Patents

Literature

728 results about "Injection equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

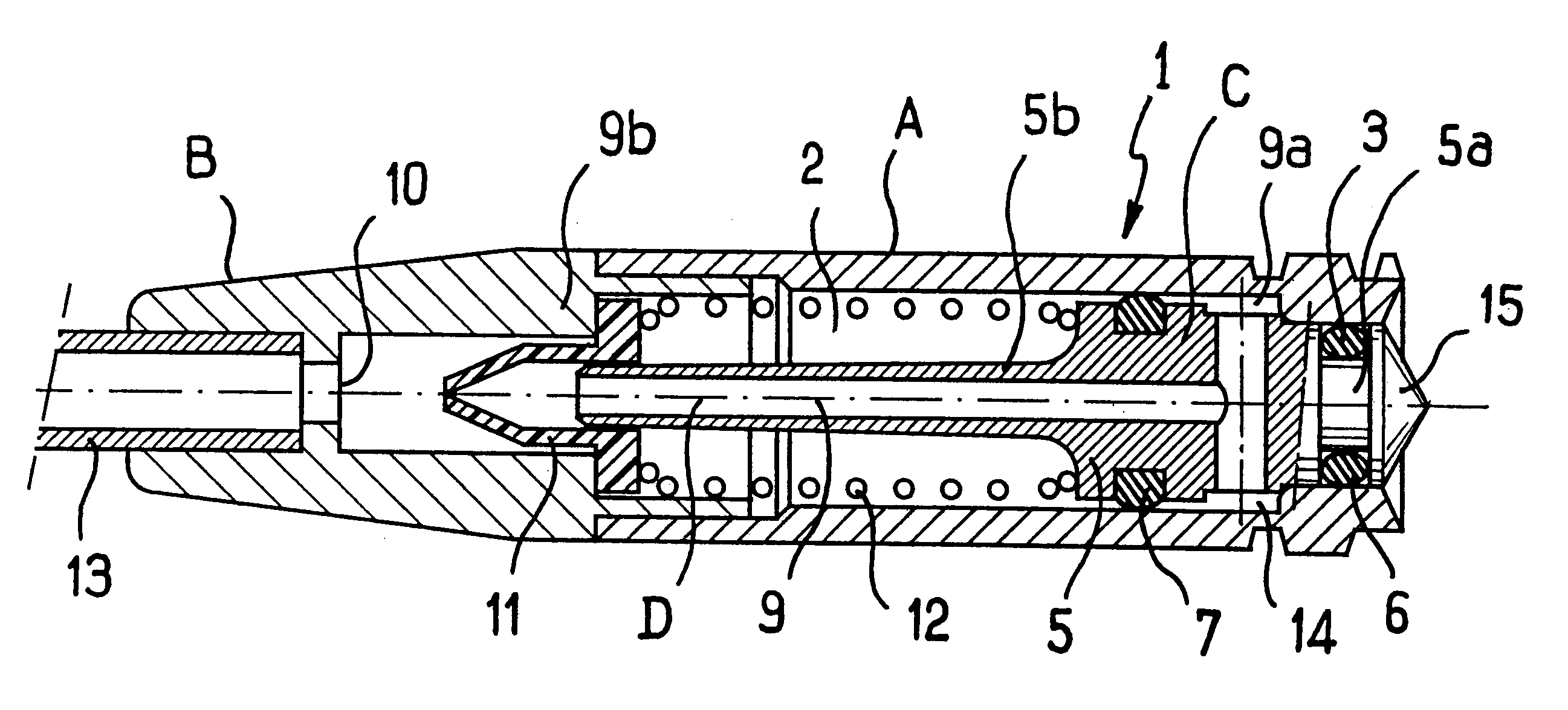

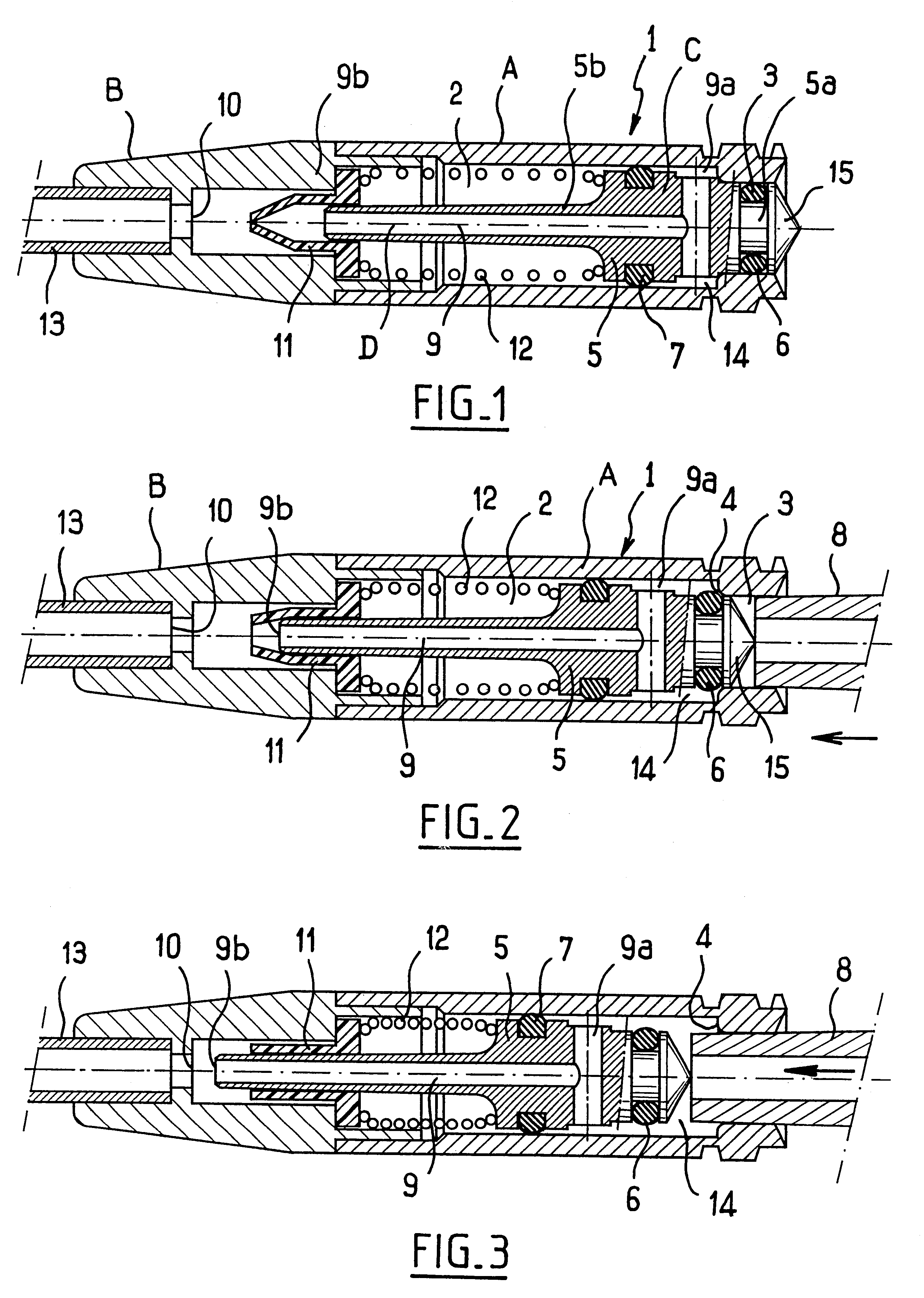

Automatically-closing connector for connecting a liquid injection head to an injection outlet

The invention relates to an automatically-closing connector. The connector has a closing piston which is rigid and non-deformable; a compression chamber is constituted around the closing piston and is defined upstream by the end wall of the housing and downstream by a peripheral sealing gasket carried by the piston; the outlet of the connector is situated downstream from this gasket and the closing piston has an internal passage with an inlet that opens out into the compression chamber and an outlet that communicates with the outlet of the connector. The connector is applicable to injection devices in the medical field.

Owner:VIGON

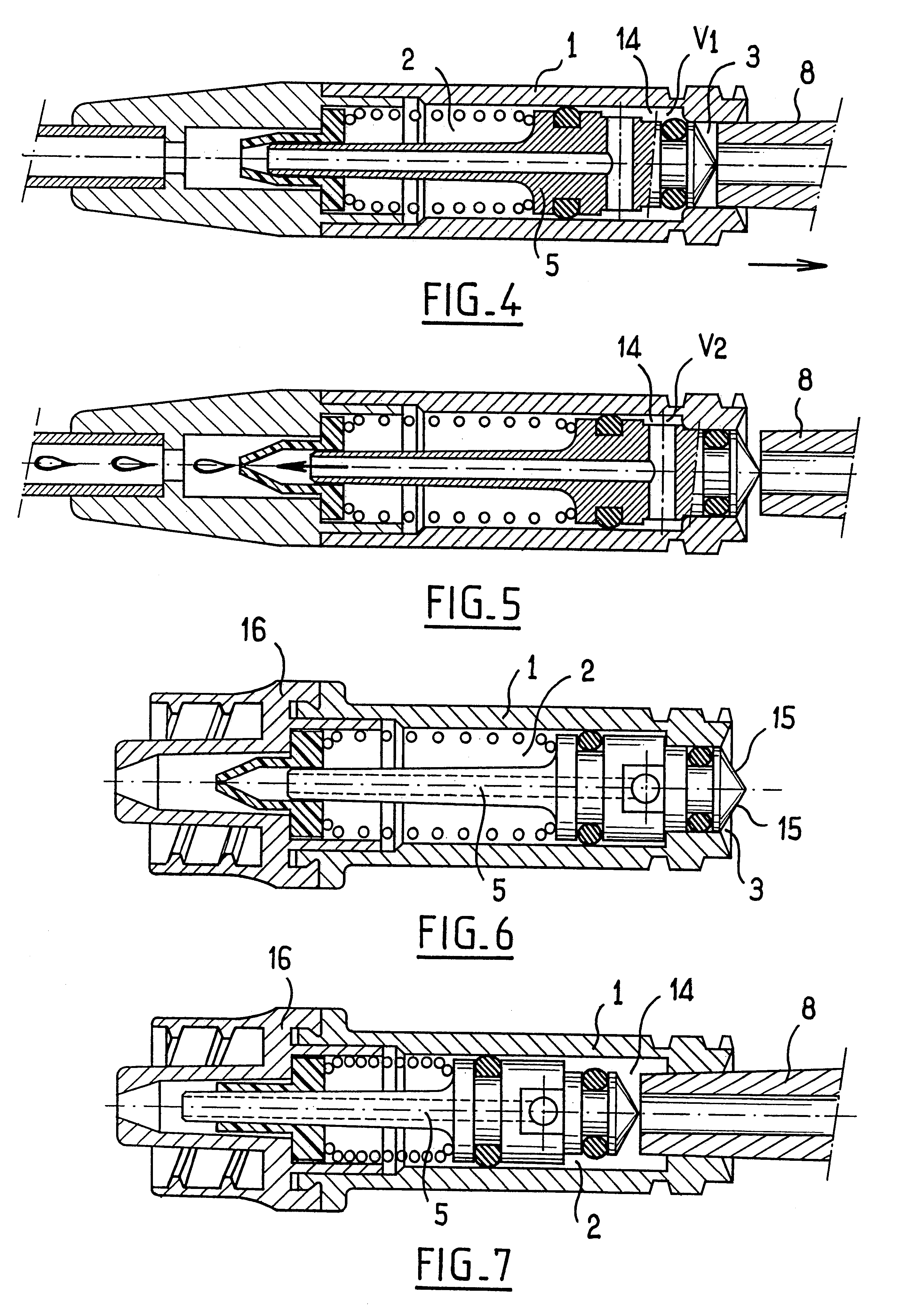

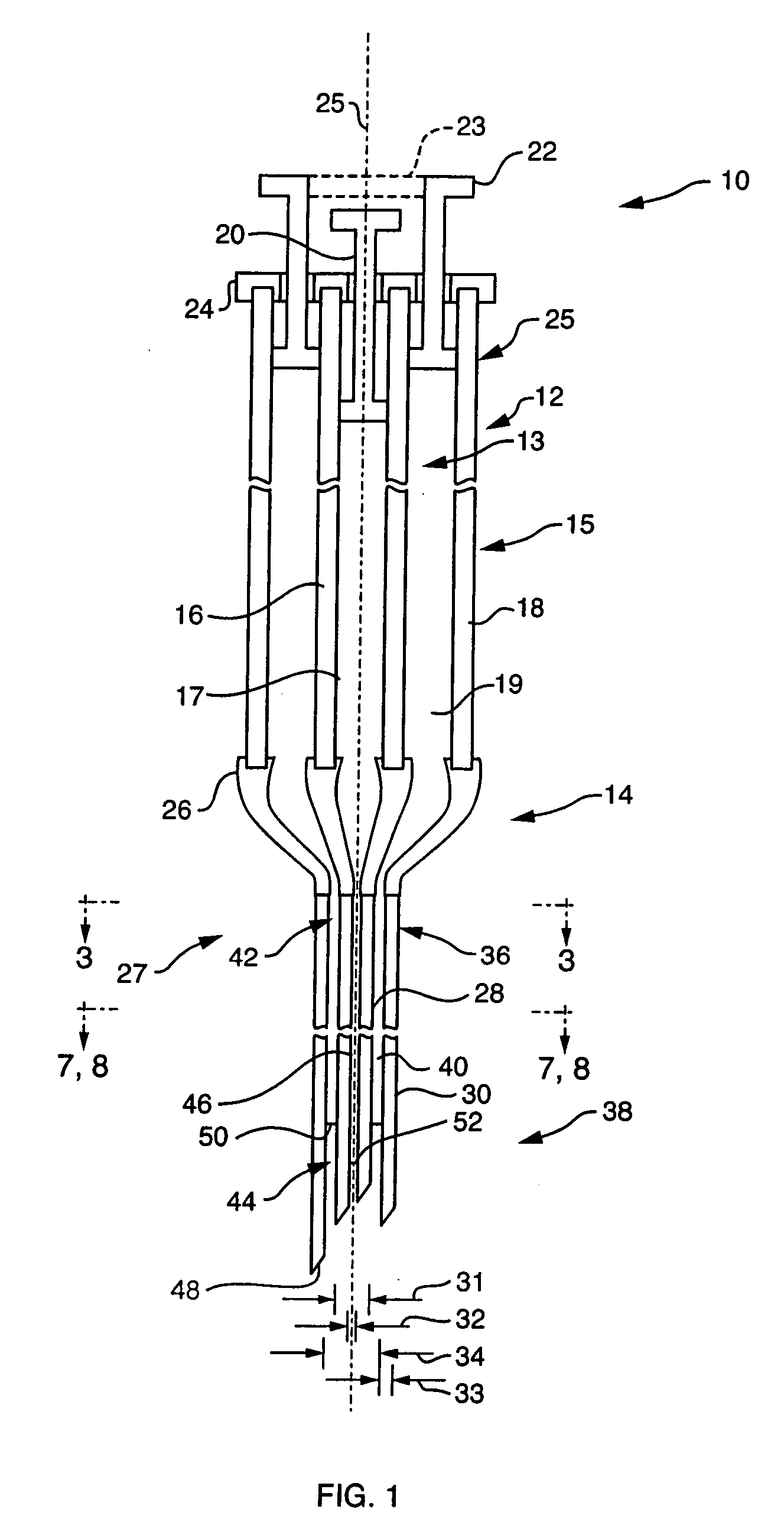

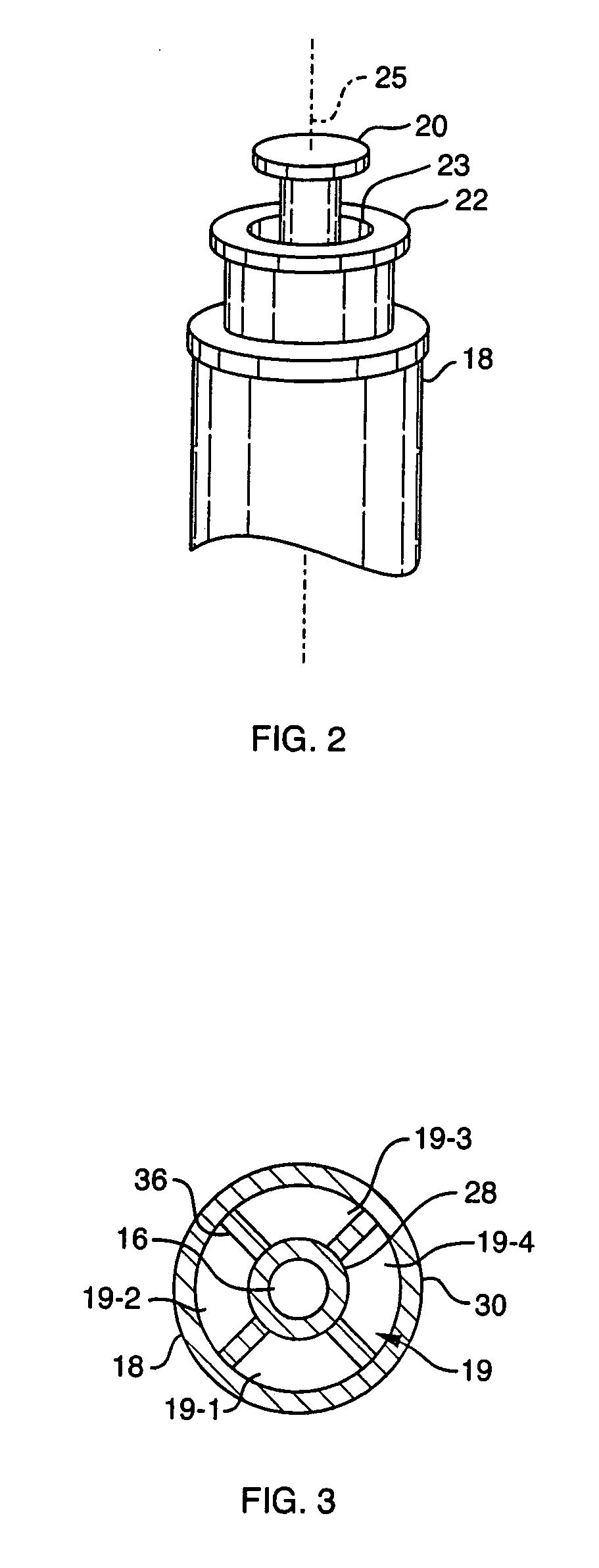

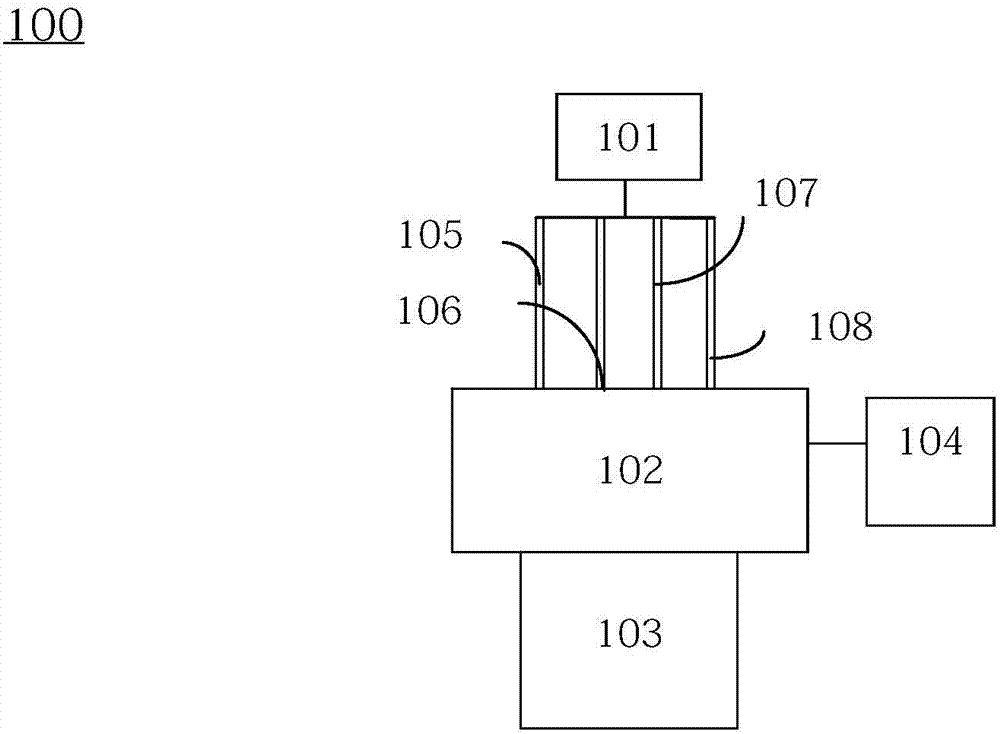

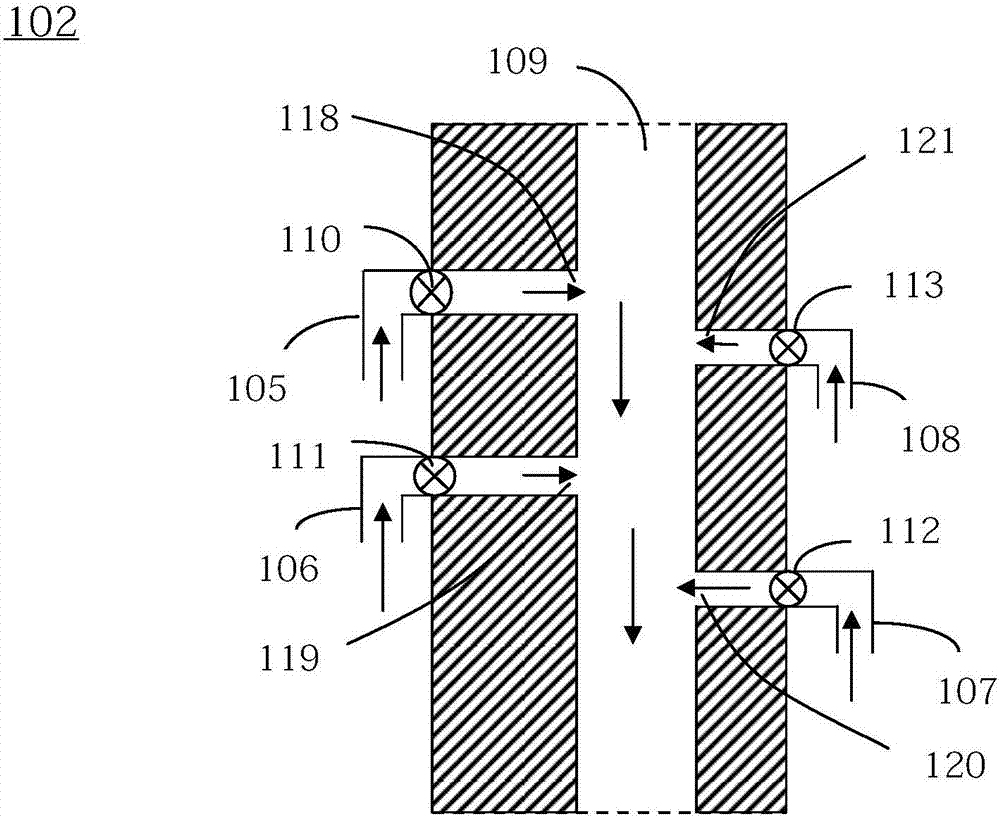

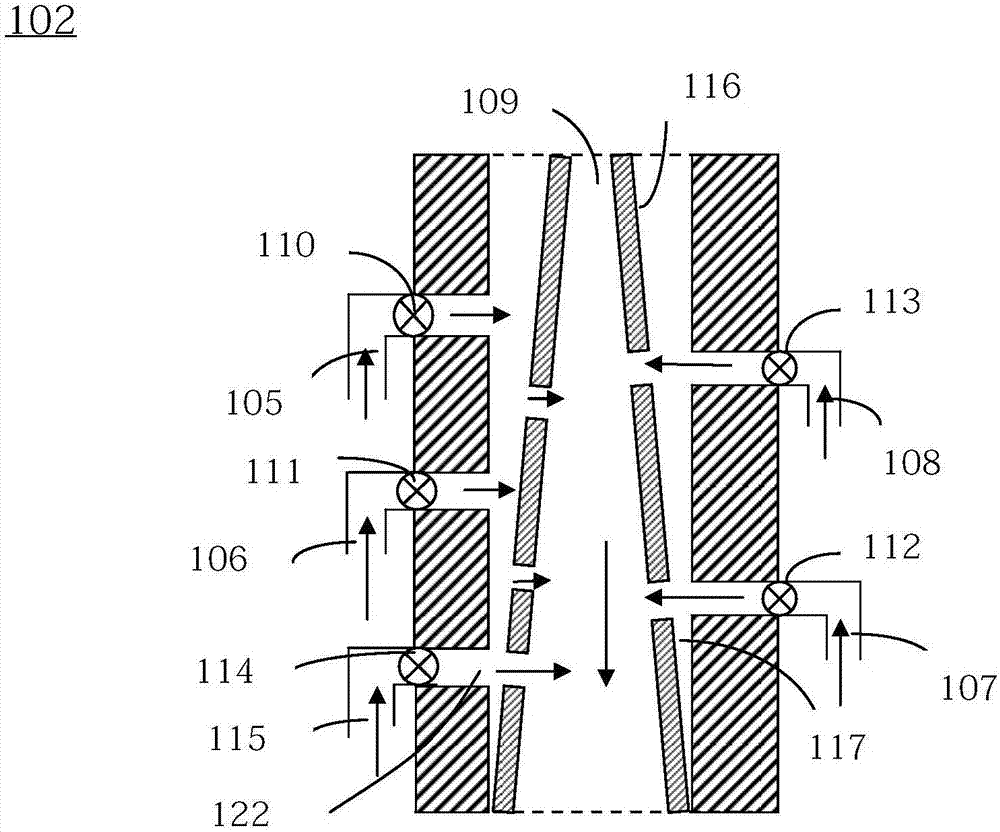

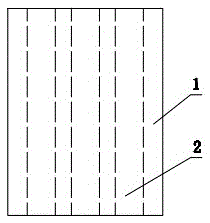

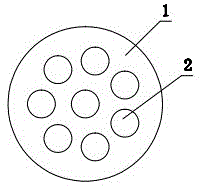

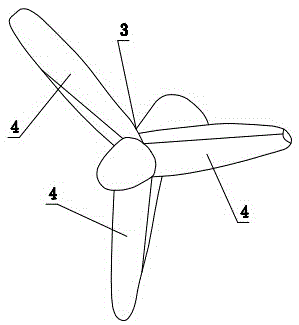

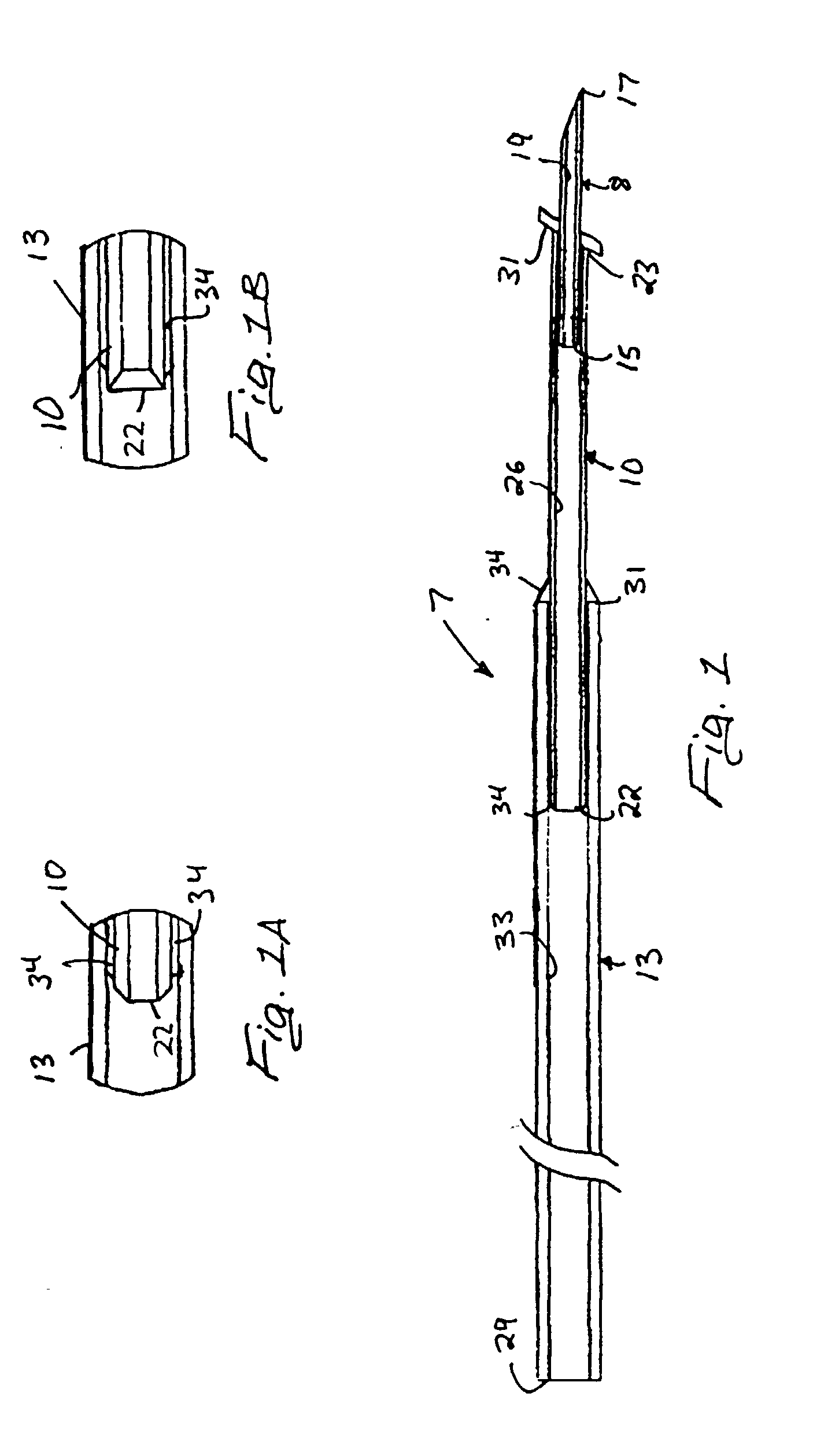

Low-loss multi-lumen injection apparatus

InactiveUS20070073267A1Reduce residual lossInfusion syringesMedical devicesDrug reservoirInjection site

Injection devices, systems and methods are disclosed for injecting two or more medicaments to a patient at a single injection site while preferably minimizing any mixing of the medicaments prior to delivery to the patient. The invention can also be used to sequentially deliver the medicaments to the patient in a repetitive manner. For example, the injection apparatus can sequentially provide a first medicament and then a second medicament to the patient during a first injection procedure. During a second injection procedure, the injection apparatus can again sequentially provide the first medicament and the second medicament to the patient either at the injection site of the first injection procedure or at a different injection site. Multi-lumen manifolds are disclosed for coupling to conventional drug ampoules, to permit the user to sequentially delivery different medicaments via a single skin penetration and to reduce losses associated with usage. Systems including multiple drug reservoirs and filling adaptors are also disclosed.

Owner:MILE CREEK CAPITAL

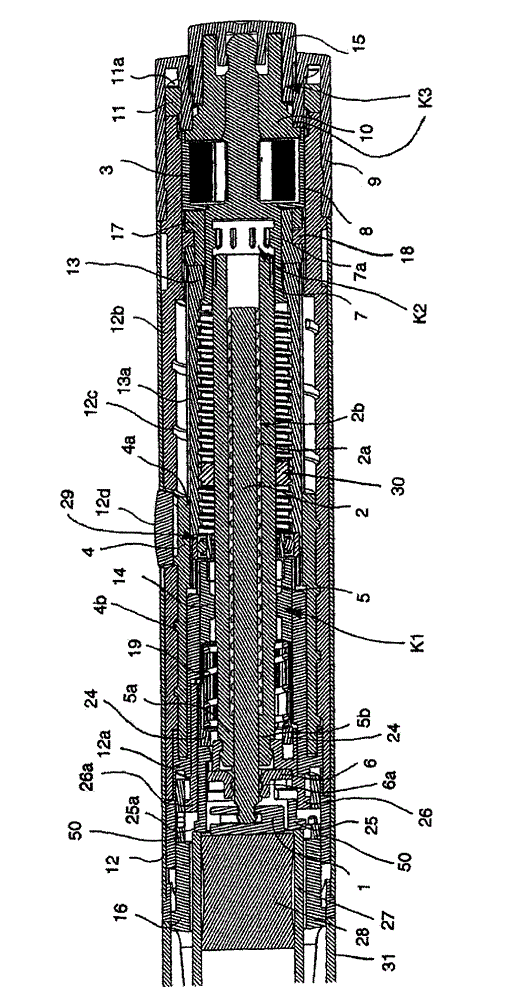

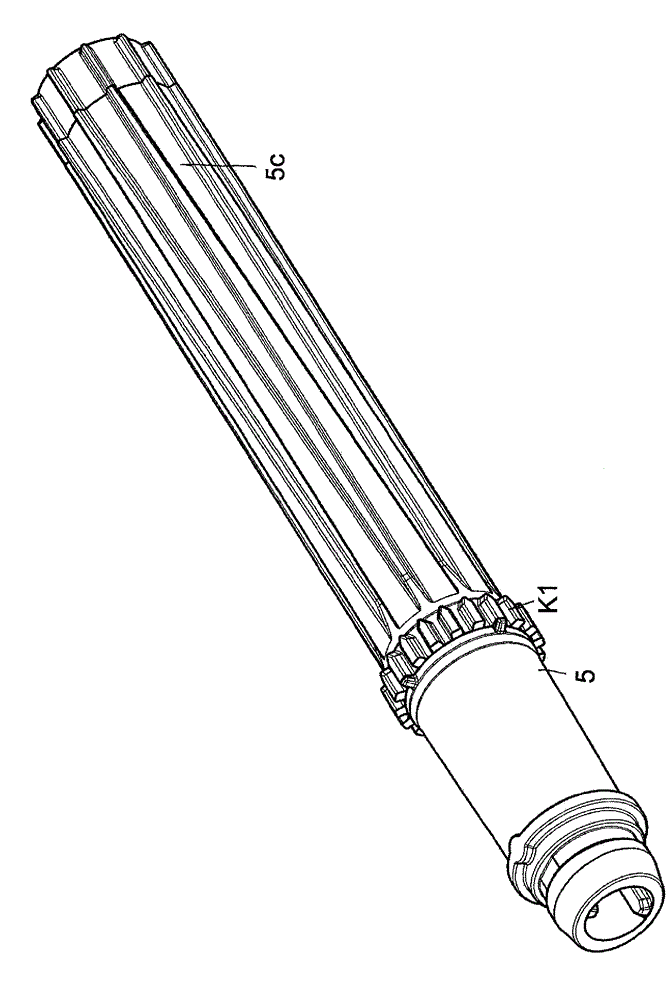

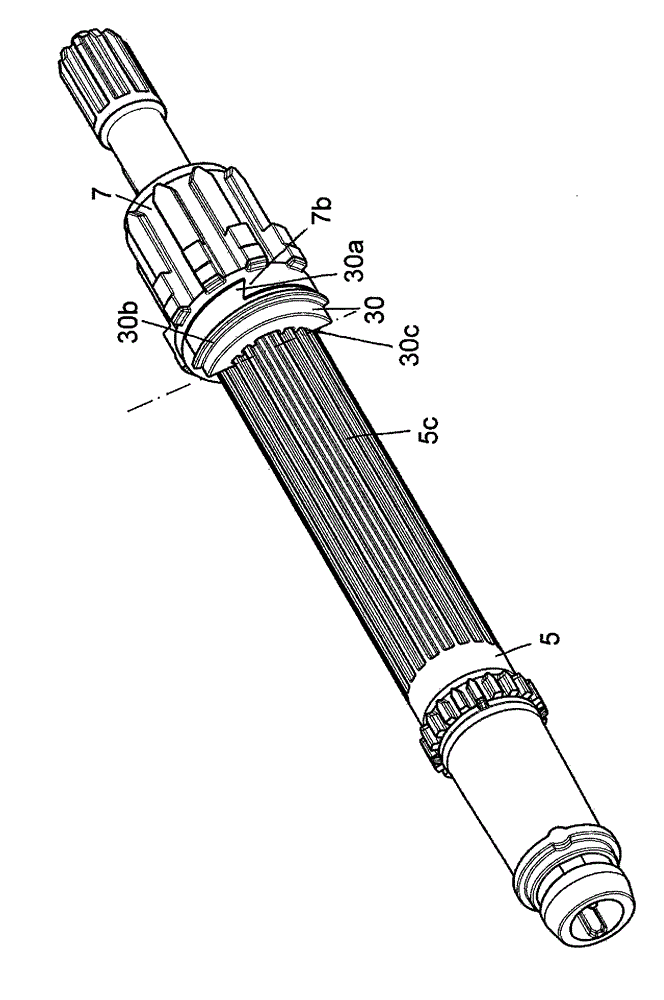

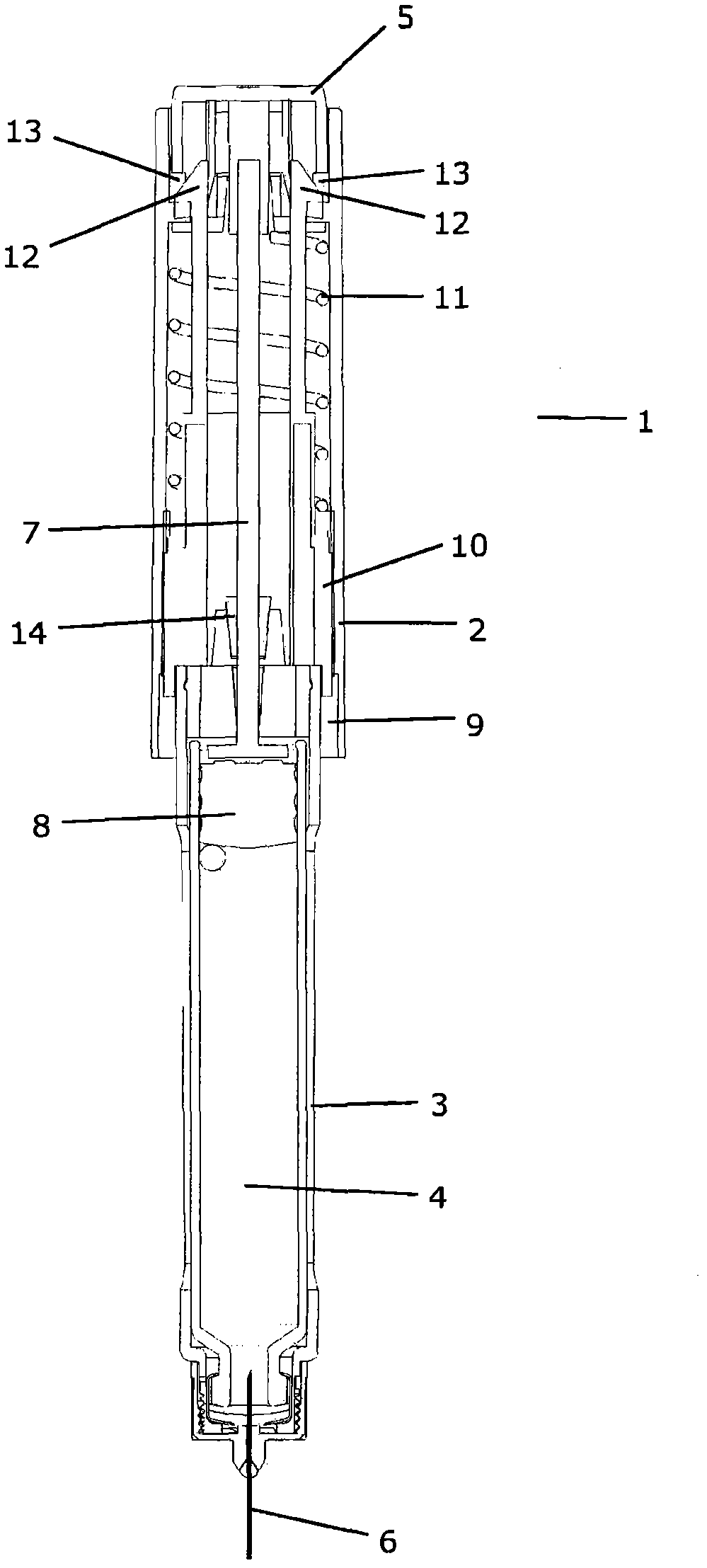

Injection device having a dosing mechanism for limiting a dose setting

The invention relates to an injection device comprising: a) a dose setting element (9; 10; 7; 4) and a first element (13) coupled thereto, which first element can be rotated relative to another second element (2; 5; 100) during a dose setting and is rotationally fixed relative to the second element (2; 5; 100) during a dose discharge, wherein the first element (13) and the second element (2; 5; 100) are coupled by means of a coupling element (30), and b) a stop (7b; 100a), wherein the coupling element (30) moves to a stop position during a dose setting, wherein the coupling element (30) in the stop position prevents the setting of a dose.

Owner:YPSOMED AG

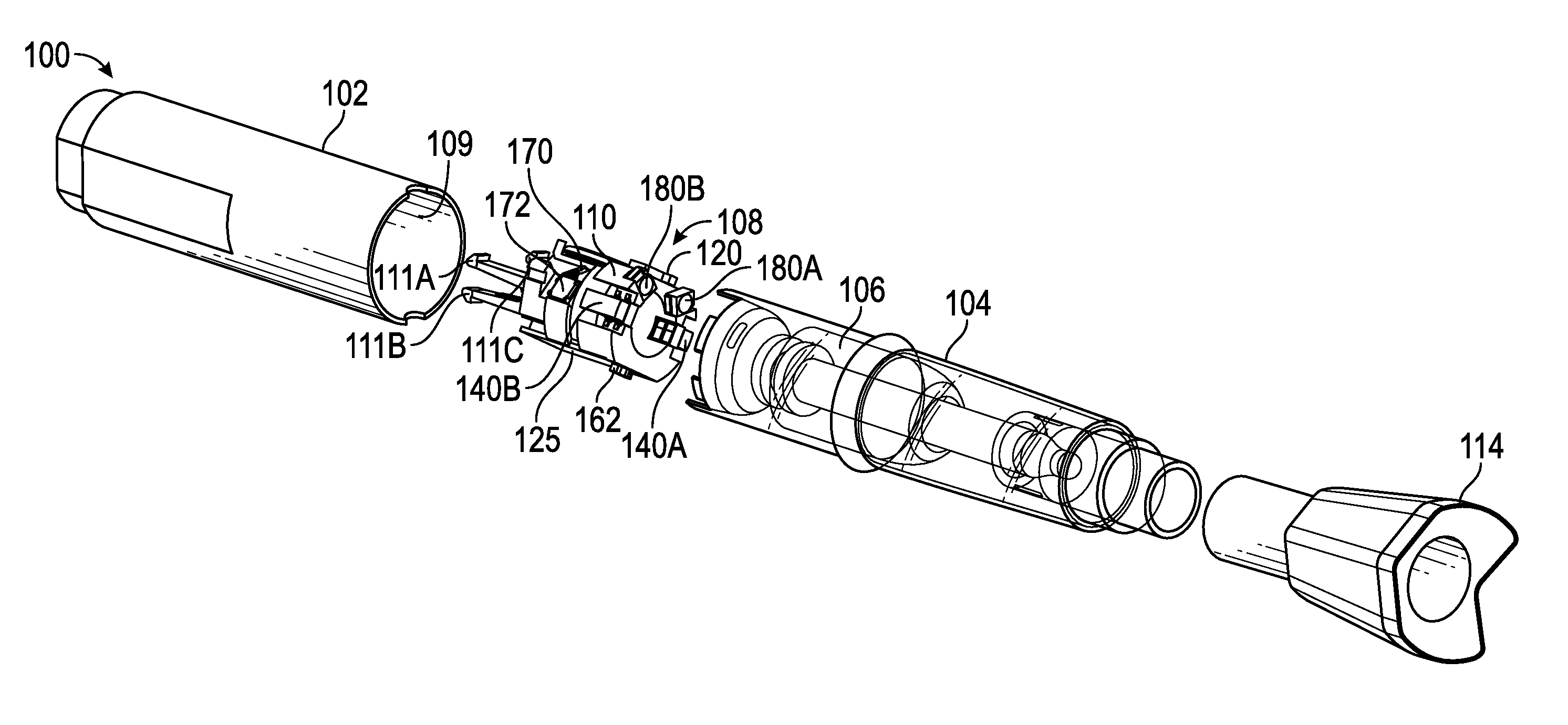

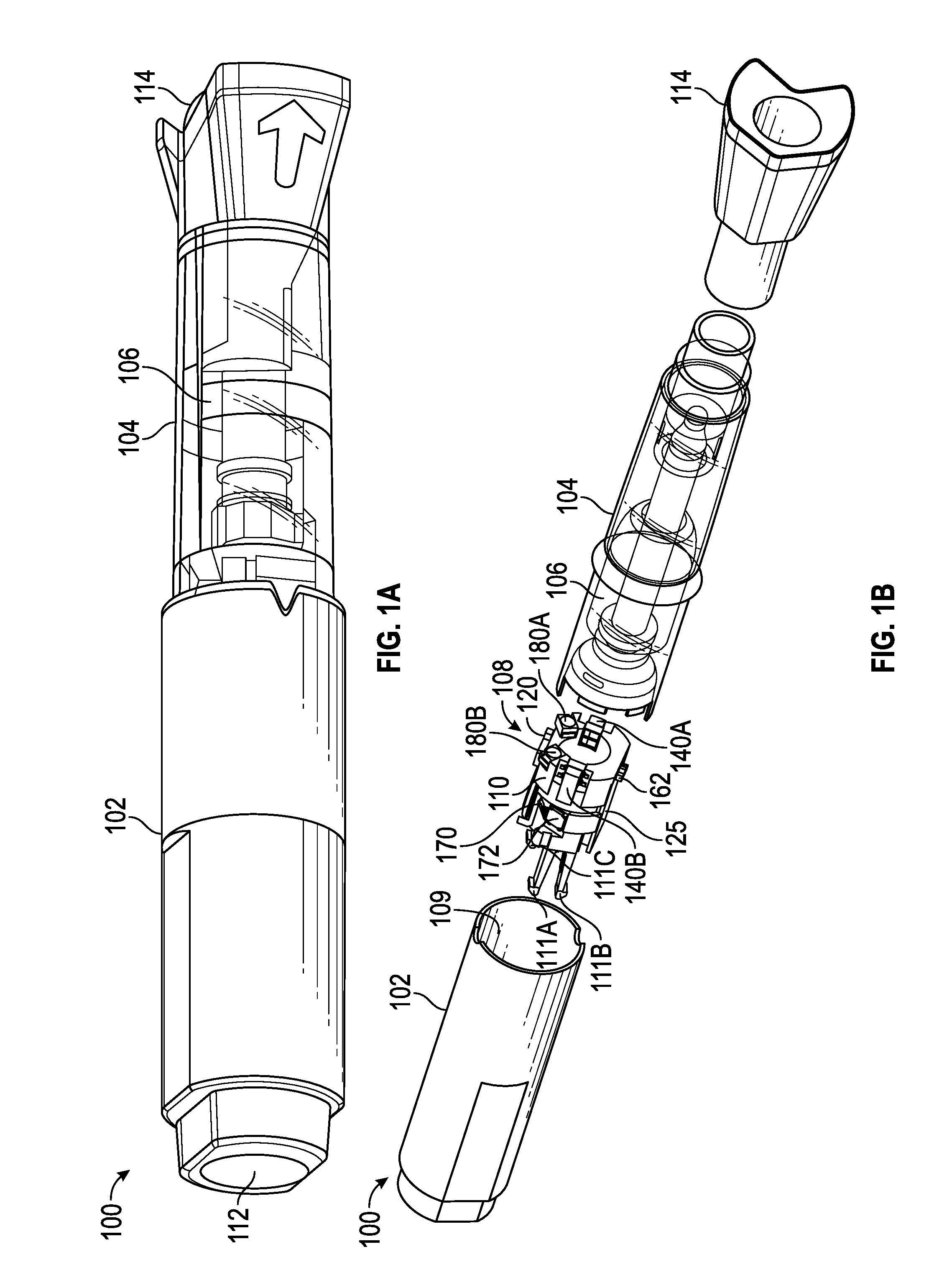

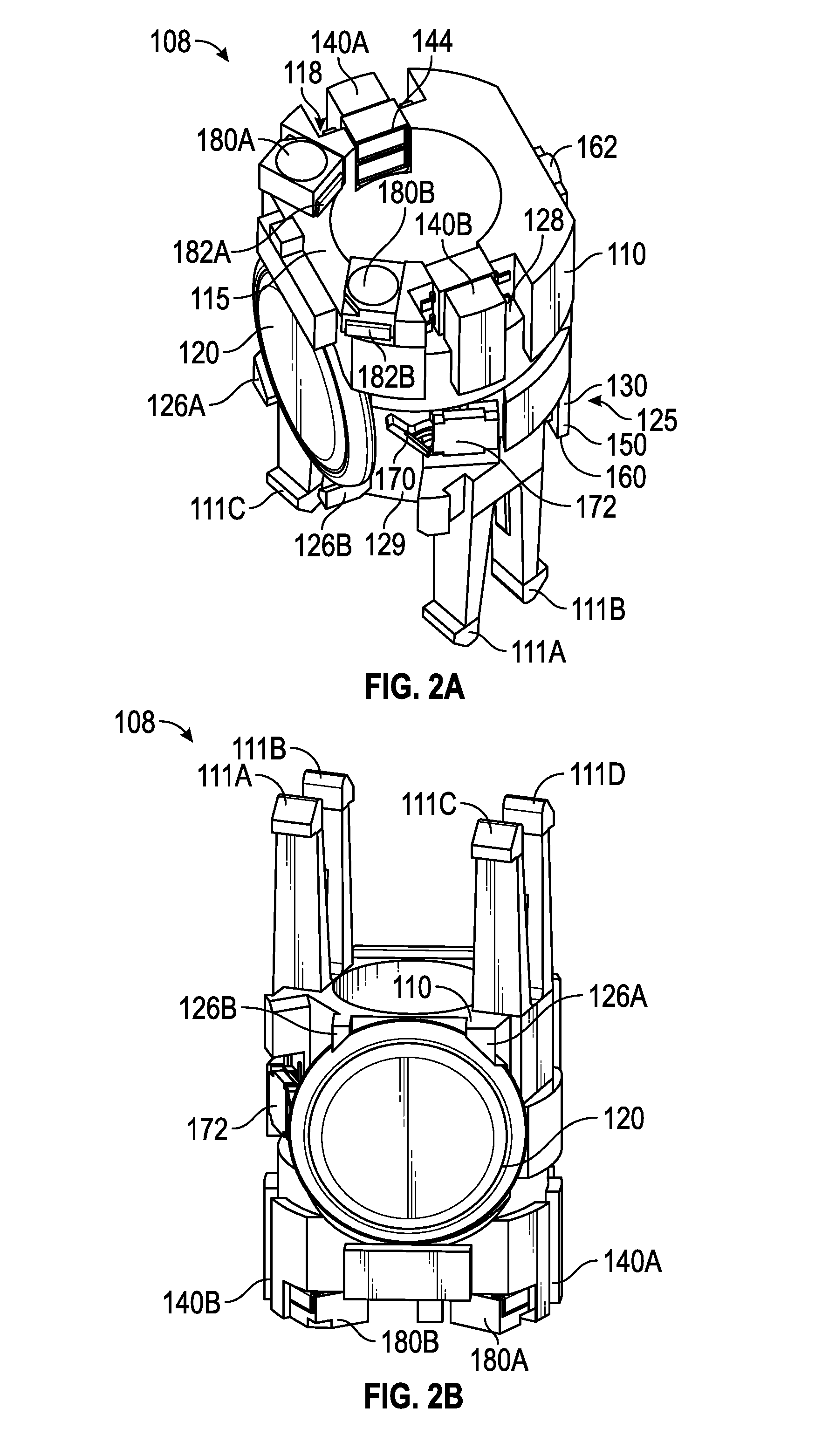

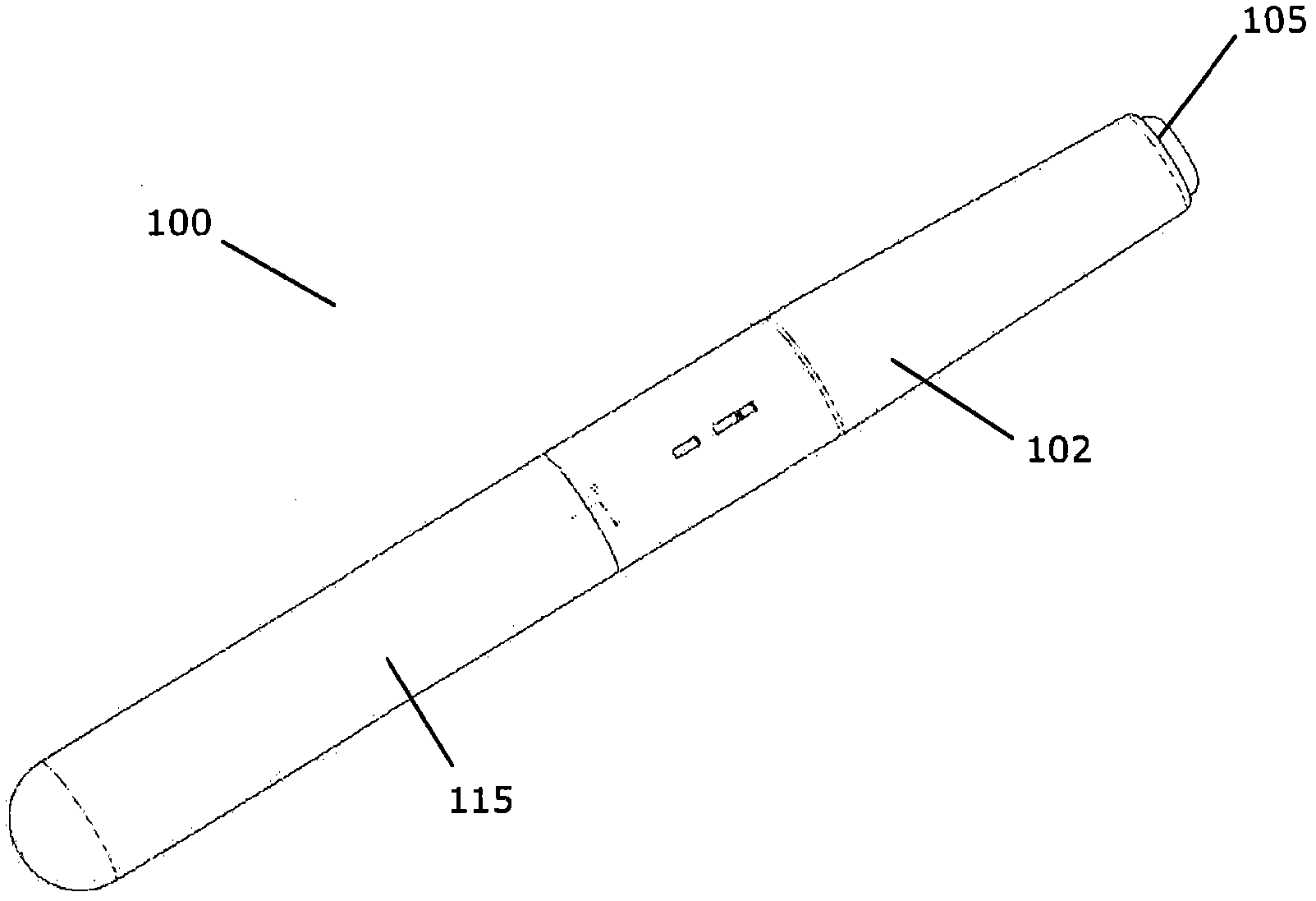

Smart module for autoinjection devices

Described herein is a smart module configured to work with injection devices. The smart module may include electronics such as sensors and indicators, and be programmed to detect environmental parameters. If the sensors detect that a parameter is outside of a predetermined boundary or range, then the indicators may be activated to notify the user that the injection device may not be safe for administering medicine.

Owner:BECTON DICKINSON & CO

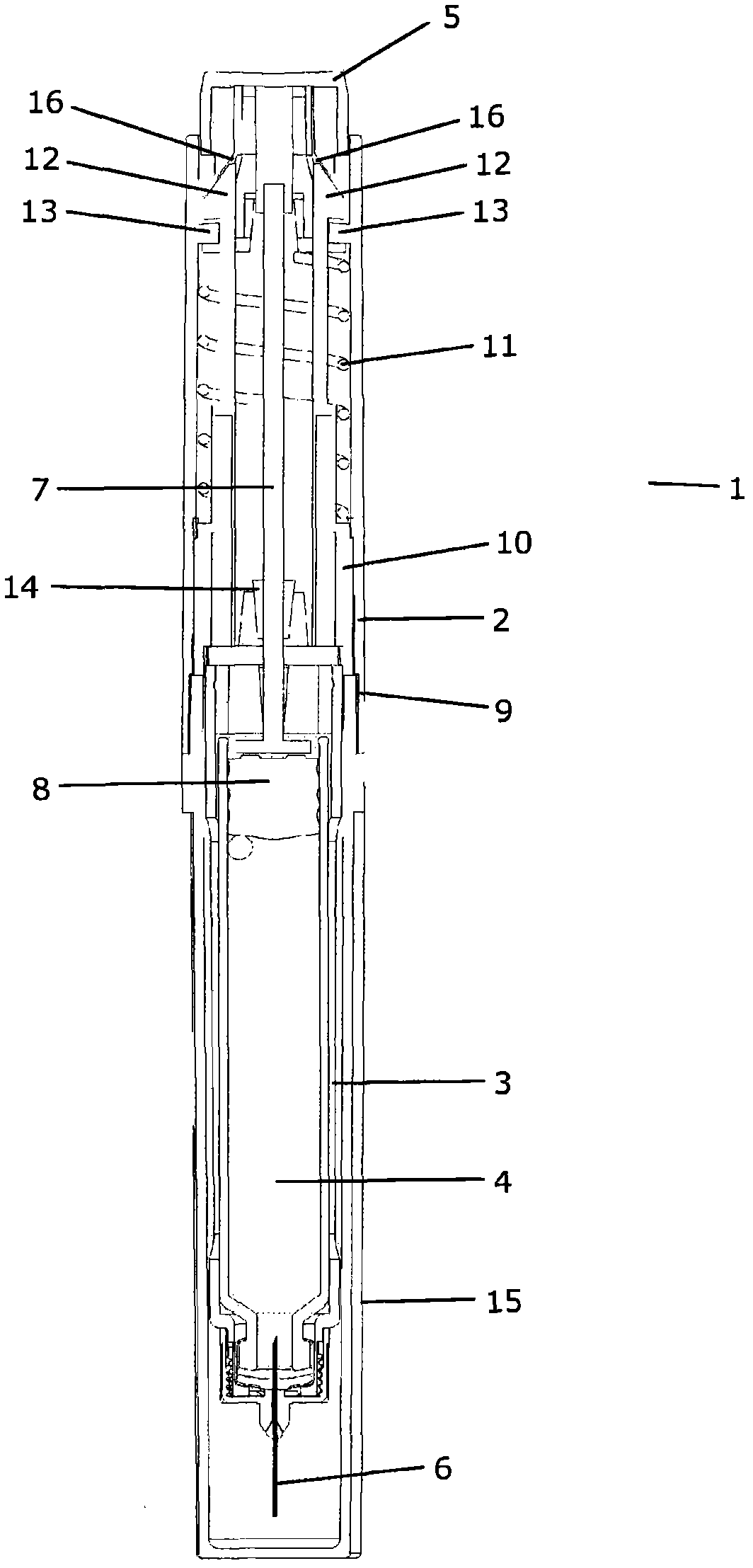

Device for injecting apportioned doses of liquid drug

InactiveCN101912650APrevent axial movementAmpoule syringesAutomatic syringesInjection equipmentDrug doses

A mechanical injection device (1) for injecting apportioned doses of liquid drug. The injection device (1) comprises a dose setting means, an injection means, a removable cap (15) and a cap receiving part (9) adapted to abut or engage with the cap (15) when the cap (15) is mounted on the injection device (1). The dose setting means is operatively coupled to the cap receiving part (9) in such a manner that mounting and / or dismounting of the cap (15) on / from the injection device (1) causes the dose setting means to set a dose. Thereby a correct dose of drug is automatically set during a cap on / cap off cycle. Since such a cycle is normally performed between two subsequent injections, the number of steps required to be performed by the user is reduced.

Owner:NOVO NORDISK AS

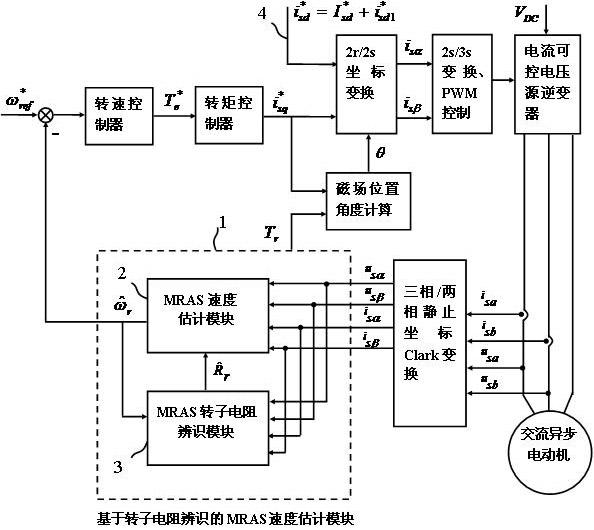

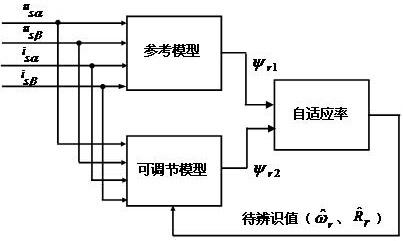

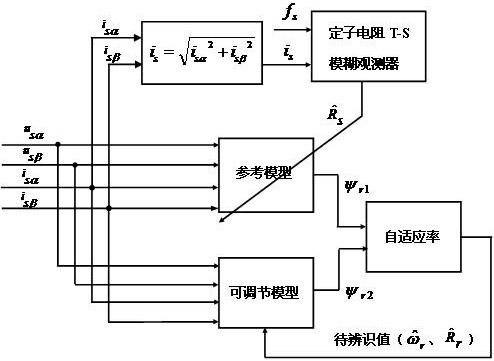

Electromotor dynamic/stable stage parameter identification method based on stator resistance observer

InactiveCN102624320AResolve imprecisionImproved low-speed running performanceElectronic commutation motor controlVector control systemsReference modelingInjection equipment

The invention discloses an electromotor dynamic / stable stage parameter identification method based on a stator resistance observer. For the parameter identification at a dynamic stage of an electromotor, a stator resistance T-S (Takagi-Sugeno) fuzzy observer is introduced to obtain an actually-measured value of stator resistance on the basis that the existing MRAS (Model Reference Adaptive System) method is still adopted, and dynamic correction is carried out on a rotating speed reference model and a resistance reference model according to the actually-measured value of the stator resistance; and for the parameter identification at a stable stage, the identification method for the rotating speed of a rotor is achieved by adopting the MRAS method and the stator resistance T-S fuzzy observer which are the same as those adopted in the parameter identification at the dynamic stage, and the identification method for the resistance of the rotor is achieved by adopting simple conversion. The electromotor dynamic / stable stage parameter identification method based on the stator resistance observer has the beneficial technical effects that the problem of inaccurate reference models is solved, the low-speed operating performance of the electromotor can be improved, the adoption of a current injection method is avoided, the current injection equipment is saved, the complexity of a system is lowered, the introduction of torque ripple is avoided, and the like.

Owner:CHONGQING JIAOTONG UNIVERSITY

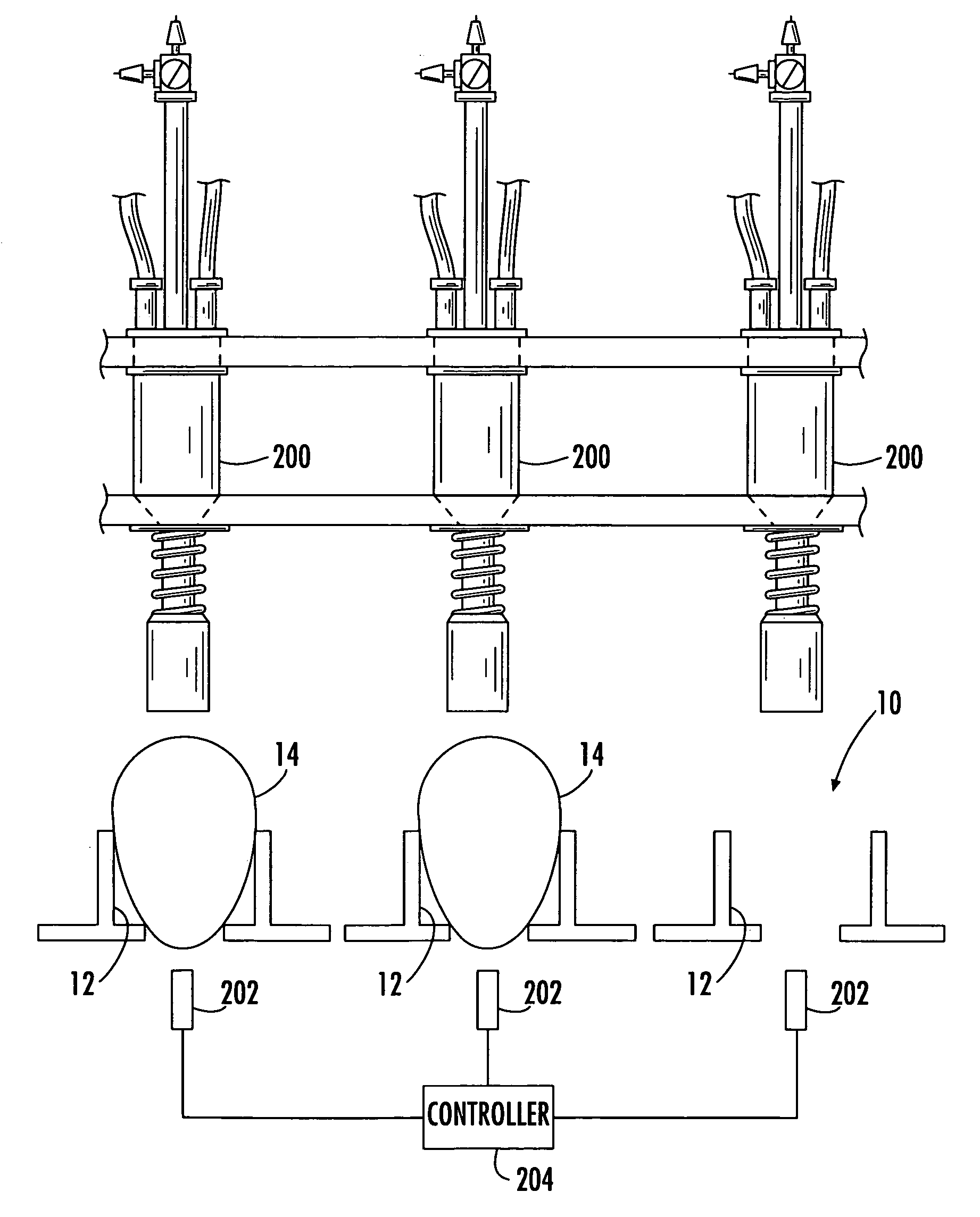

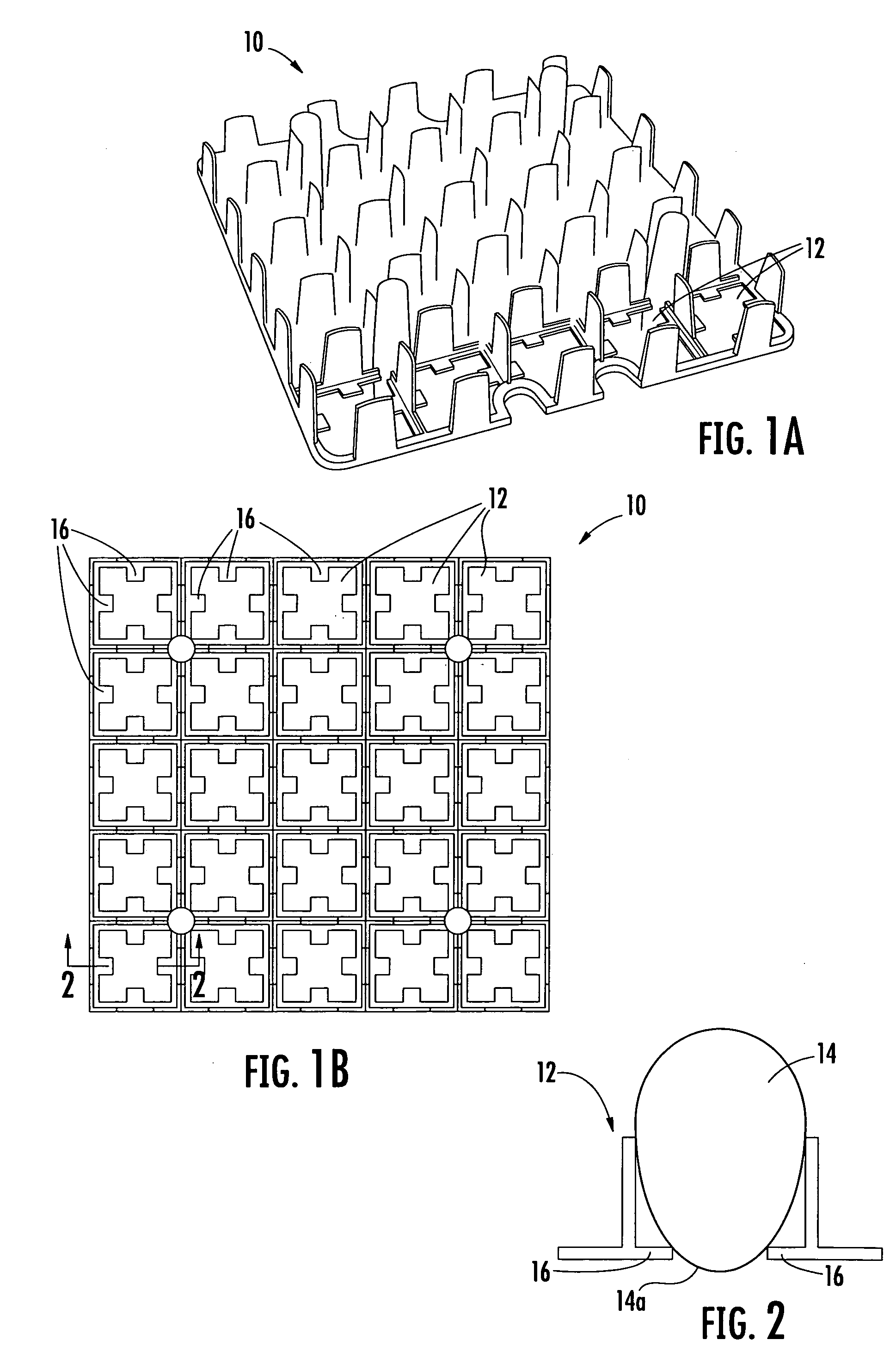

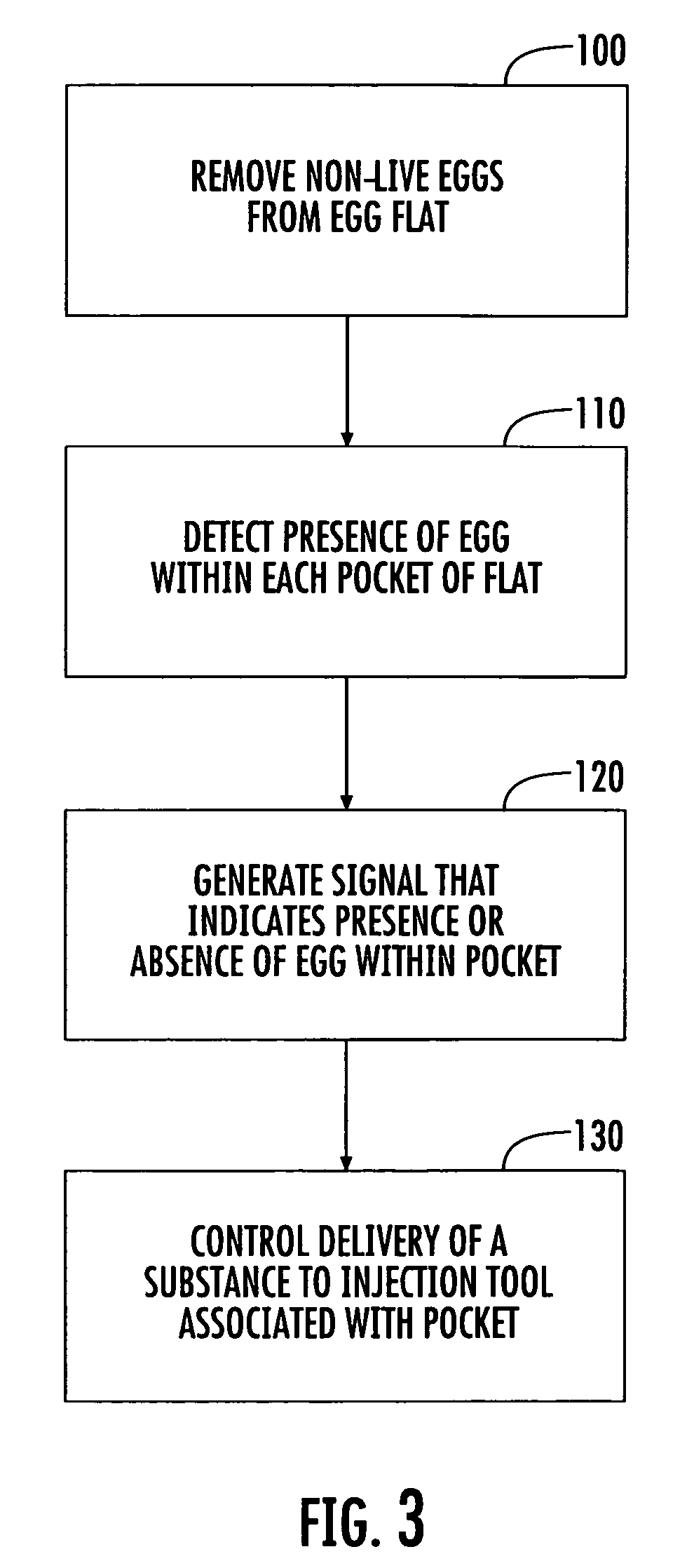

Methods and apparatus for detecting the presence of eggs in an egg flat

InactiveUS20060156989A1Accurate and reliable detectionAvicultureInjection equipmentInjected substance

Methods and apparatus for accurately and reliably detecting the presence of eggs within pockets of an egg flat are provided. An in ovo injection apparatus includes a plurality of injection devices configured to inject substances into a respective plurality of eggs held within respective pockets of an egg flat, and a sensor associated with each pocket of the egg flat that detects the presence of an egg therewithin. Each sensor communicates whether an egg is present or not within a respective pocket to a respective injection device. Each sensor may be configured to detect injection tool position, wherein injection tool position indicates whether an egg is present or not within a respective pocket.

Owner:EMBREX INC

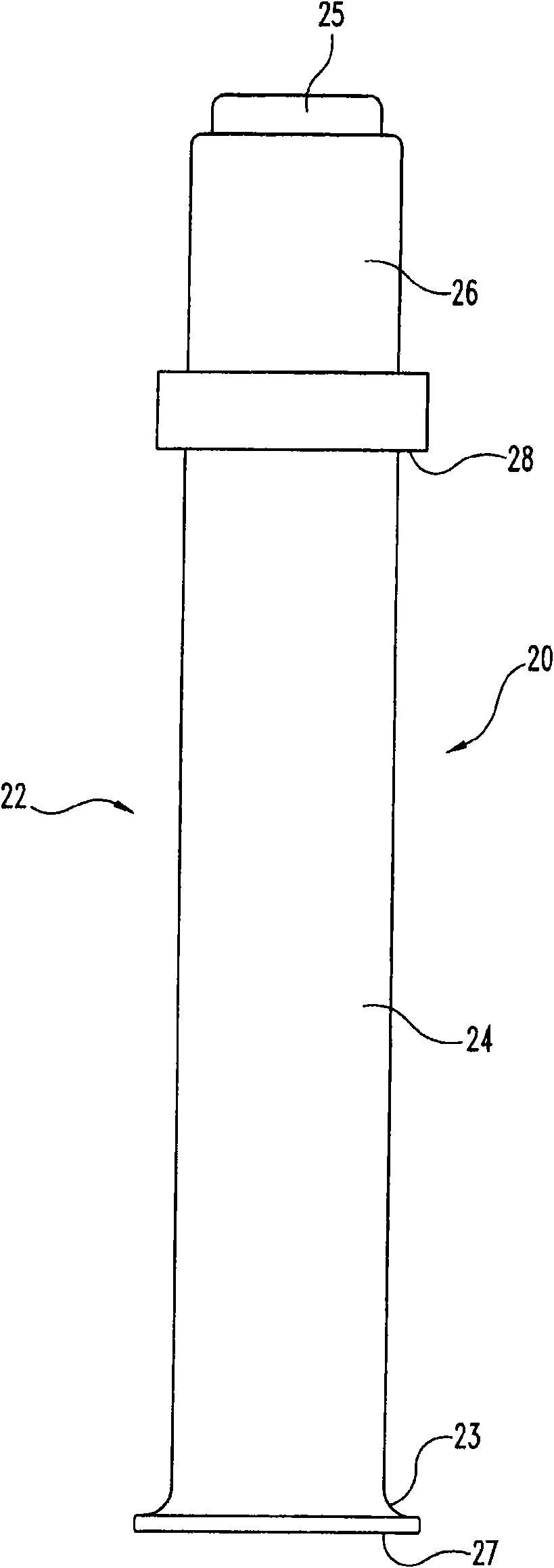

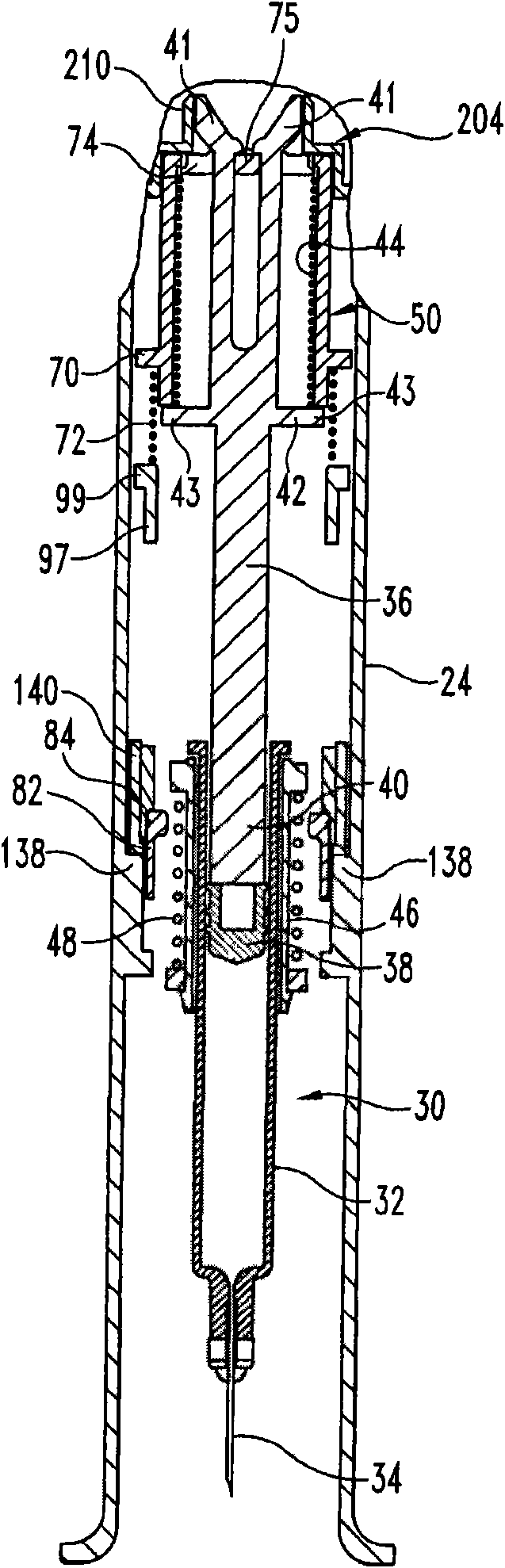

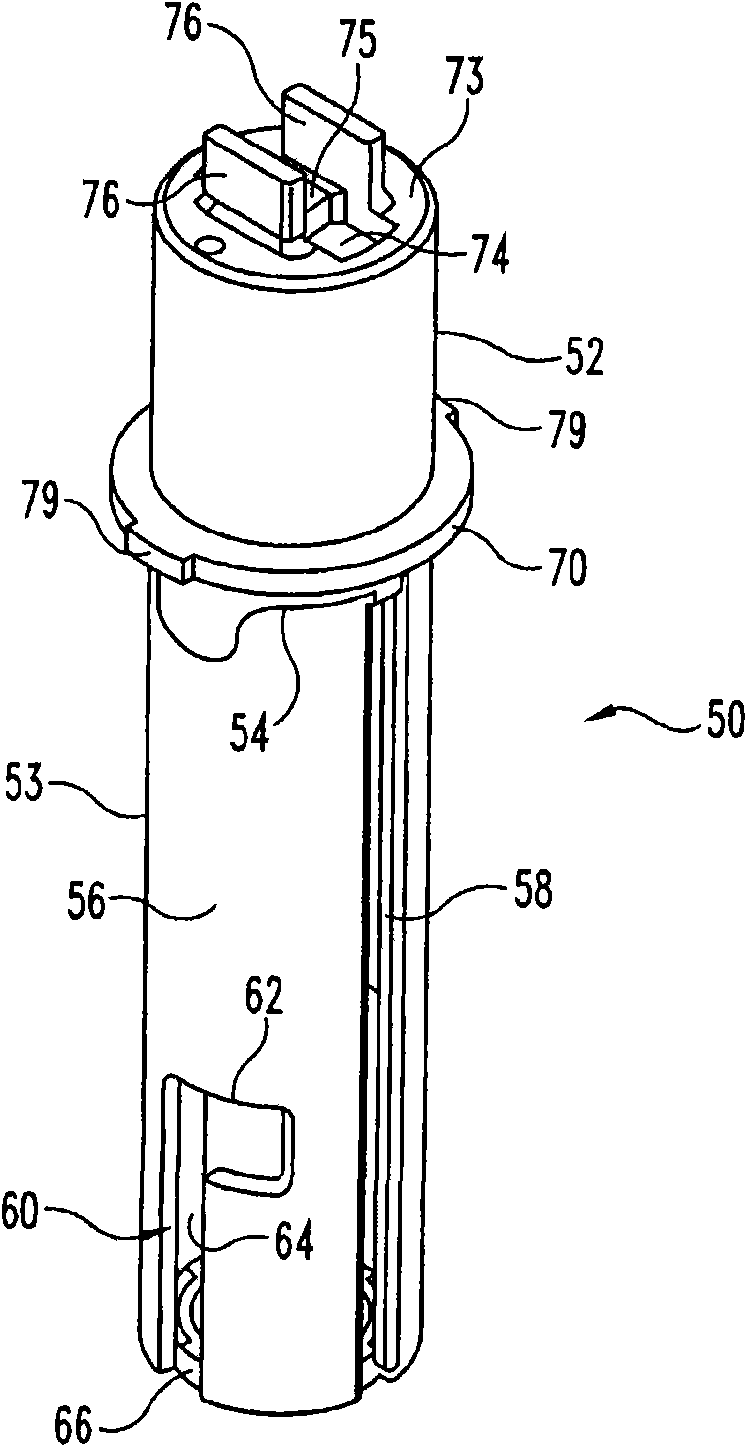

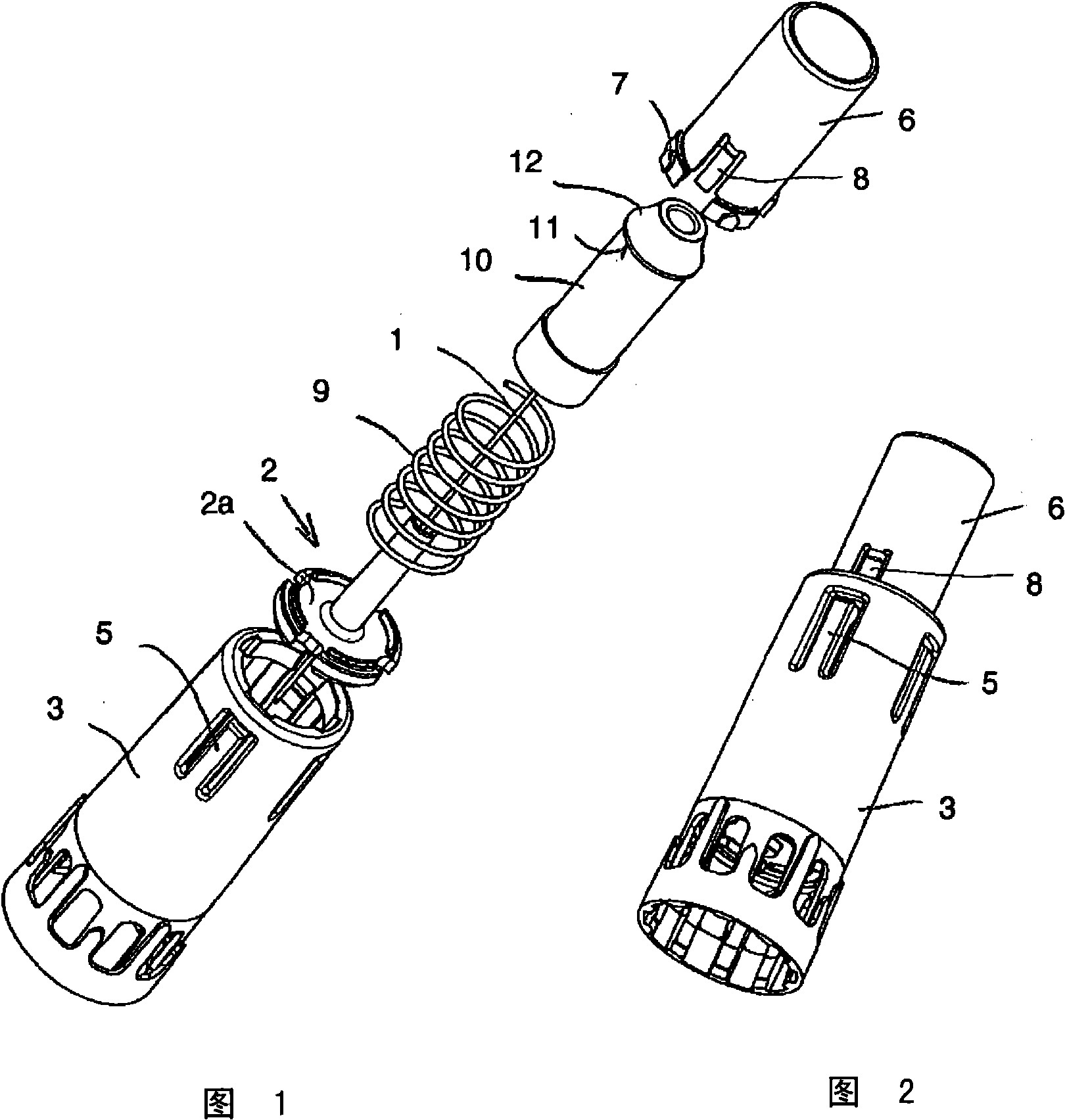

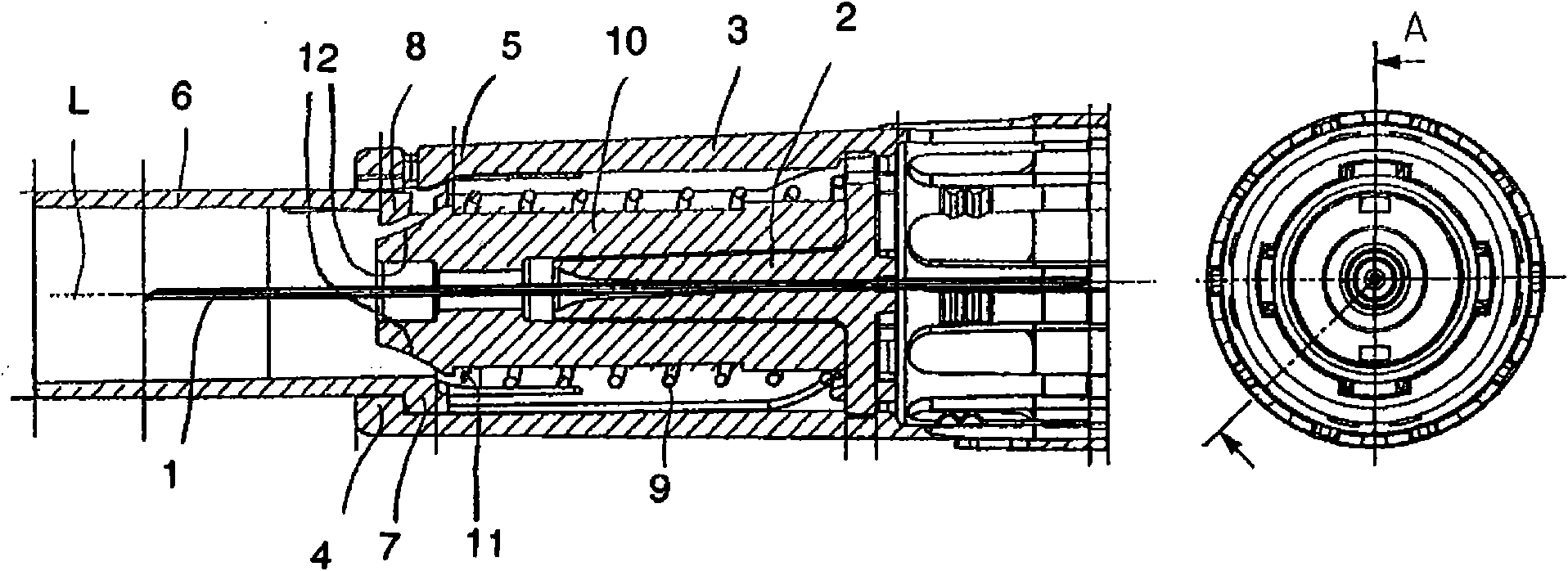

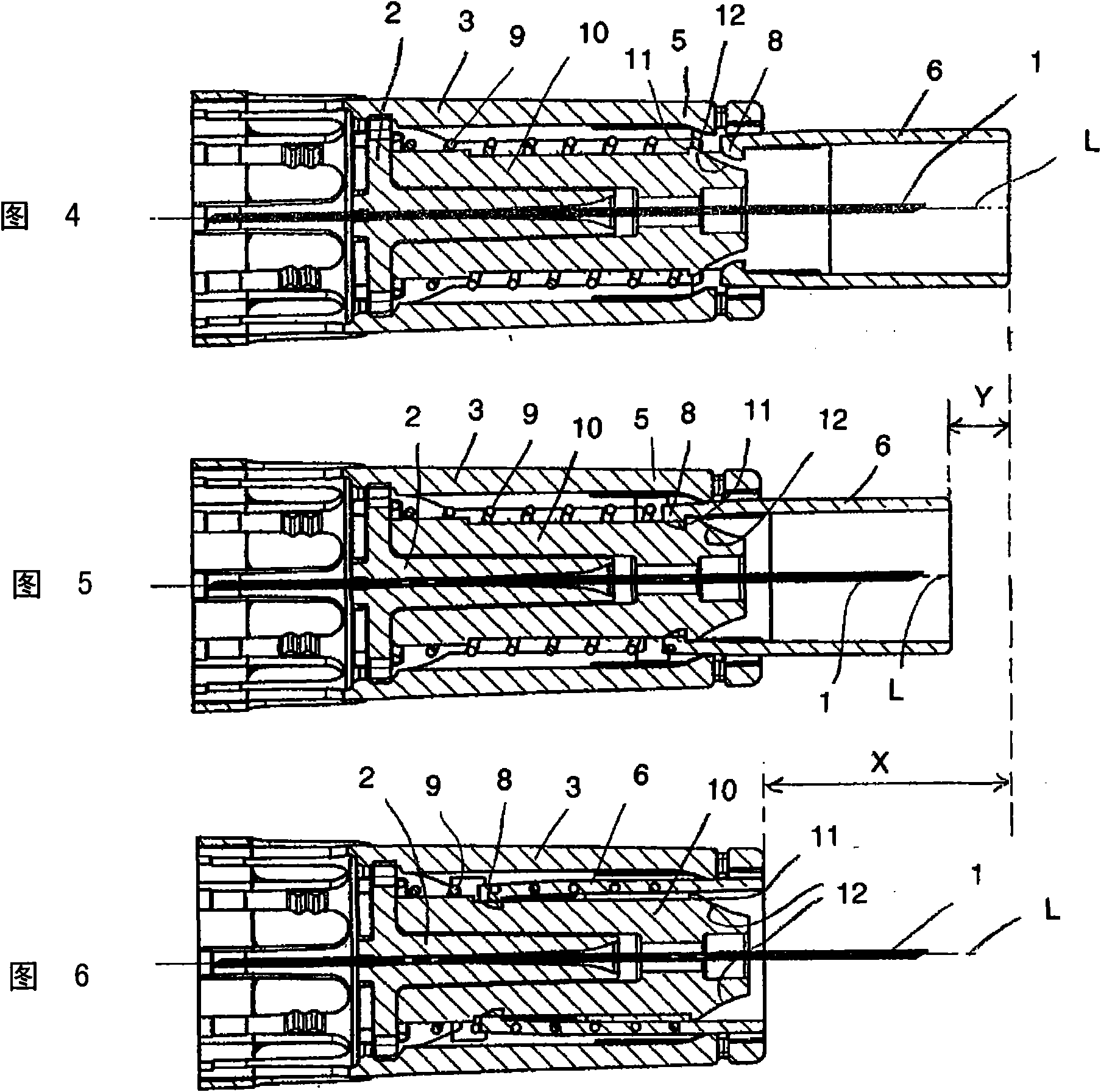

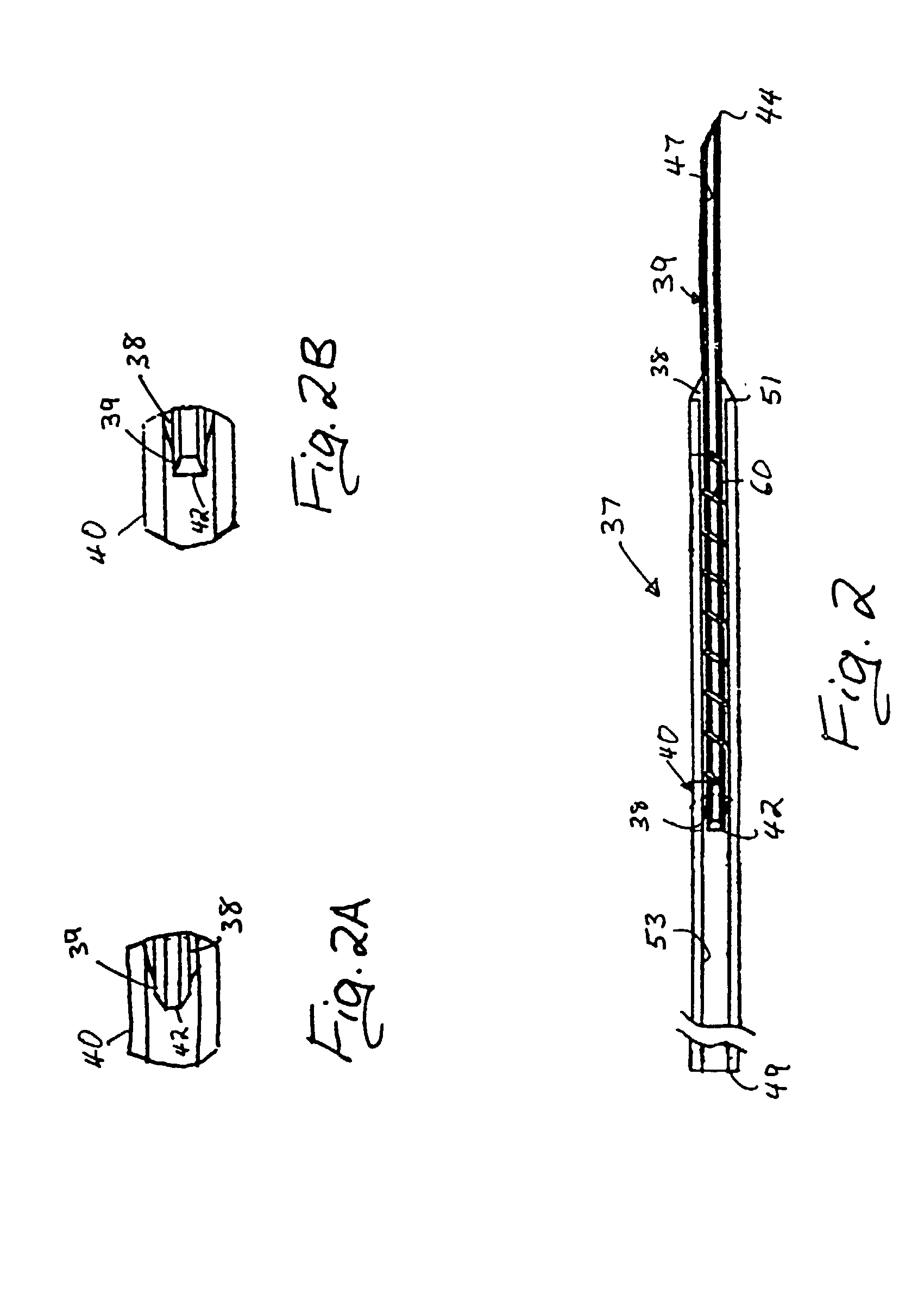

Delay mechanism for automatic injection device

InactiveCN101641125ADoes not affect operating forceNo need to overcome resistanceAutomatic syringesInfusion needlesInjection equipmentCam

A delay mechanism for staging the operation of an automatic injection apparatus (20) to ensure medication contents are properly delivered prior to the needled syringe (32) of the apparatus being retracted. In one form, the delay mechanism includes a shuttle (50), a follower (110), a locking member, a damping compound, and a driver and a driver biasing element (44). The shuttle is for a needled syringe of the apparatus and includes a first latching element. The follower includes a second latching element and a cammable surface, which second latching element is for cooperating with the first latching element to limit motion of the shuttle relative to the follower in a second direction opposite the first direction. The locking member is movable from a locking position to a release position by engagement with the syringe plunger during an injection, the locking member, when in the locking position, preventing rotation of the follower relative to the shuttle, the locking member, when in the release position, allowing rotation of the follower relative to the shuttle. The damping compound is between the follower and a supporting surface to dampen rotation of the follower relative to the shuttle. The driver is rotatably fixed relative to the shuttle and includes a camming surface. The shuttle allowing retracting of the syringe needle into the housing of the automatic injection apparatus after injection.

Owner:ELI LILLY & CO

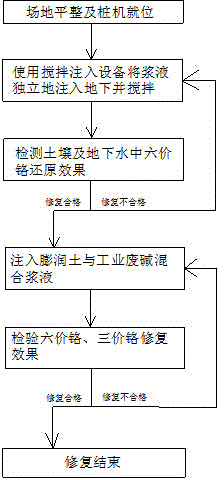

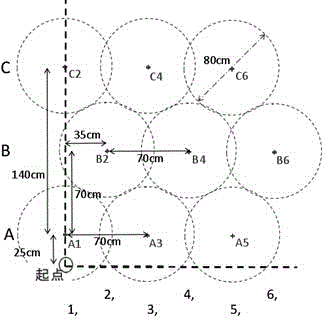

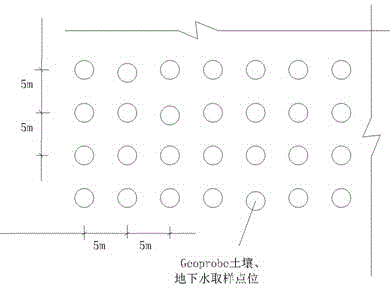

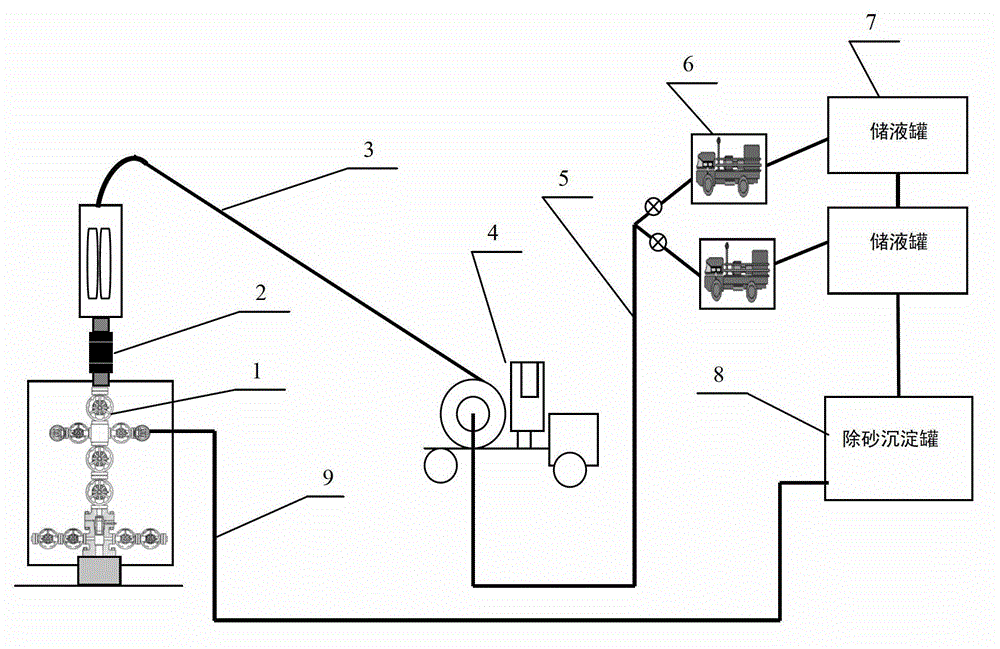

Remediation method for hexavalent chromium polluted soil and underground water

ActiveCN104624632AComplete restorationEfficient removalWater contaminantsContaminated soil reclamationSodium BentoniteInjection equipment

The invention discloses a remediation method for hexavalent chromium polluted soil and underground water. The remediation method comprises the following steps: step (10): putting a pile machine in place; step (20): independently injecting acidified bentonite slurry loaded with active carbon powder and bentonite slurry loaded with zero-valent iron powder into the ground by using stirring and injection equipment and stirring; step (30): detecting the reduction effect of hexavalent chromium in the soil and the underground water; step (40): injecting bentonite and industrial waste alkali mixed slurry; and step (50): detecting the remediation effect of hexavalent chromium and trivalent chromium. By virtue of the remediation method, remediation chemicals can be in direct and sufficient contact with the soil and the underground water to react, so that the hexavalent chromium in the soil and the underground water can be completely reduced; meanwhile, an indissolvable stable compound is formed by the trivalent chromium and the useless loss of the remediation chemicals can be reduced; the potential of hydrogen of a stratum is balanced; and the remediation method is suitable for the large-area hexavalent chromium polluted stratums different in potential of hydrogen and moisture content.

Owner:SOUTHEAST UNIV

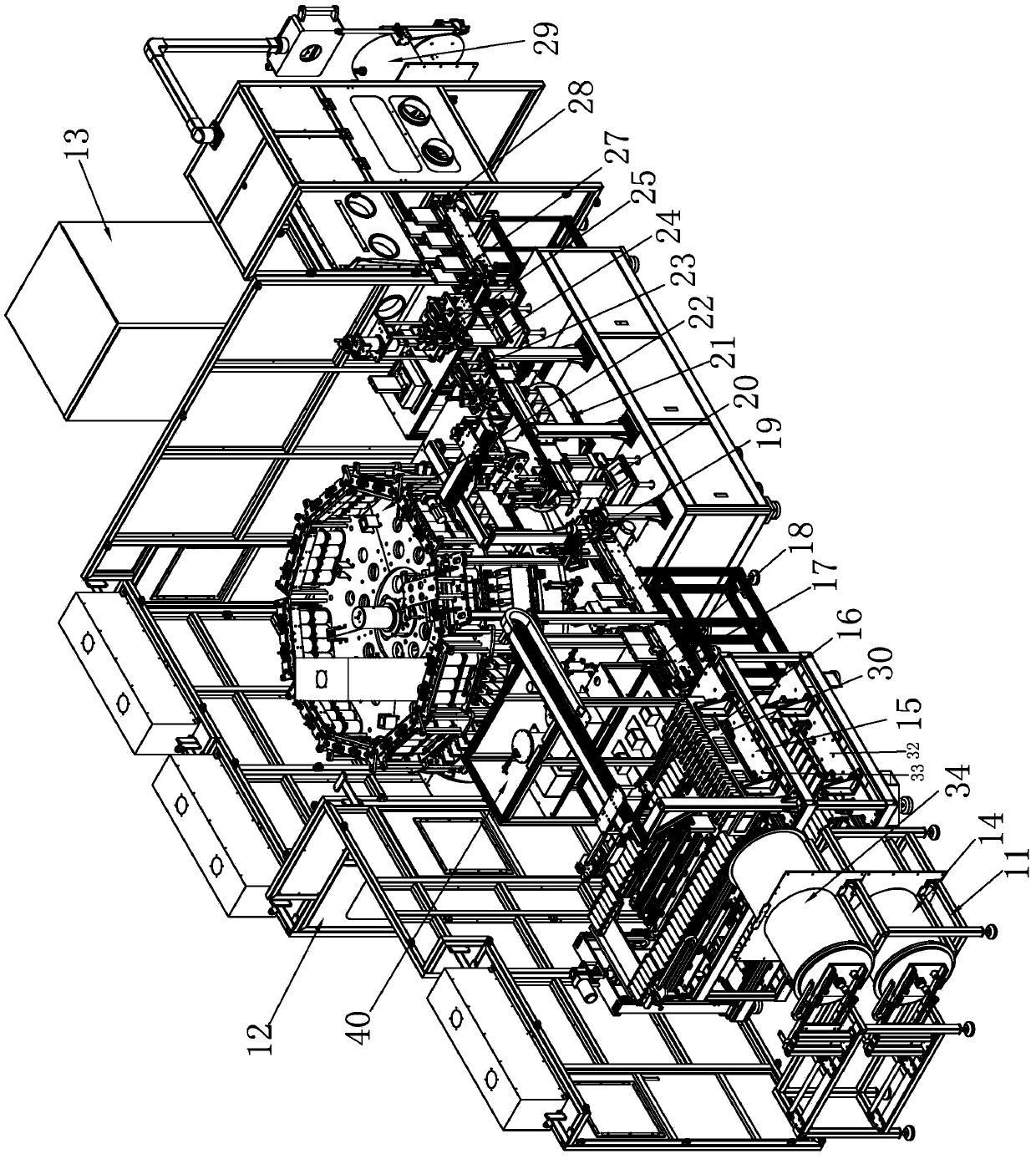

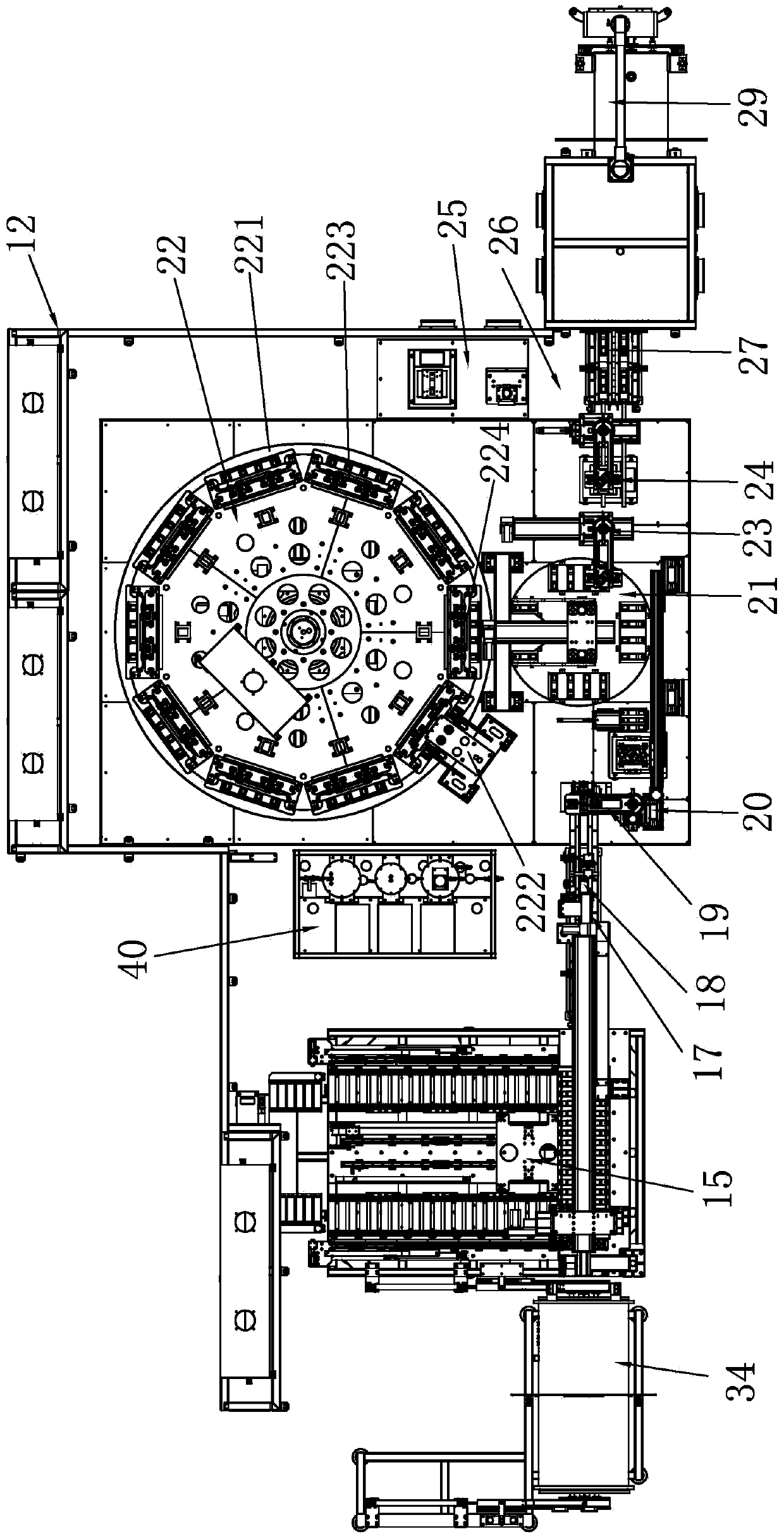

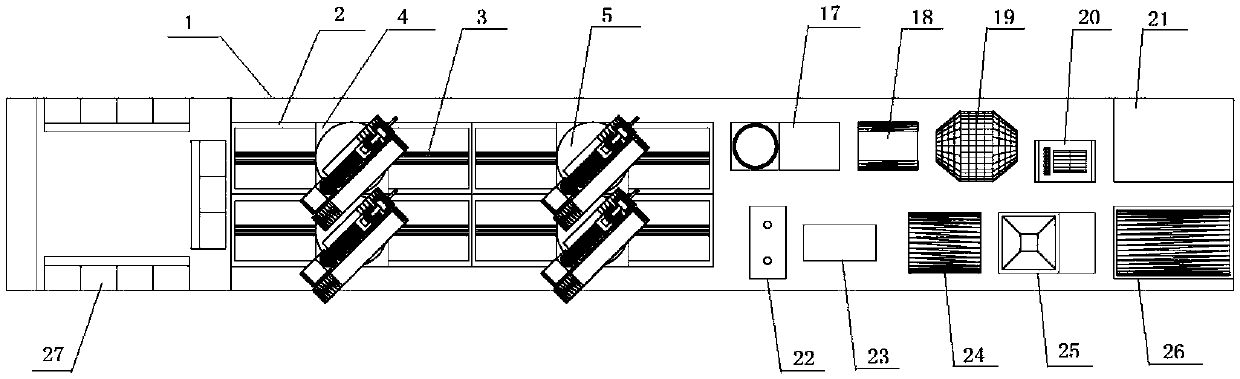

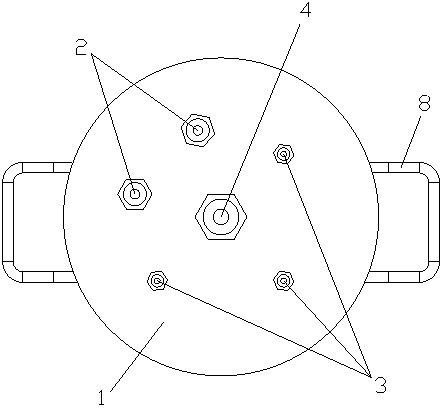

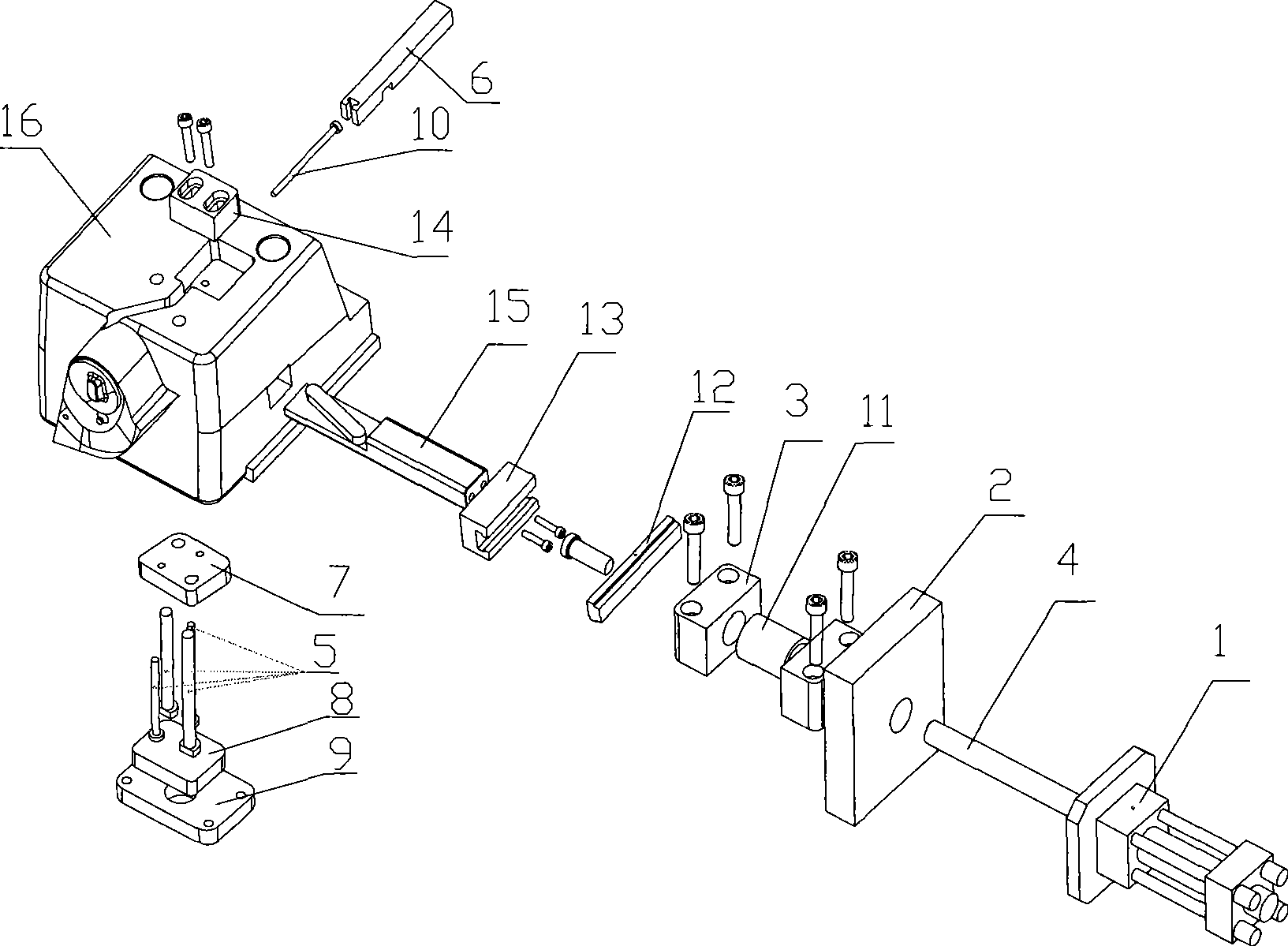

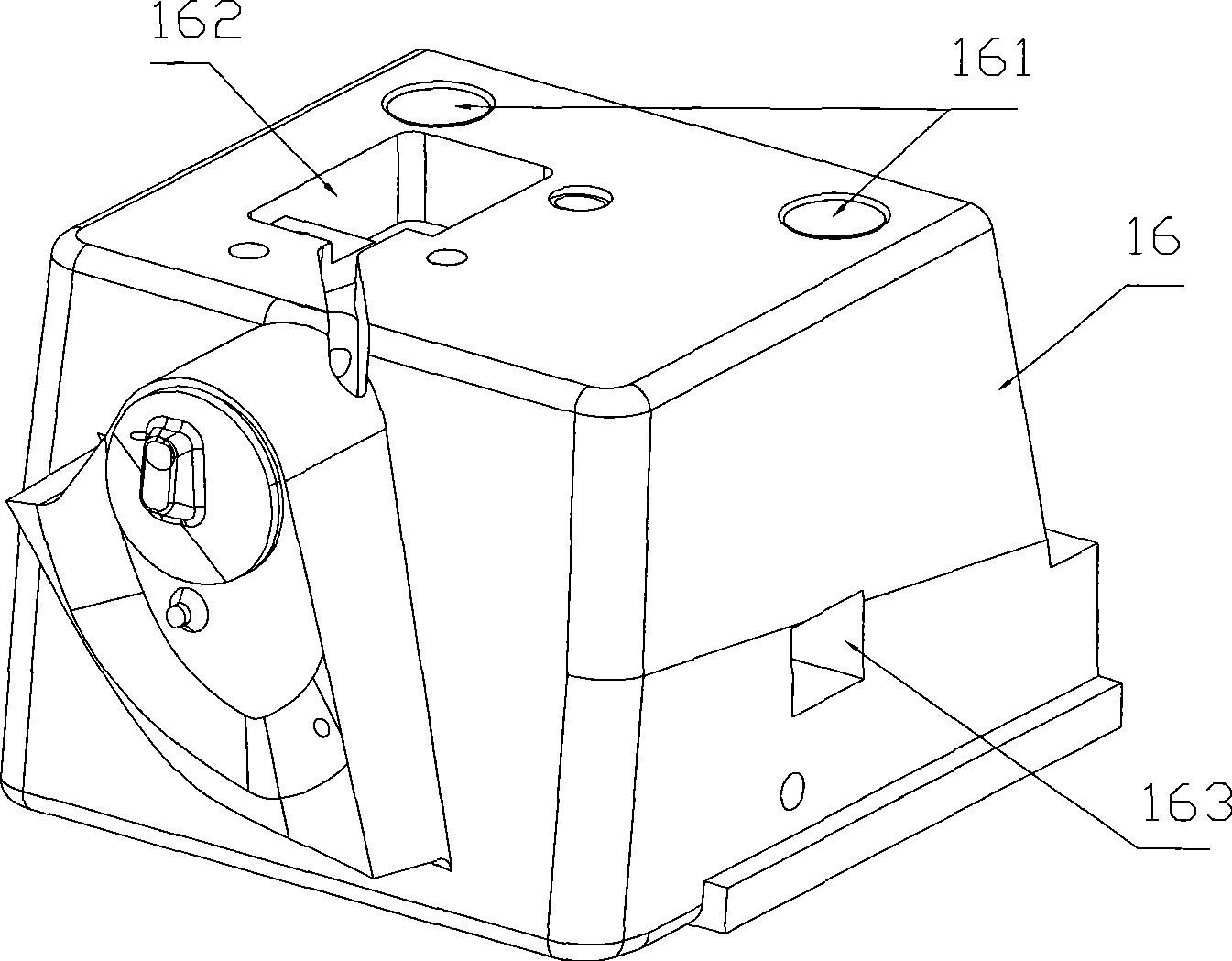

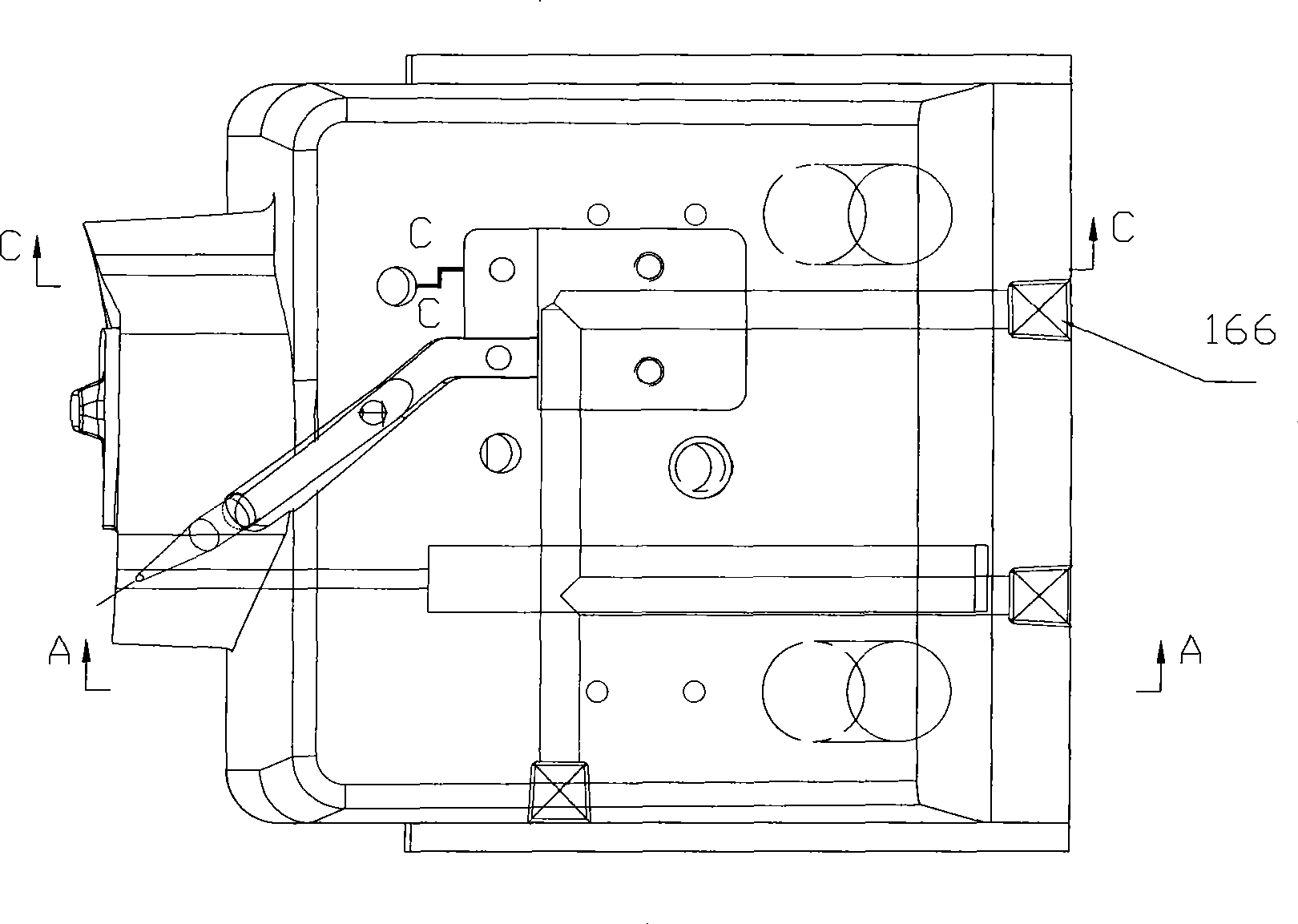

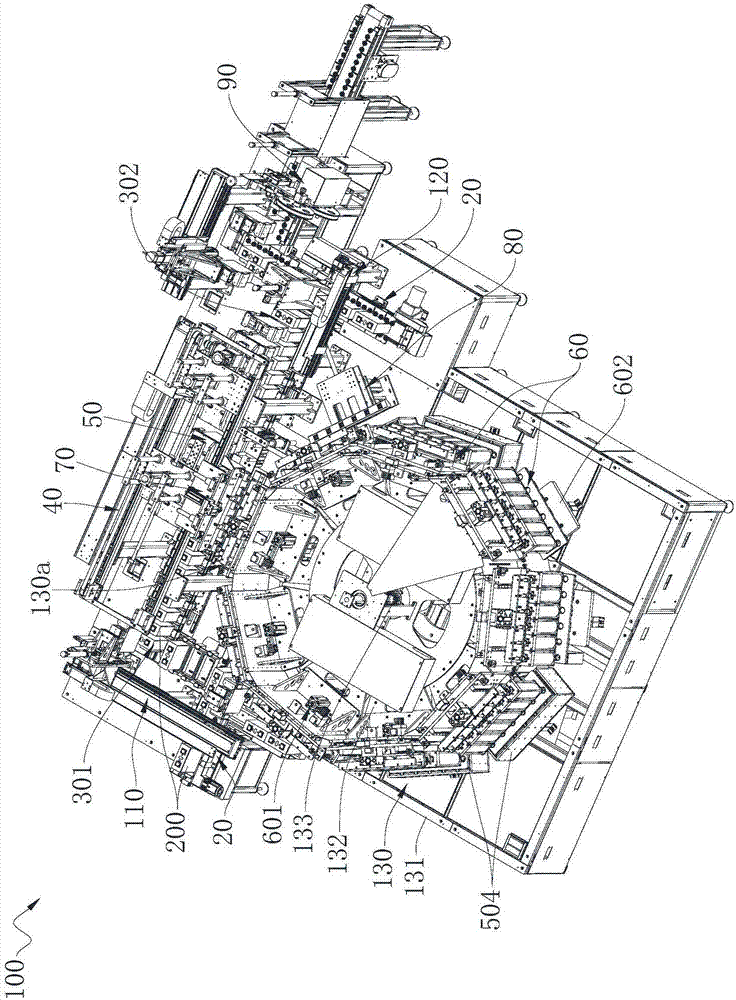

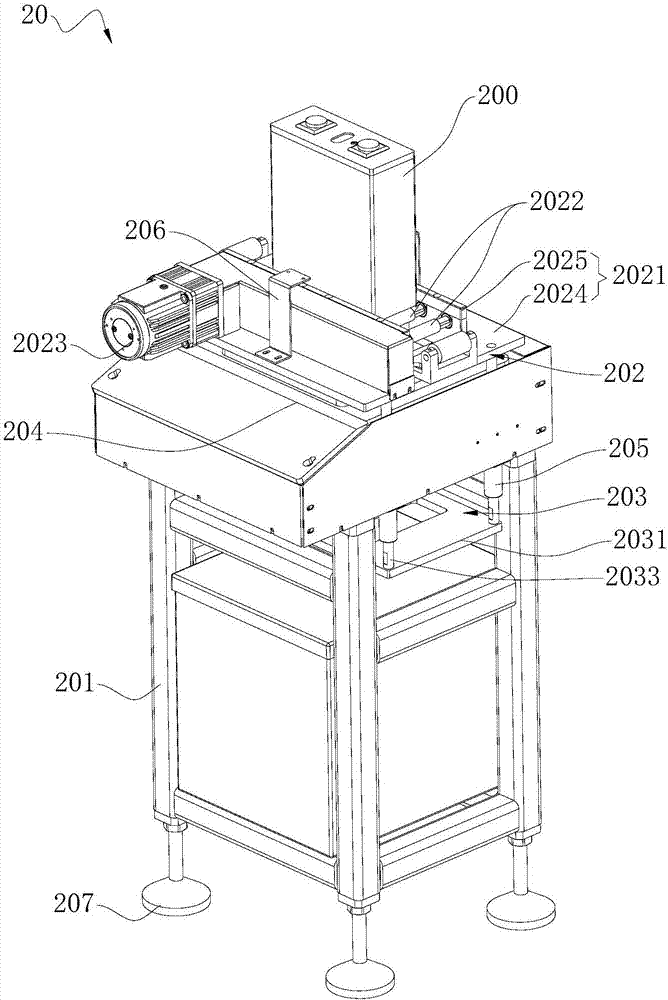

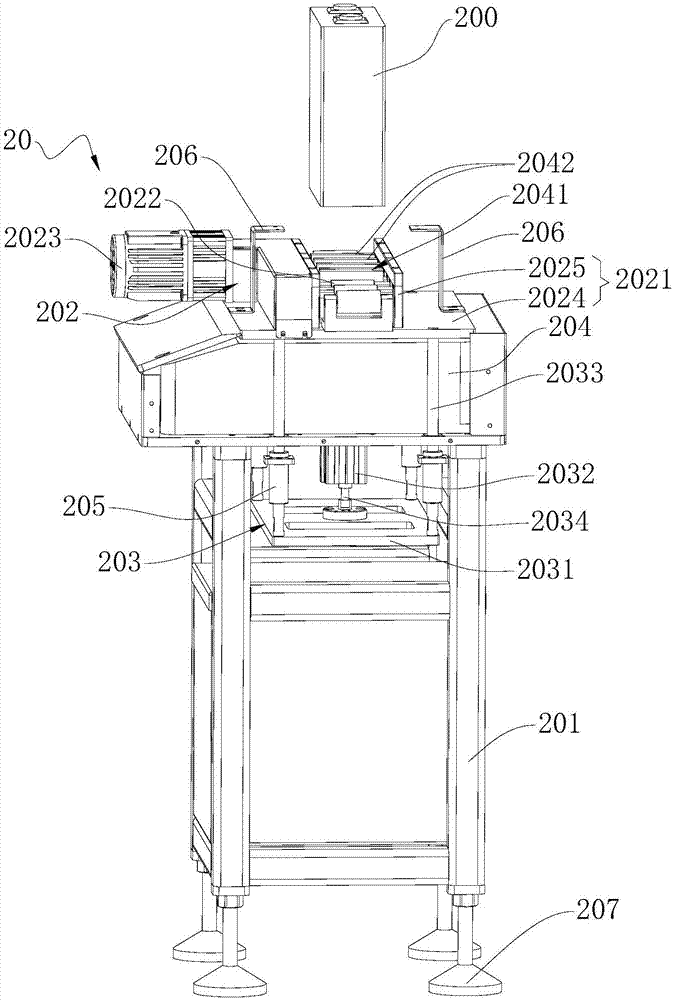

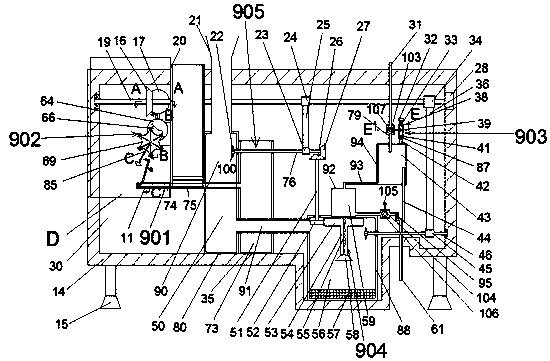

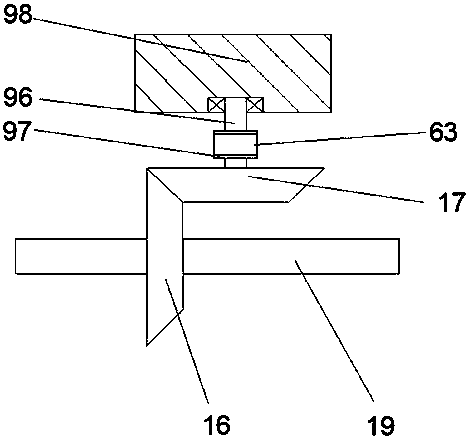

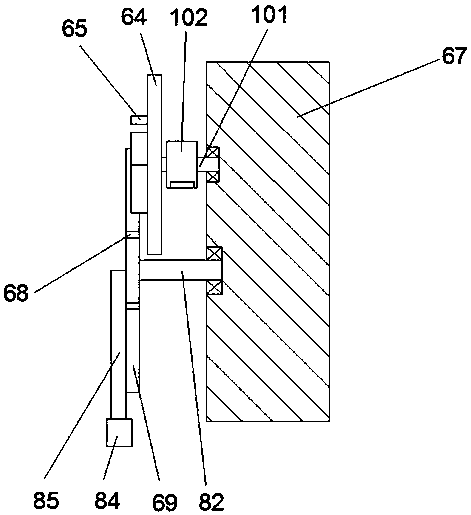

Automatic electrolyte injection equipment for batteries

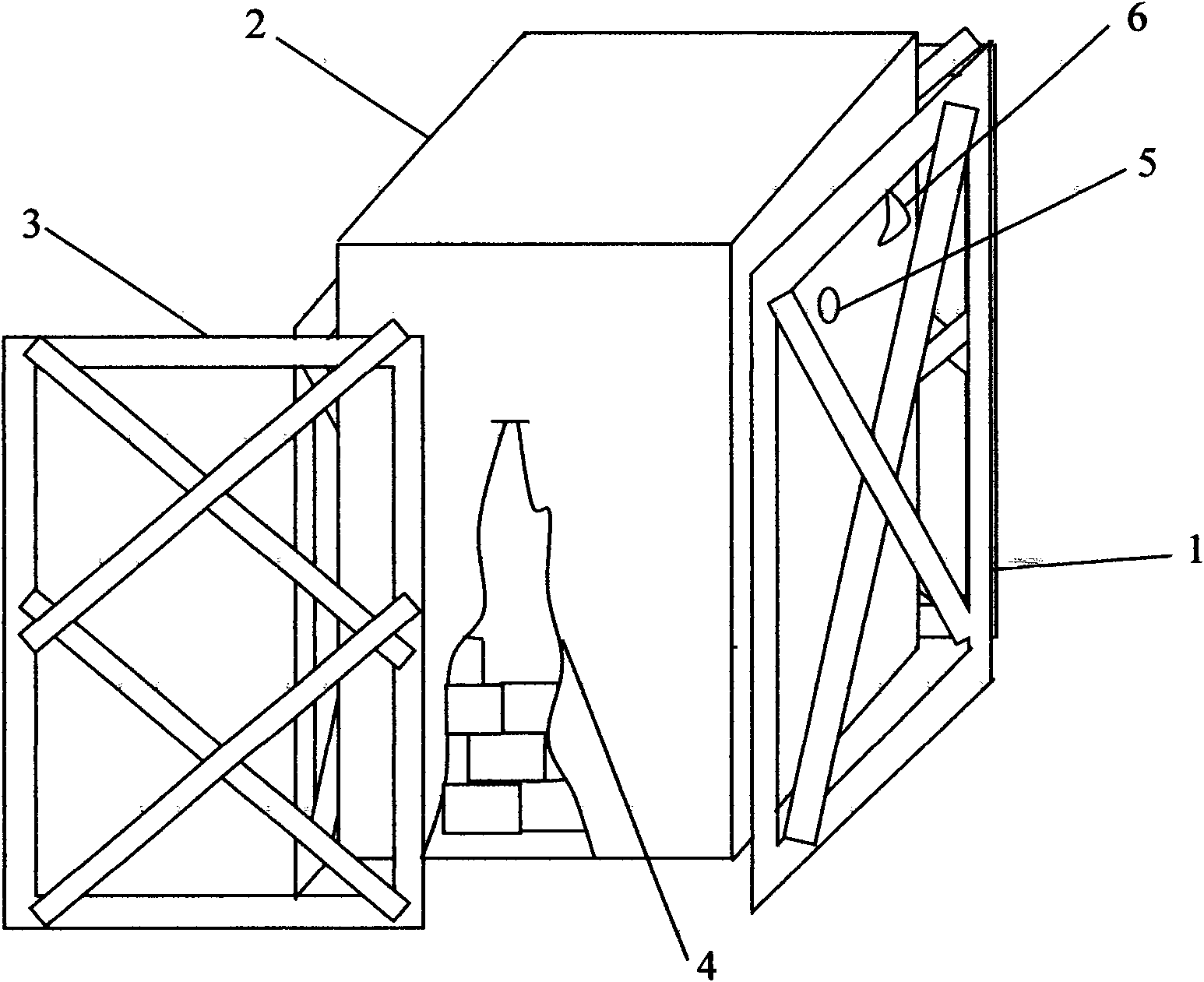

ActiveCN104241592AQuality improvementExtended service lifeCell component detailsInjection equipmentEngineering

The invention discloses automatic electrolyte injection equipment for batteries. The automatic electrolyte injection equipment comprises a stander, a closed box body covering the stander, an electric cabinet independently arranged outside the closed box body, as well as a loading vacuum transition cabin, a drying and cooling mechanism, a loading manipulator, a loading conveyer belt, an insulation resistance test mechanism, a loading code-scanning and weighing manipulator, a pre-injection weighing mechanism, a turntable loading mechanism, an injection electrolyte circulation standing turntable mechanism, an unloading code-scanning and weighing manipulator, a post-injection weighing mechanism, an electrolyte supplement station, a rubber plug insertion station, an unloading conveyor belt, an unloading transfer tray and an unloading vacuum transition cabin which are sequentially arranged on the stander along the battery conveying direction, and the automatic electrolyte injection equipment further comprises a drying tray used for bearing a battery. Therefore, through the cooperation of each part, the whole automation degree of the equipment is improved, and the production efficiency is greatly improved; meanwhile, the equipment ensures that no bubble exists in the injected electrolyte, realizes stable and reliable electrolyte injection, improves the battery quality and prolongs the service life of the battery.

Owner:DONGGUAN HONBRO LI BATTERY EQUIP TECH

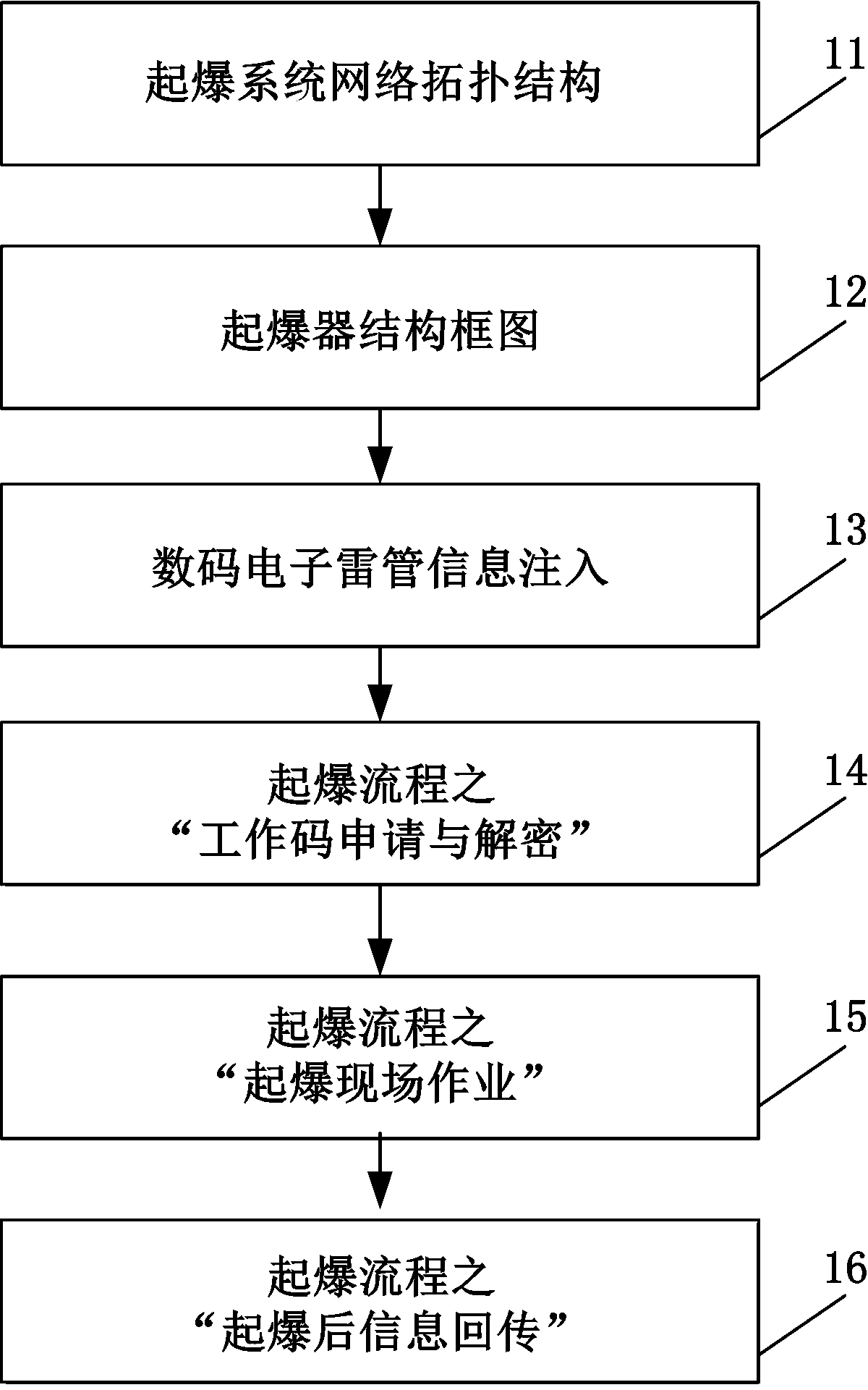

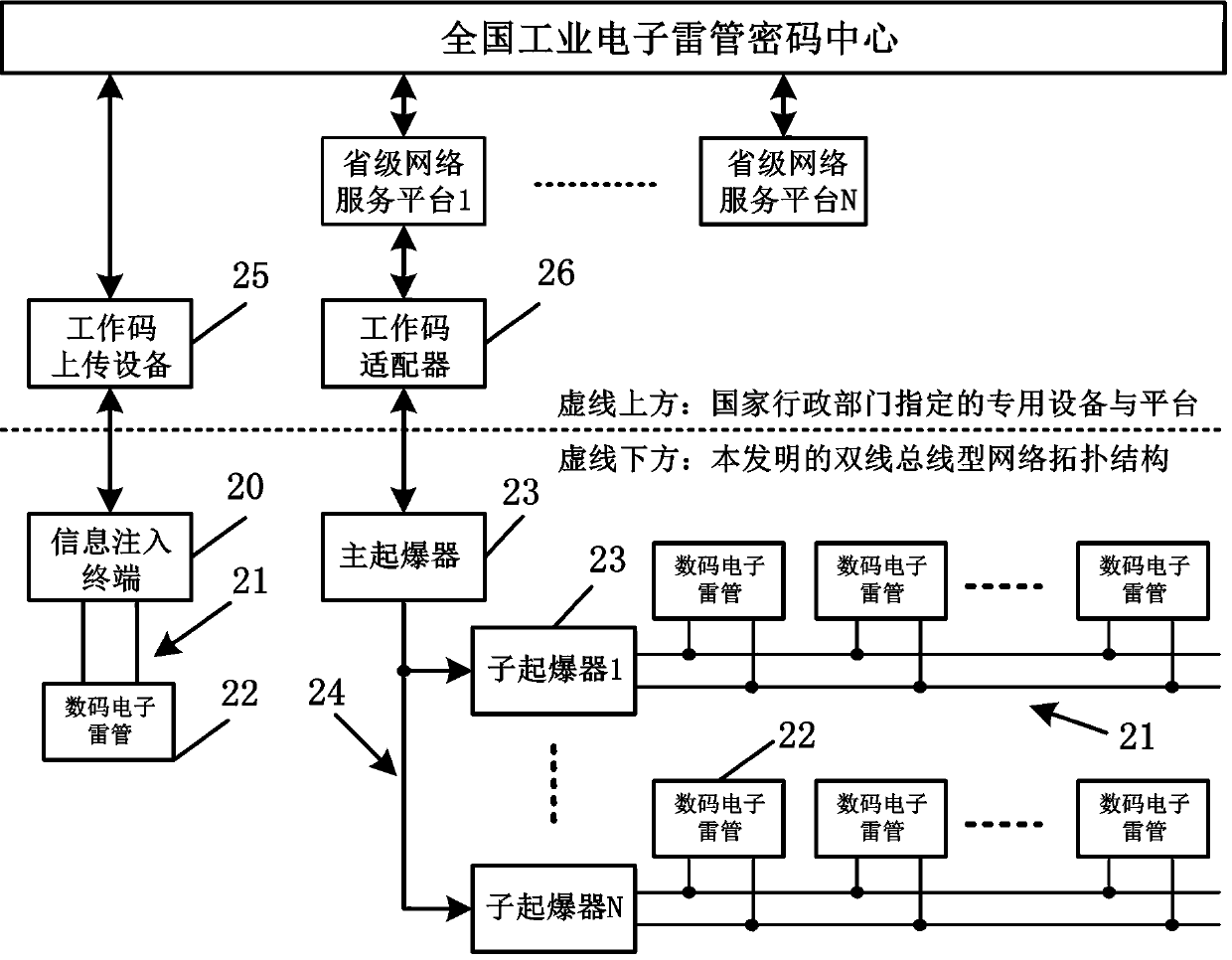

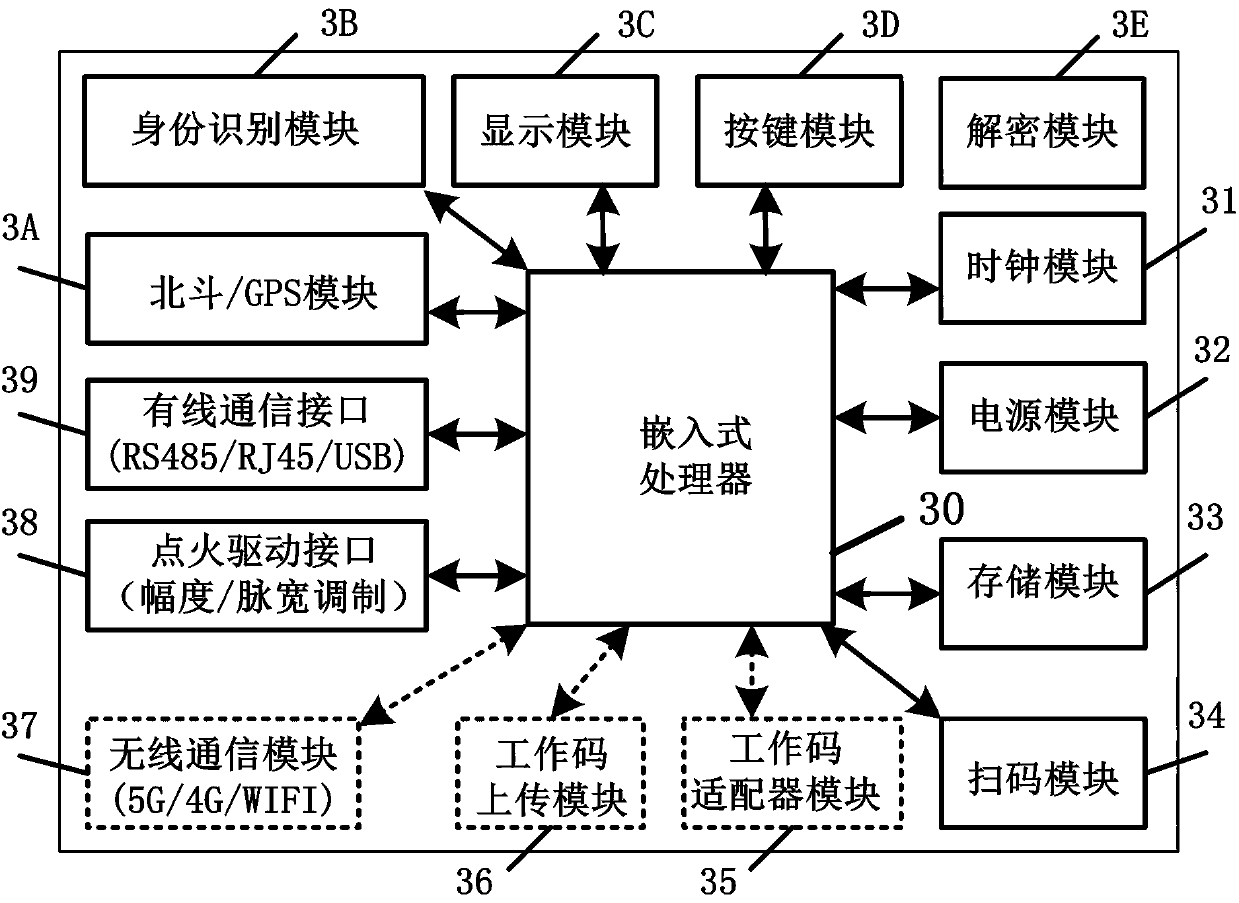

Digital electronic detonator initiation system and method based on two-wire bus

ActiveCN109764779AImprove safety and reliability performanceImprove construction convenienceBlastingDetonatorExtensibility

The invention discloses a digital electronic detonator initiation system and method based on a two-wire bus. A initiation system network topology structure is constructed, and an initiation system network comprises a detonator, detonator information injection equipment, a digital electronic detonator, a non-polar dual-wire bus capable of performing communication and power supply and the other constitutional unit; the structure of the detonator, the functions of a required module and an optional module and a supported communication instruction set are defined; equipment and specific process ofdigital electronic detonator information injection are listed; and the initiation process is defined and standardized, and working code application and decryption, initiation site operation and post-initiation information return are included. According to the digital electronic detonator initiation system and method based on the two-wire bus, the requirements of a latest standard and the practicalapplication can be met, flexibly networking reduces the complexity of the initiation system, and the ease of use and maintenance are improved; the process is standardized to improve the safety and control of the operation; the detonator based on the two-wire bus improves the communication reliability and functional extensibility, the comprehensive cost of the initiation operation is reduced, andthe digital electronic detonator initiation system and method based on the two-wire bus can be widely used in various initiation operation application scenarios.

Owner:华夏世昌(北京)科技有限公司

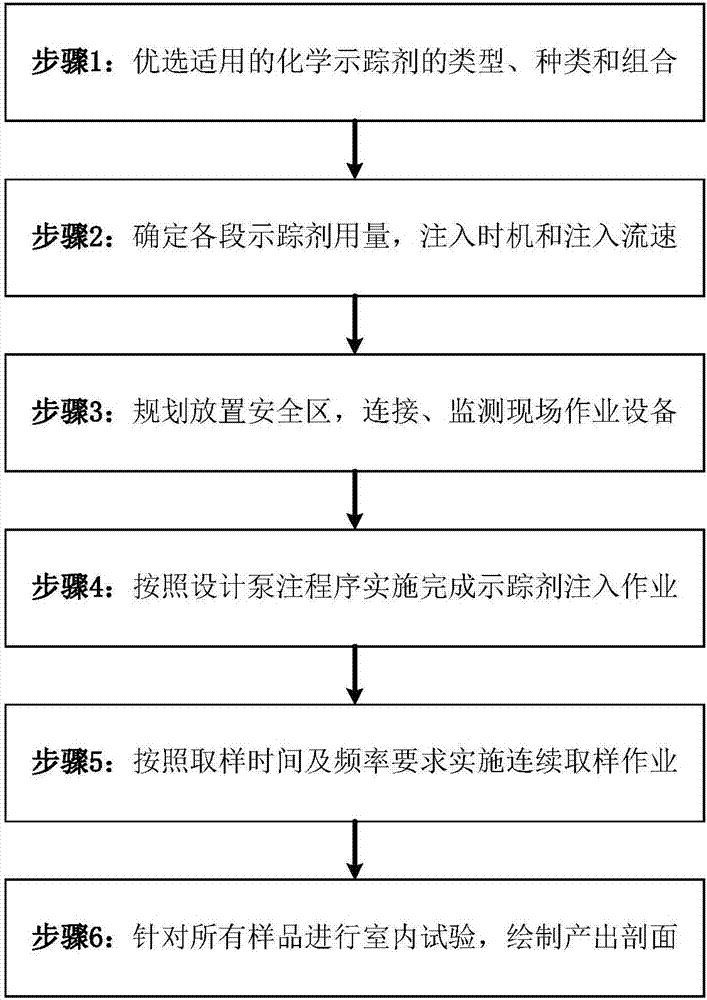

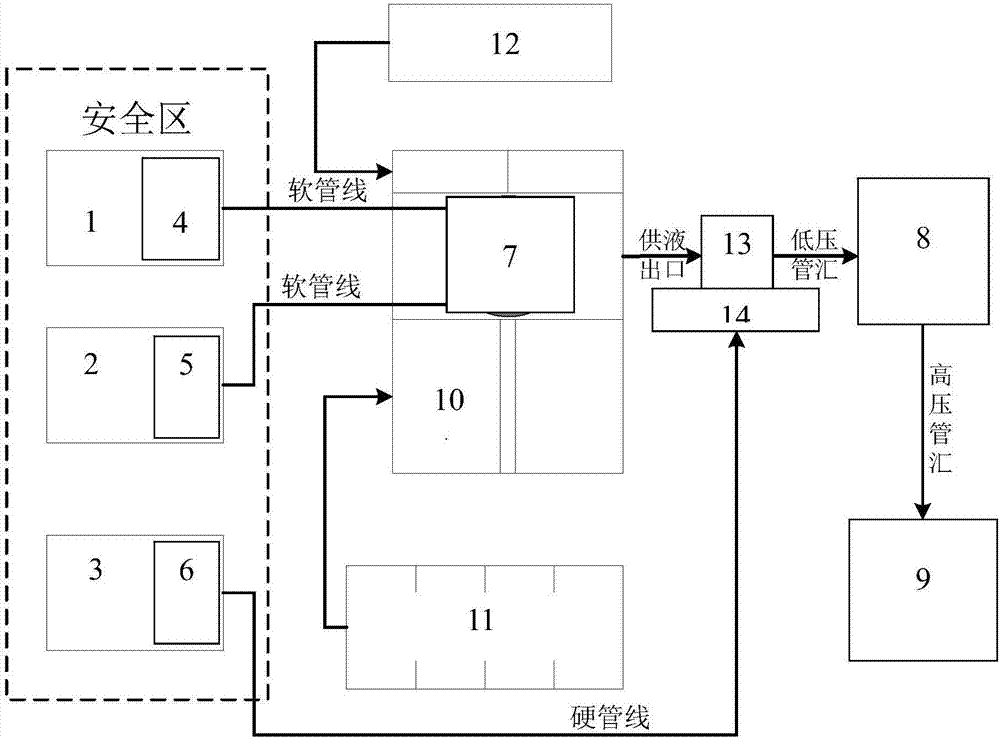

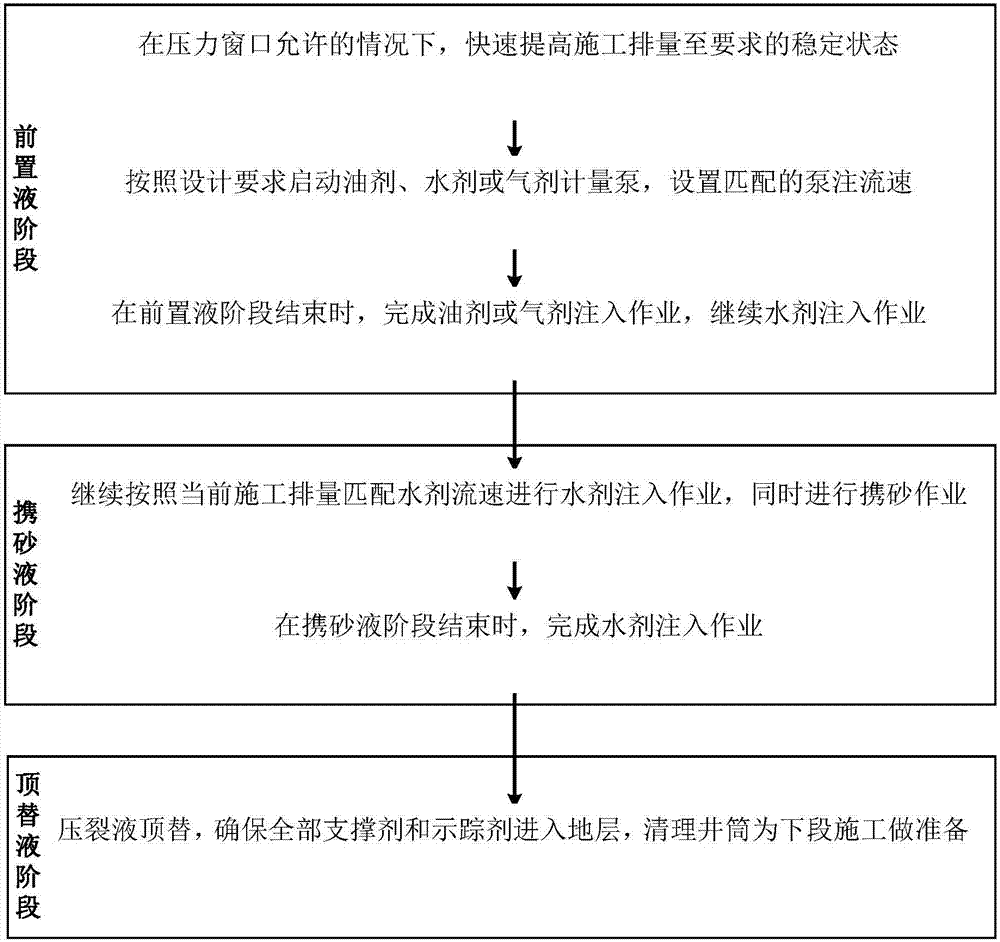

Method and system for testing oil-gas-water profile of each section of horizontal well by using environmental protection type tracers

ActiveCN107989588AEasy to operateNo obvious HSE riskConstructionsFluid removalReservoir typeThermodynamics

The invention provides a method and system for testing the oil-gas-water profile of each section of a horizontal well by using environmental protection type tracers. The method comprises the steps that according to information containing the oil and gas reservoir type, the fracturing fluid type and the number of test sections, the kinds and the compositions of the chemical tracers are determined;the designed using quantity, the injection time and the injection velocity of the chemical tracer used at each section are determined; injection equipment of the tracers used for testing is determined, and the connecting process of equipment for completing on-site operation is determined and laid out before construction; injection operation of the corresponding chemical tracers required by construction sections is completed according to the designed pump injection procedure; after fracturing construction of the whole horizontal well is completed, continuous tracer test sampling operation is implemented according to the designed sampling time and frequency, and samples are tested in time after all sampling is completed; and a production profile map or a contribution ratio map of each layersection of the oil and gas reservoir horizontal well within the sampling period is drawn.

Owner:ORIENT BAOLIN TECH DEV BEIJING

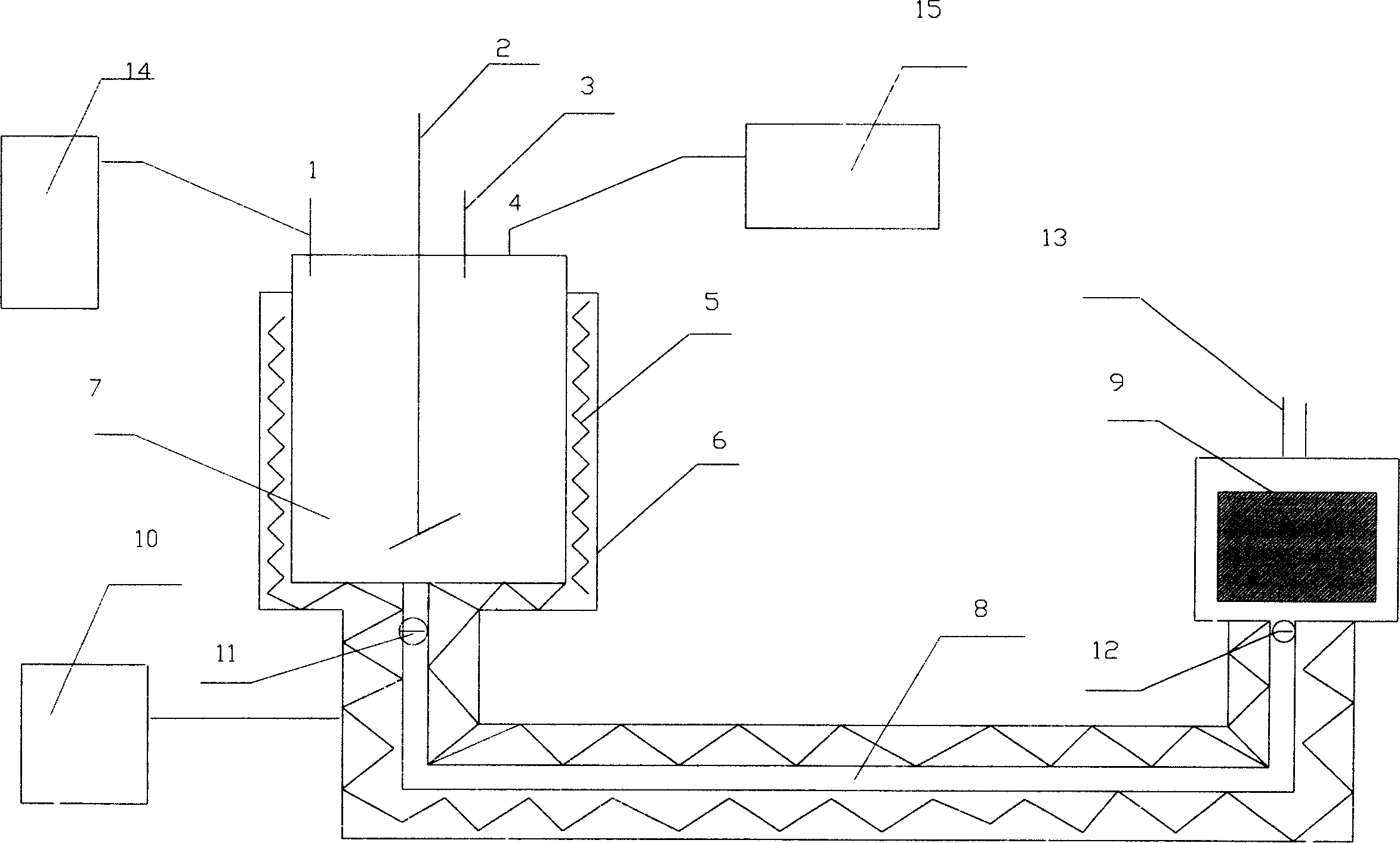

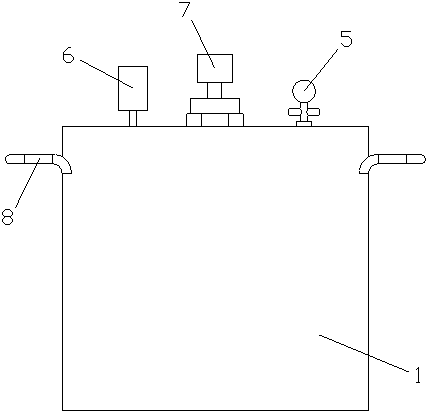

Injection apparatus for resin transfer moulding technology

The present invention relates to an injection equipment capable of utilizing resin to transfer moulding technique. It includes air supply, vacuum pump, resin tank, delivery pipeline and mould device. In the interior of the described resin tank a stirrer is mounted, on the tank cover are set an air nozzle connected with external air supply, an injection port and a mouthpiece connected with vacuum pump. The resin tank is communicated with delivery pipeline by means of output switch, another end of the delivery pipeline is connected with mould device whose top face is equipped with an exhaust hole by means of input switch, the exterior of the resin tank and delivery pipeline is covered with oil-bath heating system, and said oil-bath heating system is communicated with oil-bath circulating pump.

Owner:TIANJIN POLYTECHNIC UNIV

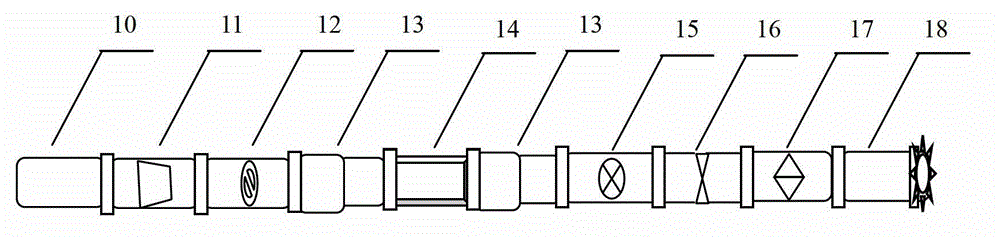

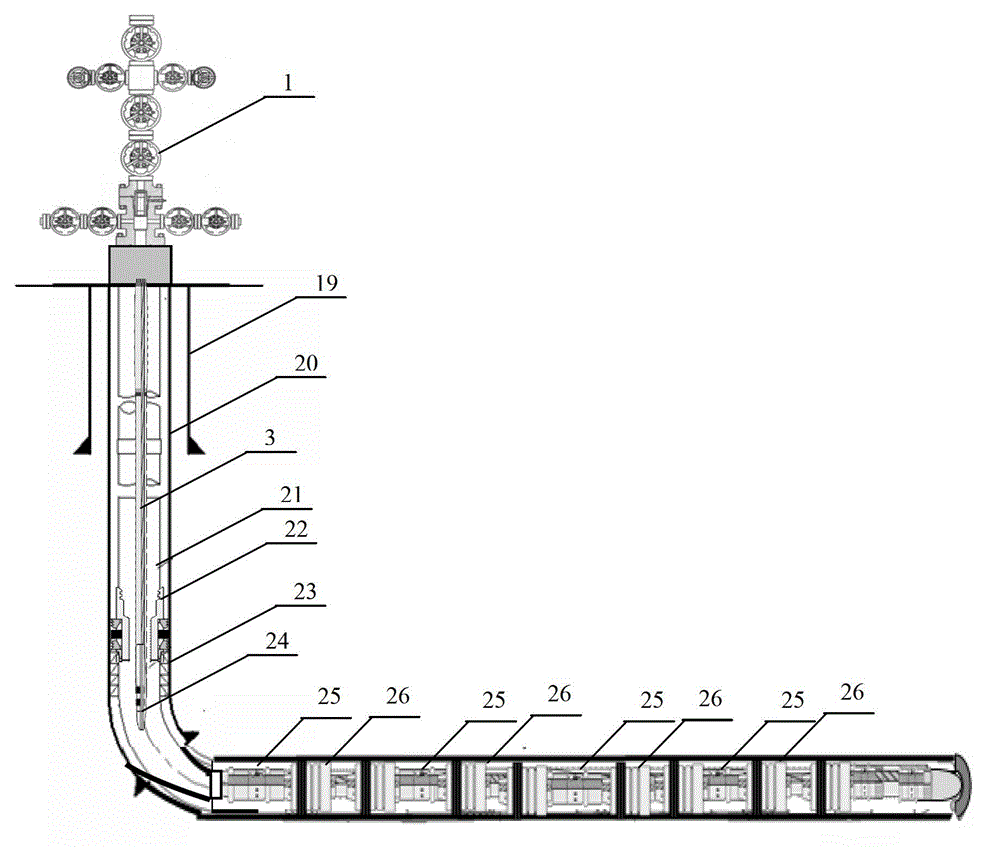

Method for drilling and milling sliding sleeves and ball seats of horizontal well by continuous oil pipe

ActiveCN102913166ASolve drilling and milling problemsSmall sizeFluid removalInjection equipmentCoiled tubing

The invention discloses a method for drilling and milling sliding sleeves and ball seats of a horizontal well by a continuous oil pipe. The method comprises the following steps of: (1) driving a combination of a sleeve and a back insertion sealing pipe string; (2) mounting ground equipment and connecting through a pipeline; (3) driving the continuous oil pipe and a drilling and milling tool; (4) detecting the positions of the sliding sleeves and the ball seats; (5) starting a pump, injecting drilling and milling liquid, and slowly driving the continuous oil pipe; (6) performing drilling and milling operation, and controlling weighting within the range of 0.5-1.5 tons during drilling and milling; and (7) upwards lifting the continuous oil pipe 5-10m when every sliding sleeve and the ball seat are completely drilled, enabling the drilling and milling liquid to circulate one cycle and operating till the completion of drilling and milling of all the sliding sleeves and the ball seats in a shaft. According to the method for drilling and milling the sliding sleeves and the ball seats of the horizontal well by the continuous oil pipe, disclosed by the invention, an underground tool combination of the sliding sleeves and the ball seats can be continuously drilled and milled through the continuous oil pipe, the ground pump injection equipment and a liquid drive drilling and milling tool are utilized for drilling and milling the sliding sleeves and the ball seats of the horizontal well, the drilling and milling efficiency and the utilization rate of the drilling and milling liquid are improved, and the well workover cost is also reduced.

Owner:CHINA PETROLEUM & CHEM CORP +2

Needle protection device with a blocked protection position

Owner:YPSOMED AG

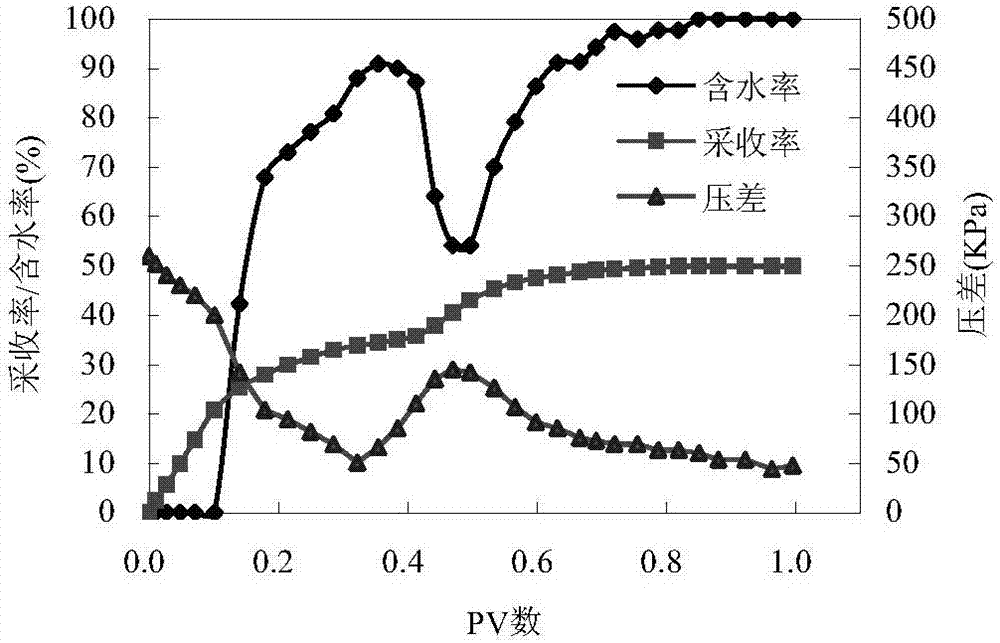

Foamer and foam gas flooding method

ActiveCN107227147APlugged channelingFoaming fastFluid removalDrilling compositionAlcoholInjection equipment

The invention relates to the field of foam flooding and discloses a foamer and a foam gas flooding method. The foamer comprises a weak-cationic amphoteric surfactant, water and at least one of cationic surfactant, amphoteric surfactant and alcohol. The foam gas flooding method comprises the steps of injecting the weak-cationic amphoteric surfactant containing foamer and gas into an oil reservoir, and carrying out foam profile control and oil displacement. According to the foamer and the method, disclosed by the invention, the foamer has high foamability, stability and profile control and oil displacement capability, so that the corrosion action on injection equipment and an oilfield injection-production system caused by air foam in an air foam flooding profile control and oil displacement process can be obviously lowered; and the foamer not only can be applied to a foam profile control and oil displacement process of ordinary strata, but also can be applicable to the foam profile control and oil displacement process under the condition that stratum water is high in degree of mineralization and high in calcium and magnesium ion content.

Owner:CHINA PETROLEUM & CHEM CORP +1

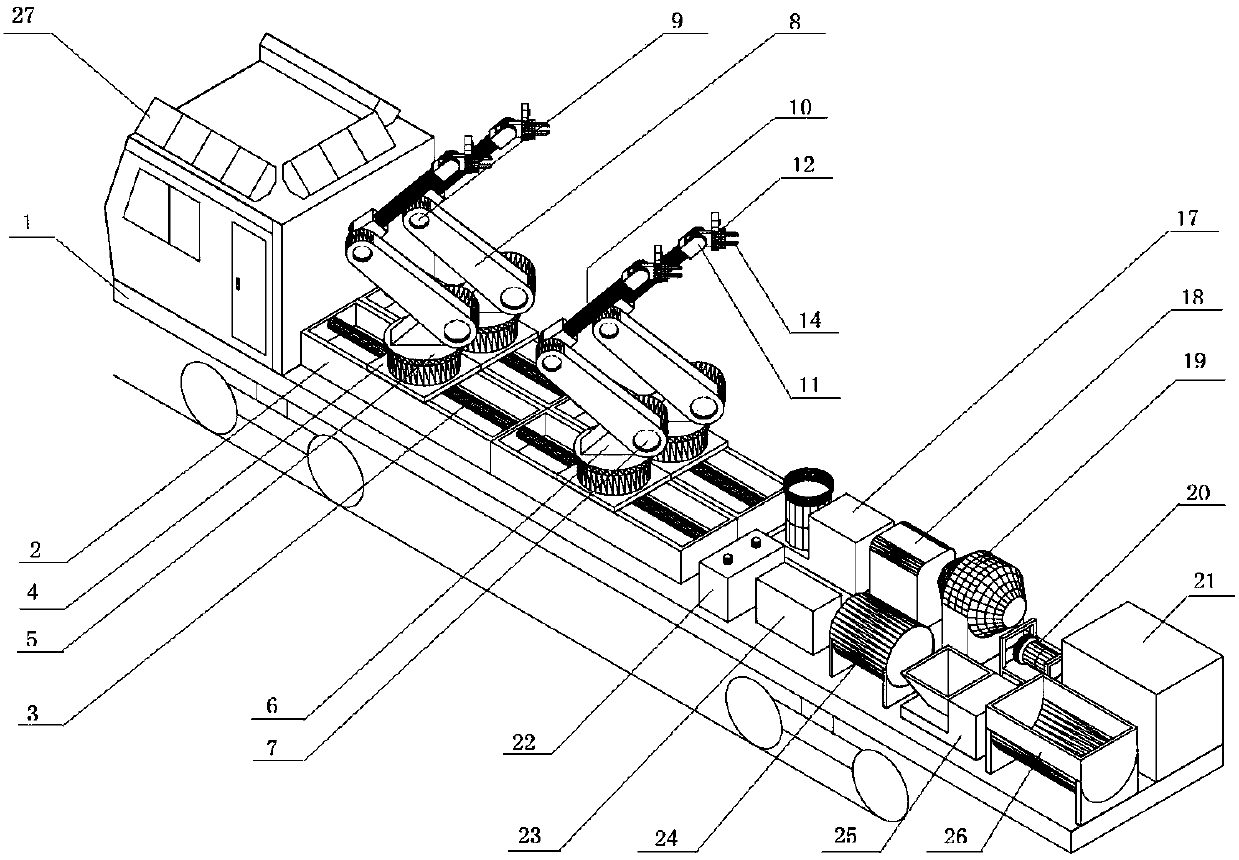

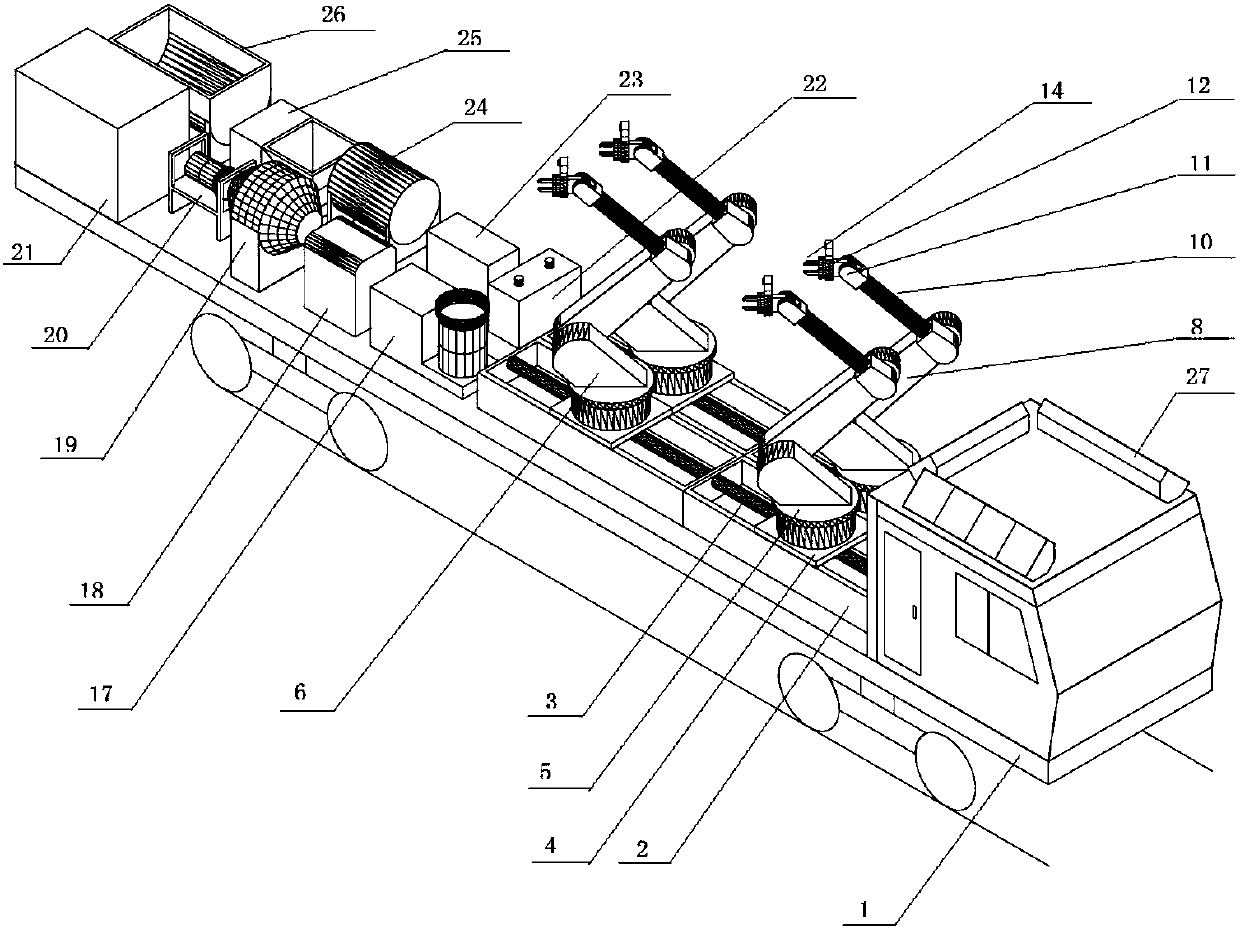

Automatic operation system for comprehensive tunnel defect treatment and method

PendingCN108019219AAvoid time-consuming and inefficientMeet complex job requirementsMining devicesUnderground chambersRailway tunnelHand parts

The invention belongs to the technical field of treatment of tunnel defects and discloses an automatic operation system for comprehensive tunnel defect treatment. The automatic operation system comprises a vehicle-mounted platform, a guiding device, horizontal rotating mechanisms, mechanical arms, auxiliary sensing devices, concrete construction equipment, mortar injection equipment and high-pressure cleaning equipment. The guiding device comprises a track, guide rails and bases; each mechanical arm comprises a machine body, a large arm body, a small arm body, a hand part and pneumatic paws; each auxiliary sensing device comprises an image sensor and a laser distance measuring instrument which are both mounted on the corresponding hand part; and the concrete construction equipment, the mortar injection equipment and the high-pressure cleaning equipment are all mounted on the vehicle-mounted platform so as to be matched with the mechanical arms for defect treatment of tunnels. The automatic operation system for comprehensive tunnel defect treatment is suitable for defect treatment of the road and highway tunnels and carries operation equipment such as the drilling equipment, the mortar injection equipment, the cleaning equipment and the concrete pouring equipment, so that the automatic operation system can rapidly arrive at the defect parts of the tunnels to comprehensively treat the tunnel defects, and the problems that during manual building of an operation platform in the prior art, much labor and time are consumed, and the efficiency is low are avoided.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

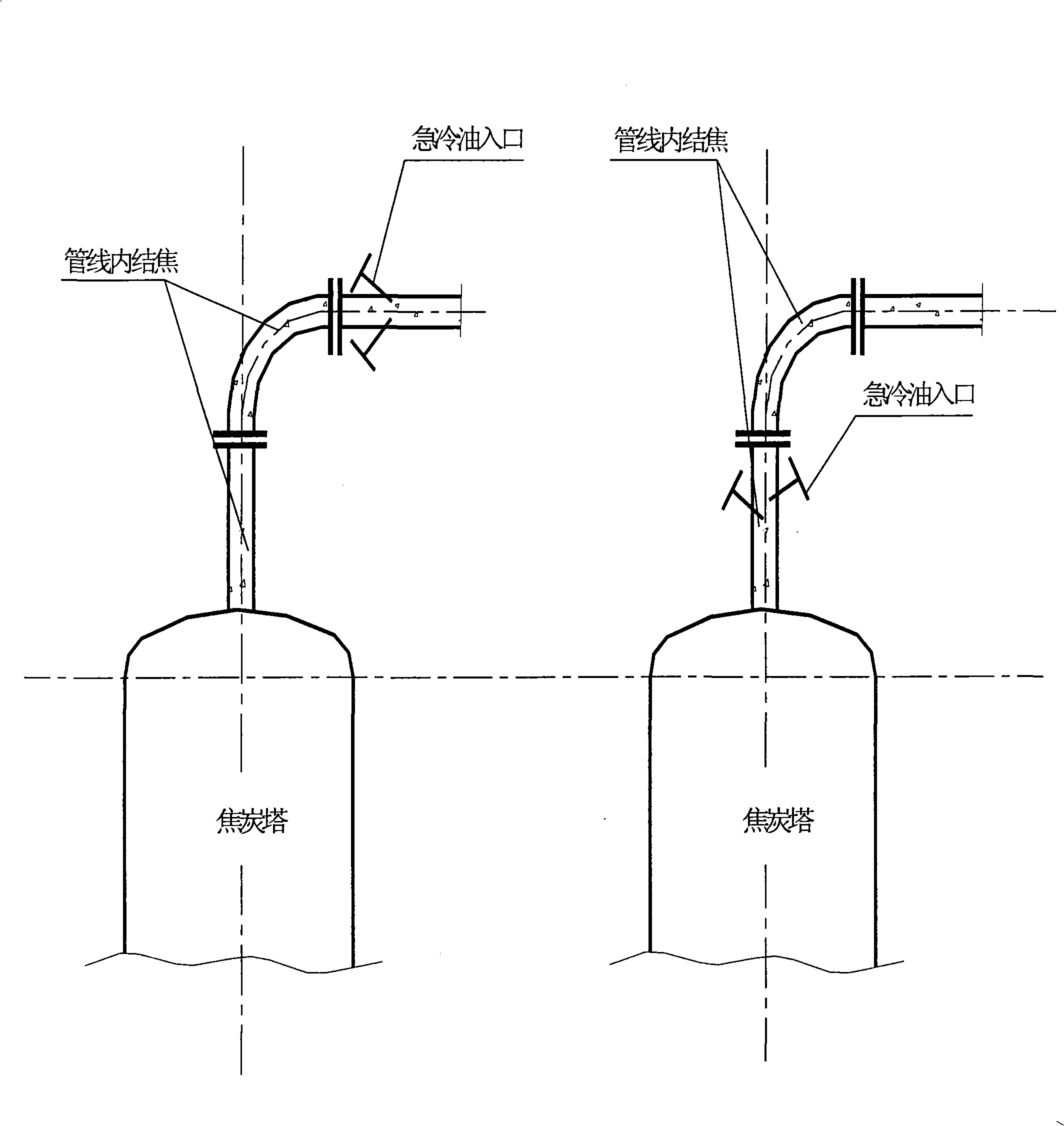

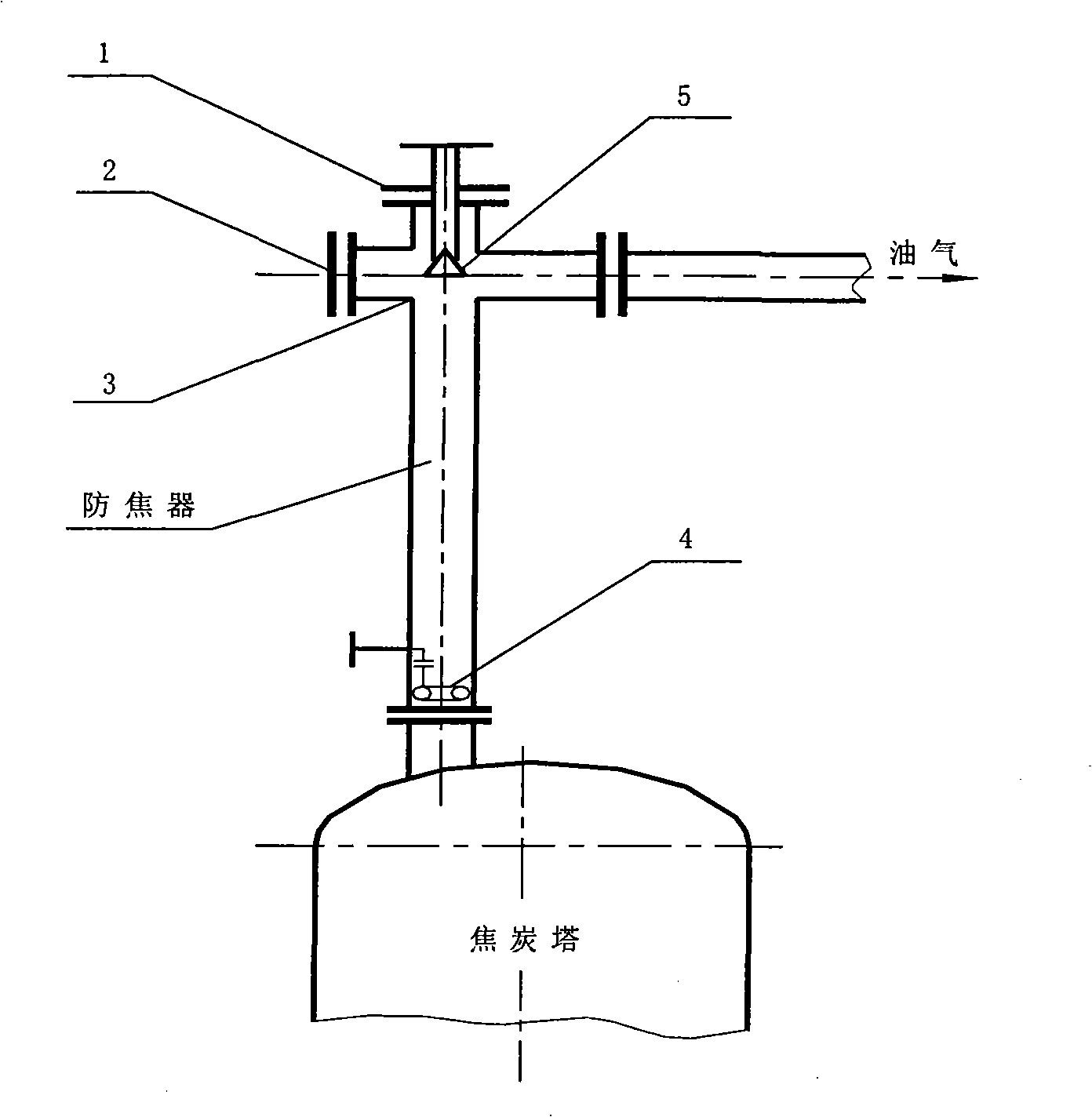

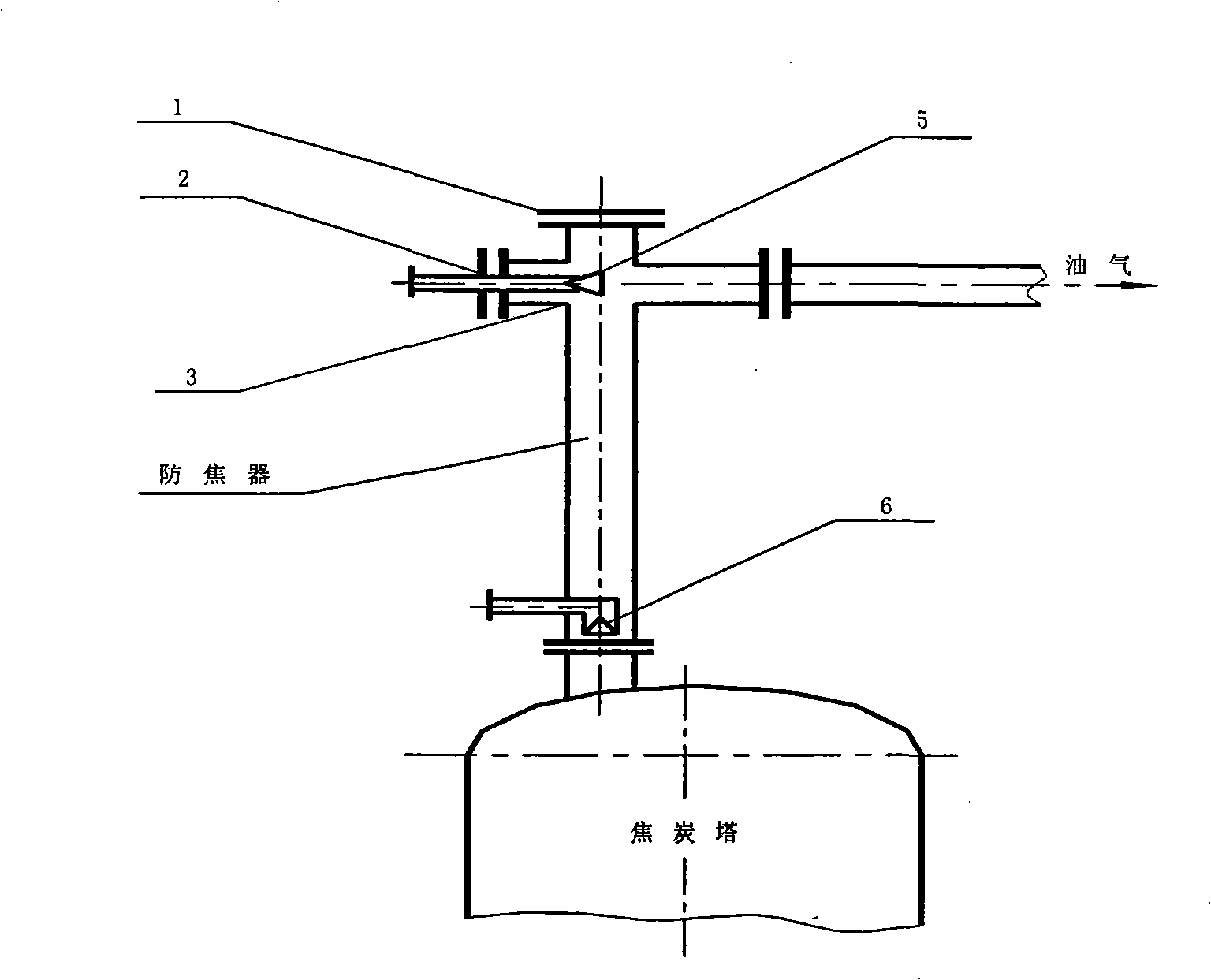

Apparatus and method for preventing coking drum oil gas vent from coking

InactiveCN101343553AEven contactReduces the possibility of cokingThermal non-catalytic crackingLiquid hydrocarbon mixture recoveryLiquid productInjection equipment

The invention relates to a device for preventing the oil and gas outlet of a coking tower from being coked and the application method, which comprises that at least two levels of quenching oil injection equipments are adopted on the oil and gas pipeline at the oil and gas outlet position at the top of the coking tower. Wherein a first level injection is arranged at the oil and gas outlet position at the top of the tower, which is close to the cover head of the coking tower as much as possible and can stop pyrogenic reaction as early as possible; quenching oil is mainly centralized at the oil and gas outlet position at the top of the tower through a multi points injection mode, thus the first level injection is ensured to be fully contaced with the oil and gas to reduce the temperature; a second level injection is arranged at the oil and gas pipeline after the first level injection is injected. The method further improves the processing capacity of the coking tower, and ensures the operating pressure of the coking tower is reduced, the method is favorable for improving the yield of the liquid products of the device, thus to ensure the applicability of the device on processing the residual oil with high asphaltine content to be improved.

Owner:CHINA PETROCHEMICAL CORP +1

Water block removal agent and preparation method thereof

ActiveCN107142098AImprove permeabilityImprove hydrophilicityFluid removalDrilling compositionInjection equipmentWater block

The invention relates to a water block removal agent and a preparation method thereof. The water block removal agent at least comprises the following components in percentages by mass: 0.1-0.5% of first modified nano silicon dioxide modified by a lipopeptid biological surfactant, 0.5-1.0% of second modified nano silicon dioxide modified by a fluorocarbon surfactant, 10-30% of ethylene glycol and the balance of water, wherein the first modified nano silicon dioxide, the second modified nano silicon dioxide, ethylene glycol and water are injected in proportion through injection equipment of the water block removal agent and the components are mixed in the injection equipment to form the water block removal agent. The water block removal agent provided by the invention has the advantages of being convenient to prepare, strong in surface activity, high-temperature-resistant, high-salt-resistant, strong in rock absorption, low in cost and the like.

Owner:成都百联油田技术服务有限公司

Sealing monitoring method for simulating sealing conditions of transformer bushing

ActiveCN104198125AAvoid failureReduce volumeFluid-tightness measurement using fluid/vacuumTransformerInjection equipment

The invention relates to a sealing monitoring method for simulating sealing conditions of transformer bushing. The sealing monitoring method includes the following steps: providing a device for simulating the sealing conditions of the transformer bushing; oiling and sealing; installing an SF6 gas density meter and a silicone pot; installing an SF6 gas online testing sensor; for connecting a vacuum pump with SF6 gas injection equipment, vacuumizing the device with a vacuum pump, injecting SF6 gas into the device prior to well sealing; utilizing the SF6 gas density meter to monitor changes of SF6 gas density, and judging the sealing conditions of the device by monitoring the SF6 gas density. Poor sealing of the transformer bushing and internal water inflowing conditions of the transformer bushing are simulated by sealing of the position of an oil filling port and dripping to the interior of the device, temperature of the device can be regulated through external measures, changes of internal oil temperature can be simulated during operation of the transformer bushing, the changes of SF6 gas state quantity and silica gel can be acquired when sealing of the transformer bushing is not good, and active role is played in study of preventing failure of the bushing from occurring.

Owner:STATE GRID CORP OF CHINA +2

Composite multifunctional slipper mechanism

InactiveCN101422952AWith core pulling and demoulding functionReasonable structural designOperating means/releasing devices for valvesInjection equipmentComposite structure

The invention relates to a composite structure with the function of a sliding block of an injection equipment mold, in particular to a composite multi-function slider mechanism, which is provided with a flash mechanism and a flash ejection mechanism in the sliding block and has both the flash function and the flash ejection function in gas-assisted molding, simultaneously, the core-pulling and demoulding function of the sliding block. The slider mechanism comprises a mold body, a core plate and a sliding block body, on which the flash mechanism and the flash ejection mechanism are arranged; the flash mechanism comprises a flash valve and a hydraulic drive mechanism, the flash valve is installed in the sliding block body and the hydraulic drive mechanism is fixed on the core plate of the mold body; the auxiliary ejection rod in the flash ejection mechanism is arranged in the main ejection system of the mold. The composite structure solves the problem that different flash position points can be arranged in the flash procedure of gas-assisted molding, expands the freedom degree of product design, increases the utilization rate and functions of the mold structure and also solves the anisotropic flash problem.

Owner:NINGBO SUNNY MOLD

Special foam drainage method for low-gas-yield water-flooded well, foam drainage agent and foam drainage device

InactiveCN105525899AEfficient use ofContinuous gas recoveryFluid removalDrilling compositionUltrasound deviceFoaming agent

The invention relates to foam drainage gas production, in particular to a special foam drainage method for a low-gas-yield water-flooded well, a foam drainage agent and a foam drainage device. A chemical mode or / and a physical mode is / are adopted to stir accumulated liquid in the low-gas-yield water-flooded well and generate fluctuation, the fluctuating accumulated liquid makes the foam drainage agent put into the accumulated liquid mix with air water in the accumulated liquid to generate foam, and accordingly foam drainage gas production of the low-gas-yield water-flooded well is achieved. The foam drainage agent is prepared from, by weight percentage, 10-25% of non-ionic surfactant, 20-45% of zwitter-ion surfactant, 15-25% of anion surfactant and the balance a foaming agent. Ultrasonic equipment, a micro fan and carbon dioxide injection equipment are adopted as the foam drainage device. Due to the structure, the special foam drainage method for the low-gas-yield water-flooded well, the foam drainage agent and the foam drainage device have the advantage of breaking the technical bottleneck that the effective technology of foam drainage cannot be applied to the low-gas-yield water-flooded well.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

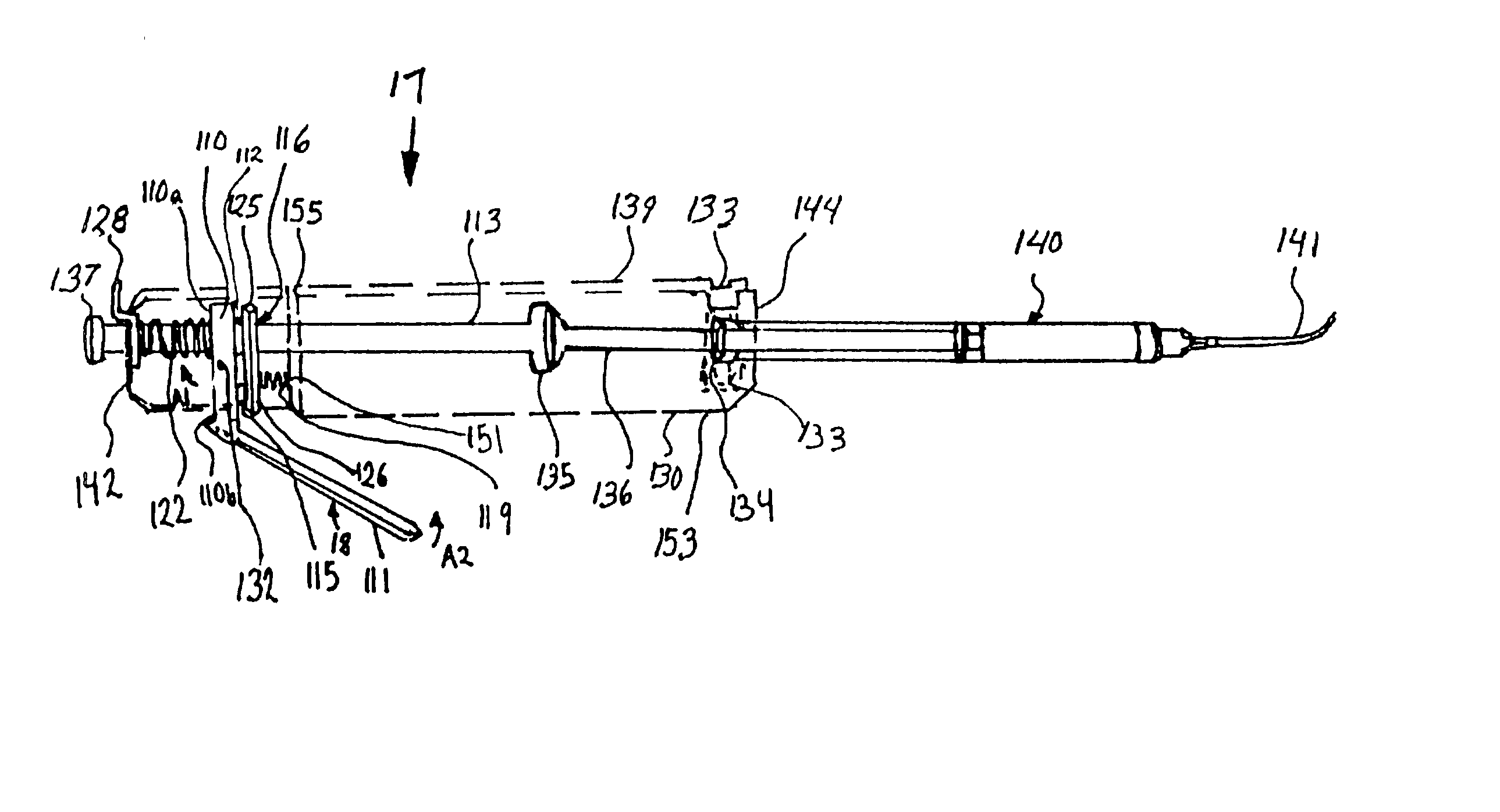

Medical injection apparatus

An injection apparatus includes components that facilitate injection of relatively viscous materials into a patient. An injection apparatus may include a transition-bore needle apparatus, which has a proximal end, a distal end, and a lumen extending from the proximal end to the distal end, in which the diameter of the proximal end is greater than the diameter of the distal end. An injection apparatus may include a hand-held injection facilitation apparatus, which may be coupled to a syringe. The hand-held injection facilitation apparatus can include a pivot arm and a body with a rod disposed within the body and coupled to the pivot arm. Movement of the pivot arm results in a proximal or distal movement of the rod within the body to effectively cause material to be expelled from the syringe. An injection apparatus may include a transition-bore needle apparatus and a hand-held injection facilitation apparatus in combination.

Owner:SUNEVA MEDICAL

Template with rigid-flexible composite structure and partition wall construction method by retaining roadway along goaf thereof

InactiveCN101936065ASimple structureEasy to useForms/shuttering/falseworksMaterial fill-upBrickInjection equipment

The invention relates to a template with a rigid-flexible composite structure, which is composed of two parts: an external rigid template and internal flexible loose tooling arranged in the external rigid template, wherein, the internal flexible loose tooling is an enclosed bag with an expandable opening. The construction method of the template comprises the following steps: fixing the internal flexible loose tooling on a roadway roof or the external rigid template and then connecting pump injection equipment for a concrete conveying pipe for filling concrete into the whole internal loose tooling. If a hard kernel needs to be added to the internal loose tooling, the expandable opening can be opened, building blocks, bricks, detritus or gangue are placed into the opening, and grouting is carried out after sealing. The template with the rigid-flexible composite structure has simple structure, convenient use, and positioning and reshaping features of the rigid template as well as variability of the internal flexible loose tooling so that the whole concrete structural wall can apply a certain setting force to the roof. The method has fast construction speed, high efficiency and good construction effect. The template and the device can be widely applied to industries such as a coal mine, civil engineering, a metallurgical mine, water conservancy, underground construction, national defense and the like.

Owner:惠兴田

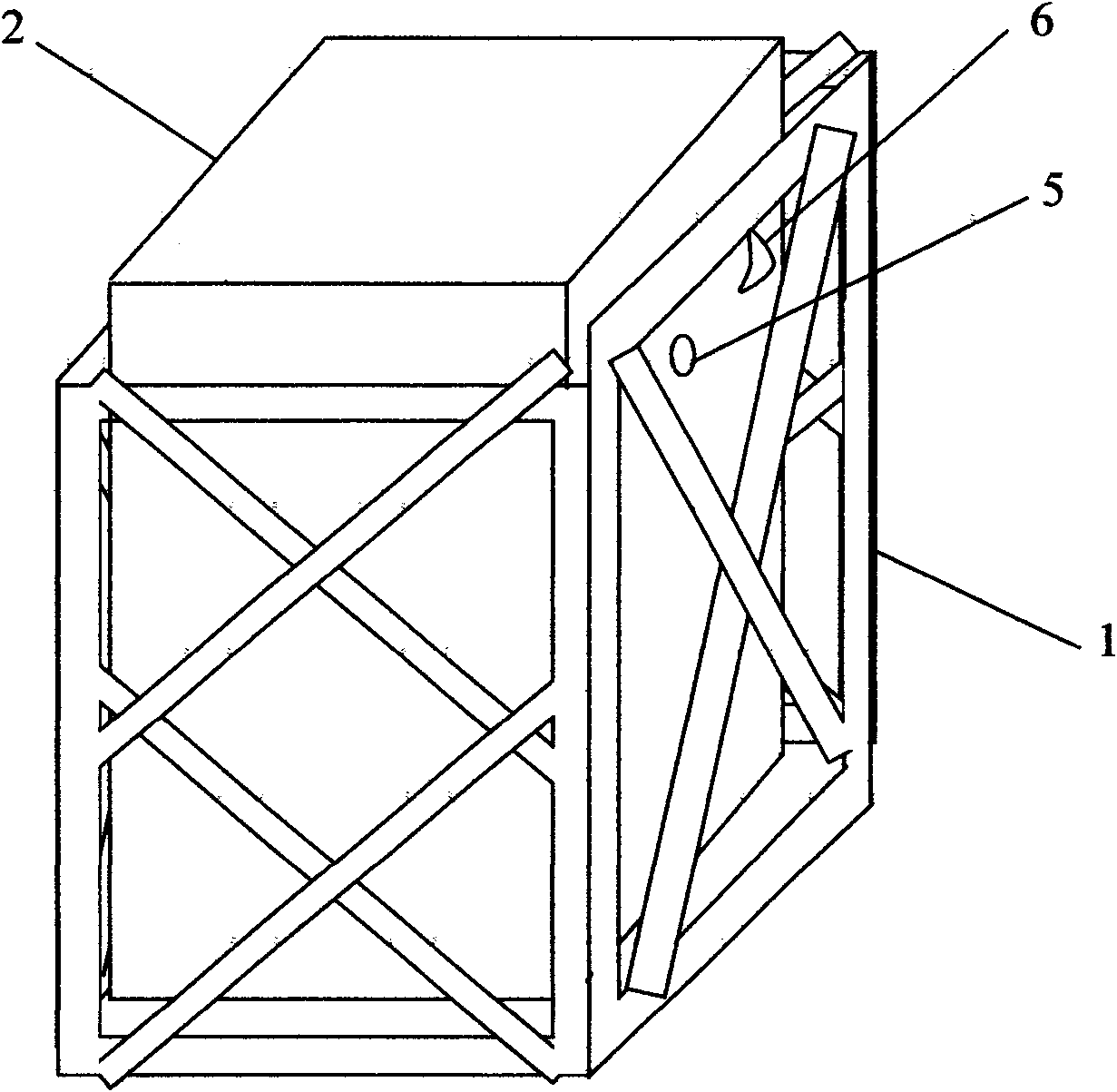

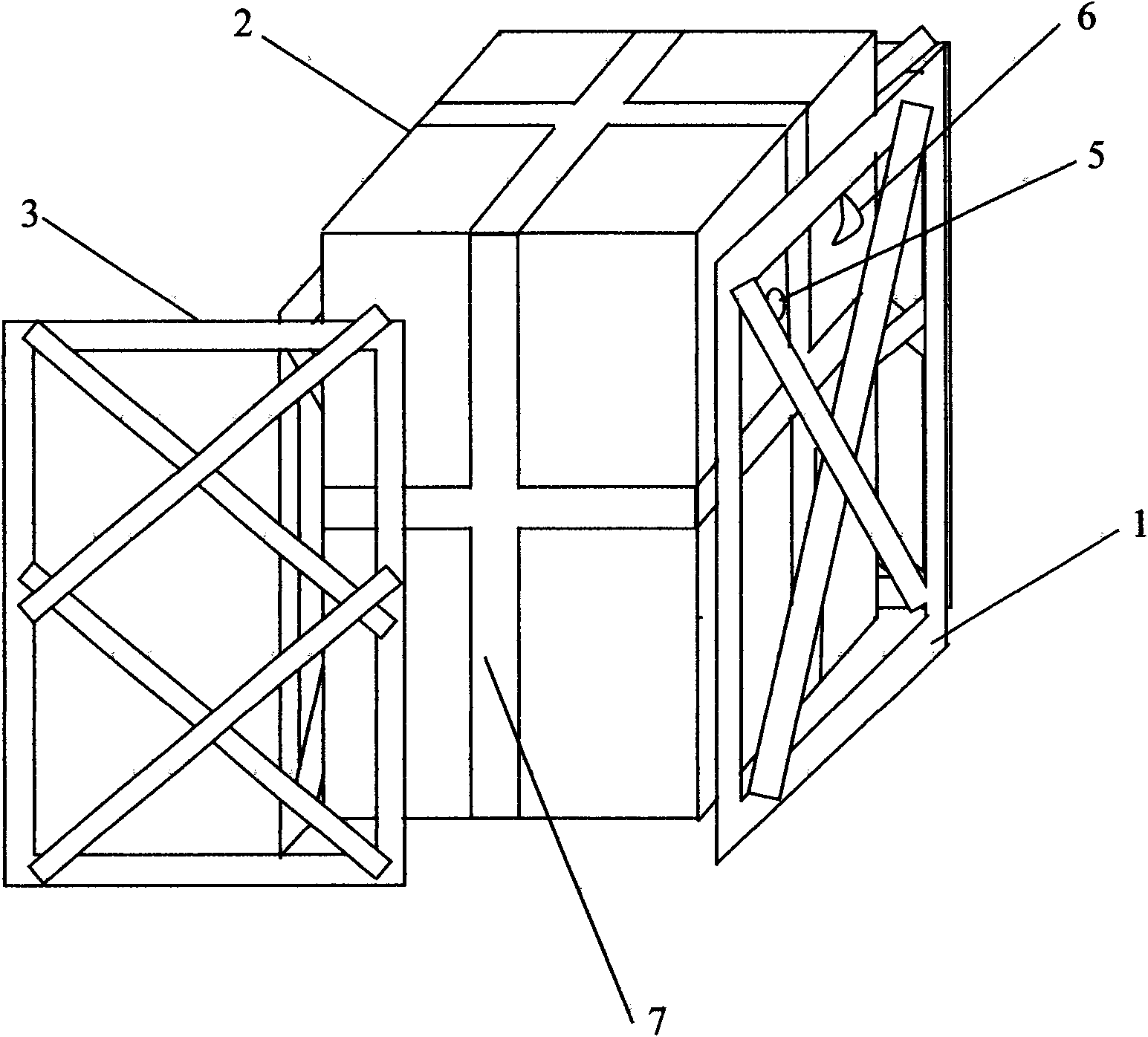

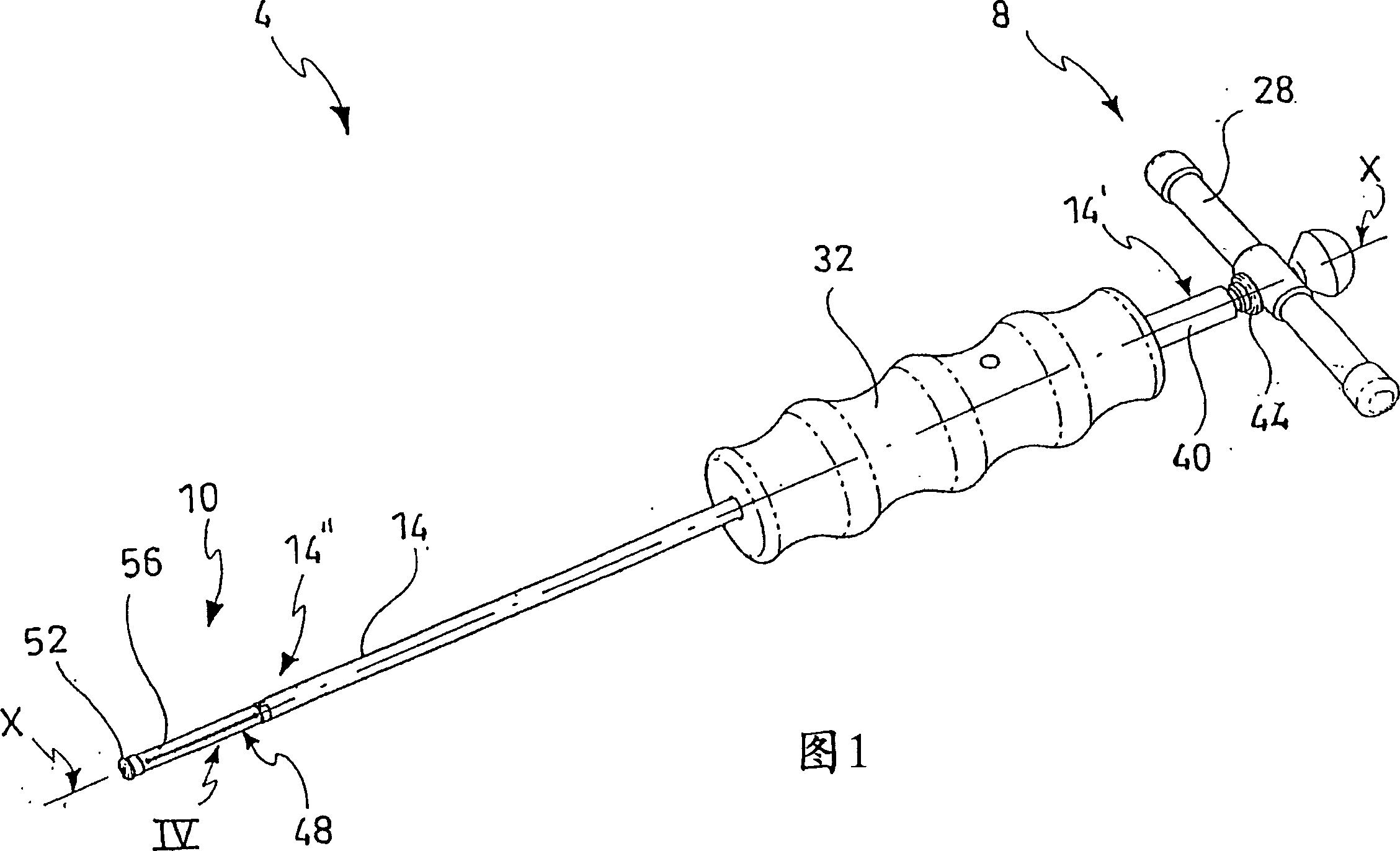

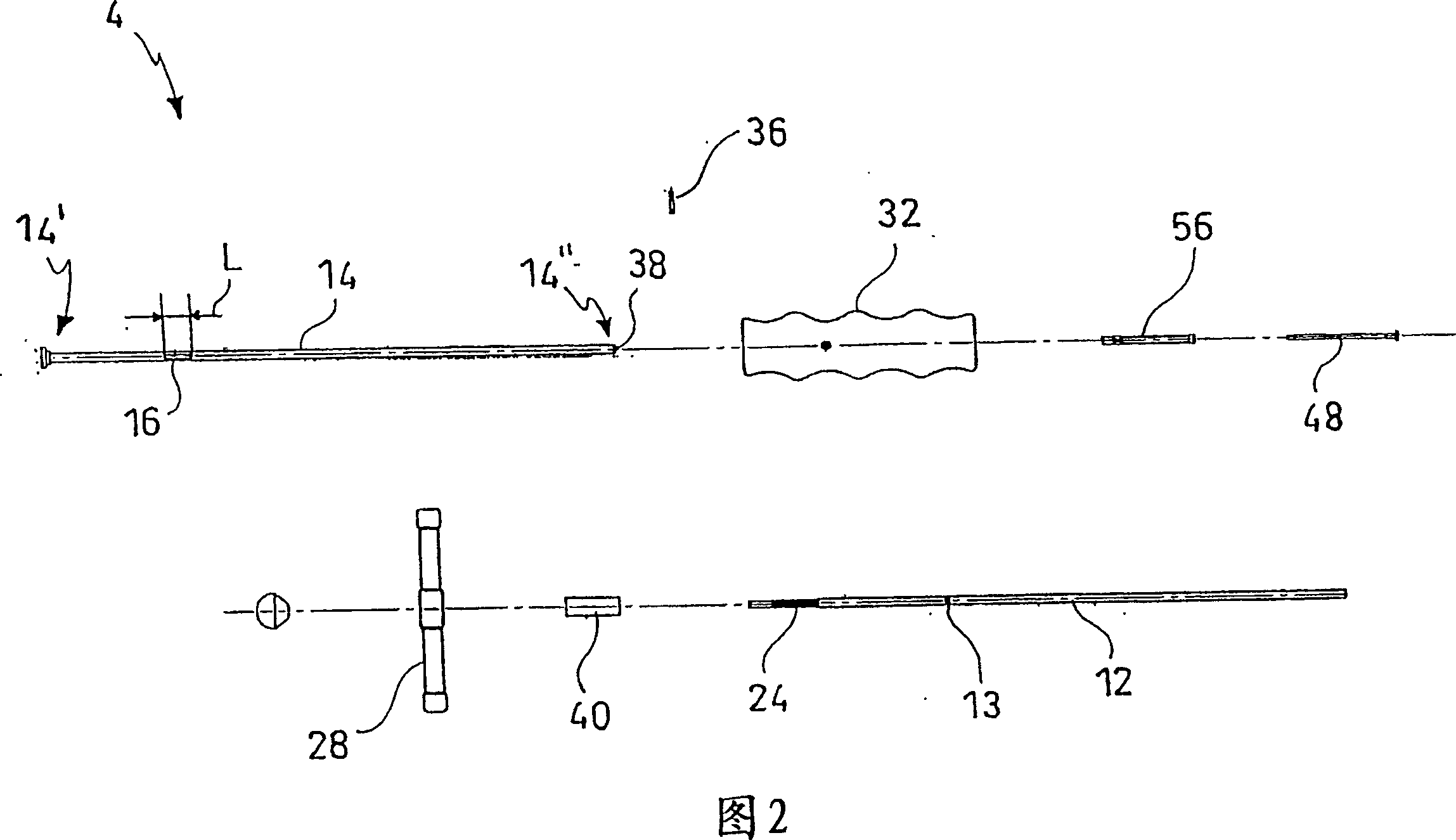

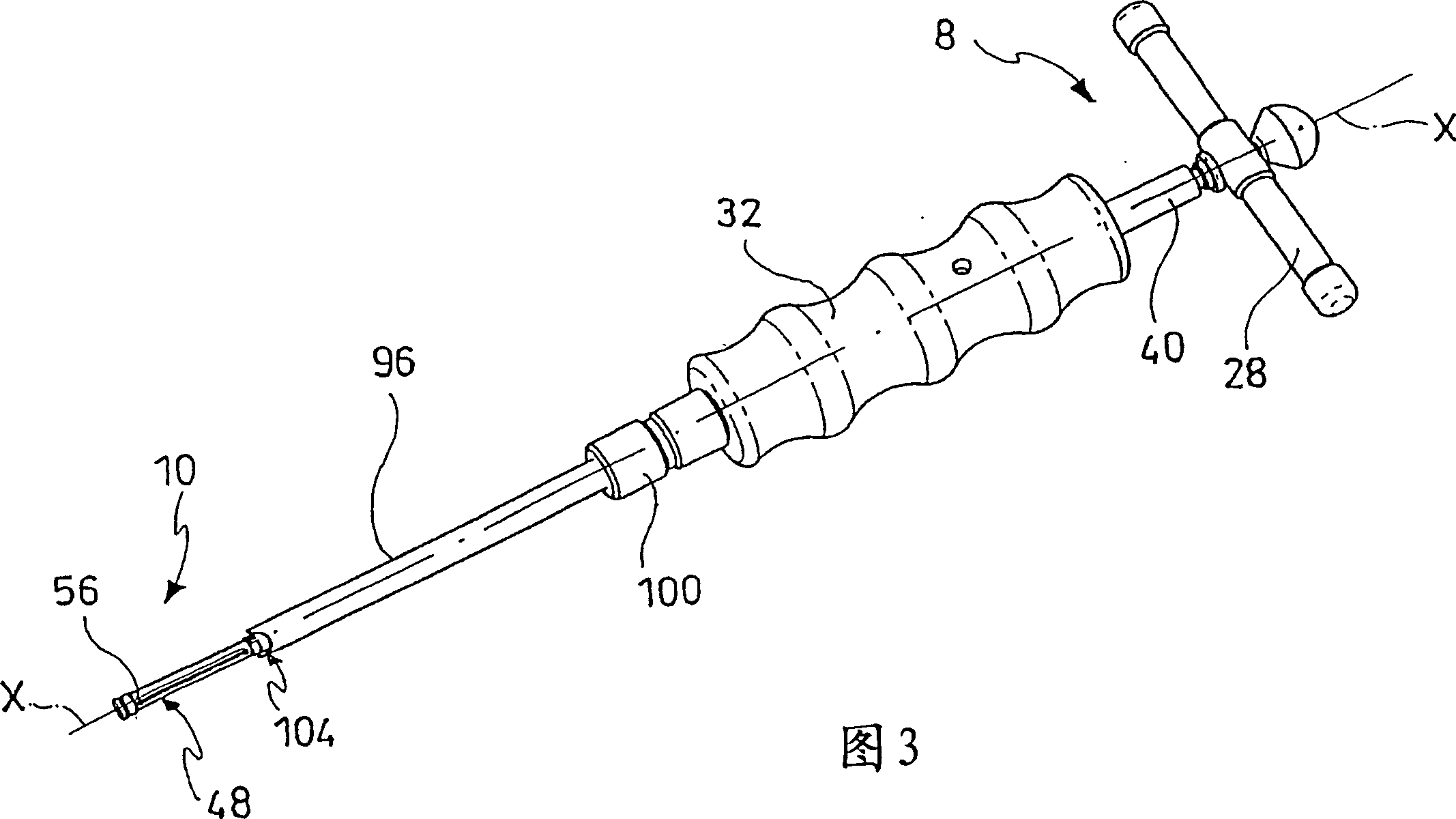

Intravertebral widening device, injection device, and kit and method for kyphoplasty

InactiveCN1984613AEasy to understandInternal osteosythesisCannulasInjection equipmentVarying thickness

An intravertebral widening device (4) extends from a proximal end (8) to a distal end (10) along an extension axis (X), said distal end (10) having an elastically deformable element (56) suitable to pass from a relaxed configuration for placing the distal end (10) within a vertebral body (6) to a deformed configuration for forming a cavity within said vertebral body (6). The elastically deformable element (56) comprises at least one tab (60) having, along the longitudinal extension thereof, a varying thickness relative to a radial direction incident with said extension axis (X) and contained in a perpendicular plane to said extension axis (X), such as to vary the stiffness of at least one tab (60) along the extension thereof.

Owner:SINTEA BIOTECH

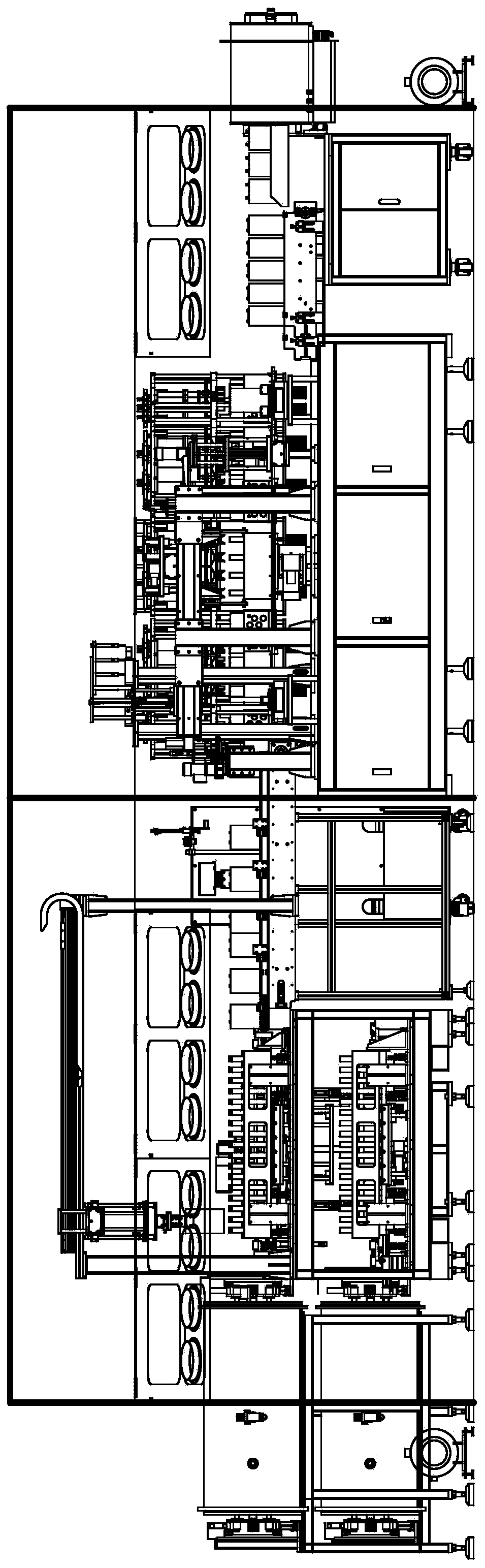

Automatic electrolyte injection equipment

PendingCN107195853AFully absorbedImprove efficiencyCell component detailsInjection equipmentEngineering

The invention relates to the technical field of battery electrolyte injection, and provides automatic electrolyte injection equipment. The automatic electrolyte injection equipment comprises a first caching apparatus, a second caching apparatus, a feeding apparatus, a discharging apparatus, a rotation apparatus, a plurality of battery electrolyte injection apparatuses, a battery transferring apparatus and a material inlet and outlet apparatus; the rotation apparatus comprises a rack with a material feeding and discharging station, a rotary plate rotationally supported on the rack and a rotary plate power part used for driving the rotary plate to rotate; each battery electrolyte injection apparatus comprises an electrolyte injection supporting base, an electrolyte injection up and down movement mechanism for lifting the electrolyte injection supporting base, and a plurality of electrolyte injection cups arranged on the electrolyte injection supporting base and used for performing electrolyte injection for batteries; and the multiple battery electrolyte injection apparatuses are distributed in the circumferential direction of the rotary plate in sequence. Compared with the prior art, the automatic electrolyte injection equipment provided by the invention can ensure complete absorption of electrolyte and save time, and also has the advantages of high efficiency, high automatic degree and the like.

Owner:SHENZHEN YUCHEN AUTOMATION EQUIP CO LTD

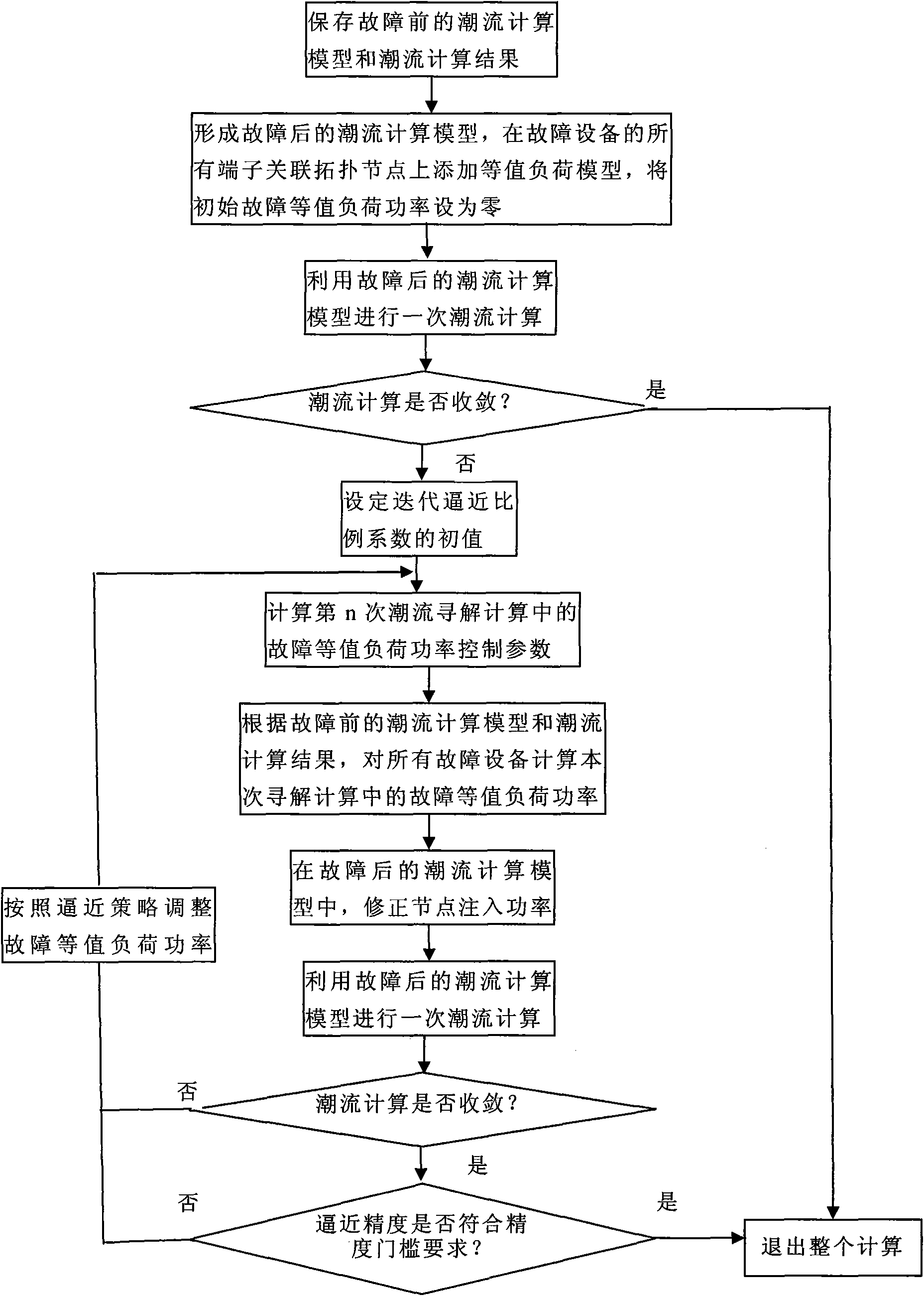

Method for solving critical approximate power flow after failure of electric system

ActiveCN101562340ARationally Critical Approximate Power FlowQuick calculationAc network circuit arrangementsPower flowInjection equipment

The invention discloses a method for solving critical approximate power flow after the failure of an electric system. The method comprises the steps of: utilizing the technical condition of original power flow convergence, making full uses of the information of power flow convergence section before failure, unifying all failure types into the node injection calculated by the traditional power flow for correction control, correcting failure linked nodes based on a power flow calculation model after failure and obtaining the solution of critical approximate power flow by sequential interactive approximation. The method can quite easily handle failures such as the disconnection of the electric system and the exiting of node injection equipment and has fast calculation, strong universality and wide application range.

Owner:STATE GRID HUNAN ELECTRIC POWER +2

Air humidifier for keeping humidity of cultural relics

InactiveCN110513804AImplement automatic injectionSimplify workDispersed particle filtrationLighting and heating apparatusWater sourceInjection equipment

The invention discloses an air humidifier for keeping the humidity of cultural relics. The air humidifier comprises a shell, wherein a working chamber is arranged in the shell, and a storage containeris arranged on the inner wall of the upper side of the working chamber and communicates with the outside. The air humidifier adopts the design of an electromagnet and a spring, and realizes the automatic injection equipment of an external water source; a plurality of mechanisms in the humidifier use one power source through the connection modes of bevel gears, belts and the like; through a grooved pulley, a pushing plate and other mechanisms, the operation of replacing a filter plate is delayed, and the filter plate is automatically replaced at regular time; and through a container that can store the used filter plate, the maintenance work after the humidifier is used is simplified, and the current situation that the filter plate needs to be replaced manually and a large amount of manpower is needed when most of the humidifiers operate in the prior art is improved.

Owner:JINYUN XINYANG CRAFTS&GIFTS CO LTD

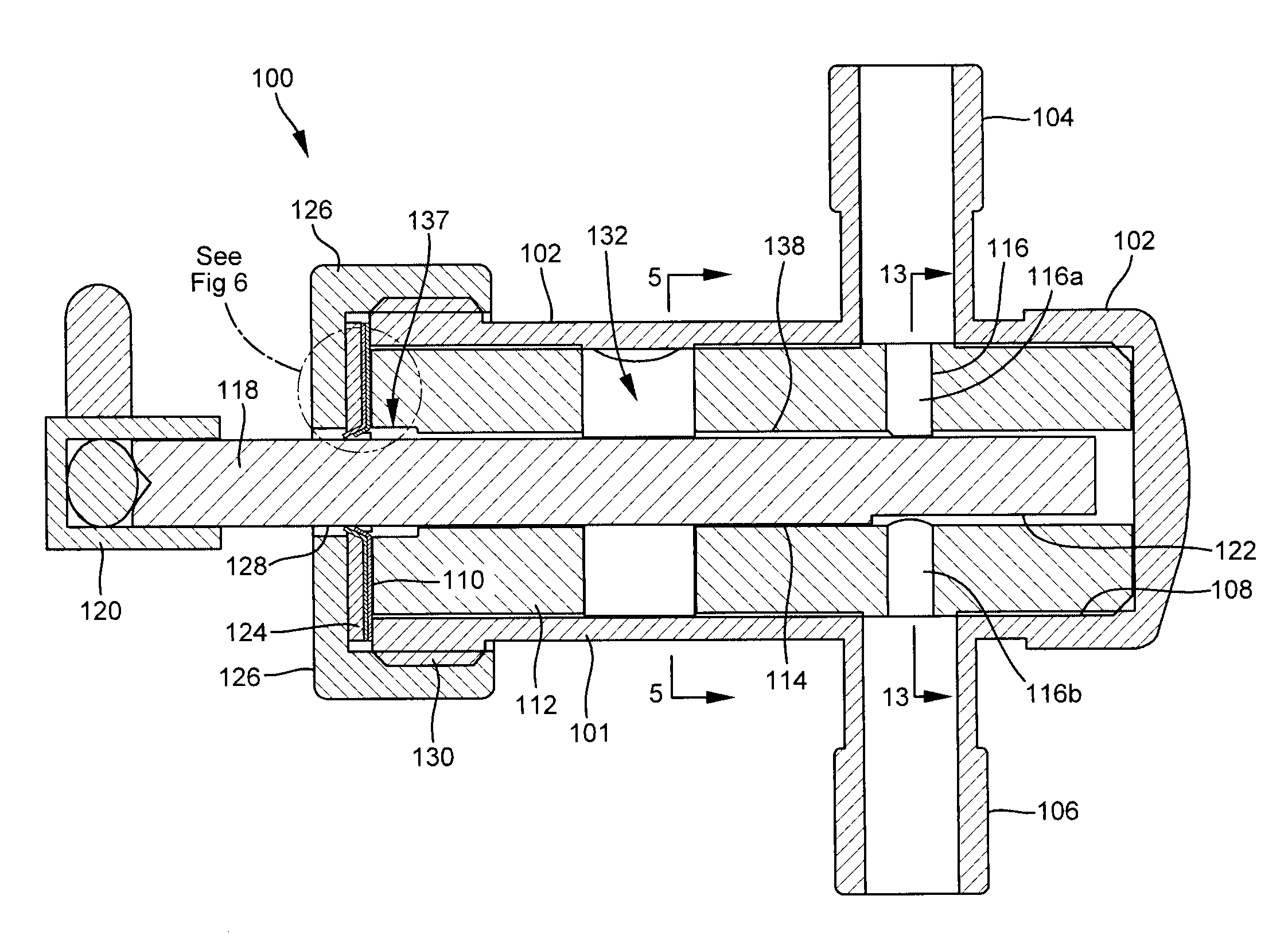

Method and apparatus for elimination of gases in pump feed/injection equipment

ActiveUS7785084B1Suitable for useInhibition formationPositive displacement pump componentsCylindersInjection equipmentEngineering

A pumping apparatus for pumping a liquid from a source to a target includes a pump having a pump housing and a pump piston. The pump housing defines a central longitudinal bore, a transverse bore communicating with the central bore for conveying a liquid through the pump housing and a liquid reservoir communicating with the central bore and the transverse bore for retaining an amount of the liquid conveyed through the transverse bore. The pump piston is axially and rotatably slidable within the central longitudinal bore for pumping the liquid through the transverse bore.

Owner:FLUID METERING INC

Double-shot molding method for vehicle internal decoration seat armrest

The invention provides a two-tone color injection method of automobile inner decoration handrail, which heat and smelt a first injection material, then inserts the smelting liquid material into the module cavity of a handrail baseboard by the screw rod of the injection equipment and through a flow passage. After dwelling and cooling, form a handrail baseboard; when heating and smelting the first injection material, another existing group of heating device heats and smelts a second injection material with different color from the first injection material, then inserts the smelting second injection liquid material into another module cavity of a handrail baseboard by the screw rod of the injection equipment and through a flow passage, after dwelling and cooling, form the second injection material flexible body cover on the handrail baseboard formed by the first injection material, finish the forming production of the handrail. The advantage of the invention is that: the invention not only has high efficiency and suitable for industrial application, but after compositing, the handrail is not worse than dermis in color and hand feel. The whole technics is simple and is easy to realize.

Owner:JIANGSU CHANGSHU AUTOMOTIVE TRIM GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com