Fermentation tank, equipment system for preparing probiotics and method for preparing probiotics

A fermenter and probiotic technology, which is applied in the field of fermenter and probiotic preparation equipment system, can solve the problems of expensive freeze dryer, high processing cost, uneven particle size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] (Example 1, equipment system for preparing probiotics)

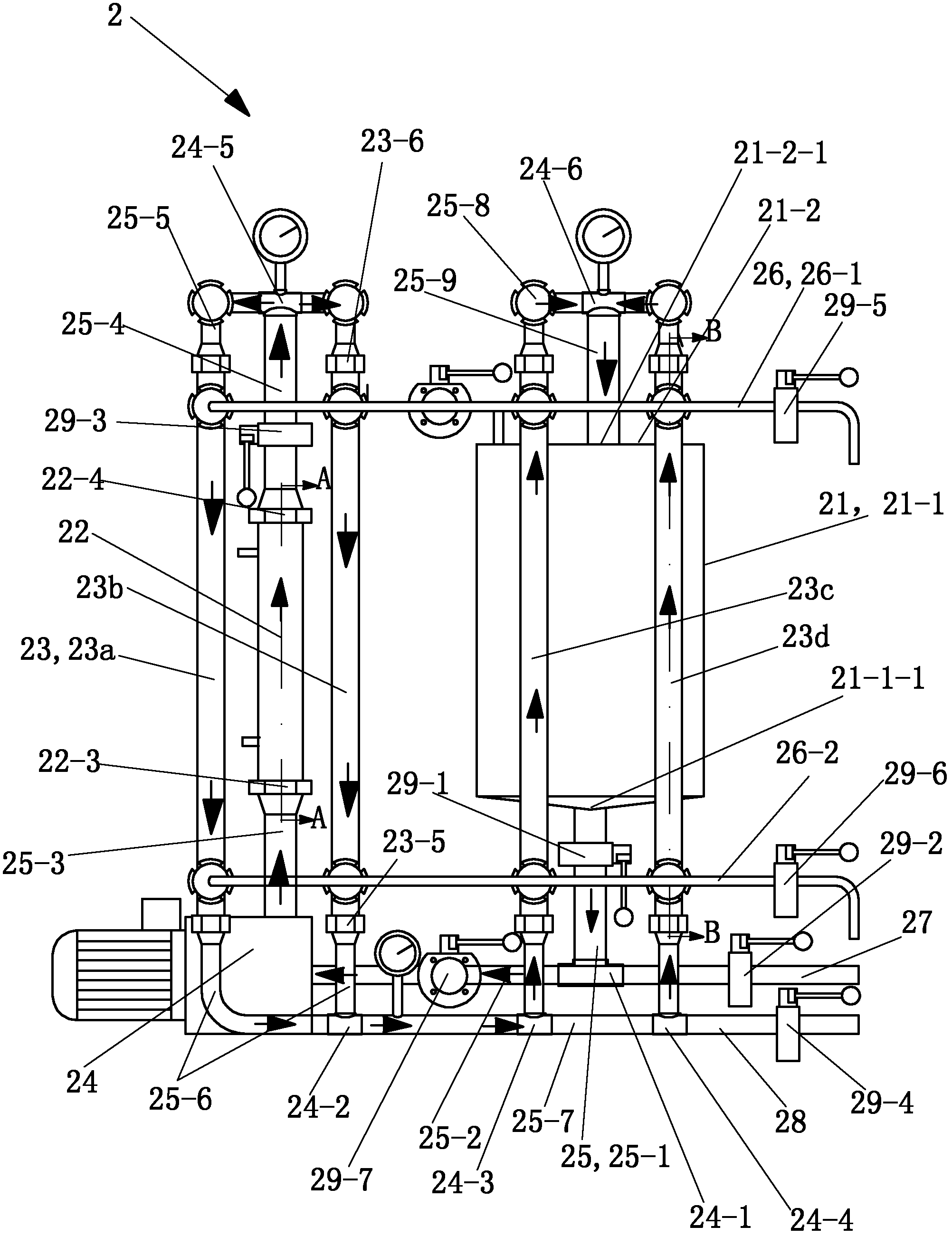

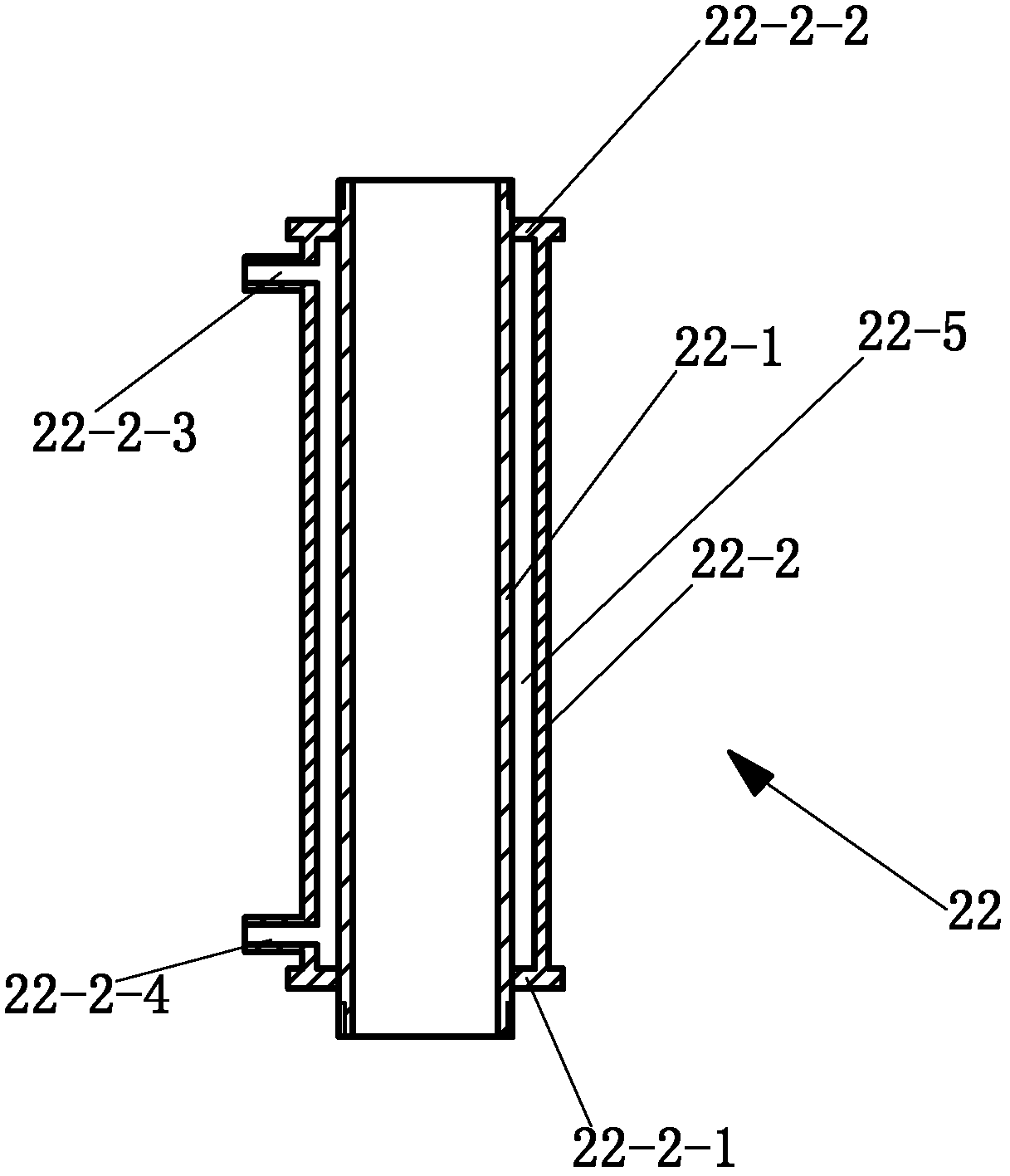

[0076] The equipment system for preparing probiotics in this embodiment includes a fermenter 1 , a filtering device 2 , a freeze-drying device, a pulverizer 4 and a stirrer 5 .

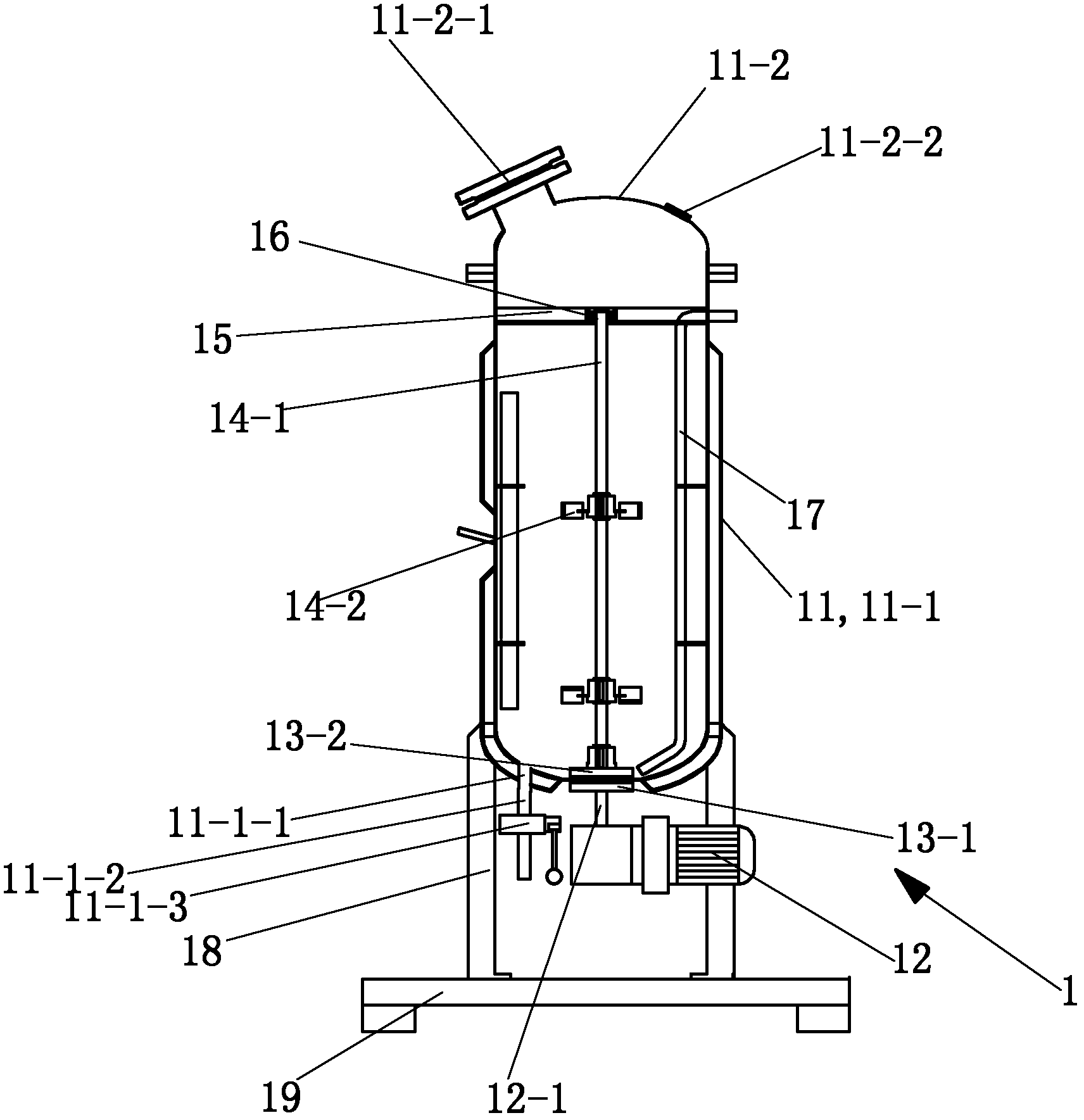

[0077] See figure 1 , the fermenter 1 includes a tank body 11, a motor 12, an outer magnetic steel 13-1, an inner magnetic steel 13-2, a stirring shaft 14-1, a stirring blade 14-2, a beam 15, a bearing 16, a water inlet pipe 17, a bracket 18 and base 19.

[0078] The base 19 is placed on the ground, and the support 18 is fixed on the upper surface of the base 19 from above by its lower end, and the upper end of the support 18 is fixedly connected with the bottom of the tank body 11, so that the tank body 11 is positioned above the base 19 and is held by the support 18. The fixed support is separated from the upper surface of the base 19 .

[0079] Tank body 11 comprises tank main body 11-1 and loam cake 11-2, and the upper end of tank...

Embodiment 2

[0121] (Example 2, the method for preparing probiotics)

[0122] The method for preparing probiotics in this embodiment adopts the equipment system of Embodiment 1.

[0123] The method for preparing probiotics comprises the following steps:

[0124] ①Prepare the culture medium and sterilize it at 121°C for 15 minutes; the formulations of the culture medium of Lactobacillus bulgaricus and Streptococcus thermophilus prepared in this example are as follows: 10wt% skim milk powder, 2.5wt% whey powder, lactose 2 wt %, yeast extract 1.5 wt %, vitamin C 0.5 wt % and the balance of purified water.

[0125] ②Inoculation, pour the culture solution prepared in step ① into the fermenter 1, mix Lactobacillus bulgaricus and Streptococcus thermophilus at the ratio of initial bacteria number of 1:1, inoculate into the medium, Lactobacillus bulgaricus and Streptococcus thermophilus Cocci accounted for 1% by weight of the inoculated material.

[0126] ③ Fermentation, culture the material ino...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com