Method for sintering multiferroic bismuth ferrite-based electronic functional ceramics

A technology of functional ceramics and bismuth ferrite, which is applied in the field of functional ceramics, can solve the problems of high calcination temperature, easy mixing, and failure to obtain powder, and achieve low discharge plasma sintering temperature, good phase structure and compactness, and piezoelectricity. sex enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

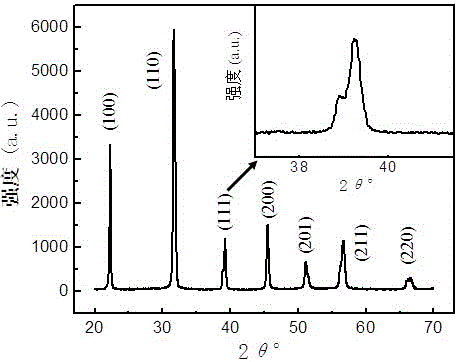

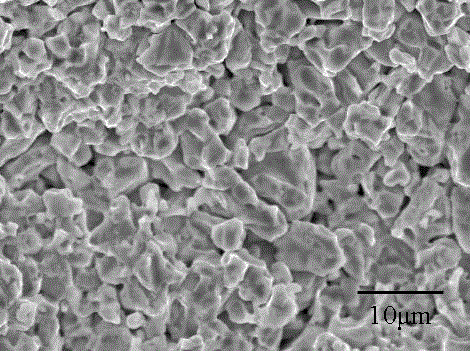

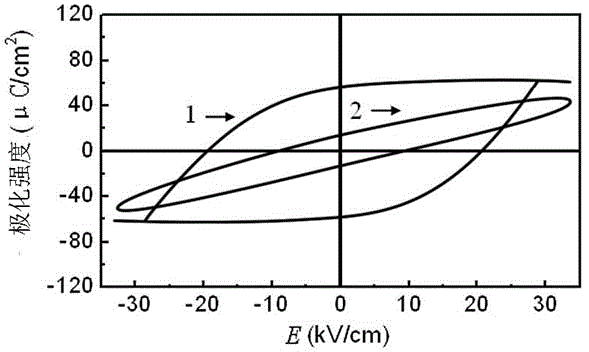

Embodiment 1

[0027] Will Fe 2 o 3 、 Bi 2 o 3 、BaCO 3 、TiO 2 and MnO 2 Mix and ball mill for 15 hours at a molar ratio of 39:39:22:22:0.4, dry, press into tablets, place the pressed columnar block in a sintering furnace for sintering, and pre-sinter at 850°C for 5 hours , cooled naturally; the pre-sintered ceramic sheets were crushed and ball-milled into powder, then pressed into tablets, and the pressed columnar block was sintered in a sintering furnace, solid-phase sintered at 950 ° C for 2 hours and then cooled naturally to obtain a solid Phase-sintered ceramic sheets; turn on the cooling water of the sintering furnace, crush the prepared solid-phase sintered ceramic sheets and put them into the sintering chamber, apply an axial pressure of 50 MPa at both ends, and vacuumize, and the air pressure of the sintering chamber is 80Pa Start heating when the vacuum degree is reached, and the heating rate is 100°C / min. When the temperature rises to 650°C, start discharge plasma sintering a...

Embodiment 2

[0030] Will Fe2 o 3 、Bi 2 o 3 、BaCO 3 、TiO 2 and MnO 2 Mix and ball mill at a molar ratio of 34:34:32:32:0.4 for 20 hours, dry, press into tablets, place the pressed columnar block in a sintering furnace for sintering, and pre-sinter at 880°C for 6 hours , natural cooling; the pre-sintered ceramic sheet is crushed and ball-milled into powder, then pressed into a tablet, the pressed columnar block is placed in a sintering furnace for sintering, solid-phase sintering at 960 ° C for 3 hours and then naturally cooled to obtain a solid Phase-sintered ceramic sheets; turn on the cooling water of the sintering furnace, crush the prepared solid-phase sintered ceramic sheets and put them into the sintering chamber, apply an axial pressure of 50 MPa at both ends, and vacuumize, and the air pressure of the sintering chamber is 80 Pa Start heating when the vacuum degree is reached, and the heating rate is 100°C / min. When the temperature rises to 660°C, start discharge plasma sinterin...

Embodiment 3

[0032] Will Fe 2 o 3 、Bi 2 o 3 、BaCO 3 、TiO 2 and MnO 2 Mix and ball mill for 10 hours at a molar ratio of 40:40:20:20:0.4, dry, press into tablets, place the pressed columnar block in a sintering furnace for sintering, and pre-sinter at 800°C for 3 hours , cooled naturally; the pre-sintered ceramic sheets were crushed and ball-milled into powder, then pressed into tablets, and the pressed columnar blocks were sintered in a sintering furnace, solid-phase sintered at 900°C for 2 hours, and then cooled naturally to obtain a solid Phase-sintered ceramic sheets; turn on the cooling water of the sintering furnace, crush the prepared solid-phase sintered ceramic sheets and put them into the sintering chamber, apply an axial pressure of 30MPa at both ends, and vacuumize, and the air pressure of the sintering chamber is 80Pa Start heating when the vacuum is high, and the heating rate is 50°C / min. When the temperature rises to 630°C, start discharge plasma sintering and keep it f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Piezoelectric coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com