Preparation method of slow-release torreya grandis shell essence

A slow-release technology of torreya shell flavor and shell flavor, which is applied in the field of flavors and fragrances, and can solve problems such as low boiling point, complex flavor components, and reduced flavor effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

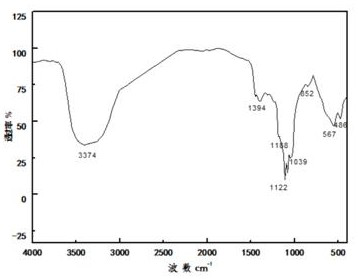

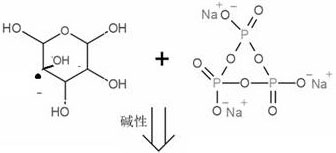

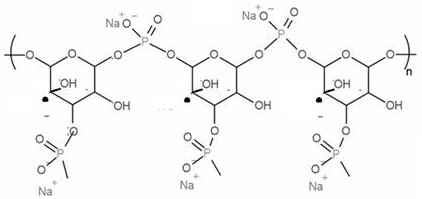

Method used

Image

Examples

Embodiment 1

[0034] A preparation method for slow-release Chinese torreya shell essence, is characterized in that, comprises the steps:

[0035] (1) Drying: wash the torreya shell with water to remove impurities, and dry it through a microwave oven, controlling the temperature of the material to be 70 o C, the passing time is 1h, and the dried Chinese torreya shell is obtained;

[0036] (2) Pulverizing: the dry Torreya husk is pulverized into particle diameter with a high-speed pulverizer and is 100 mesh powders;

[0037] (3) Extraction: put the torreya shell powder into a supercritical carbon dioxide extraction kettle for extraction, the extraction pressure is 10MPa, and the temperature is 40 o C, the time is 1h, the solvent flow rate is 10mL / min, separate the solute to obtain the essential oil;

[0038] (4) Adsorption: Mix 400g of essential oil, 10g of porous microsphere powder, and 10g of fixative evenly. o Stir at C for 1 hour to make the porous microsphere powder fully absorb the e...

Embodiment 2

[0046] A preparation method for slow-release Chinese torreya shell essence, is characterized in that, comprises the steps:

[0047] (1) Drying: wash the torreya shell with water to remove impurities, and dry it through a microwave oven, controlling the temperature of the material to be 72 o C, the passage time is 1.2h, and the dried Chinese torreya shell is obtained;

[0048] (2) Pulverizing: the dry Torreya husk is pulverized into particle diameter with a high-speed pulverizer and is 120 mesh powders;

[0049] (3) Extraction: put the torreya shell powder into a supercritical carbon dioxide extraction kettle for extraction, the extraction pressure is 10-20MPa, and the temperature is 41 o C, the time is 1.5h, the solvent flow rate is 12mL / min, separate the solute to obtain essential oil;

[0050] (4) Adsorption: Mix 400g of essential oil, 14g of porous microsphere powder, and 15g of fixative evenly. o Stir at C for 1.2h to make the porous microsphere powder fully absorb the ...

Embodiment 3

[0058] A preparation method for slow-release Chinese torreya shell essence, is characterized in that, comprises the steps:

[0059] (1) Drying: wash the torreya shell with water to remove impurities, and dry it through a microwave oven, controlling the temperature of the material to be 70-80 o C, the passage time is 1.8h, and the dried Chinese torreya shell is obtained;

[0060] (2) pulverizing: the dried Chinese torreya shell is pulverized into a particle diameter with a high-speed pulverizer and is 140 mesh powders;

[0061] (3) Extraction: put the torreya shell powder into a supercritical carbon dioxide extraction kettle for extraction, the extraction pressure is 18MPa, and the temperature is 44 o C, the time is 2h, the solvent flow rate is 14mL / min, separate the solute to obtain the essential oil;

[0062] (4) Adsorption: Mix 400g of essential oil, 18g of porous microsphere powder, and 16g of fixative evenly, 42 o Stir for 2 hours at C to make the porous microsphere pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com