Patents

Literature

1878 results about "Succinic anhydride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

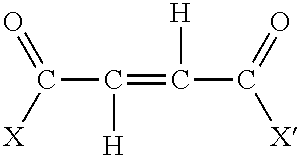

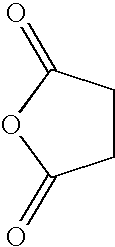

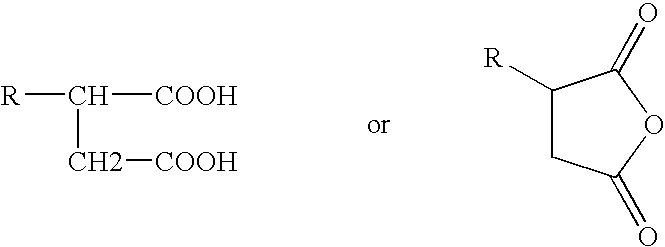

Succinic anhydride, is an organic compound with the molecular formula (CH₂CO)₂O. This colorless solid is the acid anhydride of succinic acid.

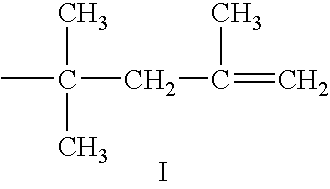

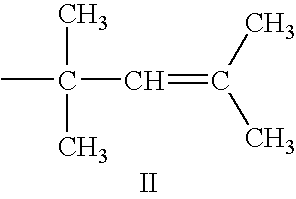

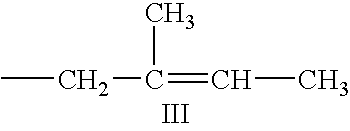

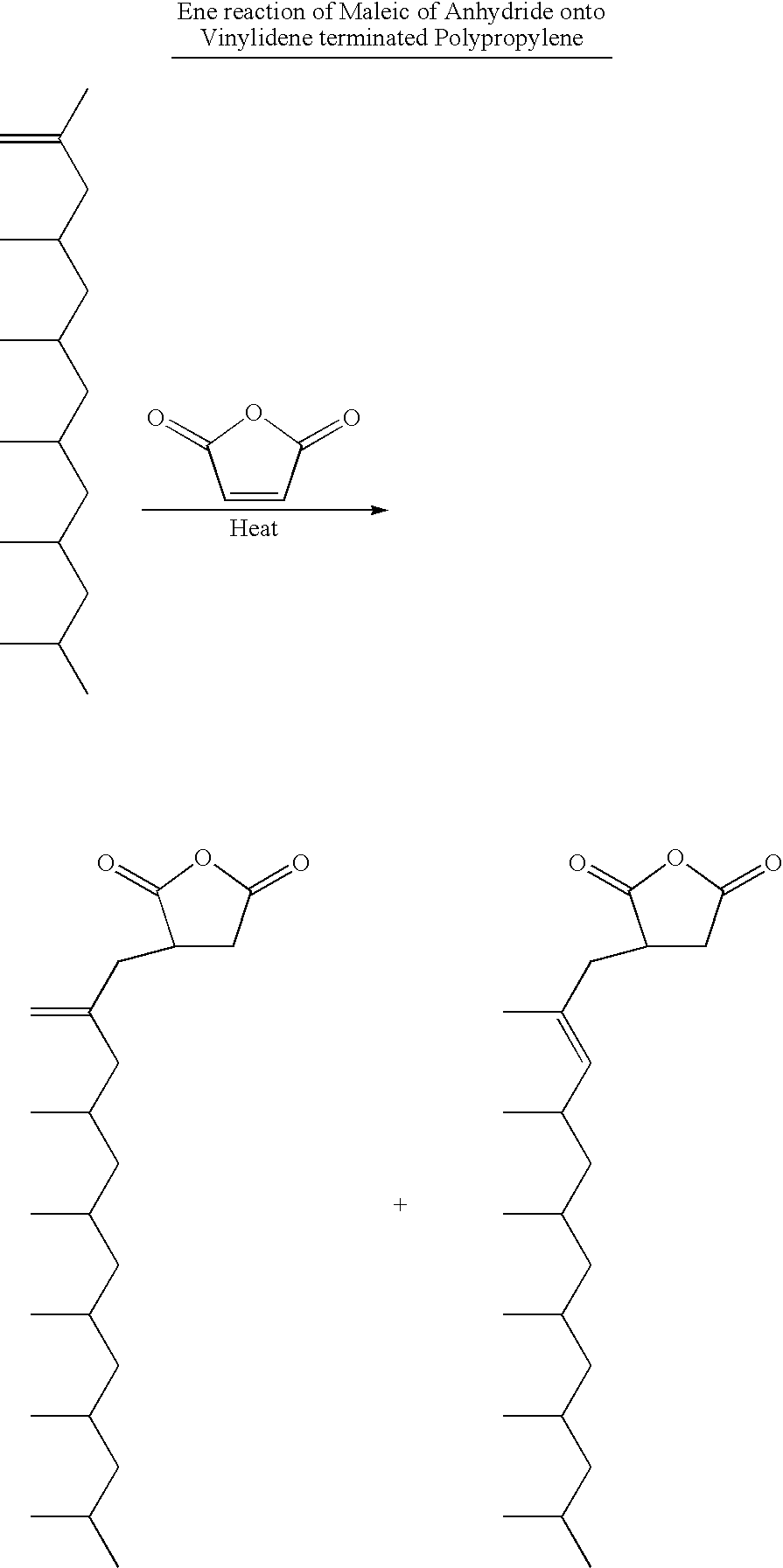

Process for the preparation of polyalkenyl succinic anhydrides

A polyalkenyl succinic anhydride is prepared with low amounts of resinous or chlorinated byproducts in a two-step process whereby a polyalkene is first reacted with an unsaturated organic acid in a thermal ene reaction, followed with exposure to a gaseous halogen in presence of an additional amount of the unsaturated organic acidic reagent. The foregoing process produces a polyisobutenyl succinic anhydride having a high ratio of succinic anhydride functional groups to polyisobutenyl backbone groups. Such a polyisobutenyl succinic anhydride is particular suitable for the production of oil-soluble hydrocarbyl succinimides that have good dispersant properties when added to lubricating oil compositions.

Owner:AFTON CHEMICAL

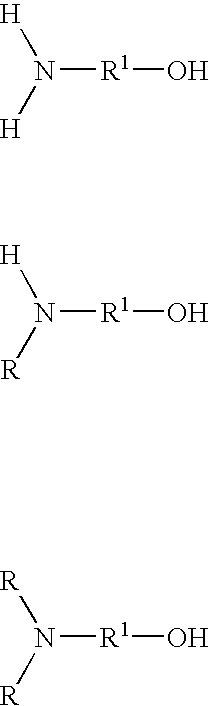

Mixed dispersants for lubricants

A dispersant composition comprising the product of an amine, an alcohol, or an amino alcohol, with a hydrocarbyl-substituted succinic anhydride component exhibits improved viscosity stability and reduced chlorine content, when the hydrocarbyl-substituted succinic anhydride component comprises: (a) 10 to 95 weight percent of a component prepared by reacting a polyisobutylene with maleic anhydride in the presence of chlorine; and (b) 5 to 90 weight percent of a component prepared by reacting a polyisobutylene with maleic anhydride in the substantial absence of chlorine.

Owner:THE LUBRIZOL CORP

Elemental nutritional products

InactiveUS6077558ALittle to no observable browning effectSugar food ingredientsDough treatmentACETYLATED MONOGLYCERIDEHypoallergenic infant formula

An emulsifying system for elemental diet compositions is provided that comprises a protein source that may be a extensively hydrolyzed protein, free amino acids, short-chain peptides, or a mixture thereof; a lipid source; a carbohydrate source; and an emulsifying system comprising an ocentyl succinic anhydride modified starch and an acetylated monoglyceride emulsifier. The composition may be prepared as a powder or liquid nutritional composition for formulas prepared for infant, pediatric and adult populations in need of an elemental diet. The invention provides a commercially acceptable product in terms of desired stability and physical characteristics and is particularly useful for hypoallergenic infant formula preparations.

Owner:NESTEC SA

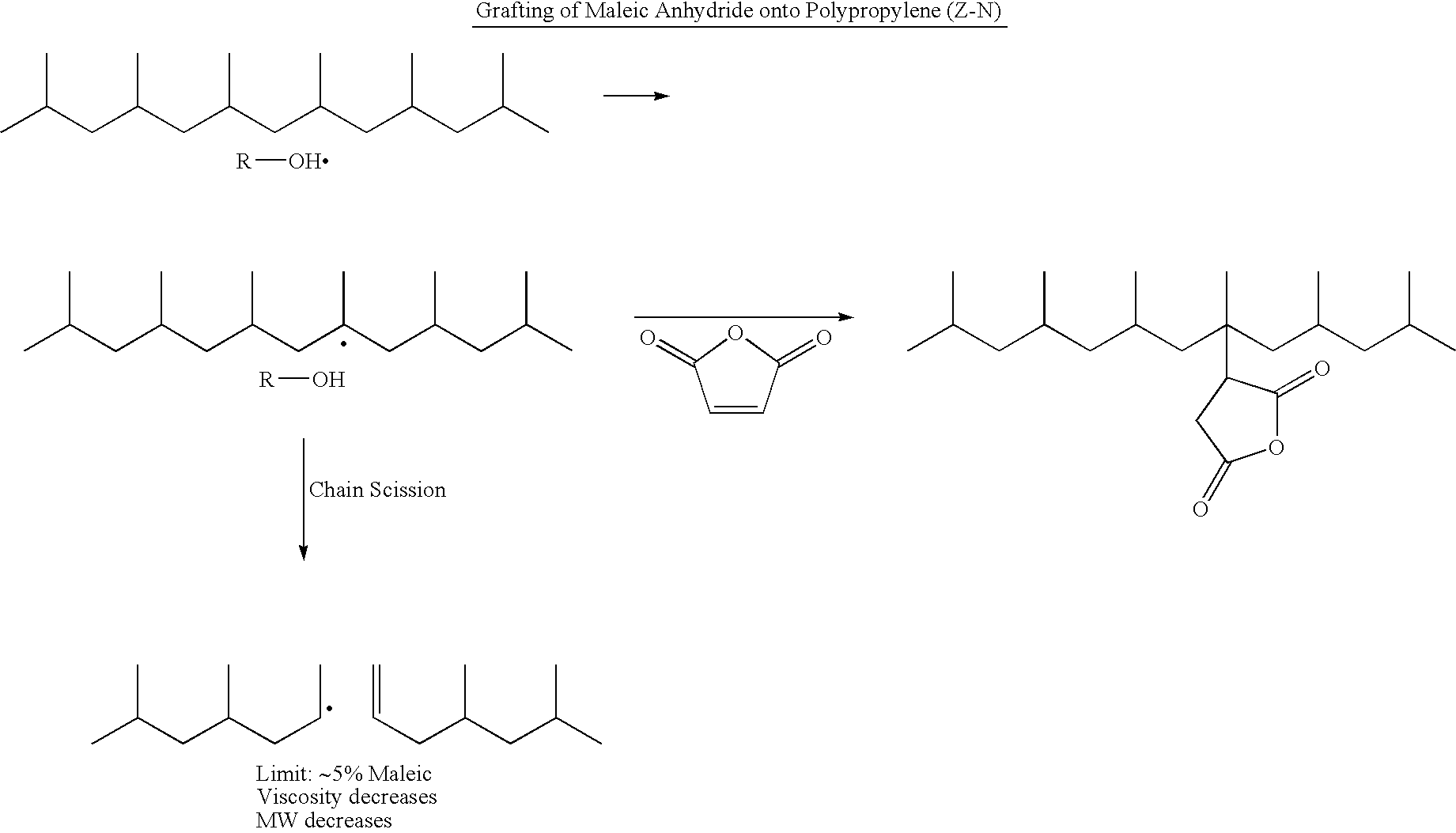

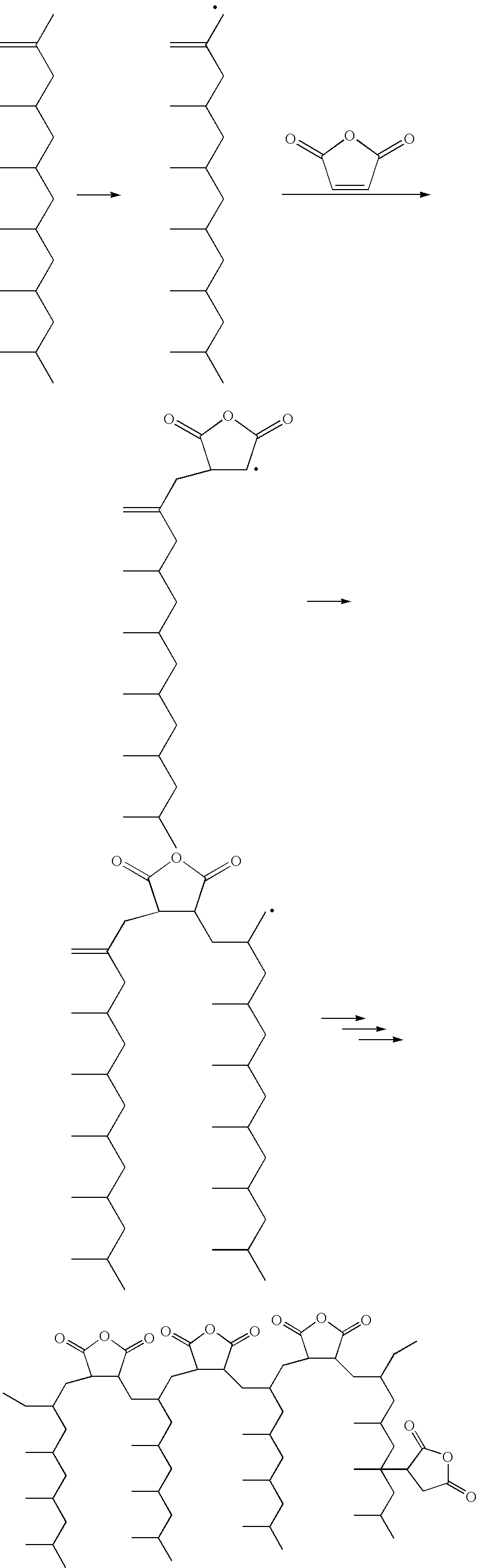

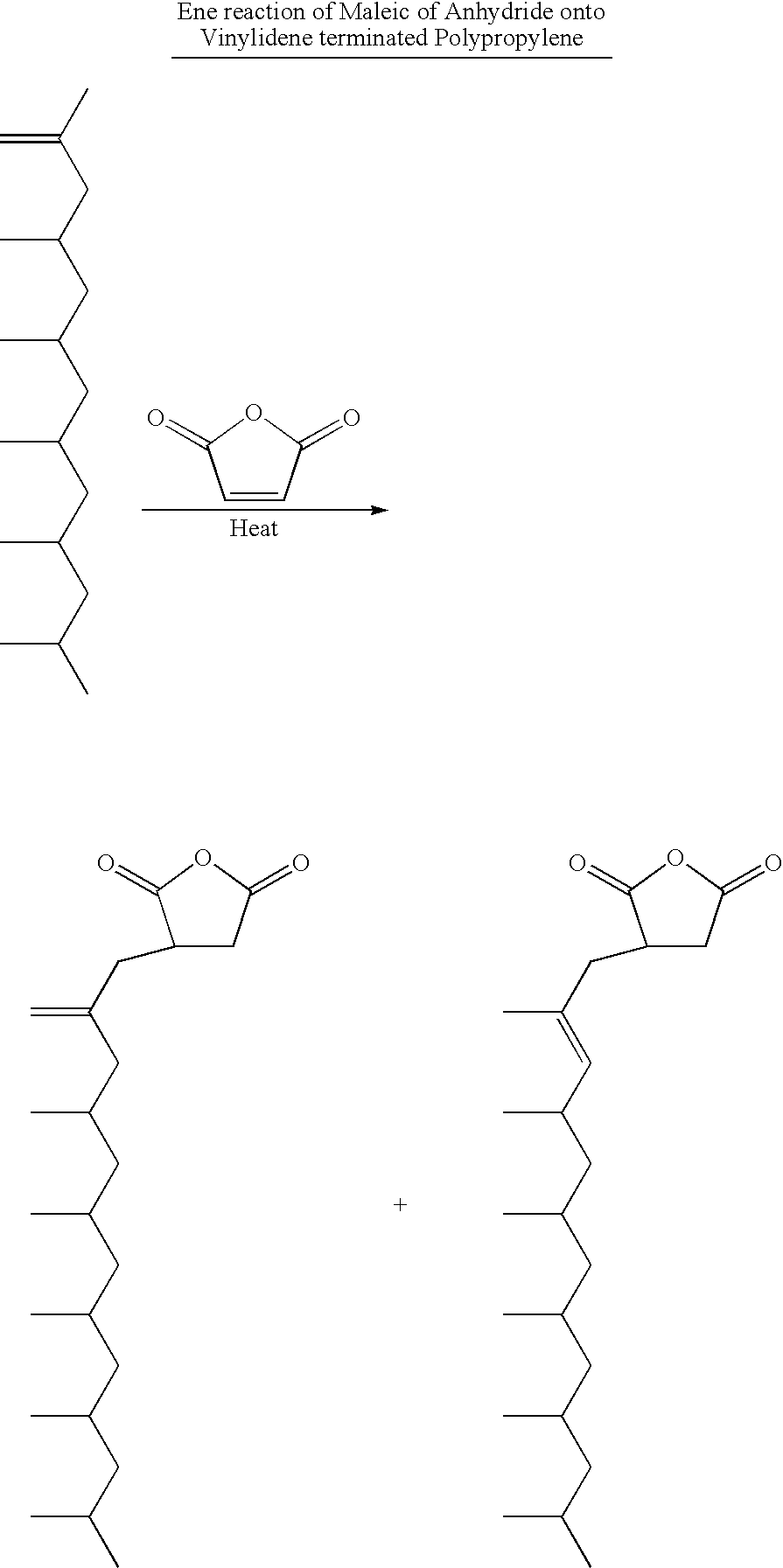

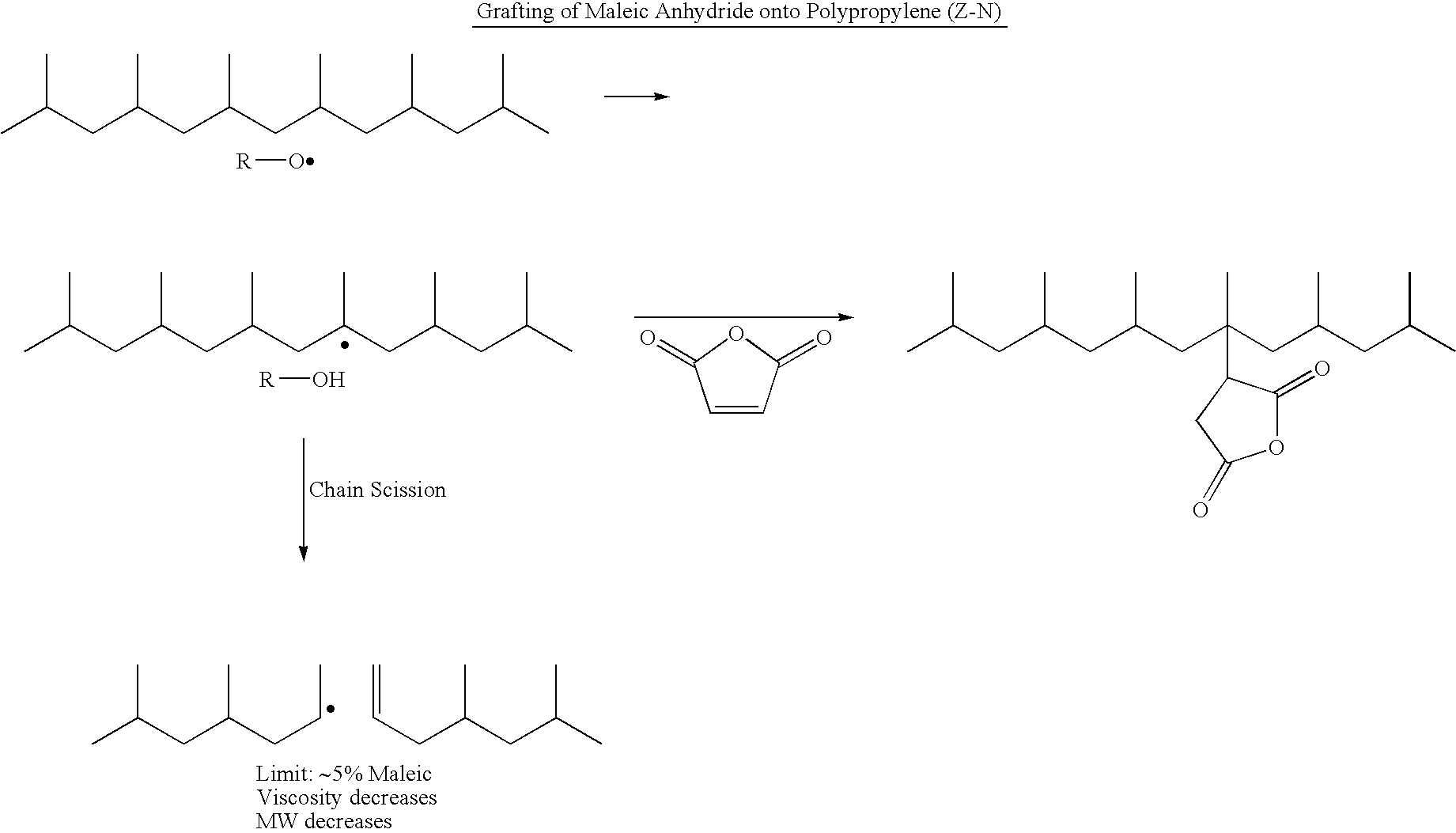

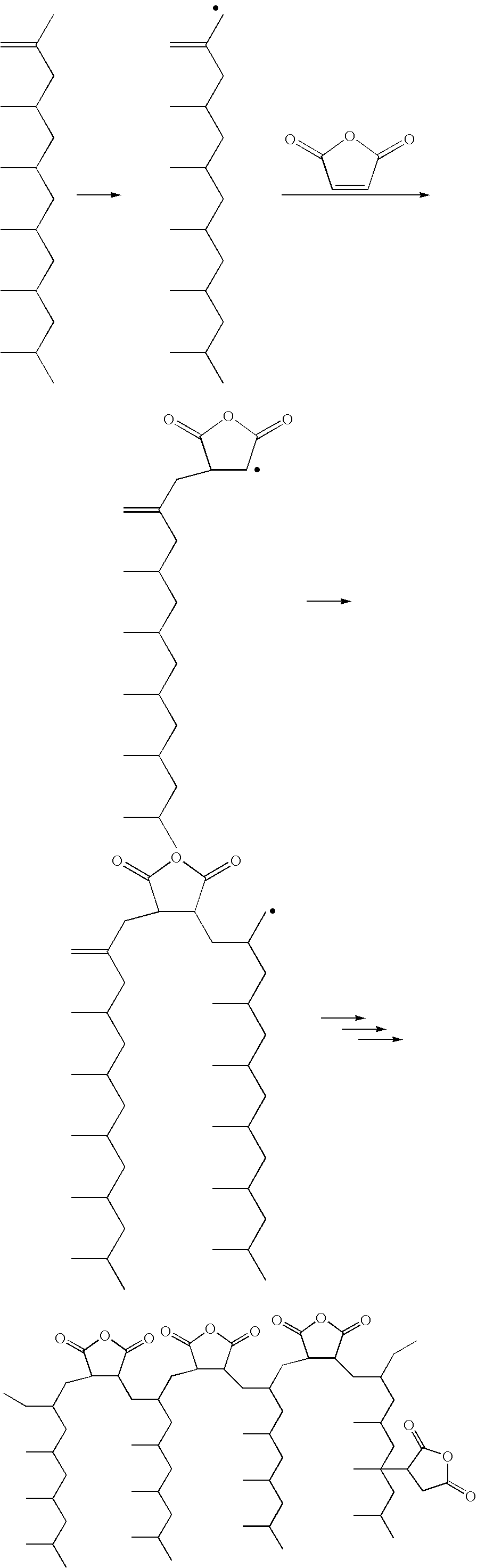

Polypropylene having a high maleic anhydride content

InactiveUS20060084764A1Increased succinic anhydride contentIncrease and decrease and viscosityPolymer sciencePolypropylene

Polypropylene having high maleic anhydride content, between about 5 and about 45 g wt %, may be prepared by first reacting a metallocene-prepared polypropylene having terminal unsaturation with one mole equivalent of maleic anhydride to give polypropylene having a single unsaturation and a terminal succinic anhydride moiety. This product is then reacted with additional maleic anhydride in the presence of a free radical initiator (such as a peroxide or UV radiation) to give a polypropylene with maleic anhydride moieties along the backbone. The polypropylene product does not suffer scission or crosslinking with subsequently undesirable increases in molecular weight or viscosity. The maleic anhydride moieties provide reactivity to the polypropylene and thus expand its uses and applications.

Owner:BAKER HUGHES INC

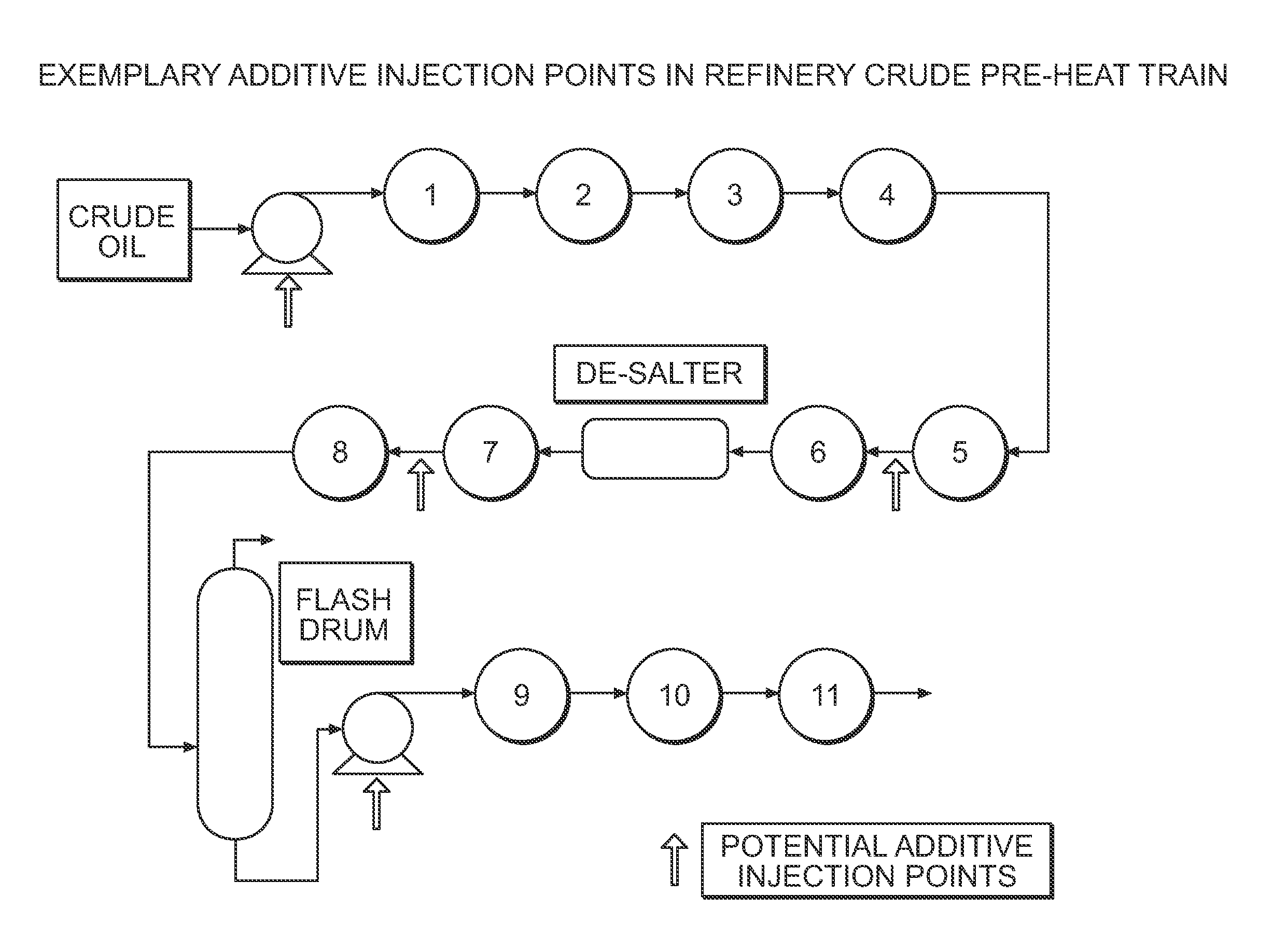

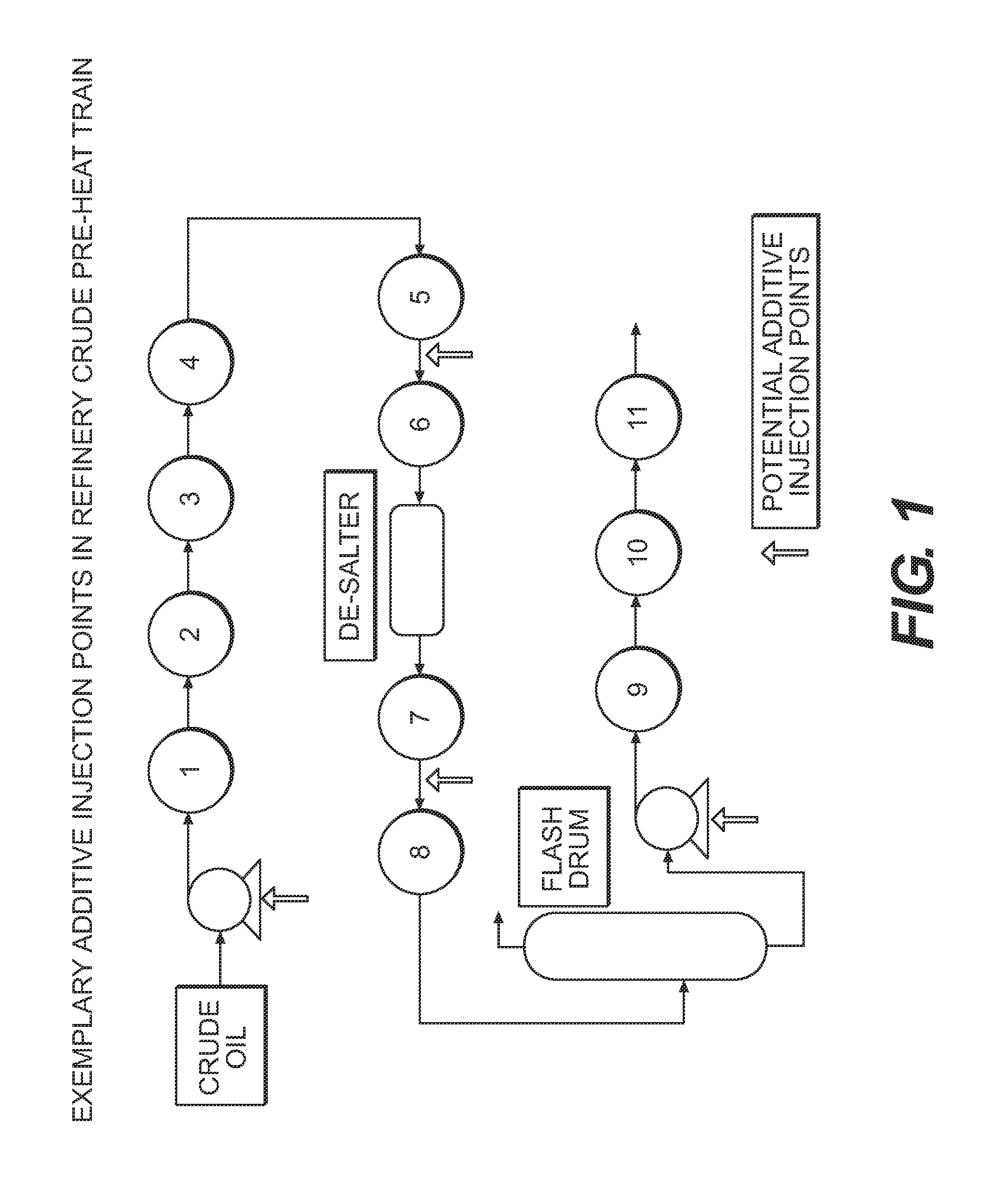

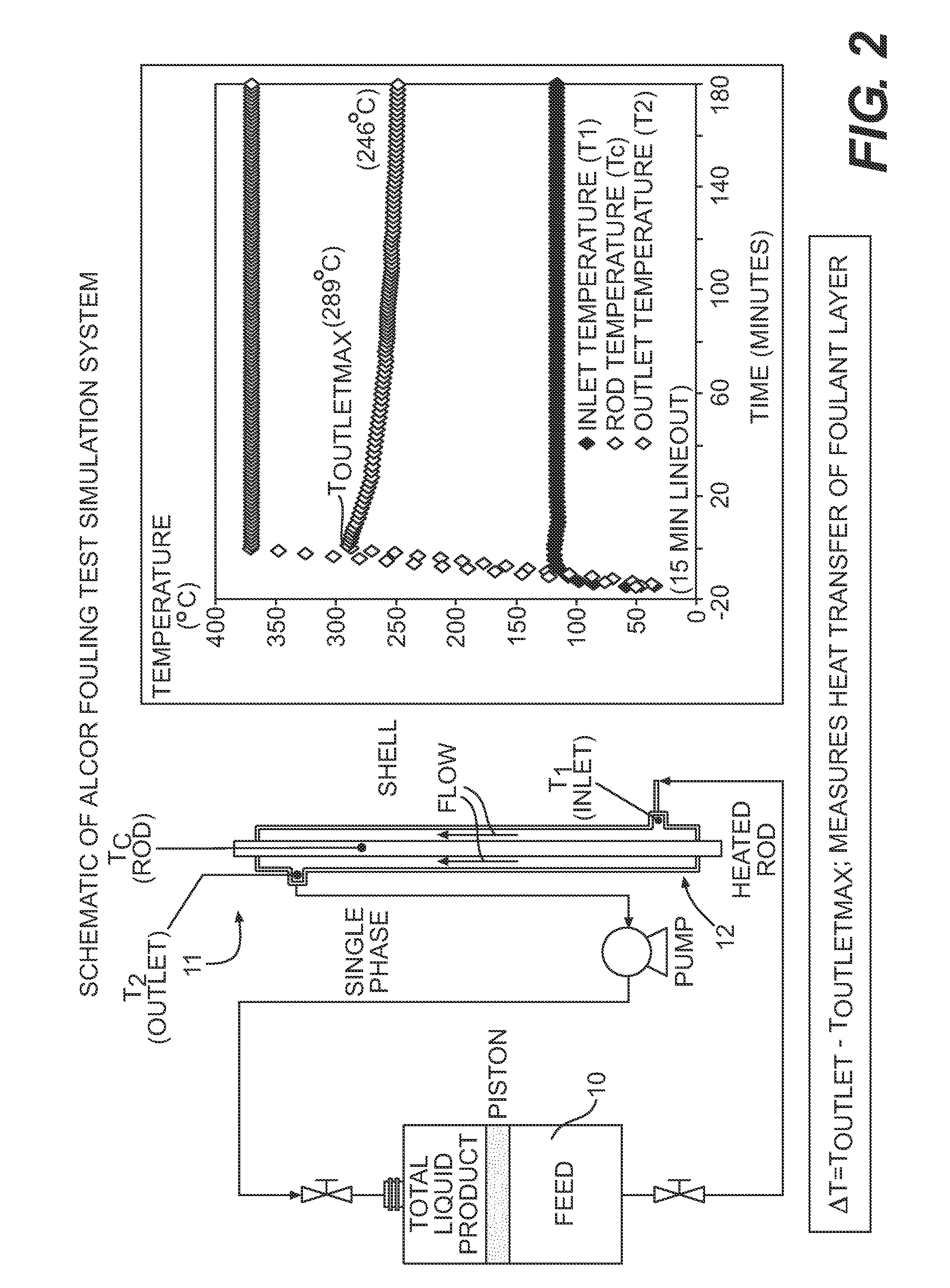

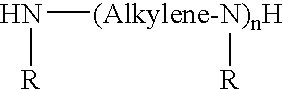

Polyalkyl succinic anhydride derivatives as additives for fouling mitigation in petroleum refinery processes

InactiveUS20100170829A1Thermal non-catalytic crackingOrganic chemistryParticulatesFouling mitigation

The present invention provides a method for reducing fouling, including particulate-induced fouling, in a hydrocarbon refining process including the steps of providing a crude hydrocarbon for a refining process; adding at least one polyalkyl succinic anhydride derivative additive disclosed herein. The additive can be complexed with a boronating agent, such as boric acid, to yield a boron-containing polyalkyl succinic anhydride derivative.

Owner:EXXON RES & ENG CO

Polypropylene having a high maleic anhydride content

InactiveUS7183359B2Increase and decrease and viscosityIncrease or decrease weightPolymer sciencePolypropylene

Polypropylene having high maleic anhydride content, between about 5 and about 45 wt %, may be prepared by first reacting a metallocene-prepared polypropylene having terminal unsaturation with one mole equivalent of maleic anhydride to give polypropylene having a single unsaturation and a terminal succinic anhydride moiety. This product is then reacted with additional maleic anhydride in the presence of a free radical initiator (such as a peroxide or UV radiation) to give a polypropylene with maleic anhydride moieties along the backbone. The polypropylene product does not suffer scission or crosslinking with subsequently undesirable increases in molecular weight or viscosity. The maleic anhydride moieties provide reactivity to the polypropylene and thus expand its uses and applications.

Owner:BAKER HUGHES INC

Enhanced surface sizing of paper

Size press compositions and methods for producing sized paper products, including liner board, are disclosed. The size press compositions contain at least one non-reactive cationic surface sizing agent, at least one reactive sizing agent, at least one promoter resin, at least one binder, and water. The at least one non-reactive cationic surface sizing agent may be a polymer in the form of a dispersion, an emulsion or a latex with a positive zeta potential below about pH 6. The at least one reactive sizing agent may be a dispersion, an emulsion or a latex including an alkyl ketene dimer or an alkyl succinic anhydride. The at least one promoter resin may be a polyaminoamide-epichlorohydrin resin or poly (dimethyldiallylammonium chloride).

Owner:SOLENIS TECH CAYMAN

Electrolyte for lithium secondary battery and a lithium secondary battery including the same

ActiveUS20070009806A1Improve battery performanceInhibit swellingElectrolytic capacitorsCell electrodesOrganic solventPhysical chemistry

An electrolyte for a lithium secondary battery and a lithium secondary battery having the electrolyte, the electrolyte including a lithium salt; a non-aqueous organic solvent including γ-butyrolactone-; and a succinic anhydride.

Owner:SAMSUNG SDI CO LTD

Wax compositions comprising alkenyl succinic anhydride-capped poly (oxyalkylenated) colorants

This invention relates to wax formulations comprised of specific poly(oxyalkylenated) colorants having alkenyl succinic anhydride (ASA) terminal groups. Preferably the wax formulation is a crayon. Such polymeric ASA-capped colorants provide excellent coloring, decreased migratory properties, and improved balanced burning characteristics over traditional crayon colorants, pigments, and dyestuffs. This invention also concerns methods of making the aforementioned colored crayon formulations as well as other colored wax articles, such as candles.

Owner:MILLIKEN & CO

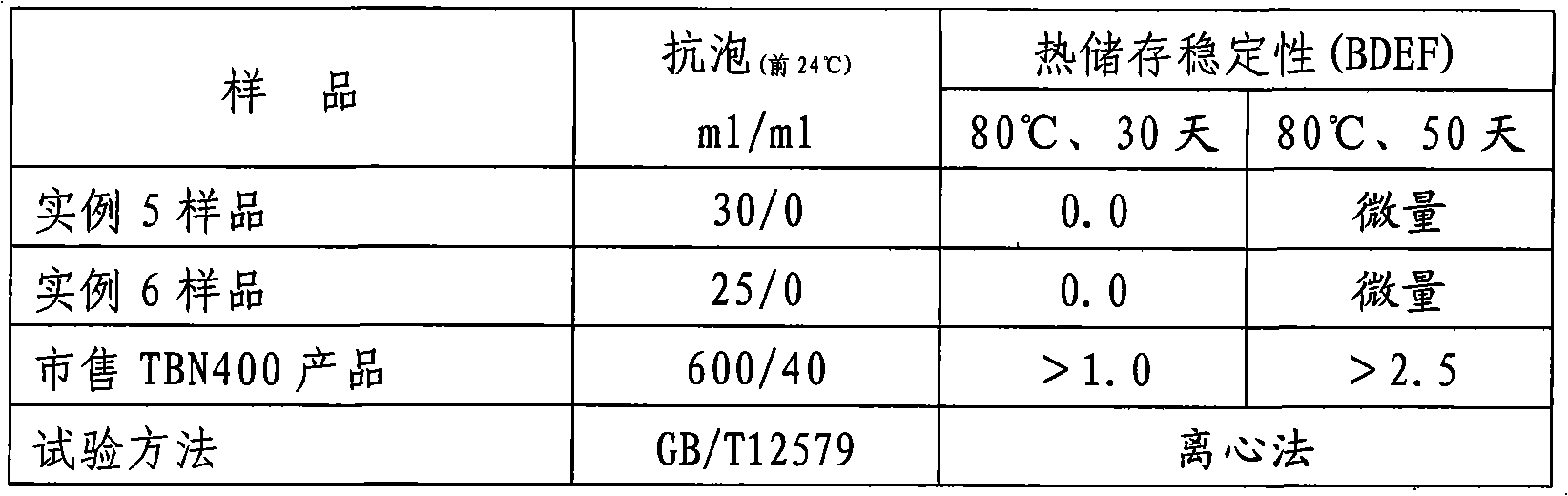

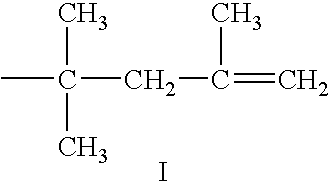

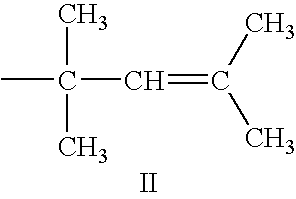

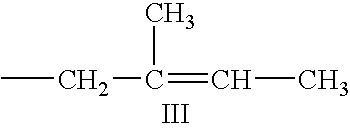

Method for preparing high-alkali value (TBN400) synthesized calcium alkyl benzene sulfonate

ActiveCN101318915AImprove cleanlinessGood dispersionAdditivesSulfonic acid preparationTotal Base NumberAlkaline earth metal

The invention provides a method for preparing high base number (TBN400) synthetic calcium alkyl-benzene sulfonate. The method comprises the following steps of: adopting a mixed acid of long-chain linear alkyl-benzene sulfonic acid and high-boiling heavy alkyl-benzene sulfonic acid, calcium oxide and / or calcium hydroxide, low-carbon alcohol, alkaline-earth metal halide or nitrate, and a mixture of alkaline-earth metal alkylphenol or alkaline-earth metal alkylphenate and polyisobutylene succinic anhydride for a neutralization reaction in the presence of a solvent and cutback oil at a temperature of between 40 and 80 DEG C; then, passing through carbon dioxide to a product of the neutralization reaction at a temperature of between 40 and 60 DEG C for a carbonation reaction; and producing high base synthetic alkyl-benzene sulfonate with a total base number (TBN) of 400mgKOH / g by adopting a process of a one-step method. The product is divided into high-base number (TBN400) synthetic alkyl-benzene sulfonate containing chlorine and high-base number (TBN400) synthetic alkyl-benzene sulfonate without the chlorine. The product produced by adopting the method with low viscosity, small turbidity, easy filtration, light color and no skin formation has the advantages of excellent high-temperature detergency, excellent anti-foaming property and excellent heat storage stability.

Owner:JINZHOU DPF TH CHEM CO LTD

Mixed dispersants for lubricants

A dispersant composition comprising the product of an amine, an alcohol, or an amino alcohol, with a hydrocarbyl-substituted succinic anhydride component exhibits improved viscosity stability and reduced chlorine content, when the hydrocarbyl-substituted succinic anhydride component comprises: (a) 10 to 95 weight percent of a component prepared by reacting a polyisobutylene with maleic anhydride in the presence of chlorine; and (b) 5 to 90 weight percent of a component prepared by reacting a polyisobutylene with maleic anhydride in the substantial absence of chlorine.

Owner:THE LUBRIZOL CORP

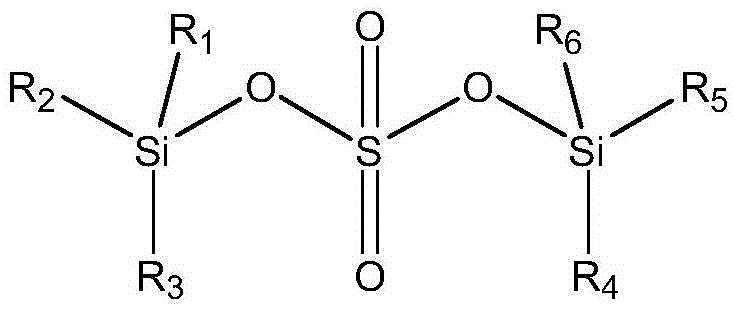

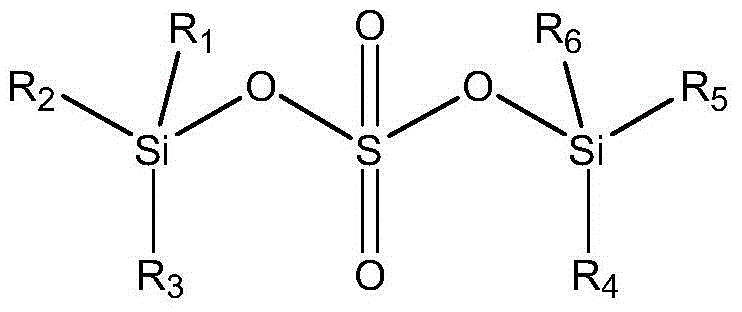

Power battery and lithium ion electrolyte thereof

InactiveCN104600362AImprove low temperature discharge performancePromote circulationSecondary cellsSilanesKetone solvents

The invention provides a power battery and a lithium ion electrolyte thereof. The lithium ion electrolyte comprises a non-aqueous organic solvent, lithium salt and an additive, wherein the additive comprises a first additive and a second additive, and the first additive comprises silane sulfate; the first additive accounts for 0.05 to 10% of the total weight of the electrolyte, and the second additive is an auxiliary additive and comprises one or more of vinylene carbonate, propane sultone, fluoroethylene carbonate, vinyl ethylene carbonate, ethylene sulfite, adiponitrile, and succinic anhydride in any proportion; the second additive accounts for 0.1-5wt% of the total weight of the electrolyte, and the non-aqueous organic solvent is a carbonic ester solvent, a carboxylic ester solvent, an ether solvent or a ketone solvent; and the lithium salt comprises primary lithium salt and secondary lithium salt.

Owner:SHENZHEN 3SUN ELECTRONICS

Low color polyisobutylene succinic anhydride-derived emulsifiers

InactiveUS20060223945A1Good colorMinimizing reactionCosmetic preparationsHair cosmeticsSuccinic anhydrideCompatibilization

The invention relates to new synthesis techniques to form emulsifiers of low color from maleic anhydride and polymers of isobutylene. These emulsifiers satisfy a need for a low color component with a long oil compatible hydrophobic tail and a short hydrophilic moiety.

Owner:THE LUBRIZOL CORP

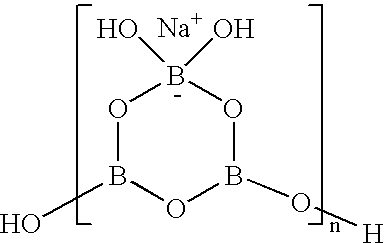

Lubricant composition comprising alkali metal borate dispersed in a polyalkylene succinic anhydride and a metal salt of a polyisobutenyl sulfonate

Disclosed are lubricant compositions comprising a dispersed hydrated alkali metal borate, a polyalkylene succinic dispersant selected from a polyalkylene succinic anhydride, a mixture of polyalkylene succinic anhydrides or derivatives thereof; and a metal salt of a polyisobutenyl sulfonate. Also disclosed are methods for improving the water tolerance of a lubricant composition and methods for preparing such lubricants comprising a dispersed hydrated alkali metal borate and a dispersant mixture.< / PTEXT>

Owner:CHEVRON ORONITE CO LLC

Overbased magnesium deposit control additive for residual fuel oils

An overbased magnesium composition deposit control additive for residual fuel oils and turbine fuels is an overbased magnesium sulfonate, carboxylate or phenate or mixtures thereof containing at least 14% and upwards to about 18% by weight of magnesium and containing a succinic anhydride and lower carboxylic acid co-promoter reaction product. The additive when added to fuel oils, such as residual fuel oils containing high asphaltenes, reduces, if not eliminates, magnesium / asphaltene deposits or sediment and the consequential plugging of filters. The additive also reduces, if not eliminates, vanadium caused corrosion in the turbine. The invention is also the process for preparing the overbased composition or deposit control additive, wherein the overbasing reaction incorporates the combination of a lower carboxylic acid, preferably acetic acid and a succinic anhydride, preferably dodecenyl succinic anhydride (DDSA), as the co-promoter.

Owner:CK WITCO

Epoxy asphalt material for express highway and bridge, and preparation method

ActiveCN1546571AHigh strengthImprove performanceIn situ pavingsBuilding insulationsAsphaltSuccinic anhydride

An epoxy asphalt material for express highway and bridge wherein the mass portion of the composition is, part A, asphalt 50-80 parts, aliphatic diacid or substituted carboxylic acid 10-25 parts, aliphatic acid anhydride 1-20 parts, polyisobutylene succinic anhydride 2-15 parts, epoxy resin 0-30 parts, epoxy resin hardening accelerating agent 0.1-1.0 part. Part B, epoxy resin, the mass ratio of part an and part B is 2-8:1. The invention also discloses the process for preparing the epoxy asphalt material.

Owner:JURONG NINGWU SCI & TECH DEV

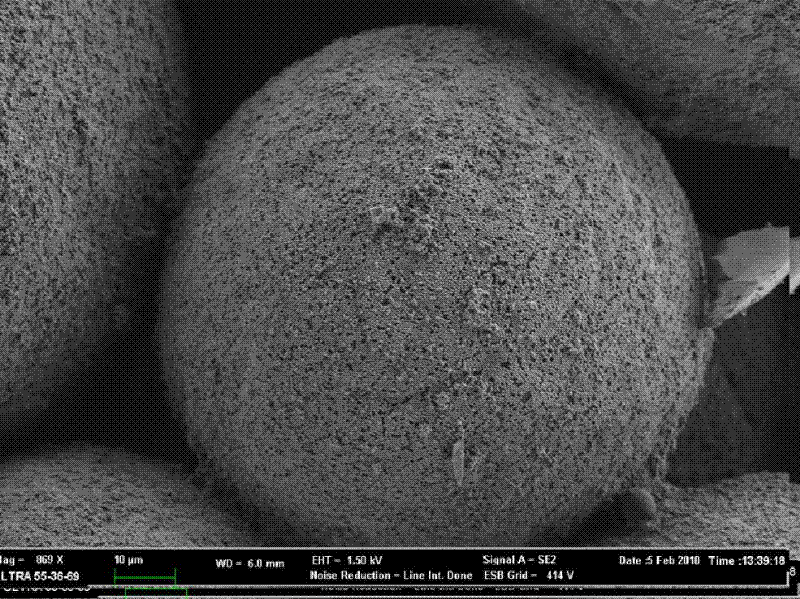

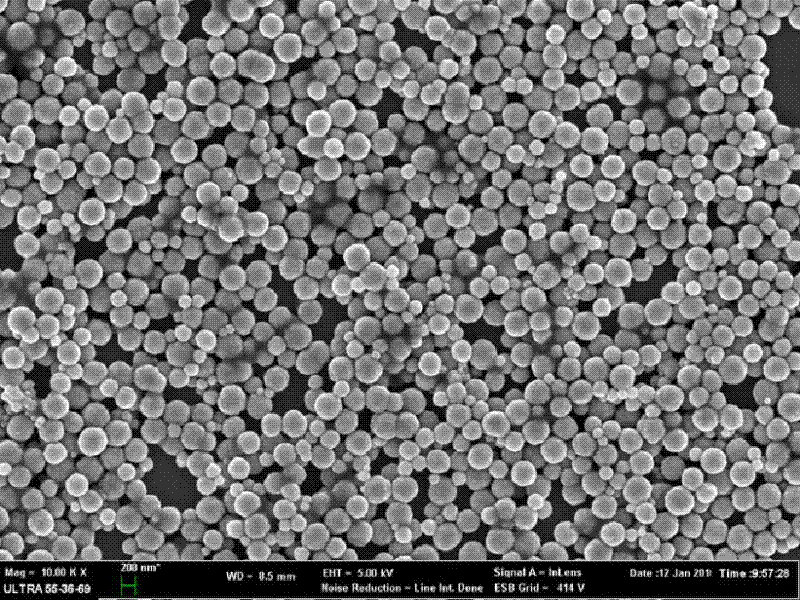

Magnetic silicon dioxide microspheres with nuclear shell and surface anisotropic double functional groups and preparation method thereof

ActiveCN102160985ARegular shapeQuantity is easy to controlInorganic material magnetismMicroballoon preparationCarboxyl radicalButanedioic acid

The invention relates to magnetic silicon dioxide microspheres with a nuclear shell and surface anisotropic double functional groups and a preparation method thereof. The preparation method comprises the following steps of: preparing superparamagetic microspheres by a solvothermal process; preparing magnetic microspheres which are coated by silicon dioxide by a sol-gel process; preparing the magnetic silicon dioxide microspheres of which the surface has amino group by taking the magnetic silicon dioxide microspheres as seeds and by the copolycondensation of alkyl ester orthosilicate and a silane coupling agent, and drying the magnetic silicon dioxide microspheres to obtain samples; and by a PICKERING emulsion technology, stabilizing a paraffin / aqueous emulsion system with a micrometer scale by using the aminated magnetic microspheres to form single-layer close packing of the magnetic microspheres on the surface of paraffin spheres, then reacting the amino group on the surface of the magnetic microspheres which is exposed in a liquid phase with succinic anhydride to introduce carboxyl into the partial surface of the microspheres, so that the surfaces of the magnetic microspheres have the anisotropic double functional groups. The obtained magnetic microspheres with the double functional groups have the advantages that: magnetic responsiveness is high; grain size can be controlled between 200 and 800 namometers; and the density of the surface functional groups can be adjusted.

Owner:SUZHOU WIN BIO TECH CO LTD

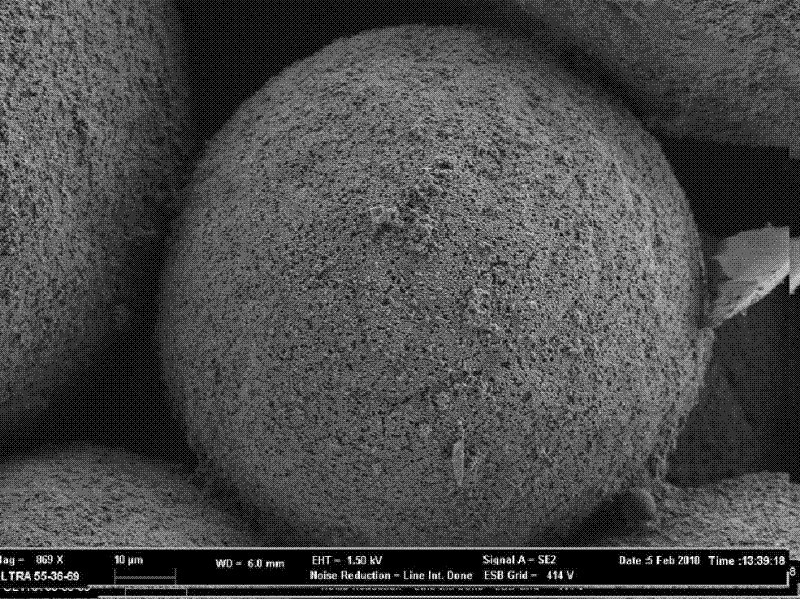

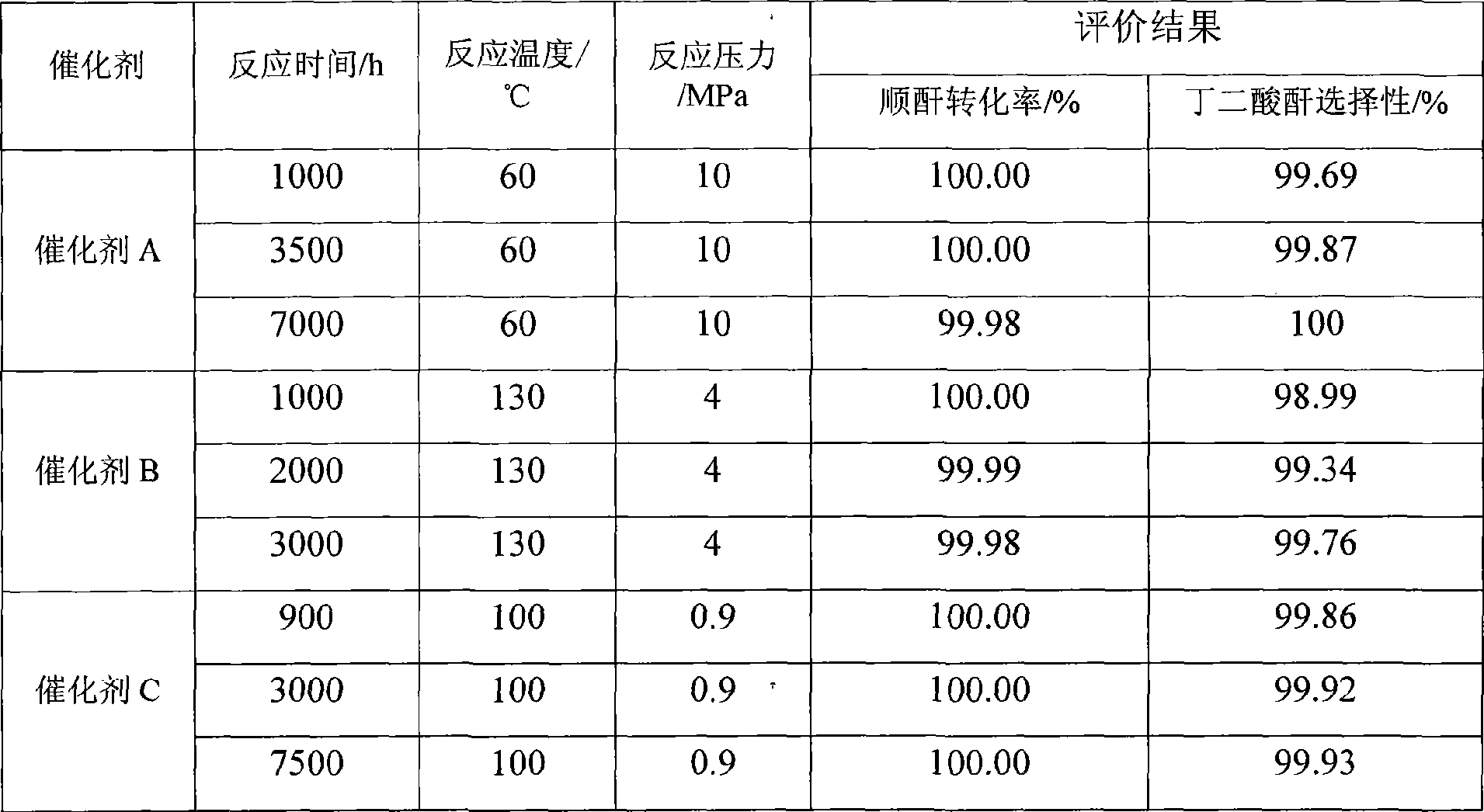

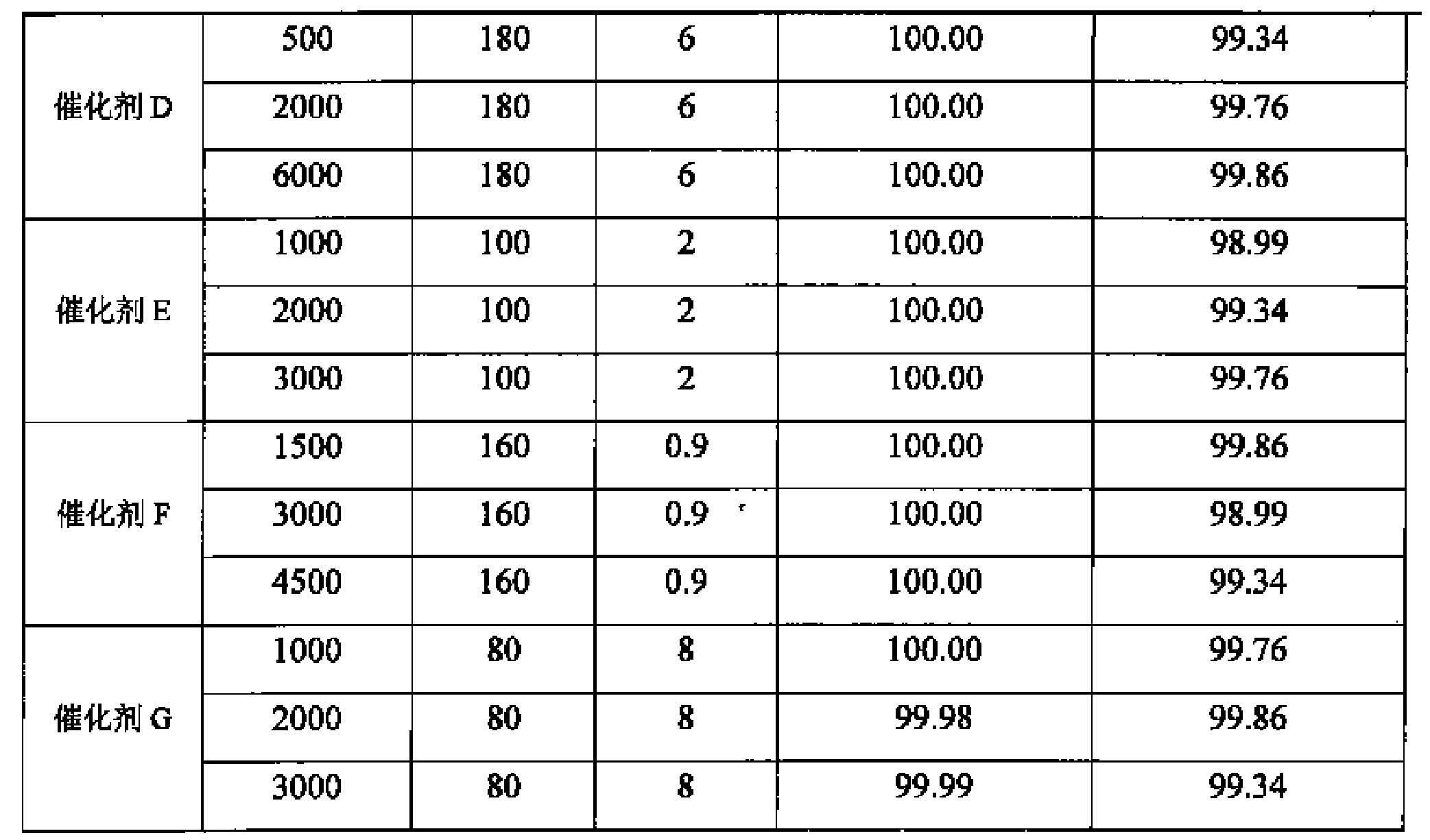

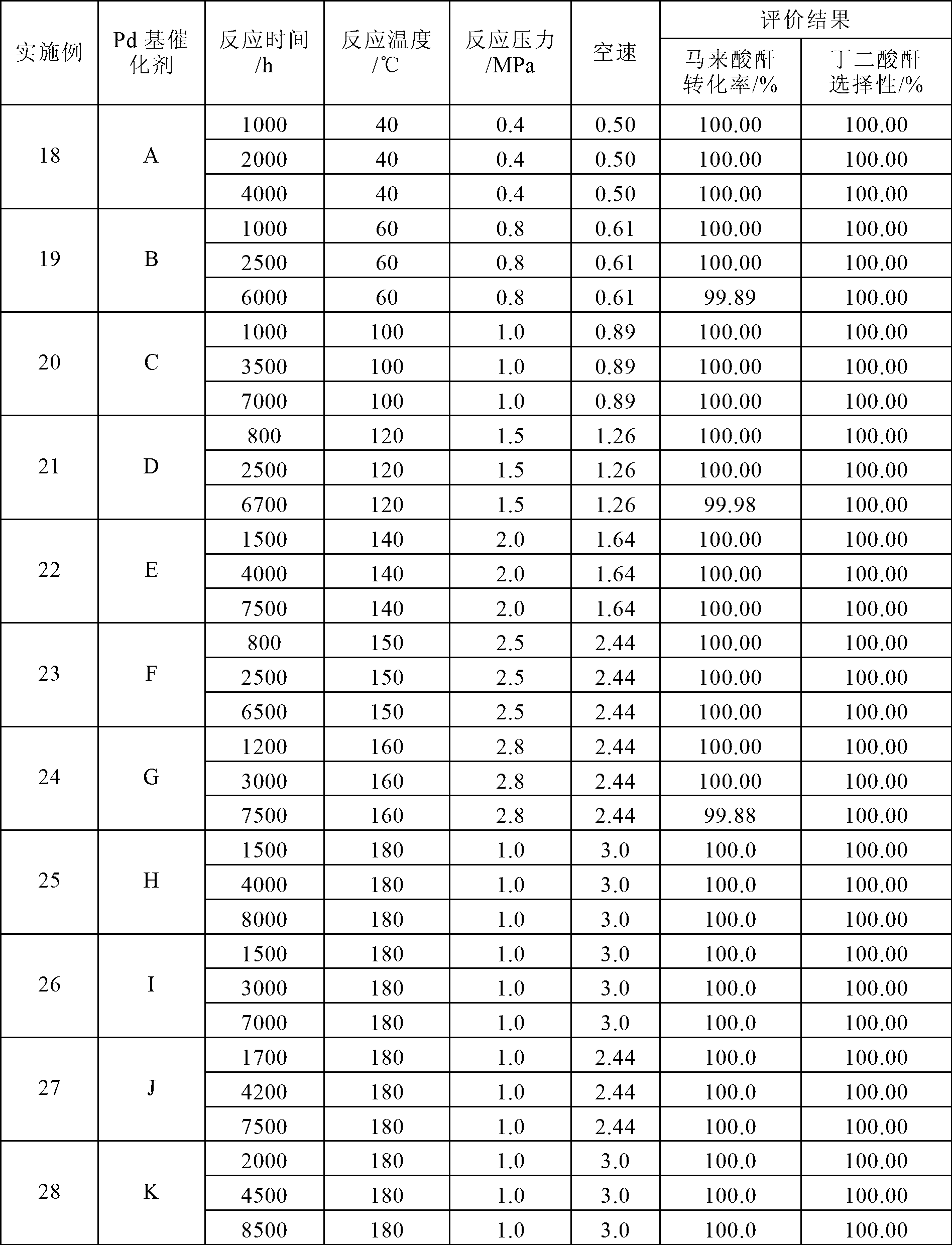

Catalyst for continuous production of succinic anhydride from hydrogenation of maleic anhydride and preparation method thereof

ActiveCN101502802AHigh yieldHigh activityOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsFixed bedHigh activity

The invention provides a catalyst for continuously producing butanedioic anhydride by maleic anhydride hydrogenation. The catalyst is a nickel loaded catalyst prepared by an equivalent-volume impregnation method, wherein in the catalyst, the content of nickel is 13 to 20 weight percent, the content of accelerating agent is 1 to 7 weight percent, and a carrier is a composite oxide of SiO2 and Al2O3 or SiO2-Al2O3. A preparation method for the catalyst comprises the following steps: impregnating impregnation solution blended by ammonia water and active metal salt solution on a carrier subjected to baking pretreatment at a temperature between 400 and 800 DEG C by the equivalent-volume impregnation method to form the catalyst through drying, baking and reducing treatment. The catalyst is applied to continuously preparing the butanedioic anhydride by maleic anhydride hydrogenation on a fixed bed reactor, the conversion rate of maleic anhydride is more than or equal to 99.98 percent, and the selectivity of the butanedioic anhydride is more than or equal to 98.85 percent. The catalyst achieves the technical-scale continuous production of the butanedioic anhydride, and has the advantages of high activity, good selectivity, high yield (more than or equal to 98.83 percent) and long service life.

Owner:SHANXI UNIV

Electrolytes for lithium ion secondary batteries

ActiveUS20060147808A1Improve propertiesNot prone to and explosionElectrolytic capacitorsOrganic electrolyte cellsBenzenePropane sultone

The present invention relates to additives for electrolytes of lithium ion secondary batteries that include one or more of the following: 1,3-propane sultone, succinic anhydride; ethenyl sulfonyl benzene, and halobenzene. It can also include biphenyl, cyclohexylbenzene; and vinylene carbonate. The weight of said 1,3-propane sultone is between 0.5 wt. % and 96.4 wt. %, said succinic anhydride is between 0.5 wt. % and 96.4 wt. %; said ethenyl sulfonyl benzene is between 0.5 wt. % and 95.2 wt. %; and said halobenzene is between 0.5 wt. % and 95.2 wt. % of the weight of the additive. Batteries with electrolytes containing said additives have improved over-charge characteristics and low temperature properties, and reduced gas generation during charging and discharging.

Owner:BYD CO LTD

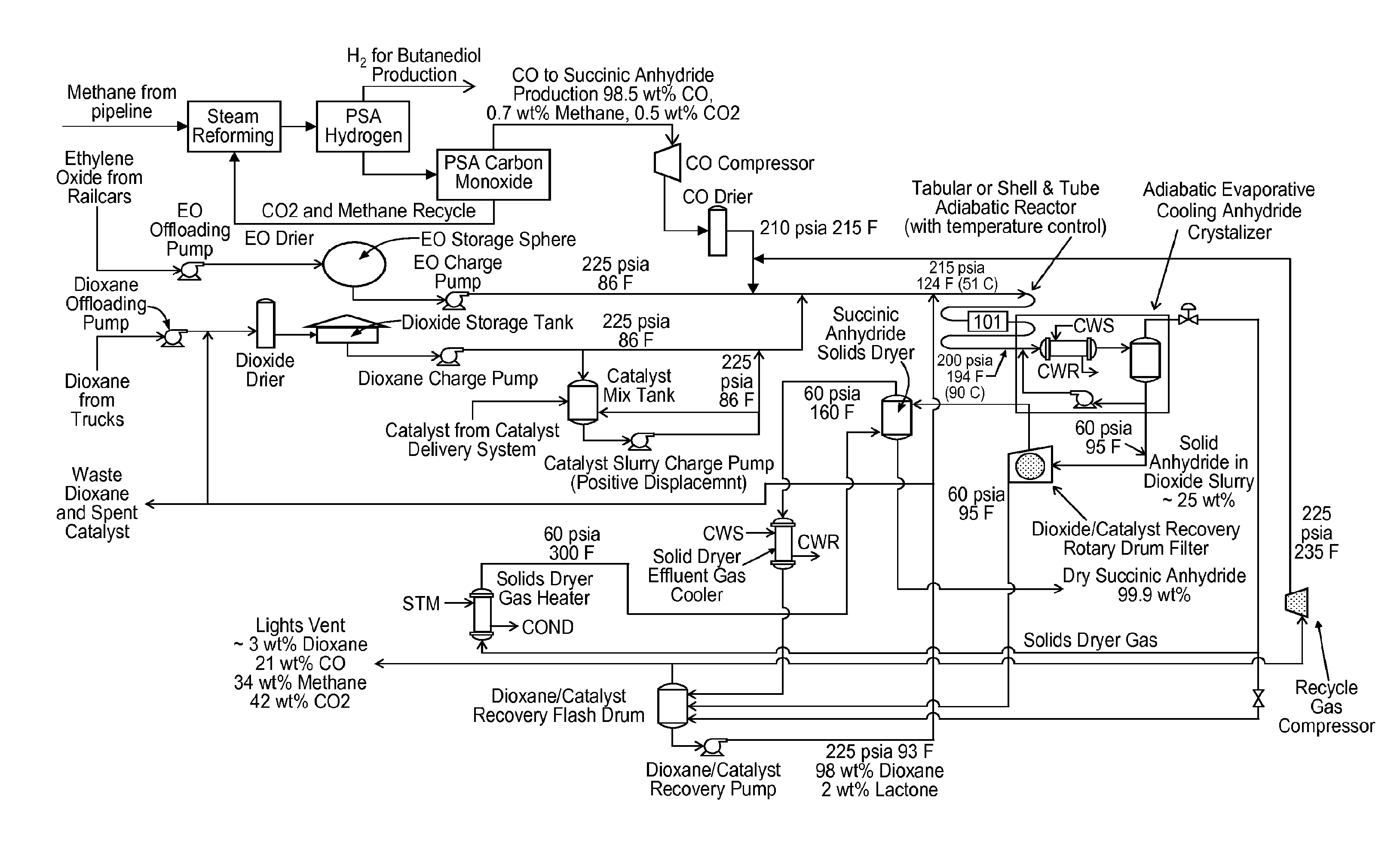

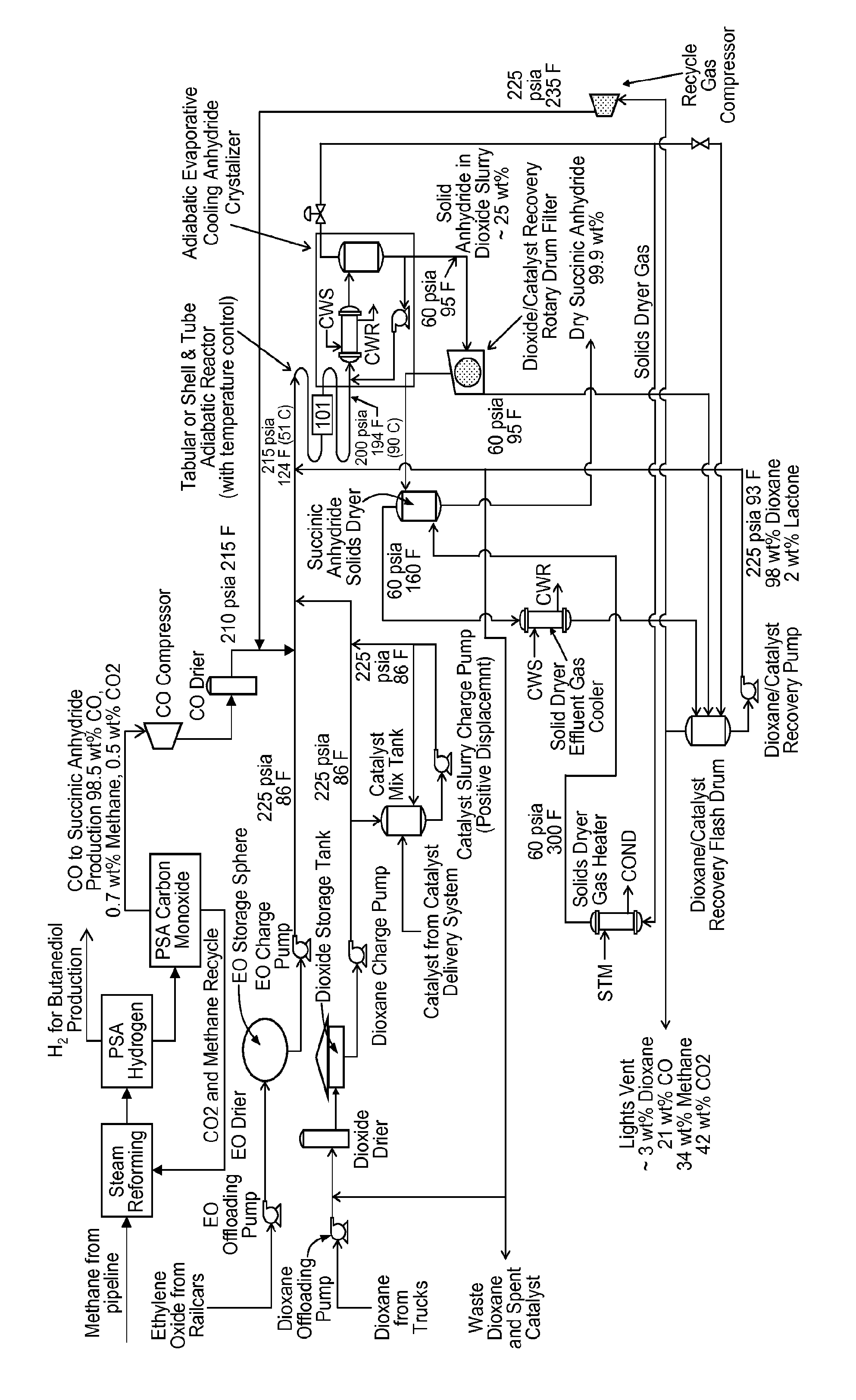

Succinic anhydride from ethylene oxide

ActiveUS9156803B2Organic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsEthylene oxideContinuous flow

Owner:NOVOMER INC

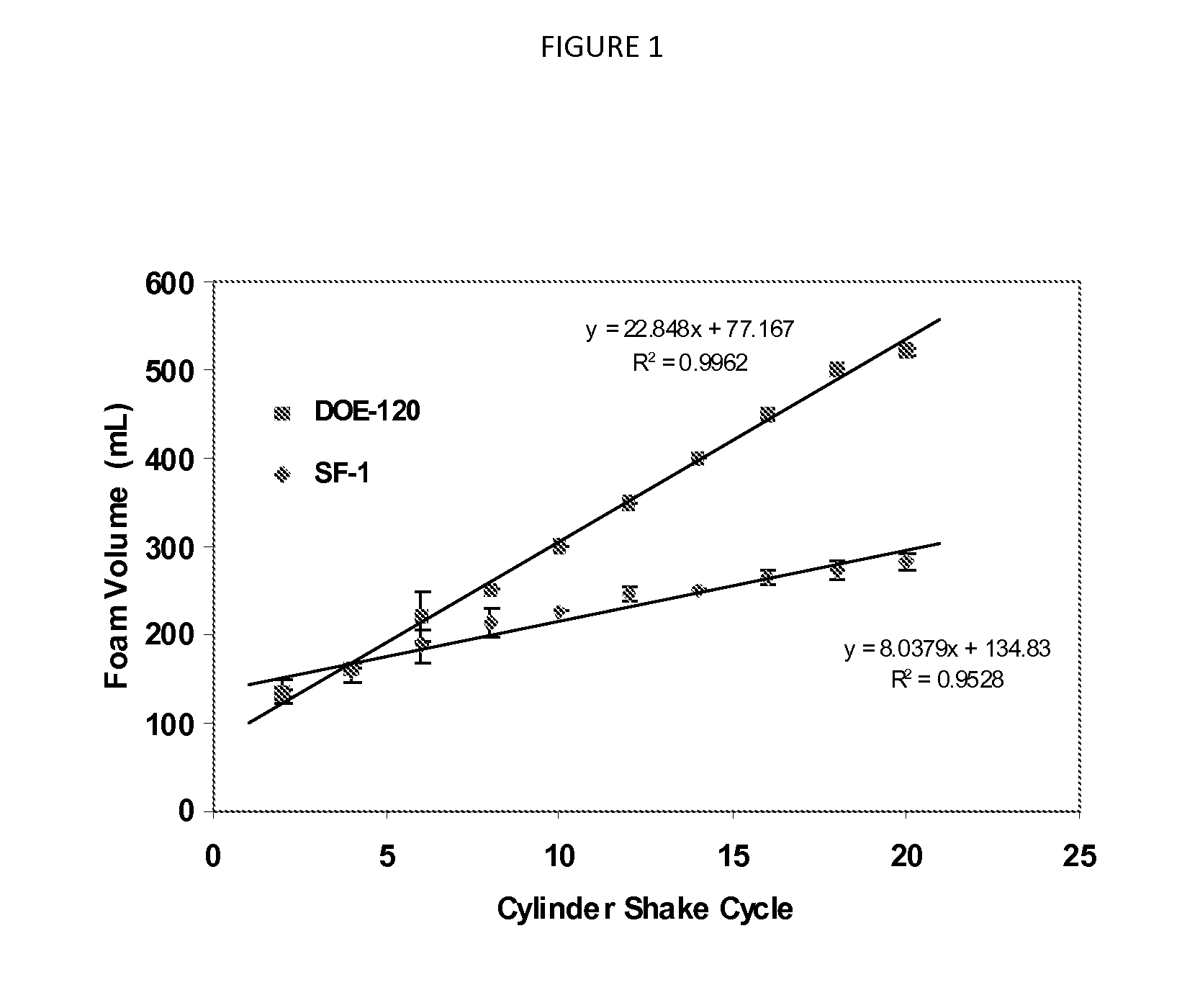

Superhydrophilic amphiphilic copolymers and processes for making the same

A superhydrophilic amphiphilic copolymer and process for making the superhydrophilic amphiphilic copolymer includes a low molecular weight polysaccharide modified with a hydrophobic reagent, such as substituted succinic anhydride. The superhydrophilic amphiphilic copolymer system generates stable foam for use in applications, such as healthcare formulations, with low irritation of the eyes and skin.

Owner:AKZO NOBEL CHEM INT BV

Pd-based catalyst prepared through colloid deposition, preparation method and application

ActiveCN103007929AEasy to prepareEasy to industrializeOrganic chemistryMolecular sieve catalystsFixed bedSuccinic acid

The invention discloses a Pd-based catalyst prepared through colloid deposition, a preparation method and application and specifically to a Pd-based catalyst prepared through addition of a protective agent PVP or PVA by using a colloid deposition process, a preparation method for the catalyst and application of the catalyst in preparation of succinic anhydride through hydrogenation of maleic anhydride. Under a mild condition, the Pd-based catalyst can realize continuous and high-activity catalysis of production of succinic anhydride through hydrogenation of maleic anhydride both in an intermittent high-pressure reaction vessel and on a fixed bed reactor, and high selectivity of succinic anhydride and good stability of the catalyst are achieved; the conversion rate of maleic anhydride is no less than 99.99%, and selectivity of succinic acid is no less than 99.99%. The Pd-based catalyst prepared in the invention has the advantages of small usage amount of the precious metal Pd, high activity and a long service life; and the catalyst can be repeatedly and indiscriminately used, so production cost is reduced, and the catalyst is suitable for industrial production.

Owner:SHANGHAI HUAYI GRP CO +1

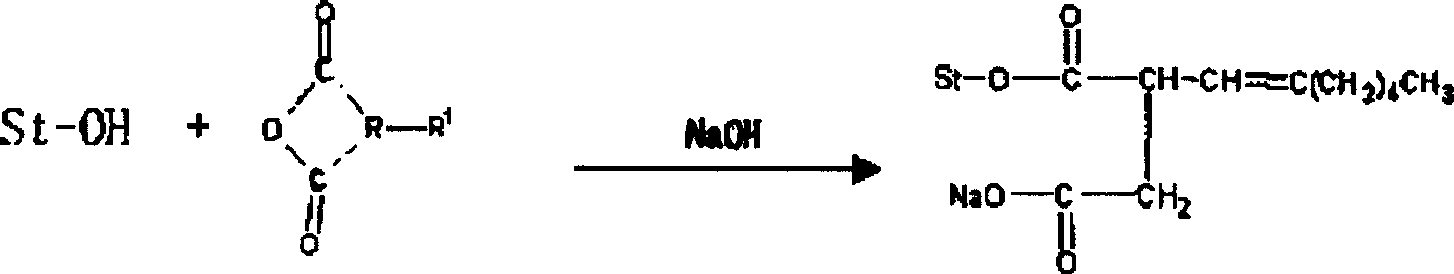

Process for producing starch octenylsucciniate

The invention discloses a manufacturing method of octal-olefin succinic starch ester, which comprises the following steps: 1) blending potato starch and water in the thermostatic magnetic stirrer into emulsion; 2) adopting 3% sodium hydroxide to adjust the pH value of emulsion to 7.5-8.0; 3) adopting anhydrous alcohol to dilute octal-olefin succinic anhydride; 4) blending the diluted octal-olefin succinic anhydride and emulsion phase in the step 2) to form reacting system; adding 3% NaOH solution to maintain the pH value of reacting system; reacting 2-4h; 5) using 2mol / L alcaine to adjust the pH value to 6.4-6.6; washing through water and 70% alcohol separately; drying; grinding.

Owner:ZHEJIANG UNIV

Use of alkenyl succinic anhydride compounds derived from symmetrical olefins in internal sizing for paper production

A method of sizing paper for use in applications which require resistance to liquids comprising incorporating in the paper a size composition comprising one or more alkenyl succinic anhydride (ASA) compounds prepared from the reaction of maleic anhydride and one or more substantially symmetrical C20-C28 internal olefins.

Owner:ECOLAB USA INC

Preparation method of potassium sodium dehydroandroan drographolide succinate, potassium sodium dehydroandroan drographolide succinate preparation and preparation method thereof

ActiveCN1927854ADifficult to purifyImprove responsePowder deliveryOrganic active ingredientsNitrogen gasAndrographolide

The present invention relates to the preparation process and preparation of Yanuning. Yanuning is prepared through an esterification reaction and a salt-forming reaction. During the esterification reaction, andrographolide and succinic anhydride react in pyridine solution and the resultant is post-treated to obtain dehydroandrographolide semi-succinate. During the salt-forming reaction, dehydroandrographolide semi-succinate and KOH, KHCO3 or K2CO3 react in water to form monopotassium salt of dehydroandrographolide semi-succinate, and through post-treatment, Yanuning is prepared. The present invention has mild reaction condition and nitrogen protection to avoid oxidation and degradation, excessive pyridine added into the reaction for dewatering without need of vacuumizing, and heating reflux in the later reaction stage for complete reaction.

Owner:珠海晨安医药有限公司

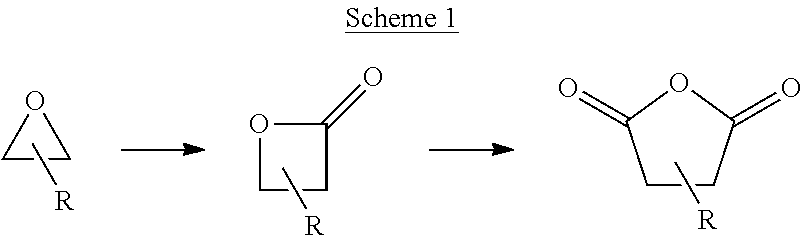

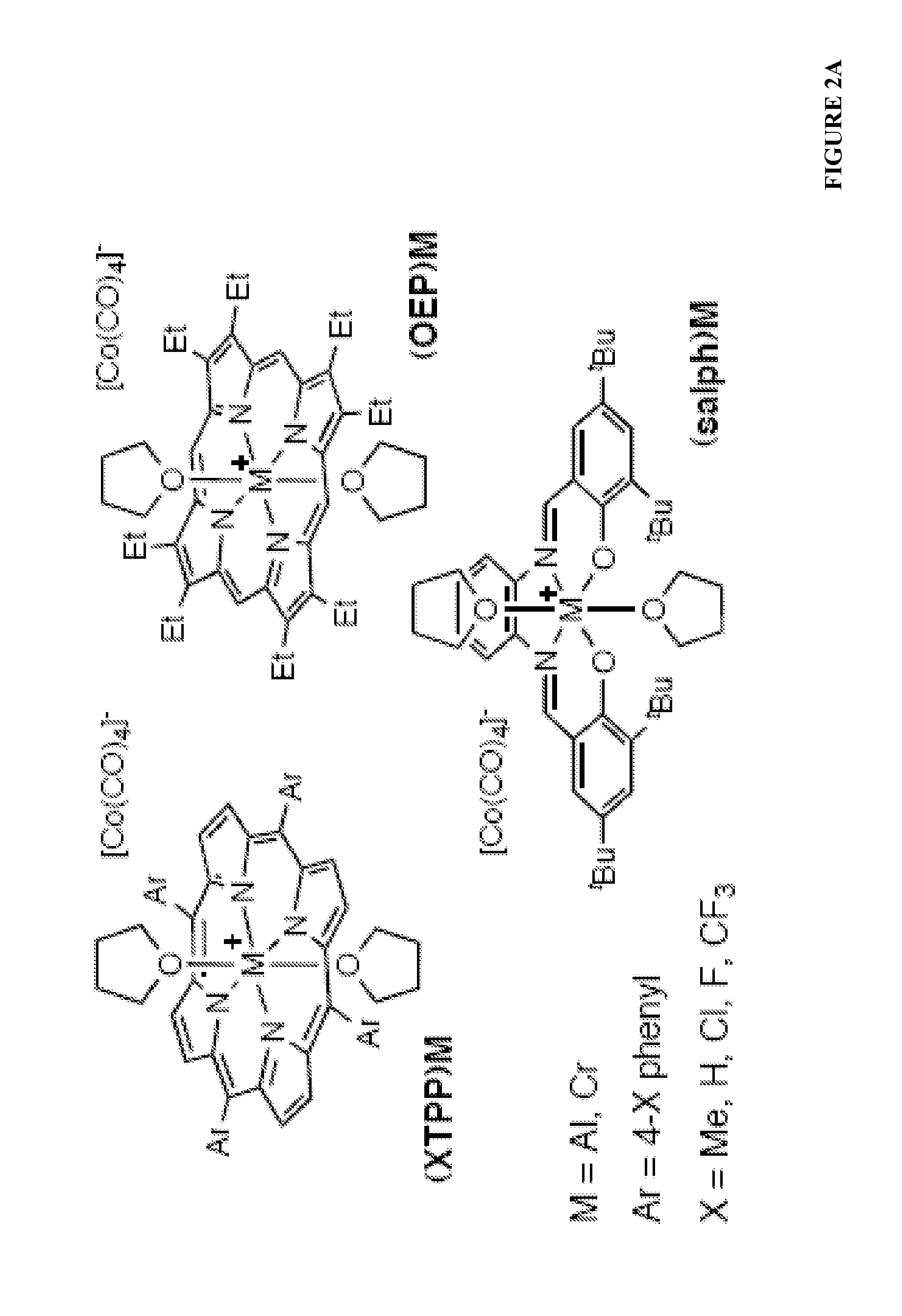

Succinic anhydrides from epoxides

Catalysts and methods for the double carbonylation of epoxides are disclosed. Each epoxide molecule reacts with two molecules of carbon monoxide to produce a succinic anhydride. The reaction is facilitated by catalysts combining a Lewis acidic species with a transition metal carbonyl complex. The double carbonylation is achieved in single process by using reaction conditions under which both carbonylation reactions occur without the necessity of isolating or purifying the product of the first carbonylation.

Owner:CORNELL UNIVERSITY

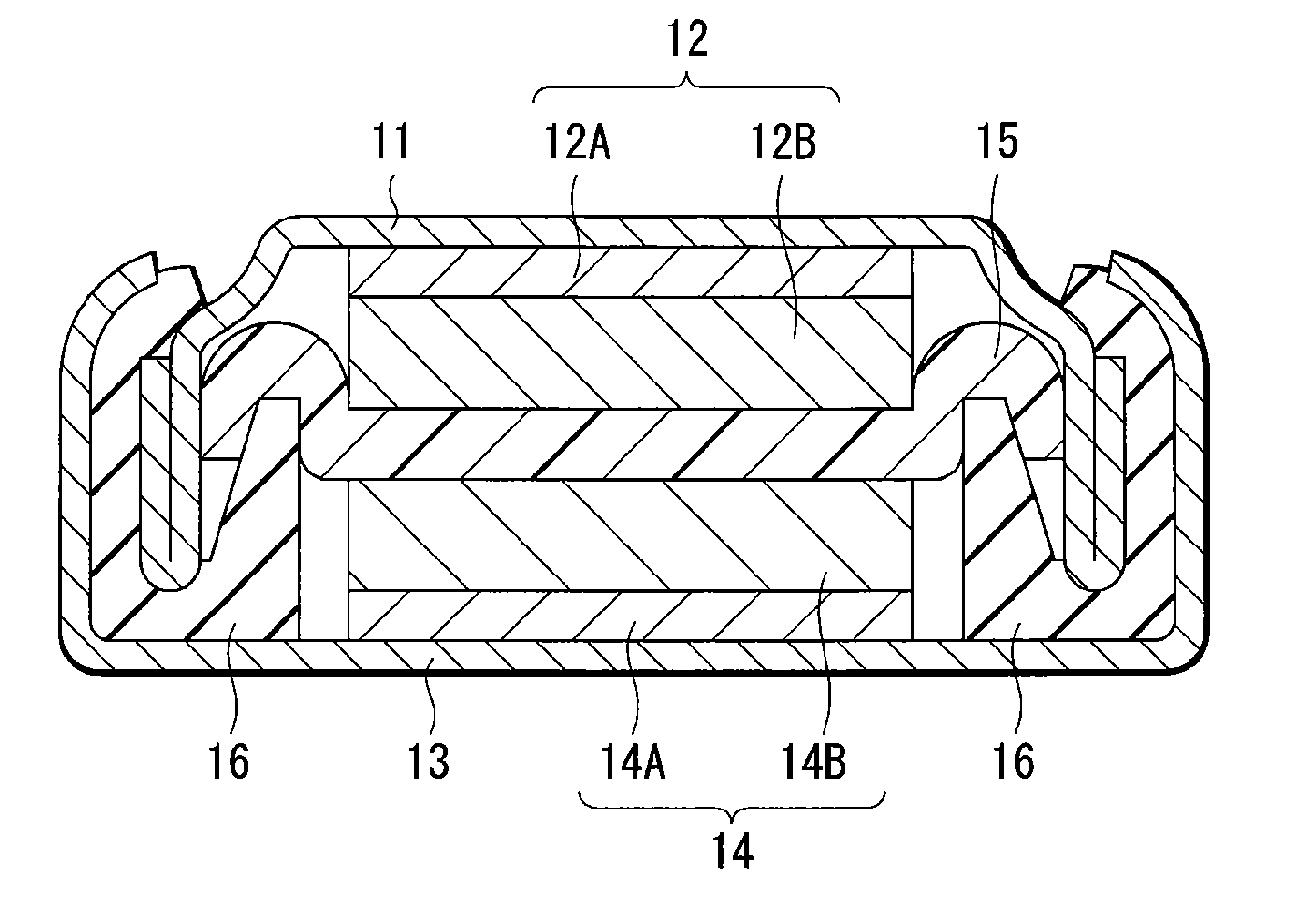

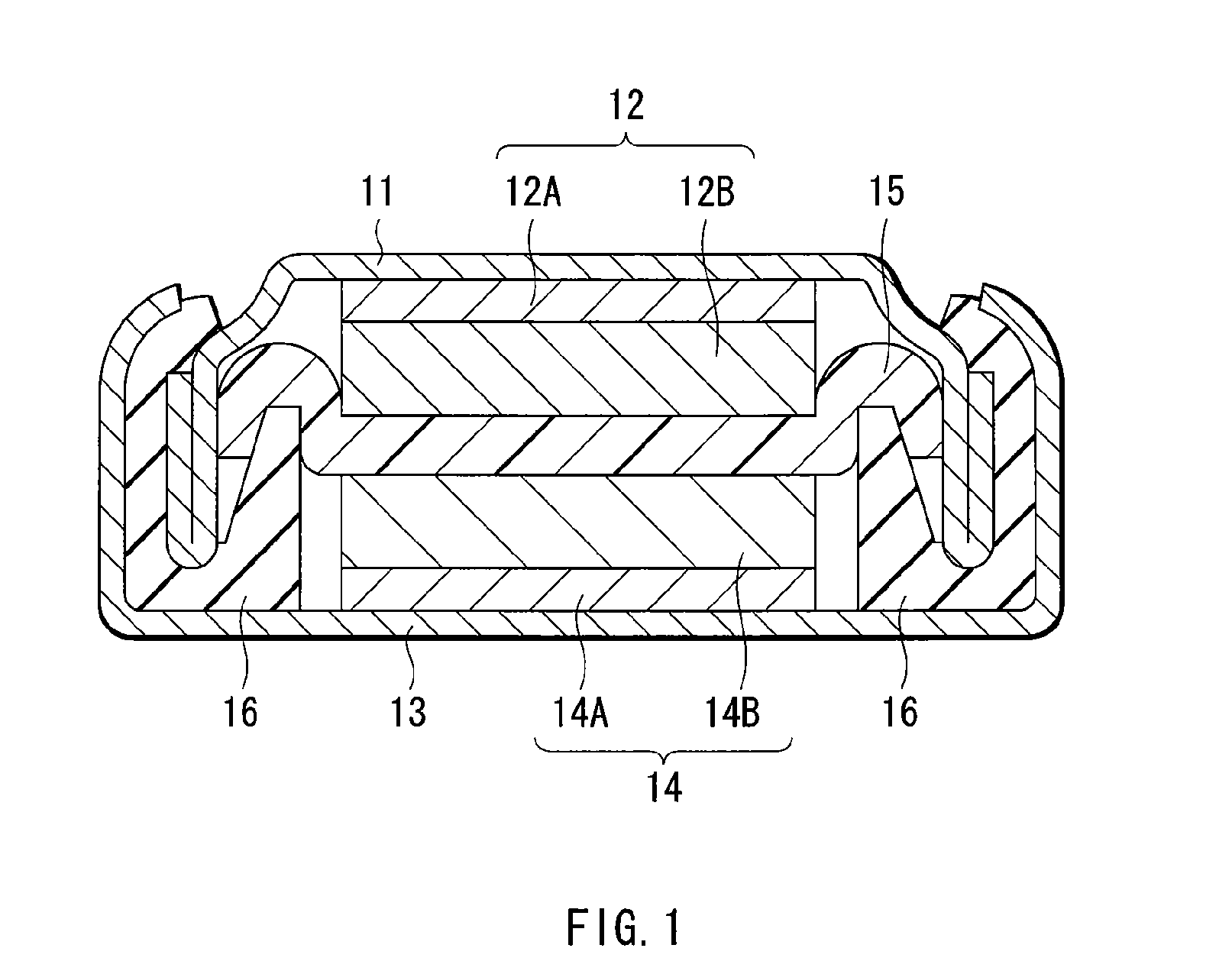

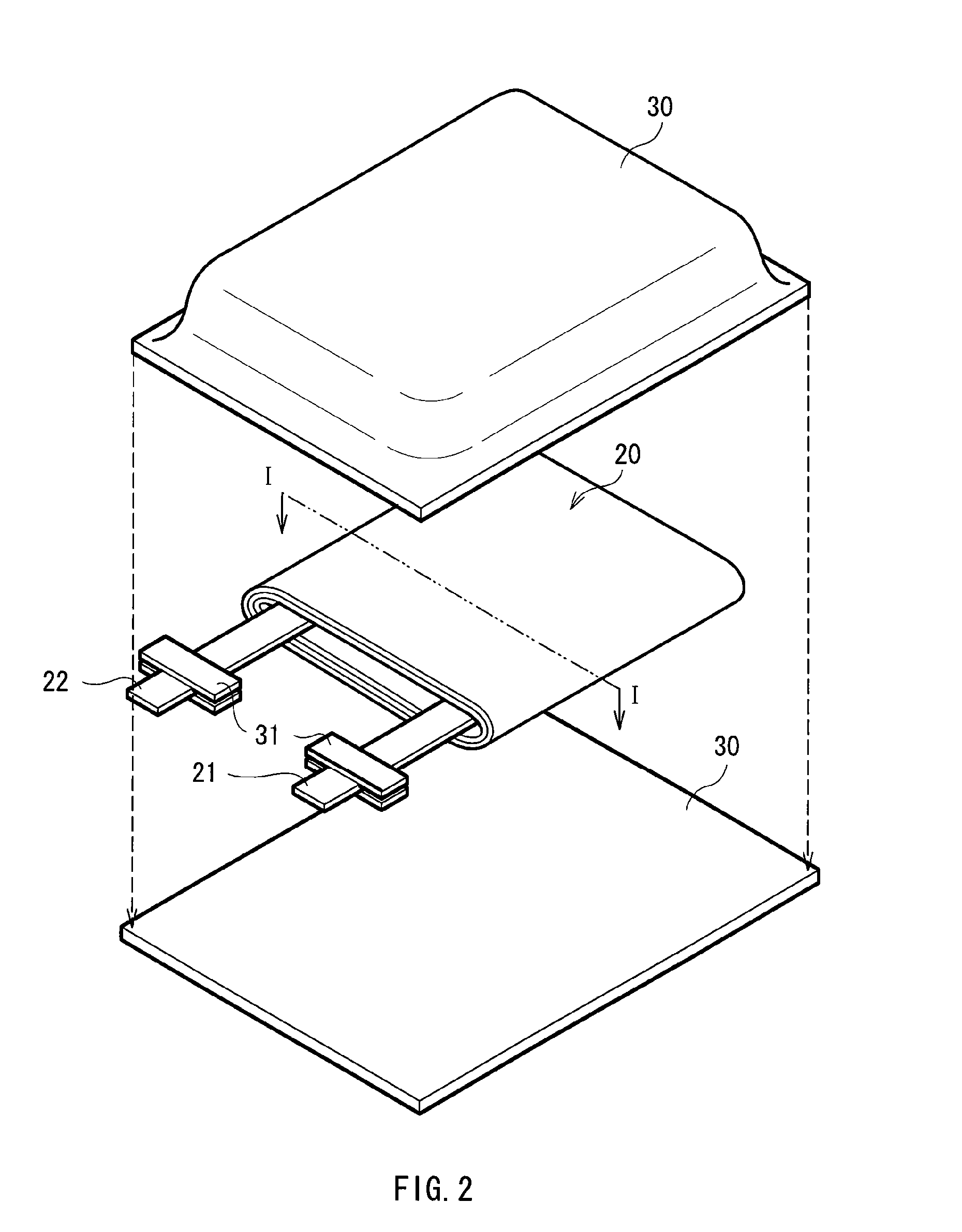

Battery

InactiveUS20060228625A1Improve featuresAvoid reactionOrganic electrolyte cellsActive material electrodesHalogenSuccinic anhydride

A battery capable of improving cycle characteristics is provided. A cathode and an anode are oppositely arranged with a separator in between. An electrolytic solution is impregnated in the separator. The electrolytic solution contains a derivative of cyclic carbonate having halogen atoms such as 4-fluoro-1,3-dioxolane-2-one and 4-chloro-1,3-dioxolane-2-one; and a cyclic acid anhydride such as succinic anhydride. The anode has an anode current collector and an anode active material layer which is provided on the anode current collect and is alloyed with the anode current collector at least at part of the interface with the anode current collector

Owner:MURATA MFG CO LTD

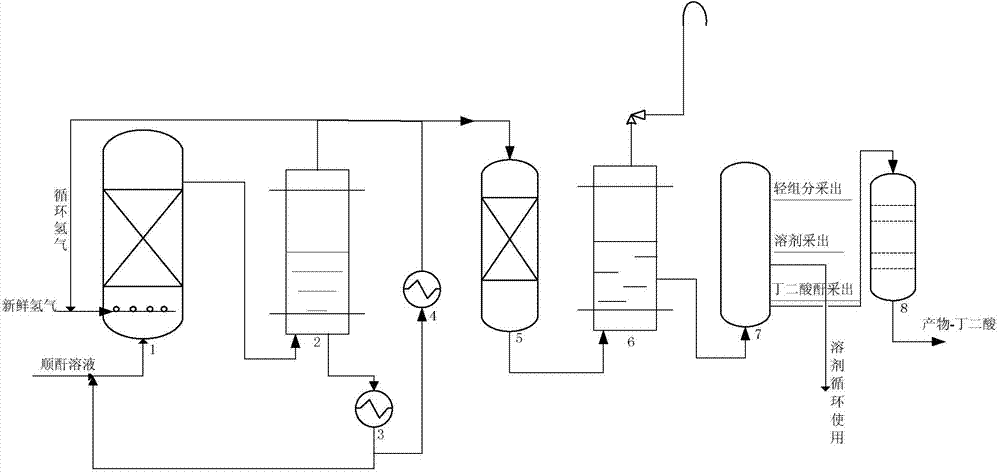

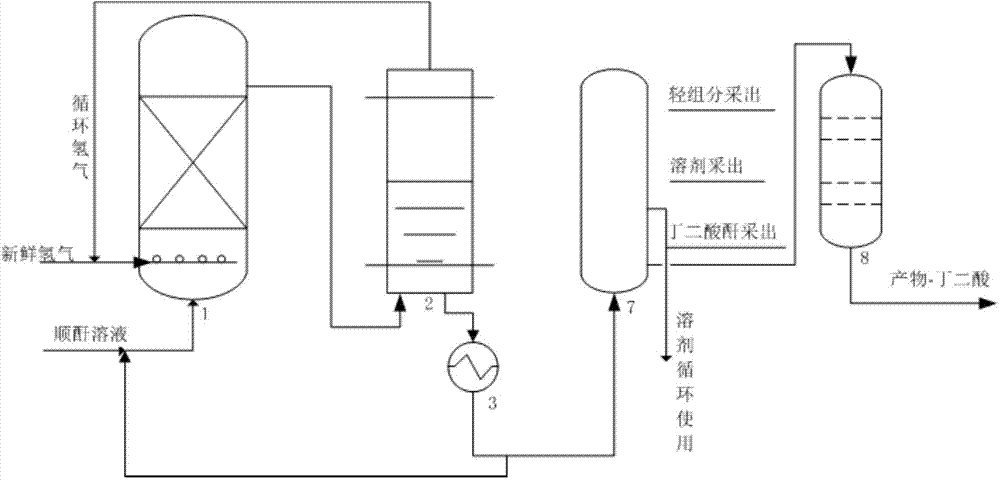

Technological process for continuously producing succinic anhydride and co-producing succinic acid through maleic anhydride hydrogenation

ActiveCN103570650AControl the average operating temperatureUniform reaction temperaturePreparation from carboxylic acid anhydridesFixed bedReaction temperature

The invention discloses a technological process for continuously producing succinic anhydride and co-producing succinic acid through maleic anhydride catalytic hydrogenation. The whole process comprises three steps, namely, reaction, rectification and hydrolysis, wherein two stages of hydrogenation reactors are used for reaction, a primary hydrogenation reactor is a fixed bed reactor with hydrogen entering from the lower part and reaction liquid exiting from the upper part, and a secondary hydrogenation reactor is a trickle bed reactor with hydrogen and reaction liquid entering from the upper part and exiting from the lower part. The technological process adopts an external circulating heat radiation manner, and reaction heat is uniformly removed, so that the average operation temperature of the whole reactor is effectively controlled, and the reaction temperature in the whole main reactor is balanced. Furthermore, the primary hydrogenation reactor adopts the manner that both the maleic anhydride solution and hydrogen flow upward simultaneously, so that the reaction temperature of the whole reactor is controlled to be balanced, local hot spot temperature is effectively controlled and lowered, and the reactants are prevented from polymerizing and depositing carbon or coking.

Owner:SHANXI UNIV

Method for preparing potassium dehydroandrographolide succinate or potassium sodium dehydroandroan drographolide succinate

The invention discloses a method for preparing potassium dehydroandrographolide succinate or potassium sodium dehydroandroan drographolide succinate, which comprises that firstly, andrographolide serves as a raw material, the andrographolide reacts with succinic anhydride to produce dehydroandroan drographolide disuccinate in a specific non-pyridine solvent under the heating reflux in the presence of a catalyst, and the usage amount ratio (W / W) of the andrographolide and the catalyst is (1:10)-(1:1); and secondly, the purified dehydroandroan drographolide disuccinate reacts with potassium hydroxide, sodium hydroxide, alkalinity sylvite or alkalinity sodium salt to produce the potassium dehydroandrographolide succinate or the potassium sodium dehydroandroan drographolide succinate in methanol, ethanol or hydrosolvent. The method is practical, convenient to operate, low in cost and nontoxic. The potassium dehydroandrographolide succinate or the potassium sodium dehydroandroan drographolide succinate is prepared easily under the normal atmosphere through usage of the solvent, the product quality is guaranteed, and the method is suitable for industrial production particularly.

Owner:HUBEI HOPE PHARMA

Alkenyl succinic acid anhydride half ester emulsifier

The present invention relates to a starch emulsifier product prepared by sufficiently solubilizing a starch and subsequently sufficiently derivatizing the sufficiently solubilized starch product, in one embodiment by reacting the sufficiently solubilized starch with an alkenyl succinic anhydride. Such starch emulsifier products are useful as emulsifying and / or encapsulating agents, particularly in systems where high load and retention of the active ingredient, low surface oil exposure, and excellent oxidation resistance is desired.

Owner:CORN PROD DEV INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com