Cu-doped ZnFe2O4 nano particles as well as preparation method and application thereof

A nanoparticle, znfe2o4 technology, applied in nanotechnology, chemical instruments and methods, instruments, etc., can solve the problems of poor selectivity and high working temperature, and achieve the effects of good crystallization, good dispersion and uniform morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

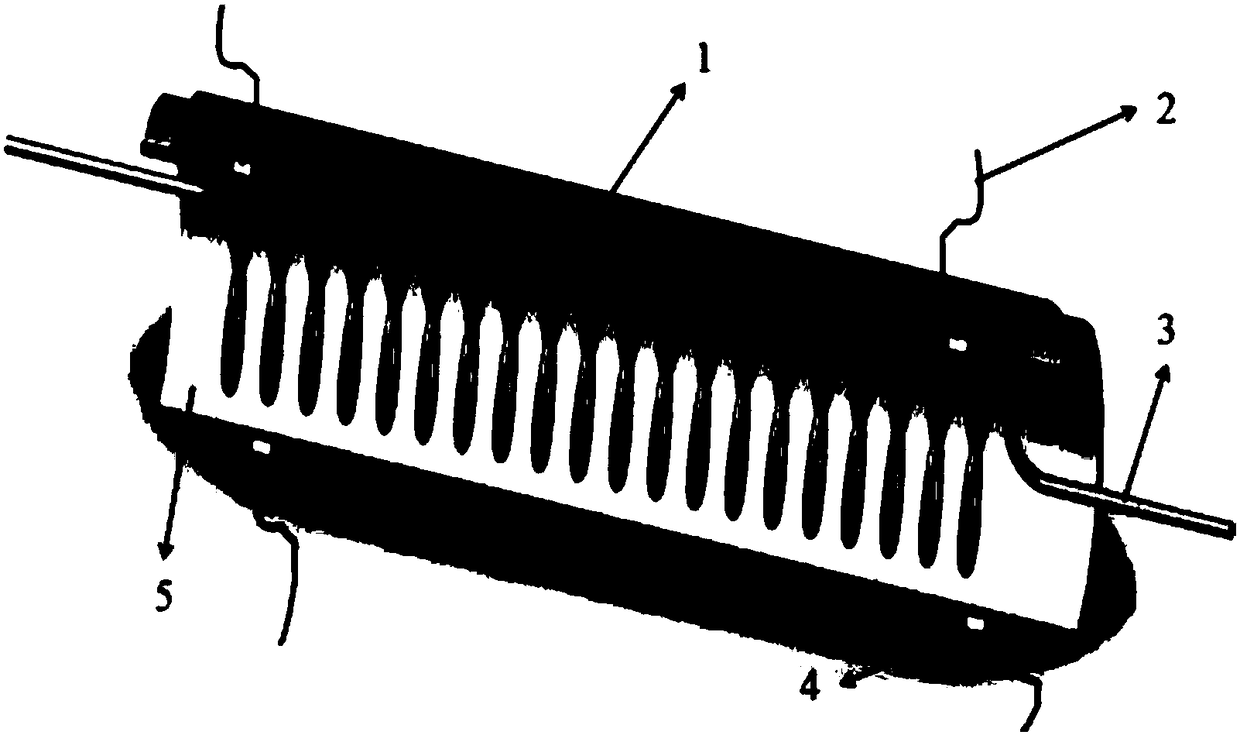

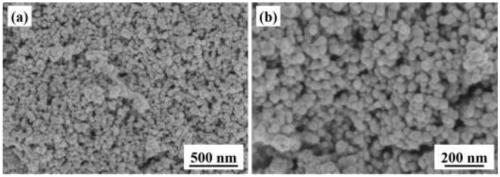

[0034] The gas sensitive coating of this embodiment is Cu-doped ZnFe 2 o 4 Schematic diagram of the main structure of the nanoparticle low-temperature gas sensor, such as figure 1 As shown, it includes a gas-sensitive coating 1; a platinum wire 2; a heating wire 3; a gold electrode 4; a ceramic tube 5; On the heating electrode, the gold electrode 4 is covered on the two ends of the outer surface of the ceramic tube 5 and welded on the four measuring electrodes of the base through the platinum wire 2, and the gas-sensitive coating 1 is coated on the outer surface of the ceramic tube 5 and the gold electrode 4 completely covered; the composition of the gas-sensitive coating 1 is Cu-doped ZnFe 2 o 4 Nanoparticles, Cu-doped ZnFe 2 o 4 The nanoparticles have a single hexagonal spinel crystal structure, the spheres are uniform in size and have good individual dispersion, and the diameter is between 30 and 50 nm.

[0035] The gas sensitive coating of this embodiment is Cu-doped...

Embodiment 2

[0045] The gas sensitive coating of this embodiment is Cu-doped ZnFe 2 o 4 Low-temperature gas sensors based on nanoparticles, such as figure 1As shown, it includes a gas-sensitive coating 1; a platinum wire 2; a heating wire 3; a gold electrode 4; On the heating electrode, the gold electrode 4 covers the two ends of the outer surface of the ceramic tube 5 and is welded on the measuring electrode of the base through the platinum wire 2, and the gas-sensitive coating 1 is coated on the outer surface of the ceramic tube 5 and the gold electrode 4 Complete coverage; the composition of the gas-sensitive coating 1 is Cu-doped ZnFe 2 o 4 Nanoparticles, Cu-doped ZnFe 2 o 4 The nanoparticles have a single hexagonal spinel crystal structure, the spheres are uniform in size and have good individual dispersion, the diameter is between 30-50nm, and they have a large specific surface area.

[0046] The present embodiment based on Cu-doped ZnFe 2 o 4 The preparation method of the lo...

Embodiment 3

[0054] The gas sensitive coating of this embodiment is Cu-doped ZnFe 2 o 4 Low-temperature gas sensors based on nanoparticles, such as figure 1 As shown, the gas-sensitive coating 1; the platinum wire 2; the heating wire 3; the gold electrode 4; the ceramic tube 5; On the electrodes, the gold electrodes 4 are covered on both ends of the outer surface of the ceramic tube 5 and welded on the measuring electrodes of the base through the platinum wire 2, and the gas-sensitive coating 1 is coated on the outer surface of the ceramic tube 5 and completely covered by the gold electrodes 4 ; The composition of the gas-sensitive coating 1 is Cu-doped ZnFe 2 o 4 Nanoparticles, Cu-doped ZnFe 2 o 4 Nanoparticles have a single hexagonal spinel crystal structure, uniform sphere size and good individual dispersion, with a diameter between 30-50nm and a large specific surface area.

[0055] The present embodiment based on Cu-doped ZnFe 2 o 4 The preparation method of the low-temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com