Red jujube flavor and preparation method thereof

A jujube essence and jujube technology, which is applied in the field of essence, can solve the problems of lack of natural sense and authenticity of taste, insufficient aroma intensity of red dates, and weakened aroma intensity, etc., so as to achieve improved taste and aroma, good aroma effect and high added value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

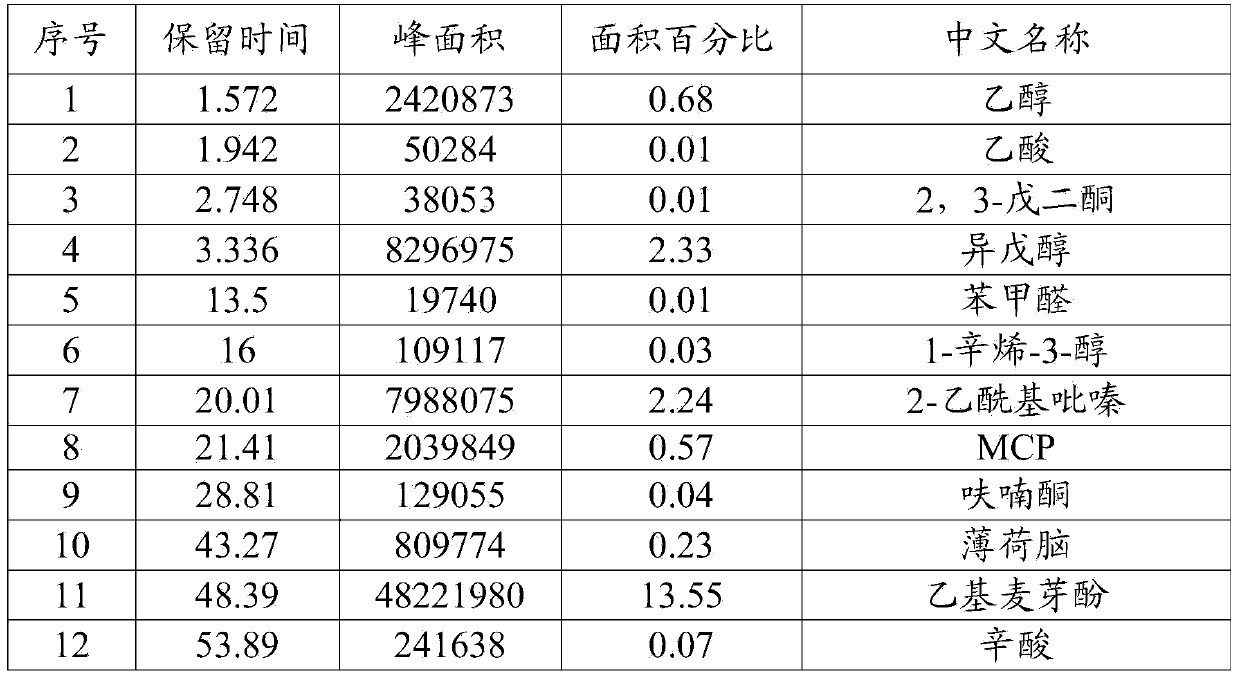

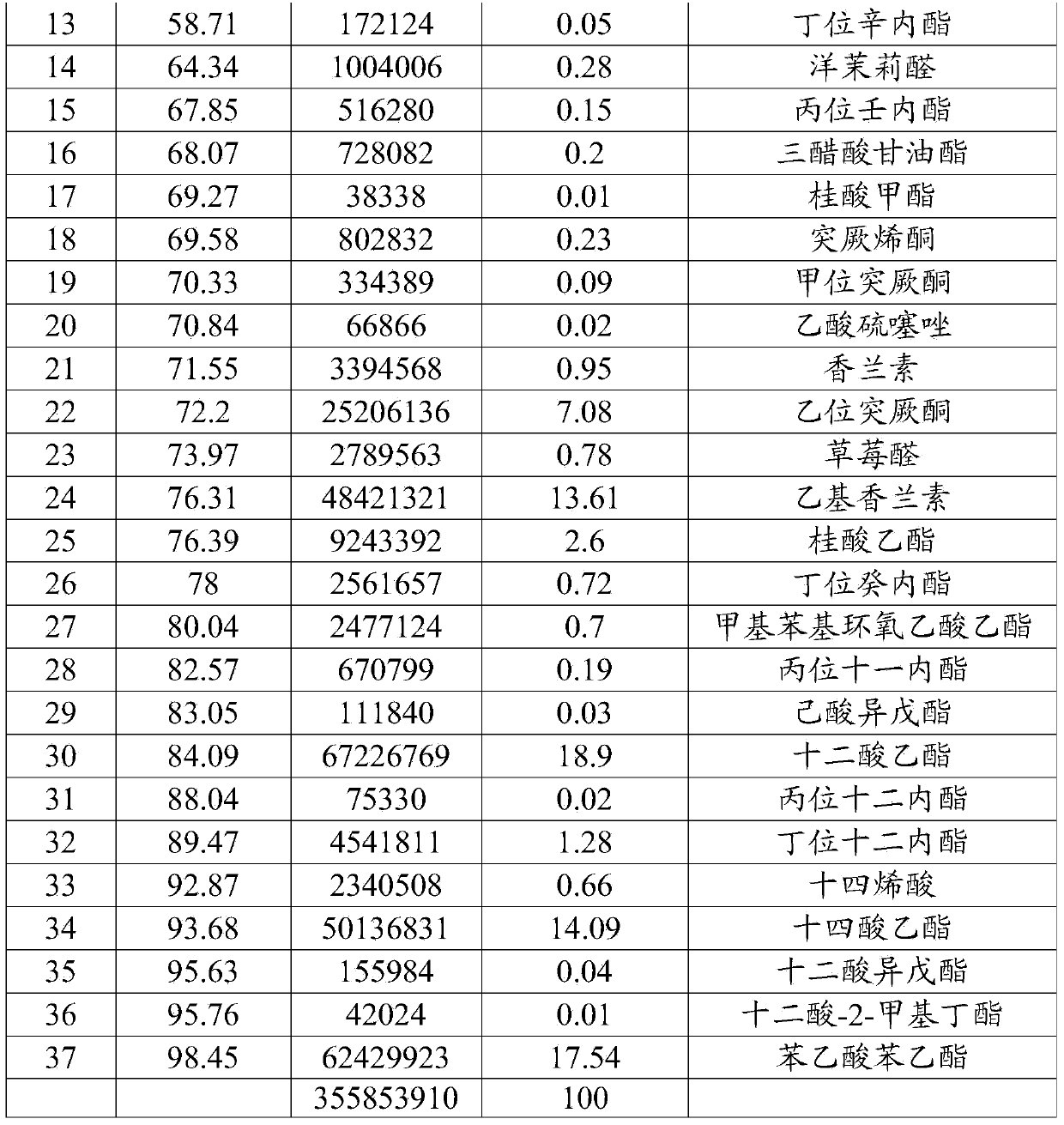

Image

Examples

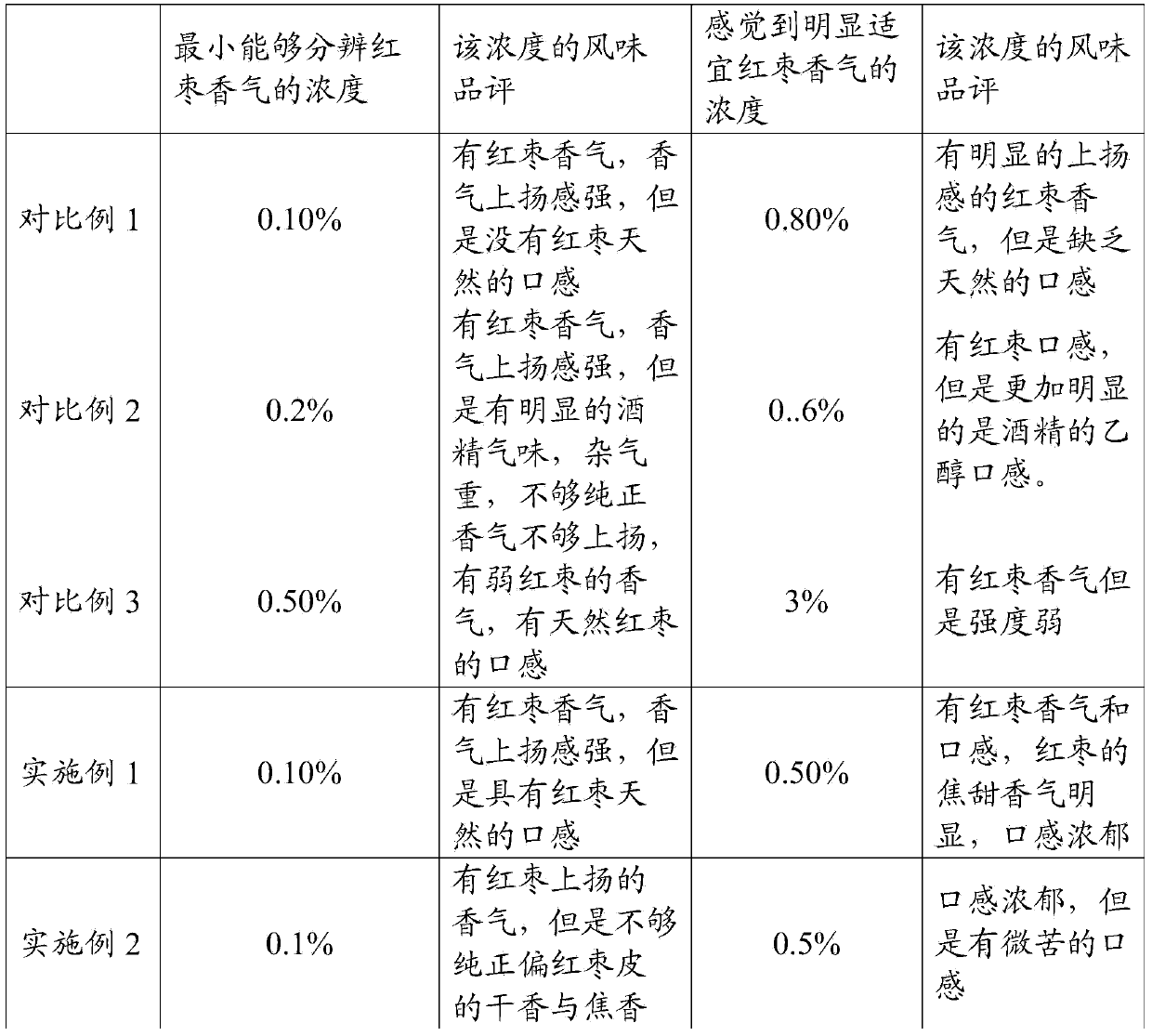

Embodiment 1

[0034] A jujube essence, mainly prepared from the following raw materials in parts by weight: 1000 g of jujube enzymatic hydrolyzate, 30 g of jujube fragrance base, 150 g of maltodextrin and 30 g of sodium starch octenyl succinate;

[0035] The jujube fragrance base is mainly prepared from the following raw materials in parts by weight: 0.01 part of furfural, 0.034 part of 2-acetylfuran, 0.012 part of 2-acetylthiazole, 0.042 part of 2-acetylpyrazine, 0.052 part of MCP, 0.03 parts of ethyl decanoate, 0.12 parts of menthyl acetate, 0.12 parts of ethoxyturkone, 0.06 parts of vanillin, 0.4 parts of furanone, 0.02 parts of ethyl myristate, 50 parts of salad oil.

[0036] In some of these embodiments, the preparation method of the jujube hydrolyzate comprises the following steps:

[0037] (1) Pretreatment: Mix the jujube with water at a weight ratio of 1:5, and pass through a colloid mill to obtain jujube paste;

[0038] (2) Enzymolysis: mix 1000g of jujube paste and 0.2g of plant ...

Embodiment 2

[0049] A jujube essence, mainly prepared from the following raw materials in parts by weight: 950 g of jujube enzymatic hydrolyzate, 10 g of jujube fragrance base, 120 g of maltodextrin and 25 g of sodium starch octenyl succinate;

[0050] The jujube fragrance base is mainly prepared from the following raw materials in parts by weight: 0.004 parts of furfural, 0.03 parts of 2-acetylfuran, 0.005 parts of 2-acetylthiazole, 0.003 parts of 2-acetylpyrazine, 0.04 parts of MCP, 0.02 parts of ethyl decanoate, 0.11 parts of menthyl acetate, 0.07 parts of ethoxyturkone, 0.04 parts of vanillin, 0.2 parts of furanone, 0.02 parts of ethyl myristate, 45 parts of salad oil.

[0051] In some of these embodiments, the preparation method of the jujube hydrolyzate comprises the following steps:

[0052] (1) Pretreatment: Mix the jujube with water at a ratio of 1:2 by weight, and pass through a colloid mill to obtain jujube paste;

[0053] (2) Enzymolysis: mix 1000g of jujube paste and 0.5g of pl...

Embodiment 3

[0057] A jujube essence, mainly prepared from the following raw materials in parts by weight: 1050 g of jujube enzymatic hydrolyzate, 30 g of jujube fragrance base, 180 g of maltodextrin and 35 g of sodium starch octenyl succinate;

[0058] The jujube fragrance base is mainly prepared from the following raw materials in parts by weight: 0.02 part of furfural, 0.06 part of 2-acetylfuran, 0.02 part of 2-acetylthiazole, 0.06 part of 2-acetylpyrazine, 0.08 part of MCP, 0.05 parts of ethyl decanoate, 0.15 parts of menthyl acetate, 0.2 parts of ethurkone, 0.1 parts of vanillin, 0.5 parts of furanone, 0.04 parts of ethyl myristate, and 55 parts of salad oil.

[0059] In some of these embodiments, the preparation method of the jujube hydrolyzate comprises the following steps:

[0060] (1) Pretreatment: Mix the jujube with water at a weight ratio of 1:3, and pass through a colloid mill to obtain jujube paste;

[0061] (2) Enzymolysis: mix 1000g of red date paste and 0.5g of plant hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com