Patents

Literature

269 results about "Octenyl succinate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

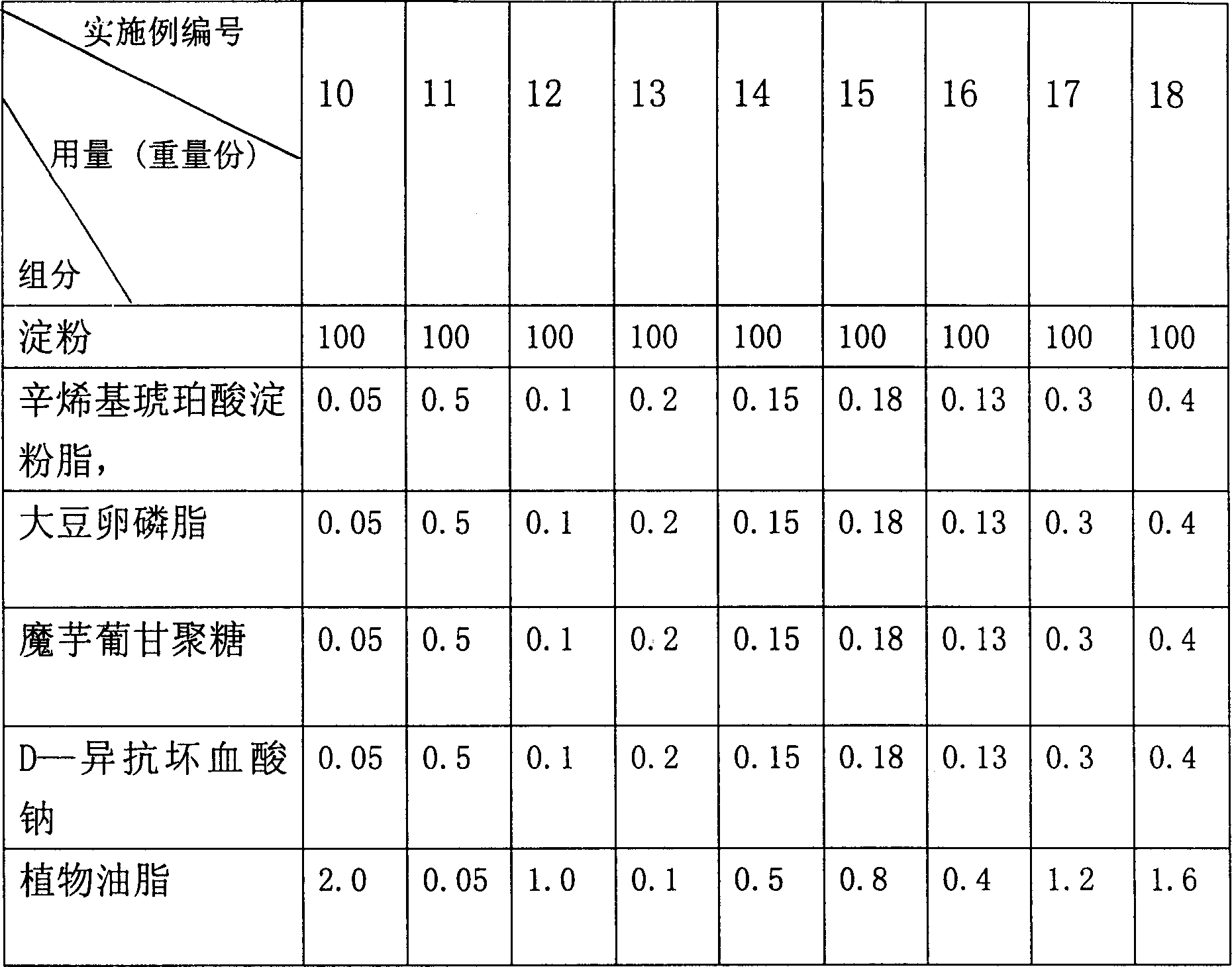

Method to Prepare a Stable High-Load Paprika Extract in Powder Form

The invention relates to a preparation for foodstuffs. It is proposed in this case that the preparation comprise at least a fat soluble dye, dispersed in a lipid-based carrier medium; polyglycerol esters of edible fatty acids; citric acid esters of monoglycerides and / or diglycerides of edible fatty acids; or mixtures of these esters; and starch sodium octenyl succinate.

Owner:SENSIENT FOOD COLORS GERMANY

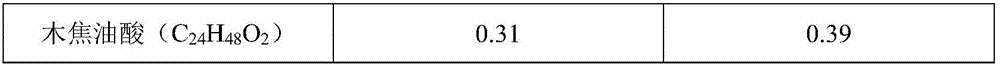

Compound microcapsule wall material and application thereof in essence microcapsules for cigarettes

InactiveCN103396886AImprove solubilityGood emulsifying effectEssential-oils/perfumesSucroseSodium Caseinate

The invention provides a compound microcapsule wall material and an application thereof in essence microcapsules for cigarettes. The compound microcapsule wall material is mixed by the following components in percentage by weight: 30.0-50.0% of starch octenylsuccinate, 15.0-30.0% of maltodextrin, 10.0-30.0% of sodium carboxymethyl starch, 10.0-30.0% of soy isolate protein, 1.0-5.0% of Arabic gum, 1.0-5.0% of sodium caseinate, 1.0-5.0% of saccharose, 0.1-0.5% of sodium alginate, 0.1-0.5% of xanthan gum and 0.1-0.5% of pullulan. The compound microcapsule wall material provided by the invention is good in solubleness, good in emulsibility, good in film-forming property, low in solution viscosity, and economical and practical benefits. Higher embedding rate can be obtained by using the wall material to prepare the essence microcapsules for cigarettes, and the product is good in sensory performance, smooth and uniform in particle, compact in capsule wall, lower in moisture content, good in dispersibility and stronger in practicality.

Owner:HUBEI CHINA TOBACCO IND +1

Method for preparing vitamin A and vitamin E nano-sphere/microsphere double-embedding system

InactiveCN101214219AAvoid mutual interferenceImprove bioavailabilityPowder deliveryHydroxy compound active ingredientsMonoglycerideMicrosphere

A preparation method of vitamin A and vitamin E nano-sphere / microsphere double-embedding system belongs to the technical field of biological active substance control release microencapsulation. In the present invention, food grade vitamin A is nano-sphere core material and monoglyceride or beeswax is nano-sphere wall material to be made into nano-sphere suspension which is used as microsphere core material together with the vitamin E; ocentyl succinate esterified starch containing tween-80 is used as microsphere wall material; the nano-sphere / microsphere double-embedding system is manufactured by a thermal homogenization-spray drying method. The encapsulation rate towards the vitamin A of vitamin A nano-sphere manufactured by the present invention can reach to 82 percent to 94 percent, and the particle size of the nano-sphere is 200nm to 370nm. The encapsulation rate towards the vitamin A of the double-embedding system is 86 percent to 91 percent and the encapsulation rate towards the vitamin E is 89 percent to 93 percent. The double-embedding system can embed the vitamin A and the vitamin E synchronously and has the effect of releasing step be step, so as to avoid the mutual interference of active components, improve the biological utilization rate and can be added into various foods as vitamin intensifier and extender.

Owner:JIANGNAN UNIV

Red jujube flavor and preparation method thereof

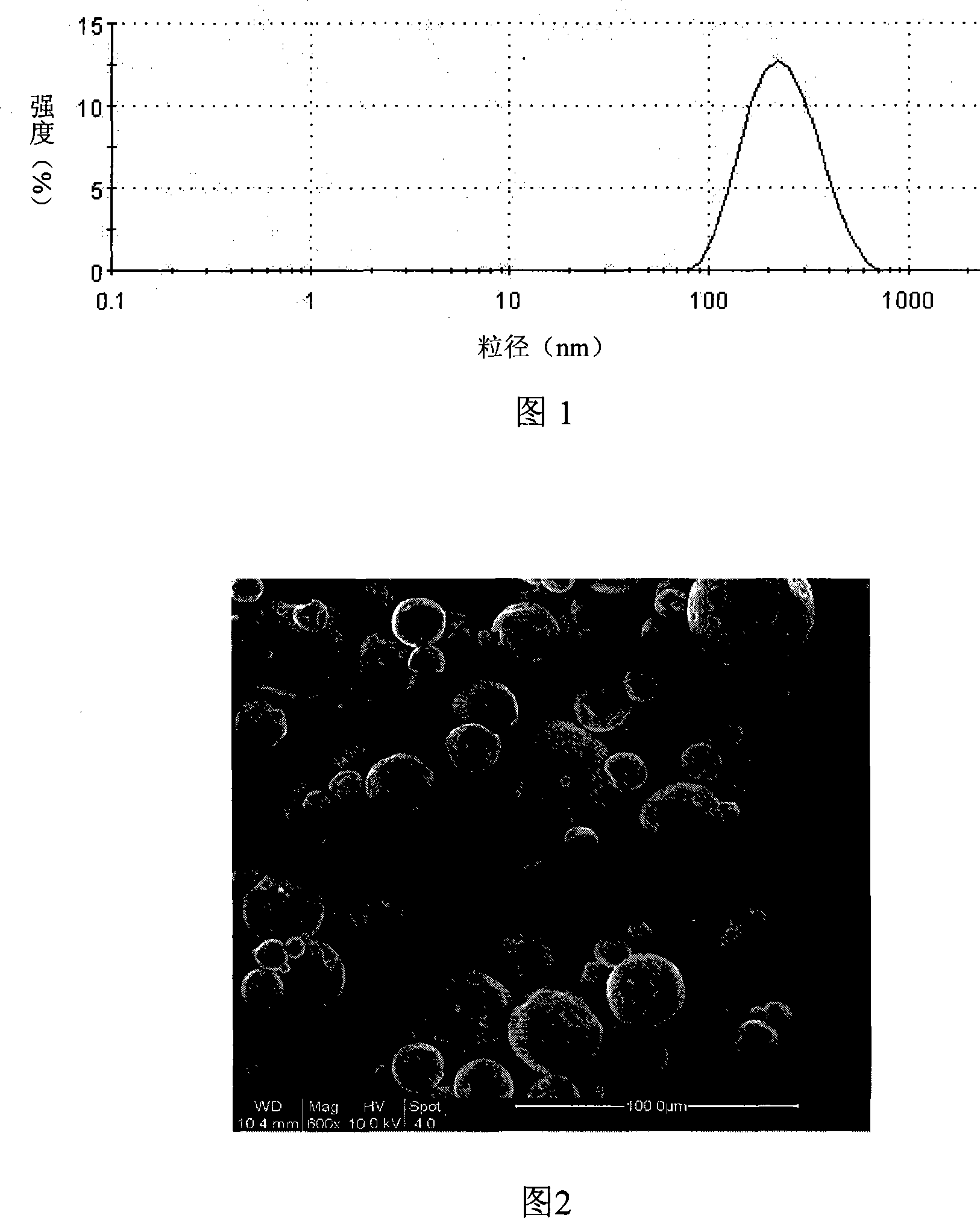

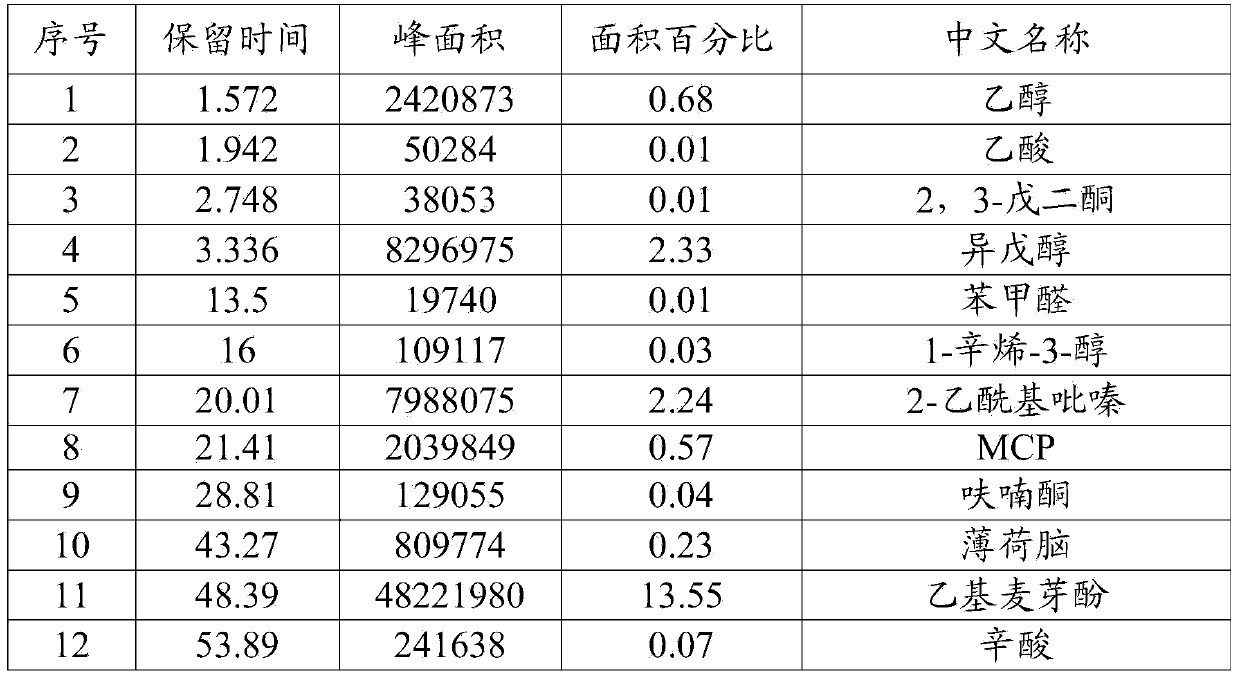

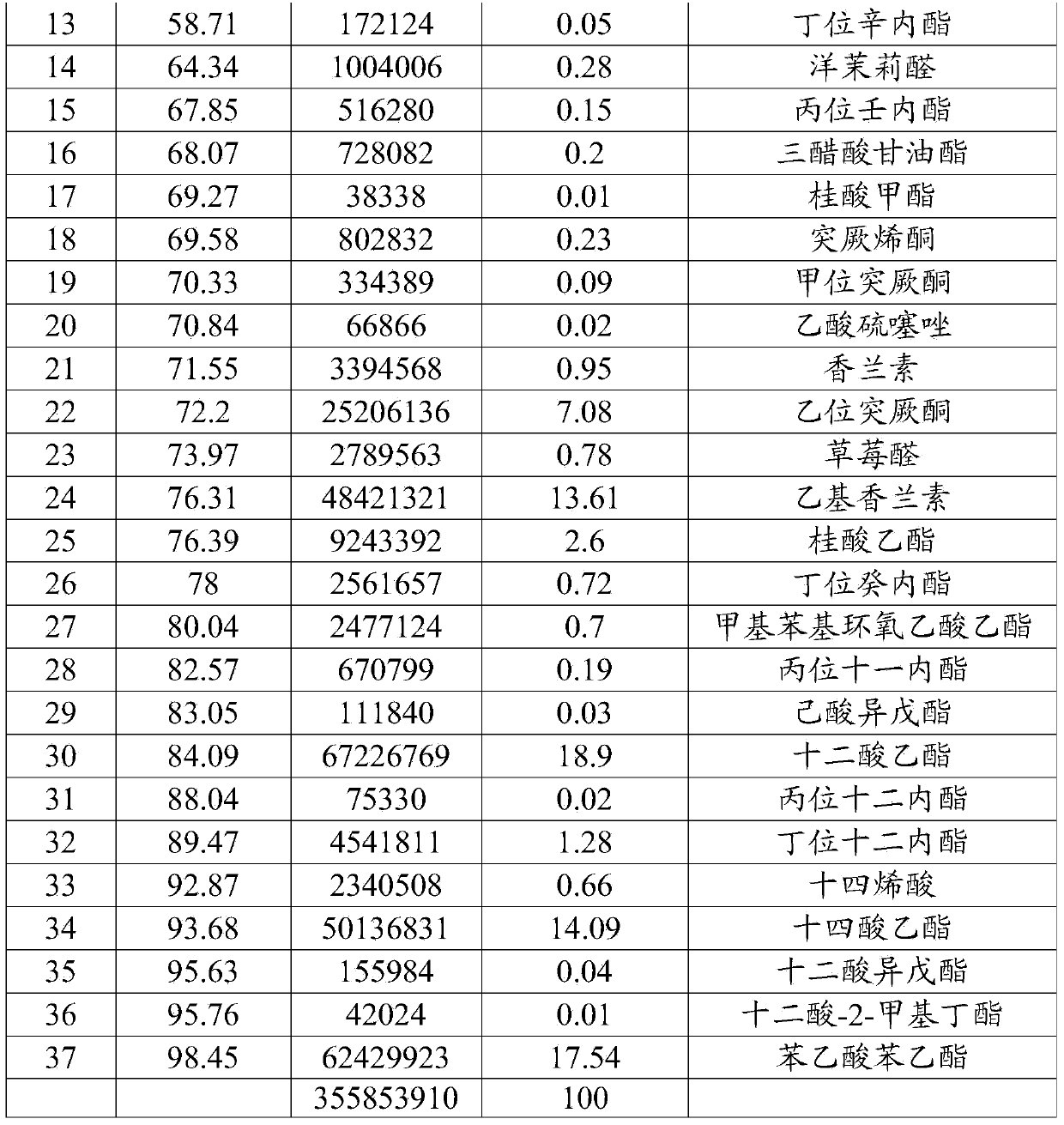

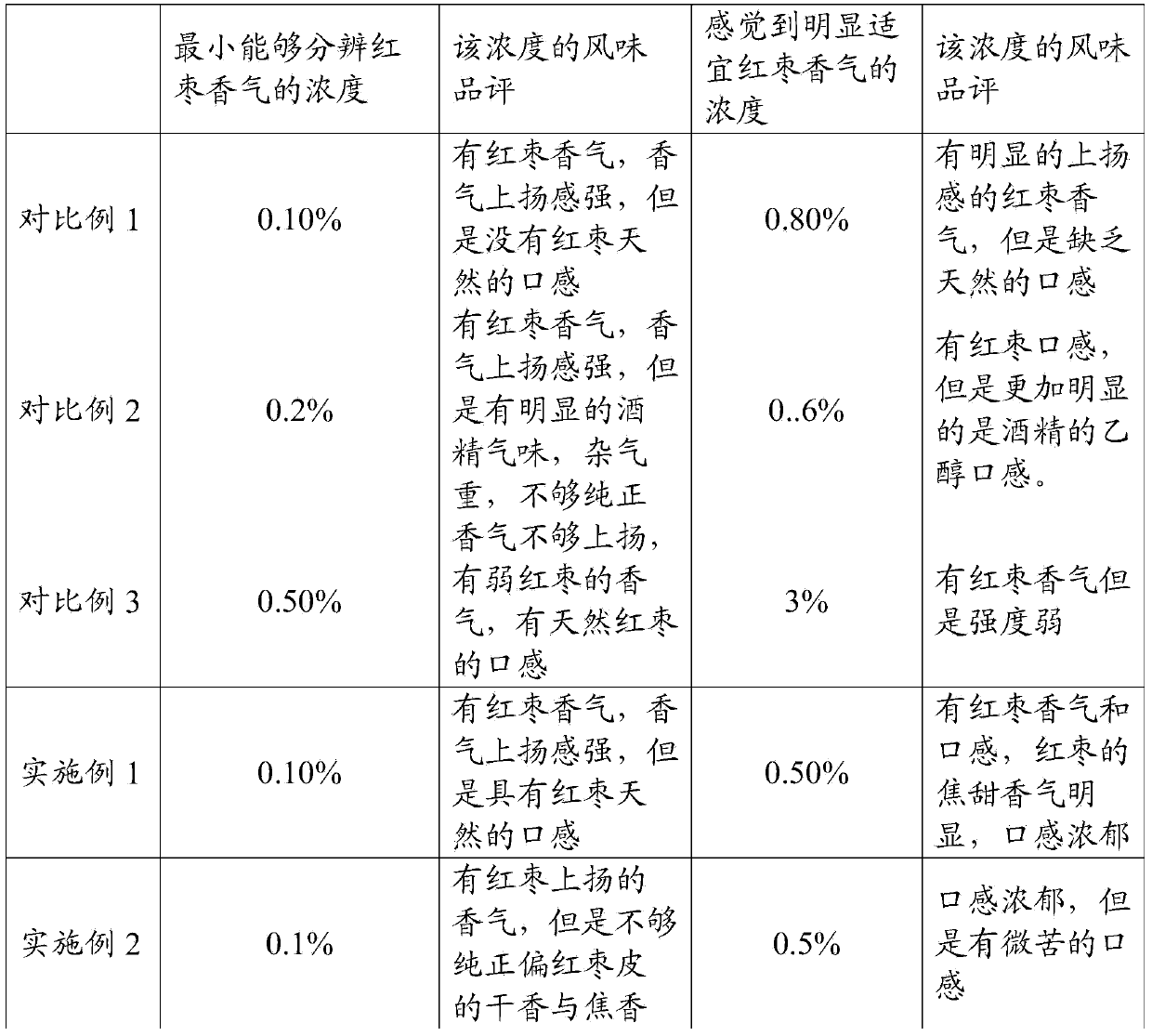

InactiveCN103695177AImprove the effect of fragranceAdd lessEssential-oils/perfumesFood preparationFlavorOctenyl succinate

The invention discloses red jujube flavor and a preparation method thereof. The red jujube flavor is mainly prepared by the following materials by weight: 95-105 parts of red jujube enzymes, 1-3 parts of red jujube bases, 12-18 parts of maltodextrin and 2.5-3.5 parts of sodium starch octenyl succinate. The preparation method of the red jujube enzymes comprises the following steps: pretreatment: mixing red jujube with water according to the weight ratio of 1 : (2 to 5), and processing by a colloid grinder to prepare red jujube paste; enzymolysis: mixing the red jujube paste with plant enzyme hydrolysis (the Danish Novozymes) according to the weight ratio of 10 : (0.02 to 0.05) and enzymolysis, wherein, the temperature of the enzymolysis is from 50 DEG C to 60 DEG C, and the time is from 1 to 5 hours; deactivating the enzymes. The red jujube flavor has the advantages of good flavor enhancing effect, little additive amount in the practical application and high added-value. The preparation method is simple and easy to operate.

Owner:广东江大和风香精香料有限公司

Method for preparing starch ester by recycling octenyl succinic anhydride

The invention discloses a method for utilizing octenyl succinic anhydride to produce starch ester in circulation. The method comprises steps that: water is added to 100 parts of dry basis starch; the starch is homogenized and emulsified; the pH value of the starch is regulated to 8 to 10; the starch is added to an octenyl succinic anhydride solution containing 3 parts of octenyl succinic anhydride, and is subject to a reaction; when the reaction is finished, the pH value of a reaction liquid is regulated to 5.5 to 6.5; the reaction liquid is filtered, and is processed from processes of washing, drying, crushing and sieving three times, such that white starch sodium octenyl succinate is obtained; a residual from the filtering process is mixed with the filtered washing solution, such that an octenyl succinic anhydride mixed solution is obtained; the solution is distilled, octenyl succinic anhydride is supplemented, and a solvent is added for dissolving, such that an octenyl succinic anhydride solution is obtained; water and ethanol obtained from distillation are fractionated, ethanol concentration is adjusted, and the materials can be repeatedly used. The method provided by the invention is advantaged in that: the technology is simple and is easy to control; recycling of octenyl succinic anhydride and recycling of the solvent can both be realized.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

New technique for producing starch of octane succinate

InactiveCN1563096APromote safe productionProduct quality is easy to controlOctenyl succinateOCTENYLSUCCINIC ACID

The invention provides a new production process of octoalkenyl succinate starch, and adopts a method of thermal dextrinization to implement industrialization production of octoalkenyl succinate starch. Its step includes two processes of esterization raw material starch into starch milk, adding dilute alkali to regulate pH value to 8.0-9.0, then adding octoalkenyl succinyl oxide to make heating reaction, after the reaction is completed, adding dilute acid to regulate pH value to about 5.0, then washing and centrifugally-drying; and the dextrinization process includes the following steps: placing the above-mentioned esterized octoalkenyl succinate starch semifinished product in mixer, and adding dilute acid to regulate pH value to 2.4-2.5, predrying, feeding the above-mentioned material into double-cone reactor to make high-temp. vacuum reaction, then discharging material, cooling and packaging finished product.

Owner:BAISHIDA STARCH GUANGXI

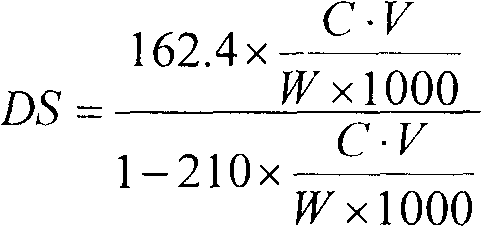

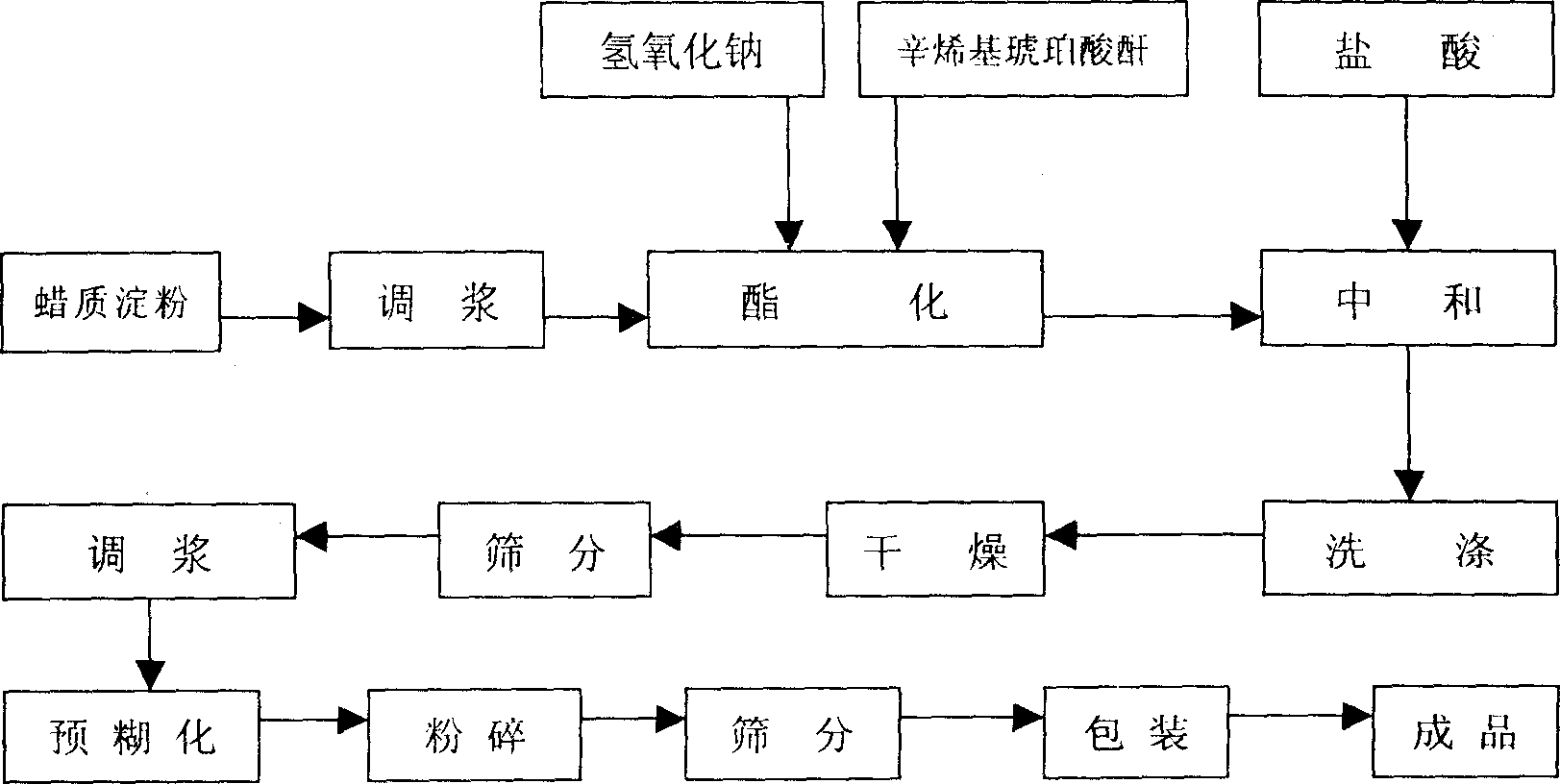

Predextrinization octeneyl succinate starch and its preparation method

InactiveCN1903883AWide variety of sourcesThe process flow is simple and applicableSolubilityOctenyl succinate

The present invention discloses a kind of pregelatinized octalkenyl succinate starch and its preparation method. It is made up by using waxy starch, octalkenyl succinic anhydride, hydrochloric acid and sodium hydroxide as raw material and making said raw materials undergo the processes of mixing paste, esterification, neutralization, washing, drying, screening, mixing paste, pregelatinizing, pulverizing, screening and packaging. Besides, said invention also provides its concrete application range.

Owner:四平帝达变性淀粉有限公司

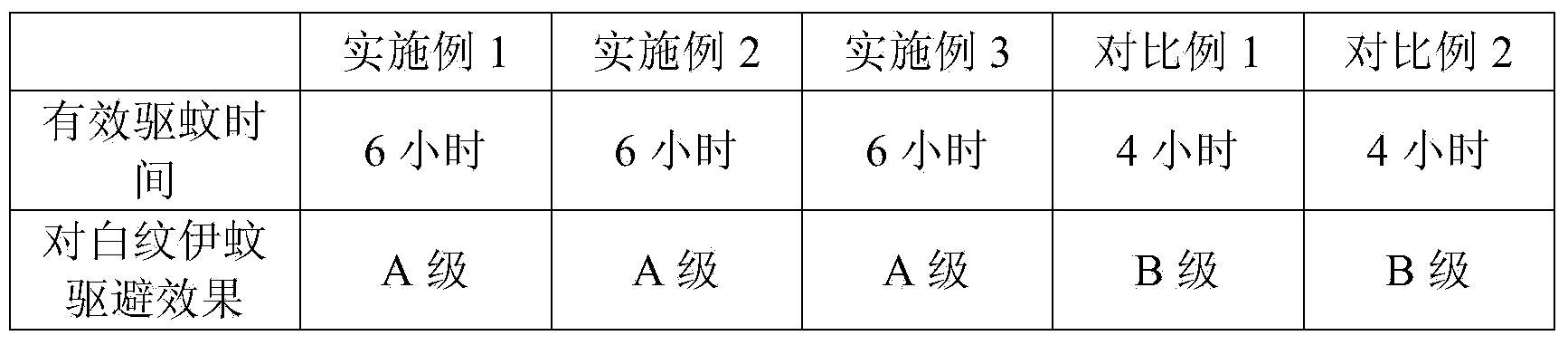

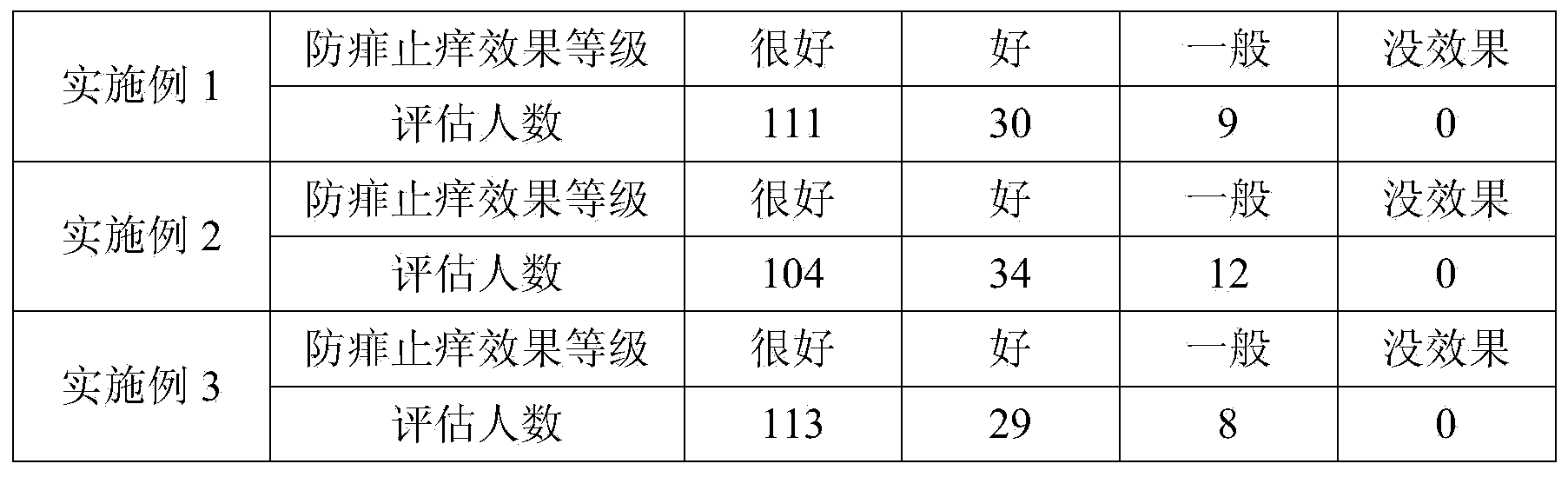

Mosquito-repellent composition microcapsule and preparation method and application of composition microcapsule

ActiveCN103520005AQuality improvementBoth anti-prickly heatCosmetic preparationsToilet preparationsJojoba oilBeta-Cyclodextrins

The invention provides a mosquito-repellent composition microcapsule and a preparation method and application of the composition microcapsule. The microcapsule is prepared by the following steps: mixing a plant extract with a mosquito-repellent effect with starch aluminum octenyl succinate, maltodextrin, beta-cyclodextrin, gelatin, chitosan, sodium alginate, soya bean lecithin, jojoba oil and water; and performing spray drying to obtain powder which is the mosquito-repellent composition microcapsule. The mosquito-repellent composition microcapsule provided by the invention can directly act on a human body or can be used for producing cosmetics to act on the human body to realize a long-time mosquito-repellent effect; moreover, the mosquito-repellent composition microcapsule also has a miliaria preventing and itching relieving effect.

Owner:TIANJIN YU MEI JING GRP

Camellia oil microcapsule powder and preparation method thereof

InactiveCN102048159AImprove liquidityImprove stabilityFood shapingFood preparationEmulsionFreeze-drying

The invention discloses camellia oil microcapsule powder and a preparation method thereof. The camellia oil microcapsule powder comprises a core material and a capsule material for coating the core material, wherein the core material includes 1 part of camellia oil by weight, and the capsule material includes 0.8-9 parts of modified polysaccharide-SSOS (starch sodium octenyl succinate) by weight.The preparation method is as follows: camellia oil is added into an aqueous solution of SSOS, the solution is stirred to be a uniform emulsion system, the emulsion is subjected to high-pressure homogenizing through a high-pressure homogenizing machine to form a camellia oil emulsion, then camellia oil emulsion is subjected to spray drying or freeze drying, and finally the while camellia oil microcapsule powder with the grain size less than 1000 nm can be obtained and has high stability and good flowability. The camellia oil microcapsule powder keeps the activity of camellia oil, improves the stability and the bioavailability of camellia oil, and can be applied to food and health care products.

Owner:WUXI RES INST OF APPLIED TECH TSINGHUA UNIV +1

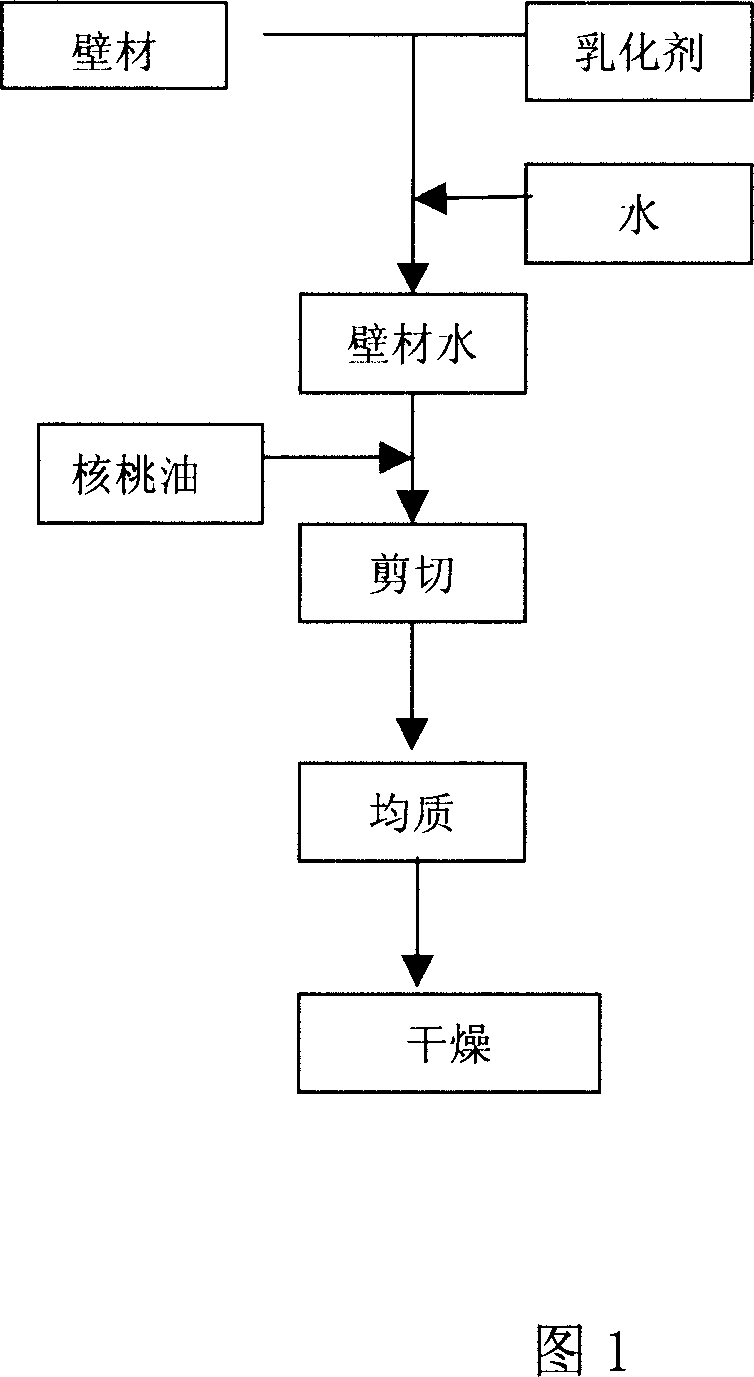

Method for making high-embedding-ratio powder walnut oil

InactiveCN101023763AIncrease contentHigh nutritional valueEdible oils/fatsMonoglycerideSuccinic acid

The present invention discloses a method for preparing powder walnut oil with high embedding rate. Said method includes the following steps: (1), after the monoglyceride, lecithine and Tween-60 as emulsifying agent are dissolved in water, successively adding octylene succinic acid esterified starch HI-CAP100 and maltodextrin as wall material to obtain wall material aqueous solution for stand-by; (2), adding walnut oil into the above-mentioned wall material aqueous solution, shearing and homogenizing to make the walnut oil be uniformly dispersed in the wall material aqueous solution; under the action of emulsifying agent forming O / W (oil-in-water) type emulsion with good emulsification stability; and (3), utilizing drying process to remove water content from emulsion, making wall material be formed into film, then the walnut oil can be uniformly embedded by all material film so as to obtain the invented powder walnut oil with high embedding rate.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

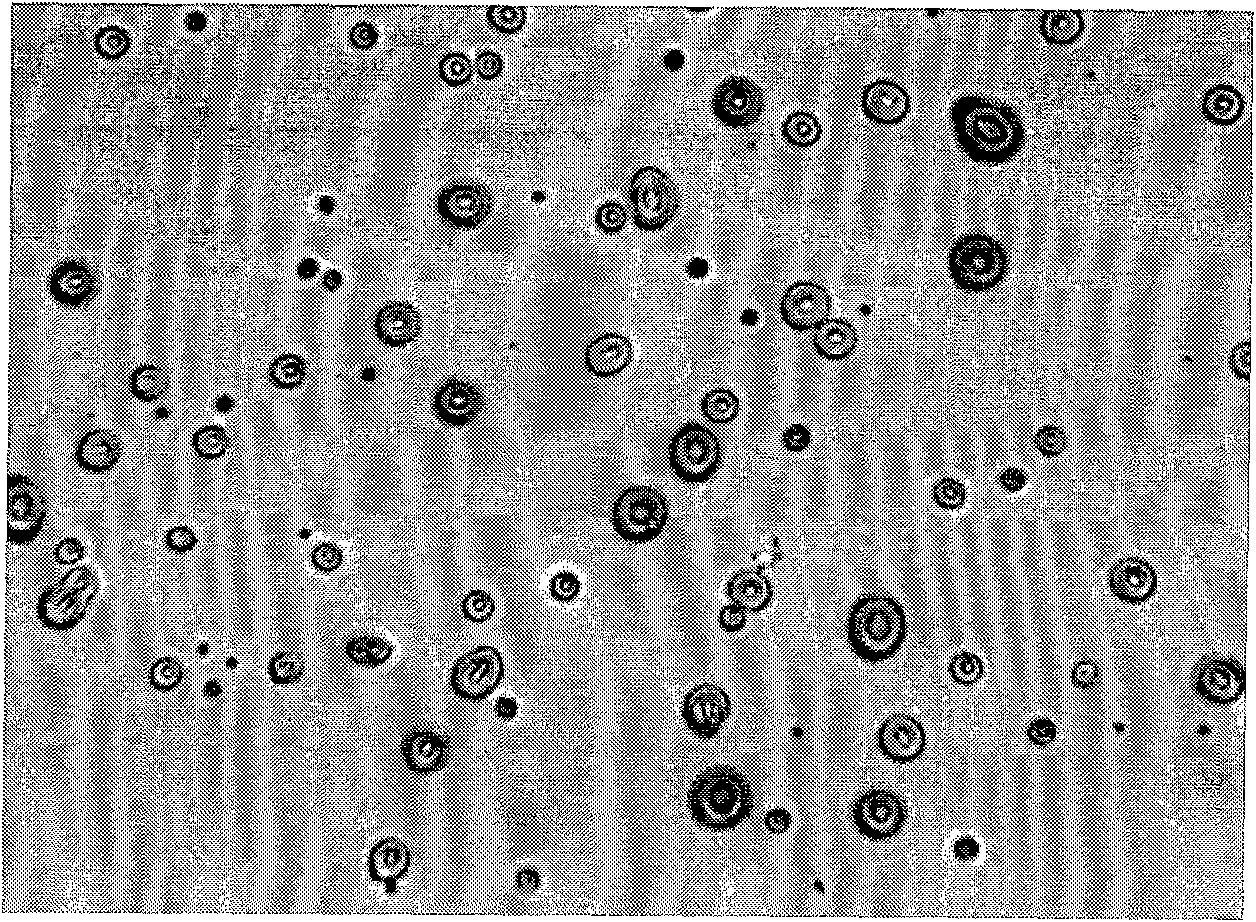

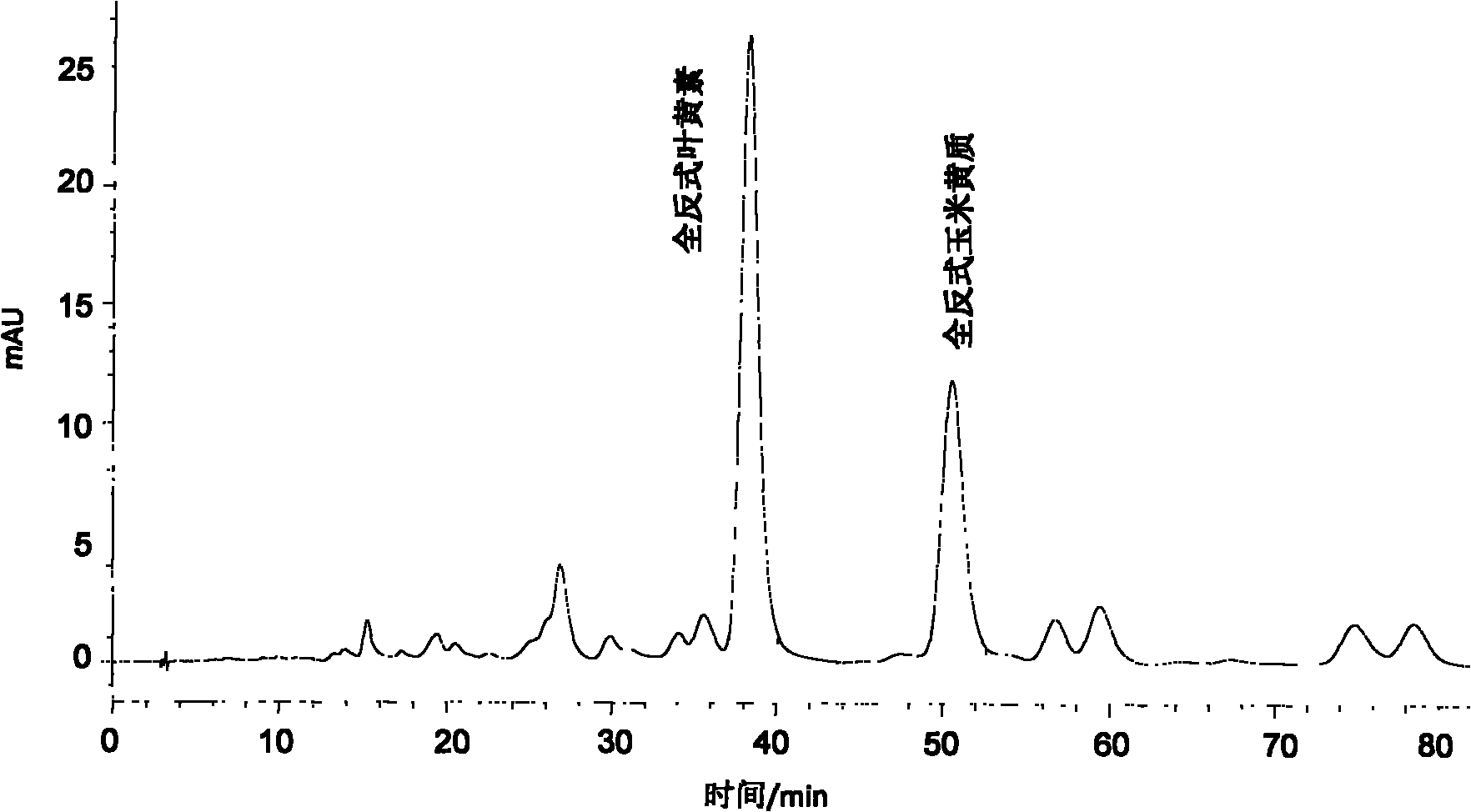

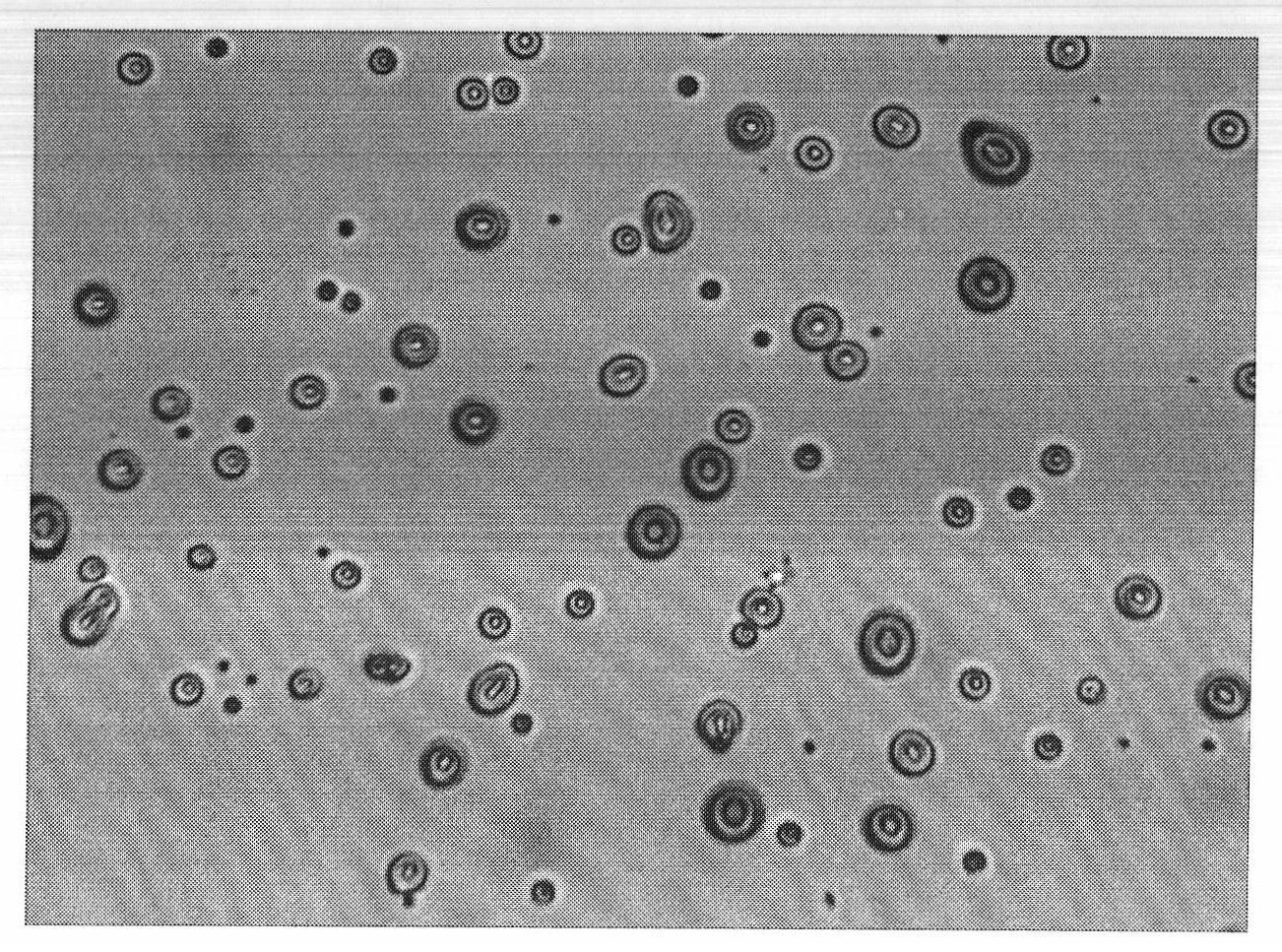

Xanthophyll-reinforced sweet corn beverage and preparation method thereof

The invention relates to a xanthophyll-reinforced sweet corn beverage prepared by adding a xanthophyll microcapsule into sweet corn juice. A trans-xanthophyll crystal is taken as a core, starch octenylsuccinate and sucrose are taken as wall materials, the xanthophyll microcapsule is prepared by the processes of emulsifying, homogenizing, spray drying and the like, the efficiency and yield of the product microcapsule can reach 90 percent respectively, and the microcapsule has high quality. A preparation method comprises the following steps of: unfreezing quick-frozen sweet corn kernels serving as a raw material, pulping, regulating the pH, performing enzymolysis, filtering, adding a compound stabilizer (xanthan gum and sodium alginate), fructose, citric acid, sodium ascorbate and the xanthophyll microcapsule for mixing, and sterilizing and filling to obtain the xanthophyll-reinforced sweet corn beverage. The sweet corn beverage has unique flavor, fine and smooth mouthfeel and rich nutrition, has certain effect of preventing and treating impaired vision and blindness caused by age-related macular degeneration (AMD), and is particularly suitable for old people; and 100g of sweet corn beverage comprises 2.03mg of trans-xanthophyll, and the trans-xanthophyll content is higher than that of the common sweet corn beverage.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Octenyl succinate distarch phosphate and preparation method and applications thereof

InactiveCN102070722AAbundant raw materialsEasy to operateCosmetic preparationsToilet preparationsPhosphoric Acid EstersPotato starch

The invention provides a preparation method and applications of octenyl succinate distarch phosphate. The preparation method comprises the following steps: using potato starch and sodium trimetaphosphate (STMP) to perform crosslinking reaction, and then adding octenyl succinic anhydride which is diluted with absolute alcohol to perform esterification reaction. The octenyl succinate distarch phosphate prepared by the method has the advantages that the product has high viscosity and stability, excellent free fluidity and hydrophobicity, good emulsion stability and high temperature resistance, has acid resistance, alkali resistance and saline environment resistance and also has high freeze-thaw stability; and the special properties of potato starch can be maintained.

Owner:内蒙古奈伦农业科技股份有限公司

Olive oil microcapsule and preparation method thereof

InactiveCN102511570AGood embedding rateReduce moisture contentEdible oils/fatsOctenyl succinateOCTENYLSUCCINIC ACID

The invention relates to an olive oil microcapsule and a preparation method of the olive oil microcapsule. The olive oil microcapsule consists of a core material and a wall material covered outside the core material, wherein the core material is olive oil, and the wall material is a mixture formed by waxy maize starch and starch octenyl succinate anhydride. The olive oil microcapsule has the advantages that the covering rate is high, the production cost is low, and in addition, the preparation method is simple.

Owner:CHINA AGRI UNIV

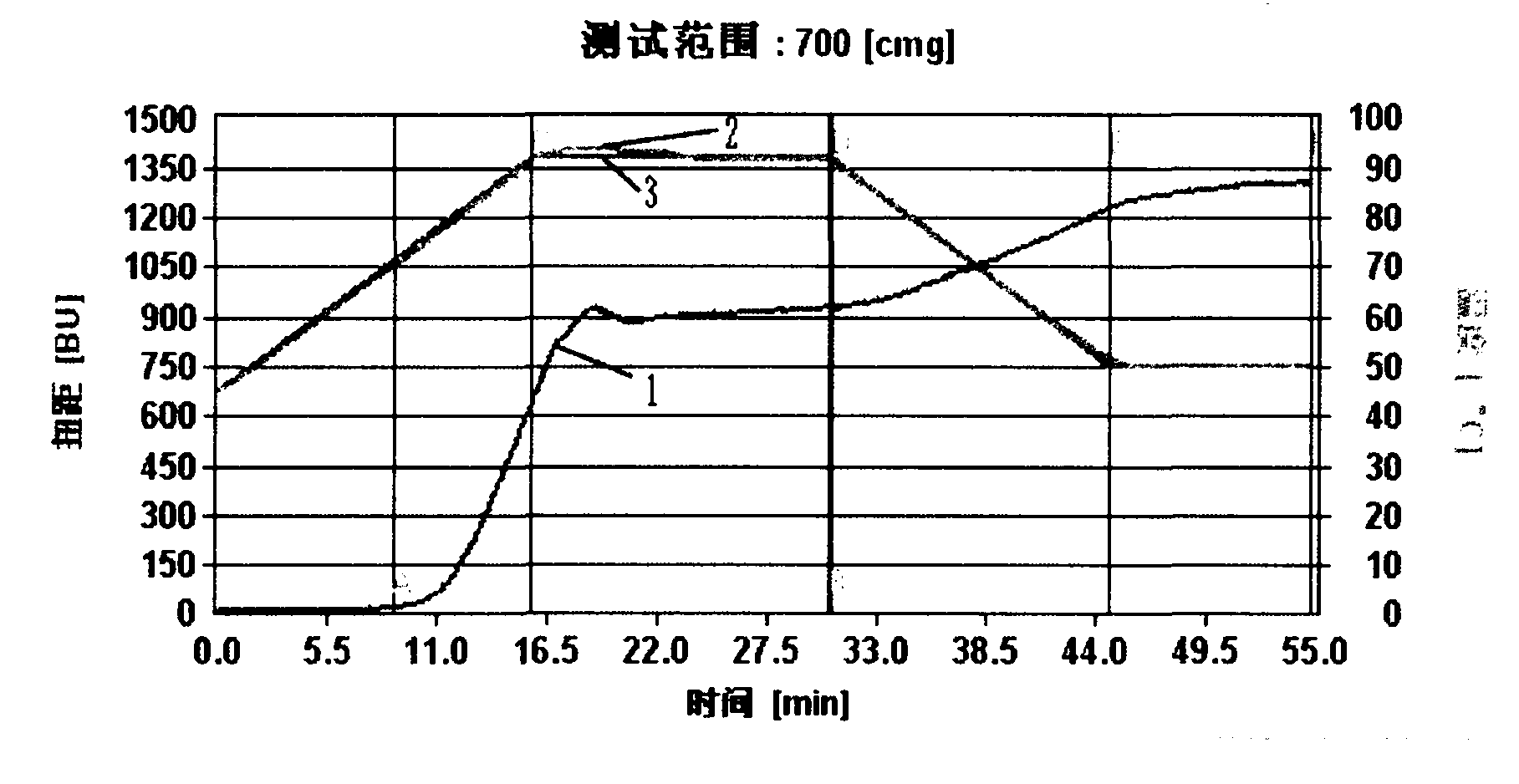

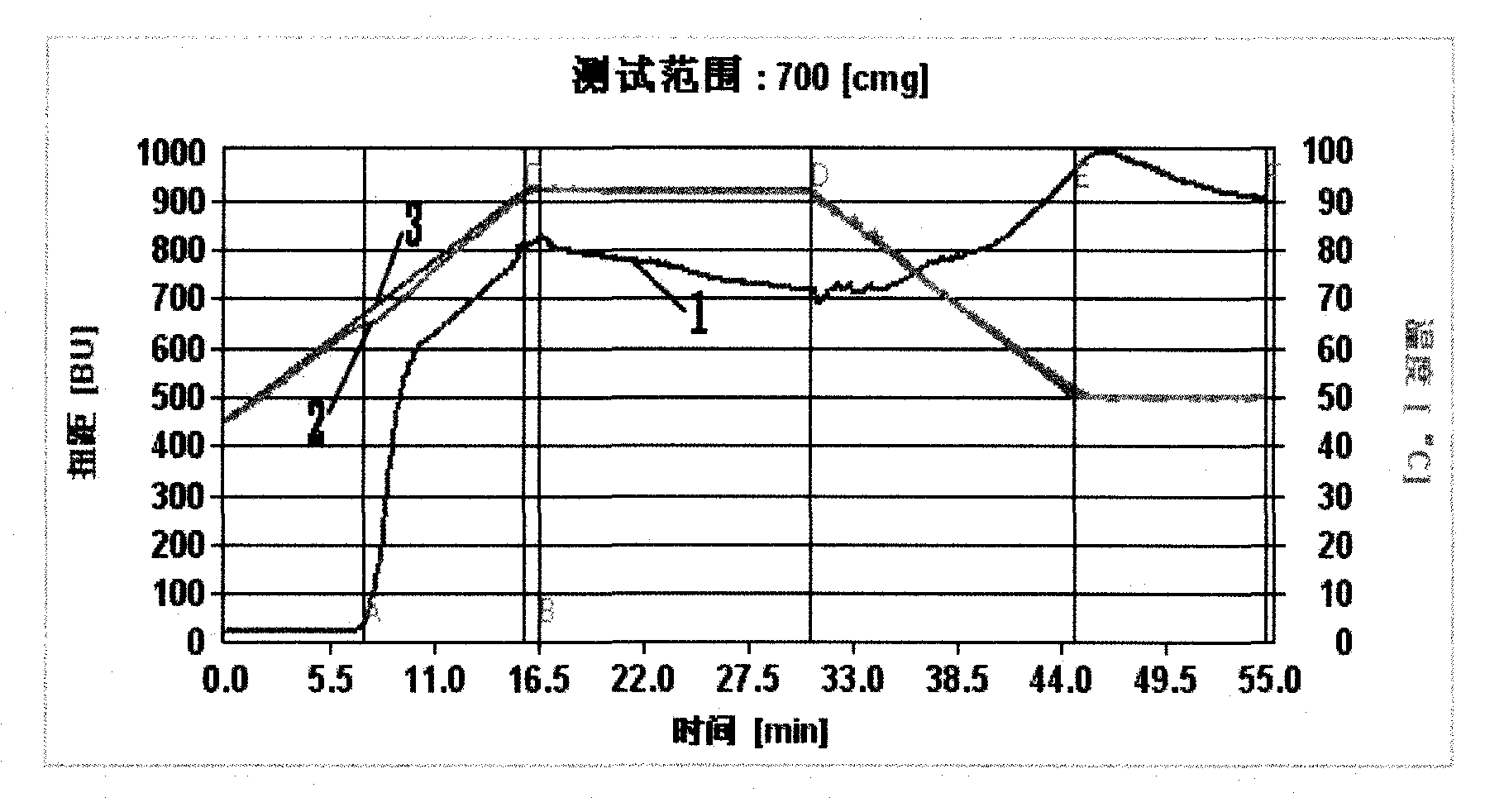

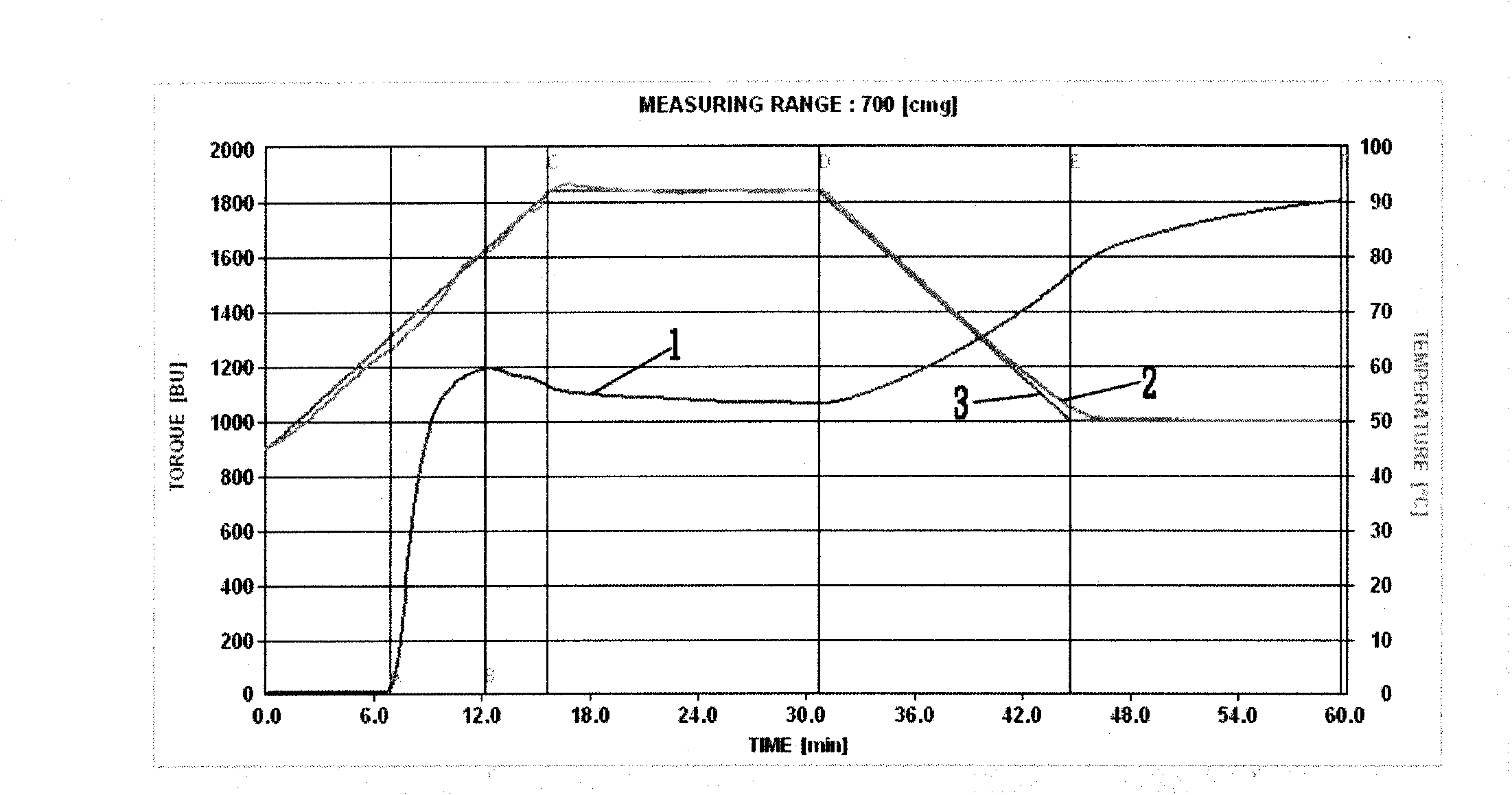

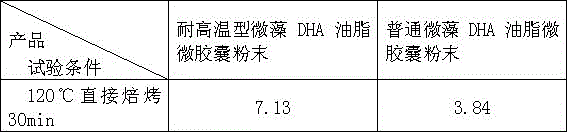

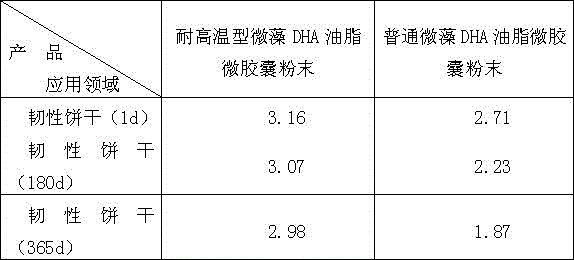

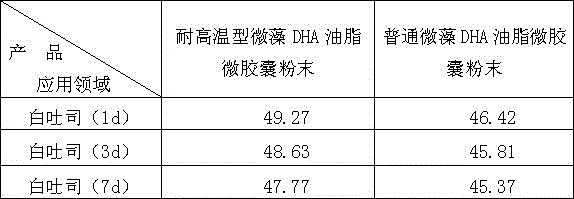

Preparation method of high-temperature-resistant microalgae DHA (docosahexenoic acid) oil microcapsule powder

ActiveCN105707894AImprove high temperature resistanceImprove oxidation stabilityFood shapingBiotechnologyEngineering

A preparation method of high-temperature-resistant microalgae DHA (docosahexenoic acid) oil microcapsule powder comprises steps as follows: (1) raw materials are prepared; (2) whey protein and / or starch sodium octenyl succinate, lyophilic colloid, a food emulsifier, an acidity regulator and a sweetening agent are put into water, heat preservation and stirring are performed, and an aqueous phase liquid is obtained; (3) the aqueous phase liquid is heated to 90-95 DEG C, subjected to heat preservation for 20-30 min, stirred to be fully dissolved and then cooled; (4) a small amount of microalgae DHA oil and an oil-soluble antioxidant are evenly mixed, and a premix is obtained; (5) then the rest microalgae DHA oil is stirred evenly, then added to the premix and stirred to be evenly mixed, and a core material is obtained; (6) the core material is put into the aqueous phase liquid, a water-soluble antioxidant is added, the mixture is stirred and sheared, and an emulsion is obtained; (7) the emulsion is homogenized twice and then sterilized at 80-90 DEG C for 20-25 min; (8) spray drying is performed. The prepared microalgae DHA oil microcapsule powder has excellent high-temperature resistance.

Owner:RUNKE BIOENG FUJIAN

Preparation method of peony seed oil microcapsule

The invention relates to a preparation method of a peony seed oil microcapsule and belongs to the technical field of oil microencapsulation. The method uses peony seed oil as a core material, monoglyceride, stearyl citrate, sucrose ester and starch sodium octenyl succinate as core material emulsifiers, and maltodextrin, beta-cyclodextrin and sodium caseinate as wall materials. The monoglyceride, monoglyceride, stearyl citrate, sucrose ester and starch sodium octenyl succinate are prepared in accordance with a specific ratio provided by the present invention to produce good emulsifying effect; if the ratio of the four exceeds the scope of the present invention, the emulsification occurs and stabilization effect is decreased significantly; if one of the four is missed, the mixed liquor rapidly stratifies after the homogenization. The maltodextrin, beta-cyclodextrin and sodium caseinate are prepared in accordance with a certain proportion provided by the present invention to produce good coating effect; if the ratio of the four exceeds the scope of the present invention, the phenomena of embedding rate decrease, non-uniform particle size, granularity increase and decrease of product sensory and quality occur.

Owner:INST OF AGRO FOOD SCI & TECH SHANDONG ACAD OF AGRI SCI

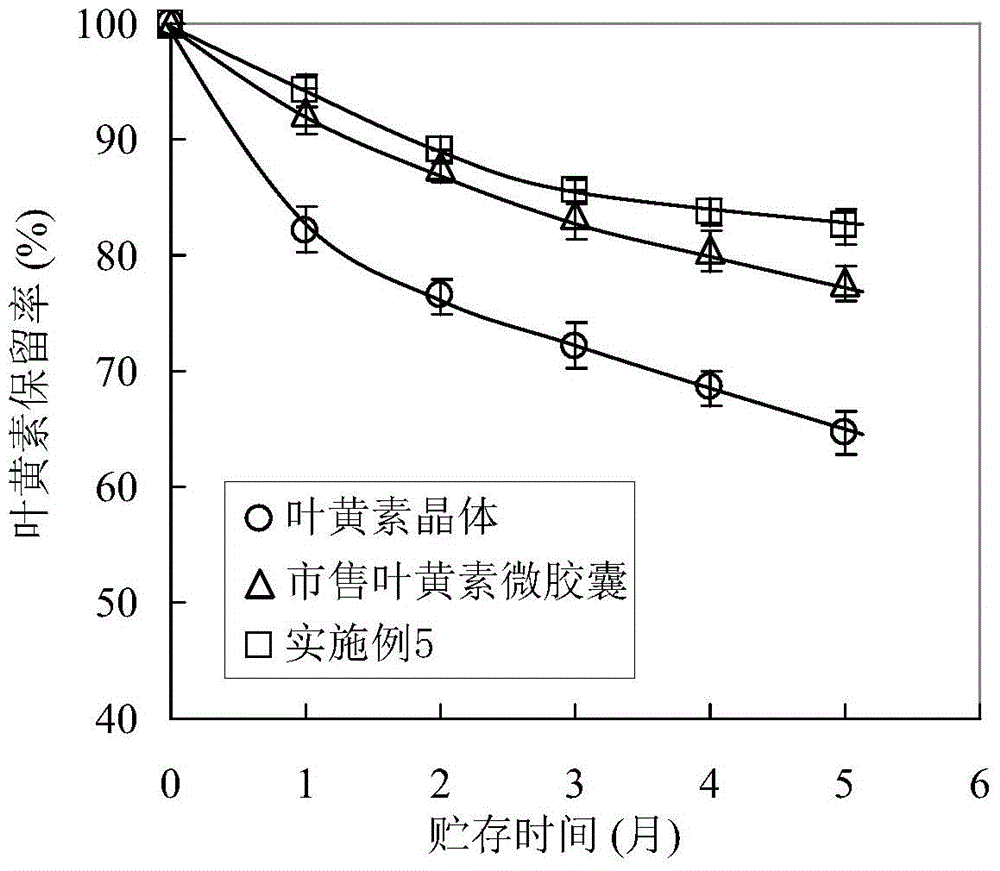

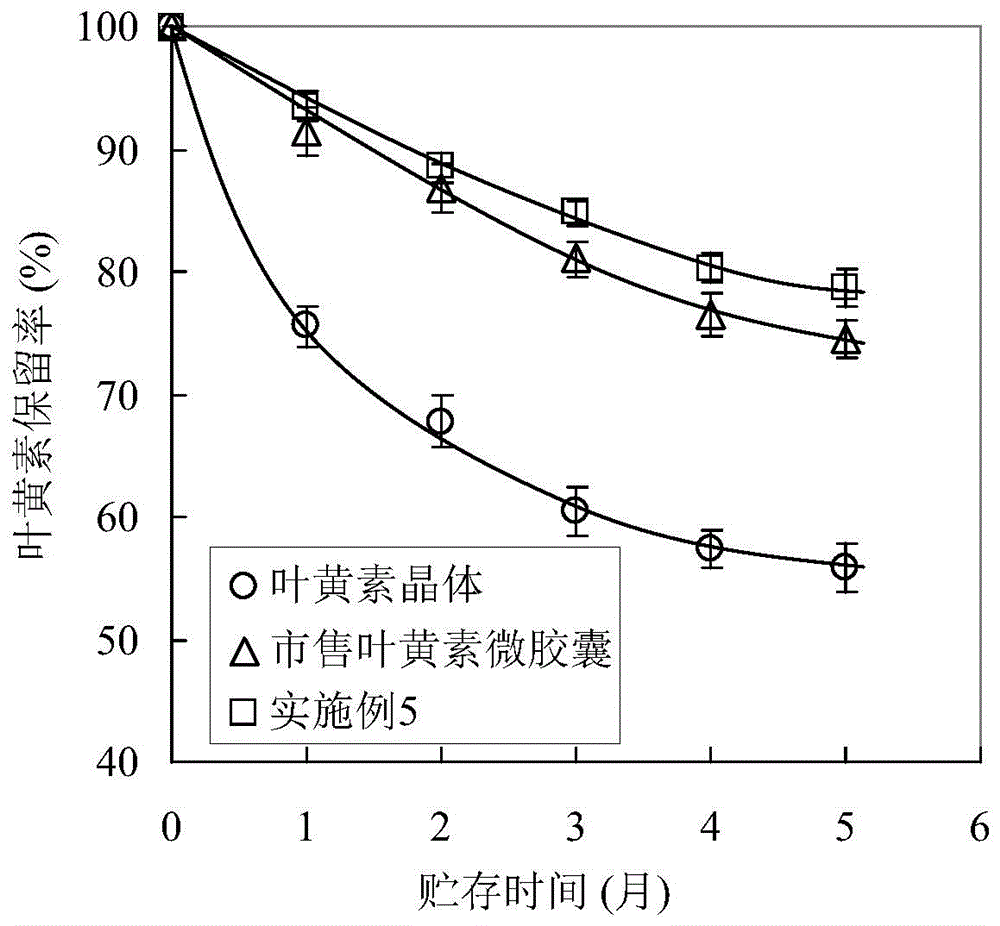

High-inoxidizability lutein microcapsules and preparation method thereof

ActiveCN105663082AImprove oxidation stabilityHigh yieldSenses disorderHydroxy compound active ingredientsSodium CaseinateSodium ascorbate

The invention discloses high-inoxidizability lutein microcapsules.The microcapsules are prepared from a core material, a wall material, an auxiliary material and an antioxidant, the core material is a combination of lutein crystals and sunflower seed oil, the wall material is one of or a mixture of starch sodium octenyl succinate, gelatin and Arabic gum, the auxiliary wall material is one of or a mixture of sucrose stearate, sodium caseinate, lactose and sucrose, the antioxidant is one of or a mixture of L-ascorbyl palmitate, L-sodium ascorbate and lecithin, and a mass ratio of the core material, the wall material, the auxiliary wall material and the antioxidant is 5-30:20-60:10-40:0.3-3.The invention further discloses a preparation method of the microcapsules.Spray granulation and cold air boiling drying technologies are improved, and yield of the microcapsules is obviously increased while waste of raw materials is reduced.By using the preparation method, oxidization stability of the lutein microcapsules can be improved greatly, so that shelf life of the microcapsules is prolonged.

Owner:江苏九如食品有限公司

DHA emulsion, preparation method thereof and applications thereof in UHT liquid milk

InactiveCN103416759AImprove thermal stabilityIncrease flexibilityMilk preparationFood preparationSucroseSodium Caseinate

The invention relates to a DHA emulsion, and particularly to a DHA emulsion with good thermal stability. Every 100 g of raw material for preparing the DHA emulsion comprises 10 to 20 g of algae oil or fish oil, 2 to 12 g of emulsifiers, 0.1 to 1 g of stabilizers, and 0.2 to 1.0 g of antioxidants, with the balance being water. The antioxidants comprise water-soluble antioxidants and fat-soluble antioxidants. The emulsifiers comprise one type or a combination of several types of emulsifiers selected from starch sodium octenyl succinate, soy lecithin, mono- and diglycerides, sorbitan esters, polyoxyethylene sorbitan esters, sucrose fatty acid ester, whey protein, and sodium caseinate. The DHA emulsion has good thermal stability, and thus when the DHA emulsion is added into a product, the DHA emulsion and the product can be sterilized together at a high temperature, so that the DHA emulsion is improved in flexibility and range of application in production. The invention also provides a preparation method of the DHA emulsion and applications of the DHA emulsion in UHT liquid milk.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Process for making vermicelli without alums

A method for preparing to long-thread vermicelli (or sheet jelly) includes such steps as proportionally mixing starch, starch ester of octenyl succinate, soya bean lecithin, konjak glucomannan, D-sodium isoascorbate, edible vegetative oil and water, stirring, and heating while shaping. It features no use of alum.

Owner:SICHUAN GUANGYOU SWEET POTATO & FOOD PROD CO LTD

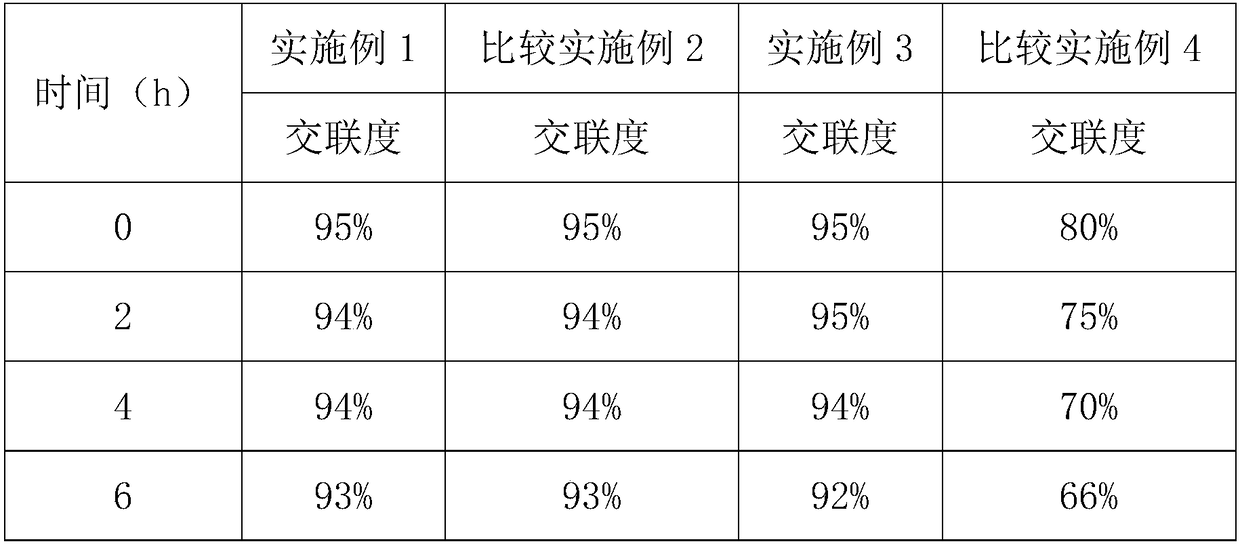

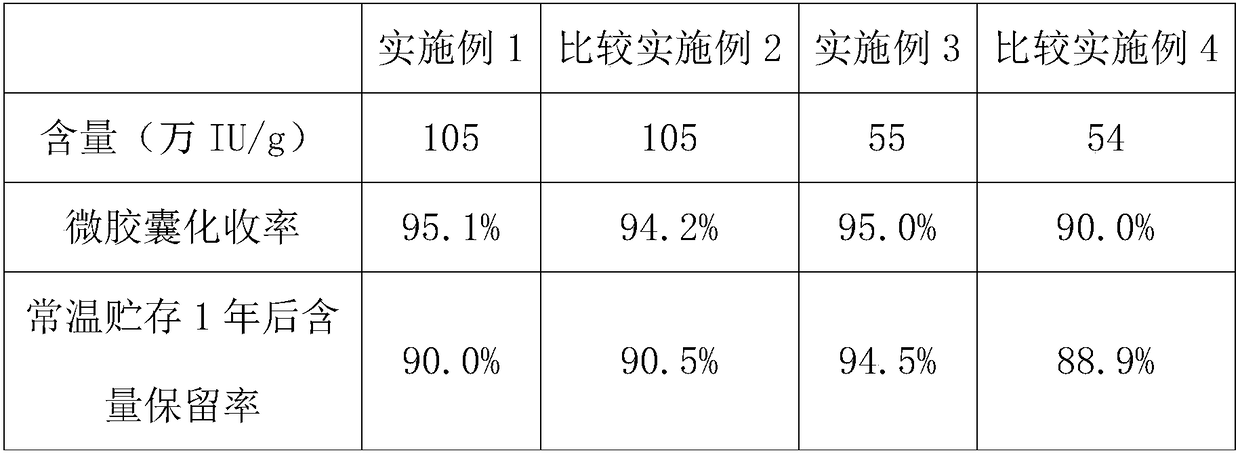

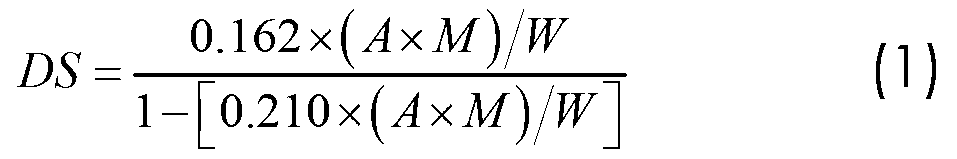

Preparation method of novel hydrophilic fat-soluble vitamin microcapsules

ActiveCN109418541AHigh yieldImprove stabilityAccessory food factorsWorking-up animal fodderCross-linkHigh humidity

The invention provides a preparation method of novel hydrophilic fat-soluble vitamin microcapsules. Different from a conventional protein (gelatin) microencapsulated cross-linking coating technique, amicroencapsulated cross-linking coating technique adopted by the preparation method disclosed by the invention lies in that fat-soluble vitamin oil is dispersed in a sodium starch octenyl succinate-reducing sugar coating substrate in a micro dropping manner, and then a new processing technology is adopted for enabling sodium starch octenyl succinate to react with reducing sugar, so that cross-linking coated granules being interlaced in vertical and horizontal directions, airtight and watertight, are formed; and a solid protection layer is formed on the surfaces of the microcapsules, so that the destroying of chemistry, high temperature, high humidity and machinery for fat-soluble vitamins can be resisted to the maximum extent.

Owner:ZHEJIANG MEDICINE CO LTD XINCHANG PHAMACEUTICAL FACTORY +1

Voltage endurance vitamin E microcapsule and its preparing process

InactiveCN1927188AHigh mechanical strengthWhite appearanceOrganic active ingredientsMetabolism disorderChemistryOctenyl succinate

The invention relates to pressure resistant vitamin E capsules, wherein the constituents include (by weight percent) vitamin E oil 50-70%, capsule material 1-25%, auxiliary capsule material 5-30%, octenylsuccinate starch 10-30%, flow aid 0.5-2%. The invention also relates to the process for preparing the capsules.

Owner:PKU HEALTHCARE CORP LTD

Starch octenyl succinate anhydride preparation process

The invention discloses a starch octenyl succinate anhydride preparation process, which includes: preparing starch milk by water and starch, circulating the starch milk between a pipeline and a reactor by pumping, applying an ultrasonic field to the material on the pipeline for material circulation by a forceps type ultrasonic generator with the ultrasonic frequency ranging from 15-25KHz and the ultrasonic strength ranging from 0.05W / cm3-0.20W / cm3, then regulating the pH(potential of hydrogen) value of the starch milk to be 8.0-9.0, controlling the temperature of the starch milk below 40 DEG C, adding a surfactant which takes 0.01%-1% of the dry basis weight of starch, mixing uniformly, then adding octenyl succinic anhydride into the mixture for reacting, and finally obtaining the starch octenyl succinate anhydride through neutralizing, washing and drying after finishing reaction. The preparation process has the advantages that reaction efficiency of octenyl succinate anhydride is increased greatly, reaction time is shortened remarkably and the like, and has good market popularization prospects.

Owner:GUANGZHOU FOBIBER BIOLOGICAL IND CO LTD

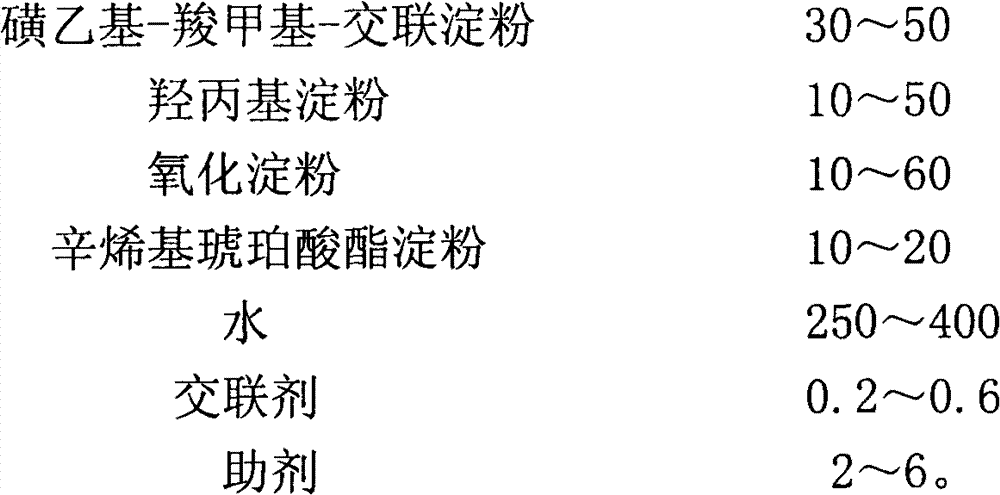

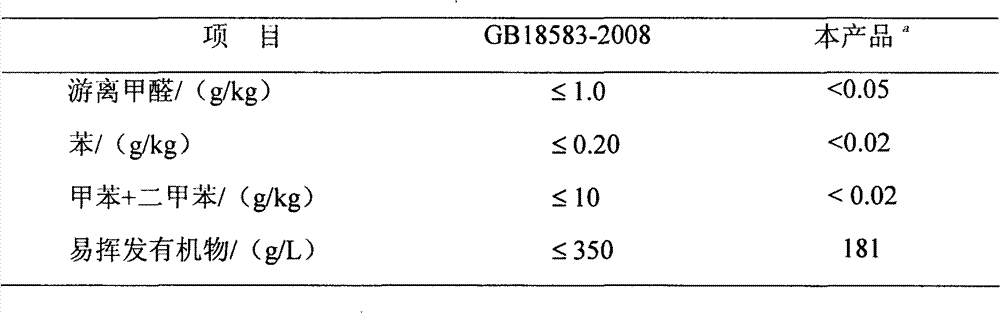

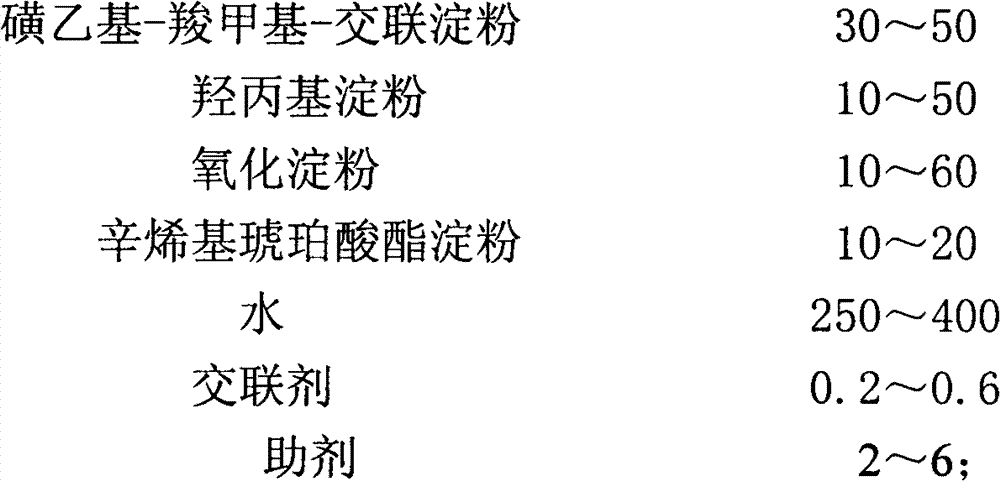

Method for preparing sulfoethyl-carboxymethyl-crosslinked starch based wallpaper adhesive

Owner:GANSU GLDARK NEW MATERIAL +1

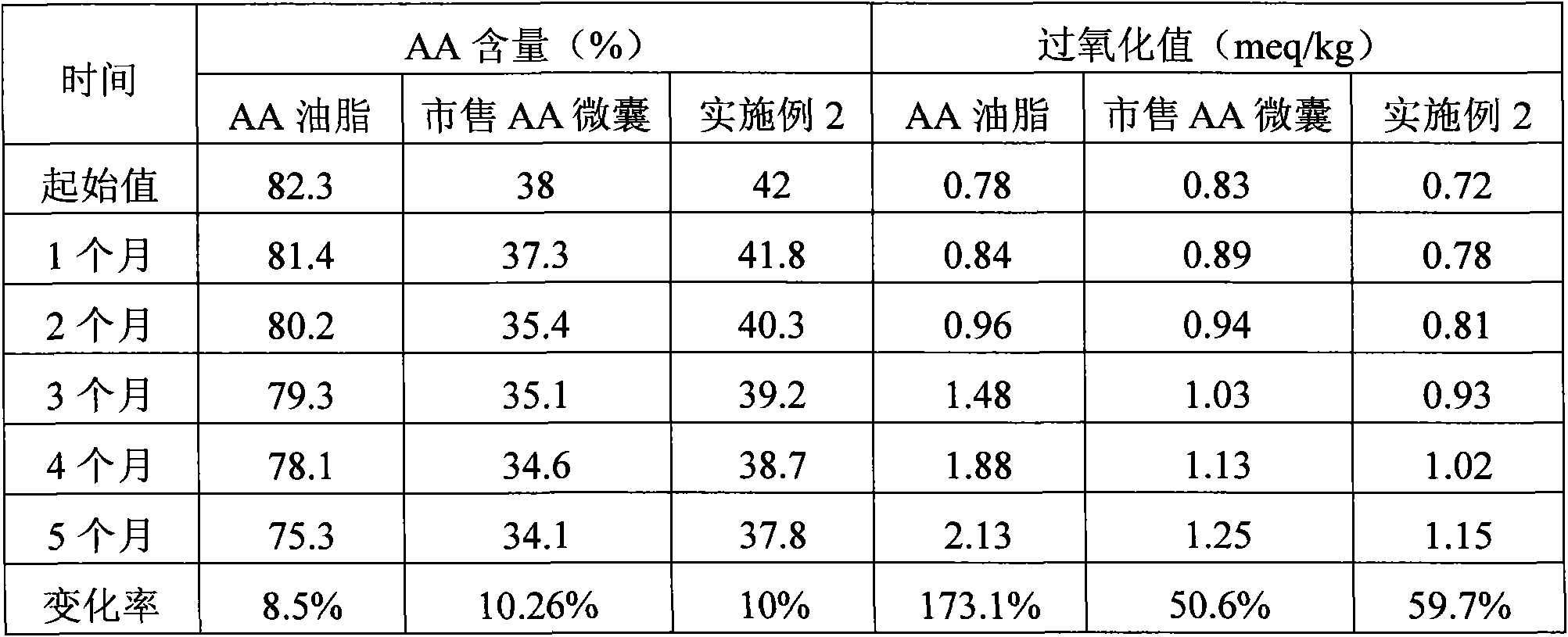

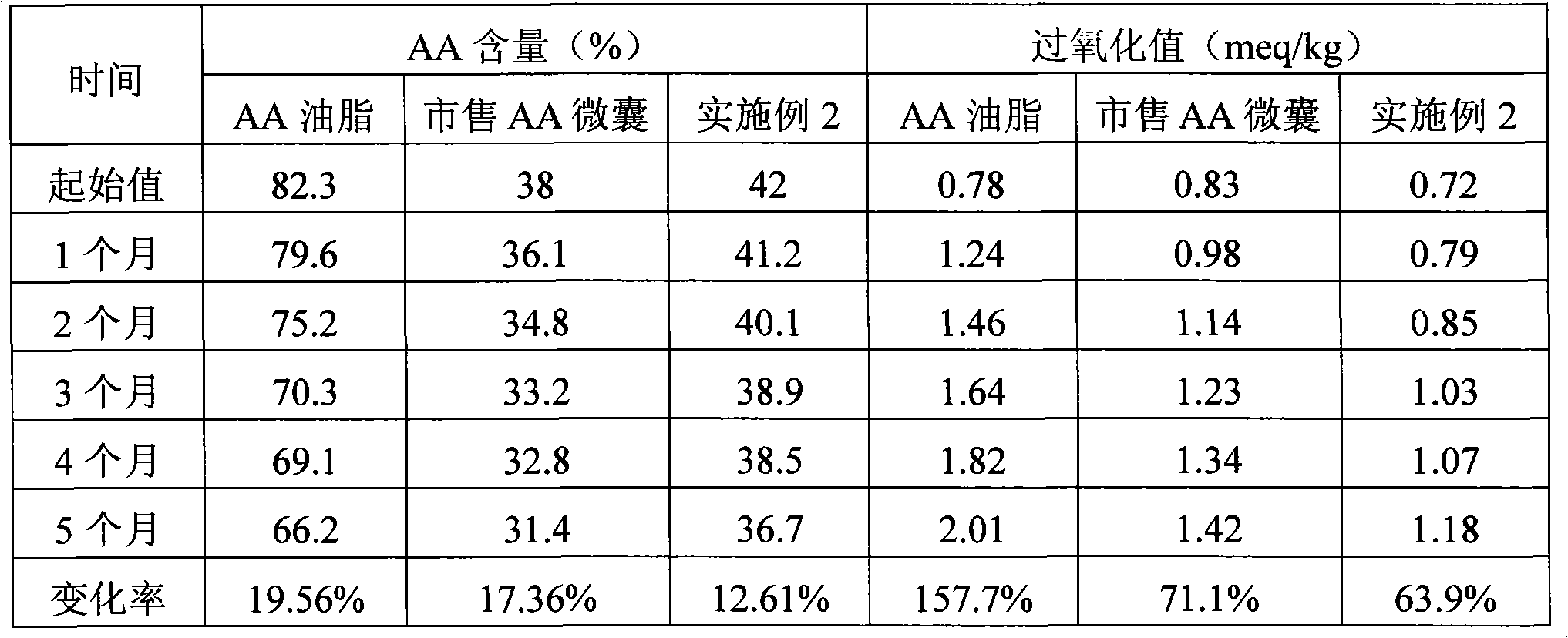

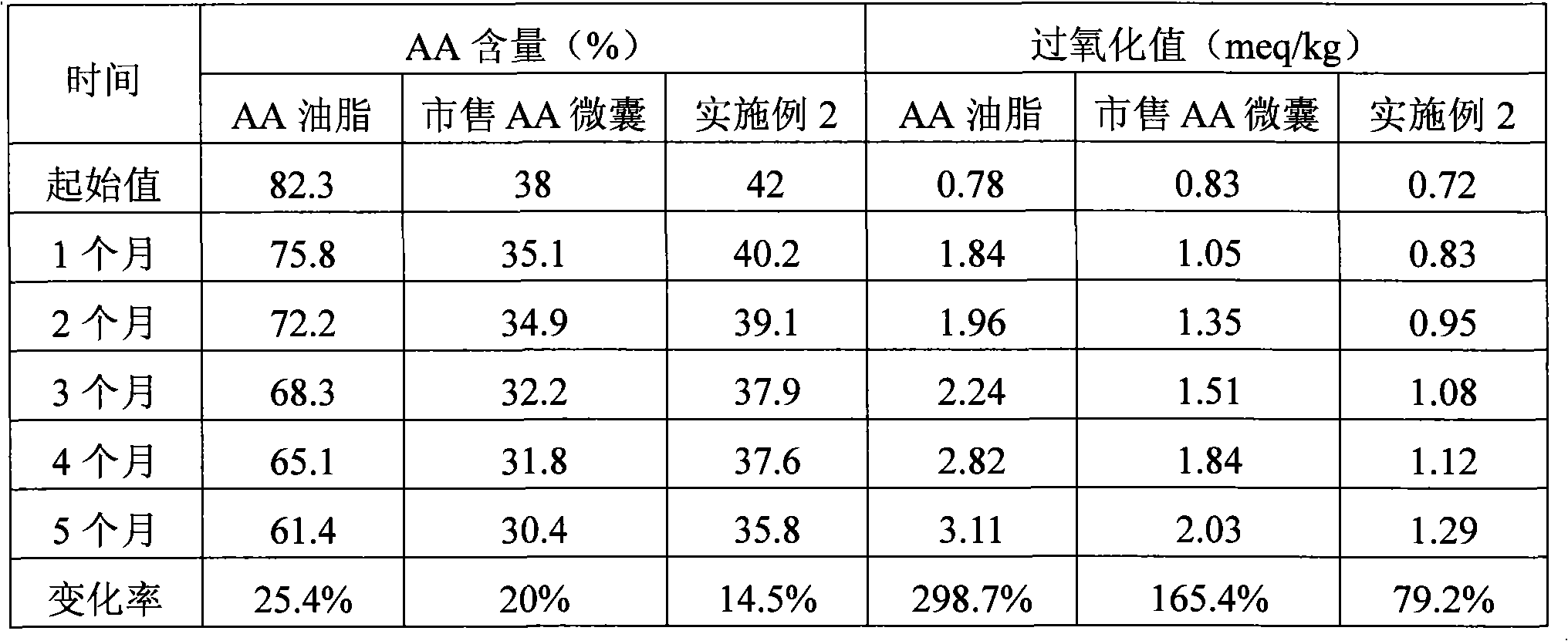

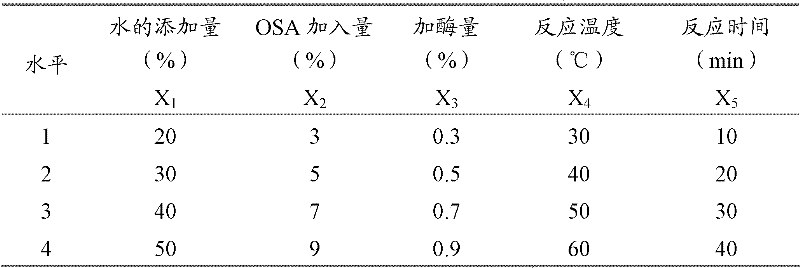

Arachidonic acid nutrition microcapsule with high temperature resistance and preparation method thereof

InactiveCN101559045AHigh yieldReduce wasteOrganic active ingredientsMetabolism disorderAntioxidantAdditive ingredient

The invention discloses an arachidonic acid nutrition microcapsule with high temperature resistance. Arachidonic acid is taken as a core material and is wrapped in the microcapsule. The wall of the microcapsule is two-layered, wherein, the inner layer is a mixture of a capsule wall material I and an antioxidant, the outer layer is a capsule wall material II. The weight percentages of the ingredients are as follows: the arachidonic acid: 10-30%, the capsule wall material I: 40-60%, the antioxidant: 1-2% and the capsule wall material II: 10-30%. The capsule wall material I is a mixture of any one or two of maltodextrin, cyclodextrine and hydroxyl propyl cellulose in arbitrary proportion, while the capsule wall material II is a mixture of any one or two of starch anhydride of octenyl succinic, alginate, corn dextrin, gelatin and acacia in arbitrary proportion. The invention also discloses a preparation method of the arachidonic acid nutrition microcapsule with high temperature resistance. The invention greatly improves heat resistance and oxidation stability of the arachidonic acid nutrition microcapsule, thus extending the shelf life of products.

Owner:江苏怀仁生物科技有限公司

Synthesis method of octenyl succinate starch ester

ActiveCN102337310AIncrease contact areaImprove reaction efficiencyFermentationSynthesis methodsSolvent

The invention relates to a synthesis method of octenyl succinate starch ester, belonging to the technical field of food biochemical industry. By using a mixed solvent of normal hexane and water as the solvent for esterification reaction, the synthesis method comprises the following steps: adding a right amount of octenyl succinate anhydride and lipase into pretreated starch, reacting while stirring, filtering, recycling the organic solvent, and drying filter cakes to obtain the octenyl succinate starch ester. The invention realizes the synthesis of the octenyl succinate starch ester in a nonaqueous phase system through the catalysis of the lipase, and determines the optimal production process conditions. The method has the characteristics of mild reaction conditions, uniform reaction and the like, and the enzyme catalysis in the nonaqueous phase leads to higher esterification reaction efficiency.

Owner:QILU UNIV OF TECH

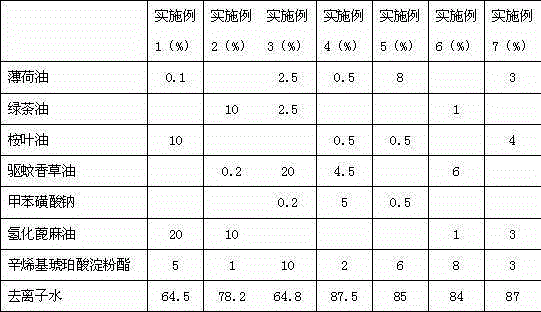

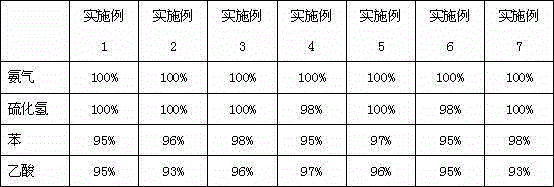

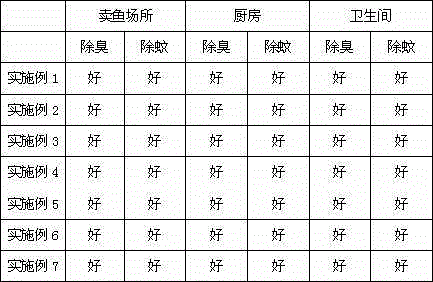

Plant extract air purifying agent and preparation method thereof

InactiveCN105214120AEliminate odorConstant fragranceBiocidePest repellentsOctenyl succinateEngineering

The invention provides a plant extract air purifying preparation and a preparation method to solve the problems that a covering type deodorizing product contained in an air purification product in the prior art is a pollutant and easily causes allergic reactions, an adsorbing type air purifying agent easily causes secondary pollution, and the air purification product in the prior art and the adsorbing type air purifying agent both cannot be used for repelling mosquitoes and performing disinfection while purifying the air. The plant extract air purifying preparation is prepared from the following components in percentage by weight: 0.1-10 percent of plant essence, 0.2-20 percent of plant sterilization and mosquito-repellent extract, 0.2-20 percent of a solubilizer, 1-10 percent of starch octenyl succinate and the balance of deionized water. The plant extract air purifying agent and the preparation method have the beneficial technical effects of killing harmful bacteria in the air, removing odor and repelling mosquitoes and flies, is safe and non-toxic, is not irritative, and has constant fragrance and long duration.

Owner:重庆市涣颜环保科技有限公司

High-temperature-resistant milky essence composition and preparation method thereof

ActiveCN103549357AImprove high temperature stabilityAchieve double fragrance effectFood preparationMaillard reactionFlavor

The invention provides a high-temperature-resistant milky essence composition and a preparation method thereof. The high-temperature-resistant milky essence composition comprises the following components according to weight percent: 1.0%-2.5% of sodium starch octenyl succinate, 0.1%-0.3% of sodium carboxymethylcellulose, 0.1%-0.5% of gelatin, 1.0%-5.0% of maltodextrin, 0.1%-0.5% of sorbitol, 0.003%-0.009% of potassium sorbate, 4.0%-7.0% of whole milk powder zymolyte, 1.0%-5.0% of anhydrous cream zymolyte, 0.1%-0.3% of caprylic capric triglycerride, 0.1%-0.5% of delta-Decalactone, 0.1%-0.5% of delta-Dodecalactone, 0.02%-0.1% of Peru extract, 0.001%-0.003% of 4-ethlycoctanoate, 0.1%-0.3% of ethyl vanillin and the balance being de-ionized water. The high-temperature-resistant milky essence composition prepared by the preparation method has good high temperature stability; furthermore, Maillard reaction occurs in a baking process to produce flavor substances, so that a dual aroma enhancement effect is achieved.

Owner:GUANGZHOU FLOWER FLAVOURS & FRAGRANCES

Adsorption treatment method for waste water containing octenyl succinate

ActiveCN103130298AImprove adsorption capacityMeet the needs of environmental protection and energy savingWater contaminantsSilicon compoundsSorbentOctenyl succinate

The invention discloses an adsorption treatment method for waste water containing octenyl succinate, which comprises the following steps: grinding a dried ore material, screening, and reacting with a phosphotungstic acid solution to become ore adsorbent; adding the ore adsorbent into waste water containing 1-20 g / L octenyl succinate, regulating the pH value to 2-5, and oscillating at 5-40 DEG C for 1-12 hours; filtering, adding the ore adsorbent into the filtrate, and oscillating at 5-40 DEG C for 0.5-12 hours; further filtering, and determining that the octenyl succinate removal rate of the filtrate is up to 99% or above and the COD (chemical oxygen demand) value is less than 100 mg / L, so that the filtrate can be circularly utilized or directly discharged; and collecting the filter cakes in the previous two steps, drying, and firing to obtain the regenerated dried ore material. The invention has the advantages that the cheap ore material is prepared into the ore adsorbent, waste water containing octenyl succinate can be efficiently subjected to adsorption treatment by using the ore adsorbent, the ore material can be regenerated and recycled, and the requirements for environment protection and energy saving are met.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Preparation method of starch octenyl succinate

The invention provides a preparation method of starch octenyl succinate, which aims to solve the problems that the existing preparation methods of starch octenyl succinate have low production efficiency, long time, complicated process, severe environmental pollution and the like. The preparation method sequentially comprises the following steps of: 1) preparing a starch suspension; 2) adjusting the pH value of the starch suspension; 3) diluting octenyl succinic anhydride; 4) adding diluted octenyl succinic anhydride to the starch suspension; 5) adjusting the pH value of the system; 6) rapidlyadding emulsion to a soft packaging bag; 7) placing the soft packaging bag in ultrahigh-pressure equipment for pressurizing; 8) adjusting the pH value to 6.0-6.5; 9) washing away unreacted anhydride;and 10) drying the product, pulverizing and screening to obtain the starch octenyl succinate. The preparation method has the advantages of uniform reaction, simple production process, no environmental pollution and low production cost; and by the preparation method, the reaction time is greatly shortened, the reaction time of the traditional water phase method is shortened to 10-60 minutes from 6hours, and the production efficiency is greatly improved.

Owner:HARBIN UNIV OF COMMERCE

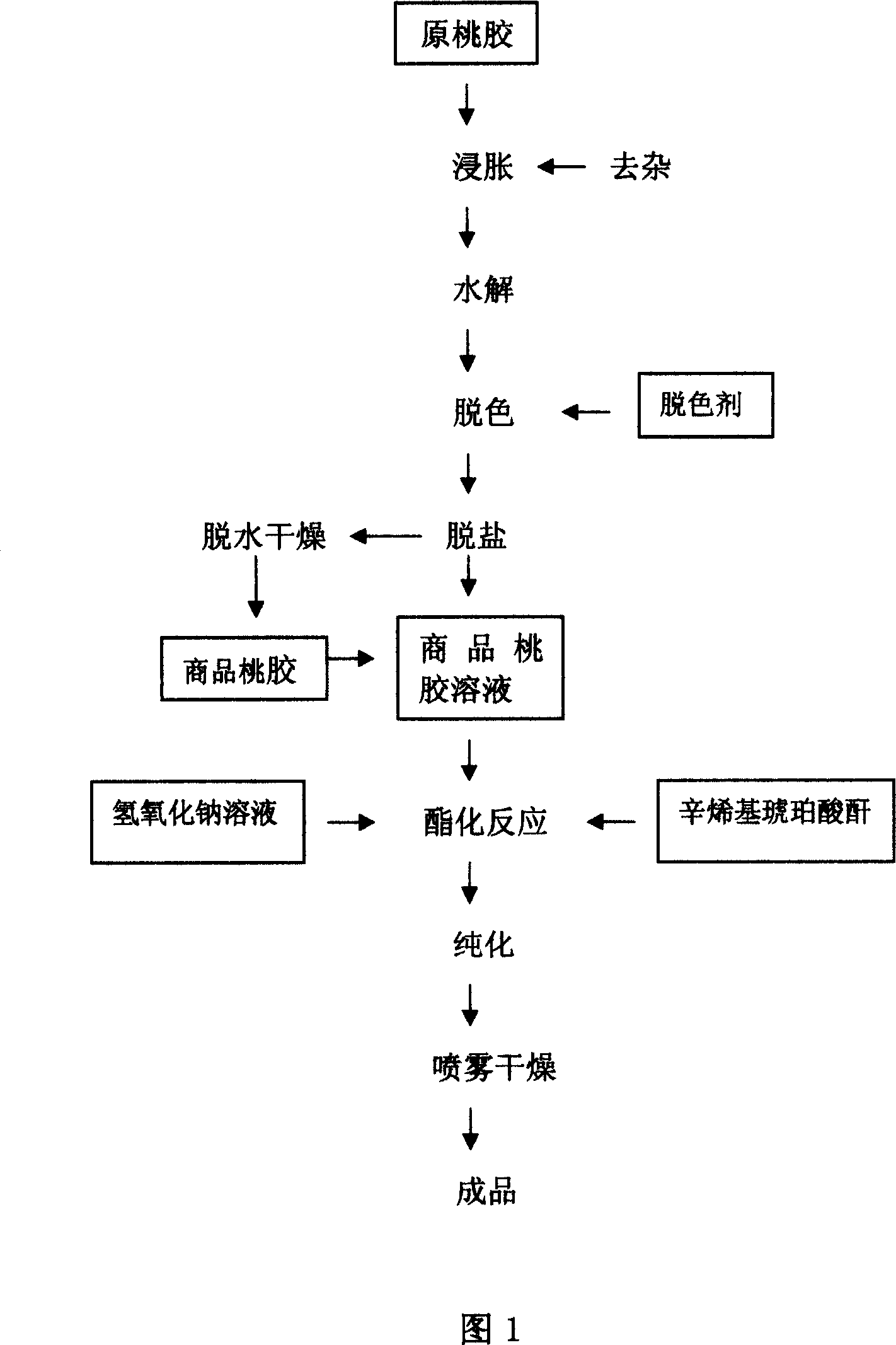

Method of preparing peach gum octenyl succinate

InactiveCN101012355AImprove acid resistanceImprove shear resistanceNatural resin chemical modificationFood preparationOctenyl succinateOCTENYLSUCCINIC ACID

The invention discloses a making method of octal-olefin succinic peach-gel ester, which comprises the following steps: adopting original peach gel, octal-olefin succinic anhydride as raw maerial; hydrolyzing original peach gel; esterifying; removing impurity in the esterifying liquid; dehydrating; drying to obtain the product with cutting-proof force and emulsifying stability.

Owner:JINAN UNIVERSITY

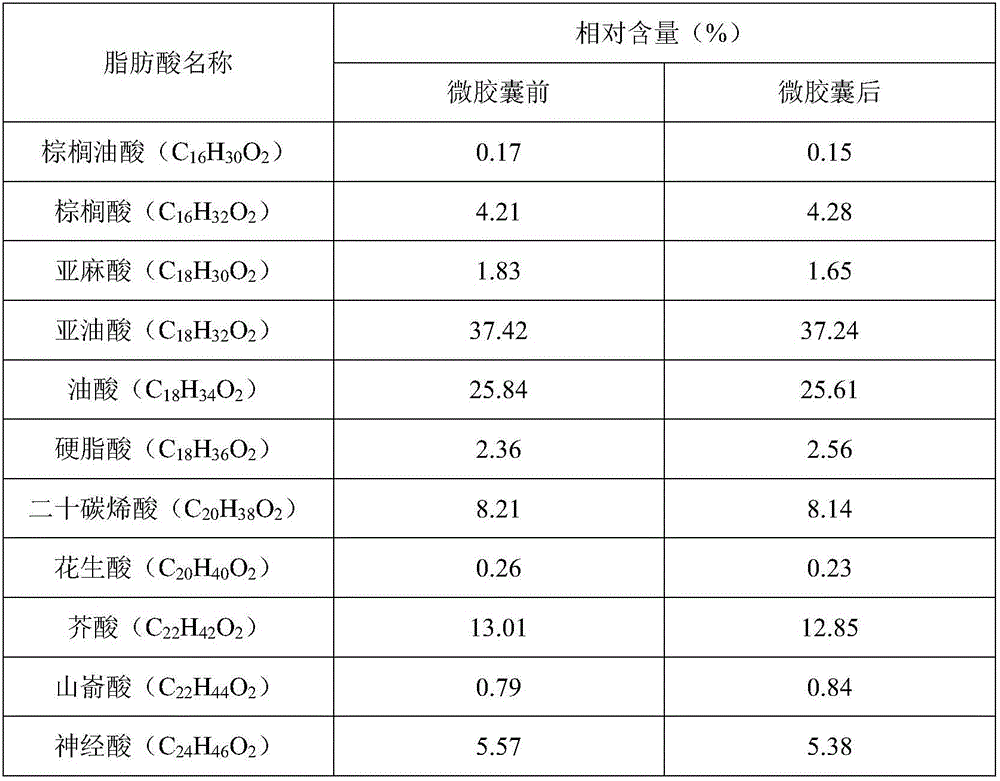

Acer truncatum oil microcapsule and preparation method thereof

InactiveCN106262927AFunction increaseHigh embedding rateSugar food ingredientsFood shapingMonoglyceridePhosphate

The invention discloses an acer truncatum oil microcapsule and a preparation method thereof, and belongs to the technical field of oil. The acer truncatum oil microcapsule is prepared by the following steps: (1) mixing modified starch, maltodextrin and distilled water, heating to 60-70 DEG C and stirring for 20-40 minutes; (2) mixing and stirring acer truncatum oil, vitamin E, sodium starch octenyl succinate, molecular distilled monoglyceride, soyabean lecithin and gellan gum for 20-40 minutes; (3) mixing the mixed solution at room temperature and stirring the mixed solution for 2-5 minutes; (4) adding the mixed solution into a homogenizer for homogenizing; (5) adding d-sodium erythorbate, tert-butylhydroquinone, hydroxy propyl distarch phosphate and glucose, and continuing to homogenize for 2-5 minutes; and (6) adding the solution into a spray dryer for spray drying to obtain the acer truncatum oil microcapsule. The acer truncatum oil microcapsule is high in embedding rate, high in stability, rich in unsaturated fatty acid and slight in change of composition of fatty acid before and after microencapsulation, and can effectively retain the intrinsic good functions and properties of the acer truncatum oil.

Owner:SHAANXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com