Preparation method of carbon-nanotube-modified lithium iron phosphate lithium ion battery positive electrode material

A lithium iron phosphate, lithium ion battery technology, applied in battery electrodes, chemical instruments and methods, circuits, etc., can solve the problems of low electronic conductivity, poor rate charge and discharge performance, etc., and achieve good crystallization and controllable thickness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 0.1 g of lithium chloride, 0.16 g of ferrous chloride tetrahydrate, and 72 μL of phosphoric acid into 8 mL of absolute ethanol, stir for 2 minutes, add 6 mg of carbon nanotubes into the above-mentioned absolute alcohol solution, ultrasonicate and stir for 3 minutes each. Pour the anhydrous alcohol solution containing carbon nanotubes into the crucible, and then place the crucible on the upper part of the sealable container. 3mL ammonia water (0.05mol / L) is placed in the bottom of the sealable container in advance. After sealing the container, put it into an oven, start heating to 200°C, the heating rate is 10-20°C / min, and keep it warm for 10 hours after the temperature reaches the set temperature. Cool down to room temperature naturally after heat preservation, open the airtight container, take out the crucible, pour out the powder, wash with distilled water and absolute alcohol three times respectively, and dry in vacuum at 60°C for 8 hours.

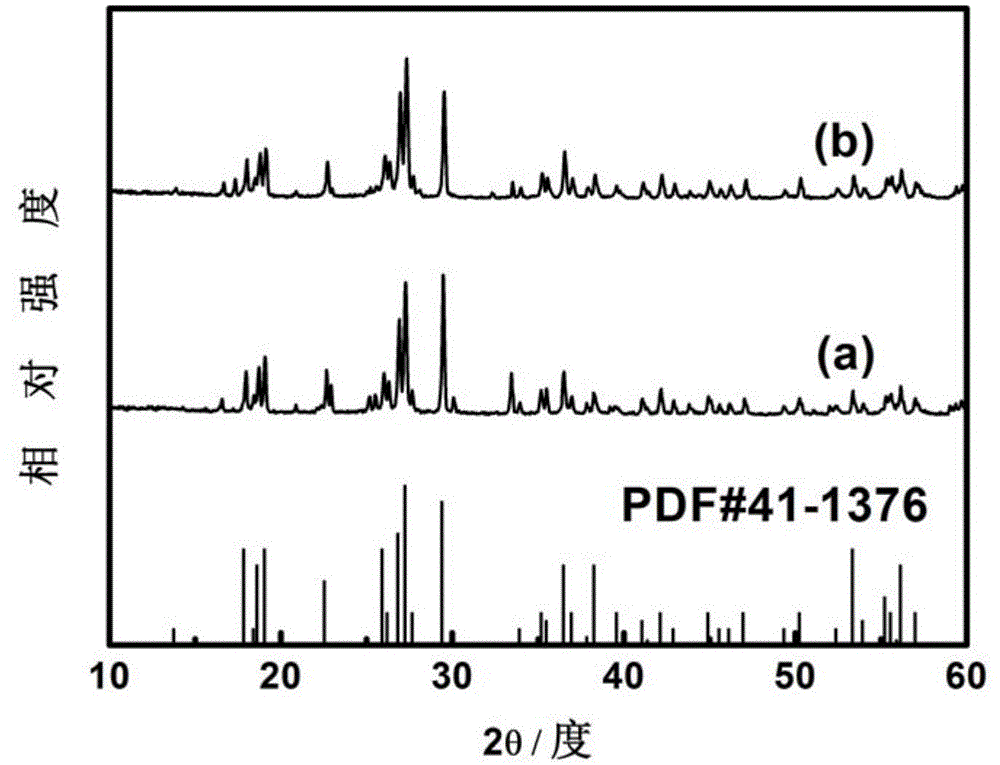

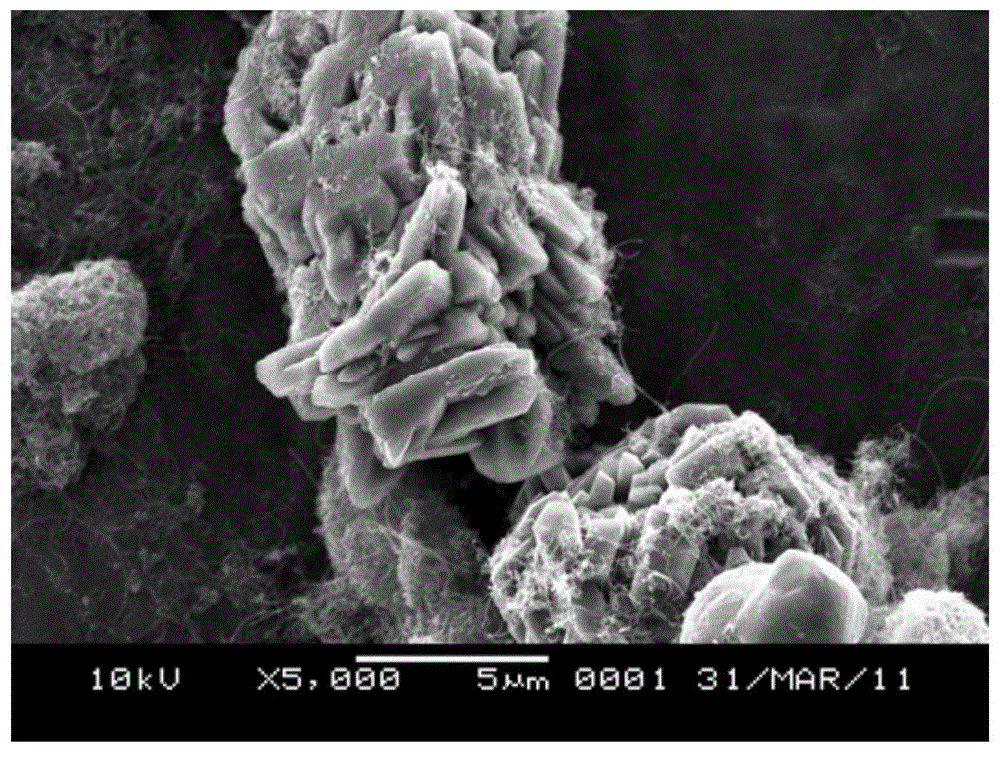

[0024] figure 1 (a...

Embodiment 2

[0027] Add 0.1 g of lithium chloride, 0.16 g of ferrous chloride tetrahydrate, and 72 μL of phosphoric acid into 8 mL of absolute ethanol, stir for 2 minutes, add 12 mg of carbon nanotubes into the above-mentioned absolute alcohol solution, ultrasonicate and stir for 3 minutes each. Pour the anhydrous alcohol solution containing carbon nanotubes into the crucible, and then place the crucible on the upper part of the sealable container. 3mL ammonia water (0.05mol / L) is placed in the bottom of the sealable container in advance. After sealing the container, put it into an oven, start heating to 200°C, the heating rate is 10-20°C / min, and keep it warm for 10 hours after the temperature reaches the set temperature. Cool down to room temperature naturally after heat preservation, open the airtight container, take out the crucible, pour out the powder, wash with distilled water and absolute alcohol three times respectively, and dry in vacuum at 60°C for 8 hours.

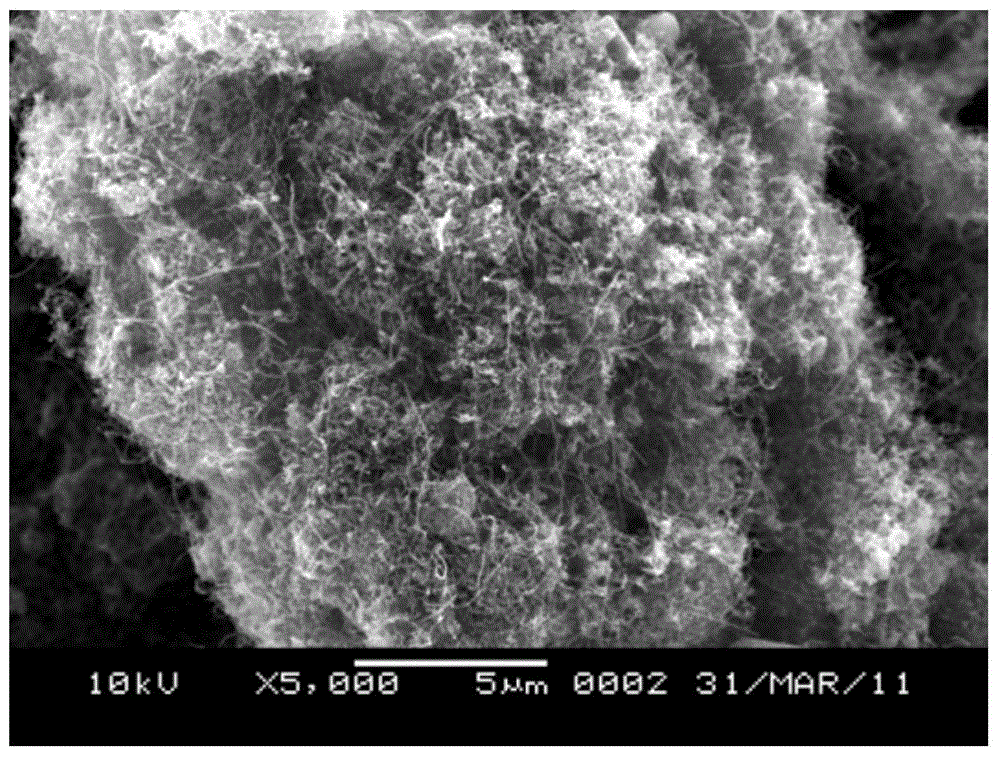

[0028] figure 1 (...

Embodiment 3

[0031] Add 0.1 g of lithium chloride, 0.16 g of ferrous chloride tetrahydrate, and 72 μL of phosphoric acid into 8 mL of absolute ethanol, stir for 2 minutes, add 6 mg of carbon nanotubes into the above-mentioned absolute alcohol solution, ultrasonicate and stir for 3 minutes each. Pour the anhydrous alcohol solution containing carbon nanotubes into the crucible, and then place the crucible on the upper part of the sealable container. The bottom of the sealable container is pre-placed with 3mL ammonia water (0.1mol / L). After sealing the container, put it into an oven, start heating to 170°C, the heating rate is 10-20°C / min, and keep it warm for 24 hours after the temperature reaches the set temperature. Cool down to room temperature naturally after heat preservation, open the airtight container, take out the crucible, pour out the powder, wash with distilled water and absolute alcohol three times respectively, and dry in vacuum at 60°C for 8 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com