Modifying method of lithium nickel manganese oxide

A lithium nickel manganese oxide modification technology, which is applied in the field of lithium ion battery cathode material preparation, can solve the problems of poor capacity and rate performance of lithium nickel manganese oxide materials, increased electrode/electrolyte interface impedance, and rapid cycle performance decay. Achieve capacity and cycle performance guarantee, easy continuous industrial production, and reduce the effect of side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

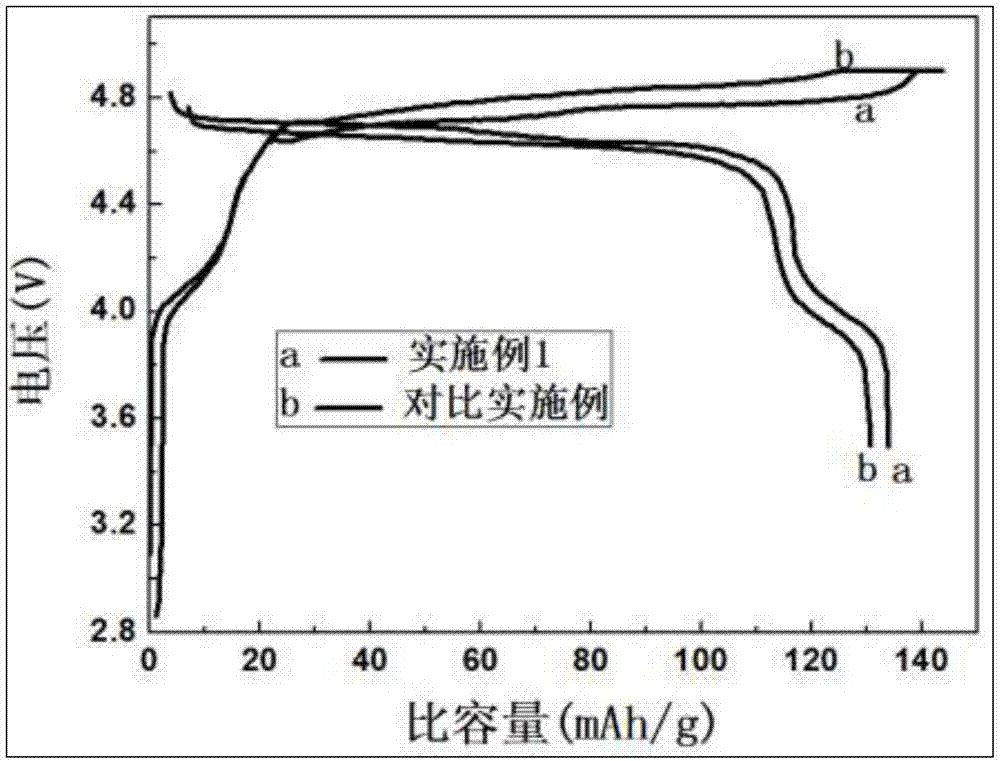

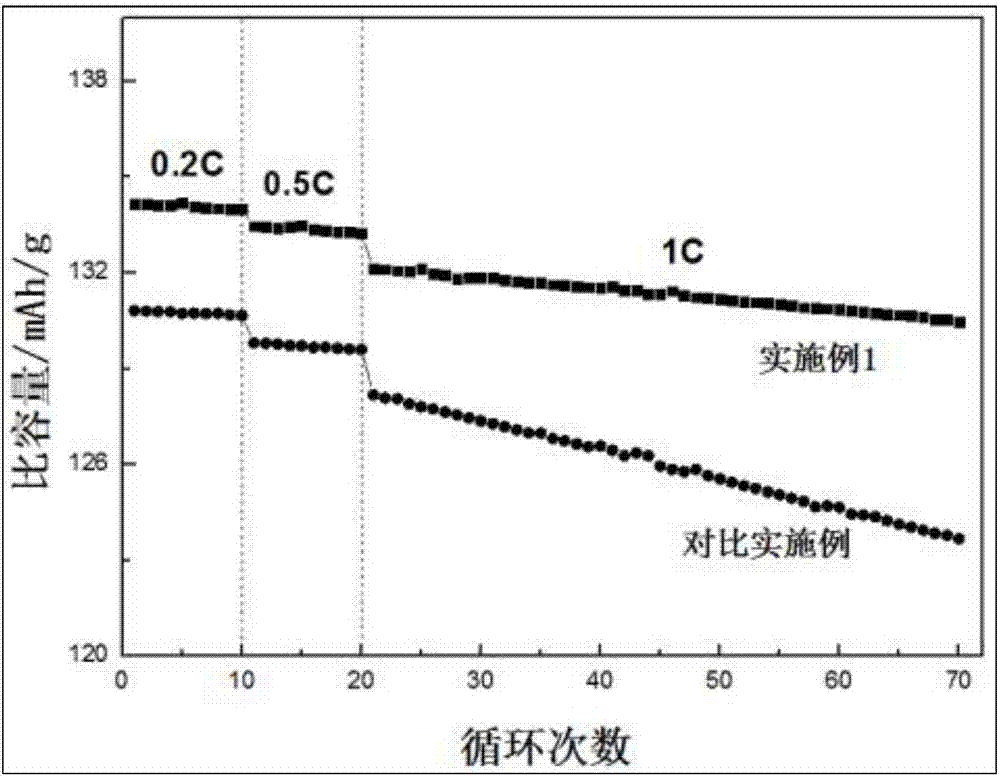

Embodiment 1

[0025] A modification method of lithium nickel manganese oxide, comprising the steps of:

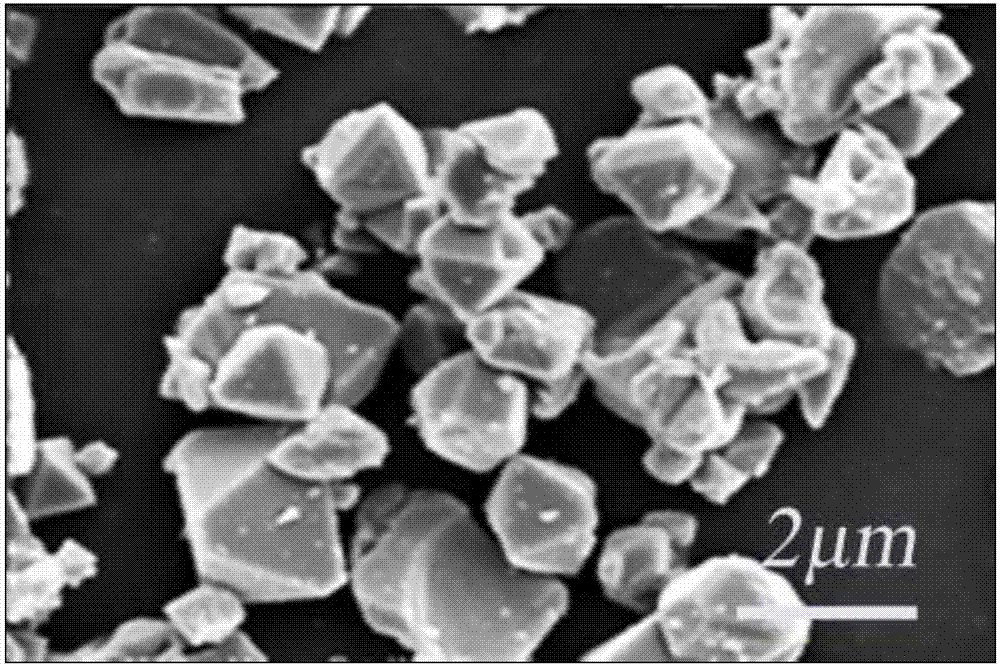

[0026] (1) Accurately weigh lithium carbonate, nickel sulfate, and manganese sulfate according to Li:Ni:Mn element ratio of 2:1:3, disperse by ball milling with isopropanol for 5 hours, and dry the obtained slurry in vacuum at 90°C , after grinding, pre-fire in an air atmosphere at 500°C for 4 hours, take it out after natural cooling, and grind to obtain a pure-phase lithium nickel manganese oxide precursor;

[0027] (2) Press Ba 5 Nb 4 o 15 : BaWO 4 : PVA=1:0.5:0.025 mass ratio to weigh Ba 5 Nb 4 o 15 、BaWO 4 , PVA, mixed to form Ba 5 Nb 4 o 15 -0.5BaWO 4 -0.025PVA composite; 2% of the mass fraction of lithium nickel manganese oxide precursor was synthesized theoretically, and Ba was weighed 5 Nb 4 o 15 -0.5BaWO 4 -0.025 PVA composite, mixed with the pure-phase lithium nickel manganese oxide precursor in step (1), using isopropanol as a dispersant, performing ball milling...

Embodiment 2

[0031] A modification method of lithium nickel manganese oxide, comprising the steps of:

[0032] (1) Accurately weigh lithium carbonate, nickel sulfate and manganese sulfate according to Li:Ni:Mn element ratio of 2:1:3, disperse by ball milling with isopropanol for 2 hours, and dry the obtained slurry under vacuum at 80°C , after grinding, pre-calcine in an air atmosphere at 450°C for 2 hours, take it out after natural cooling, and grind to obtain a pure-phase lithium nickel manganese oxide precursor;

[0033] (2) Press Ba 5 Nb 4 o 15 : BaWO 4 : PVA=1:0.1:0.01 mass ratio to weigh Ba 5 Nb 4 o 15 、BaWO 4 , PVA, mixed to form Ba 5 Nb 4 o 15 -0.1 BaWO 4 -0.01PVA compound; according to the theoretical synthesis of 0.05% of the mass fraction of lithium nickel manganese oxide precursor, weigh Ba 5 Nb 4 o 15 -0.1 BaWO 4 - 0.01 PVA composite, mixed with the pure-phase lithium nickel manganese oxide precursor in step (1), using isopropanol as a dispersant, performing bal...

Embodiment 3

[0037] A modification method of lithium nickel manganese oxide, comprising the steps of:

[0038] (1) Accurately weigh lithium acetate, nickel nitrate, and manganese nitrate according to Li:Ni:Mn element ratio of 2:1:3, disperse by ball milling with absolute ethanol for 4 hours, and dry the obtained slurry under vacuum at 90°C , after grinding, pre-calcine in an air atmosphere at 500°C for 3 hours, take it out after natural cooling, and grind to obtain a pure-phase lithium nickel manganese oxide precursor;

[0039] (2) Press Ba 5 Nb 4 o 15 : BaWO 4 : PVA=1:0.2:0.02 mass ratio to weigh Ba 5 Nb 4 o 15 、BaWO 4 , PVA, mixed to form Ba 5 Nb 4 o 15 -0.2BaWO 4 -0.02PVA compound; synthesize 1% of the mass fraction of lithium nickel manganese oxide precursor according to theory, weigh Ba 5 Nb 4 o 15 -0.2BaWO 4 -0.02 PVA composite, mixed with the pure-phase lithium nickel manganese oxide precursor in step (1), using alcohol as a dispersant, performing ball milling for 4 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com