Patents

Literature

427results about How to "Improve ferroelectric properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

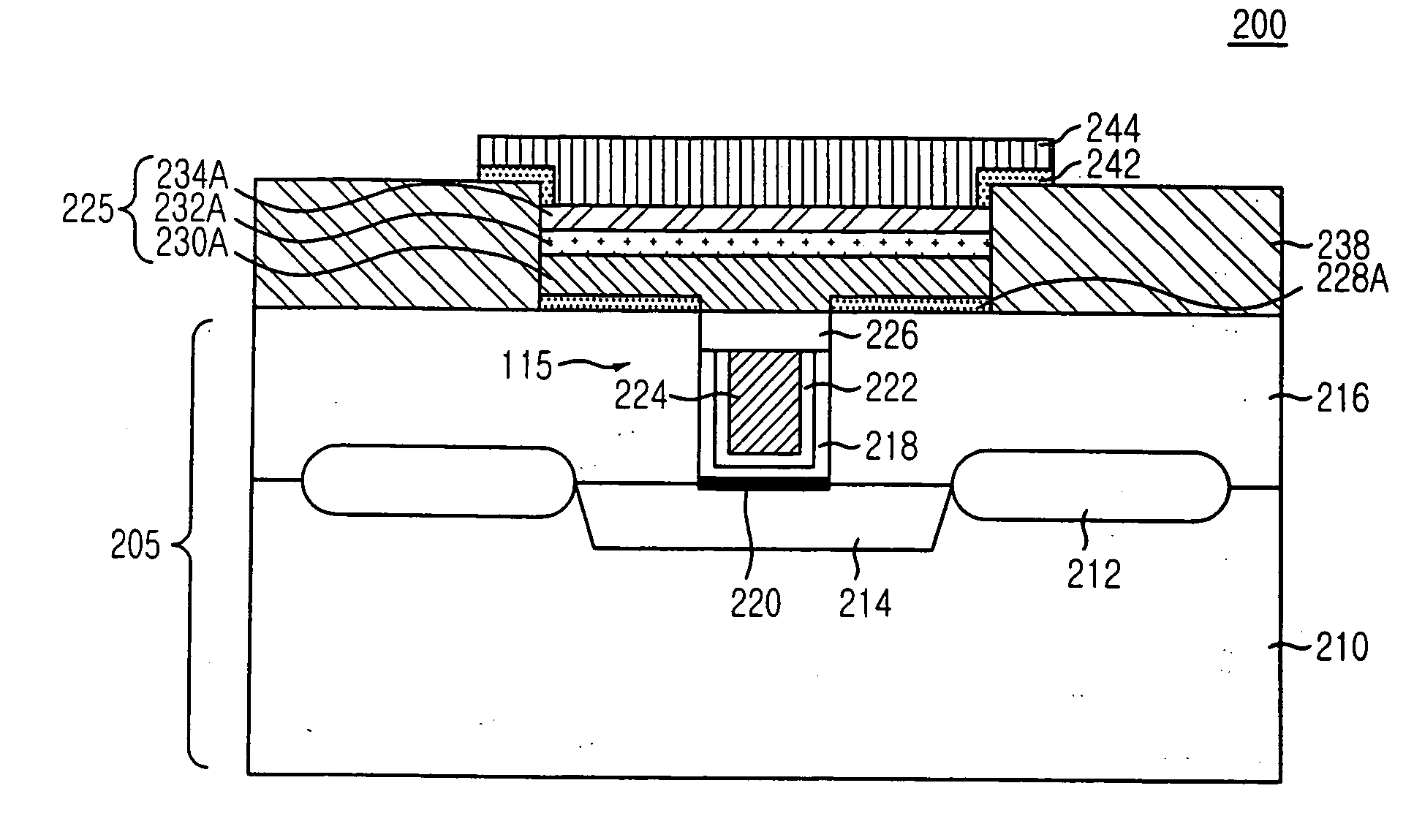

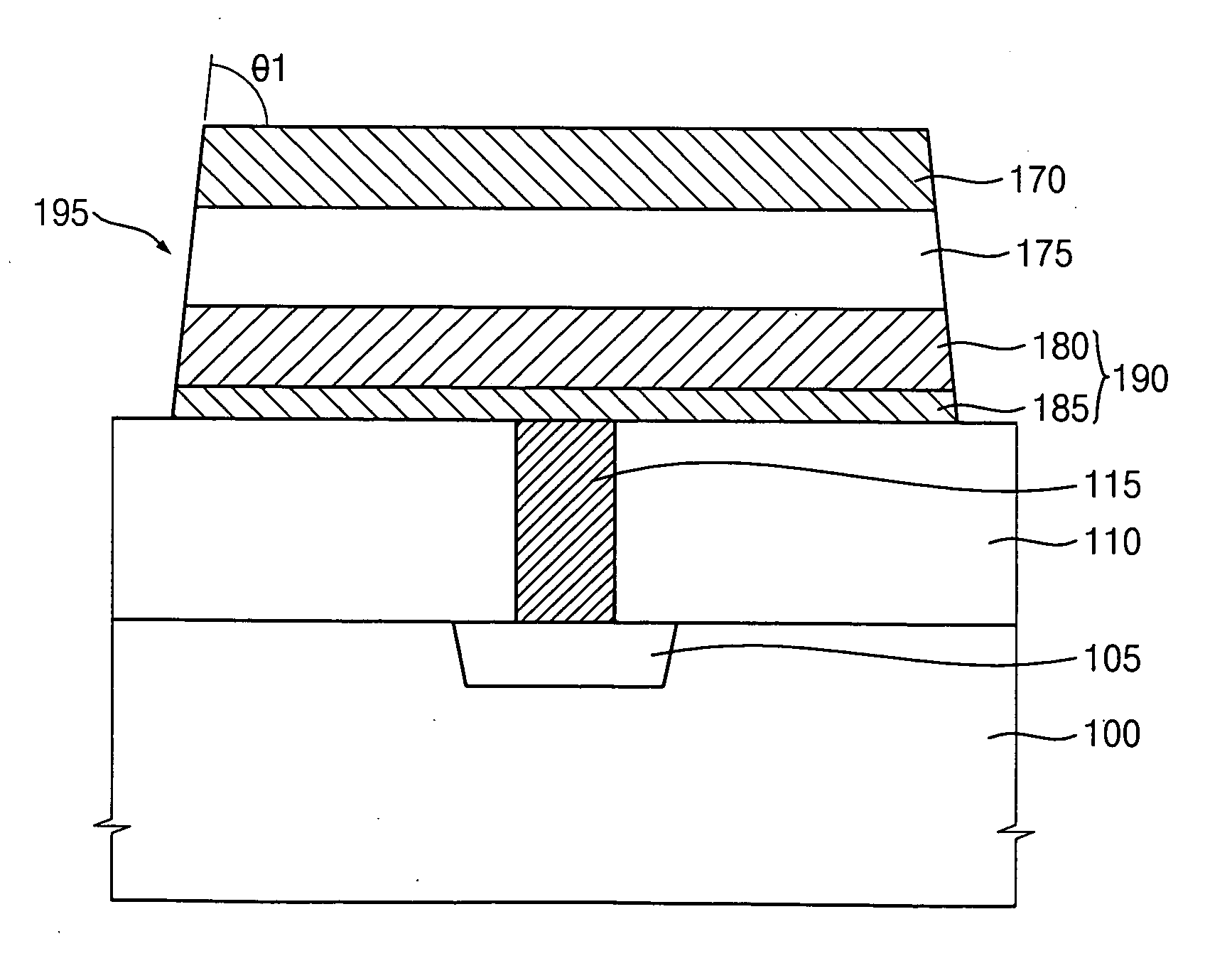

Ferroelectric random access memory capacitor and method for manufacturing the same

ActiveUS20060014307A1Avoid crackingImprove ferroelectric propertiesSolid-state devicesSemiconductor/solid-state device manufacturingCapacitanceActive matrix

The method for manufacturing an FeRAM capacitor with a merged top electrode plate line (MTP) structure is employed to prevent a detrimental impact on the FeRAM and to secure a reliable FeRAM device. The method includes steps of: preparing an active matrix obtained by a predetermined process; forming a first conductive layer, a dielectric layer and a second conductive layer on the active matrix in sequence; forming a hard mask on the second conductive layer; patterning the second conductive layer, the dielectric layer and the first conductive layer by using the hard mask, thereby forming a vertical capacitor stack, a width of the capacitor stack being larger than that of the storage node contact; forming a second ILD embracing the capacitor stack; planarizing the second ILD till the top face of the hard mask is exposed; removing the hard mask to form an opening above the top electrode; and forming a plate line of which a width is larger than that of the capacitor stack.

Owner:SK HYNIX INC

Niobic acid sodium potassium lithium radical leadless piezo-electric ceramic and preparation method thereof

InactiveCN101062864AExcellent piezoelectric propertiesImprove ferroelectric propertiesCeramicsPiezoelectric/electrostrictive/magnetostrictive devicesLithiumPotassium

The invention discloses a preparing method of niobic acid sodium potassium lithium group leadless piezoelectric ceramic in green energy source material domain, which comprises the following steps: expressing component of niobic acid sodium potassium lithium group as non-stoichiometric ratio general formula (NaaKbLic)(NbxTaySbz)O3 or -nM; expressing a, b, c as A bit element; expressing x, y, z as mole fraction of B bit element; setting the selective rage as (0<=a<=1. 5, 0<=b<=1. 5, 0 C04B 35 / 495 C04B 35 / 64 H01B 3 / 12 H01L 41 / 187 1 6 1 2007 / 5 / 28 101062864 2007 / 10 / 31 100465131 2009 / 3 / 4 2009 / 3 / 4 2009 / 3 / 4 University of Science and Technology Beijing Beijing 100083 Zhang Boping Zhao Pei Li Songjie Ding Xiaonian Zhang Hailong liuru e 11207 The Patent Agency of Beijing University of Science and Technology No.30 Xueyuan Road, Beijing 100083

Owner:UNIV OF SCI & TECH BEIJING

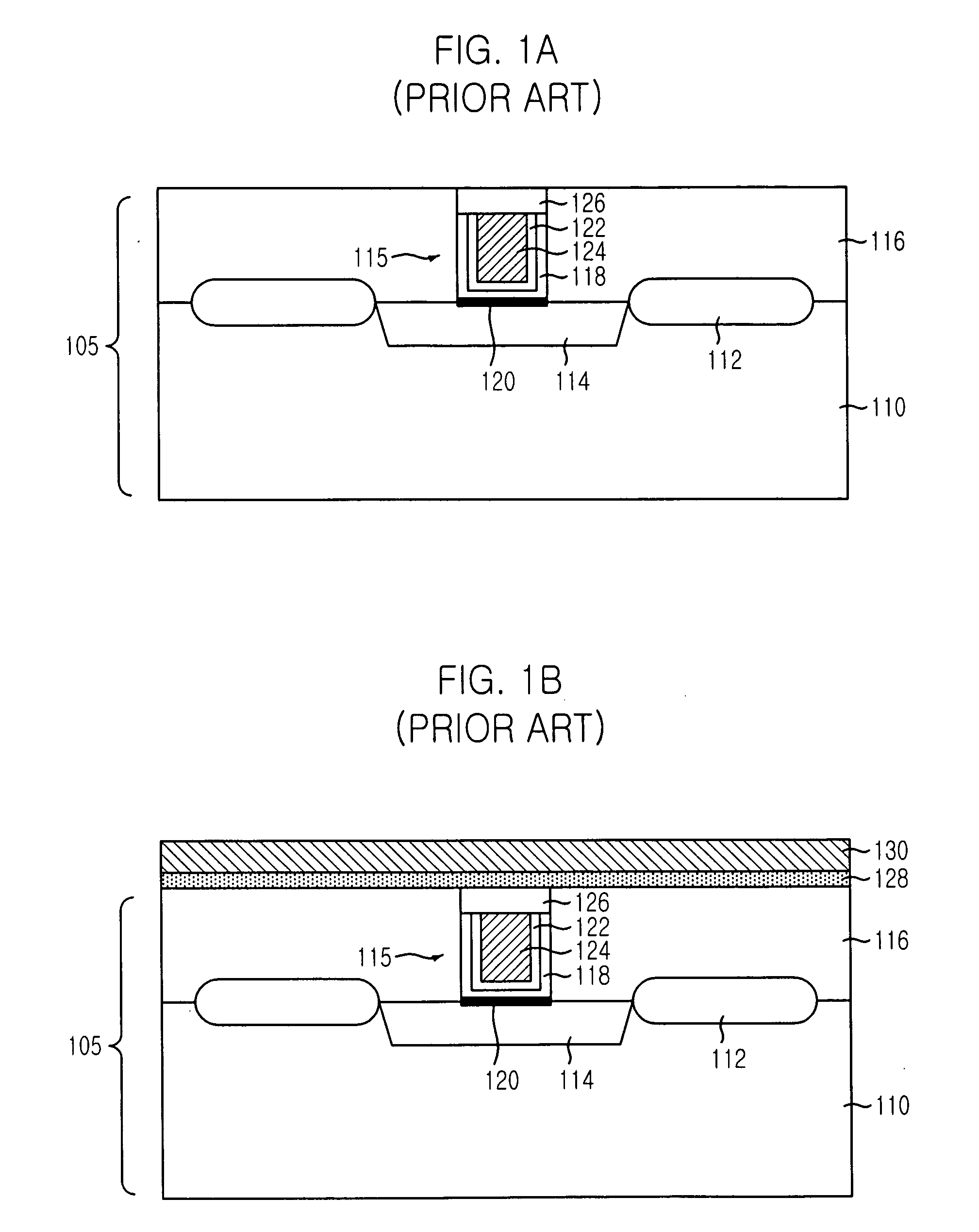

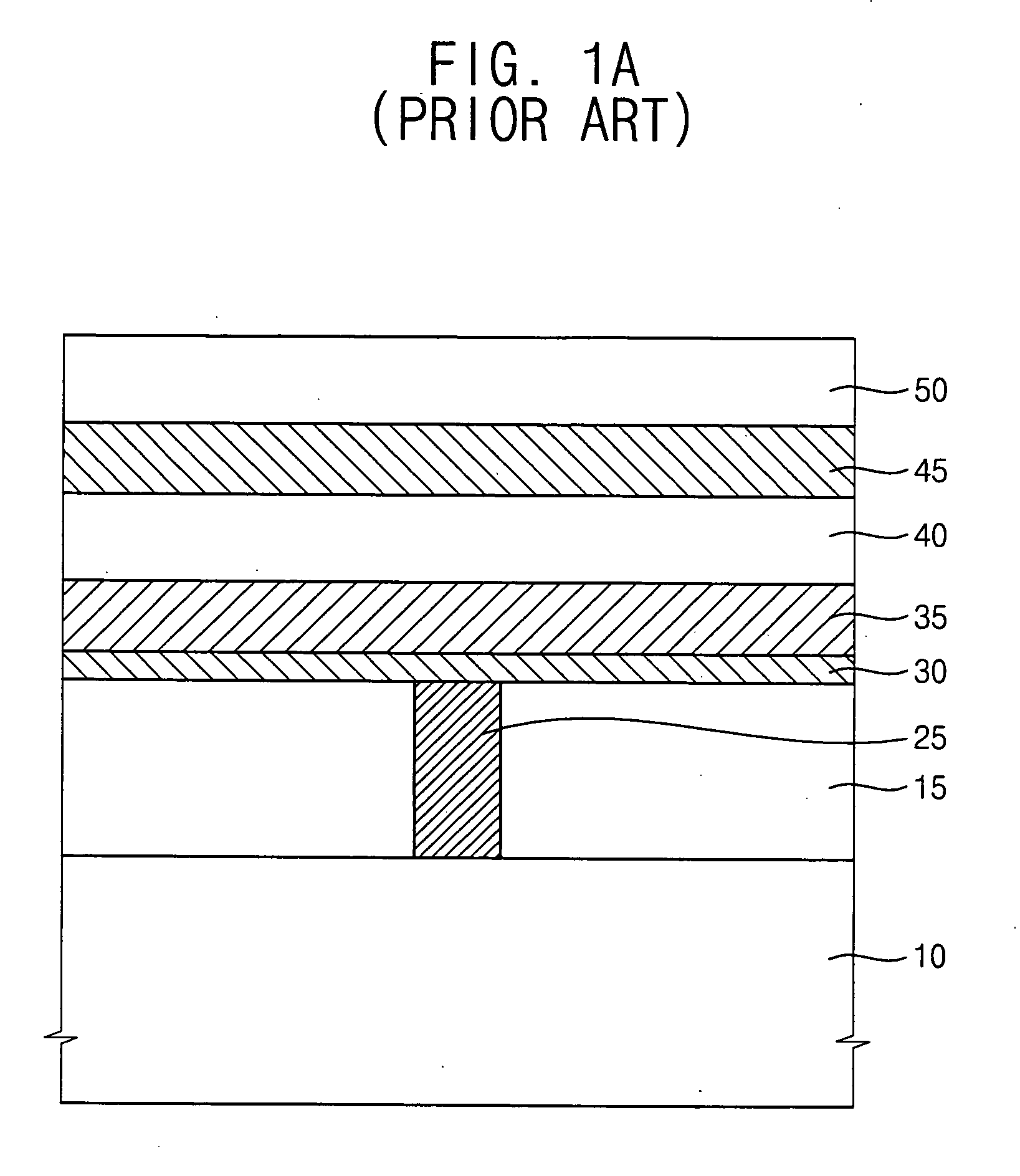

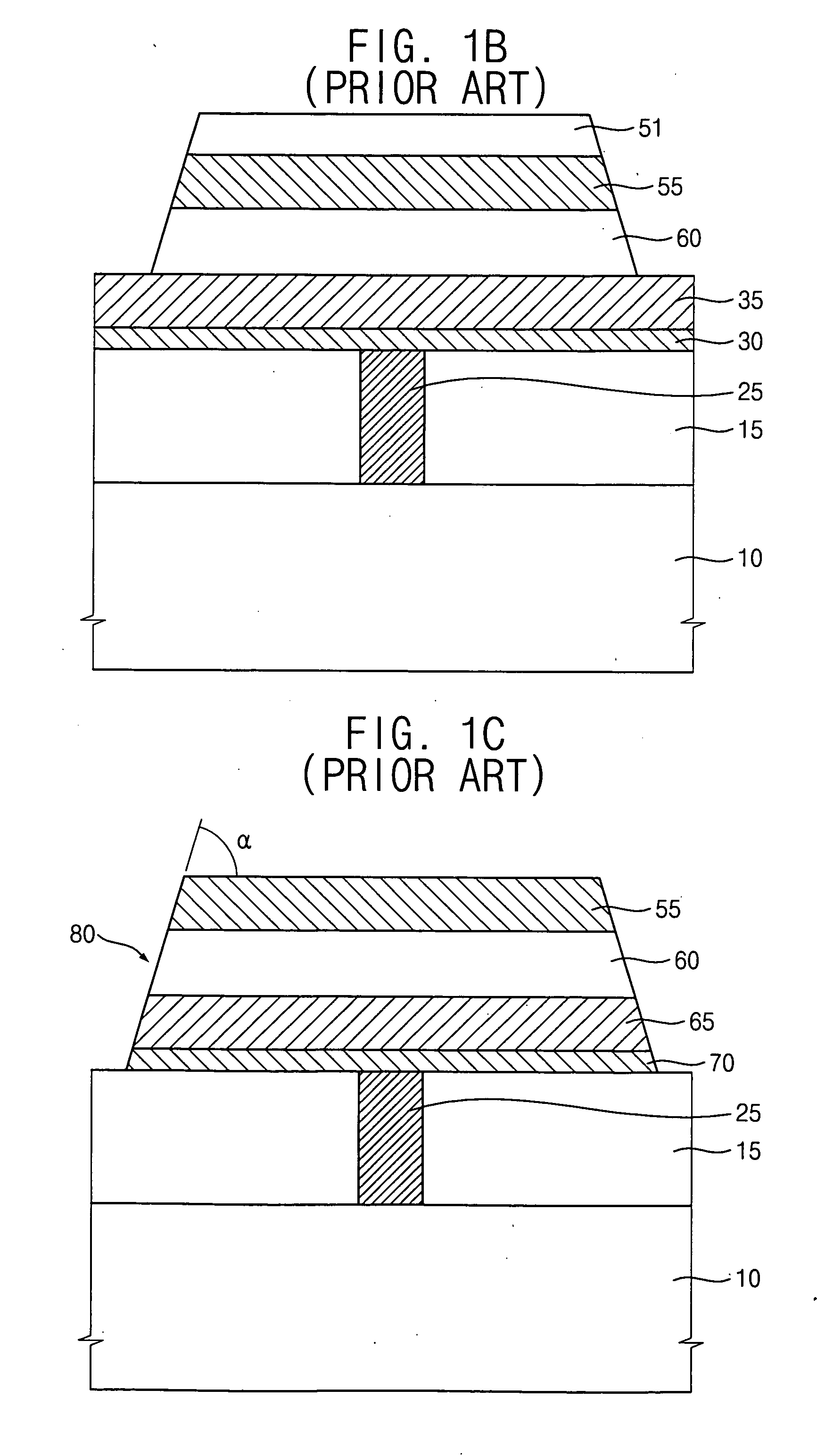

Methods of manufacturing ferroelectric capacitors and semiconductor devices

InactiveUS20060273366A1Enhance characteristicImprove data sense marginSolid-state devicesSemiconductor/solid-state device manufacturingFerroelectric capacitorSemiconductor

In a method of manufacturing a ferroelectric capacitor, a lower electrode layer is formed on a substrate. The lower electrode layer includes at least one lower electrode film. A ferroelectric layer is formed on the lower electrode layer, and then an upper electrode layer is formed on the ferroelectric layer. A hard mask structure is formed on the upper electrode layer. The hard mask structure includes a first hard mask and a second hard mask. An upper electrode, a ferroelectric layer pattern and a lower electrode are formed by partially etching the upper electrode layer, the ferroelectric layer and the lower electrode layer using the hard mask structure. The hard mask structure may prevent damage to the ferroelectric layer and may enlarge an effective area of the ferroelectric capacitor so that the ferroelectric capacitor may have enhanced electrical and ferroelectric characteristics.

Owner:SAMSUNG ELECTRONICS CO LTD

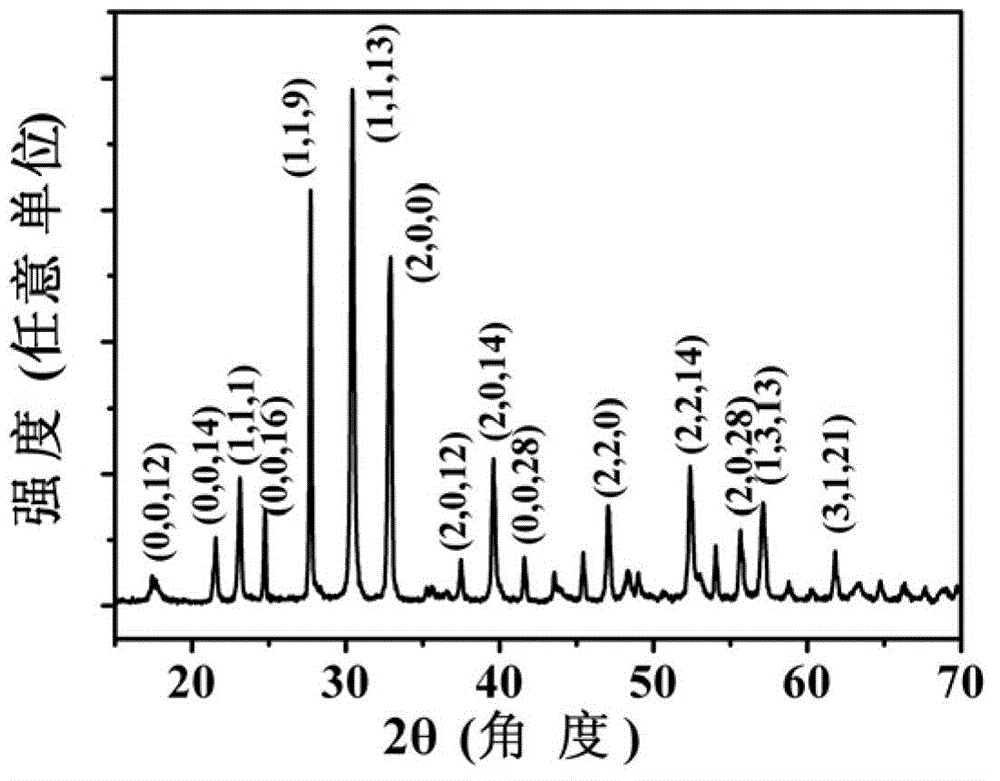

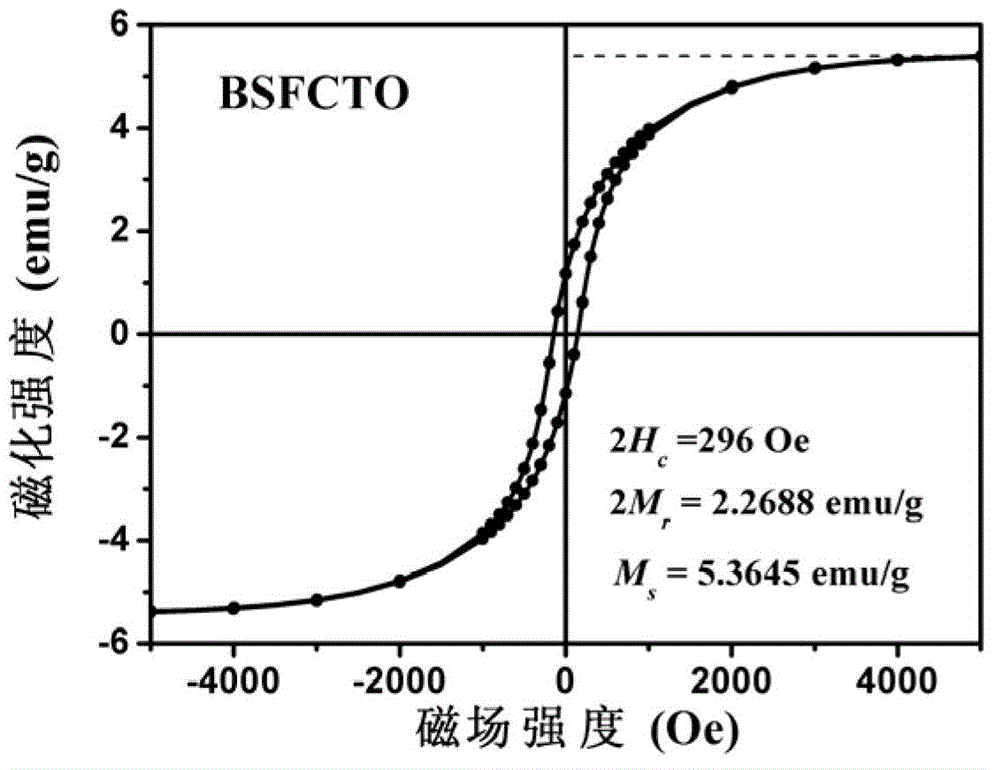

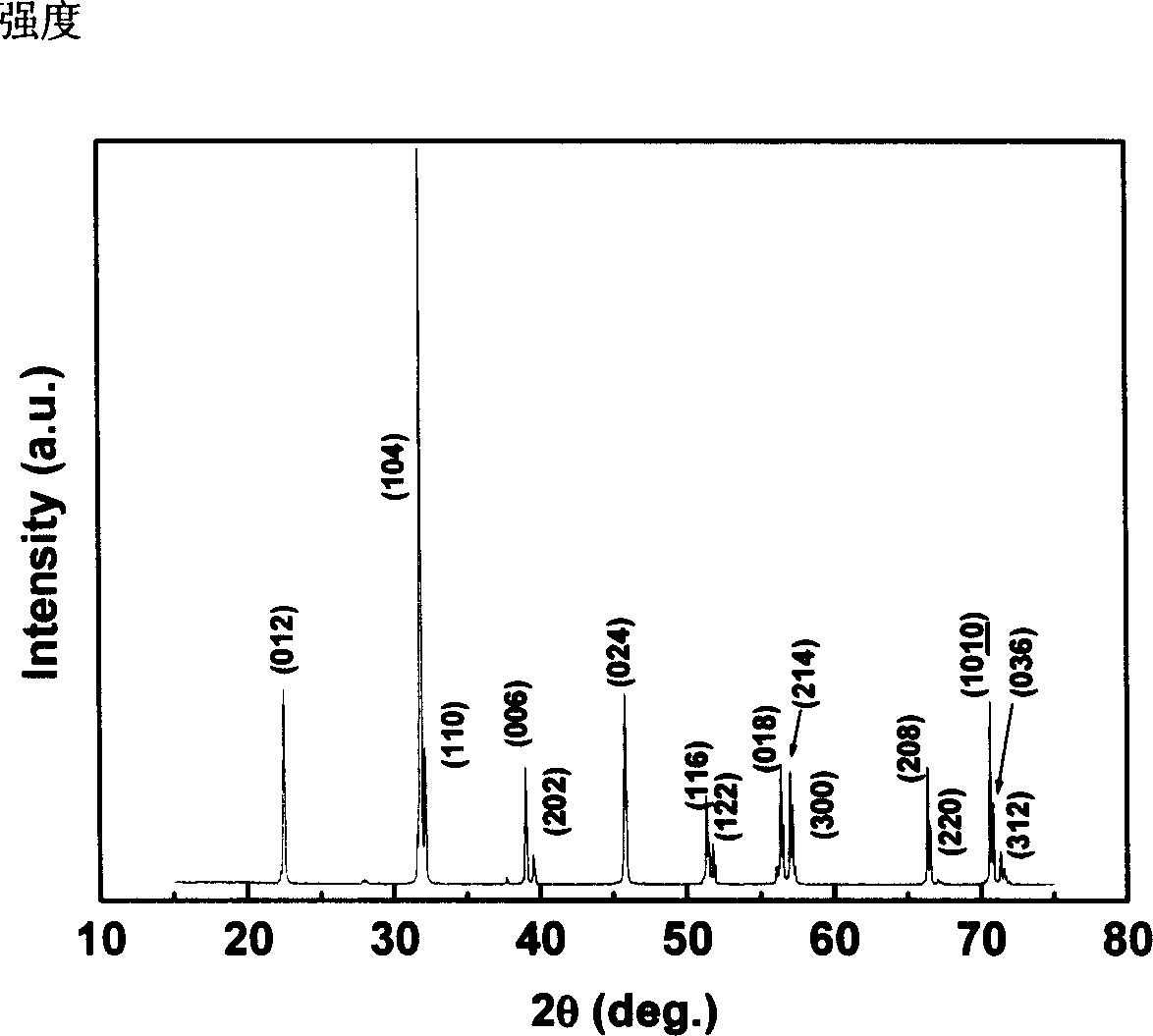

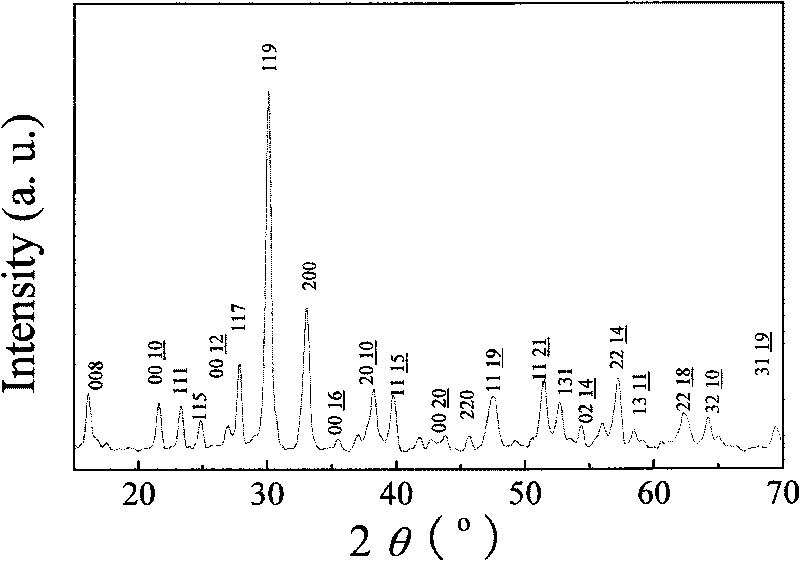

Layered perovskite structural ceramic and preparation method thereof

The invention provides layered perovskite structural ceramic and a preparation method thereof. The preparation method includes mixing well titanate compounds, bismuth compounds, strontium compounds, iron compounds, cobalt compounds and complexing agent in solvent, heating, drying and combusting to obtain powder, and presintering to obtain powder; performing the powder, and performing hot-pressing sintering to obtain the structural ceramic in in a formula (I). Compared with ceramics prepared in the prior art by solid phase sintering process, the structural ceramic in the formula (I) is prepared by solution process and hot pressing sintering. The preparation method has the advantages that less volatile low-valence strontium ions are introduced, increased leakage current due to volatilization of the strontium ions is improved, and ferroelectric properties are improved; the raw materials are evenly spread by the solution process, the power is even in component and has high reactivity, and Fe-Co ions are coupled fully; and the materials processed by hot pressing sintering are high in density and orientation, and the layered perovskite structural material can be obtained, namely Bi(n+1-x)SrxF3(n-3) / 2Co(n-3) / 2Ti3O3(n+1) (I).

Owner:UNIV OF SCI & TECH OF CHINA

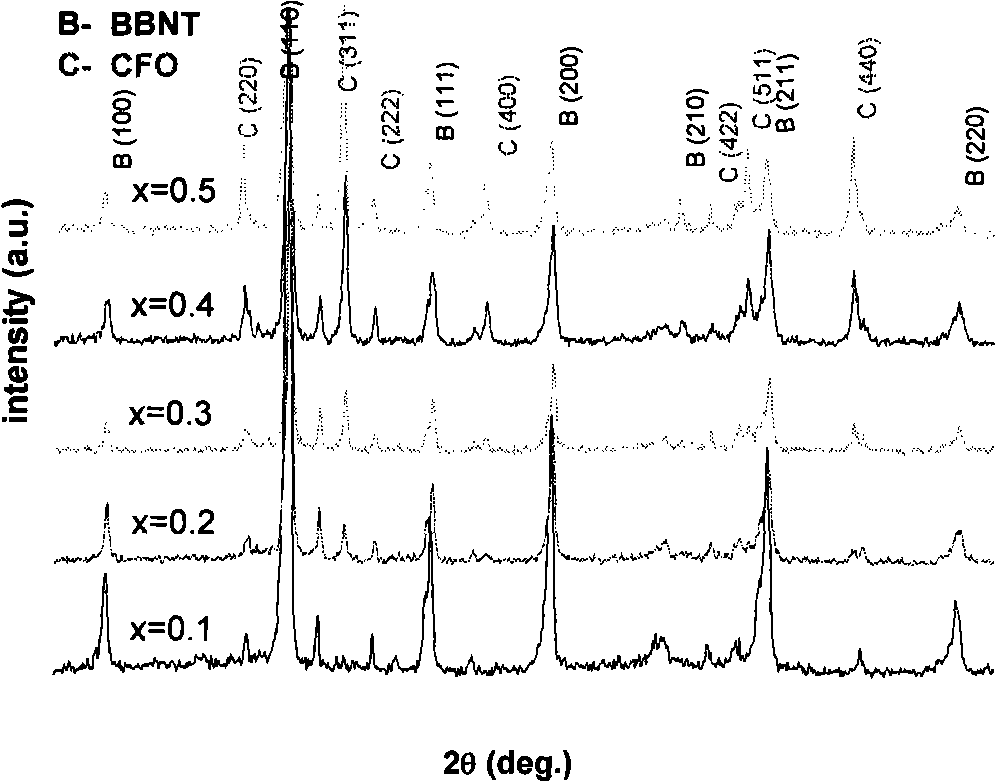

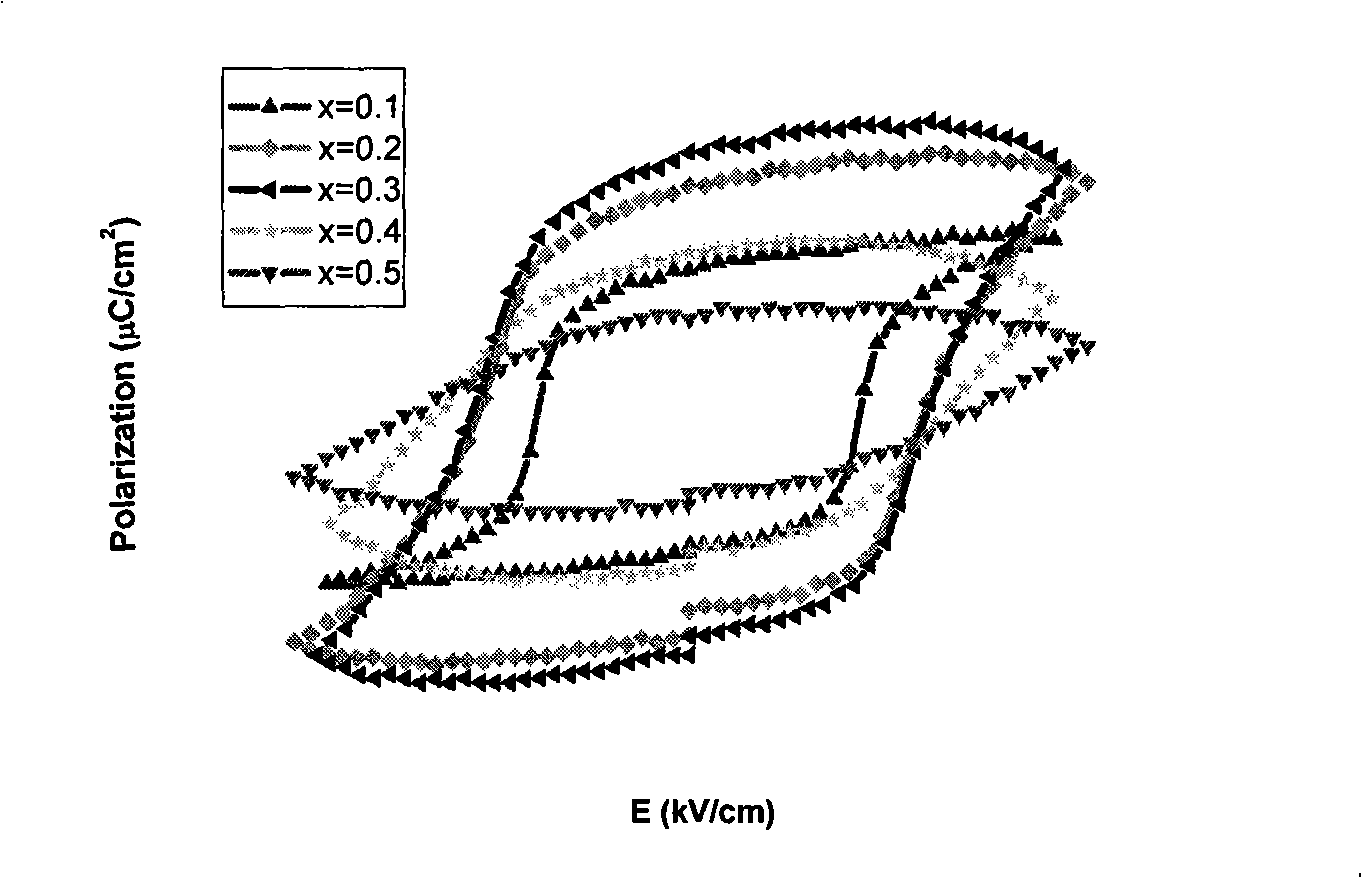

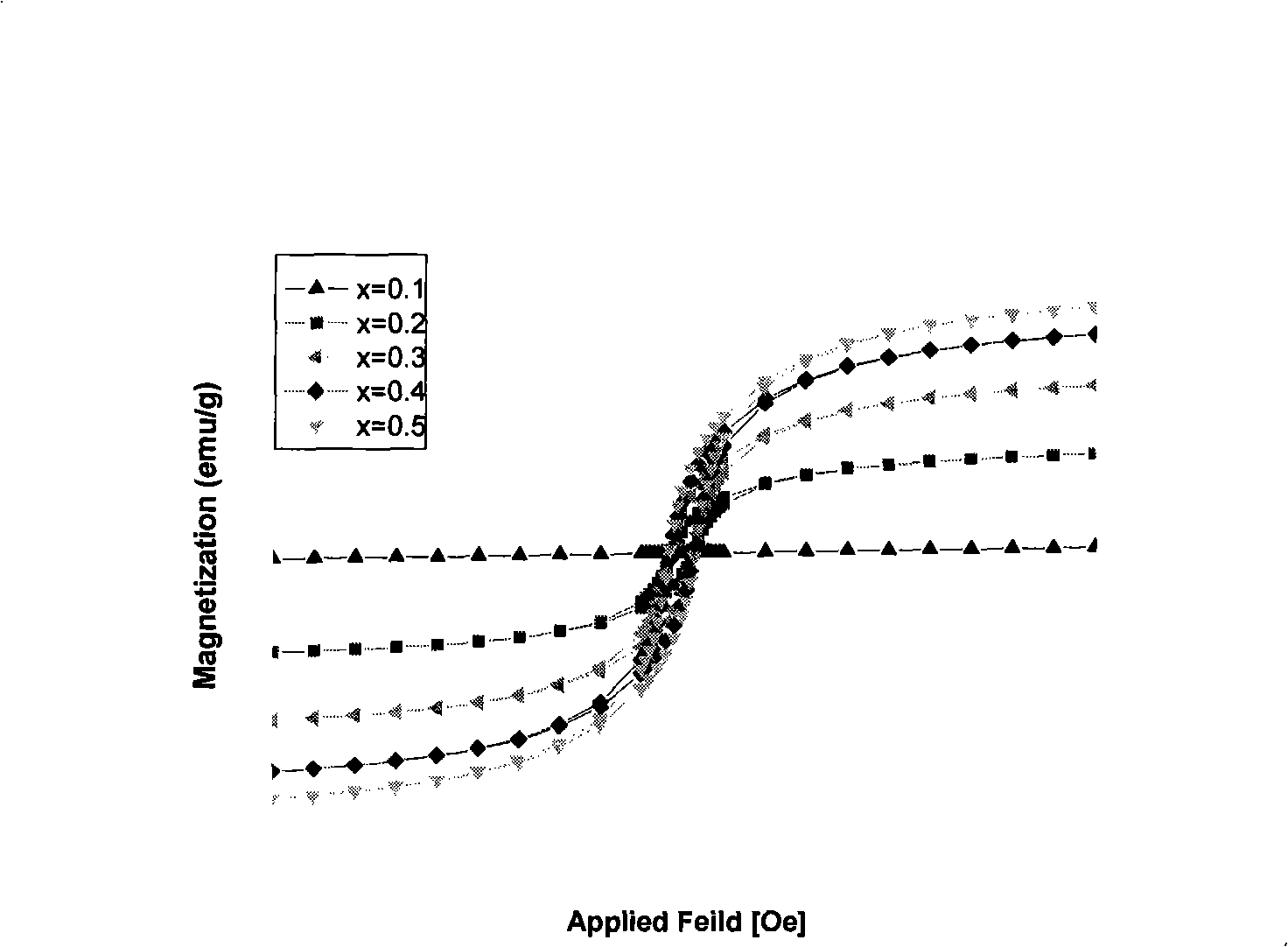

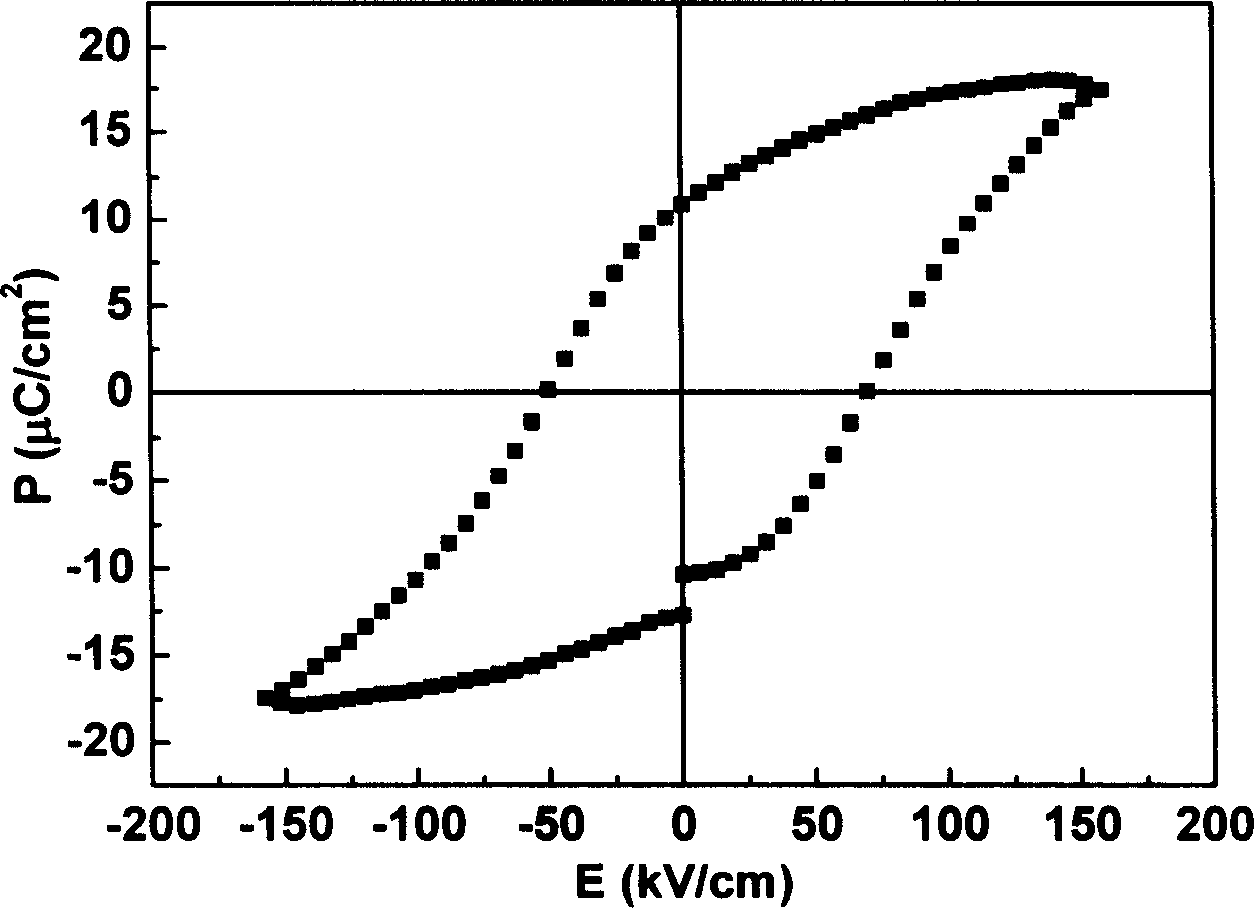

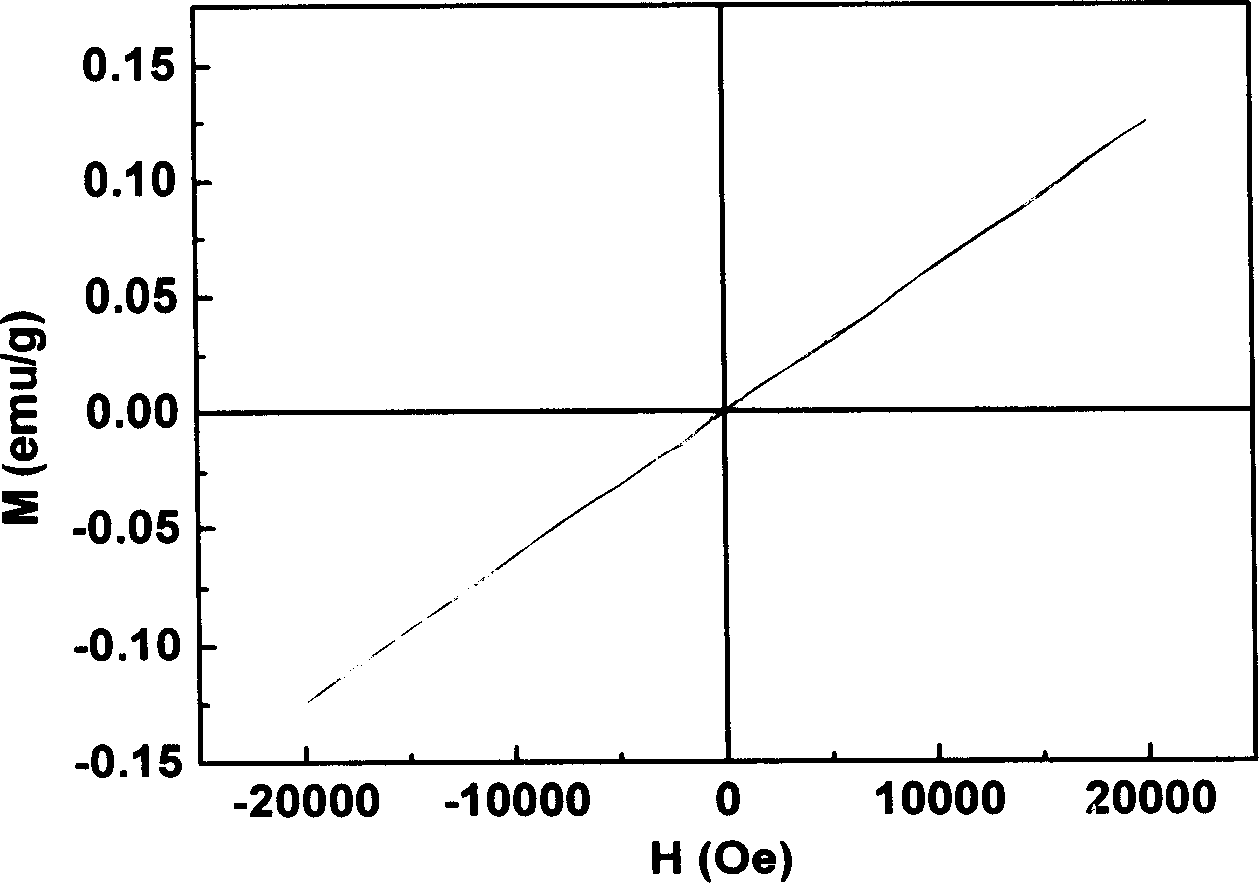

(1-x)(ba,bi,na)tio3-xcofe2o4 composite multi-iron ceramic and preparation method thereof

InactiveCN101265084AImprove ferroelectric propertiesExcellent piezoelectric propertiesCompression moldingAdhesive

The invention relates to a composite multiferroic ceramic (1-x)(Ba, Bi, Na)TiO3-xCoFe2O4, wherein x is more than or equal to 0.1 but less than or equal to 0.5. A production method of the composite multiferroic ceramic is also disclosed. The method comprises the following steps: 1) weighing Bi2O3, Na2CO3, BaTiO3, Co2O3 and Fe2O3 at the given ratio mentioned above, grinding and mixing thoroughly; 2) mixing the fine powder obtained in the step 1) with a binder and mixing thoroughly; 3) compression-molding the powder obtained in the step 2) under 10-20 MPa to obtain sheet with a thickness of 2.0 plus or minus 10% mm; and 4) in a sealed container, placing the sheet obtained in the step 3) over the fine powder obtained in the step 1), covering the sheet with the fine powder, placing the sealed container loading the sheet and powder in a heating furnace, and sintering, to obtain the composite multiferroic ceramic (1-x)(Ba, Bi, Na)TiO3-xCoFe2O4, wherein the sintering temperature is 1000-1250 DEG C and the sintering time lasts 2-3 hours. The product is free of lead and environment-friendly. The production equipment and process are simplified.

Owner:NANJING UNIV

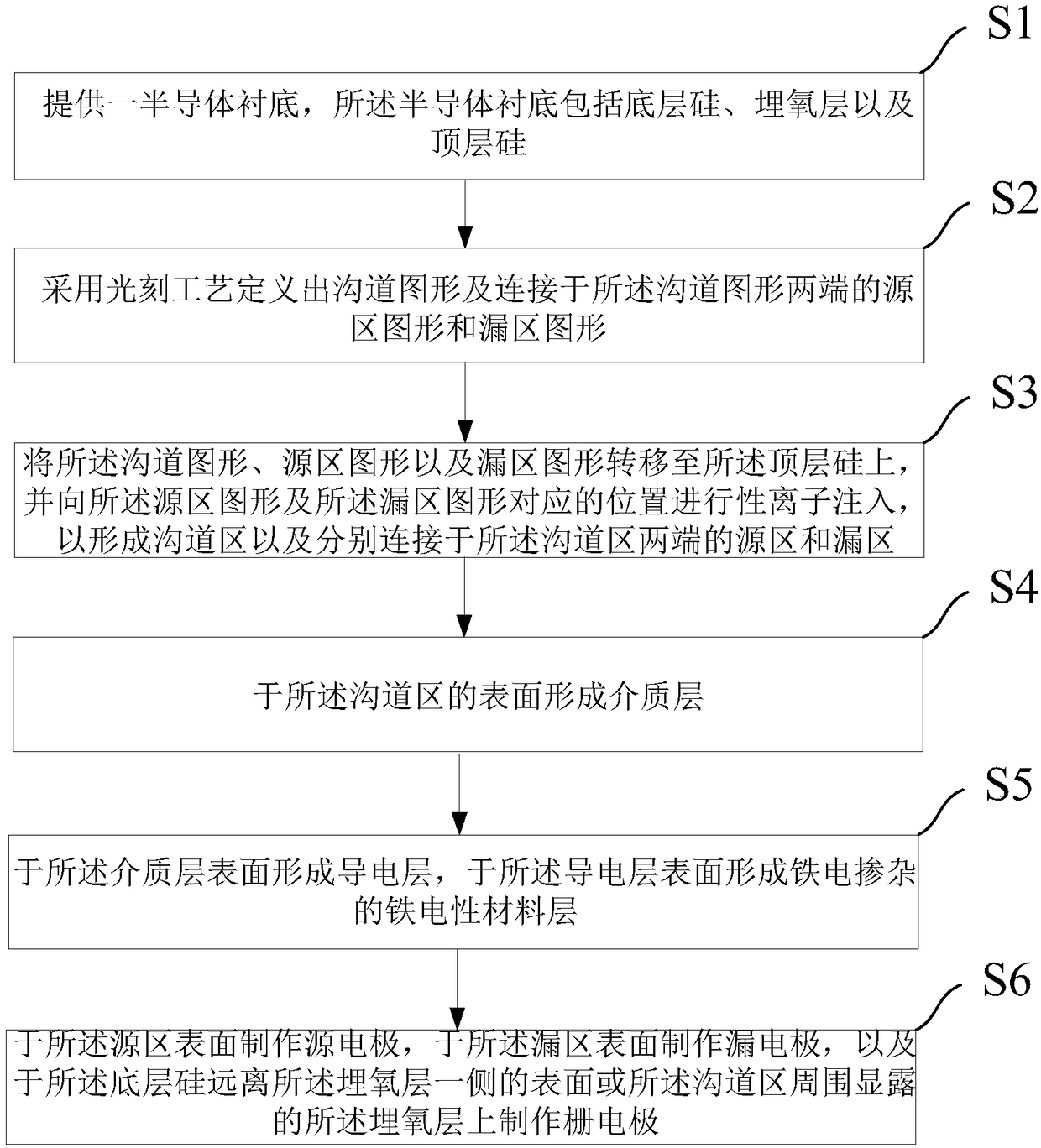

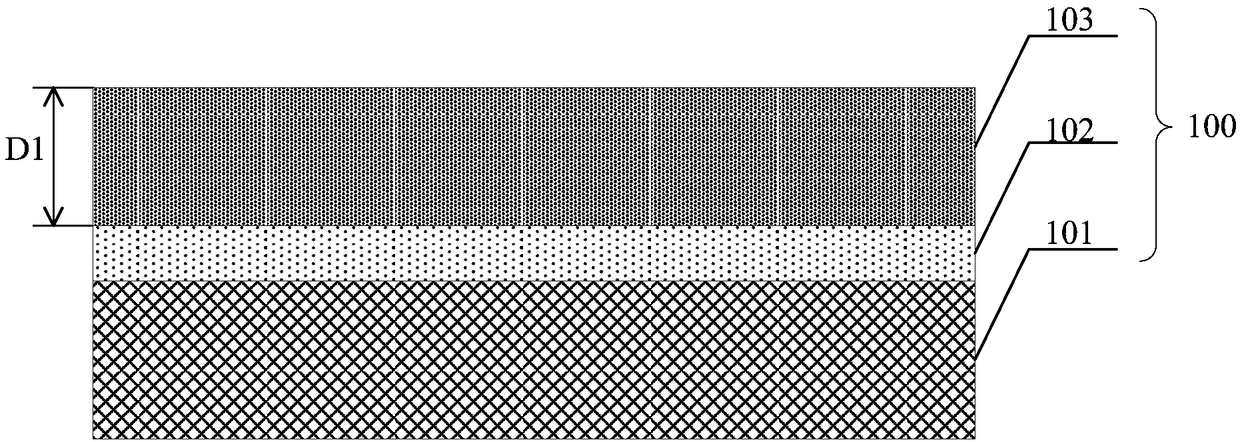

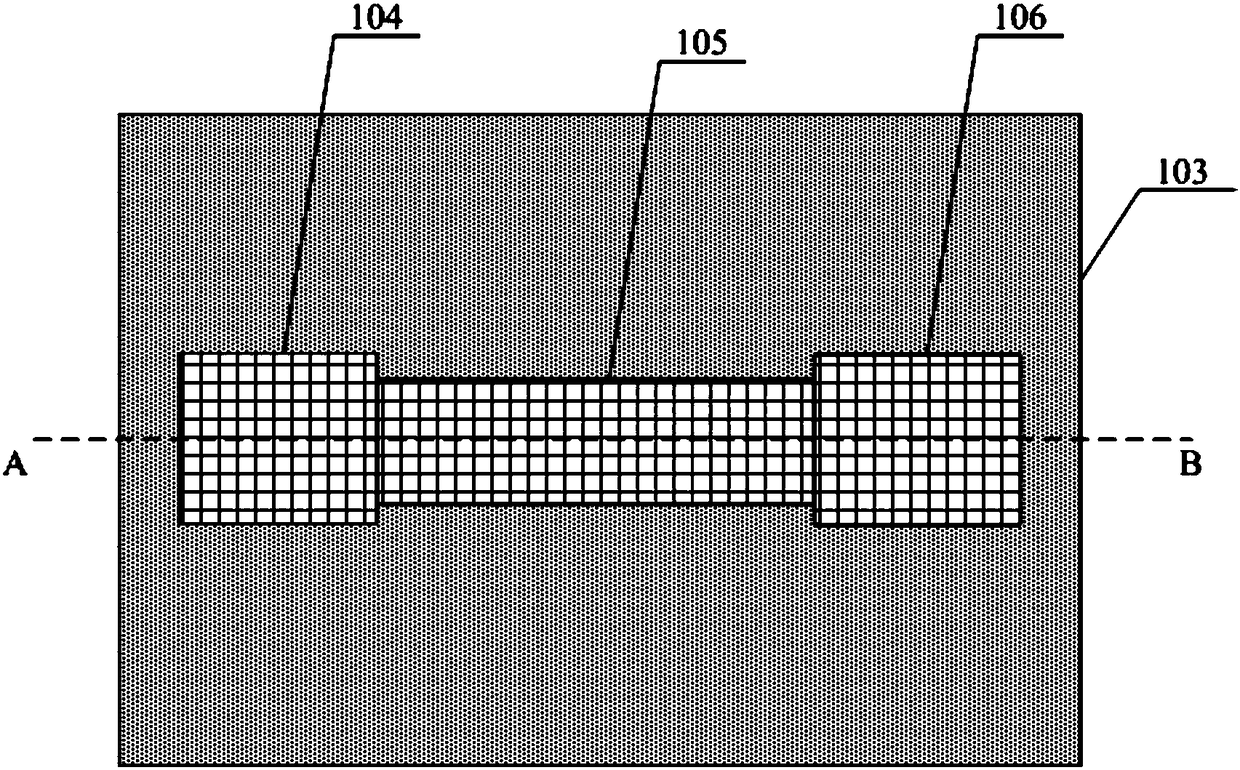

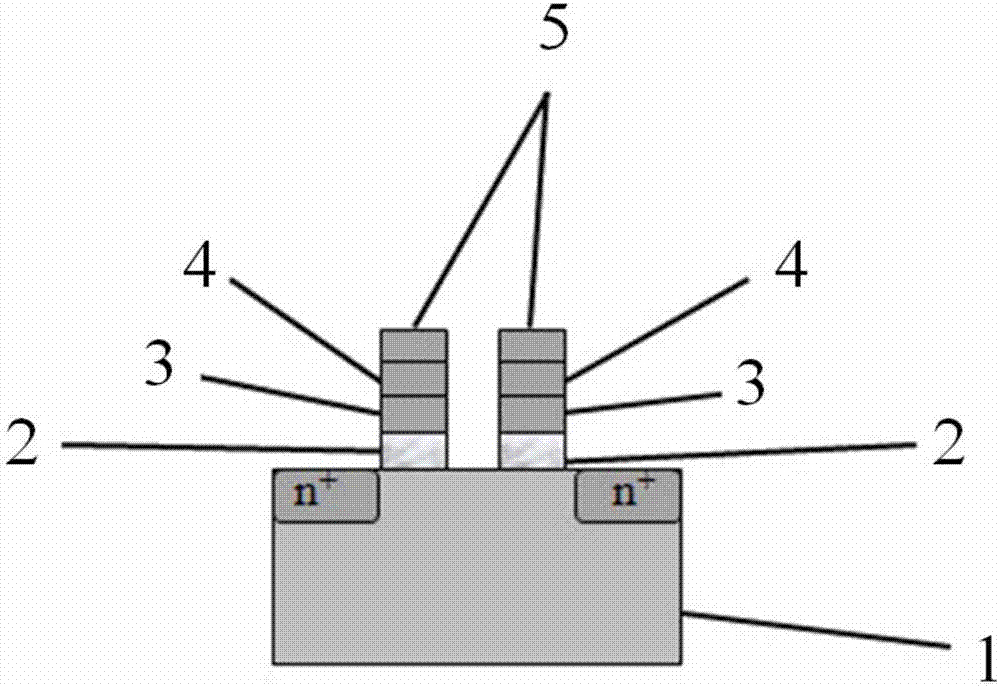

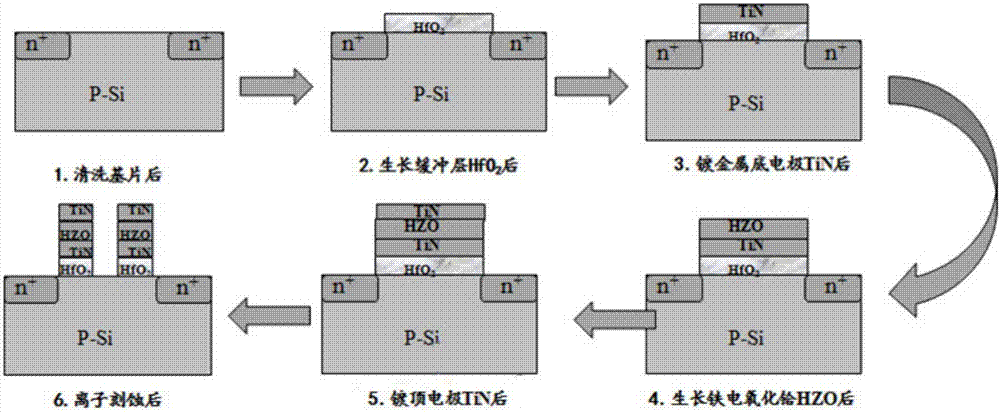

Field effect transistor based on negative capacitance and preparation method thereof, and biosensor and preparation method thereof

InactiveCN108231901AReduced subthreshold swingLow powerTransistorMaterial analysis by electric/magnetic meansCapacitanceCMOS

The present invention provides a field effect transistor based on negative capacitance and a preparation method thereof, and a biosensor and a preparation method thereof. The preparation method of thefield effect transistor comprises the steps of: providing a semiconductor substrate comprising underlying silicon, buried oxide and top silicon; defining a channel figure, and a source figure and a drain figure which are connected with two ends; performing ion implantation to positions corresponding to the source figure and the drain figure to form a channel region, a source region and a drain region; forming a dielectric layer at the surface of the channel region; forming a conductive layer at the surface of the dielectric layer, and forming a ferroelectricity material layer at the surface of the conductive layer; and making a source electrode, a drain electrode and a gate electrode. According to the scheme, a traditional field effect transistor is integrated with the ferroelectricity negative capacitance to reduce the subthreshold amplitude of a device, improve the sensing sensitivity and the response speed and facilitate reduction of the device power; and moreover, the ferroelectric-doping hafnium oxide is taken as a ferroelectric negative capacitance medium so as to solve the problem that inorganic ferroelectric materials are difficult to a CMOS technology.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

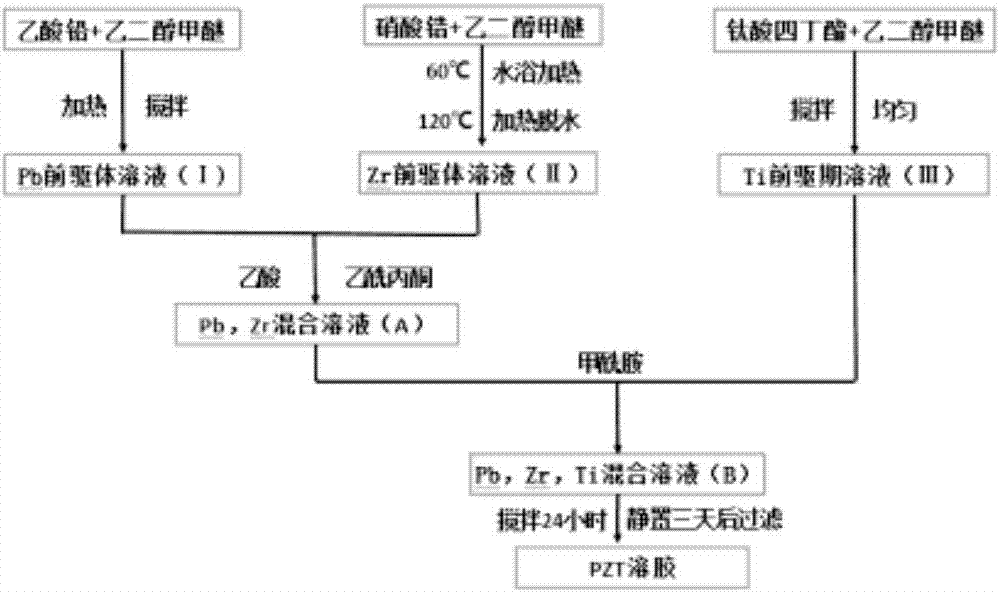

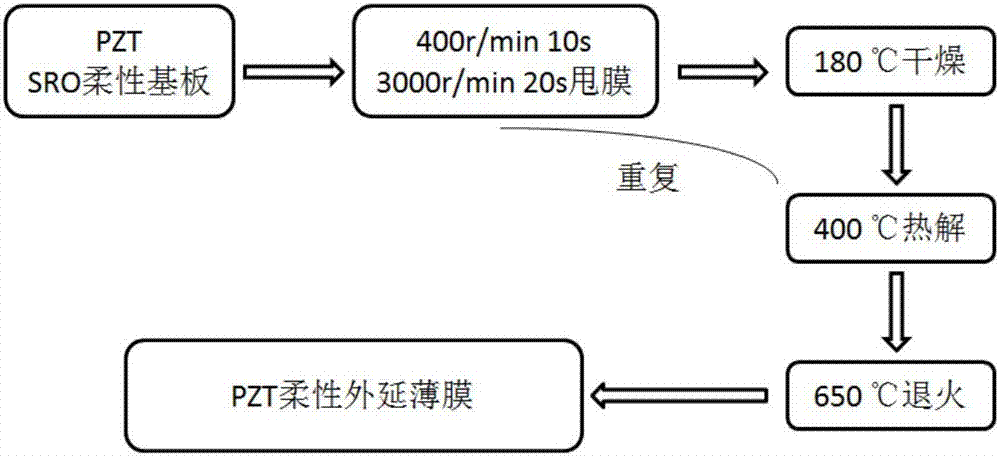

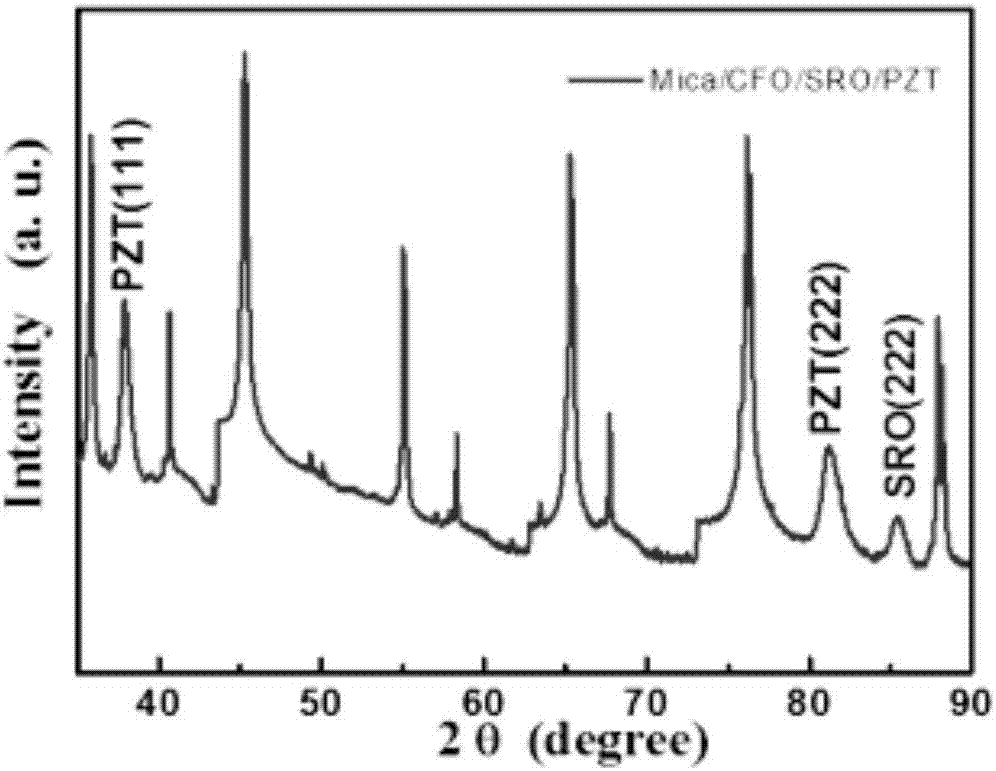

Preparation method of flexible epitaxial ferroelectric film

ActiveCN107256866AExcellent ferroelectric propertiesFormulation technology optimizationSolid-state devicesVacuum evaporation coatingStrontium ruthenateFilm material

The invention discloses a preparation method of a flexible epitaxial ferroelectric film. The preparation method is characterized by 1) preparing a perovskite structure oxide strontium ruthenate bottom electrode by a laser pulse deposition method; 2) preparing a precursor solution of the ferroelectric film by means of a sol-gel method, wherein the concentration of the precursor solution is 0.1-0.5mol / L, the ferroelectric film material is selected from any one of lead zirconate titanate, barium titanate or bismuth ferrite; 3) preparing the flexible epitaxial ferroelectric film, spin-coating the above-mentioned strontium ruthenate bottom electrode with the precursor solution by means of a spin coating method to obtain a uniform wet film; 4) drying, pyrolyzing and annealing the obtained uniform wet film; and (5) repeating steps 3) and 4) for 3-8 times to obtain the target flexible epitaxial ferroelectric film, and the thickness of the film is in the range of 100nm-300nm. The flexible epitaxial ferroelectric film is simple in technology and excellent in ferroelectric performance.

Owner:XIANGTAN UNIV

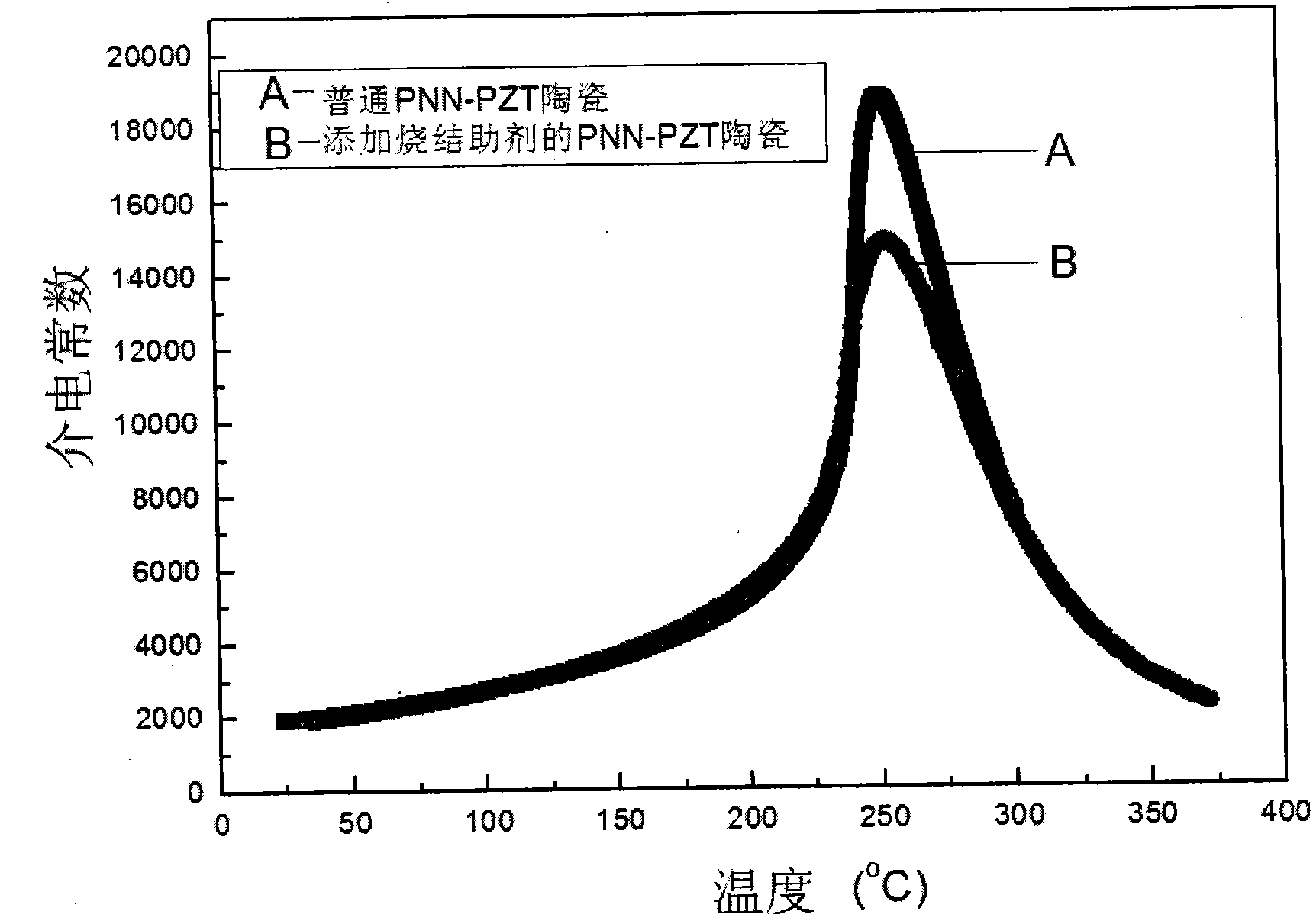

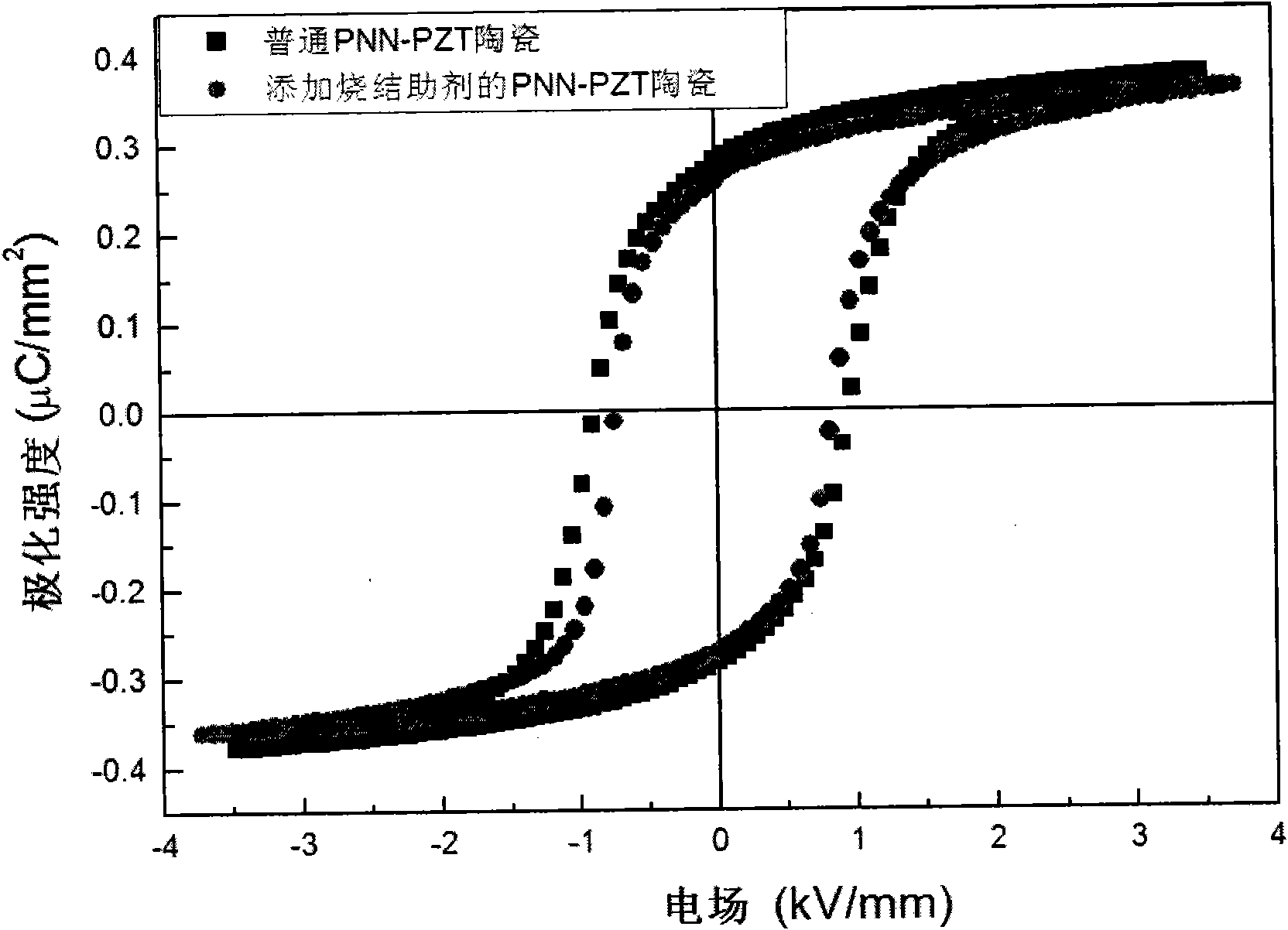

Pb (Ni1/3 Nb2/3) O3-Pb (Zr, Ti) O3 ceramic powder sintered under low temperature and fabrication method thereof

ActiveCN101805183AExcellent ferroelectric propertiesLower sintering temperaturePiezoelectric/electrostrictive/magnetostrictive devicesSolid phasesCeramic

The invention belongs to the field of new inorganic material preparation and technical study, in particular relates to the low-temperature sintering formulation of a high-performance piezoelectric ceramics and the technology thereof. By adding the sintering auxiliary combination of Ba (CU 0.5w 0.5) O3, LiBiO2 and CuO, and adopting the common solid-phase combinatorial synthesis, the method of the invention can prepare ceramics Pb (Ni1 / 3 Nb2 / 3) O3-Pb (Zr, Ti) O3. The ceramics can be sintered under the temperature as low as 950 DEG C. The ceramics also boost a sound ferro-voltage electrical property. The key steps of the technical scheme are: synthesizing Pb (Ni1 / 3 Nb2 / 3) O3-Pb (Zr, Ti) O3 ceramic powders using Pb3O4, NiO, Nb2O5, TiO2, ZrO2 as ingredients, sintering the ceramic powders into ceramics under different temperatures with additives of Ba (CU 0.5w 0.5) O3, LiBiO2 and CuO. By adding low-melting point sintering auxiliary combination, the sintering temperature can be lowered to 950 DEG C, and the property of the ceramics sintered under low temperature is enhanced.

Owner:江苏先进无机材料研究院

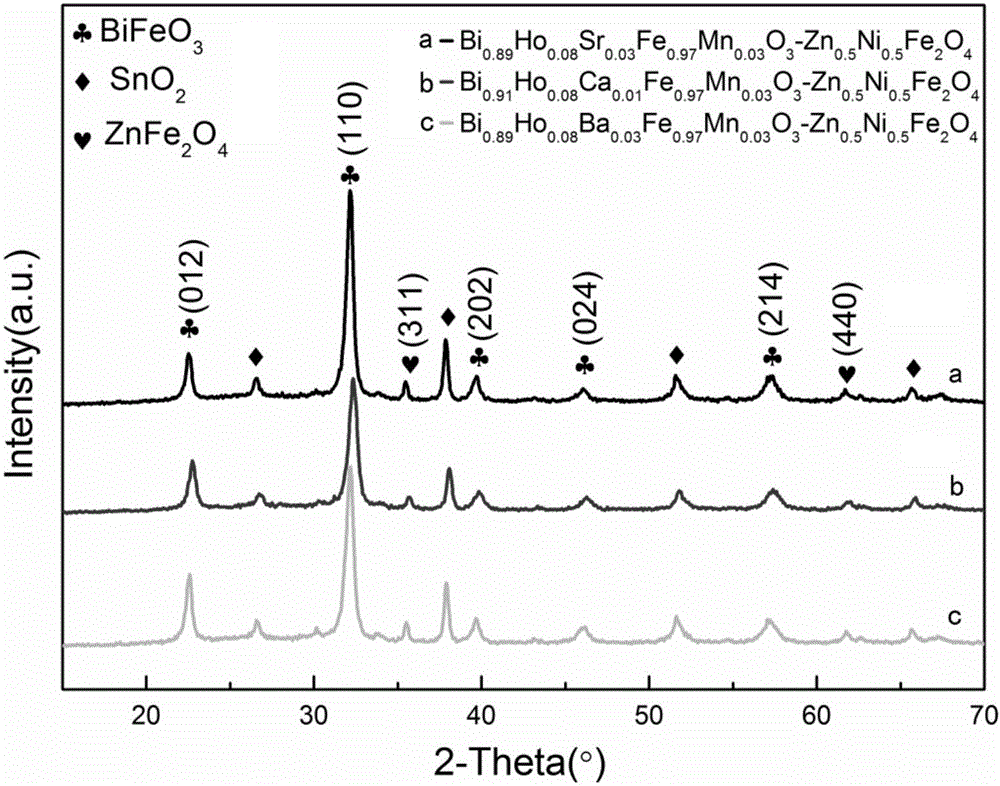

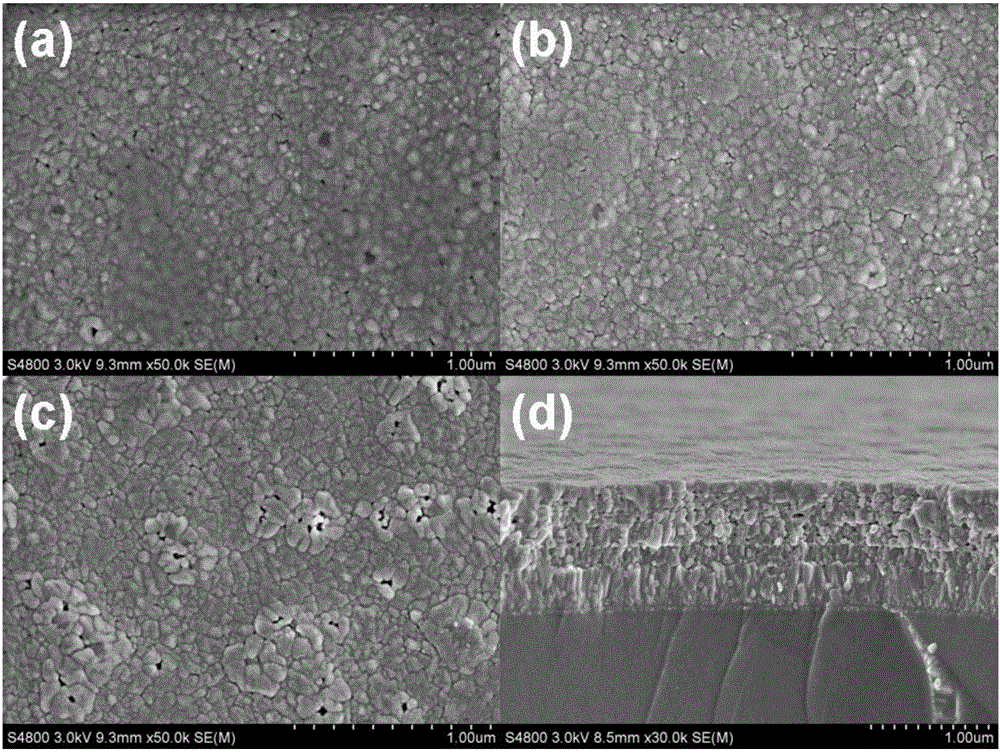

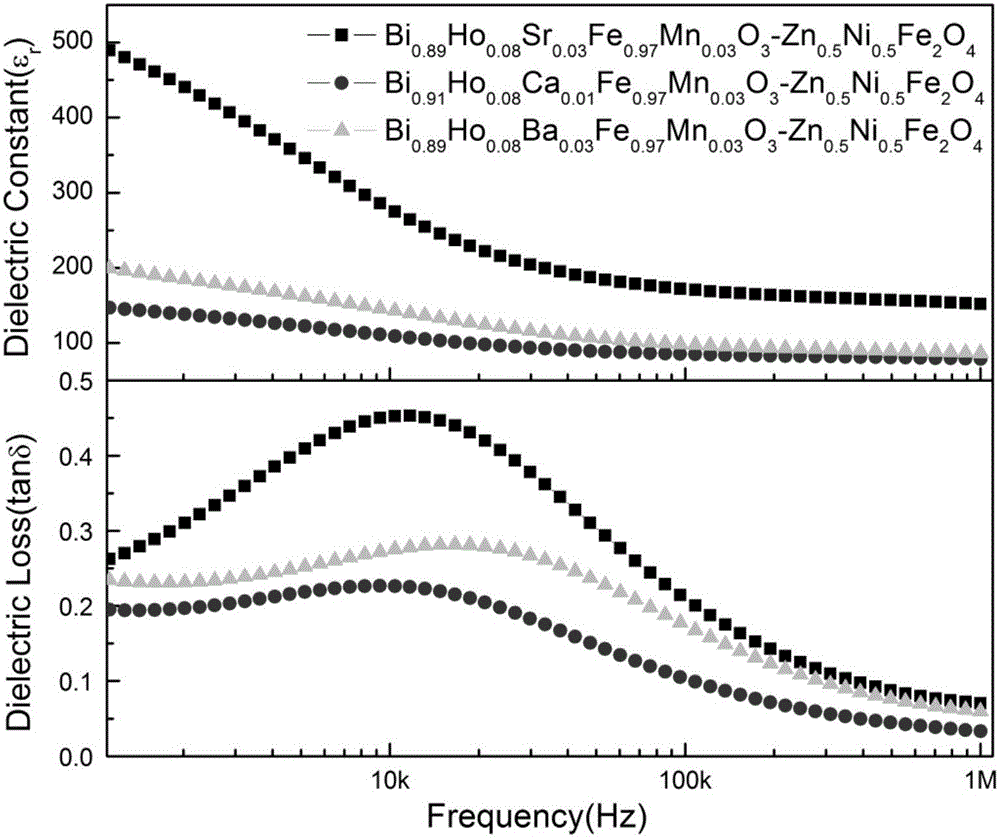

Bi0.92-xHo0.08AExFe0.97Mn0.03O3-Zn1-yNiyFe2O4 ferromagnetic composite film and preparation method thereof

InactiveCN105837196AReduce contentHigh polarizationCeramic layered productsMagnetic layerMagnetic composite

The invention provides a Bi0.92-xHo0.08AExFe0.97Mn0.03O3-Zn1-yNiyFe2O4 ferromagnetic composite film and a preparation method thereof. The ferromagnetic composite film comprises a Bi0.92-xHo0.08AExFe0.97Mn0.03O3 crystalline film and a Zn1-yNiyFe2O4 crystalline film, which are compounded together. The preparation method is as below: first respectively preparing a Zn1-yNiyFe2O4 precursor solution and a Bi0.92-xHo0.08AExFe0.97Mn0.03O3 precursor solution, wherein AE is Sr, Ca, Ba or Pb, x equals to 0.01-0.04, and y equals to 0.1-0.9; preparing a plurality of Zn1-yNiyFe2O4 films on a substrate by spin coating; and then preparing plurality of Bi0.92-xHo0.08AExFe0.97Mn0.03O3 films on the Zn1-yNiyFe2O4 films by spin coating, so as to obtain the ferromagnetic composite film. The method regulates the crystal structure of BiFeO3 by doping, and uses ferromagnetic Zn1-yNiyFe2O4 as the magnetic layer, so as to substantially increase the ferroelectric and ferromagnetic properties of the film, and effectively reduce the leakage current density of the film.

Owner:SHAANXI UNIV OF SCI & TECH

Ferroelectric thin-film transistor and preparation method thereof

ActiveCN107170812AReduce power consumptionImprove ferroelectric propertiesTransistorSemiconductor/solid-state device manufacturingFerroelectric thin filmsBottom gate

The invention discloses a ferroelectric thin-film transistor, which comprises a substrate; a bottom gate electrode formed on the substrate; a ferroelectric film layer formed on the bottom gate electrode; a channel layer formed on the ferroelectric film layer; a source electrode formed on the channel layer; and a drain electrode formed on the channel layer and separated from the source electrode. The invention also discloses a preparation method of the ferroelectric thin-film transistor. By introducing a hafnium-oxide-based material and SnO to the transistor to serve as a gate medium material and a channel material of the transistor respectively, the transistor is allowed to be compatible with existing silicon process in the preparation process, and can realize low power consumption; and the ferroelectric thin-film transistor can be widely applied to high-performance and low-power-consumption large-scale storage integrated circuits.

Owner:XIANGTAN UNIV

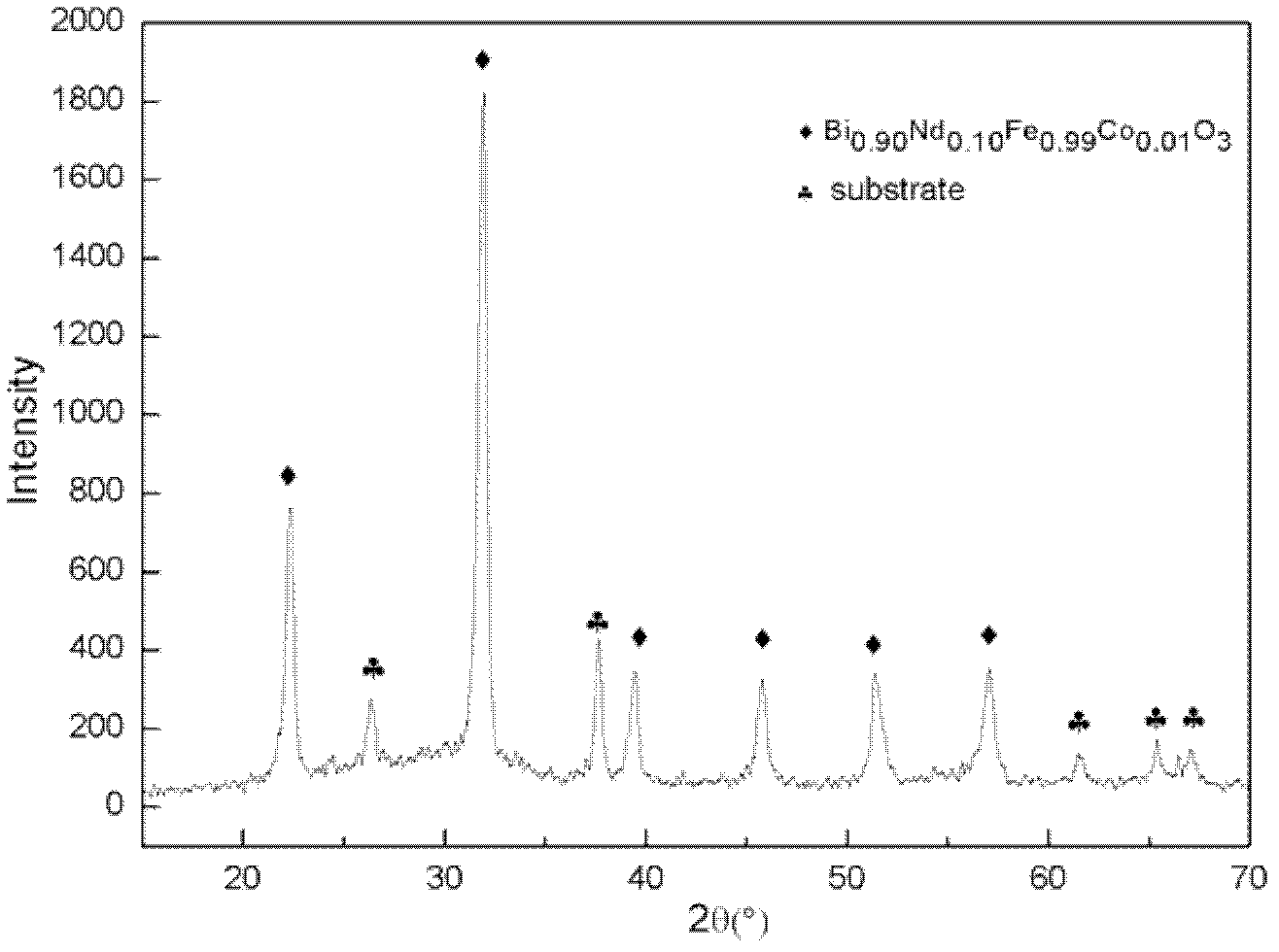

Method for preparing Nd/Co-codoped BiFeO3 film on FTO (fluorine-doped tin oxide)/glass substrate surface

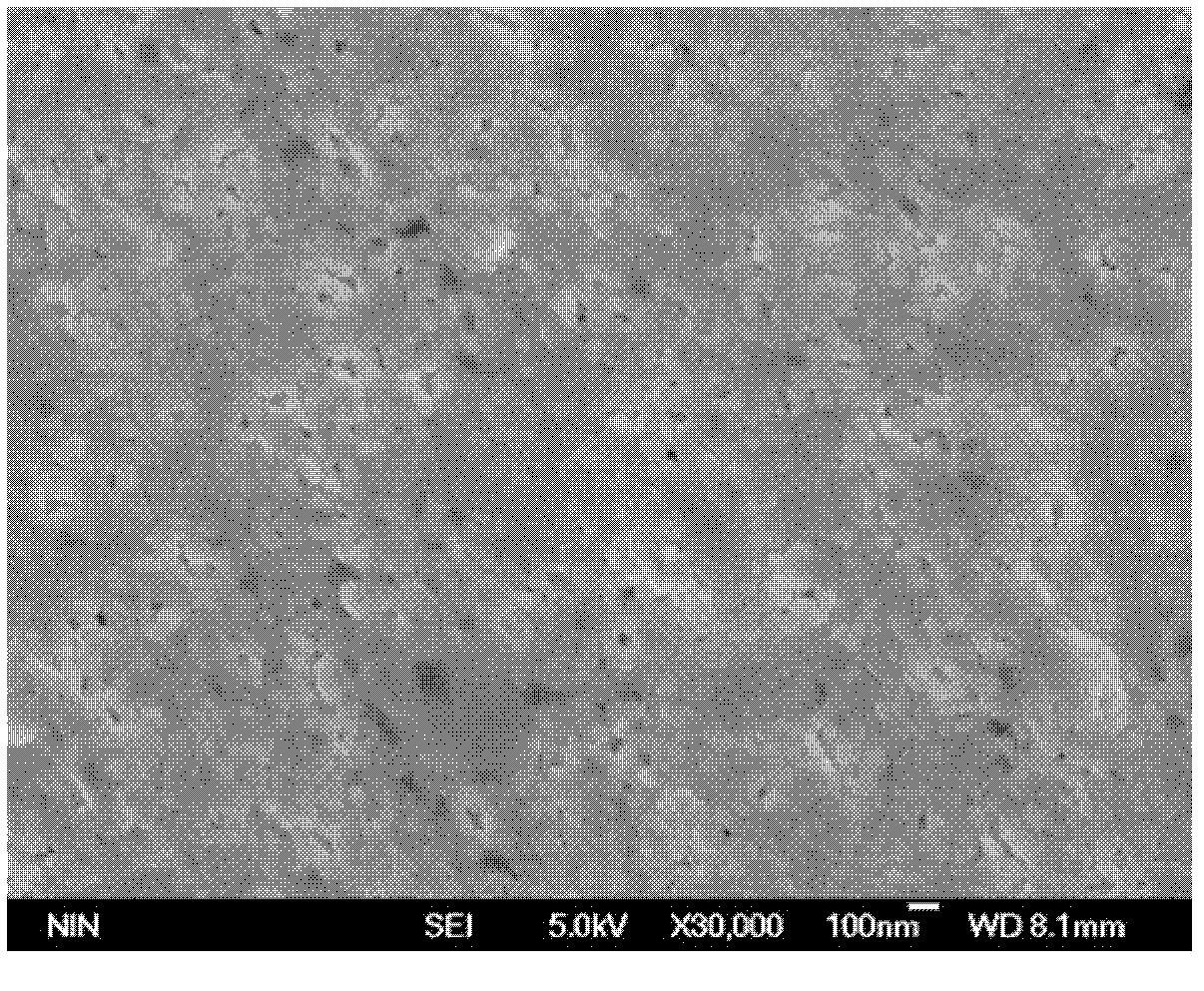

InactiveCN102534588AImprove uniformityExcellent dielectric propertiesSolid/suspension decomposition chemical coatingPolymer scienceAcetic anhydride

The invention provides a method for preparing an Nd / Co-codoped BiFeO3 film on an FTO (fluorine-doped tin oxide) / glass substrate surface, which comprises the following steps: after cleaning an FTO substrate, carrying out ultraviolet irradiation, and dissolving bismuth nitrate (8% excessive), ferric nitrate, neodymium nitrate and cobalt nitrate which serve as raw materials in mixed ethylene glycol monomethyl ether and acetic anhydride in a mol ratio of 0.98:(1-x):0.1:x (x=0.01-0.05), thereby obtaining a stable BiFeO3 precursor solution of which the metallic ion concentration is 0.1-0.5mol / L; and after spin coating, drying to obtain a dry film, preannealing, naturally cooling, repeating the process above to obtain the film with expected thickness, and finally, annealing to obtain the crystalline BiFeO3 film. In the invention, the facility requests are simple, the experiment conditions can be easily achieved, the prepared film has good uniformity, the doping amount is easy to control, andthe dielectric properties of the film can be greatly enhanced by doping.

Owner:SHAANXI UNIV OF SCI & TECH

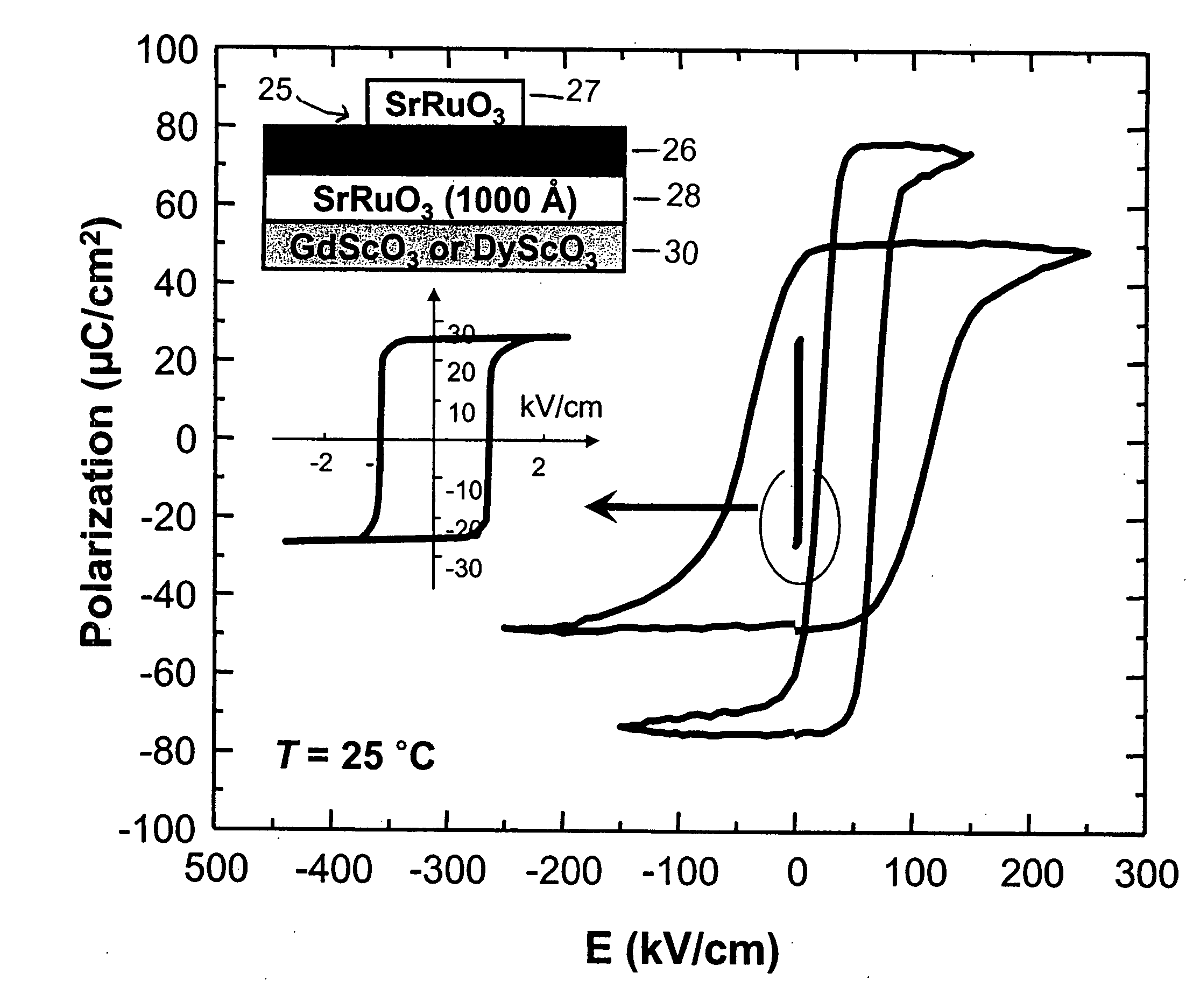

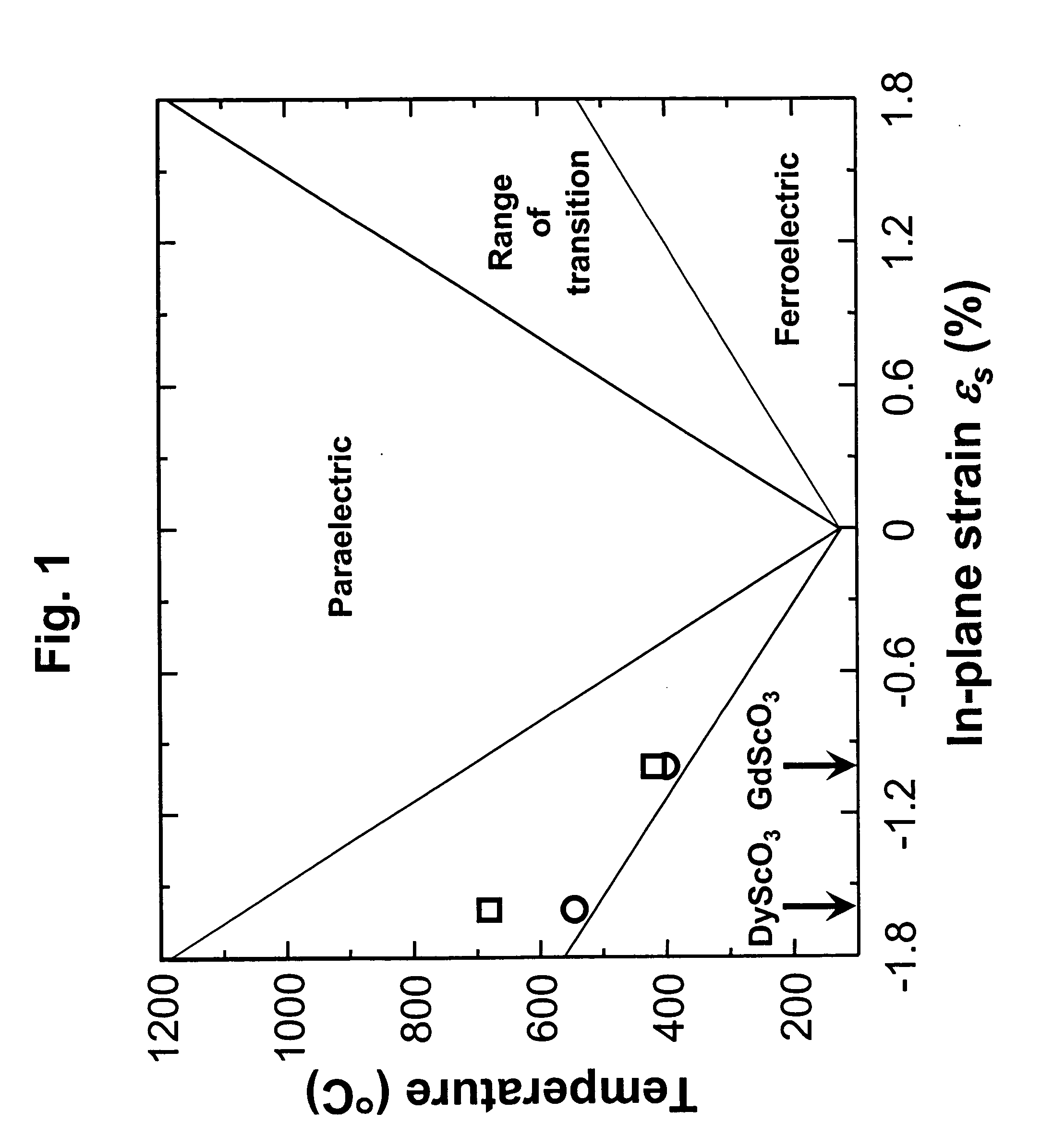

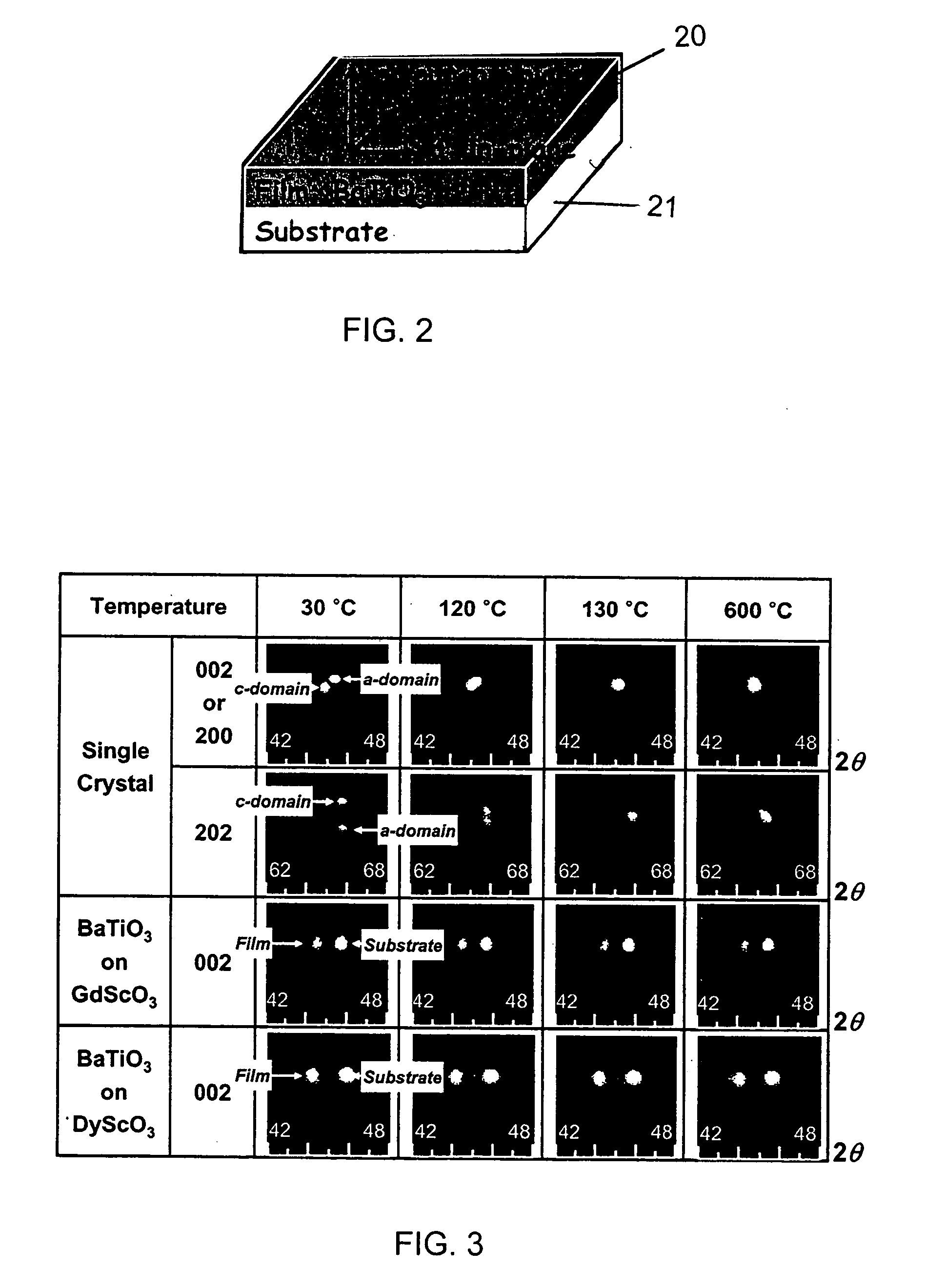

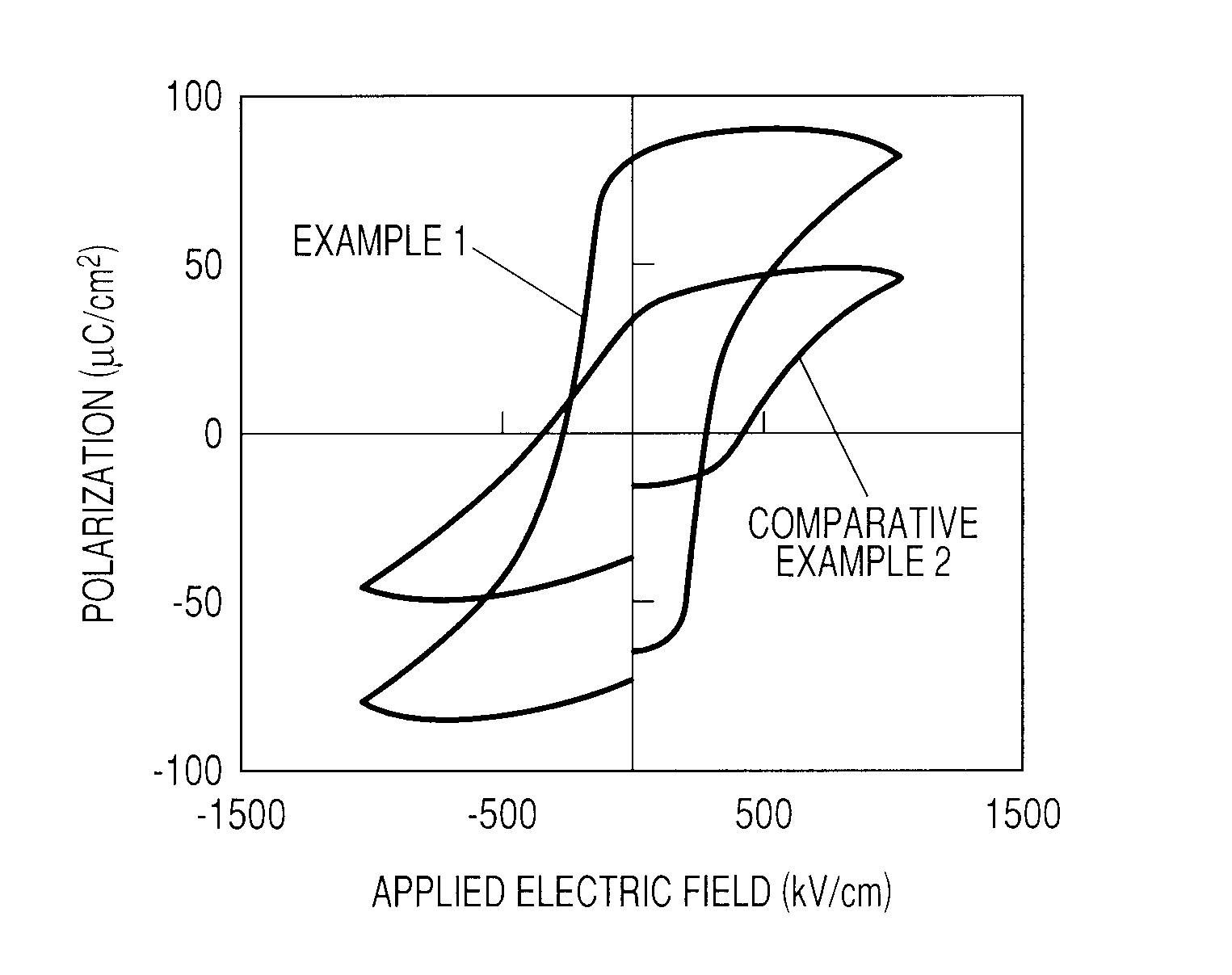

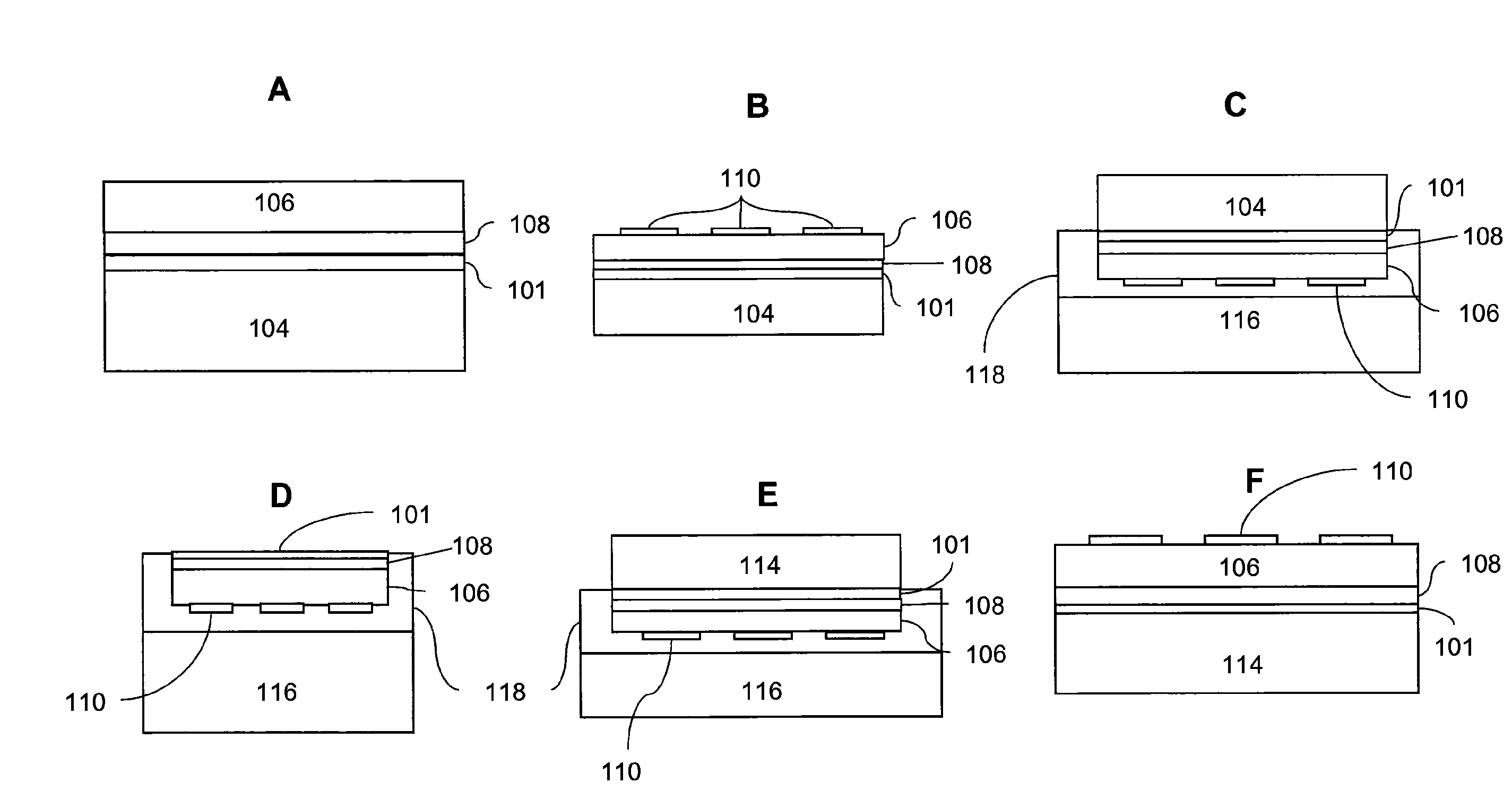

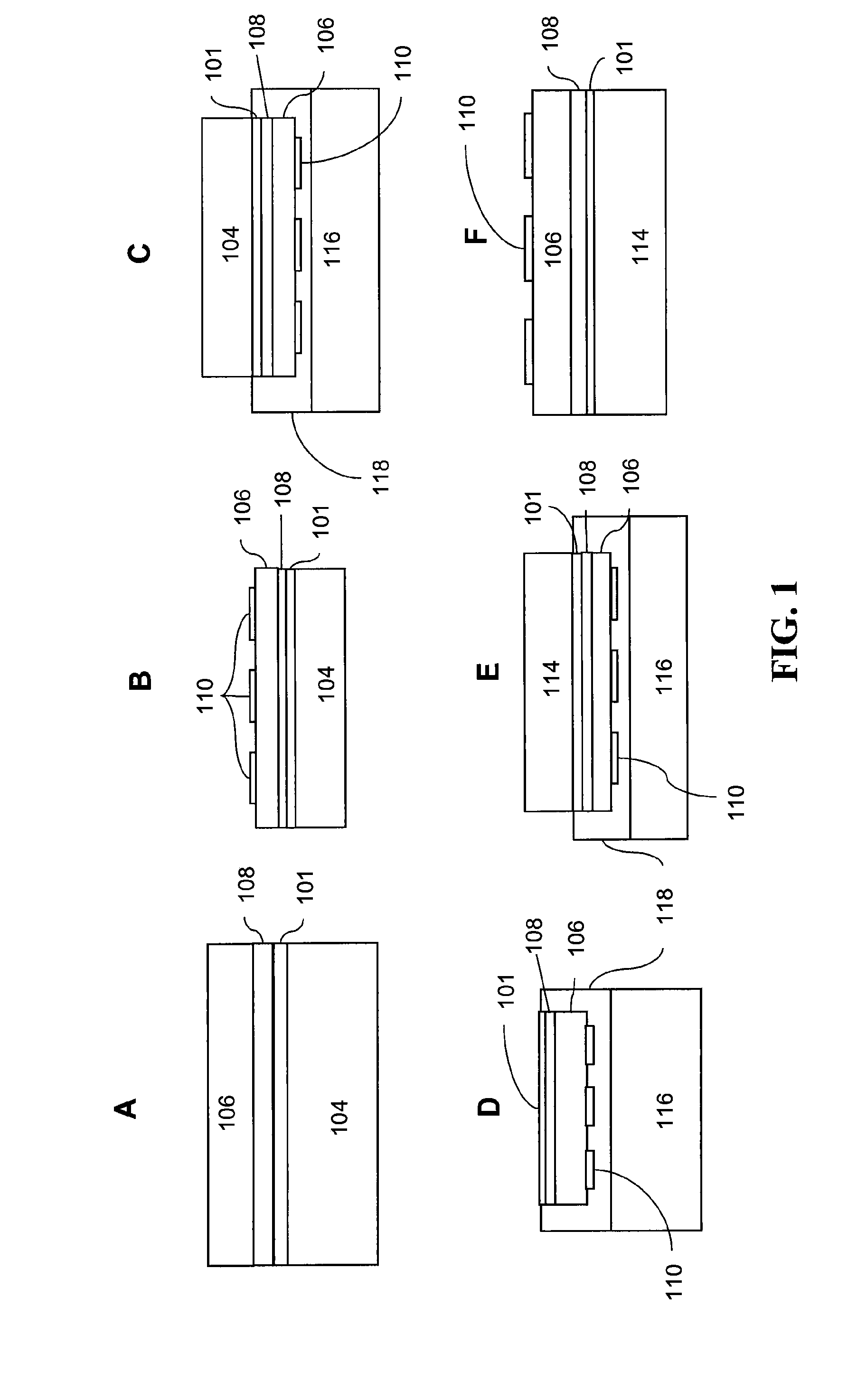

Strain-engineered ferroelectric thin films

ActiveUS20060091434A1Improve ferroelectric propertiesRaise the transition temperatureSemiconductor/solid-state device manufacturingSemiconductor devicesInter layerFerroelectric thin films

A strained thin film structure includes a substrate layer formed of a crystalline scandate material having a top surface, and a strained layer of crystalline ferroelectric epitaxially grown with respect to the crystalline substrate layer so as to be in a strained state and at a thickness below which dislocations begin to occur in the crystalline ferroelectric layer. An intermediate layer may be grown between the top surface of the substrate layer and the ferroelectric layer wherein the intermediate layer carries the lattice structure of the underlying substrate layer. The properties of the ferroelectric film are greatly enhanced as compared to the bulk ferroelectric material, and such films are suitable for use in applications including ferroelectric memories.

Owner:PENN STATE RES FOUND +1

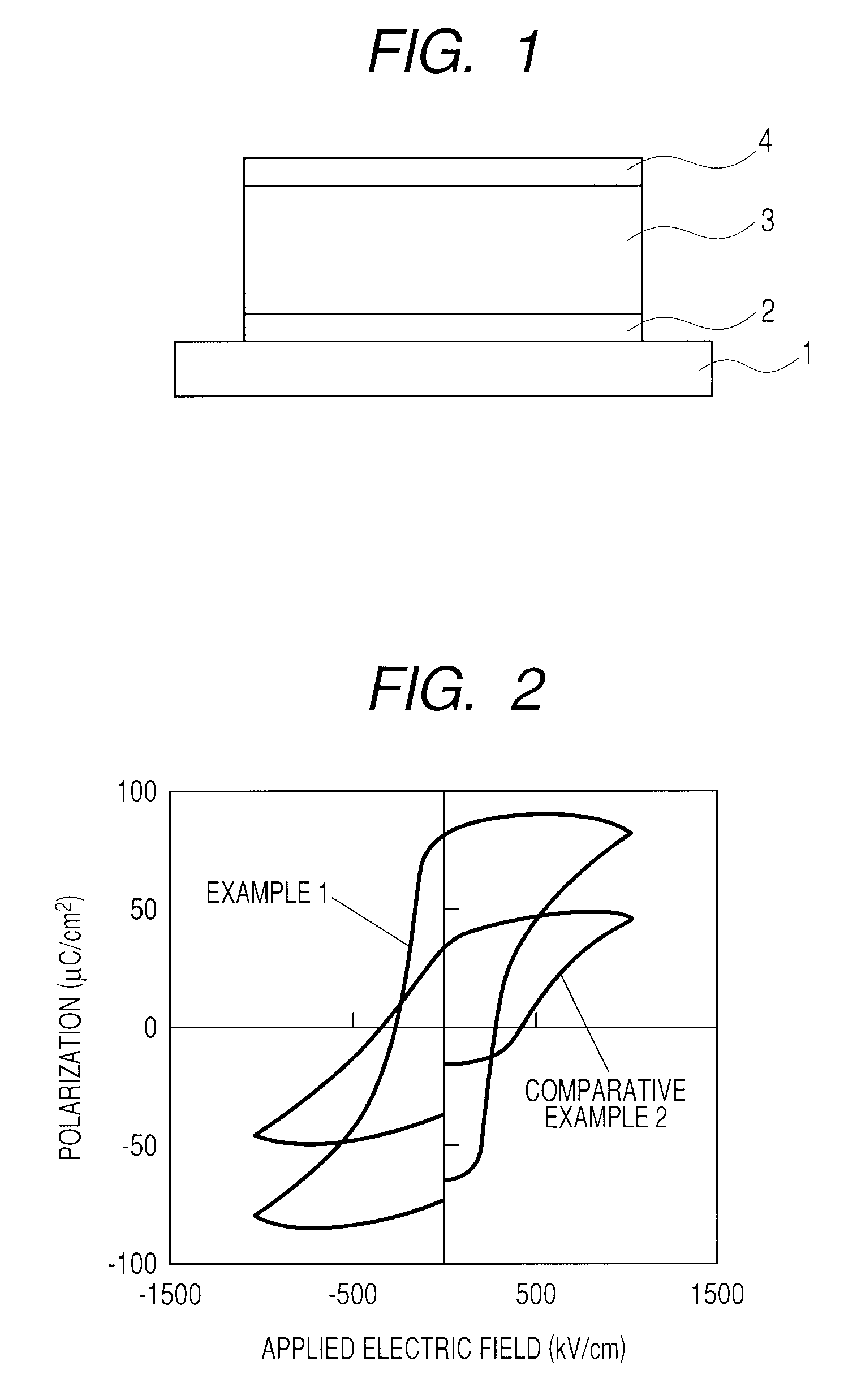

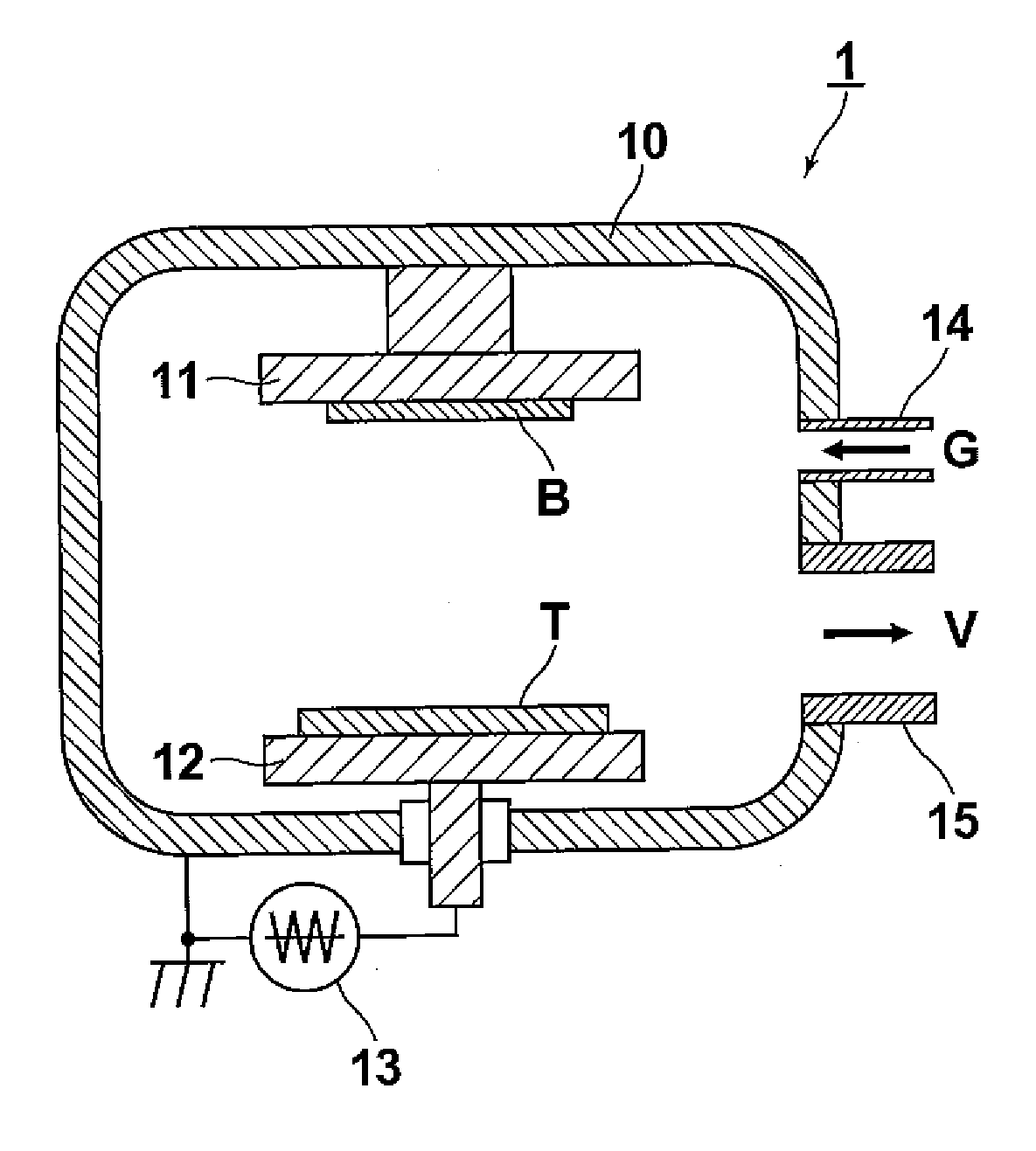

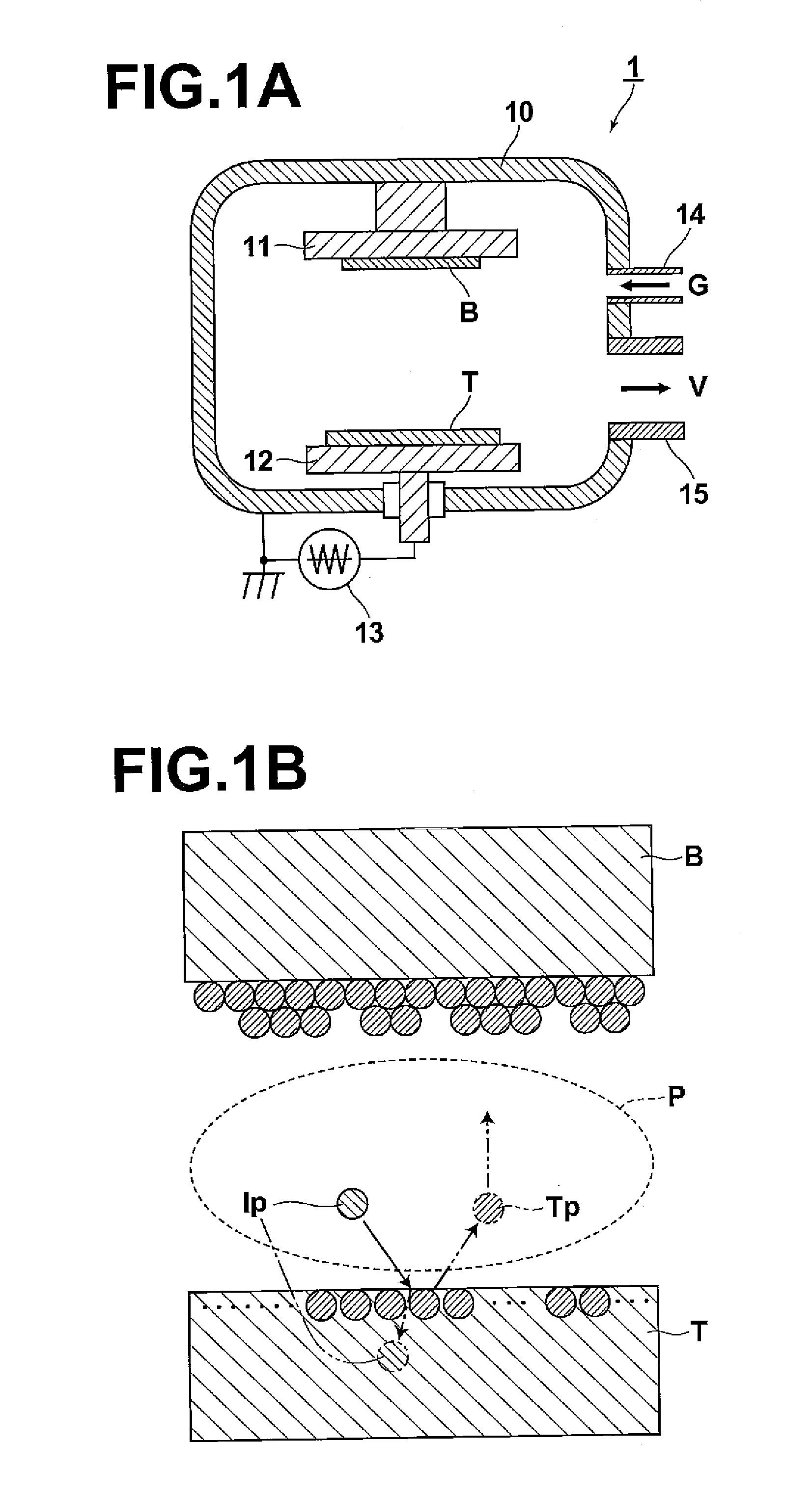

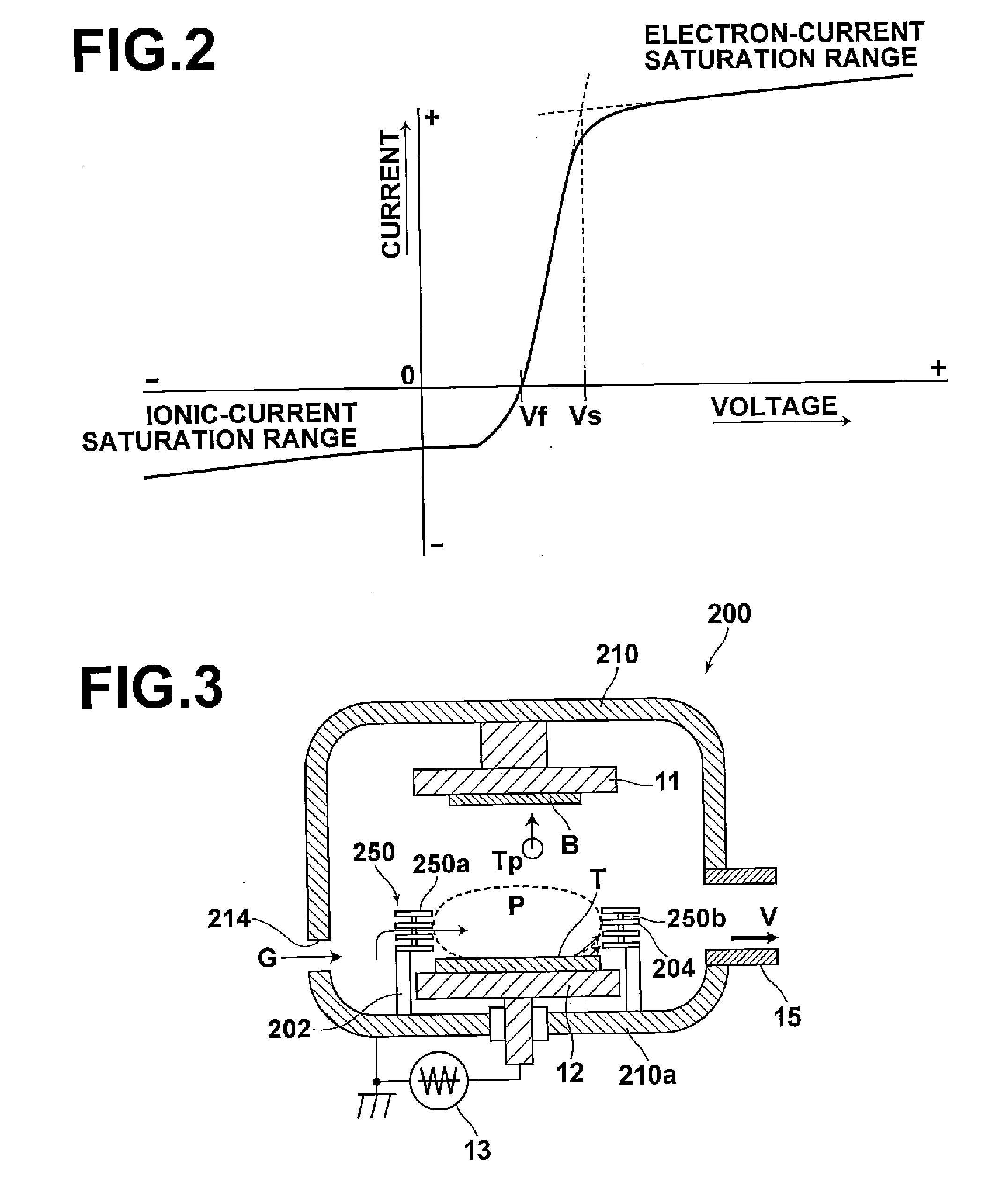

Ferroelectric material, method of producing ferroelectric material, and ferroelectric device

ActiveUS8216858B2Improve ferroelectric propertiesImprove insulation performanceMaterial nanotechnologySolid-state devicesCrystal structureManganese

Provided are a ferroelectric material having good ferroelectricity and good insulation property, and a ferroelectric device using the ferroelectric material. In the present invention, the ferroelectric material includes a metal oxide having a perovskite-type crystal structure, in which: the metal oxide contains bismuth ferrite whose iron is substituted by manganese, and at least one of a copper oxide and a nickel oxide; the bismuth ferrite is substituted by manganese at a substitution ratio of 0.5 at. % or more to 20 at. % or less with respect to a total amount of iron and manganese; and at least one of the copper oxide and the nickel oxide is added in an amount of 0.5 mol % or more to 20 mol % or less with respect to the bismuth ferrite whose iron is substituted by manganese.

Owner:CANON KK +1

Method for preparing single-phase BiFeO3 ceramics through hardening process

InactiveCN1686932AImprove insulation performanceImprove ferroelectric propertiesCrucibleHeating furnace

The present invention relates to a method for preparing single-phase BiFeO3 ceramic by utilizing quenching process. It is characterized by quickly cooling sintered BiFeO3 ceramic. Said method includes the following steps: weighing Bi2O3 powder and Fe2O3 powder according to the mole ratio of 1:1, ball-grinding for 4-12 hr according to 100-500 rpm, uniformly mixing two powdes, drying the above-mentioned mixed powder, pressing the mixed powder into thin sheet, then placing proper quantity of the above-mentioned mixed powder into Al2O3 crucible, placing the thin sheet into the crucible, and using correspondent powder to cover the thin shet to make the thin sheet and powder be in sealed state, then placing the above-mentioned crucible into heating furnace, heating to sintering temperature, heating speed is 2-8 deg.C / min, sintering temperature is 830-920 deg.C and sintering time is 30-60 min., after sintering process is completed, promptly quenching so as to obtain the invented product.

Owner:NANJING UNIV

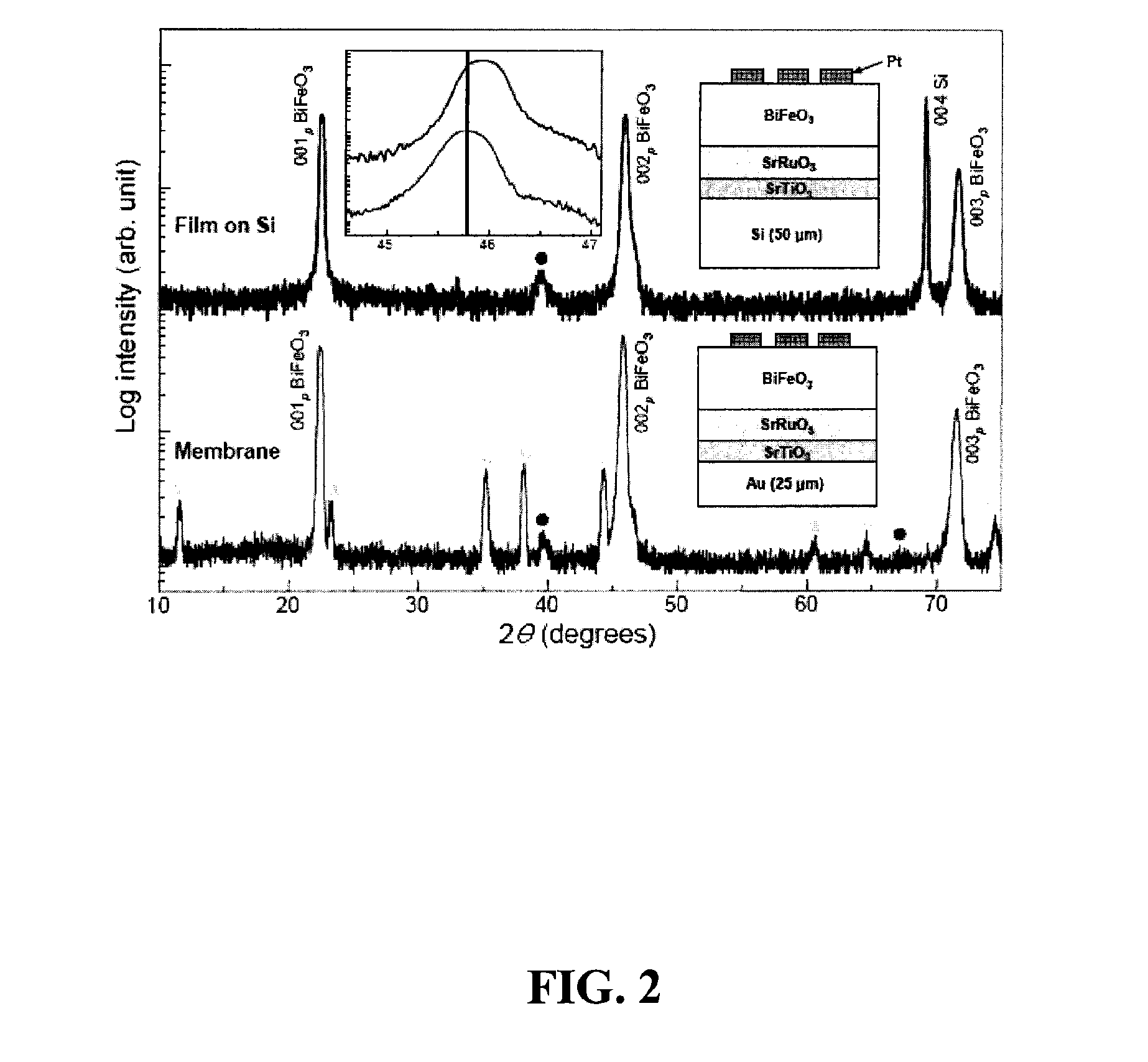

EPITAXIAL (001) BiFeO3 MEMBRANES WITH SUBSTANTIALLY REDUCED FATIGUE AND LEAKAGE

ActiveUS20090280355A1Improve ferroelectric propertyReduce coercive fieldPolycrystalline material growthLaminationEngineeringPerovskite

The present invention provides free-standing heterostructures including a layer of BiFeO3 and a layer comprising a perovskite over which the BiFeO3 is epitaxially grown. The layer comprising the perovskite has been released from a substrate upon which it was originally grown. Also provided are methods for forming the free-standing heterostructures, which may include transferring the free-standing heterostructures to other host substrates.

Owner:WISCONSIN ALUMNI RES FOUND

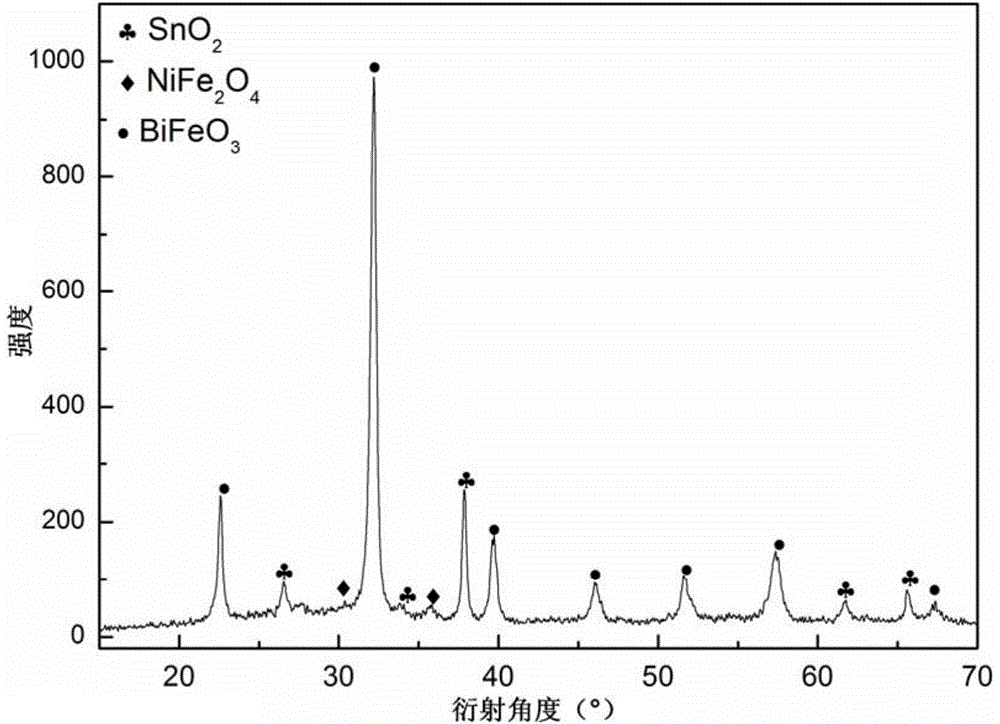

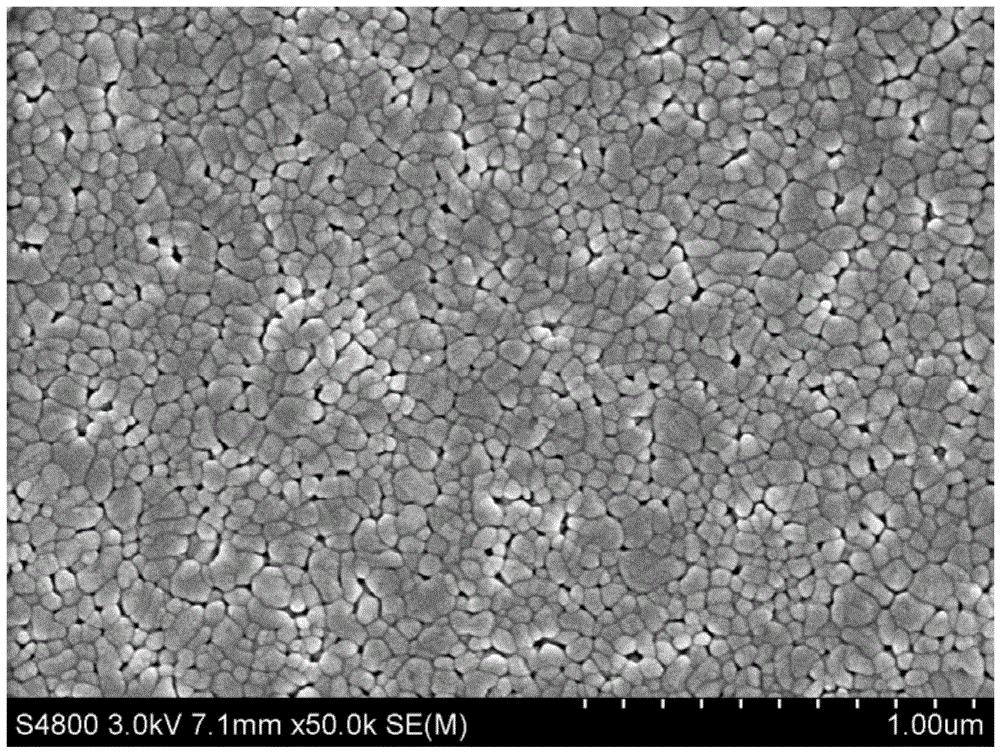

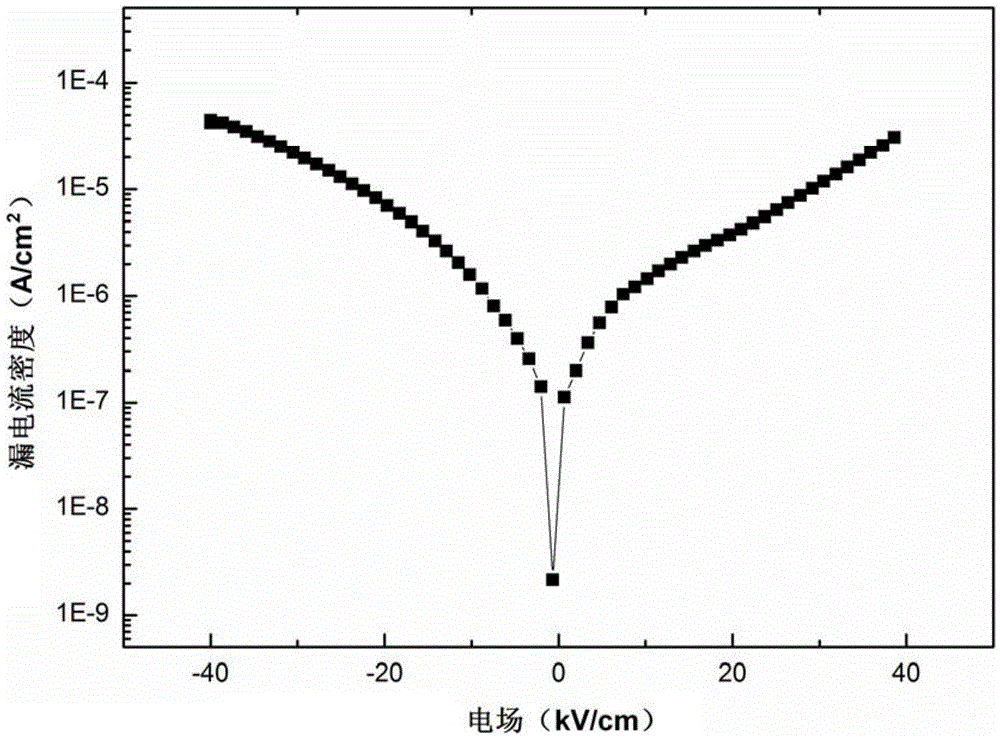

Multiferroic Bi0.96-xSr0.04RExFe0.94Mn0.04Cr0.02O3-NiFe2O4 composite film and preparation method thereof

The invention discloses a multiferroic Bi0.96-xSr0.04RExFe0.94Mn0.04Cr0.02O3-NiFe2O4 composite film and a preparation method thereof. The composite film comprises a Bi0.96-xSr0.04RExFe0.94Mn0.04Cr0.02O3 crystalline state film and a NiFe2O4 crystalline state film which are compounded together. The preparation method comprises the following steps: respectively preparing a Bi0.96-xSr0.04RExFe0.94Mn0.04Cr0.02O3 precursor solution and a NiFe2O4 precursor solution; and spinning on a substrate to prepare a multilayer NiFe2O4 film, and spinning on the NiFe2O4 film to prepare a multilayer Bi0.96-xSr0.04RExFe0.94Mn0.04Cr0.02O3 film, thereby obtaining the target product. The equipment requirement is simple, the prepared film is high in uniformity, the doping amount is easy to control, and the ferroelectric properties and ferromagnetic properties of the film are greatly improved. Meanwhile, the leakage current density of the film is effectively reduced.

Owner:SHAANXI UNIV OF SCI & TECH

Perovskite oxide, ferroelectric film and ferroelectric device containing the perovskite oxide

InactiveUS20090114875A1Improve ferroelectric propertiesPiezoelectric/electrostrictive device manufacture/assemblySynthetic resin layered productsMaterials sciencePerovskite

A perovskite oxide having a composition expressed by a compositional formula,(Pb1-x+δAx)(ZryTi1-y)1-zMzOw,where Pb and A are A-site elements, Zr, Ti, and M are B-site elements, A represents one or more A-site elements other than Pb, M represents one or more of elements Nb, Ta, V, Sb, Mo, and W, x, y, and z satisfy inequalities,0.01<x≦0.4,0<y≦0.7, and0.1≦z≦0.4, andδ is approximately 0, w is approximately 3, δ and w may deviate from 0 and 3, respectively, within ranges of δ and w in which the composition expressed by the compositional formula (Pb1-x+δAx)(ZryTi1-y)1-z-MzOw can substantially realize a perovskite structure.

Owner:FUJIFILM CORP

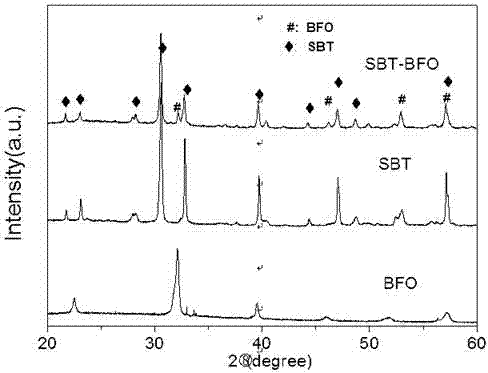

Bismuth ferrite-strontium bismuth titanatemultiferroic composite film and preparation method thereof

InactiveCN103496747AControl UniformityLow preparation temperatureIron compoundsBismuth compoundsLeakage current densityNitrate

The invention belongs to the technical field of electronic ceramics, and specifically relates to a bismuth ferrite-strontium bismuth titanatemultiferroic composite film and a preparation method thereof. The bismuth ferrite-strontium bismuth titanatemultiferroic composite film comprises the following raw materials: ferric nitrate, bismuth nitrate, tetrabutyltitanate and strontium acetate. The bismuth ferrite-strontium bismuth titanatemultiferroic composite film has stable structure, and is substantially reduced in leakage current density and strengthened in ferroelectric performance.

Owner:SHANDONG JIANZHU UNIV

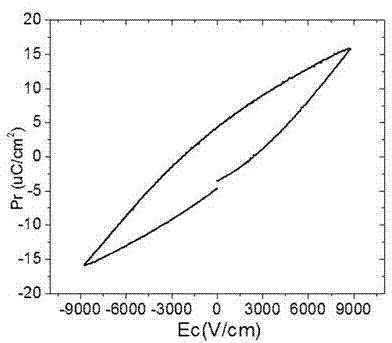

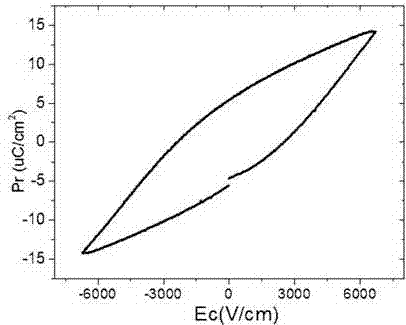

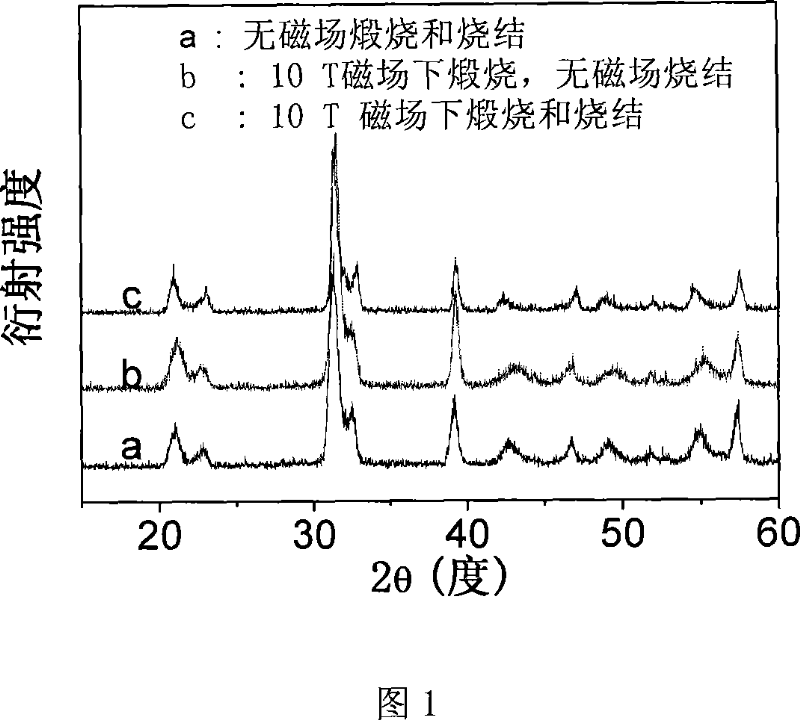

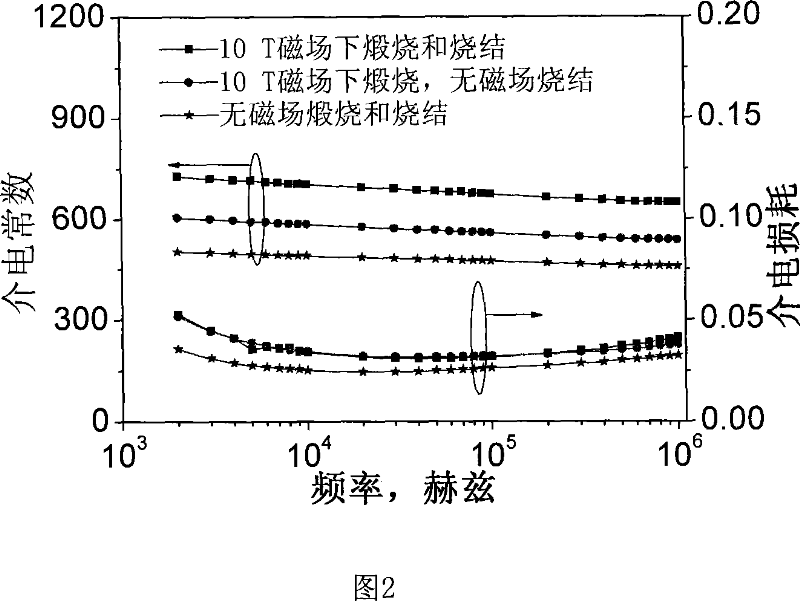

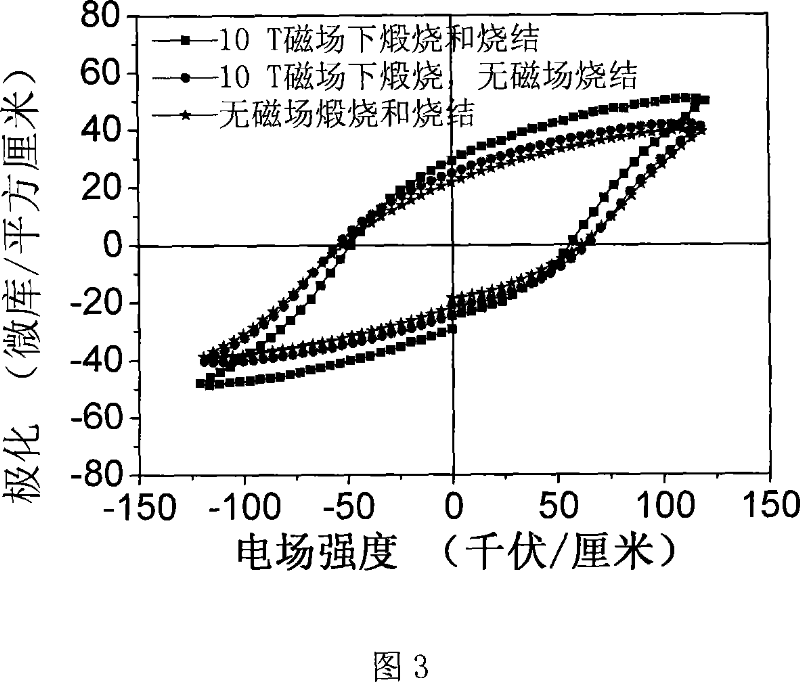

Method for preparing ferrite bismuth lanthanum-titanate lead solid solution ceramic under strong magnetic field action

The invention relates to a method for producing ferric acid bismuth lanthanum-lead titanate solid solution ceram in an intense magnetic field, belonging to the technical field of inorganic non-metal material and solid solution ceram material. The designed chemical formula of ferric acid bismuth lanthanum-lead titanate solid solution ceram is: (1-x)(Bil-yLay)FeO3-xPbTiO3; wherein: 0.2<=x<=0.6, y=0-0.4; weighing and preparing materials according to the chemical dosage rate of the chemical formula; weighing and mixing the Bi2O3, La2O3, Fe2O3, PbCO3 and TiO2 powder with a purity more than 99.9%, adding ethanol as abrasive, zirconia grain as abrasing medium; ball milling for 24 hours in the ball mill, mixing sufficiently and levigating; calcining and synthesizing in 750 DEG C in the magnetic intensity of 7-14T for 24 hours; ball milling for 24 hours; then doing a secondary ball milling; then prilling, tabletting; finally sintering the pressed compact in 1080-1100 DEG C, meanwhile introducing the intense magnetic field and obtaining the ferro-electricity ferromagnetism ceramic material.

Owner:SHANGHAI UNIV

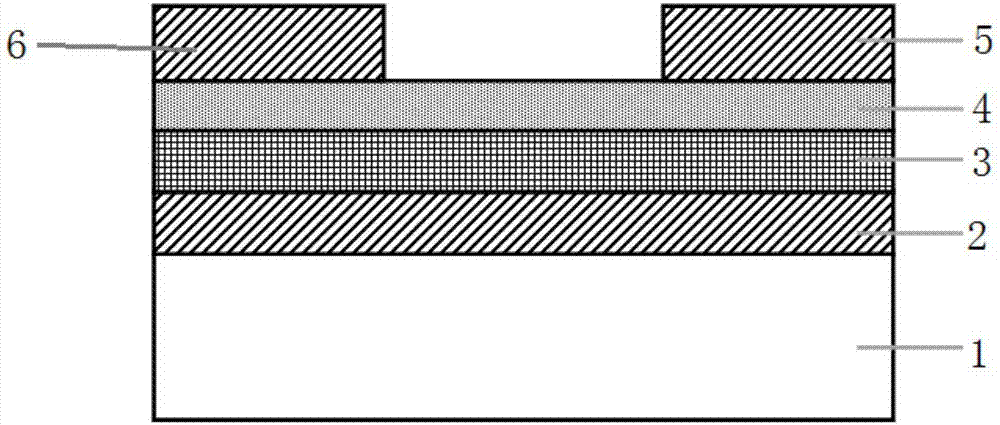

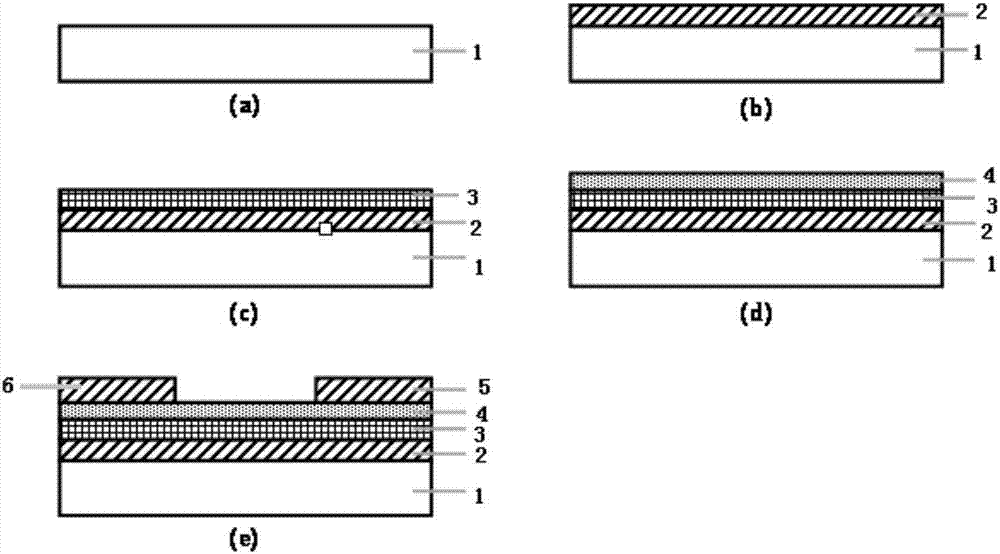

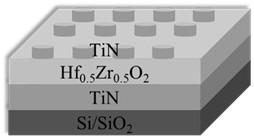

Hafnium oxide based ferroelectric grid structure and preparation technology thereof

ActiveCN107134487ALarge polarization valueSmall sizeSemiconductor/solid-state device manufacturingSemiconductor devicesElectrical performanceSilicon

The invention discloses a hafnium oxide based ferroelectric grid structure. The structure comprises a substrate, and a buffer layer, a bottom electrode layer, a ferroelectric layer and a top electrode layer are laminated on the surface of the substrate successively, and the material of the ferroelectric layer comprises hafnium oxide. The invention also discloses a preparation technology of the hafnium oxide based ferroelectric grid structure. The hafnium oxide based ferroelectric grid structure has high electrical performances, the vertical size of the whole storage medium of a ferroelectric memory is reduced by 10 to 20 times, and the structure and technology are compatible with the silicon technology.

Owner:XIANGTAN UNIV

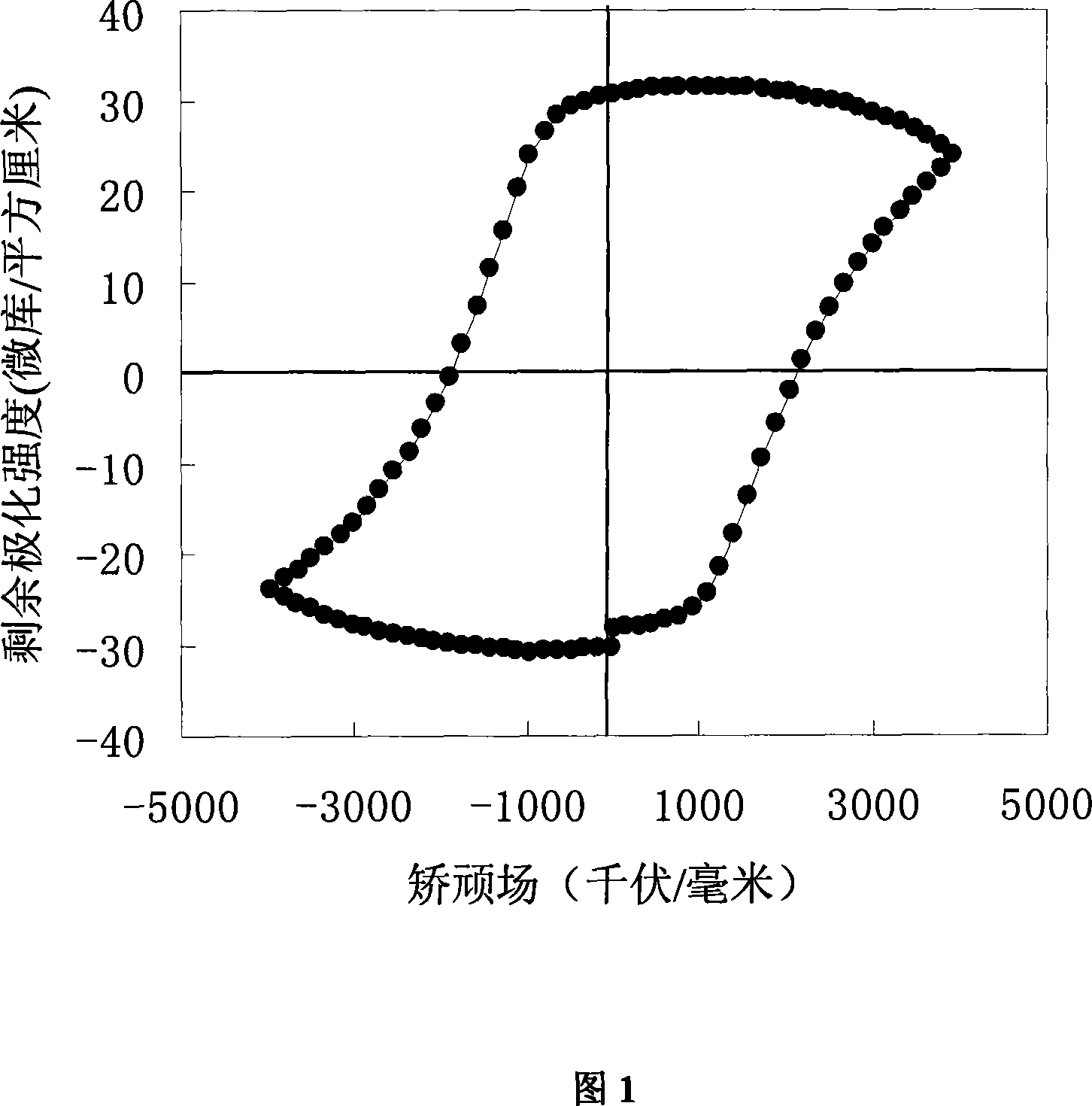

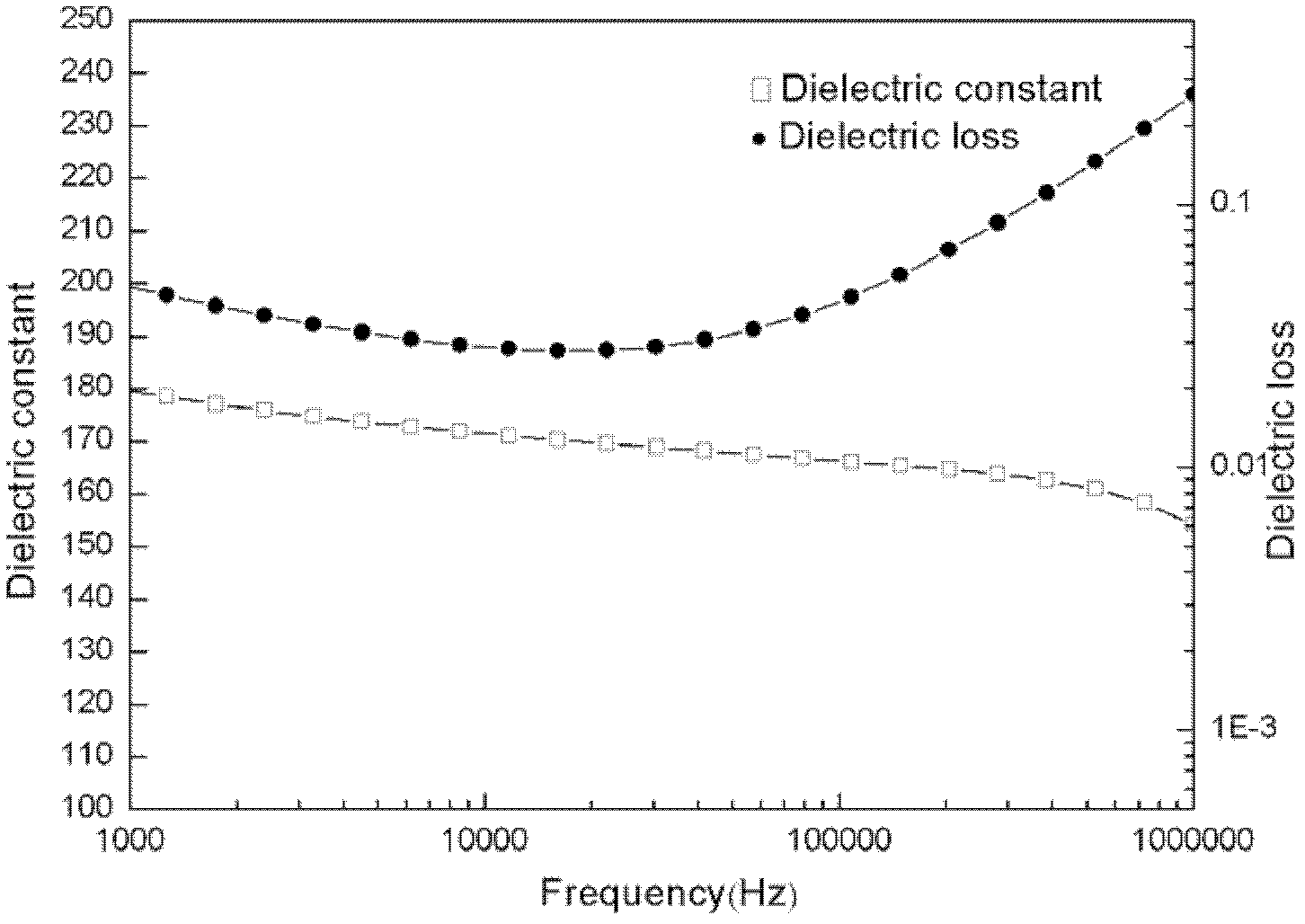

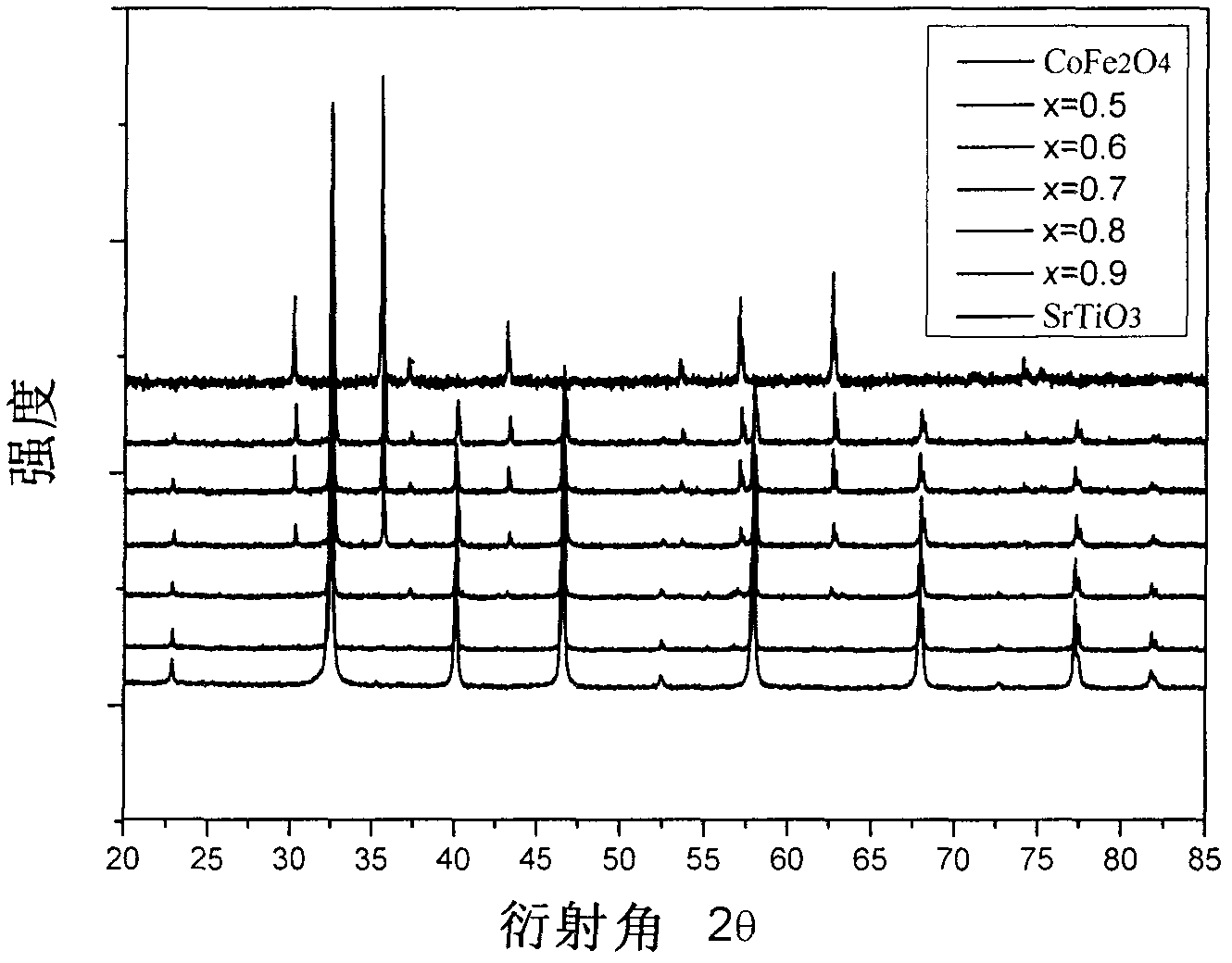

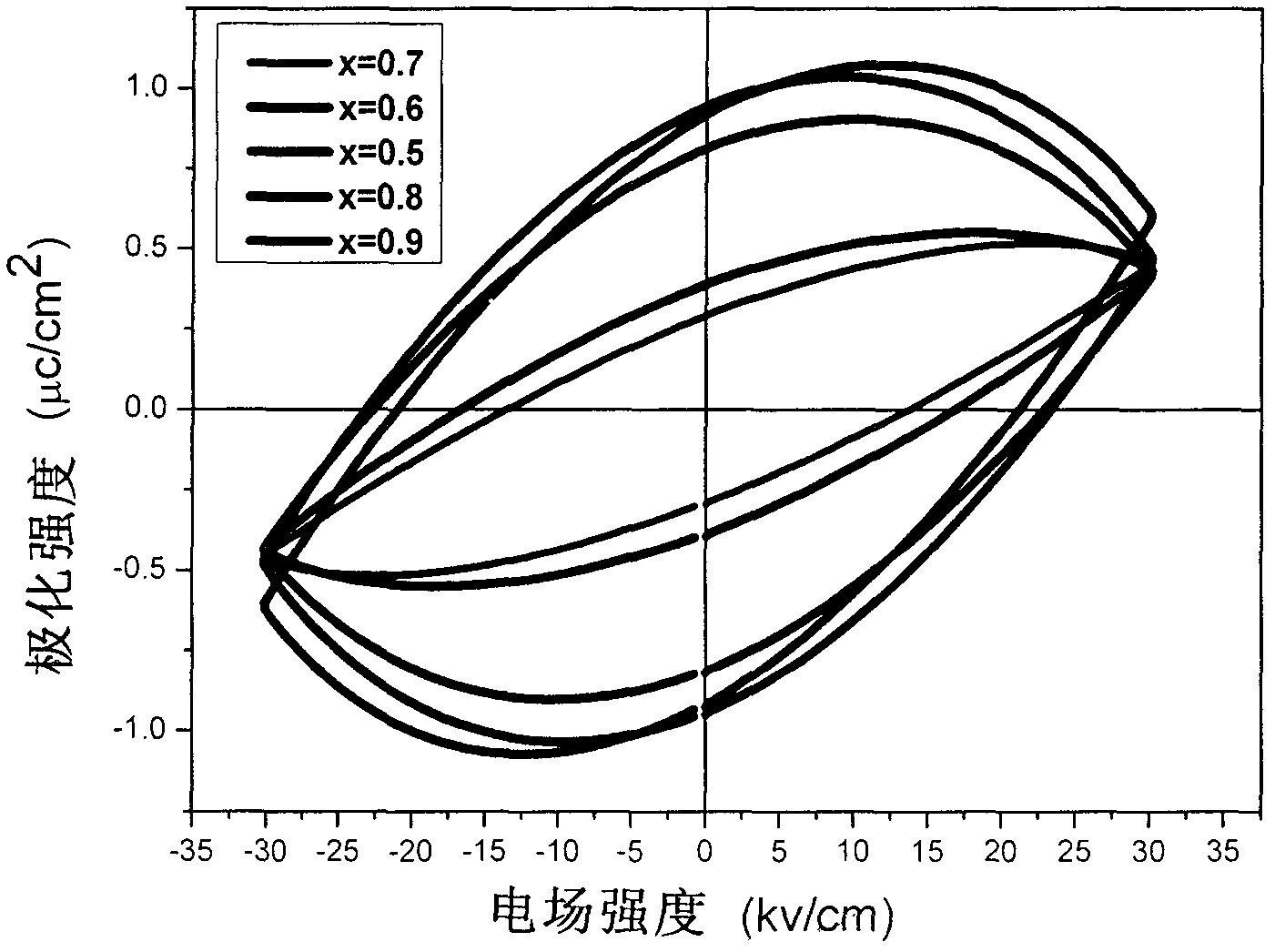

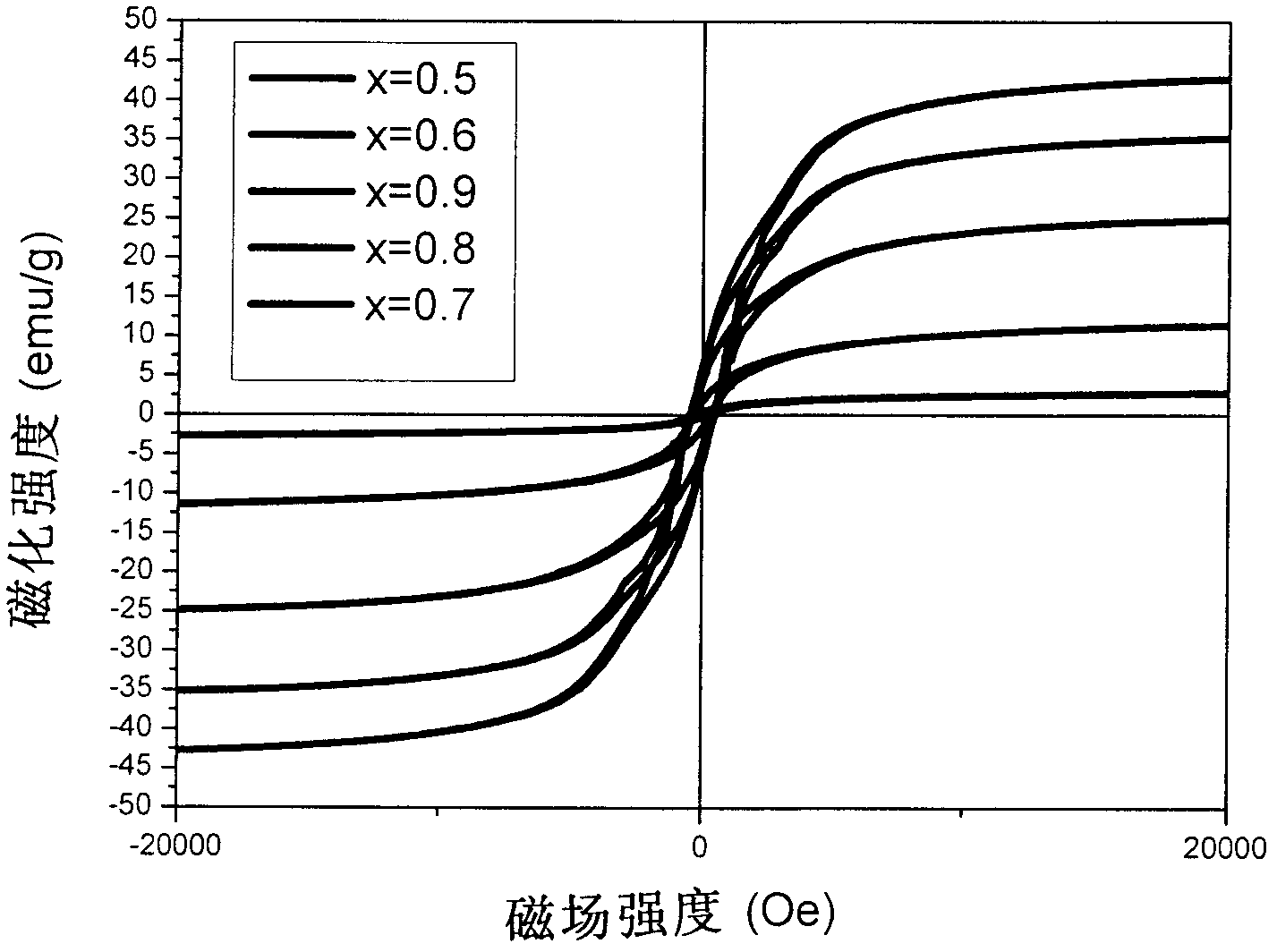

Xsrtio3-(1-x) cofe2o4 composite material and preparation method thereof

InactiveCN102643088AGood calcination temperatureHelpful for practical applicationComposite ceramicCobalt

The invention discloses an xSrTiO3-(1-x) CoFe2O4 composite material having ferromagnetism and ferroelectricity and a preparation method thereof. In the formula, x ranges from 0.5 or 0.6 or 0.7 or 0.8 or 0.9. Compared with single-phase ceramics, the composite ceramics have certain changes in ferroelectricity and ferromagnetism. The preparation method is an improved sol gel method and uses strontium nitrate, citric acid, cobalt nitrate, butyl titanate, absolute ethyl alcohol, glacial acetic acid and ferric nitrate as raw materials. The preparation method simplifies compound steps, effectively avoids outside affecting factors of particle compound, and reduces material compound temperature. The ferroelectricity of the xSrTiO3-(1-x) CoFe2O4 composite material is improved compared with single-phase SrTiO3, and a ferroelectric hysteresis loop tending to be saturated is obtained. The ferromagnetism has regularity along with increase of content of cobalt ferrite, and therefore actual application of composite materials is facilitated.

Owner:HEBEI NORMAL UNIV

Sodium niobate barium-bismuth-potassium titanate lead-free piezoelectric ceramic composition

InactiveCN102515762AExcellent piezoelectric ferroelectric propertiesImprove ferroelectric propertiesOxygenSodium niobate

The invention provides a novel sodium niobate barium-bismuth-potassium titanate lead-free piezoelectric ceramic composition. The composition comprises perovskite antiferroelectric NaNbO3 and strong ferroelectric Ba1-y(Bi0.5K0.5)yTiO3. A general formula of the composition is (1-x)NaNbO3-xBa1-y(Bi0.5K0.5)yTiO3, wherein x and y in the formula satisfy the following equations: 0.025<=x<=0.25 and 0

Owner:SICHUAN NORMAL UNIVERSITY

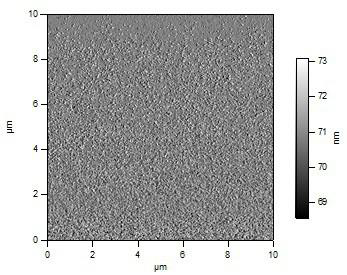

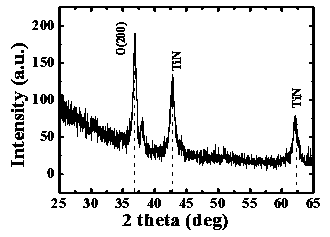

Method for preparing Hf0.5Zr0.5O2 ferroelectric film by ALD for ferroelectric memory applications

PendingCN110165053AThe preparation process is simpleShort manufacturing timeSolid-state devicesCapacitorsFerroelectric thin filmsHafnium

The invention discloses a method for preparing a Hf0.5Zr0.5O2 ferroelectric film by ALD for ferroelectric memory applications, characterized by preparing the ferroelectric film by using atomic layer deposition, using a hafnium source and a zirconium source as reaction precursors, using ozone or water as an oxygen source, using a cavity temperature of 250 to 280 degrees centigrade, and using a reaction precursor heating temperature of 75 to 80 degrees centigrade. Compared with a ferroelectric film having a perovskite structure obtained by a conventional process, the ferroelectric film preparedby the method is more liable to be compatible with a standard semiconductor manufacturing process, has higher integration, a lower annealing temperature, a higher annealing rate, shorter annealing time, and a lower ferroelectric layer thickness. The film obtained by a high annealing rate heat treatment process has high remanent polarization, a large dielectric constant, and low leakage current. The preparation method of the invention has high repeatability and can obtain uniform ferroelectric film, and contributes to realizing the wide application prospect of the ferroelectric film in the fields of information storage and integrated circuits.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

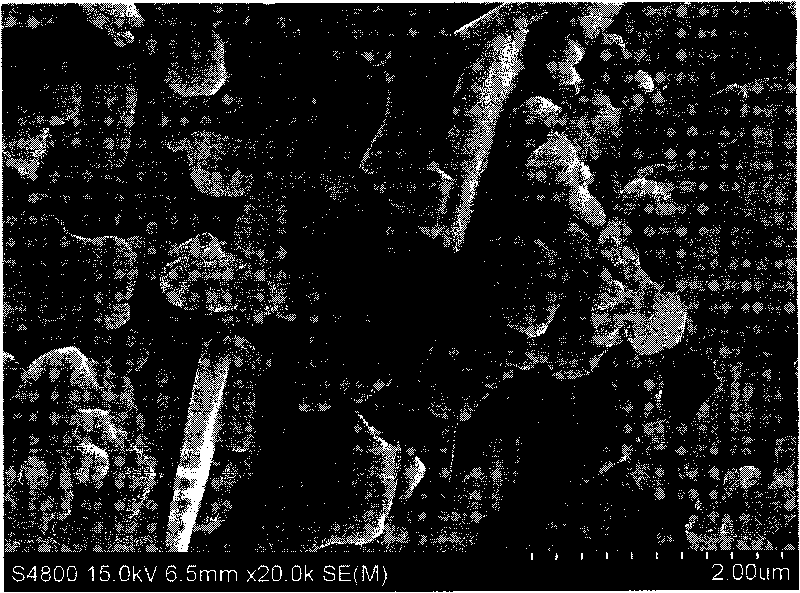

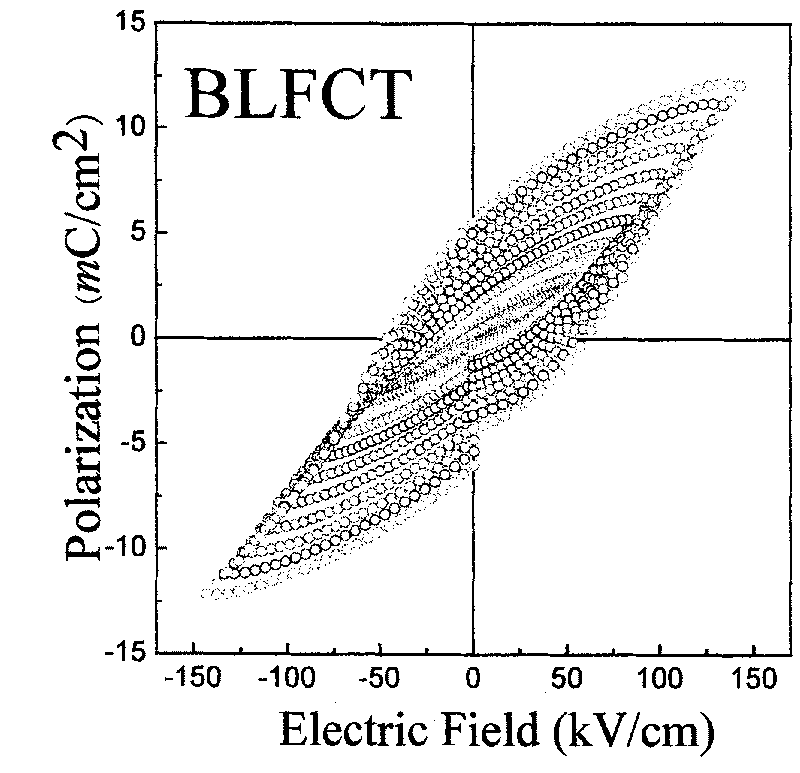

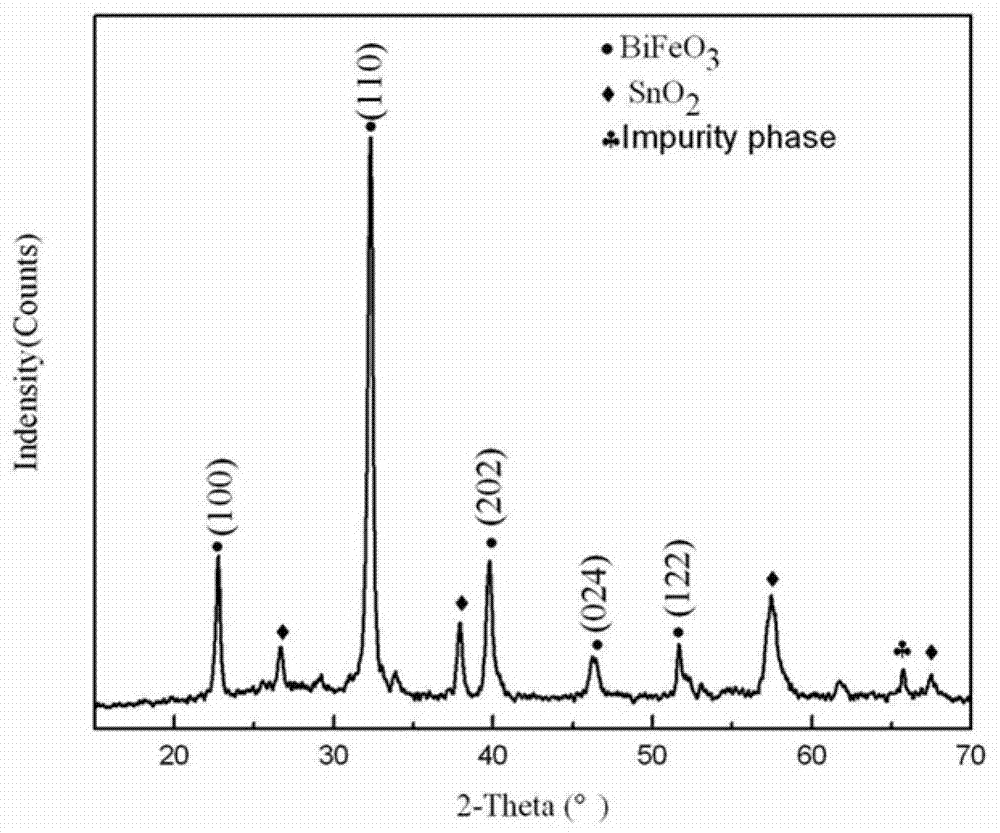

Layered structure ferrotitanium lanthanum bismuth cobaltate ceramic with multiferroic and preparation method thereof

InactiveCN101704669AImproved ferroelectric and magnetic propertiesThe process is simple and reasonableLayered structureLanthanum

The invention relates to a layered structure ferrotitanium lanthanum bismuth cobaltate ceramic with multiferroic and a preparation method thereof, relating to the technical field of oxide ceramic material preparation. The method comprises the following steps: firstly preparing Bi3.25L0.75Ti3O15 powder, then implanting BiCoO3 and BiFeO3 in Bi3.25L0.75Ti3O15 to form Bi4.25L0.75Fe0.5Co0.5Ti3O15 ceramic. In the obtained BLFCT sample, the octahedral arrangement of Fe-O and Co-O is relatively orderly so that the local coupling between Fe-O-Co and La-O-Co / Fe can be obtained and the ferroelectric property and magnetic property of the sample can be improved. The ceramic of the invention has simple and reasonable technology and good compatibility with the current technology, and the sample preparation temperature is much lower than the preparation temperature of the current technology so as to greatly reduce the energy consumption, thus the ceramic is applicable to industrial production.

Owner:YANGZHOU UNIV

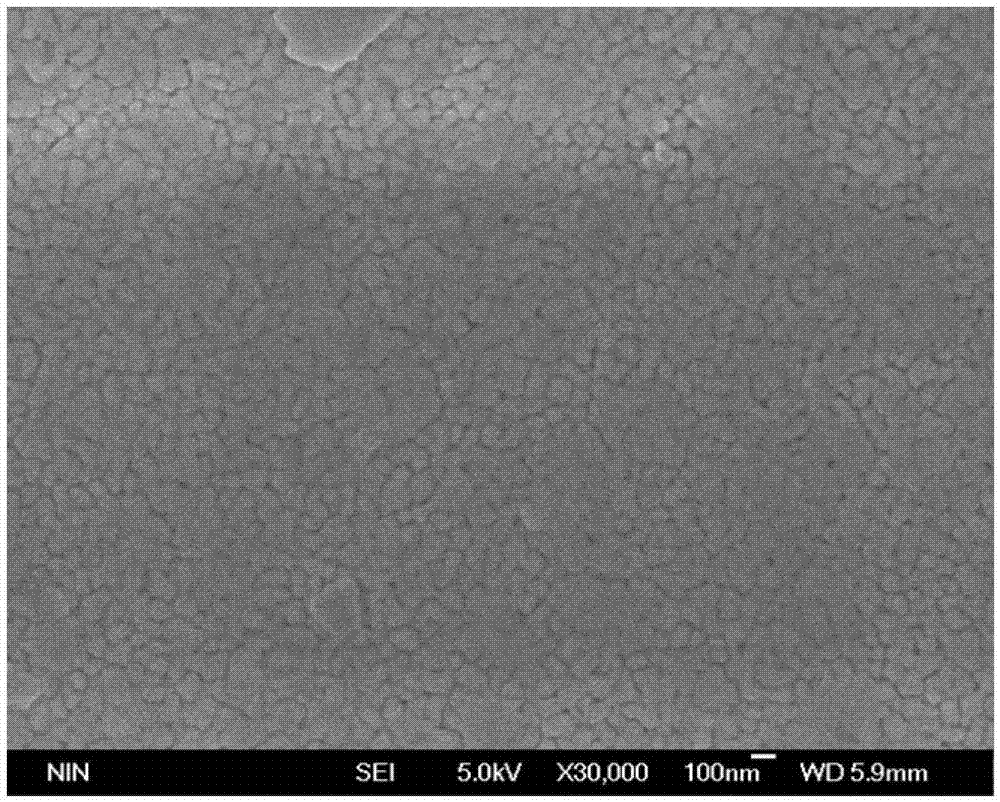

Method for preparing Bi0.85Sm0.15Fe1-xCrxO3 ferroelectric film via sol-gel process

The invention discloses a method for preparing a Bi0.85Sm0.15Fe1-xCrxO3 ferroelectric film via a sol-gel process. The method is carried out by the following steps of: washing an FTO (Fluorinedoped Tin Oxide) substrate and subsequently irradiating via ultraviolet light; using bismuth nitrate, ferric nitrate, samarium nitrate and chromic nitrate as raw materials (the bismuth nitrate excesses by 5%), dissolving the above raw materials in mixed ethylene glycol monomethyl ether and acetic anhydride according to a mole ratio of 0.90: (1-x):0.15:x (x is 0.00, 0.01, 0.02 or 0.03), then adding ethanol amine to adjust a viscosity and obtain a stable BiFeO3 (bismuth ferrite) precursor solution with a metal ion concentration of 0.003-0.3mol / L; and homogenizing and subsequently obtaining a dry film, then using a layer-by-layer annealing process to obtain a crystal-state Bi0.85Sm0.15Fe1-xCrxO3 ferroelectric film. The method disclosed by the invention has the advantages of simple device requirement, easy achievement of experiment condition, good uniformity of the prepared films and easy control of the doping amount, so that the ferroelectric performance of the film is greatly enhanced.

Owner:SHAANXI UNIV OF SCI & TECH

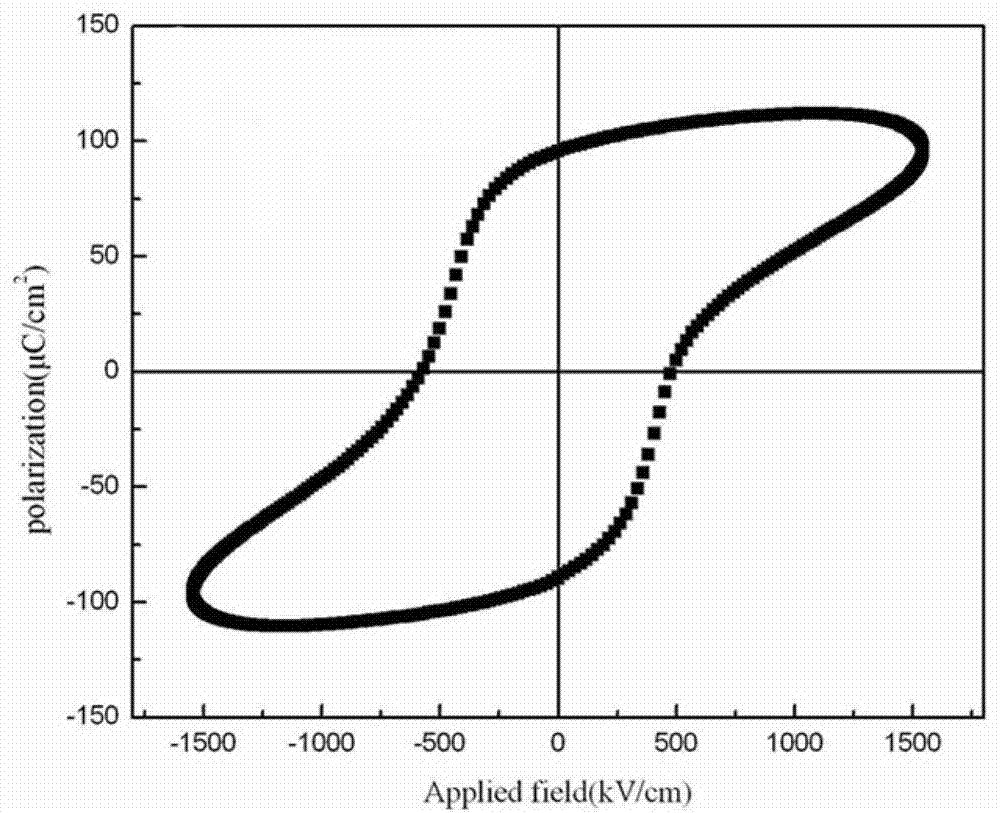

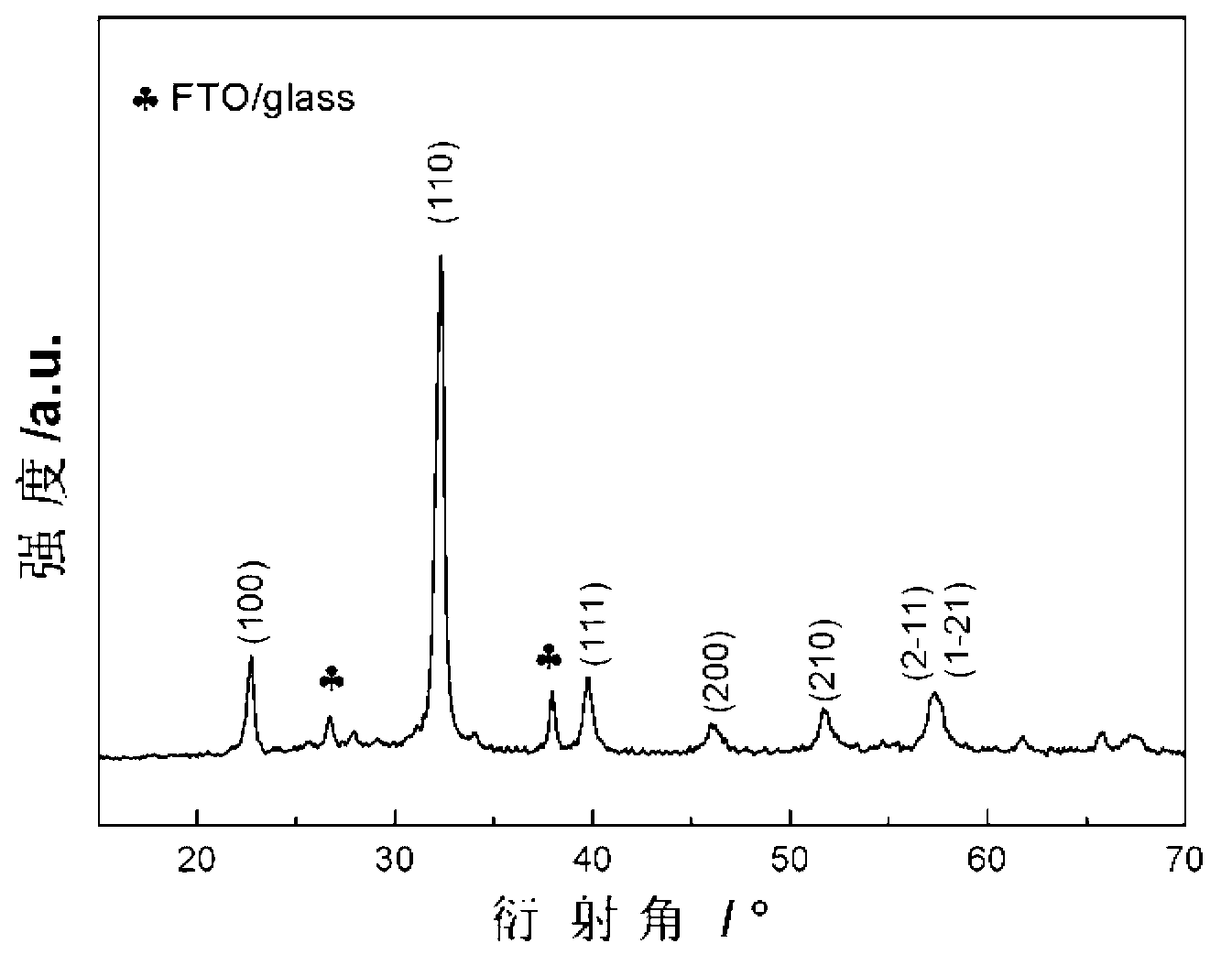

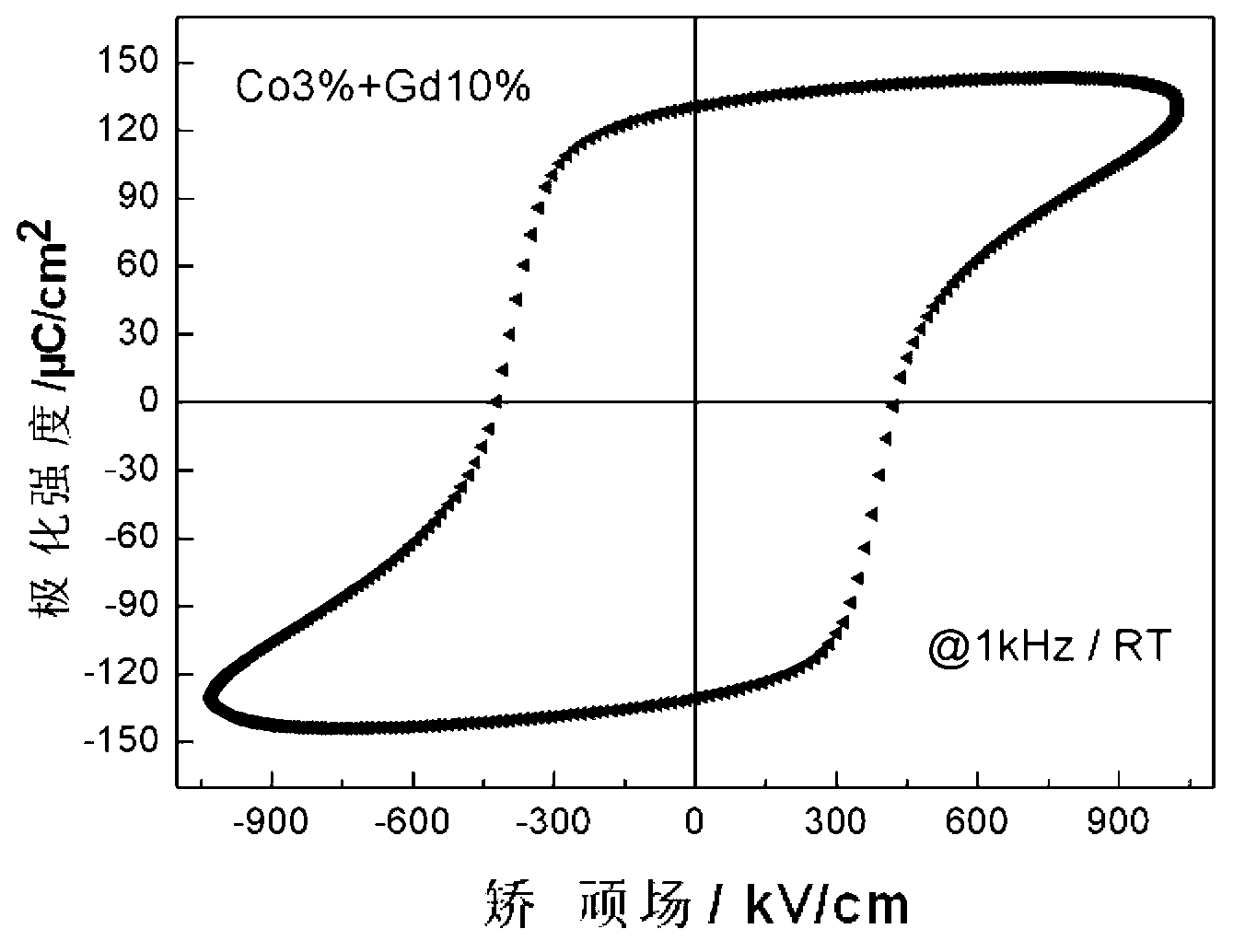

Method for preparing Gd and Co codoped high-remanent-polarization BiFeO3 thin film by sol-gel method

ActiveCN103073064AImprove multiferroic performanceImprove ferroelectric propertiesIron compoundsEthylene glycol monomethyl etherSol-gel

The invention provides a method for preparing a Gd and Co codoped high-remanent-polarization BiFeO3 thin film by a sol-gel method. The method comprises the steps that Bi(NO3)3*5H2O, Fe(NO3)3*9H2O, Gd(NO3)3*6H2O and Co(NO3)2*6H2O are dissolved in ethylene glycol monomethyl ether, and then heated and stirred in an 80 DEG C water bath for 1h; acetic anhydride is added and stirred for 1h; a BiFeO3 precursor solution is obtained and stands for 24h; an FTO (Fluorinedoped Tin Oxide) / glass substrate is subjected to spin coating with the BiFeO3 precursor solution for preparing a thin film; the thin film is subjected to rapid annealing at 550 DEG C, and then cooled to a room temperature; and spin coating and rapid annealing processes are repeated till the BiFeO3 thin film with the required thickness is prepared. The adopted sol-gel method does not require expensive equipment, and is suitable for preparing the thin film on a large surface and a surface with an irregular shape; in addition, chemical constituents are precise and controllable; the ferroelectric property of the prepared BiFeO3 thin film is improved under coaction of Gd and Co.

Owner:盐城市枯枝牡丹旅游开发投资有限公司

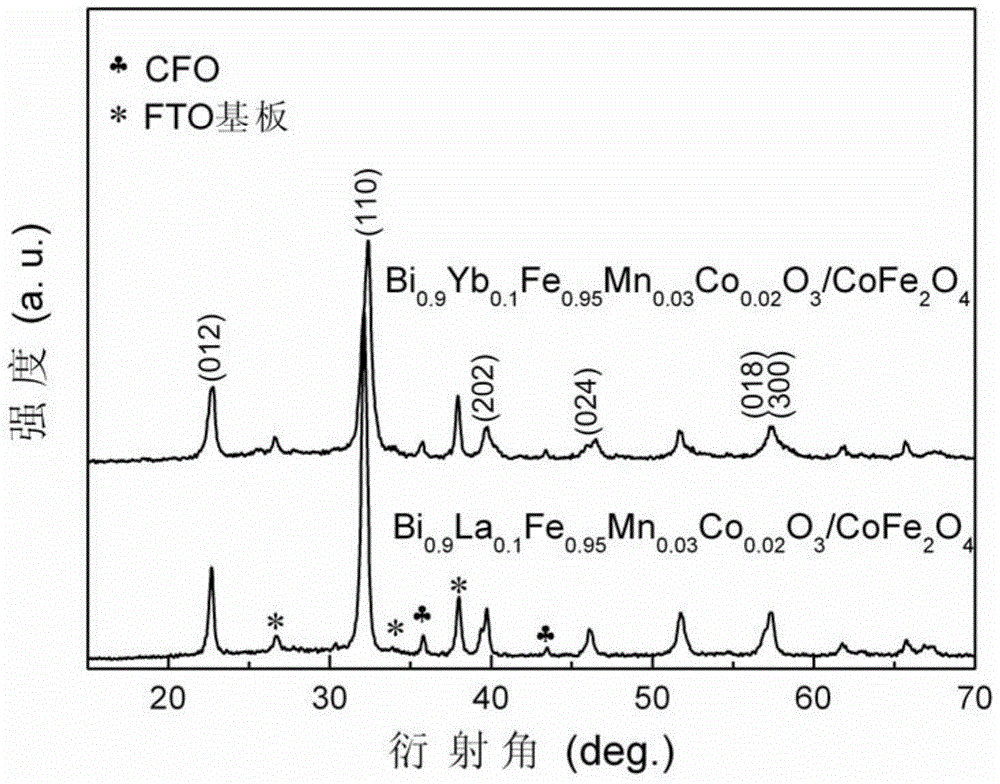

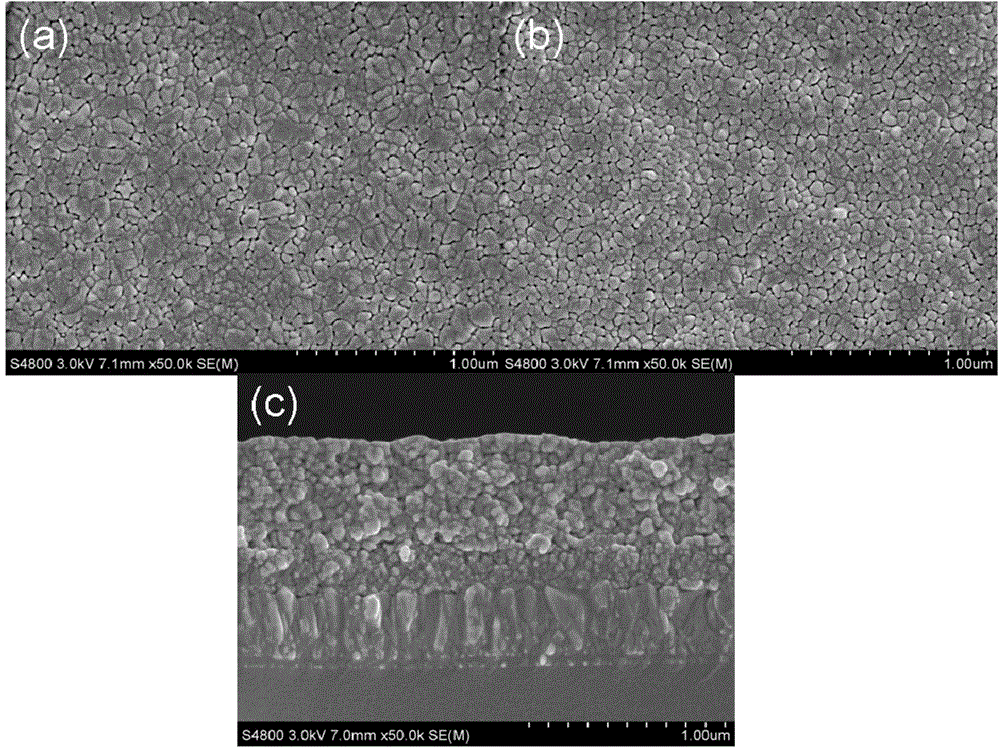

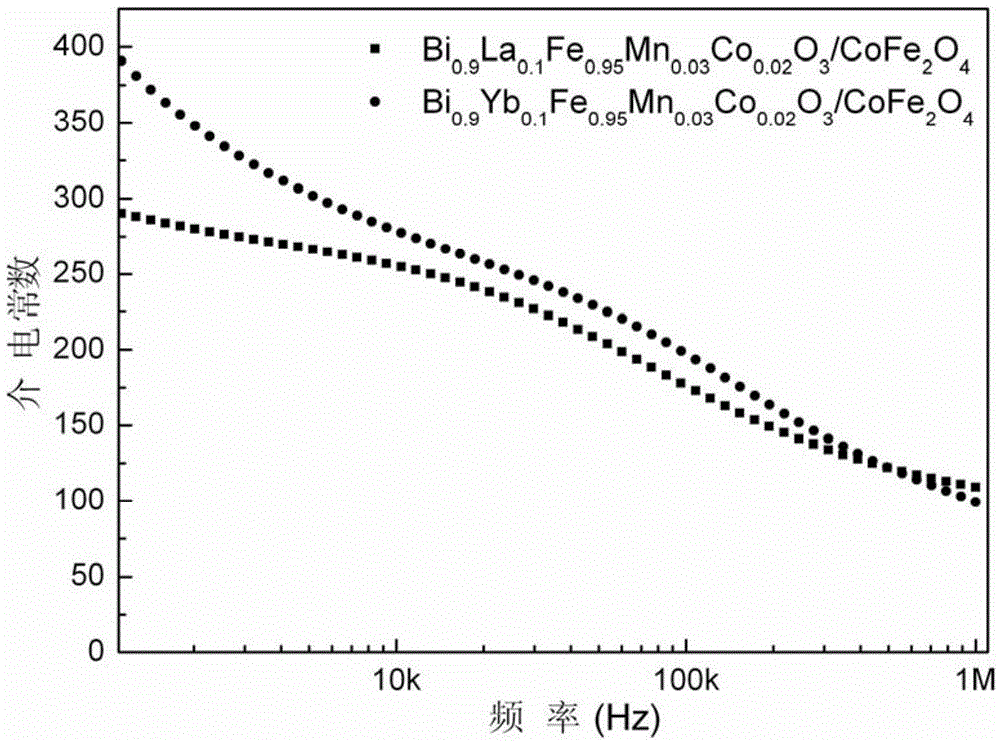

Multiferroic Bi1-xRExFe0.97-yMn0.03TMyO3/CoFe2O4 composite film and preparation method thereof

ActiveCN104538140AImprove multiferroic propertiesImprove ferroelectric propertiesInorganic material magnetismInductances/transformers/magnets manufactureComposite filmMultiferroics

The invention provides a multiferroic Bi1-xRExFe0.97-yMn0.03TMyO3 / CoFe2O4 composite film and a preparation method thereof. The composite film comprises a Bi1-xRExFe0.97-yMn0.03TMyO3 crystalline state film and a CoFe2O4 crystalline state film. The preparation method comprises the following steps of respectively preparing Bi1-xRExFe0.97-yMn0.03TMyO3 precursor solution and CoFe2O4 precursor solution; spin coating on a substrate to prepare a plurality of layers of CoFe2O4 films, spin coating on the CoFe2O4 films to prepare a plurality of layers of Bi1-xRExFe0.97-yMn0.03TMyO3 films and accordingly obtaining a target product. According to the multiferroic Bi1-xRExFe0.97-yMn0.03TMyO3 / CoFe2O4 composite film and the preparation method thereof, the device requirement is simple, the prepared film is good in homogeneity, the doping content is easy to control, the ferroelectric property and the ferromagnetic property of the film are improved to a large extent, and the film is high in residual polarization value and residual polarization value.

Owner:SHAANXI UNIV OF SCI & TECH

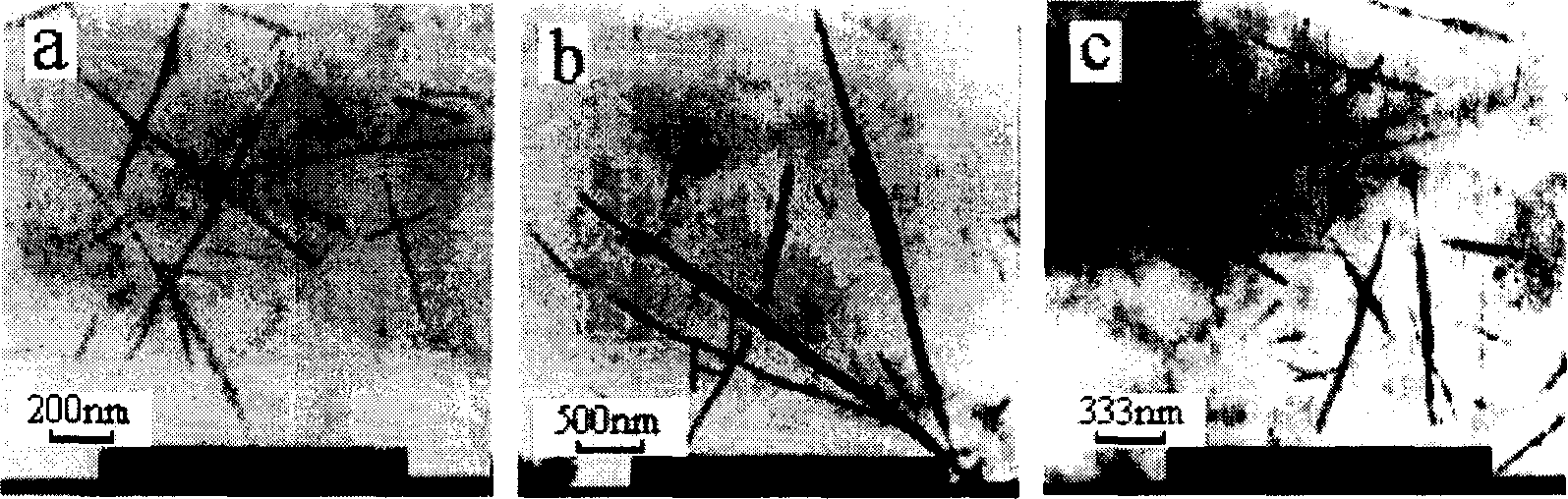

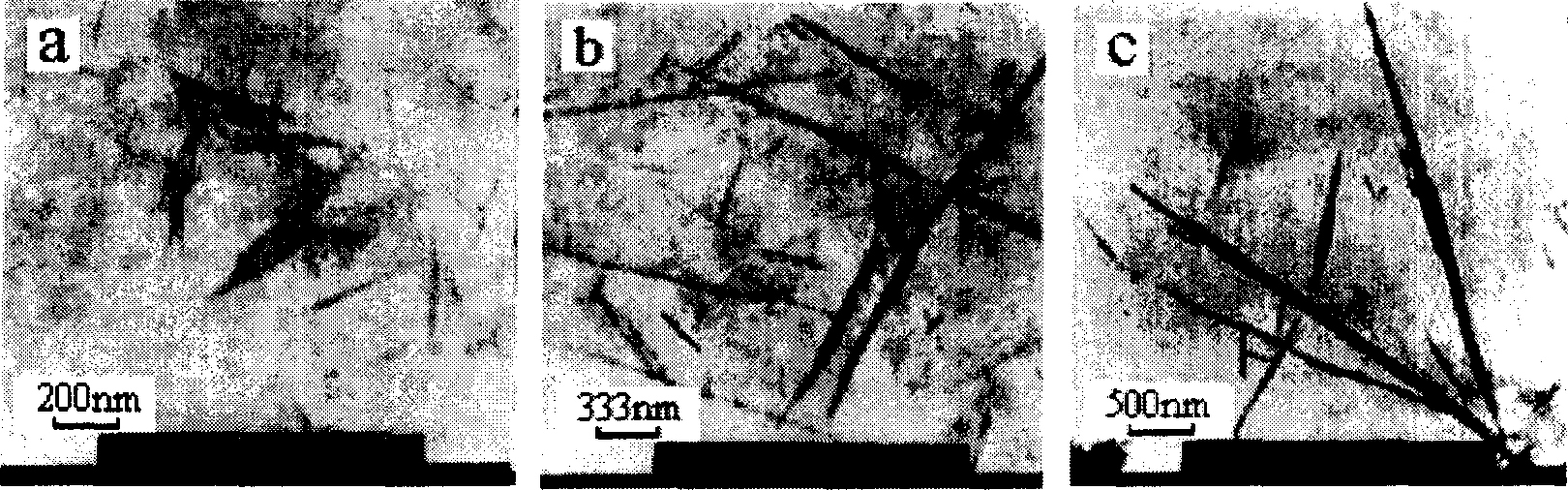

Process for preparing barium titanate nano-rod

InactiveCN1800030ASimple production processControllable size and shapeCalcium/strontium/barium compoundsTitanium compoundsCyclohexanoneBarium titanate

The invention discloses a making method of barium titanate nanometer bar, which comprises the following steps: selecting polyoxyethylated alkyl (10) phenol (OP-10), positive hexanol, cyclohexanone and water to form microemulsion; taking the titanic butonat and Ba (OH) 2 as reactant; mixing each composition of inversed-phase microemulsion; stirring the mixture strongly in the magnetic stirrer; producing the inversed-phase microemulsion of even transparency and stable property; dripping the titanic butonat solution; producing the barium titanate nanometer bar with 15-85 nm diameter and 300-4000 nm length through reacting, aging, centrifugal separating and cleaning by waterless alcohol. The invention can control the particle dimension and shape of barium titanate nanometer bar, which can be used in the inorganic functional material equipment.

Owner:XIANGTAN UNIV

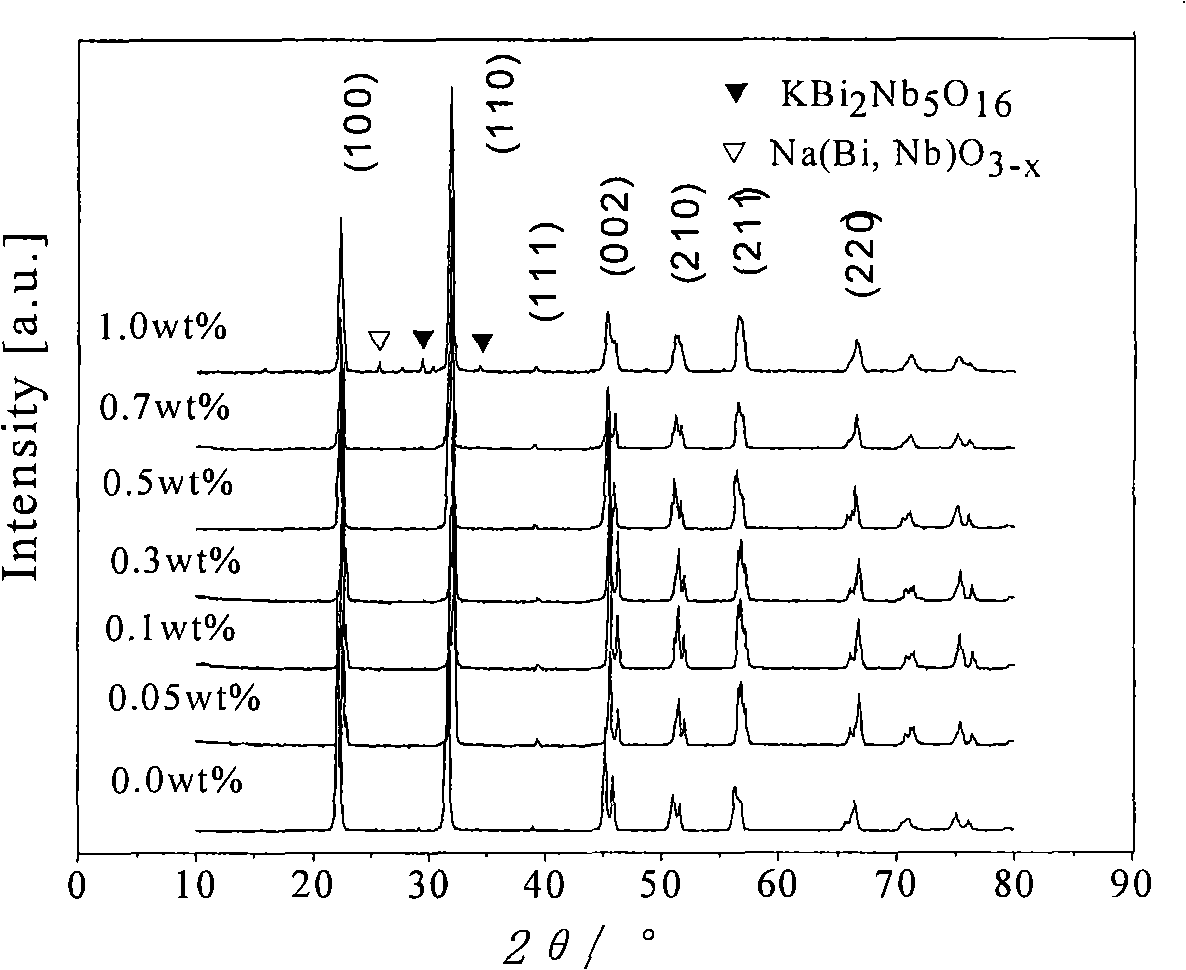

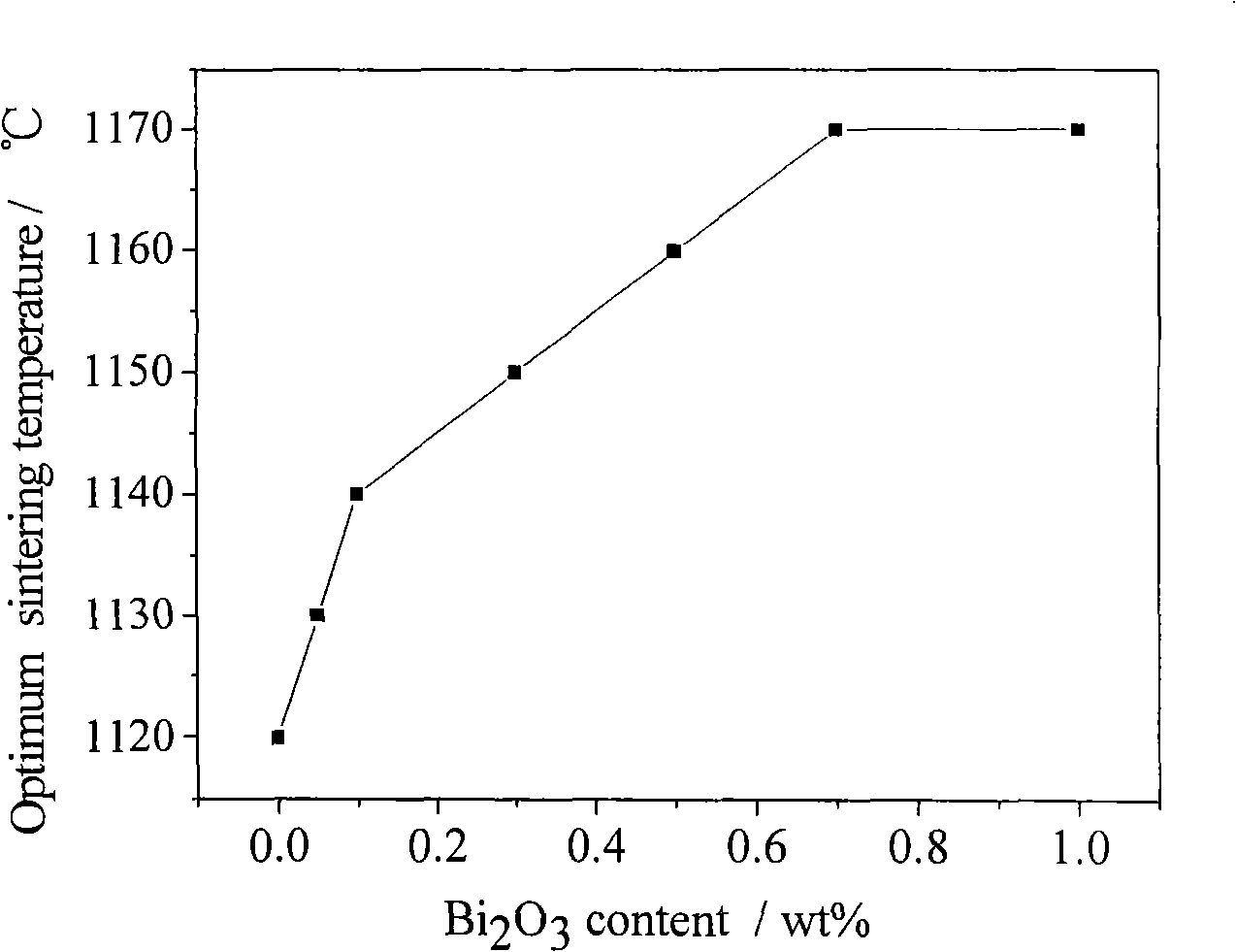

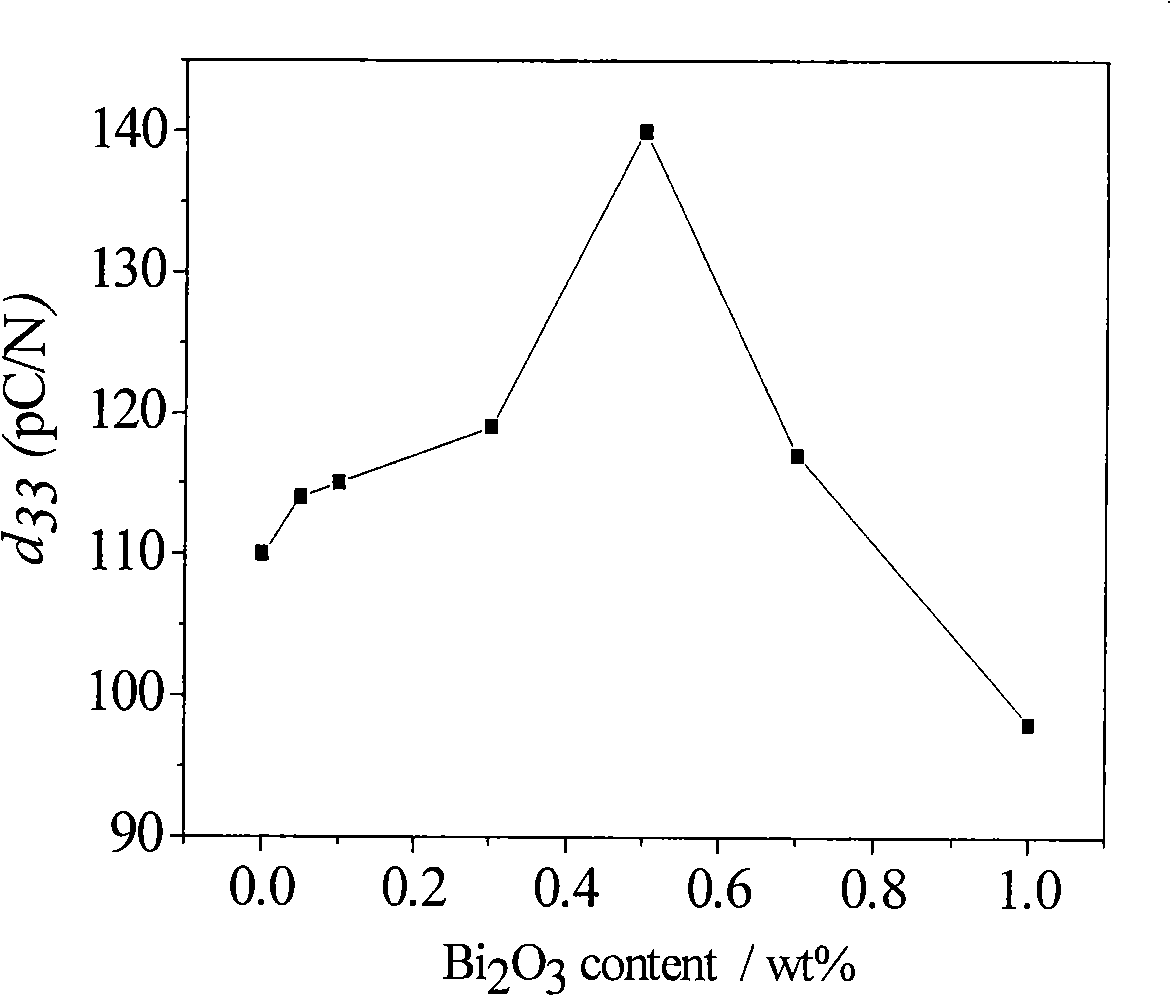

Potassium-sodium niobate-based leadless piezoelectric material and preparation thereof

InactiveCN101302106AImprove sintering propertiesHigh degree of densificationSilver electrodeDrain current

The invention discloses a piezoelectric material for lead-free piezoelectric ceramic with potassium-sodium niobate and a preparing method, which strengthens the ferroelectric performance of potassium-sodium niobate ceramic and further improves the piezoelectric performance. The material of the invention comprises anhydrous potassium carbonate, natrium carbonicum calcinatum, niobium pentaoxide and dibismuth trioxide, the stoichiometric proportion of the lead-free piezoelectric ceramic is (K0.5 Na0.5) Nb3 + x weight percent Bi 2O3, wherein the x is more than or equal to 0 and less than or equal to 1, the piezoelectric material for lead-free piezoelectric ceramic with potassium-sodium niobate is obtained through mixture making, drying and burnishing, granulation, molding, sintering and after polarization by a silver electrode; therefore, the densification of the ceramic is improved, polarized drain current of the ceramic is reduced, and the polarization process is carried out more easily; moreover, the piezoelectric material adopts the material from a conventional process and industry, has the characteristics of good process stability and no pollution.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Sodium niobate lithium tantalate series lead-free piezoelectric ceramic composite

InactiveCN102557635AExcellent piezoelectric ferroelectric propertiesExcellent piezoelectric propertiesSolid-stateElectricity

A novel sodium niobate lithium tantalate series lead-free piezoelectric ceramic composite comprises perovskite anti-ferroelectrics NaNbO3 and lithium niobate ferroelectrics LiTao3 and is represented as formula (1-x)NaNbO3-xLiTaO3, wherein 0.025<=x<=0.25. The lead-free piezoelectric ceramic composite further comprises one kind or a plurality of kinds of oxides, formula of the lead-free piezoelectric ceramic composite is (1-x)NaNbO3-xLiTaO3 ((110-a)mol%)+M alpha O beta (amol%), the M alpha O beta is one kind or a plurality of kinds of oxides, molar ratio of a content to main component (1-x)NaNbO3-xLiTaO3 is 0-3%, M is an element which is from +1 to +6 and capable of forming a solid-state oxide with oxygen, and the alpha and the beta respectively show atomic numbers of corresponding element M and the oxygen in the oxide. The optimal value d33 of the piezoelectric ceramic composite can reach above 70pC / N, kp can reach above 20%, and Qm can reach above 1200. The composite is good in compactness, high in Curie temperature, good in heat stability and stable in process, is obtained by adopting the tradition piezoelectric ceramic manufacturing technology, and has practicability.

Owner:SICHUAN NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com