Patents

Literature

64 results about "Antiozonant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An antiozonant, also known as anti-ozonant, is an organic compound that prevents or retards the degradation of material caused by ozone (ozone cracking). Antiozonants are used as additives to plastics and rubber, especially in tire manufacturing.

Antiozonant cum antioxidant, process for preparation

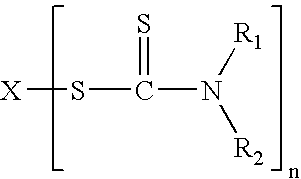

InactiveUS6770785B1Organic compound preparationAmino compound preparationOrganic solventSolvent evaporation

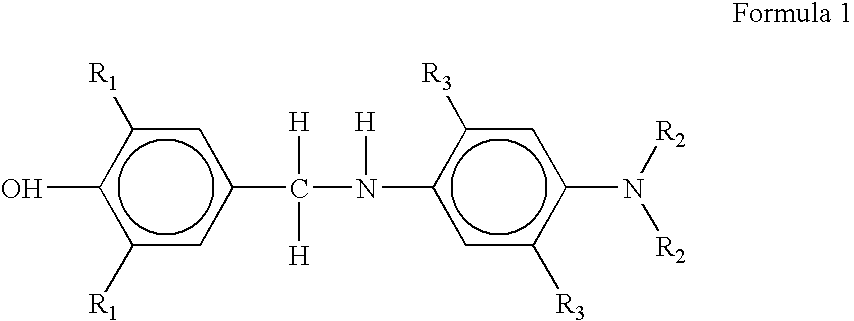

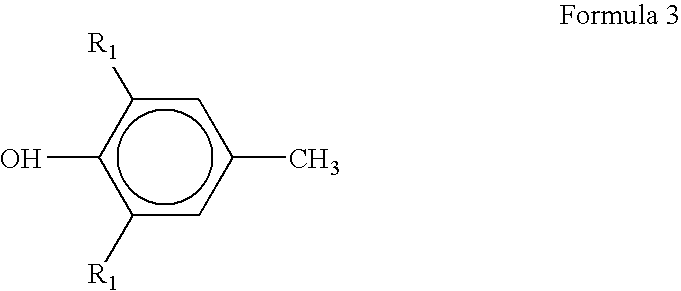

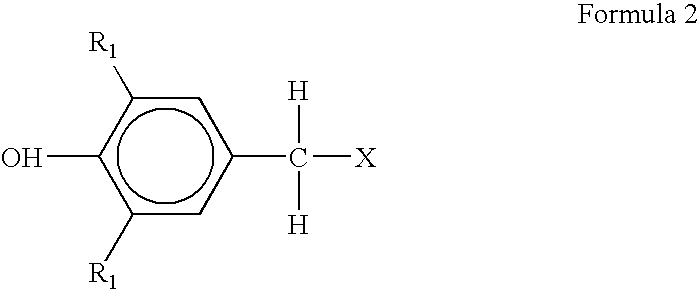

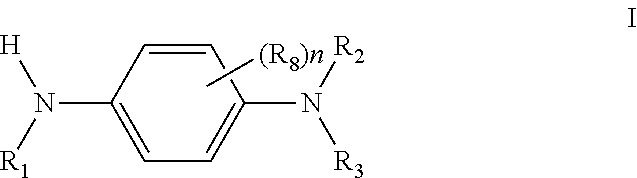

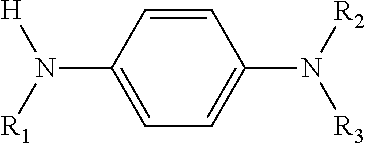

The present invention relates to a novel antiozonant as well as antioxidant based on functionalized hindered phenol and the process for the preparation thereof of formula 1wherein R1 is tert-butyl and R2 and R3 are C1 to C8 linear or branched alkyl. The present invention also relates to a process for the preparation thereof comprising dissolving a compound of formula 3wherein R1 is tert-butyl, with liquid bromine in a non polar organic solvent at temperature range 80 to 95° C. for a period of 4 to 7 hours, evaporating the solvent under reduced pressure to obtain a compound of formula 2wherein R1 is a tertiary butyl group and X is Br, reacting the compound of formula 2 with a compound of formula 4wherein R2 and R3 are C1 to C8 linear or branched alkyl, dissolved in an organic solvent in presence of a suitable mild base at a temperature ranging from 80 to 95° C. for a period of 4 to 7 hours, bringing the reaction mixture to room temperature, separating the organic layer and concentrating the product by solvent evaporation under reduced pressure and purifying the final product by column chromatography to obtain compound of formula 1.

Owner:COUNCIL OF SCI & IND RESEARACH

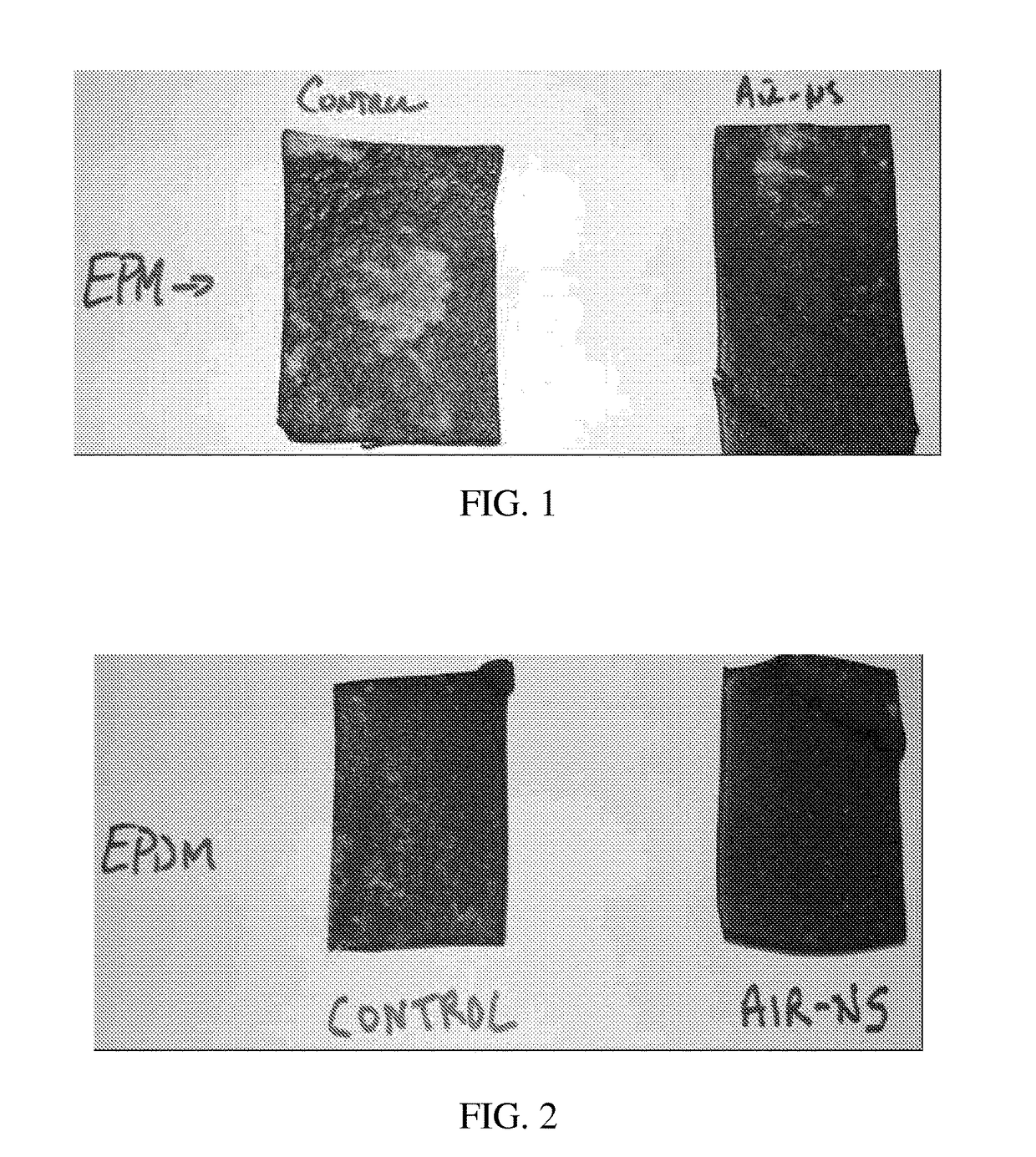

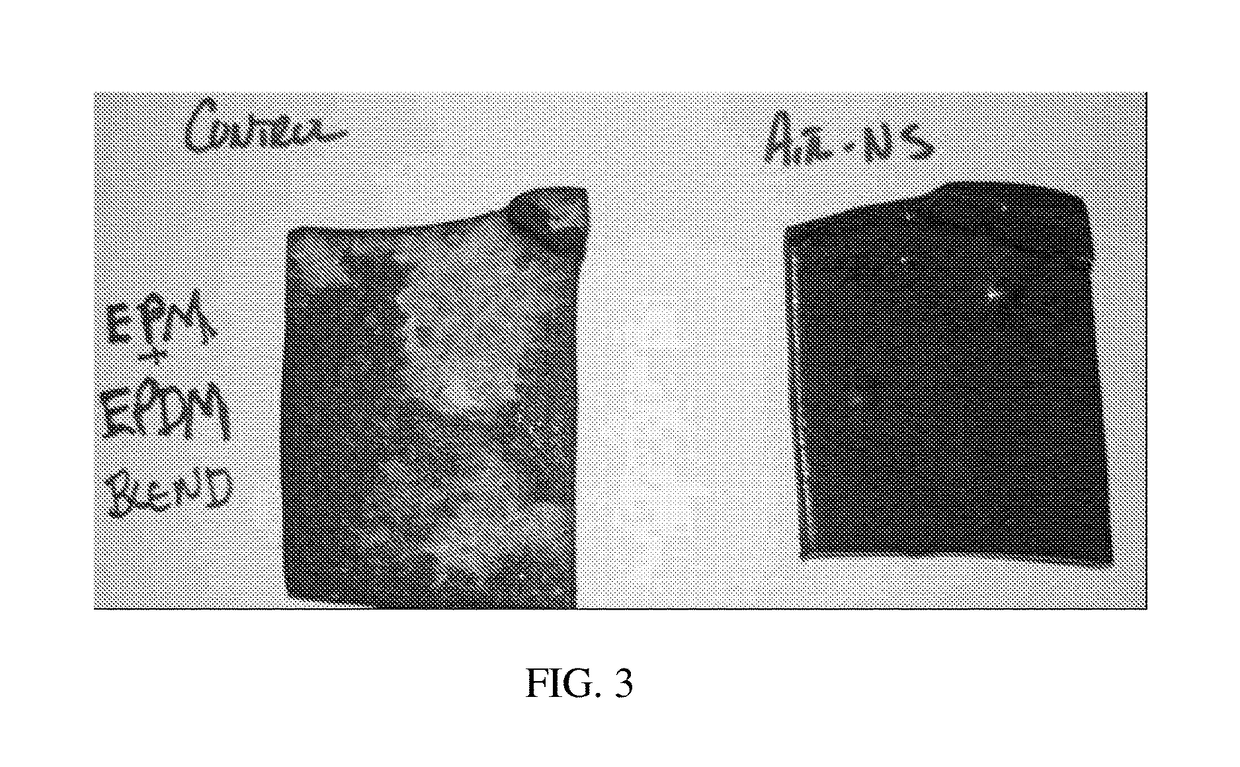

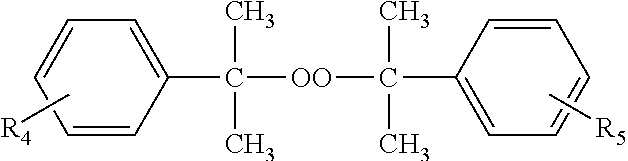

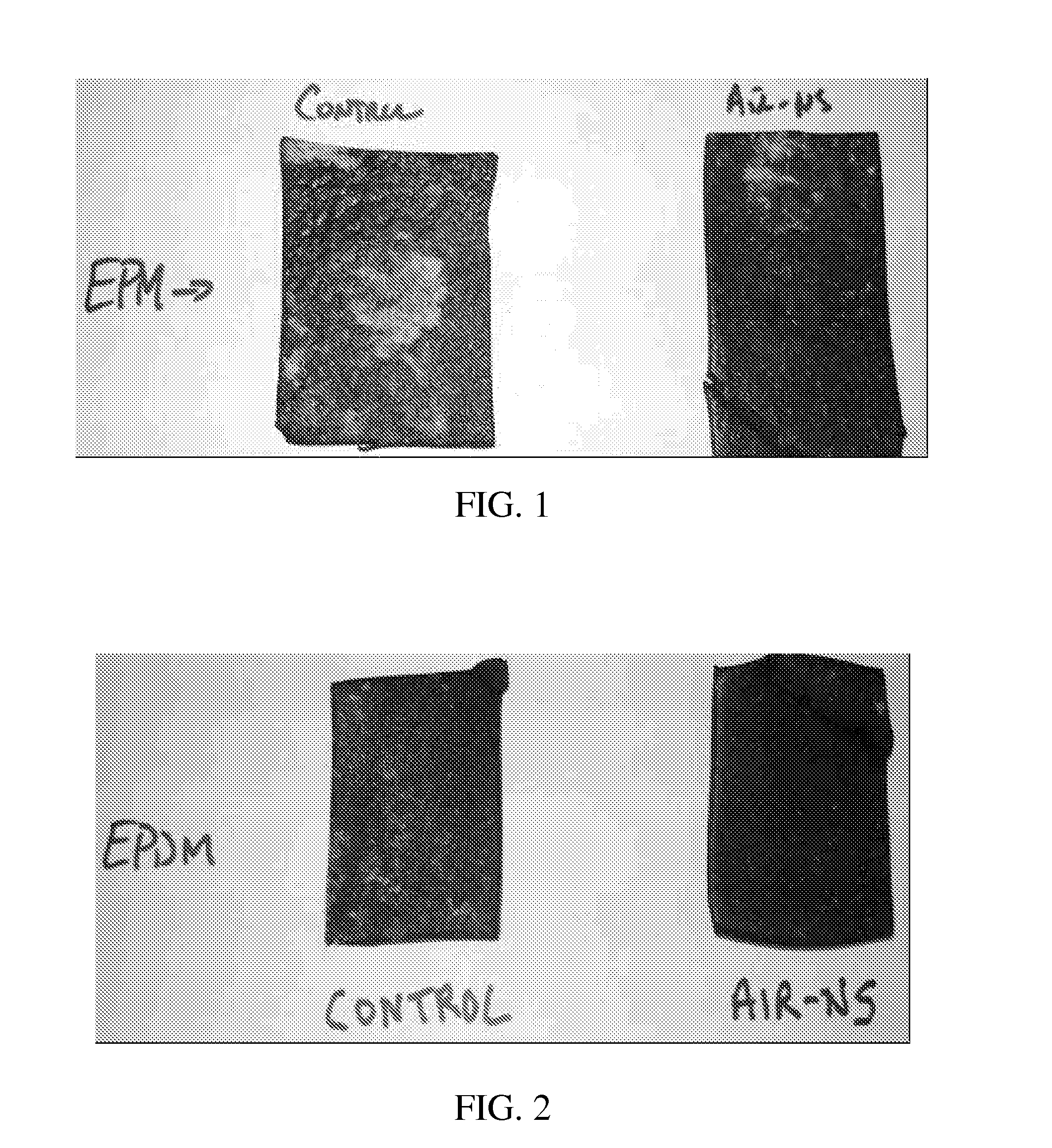

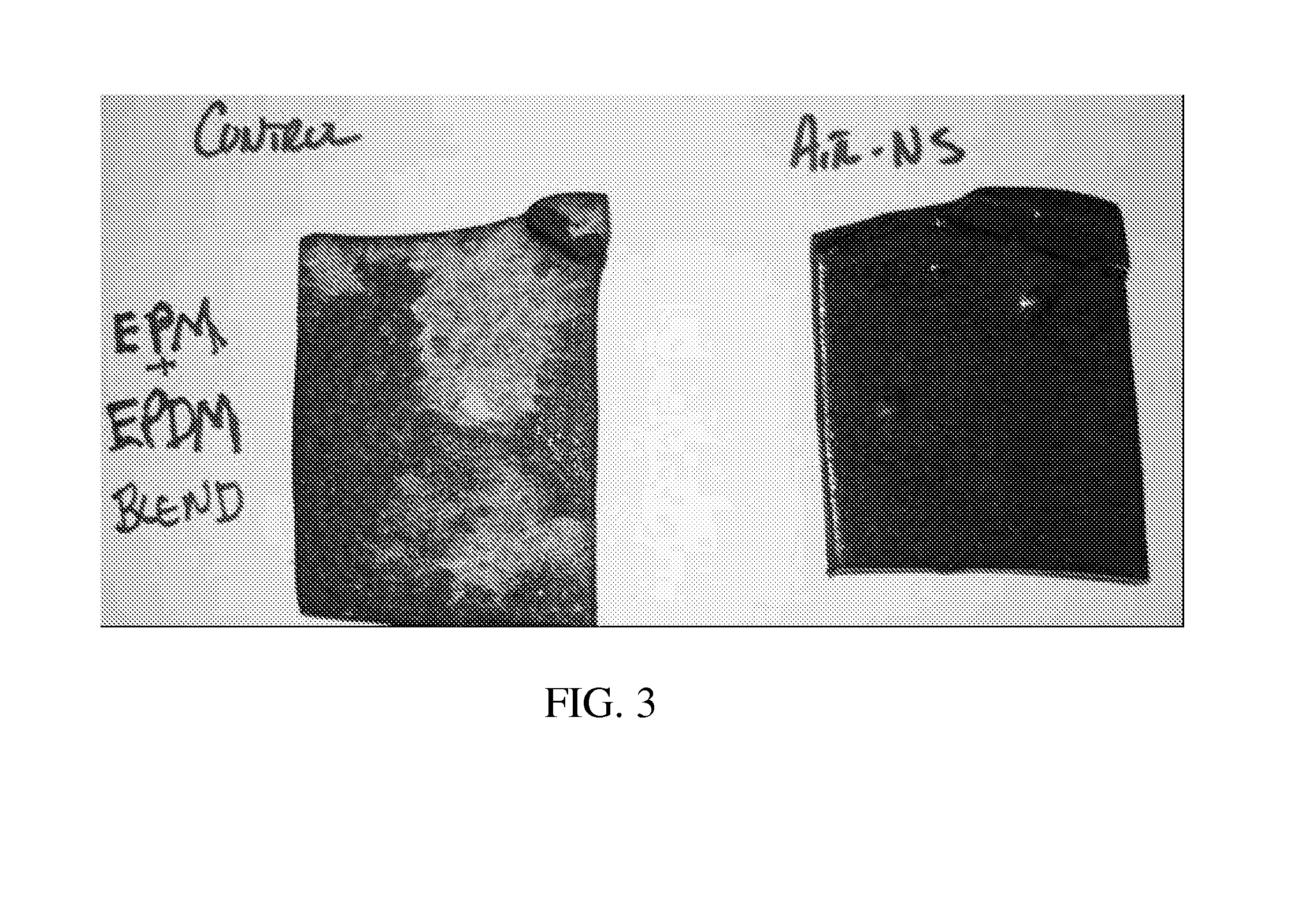

Tack free surface cures of polymers by organic peroxides in the presence of air

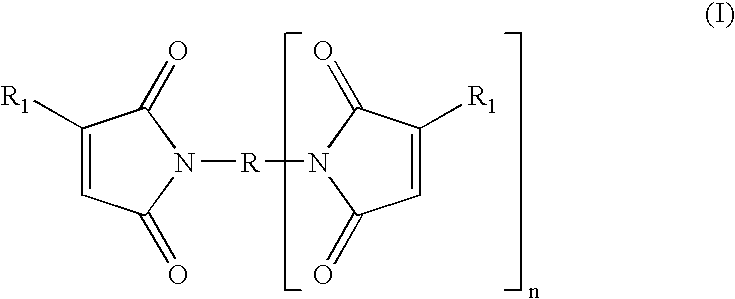

Compositions are disclosed which comprise mixtures of at least one compound selected from silicone elastomers, bis-, tri- or higher polymaleimides and / or bis-, tri- or higher polycitraconimides, and at least one compound selected from p-phenylene-diamine based antiozonants, sulfur compounds capable of accelerating sulfur vulcanization of polymers capable of being crosslinked by sulfur and polysulfide polymers which when compounded into polymers curable by free radical initiators in the presence of free radical initiators permit substantially tack free surface cure of the polymers by decomposition of the free radical initiator in the presence of molecular oxygen. Compositions containing the above ingredients and at least one free radical initiator, curable compositions containing the combination and processes for making and using the compositions are also disclosed.

Owner:ARKEMA INC

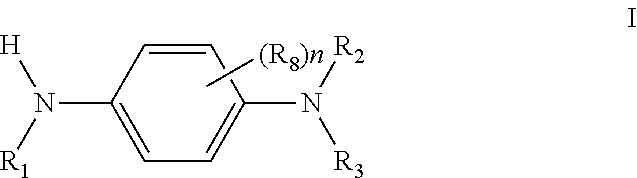

Cross products and co-oligomers of phenylenediamines and aromatic amines as antioxidants for lubricants

Radical initiated reactions of phenylenediamines with alkylated aromatic amines produce an antioxidant mixture containing cross reaction products of the phenylenediamines and alkylated aromatic amines which are useful, for example, as antioxidants, stabilizers, and antiozonants for lubricants, electronic chemicals, rubbers, urethanes and other polymer resins, crop protection, pharmaceuticals, dyes and toners.

Owner:CHEMTURA CORP

Carbon black reinforced rubber composition with aromatic guanidine antiozonant and tire having component thereof

This invention relates to a carbon black reinforced rubber composition with aromatic guanidine antiozonant. The invention particularly relates to a sulfur curable rubber composition which contains a primary sulfenamide sulfur vulcanization accelerator and an antiozonant as a combination of amine antiozonant and a sufficient amount of secondary aromatic guanidine sulfur vulcanization accelerator to require a sulfur vulcanization retarder. Representative of such aromatic guanidine sulfur vulcanization compounds are diphenyl guanidine and di-ortho-tolyl guanidine. The invention further relates to rubber products, including tires, particularly tire sidewalls, comprised of such rubber composition, which are intended to have exposure to atmospheric ozone.

Owner:SANDSTROM PAUL HARRY

Open-cell polyurethane foam and process for its manufacture

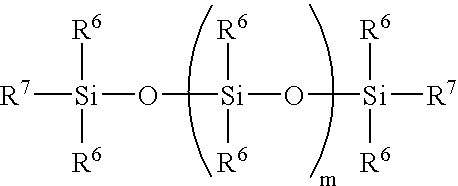

There is provided a predominantly open-cell polyurethane foam obtained from a predominantly open-cell polyurethane foam-forming reaction medium which comprises:a) at least one polyol;b) at least one polyisocyanate;c) at least one catalyst;d) water;e) a predominantly open-cell polyurethane foam-forming amount of at least one surfactant which is a balanced, substantially linear polyether-polysiloxane ABA′ block copolymer; and,f) optionally, at least one additional component selected from the group consisting of other polymer and / or copolymer, chain extender, crosslinker, non-aqueous blowing agent, filler, reinforcement, pigment, tint, dye, colorant, flame retardant, antioxidant, antiozonant, UV stabilizer, anti-static agent, biocide and biostat.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

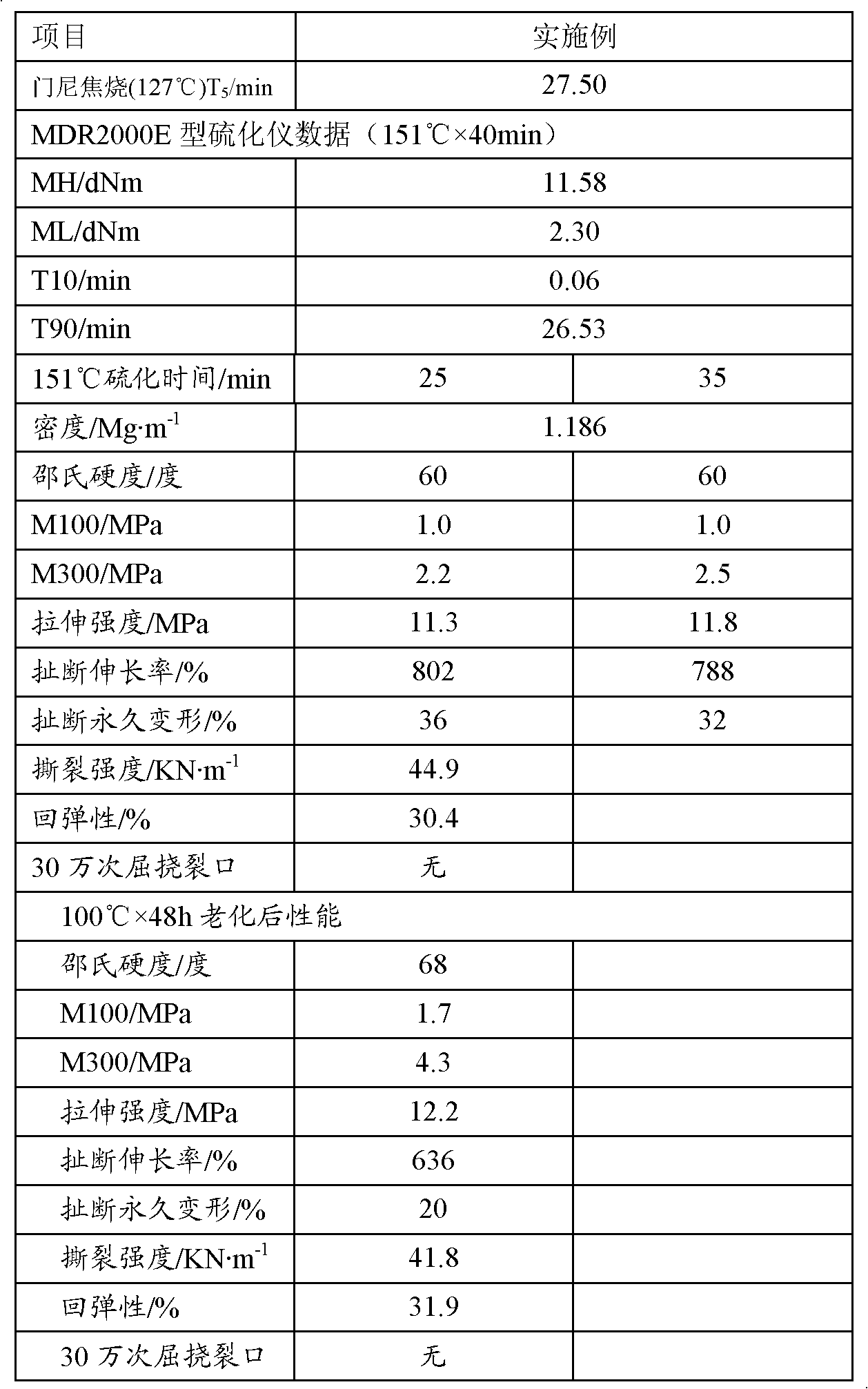

Rubber composite for sidewall of colored truck radial tire

The invention discloses a rubber composite for a sidewall of a colored truck radial tire, comprising the following components in parts by weight: 100 parts of matrix rubber, 5-8 parts of activating agent, 40-70 parts of white carbon black, 3-9 parts of silane coupling agent, 6-10 parts of light-colored rubber oil, 2-6 parts of light-colored tackifying resin, 0.5-3 parts of accelerating agent, 4-8parts of anti-ageing agent, 1-2 parts of vulcanizing agent, 5-8 parts of antistatic agent and 3-6 parts of coloring agent, wherein the matrix rubber is composed of natural rubber, halogenated butyl rubber and rare-earth butadiene rubber; the white carbon black is precipitation-method white carbon black; the accelerating agent is composed of an accelerating agent DM (2,2'-dibenzothiazole disulfide) and an accelerating agent DPG (Dipropylene Glycol); the anti-ageing agent is composed of a non-polluted type light-colored antiozonant, a non-polluted type light-colored antioxidant and an anti-ageing agent TMQ (2,2,4-trimethyl-1,2-dihydroquinoline); the vulcanizing agent is sulfur; and the antistatic agent is a polyethers antistatic agent. The sidewall prepared from the rubber composite provided by the invention not only has a bright color, but also has good flex fatigue resistance; and the rubber composite is mainly used for the sidewall of the colored truck radial tire.

Owner:QINGDAO DOUBLESTAR TIRE IND CO LTD

Anti-ozonants covalently attached to silica gel for use in glossy print media

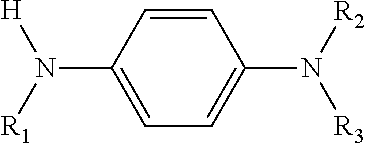

InactiveUS6767640B2Fix fadingPigmenting treatmentOrganic chemistry methodsPrint mediaSilica particle

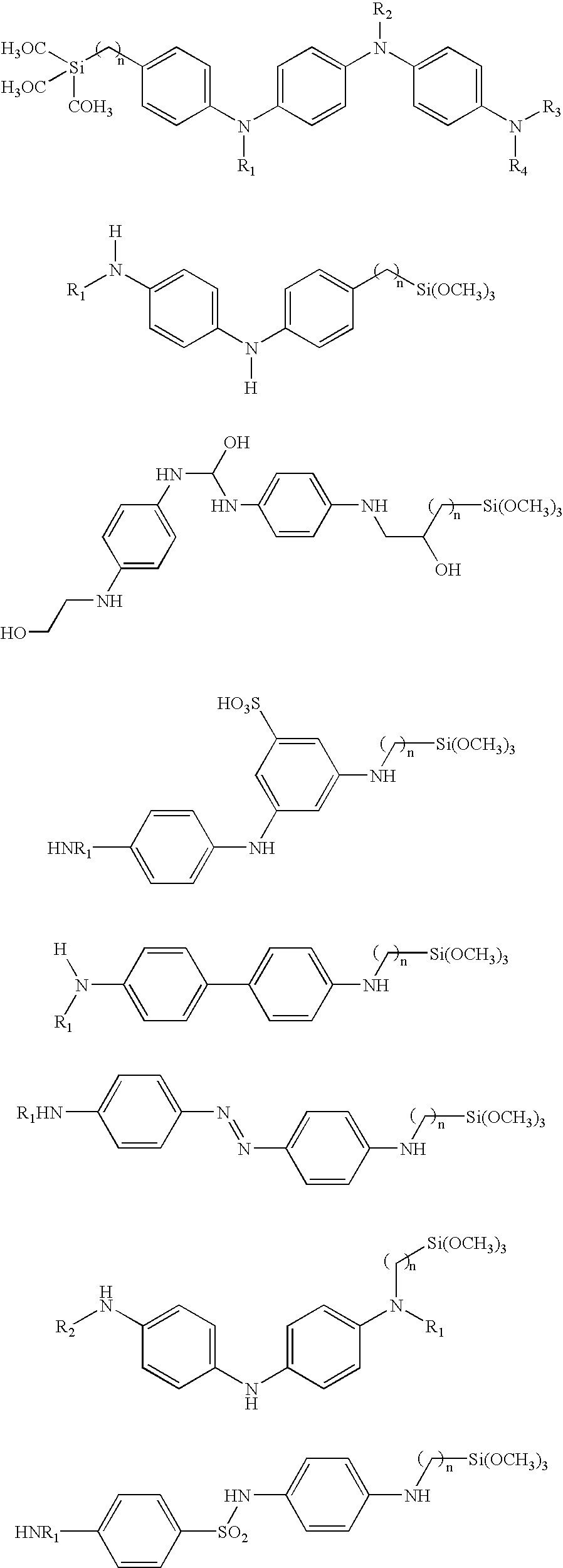

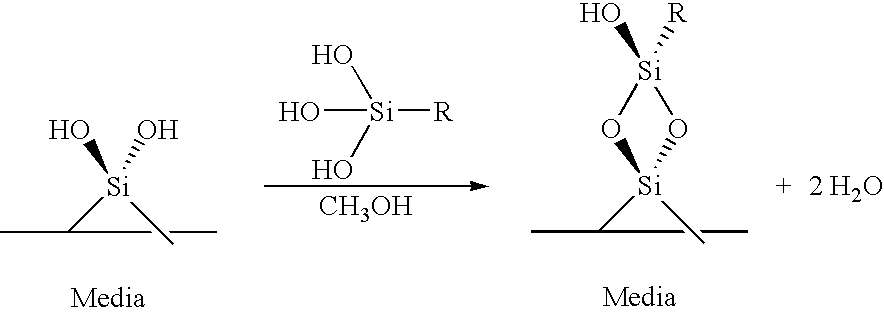

A method of protecting dyes printed on print media against ozonolysis is provided. The method comprises: (a) providing a first reaction product comprising the reaction of a phenylenediamine or derivative thereof (an anti-ozonant) with a silica or silicate; and (b) reacting the first reaction product in the presence of a water-free solvent with silica groups to form a second reaction product. Also provided is the reaction product resulting from the reaction of (1) the anti-ozonant-silica (or silicate) and (2) silica groups on a substrate. The anti-ozonant-silica (or silicate) is covalently attached to the particles of silica in the media and cannot escape or evaporate away. The use of phenylenediamines as anti-ozonants solves the problem of the fading of dyes on porous media by ozone pollution.

Owner:HEWLETT PACKARD DEV CO LP

Tack free surface cures of polymers by organic peroxides in the presence of air

Compositions are disclosed which comprise mixtures of at least one compound selected from silicone elastomers, bis-, tri- or higher polymaleimides and / or bis-, tri- or higher polyciraconimides, and at least one compound selected from p-phenylene-diamine based antiozonants, sulfur compounds capable of accelerating sulfur vulcanization of polymers capable of being crosslinked by sulfur and polysulfide polymers which when compounded into polymers curable by free radical initiators in the presence of free radical initiators permit substantially tack free surface cure of the polymers by decomposition of the free radical initiator in the presence of molecular oxygen. Compositions containing the above ingredients and at least one free radical initiator, curable compositions containing the combination and processes for making and using the compositions are also disclosed.

Owner:ARKEMA INC

Environment-friendly corrosion-resistant epichlorohydrin rubber

The invention relates to the field of rubber, particularly an environment-friendly corrosion-resistant epichlorohydrin rubber which is composed of the following components in parts by weight: 50-80 parts of epichlorohydrin rubber, 10-15 parts of silicon dioxide, 20-30 parts of quick-extrusion carbon black, 1-5 parts of anti-aging agent, 0-5 parts of antiozonant, 0.5-1.5 parts of vulcanizing agent, 0.5-1.5 parts of stearic acid, 2-5 parts of magnesium oxide and 1-3 parts of calcium carbonate. By using microcrystalline wax, which has the advantages of high melting point, low migration rate and small and uniform crystals, as the anti-aging agent, the film formed by the wax, which has the advantages of high binding firmness with rubber, favorable flexibility and favorable shielding property, can have an anti-aging action, and can also generate an isolating layer on the rubber surface to perform the demolding function and reduce the contact between the epichlorohydrin rubber and the metal mold, thereby decelerating the metal corrosion and resisting metal corrosion without adding any other component; and the lead-free vulcanizing agent PDM conforms to the requirement for environment friendliness.

Owner:广州市蓝欣包装材料有限公司

Rubber compositions and method for increasing the mooney scorch value

A rubber composition is disclosed wherein the rubber composition contains at least (a) a rubber component; (b) a silica filler; and, (c) at least one thiuram disulfide accelerator, it being provided that diphenyl guanidine is substantially absent in the rubber composition. The compositions may also include suitable amounts of other ingredients such as carbon black, coupling agents, antiozonants, antioxidants, etc.

Owner:UNIROYAL CHEM CO INC

Formula for temperature-sensing rubber sneaker sole and manufacturing method thereof

InactiveCN101817942AAnti-slip effectAnti-slip protrusionSolesDomestic footwearFiberMicrocrystalline wax

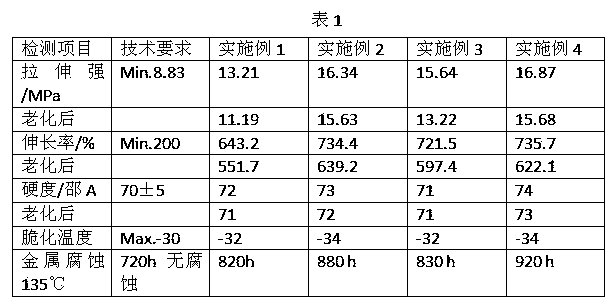

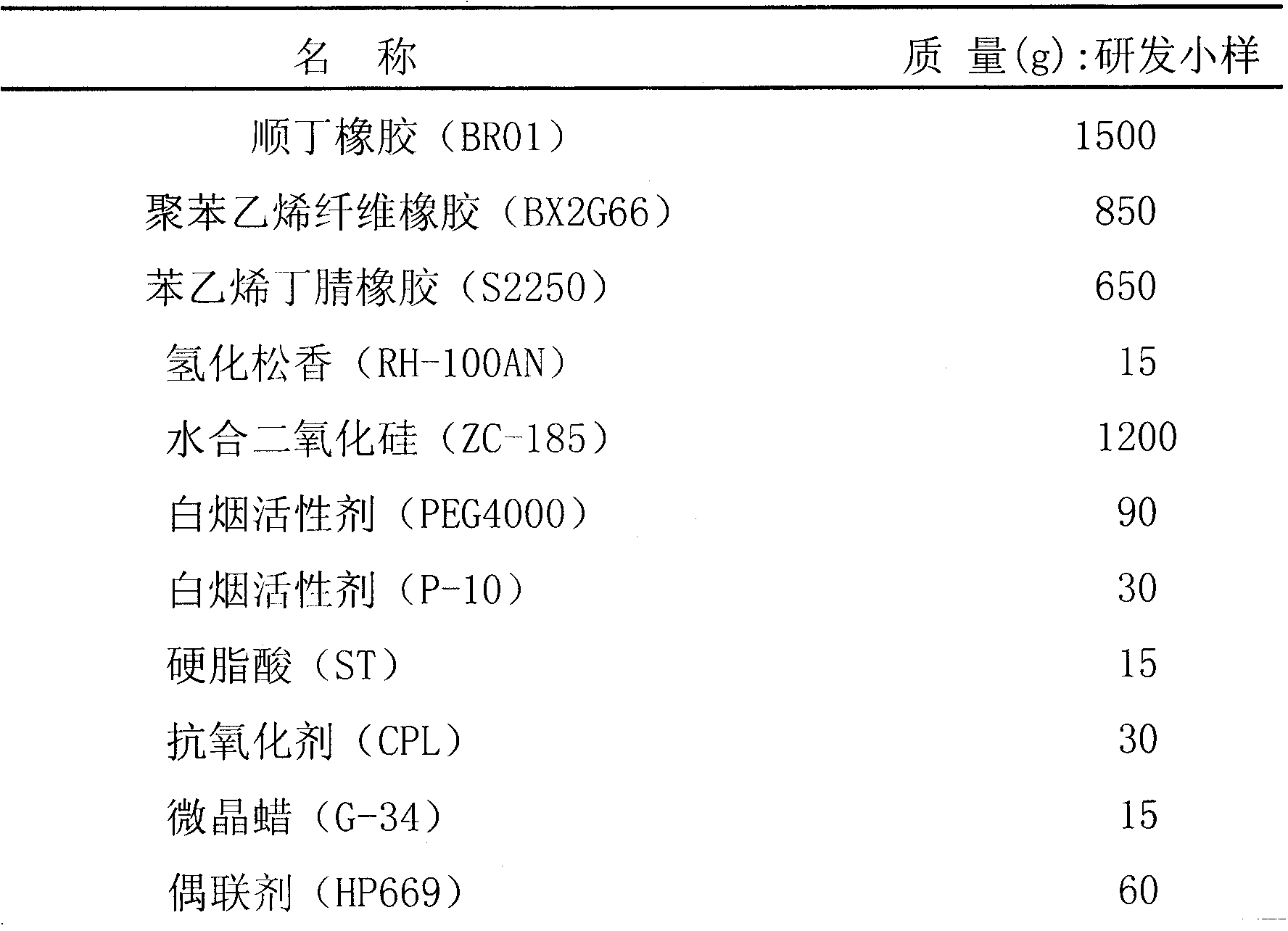

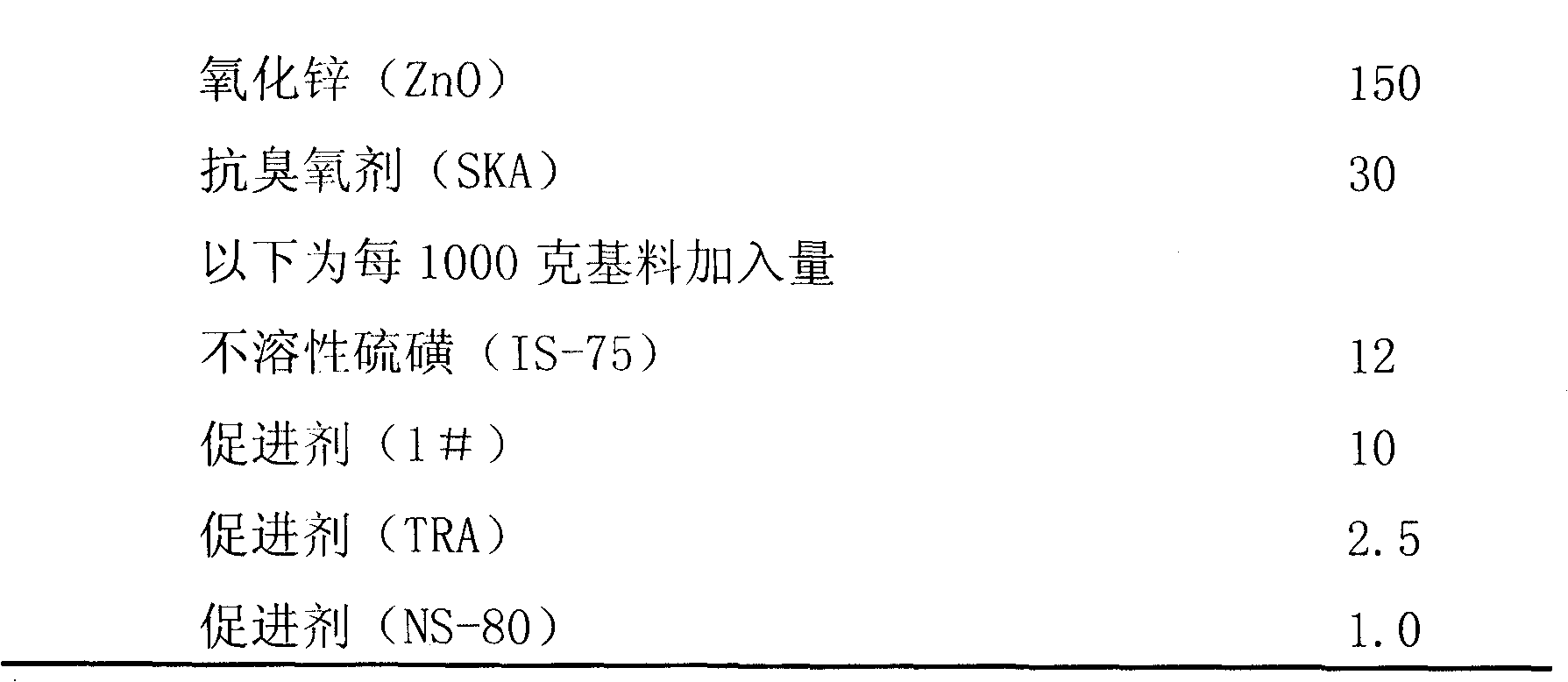

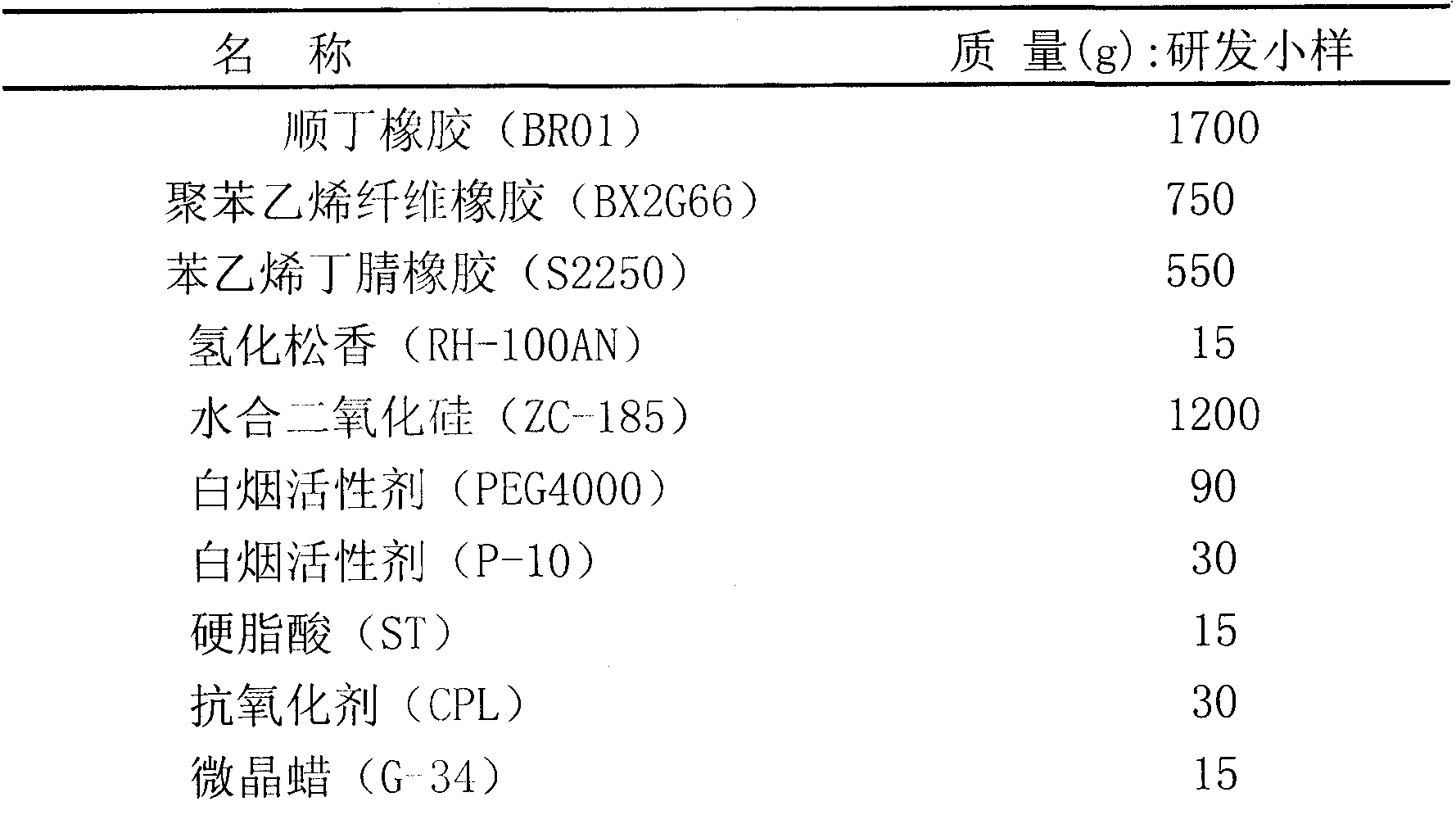

Raw material components of a temperature-sensing rubber sole are divided into two parts; a formula for the first part comprises the following components in percentage by mass: 39.1 percent of butadiene rubber (BR01), 16.3 percent of polystyrene fiber rubber (BX2G66), 9.8 percent of acrylonitrile-butadiene rubber (S2250), 26.1 percent of white smoke, 0.3 percent of hydrogenated rosin (RH-100AN), 0.3 percent of stearic acid, 3.3 percent of zinc oxide, 0.3 percent of microcrystalline wax (G-34), 2.0 percent of white smoke activator (PEG4000), 0.7 percent of white smoke activator (P-10), 0.7 percent of coupling agent (HP669), 0.7 percent of antiozonant (SKA), and 0.7 percent of antioxidant (CPL); and the second part comprises the following components in the addition amount based on the first part: 12g / kg of the first part of insoluble sulfur (IS-75), 10g / kg of the first part of promoter (No. 1), 2.5g / kg of the first part of promoter (TRA), and 1g / kg of the first part of promoter (NS-80); and a preparation method comprises the following steps of banburying, milling, hot-press forming, physical property test and the like.

Owner:恺英网络股份有限公司

Cross Products and Co-Oligomers of Phenylenediamines and Aromatic Amines as Antioxidants for Lubricants

Radical initiated reactions of phenylenediamines with alkylated aromatic amines produce an antioxidant mixture containing cross reaction products of the phenylenediamines and alkylated aromatic amines which are useful, for example, as antioxidants, stabilizers, and antiozonants for lubricants, electronic chemicals, rubbers, urethanes and other polymer resins, crop protection, pharmaceuticals, dyes and toners

Owner:CHEMTURA CORP

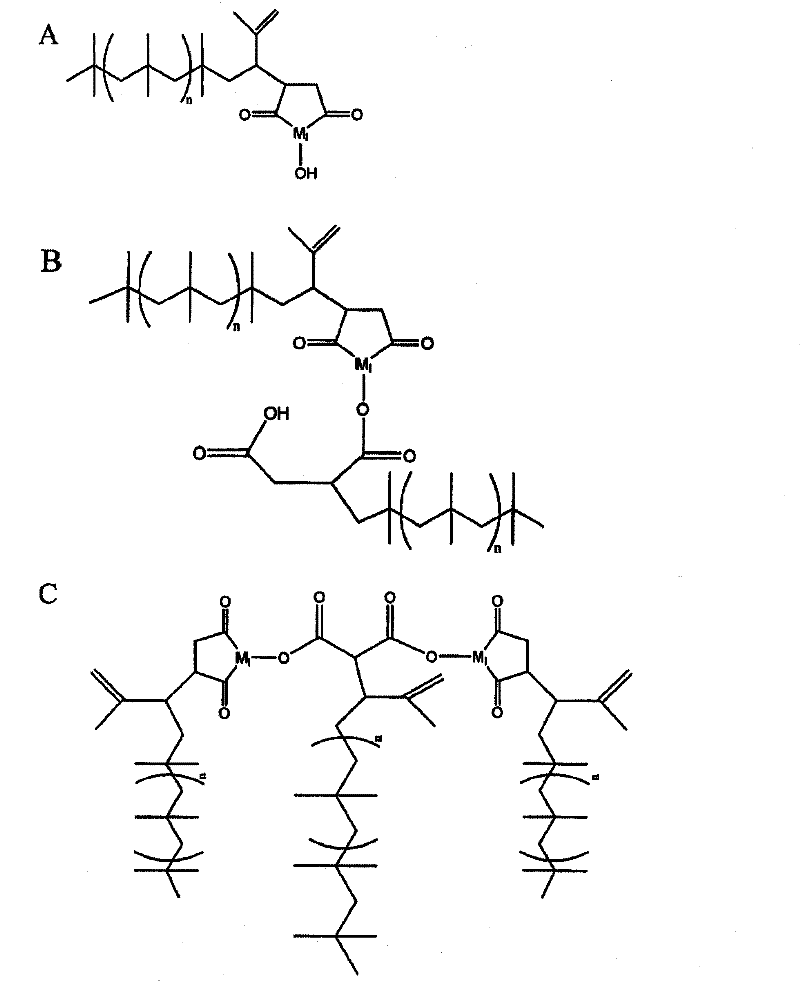

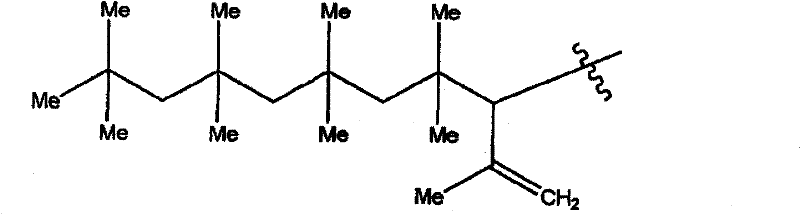

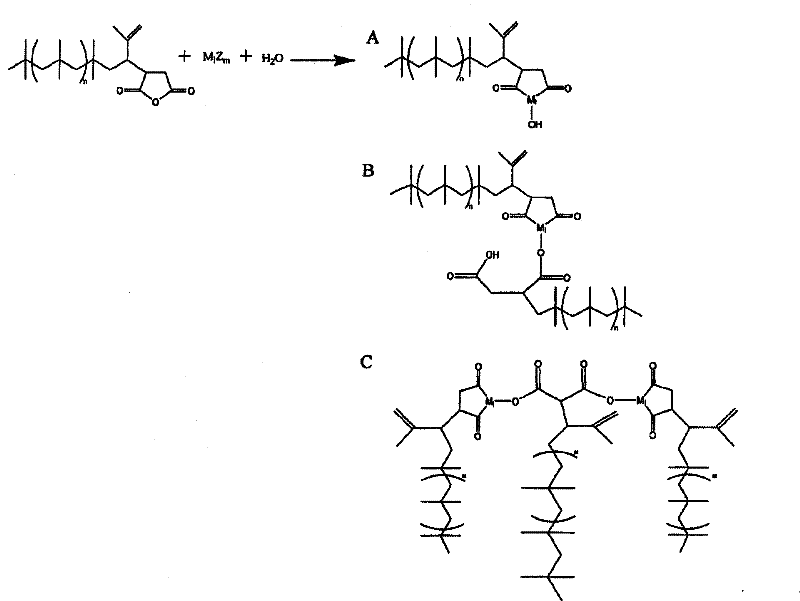

Rubber compositions including metal-functionalized polyisobutylene derivatives and methods for preparing such compositions

A composition includes a vulcanizable diene rubber, a silica filler, and a metal-functionalized polyisobutylene succinic anhydride derivative. In one embodiment the composition has a reduced amount of oil and may include no oil. A tire tread composition includes, a silica filler, a metal-functionalized polyisobutylene succinic anhydride derivative, a rubber matrix, an optional oil, and one or more components selected from the group consisting of carbon black, vulcanizing agent, vulcanization accelerator, tackifier resin, antioxidant, wax, peptizer, vulcanization retarder, activator, processing additive, plasticizer, pigments, and antiozonant. A method for making the rubber composition and the tire tread is also provided.

Owner:BRIDGESTONE CORP

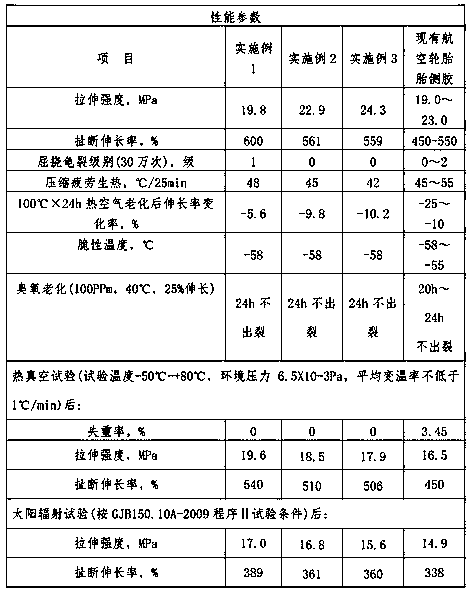

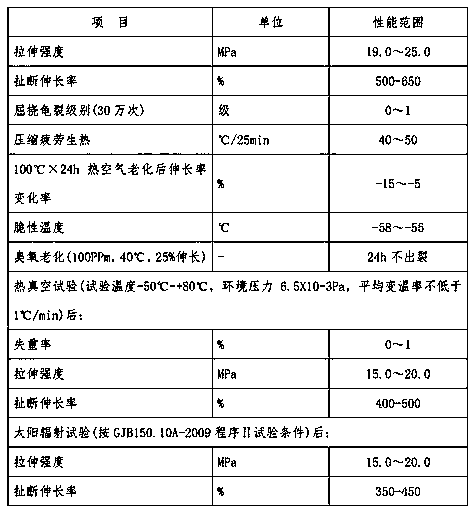

Side rubber of aircraft tire

ActiveCN110157055AReduce weight lossGood weather resistanceSpecial tyresCrack resistanceModified carbon

The invention belongs to the field of aircraft tires and particularly relates to side rubber of an aircraft tire. The side rubber is prepared from the ingredients in parts by weight: 30-70 parts of natural glue, 20-40 parts of ethylene propylene terpolymer rubber, 10-30 parts of cis-butadiene rubber, 40-60 parts of modified carbon black N330, 1-3 parts of paraffin oil, 1-3 parts of tackifying resin, 1-4 parts of leveler, 1-2 parts of crack preventing agent, 0.1-0.5 part of antiozonant H, 1-2 parts of p-phenylenediamine type anti-aging agent, 3-8 parts of zinc oxide, 1-4 parts of stearic acid,0.1-1 part of insoluble sulfur, 1-3 parts of vulcanizer DTDM and 1-3 parts of sulfenamide type accelerator DZ. The side rubber of the aircraft tire, disclosed by the invention, can adapt to high-temperature low-temperature diurnal-cycle thermal vacuum environments and harsh working conditions such as radiation and has more excellent property performance, i.e., heat resistance, cold resistance, ozone resistance, radiation resistance, elongation at rupture and flex cracking resistance.

Owner:中国化工集团曙光橡胶工业研究设计院有限公司

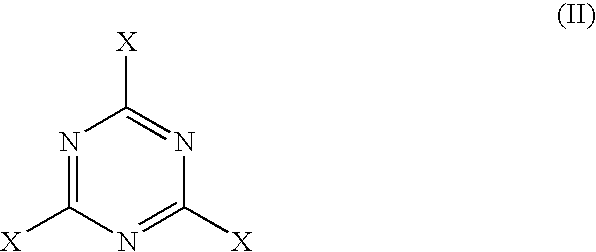

Substituted triazine compositions and methods for producing same

Compositions comprising substituted phenylenediamine and substituted triazine compounds, including tris-(N-alkyl-p-phenylenediamino)-1,3,5-triazines. The compositions are liquid and do not sinter during storage or transportation. The compositions are used as antiozonants for elastomer articles, including rubber articles.

Owner:CHEMTURA CORP

Methods for crosslinking polymer compositions in the presence of atmospheric oxygen

A process for crosslinking an elastomer composition in the presence of an organic peroxide formulation is disclosed. The organic peroxide formulation may comprise additional compounds chosen from bis-, tri- and higher poly-maleimides, bis-, tri- and higher poly-citraconimides, peroxide-crosslinkable silicone elastomers, p-phenylenediamine based antiozonants, sulfur containing organic compounds which are accelerators for the sulfur curing (crosslinking) of polymers which are curable / crosslinkable by sulfur, and polysulfide polymers. Methods of manufacturing elastomer articles, methods of reducing mold-fouling, elastomer compositions, and elastomer articles made from the elastomer compositions are also disclosed.

Owner:ARKEMA INC

Nitrile butadiene rubber

The invention relates to the field of rubber, and particularly relates to nitrile butadiene rubber which consists of the following components in parts by weight: 50-80 parts of nitrile butadiene rubber, 0.5-1.0 part of stearic acid, 2-3 parts of zinc oxide, 3-8 parts of diethyl phthalate, 1-3 parts of polyethylene wax, 0.5-1.5 parts of accelerant, 3-5 parts of alkyl ether adipate, 2-5 parts of calcium silicate, 1-3 parts of antiozonant, 0-3 parts of anti-aging agent and 20-30 parts of carbon black. The nitrile butadiene rubber provided by the invention has the beneficial effects that the anti-ozone property of nitrile butadiene rubber is effectively improved due to addition of polyethylene wax and antiozonant and the heat resistance and hardness of nitrile butadiene rubber are effectively improved due to addition of the filler agents including diethyl phthalate and calcium silicate,.

Owner:临沂星火知识产权服务有限公司

Graphene composite damping rubber material and preparation method thereof

The invention relates to a graphene composite damping rubber material and a preparation method thereof. The rubber material comprises the following substances in parts by mass: 100 parts of rubber, 40-60 parts of a reinforcing filler, 3-4 parts of an anti-aging agent, 5-8 parts of nano-zinc oxide, 1-1.5 parts of stearic acid, 0.8-1.5 parts of a vulcanizing agent, 2-3.5 parts of a vulcanizing aid,0.4 to 0.75 part of graphene, 2 to 3 parts of a coupling agent and 3 to 5 parts of an anti-ozone agent, wherein the number of layers of the graphene is not more than 10, and the 100 parts of rubber iscomposed of 75-85 parts of natural rubber, 10-15 parts of high-vinyl polybutadiene rubber and 5-10 parts of chloroprene rubber. The graphene composite damping rubber material disclosed by the invention has good elasticity, good fatigue resistance, low heat generation, small creep deformation, good adhesion to a metal part, cold resistance and excellent processability, and has relatively high economic value and good application prospects.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

Liquid antiozonants and rubber compositions containing same

Liquid antiozonant mixtures obtained from the process comprising simultaneously reacting at least one unsubstituted and / or substituted paraphenylenediamine compound with a carbonyl compound mixture comprising acetone and at least one other carbonyl compound selected from the group consisting of ketones containing from 4 to about 12 carbon atoms, aldehydes containing from 1 to about 12 carbon atoms and mixtures thereof in the presence of a reductive alkylation catalyst is provided. Rubber compositions containing the liquid antiozonant mixtures is also provided.

Owner:DEUT BANK AG NEW YORK BRANCH +1

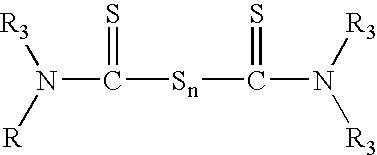

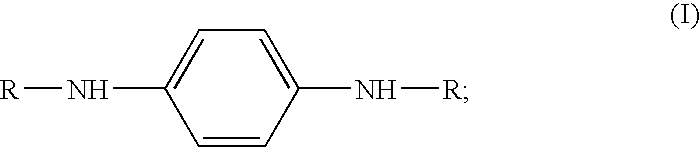

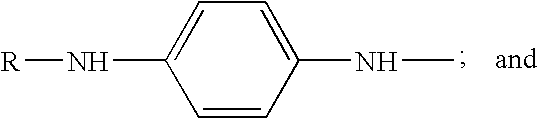

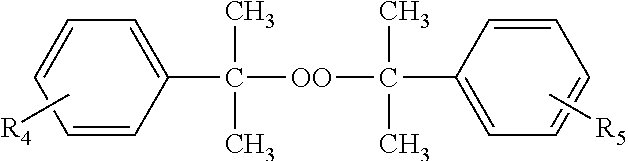

Antiozonant blends

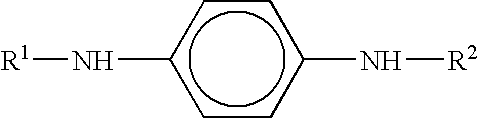

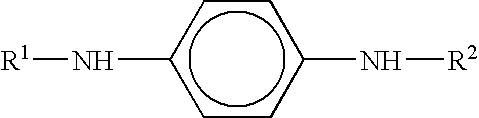

InactiveUS20070260000A1Improve durabilityLayered productsChemical inhibitorsAntioxidantPhotochemistry

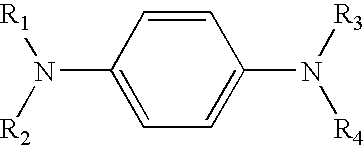

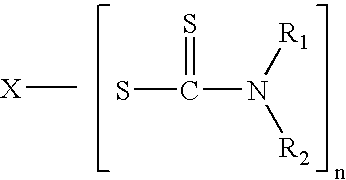

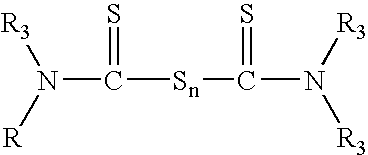

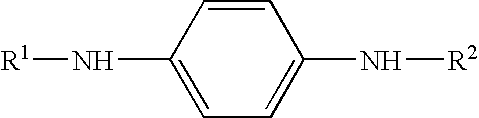

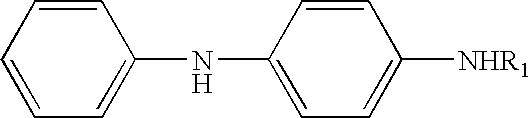

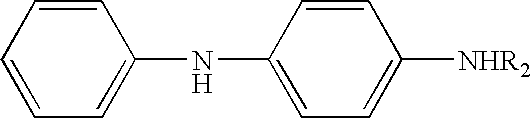

An antiozonant mixture is disclosed wherein said mixture comprises at least two compounds, (A) at least one of which is of the structure and (B) at least one other of which is of the structure wherein R1 is a straight chain, branched, or cyclic alkyl group comprising from three to seven carbon atoms, and R2 is a straight chain, branched, or cyclic alkyl group comprising at least eleven carbon atoms.

Owner:ADDIVANT USA

Antibacterial environment-friendly rubber

The invention relates to an antibacterial environment-friendly rubber. The rubber comprises the following raw materials in parts by weight: 40-55 parts of silicone rubber, 4-7 parts of an antiozonant, 4-7 parts of a nano-silver antibacterial agent, 6-12 parts of vinyl silicone resin, 9-14 parts of boric acid, 2-5 parts of hydroxyl silicone oil, 1-4 parts of a nanometer heat-resistant additive, 2-4 parts of carbon fiber and 1-3 parts of sodium stearate. The rubber disclosed by the invention has the beneficial effects that the rubber material disclosed by the invention has the advantages of excellent antibacterial effect and no harm to the environment and human body.

Owner:QINGDAO GUOQIANG ENVIRONMENTAL PROTECTION TECH

Methods for crosslinking polymer compositions in the presence of atmospheric oxygen

ActiveUS20160017135A1Microwave heatingArtifical filament manufactureSilicone ElastomersOrganic compound

A process for crosslinking an elastomer composition in the presence of an organic peroxide formulation is disclosed. The organic peroxide formulation may comprise additional compounds chosen from bis-, tri- and higher poly-maleimides, bis-, tri- and higher poly-citraconimides, peroxide-crosslinkable silicone elastomers, p-phenylenediamine based antiozonants, sulfur containing organic compounds which are accelerators for the sulfur curing (crosslinking) of polymers which are curable / crosslinkable by sulfur, and polysulfide polymers. Methods of manufacturing elastomer articles, methods of reducing mold-fouling, elastomer compositions, and elastomer articles made from the elastomer compositions are also disclosed.

Owner:ARKEMA INC

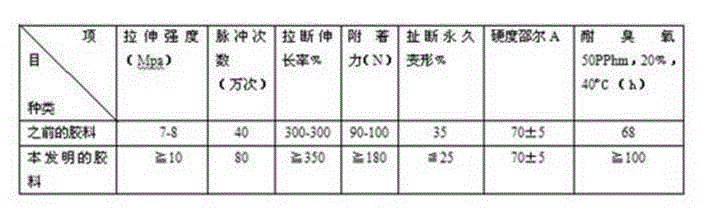

Novel high-performance high-polymer mixed material for steel-wire-wound hydraulic rubber tubes

InactiveCN104371212AIncrease the number of pulsesQuality improvementFlexible pipesMicrocrystalline waxCrazing

The invention discloses a novel high-performance high-polymer mixed material for steel-wire-wound hydraulic rubber tubes, which is prepared from the following raw materials in parts by weight: 15-20 parts of butyronitrile 6420, 35-40 parts of alloy PVC (polyvinyl chloride), 30-40 parts of chlorinated polyethylene CM352F, 1.5-2 parts of zinc oxide, 8-10 parts of magnesium oxide, 1-1.5 parts of anti-aging agent, 10-15 parts of silicon dioxide, 50-60 parts of carbon black, 2-4 parts of antiozonant, 25-35 parts of light calcium carbonate, 30-40 parts of dioctyl ester, 1-1.5 parts of sulfur, 0.5-1 part of accelerator CBS and 2-3 parts of vulcanizing agent P1682. The antiozonant is microcrystalline wax B10; the carbon black is N330 carbon black; and the anti-aging agent is nickel N,N-dibutyldithiocarbamate. The external rubber mixed material prepared according to the formula increases the number of times of pulses in the use process, improves the phenomena of cracking, bubbling and the like, enhances the quality of the product and prolongs the service life of the product.

Owner:LUOHE GUTEWEI RUBBER PROD

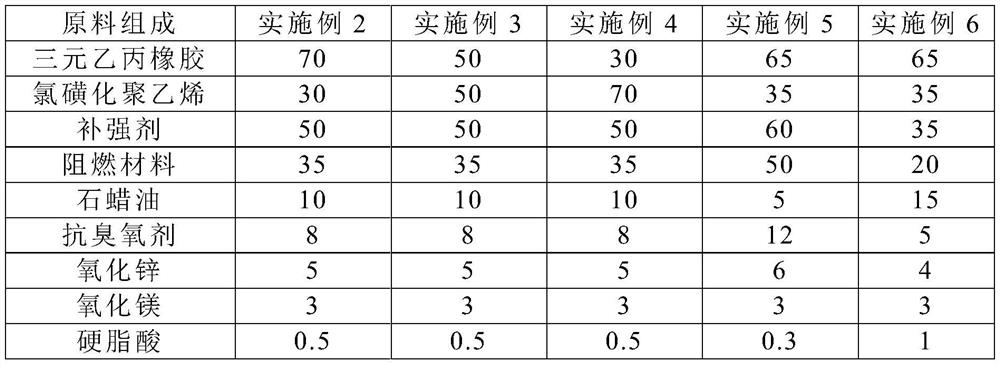

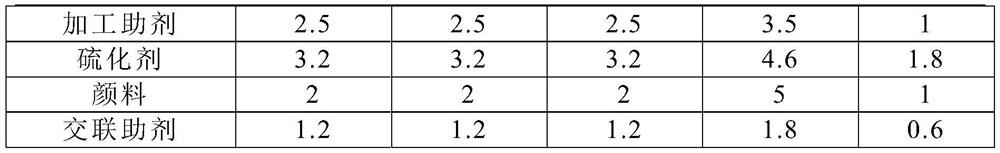

Flame-retardant composite rubber material capable of resisting high-concentration ozone and preparation method thereof

The invention belongs to the field of rubber materials, and particularly relates to a flame-retardant composite rubber material capable of resisting high-concentration ozone and a preparation method thereof. The composite rubber material comprises the following raw materials in parts by weight: 70-30 parts of ethylene propylene diene monomer, 30-70 parts of chlorosulfonated polyethylene, 30-60 parts of a reinforcing agent, 25-50 parts of a flame-retardant material, 5-15 parts of paraffin oil, 5-12 parts of an anti-ozone agent, 4-6 parts of zinc oxide and 0.3-1 part of stearic acid. In the preparation process of the flame-retardant composite rubber, the ethylene propylene diene monomer, the chlorosulfonated polyethylene and the magnesium oxide are mixed, then the active agent, the aniseed and the oil material are added step by step, low-temperature mixing is performed, high-temperature conditions are not needed, and the production process is simple, energy-saving and efficient. Throughreasonable formula design and process optimization, the prepared composite rubber material has the characteristics of high-concentration ozone resistance and favorable flame retardancy, and can resistthe ozone concentration of 200ppm on an ozone generator so as to keep intact.

Owner:宁波柯林斯橡塑科技有限公司

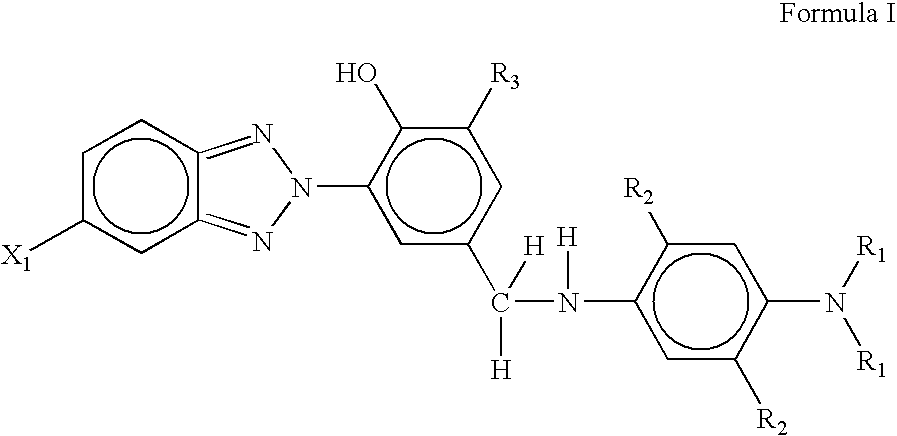

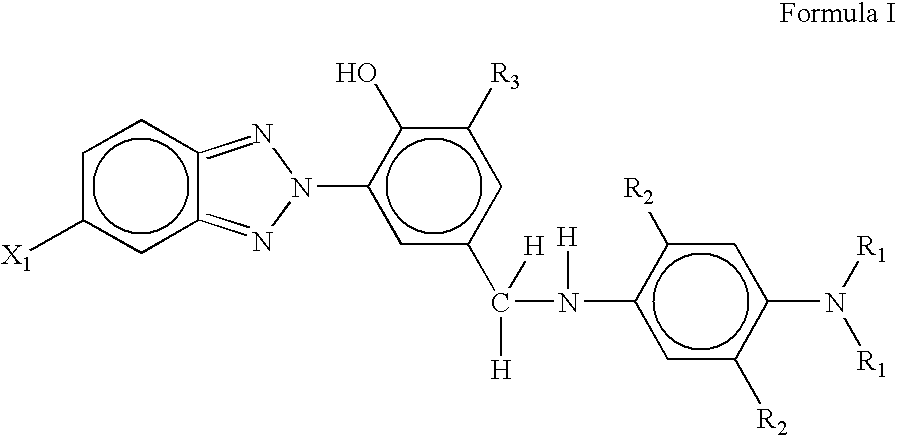

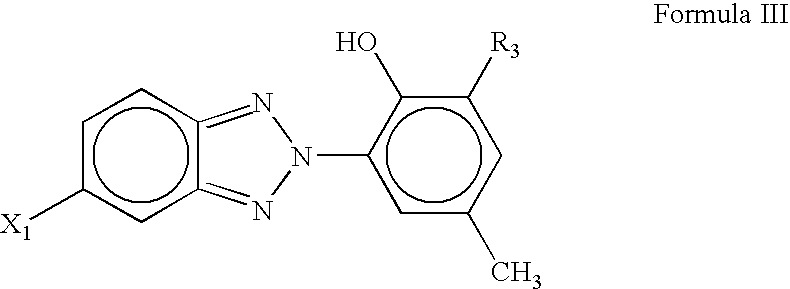

Antiozonant based on functionalized benzotriazole UV absorbers and the process thereof

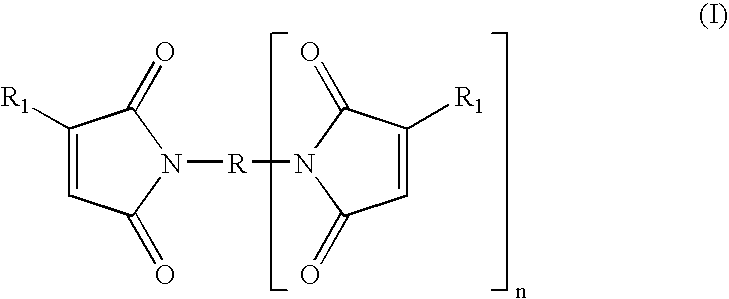

A process for the preparation of a novel antiozonant and antioxidant, based on functionalized benzotriazole UV absorbers, and the process for the preparation thereof having a general Formula I:wherein R1 and R2 are C1 to C8 linear or branched alkyl; R3 is hydrogen, tert-butyl; X1 is select the group consisting of hydrogen, halogen, tert-butyl and C1 to C12 alkoxy.

Owner:COUNCIL OF SCI & IND RES

Antiozonant for polymers

Provided are an antiozonant for polymers capable of providing excellent ozone resistance, and an ozone resistant rubber composition and an ozone resistant tire formed using the antiozonant. The present invention relates to an antiozonant for polymers, including alumina.

Owner:SUMITOMO RUBBER IND LTD

A bite - resistant dog biting toy for resisting and resisting bite and a preparation method thereof

ActiveUS20180303067A1Simple structureLong-lasting fragranceTaming and training devicesMicrocrystalline waxRapeseed

A compression resistant and long-lasting scented dog toy and its preparation method. The compression resistant and long-lasting scented dog toy comprises a rubber body and cloth fluidized on it. The rubber body is made of following raw materials by weight: natural rubber, zinc oxide, camphene, stearic acid, anti-aging agent, edible gum, starch, microcrystalline wax, white carbon black, naphthenic oil, silicone rubber, butyl rubber, accelerant, antiozonant, medical light calcium carbonate, edible rapeseed oil, flavor enhancer, sour agent, talcum powder and fatty acid softening agent. The invention is made of a rubber body and cloth fluidized on it. Flavouring agents are mixed in the rubber body so as to produce a compression resistant and long-lasting scented body with durable fragrance.

Owner:SHANGHAI JIAYUANHUI TRADING CO LTD

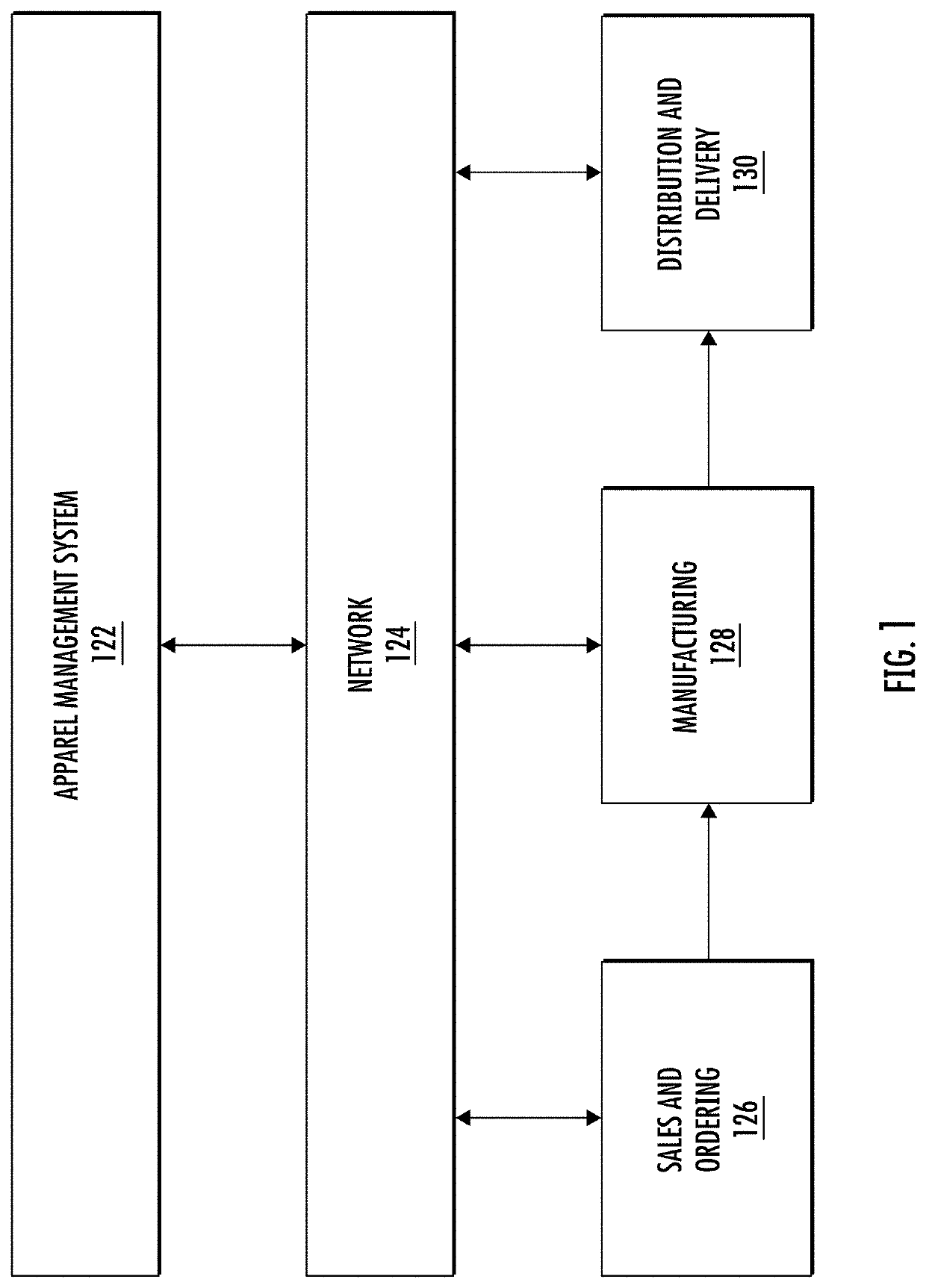

Anti-ozone treatment of base templates in laser finishing

ActiveUS11299832B2Prevent ozone-related degradationLaser beam fibre treatmentTwo or more solvent application treatmentVitamin CColor changes

Indigo-dyed garments are treated with an anti-ozone agent to prevent ozone-related degradation of the garments before laser finishing. Without treatment, the garments can exhibit color loss (e.g., color change or fading) from exposure to ozone in the atmosphere. The indigo-dyed garments with anti-ozone treatment can serve as base templates in a laser finishing process flow. The anti-ozone treatment of the base templates can include a rinse including an ascorbic acid or vitamin C constituent during a base preparation process. Then quantities of these base templates can manufactured and stored for periods of time without exhibiting ozone-related degradation effects.

Owner:LEVI STRAUSS & CO

Outer coating layer for plastic pencil and preparation method thereof

InactiveCN108976544AExcellent solutionAddressing Vulnerable IssuesNon-propelling pencilsMasterbatchHost material

The invention discloses an outer coating layer for a plastic pencil and a preparation method thereof, and relates to the technical field of pencil preparation. The outer coating layer is prepared fromthe following components in parts by weight: 60-80 parts of polyethylene, 10-15 parts of SBS, 2-5 parts of coupler, 20-60 parts of modified modified bentonite, 1-3 parts of an antiaging agent, 1-3 parts of antioxidant, 2-5 parts of color masterbatch, 2-5 parts of an odor removing agent, 2-5 parts of a crosslinking agent, 2-10 parts of mineral oil, 5-15 parts of titanium dioxide, 3-7 parts of zincoxide and 5-15 parts of fatty acid. According to the outer coating layer, the polyethylene and modified bentonite are used as main materials, and are added with additives to prepare a coating film, which coats the outer part of a pen-holder, and the problem that an existing plastic pencil coating layer is over hard or easily broken can be solved.

Owner:安徽得亿文教用品有限公司

Long-life sealing ring for large-sized hydraulic equipment

InactiveCN108239311AResistant to hydraulic oilHigh temperature resistantSaturated fatty acid esterThiourea

The invention discloses a long-life sealing ring for large-sized hydraulic equipment. The long-life sealing ring is prepared from the following raw materials in parts by weight: 80-120 parts of nitrile rubber, 100-120 parts of high-wear resistance furnace black, 3-5 parts of a multiwalled carbon nanotube, 0.5-1 parts of insoluble sulfur, 1-3 parts of tetrabenzylthiuramdisulfide, 1-3 parts of N-cyclohexane-2-benzothiazolyl sulfonamide, 5-8 parts of indirect process zinc oxide, 1-2 parts of stearic acid 1-2, 1.5-3 parts of 2,2,4-trimethyl-1,2-dihydroquinoline polymer, 1.5-3 parts of a thiourea antiozonant, 5-15 parts of trioctyl trimellitate, 1-2 parts of saturated isoparaffin and 1.5-3 parts of saturated fatty acid ester. The long-life sealing ring has the characteristics of hydraulic oil resistance, high temperature resistance, low temperature resistance, high pressure resistance, wear resistance, ozone resistance and the like; compared with a common sealing ring, the long-life sealingring has the advantages of reliability in the sealing, wide high and low temperature ranges, strong applicability, long life, environmental friendliness and the like.

Owner:ANHUI ZHONGDING SEALING PARTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com