Patents

Literature

67results about How to "No need for calcination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multi-element composite nano-material, preparation method thereof and application thereof

ActiveCN103117175AComponents are easy to controlImprove stabilityHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceHigh energy

The invention provides a multi-element composite nano-material for a super capacitor, and a preparation method of the nano-material. The nano-material comprises a carbon material, metal oxide and conducting polymer, and components of the nano-material can be two or more than two materials. By the aid of the characteristics such as fine electrical conductivity, long cycle life and high specific surface area of the carbon material, high pseudo-capacitance of the metal oxide and low internal resistance, low cost and high operating voltage of the conducting polymer, different types of electrode materials generate synergistic effects, advantages are mutually combined, shortcomings are mutually weakened, the energy storage characteristics of an electric double-layer capacitor and a pseudo-capacitor are simultaneously made full use of, a composite electrode material with high power density, fine circulating stability and higher energy density is prepared, and the multi-element composite nano-material is excellent in comprehensive performance when used for an electrode of the super capacitor, has the advantages of simple preparation process, short cycle, low cost and the like, and is suitable for large-scale industrial production.

Owner:中科(马鞍山)新材料科创园有限公司

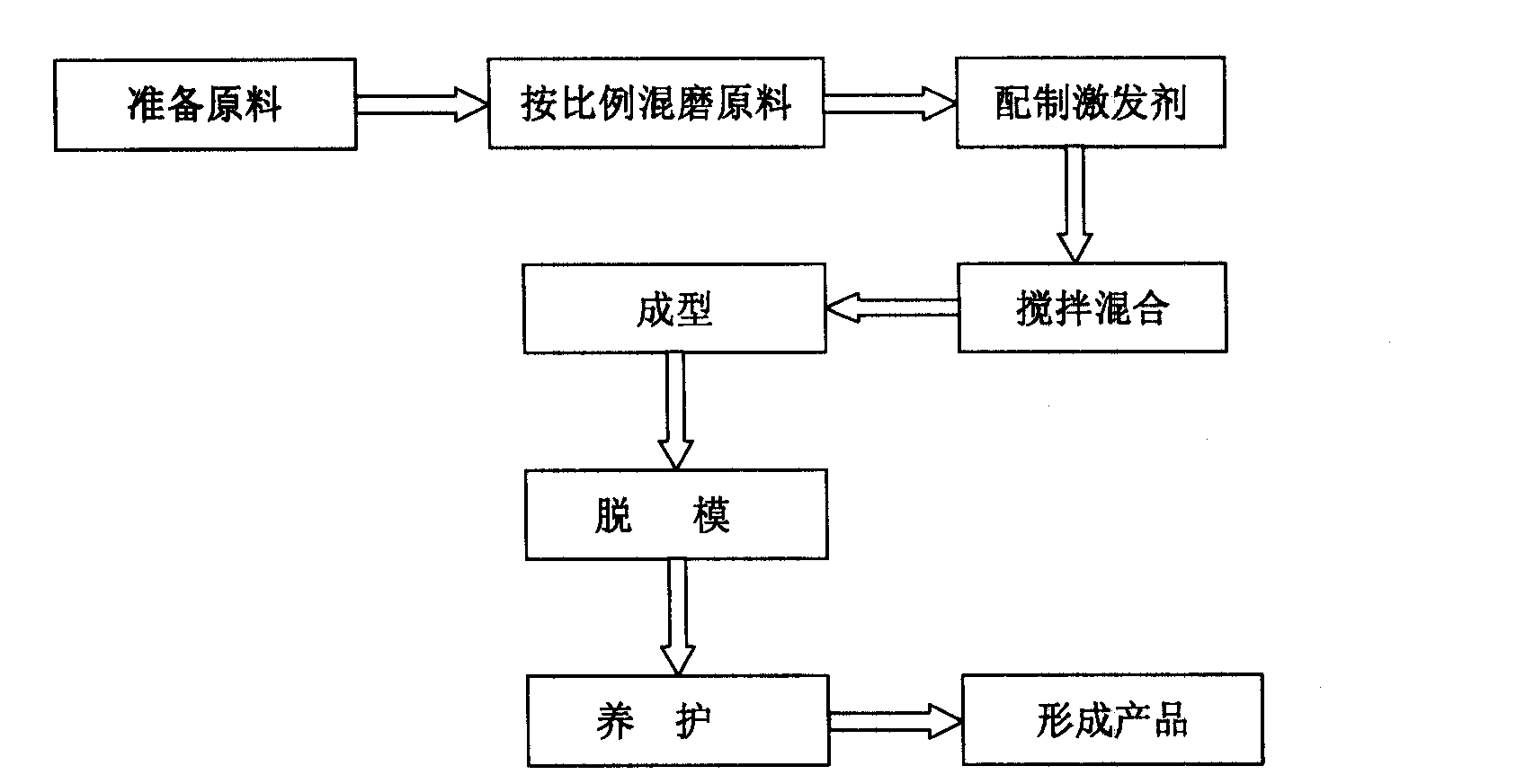

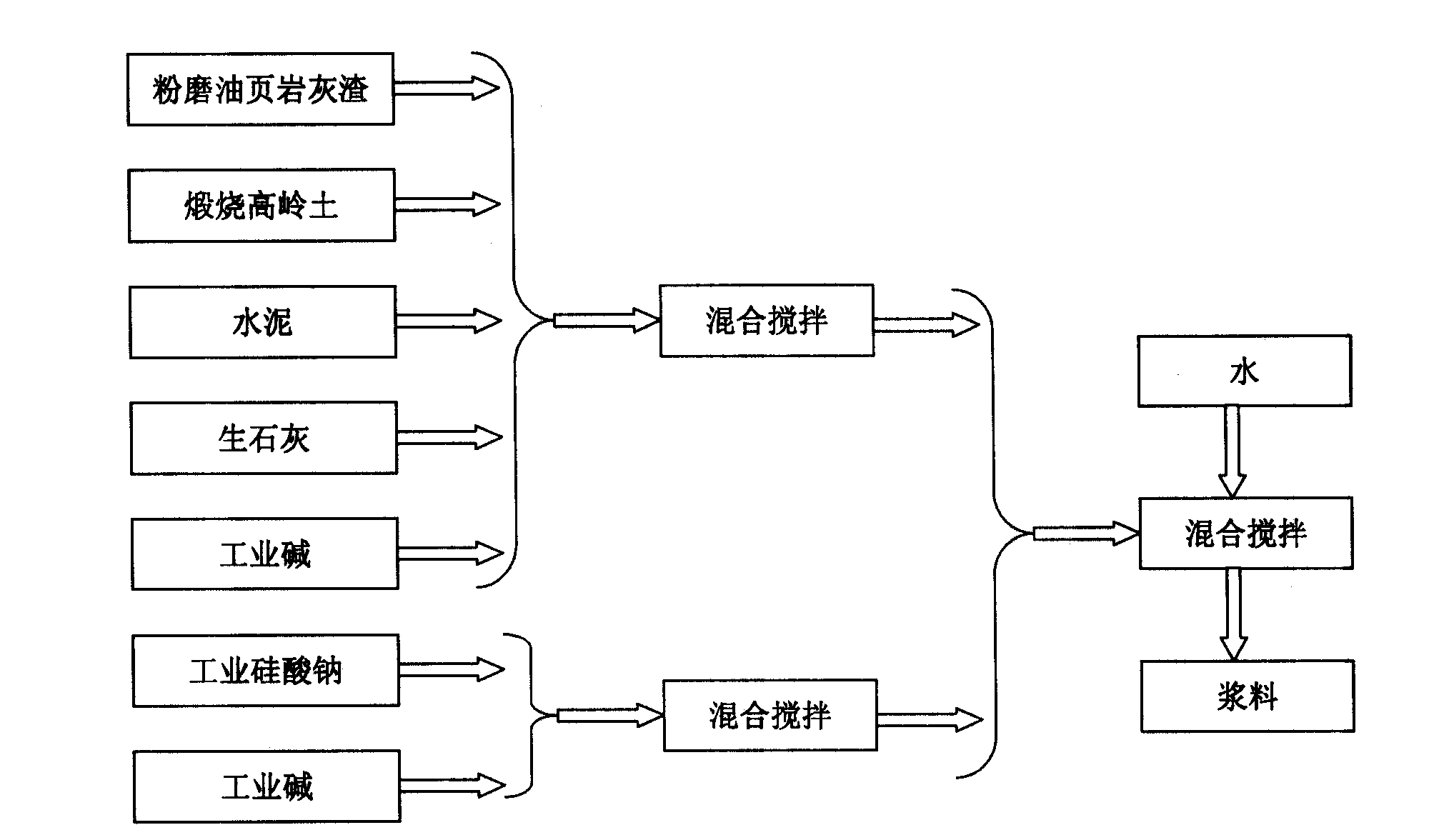

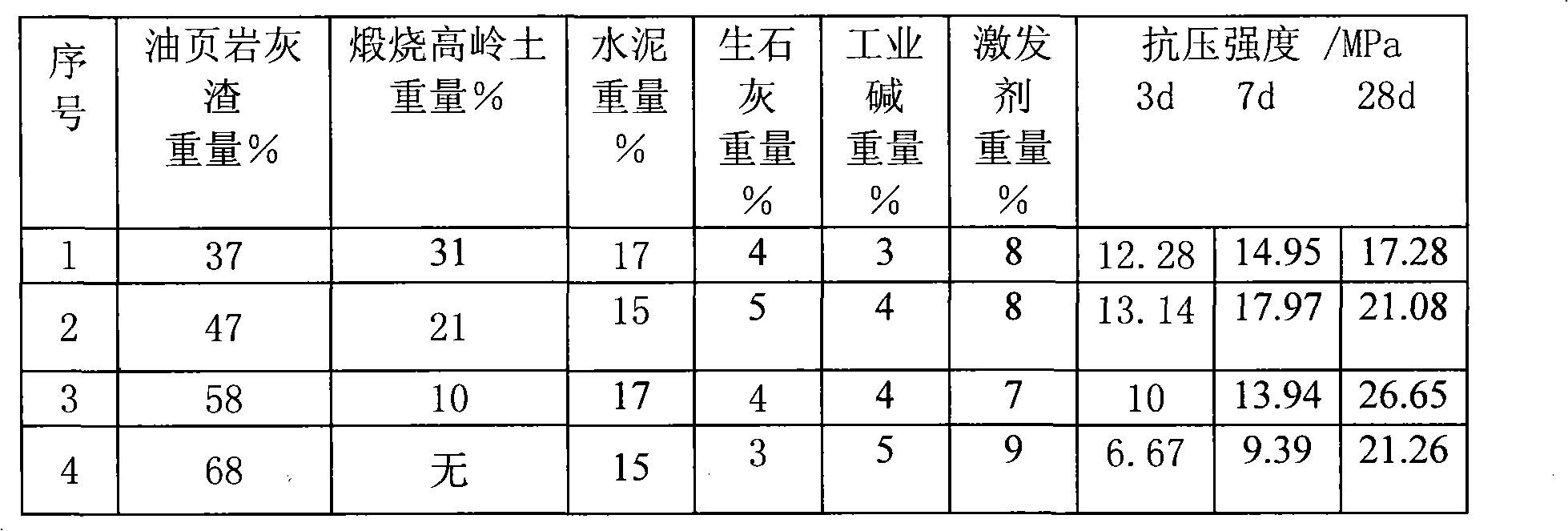

Wax shale gray slag base polymer gelled material

The invention relates to a cementing material of an oil shale clinker matrix polymer and a preparation method thereof, and belongs to the field of environment-friendly materials. The cementing material comprises the following components in percentage by weight: 30 to 70 percent of oil shale clinker with the particle diameter of 200 meshes, 0 to 70 percent of low-temperature calcined kaolin with particle diameter of 200 meshes, 0 to 10 percent of calcium lime with the fineness of 150 meshes, 5 to 30 percent of P32.5 cement, and 5 to 10 percent of exciting agent, wherein the exciting agent is a mixed solution of industrial sodium silicate of which modulus M is 3.3 and industrial alkali. The cementing material can replace the prior cementing material gypsum and cement, and is suitable for manufacturing stone imitated artworks, embossing wall bricks, sculptures and ground tiles for building decoration and products such as hollow bricks, light bricks, and the like for building materials. The cementing material has low cost and performance superior to the prior material.

Owner:FUSHUN MINING IND GROUP

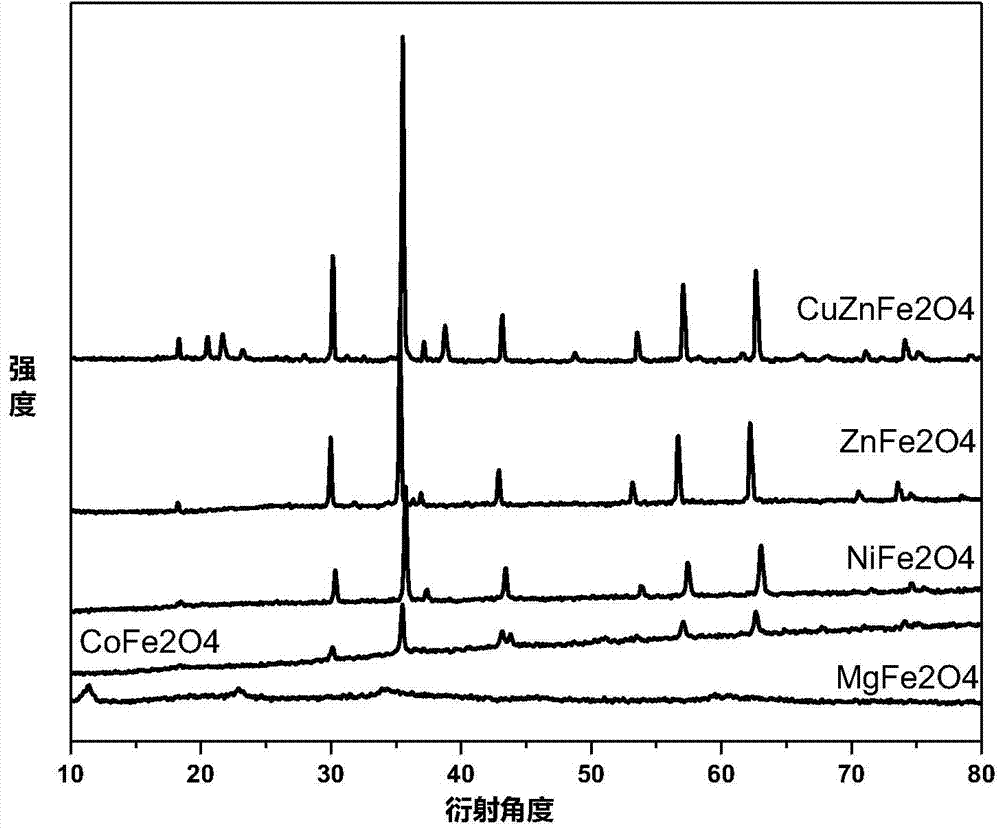

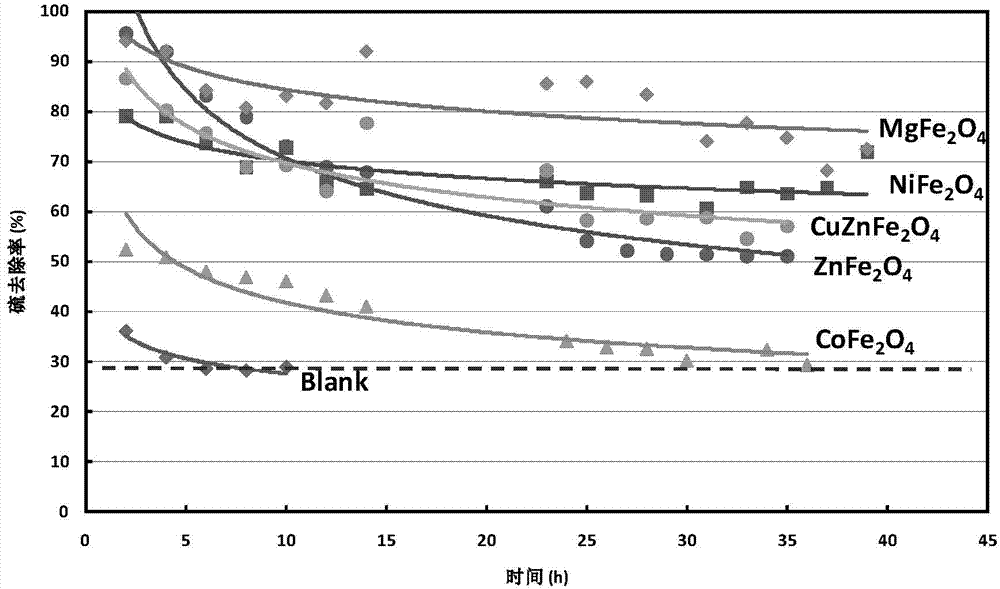

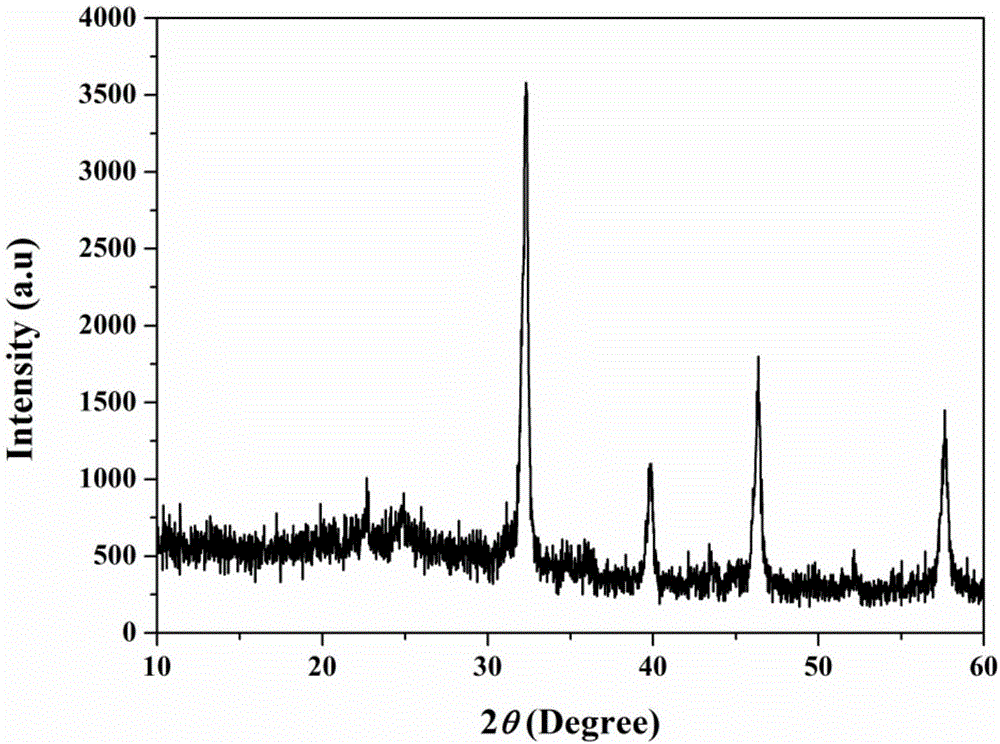

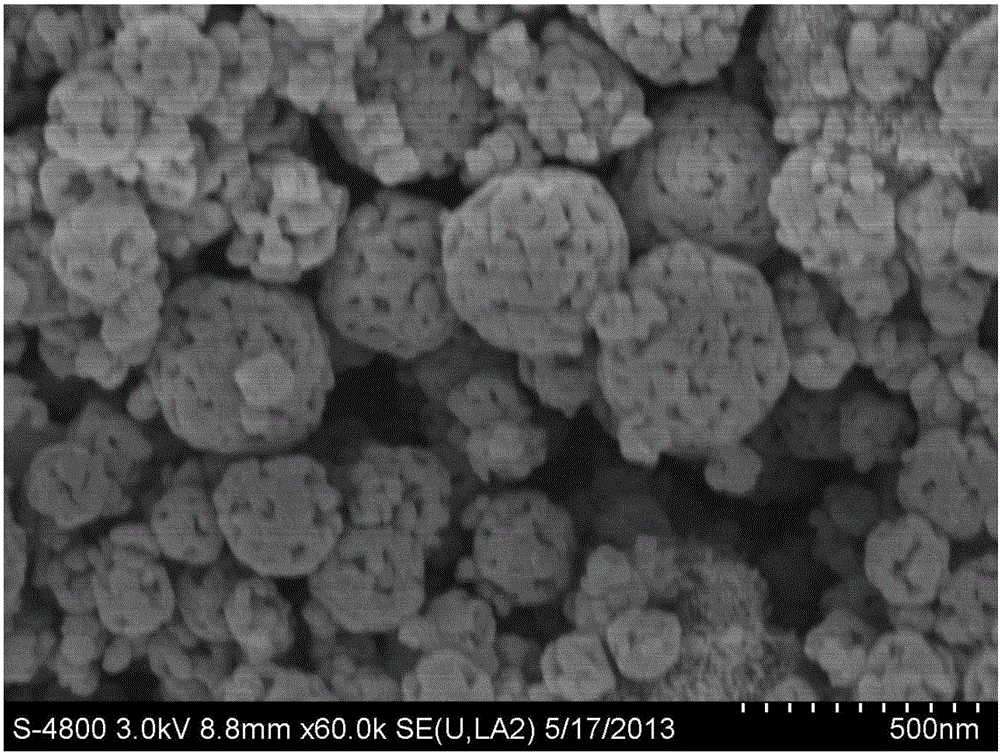

Novel nano ferrite adsorption desulfurization catalyst and preparation method thereof

InactiveCN104741123AHigh desulfurization selectivityRealize deep desulfurizationHydrocarbon oils refiningMetal/metal-oxides/metal-hydroxide catalystsFuel oilPetroleum

The invention belongs to the technical field of fuel processing and petroleum chemical engineering, and relates to a novel nano ferrite adsorption desulfurization catalyst MeFe2O4, wherein Me comprises but not the same with Mg, Zn, Ni, Co and Cu. The preparation method comprises the following steps: dissolving transition metal nitrate, Fe-containing nitrate and fuels in water, heating the obtained solution in a microwave furnace rapidly, decomposing so as to generate a great quantity of combustible gases and emit a great amount of heat, and combusting reactants reaching the spontaneous ignition point; and reacting so as to obtain a solid material, namely the novel nano ferrite adsorption desulfurization catalyst. The novel nano ferrite adsorption desulfurization catalyst is relatively high in desulfurization selectivity, can prevent the loss of octane value and cetane value due to olefins hydrogenation while deeply removing sulfocompound in fuel oil, and has relatively good industrial application prospect.

Owner:DALIAN UNIV OF TECH +1

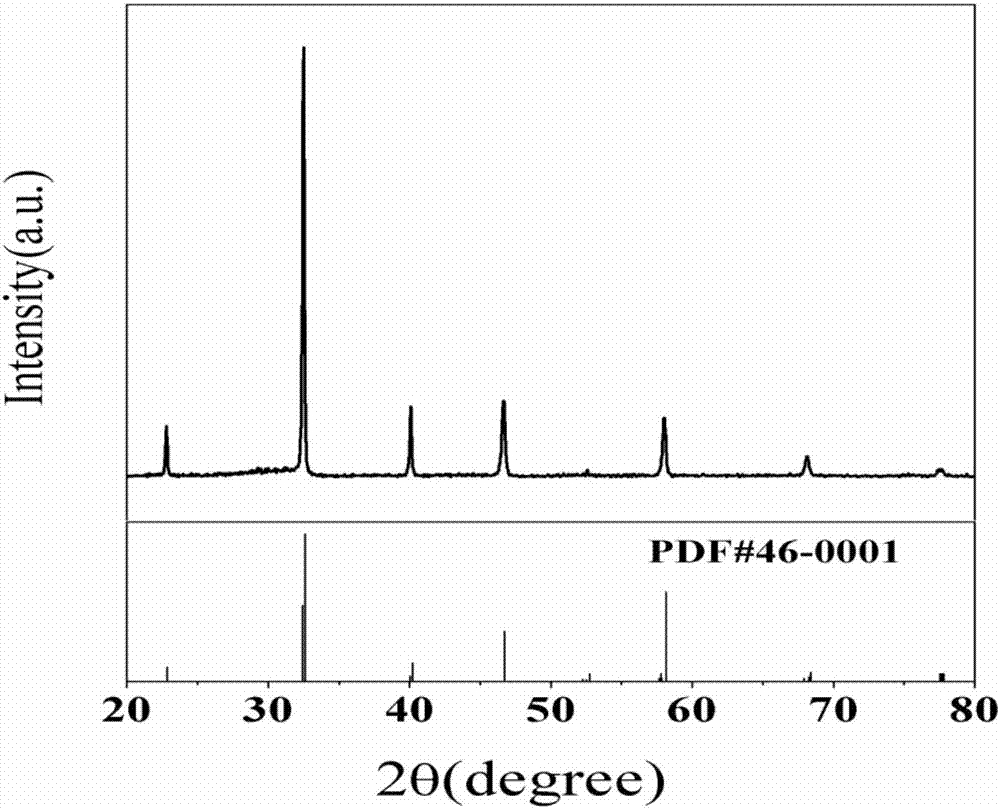

Low-temperature preparation method of morphology-controllable zinc oxide nano materials

InactiveCN104229864AThe size is easy to controlGood dispersionMaterial nanotechnologyZinc oxides/hydroxidesEmulsionAlcohol

The invention relates to a preparation method of morphology-controllable zinc oxide nano materials. The preparation method comprises the following steps: adding 0.01-0.2mol / L of a surfactant into an alcohol-aqueous solution with a volume ratio of 5 to 1, quickly stirring the solution at 20-100 DEG C to uniformly mix the solution; then, weighing and dispersing 0-0.2mol / L of a stabilizer and a zinc source into micro emulsion respectively; preparing 0.1-0.6mol / L of alkali liquor, adding the alkali liquor into zinc source micro emulsion at a speed of 2-3 days / second, continuously stirring for 20 minutes at 20-100DEG C; standing for 2-12 hours after the reaction is ended, washing precipitation products and drying the washed precipitation products to obtain zinc oxide nano material products with different morphologies. According to the preparation method disclosed by the invention, the process and the flow are simple and convenient, the adjustable range of the parameters is wide, the product size is controllable, the dispersion is good, the repeatability is good, the cost is low, the calcination is not needed, low carbon and environment-friendliness can be achieved, and various nano zinc oxide products with different morphologies can be prepared at the normal temperature or a low temperature.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

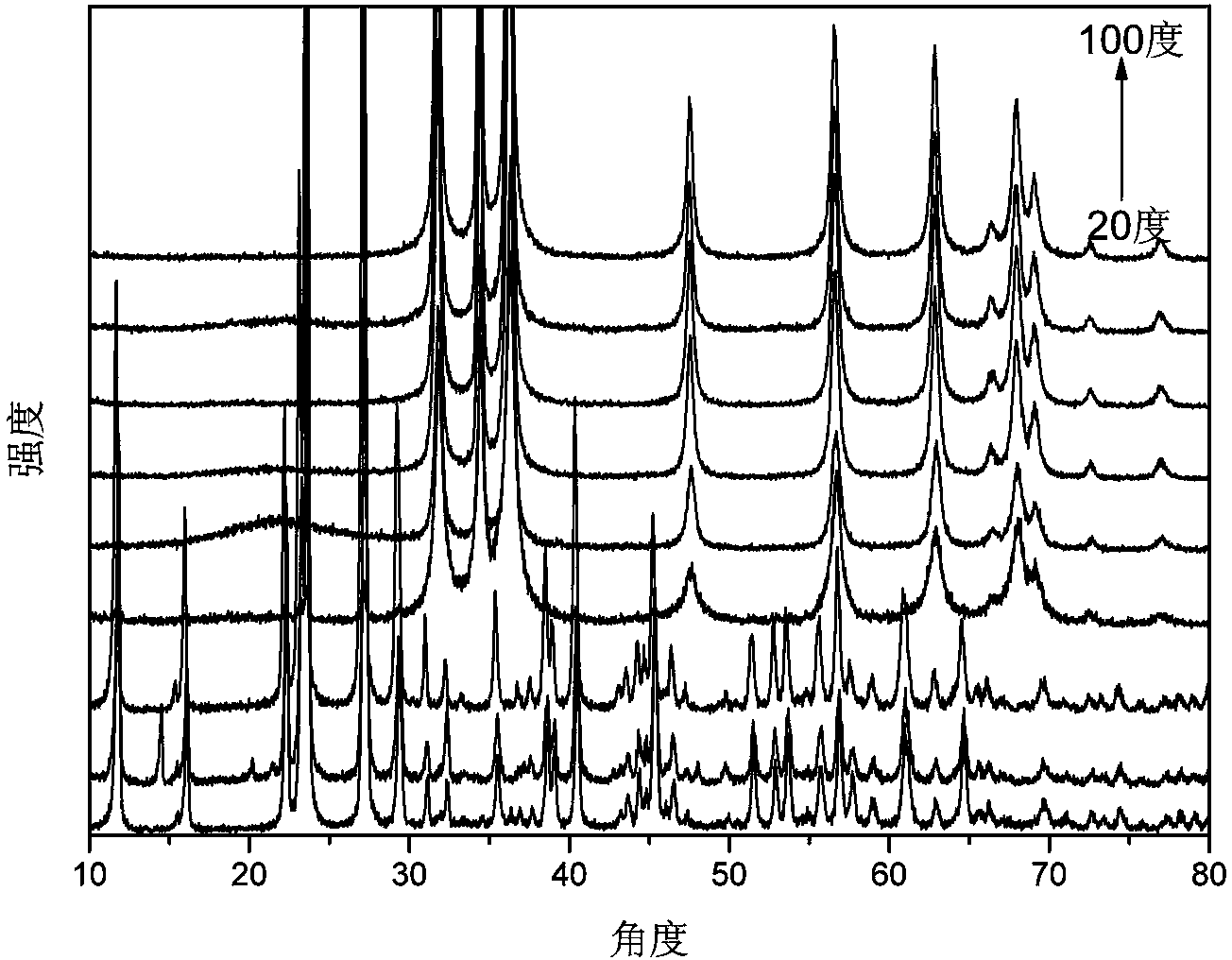

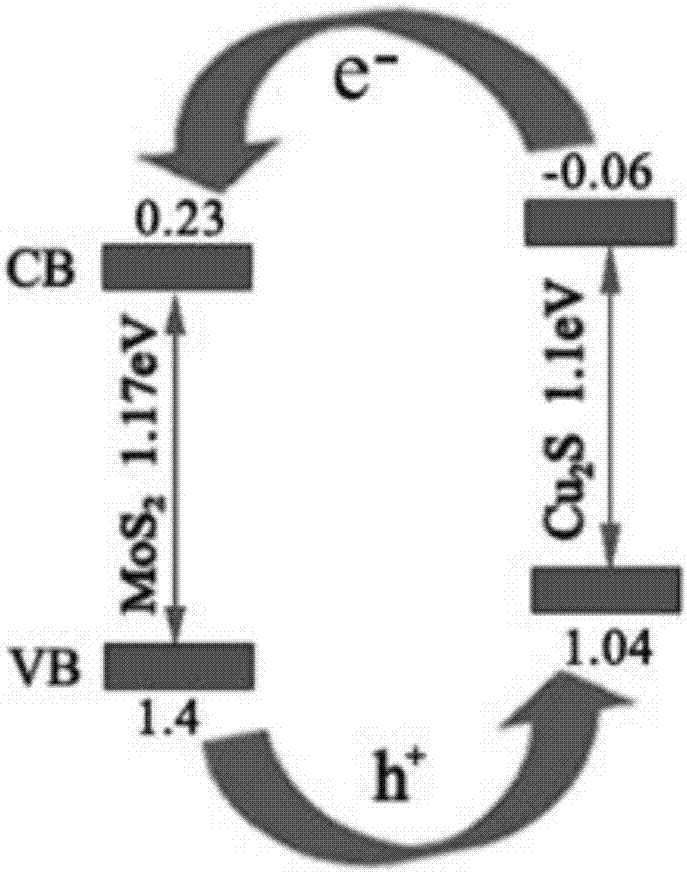

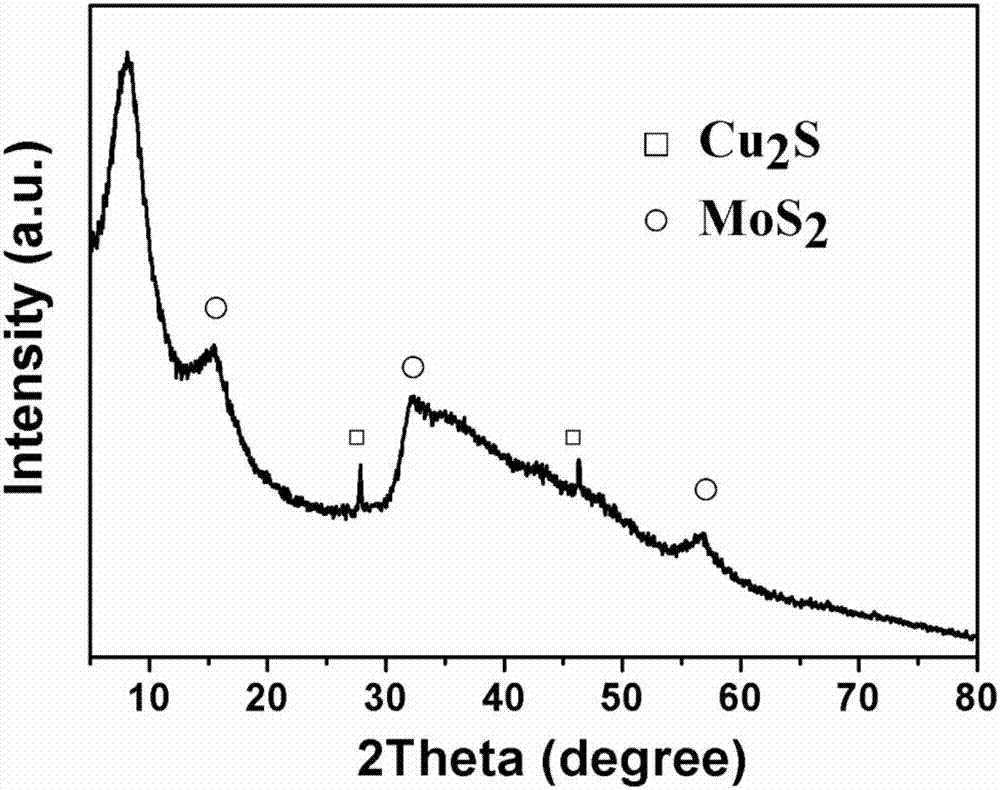

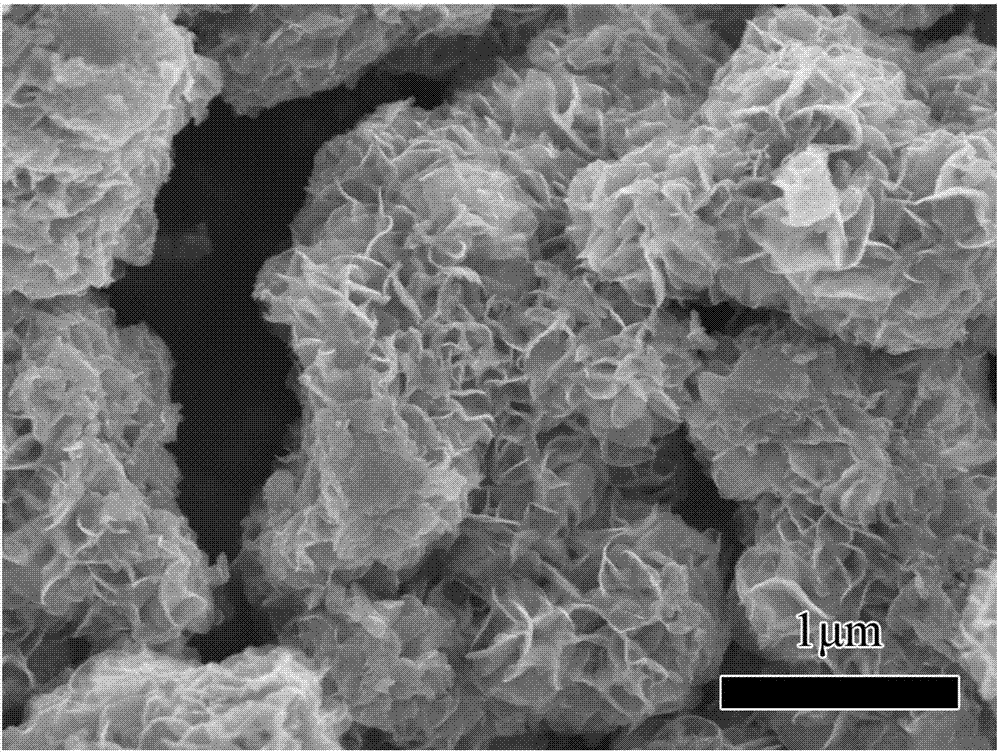

Hierarchy MoS2/Cu2S composite material and preparation method thereof

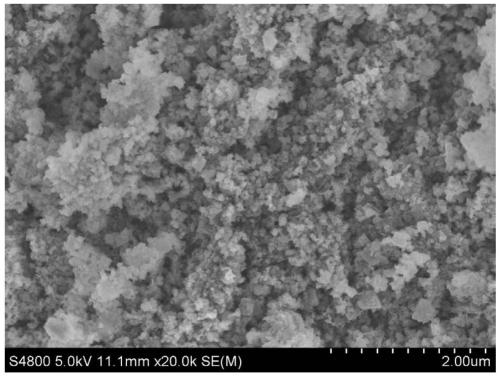

InactiveCN107262116AEffective compoundGood photocatalysisMaterial nanotechnologyCatalyst activation/preparationElectricityMicro nano

The invention discloses a hierarchy MoS2 / Cu2S composite material. The hierarchy MoS2 / Cu2S composite material is a micro-nano sphere with a flower-like structure formed by assembling MoS2 nanosheets and Cu2S nanosheets and is obtained by carrying out hydrothermal reaction on a molybdenum source, a sulfur source, a copper source and a reducing agent which serve as raw materials. The MoS2 / Cu2S composite material disclosed by the invention is prepared by using a hydrothermal method, and has the advantages of wide source of the related raw materials, low cost, simple and feasible technology and high yield; the difficult point that MoS2 is difficultly compounded with other materials at present can be solved; besides, the problem of low conductivity of the MoS2 in the catalytic reaction process also can be solved; the obtained composite material shows excellent photocatalytic performance and excellent electrocatalytic performance and is suitable for being popularized and applied.

Owner:WUHAN UNIV OF TECH

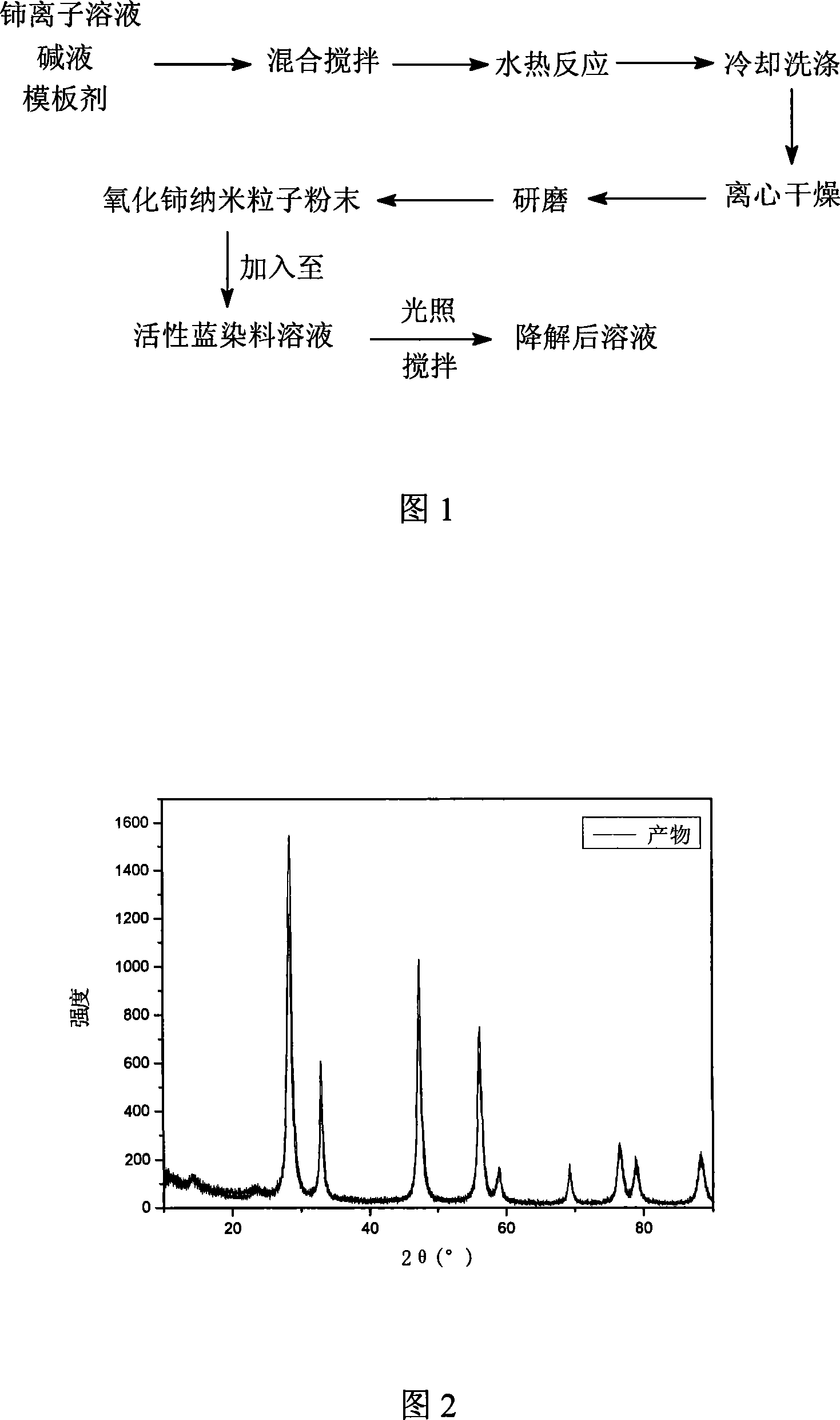

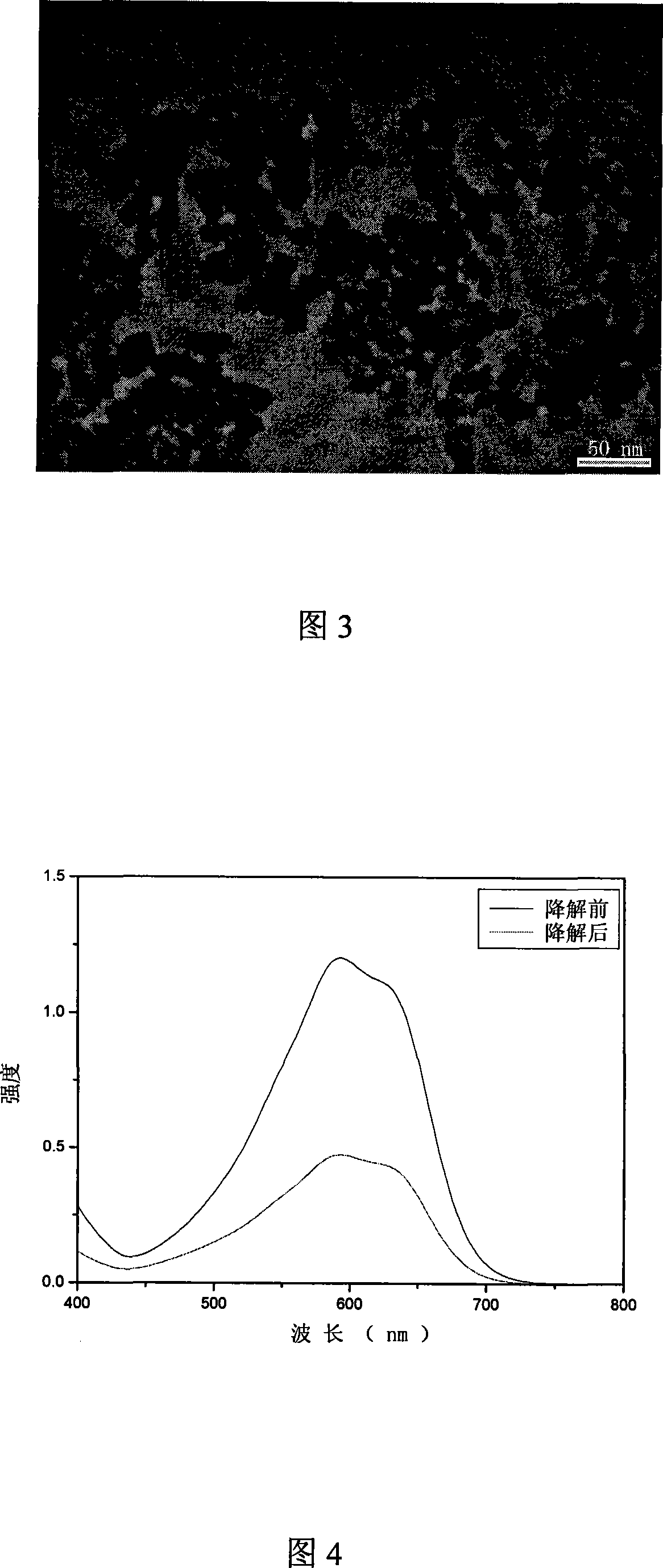

Method for degrading dyeing waste water by using cerium oxide nano particle as catalyst

InactiveCN101125704ASimple preparation processHigh product purityWater/sewage treatment by irradiationRare earth metal compoundsChemistryNanometre

A method for degrading dye waste water with ceria nano particles as catalyst pertains to the application technical field of ceria nano particles. The invention is characterized in that: firstly, powder of ceria nano particles is produced with a hydro-thermal method; secondly, the powder of ceria nano particles is added into activated blue dye waste water to degrade the activated blue dye waster water by illumination. The preparation technique of the catalyst of the invention is simple without calcinations or load, thereby, the purity of the product is high; the operation technique of the degradation is simple with easily controlled conditions and rapid degradation speed and the reaction can be taken placed by illumination under normal temperature and atmosphere, thereby being energy conservation.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing gold nano particle modification zinc oxide

InactiveCN101670288AEvenly dispersedEasy to makeWater/sewage treatment by irradiationEnergy based wastewater treatmentOrganic solventTetramine

The invention relates to a method for preparing gold nano particle modification zinc oxide for processing sewage in environmental protection. The method comprises the following steps: (a) stirring a zinc salt solution and a sextic methyl tetramine solution evenly, wherein the proportion of the quantity of the zinc salt solution and the sextic methyl tetramine solution substance is 1:1-4; (b) adding a gold salt solution into mixed liquid A of the zinc salt solution and the sextic methyl tetramine solution and stirring evenly, wherein the proportion of the quantity of the gold salt solution andthe zinc salt solution substance is 1:100-1000; (c) transferring mixed liquid B of the zinc salt solution, the sextic methyl tetramine solution and the gold salt solution into a reaction kettle with the reaction temperature of 80-180 DEG C and reacting for 2-24 hours; and (d) after cooling to the normal temperature naturally, separating the mixed liquid B after reacting, washing and drying. The invention has simple preparation method, and adopts no strong acid, strong alkali and organic solvents; and compared with other preparation methods, the invention has the advantages of no environmentalpollution, no calcination and the like.

Owner:SHANGHAI INST OF MEASUREMENT & TESTING TECH

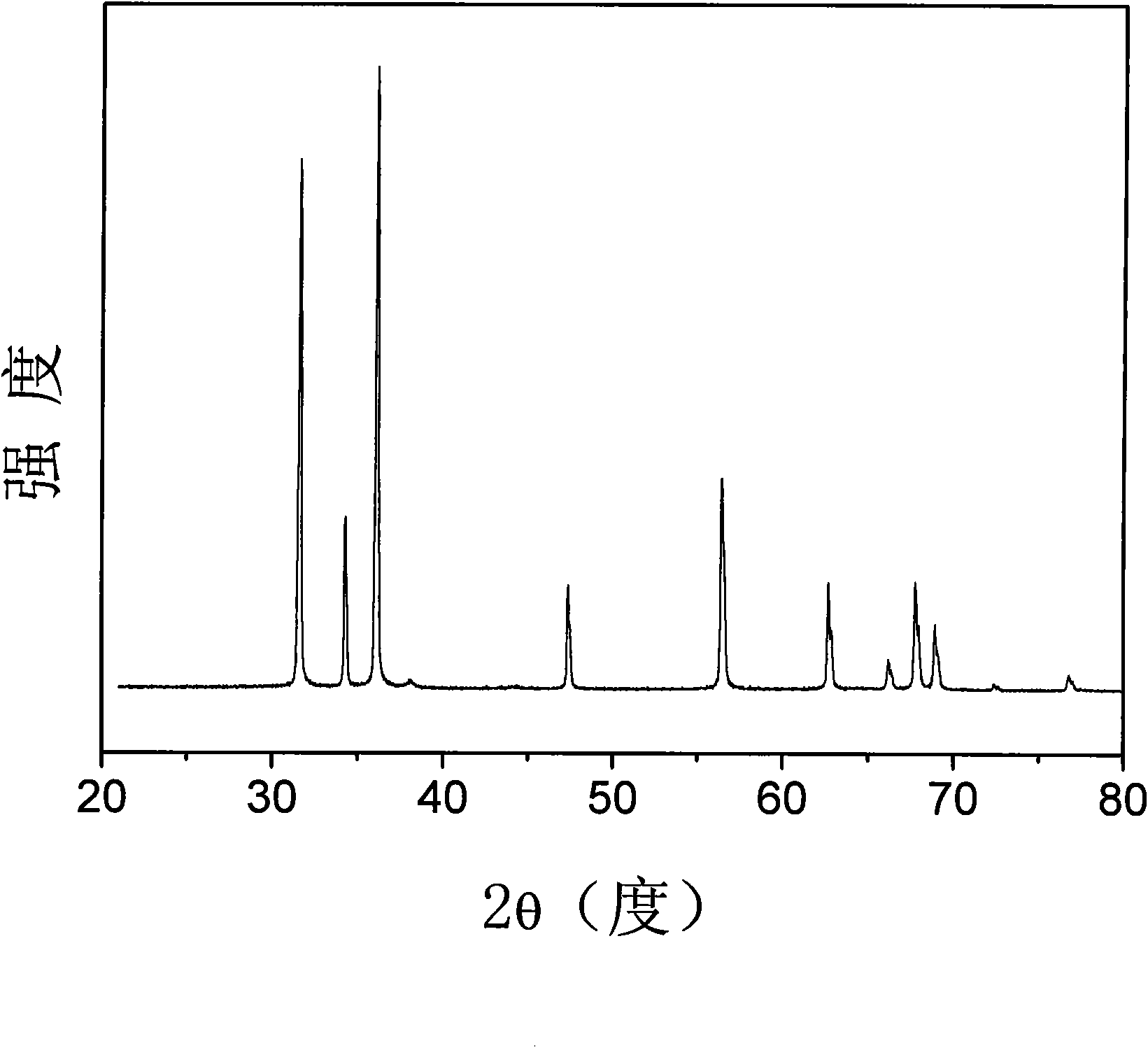

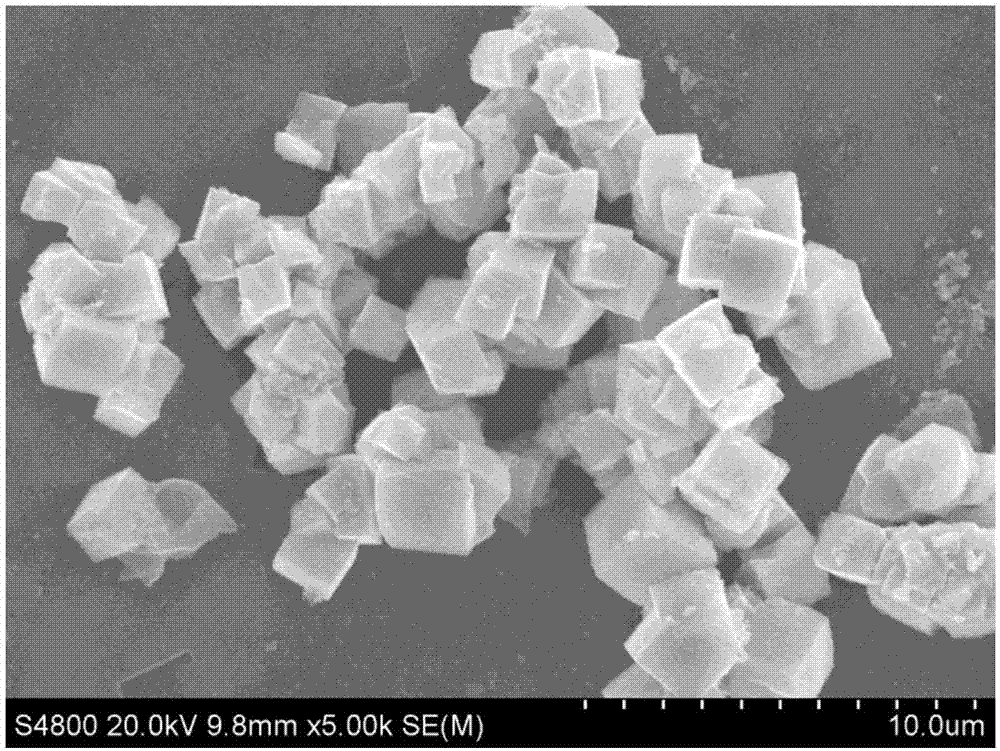

Method for quickly preparing cubic sodium bismuth titanate at low temperature

The invention provides a method for quickly preparing cubic sodium bismuth titanate at low temperature. The method comprises the following steps that firstly, a NaOH clear solution with the concentration of 10-16 mol / L is prepared; secondly, a Bi(NO3)3 5H2O solution at the concentration of 0.1-0.2 mol / L is prepared, and a clear solution A is obtained; thirdly, Ti(OC4H9) is dropwise added into the clear solution A, and a mixed solution B is obtained after stirring; fourthly, the NaOH clear solution is dropwise added into the mixed solution B and stirred and mixed evenly, and a Na0.5Bi0.5TiO3 precursor solution is obtained; fifthly, the Na0.5Bi0.5TiO3 precursor solution is subjected to a microwave hydrothermal reaction; sixthly, after the microwave hydrothermal reaction is finished and the reaction product is cooled to the room temperature, sediment obtained after the reaction is washed, dried at a constant temperature and screened, and then the cubic Na0.5Bi0.5TiO3 powder is obtained.

Owner:SHAANXI UNIV OF SCI & TECH

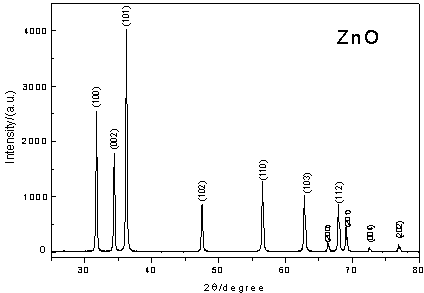

Method for preparing monodisperse spherical nano ZnO

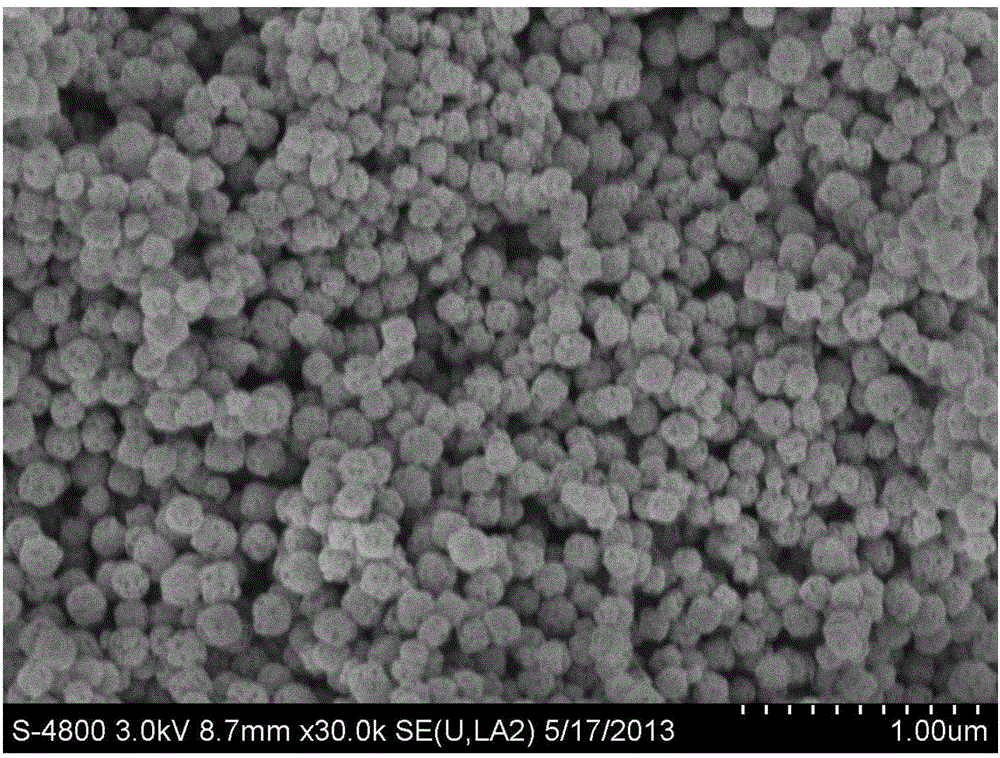

InactiveCN103482681AThe materials are cheap and easy to getNo need for calcinationMaterial nanotechnologyZinc oxides/hydroxidesWater bathsDispersity

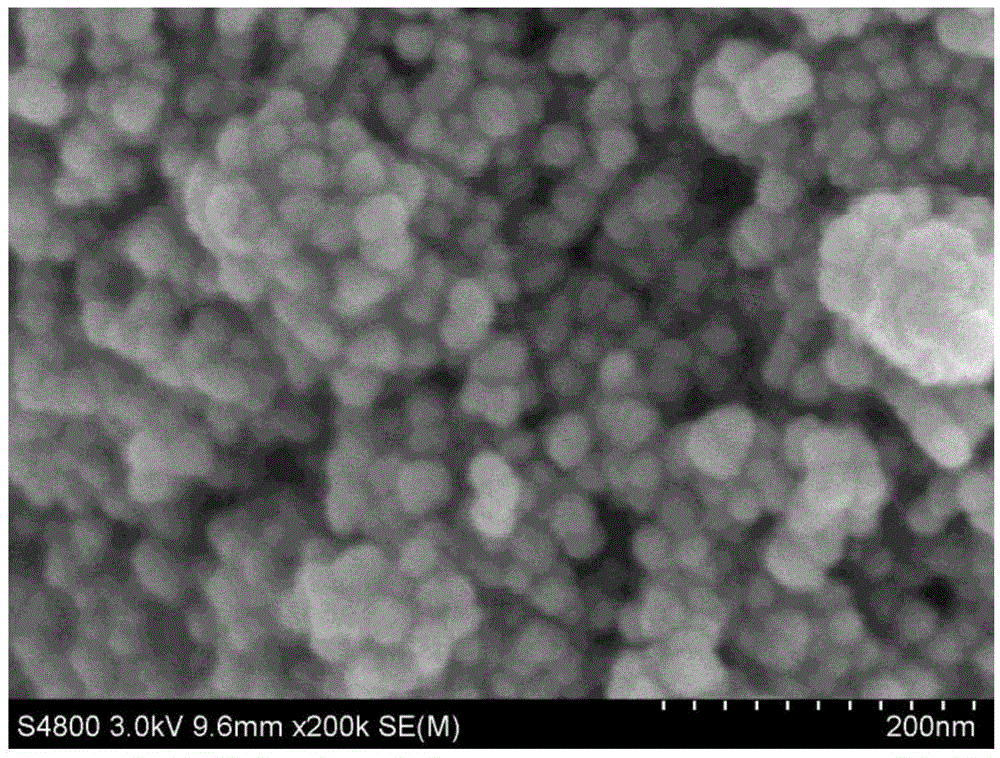

The invention belongs to the field of semiconductor inorganic materials, and particularly relates to a method for preparing monodisperse spherical nano ZnO. The method particularly comprises the following steps: weighing and dissolving PEG-6000 in distilled water, adding 0.75g of PEG-6000 per 1 ml of distilled water, heating and stirring to enable the PEG-6000 to be completely dissolved; mixing the PEG-6000 solution with 0.4 M of a zinc salt solution, heating in water bath at the temperature of 95 DEG C, and stirring at the same time so as to enable the solutions to be fully mixed; weighing 4 M of a NaOH aqueous solution, adding the aqueous solution into the mixed solution quickly, stirring fiercely at the same time, performing constant temperature bath at the temperature of 95 DEG C, and continuously stirring for 2-4 hours; cooling the mixture to the indoor temperature after completion of reaction, filtering, washing by adopting ethyl alcohol and distilled water, and placing the obtained mixture into a drying oven for drying so as to obtain white ZnO powder. The method has the advantages that the zinc salt, NaOH and the PEG-6000 are used as the raw materials, a one-step method is adopted to prepare spherical nano ZnO with the particle diameter of 30 nanometers, the ZnO is good in dispersity and narrow in particle size distribution, and the method has the excellent prospect for preparing ZnO voltage-dependent functional materials.

Owner:CHANGZHOU UNIV

Preparation method of porous barium strontium titanate powder

ActiveCN106268612ALow costImprove environmental friendlinessOther chemical processesAlkali metal oxides/hydroxidesMicro nanoDispersity

The invention discloses a preparation method of barium strontium titanate powder of a micro-nano porous structure and especially synthesis of the barium strontium titanate powder of the micro-nano porous structure in the hydrothermal high-temperature mixing state. In the method, two solutions serving as reaction precursors are put in two cavities of a tetrafluoroethylene dual-cavity lining respectively, and mixing high-temperature reaction is conducted when the temperature is raised to 180-220 DEG C. Compared with the prior art, the method has the advantages that no organic foaming agent is used in the reaction process, raw materials are lower in cost, and better environmentally friendliness is achieved; reaction is conducted in a mild hydrothermal environment, no calcining treatment is needed, energy consumption is low, and high stability and repeatability are achieved; the prepared porous barium strontium titanate powder is of the unique micro-nano porous structure, has larger specific surface area and higher stability, has excellent size uniformity and dispersity, and has wide application prospects on the aspects of functional ceramic, catalysis and adsorption.

Owner:南京宇热材料科技有限公司

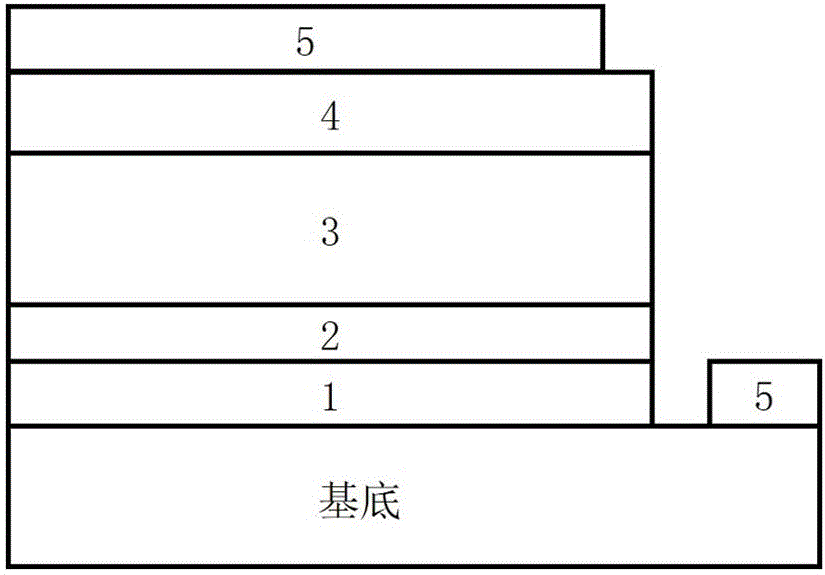

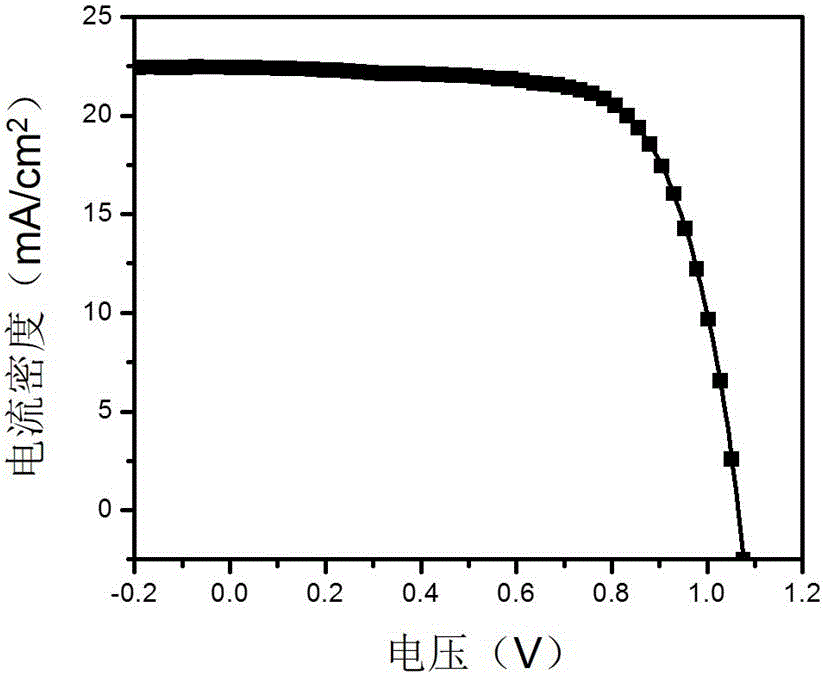

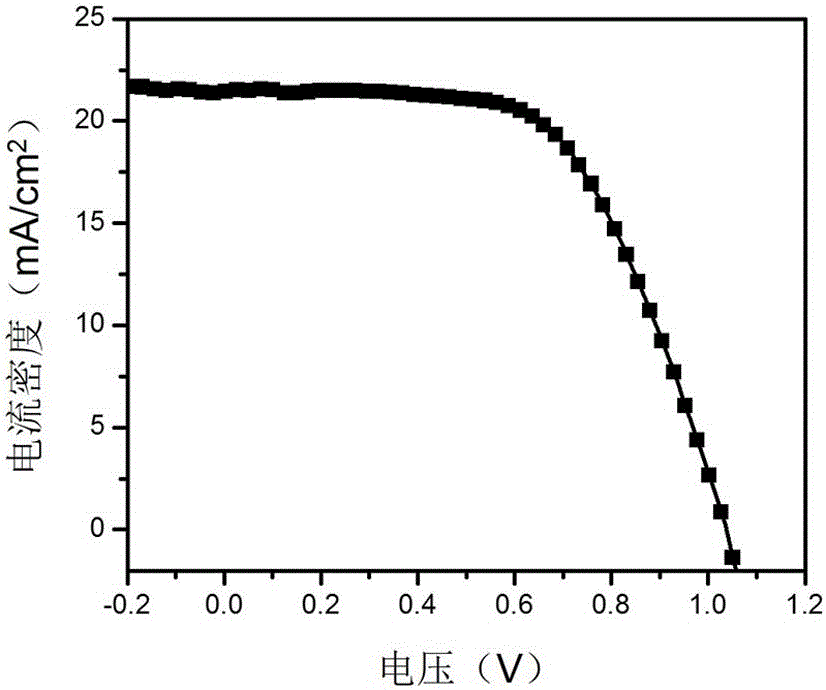

Perovskite solar battery and preparation method thereof

ActiveCN106449989AImprove uniformityGood repeatabilityFinal product manufactureSolid-state devicesPerovskite solar cellRadio frequency magnetron sputtering

The invention discloses a perovskite solar battery and a preparation method thereof. The preparation method comprises the following steps: on a cathode substrate, preparing a niobium oxide film through radio frequency magnetron sputtering at room temperature so as to form an electron transmission layer for transmitting electrons; preparing a perovskite light absorption layer on the electron transmission layer, and furthermore sequentially preparing a hole transmission layer for transmitting holes and an anode for collecting the holes to obtain the perovskite solar battery. The preparation method for preparing a niobium oxide electron transmission layer under the room temperature condition has the characteristics of being simple and controllable in process, and good in uniformity and repeatability of the prepared niobium oxide film, and large-scale production can be achieved; meanwhile, as the electron transmission layer, the niobium oxide film prepared by using a radio frequency magnetron sputtering method under the room temperature condition does not need high-temperature calcinations, so that the whole production process of the perovskite solar battery can be implemented at low temperature (less than or equal to 100 DEG C), and is particularly applicable to a flexible substrate.

Owner:SUZHOU UNIV

Method for extracting vanadium from acid-leaching vanadium solution

The invention discloses a method for extracting vanadium from an acid-leaching vanadium solution. The method comprises the following steps: firstly, carrying out dust removal on the acid-leaching vanadium solution by adopting the technical scheme disclosed in CN104831069A; then, carrying out ammonia-free vanadium precipitation on the acid-leaching vanadium solution subjected to dust removal by utilizing sulfuric acid to obtain polyvanadate precipitates; and dehydrating and drying the polyvanadate precipitates to obtain powdered V2O5. According to the method, for the acid-leaching vanadium solution obtained by vanadium slag calcifying-roasting and diluted acid leaching, after Ca, Mg, Al and Si are removed by a single impurity removal agent, an ammonia-free vanadium precipitation method is adopted to obtain the polyvanadate precipitates; and roasting is not needed after filtering, and powdered V2O5 with grade higher than 98% can be obtained by simple drying. Vanadium loss of an impurity removal process is lower than 0.3%; a vanadium extracting process is simple, an ammonium salt is not introduced, a follow-up roasting and ammonia-removal process is avoided, wall sticking is avoided in a vanadium precipitation process, and a vanadium precipitation rate can be as high as 99%.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Gasification process and preparation method of heavy metal ion adsorbent for gasification process

ActiveCN106955660AReduce concentrationObvious economic advantagesOther chemical processesGasification processes detailsSorbentWastewater

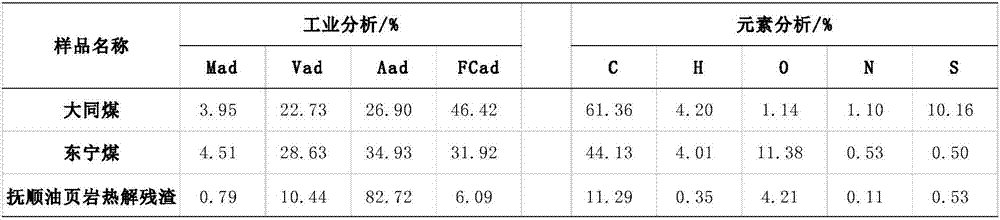

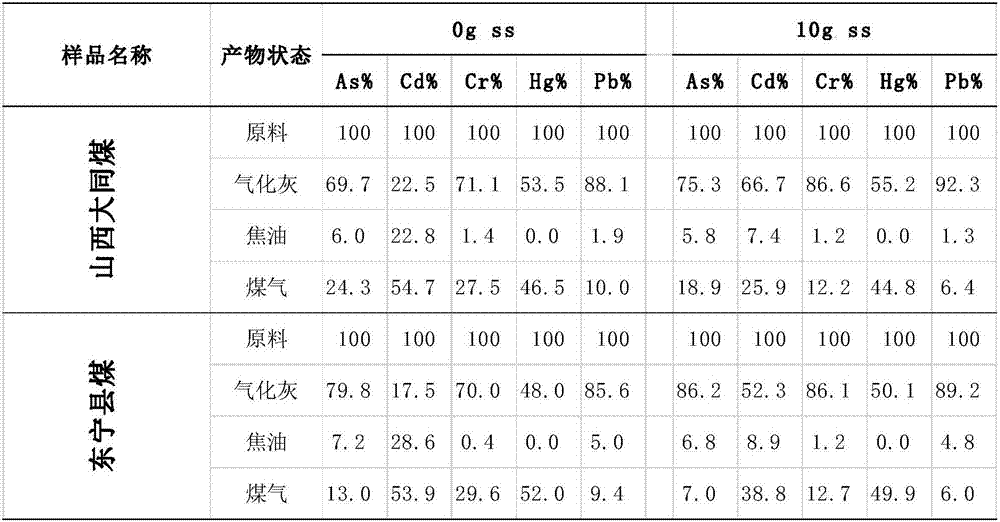

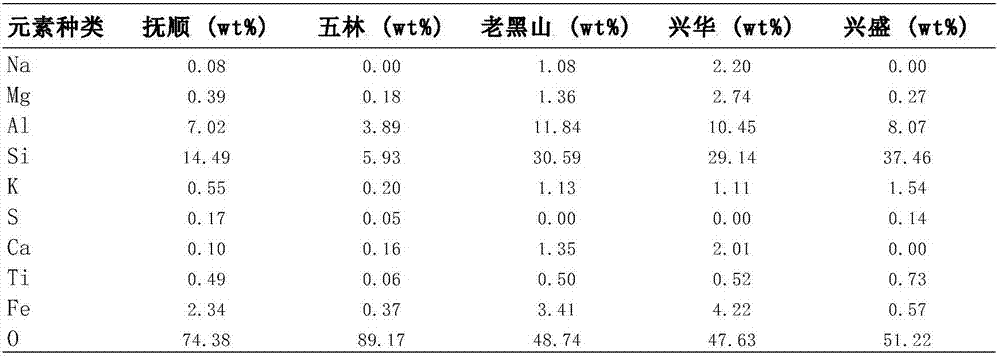

The invention discloses a preparation method of heavy metal ion adsorbent for a gasification process. A raw material of the adsorbent is single or mixed oil shale pyrolysis residue. The method comprises the following steps: (1) recycling various oil shale pyrolysis residues; (2) testing the characteristics of coal and the collected oil shale pyrolysis residues; (3) testing the adsorption capacity of the collected oil shale pyrolysis residues; and (4) obtaining the adsorbent recipes of different coals according to the characteristics of the coal and the adsorption capacity of the collected oil shale pyrolysis residues. The invention further discloses the gasification process. The gasification process comprises the steps of burning, pyrolyzing and gasifying the coal or biomass; the heavy metal ion adsorbent is added in a gasifying furnace in the gasification process, and the heavy metal ion adsorbent is single or mixed oil shale pyrolysis residue. The oil shale pyrolysis residues are used as the solid adsorbent of the gasification process, thereby realizing the integral purification of the organics and the inorganics in the furnace, the pollutant concentration is effectively lowered, the process water and the wastewater pollutant concentration are reduced.

Owner:NINGBO NOTTINGHAM NEW MATERIALS INST CO LTD +1

Fluorgypsum-based plastering material as well as preparation method and application thereof

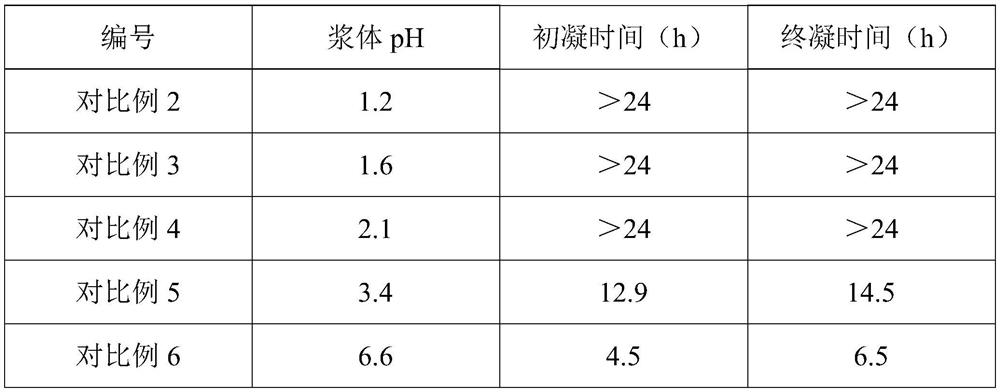

The invention provides a fluorgypsum-based plastering material as well as a preparation method and application thereof. The fluorgypsum-based plastering material is prepared from fluorgypsum, an admixture, aggregate, an expansion inhibitor, an excitant, a water retention thickener and an acid-base regulator. The preparation method comprises the following steps: crushing fluorgypsum to obtain fluorgypsum particles; and mixing the fluorgypsum particles with the admixture, the aggregate, the expansion inhibitor, the excitant, the water retention thickener and the acid-base regulator to obtain thefluorgypsum-based plastering material. The fluorgypsum-based plastering material has the characteristics of short setting time, high strength, small stacking density, good volume stability, high bonding strength, excellent water-retaining property and the like; the preparation method is simple, and the fluorgypsum-based plastering material has a wide application prospect in the field of preparation of building materials.

Owner:JIANGSU EFFUL SCIENCE AND TECHNOLOGY CO LTD

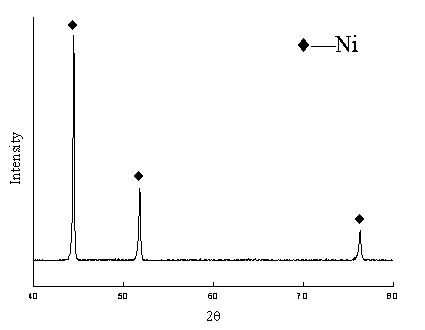

Method for preparing superfine simple-substance nickel powder

The invention relates to a method for preparing nickel powder, in particular to a method for preparing superfine simple-substance nickel powder. The method comprises the following steps that reaction materials are added to a reactor, the reactor is heated to 100-350 DEG C, pressure reaches 0.1-30MPa, and the reactor is kept for 0.05-2h under the condition; under the condition that the temperature is not changed, the pressure of the reactor is reduced to 0-2MPa, solvents are filtered out, heating is stopped, the reactor is cooled to indoor temperature, products are taken out, and ultrasonic dispersion, washing and vacuum drying are carried out on the products to obtain the superfine simple-substance nickel powder. The preparing method is short in reaction time, low in reaction temperature and free of pollution. The whole process is simple in process. The preparing method is strong in raw material applicability. The adopted raw materials are low in price. The prepared products are easy to separate, and the obtained simple-substance nickel is controllable in particle diameter and good in dispersibility.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Method for synthesis of calcium alginic acid monosaccharide from shells and alginic acid

InactiveCN103408604AGood water solubilityEasy to absorb and utilizeSugar derivativesSaccharide compounds with non-saccharide radicalsChemistryCalcium supplement

The invention relates to a method for synthesis of calcium alginic acid monosaccharide from shells and alginic acid. The method comprises shell pre-treatment, alginic acid degradation, synthesis, crystallization, and drying. The method comprises the following steps of 1, immersing shells in hydrochloric acid having the content of 0.05M, carrying out drying, carrying out crushing, carrying out treatment by an elutriation method to obtain calcium-source shell powder, adding alginic acid into an appropriate amount of a H2O2 solution having the content of 3%, carrying out heating degradation by a water-bath heating and microwave heating combined method, wherein in the heating degradation, a water-bath heating process is carried out at a temperature of 80 DEG C for 1h, then a microwave heating process is carried out for 1.5h, then a water-bath heating process is carried out at a temperature of 80 DEG C for 1h and then a microwave heating process is carried out for 1h, and carrying out centrifugation, purification, concentration and drying of the degradation products to obtain white alginic acid monosaccharide, and 2, dissolving the white alginic acid monosaccharide in an appropriate amount of distilled water, adding the calcium-source shell powder into the alginic acid monosaccharide solution according to a mole ratio of the alginic acid monosaccharide to the shell powder of 2: 1.0-1.2, wherein the calcium carbonate content is 95%, carrying out a reaction in a water bath at a temperature of 30 DEG C for 0.75h, carrying out suction filtration, and carrying out reduced pressure concentration, alcohol precipitation crystallization and drying of the supernatant. The method has simple processes. The calcium alginic acid monosaccharide can be used as a novel calcium supplement agent. The method realizes high-value utilization of alginic acid and a plurality of shells.

Owner:QINGDAO UNIV

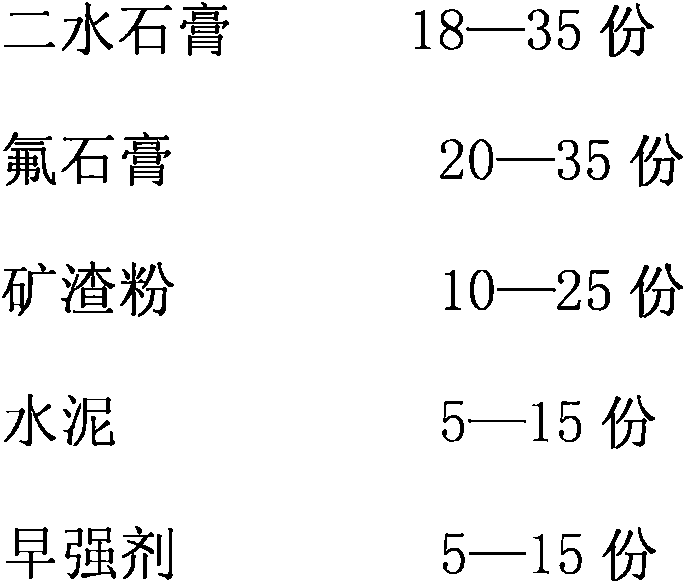

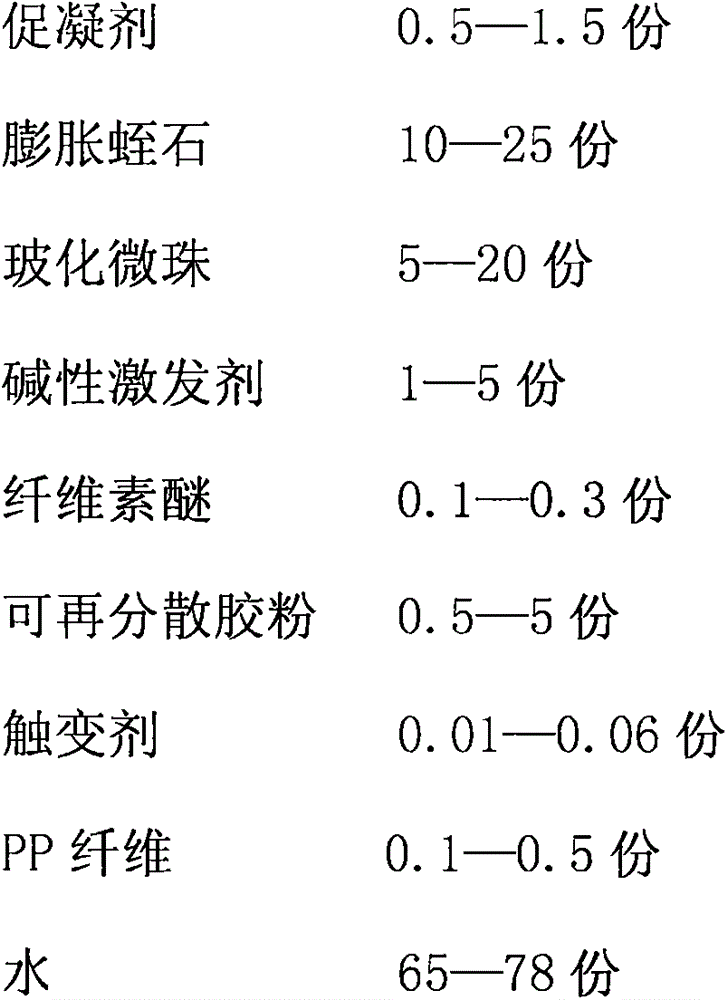

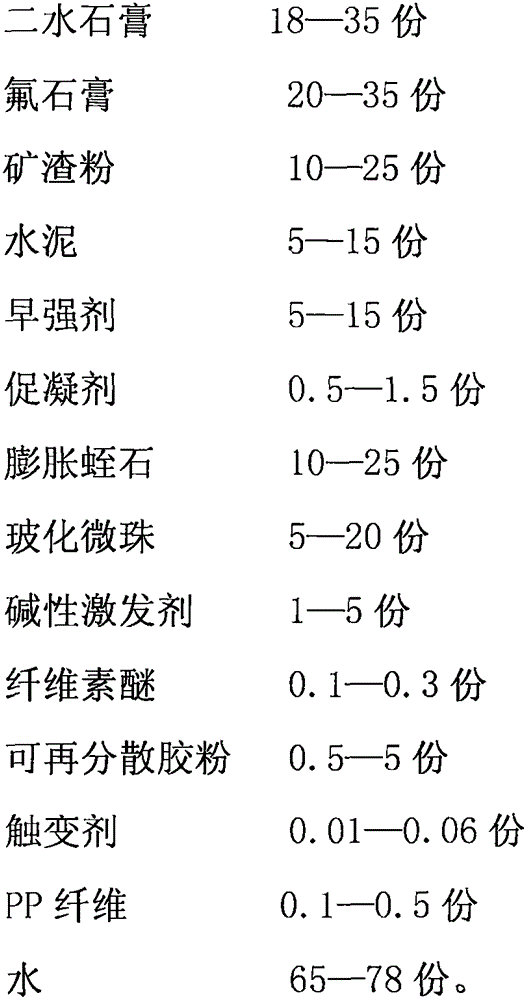

Dihydrate gypsum based fireproof coating material

The invention discloses a dihydrate gypsum based fireproof coating material and relates to the fields of resource-converting comprehensive utilization of industrial wastes and fireproof coating materials. The dihydrate gypsum based fireproof coating material disclosed by the invention contains the following ingredients in parts by weight: 18-35 parts of dihydrate gypsum, 20-35 parts of fluorgypsum, 10-25 parts of slag powder, 5-15 parts of cement, 5-15 parts of early strength agent, 0.5-1.5 parts of setting accelerator, 10-25 parts of expanded vermiculite, 5-20 parts of vitrified microbeads, 1-5 parts of alkaline excitant, 0.1-0.3 part of cellulose ether, 0.5-5 parts of redispersible glue powder, 0.01-0.06 part of thixotropic agent, 0.1-0.5 part of PP fibers and 65-78 parts of water. According to the dihydrate gypsum based fireproof coating material, the fireproof capability is good, the raw materials are not required to be calcined and baked, the energy consumption is low, and the cost is low.

Owner:马振义

Titanate oxide nano catalyst for synthesizing fatty long-chain carbonic dialkyl ester and carbonic diphenyl ester

InactiveCN1775346ASave energyReduce dosageMetal/metal-oxides/metal-hydroxide catalystsPreparation from organic carbonatesNano catalystOxide

The present invention discloses a catalyst for synthesizing aliphatic long-chain dialkyl carbonate and diphenyl carbonate by utilizing dimethyl carbonate ester exchange reaction. Said invention contains some dozens of nano catalysts containing titanate oxide. Said catalyst can shorten the ester exchange reaction time, can raise selectivity for dialkyl carbonate and diphenyl carbonate and can reduce catalyst use level, and its property is stable and reliable in the circulation use process.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

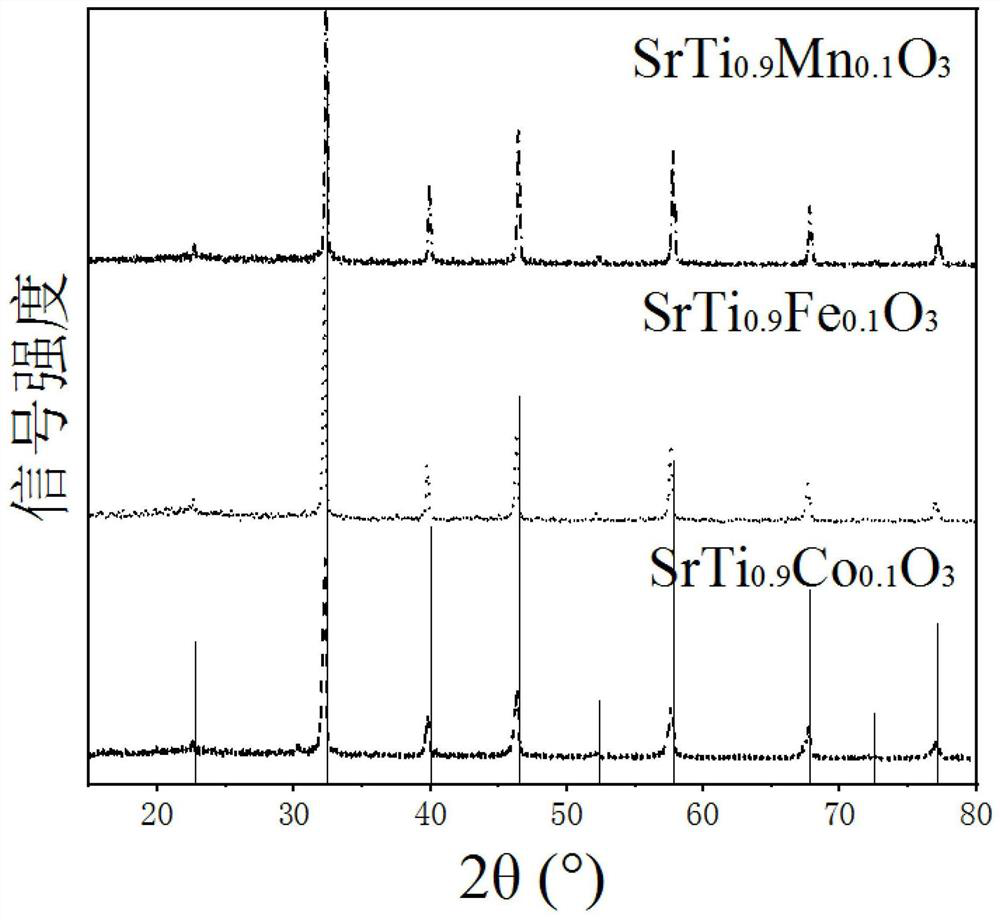

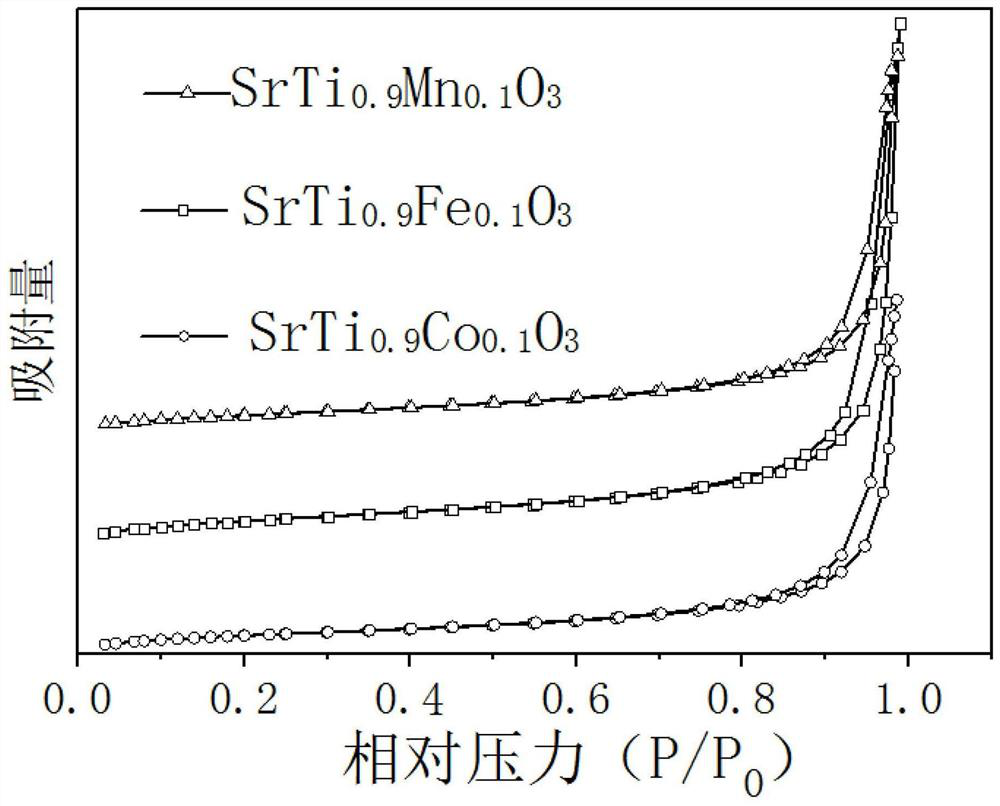

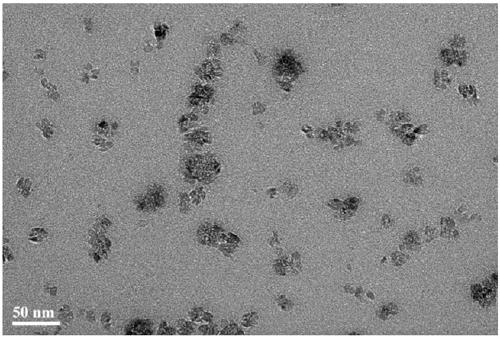

Perovskite nanoparticle catalyst and preparation method and application thereof

ActiveCN112569948APrevent sinteringGood retention of lattice structureAlkaline earth titanatesHeterogenous catalyst chemical elementsPtru catalystLiquid fuel

The invention discloses a perovskite nanoparticle catalyst and a preparation method and application thereof, and belongs to the field of nano material synthesis. The perovskite nano particles are Sr1-yAyTi1-xBxO3; and the preparation method of the perovskite nanoparticles adopts a flame spray pyrolysis technology, and comprises the following main preparation steps: sequentially mixing a metal precursor and a liquid fuel, and carrying out ultrasonic treatment to uniformly mix the metal precursor and the liquid fuel to obtain a precursor solution; introducing the precursor solution into a flamespray pyrolysis device, igniting the precursor solution by ignition flame after the precursor solution is atomized, then combusting liquid fuel to form high-temperature flame, and pyrolyzing the precursor in the high-temperature flame to obtain the perovskite catalyst. According to the invention, the perovskite catalyst can be rapidly synthesized in one step by adjusting the type and preparation method of the precursor; the precursor is wide in range and can be flexibly combined; and the synthesized perovskite nanoparticles have good thermal stability, and obtain extremely high catalytic activity in the catalytic fields of photocatalysis, catalytic combustion and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

Alginate monosaccharide calcium synthesis method using shells and alginic acid as raw materials

InactiveCN103408604BGood water solubilityPromote absorptionSugar derivativesSaccharide compounds with non-saccharide radicalsFiltrationCentrifugation

Owner:QINGDAO UNIV

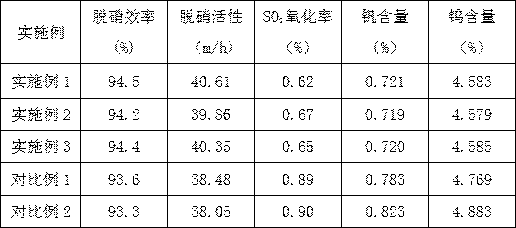

Regeneration technology of denitration catalyst

InactiveCN108014818ANo calcination treatmentNo need for calcinationCatalyst regeneration/reactivationMetal/metal-oxides/metal-hydroxide catalystsVanadium oxideAtomic layer deposition

The invention discloses a regeneration technology of a denitration catalyst. The regeneration technology comprises steps as follows: 1), an inactivated denitration catalyst is pretreated; 2), active substances including vanadium oxide and tungsten oxide are implanted to the inactivated denitration catalyst with an atomic layer deposition method, and a regenerated denitration catalyst is obtained,wherein vanadium oxide accounts for 0.1%-0.5% by mass of the regenerated denitration catalyst and tungsten oxide accounts for 0.3%-1% by mass of the regenerated denitration catalyst. According to theregeneration technology of the denitration catalyst, the active substances are supplemented with the atomic layer deposition method and adsorbed inside and outside a catalyst pore channel, have strongacting force with the inactivated denitration catalyst and are distributed in the catalyst uniformly; the quantity of the supplemented active substances is regulated and controlled by controlling thenumber of atom deposition, and the implanted active substances including vanadium oxide and tungsten oxide are accurate and controllable.

Owner:JIANGSU LONGKING COALOGIX CATALYST REGENERATION CO LTD

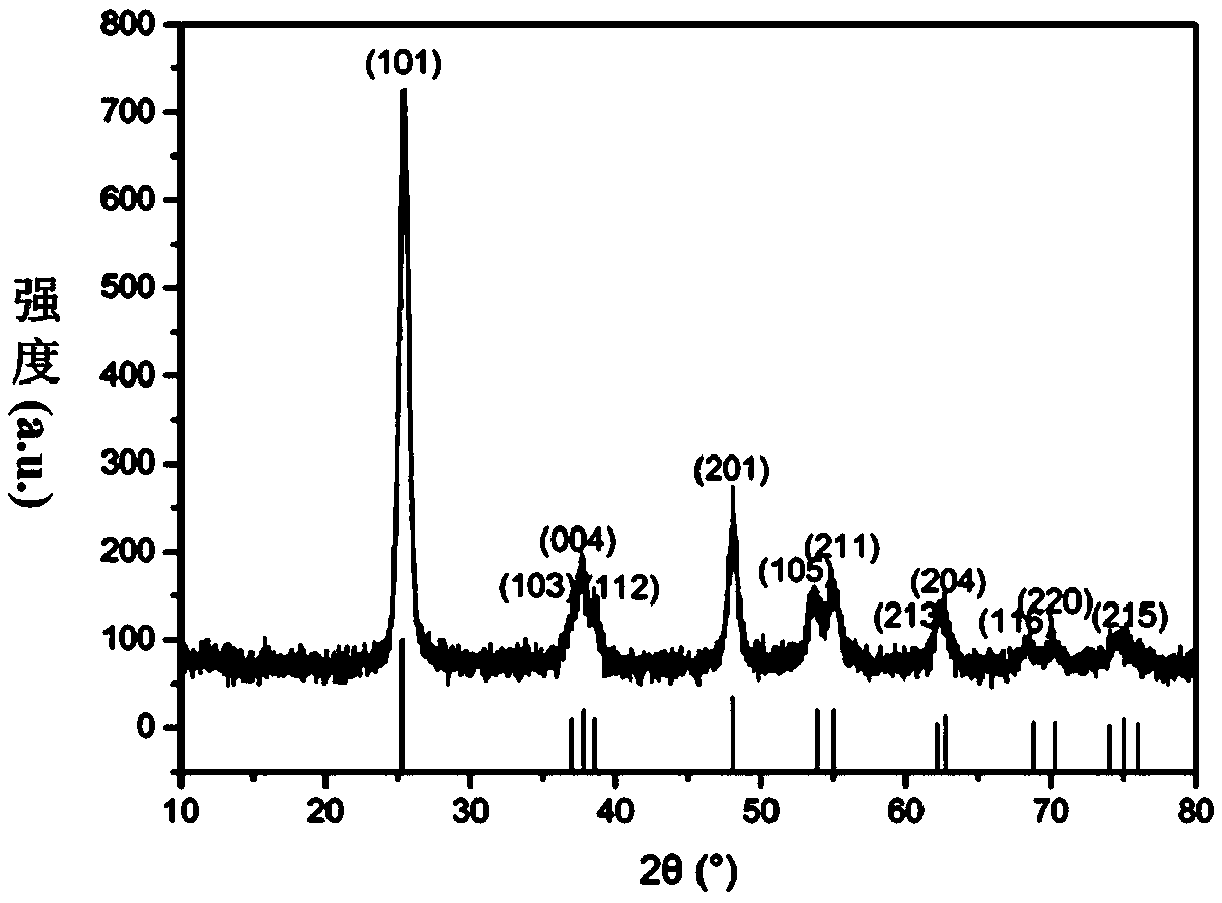

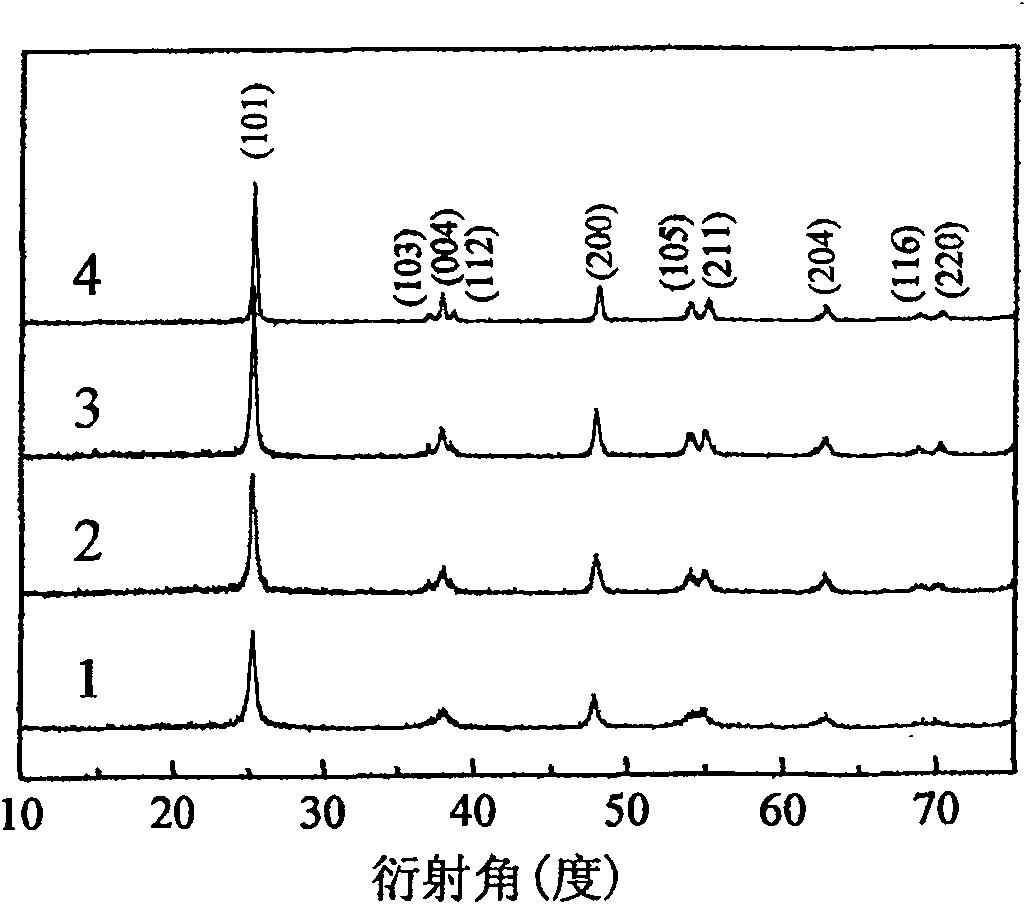

Anatase type nanometer titanium dioxide, and preparation method and use thereof

InactiveCN109179499AGrowth inhibitionHigh purityNanotechnologyTitanium dioxideUltraviolet lightsTitanium

The invention relates to an anatase type nanometer titanium dioxide, and a preparation method f and a use thereof. The preparation method of the nanometer titanium dioxide comprises the following steps: (1) preparing a precursor containing titanium halide; and (2) heating the precursor in a closed environment to carry out solvothermal treatment in order to obtain the anatase type nanometer titanium dioxide. The anatase type nanometer titanium dioxide has a purity of 99.9% or above, a particle diameter of 20 nm or less and a distribution coefficient of 0.5 or less, and has an absorption effecton ultraviolet lights. The pure anatase type nanometer titanium dioxide product with a controllable particle size is prepared through a one-step solvothermal technology without calcination, so the method has the advantages of low energy consumption, simple process, and rapidness in industrial production.

Owner:ASIA PAINT SHANGHAI

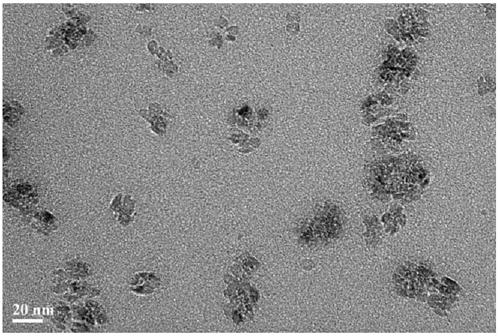

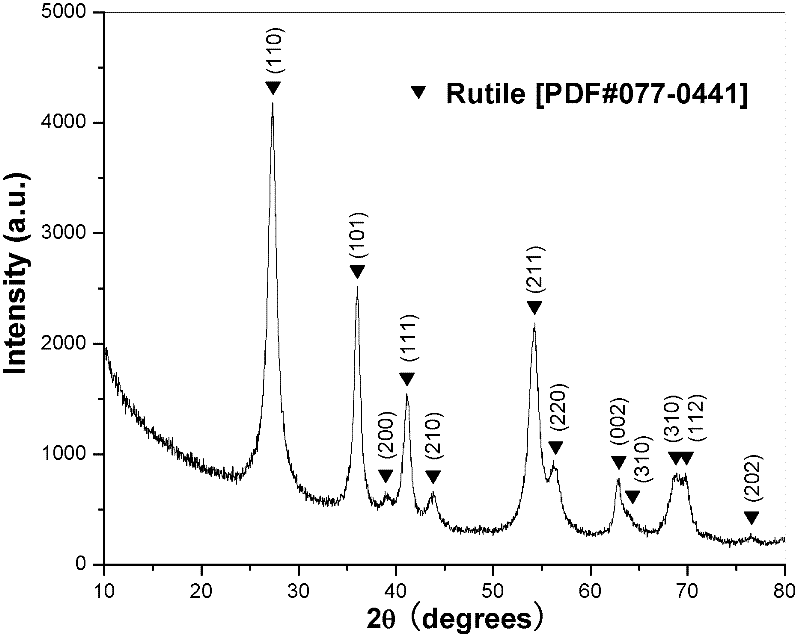

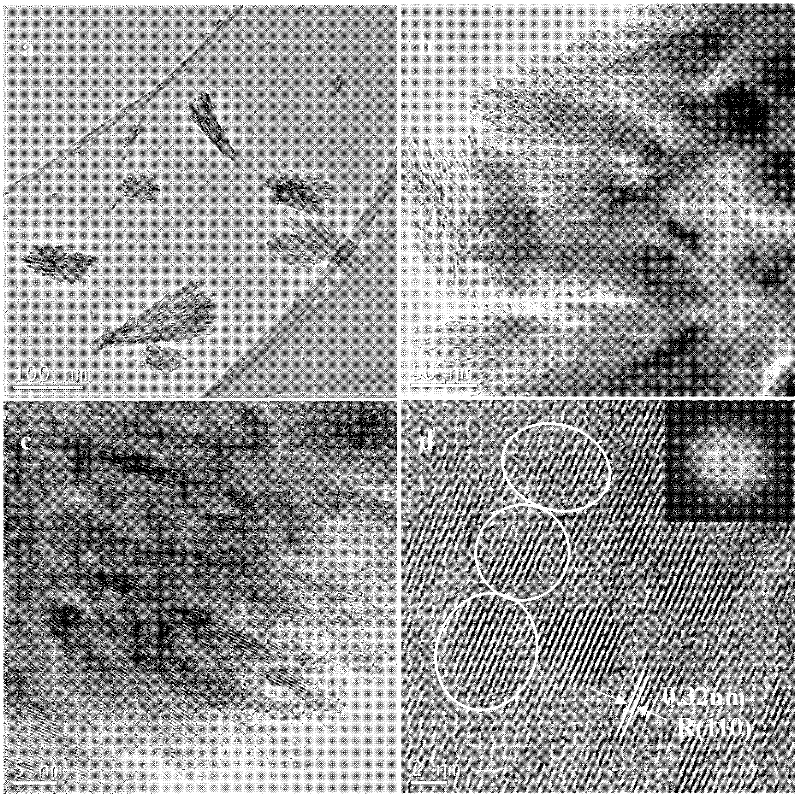

Sunlight-induced method for preparing fasciculate rutile titanium dioxide

The invention discloses a sunlight-induced method for preparing fasciculate rutile titanium dioxide at room temperature. The method comprises the following steps of: forming a hydrosol by using titanium tetrachloride and water; diluting the hydrosol by adding water after the hydrosol is fully aged; obtaining a large number of white precipitates through sunlight irradiation outdoors; and filtering, washing and drying the obtained white precipitates to obtain fasciculate rutile titanium dioxide powder. The sunlight-induced method for preparing the fasciculate rutile titanium dioxide, disclosed by the invention, has the main advantages that: the crystal form of titanium dioxide is rutile, the purity of the titanium dioxide is high, and the calcination is not needed; the temperature for preparation is low, the heating is not needed, and the adding of other reagents or seed crystals is not needed; the preparation is carried out under normal pressure; only the sunlight irradiation is needed, so that the method has low carbon and energy-saving performance; and the preparation process is simple and is easy in operation.

Owner:嘉善县国创新能源研究院

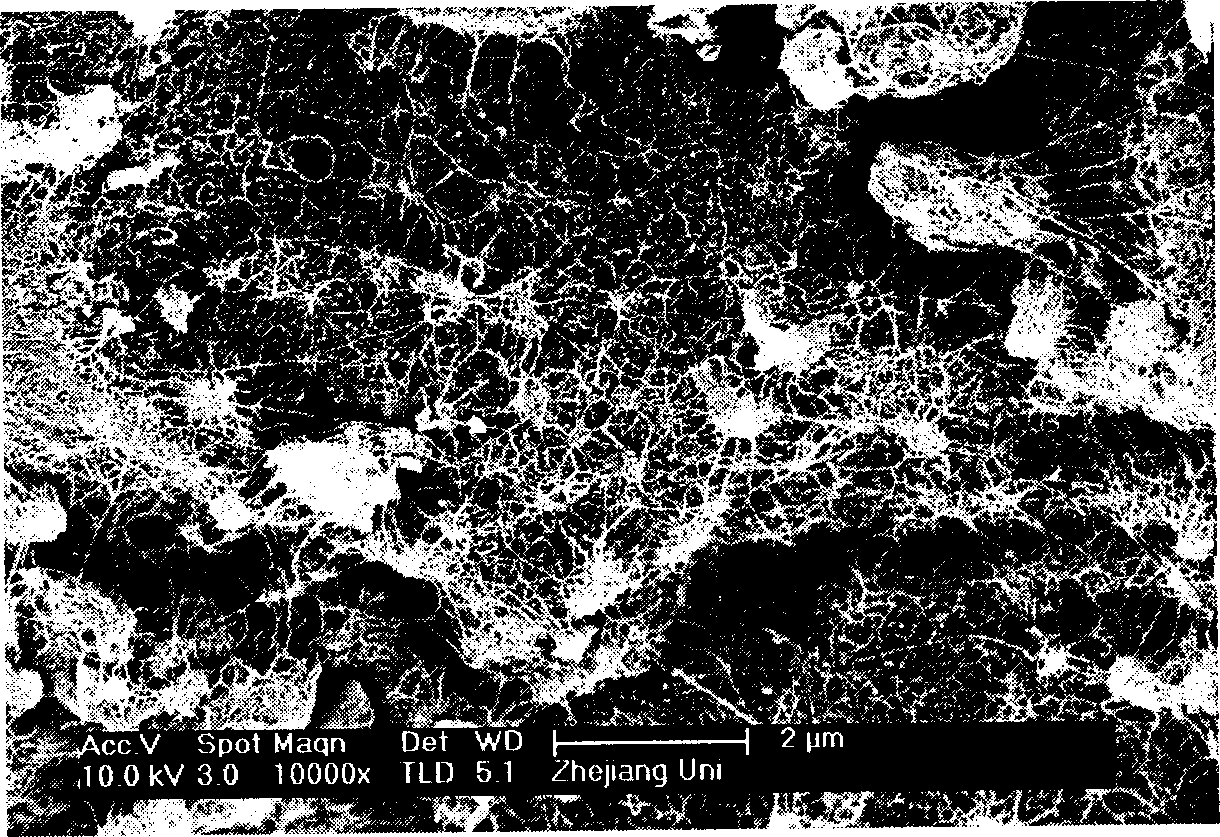

Catalyst of metallic oxide for preparing nanowall nano carbon pipe and preparation process thereof

InactiveCN1724345AHigh activityIncrease profitMetal/metal-oxides/metal-hydroxide catalystsAlcoholNano carbon

A metallic oxide catalyst Fe / Mo / MgO for preparing single-wall carbon nano-tubes is proportionally composed of MgO as carrier, oxide of Fe as primary catalyzing component and Mo as co-catalyst. Its preparing process includes such steps as proportionally mixing the Fe salt, Mo salt (or oxide) and Mg salt in de-ionized water or alcohol solution, freezing at -100--40 deg. C, drying at -40--10 deg. C for 12-48 hr, and drying again at 20-60 deg. C for 6-12 hr. Its advantage is high catalytic activity.

Owner:ZHEJIANG UNIV

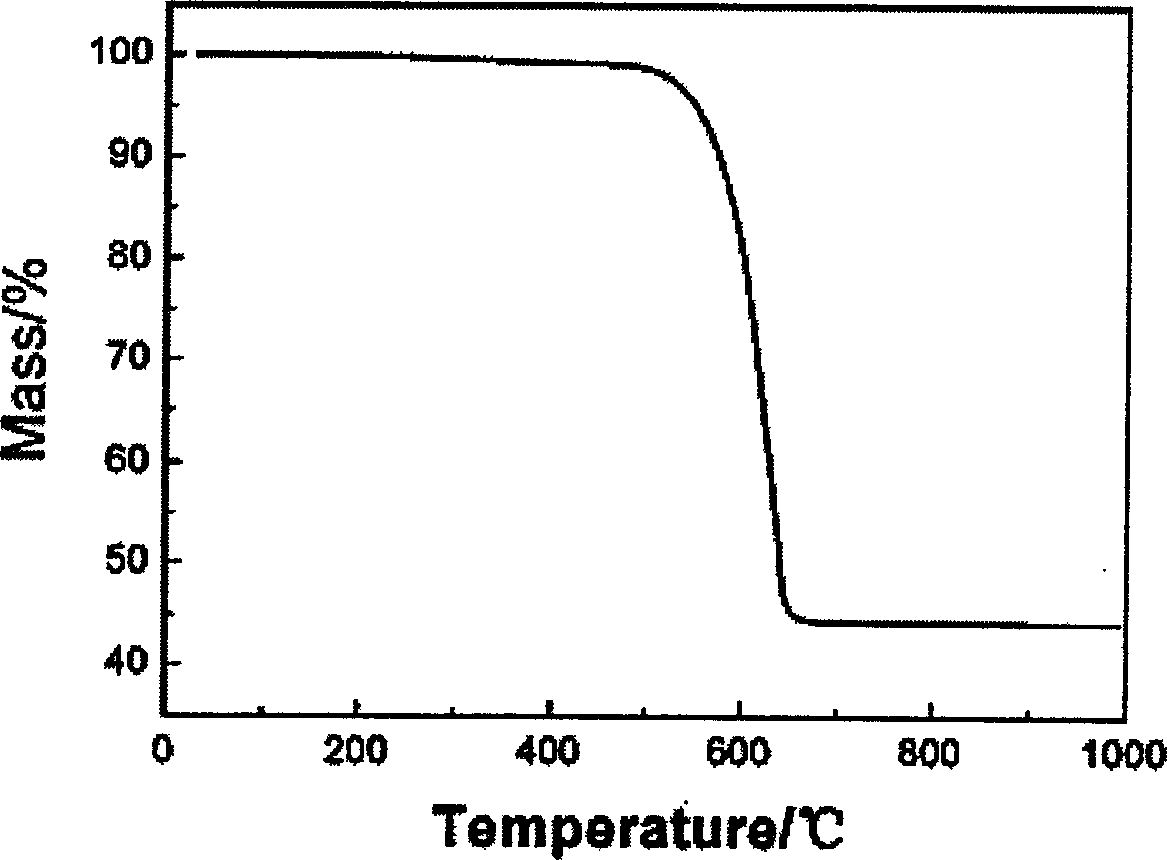

Preparation method of metal cation doped modified lithium ion sieve

PendingCN111204812AIncrease the average valenceImprove stabilityOther chemical processesManganates/permanganatesLithiumPhysical chemistry

The invention provides a preparation method of a metal cation doped modified lithium ion sieve. The molecular formula of the metal cation doped modified lithium ion sieve is HGaxMn2-xO4, and x is equal to 0.05-1. The preparation method comprises the following specific steps: preparing a mixed salt solution from a gallium source and a manganese source according to a molar ratio of n(Ga<3+>: Mn<2+>)of x:(2-x) at normal temperature; mixing a lithium source and a hydrogen peroxide solution according to a certain proportion to prepare a lithium solution; slowly dropwise adding the lithium solutioninto the mixed solution, and carrying out a hydrothermal reaction at a certain temperature to obtain an ion sieve precursor doped with metal gallium ions; and finally, carrying out acid pickling treatment on the precursor powder material to obtain the metal gallium ion doped ion sieve adsorbent HGaxMn2-xO4. The adsorbent prepared in the invention is stable in crystal structure, the problem of solution loss of a traditional ion sieve is effectively reduced, and the reusability is improved.

Owner:NANJING UNIV OF TECH

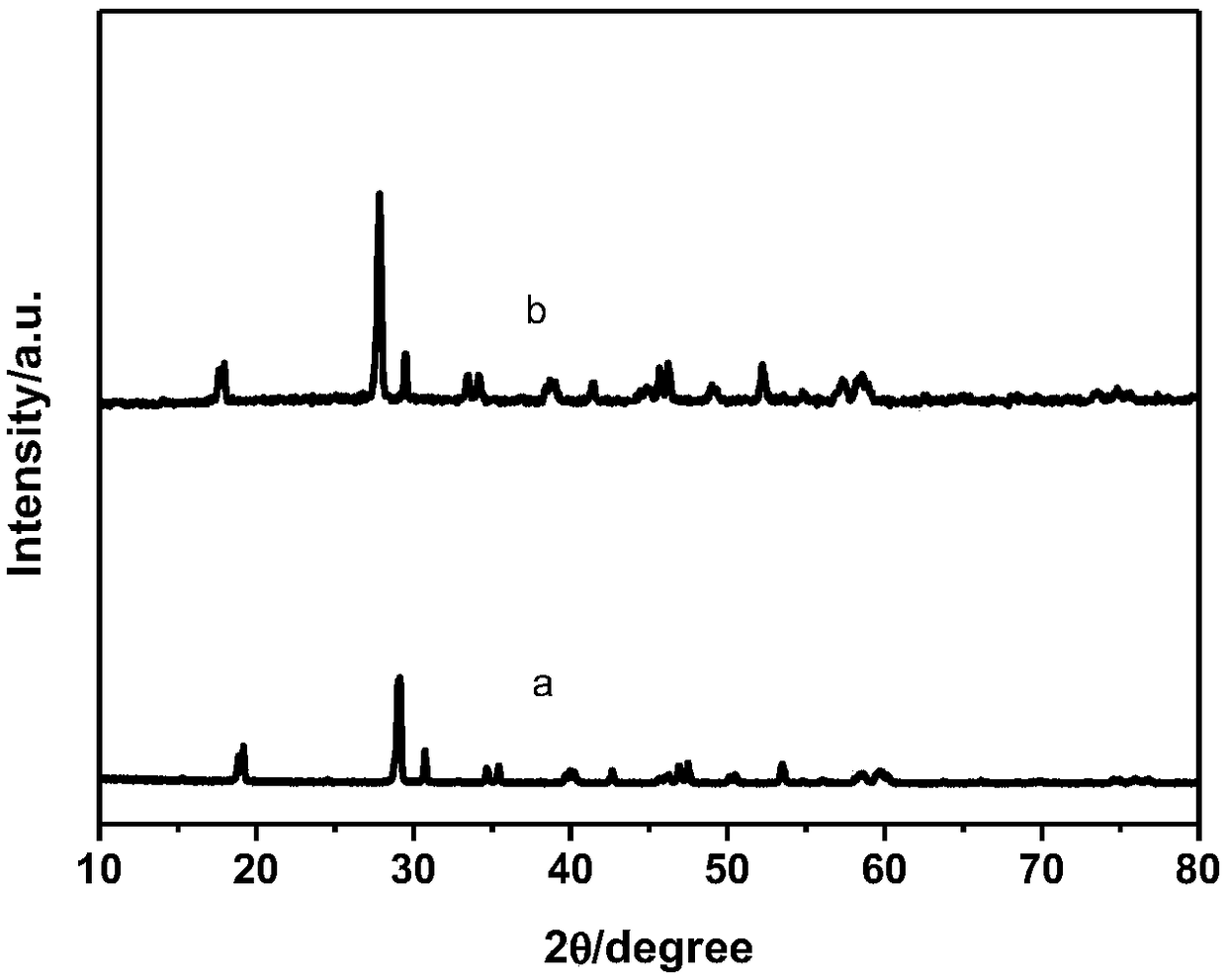

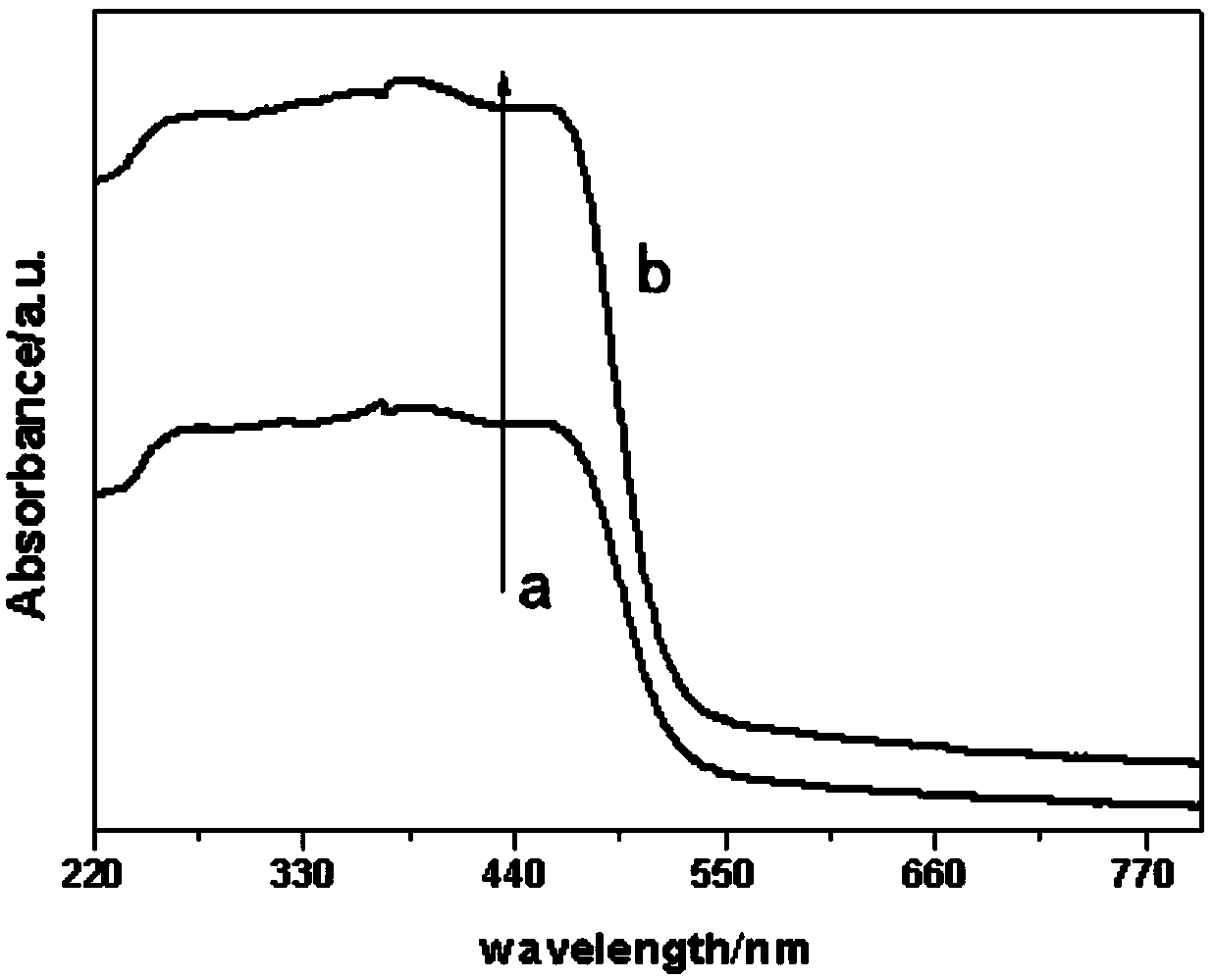

Method for synthesizing nitrogen-doped bismuth vanadate photocatalyst and application thereof

ActiveCN109317177AAchieve the purpose of modificationImproving the performance of photocatalytic degradation of organic matterPhysical/chemical process catalystsWater/sewage treatment by irradiationBismuth vanadateAmmonium metavanadate

The invention discloses a preparation method and application for synthesizing a nitrogen-doped bismuth vanadate photocatalyst through a hydrothermal method. The method comprises the steps: dissolvingbismuth vanadate pentahydrate and polyvinylpyrrolidone into concentrated nitric acid to be prepared into a bismuth salt solution, dissolving ammonium metavanadate into an ammonium hydroxide solution to form a vanadium salt solution, adding urea into the vanadium salt solution according to the molar ratio of N to Bi is equal to (1 to 1.5) to 1 to form a mixed solution, then adding the bismuth saltsolution into the mixed solution and adjusting a pH to be 7 to obtain a precursor solution, then transferring the precursor solution into a high-pressure kettle to perform hydrothermal reaction and centrifuging, washing and drying a product to obtain the nitrogen-doped bismuth vanadate photocatalyst after reaction finishes.

Owner:JIANGSU UNIV OF TECH

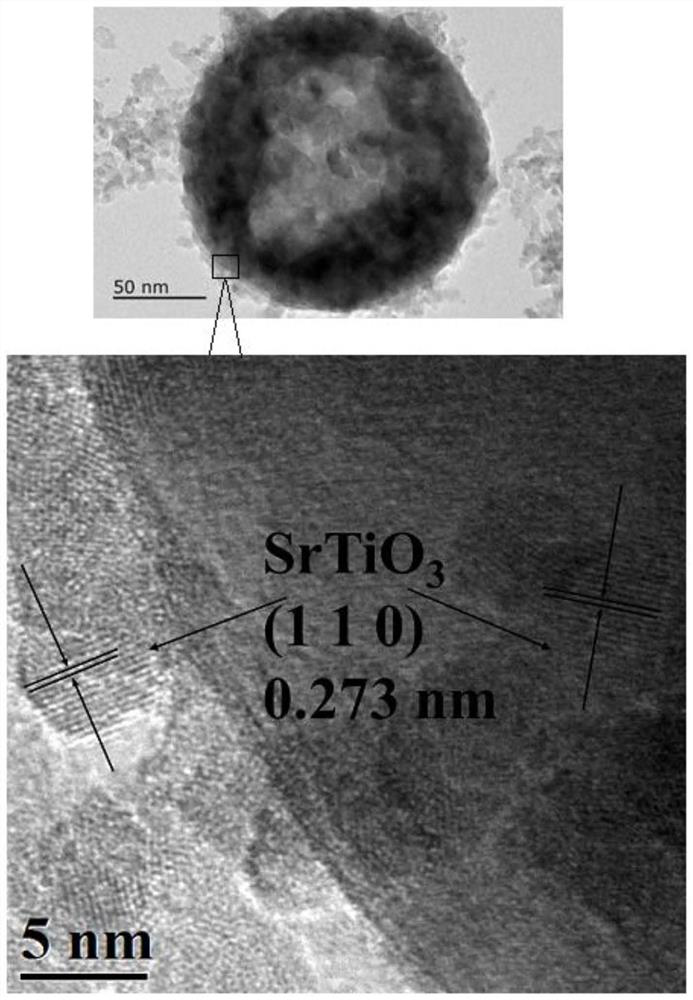

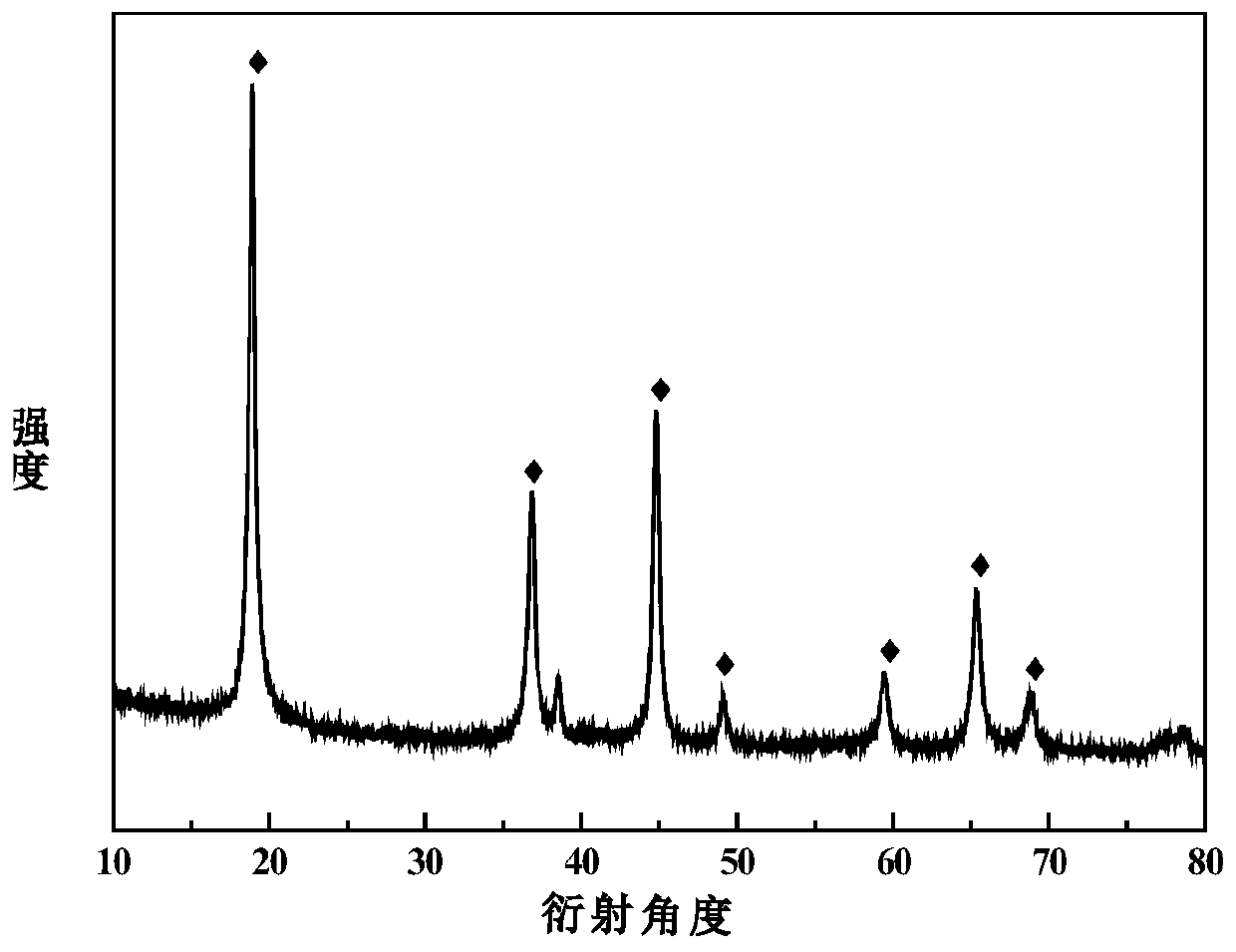

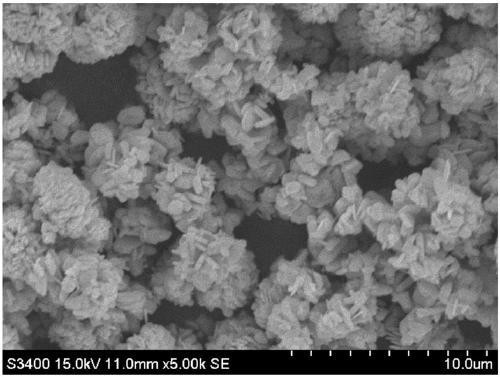

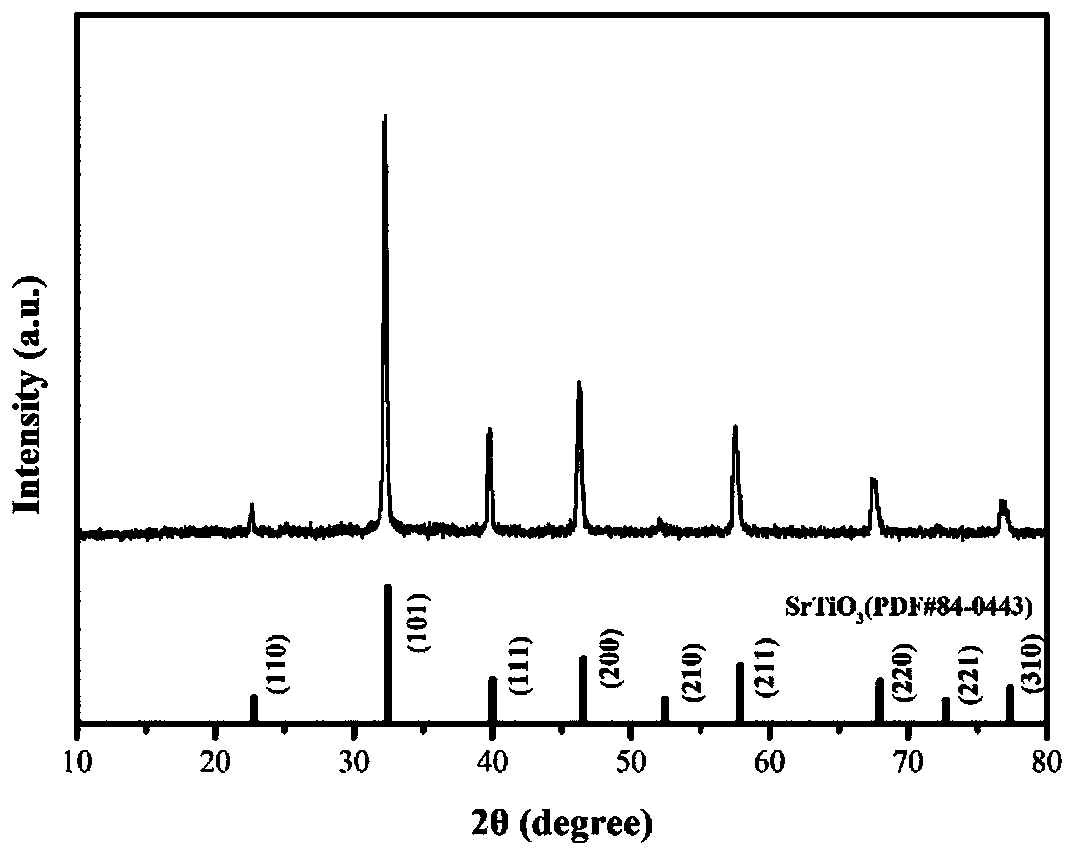

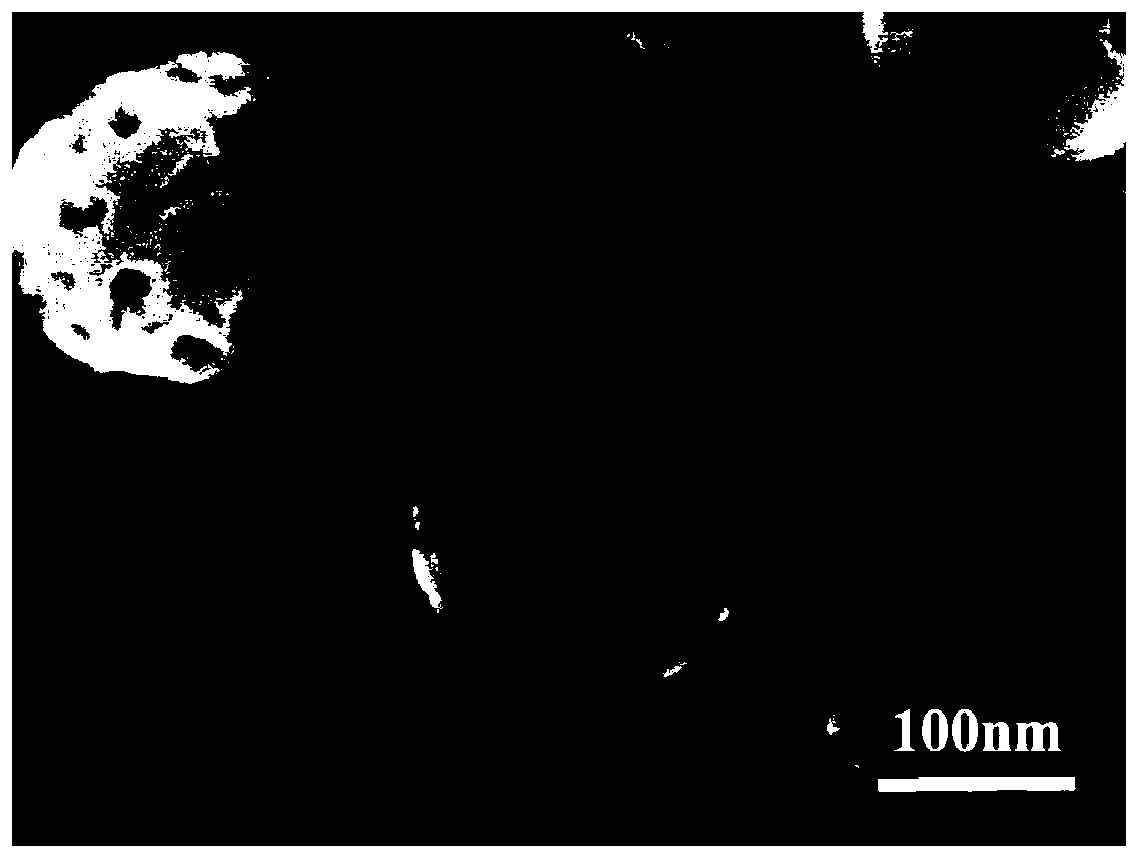

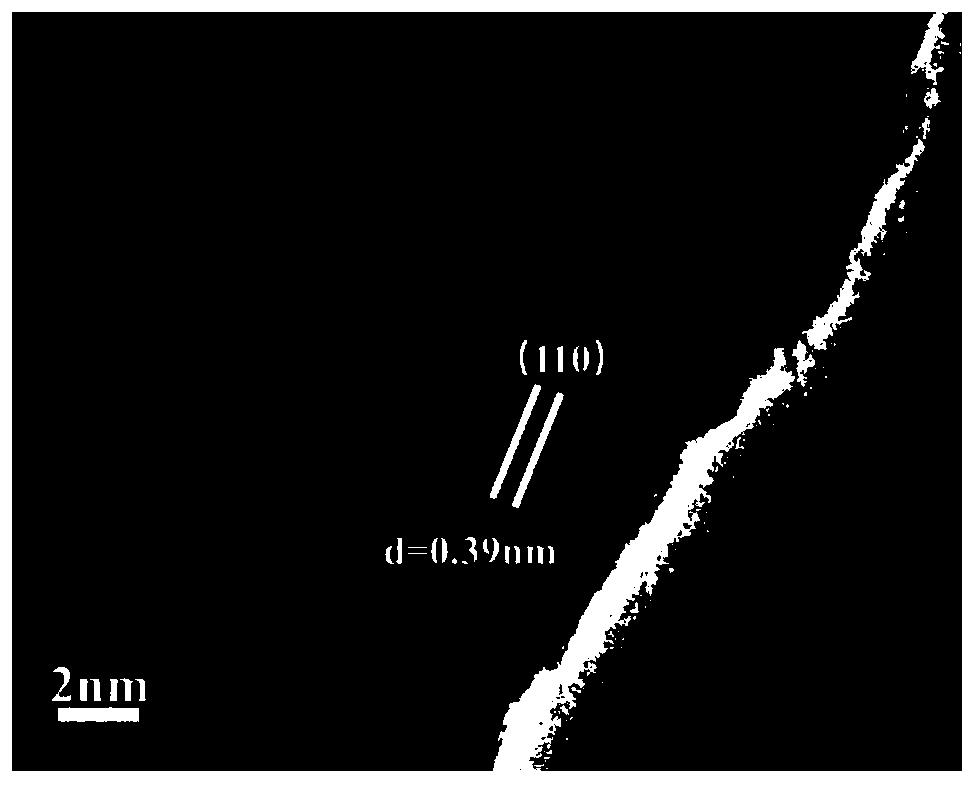

Synthesis method of mesoporous single crystal strontium titanate

ActiveCN110952143AReduce synthesisEasy to synthesizePolycrystalline material growthFrom normal temperature solutionsStrontium titanatePhysical chemistry

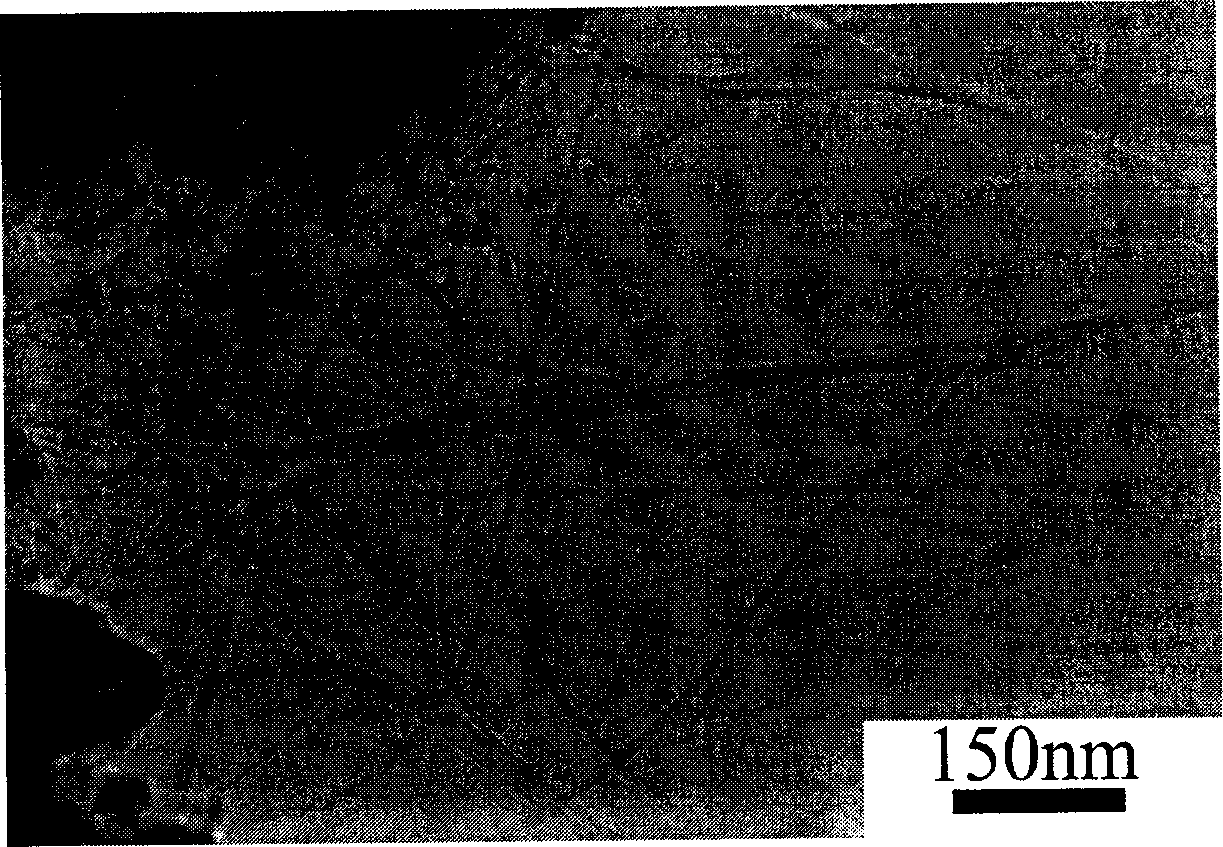

The invention relates to a synthesis method of mesoporous single crystal strontium titanate. In the hydrothermal synthesis process of strontium titanate, spontaneously growing is performed to form mesoporous structures, and centrifugal drying is performed after the reaction is completed to obtain mesoporous single crystal strontium titanate powder. Synthesized strontium titanate single crystal particles are between 100 nanometers and 300 nanometers, have rough surfaces and porous structures, and have high specific surface areas. The single crystal particles with the mesoporous structure have very important application in the fields of environmental science and solar energy conversion.

Owner:EAST CHINA UNIV OF SCI & TECH

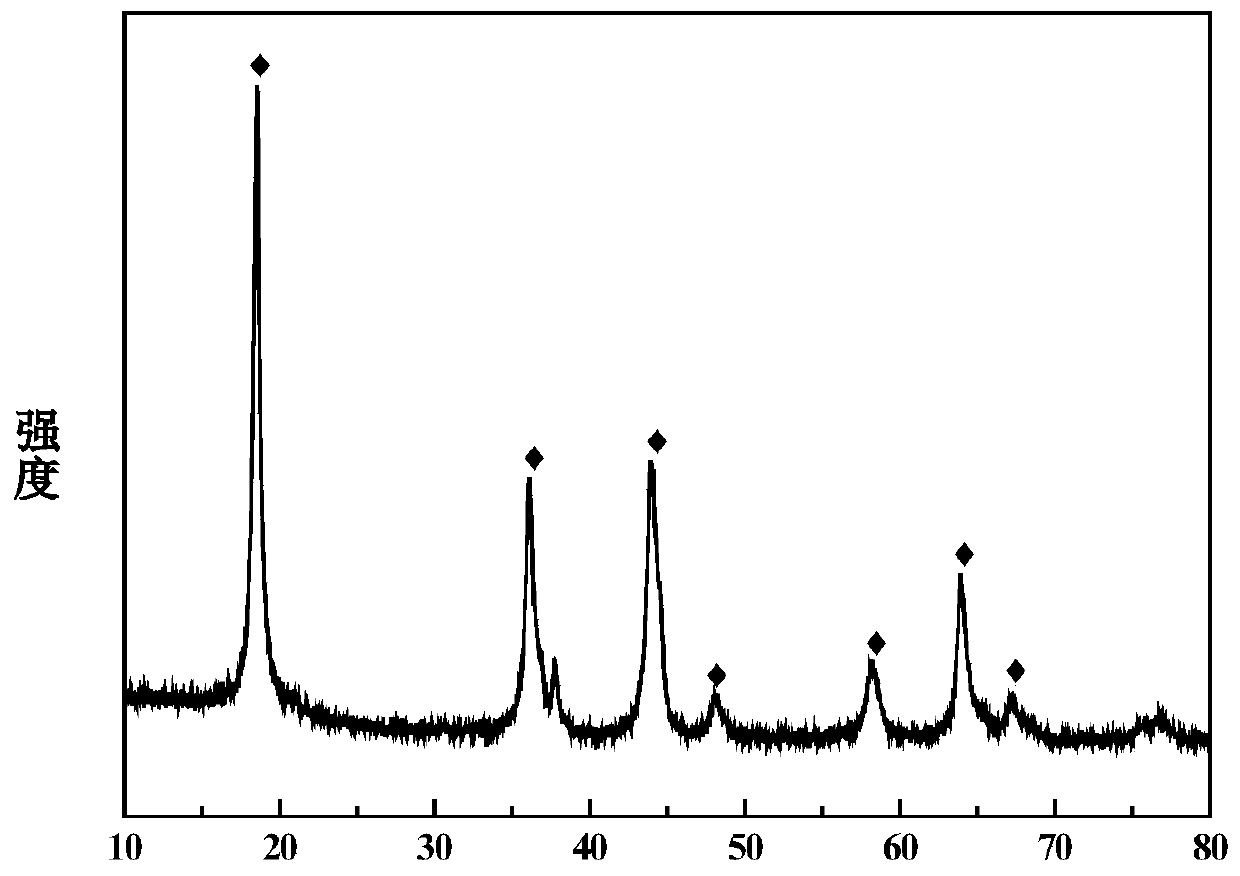

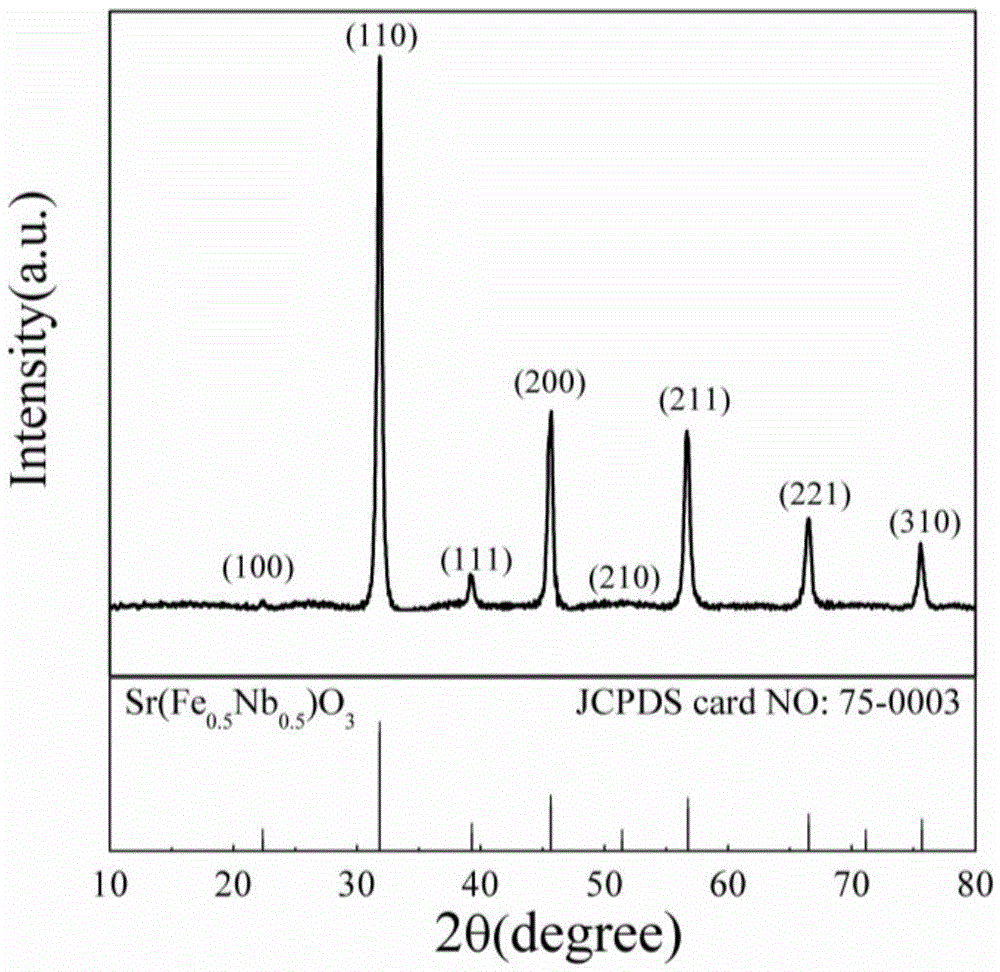

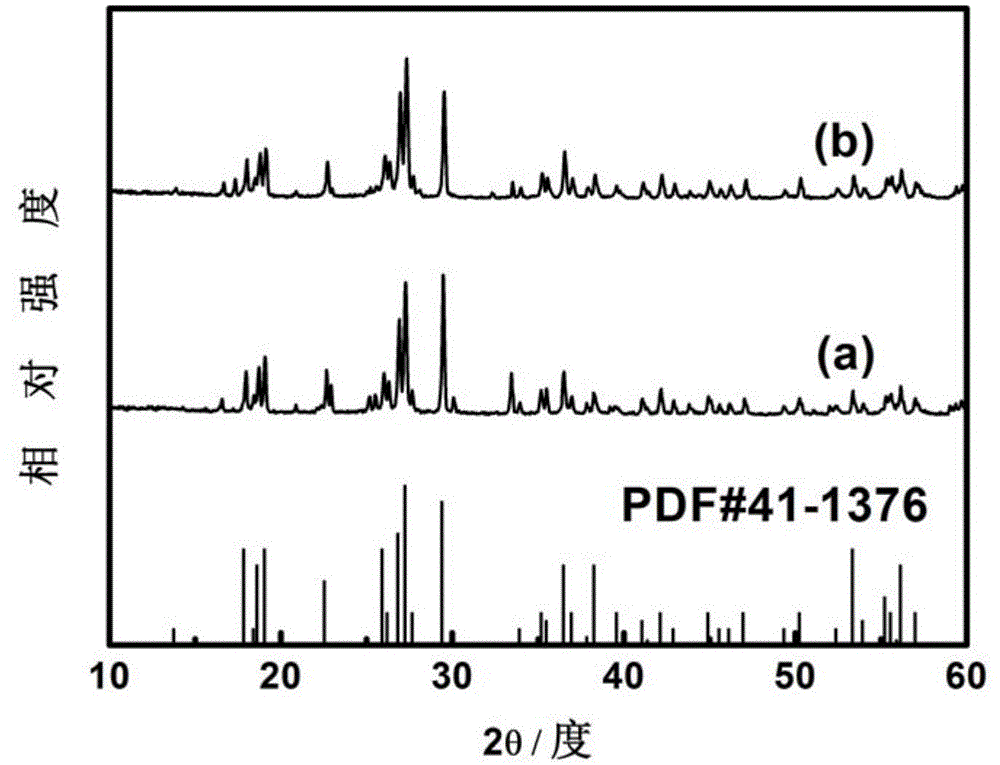

Method for preparing nano Sr(Fe0.5Nb0.5)O3 powder by microwave-hydrothermal method

ActiveCN105645476AHigh puritySimple particle size distributionNanotechnologyIron compoundsMicrowaveCoprecipitation

The invention provides a method for preparing nano Sr(Fe0.5Nb0.5)O3 powder by a microwave-hydrothermal method, comprising the following steps of (1) weighing raw materials, namely, Sr(NO3)2, Fe(NO3)3.9H2O and NbCl5; (2) adding the Sr(NO3)2 into deionized water; (3) adding the Fe(NO3)3.9H2O into an Sr(NO3)2 aqueous solution, dripping 8 to 15 drops of hydrogen peroxide into a mixture to obtain a mixed solution A; (4) adding the NbCl5 into a dilute hydrochloric acid solution; then dropwise adding the NbCl5 hydrochloric acid solution into the mixed solution A, and uniformly mixing to obtain a mixed solution B; (5) titrating the mixed solution B with an NaOH solution to form a coprecipitation precursor of the Sr(Fe0.5Nb0.5)O3; (6) transferring a precursor solution of the Sr(Fe0.5Nb0.5)O3 to a microwave hydrothermal reaction kettle, reacting to obtain powder, anddrying the powder after washing the powder for several times, so as to obtain the nano-sized Sr(Fe0.5Nb0.5)O3 powder.

Owner:SHAANXI UNIV OF SCI & TECH

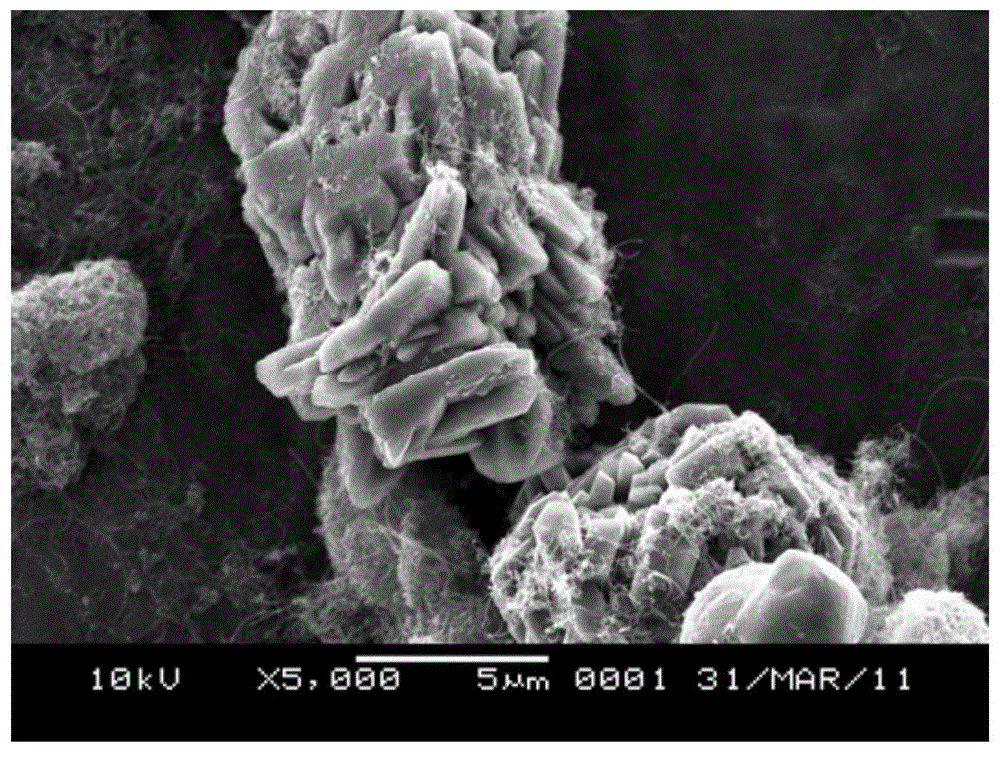

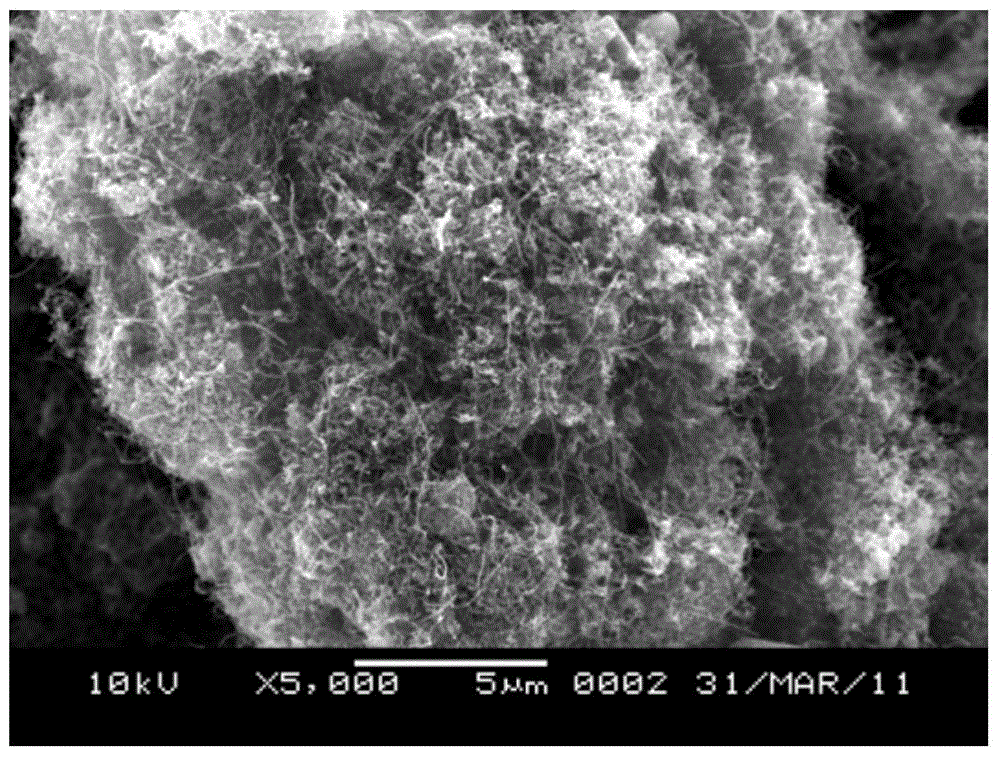

Preparation method of carbon-nanotube-modified lithium iron phosphate lithium ion battery positive electrode material

InactiveCN103553015AWell crystallizedControllable thicknessCell electrodesPhosphorus compoundsCarbon nanotubeLithium electrode

The invention relates to a preparation method of a carbon-nanotube-modified lithium iron phosphate lithium ion battery positive electrode material. The method comprises the steps that: (1) lithium salt, ferrous salt, and a raw material comprising phosphate ions are dissolved in anhydrous lower alcohol, such that an anhydrous alcohol solution comprising lithium ions, ferrous ions, and phosphate ions is obtained; (2) carbon nanotubes are added into the anhydrous alcohol solution comprising lithium ions, ferrous ions, and phosphate ions; and a uniform mixture is obtained after ultrasonic processing and stirring; and (3) a crucible containing the mixture is placed on an upper part of a sealed container with a proper amount of ammonia water placed on the bottom in advance; the mixture and the ammonia water do not contact directly; the sealed container is heated to 150-250 DEG C, and the temperature is maintained for 72h; and the obtained powder is washed and dried, such that the material is obtained. The carbon-nanotube-modified lithium iron phosphate positive electrode material provided by the invention has the advantages of good crystallization and controllable carbon nanotube modification layer thickness. The preparation process requires no calcination treatment, such that the material is energy-saving and environment-friendly.

Owner:DONGHUA UNIV

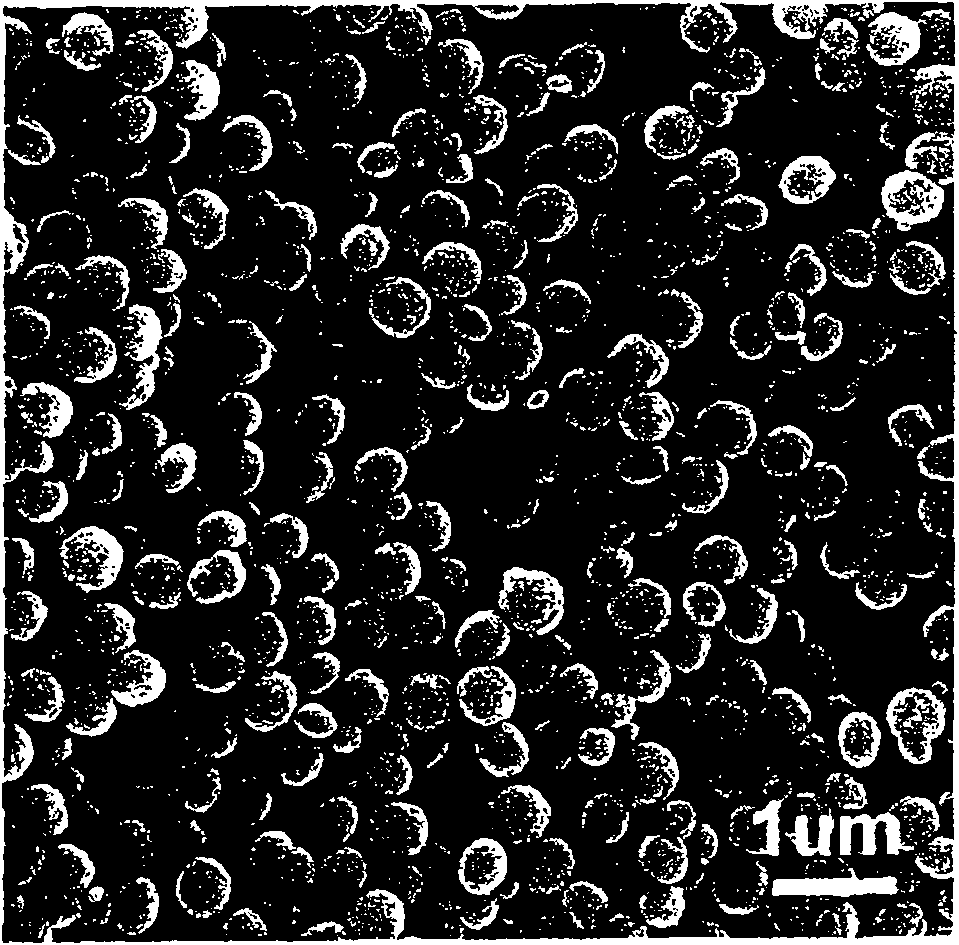

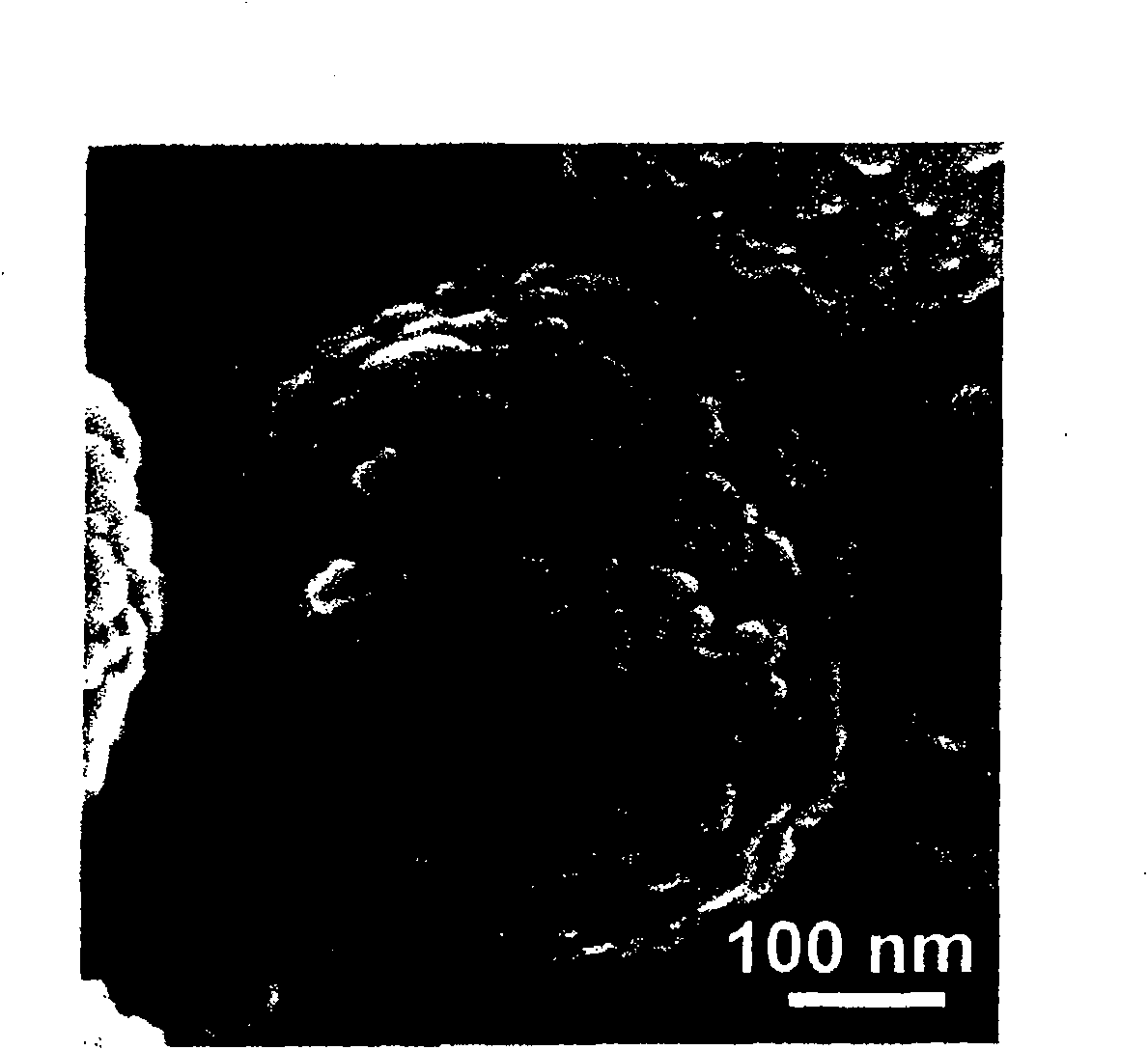

Method for preparing titanium dioxide hollow micro-sphere

InactiveCN100551829CReduce manufacturing costThe synthesis method is simpleTitanium dioxideMicrosphereTitanium oxide

The invention discloses a preparation method of titanium dioxide hollow microspheres. The method is to put industrial titanium liquid into an autoclave lined with polytetrafluoroethylene, conduct a hydrothermal reaction at 140-220°C for 4-24 hours, wash, filter and dry after cooling, and then obtain the nano-particle accumulation and The resulting titanium dioxide hollow microspheres have a particle size of 200-300 nm. The invention uses cheap industrial titanium liquid as a raw material, does not need to add other chemical reagents, and adopts hydrothermal method to synthesize titanium dioxide hollow microspheres.

Owner:SUN YAT SEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com