Automatic screening machine for steel balls

A screening machine and steel ball technology, applied in screening, conveyor, mechanical conveyor and other directions, can solve the problems of high labor intensity of construction personnel, occupation of human and mechanical resources, endangering the health of workers, etc., to reduce operating environment pollution, Improve the screening efficiency and avoid the effect of dust flying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

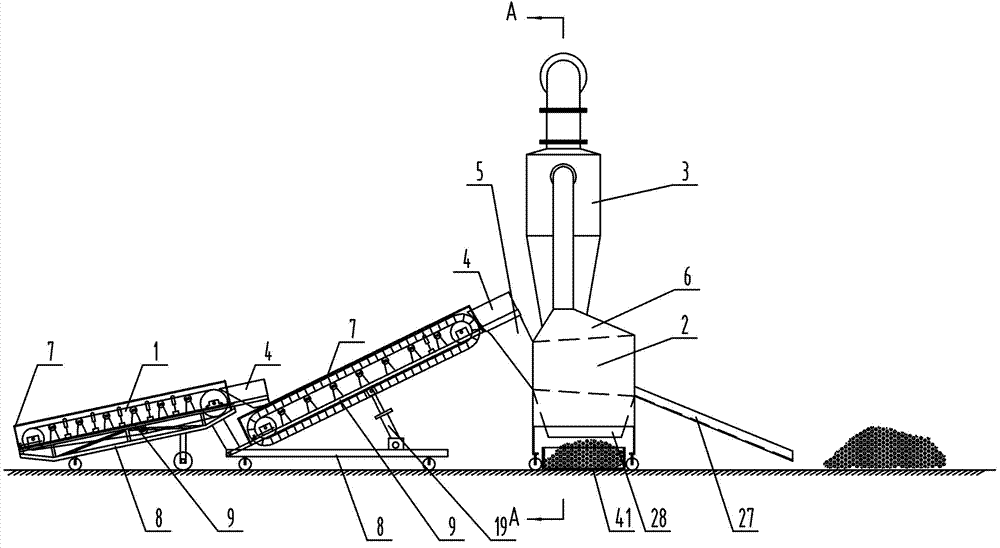

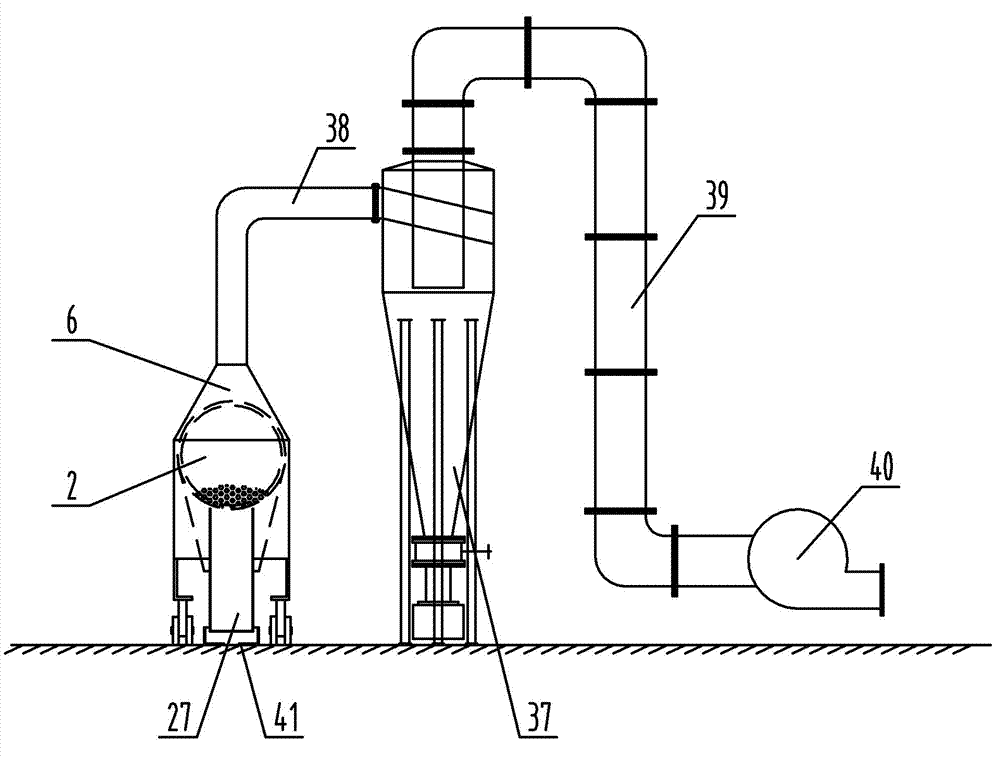

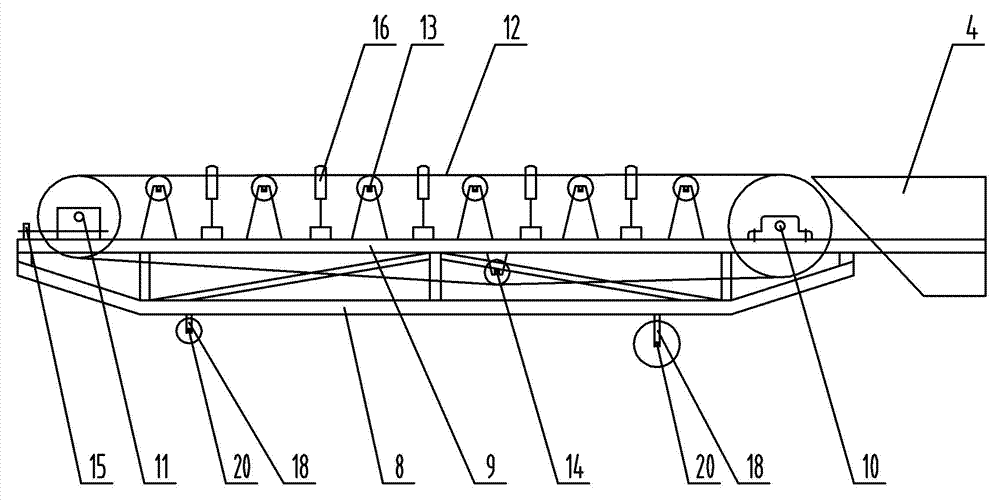

[0032] see Figure 1 to Figure 7, in the figure, the steel ball automatic screening machine of the present invention includes a conveying device 1, a screening device 2 and a dust removal device 3, the lower hopper 4 at the end of the conveying device 1 is fixedly connected with the feeding hopper 5 of the screening device 2, and the screening device 2 The top is fixedly connected with the dust collection cover 6 of the dust removal device 3 , and a sealing cover 7 is installed on the outside of the conveying device 1 and the screening device 2 . Described conveying device comprises two-stage belt conveyor, and the end of every stage belt conveyor is provided with lower hopper 4 respectively, and the bottom of every stage belt conveyor is all provided with angle-adjustable mechanism, and the junction of adjacent two stage belt conveyors, The connection between the last stage belt conveyor and the lower hopper 4 of the screening device 2 is a soft fixed connection. The belt co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com