Multiferroic Bi1-xRExFe0.97-yMn0.03TMyO3/CoFe2O4 composite film and preparation method thereof

A cofe2o4, multiferroic technology, applied in the manufacture of inductors/transformers/magnets, inorganic material magnetism, electrical components, etc., can solve the problems of weak magnetism and large leakage current, and achieve high permeability and improved ferroelectric performance. , the effect of high chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

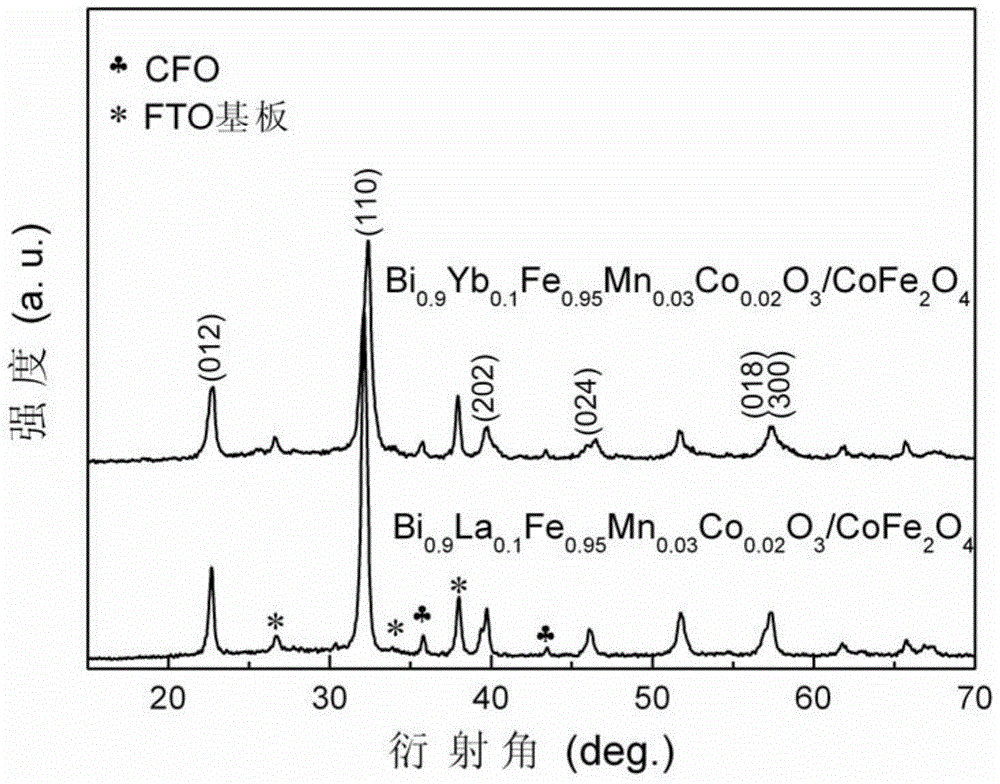

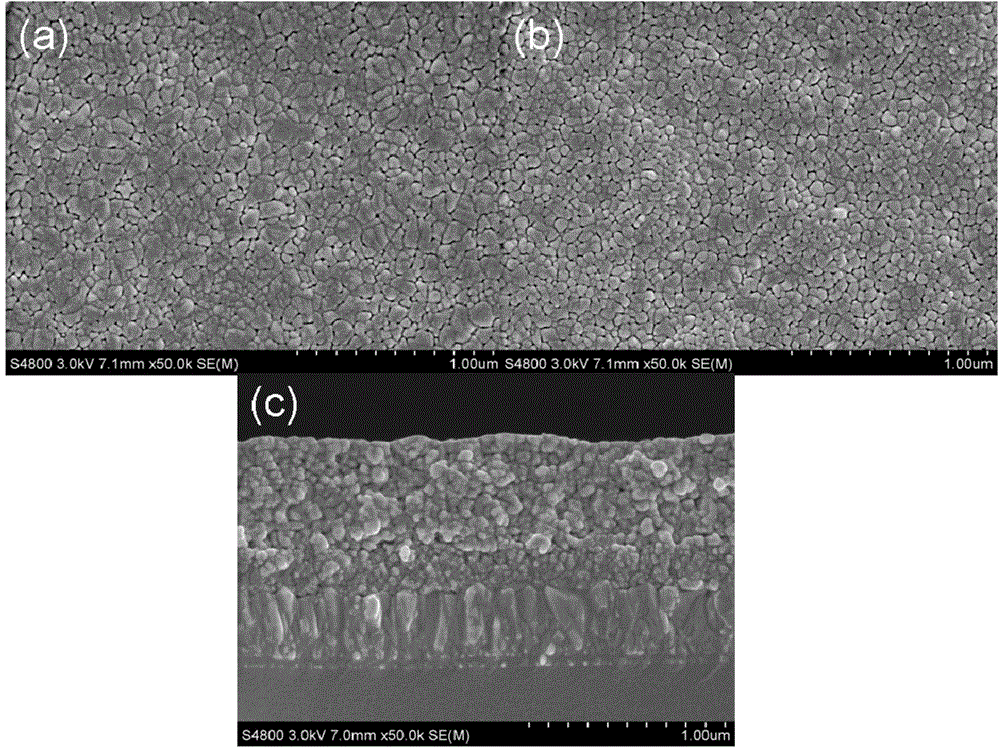

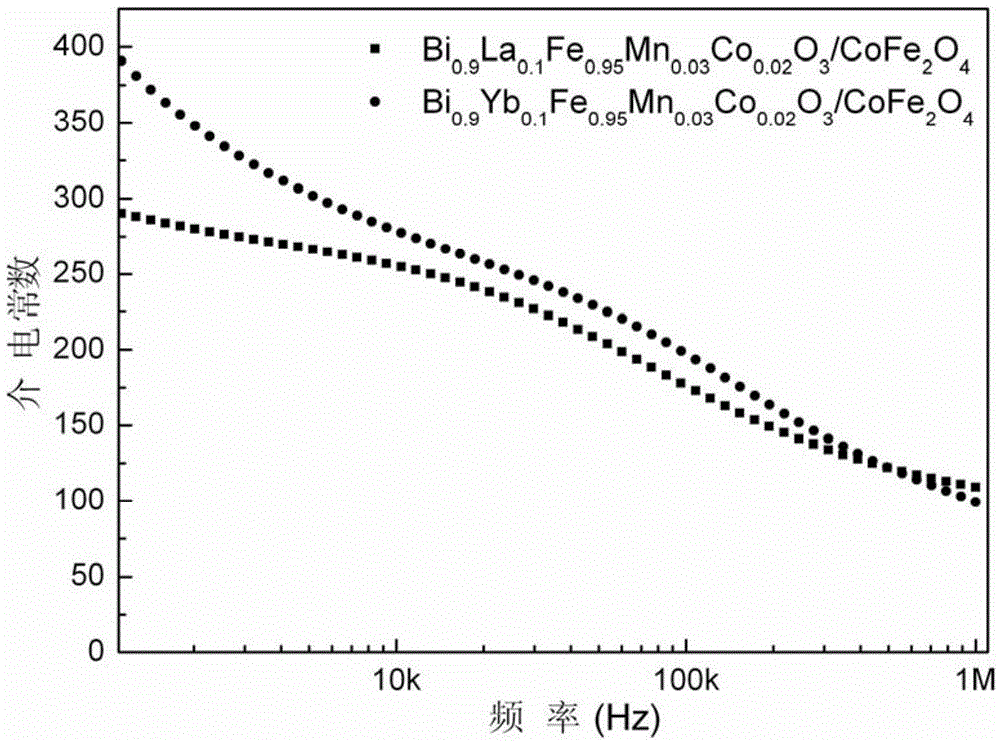

Embodiment 1

[0043] Step 1: Add Co(NO 3 ) 2 ·6H 2 O and Fe(NO 3 ) 3 9H 2 O is dissolved in the mixed solution of ethylene glycol methyl ether and acetic anhydride at a molar ratio of 1:2, and stirred for 2 hours to obtain a uniformly mixed CoFe 2 o 4 Precursor, CoFe 2 o 4 The concentration of Co ions in the precursor solution is 0.1mol / L, and the volume ratio of ethylene glycol methyl ether and acetic anhydride is 3:1;

[0044] Step 2: Bi(NO 3 ) 3 ·5H 2 O, La(NO 3 ) 3 ·6H 2 O, Fe(NO 3 ) 3 9H 2 O, C 4 h 6 MnO 4 4H 2 O and Co(NO 3 ) 2 ·6H 2 O is 0.95:0.1:0.95:0.03:0.02 (RE=La, TM=Co, x=0.1, y=0.02, excessive bismuth nitrate) is dissolved in the mixed solution of ethylene glycol methyl ether and acetic anhydride by molar ratio, Stir for 2h to obtain a uniformly mixed Bi 0.9 La 0.1 Fe 0.95 mn 0.03 co 0.02 o 3 Precursor, Bi 0.9 La 0.1 Fe 0.95 mn 0.03 co 0.02 o 3 The total concentration of metal ions in the precursor solution is 0.3mol / L, and the volume ratio ...

Embodiment 2

[0050] Step 1: Add Co(NO 3 ) 2 ·6H 2 O and Fe(NO 3 ) 3 9H 2 O is dissolved in the mixed solution of ethylene glycol methyl ether and acetic anhydride at a molar ratio of 1:2, and stirred for 2 hours to obtain a uniformly mixed CoFe 2 o 4 Precursor, CoFe 2 o 4 The concentration of Co ions in the precursor solution is 0.15mol / L, and the volume ratio of ethylene glycol methyl ether and acetic anhydride is 3:1;

[0051] Step 2: Bi(NO 3 ) 3 ·5H 2 O, Yb(NO 3 ) 3 ·6H 2 O, Fe(NO 3 ) 3 9H 2 O, C 4 h 6 MnO 4 4H 2 O and Co(NO 3 ) 2 ·6H 2 O is 0.95:0.1:0.95:0.03:0.02 (RE=Yb, TM=Co, x=0.1, y=0.02, excessive bismuth nitrate) is dissolved in the mixed solution of ethylene glycol methyl ether and acetic anhydride by molar ratio, Stir for 2h to obtain a uniformly mixed Bi 0.9 Yb 0.1 Fe 0.95 mn 0.03 co 0.02 o 3 Precursor, Bi 0.9 Yb 0.1 Fe 0.95 mn 0.03 co 0.02 o 3 The total concentration of metal ions in the precursor solution is 0.3mol / L, and the volume ratio...

Embodiment 3

[0057] Step 1: Add Co(NO 3 ) 2 ·6H 2 O and Fe(NO 3 ) 3 9H 2 O is dissolved in the mixed solution of ethylene glycol methyl ether and acetic anhydride at a molar ratio of 1:2, and stirred for 1.5h to obtain a uniformly mixed CoFe 2 o 4 Precursor, CoFe 2 o 4 The concentration of Co ions in the precursor solution is 0.2mol / L, and the volume ratio of ethylene glycol methyl ether and acetic anhydride is 2.5:1;

[0058] Step 2: Bi(NO 3 ) 3 ·5H 2 O, Sm(NO 3 ) 3 ·6H 2 O, Fe(NO 3 ) 3 9H 2 O, C 4 h 6 MnO 4 4H 2 O and Cr(NO 3 ) 3 9H 2 O is 0.95:0.1:0.95:0.03:0.02 (RE=Sm, TM=Cr, x=0.1, y=0.02, excessive bismuth nitrate) is dissolved in the mixed solution of ethylene glycol methyl ether and acetic anhydride by molar ratio, Stir for 1.5h to obtain a uniformly mixed Bi 0.9 SM 0.1 Fe 0.95 mn 0.03 Cr 0.02 o 3 Precursor, Bi 0.9 SM 0.1 Fe 0.95 mn 0.03 Cr 0.02 o 3 The total concentration of metal ions in the precursor solution is 0.3mol / L, and the volume ratio ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| remanent polarization | aaaaa | aaaaa |

| remanent polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com