A treatment method for improving the service temperature and performance of silicon carbide fiber

A processing method and fiber technology, which are applied in the field of ceramic matrix composite materials preparation technology, can solve the problems of crystallization and grain growth, limit the application of SiC fibers, and damage the fiber microstructure, and achieve good crystallization and uniform microstructure. dense effect

Active Publication Date: 2011-02-16

SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

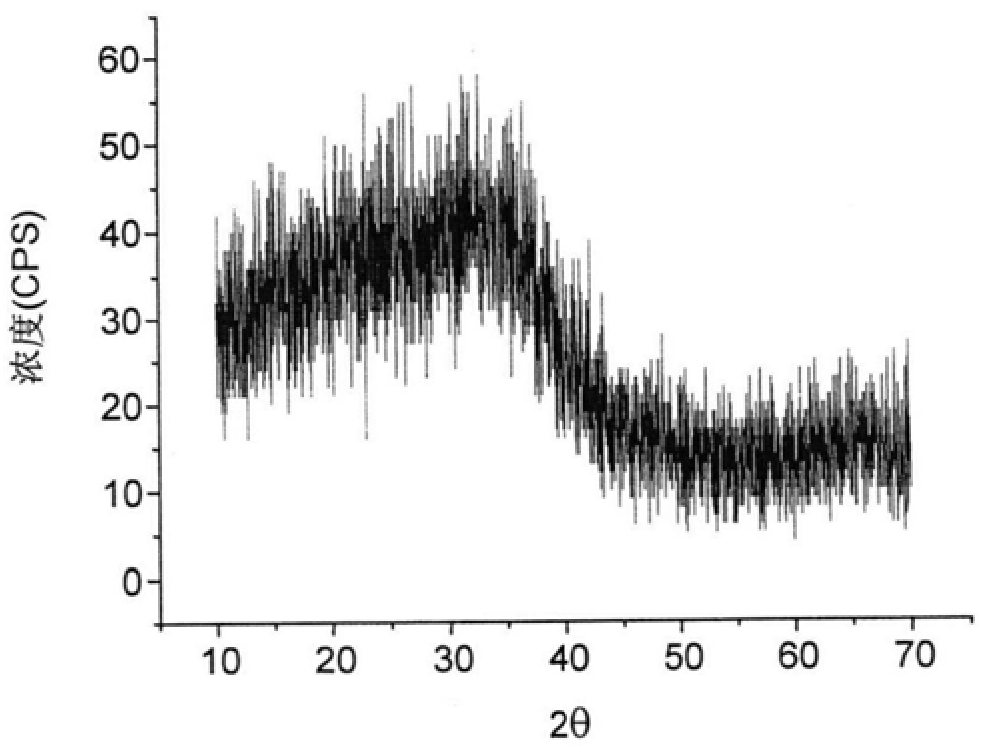

In addition, the amorphous microstructure makes it unstable at high temperature. As the temperature increases, crystallization and grain growth will also destroy the microstructure of the fiber and cause fiber degradation.

This non-stoichiometric, oxygen-containing amorphous fiber greatly limits the application of SiC fibers

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

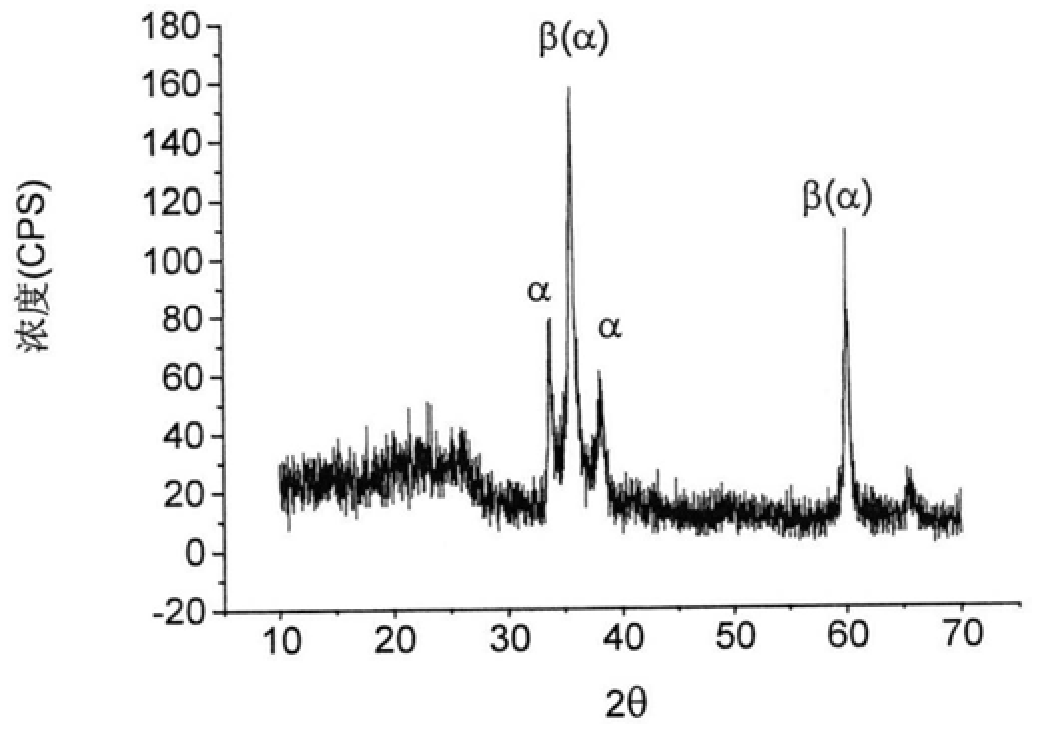

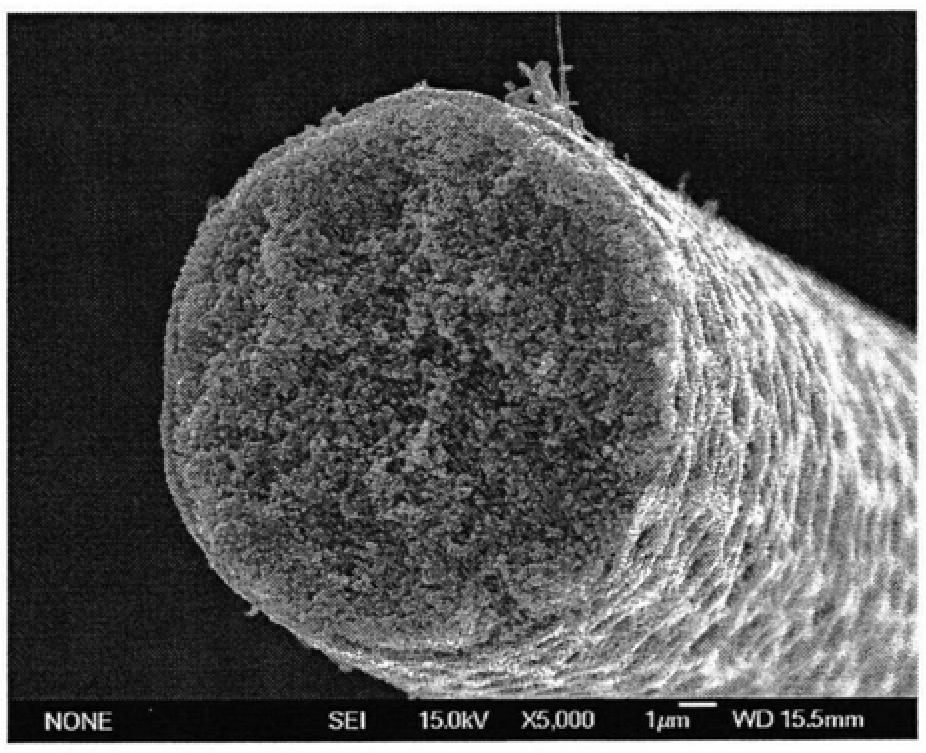

The invention relates to a treatment method for improving the use temperature and performance of SiC fibers, which is characterized in that two treatment methods are used, one of which is to immerse commercially available SiC fibers in a 15-35vol% organic polymer solution and dry After winding on the graphite tube, heat treatment in a high-temperature furnace at 30-200Mpa, 1600-2000°C in an argon atmosphere, so that the carbon formed by the pyrolysis of the organic polymer and the SiO decomposed by the SiC fiber under high temperature and low pressure are in situ Reaction to generate SiC; another method is to directly wind SiC on the graphite cylinder, and use the same heat treatment conditions as described in the first method to make free carbon in the fiber react with SiO in situ to generate SiC. The characteristics of the present invention avoid SiC fiber Degradation at high temperature leads to performance attenuation, and the oxygen content of the SiC fiber drops from 21wt% to 5wt% after being treated by the method provided by the invention.

Description

A treatment method for improving the service temperature and performance of silicon carbide fiber technical field The invention relates to a treatment method for improving the properties of ordinary SiC fibers, increasing their use temperature and performance, more precisely, relates to a treatment process for ordinary SiC fibers to avoid degradation at high temperatures, and belongs to the field of preparation technology of ceramic matrix composite materials. Background technique High-performance silicon carbide ceramics have high strength and high hardness, and the strength can be maintained up to 1600 ° C. It has good oxidation resistance, high thermal conductivity, acid and alkali corrosion resistance, low thermal expansion coefficient and good thermal shock resistance, etc. , Widely used in industry and national defense military industry. By reinforcing SiC ceramics with fibers, the fracture toughness of SiC ceramics can be improved, so that the composite material has...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B41/46C04B35/565D01F9/08

Inventor 董绍明丁玉生周清江东亮

Owner SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com