Patents

Literature

288results about How to "Fully screened" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

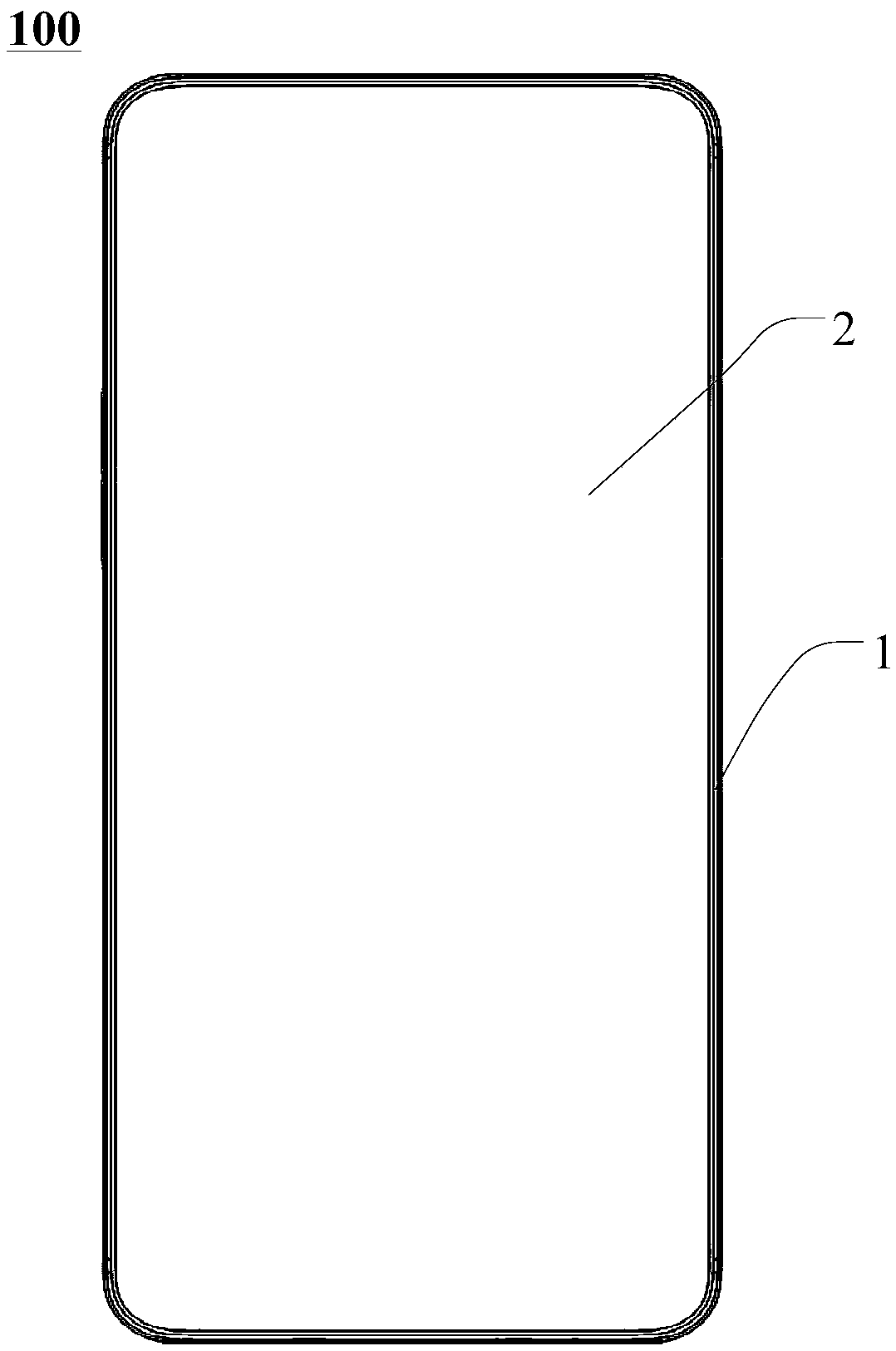

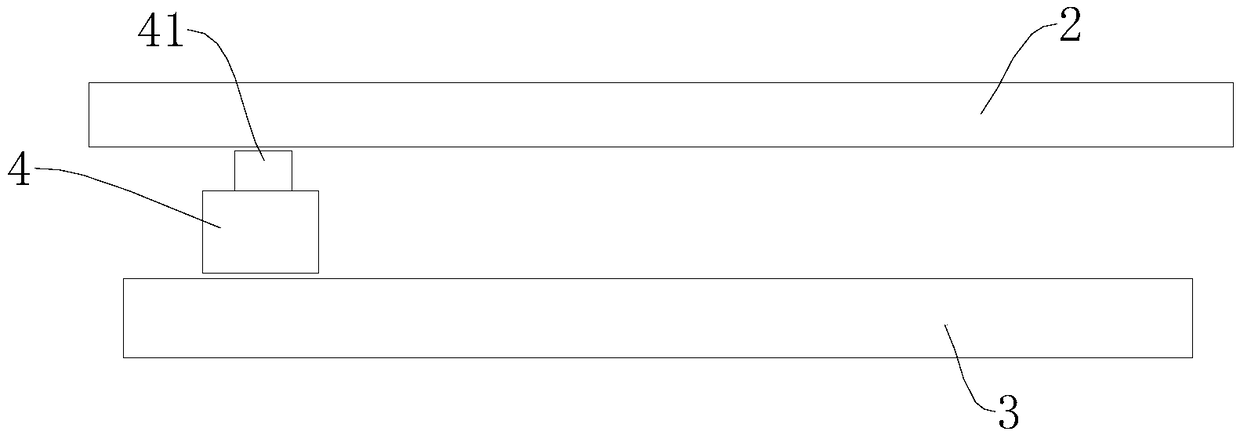

Electronic device

PendingCN108881530AIncrease the screen ratioImprove image qualityTelevision system detailsColor television detailsPixel densityImaging quality

The application discloses an electronic device. The electronic device comprises a motherboard, a display screen and a camera; wherein the display screen is connected to the motherboard, and the display screen comprises a first display area and a second display area; the pixel density of the first display area is smaller than the pixel density of the second display area, the first display area comprises at least one first pixel unit, and the second display area comprises a plurality of second pixel units arranged in an array; each of the first pixel unit and the second pixel unit comprises three sub-pixels R, G, and B; and the pixel area of at least one of the three sub-pixels R, G, and B of the first pixel unit is larger than the pixel area of any one of the sub-pixels R, G, B of the second pixel unit; and the camera is connected to the motherboard, the camera is arranged on a side of the display screen adjacent to the motherboard, and the lens of the camera is opposite to the first display area. According to the electronic device disclosed by the application, the screen ratio of the electronic device can be improved, and the imaging quality of the camera can be ensured.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

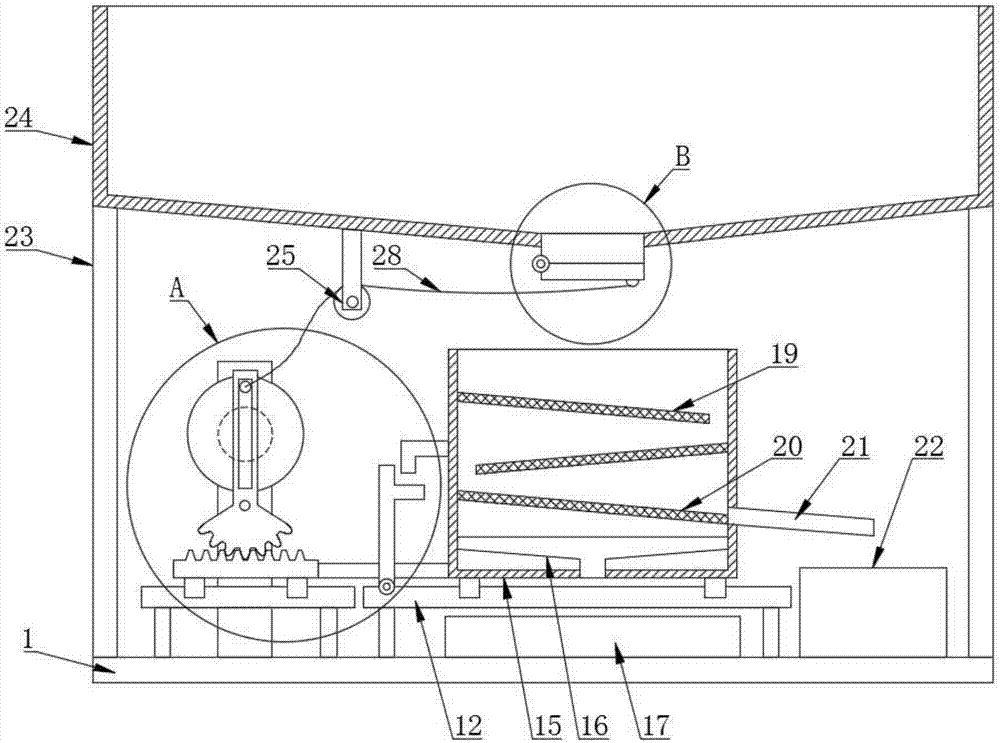

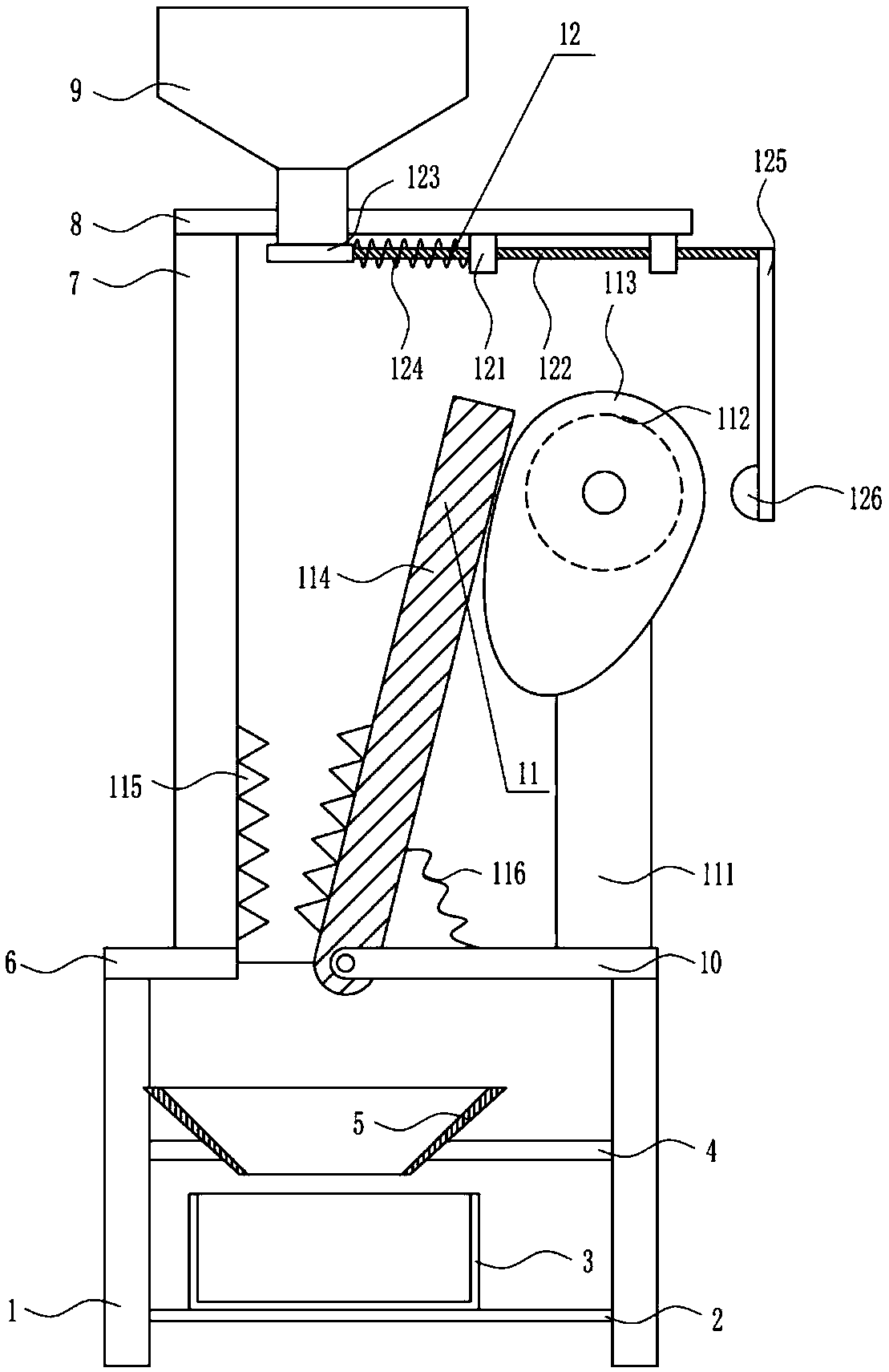

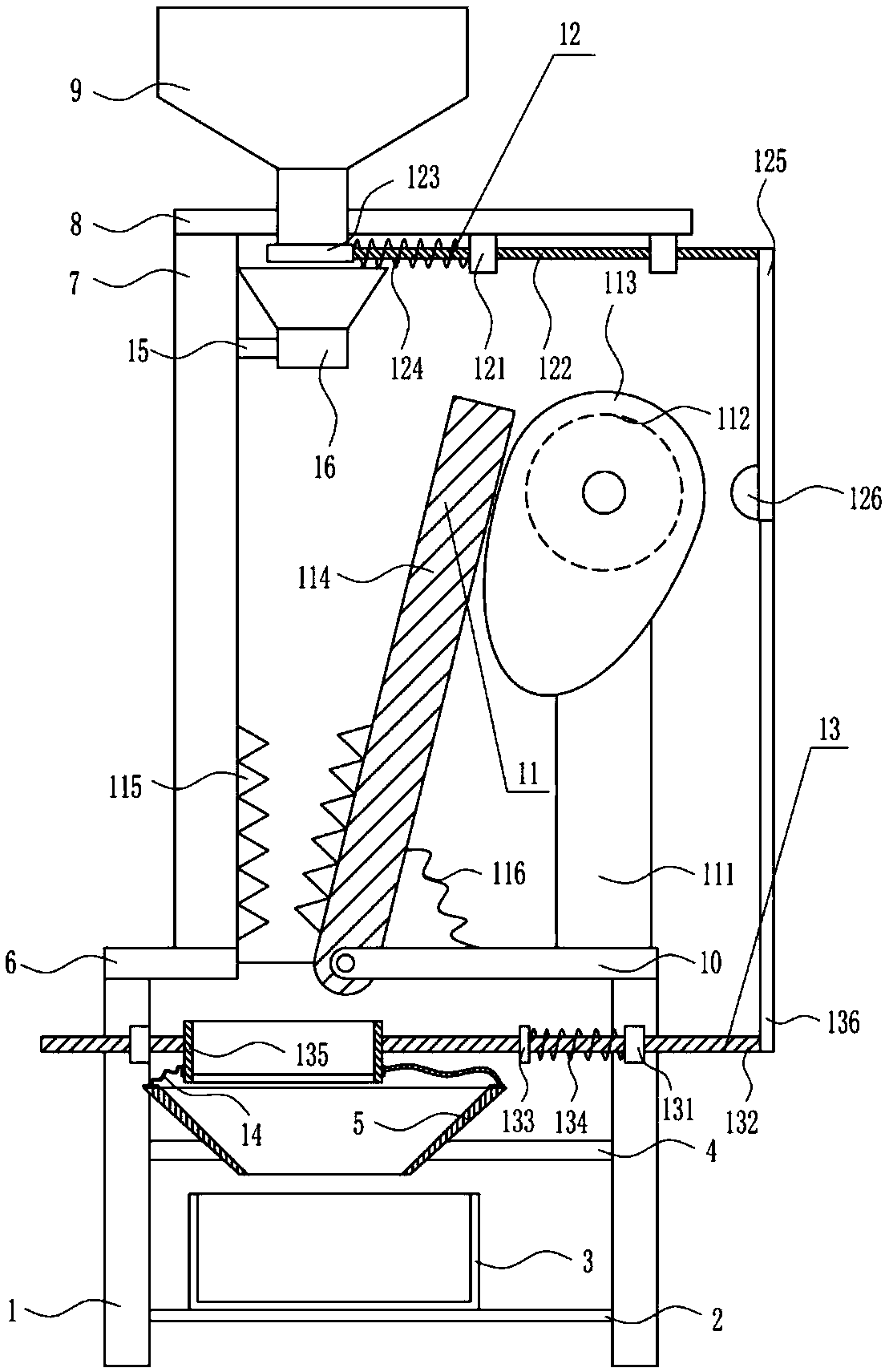

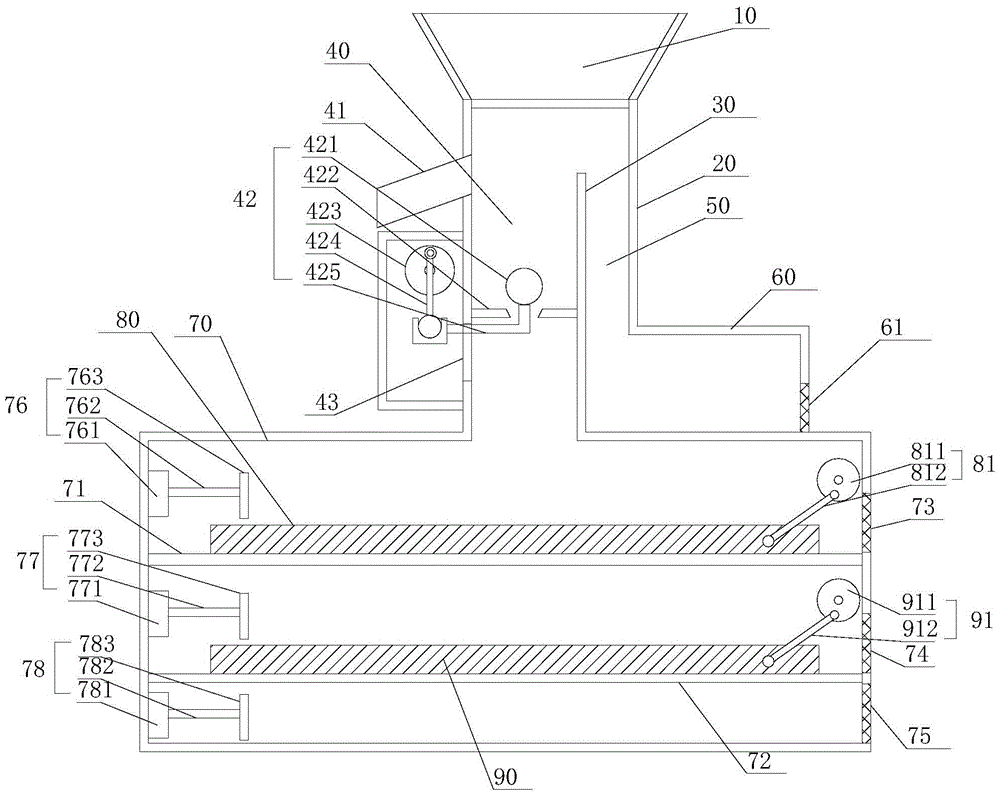

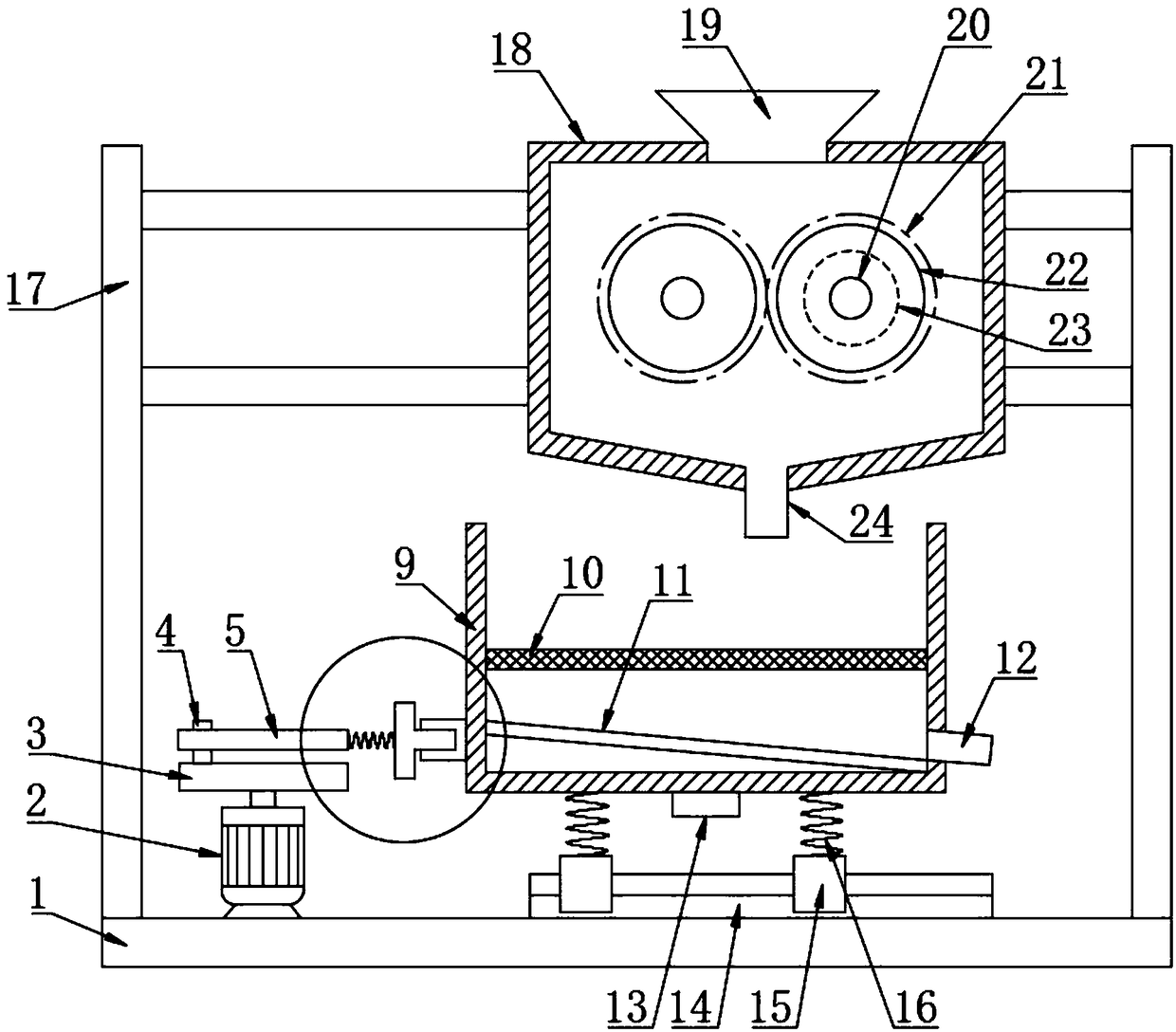

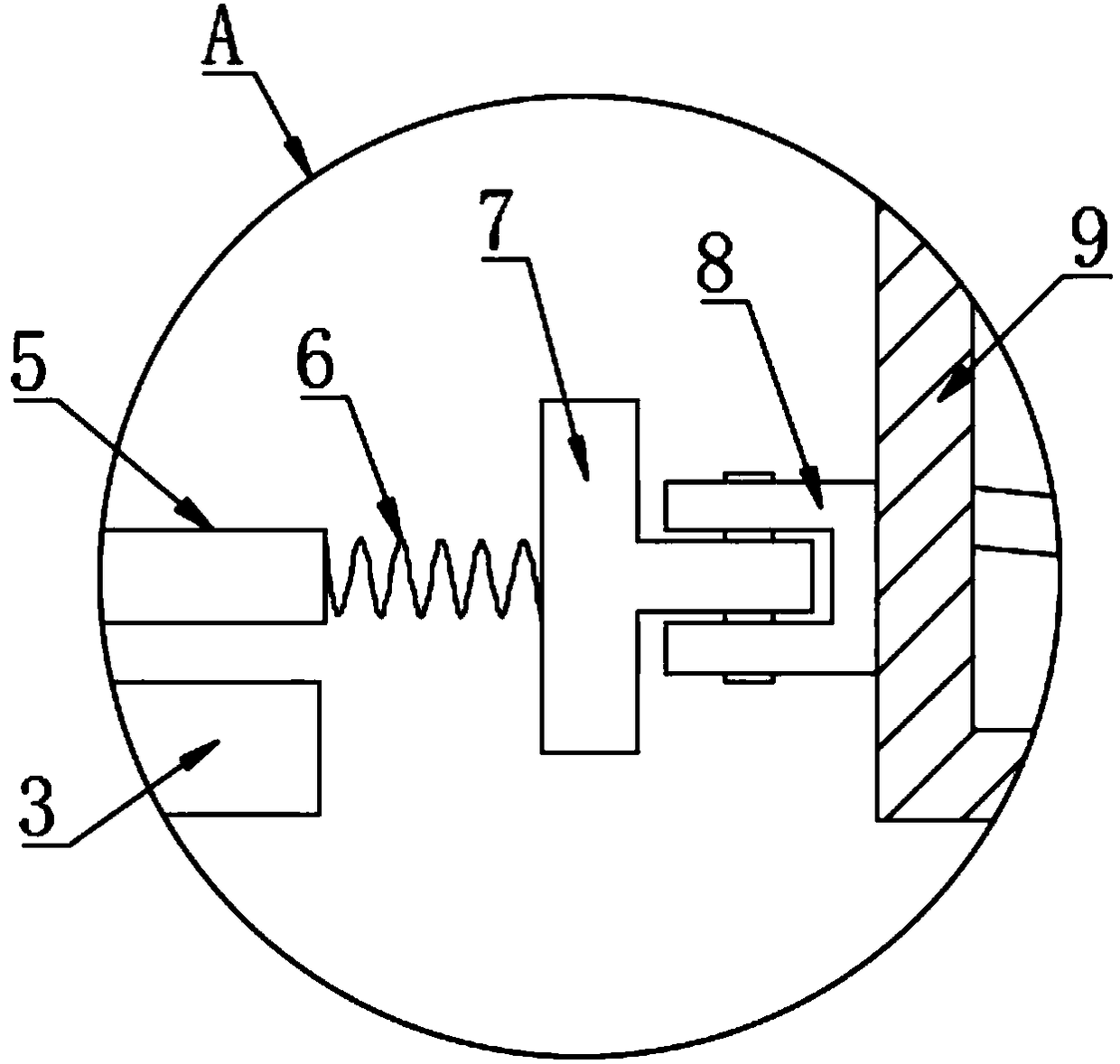

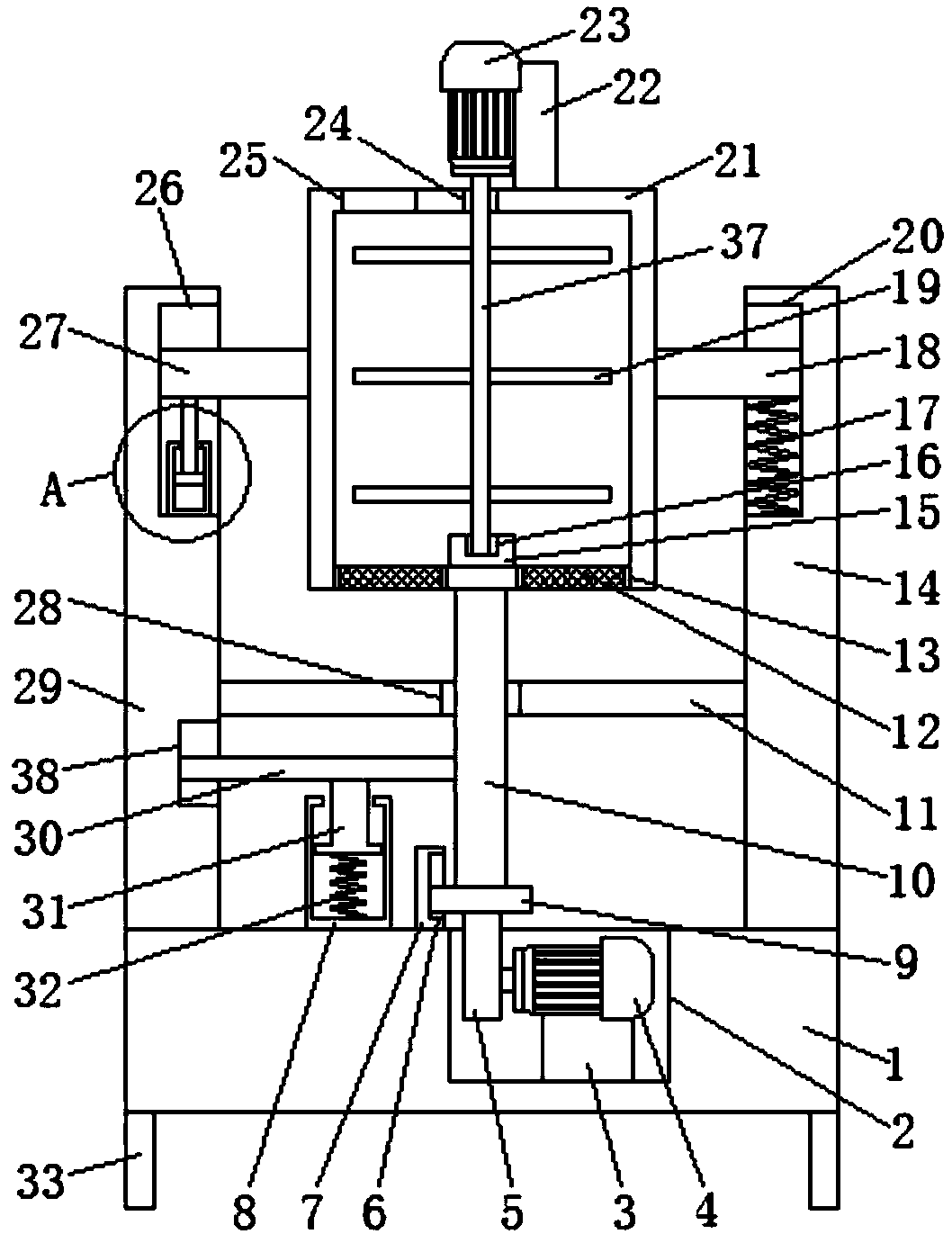

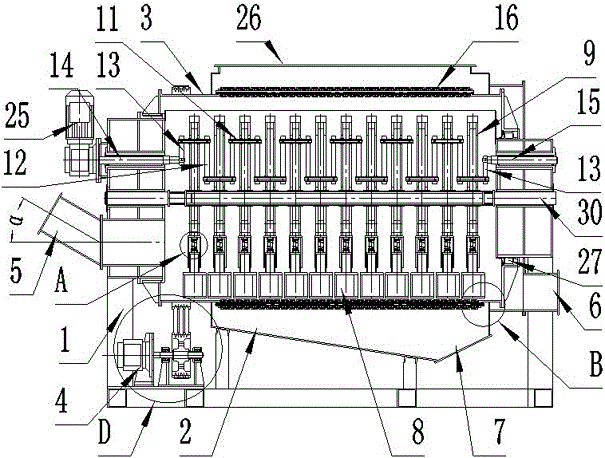

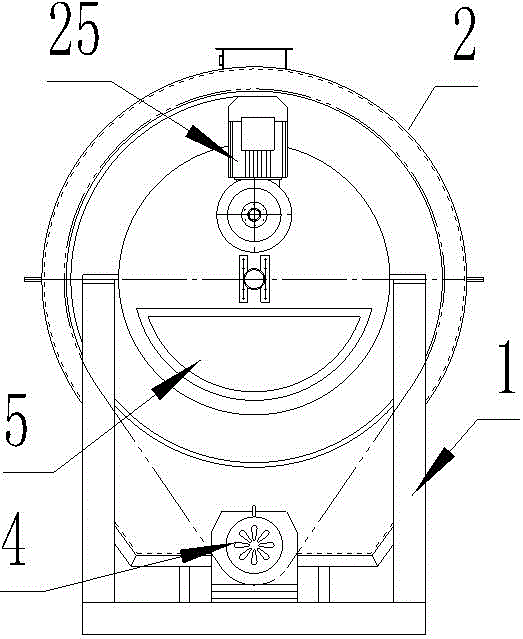

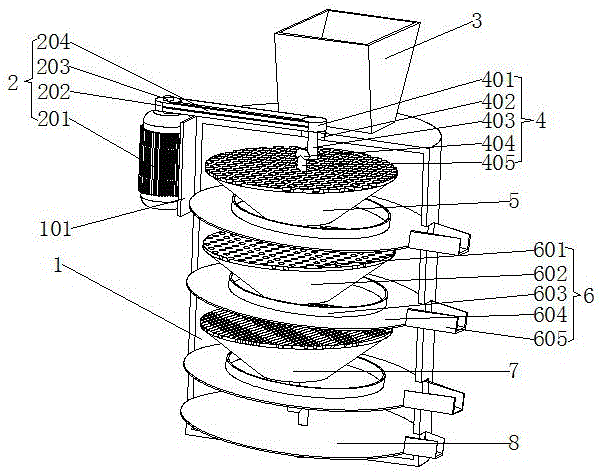

Self-feeding swinging sand-screening device

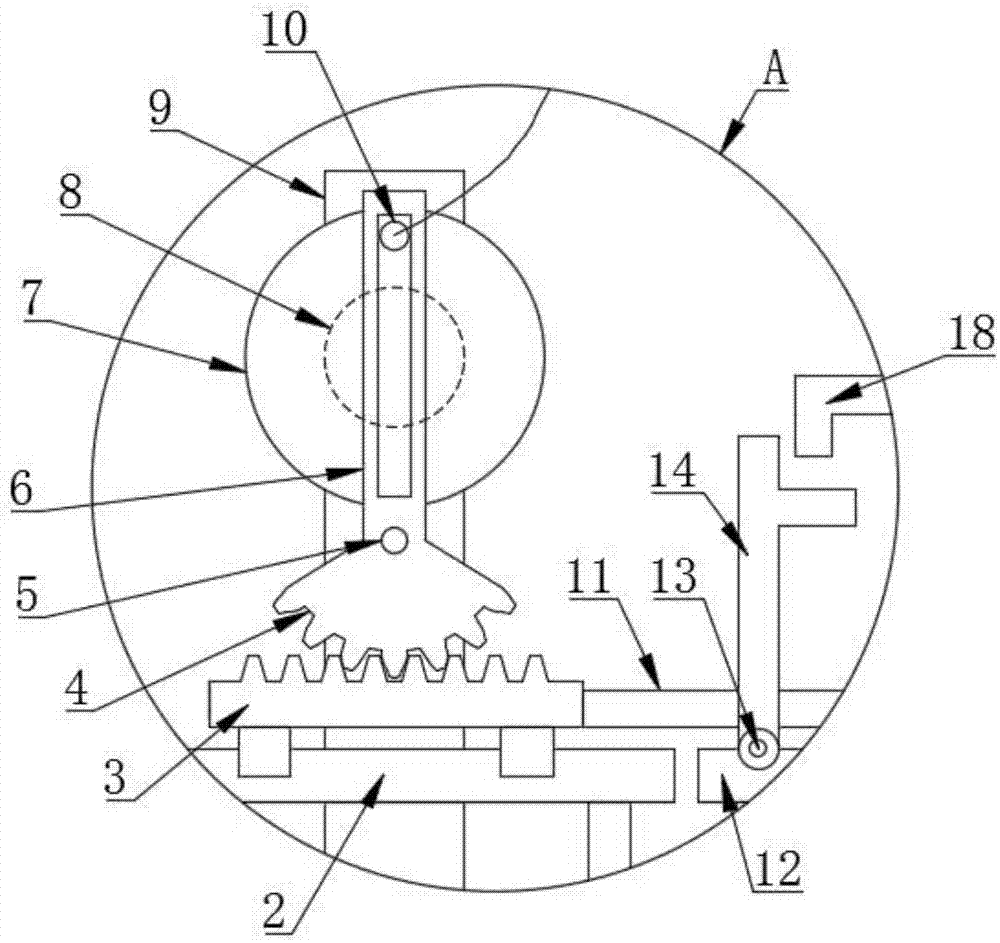

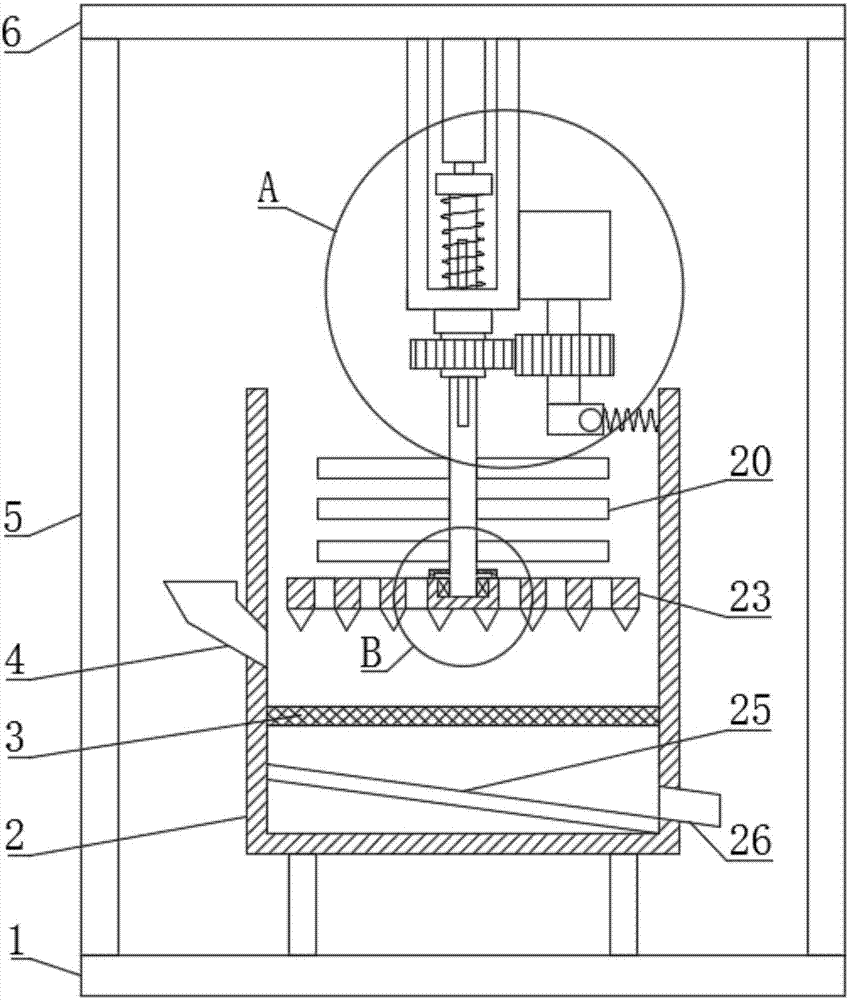

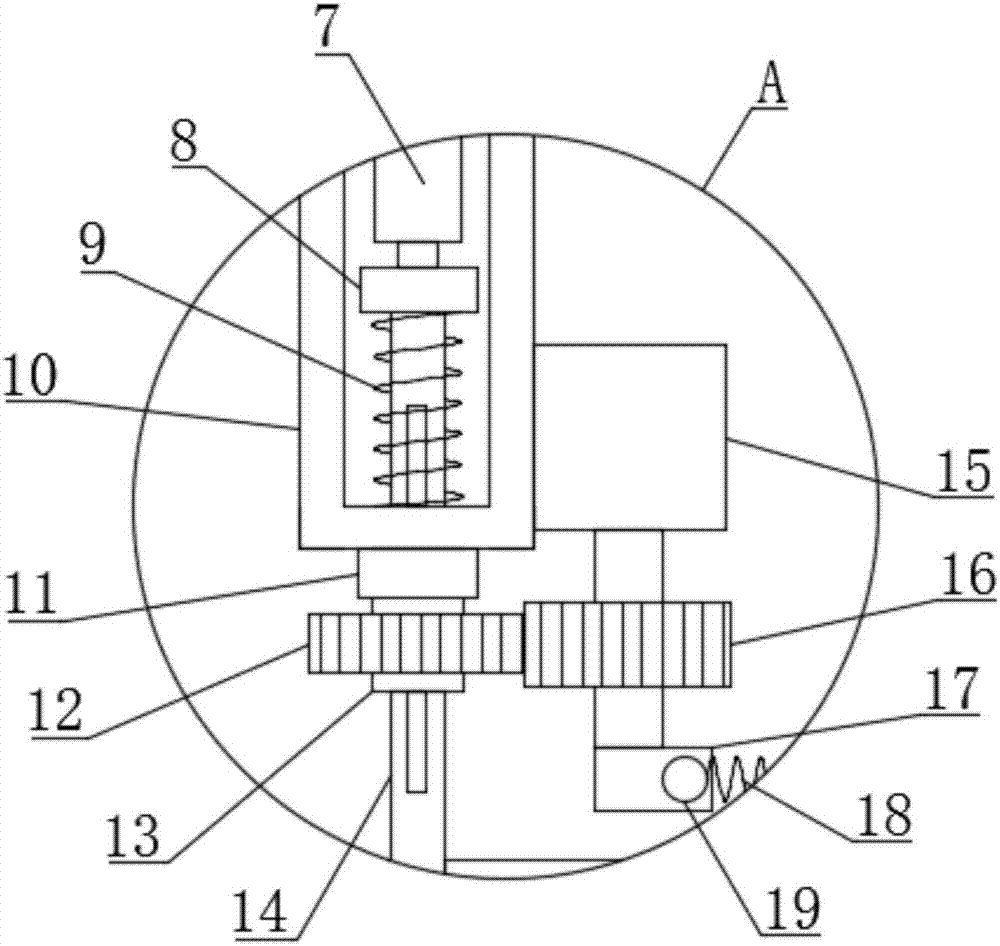

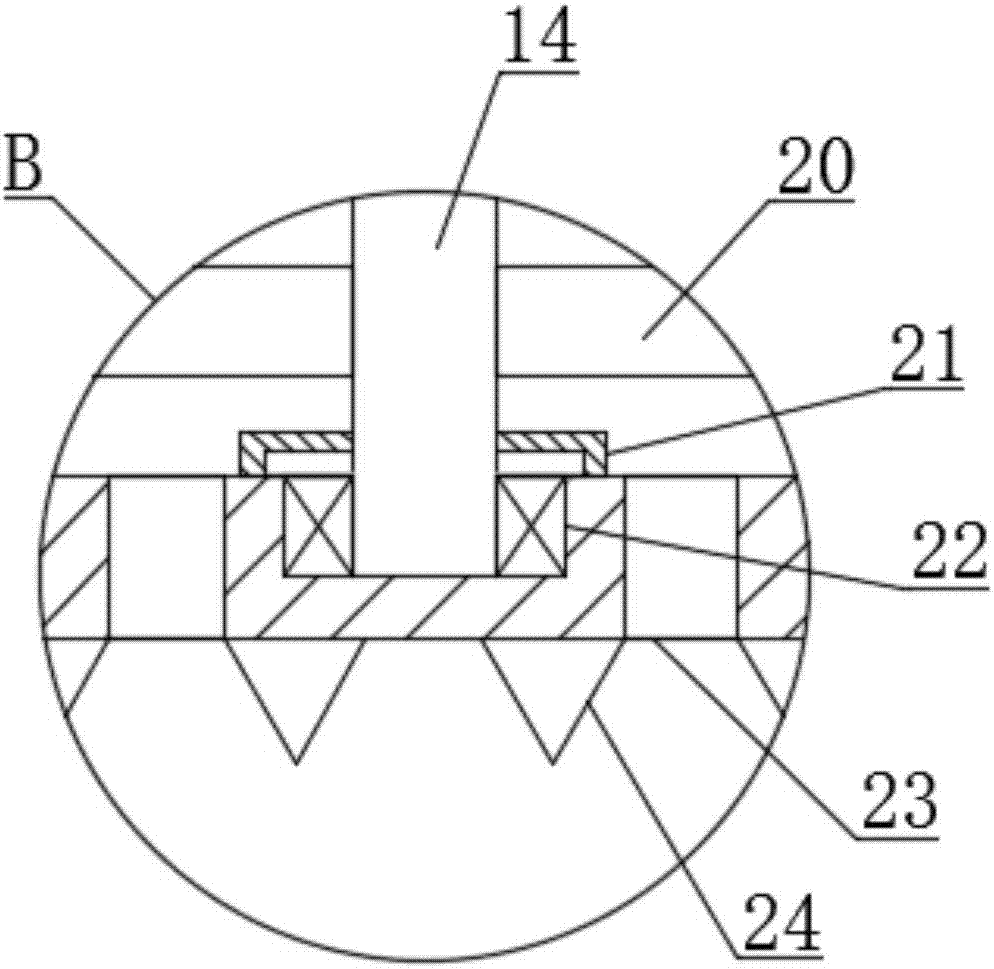

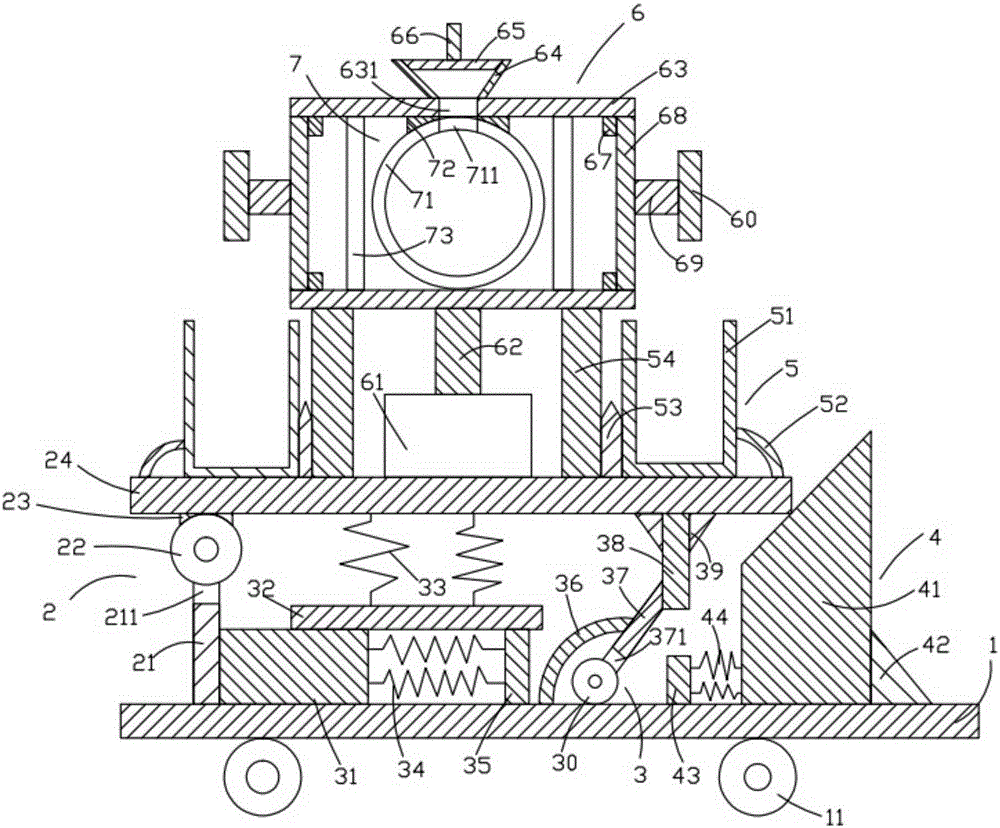

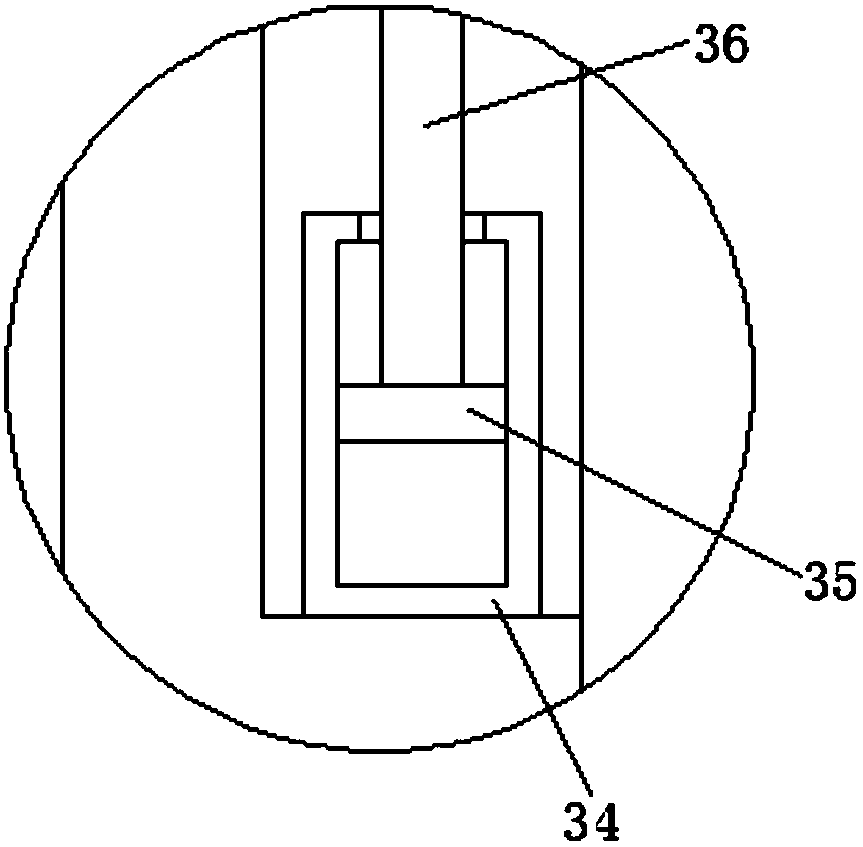

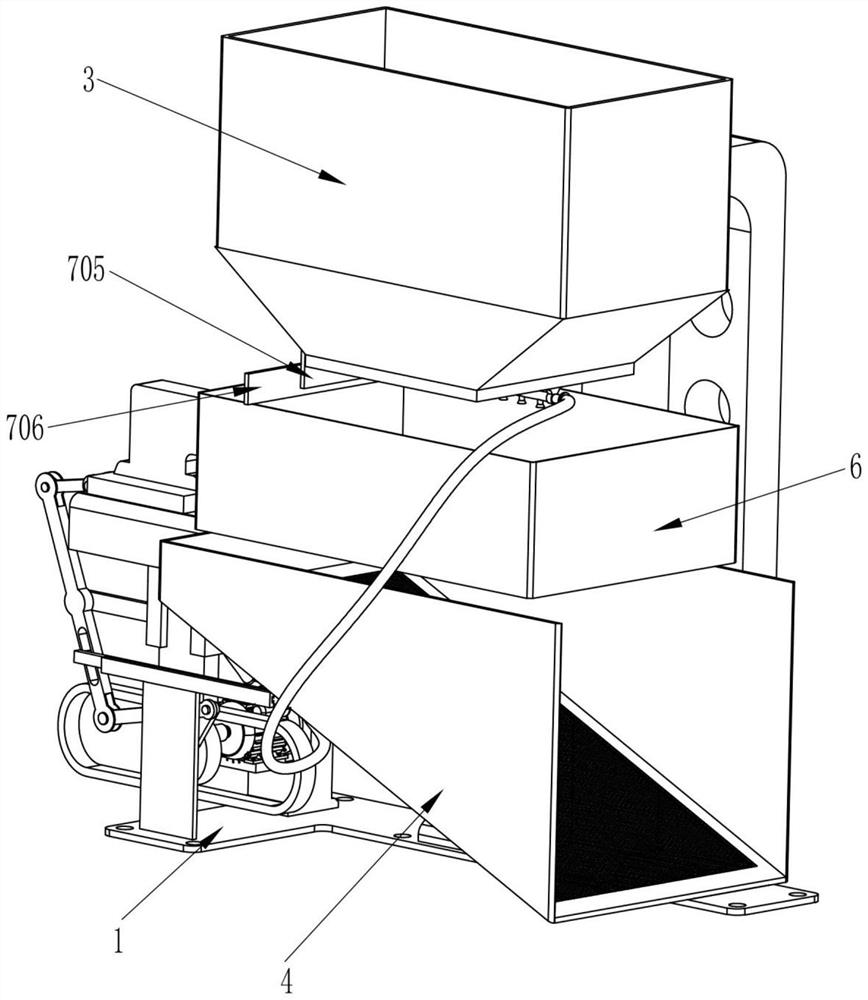

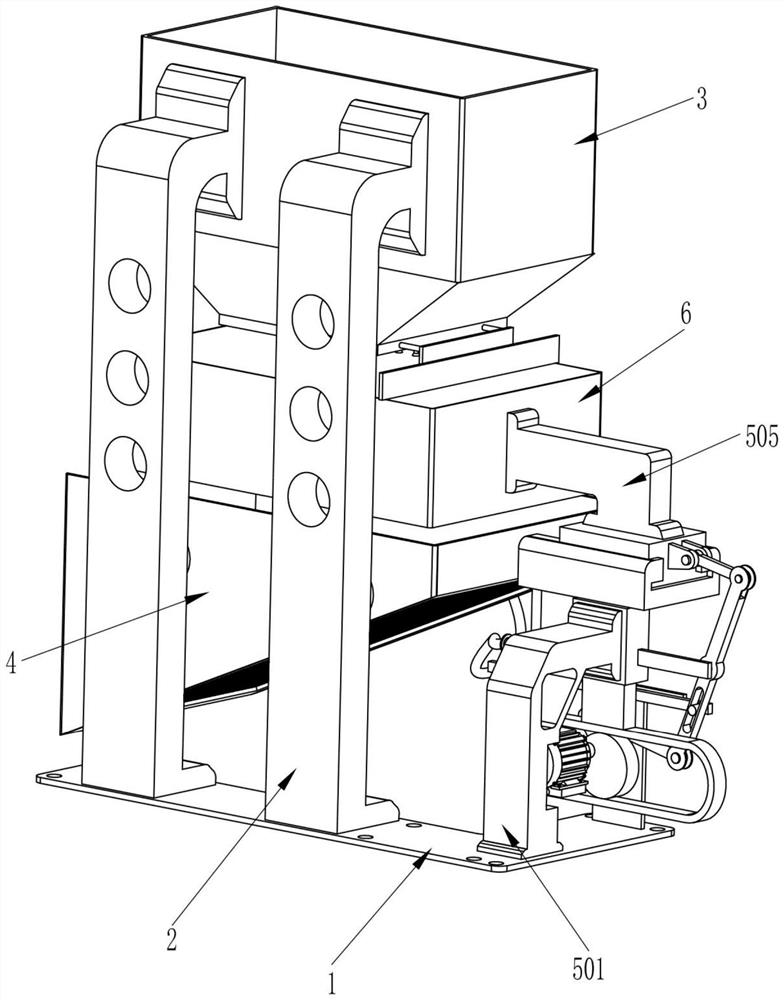

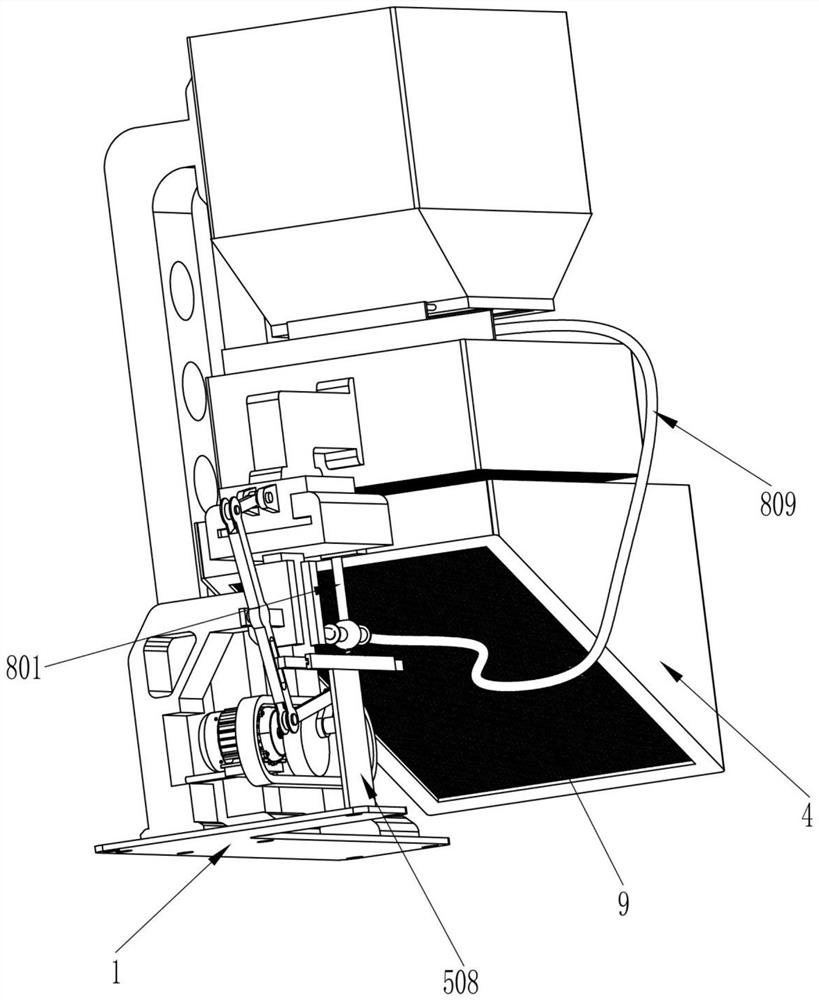

The invention discloses a self-feeding swinging sand-screening device. The self-feeding swinging sand-screening device comprises a base, wherein a second slide rail is fixedly arranged at the top of the base through a support, a screening box is slidably connected to the top of the second slide rail through a slide block, and a first sieve screen and a second sieve screen are fixedly arranged in the screening box; a first slide rail is further fixedly arranged at the top of the base through a support, and a rack is slidably connected above the first slide rail through a slide block; and a fixed plate is further fixedly arranged at the top of the base, a sector gear is rotationally connected to the front end surface of the fixed plate through a first pin shaft; the sector gear is engaged with the rack; a swinging rod is further fixedly connected to the top of the sector gear; a rectangular hole is formed in the swinging rod; a speed reduction motor is fixedly arranged on the rear end surface of the fixed plate; the speed reduction motor is connected with a rotary disc; a second pin shaft is fixedly connected to the top of the front end surface of the rotary disc; and the second pinshaft is located in the rectangular hole in the swinging rod. According to the self-feeding swinging sand-screening device disclosed by the invention, the rack is driven to carry out left-right movement through the swinging of the sector gear, and then the screening box is driven to carry out left-right movement, so that the screening effect is improved, and the screening speed is increased.

Owner:ANHUI YONSENT PHARMA

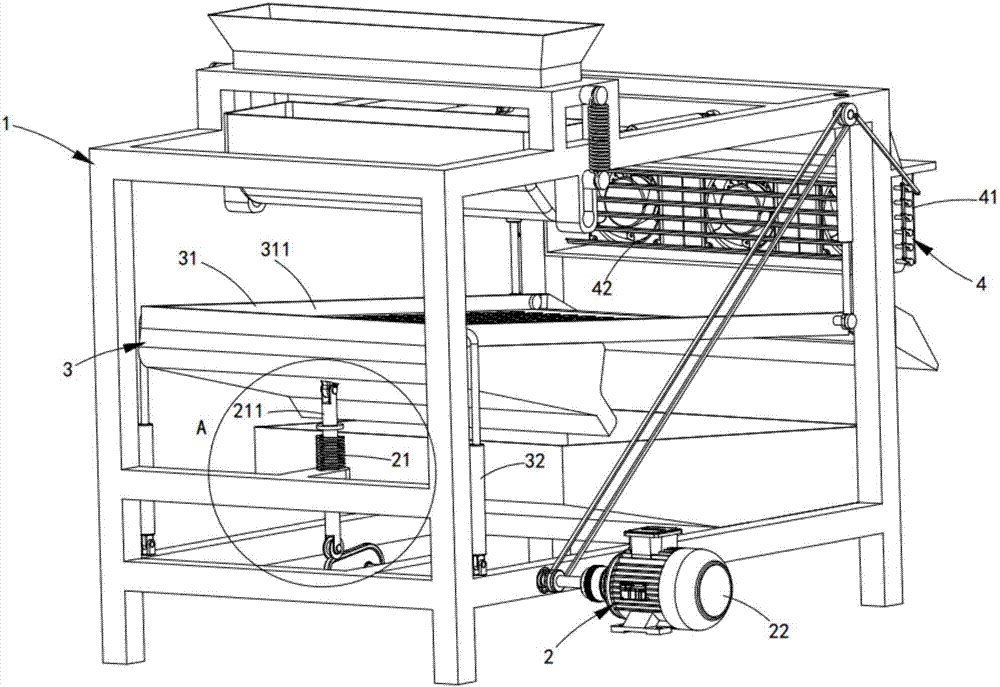

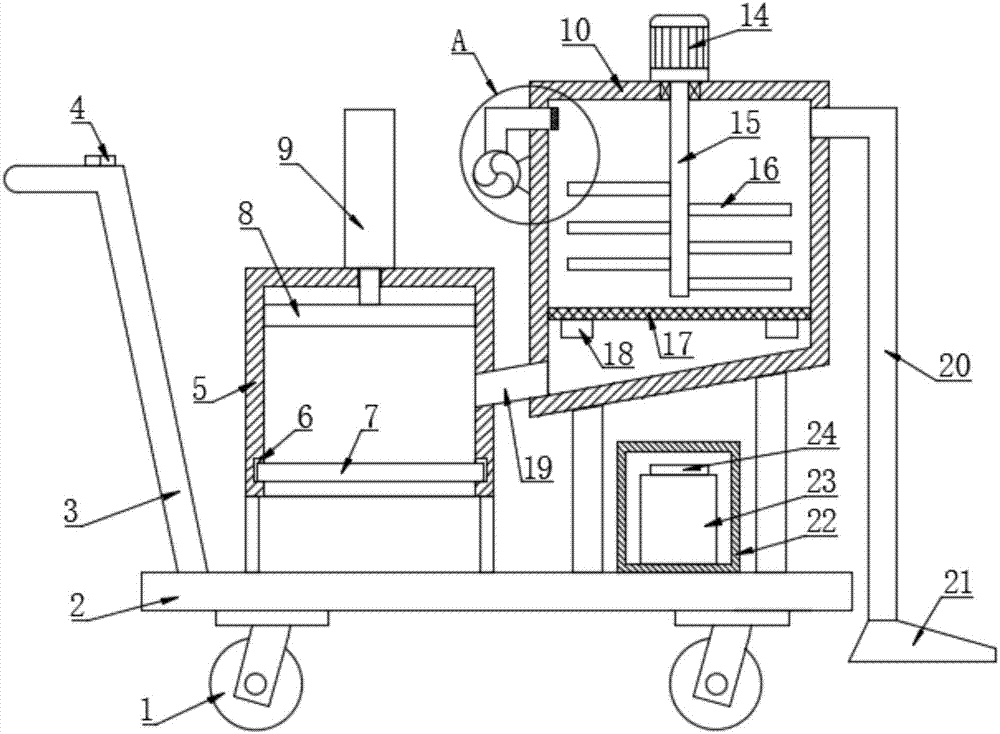

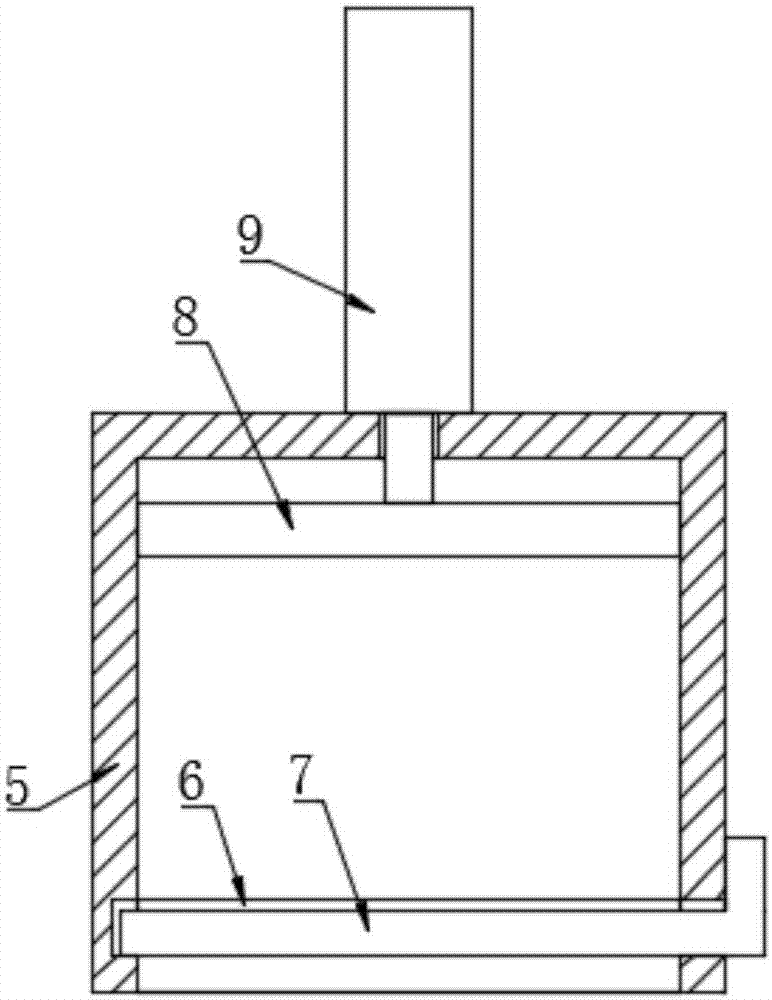

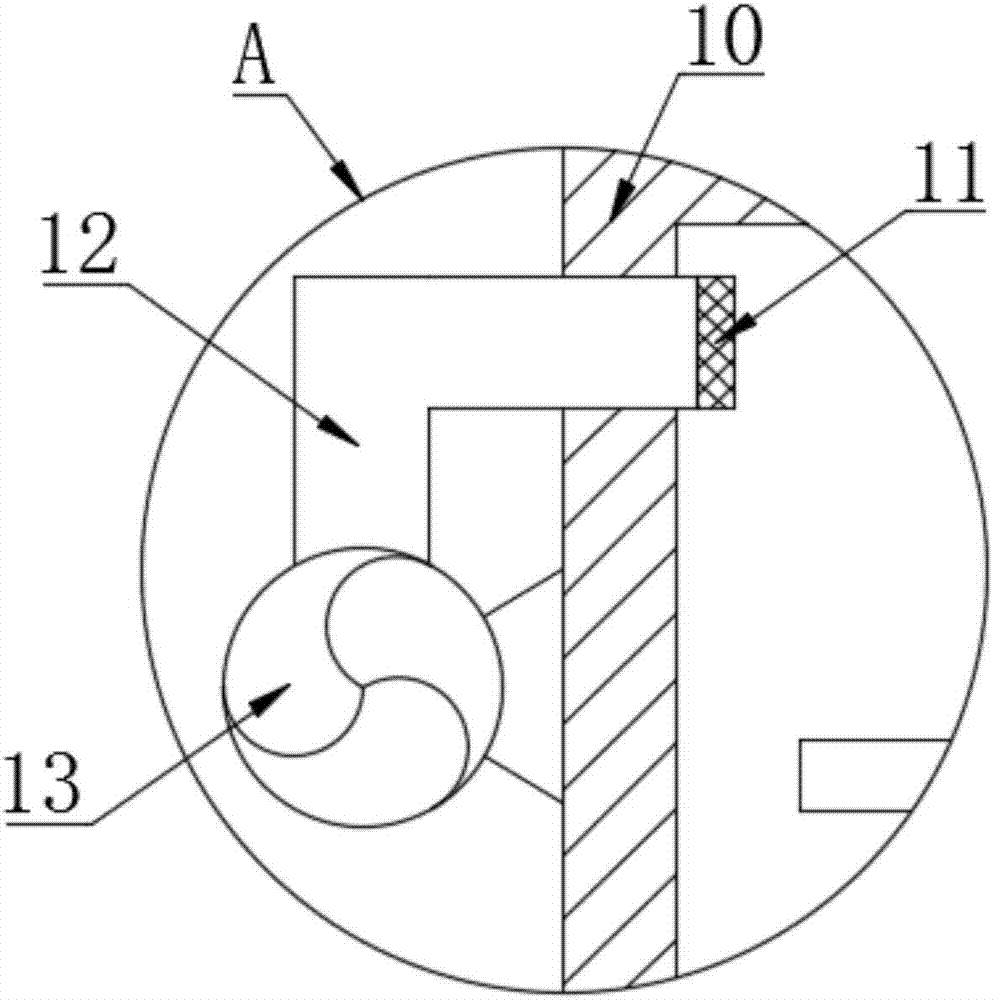

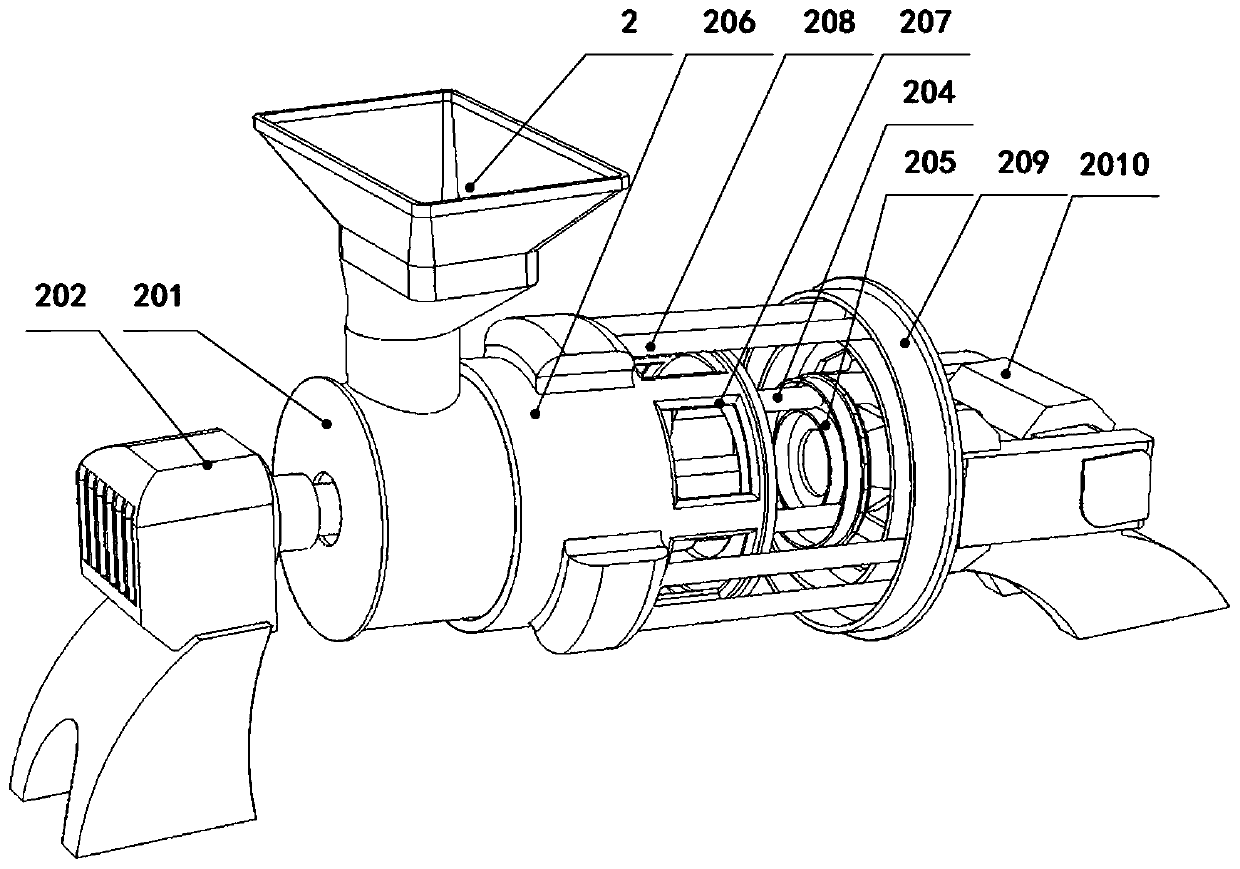

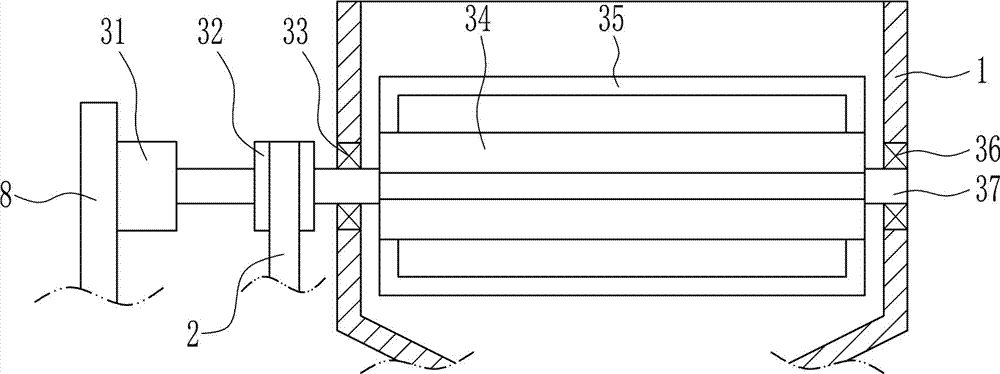

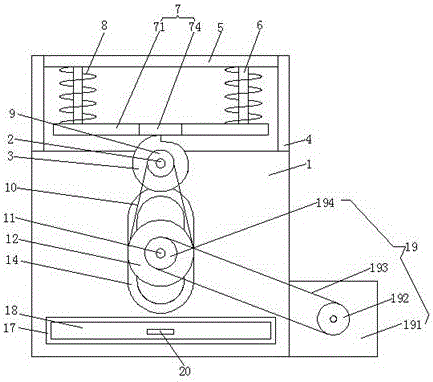

Small-size oscillation grain dehuller

InactiveCN106862081AImprove efficiencyAvoid rigid contactSievingGas current separationEngineeringImpurity

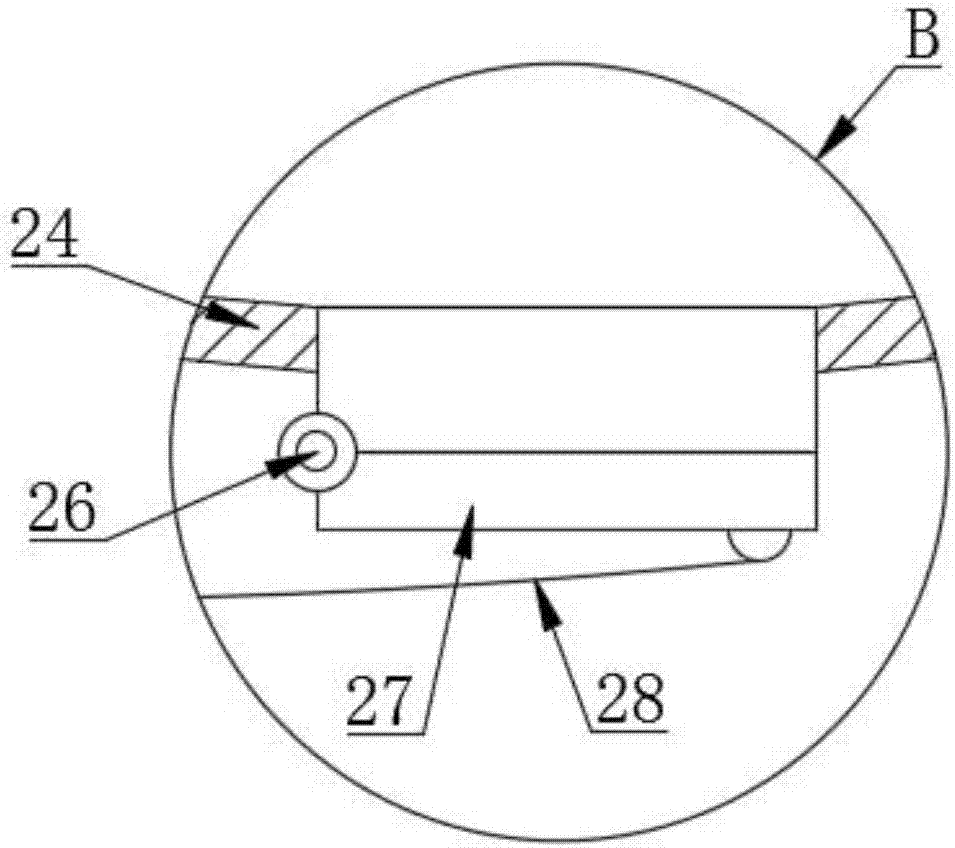

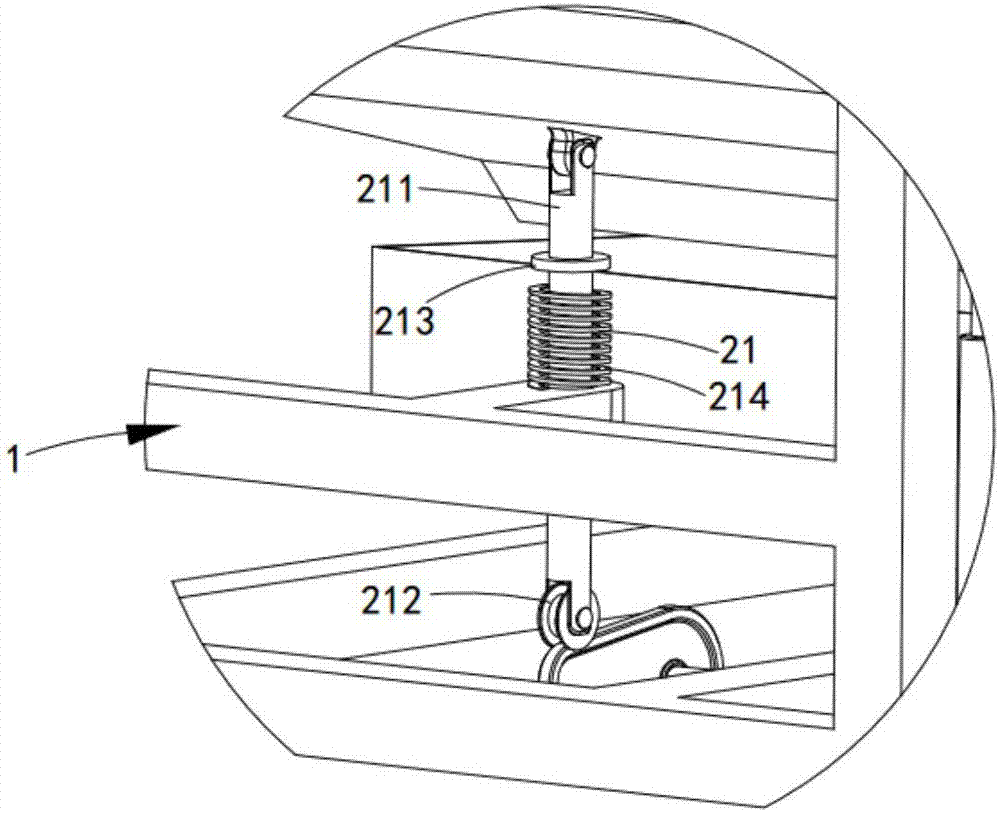

The invention discloses a small oscillating grain hulling machine, which comprises a frame, an oscillating mechanism, a screening mechanism and an air outlet mechanism. The air outlet component and the damper component drive the vibration component to run through the driving component. After the vibration component pushes the screening net in the screening component to a high place, the screening net drops rapidly by gravity, throws the grain on the screening net into the air, and is removed by the wind component. Light impurities such as chaff in the grain, and then the grain is returned to the screening net, and the granular impurities in the grain are screened and removed by the screening net. Repeat this process to completely remove the chaff impurities and granular impurities in the grain, and improve the screening efficiency.

Owner:奥林精密机械科技(长兴)有限公司

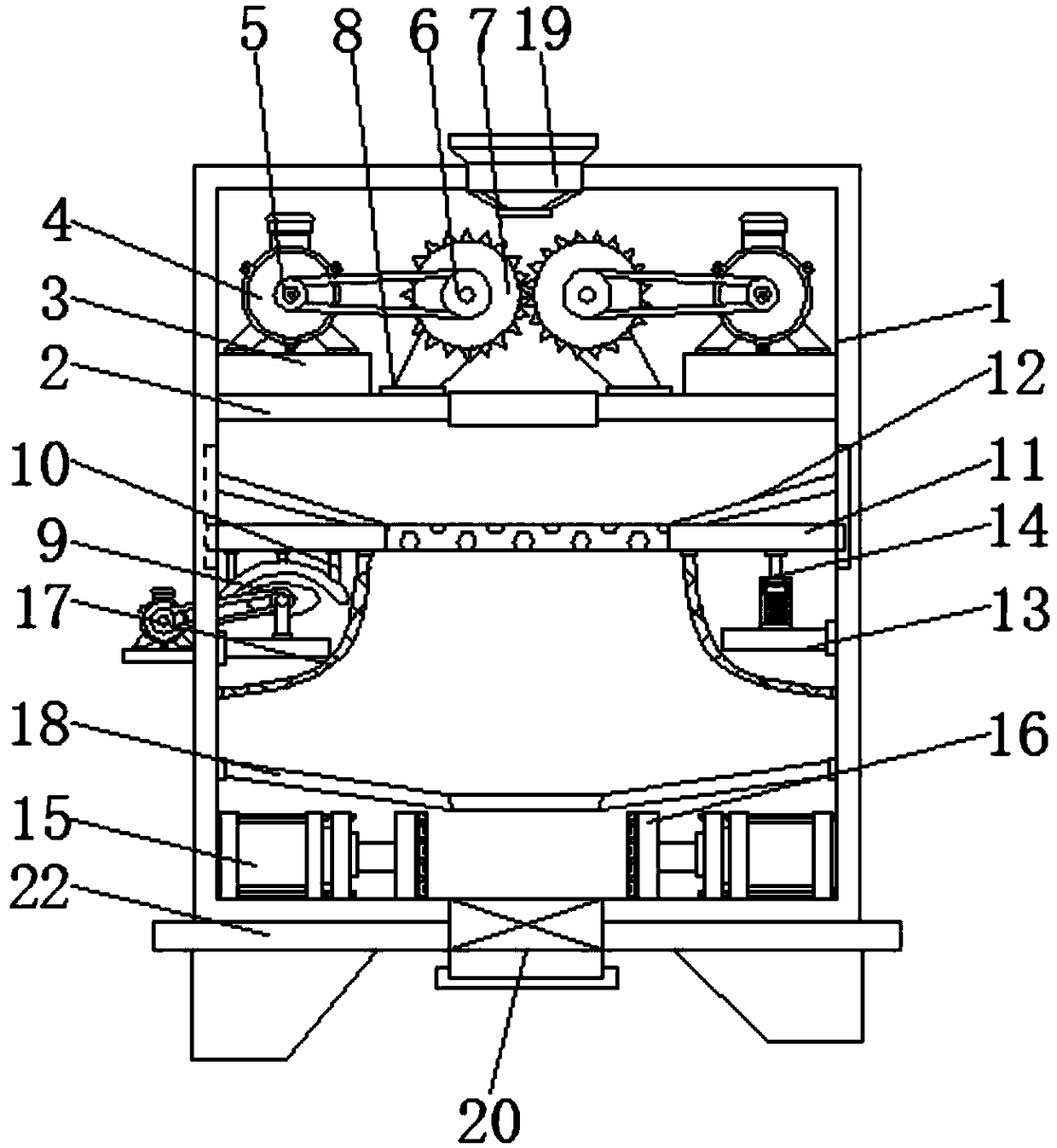

Construction waste dual-crushing and screening device

PendingCN107469940AFully brokenPromote fragmentationGrain treatmentsConstruction waste recoveryHydraulic cylinderGear wheel

The invention discloses a construction waste dual-crushing and screening device which comprises a base, wherein a crushing box is fixedly arranged on the base through a bracket; a sieve plate is fixedly arranged in the crushing box; support plates are arranged on left and right sides of the top of the base; a top plate is arranged at the tops of the support plates; a U-shaped plate is fixedly arranged at the bottom of the top plate; a hydraulic cylinder is further arranged at the bottom of the top plate; the bottom end of the piston rod of the hydraulic cylinder is rotatably connected with a first mounted bearing; a spline shaft is fixedly connected with the bottom of the first mounted bearing; a compression spring is connected onto the spline shaft in a sleeving manner; a second mounted bearing is further arranged at the bottom of the U-shaped plate; a rotary sleeve is rotatably connected below the second mounted bearing; a first gear is mounted on the rotary sleeve; smashing blades are further mounted on the spline shaft; and the bottom end of the spline shaft is rotatably connected with a crushing plate through a bearing. According to the construction waste dual-crushing and screening device, construction waste is first extruded and crushed by the crushing plate, and then, the crushed construction waste penetrates through through holes in the crushing plate to be crushed by the smashing blades rotating at a high speed, so that the construction waste is more sufficiently crushed.

Owner:ZHENGZHOU UNIV

Compound fertilizer screening device for automatic cleaning

InactiveCN107051854AImprove cleaning efficiencyAvoid squeezingSievingScreeningReciprocating motionAir blower

The invention discloses a compound fertilizer screening device for automatic cleaning, and relates to a rotary screen cleaning device. The device comprises a stand, a shell, a rotary screen scraping cleaning part and a air blowing cleaning part; the scraping cleaning part comprises a support frame, a scraper and a cleaning brush; two ends of the support frame are slidingly connected to the stand; the scraper is fixed on the support frame; the cleaning brush is contacted with the inner wall of the top of a rotary screen; the air blowing cleaning part comprises an air blower and a cleaning air pipe; the cleaning air pipe is fixed in the shell, and is positioned above the rotary screen; the air blower is connected with the cleaning air pipe; the cleaning air pipe is provided with multiple air blowing holes towards the side wall of the rotary screen; the rotary screen is divided into a screening part and a pushing part through one plane of a central shaft of the rotary screen; multiple pushing plates are fixedly arranged on the inner wall of the pushing part at equal intervals; the scraper is provided with a gap for passing through the pushing plates; and when the rotary screen rotates, the support frame performs a left-right reciprocating motion, so that the interference between the pushing plates and the scraper can be prevented when bonded materials are removed.

Owner:徐州致诚会计服务有限公司

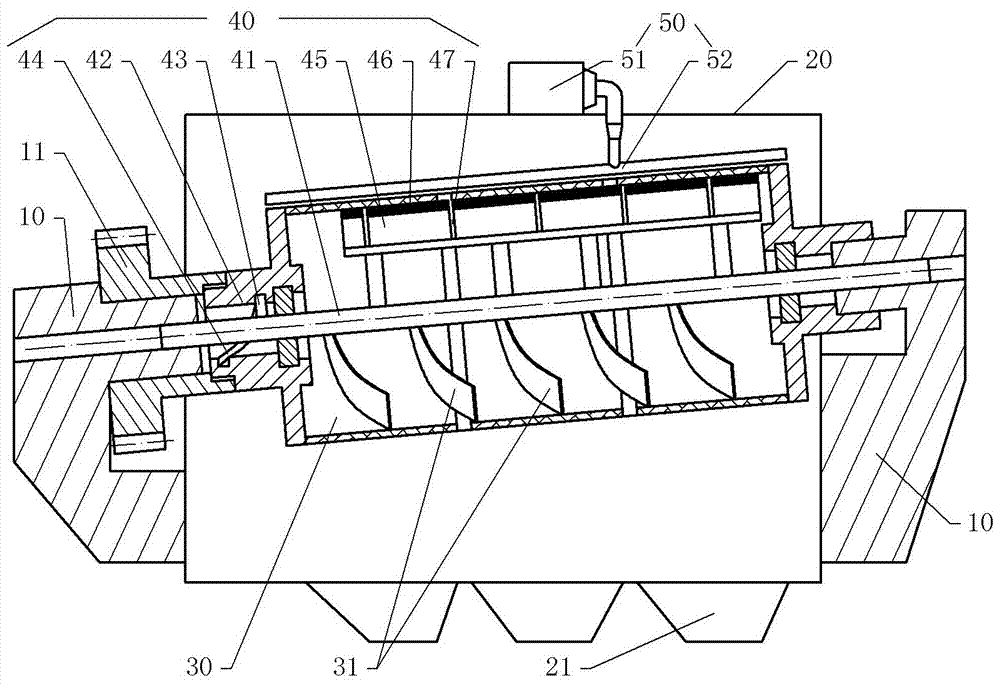

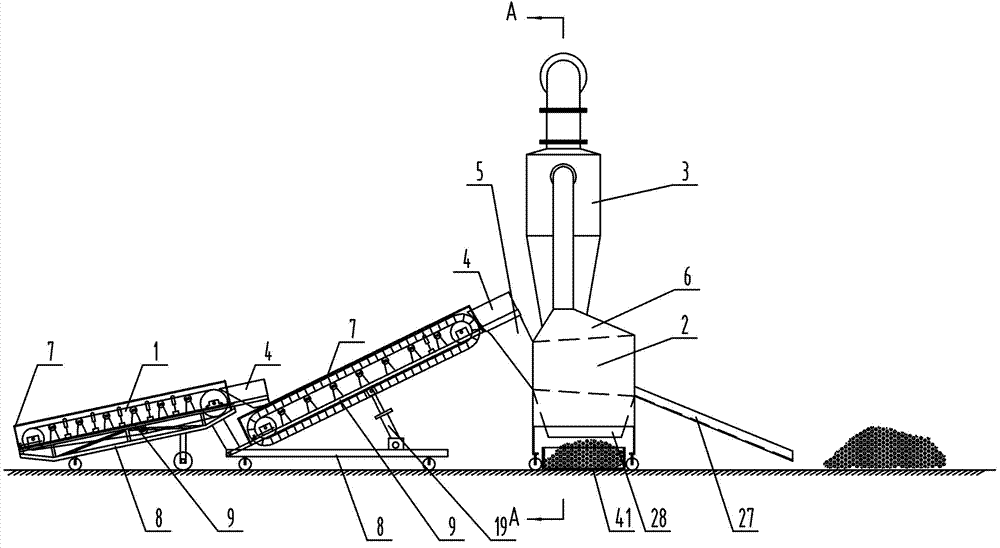

Automatic screening machine for steel balls

ActiveCN102921624AReasonable structural designHigh degree of automationSievingScreeningProcess engineeringPower station

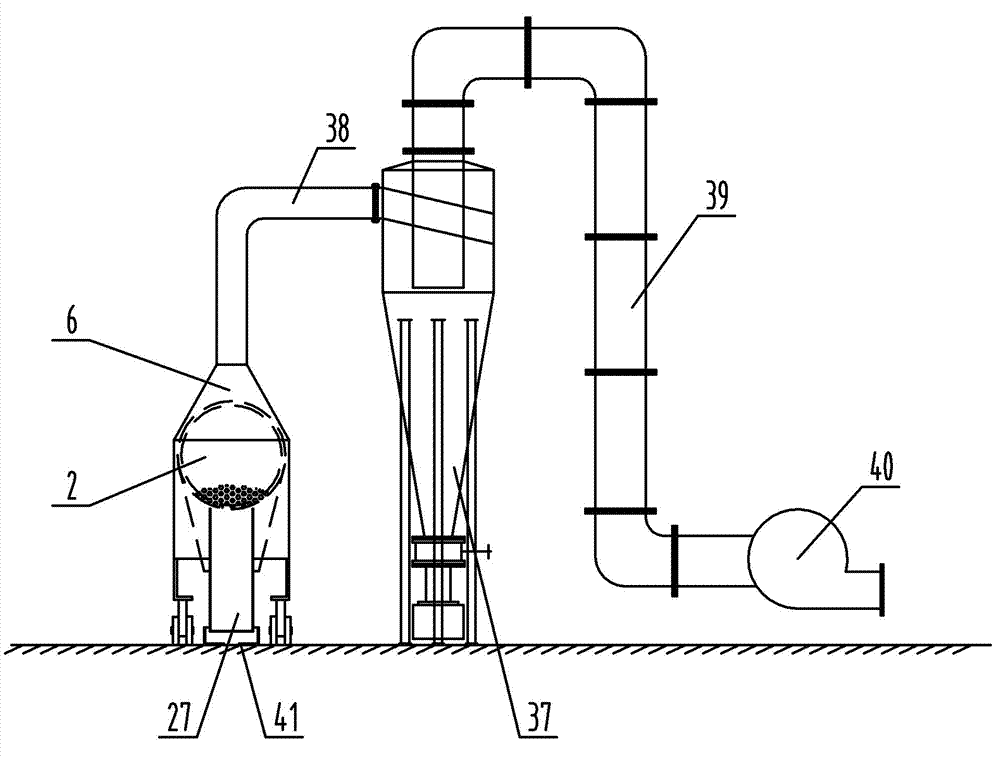

The invention belongs to the technical field of auxiliary equipment of a steel ball coal mill for a boiler in a thermal power plant and particularly relates to an automatic screening machine for steel balls. The machine comprises a conveyer, a screening device and a dust collector, wherein a discharge hopper arranged at the tail end of the conveyor is fixedly connected with a feed hopper of the screening device, the top of the screening device is fixedly connected with a dust hood of the dust collector, seal covers are arranged outside the conveyer and the screening device respectively, and the conveyor comprises at least one level of belt conveyor. The machine has the advantages that the structural design is reasonable, the automation degree is high, the steel ball screening efficiency can be improved, the labor intensity of workers can be reduced, the operating environment of workers can be improved, the production cost is saved for purchasers, and the economical benefits are remarkable, so that the machine is quite suitable for being popularized for implementation.

Owner:河南博奥建设有限公司

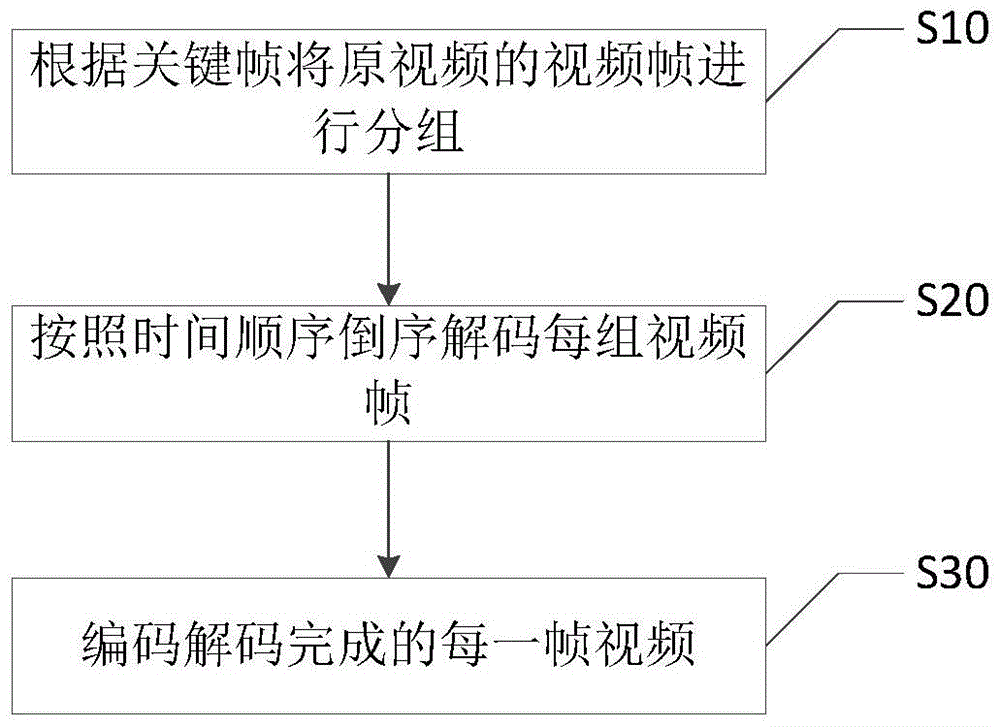

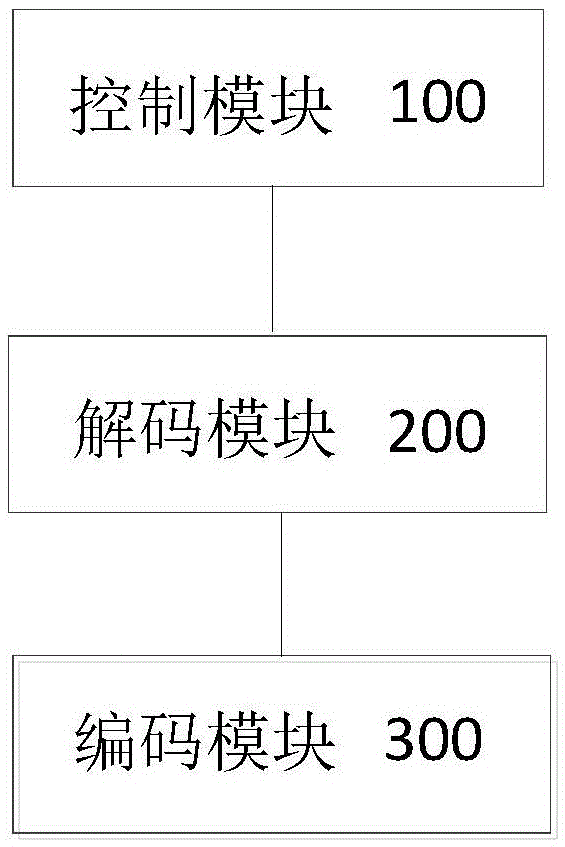

Rewound video generating method and device and play device

InactiveCN105898626AFully screenedClear pictureSelective content distributionComputer graphics (images)Video image

The invention discloses a rewound video generating method and device and a play device, and relates to the field of videos. The method comprises that frames of an original video are grouped according to key frames, and each frame and a non-key frame thereafter form one group; the video frame groups are decoded in inverted time sequence, the last group is decoded at first, and the first group is decoded at last; and video images of all the decoded frames are recoded, the last group of the original video is coded as the first group of a new video, the last but one group of the original video is coded as the second group of the new video, and the rest can be done in the same manner. The new video generated finally is a rewound video relative to the original video. The sequence of frame videos in each video frame group is kept unchanged. Thus, the generated rewound video is complete in frames, clear and coherent, and the realization method is rapid.

Owner:LETV INFORMATION TECH BEIJING

Pulverizing and sieving recycling device for waste batteries

The invention discloses a pulverizing and sieving recycling device for waste batteries. The pulverizing and sieving recycling device comprises a fixed box, wherein a fixed plate is fixedly connected between the two sides of the inner wall of the fixed box, and a material leaking opening is arranged in the fixed plate; the two sides of the top of the fixed plate are both fixedly connected with a fixing bracket; the top of the fixing bracket is fixedly connected with a first motor, an output shaft of the first motor is fixedly connected with a first belt pulley through a coupling, and the surface of the first belt pulley is in transmission connection with a second belt pulley through a belt; and the back of the second belt pulley is fixedly connected with a pulverizing wheel. The invention relates to the technical field of environmental protection. The pulverizing and sieving recycling device for the waste batteries solves the problems that the existing pulverizing recycling device for the waste batteries cannot rapidly carry out treatment and the recycling working efficiency of the waste batteries is reduced, and can thoroughly sieve the pulverized batteries, improve the sieving quality and avoid excessive repeated steps.

Owner:贵州中伟资源循环产业发展有限公司

Automatic closed-type screening device for corn grains

Owner:全椒县汊河农机服务专业合作社

Whithered leaf recycling, crushing, compressing and re-utilizing device

The invention discloses a whithered leaf recycling, crushing, compressing and re-utilizing device. The whithered leaf recycling, crushing, compressing and re-utilizing device comprises a bottom plate;a compressing box is fixedly arranged on the left side of the top of the bottom plate through a bracket; the bottom of the compressing box is opened; a chute is formed in the bottom of the compressing box; a supporting plate is arranged in the chute in a sliding manner; the front end of the supporting plate penetrates through the front wall of the compressing box; an electric hydraulic pushing rod is fixedly arranged at the top of the compressing box; a pushing rod at the bottom end of the electric hydraulic pushing rod penetrates through the top of the compressing box and is fixedly connected with a pressing plate; a crushing box is fixedly arranged on the right side of the top of the bottom plate through the bracket; the lower left corner of the crushing box is connected with a discharging pipe; the discharging pipe penetrates through the side wall of the compressing box and is connected to the interior of the compressing box. According to the whithered leaf recycling, crushing, compressing and re-utilizing device, crushed and screened whithered leaves enter the compressing box; the electric hydraulic pushing rod elongates and drives the pressing plate to descend to compress thecrushed leaves; the compressed whithered leaves occupy small space and are convenient to transport; the supporting plate is withdrawn so that the whithered leaves can be recycled and re-utilized; resources are saved; the whithered leaf recycling, crushing, compressing and re-utilizing device is environment-friendly.

Owner:SUZHOU RUISHUO ENVIRONMENT TECH CO LTD

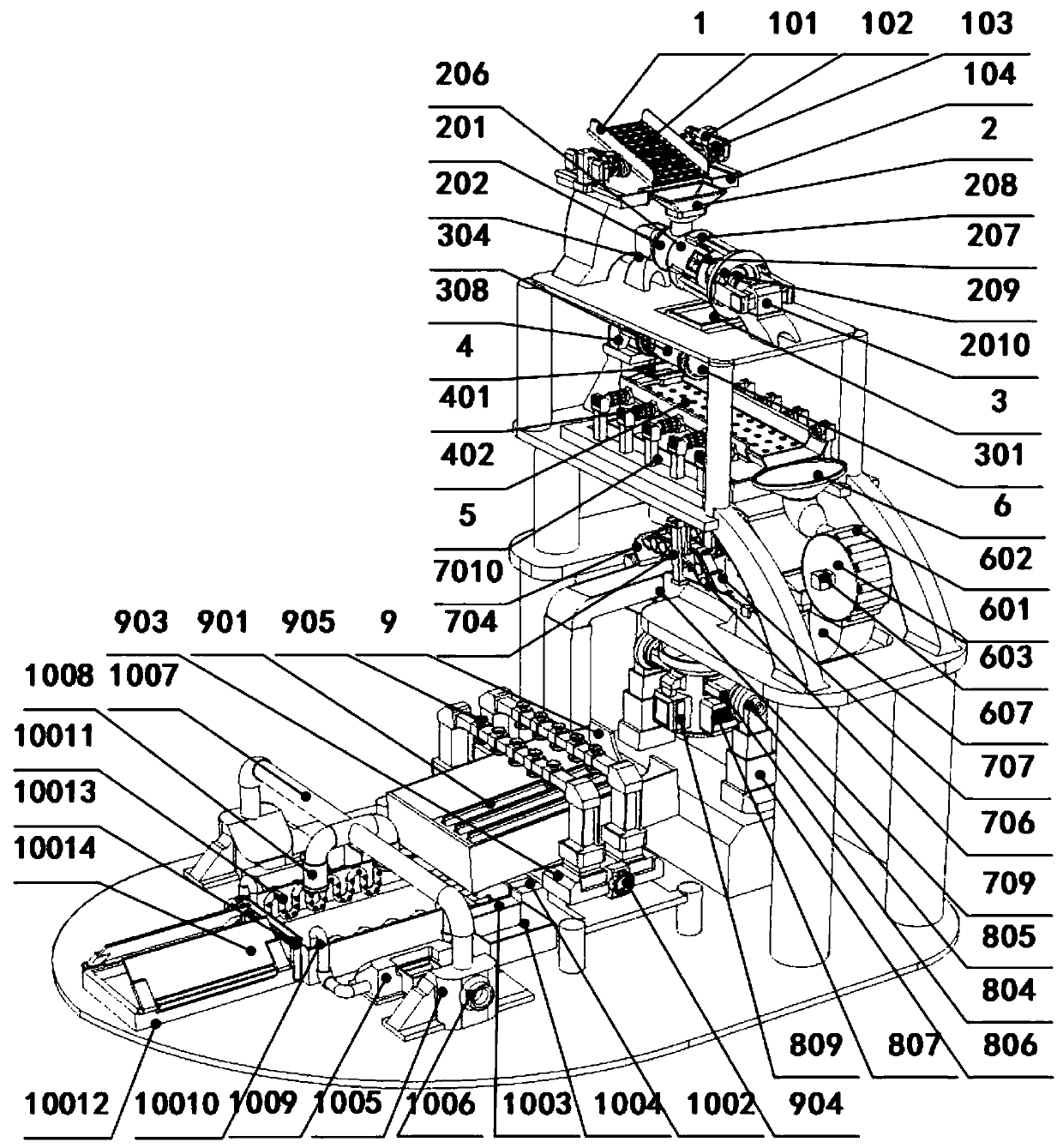

Deep processing device for magnetic iron ore

ActiveCN109894246AGuaranteed purityReduce loss rateMagnetic separationCleaning using liquidsSolid phasesMachining process

The invention relates to a deep processing device for magnetic iron ore. The deep processing device comprises a screening system, a deflection crushing system, a vibrating mill system, a sieving system, a multilayer funnel, a fine grinding system, a solid-phase magnetic separation system, a liquid-phase magnetic separation system, a spray-washing system and a washing system, which are arranged from top to bottom in sequence. Raw material vein ore in mining can be preliminarily screened through the screening system, the deep processing device can ensure that a machine cannot be damaged due to the huge size difference of ore in the following processing process. Moreover, according to a scientific processing order, the ore is successively broken from large size to small size through the deflection crushing system, the vibrating mill system and the fine grinding system in sequence, so the processing effect is good, and the wastage rate of a grinding head or crushing components is reduced.By the cooperative work of the sieving system and crushing operation, the deep processing device can ensure that small-size ore cannot enter a large-size crushing process link to jam or damage the machine.

Owner:承德旭升矿业有限公司

Agricultural rice thresher

The invention relates to a thresher, in particular to an agricultural rice thresher. The agricultural rice thresher aims at achieving the technical purposes of high threshing efficiency and timely grain-leaf separation. To achieve the technical purposes, the agricultural rice thresher comprises a threshing frame, a first flat belt, a threshing mechanism, a linkage mechanism, a dropping mechanism, a hitting mechanism, a buffering mechanism, a side plate, a bottom plate, a collecting frame, universal wheels, a sieve frame, a sieve plate and a first supporting rod, wherein the universal wheels are fixedly connected to the bottom of the bottom plate, the side plate is fixedly connected to the end of the bottom plate in the vertical direction, the buffering mechanism is fixedly connected to the top of the bottom plate, the collecting frame is placed at the top of the bottom plate and located on the lower portion of the buffering mechanism, and the threshing frame is fixedly connected to the side plate through the first supporting rod. By means of the agricultural rice thresher, grains can be fully separated, and thus the effect of quickening threshing can be achieved.

Owner:连云港市连发机械有限公司

Rolling and screening device with drying function for tea leaves

PendingCN107549355AIncrease productivitySolve screeningSievingPre-extraction tea treatmentRotational axisAgricultural engineering

The invention discloses a rolling and screening device with a drying function for tea leaves. The device comprises a fixed box. A first motor is fixedly connected to the top of the fixed box and the output shaft of the first motor is fixedly connected to a rotary shaft through a coupling; a first belt wheel is fixedly connected to the surface of the rotary shaft; the surface of the first belt wheel is in transmission connection to a second belt wheel through a belt; a rotary shaft penetrates through the middle of the second belt wheel; a rotary column between two sides of the inner wall of thefixed box is fixedly connected to a rotary barrel; and one side of the fixed box is fixedly connected to the second motor through a base. The invention relates to the technical field of tea leaf production. The rolling and screening device with the drying function for tea leaves disclosed by the invention solves the problem that screening and rolling are separated commonly in existing tea leaf production, and realizes an integrated operation of rolling, screening and drying, so that the tea leaf production efficiency is increased, the workload of people is alleviated, and a lot of time of people is saved.

Owner:安吉十万亩白茶有限公司

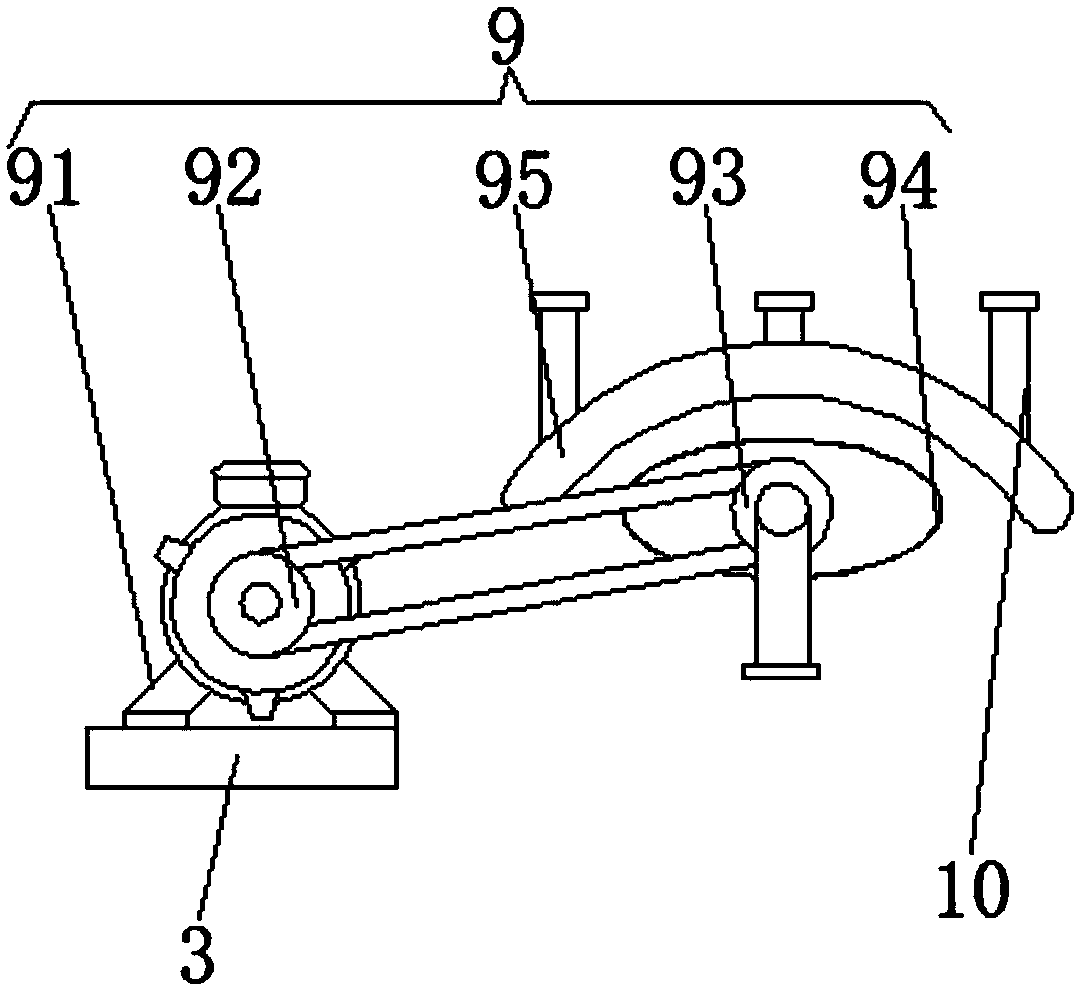

Ore pulverizing and screening device

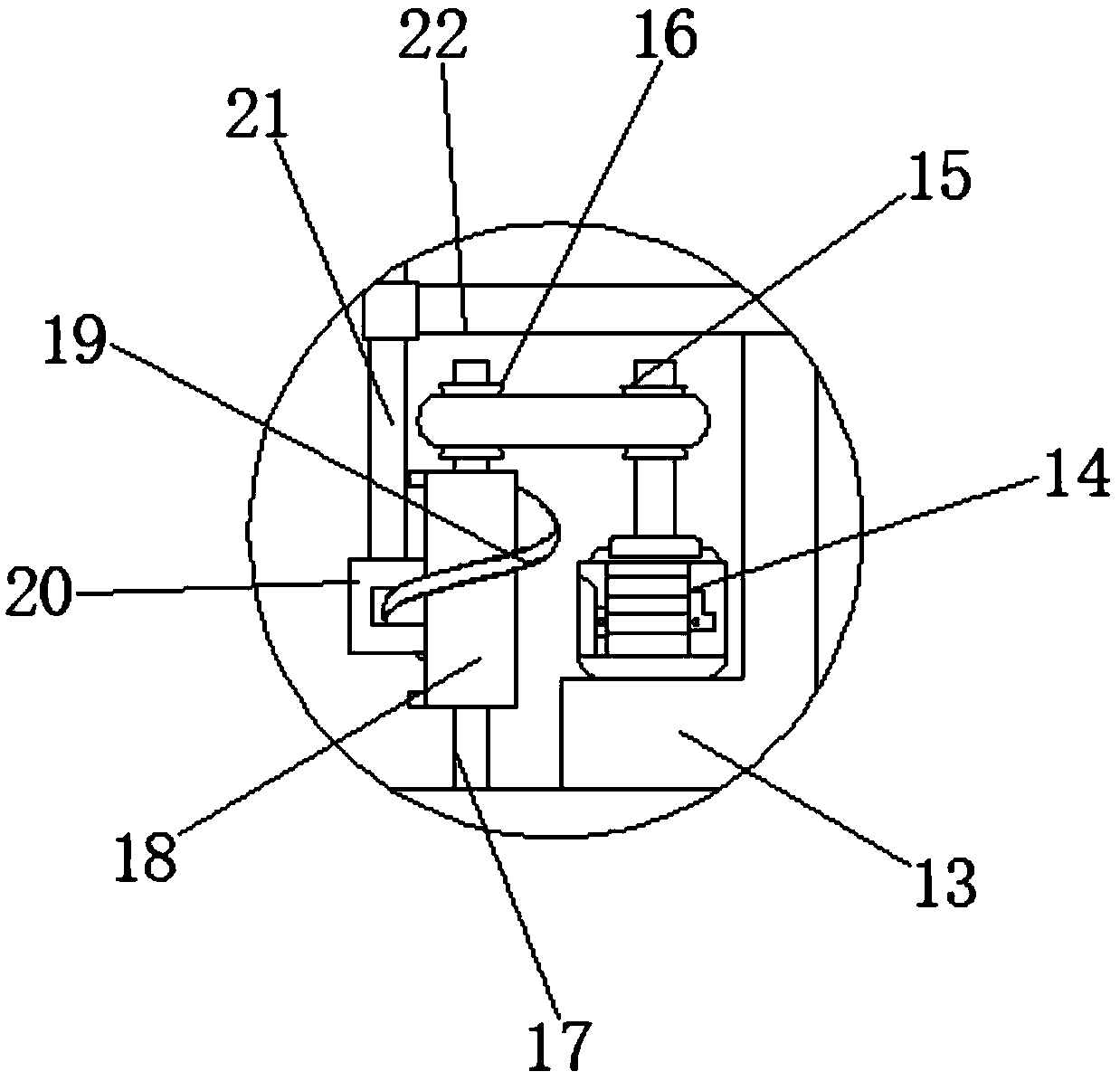

InactiveCN108097362ASustainable additionImprove processing efficiencySievingScreeningEngineeringMotor shaft

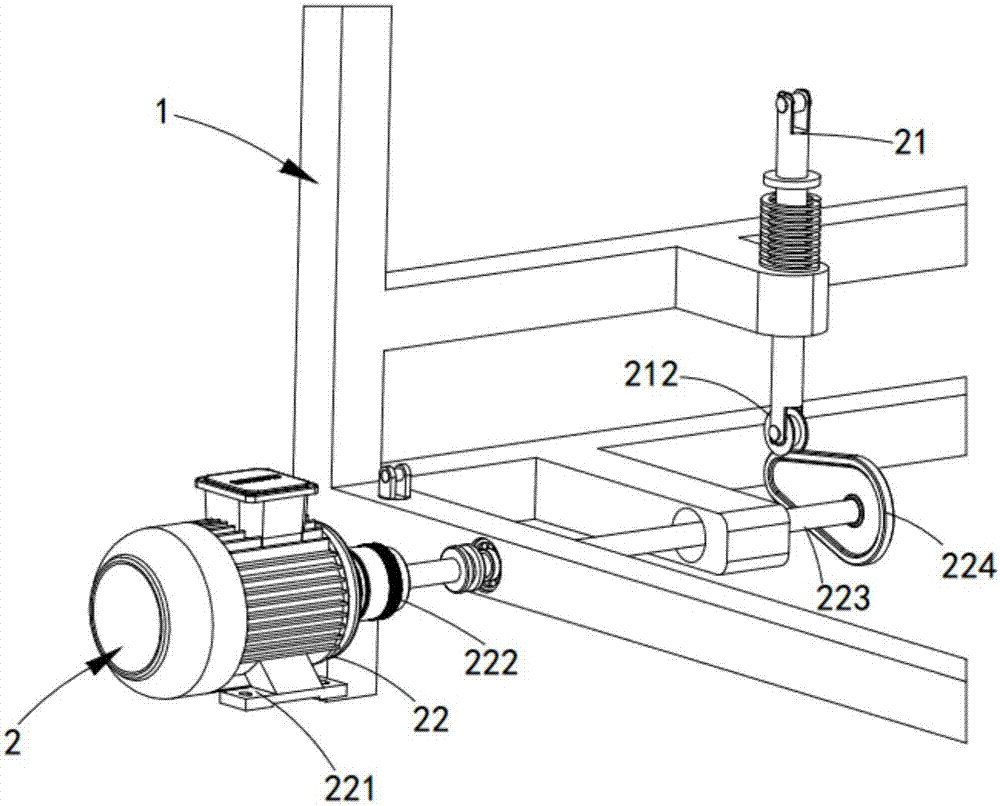

The invention discloses an ore pulverizing and screening device which comprises a base, wherein a front slide rail and a rear slide rail are fixedly arranged at the top of the base, each slide rail isin slide connection with a left slide block and a right slide block, a screen box is arranged above the slide blocks, and the top of each slide block is respectively connected with the bottom of thescreen box through a second spring; a screen stencil fixedly connected with the inner side wall of the screen box is arranged in the screen box; a speed reducing motor is fixedly arranged at the top of the base; a disk is fixedly mounted on a motor shaft at the top end of the speed reducing motor; a hinge pin is fixedly arranged at the left side of the top of the disk; the hinge pin is rotationally connected with a connecting rod; the left side wall of the screen box is also hinged to a push plate through a connecting seat; and the right end of the connecting rod is connected with the left endof the push plate through a first spring. The ore pulverizing and screening device disclosed by the invention has the advantages that the disk rotates to drive the hinge pin to make circumferential motion so as to drive the screen box to move left and right and incline to a certain degree, thereby driving ores to sway left and right in the screen box to obtain a good screening effect.

Owner:COMMON TECH DEV CO LTD

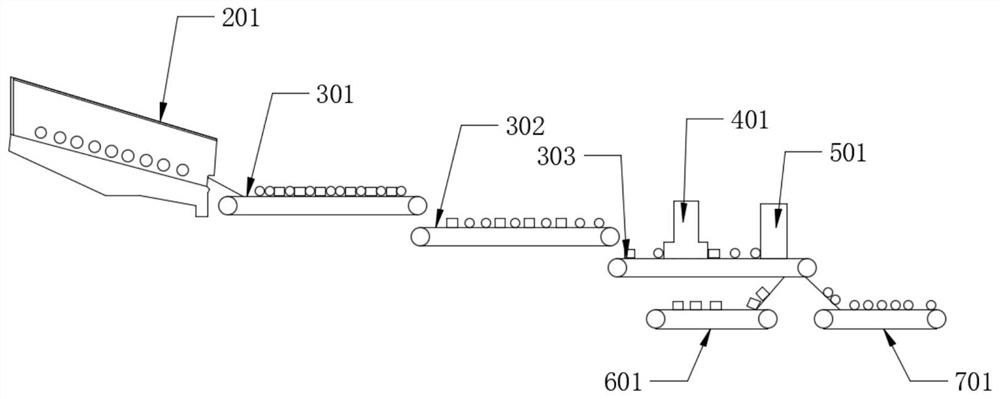

Intelligent automatic sorting system for coal

PendingCN111617987AEvenly distributedAccurate sortingSievingScreeningControl systemProcess engineering

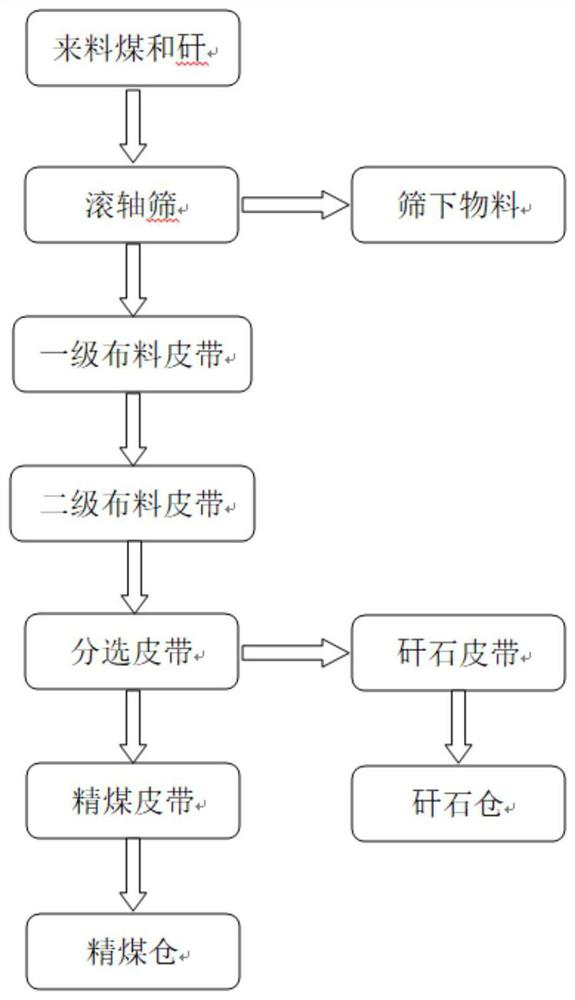

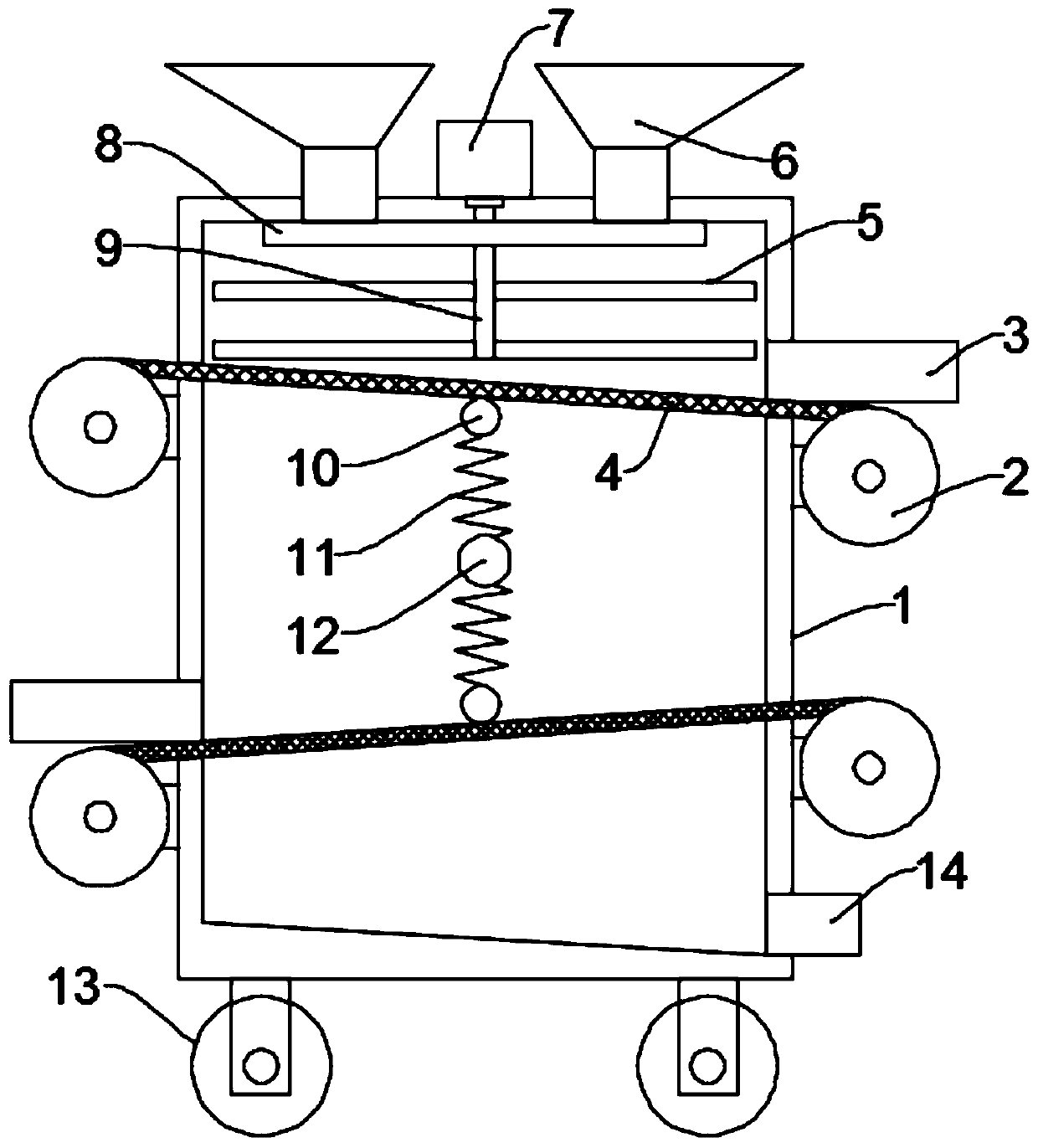

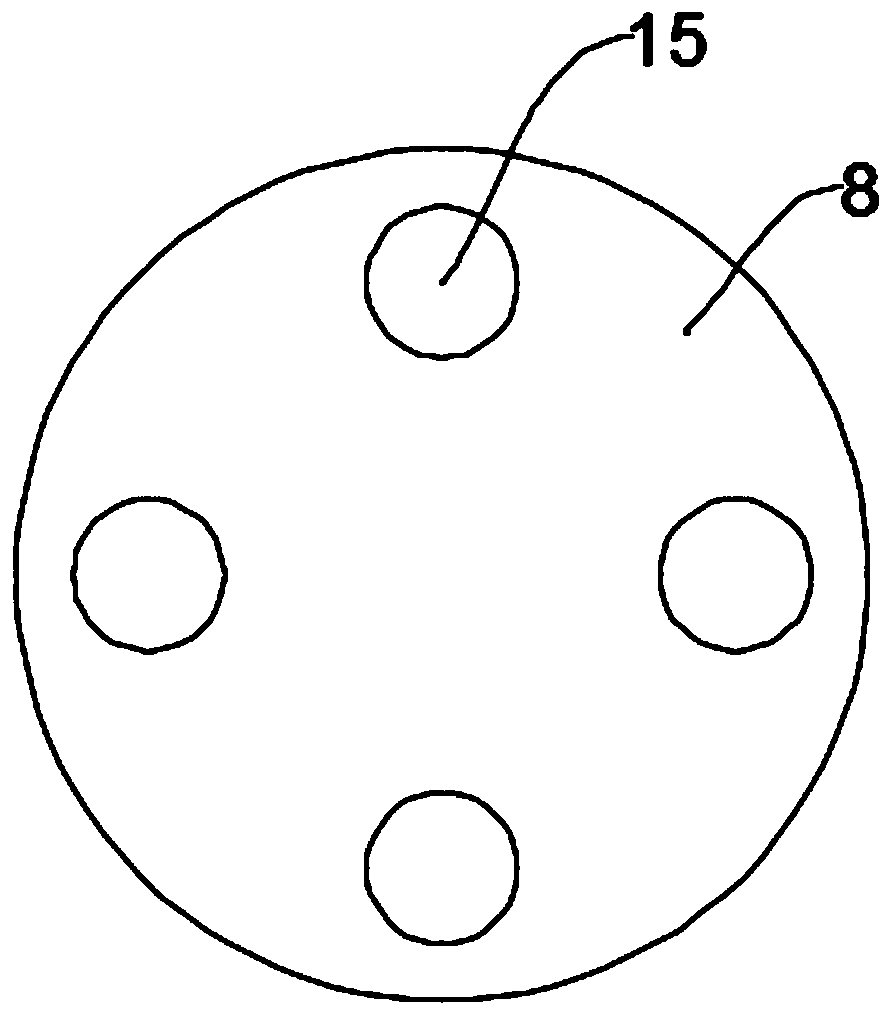

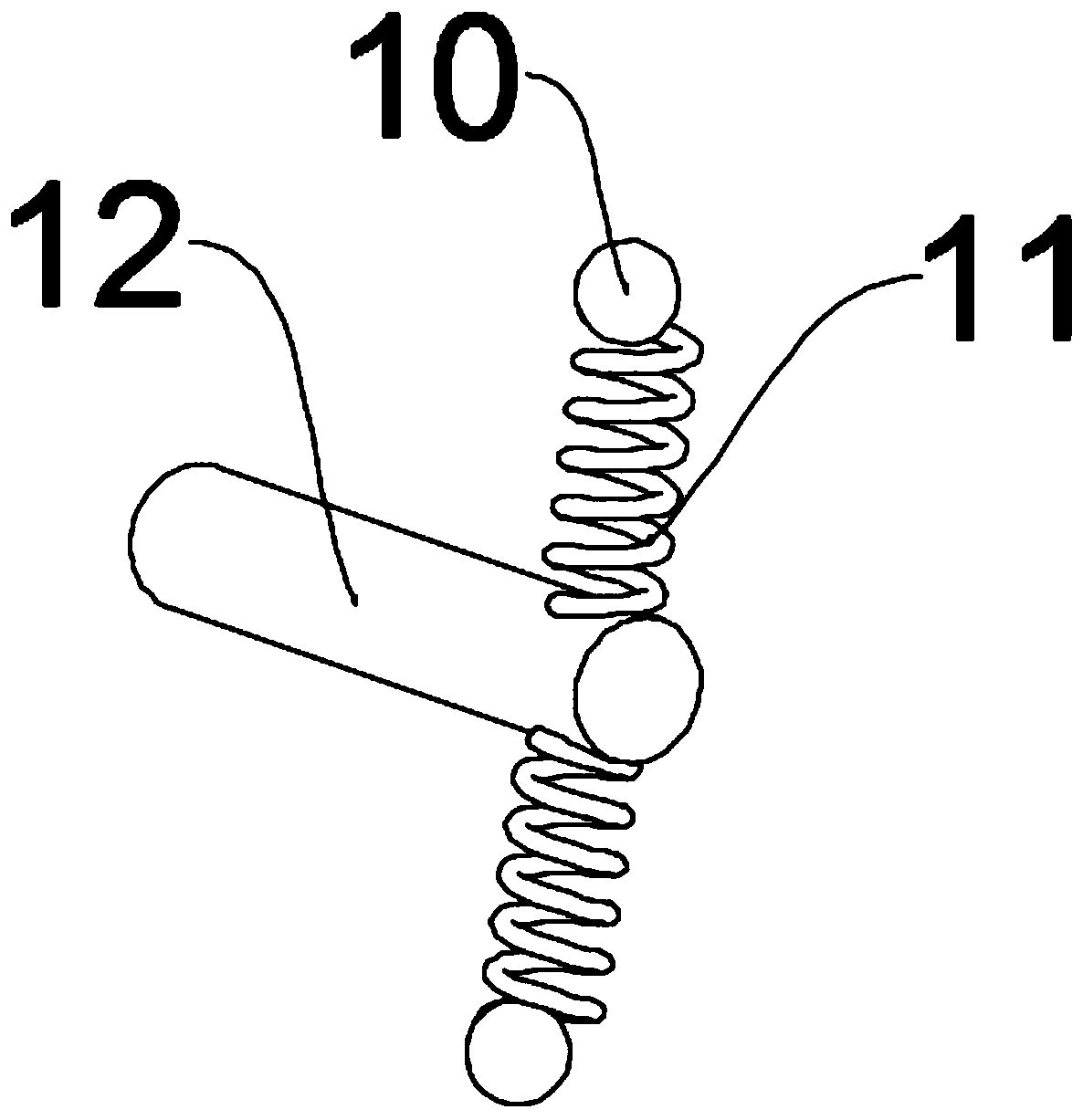

The invention discloses an intelligent automatic sorting system for coal. The intelligent automatic sorting system comprises a roll screen, a first-grade distribution belt conveyor, a second-grade distribution belt conveyor, a sorting belt conveyor, a recognition system, an execution system, a gangue belt conveyor and a clean coal belt conveyor; and the roll screen is used for screening supplied materials, small materials are removed, and meanwhile, materials distribution is completed. The first-grade distribution belt conveyor, the second-grade distribution belt conveyor and the sorting beltconveyor are sequentially connected, and uniform distribution of the materials is realized. The intelligent automatic sorting system for the coal can be used for realizing efficient and automatic material sorting, sorting of the coal and gangue is included, and sorting of gold ores, tungsten ores, iron ores and other ores is further included. The dry method sorting of the materials is realized through the recognition of the radial recognition system and the calculation of a centralized control system.

Owner:BIRTLEY TIANJIN IND EQUIP

Gravel sieving device capable of conveniently adjusting sieving sizes

The invention discloses a gravel sieving device capable of conveniently adjusting sieving sizes, relates to the technical field of gravel sieving and mainly aims at solving the problem that the sieving size of the existing device is inconvenient to adjust. The gravel sieving device comprises a sieving box and sieve nets, wherein two groups of sieve net assemblies vertically separated are mounted in the sieving box; and each sieve net assembly comprises multiple sizes of sieve nets and winding rollers. The gravel sieving device further comprises a crushing mechanism, wherein the crushing mechanism comprises a first motor, a rotating shaft and a crushing shaft, a disc is mounted on the rotating shaft and located below a bottom opening of a feeding hopper, a leaking hole matched with the bottom opening of the feeding hopper is formed in the disc, and a vibrating mechanism is arranged in the sieving box and located between two groups of sieve net assemblies; and the vibrating mechanism comprises a mounting shaft, a first spring and a vibrating ball. By arranging the sieve net assemblies in the application, the effect of adjusting the sieving sizes is realized. The structure is simple,the operation is convenient, and the practicability is high. By arranging the vibrating mechanism, multiple sizes of sieve nets can be driven to vibrate, and the sieving efficiency is increased.

Owner:曾钰云

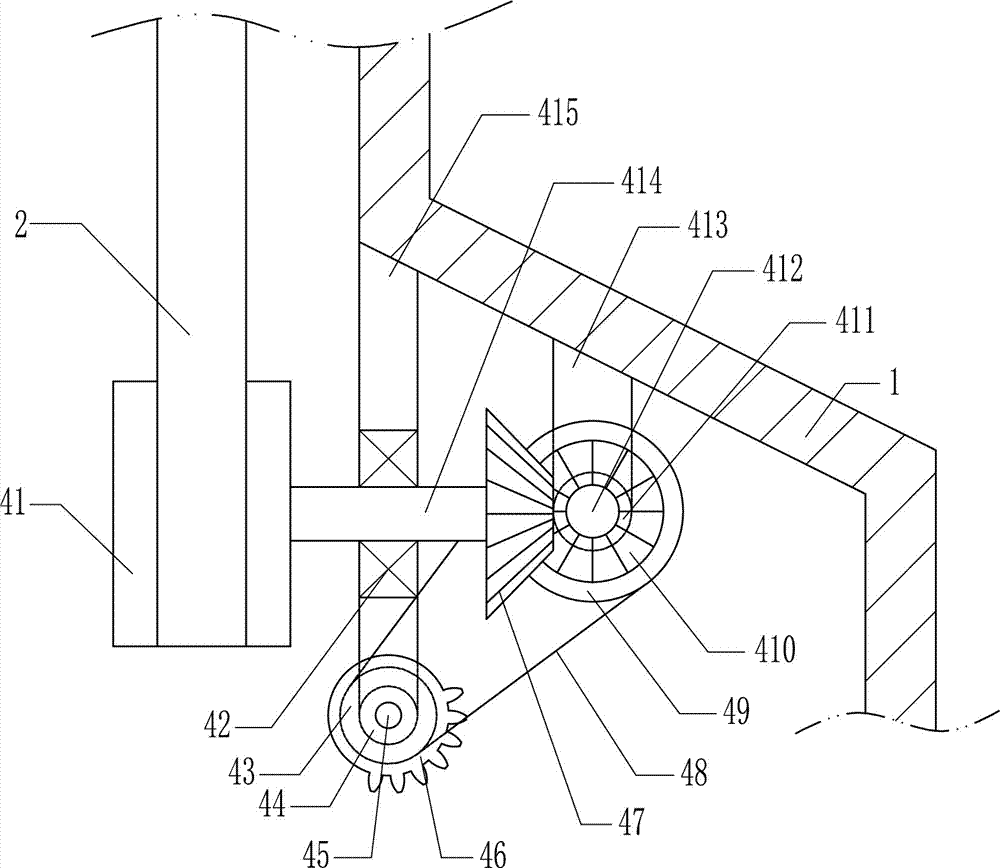

Sand grain screening system for construction site

ActiveCN105234082ASimple structureEasy to useSievingGas current separationScreening effectArchitectural engineering

A sand grain screening system for a construction site comprises a bottom plate, a rotating device, an ejecting device, a positioning device, a recycling device, a motor device and a screening device. Wheels are arranged on the bottom plate. The rotating device comprises a first supporting rod, a first rotating shaft, a first cushion block and a supporting plate. The ejecting device comprises a first fixing block, a first positioning rod, first springs, second springs, an ejecting block, a bent rod, a first inclined rod, a runner, a second supporting rod and a first triangular block. The positioning device comprises a second fixing block, third springs, a positioning block and a second triangular block. The recycling device comprises a recycling box, a second positioning rod, a third positioning rod and a third supporting rod. The motor device comprises a motor, a second rotating shaft, a rotating frame, a feeding hopper, a cover plate, a first vertical rod, a third fixing block, a baffle, a connecting rod and a second vertical rod. The screening device comprises a filtering ball, a second cushion block and a filter net. The sand grain screening system can sufficiently screen sand grains, the screening efficiency is high, and the screening effect is good.

Owner:广州恒驰建设工程有限公司

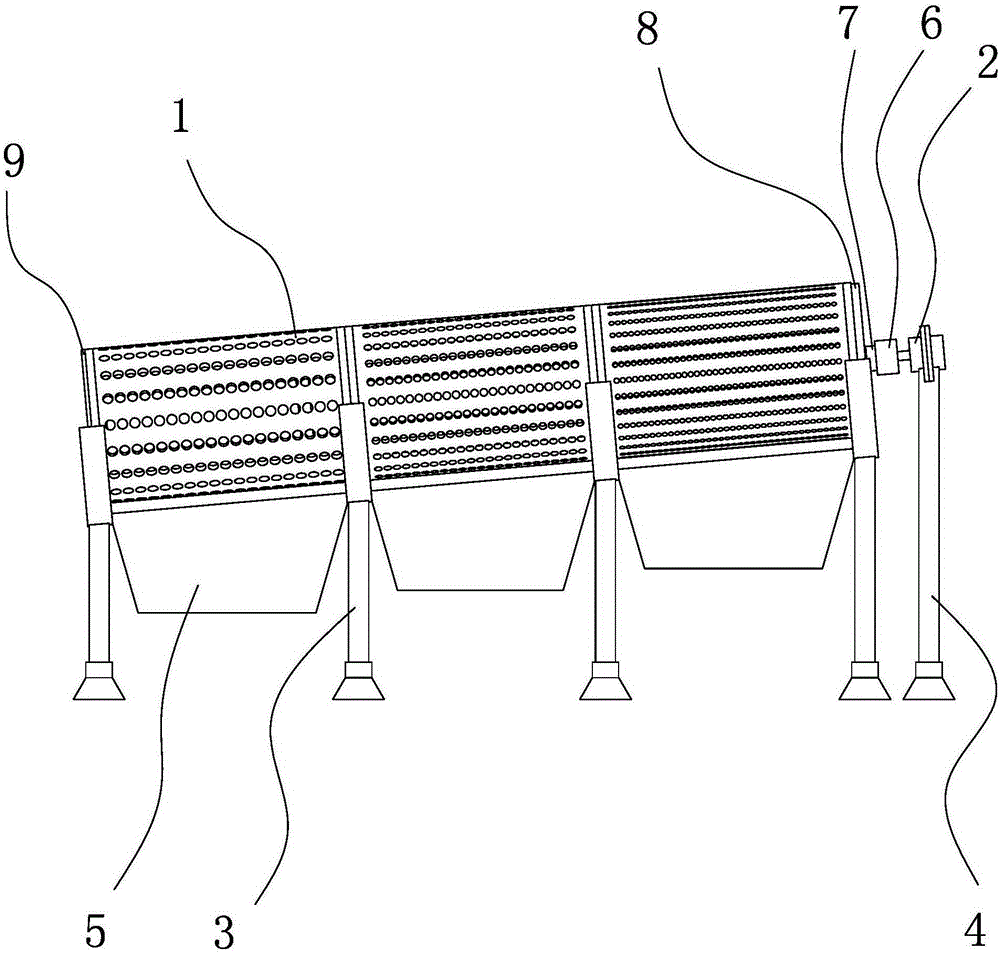

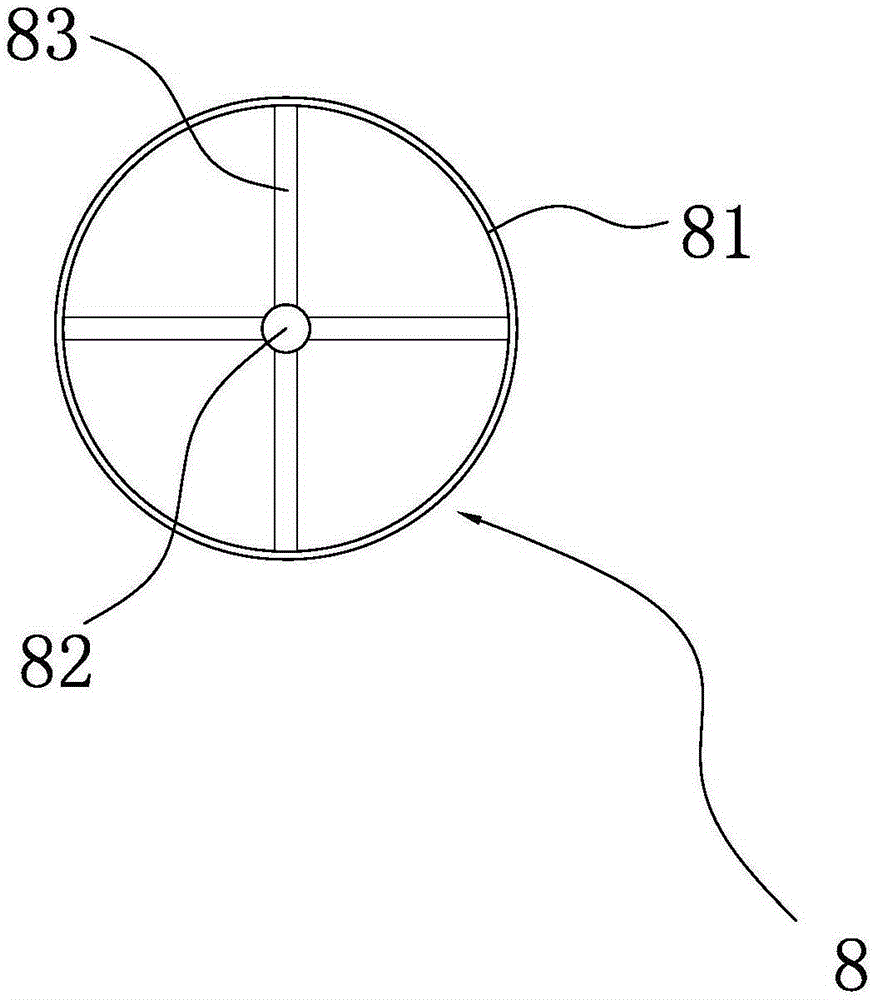

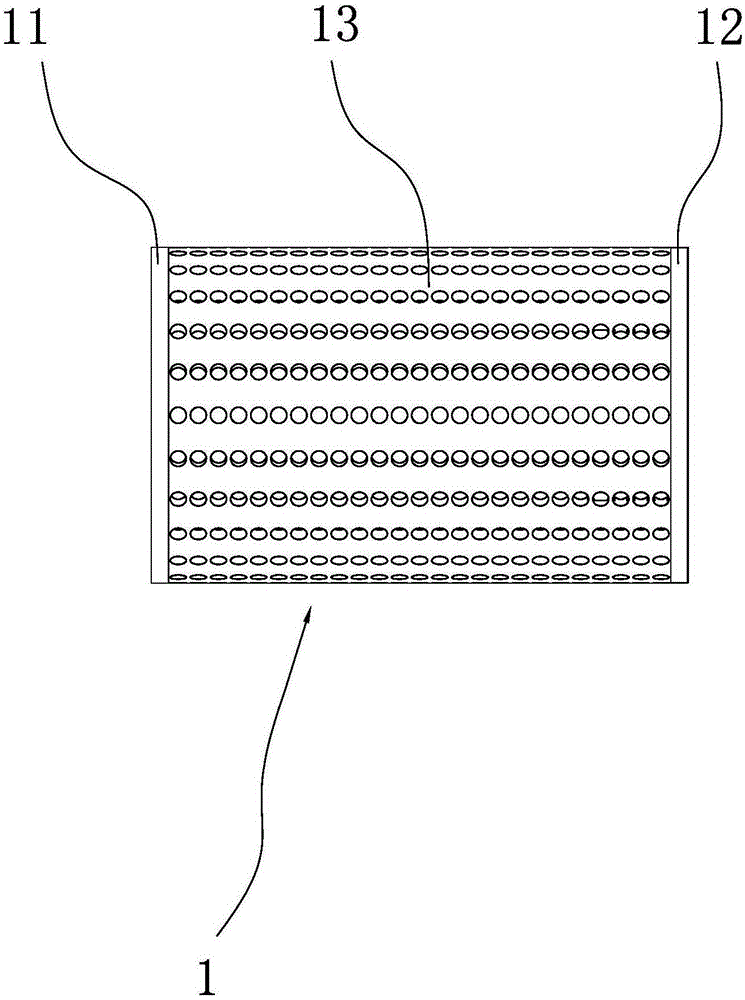

Grading type screening plant used for screening haycite

The invention provides a grading type screening plant used for screening haycite, and belongs to the technical field of building material machining. The problems that meshes of an existing haycite screen are prone to being blocked, the earpiece screening tension is insufficient, and the using stability is not high are solved. The grading type screening plant used for screening the haycite comprises a rack, a plurality of rotary screens which are sequentially connected in series and a motor used for driving the rotary screens to rotate; the rack comprises a first support used for supporting the rotary screens and a second support used for supporting the motor; and the mesh sizes of the rotary screens are all different, the mesh sizes of the rotary screens connected in series are sequentially increased from back to front, the rotary screen located at the backmost end is connected with the motor, the rotary screens are coaxially arranged, adjacent rotary screens are fixedly connected, and a receiving hopper is connected to the lower portion of each rotary screen. By means of the grading type screening plant, grading screening can be carried out, and the meshes are not prone to being blocked.

Owner:ZHEJIANG FANGYUAN BUILDING MATERIALS TECH

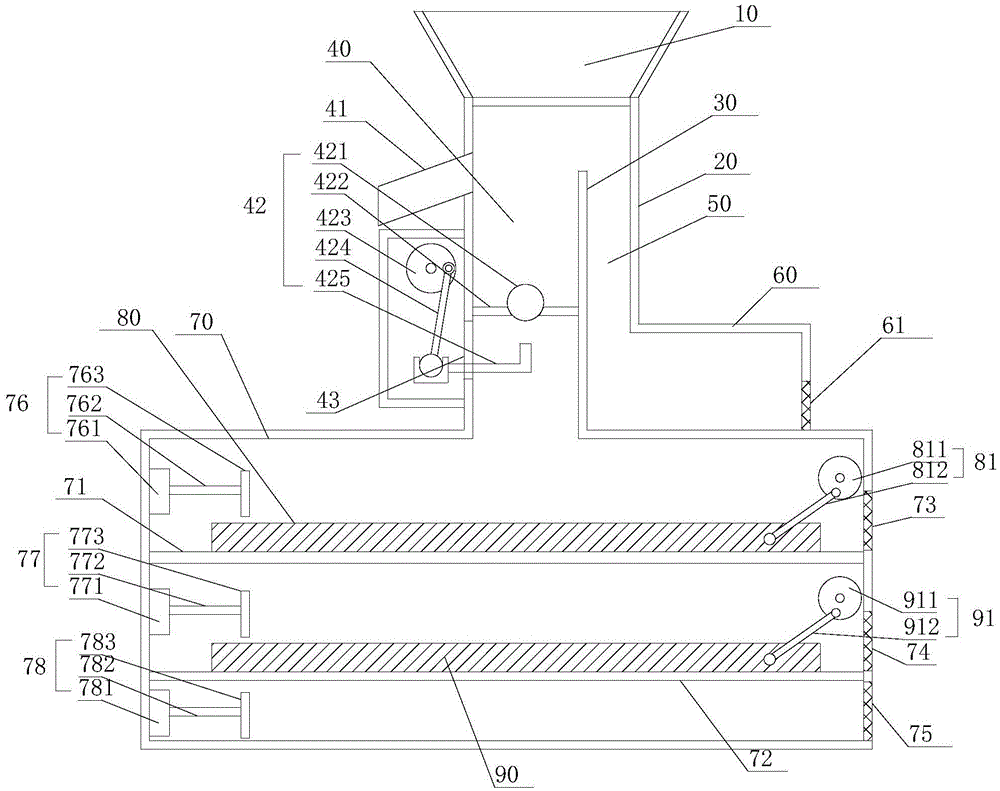

Soybean crushing and grading recycling device

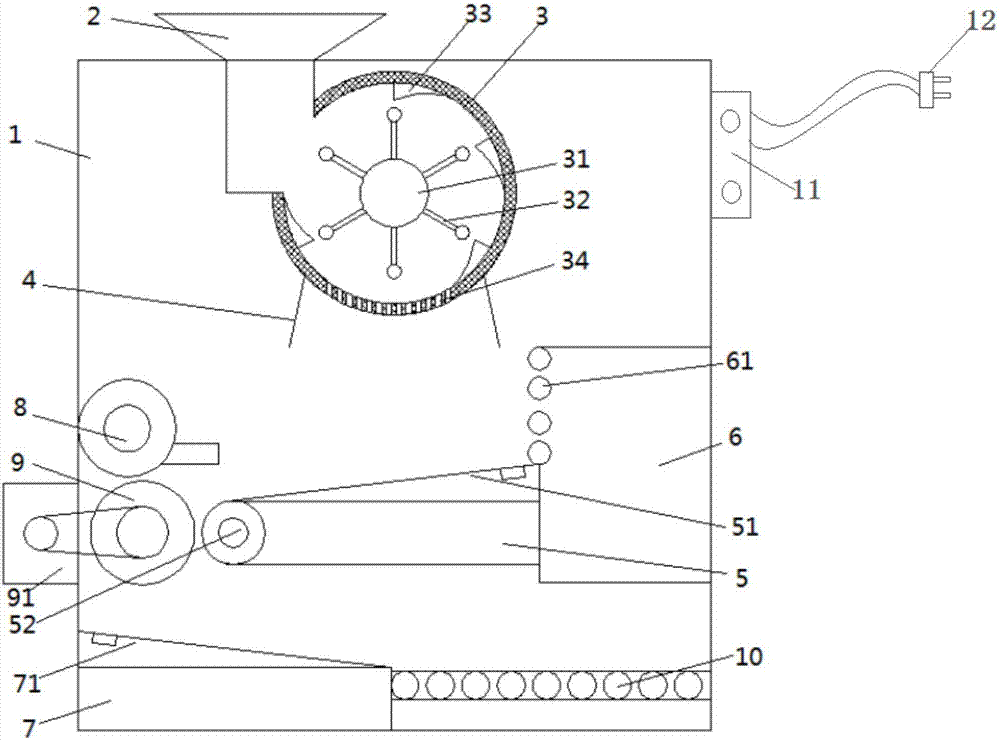

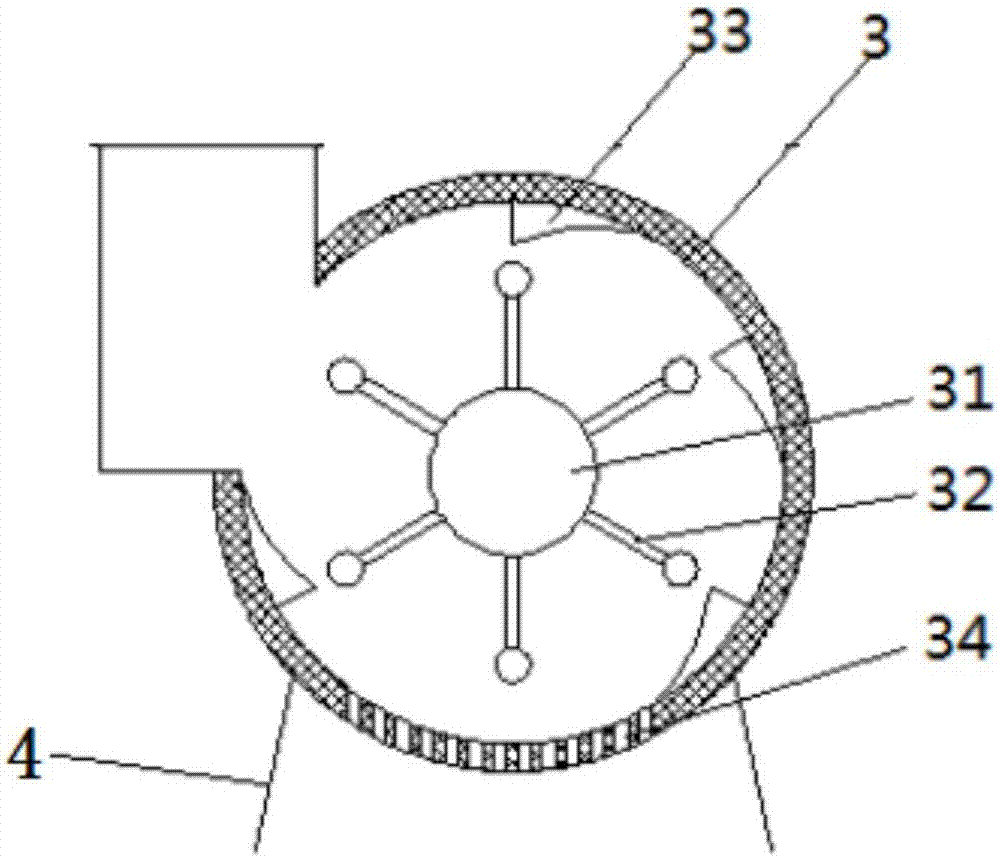

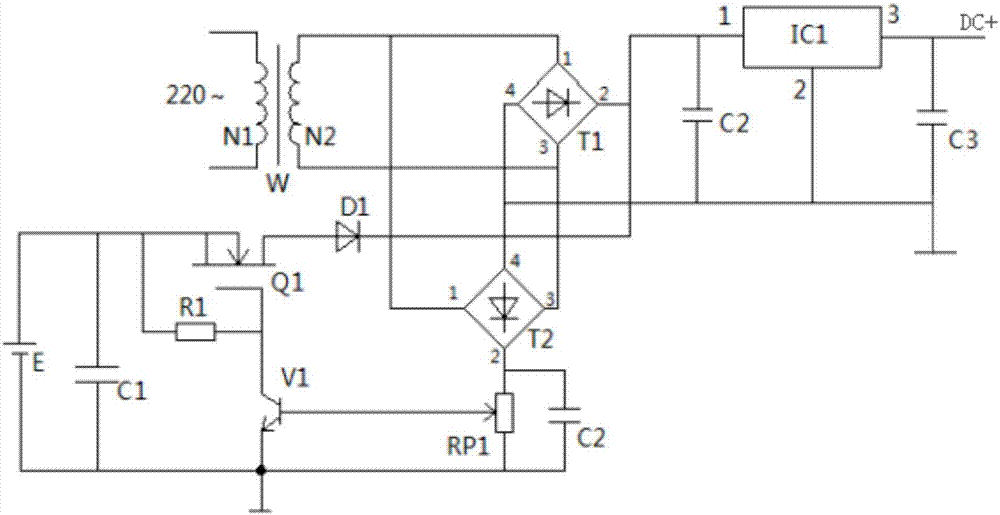

ActiveCN107876150AImplement classification processingFully screenedGrain treatmentsEmergency power supply arrangementsEngineeringClassification treatment

The invention discloses a soybean crushing and grading recycling device. The soybean crushing and grading recycling device comprises a box. The upper portion of the top of the box is provided with a feeding opening. A crushing cavity is formed in the top of the interior of the box. A power adapter is arranged on the outer side wall of the box and connected with a plug through a power wire. According to the soybean crushing and grading recycling device, by arranging a strong wind blower and a soybean powder collecting box in the box, existed small granular soybean powder after first-stage crushing is pre-collected, so that classification treatment of soybean crushing is achieved; soybean raw materials are crushed repeatedly through the crushing cavity and a driving extruding roller and arescreened and separated through a first vibration belt and a second vibration belt, so that it is ensured that the soybean raw materials can be crushed completely and screened fully, subsequent processing treatment of the different sizes of soybean raw materials is facilitated, meanwhile, the soybean crushing and grading recycling device adopts uninterruptible power supplying, so that normal work of the soybean crushing and grading recycling device cannot be affected even if power outage, and the situation of material waste caused by power outage is avoided.

Owner:江西盐津铺子食品有限公司

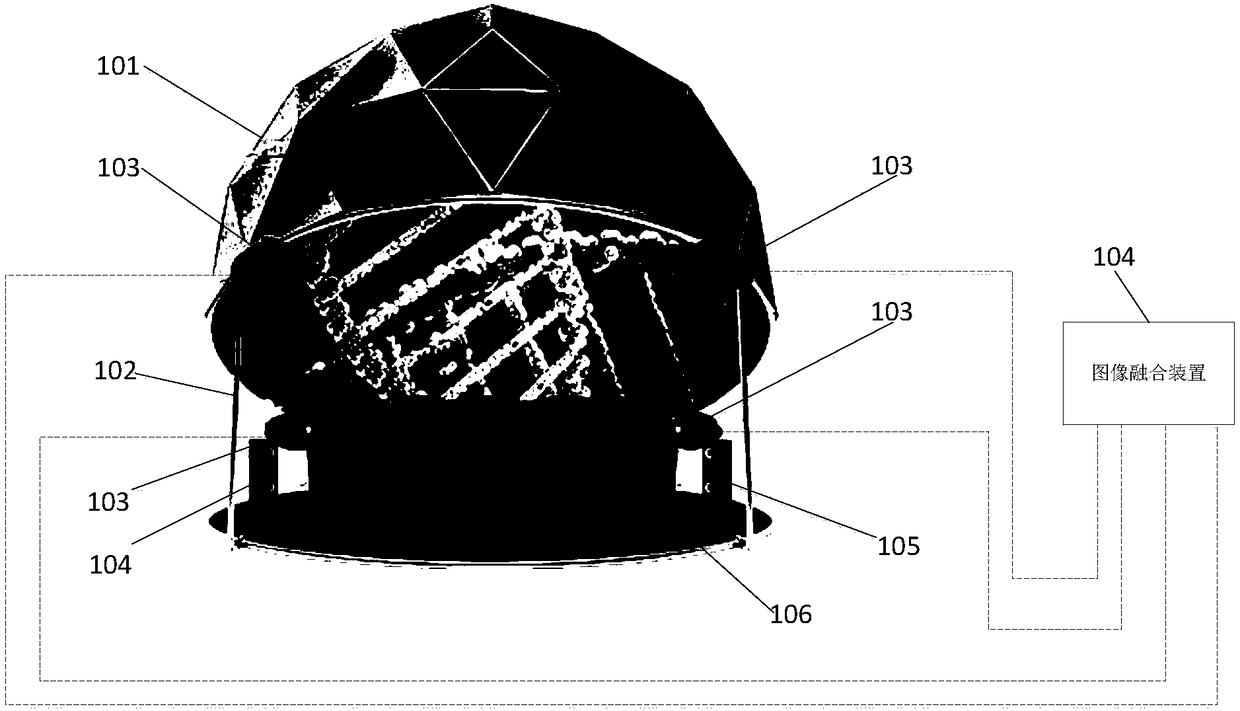

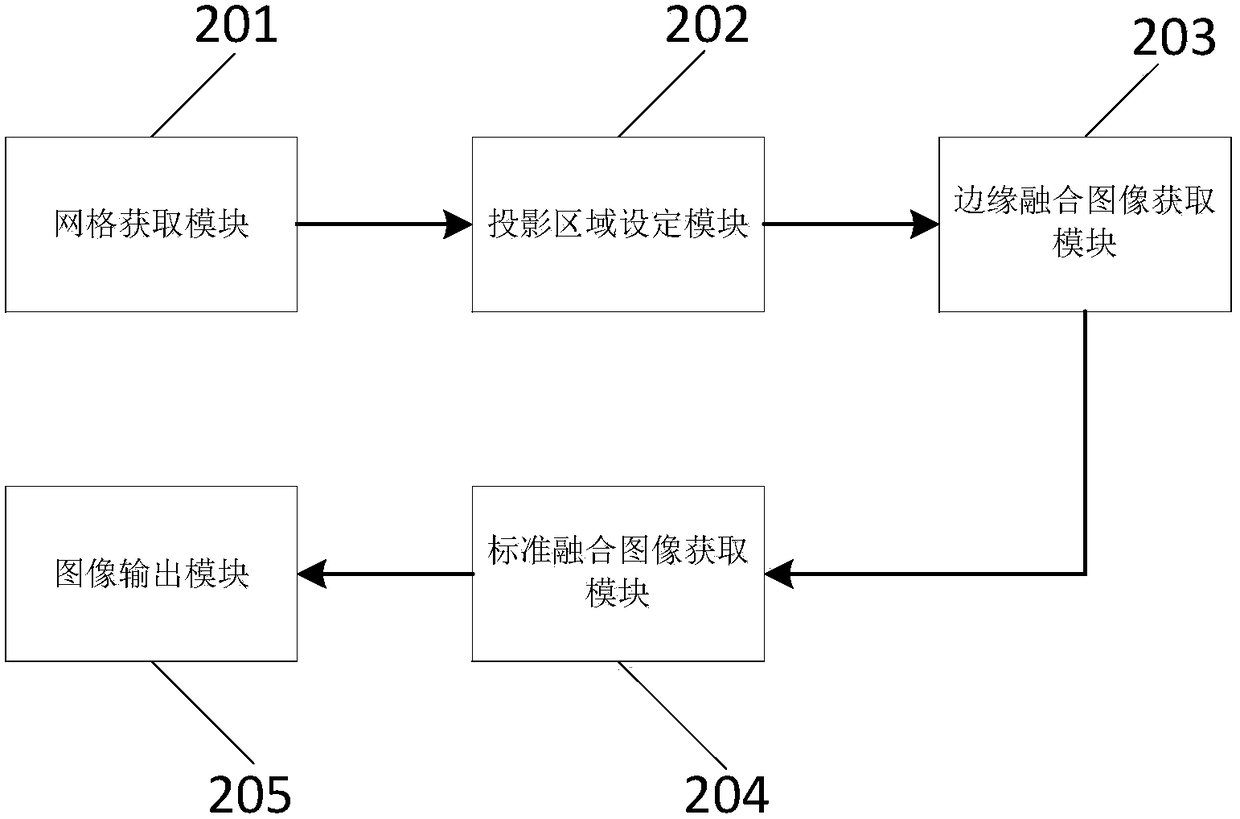

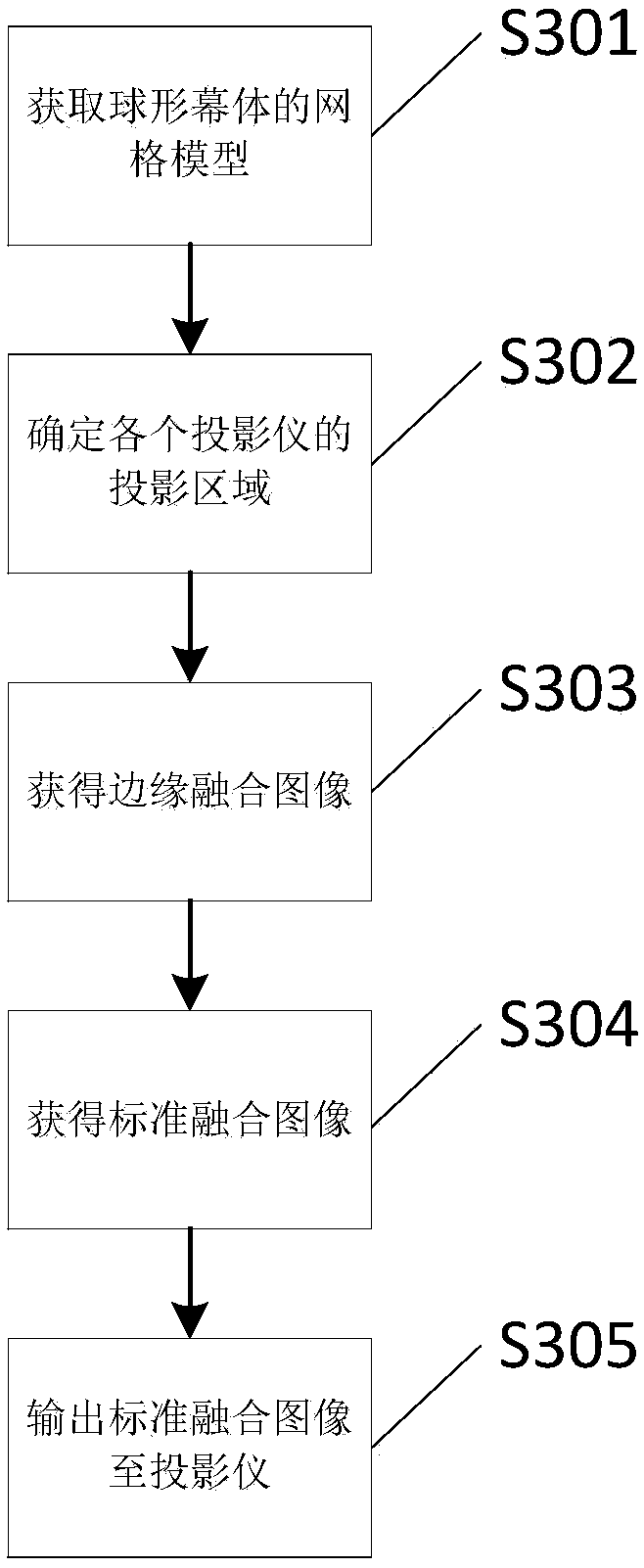

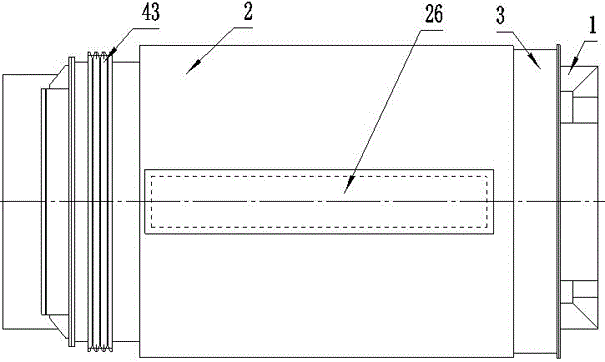

Image fusion method for dome screen system, and image fusion device thereof

InactiveCN108269231AEliminate color differencesUniform colorImage enhancementImage analysisProjection imageColor processing

The invention relates to an image fusion method for a dome screen system. The image fusion method for a dome screen system is characterized by determining the projection area of each projector by means of a mesh model of the dome screen body so as to enable each projector to have adjustability for the projection position; performing edge fusion on each projection area by means of polar coordinatesgeometrical correction processing, so as to enable the projection area image at different position and in different size to achieve the effect of accurate splicing; and respectively performing colorcalibration of the projectors and fusion band blanking operation of projection images by means of unified color processing and light leakage compensation processing, thus effectively avoiding color variation and luminance variation between each edge fusion image. By means of the steps provided by the image fusion method for a dome screen system, the stereo projection image on the dome screen bodycan achieve the display effect of complete frames, unified color and suitable luminance, and comfortable and perfect film watching experience can be brought to spectators. The image fusion device employing the image fusion method for a dome screen system can generate a standard fusion image with better display effect, and the dome screen system employing the image fusion method can have excellentprojection effect and can improve the film watching experience of spectators.

Owner:深圳市艺博堂文化科技集团有限公司

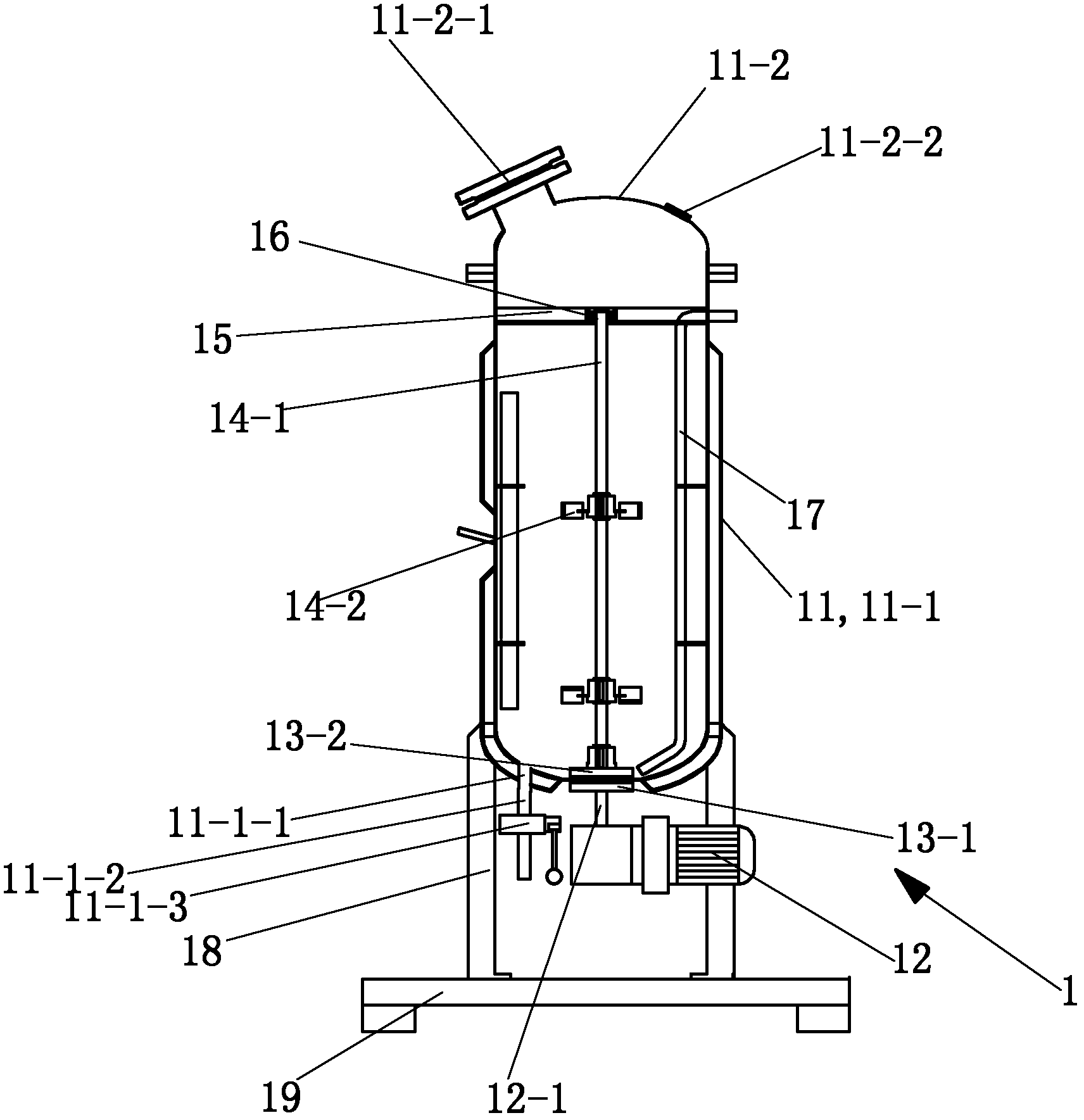

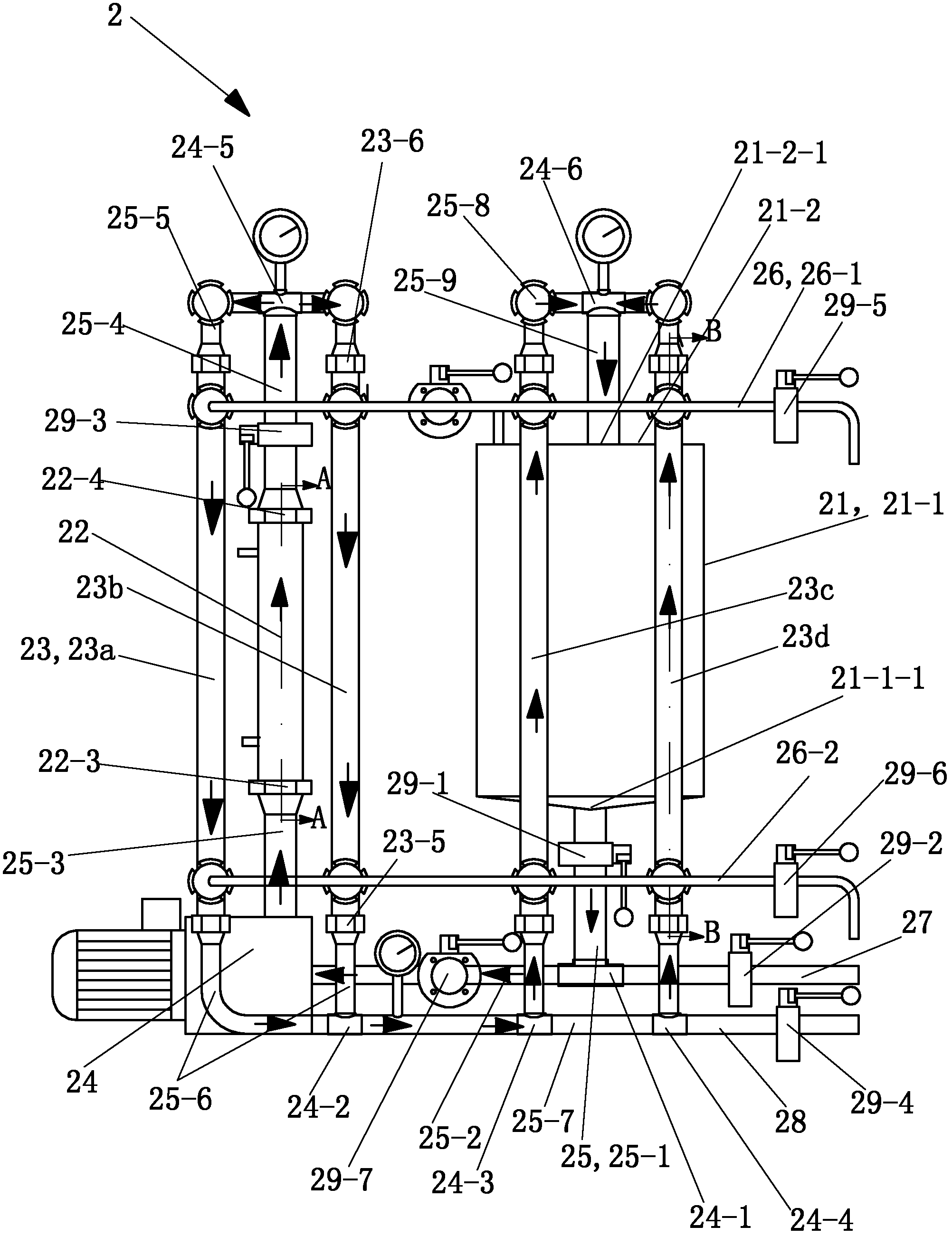

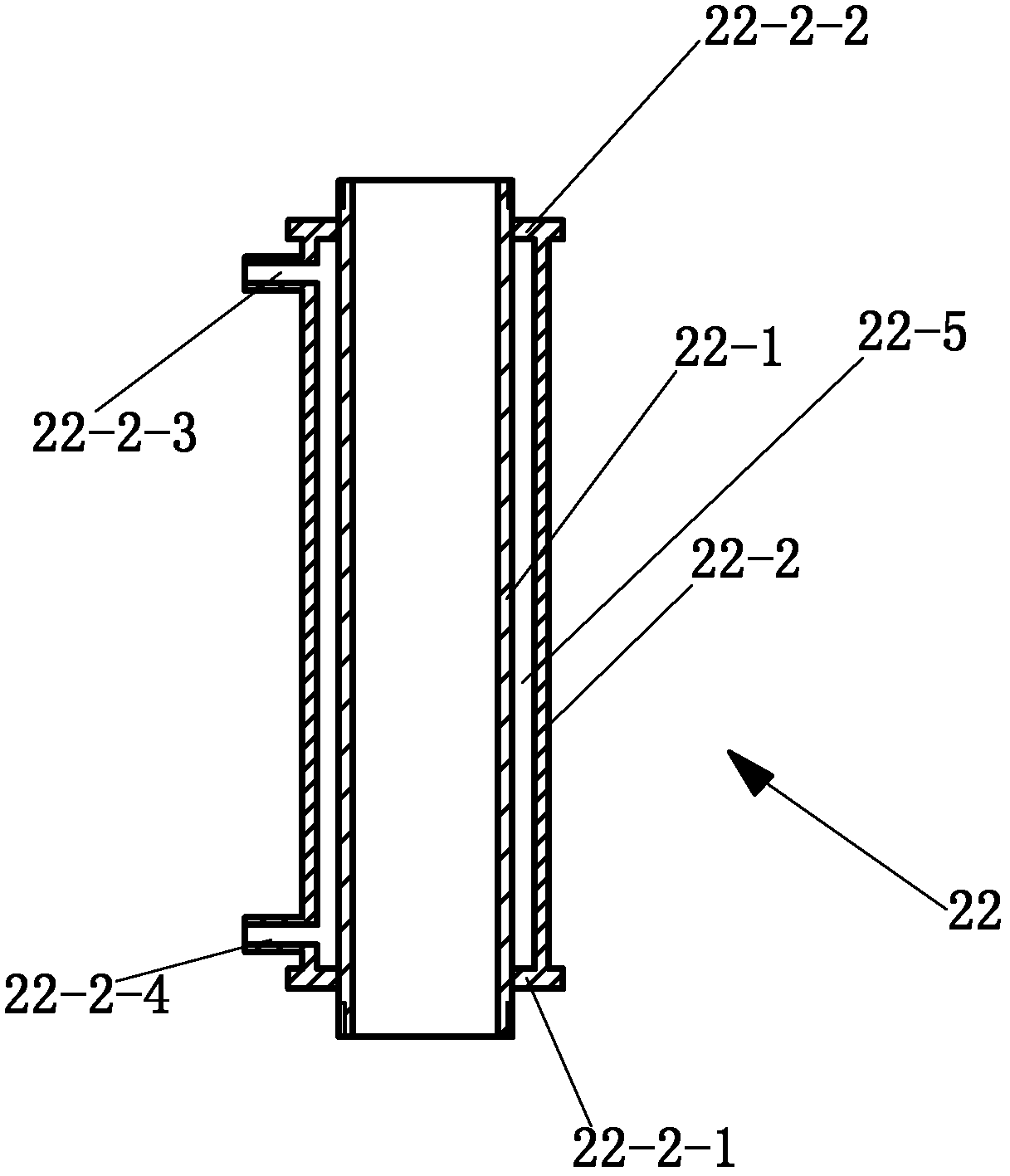

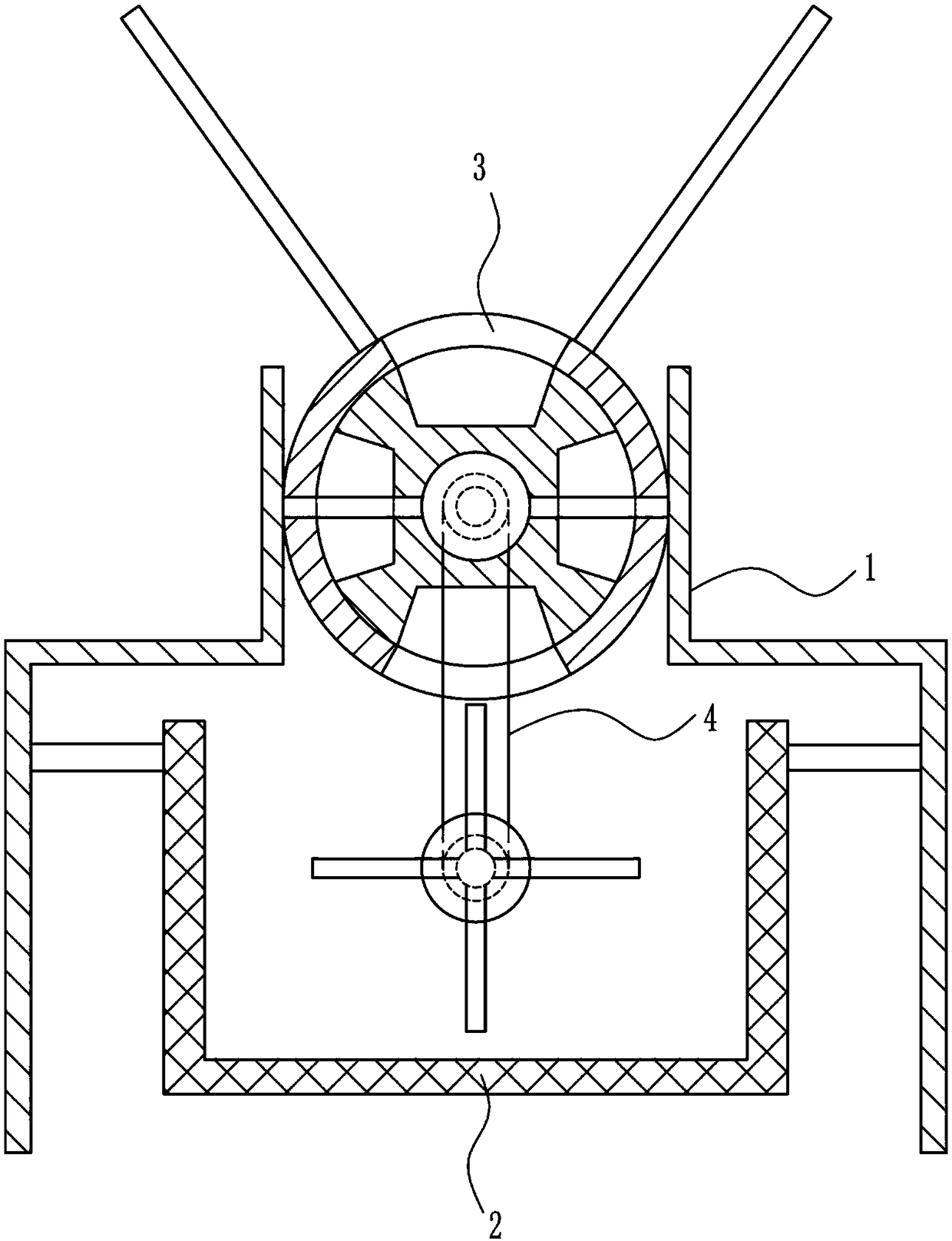

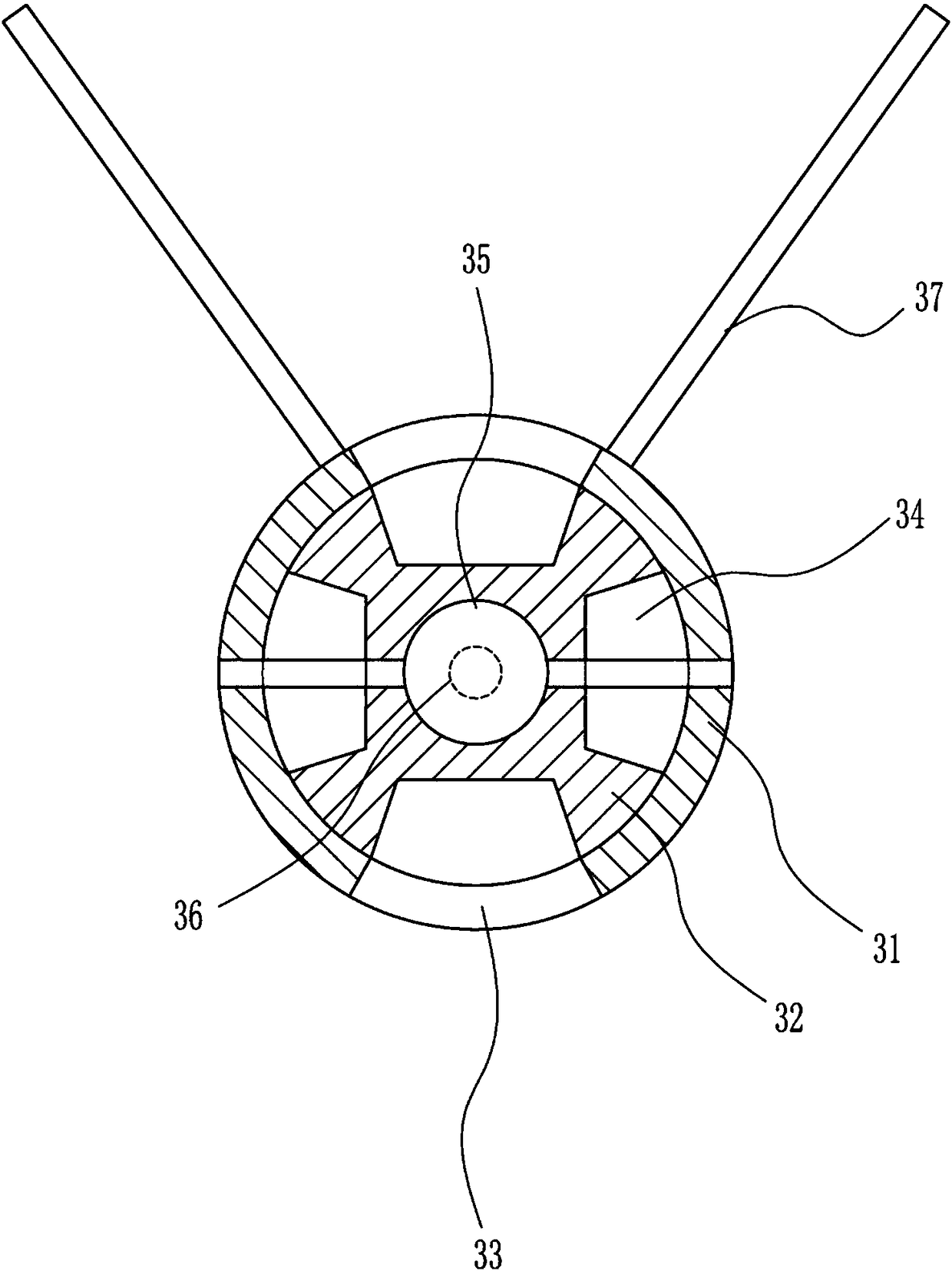

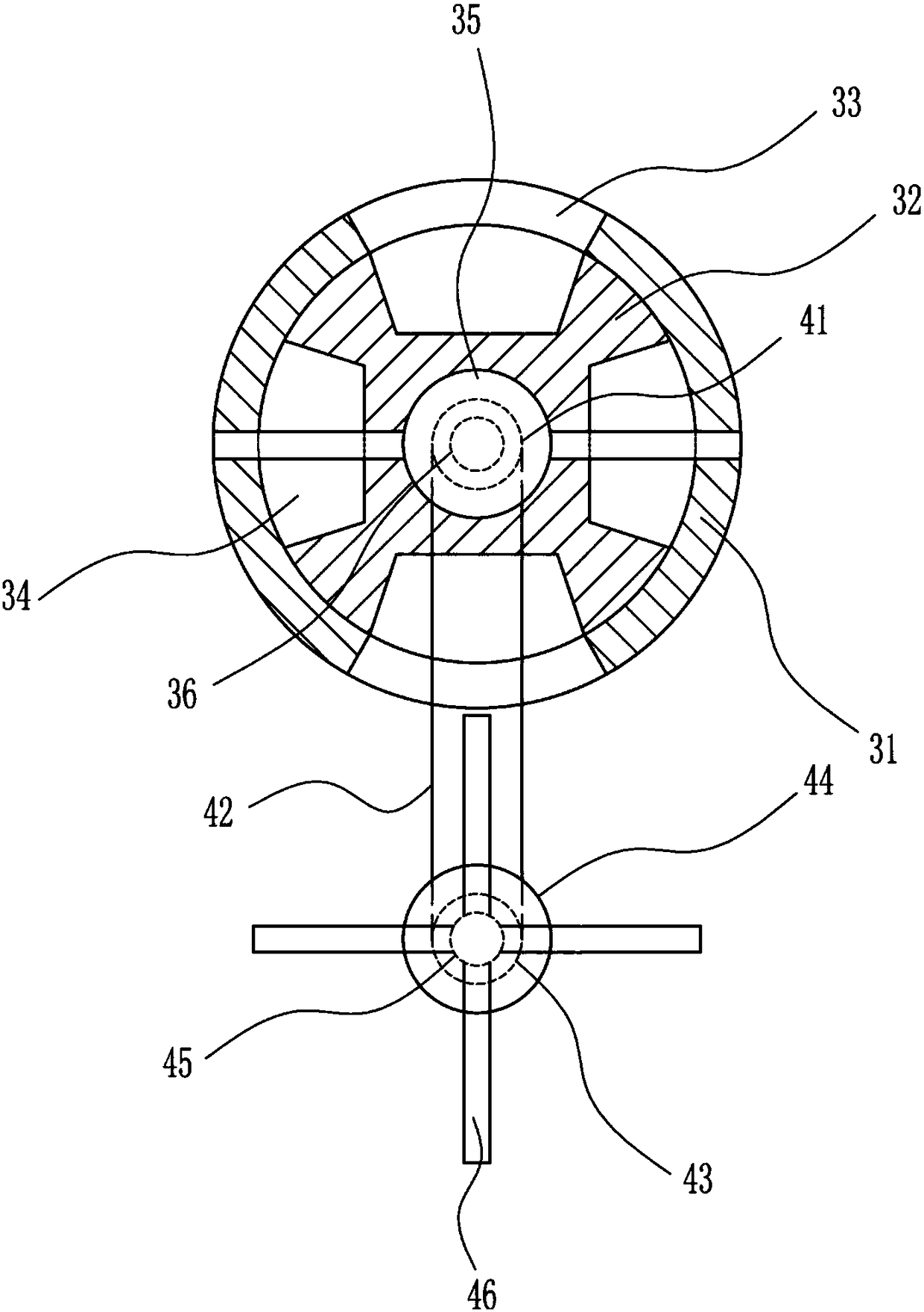

Fermentation tank, equipment system for preparing probiotics and method for preparing probiotics

ActiveCN102492611AGuaranteed cleanlinessLess impuritiesBioreactor/fermenter combinationsBiological substance pretreatmentsProcess engineeringCross-flow filtration

The invention discloses a fermentation tank, an equipment system for preparing probiotics and a method for preparing probiotics. The motor of the fermentation tank is positioned under a tank body, and facilitates convenient tank opening cleaning as well as scale removing through magnetic stirring. The equipment system for preparing probiotics comprises the fermentation tank, a filtering device, afreeze-drying device, a comminuter, and a stirrer. Specifically, the filtering device is added with a heat exchanger, employs a ceramic membrane prepared from an inorganic ceramic material by a special technology, and can reach the purposes of separation, concentration and purification by means of crossflow filtration and pressure driving during using; and the freeze-drying device consists of a cryogenic refrigerator and a freeze dryer, the temperature sensor of which is fixed on the sidewall of a material plate. During preparing probiotics, the material freezing step undergoes in the cryogenic refrigerator, and the material drying process undergoes in the freeze dryer, thus reducing energy consumption and improving production efficiency.

Owner:善恩康生物科技(苏州)有限公司

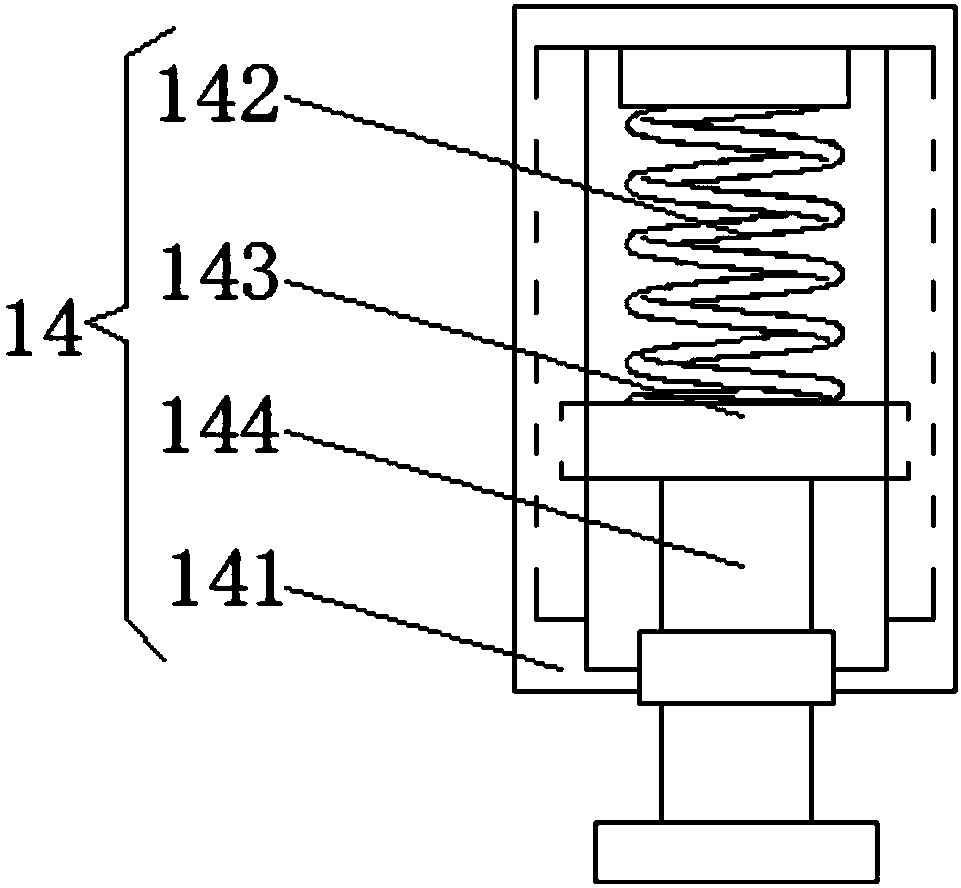

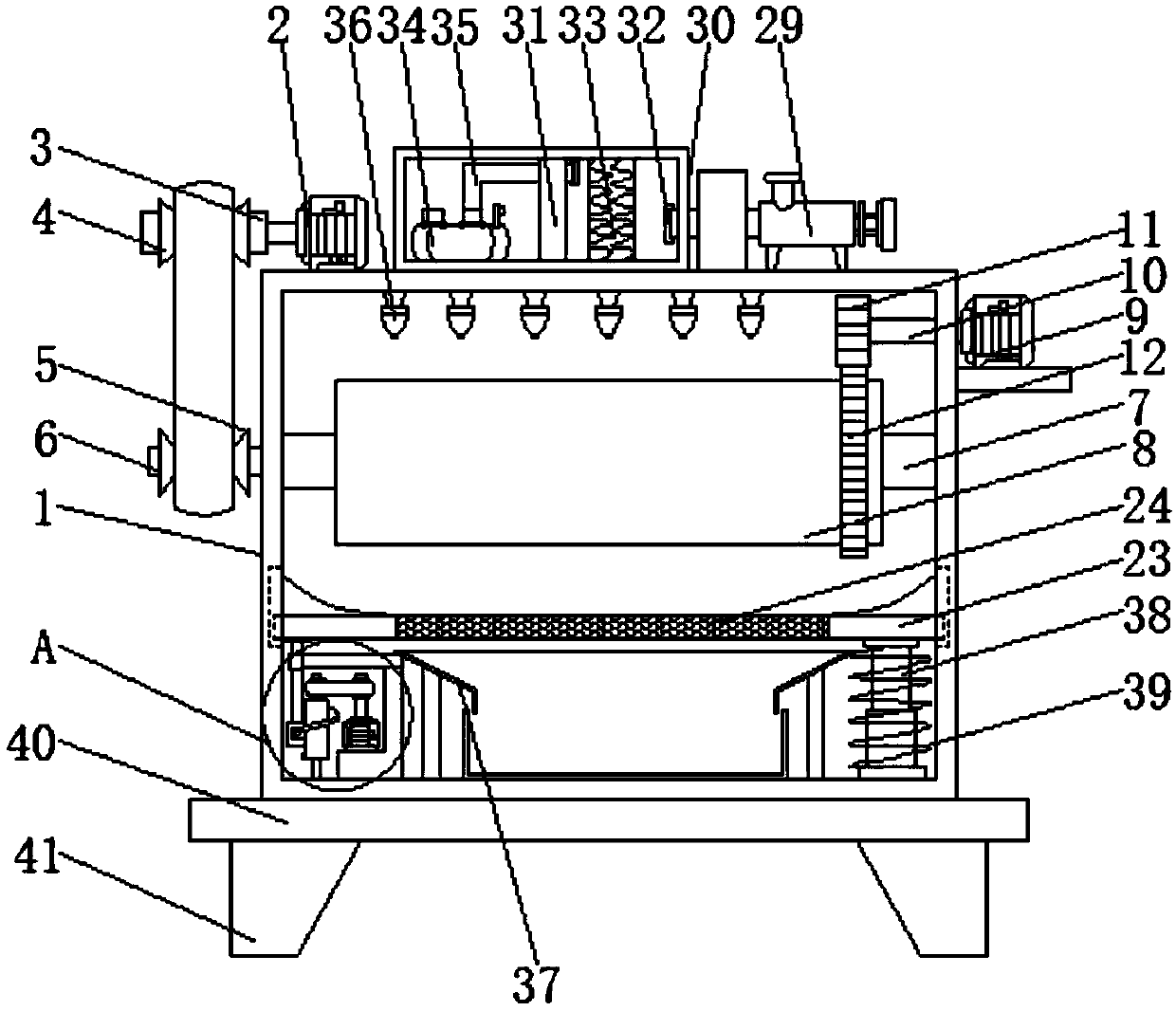

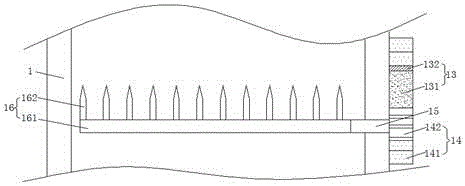

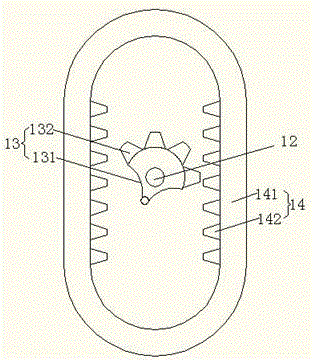

Blockage-proof high-frequency vibration separate-screening machine

InactiveCN106733626AImprove the vibration effectFully screenedSievingScreeningEngineeringHigh frequency vibration

The invention discloses a blockage-proof high-frequency vibration separate-screening machine which comprises a metal shell. A first rotary shaft is connected to the surface of the metal shell in an inserted manner. The two ends of the first rotary shaft penetrate the front face and the back face of the metal shell correspondingly and are fixedly connected with vibration wheels correspondingly. The two sides of the metal shell are fixedly connected with stand columns. The top ends of the stand columns are fixedly connected with a cross beam. The lower surface of the cross beam is fixedly connected with two limiting rods. The bottom ends of the two limiting rods are connected with a screening hopper in a sleeved manner. According to the blockage-proof high-frequency vibration separate-screening machine, through the arrangement of the cross beam, the limiting rods and springs, the screening hopper can move only in the vertical direction, downward pushing force is applied to the screening hopper through the springs, the vibration effect of the separate-screening machine is enhanced, and part of materials clamped in screen meshes can be vibrated out through vibration by enhancing the vibration effect of the separate-screening machine; and through the arrangement of a special-shaped gear, a gear ring and a dredging frame, when the special-shaped gear rotates, the dredging frame is driven to do back and forth movement in the vertical direction together, and therefore a screen is periodically dredged.

Owner:广州品帝智能科技有限公司

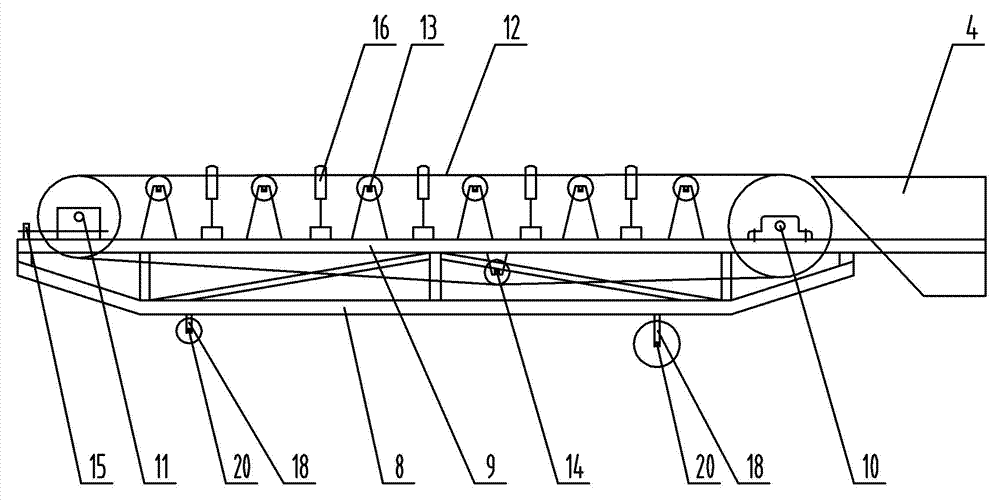

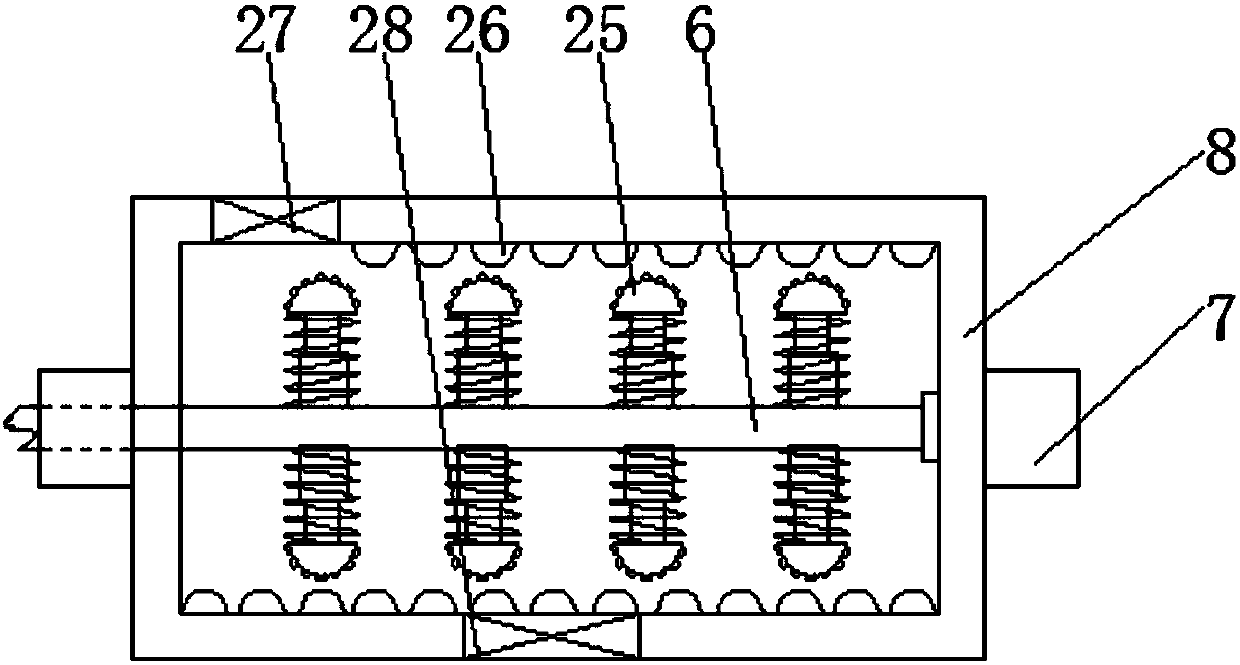

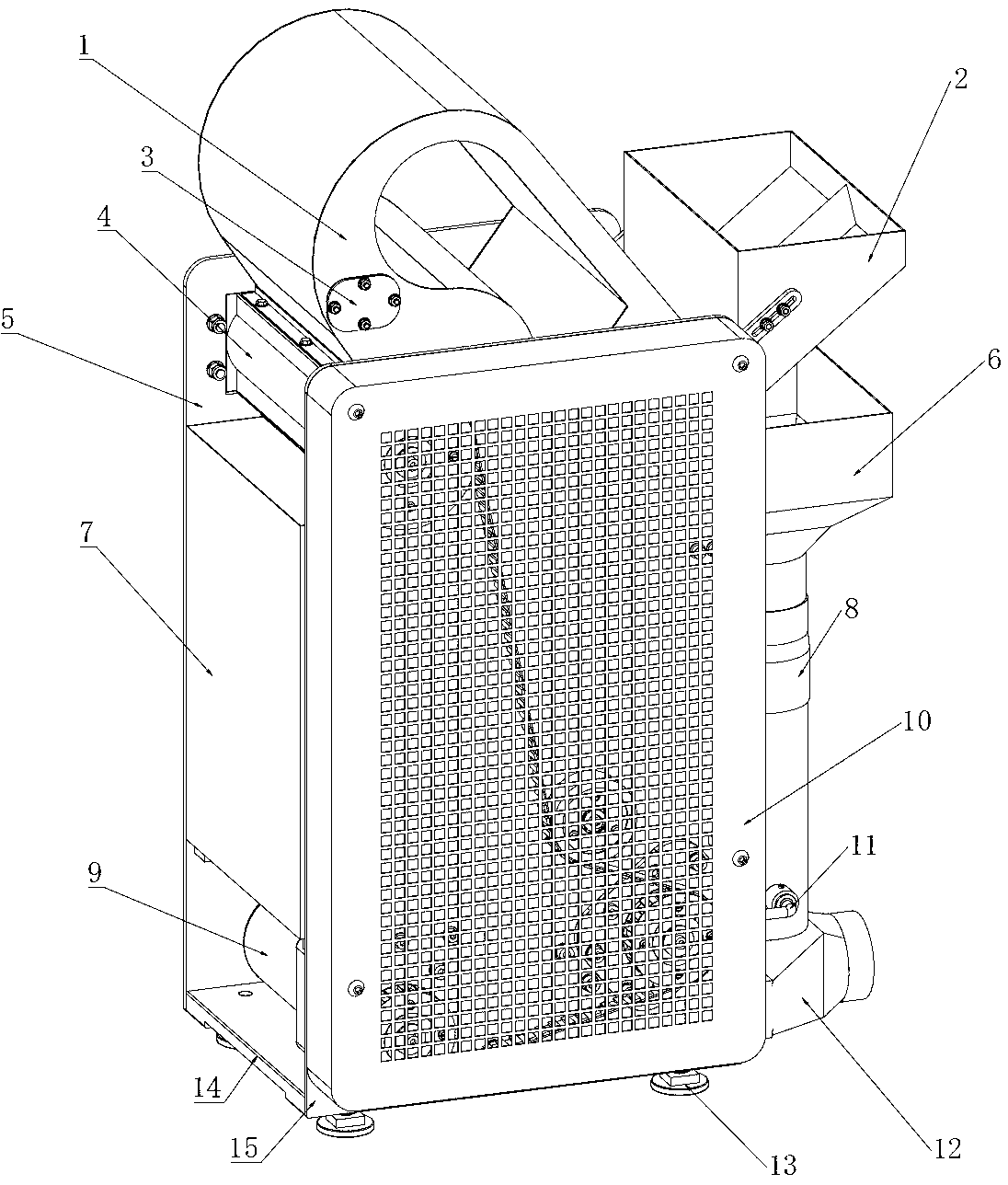

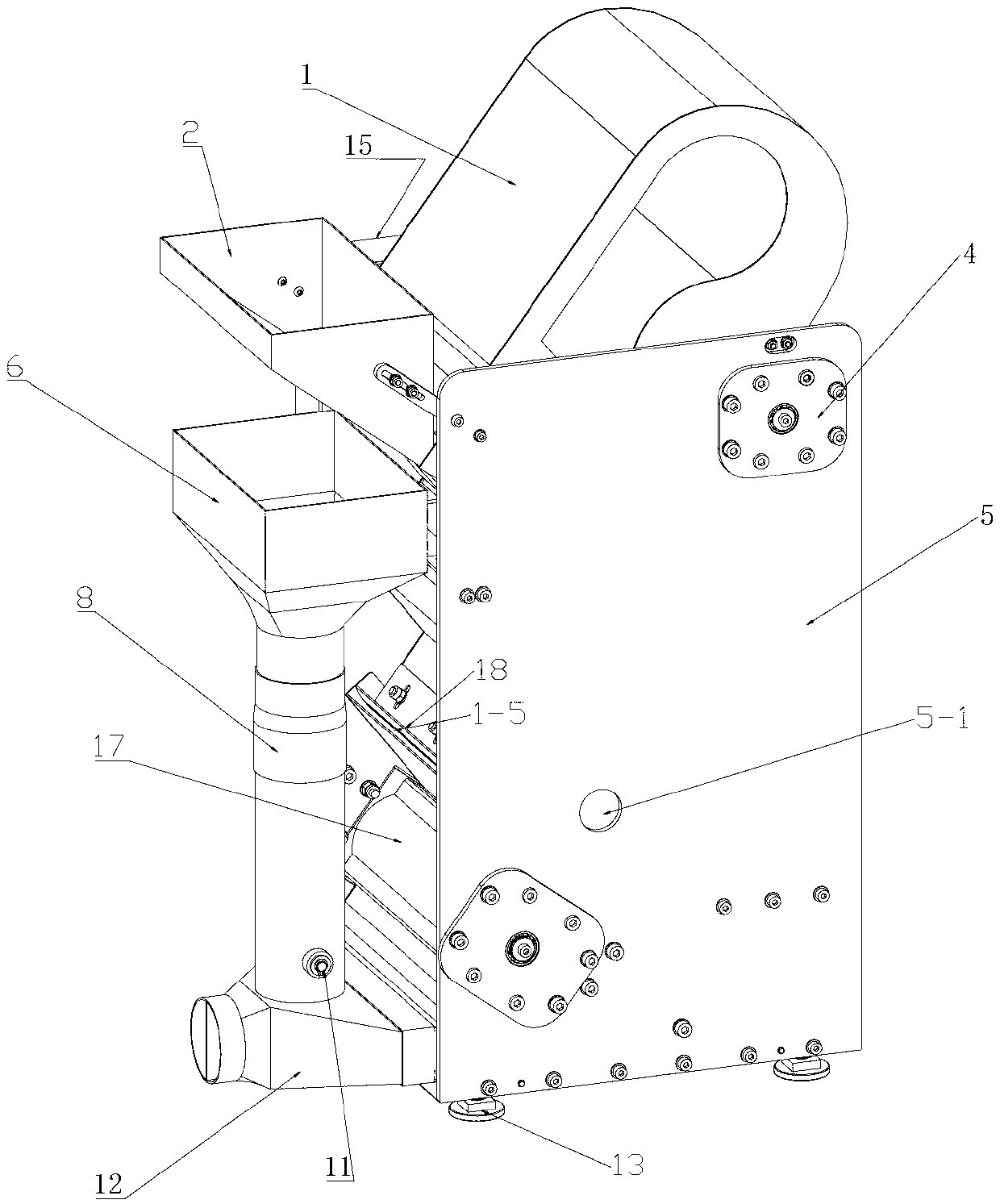

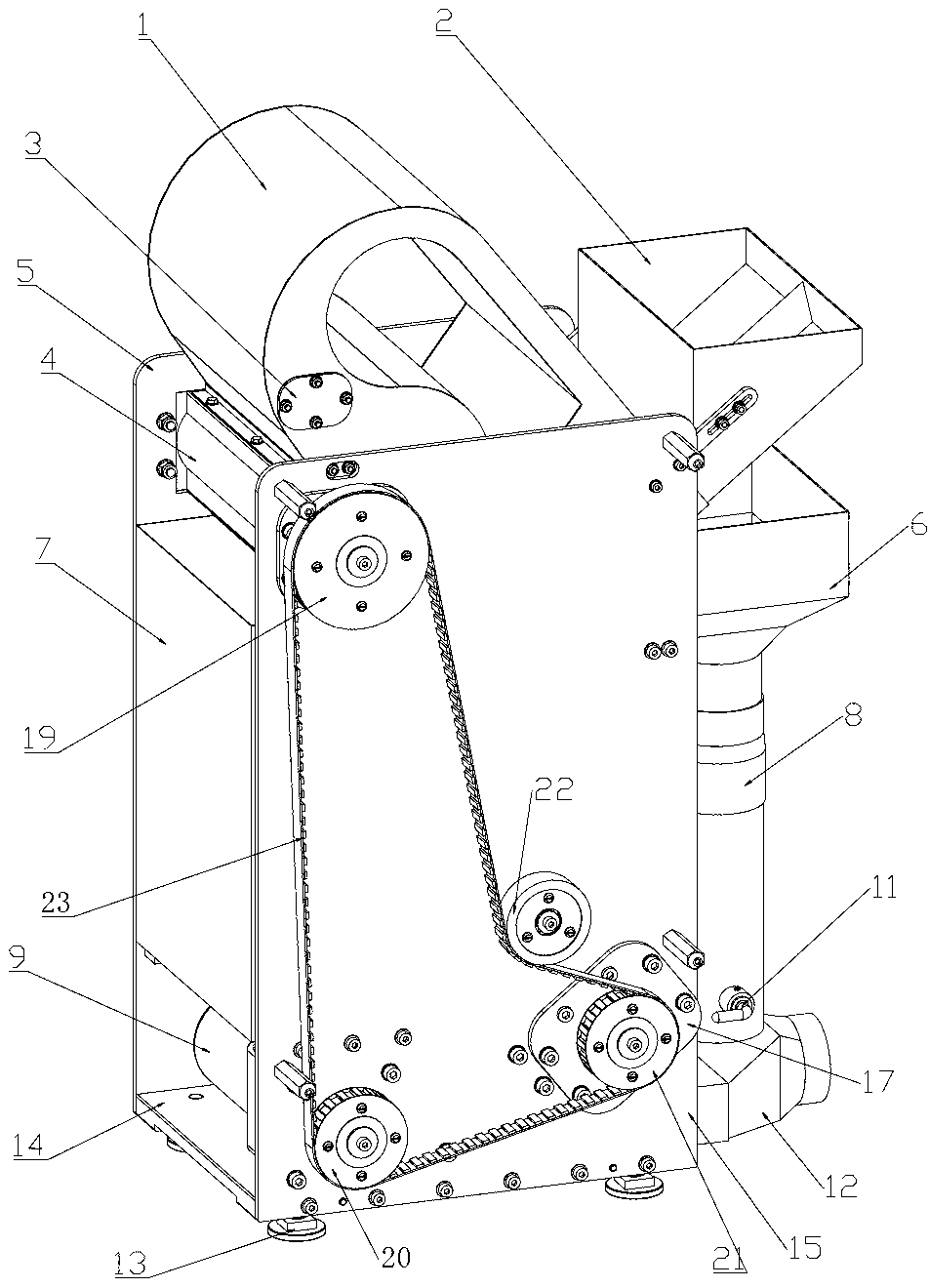

Device for offline and online screening of cut tobacco from removed stem slivers of cigarette maker

ActiveCN103126067AAdjustable sizeEasy to separateGas current separationCigarette manufactureCigarette MakersDrivetrain

The invention discloses a device for the offline and online screening of cut tobacco from removed stem slivers of a cigarette maker. The device a left side wallboard and a right side wallboard, the left and right side wallboards are fixed on a baseboard respectively, an airflow channel fixedly arranged on the baseboard is arranged among the left and right side wallboards and the baseboard, the airflow channel has a segment of a continuous Z-shaped separation channel, the side surface of the upper half portion of the continuous Z-shaped separation channel is provided with a funnel communicated with the continuous Z-shaped separation channel, and the side surface of the lower half portion of the continuous Z-shaped separation channel is provided with a gas inlet communicated with the continuous Z-shaped separation channel; the airflow channel is provided with a cut tobacco rotation air-valve and a stem sliver rotation air-valve, and the tail end of the airflow channel is connected with a tapered connecting pipeline; the lower portion of the cut tobacco rotation air-valve is correspondingly provided with a cut tobacco collection tank movably connected to the left and right side wallboards, the lower portion of the cut tobacco collection tank is provided with a power transmission system fixed on one of the left and right side wallboards, and the cut tobacco rotation air-valve and the stem sliver rotation air-valve are respectively connected with the power transmission system; and the cut tobacco rotation air-valve, the stem sliver rotation air-valve and the funnel are fixed on the left and right side wallboards respectively.

Owner:CHINA TOBACCO SHANDONG IND

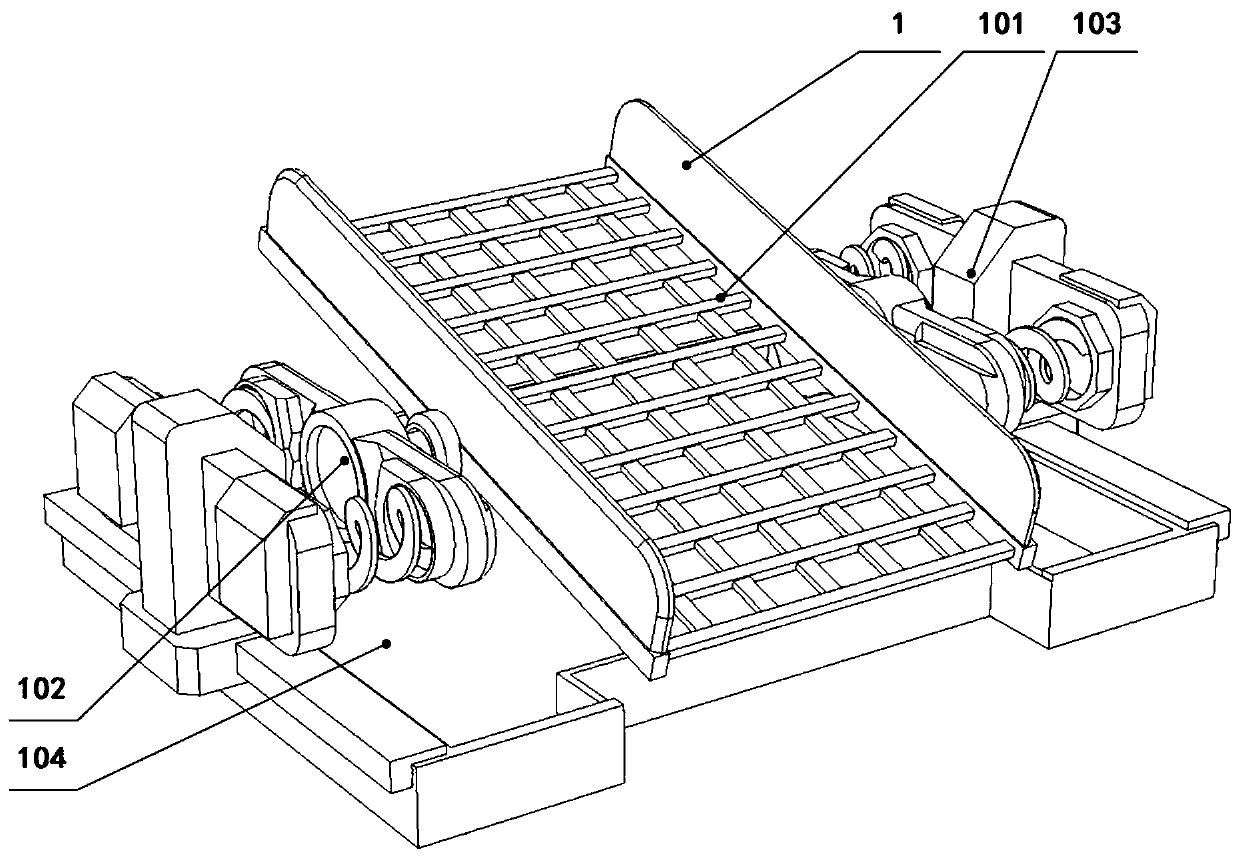

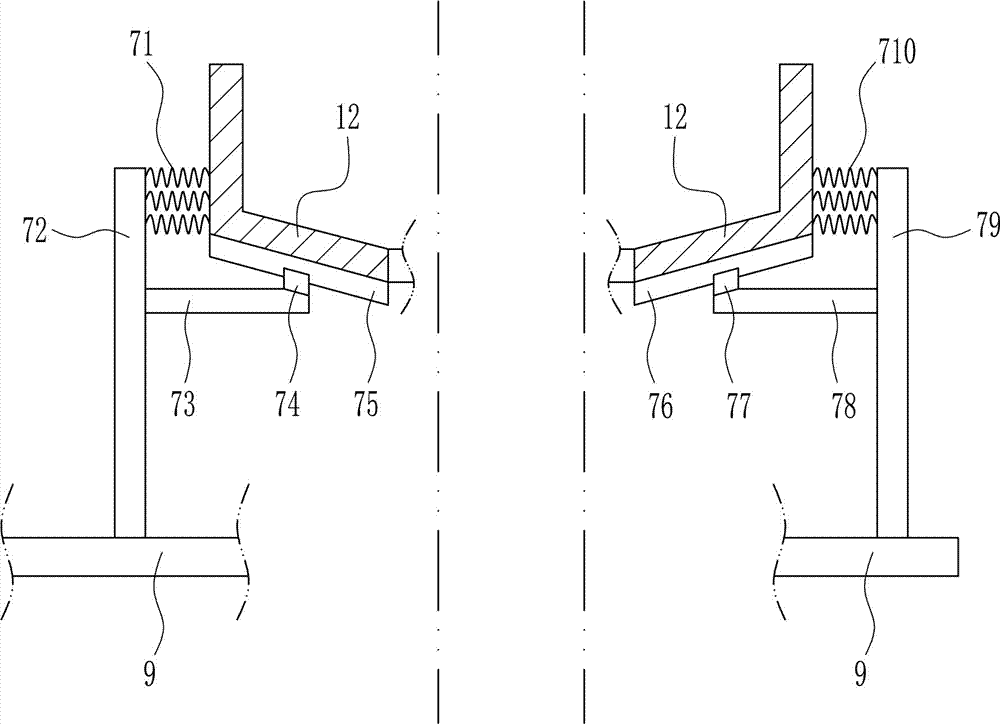

Sand-gravel screening machine sufficient in screening

The invention provides a sand-gravel screening machine sufficient in screening and relates to the field of construction machinery. The sand-gravel screening machine sufficient in screening comprises abase; a left supporting plate and a right supporting plate are fixedly connected to the upper surface of the base and symmetrically arranged with respect of the central axis of the base; the left side of the right supporting plate is provided with a vibration groove, and a spring is fixedly connected to the inner bottom wall of the vibration groove; and a right slide rod is fixedly connected to the end, away from the inner bottom wall of the vibration groove, of the spring and movably connected with the interior of the vibration groove. According to the sand-gravel screening machine sufficient in screening, through cooperation of a stirring motor, a transmission rod, stirring rods, a fixing block, a movable groove, a motor groove, a vibration motor, a screening tank, a rotary block, a vibration plate, a vibration rod, the vibration groove and a buffer groove, the effect that screening is more sufficient when the sand-gravel screening machine does sand and gravel screening work is achieved, and the problem that sand and gravel in an existing screening machine are stacked and cannot be screened sufficiently due to the existing screening machine screen the sand and the gravel only through vibration is solved.

Owner:赵顺豪

Black soya bean screening machine with cleaning function before fermented soya bean production

ActiveCN111804570AFully screenedImprove screening efficiencySievingScreeningEngineeringProcess engineering

The invention provides a black soya bean screening machine with a cleaning function before fermented soya bean production, which can automatically and accurately screen black soya beans, clean while screening and improve the screening efficiency, relates to the technical field of fermented soya bean production, and solves the problems of low efficiency and troublesome cleaning of traditional manual black soya bean screening. The invention discloses the black soya bean screening machine with the cleaning function before fermented soya bean production. The black soya bean screening machine comprises an L-shaped plate, fixing seats, a storage frame, a guide frame, a screening frame shaking mechanism, a screening frame body and the like, wherein the two fixing seats provided with a plurality of round holes are fixedly installed on the L-shaped plate and are symmetrically arranged, the material storage frame is fixedly installed on the two fixing seats, and the material guide frame is fixedly installed on one sides of the two fixing seats. By means of the screening frame shaking mechanism and a black soya bean intermittent blanking mechanism, black soya beans in the storage frame can intermittently fall into the screening frame body, the screening frame body sufficiently screens the black soya beans in a shaking mode, and the screening efficiency of the black soya beans is improved.

Owner:双峰县昊达农业开发有限公司

Production method of efficient phosphorus-dissolving epicoccum sorghinum with characteristic of resisting heavy metals

InactiveCN110577909AFully screenedEvenly mixedBacteriaMicroorganism based processesBiologyEpicoccum sorghinum

The invention belongs to the field of environmental microorganisms, and particularly relates to a production method of efficient phosphorus-dissolving epicoccum sorghinum with the characteristic of resisting heavy metals. Through classification, the epicoccum sorghinum is identified. The production method includes the steps that copper tailing soil and sterile water are cultured in a mixed mode, and a heavy metal sterile mixed solution with the concentration suitable for the growth of thalluses is screened; repeated culture is conducted for six times; fourth-time culture liquid, fifth-time culture liquid and sixth-time culture liquid are sucked and added into culture mediums containing organic phosphorus and inorganic phosphorus for plate spread culture, culture dishes with a large numberof bacterial colonies are selected, plate streaking culture is conducted in the culture mediums containing the organic phosphorus and the inorganic phosphorus, and the bacterial colonies with obviousphosphorus-dissolving rings are screened; and culture purification results are subjected to shake cultivation, and finally screening purification is conducted to obtain phosphorus-dissolving bacterialstrains resisting the heavy metals. Efficient phosphorus-dissolving funguses resisting the heavy metals are screened from contaminated land, the soil phosphorus supply and demand contradiction can beadjusted, reclamation land soil in a mining area is improved, vegetation growth is promoted, the utilization ratio of heavy metal contaminated plowland soil phosphorus by crops is increased, and useof fertilizer is reduced.

Owner:HEFEI NORMAL UNIV

Sorting machine and kitchen waste treatment equipment

The invention discloses a sorting machine and kitchen waste treatment equipment comprising the sorting machine and relates to the technical field of garbage treatment. The sorting machine comprises a rack, a stock bin and a cylindrical roller with sieve pores at excircle. The roller is arranged in the stock bin and is driven by a first driving mechanism to rotate, the stock bin and a rotary shaft of the roller are arranged on the rack, a feed inlet is formed in one end of the stock bin while a slag outlet is formed in the other end, and a discharge port is formed in the lower portion of the stock bin; a sorting mechanism and a second driving mechanism thereof are separately arranged inside and outside the roller, the sorting mechanism in the roller is driven by the second driving mechanism to screen materials, the materials which are small in grain size enter the bottom of the stock bin from the sieve pores in the wall of the roller and are discharged from a discharge port, and the materials which are large in grain size are discharged from the slag outlet. By way of rotating the roller, the stirring and screening speeds of the materials can be accelerated, and large-grain-size materials are detained to plug the sieve pores as the materials stay on the inner wall of the roller for a long time, so that the materials are fully screened, the sorting efficiency is improved, and the sorting quality of kitchen wastes is guaranteed.

Owner:WEIDE ENVIRONMENT TECH CO LTD

Intermittent discharging type screening device for glitter powder for decoration

InactiveCN108212749AFully screenedScreening fully and thoroughlySievingScreeningEngineeringMechanical engineering

The invention relates to an intermittent discharging type screening device for glitter powder for decoration. The intermittent discharging type screening device for the glitter powder for decoration has the advantages that the glitter powder can be fully screened, and the screening efficiency is relatively high. The intermittent discharging type screening device for the glitter powder for decoration comprises a placing rack and the like; a filter screen frame is connected to the lower part of the placing rack; a feeding mechanism is connected to the upper part of the placing rack; and a screening mechanism is connected to the feeding mechanism and the filter screen frame and is located below the feeding mechanism. According to the intermittent discharging type screening device for the glitter powder for decoration, the feeding mechanism realizes intermittent discharging of the glitter powder, so that the screening mechanism only needs to screen a small amount of the glitter powder every time, and therefore the screening efficiency can be improved; and the screening mechanism continuously stirs the glitter powder falling downwards into the filter screen frame from a discharging groove, and therefore the glitter powder can be fully screened.

Owner:戚展鹏

Multistage whirling vibration screening method

InactiveCN106111518APlay the role of shock absorptionFully screenedSievingScreeningScreening methodEngineering

The invention introduces a multi-stage rotary vibration screening method, which includes the use of a multi-stage rotary vibration screening device. The process is as follows: a power mechanism and a rotary mechanism are installed on the multi-stage rotary vibration screening device, and the power mechanism is connected to the motor support through bolts. On the top, weld the motor support to the left side of the box, and connect the power mechanism to the rotating mechanism through a V-shaped belt; connect the rotating mechanism to the upper support plate of the box through rolling bearings, and set the feeding port on the upper support plate ;The secondary screening mechanism is installed on the eccentric shaft of the rotating mechanism through the sleeve, and the primary, tertiary, and quaternary screening mechanisms are set; the raw materials are added to the primary screening mechanism, the device is started, and the raw materials pass through the primary screening in turn Mechanism, second-level screening mechanism, third-level screening mechanism, and finally discharge through the fourth-level discharge device. The multi-stage screening device adopted by Lili adopts belt transmission, which plays the role of buffering and absorbing vibration. The eccentric shaft drives the concave screening device to vibrate and rotate, and the screening is sufficient. The device occupies a small area. demand.

Owner:洛阳益矿机械设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com