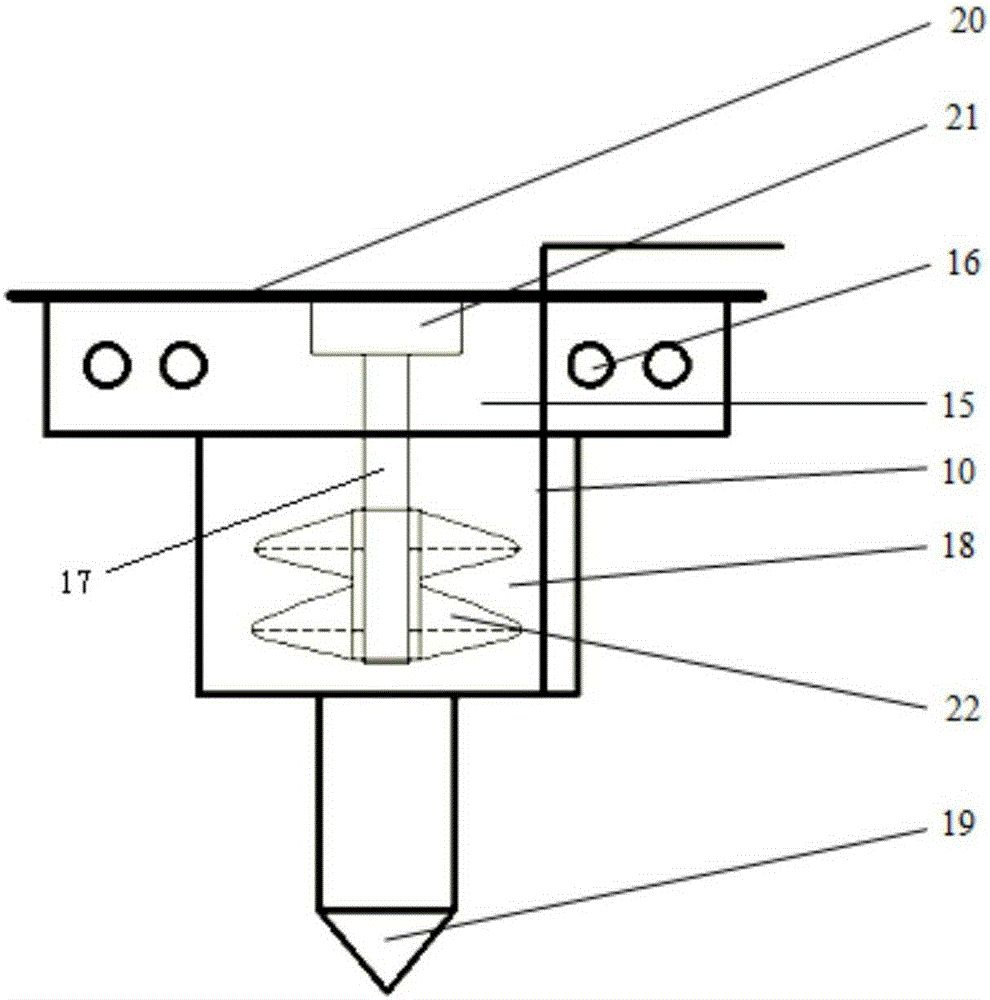

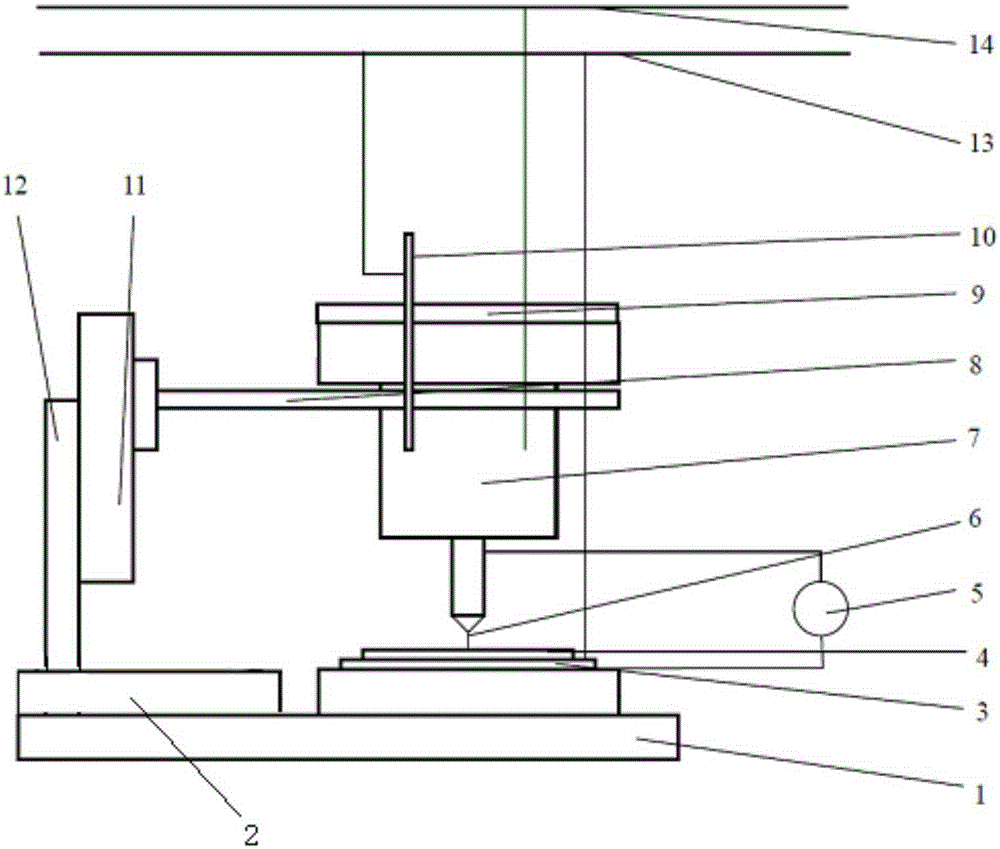

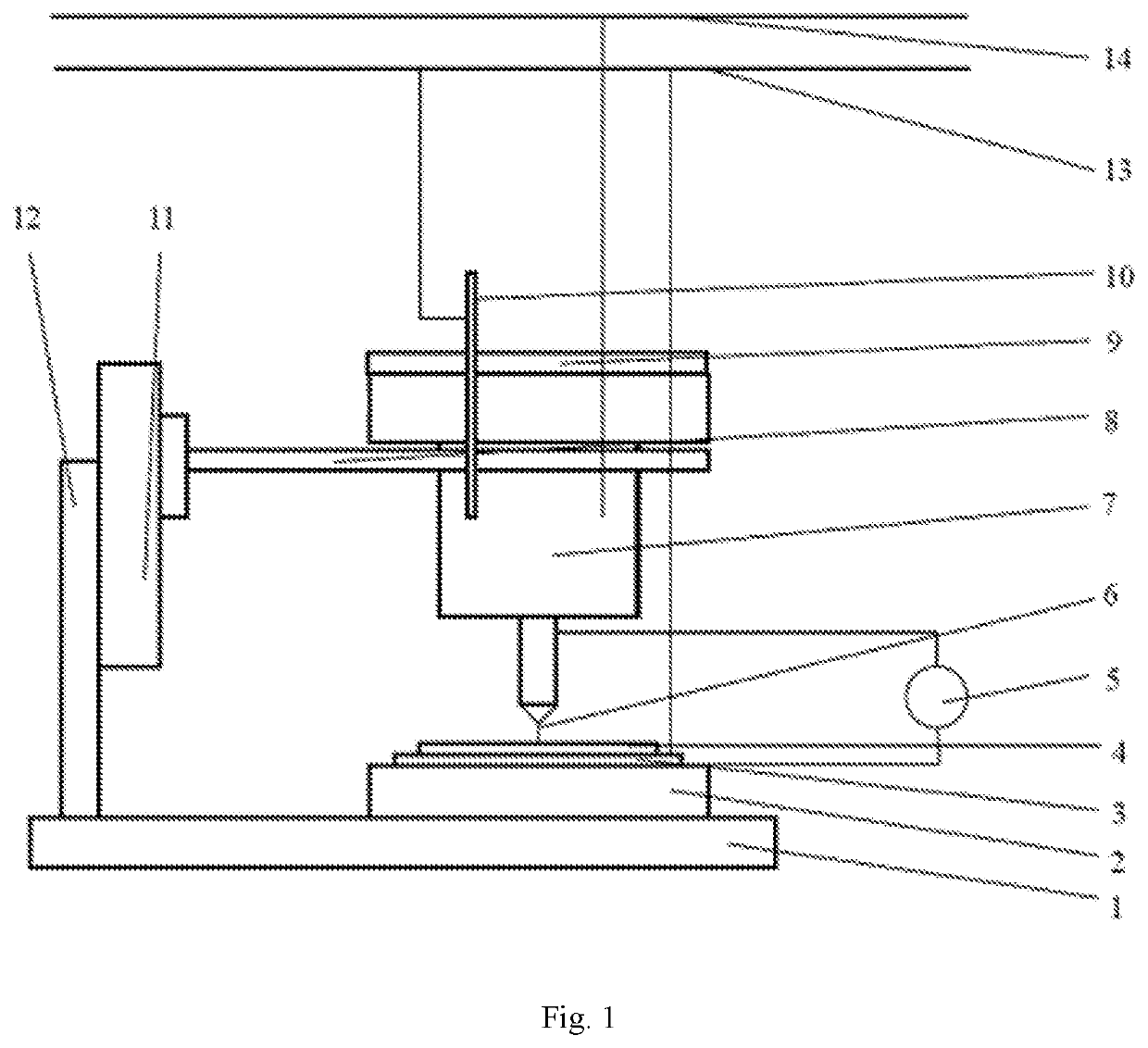

Multi-material multi-scale 3D (3-dimensional) printing device provided with single spray nozzle as well as working method of 3D printing device

ActiveCN105196550ARealize printingReasonable control of macro geometryManufacturing platforms/substratesTransportation and packagingMulti materialSpray nozzle

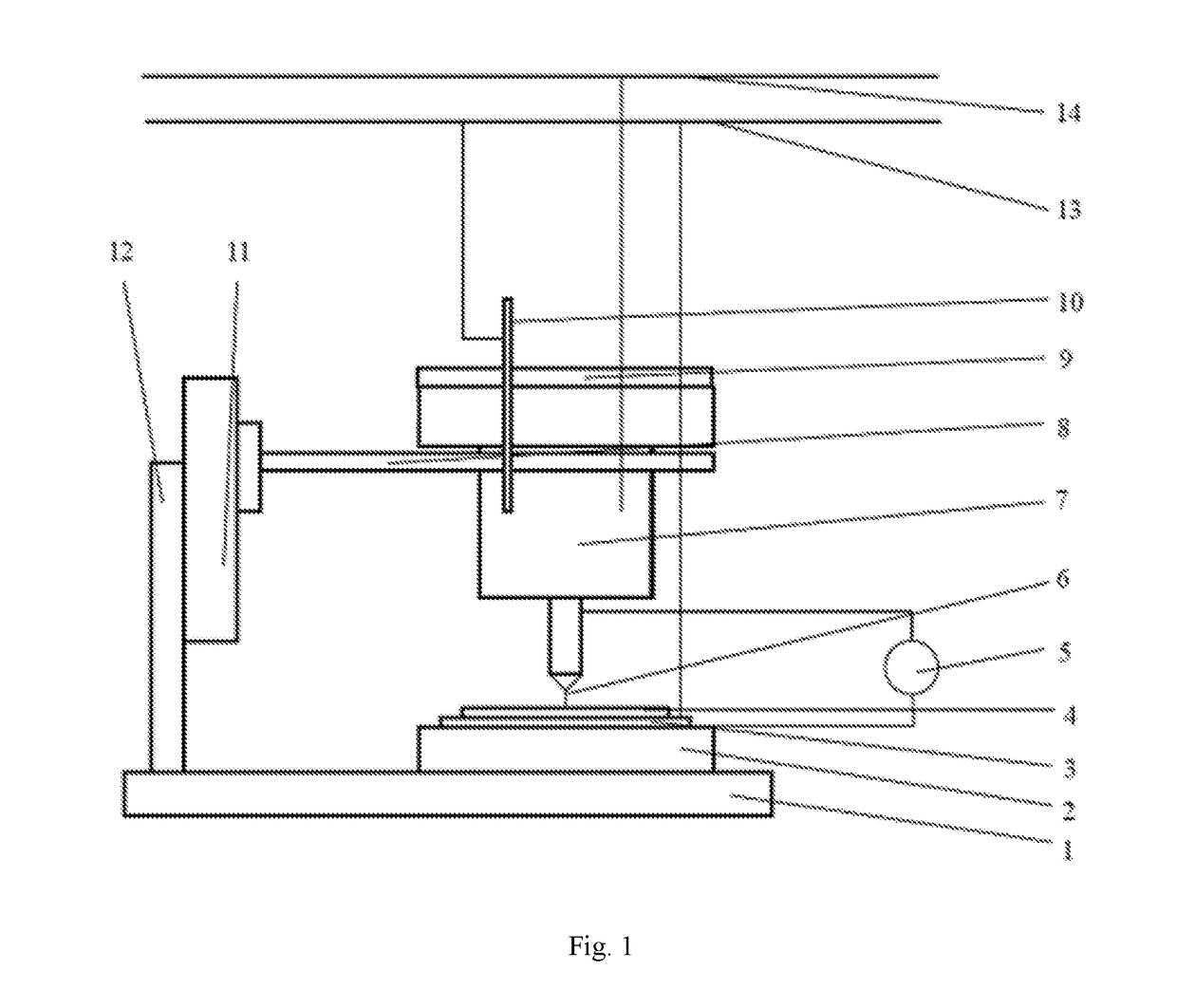

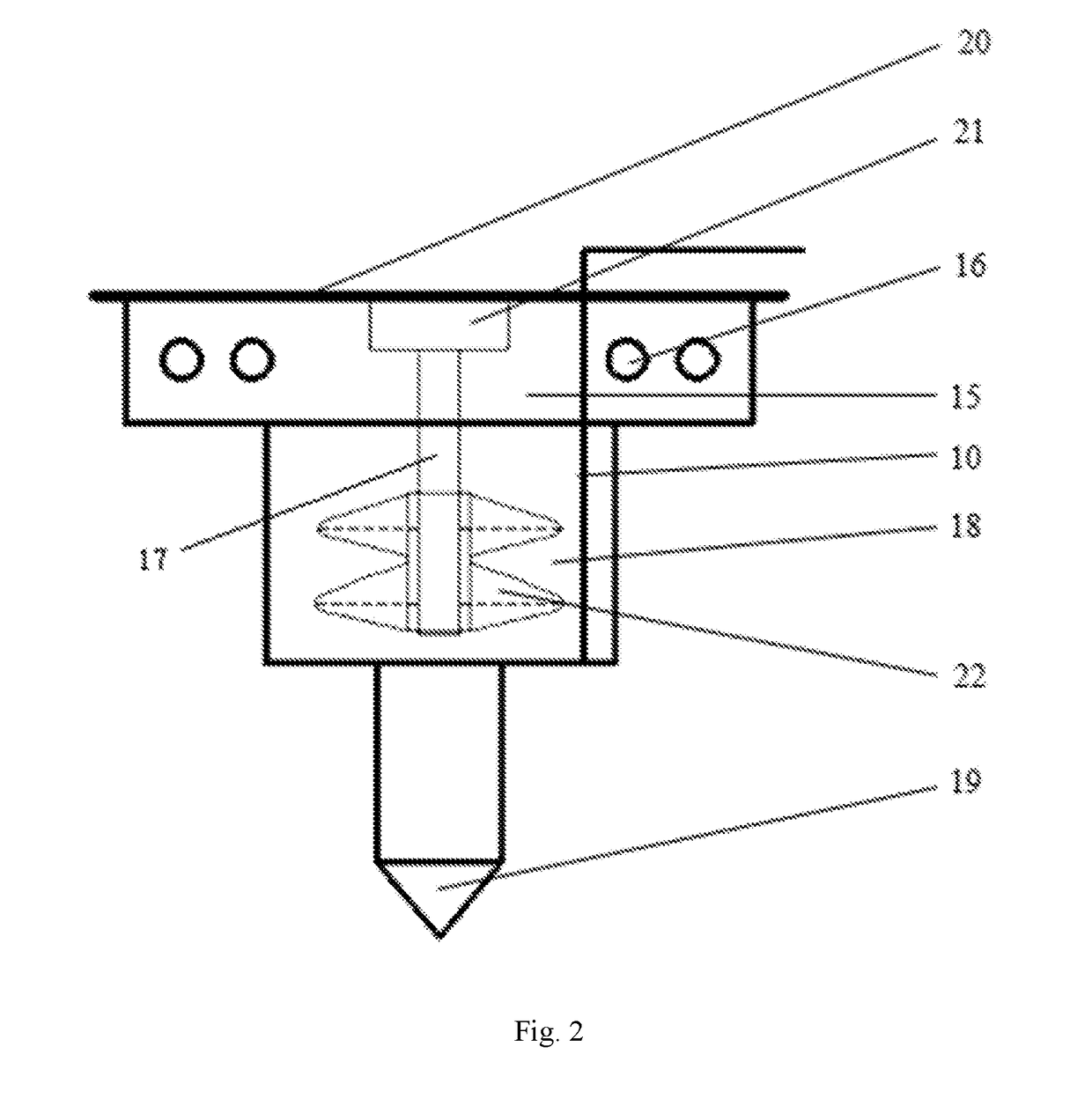

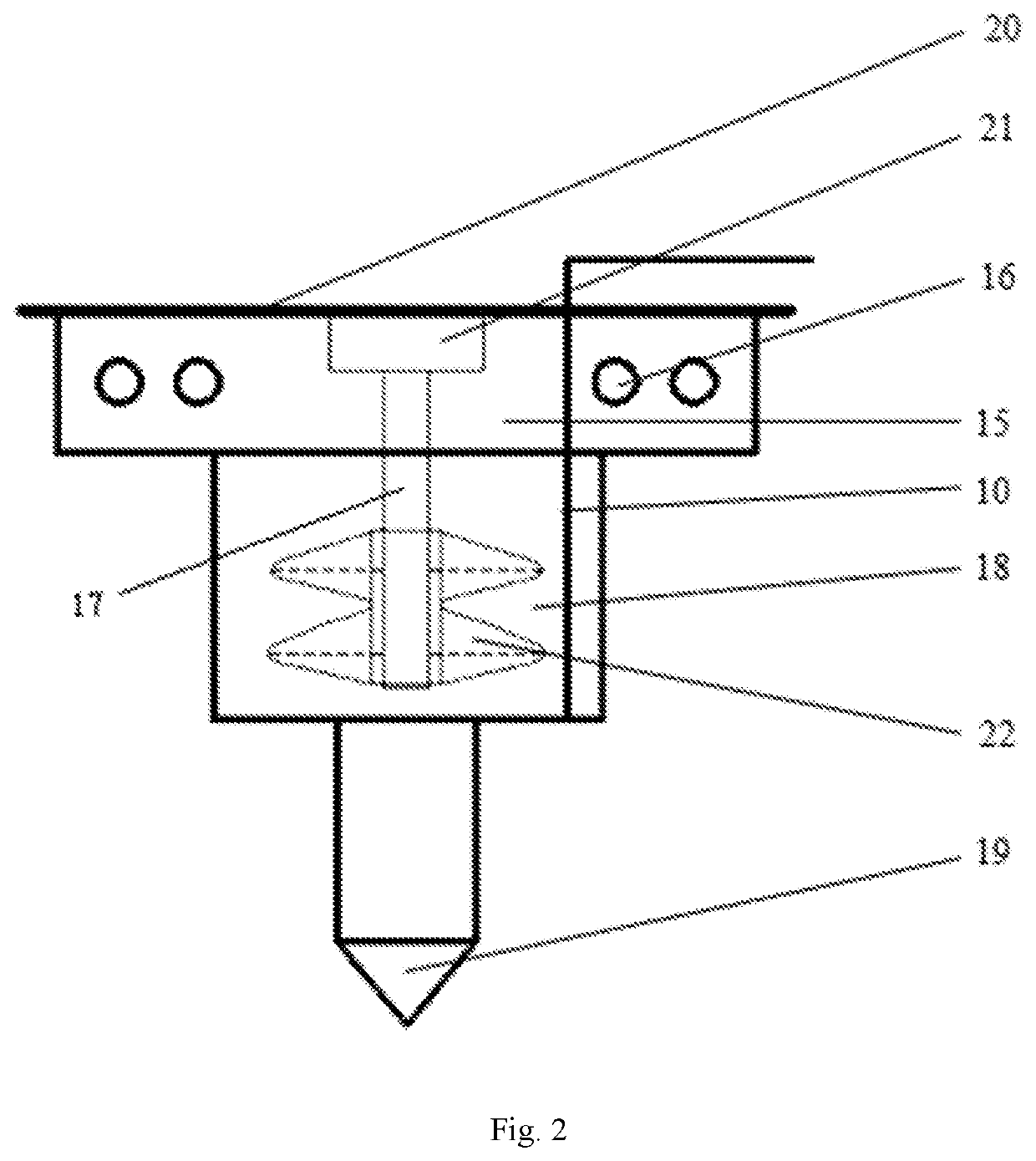

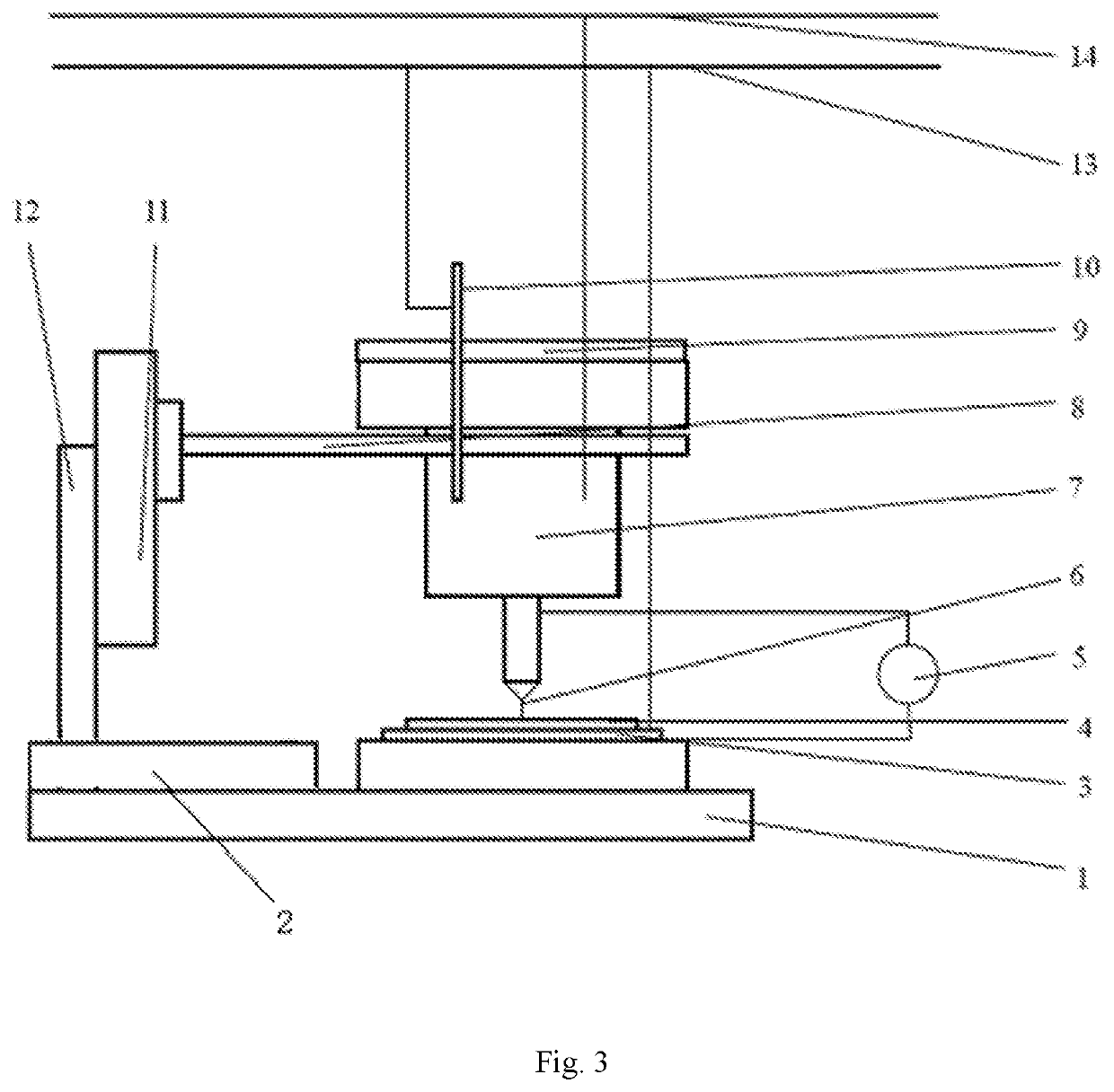

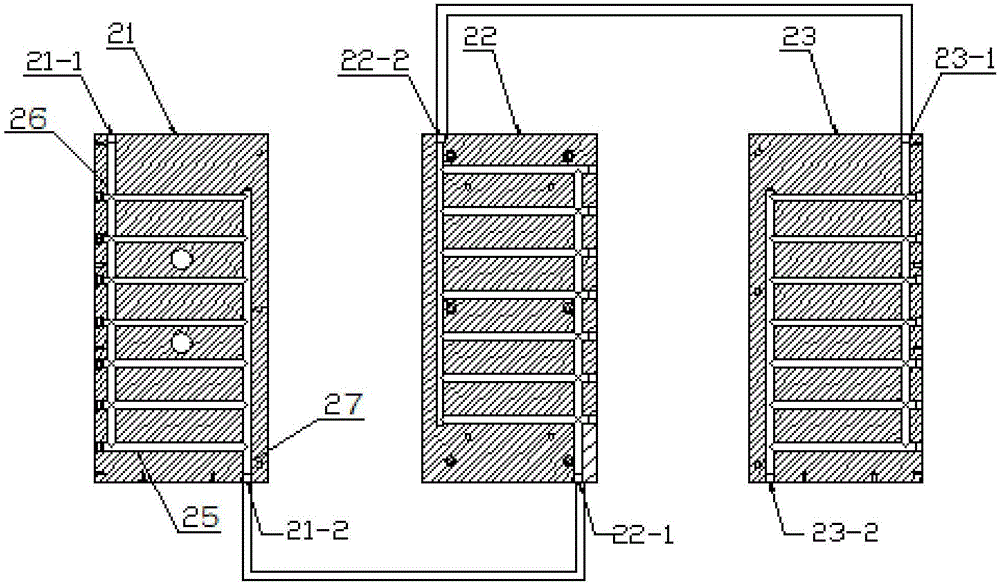

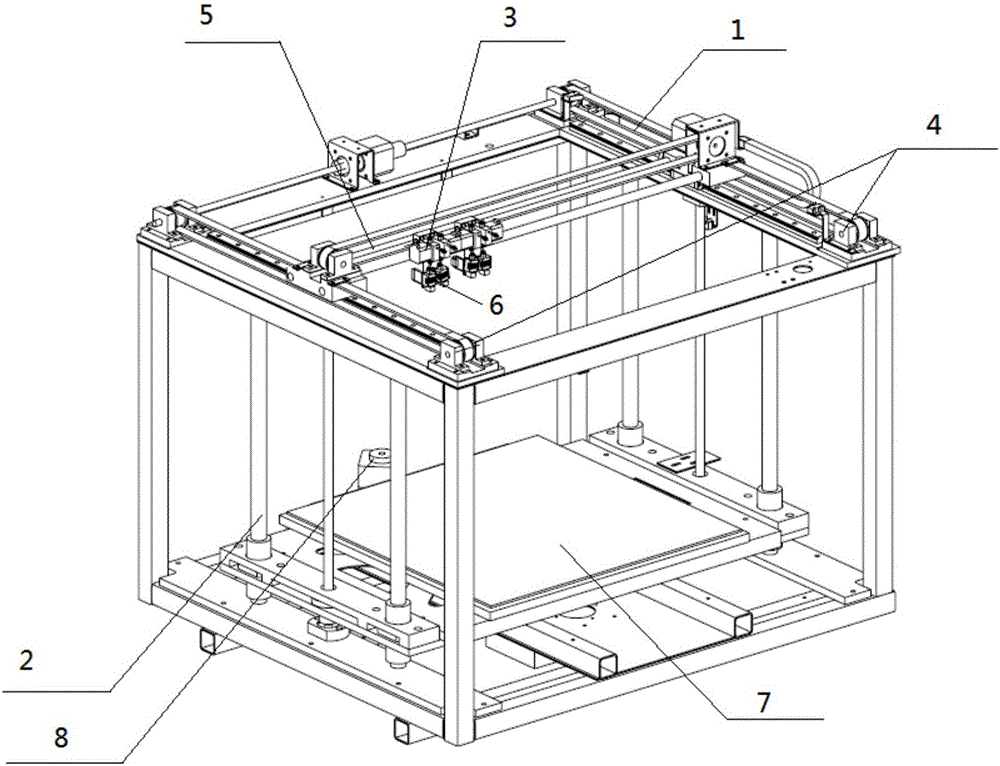

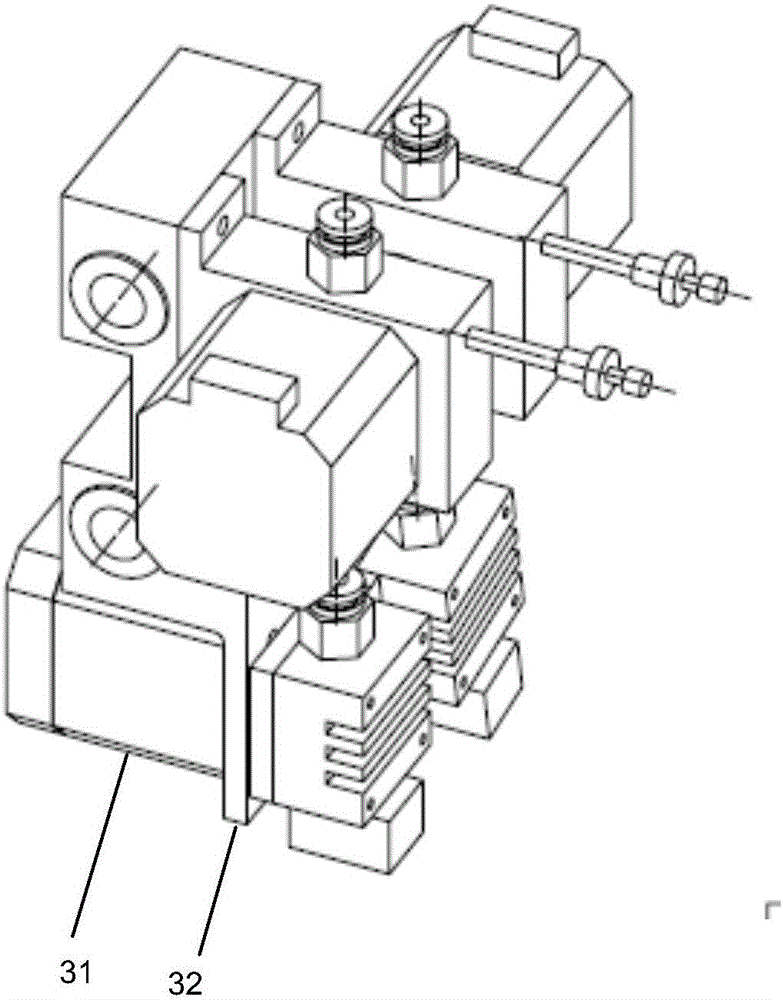

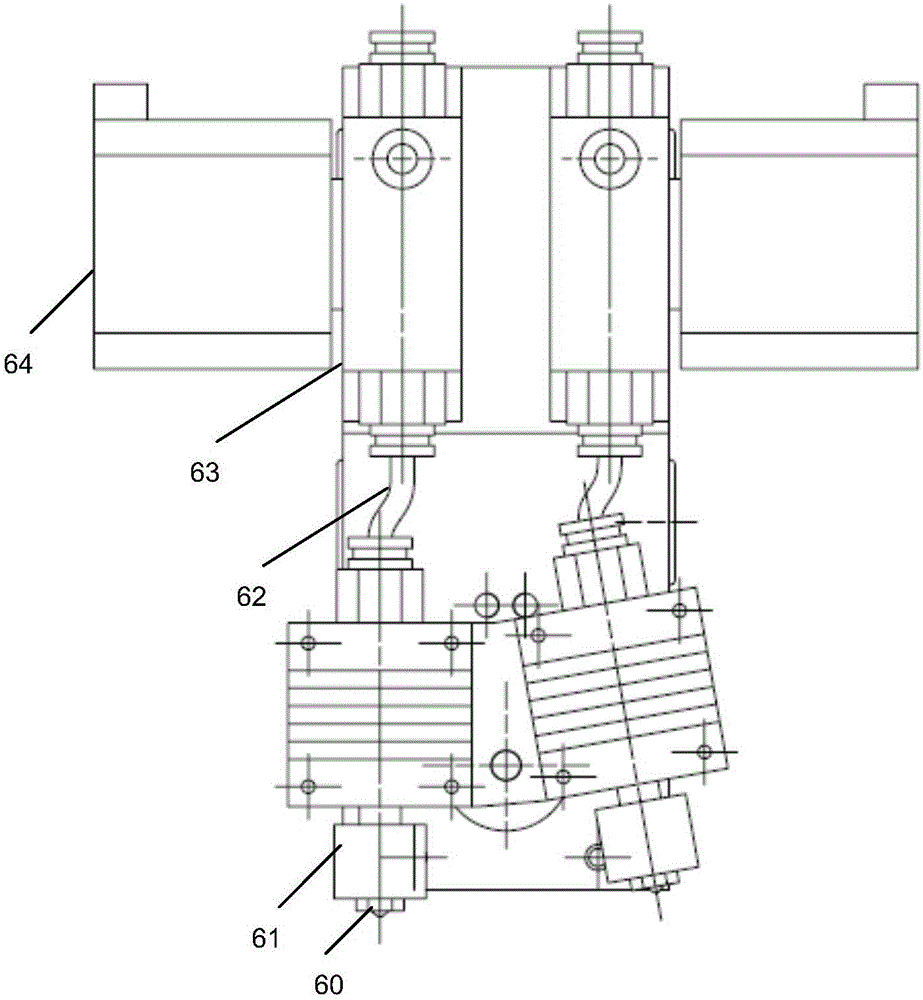

The invention discloses a multi-material multi-scale 3D (3-dimensional) printing device provided with a single spray nozzle as well as a working method of the 3D printing device. The 3D printing device comprises a base, a work table, a bearing table, a substrate, a power supply, the spray nozzle and a bracket, wherein the base is mounted at the bottommost part, the bracket and the work table are mounted above the base, the spray nozzle is mounted on the bracket, the bearing table is fixed on the work table, and the substrate is fixed above the bearing table; an anode and a cathode of the power supply are connected with a nozzle body of the spray nozzle and the bearing table respectively; relative motion between the spray nozzle and the substrate in x, y and z directions is realized by the aid of relative motion between the work table and the bracket. The spray nozzle is provided with a plurality of feed openings connected with different trace feeding pumps, multiple materials are thoroughly mixed under the action of a stirrer after entering the spray nozzle, and multi-material printing is realized. The macroscopic geometrical shape as well as microstructures in an object and on the surface of the object is controlled reasonably, and multi-scale structural integrated manufacture is realized.

Owner:兰红波

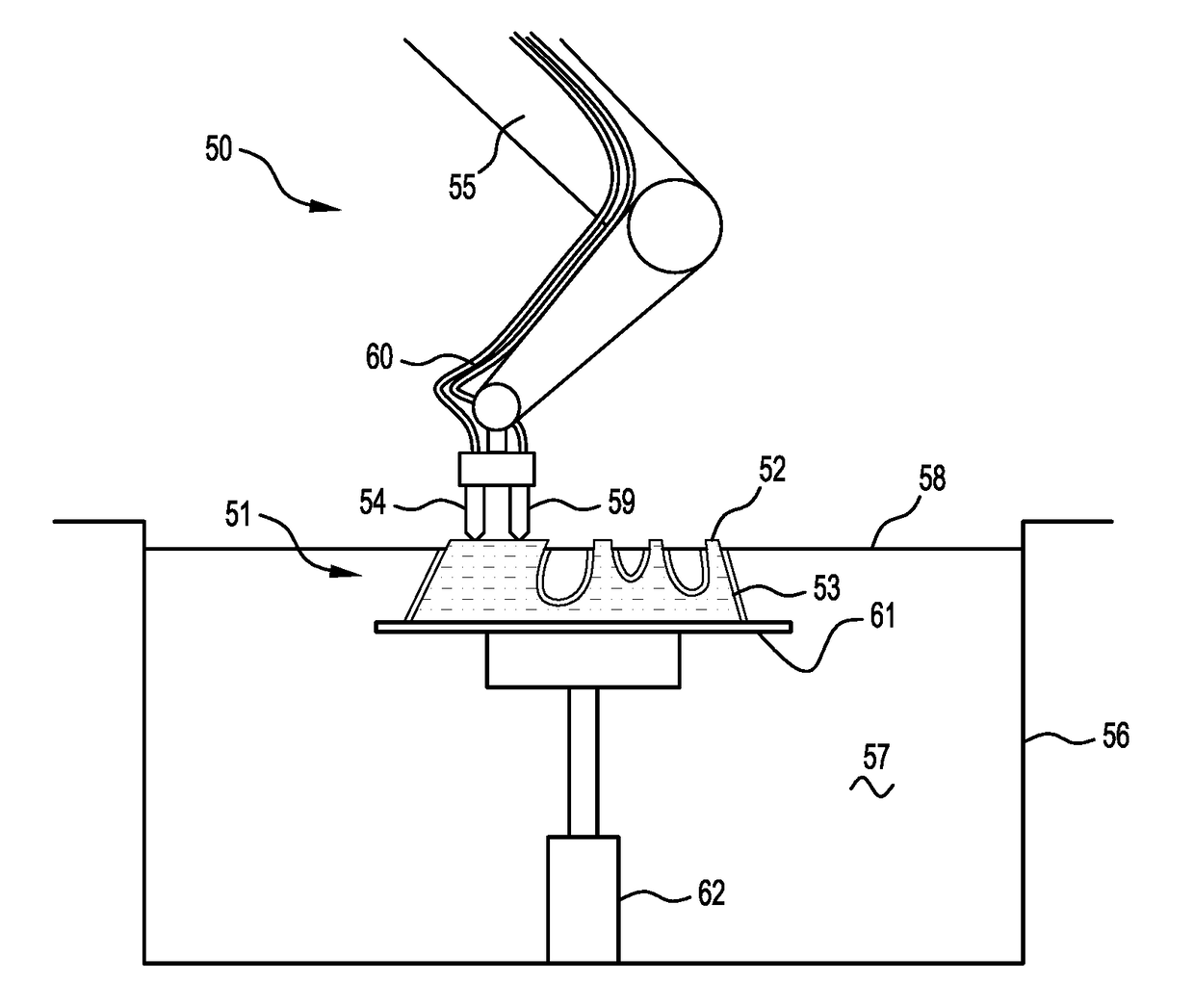

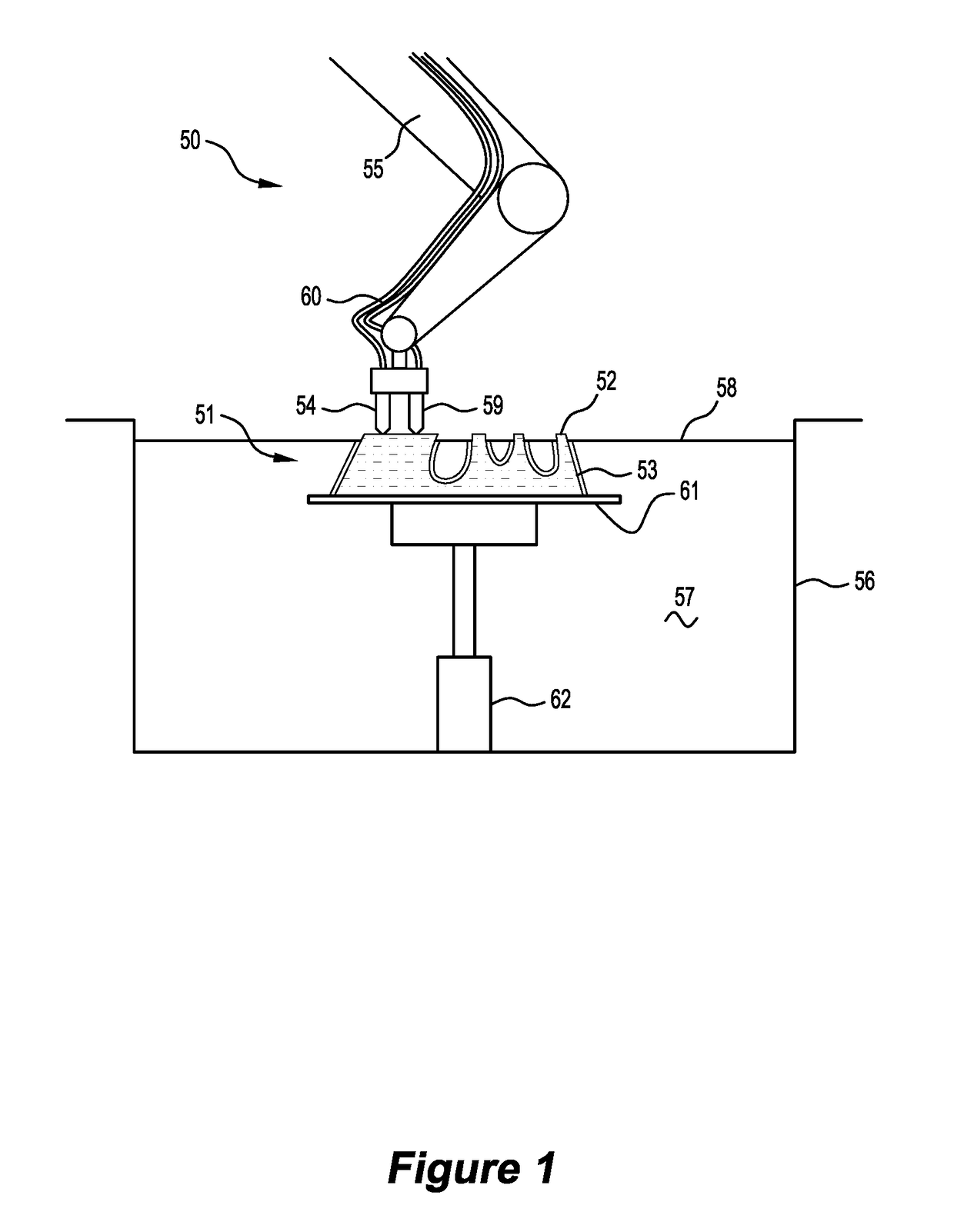

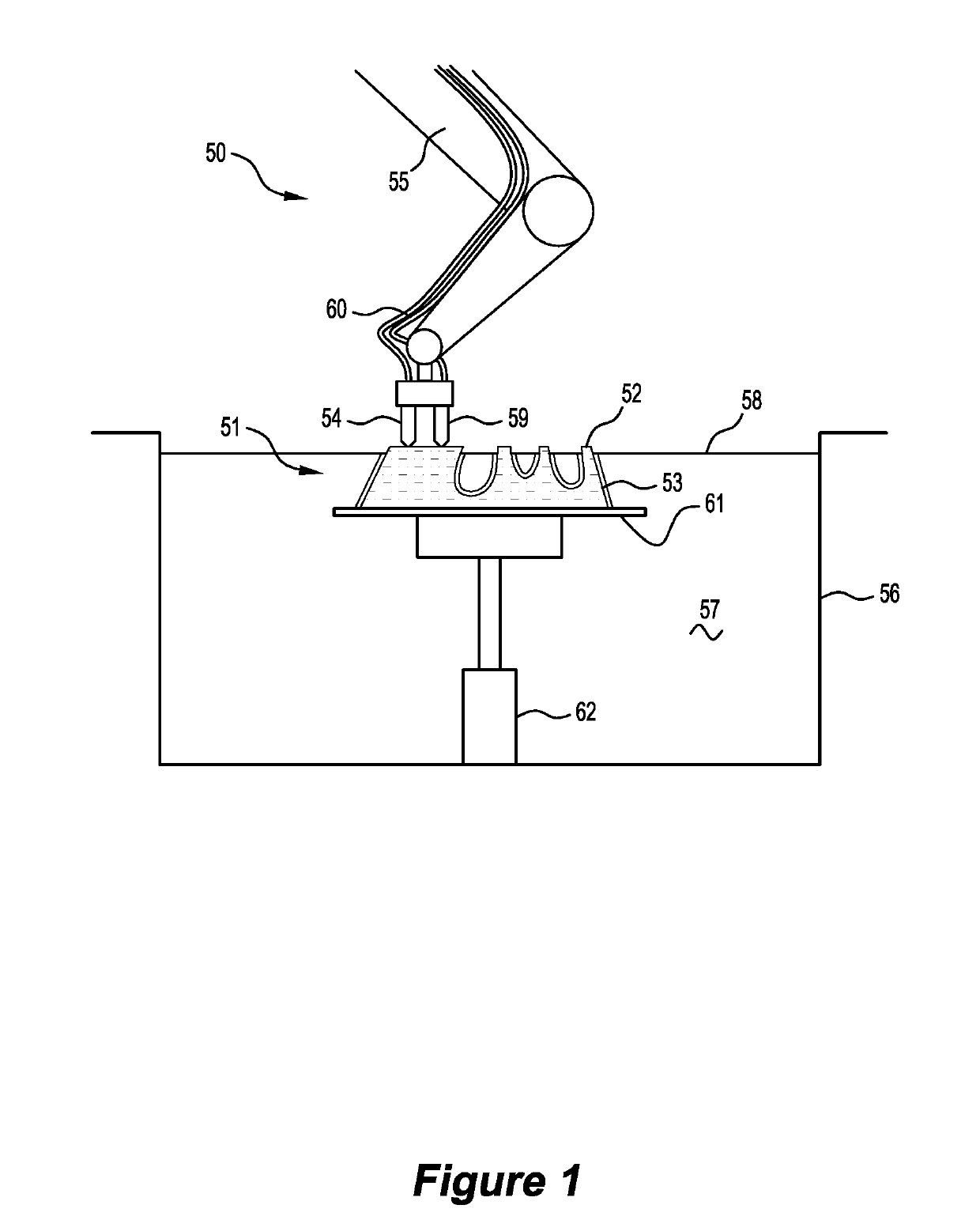

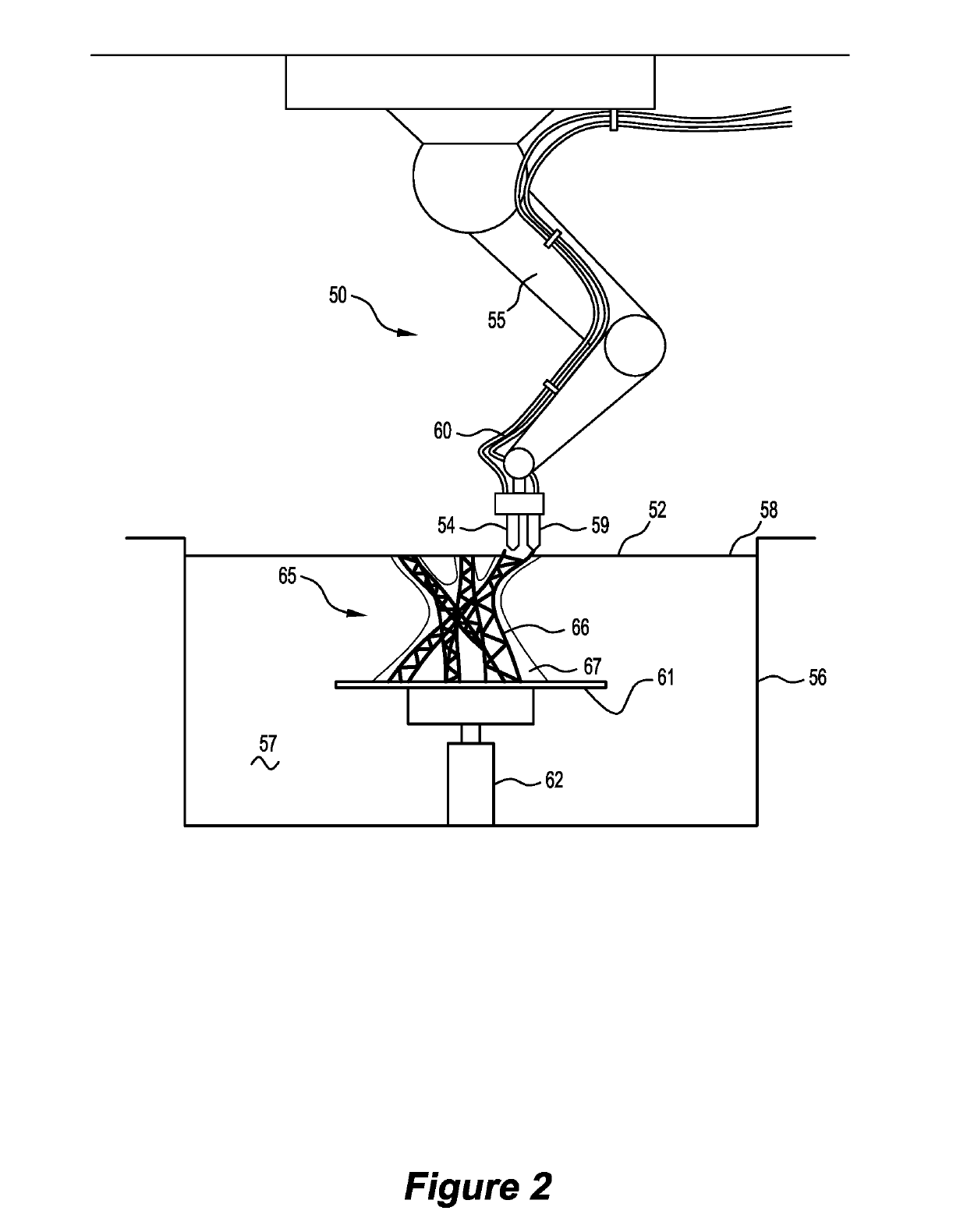

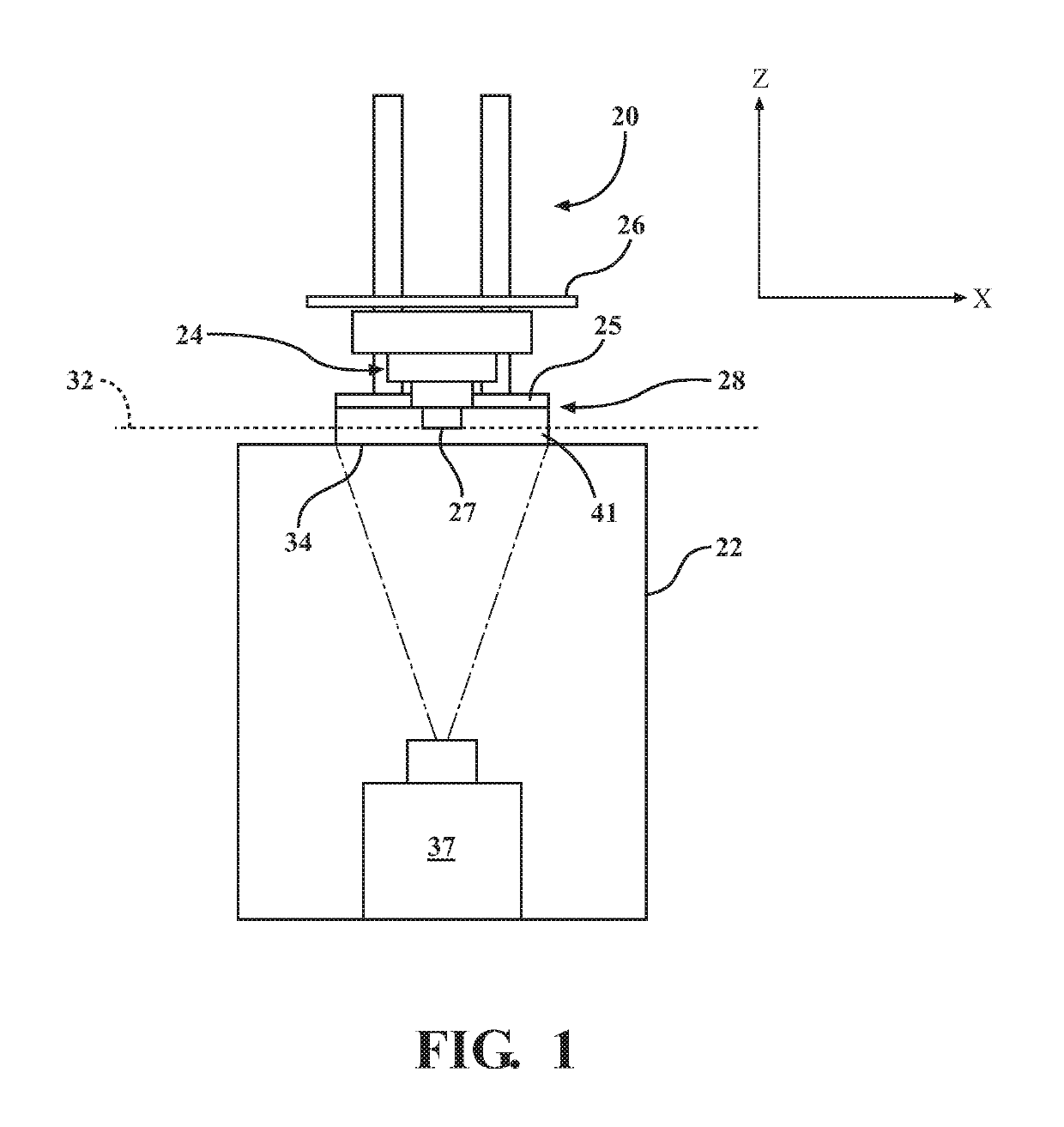

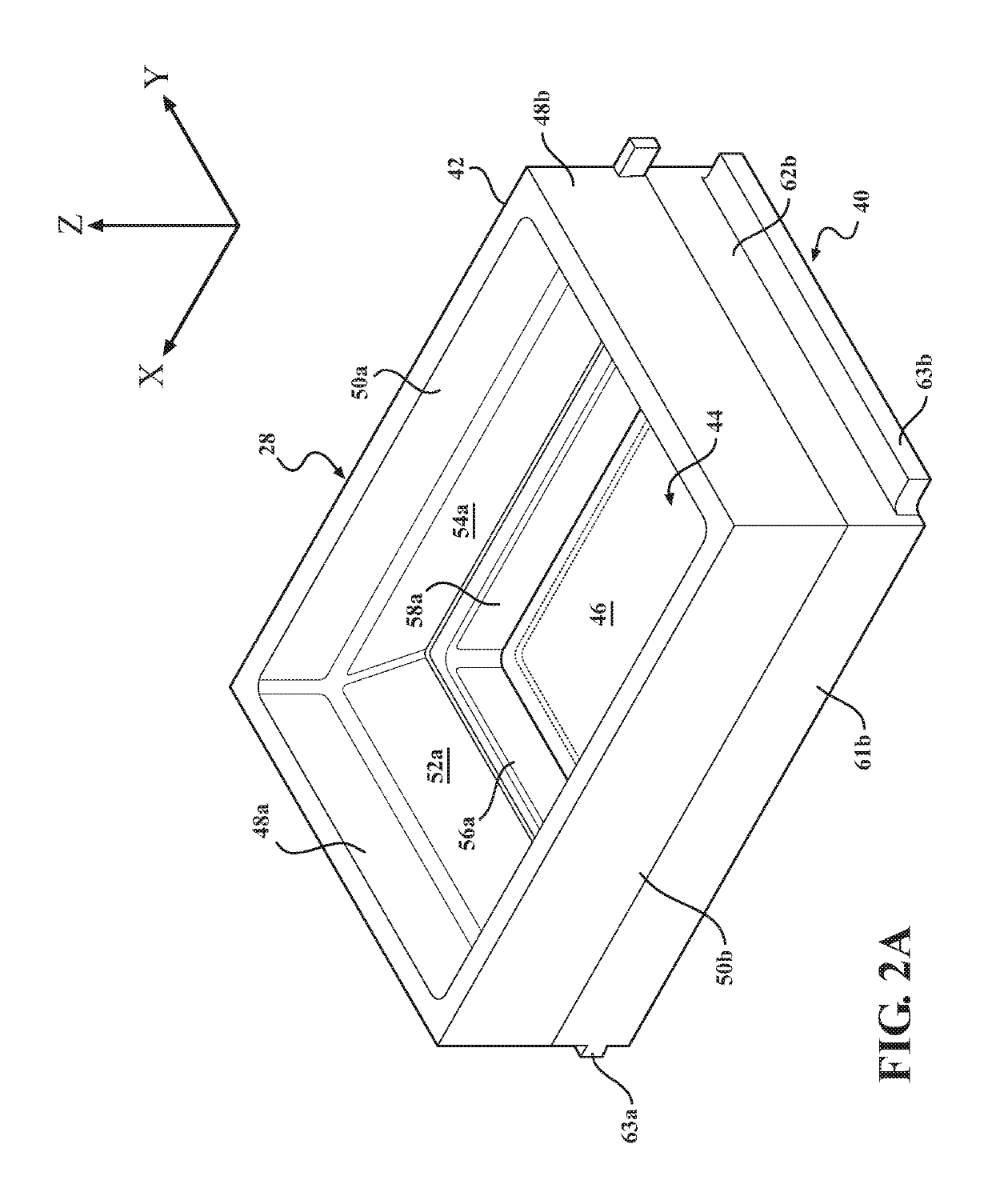

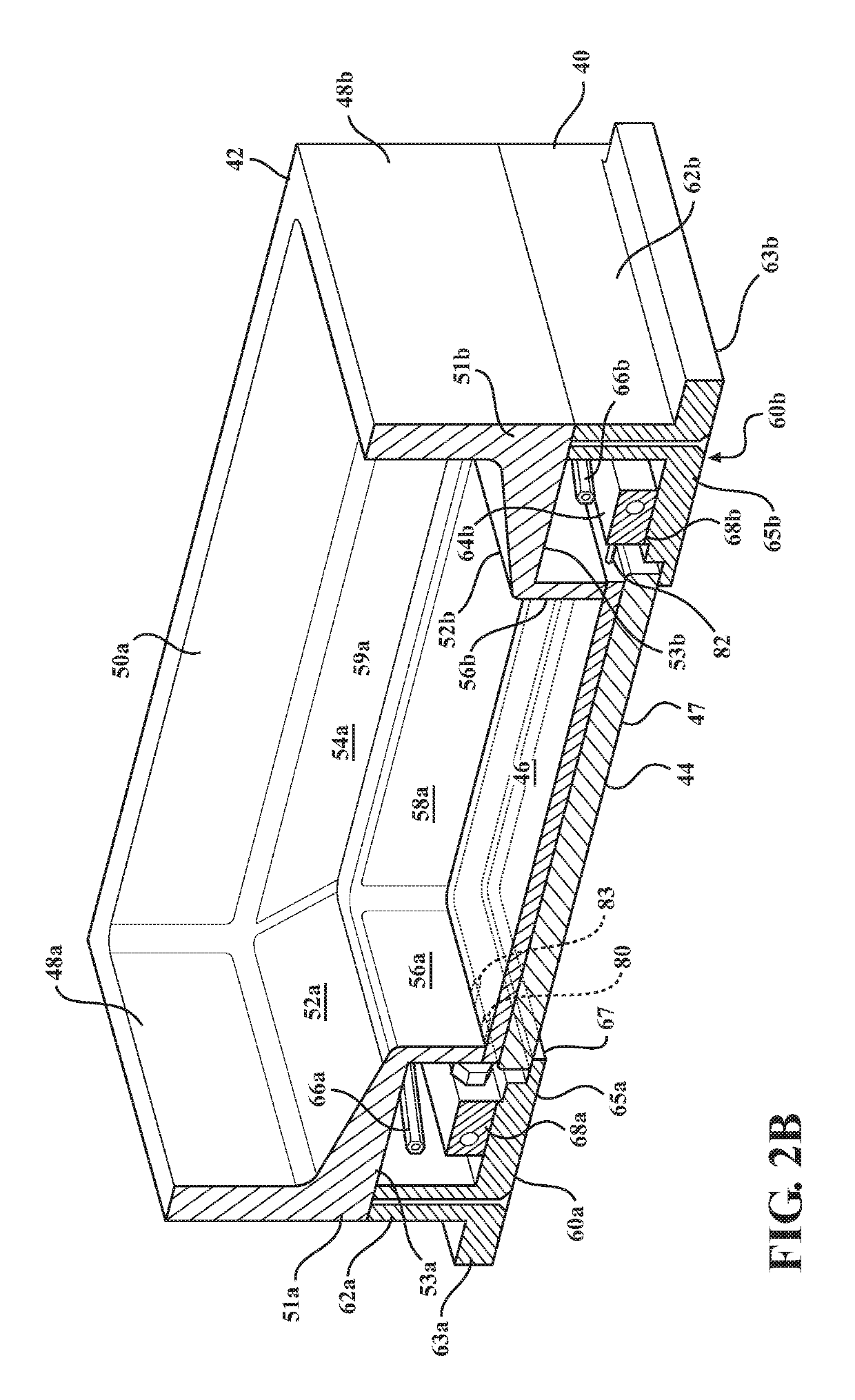

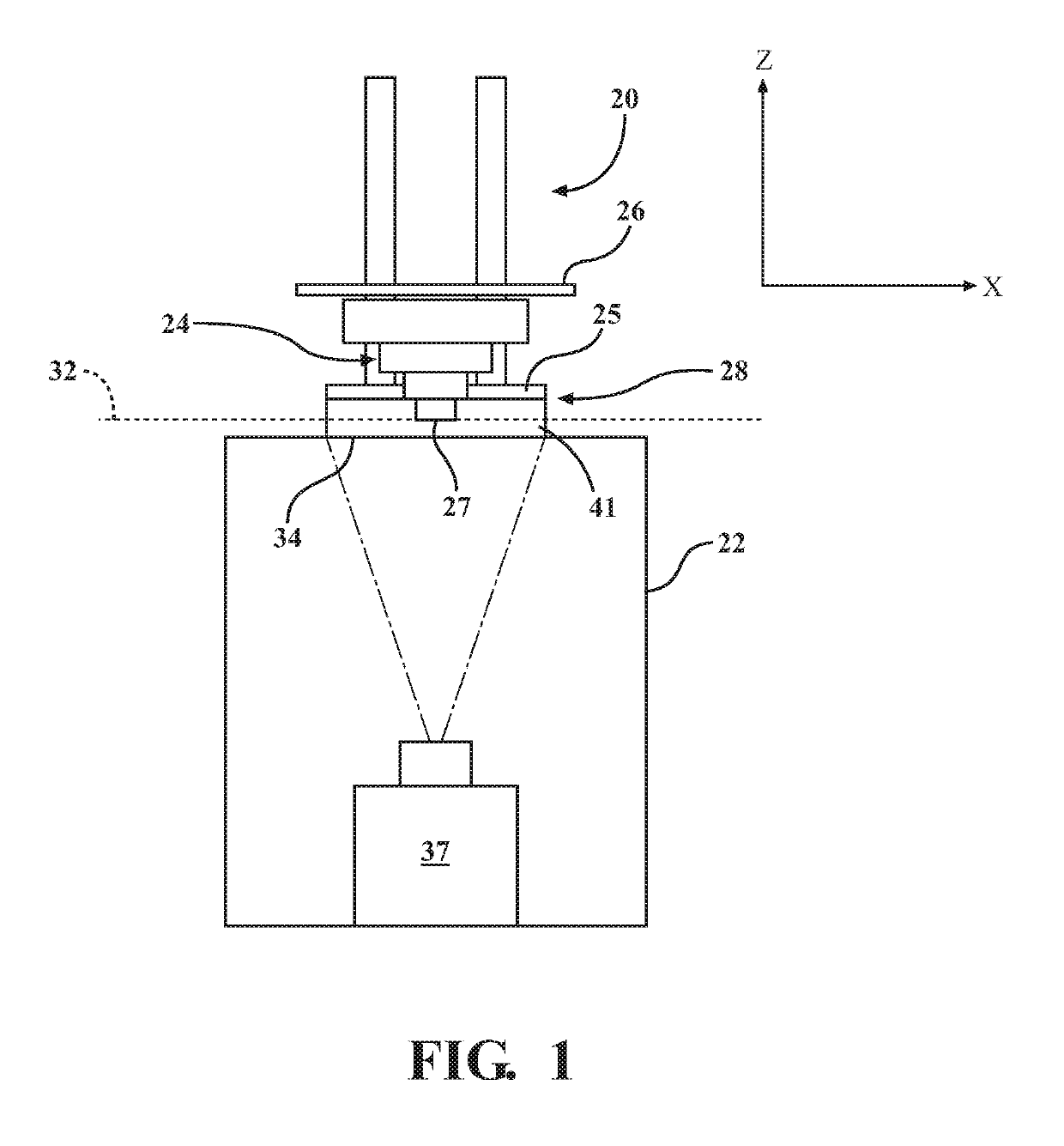

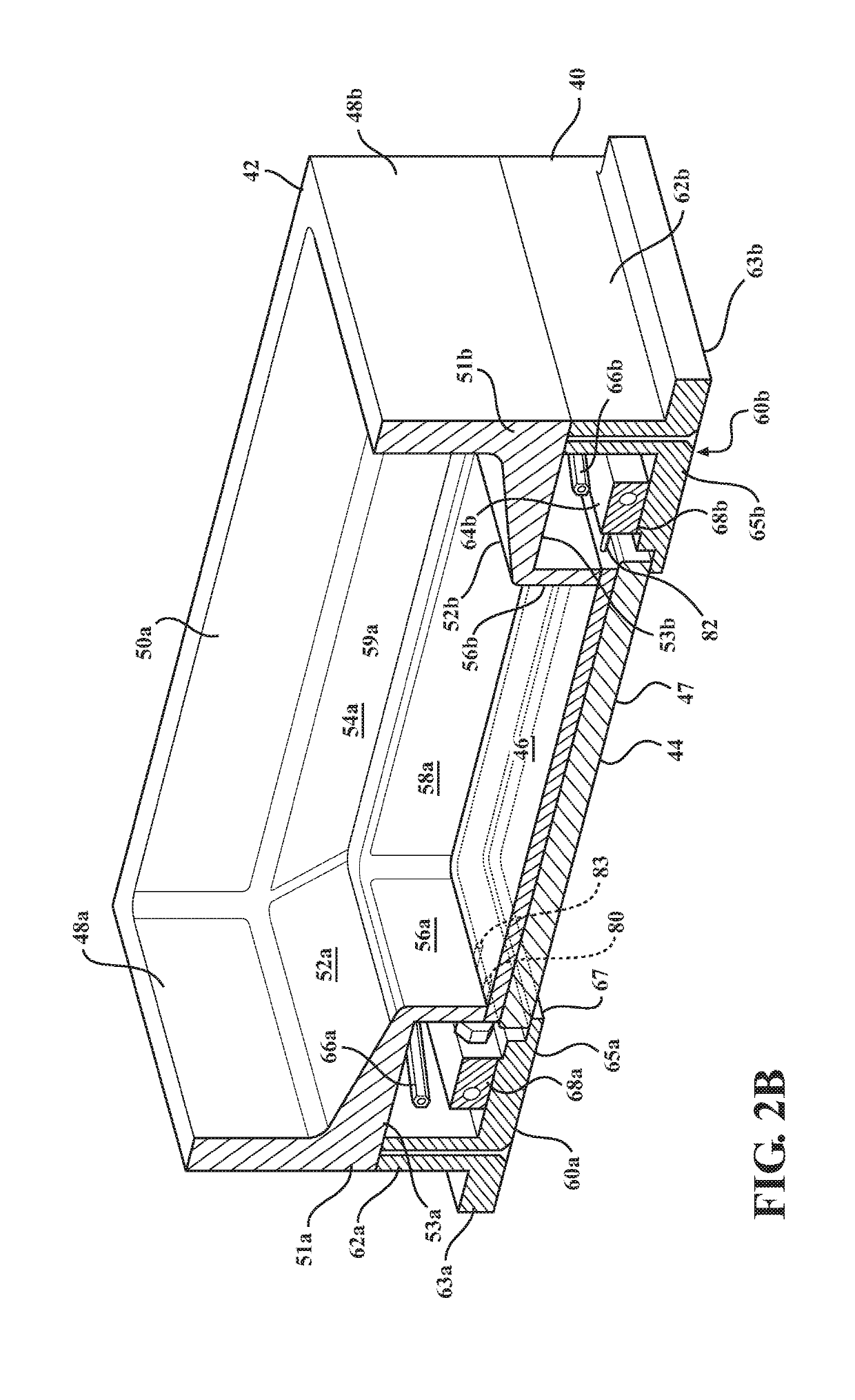

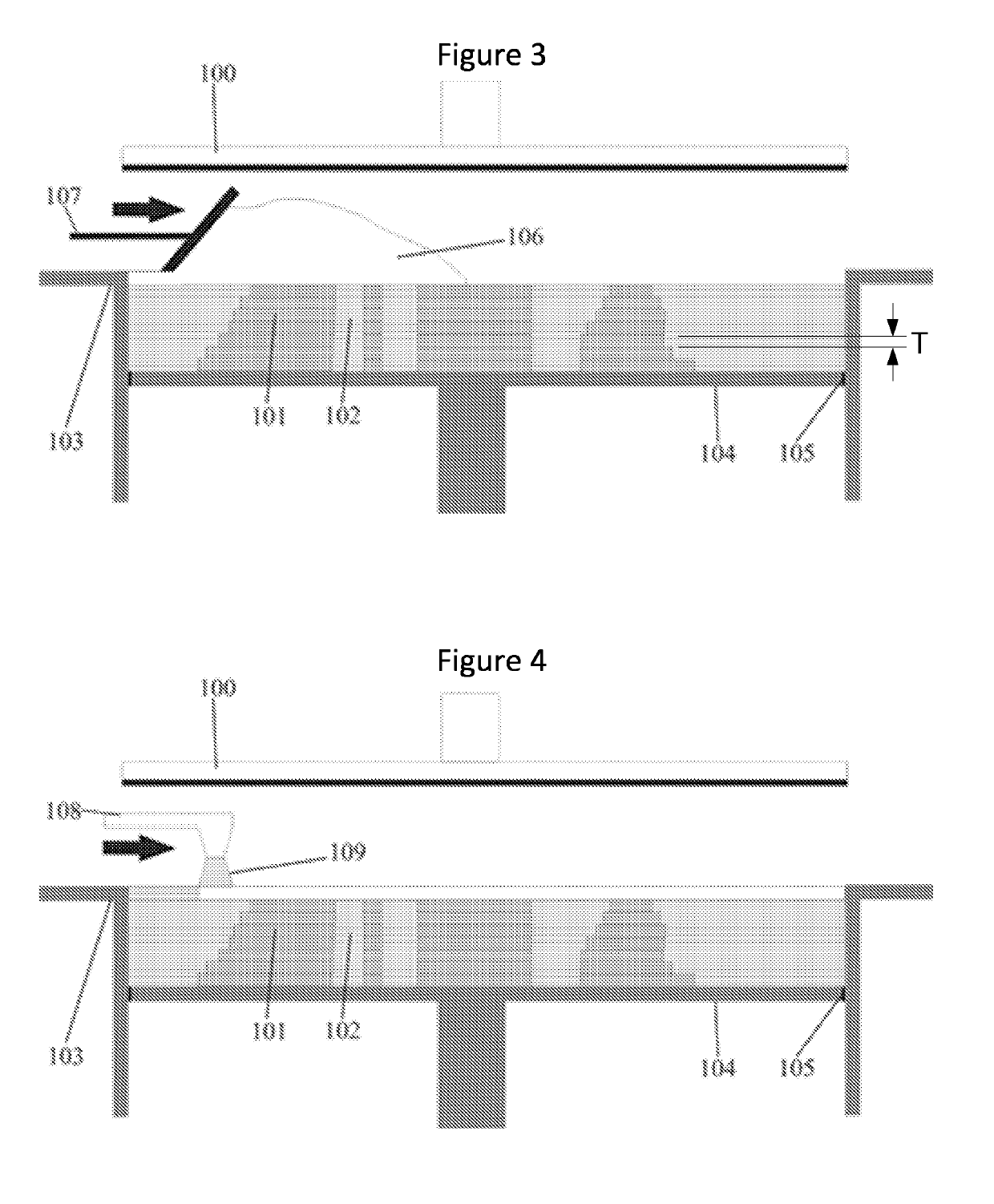

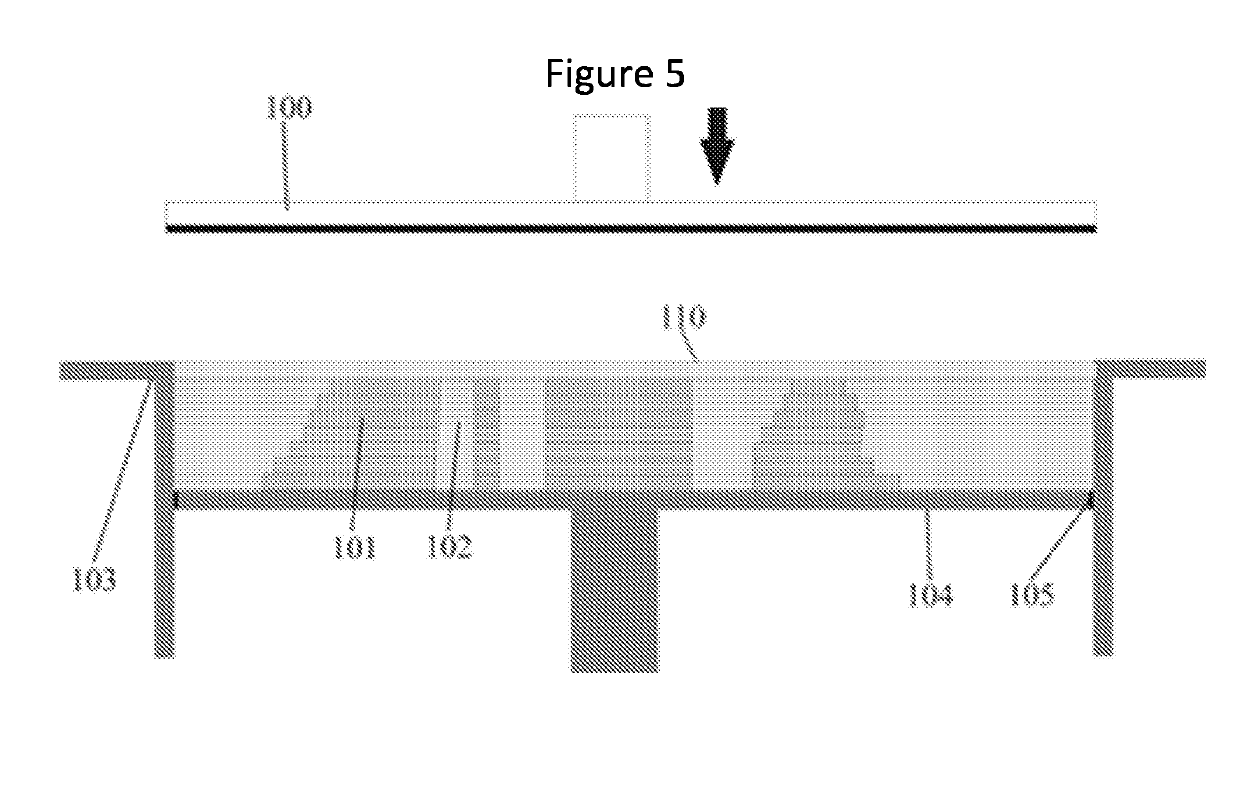

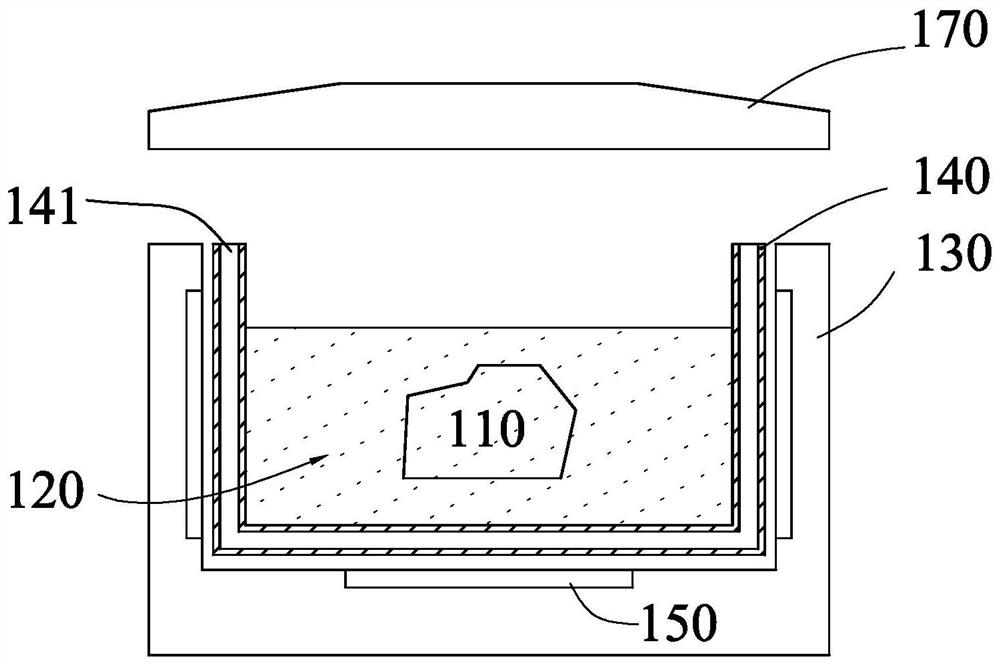

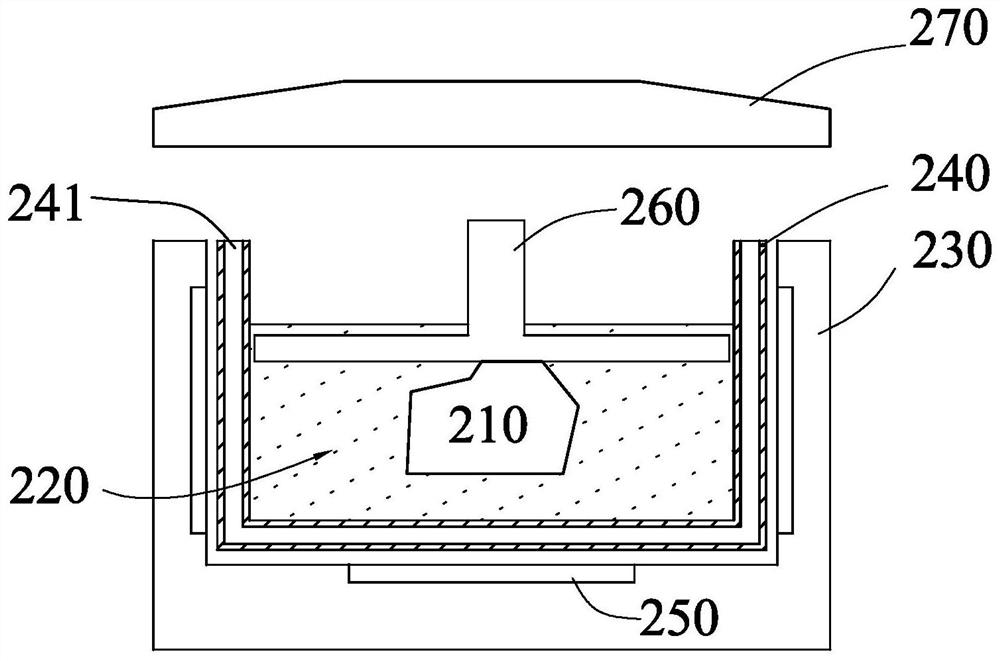

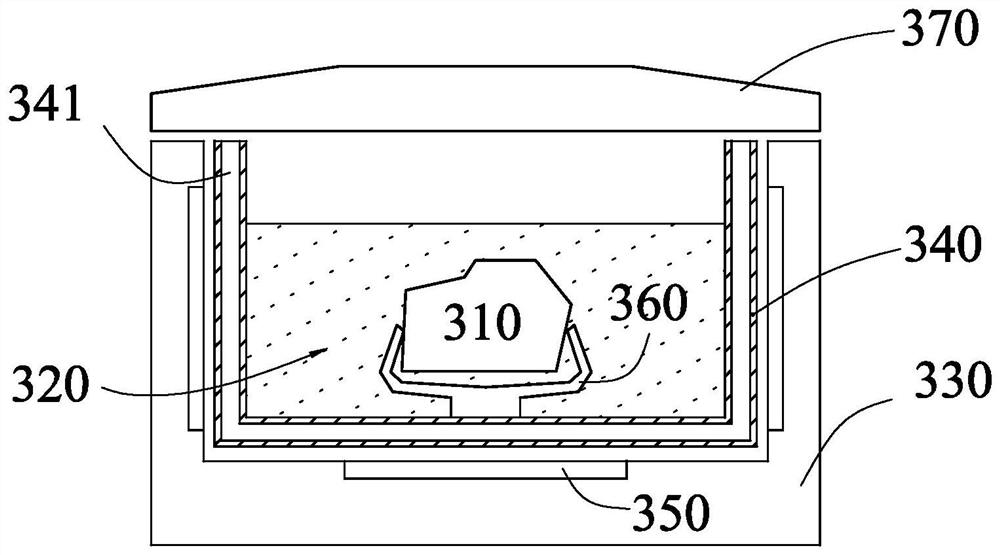

Method and Apparatus for Fabricating a Composite Object

ActiveUS20170106594A1Manufacturing platforms/substratesManufacturing driving meansComposite objectMaterials science

A method for fabricating a composite object with a computer-controlled apparatus, and the apparatus therefor. The comprises a reservoir containing liquid, curable first material, means to selectively solidify the first material and means to selectively deposit a second material. The method involves the steps of selectively depositing portions of the second material, and selectively solidifying portions of the first material, such that the solidified portions of the first material and the deposited portions of the second material form the composite object.

Owner:LAING OROURKE AUSTRALIA PTY LTD

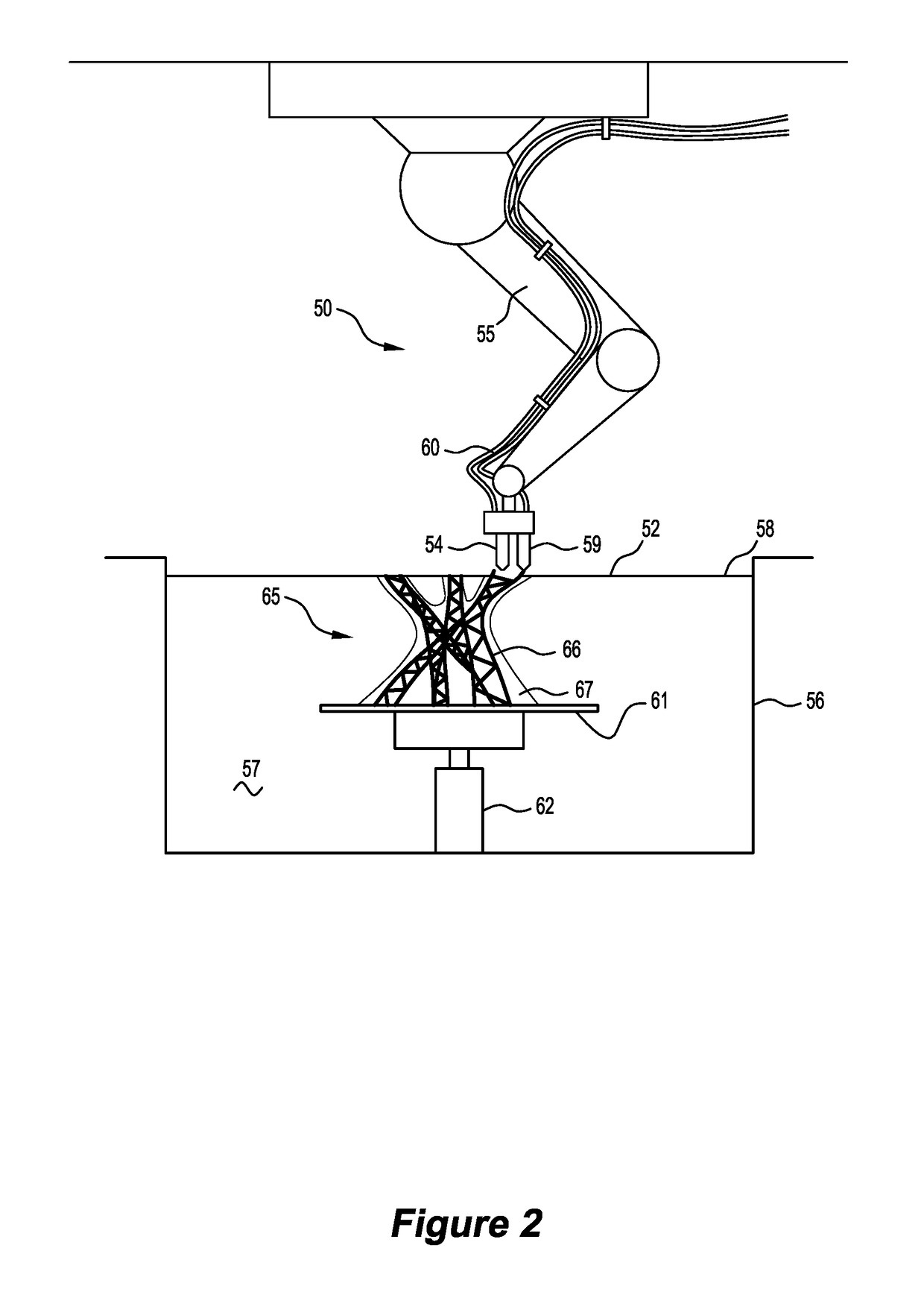

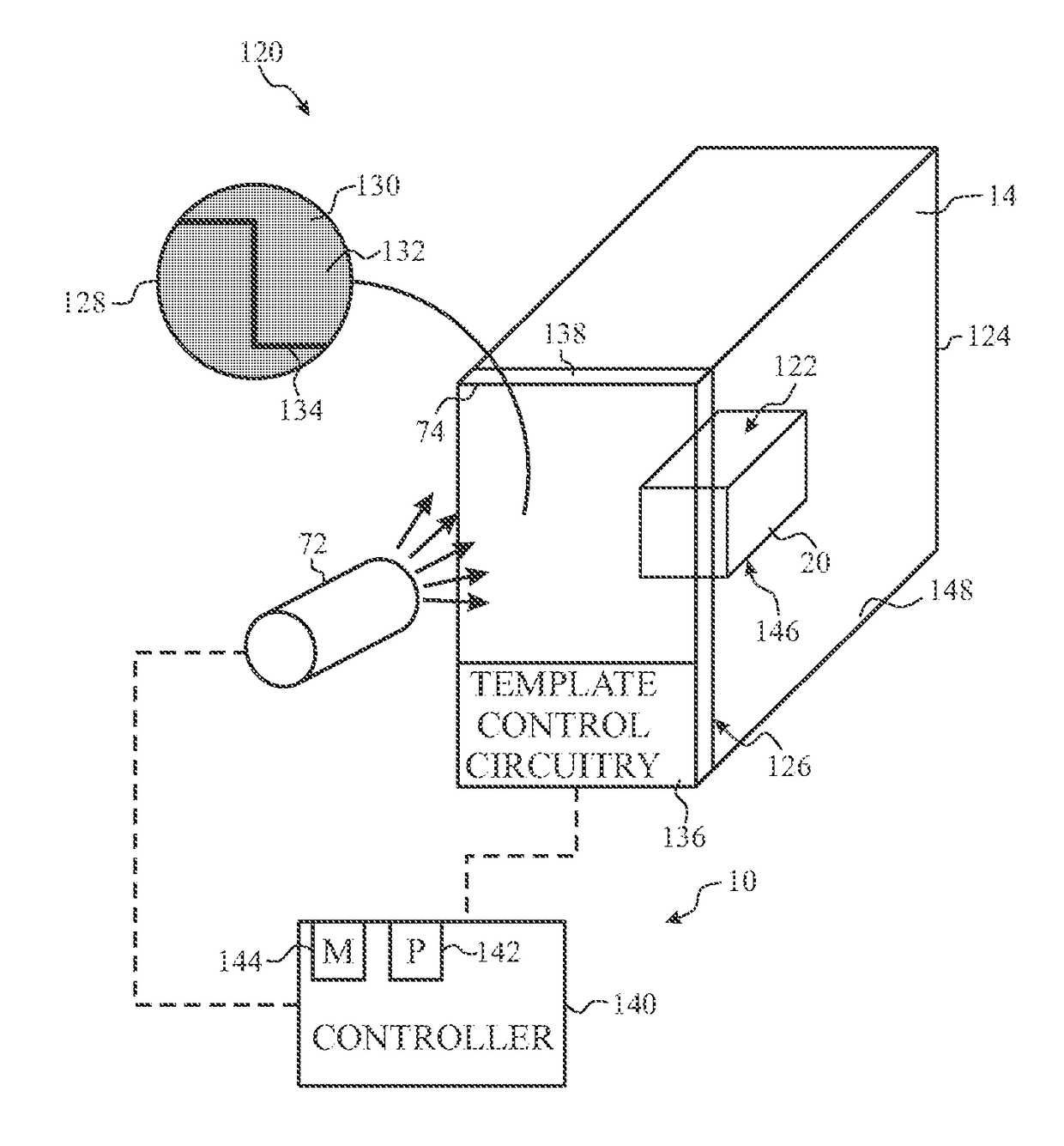

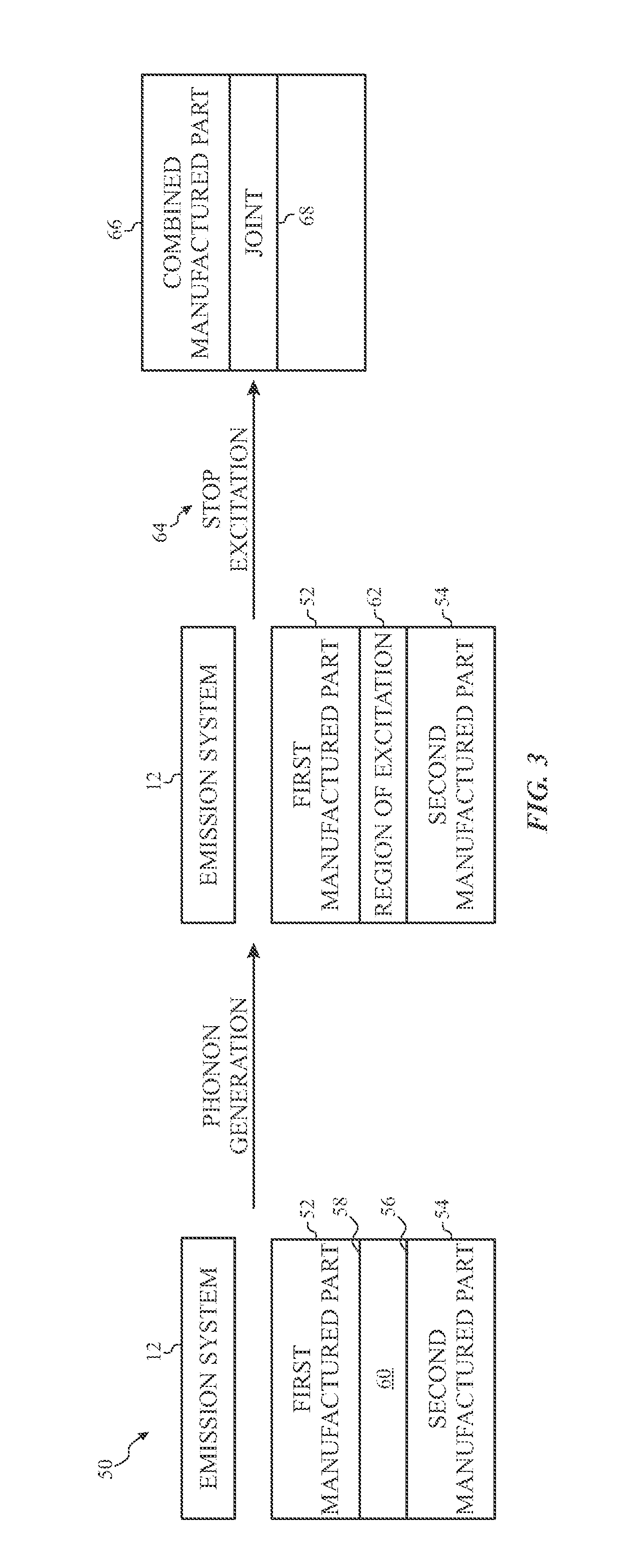

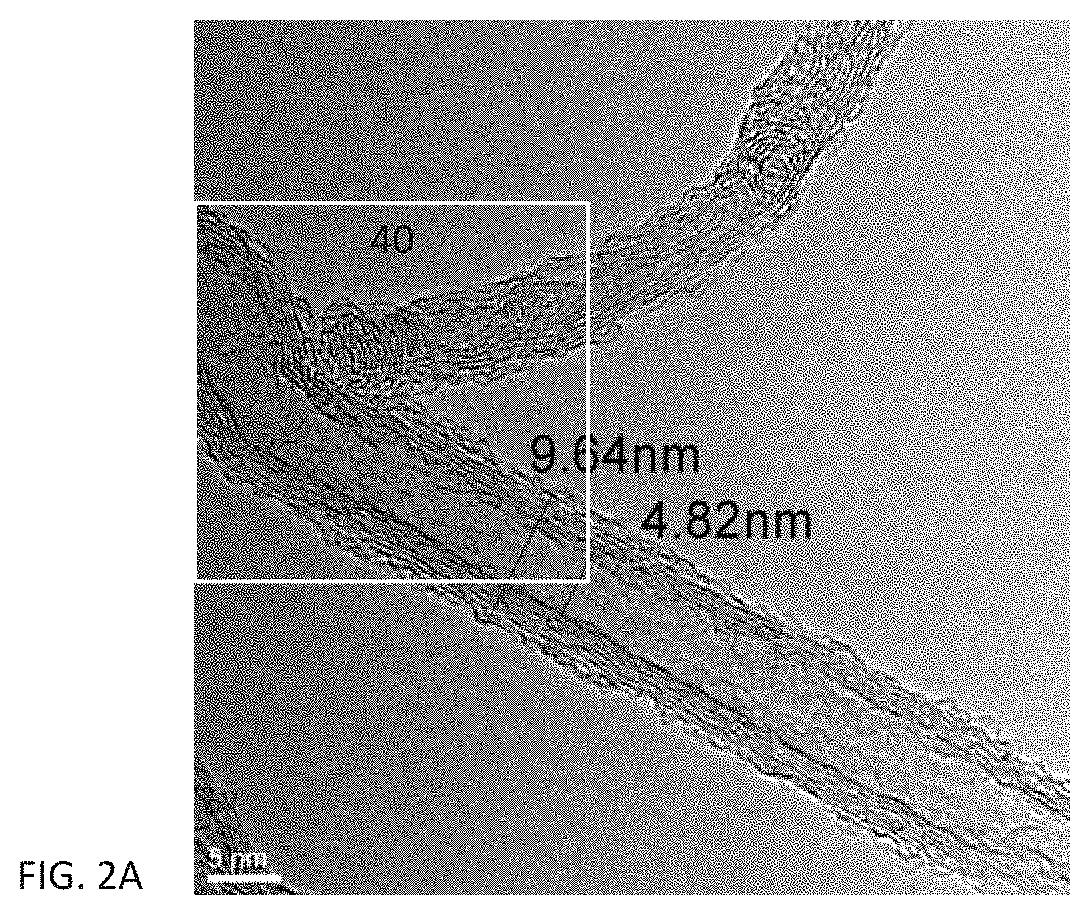

Phonon generation in bulk material for manufacturing

ActiveUS10065367B2Manufacturing irradiation arrangementsCeramic shaping apparatusEngineeringMechanical engineering

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

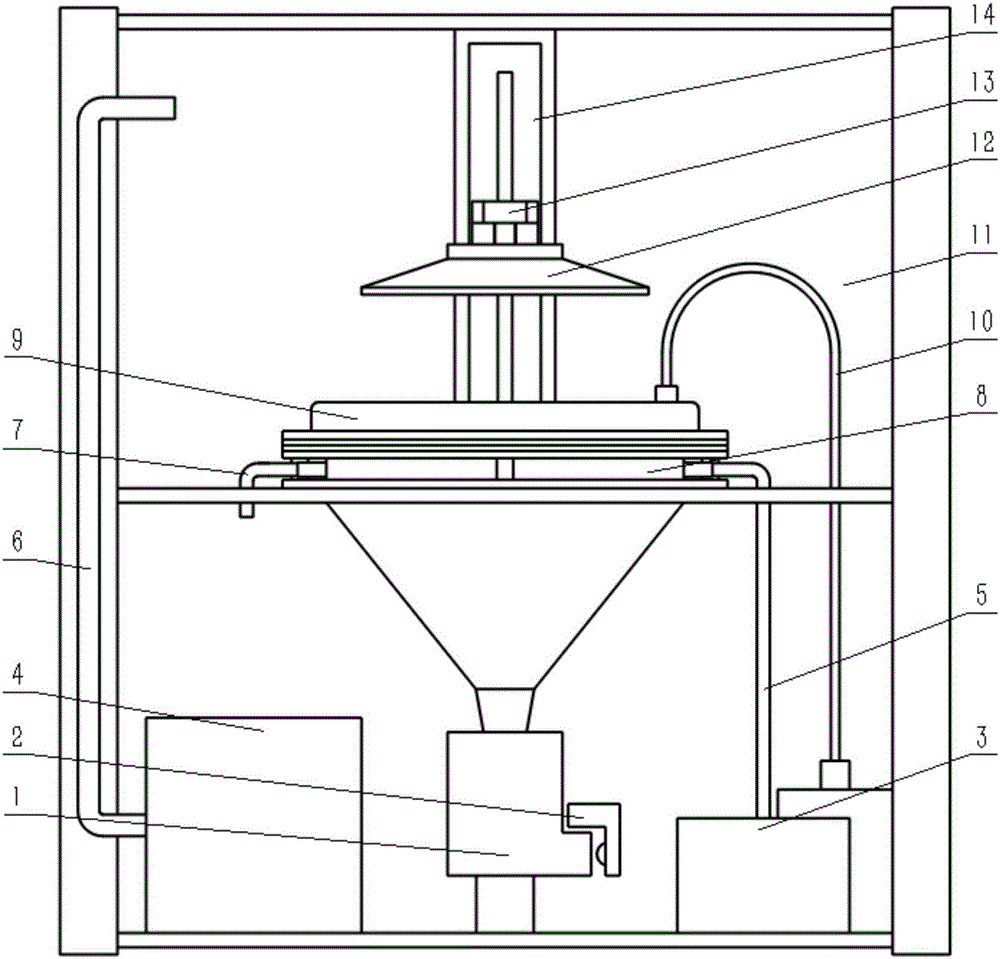

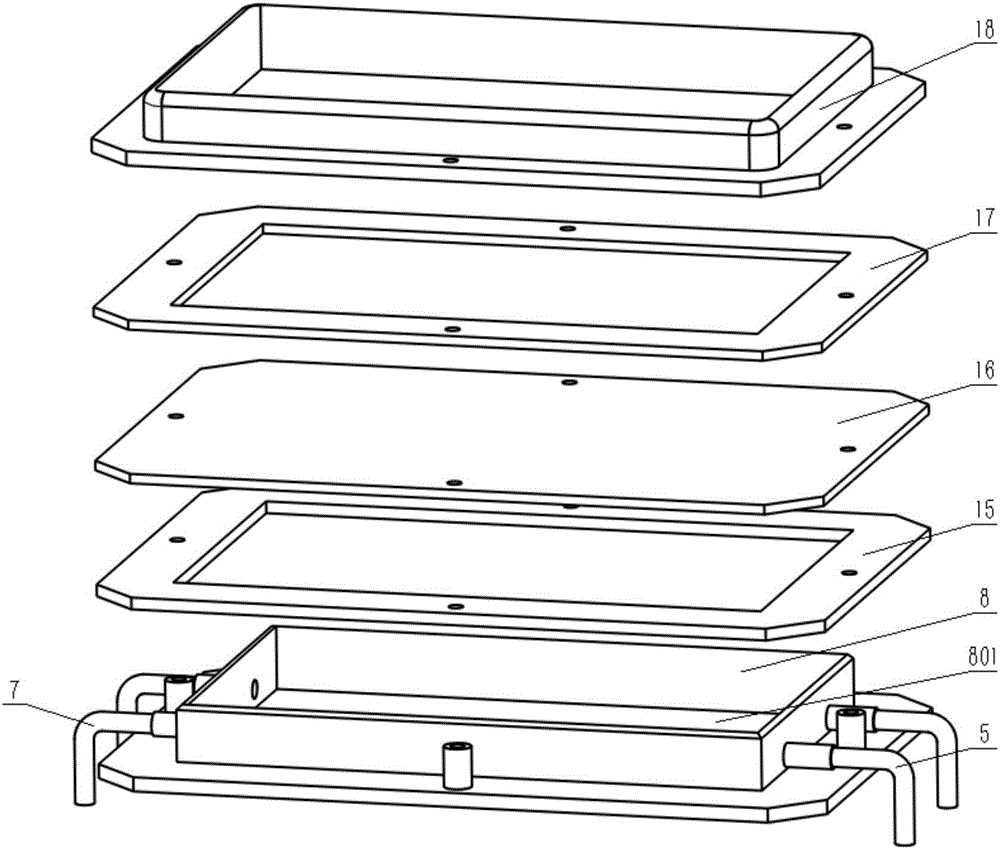

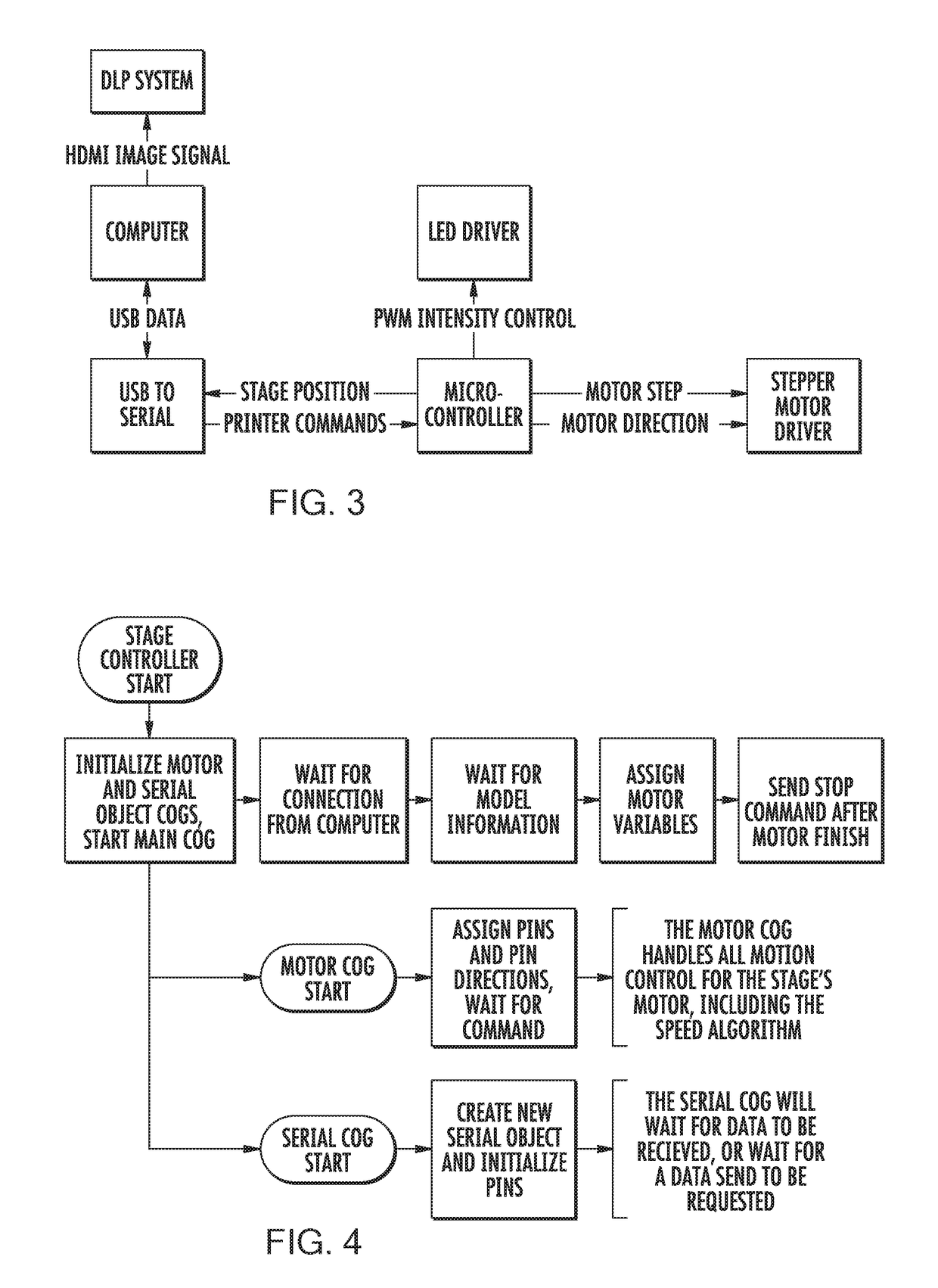

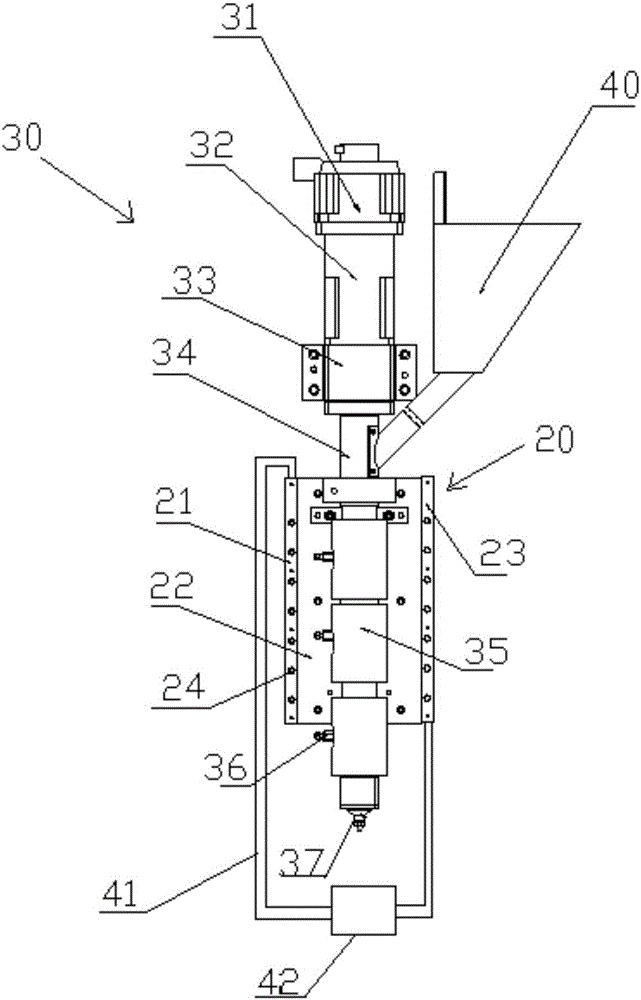

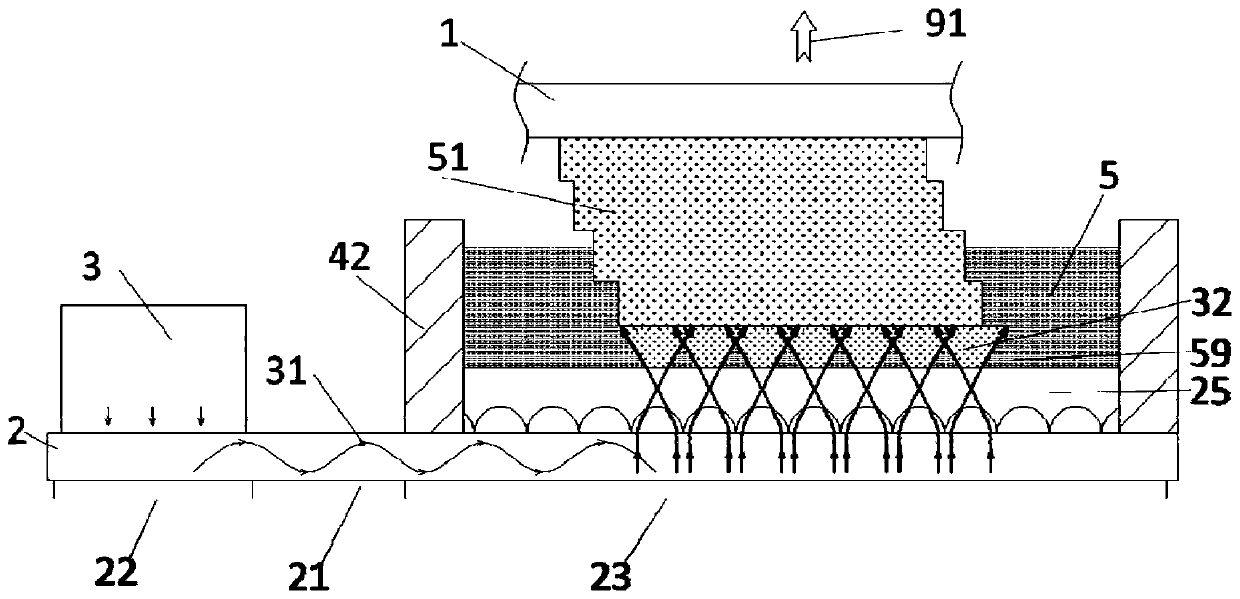

High-speed continuous photocuring type 3D printing device and working method thereof

ActiveCN106426915ALow costEfficient continuous printingManufacturing irradiation arrangementsManufacturing material handlingLiquid surfacesOxygen rich

The invention discloses a high-speed continuous photocuring type 3D printing device and a working method thereof. The 3D printing device comprises a machine case body which is divided into an upper cavity and a lower cavity by a middle partition board, wherein an image forming module is arranged in the lower cavity, a window box and an oxygen supply cooling module are arranged in the upper cavity and are combined to be fixedly mounted on the middle partition board, the oxygen supply cooling module is arranged right below the window box, and the image forming module I is arranged right below the window box; a printing platform is arranged right above the window box and is mounted on a Z-direction worktable; and the window box is connected with a raw material feeding unit. The 3D printing device is integrated with the advantages of a compound oxygen-rich film, oxygen supply cooling and liquid surface auxiliary pressurization of the window box, so that the low-cost and efficient continuous printing of large-sized products with arbitrary shapes is realized, the range of applicable materials is wide, the printed products are high in precision and quality and good in uniformity, and the process is stable and reliable. An industrial-grade solution is provided for the high-speed continuous photocuring type 3D printing.

Owner:SHENZHEN ELEGOO TECH CO LTD

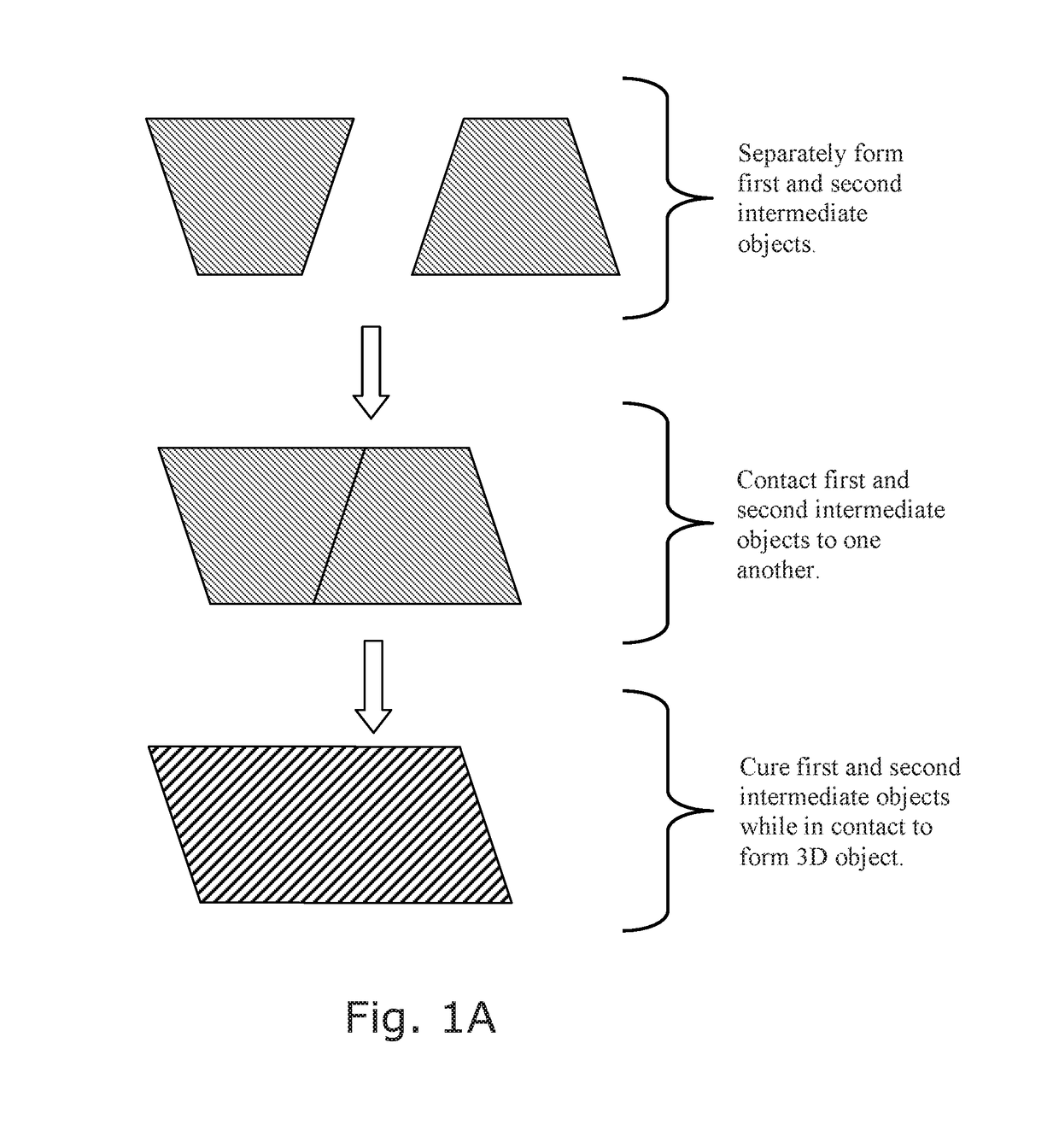

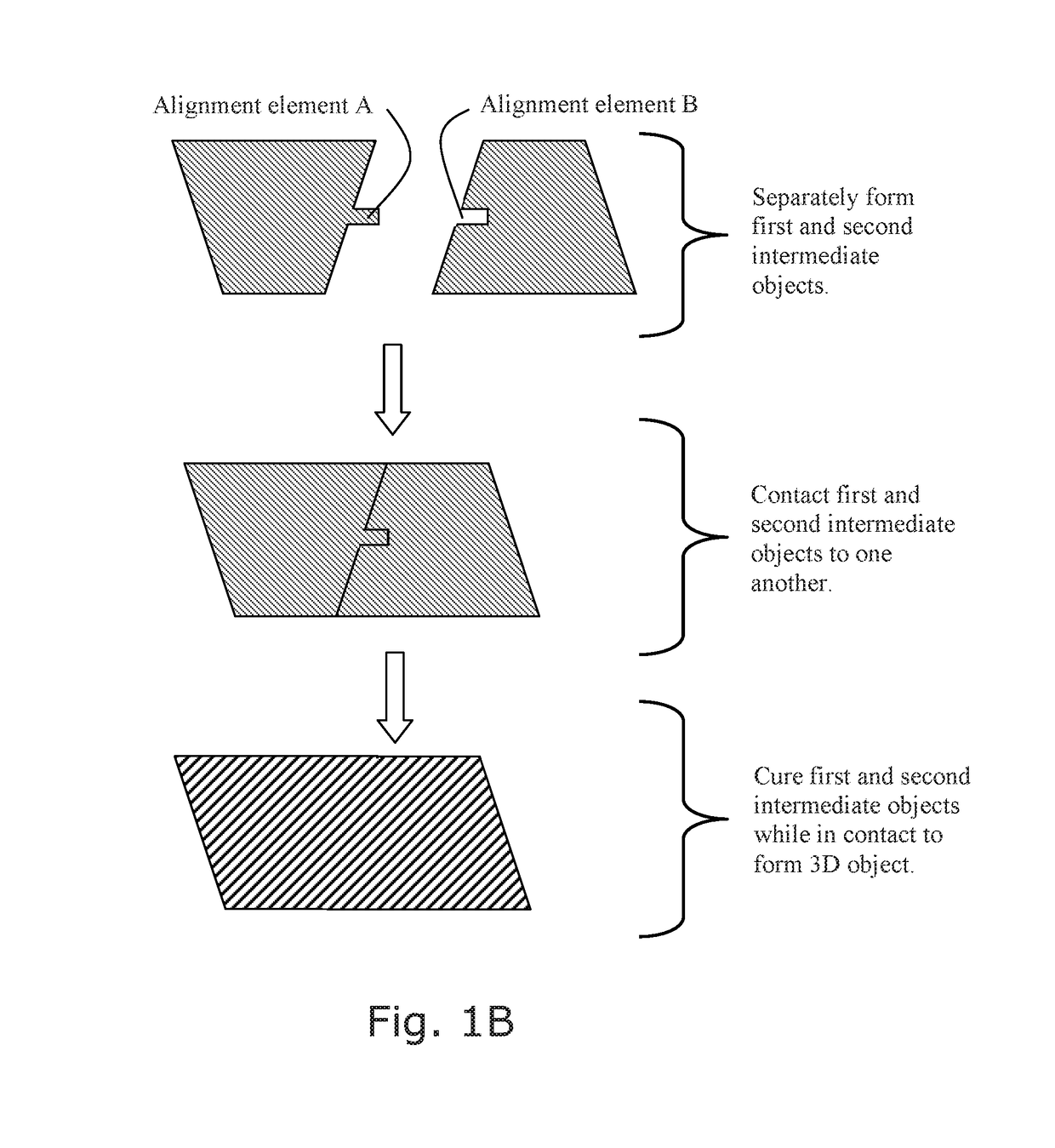

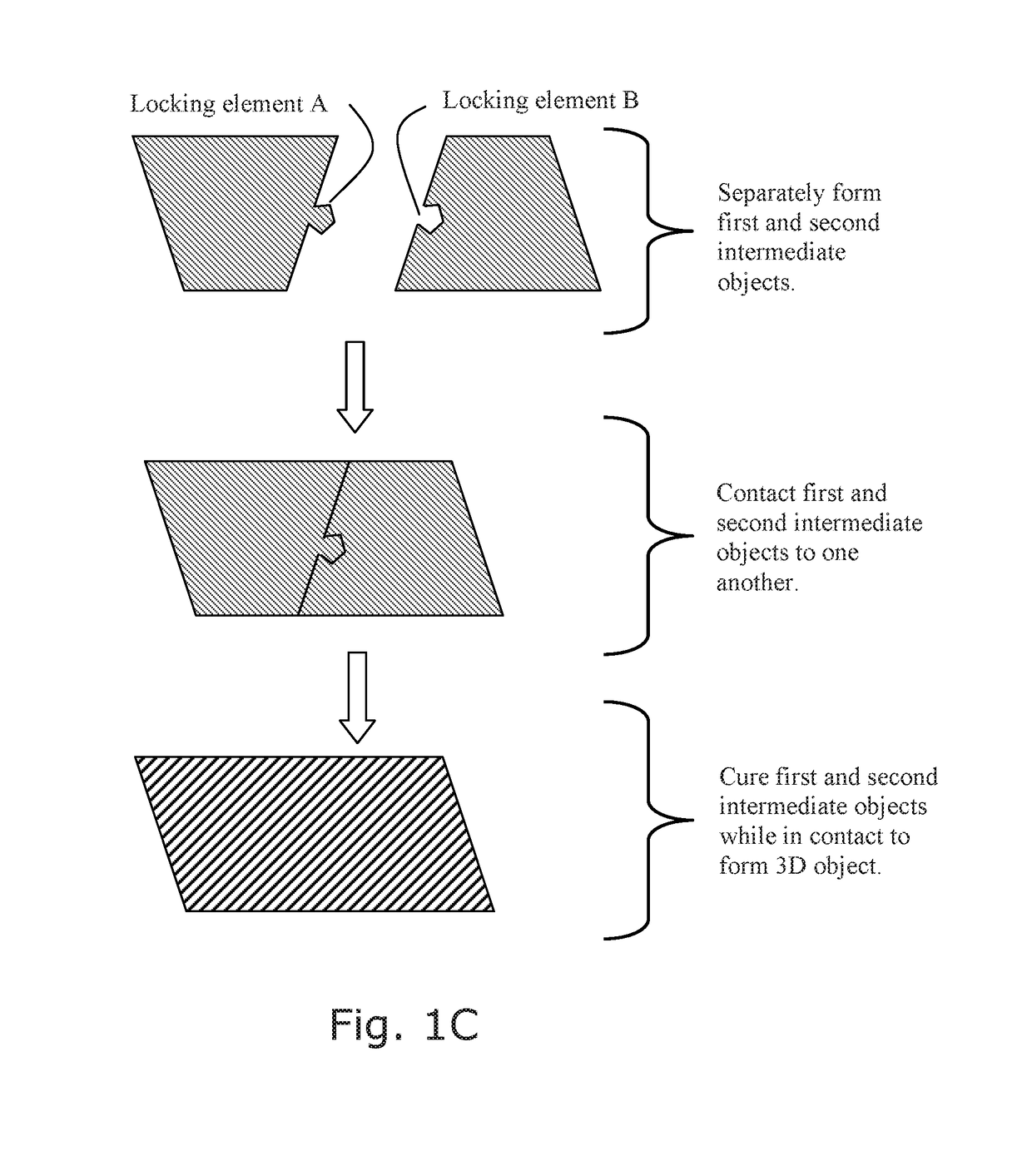

Fabrication of compound products from multiple intermediates by additive manufacturing with dual cure resins

ActiveUS20180370125A1Reduce stiffnessIncrease elasticityManufacturing platforms/substratesManufacturing irradiation arrangementsDual cureReactive components

Owner:CARBON INC

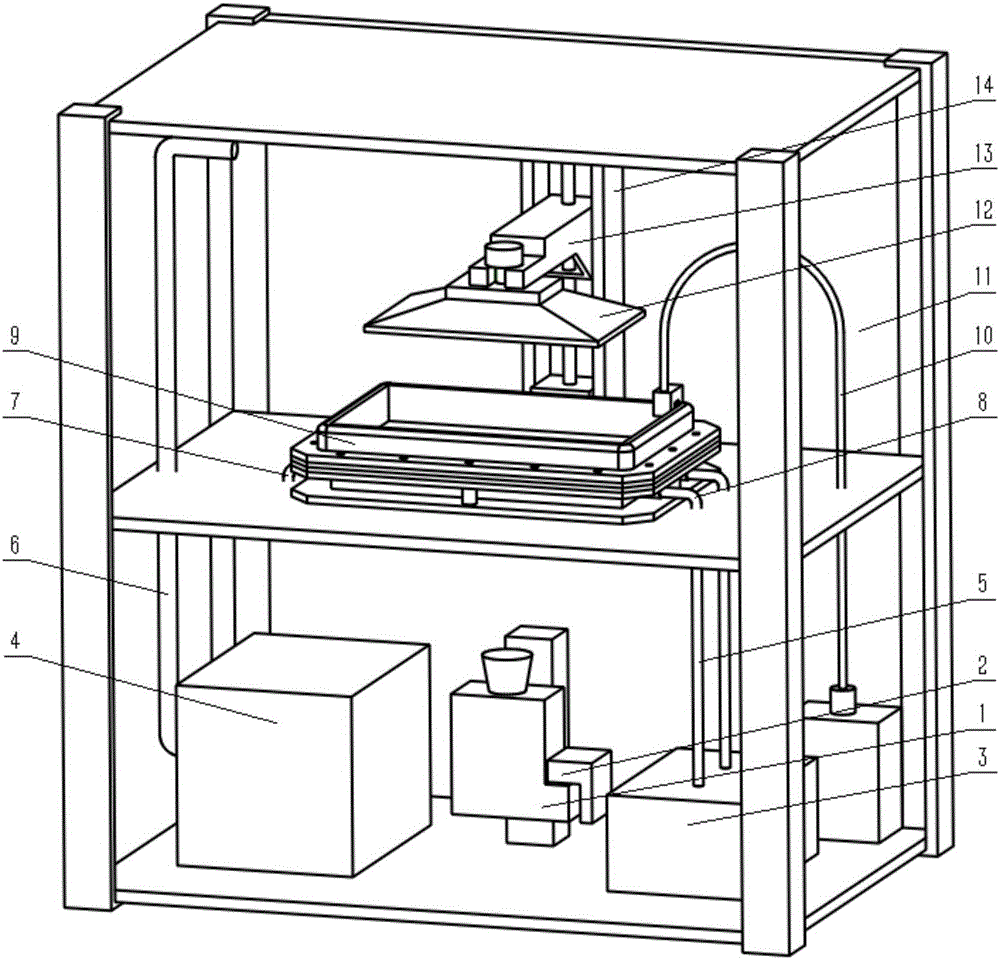

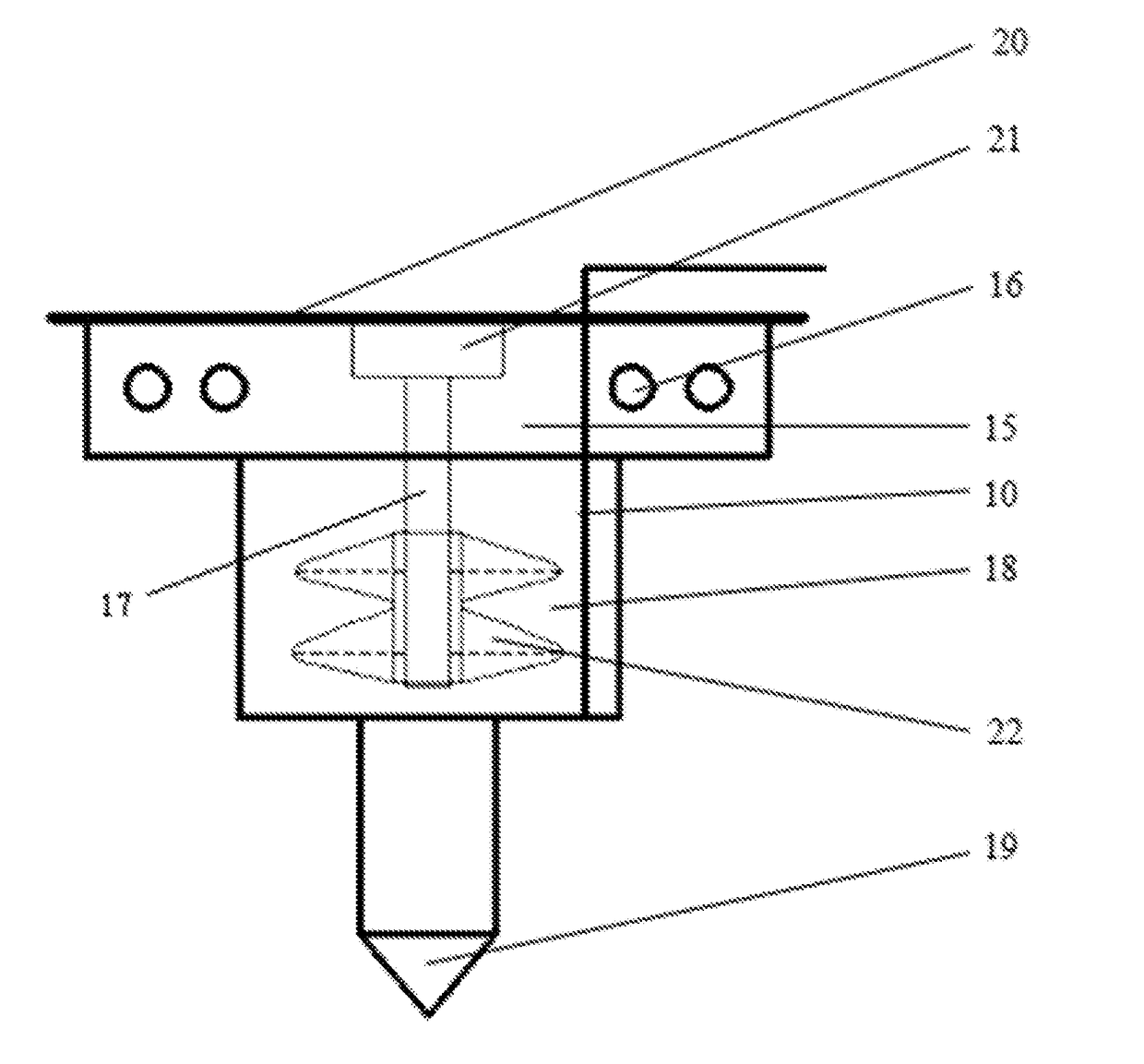

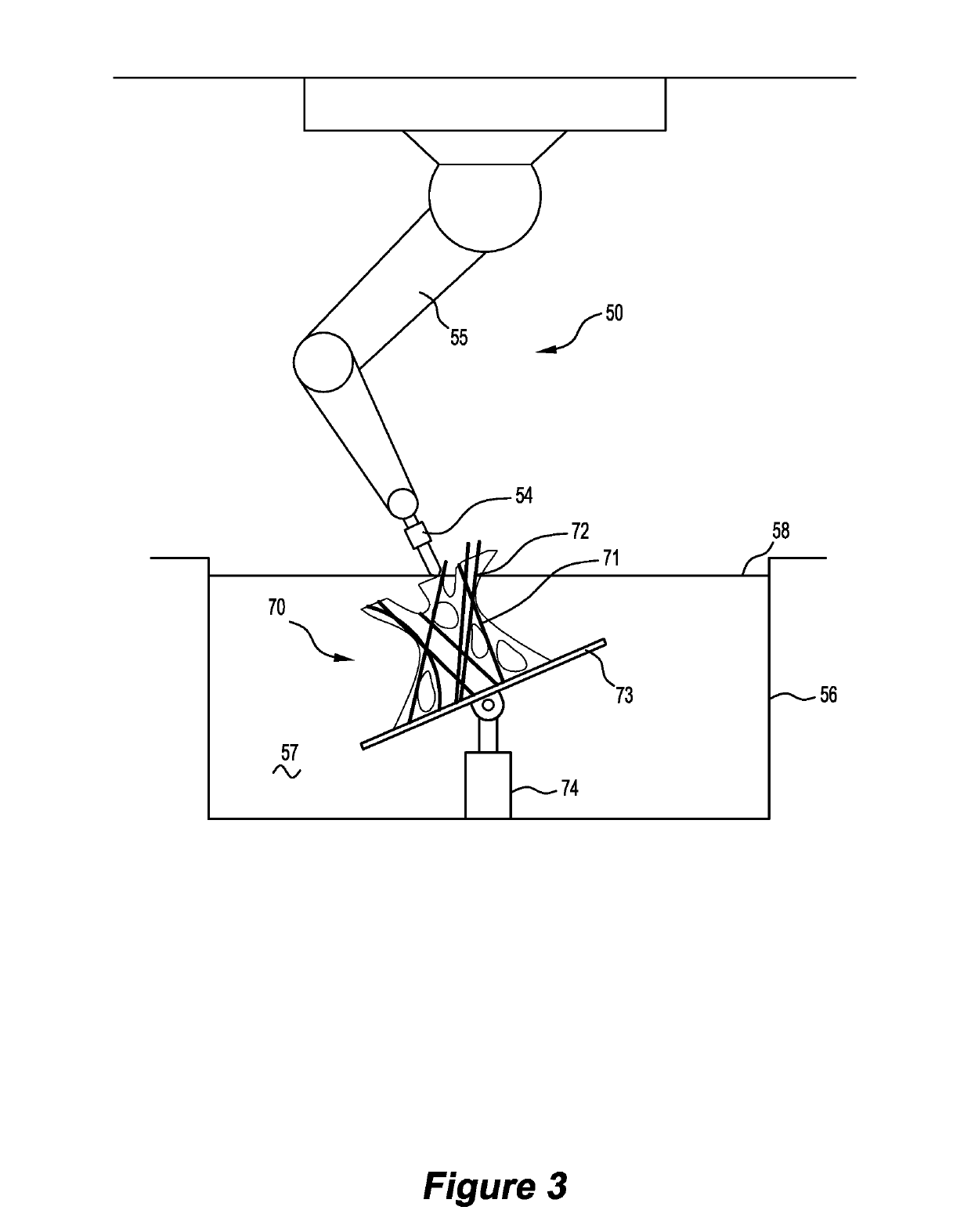

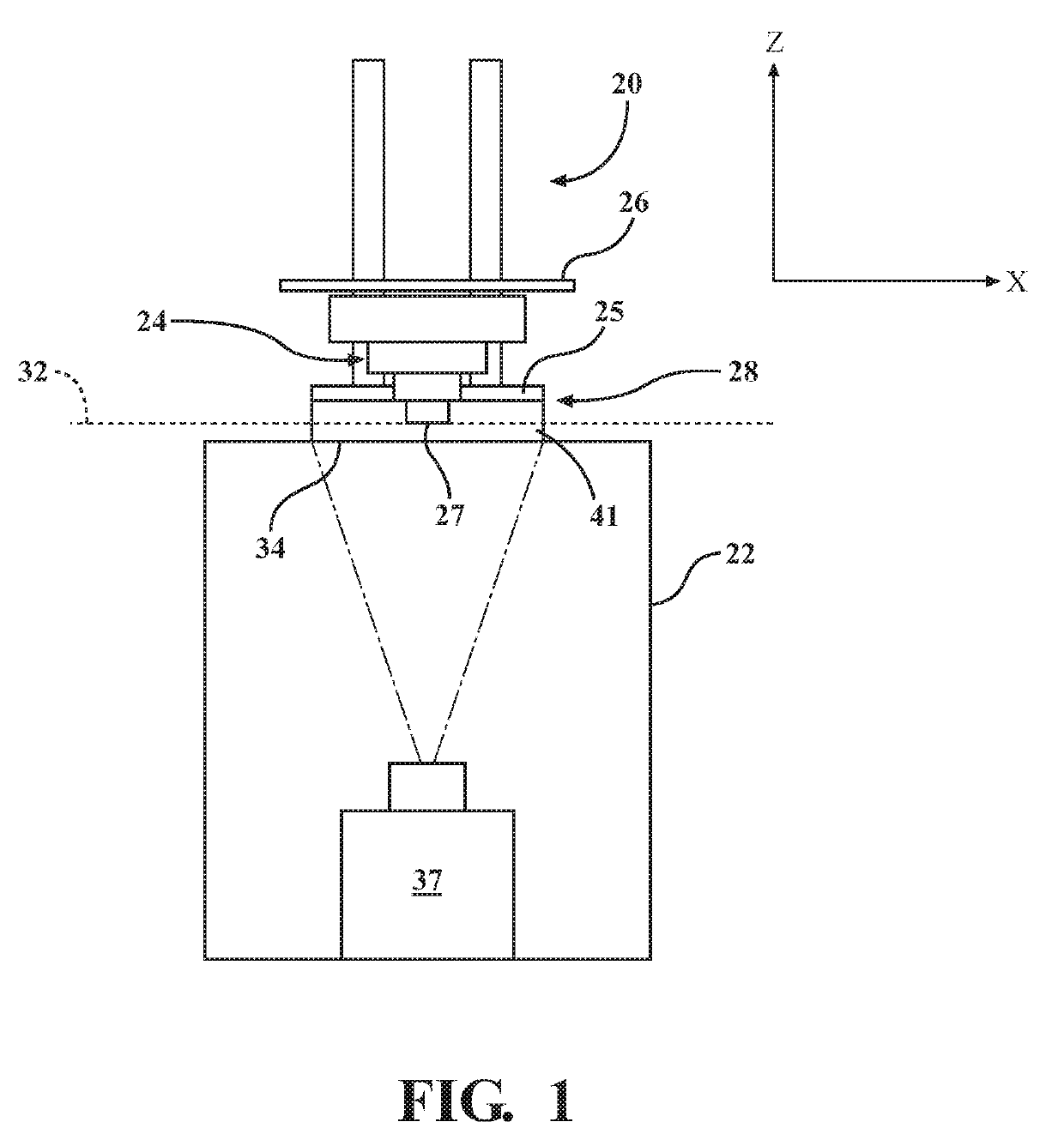

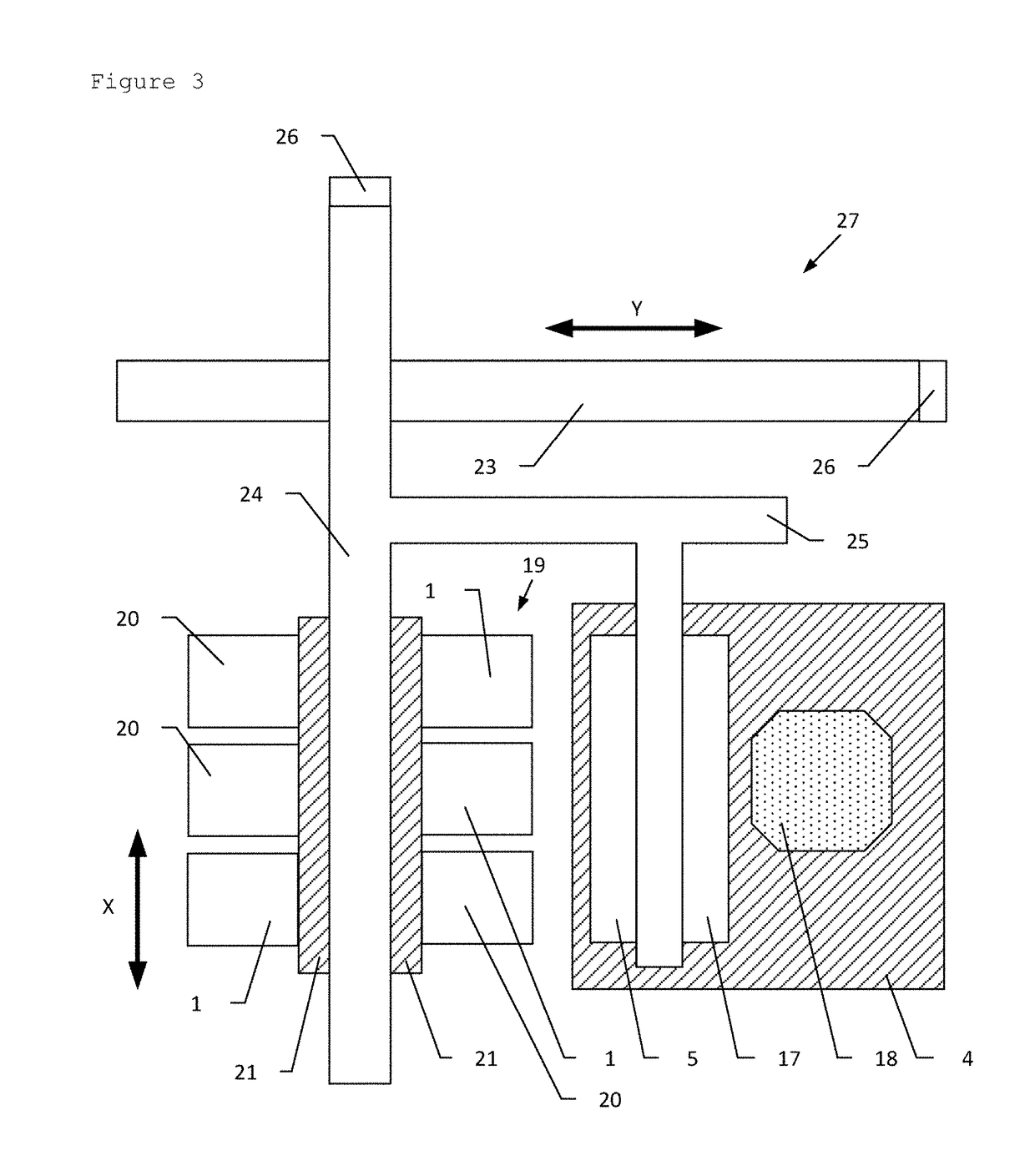

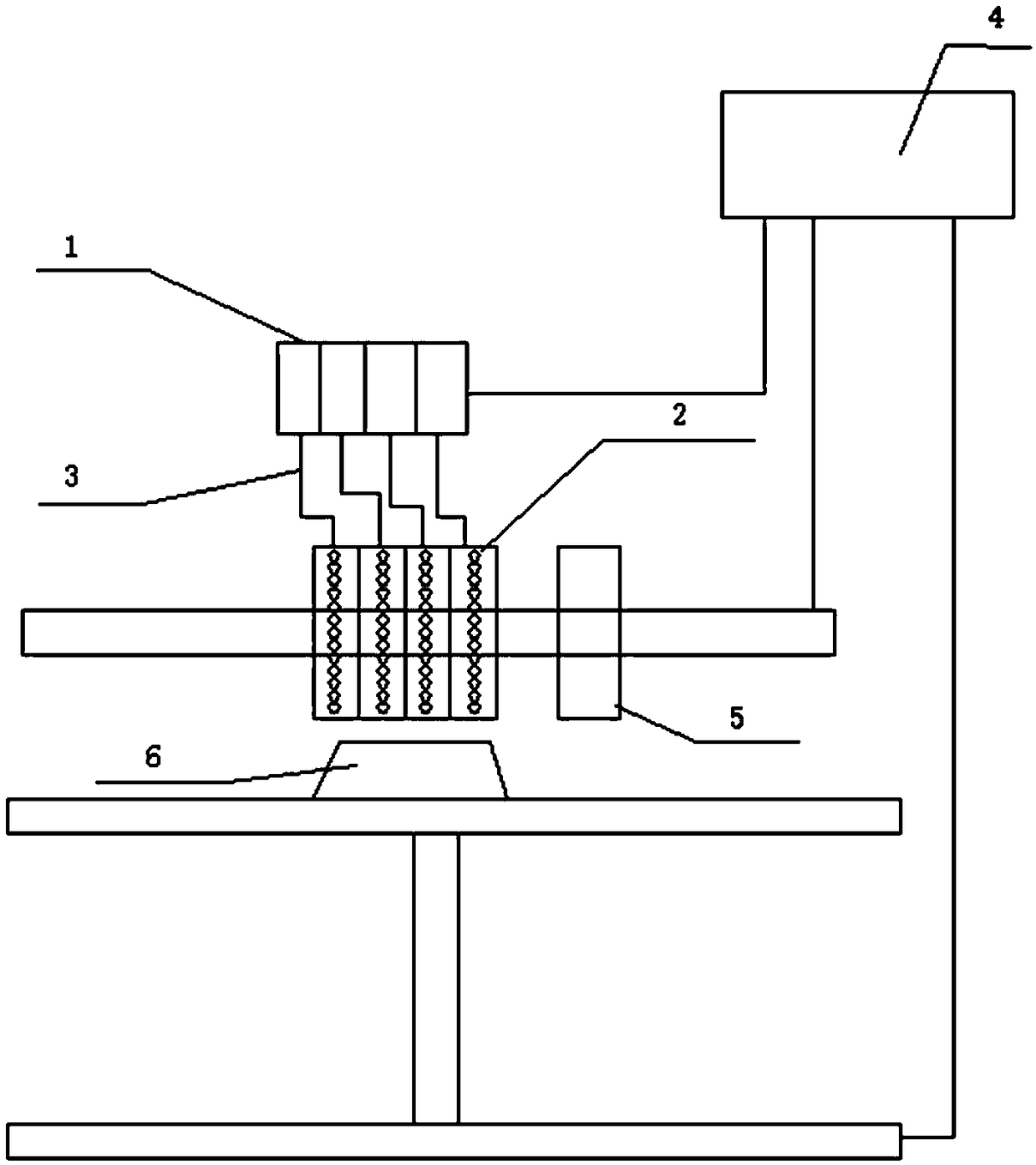

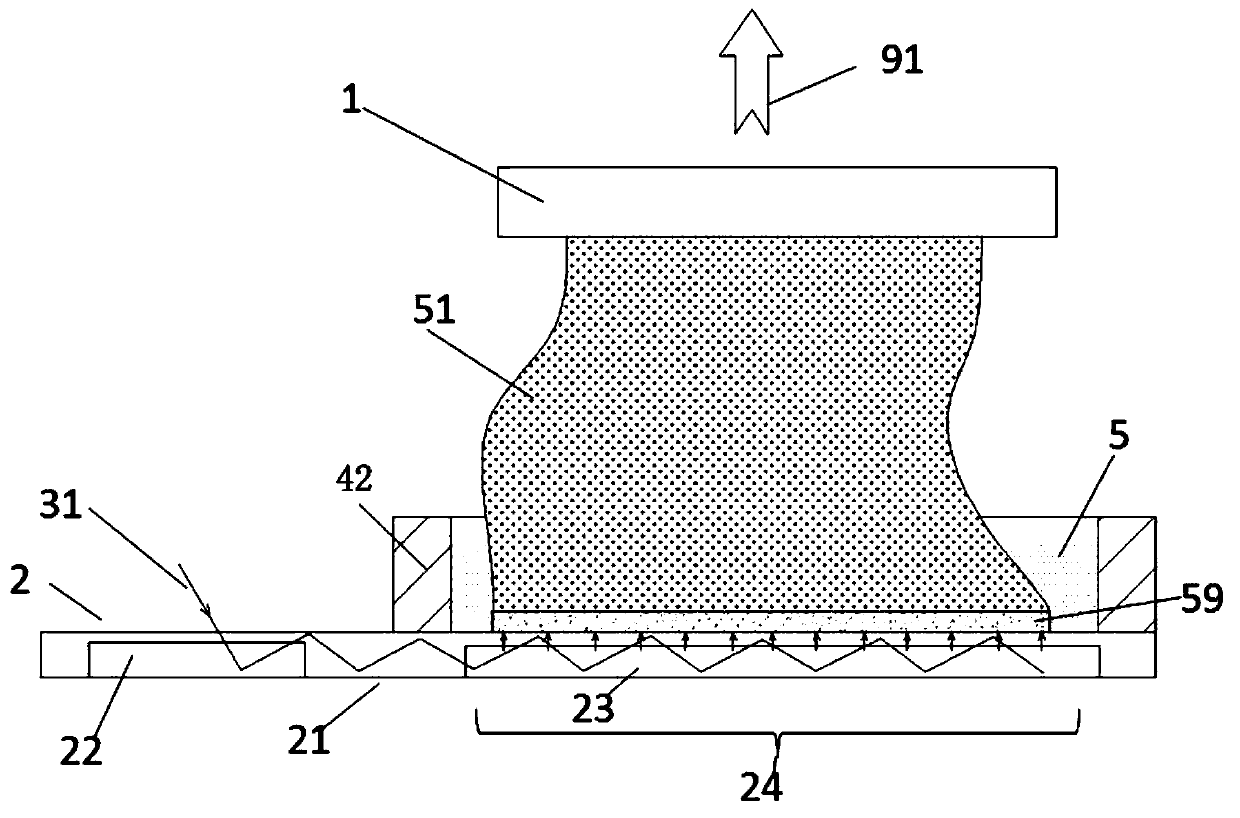

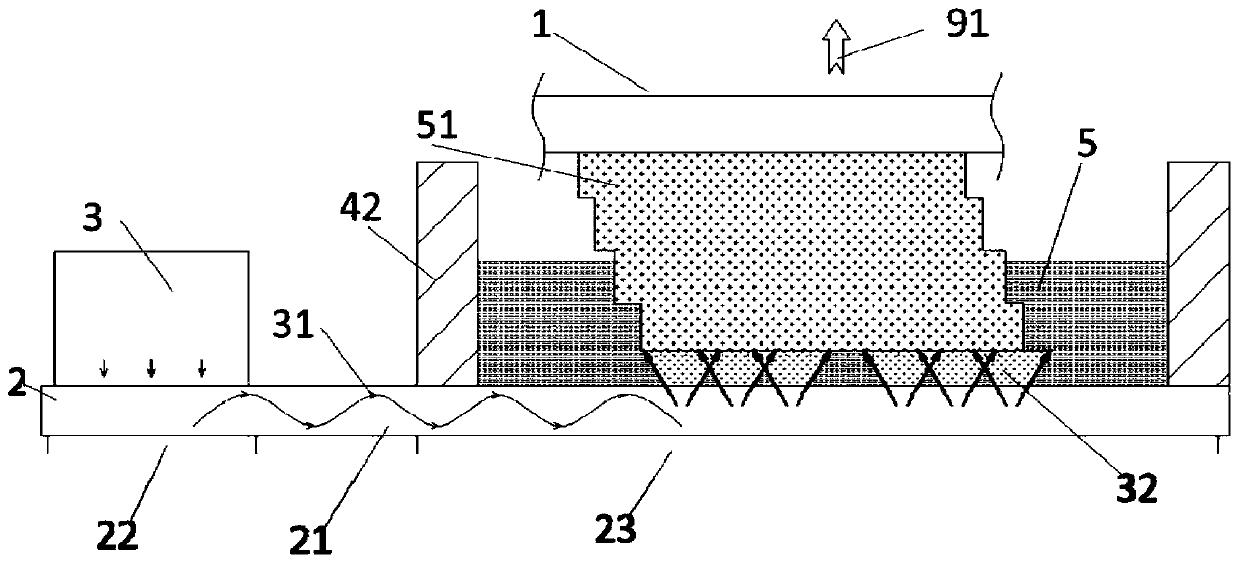

3D printing apparatus and method of using the single-printhead achieved multi-material and multi-scale printing

ActiveUS20180229433A1Easy to controlImprove performanceManufacturing platforms/substratesRotary stirring mixersMulti materialScale structure

The present invention discloses a 3D printing apparatus and method of using a single-printhead to achieve multi-material and multi-scale printing. The apparatus comprises a base, a worktable, a wafer stage, a substrate, a power source, a printhead, and a support. The printhead is provided with a plurality of material inlets, each of which is connected to a different micro-feeding pump; and multiple materials are thoroughly mixed under the action of an agitator after being fed into the printhead, thereby achieving multi-material printing. In the present invention, a macroscopic geometrical shape of a printed object, microstructures in the interior and on the surface of the object are reasonably controlled, and integrated manufacturing of multi-scale structures is achieved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Method and apparatus for fabricating a composite object

InactiveUS10293594B2Manufacturing platforms/substratesManufacturing driving meansComposite objectMaterials science

A method for fabricating a composite object with a computer-controlled apparatus, and the apparatus therefor. The comprises a reservoir containing liquid, curable first material, means to selectively solidify the first material and means to selectively deposit a second material. The method involves the steps of selectively depositing portions of the second material, and selectively solidifying portions of the first material, such that the solidified portions of the first material and the deposited portions of the second material form the composite object.

Owner:LAING OROURKE AUSTRALIA PTY LTD

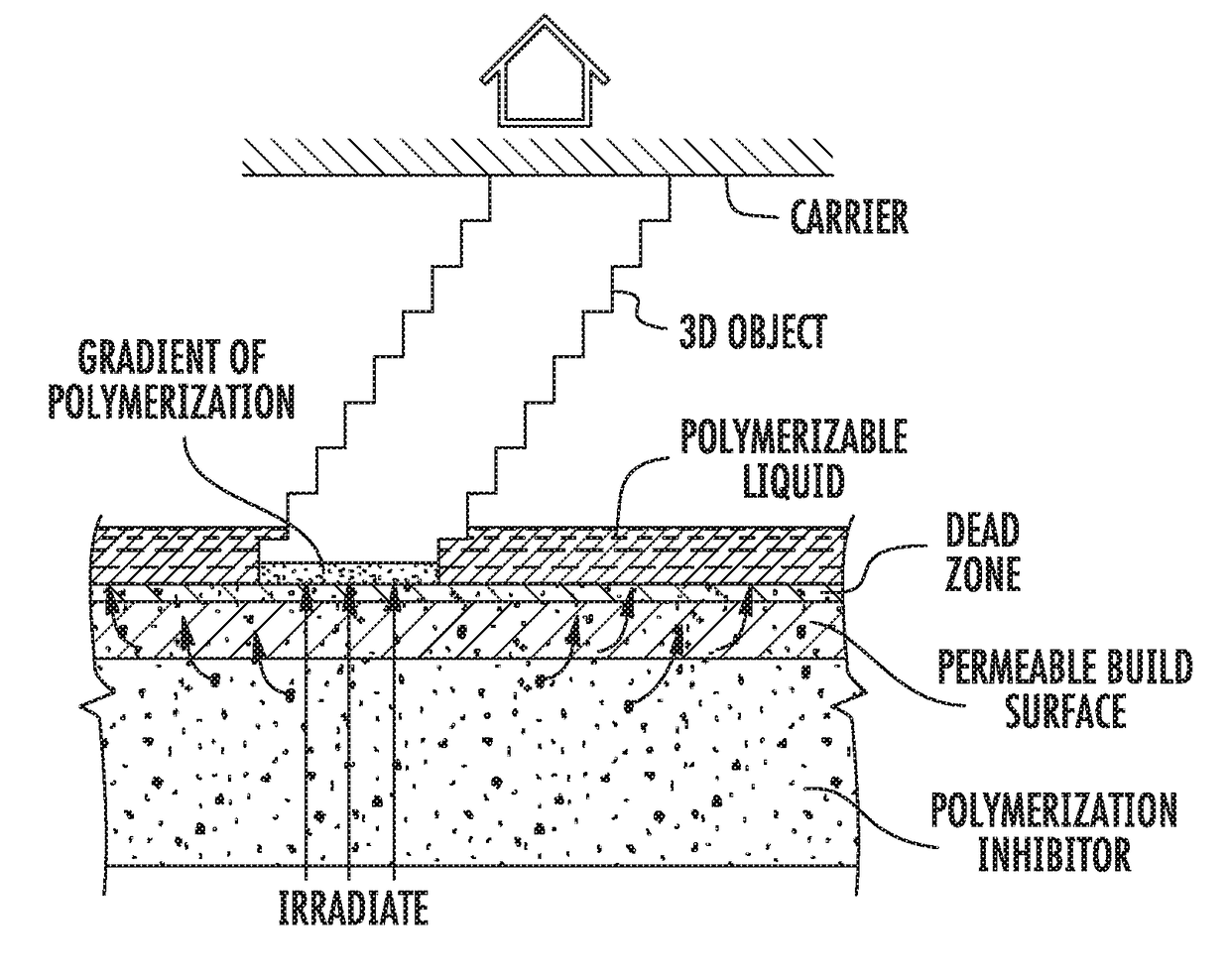

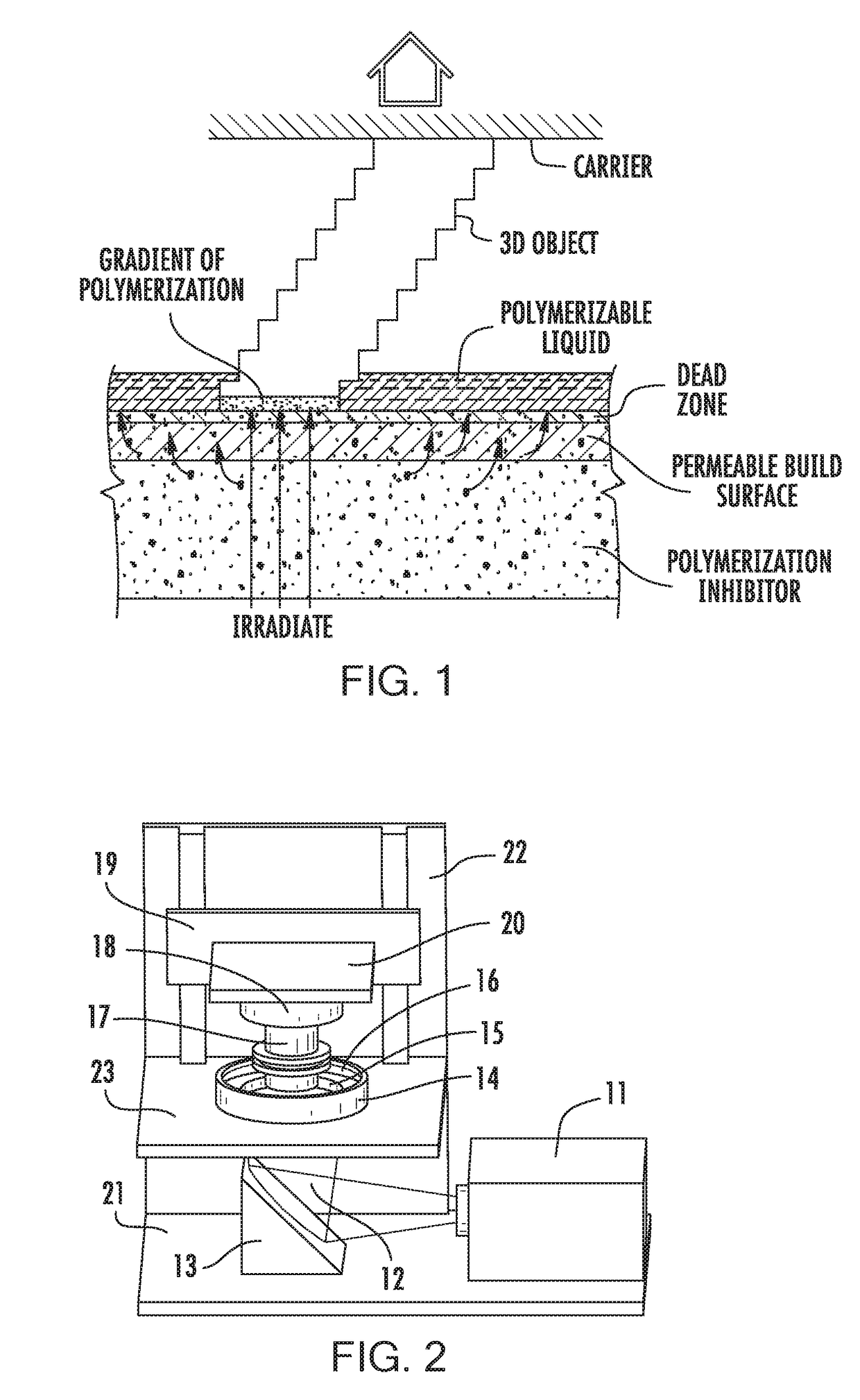

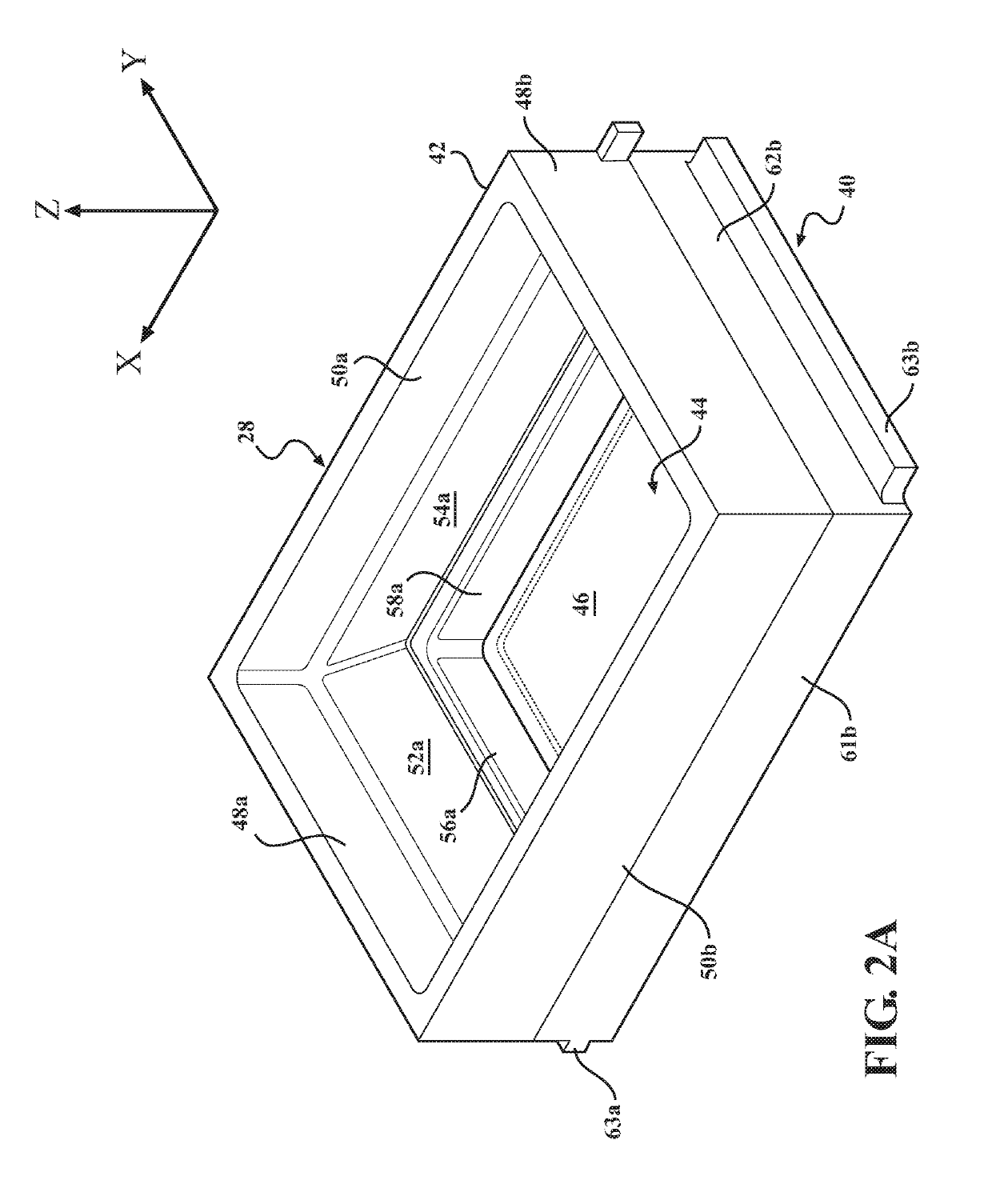

Fabrication of three dimensional objects with variable slice thickness

InactiveUS20180015662A1Enhance or speed the refilling of the build regionEnhance or speed the refilling of said build regionManufacturing platforms/substratesManufacturing irradiation arrangementsSlice thicknessMechanical engineering

A method of forming the body portion of a three-dimensional object from a polymerizable liquid by the process of continuous liquid interface printing is described. The process includes advancing a carrier for the object away from a build surface while irradiating a build region between the carrier and build surface in a pattern of advancing and irradiating defined by an operating mode, with the body portion having a plurality of contiguous segments and with the irradiating carried out in sequentially presented slices of exposure, each having a pattern that corresponds to a segment of the body portion. Each segment has a thickness (e.g., in Z or vertical dimension) during the forming thereof. In the present invention, slice thickness is changed among the slices at least once during the formation of the body portion.

Owner:CARBON INC

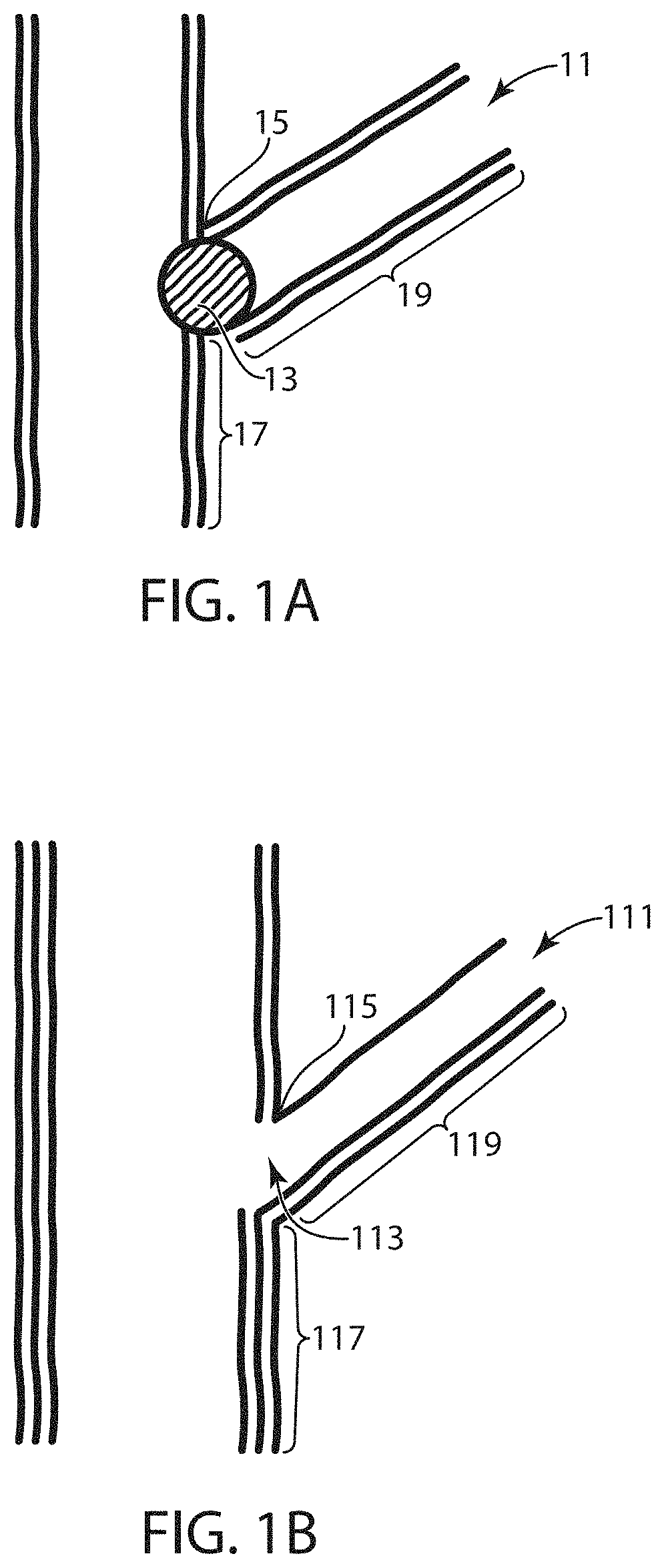

Deflecting Member for Making Fibrous Structures

Owner:THE PROCTER & GAMBLE COMPANY

Method of stabilizing a photohardening inhibitor-permeable film in the manufacture of three-dimensional objects

ActiveUS20190270243A1Manufacturing enclosuresManufacturing irradiation arrangementsMaterials scienceThin membrane

Owner:GLOBAL FILTRATION SYST

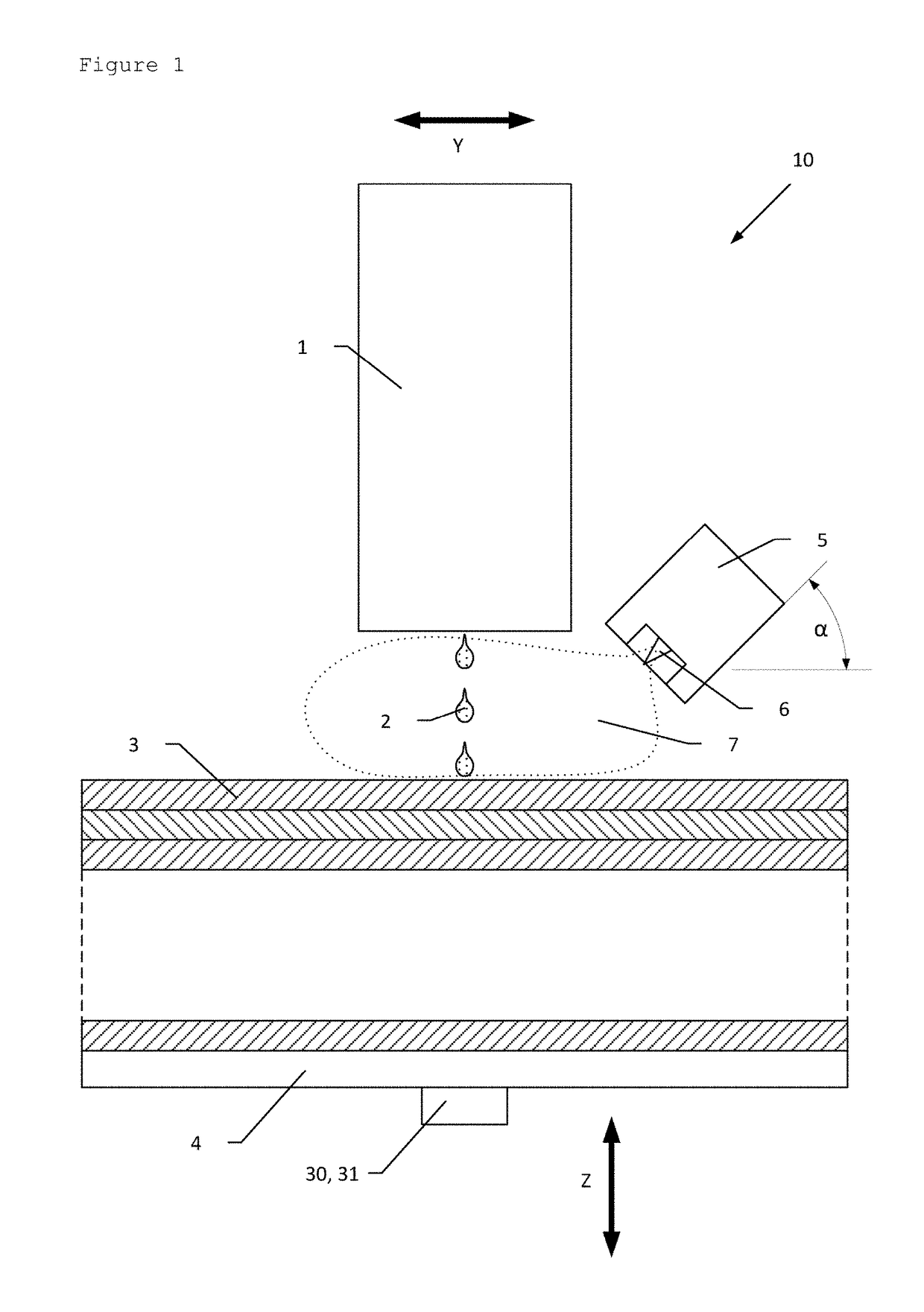

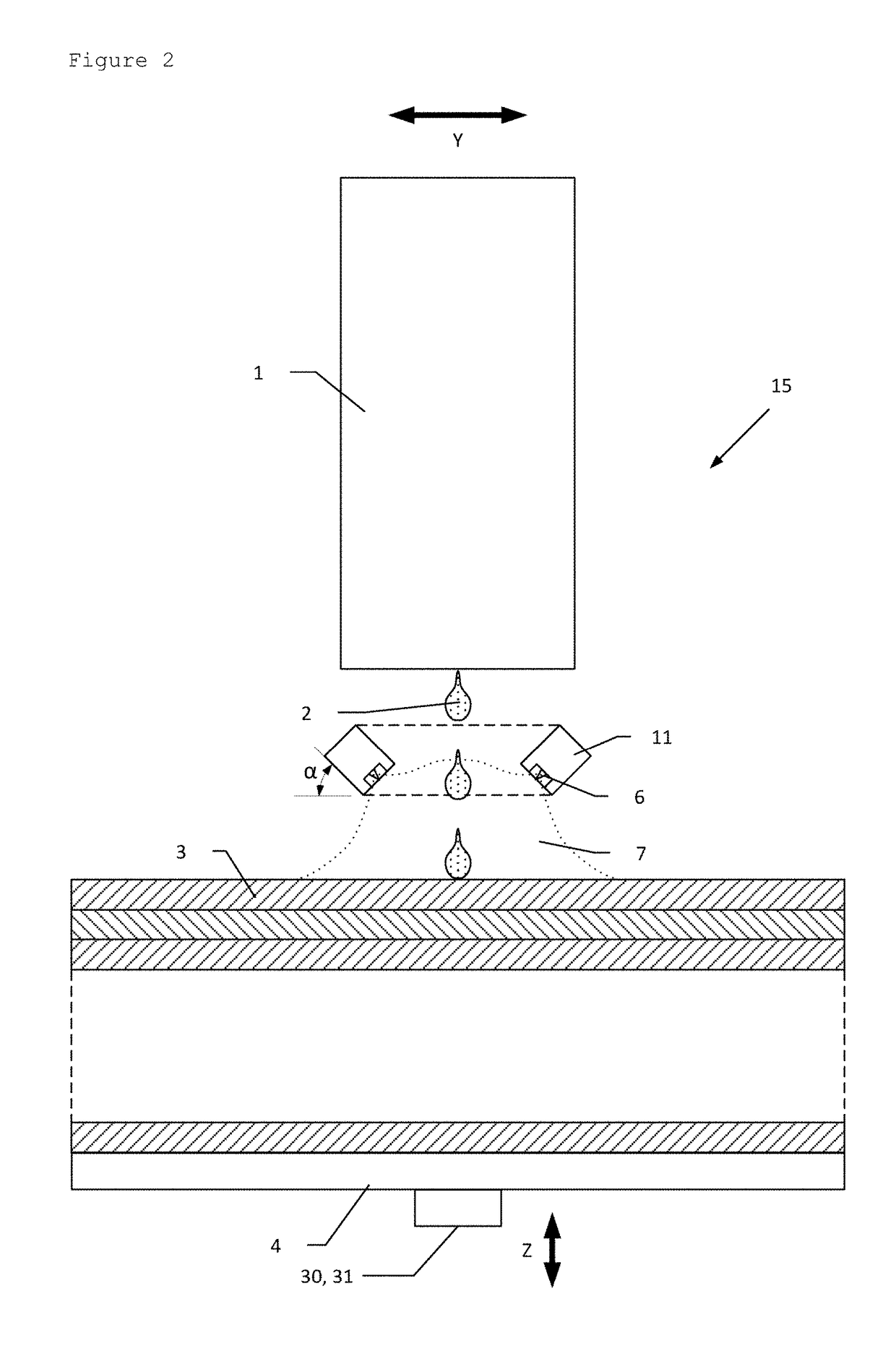

Method for producing silicone elastomer articles with elevated print quality

ActiveUS20180370141A1Improve throughputElevated and uniform print qualityManufacturing irradiation arrangementsAdditive manufacturing with liquidsEngineeringSilicone Elastomers

In an additive 3D printing method for production of shaped articles from silicone elastomers, an elastomeric shaped body is built up step by step, by repeatedly precisely positioning portions of the crosslinkable silicone material and crosslinking by means of electromagnetic radiation. Charges that occur on the surface of the print material or on the article are neutralized by means of an ionization system.

Owner:WACKER CHEM GMBH

Method of stabilizing a photohardening inhibitor-permeable film in the manufacture of three-dimensional objects

Owner:GLOBAL FILTRATION SYST

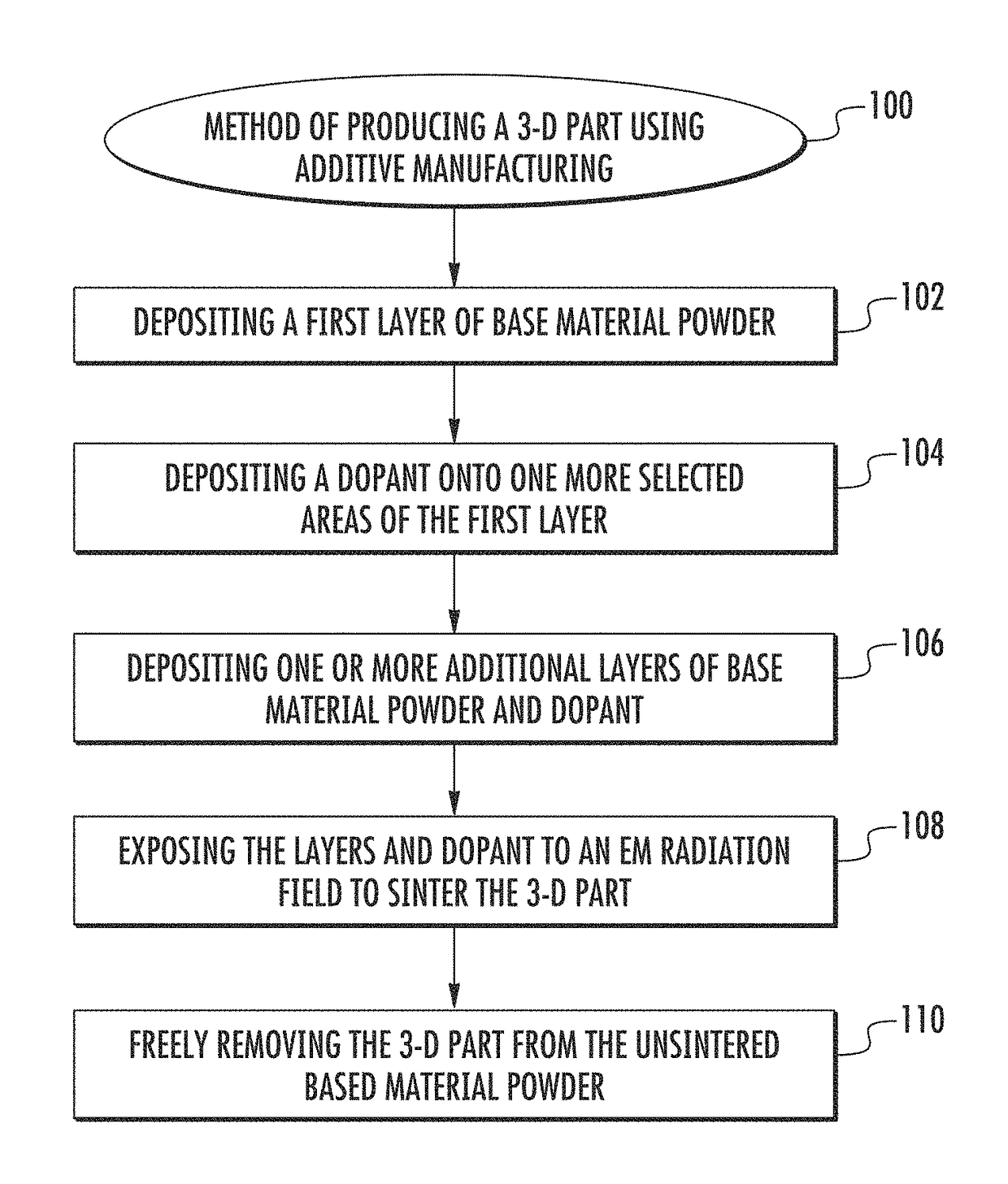

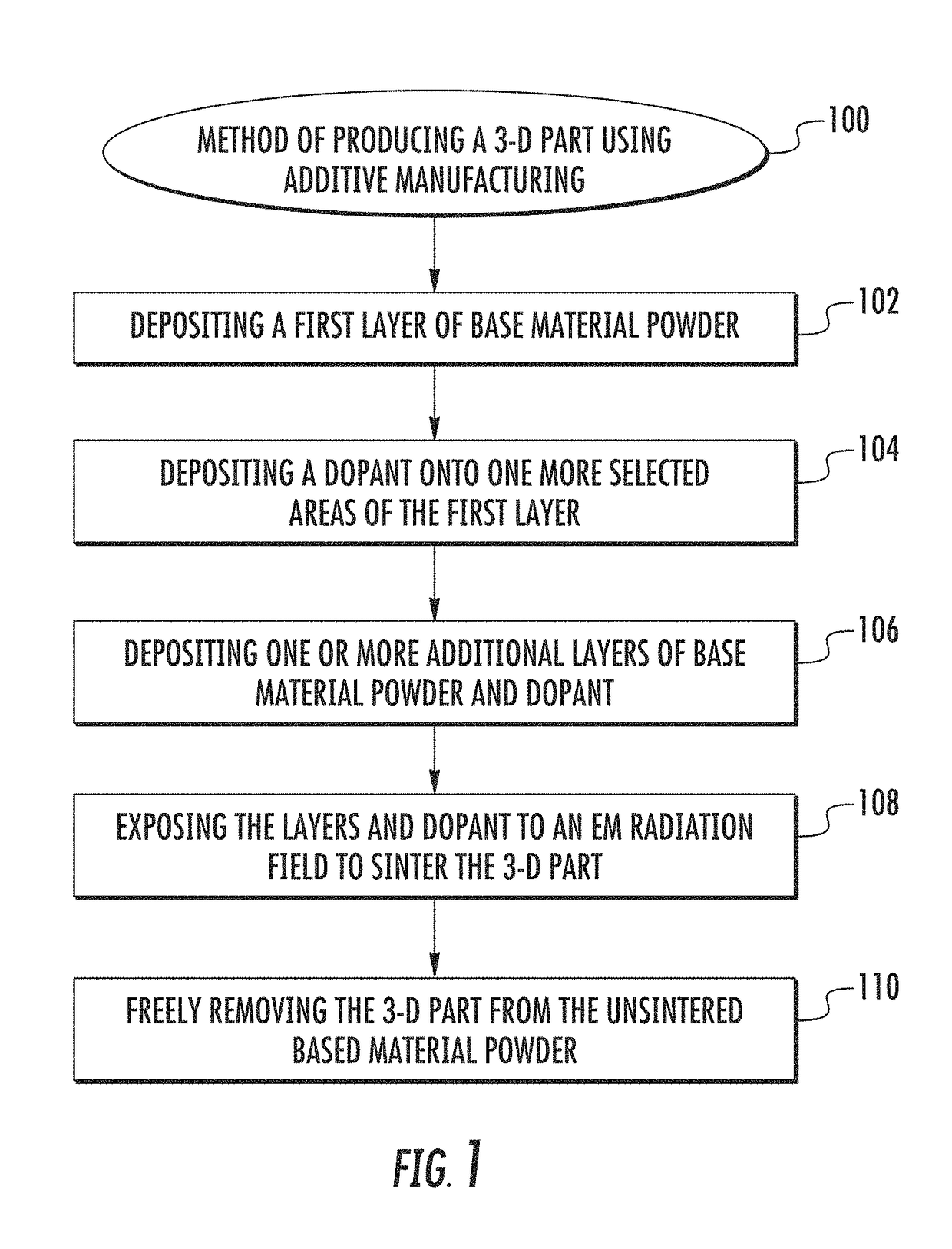

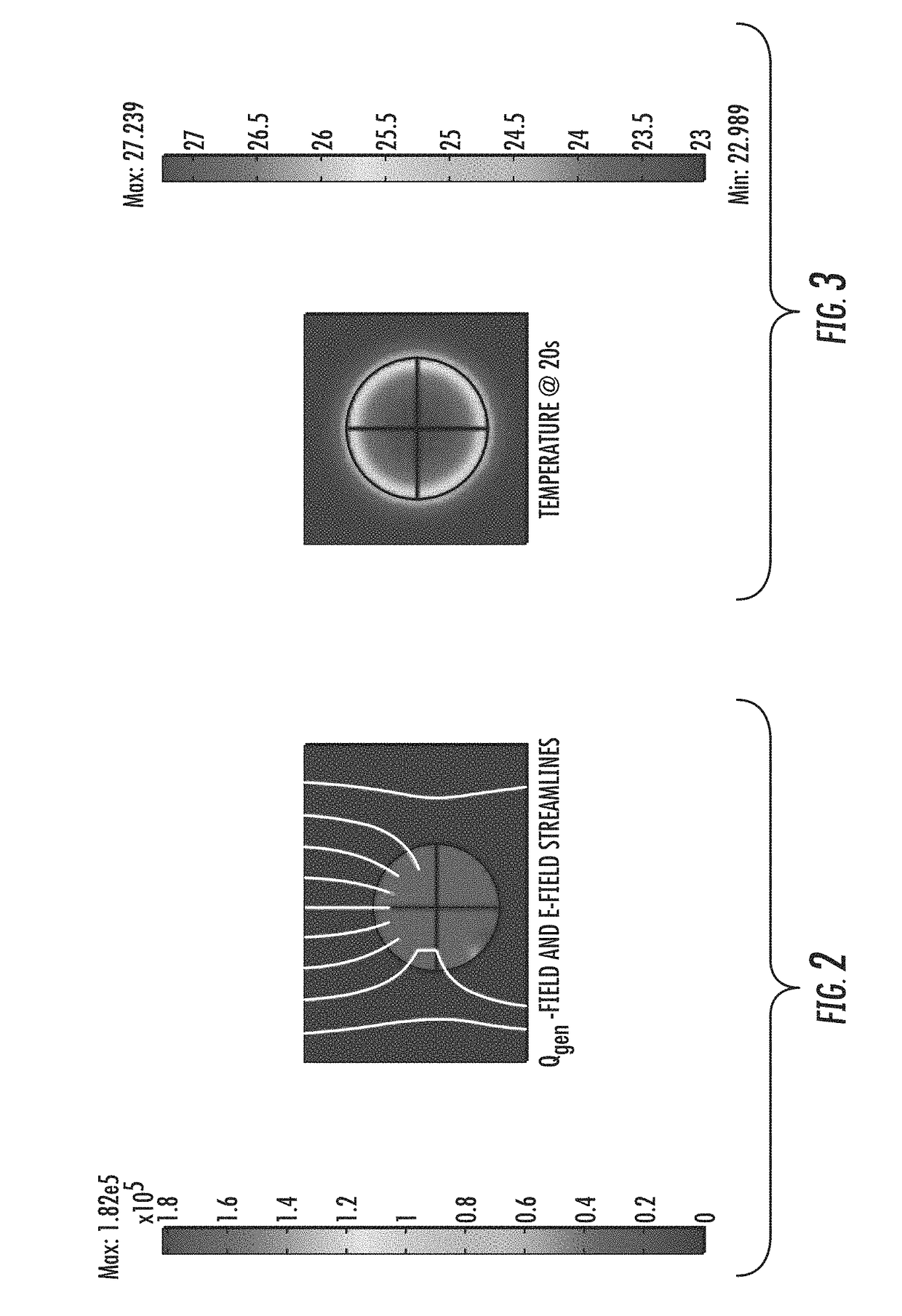

Systems and methods for volumetric powder bed fusion

InactiveUS20170326816A1Manufacturing irradiation arrangementsAdditive mnaufacturing with solid and fluidMicrowaveEnergy absorption

Various implementations utilize electromagnetic energy in the microwave and / or radio frequency (RF) spectrum to volumetrically solidify selective regions of a base material powder bed (e.g., polymer or ceramic). When they are dry, base materials utilized in powder bed fusion and other additive manufacturing processes are relatively transparent to microwave and RF energy, making it very difficult to heat them with those energy sources. However, mixing or doping the base material powders with conducting particles, such as graphite or carbon black, enhances energy absorption at microwave and radio frequencies, enabling heating and melting. Thus, volumetric additive manufacturing may be achieved by selectively doping a 3D powder bed with energy-absorbing particles in the shape of the desired object and exposing the powder bed to microwave and / or RF energy fields, such that the doped regions are volumetrically sintered into desired objects, leaving the surrounding powder unaffected.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

3D printing apparatus and method of using the single-printhead achieved multi-material and multi-scale printing

ActiveUS10603839B2Easy to controlImprove performanceManufacturing platforms/substratesRotary stirring mixers3d printMulti material

The present invention discloses a 3D printing apparatus and method of using a single-printhead to achieve multi-material and multi-scale printing. The apparatus comprises a base, a worktable, a wafer stage, a substrate, a power source, a printhead, and a support. The printhead is provided with a plurality of material inlets, each of which is connected to a different micro-feeding pump; and multiple materials are thoroughly mixed under the action of an agitator after being fed into the printhead, thereby achieving multi-material printing. In the present invention, a macroscopic geometrical shape of a printed object, microstructures in the interior and on the surface of the object are reasonably controlled, and integrated manufacturing of multi-scale structures is achieved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Method of stabilizing a photohardening inhibitor-permeable film in the manufacture of three-dimensional objects

ActiveUS20190099948A1Manufacturing enclosuresManufacturing irradiation arrangementsMaterials science

Owner:GLOBAL FILTRATION SYST

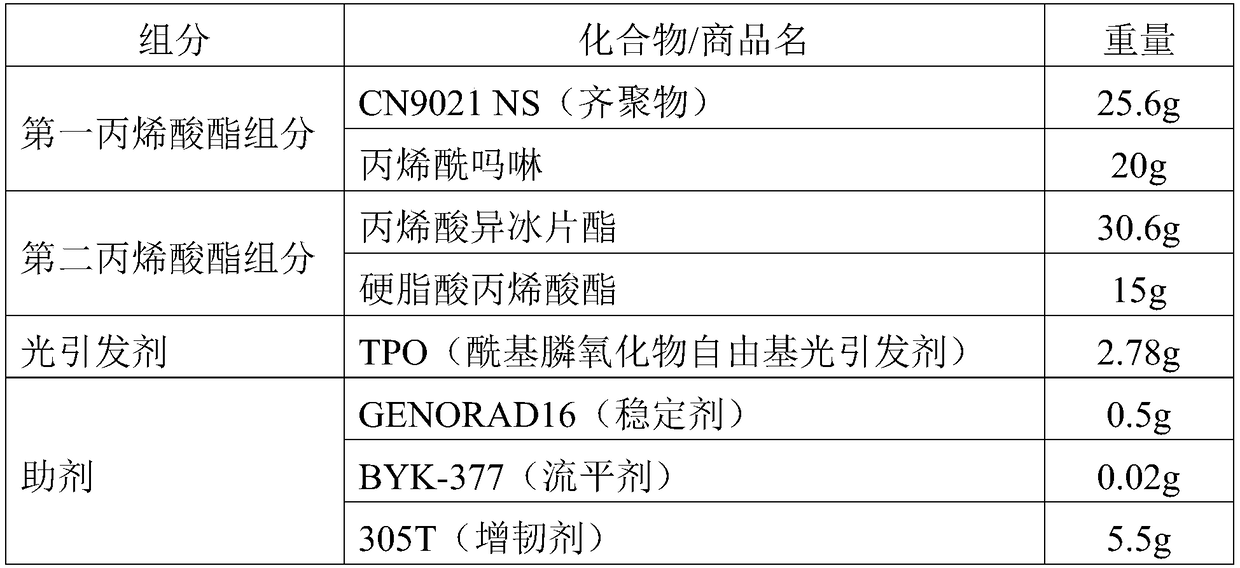

Photocurable non-transparent material for 3D printing, preparation method thereof, 3D printing product and 3D printer

ActiveCN109232791AImprove qualityAvoid easy cloggingManufacturing irradiation arrangements3D object support structuresDiacrylate esterEngineering

The invention provides a photocurable non-transparent material for 3D printing, a preparation method thereof, a 3D printing product and a 3D printer. The photocurable non-transparent material for 3D printing comprises the following components in parts by weight: 30-70 parts of a first acrylate component, 20-60 parts of a second acrylate component, 0.5-5 parts of a photoinitiator, 0.5-8 parts of anauxiliary agent and 0-4 parts of a colorant, wherein the first acrylate component is a polar acrylate component; and the second acrylate component is selected from at least one of weakly polar and non-polar acrylate components. According to the photocurable non-transparent material for 3D printing provided by the invention, a 3D printing product can be made non-transparent without adding white pigments such as titanium dioxide, so that the photocurable non-transparent material for 3D printing has the characteristics of high stability, the smoothness in a 3D printing process is ensured, the 3Dprinting product has good quality, and the 3D printer containing the photocurable non-transparent material for 3D printing has good performance.

Owner:ZHUHAI SAILNER 3D TECH CO LTD

Cooling device for printing head of 3D printing apparatus

InactiveCN106626352AHeating temperature does not spreadImproved cooling stabilityManufacturing irradiation arrangementsAdditive manufacturing with liquidsExtrusion3D printing

The invention provides a cooling device for a printing head of a 3D printing apparatus. The printing head comprises an extrusion screw machine barrel and a heater arranged on the extrusion screw machine barrel. The cooling device comprises cooling plates arranged around the heater, wherein cooling water channels for cooling water to pass by are formed inside each cooling plate. According to the cooling device for a printing head of a 3D printing apparatus, the cooling stability of the printing head is high, and the cooling noise of the printing head is low.

Owner:NINGXIA KOCEL MOLD

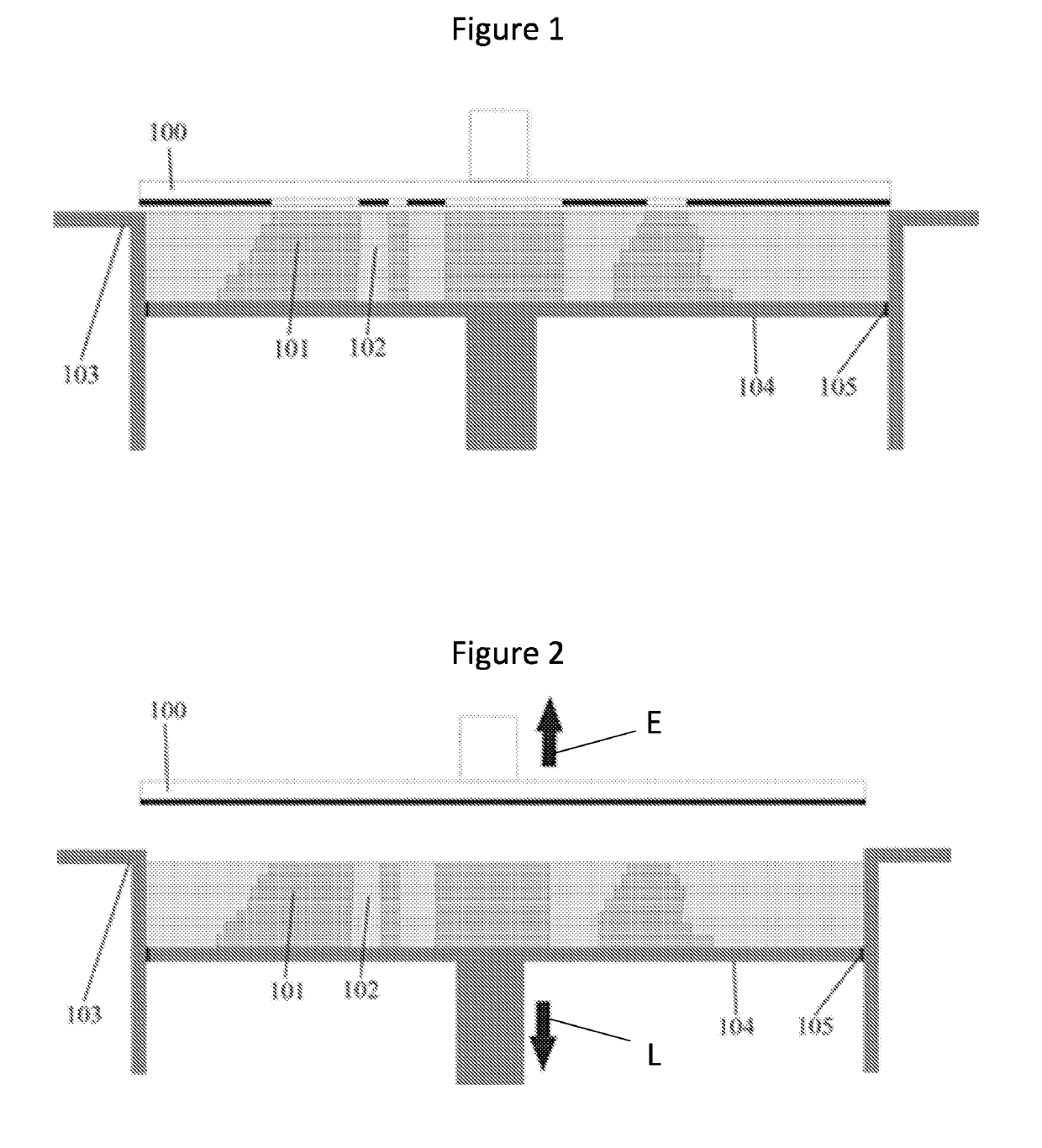

Medical image three dimensional entity reconstruction system and reconstruction method thereof

InactiveCN106393666AOvercome molding errorsHigh precisionManufacturing platforms/substratesManufacturing driving meansReconstruction methodEngineering

The invention discloses a medical image three dimensional entity reconstruction system and a reconstruction method thereof. The system comprises a horizontal moving device, a vertical lifting device and rotating devices. The horizontal moving device comprises two parallel shafts and a vertical shaft, and the two ends of the vertical shaft are slidably connected with the two parallel shafts correspondingly. The rotating devices are arranged on the vertical shaft and can move in the direction of the vertical shaft. A plurality of spray head modules are installed on the rotating devices and conduct rotating and angle adjusting under driven of the rotating devices. The vertical lifting device is arranged under the horizontal moving device and is provided with a printing platform capable of going up and down. According to the medical image three dimensional entity reconstruction system and the reconstruction method thereof, the precision of a formed workpiece and the working efficiency of a machine can be improved, much abundant information difficult to display through traditional imageological examination is provided for doctors, and comprehensive and intuitive bases are provided for personalized treatment plans.

Owner:武汉因泰莱激光科技有限公司

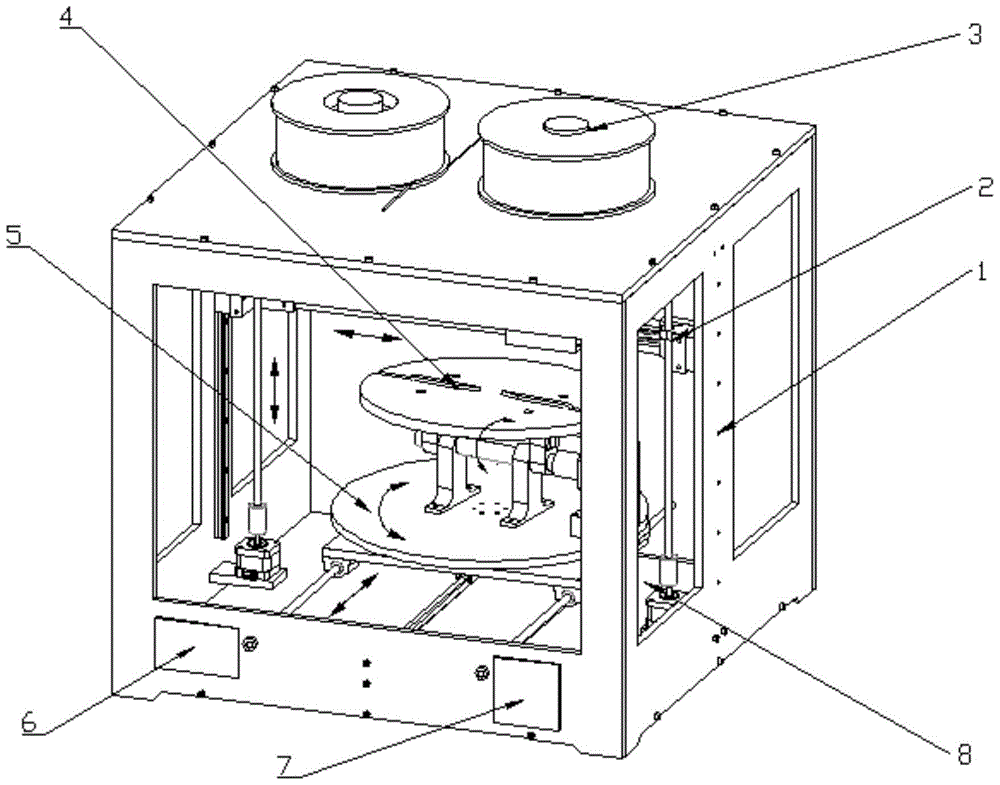

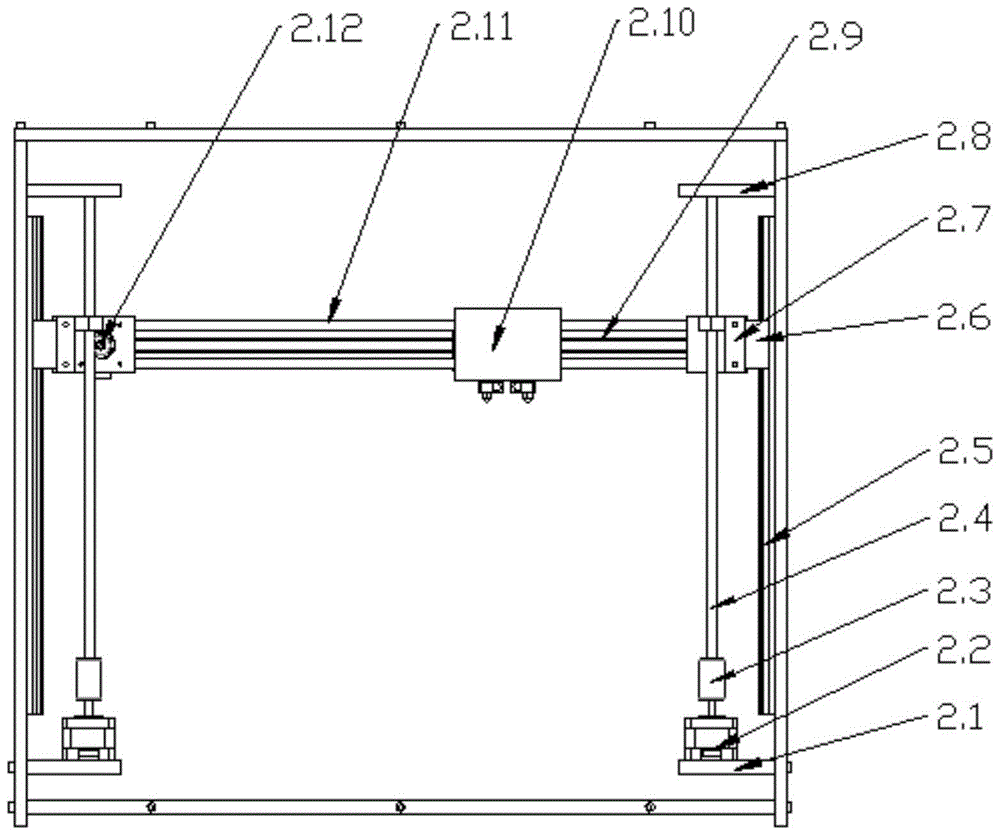

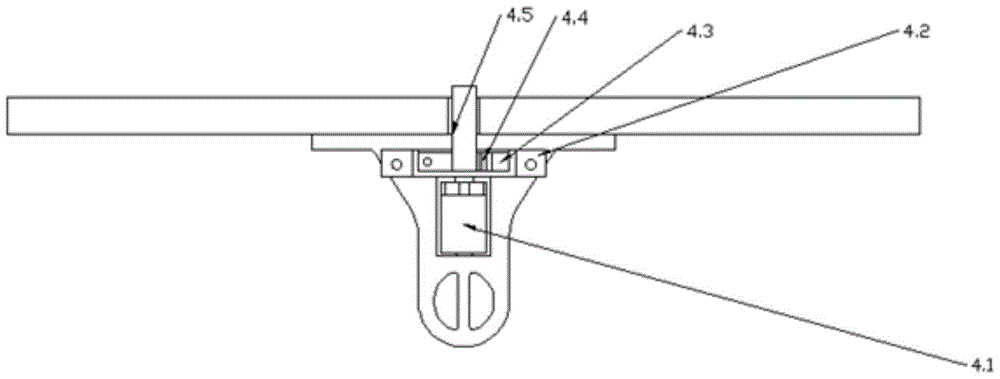

A five-degree-of-freedom rapid prototyping device

InactiveCN104842557BImprove surface qualityEliminate the "step effect"Manufacturing platforms/substratesManufacturing irradiation arrangementsEngineeringDegrees of freedom

The present invention discloses a five-freedom-degree rapid forming processing apparatus, which comprises a frame (1), material disks (3) on the top portion of the frame (1), an operating plate (6), a screen (7), and a control plate (8), and further comprises a two-freedom-degree spraying head assembly (2) capable of freely moving along X axis and Z axis, a clamping device (4), and a three-freedom-degree platform assembly (5) capable of freely rotating along Y axis, Z axis and A axis, wherein the operating plate (6) and the screen (7) are arranged on the bottom portion in front of the frame (1). With the five-freedom-degree rapid forming processing apparatus of the present invention, the step effect can be eliminated, the surface quality of the printed inclined plane can be increased, the processing efficiency on the circular cross-section parts is high, the processing on the spherical platform can be achieved, and the space utilization rate is good.

Owner:CHINA UNIV OF MINING & TECH

Methods For Making A Metal, Sand or Ceramic Object By Additive Manufacture and Formulations For Use In Said Methods

InactiveUS20190329321A1Accurate representationMore energyScreen printersManufacturing irradiation arrangementsPhotosensitive polymerPhotopolymer

This invention relates to compositions and methods for making three-dimensional (3D) images by additive manufacturing or 3D printing. Specifically, it describes techniques that allow images consisting of sand, metal or ceramic particles to be formed by the polymerisation of a photopolymer mixed with the particles.

Owner:PHOTOCENTRIC

Photocuring 3D printing device

ActiveCN110524875AFlexible layoutSimplify the installation processManufacturing irradiation arrangements3D object support structuresCouplingLight guide

The invention relates to a photocuring 3D printing device. The device comprises a model plate, a curing model is combined on the model plate, and the photocuring 3D printing device also comprises a light guide assembly. The light guide assembly comprises a coupling-in part, an optical waveguide and a coupling-out part, the coupling-out part is arranged to correspond to the model plate, the coupling-in part converts an incident light beam, introduces the light beam into the optical waveguide, conducts the light beam to the coupling-out part and emits the light beam out of the coupling-out areabetween the light guide assembly and the model plate through conversion of the coupling-out part, and the model plate and the light guide assembly can move relatively. According to the present invention, the relative fixation of the position relation between a light source and a printing material container in the prior art is avoided, the flexible arrangement of the relative position relation between the light source and the printing material container can be achieved, the overall performance of the device is improved, and the printing efficiency and the printing precision can be improved.

Owner:YUANZHI TECH SHANGHAI CO LTD

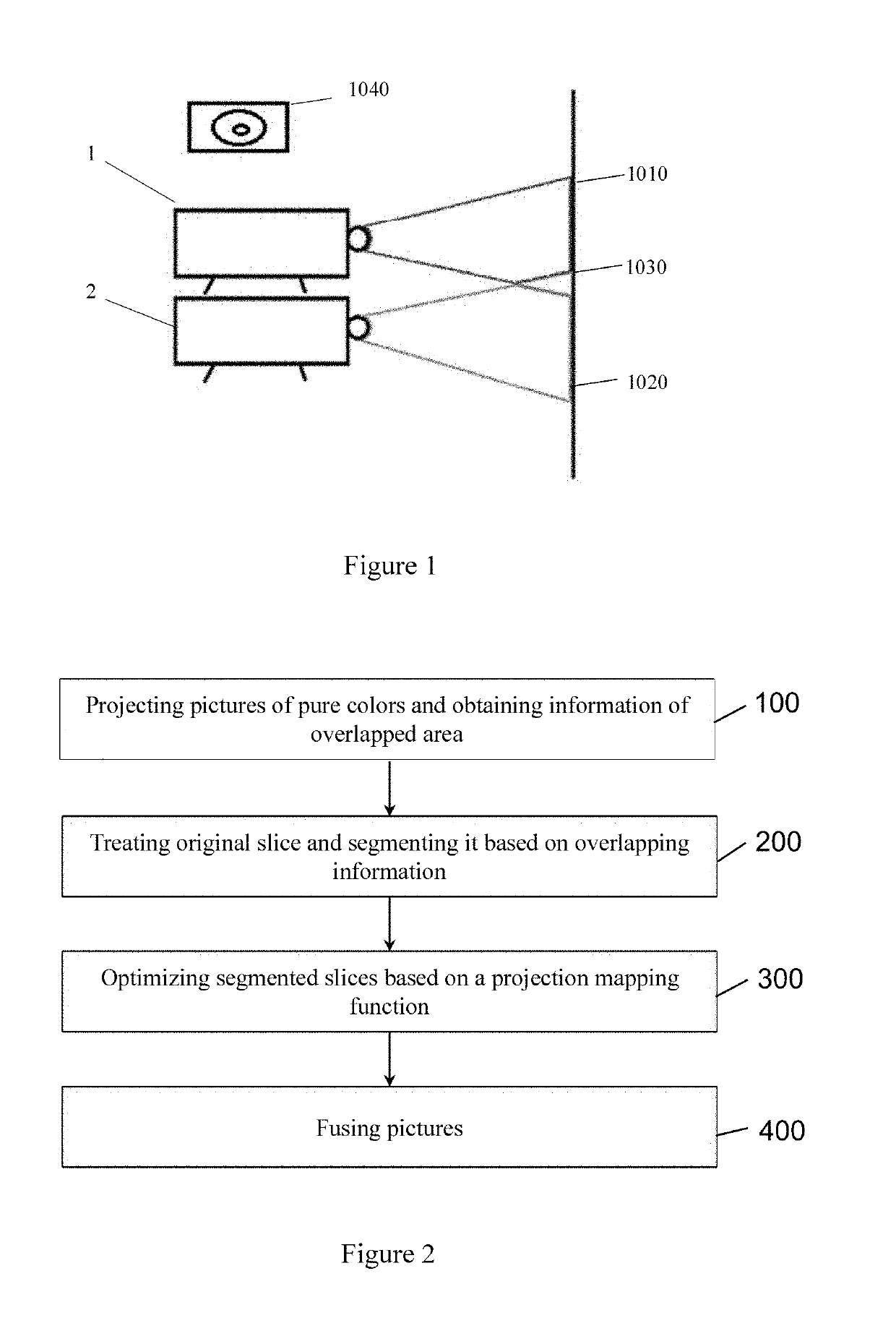

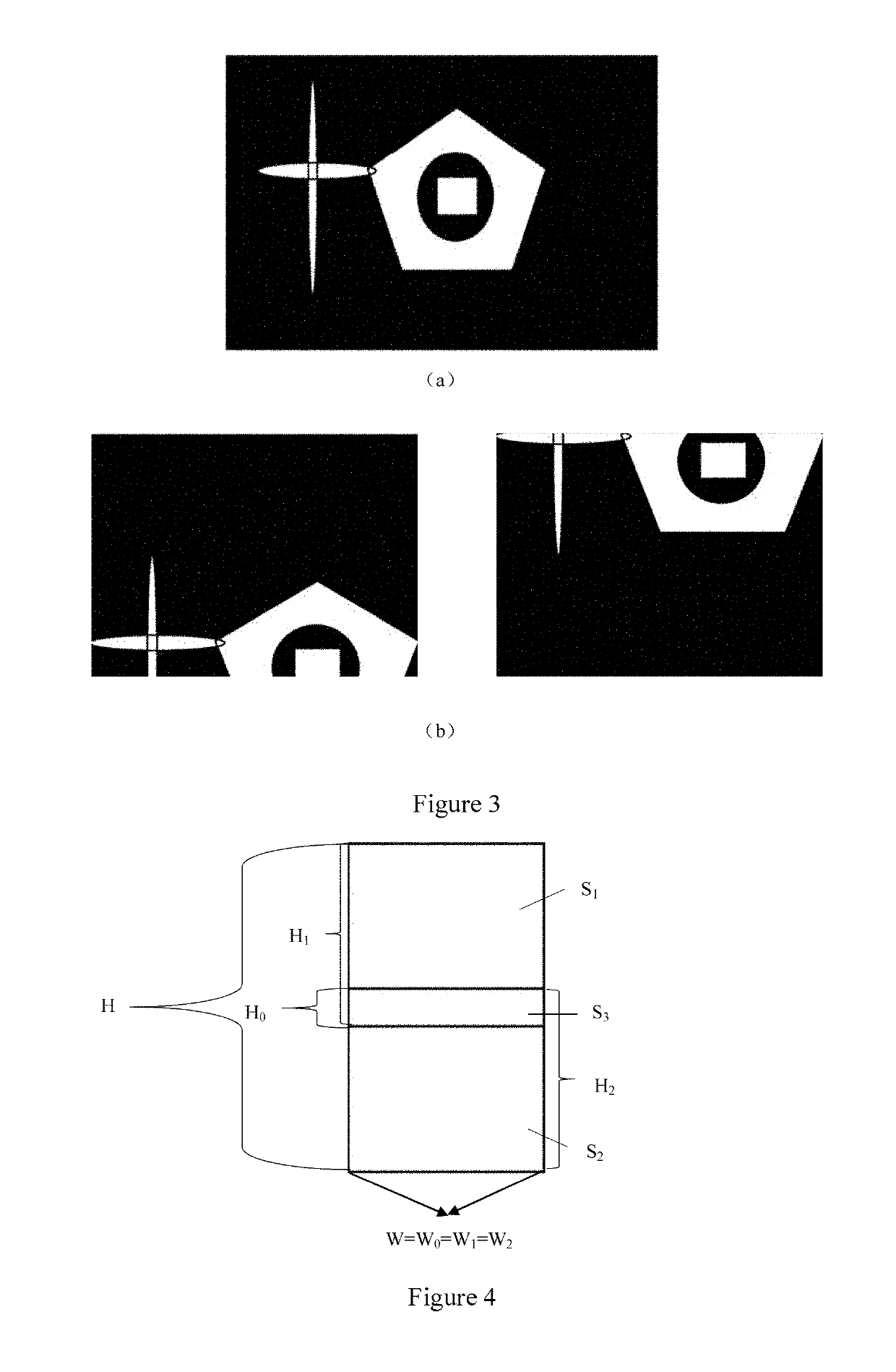

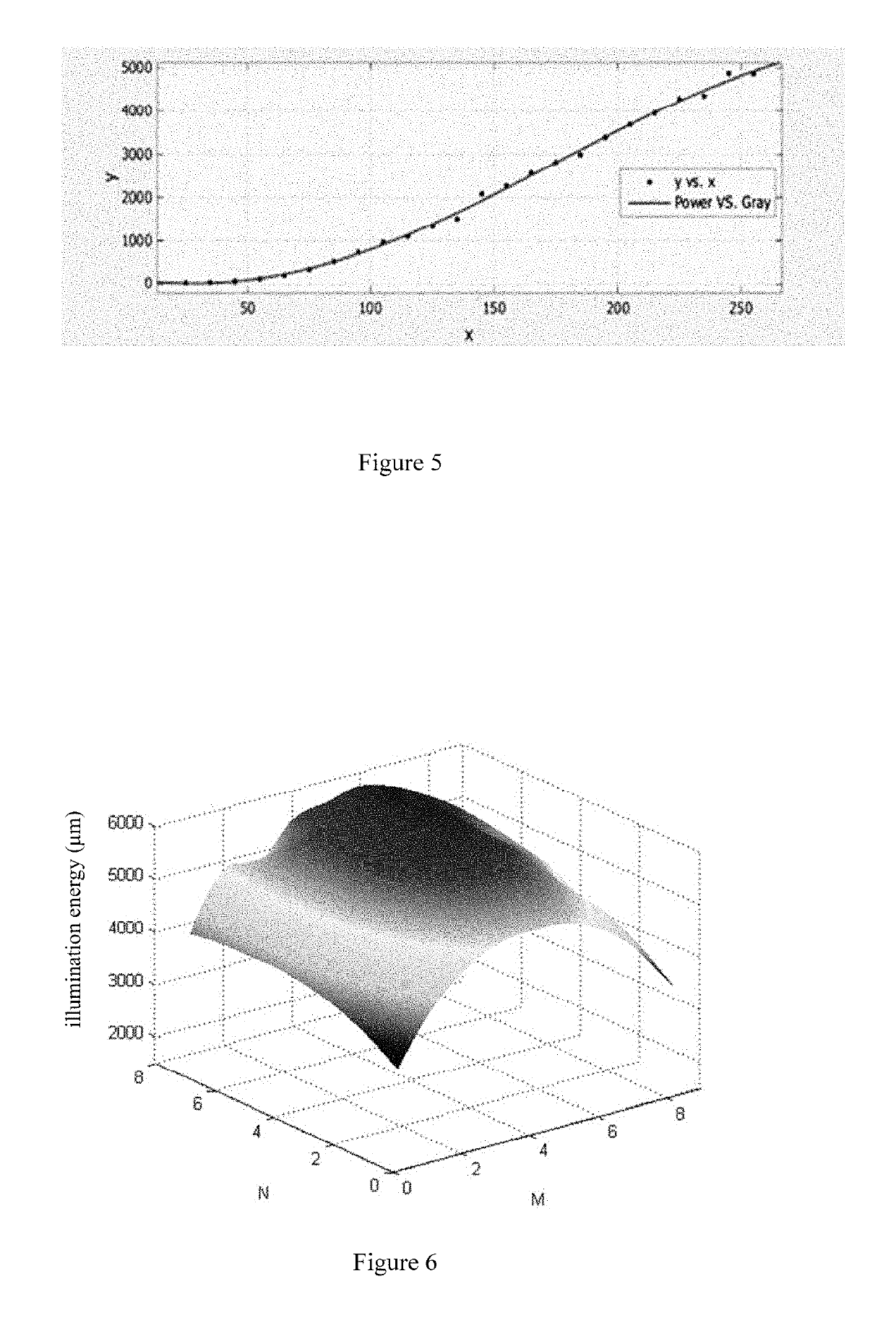

Light Homogenization Method for Multi-Source Large-Scale Surface Exposure 3D Printing

ActiveUS20190291341A1Easy to liftEasy to transplantManufacturing irradiation arrangements3D object support structuresColor imagePre treatment

A light homogenization method for multi-source large-scale surface exposure 3D printing, comprising the following steps: projecting pure-color images of a first color and a second color having identical attributes, capturing an image of an overlapping portion and calculating height and width information of the overlapping portion; splitting a pre-processed slice and respectively recording width and height information of two slices resulting from the splitting and generating two grayscale images having identical attributes thereto; counting power values of identical positions of slices in different grayscale values, performing a further calculation to obtain a projection mapping function, using the projection mapping function as a basis for performing optimization on grayscale interpolation of the generated images; and fusing the processed grayscale images and the originally split two slices to obtain a surface exposure 3D printing slice having a uniform brightness in final shaping.

Owner:BEIJING UNIV OF TECH

Photocuring device and method

InactiveCN112318871AAvoid damageAchieve secondary curingManufacturing irradiation arrangements3D object support structuresEngineeringMechanical engineering

The invention discloses a photocuring device and method. The photocuring device comprises a shell, a transparent inner box and curing lamps. The transparent inner box is arranged in the shell, and thecuring lamps are arranged between the shell and the transparent inner box and located around the transparent inner box. The transparent inner box is used for containing specific liquid, and the specific liquid is configured in the manner that the specific liquid does not react with photosensitive resin, is lower than water in oxygen dissolving rate and is transparent. According to the photocuringdevice and method, the product surface quality can be further improved, and the surface curing effect can be improved.

Owner:GUANGZHOU HEIGE ZHIZAO INFORMATION TECH CO LTD

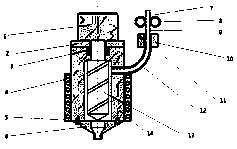

Novel screw rod type nozzle with fused deposition forming technology

InactiveCN108215162ASolve uneven heatingEvenly heatedManufacturing enclosuresManufacturing irradiation arrangementsMelting tankMolten state

The invention provides a novel screw rod type nozzle with fused deposition forming technology. The novel screw rod type nozzle comprises a motor, a motor end cover, a rolling bearing, an electromagnetic heating ring, a bolt, a nozzle, a U-shaped bearing, a customized gear, a preheating device, a heating rod, a material channel, a molten pool, a screw rod extruding device, a material cylinder and thermoplastic materials. The electromagnetic heating ring is arranged on the outer boundary of the material cylinder and replaces an original heating block device; and the screw rod extruding device isarranged in a molten pool, and an original straight barrel type feeding device is replaced. According to the novel screw rod type nozzle, the preheating device is arranged, so that the thermoplasticmaterials flow into the molten pool after reaching the semi-molten state. The electromagnetic heating ring is arranged on the periphery of the material cylinder, so that the thermoplastic materials can be uniformly heated, and the phenomenon that the fusion material is "cast" due to the fact that the local temperature is too high in the process of using the heating rod is avoided. The molten poolis mainly added, so that the evolution of the fused deposition forming technology from the desktop level to the industrial level is promoted.

Owner:WUHAN UNIV OF SCI & TECH

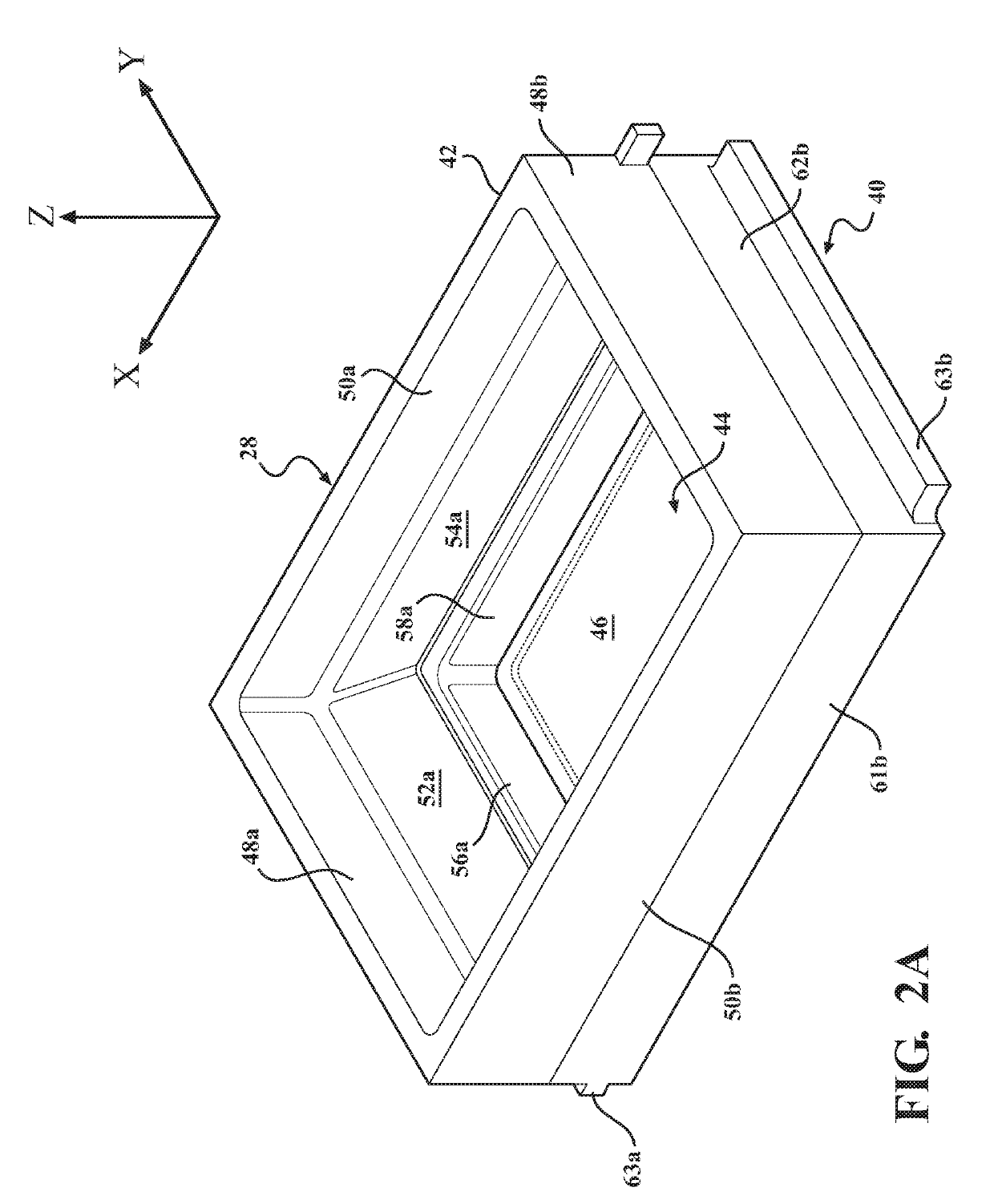

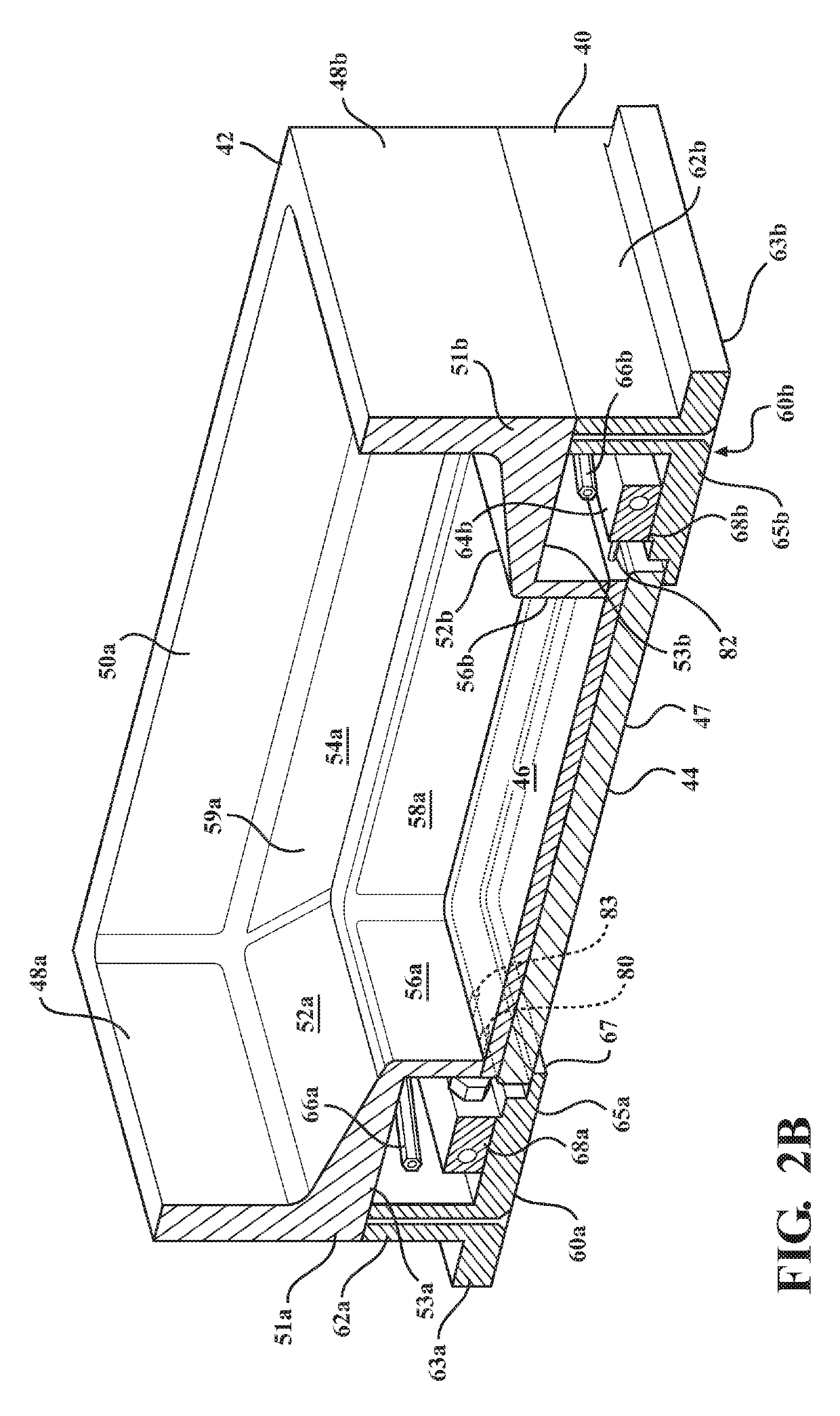

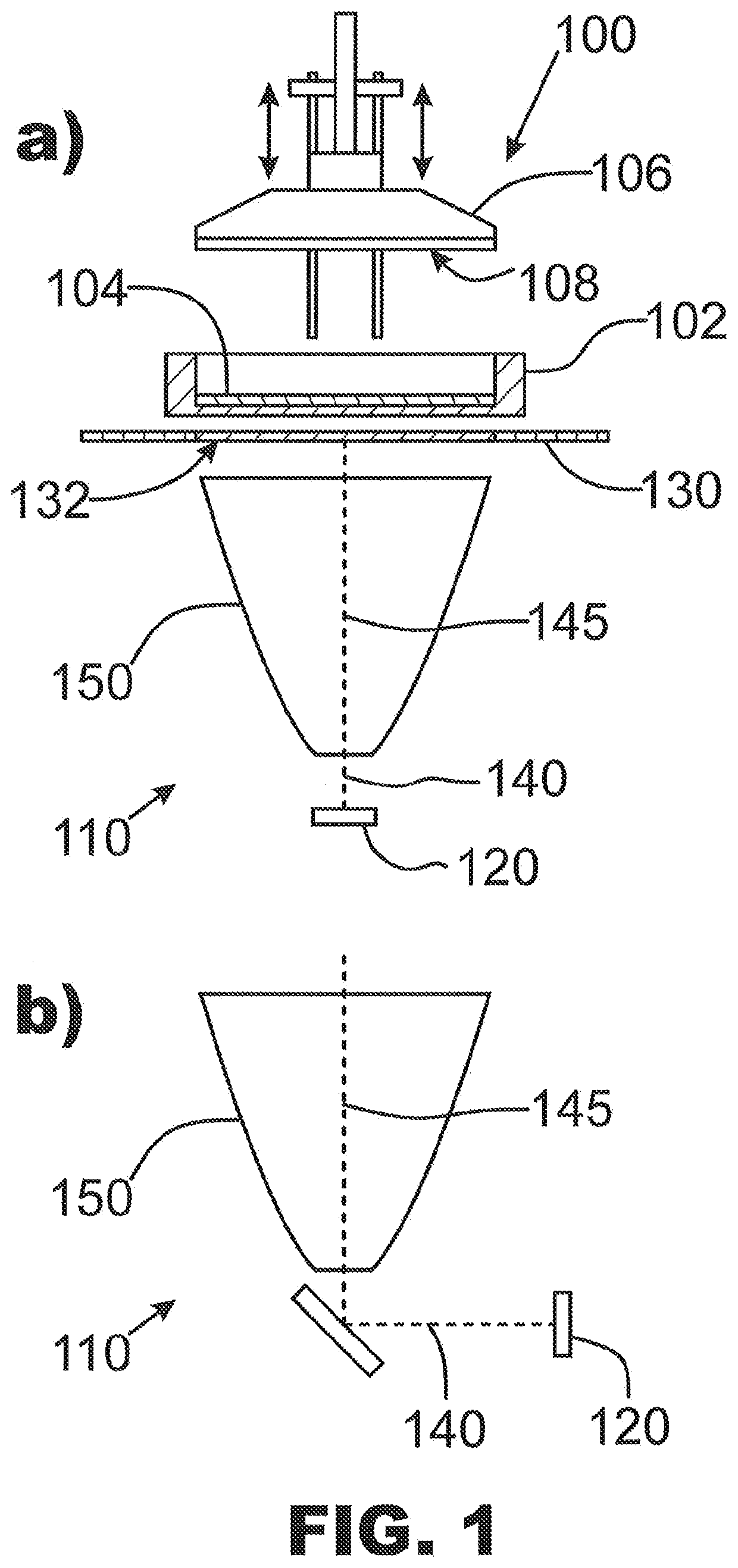

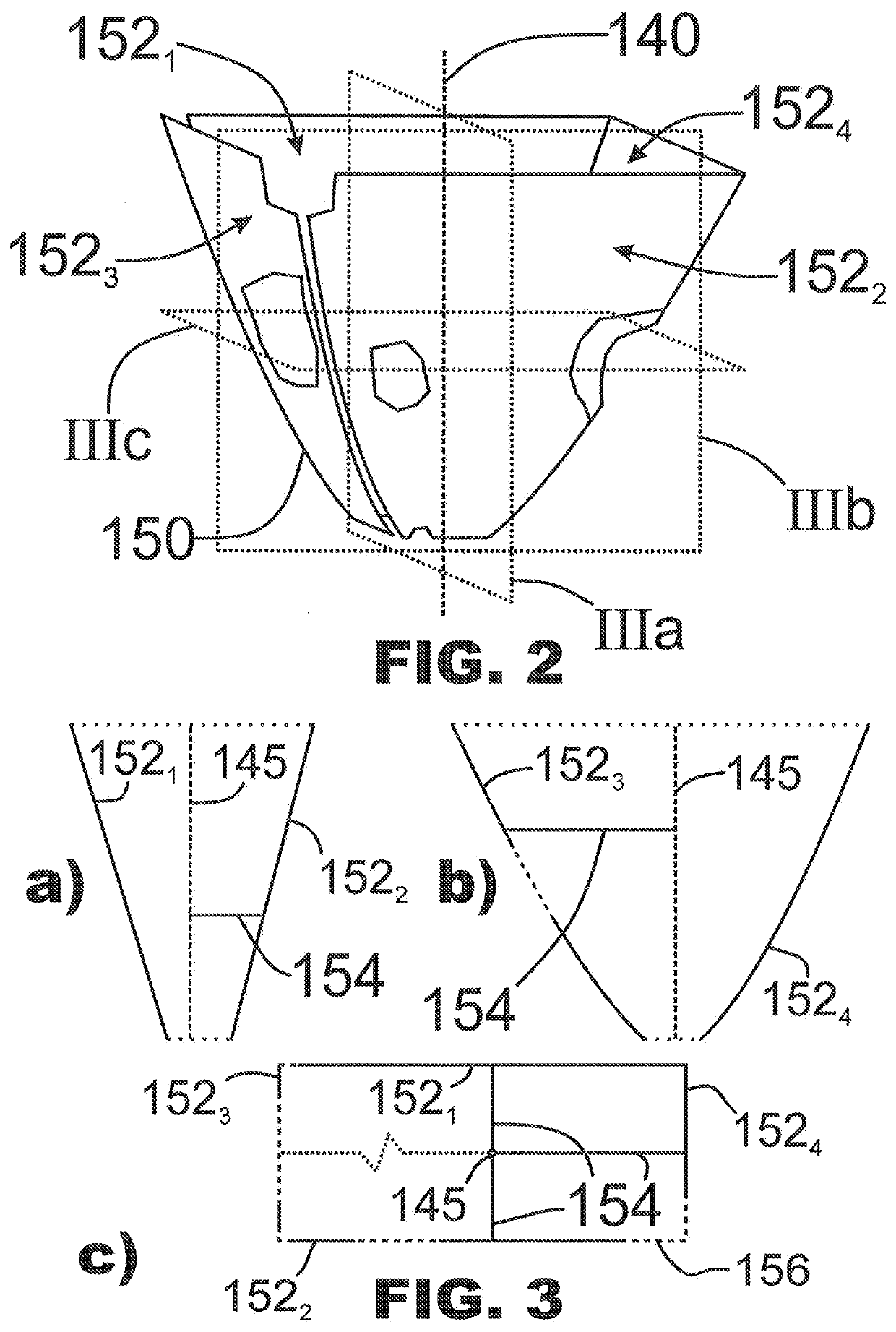

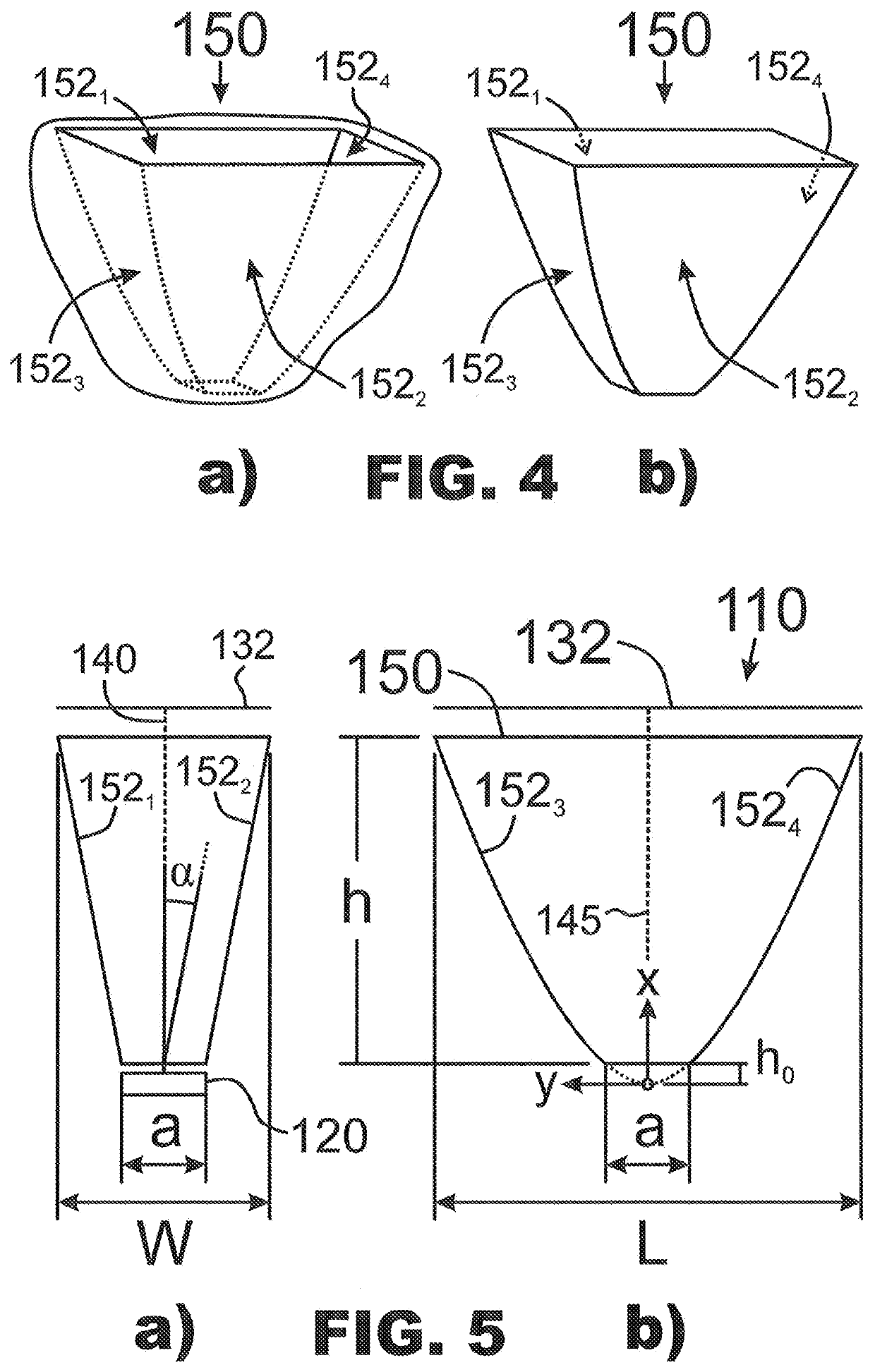

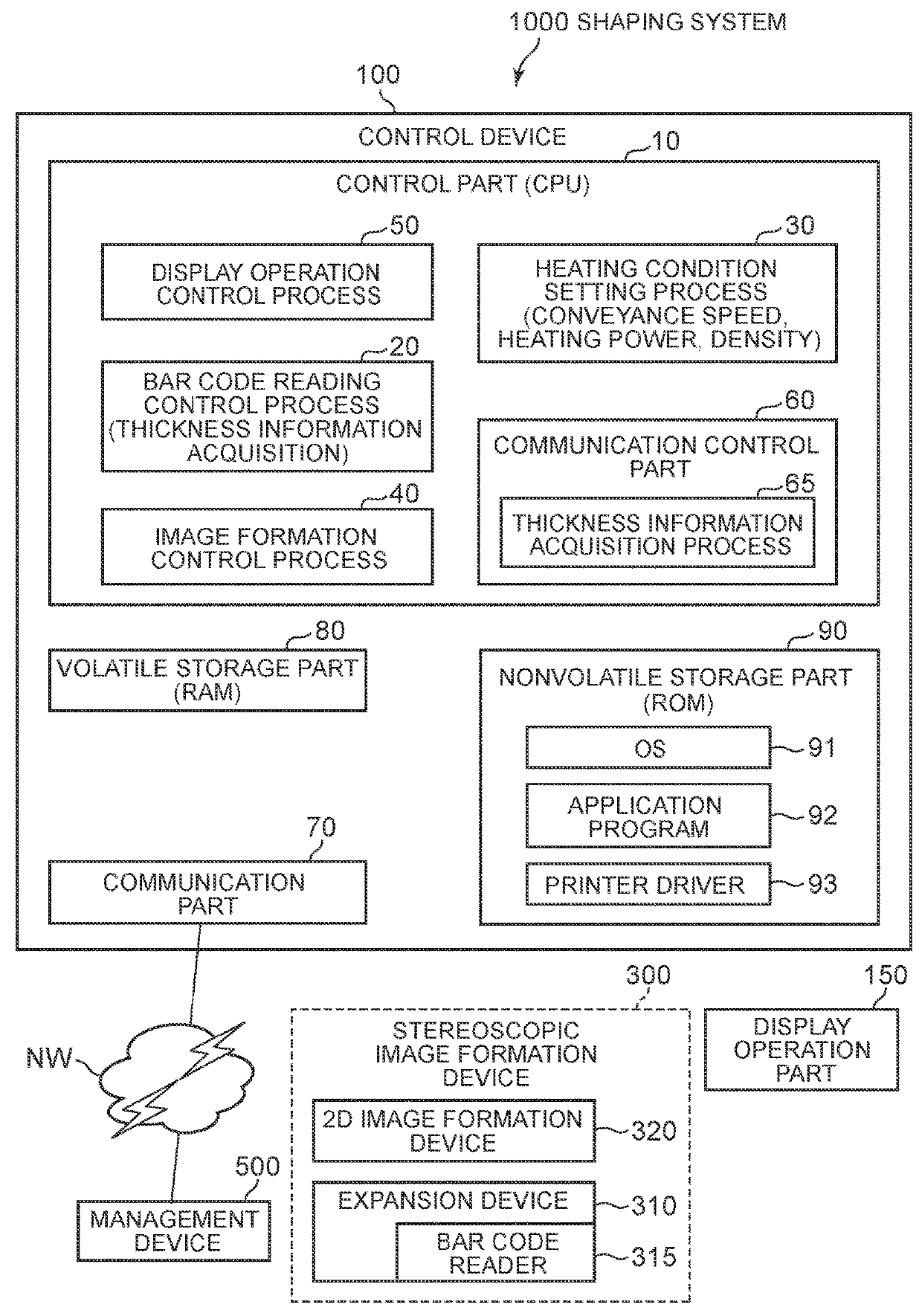

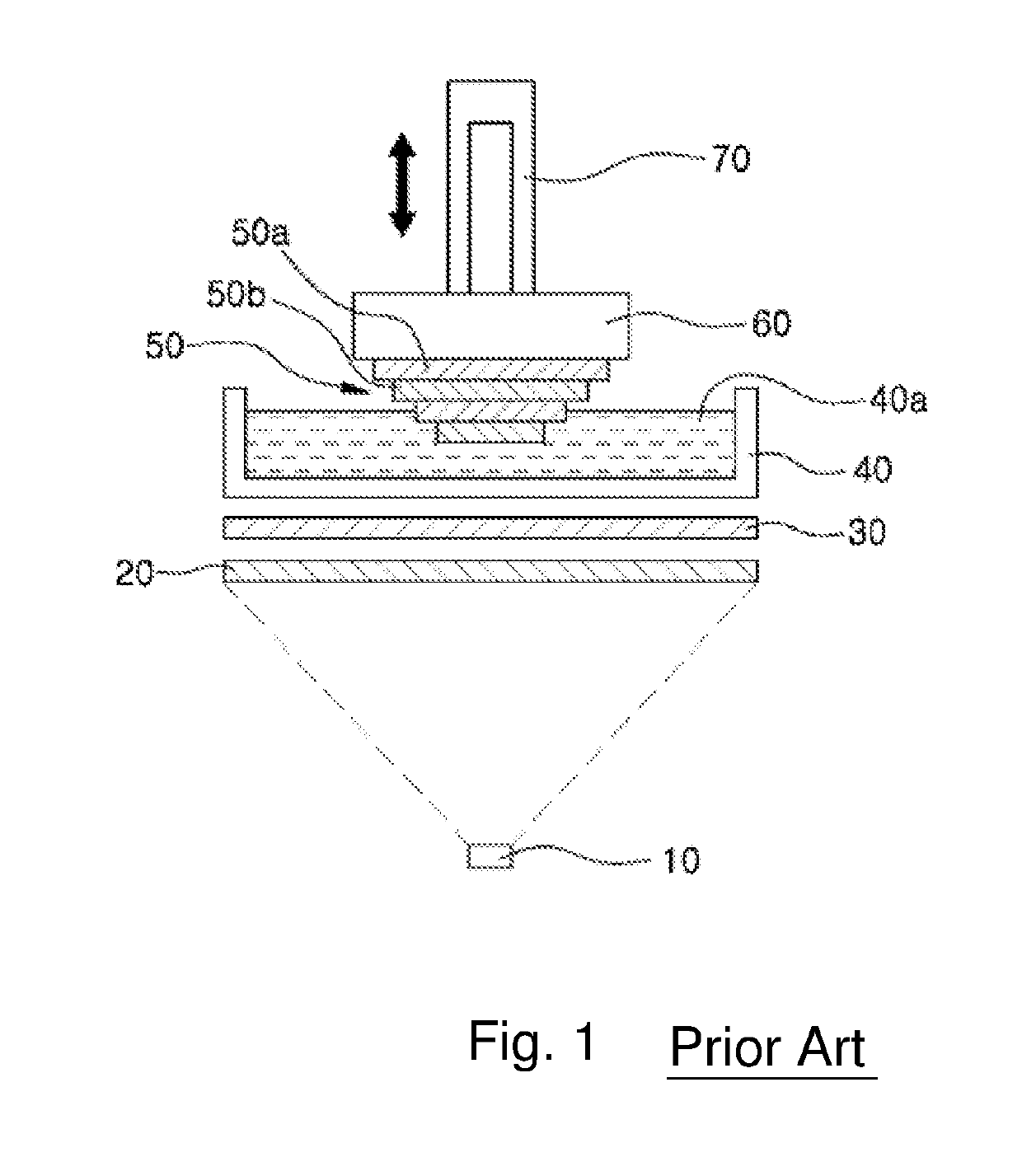

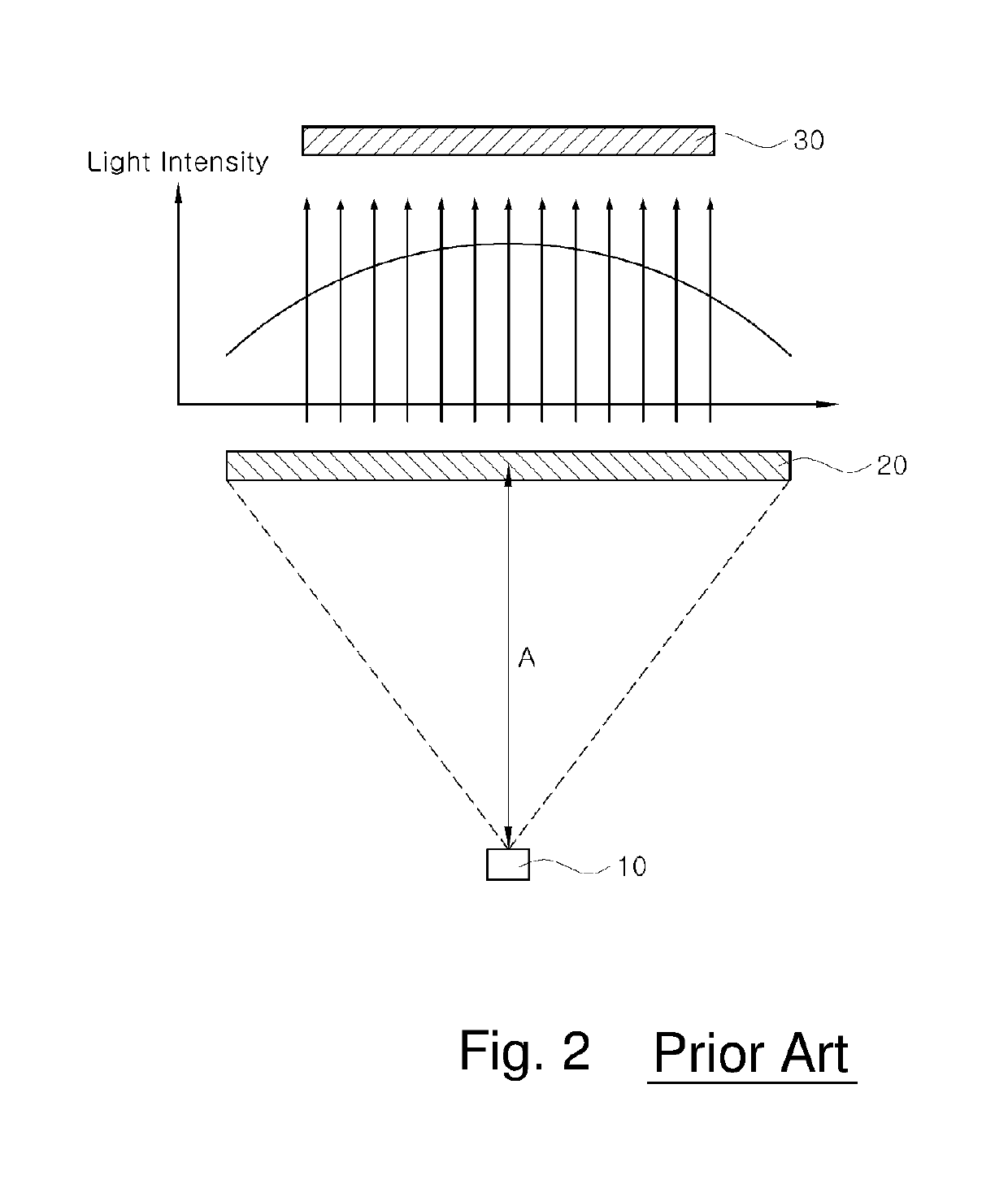

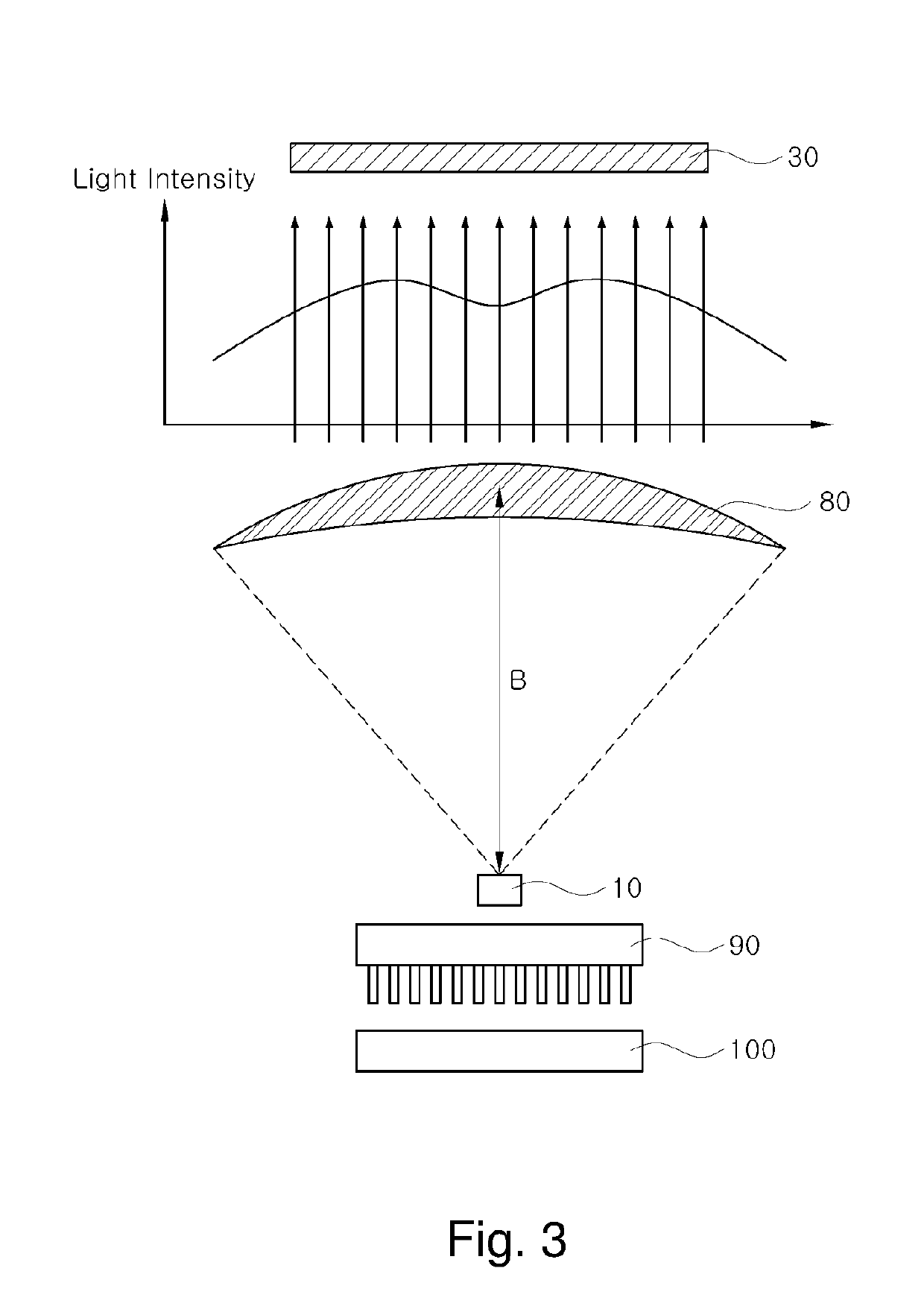

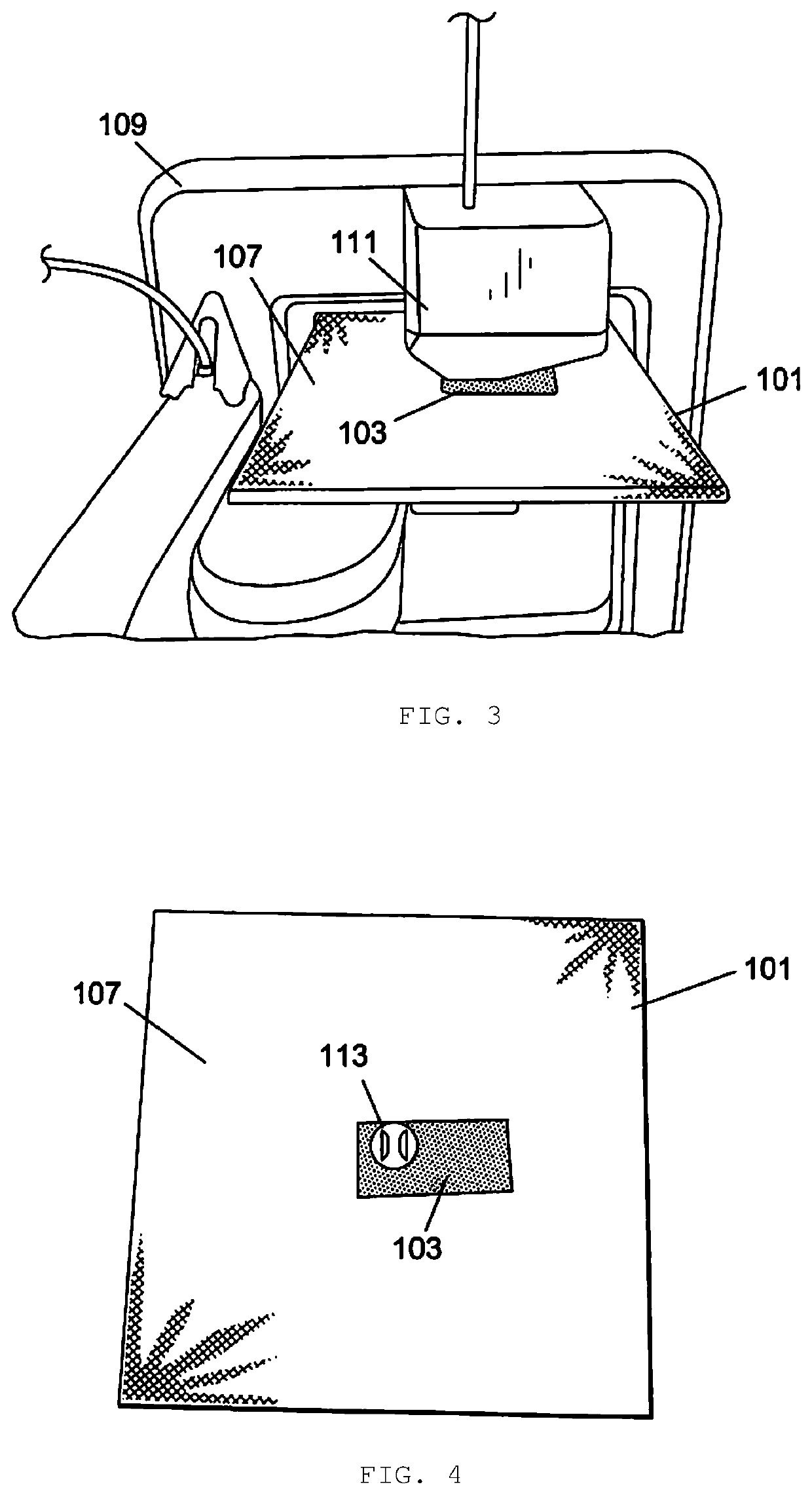

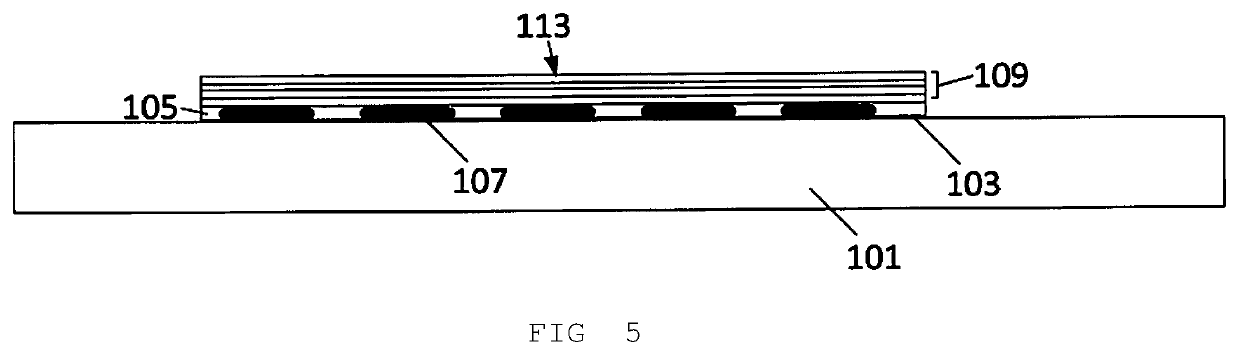

Stereolithography apparatus

PendingUS20210146620A1Manufacturing irradiation arrangements3D object support structuresReflective surfacesStereolithography

A stereolithography apparatus (100) has an exposure arrangement (110), comprising a radiative element (120); a masking element (130), having a substantially rectangular masking area (132); an optical path (140) between the radiative element (120) and the masking area (132), having a linear segment (145); and an intensity-unifying arrangement (150), having a first, a second, a third, and a fourth reflective surface (1521, 1522, 1523, 1524) The first and second reflective surfaces (1521, 1522,) are arranged on opposite sides of the linear segment (145), and the third and fourth reflective surfaces (1523, 1524) are arranged on opposite sides of the linear segment (145). In a cross section of the intensity-unifying arrangement (150) along any plane, perpendicularly intersecting the linear segment (145), the reflective surfaces (1521, 1522, 1523, 1524) follow a boundary (156) of a rectangle.

Owner:PLANMECA

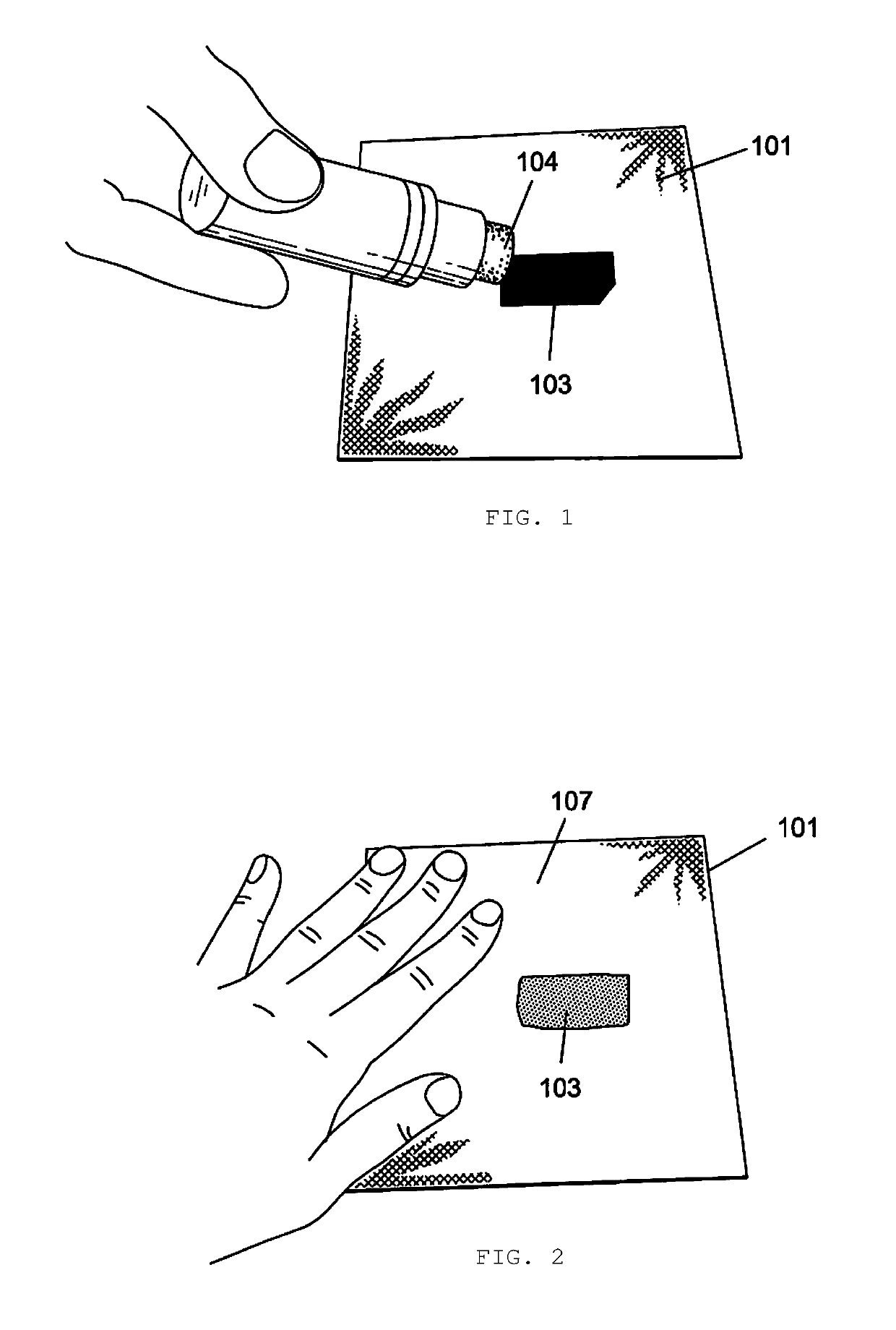

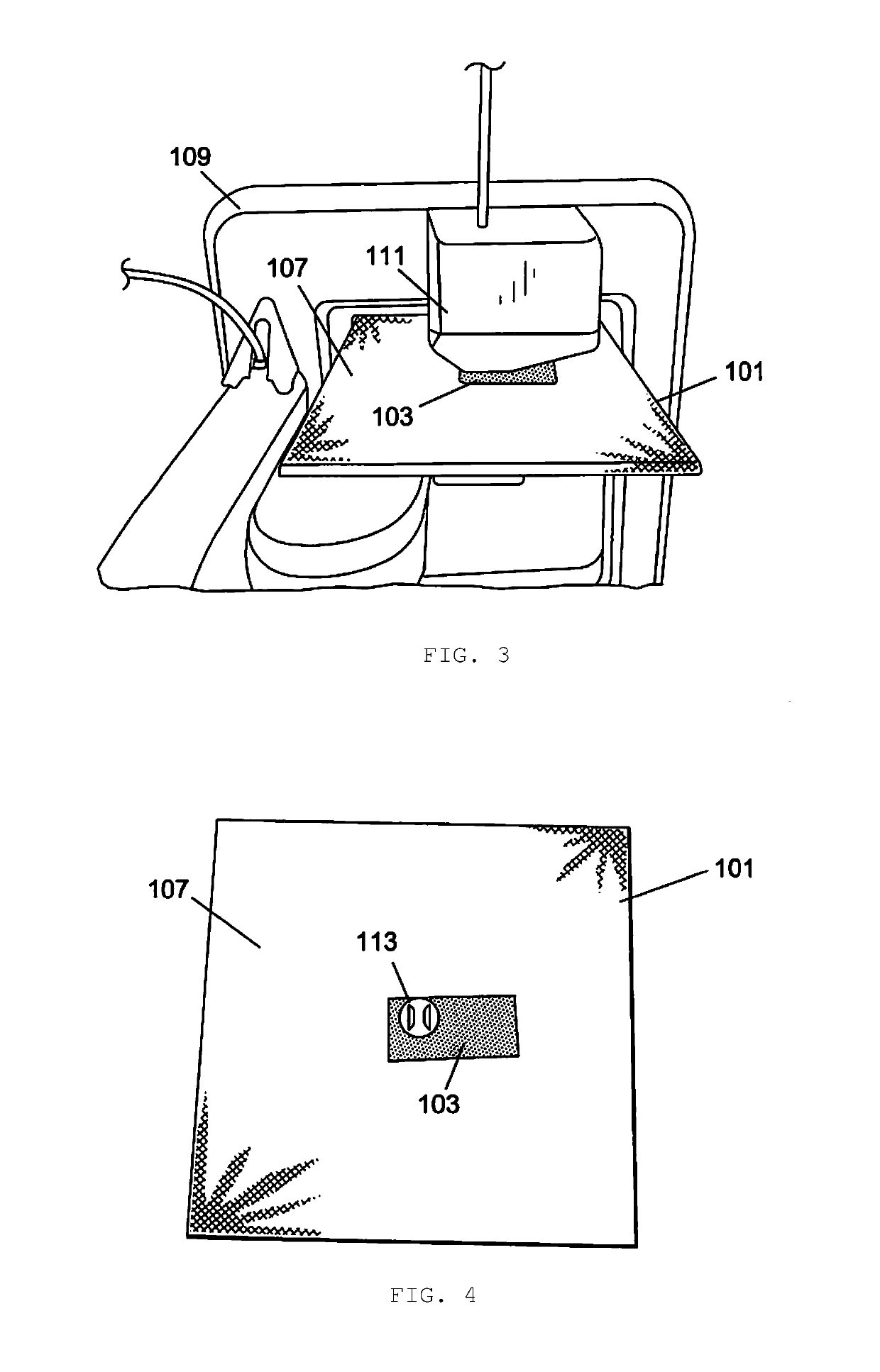

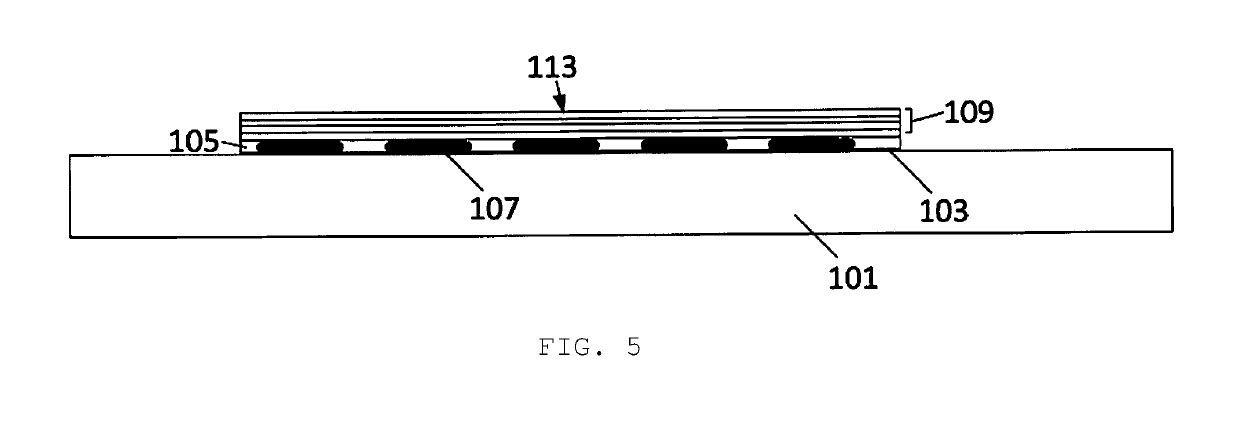

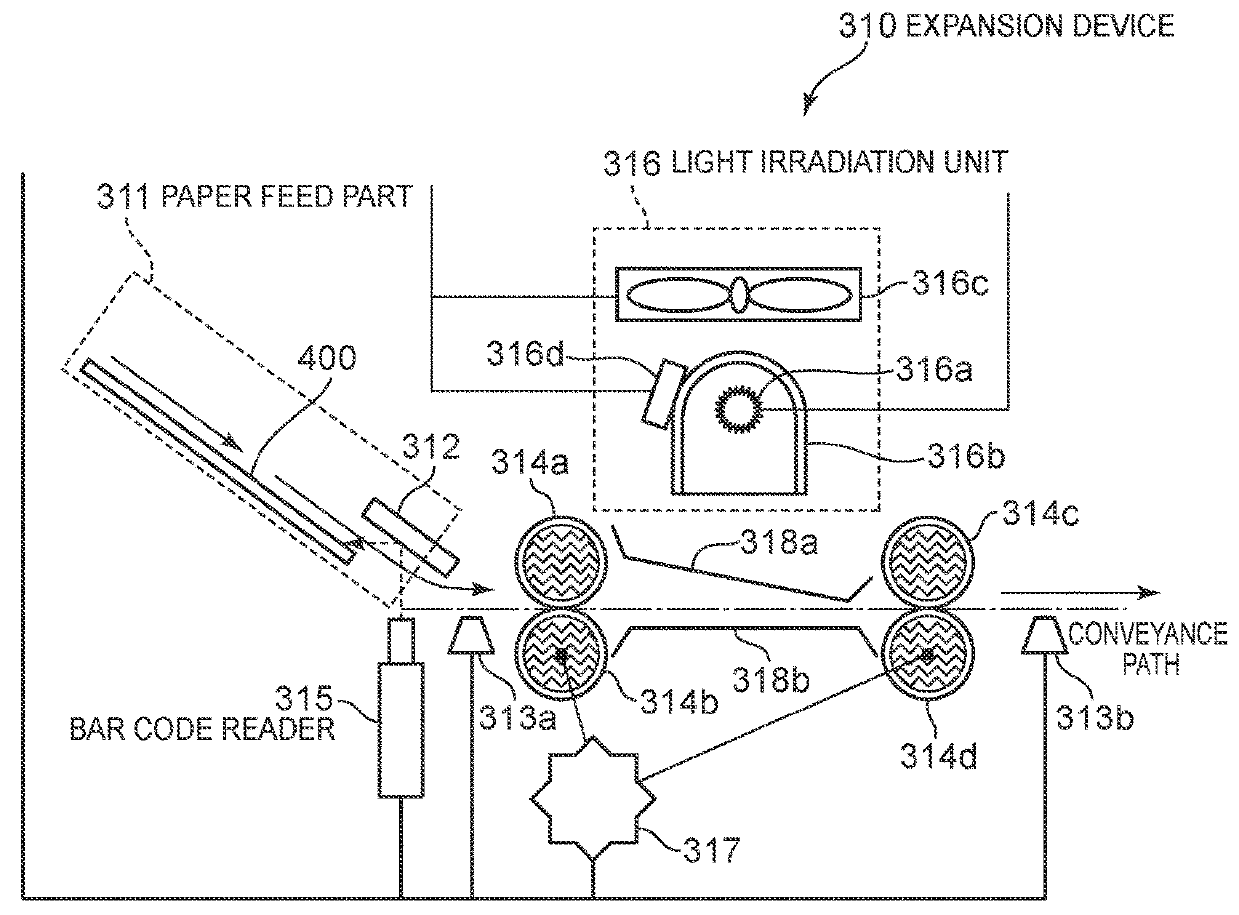

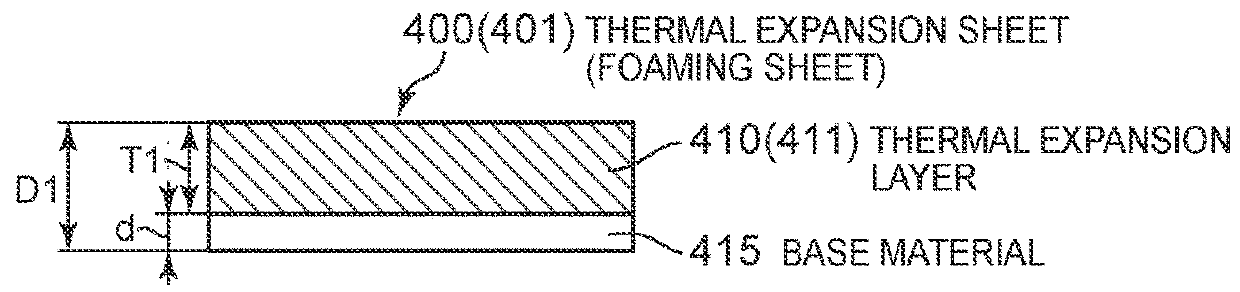

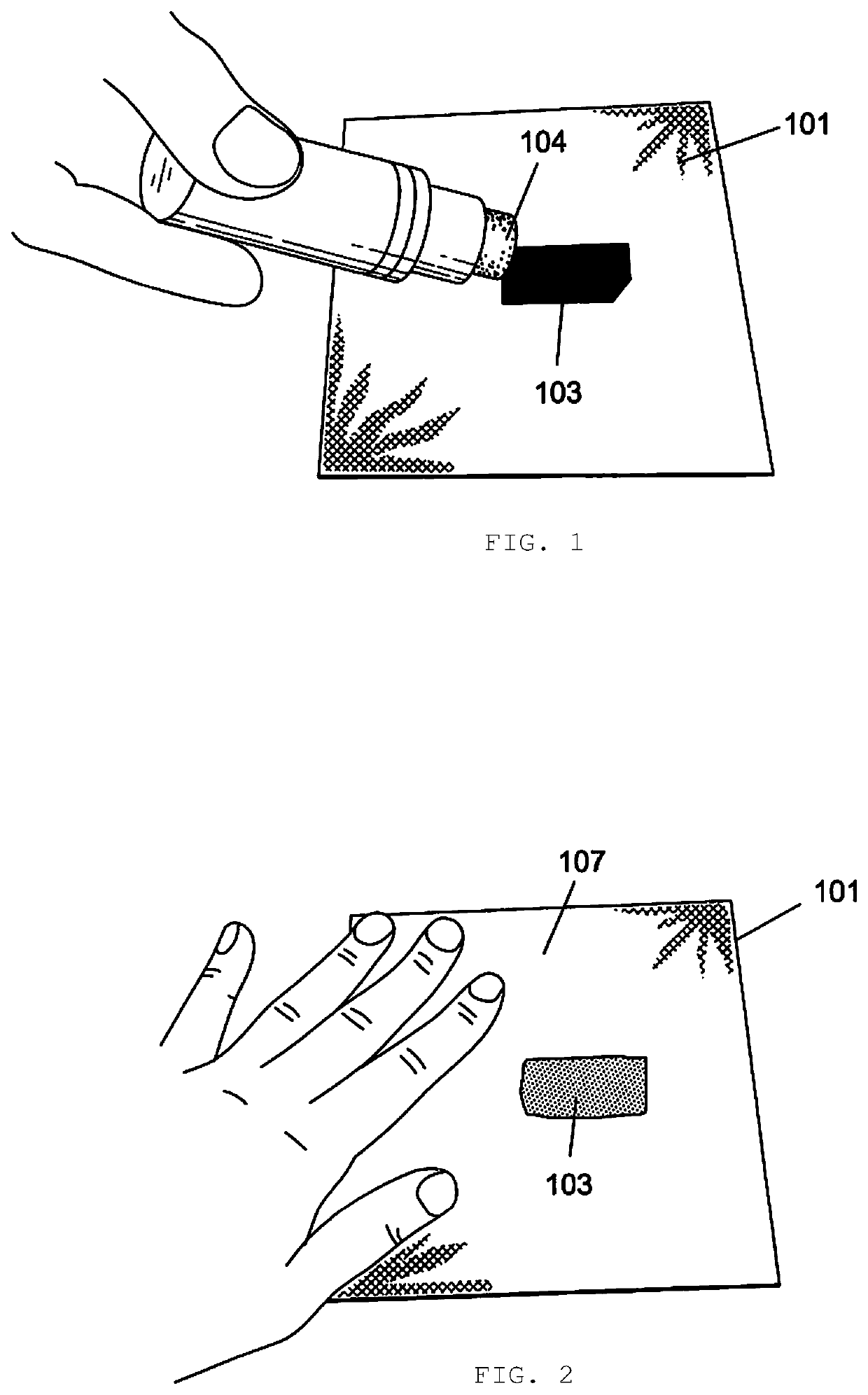

Shaping system, shaped object formation method, and computer-readable storage medium

ActiveUS20180162054A1Pattern printingManufacturing irradiation arrangementsThermal expansionEngineering

A shaping system includes: a printing device that prints an image using predetermined ink on a thermal expansion sheet having a thermal expansion layer on one side; and a heating device that performs: an identifier detection process of detecting an identifier provided on the thermal expansion sheet; a heating condition setting process of setting a heating condition for heating the thermal expansion sheet, based on the identifier; and a heating process of heating the thermal expansion sheet based on the set heating condition.

Owner:CASIO COMPUTER CO LTD

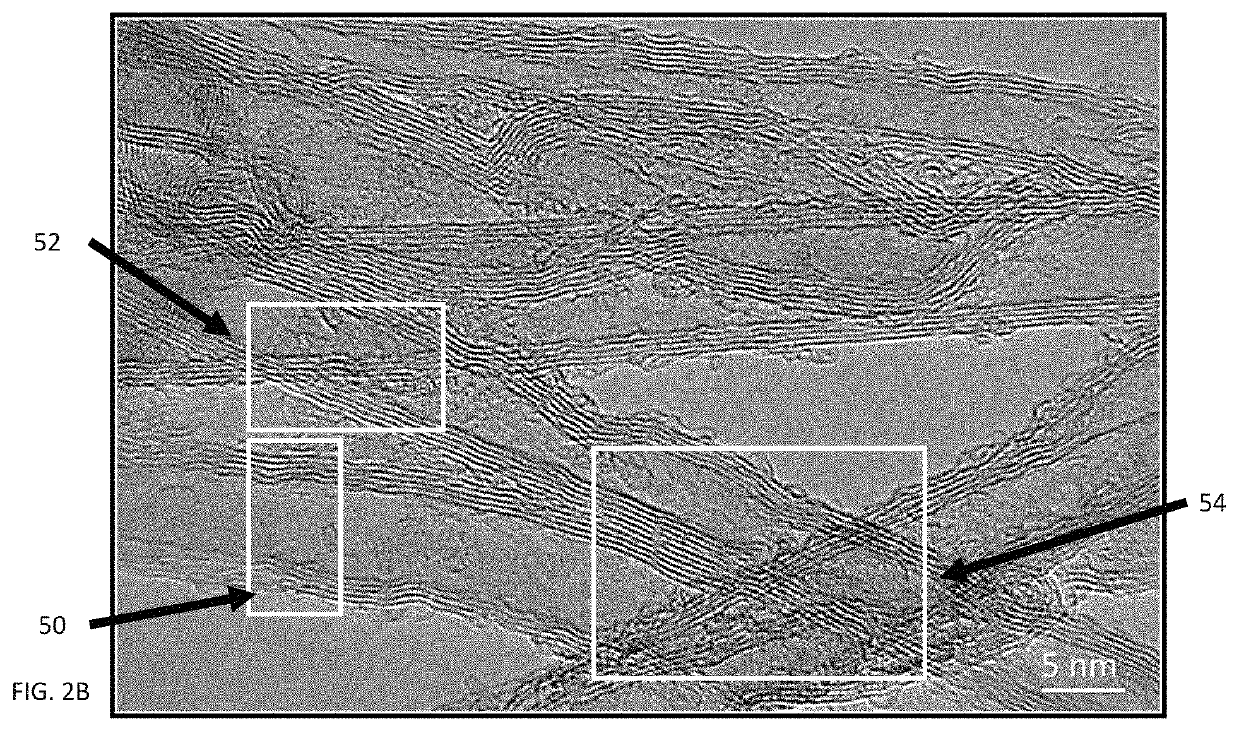

Conductive photo-curable compositions for additive manufacturing

PendingUS20220111582A1Electrostatic chargeAccelerated dissipationManufacturing irradiation arrangements3D object support structuresPolymer scienceOligomer

A photo-curable composition for use in additive manufacturing, said composition comprising: a) at least one photocurable monomer or oligomer; b) a photoinitiator for polymerization of the monomer; and, from 0.01 to 1 wt. %, based on the weight of the composition, of c) CNS-derived materials. Following polymerization, the resulting polymerized composition has a volume resistivity no greater than 105 ohm·cm.

Owner:CABOT CORP

Method of stabilizing a photohardening inhibitor-permeable film in the manufacture of three-dimensional objects

ActiveUS20190099947A1Manufacturing enclosuresManufacturing irradiation arrangementsMaterials science

Owner:GLOBAL FILTRATION SYST

LCD type 3D printer

InactiveUS20190299525A1Avoid overexposureExtended service lifeManufacturing platforms/substratesManufacturing enclosuresLight irradiationEngineering

An LCD type 3D printer includes a light source provided at a lower portion of the 3D printer to irradiate light upward, a lens disposed at a predetermined distance from an upper portion of the light source, an LCD panel provided above the lens, a storage container provided above the LCD panel to store a liquid molding material, a build plate provided above the storage container to hold a molded product, and an elevating member provided at an upper portion of the build plate to move up and down. The lens includes an upwardly-convex meniscus lens or a convex lens provided between the light source and the LCD panel to reduce a light irradiation angle.

Owner:RAY

Deflecting member for making fibrous structures

ActiveUS11396725B2Manufacturing irradiation arrangementsPaper/cardboardPolymer scienceComputer printing

Owner:PROCTER & GAMBLE CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com