Double-cylindered magnetite fine powder grade improver

A magnetite and double-barrel technology, which is applied in the field of double-barrel magnetite concentrate taste elevators, can solve the problems of adding multiple sets of magnetic separation mechanisms, the scraper cannot be efficiently separated, and the iron powder adsorption is not in place. Achieve the effect of uniform slurry distribution, efficient wet magnetic separation work, and increased contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

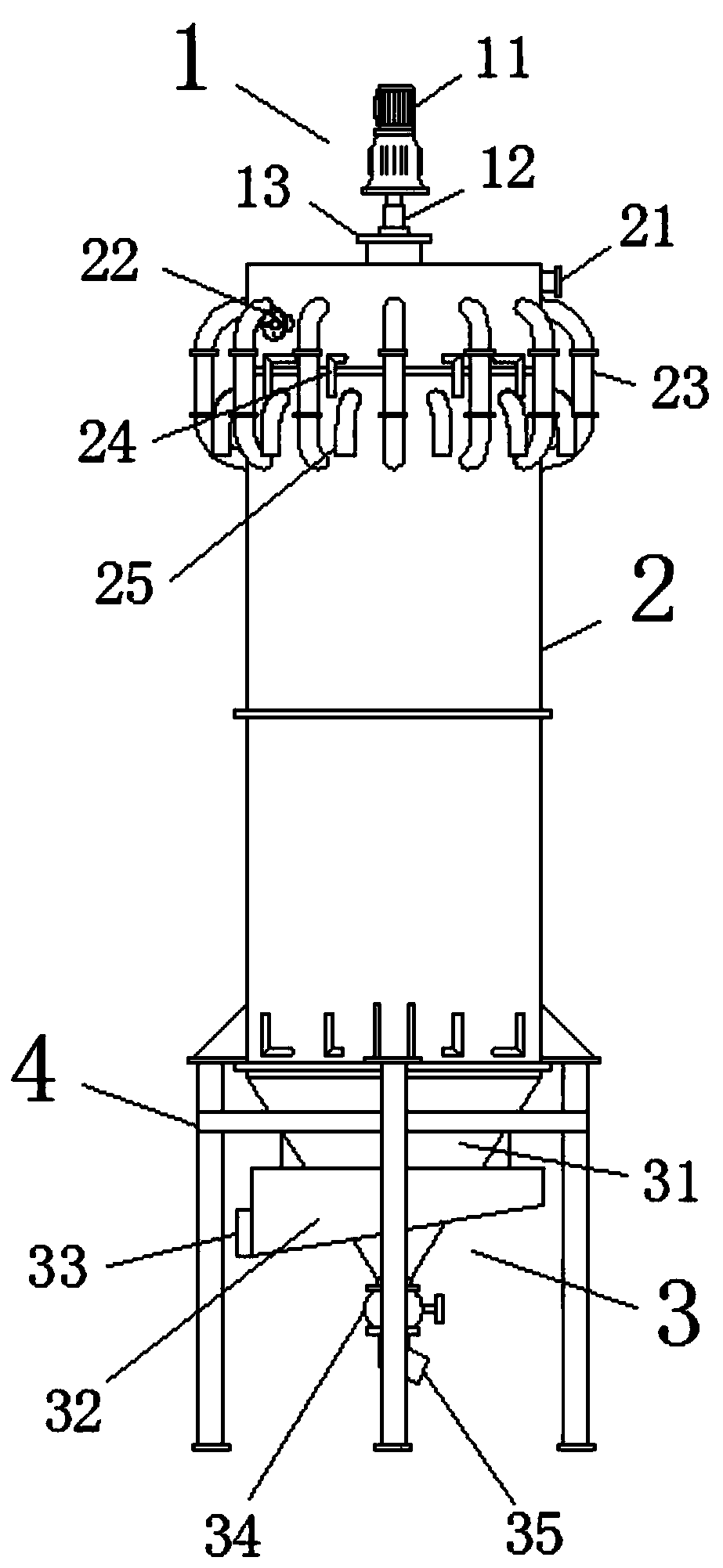

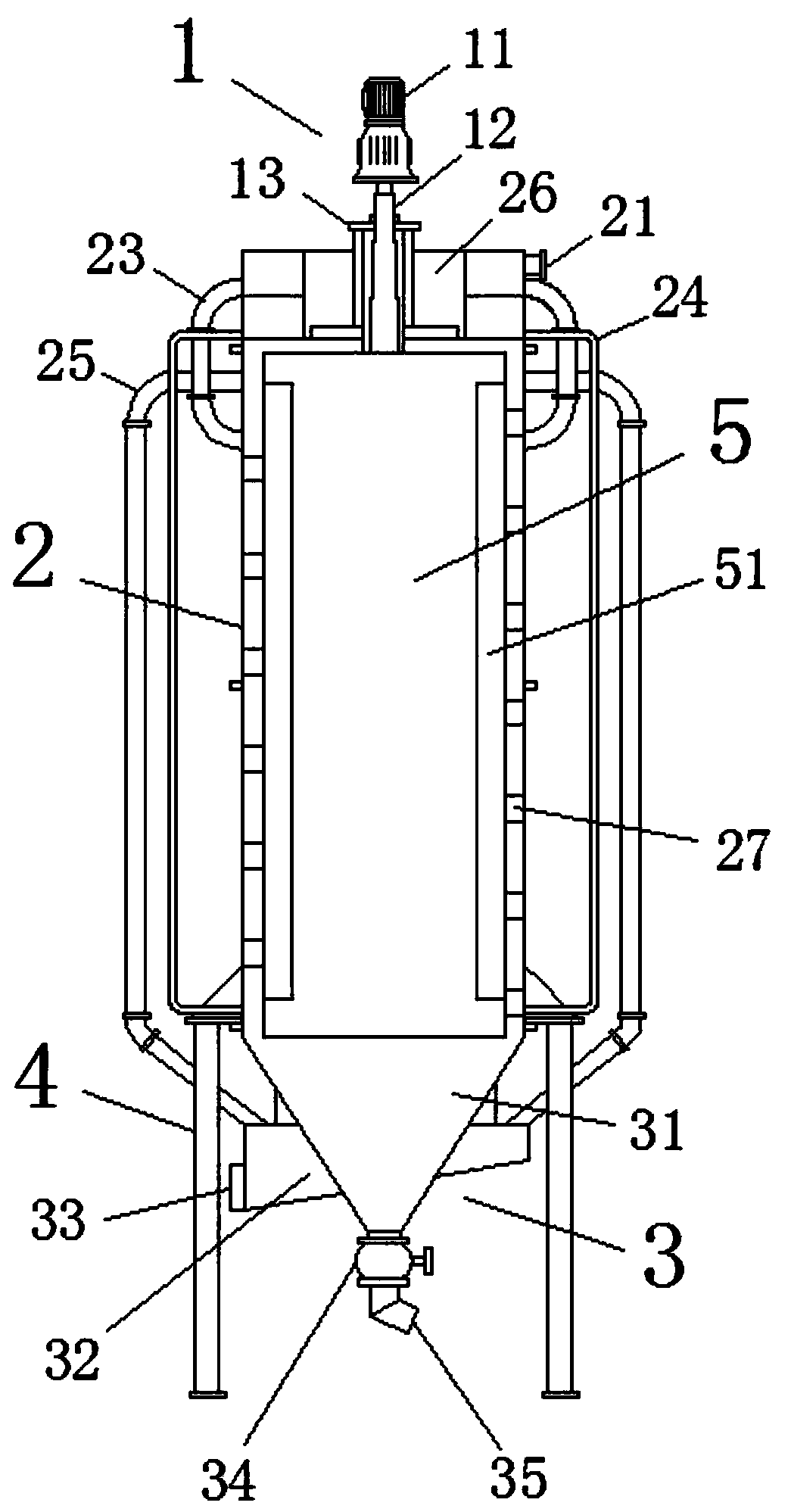

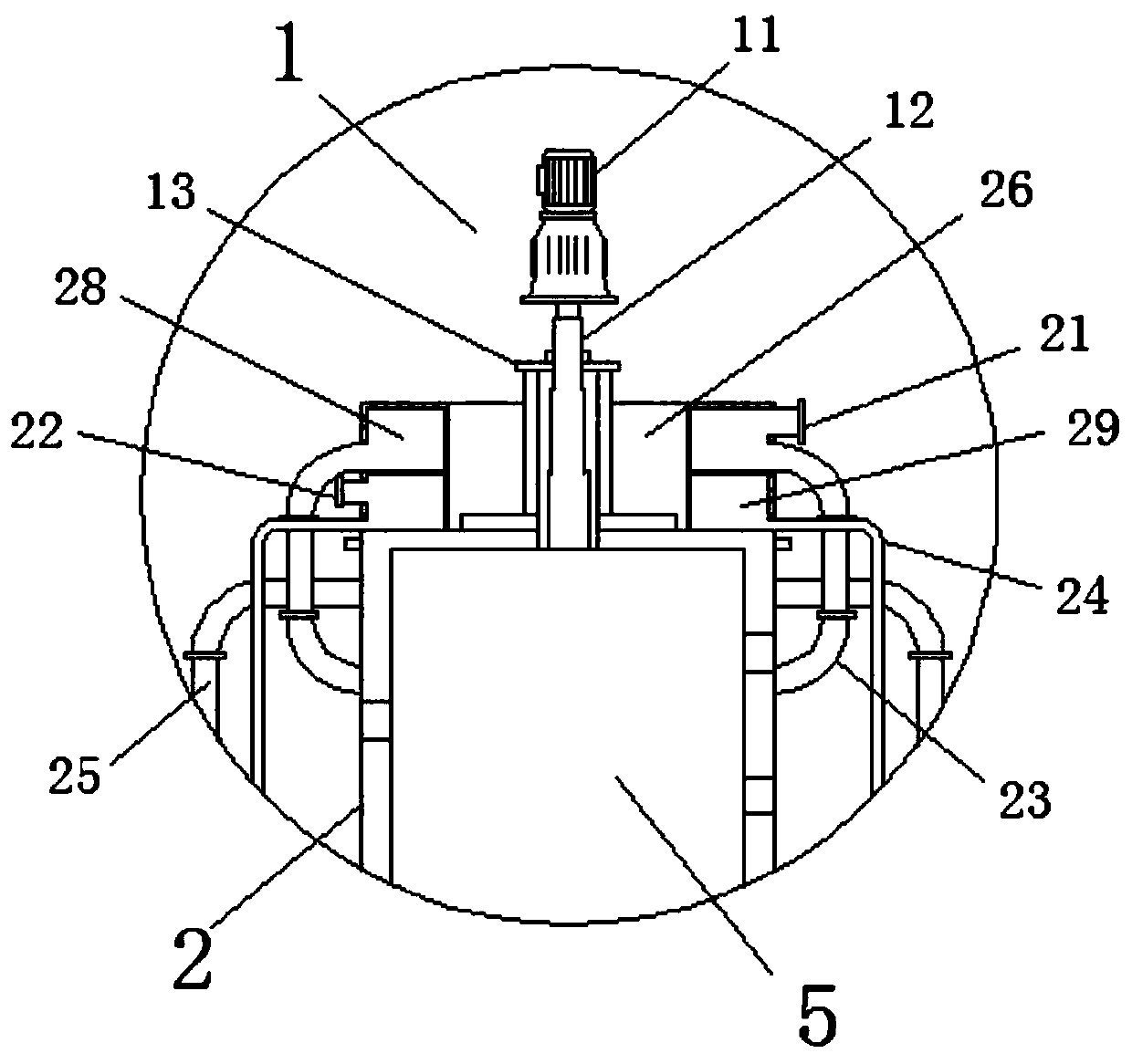

[0024] Such as Figure 1 to Figure 5 The shown double-tube type magnetite fine powder taste hoist is composed of a driving device 1, an outer cylinder 2, a discharge device 3, a support frame 4 and an inner cylinder 5. The upper surface of the outer cylinder 2 is provided with a ring-shaped partition A water dispenser 29, the upper end of the annular water distributor 29 is provided with an annular distributor 28, and the side surfaces of the annular distributor 28 and the annular water distributor 29 are respectively provided with a feed port 21 and a water inlet 22, The middle hollow part of the annular feeder 28 and the annular water distributor 29 and the top surface of the outer cylinder 2 form a groove 26, the groove 26 is installed with the bearing bracket 13 through the flange, and the drive shaft 12 is installed inside the bearing bracket 13 , the drive motor 11 is installed on the top of the transmission shaft 12, the inner cylinder 5 is installed on the lower end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com