Patents

Literature

47results about How to "Eliminate the "step effect"" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

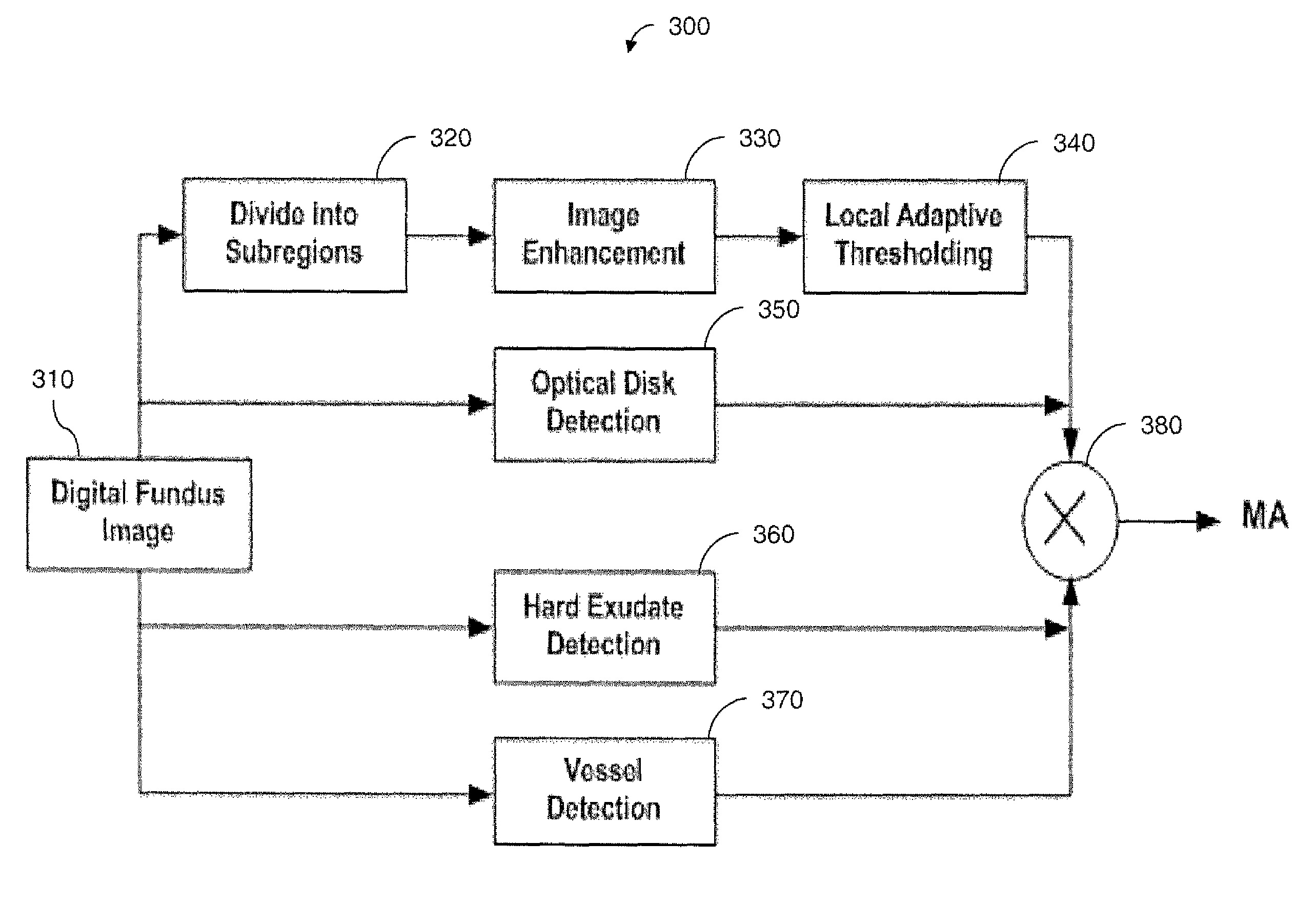

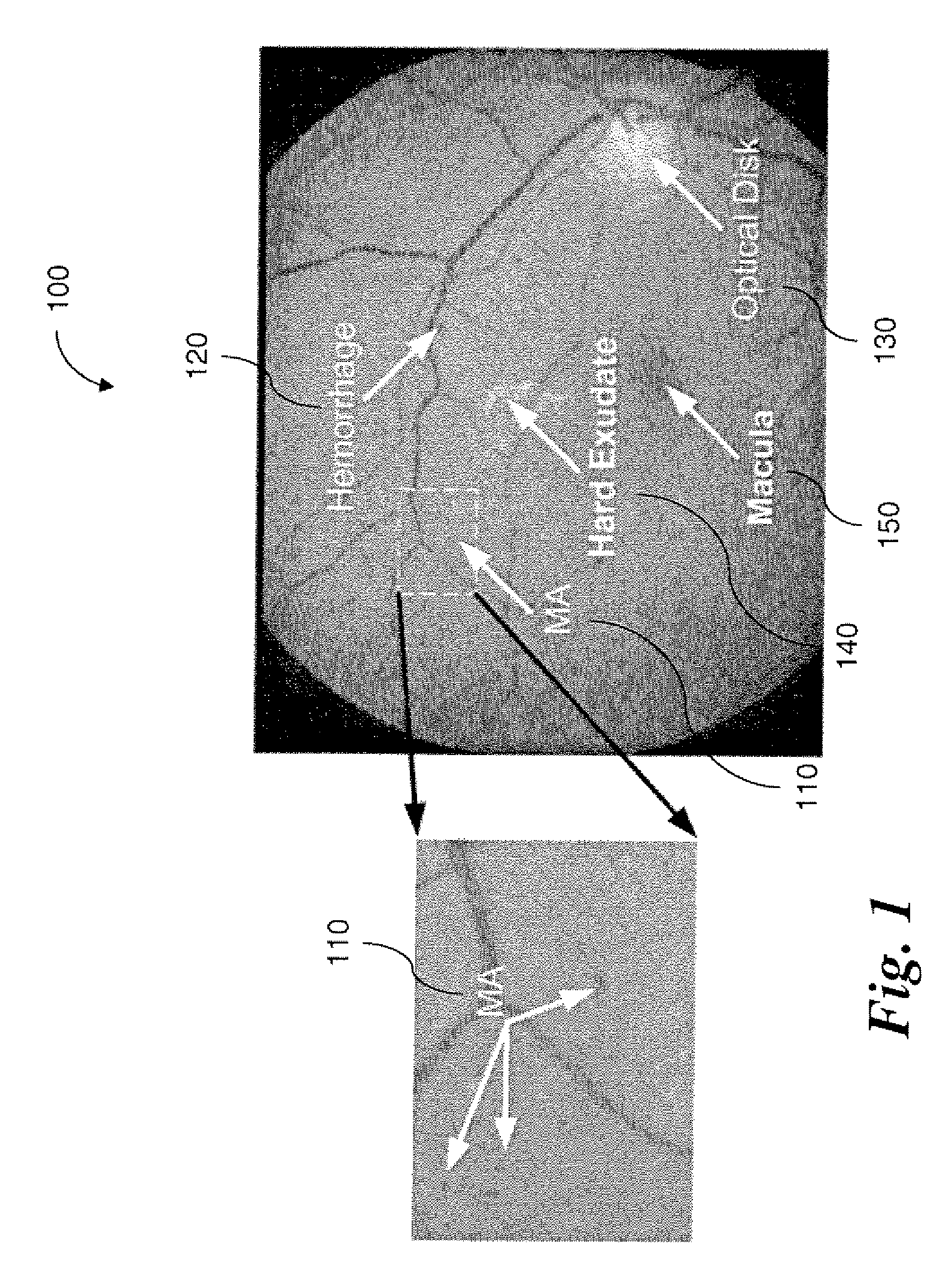

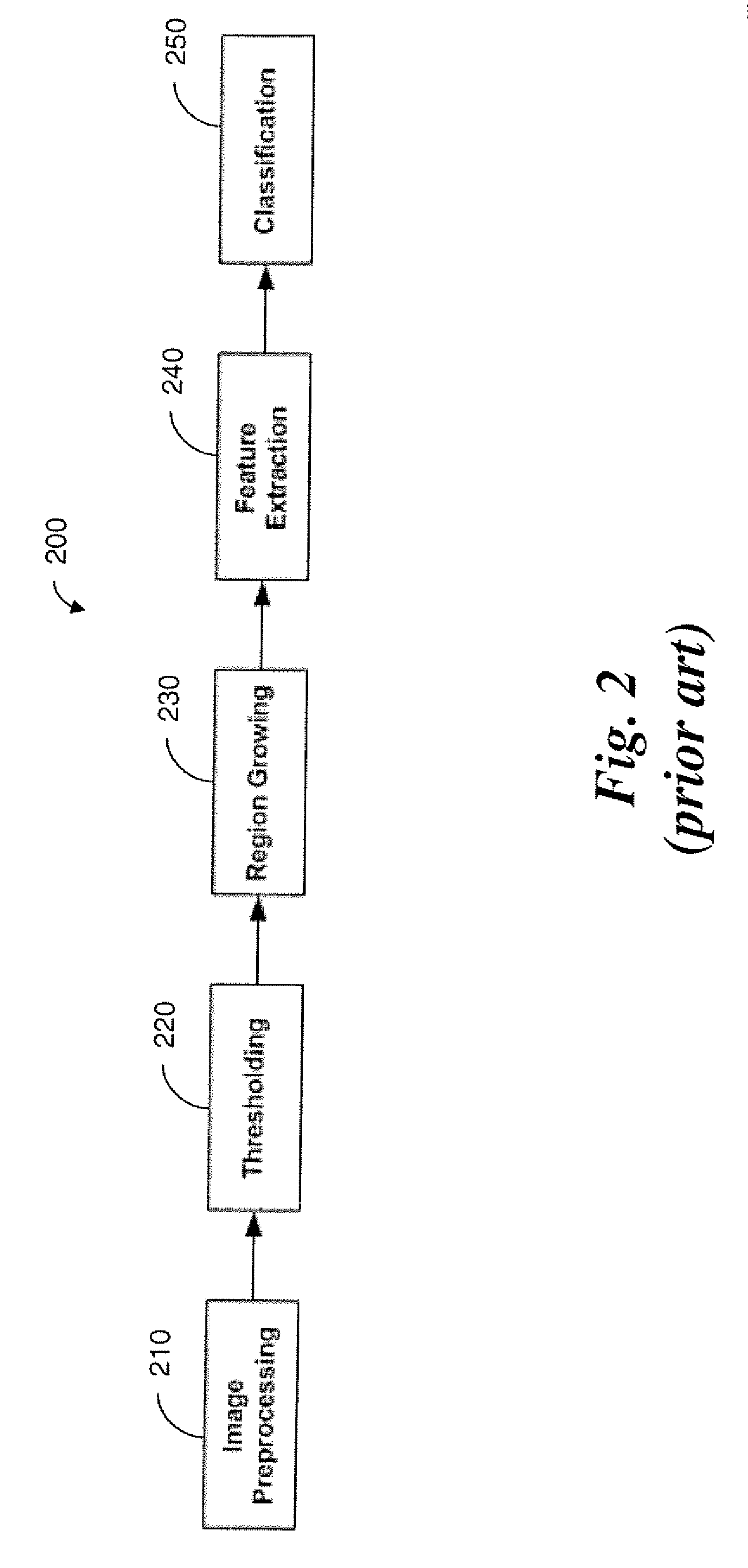

Method and System For Local Adaptive Detection Of Microaneurysms In Digital Fundus Images

ActiveUS20070002275A1Improve detection accuracyStrong specificityImage enhancementImage analysisPattern recognitionSelf adaptive

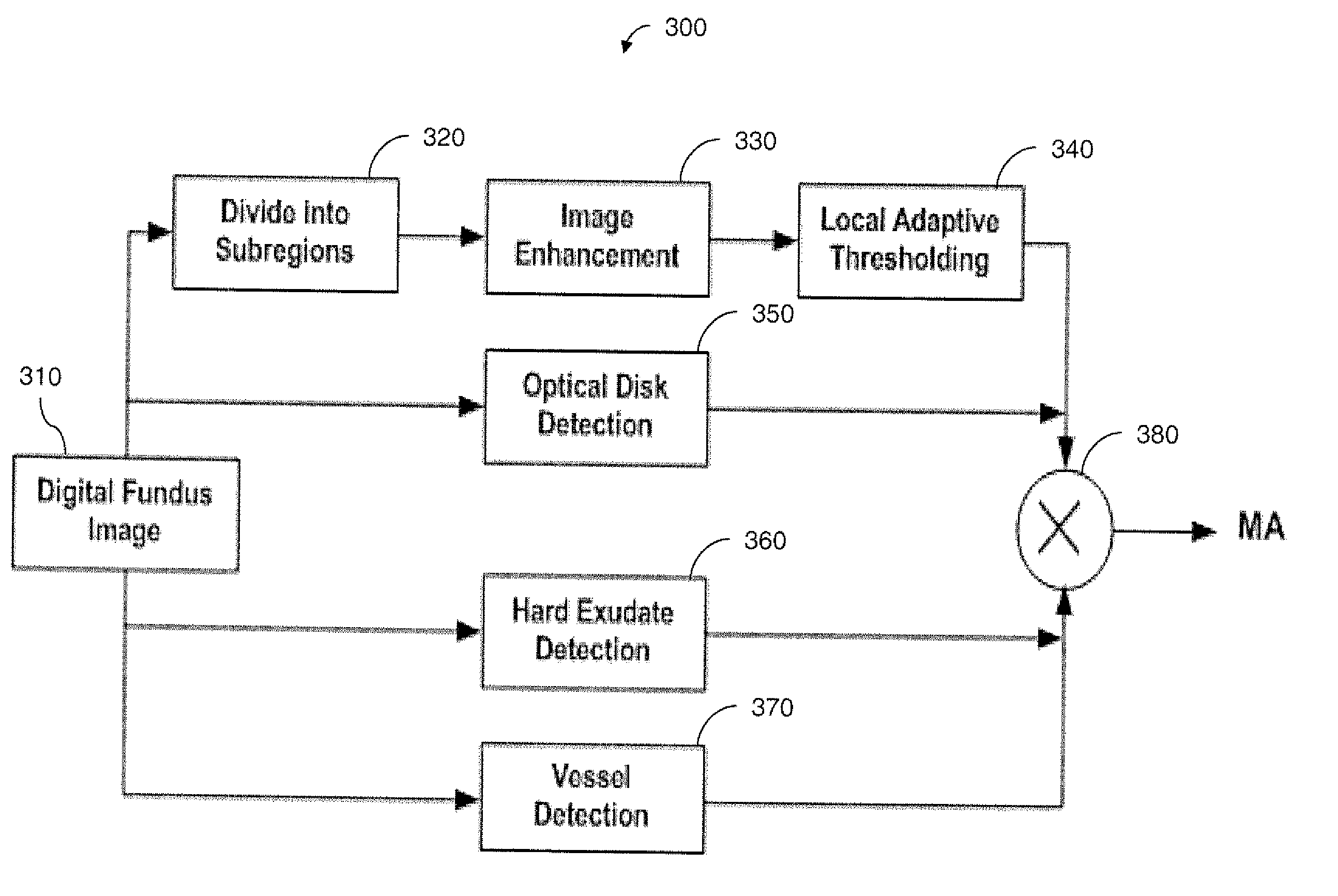

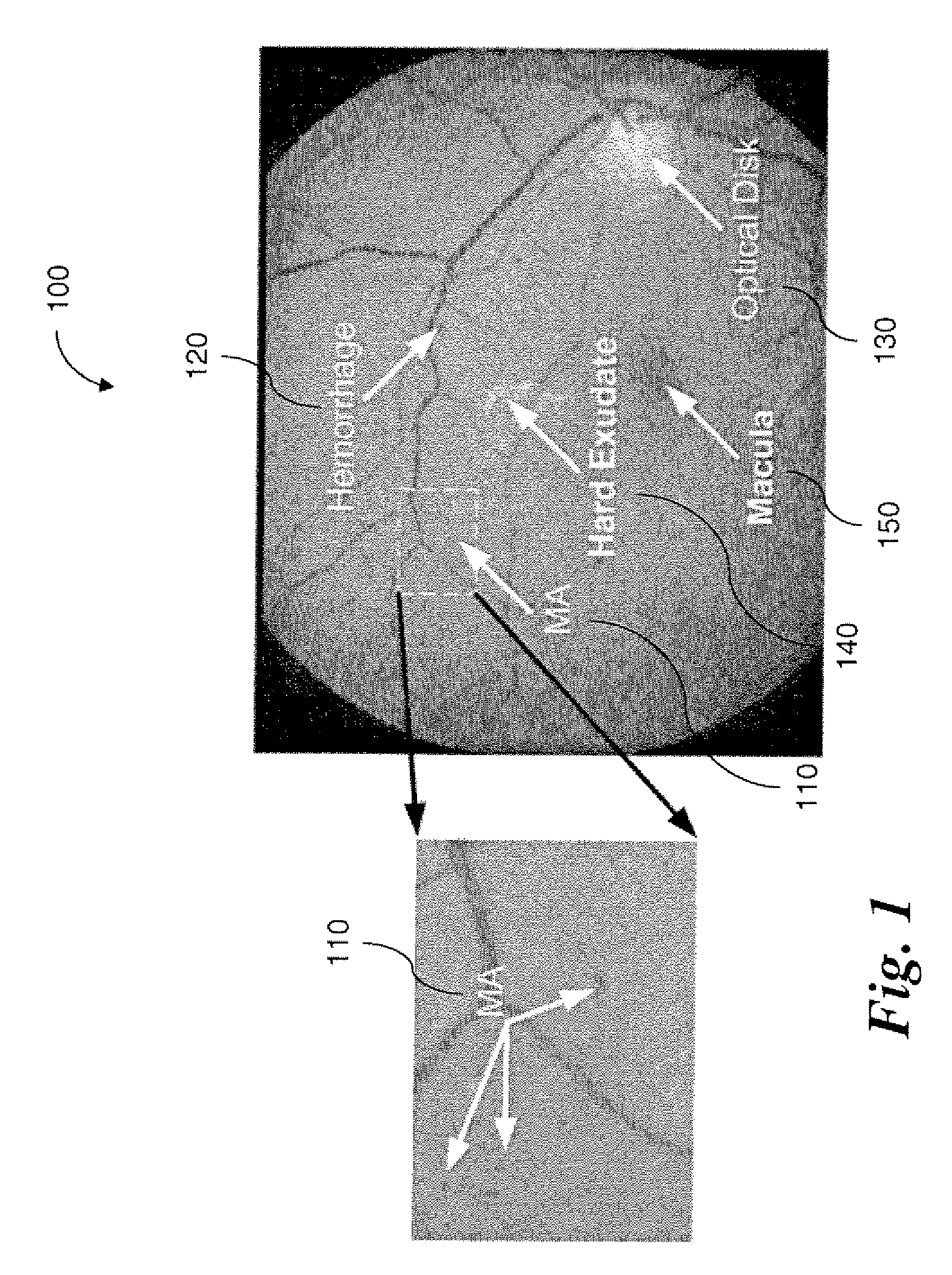

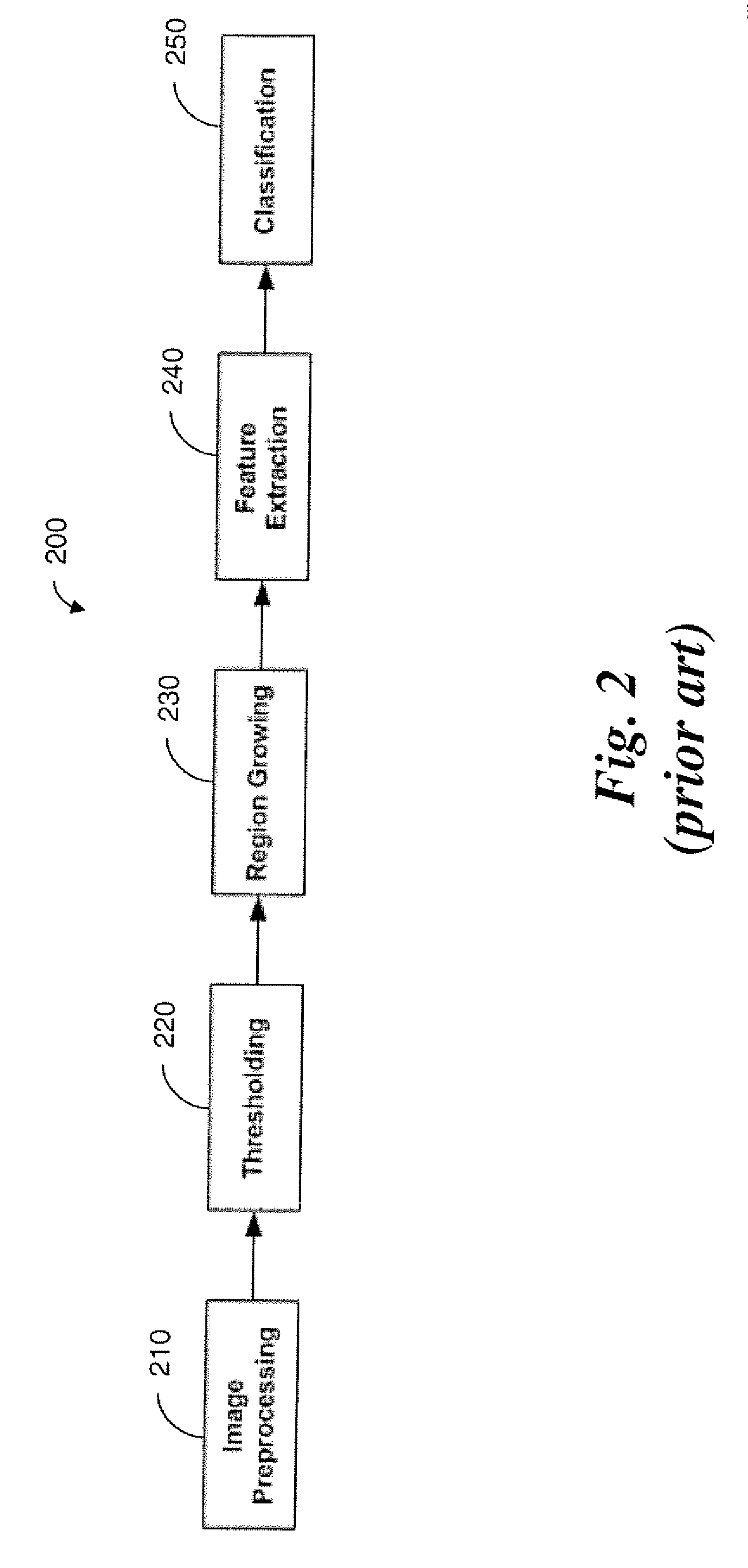

A local adaptive method is proposed for automatic detection of microaneurysms in a digital ocular fundus image. Multiple subregions of the image are automatically analyzed and adapted to local intensity variation and properties. A priori region and location information about structural features such as vessels, optic disk and hard exudates are incorporated to further improve the detection accuracy. The method effectively improves the specificity of microaneurysms detection, without sacrificing sensitivity. The method may be used in automatic level-one grading of diabetic retinopathy screening.

Owner:SIEMENS HEALTHCARE GMBH

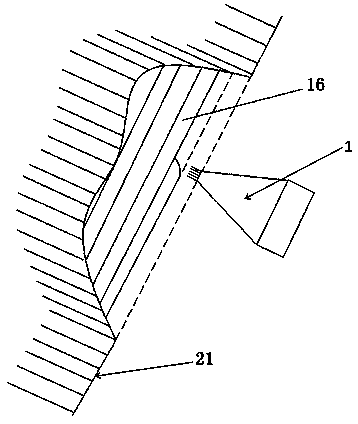

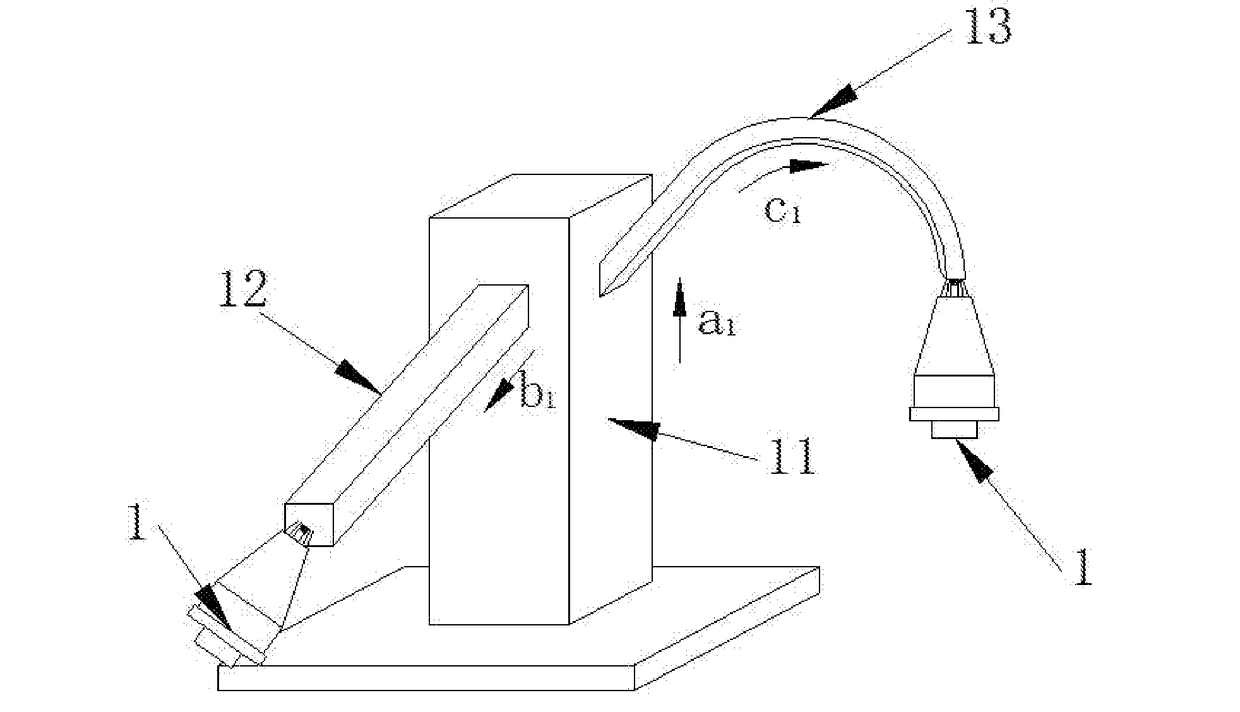

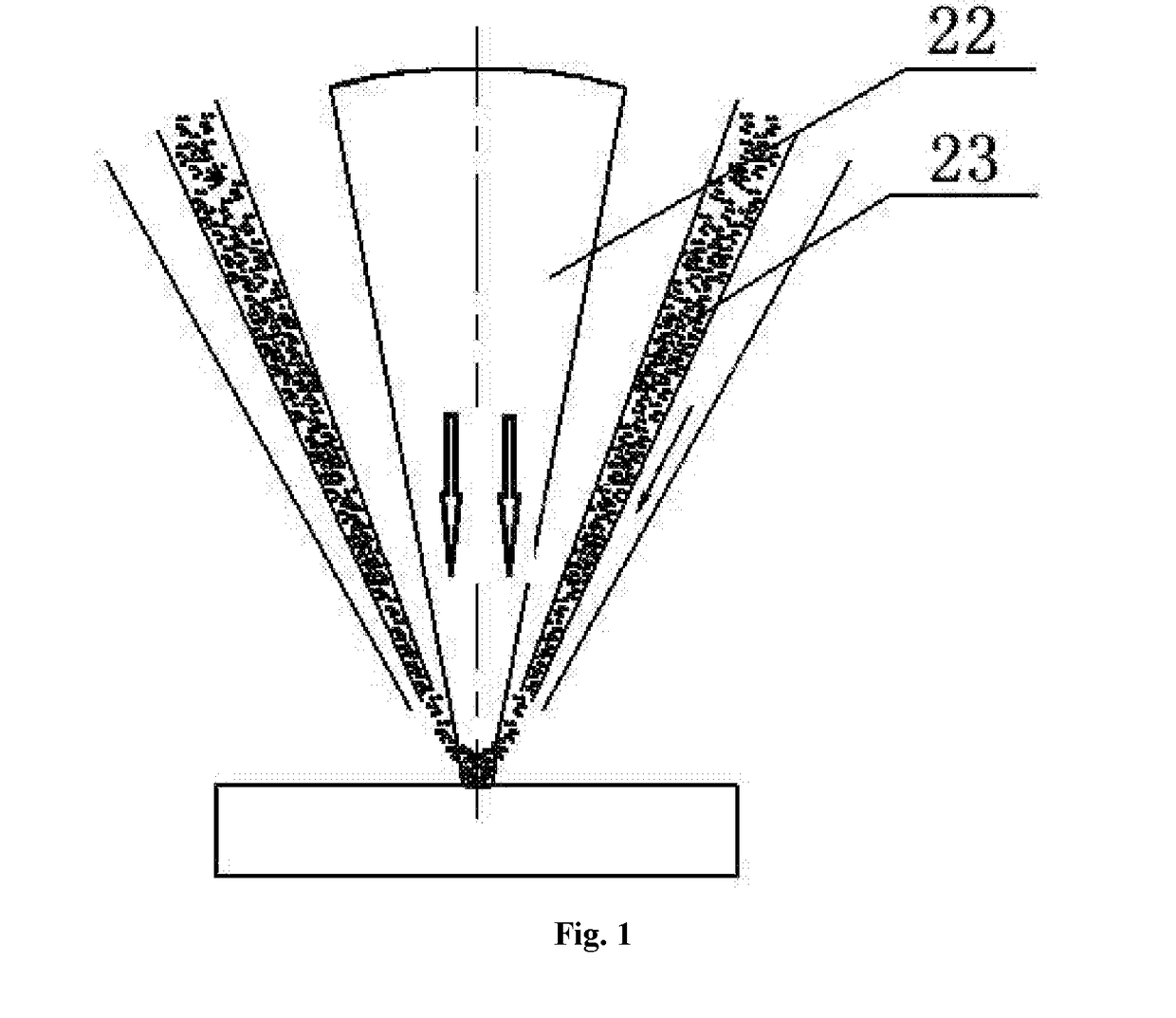

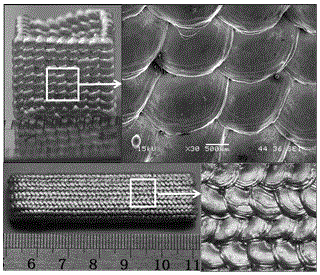

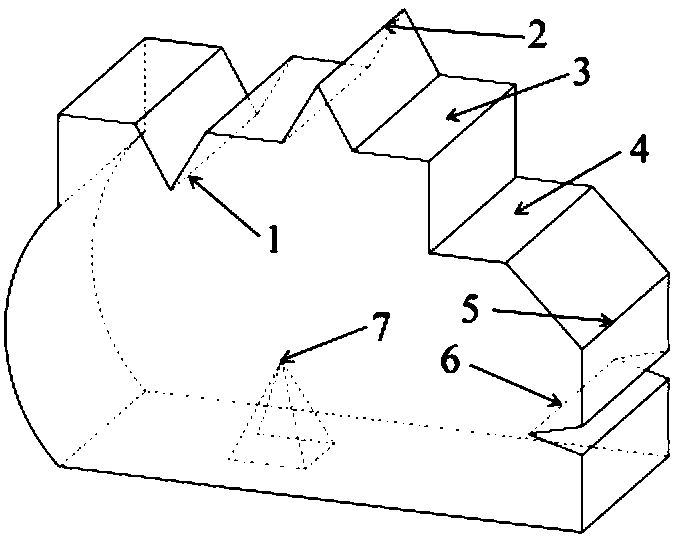

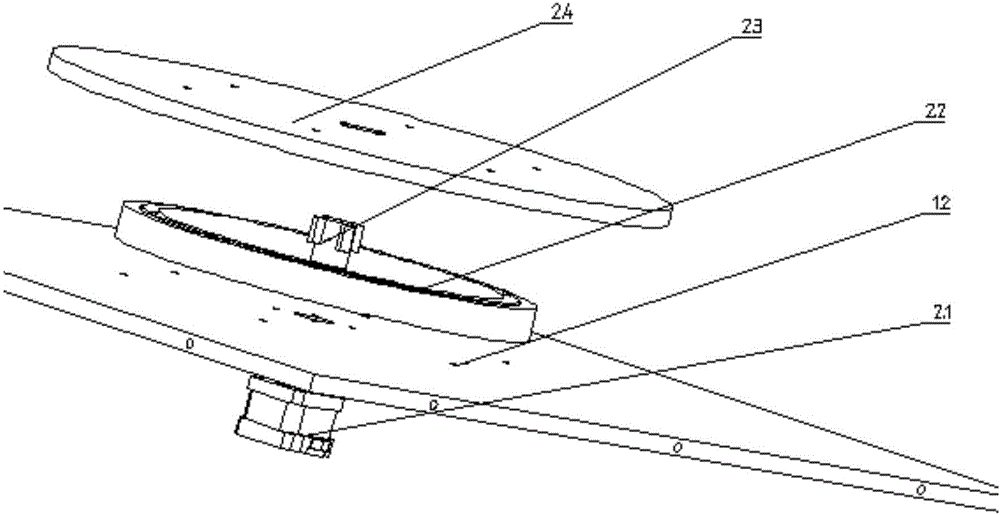

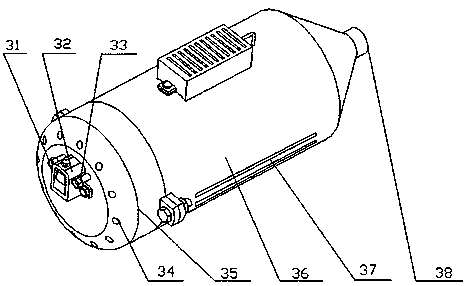

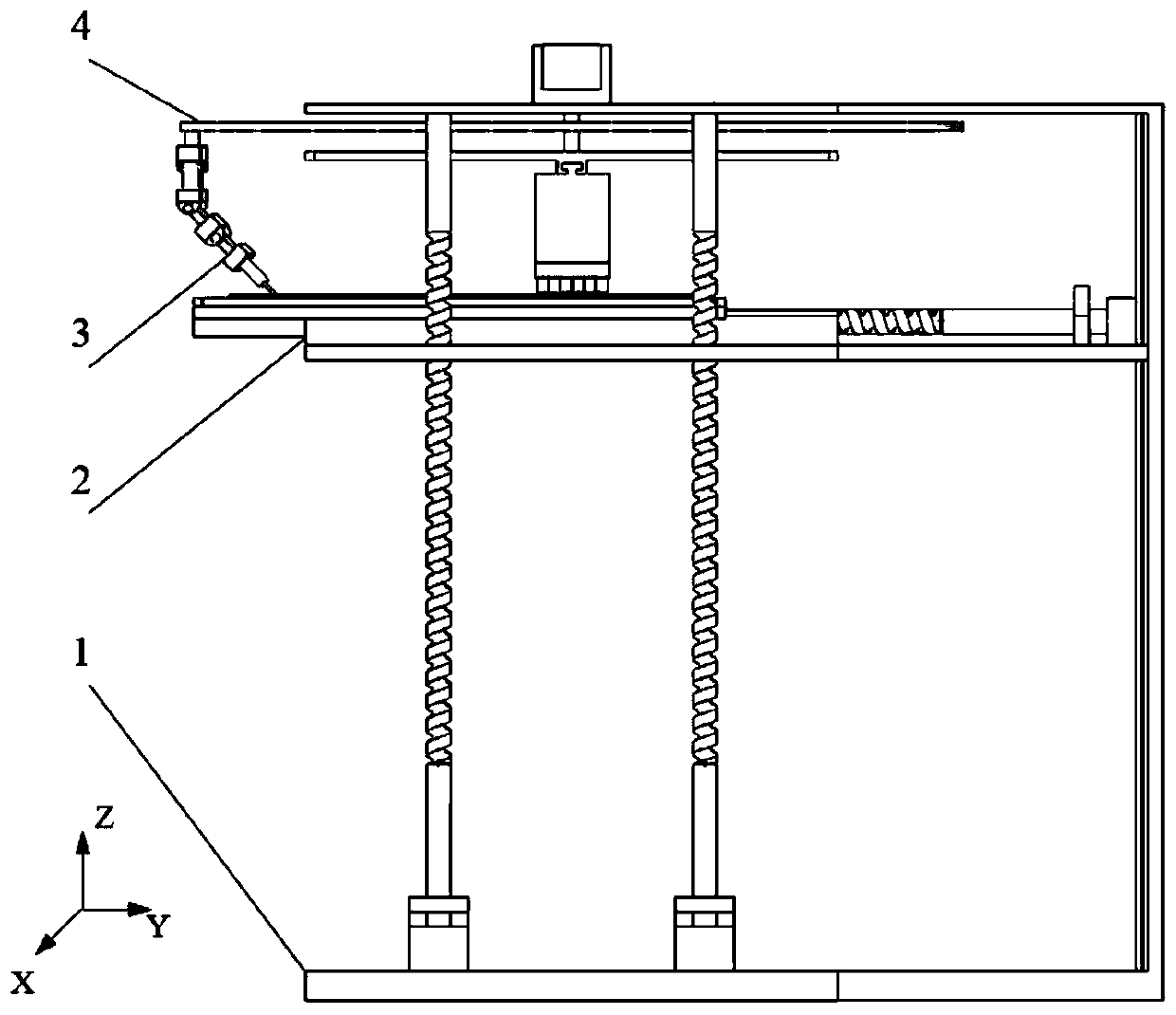

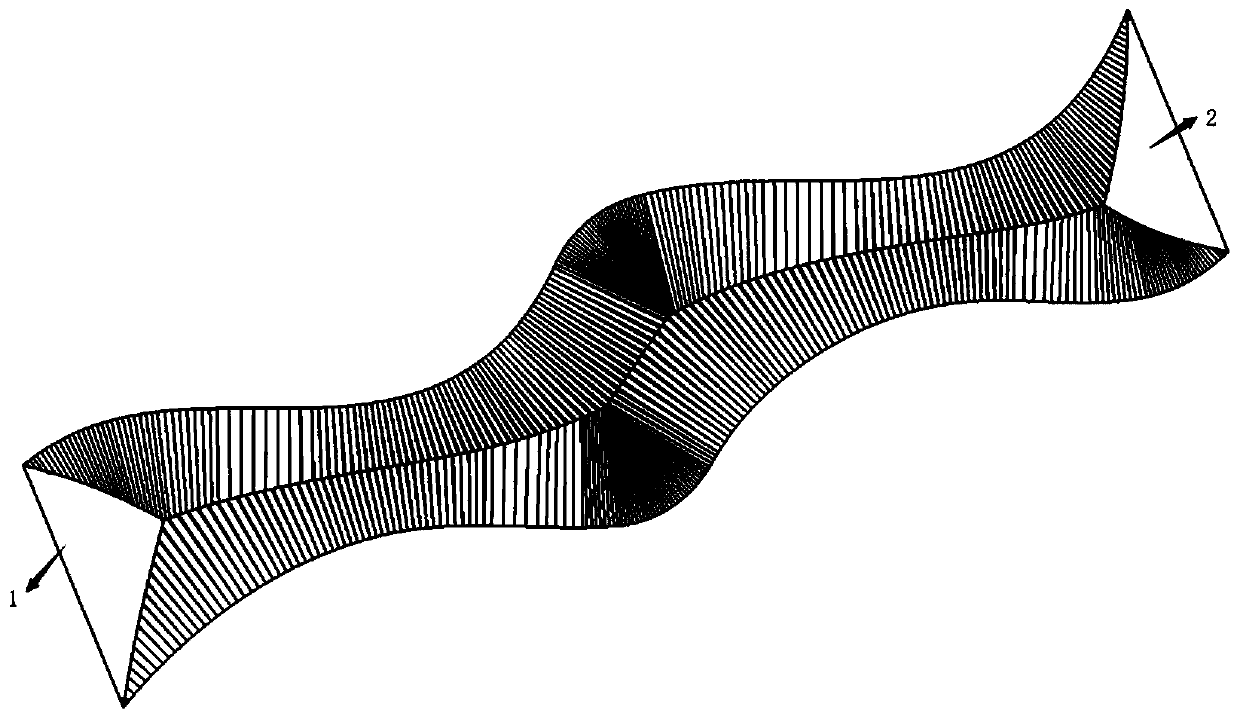

Synchronous powder feeding space laser machining and three-dimensional forming method and device

ActiveCN104190927APrecise couplingWon't flowAdditive manufacturing apparatusIncreasing energy efficiencySynchronous motorComputer module

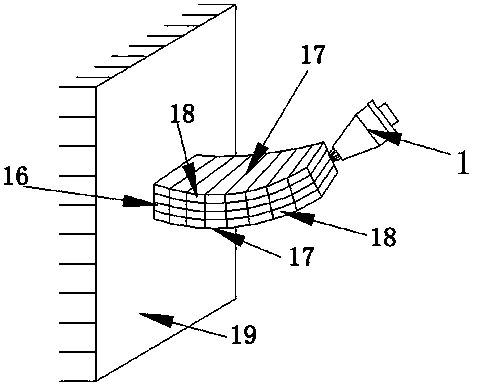

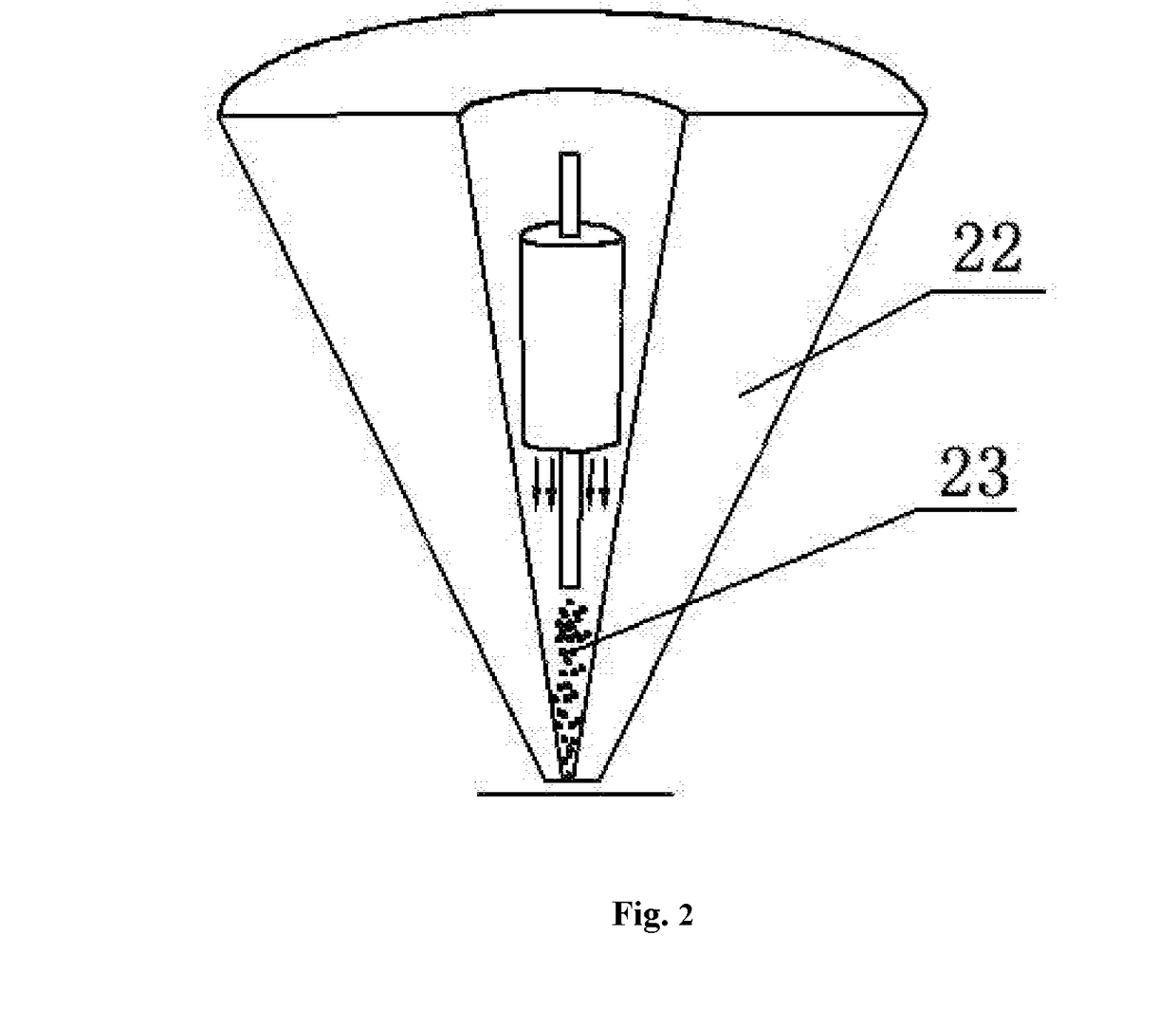

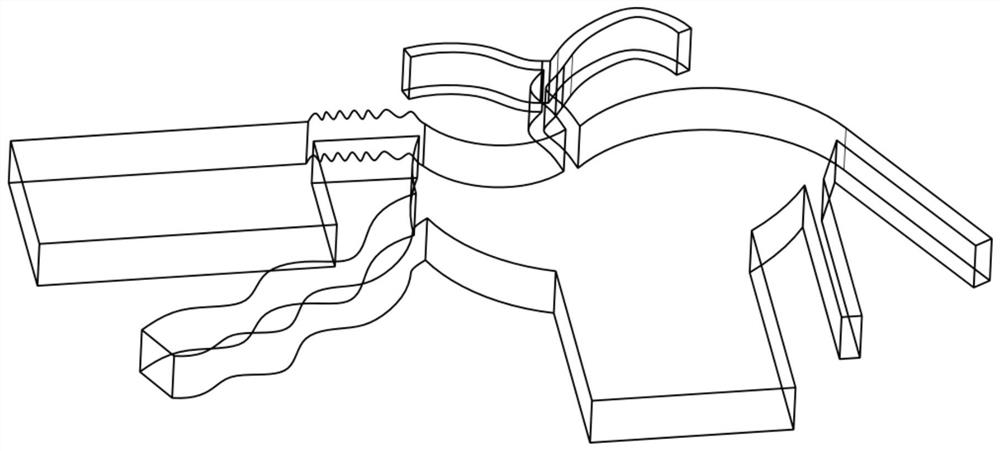

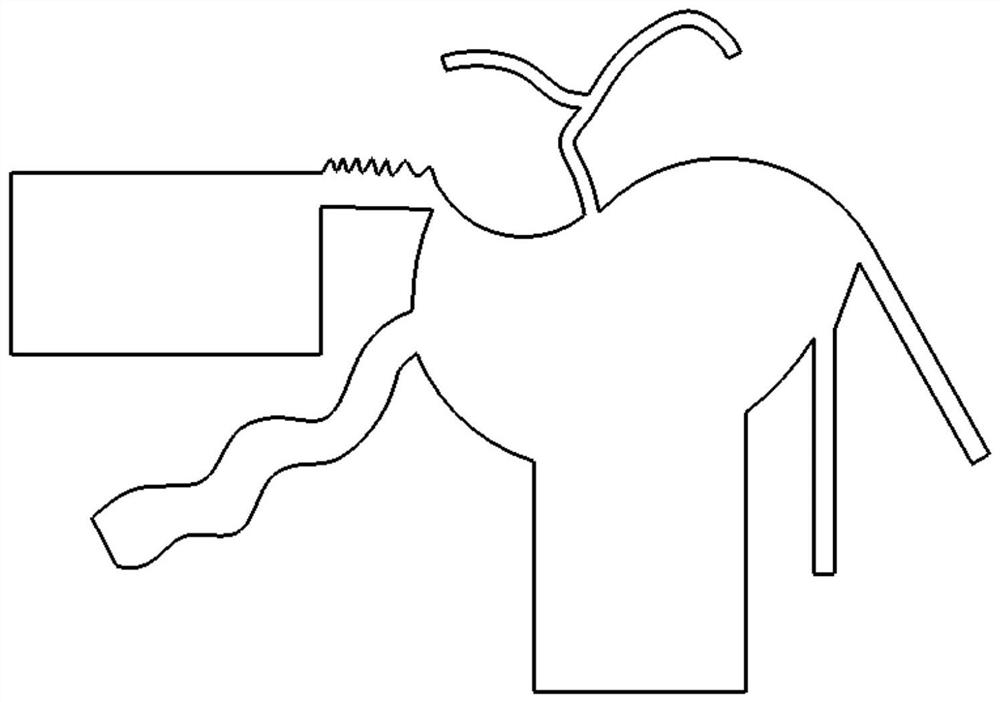

The invention discloses a synchronous powder feeding space laser machining and three-dimensional forming method and device. A three-dimensional solid is divided into a plurality of forming units according to the form simplification and nozzle fusion covering scanning accessibility principle, each forming unit is divided into a plurality of laminates, a mode for single-beam gas-carried powder feeding in a hollow annular laser is adopted, a mechanical arm is controlled to drive an in-laser powder feeding nozzle to move for scanning in filling areas and boundary areas of the laminates according to a preset trajectory, and forming fusion covering and stacking forming of the laminates are sequentially completed, so that forming fusion covering and stacking forming of the whole unit are completed. The device comprises the in-laser powder feeding nozzle, a laser generator, the mechanical arm, a control module, a transmission optical fiber, a gas-carried powder feeder and a gas source. The control module is connected with the mechanical arm, the laser generator and the gas-carried powder feeder. The in-laser powder feeding nozzle is fixed to the front end of the mechanical arm and can make spatial motion along with the mechanical arm. Through the method and device, fusion covering and three-dimensional stacking forming on any surface of the space can be achieved, and supportless three-dimensional forming of parts with complex structures such as a hanging structure and a cavity can be achieved.

Owner:SUZHOU UNIV

Synchronous powder-feeding space laser machining and three-dimensional forming method and device

InactiveUS20170232518A1Simple trackEasy to controlAdditive manufacturing apparatusIncreasing energy efficiencyLight beamLaser

A method for synchronous powder-feeding space laser cladding and three-dimensional forming includes: dividing a three-dimensional solid into a plurality of forming units according to a form simplification and nozzle cladding scanning accessibility principle, and dividing each forming unit into a plurality of layers; employing a single-beam gas-carried power-feeding mode in a hollow annular laser; controlling a mechanical arm (7) to drive an in-laser powder-feeding nozzle (1) to move and scan along a predetermined trajectory in a filling area and a boundary area of the layer; and sequentially conducting cladding and stacking formation of the layer for the entire unit. A device includes an inside-laser powder-feeding nozzle (1), a laser generator (6), a mechanical arm (7), a control module (4), a transmission optical fiber (5), a gas-carried powder feeder (3) and a gas source (2).

Owner:SUZHOU UNIV

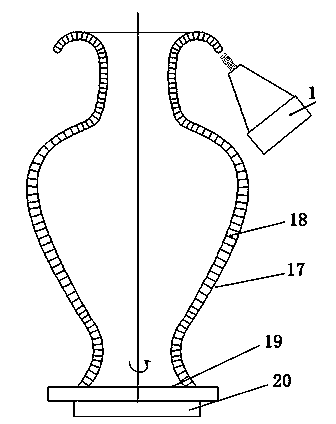

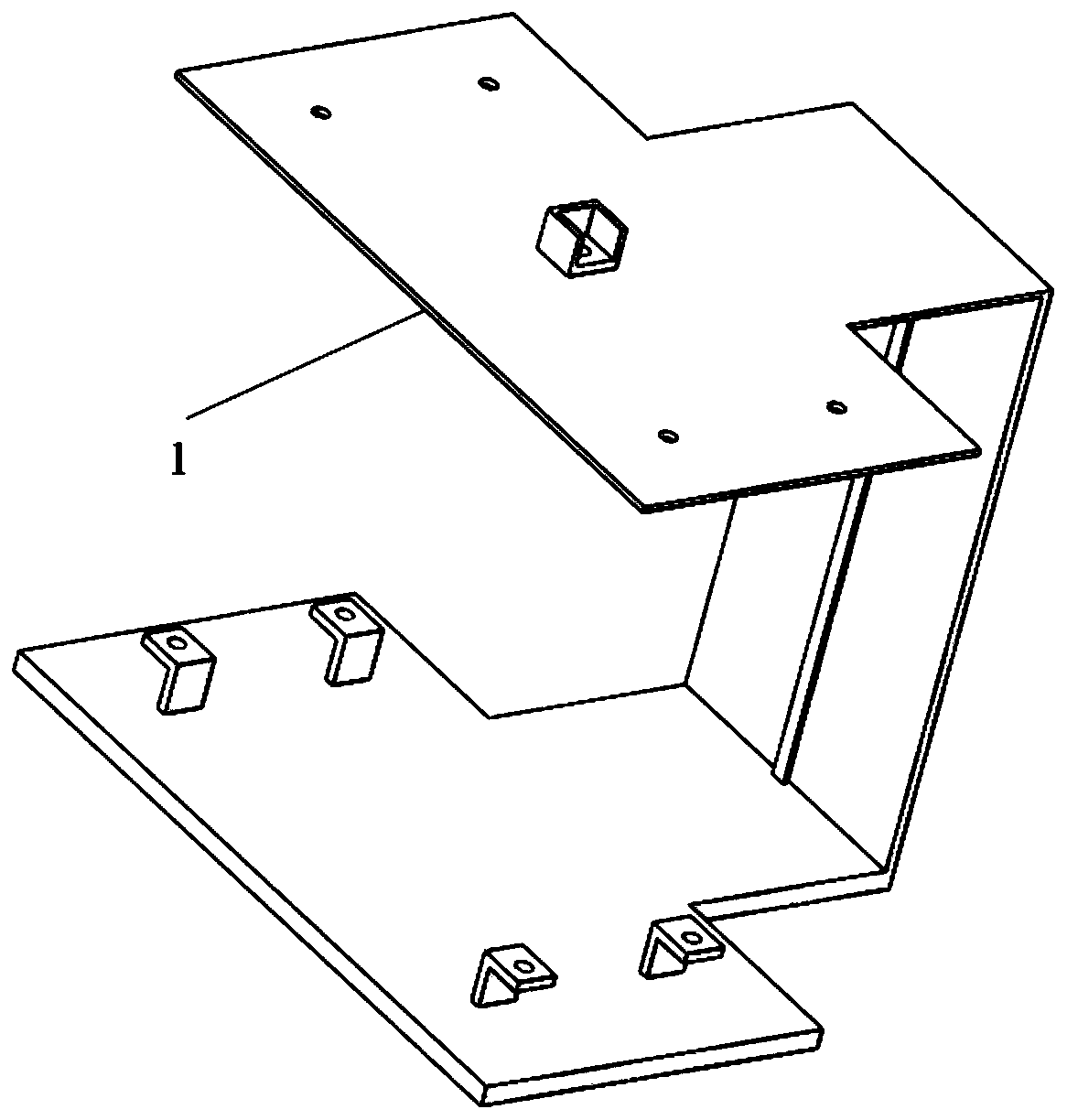

Five-freedom-degree rapid forming processing apparatus

InactiveCN104842557AEliminate the step effectImprove laying efficiencyAdditive manufacturing apparatusForm processingForms processing

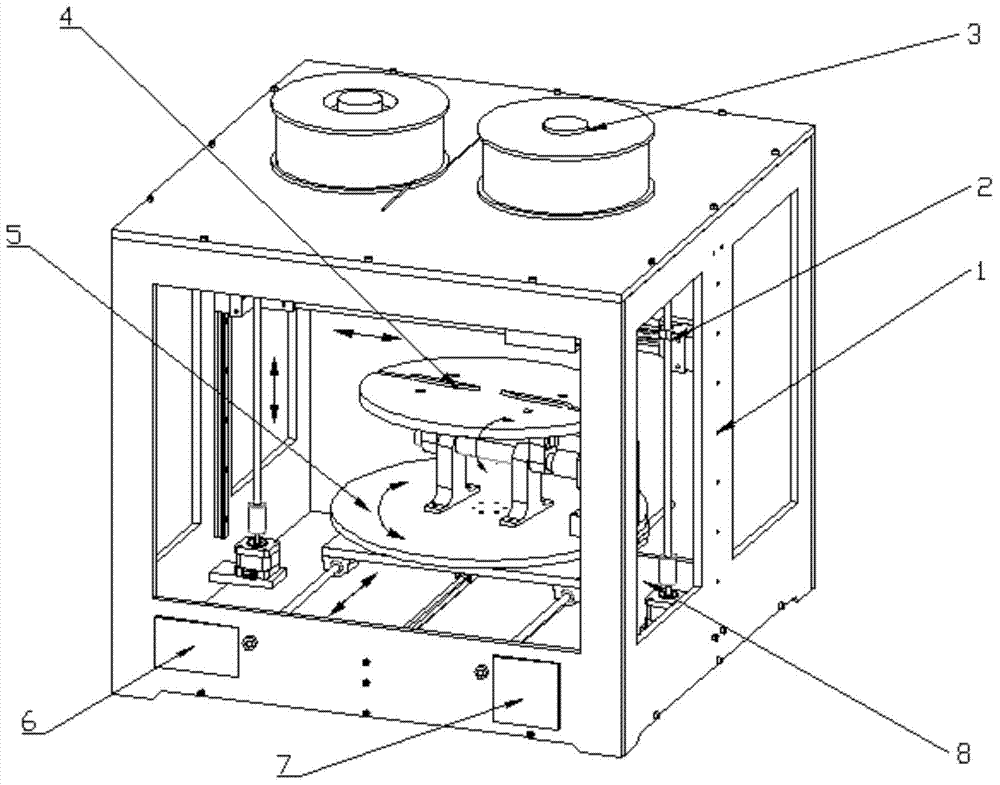

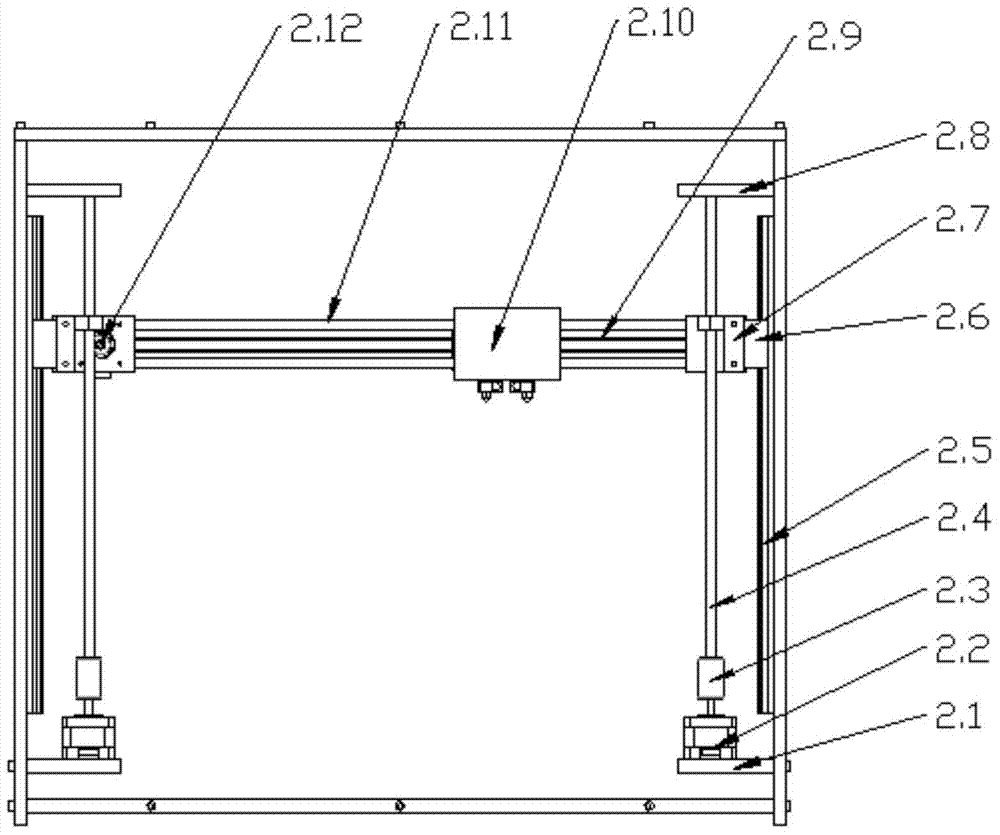

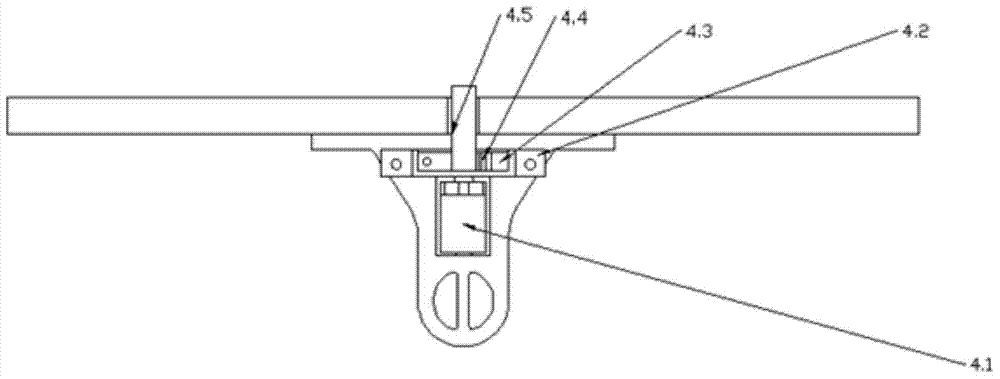

The present invention discloses a five-freedom-degree rapid forming processing apparatus, which comprises a frame (1), material disks (3) on the top portion of the frame (1), an operating plate (6), a screen (7), and a control plate (8), and further comprises a two-freedom-degree spraying head assembly (2) capable of freely moving along X axis and Z axis, a clamping device (4), and a three-freedom-degree platform assembly (5) capable of freely rotating along Y axis, Z axis and A axis, wherein the operating plate (6) and the screen (7) are arranged on the bottom portion in front of the frame (1). With the five-freedom-degree rapid forming processing apparatus of the present invention, the step effect can be eliminated, the surface quality of the printed inclined plane can be increased, the processing efficiency on the circular cross-section parts is high, the processing on the spherical platform can be achieved, and the space utilization rate is good.

Owner:CHINA UNIV OF MINING & TECH

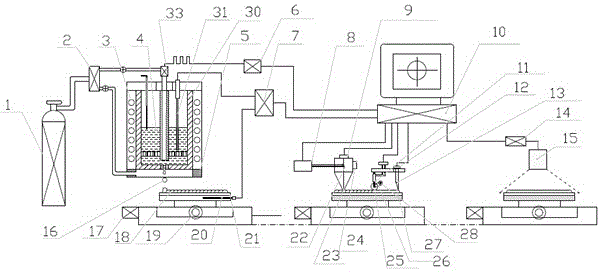

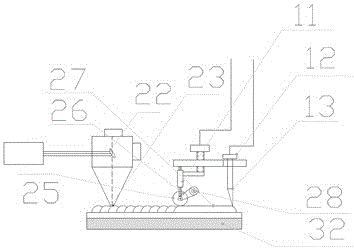

Surface quality control device for three-dimensional (3D) part formed through metal drop printing and control method of surface quality control device

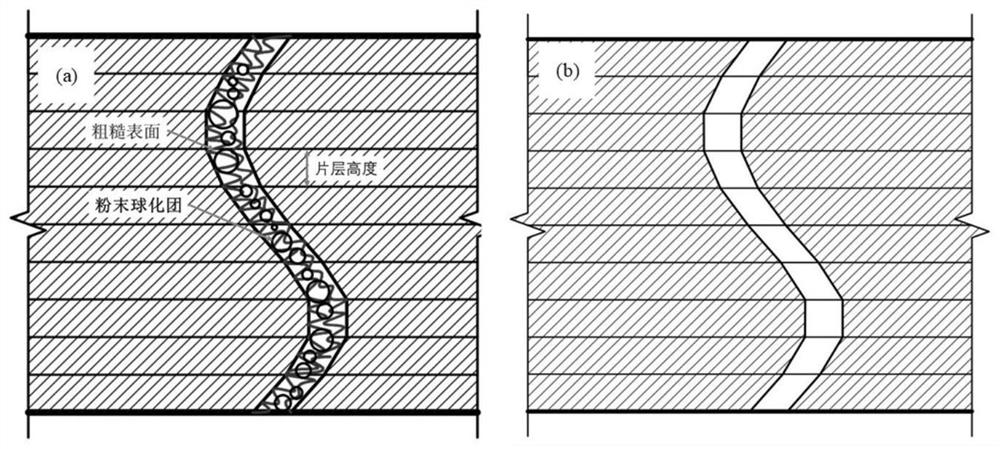

ActiveCN105081325AEliminate the step effectAvoid flattening defectsAdditive manufacturing apparatusImage detectionEngineering

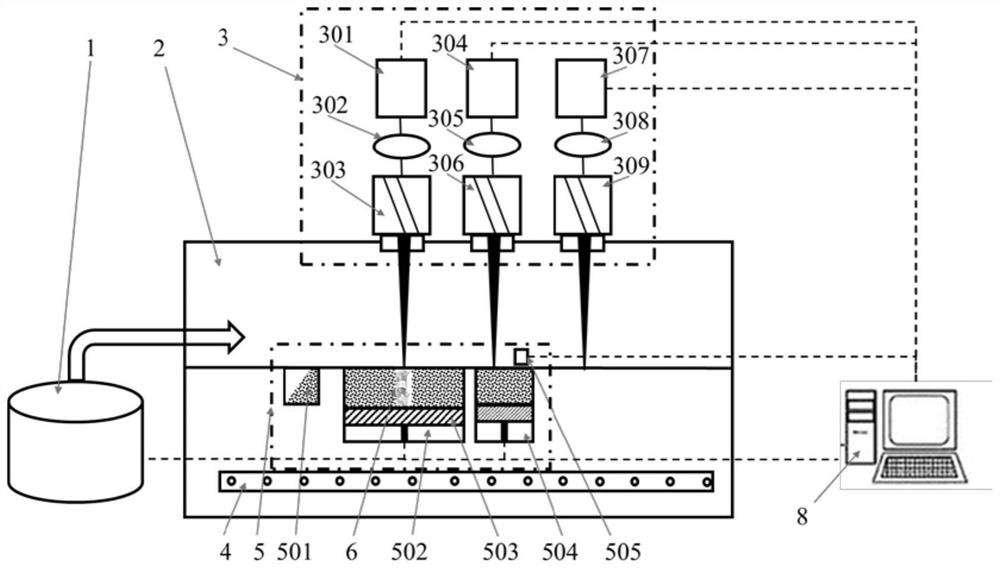

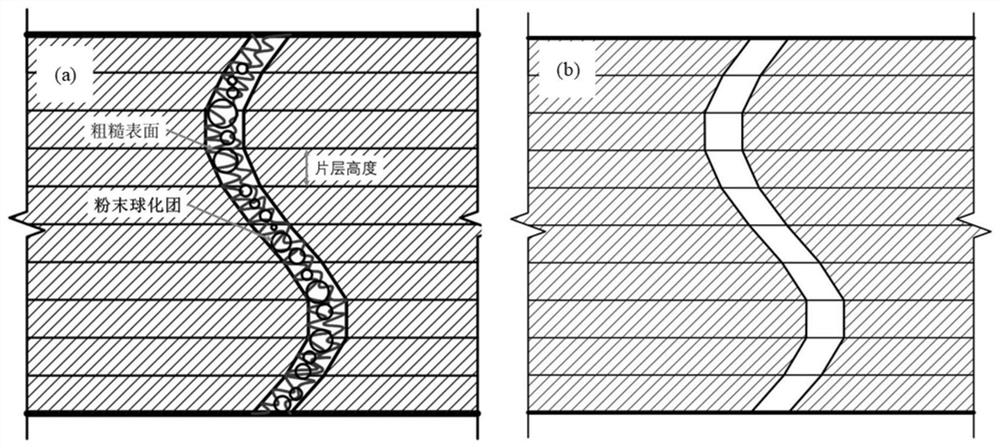

The invention discloses a surface quality control device for a three-dimensional (3D) part formed through metal drop printing and a control method of the surface quality control device. The surface quality control device comprises a computer system, a metal drop spraying head, a laser device, a scanning galvanometer, a galvanometer motor, a movement platform, a deposition base plate, a driving motor, a flat covering roller, a roller motor and a charge-coupled device (CCD) camera. The surface quality control device is characterized by further comprising a laser power regulator, a flat covering roller height adjuster, a base plate temperature control device, a flow edge scraper and the like. According to the surface quality control device, the laser device is used as an energy source, rapid surface fusion covering of a formed layer is achieved through laser beams through the scanning galvanometer, and the flat covering depth and the pressure of the roller are controlled through the flat covering roller height adjuster; in the state that metal drops or melt on the surface layer is not completely solidified, the metal surface which is fusion-covered rapidly is scraped and pressed in a directional mode by controlling the speed of the movement platform and the speed of the flat covering roller, so that secondary spreading and filling of the metal surface are achieved, the formed layer which is scraggly originally is flattened through rolling, and control over the surface quality of the layer is completed; in addition, real-time detection and feedback of the rolling flattening effect are achieved through a CCD image detection system.

Owner:XUCHANG UNIV

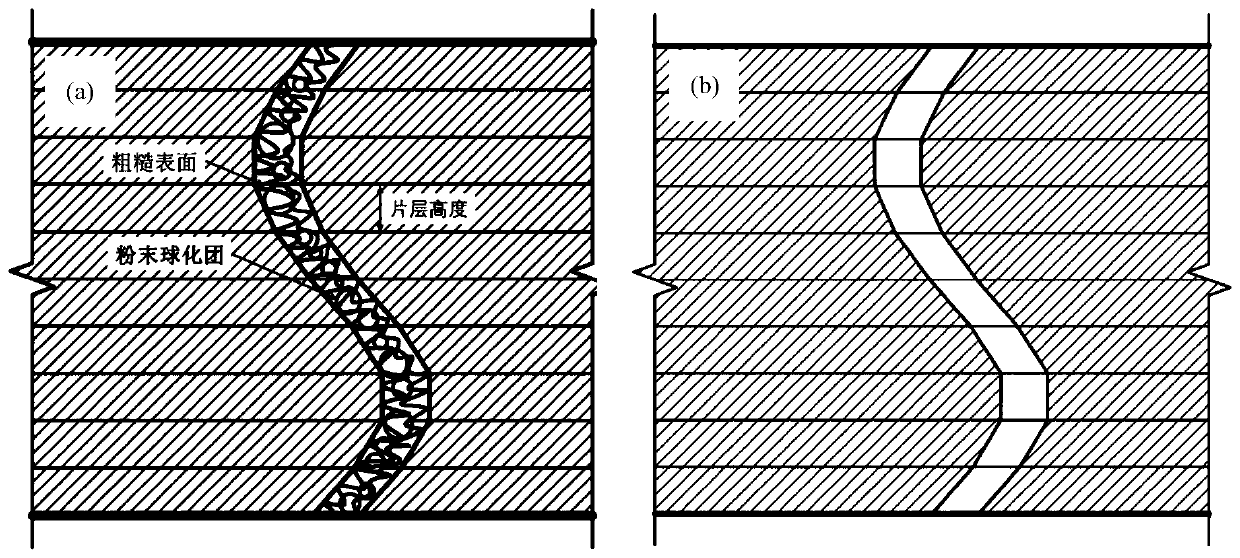

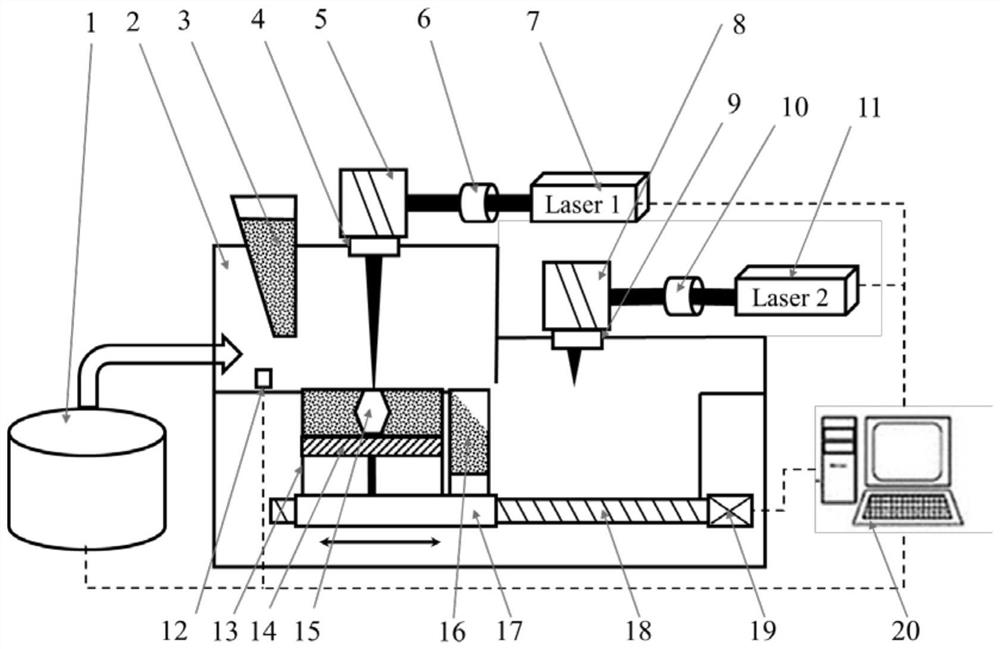

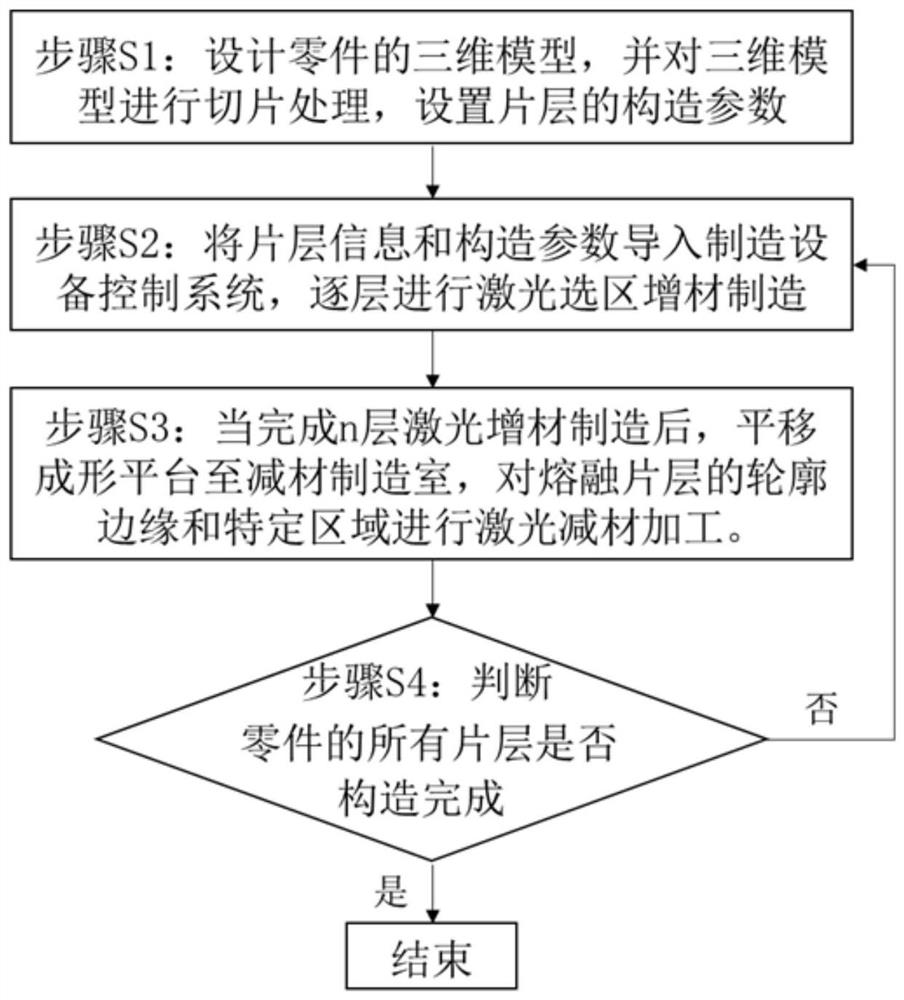

Near-net forming method and device for composite manufacturing fine workpiece based on laser additive manufacturing and subtractive manufacturing

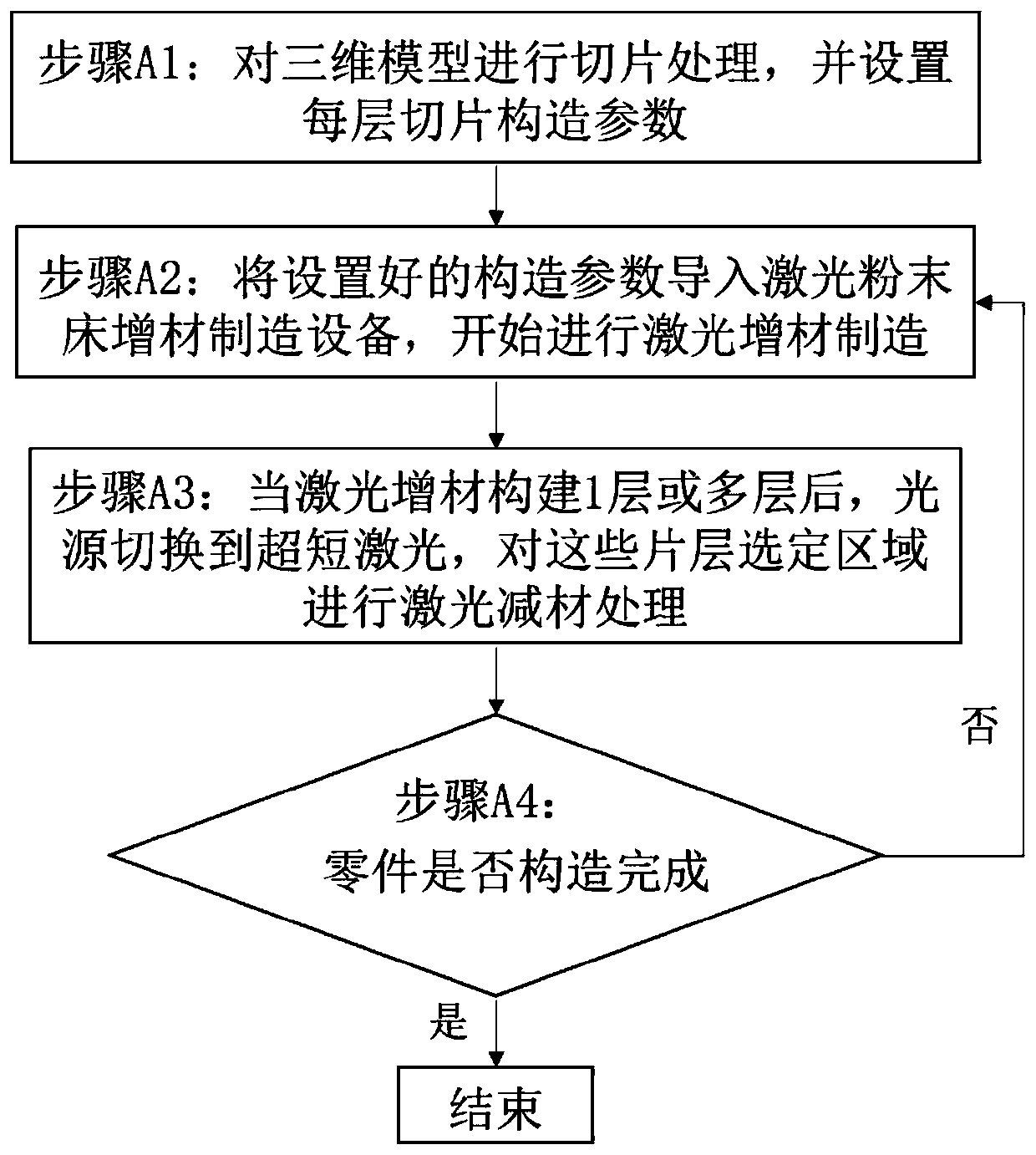

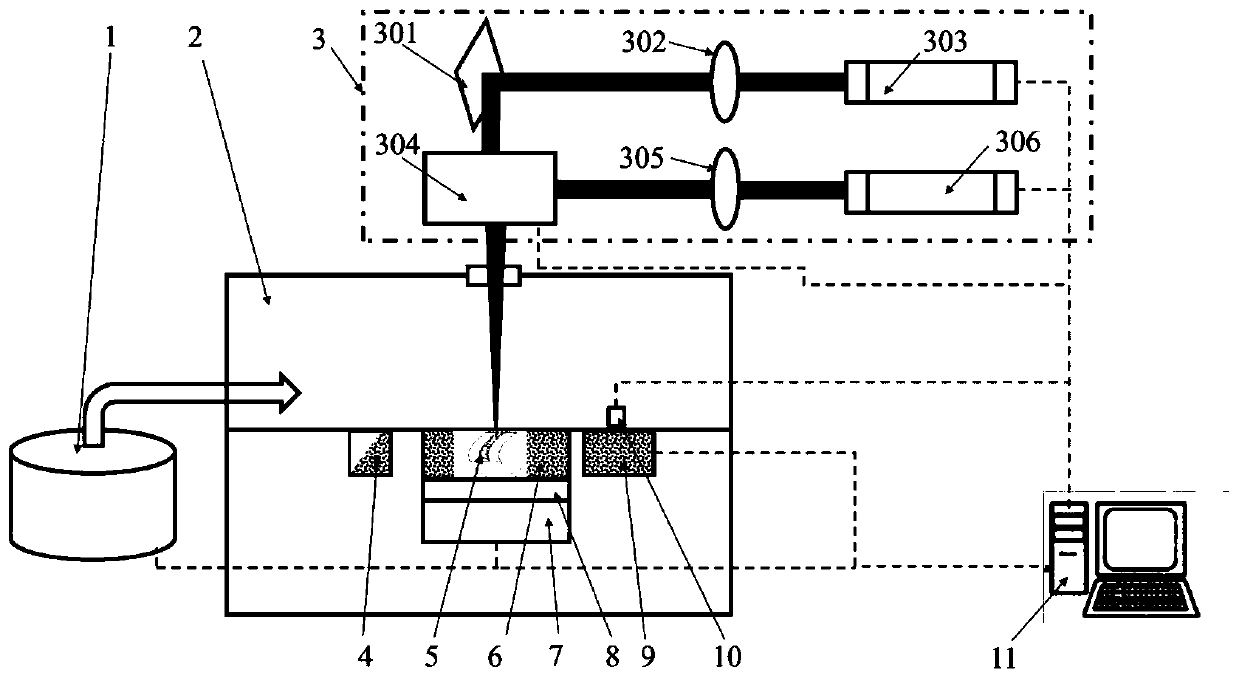

PendingCN110369725AShort duration of actionChange the surface morphologyAdditive manufacturing apparatusIncreasing energy efficiencyFine structureLaser processing

The invention belongs to the field of laser processing, and relates to a near-net forming method and device for composite manufacturing a fine workpiece based on laser additive manufacturing and subtractive manufacturing. According to the method, the construction parameters of a three-dimensional digital-to-layer slicing layer are generated by utilizing software, laser additive manufacturing processing is carried out, and ultrafast pulse laser subtractive manufacturing processing is carried out alternately in the laser additive manufacturing processing process to form a three-dimensional entity. The device comprises a computer control device, a sealing molding chamber, a light path selecting system and an inert protection gas source; during additive manufacturing processing, the computer control device controls the light path selecting system to select the laser emitted by an additive manufacturing laser device and perform laser additive manufacturing processing; and during subtractivemanufacturing processing, the computer control device controls the light path selecting system to select ultrafast pulse lasers emitted by a subtractive manufacturing laser device and perform the ultrafast pulse laser subtractive manufacturing processing. According to the near-net forming method and device, the preparation of complex and fine-structure parts can be completed in a high-precision and integrated manner, the defects that traditional laser additive manufacturing is low in the forming precision, high in roughness and cannot be used for preparing a fine and complex inner cavity areovercome.

Owner:SHANGHAI UNIV OF ENG SCI

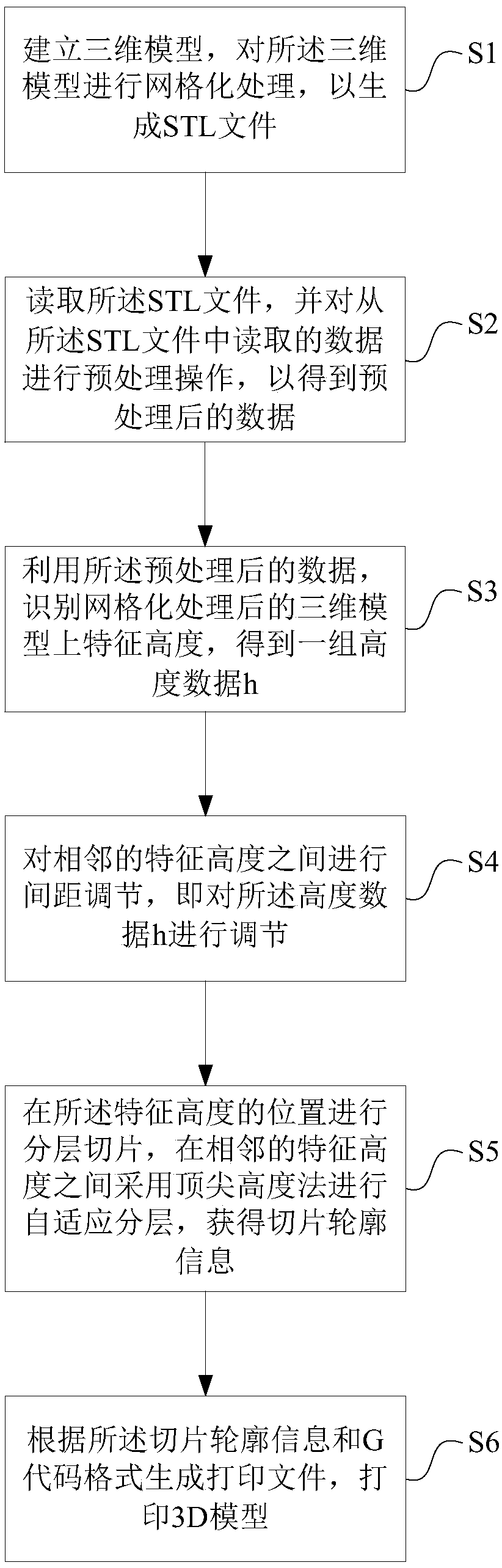

An adaptive layering method for preventing feature deviation of 3D printing model

ActiveCN109522585AAvoid lossGuaranteed locationSpecial data processing applications3D modellingStl fileComputer vision

The invention discloses an adaptive layering method for preventing feature deviation of 3D printing model, including the creation of three-dimensional models, A mesh process is carried out on that three-dimensional model, to generate the STL file, reading the STL file, and preprocessing the data read from the STL file, to obtain the preprocessed data, recognizing the feature height on the three-dimensional model after gridding, A set of height data is obtained to adjust the spacing between adjacent feature heights, the height data is adjusted, The feature height is sliced at a position of thefeature height, and an adaptive slicing is performed between adjacent feature heights to obtain slice outline information, generate a print file, and print a 3D model. The invention ensures that the layered plane passes through the position where the model features are located, thereby retaining the three-dimensional model features, effectively preventing the feature deviation and loss caused by the layer-by-layer accumulation of materials in the printing process of the 3D printing model, and reducing the step error.

Owner:HEFEI UNIV OF TECH

Method and system for local adaptive detection of microaneurysms in digital fundus images

ActiveUS8098907B2Strong specificitySacrificing sensitivityImage enhancementImage analysisPattern recognitionUltimate tensile strength

Owner:SIEMENS HEALTHCARE GMBH

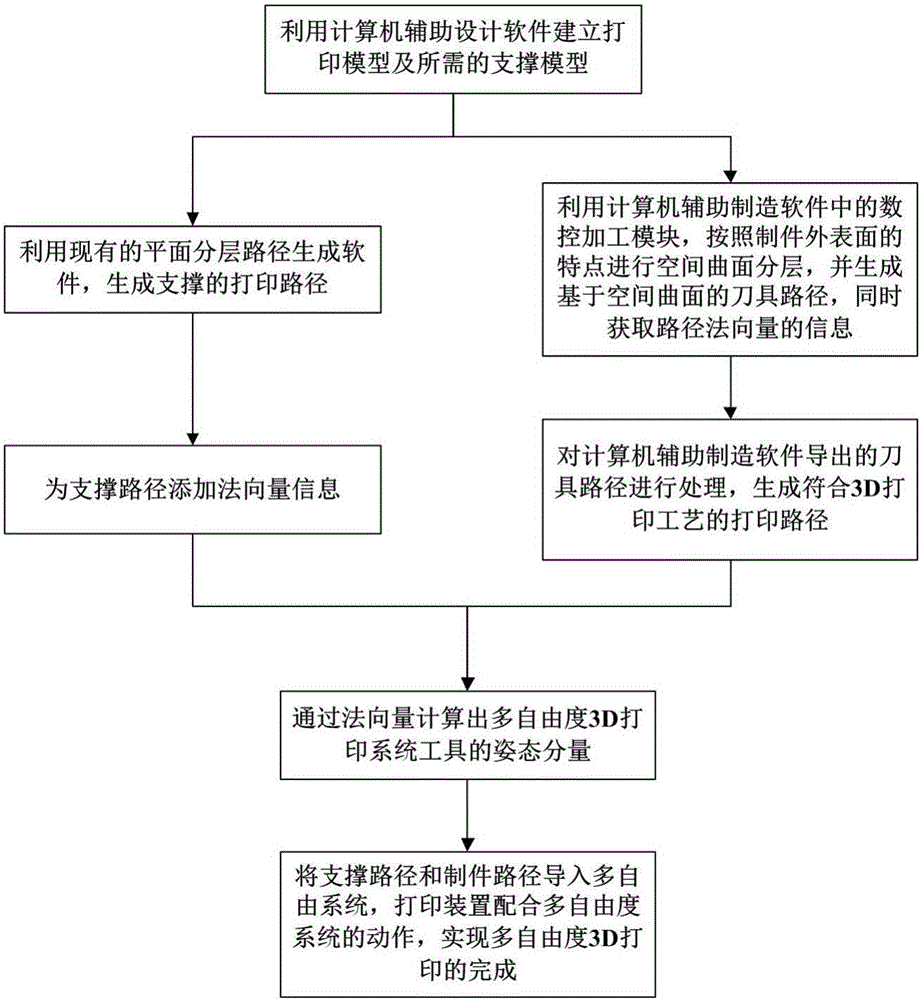

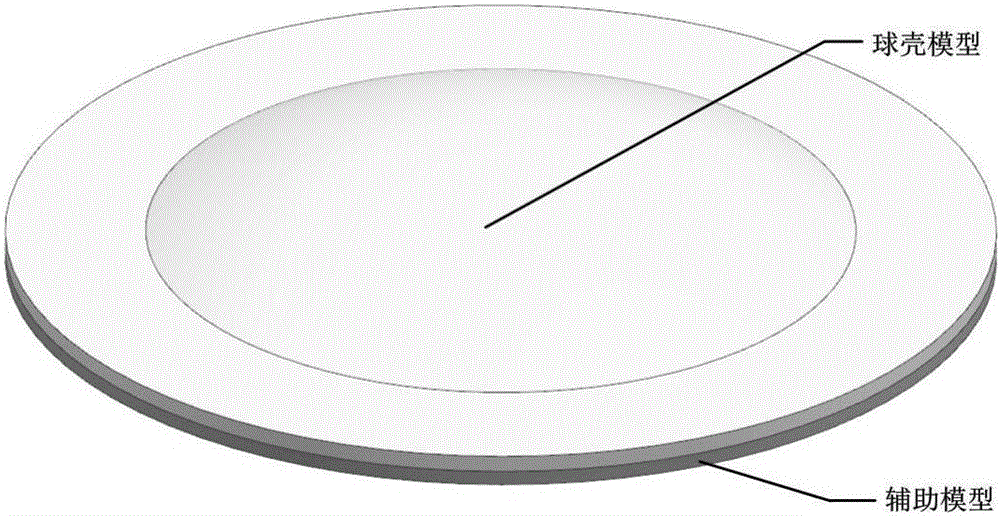

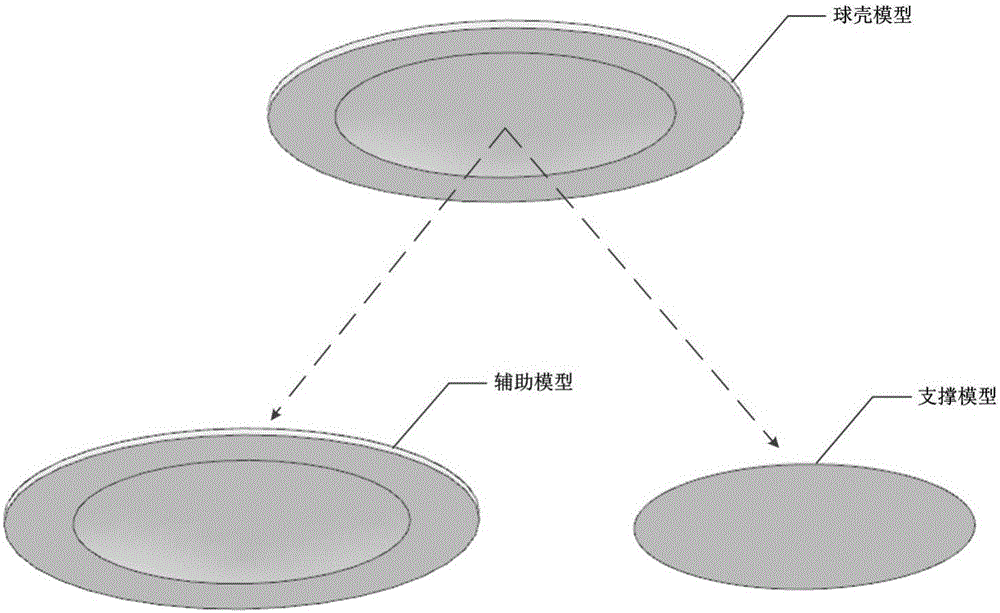

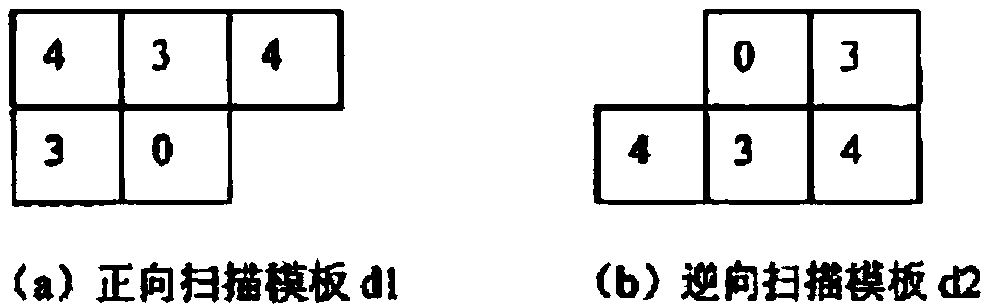

Space path generating methodorientedto multi-freedom-degree 3D printing

ActiveCN106202754AImprove mechanical propertiesImprove isotropyDesign optimisation/simulationSpecial data processing applicationsComputer Aided DesignDegrees of freedom

A space path generating methodorientedto multi-freedom-degree 3D printing comprises the steps that a three-dimensional part model is firstly established and an auxiliary model and a supporting model are generated by utilizing computer aided design (CAD) software, and then a part path is generated; then, the part path undergoes reverse ranking to generate a front-inside-to-outside 3D printing path, meanwhile printing action matching parameters required by a motion mechanism moving along the printing path are calculatedby adopting a 3D printing process; then the supporting model is introduced to the 3D printing path to generate software, and a supporting path is generated; normal vector information is added for the supporting path, and a posturecomponent of a printing head in a multi-freedom-degree 3D printing system is calculated through normal vectors; finally the generated supporting path and the part path are introduced to the multi-freedom-degree 3D printing system, and multi-freedom-degree 3D printing is completed. The space path generating method eliminates the step effect existing in an existing 3D printing technology, improves the mechanical properties of parts and increases the isotropy of the parts.

Owner:深圳协同创新高科技发展有限公司

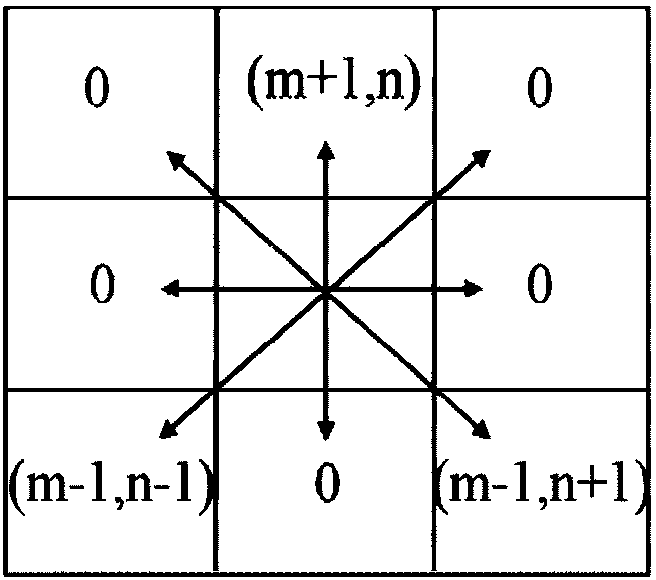

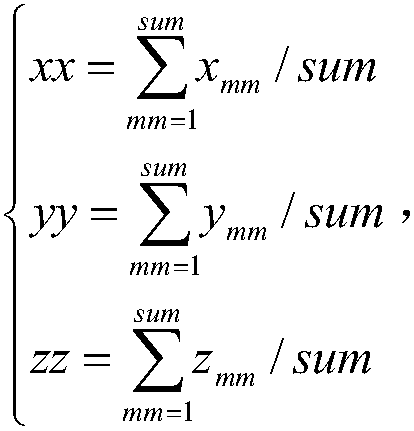

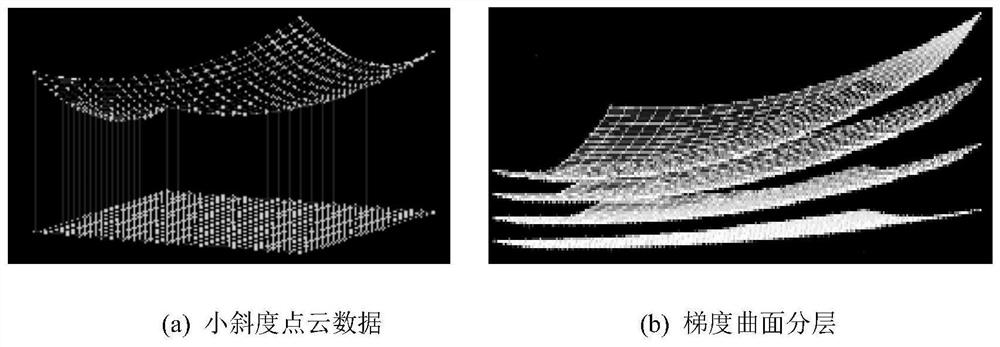

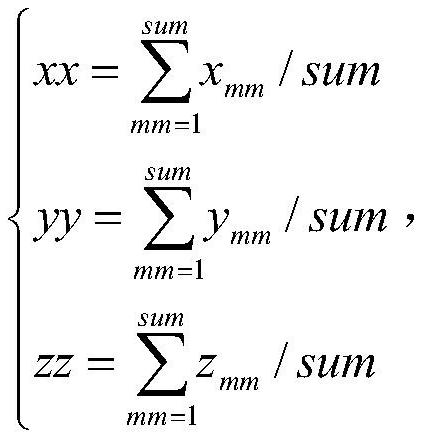

Adaptive plane layering method based on additional material remanufacturing point cloud model

ActiveCN108022307ASkip the resurfacing processImprove efficiencyAdditive manufacturing apparatusImage data processingPoint cloudInter layer

The invention relates to an adaptive plane layering method based on an additional material remanufacturing point cloud model. The method comprises: step one, a layering direction is determined; step two, a layering height is determined; to be specific, traverse of point cloud coordinates is carried out to obtain a zmin and a zmax, difference processing is carried out on the zmin and the zmax to obtain a layering height; step three, an inter-layer point cloud mapping relationship is constructed; step four, a surface error is defined; to be specific, a surface error P is defined to express a surface difference degree between two slices, wherein sigma is equal to Rmax and the Rmax expresses a maximum value a radial width R of a projection point cloud; and step five, a layering thickness is determined. According to the adaptive plane layering method, the maximum value of the radial width R of the projection point cloud is used as a surface error and thus an adaptive layering height is determined by iteration; the algorithm implementation process is clear; and both efficiency and precision are considered.

Owner:ARMOR ACADEMY OF CHINESE PEOPLES LIBERATION ARMY

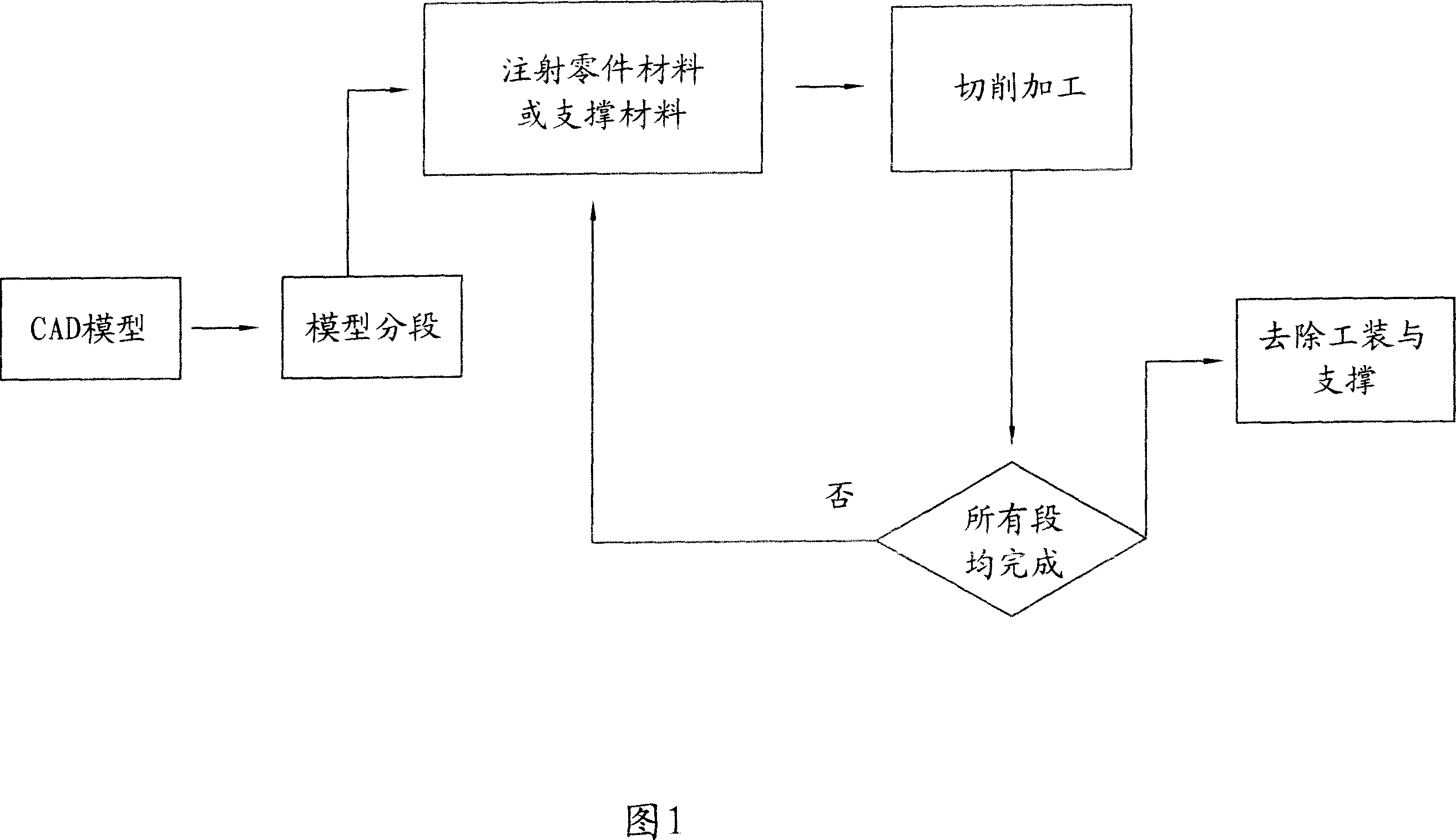

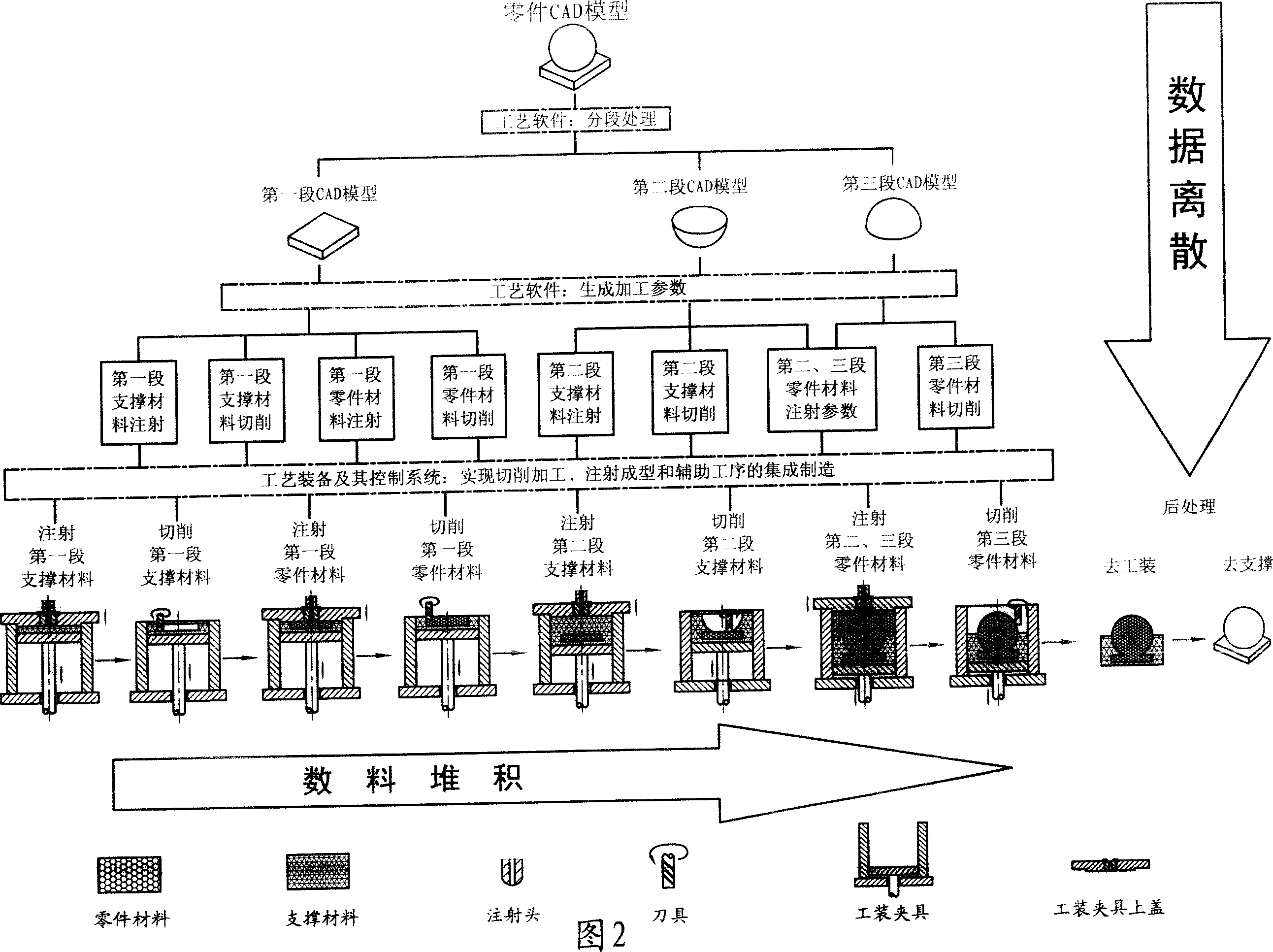

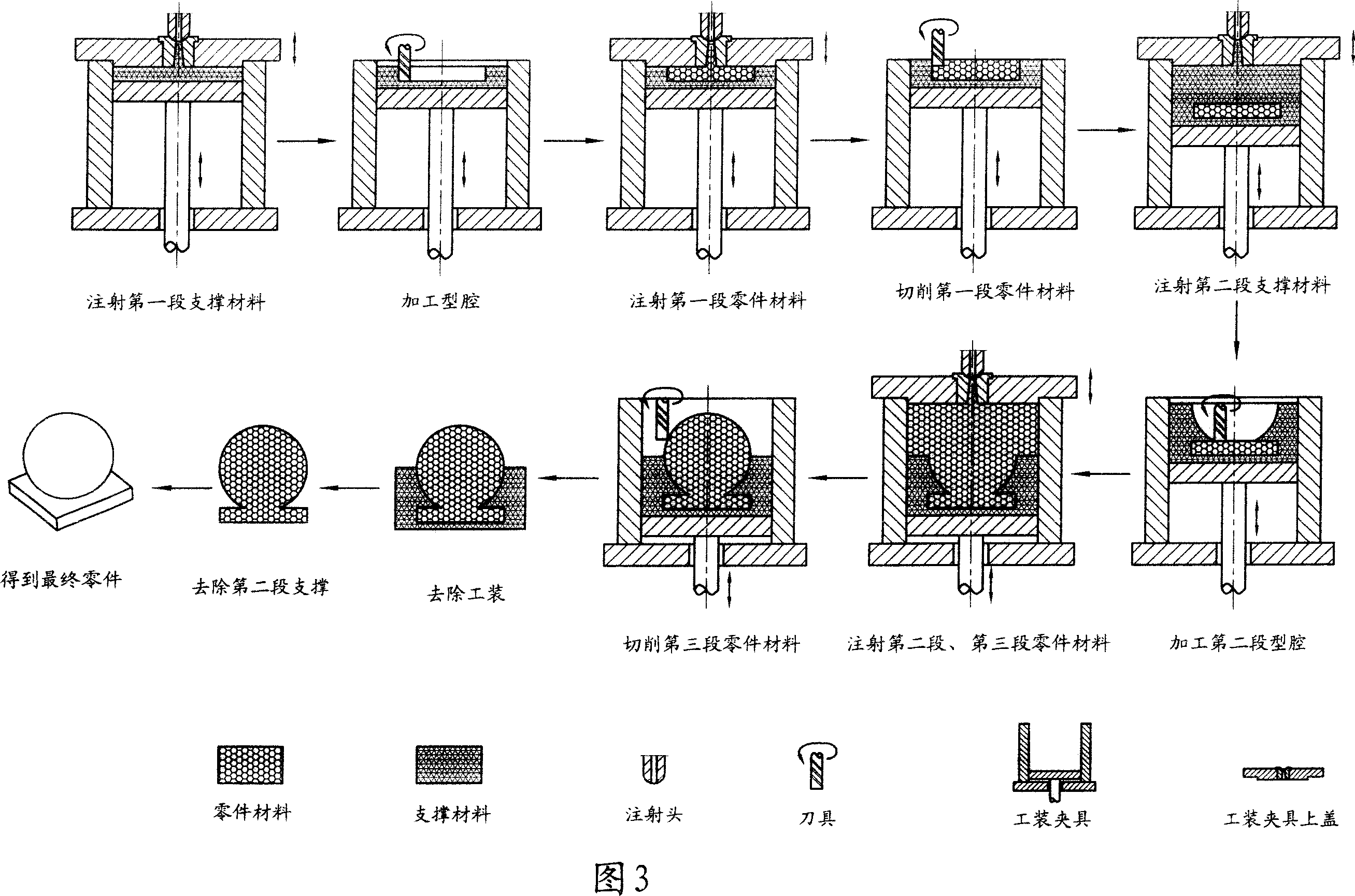

Stage injection/carving composite fast shaping technology

InactiveCN100999123AIncrease flexibilityImprove densification performanceProgramme controlComputer controlMaterial removalEngineering

The present invention discloses a sectional injection / carving combined quick forming process, it is a integrated combined forming process including material accumulation, material removal and material injection forming. Said invention provides the working principle of said sectional injection / carving combined quick forming process and its concrete operation steps. Said invention can be used for making any complex component, and making said component have high accuracy and surface quality.

Owner:HUAQIAO UNIVERSITY

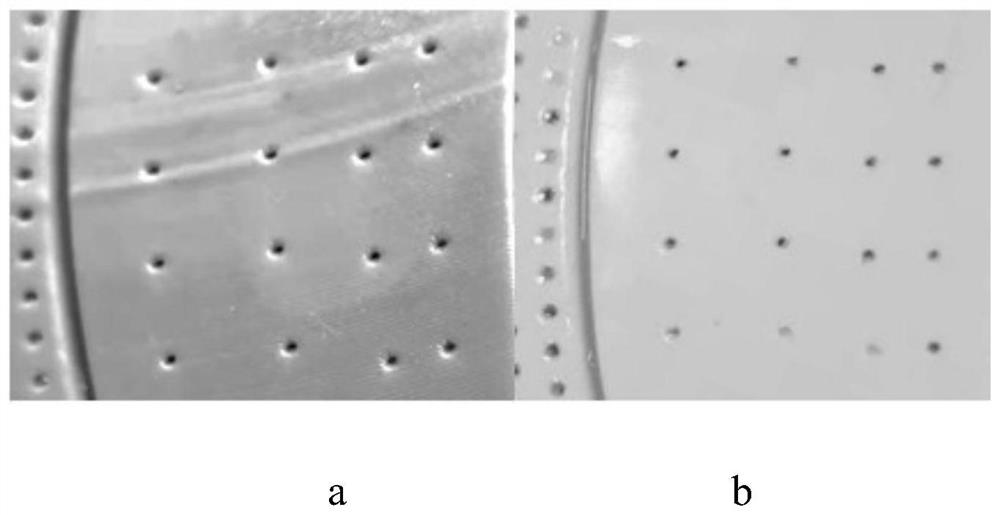

Silicon-based ceramic core slurry and application thereof

ActiveCN112500143AHigh thermal shock resistancePromote absorptionAdditive manufacturing apparatusFoundry mouldsSilicon oxidePhoto curing

The invention discloses a preparation method and application of a silicon-based ceramic core. Mixed slurry obtained according to the mixing ratio is formed by using a photocuring method to obtain a mold core biscuit, the mold core biscuit is degreased and then impregnated with a ceramic slurry, the impregnated mold core biscuit is dried, and the dried mold core biscuit is sintered in an air atmosphere by using a buried powder sintering method to obtain the silicon-based ceramic core. By means of the method, forming of a high-surface-precision silicon-based ceramic core blank can be achieved, the forming precision of the silicon-based ceramic core is improved, the production process of the ceramic core is accelerated, and the forming difficulty of the silicon-based ceramic core of a complexstructure is lowered. Degreasing and sintering treatment are carried out on the mold core biscuit obtained through the photocuring method, dipping lifting treatment is carried out on the mold core biscuit through the silicon oxide inorganic slurry, and the surface precision of the silicon-based ceramic mold core blank can be effectively improved. The method is simple, and the forming difficulty of the silicon-based ceramic mold core with a complex structure is reduced.

Owner:西安国宏天易智能科技有限公司

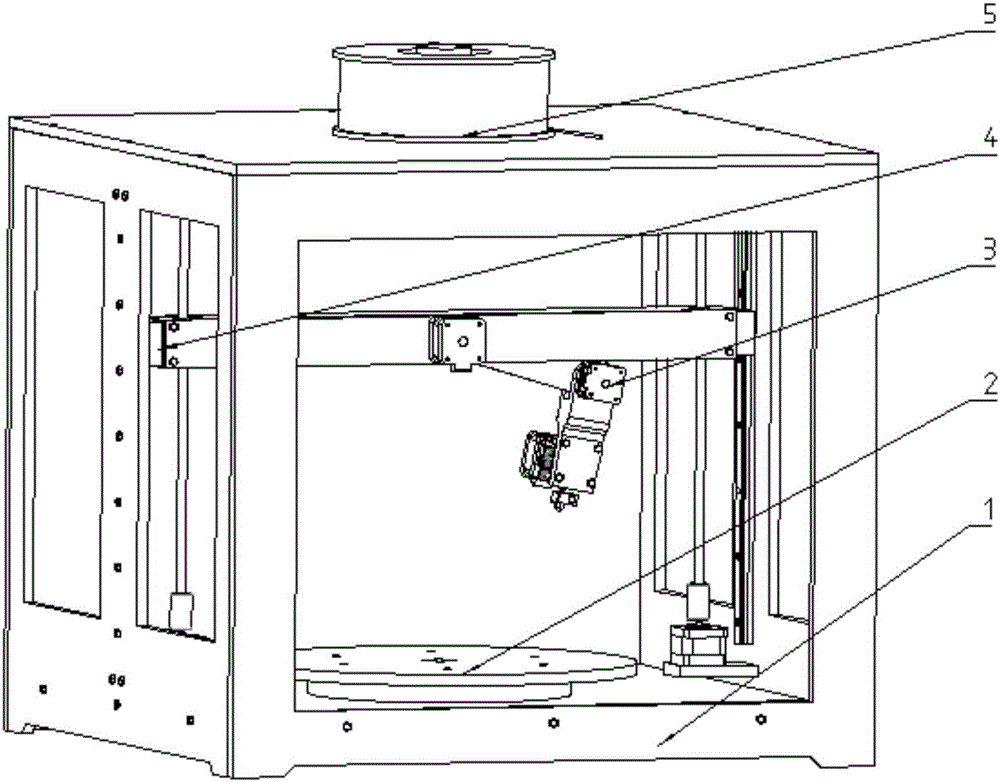

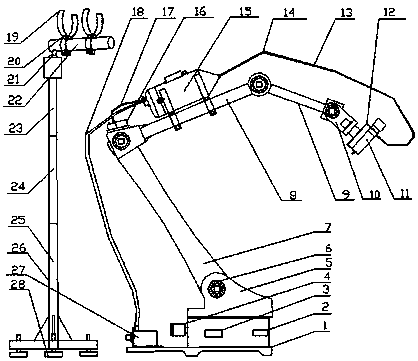

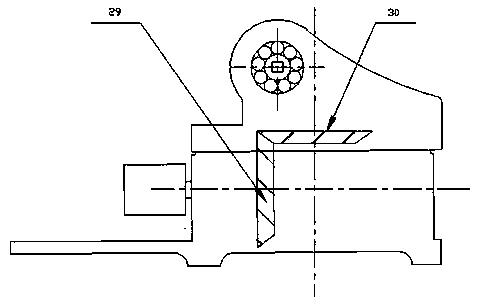

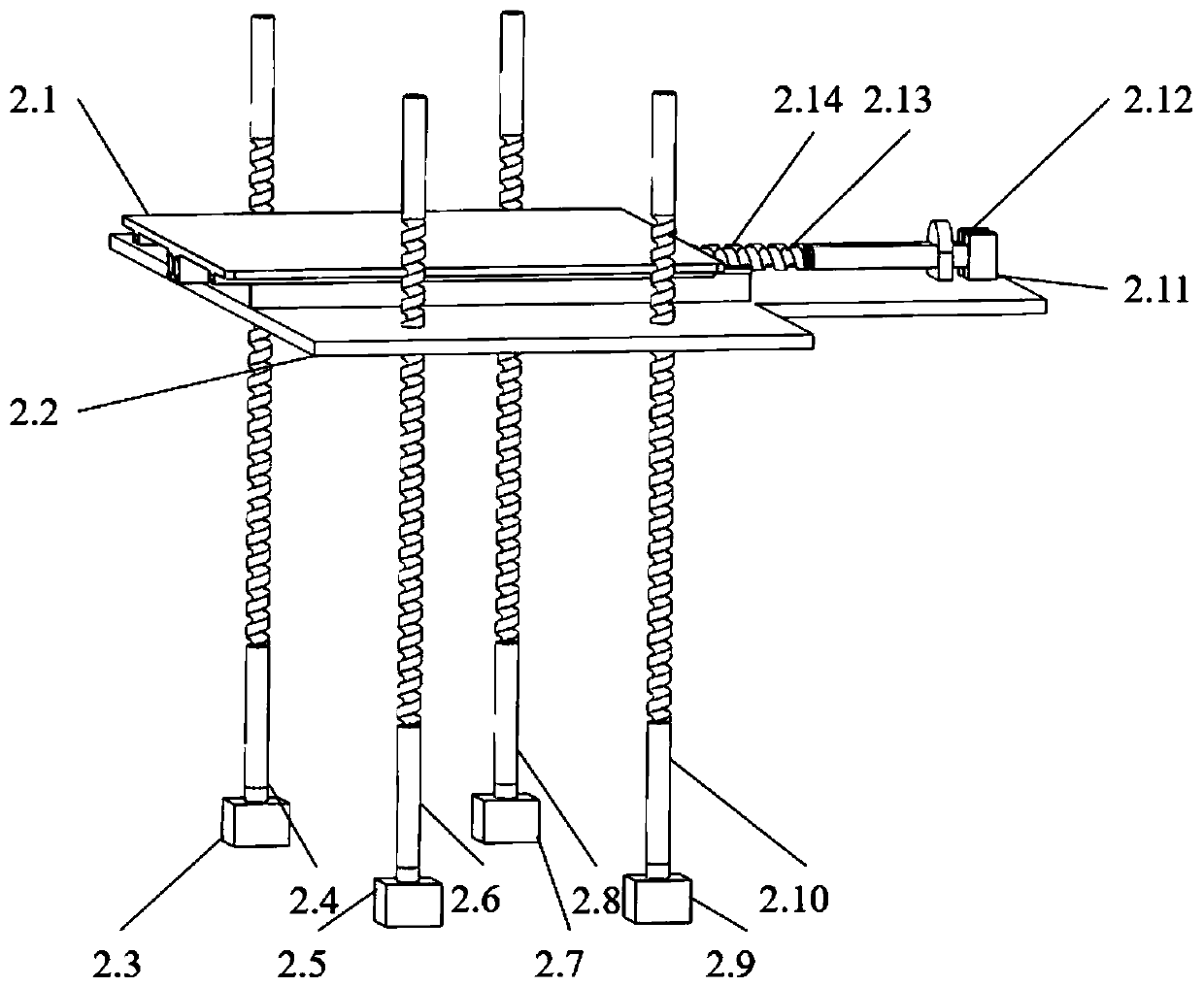

Four-axis three-dimensional printer

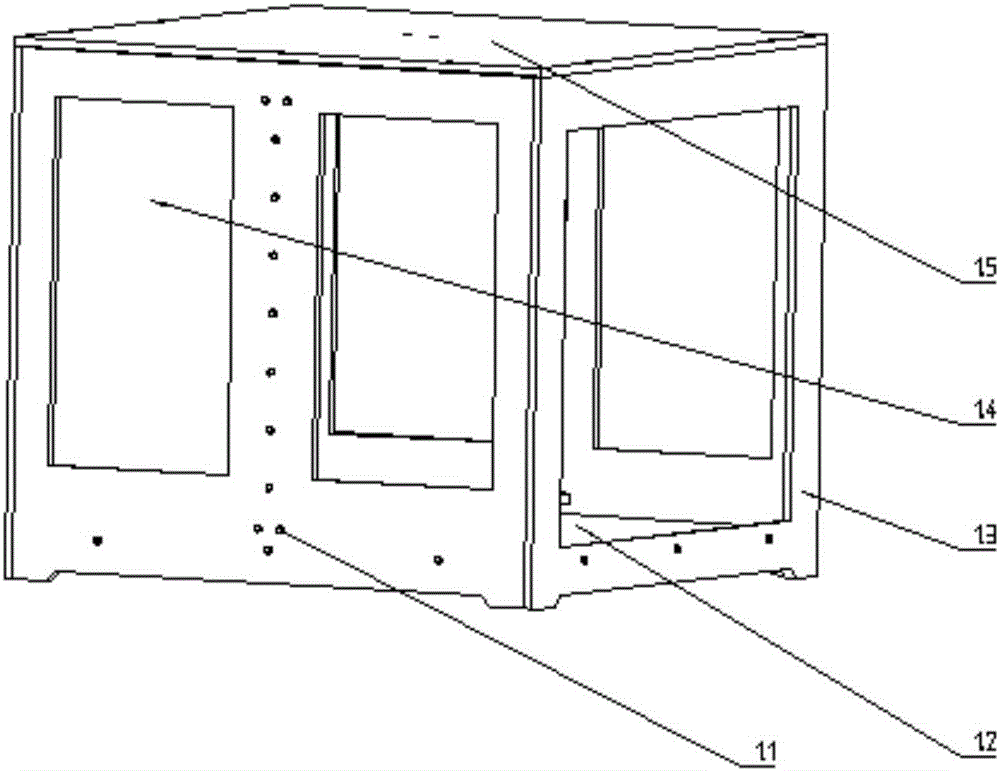

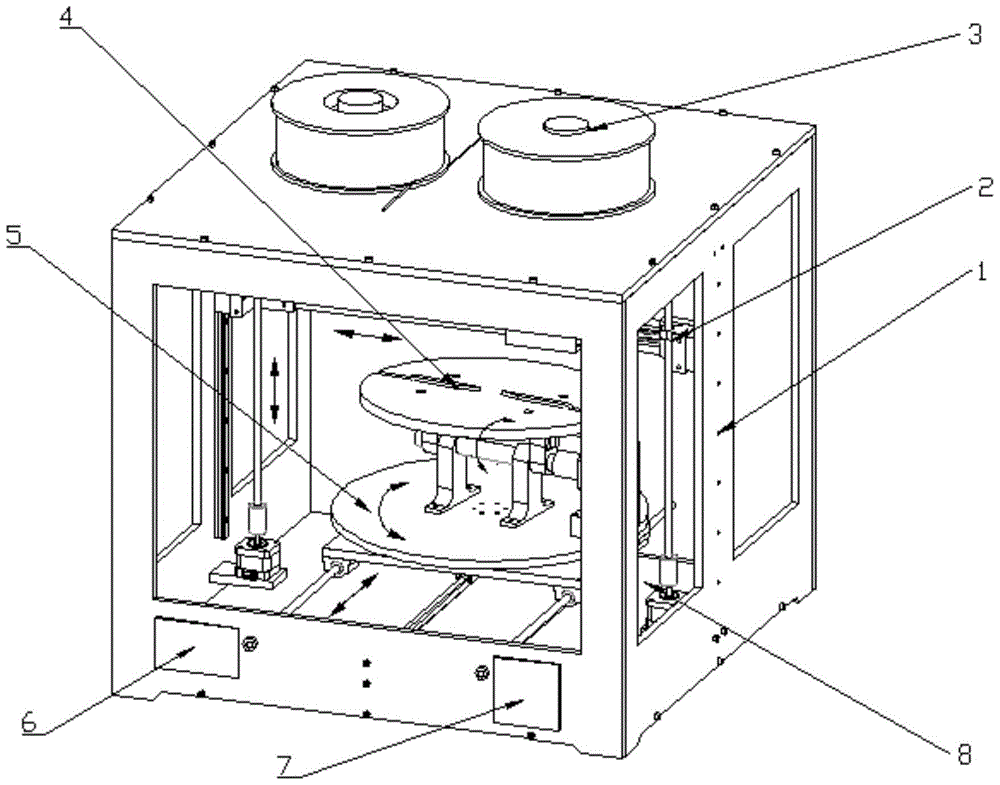

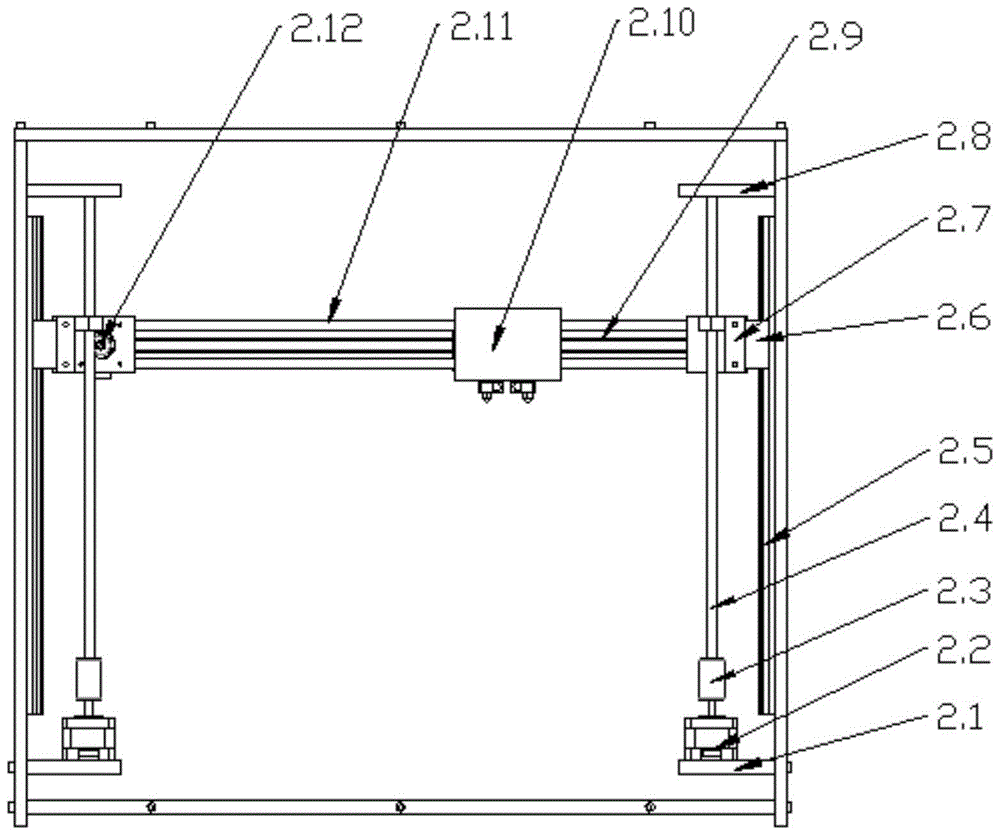

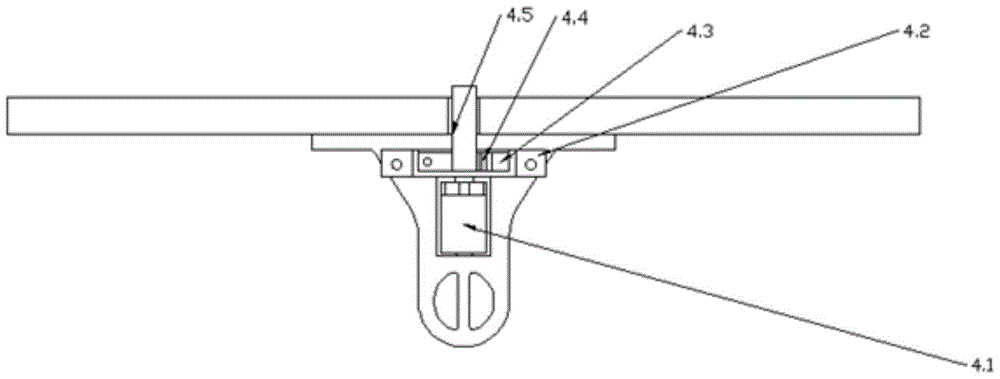

InactiveCN106217874AImprove surface qualityEliminate the "step effect"Additive manufacturing apparatusEngineeringHead moving

The invention discloses a four-axis three-dimensional printer. The four-axis three-dimensional printer comprises a frame assembly (1), a material plate (5) arranged on the top of the frame assembly (1), a platform rotating assembly (2) capable of rotating round the Z axis, a crank-connecting rod print head assembly (3) capable of moving flexibly and freely and a print head moving assembly (4) driving the print head assembly (3) to move along the Z axis, wherein the platform rotating assembly (2), the crank-connecting rod print head assembly (3) and the print head moving assembly (4) move cooperatively to realize high-efficiency and high-accuracy three-dimensional printing. According to the four-axis three-dimensional printer, the step effect can be removed, the surface quality of printing slopes can be improved, the processing efficiency of circular-section parts is high, and control is simple.

Owner:攸潇潇

High-precision laser additive and subtractive material combined manufacturing device

PendingCN111992877AEfficient removalEliminate the step effectAdditive manufacturing apparatusIncreasing energy efficiencyElectric machineryLaser light

The invention discloses a high-precision laser additive and subtractive material combined manufacturing device. The device comprises a sealed forming chamber, an inert protective gas source and a machining forming platform. The inert protective gas source is connected with the sealed forming chamber. The machining forming platform is arranged in the sealed forming chamber, and a light path selection system is arranged over the machining forming platform. A machining station is arranged on the machining forming platform, a lead screw is arranged at the bottom of the machining forming platform,the machining forming platform is fixed to a sliding block of the lead screw, the lead screw is connected with a lead screw motor, and the machining forming platform can be driven by the lead screw motor to slide forwards and backwards on the lead screw. The light path selection system comprises an additive material independent laser light path and a subtractive material independent laser light path. The additive material independent laser light path and the subtractive material independent laser light path are parallel to each other, are arranged in the direction of the lead screw and do notshare equipment. According to the device, the laser additive and subtractive material technology is integrated, the forming precision, the surface quality, the structure performance and the residual stress state of a complex fine additive workpiece are improved, and one-stop high-efficiency high-precision and high-performance additive workpiece manufacturing operation is achieved.

Owner:SHANGHAI UNIV OF ENG SCI

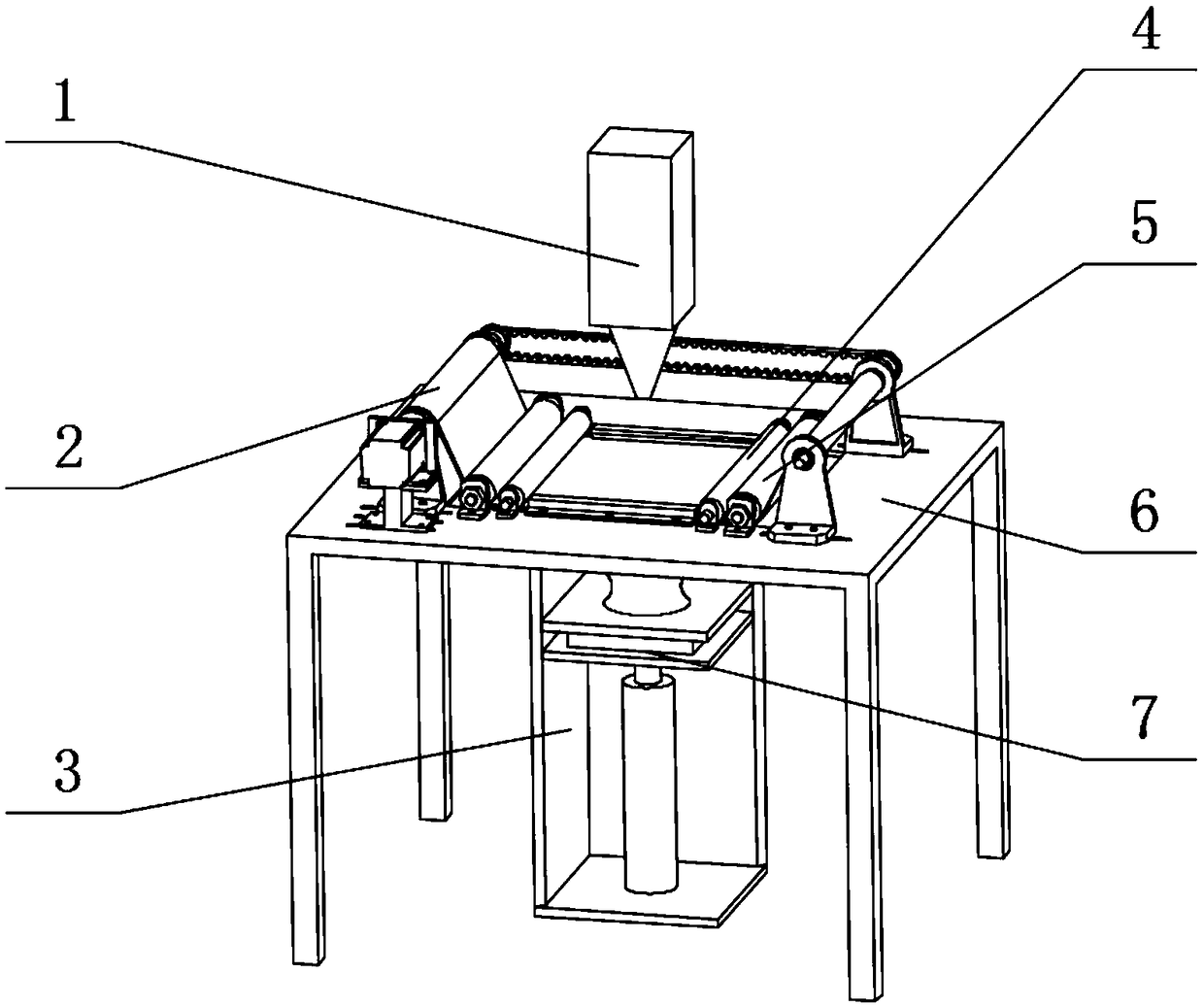

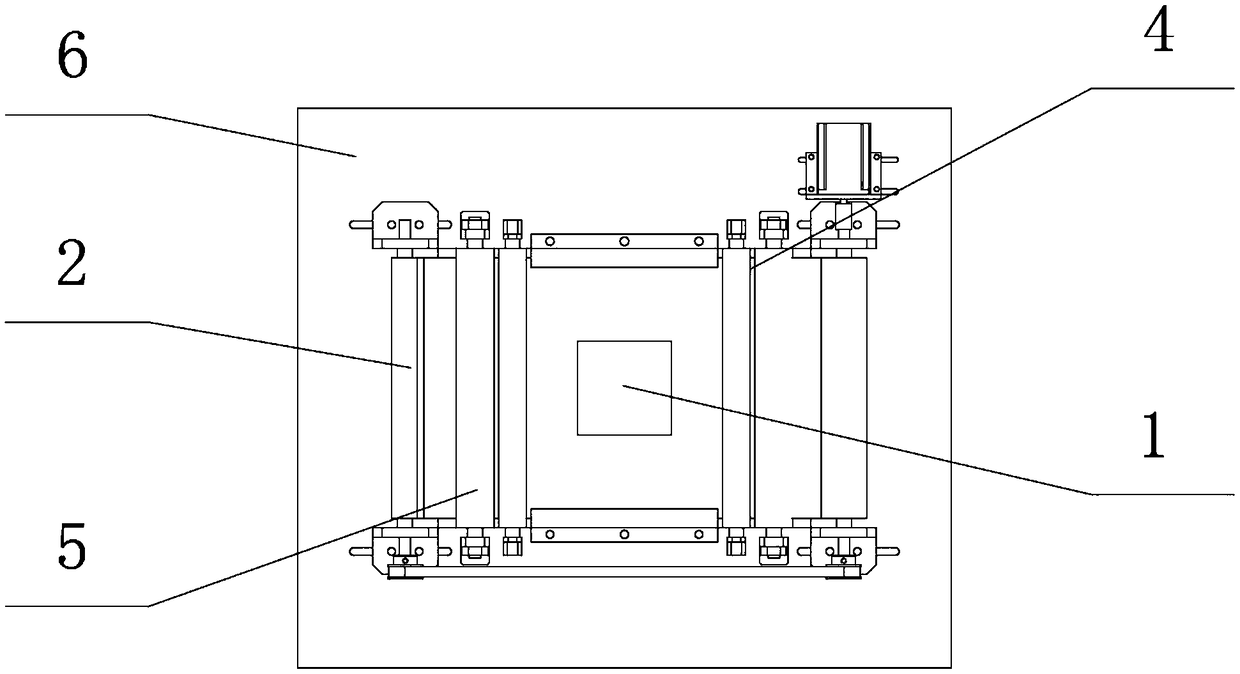

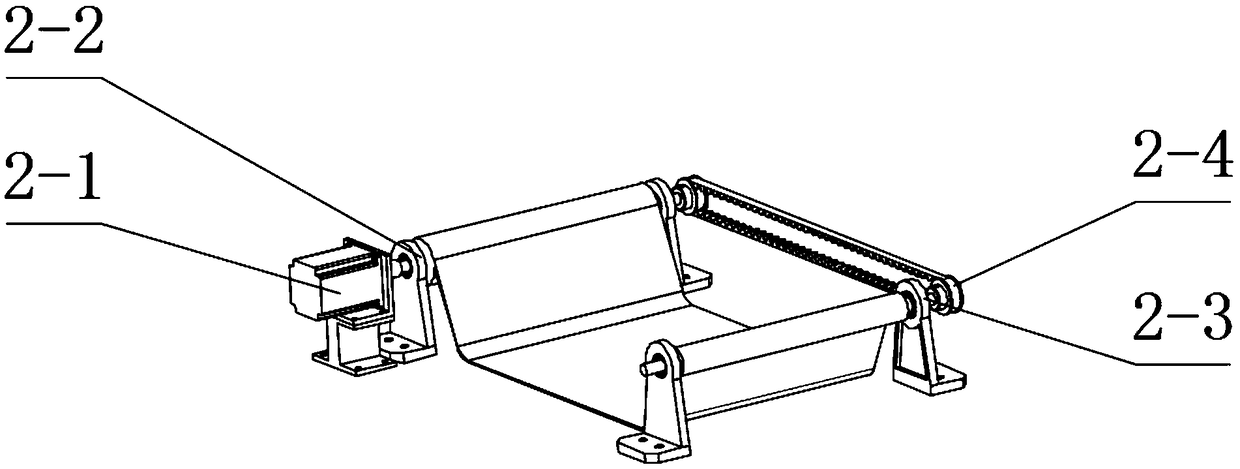

A five-degree-of-freedom rapid prototyping device

InactiveCN104842557BImprove surface qualityEliminate the "step effect"Manufacturing platforms/substratesManufacturing irradiation arrangementsEngineeringDegrees of freedom

The present invention discloses a five-freedom-degree rapid forming processing apparatus, which comprises a frame (1), material disks (3) on the top portion of the frame (1), an operating plate (6), a screen (7), and a control plate (8), and further comprises a two-freedom-degree spraying head assembly (2) capable of freely moving along X axis and Z axis, a clamping device (4), and a three-freedom-degree platform assembly (5) capable of freely rotating along Y axis, Z axis and A axis, wherein the operating plate (6) and the screen (7) are arranged on the bottom portion in front of the frame (1). With the five-freedom-degree rapid forming processing apparatus of the present invention, the step effect can be eliminated, the surface quality of the printed inclined plane can be increased, the processing efficiency on the circular cross-section parts is high, the processing on the spherical platform can be achieved, and the space utilization rate is good.

Owner:CHINA UNIV OF MINING & TECH

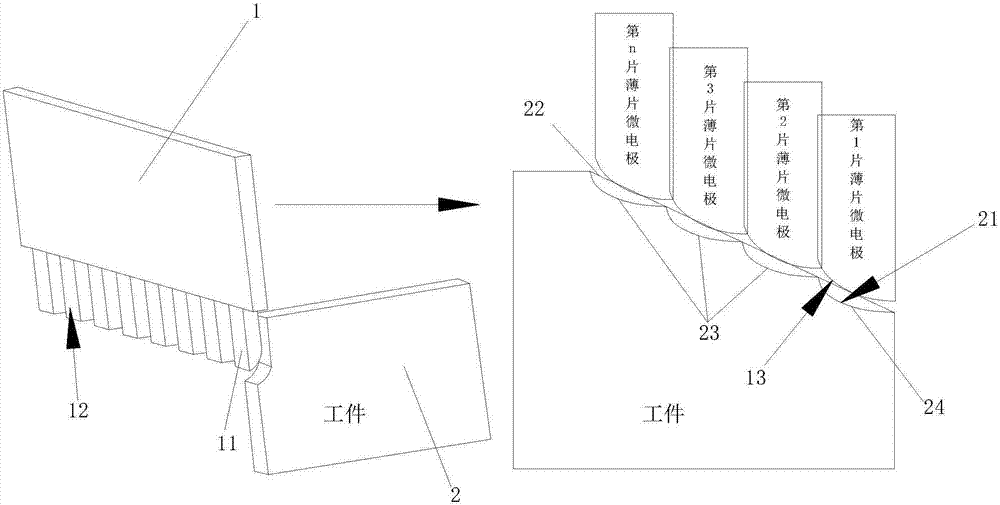

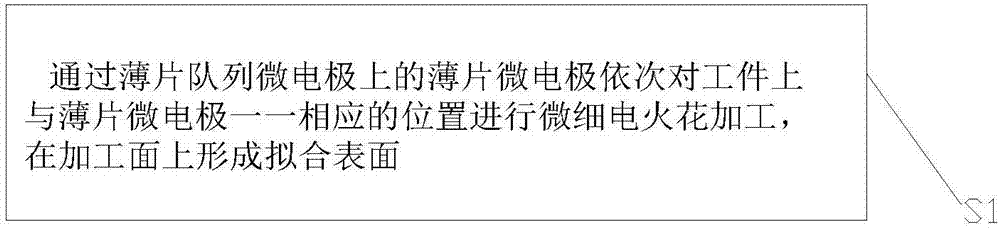

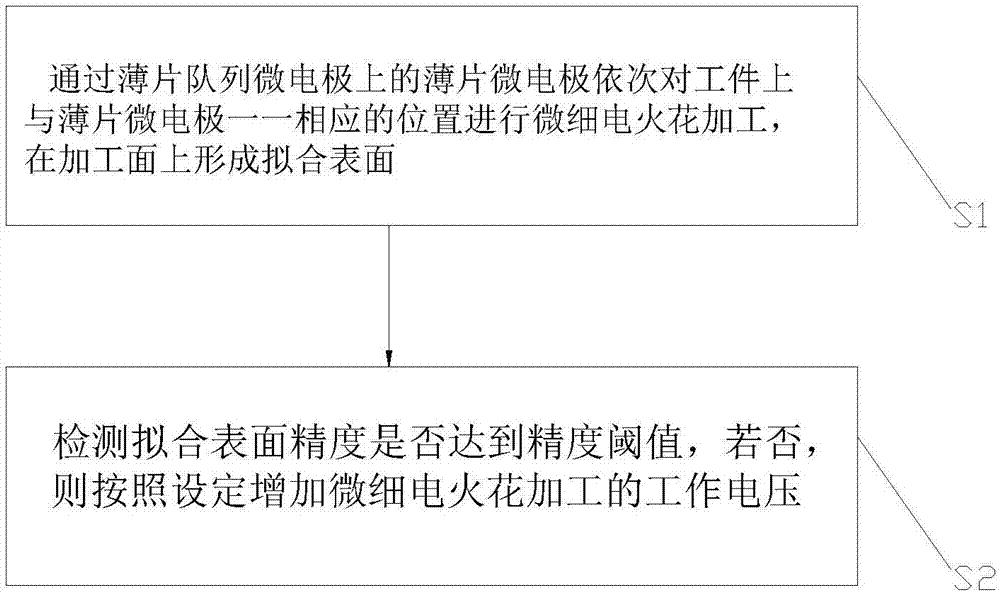

Novel method and device for carrying out micro electrical discharge machining on thin-sheet microelectrode array

ActiveCN107243679AEliminate the step effectHigh precisionElectrical-based machining electrodesElectricityThree dimensional microstructure

The invention discloses a novel method and device for carrying out electrical discharge machining on a thin-sheet microelectrode array. The thin-sheet microelectrode array comprises a plurality of thin-sheet microelectrodes which are arrayed in sequence, and machining end faces of the thin-sheet microelectrodes are worn to form convex arc shapes under the influence of the skin effect. The novel method for carrying out the micro electrical discharge machining on the thin-sheet microelectrode array comprises the step of carrying out the micro electrical discharge machining on the positions, corresponding to the thin-sheet microelectrodes in a one-to-one mode, on a workpiece through the thin-sheet microelectrodes of the thin-sheet microelectrode array to form a fitting surface on the machined surfaces. According to the novel method for carrying out the micro electrical discharge machining on the thin-sheet microelectrode array, the characteristic of the filleted corner wear of the machining end faces of conventional thin-sheet microelectrodes is fully utilized to effectively eliminate the step effect of the fitting surface with a three-dimensional microstructure, so that the precision of the machined fitting surface is improved; and the step effect of the fitting surface with the three-dimensional microstructure and filleted corner discharge marks of the fitting surface with plane characteristics can be eliminated.

Owner:SHENZHEN UNIV

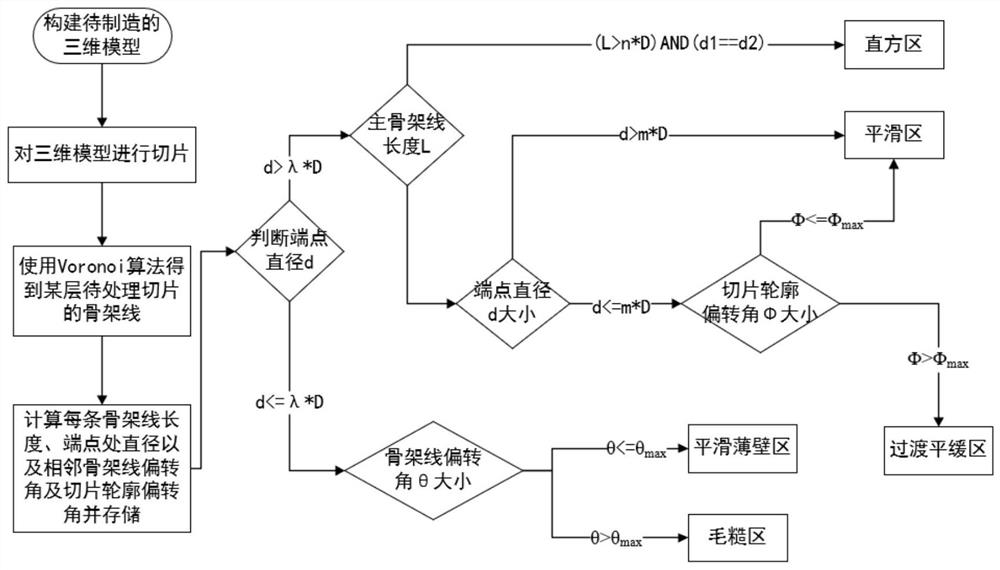

3D printing forming method based on skeleton line contour recognition and area segmentation

ActiveCN113478833AHigh forming precisionTo achieve the effect of adapting measures to "area" conditionsAdditive manufacturing apparatusIncreasing energy efficiencyComputer visionDeflection angle

The invention belongs to the technical field related to 3D printing, and discloses a 3D printing forming method based on skeleton line contour recognition and area segmentation. The method comprises the following steps: S1, calculating a skeleton line in each slice layer forming contour; S2, calculating and solving the length of the main skeleton line, the diameter of the end point of each skeleton line, the deflection angle between every two adjacent skeleton lines and the deflection angle between every two adjacent edges in each forming contour; S3, dividing the area types in each forming contour into a straight square area, a smooth area, a transition smooth area, a smooth thin-wall area and a rough area, establishing an area division standard by multiple parameter values obtained through calculation in the step S2, and dividing the areas in each forming contour; and S4, planning a forming path of each area for 3D printing forming. According to the method, the problems of contour recognition and segmentation of complex contour parts are solved, and a complex path planning method with high efficiency and high robustness is provided.

Owner:HUAZHONG UNIV OF SCI & TECH

Device conducting composite manufacturing on basis of laser technology

PendingCN111992712AImprove mechanical propertiesImprove the finishAdditive manufacturing apparatusIncreasing energy efficiencyLaser technologyEngineering

The invention discloses a device conducting composite manufacturing on the basis of a laser technology. The device comprises a sealed forming chamber, an inert protective gas source and a machining forming platform. The inert protective gas source is connected with the sealed forming chamber. The machining forming platform is arranged in the sealed forming chamber, and a light path selection system is arranged over the machining forming platform. A machining station is arranged on the machining forming platform, and the machining forming platform is arranged on a guide rail and can slide forwards and backwards through the guide rail. The light path selection system comprises a shock reinforcing independent laser light path, an additive independent laser light path and a subtractive independent laser light path. The light paths are arranged in the direction of the guide rail, and all the independent laser light paths do not share equipment and are arranged over the machining forming platform. According to the device, the laser shock reinforcing technology and the laser additive and subtractive technology are integrated, the forming precision, the surface quality, the organization performance and the residual stress state of a complex fine additive workpiece are improved, and one-stop high-efficiency high-precision and high-performance additive workpiece preparation is achieved.

Owner:SHANGHAI UNIV OF ENG SCI

Roughness-controllable polishing method for stereolithographic resin prototype models

ActiveCN103433853AImprove surface accuracyReduce work intensityPolishing compositions with abrasivesParticle flowDimensional precision

The invention discloses a roughness-controllable polishing method for stereolithographic resin prototype models. According to the invention, the fluid of a prepared chemical etching abrasive particle flow is used on abrasive particle flow equipment for respective polishing of the stereolithographic resin prototype models; then distilled water or deionized water is used for cleaning, surface roughness of the obtained stereolithographic resin prototype models is reduced to Ra 0.8 to 2 mu m from original Ra 8.0 to 20.0 mu m, surface roughness is uniform, texture is regular, postprocessing of the stereolithographic resin prototype models is realized, operation is simple, and labor intensity is reduced. The polishing method eliminates step effects of the stereolithographic resin prototype models, improves surface precision of the resin prototype models and does not influence dimensional precision of the resin prototype models.

Owner:XI AN JIAOTONG UNIV +1

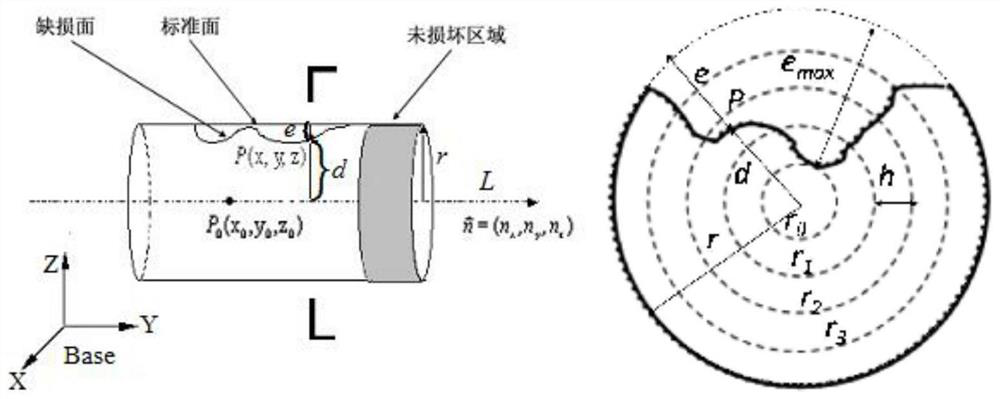

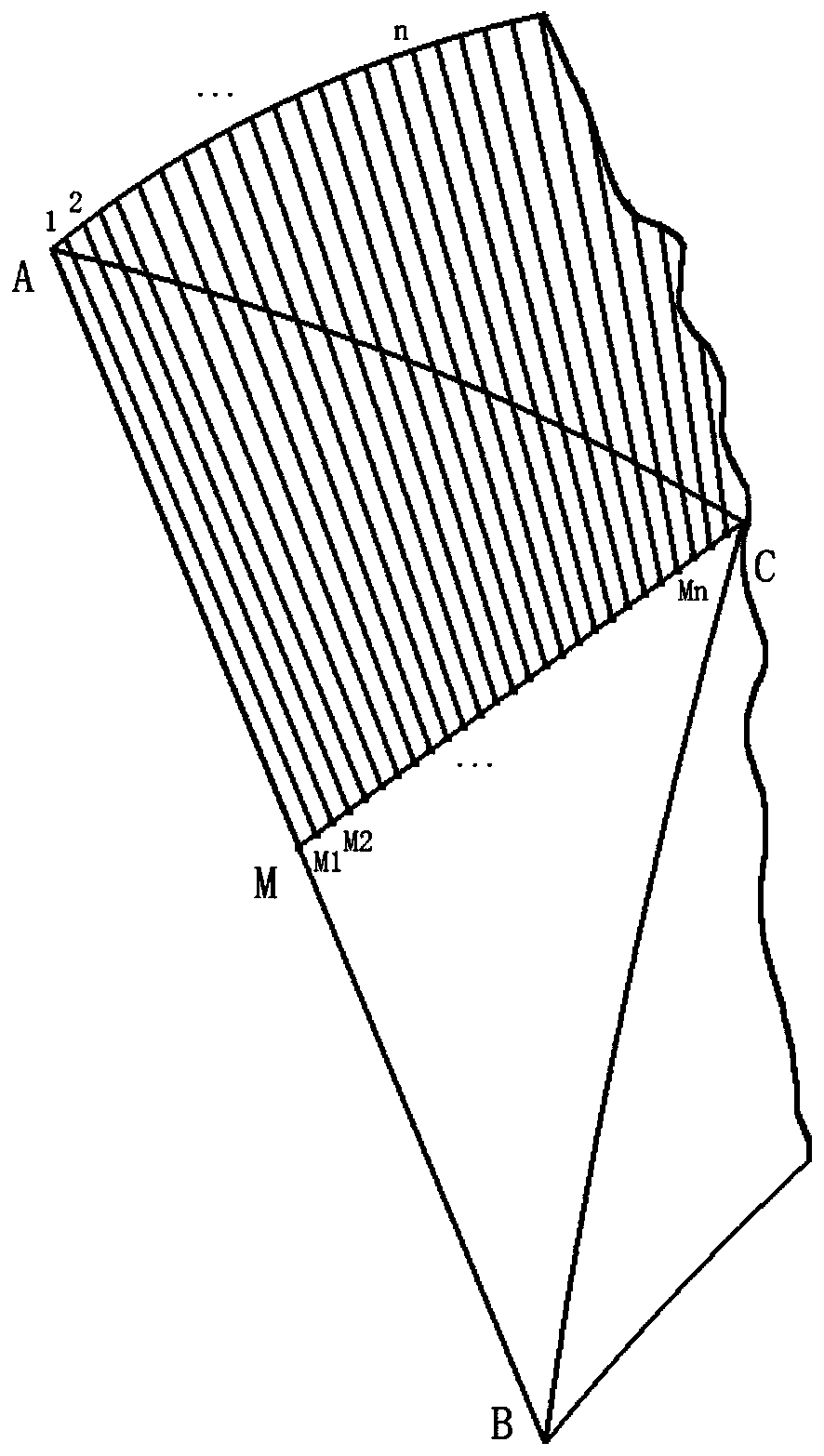

Gradient curved-surface layering method based on additive remanufacturing point cloud model

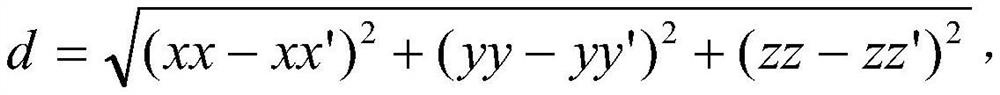

ActiveCN108062433ASkip the resurfacing processImprove efficiencyGeometric CADDesign optimisation/simulationSurface layerPoint cloud

The invention relates to a gradient curved-surface layering method based on an additive remanufacturing point cloud model. The method includes the following steps: (1) forming distance calculation, wherein a Euclidean distance d corresponding to a centroid point of a grid is calculated, and the distance d reflects a defect degree of a defect point cloud at the point, that is, the same is a formingdistance of needed additive remanufacturing; (2) gradient distance determination; and (3) generation of layering data, wherein in gradient layering, no really-existing layering curved-surface familyneeds to be exactly described, it is enough to carry out interpolation representation only by the layering data on all curved surfaces, the layering data include two parts of outline data and outlineinternal-data, and for layering data of an i-th layer, outline data thereof are directly recorded as data points of which a layering interval number num = i, and outline internal-data P'(x', y', z') can be obtained by adopting point clouds which are lower than a layer cutting curved-surface (num < i) and gradient distance increasing.

Owner:ARMOR ACADEMY OF CHINESE PEOPLES LIBERATION ARMY

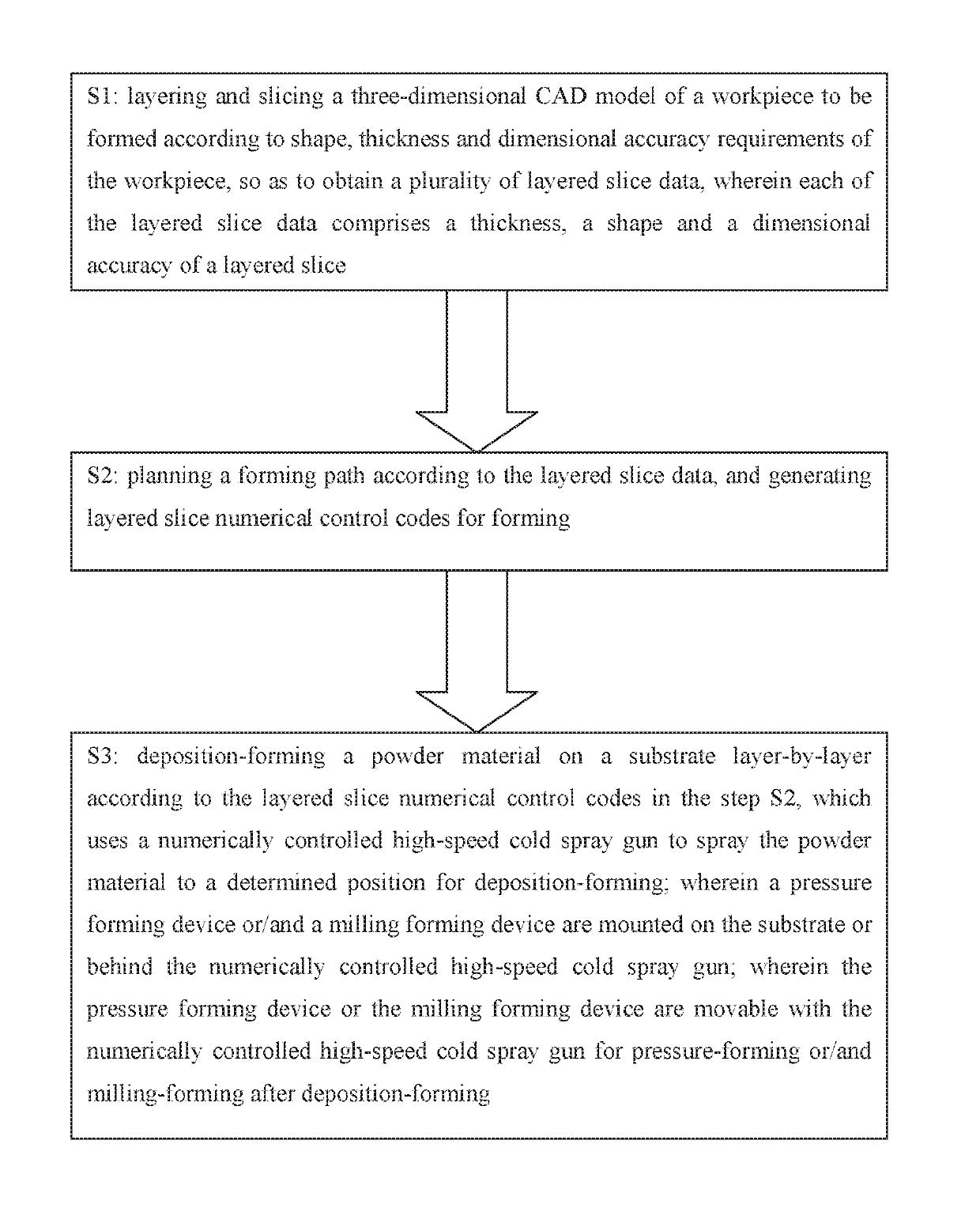

Combined additive manufacturing method applicable to parts and molds

ActiveUS20190329374A1Avoid effectLow costAdditive manufacturing apparatusCeramic shaping apparatusAdverse effectComputer Aided Design

A combined additive manufacturing method applicable to parts and molds relates to moldless-growth manufacturing of parts and molds, which includes steps of: S1: layering and slicing a three-dimensional CAD (computer-aided design) model of a workpiece to be formed according to shape, thickness and dimensional accuracy requirements of the workpiece, so as to obtain a plurality of layered slice data; S2: planning a forming path according to the layered slice data, and generating layered slice numerical control codes for forming; and S3: deposition-forming a powder material on a substrate layer-by-layer and performing pressure forming or milling forming according to the layered slice numerical control codes in the step S2, which uses a numerically controlled high-speed cold spray gun to spray the powder material to a determined position for deposition-forming. The method of the present invention overcomes thermally induced adverse effects of hot processing and drawbacks of cold spray deposition.

Owner:HUAZHONG UNIV OF SCI & TECH

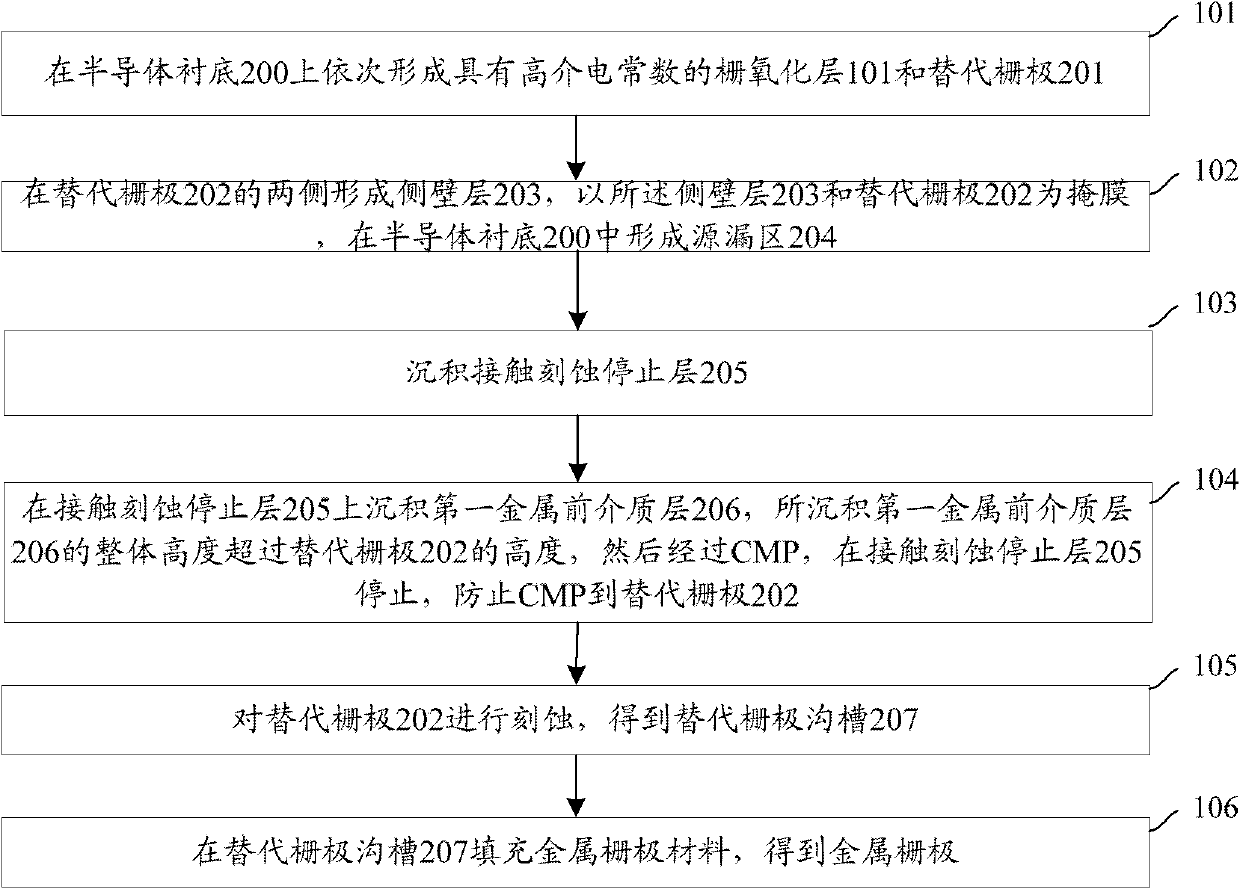

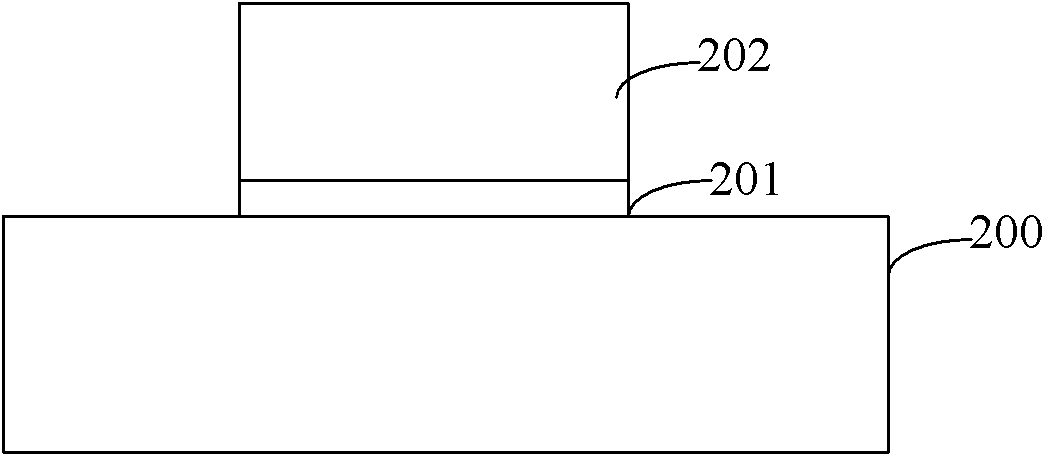

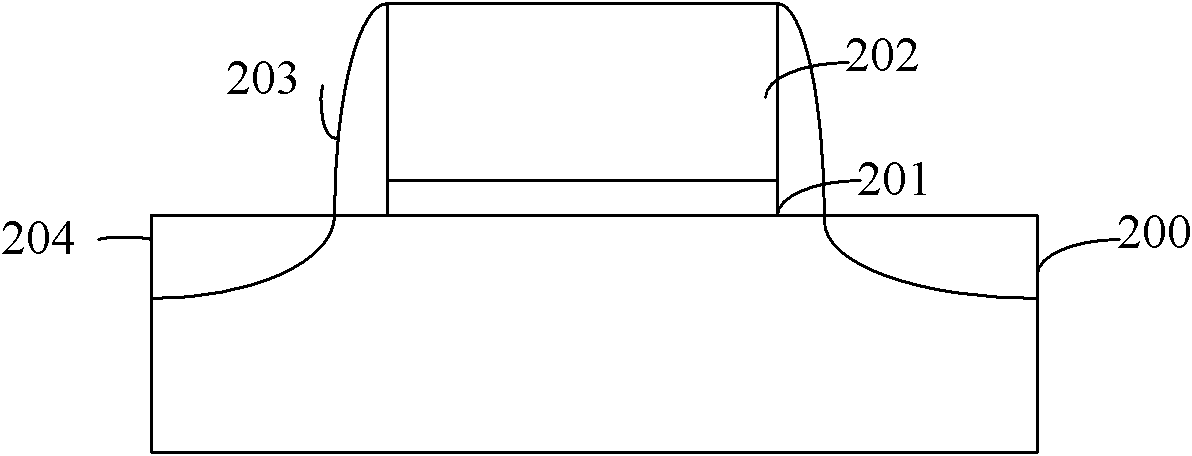

Manufacture method of metal grid electrode

ActiveCN102569049AEliminate the step effectSemiconductor/solid-state device manufacturingSemiconductor devicesMetal gridOptoelectronics

A manufacture method of a metal grid electrode comprises forming a gate oxide and a substitution grid electrode on a provided semiconductor substrate and then forming lateral wall layers on two sides of the substitution grid electrode; considering the lateral wall layers and the substitution grid electrode as masks and conducting ion implantation on the semiconductor substrate to form a source and drain region; depositing a contact etching stopping layer on the surfaces of the semiconductor substrate, the lateral wall layers and the substitution grid electrode; depositing a first metal front medium layer on the contact etching stopping layer, enabling the height of the deposited first metal front medium layer to be higher than the surface of the substitution grid electrode, polishing to reach the first metal front medium layer, and forming footsteps on the surfaces of the contact etching stopping layer and the first metal front medium layer which are in a same plane; depositing a second metal front medium layer on the surfaces of the first metal front medium layer and the contact etching stopping layer, completely covering the footsteps, polishing again to reach the substitution grid electrode; and etching the substitution grid electrode to obtain a substitution grid electrode channel and filling the metal grid electrode in the substitution grid electrode channel. The manufacture method removes the footstep effect produced in a manufacture process.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Snow sculpture 3D printer integrating snowmaking equipment

InactiveCN110758002ASimple structureEasy to assembleAdditive manufacturing apparatusOrnamental structuresComputer printingAir pump

The invention discloses a snow sculpture 3D printer integrating snowmaking equipment. The composition structure comprises a base, an information access port, a speed regulation device, a plurality ofmotors, a base end cover, a plurality of rotary pairs, a connection rod 1, a connection rod 2, a connection rod 3, a connection rod 4, a spray head, a spray head frame, a feed hose, the snowmaking equipment, a micro high-pressure gas pump, a gas inlet pipe, a water inlet pipe, a screw nut, a U-shaped clamping piece, an independent support, a small water pump, a gear 1 and a gear 2. The snowmakingequipment is fixed to the connection rod 2, can also be installed on an independent support installation supporting rod and comprises a cold chamber and a cold chamber rear end cover. The snow sculpture 3D printer integrating the snowmaking equipment is simpler in structure, the spray head can complete printing motion of multiple angles, the problem of printing precision of a suspended part is solved, thus the treatment effect of a hollowed-out part is improved, meanwhile, the snow sculpture 3D printer is not limited to X-Y-plane slice type printing, the step effect of the printed part can belowered, and printing efficiency and precision are improved.

Owner:HARBIN UNIV OF COMMERCE

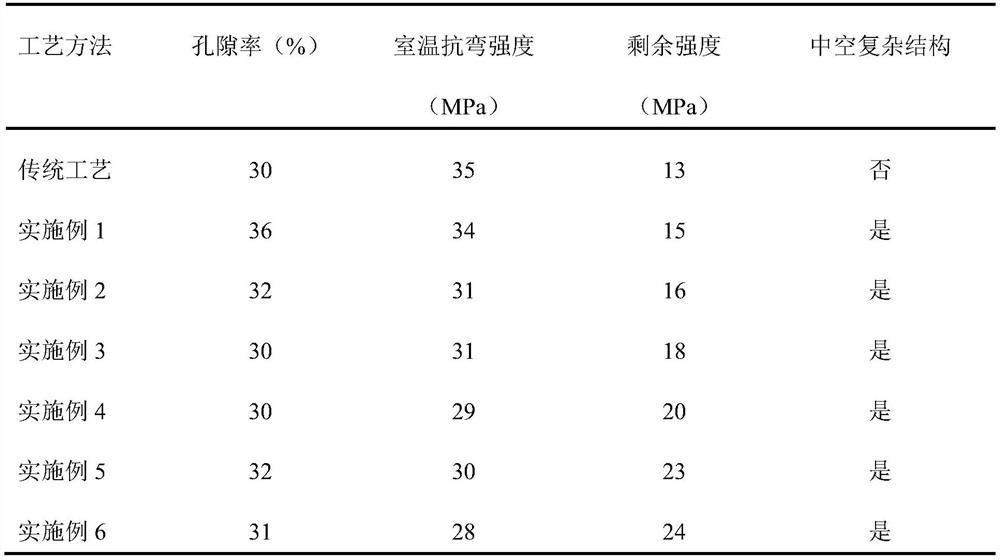

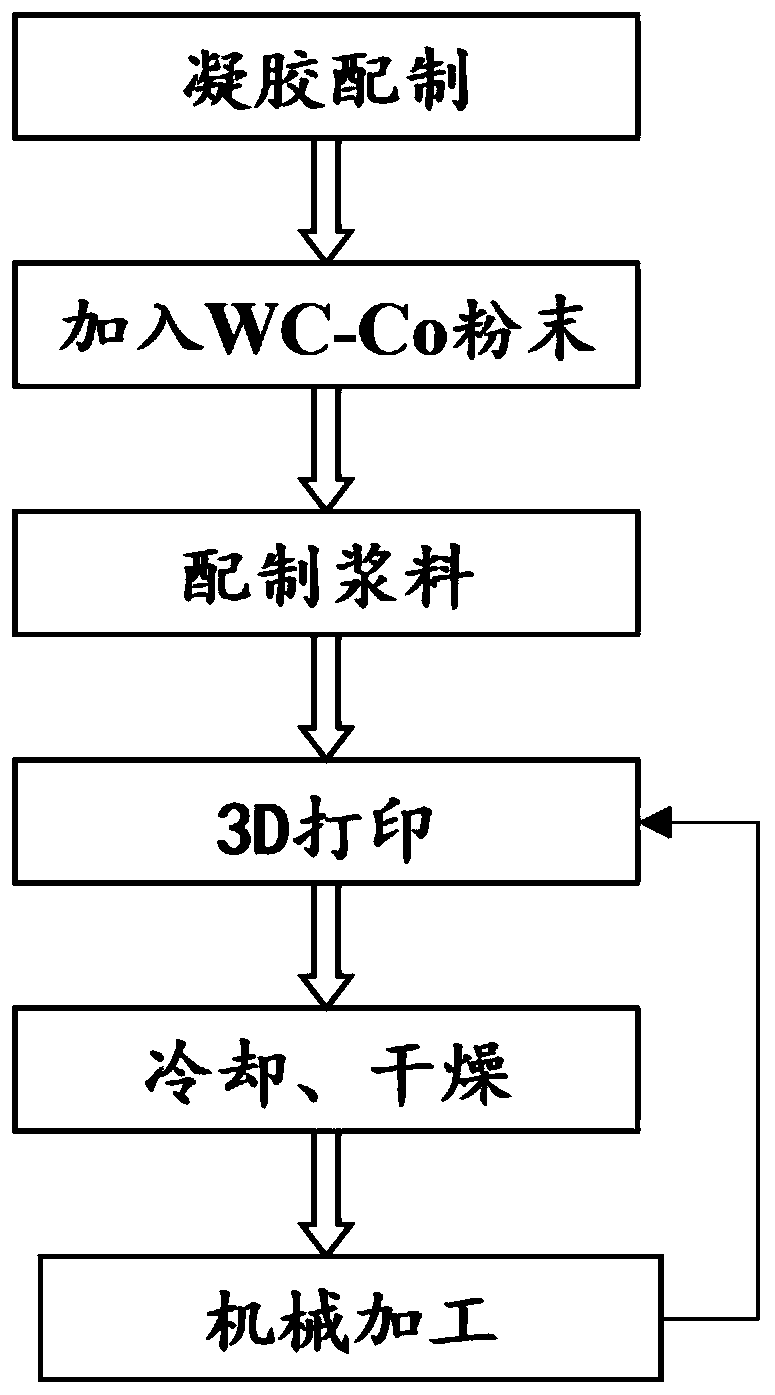

Material increase and material decrease comprehensive manufacturing method of hard alloy part with complex shape

InactiveCN110508818ASuitable for small batch complex productionQuality assuranceAdditive manufacturing apparatusTransportation and packagingOrganic solventSlurry

The invention relates to a material increase and material decrease comprehensive manufacturing method of a hard alloy part with the complex shape. The method comprises the steps that segmented copolymer is dissolved in organic solvent, and a reversible gelatin system is prepared; hard alloy powder is added into the gelatin system, and slurry is prepared; the slurry is conveyed to a 3D printing device, and a multi-layer green body layer is formed according to the design requirement of a drawing; and a green body layer with a certain thickness is formed, and machined mechanically after being cooled and cured. According to the method, the 3D printing technology is utilized for directly forming the part with the complex shape, a mould does not need to be customized, meanwhile, a mechanical machining method helps to carry out milling machining, the step effect in the 3D printing process is eliminated, and the manufacturing precision of the part is ensured.

Owner:DONGHUA UNIV

A 3D printing device and method with external edge patrol function

ActiveCN107696487BImprove printing efficiencyEliminate the step effectManufacturing platforms/substratesManufacturing driving meansComputer moduleEngineering

The invention discloses a 3D printing device with an external side polling function and a method. The device comprises a supporting rack, and a side polling driving module, an external side polling printing module and a side polling rotating module mounted on the supporting rack; a printing table is arranged on the side polling driving module which drives the printing table to lift up and down andmove horizontally; the side polling rotating module is mounted on the top of the supporting rack, the external side polling printing module is mounted on the bottom surface of the side polling rotating module, the side polling rotating module and the external side polling printing module are provided with nozzles, and the side polling rotating module drives the nozzle of the external side pollingprinting module to rotate and the side polling rotating module drives the nozzle to move horizontally, so that the two nozzles perform printing toward the printing table on the side polling driving module. The device disclosed by the invention can increase the 3D printing efficiency, provides a higher printing precision, and can effectively reduce the step effect of 3D printing.

Owner:ZHEJIANG UNIV

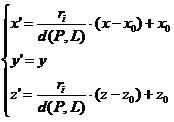

Layering Method of Isometric Surface Based on Additive Remanufacturing Point Cloud Model

ActiveCN107945277BSkip the resurfacing processImprove efficiencyImage enhancement3D modellingLayered modelPoint cloud

The present invention relates to an equidistant curved surface layering method based on the point cloud model of additive remanufacturing, which includes the following steps: ① Fitting the cylindrical surface: selecting the point cloud of the undamaged area of the shaft part to fit the cylindrical surface, as a standard The model is the standard cylindrical surface; ② Extract the point cloud model of additive remanufacturing: select the point cloud of the defective part, calculate the distance from each point to the standard cylindrical surface as the defect amount e of each point, and follow the principle to extract the data points with serious defects Cloud and its e, as the point cloud model of additive remanufacturing; solve the distance from any point P(x,y,z) of the defective point cloud to the standard cylindrical surface, that is, the defect amount e, and convert it into the point P to the axis L. The difference between the distance and the radius of the cylinder; ③Establish the equidistant surface family of the standard cylindrical surface; ④Construct the contour data P'(x',y',z'), traverse all the points in the additive remanufacturing point cloud, and find out The corresponding contour data is layered, and the equidistant surface layered model diagram of the shaft parts is obtained.

Owner:ARMOR ACADEMY OF CHINESE PEOPLES LIBERATION ARMY

Electron beam metal 3D printing device and printing method

PendingCN109226763AEasy to manufactureLow costAdditive manufacturing apparatusIncreasing energy efficiencyElectron beam machiningEngineering

The invention relates to an electron beam metal 3D printing device and a printing method, and belongs to the field of precision additive manufacturing. An electron gun is located over a forming chamber, the forming chamber is located below a working table, a square opening of the forming chamber is connected with a working table square opening, a lifting platform capable of moving up and down is located in the forming chamber, a feeding module and a tensioning module are fixedly connected with the upper surface of the working table and symmetrically distributed on the two sides of the workingtable square opening, and preheating modules are fixedly connected with the upper surface of the working table and distributed around the working table square opening. The electron beam metal 3D printing device and the printing method have the advantages of achieving the technical purposes of high-quality powder preparation, uniform powder spreading, feeding and recycling, processing environment cleaning and the like, improving the surface quality of formed parts, greatly improving the electron beam processing efficiency, reducing the processing cost and lowering the system control difficulty.

Owner:JILIN UNIV

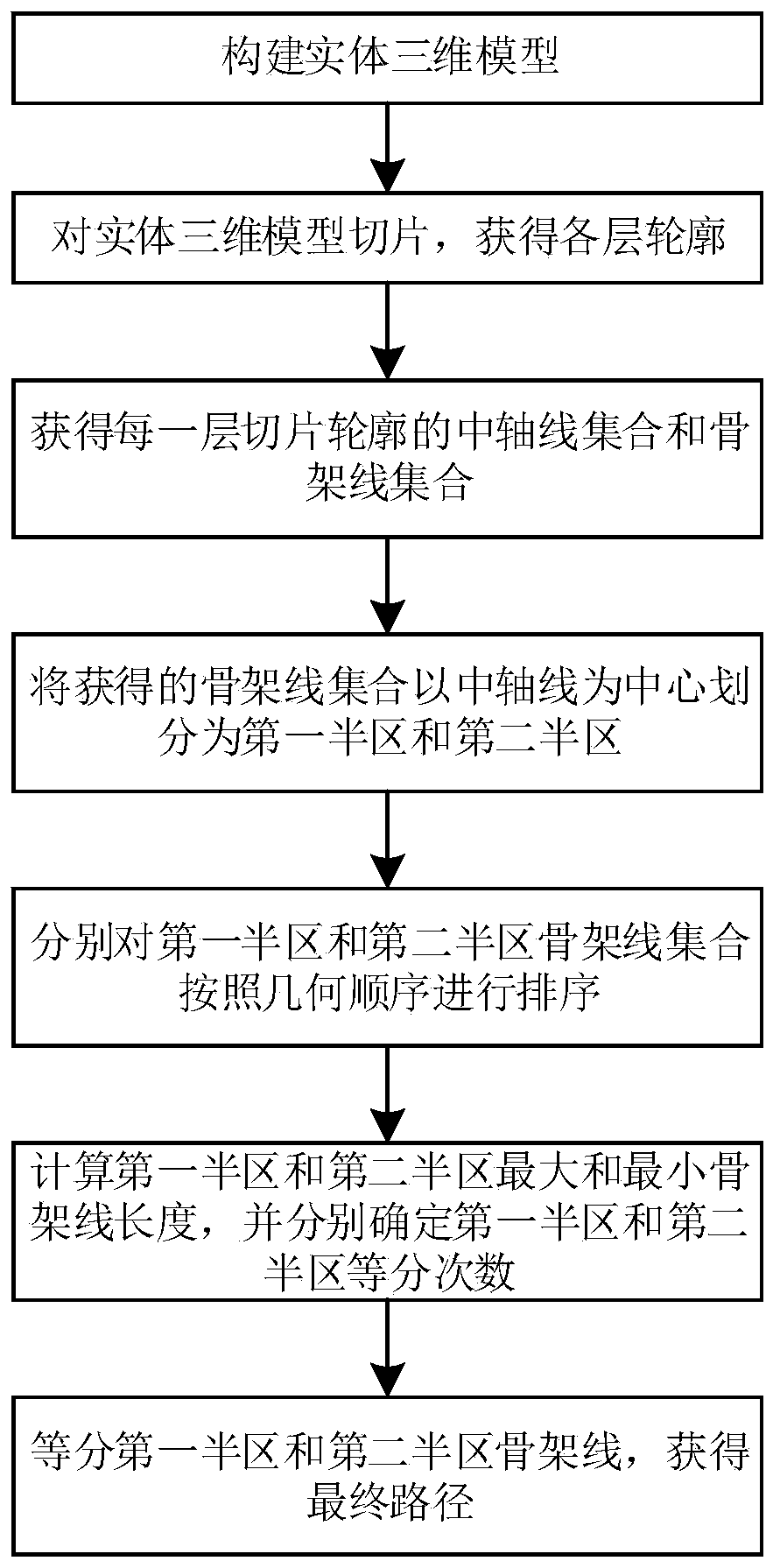

A real-time variable width 3D printing path construction method

ActiveCN109732928BShort travel distanceImprove processing efficiencyAdditive manufacturing apparatusManufacturing data aquisition/processingMachining processComputer science

The invention belongs to the technical field of three-dimensional (3D) printing, and particularly discloses a construction method for a three-dimensional (3D) printing path with the real-time variablewidth. The method comprises the following steps of constructing a 3D model of a part to be manufactured; layering the 3D model, and obtaining a slice at each layer; obtaining a central axis and a skeleton line of each slice; dividing the skeleton line into two parts by adopting the corresponding central axis as a center, and recording as a first half area and a second half area; sequentially ranking the skeleton lines along the directions of the central axes; calculating the maximum skeleton line length and the minimum skeleton line length in the skeleton lines at the first half area and thesecond half area, and determining the optimal path points of the first half area and the second half area; and determining the position of each path point according to the optimal path points, and then sequentially connecting the path points so as to generate the printing path. According to the construction method for the 3D printing path with the real-time variable width provided by the invention, the occurrence of a step effect and a cavity can be reduced, the idling stroke during the processing process is less, and the method has high processing efficiency.

Owner:HUAZHONG UNIV OF SCI & TECH

Gradient Surface Layering Method Based on Additive Remanufacturing Point Cloud Model

ActiveCN108062433BSkip the resurfacing processImprove efficiencyGeometric CADDesign optimisation/simulationPoint cloudAlgorithm

The present invention relates to a gradient surface layering method based on additive remanufacturing point cloud model, comprising the following steps: ① forming distance calculation; calculating the Euclidean distance d of the centroid point corresponding to the grid: the distance d reflects the defect point cloud in the The degree of defect at the point, that is, the forming distance that needs to be remanufactured by additive; ②The determination of the gradient distance; ③The generation of layered data; when the gradient is layered, the real layered surface family does not need to be accurately described. It is enough to interpolate the layered data on each surface; the layered data includes two parts: contour data and contour internal data; for the layered data of the i-th layer, its contour data is directly recorded as the layered interval number num=i data points; the internal data P'(x', y', z') of the contour can be obtained by the lower layer surface (num

Owner:ARMOR ACADEMY OF CHINESE PEOPLES LIBERATION ARMY

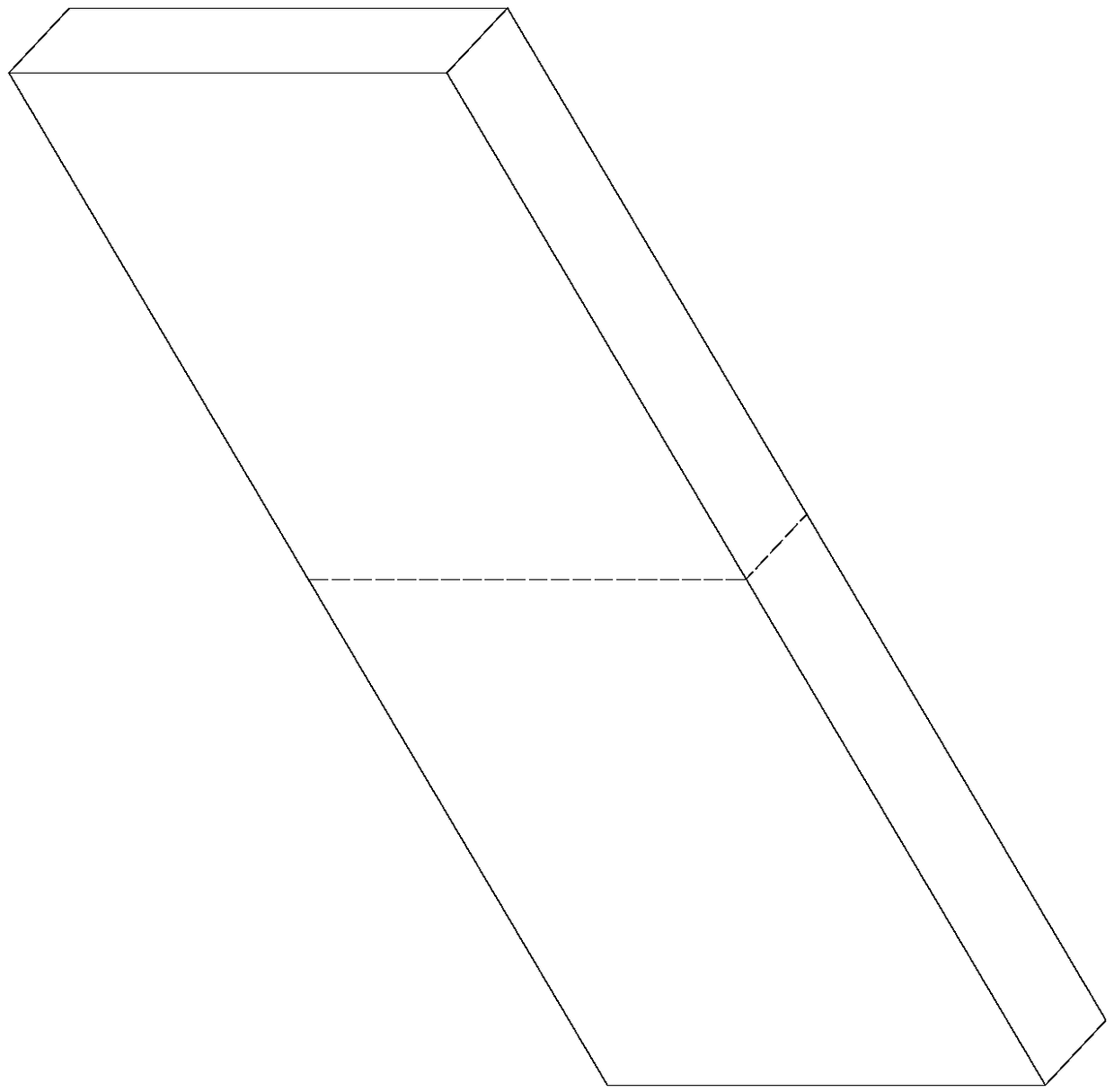

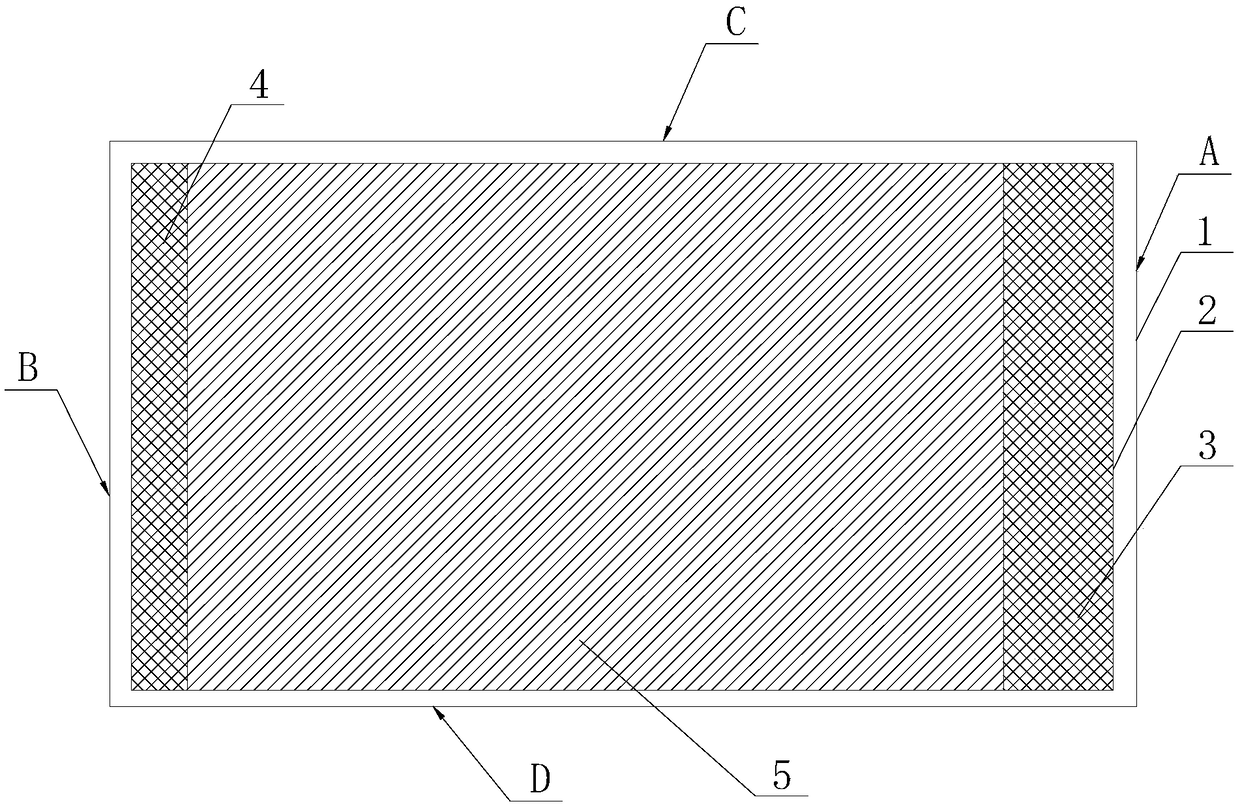

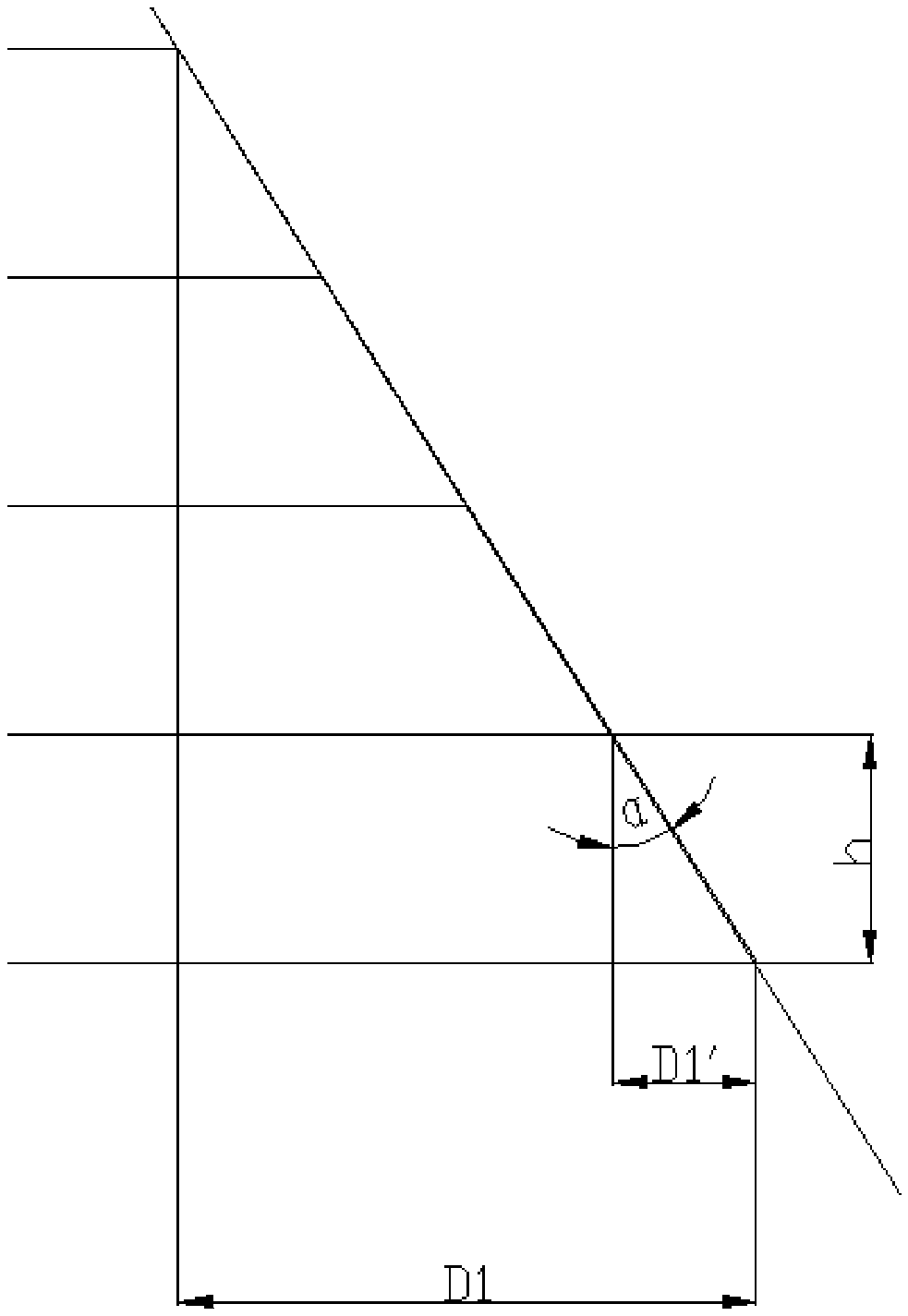

Laser Selective Melting Scanning Method

ActiveCN108380873BGood metallic lusterImprove surface qualityAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingSurface layer

The invention relates to the field of additive manufacturing, and discloses a laser selective melting scanning method. In the laser selective melting scanning method, the layer scan includes the following area scans: contour scan: scan along the outer contour line of the layer; internal filling line scan: perform filling scan in the inner area of the layer; upper epidermis scan: scan inside the contour line The upper epidermis area is scanned, and the width D1 of the upper epidermis area satisfies the following relationship: D1=ah·tanα, the lower epidermis scan: the lower epidermis area inside the contour line is scanned, and the width D1 of the upper epidermis area satisfies the following Relational formula: D2=bh·tanβ. Using this method, the surface of the formed part has obvious metallic luster, and the surface quality is better; the combination of powder metallurgy is sufficient, and the performance of the formed part is better; the scanning speed can also be improved, and the forming efficiency is higher, especially for the overhanging surface of the formed part. , can reduce the step effect of its surface, thereby improving its molding quality.

Owner:OPTIMAL MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com