Construction method of high-density polarized topological domain array

A construction method and topological domain technology, applied in the direction of digital memory information, instruments, capacitors, etc., can solve the problems of poor visualization, sample destruction, lead poisoning, etc., and achieve the effect of advanced technology, efficient preparation, and good ferroelectricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

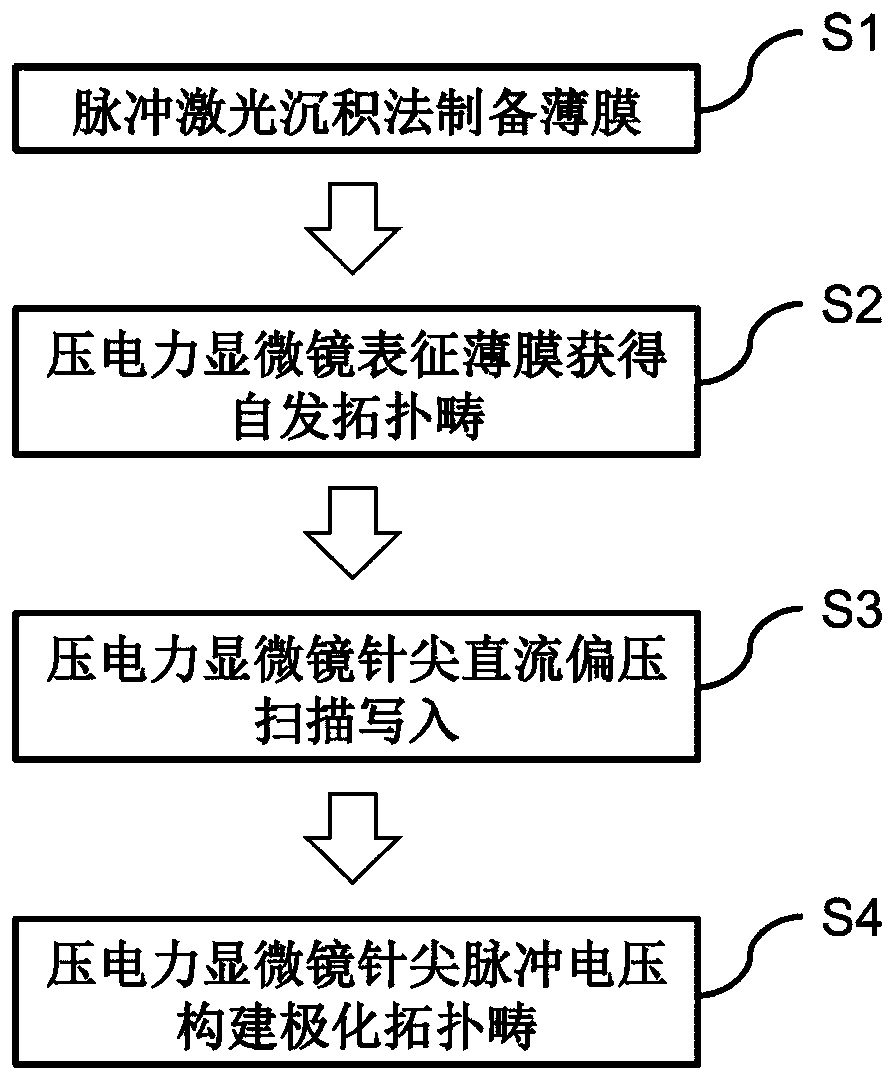

[0044] Such as Figure 1-8 as shown, figure 1 It is a schematic diagram of the construction process of a high-density polarized topological domain array of the present invention. Combine below Figure 2-6 , and describe this embodiment in detail.

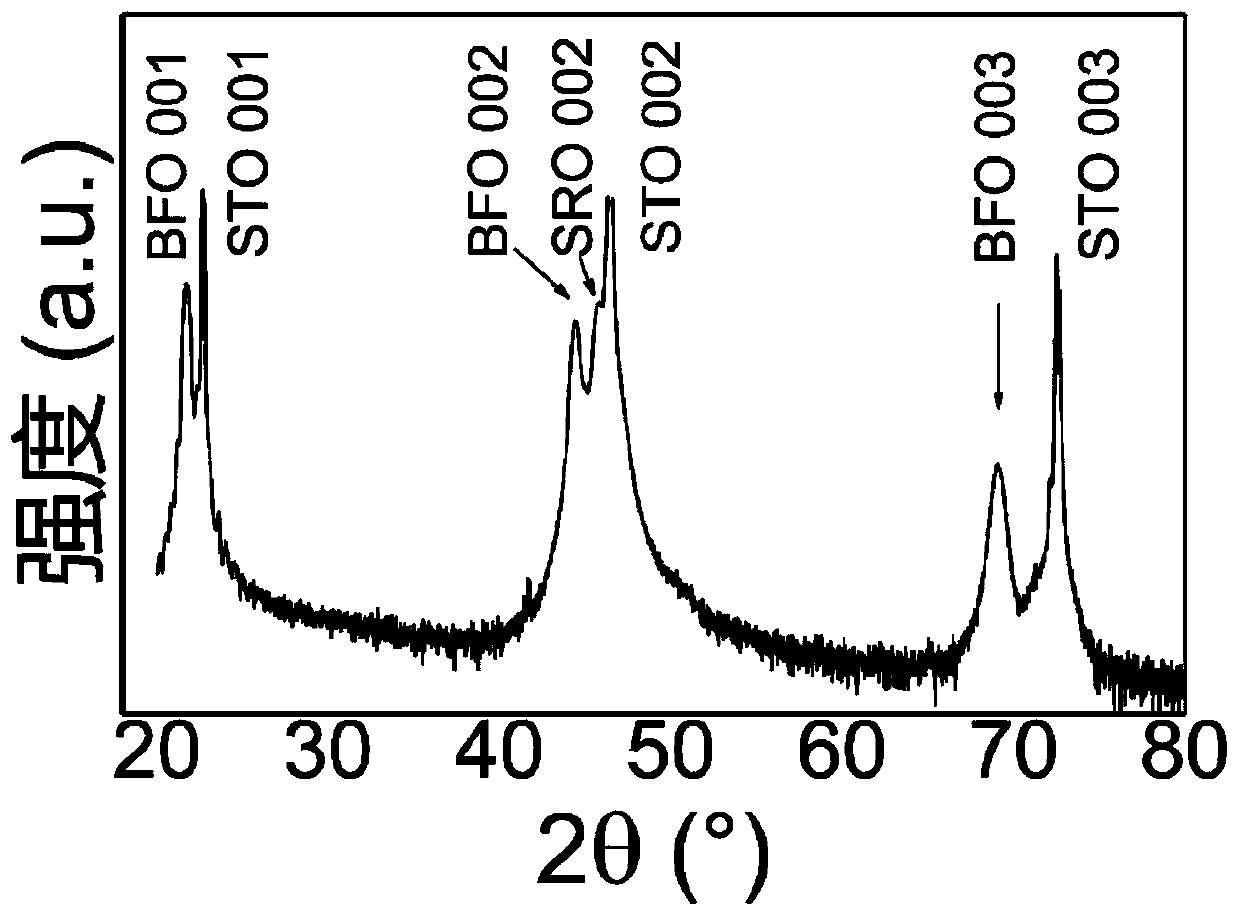

[0045] First prepare high-quality, high-performance epitaxial ferroelectric thin films: X-ray diffraction θ-2θ scanning characterization, such as figure 2 As shown, the results clearly show the epitaxial structure of STO / SRO / BFO, and the lattice constant calculated from the out-of-plane (002) peak shows that the BFO film is a rhombohedral structure; AFM characterization gives the morphology, such as image 3 As shown, the roughness (rms, root mean square value) is 0.5nm, indicating that the film surface is flat ( image 3 a), 3D topography ( image 3 b) This is also proved; use the "piezo-hysteresis" mode to characterize the PFM piezoelectric loop of the sample, as Figure 4 As shown, the PFM phase diagram ( Figure 4 a) A 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com