Periodic stripe domain structure of ferroelectric thin film and method for characterizing same

A ferroelectric thin film, periodic technology, applied in circuits, electrical components, electric solid devices, etc., can solve the problem of not conducting more detailed analysis, and achieve the effect of large polarization value and good ferroelectricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

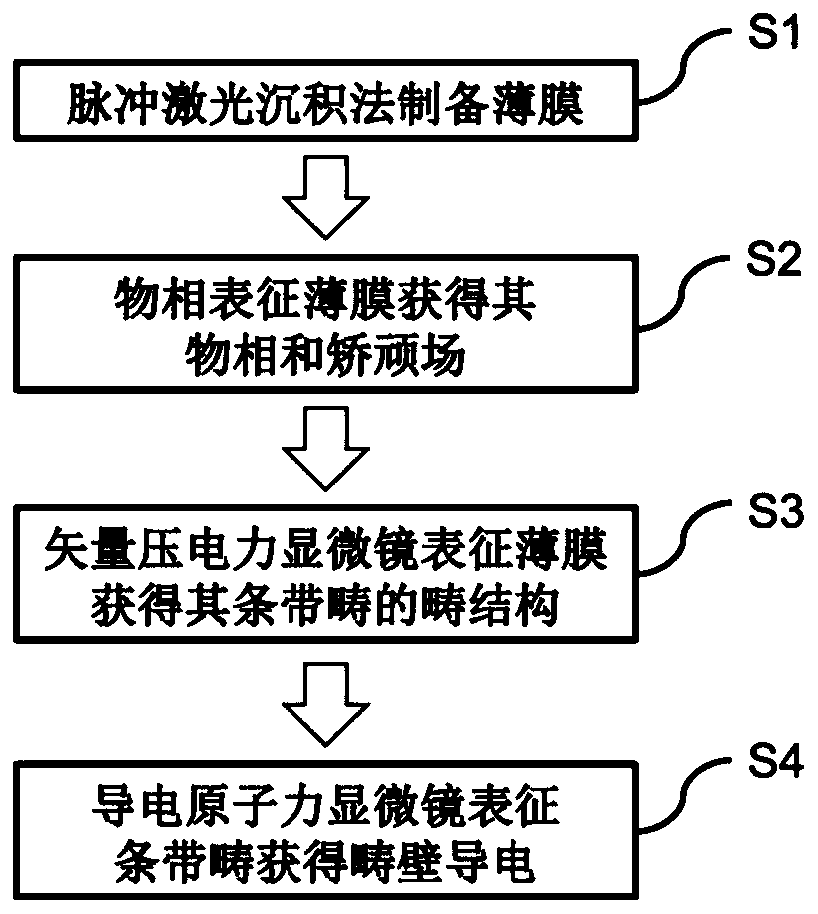

[0041] like Figure 1-8 as shown, figure 1 It is a schematic flowchart of a periodic striped domain structure of a ferroelectric thin film and a characterization method thereof in the present invention. The operation and implementation parameters of using the PLD method to prepare the BFO thin film have been described in detail in the summary of the invention and the specific implementation manner. Combine below Figure 2-8 , describe this embodiment in detail.

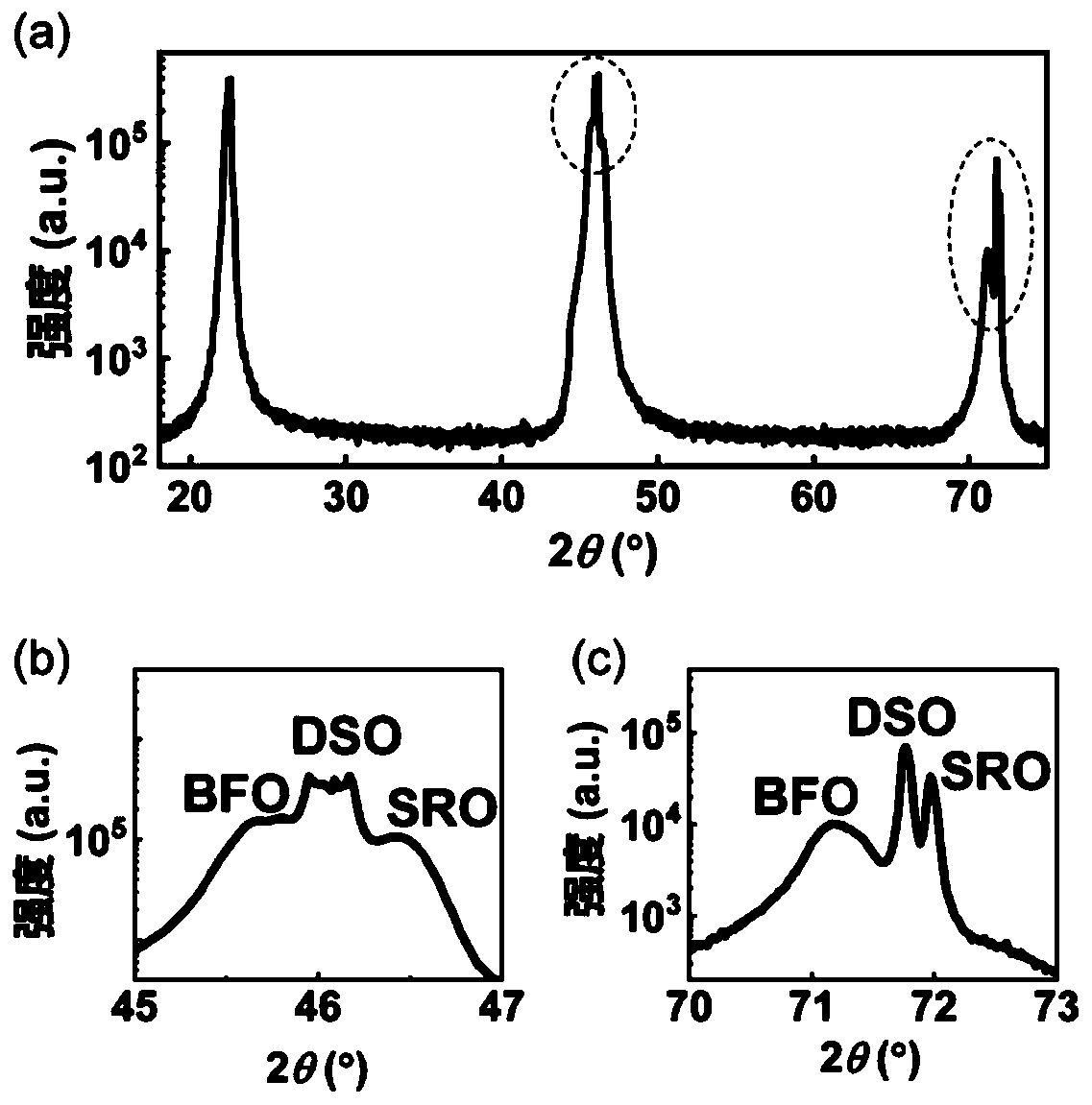

[0042] (1) According to step S2, phase characterization of film samples, please refer to Figure 2-4 .

[0043] figure 2 : X-ray θ-2θ scanning results of thin film samples, (a) is the result of wide range angle scanning, (b) is the enlarged view of 45°-47° range scanning results, where the DSO peak intensity exceeds the range, (c) is Enlarged view of the scanning results in the range of 70°-73°; one is to confirm the structure of the sample as DSO / SRO / BFO; The phase structure is close.

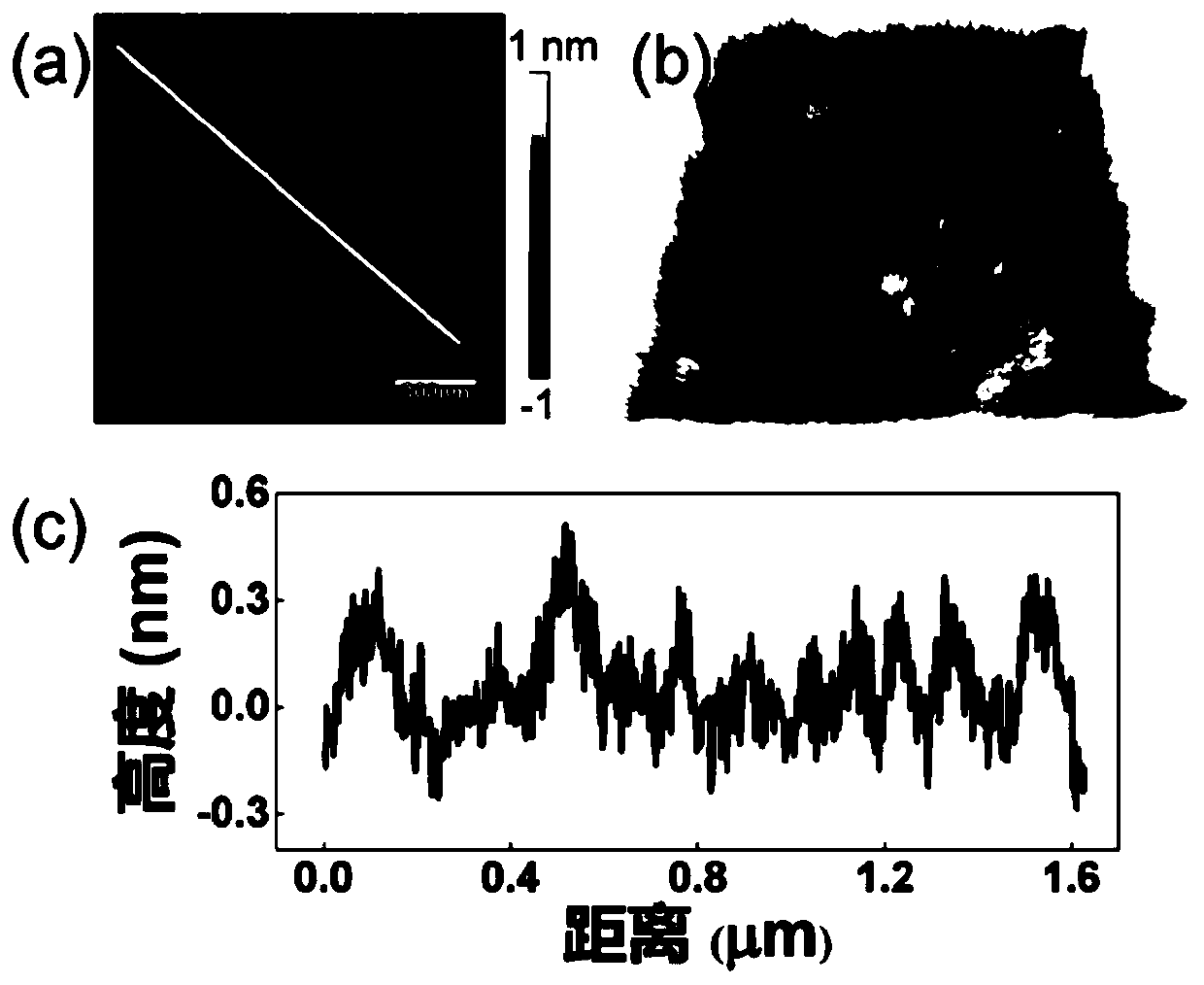

[0044] image 3 : AF...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com