Process for producing starch octenylsucciniate

A technology of octenyl succinic acid and octenyl succinic anhydride, which is applied in the field of food chemistry, can solve the problem of low product viscosity, and achieve the effects of wide sources, easy preparation, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

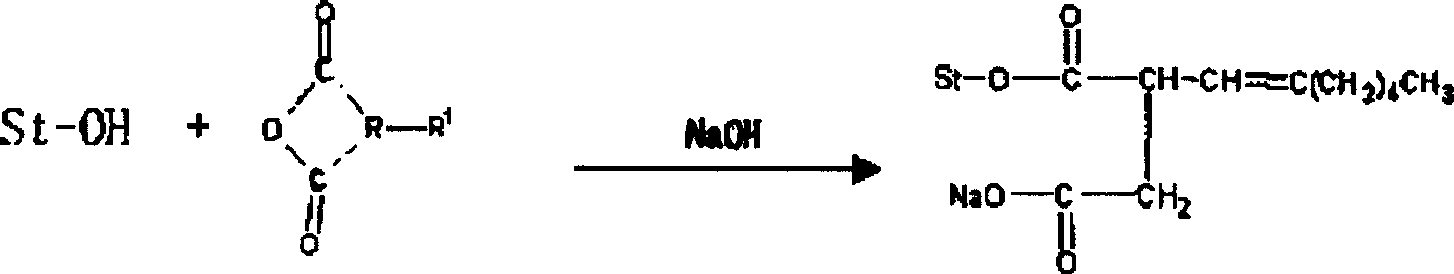

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1, a kind of potato octenyl starch succinate degree of substitution assay method:

[0043] Accurately weigh 2.0 g of the sample and place it in a 250 mL beaker, wet it with 10 mL of 90% isopropanol, stir for 10 min, add 15 mL of 2.5 mol / L hydrochloric acid-isopropanol solution, stir for 30 min by magnetic force, and then add 50 mL of 90% isopropanol Isopropanol solution, continue to stir for 10min. The sample was transferred to a Buchner funnel and washed with 90% isopropanol until there was no Cl- (checked with 0.1 mol / L silver nitrate). Then transfer the sample into a 500mL beaker, add distilled water to 300mL, boil in water bath for 20min, add 2 drops of phenolphthalein, and titrate with 0.1mol / L NaOH to pink while hot.

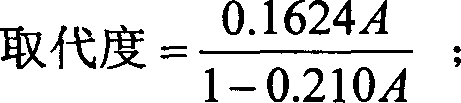

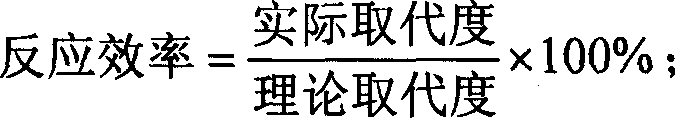

[0044] The formula for calculating degree of substitution (DS) is as follows:

[0045]

[0046] A: the amount of substance that consumes 0.1mol / L NaOH standard solution for every gram of sodium starch octenyl succinate (SSOS), mmol; ...

Embodiment 2

[0047] Embodiment 2, a kind of production method of potato octenyl starch succinate, carry out following steps successively:

[0048] 1. Potato starch and water are mixed into an emulsion under the action of a constant temperature magnetic stirrer, and potato starch accounts for 30% of the total weight of the emulsion; the reaction temperature is 30°C, and the stirring speed is 100r / min;

[0049] 2. Adjust the pH value of the above-mentioned emulsion to 7.5 by using sodium hydroxide with a weight concentration of 3%;

[0050] 3. Dilute octenyl succinic anhydride with absolute ethanol, and the volume ratio of absolute ethanol to octenyl succinic anhydride is 5 times;

[0051] 4. The diluted octenyl succinic anhydride obtained in step 3) is mixed with the emulsion obtained in step 2) to form a reaction system, and the weight ratio of the diluted octenyl succinic anhydride to the potato starch in the emulsion is 3% ; Add a NaOH solution with a weight concentration of 3% to maint...

Embodiment 3

[0054] Embodiment 3, a kind of production method of potato octenyl starch succinate, carries out following steps successively:

[0055] 1. Potato starch and water are mixed into an emulsion under the action of a constant temperature magnetic stirrer, and potato starch accounts for 35% of the total weight of the emulsion; the reaction temperature is 35°C, and the stirring speed is 100r / min;

[0056] 2. Adjust the pH value of the above-mentioned emulsion to 8.0 by using sodium hydroxide with a weight concentration of 3%;

[0057] 3. Dilute octenyl succinic anhydride with absolute ethanol, and the volume ratio of absolute ethanol to octenyl succinic anhydride is 5 times;

[0058] 4. The diluted octenyl succinic anhydride obtained in step 3) is mixed with the emulsion obtained in step 2) to form a reaction system, and the weight ratio of the diluted octenyl succinic anhydride to the potato starch in the emulsion is 3% ; Add a NaOH solution with a weight concentration of 3% to mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com