Polyurea resin compound and hardener

A technology of polyurea resin and composition, applied in the field of polyurea resin composition and curing agent, can solve the problems of long time and excessive curing time, and achieve the effect of high curing reaction rate and realizing curing reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

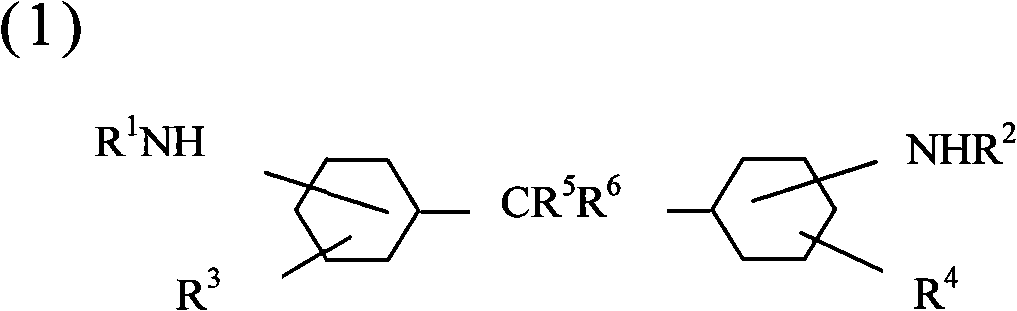

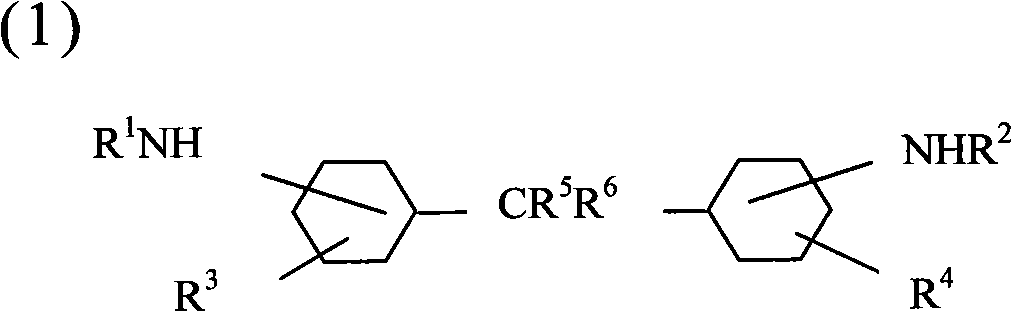

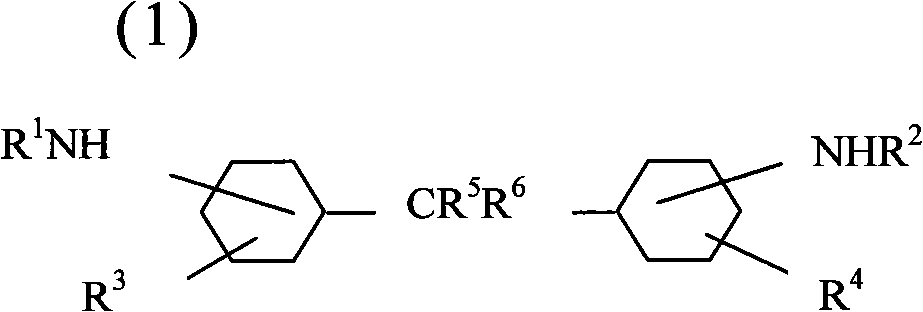

Method used

Image

Examples

Embodiment 1

[0091] 100.0 parts by mass of the alicyclic polyisocyanate prepared above and 88.7 parts by mass of a curing agent were mixed using a planetary centrifugal mixer (AWATORI RENTAROAR-100, manufactured by Thinky Co.). These components were mixed at a room temperature of 25°C and a humidity of RH50±10% for a total of 1 minute consisting of a stirring mode for 0.5 minutes and a defoaming mode for 0.5 minutes, thereby obtaining a polyurea resin composition. The viscosity of the polyurea resin composition immediately after production was measured by the method described below, and the pot life was evaluated. The results are shown in Table 1.

[0092] The polyurea resin composition thus obtained was poured into a frame having a height of 2 mm mounted on a polypropylene plate (thickness: 3 mm), and formed into a 2-mm thick sheet. The sheet was left to stand at 25° C. and RH 50% for 7 days. The hardness of the sheet thus obtained was measured as described below. The results are shown...

Embodiment 2-4

[0113] (embodiment 2-4, comparative example 1-4)

[0114] A polyurea resin composition was prepared in the same manner as in Example 1 except that the polyisocyanate, curing agent, and ketimine or aldimine were changed to those listed in Tables 1 and 2. Tablets were prepared and evaluated using these compositions. The results are shown in Tables 1 and 2.

[0115] (Table 1)

[0116]

[0117] (Table 2)

[0118]

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com