Rubber compositions including metal-functionalized polyisobutylene derivatives and methods for preparing such compositions

A metal functional, polyisobutylene succinic anhydride technology, applied in the direction of transportation and packaging, rolling resistance optimization, special tires, etc., can solve problems such as difficult to maintain

- Summary

- Abstract

- Description

- Claims

- Application Information

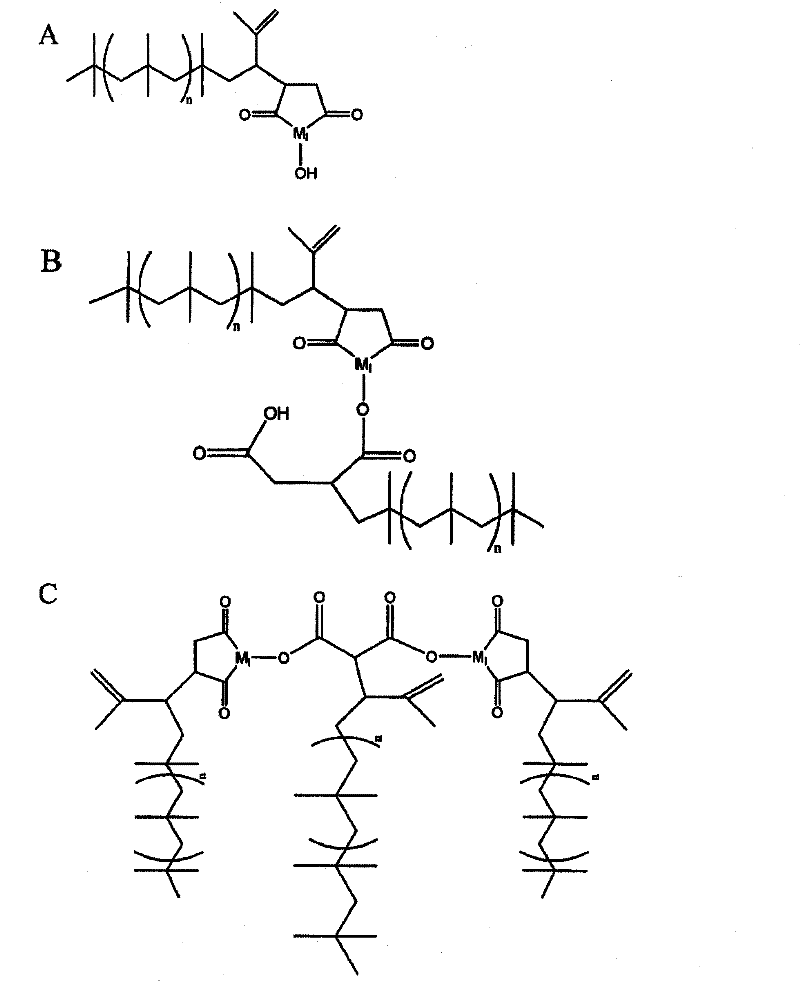

AI Technical Summary

Problems solved by technology

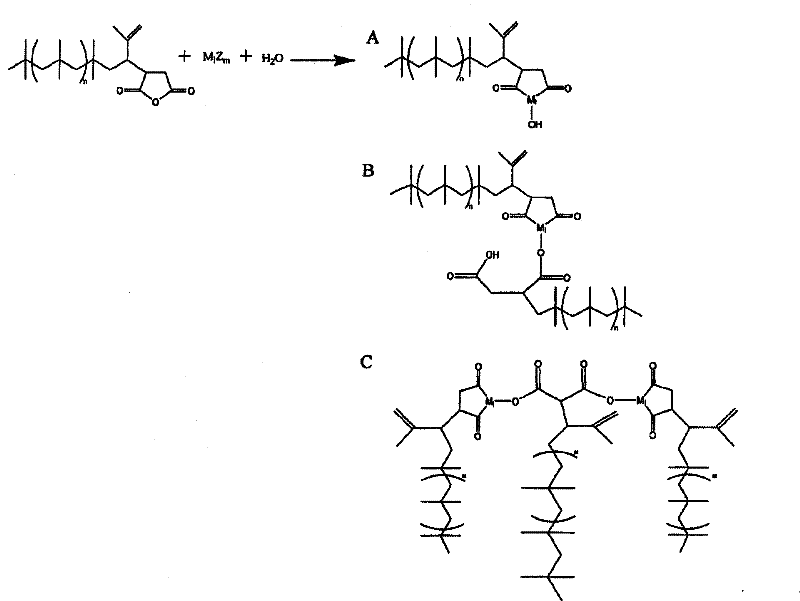

Method used

Image

Examples

Embodiment 1

[0078] To a 1 gallon glass bottle was added 4000 ml of water and 40 g of sodium hydroxide (99% pure, purchased from Aldrich). After the sodium hydroxide was completely dissolved, 500 g of polyisobutylene succinic anhydride (Mw=1900, Mn=1000, purchased from Chevron Chemicals, trade name OLOA15500, acid value 95) was added to the bottle. The mixture was then vigorously mixed for 1 hour at 90°C. The resulting solution was a milky solution. This solution is referred to as Solution-A.

[0079] To a half gallon sized glass bottle was added 2000 ml of water and 238 g of potassium aluminum sulfate dodecahydrate (98%+ purity, purchased from Aldrich). The mixture was then vigorously mixed at 80° C. for 1 hour until the solution was completely transparent. This solution is referred to as Solution-B.

[0080] Solution-A and Solution-B were then combined while still warming with vigorous stirring. Combination produces a gel-like material. The material was washed 8 times with deionize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com