Hafnium oxide based ferroelectric grid structure and preparation technology thereof

A preparation process, the technology of hafnium oxide, applied in the field of memory, can solve the problems of small storage window, silicon process incompatibility, interface effect, etc., and achieve the effect of vertical dimension reduction, excellent electrical performance and excellent ferroelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

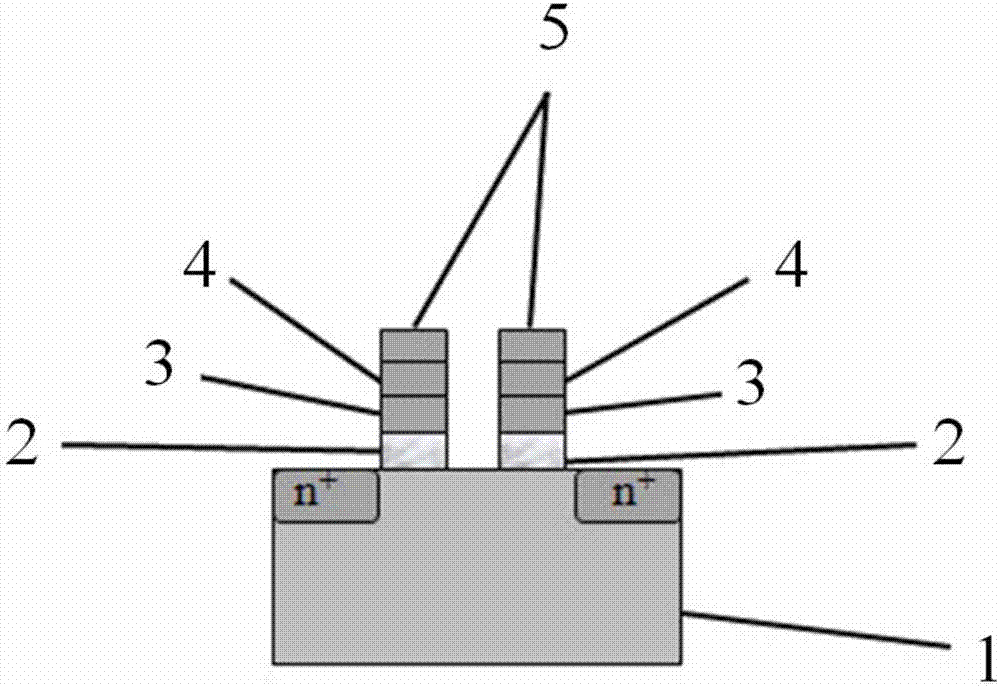

[0042]An embodiment of the hafnium oxide-based ferroelectric gate structure of the present invention includes a substrate, and a buffer layer, a bottom electrode layer, a ferroelectric storage layer and a top electrode layer are sequentially stacked on the surface of the substrate; wherein, The material of the substrate is P-type silicon; the material of the buffer layer is 3nm hafnium oxide; the material of the bottom electrode layer is 55nm TiN; the material of the ferroelectric storage layer is 15nm hafnium oxide doped with zirconium. The material ratio of the elements is: hafnium: zirconium = 1:1; the material of the top electrode is 20nm metal TiN.

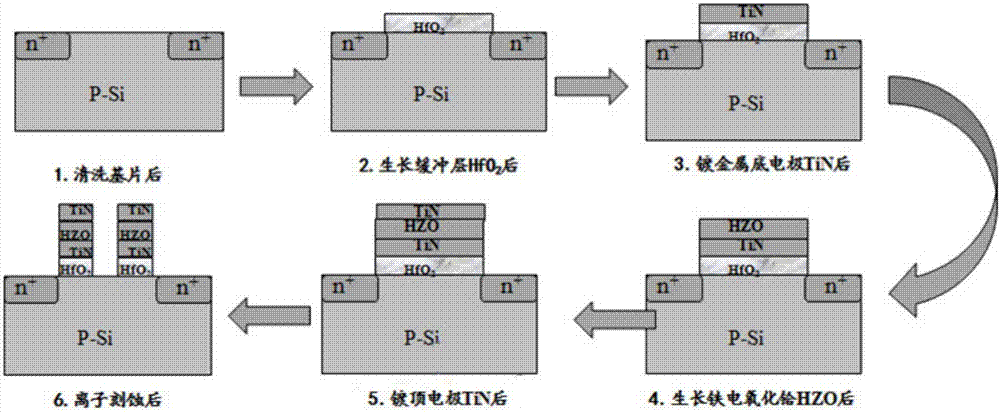

[0043] The preparation process of the ferroelectric gate structure based on hafnium oxide described in this embodiment, as shown in the attached figure 2 shown, including the following steps:

[0044] (1) Clean the P-type silicon with a standard cleaning process;

[0045] (2) A hafnium oxide buffer layer is formed on the P...

Embodiment 2

[0050] An embodiment of the ferroelectric grid structure based on hafnium oxide in the present invention includes a substrate, and a buffer layer, a bottom electrode layer, a ferroelectric layer and a top electrode layer are sequentially stacked on the surface of the substrate; wherein, the substrate The bottom material is N-type silicon; the buffer layer material is 5nm hafnium oxide; the bottom electrode layer material is 45nm metal TaN; the ferroelectric layer material is 18nm zirconium-doped hafnium oxide, in which hafnium and zirconium elements The ratio of the amount of substances is: hafnium: zirconium = 0.55:0.45; the material of the top electrode is 55nm metal TiN.

[0051] The preparation process of the hafnium oxide-based ferroelectric gate structure described in this embodiment includes the following steps:

[0052] (1) Clean the N-type silicon with a standard cleaning process;

[0053] (2) A hafnium oxide buffer layer is formed on the N-type silicon, and the hafn...

Embodiment 3

[0058] An embodiment of the ferroelectric grid structure based on hafnium oxide in the present invention includes a substrate, and a buffer layer, a bottom electrode layer, a ferroelectric layer and a top electrode layer are sequentially stacked on the surface of the substrate; wherein, the substrate The bottom material is P-type silicon; the buffer layer material is 7nm hafnium oxide; the bottom electrode layer material is 20nm metal TiN; the ferroelectric layer material is 16nm silicon-doped hafnium oxide, in which hafnium and silicon elements The ratio of the amount of substances is: hafnium:silicon=0.75:0.25; the material of the top electrode is 20nm TiN and 30nm Al.

[0059] The preparation process of the hafnium oxide-based ferroelectric gate structure described in this embodiment includes the following steps:

[0060] (1) Clean the P-type silicon with a standard cleaning process;

[0061] (2) A hafnium oxide buffer layer is formed on the P-type silicon, and the hafnium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com