Patents

Literature

164 results about "Electron beam processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electron-beam processing or electron irradiation (EBI) is a process that involves using electrons, usually of high energy, to treat an object for a variety of purposes. This may take place under elevated temperatures and nitrogen atmosphere. Possible uses for electron irradiation include sterilization and cross-linking of polymers.

Post treatment of low k dielectric films

ActiveUS7018941B2Semiconductor/solid-state device manufacturingOptoelectronicsDielectric permittivity

A method of depositing a low dielectric constant film on a substrate and post-treating the low dielectric constant film is provided. The post-treatment includes rapidly heating the low dielectric constant film to a desired high temperature and then rapidly cooling the low dielectric constant film such that the low dielectric constant film is exposed to the desired high temperature for about five seconds or less. In one aspect, the post-treatment also includes exposing the low dielectric constant film to an electron beam treatment and / or UV radiation.

Owner:APPLIED MATERIALS INC

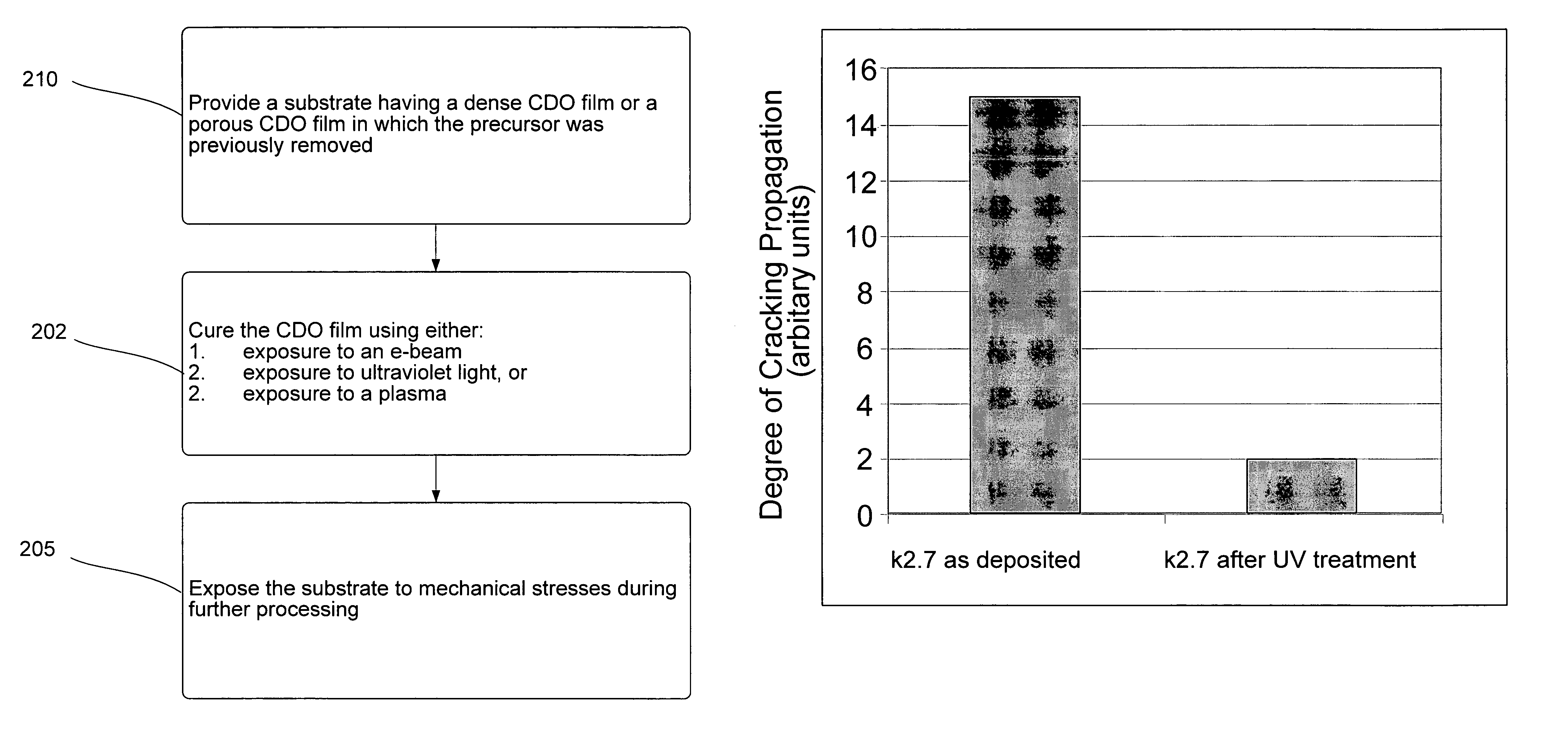

Methods for improving the cracking resistance of low-k dielectric materials

ActiveUS7094713B1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingCrack resistanceLight treatment

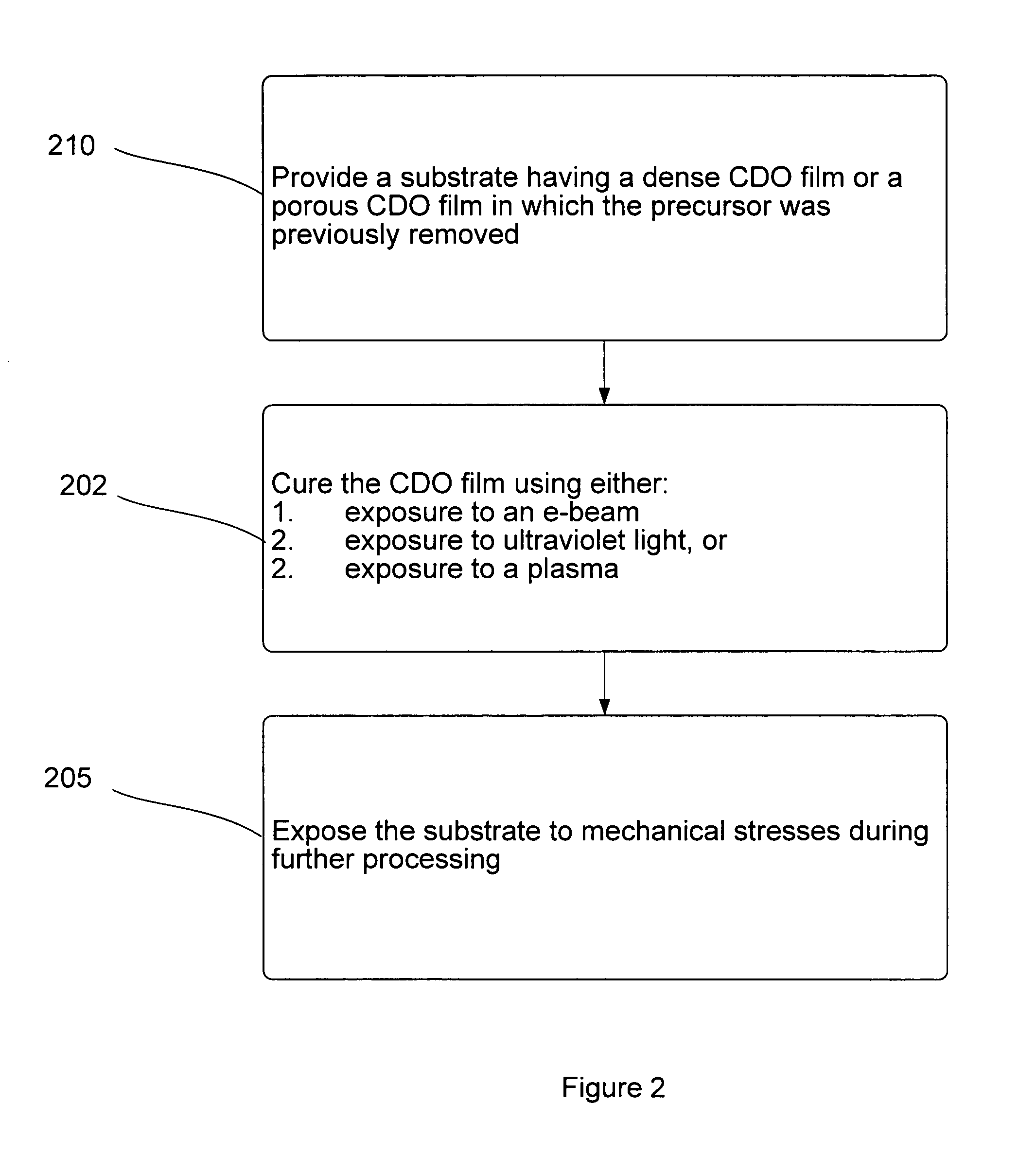

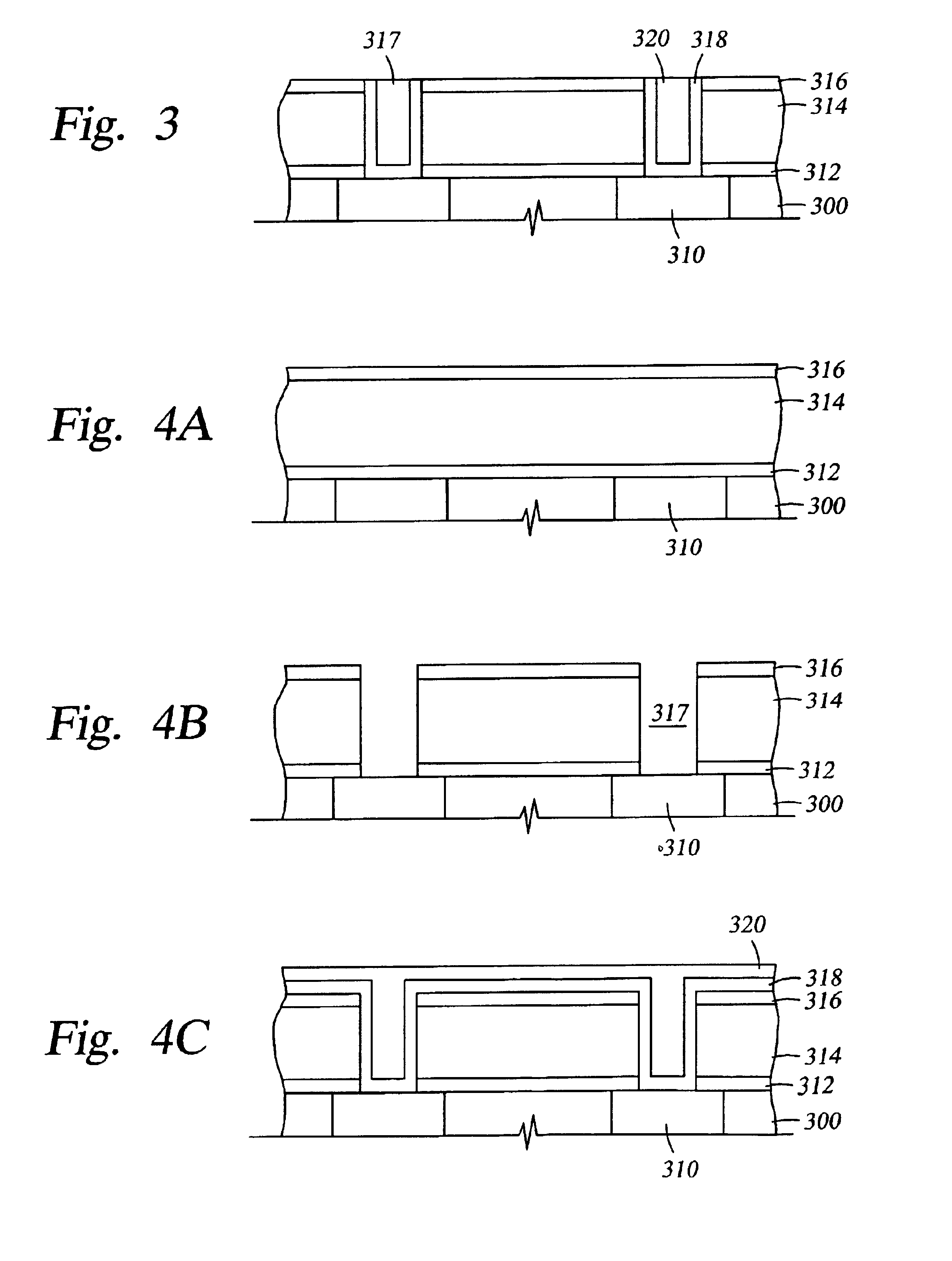

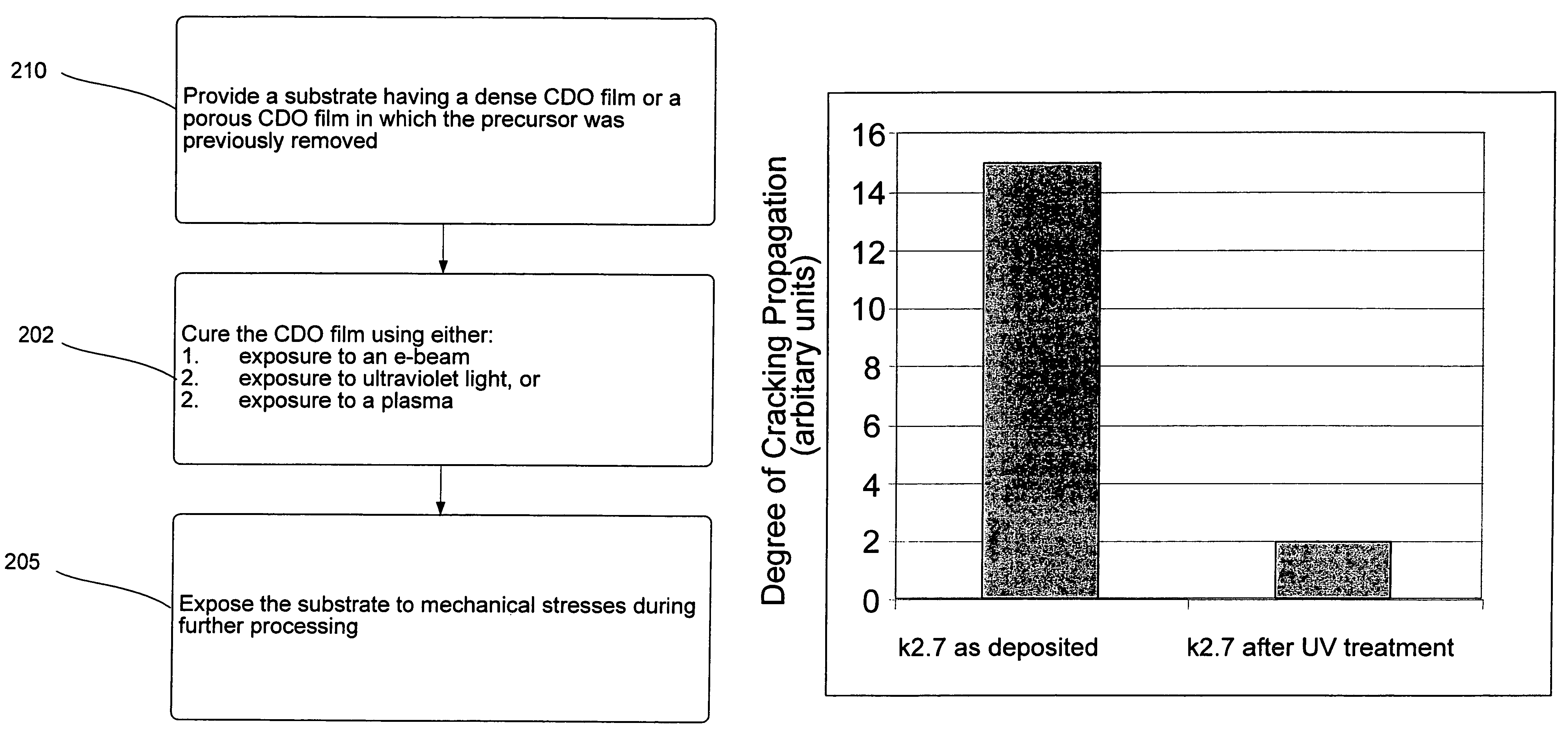

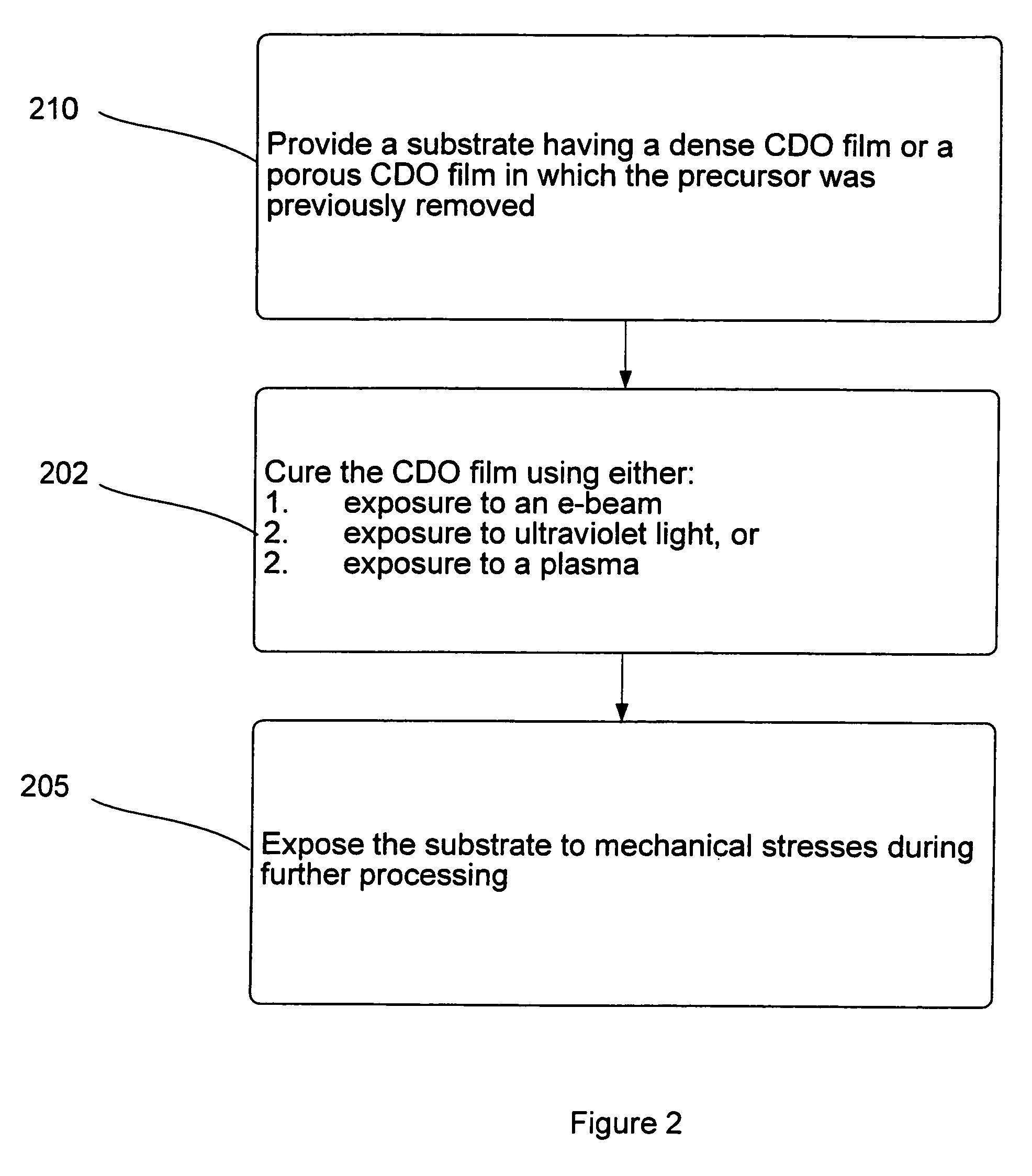

Methods for improving the mechanical properties of a CDO film are provided. The methods involve, for instance, providing either a dense CDO film or a porous CDO film in which the porogen has been removed followed by curing the CDO film at an elevated temperature using either a UV light treatment, an e-beam treatment, or a plasma treatment such that the curing improves the mechanical toughness of the CDO dielectric film.

Owner:NOVELLUS SYSTEMS

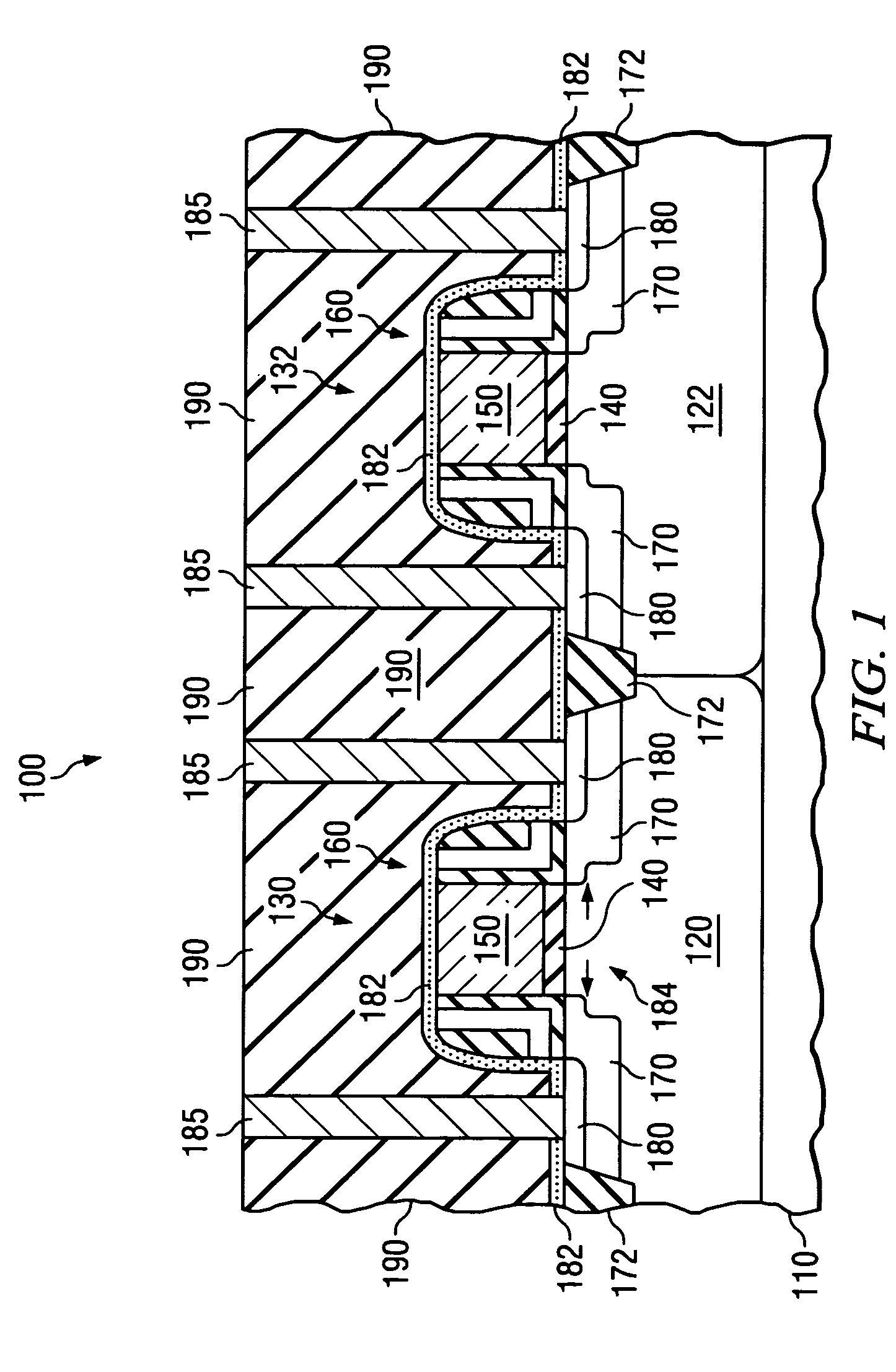

Methods and apparatus for E-beam treatment used to fabricate integrated circuit devices

InactiveUS6936551B2Improves property and performance of filmImprove mechanical propertiesPretreated surfacesSemiconductor/solid-state device manufacturingEngineeringTreatment use

One embodiment of the present invention is a method for fabricating a low-k dielectric film that includes steps of: (a) chemical vapor depositing a lower-k dielectric film; and (b) e-beam treating the lower-k dielectric film.

Owner:APPLIED MATERIALS INC

Ultra low dielectric materials based on hybrid system of linear silicon precursor and organic porogen by plasma-enhanced chemical vapor deposition (PECVD)

InactiveUS7056560B2Pretreated surfacesSemiconductor/solid-state device manufacturingHybrid systemDouble bond

A method for depositing a low dielectric constant film is provided by reacting a gas mixture including one or more linear, oxygen-free organosilicon compounds, one or more oxygen-free hydrocarbon compounds comprising one ring and one or two carbon-carbon double bonds in the ring, and one or more oxidizing gases. Optionally, the low dielectric constant film is post-treated after it is deposited. In one aspect, the post treatment is an electron beam treatment.

Owner:APPLIED MATERIALS INC

Methods and apparatus for e-beam treatment used to fabricate integrated circuit devices

InactiveUS20050130404A1Improves property and performance of filmImprove mechanical propertiesSemiconductor/solid-state device detailsSolid-state devicesEngineeringTreatment use

One embodiment of the present invention is a method for fabricating a low-k dielectric film that included steps of: (a) chemical vapor depositing a lower-k dielectric film; and (b) e-beam treating the lower-k dielectric film.

Owner:APPLIED MATERIALS INC

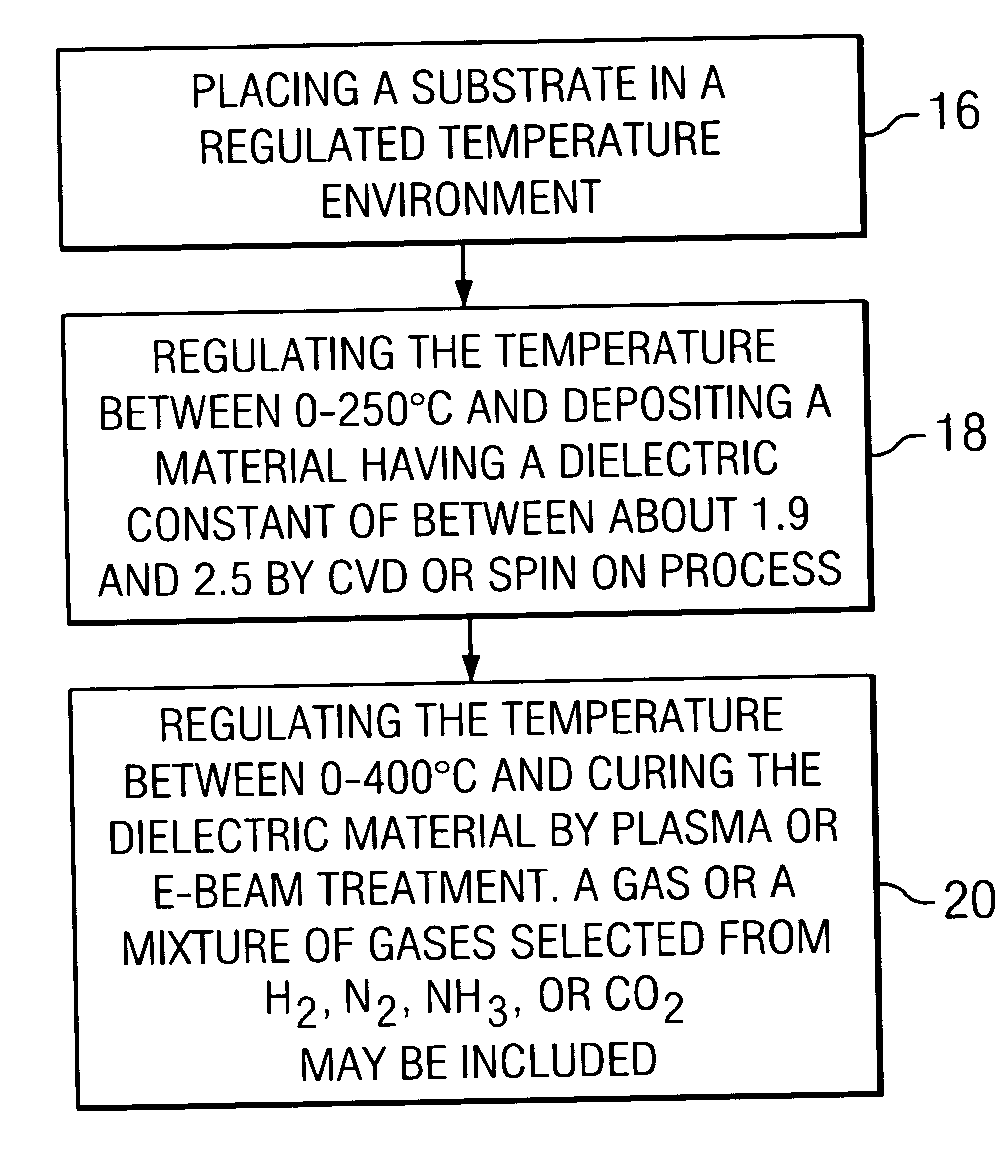

Method for ultra low-K dielectric deposition

InactiveUS20050048795A1Improve structural strengthSemiconductor/solid-state device manufacturingSemiconductor structureUv treatment

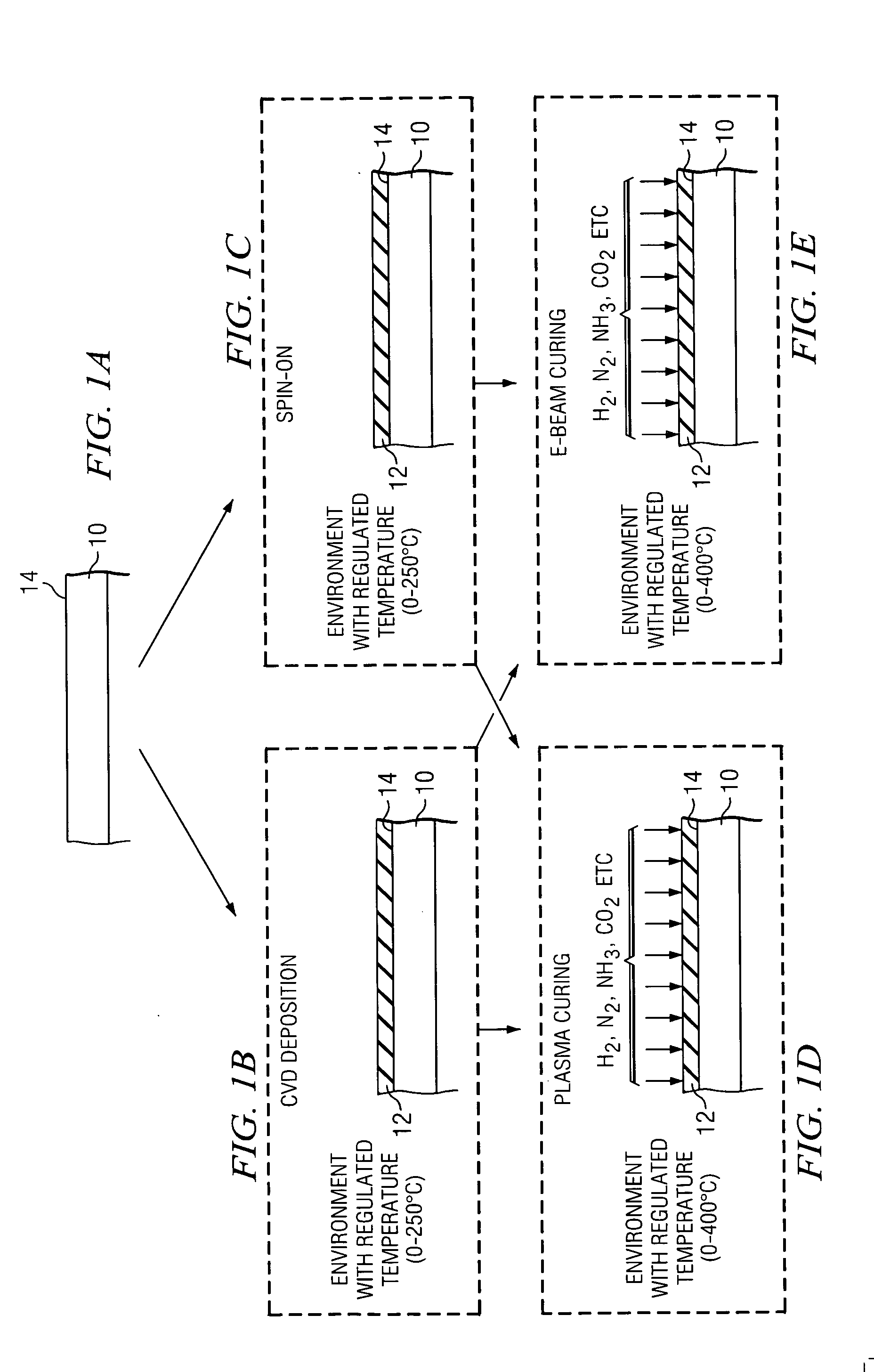

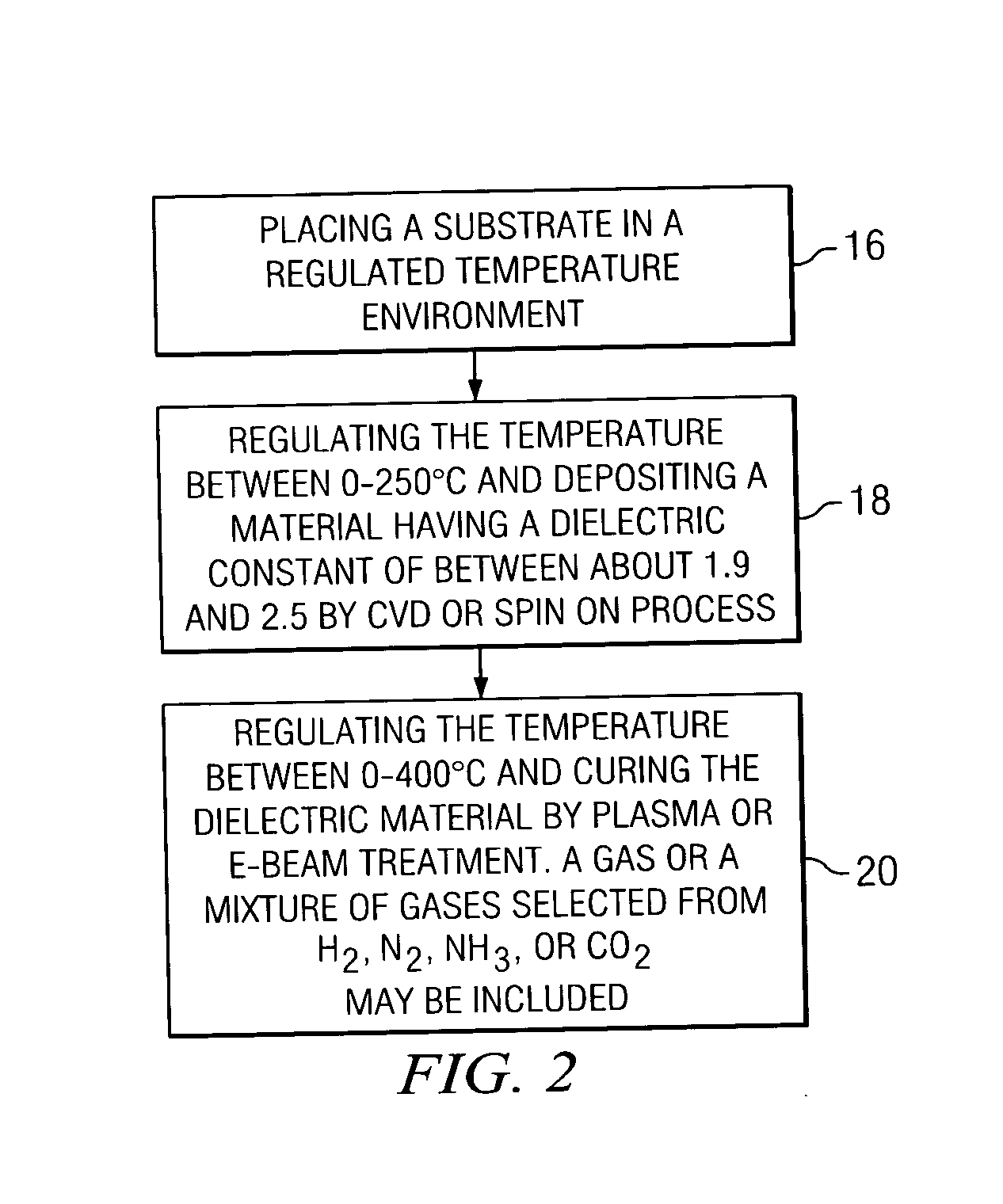

The present invention provides a method of forming a semiconductor structure having an ultra low-K dielectric material that adheres well to the substrate. The method includes depositing a low-K material on the top surface of a substrate at a low temperature of no more than 250° by a CVD or spin-on process. The dielectric material is then cured by placing the substrate with the dielectric film in an environment where the temperature is regulated at about 400° or less as the dielectric film is being subjected to a plasma treatment or an E-beam treatment or UV treatment. The environment may further include one or more gases or a mixture of gases selected from the group consisting of H2, N2, NH3, CO2, all hydride gases and a mixture of these gases.

Owner:TAIWAN SEMICON MFG CO LTD

Method for forming ultra low k films using electron beam

The present invention generally provides a method for depositing a low dielectric constant film using an e-beam treatment. In one aspect, the method includes delivering a gas mixture comprising one or more organosilicon compounds and one or more hydrocarbon compounds having at least one cyclic group to a substrate surface at deposition conditions sufficient to deposit a non-cured film comprising the at least one cyclic group on the substrate surface. The method further includes substantially removing the at least one cyclic group from the non-cured film using an electron beam at curing conditions sufficient to provide a dielectric constant less than 2.5 and a hardness greater than 0.5 GPa.

Owner:APPLIED MATERIALS INC

Methods for improving the cracking resistance of low-k dielectric materials

InactiveUS7381662B1Improve mechanical propertiesSemiconductor/solid-state device manufacturingChemical vapor deposition coatingCrack resistanceLight treatment

Methods for improving the mechanical properties of a CDO film are provided. The methods involve, for instance, providing either a dense CDO film or a porous CDO film in which the porogen has been removed followed by curing the CDO film at an elevated temperature using either a UV light treatment, an e-beam treatment, or a plasma treatment such that the curing improves the mechanical toughness of the CDO dielectric film.

Owner:NOVELLUS SYSTEMS

Method for forming ultra low k films using electron beam

The present invention generally provides a method for depositing a low dielectric constant film using an e-beam treatment. In one aspect, the method includes delivering a gas mixture comprising one or more organosilicon compounds and one or more hydrocarbon compounds having at least one cyclic group to a substrate surface at deposition conditions sufficient to deposit a non-cured film comprising the at least one cyclic group on the substrate surface. The method further includes substantially removing the at least one cyclic group from the non-cured film using an electron beam at curing conditions sufficient to provide a dielectric constant less than 2.5 and a hardness greater than 0.5 GPa.

Owner:APPLIED MATERIALS INC

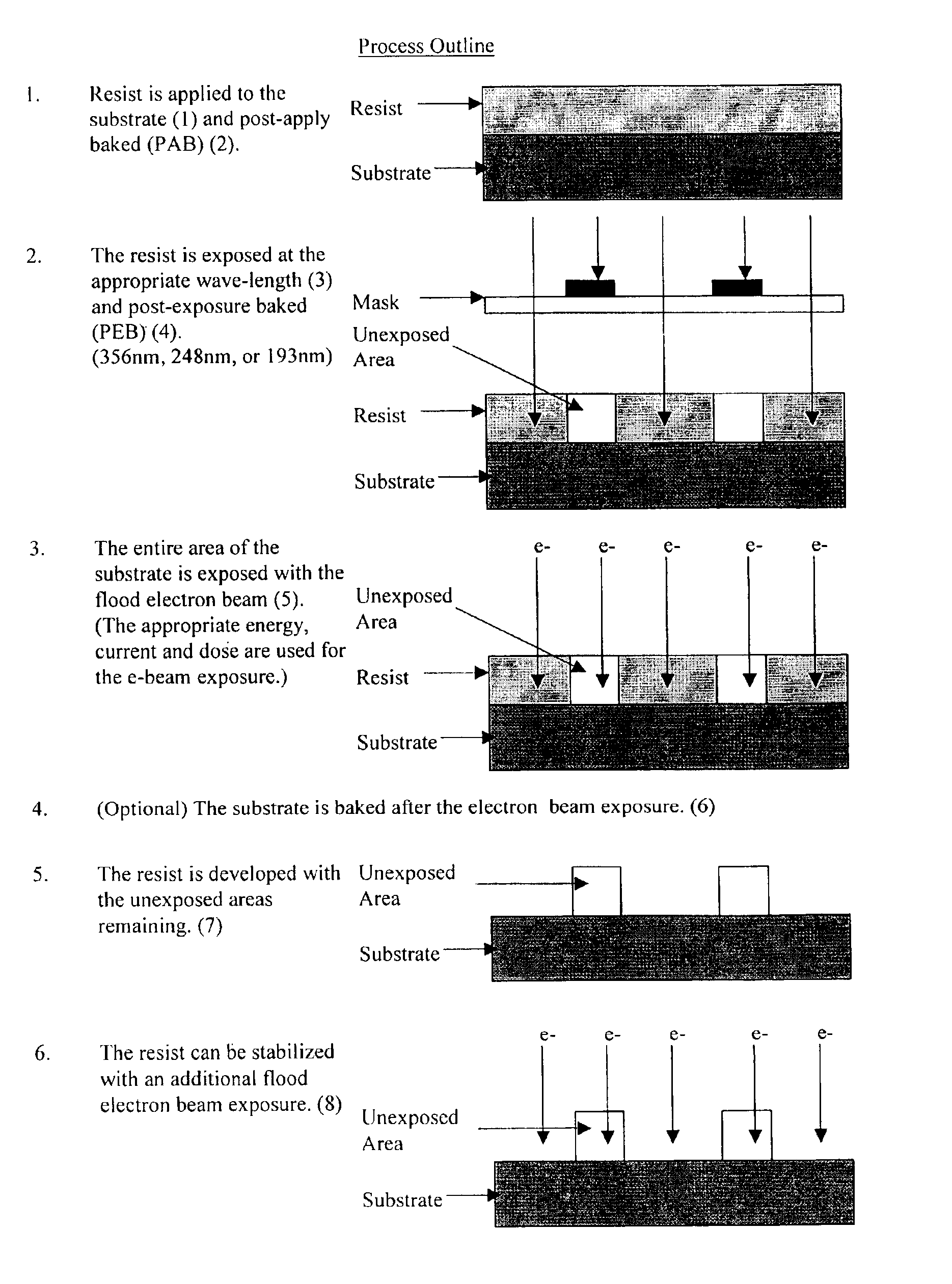

Method for modifying resist images by electron beam exposure

InactiveUS6900001B2Electric discharge tubesPhotomechanical exposure apparatusResistElectron-beam lithography

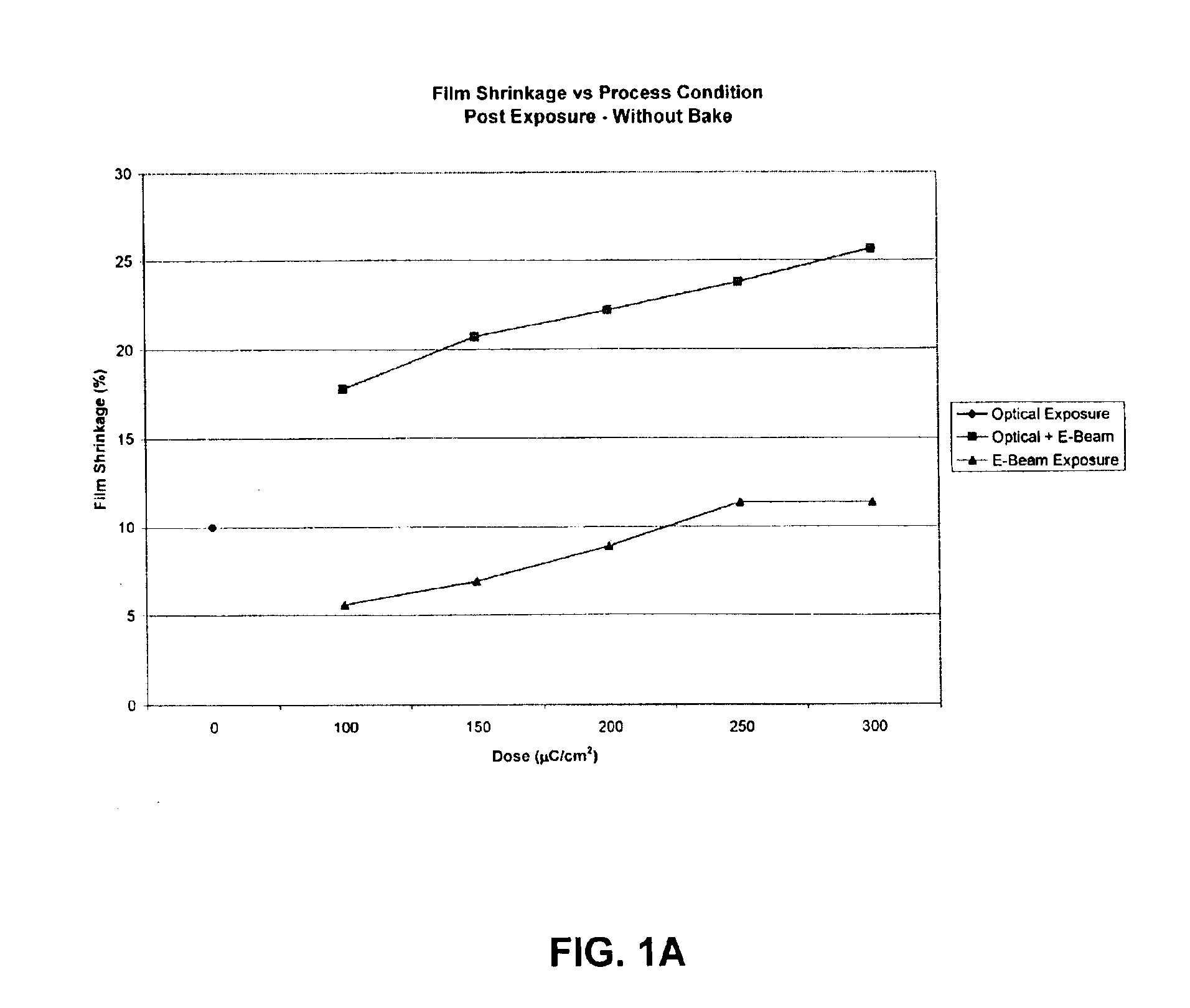

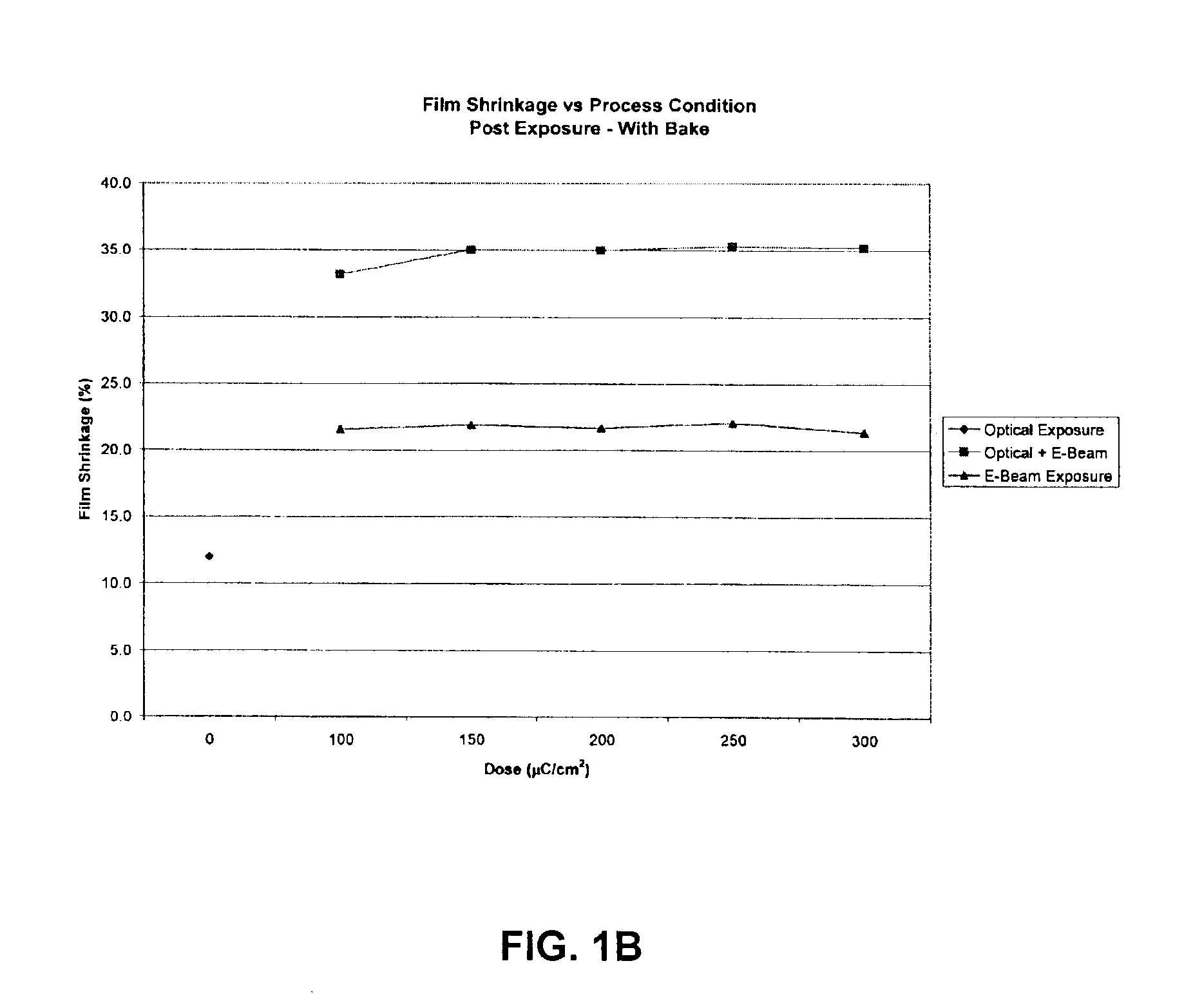

It has now been surprisingly found that by exposing a photoresist to flood electron beam exposure in combination with optical exposure, that the pullback on the upper region of lithographic images in resist can be virtually eliminated during electron beam processing. This unexpected result is due to the fact that the electron beam exposure and optional bake are carried out prior to development of the resist. This means that the resist shrinkage that is seen as a result of these steps is constrained laterally by the resist film itself. Thus, the resist is free to shrink vertically, and the resulting shrinkage provides a reduction in the line slimming and an improvement in the etch rate of the resist. This leads to the formation of a better resist image.

Owner:ELECTRON VISION CORP

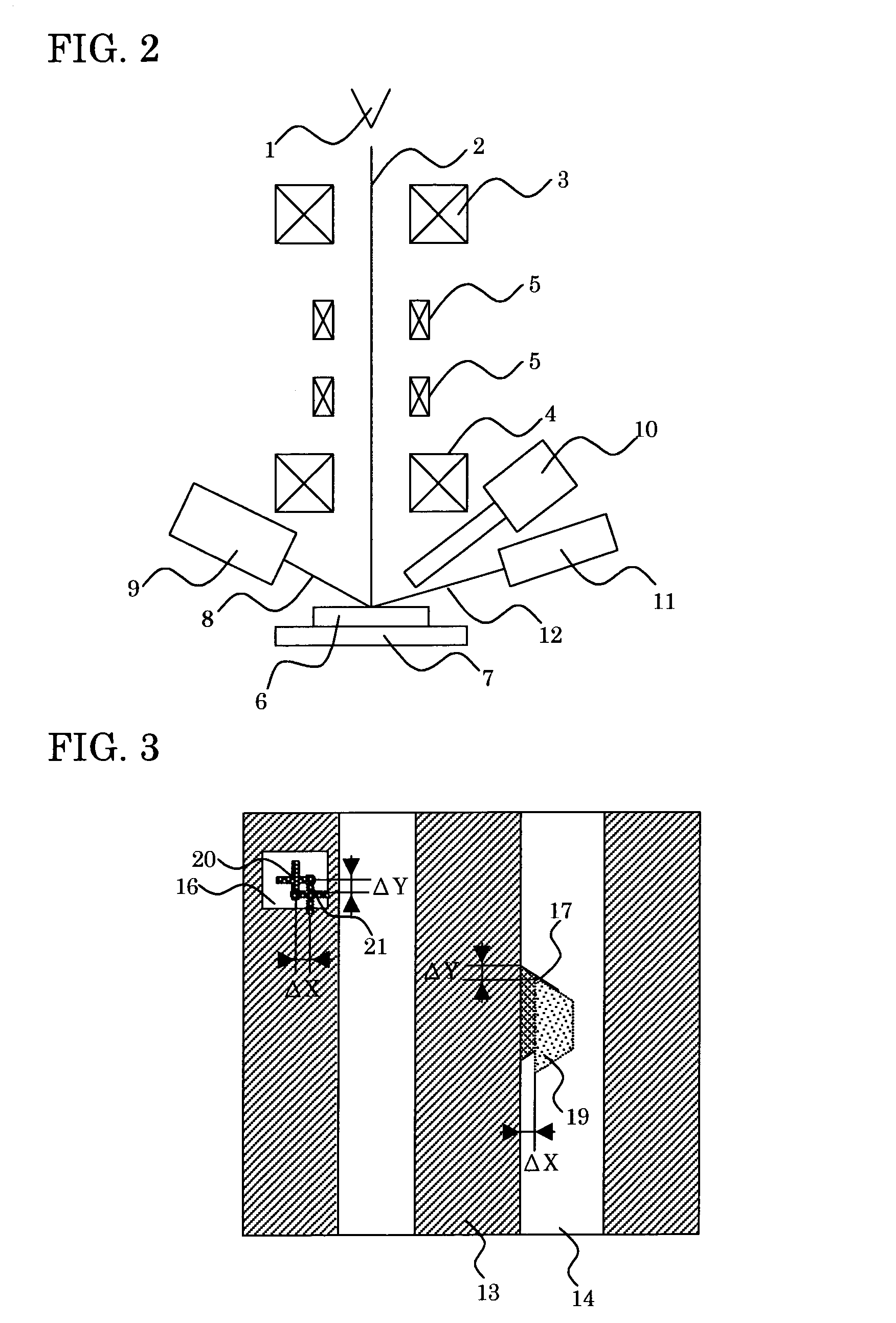

Electron beam processing method

ActiveUS7018683B2Precise positioningShort timeElectric discharge heatingVacuum evaporation coatingPhysicsElectron beam processing

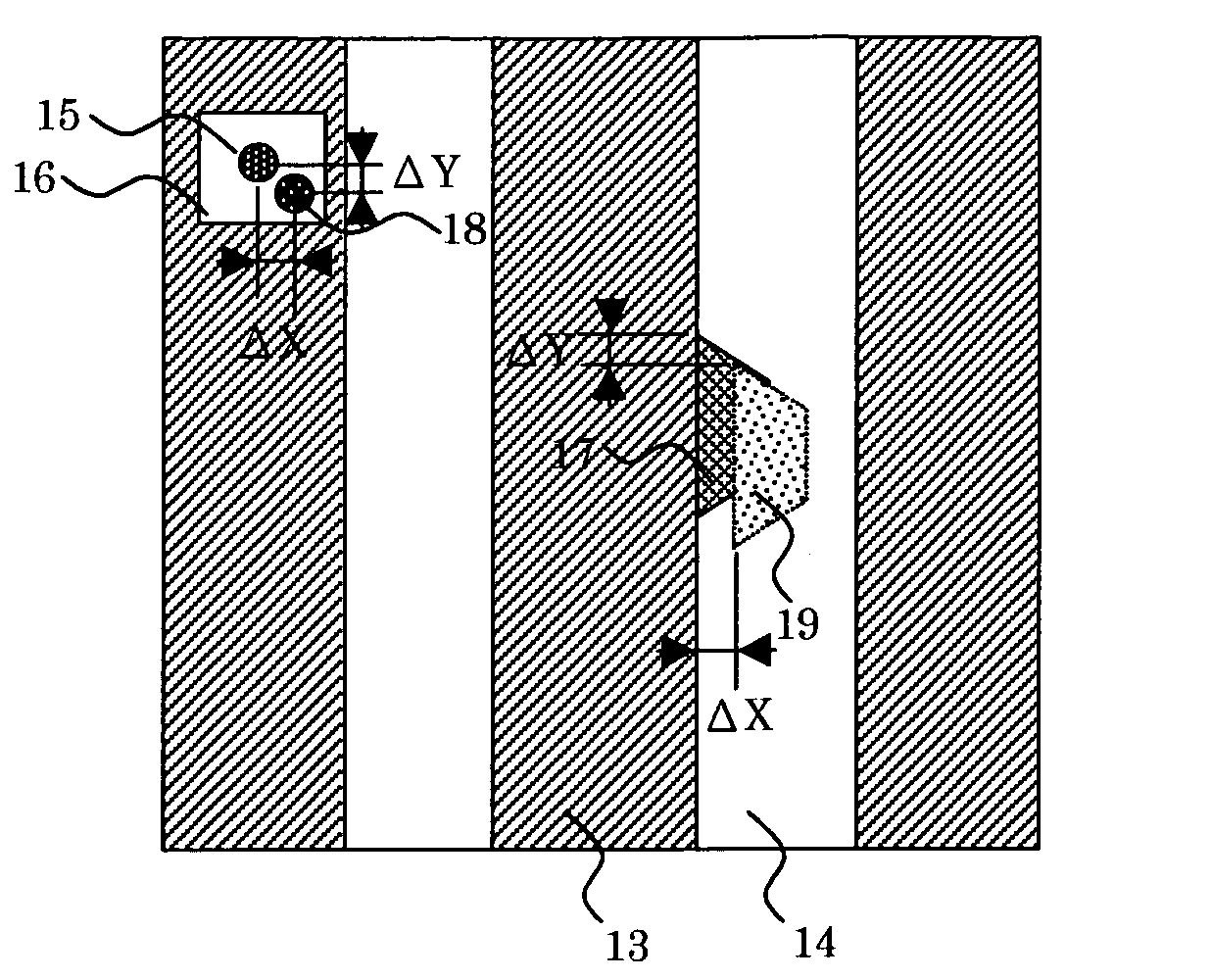

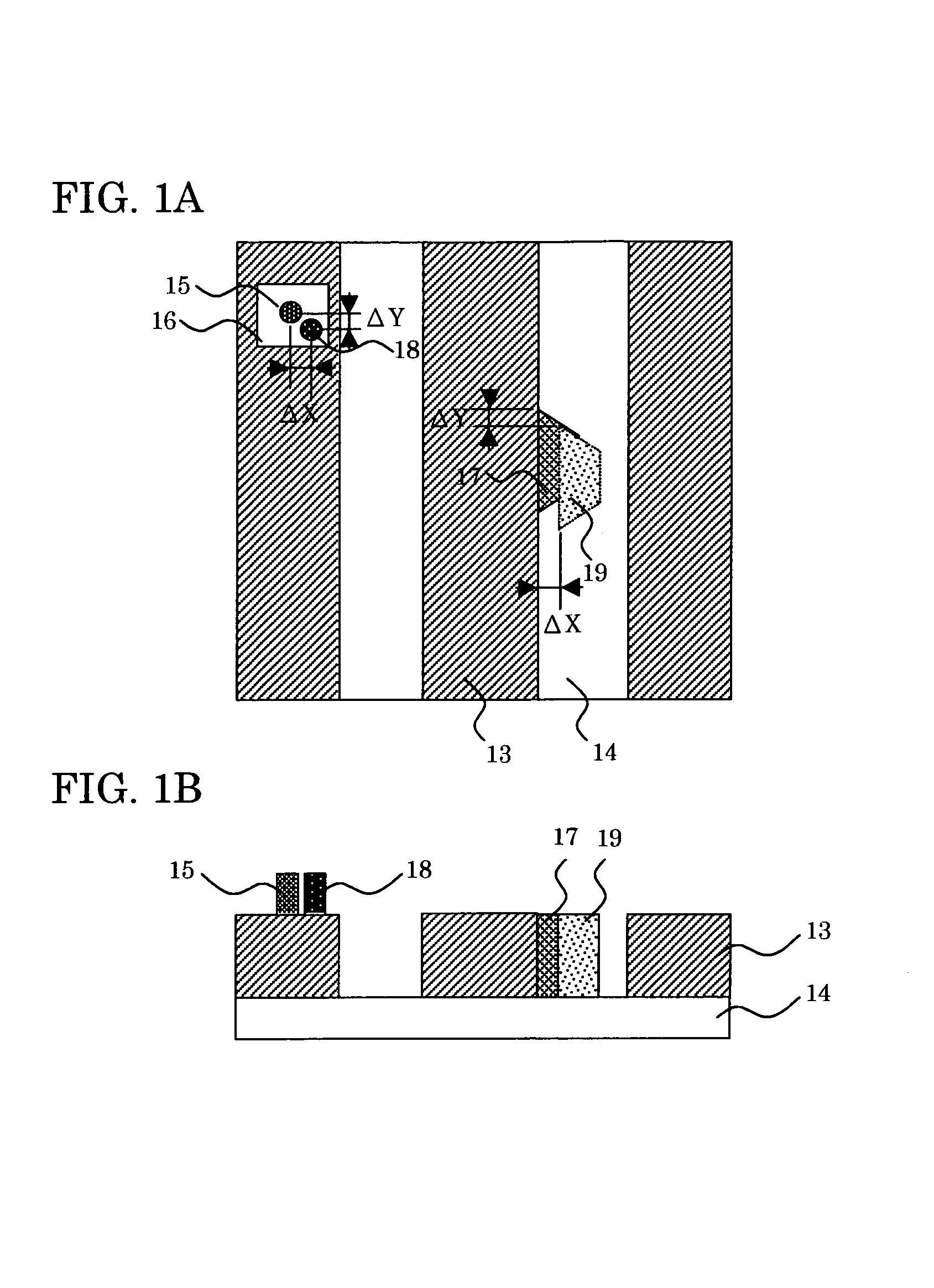

A microscopic projection or a characteristic pattern are formed in the vicinity of a region to be processed before processing using electron beam CVD, during processing an image of a region containing the projection or pattern formed by electron beam CVD is captured to obtain a current position of the projection or pattern, a difference between the position before staring and the current position is treated as a drift amount and processing is restarted at a region that has been subjected to microscopic adjustment of the electron irradiation region.

Owner:HITACHI HIGH TECH SCI CORP

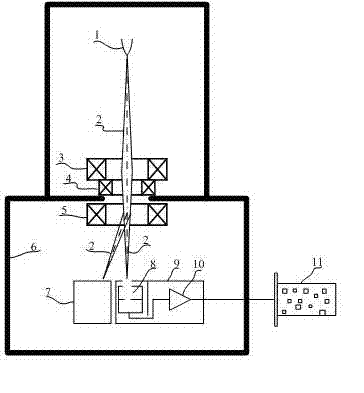

Faraday cup sensing device used in electron beam processing beam quality test

ActiveCN102353978APrevent escapeImprove collection efficiencyX/gamma/cosmic radiation measurmentWeak currentAlloy

The invention discloses a Faraday cup sensing device used in an electron beam processing beam quality test. The Faraday cup sensing device comprises: a Faraday cup, an aluminum shell and a signal switching and amplification circuit. The Faraday cup and the signal switching and amplification circuit are arranged in the aluminum shell. The signal switching and amplification circuit is connected with an acquisition card of an industrial personal computer which is out of a vacuum chamber of an electron beam quality test system. Electron beam of the electron beam quality test system is collected by the Faraday cup and is flowed into the signal switching and amplification circuit through a cable. A weak current signal is processed by the signal switching and amplification circuit, then is converted into a digital signal by the acquisition card and is stored in the industrial personal computer. The Faraday cup comprises two electron beam aperture collection electrodes and one electron beam seam collection electrode. The aluminum shell comprises: an aluminum alloy shell and an aluminum alloy cover. By using the device, collection efficiency of the electron beam can be raised; multiple vacuum-pumping processes can be avoided. Amplifying the signal can obviously raise a signal to noise ratio.

Owner:NANJING UNIV OF SCI & TECH

Low dielectric constant porous films

ActiveUS20050215065A1Low dielectric constantImprove electricityPlastic/resin/waxes insulatorsSemiconductor/solid-state device manufacturingSilicon oxideBoron oxide

A porous dielectric film for use in electronic devices is disclosed that is formed by removal of soluble nano phase porogens. A silicon based dielectric film having soluble porogens dispersed therein is prepared by chemical vapor deposition (CVD) or by spin on glass (S.O.G.). Examples of preferable porogens include compounds such as germanium oxide (GeO2) and boron oxide (B2O3). Hot water can be used in processing to wet etch the film, thereby removing the porogens and providing the porous dielectric film. The silicon based dielectric film may be a carbon doped silicon oxide in order to further reduce the dielectric constant of the film. Additionally, the porous dielectric film may be treated by an electron beam to enhance the electrical and mechanical properties of the film.

Owner:APPLIED MATERIALS INC

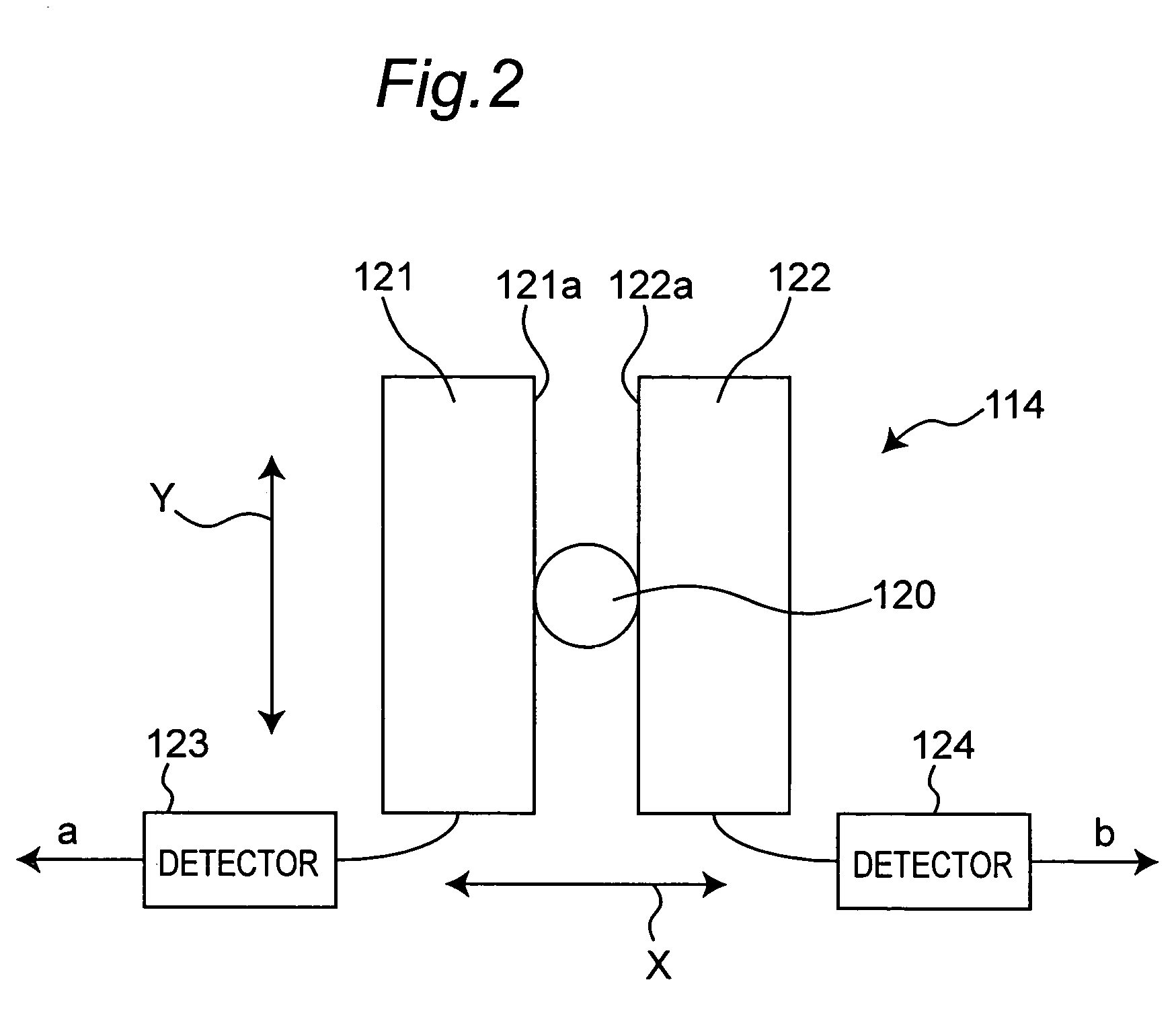

Electron beam recorder and electron beam irradiation position detecting method

InactiveUS7359305B2Improve accuracyAccuracy of a track pitchElectron beam carrier recordingElectric discharge tubesLocation detectionAtomic physics

An electron beam recorder includes an electron optical system for irradiating an electron beam on a master of an information recording medium and an electron beam irradiation position detecting unit for detecting an irradiation position of the electron beam in the electron optical system while the electron beam is being irradiated on the master by the electron optical system.

Owner:PANASONIC CORP

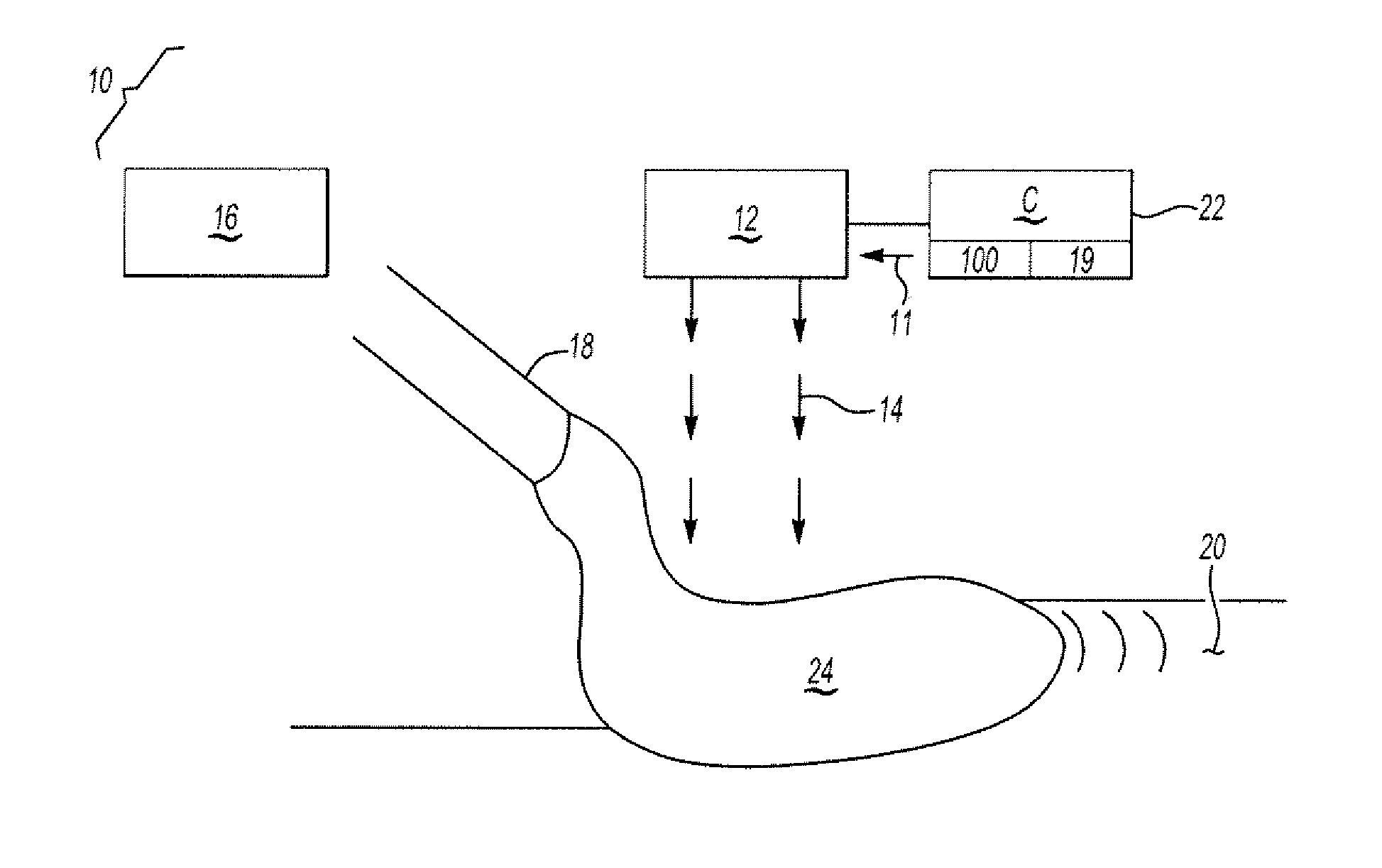

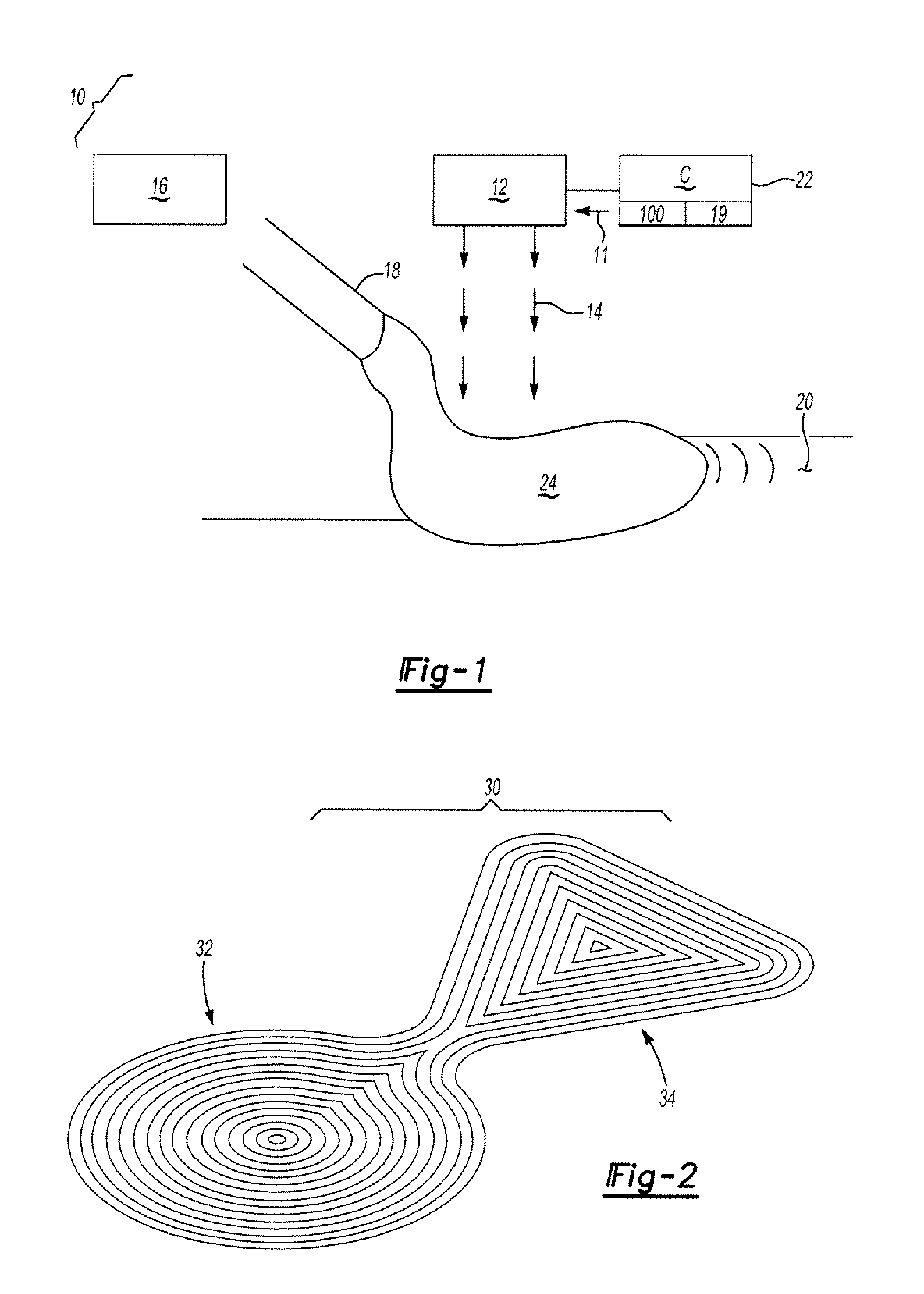

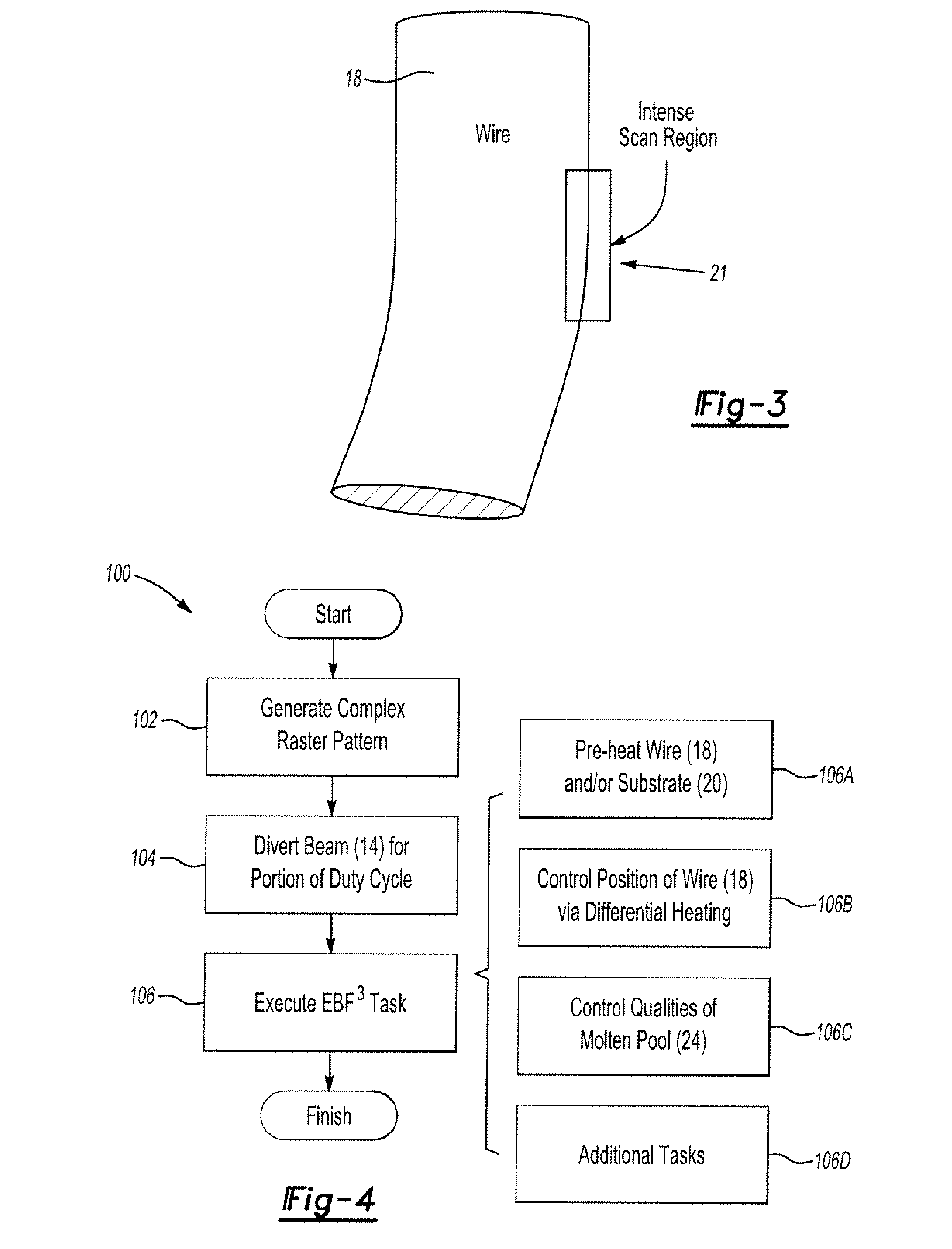

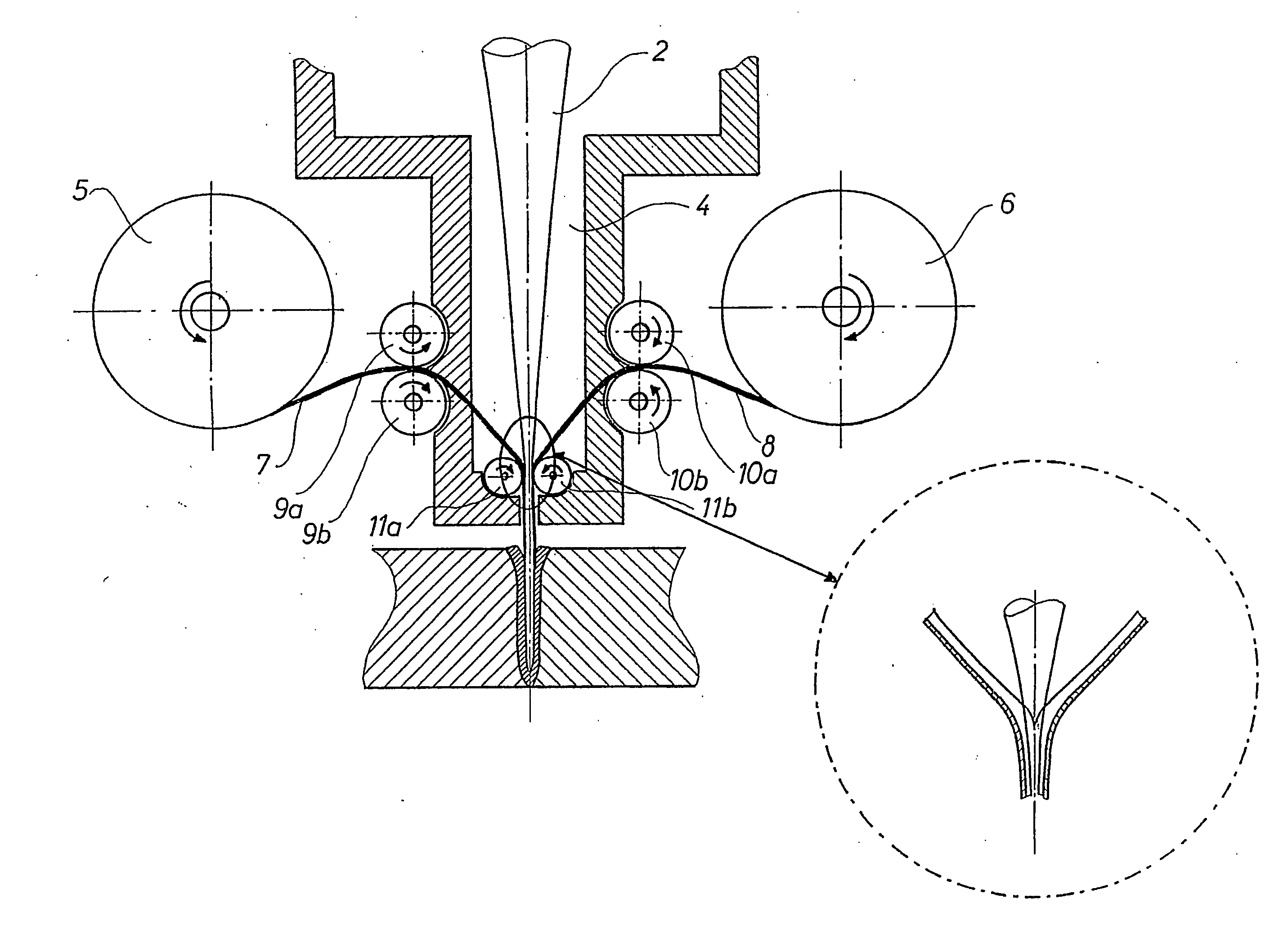

Use of beam deflection to control an electron beam wire deposition process

ActiveUS8344281B2Reduce in quantityLower Level RequirementsElectron beam welding apparatusGratingLight beam

A method for controlling an electron beam process wherein a wire is melted and deposited on a substrate as a molten pool comprises generating the electron beam with a complex raster pattern, and directing the beam onto an outer surface of the wire to thereby control a location of the wire with respect to the molten pool. Directing the beam selectively heats the outer surface of the wire and maintains the position of the wire with respect to the molten pool. An apparatus for controlling an electron beam process includes a beam gun adapted for generating the electron beam, and a controller adapted for providing the electron beam with a complex raster pattern and for directing the electron beam onto an outer surface of the wire to control a location of the wire with respect to the molten pool.

Owner:NASA

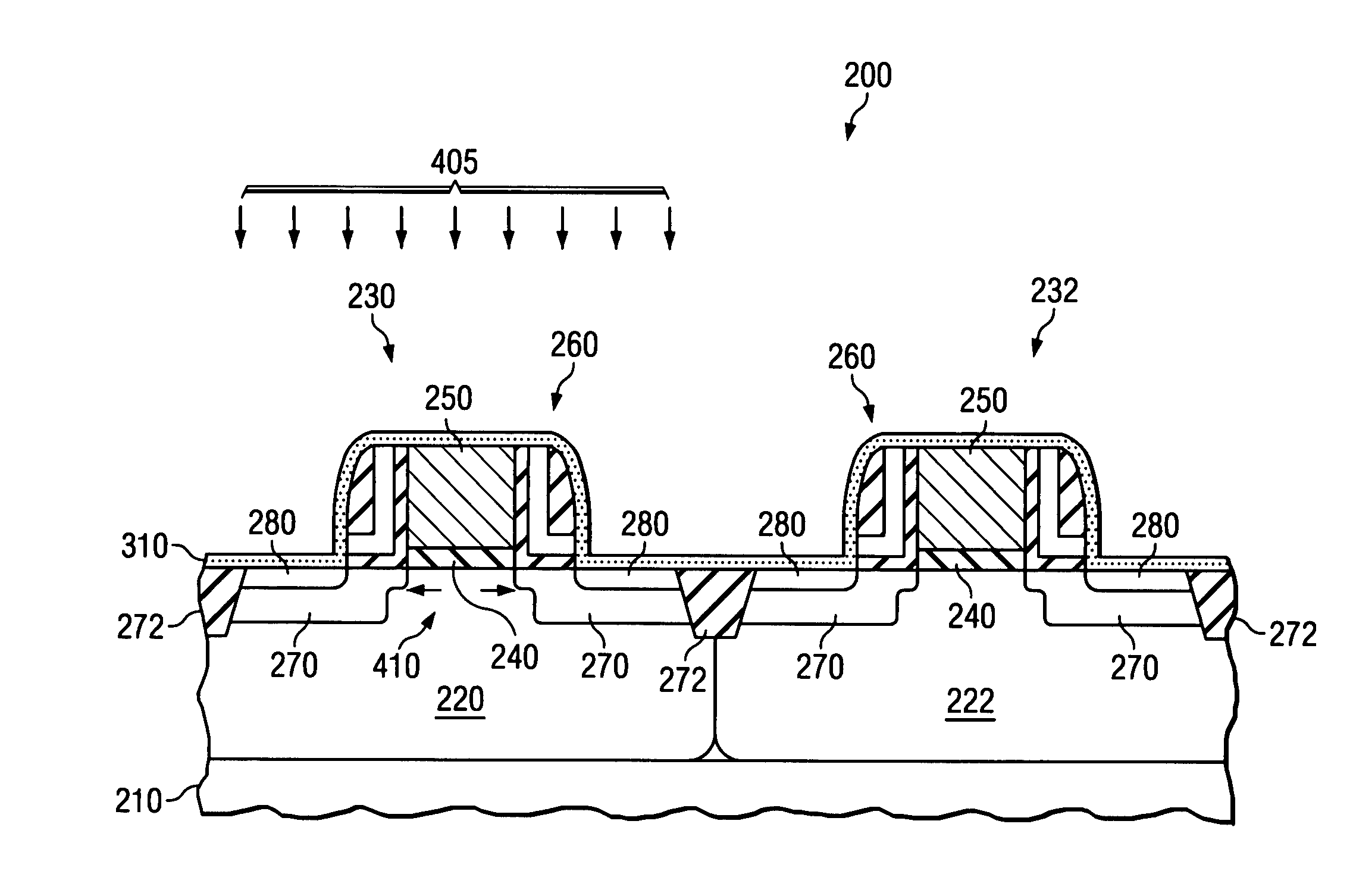

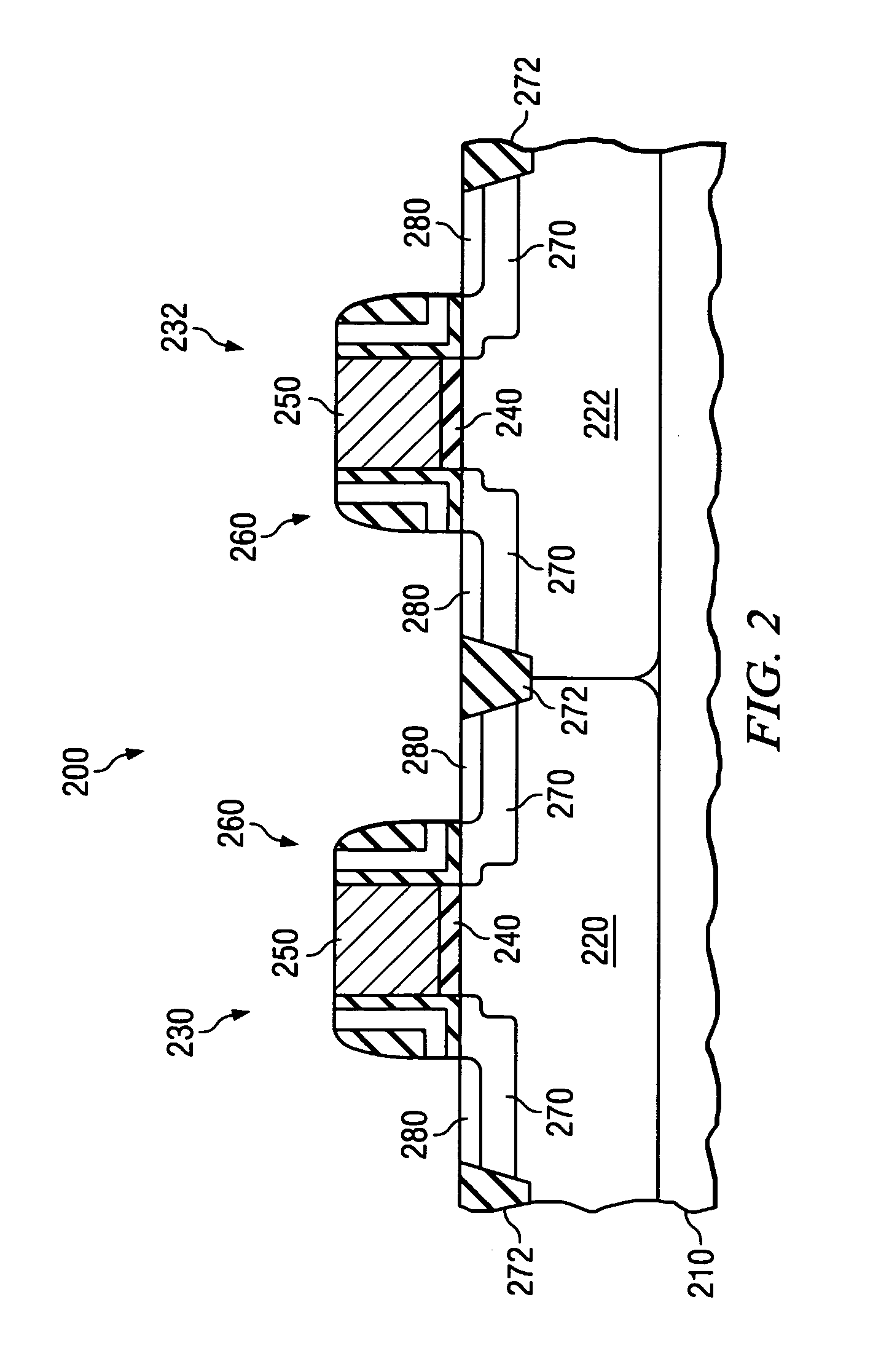

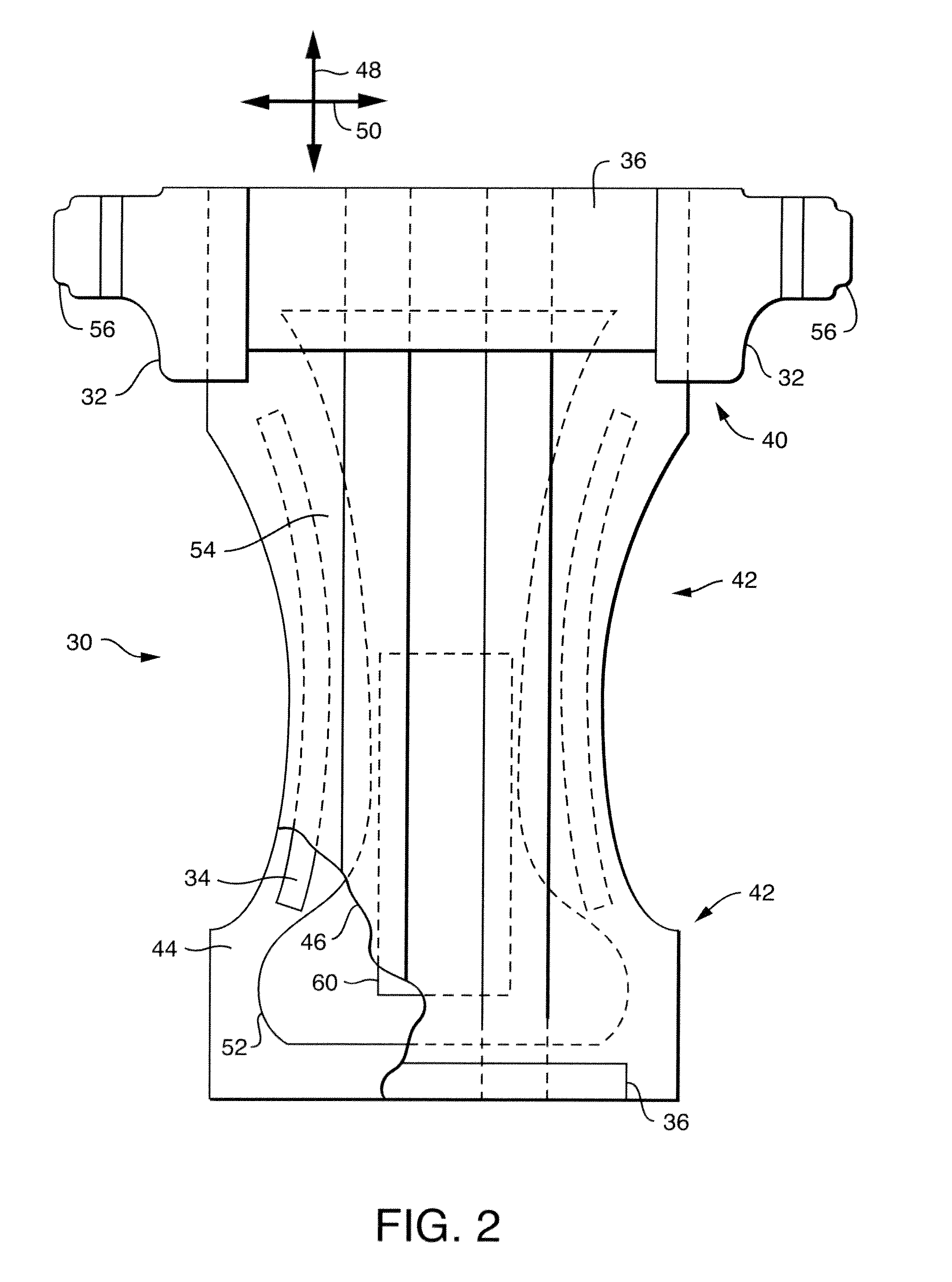

Method of fabricating a microelectronic device using electron beam treatment to induce stress

The present invention, in one embodiment, provides a method of fabricating a microelectronics device 200. This embodiment comprises forming a liner 310 over a substrate 210 and a gate structure 230, subjecting the liner 310 to an electron beam 405 and depositing a pre-metal dielectric layer 415 over the liner 310.

Owner:TEXAS INSTR INC

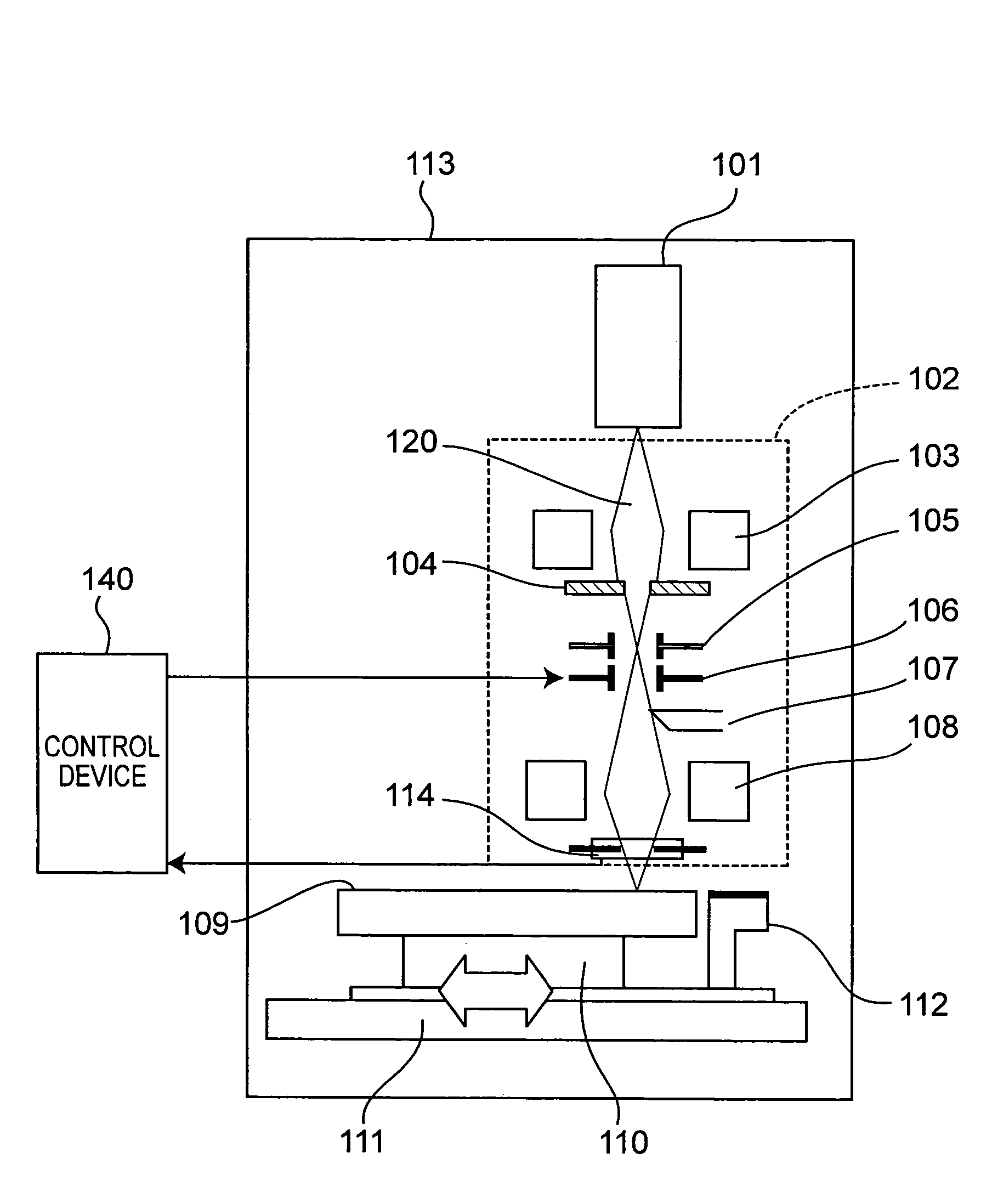

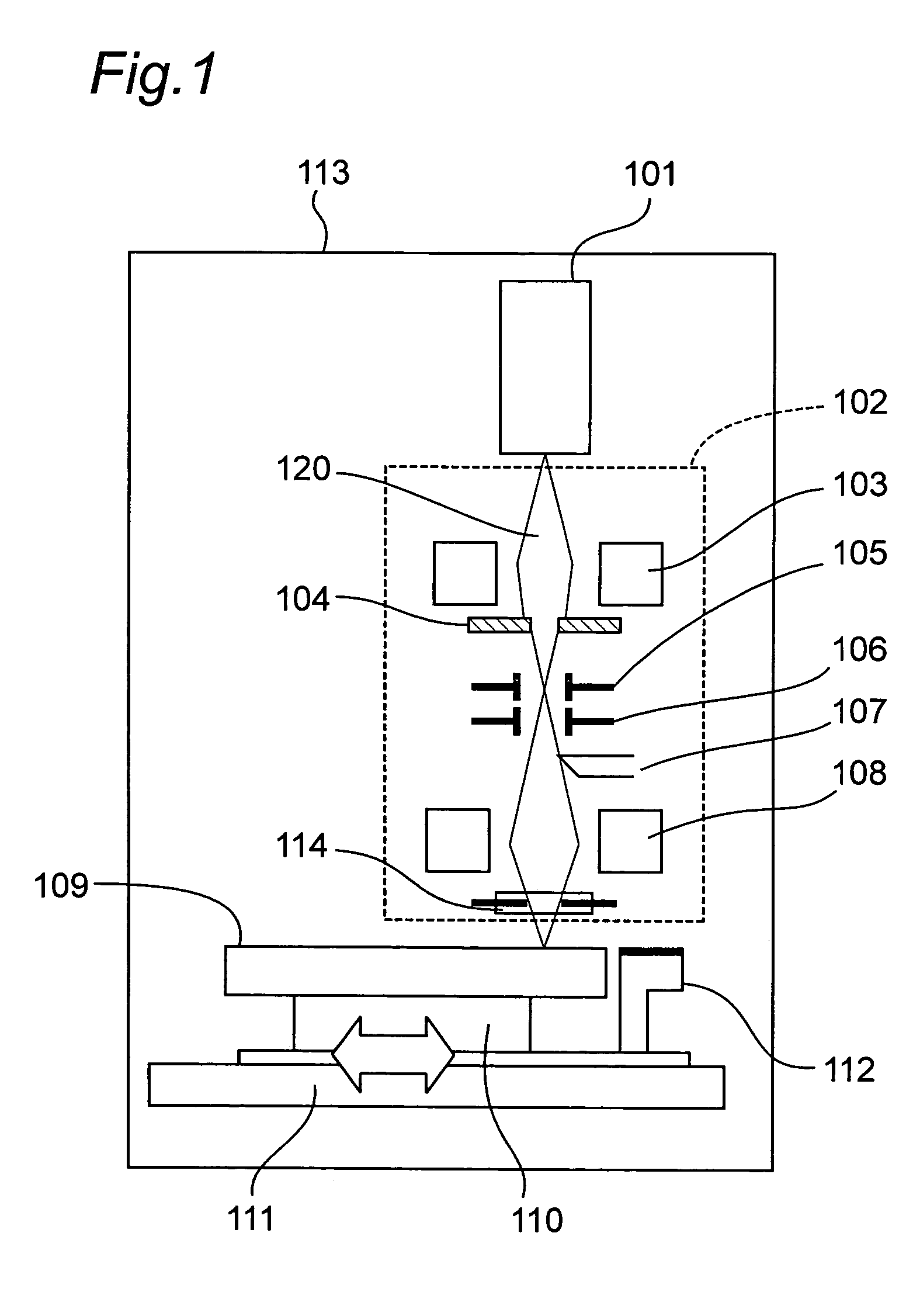

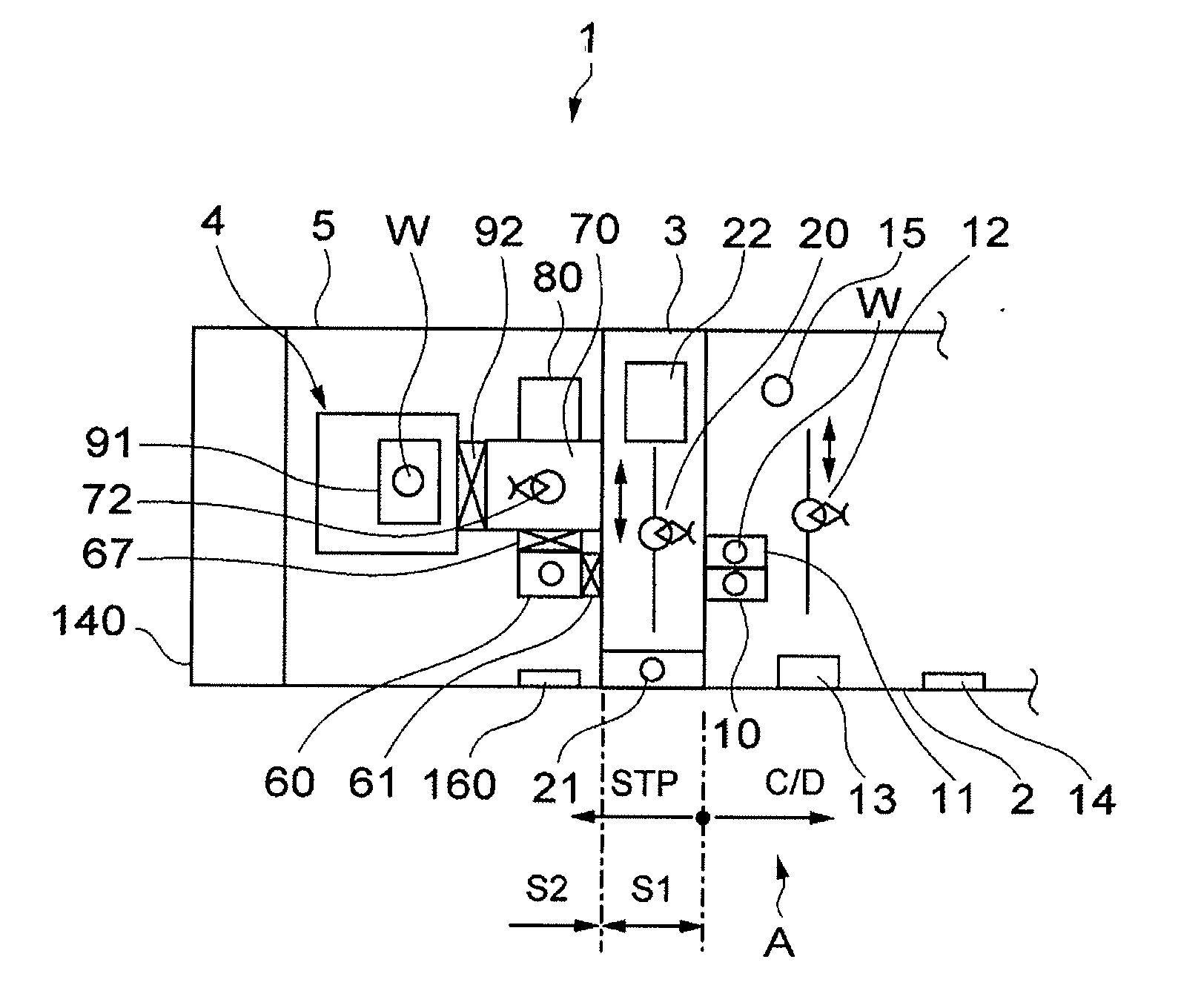

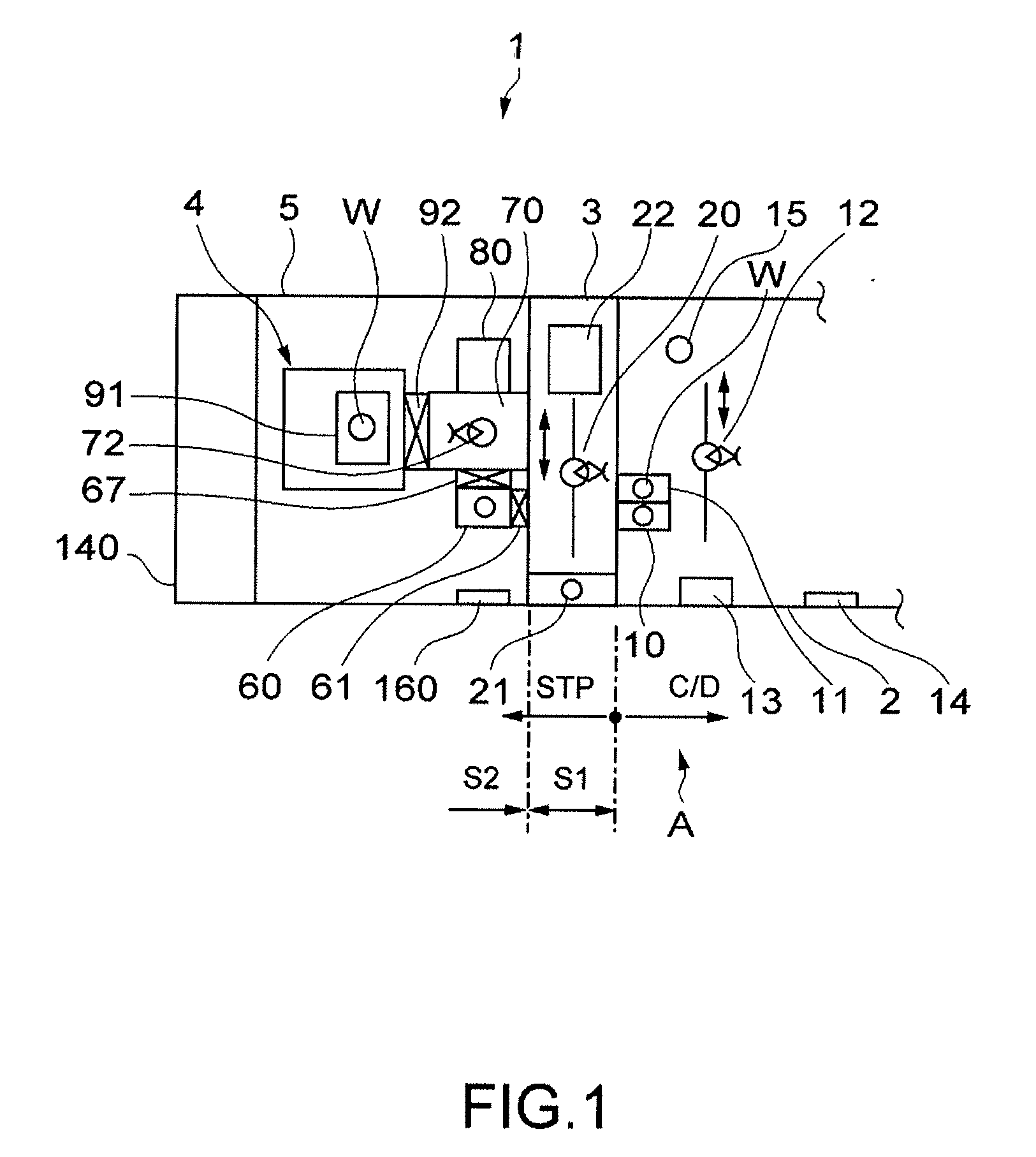

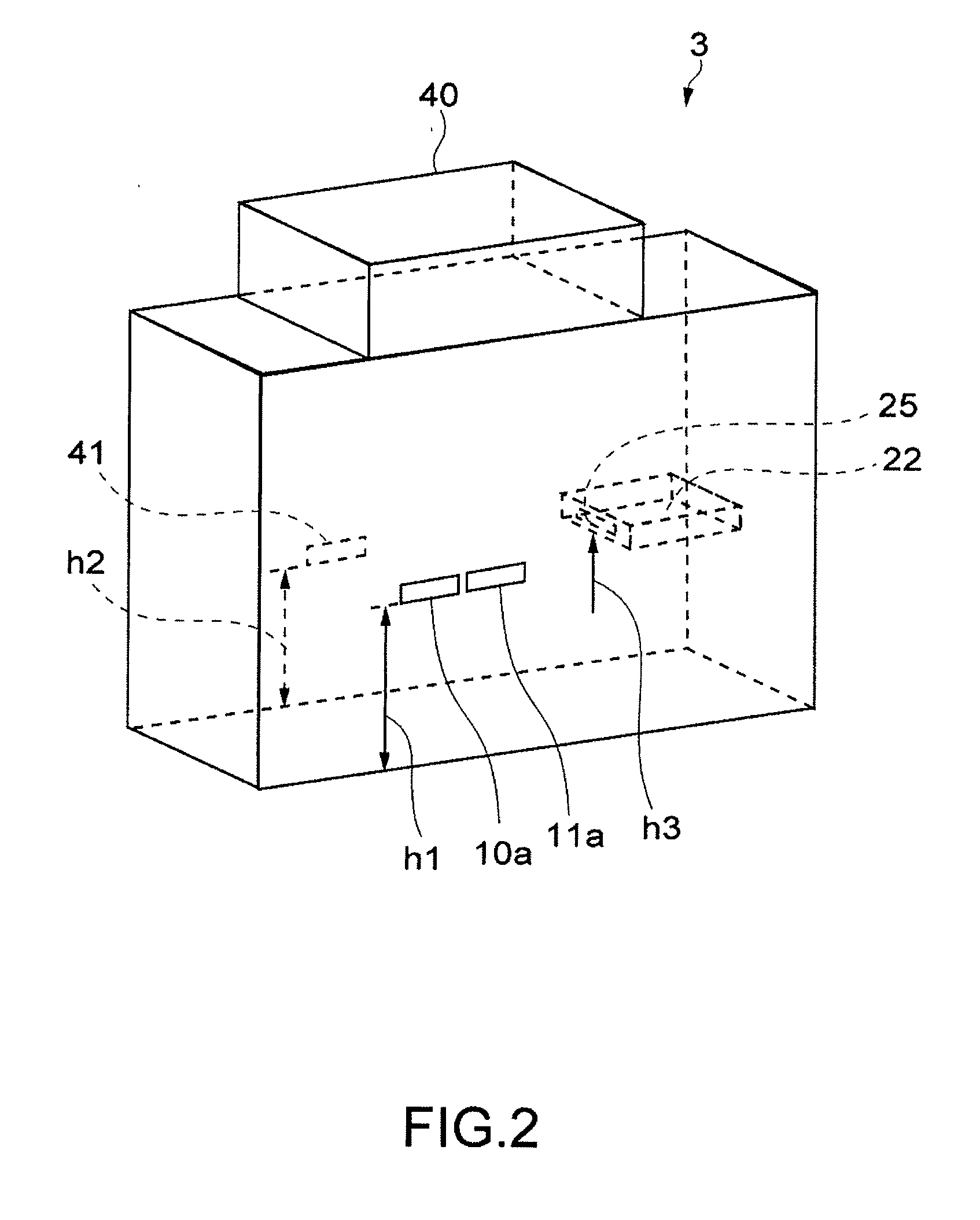

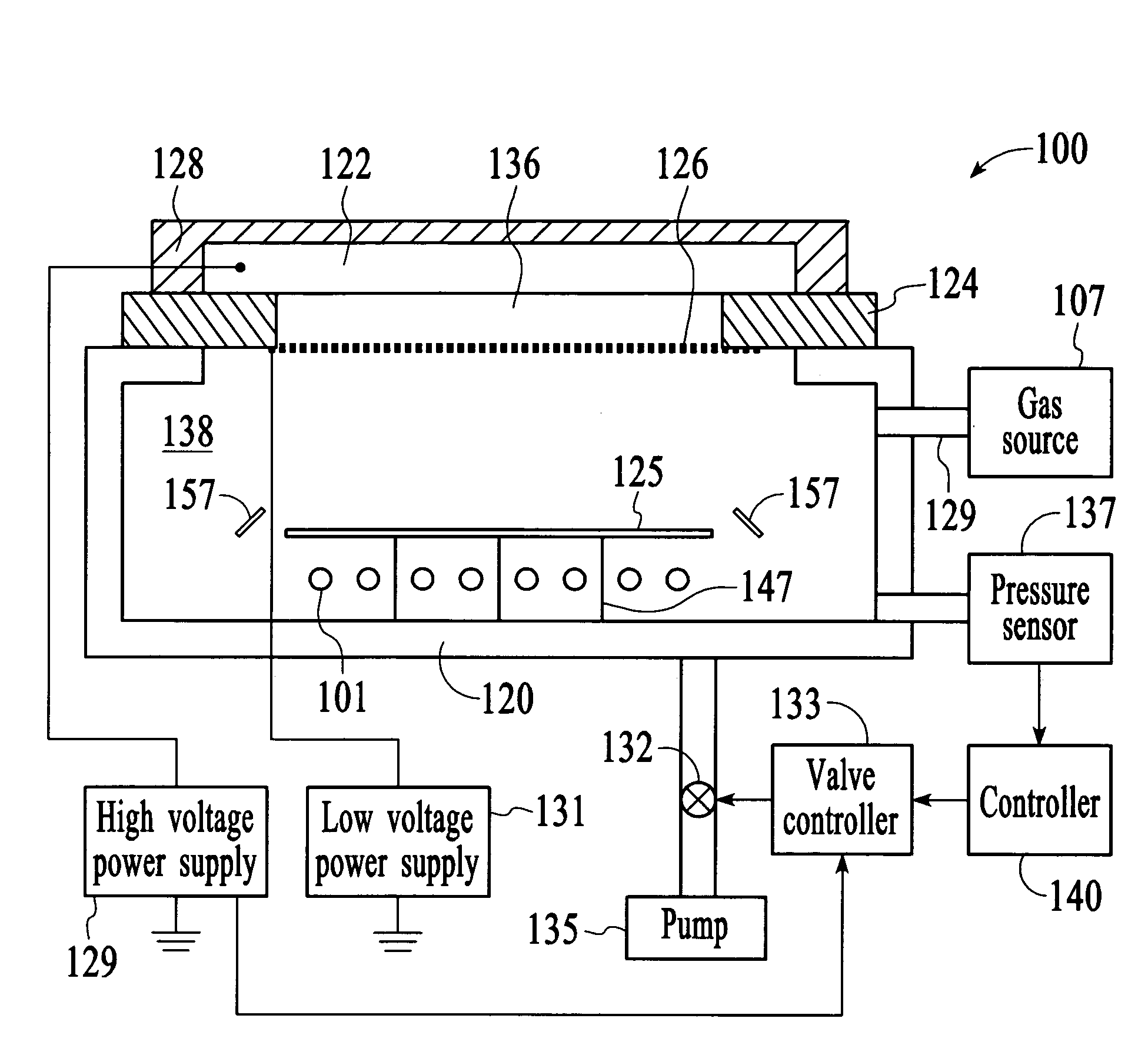

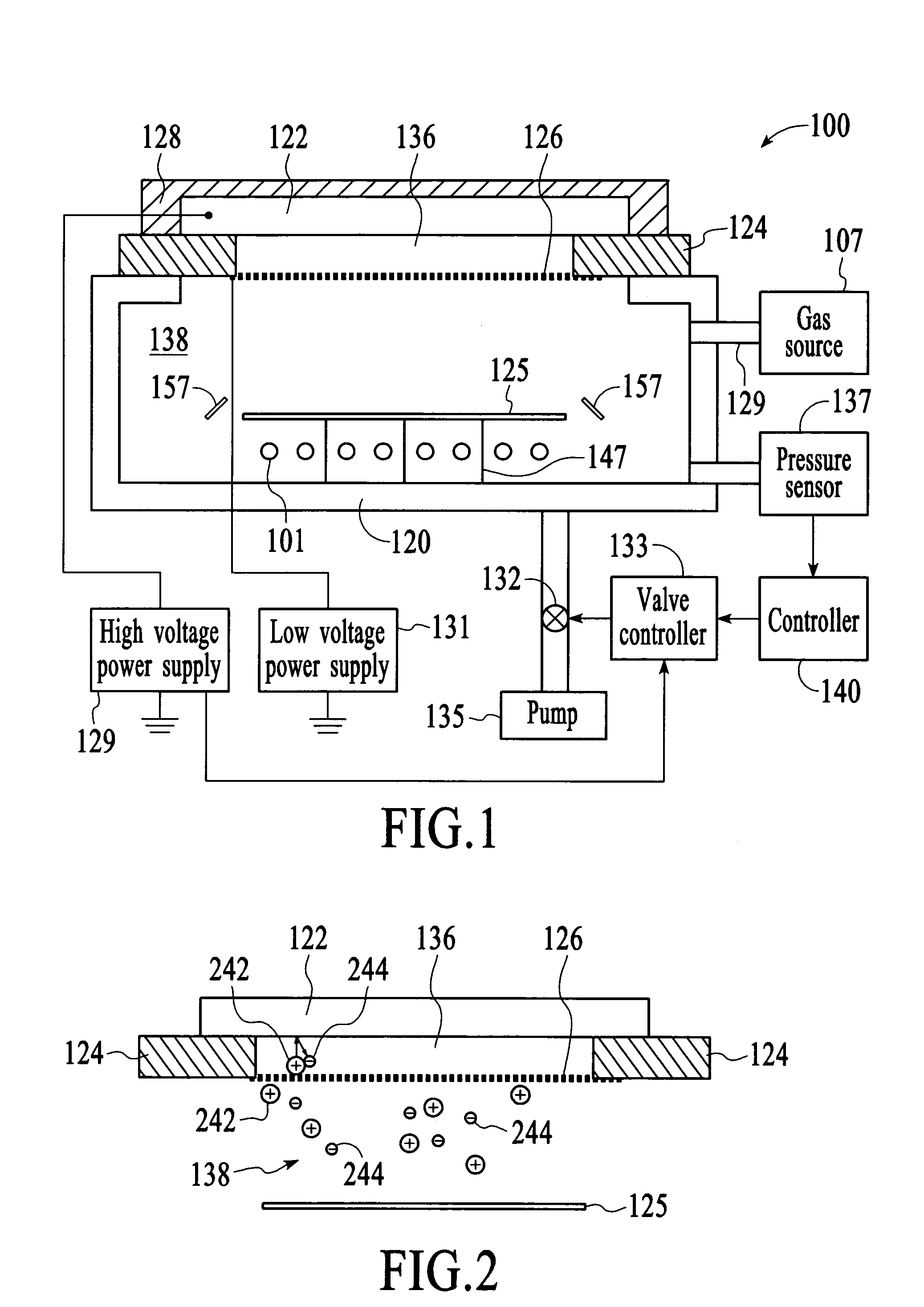

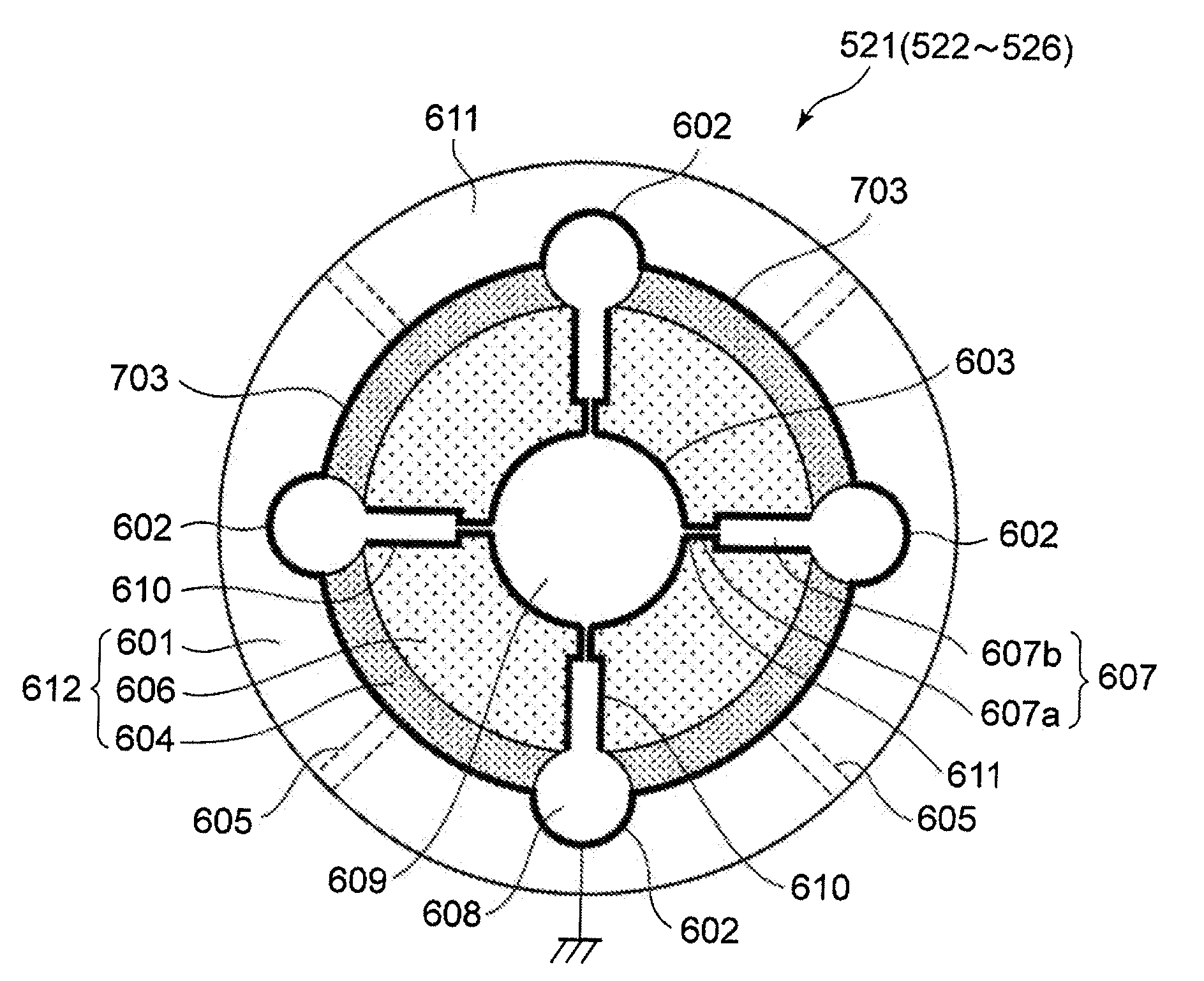

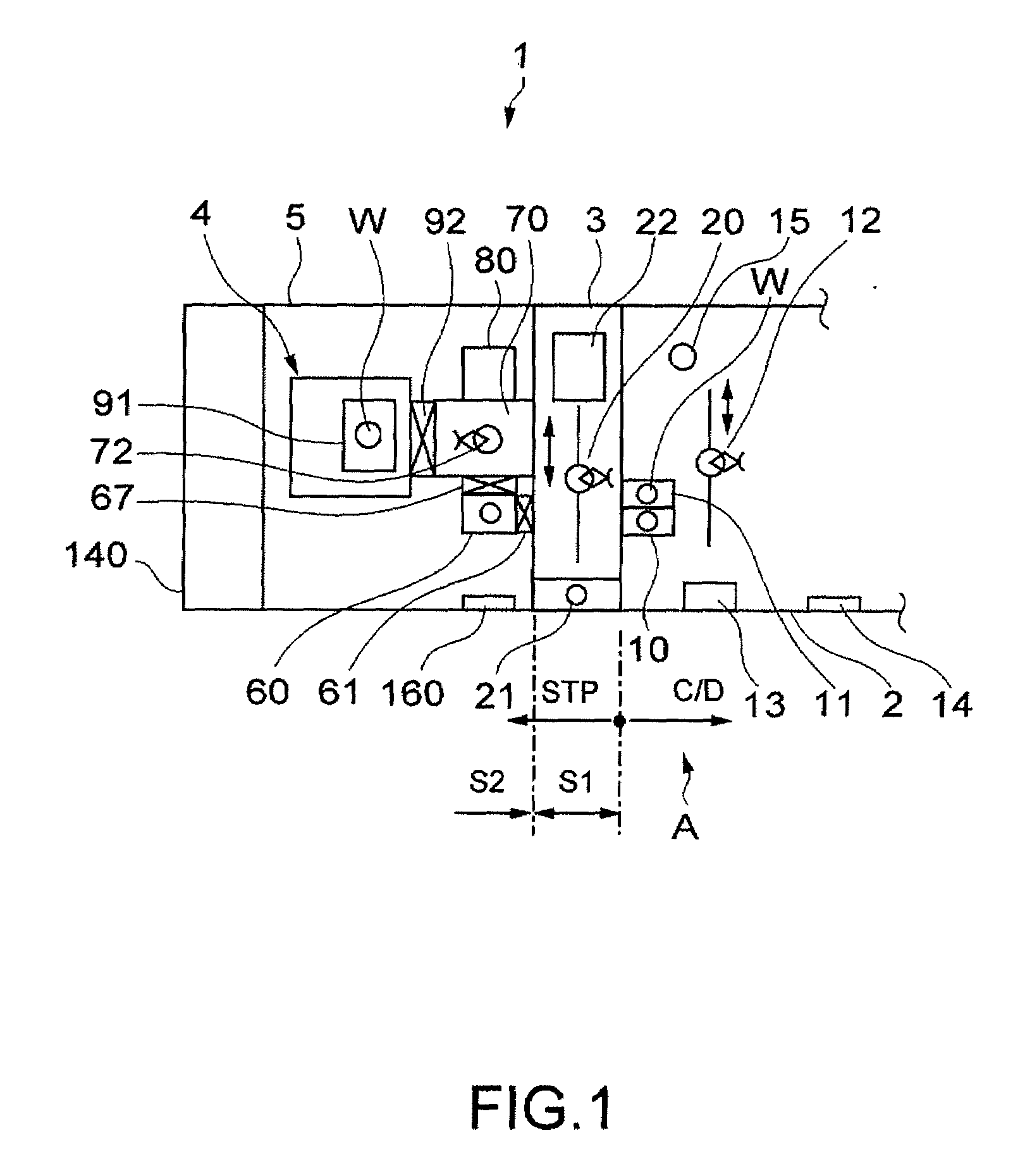

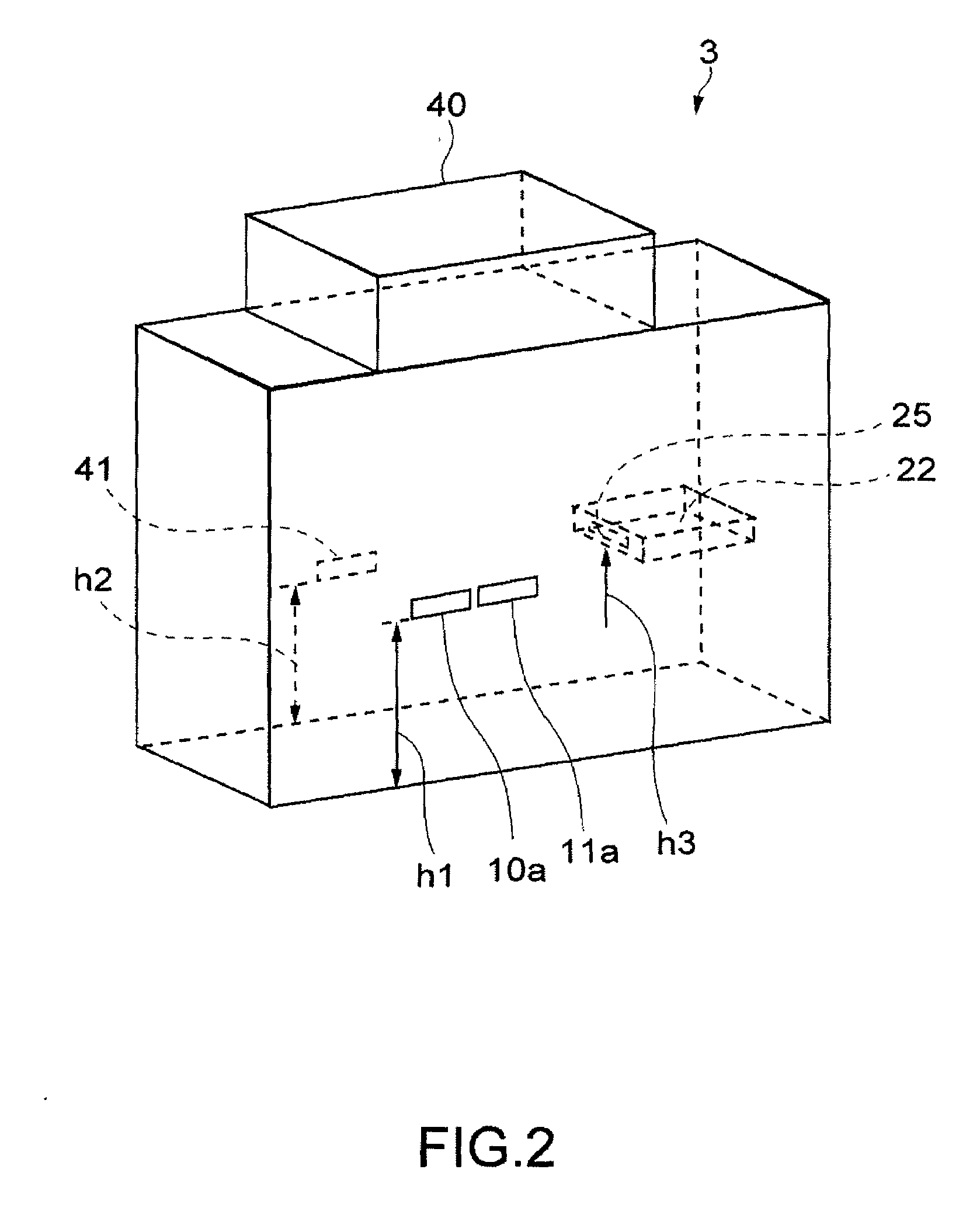

Static electricity deflecting device, electron beam irradiating apparatus, substrate processing apparatus, substrate processing method and method of manufacturing substrate

InactiveUS20070228275A1Occurrence is suppressedImprove accuracyMaterial analysis using wave/particle radiationElectric discharge tubesAtomic physicsStatic electricity

A substrate processing apparatus which irradiates a substrate under processing with an electron beam and processes the substrate with the electron beam is disclosed. The substrate processing apparatus includes an electron beam generation mechanism which generates the electron beam, first area having a plurality of first static electricity deflecting devices whose thicknesses gradually increase in a traveling direction of the electron beam, and a second area disposed on a downstream side of the electron beam of the first area and having a plurality of second static electricity deflecting devices whose thicknesses are nearly same in the traveling direction of the electron beam. The substrate processing apparatus may further include a plurality of lenses whose thicknesses gradually decrease in the traveling direction of the electron beam, at least one of the plurality of lenses being disposed in each of the first area and the second area.

Owner:TOKYO ELECTRON LTD

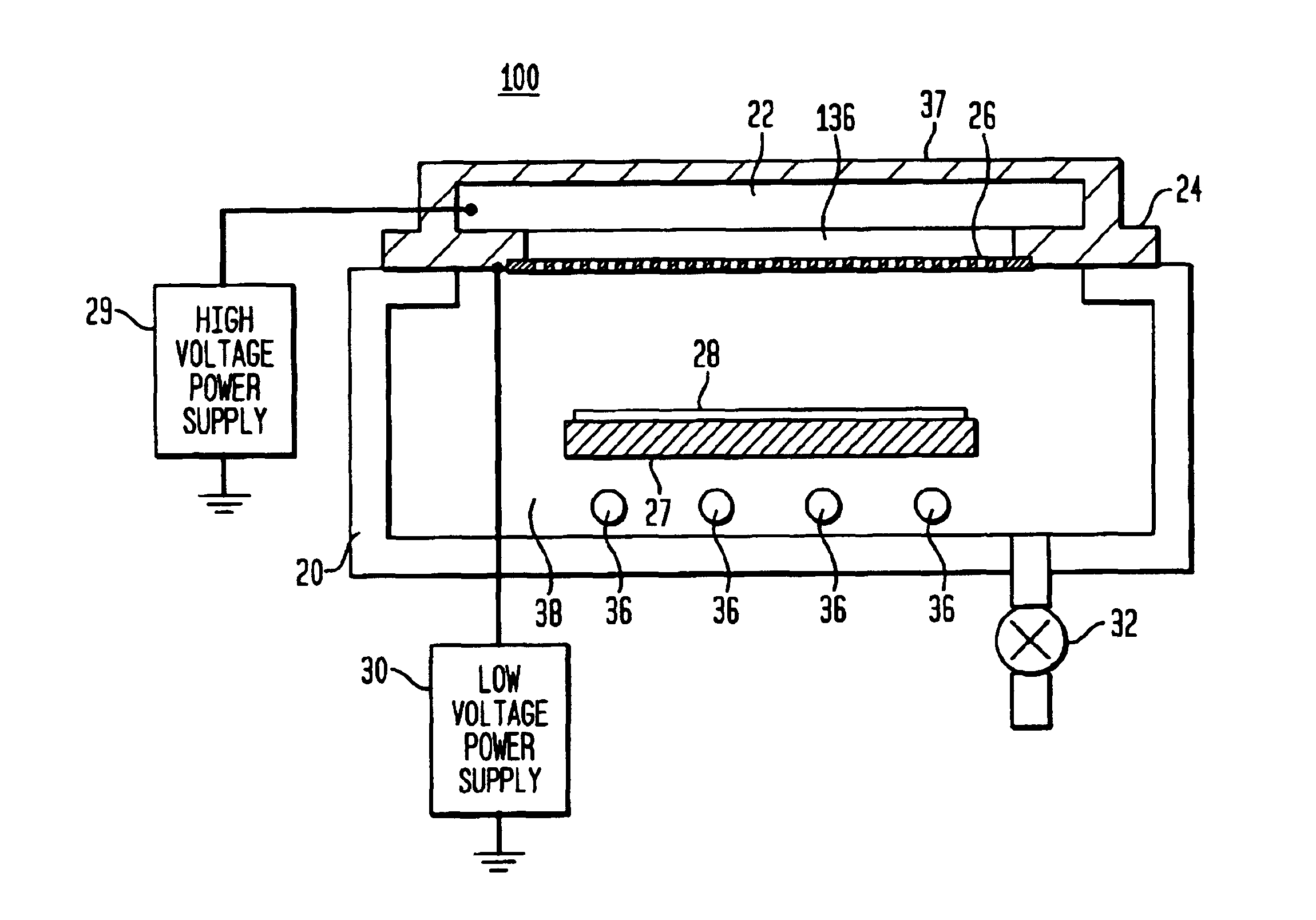

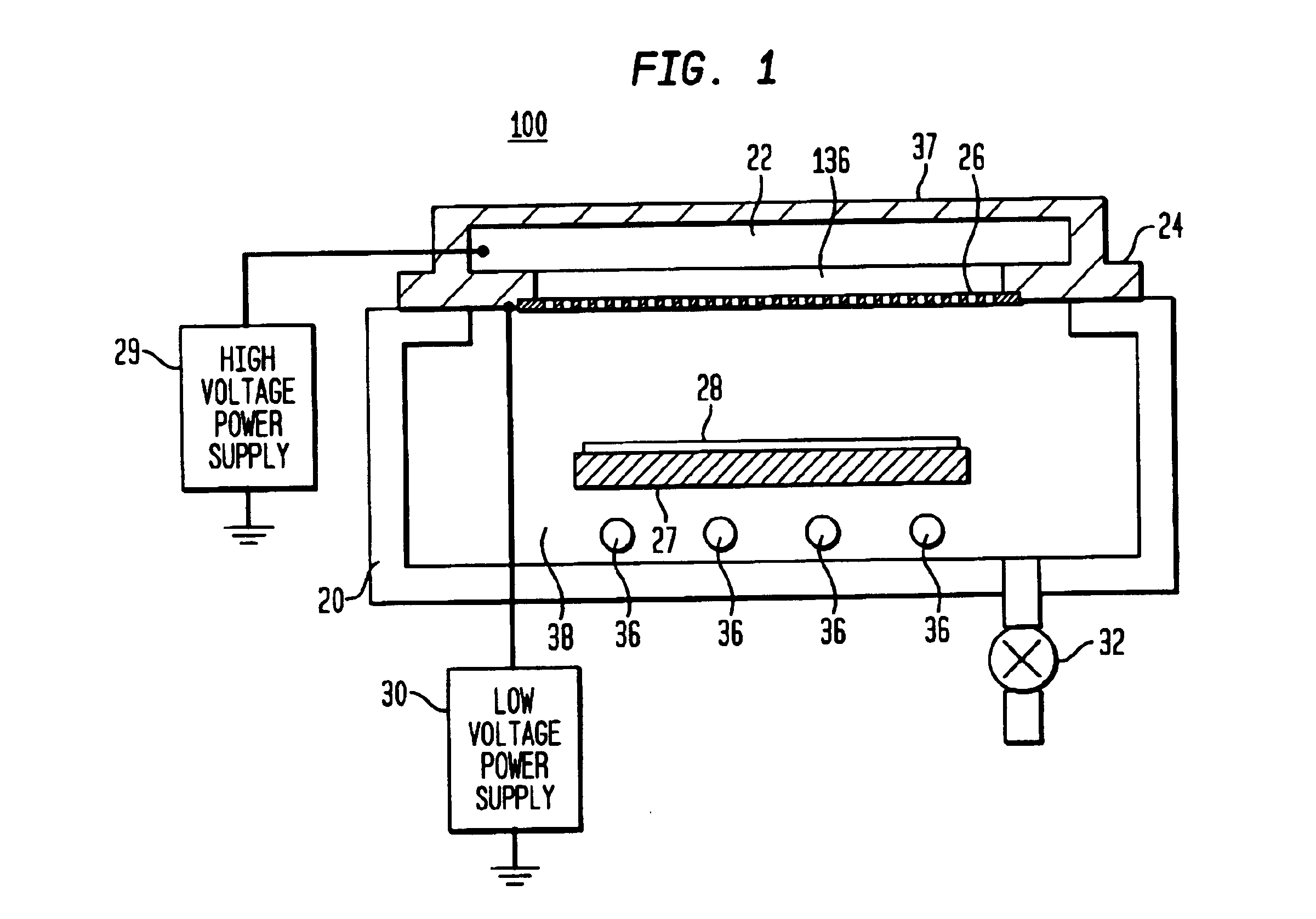

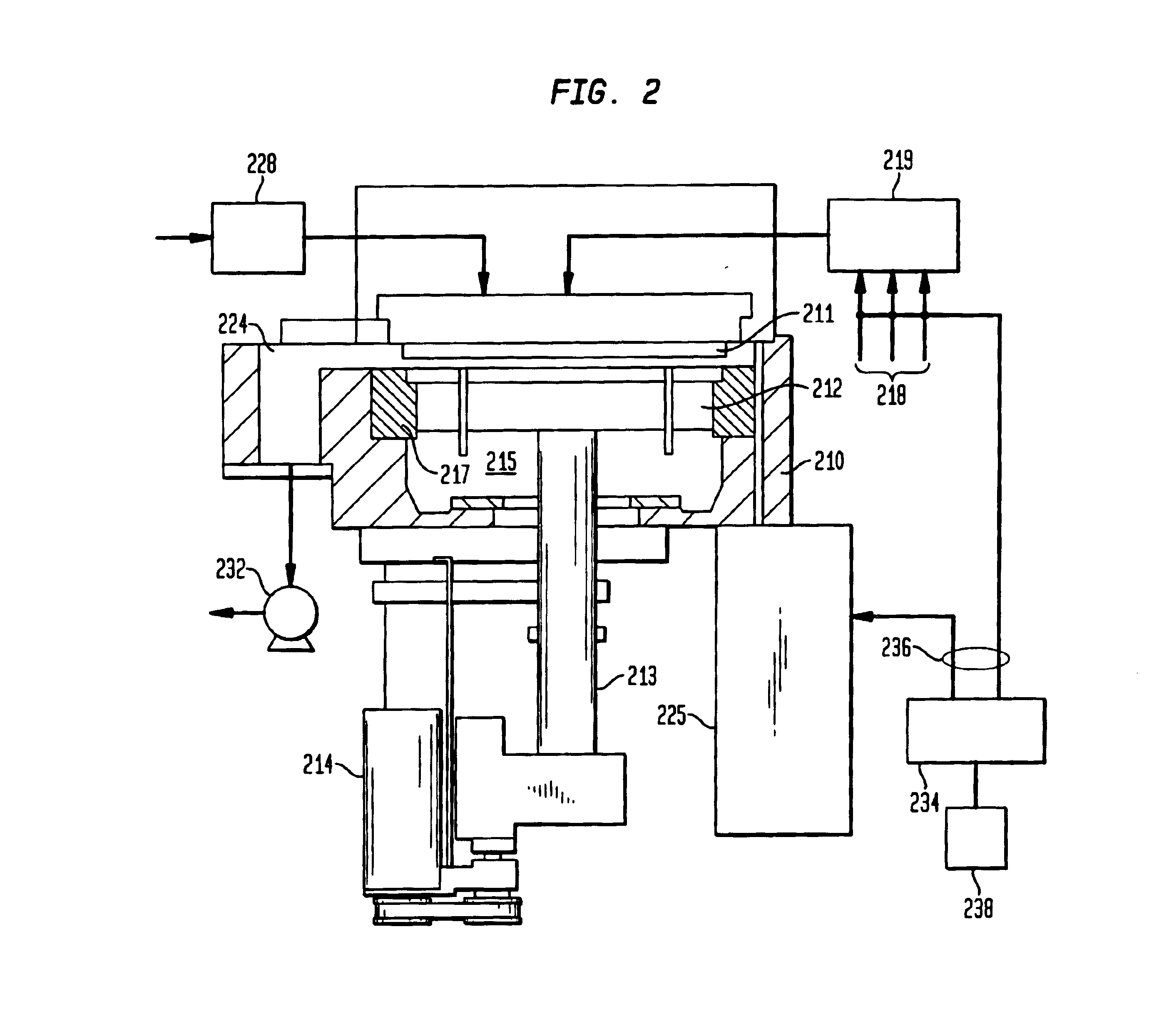

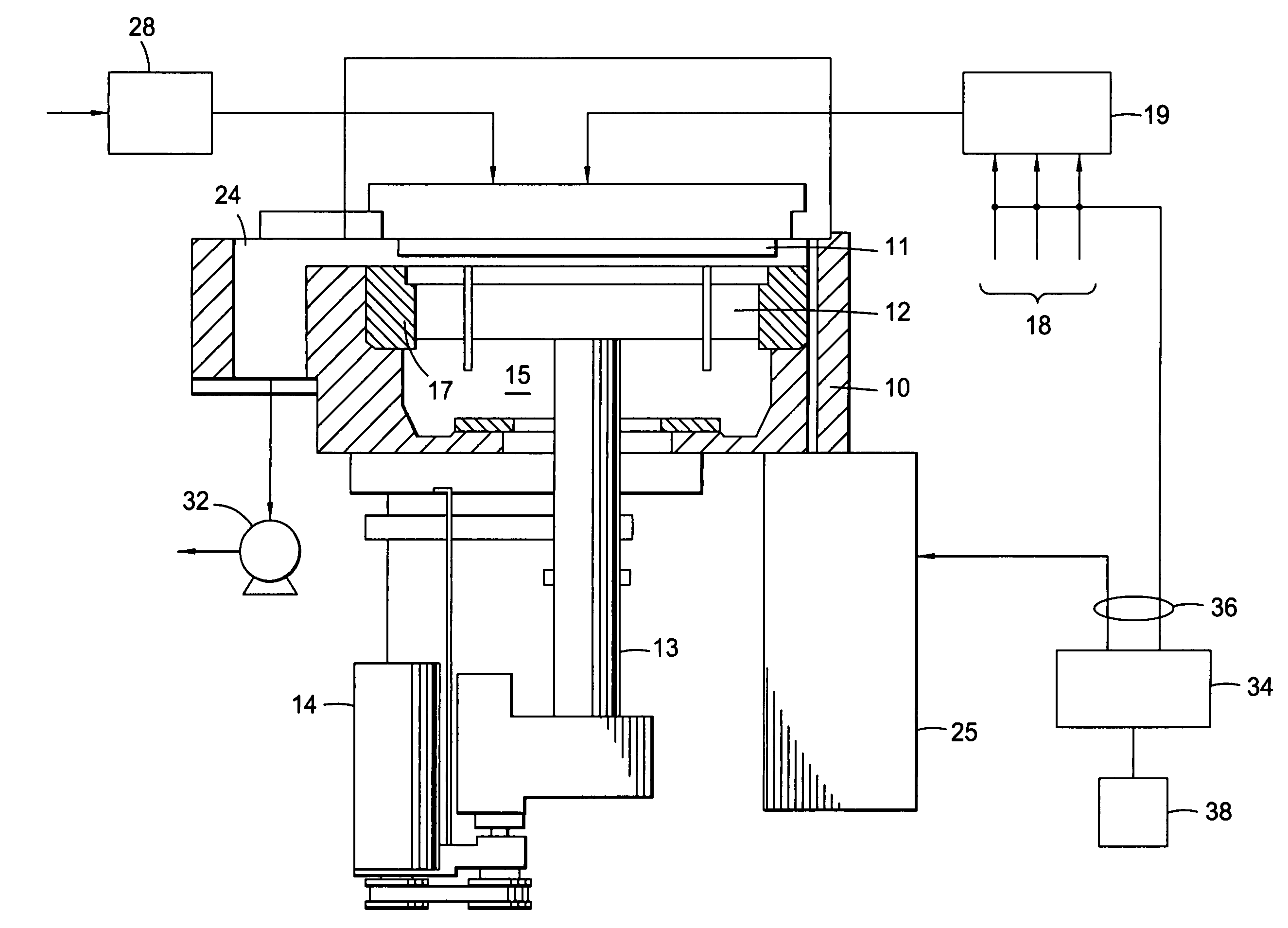

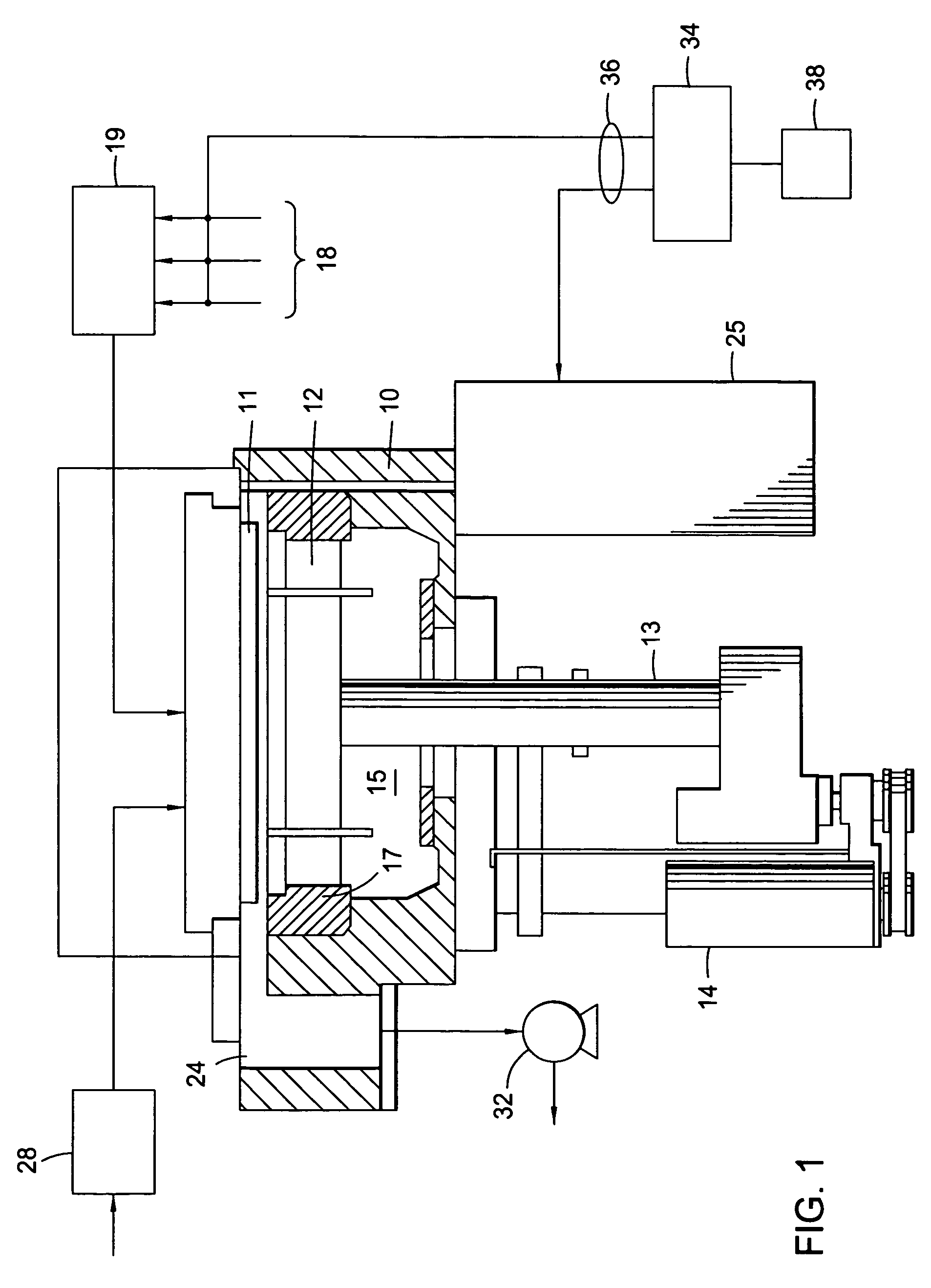

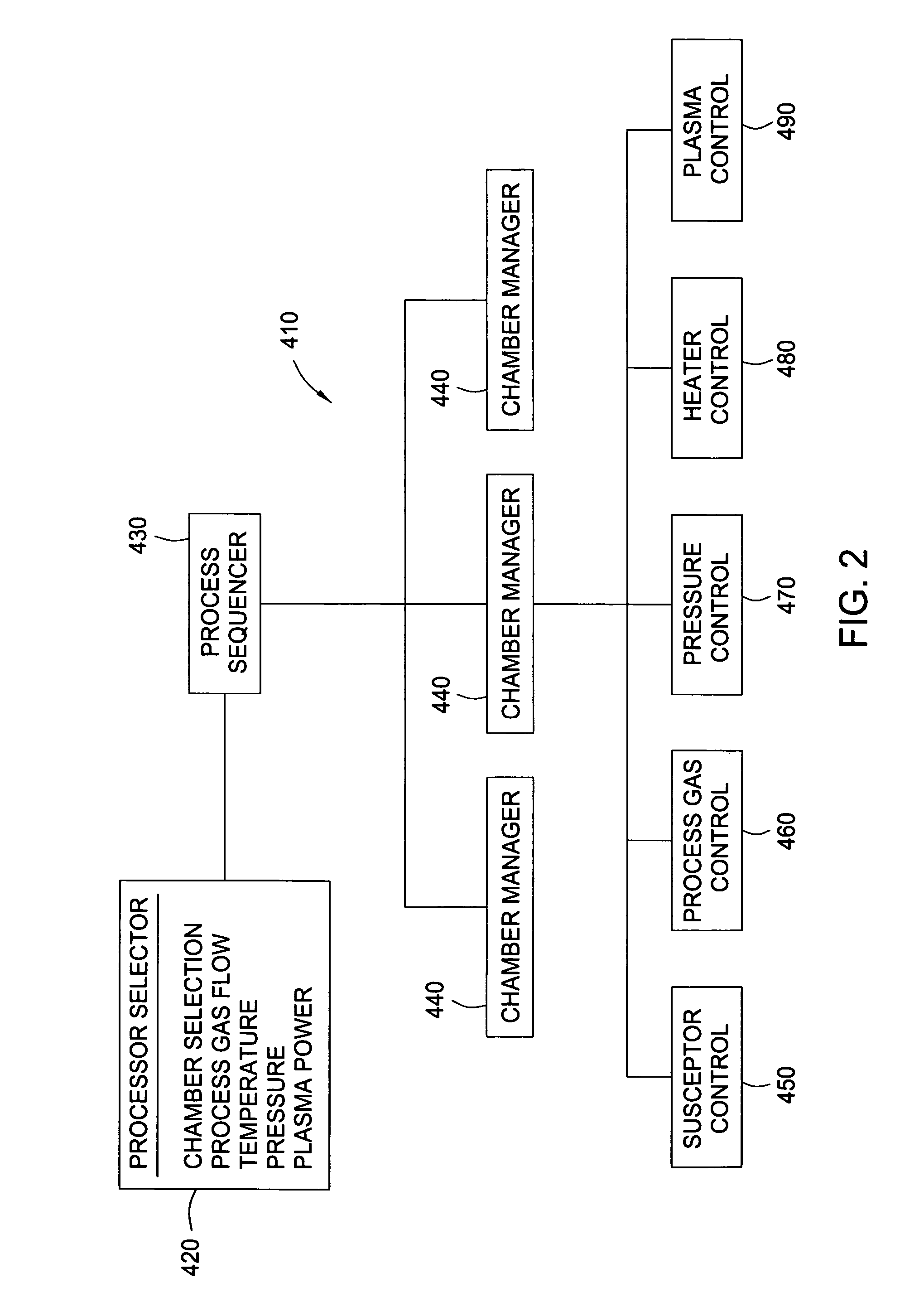

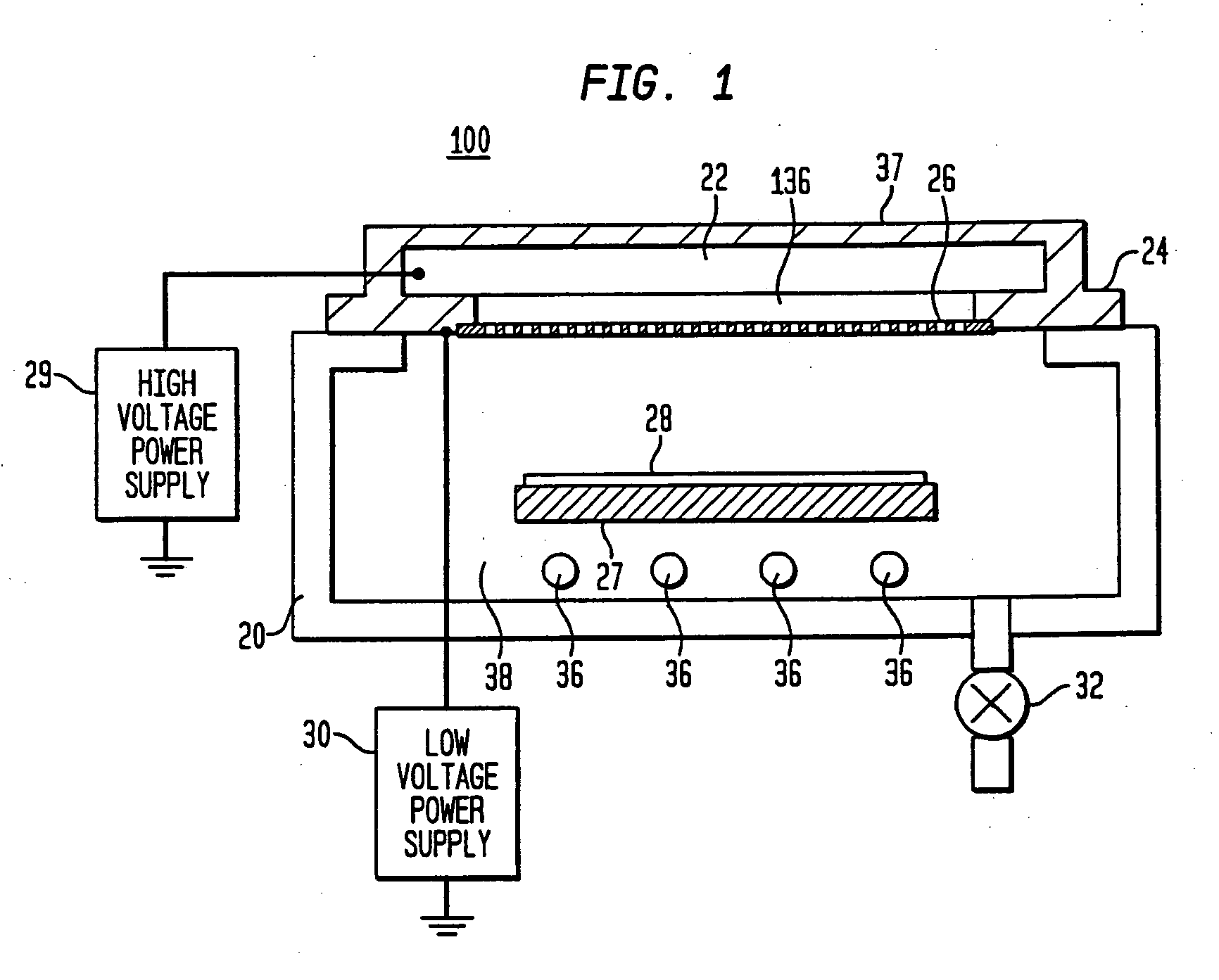

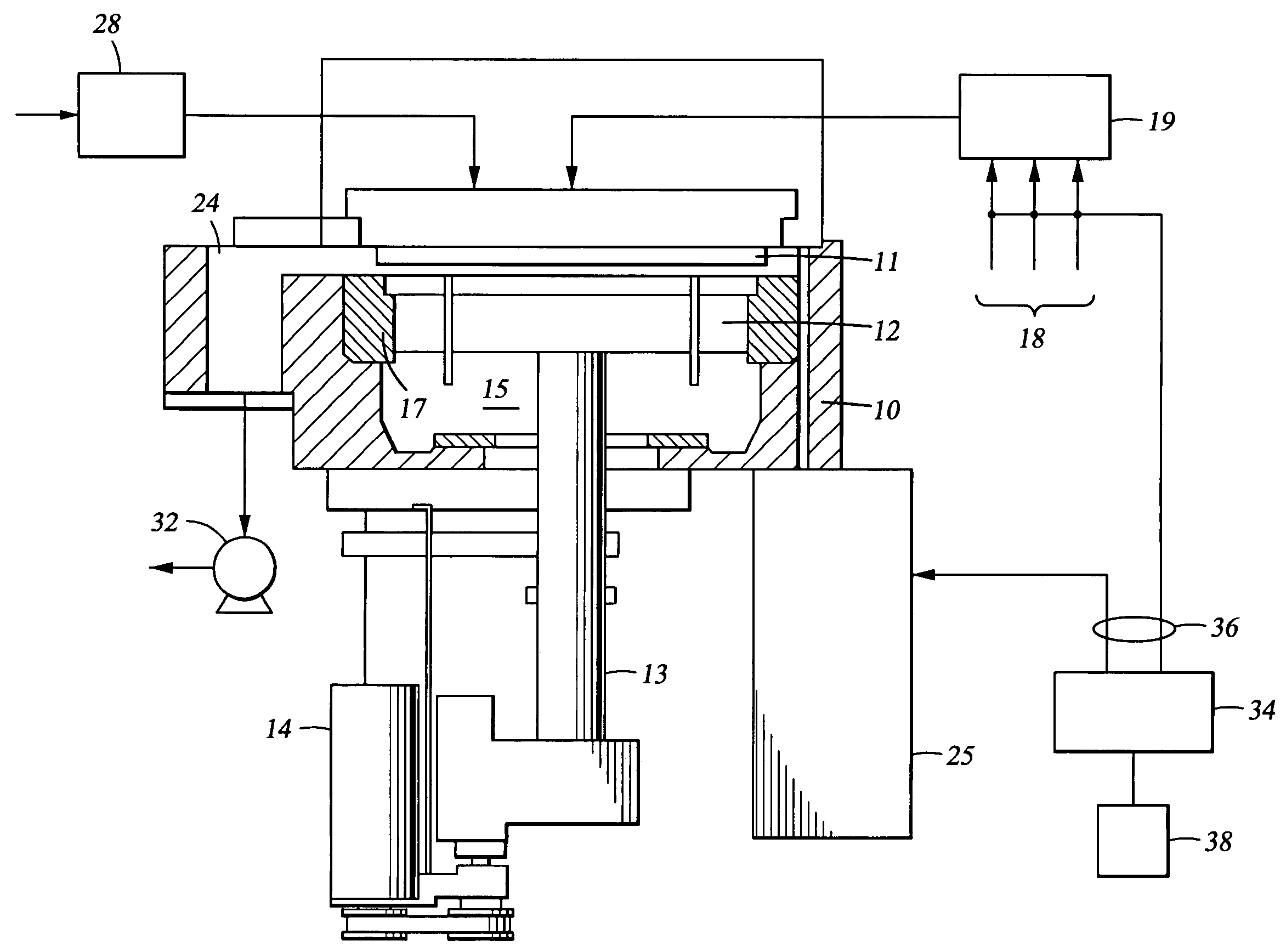

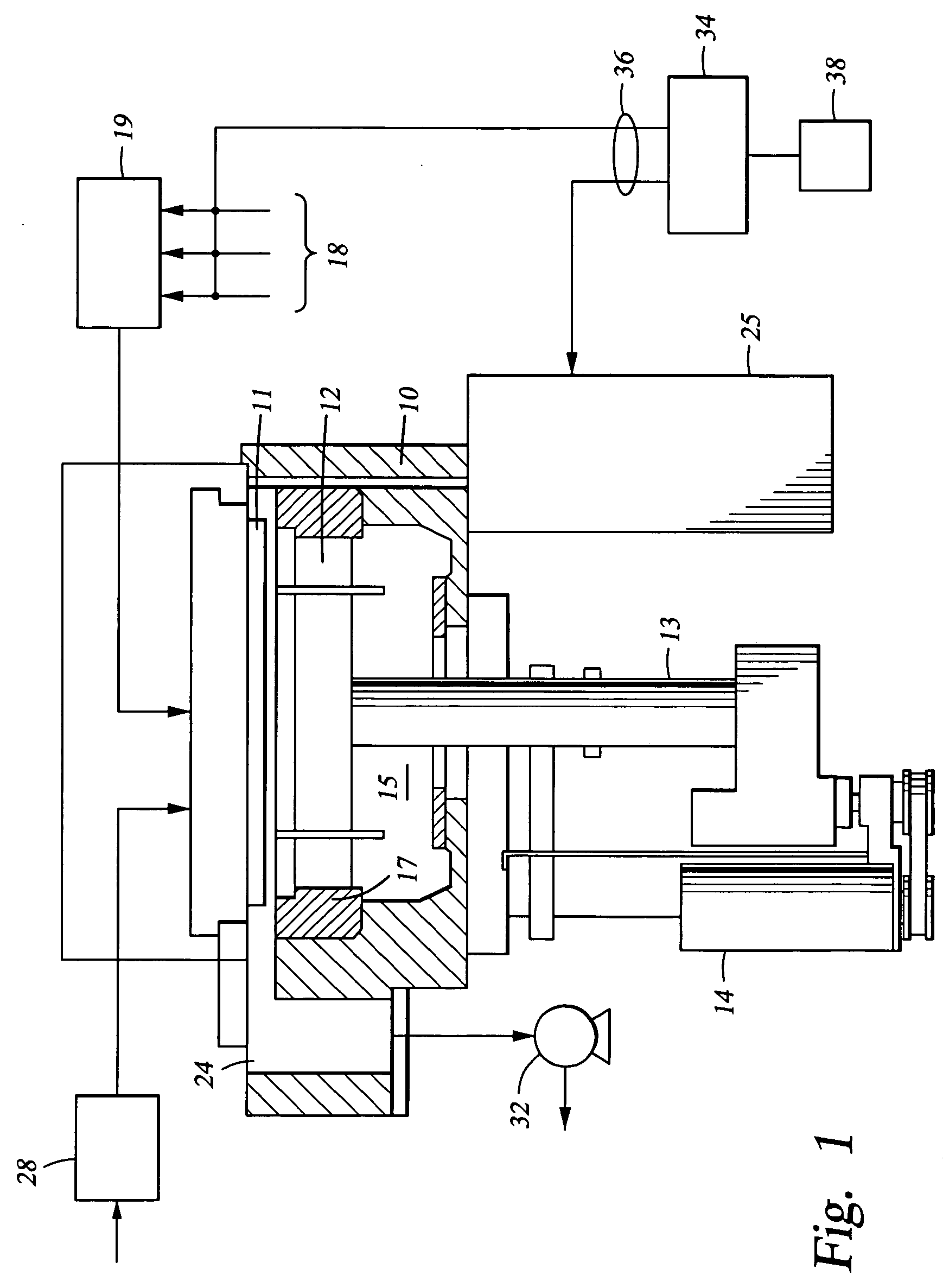

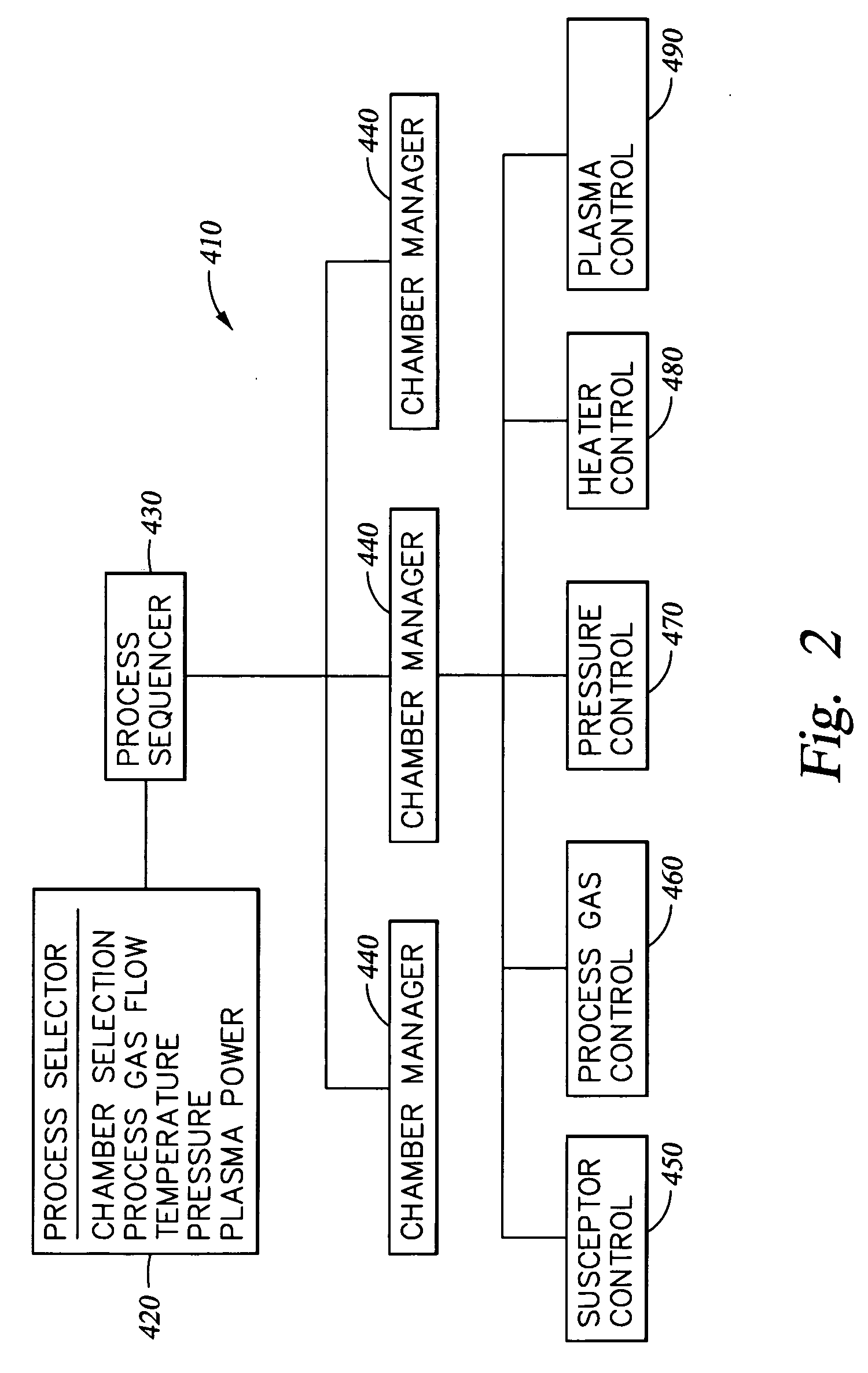

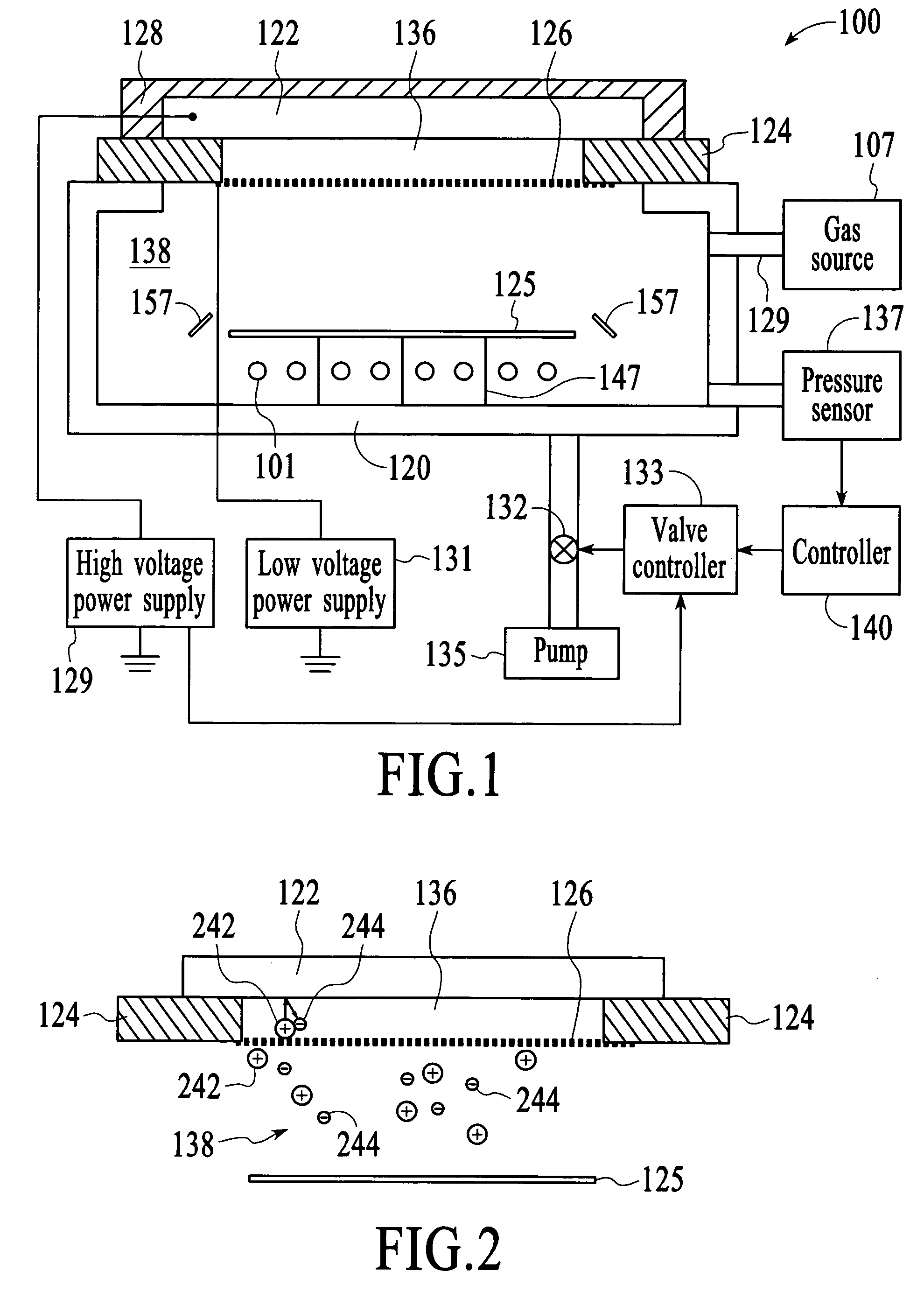

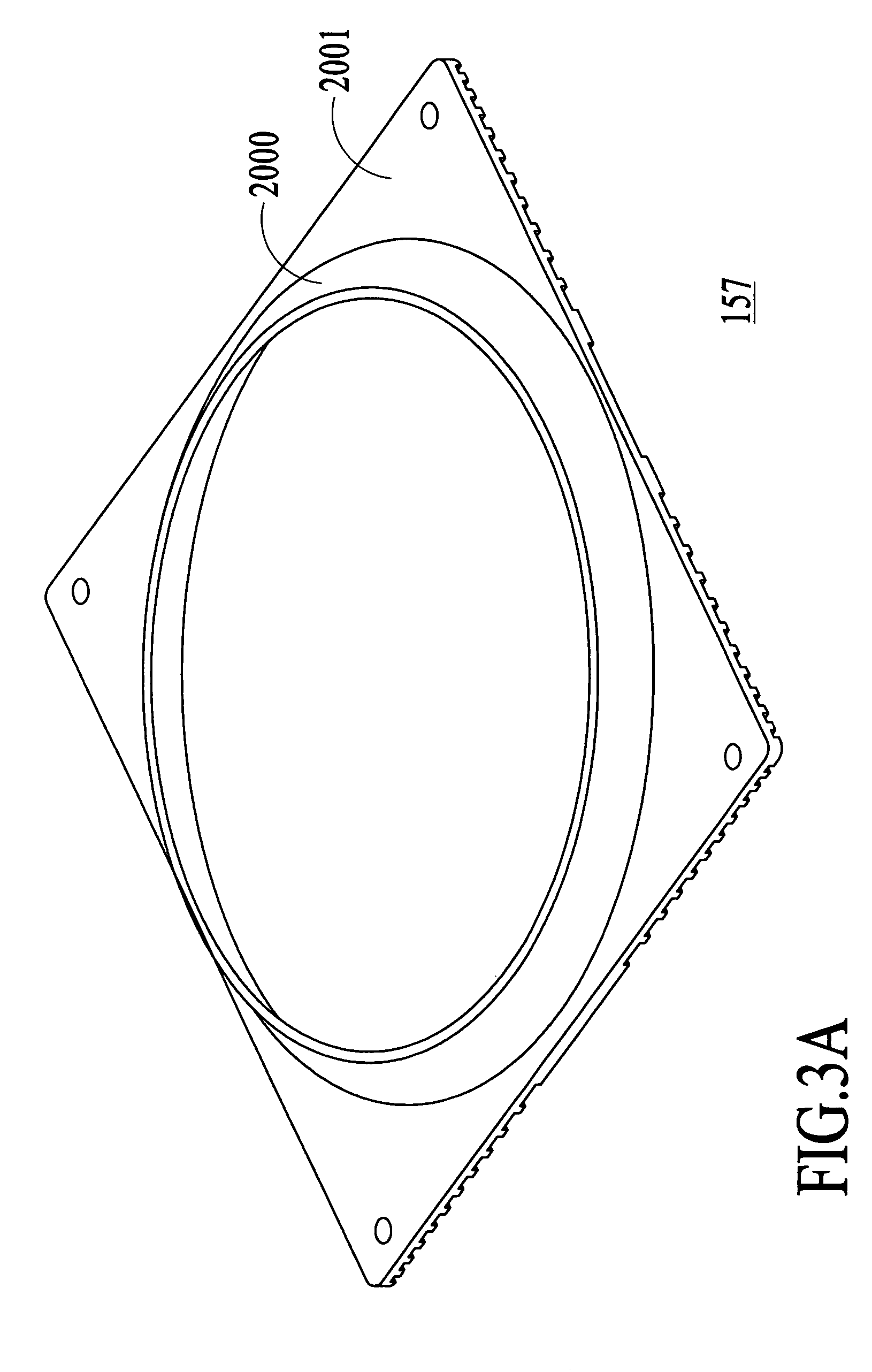

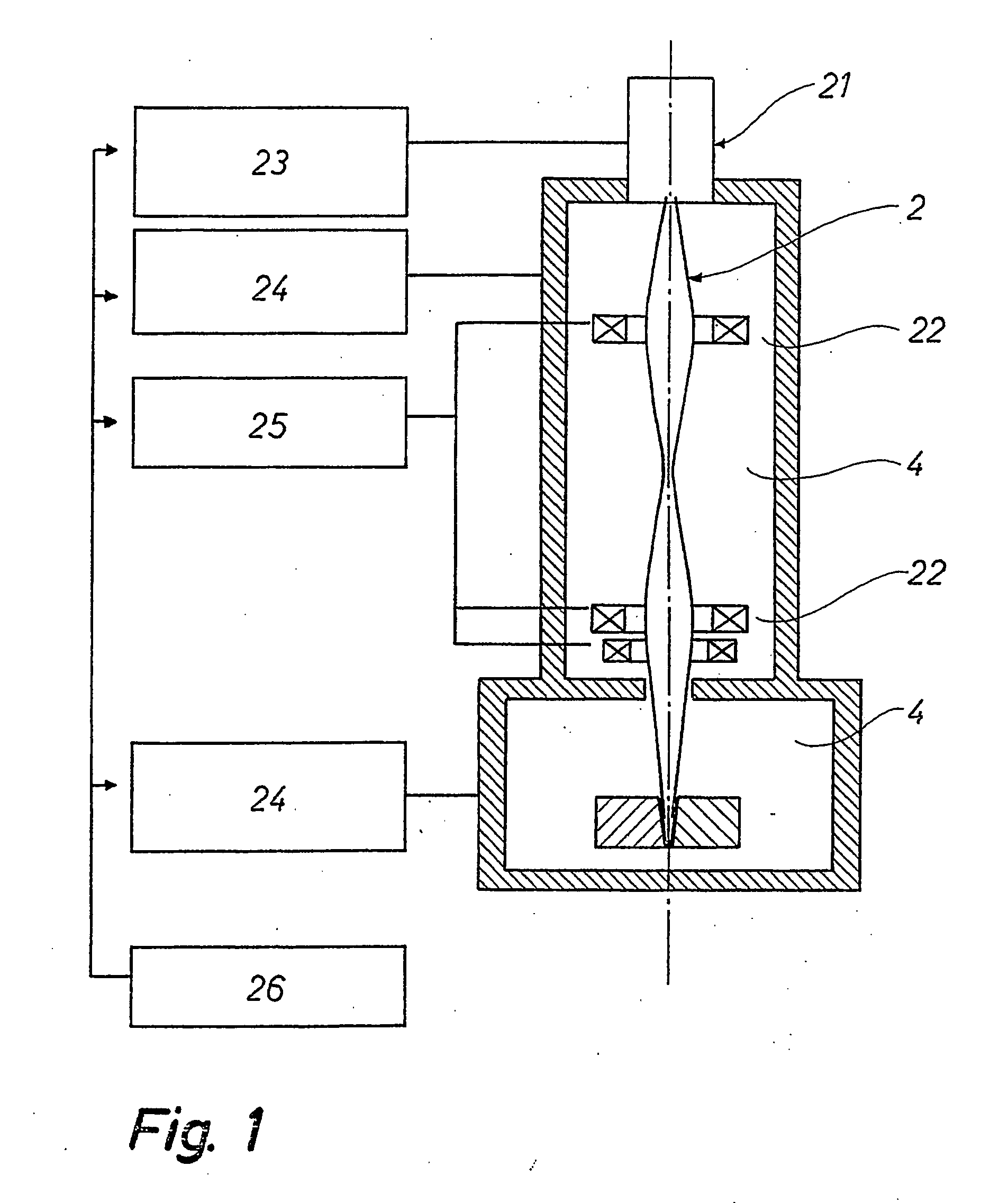

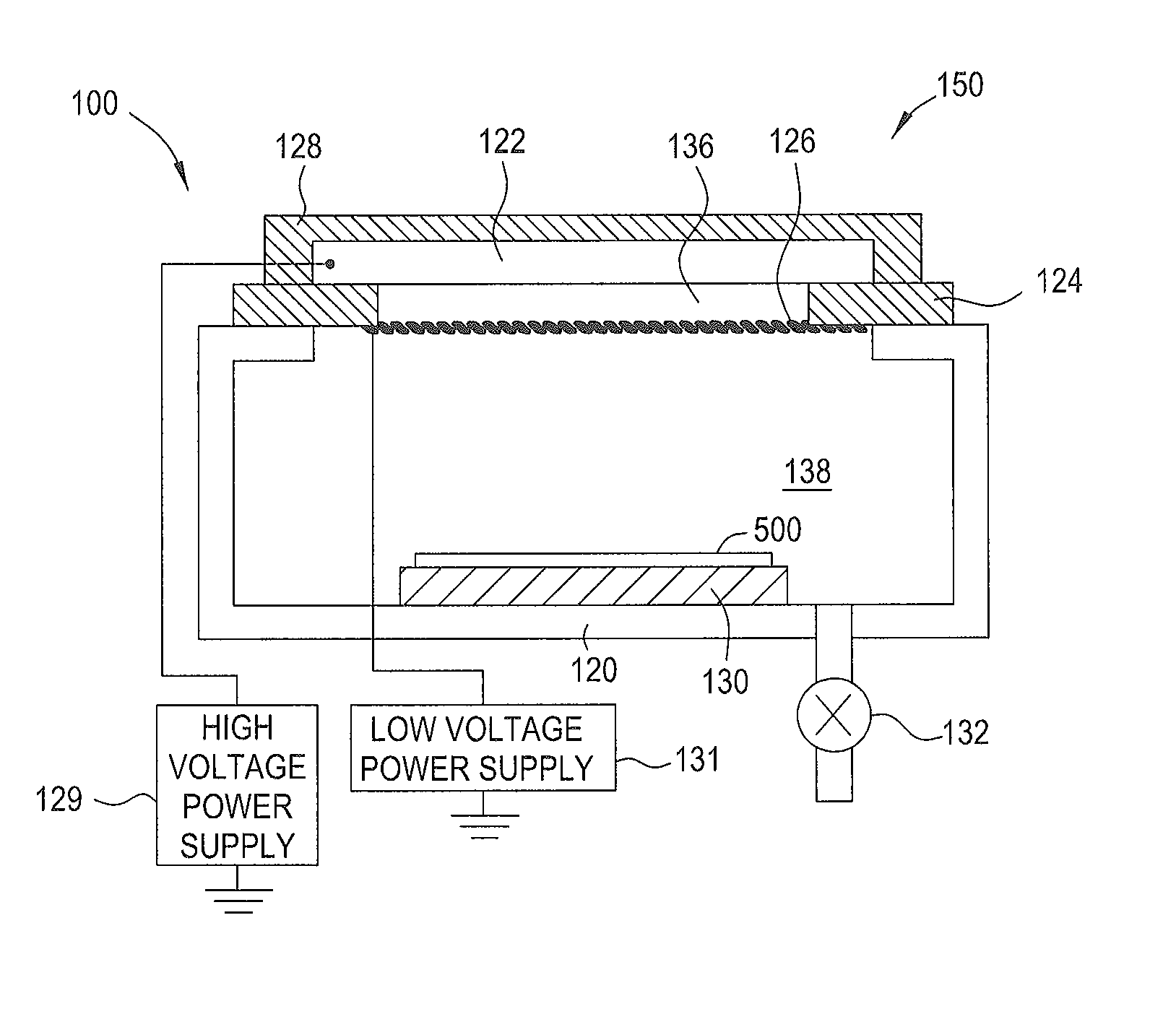

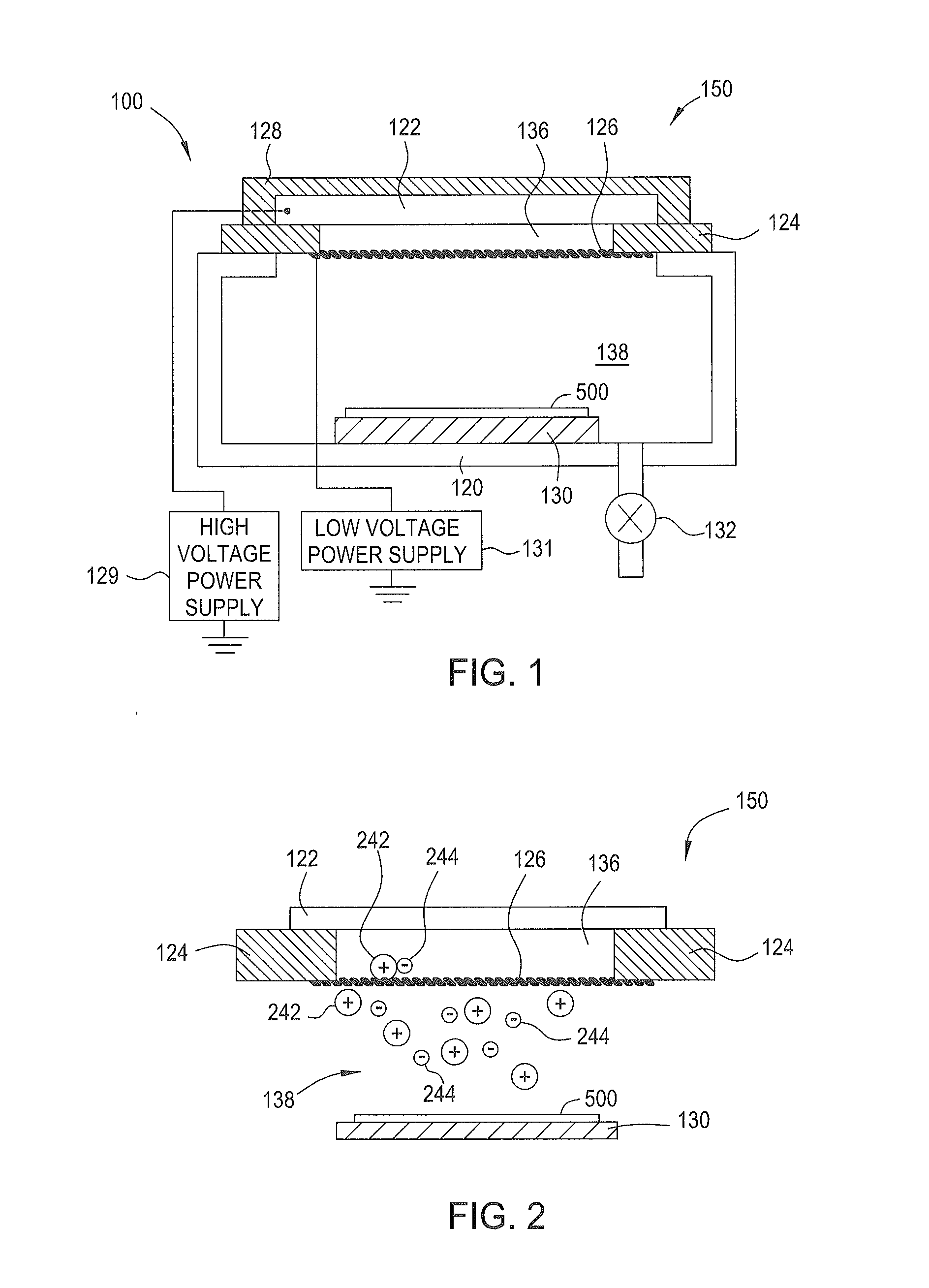

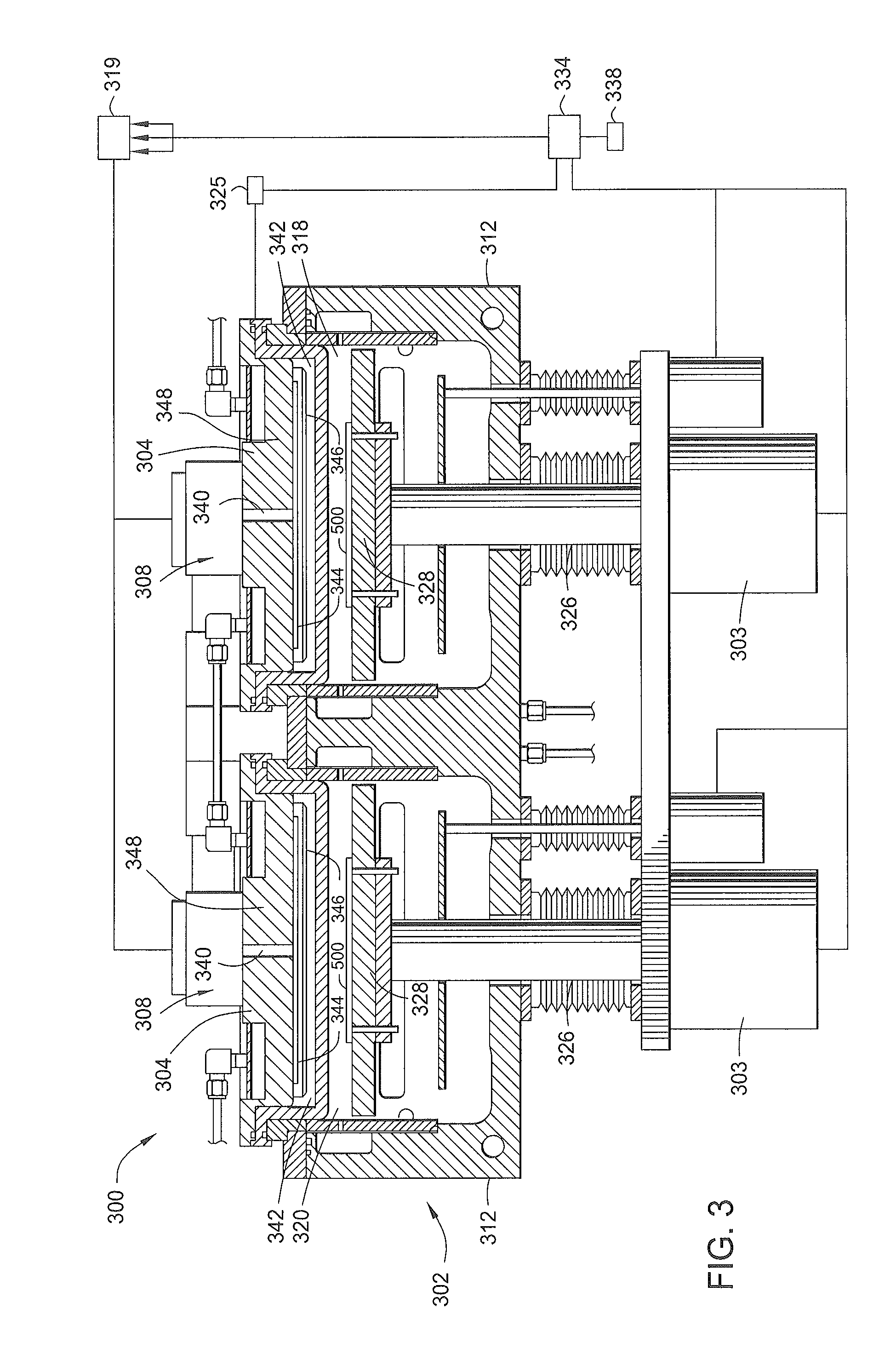

Vacuum reaction chamber with x-lamp heater

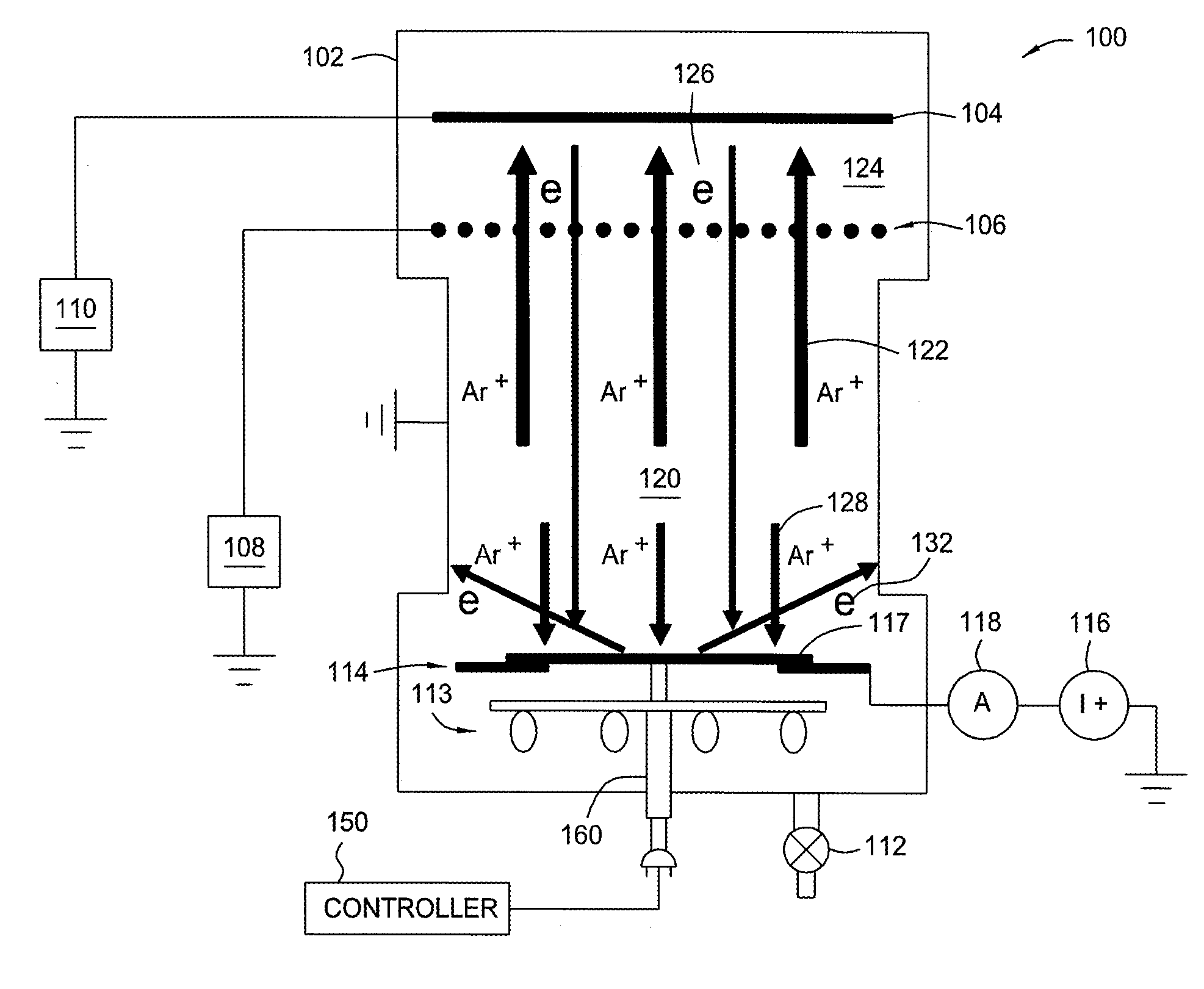

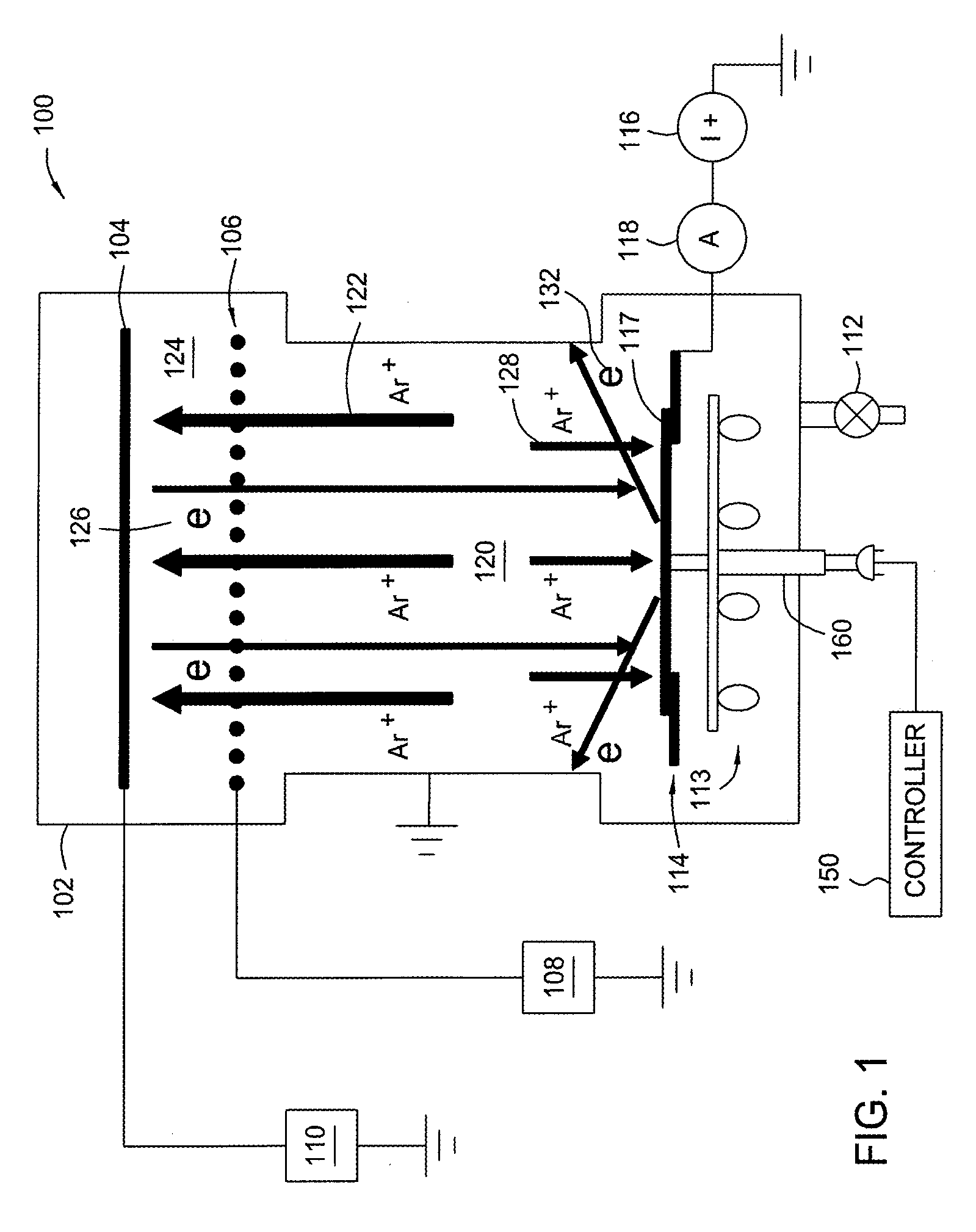

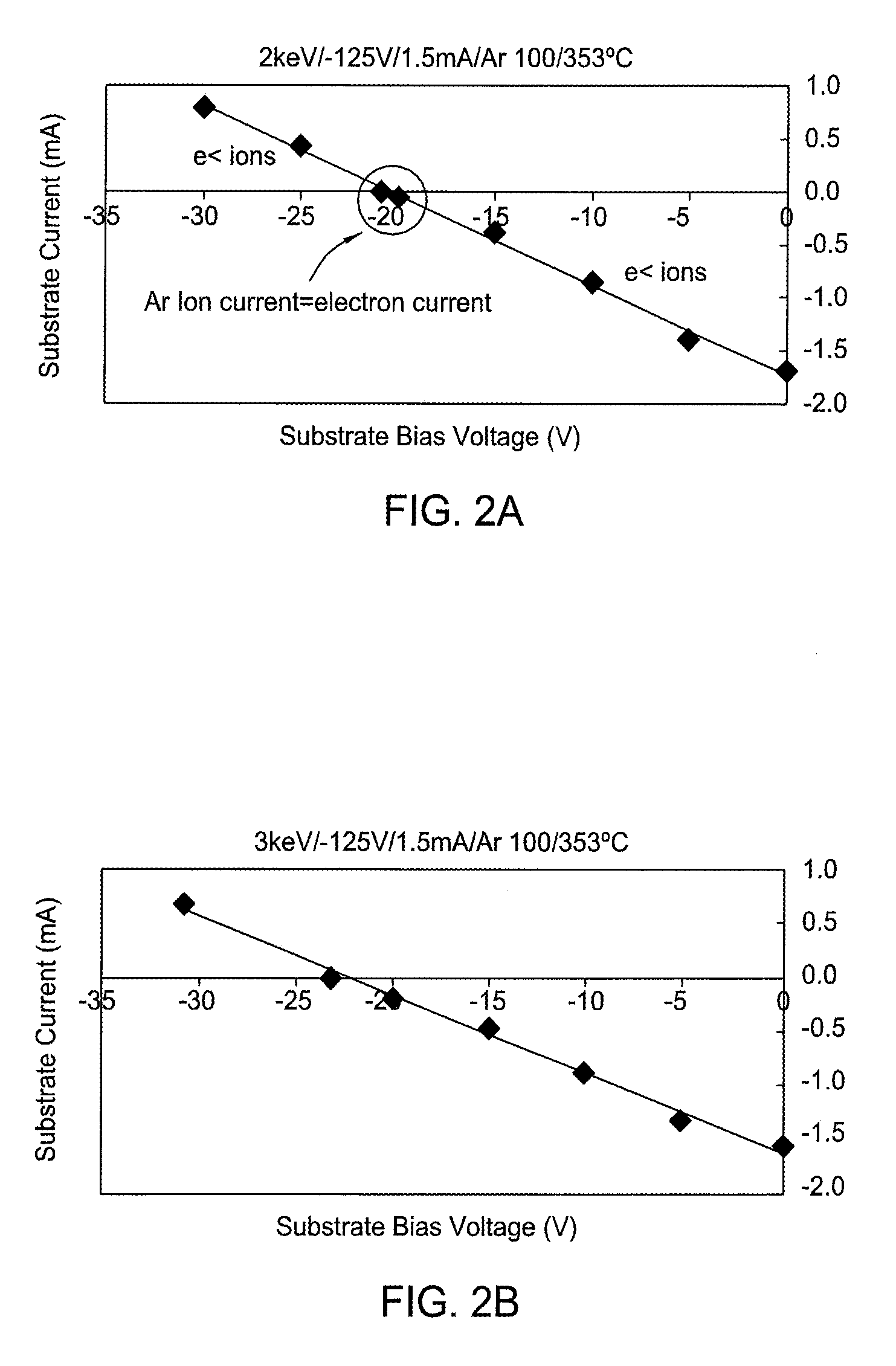

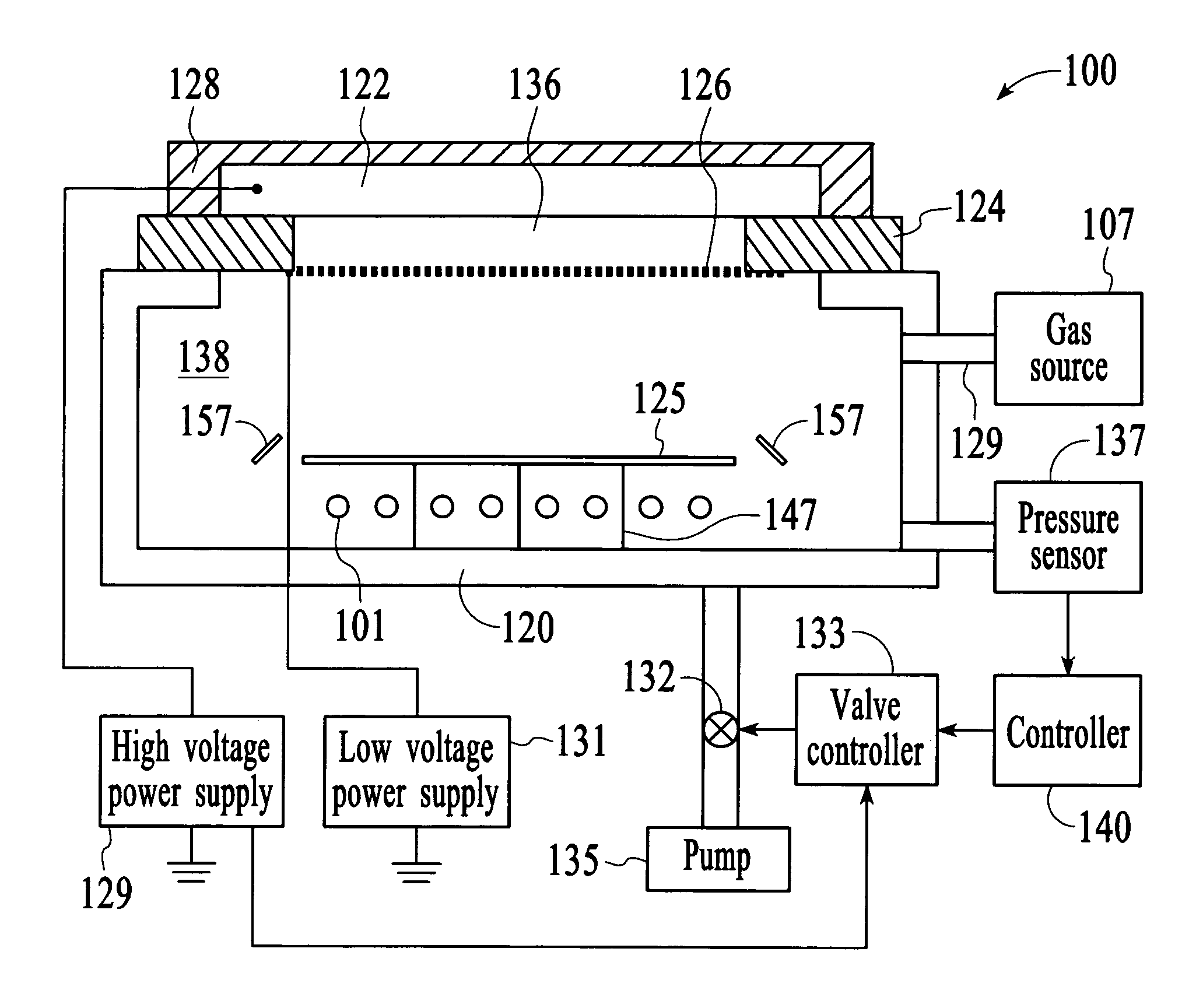

InactiveUS20060272772A1Reduce harmReduce chargeMaterial analysis using wave/particle radiationElectric discharge tubesElectron sourceLow voltage

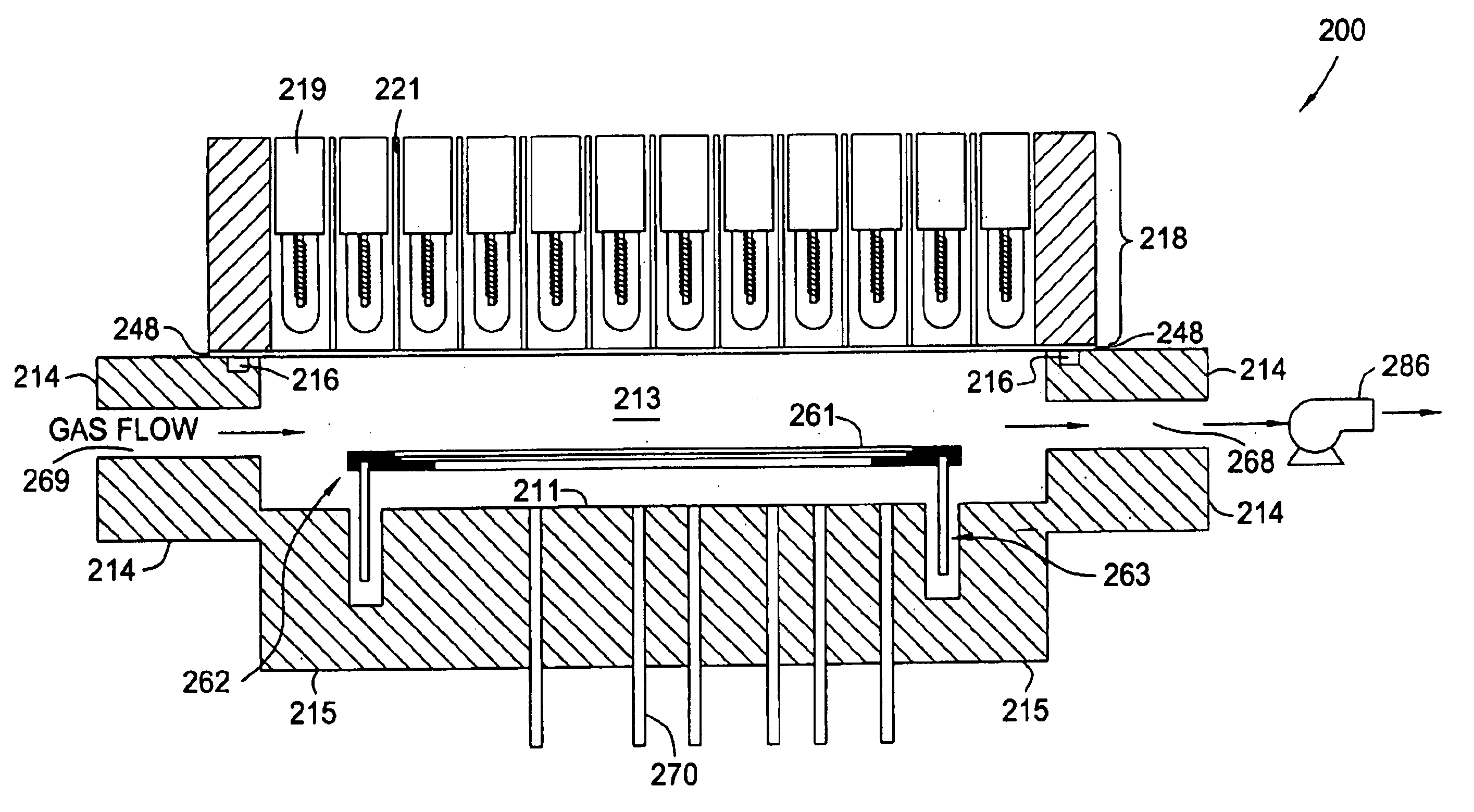

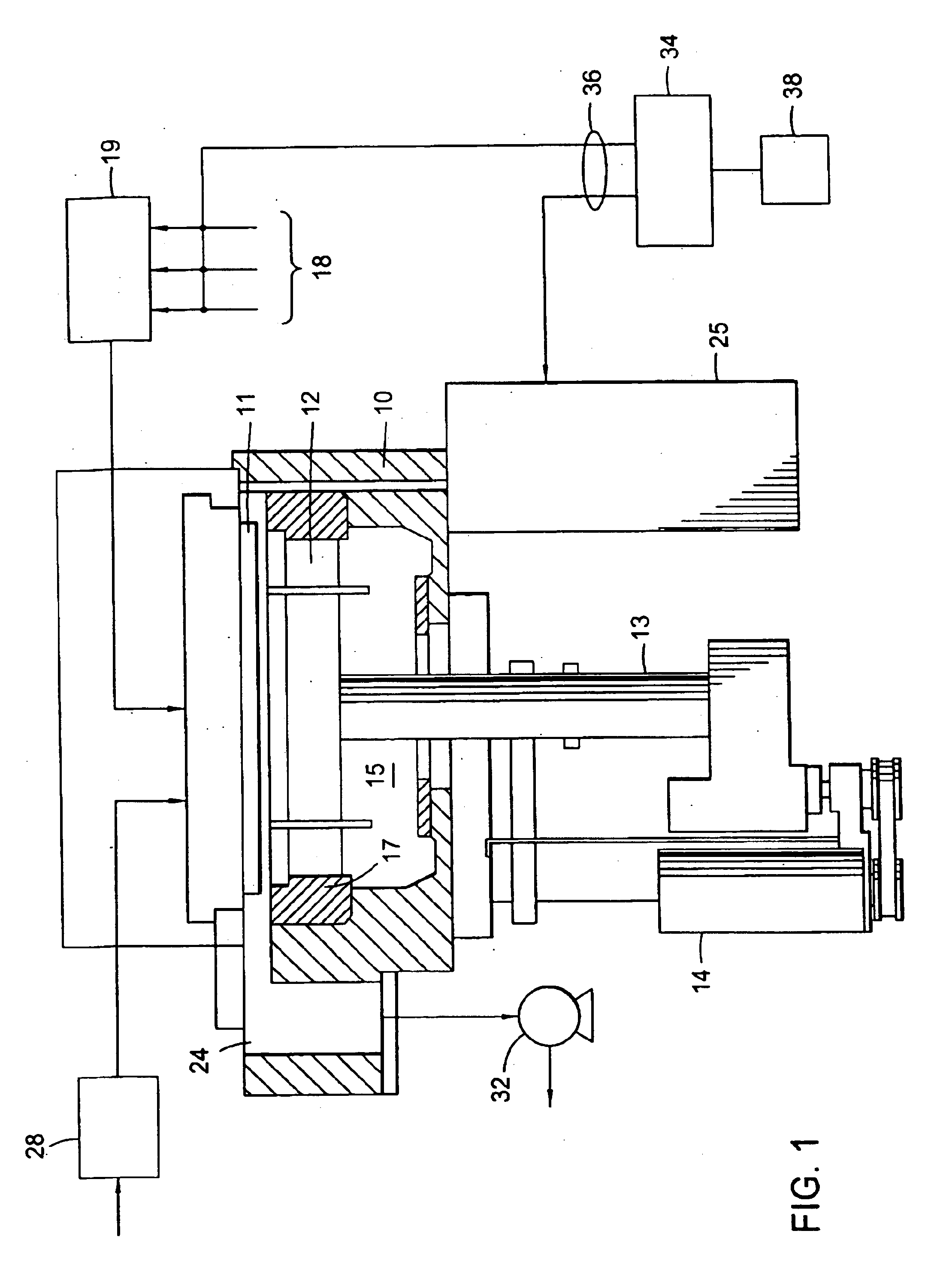

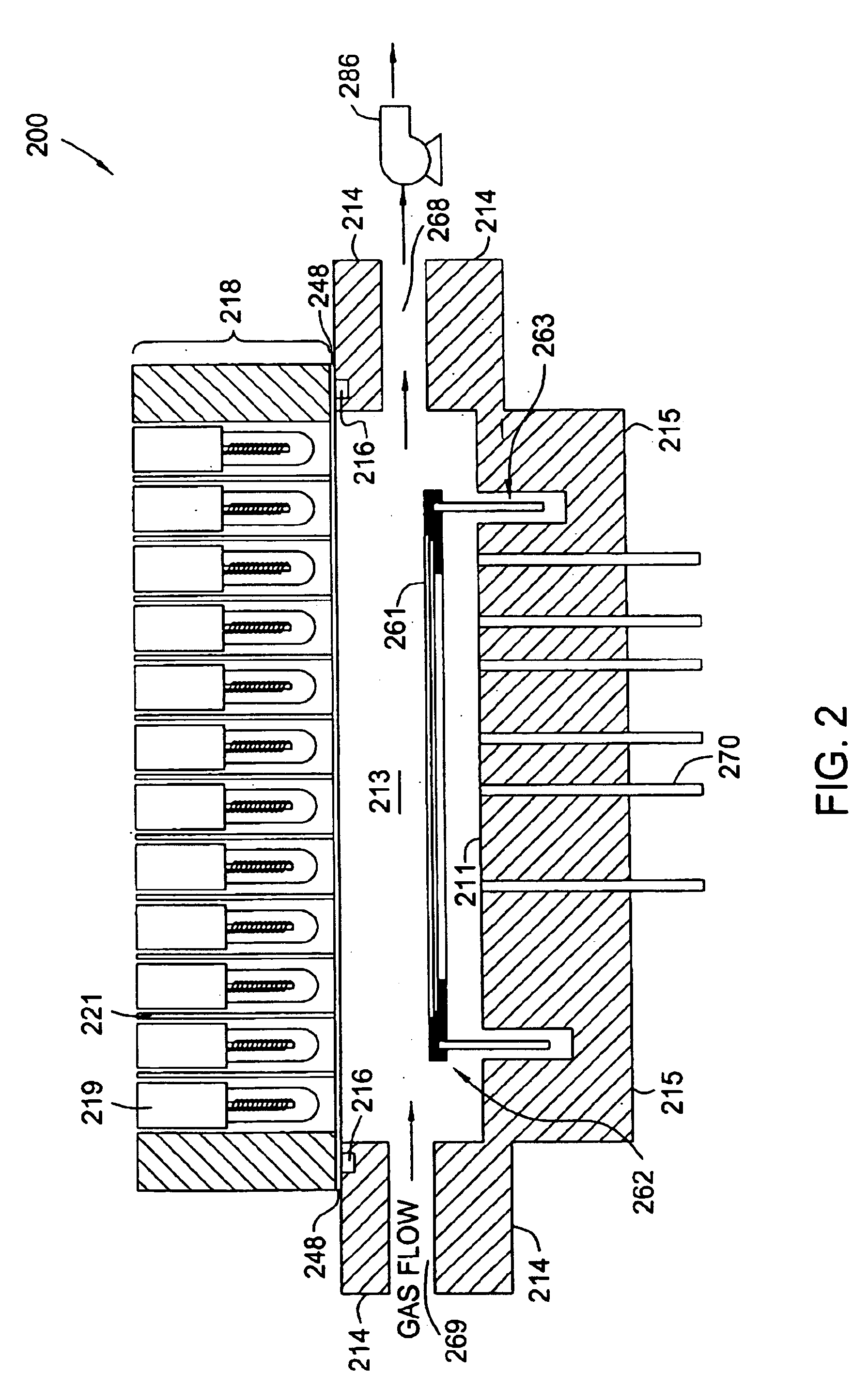

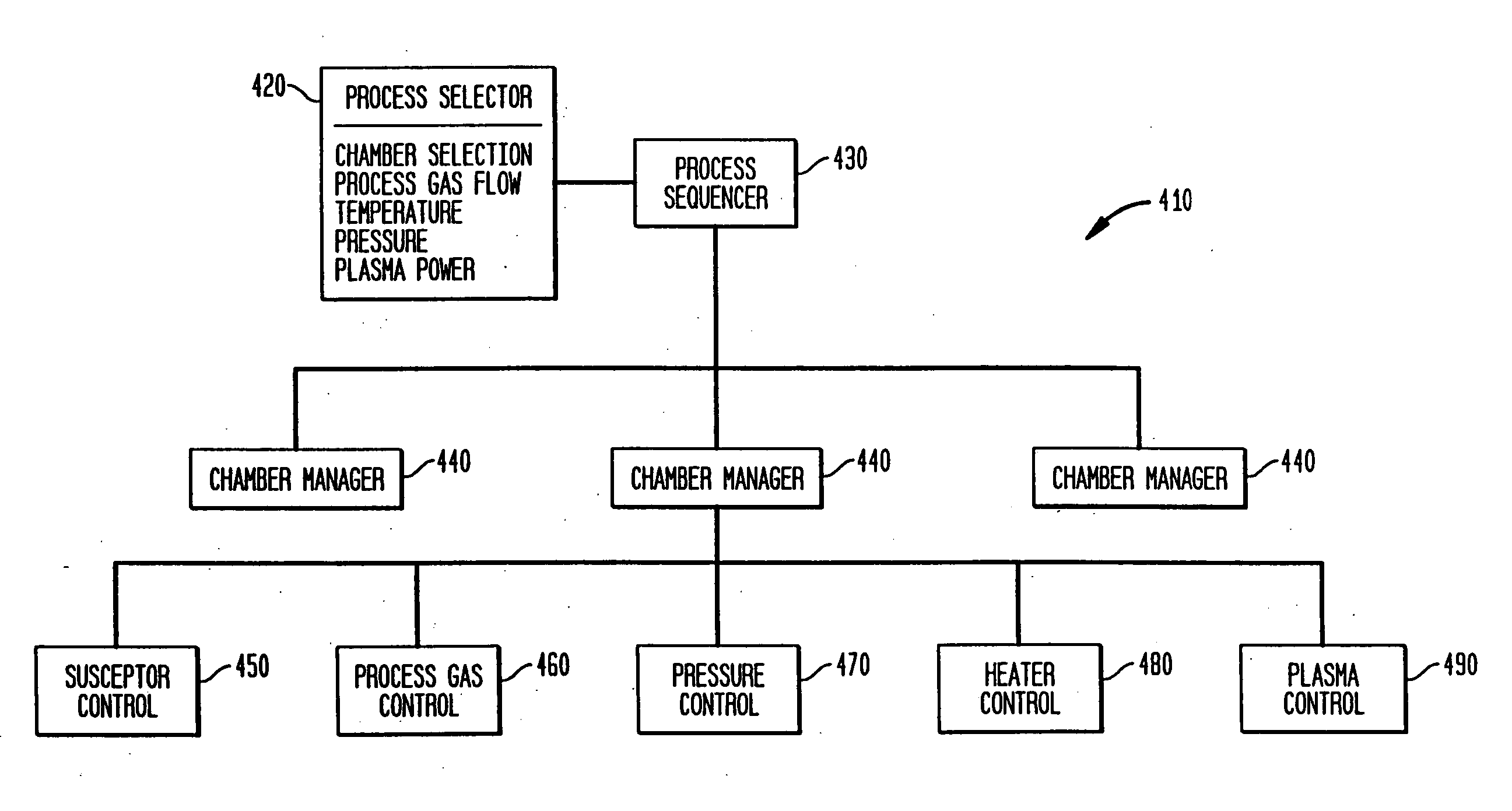

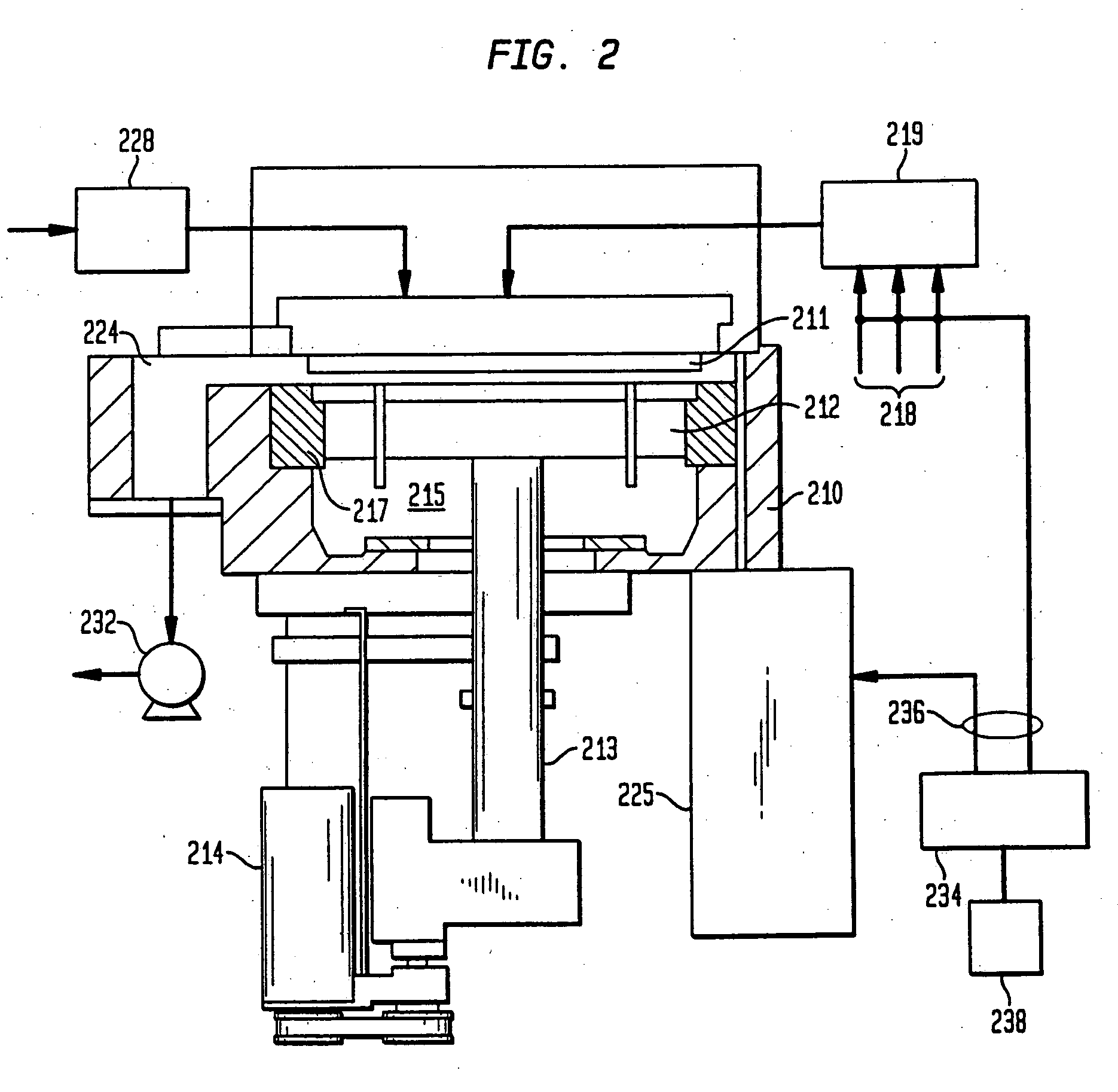

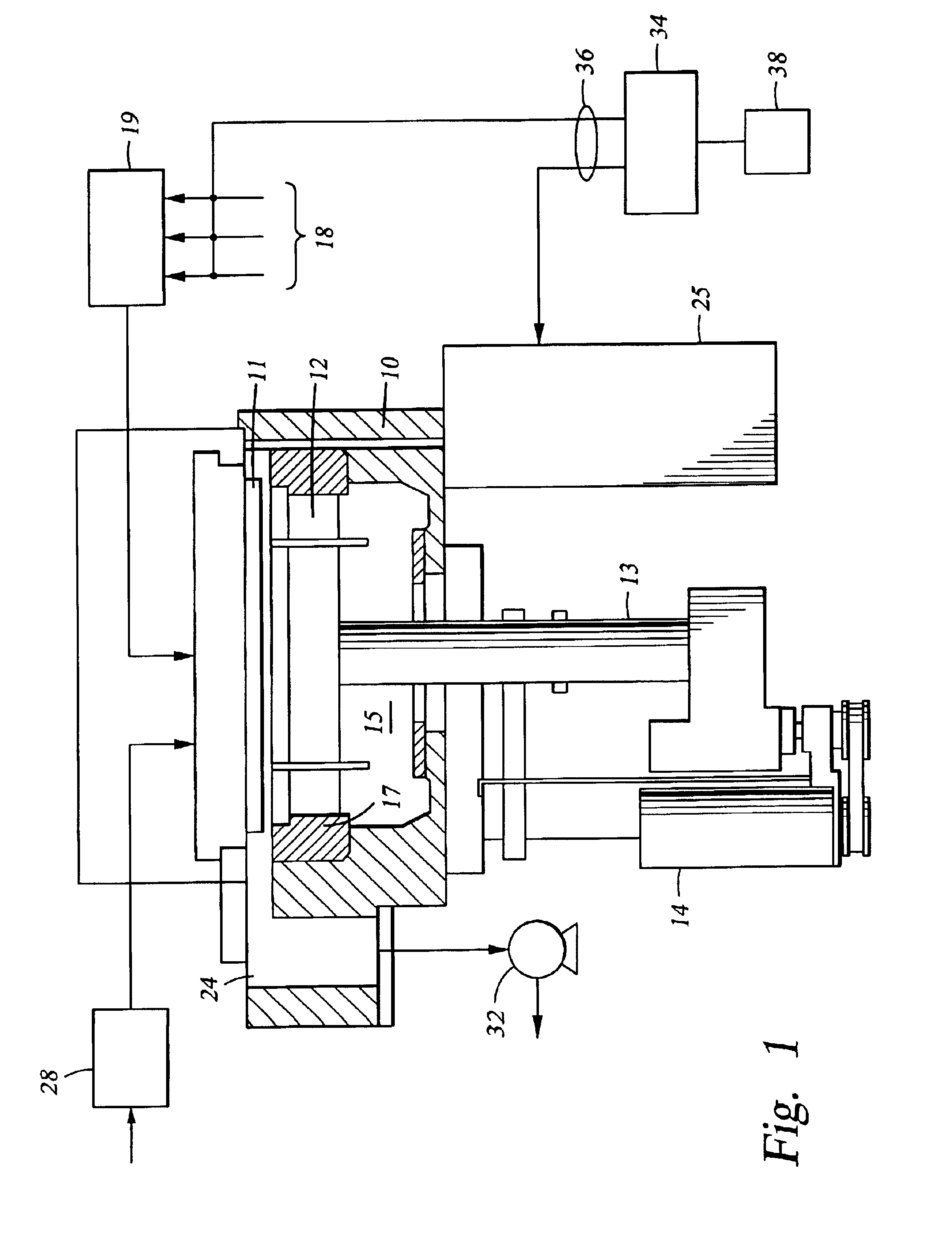

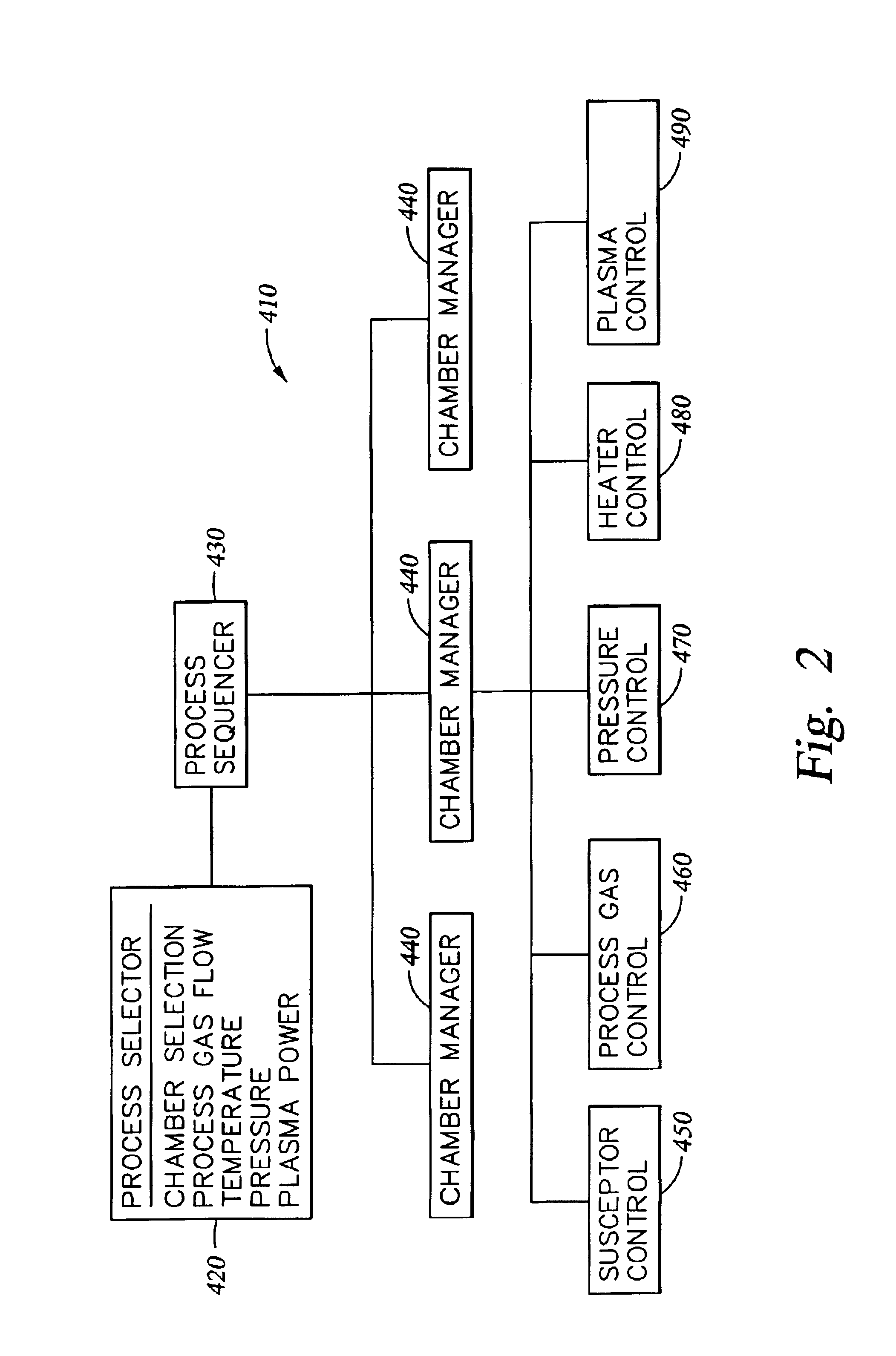

Methods and apparatus for electron beam treatment of a substrate are provided. An electron beam apparatus that includes a vacuum chamber, at least one thermocouple assembly in communication with the vacuum chamber, a heating device in communication with the vacuum chamber, and combinations thereof are provided. In one embodiment, the vacuum chamber comprises an electron source wherein the electron source comprises a cathode connected to a high voltage source, an anode connected to a low voltage source, and a substrate support. In another embodiment, the vacuum chamber comprises a grid located between the anode and the substrate support. In one embodiment the heating device comprises a first parallel light array and a second light array positioned such that the first parallel light array and the second light array intersect. In one embodiment the thermocouple assembly comprises a temperature sensor made of aluminum nitride.

Owner:APPLIED MATERIALS INC

Method of producing textured mold-formed body, and mold-formed body manufactured according to the method

ActiveUS20050173047A1Satisfied with stabilityGood suitDielectric heatingLamination ancillary operationsGramCrosslinked polymers

Owner:BENECKE-KALIKO

Electron beam treatment apparatus

InactiveUS7049612B2Material analysis using wave/particle radiationElectric discharge tubesHeat shieldElectron beam processing

One embodiment of the present invention is an electron beam treatment apparatus that includes: (a) an array of lamps that output radiation; (b) a support mechanism adapted to support a substrate at a treatment position above the lamps; and (c) a lamp heat shield, disposed above the array, having a radiation absorption portion adapted to absorb radiation from at least a portion of the array, and a radiation reflection portion adapted to reflect radiation from at least a portion of the array towards the substrate when disposed at the treatment position.

Owner:APPLIED MATERIALS INC

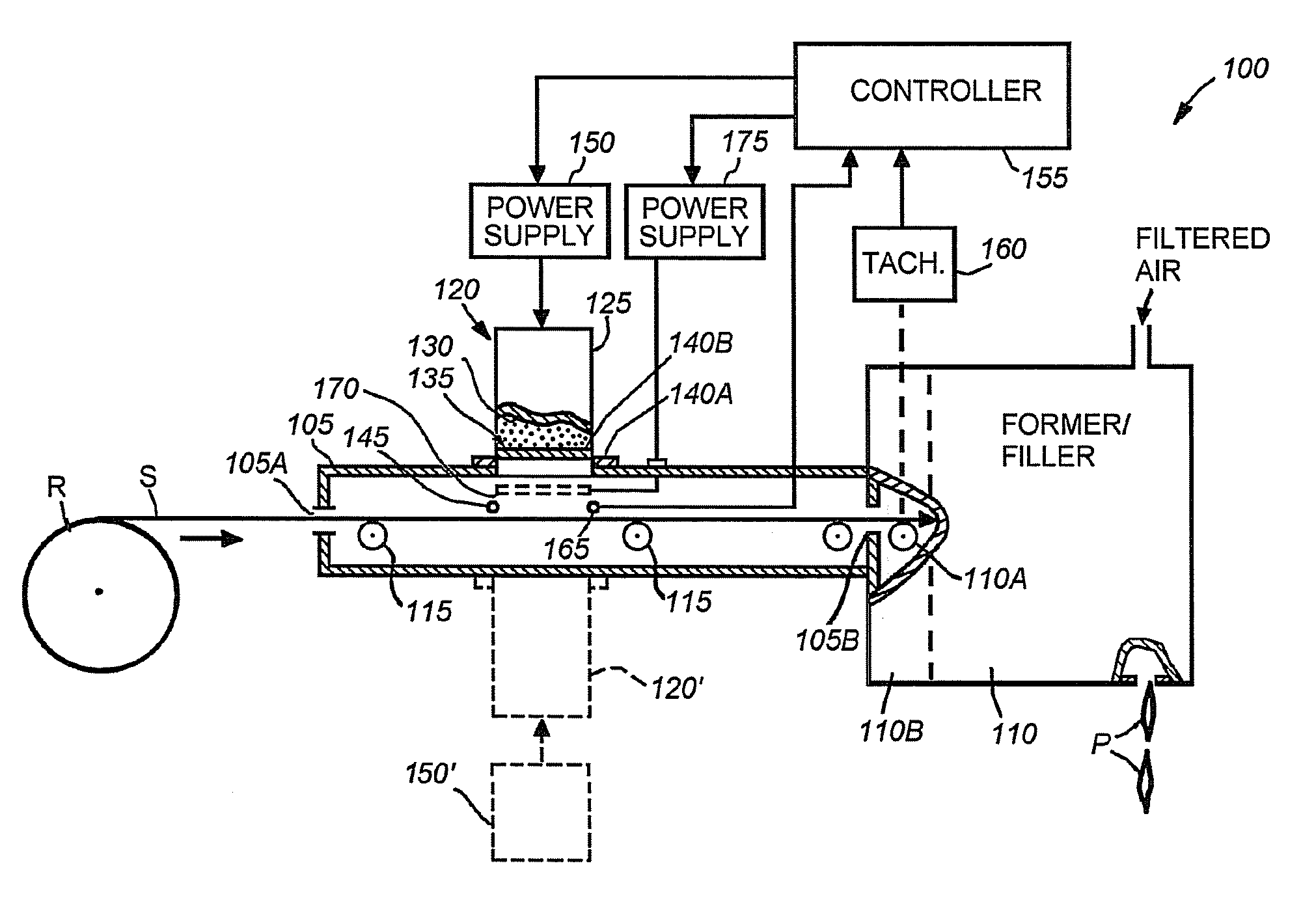

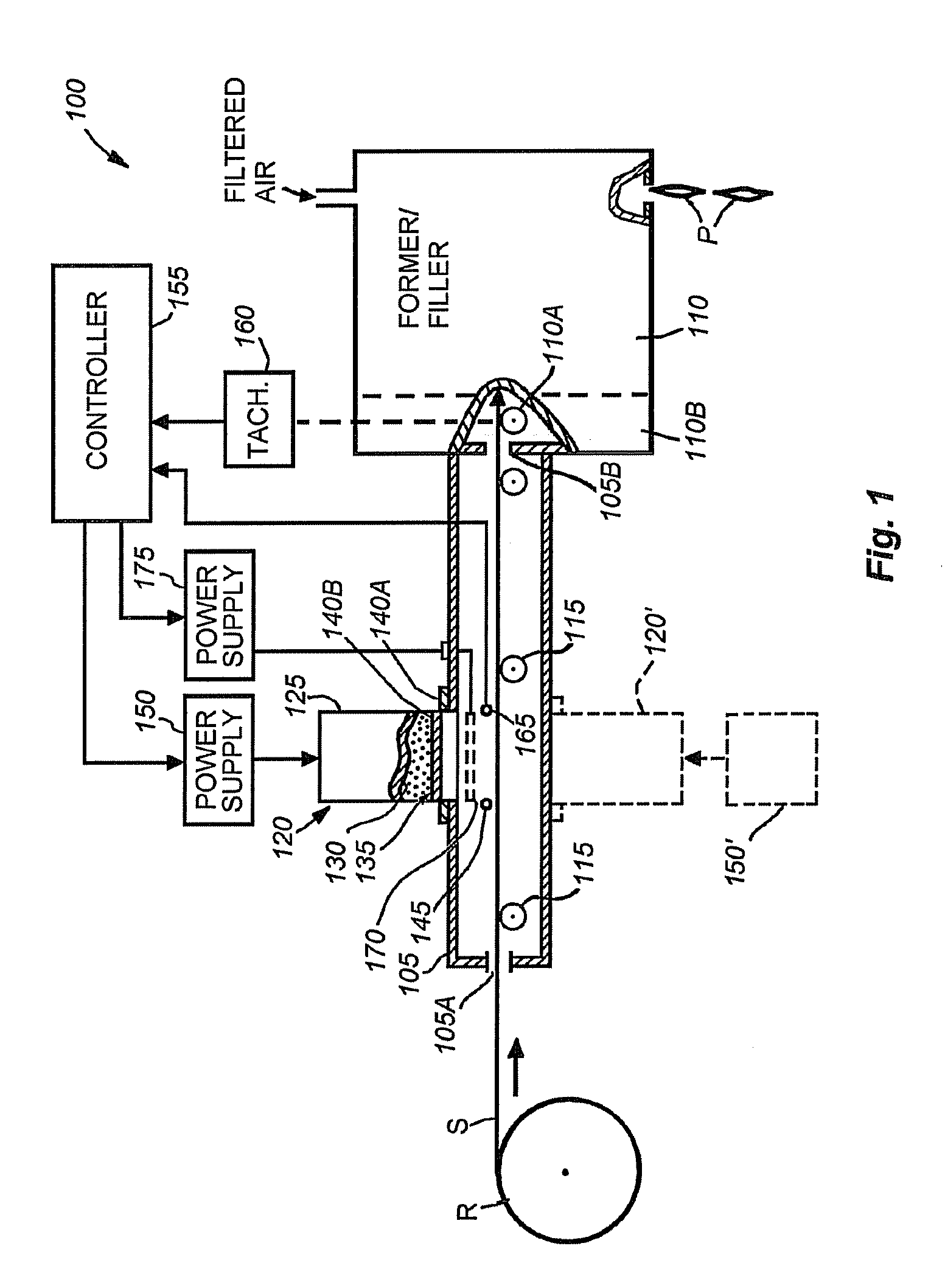

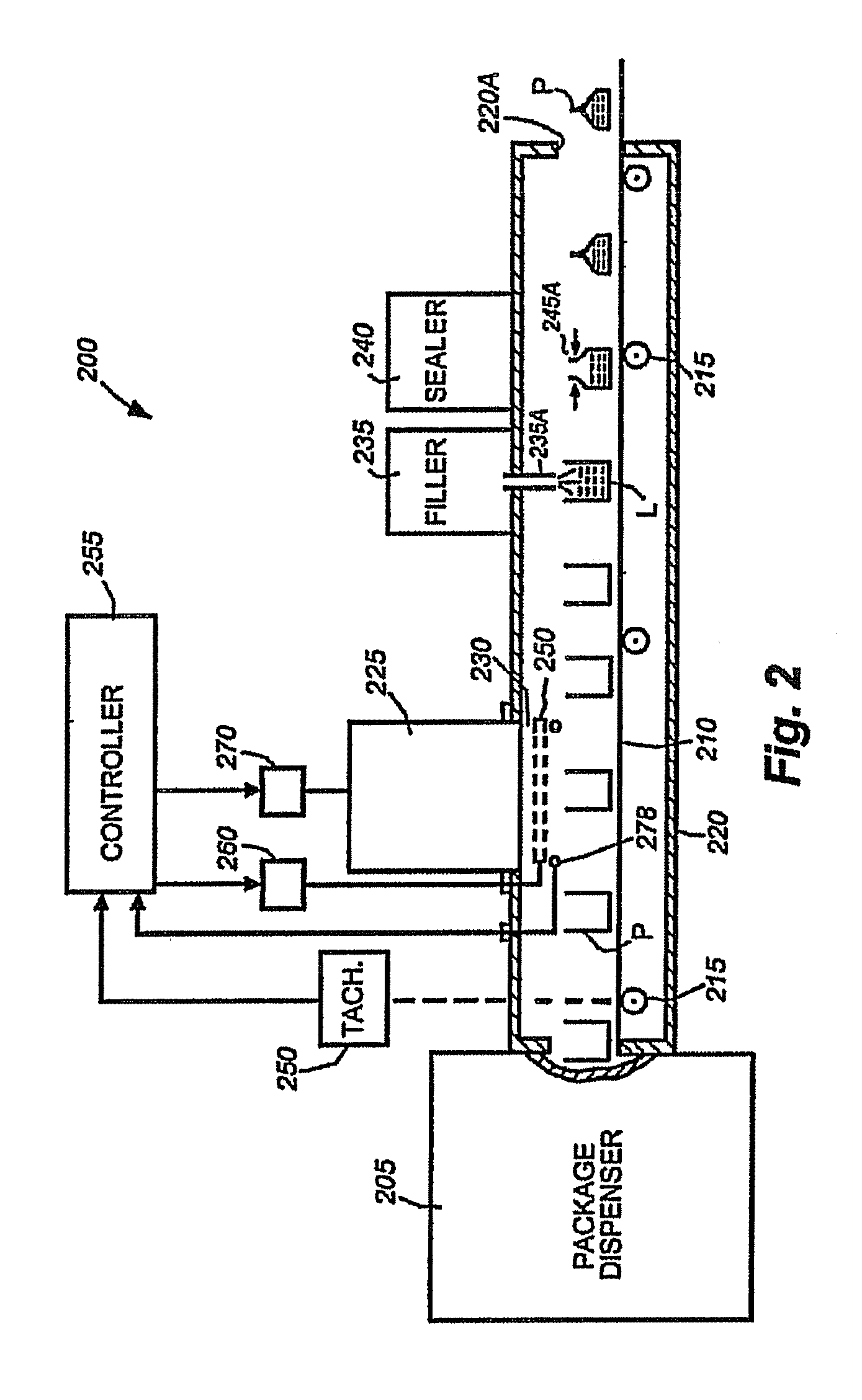

Method and apparatus for ebeam treatment of webs and products made therefrom

ActiveUS20110006225A1Effective sterilizationMaximum service lifePackage sterilisationSolid materialEngineeringElectron beam processing

A method and apparatus for sterilization of webs and products made therefrom using electron beams (ebeams) is provided. A controller is configured to modulate an ebeam to ensure that a non-continuously moving web is sterilized within a desired range of exposure. During sterilization in place operations, manifolds are configured to operate to ensure that sterilants do not enter an irradiation zone to prevent damage to ebeam emitters.

Owner:HITACHI ZOSEN CORP

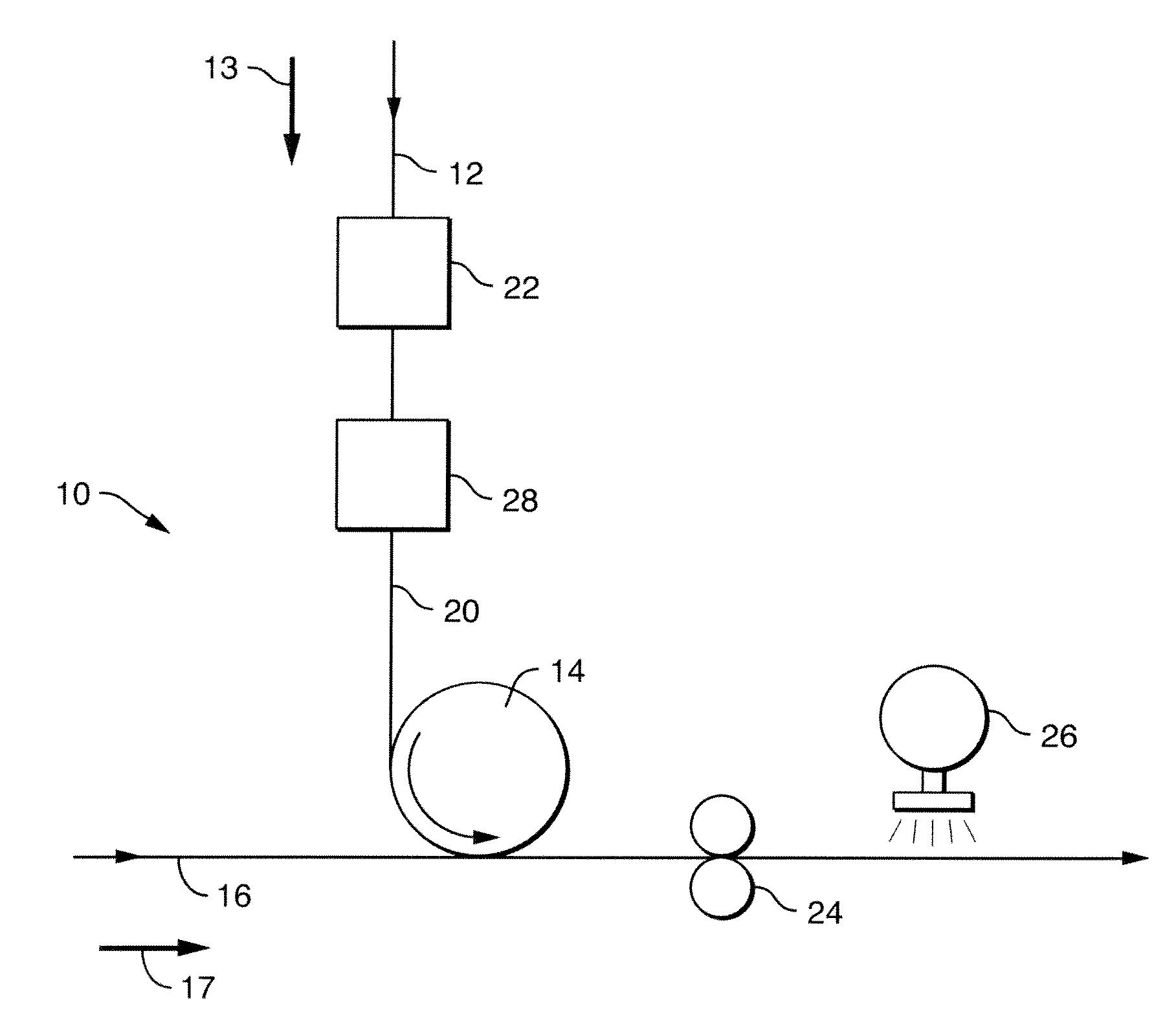

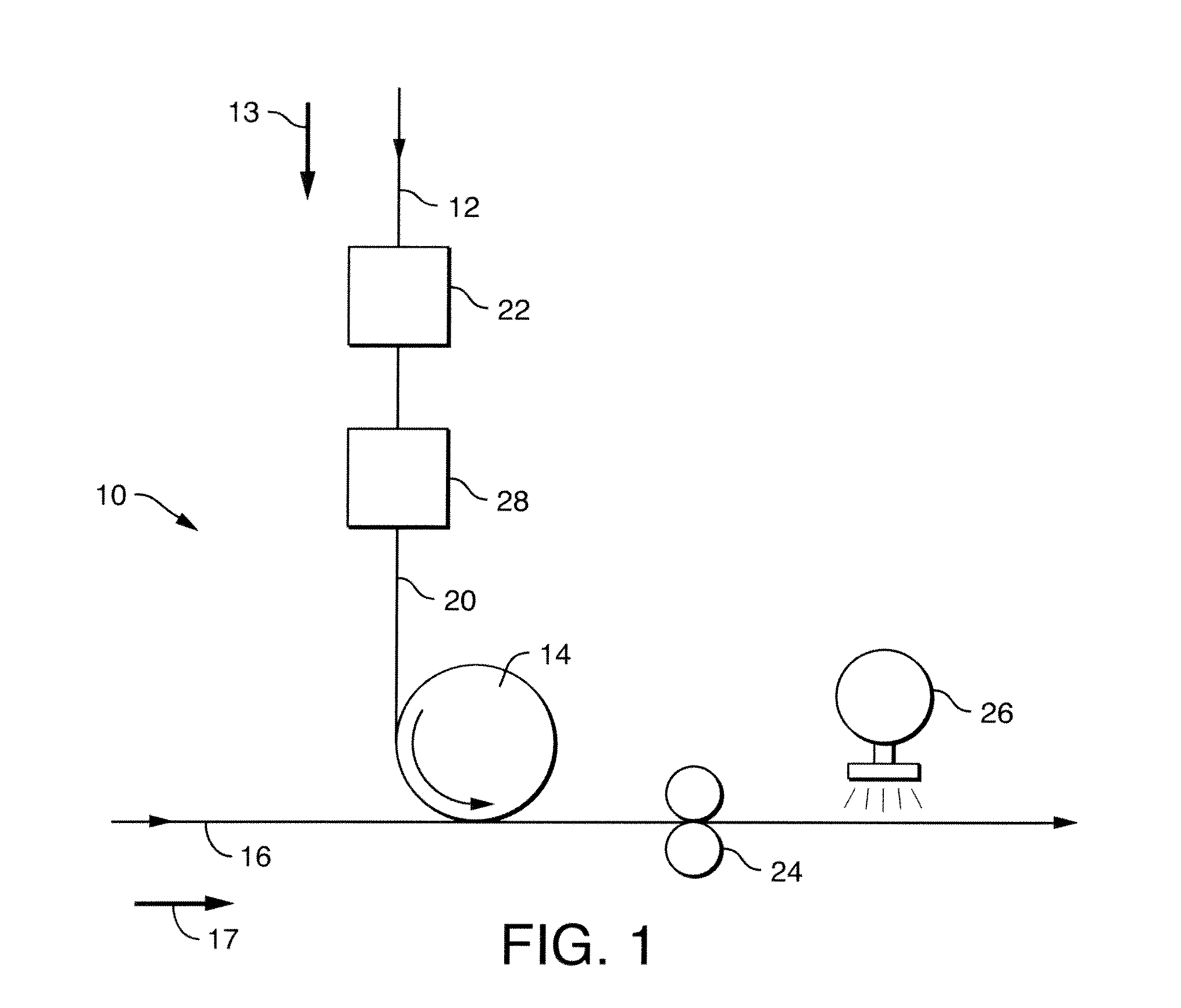

Method and Apparatus for Manufacturing an Absorbent Article with Crosslinked Elastic Components

InactiveUS20120291949A1Mechanical working/deformationLamination ancillary operationsElastic componentEngineering

Generally, a method and apparatus for forming an elastic portion of an absorbent article is disclosed. An elastic material web having at least one crosslinkable elastic styrenic block copolymer sized to correspond to at least one discrete elasticized portion of the absorbent article is provided. The elastic material web may be unwound or otherwise supplied and then attached to a continuous moving web to form at least one discrete elasticized portion of the absorbent article. The elastic material web is crosslinked by subjecting the elastic material web to electromagnetic radiation with an electron beam processing unit sufficient to provide a crosslinked elastic styrenic block copolymer. The electromagnetic radiation is sized to correspond to at least one discrete elasticized portion of the absorbent article. A variety of absorbent article components may possess elastic characteristics, including waistbands, leg / cuff gasketing, side panels, and outer covers.

Owner:KIMBERLY-CLARK WORLDWIDE INC

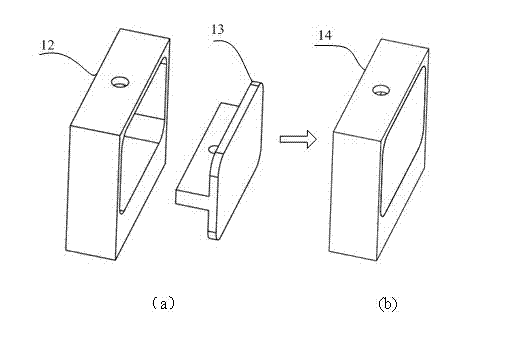

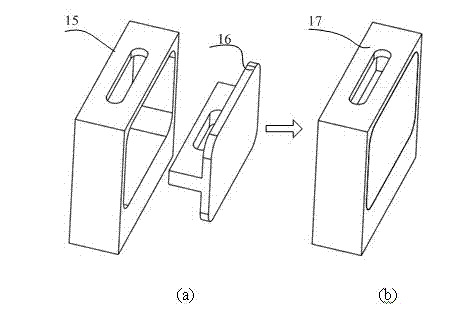

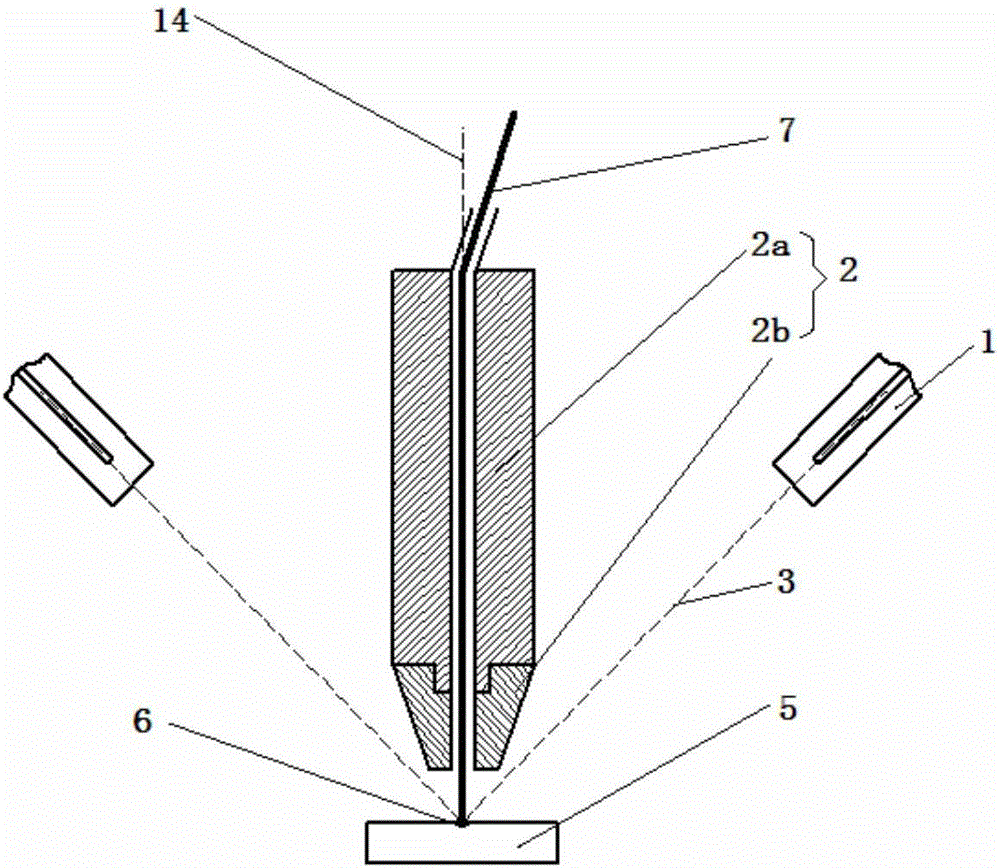

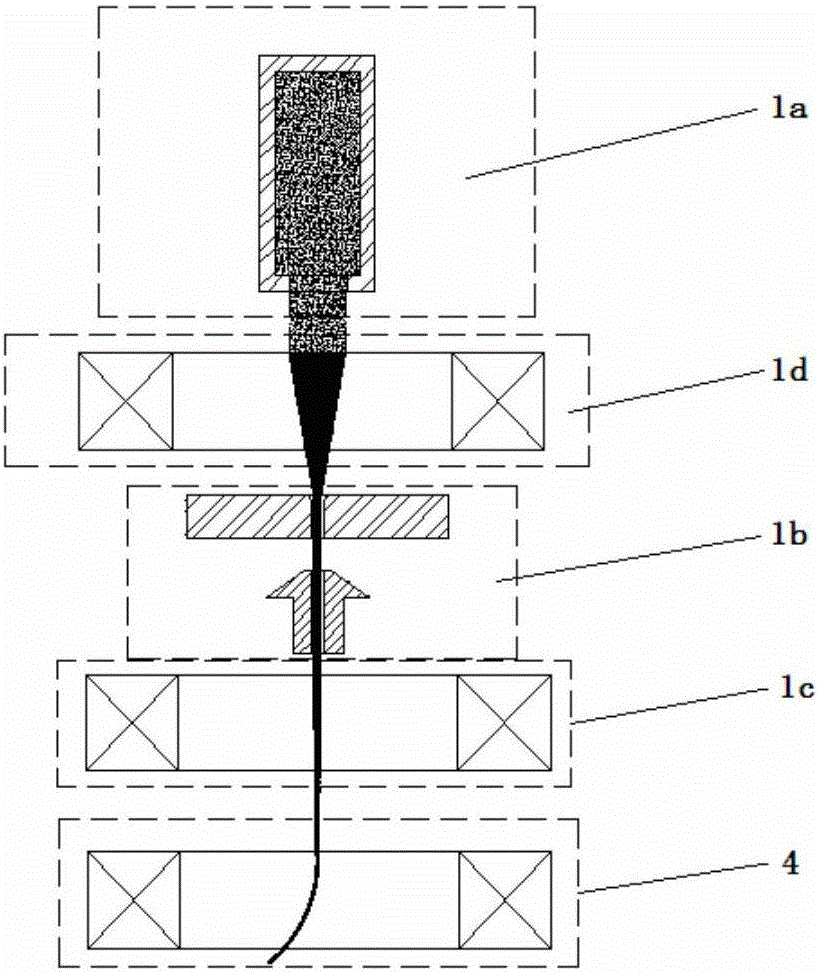

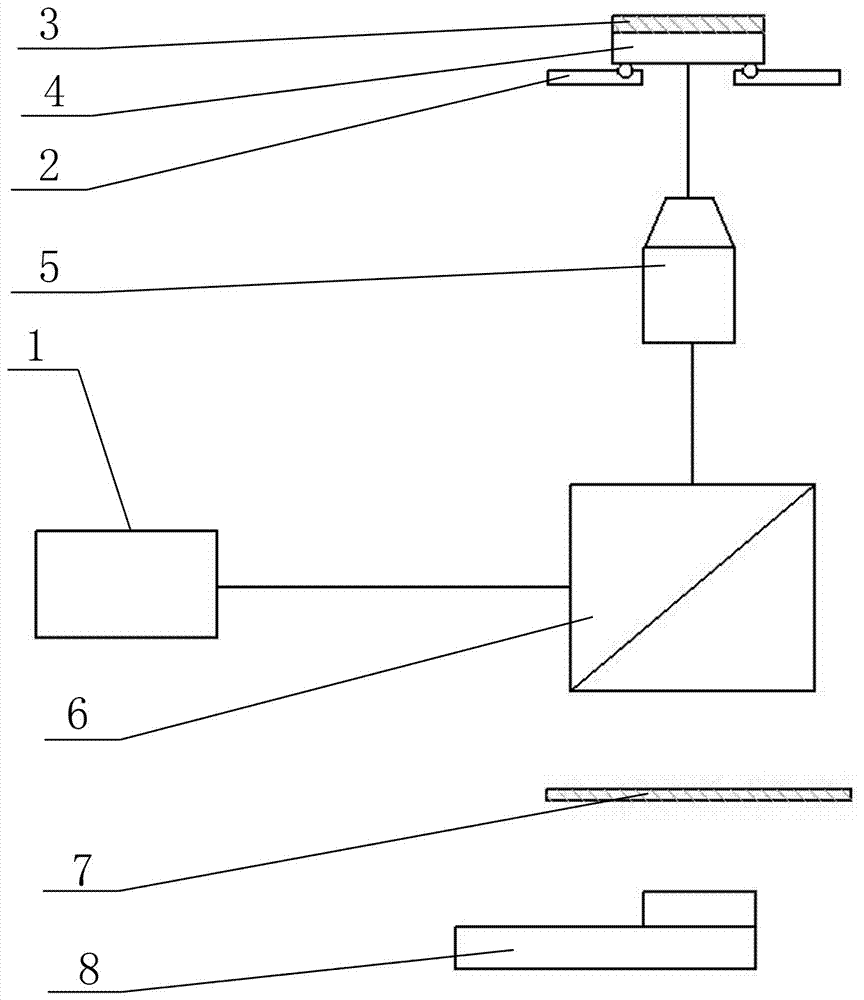

Electron beam processing system and processing method of multi-electron beam central wire feeding

ActiveCN106392290AGood uniformity of energy distributionSimple structureElectron beam welding apparatusElectron beam machiningAtomic physics

The invention discloses an electron beam processing system and processing method of multi-electron beam central wire feeding. The electron beam processing system comprises a plurality of electron beam guns and a wire feeding system, wherein the electron beam guns comprise electron beam generation systems, electron beam acceleration systems, electron beam accumulation systems and electron beam deflection systems; the wire feeding system comprises a wire feeding pipe and a wire feeding nozzle; the wire feeding nozzle is connected at the lower part of the wire feeding pipe; the wire feeding pipe and the wire feeding nozzle are arranged on a central axis of the structure; and the plurality of electron beam guns are in uniform lattice distribution along the circumference of the central axis. According to the electron beam processing system, the isotropy of electron beams on the surface of a workpiece can be guaranteed, the quality uniformity of the processed workpiece is improved, the processing process is continuous and unintermittent, the electron beam gun structures and a central wire feeding structure do not interfere with each other, and the processing system is applicable to electron beam processing fields of electron beam welding, electron beam cladding, electron beam metal 3D printing, and the like.

Owner:辽宁新锋精密光电科技有限公司

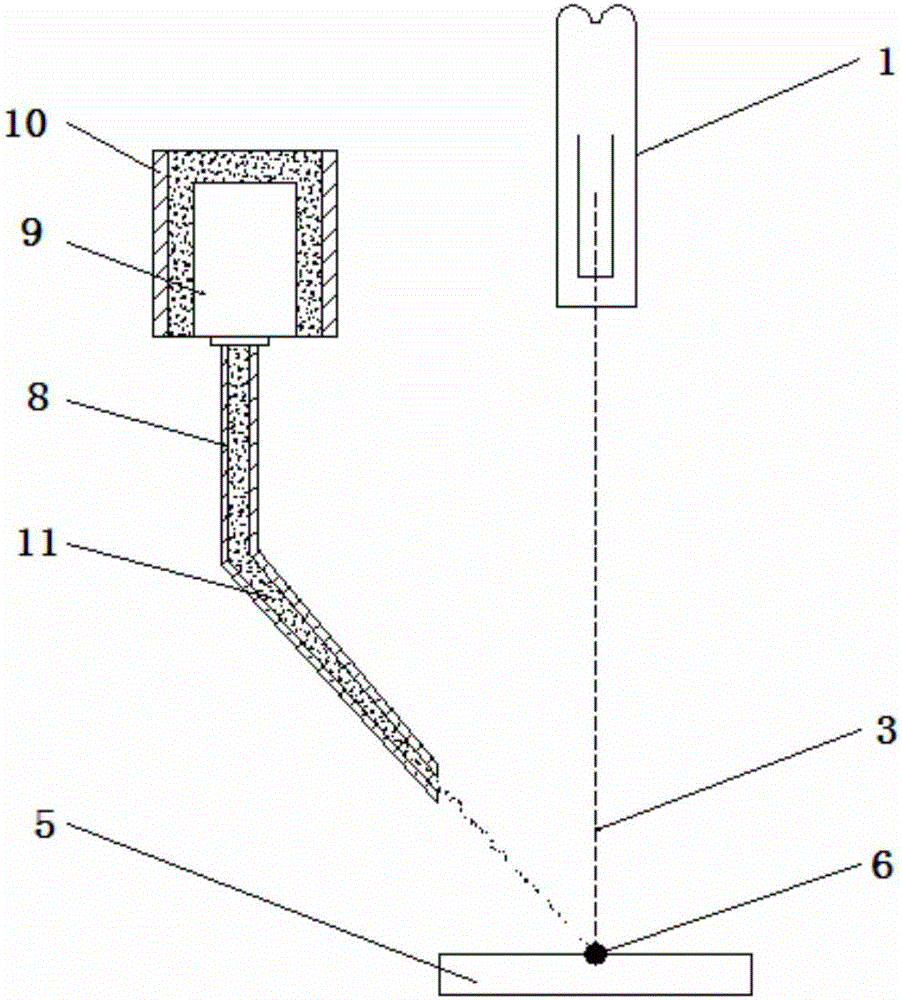

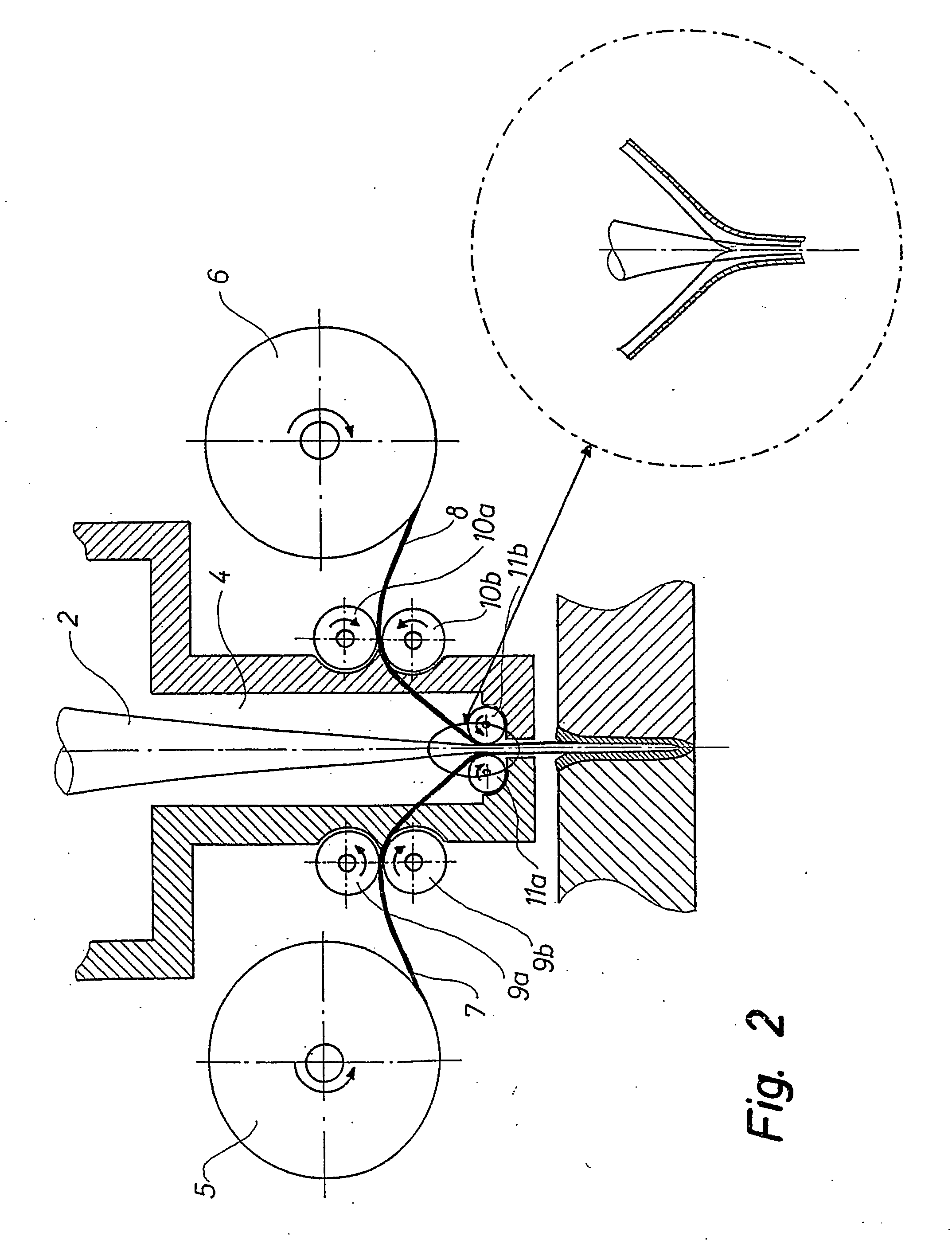

Method of electron beam processing

InactiveUS20050103754A1Reduce wire diameterElectron beam welding apparatusWelding/soldering/cutting articlesEngineeringVacuum chamber

As a rule, electron beam welding takes place in a vacuum. However, this means that the workpieces in question have to be placed in a vacuum chamber and have to be removed therefrom after welding. This is time-consuming and a serious limitation of a process the greatest advantage of which is the option of welding workpieces of large thicknesses. Therefore the idea is to guide the electron beam (2) to the workpiece via a hollow wire, said wire thereby acting as a prolongation of the vacuum chamber (4) down to workpiece. Thus, a workpiece need not be placed inside the vacuum chamber, thereby exploiting the potential of electron beam processing to a greater degree than previously possible, for example by means of electron beam welding.

Owner:DANMARKS TEKNISKE UNIV

Non-magnetic temperature control system of solid-state atomic spin sensor

The invention relates to the field of quantum sensing and particularly relates to a non-magnetic temperature control system of a solid-state atomic spin sensor. The system comprises a diamond substrate. The diamond substrate is provided with a diamond NV color-center waveguide (4). The diamond substrate is further provided with a porous magnetic PDMS film (3) configured to cover the diamond NV color-center waveguide (4). The two sides of the lower surface of the diamond substrate are provided with a micro-strip antenna array (2). The micro-strip antenna array (2) is connected with a microwave source. According to the technical scheme of the invention, a nitrogen-doped diamond structure, larger than 1018 cm<-1> in concentration, is prepared by adopting the MPCVD magneto-electric restraint method, and a diamond color-center structure is prepared by adopting the micro-nano processing technology. Therefore, the excitation and fluorescence collection of the NV color-center structure are realized. Meanwhile, the coplanar manufacturing of a microwave antenna is realized in combination with the electron beam processing method. Moreover, the high signal-to-noise ratio detection of magnetic variation signals is carried out by adopting the time sequence control method, so that the effect of a temperature-modulated magnetic field is realized. The magnetic noise is effectively inhibited, and the purpose of non-magnetic temperature control is achieved.

Owner:ZHONGBEI UNIV

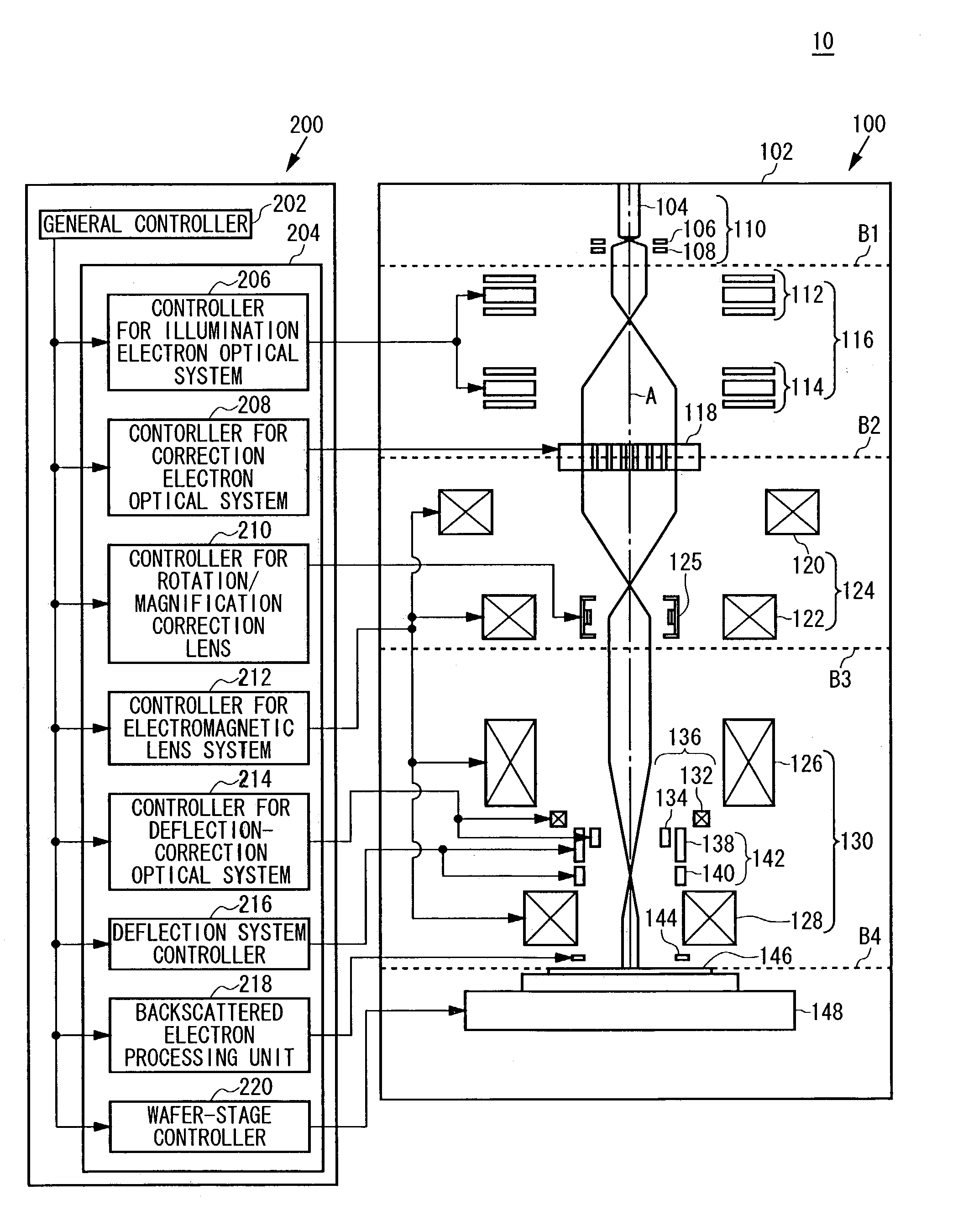

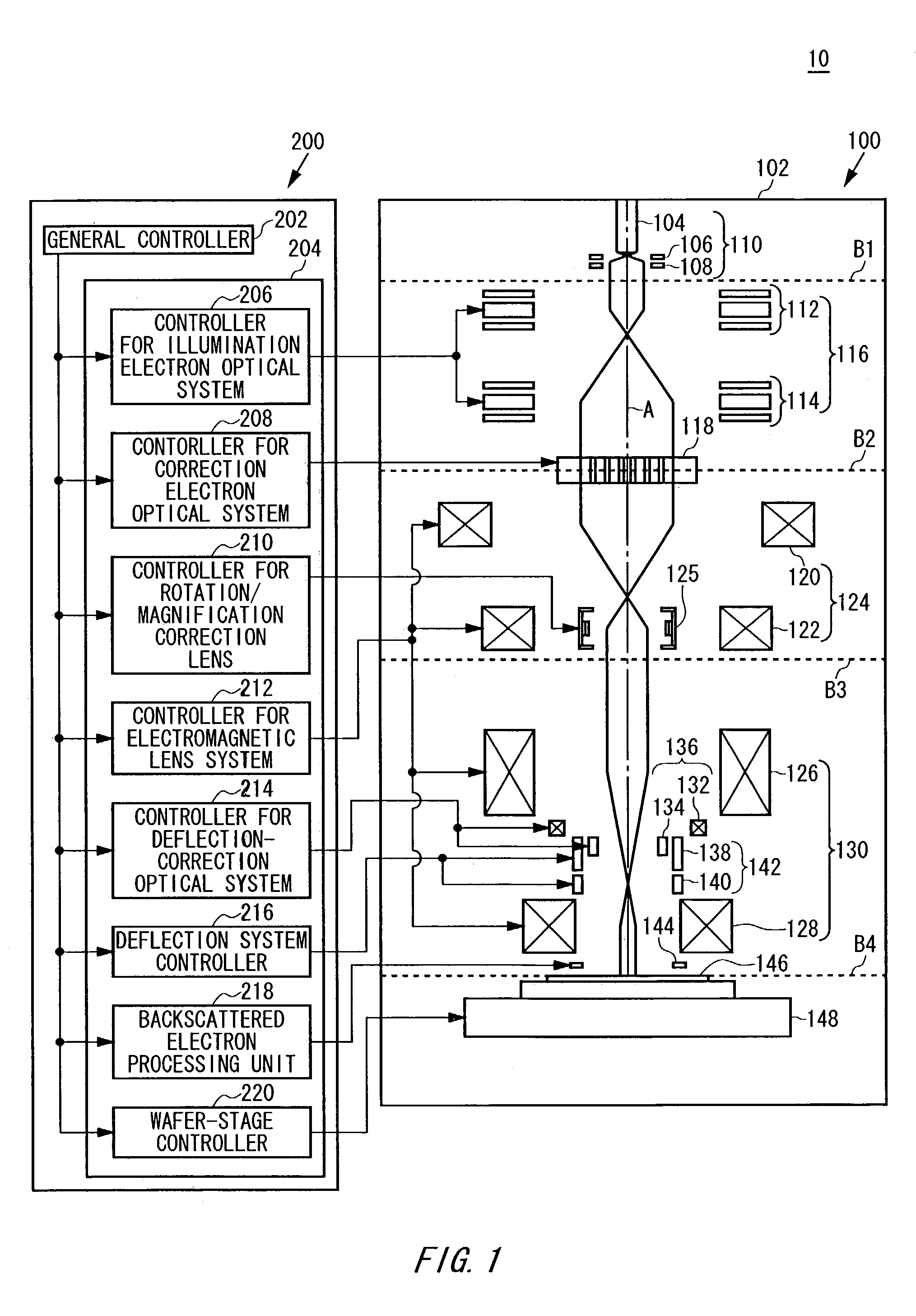

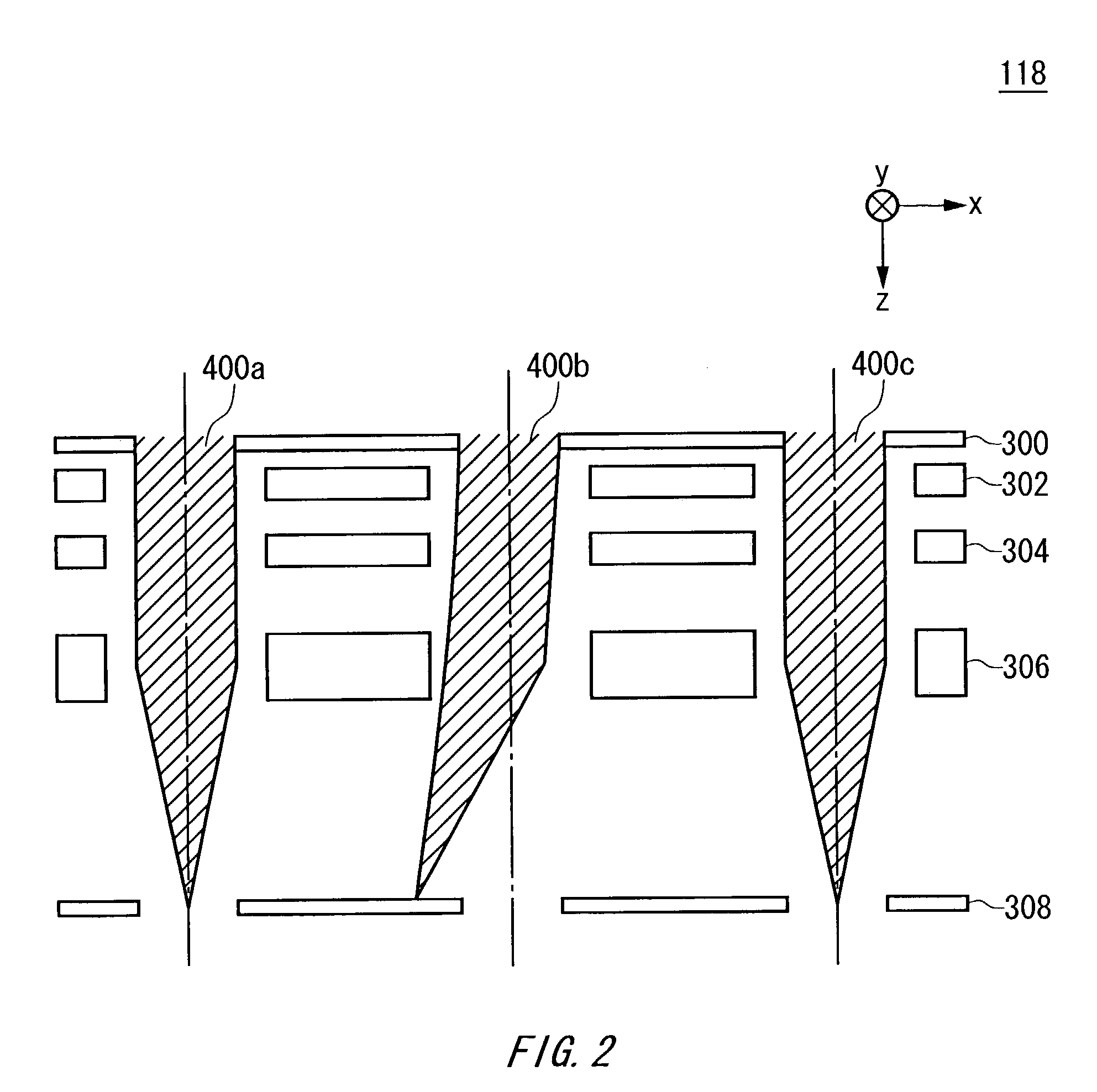

Electron beam exposure apparatus and electron beam processing apparatus

InactiveUS7041988B2Precise rotationReduce morbidityThermometer detailsBeam/ray focussing/reflecting arrangementsElectromagnetic shieldingElectron-beam lithography

An electron beam exposure apparatus for exposing wafer with an electron beam, includes: a first electromagnetic lens system for making the electron beam incident substantially perpendicularly on a first plane be incident on a second plane substantially perpendicularly; a second electromagnetic lens system for making the electron beam that was substantially perpendicularly incident on the second plane be incident on the wafer substantially perpendicularly; a rotation correction lens provided within the first electromagnetic lens system for correcting rotation of the electron beam caused by at least the first electromagnetic lens system; a deflection system for deflecting the electron beam to a position on the wafer; and a deflection-correction optical system provided within the second electromagnetic lens system for correcting deflection aberration caused by the deflection system.

Owner:ADVANTEST CORP +2

Methods for improving etching resistance for an amorphous carbon film

InactiveUS20140263173A1Improve corrosion resistanceElectric discharge tubesDecorative surface effectsMetallurgyElectron beam processing

Methods for using an electron beam treatment performed on an amorphous carbon layer to form a treated amorphous carbon layer with high etching resistance are provided. In one embodiment, a method of treating an amorphous carbon film includes providing a substrate having a material layer disposed, forming an amorphous carbon layer on the material layer, and performing an electron beam treatment process on the amorphous carbon layer.

Owner:APPLIED MATERIALS INC

Methods for packaging and sterilizing elastomeric articles, and packaged elastomeric articles produced thereby

ActiveUS20110203227A1Reduced ozone attackReduce degradationFlexible coversWrappersGamma irradiationEngineering

The present invention relates generally to methods of sterilizing elastomeric articles in a manner that prevents and / or reduces degradation to the articles, particularly degradation that may be caused and / or accelerated by sterilization techniques such as gamma irradiation, x-ray irradiation, and electron-beam processing. The methods include packaging the elastomeric articles in order to improve their resistance to degradation. In certain aspects of the invention, packaged elastomeric articles, optionally containing one or more antidegradants, such as antioxidant and / or antiozonant compounds, are also provided. The methods of providing degradation-resistant elastomeric articles in accordance with the present invention may also be used to reduce the occurrence of cracking and discoloration in elastomeric articles, regardless of whether they are subjected to sterilization.

Owner:ALLEGIANCE CORP

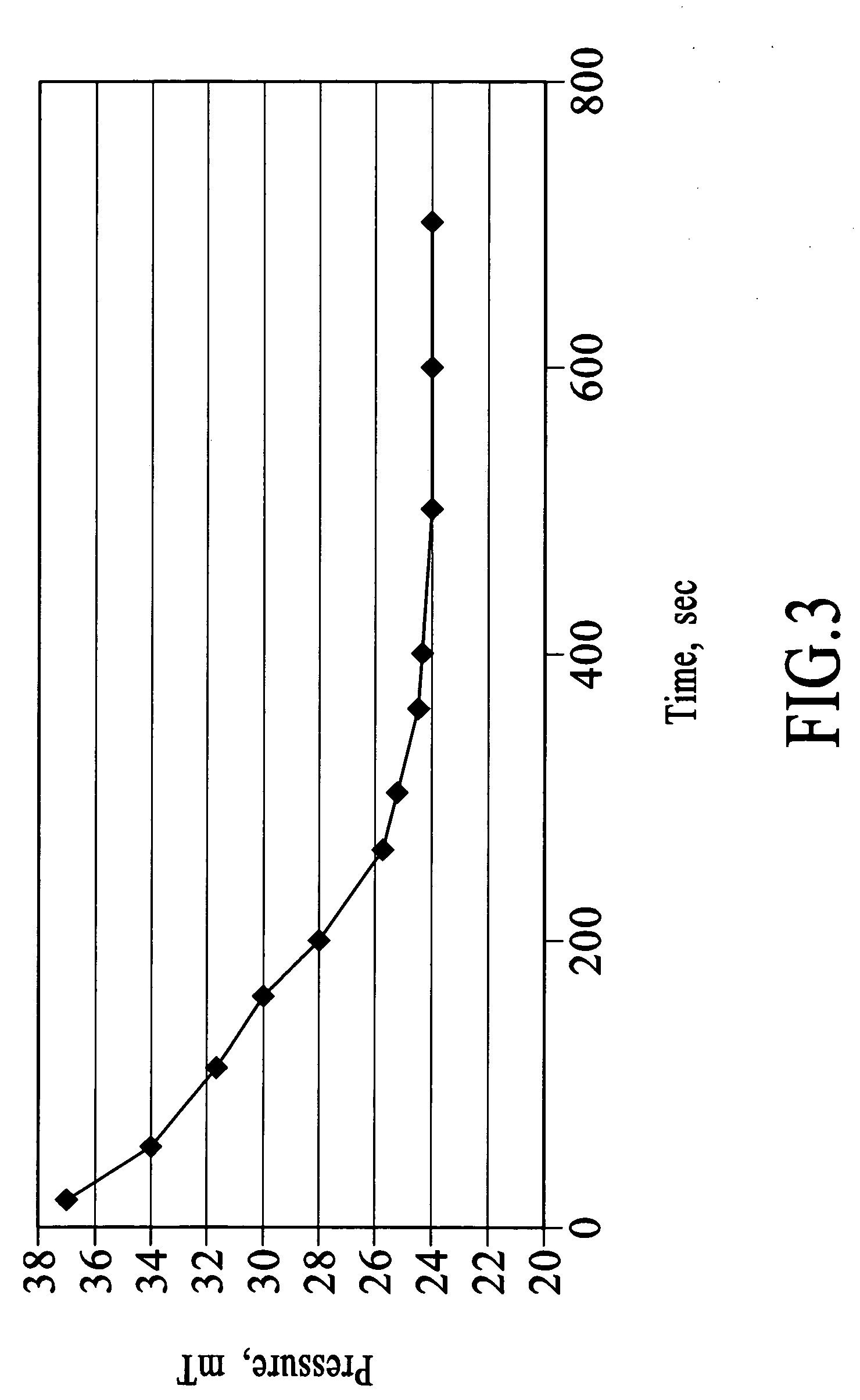

Clean process for an electron beam source

InactiveUS7323399B2Pretreated surfacesSemiconductor/solid-state device manufacturingBeam sourceAtomic physics

One embodiment of the present invention is a method for cleaning an electron beam treatment apparatus that includes: (a) generating an electron beam that energizes a cleaning gas in a chamber of the electron beam treatment apparatus; (b) monitoring an electron beam current; (c) adjusting a pressure of the cleaning gas to maintain the electron beam current at a substantially constant value; and (d) stopping when a predetermined condition has been reached.

Owner:APPLIED MATERIALS INC

Static electricity deflecting device, electron beam irradiating apparatus, substrate processing apparatus, substrate processing method and method of manufacturing substrate

InactiveUS20070228285A1Occurrence is suppressedImprove accuracyStability-of-path spectrometersContact member manufacturingAtomic physicsStatic electricity

A substrate processing apparatus which irradiates a substrate under processing with an electron beam and processes the substrate with the electron beam is disclosed. The substrate processing apparatus includes an electron beam generation mechanism which generates the electron beam, first area having a plurality of first static electricity deflecting devices whose thicknesses gradually increase in a traveling direction of the electron beam, and a second area disposed on a downstream side of the electron beam of the first area and having a plurality of second static electricity deflecting devices whose thicknesses are nearly same in the traveling direction of the electron beam. The substrate processing apparatus may further include a plurality of lenses whose thicknesses gradually decrease in the traveling direction of the electron beam, at least one of the plurality of lenses being disposed in each of the first area and the second area.

Owner:TOKYO ELECTRON LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com