Normal-temperature-curing epoxy resin flexible pouring sealant

An epoxy resin, room temperature curing technology, applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problems of low colloid viscosity, high viscosity, environmental pollution, etc., to achieve simple preparation process, smooth surface , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

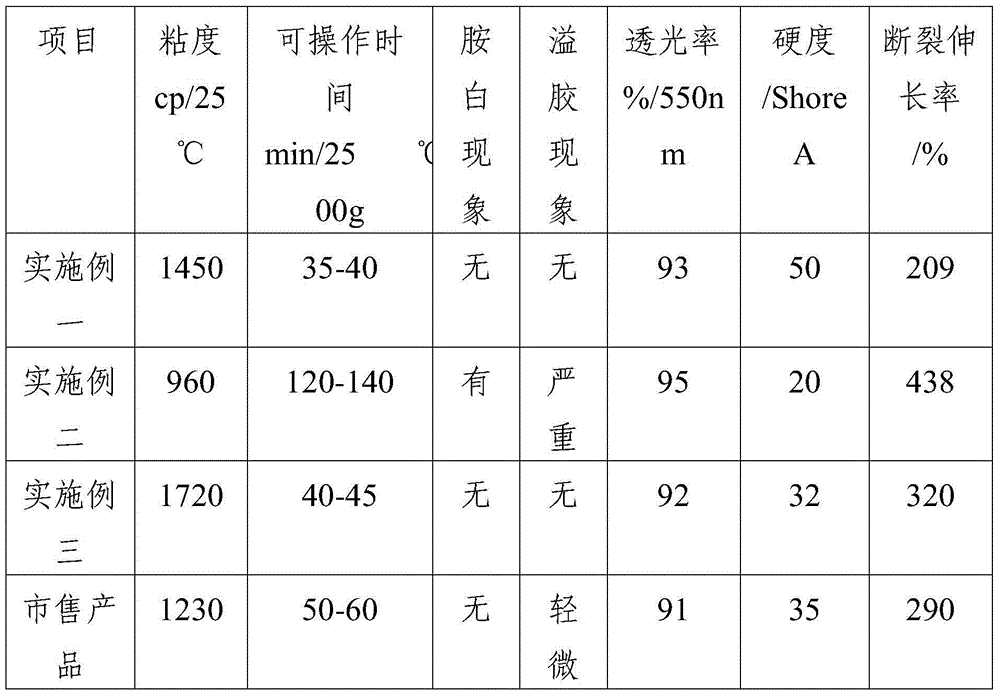

Examples

Embodiment 1

[0034](1) Preparation of component A: 70g bisphenol A type epoxy resin E51, 23g benyl glycidyl ether, 5g dioctyl phthalate, 1.5g 2,6-di-tert-butyl-4-methyl Add phenol and 0.5g of ultraviolet absorber UV531 into a three-necked flask, heat to 70-80°C, and stir well. After the solid raw material is completely dissolved, add 1g of epoxycyclohexylmethyltrimethoxysilane (KH-530), 0.5g defoamer BYK-A530, keep stirring to make it transparent and clear liquid, vacuum defoaming for 15 minutes (at vacuum degree -0.1Mpa) and then cool to room temperature to obtain component A, set aside;

[0035] (2) Preparation of component B:

[0036] 1. Preparation of modified amine prepolymer I: Slowly add 30g of isophorone diamine (IPDA) dropwise into a three-necked flask filled with 100g of bisphenol A epoxy resin E51 and equipped with a stirring paddle and a thermometer, and stir 1. Heating to 50-60°C and reacting for 2 hours, the obtained colorless, transparent and viscous target product is the m...

Embodiment 2

[0040] (1) Preparation of component A: add 60g bisphenol A type epoxy resin E54, 27g butyl glycidyl ether, 10g epoxy soybean oil, 1.2g pentaerythritol ester, 0.8g ultraviolet absorber UV326 into a three-necked flask respectively, and heat To 70-80 ℃, and stir well, after the solid material is completely dissolved, add 2g of aminoethylaminopropyl trimethoxy silicon (KH-540), 1g of defoamer BYK-A141, continue to stir to make it transparent and clear Liquid, vacuum defoaming for 15 minutes (under vacuum degree -0.1Mpa) and then cooled to room temperature to obtain component A, which is set aside;

[0041] (2) Preparation of component B:

[0042] ①. Preparation of modified amine prepolymer II: Slowly add 30g of polyetheramine D230 dropwise into a three-neck flask filled with 100g of polyurethane modified epoxy resin and equipped with a stirring paddle and a thermometer, stir and heat to 45-50°C After reacting for 1.5 hours, the obtained colorless, transparent and viscous target p...

Embodiment 3

[0046] (1) Preparation of component A: 68g bisphenol A type epoxy resin E51, 22g C12-14 aliphatic glycidyl ether (AGE), 7g dibutyl phthalate, 0.5g 2,6-di-tert-butyl 1-4-hydroxyphenyl propionate isooctyl alcohol ester, 1g UV absorber UV1130, 2g glycidyl ether propyl trimethoxy silicon (KH-560), 1g defoamer BYK-A530, fully stir to become transparent and clear Liquid, vacuum defoaming for 15 minutes (vacuum degree -0.1Mpa) and then cooling to room temperature to obtain component A, set aside;

[0047] (ii) Preparation of component B: 1.5g of DMP-30, 37g of polyetheramine D400, 28g of modified amine prepolymer I prepared by the method of Example 1, 35g of modified amine prepolymer prepared by the method of Example 2 Polymer II was fully stirred at room temperature, and then vacuum degassed for 15 minutes (under vacuum degree -0.1Mpa) to obtain component B, which was set aside;

[0048] Ⅲ. Use: Store the spare A and B components in dry, airtight plastic containers respectively. Wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com