Patents

Literature

37results about How to "Convenient for magnetic separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

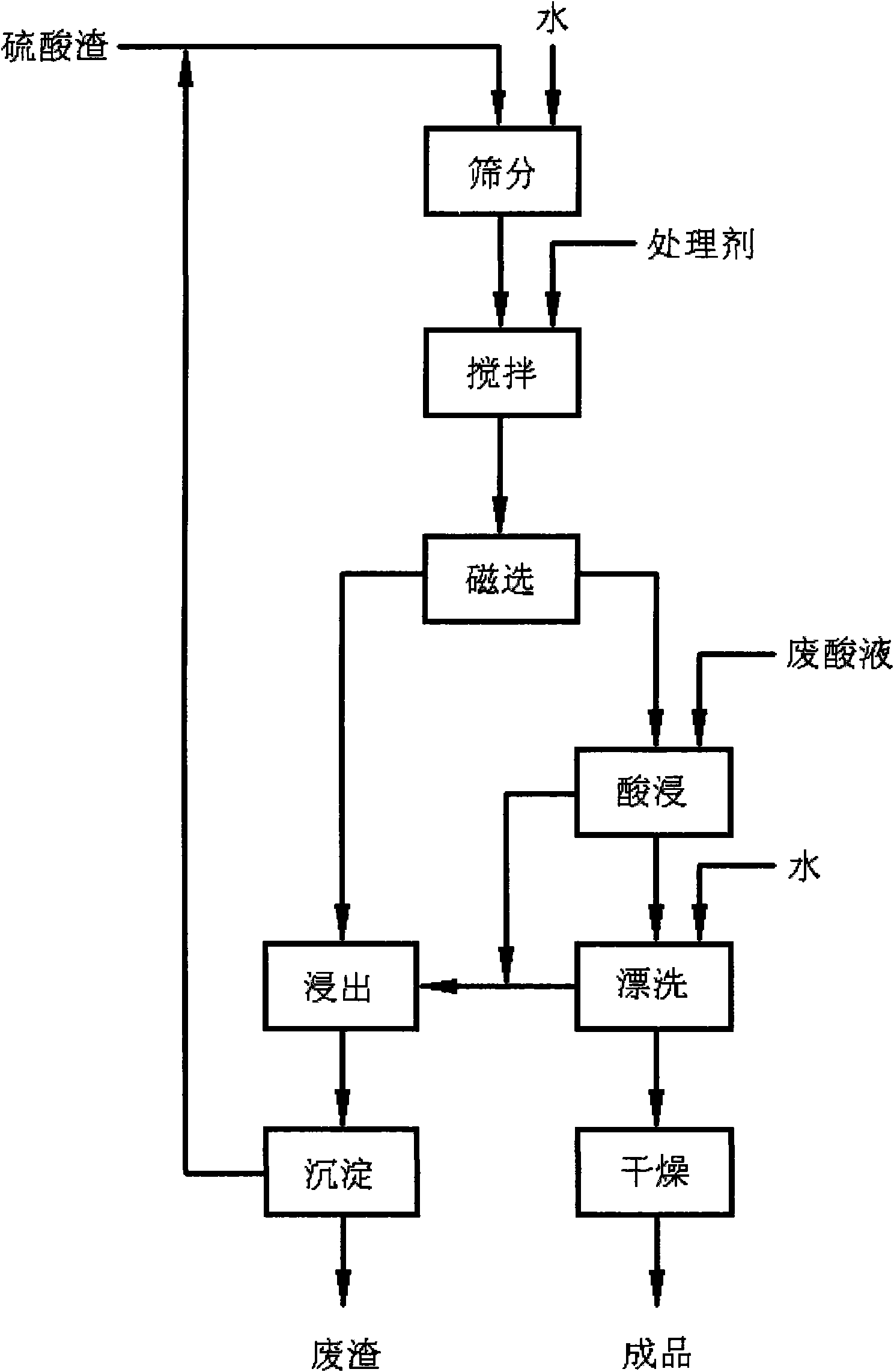

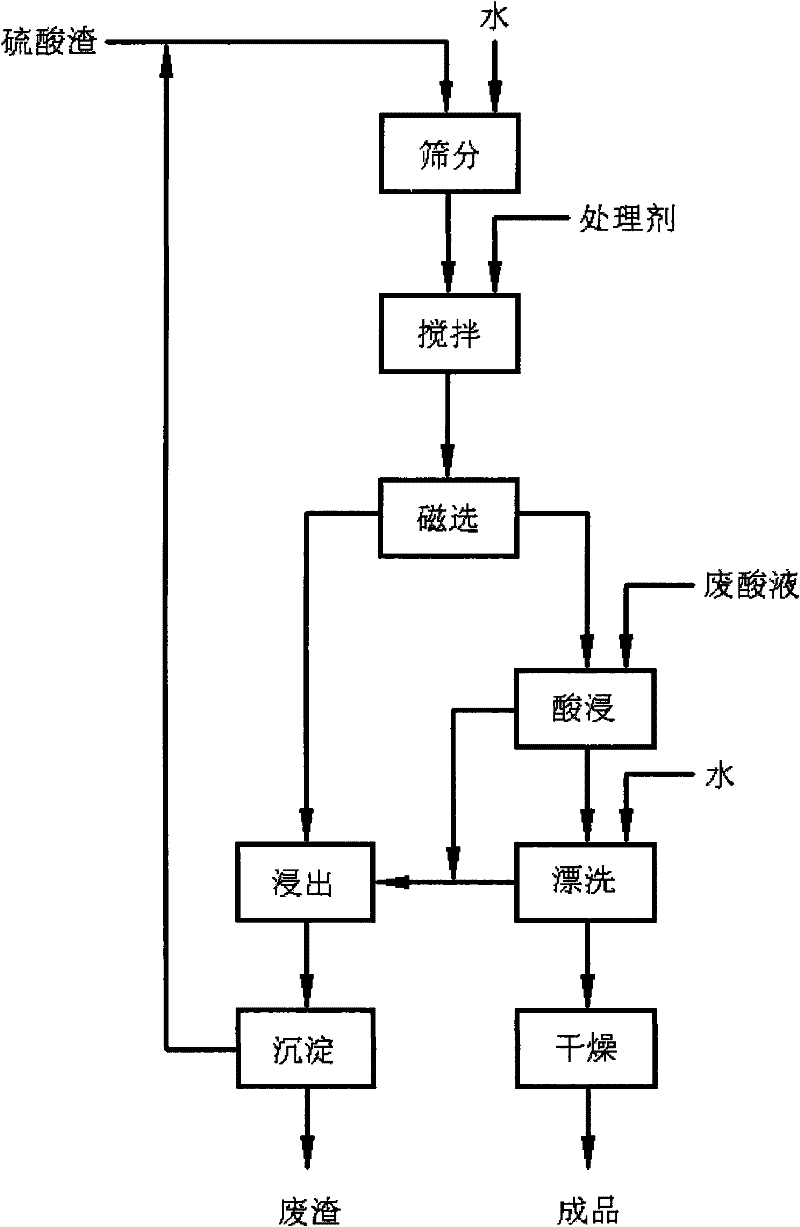

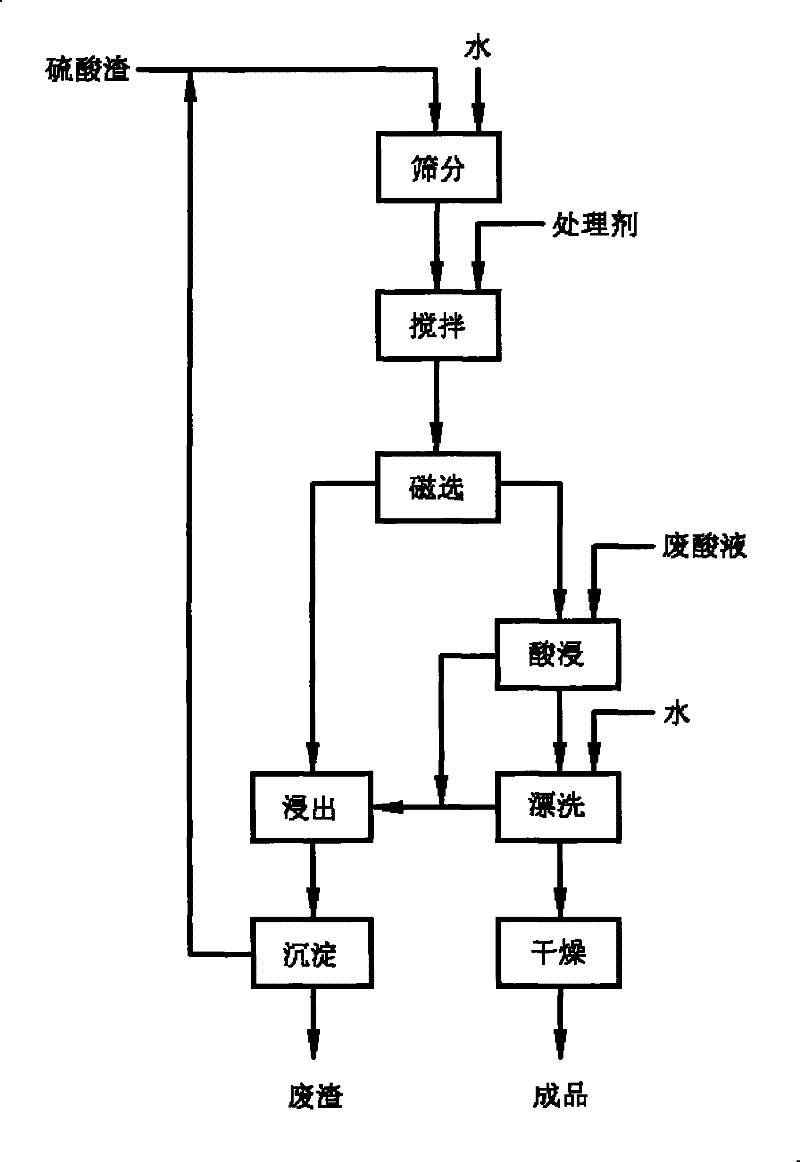

Method for recycling industrial waste sulfate slag

InactiveCN101554613ANo change in physical propertiesHigh recovery rateSolid waste disposalWet separationSocial benefitsSlag

The invention provides a method for recycling industrial waste sulfate slag, which comprises the steps of sieving, stirring, magnetic separation, acid dipping, rinsing and drying to obtain iron-bearing materials. The method not only reallocates the available resource of the sulfate slag which is difficult to be processed and has high pollution, but also reduces the severe contamination of the sulfate slag to the environment and simultaneously lowers the production cost greatly; the metal recovery rate is 50 to 82 percent, high quality iron concentrate with the grade of iron being larger than 60 percent, the grade of sulfur being smaller than 0.3 percent and the grade of arsenic being smaller than 0.1 percent is obtained; simultaneously the recovery processing capacity is large, the equipment is simple, the investment is small, the operation is convenient, the sulfate slag material is not limited, both the sulfate slag with high iron content and the sulfate slag with low iron content can be recycled, and the method has good social benefit and remarkable economic effect.

Owner:房志强 +1

Hot braising method for phosphorus removed slag and carbon removed slag

ActiveCN103397120AGood for turning overEasy to crushRecycling and recovery technologiesSlagEconomic benefits

The invention provides a hot braising method for phosphorus removed slag and carbon removed slag. The method comprises the following steps of: pouring hot phosphorus removed slag into a slag braising pit to parch the slag braising pit; pouring the phosphorus removed slag or the carbon removed slag into multiple parched slag braising pits respectively, turning over, dewatering and breaking the slag in each slag braising pit, then pouring another slag respectively, and repeating the operations of turning over, dewatering and breaking the slag till each slag braising pit is full of the slag; and covering the slag braising pits full of the slag with slag braising covers, and braising the slag in a three-section dewatering and braising mode. The hot braising method for the phosphorus removed slag and the carbon removed slag is simple and feasible, can reduce the potential safety hazard of blasting of the slag braising pits and effectively improve the slag braising efficiency and slag braising quality, and has remarkable economic benefits.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

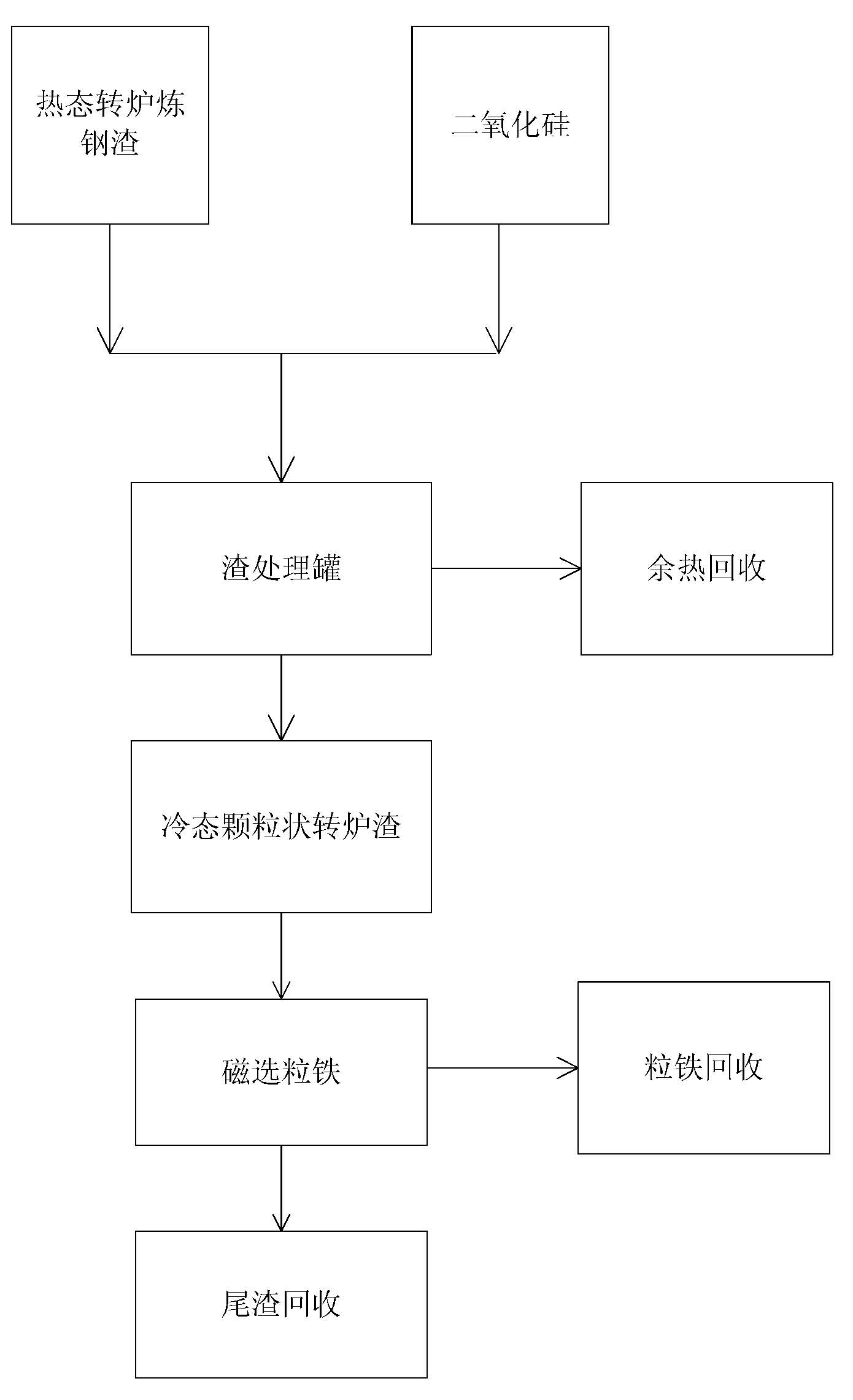

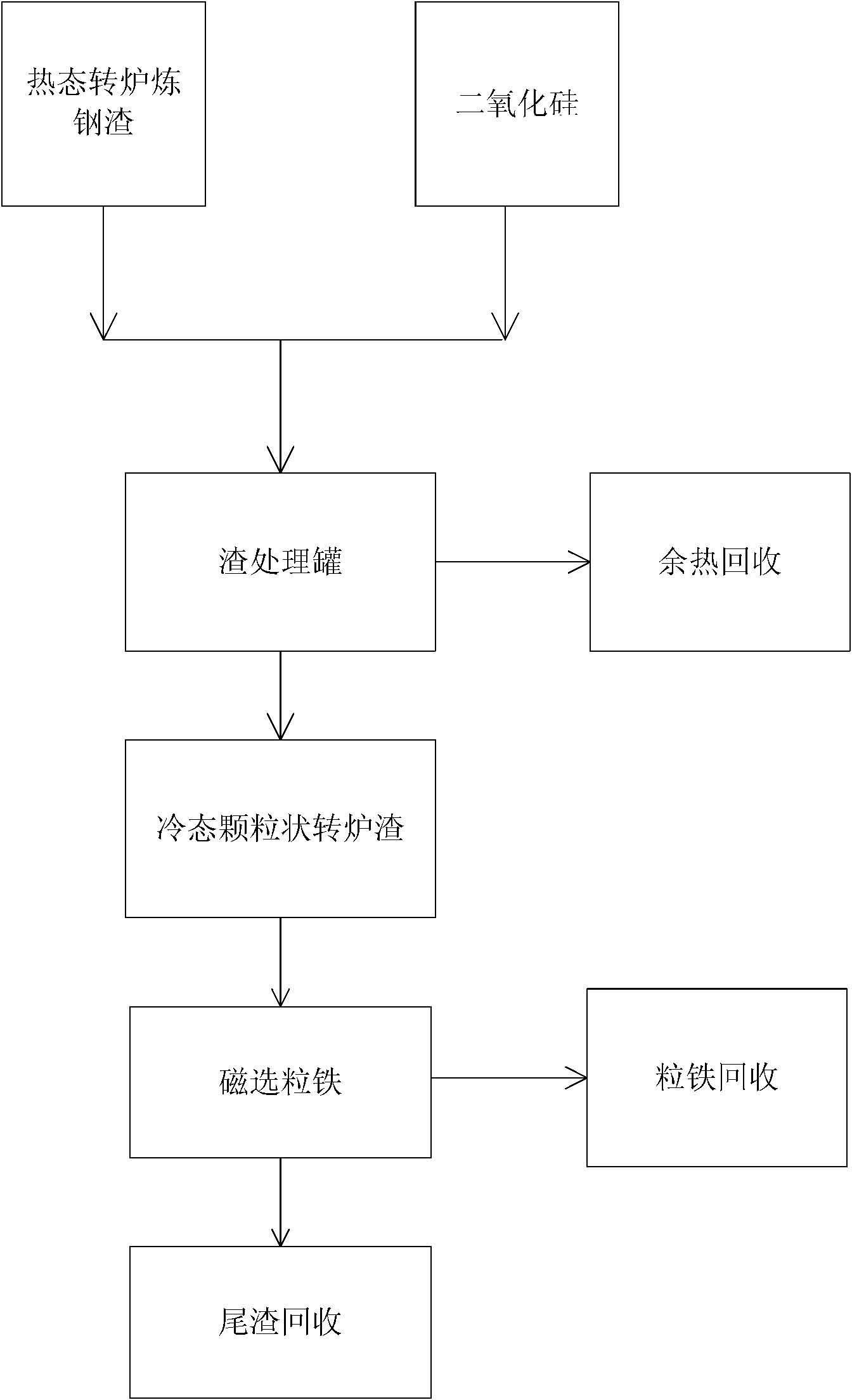

Method for processing convertor steelmaking slag

InactiveCN102534070AAchieve natural pulverizationUniform particle sizeRecycling and recovery technologiesSteelmakingVolume expansion

The invention relates to a method for processing convertor steelmaking slag. A raw material containing SiO2 is added into thermal convertor steelmaking slag, so that CaO in the convertor steelmaking slag generates 2CaO.SiO2 through a solid-phase reaction in a high temperature. The 2CaO.SiO2 generating crystal transformation and volume expansion in a cooling process of the convertor steelmaking slag is utilized to realize the natural pulverization of the convertor steelmaking slag, convertor slag with even grain sizes is obtained, and grained iron is magnetically separated. According to the technical scheme, the raw material containing the SiO2 is added into the convertor steelmaking slag in the high temperature, the crystal transformation and the volume expansion of the 2CaO.SiO2 in the cooling process of the convertor steelmaking slag are utilized to realize the natural pulverization of the convertor steelmaking slag, the convertor slag with even grain sizes is obtained, the grained iron is magnetically separated, tailings are recovered, and large amounts of heat energy of high-temperature convertor steelmaking slag in the cooling process are recovered.

Owner:WISDRI ENG & RES INC LTD

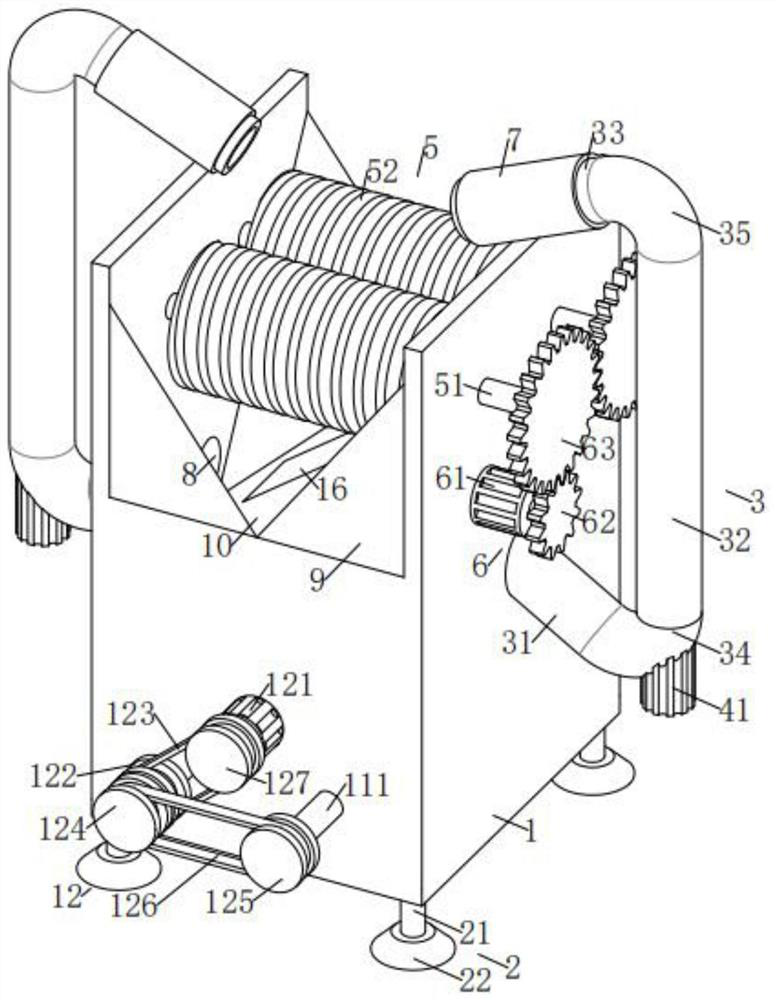

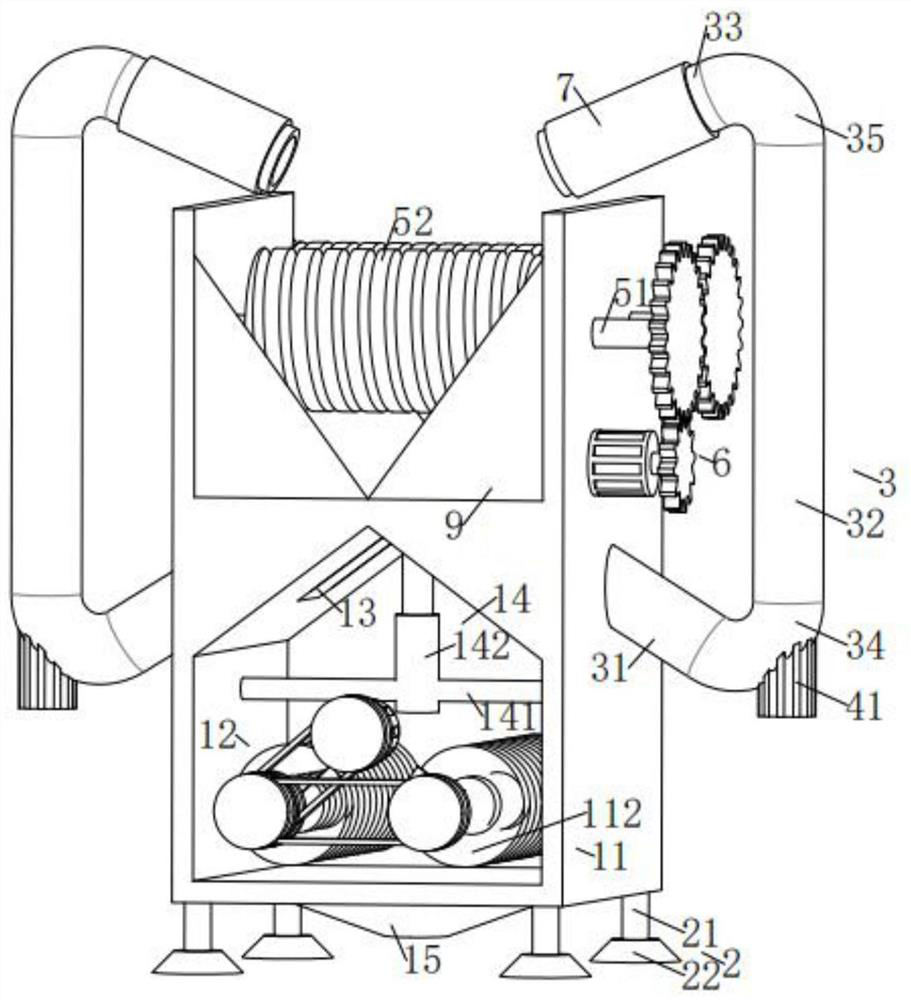

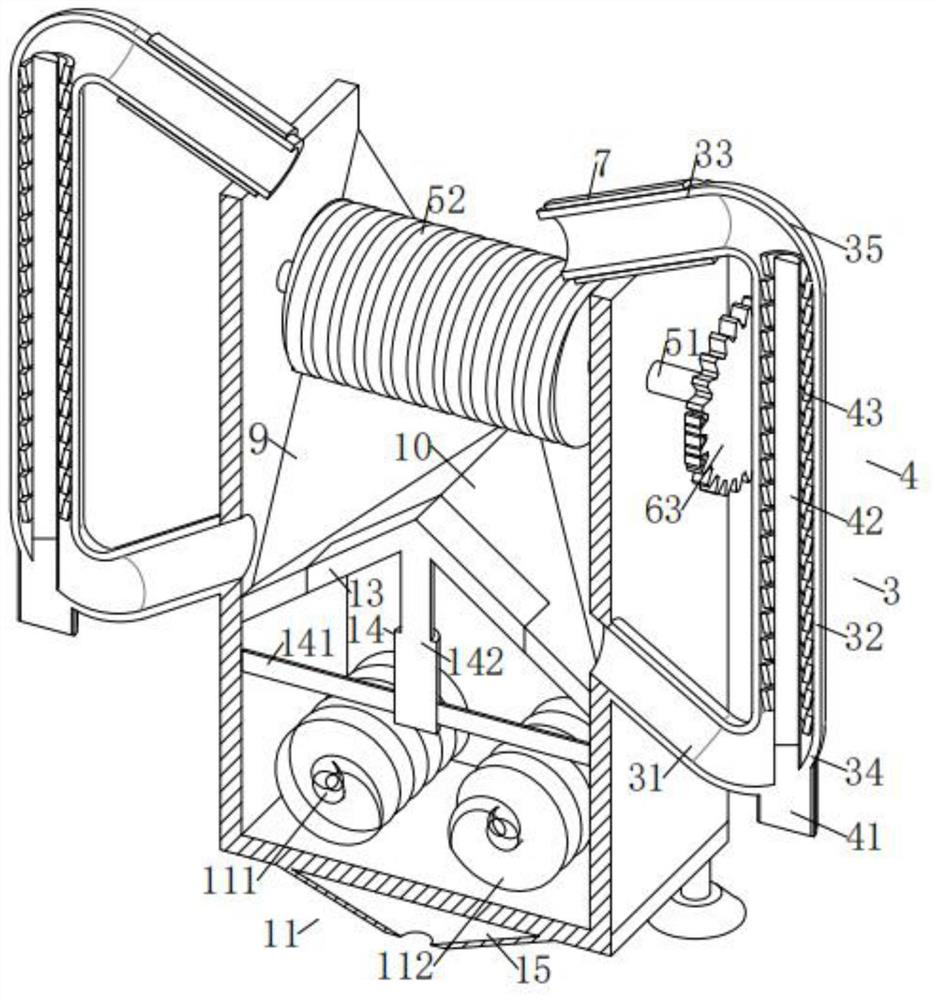

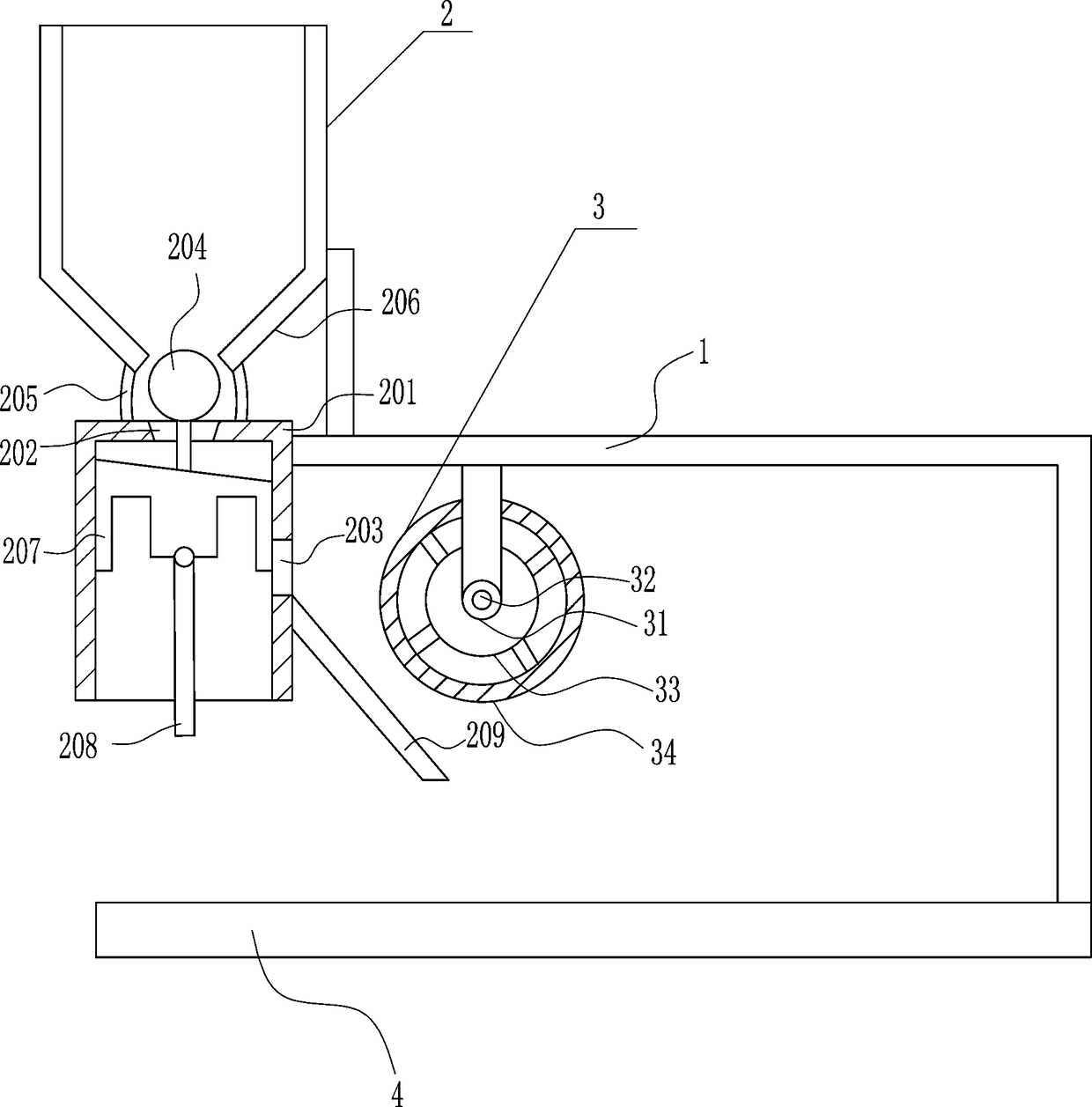

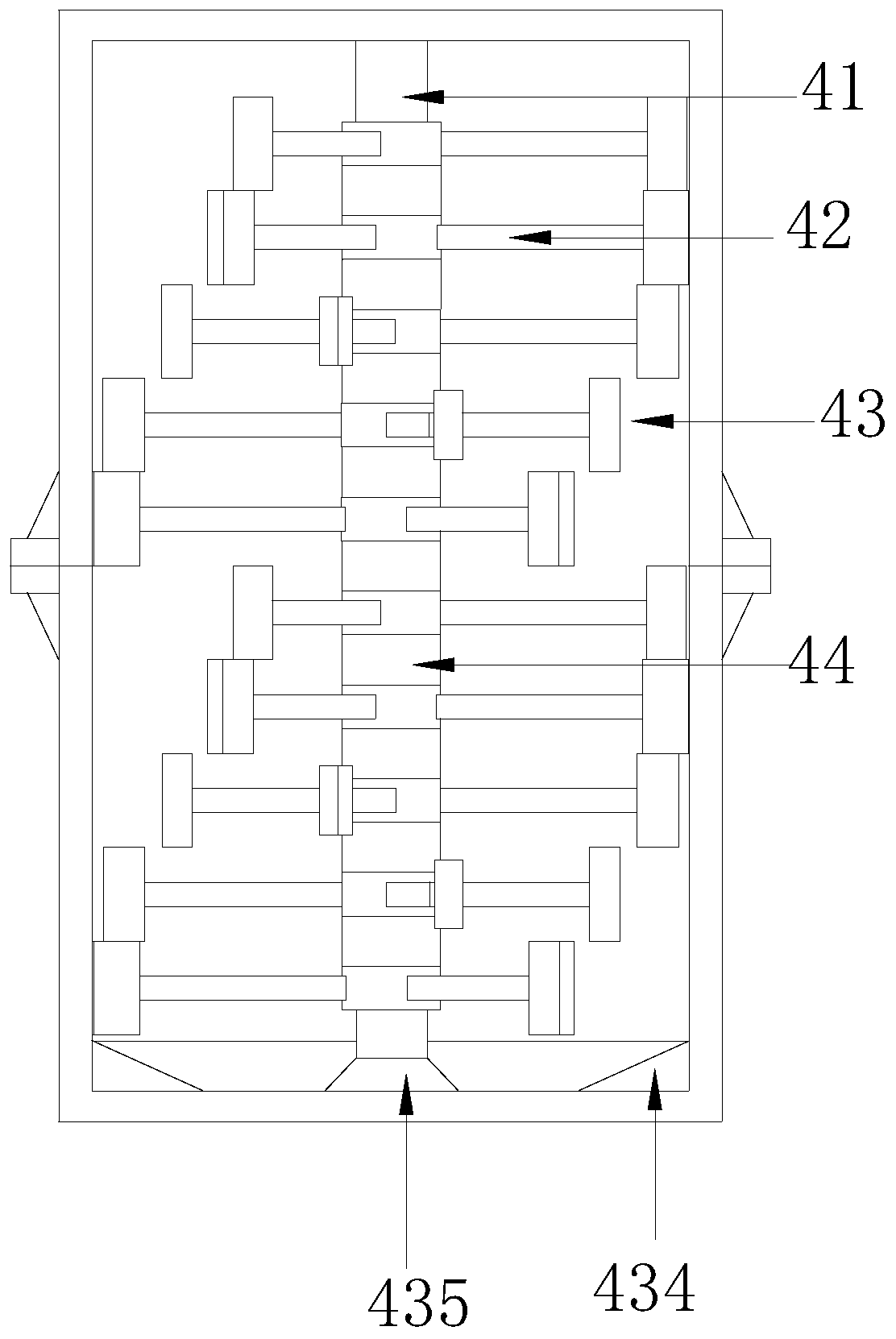

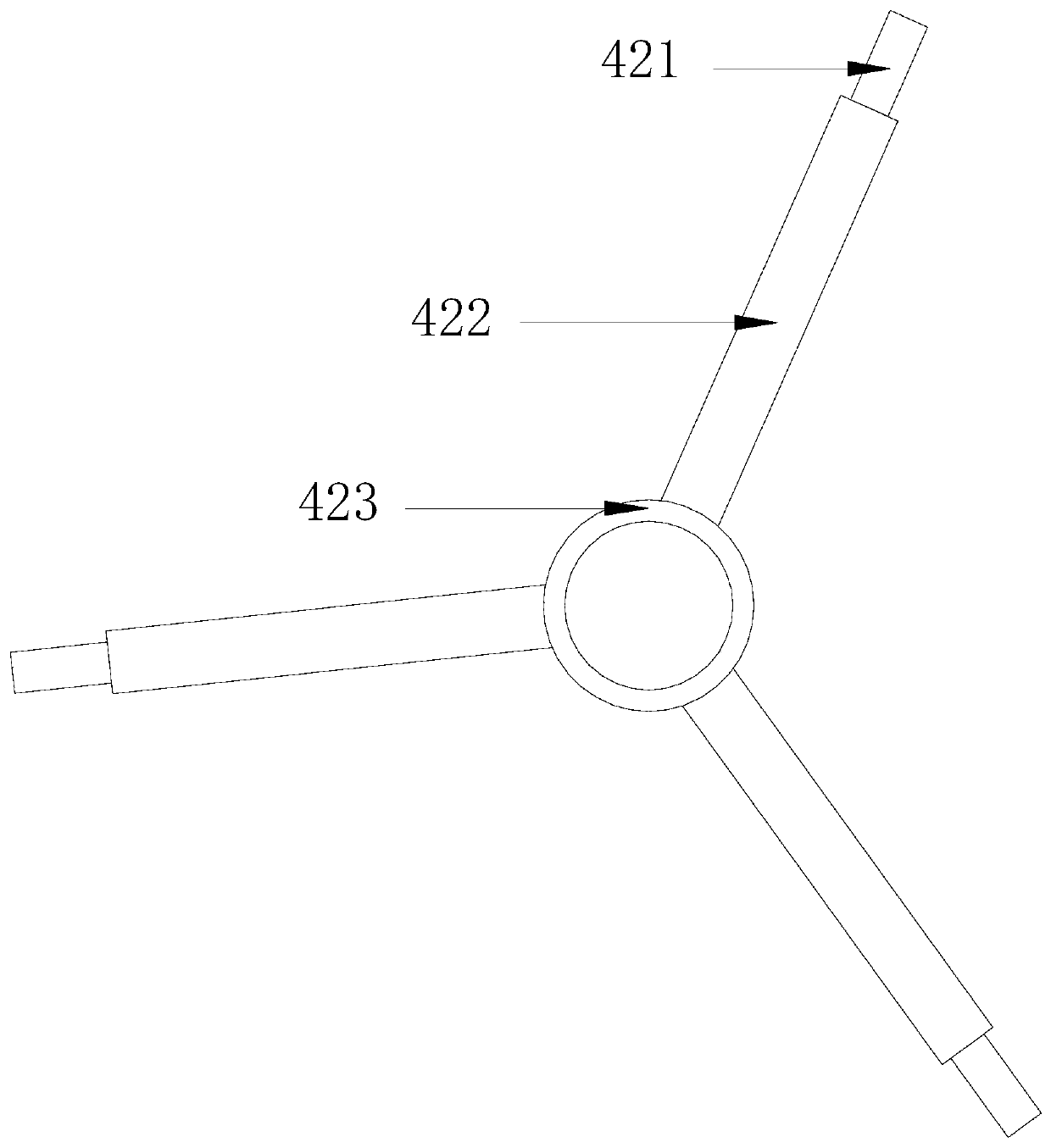

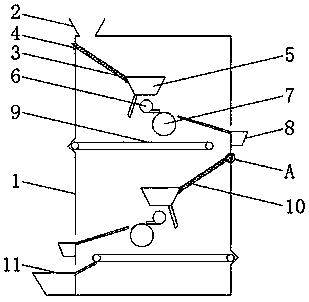

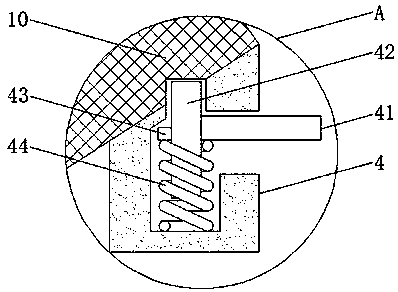

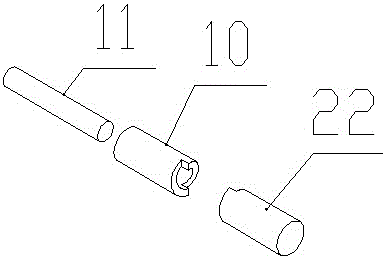

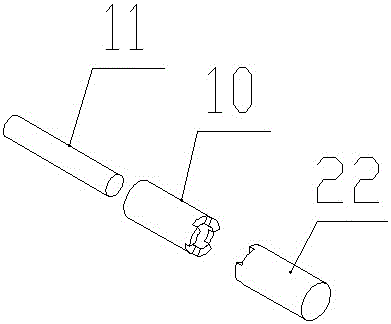

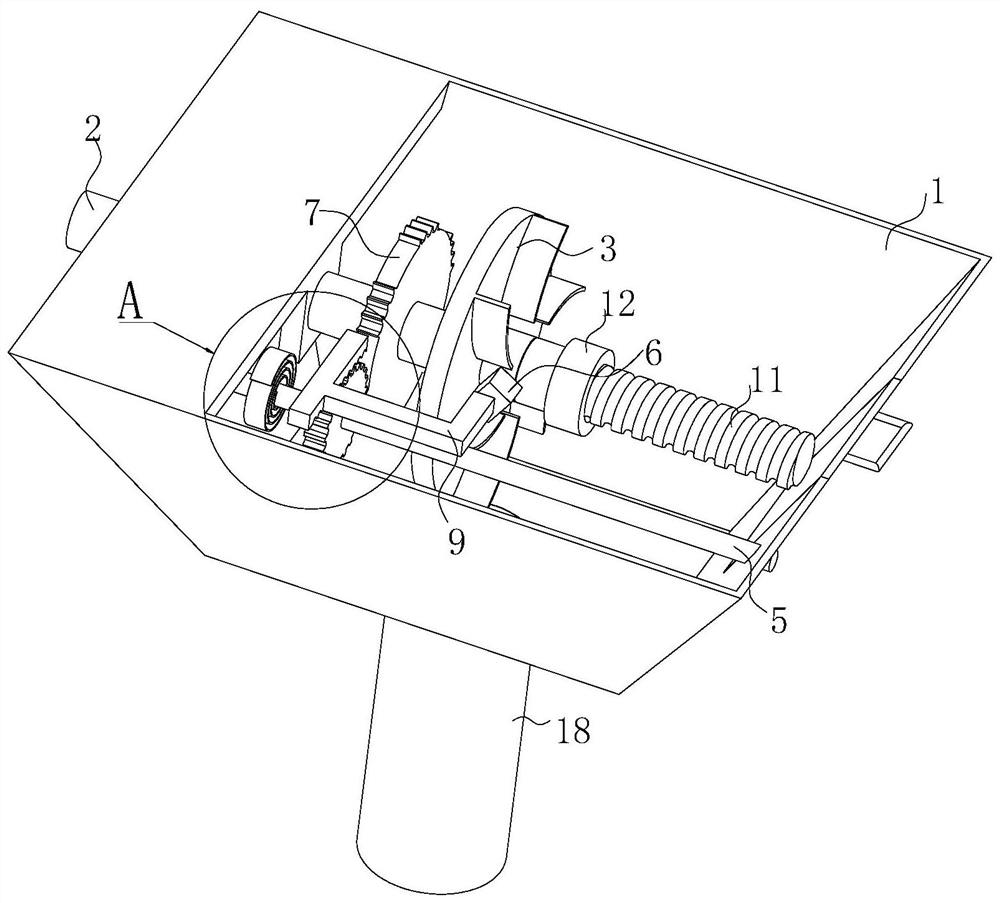

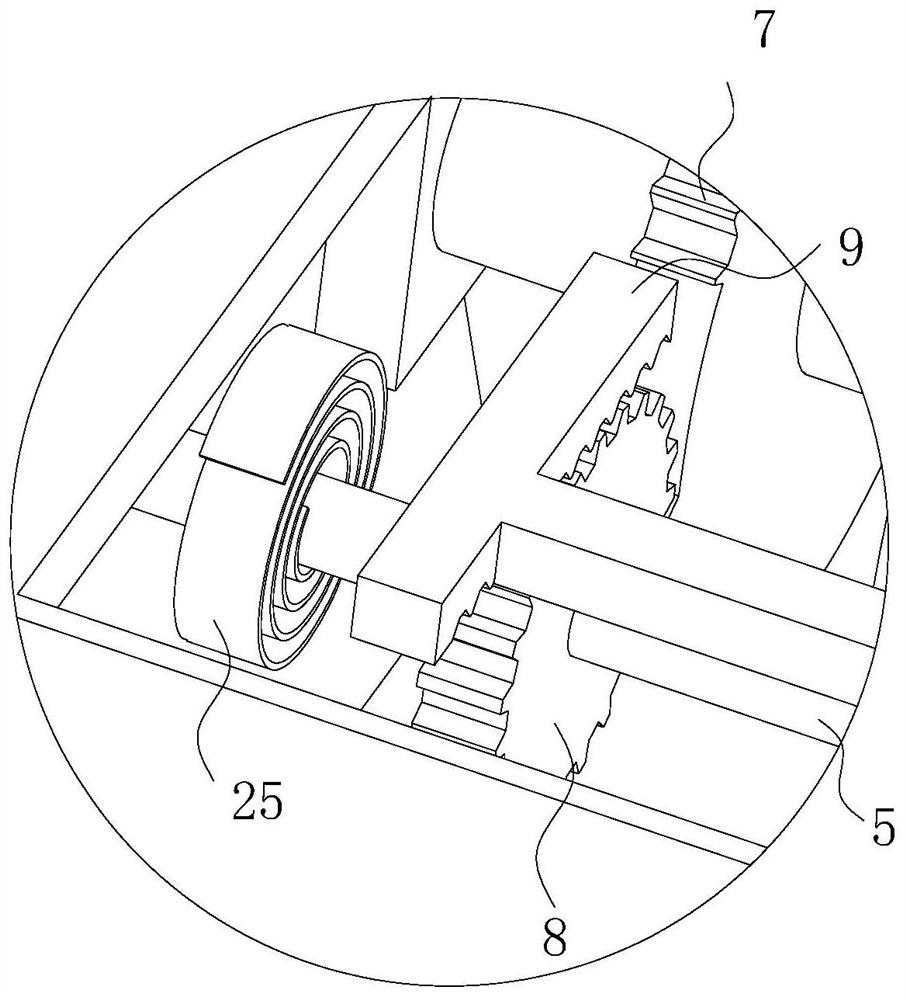

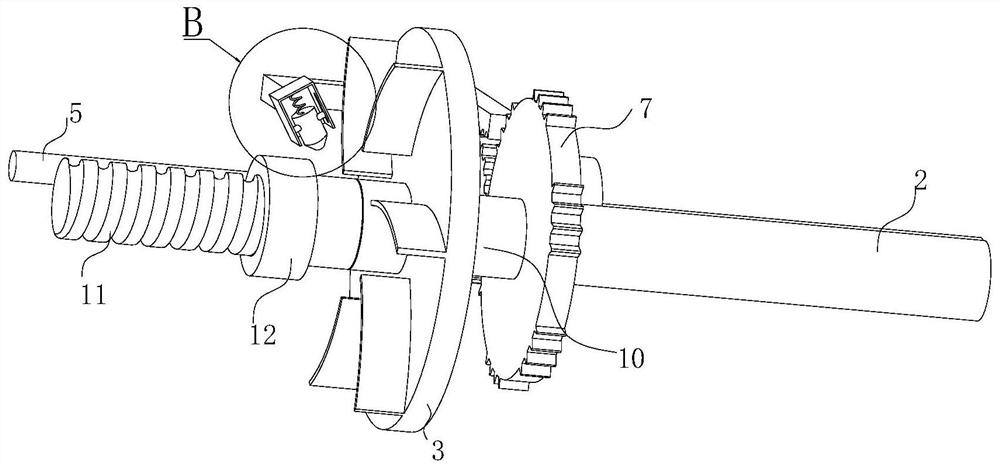

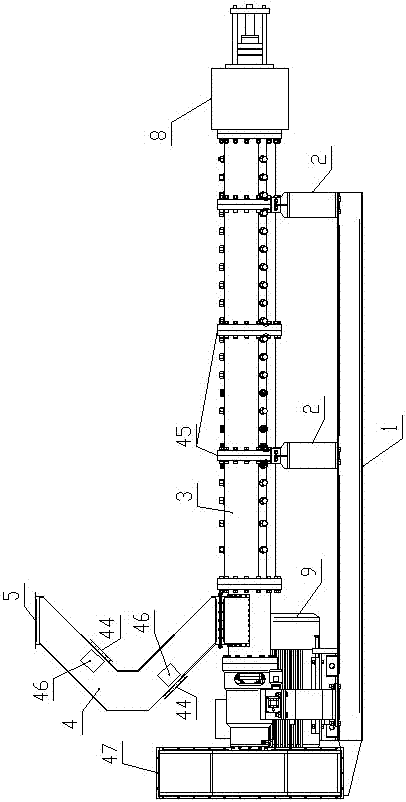

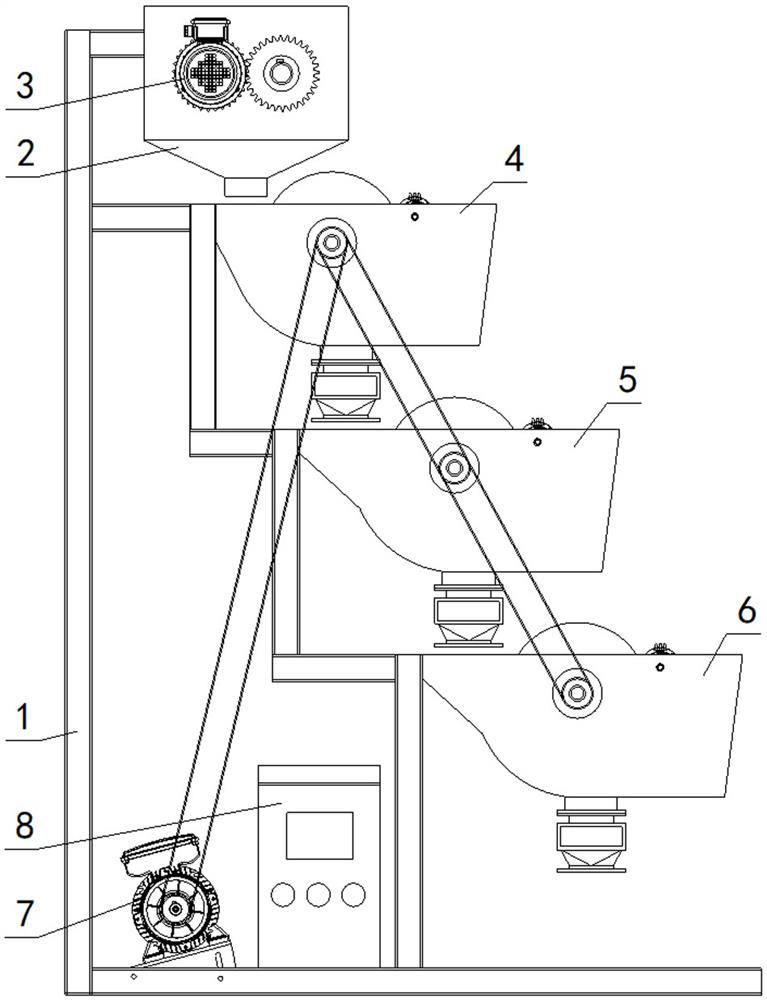

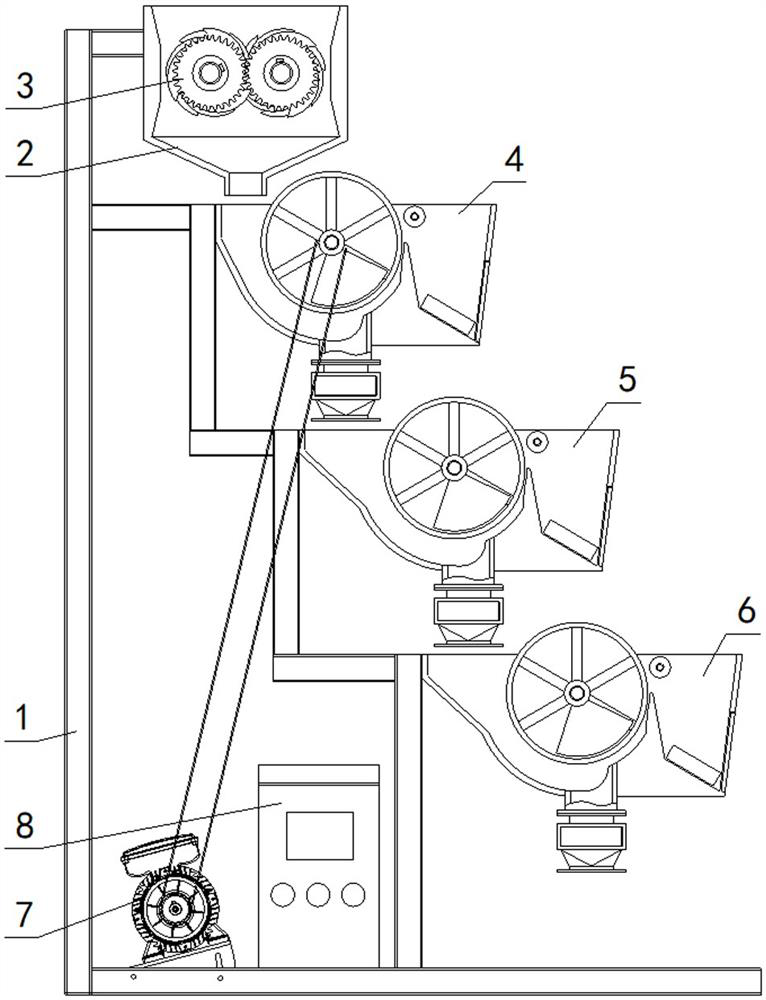

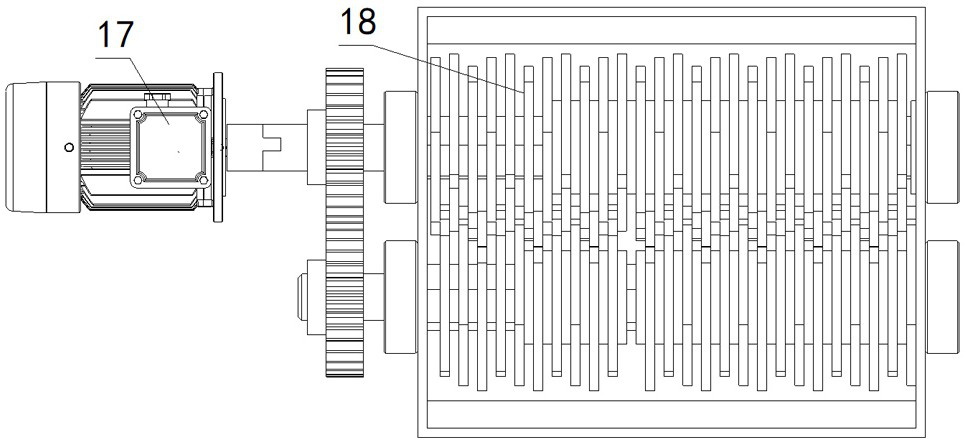

Efficient rubber crushing and recycling device and crushing and recycling method thereof

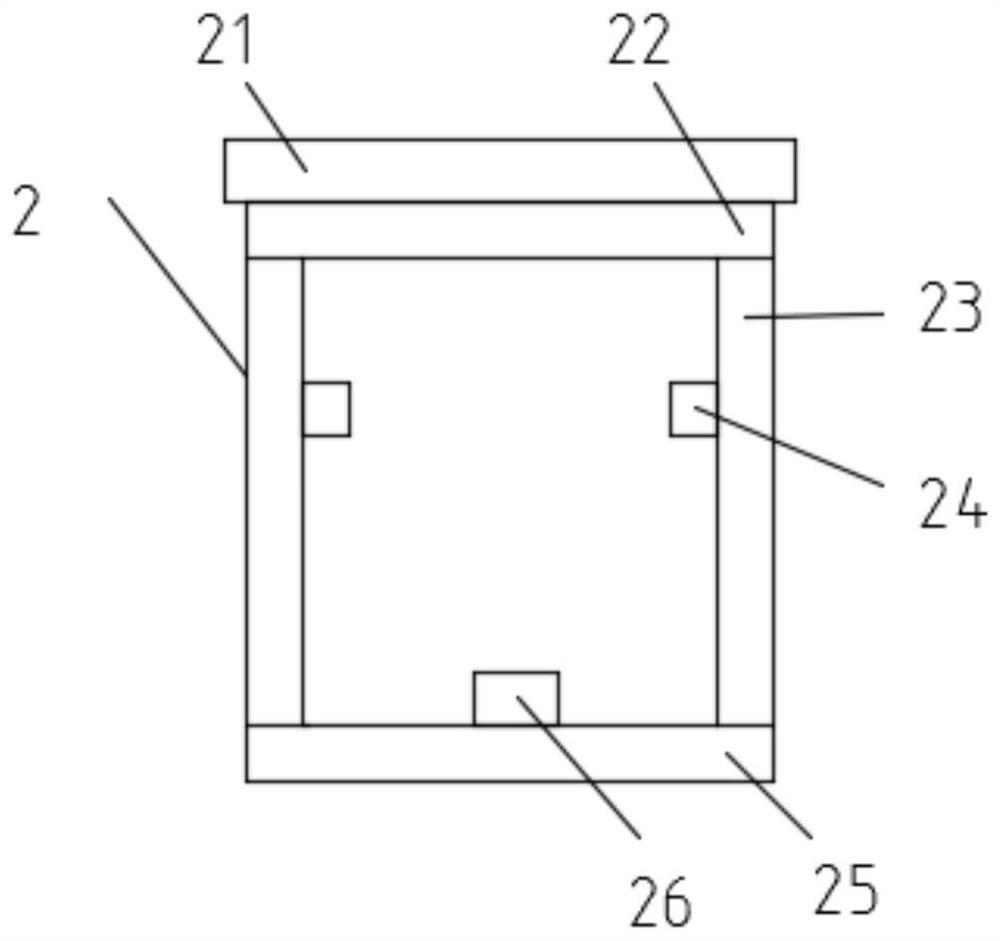

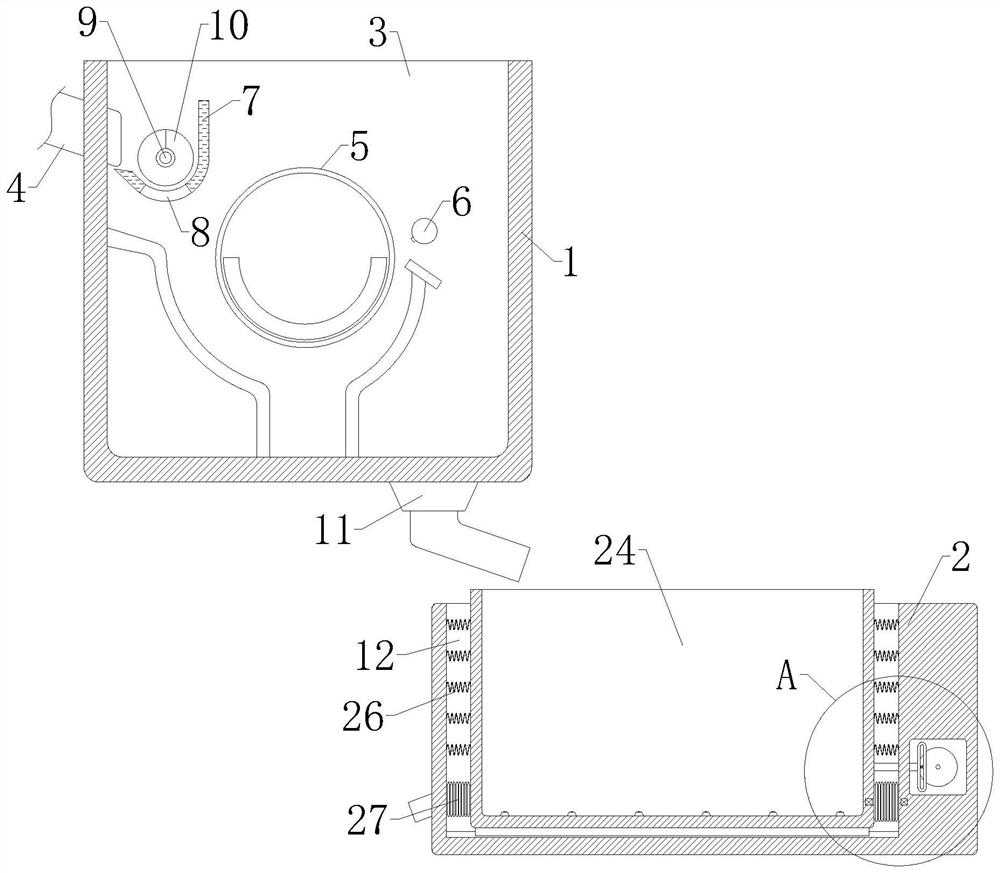

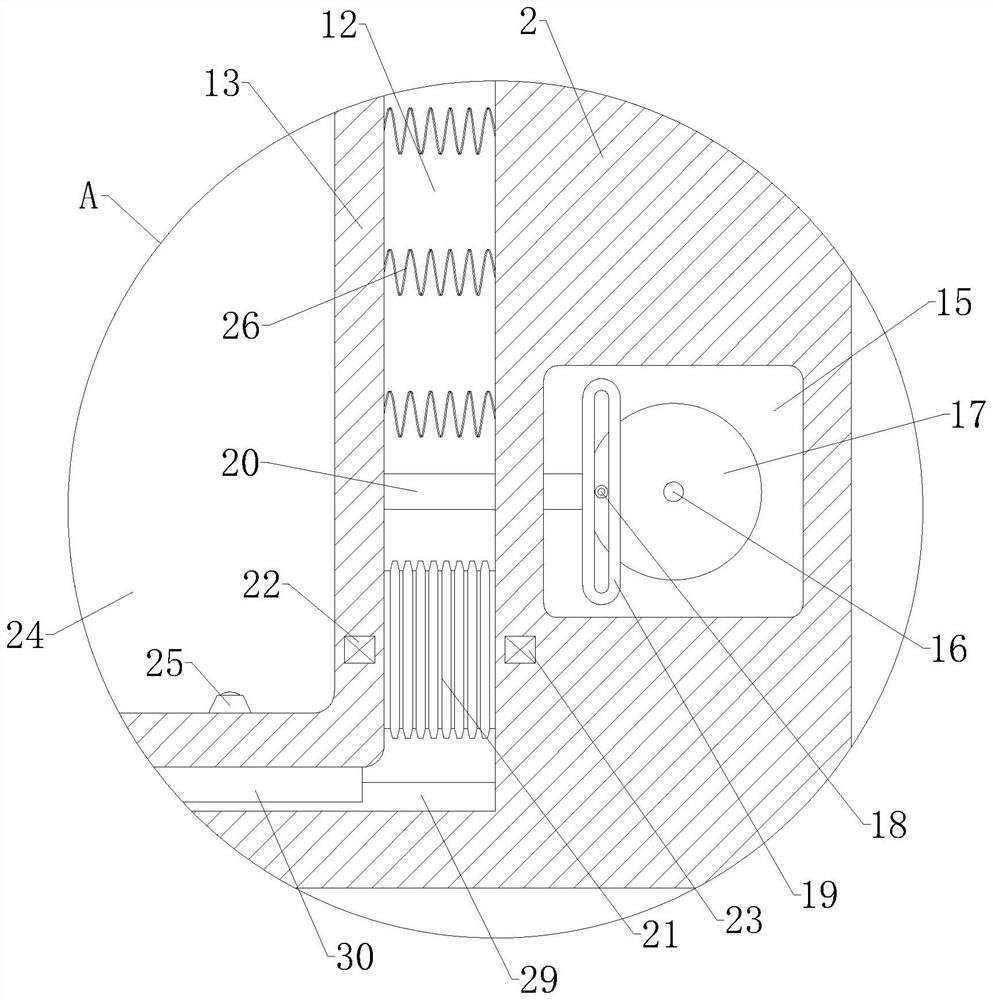

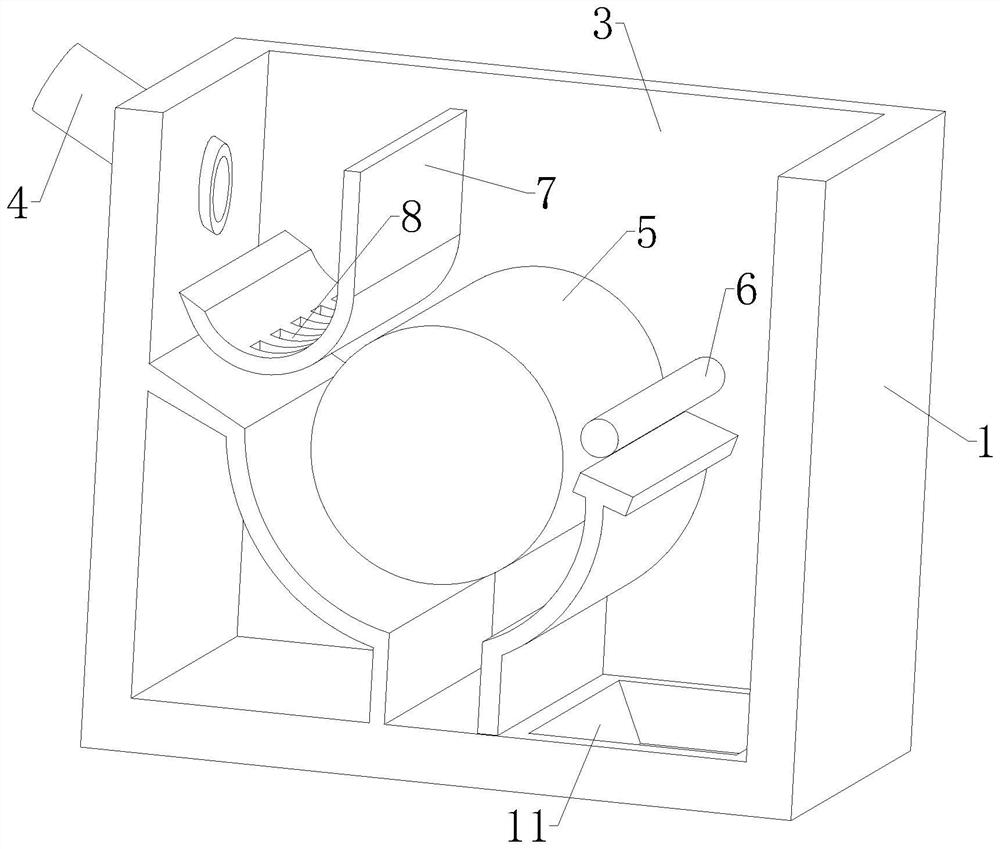

ActiveCN111688069AConvenient for magnetic separationImprove crushing efficiencyPlastic recyclingMagnetic separationGear driveGear wheel

The invention discloses an efficient rubber crushing and recycling device and a crushing and recycling method thereof, and belongs to the technical field of rubber crushing. The efficient rubber crushing and recycling device comprises a U-shaped outer frame, a herringbone blanking plate, two sets of triangular pyramid guide stop blocks, discharging holes, a crushing mechanism and a gear transmission mechanism, the lower side parts of the front end and the rear end of the U-shaped outer frame are closed, and the U-shaped outer frame is hollow and has a thickness; the herringbone blanking plateis arranged between the left inner wall and the right inner wall of the U-shaped outer frame; the two sets of triangular pyramid guide stop blocks are arranged at the top of the herringbone blanking plate, the number of each set of triangular pyramid guide stop blocks is two, and the outer sides of the triangular pyramid guide stop blocks are flush with the U-shaped outer frame; the two discharging holes are formed in the left end and the right end of the U-shaped outer frame correspondingly and located in the bottoms of the left side and the right side of the herringbone blanking plate correspondingly; the crushing mechanism is arranged on the U-shaped outer frame and located on the upper side of the herringbone blanking plate; and the gear transmission mechanism is arranged on the U-shaped outer frame. According to the efficient rubber crushing and recycling device, efficient crushing is facilitated, meanwhile, good magnetic separation is carried out, and the crushing and magnetic separation efficiency is effectively improved.

Owner:益阳市朝阳三鑫环保科技有限公司

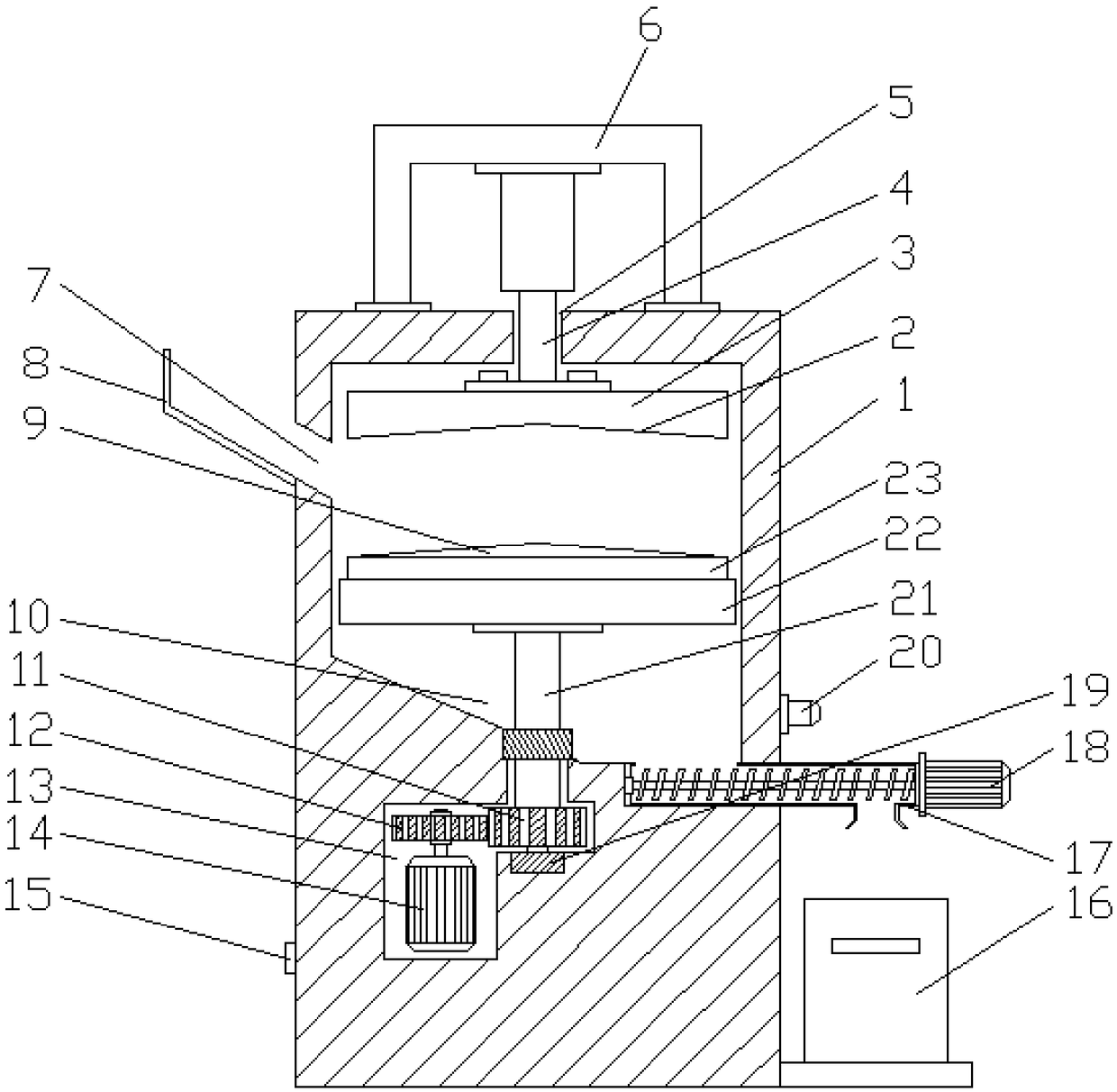

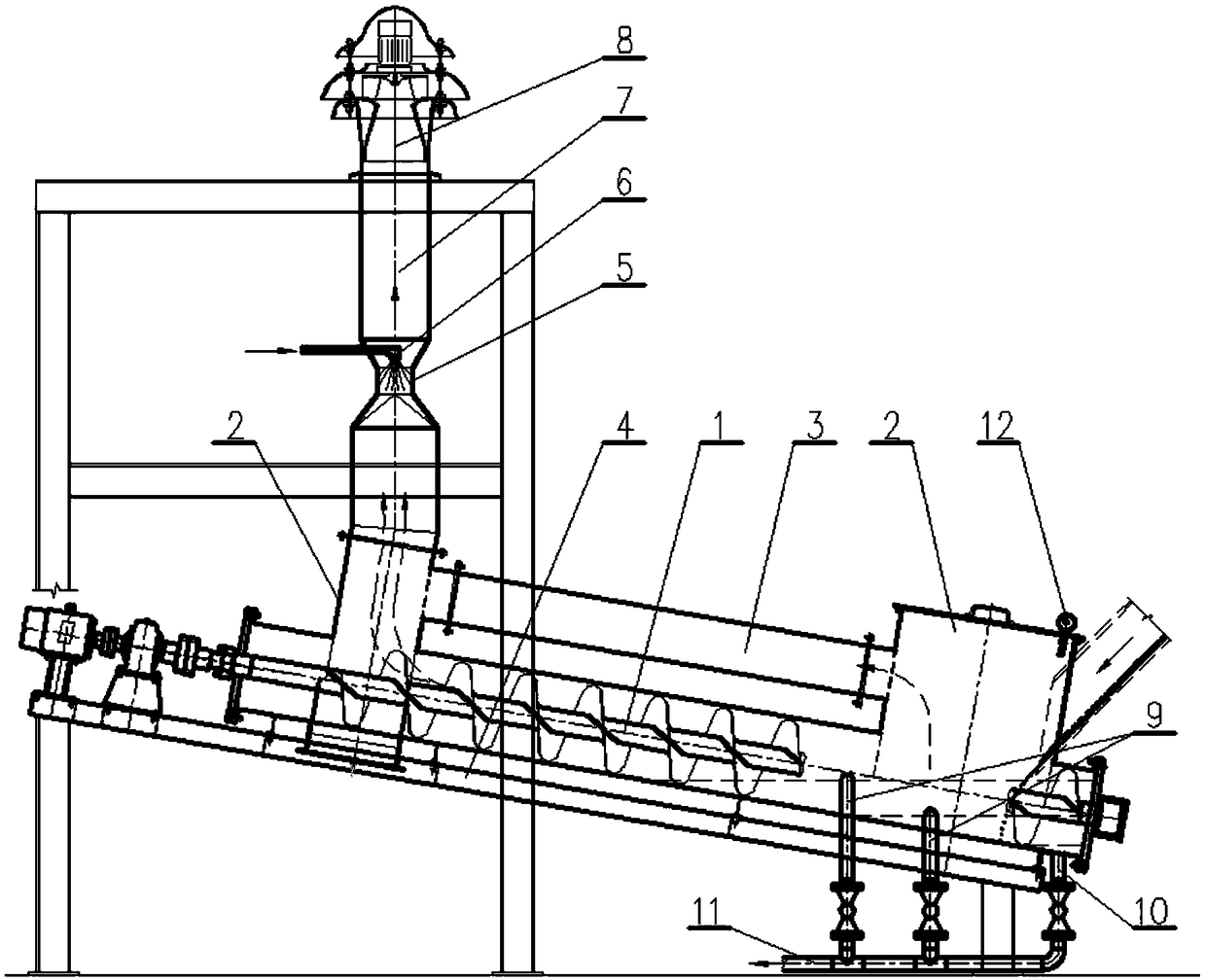

Crushing and grinding device for steelmaking slag

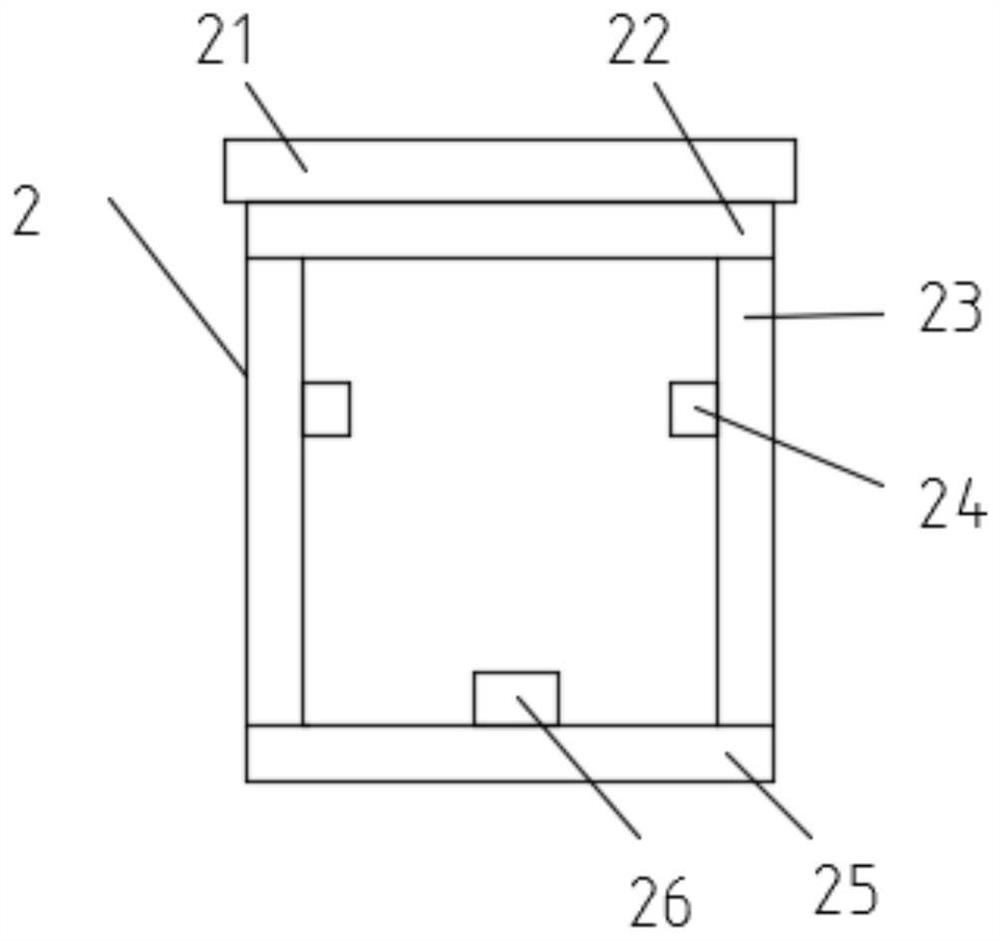

InactiveCN108421597AConvenient for magnetic separationEasy to recycleCocoaGrain treatmentsSteelmakingElectric machinery

The invention discloses a crushing and grinding device for steelmaking slag. The crushing and grinding device comprises a grinding device main body, an electric telescopic rod, a telescopic rod mounting rack, a grinding motor, a screw conveyer and a grinding plate, wherein a grinding chamber arranged at the upper part of the grinding device main body and a powder collecting chamber arranged at thelower part of the grinding device main body are arranged inside the grinding device main body; a telescopic rod mounting groove communicated with the grinding chamber is formed in the center of the top surface of the grinding device main body; the telescopic rod mounting rack is welded on the top surface of the grinding device main body; and the telescopic rod is arranged at the bottom of the telescopic rod mounting rack. According to the crushing and grinding device disclosed by the invention, the telescopic rod rotates and extends to drive a pressing plate to downward move, and steel slag is enabled to support against the surface of the grinding plate and is extruded and crushed; and the grinding motor rotates to drive a rotating shaft to rotate and to further drive the grinding plate to rotate, so that crushed steel slag is ground, and the whole steel slag is directly processed to form steel slag powder.

Owner:袁文林

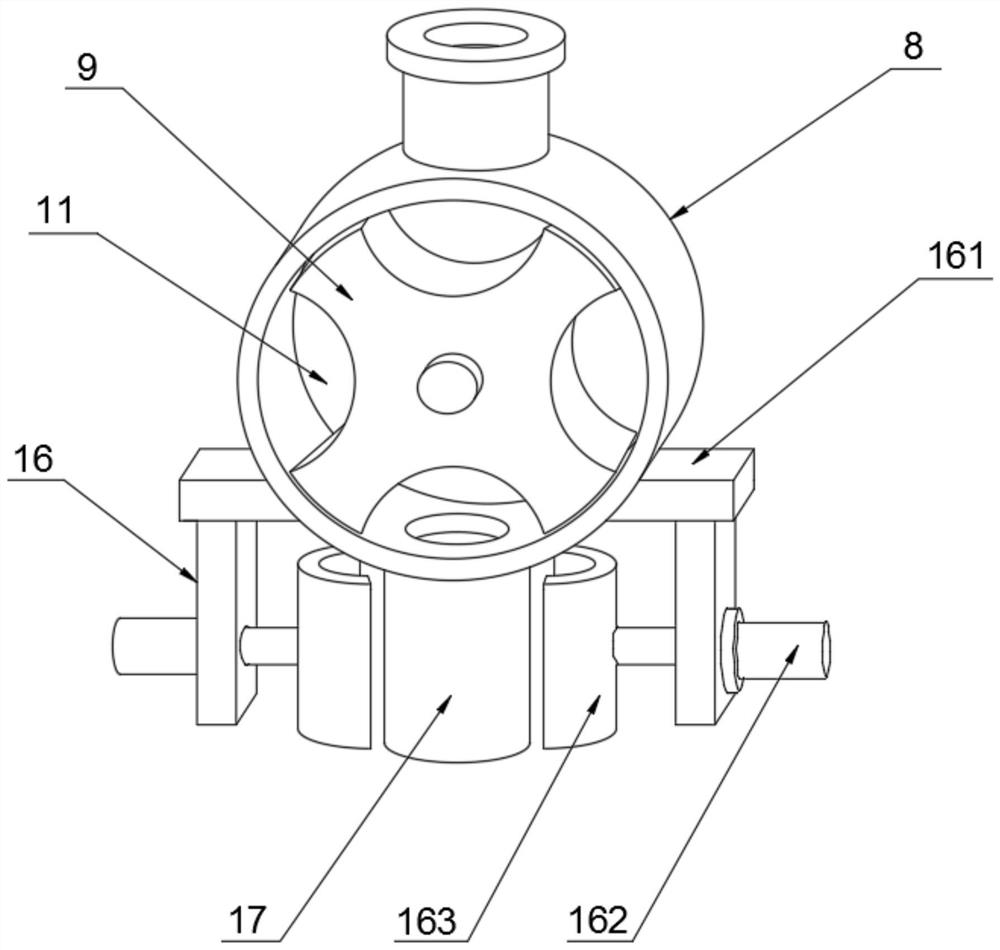

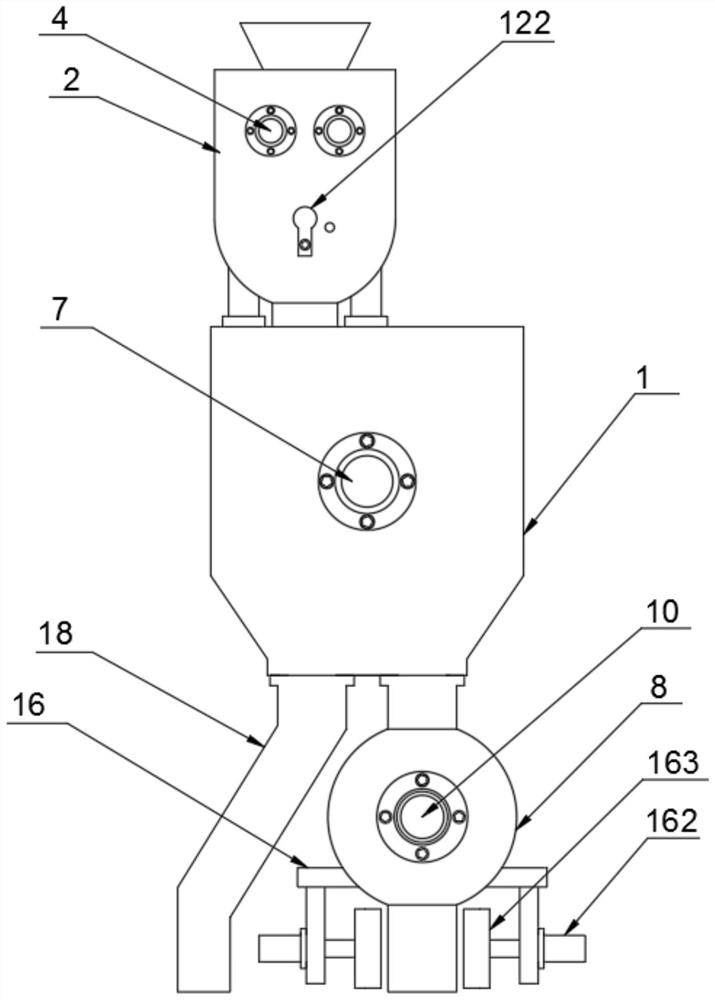

Double-cylindered magnetite fine powder grade improver

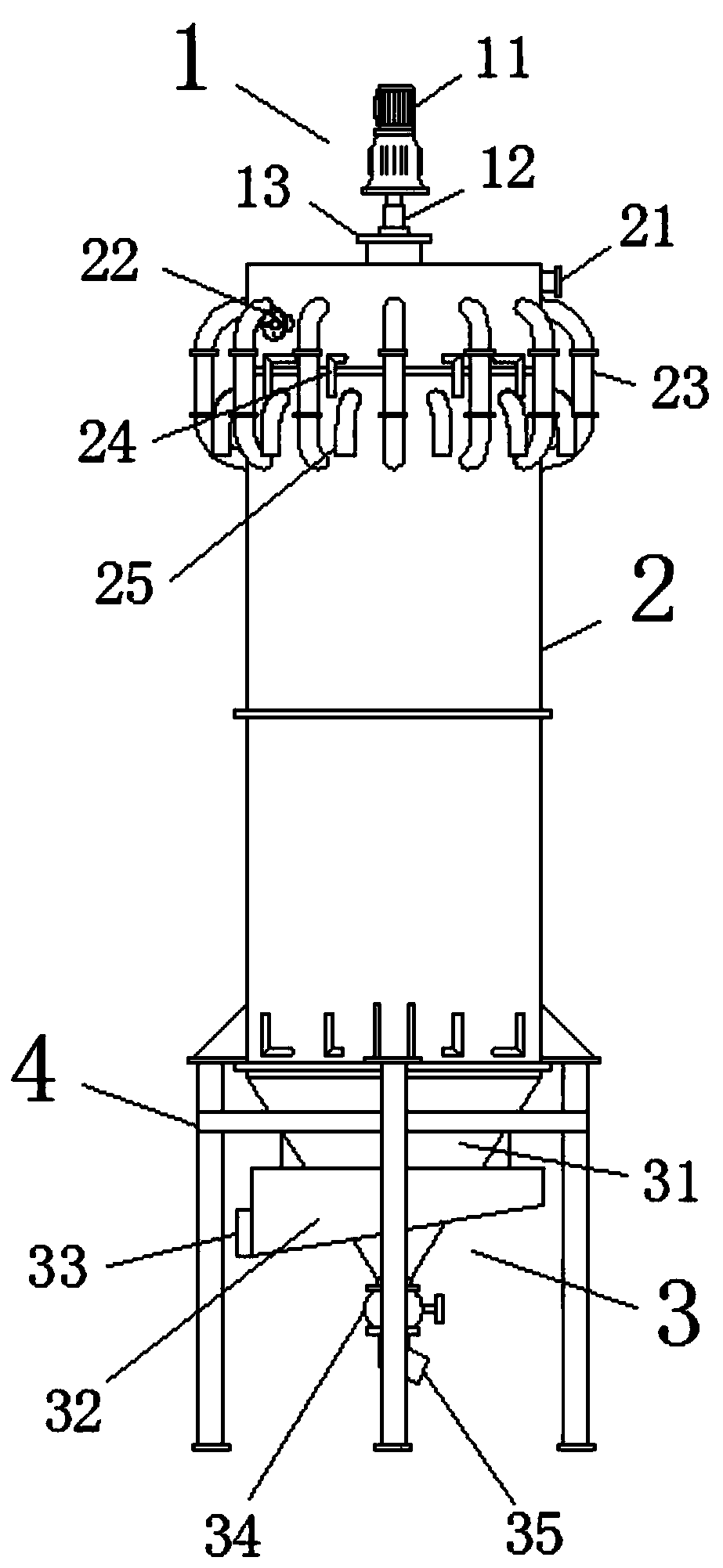

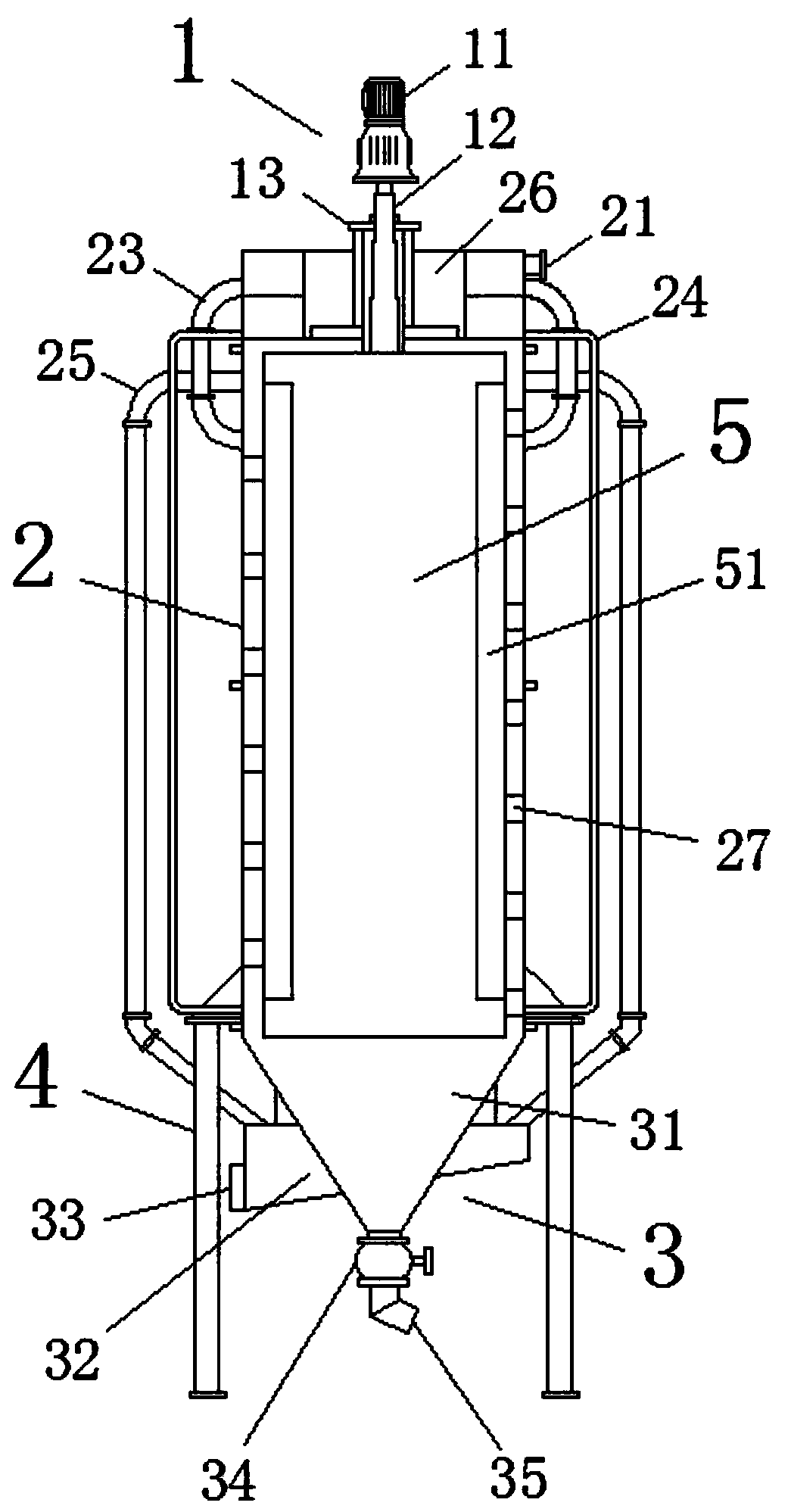

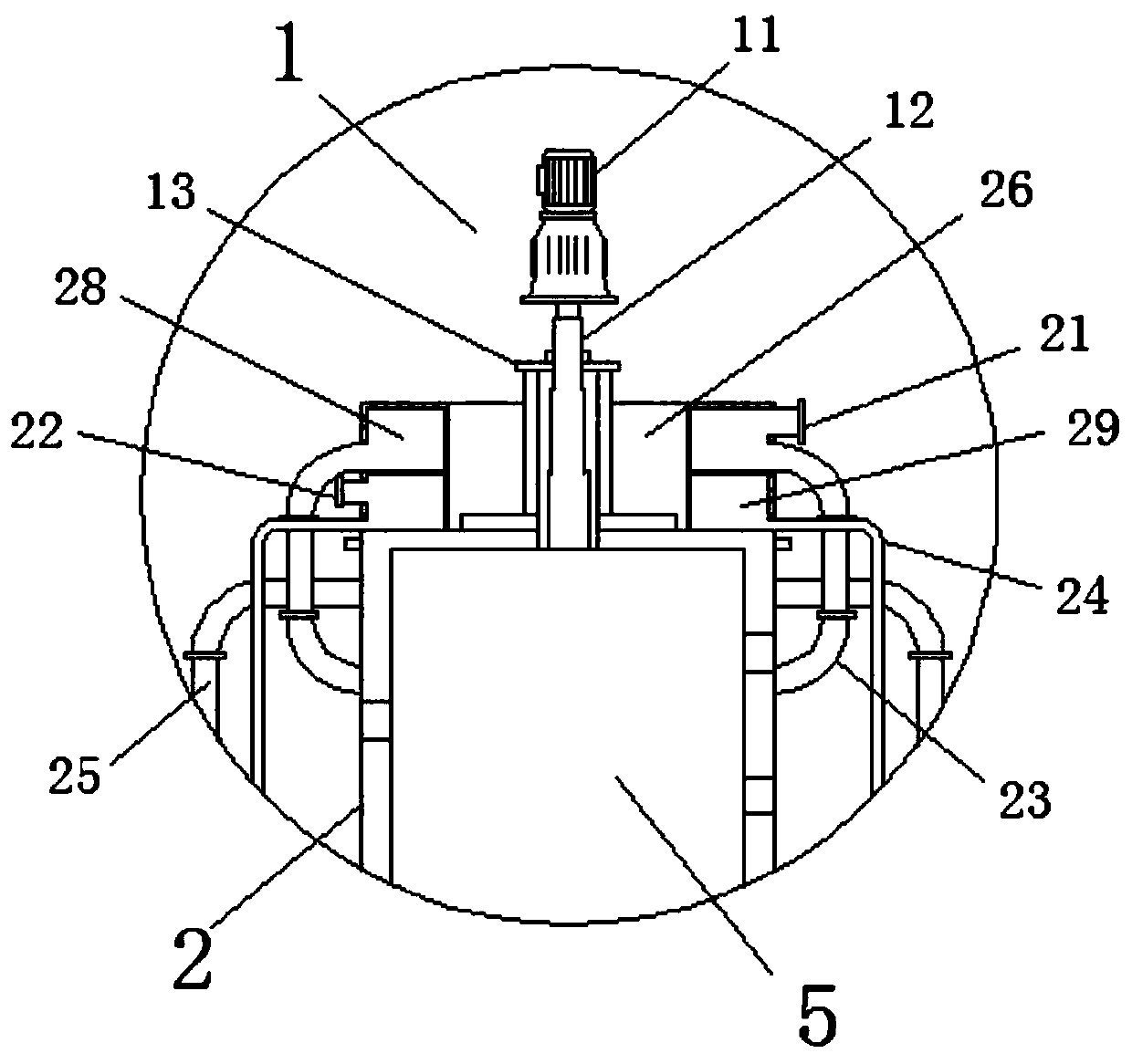

PendingCN110302898AStir wellUniform concentrationMagnetic separationWet separationEngineeringDrive motor

The embodiment of the invention discloses a double-cylindered magnetite fine powder grade improver, comprising a driving device, an outer cylinder, a discharging device, a support frame and an inner cylinder, wherein the driving device comprises a driving motor, a transmission shaft and a bearing bracket; the upper end surface of the outer cylinder is provided with an annular water distributor; the upper end of the annular water distributor is provided with an annular material distributor; and the side surfaces of the annular distributor and the annular water distributor are provided with a material inlet and a water inlet respectively. A clearance space between the outer cylinder and the inner cylinder of the double-cylindered structure increases the contact area between the magnetite material and the clean water and increases the washing speed of the slurry. A plurality of magnets are annularly arranged side by side to define a cylindrical inner cylinder permanent magnet mechanism soas to increase the magnetic separation area and increase the number of mineral rubbing and overturning times. The outer cylinder is provided therein with a scraper arranged in a spiral shape to scrape off the fine iron powder in the outer cylinder downward. The water rinses the fine iron powder from the bottom to the top to achieve efficient wet magnetic separation. The double-cylindered magnetite fine powder grade improver improves work efficiency and is easy to operate.

Owner:山西建兴机械设备有限公司

Industrial waste renewable resource recovery device

PendingCN113976590AEasy to bagHigh purityWaste processingSolid waste disposalResource recoveryElectric machinery

A disclosed industrial waste renewable resource recovery device comprises a magnetic separation chamber and a crushing chamber, a feeding hopper is welded to the upper end of the crushing chamber, the caliber of the feeding hopper is in a big-end-up shape, the bottom side of the crushing chamber is fixedly connected to the top end of the magnetic separation chamber through a connecting column, a discharging pipe at the bottom end of the crushing chamber is inserted into a feeding opening in the top end of the magnetic separation chamber, two crushing rollers are oppositely arranged in the upper portion between the inner walls of the two sides of the crushing chamber, and two first motors are fixedly connected to the positions, opposite to the two crushing rollers, of the upper portion of the outer wall of the crushing chamber. The industrial waste renewable resource recovery device has the advantages that a magnetic selection cylinder is arranged to carry out magnetic selection on steel waste to separate non-steel parities from the waste, and the purity of the steel renewable resources is improved; according to the waste magnetic separation device, crushing rollers are arranged for cooperation, and the waste can be crushed before magnetic separation is conducted on the waste, so that the waste is changed into small particles, and subsequent magnetic separation is facilitated.

Owner:SHANGHAI CHANAN RENEWABLE RESOURCES

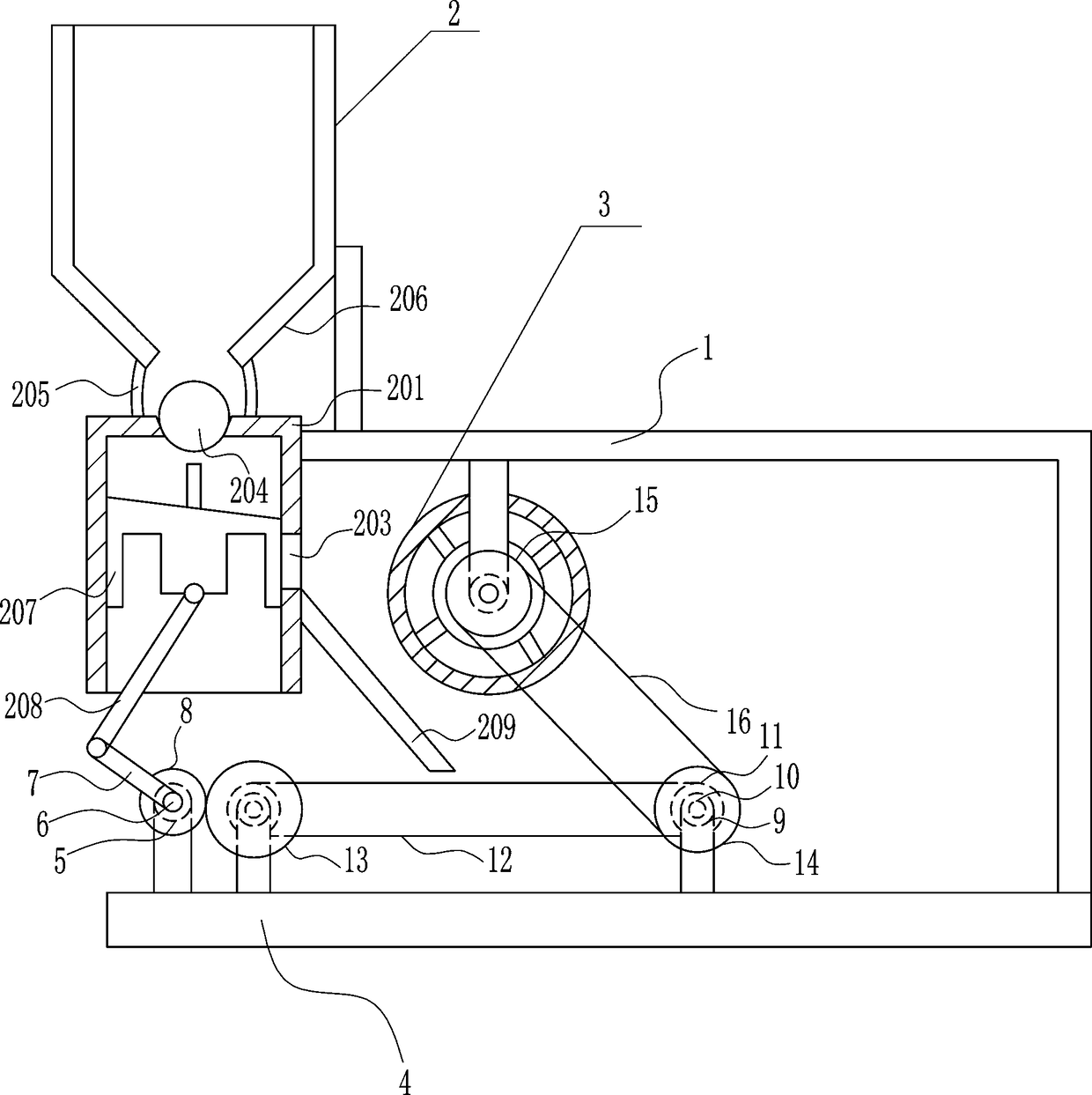

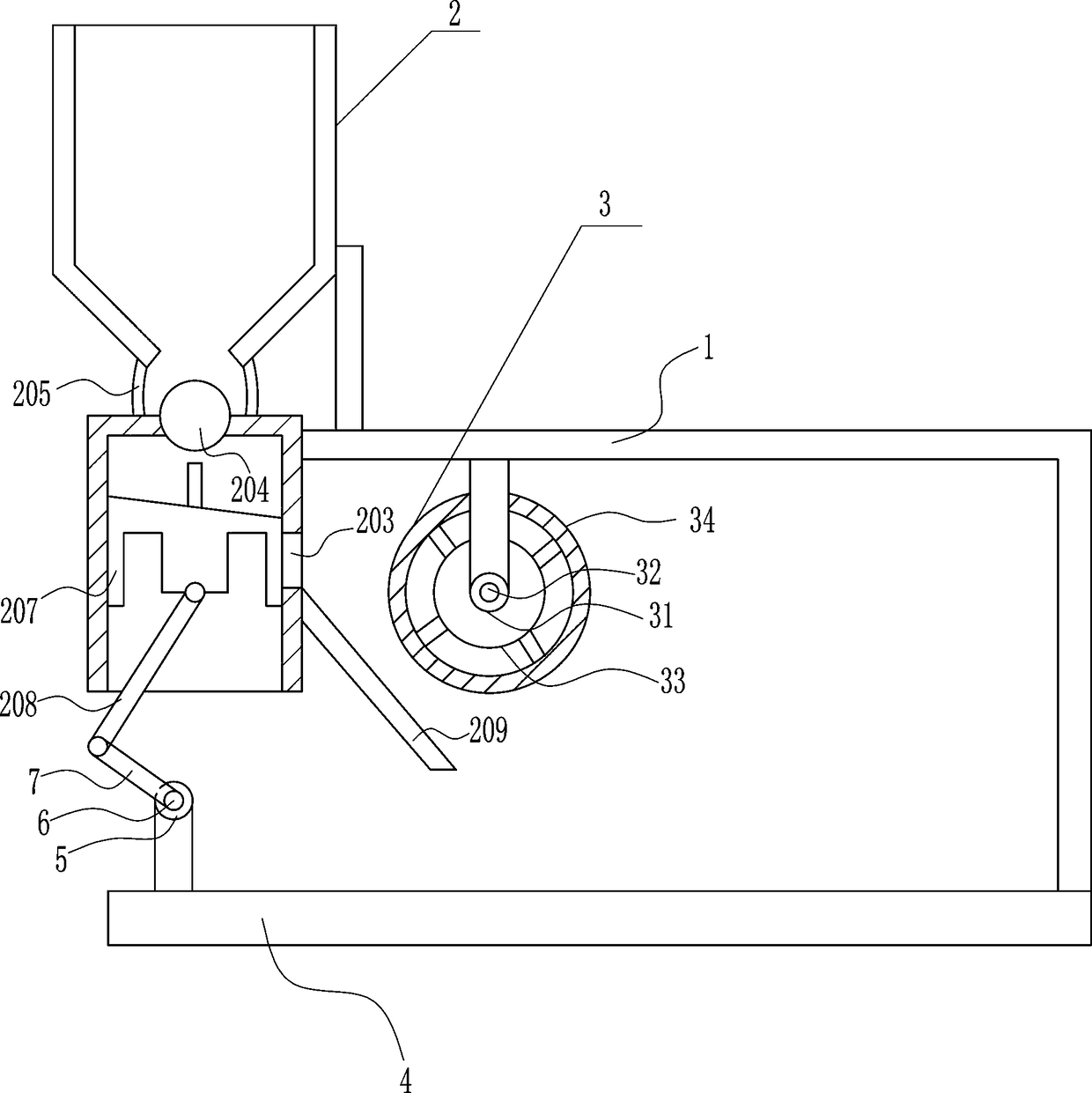

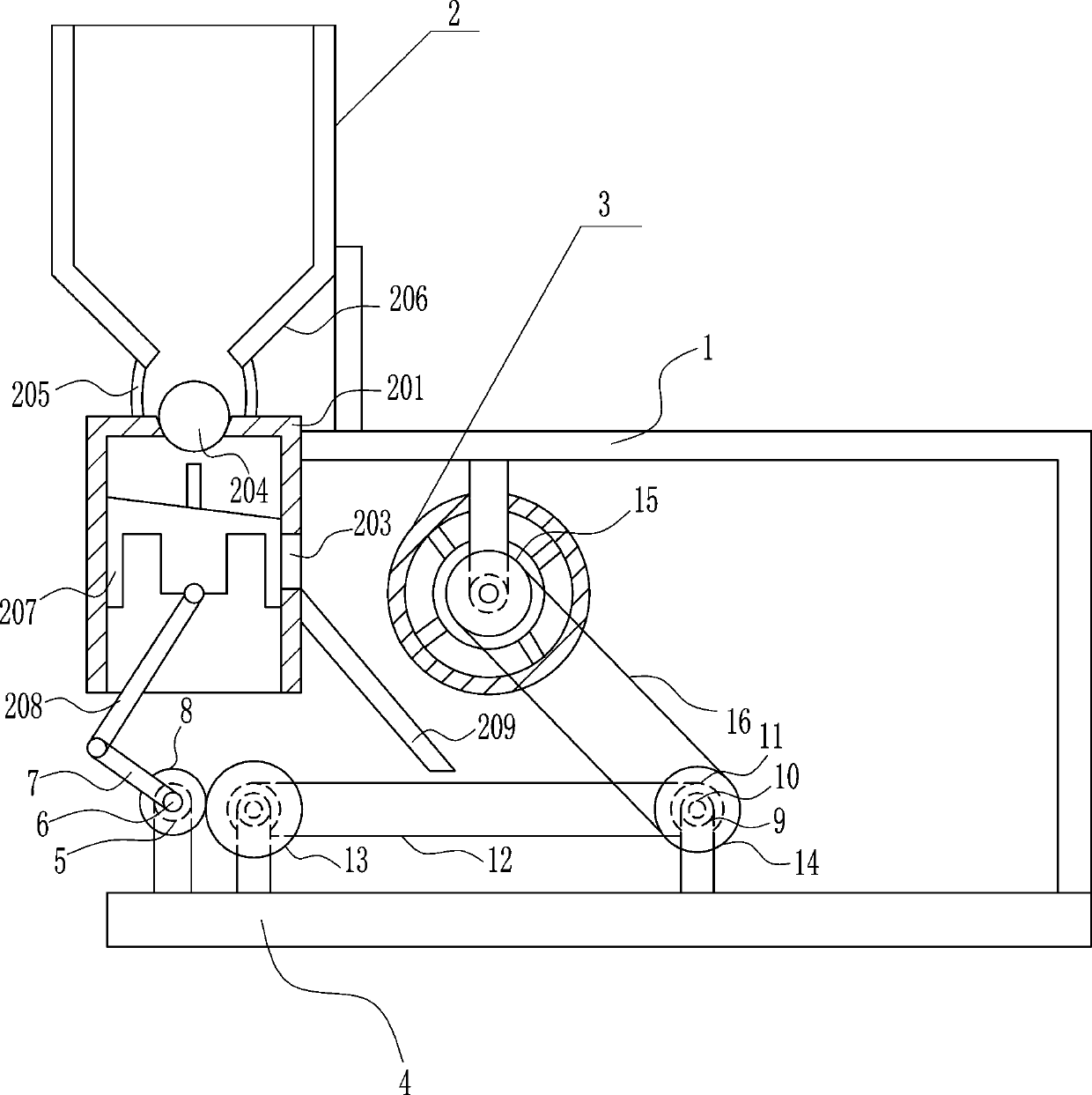

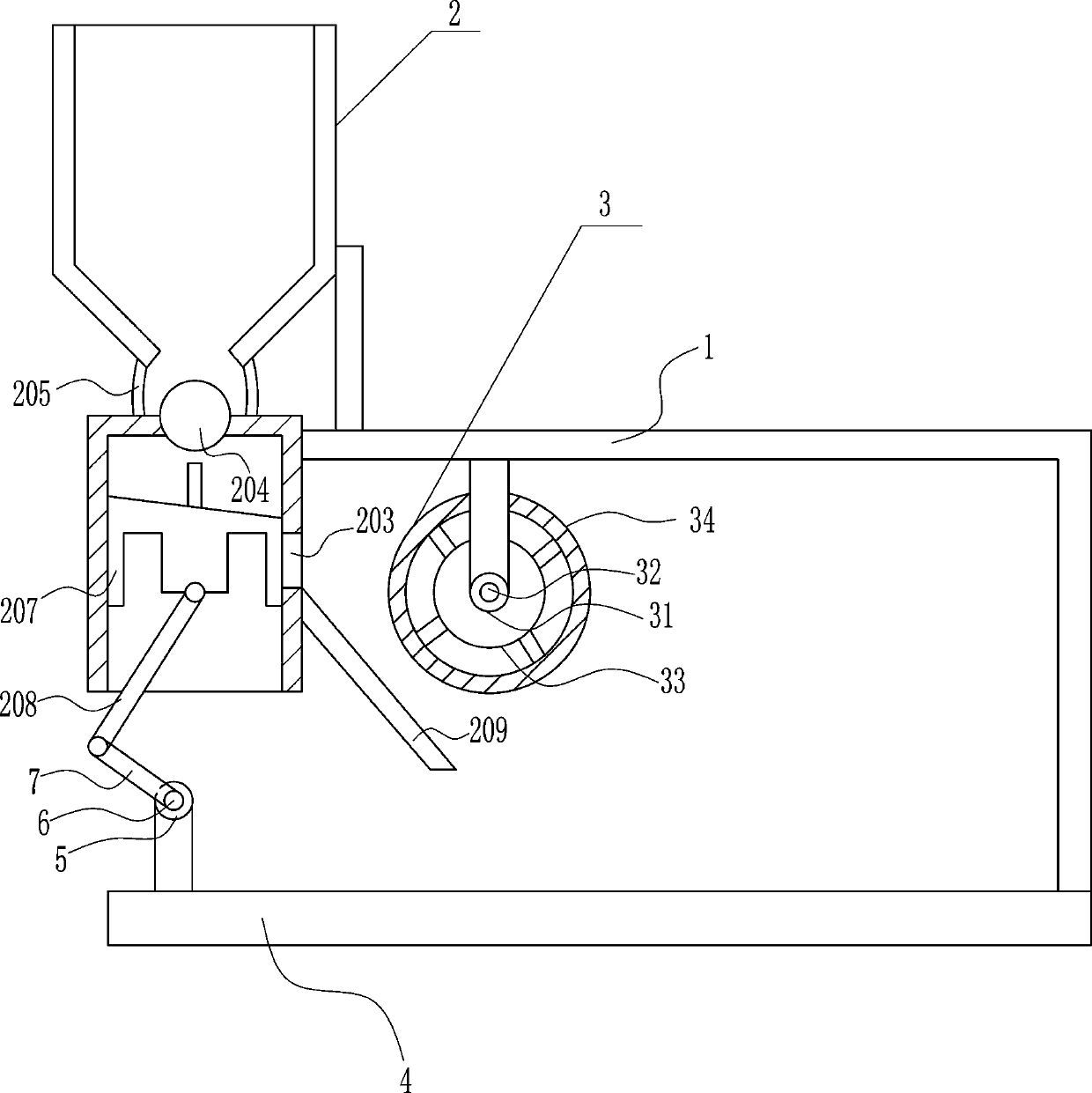

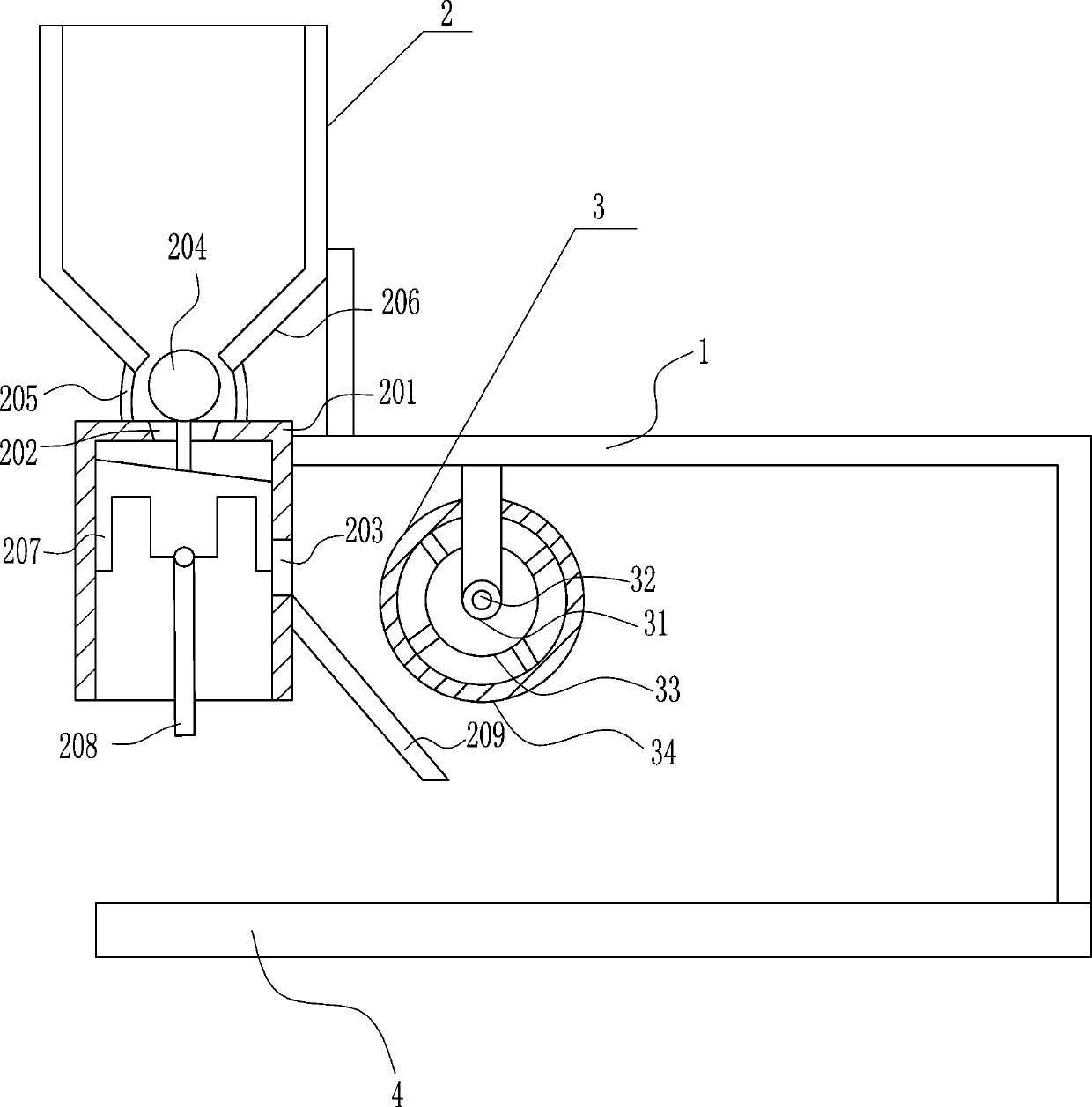

Rotary magnetic separation equipment for quartz sand utilized as building material

ActiveCN108405174AConvenient for magnetic separationUniform magnetic separationMagnetic separationConveyor partsBuilding materialEngineering

The invention relates to a feeding device, in particular to rotary magnetic separation equipment for quartz sand utilized as a building material, and aims to solve technical problems in the prior art.In order to solve the above technical problems, the rotary magnetic separation equipment which is applicable to the quartz sand utilized as the building material, has the intermittent adding function, and is good in magnetic separation effect is provided. The rotary magnetic separation equipment for the quartz sand utilized as the building material comprises ab racket and the like, wherein the bracket is connected with the right side of the top of a base; a discharging mechanism is connected with the left end of the bracket; and a magnetic separation mechanism is connected with the left sideof the inner top of the bracket and positioned on the right side of the discharging mechanism. By adoption of the designed rotary magnetic separation equipment for the quartz sand utilized as the building material, the quartz sand can be quantitatively and intermittently added; the manual adding operation is not needed; more convenience is brought; and through the arrangement of a motor, a secondrotating rod and a third rotating rod, the automatic, quantitative and intermittent adding operation can be achieved without manually moving a connecting rod.

Owner:HAIMEN THE YELLOW SEA ENTREPRENEURSHIP PARK SERVICE CO LTD

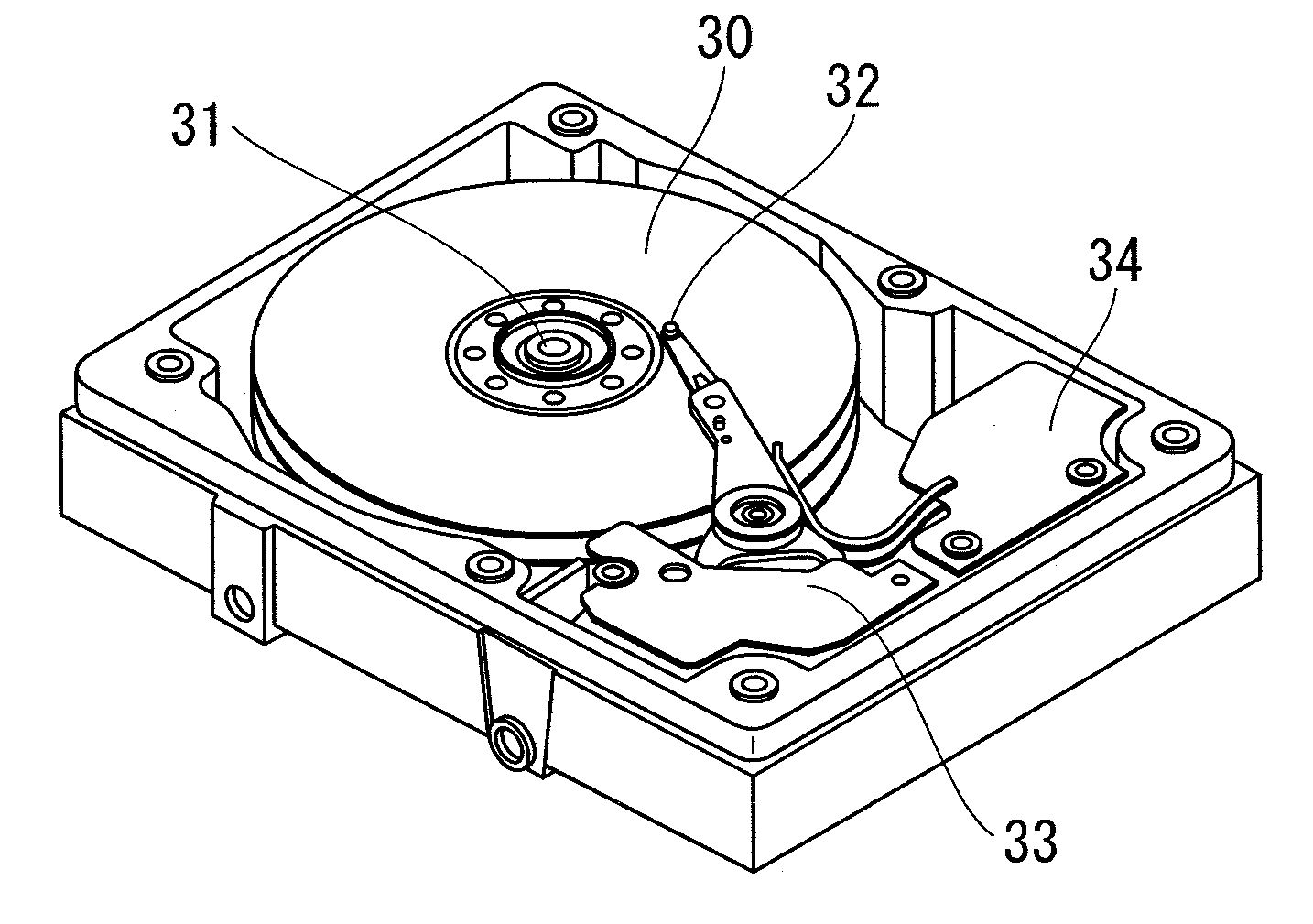

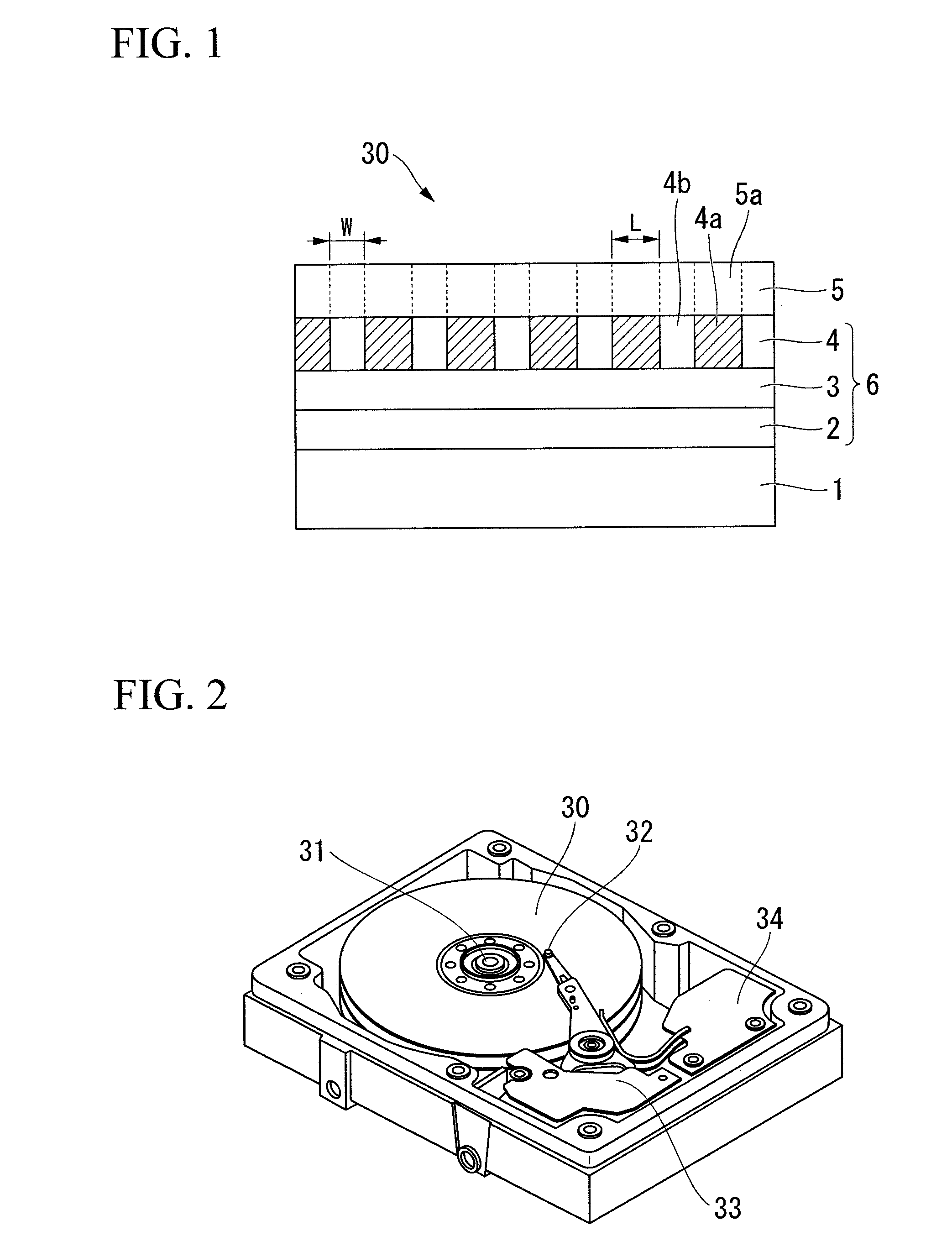

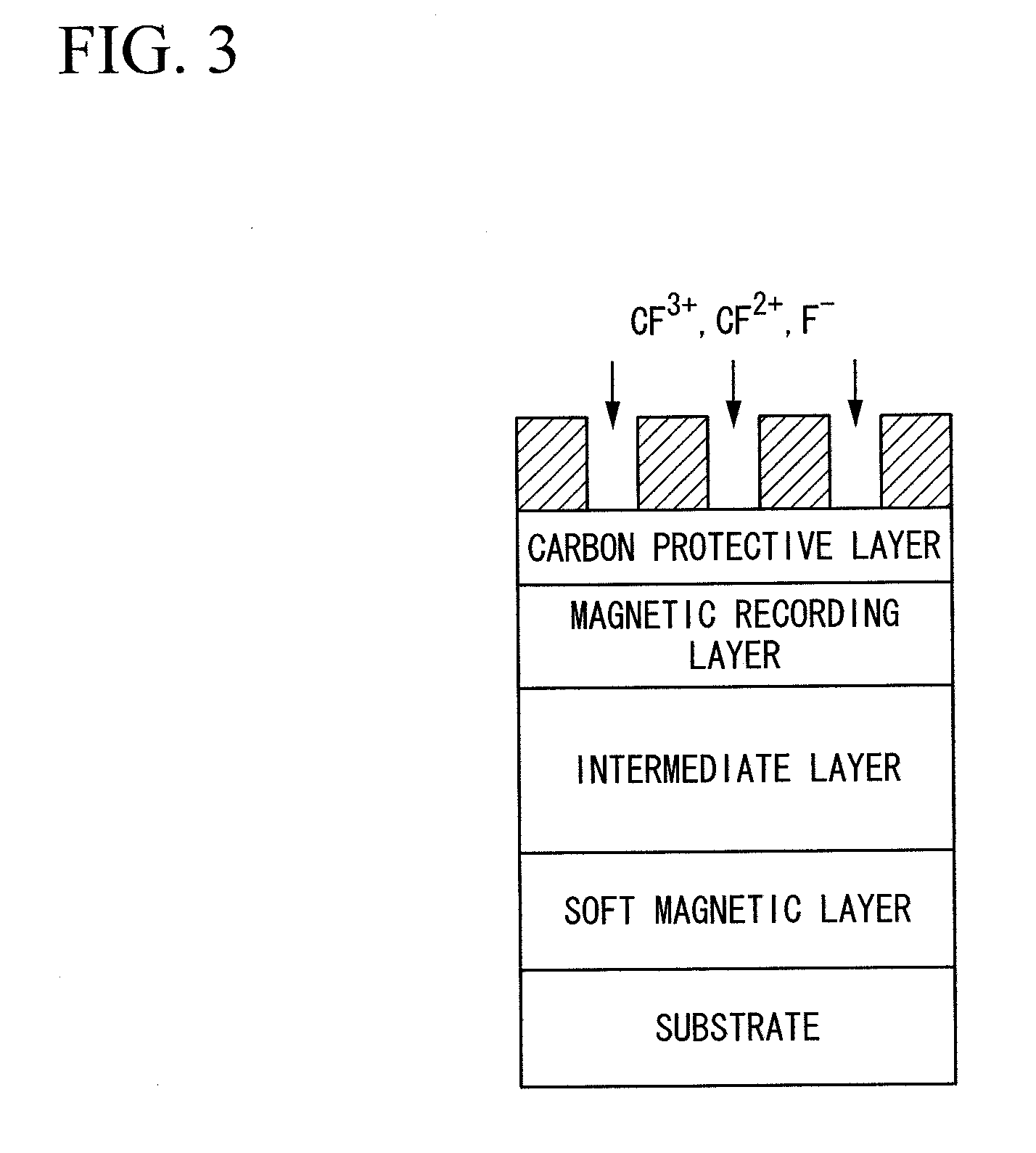

Method for producing magnetic medium, magnetic record reproduction device, and magnetic recording medium

InactiveUS20100007985A1Improve productivityLess pollutionLamination ancillary operationsPatterned record carriersHalogenMagnetic media

One object of the present invention is to provide a method for producing a magnetic recording medium which has excellent magnetic separation properties of the magnetic recording pattern, the present invention providing a method for producing a magnetic recording medium having a magnetic recording pattern which is magnetically separated, comprising the steps of: after laminating at least a magnetic layer and a carbon protective layer on a non-magnetic substrate in this order, partially irradiating with a reactive plasma containing carbon and a halogen or reactive ions which are generated in the reactive plasma on a surface of the carbon protective layer, and thereby forming a halogenated carbon protective layer, which is obtained by partially halogenating the carbon protective layer, and the magnetic recording pattern separated magnetically which is obtained by partially improving the magnetic layer.

Owner:SHOWA DENKO KK

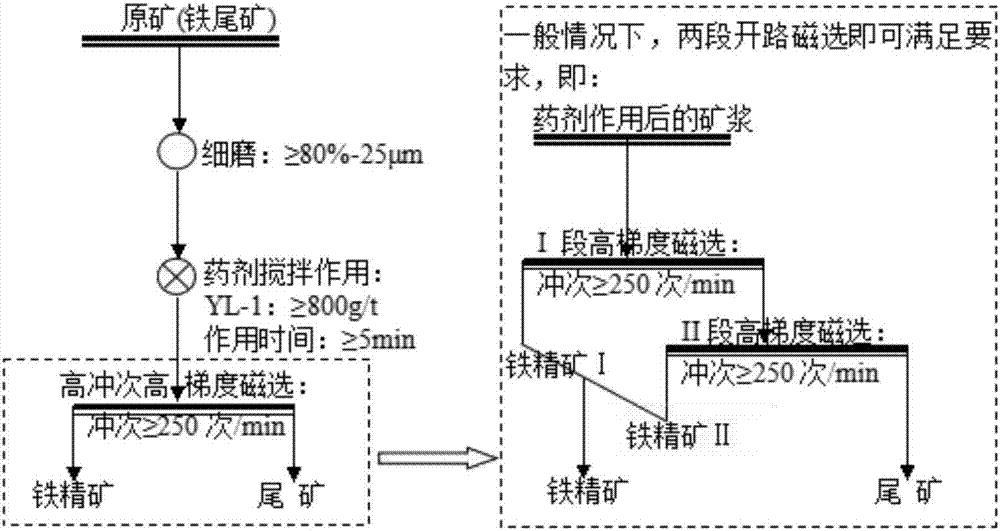

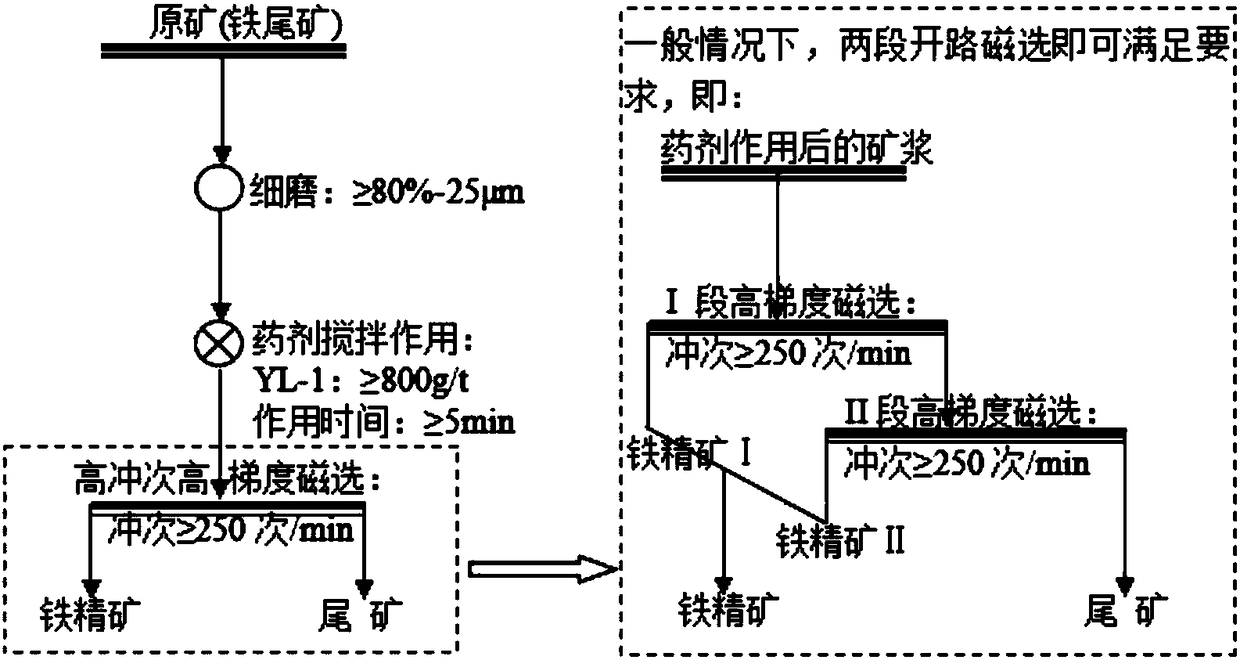

Novel technology for iron tailing reconcentration

ActiveCN107029873ALow iron gradeFully dissociatedSolid separationMechanical material recoveryLower gradeLow graded

The invention relates to a technological method for iron tailing reconcentration, in particular to a novel technology for iron tailing reconcentration and belongs to the field of mineral concentration and resource comprehensive utilization. The novel technology for iron tailing reconcentration is particularly suitable for fine-sized low-grade iron tailings. The novel technology for the iron tailing reconcentration comprises the steps that (1) fine grinding is conducted, wherein the iron tailings are further grinded, the fineness of the grounded tailing products are controlled to be that the products with the fineness being -25 microns accounting for over 80%; (2) an agent acts, wherein the agent YL-1 is added to the fine grinded pulp, the agent and the pulp mutually act for over 5 min under the stirring condition, the dosage of the agent YL-1 is not lower than 800 g / (t raw ores), and the agent YL-1 comprises, by weight, 80%-90% of sodium silicate, 8%-18% of ammonium sulfate and 0.5%-2% of nonionic polyacrylamide; (3) high-jig-frequency high-gradient magnetic separation is conducted, wherein the pulp obtained after the agent acts is fed into a high-gradient strong magnetic separation machine, magnetic separation is conducted under the condition of the high jig frequency, and during high-gradient magnetic separation, the jig frequency is not lower than 250 times / min. By the adoption of the novel technology for the iron tailing reconcentration, reconcentration of the iron tailings can be effectively achieved, namely efficient recycling of iron in the tailings is achieved, the process is simple, the production cost is low, and operation and implementation are easy.

Owner:KUNMING UNIV OF SCI & TECH

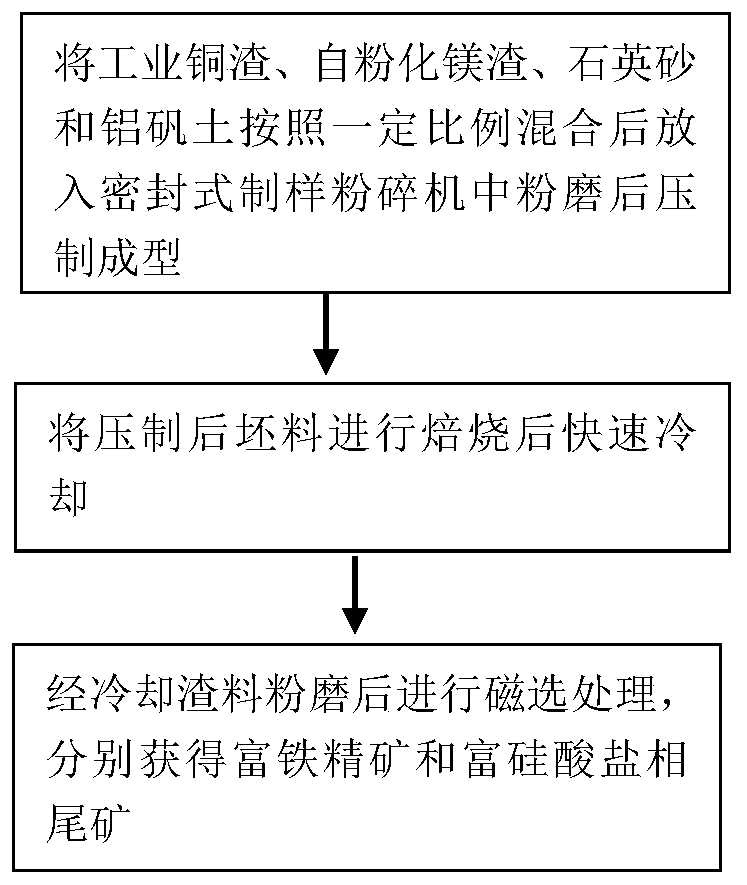

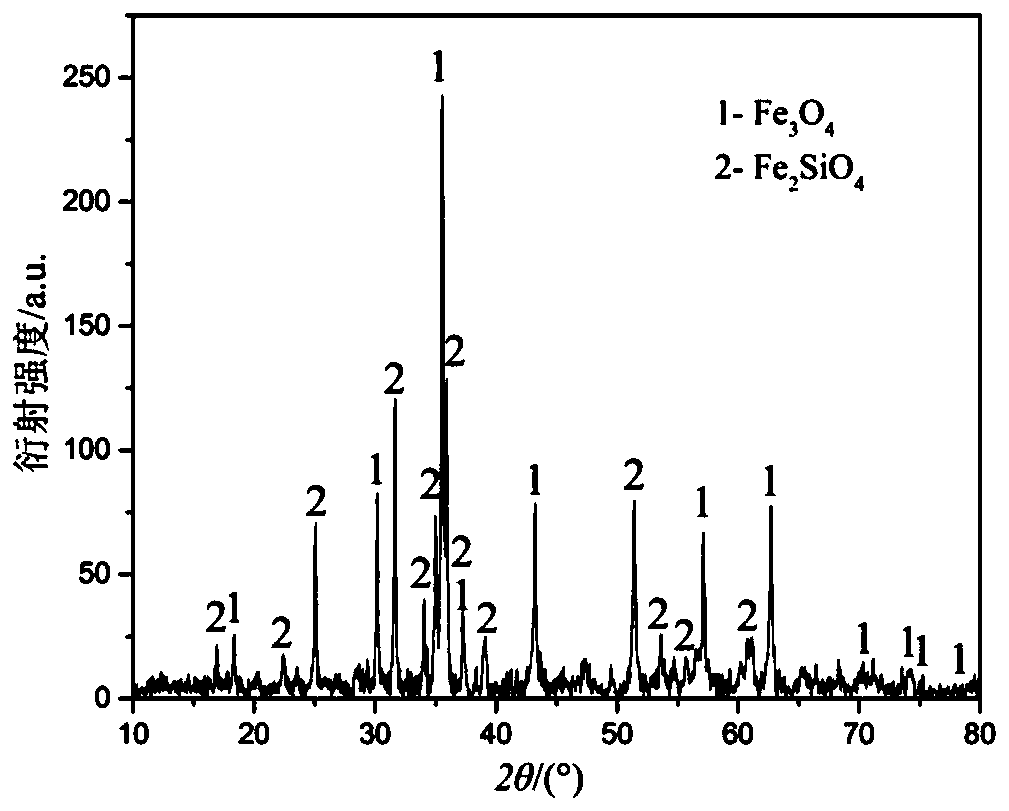

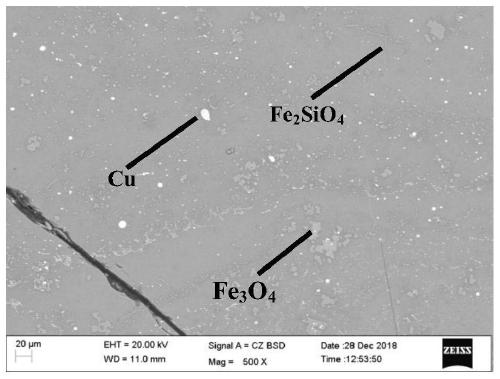

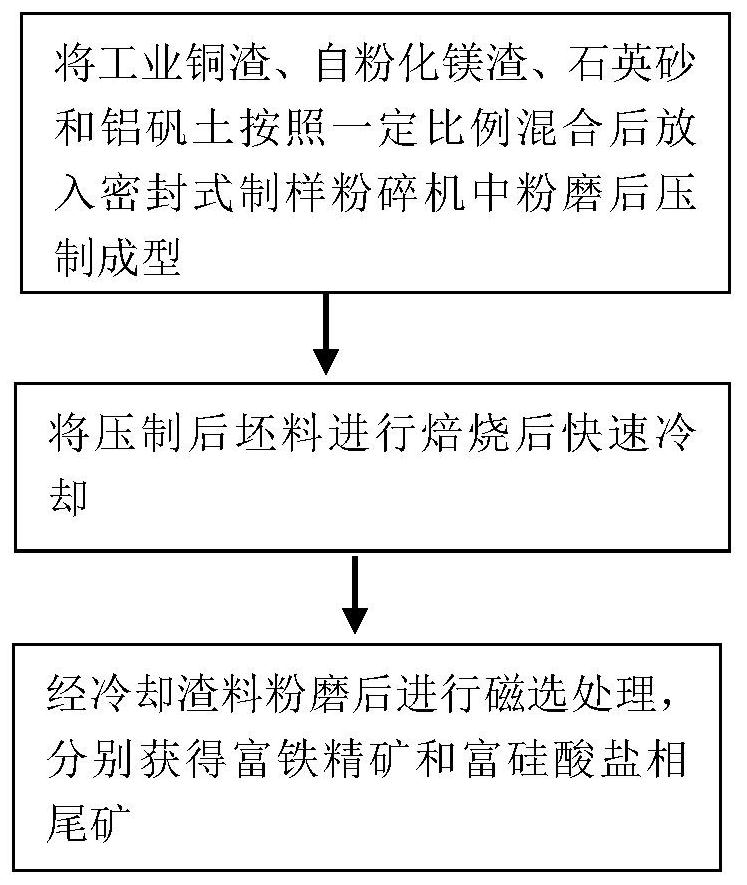

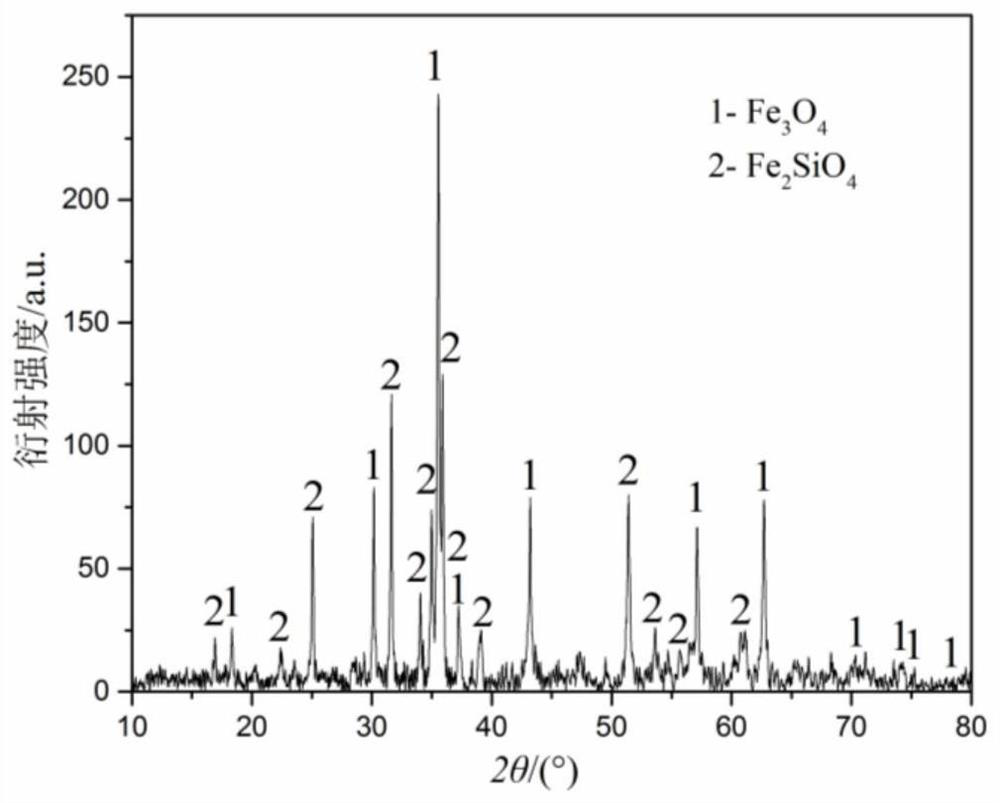

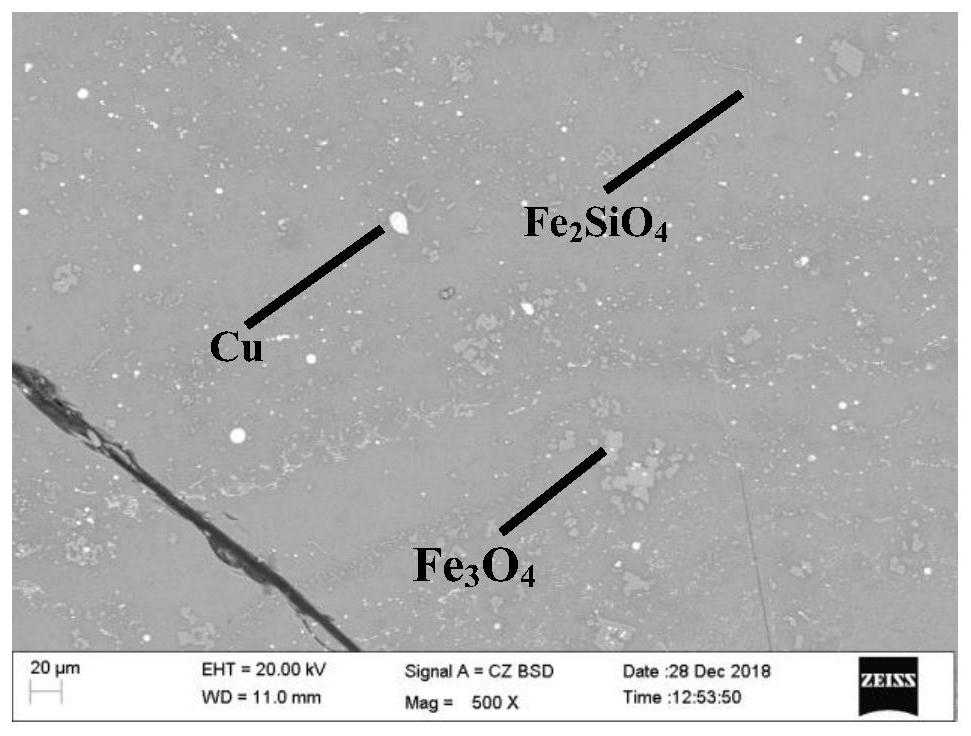

Method used for combined treatment of copper slag and magnesium slag, and applications thereof

The invention relates to a method used for combined treatment of copper slag and magnesium slag, and applications thereof, and belongs to the technical field of metallurgy. The method comprises following steps: 1, industrial copper slag and self-pulverization magnesium slag are mixed at a mass ratio of (50-90):100 so as to obtain a mixed slag, the mixed slag is grinded until particle size is lowerthan 200 meshes, uniform mixing is carried out, and compacting is carried out so as to obtain pie-shaped mixed slag; and 2, the pie-shaped mixed slag is introduced into a muffle furnace, the temperature is increased to 1100 to 1300 DEG C at air atmosphere, constant temperature roasting is carried out for 1 to 3h, after roasting, obtained samples are taken out from the muffle furnace, are cooled with compressed air, and are subjected to fine grinding and magnetic separation so as to obtain iron-rich concentrate and silicate-rich phase mine tailing. The magnetic separation products can be usedin thermal insulation refractory materials and building materials; after improvement, mixed slag magnetic separation yield is increased from 38.71% to 69%; the recovery rate is increased from 52.07% to 81.14%; and mixed slag magnetic separation concentrate yield and recovery rate are increased greatly.

Owner:BEIFANG UNIV OF NATITIES

A method and application of combined treatment of copper slag and magnesium slag

The invention relates to a method and application for jointly treating copper slag and magnesium slag, belonging to the technical field of metallurgy. The treatment method of the present invention is specifically as follows: (1) industrial copper slag and self-powdering magnesium slag are mixed according to the mass ratio of (50-90): 100 to obtain mixed slag, then finely ground to below 200 mesh, mixed and pressed into a cake shape to obtain a cake-shaped mixed slag; (2) put the cake-shaped mixed slag in a muffle furnace, raise the temperature to 1100-1300°C in an air atmosphere, and then roast at a constant temperature for 1-3 hours. After the roasting is completed, take out the sample, Use compressed air to cool, then finely grind and magnetically separate to obtain iron-rich concentrate and silicate-rich tailings. The magnetic separation product of the present invention can be used for thermal insulation refractory materials and building materials respectively. After being modified by the invention, the yield of magnetic separation of mixed slag is increased from 38.71% to 69%; the recovery rate is increased from 52.07% to 81.14%, and the yield and recovery rate of magnetic separation concentrate of mixed slag are greatly improved.

Owner:BEIFANG UNIV OF NATITIES

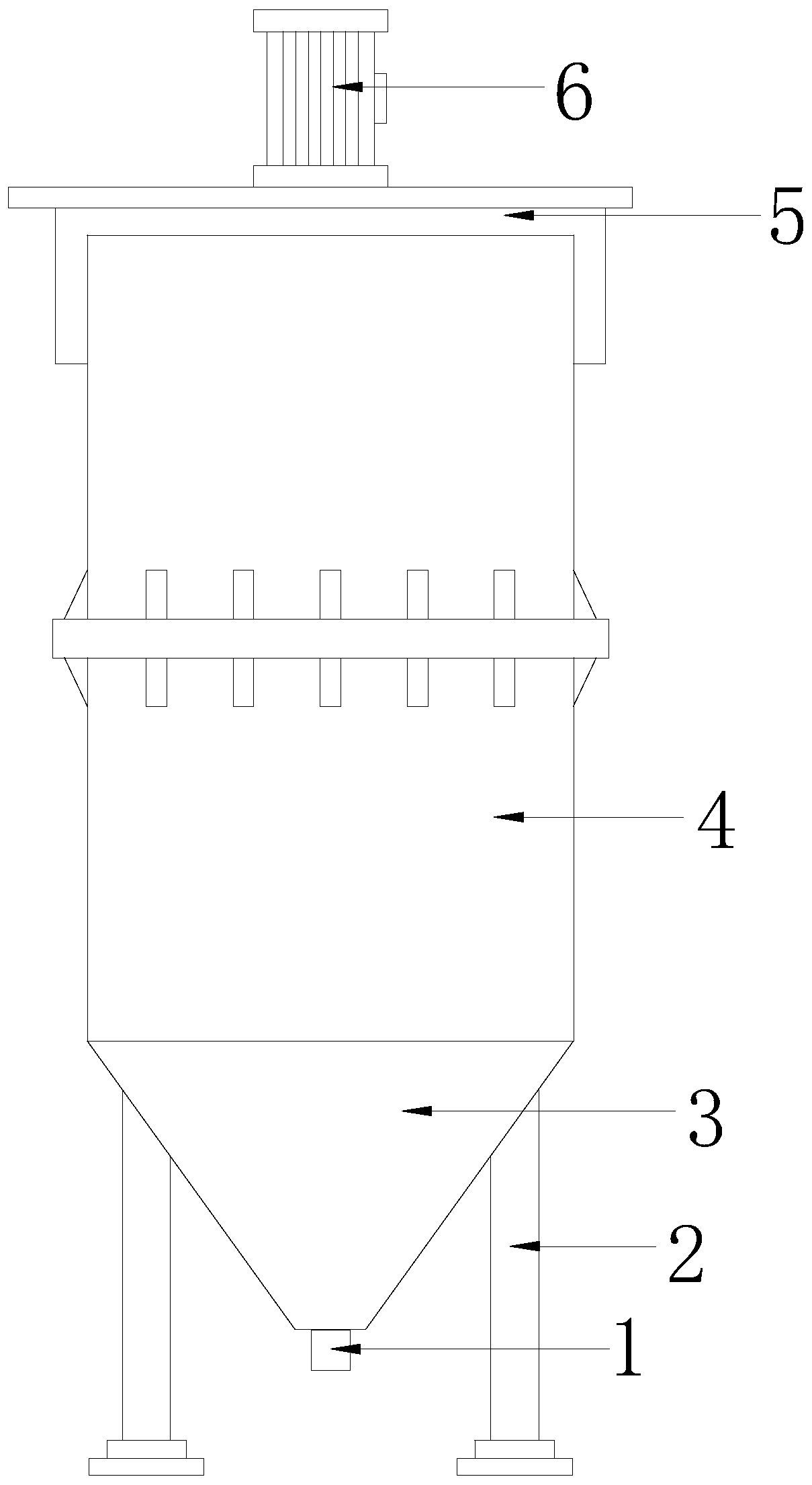

Double-cylinder magnetite fine powder grade improving machine based on centrifugal force

The invention discloses a double-cylinder magnetite fine powder grade improving machine based on centrifugal force. The grade improving machine structurally comprises an ore fine powder outlet, a bracket, a pouring hopper, an iron ore fine powder improving machine body, a top cover and a driving device, wherein the bottom of the iron ore fine powder improving machine body is connected with the pouring hopper with the iron ore fine powder outlet; the pouring hopper is vertically connected with the bracket; and the top of the iron ore fine powder improving machine body is connected with the topcover. Compared with the prior art, the grade improving machine has the beneficial effects that ore pulp can be comprehensively stirred through the combined arrangement of a rotating shaft, a stirringgroup, a double-layer cylinder and a connecting sleeve, the stirring is sufficient, the pulp is enabled to be more uniform, the ore fine powder is prevented from being wrapped by impurities, the orefine powder is prevented from being discharged without being magnetically separated, the waste of the ore fine powder is avoided, magnetic separation is carried out on light ore fine powder through aU-shaped permanent magnet, the ore fine powder is further attracted, the magnetic separation effect is improved, the ore fine powder on the wall of the cylinder body can be scraped off through a scraping plate, the situation that the magnetic force of the fine iron powder is weakened due to the fact that the cylinder body is full of the ore fine powder is avoided, and the magnetic separation is better facilitated.

Owner:南安米巢装饰设计有限公司

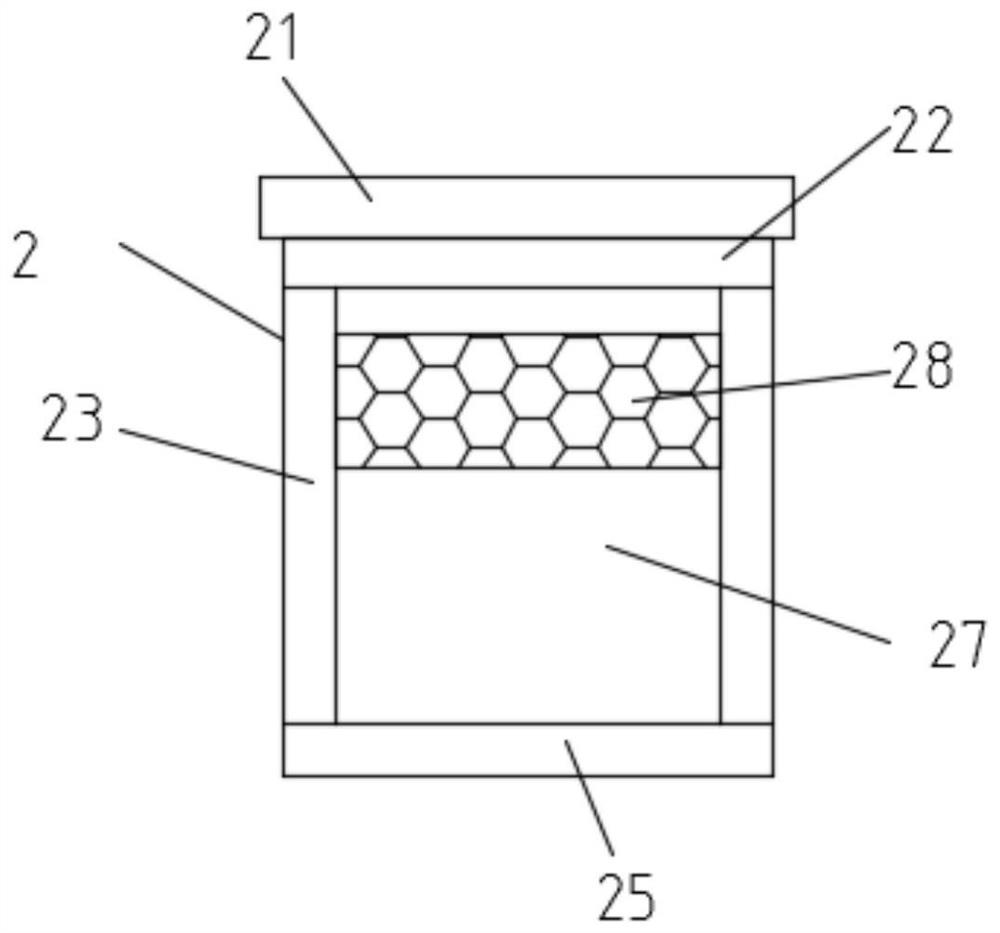

Graded screen mesh type big-lumpiness magnetic separator for producing potassium phosphate mineral substance

The invention discloses a graded screen mesh type big-lumpiness magnetic separator for producing a potassium phosphate mineral substance and relates to the technical field of potassium phosphate mineral substance screening devices. The graded screen mesh type big-lumpiness magnetic separator comprises a box body, wherein one side of the upper end in the box body is fixedly connected with a first screen mesh; one end, penetrating through the box body, of the first screen mesh is fixedly connected with a fixing device; the other end of the first screen mesh is fixedly connected with a crushing device; a washing device is fixedly connected with the lower end of the crushing device; a magnetic rotary barrel is fixedly connected with one side of the lower end of the washing device; the lower end of the magnetic rotary barrel is fixedly connected with a conveyor belt; one side of the lower end of the conveyor belt is fixedly connected with a second screen mesh; a clamping handle is fixedly connected with the middle part of one side of the fixing device; one end of the clamping handle is fixedly connected with a clamping strip; one side of the clamping strip is fixedly connected with a clamping block; a spring is sleeved with the lower end of the clamping strip. The graded screen mesh type big-lumpiness magnetic separator for producing the potassium phosphate mineral substance can beused for sufficiently sieving mineral aggregate; the magnetic concentration efficiency is improved and wastes of resources are avoided.

Owner:SUQIAN MODERN CHEM

A new process for re-election of iron tailings

ActiveCN107029873BLow iron gradeFully dissociatedSolid separationMechanical material recoveryLower gradeLow graded

The invention relates to a technological method for iron tailing reconcentration, in particular to a novel technology for iron tailing reconcentration and belongs to the field of mineral concentration and resource comprehensive utilization. The novel technology for iron tailing reconcentration is particularly suitable for fine-sized low-grade iron tailings. The novel technology for the iron tailing reconcentration comprises the steps that (1) fine grinding is conducted, wherein the iron tailings are further grinded, the fineness of the grounded tailing products are controlled to be that the products with the fineness being -25 microns accounting for over 80%; (2) an agent acts, wherein the agent YL-1 is added to the fine grinded pulp, the agent and the pulp mutually act for over 5 min under the stirring condition, the dosage of the agent YL-1 is not lower than 800 g / (t raw ores), and the agent YL-1 comprises, by weight, 80%-90% of sodium silicate, 8%-18% of ammonium sulfate and 0.5%-2% of nonionic polyacrylamide; (3) high-jig-frequency high-gradient magnetic separation is conducted, wherein the pulp obtained after the agent acts is fed into a high-gradient strong magnetic separation machine, magnetic separation is conducted under the condition of the high jig frequency, and during high-gradient magnetic separation, the jig frequency is not lower than 250 times / min. By the adoption of the novel technology for the iron tailing reconcentration, reconcentration of the iron tailings can be effectively achieved, namely efficient recycling of iron in the tailings is achieved, the process is simple, the production cost is low, and operation and implementation are easy.

Owner:KUNMING UNIV OF SCI & TECH

Stone cutting sewage treatment device and use method thereof

ActiveCN112776191AEasy to pull outEasy to cleanWorking accessoriesStone-like material working toolsIron powderSewage

The invention discloses a stone cutting sewage treatment device and a use method thereof. The device comprises a sewage pipeline, three filtering mechanisms, a first-stage separation mechanism, a sorting mechanism, a second-stage separation mechanism, a separation motor, a settling tank, a mounting plate and a driving motor, wherein the sewage pipeline and the filtering mechanisms are located at the upper end of the first-stage separation mechanism, the sewage pipeline is located at the upper ends of the filtering mechanisms, and the three filtering mechanisms are arranged at equal intervals. According to the device, by arranging the filtering mechanisms, the first-stage separation mechanism, the sorting mechanism, the second-stage separation mechanism and the settling tank, product packaging materials, iron powder, rock ballast and powder residues which are contained in sewage are removed or recycled, the problem of excessively frequent cleaning due to excessively fast accumulation of the powder residues at the bottom of the settling tank is solved, the device has important significance in environmental protection, the treatment efficiency and treatment effect of stone processing sewage are improved, and the economic benefit of production is increased.

Owner:中兴惠和(山东)环保科技有限公司

Hot braising method for phosphorus removed slag and carbon removed slag

The invention provides a hot braising method for phosphorus removed slag and carbon removed slag. The method comprises the following steps of: pouring hot phosphorus removed slag into a slag braising pit to parch the slag braising pit; pouring the phosphorus removed slag or the carbon removed slag into multiple parched slag braising pits respectively, turning over, dewatering and breaking the slag in each slag braising pit, then pouring another slag respectively, and repeating the operations of turning over, dewatering and breaking the slag till each slag braising pit is full of the slag; and covering the slag braising pits full of the slag with slag braising covers, and braising the slag in a three-section dewatering and braising mode. The hot braising method for the phosphorus removed slag and the carbon removed slag is simple and feasible, can reduce the potential safety hazard of blasting of the slag braising pits and effectively improve the slag braising efficiency and slag braising quality, and has remarkable economic benefits.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

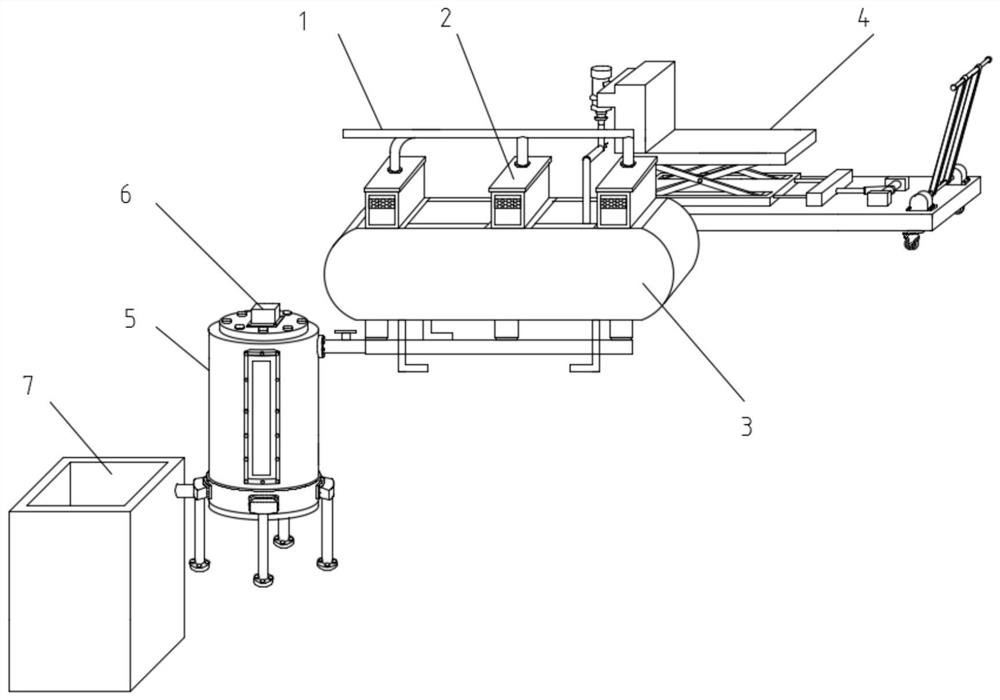

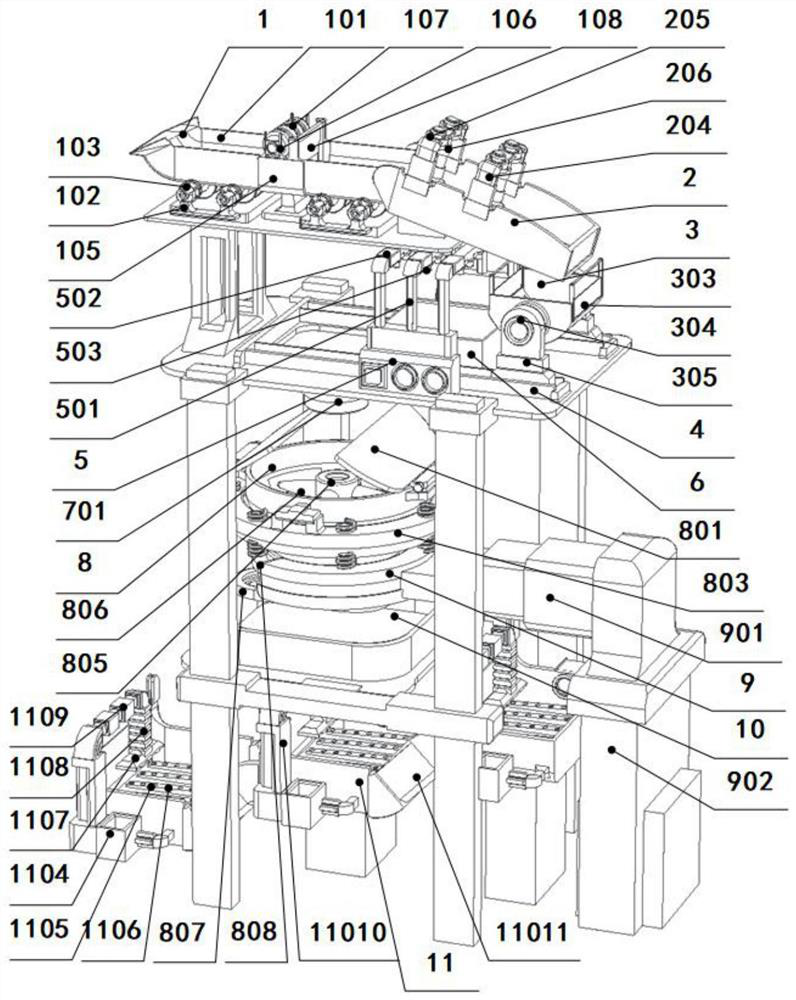

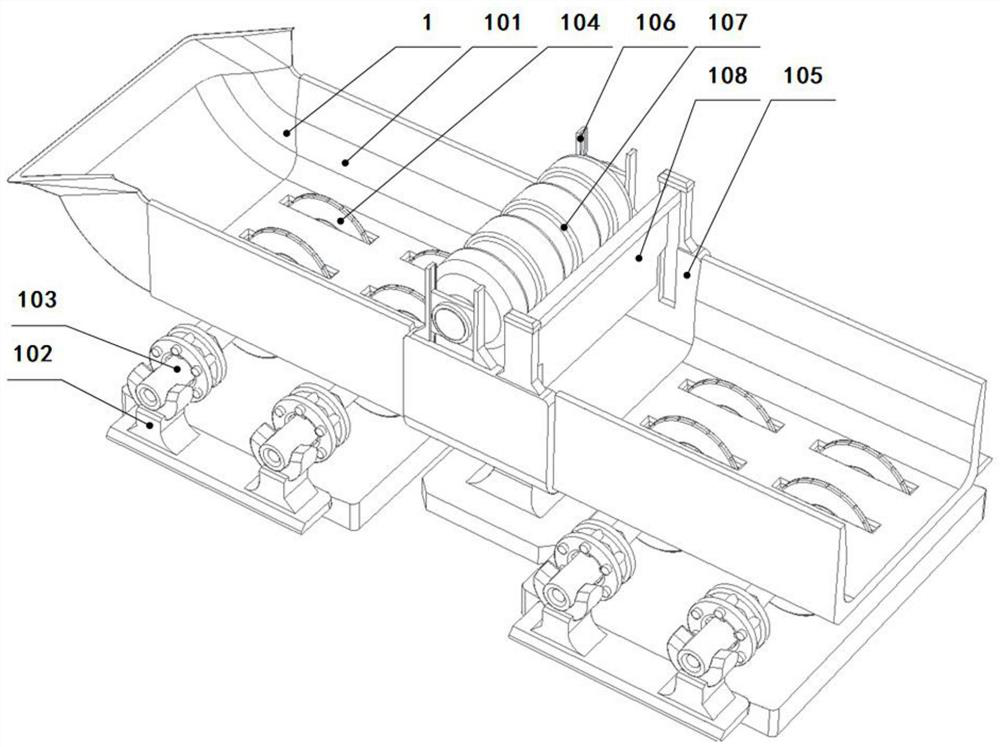

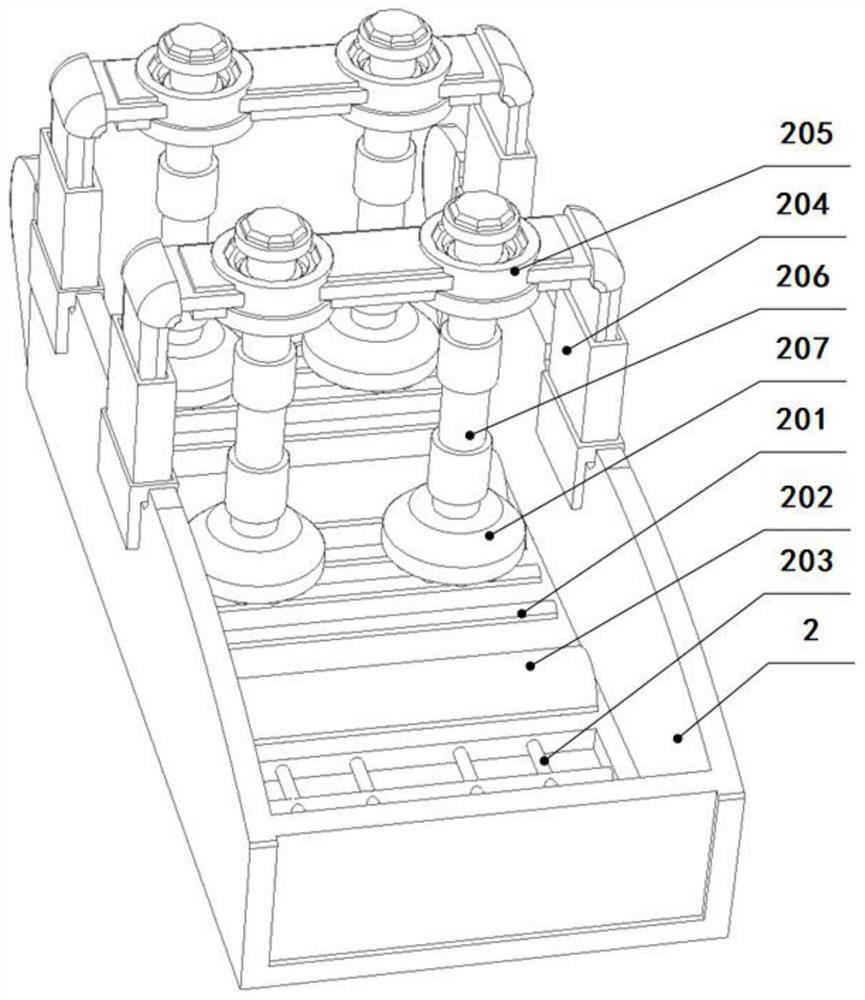

A magnetite beneficiation device

ActiveCN110420726BEliminate potential safety hazardsThe crushing effect is uniform and betterCocoaFlotationMagnetiteEngineering

Owner:山东域潇锆钛矿业股份有限公司

Method for recycling industrial waste sulfate slag

InactiveCN101554613BNo change in physical propertiesHigh recovery rateSolid waste disposalWet separationSocial benefitsSlag

The invention provides a method for recycling industrial waste sulfate slag, which comprises the steps of sieving, stirring, magnetic separation, acid dipping, rinsing and drying to obtain iron-bearing materials. The method not only reallocates the available resource of the sulfate slag which is difficult to be processed and has high pollution, but also reduces the severe contamination of the sulfate slag to the environment and simultaneously lowers the production cost greatly; the metal recovery rate is 50 to 82 percent, high quality iron concentrate with the grade of iron being larger than 60 percent, the grade of sulfur being smaller than 0.3 percent and the grade of arsenic being smaller than 0.1 percent is obtained; simultaneously the recovery processing capacity is large, the equipment is simple, the investment is small, the operation is convenient, the sulfate slag material is not limited, both the sulfate slag with high iron content and the sulfate slag with low iron content can be recycled, and the method has good social benefit and remarkable economic effect.

Owner:房志强 +1

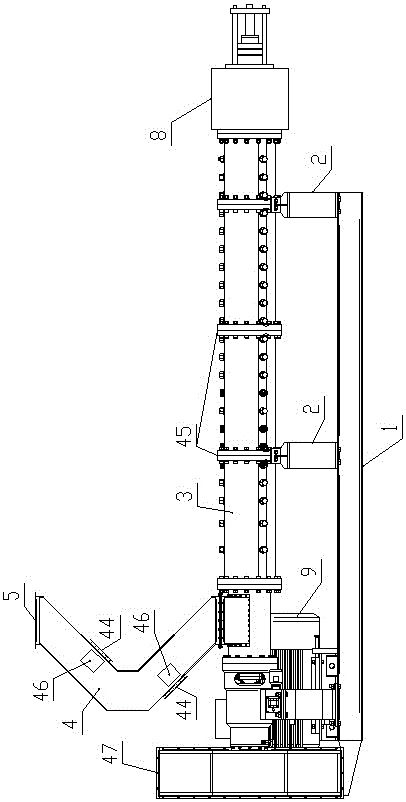

High-temperature pellet cooling device

The invention discloses a high-temperature pellet cooling device which comprises a spiral discharging device,a steam cooling device and a water discharging device. The problems of high-temperature pellet cooling,discharging and steam recovery are systematically solved,the problems of high energy consumption and likely pellet breakage of an indirect cooling mode are avoided,and the problems of inorganized steam discharging and silting caused by a slag basin water quenching mode are also eliminated. The high-temperature pellet cooling device is simple and easy to control,high in production efficiency and wide in application prospect.

Owner:CHONGQING CISDI THERMAL & ENVIRONMENTAL ENG CO LTD +1

Grain bulking machine

InactiveCN105054267AIncrease the heat exchange areaImprove heat transfer efficiencyFood shapingElectric machineryLeather belt

The invention discloses a grain bulking machine which comprises an engine base, wherein a barrel is connected to the engine base; a feeding pipe is upwards communicated to the feeding end of the barrel; an electric motor is arranged at the front side of the engine base and is connected with a small belt pulley; a large belt pulley is connected to the small belt pulley through a driving belt; a pressing bolt assembly is arranged in an inner cavity of the barrel; a discharge opening is connected to the rear end of the barrel; a discharging tail box is connected to the discharge opening; a hydraulic cylinder is arranged on the discharging tail box; an expansion control head in a shape like a frustum with a small front part and a large rear part is arranged at the front end of a piston rod of the hydraulic cylinder; the pressing bolt and a spindle are coaxially arranged and are connected together through a connecting bolt; the large belt pulley is in key connection with the spindle; a cooling heat exchange box is arranged at the front end of the engine base; a front spiral seal and a rear spiral seal are correspondingly arranged on the spindle of the front and rear end parts of a bearing chamber. The grain bulking machine disclosed by the invention has the advantages of good sealing property, uniformity in material stirring, and stability and reliability in work; the thickness of the materials can be controlled, and the cooling of lubricating oil can be kept excellent.

Owner:HUANGHE S & T COLLEGE

Polishing equipment for centrifugal pump parts

ActiveCN113263455AHigh geometric accuracyHigh surface finishAbrasive machine appurtenancesAbrasive blasting machinesPolishingEngineering

The invention discloses polishing equipment for centrifugal pump parts, and relates to the field of centrifugal pump intelligent machining. The grinding equipment mainly comprises a first rotating shaft rotationally arranged on a rack, the first rotating shaft is externally connected with a driving source, a positioning mechanism for fixing an impeller to be machined is arranged on the first rotating shaft, a second rotating shaft rotationally arranged on the rack is arranged beside the first rotating shaft, a spray head unit for polishing a welding seam on the impeller is arranged on the second rotating shaft, the first rotating shaft and the second rotating shaft are connected through a transmission mechanism, and the transmission mechanism is used for controlling the spray head unit to move to align to welding seams on the impeller when the first rotating shaft rotates. According to the polishing equipment, the plurality of welding seams of the centrifugal pump impeller can be automatically polished in sequence, the geometric accuracy and the surface smoothness of the centrifugal pump impeller are improved, and the labor intensity of workers is reduced.

Owner:ANHUI KANGYU HYDROPOWER MACHINERY COMPLETE EQUIP CO LTD

Biochemical preparation method of steel slag powder, cement mixed material and concrete admixture

PendingCN113493316AThe granular structure is looseEliminates magnetic separation processMicroorganism based processesCement productionSlagAqueous solution

The invention relates to a biochemical preparation method of steel slag powder, a cement mixed material and a concrete admixture, and the biochemical preparation method comprises the following steps: S1, biochemical treatment: soaking steel slag in an aqueous solution of iron-oxidizing bacteria to convert elemental iron and Fe < 2 + > in the steel slag into Fe < 3 + > until the concentration of Fe < 2 + > in the aqueous solution is reduced and is kept stable to form a reaction solution; and S2, drying and grinding: taking out a solid-phase product from the reaction solution, drying and grinding to form steel slag powder. The prepared steel slag powder is applied as the cement mixed material or concrete admixture. The steel slag is subjected to early-stage biochemical treatment, so that the particle compact structure of the steel slag becomes loose, and the grindability is greatly improved. The powder abrasion energy of the treated steel slag is reduced in the grinding process, the grinding efficiency of the steel slag is improved, the reutilization rate of the steel slag is further improved, and resource waste and environmental pressure caused by discharge of a large amount of steel slag are reduced.

Owner:BUILDERA CONSTR TECH SHANGHAI CO LTD

A rotary magnetic separation equipment for building material quartz sand

ActiveCN108405174BConvenient for magnetic separationUniform magnetic separationMagnetic separationConveyor partsMagnetic separatorElectric machinery

Owner:HAIMEN THE YELLOW SEA ENTREPRENEURSHIP PARK SERVICE CO LTD

Grain extruder

InactiveCN105054267BImprove cooling effectImprove heat transfer efficiencyFood shapingHydraulic cylinderEngineering

The invention discloses a grain bulking machine which comprises an engine base, wherein a barrel is connected to the engine base; a feeding pipe is upwards communicated to the feeding end of the barrel; an electric motor is arranged at the front side of the engine base and is connected with a small belt pulley; a large belt pulley is connected to the small belt pulley through a driving belt; a pressing bolt assembly is arranged in an inner cavity of the barrel; a discharge opening is connected to the rear end of the barrel; a discharging tail box is connected to the discharge opening; a hydraulic cylinder is arranged on the discharging tail box; an expansion control head in a shape like a frustum with a small front part and a large rear part is arranged at the front end of a piston rod of the hydraulic cylinder; the pressing bolt and a spindle are coaxially arranged and are connected together through a connecting bolt; the large belt pulley is in key connection with the spindle; a cooling heat exchange box is arranged at the front end of the engine base; a front spiral seal and a rear spiral seal are correspondingly arranged on the spindle of the front and rear end parts of a bearing chamber. The grain bulking machine disclosed by the invention has the advantages of good sealing property, uniformity in material stirring, and stability and reliability in work; the thickness of the materials can be controlled, and the cooling of lubricating oil can be kept excellent.

Owner:HUANGHE S & T COLLEGE

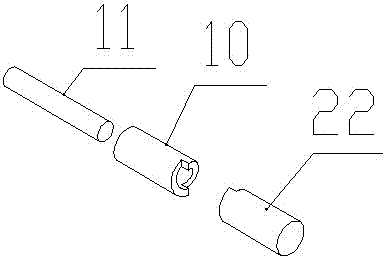

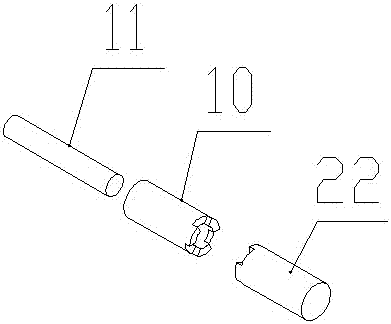

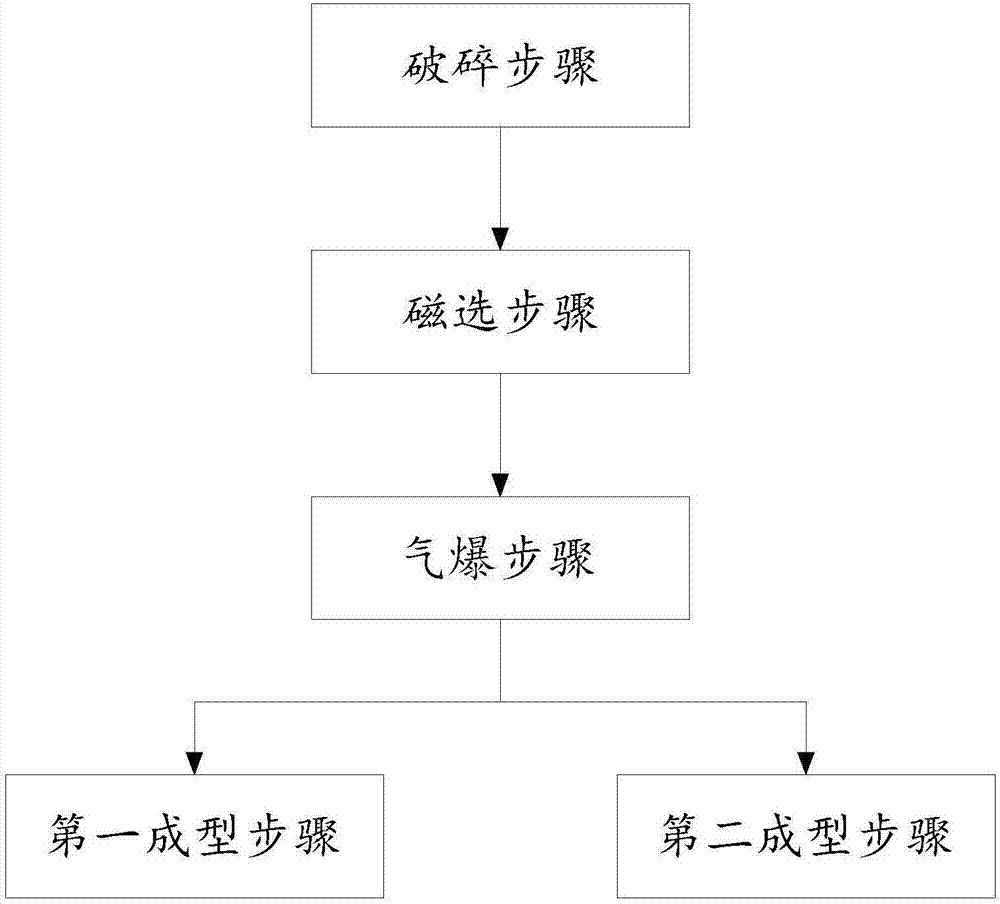

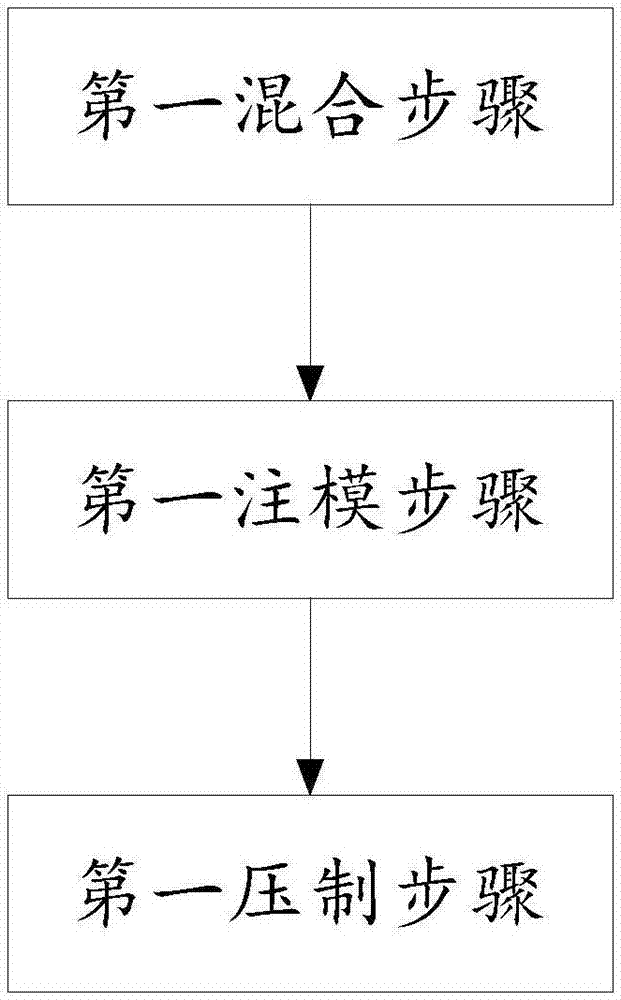

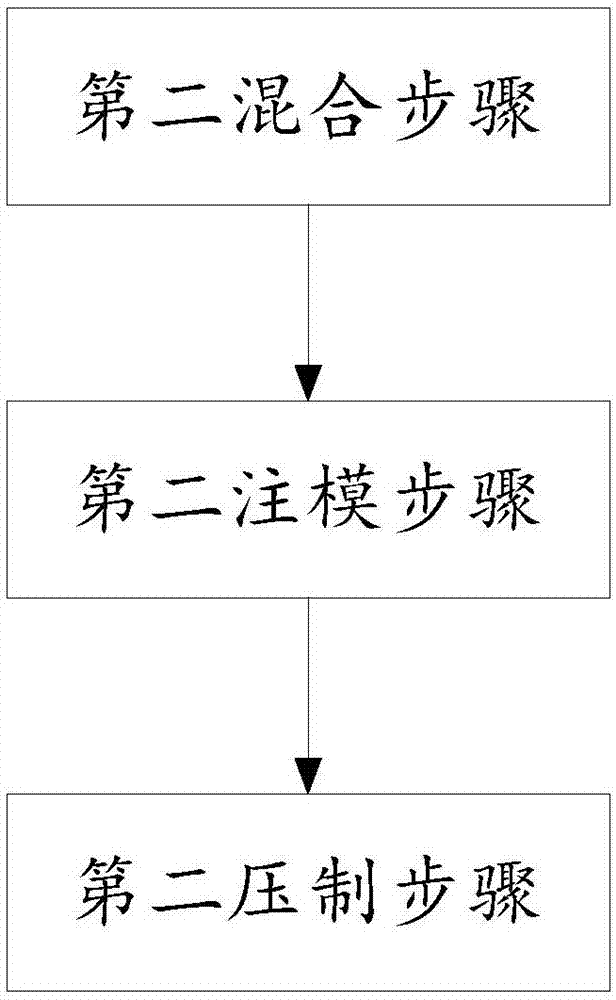

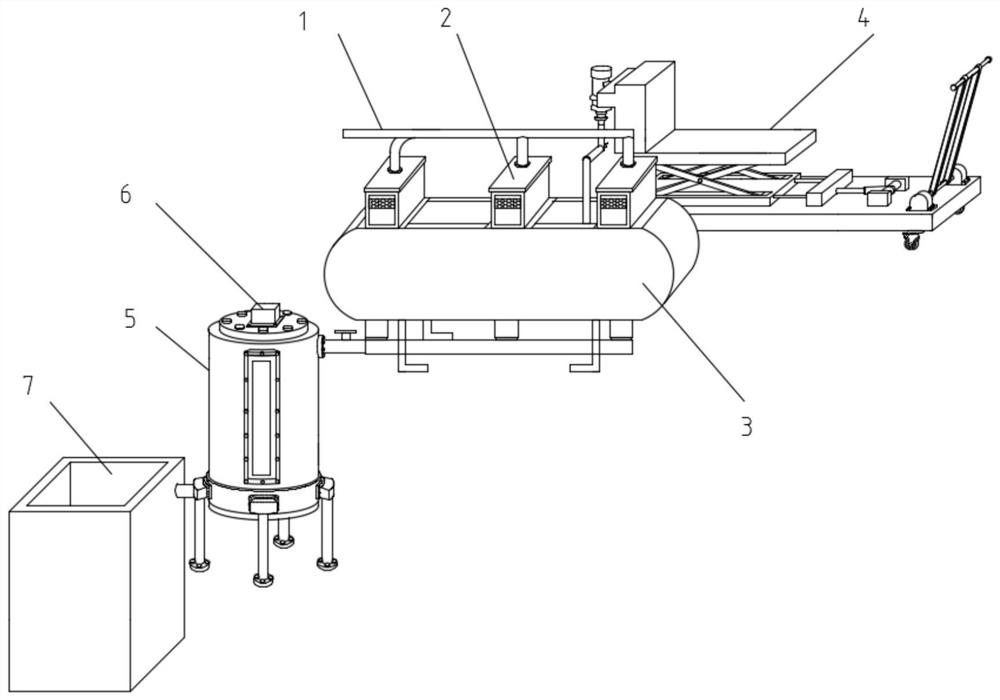

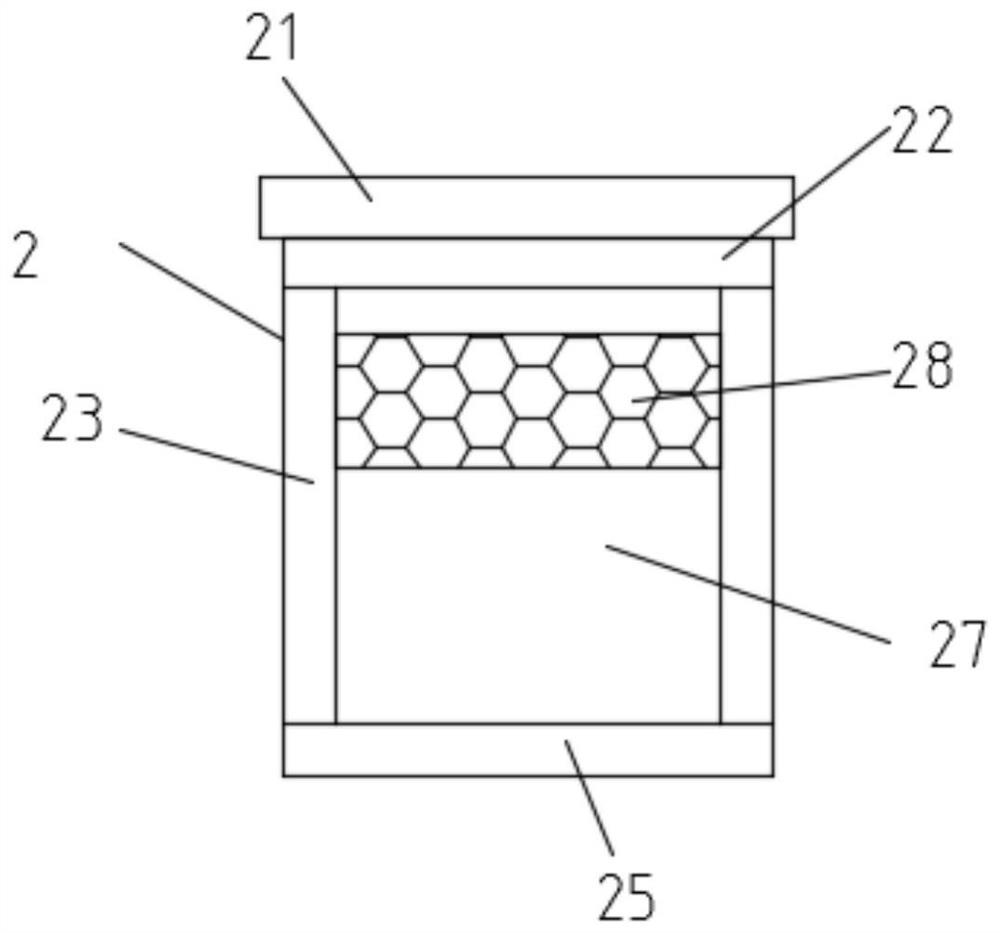

Solid waste material regeneration method and solid waste material regeneration device

InactiveCN107226631AAchieve regenerationSolve pollutionSolid waste managementEnvironmental engineeringGas explosion

The invention provides a solid waste material regeneration method and a solid waste material regeneration device, and belongs to the field of waste material treatment. The solid waste material regeneration method comprises the following steps of a crushing step: performing crushing treatment on solid waste materials to obtain crushed materials; a magnetic separation step: separating the crushed materials into magnetic materials and demagnetized materials; a gas explosion step: separating the demagnetized materials into solid-state mixtures and muddy-state mixtures; a first shaping step: combining the solid-state mixtures with first bonding materials to form first materials; a second shaping step: bonding the muddy-state mixtures with second bonding materials to form second materials. The solid waste material regeneration device comprises a crushing device, a magnetic separation device, a gas explosion generation device, a shaping device and a pressing device. The solid waste material regeneration method and the solid waste material regeneration device have the advantages that the regeneration of the solid waste materials can be realized; the pollution problem due to improper treatment of the solid waste material can be effectively solved.

Owner:林朴

A kind of steel slag hair slag method

ActiveCN106521055BReduce moisture contentEasy to separateRecycling and recovery technologiesProcess efficiency improvementSlagBall mill

The invention discloses a slagging method for slag. The slagging method for slag comprises the steps of: stopping spraying water when the inner side of the slag is red, shortening the slagging time and controlling the slagging water quantity; and evaporating the slag on the surface by virtue of the temperature of the red slag, blending the high-temperature red slag with the slag and conveying the mixture to a magnetic separation work section site to be continuously cured to prolong the curing time and accelerate separation of the slag and iron, wherein magnetic separation is further facilitated and free calcium oxide in the slag is further exerted to the maximum extent. Meanwhile, the water content of the slag is reduced, the hidden danger that the slag which is high in humidity is sticky to equipment such as a belt and a magnetic separation barrel is eliminated, the metal iron recovery rate is improved, and the purposes of directly improving the output of washed grained iron and washed ball-milled waste slag steel, decreasing the cost and increasing the benefit are achieved.

Owner:WUKUN STEEL

A stone cutting sewage treatment device and its application method

ActiveCN112776191BEasy to pull outEasy to cleanWorking accessoriesStone-like material working toolsIron powderSlag

Owner:中兴惠和(山东)环保科技有限公司

Iron ore classificator

PendingCN114798165AConvenient for magnetic separationEvenly dispersedMagnetic separationCleaning using liquidsMining engineeringElectric machinery

The invention relates to the technical field of classifiers, in particular to an iron ore classification.The iron ore classification.The iron ore classificationcomprises a classificationequipment body, a first shell, a device groove, a feeding pipe, a barrel and a water spraying pipe, an arc-shaped plate is further fixedly installed in the device groove, and a transmission mechanism used for improving the screening efficiency of iron ore raw materials is arranged above the arc-shaped plate. Iron ore raw materials are fed into the device groove through the feeding pipe, then a first motor outside the fine selection equipment body is started, the materials can fall down through a plurality of material guiding openings in the bottom of an arc-shaped plate in the moving process, magnetic separation can be conveniently conducted on the materials through a rotating barrel, the falling materials can be evenly dispersed in the device groove, and the magnetic separation efficiency is improved. And therefore, the situation that separation is not timely enough due to too fast ore feeding is effectively avoided.

Owner:陈俊

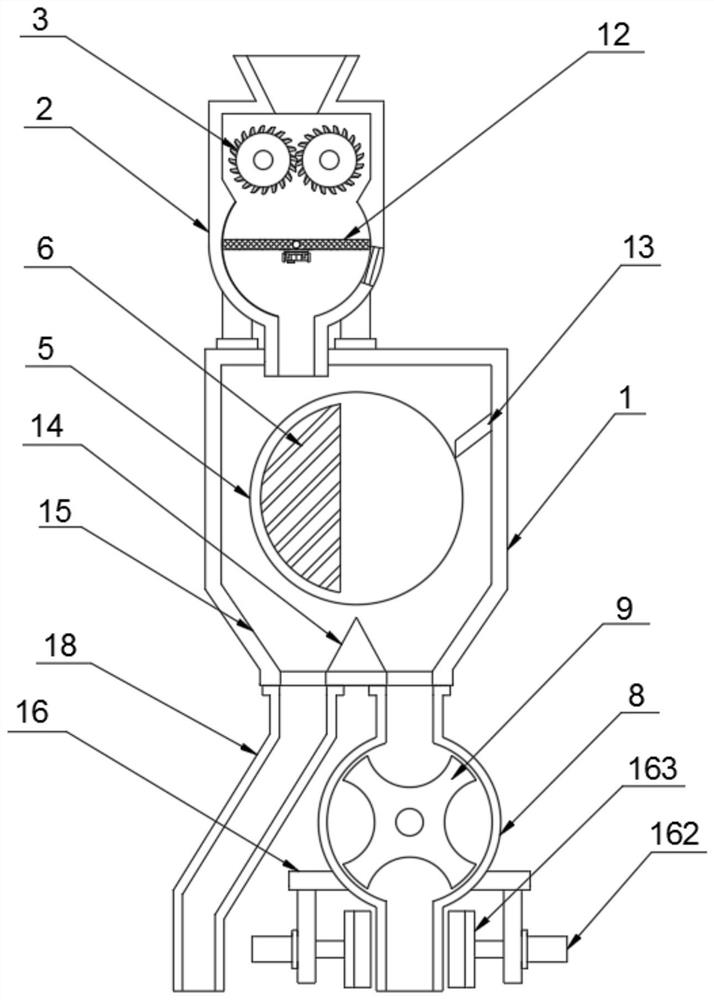

Multi-stage magnetic separation device for pyrolysis carbon black and working method

PendingCN114749274AImprove machining accuracyConvenient for magnetic separationMagnetic separationGrain treatmentsTransmission beltMagnetic separator

The invention discloses a multi-stage magnetic separation device for cracked carbon black and a working method, and relates to the technical field of waste tire thermal cracking equipment, the multi-stage magnetic separation device comprises a rack, and the rack is sequentially provided with a feeding hopper, a crushing mechanism, a first-stage magnetic separation mechanism, a second-stage magnetic separation mechanism, a third-stage magnetic separation mechanism, a speed reducer and an electric cabinet from top to bottom; the crushing mechanism is installed in the feeding hopper, the first-stage magnetic separation mechanism is in transmission connection with the speed reducer through a transmission belt, the second-stage magnetic separation mechanism is in transmission connection with the first-stage magnetic separation mechanism through a transmission belt, and the third-stage magnetic separation mechanism is in transmission connection with the second-stage magnetic separation mechanism through a transmission belt. According to the multi-stage magnetic separation device for the cracked carbon black and the working method, after the cracked carbon black material is conveyed into the feeding hopper, the material is crushed under the action of the crushing mechanism, so that the caked carbon black and steel wires can be separated, the subsequent magnetic separation operation is facilitated, and the processing precision of magnetic separation is improved.

Owner:安徽省克林泰迩再生资源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com