Patents

Literature

700results about How to "No chemical reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bi-component cement based composite material for 3D printing as well as preparation method and application thereof

The invention discloses a bi-component cement based composite material for 3D (three dimensional) printing as well as a preparation method and application thereof. The bi-component cement based composite material for 3D printing comprises a component A and a component B, wherein the component A is prepared from 34 to 40 percent of sulphate aluminium cement, 0 to 6 percent of inorganic powder, 40 to 44 percent of tailing machine-made sand, 2.5 to 3 percent of high-molecular polymer and the balance of a retarder, a water reducer, a size stabilizer, a defoaming agent and water, the pumping performance can be well kept for a long time, an industrialized process of pre-stirring production in a mixing plant, transportation, and using in a construction site can be realized; the B component is prepared from a coagulate promoting agent, a thixotropic agent, a defoaming agent and water, the component is stable in form and can be stored for a long time or produced in a concentrated manner. After A and B are respectively pumped in a 3D printer, through high-speed stirring and being mixed by an extrusion head, the composite printing material can be extruded out, the time of coagulation is short, the strength is high, the adhesion is good, the stability is strong, the constructive continuity and building strength requirements of building 3D printing can be met, the industrial production and promotion of the cement based 3D printing material are facilitated, and the application of a 3D printing technology in buildings can be effectively promoted.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

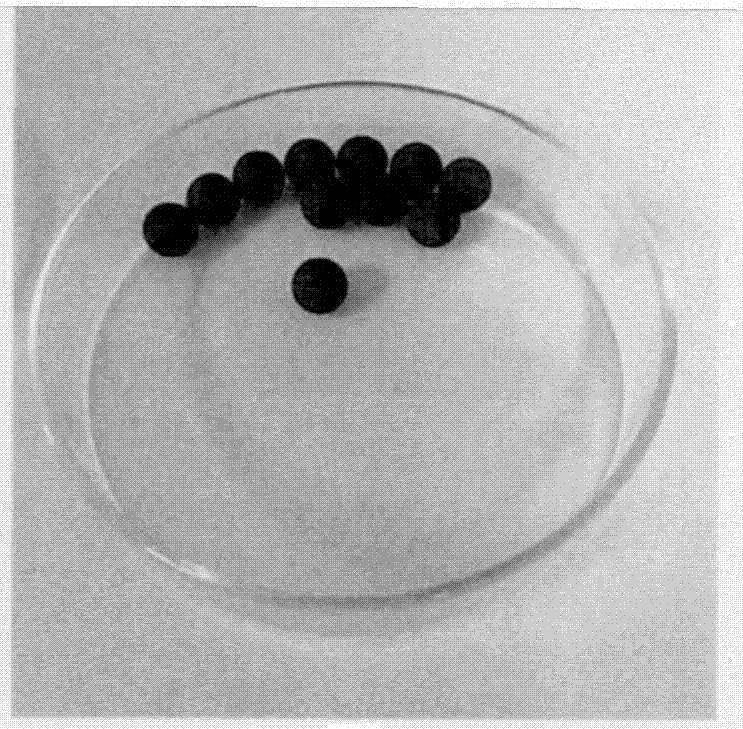

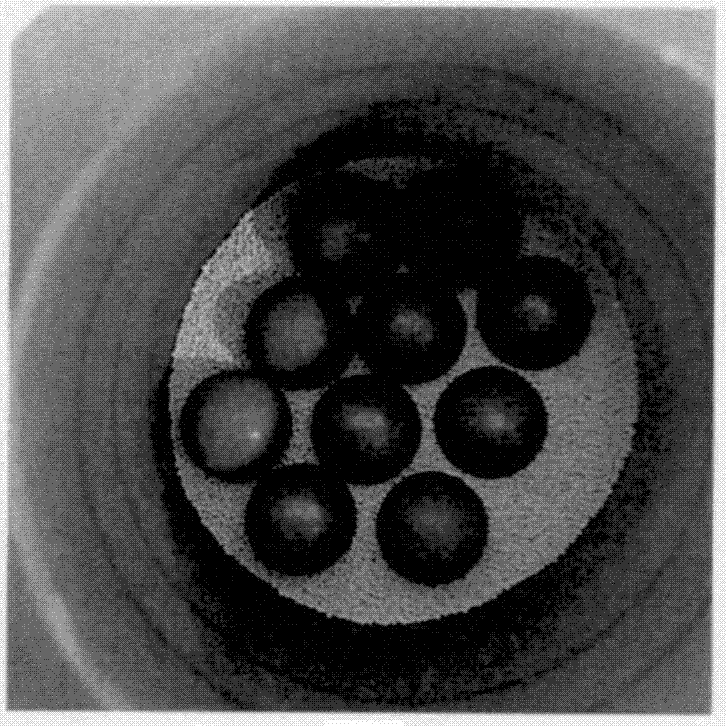

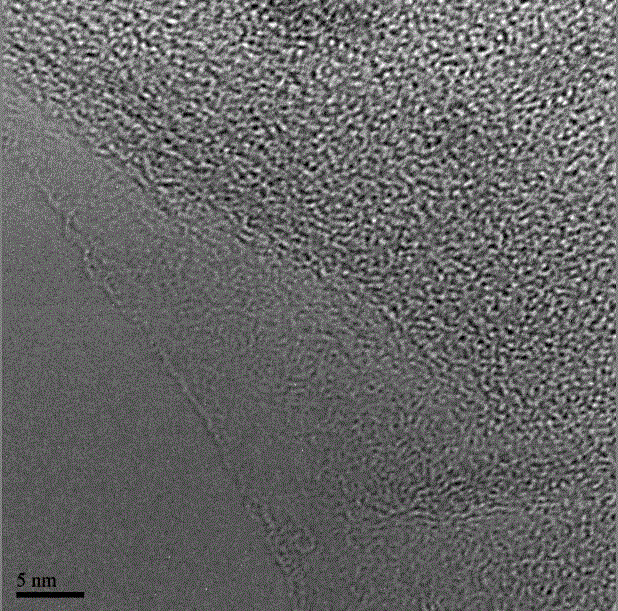

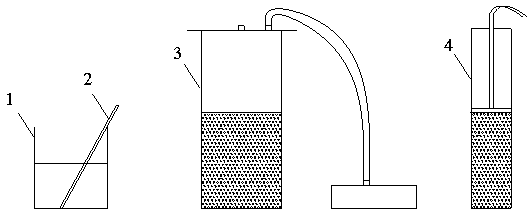

Two-dimensional thin film material coated on microsphere surfaces and simple method for stripping two-dimensional thin film material

The invention discloses a simple method for performing coating modification on microsphere surfaces by using a two-dimensional material thin film, a simple method for stripping the two-dimensional material, and products formed by coating and stripping. In the coating process, no solvent is used, a physical friction transfer method is adopted to transfer a lamellar compound thin film from the surface of a lamellar compound sphere to the surface of the microsphere, and screening is performed to obtain the coated product by utilizing the size difference between the product (coated microsphere) and the lamellar compound sphere. The whole process has the advantages of simple technique, low cost, high efficiency and high product purity, and is suitable for industrial production. In addition, the lamellar compound can be transferred from the microsphere surface into the solution by simple ultrasonic treatment in the solution; and thus, the invention provides a simple non-chemical method for stripping the lamellar compound, which is suitable for industrial production.

Owner:西安一九零八新能源科技有限公司

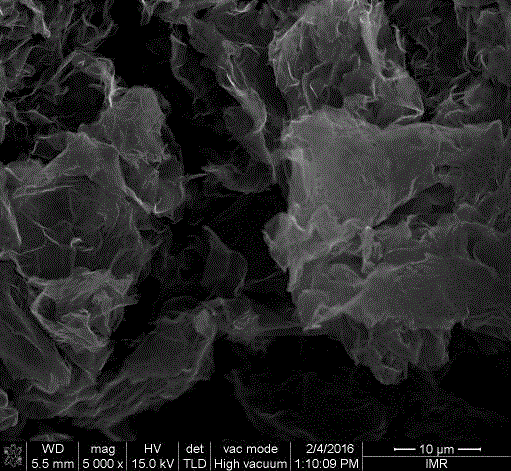

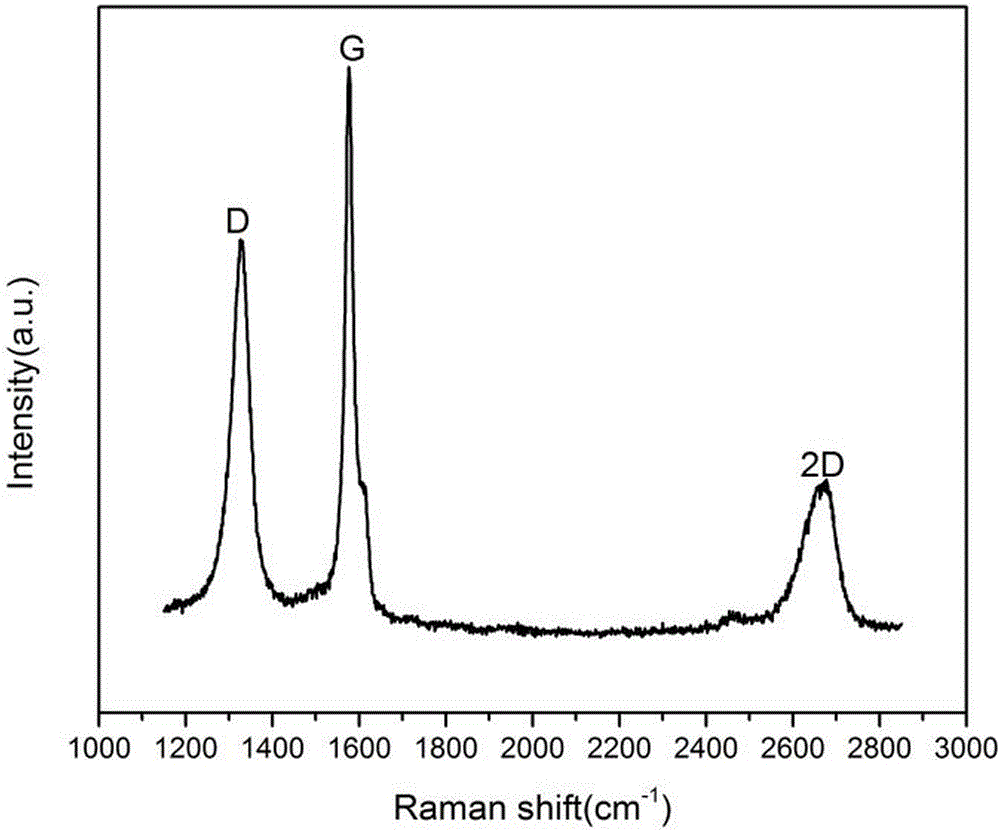

Method for electrochemically preparing graphene

The invention discloses a method for electrochemically preparing graphene. The method comprises the following steps: 1, intercalating and expanding graphite paper by adopting graphite paper as a positive electrode and an aqueous intercalator solution as an electrolyte to obtain expanded graphite; 2, filtering and washing the expanded graphite, and carrying out ultrasonic peeling treatment on the expanded graphite to obtain a flocculent graphene slurry; and 3, filtering the graphene slurry, and drying the graphene slurry through adopting a microwave vacuum drier to obtain fluffy graphene powder. The electrochemical method solves the problem of use of heavy metal-containing reagents, strong acids, strong oxidants and expensive organic liquids in the graphene preparation process in the prior art, and has the advantages of simple preparation technology, low energy consumption and low cost.

Owner:DEYANG CARBONENE TECH

Method for dissolving cellulos

The invention discloses a method for dissolving the cellulose, including having the sodium hydroxide and urea as material, firstly pre-cooling the 12-20 wt.% of sodium hydroxide water solution to -4-10 DEG C, adding cellulose to produce an alkaline cellulase, or mixing the cellulase and 12-20 wt.% of sodium hydroxide water solution, mixing and pre-cooling to -4-10 DEG C to produce an alkaline cellulase, than adding -4-10 DEG C 0-40 wt.% urea water solution, blending uniformly, immediately getting the transparent cellulose solution. The method can swiftly dissolve the natural cellulose with a molecular weight under 13*104 and the II-type cellulose with a molecular weight under 15*104 and may obtain a dense cellulose solution with a high solubility (100%).

Owner:WUHAN UNIV

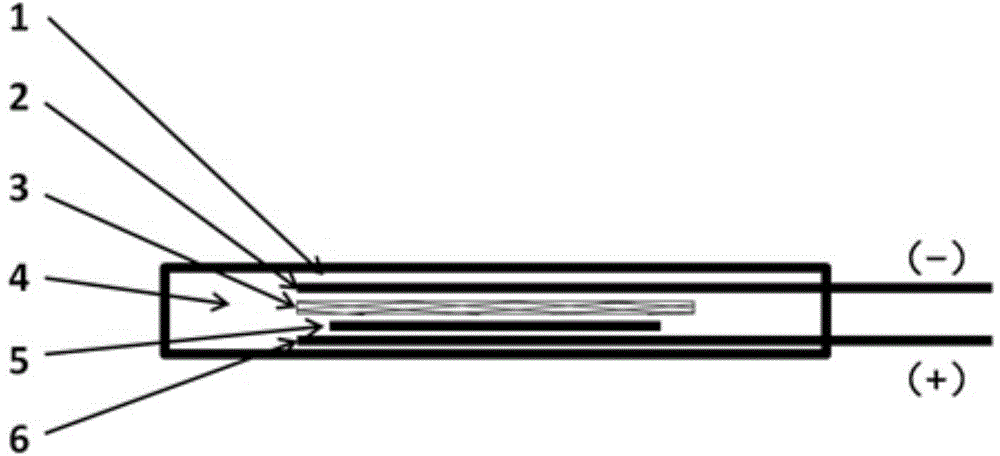

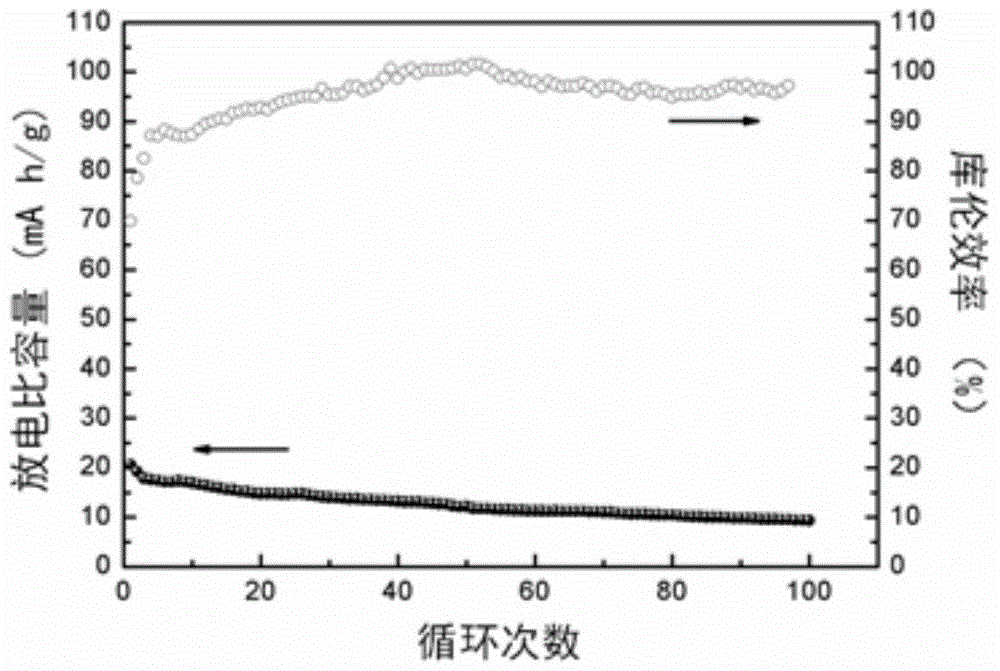

Non-aqueous solution aluminum ion secondary battery and preparation method thereof

InactiveCN104993130ARich reservesLow priceCell electrodesFinal product manufactureCarbon nanotubeAluminum Ion

Belonging to the technical field of batteries, the invention relates to a non-aqueous solution aluminum ion secondary battery and a preparation method thereof. The secondary battery can be widely applied in electronics, communication, electric vehicle and other fields. The aluminum ion battery provided by the invention contains a battery anode, a battery cathode, a diaphragm and an aluminum-containing non-aqueous solution electrolyte. Specifically, the cathode active material can be carbon, graphite, carbon nanotube, graphene, super carbon, WS2 and MoS2, V2O5, TiO2 and other materials having nano-layered, tubular, linear and other structures, and the anode is aluminum-containing metal or alloy. The non-aqueous solution aluminum ion secondary battery provided by the invention has the characteristics of high specific capacity, high coulomb efficiency, long service life and environmental protection, safety and reliability, stable cycle performance, and quick charging, etc.

Owner:BEIJING ALUMINUM ENERGY S&T

High-efficiency formaldehyde scavenging agent

InactiveCN101181677AThorough responseTo achieve the purpose of removing formaldehydeDispersed particle separationWastewaterSURFACTANT BLEND

The invention discloses a high effect formaldehyde dispelling agent. The formaldehyde dispelling agent of the invention comprises formaldehyde dispelling factors, a stabilizing agent, a synergistic agent, surfactants and water, etc. The product is nonpoisonous and tasteless, safe and environmental friendly, which can quickly and thoroughly dispel free formaldehyde in air, waste water and various boards and furniture, and a dense protecting film is formed on the surface of solid, working for a long time. The method of the invention is characterized by simple production technique and devices, no three wastes pollution and low production cost.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Preparation method for artificially synthesized transparent soil material

InactiveCN103969099AHigh purityWide range of gradingPreparing sample for investigationAlkaneVisual observation

The invention discloses a preparation method for an artificially synthesized transparent soil material. The transparent soil material comprises baked silica sand particles and colorless pore fluids which have the same refractive index, wherein the pore fluids are mixed fluids of 12, alkane and 15# white oil; during preparation, a glass bar is used to stir constantly so as to ensure intensive mixing; a vacuum chamber is adopted for vacuumizing so as to remove residual air in a mixture until the mixture is transparent; finally, a consolidometer is adopted for consolidation. According to the invention, the preparation method is simple and convenient to operate and easy to implement; compared with other preparation methods, the preparation method is wide in material sources, low in cost, pollution-free and non-hazardous and can achieve a better transparent effect; the prepared transparent soil can be effectively used for model tests, and metabolic un-embedding visual observation in soil bodies can be realized.

Owner:HOHAI UNIV

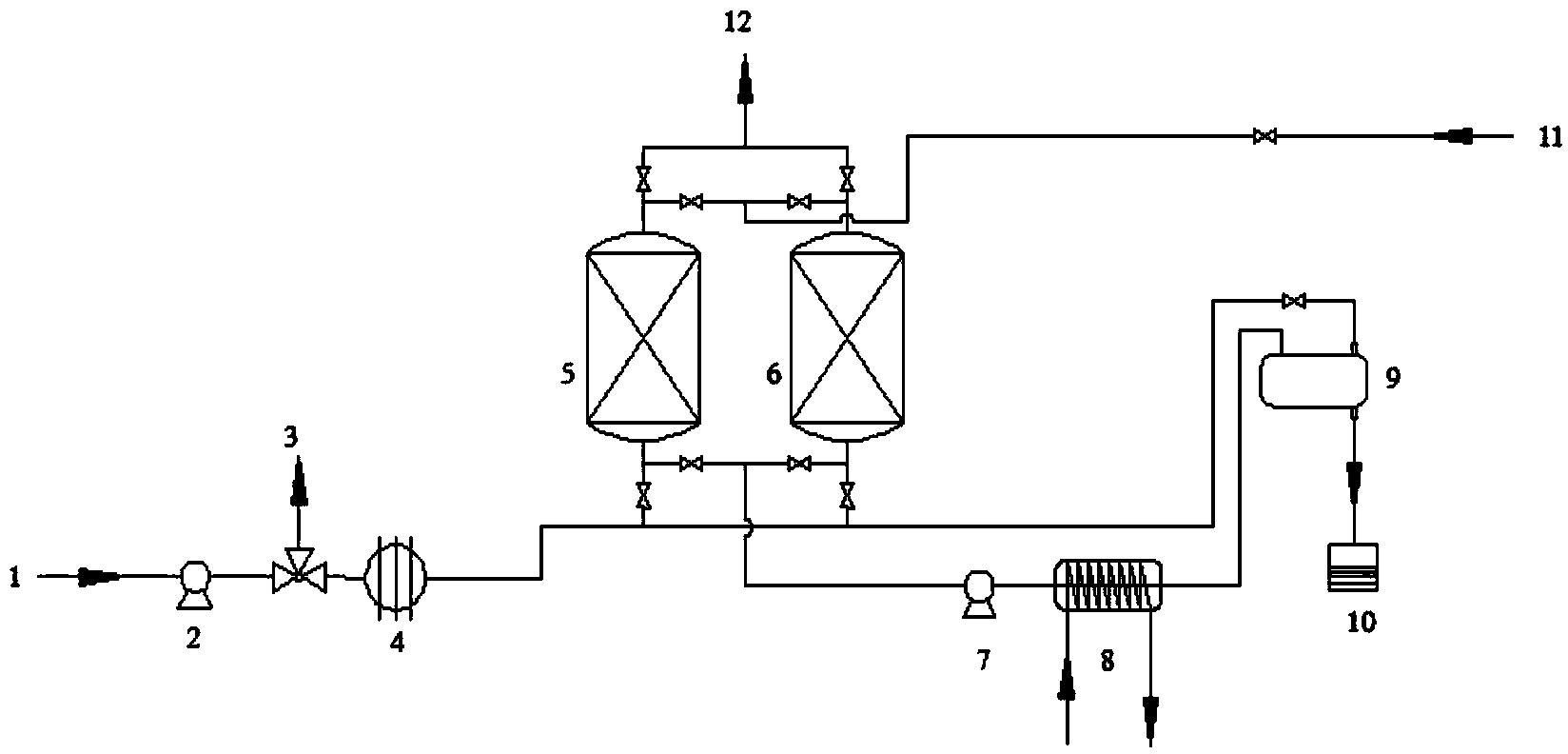

Nitrogen purging-assisted organic exhaust gas recycling method through pressure swing adsorption of adsorbent resin

ActiveCN104107621ALarge volume adsorption capacityNo chemical reactionDispersed particle separationSolubilityCollection system

The invention discloses a nitrogen purging-assisted organic exhaust gas recycling method through the pressure swing adsorption of adsorbent resin. The organic exhaust gas recycling method comprises the following steps: (1) adsorption, namely performing adsorption when exhaust gas including volatile organic compounds (VOCs) enters an adsorber filled with the macroporous adsorption resin by a gas collection system; (2) desorption, namely vacuumizing the adsorbent resin in the adsorber and purging the adsorbent resin by using nitrogen in an auxiliary manner to desorb the adsorbed VOCs from the adsorbent resin to obtain the desorbed gas; and (3) recycling, namely condensing or absorbing the desorbed gas to recycle the VOCs. The adsorbent adopted by the method disclosed by the invention is the macroporous adsorption resin, the surface of the macroporous adsorption resin has no catalytic performance and has the characteristics of being easy to regenerate, high in mechanical strength, great in volumetric adsorption capacity and the like. A adsorption technique assisted by nitrogen purging in vacuum at normal temperature is high in adsorption efficiency and has the very excellent recycling effect on VOCs gas which can be easily oxidized and hydrolyzed or is high in solubility.

Owner:NANJING UNIV

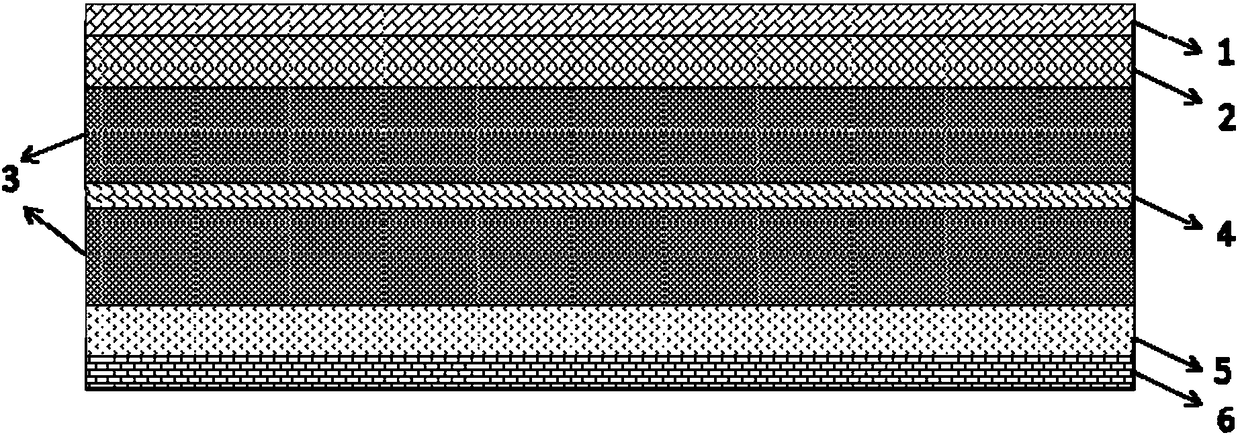

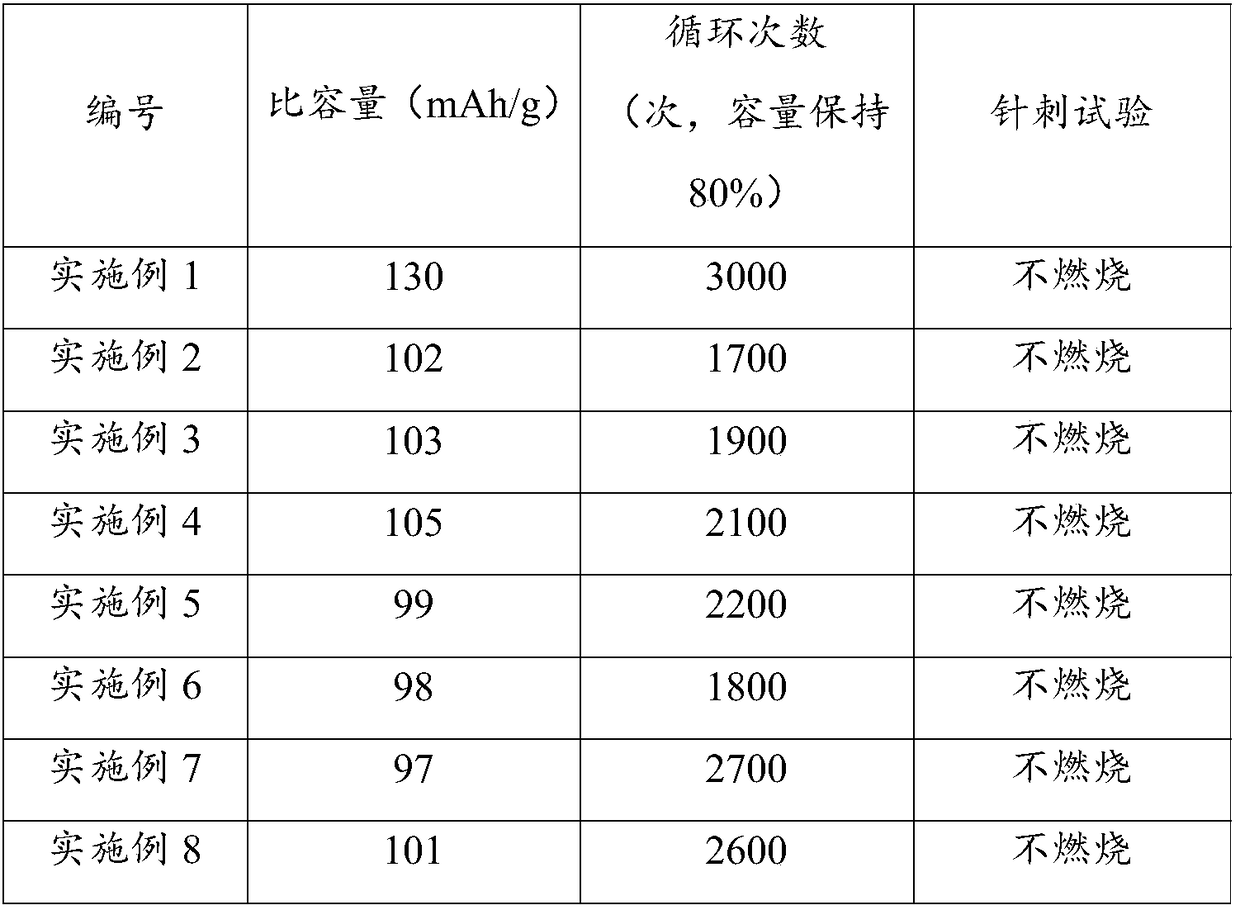

Potassium-based dual-ion battery and preparation method thereof

ActiveCN108063217AReduce manufacturing costImprove power densityNon-aqueous electrolyte accumulatorsCell electrodesGraphite carbonPorous carbon

The invention discloses a potassium-based dual-ion battery and a preparation method thereof and relates to the field of electrochemical energy storage devices. The potassium-based dual-ion battery comprises a negative electrode, a positive electrode, a membrane between the positive electrode and the negative electrode and an electrolyte, wherein an active material of a negative electrode materialis a porous carbon material capable of reversibly absorbing and desorbing potassium ions; the active material of a positive electrode material is a graphite carbon material capable of reversibly intercalating and deintercalating anions in the electrolyte; and the electrolyte comprises a potassium salt and a non-aqueous solvent. The defects that an existing lithium-ion battery is limited in lithiumresource reserves and high in cost are alleviated, and the problems that an existing potassium-ion battery is limited in electrode material and not ideal in electrochemical properties are solved. According to the dual-ion battery disclosed by the invention, potassium is taken as an energy storage medium, the porous carbon material capable of absorbing and desorbing the potassium ions is taken asa negative active material and expanded graphite capable of being reversibly intercalated and deintercalated is taken as a positive active material, so that the potassium-based dual-ion battery has the advantages of high specific capacity, long cycle life and good security performance.

Owner:SHENZHEN INST OF ADVANCED TECH

Water purification ceramic material and preparation method thereof

InactiveCN102219498ATo promote metabolismEfficient dischargeWater/sewage treatment by irradiationWater/sewage treatment by substance additionCalciteRare earth

The invention discloses a water purification ceramic material and a preparation method thereof, relating to a ceramic material. The invention provides a water purification ceramic material capable of releasing negative ions, radiating far infrared rays, resisting bacteria, removing residual chlorine, removing heavy metal and purifying water, and a preparation method thereof. Main components of the water purification ceramic material are tourmaline, copper oxide and iron trioxide. Auxiliary components of the water purification ceramic material are at least one of quartz, calcite, kaolin, feldspar, talc, zirconium oxide, titanium oxide, manganese dioxide, cobalt trioxide and the like. The preparation method comprises the following steps of: mixing the main components; then, mixing the mixedmain components with at least one of the auxiliary components; crushing; screening; ball-milling to obtain a mixture; then sintering to synthesize a spinel type copper oxygen body substrate material;crushing and ball-milling the spinel type copper oxygen body substrate material to form a substrate material; with at least one of copper salt, zinc salt, inorganic silver salt and rare earth metal as a metal source, dissolving the metal source in water to prepare a solution; adding the copper oxygen body substrate material to the solution and adsorbing to form a combination body; after sintering, introducing reducing gas; and forming to obtain the water purification ceramic material.

Owner:XIAMEN BAILIN WATER PURIFICATION TECH CO LTD

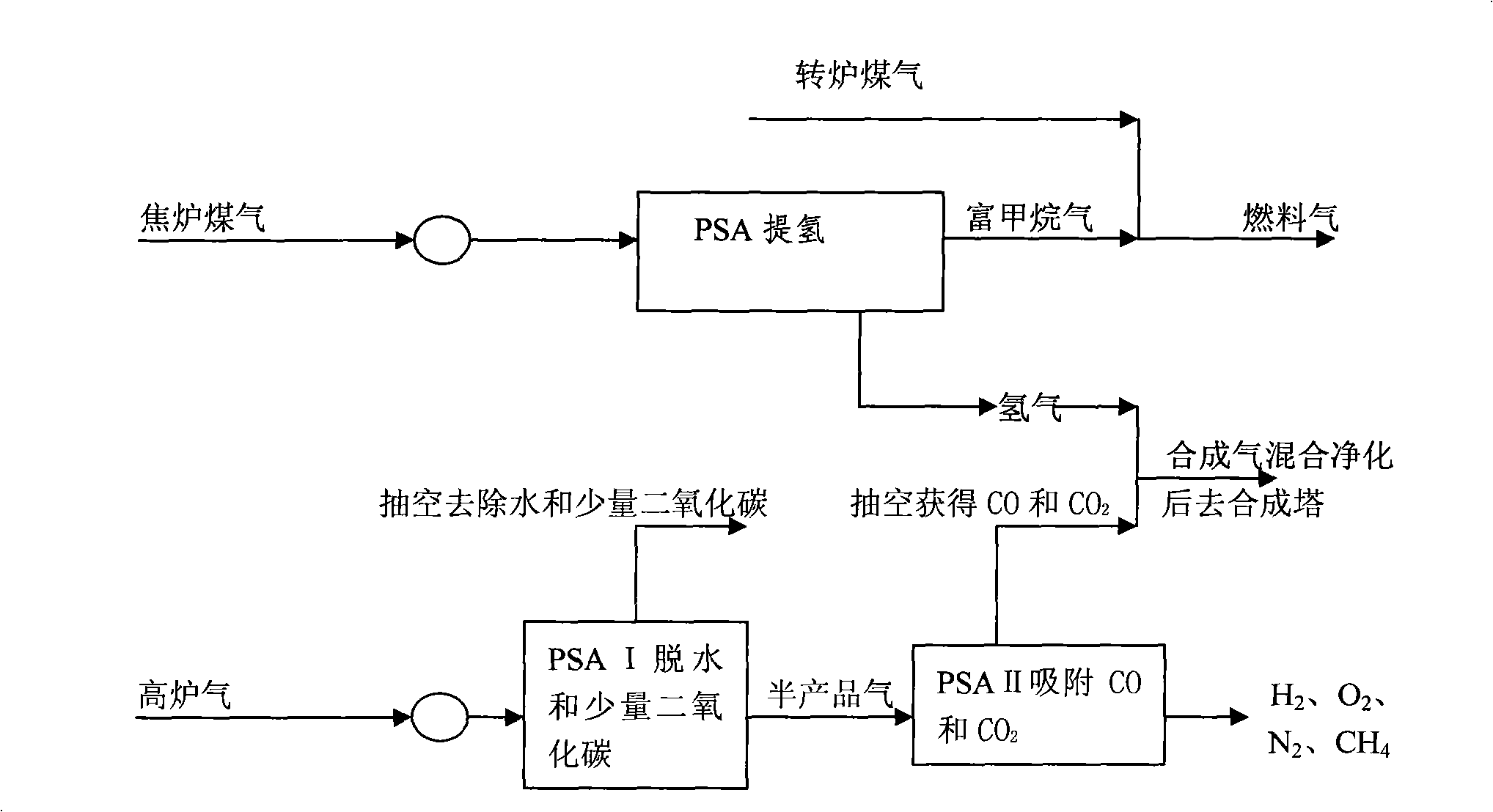

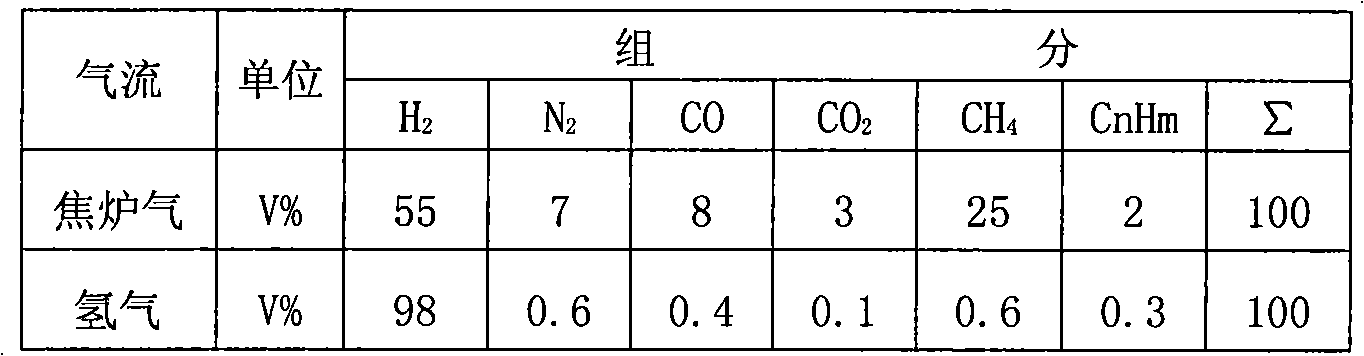

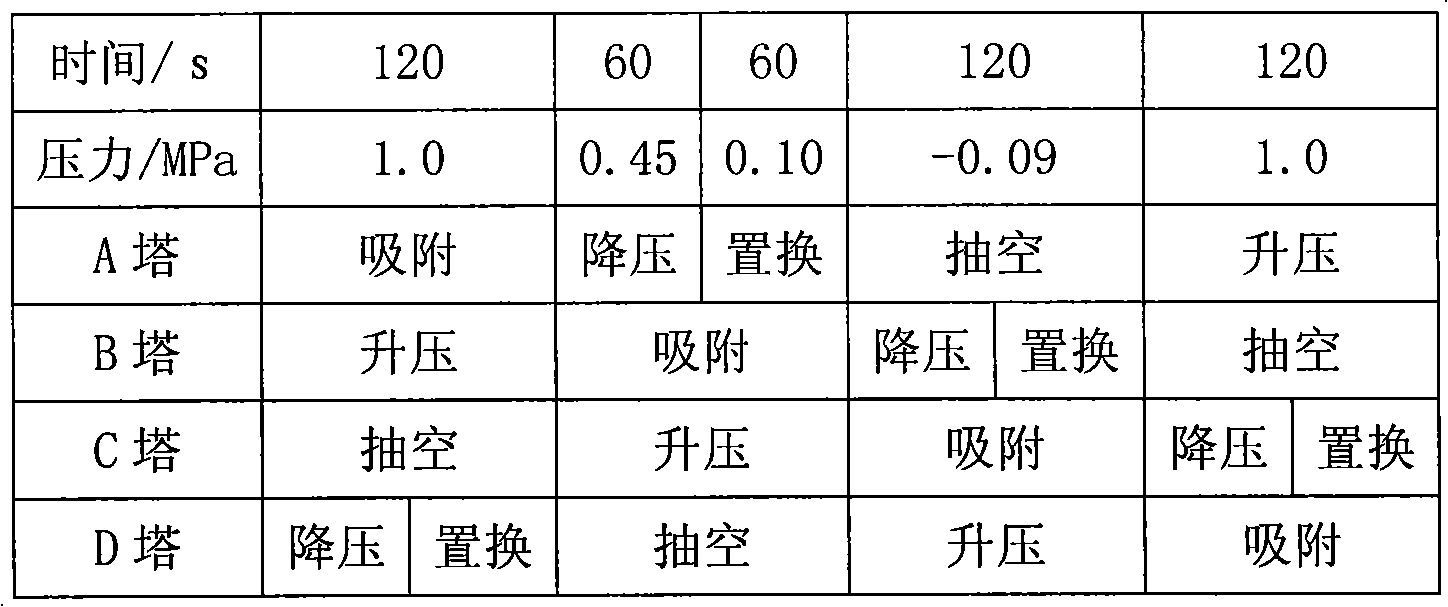

Method for preparing methanol synthesis gas with oven gas and blast furnace gas

InactiveCN101343580AEmission reductionReduce chemical reactionsGaseous fuelsChemical reactionSorbent

The invention discloses a preparation method for methanol synthetic gas through coke oven gas and blast furnace gas. The preparation method adopts coke oven gas as the raw material, and H2 is extracted through pressure swing adsorption; the blast furnace gas with high yield and relatively low calorific value is adopted as the raw material, an adsorbent which can adsorb CO and CO2 is utilized to simultaneously extract and reclaim the CO and the CO2 in the blast furnace gas, and then the H2, the CO and the CO2 are mixed and prepared into the methanol synthetic gas. The hydrogencarbon ratio f value of the methanol synthetic gas prepared according to the method is within the optimum range of 2.05 to 2.60, and the contents of nitrogen gas and other impure gases are suitable for the methanol production. The by-product gas generated during the steel production process is utilized to prepare the methanol synthetic gas, the useful components in the gas are utilized, the discharging of harmful substances into the environment is reduced, and not only the chemical reaction can not occur during the process, but also the carbon adding is not required, the technical process is short, the process is simple, and the cost is low, so the preparation method is one of the preferable methods for the preparation of methanol synthetic gas.

Owner:SICHUAN TIANYI SCI & TECH

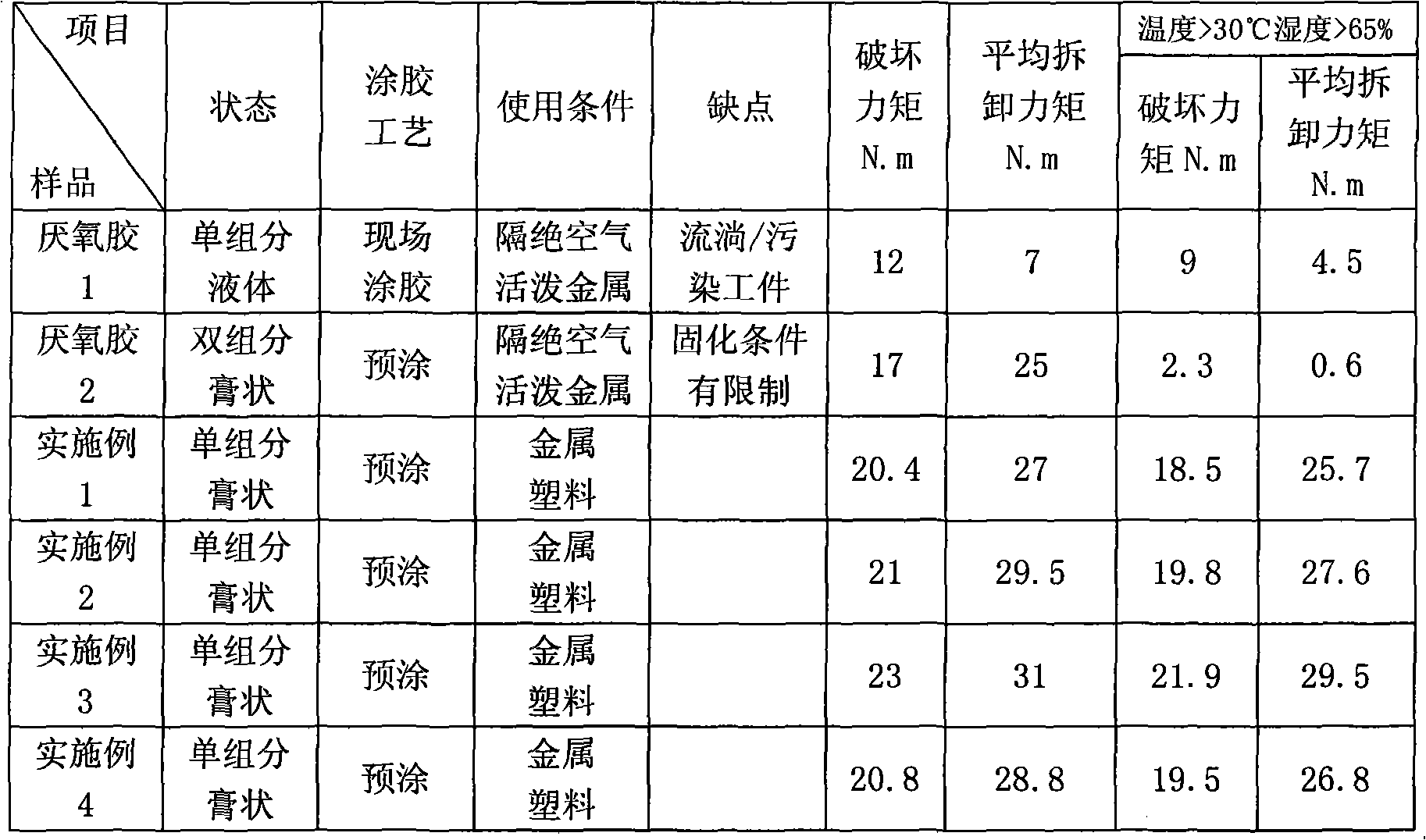

Single-component thread locking epoxy precoated adhesive and preparation method thereof

InactiveCN101665674AStable storageNo chemical reactionNon-macromolecular adhesive additivesOther chemical processesEpoxyAdhesive

The invention discloses a single-component thread locking epoxy precoated adhesive which is characterized by being prepared from the following components in proportion by weight: 40-70 parts of epoxyresin, 10-80 parts of activated thinner, 20-60 parts of epoxy hardener, 8-20 parts of urea, 30-60 parts of formaldehyde solution, 10-30 parts of hydroxyphenol, 0.5-5 parts of stuffing, 5-15 parts of surfactant, 80-200 parts of distilled water, 0.5-2 parts of membrane material, 0.1-1 part of hydrolysis inhibitor and 5-10 parts of solvent; and a preparation method comprises the steps: firstly, respectively microencapsulating the epoxy resin and the epoxy hardener are and then uniformly mixing with other components in proportion. The single-component thread locking epoxy precoated adhesive has the characteristics of convenient construction, applicable workpiece material diversification, less curing condition restriction, good moisture resistance and high destabilizing moment and average disassembly moment, ensures the locking performance and better guarantees the safe reliability of products.

Owner:YANTAI DARBOND TECH

Aqueous glue, lithium battery applying the aqueous glue and manufacturing method for the lithium battery

ActiveCN101286563ALow costLow investment costElectrode manufacturing processesFinal product manufactureIonChemistry

The invention provides a water-base cement which consists of a main adhesion agent, an auxiliary adhesion agent and a defoaming agent which are mixed according to the weight ratio of 20-30:1-3:1-5, wherein, the main adhesion agent is a mixed liquor prepared by one or a plurality of polyethylene glycol oxide, sodium carboxymethyl cellulose or polyvinyl alcohol with de-ionized water, and the solid content thereof is between 1 percent and 10 percent; the auxiliary adhesion agent is the mixed liquor prepared by one or two of butadiene styrene rubber or polyfluortetraethylene with the de-ionized water, and the solid content thereof is between 30 percent and 70 percent; the defoaming agent is one or a plurality of ethanol, glycol or propanediol which are mixed for use. The water-base cement has low cost, is innoxious and environment-friendly. The invention also provides a lithium battery which uses the water-base cement and a manufacturing method for the lithium battery.

Owner:袁植良

Biological compound fertilizer and production process thereof

InactiveCN101555173ASolve watering and irrigation problemsLow input costBio-organic fraction processingWaste based fuelContinuous croppingChemical reaction

The invention relates to a biological compound fertilizer and a production process thereof, which relates to the field of agricultural fertilizers and the production thereof. The prior biological bacterial fertilizer has the problems of not comprehensive enough nutrition, poorer water retention and drought-resistant degree and lower survival rate of biological bacteria. The invention provides a prescription that the biological compound fertilizer contains liquid-fertilizer sustained release agent with micropores, compound biological fertilizer, high-efficient organic matters, inorganic N P, K and micro elements in the lack of soil; and the production process adopts a method of roller- extrusion cold prilling and has no drying and air-cooling procedures and no any chemical actions. The invention has the advantages of more comprehensive nutrition, water retention, drought and continuous cropping resistance, the improvement of the survival rate and the reproduction rate of biological bacteria and balanced crop growth.

Owner:NANYANG BOLIDA FERTILIZER

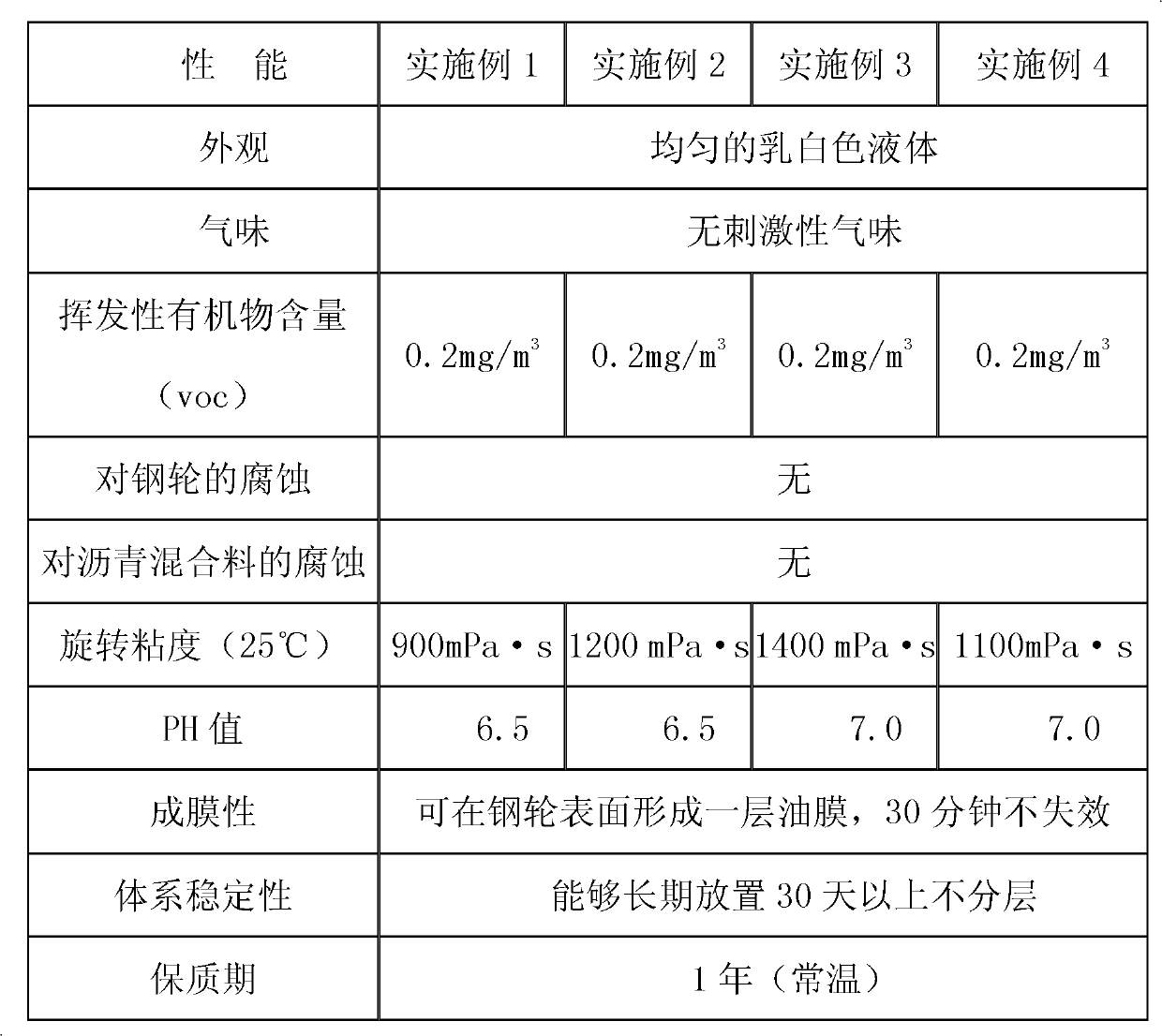

Insulator for low-temperature construction of asphalt pavement road roller and method for preparing same

ActiveCN102167939ANo pollution in the processNo chemical reactionClimate change adaptationCoatingsGreenhouseEngineering

The invention belongs to the technical field of preparation of insulators for the construction of asphalt pavement road rollers and relates to an insulator for the low-temperature construction of road rollers and a method for preparing the same. The insulator is mainly prepared by mixing silicone oil, compound emulsifier, glycerin, pH regulator, preserving agent and water. The insulator has the advantages of high chemical stability, high high-low temperature resistance, no corrosion to steel wheels, small amount of coating, lasting insulating effect, environment friendliness and the like. By using the insulator, the asphalt mixture pavement is guaranteed to be constructed at the ultralow temperature (15 DEG C below zero), so that the working season is greatly prolonged; and during normal-temperature construction, by using the insulator, the mixing temperature of the asphalt mixture is reduced to 15 to 20 DEG C under the condition of unchanging the compaction degree and the emitted greenhouse gases are reduced in the mixing process and the environment-friendly and energy saving requirements are met.

Owner:山西省交通科技研发有限公司

Method for preparing steel/aluminium composite material

InactiveCN1752266APrevent oxidationAvoid generatingSolid state diffusion coatingPower railsChemical reactionMaterials science

A process for preparing steel-aluminium composition includes such steps as dipping the deforming Al-alloy in Sn (or Zn) solution for generating a layer of low-smelting-point antioxidizing metal film on its surface, coating a metallic transition layer not reacting on steel and Al on the surface of stainless steel, and hot pressing them in a vacuum hot extruding furnace. Its advantages are high electric conductivity and no generation of FeAl3.

Owner:XI AN JIAOTONG UNIV

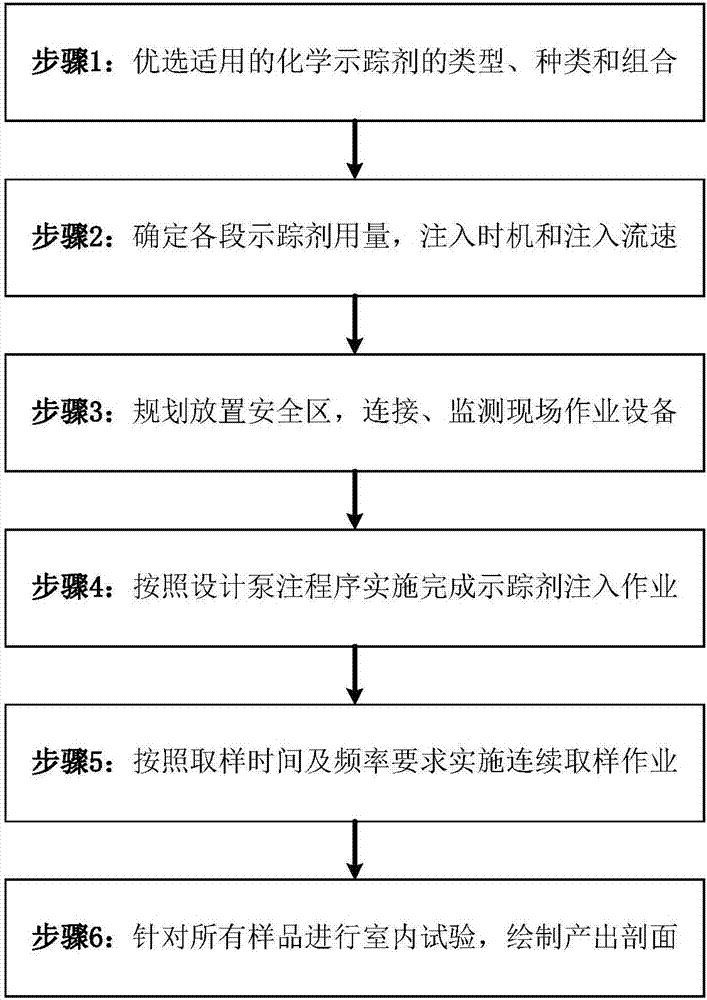

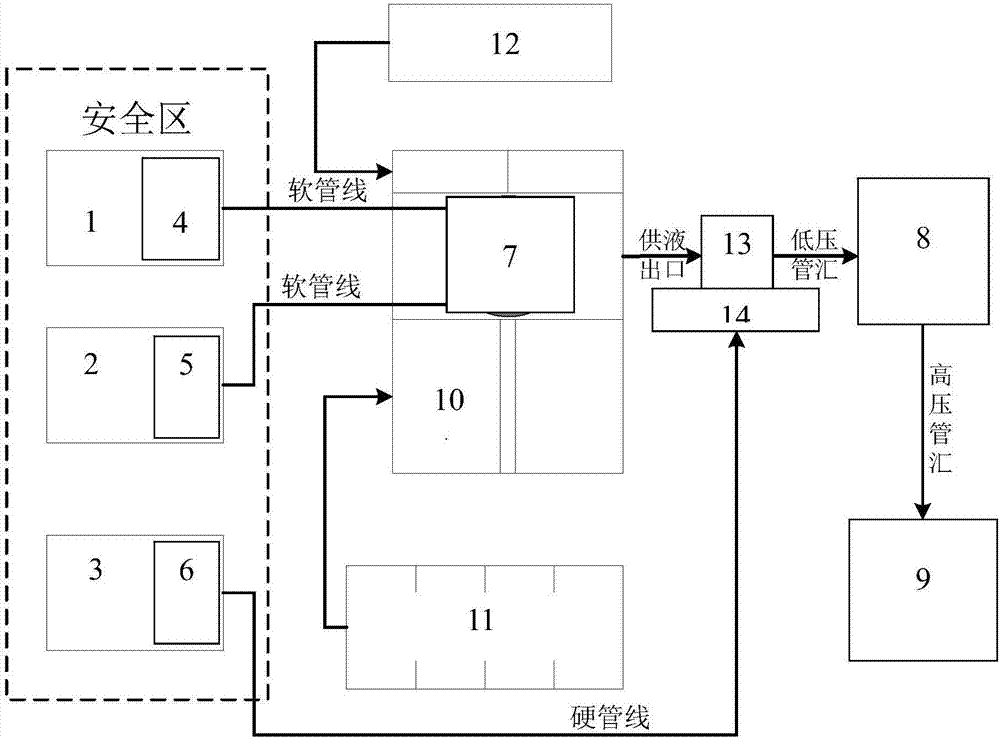

Method and system for testing oil-gas-water profile of each section of horizontal well by using environmental protection type tracers

ActiveCN107989588AEasy to operateNo obvious HSE riskConstructionsFluid removalReservoir typeThermodynamics

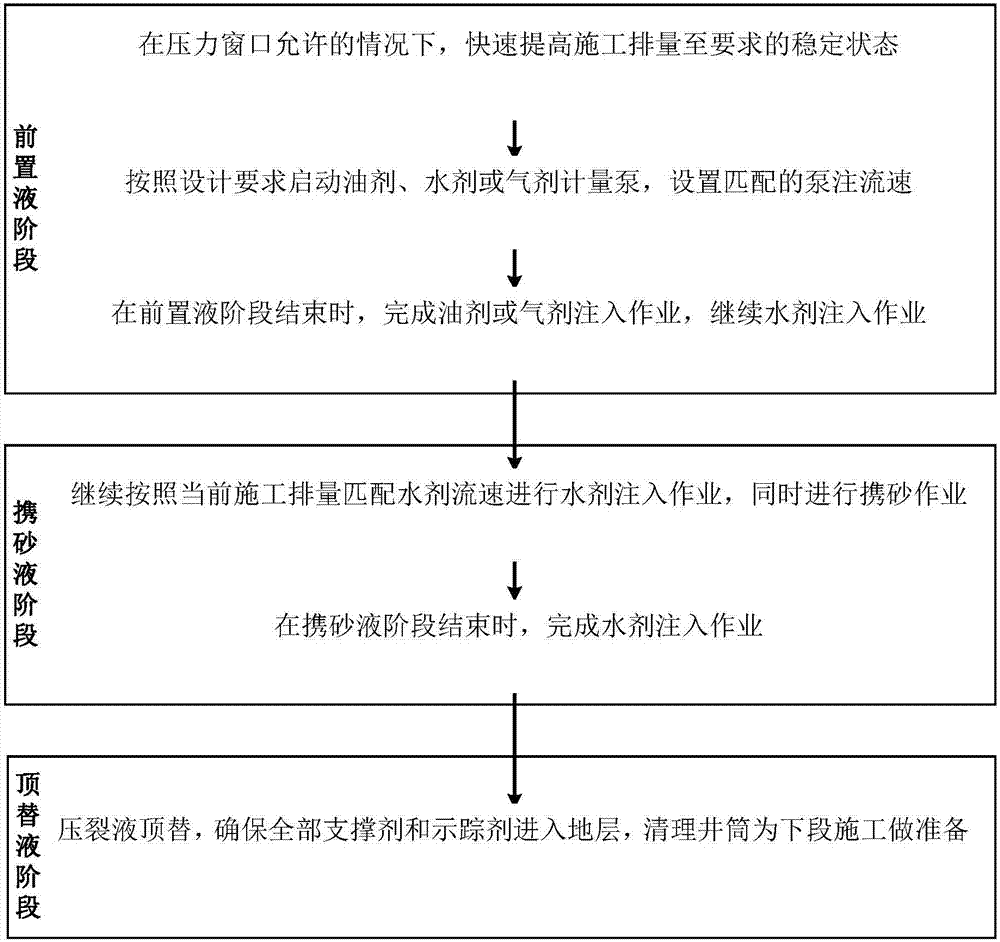

The invention provides a method and system for testing the oil-gas-water profile of each section of a horizontal well by using environmental protection type tracers. The method comprises the steps that according to information containing the oil and gas reservoir type, the fracturing fluid type and the number of test sections, the kinds and the compositions of the chemical tracers are determined;the designed using quantity, the injection time and the injection velocity of the chemical tracer used at each section are determined; injection equipment of the tracers used for testing is determined, and the connecting process of equipment for completing on-site operation is determined and laid out before construction; injection operation of the corresponding chemical tracers required by construction sections is completed according to the designed pump injection procedure; after fracturing construction of the whole horizontal well is completed, continuous tracer test sampling operation is implemented according to the designed sampling time and frequency, and samples are tested in time after all sampling is completed; and a production profile map or a contribution ratio map of each layersection of the oil and gas reservoir horizontal well within the sampling period is drawn.

Owner:ORIENT BAOLIN TECH DEV BEIJING

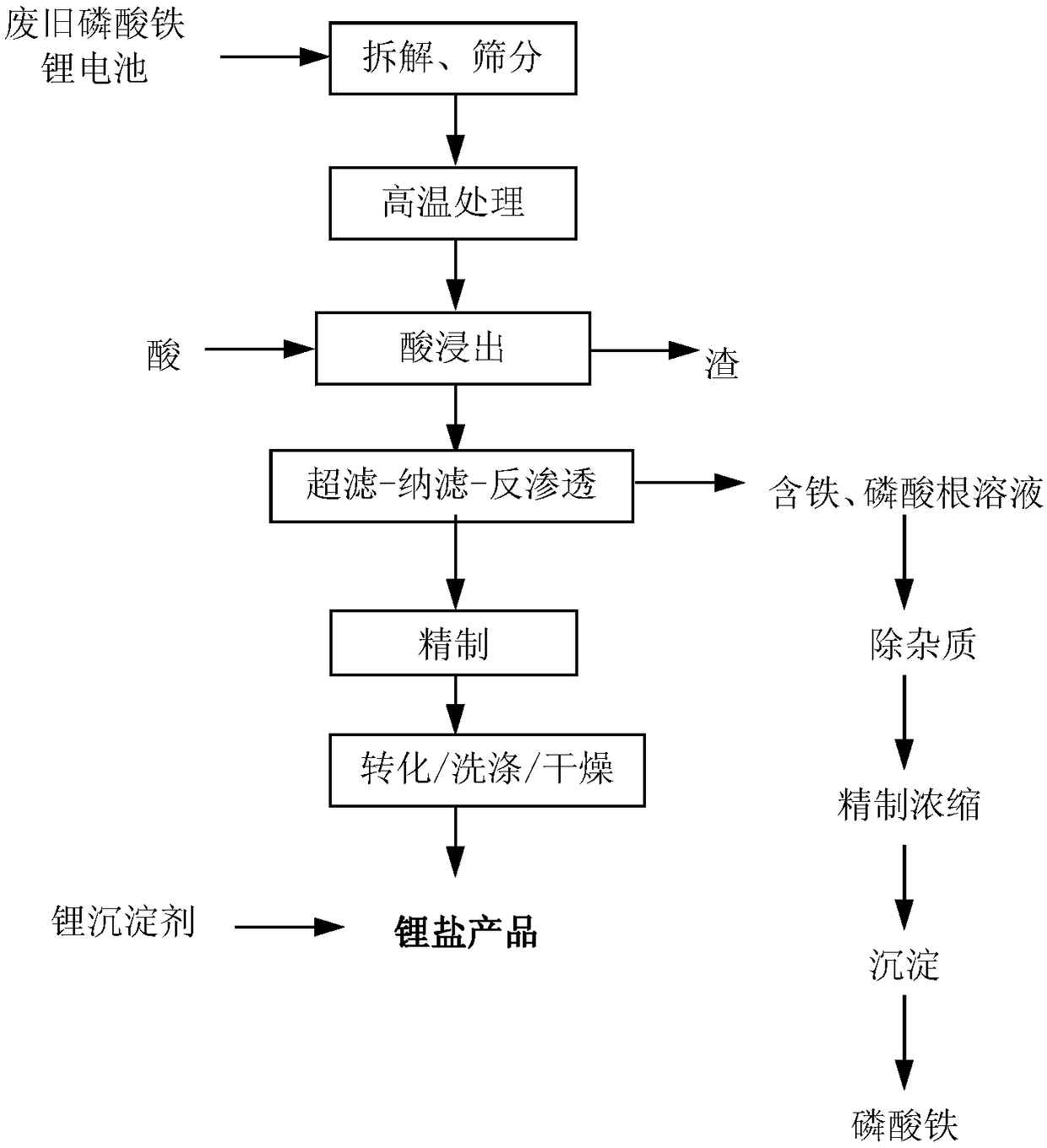

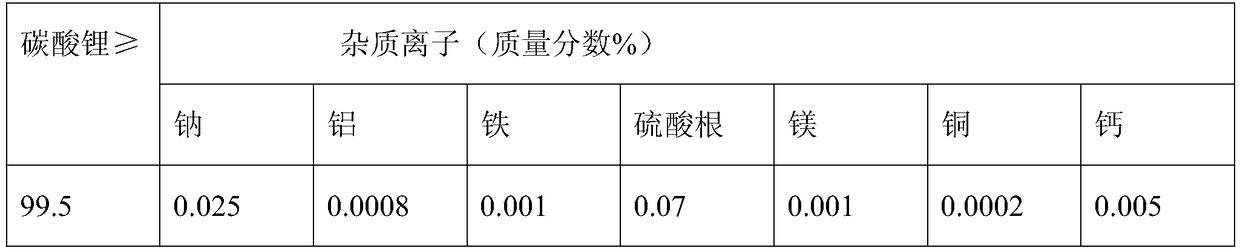

Method and system for recovering lithium from waste lithium iron phosphate battery

ActiveCN109207730AAdvanced separation technologyEasy to separateWaste accumulators reclaimingProcess efficiency improvementPregnant leach solutionLithium iron phosphate

The invention discloses a method and system for recovering lithium from a waste lithium iron phosphate battery. The method comprises the following steps that a positive plate is disassembled from thewaste lithium iron phosphate battery; a binder in the positive plate is removed, valuable metal elements in the positive plate are leached by an acid solution, and an acidified leaching solution is obtained; ultrafiltration treatment is carried out on the acidified leachate by using an ultrafiltration membrane; by using a nanofiltration membrane technology, lithium ions in the acidified leachate are separated from other cations different from lithium ions, a solution containing lithium and a solution containing other cations are obtained, and then a reverse osmosis technology is adopted for concentration and enrichment correspondingly, wherein the other cations comprise iron ions; and a lithium precipitant is adopted to precipitate and separate lithium ions in the lithium-containing solution, alkaline substances are adopted to precipitate and separate iron ions in the solution containing other cations, and lithium recovery is realized. According to the method and system, the ultrafiltration-nanofiltration-reverse-osmosis combined technology is adopted, and the method and system have the beneficial effects of simple process, environmental protection, less acid and alkali consumption, good and stable membrane separation effect and the like.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Coated granular microbial agent and production method thereof

ActiveCN102925426ANo chemical reactionImprove liquidityOn/in inorganic carrierFertilizer mixturesChemical reactionMicrobial agent

The invention relates to a coated granular microbial agent and a production method thereof. The coated granular microbial agent is prepared by the following raw materials by weight percent in a mixing way: 7-20 percent of a microbial liquid, 50-85 percent of an adsorption carrier, 0-40 percent of a binding agent and 1-10 percent of a coating agent. The production method comprises the following steps: firstly weighing the raw materials with corresponding percent, mixing the adsorption carrier with the binding agent, adding the microbial liquid to adsorb and then crushing, performing granulation on the crushed material, drying the material after granulation and screening to obtain the finished product granular material through a screening machine, performing aeration-cooling on the finished product granular material and conveying the material after cooling to a coating machine and adding the coating agent for coating, and performing aeration-cooling and drying on the material after coating. The coated granular microbial agent has the benefits of no chemical reaction, no air slaking, no crushing for granules, no formation like sticky mud, good fluidity, high strength, soil adjustment, soil improvement and fertilizer effect enhancement when being mixed with chemical fertilizers such as urea, compound fertilizer and the like for use, and reduces the use cost.

Owner:北京世纪阿姆斯生物技术有限公司

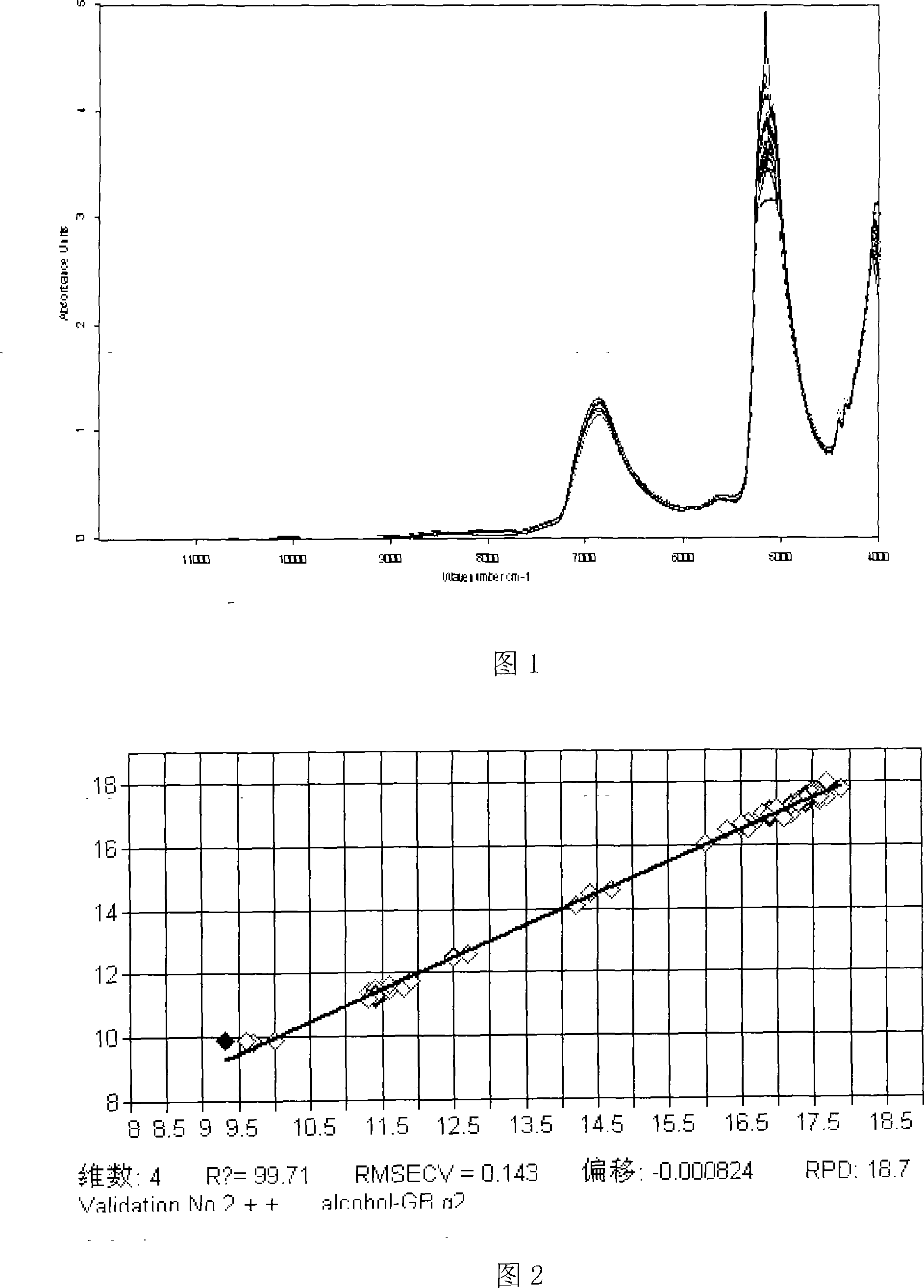

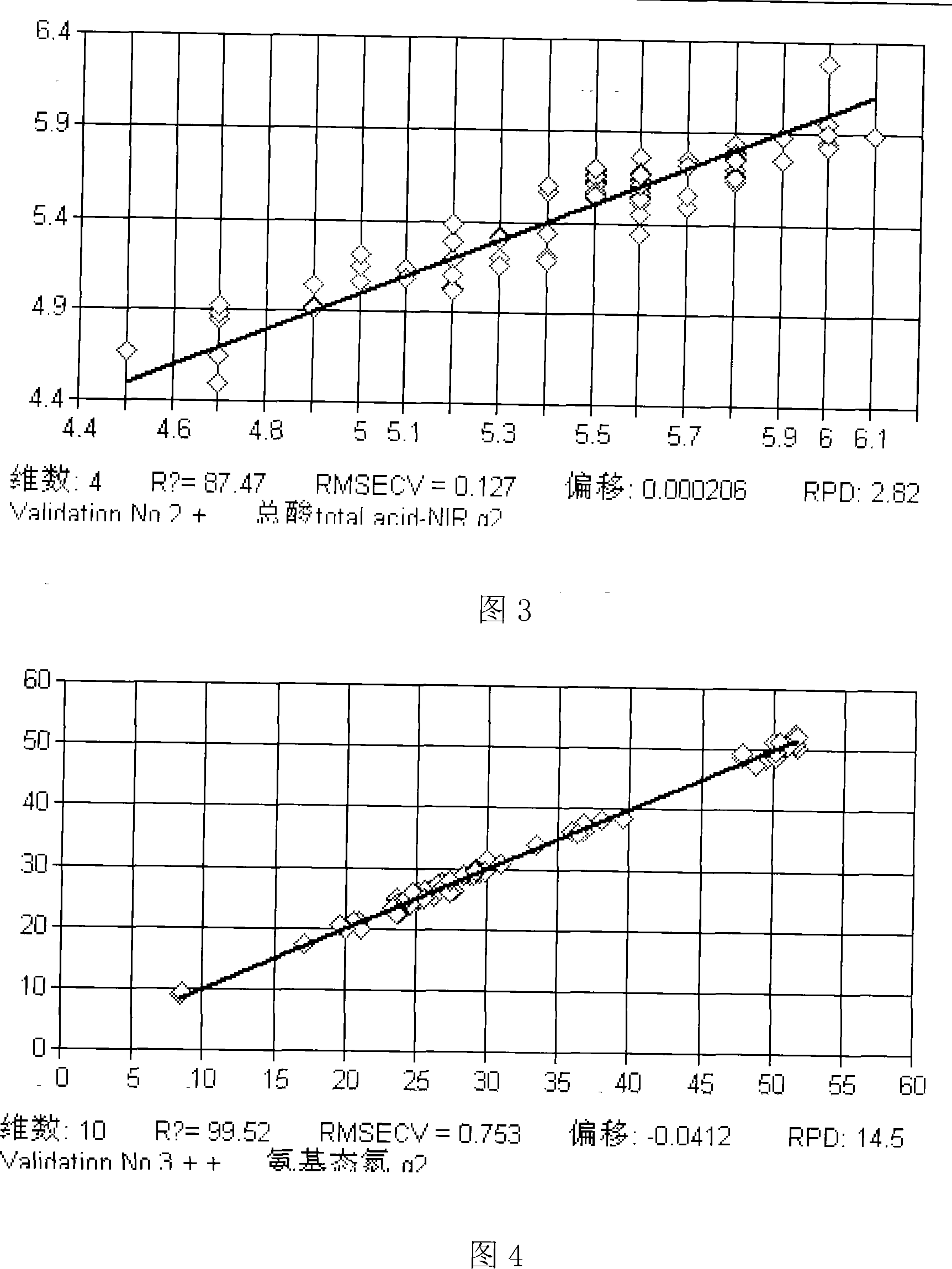

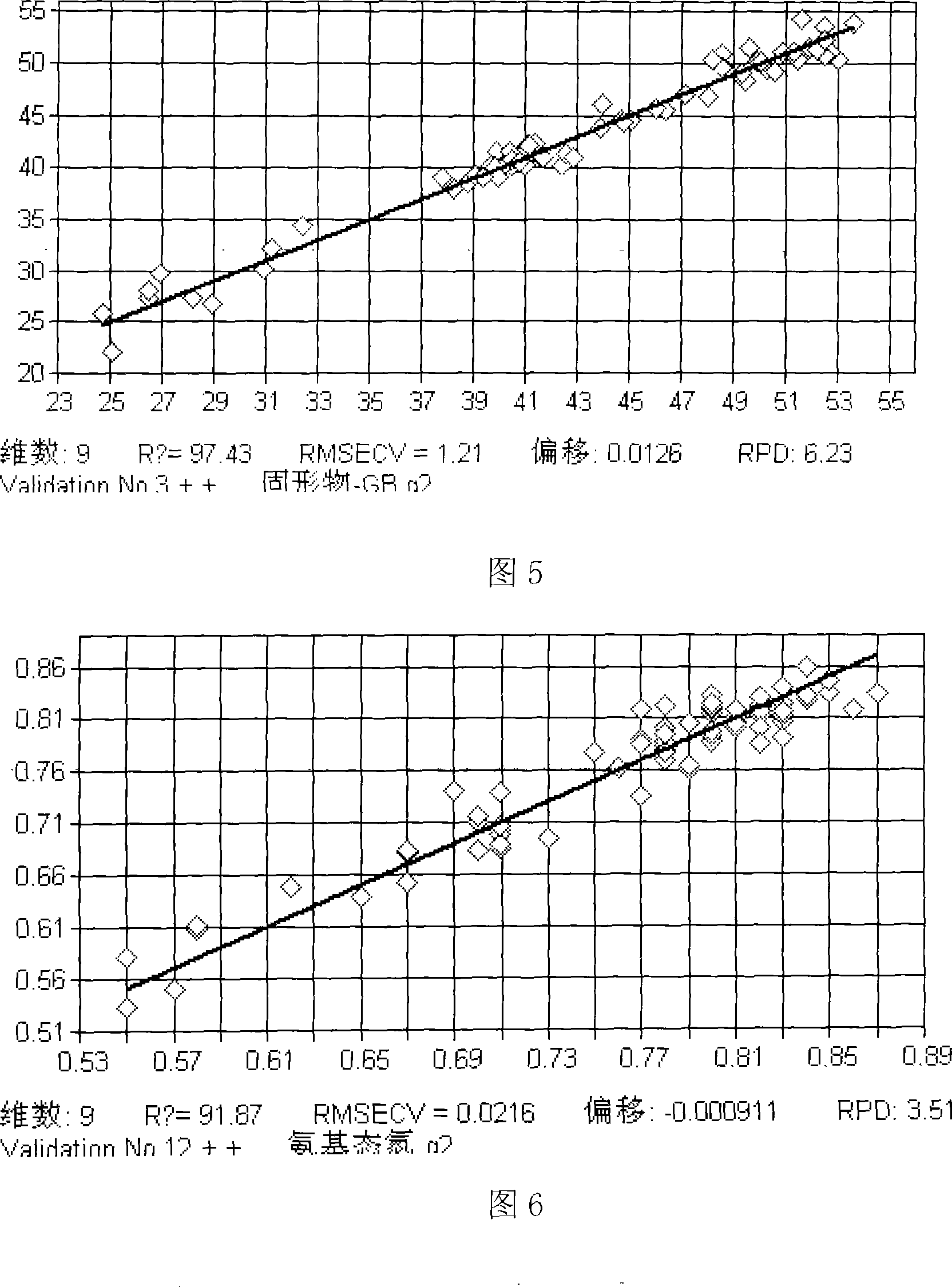

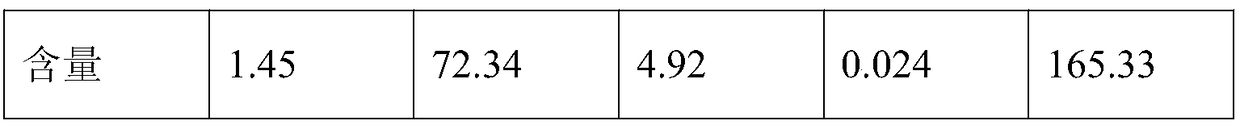

Method for quickly detecting yellow wine quality index

InactiveCN101216419AEasy to operateFast testColor/spectral properties measurementsComplex mathematical operationsFourier transform on finite groupsBiology

The invention relates to a detection method of quality index of yellow rice wine, in particular to a method for rapidly detecting quality index of yellow rice wine, which has simple operation, improved detection speed and greatly improved time efficiency and production efficiency. The method comprises the following steps of: (1) scanning a yellow rice wine sample to be detected by Fourier transform near infrared spectrometer and a liquid fiber probe to obtain the spectrum of the yellow rice wine sample; and (2) sending the spectrum of the yellow rice wine sample obtained in step (1) to a quantitative spectrum analysis software package, and calculating the contents of quality indexes of the yellow rice wine sample by using a pre-constructed quality index model of the yellow rice wine, wherein the quality indexes comprise one or more of alcohol degree, total acid, total sugar, ammonia nitrogen, non-sugar solids, volatile ester and color ratio. The invention has the advantages of simple operation, improved detection speed, no pollution in the detection process and nondestructive detection, and can be further used for production line to achieve online detection and control.

Owner:陈郁

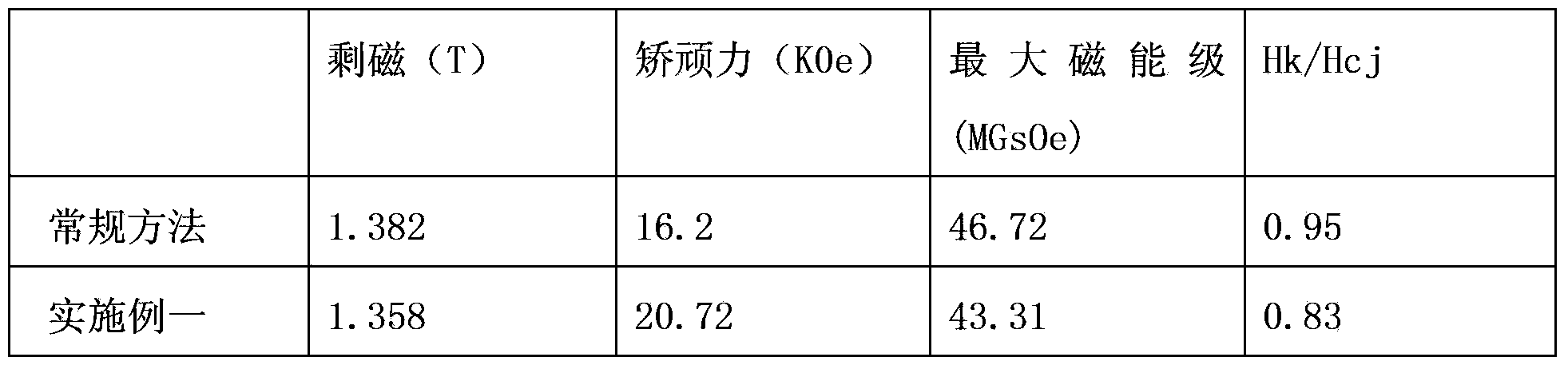

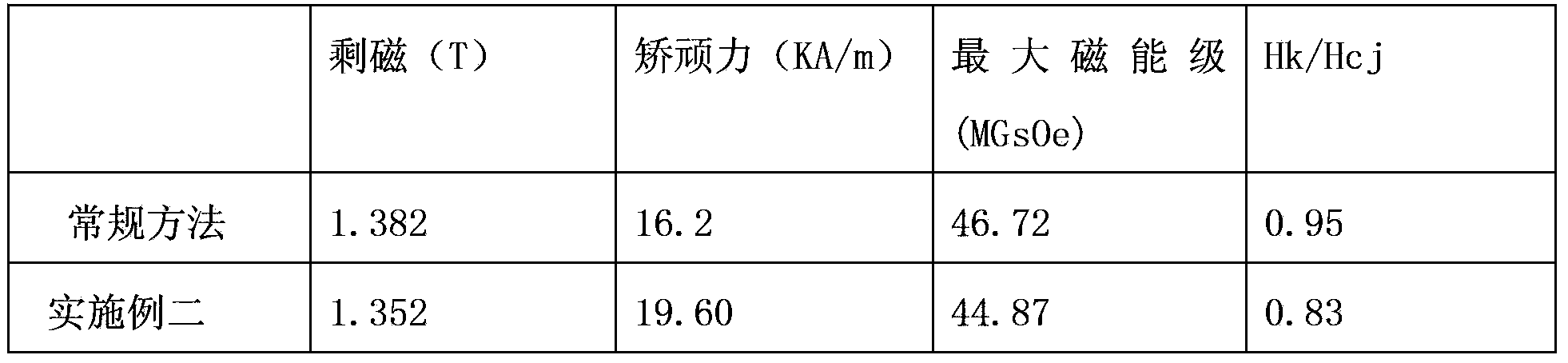

Method for improving performance of sintered neodymium-iron-boron magnet

ActiveCN103366944AImprove coercive forceWide range of applicationsInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementCrystallite

The invention discloses a method for improving the performance of a sintered neodymium-iron-boron magnet. Two pieces of heavy rare earth, a sintered neodymium-iron-boron magnet green body and two separation nets are arranged on a separation board in an evaporation diffusion box one above another; the sintered neodymium-iron-boron magnet green body is positioned between the two pieces of heavy rare earth; the two pieces of heavy rare earth cover the upper surface and the lower surface of the sintered neodymium-iron-boron magnet green body; and when the sintered neodymium-iron-boron magnet green body is subjected to vacuum sintering under the condition that the vacuum degree is less than 1*10<-2>Pa, the two pieces of heavy rare earth are evaporated and diffused in an enclosed space, and heavy rare earth elements are diffused into the sintered neodymium-iron-boron magnet green body and are better distributed in the grain boundary and on the crystalline grain edge of the sintered neodymium-iron-boron magnet green body. The method has the advantages that specific to the sintered neodymium-iron-boron magnet of which the thickness surpasses 3 millimeters, the coercive force can be increased on the basis of ensuring that the residual magnetism does not fall basically; and the method is suitable for sintered neodymium-iron-boron magnets of which the thicknesses do not surpass 3 millimeters as well as sintered neodymium-iron-boron magnets of which the thicknesses surpass 3 millimeters, and has a wide application range.

Owner:NINGBO YUNSHENG +5

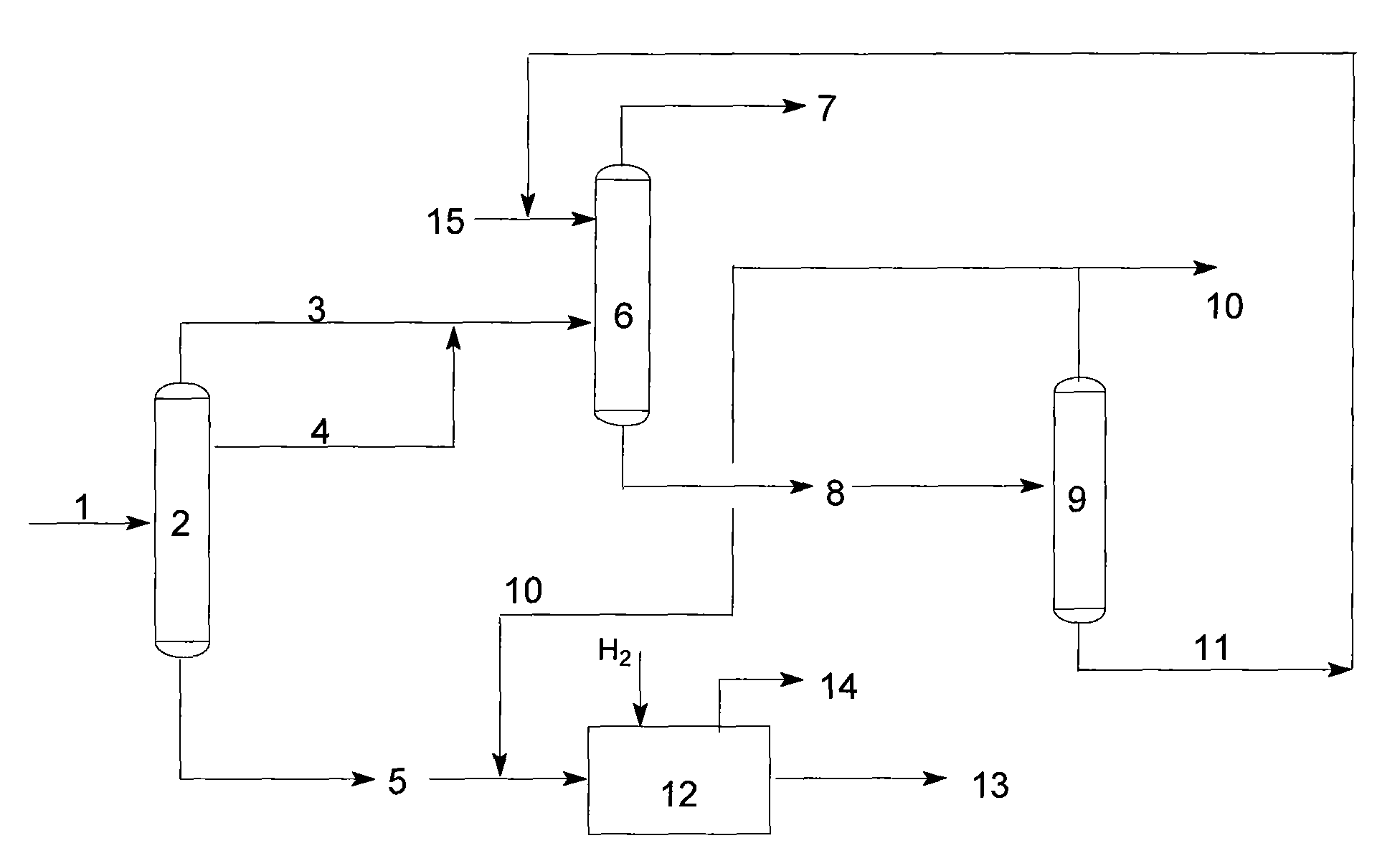

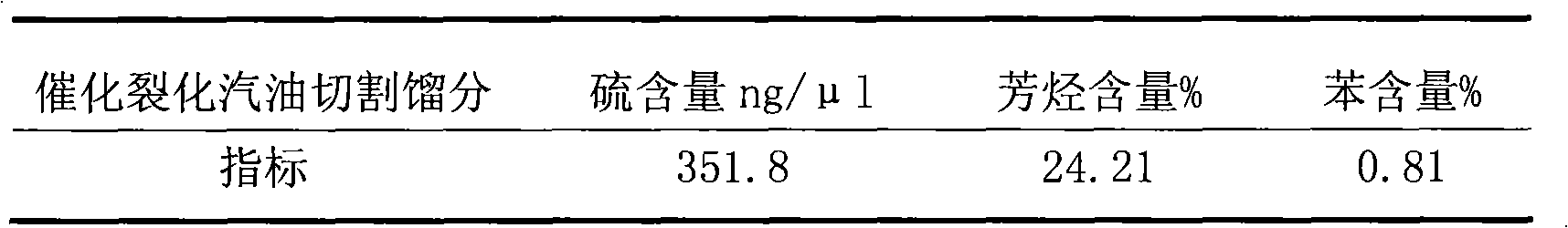

Method for producing reforming feedstock by light and medium gasoline distillates

ActiveCN101649221ASolve protection problemsRelieve pressureCatalytic naphtha reformingHydrocarbon oils refiningCatalytic reformingFractionation

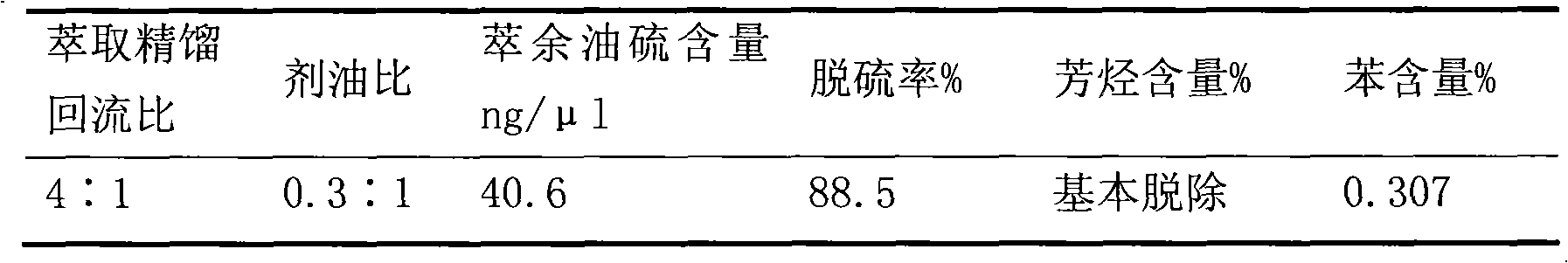

The invention relates to a method for producing catalytic reformed feedstock by taking light and medium gasoline distillates as raw materials and extracting selective solvent to extract and rectify catalytically cracked gasoline in the absence of hydrogen. The method comprises the following steps: 1, fractionation prefabrication of light and medium distillate raw materials of catalytically cracked gasoline; and 2, extraction, rectification, desulfuration and dearomatization of light and medium distillates of catalytically cracked gasoline, wherein light and medium distillates of catalyticallycracked gasoline obtained in step 1 are fed into the middle-lower part of an extraction-rectification tower, while fresh extraction agent or recycled extraction agent is added from the upper part of the extraction-rectification tower; thus, the light and medium distillates contact the extraction agent inside the tower to generate desulfurized and dearomatized light-component raffinate phase (i.e.catalytic reformed feedstock product) rich in olefin hydrocarbon at the top of the tower after extraction, rectification, desulfuration and dearomatization. The method carries out desulfuration and dearomatization of catalytically cracked gasoline at the same time and reclaims solvent, thereby having the advantages of simple process, moderate operation conditions, hydrogen source saving and low production cost.

Owner:PETROCHINA CO LTD +1

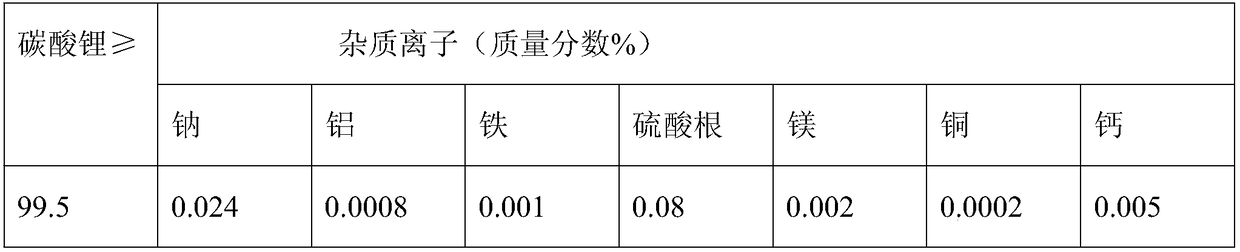

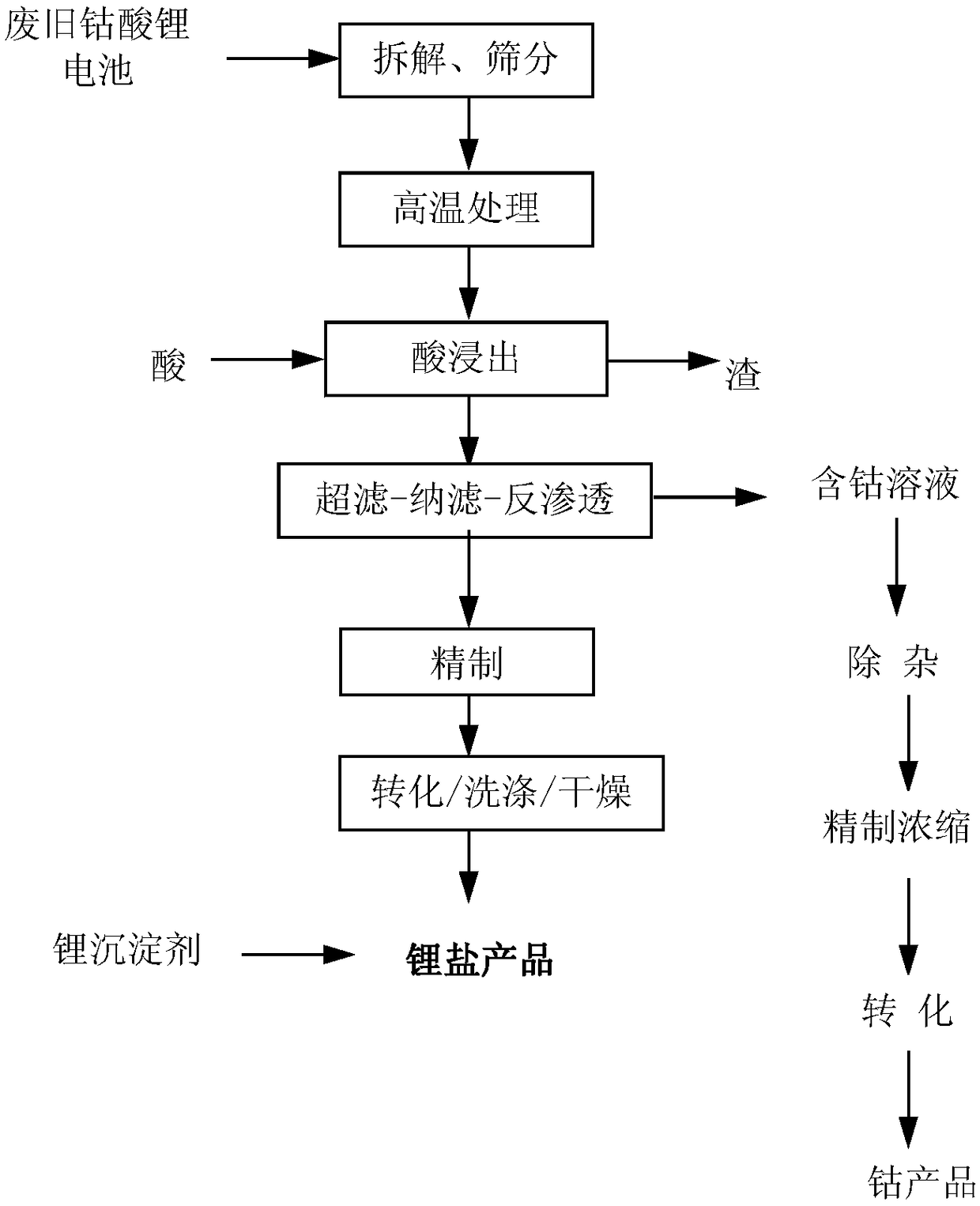

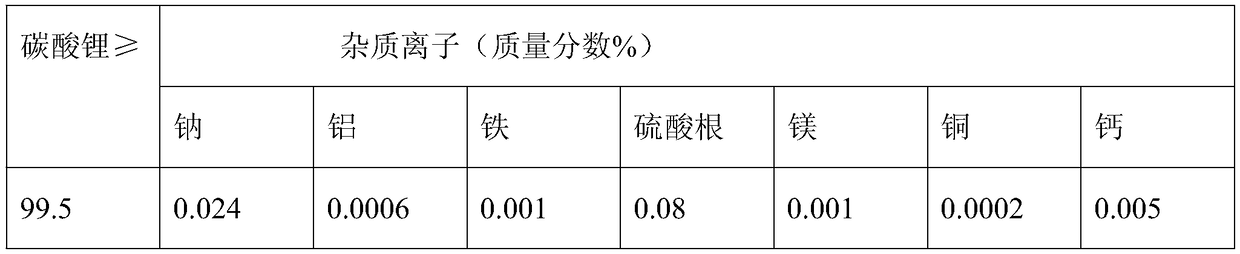

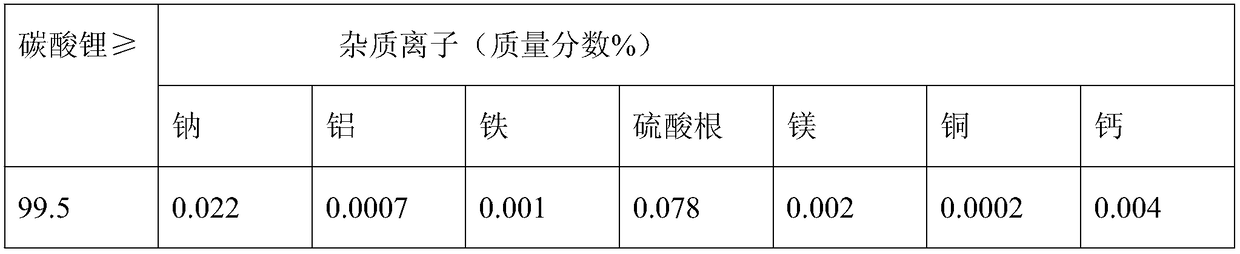

A method and system for recovering lithium and cobalt from spent lithium cobalt oxide batteries

ActiveCN109256597AAdvanced separation technologyEasy to separateWaste accumulators reclaimingProcess efficiency improvementPregnant leach solutionLithium

The invention discloses a method and a system for recovering lithium and cobalt from waste lithium cobalt oxide batteries. The method comprises the following steps of: disassembling a positive electrode sheet from a waste lithium cobalt oxide battery; Removing the binder in the positive electrode sheet, and then acid leaching the valuable metal elements in the positive electrode sheet to obtain anacidizing leaching solution; The acidified leachate was treated by ultrafiltration membrane. Separating lithium ions in acidified leaching solution from other cations different from lithium ions by using nanofiltration membrane technology to obtain lithium-containing solution and solution containing other cations, and concentrating and enriching the lithium-containing solution and the solution containing other cations respectively by reverse osmosis technology, wherein the other cations include cobalt ions; And a lithium precipitant is used to precipitate lithium ions from a lithium-containing solution, and an alkaline substance is used to precipitate cobalt ions from a solution containing other cations, thereby realizing the recovery of lithium and cobalt. The adoption of ultrafiltration-Nanofiltration-Reverse osmosis combined technology has the characteristics of simple process, less acid and alkali consumption, good and stable membrane separation effect and so on.

Owner:青海中科德方能源科技研究有限公司

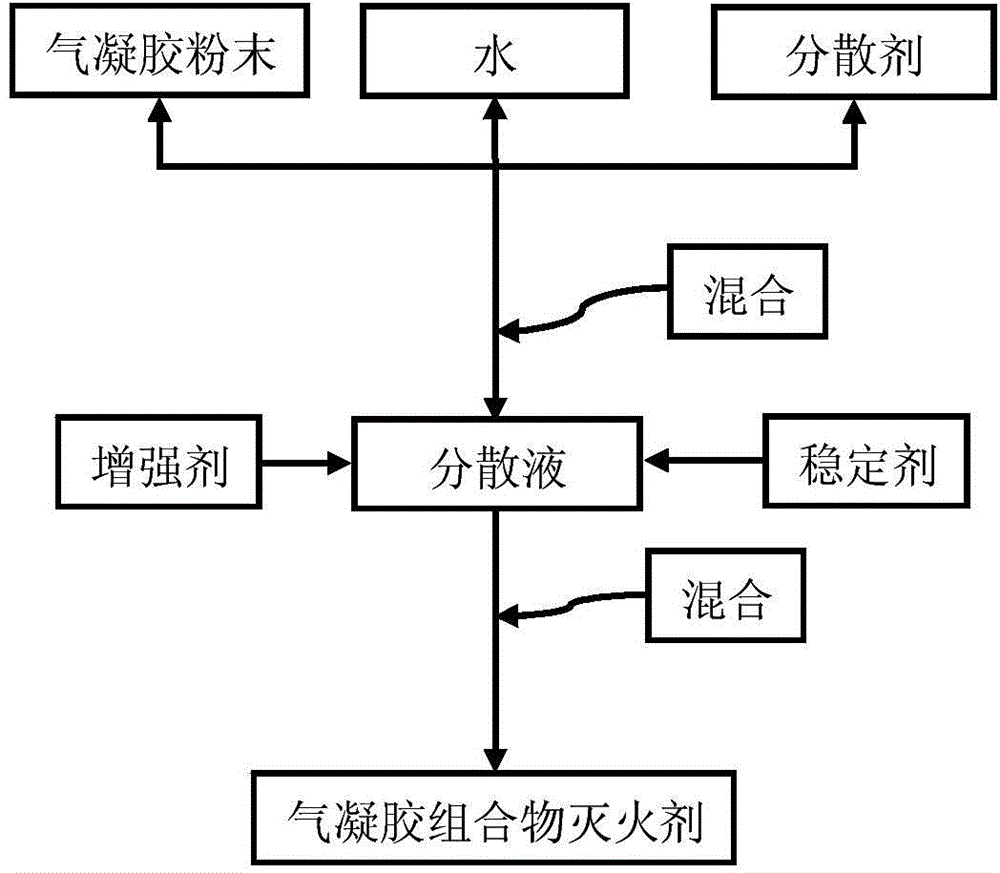

Aerogel material-containing high efficiency liquid composition extinguishing agent and its preparation method and use

The invention discloses an aerogel material-containing high efficiency liquid composition extinguishing agent and its preparation method and use. The high efficiency liquid composition extinguishing agent comprises aerogel powder, water, a surfactant, a fire extinguishing enhancer and a stabilizing agent. The aerogel powder is used in the extinguishing agent so that in fire extinguishing, the aerogel powder and extinguishing agent produce interaction and the product well covers the surface of a substrate and can effectively obstruct heat transmission and prevent flame propagation and heat transfer. In fire extinguishing, the aqueous extinguishing agent system does not undergo a chemical reaction, does not produce heat and prevents secondary fire hazard. The liquid composition extinguishing agent utilizes a simple air-atomizing technology, is prepared through simple equipment and can be operated easily. The liquid composition extinguishing agent has extremely low organic component content, can effectively control organic matter release and combustion in fire extinguishing, does not produce harmful gas and does not release powder.

Owner:苏州同玄新材料有限公司

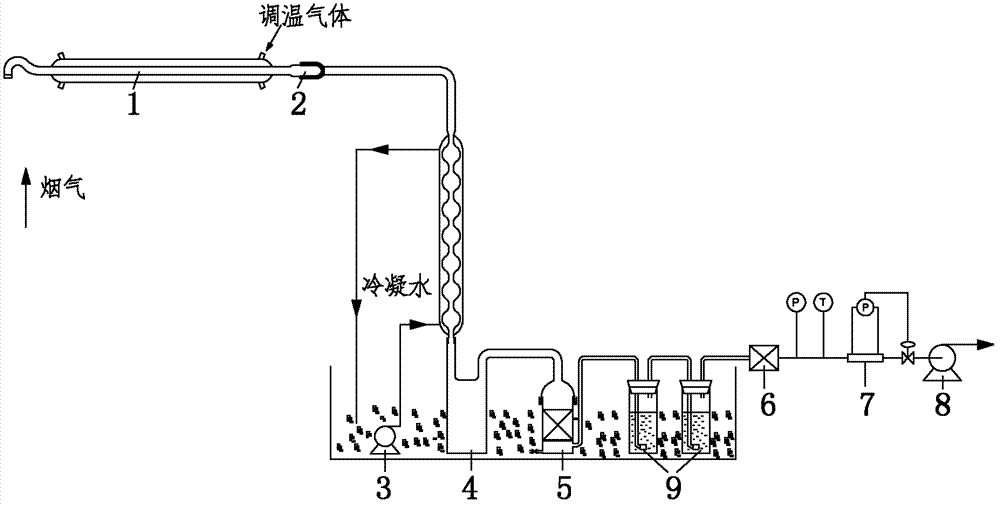

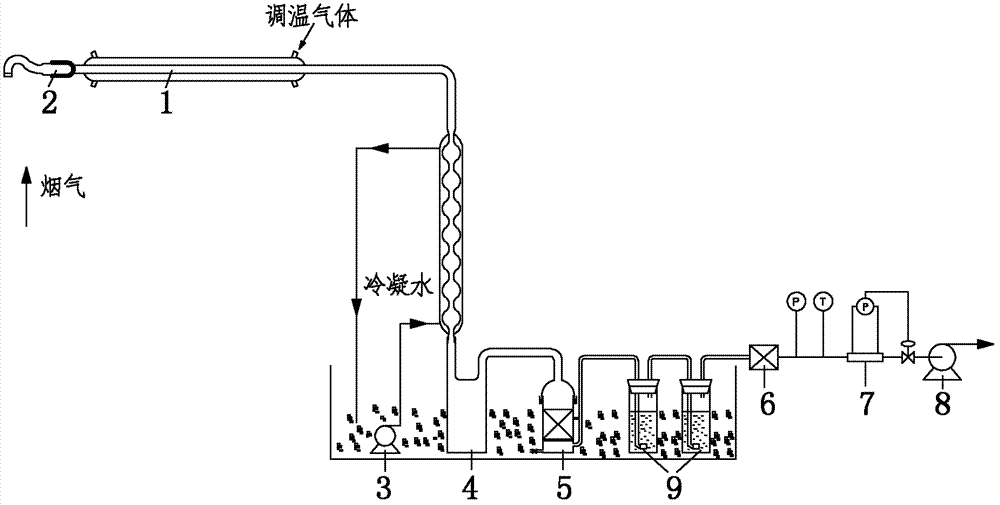

Method for sampling special organic gas in flue gas

The invention relates to a method for sampling a special organic gas in a flue gas. The method comprises the following steps: allowing the flue gas to enter through the inner tube of a sleeve from the inlet of a sampling gun, adjusting the temperature, intercepting particles by a filter cylinder, condensing the flue gas by a condensation device, allowing the obtained condensate liquid into a cooling and liquid removing bottle, trapping the cooled and dried gas by a trapping bottle to remove dioxin substances, further collecting by a washing bottle, and allowing the gas to go through a dryer, a gas flow meter, a thermometer and a sampling pump to complete the whole sampling process. A whole flue gas sampling pipeline adopting a full glass structure has the advantages of corrosion resistance, no chemical reaction, convenient cleaning, and prevention of the loss caused by the adsorption or contamination of the acquired sample by the wall surface of a tube wall utensil; the jacket glass sampling gun can heat or cool the acquired flue gas by hot or cold air entering through an external layer; the condensate liquid collection bottle having scales can rapidly judge whether there is severe gas leakage in the sampling process or not; and the flue gas is cooled, condensed, and dehydrated, and then adsorbs a sampling agent to guarantee a high sampling efficiency.

Owner:TONGJI UNIV

Metallic powder injection molding adhesive

The invention relates to a binder which comprises the following components according to weight percentage: 15 percent to 25 percent of chlorinated polyethylene, 15 percent to 25 percent of polyformaldehyde, 3 percent to 10 percent of rubber, 20 percent to 30 percent of petroleum wax, 15 percent to 25 percent of Brazil wax (palm wax), 1 percent to 5 percent of stearic acid and 1 percent to 5 percent of epoxidized soybean oil. In the forming technique of metal powder, the binder can improve the strength of blank, reduce the damage of the blank and improve the finished yield and the production efficiency.

Owner:PINGHU HAITE ALLOY

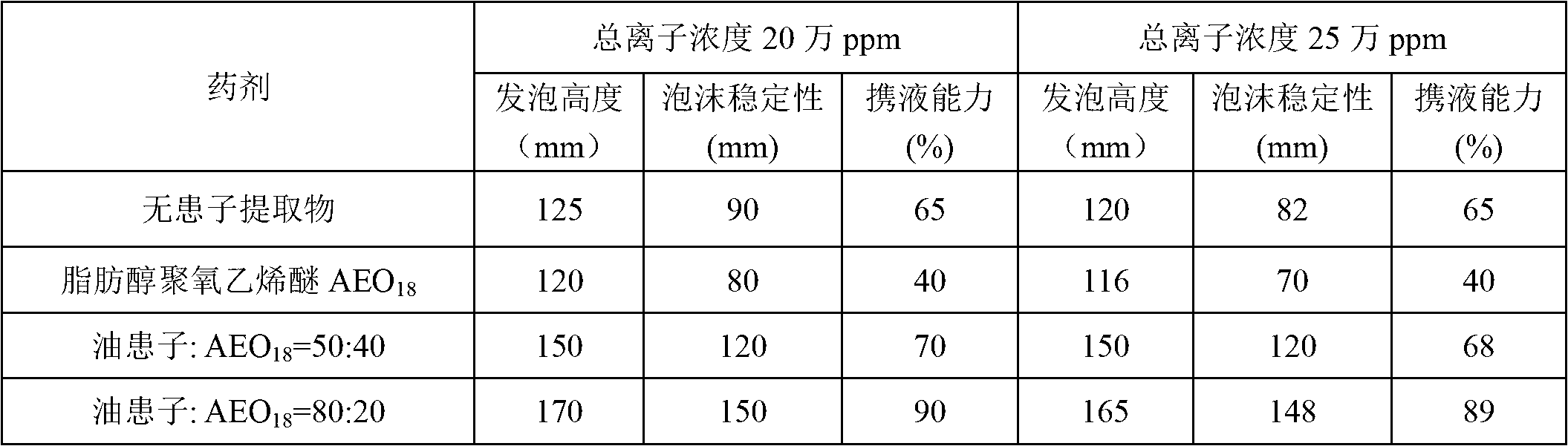

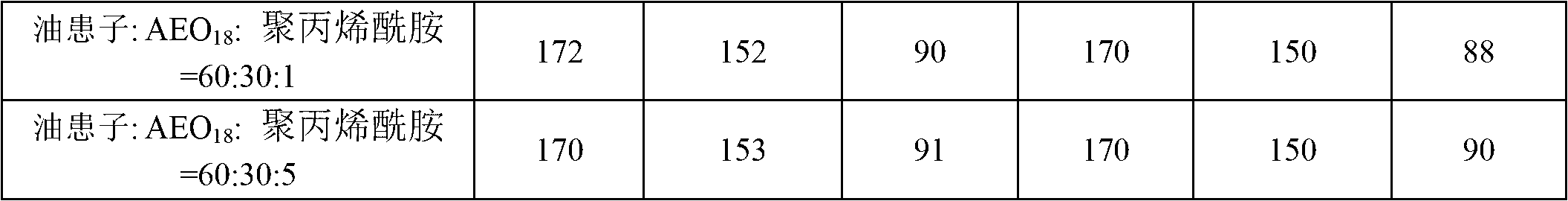

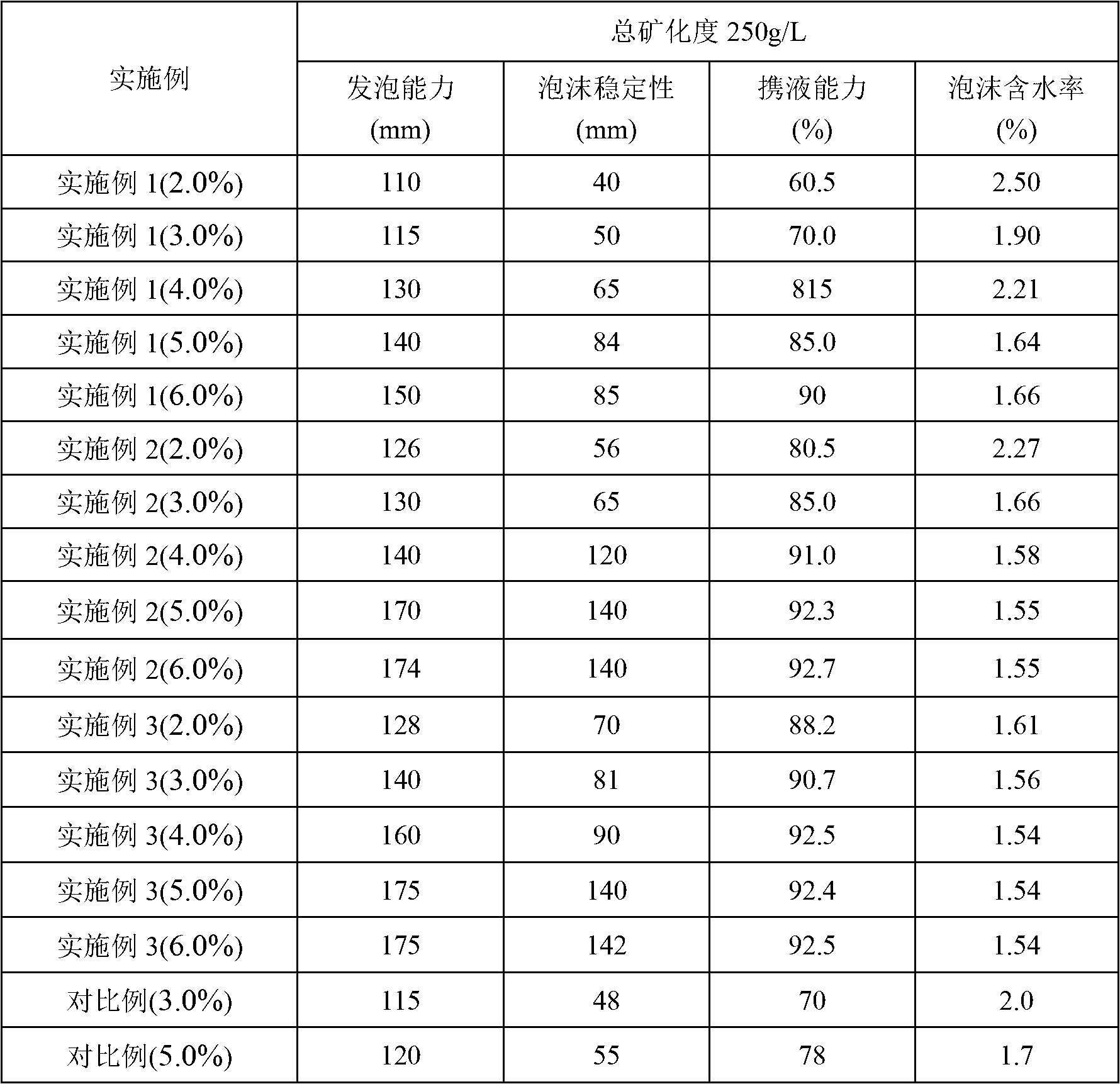

Foam water-drainage agent and its aqueous solution

ActiveCN103059826APromote degradationHigh resistance to mineralizationDrilling compositionChemical reactionTemperature resistance

The invention discloses a foam water-drainage agent and its aqueous solution, and belongs to the technical field of the oilfield chemical engineering. The foam water-drainage agent is composed of 50-80 parts by weight of a Sapindus mukurossi Gaertn extract, 20-40 parts of fatty alcohol polyoxyethylene ether AEO18, 1-5 parts by weight of polyacrylamide and 5-10 parts by weight of triethanolamine. The foam water-drainage agent has the characteristics of strong foaming capability after meeting water, good foam stability, and high liquid carrying capability and high mineralization resistance of foams, and is suitable for the use in natural gas wells containing gas condensate and having a high mineralization and a large water output; the foam water-drainage agent has a foam stability of 170mm, has a foam water content of not more than 2.0%, has a mineralization resistance of 250g / L, has a gas condensate resistance of 30%, has a temperature resistance of 90DEG C, is non-toxic, is easy to degrade, and does not pollute the environment; and the foam water-drainage agent has the advantages of compatibility with chemicals comprising methanol, a corrosion inhibitor, a scale inhibitor and the like, no chemical reaction with gas or liquid components, no increase to the toxicities of gases or combustion products, and no corrosion to equipment or pipelines.

Owner:CHINA PETROLEUM & CHEM CORP +1

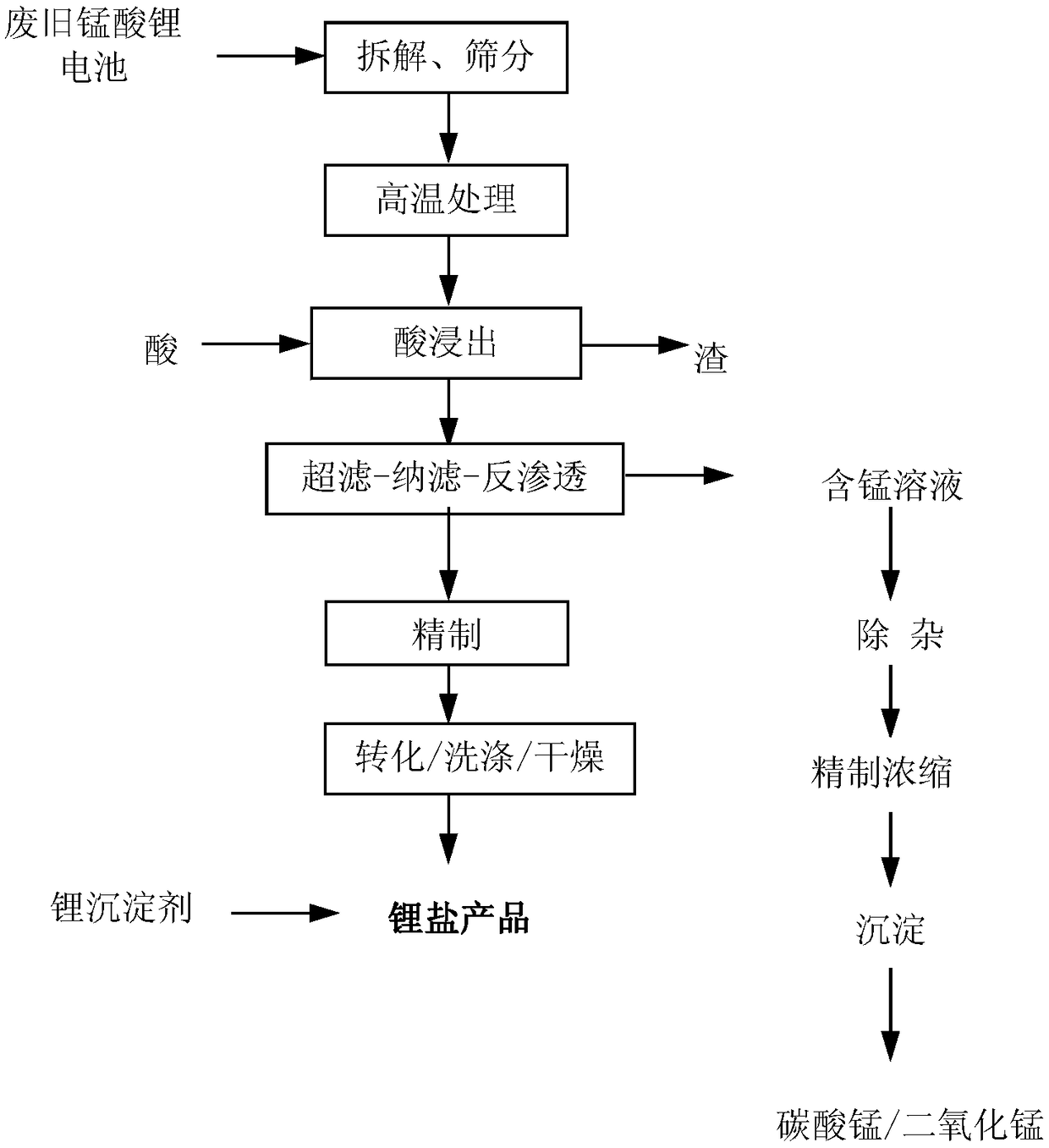

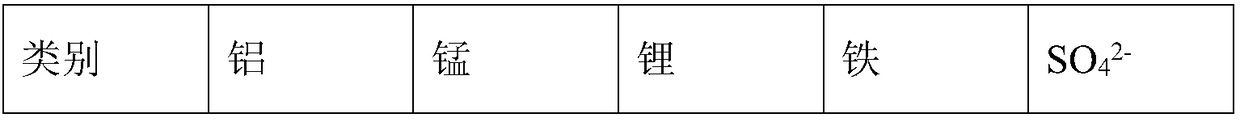

Method and system for recovering lithium and manganese from waste lithium manganate battery

ActiveCN109207725AAdvanced separation technologyEasy to separateWaste accumulators reclaimingBattery recyclingMembrane technologyManganese

The invention discloses a method and system for recovering lithium and manganese from a waste lithium manganate battery. The method comprises the following steps that a positive plate is disassembledfrom the waste lithium manganate battery; a binder in the positive plate is removed, valuable metal elements in the positive plate are leached by acid dissolution, and acidified leachate is obtained;ultrafiltration treatment is carried out on the acidified leachate by using an ultrafiltration membrane; by using a nanofiltration membrane technology, lithium ions in the acidified leachate are separated from other cations different from lithium ions, a solution containing lithium and a solution containing other cations are obtained, and then a reverse osmosis technology is adopted for concentration and enrichment correspondingly, wherein the other cations comprise manganese ions; and a lithium precipitant is adopted to precipitate and separate lithium ions in the lithium-containing solution,and alkaline substances are adopted to precipitate and separate manganese ions in the solution containing other cations, so that the recovery of lithium and manganese is realized. According to the method and system, the ultrafiltration-nanofiltration-reverse osmosis combined technology is adopted, and the method and system have the beneficial effects of simple process, environmental protection, less acid and alkali consumption, good and stable membrane separation effect and the like.

Owner:青海中科德方能源科技研究有限公司

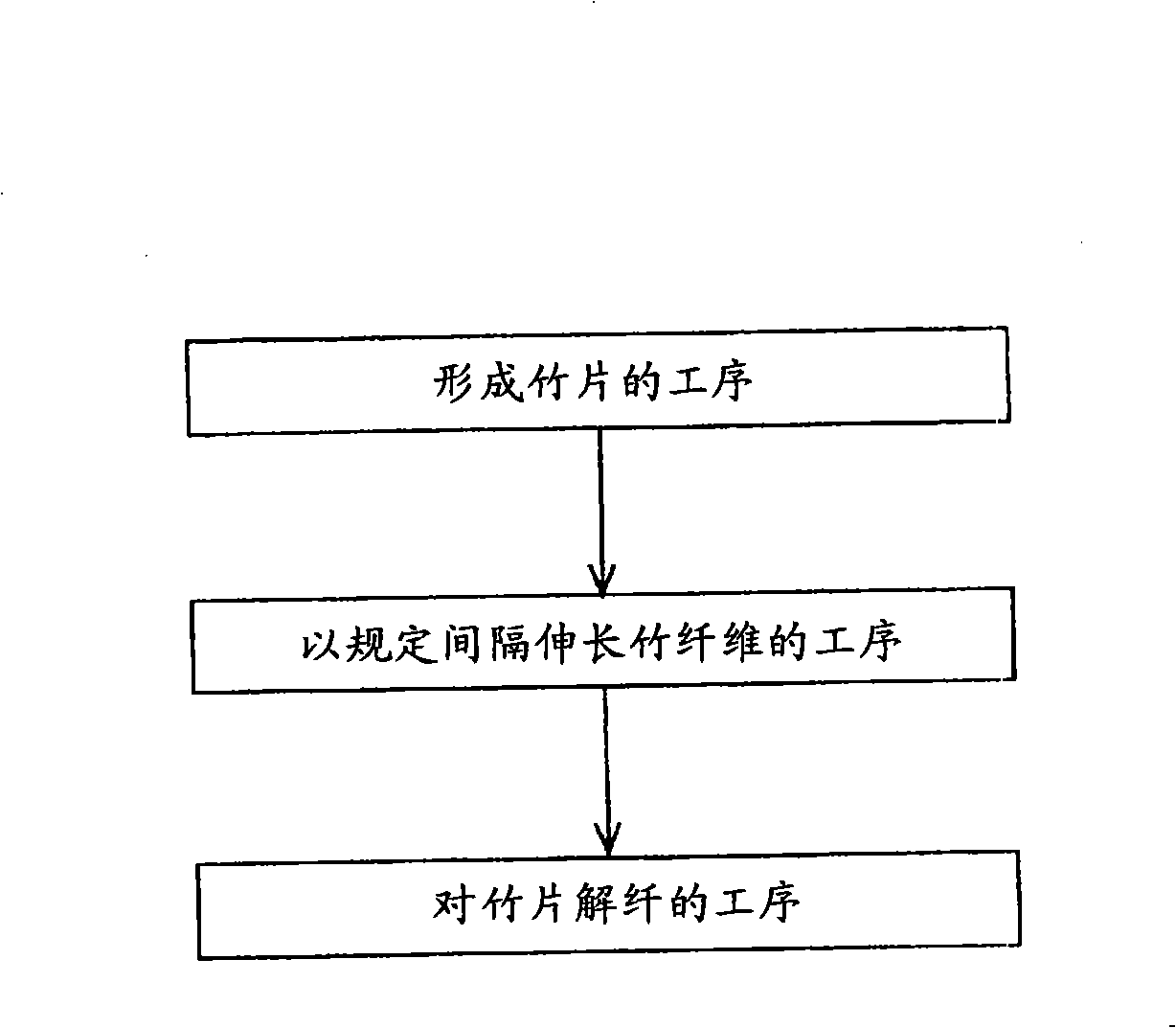

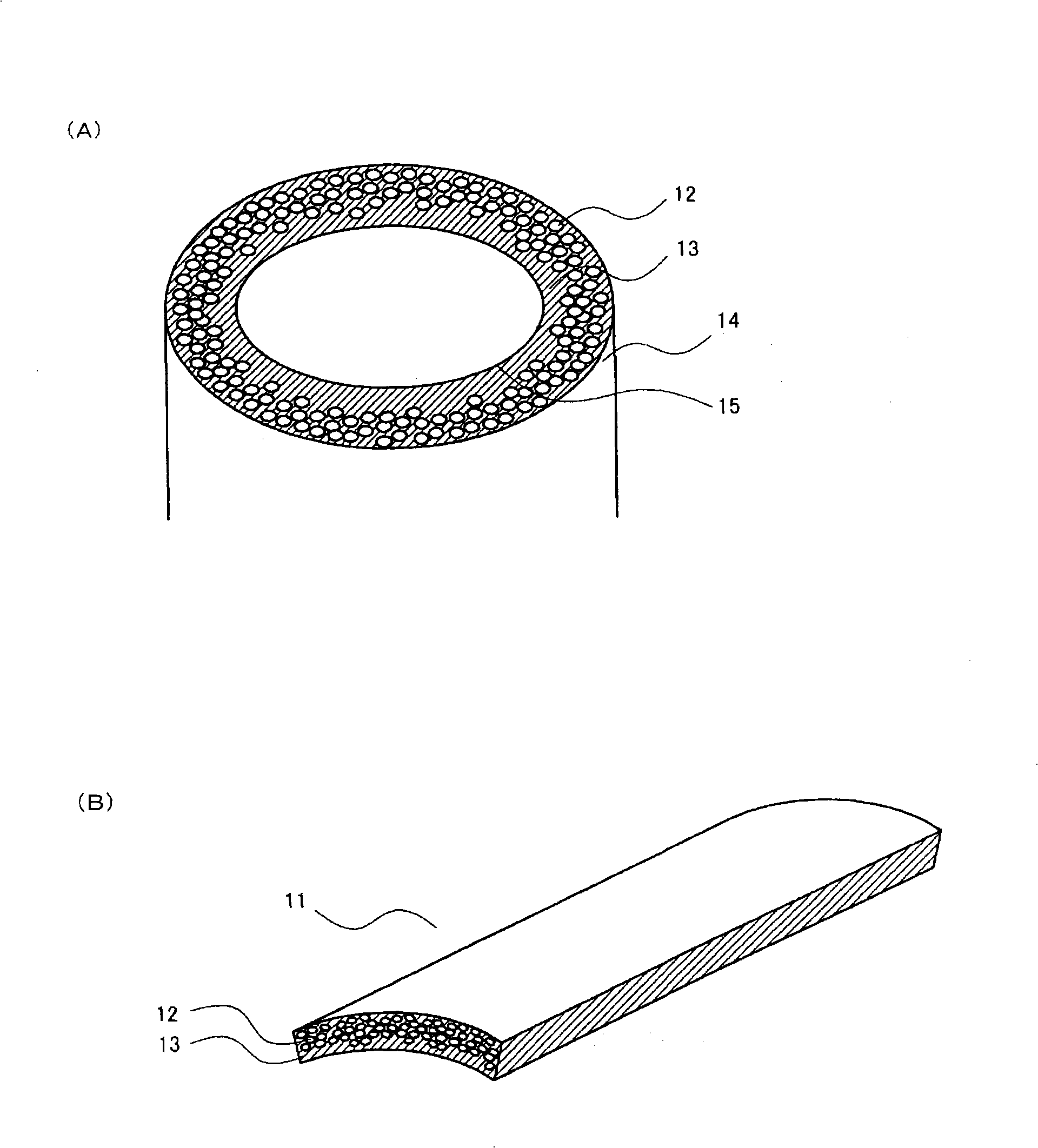

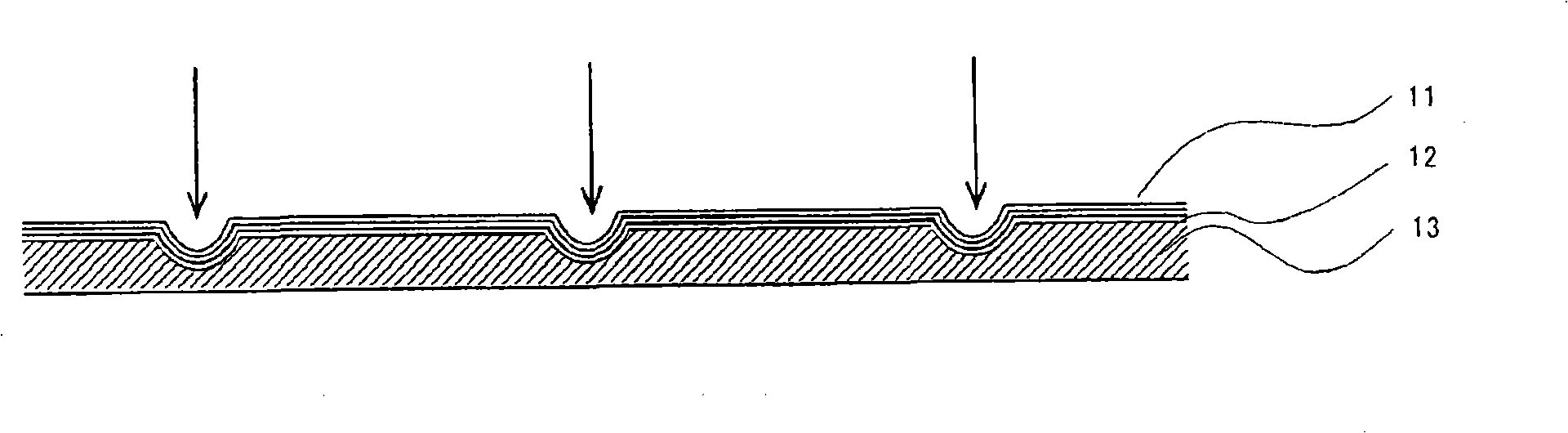

Method and apparatus for manufacturing bamboo fiber

InactiveCN101323119AAchieve mass productionNo chemical reactionCane mechanical workingWood working apparatusBamboo shootEngineering

The aim of the invention is to provide a method for producing bamboo fibre with a certain length in bulk at atmospheric temperature and normal pressure, and a device for producing the same. The method includes forming bamboo strip which integrates fibre and bamboo shoot as a whole, pressing the bamboo strip at intervals of determined length, and carrying out fibrillating after extending the inner bamboo fibre at the press position. Since the intension of the extending part of the bamboo fibre is weakened and can be naturally cut, the bamboo fibre with the same length and determined length intervals can be produced in bulk. In addition, the fibrillating can be easily performed due to weakening combination of the bamboo fibre and bamboo shoot in the bamboo strip by means of vibration, accordingly, the bamboo fibre with a burr shape can be obtained.

Owner:吉田义臣

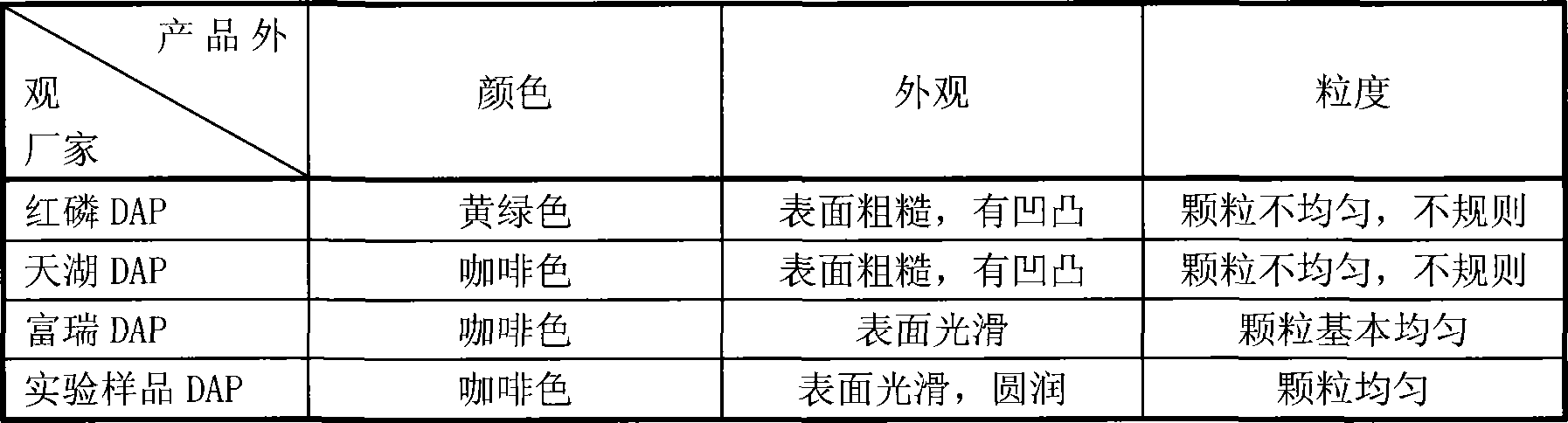

Method for dyeing phosphorus complex fertilizer

InactiveCN101234926AComponents that do not changeUniform colorFertiliser formsFertilizer mixturesDiammonium phosphatePhosphoric acid

The invention relates to a method for processing chemical fertilizer, in particular to a method for dyeing chemical fertilizer. The invention includes the preparation, addition, dyeing, and granulation of colorant, and comprises the following steps: A. adding weighted colorant into a phosphoric acid tank, an acid pump outlet or a pre-neutralization slot for producing phosphate compound fertilizer; B. mixing water solution with phosphate compound fertilizer for dyeing; C. spraying the slurry for granulation after dyeing. The method for dyeing chemical fertilizer is mainly used for appearance dyeing of various nitrogen and phosphate fertilizers and products, and can dye coffee on products evenly and effectively. The dyed products with high-quality appearance color do not have discoloration and color change so as to hit the target of unifying product color. Compared with that imported from America, diammonium phosphate dyed through the method for dyeing chemical fertilizer has the equal and even better color. As coffee color products sell well in the market, the invention can reduce sales cost.

Owner:云南云天化国际化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com