Method and system for testing oil-gas-water profile of each section of horizontal well by using environmental protection type tracers

A tracer and horizontal well technology, applied in the direction of earthwork drilling, wellbore/well components, production fluid, etc., can solve the problems of long time period span, hidden danger of formation pollution, large usage, etc., and achieve small evaluation error, No formation pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

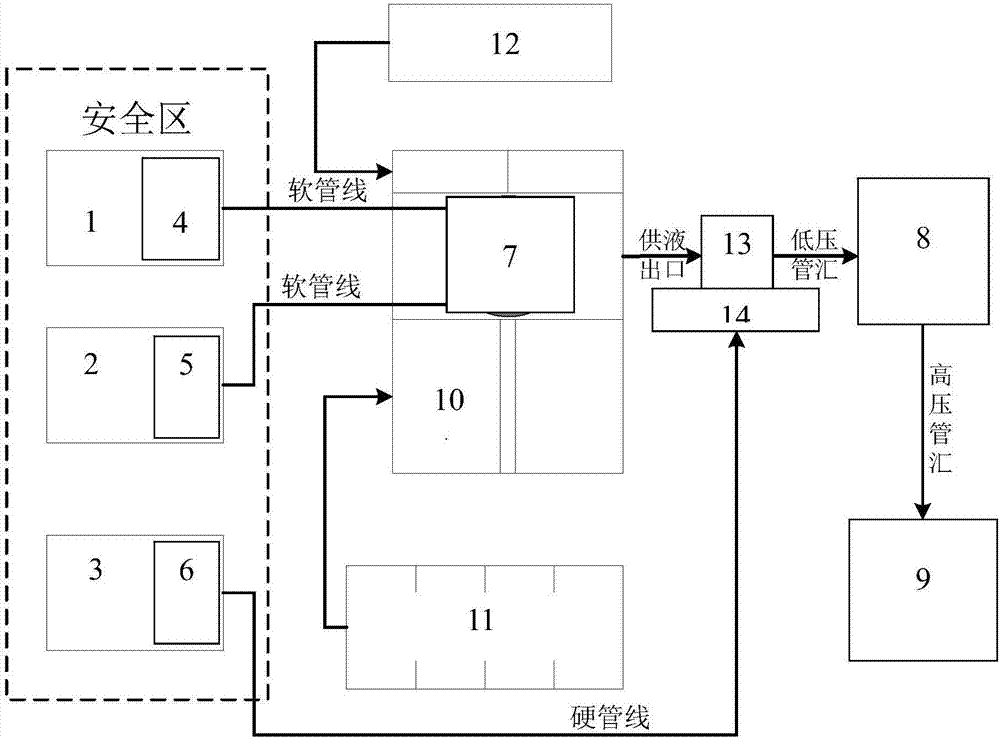

[0106] This embodiment provides a system for testing the oil, gas and water profiles of each section of a horizontal well using an environmentally friendly tracer. Its structural diagram is as follows figure 2 shown, from figure 2 It can be seen that it includes: oil agent and / or air agent injection equipment, water agent injection equipment;

[0107] Wherein, the oil agent injection equipment includes an oil agent storage tank 1, an oil agent metering pump 4 and a hose line, and the oil agent storage tank 1 passes through the hose line through the oil agent metering pump 4 and the sand mixing vehicle 10 stirring tank 7 tanks Connected to the port, after fixing it, test whether the equipment is running normally;

[0108] The water agent injection equipment includes the water agent storage tank 2, the water agent metering pump 5 and the hose line, and the water agent storage tank 2 is connected to the mixing tank 7 tank port of the sand mixer 10 through the water agent meter...

Embodiment 2

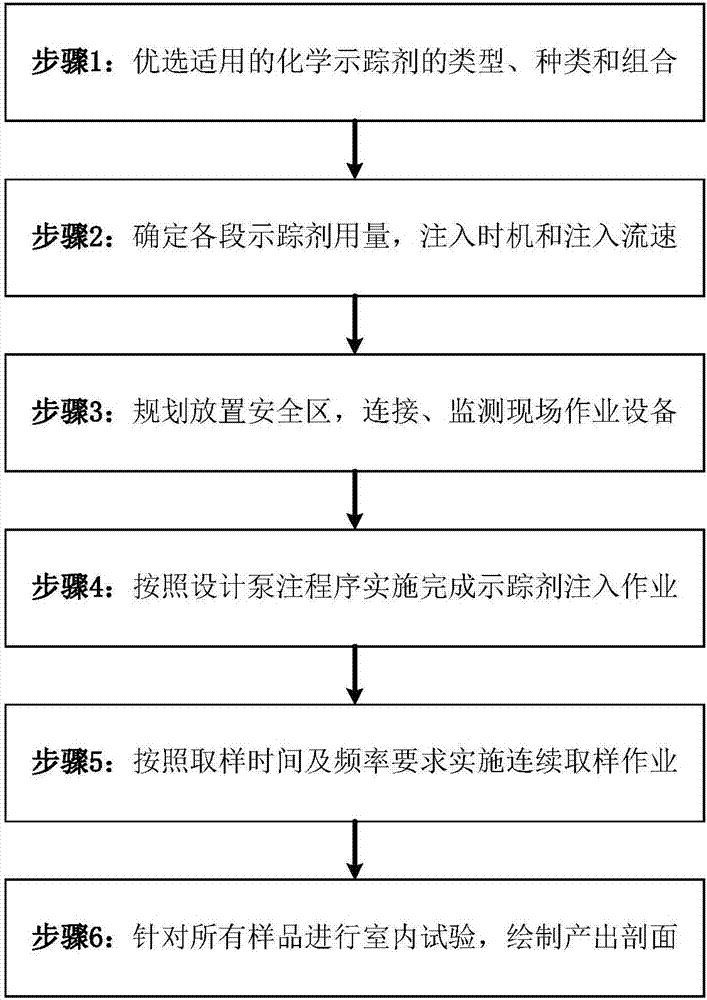

[0114] This embodiment provides a method for testing the oil, gas and water profiles of each section of a horizontal well using an environmentally friendly tracer. The process flow chart is as follows figure 1 shown, from figure 1 It can be seen that the method includes the following steps:

[0115] 1. Implementation steps:

[0116] Step (1), according to conditions such as the type of oil and gas reservoir to which the target well belongs, reservoir temperature and pressure, design the type of fracturing fluid used and the number of design test sections, etc., preferably the combination of fracturing fluid and reservoir mentioned in the present invention Chemical tracers with good compatibility and stable performance, determine the type and combination of chemical tracers.

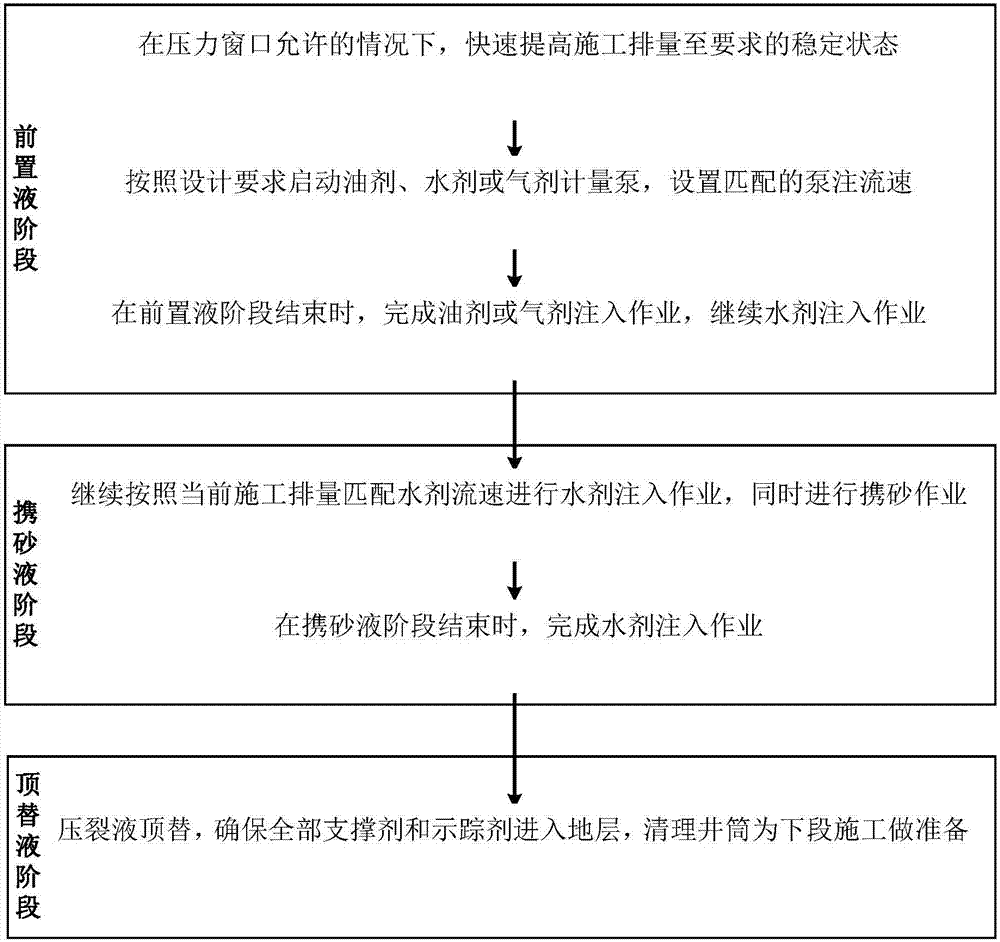

[0117] Taking a horizontal well as an example, it is used to develop unconventional shale gas reservoirs. The fracturing system used in the design fracturing operation is slick water and glue hydrauli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com