Automatic electrolyte injection equipment for batteries

A liquid injection and battery technology, applied in the direction of battery components, circuits, electrical components, etc., can solve the problems that affect the battery capacity and cycle life, it is difficult to ensure the consistency of the battery electrolyte, and the performance of the equipment is unstable, etc., to achieve The effect of improving the overall automation degree, good vacuum environment and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

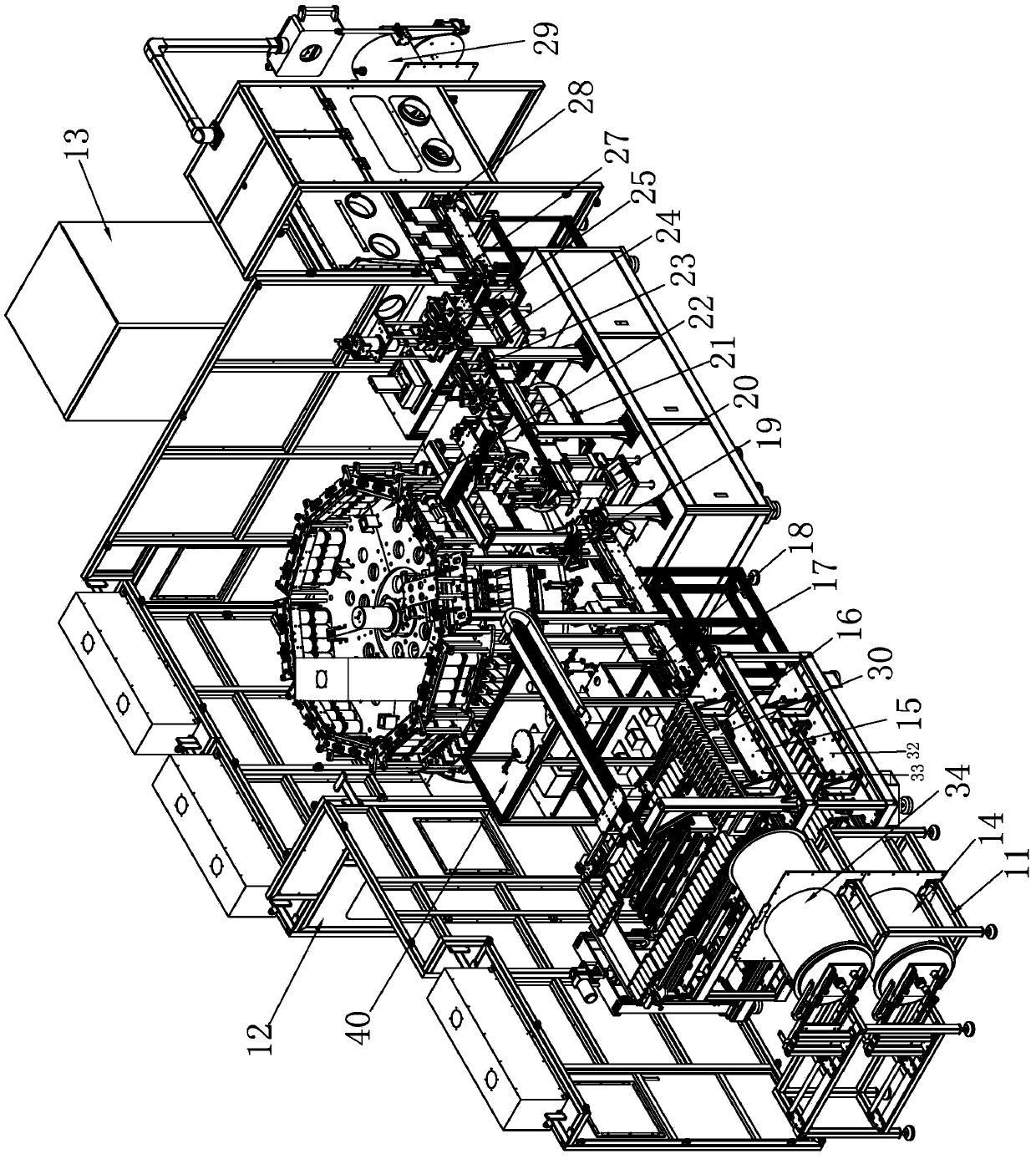

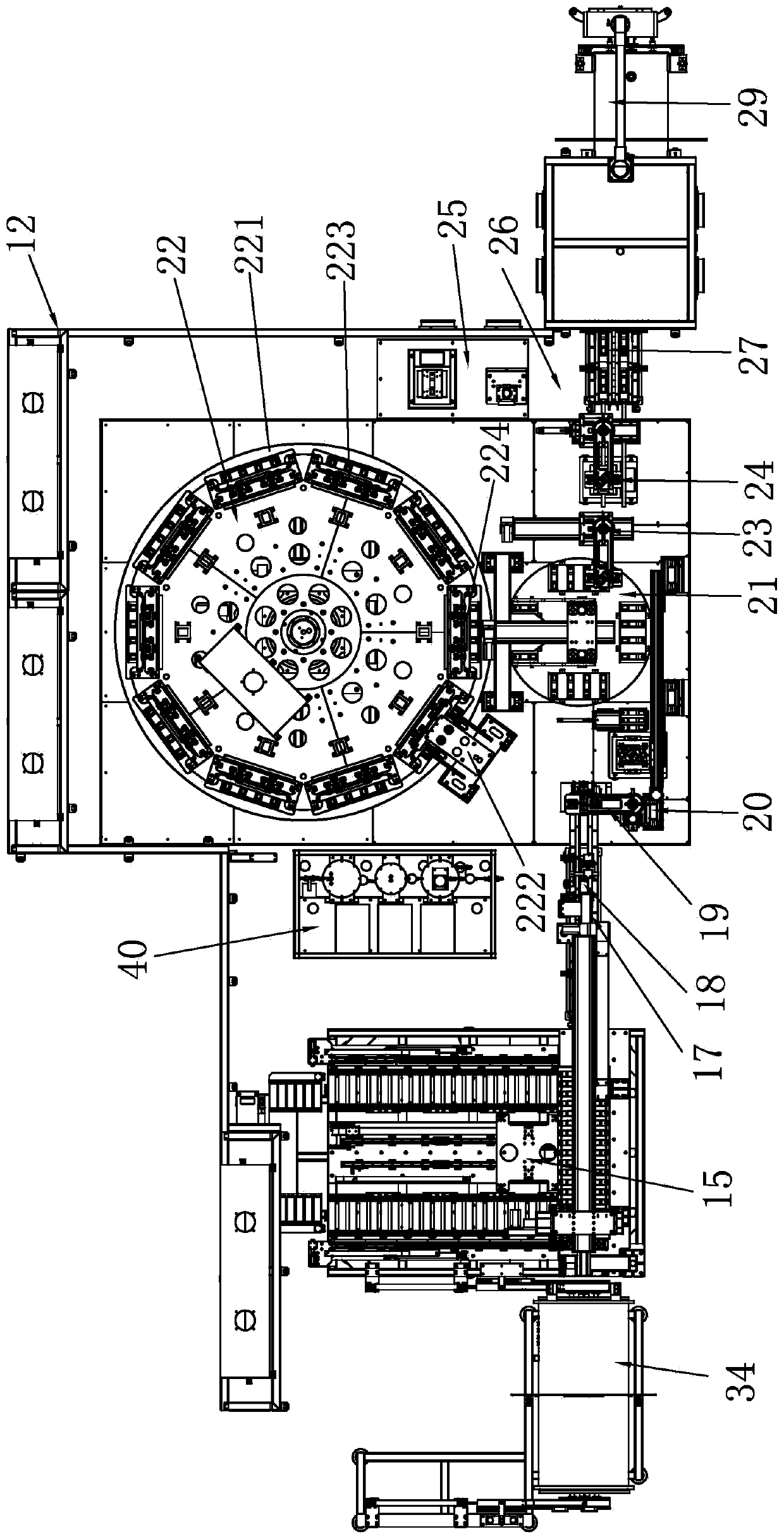

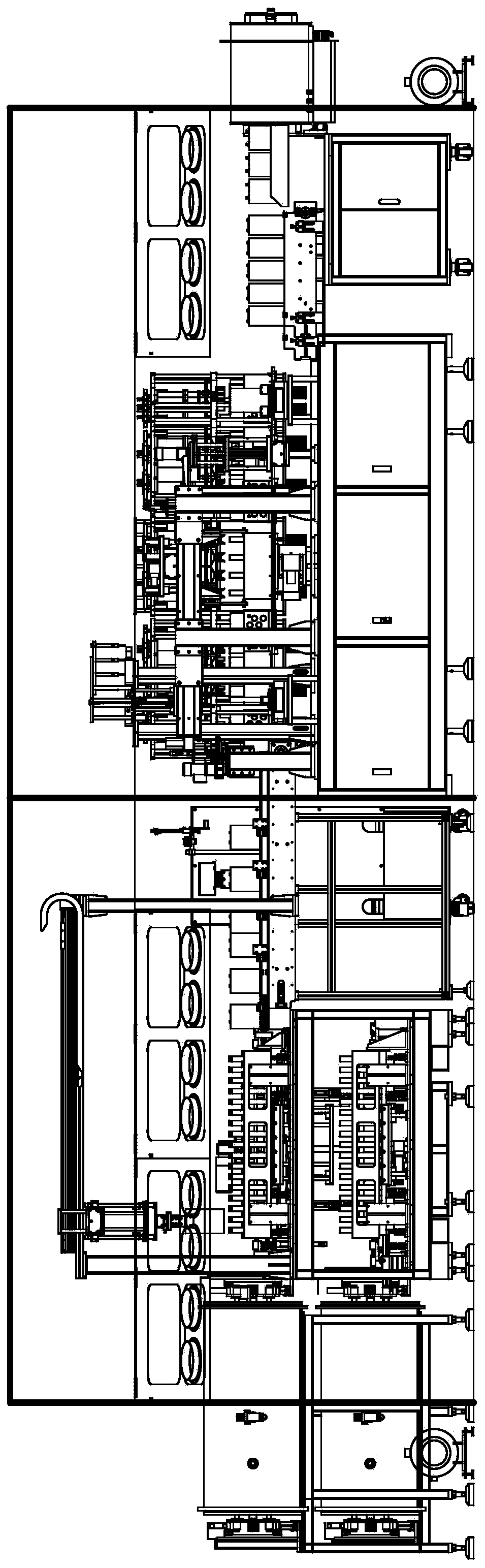

[0071] Please refer to Figure 1 to Figure 13 As shown, it has shown the specific structure of the preferred embodiment of the present invention, the battery automatic liquid injection equipment includes a frame 11, a closed box 12 that is covered outside the frame 11, and is independently arranged in the closed box. The electric control box 13 outside 12 and the vacuum transition cabin 14, drying and cooling mechanism 15, feeding manipulator 16, feeding conveyor belt 17, insulation resistance testing mechanism 18, Loading scanning code weighing manipulator 19, weighing mechanism before liquid injection 20, turntable feeding mechanism 21, liquid injection circulation static turntable mechanism 22, unloading scanning code weighing manipulator 23, weighing mechanism after liquid injection 24, rehydration Station 25, rubber plug station 26, blanking conveyor belt 27, blanking transfer tray 28 and blanking vacuum transition cabin 29, and also includes a drying tray 30 for carrying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com