Patents

Literature

32results about How to "Increase the number of flips" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Active carbon activation furnace and active carbon production method

The invention discloses an active carbon activation furnace and an active carbon production method and relates to the field of active carbon production equipment and active carbon production technologies. The safety of an active carbon production process can be improved to a certain extent; the activation furnace works stably for a long term; and the quality and the productive capacity of produced active carbon are greatly improved. The active carbon activation furnace comprises a furnace body, a material entry device and a discharge mechanism, wherein the furnace body is internally provided with a burning passage communicated with the interior of the furnace body; air is admitted to the burning passage; the interior of the furnace body is in a negative pressure state; and air pressure in the burning passage is lower than that in the furnace body. The active carbon production method comprises the following steps: A: arranging the burning passage and material passages, B: admitting steam into the material passages, C: leading liberated gas in the material passages into the burning passage, D: heating materials in the material passages, and E: admitting flue gas generated by burning into a steam generator for heat exchange. The active carbon activation furnace and the active carbon production method are mainly used for active carbon production.

Owner:张西进

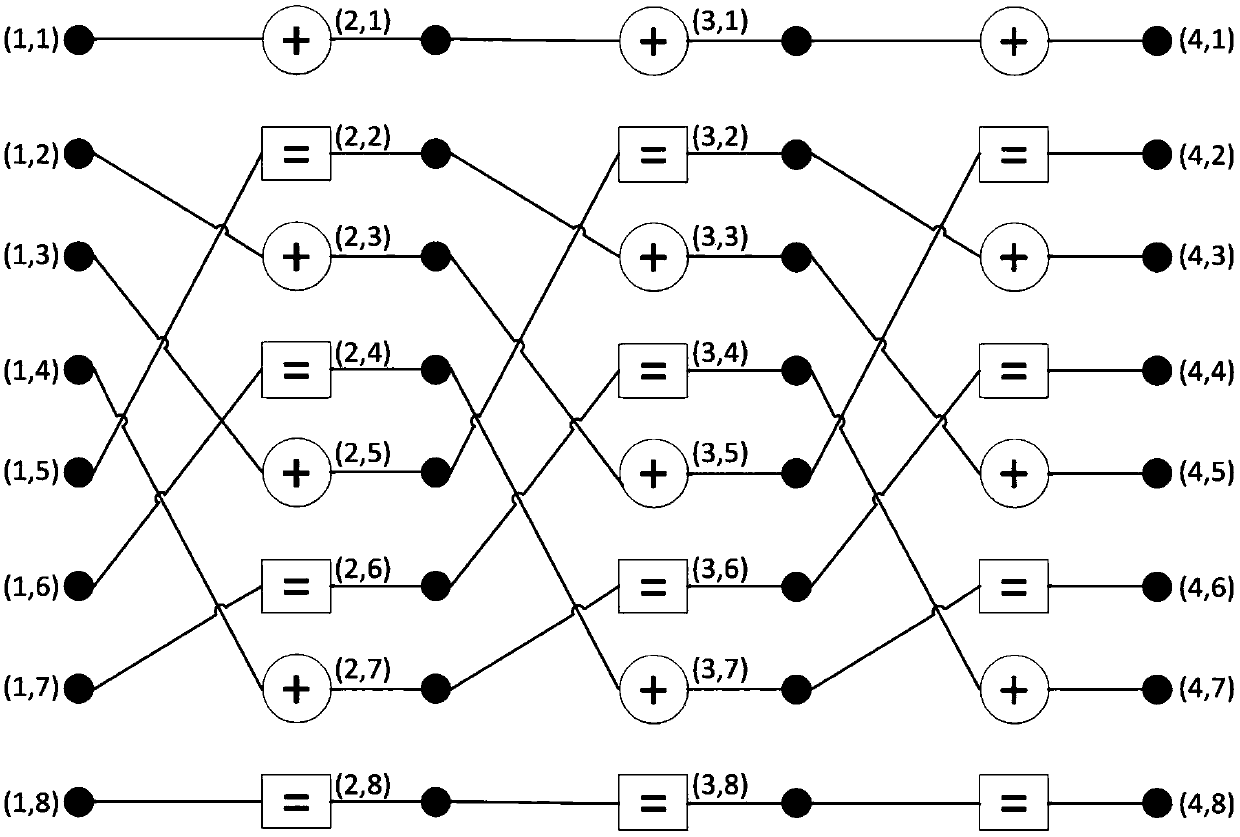

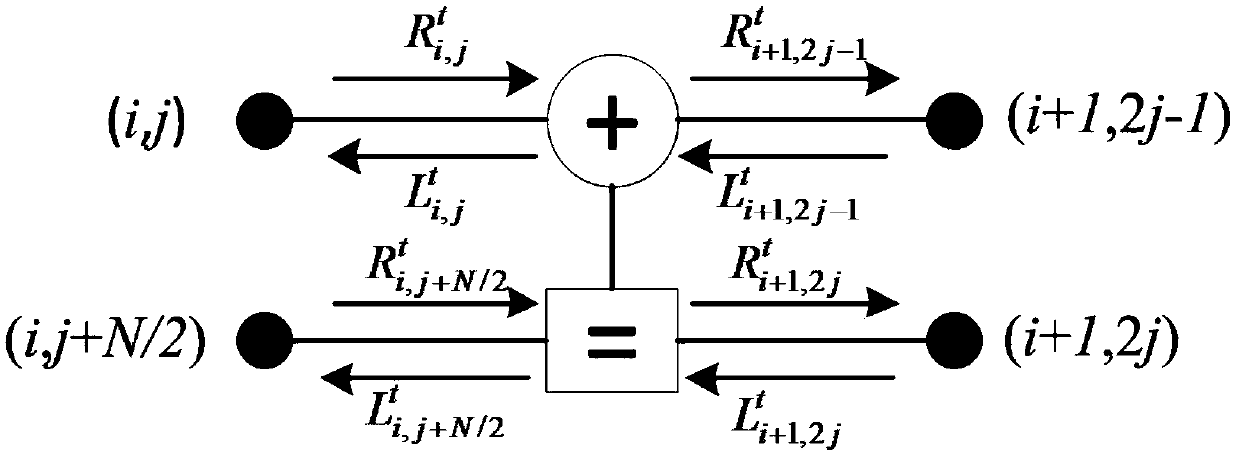

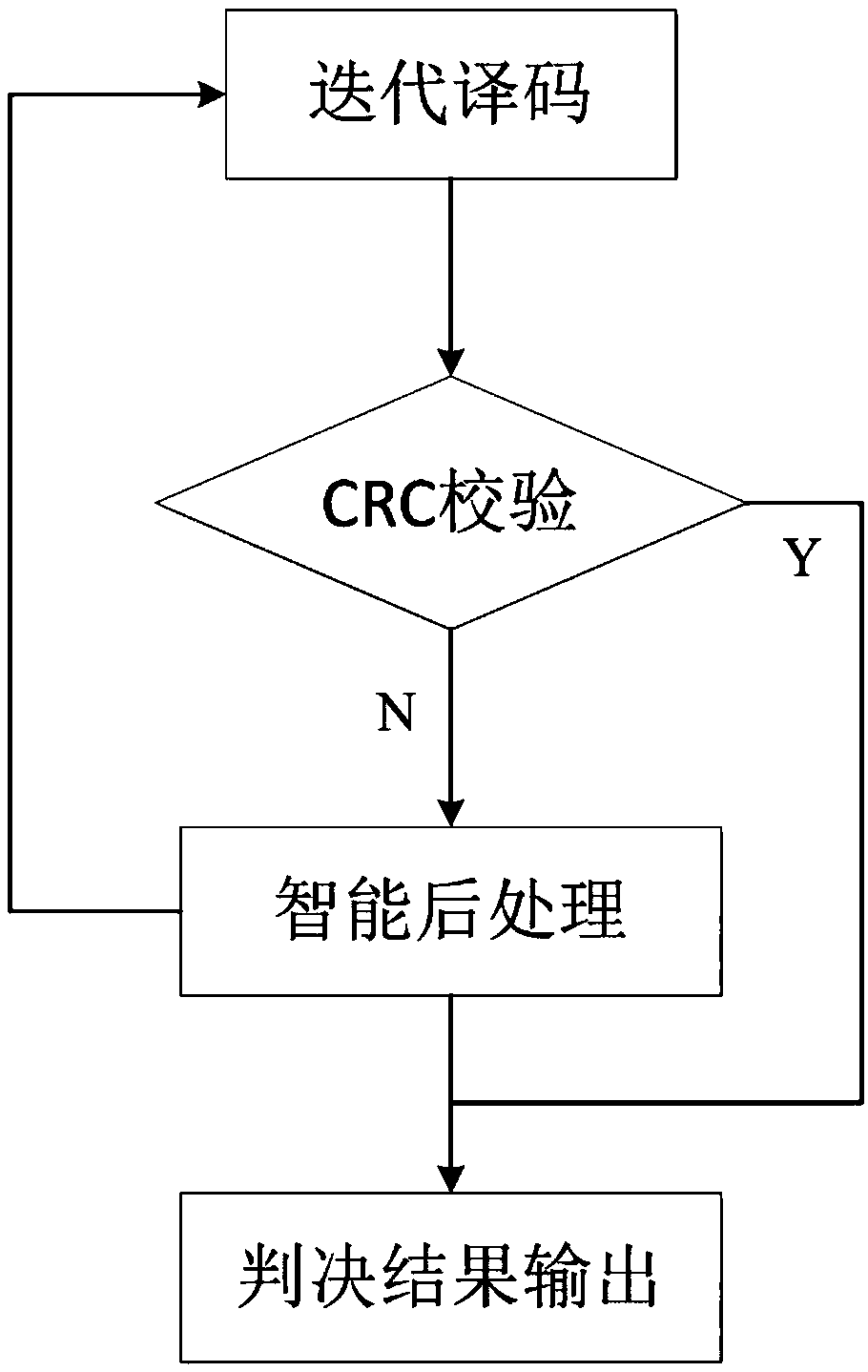

Polarization code BP (Belief Propagation) decoding algorithm based on intelligent post-processing

ActiveCN109586730AIncrease the number of flips and iterationsIncrease decoding gainError correction/detection using linear codesError detection onlyBelief propagationComputer engineering

The invention discloses a polarization code BP (Belief Propagation) decoding algorithm based on intelligent post-processing. An intelligent post-processing step is added on the basis of a traditionalBP algorithm, concretely, when the number of iteration times of the iteration decoding reaches the maximum number of iteration times and does not pass the CRC verification, the intelligent post-processing step is accessed, soft information obtained by employing information obtained in each iteration is taken as data features of each bit and is input into a binary classifier based on a deep neuralnetwork trained in advance to obtain an error bit set and a correct bit set, estimation bit information is respectively selected from the error bit set and the correct bit set to perform information overturning and assignment, symbols of the estimation bit information after processing are taken as symbols of initial freezing bit information, and according to the regulated initial freezing bit information and the received channel information, the iteration decoding is re-executed. Therefore, though the number of overturning times and the number of iteration times are added, the decoding gain can be obviously improved.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

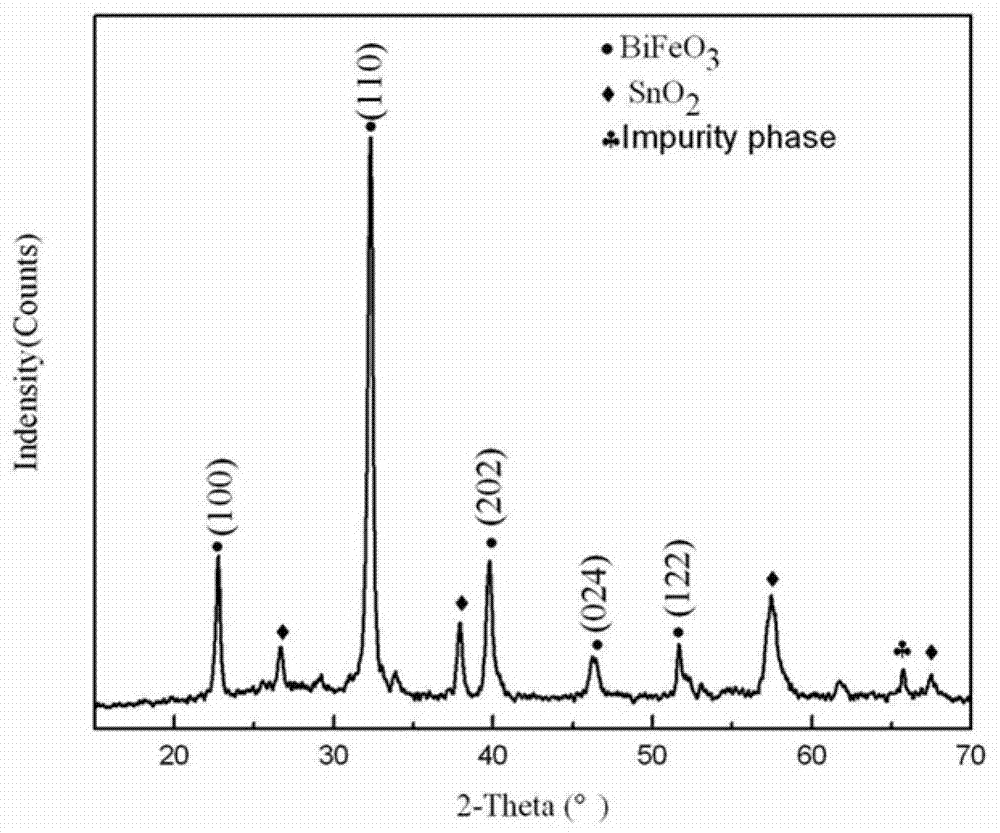

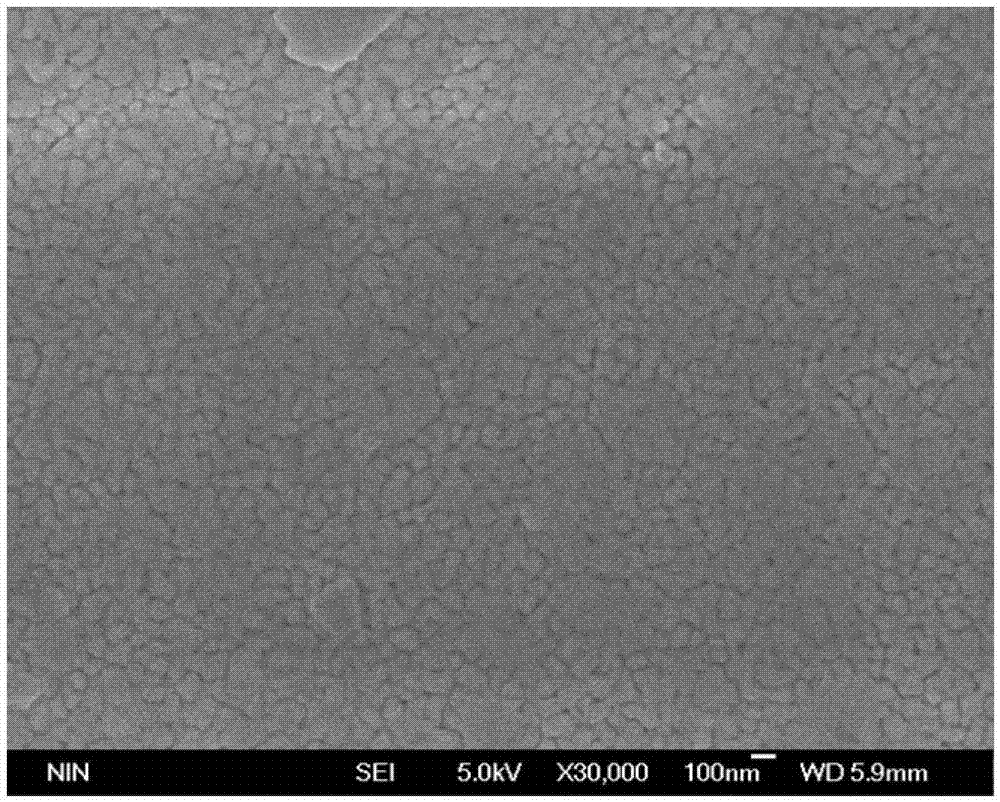

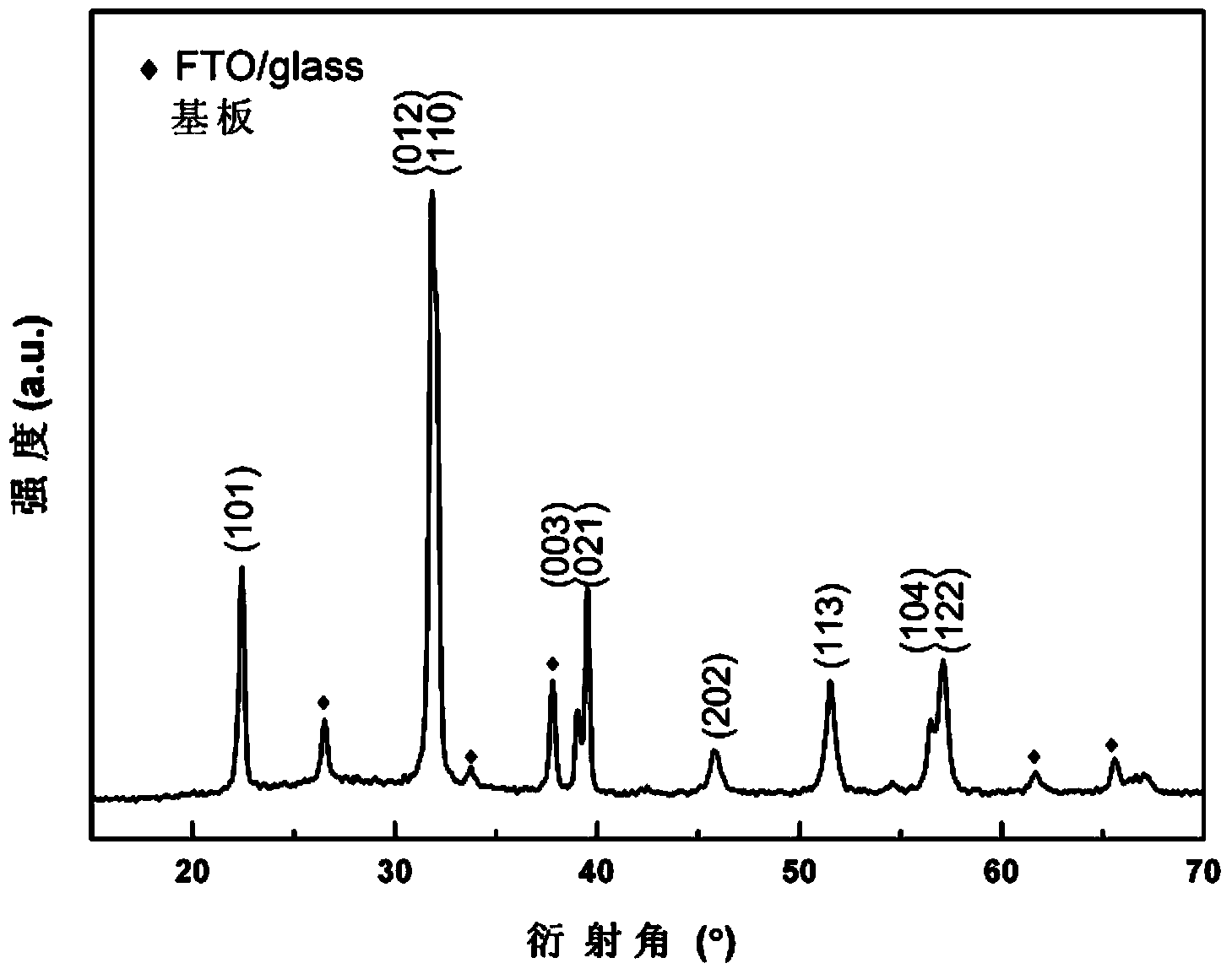

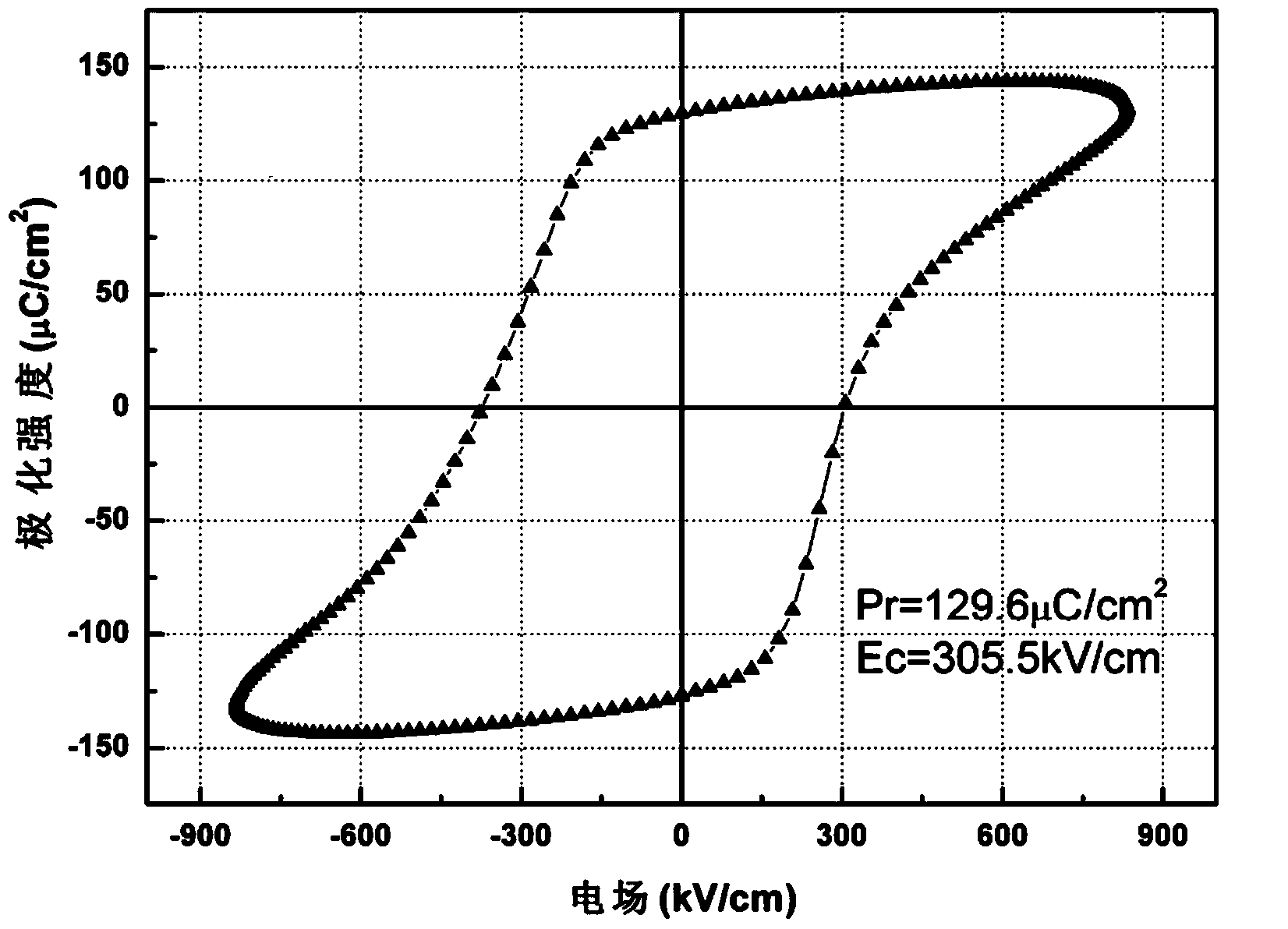

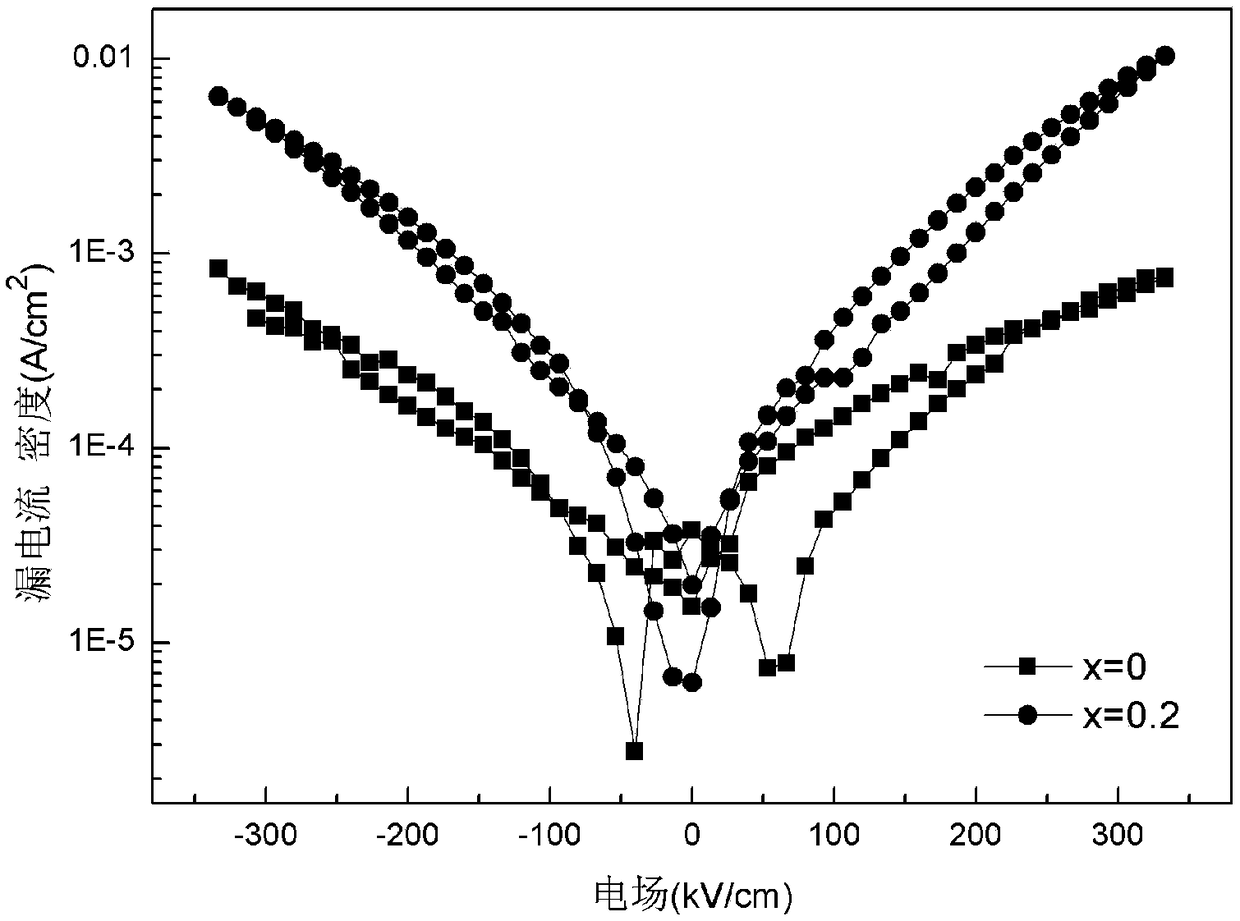

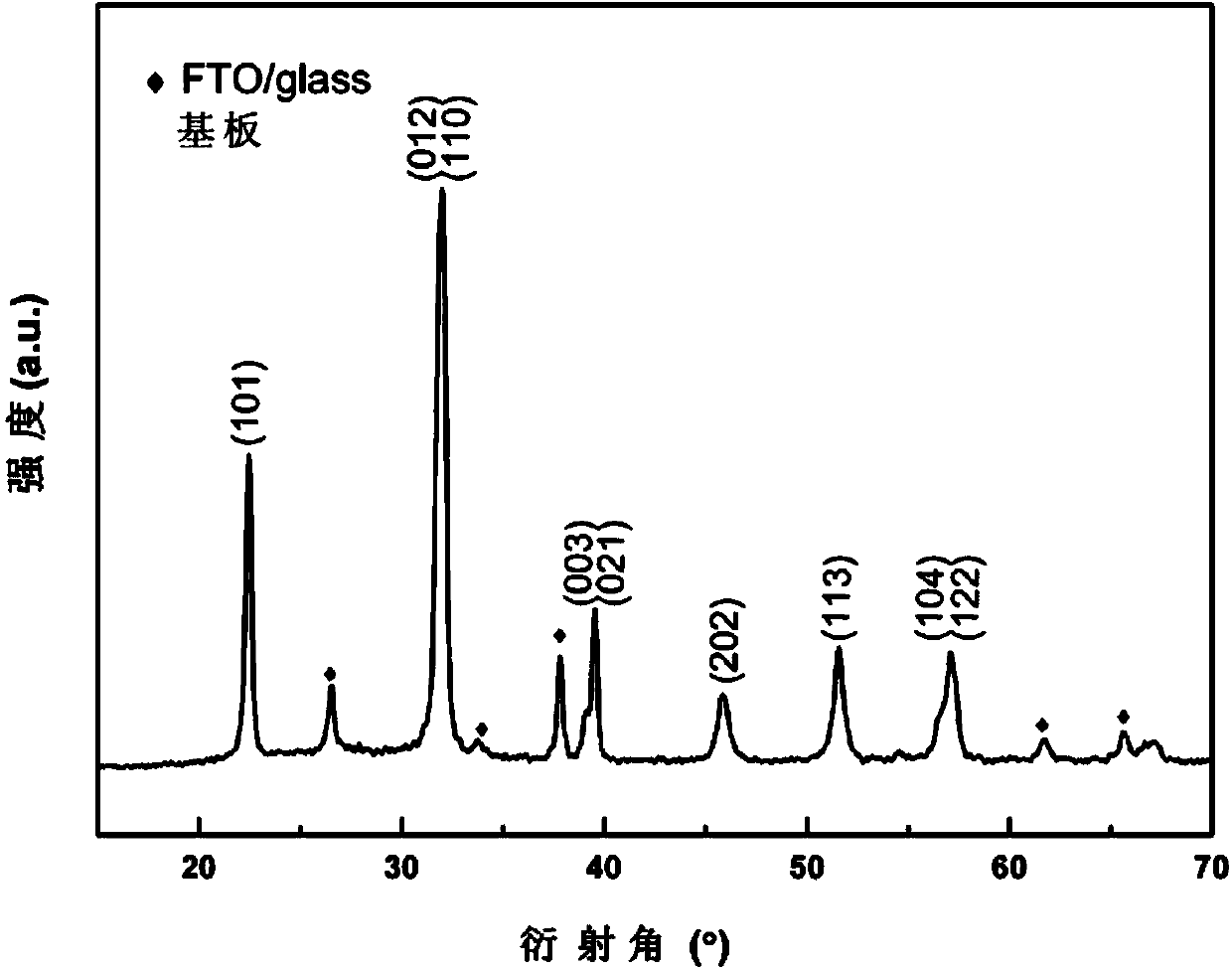

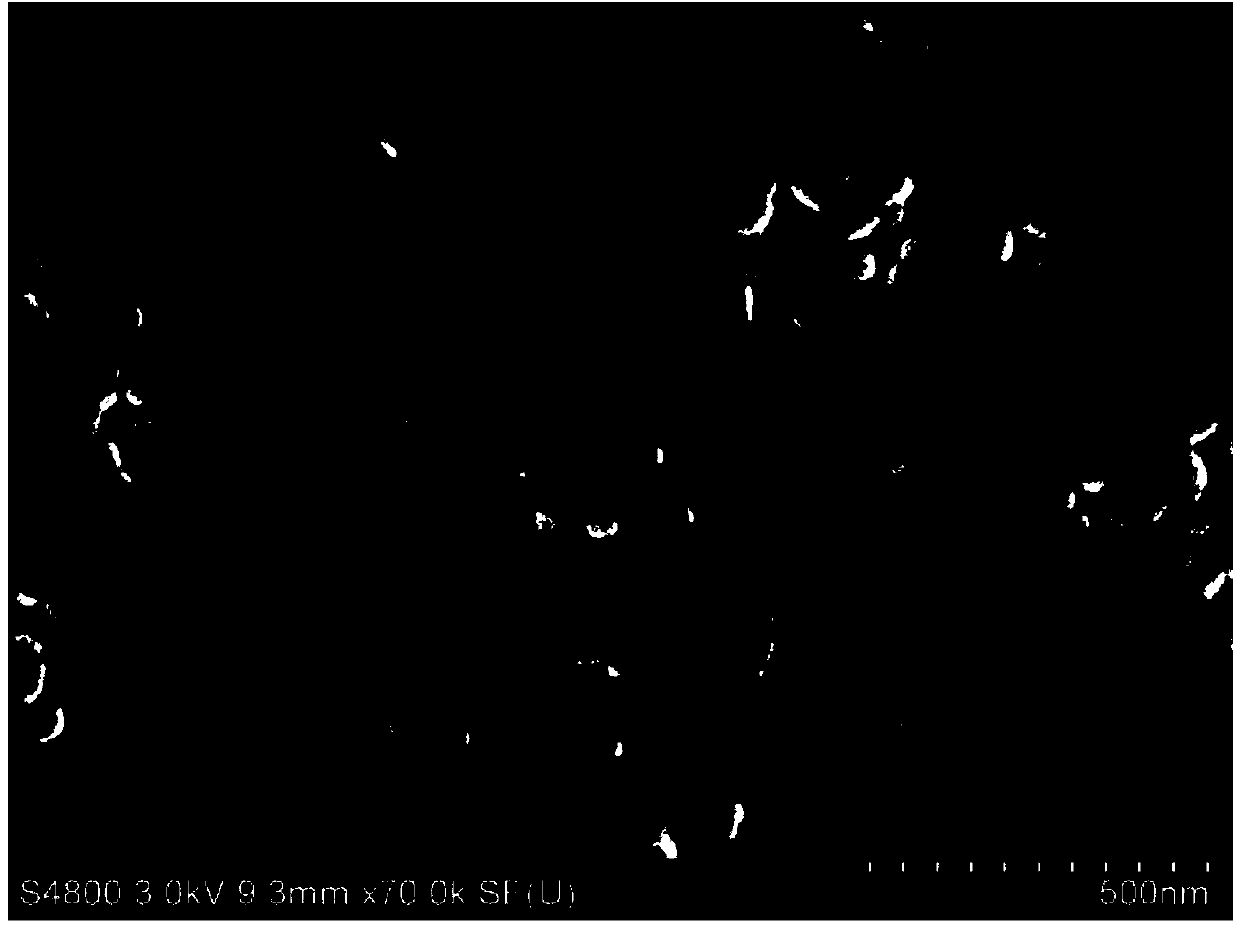

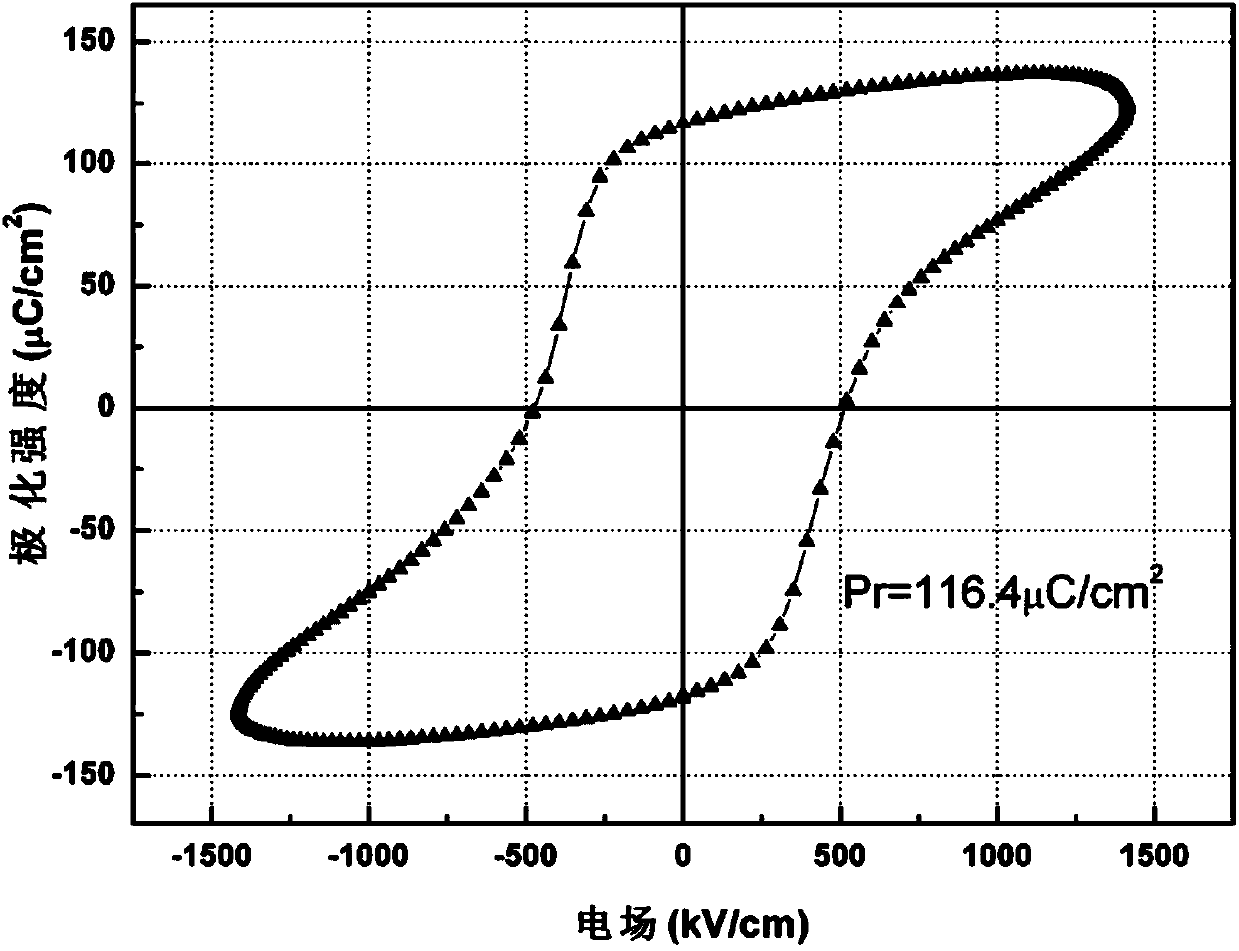

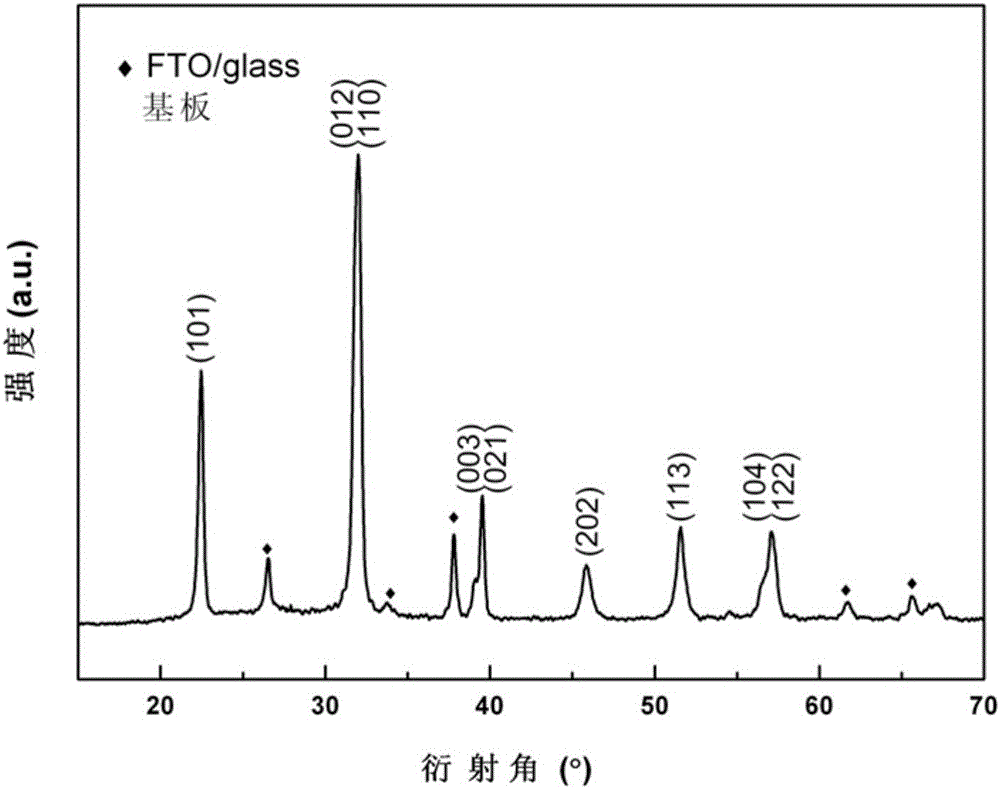

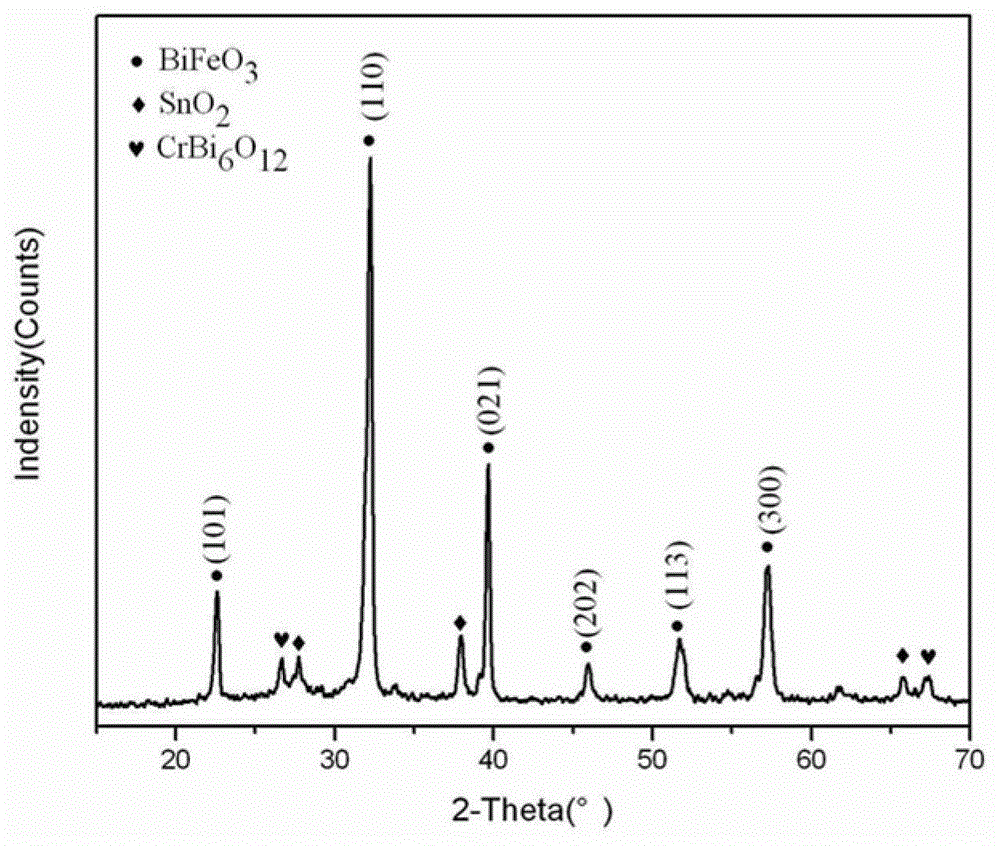

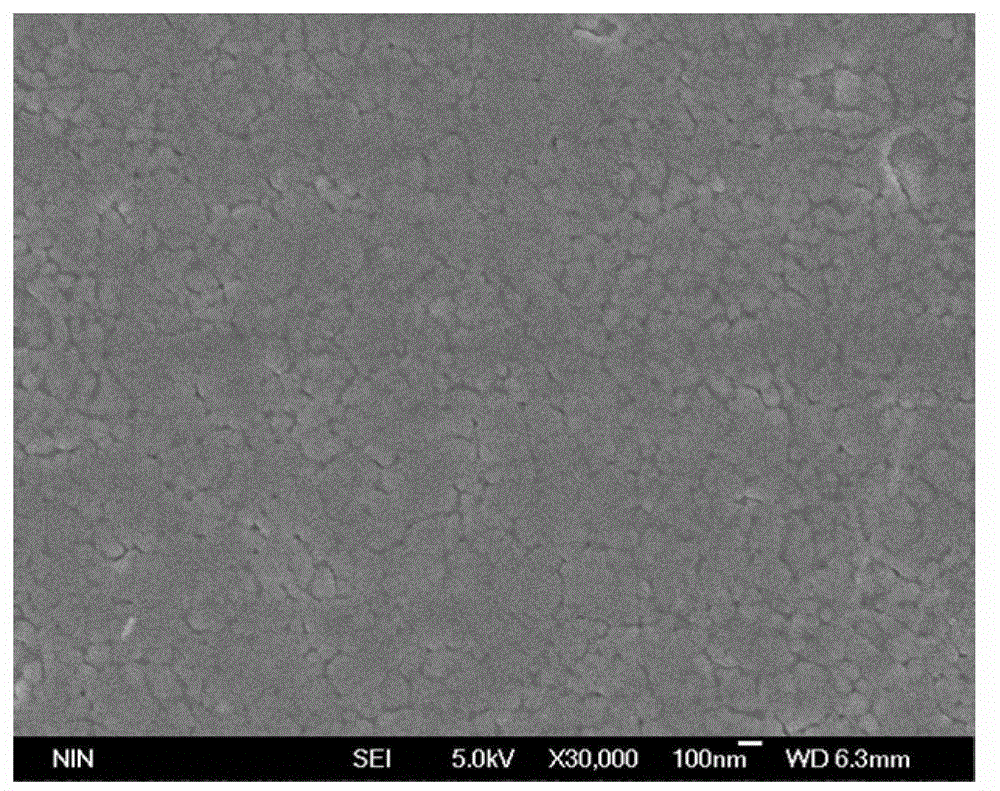

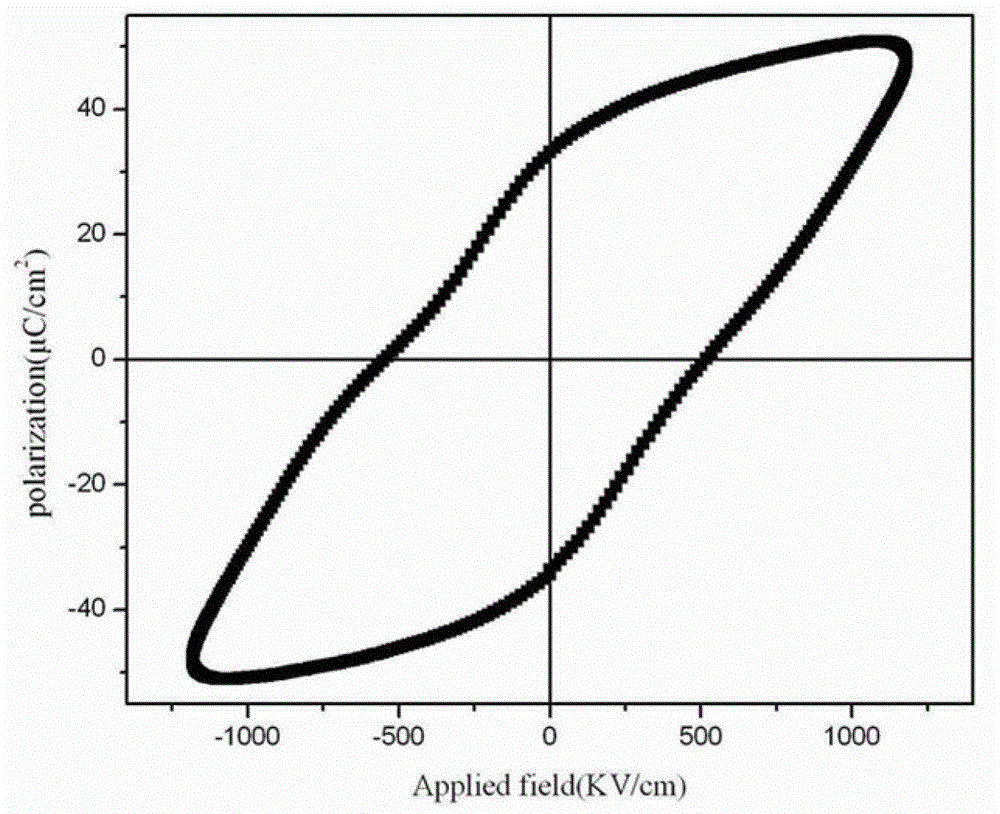

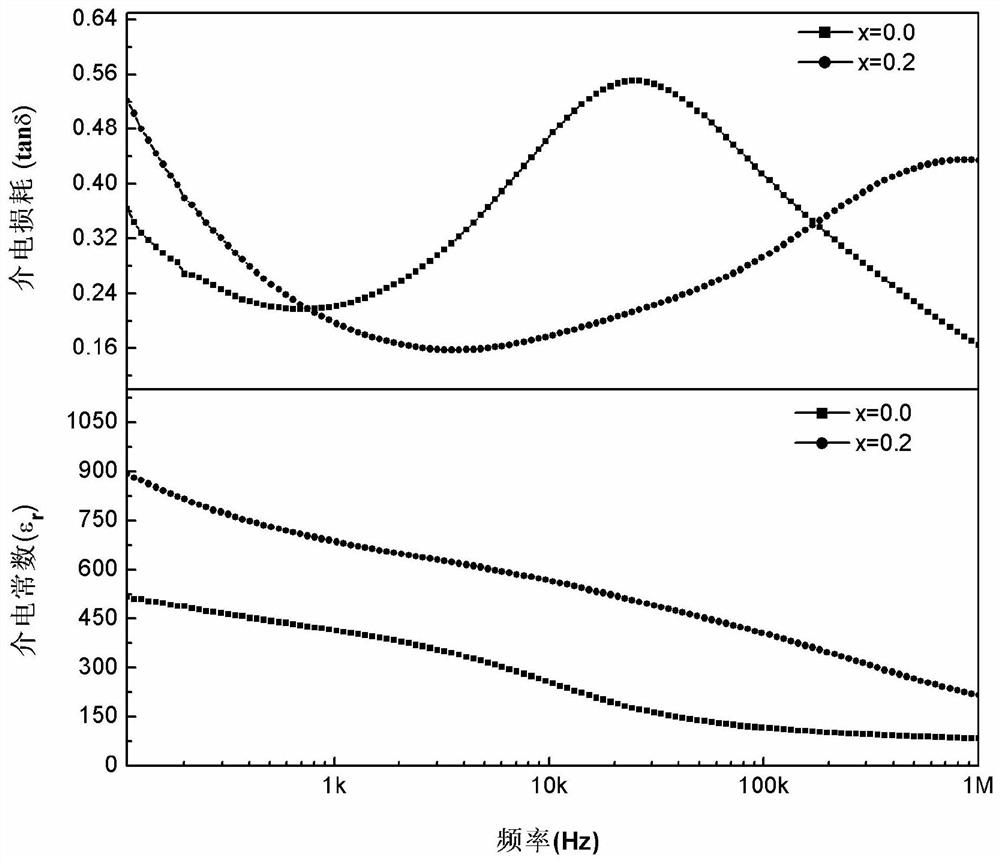

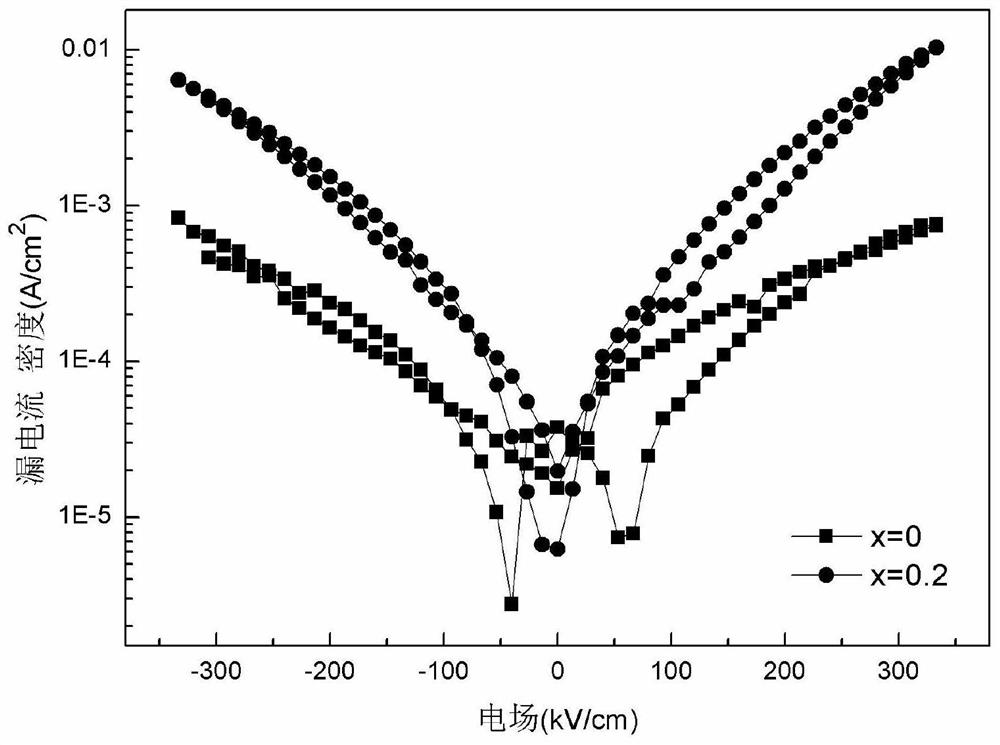

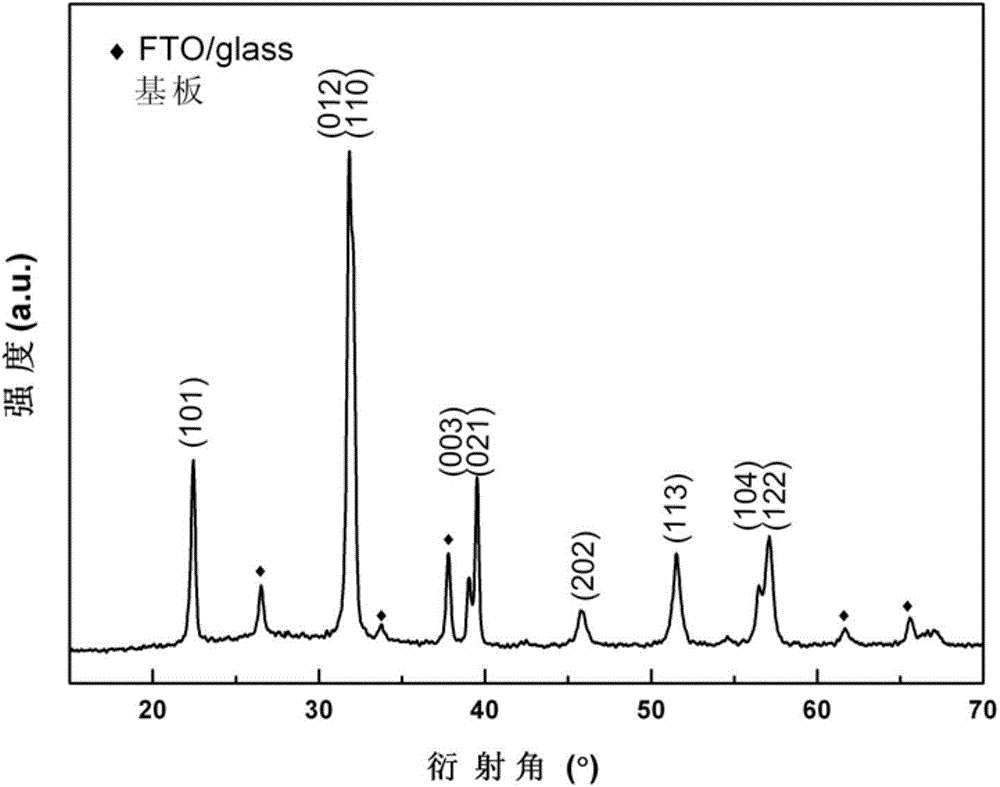

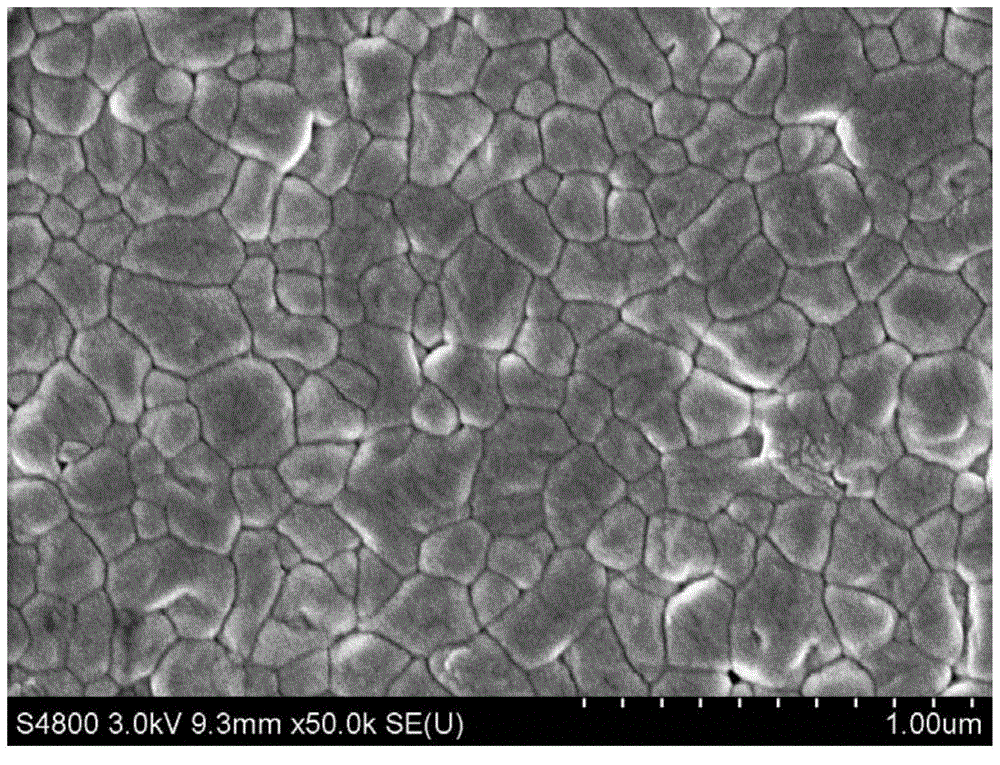

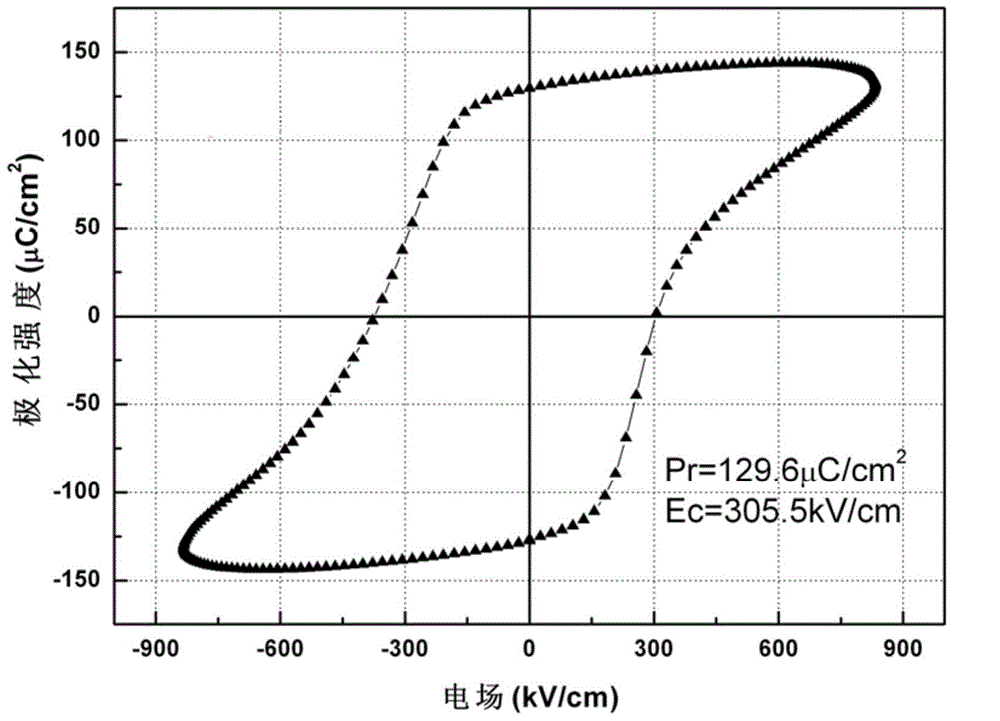

Method for preparing Bi0.85Sm0.15Fe1-xCrxO3 ferroelectric film via sol-gel process

The invention discloses a method for preparing a Bi0.85Sm0.15Fe1-xCrxO3 ferroelectric film via a sol-gel process. The method is carried out by the following steps of: washing an FTO (Fluorinedoped Tin Oxide) substrate and subsequently irradiating via ultraviolet light; using bismuth nitrate, ferric nitrate, samarium nitrate and chromic nitrate as raw materials (the bismuth nitrate excesses by 5%), dissolving the above raw materials in mixed ethylene glycol monomethyl ether and acetic anhydride according to a mole ratio of 0.90: (1-x):0.15:x (x is 0.00, 0.01, 0.02 or 0.03), then adding ethanol amine to adjust a viscosity and obtain a stable BiFeO3 (bismuth ferrite) precursor solution with a metal ion concentration of 0.003-0.3mol / L; and homogenizing and subsequently obtaining a dry film, then using a layer-by-layer annealing process to obtain a crystal-state Bi0.85Sm0.15Fe1-xCrxO3 ferroelectric film. The method disclosed by the invention has the advantages of simple device requirement, easy achievement of experiment condition, good uniformity of the prepared films and easy control of the doping amount, so that the ferroelectric performance of the film is greatly enhanced.

Owner:SHAANXI UNIV OF SCI & TECH

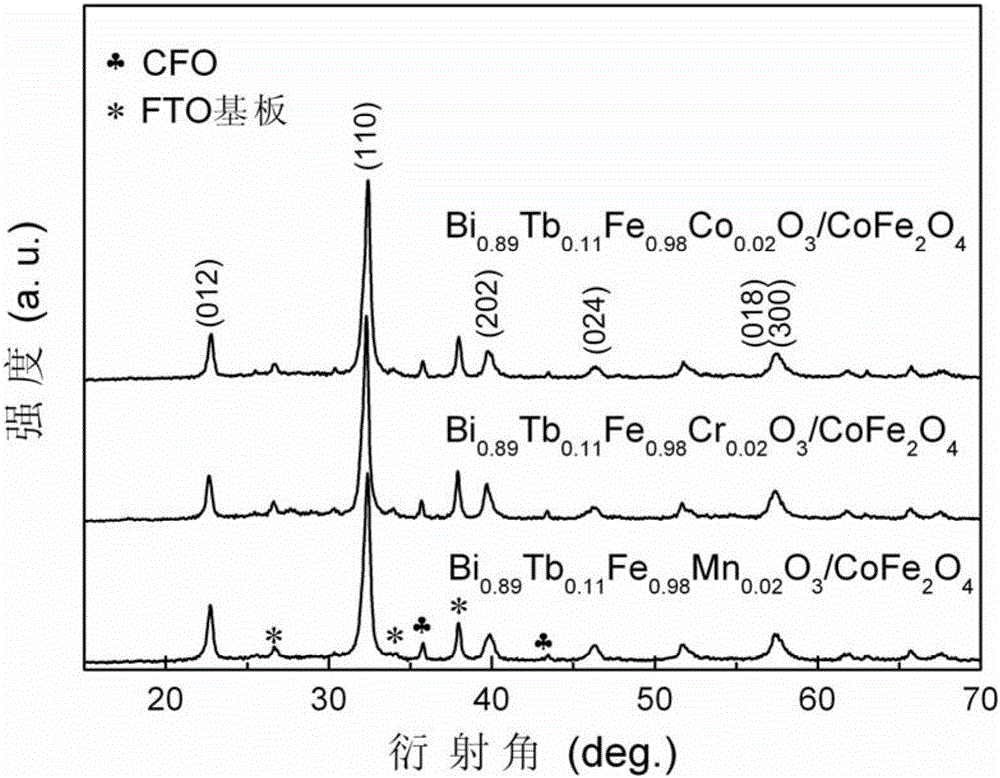

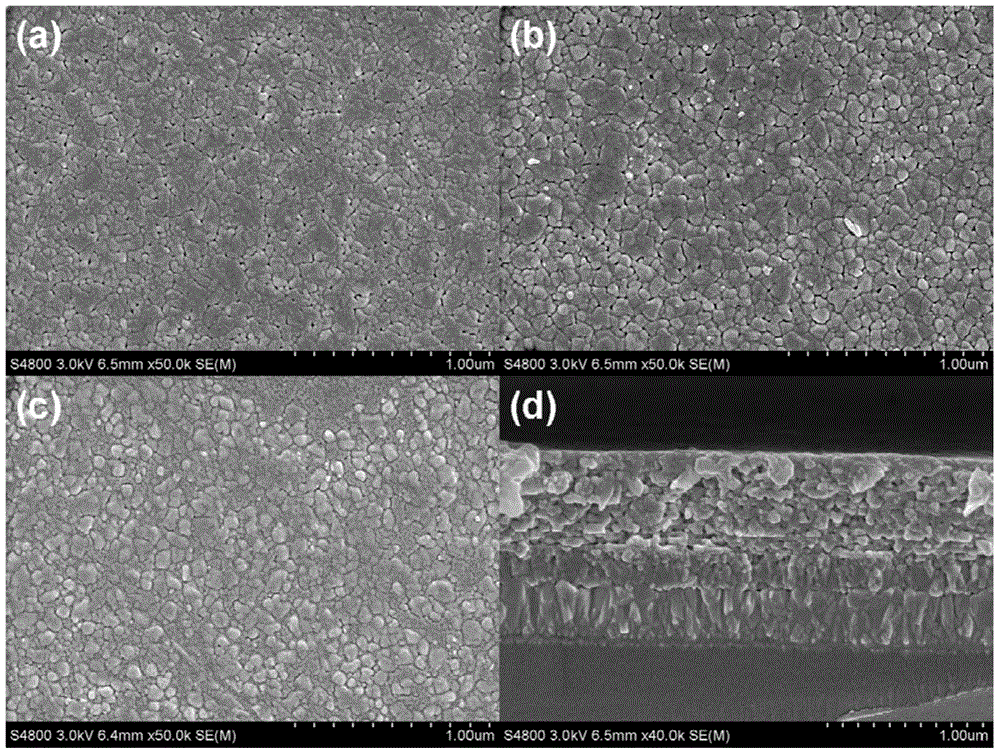

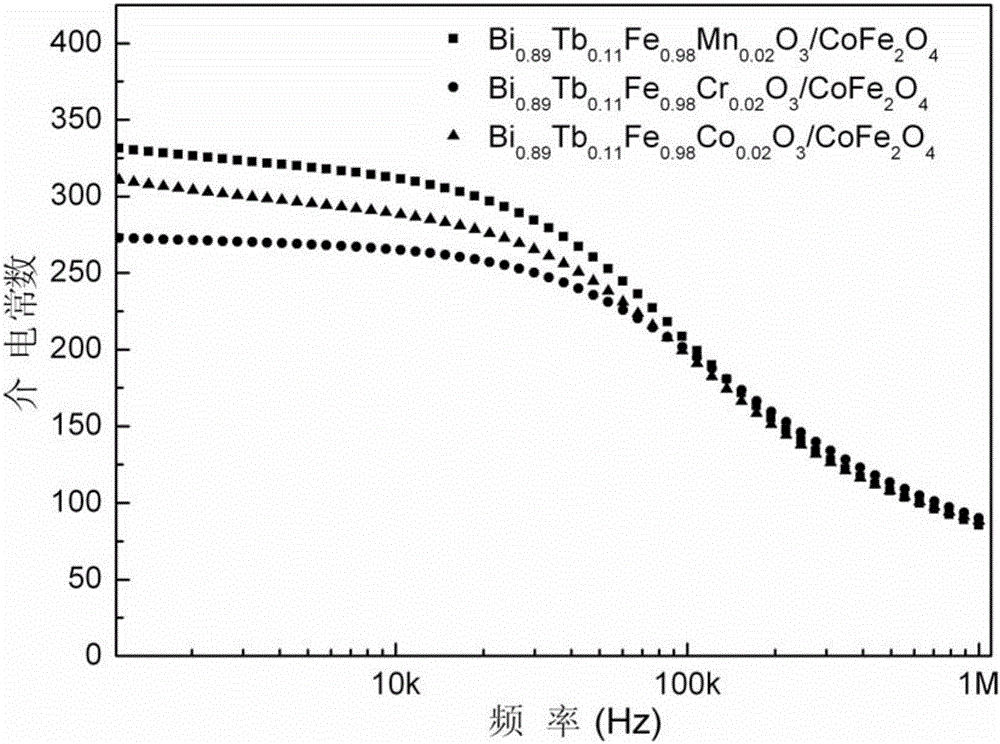

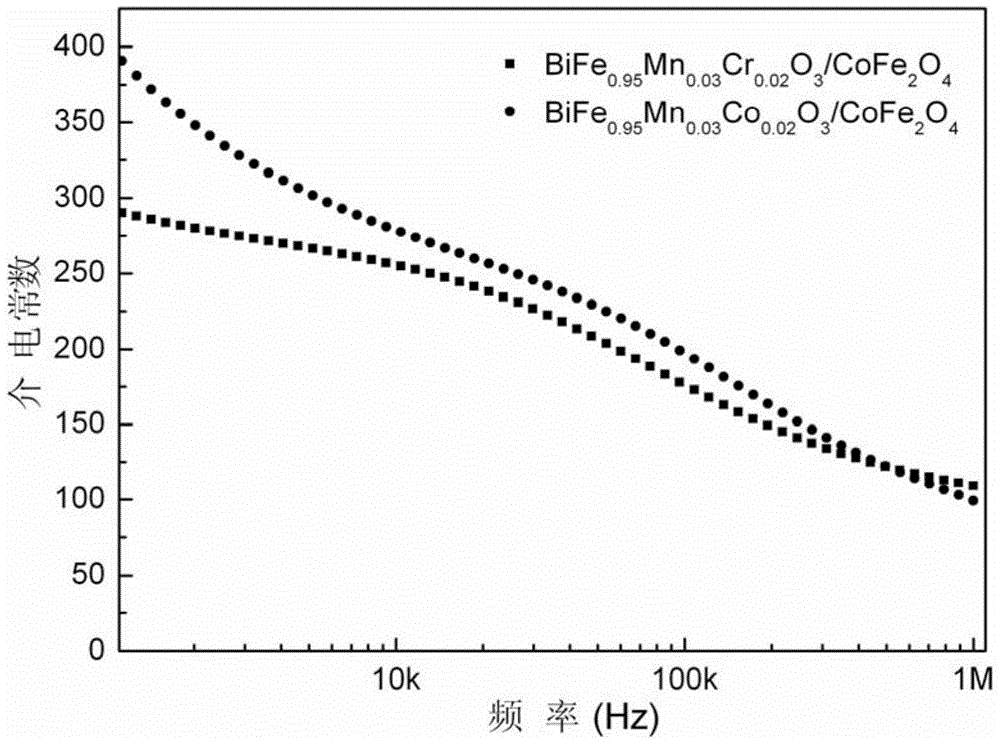

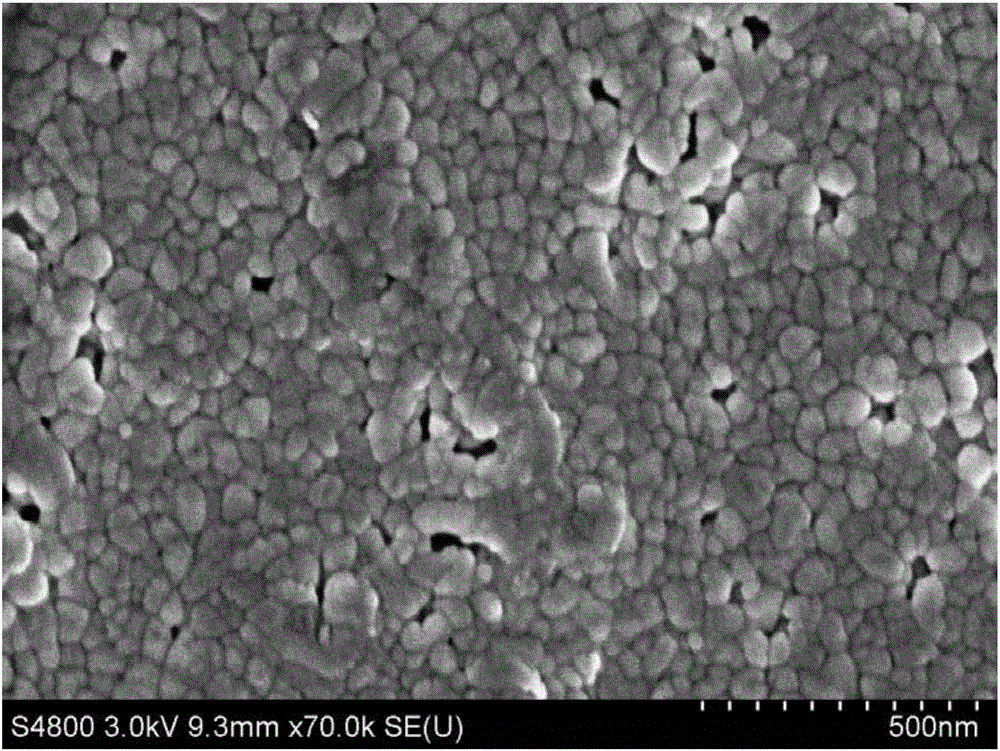

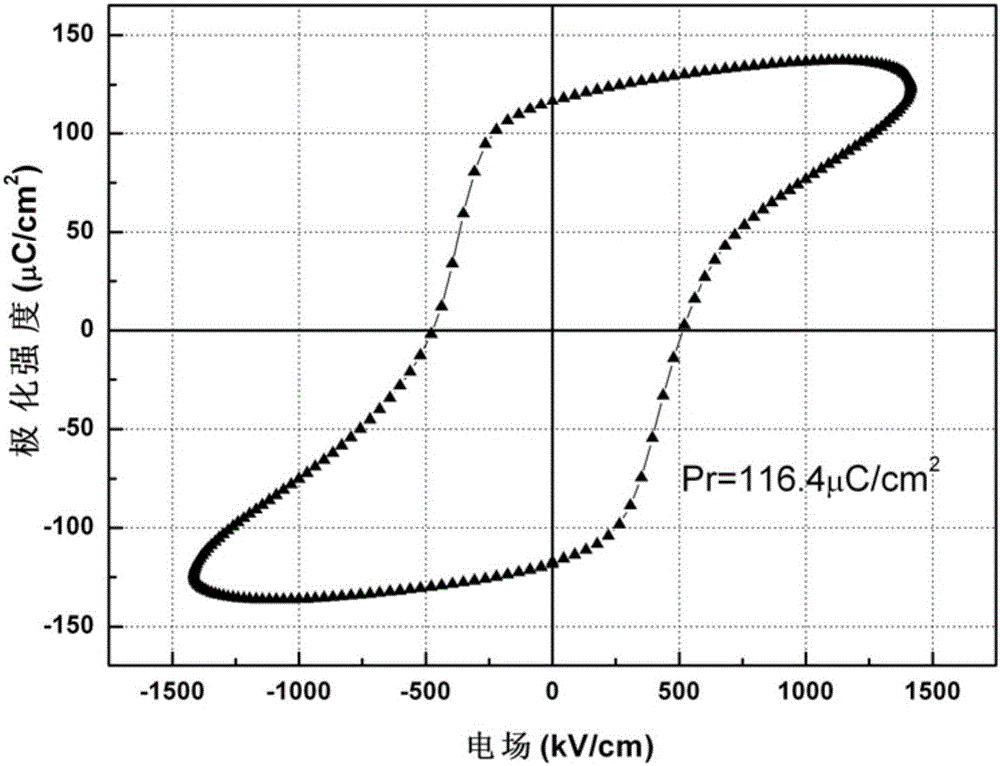

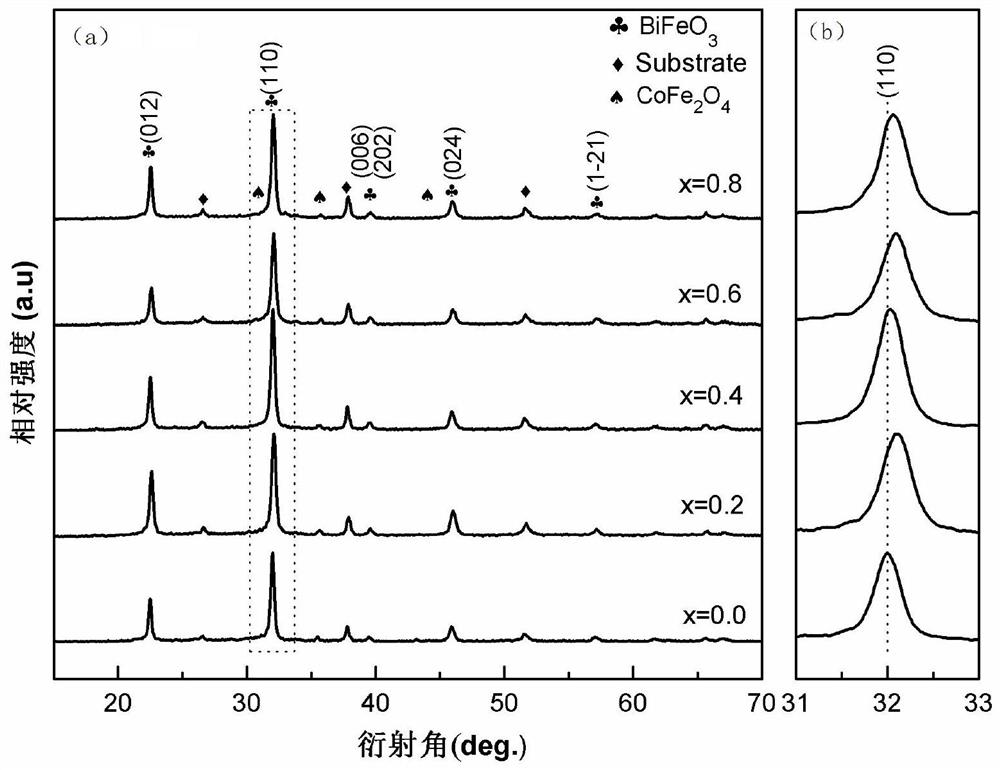

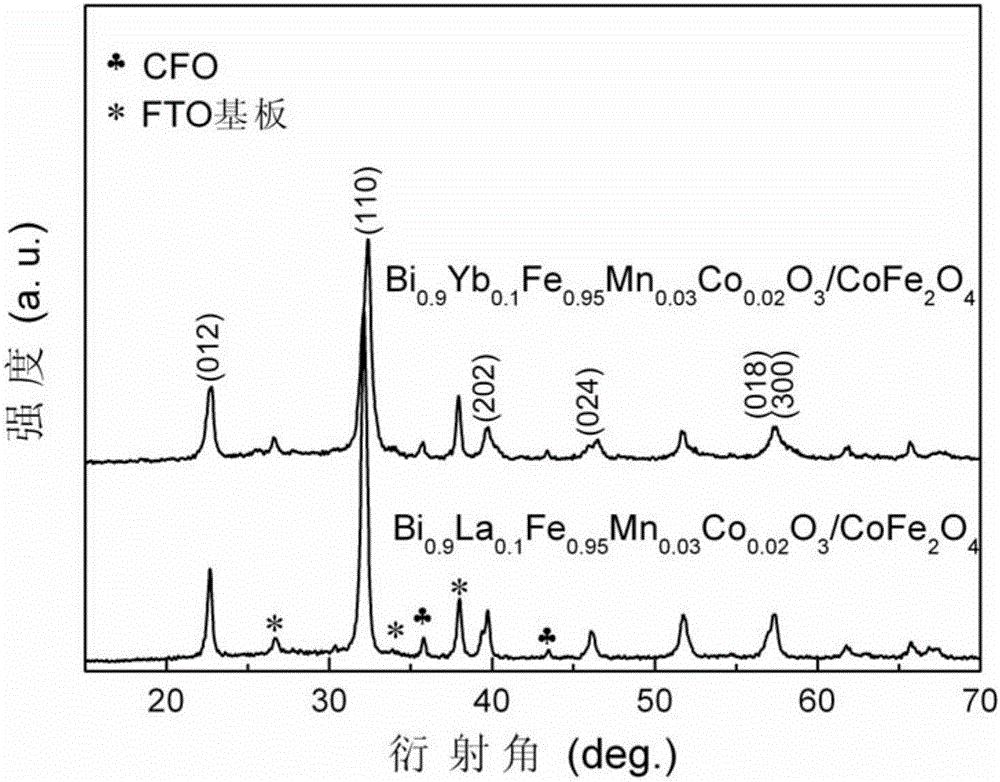

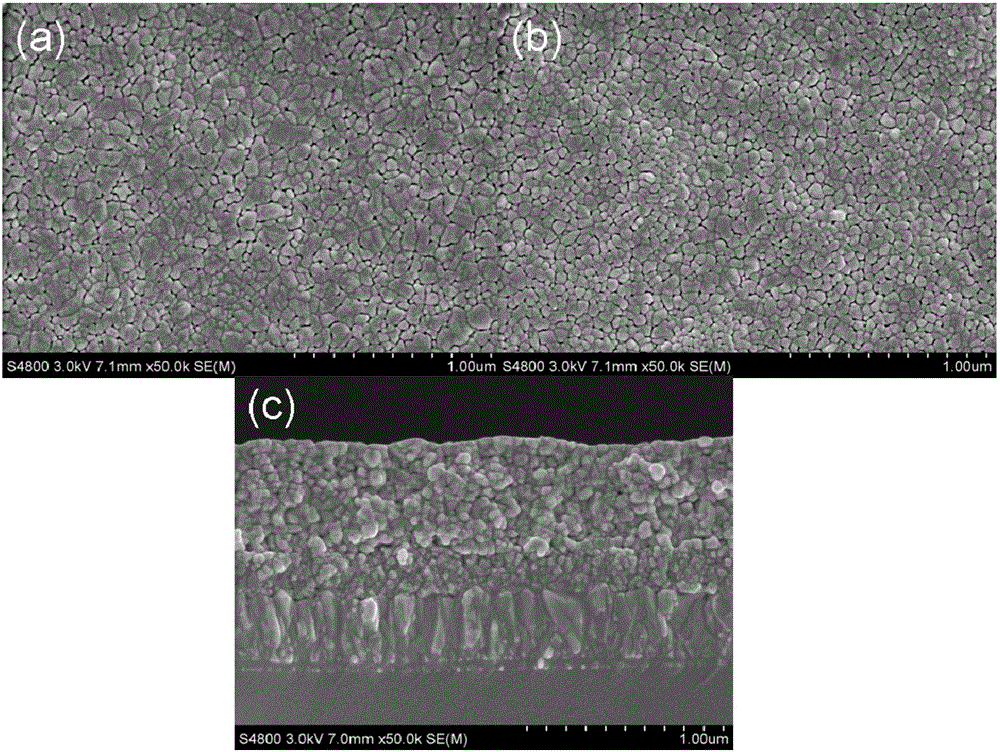

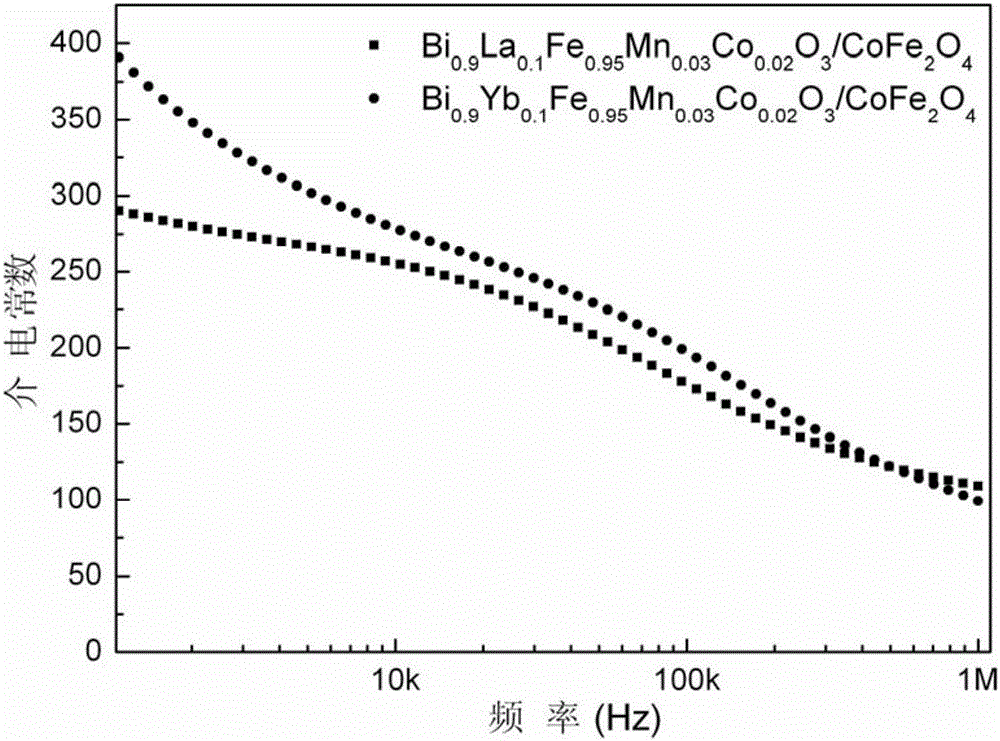

Multiferroic Bi1-xRExFe0.97-yMn0.03TMyO3/CoFe2O4 composite film and preparation method thereof

ActiveCN104538140AImprove multiferroic propertiesImprove ferroelectric propertiesInorganic material magnetismInductances/transformers/magnets manufactureComposite filmMultiferroics

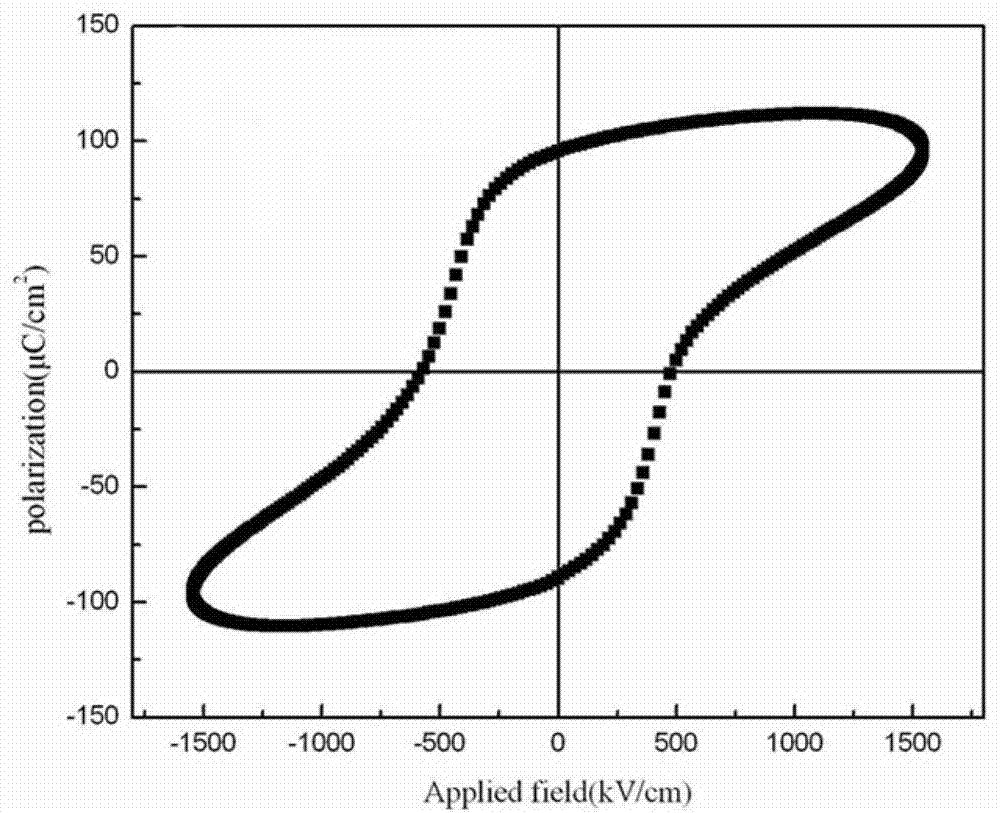

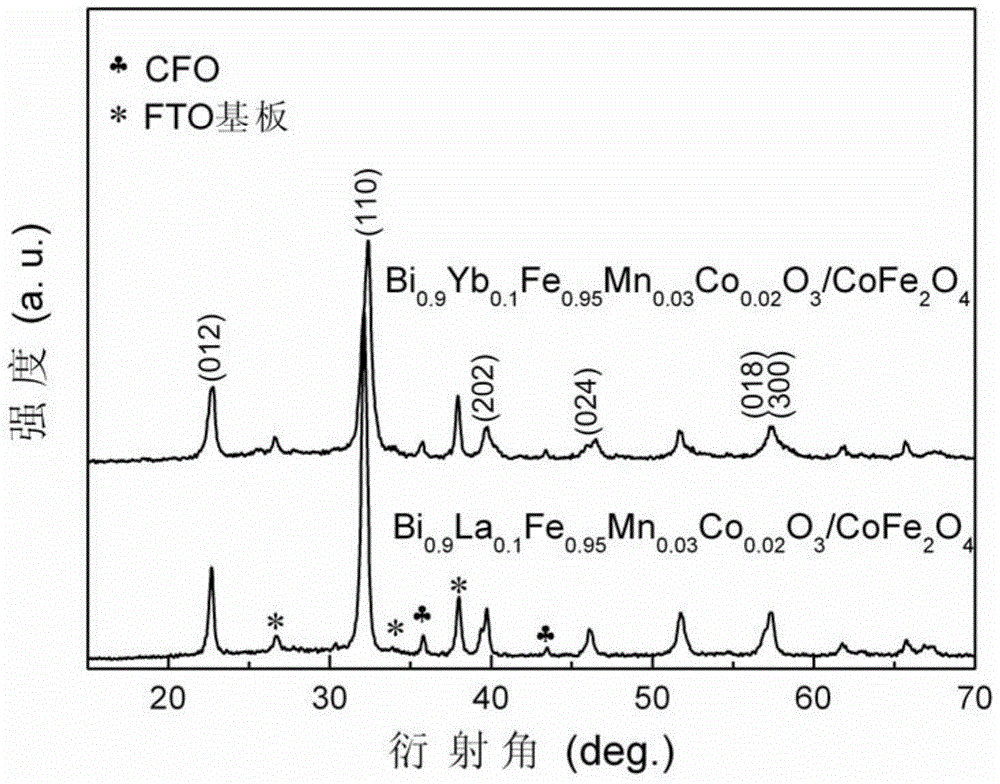

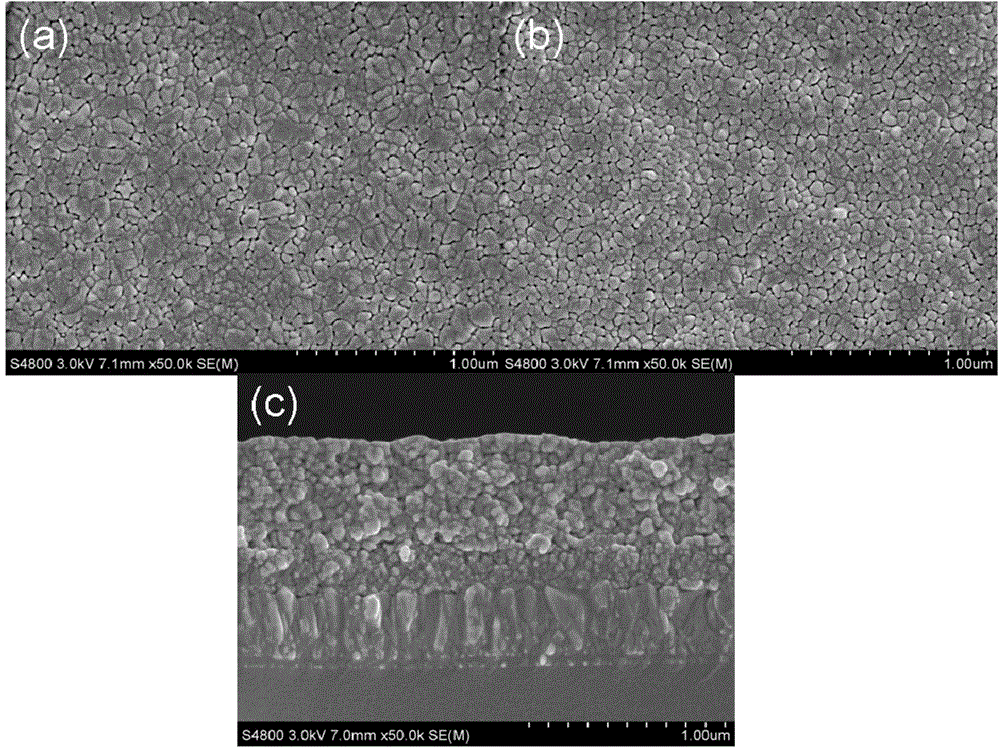

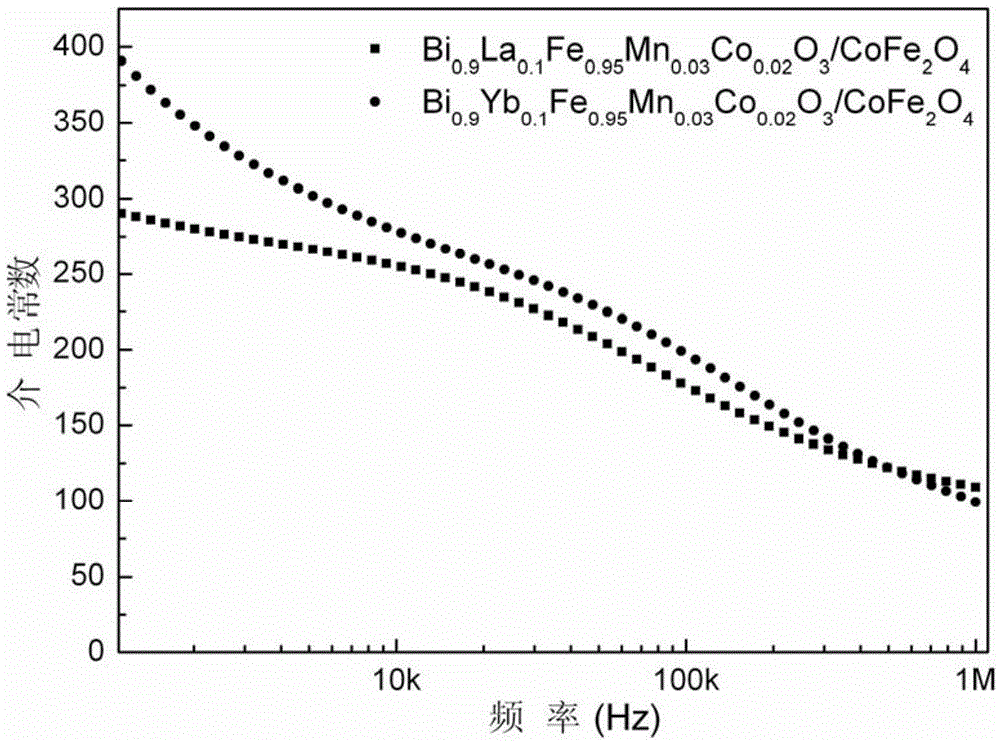

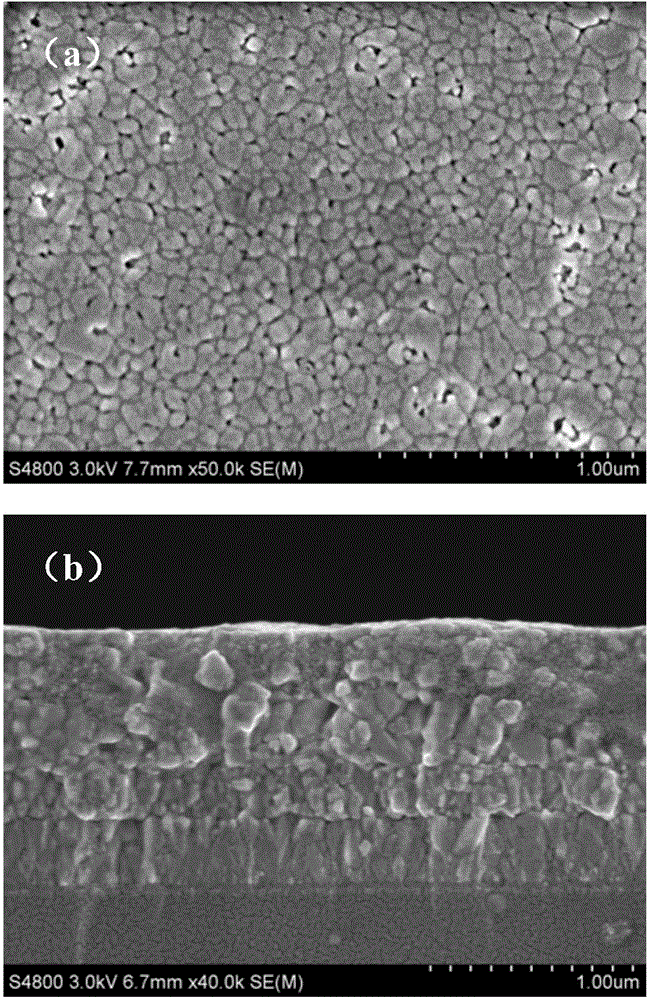

The invention provides a multiferroic Bi1-xRExFe0.97-yMn0.03TMyO3 / CoFe2O4 composite film and a preparation method thereof. The composite film comprises a Bi1-xRExFe0.97-yMn0.03TMyO3 crystalline state film and a CoFe2O4 crystalline state film. The preparation method comprises the following steps of respectively preparing Bi1-xRExFe0.97-yMn0.03TMyO3 precursor solution and CoFe2O4 precursor solution; spin coating on a substrate to prepare a plurality of layers of CoFe2O4 films, spin coating on the CoFe2O4 films to prepare a plurality of layers of Bi1-xRExFe0.97-yMn0.03TMyO3 films and accordingly obtaining a target product. According to the multiferroic Bi1-xRExFe0.97-yMn0.03TMyO3 / CoFe2O4 composite film and the preparation method thereof, the device requirement is simple, the prepared film is good in homogeneity, the doping content is easy to control, the ferroelectric property and the ferromagnetic property of the film are improved to a large extent, and the film is high in residual polarization value and residual polarization value.

Owner:SHAANXI UNIV OF SCI & TECH

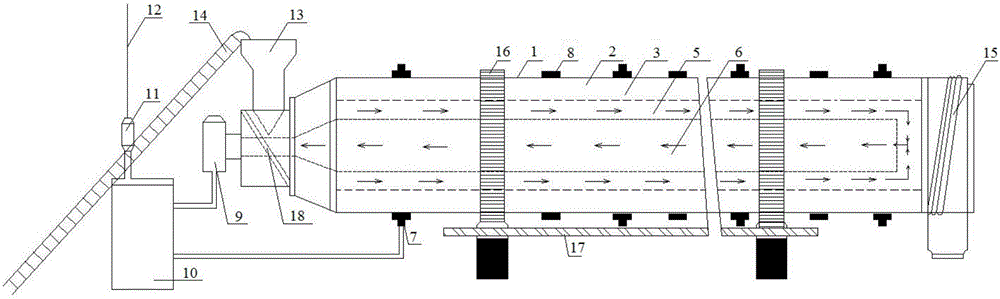

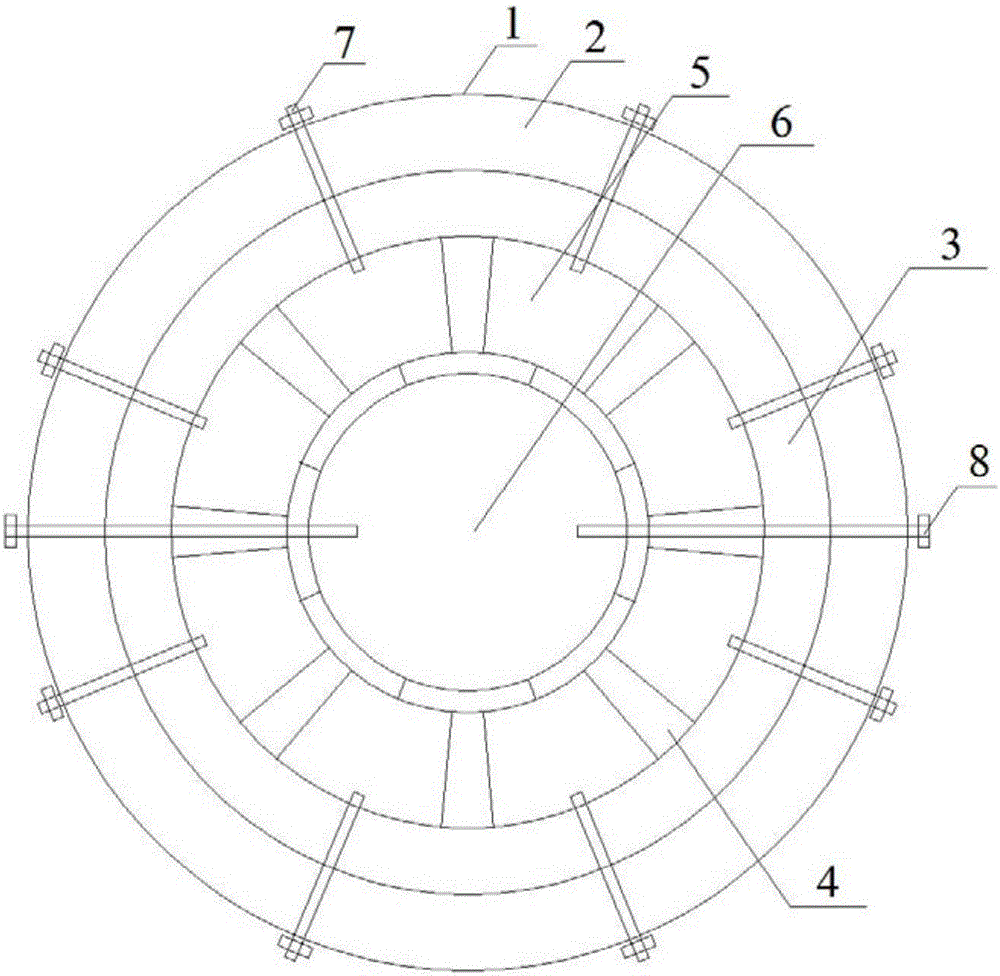

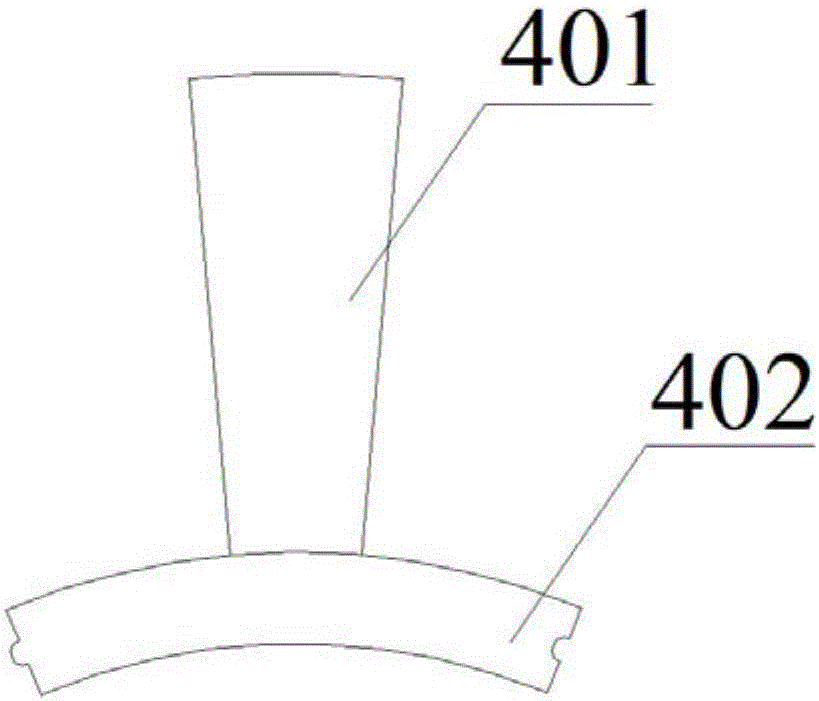

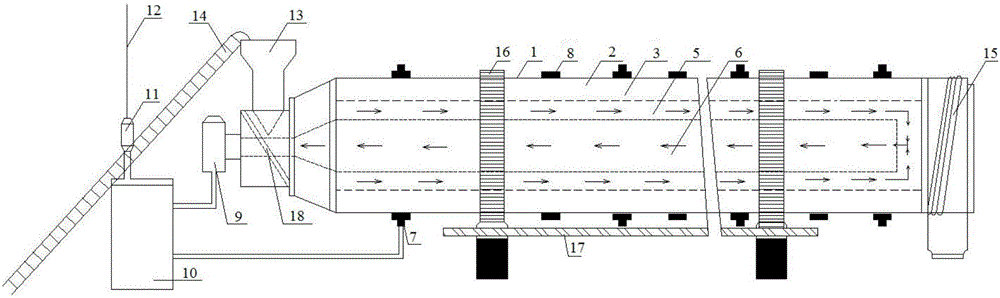

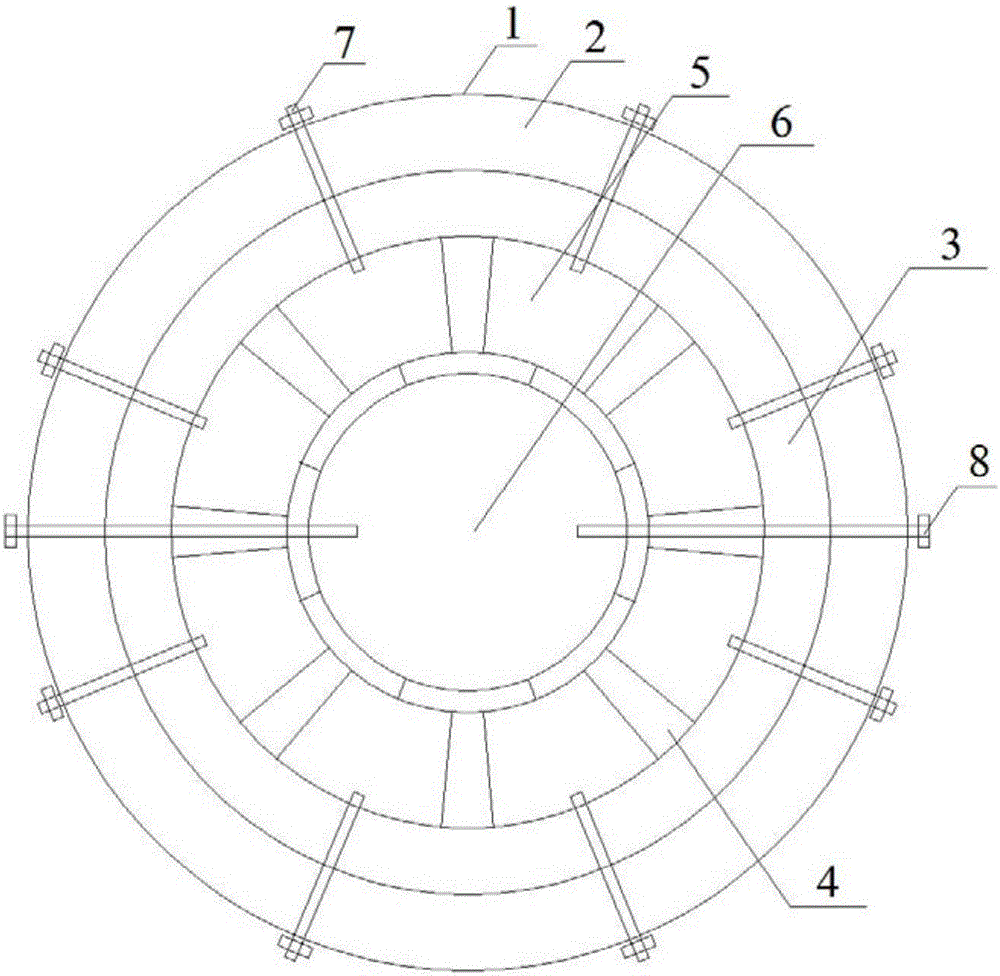

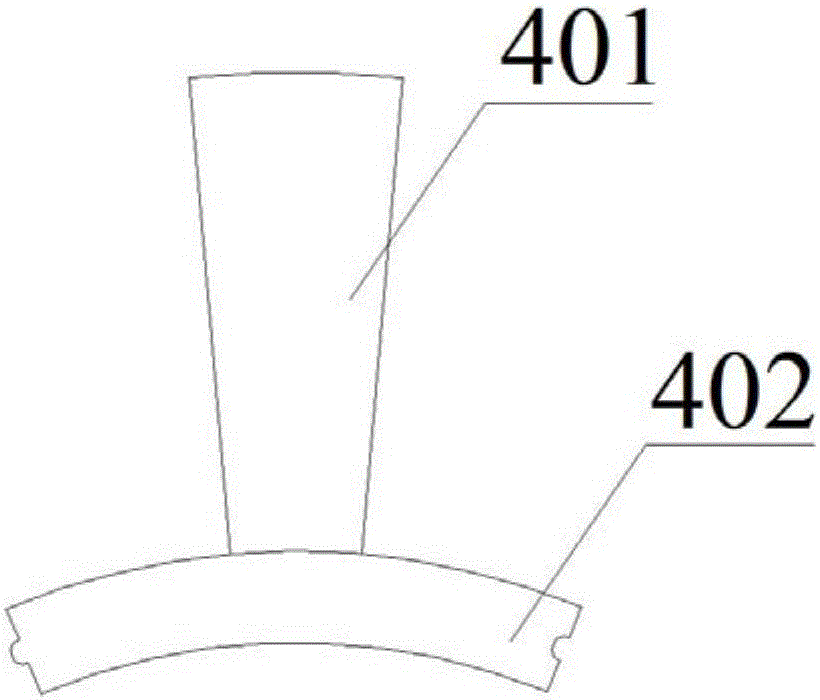

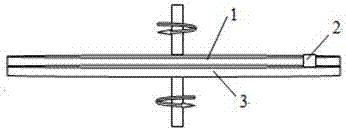

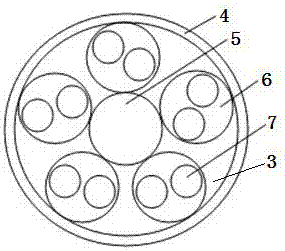

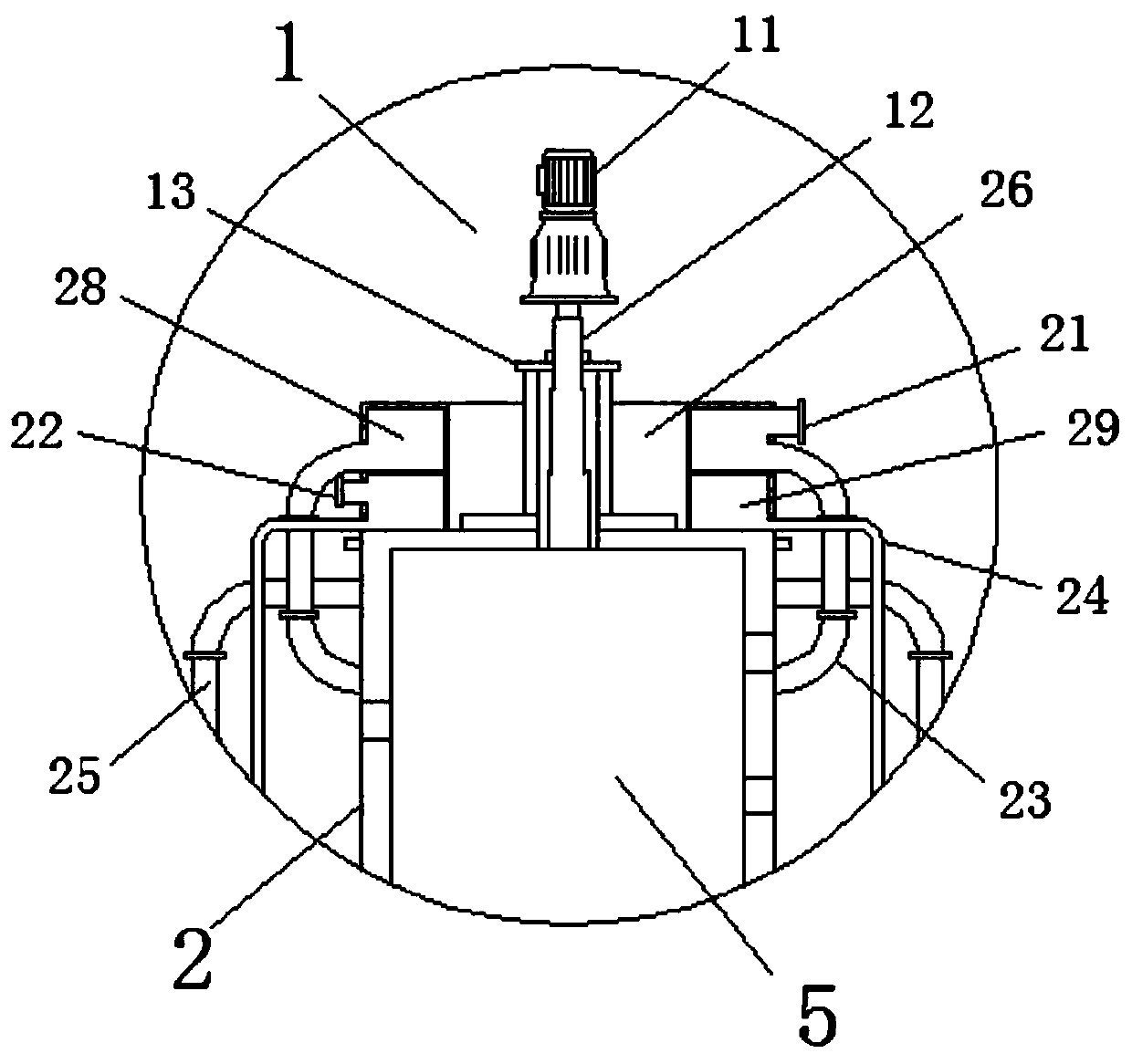

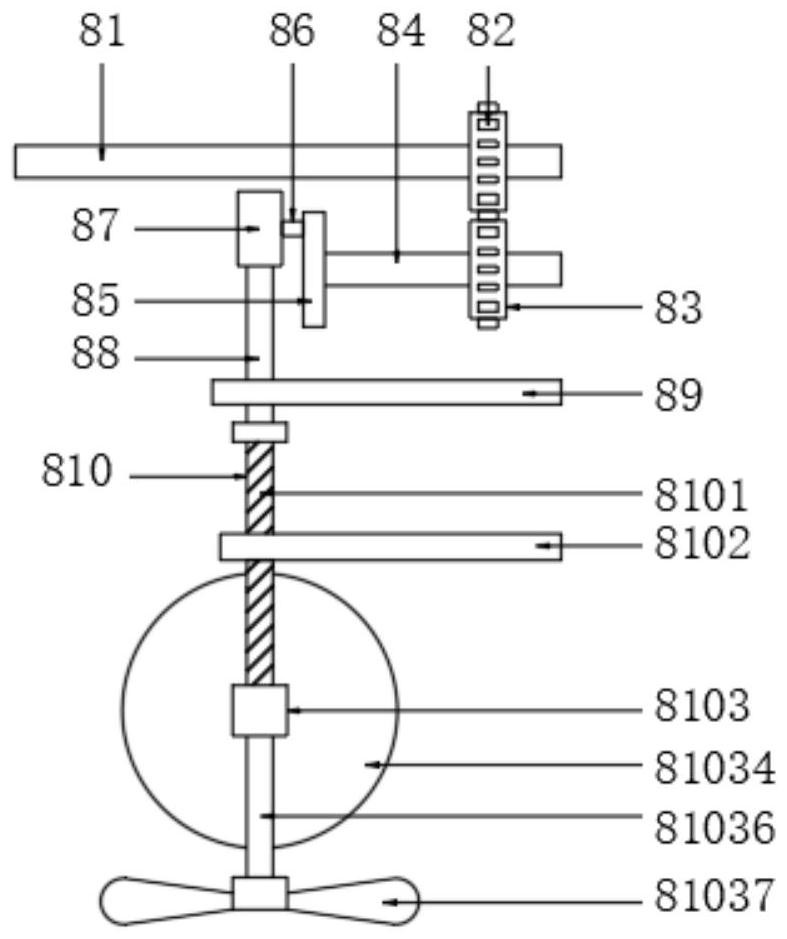

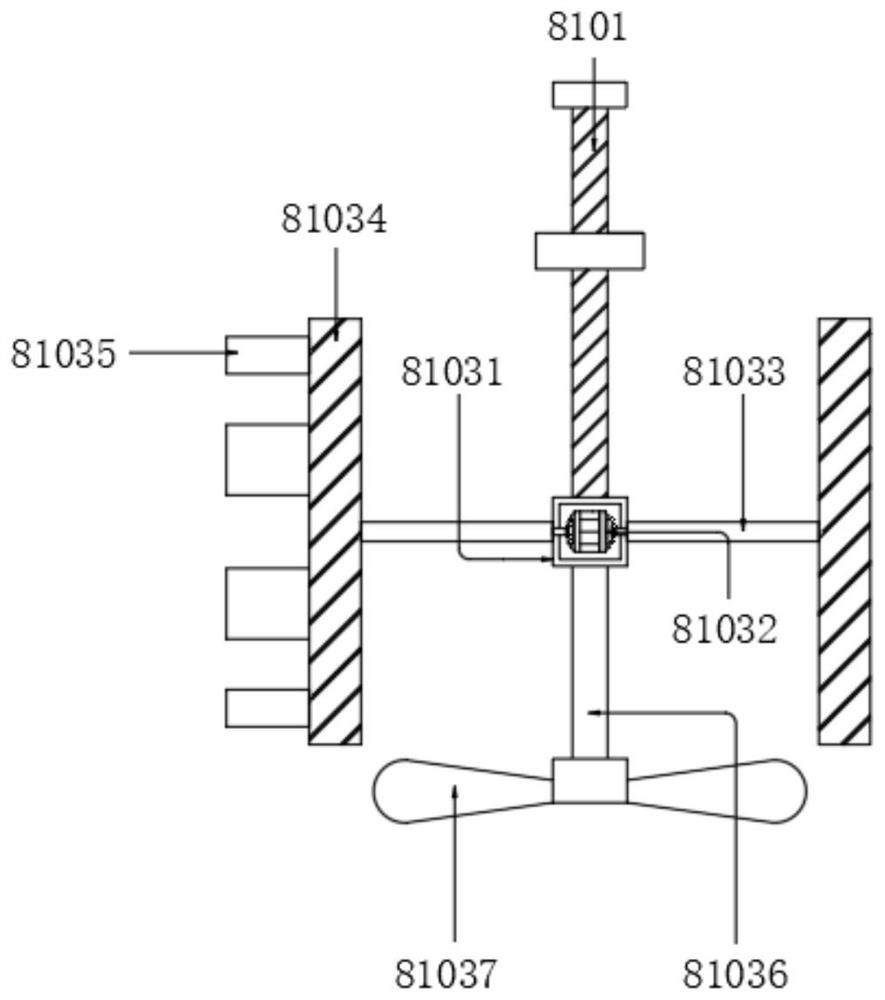

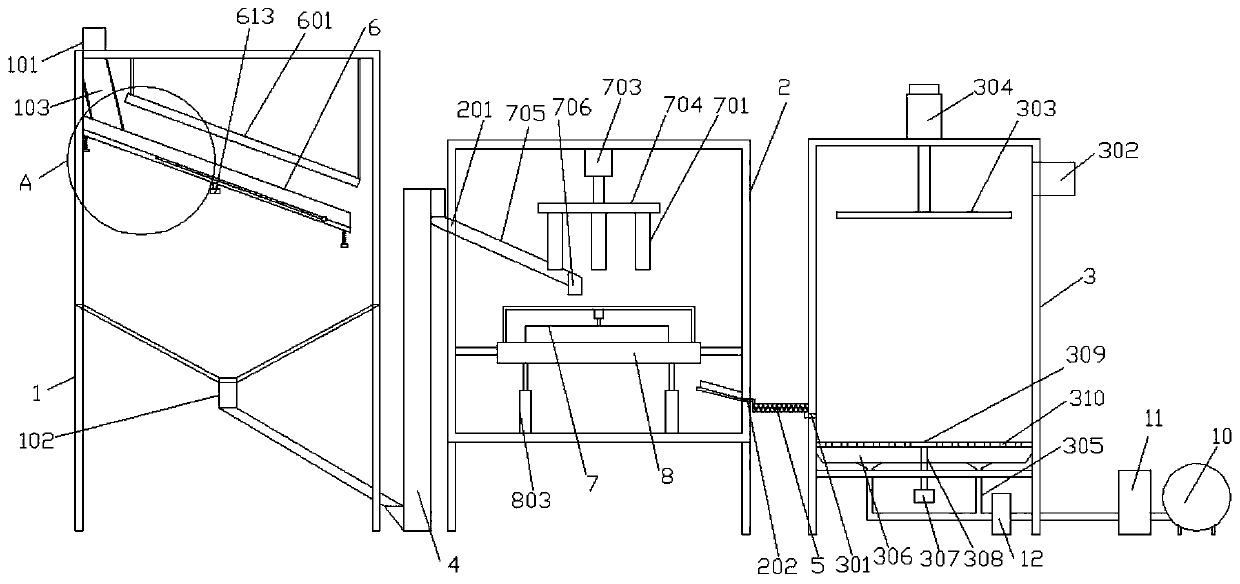

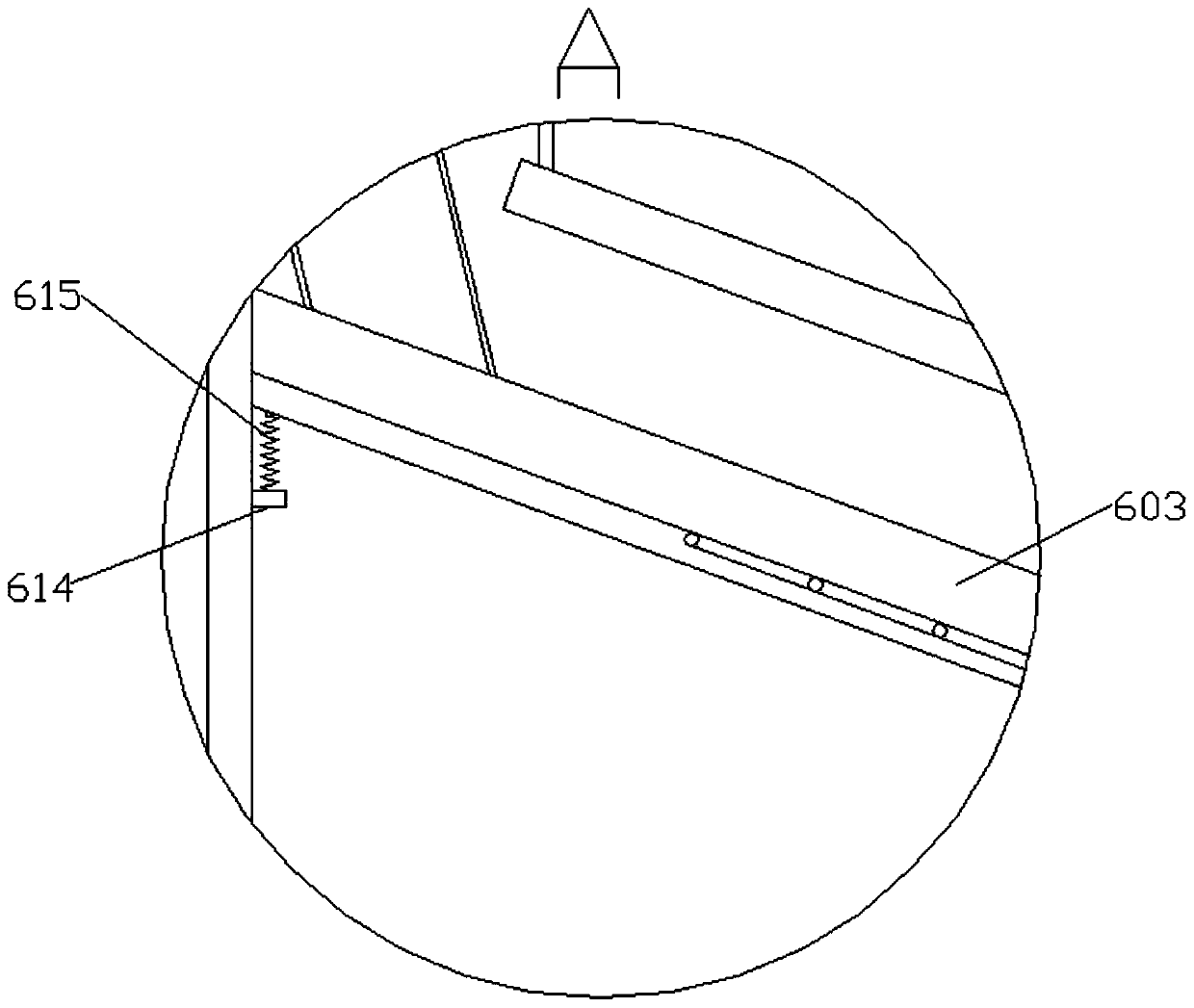

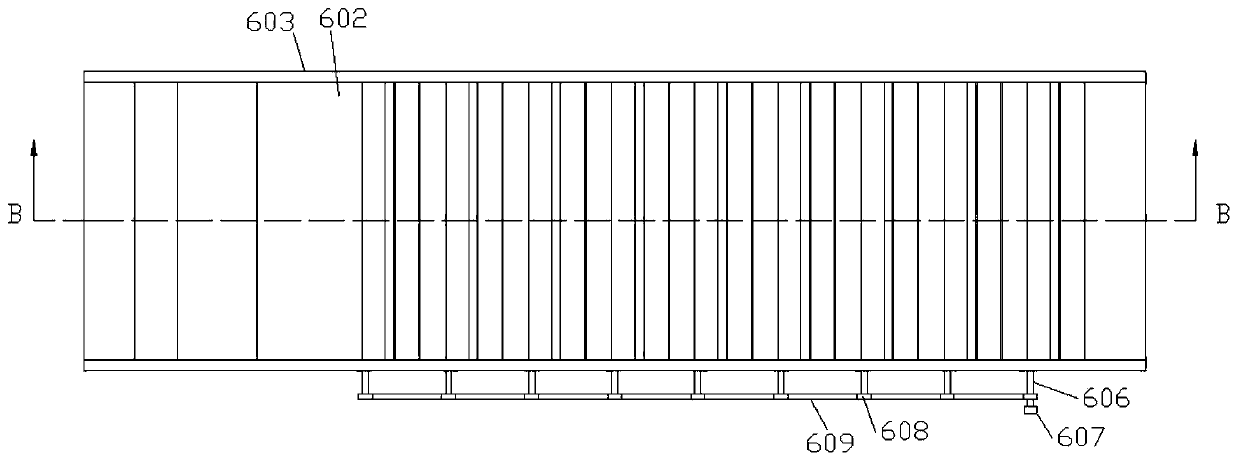

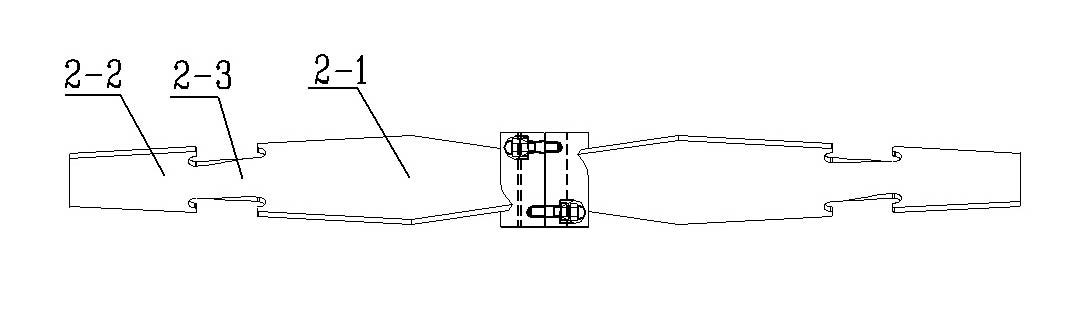

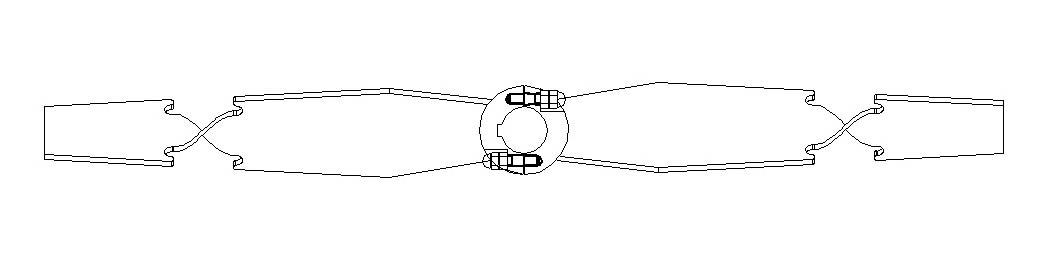

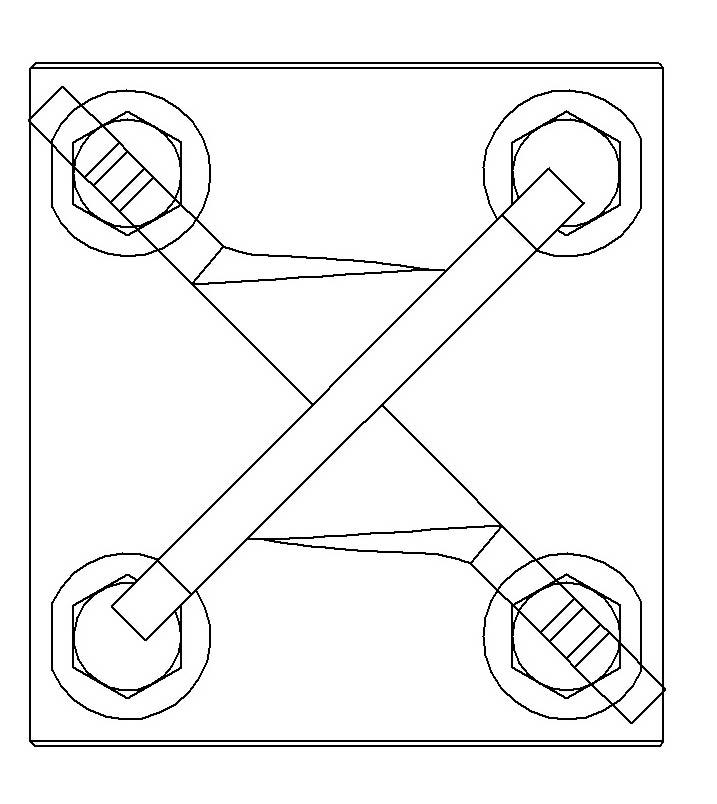

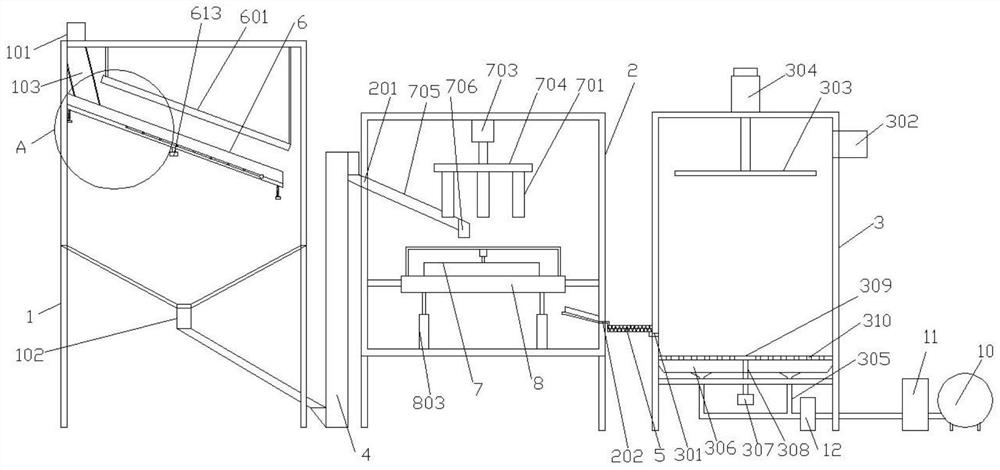

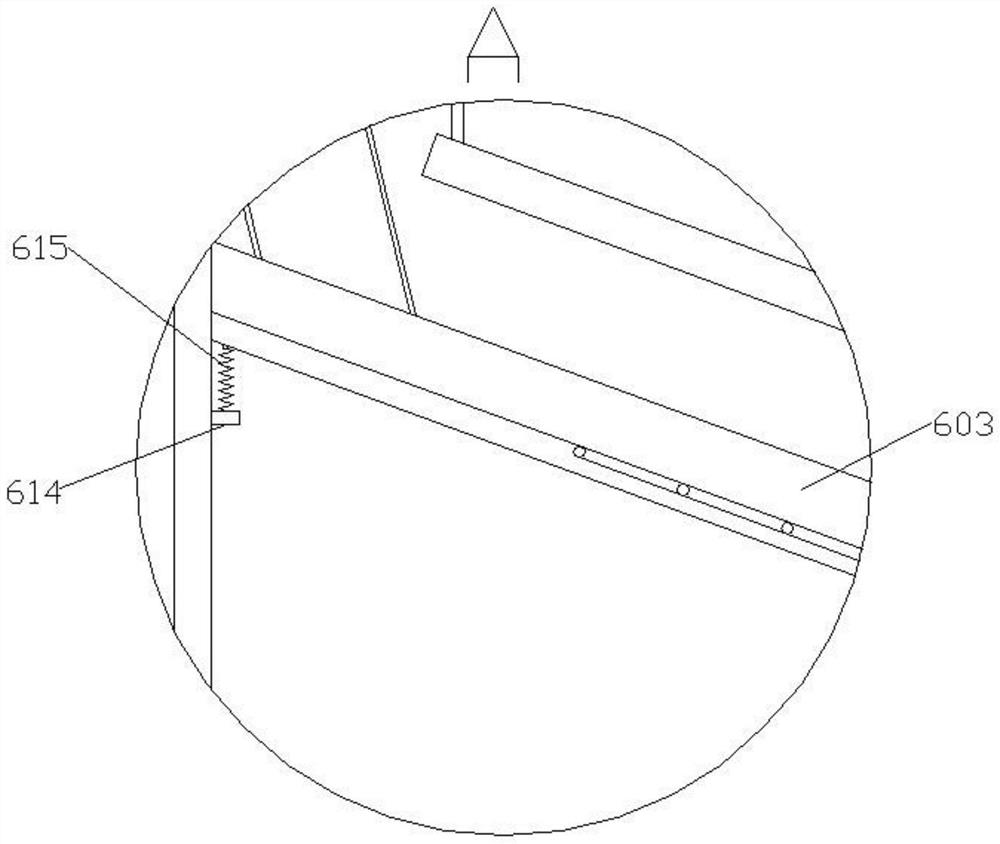

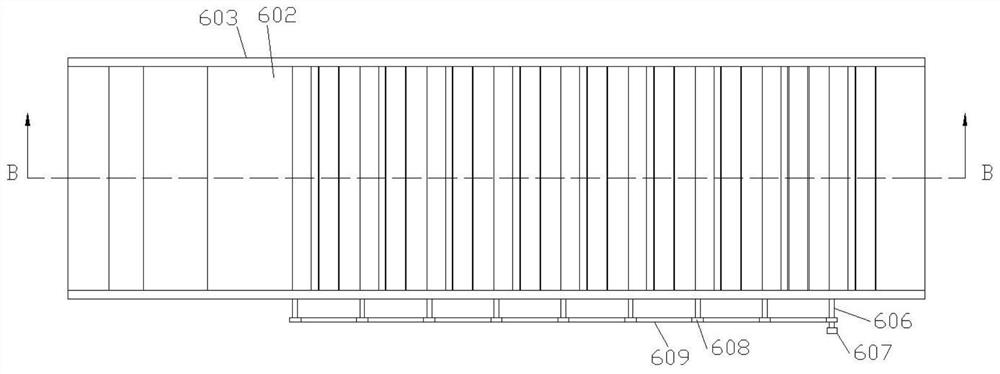

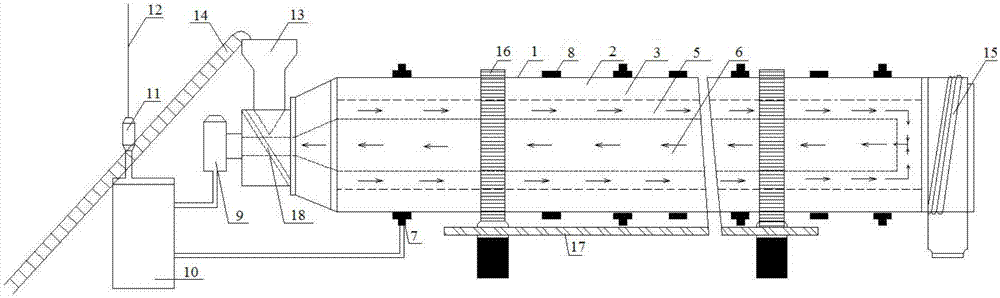

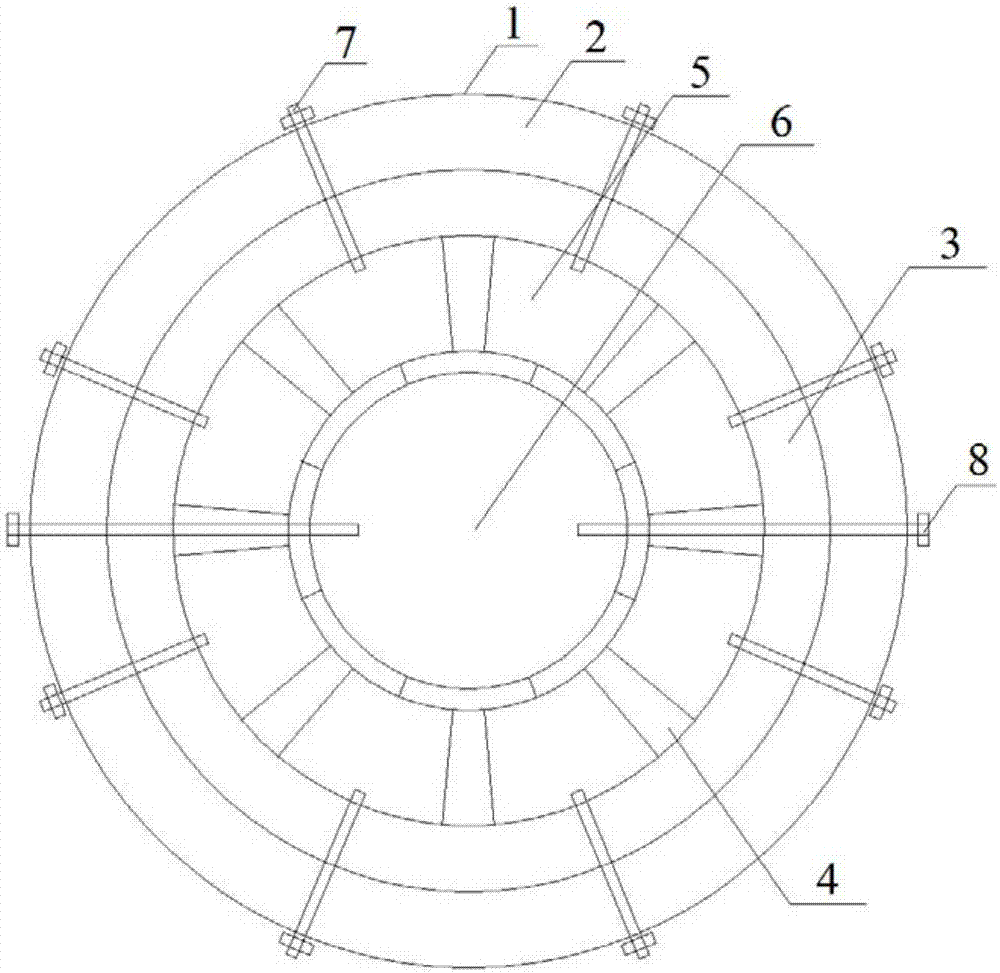

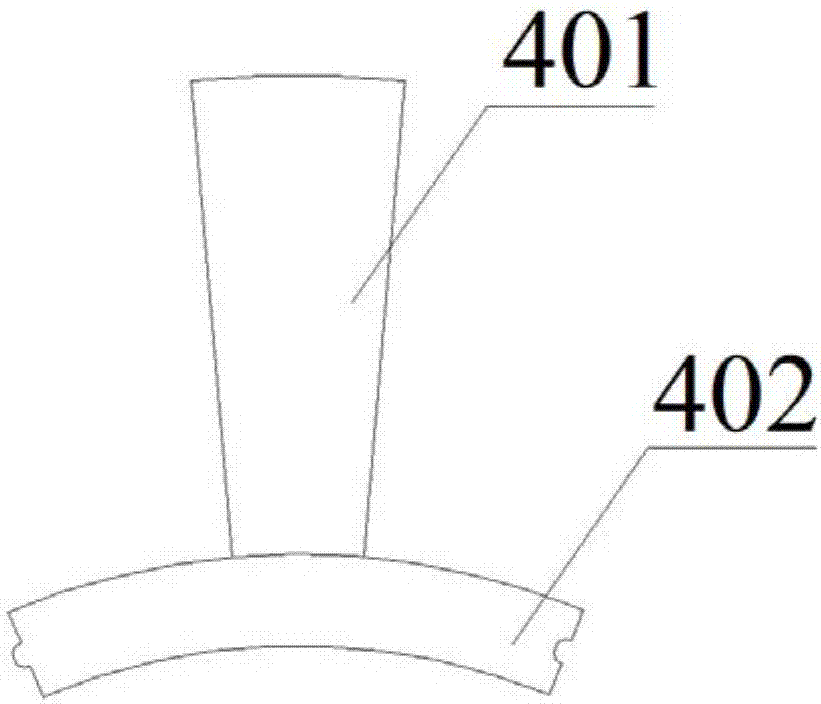

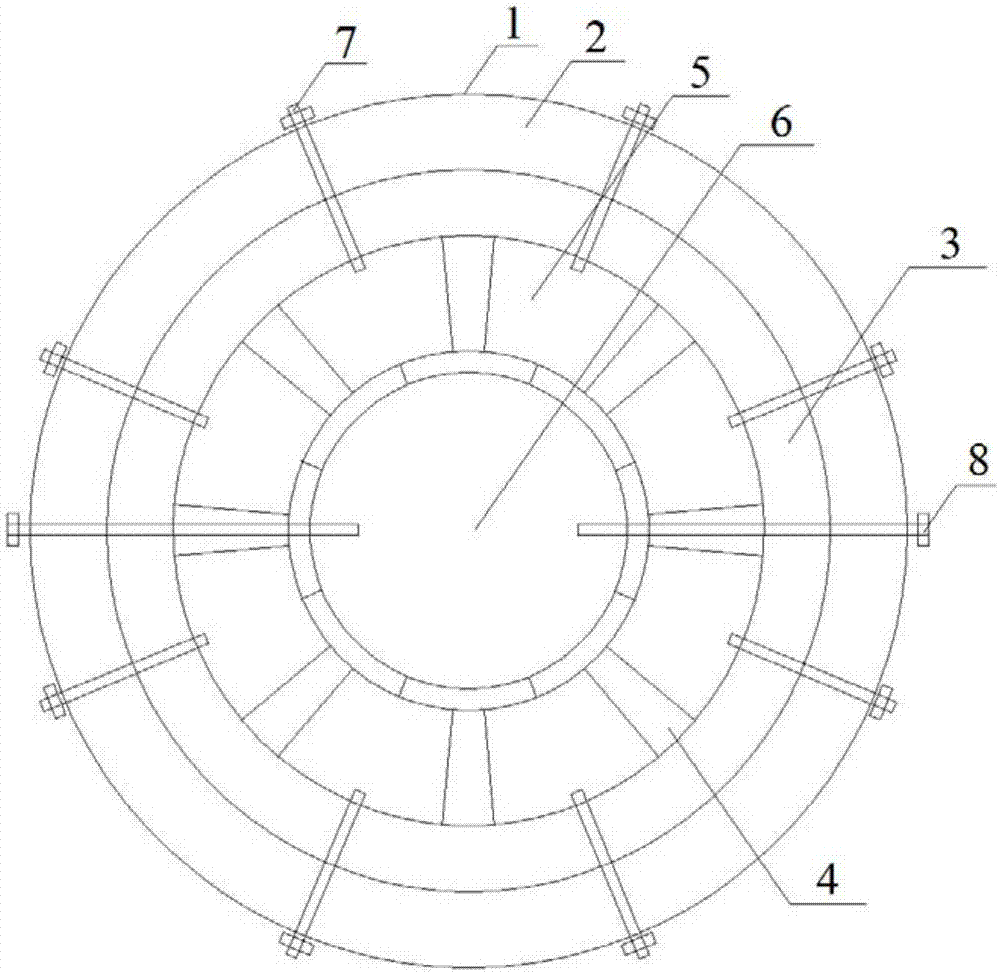

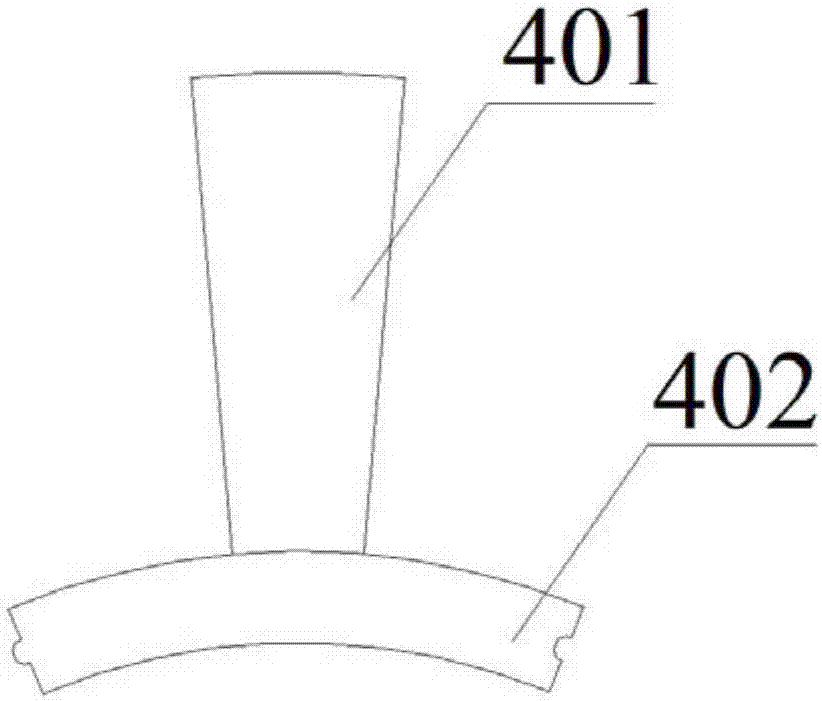

Furnace body of activated carbon activation furnace

ActiveCN106276889AIncrease the number of flipsFlip fullRotary drum furnacesActivated carbonCombustion chamber

The invention discloses a furnace body of an activated carbon activation furnace, and relates to the field of activated carbon production devices. The furnace body can improve the safety of the activated carbon production process to a certain degree, can stably run for a long time, and can greatly improve the quality and yield of produced activated carbon. The furnace body is internally provided with a combustion channel communicated with the interior of the furnace body. Air is introduced in the combustion chamber. The interior of the furnace body is divided into at least two material channels. The material channels are arranged in the length direction of the furnace body. Vapor is introduced in each material channel. The furnace body comprises an outer cylinder. At least two branch warehouse supporting pieces are arranged in the circumferential direction of the inner wall of the outer cylinder and form the combustion chamber. One material channel is formed among two adjacent branch warehouse supporting pieces, the inner wall of the outer cylinder and the outer wall of the combustion chamber. The furnace body is mainly used for producing activated carbon.

Owner:张西进

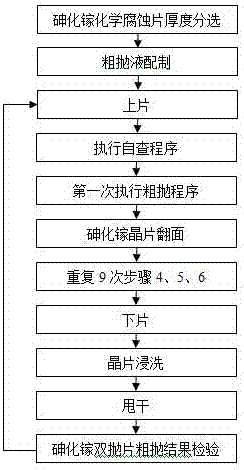

Rough polishing process for reducing overall flatness of gallium arsenide double-polished sheet

ActiveCN107978522AReduce speedReduce lossSemiconductor/solid-state device manufacturingEpoxyEngineering

The invention discloses a rough polishing process for reducing the overall flatness of the gallium arsenide double-polished sheet, which comprises the following steps: after a rough polishing solutionis prepared, uniformly placing epoxy resin planetary wheels on a polishing disk surface; then, upwards placing the front side of the gallium arsenide double-polished sheet with the thickness deviation of 3 [mu] m in the hole of the epoxy resin planetary wheel; executing a self-checking program; checking the self-spinning conditions of the epoxy resin planetary wheels and the gallium arsenide double-polished sheet; after the self-checking program is executed, descending the upper polishing disc to finish execution of the rough polishing program for the first time; after the first rough polishing program is finished, turning over the gallium arsenide double-polished sheet; placing the back side of the double-polished sheet upwards and executing the self-checking program; then, executing therough polishing program for the second time; after ten times of operation are repeated, taking out the gallium arsenide double-polished sheet from the epoxy resin planetary wheels; and putting into awhite basket for cleaning and spin-drying. According to the embodiment of the invention, the overall flatness of the gallium arsenide double-polished sheet is effectively improved.

Owner:CHINA ELECTRONICS TECH GRP NO 46 RES INST

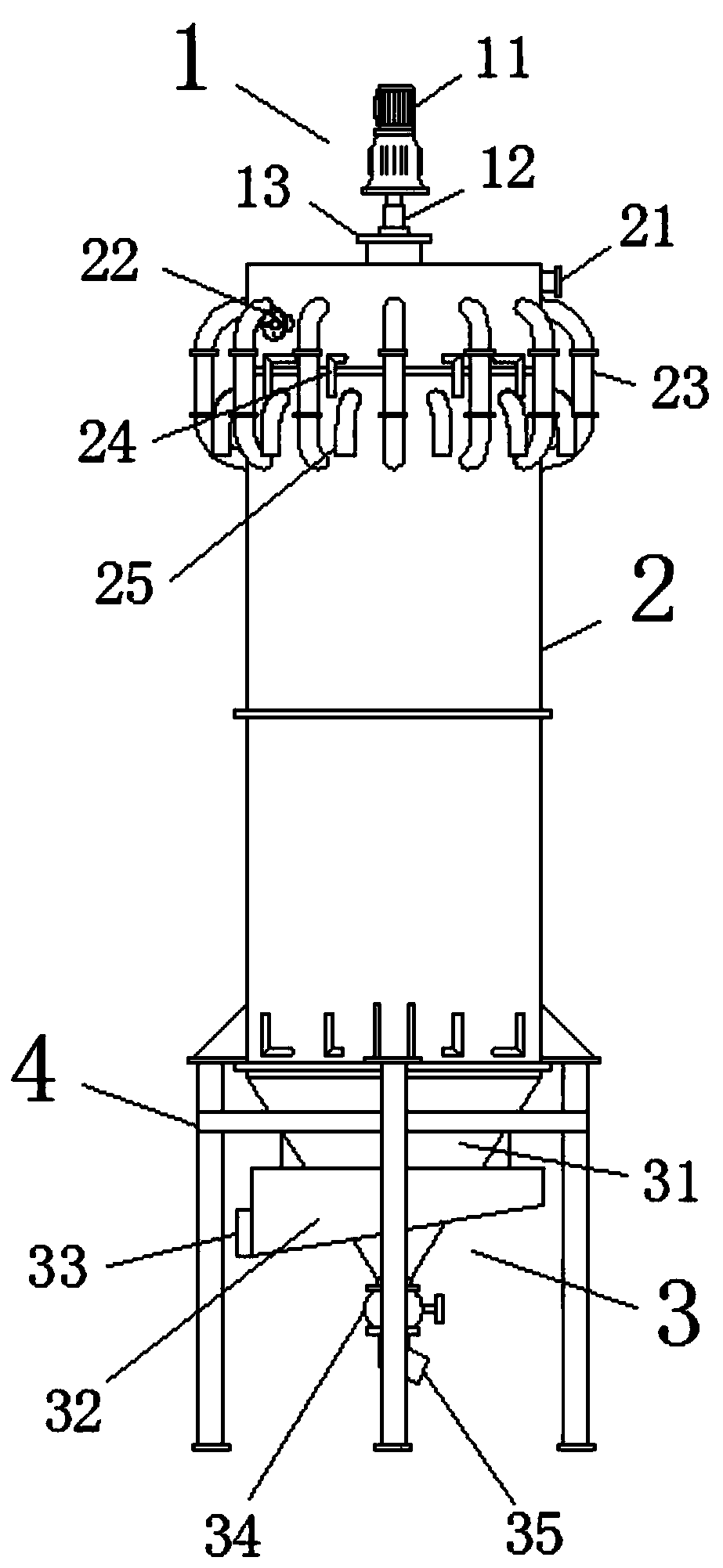

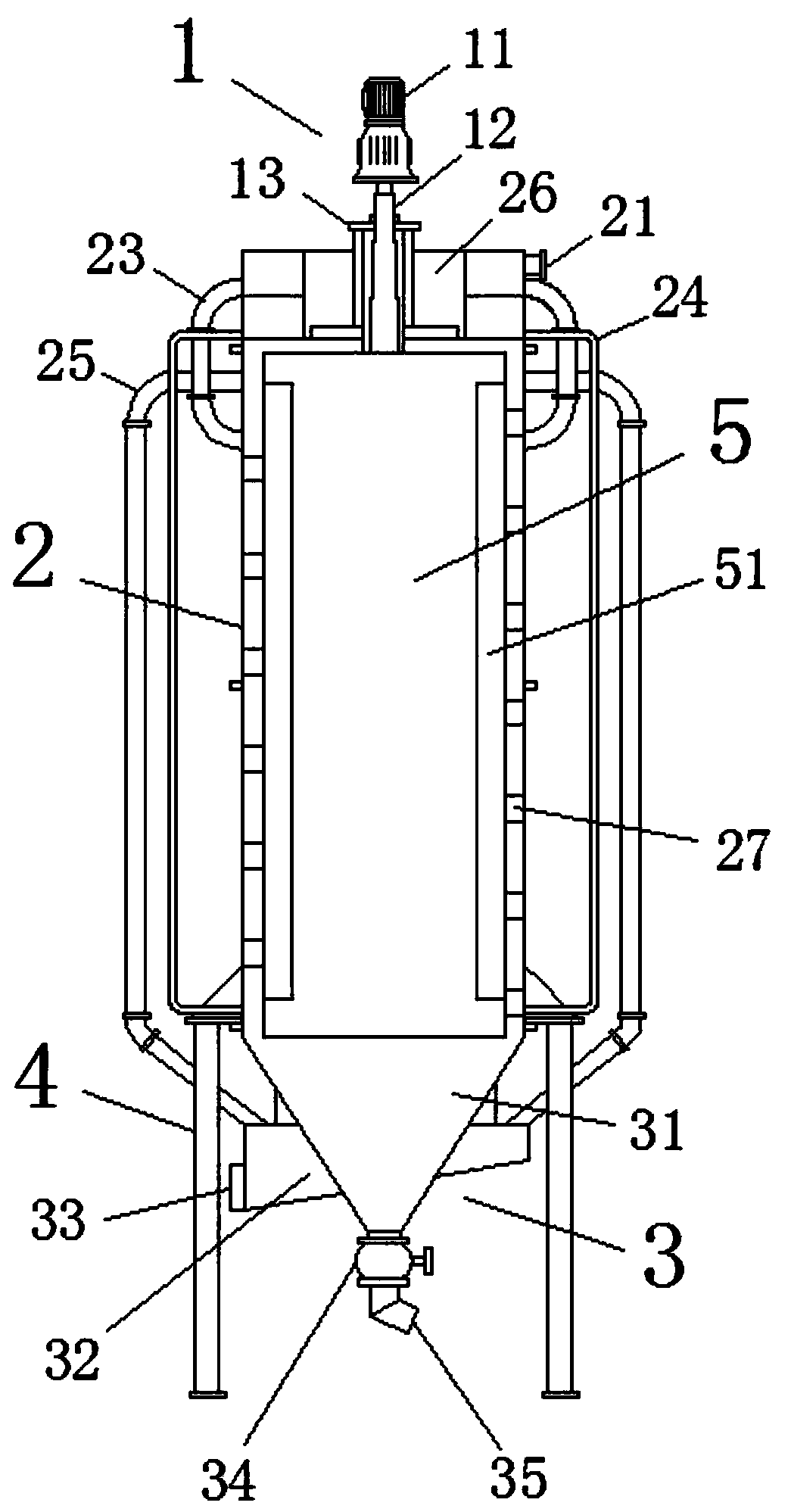

Double-cylindered magnetite fine powder grade improver

PendingCN110302898AStir wellUniform concentrationMagnetic separationWet separationEngineeringDrive motor

The embodiment of the invention discloses a double-cylindered magnetite fine powder grade improver, comprising a driving device, an outer cylinder, a discharging device, a support frame and an inner cylinder, wherein the driving device comprises a driving motor, a transmission shaft and a bearing bracket; the upper end surface of the outer cylinder is provided with an annular water distributor; the upper end of the annular water distributor is provided with an annular material distributor; and the side surfaces of the annular distributor and the annular water distributor are provided with a material inlet and a water inlet respectively. A clearance space between the outer cylinder and the inner cylinder of the double-cylindered structure increases the contact area between the magnetite material and the clean water and increases the washing speed of the slurry. A plurality of magnets are annularly arranged side by side to define a cylindrical inner cylinder permanent magnet mechanism soas to increase the magnetic separation area and increase the number of mineral rubbing and overturning times. The outer cylinder is provided therein with a scraper arranged in a spiral shape to scrape off the fine iron powder in the outer cylinder downward. The water rinses the fine iron powder from the bottom to the top to achieve efficient wet magnetic separation. The double-cylindered magnetite fine powder grade improver improves work efficiency and is easy to operate.

Owner:山西建兴机械设备有限公司

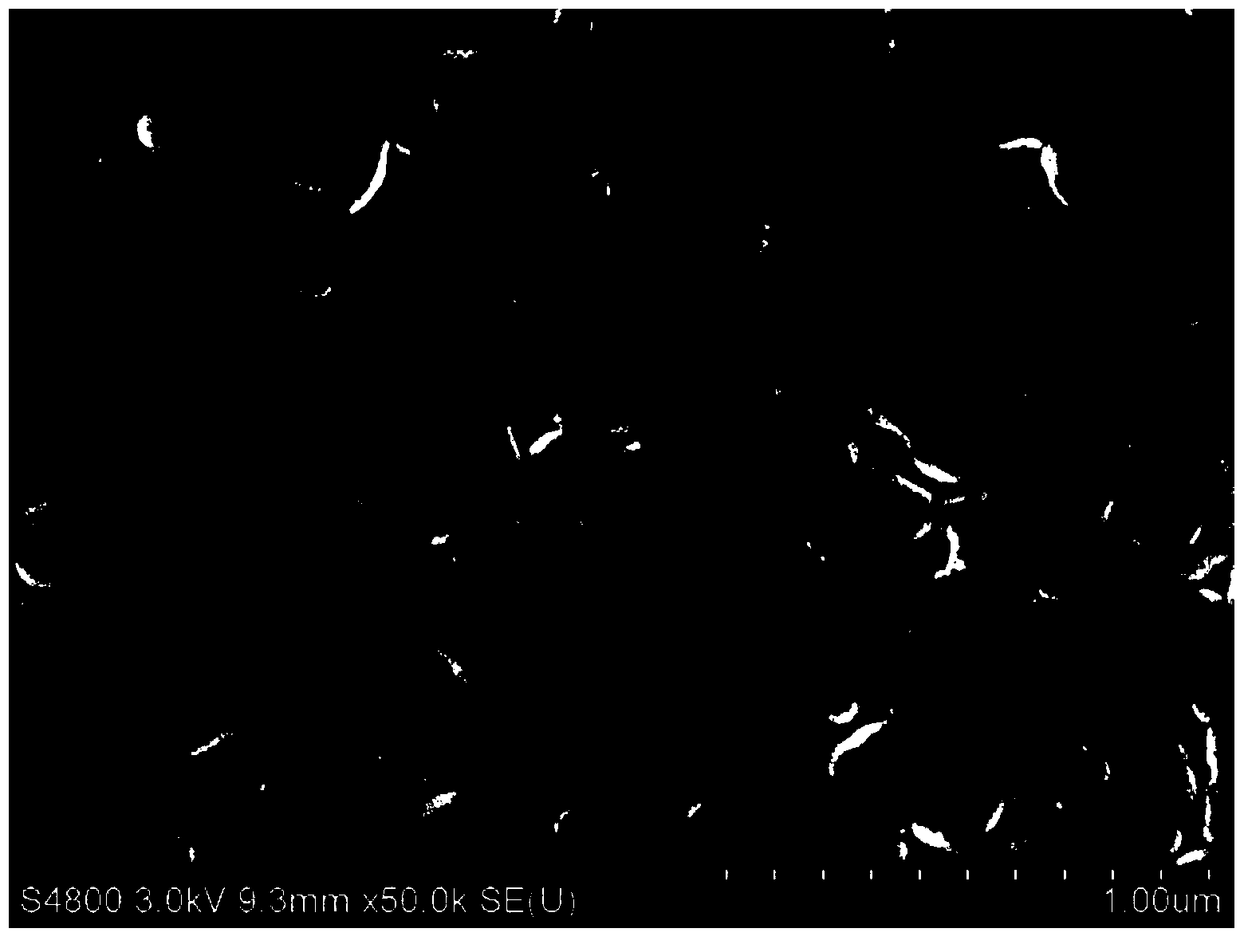

B-site Mn and Cu codoped high remanent polarization BiFeO3 film and preparation method

ActiveCN103613144AImprove multiferroic propertiesDistortionIron compoundsIonEthylene glycol monomethyl ether

The invention relates to a B-site Mn and Cu codoped high remanent polarization BiFeO3 film and a preparation method, the method comprises the following steps: dissolving bismuth nitrate, ferric nitrate, manganese acetate and cupric nitrate according to mol ratio of 1.05: [(0.92-0.98)-x]: (0.02-0.08):x in a mixed liquor of ethylene glycol monomethyl ether and acetic anhydride, then uniformly stirring to obtain a BiFeO3 precursor; wherein total metal ion concentration of the BiFeO3 precursor is 0.1-0.5mol / L, X is 0.01-0.03; performing spin coating of the BiFeO3 precursor on a FTO / glass substrate to prepare a wet membrane, baking the wet membrane to obtain a dry membrane, then annealing at 550 DEG C to obtain the crystalline state BiFeO3 film; cooling the crystalline state BiFeO3 film, and repeatedly making the crystalline state BiFeO3 film to reach a required thickness to obtain the B-site Mn and Cu codoped high remanent polarization BiFeO3 film. According to the invention, a sol gel technology is employed, the equipment requirement is simple, the film is prepared on large surface and surfaces with irregular shapes, the chemical component is accurate and controllable, and the regulation and control to its crystal structure can be carried out by codoping thereby the ferroelectric performance of the film is greatly increased.

Owner:盐城梦心缘鞋服有限公司

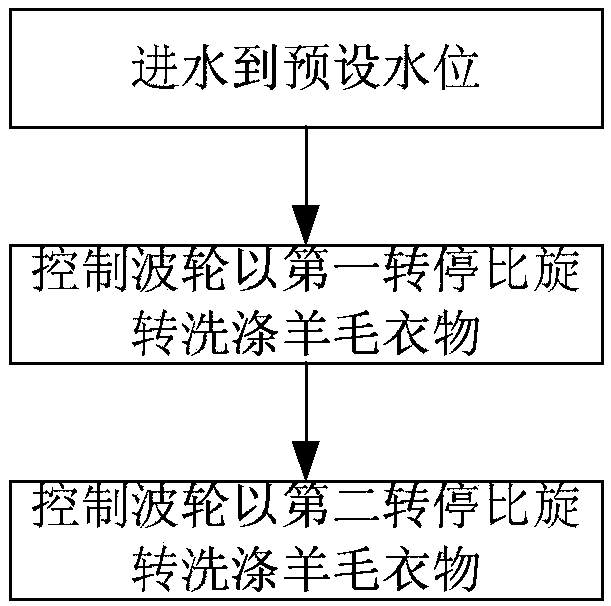

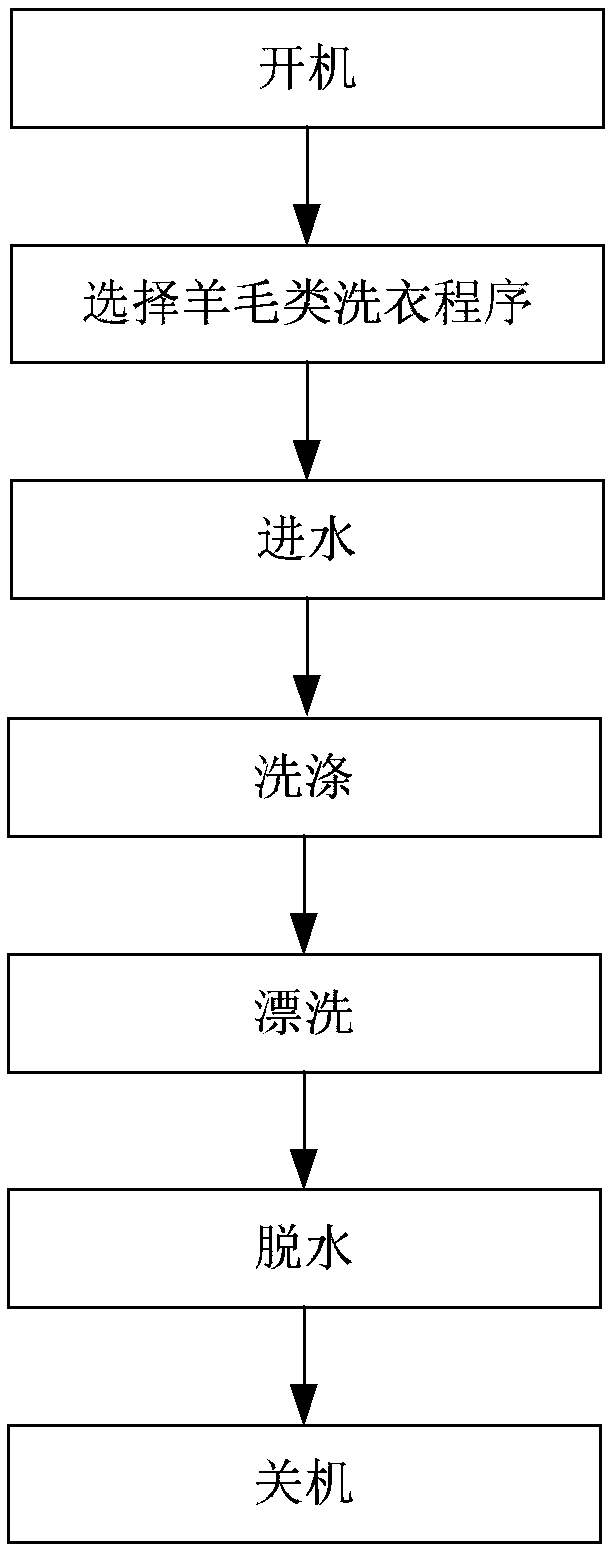

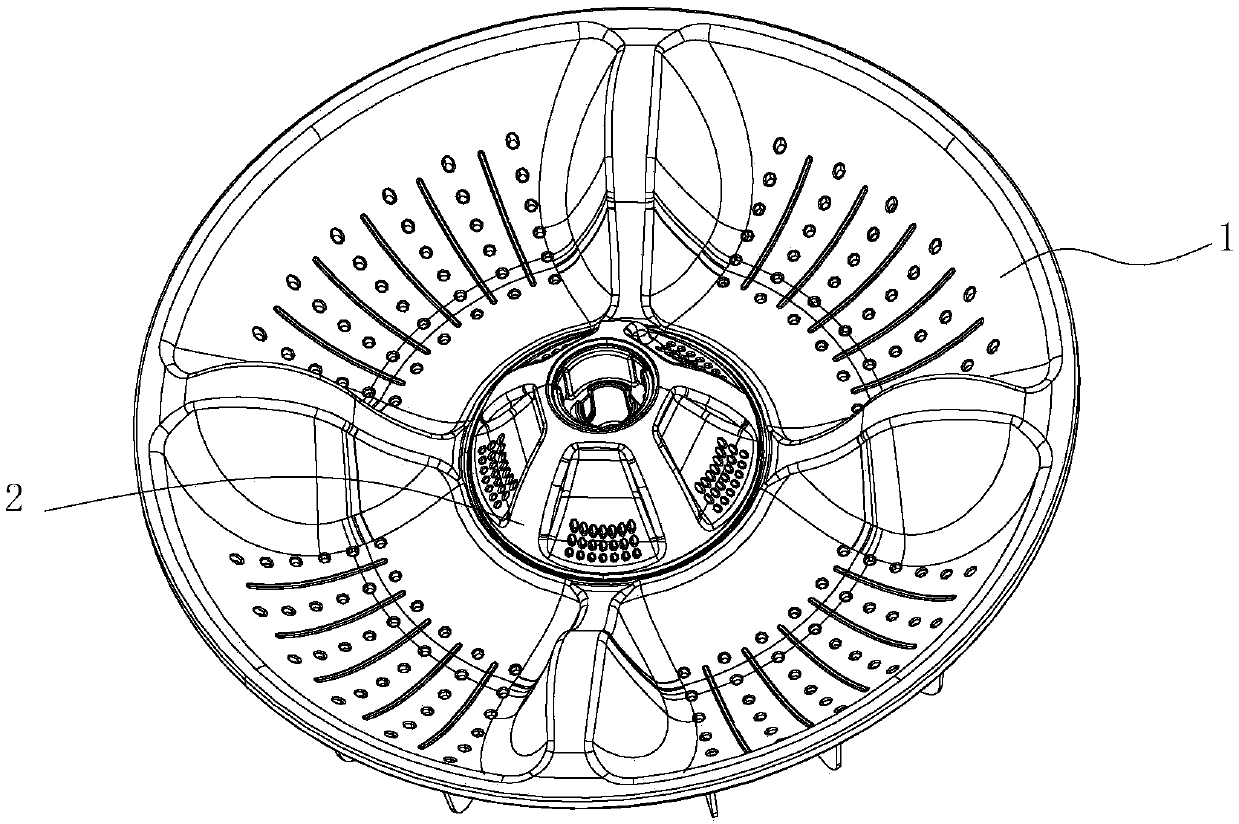

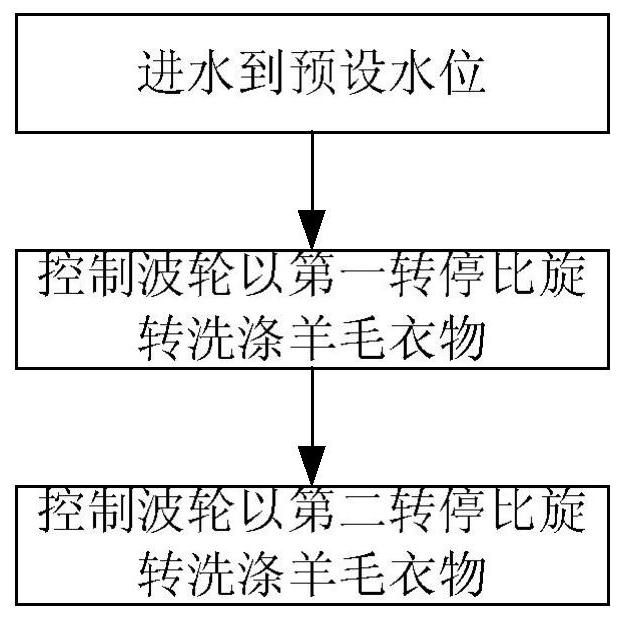

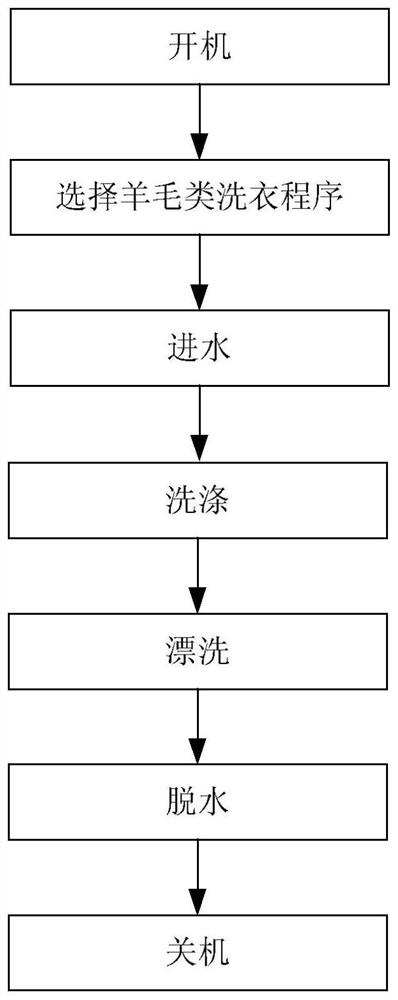

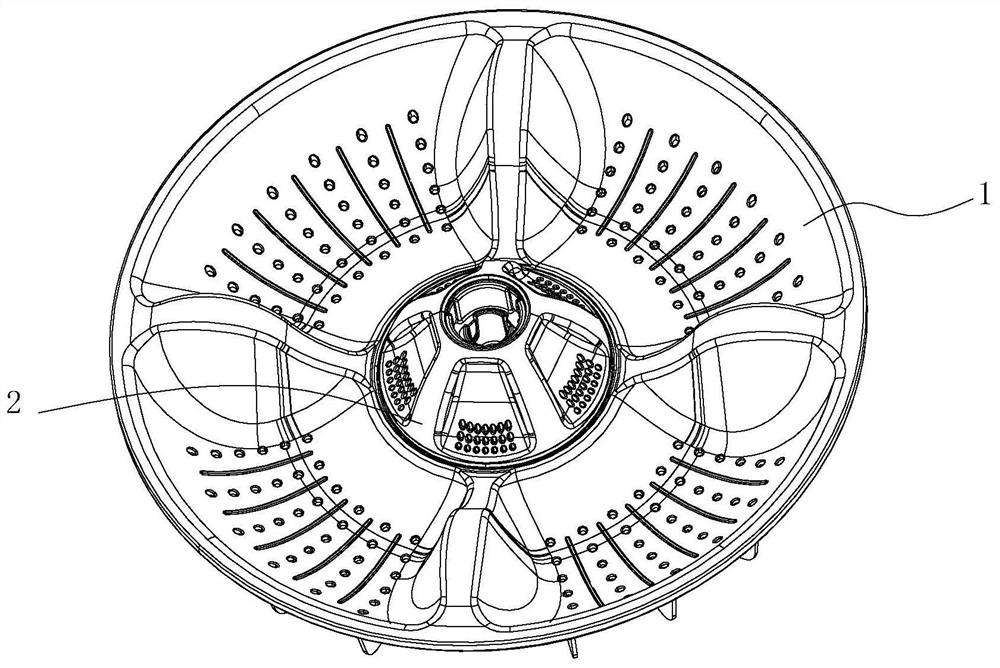

Wool clothes washing method of washing machine and washing machine

ActiveCN107663738AIncrease friction timeImprove cleaning rateOther washing machinesTextiles and paperStop timeImpeller

The invention relates to a wool clothes washing method and a washing machine. The washing machine includes an impeller; when water is put in the washing machine and reaches a preset water level, the washing function is enabled, and the impeller conducts washing at different rotation stop ratios during washing; the method includes the following steps that in the first washing process, the impelleris controlled to rotate at the first rotation stop ratio to achieve fast washing of wool clothes, and the rotation time within a rotation stop cycle is longer than stop rotation time; in a second washing process, the impeller is controlled to rotate at the second rotation stop ratio to achieve rotary washing of clothes, and the rotation time within a rotation stop cycle is shorter than the stop rotation time; the second washing process includes a clothes washing procedure and a rinsing procedure. In the first washing process, the rotation speed of water flow is high, the wool clothes can be fully stirred, and the cleaning rate of the wool clothes is increased; in the second washing process, the rotation stop time is long, and the shrinkage rate is decreased. The washing machine can reducefriction among the wool clothes, an inner barrel and the impeller in the washing processes, the shrinkage rate of the wool clothes is reduced, the impeller rotates periodically, and the cleaning rateis increased.

Owner:CHONGQING HAIER WASHING MASCH CO LTD +1

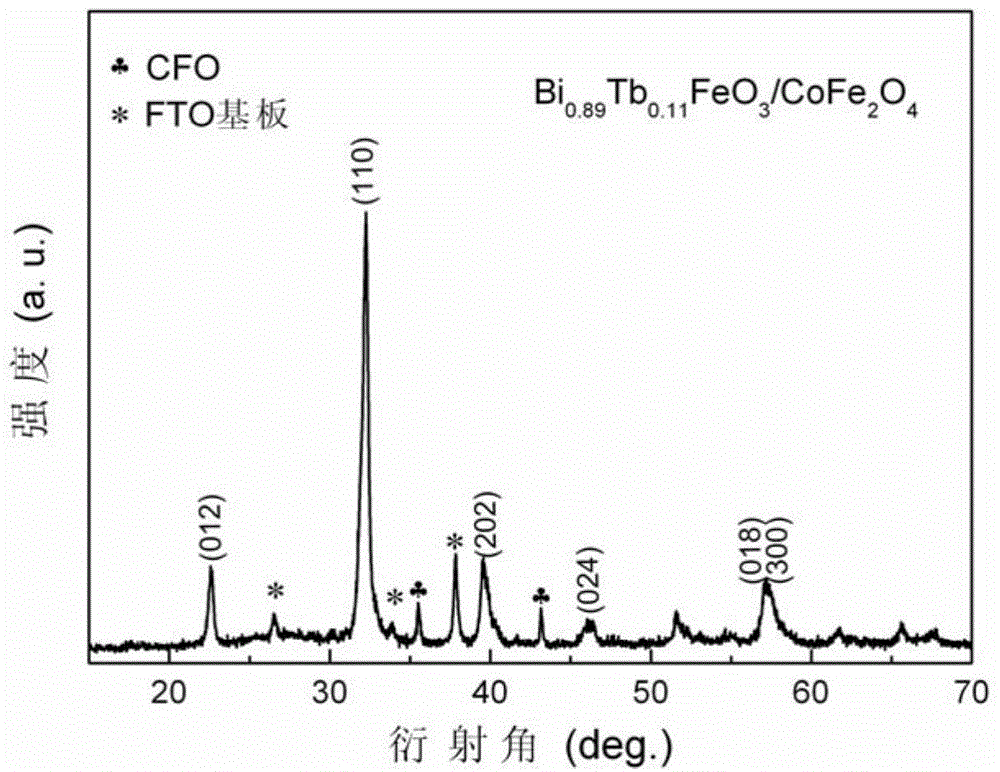

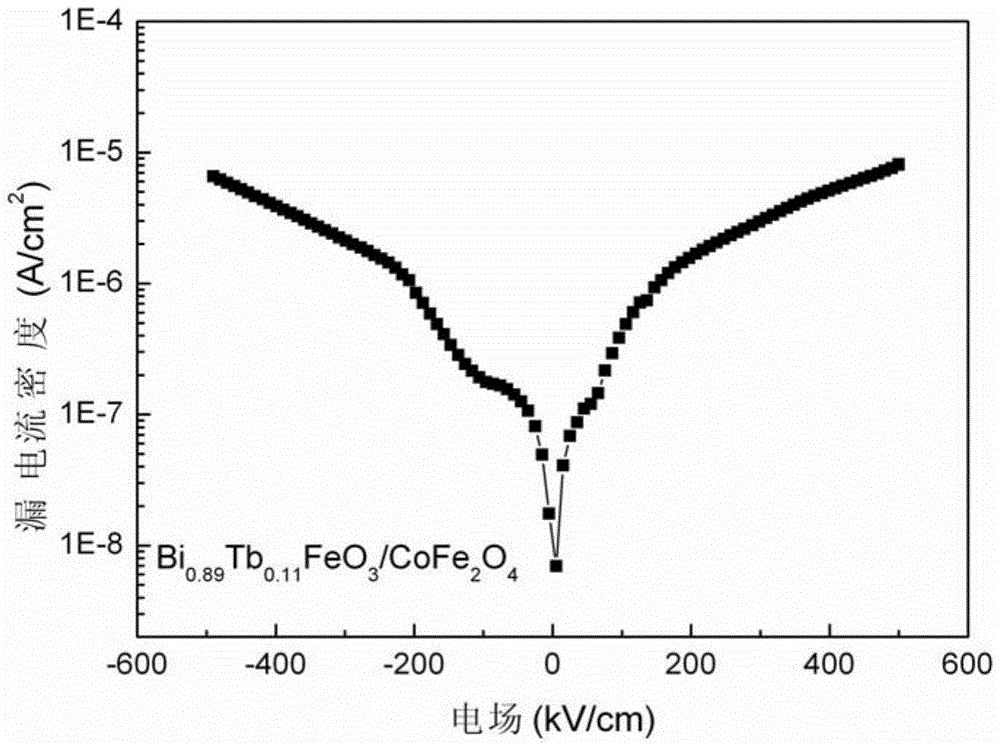

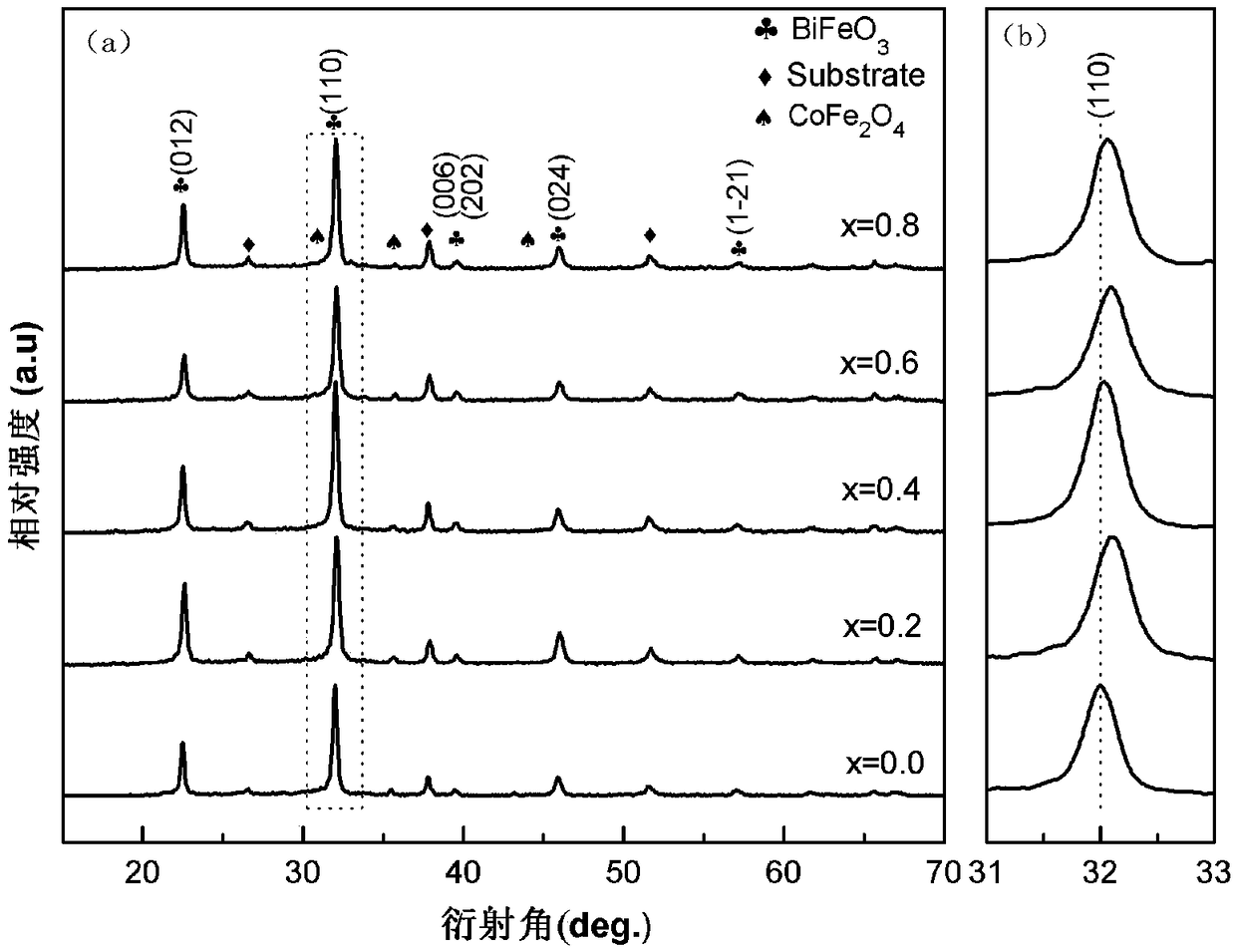

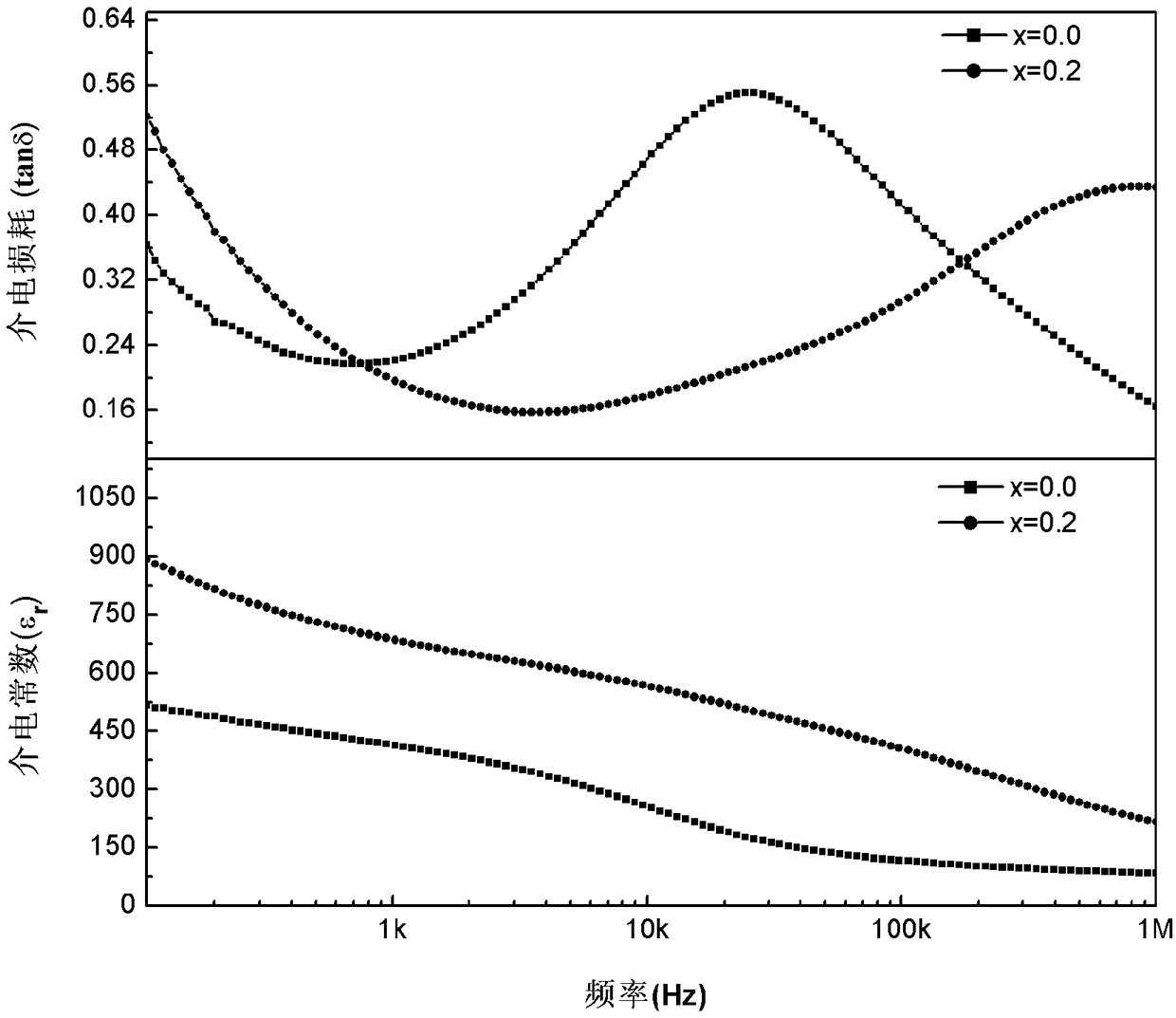

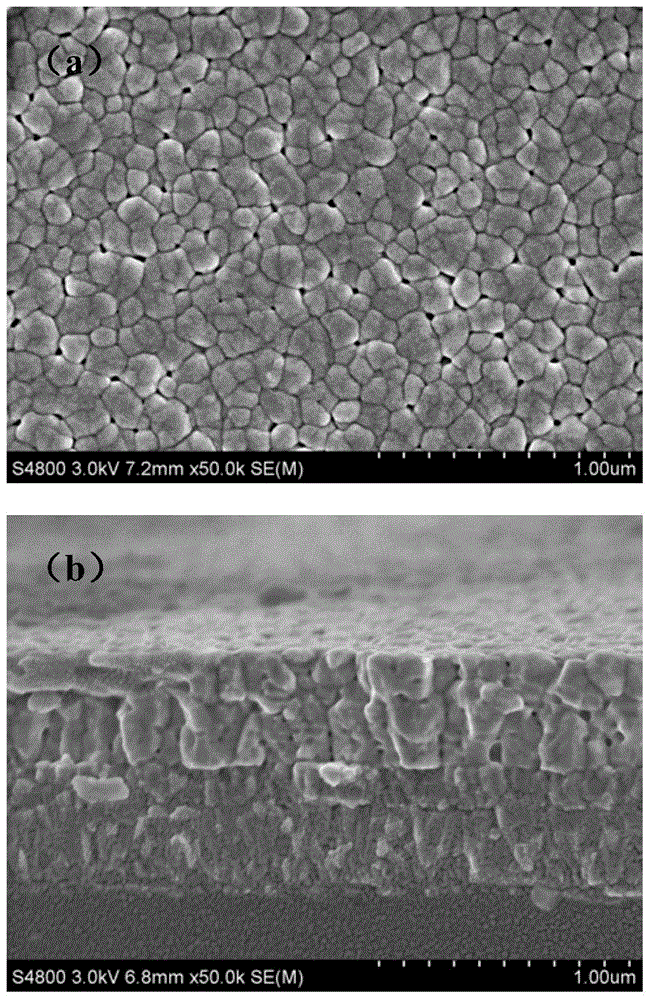

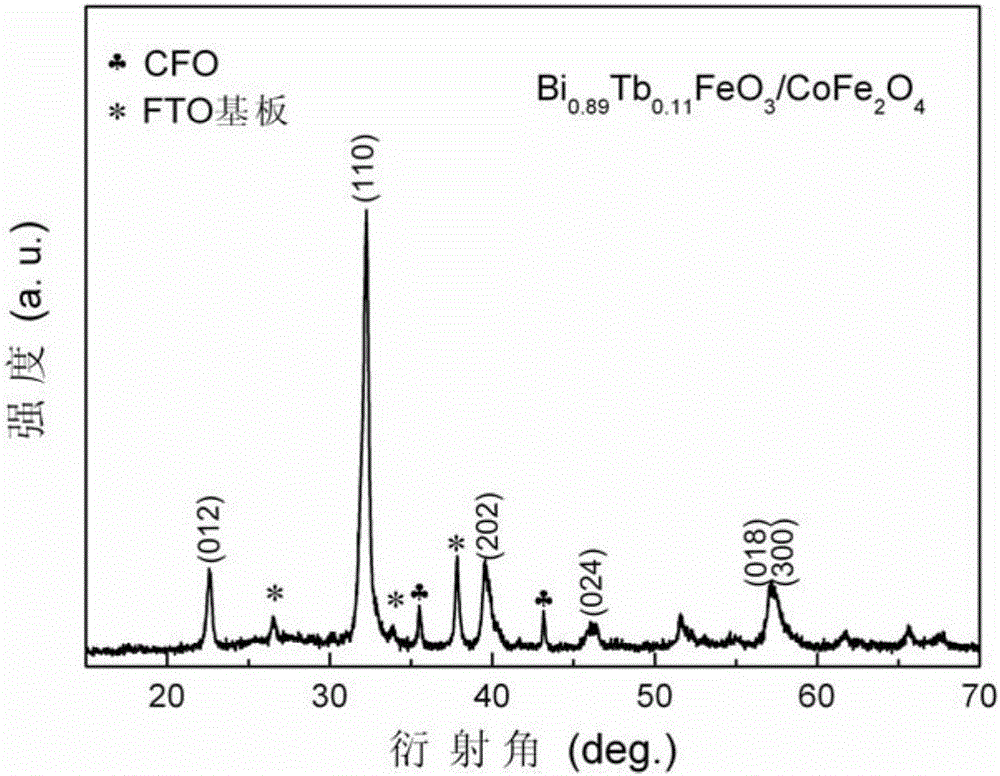

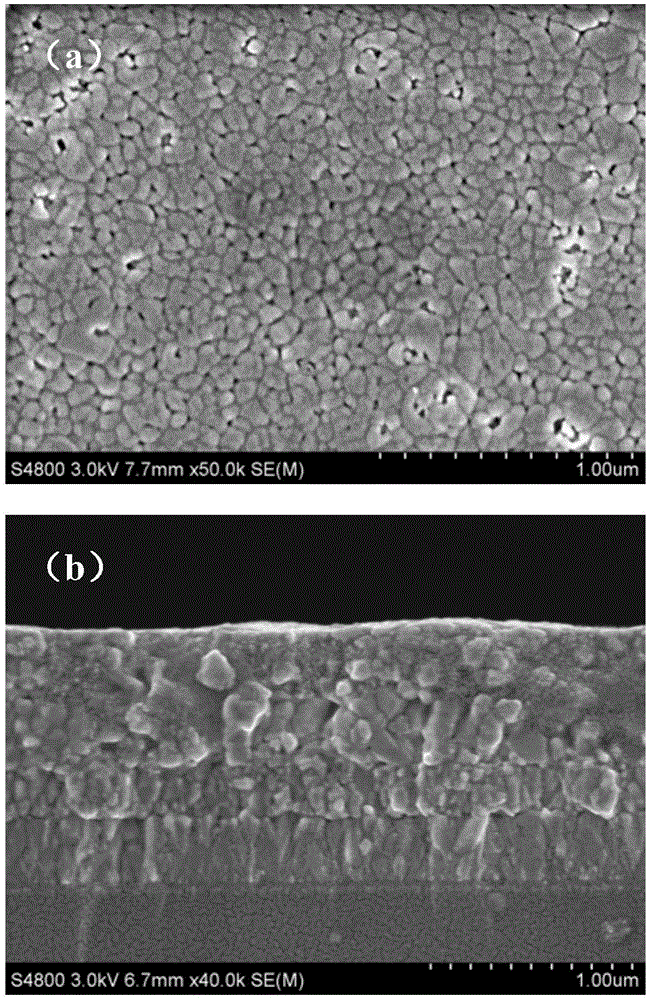

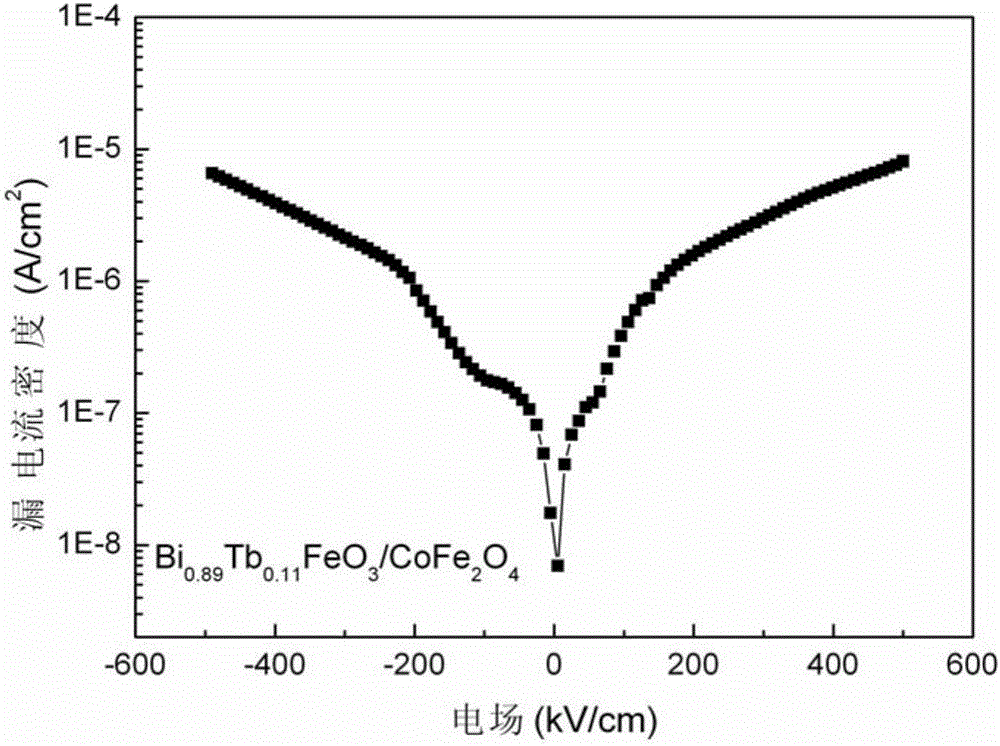

Bi1-xRExFeO3/CoFe2O4 multiferroic composite membrane and preparation method thereof

ActiveCN104538139APrecise and controllable chemical compositionSimple equipment requirementsInorganic material magnetismInductances/transformers/magnets manufactureChemistryChemical composition

The invention provides a Bi1-xRExFeO3 / CoFe2O4 multiferroic composite membrane and a preparation method thereof. The composite membrane comprises a Bi1-xRExFeO3 crystalline state membrane and a CoFe2O4 crystalline state membrane which are combined together, wherein RE is Ce, Pr, Tb, Eu or Yb, x is equal to 0.05-0.15; in the preparation, Bi1-xRExFeO3 precursor solution and CoFe2O4 precursor solution are firstly prepared respectively; and then, multi-layer CoFe2O4 membrane is prepared by spinning on a substrate, and the multi-layer Bi1-xRExFeO3 membrane is prepared by spinning on the CoFe2O4 membrane, so the target product is obtained. The facility request is simple, the homogeneity of the prepared membrane is good, the chemical composition can be accurately controlled, the doping content is easily controlled, and the ferroelectric property and ferromagnetic property of the membrane are greatly improved, so the Bi1-xRExFeO3 / CoFe2O4 multiferroic composite membrane has high residual polarization value and residual magnetization value.

Owner:SHAANXI UNIV OF SCI & TECH

BLSFMC/CMFO film with resistance switch effect and preparation method thereof

ActiveCN109111127AImprove multiferroic performanceReduce leakage current densityComposite filmSpace group

The invention provides a BLSFMC / CMFO film with a resistance switch effect and a preparation method thereof. The BLSFMC / CMFO film comprises an upper layer film and a bottom layer film which are composited together; a chemical formula of the bottom layer film is Co1-xMnxFe2O4, the bottom layer film is a distorted cubic inverse spinel structure, and a space group is Fd3m; and a chemical formula of the upper layer film is Bi0.79La0.19Sr0.03Fe0.94Mn0.04Co0.0203, the upper layer film is a distorted rhombohedral perovskite structure, and a space group is R3c, wherein x is equal to 0 to 0.8. The BLSFMC / CMFO film is prepared by adopting a sol-gel method and a layer-by-layer annealing process. By virtue of the doping for the BiFeO3 film, the ferroelectric performance is improved; and the BiFeO3 filmis composited with a CoFe2O4 magnetic layer, so that the resistance switch effect of the ferroelectric polarization-regulated ferroelectric / ferromagnetic composite film can be realized.

Owner:SHAANXI UNIV OF SCI & TECH

Rice quantity-control processing and integrated cleaning and cooking device and method

ActiveCN112246742AImprove dust removal efficiencySave waterCombination devicesFood thermal treatmentWater pipeEngineering

Owner:武汉什湖知音粮油食品有限公司

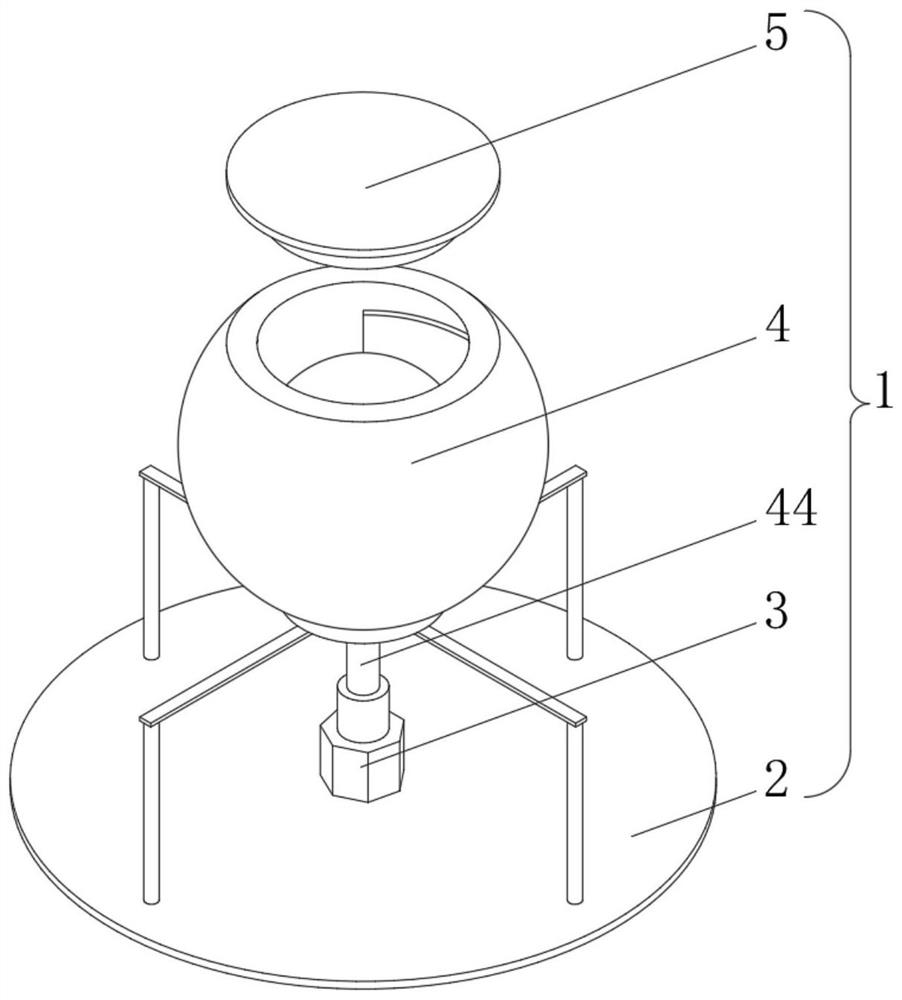

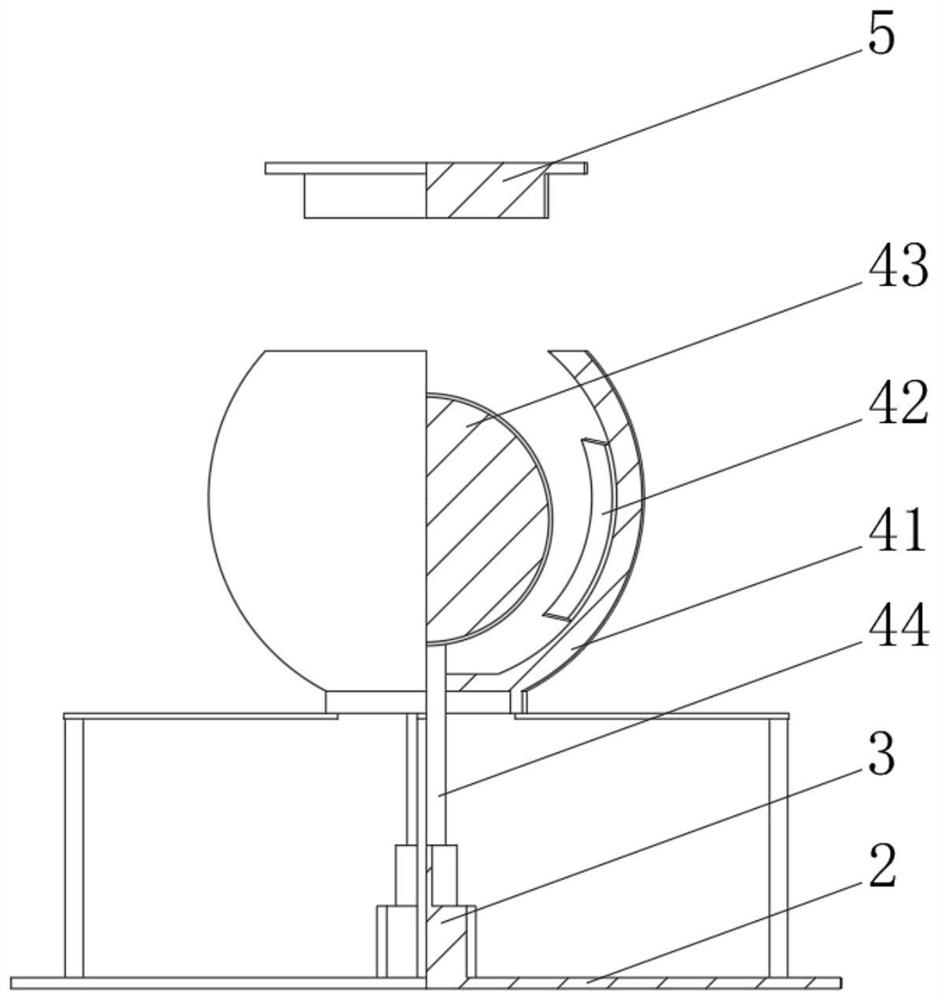

Ganoderma lucidum spore wall breaking device

The invention discloses a ganoderma lucidum spore wall breaking device which comprises a pretreatment box, a punching box and an airflow smashing machine. The pretreatment box is provided with a firstfeeding port and a first discharging port. The punching box is provided with a second feeding port and a second discharging port. The airflow smashing machine is provided with a third feeding port and a third discharging port. The first discharging port communicates with a feeding port of a bucket elevator. A discharging port of the bucket elevator communicates with the second feeding port. The second discharging port communicates with a feeding port of a spiral conveyor. A discharging port of the spiral conveyor communicates with the third feeding port. An ultraviolet treatment mechanism isarranged in the pretreatment box and used for carrying out ultraviolet irradiation on ganoderma lucidum spore. A punching mechanism and a discharging mechanism are arranged in the punching box. The ganoderma lucidum spore wall breaking device can increase the wall breaking rate.

Owner:安徽黄山云乐灵芝有限公司 +1

B-site Mn and Ni co-doped high-remanent-polarization BiFeO3 film and preparation method thereof

ActiveCN103626236AImprove multiferroic propertiesPromote productionIron compoundsMANGANESE ACETATEAcetic anhydride

The invention discloses a B-site Mn and Ni co-doped high-remanent-polarization BiFeO3 film and a preparation method thereof. The preparation method comprises the following steps: dissolving bismuth nitrate, ferric nitrate, manganese acetate and nickel acetate according to a molar ratio of 1.05:[(0.92-0.98)-x]:(0.02-0.08):x in a mixed solution of ethylene glycol monomethyl ether and acetic anhydride, uniformly stirring to obtain a BiFeO3 precursor solution, wherein the total metal ion concentration in the BiFeO3 precursor solution is 0.1-0.5mol / L, and x is equal to 0.01 to 0.03; spin coating the BiFeO3 precursor solution on a FTO / glass substrate to prepare a wet film, baking the wet film to obtain a dried film, annealing at the temperature of 550 DEG C for 8-13 minutes, thus obtaining a crystalline state BiFeO3 film; repeatedly operating until the BiFeO3 film reaches the needed thickness after the crystalline state BiFeO3 film is cooled, thus obtaining the B-site Mn and Ni co-doped high-remanent polarization BiFeO3 film. According to the method, a sol-gel process is adopted, the equipment requirement is simple, the method is suitable for preparing films on large surfaces and out-of-shape surfaces, the chemical constituents are accurately controlled, and the crystal structure is regulated through co-doping, so that the ferroelectric properties of the film are greatly improved.

Owner:SHAANXI UNIV OF SCI & TECH

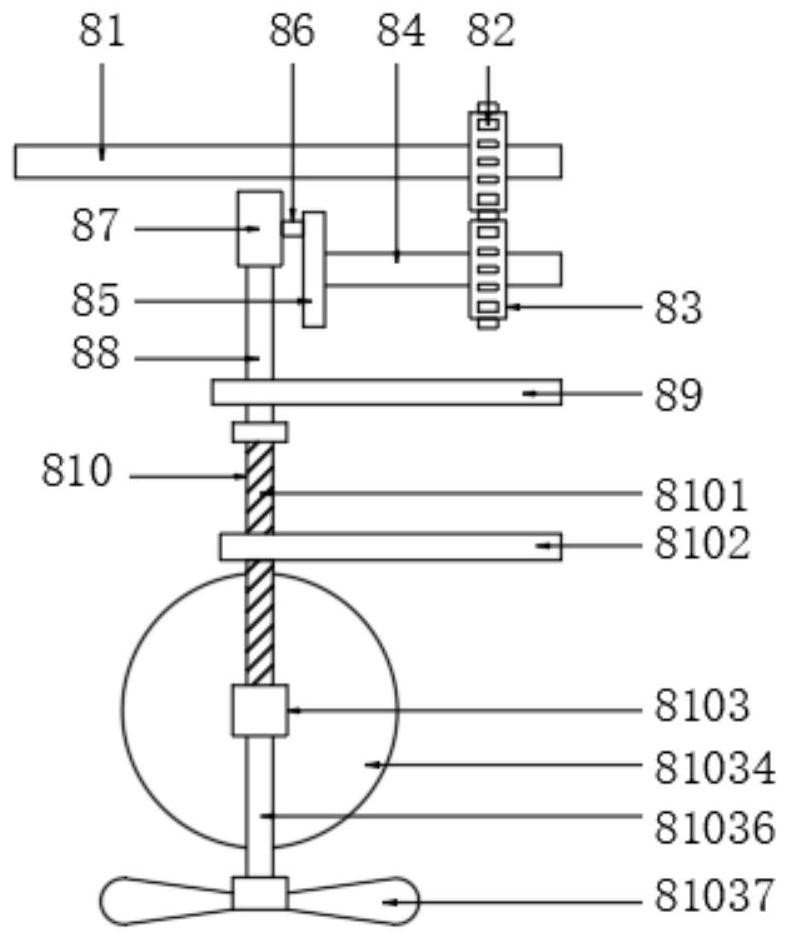

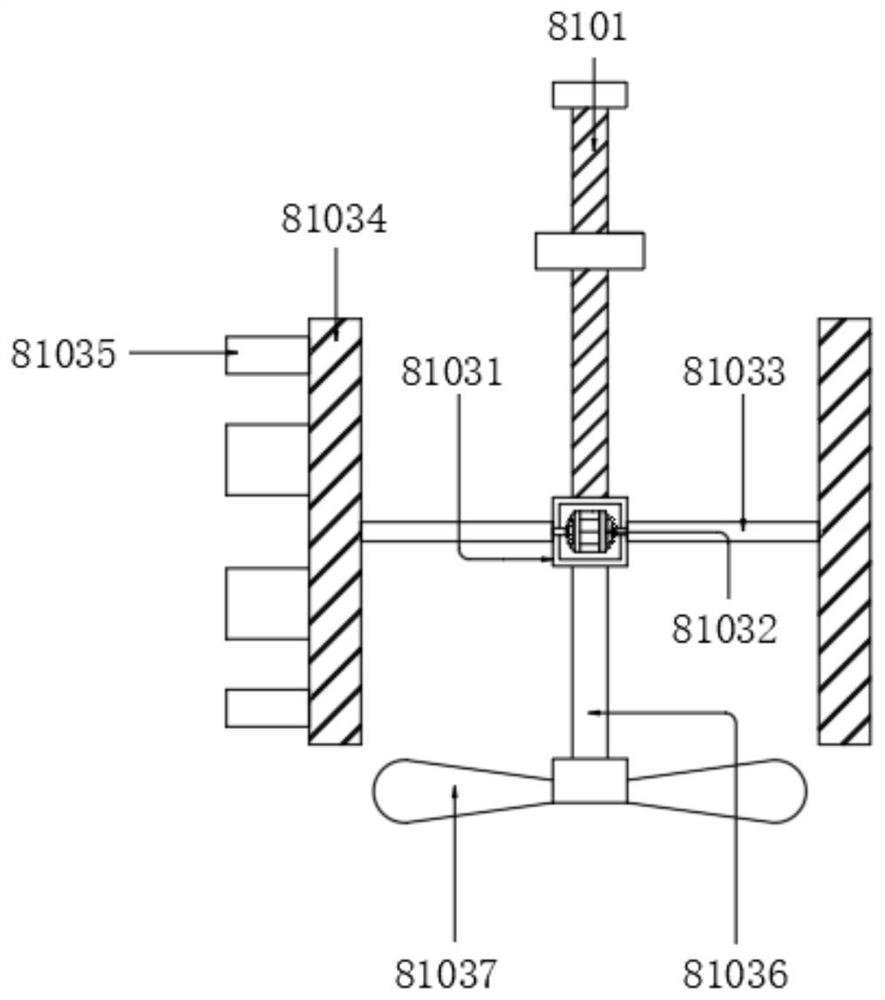

Improved structure of blender in polymerization kettle

InactiveCN102350290AStir wellIncrease the number of flipsRotary stirring mixersTransportation and packagingTemperature differenceEngineering

The invention provides an improved structure of a blender in a polymerization kettle, which is capable of increasing times for overturning materials, reducing a temperature difference of the materials in the kettle in the process of blending, increasing the blending efficiency, avoiding the generation of gel and prolonging the cycle of cleaning the kettle. The improved structure comprises a reaction kettle body, a blending shaft and the blender; the blender comprises a pitched blade type blender and a wide blade type blender which is located on a lower seal head; the blender is fixed on the blending shaft, wherein blades of the pitched blade type blender respectively include an inner semi-blade and an outer semi-blade, and an included angle is kept between the inner semi-blade and the outer semi-blade after the inner semi-blade and the outer semi-blade are screwed at a connection part.

Owner:WUXI SHUANGXIONG GENERAL MACHINERY

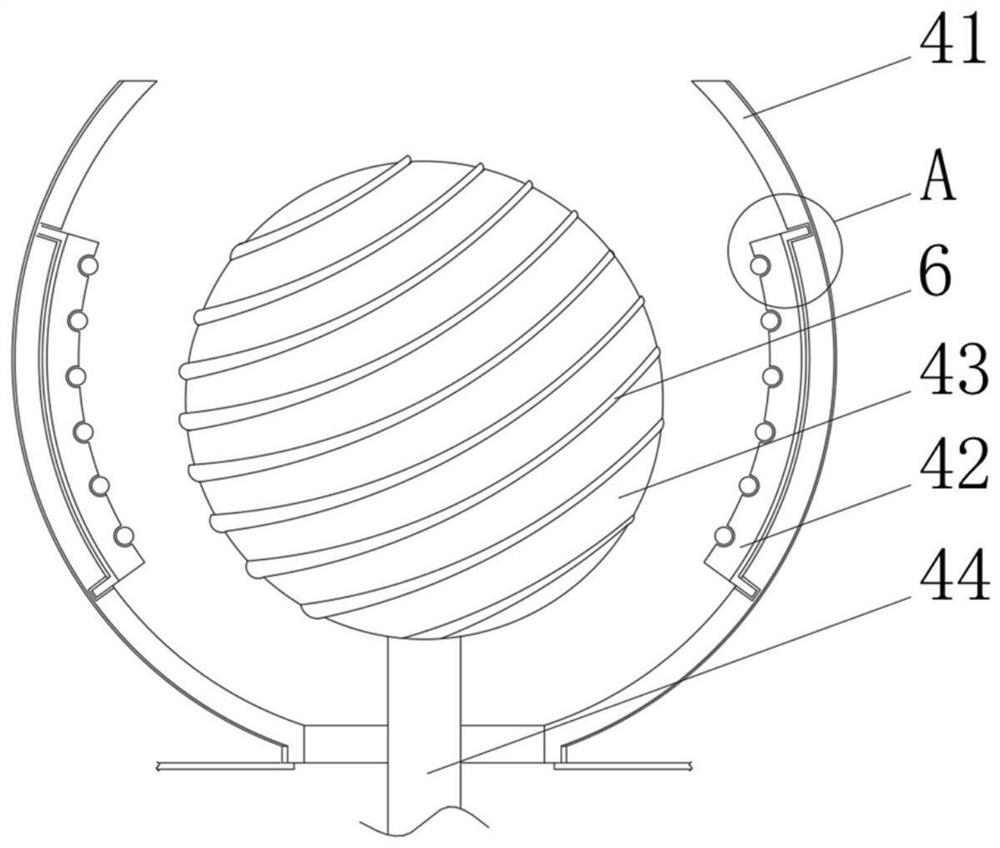

Tea rolling machine

PendingCN112841349AGood kneadingIncrease concentrationPre-extraction tea treatmentElectric machineryTea leaf

The invention discloses a tea rolling machine comprising a tea rolling machine body composed of a base, a motor, a rolling bin and a rolling cover, the top of the base is fixedly connected with the bottom of the motor, the top of the base is fixedly connected with the bottom of the motor through a support, and the top of the rolling bin is in threaded connection with the bottom of the rolling cover; the rolling bin comprises a spherical shell, a pressurizing mechanism is slidably connected to the interior of the spherical shell, a rolling device is arranged in the spherical shell, and a bearing rod is fixedly connected to the bottom of the rolling device. The invention relates to the technical field of tea processing. The tea leaf rolling machine solves problems that in the tea leaf processing process, manual rolling is carried out in a generally small workshop, the labor intensity is greatly increased, the efficiency is low, tea leaf veins are not uniformly rolled into strips, tea leaf cells are not fully broken, and the color and the quality of tea leaves are influenced in the rolling process of a common rolling machine.

Owner:张元德

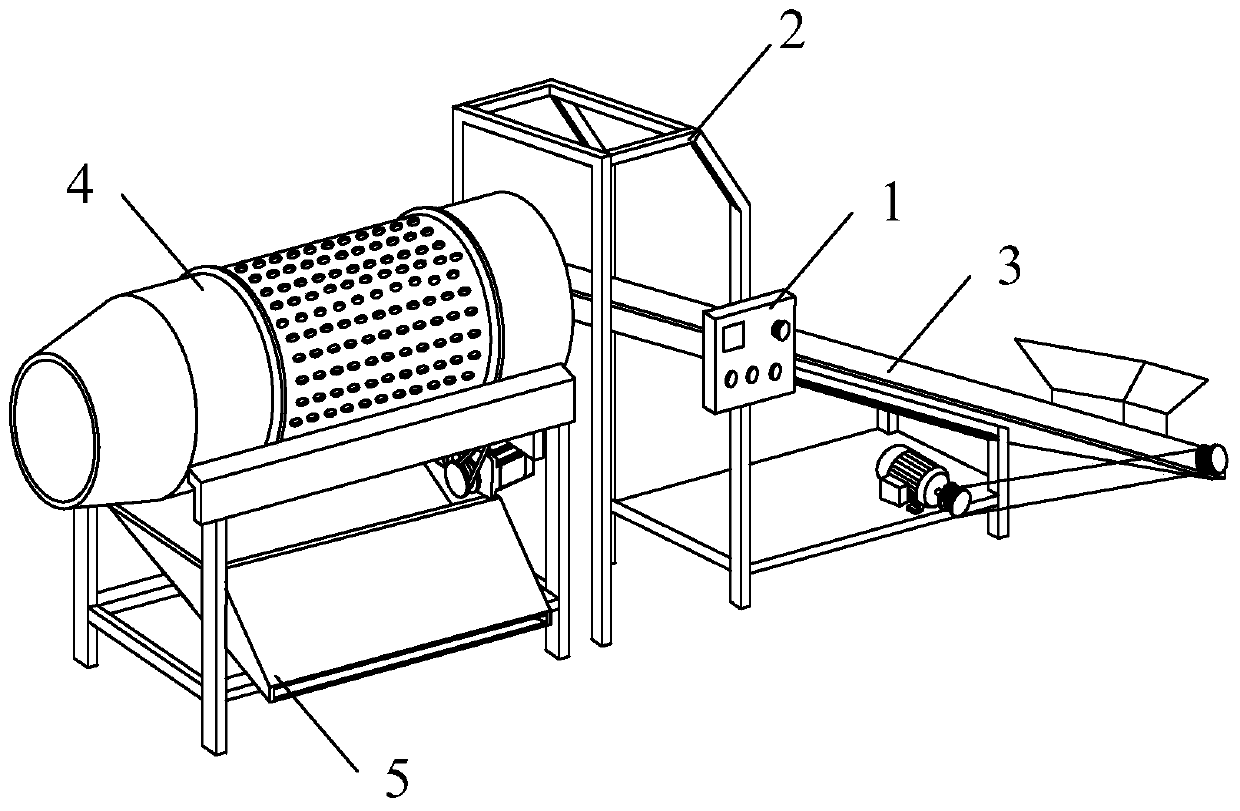

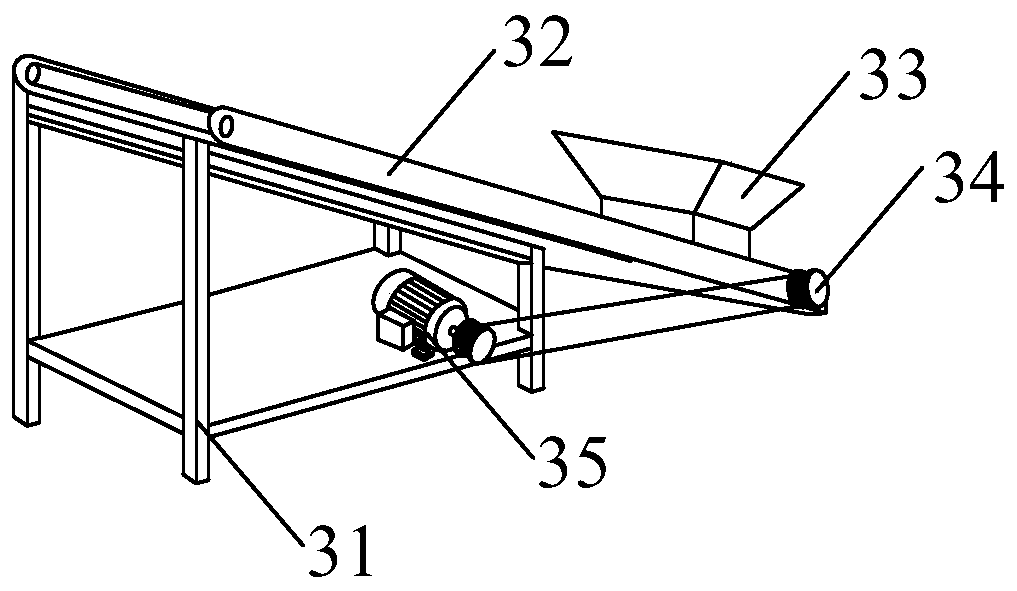

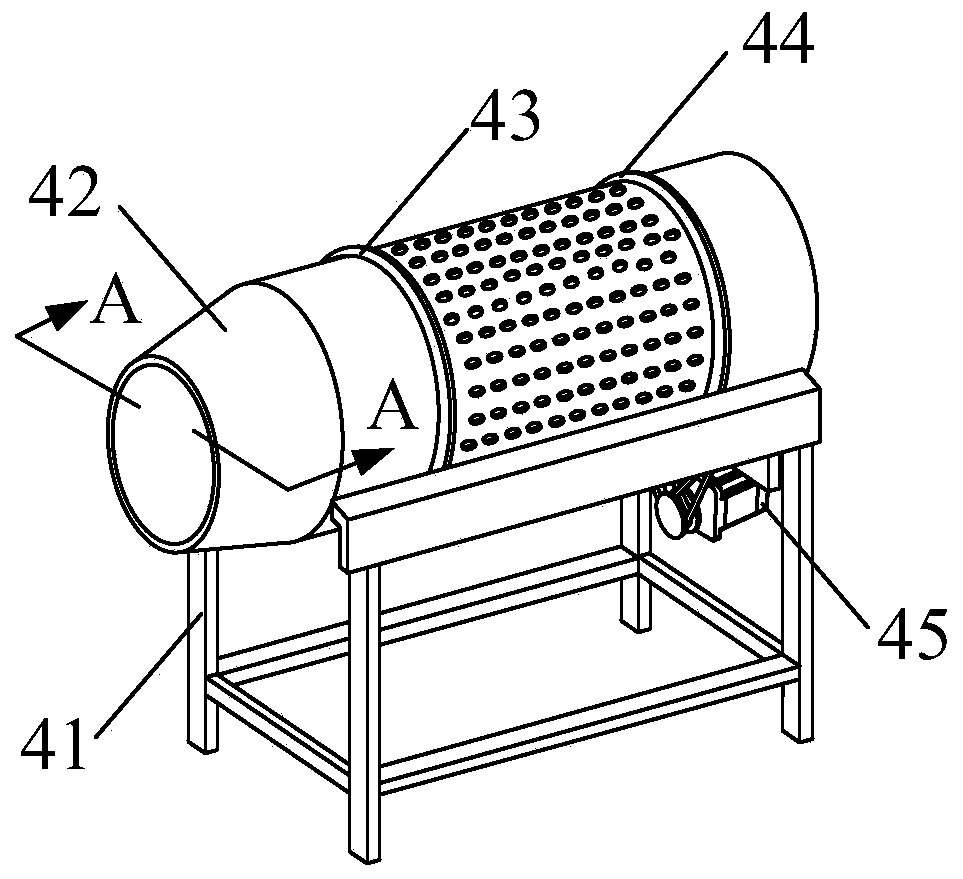

Drum type rice screening device

InactiveCN111389702AImprove feeding efficiencyIncrease the number of flipsSievingConveyorsAgricultural engineeringAgricultural science

The invention discloses a drum type rice screening device. The drum type rice screening device comprises a control cabinet, a support body, a feeding mechanism, a drum rice screening mechanism and a residue collecting cover. Through the arrangement of the feeding mechanism, when rice is screened, a servo motor drives a conveyor to act through a belt and belt wheels, the rice is poured into a hopper, the rice is conveyed into a drum through the conveyor, streamlined operation is achieved, the trouble of manual feeding and discharging is saved, and the feeding efficiency is effectively improved;through the arrangement of the drum rice screening mechanism, a rolling assembly drives a gear ring to rotate, a sliding ring and a bottom frame slidingly rotate, the drum rotates, and therefore therice is screened; and through the arrangement of the drum, as the drum is inclined, the flow rate of the rice in the drum can be reduced through partitions, the overturning frequency of the rice in the drum is increased, thus, better screening is achieved, then the rice is left in the drum, and impurities and disintegrating residues fall into the residue collecting cover through through holes in the drum.

Owner:赵明亮

a bi 1‑x re x fe 1‑y tm y o 3 /cofe 2 o 4 Multiferroic composite film and preparation method thereof

ActiveCN104575907BImprove ferroelectric propertiesReduce volatilityInorganic material magnetismInductances/transformers/magnets manufactureComposite filmNanotechnology

The invention provides a Bi1-xRExFe1-yTMyO3 / CoFe2O4 multiferroic composite film and a preparation method thereof. The composite film comprises a Bi1-xRExFe1-yTMyO3 crystalline film and a CoFe2O4 crystalline film which are compounded together. The preparation comprises the following steps: firstly preparing Bi1-xRExFe1-yTMyO3 precursor solution and CoFe2O4 precursor solution respectively; then spin-coating to prepare a plurality of layers of CoFe2O4 films on a substrate; next preparing a plurality of layers of Bi1-xRExFe1-yTMyO3 films on the CoFe2O4 films through spin coating to obtain a target product. The equipment requirement is simple, the prepared film is good in uniformity, chemical components are accurate and controllable, the doping content is easy to control, and the ferroelectric property and the ferromagnetic property of the film are greatly improved, and the film has high residual polarization value and residual magnetization value.

Owner:SHAANXI UNIV OF SCI & TECH

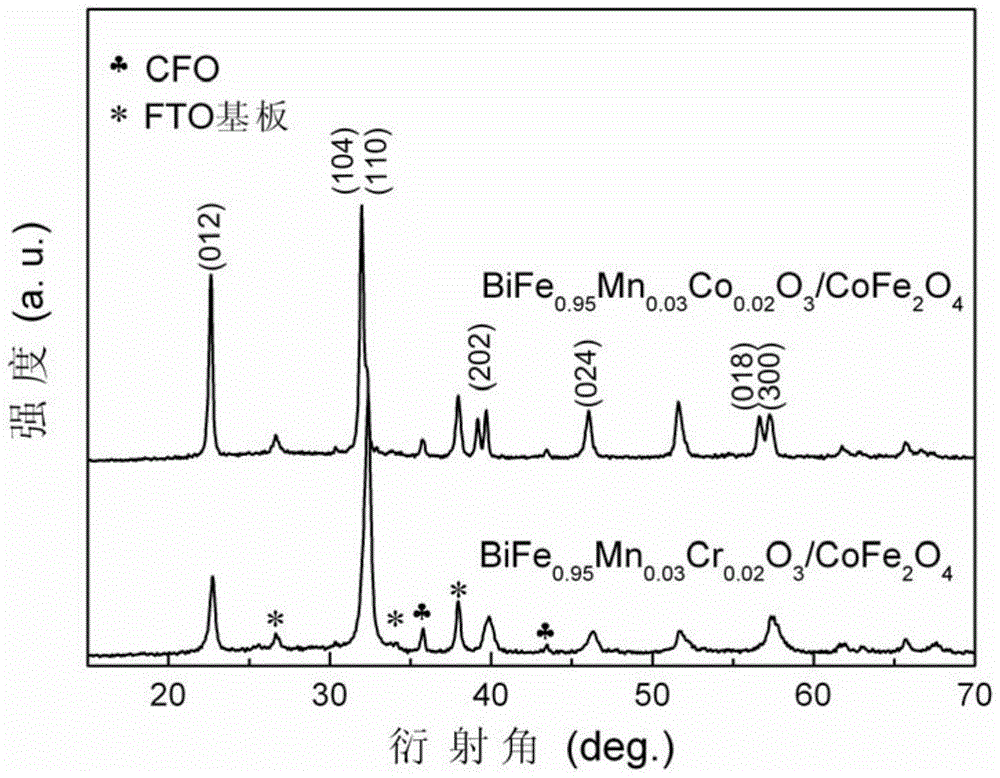

a laminated bife 0.97-x mn 0.03 tm x o 3 /cofe 2 o 4 Multiferroic composite film and preparation method thereof

ActiveCN104476832BImprove multiferroic propertiesHigh saturation magnetizationLaminationLamination apparatusComposite filmNanotechnology

The invention provides a laminated BiFe(0.97-x)Mn0.03TMxO3 / CoFe2O4 multiferroic composite film and a preparation method thereof. The composite film comprises a BiFe(0.97-x)Mn0.03TMxO3 / CoFe2O4 crystallized film and a CoFe2O4 crystallized film which are compounded together. The preparation method comprises the following steps of firstly, preparing a BiFe(0.97-x)Mn0.03TMxO3 / CoFe2O4 precursor solution and a CoFe2O4 precursor solution respectively; and then carrying out spin coating on a substrate to prepare a multi-layer CoFe2O4 film, and then carrying out spin coating on the CoFe2O4 film so as to prepare a multi-layer BiFe(0.97-x)Mn0.03TMxO3 / CoFe2O4 film, thereby obtaining the target product. According to the invention, the equipment requirement is simple; the prepared film is good in uniformity; chemical components are accurate and controllable; the doped amount is easy to control; the ferroelectric properties and the ferromagnetic property of a film are improved greatly, so that the film has high residual polarization value and a residual magnetization value.

Owner:SHAANXI UNIV OF SCI & TECH

A bifeo3 thin film with high remnant polarization intensity co-doped with b-site mn and ni and its preparation method

ActiveCN103626236BImprove multiferroic propertiesPromote productionIron compoundsMANGANESE ACETATEAcetic anhydride

The invention discloses a B-site Mn and Ni co-doped high-remanent-polarization BiFeO3 film and a preparation method thereof. The preparation method comprises the following steps: dissolving bismuth nitrate, ferric nitrate, manganese acetate and nickel acetate according to a molar ratio of 1.05:[(0.92-0.98)-x]:(0.02-0.08):x in a mixed solution of ethylene glycol monomethyl ether and acetic anhydride, uniformly stirring to obtain a BiFeO3 precursor solution, wherein the total metal ion concentration in the BiFeO3 precursor solution is 0.1-0.5mol / L, and x is equal to 0.01 to 0.03; spin coating the BiFeO3 precursor solution on a FTO / glass substrate to prepare a wet film, baking the wet film to obtain a dried film, annealing at the temperature of 550 DEG C for 8-13 minutes, thus obtaining a crystalline state BiFeO3 film; repeatedly operating until the BiFeO3 film reaches the needed thickness after the crystalline state BiFeO3 film is cooled, thus obtaining the B-site Mn and Ni co-doped high-remanent polarization BiFeO3 film. According to the method, a sol-gel process is adopted, the equipment requirement is simple, the method is suitable for preparing films on large surfaces and out-of-shape surfaces, the chemical constituents are accurately controlled, and the crystal structure is regulated through co-doping, so that the ferroelectric properties of the film are greatly improved.

Owner:SHAANXI UNIV OF SCI & TECH

Method for preparing BiFe1-xCrxO3 ferroelectric film by using sol-gel method

ActiveCN103121836BImprove ferroelectric propertiesIncreased structural distortionAcetic oxideCHROMIC NITRATE

Owner:盐城青墩津邦水务有限公司

A kind of blsfmc/cmfo thin film with resistive switching effect and preparation method thereof

ActiveCN109111127BImprove multiferroic performanceReduce leakage current densityPerovskite (structure)Resistive switching

The invention provides a BLSFMC / CMFO film with a resistance switching effect and a preparation method thereof, comprising an upper film and a bottom film compounded together; the chemical formula of the bottom film is Co 1‑ x mn x Fe 2 o 4 , which is a twisted cubic inverse spinel structure, the space group is Fd3m; the chemical formula of the upper layer is Bi 0.79 La 0.18 Sr 0.03 Fe 0.94 mn 0.04 co 0.02 o 3 , which is a distorted rhombohedral perovskite structure, space group R3c; wherein, x=0˜0.8. It is prepared by sol-gel method and layer-by-layer annealing process. The present invention through the BiFeO 3 Doping the thin film improves the ferroelectric properties, by doping BiFeO 3 Thin film composite CoFe 2 o 4 The magnetic layer realizes the resistive switching effect of the ferroelectric / ferromagnetic composite thin film regulated by ferroelectric polarization.

Owner:SHAANXI UNIV OF SCI & TECH

a bi 1‑x re x feo 3 /cofe 2 o 4 Multiferroic composite film and preparation method thereof

ActiveCN104538139BImprove multiferroic propertiesReduce volatilityInorganic material magnetismInductances/transformers/magnets manufactureCrystallographyMultilayer membrane

The invention provides a Bi1-xRExFeO3 / CoFe2O4 multiferroic composite membrane and a preparation method thereof. The composite membrane comprises a Bi1-xRExFeO3 crystalline state membrane and a CoFe2O4 crystalline state membrane which are combined together, wherein RE is Ce, Pr, Tb, Eu or Yb, x is equal to 0.05-0.15; in the preparation, Bi1-xRExFeO3 precursor solution and CoFe2O4 precursor solution are firstly prepared respectively; and then, multi-layer CoFe2O4 membrane is prepared by spinning on a substrate, and the multi-layer Bi1-xRExFeO3 membrane is prepared by spinning on the CoFe2O4 membrane, so the target product is obtained. The facility request is simple, the homogeneity of the prepared membrane is good, the chemical composition can be accurately controlled, the doping content is easily controlled, and the ferroelectric property and ferromagnetic property of the membrane are greatly improved, so the Bi1-xRExFeO3 / CoFe2O4 multiferroic composite membrane has high residual polarization value and residual magnetization value.

Owner:SHAANXI UNIV OF SCI & TECH

A kind of Ganoderma lucidum spore powder breaking device

Owner:安徽黄山云乐灵芝有限公司 +1

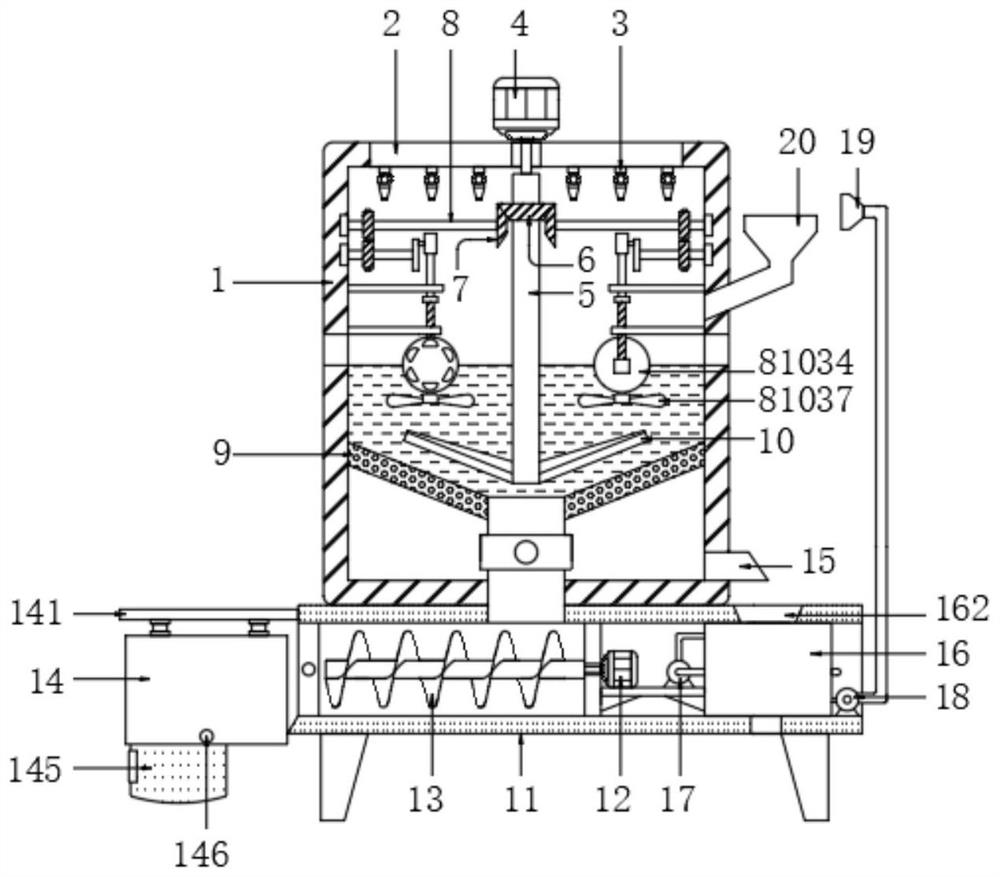

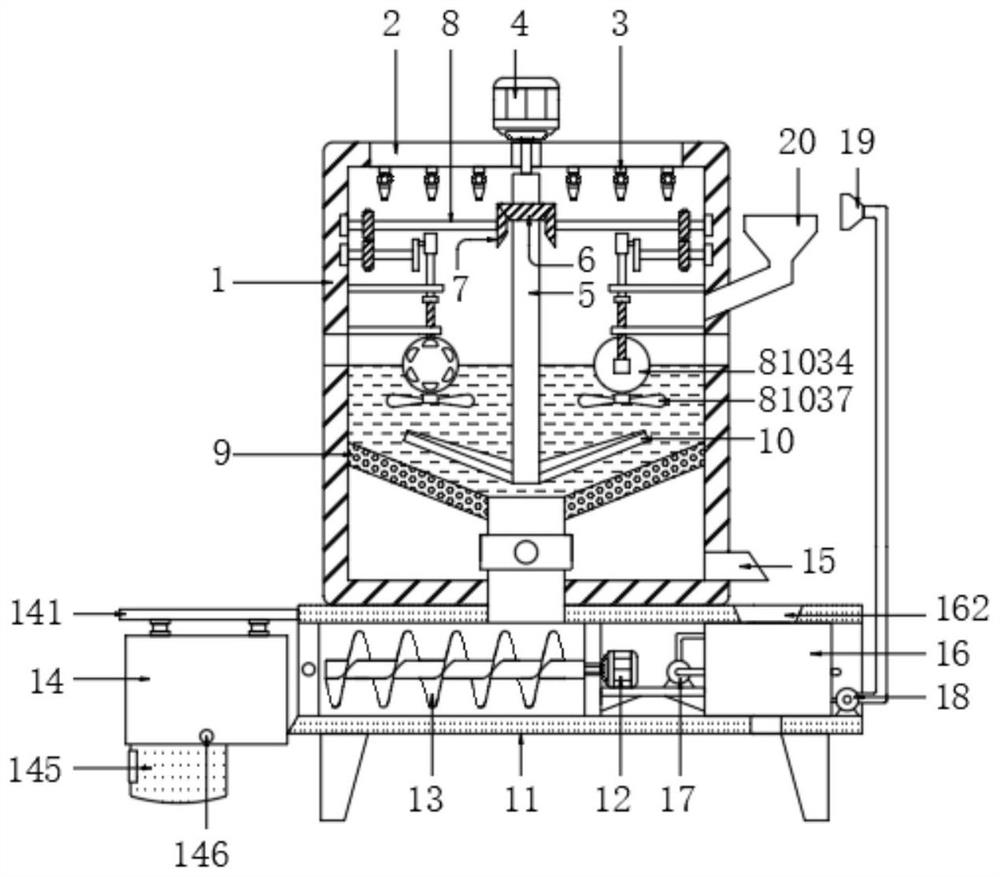

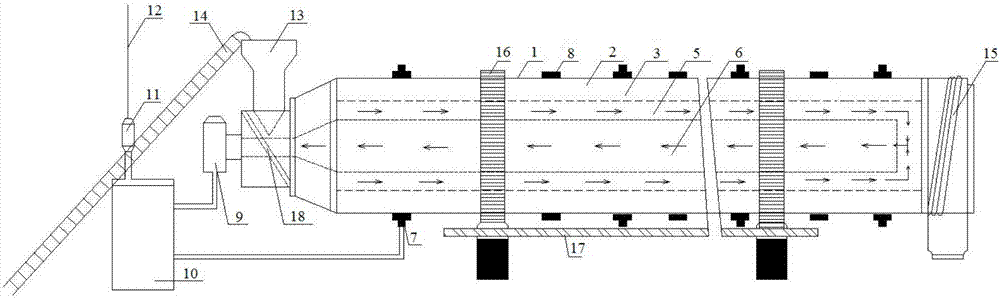

Activated carbon activation furnace and activated carbon production method

ActiveCN106430191BIncrease production capacityImprove qualityCarbon compoundsActivated carbonFlue gas

An activated-carbon activation furnace and an activated-carbon production method, which relate to the field of activated-carbon production devices and activated-carbon production technologies. The safety of an activated-carbon production process can be improved to a certain extent, the activation furnace can stably work for a long time, and the quality and the productive capacity of produced activated carbon can be greatly improved. The activated-carbon activation furnace comprises a furnace body, a material entry device (13), and a material discharge mechanism (15). A burning passage (6) communicating with the inside of the furnace body is disposed in the furnace body. Air is introduced in the burning passage (6). The inside of the furnace body is in a negative-pressure state, and the air pressure in the burning passage (6) is lower than that in the furnace body. The activated-carbon production method comprises the following steps: step A, arranging a burning passage (6) and material passages (5); step B, introducing steam into the material passages (5); step C, introducing evolved gas in the material passages (5), into the burning passage (6); step D, heating materials in the material passages (5); and step E, introducing flue gas generated in burning into a steam generator (10) for heat exchange. The activated-carbon activation furnace and the activated-carbon production method are mainly used for activated carbon production.

Owner:张西进

An integrated cleaning and cooking device and method for controlled rice processing

ActiveCN112246742BQuality improvementImprove efficiencyCombination devicesFood thermal treatmentAgricultural engineeringBevel gear

The invention discloses an integrated rice cleaning and cooking device and method in the field of rice processing technology. The bottom of the cleaning plate is evenly provided with cleaning nozzles, and the cleaning nozzles are all located inside the cleaning box. The middle part of the top of the cleaning plate is fixedly connected with a servo motor, and the power shaft at the bottom of the servo motor is provided with a rotating shaft, and the rotating shaft is located Inside the cleaning box, the rotating shaft is sleeved with a driving bevel gear, and both sides of the driving bevel gear are meshed with driven bevel gears, and the two sets of driven bevel gears are connected with cleaning components, and the rotating shaft rotates It can drive the fixed cover to rotate positively and negatively alternately, and then make the vertical rod drive the blades to rotate positively and negatively alternately, so that the blades can assist the stirring rod, increase the number of times the rice is turned, and further improve the efficiency of rice washing.

Owner:武汉什湖知音粮油食品有限公司

a multiferroic bi 1‑x re x fe 0.97‑y mn 0.03 tm y o 3 /cofe 2 o 4 Composite film and preparation method thereof

ActiveCN104538140BImprove multiferroic propertiesImprove ferroelectric propertiesInorganic material magnetismInductances/transformers/magnets manufactureMultilayer membraneComposite film

The invention provides a multiferroic Bi1-xRExFe0.97-yMn0.03TMyO3 / CoFe2O4 composite film and a preparation method thereof. The composite film comprises a Bi1-xRExFe0.97-yMn0.03TMyO3 crystalline state film and a CoFe2O4 crystalline state film. The preparation method comprises the following steps of respectively preparing Bi1-xRExFe0.97-yMn0.03TMyO3 precursor solution and CoFe2O4 precursor solution; spin coating on a substrate to prepare a plurality of layers of CoFe2O4 films, spin coating on the CoFe2O4 films to prepare a plurality of layers of Bi1-xRExFe0.97-yMn0.03TMyO3 films and accordingly obtaining a target product. According to the multiferroic Bi1-xRExFe0.97-yMn0.03TMyO3 / CoFe2O4 composite film and the preparation method thereof, the device requirement is simple, the prepared film is good in homogeneity, the doping content is easy to control, the ferroelectric property and the ferromagnetic property of the film are improved to a large extent, and the film is high in residual polarization value and residual polarization value.

Owner:SHAANXI UNIV OF SCI & TECH

Method for washing woolen clothes by washing machine and washing machine

ActiveCN107663738BIncrease the number of flipsImprove cleaning rateOther washing machinesTextiles and paperLaundry washing machineWater flow

The invention relates to a method for washing woolen clothes and a washing machine. The washing machine includes a pulsator, the water is fed to the preset water level, and the washing is started. During the washing process, the pulsator performs washing at different turn-to-stop ratios, including the following steps: the first washing process, controlling the pulsator to rotate at the first turn-to-stop ratio for fast washing For woolen clothes, the rotation time in the turn-stop cycle is greater than the stop-rot time; the second washing process, the wave wheel is controlled to rotate and wash clothes with the second turn-stop ratio, and the rotation time in the turn-stop cycle is less than the stop time; the second washing process includes Laundry process and rinse process. In the first washing process, the water flow speed rotates faster, which can fully stir the woolen clothes and improve the washing rate of the woolen clothes. The second washing process takes a long time to stop and reduce the shrinkage rate. The washing machine provided by the invention can reduce the friction between the woolen clothes, the inner tub and the pulsator during the washing process, reduce the shrinkage rate of the woolen clothes, and the pulsator rotates periodically to improve the washing rate.

Owner:CHONGQING HAIER WASHING MASCH CO LTD +1

B-site Mn and Cu codoped high remanent polarization BiFeO3 film and preparation method

ActiveCN103613144BImprove multiferroic propertiesPromote productionFrom gel stateMANGANESE ACETATEAcetic anhydride

The invention relates to a B-site Mn and Cu codoped high remanent polarization BiFeO3 film and a preparation method, the method comprises the following steps: dissolving bismuth nitrate, ferric nitrate, manganese acetate and cupric nitrate according to mol ratio of 1.05: [(0.92-0.98)-x]: (0.02-0.08):x in a mixed liquor of ethylene glycol monomethyl ether and acetic anhydride, then uniformly stirring to obtain a BiFeO3 precursor; wherein total metal ion concentration of the BiFeO3 precursor is 0.1-0.5mol / L, X is 0.01-0.03; performing spin coating of the BiFeO3 precursor on a FTO / glass substrate to prepare a wet membrane, baking the wet membrane to obtain a dry membrane, then annealing at 550 DEG C to obtain the crystalline state BiFeO3 film; cooling the crystalline state BiFeO3 film, and repeatedly making the crystalline state BiFeO3 film to reach a required thickness to obtain the B-site Mn and Cu codoped high remanent polarization BiFeO3 film. According to the invention, a sol gel technology is employed, the equipment requirement is simple, the film is prepared on large surface and surfaces with irregular shapes, the chemical component is accurate and controllable, and the regulation and control to its crystal structure can be carried out by codoping thereby the ferroelectric performance of the film is greatly increased.

Owner:盐城梦心缘鞋服有限公司

Furnace body of activated carbon activation furnace

ActiveCN106276889BIncrease the number of flipsFlip fullCarbon compoundsRotary drum furnacesActivated carbonMetallurgy

A furnace body for an activated-carbon activation furnace, which relates to the field of activated-carbon production devices. A burning passage (6) communicating with the inside of the furnace body is disposed in the furnace body. Air is introduced in the burning passage (6). At least two material passages (5) are formed in division of the furnace body, the material passages (5) are disposed along the length direction of the furnace body, and steam is introduced in each material passage (5). The furnace body comprises an outer cylinder (1). At least two sections of branch bin supporting members (4) are disposed along of the circumferential direction of the inner wall of the outer cylinder (1) to form the burning passage (6) in a surrounding manner. Adjacent two sections of branch bin supporting members (4), the inner wall of the outer cylinder (1) and the outer wall of the burning passage (6) define one material passage (5) in a surrounding manner. The safety of an activated-carbon production process can be improved to a certain extent, the furnace body can stably work for a long time, and the quality and the productive capacity of produced activated carbon can be greatly improved.

Owner:张西进

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com