Patents

Literature

33results about How to "Not yellowing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Weak solvent aliphatic polyurethane resin for synthetic leather and preparation method thereof

The invention relates to the technical field of materials for synthetic leather, in particular to weak solvent aliphatic polyurethane resin for synthetic leather and a preparation method thereof. The weak solvent aliphatic polyurethane resin for synthetic leather is prepared from the following components by weight percent: 2-30 percent of aliphatic diisocyanate compound, 5-40 percent of polyester or polyether polyalcohol compound, 0-10 percent of micromolecule polyol chain extender, 0.1-13 percent of micromolecule polyamine chain extender, 0.01-1.0 percent of catalyst, 0.05-5.0 percent of assistant and 45-85 percent of organic mild solvent. The invention also discloses the preparation method of the weak solvent aliphatic polyurethane resin for synthetic leather. By adopting the technical scheme, the polyurethane resin with different solid contents, different viscosities and different modulus can by synthesized, the requirement of the synthetic leather is satisfied, and the synthetic leather product with high temperature resistance, cold resistance, anti-sticking performance and better external tensility of pigment can be prepared.

Owner:ZHEJIANG SUNLIGHT MATERIAL TECH CO LTD

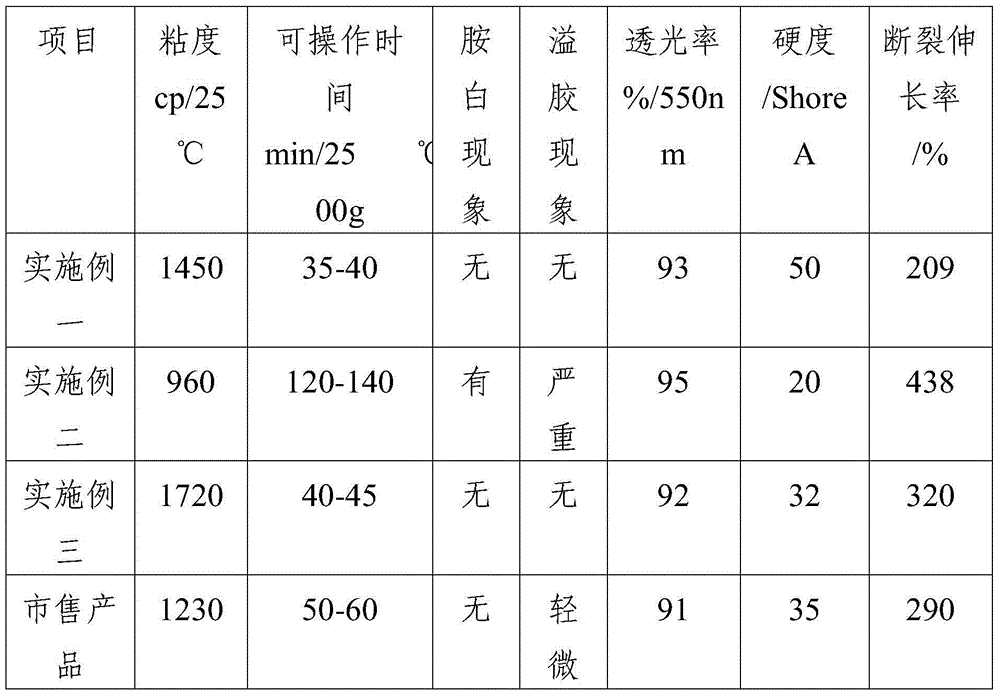

Normal-temperature-curing epoxy resin flexible pouring sealant

ActiveCN104388029AHigh light transmittanceWill not affect the light brightnessMacromolecular adhesive additivesEpoxy resin adhesivesFlexible circuitsPlasticizer

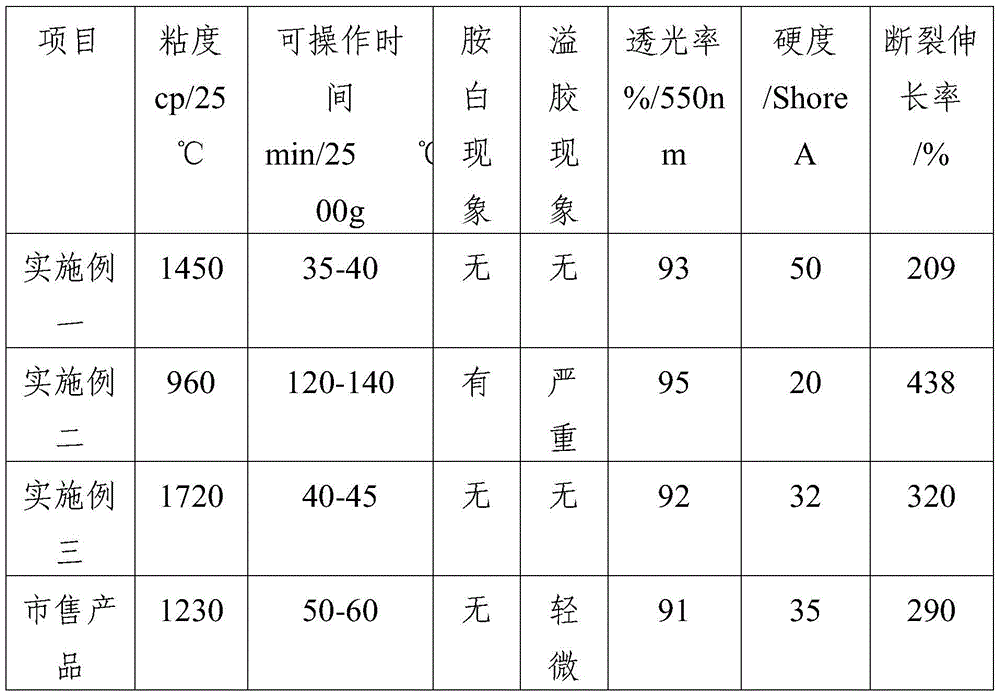

The invention discloses a normal-temperature-curing epoxy resin flexible pouring sealant and relates to the technical field of polymer materials. The normal-temperature-curing epoxy resin flexible pouring sealant is prepared by mixing a component A and a component B in equal parts by weight, wherein the component A comprises 60-90 parts of epoxy resin, 10-30 parts of reactive diluent, 5-10 parts of a plasticizer, 1-5 parts of a silane coupling agent, 0.5-2 parts of a defoaming agent, 0.5-2 parts of an antioxidant and 0.5-1 part of an ultraviolet absorber; and the component B comprises 1-3 parts of an accelerator, 30-60 parts of polyether amine and 0-50 parts of modified amine prepolymer I and 0-55 parts of modified amine prepolymer II. The ambient-curing epoxy resin flexible pouring sealant has the characteristics that the pouring sealant can be rapidly cured under the room temperature condition and is especially suitable for pouring LED flexible strips and the cured substance has better flexibility and higher elongation at break and transparency and the like and is suitable for pouring and sealing the surfaces of products having requirements on flexibility and transparency, for example, surface coating of LED flexible strips, LED module strips, flexible circuit boards and the like.

Owner:HUNAN HAOZHI TECH

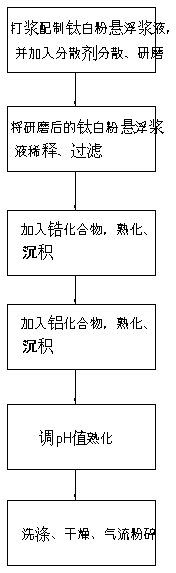

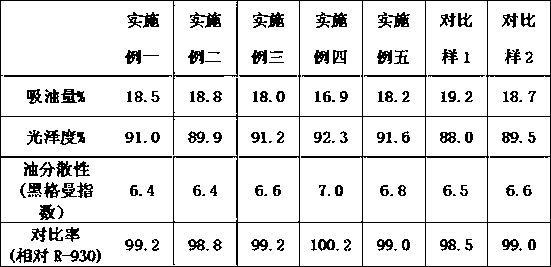

Preparation method of special titanium dioxide for oily system

InactiveCN103131212AImprove weather resistanceLow oil absorptionPigment treatment with organosilicon compoundsPigment physical treatmentHigh contrastWeather resistance

The invention discloses a preparation method of a special titanium dioxide for an oily system. The method comprises the following steps: 1, pulping to prepare a titanium dioxide suspension slurry, adding a dispersant, dispersing, and grinding; 2, diluting the ground titanium dioxide suspension slurry, and filtering; 3, adding a zirconium compound, curing, and depositing; 4, adding an aluminum compound, curing, and depositing; 5, adjusting the pH value, and curing; and 6, washing, drying, and carrying out airflow crushing. The method allows the surface of a titanium dioxide particle to be respectively coated with a zirconium oxide film and an alumina film inside out and a silane coupling agent hydrolysate to be adopted to carry out organic treatment, so the special titanium dioxide has the advantages of substantially-increased weather resistance, lipophilicity and luster, low oil absorption, good dispersity, realization of the hiding capability same to import titanium dioxide, high contrast rate, good temperature resistance, and no ink layer yellowing.

Owner:江苏镇钛化工有限公司

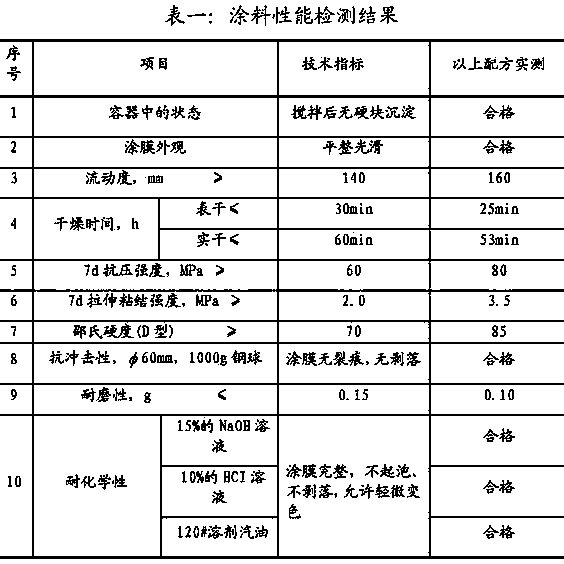

Methyl methacrylate (MMA) floor coating capable of rapidly solidifying

The invention relates to a methyl methacrylate(MMA) floor coating capable of rapidly solidifying. The methyl methacrylate(MMA) floor coating capable of rapidly solidifying can be prepared by two steps. First of all, according to a certain proportion, methyl methacrylate(MMA), butyl acrylate (BA), acrylic acid (AA) and benzoyl peroxide (BPO) are put into a reactor provided with a thermometer, a condenser and a stirrer for water bath heating to prepare an acrylate prepolymer for standby use; then at room temperature, a proper amount of the acrylate prepolymer is dissolved and diluted with a certain amount of MMA and BA, talcum powder, liquid wax, an auxiliary agent, an initiator and a solidifying accelerator are added, and fully stirred to obtain the floor coating, and the floor coating is prepared on site during construction, and can solidify 1 hour after the pavement. The MMA floor coating is short in solidifying time, less affected by temperature, excellent in performance, green, environmentally friendly, and wide in adaption field.

Owner:HARBIN UNIV OF SCI & TECH

Modified polyurethane acrylic resin and preparation method thereof

InactiveCN107353865AGood impact resistanceImprove weather resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesIsocyanatePolyester

The invention discloses a modified polyurethane acrylic resin, which is prepared by polymerization among hydroxyl acrylate, diisocyanate, alkylated 4,4'-dicyclohexanol, and polyester / polyether glycol. The invention provides a method of preparing the modified polyurethane acrylic resin at the same time. The provided modified polyurethane acrylic resin does not contain active functional group such as phenyl ring, amino group, or the like, so the modified polyurethane acrylic resin will not become yellow even if the modified polyurethane acrylic resin is irradiated by light, and the weatherability is good. The resin can be applied to an adhesive, and has a good waterproof performance, good anti-falling performance, good drug resistant property, and excellent thermal stability.

Owner:深圳市百丽春粘胶实业有限公司

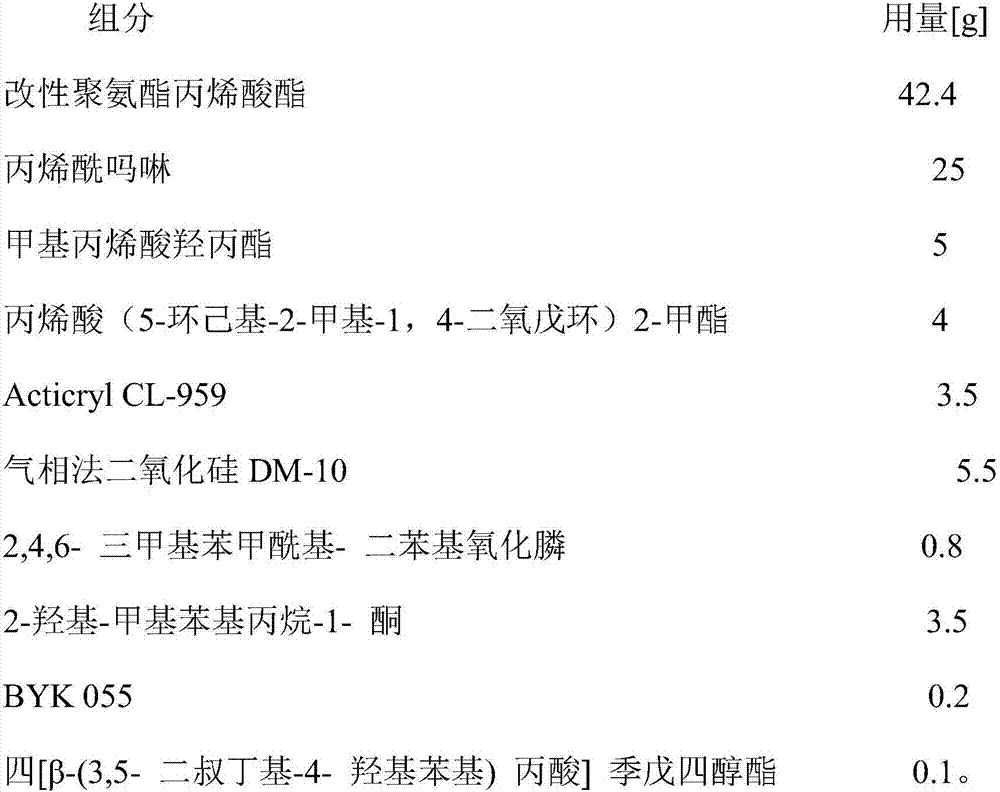

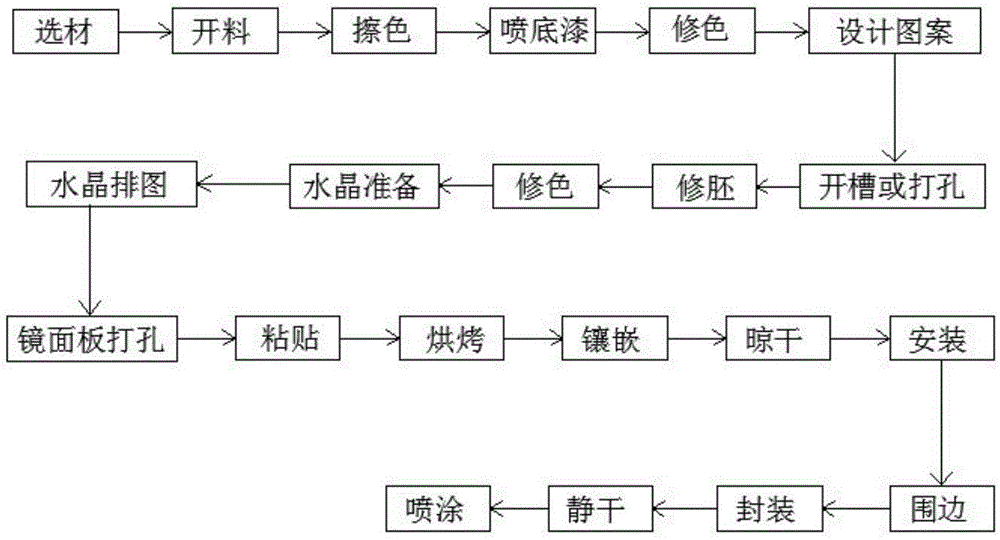

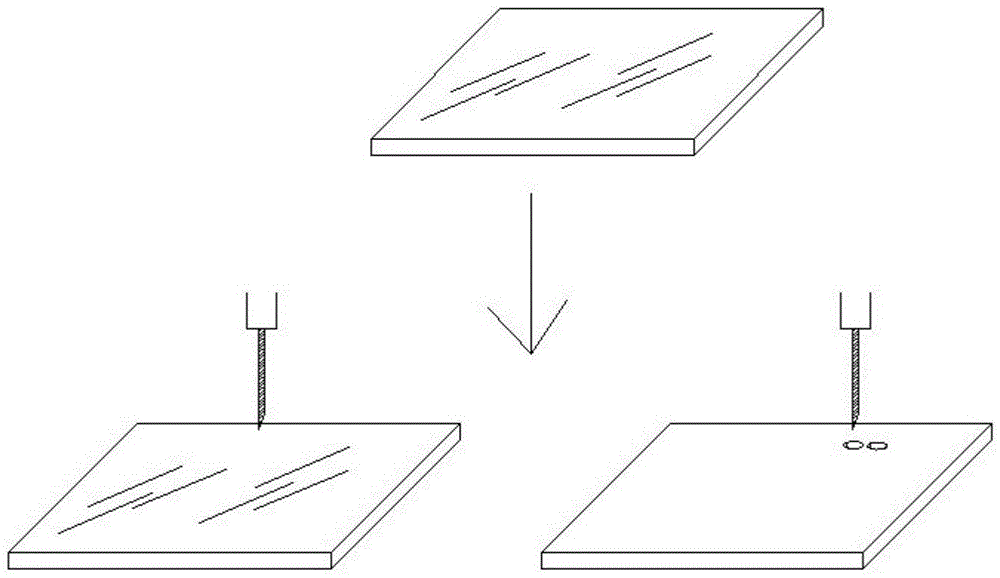

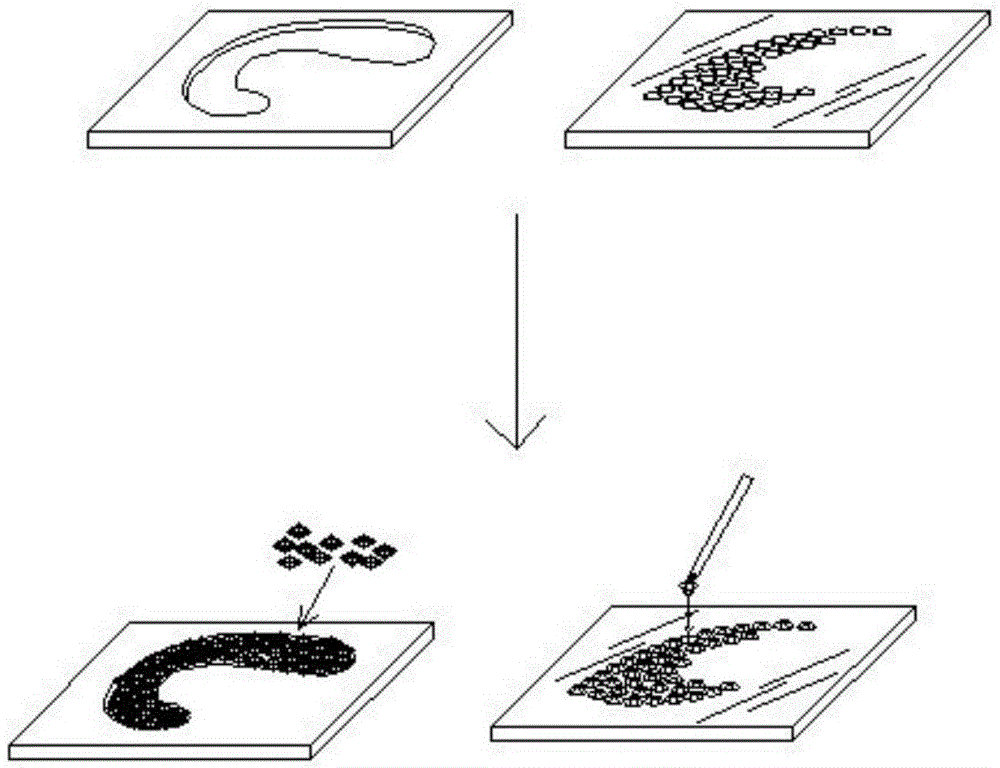

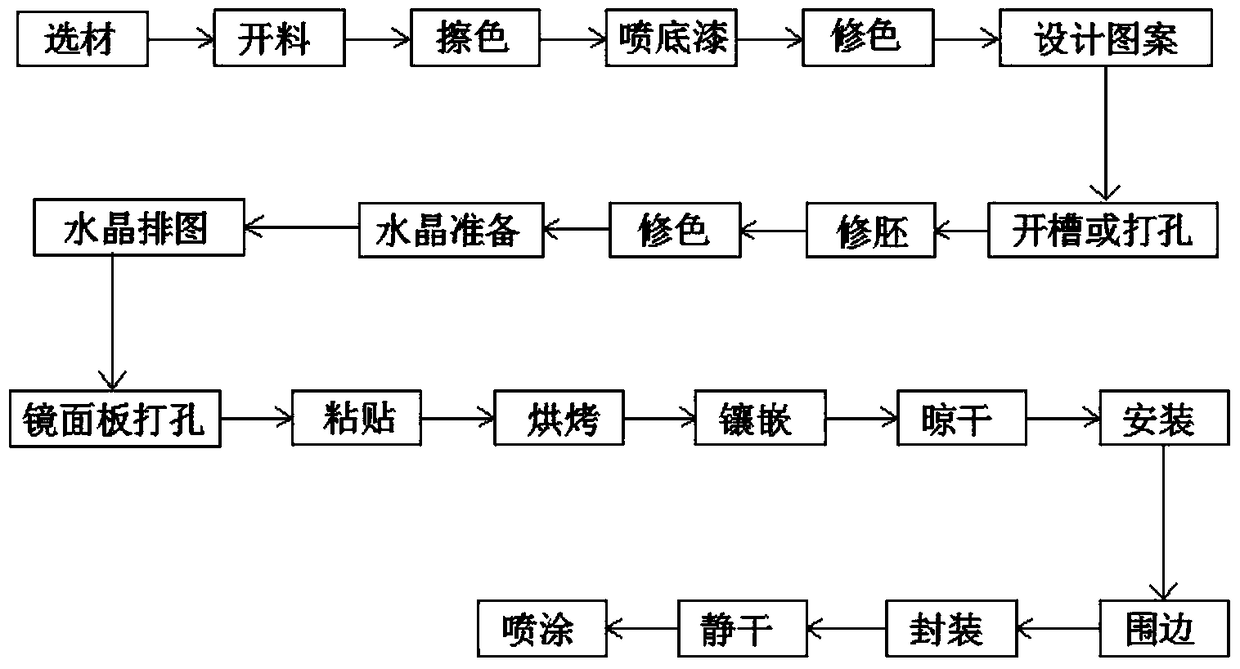

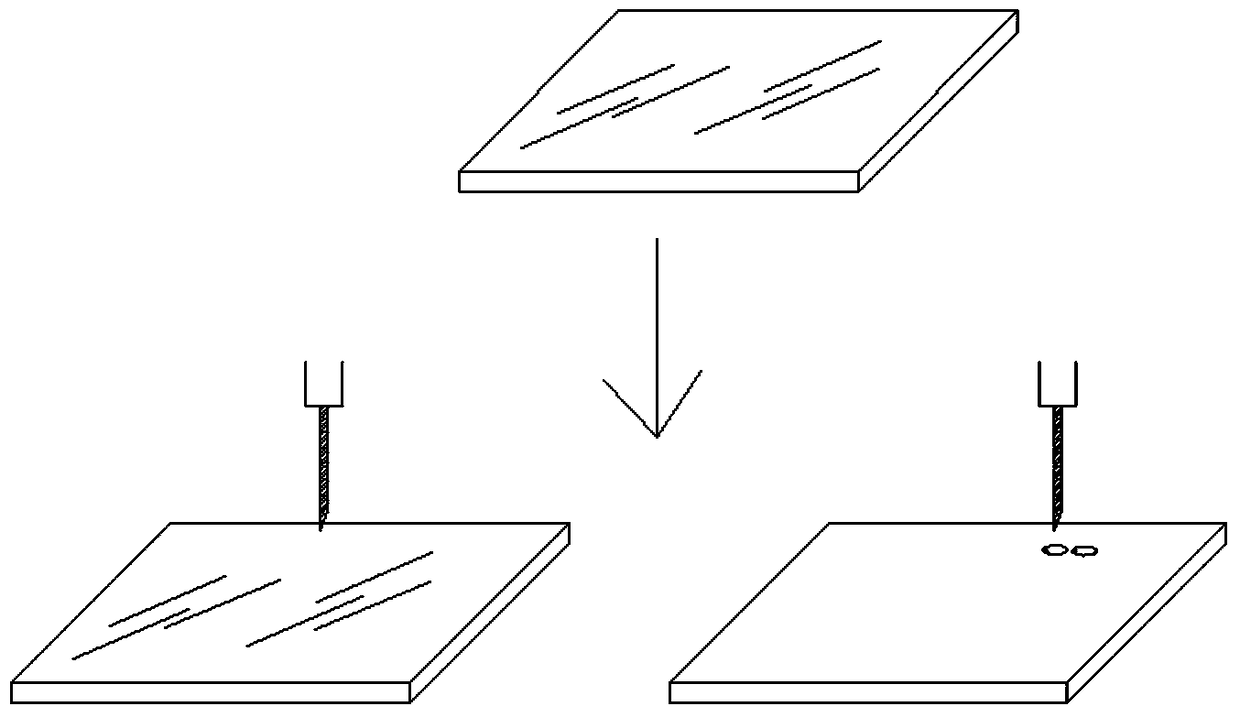

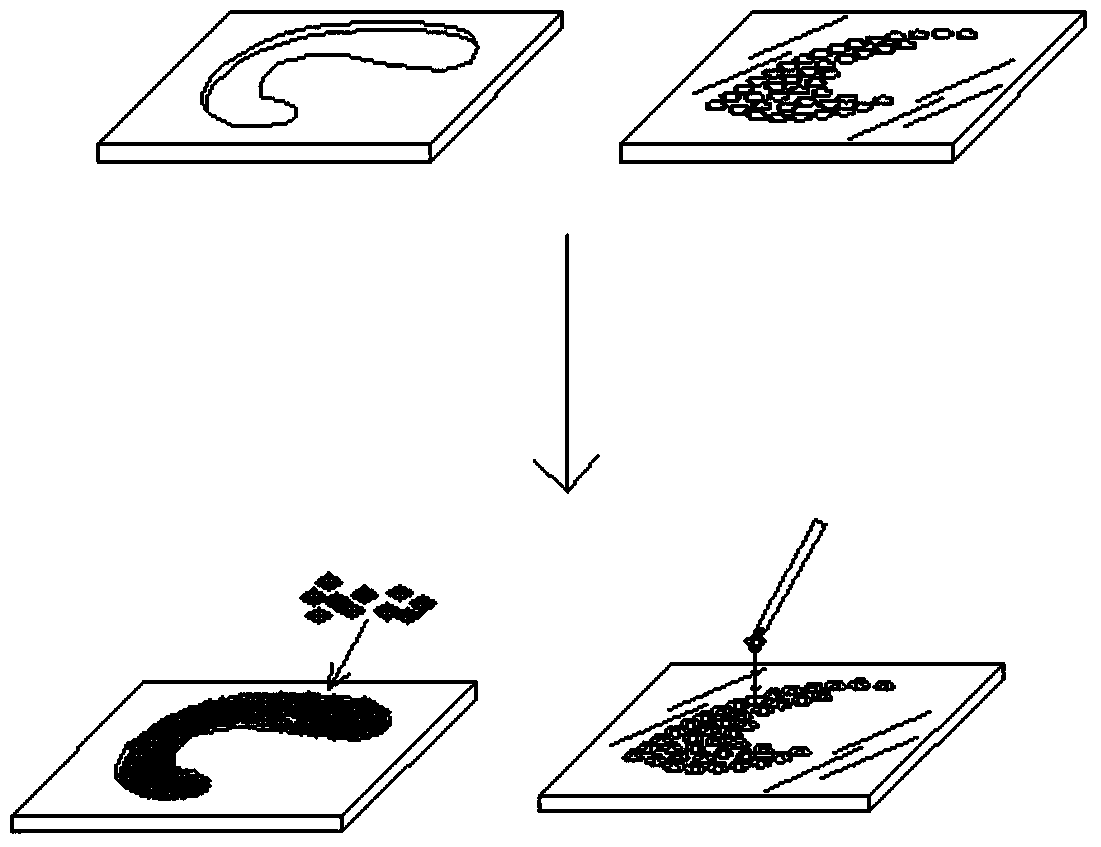

Machining method for crystal decorating plate

ActiveCN105564130AProtect the surfaceImprove refraction effectDecorative surface effectsSpecial ornamental structuresSpray coatingEngineering

The invention discloses a machining method for a crystal decorating plate, and belongs to the technical field of crystal decorating plates. The machining method comprises the following steps of material selection, cutting, color wiping, primer spraying, padding, pattern designing, grooving and perforation, blank repairing, padding, crystal preparation, crystal layout, mirror plate perforation, adhesion, baking, embedding, air-drying, mounting, edging, packaging, standing drying and spray-coating. In the steps, parameters and conditions of each step are controlled. The method has the beneficial effects that the whole process is easy to operate and suitable for industrial production, and the production efficiency is improved by over 50 percent; moreover, in the whole production process, a plate and crystals are prevented from being bruised, and the yield is increased by 95 percent compared with that of a conventional machining method; the crystals are packaged by virtue of an acrylic plate, so that the crystals on a substrate are prevented from daily pollution, and meanwhile, the flashing effect of the crystals is fully presented; the acrylic plate can be periodically polished, so that longer service life is achieved.

Owner:佛山市耀世家装饰艺术有限公司

High-lumen maintenance organosilicon material for LED packaging

ActiveCN108300408ANot yellowingIncrease luminous fluxNon-macromolecular adhesive additivesMacromolecular adhesive additivesLumen maintenanceLuminous flux

The invention discloses a high-lumen maintenance organosilicon material for LED packaging. The organosilicon material comprises a silicone component A, a silicone component B, nanometer magnesium oxide, a phosphor and an acrylic polymer, wherein the silicone component A comprises 60-85 parts of vinyl-terminated polymethylphenylsiloxane, 5-15 parts of vinyl-terminated polydimethylsiloxane, 3-8 parts of an active organic borosilicate tackifier, 10-25 parts of vinyl-terminated hyperbranched silicone resin and 0.05-0.5 part of a platinum catalyst; the silicone component B comprises 35-45 parts ofvinyl-terminated polymethylphenylvinylsiloxane, 45-55 parts of polymethylhydrosiloxane, 5-15 parts of MQ resin and 3-8 parts of a silane coupling agent A-172; and a mass part ratio of the silicone component A to the silicone component B to the nanometer magnesium oxide to the phosphor to the acrylic polymer in the organosilicon material is 100:100:(2.5-18):(3-8):(1-3). The organosilicon material has advantages of resistance to environmental hot and cold alternation, non-yellowing and high luminous flux.

Owner:NINGBO KLITE ELECTRIC MFG

Polyurethane resin preparation method

The invention relates to the technical field of materials for synthetic leather, in particular to a polyurethane resin preparation method. The method includes the steps: 1) increasing the temperature of 145 parts of polyneopentanediol adipate with the molecular weight of 2000 to 100 DEG C, performing vacuum dehydration for about 1h and cooling to 50 DEG C; 2) adding 150 parts of methylbenzene, 251 parts of IPDI (isophorone diisocyanate) and 5 parts of organic bismuth catalysts into a reactor with stirring uniformly, increasing the temperature to 90 DEG C and reacting for 2h; 3) adding 46 parts of 1,6-hexanediol to continue reaction for 2h at the temperature of 90 DEG C; 4) cooling to 50 DEG C, adding 100 parts of methylbenzene, 100 parts of normal butanol and 100 parts of isopropyl alcohol with stirring uniformly, slowly tackifying with 53 parts of isophorone diamine, and stopping adding the isophorone diamine when the viscosity is increased to 150000cps; and 5) continuing to stir for 30 minutes and cooling to 30 DEG C to discharge so that weak-solvent aliphatic polyurethane resin with 50% of solid content and 220kgf / cm<2> of modulus is obtained.

Owner:ZHEJIANG SUNLIGHT MATERIAL TECH CO LTD

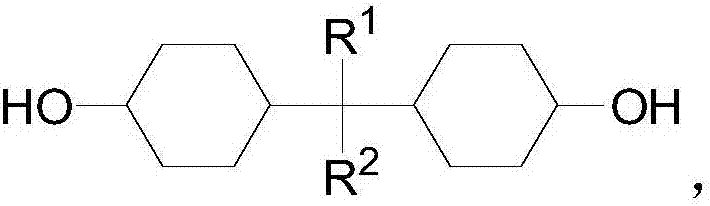

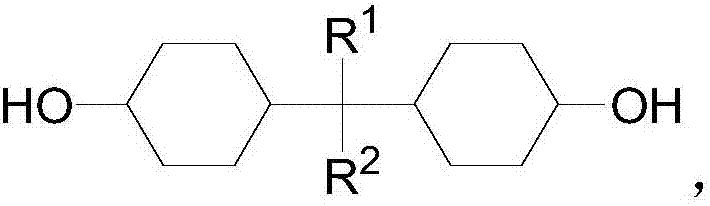

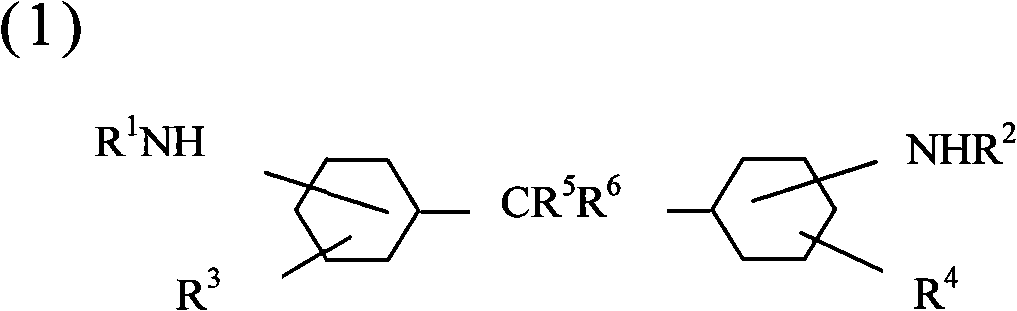

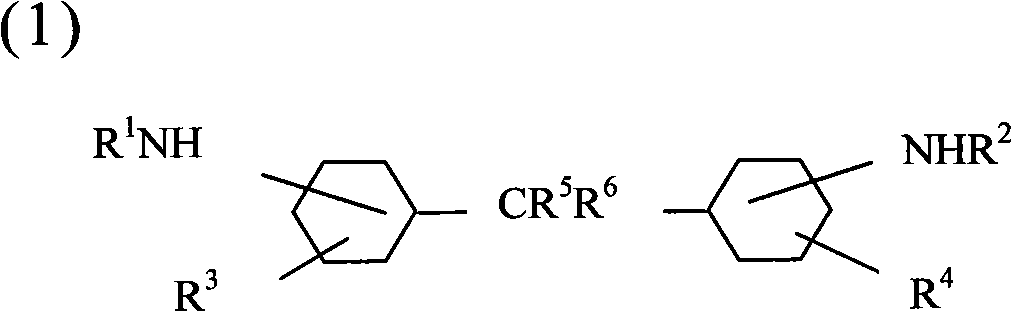

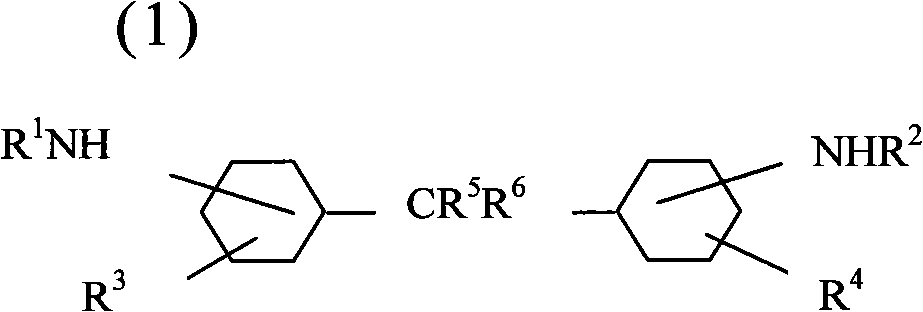

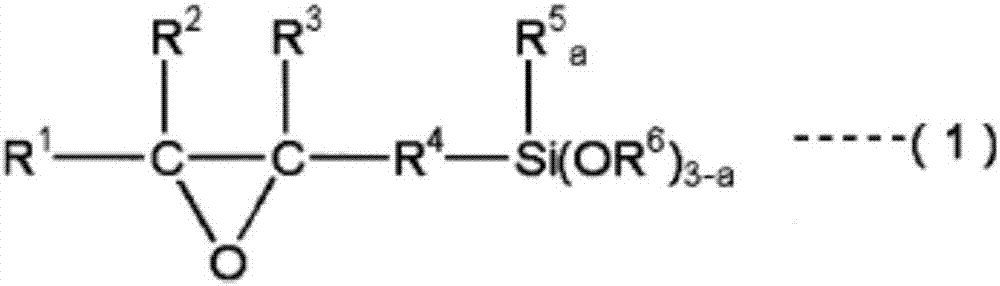

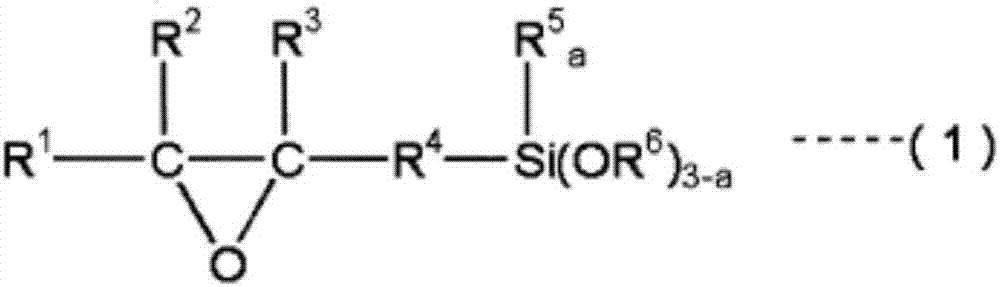

Polyurea resin compound and hardener

The invention relates to a polyurea resin compound and a hardener, with the polyurea resin compound meeting the following requirements: the resin compound provides sufficient time for formation; no long-term solidfication is required and high solidfication reaction rate is realized; the solidfication is properly carried out and not affected by the weather conditions, such as low temperature, low humidity, and the like; and no yellowing is created due to the exposure to the ultraviolet rays. The polyurea resin compound comprises aliphatic series / cycloaliphatic polyisocyanates and bi-component solidified type polyurea resin compound of a hardener for dimethyl (N-alky1 amino cycohexyl). The polyurea resin compound further comprises ketimine / aldimine. In the formula (1), R1 and R2 respectively and independently resprent alkyl having 1 to 10 carbon atoms; and R3 and R6 respectively and independently represent hydrogen atoms or having the alkyl having 1 to 5 carbon atoms.

Owner:CANON CHEMICALS INC

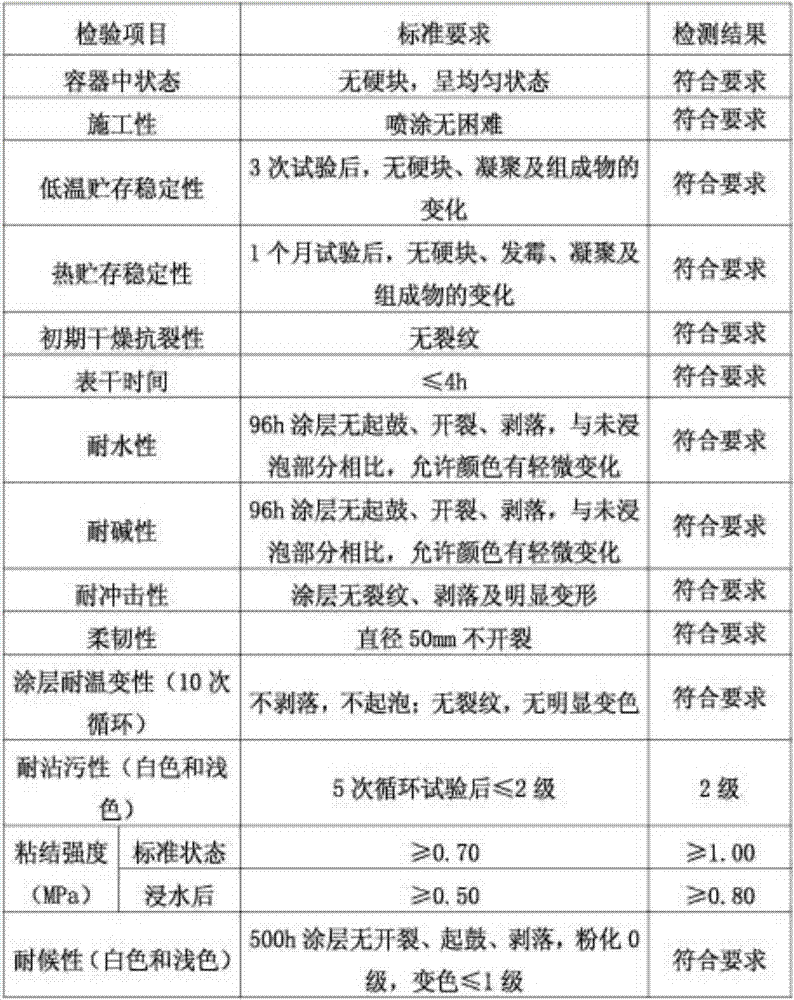

High-water-resistant colorful stone-like paint

InactiveCN106967344AHigh hardnessAnhydrous bleachingAnti-corrosive paintsEnvironmental resistanceCrack resistance

The invention provides a high-water-resistant colorful stone-like paint which comprises the raw materials of, by mass, 5-12 parts of ethylene glycol mo nobutyl ether acetate, 70-130 parts of sintering color sand, 3-8 parts of heavy calcium carbonate, 20-24 parts of silicone acrylic emulsion, 0.5-2.5 parts of water repellent, 5-10 parts of thixotropic agent, 2.5-8.5 parts of mildew preventive, 1-8 parts of kaolin, 4-9 parts of anti-freezing agent, 2-6 parts of dispersing agent and 30-50 parts of water. The high-water-resistant colorful stone-like paint has the advantages that the prepared stone-like paint product is large in film hardness, free of water blush phenomenon, capable of preventing yellowing, high in bonding strength and good in weather resistance; the construction performance, the crack resistance, the acid and base resistance, the corrosion resistance and the like are excellent, and the stone-like paint is non-toxic, odourless, free of radioactive contamination and harm to human body, safe and environment-friendly.

Owner:青岛金绮丽涂料股份有限公司

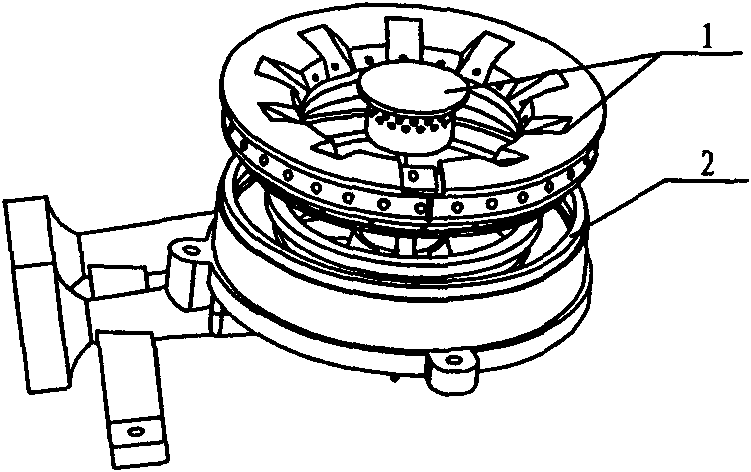

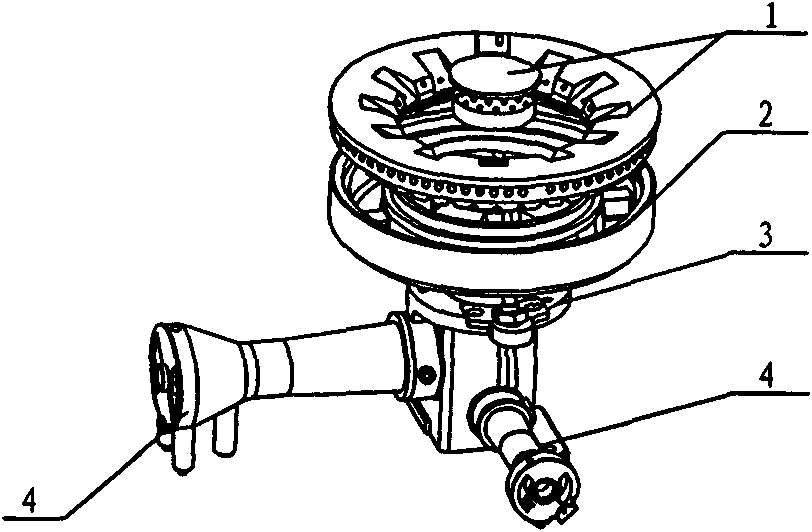

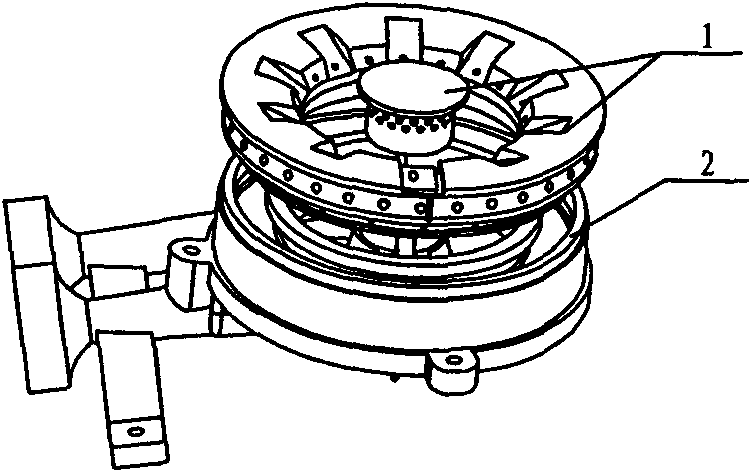

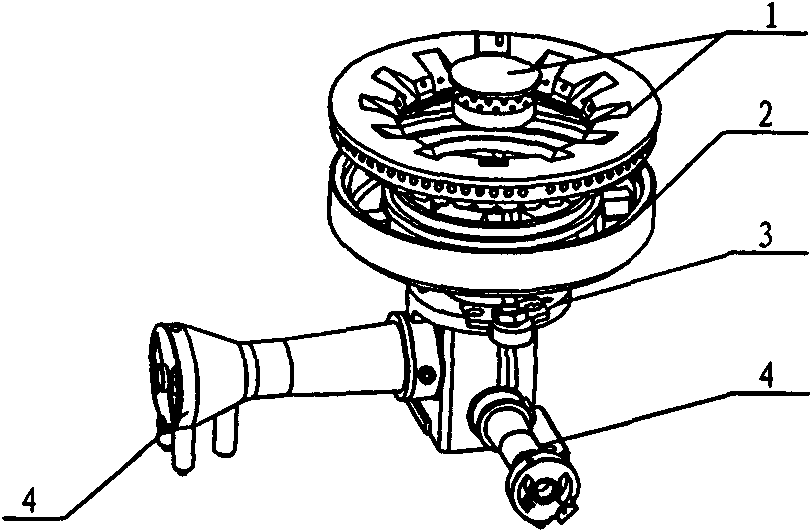

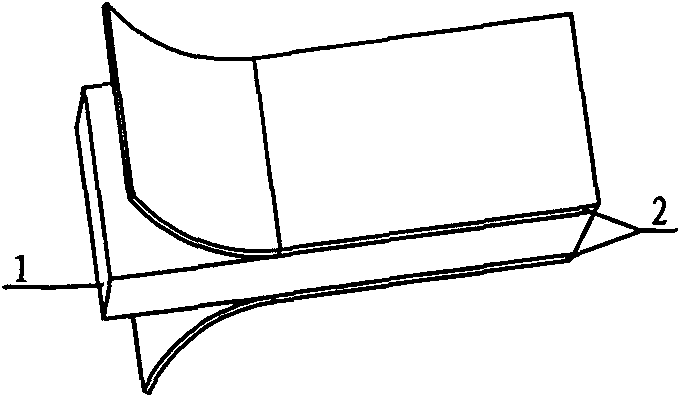

Cast iron enamel burner and preparation process thereof

ActiveCN101962772ASimple preparation processEnamelling effect is completeGaseous fuel burnerCombustorWorking environment

The invention relates to a cast iron enamel burner and a preparation process thereof. According to the high-temperature resistant cast iron burner of an enameled household stove and the preparation process thereof provided by the invention, enamel coating layers are sprayed in the cavities and on the outer surfaces of parts of the burner such as a fire cover, a burning tray, an ejector and the like according to the use requirements and the type of the burner respectively, and the coating layers have oxidation resistance and enhance the acid and alkali resistance, ageing resistance and rust resistance of the outer surfaces of the parts. When the enamel burner is used in a working environment of far higher than 600 DEG C, even burnt in open fire, the enamel burner does not become yellow or explode enamel. The enamel burner has the characteristics of resisting acid and alkali, thermal shock, high temperature and impact, containing no harmful elements to the human body and the like.

Owner:ZHEJIANG CONNAL ELECTRIC APPLIANCE CO LTD

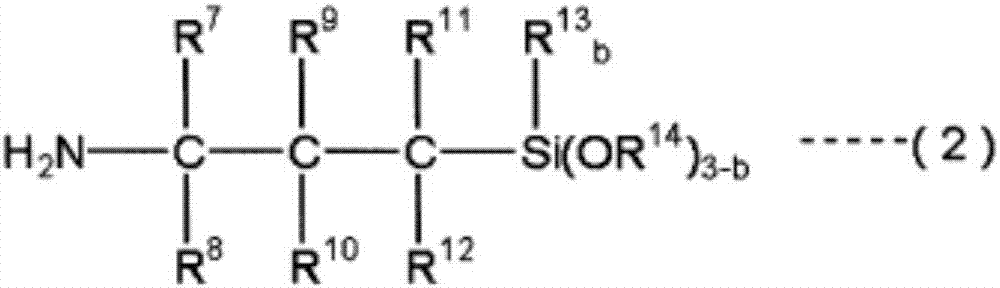

One-pack type water-based adhesive composition

ActiveCN107429141ANot yellowingGood adhesionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesWater basedSilane compounds

Provided is a one-pack type water-based adhesive composition which suffers no yellowing and is excellent in terms of adhesiveness and durability. The one-pack type water-based adhesive composition comprises (A) an aqueous dispersion of a polyurethane resin and (B) a silane compound obtained by reacting a specific epoxysilane compound with an aminosilane compound represented by the following formula (2), the amount of the epoxysilane compound being in the range of 1.5-10 mol per mol of the aminosilane compound, at a reaction temperature of 40-100oC. (In formula (2), R7 to R12 are each a hydrogen atom or an alkyl group, R13 is a monovalent hydrocarbon group, R14 is an alkyl group, and b is 0 or 1.)

Owner:CEMEDAINE CO LTD

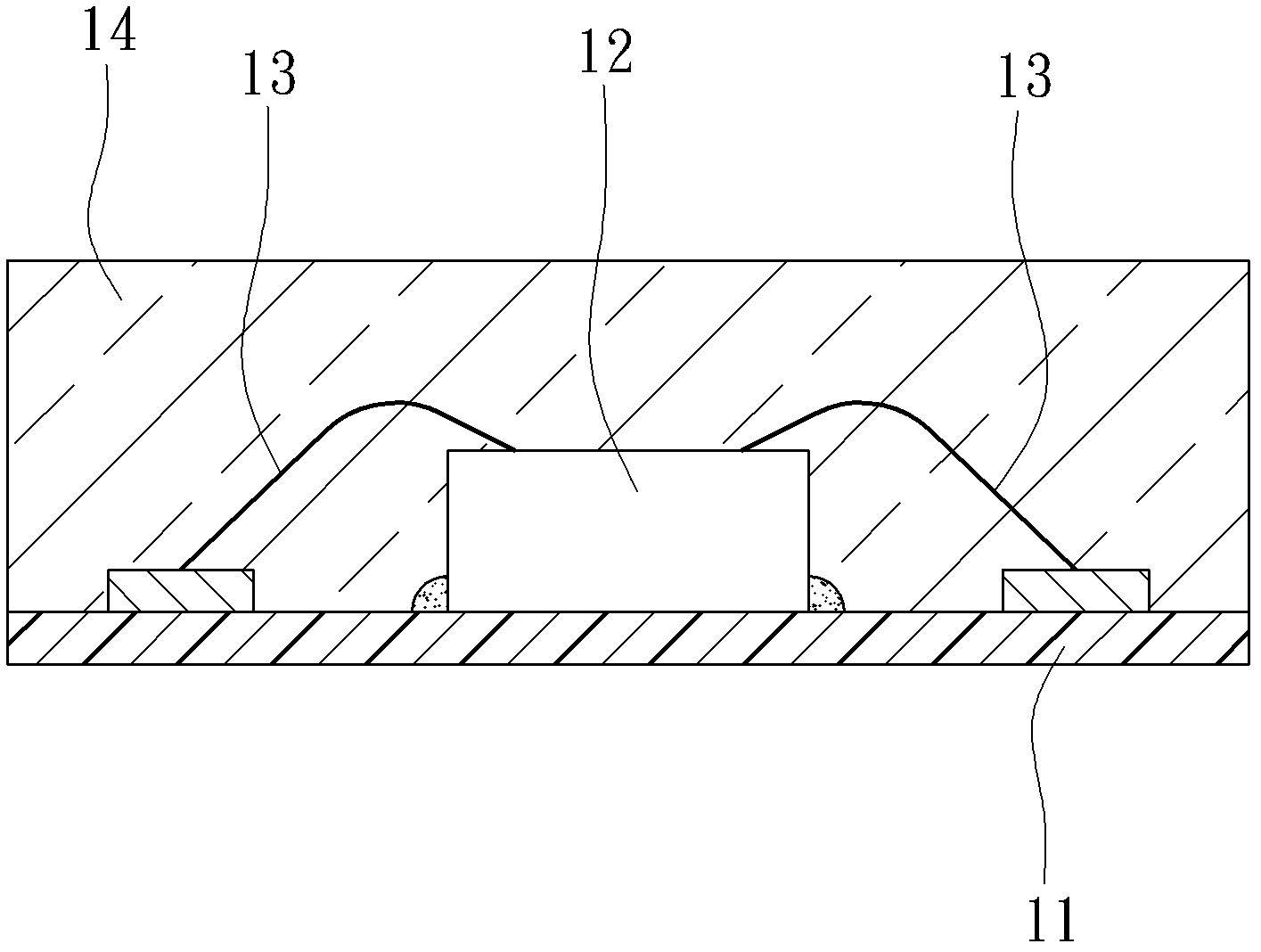

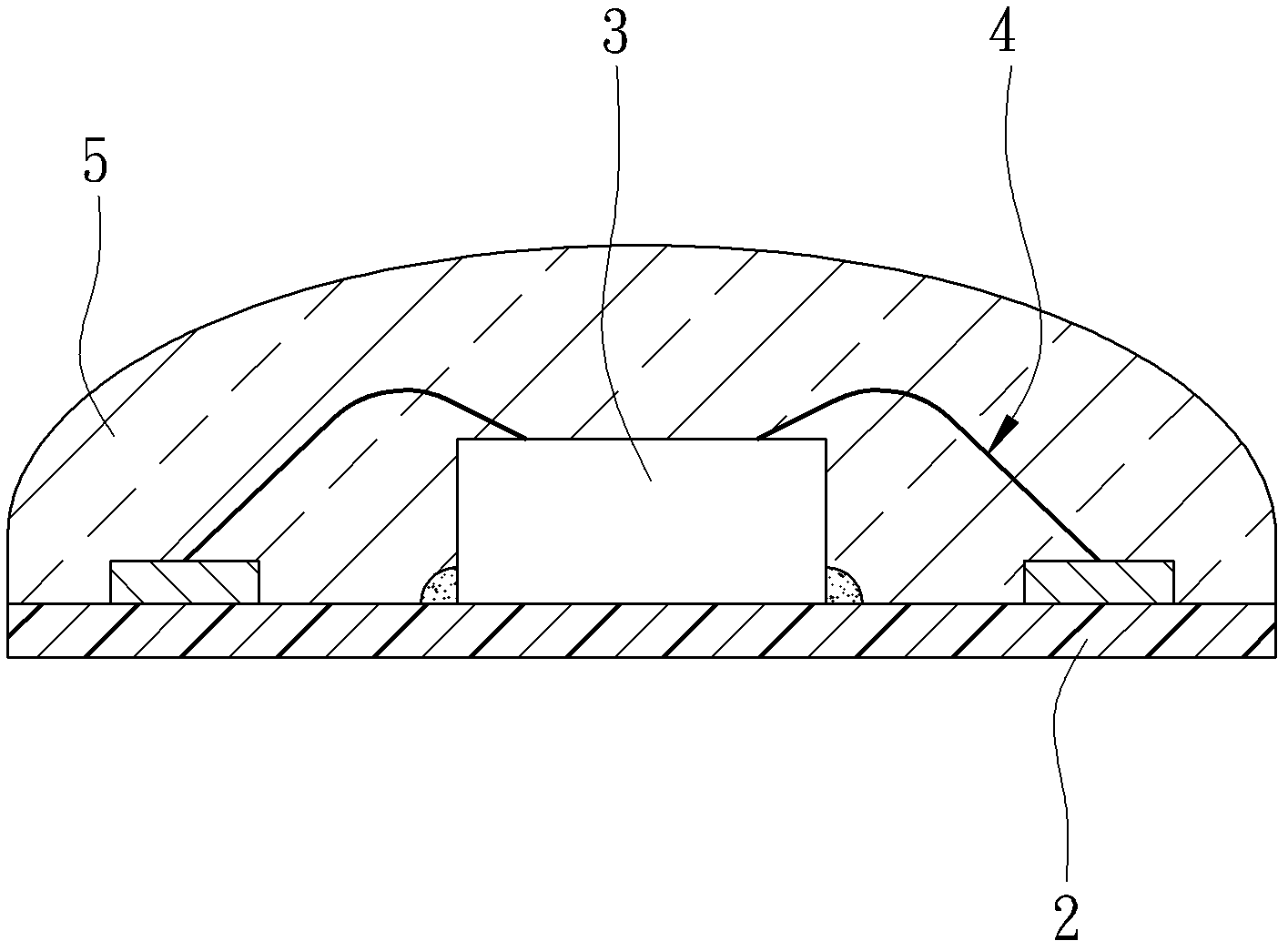

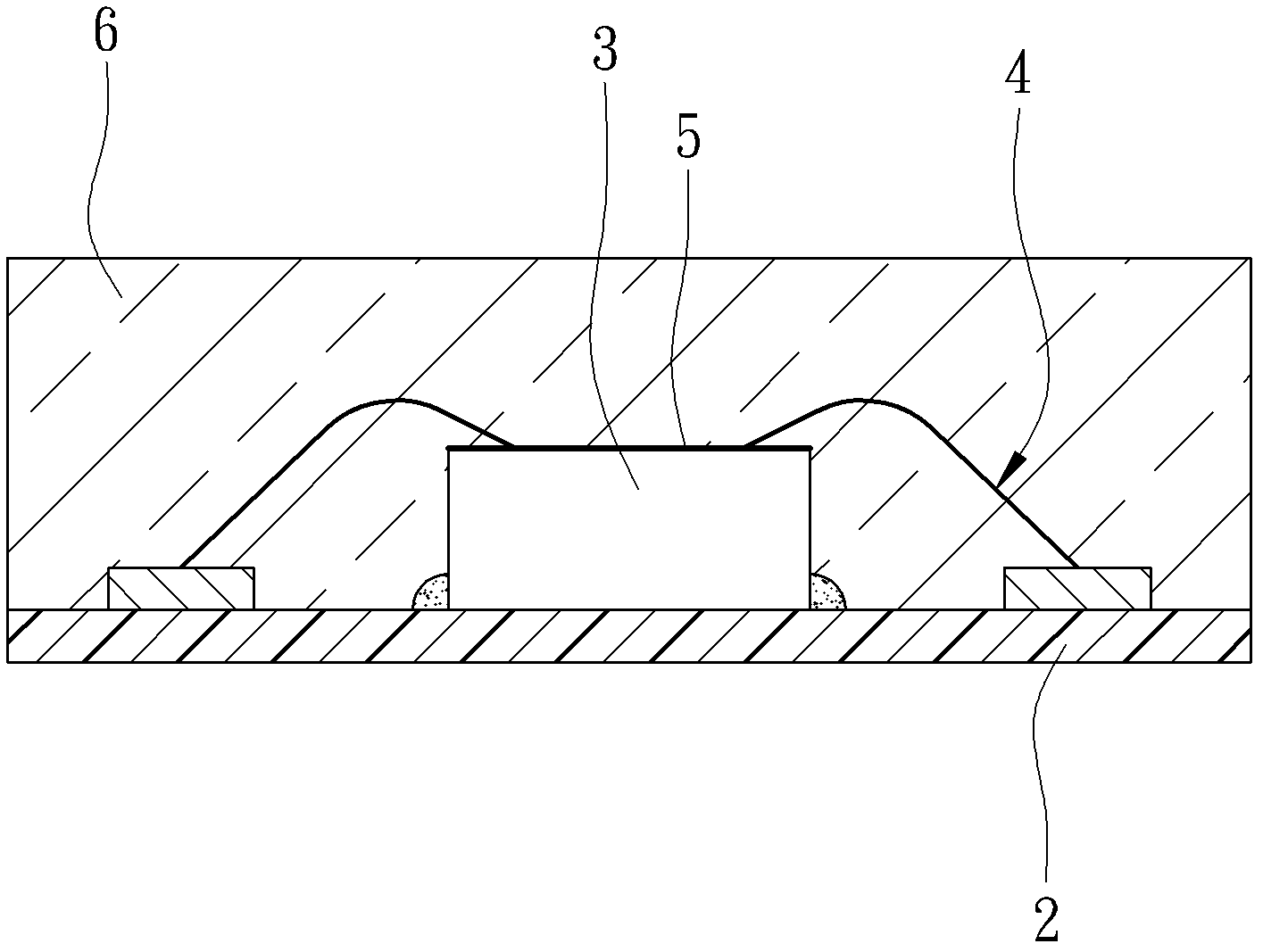

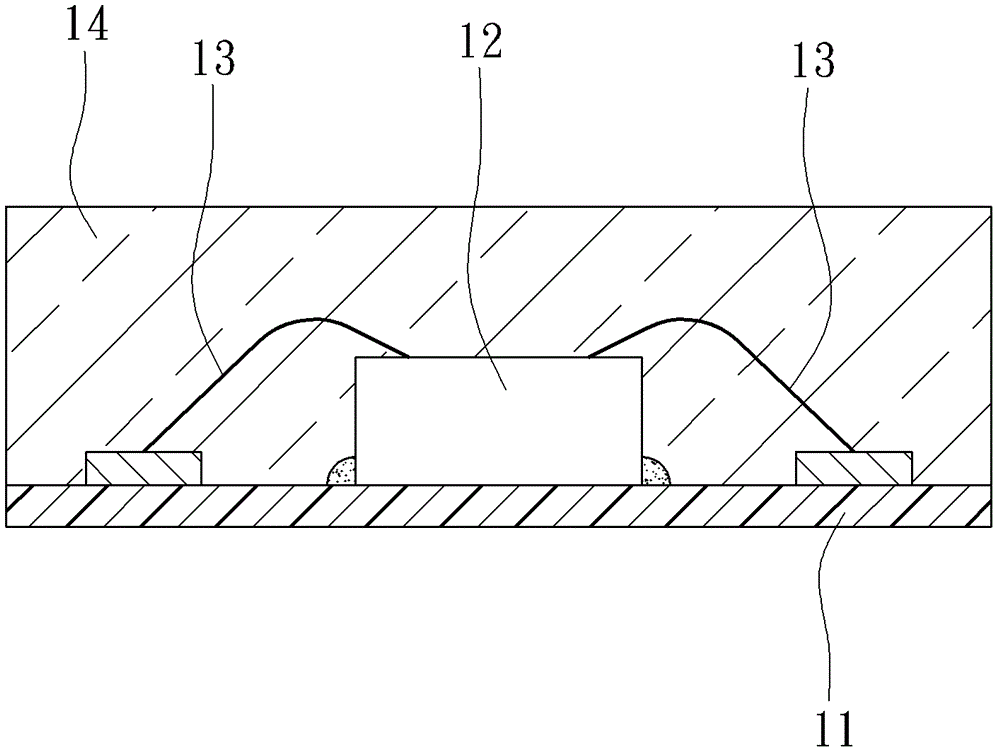

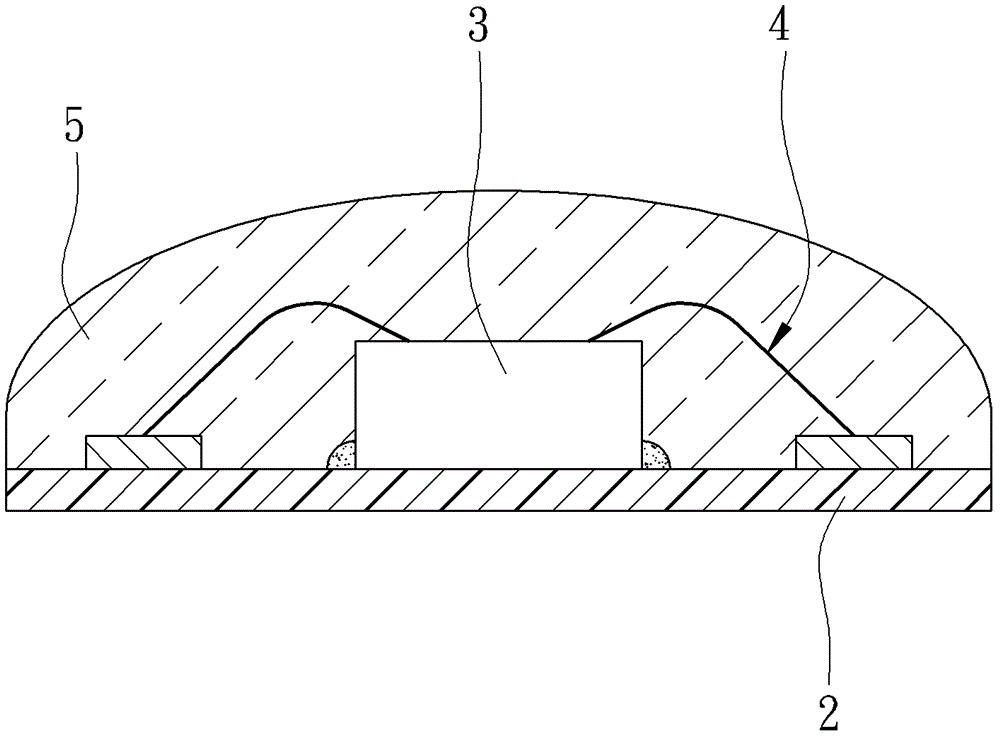

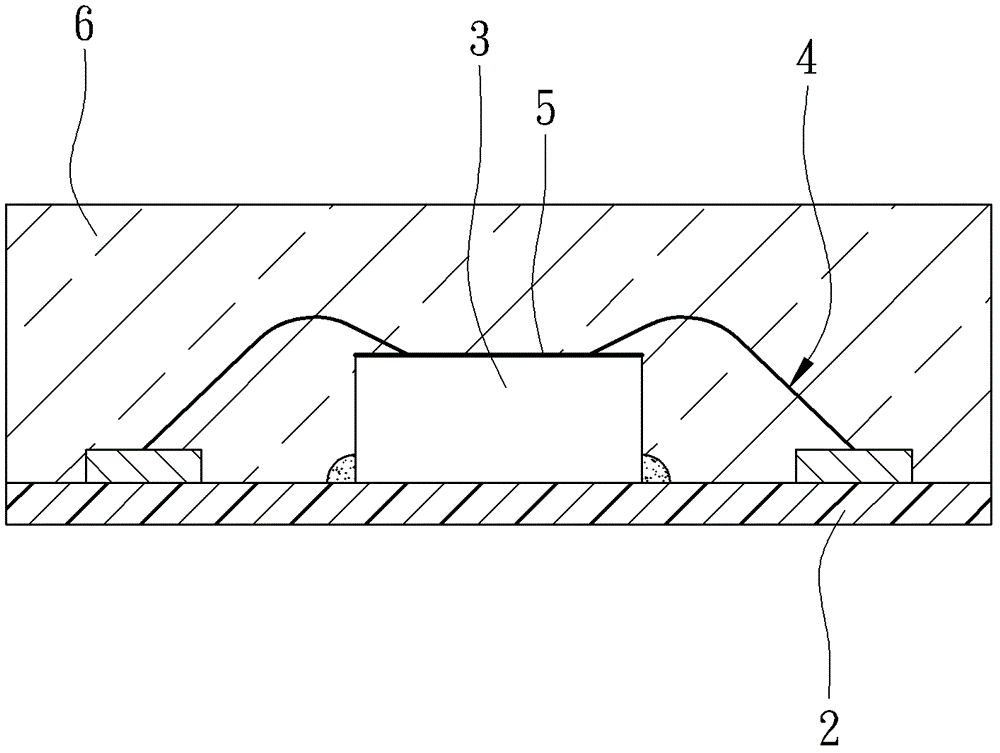

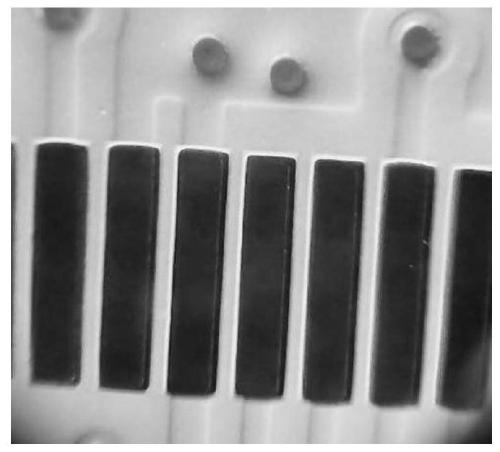

High-transmittance packaged LED (light emitting diode)

InactiveCN103208575ANot yellowingImprove adhesionSolid-state devicesSemiconductor devicesLight-emitting diodeSilicon

The invention discloses a high-transmittance packaged LED which comprises a substrate, a light emitting element, a lead unit and a heat-resistant layer. The light emitting element is formed on the substrate; the lead unit is connected with the substrate and the light emitting element; and the heat-resistant layer is at least formed on the light emitting diode and comprises light-transmitting silicon resin and 0.1%-10% of epoxy silicane by weight. Therefore, the heat-resistant layer is good in adhesive effect, high in transmittance, yellowing-free and capable of prolonging the service life of the high-transmittance packaged LED.

Owner:蔡凯雄 +1

A kind of organosilicon material for LED packaging with high lumen maintenance rate

ActiveCN108300408BNot yellowingIncrease luminous fluxNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceMeth-

The invention discloses a high-lumen maintenance organosilicon material for LED packaging. The organosilicon material comprises a silicone component A, a silicone component B, nanometer magnesium oxide, a phosphor and an acrylic polymer, wherein the silicone component A comprises 60-85 parts of vinyl-terminated polymethylphenylsiloxane, 5-15 parts of vinyl-terminated polydimethylsiloxane, 3-8 parts of an active organic borosilicate tackifier, 10-25 parts of vinyl-terminated hyperbranched silicone resin and 0.05-0.5 part of a platinum catalyst; the silicone component B comprises 35-45 parts ofvinyl-terminated polymethylphenylvinylsiloxane, 45-55 parts of polymethylhydrosiloxane, 5-15 parts of MQ resin and 3-8 parts of a silane coupling agent A-172; and a mass part ratio of the silicone component A to the silicone component B to the nanometer magnesium oxide to the phosphor to the acrylic polymer in the organosilicon material is 100:100:(2.5-18):(3-8):(1-3). The organosilicon material has advantages of resistance to environmental hot and cold alternation, non-yellowing and high luminous flux.

Owner:NINGBO KLITE ELECTRIC MFG

Weak solvent aliphatic polyurethane resin for synthetic leather and preparation method thereof

The invention relates to the technical field of materials for synthetic leather, in particular to weak solvent aliphatic polyurethane resin for synthetic leather and a preparation method thereof. The weak solvent aliphatic polyurethane resin for synthetic leather is prepared from the following components by weight percent: 2-30 percent of aliphatic diisocyanate compound, 5-40 percent of polyesteror polyether polyalcohol compound, 0-10 percent of micromolecule polyol chain extender, 0.1-13 percent of micromolecule polyamine chain extender, 0.01-1.0 percent of catalyst, 0.05-5.0 percent of assistant and 45-85 percent of organic mild solvent. The invention also discloses the preparation method of the weak solvent aliphatic polyurethane resin for synthetic leather. By adopting the technical scheme, the polyurethane resin with different solid contents, different viscosities and different modulus can by synthesized, the requirement of the synthetic leather is satisfied, and the synthetic leather product with high temperature resistance, cold resistance, anti-sticking performance and better external tensility of pigment can be prepared.

Owner:ZHEJIANG SUNLIGHT MATERIAL TECH CO LTD

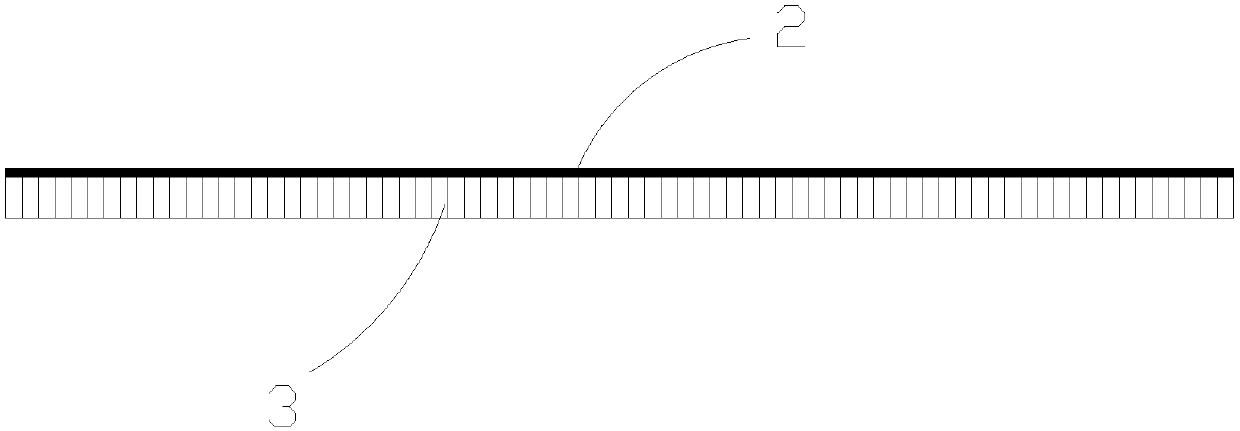

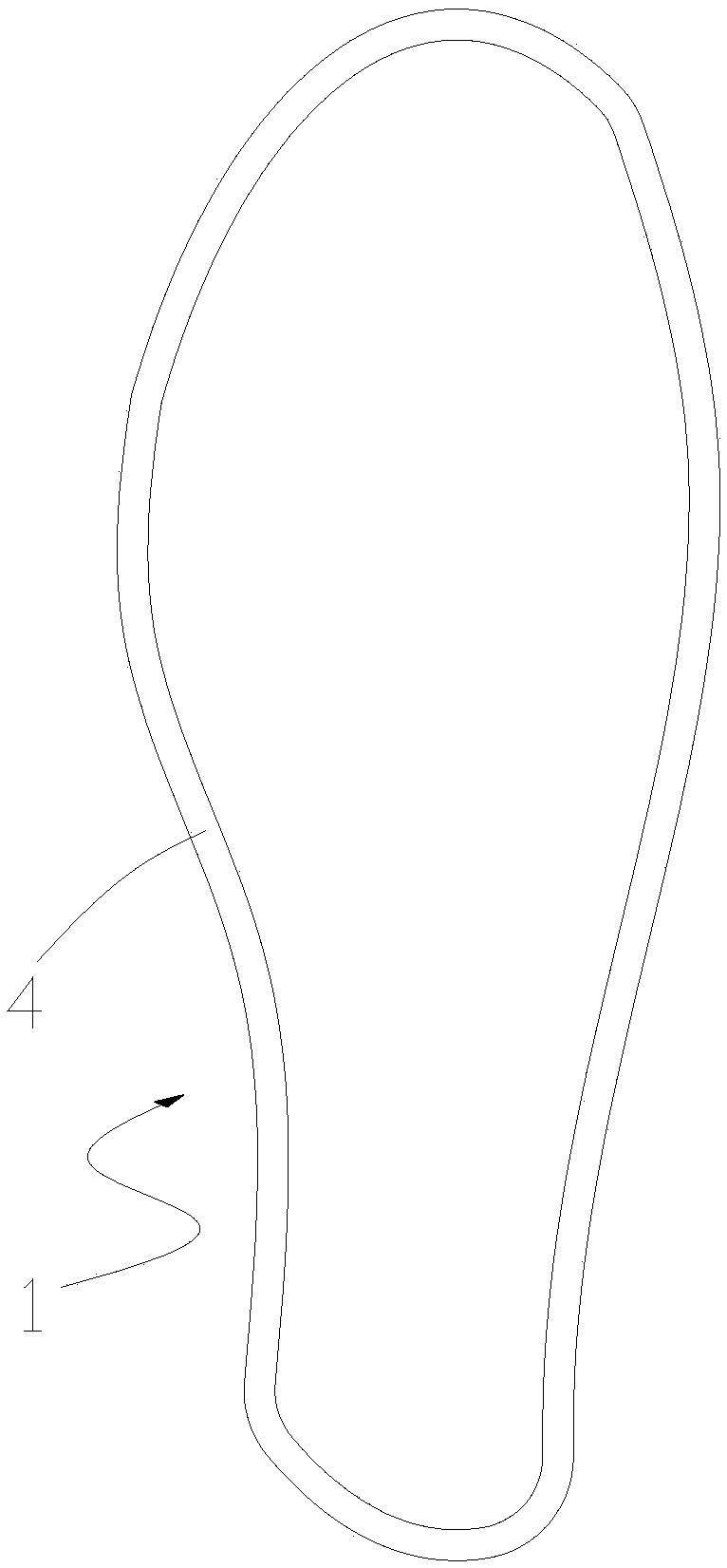

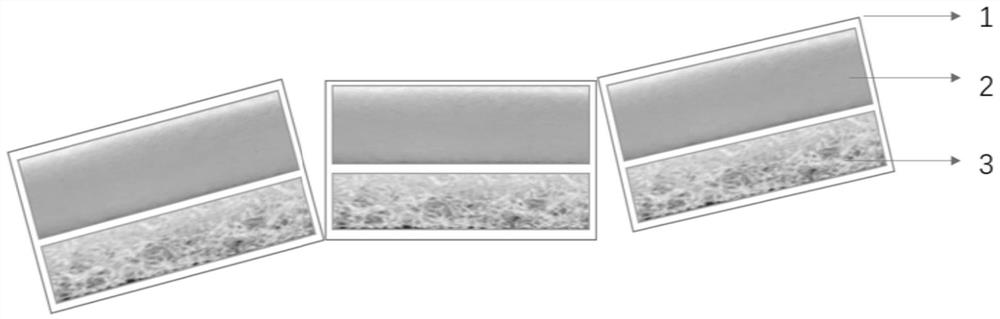

Vertical cotton insole and making method thereof

PendingCN108045009AGuaranteed structural performanceGood shape retentionInsolesSynthetic resin layered productsMoisture permeabilityEngineering

The invention discloses a vertical cotton insole and a making method thereof. The vertical cotton insole comprises a surface covering layer and a vertical cotton layer attached to the surface cover layer; the making method of the vertical cotton layer comprises the following steps that 1, materials used for making the surface covering layer are mixed with vertical cotton, and the insole material is obtained; 2, the insole material is cut into pieces of preset sizes; 3, the pieces are dried, pressed and shaped; 4, the shaped pieces are punched, and then the vertical cotton insole is obtained. The vertical cotton insole has the advantages of being good in form retention, not prone to collapse, better in rebound resilience, good in air and moisture permeability, free of yellowing and the like, use is more comfortable, and the service life is longer. The making method is simple in step, the form retention and rebound resilience of the vertical cotton layer can be improved, the machining process is simple, and the manufacturing cost is low.

Owner:苏州爱美纤维科技有限公司

Aliphatic polyurethane resin preparation method

The invention relates to the technical field of materials for synthetic leather, in particular to an aliphatic polyurethane resin preparation method. The method includes the steps: 1) increasing the temperature of 35 parts of poly adipic acid glycol-butanediol ether glycol and 35 parts of polycaprolactone glycol to 100 DEG C, performing vacuum dehydration for about 1h and cooling to 50 DEG C, wherein the molecular weight of the poly adipic acid glycol-butanediol ether glycol is 3000, and the molecular weight of the polycaprolactone glycol is 1000; 2) adding 150 parts of methylbenzene, 83 parts of IPDI (isophorone diisocyanate), 19 parts of H12MDI (dicyclohexylmethane 4,4- diisocyanate) and 0.2 part of stannous octoate into a reactor with stirring uniformly, increasing the temperature to 90 DEG C and reacting for 3h; 3) adding 5 parts of 1,4-butanediol and 9 parts of neopentyl glycol to continue reaction for 3h at the temperature of 90 DEG C; 4) cooling to 50 DEG C, adding 250 parts of methylbenzene, 200 parts of isobutyl alcohol and 200 parts of ethyl acetate with stirring uniformly, slowly tackifying with 13.8 parts of IPDA (isophorone diamine), and stopping adding the isophorone diamine when the viscosity is increased to 3000cps; and 5) continuing to stir for 30 minutes and cooling to 30 DEG C to discharge, so that weak-solvent aliphatic polyurethane resin with 20% of solid content and 180kgf / cm<2> of modulus is obtained.

Owner:ZHEJIANG SUNLIGHT MATERIAL TECH CO LTD

A kind of processing method of crystal decorative plate

ActiveCN105564130BProtect the surfaceImprove refraction effectDecorative surface effectsSpecial ornamental structuresSpray coatingEngineering

Owner:佛山市耀世家装饰艺术有限公司

Packaged light-emitting diodes with high transmittance

InactiveCN103208575BNot yellowingImprove adhesionSolid-state devicesSemiconductor devicesLight-emitting diodeSilicon

The invention discloses a high-transmittance packaged LED which comprises a substrate, a light emitting element, a lead unit and a heat-resistant layer. The light emitting element is formed on the substrate; the lead unit is connected with the substrate and the light emitting element; and the heat-resistant layer is at least formed on the light emitting diode and comprises light-transmitting silicon resin and 0.1%-10% of epoxy silicane by weight. Therefore, the heat-resistant layer is good in adhesive effect, high in transmittance, yellowing-free and capable of prolonging the service life of the high-transmittance packaged LED.

Owner:蔡凯雄 +1

A kind of room temperature curing epoxy resin flexible potting glue

ActiveCN104388029BHigh light transmittanceWill not affect the light brightnessMacromolecular adhesive additivesEpoxy resin adhesivesFlexible circuitsPlasticizer

The invention discloses a normal-temperature-curing epoxy resin flexible pouring sealant and relates to the technical field of polymer materials. The normal-temperature-curing epoxy resin flexible pouring sealant is prepared by mixing a component A and a component B in equal parts by weight, wherein the component A comprises 60-90 parts of epoxy resin, 10-30 parts of reactive diluent, 5-10 parts of a plasticizer, 1-5 parts of a silane coupling agent, 0.5-2 parts of a defoaming agent, 0.5-2 parts of an antioxidant and 0.5-1 part of an ultraviolet absorber; and the component B comprises 1-3 parts of an accelerator, 30-60 parts of polyether amine and 0-50 parts of modified amine prepolymer I and 0-55 parts of modified amine prepolymer II. The ambient-curing epoxy resin flexible pouring sealant has the characteristics that the pouring sealant can be rapidly cured under the room temperature condition and is especially suitable for pouring LED flexible strips and the cured substance has better flexibility and higher elongation at break and transparency and the like and is suitable for pouring and sealing the surfaces of products having requirements on flexibility and transparency, for example, surface coating of LED flexible strips, LED module strips, flexible circuit boards and the like.

Owner:HUNAN HAOZHI TECH

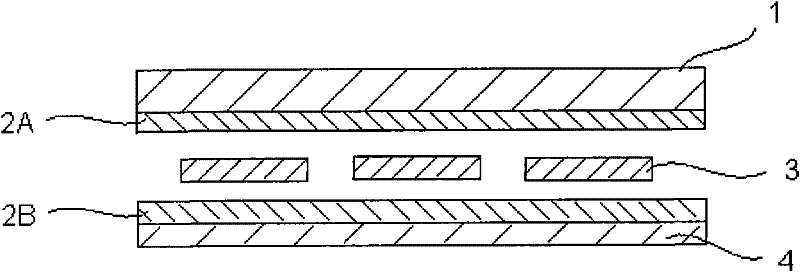

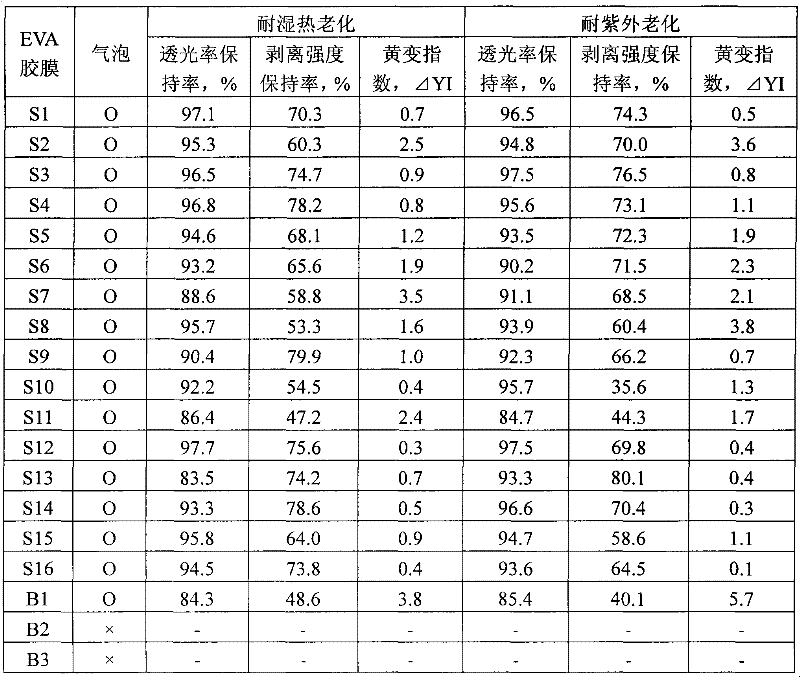

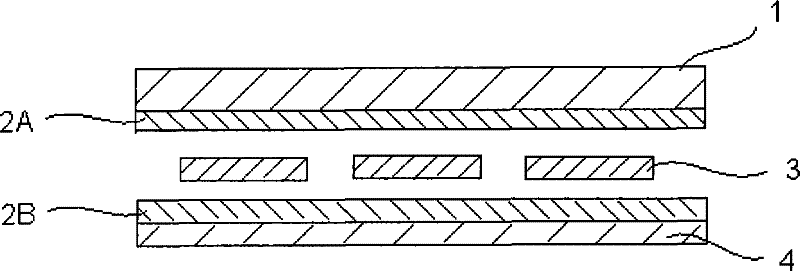

Ethylene vinyl acetate adhesive film and solar battery assembly

ActiveCN101921425BImprove temperature resistanceEasy to processPhotovoltaic energy generationSemiconductor devicesAging resistanceUltraviolet lights

The invention provides an ethylene vinyl acetate (EVA) adhesive film used for solar battery packaging. The adhesive film comprises the following components in part by mass: 100 parts of ethylene vinyl acetate, 0.01-4 parts of organic peroxides, 0.01-3 parts of cross-linking aid, 0.01-3 parts of silane coupling agent, 0.1-1 part of light stabilizing agent, 0-1 part of ultraviolet light absorbing agent and 0.0001-0.01 part of fluorescent whitening agent. The invention also provides a solar battery assembly which comprises the ethylene vinyl acetate adhesive film. The EVA adhesive film is not easy to produce air bubbles when the solar battery assembly is laminated. Both the EVA adhesive film and the solar battery assembly have excellent heat and humidity resistance, ageing resistance and ultraviolet aging resistance.

Owner:SUZHOU DUCHAMPS ADVANCED MATERIALS CO LTD

Flame-retardant antibacterial antiviral mildew-proof moisture-proof mattress and preparation method thereof

ActiveCN113679203AHigh reboundImprove stress resistanceStuffed mattressesBio-packagingPolyesterFiber

The invention discloses a flame-retardant antibacterial antiviral mildew-proof moisture-proof mattress and a preparation method thereof. The flame-retardant antibacterial antiviral mildew-proof moisture-proof mattress comprises an intrinsically flame-retardant antibacterial antiviral waterproof fabric cover, flame-retardant short fiber 3D upright cotton and a flame-retardant PE short pipe layer. The intrinsically flame-retardant antibacterial antiviral fabric cover is a high-precision fabric formed by blending and weaving flame-retardant filaments and PLA antibacterial fibers based on PHBV. The flame-retardant short fiber 3D upright cotton is of a three-dimensional disordered node-free multi-layer fiber net-shaped structure which is formed by weaving flame-retardant polyester short fibers through a 3D non-woven technology. The flame-retardant PE short pipe layer is of a disordered net-shaped three-dimensional structure formed by processing flame-retardant PE short pipes through a non-woven technology. The flame-retardant antibacterial antiviral mildew-proof moisture-proof mattress disclosed by the invention has the advantages of being good in air permeability, easy to clean, easy to air, not easy to deform, capable of absorbing moisture and releasing sweat, and not prone to bacterium propagation. The mattress can be made into a three-folding cushion, is easy to store and can be widely applied to places such as families, hotels and student dormitories.

Owner:杭州中隽科技有限公司

Insert injection moulding decoration transfer printing foil with anti-yellowing performance

InactiveCN108587332ANot yellowingImproved anti-yellowing propertiesDuplicating/marking methodsPolyurea/polyurethane coatingsLow-density polyethyleneAcrylic resin

The invention provides an insert injection moulding decoration transfer printing foil with anti-yellowing performance. The insert injection moulding decoration transfer printing foil with anti-yellowing performance comprises a base film layer, a release layer, a color layer, an aluminium coated layer, and an adhesive layer which are laminated successively; the color layer is prepared from, by weight, 10 to 25 parts of low density polyethylene, 10 to 20 parts of high density polyethylene, 1 to 10 parts of polyurethane acrylate, 1 to 5 parts of epoxy acrylate, 1 to 10 parts of trimethylolpropanetriacrylate, 8 to 12 parts of methyl methacrylate, 20 to 60 parts of n-butyl methacrylate, 1 to 10 parts of polyethylene wax powder, 10 to 20 parts of polyamide, 10 to 25 parts of a diluent, 10 to 20parts of titanium dioxide, 0.1 to 2 parts of a dispersant, 1 to 30 parts of an anti-corrosive pigment, 5 to 10 parts of a toughening auxiliary agent, and 3 to 8 parts of an anti-yellowing auxiliary agent. According to a preparation method, acrylic resins of different amounts and different kinds are adopted so as to obtain the novel color layer; the toughening auxiliary agent and the anti-yellowing auxiliary agent are added, so that yellowing is avoided under certain heating requirements, and the anti-yellowing performance is improved greatly.

Owner:KURZ STAMPING TECH HEFEI

Production method of dairy cattle chrome-free tanning fur leather and fur leather

InactiveCN109385491AReduce dosageImprove permeabilityTanning treatmentPre-tanning chemical treatmentHigh volume manufacturingSoftening

The invention belongs to the technical fields of leather processing chemistry and engineering and in particular relates to production method of dairy cattle chrome-free tanning fur leather and fur leather prepared by using the method. The production method of the dairy cattle chrome-free tanning fur leather comprises the following steps: step 1) trimming source leather, weighing, soaking into water, degreasing, and washing with water; step 2) softening, and soaking into an acid; step 3) bulging, standing still, and piling; step 4) removing the acid; step 5) cooling, washing with water, and throwing off the water; step 6) soaking into an acid, tanning; step 7) carrying out leather basifying; step 8) bulging, and carrying out water extrusion, trimming, oil brushing, drying, re-moisturizing,milling softening, dry toggling and cleaning in sequence to obtaining a dairy cattle chrome-free tanning fur leather finished product. The production method provided by the invention is simple in overall procedure and easy to operate, low in production cost, short in cycle, good in practicability and applicable to large-scale production. The leather of the prepared dairy cattle fur leather is soft, full, white, flat, good in air permeability and water permeability, and the fur is tidy, smooth and good in elasticity.

Owner:四川绵竹新市制革有限公司

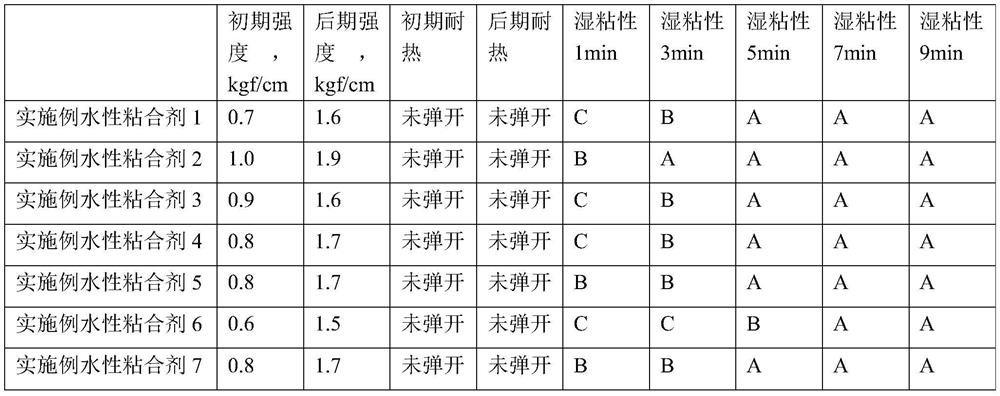

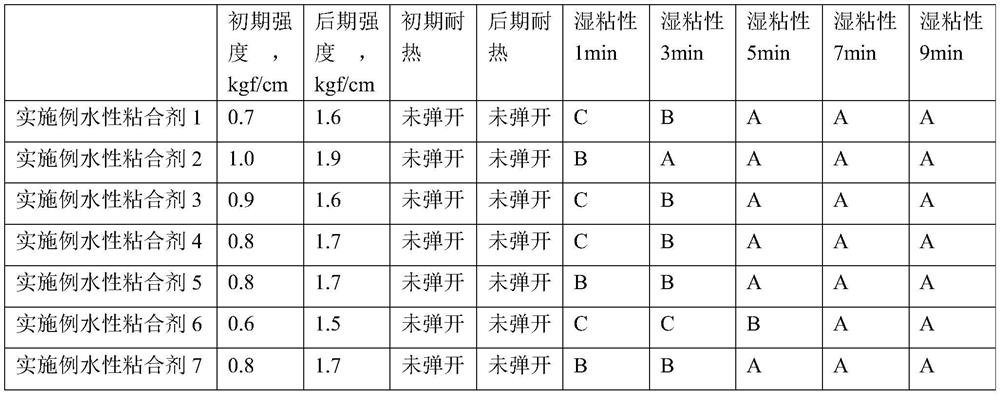

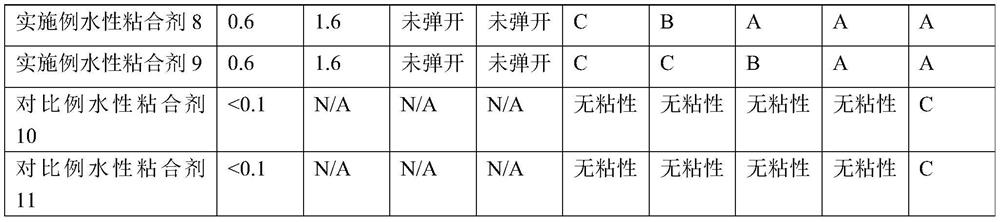

A kind of adhesive and its preparation method and application

ActiveCN112442329BNo smellNo pollution in the processNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyurethane dispersionPolymer science

The invention relates to an adhesive and a preparation method and application thereof. The adhesive comprises the following components in parts by weight: 94-99.5 parts of an aqueous polyurethane dispersion, 0.5-5 parts of a wet adhesion promoter, and 0.03-5 parts of a defoamer 0.08 part, wetting agent 0.1-0.3 part, thickening agent 0.1-1 part; wherein, the hydroxyl content of the water-based polyurethane dispersion is 3-5 mgKOH / g, and the molecular weight is 15-250,000 Daltons; wherein the wet Adhesion promoters are alcohol ethers, alcohol esters or polyoxyethylene polyoxypropylene polyethers that have a destabilizing effect on polyurethane emulsions; plasticizing films. The water-based adhesive of the present invention is suitable for composite hemming applications such as quick-setting luggage leather goods, shoe uppers, furniture mattresses and the like.

Owner:WANHUA CHEM GRP CO LTD +2

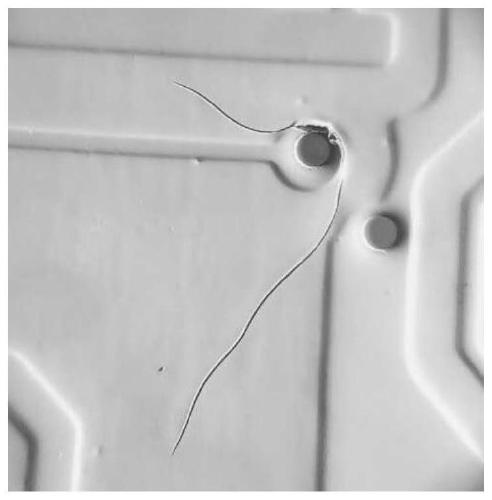

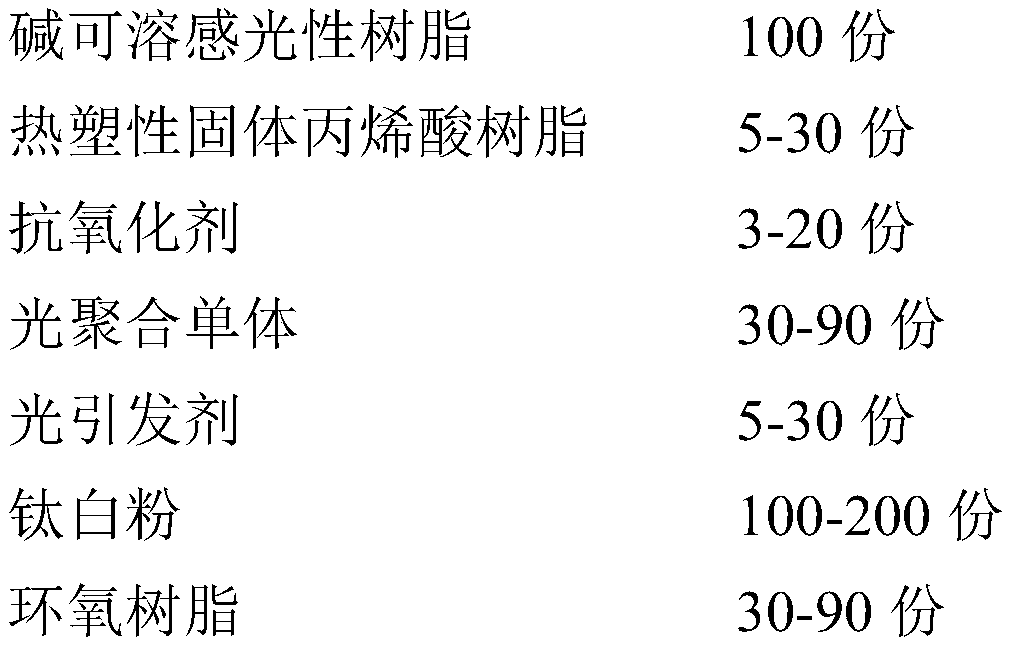

A white alkali-soluble photosensitive composition and its preparation method and application

ActiveCN107203095BWon't shrinkNot yellowingPhotosensitive materials for photomechanical apparatusEpoxyPolymer science

A white alkali-dissolvable photosensitive composition is disclosed. The composition includes, by weight, 100 parts of alkali-dissolvable photosensitive resin, 5-30 parts of thermoplastic solid acrylic resin, 3-20 parts of an antioxidant, 30-90 parts of a photopolymerizable monomer, 5-30 parts of a photoinitiator, 100-200 parts of titanium dioxide, 30-90 parts of epoxy resin, 0.05-0.5 part of an amine catalyst and 30-90 parts of a diluent. A cured film formed from the composition has advantages of no contraction or crack after thermal shock, and no yellowing at high temperature, and can be used for preparing a printed circuit board.

Owner:JIANGSU KUANGSHUN PHOTOSENSITIVITY NEW MATERIAL

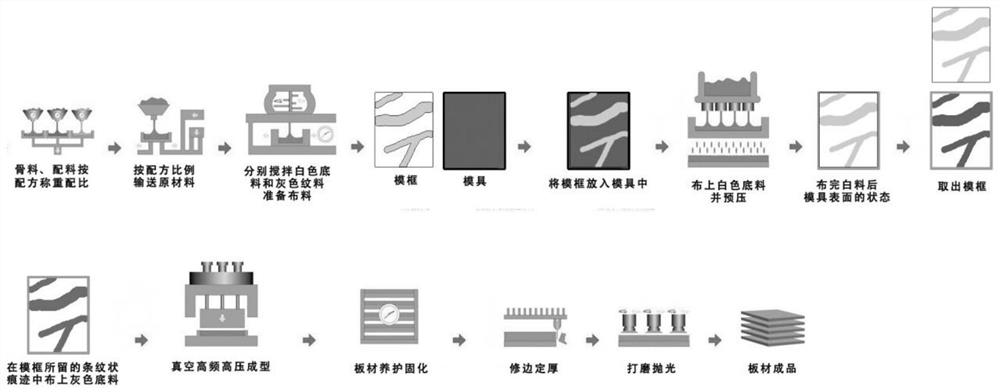

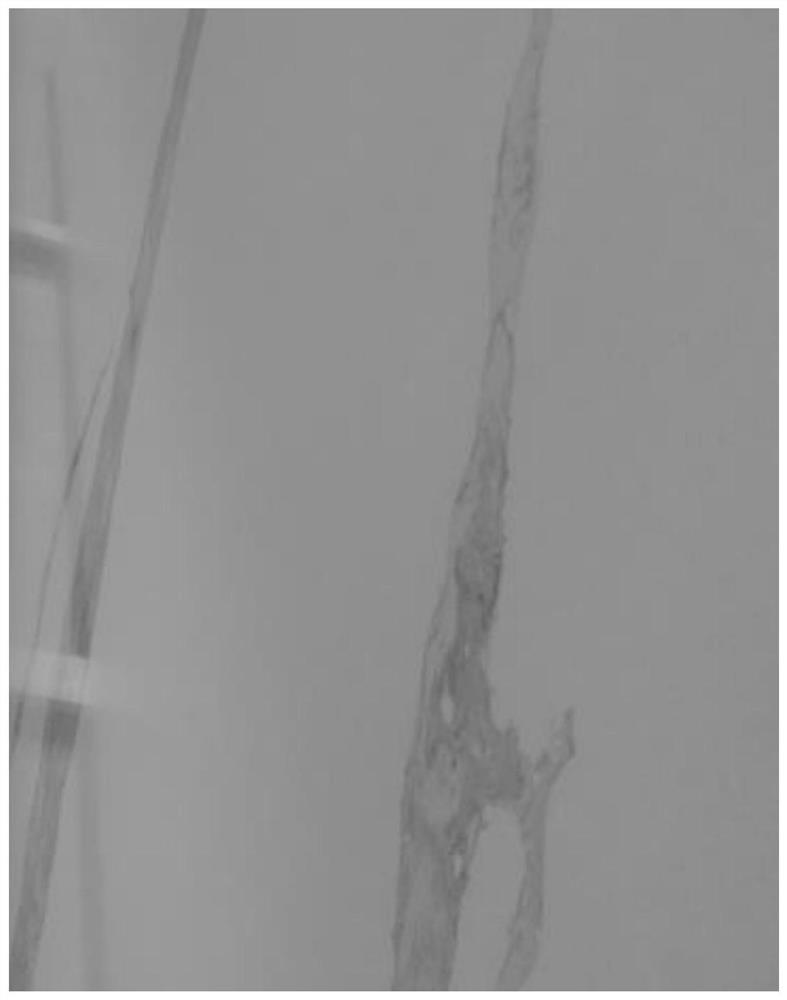

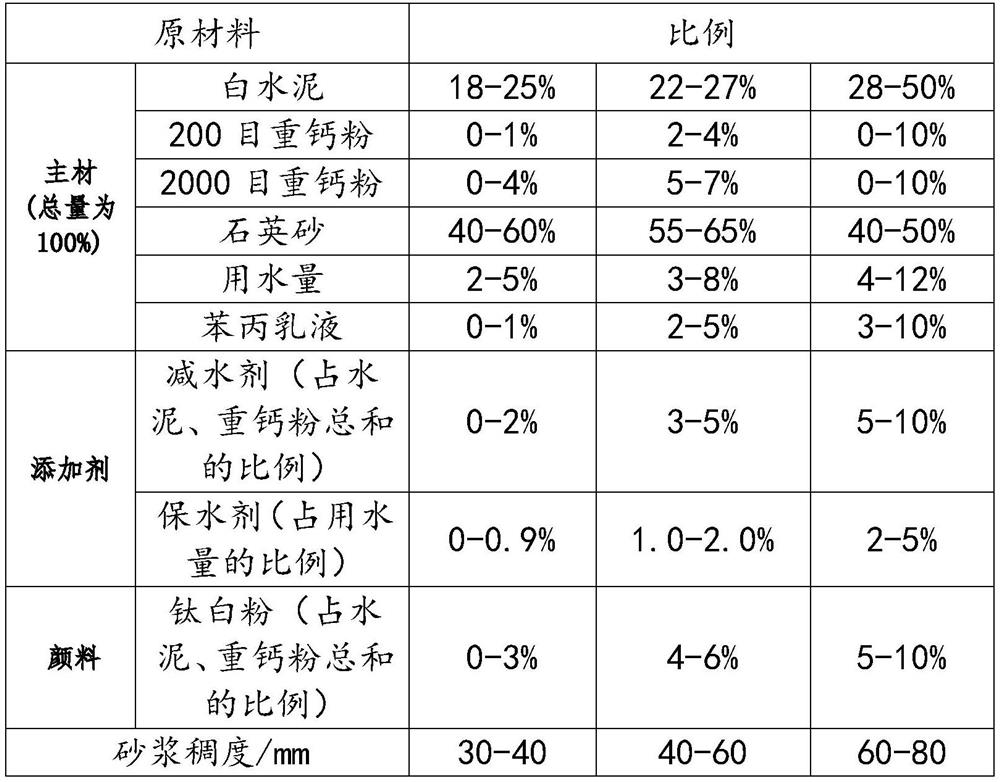

A kind of snowflake white inorganic artificial stone raw material formula and preparation method

ActiveCN111574147BNo need for calcinationReduce energy consumptionCeramic shaping apparatusArtificial stoneInorganic materials

The invention discloses a snowflake white inorganic artificial stone raw material formula and a production method, which belong to the field of decorative materials. The raw material formula consists of 22-27% of white cement, 7-11% of heavy calcium powder, 55-65% of quartz sand, and 3-3% of water. 8% and styrene-acrylic emulsion 2‑5%. The present invention uses inorganic materials such as cement to make snowflake white marble, prepares two kinds of mortar, and controls the consistency of the mortar to be 40-60mm for the white base material and 65-80mm for the gray grain material, and then add pigments and fabricate twice to complete the production , so that the surface texture of the board is similar to that of natural snowflake white marble; other properties of the board: bending strength > 18MPa, compression strength > 120MPa, water absorption < 0.5%.

Owner:深圳市润丰新材料科技有限公司

Adhesive as well as preparation method and application thereof

ActiveCN112442329ANo smellNo pollution in the processNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyurethane dispersionPolymer science

The invention relates to an adhesive as well as a preparation method and application thereof. The adhesive is prepared from the following components in parts by weight: 94-99.5 parts of waterborne polyurethane dispersion, 0.5-5 part of a wet adhesion promoter, 0.03-0.08 part of a defoaming agent, 0.1-0.3 part of a wetting agent and 0.1-1 part of a thickening agent; the hydroxyl content of the waterborne polyurethane dispersion is 3-5mgKOH / g, and the molecular weight of the waterborne polyurethane dispersion is 150000-250000 Daltons; the wet adhesion promoter is alcohol ether, alcohol ether ester or polyoxyethylene polyoxypropylene polyether which has a destabilization effect on an polyurethane emulsion and has a plasticizing effect on an adhesive film. The water-based adhesive disclosed bythe invention is suitable for being applied to composite edge folding of luggage leather products, vamps, furniture mattresses and the like which are rapidly shaped.

Owner:WANHUA CHEM GRP CO LTD +2

Cast iron enamel burner and preparation process thereof

ActiveCN101962772BSimple preparation processEnamelling effect is completeGaseous fuel burnerCast ironOpen fire

The invention relates to a cast iron enamel burner and a preparation process thereof. According to the high-temperature resistant cast iron burner of an enameled household stove and the preparation process thereof provided by the invention, enamel coating layers are sprayed in the cavities and on the outer surfaces of parts of the burner such as a fire cover, a burning tray, an ejector and the like according to the use requirements and the type of the burner respectively, and the coating layers have oxidation resistance and enhance the acid and alkali resistance, ageing resistance and rust resistance of the outer surfaces of the parts. When the enamel burner is used in a working environment of far higher than 600 DEG C, even burnt in open fire, the enamel burner does not become yellow or explode enamel. The enamel burner has the characteristics of resisting acid and alkali, thermal shock, high temperature and impact, containing no harmful elements to the human body and the like.

Owner:ZHEJIANG CONNAL ELECTRIC APPLIANCE CO LTD

Solvent-based light oil suitable for offset press

InactiveCN103132372BStamping adaptability and stabilityThere will be no problem of incomplete bronzingPaper coatingCoatingsHot stampingVitrification

The invention discloses solvent-based light oil suitable for an offset press. The solvent-based light oil comprises the components by weight percent of: 13-18% of primary connecting material resin, 6-10% of auxiliary resin, 65-80% of a solvent, 4-6% of an auxiliary solvent and 0.5-1% of an auxiliary agent. The Lower glass transition temperature can be obtained after the solvent-based light oil is dried compared with that by using UV (ultraviolet) light oil in the prior art; the solvent-based light oil is stable in the aspect of hot stamping adaptability; the problem of incomplete hot stamping is not generated; the matching characteristic of the solvent-based light oil with silk printing ink after the solvent-based light oil is applied to the offset press can be improved, and the deinking possibility is reduced due to the fact that the resin with low UV tension is selected by the solvent-based light oil.

Owner:SHENZHEN KECAI PRINTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com