Gravel sieving device capable of conveniently adjusting sieving sizes

A screening device and size technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of time-consuming, troublesome operation, decreased work efficiency, etc., and achieve the effect of improving screening efficiency, convenient operation and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

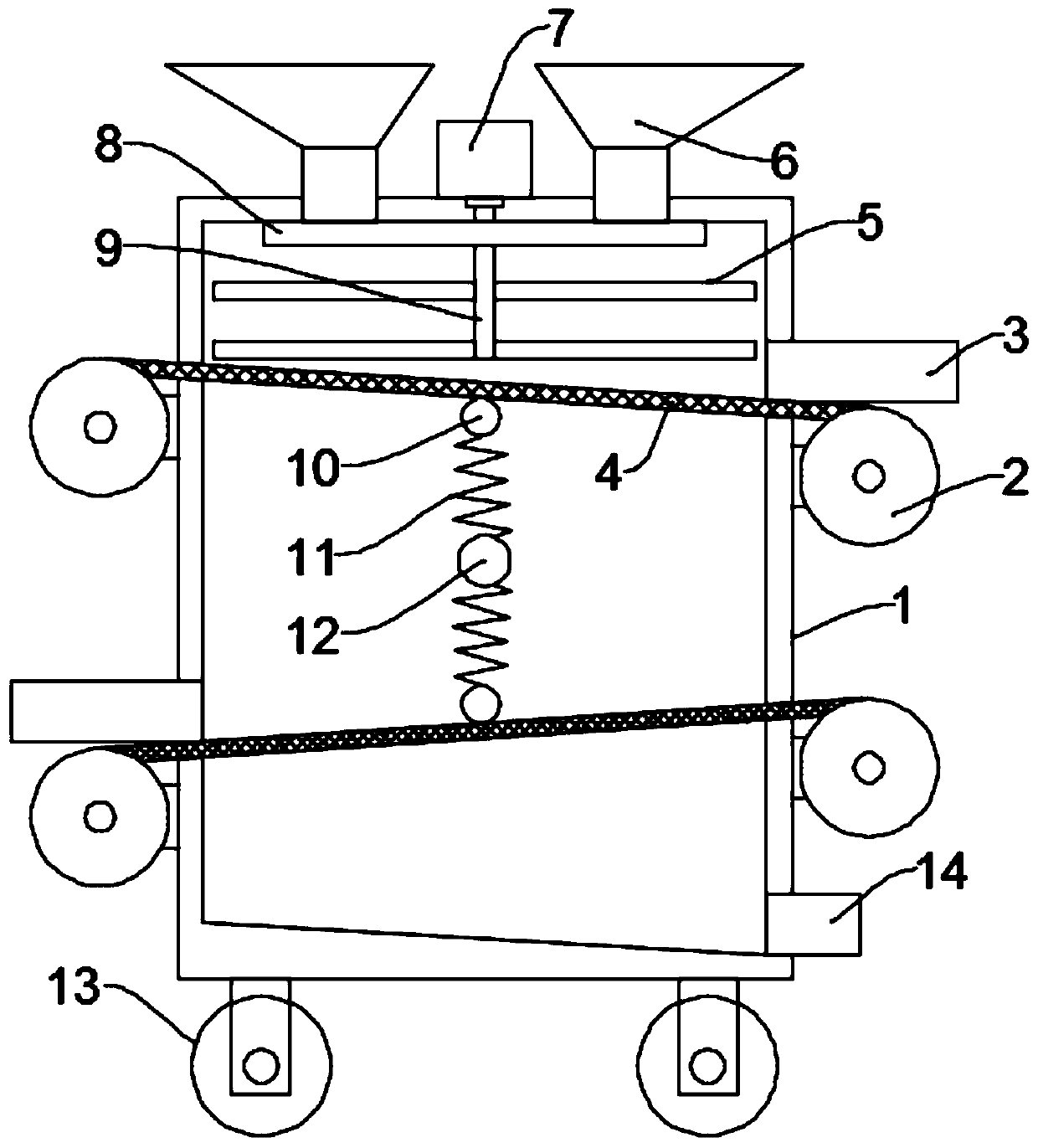

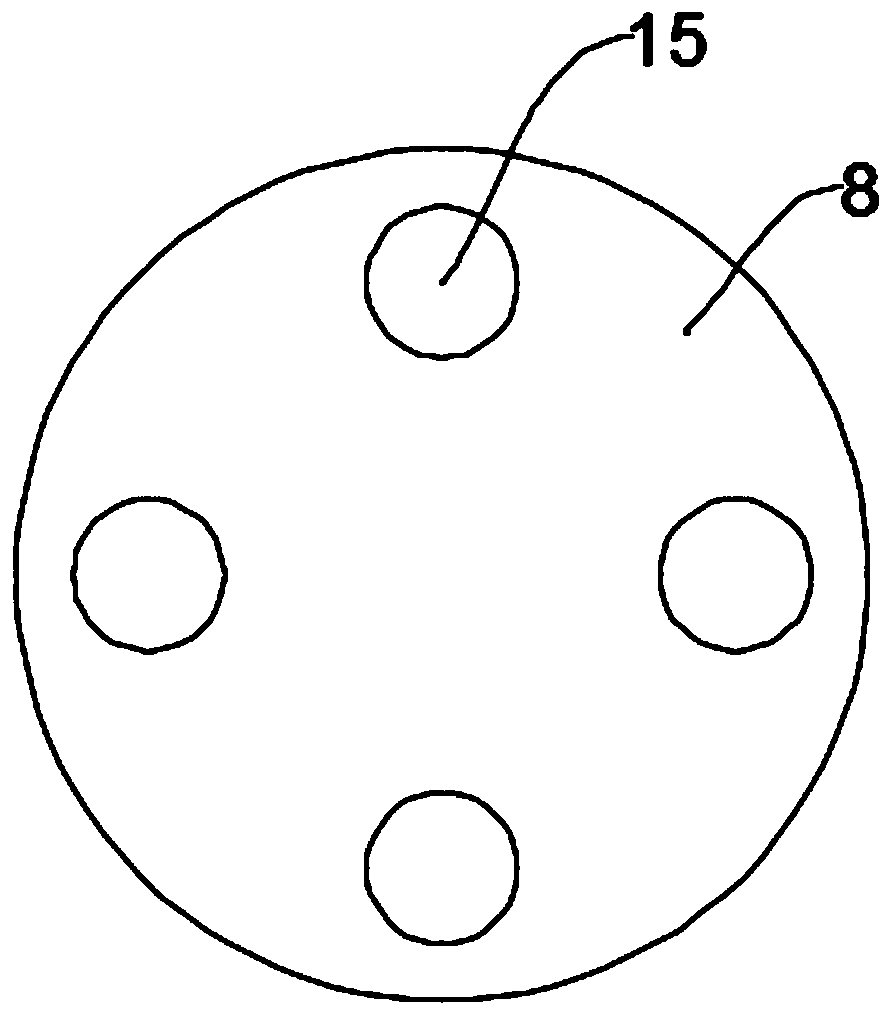

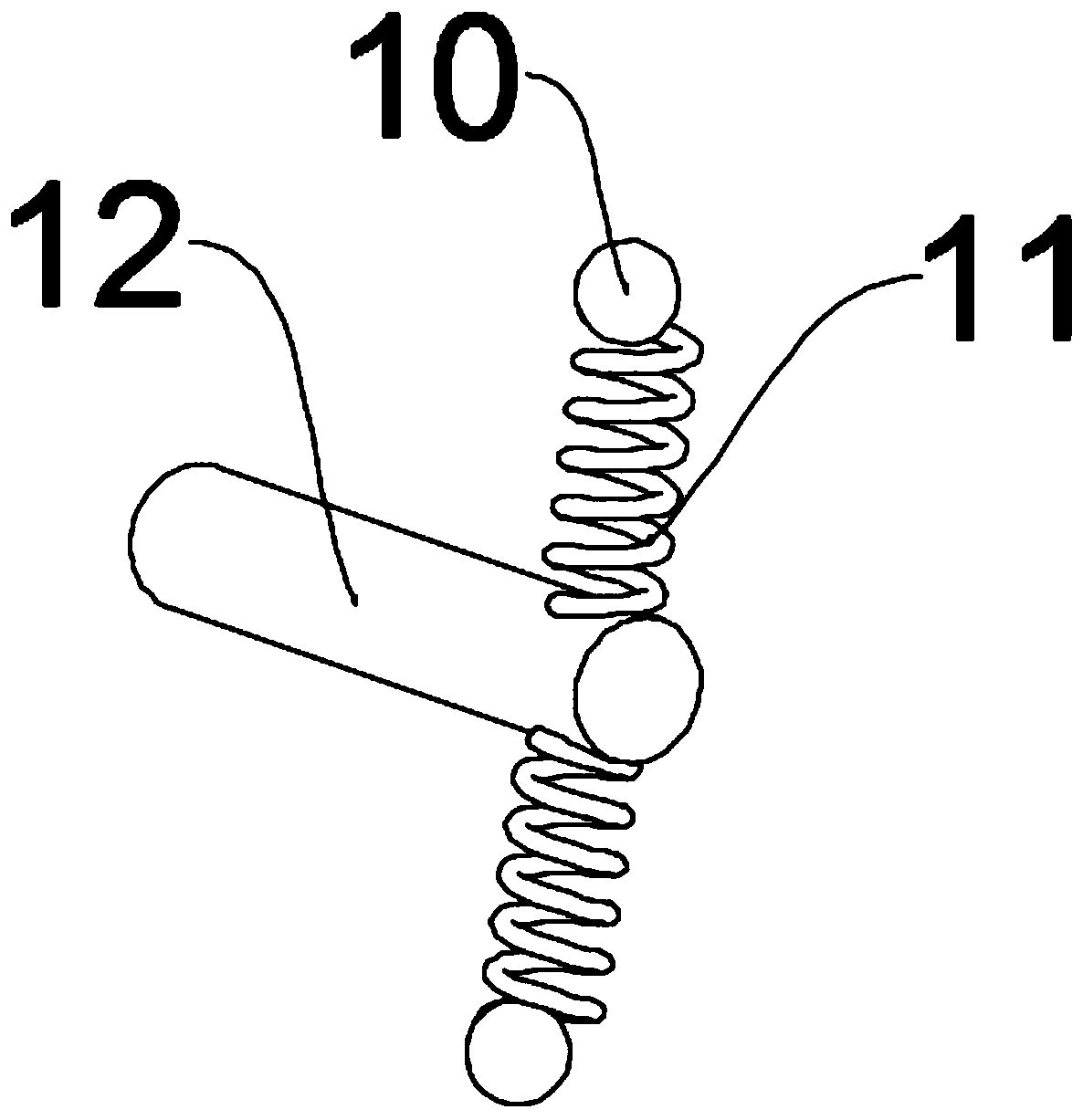

[0025] see Figure 1~3 , in the embodiment of the present invention, a kind of sand and gravel screening device that is convenient for adjusting the screening size includes a screening box 1 and a screen, the top of the screening box 1 is provided with a feed hopper 6, and the bottom of one side of the screening box 1 is There is a first discharge pipe 14, and the bottom of the screening box 1 is set obliquely downward to the side close to the first discharge pipe 14, which is convenient for discharging. The bottom of the screening box 1 is evenly and symmetrically equipped with support legs, and the bottom of the support legs There are rollers 13, and the rollers 13 are self-locking rollers, which facilitate the movement of the device. Two groups of screen assemblies are installed at intervals up and down in the screening box 1, and the screen assemblies include multi-size screens 4 and winding rollers 2. There are two winding rollers 2 and they are respectively arranged on t...

Embodiment 2

[0030] see Figure 4 The difference between this embodiment of the present invention and Embodiment 1 is that, in order to ensure sufficient screening, a knock-back mechanism is installed at the second discharge pipe 3, and the knock-back mechanism includes a second motor 16, an incomplete gear 17. Rack 19, second spring 18 and striking plate 20, the second motor 16 is installed on the end of the second discharge pipe 3 away from the screening box 1, and the end of the second discharge pipe 3 away from the screening box 1 The bottom is provided with a discharge port, an incomplete gear 17 is installed on the output shaft of the second motor 16, a rack 19 meshing with it is provided below the incomplete gear 17, and the rack 19 is slidably connected with the second discharge pipe 3, One end of the rack 19 located in the second discharge pipe 3 is fixedly equipped with a strike plate 20, and a second spring 18 is fixedly connected between the strike plate 20 and the inner wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com